Page 1

iFLEX TRS 14

Transceiver

for wireless sensors

Contents

Safety instructions

1

Product description

2

Installation

3

Commissioning

4

Configuration

5

Service and maintenance

6

Technical data

7

User manual

Issue A - 08/2010

This document has the order no.

21-810-19-0003_421830_en

Page 2

TABLE OF CONTENTS

1 Safety instructions...........................................................................................6

1.1 EU conformity declaration ............................................................................8

2 Product description .......................................................................................10

2.1 General .......................................................................................................10

2.2 Product features .........................................................................................11

2.3 Use for the intended purpose .....................................................................11

2.4 Scope of supply ..........................................................................................11

2.5 View of device.............................................................................................12

2.6 Dimensions .................................................................................................13

3 Installation.......................................................................................................14

3.1 Mounting the components ..........................................................................14

3.1.1 iFLEX TRS 14 ....................................................................................14

3.1.2 Magnetic base antenna......................................................................14

3.2 Electrical connection...................................................................................15

3.2.1 Wiring of the central connector ..........................................................16

3.2.2 Wiring of the connecting cable...........................................................16

4 Commissioning...............................................................................................17

4.1 Switching the device on..............................................................................17

4.2 Status LEDs................................................................................................19

4.3 Opening/closing the housing ......................................................................20

4.4 Preconfiguration of the output signals (current/voltage).............................22

5 Configuration..................................................................................................23

5.1 Overview of functions .................................................................................24

5.2 Registering a wireless sensor.....................................................................25

5.3 Deleting wireless sensors...........................................................................27

5.4 Setting the signal range..............................................................................28

5.5 Adjusting the zero point (load/angle sensor only) ......................................30

5.6 Erasing the EEPROM.................................................................................31

5.7 Setting the angle range (angle sensor only)...............................................32

6 Service and maintenance..............................................................................33

7 Technical data.................................................................................................34

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 2/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 3

Tables and illustrations

Table 1 Overview of wireless sensors ................................................................. 10

Table 2 Overview of status LED .......................................................................... 19

Table 3 Overview of signal ranges ...................................................................... 28

Figure 1: View of the iFLEX TRS 14.................................................................... 12

Figure 2: Dimensions of the iFLEX TRS 14 (with magnetic base antenna) ........13

Figure 3: Magnetic base antenna (art. no.536023) with mounted radiator..........14

Figure 4: Pin configuration of the central connector ............................................ 16

Figure 5: Wiring of the connecting cable ............................................................. 16

Figure 6: View of the programming button ..........................................................23

VERSION OVERVIEW

Issue Date Description Editor

A 2010-08-31 First issue, translation of the german original issue A Konopka

HIRSCHMANN Automation and Control GmbH

Hertzstr. 32-34, 76275 Ettlingen, phone +49 (0)7243-709-0

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 3/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 4

Introduction

INTRODUCTION

This manual is a component of the equipment or system supplied by Hirschmann Automation and

Control GmbH. Keep this manual in a safe place and ensure that it is available to all users.

About this manual

The contents of this manual are subject to change. Hirschmann Automation and Control GmbH

does not provide any guarantee for this material, including the associated guarantee regarding

marketability and suitability for certain intended purposes. Hirschmann Automation and Control

GmbH accepts no liability for errors in the contents of the manual or for direct or indirect damage in

connection with the provision and use of the manual.

Liability disclaimer

This manual is protected by copyright. All rights reserved. The manual may not be duplicated, reproduced or translated into another language, either wholly or partly, without the prior written permission of Hirschmann Automation and Control GmbH.

Copyright

notice

The rendition of common names, trade names, trademarks etc. in this documentation should not be

construed to mean that such names, even without special identification, are free in the sense of

trademark and trademark protection legislation and hence usable by anyone.

Trademarks

This device / system is intended exclusively for the tasks described in this manual. Any other use

shall be construed as being inappropriate. The manufacturer accepts no liability for damage caused

by inappropriate or impermissible use. This device / system may only be used if it is in perfect technical condition.

