Page 1

Description and operating instructions

Industrial Ethernet IP67 Switch

The Ethernet switch OCTOPUS 5TX-EEC has

been especially designed for use in industrial environments. It supports Ethernet

10 MBit/s and Fast Ethernet 100 MBit/s.

The Ethernet switch modules support switched Ethernet networks in accordance with

IEEE standard 802.3 (10BASE-T) or 802.3u

(100BASE-TX) using copper technology.

The switch modules are fitted at the installation site using screws.

The OCTOPUS 5TX-EEC modules have five

10/100 Mbit/s twisted pair ports (10BASET/100BASE-TX, shielded M12 connectors).

It is possible to connect up to five DTEs

(data terminal equipment) or other TP/TX

network segments to these ports using

twisted pair cabling.

The TP ports support auto negotiation,

autopolarity and autocrossing.

The IP67 switch conforms with protection

class IP67 (protection against shock and

foreign particles: dust proof, water protection: protected against the effects at temporary immersion in water).

The device with the order number

942 052-001 additionally offers an IP-based

Quality of Service function (QoS).

Order No.

OCTOPUS 5TX-EEC

943 892-001

942 052-001

Hirschmann. Simply a good Connection.

Page 2

2

The performance features described here

are binding only if they have been expressly

guaranteed in the contract. We have

checked that the contents of the technical

publication agree with the hardware and

software described. However, it is not possible to rule out deviations completely, so we

are unable to guarantee complete agreement. However, the details in the technical

publication are checked regularly. Any corrections which prove necessary are contained in subsequent editions. We are grateful

for suggestions for improvement.

We reserve the right to make technical

modifications.

Permission is not given for the circulation

or reproduction of this document, its use or

the passing on of its contents unless granted expressly. Contravention renders the

perpetrator liable for compensation for

damages. All rights reserved, in particular

in the case of patent grant or registration of

a utility or design.

Copyright

© Hirschmann

Automation and Control GmbH 2011

All Rights Reserved

Note

We would point out that the content of

these operating instructions is not part of,

nor is it intended to amend an earlier or existing agreement, permit or legal relationship. All obligations on Hirschmann arise

from the respective purchasing agreement

which also contains the full warranty conditions which have sole applicability. These

contractual warranty conditions are neither

extended nor restricted by comments in

these operating instructions.

We would furthermore point out that for

reasons of simplicity, these operating

instructions cannot describe every

conceivable problem associated with the

use of this equipment. Should you require

further information or should particular

problems occur which are not treated in

sufficient detail in the operating instructions, you can request the necessary information from your local Hirschmann sales

partner or directly from the Hirschmann

office (address: refer to chapter entitled

„Notes on CE identification“).

Safety Instructions

This manual contains instructions which

must be observed to ensure your own personal safety and to avoid

damage to devices and machinery. The

instructions are highlighted with a warning

triangle and are shown as

follows according to the degree of endangerment:

z

Danger!

means that death, serious injury or

considerable damage to property

will result if the appropriate safety

measures are not taken.

z

Warning!

means that death, serious injury or

considerable damage to property

can result if the appropriate safety

measures are not taken.

z

Caution!

means that light injury or damage to

property can result if the appropriate safety measures are not taken.

Note: is an important piece of information

about the product, how to use the product,

or the relevant section of the documentation to which particular attention is to be

drawn.

Certified usage

Please observe the following:

z

Warning

The device may only be employed

for the purposes described in the

catalog and technical description,

and only in conjunction with external

devices and components recommended or approved by Hirschmann.

The product can only be operated

correctly and safely if it is transported, stored, installed and assembled

properly and correctly. Furthermore,

it must be operated and serviced

carefully.

Safety Guidelines

Power Supply

z

Warning!

The devices may only be connected

to the supply voltage shown on the

type plate.

The devices are designed for operation with a safety extra-low voltage.