Use for the intended

purpose

Only appropriately qualified personnel may work with this device / system, i.e. persons:

Qualification of the

operating personnel

who are familiar with the operation or installation and commissioning

who know the current regulations for the prevention of accidents

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 4/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 5

Introduction

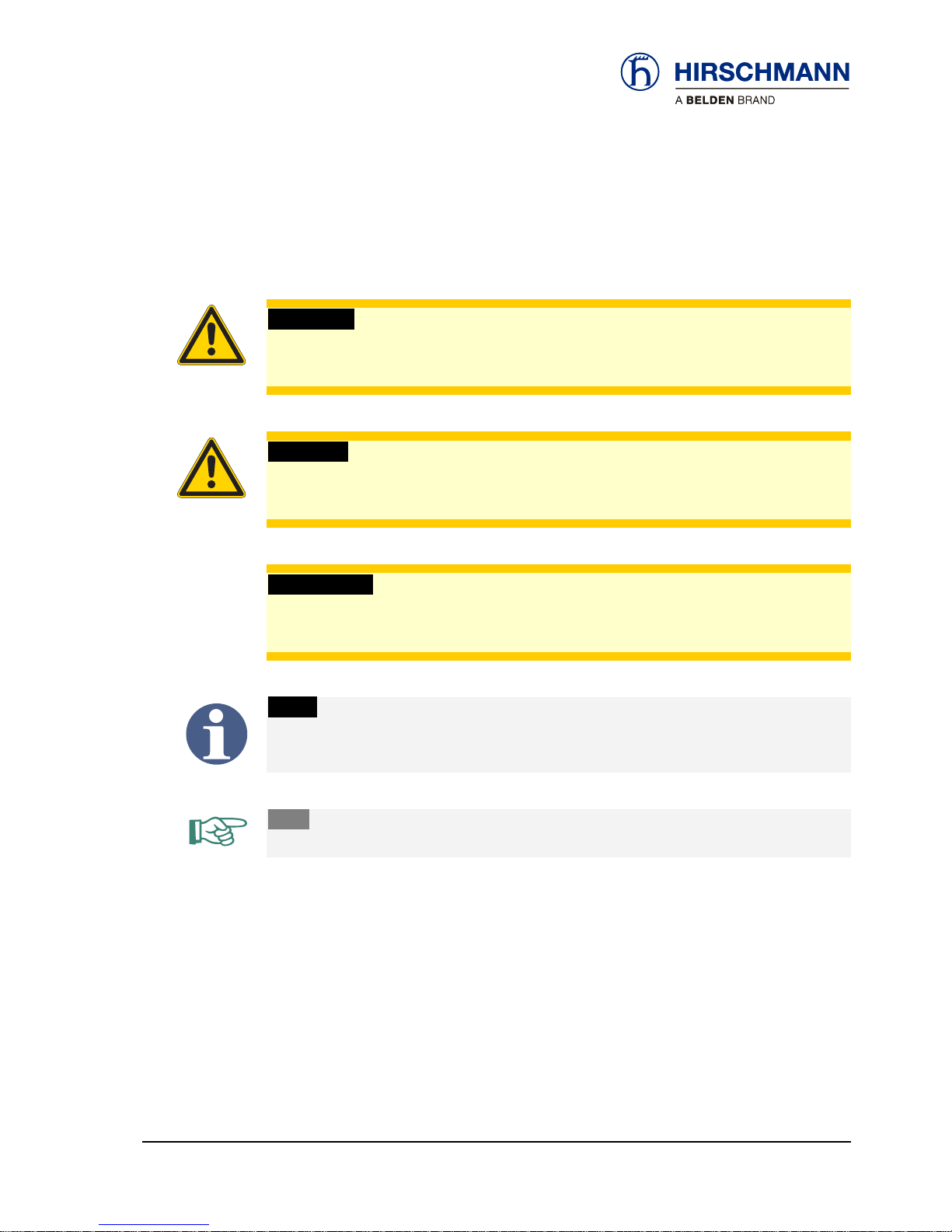

Marking of notices

Dangers and other important notices are marked as follows in this user manual:

WARNING

Warning of direct threat of personal injury and damage to property.

Instructions on precautions to avert the danger.

CAUTION

Warning of dangerous situations. Also warns of damage to property.

Instructions for averting the danger.

IMPORTANT

Warning of possibly damaging situation for the product.

Instructions for avoiding the possibly damaging situation.

NOTE

Usage instructions and information, but no dangerous situation.

HINT

Supplementary comments and recommendations for the user.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 5/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

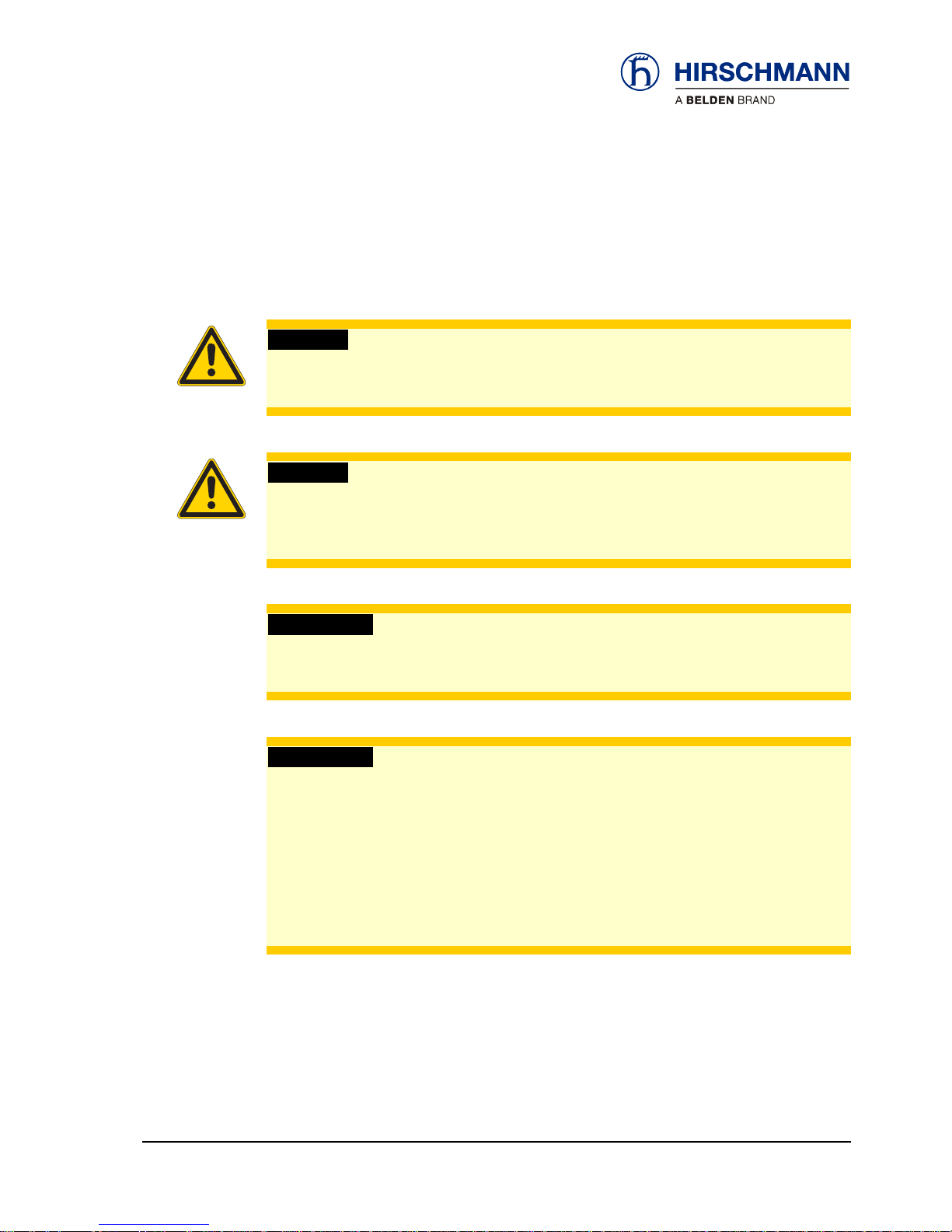

Page 6

Safety instructions

1 Safety instructions

In order to avoid possible personal injuries and damage to property when using this device, it is

essential to observe the following safety instructions:

CAUTION

Danger of electrical short-circuits.

Switch off all systems before commencing with the installatio n work!