Thus, they may only be connected

to the supply voltage connections

with PELV circuits or alternatively

SELV circuits with the voltage

restrictions in accordance with

IEC/EN 60950-1.

䡺 For the case where the module is operated with external power supply: Use only a

safety extra-low voltage in accordance with

IEC/EN 60950-1 to power the system.

䡺 First of all you connect the ground

connection, before you establish the further

connections. When you remove connections, you disconnect the ground connection last.

䡺 The device does not contain any service

components. If the device is not functioning

correctly, or if it is damaged, switch off the

voltage supply and return the device to the

plant for inspection.

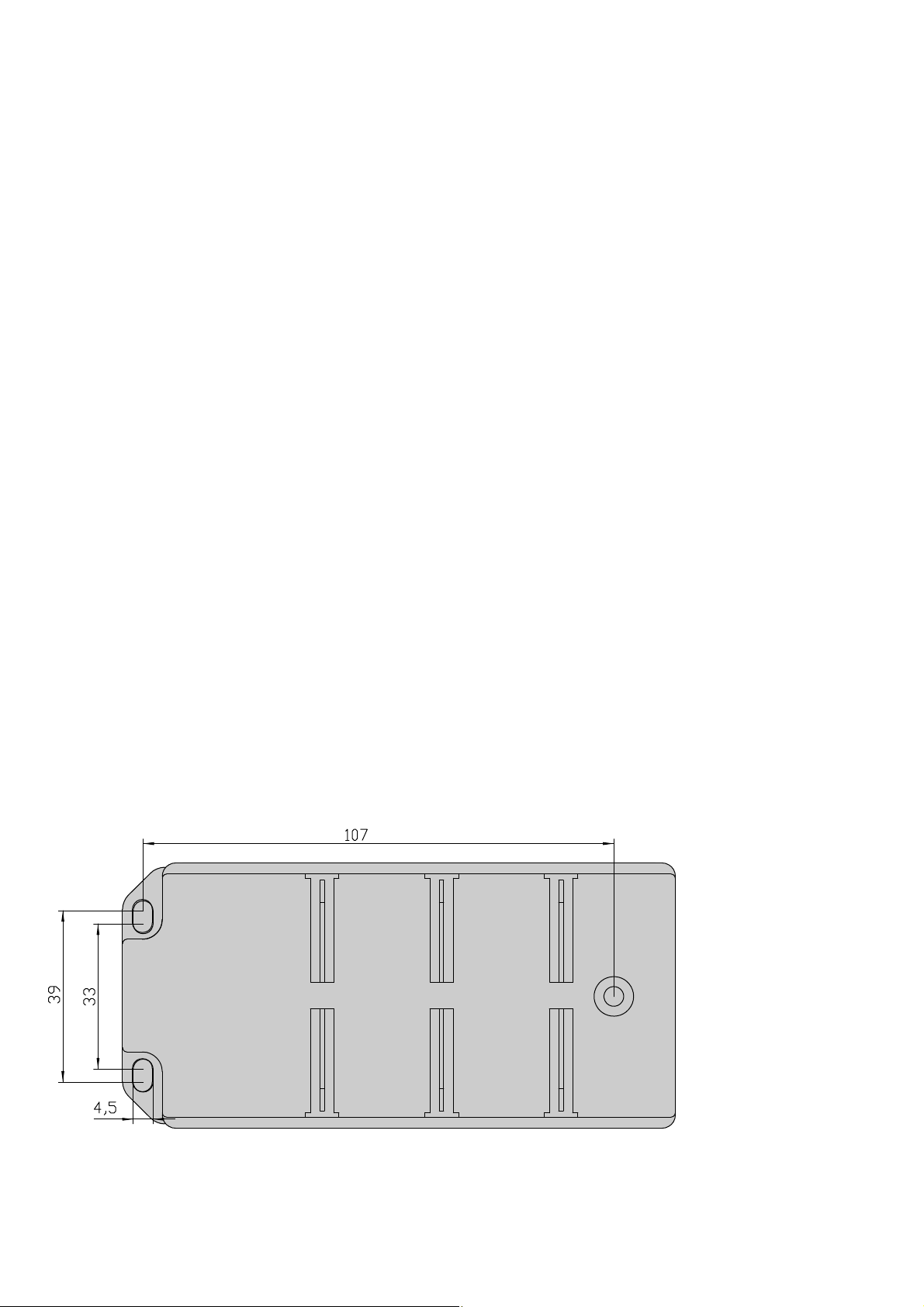

Fig. 1: Drilling template for assembling the OCTOPUS 5TX-EEC (dimensions in mm)

Page 3

3

z

Warning!

Failure to observe the information

given in the warnings could result in

serious injury and/or major damage.

Only personnel that have received

appropriate training should operate

this device or work in its immediate

vicinity. The personnel must be fully

familiar with all of the warnings and

maintenance measures in these

operating instructions.

Correct transport, storage, and

assembly as well as careful operation and maintenance are essential in

ensuring safe and reliable operation

of this device.

Use only undamaged parts!

䡺 These products are only to be used in

the manner indicated in this version of the

”Description and Operating Instructions”.

䡺 Particular attention is to be paid to all

warnings and items of information relating

to safety.

z

Warning!

Any work that may have to be performed on the electrical installation

should be performed by fully qualified technicians only.

Based specifications and

standards:

The devices fulfil the following

specifications and standards:

– EN 61000-6-2:2005 – Generic standards –

Immunity for industrial environments

– EN 55022:2006 + A1:2007 – Information

technology equipment – Radio disturbance characteristics

– EN 60950-1:2006 – Safety of Information

Technology Equipment (ITE)

– EN 61131-2:2007 – Programmable

Controllers

– FCC 47 CFR Part 15:2009 –

Code of Federal Regulations

– cUL 508:1998 – Underwriters Labratories

Inc. Safety for Industrial Control

Equipment.

The device has a certification based on a

specific standard only if the certification

indicator appears on the housing.