CAUTION

Danger due to the inadvertent registration of a nearby wireless sensor.

Make sure that the batteries of other wireless sensors are not changed during a registration

procedure on an iFLEX TRS 14.

IMPORTANT

Damage to the device if connected to an unsuitable power supply.

The device may only be connected to a DC voltage source of 10 V to 30 V!

IMPORTANT

Damage to the equipment due to non-compliance with the regulations for the handling of

equipment containing electrostatically sensitive devices (ESDs):

Pay attention to the following instructions if the device has to be opened during commissioning:

• Discharge yourself (e.g. by touching an earthed object) before opening the device

• Hold the printed circuit board only by the edges

• Do not touch components or connector pins or tracks

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 6/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 7

Safety instructions

IMPORTANT

Impairment of the system function due to the use of an unsuitable anten na radiator.

Always use the antenna radiator included in the scope of supply!

IMPORTANT

Impairment of the system function or breaching of radio transmission regulations by the use

of components or extensions not approved by the manufacturer.

Use exclusively components or extensions that are intended and approved by the manufacturer.

IMPORTANT

Possible impairment of the radio link/range in direct proximity to antenna systems with a

high HF transmission power.

The device must not be used in the direct proximity of radar systems or transmitters (e.g.

radio, TV, mobile telephone etc.) or close to power supply systems.

IMPORTANT

Damage to the device due to the penetration of water and dirt.

Never clean the device with a high pressure cleaner!

Have damage to the decorative foil repaired professionally without delay!

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 7/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 8