7

Notes on CE

identification

The devices comply with the regulations of the following European

directive:

2004/108/EC

Directive of the European Parliament and of the Council on the

approximation of the laws of the

member states relating to electromagnetic compatibility.

The EU declaration of conformity is

kept available for the responsible

authorities in accordance with the

above-mentioned EU directives at:

Hirschmann

Automation and Control GmbH

Stuttgarter Straße 45-51

D-72654 Neckartenzlingen

Telephone ++49-1805-14-1538

䡺 Relevant for North America:

The subject unit is to be suppplied by a

Class 2 power source complying with the

requirements of the National Electrical

Code, table 11(b). If power is redundant

supplied (two individual power sources) the

power sources together should comply with

the requirements of the National Electrical

Code, table 11 (b).

䡺 Relevant for North America:

Use 60/75°C or 75°C copper(CU)wire only.

Safety Guidelines

Shielding Ground

Note: The shielding of the twisted pair

wires which can be connected must be

grounded on the plug housing.

䡺 Beware of possible short circuits when

connecting a cable section with conductive

shielding braiding.

Safety Guidelines Housing

z

Warning!

Do not try to open the housing of

the device.

䡺 Make sure that the electrical installation

meets local or nationally applicable safety

regulations.

Open type UL listed product – intended to

be installed in a Type 1 or better enclosure.

Safety Guidelines Environment

z

Warning!

The device may only be operated in

the listed ambient temperature

range.

䡺 The installation location is to be selected so as to ensure compliance with the climatic limits listed in the Technical Data.

Staff qualification

requirements

Note: Qualified personnel, as understood

in this manual and in the warning signs, are

persons who are familiar with the setup,

assembly, startup, and operation of this

product and are appropriately qualified for

their job. This includes, for example, those

persons who have been:

– trained or directed or authorized to

switch on and off, to ground and to label

power circuits and devices or systems in

accordance with current safety engineering standards

– trained or directed in the care and use of

appropriate safety equipment in accordance with the current standards of safety

engineering

– trained in providing first aid.