Safety instructions

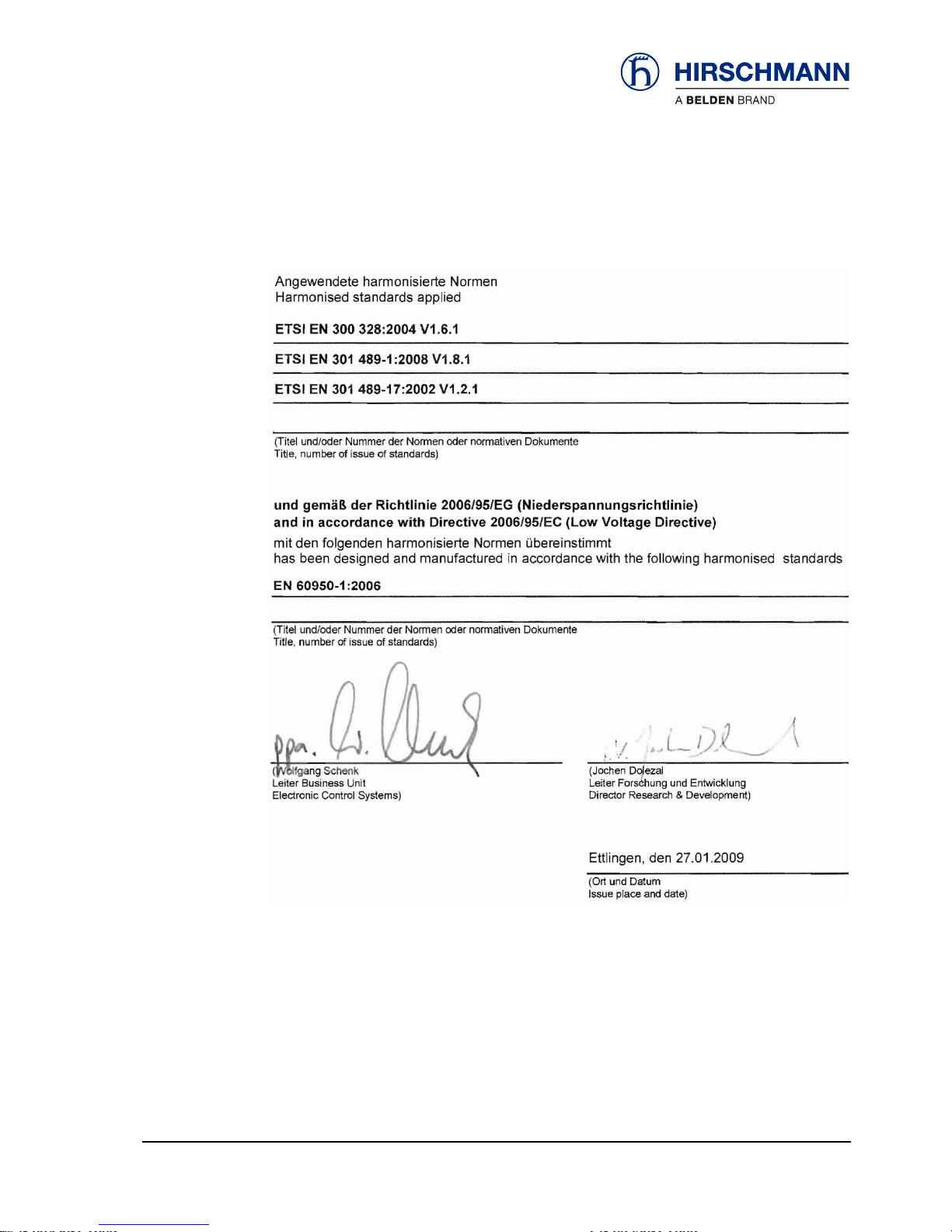

1.1 EU conformity declaration

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 8/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 9

Safety instructions

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 9/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 10

Product description

2 Product description

2.1 General

The iFLEX TRS 14 is a transceiver for the wireless coupling of wireless sensors from the Hirschmann xSENS-xxx-W1 family.

Up to 4 wireless sensors can be connected wirelessly to a single iFLEX TRS 14. The number of

wireless sensors can be extended as required by the employment of several transceivers.

How many sensors

can be connected?

All sensors from the xSENS-xxx-W1 family from Hirschmann’s extensive range of wireless sensors

can be used.

(the article numbers given on the right refer in each case to the sensors including accessories)

Application Product designation

Which wireless sen-

sors can be used?

Article no.

(set)

Load

measurement

fSENS KMD-006-W1 (up to 6 t)

Art. no. 605792

alternatively also

fSENS KMD-020-W1 (up to 20 t)

Art. no. 606345

Angle

measurement

gSENS WGF-W1 (0 to 90°)

Art. no. 608016

e.g. for boom angle measurement

or

gSENS WGS-W1 (-15 to +15°)

Art. no. 608185

for inclination measurement

Wind

measurement

iSENS WSS-W1

608179

Hoist limit

monitoring

(A2B)

iSENS HES-W1

Art. no. 608015

608180

Table 1 Overview of wireless sensors

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 10/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 11

Product description

2.2 Product features

The iFLEX TRS 14 is characterised by the following features:

Wireless coupling of up to four wireless sensors from the xSENS-xxx-W1 family

Registration of a wireless sensor to the receiver at the push of a button

Relay output for hoist limit signal

Four analog signal outputs (configurable for current/voltage)

Status LEDs for signalling various operating conditions

Monitoring of the battery condition of the connected wireless sensors

Self-diagnostic function

Sensor calibration by radio command

Protection class IP65, hence also suitable for outdoor use

Operating temperature -40 to +85 °C

Voltage supply 10 to 30 V DC

2.3 Use for the intended purpose

The iFLEX TRS 14 is a transceiver for the transmission of sensor data collected wirelessly from up

to four radio sensors from the xSENS-xxx-W1 family.

Configurable signal outputs make universal adaptation possible. Because of possible impairment of

radio communication/range in direct proximity to antenna systems with a high HF transmission

power, the device must not be used in the direct proximity of radar systems or transmitters (e.g.

radio, TV, mobile telephone etc.) or close to power supply systems.

2.4 Scope of supply

The scope of supply of the iFLEX TRS 14 with accessories (art. no. 608177) consists of the following parts:

iFLEX TRS 14

Magnetic base antenna with 4 m connecting cable

Antenna radiator

Connecting cable, 4,7 m, with prefabricated central plug at one end

User manual on CD

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 11/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 12

Product description

2.5 View of device

Operating

status

Indicators for

registered wireless sensors

channels 1 to 4

Indicator for

hoist limit

signal

Indicator for

weak sensor

battery

channels 1 to 4

Coaxial socket

for antenna

Central plug

Figure 1: View of the iFLEX TRS 14

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 12/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 13

Product description

2.6 Dimensions

Figure 2: Dimensions of the iFLEX TRS 14 (with magnetic base antenna)

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 13/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 14

Installation

3 Installation

3.1 Mounting the components

The iFLEX TRS 14 is supplied complete with all accessories required for operation. Mounting can

therefore be performed simply and quickly. For mounting the wireless sensors, please refer to the

instructions provided with the respective sensor.