General Safety Instructions

䡺 This device is electrically operated.

Adhere strictly to the safety requirements

relating to voltages applied to the device as

described in the operating instructions!

The product can be used in the industrial sphere.

– Interference immunity:

EN 61000-6-2:2005

– Radio interference level:

EN 55022:2006 + A1:2007, Class A

z

Warning!

This is a Class A device. This equipment may cause radio interference if

used in a residential area; in this

case it is the operator´s responsibility to take appropriate measures.

The precondition for compliance

with EMC limit values is strict adherence to the construction guidelines

specified in this description and

operating instructions.

FCC Note:

This device complies with part 15 of FCC

rules. Operation is subject to the following

two conditions : (1) This device may not

cause harmful interference; (2) this device

must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found

to comply with the limits for a Class A digital device, persuant to part 15 of the FCC

Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in

a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction

manual, may cause harmful interference to

radio communications. Operation of this

equipment in a residential area is likely to

cause harmful interference in which case

the user will be required to correct the interference at his own expense.

,

Recycling Note:

After its use, this product has to be

processed as electronic scrap and

disposed of according to the prevailing waste disposal regulations of

your community, district, country and

state.

Page 4

4

1. Functional description

The 10/100BASE-T(X) ports of an OCTOPUS

5TX-EEC represent a terminal connection

for the connected LAN segment. You can

connect single devices or complete network

segments.

1.1 FRAME SWITCHING FUNCTIONS

Store and Forward

All data received by the OCTOPUS 5TX-EEC

from the system bus or at the ports are stored and checked for validity. Invalid and

defective frames (> 1.522 byte or CRC error)

as well as fragments (< 64 byte) are discarded. The OCTOPUS 5TX-EEC forwards the

valid frames.

Multi address capability

An OCTOPUS 5TX-EEC learns all source

addresses per port. Only packets with

– unknown addresses

– addresses learnt at this port

– a multi/broadcast address

in the destination address field are sent to

this port.

An OCTOPUS 5TX-EEC learns up to 1,000

addresses. This becomes necessary if more

than one terminal device is connected to

one or more ports. In this way several independent subnetworks can be connected to

an OCTOPUS 5TX-EEC.

Learnt addresses

An OCTOPUS 5TX-EEC monitors the age of

the learned addresses. The OCTOPUS 5TXEEC deletes address entries from the

address table which exceed a certain age

(300 seconds).

Note: Restarting deletes the learned

address entries.

Tagging (IEEE 802.1Q)

The IEEE 802.1 Q standard designates the

VLAN tag to be included in a MAC data

frame for the VLAN and prioritizing functions. The VLAN tag consists of 4 bytes (2

bytes tag protocol identifier TPID, 2 bytes

tag control information TCI). It is inserted

between the source address field and the

type field. Data packets with VLAN tag are

transmitted unchanged by the OCTOPUS

5TX-EEC.

Quality of Service, IP-based (QoS)

Note: Exclusively the device with the order

number 942 052-001 offers this function.

The device assigns IP packets according to

a DSCP value to different traffic classes.

This function is hard-coded.

DSCP means DiffServ-Codepoint. This is a

field in the IP header which markes the individual IP packets according to traffic classes.

The device supports 2 traffic classes:

It assigns packets with DSCP values ranging

from 0 to 23 to the traffic class 0 (low priority) and packets with values ranging from 24

to 63 to traffic class 1 (high priority).

The device transmits the packets according

to the Strict Priority rule:

First, the device transmits all high prioritypackets. When there are no high priority

packets left, the device starts transmitting

the packets with low priority.

1.2 SPECIFIC FUNCTIONS OF THE

TP/TX INTERFACE

Link control

The OCTOPUS 5TX-EEC monitors the

connected TP line segments for short-circuit

or interrupt using regular link test pulses in

accordance with IEEE standard 802.3

10BASE-T/ 100BASETX. The OCTOPUS 5TXEEC does not transmit any data to a TP segment from which it does not receive a link

test pulse.

Note: A non-occupied interface is assessed

as a line interrupt. The TP line to terminal

equipment which is switched off is likewise

assessed as a line interrupt as the deenergised bus coupler cannot transmit link

test pulses.

Auto polarity exchange

If the receive line pair is incorrectly connected (RD+ and RD- switched) polarity is automatically reversed.

Autonegotiation

Autonegotiation is a procedure in which the

switch automatically selects the operating

mode of its 10/100 RJ-45 ports. When a

connection is set up for the first time, the

switch detects the speed (10 or 100 Mbit/s)

and the transmission mode of the connected network (half duplex or full duplex).

Autocrossing

The OCTOPUS 5TX-EEC detects the transmit and receive pairs (MDI, MDI-X). The

OCTOPUS 5TX-EEC automatically configures its port for the correct transmit and

receive pins. Consequently it does not matter whether you connect devices using a

cross-over or straight cable.

1.3 FURTHER FUNCTIONS

AND FEATURES

Reset

The OCTOPUS 5TX-EEC will be reset by the

following action:

– input voltages fall below a threshold

After a reset the following action is carried

through:

– initialization

1.4 DISPLAY ELEMENTS

Equipment status

These LEDs provide information about

statuses which affect the function of the

entire OCTOPUS 5TX-EEC.

P – Power

– lit green: – supply voltage present

Port Status

These LEDs display port-related

information.

DA/STAT 1 to 5 – Data, Link status

– not lit: – no valid link

– lit green: – valid link

– flashes green: – receiving data

1.5 INTERFACES

10/100 Mbit/s connection (TP port)

M12 socket (4-pin)

Five 10/100 Mbit/s ports (4-pin shielded M12

socket with D coding) allow the connection

of data terminal equipment or independent

network segments conforming to the IEEE

802.3 100BASE-TX / 10BASE-T standard.

These ports support auto negotiation and

the auto polarity function.

The shielding of the twisted pair wires

which can be connected must be grounded

on the plug housing of the M12 connector.

– Pin configuration of the M12 socket:

– pin 1: TD+ Transmit Data +

– pin 2: RD+ Receive Data +

– pin 3: TD- Transmit Data – pin 4: RD- Receive Data – housing: shield

Fig. 3: Pin configuration of an TP/TX

interface (M12 socket)

Power supply connector

M12 connector (5-pin)

The power for the OCTOPUS 5TX-EEC is

supplied via a 5-pin M12 connector (A

coding). Typically, the supply voltage is

+24 V DC. It is electrically isolated from the

function

ground.

– Pin assignment of the M12 connector:

– pin 1: input voltage +

– pin 2: not assigned

– pin 3: input voltage – pin 4: not assigned

– pin 5: function ground

Fig. 4: Pin assignment of the M12 connector

(power supply connector)

z

Warning!

The devices are designed for operation with a safety extra-low voltage.

Thus, they may only be connected

to the supply voltage connections

with PELV circuits or alternatively

SELV circuits with the voltage

restrictions in accordance with

IEC/EN 60950-1.

"

!

#

Fig. 2: Overview display elements and interfaces of the OCTOPUS 5TX-EEC

OCTOPUS 5TX

DA/STAT DA/STAT

DA/STAT DA/STAT

P

DA/STAT

Five 4-pin M12 sockets

(twisted pair ports 1 to 5)

5-pin M12 connector

(power supply

connector)

LED display

Power

LED display elements

per port

Page 5

5

3. Assembly, startup procedure

and dismantling

3.1 UNPACKING, CHECKING

䡺 Check whether the package was deliver-

ed complete (see scope of delivery).

䡺 Check the individual parts for transport

damage.

z

Warning!

Use only undamaged parts!

3.2 ASSEMBLY

The equipment is delivered in a ready-tooperate condition.

To protect the exposed contacts of the components still to be installed from dirt, the

individual system components must be

connected in a dry and clean area.

Ports which are not assigned are to be

closed with the covering caps contained in

the scope of delivery.

Note: Connectors are not electrical isolating devices. Therefore, first plug the

connector to the power supply plug and

then switch on the power supply.

The following sequence is the best for

assembly:

䡺 Prepare assembly at the installation site:

drill holes at the installation site

䡺 Mechanical assembly at the installation

site

䡺 Electrical connection with peripheral

devices

䡺 Connect the signal lines with the twisted

pair ports

Assembly:

– Fit the module on a level surface with

three M4x16 screws.

– Provide a low impedance ground connec-

tion via the clips at the screen plate, either

by mounting directly on a conductive sur-

face or by the additional connection of a

ground wire to a fastening strap on the

screen plate. Use toothed locking washers

for a good electrical connection.

– Voltage supply: The supply voltage is

electrically isolated from the housing.

Ground

The device is grounded via the fixing screws

of the chassis or via the pin 5 of the power

supply connector.

We recommend the grounding via the fixing

screws.

2. Configuration

2.1 CONNECTING DTE AND OTHER

NETWORK SEGMENTS

It is possible to connect up to five data terminal equipment (DTE) or other network

segments to the 10/100 Mbit/s ports of the

OCTOPUS 5TX-EEC using twisted pair cabling (ref. Fig. 5).

2.2 PATCH CABLES

To operate the IP67 switch, use patch cables

as shown in Figs. 5 and 6.

Notes:

– Use a shielded CAT5 cable.

– Use a shielded 4-pin M12 connector.

– Connect the cable shield to the connector

housing.

– You only need one M12-M12 patch cable

version.

Fig. 6: Patch cables for operating the

OCTOPUS 5TX-EEC

RX+

TX+

RXTX-

Shield

M12, MDI

1

2

3

4

S

TX+

RX+

TXRX-

Shield

M12

1

2

3

4

S

RX+

RXTX+

TX-

Shield

RJ45, MDI-X

1

2

3

6

S

TX+

RX+

TXRX-

Shield

M12

1

2

3

4

S

TX+

TXRX+

RX-

Shield

RJ45, MDI

1

2

3

6

S

TX+

RX+

TXRX-

Shield

M12

1

2

3

4

S

4

3

2

1 Connection M12 <-> M12, MDI-X

Connection M12 <-> M12, MDI

Connection M12 <-> RJ45, MDI-X

Connection M12 <-> RJ45, MDI

2

3

4

TX+

RX+

TXRX-

Shield

M12, MDI-X

1

2

3

4

S

TX+

RX+

TXRX-

Shield

M12

1

2

3

4

S

1

A drilling template at a scale of 1:1 for

marking the drilling holes can be found on

page 2, Fig. 1.

Connection:

– The protection class IP67 is only achieved

when bolted together.

– Empty slots must be sealed with the pro-

tective caps supplied.

Notes on wiring:

In keeping with the general installation

regulations, ensure that the signal and

power lines > 60 V are laid separately (cable

duct, clamps). The signal and 24 V supply

voltage lines should be laid off the module

as straight as possible.

Notes on strain relief:

Provide sufficient strain relief and secure

cable fastening for all connected wiring.

3.3 STARTUP PROCEDURE

䡺 You start up the OCTOPUS 5TX-EEC by

connecting the supply voltage via the 5-pin

M12 connector.

4. Further support

In the event of technical queries, please talk

to the Hirschmann contract partner responsible for looking after your account or

directly to the Hirschmann office. You can

find the addresses of our contract partners

on the Internet:

www.beldensolutions.com.

Our support line is also at your disposal:

Tel. +49(1805) 14-1538

Fax +49(7127) 14-1551

Answers to Frequently Asked Questions can

be found on the Hirschmann internet site

(www.beldensolutions.com) at the end of

the product sites in the FAQ category.

The current training courses to technology

and products can be found under

www.hicomcenter.com.

Fig. 5: Possible network configuration with the IP67 switch OCTOPUS 5TX-EEC

1

1

Rail switch,

e.g. RS2-5TX

x

RS2-5TX

i

X

1

2 3

4 5

IP67 switch

OCTOPUS

Data terminal

device

SPS

IP67 switch

OCTOPUS

OCTOPUS 5TX

DA/STAT DA/STAT

DA/STAT DA/STAT

P

DA/STAT

OCTOPUS 5TX

DA/STAT DA/STAT

DA/STAT DA/STAT

P

DA/STAT

2 or 3 2 or 3

Page 6

5. Technical data

General data

Operating voltage

Rated voltage range DC 12 V DC to 24 V DC Safety extra-low voltage (SELV)

Relevant for North America: NEC Class 2 power source max. 5 A

Max. voltage range DC min. 9.0 V DC to max. 32 V DC

(Not applicable under UL regulations)

Buffer time min. 10 ms at 20.4 V DC

Potential difference between input Potential difference to input voltage, +24 V DC: 32 V DC

voltage and housing Potential difference to input voltage, ground: -32 V DC

Current consumption at 24 V DC 2.4 W maximum; 8.2 Btu (IT)/h

Dimensions W x H x D 60 mm x 126 mm x 31 mm

Weight 210 g

Ambient temperature Surrounding air - 40 ºC to + 85 ºC

Note: Following UL508 requirements the ambient temperature is restricted to 60 °C.

Storage temperature Surrounding air - 40 ºC to + 85 ºC

Atmospheric pressure up to 2000 m (795 hPa, higher altitudes on demand)

Protection type IP 67, according to EN 60529

Protection against shock and foreign particles Full shock protection, impenetrable to dust

Water protection Protected against water penetration, during submersion under

specified pressure and time conditions

Interference proof

Discharge of static electricity

Contact discharge EN 61000-4-2 Test level 2

Air discharge EN 61000-4-2 Test level 3

Electromagnetic fields EN 61000-4-3 Test level 3

Fast transients EN 61000-4-4 Test level 3

Surge voltage symmetrical EN 61000-4-5 Test level 2

Surge voltage asymmetrical EN 61000-4-5 Test level 3

Cable-based RF faults EN 61000-4-6 Test level 3

EMC emitted immunity

EN 55022 Class A

FCC 47 CFR Part 15 Class A

Stability

Vibration IEC 60068-2-6 Test FC, testing level in line with EN 61131-2:2007

Shock IEC 60068-2-27 Test Ea, testing level in line with EN 61131-2:2007

Certifications

cUL 508 / CSA 22.2 No.14-M91 E175531

Network size

TP port 10BASE-T/100BASE-TX

Length of a twisted pair segment 100 m (328 ft) maximum

Interfaces

5 TP ports M12 sockets (4-pin, D coding), 10/100 MBit/s

Displays

Equipment status 1 x green LED P – power, supply voltage present

Port status 5 x green LEDs DA/STAT – data, link status

Scope of delivery

IP67 Switch OCTOPUS 5TX-EEC incl. covers for sealing unused ports

labels, description and operating instructions

Order number

IP67 Switch OCTOPUS 5TX-EEC 943 892-001

IP67 Switch OCTOPUS 5TX-EEC with QoS 942 052-001

Accessories

Pocket Guide 280 710-851

Hirschmann Automation and Control GmbH

Stuttgarter Straße 45-51

D-72654 Neckartenzlingen

Germany

Tel.: ++49 / 1805 / 14-1538

Fax: ++49 / 7127 / 14-1551

E-Mail: HAC.Support@Belden.com

Internet: http://www.beldensolutions.com

Printed in Germany

Subject to alterations

Loading...

Loading...