3.1.1 iFLEX TRS 14

The iFLEX TRS 14 must be mounted in a suitable place on a sufficiently firm surface with the connections at the bottom. The device may be used both indoors and outdoors and is to be mounted

such that the LEDs are visible.

The distance between the holes in the housing is 102 mm.

3.1.2 Magnetic base antenna

Antenna radiator 2.4 GHz

Antenna base

Magnetic baseplate

Figure 3: Magnetic base antenna (art. no. 536023) with mounted radiator

First of all, screw the antenna radiator

hand tight onto the thread on the top side of the antenna

base until you feel a stop. (Remove the protective cap from the thread if necessary).

Preparation of the

antenna

The antenna has a magnetic baseplate and adheres securely to all ferromagnetic surfaces thanks

to its strong magnet.

How do I mount the

antenna?

NOTE

Optimal ranges are achieved if the antenna is aligned in accordance with the alignment of

the wireless sensor antennas and can radiate as freely as possible.

Niches or recesses are therefore less suitable as mounting locations!

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 14/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 15

Installation

Please follow the instructions below for laying the antenna cable:

How should the

cable be laid?

IMPORTANT

The antenna cable can be damaged if it is squeezed or kinked.

Therefore, lay the antenna cable in such a way that it is neither squeezed nor laid around

sharp edges!

IMPORTANT

The function of the antenna and hence the whole system can be impaired if a mismatch in g

antenna radiator is used.

Always use the antenna radiator contained in the scope of supply!

After laying the cable, connect the coaxial connector of the antenna to the antenna socket on the

underside of the iFLEX TRS 14. Screw the connector on hand tight.

Where is the an-

tenna

connected?

3.2 Electrical connection

Connection of the device is simple thanks to the connecting cable (4,7 m), which is prefabricated at

one end and included in the scope of supply. The open cable end is to be connected properly using

wire end ferrules. Please refer to the following illustrations for the wiring of the connecting cable and

the pin configuration of the central plug.

CAUTION

Danger of electrical short-circuits.

Switch off all systems before commencing with the installatio n work!

IMPORTANT

Damage to the device if connected to an unsuitable power supply.

The device may only be connected to a DC voltage source of 10 V to 30 V!

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 15/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 16

Installation

3.2.1 Wiring of the central connector

Please refer to the following illustration for the pin configuration of the connector on the underside

of the iFLEX TRS 14 (top view):

Pin 1 +VDC (10 to 30 V)

Pin 2 GND

Pin 3 Ground

Pin 4 Signal output, Sensor 1

Pin 5 Ground

Pin 6 Signal output, Sensor 2

Pin 7 Ground

Pin 8 Signal output, Sensor 3

Pin 9 not connected

Pin 10 Signal output, Sensor 4

Pin 11 Relay output, hoist limit switch:

open in hoist limit condition

+U

B

if no hoist limit condition

or if no hoist limit switch exists

Pin 12 not connected

B

Figure 4: Pin configuration of the central connector

3.2.2 Wiring of the connecting cable

The cable contained in the scope of supply is prefabricated at one end with the central plug. The

open cable end must be wired according to the following illustration. The external screen should be

connected if possible:

Length:

4,7 m

Figure 5: Wiring of the connecting cable

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 16/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 17

Commissioning

4 Commissioning

At least one functional wireless sensor must be available in order to commission and operate the

system.

A guide to commissioning and configuring the signal outputs of the iFLEX TRS 14 and connecting

the wireless sensors is provided below.

NOTE

During the initial commissioning and the necessary registratio n of the wireless sensors, it is

useful if these are not yet mounted, but are available close to the iFLEX TRS14.

4.1 Switching the device on

After wiring the iFLEX TRS 14, the device switches itself on as soon as the supply voltage is present. The red ‘Power’ LED lights up. After switching on, the system begins with a self-diagnostic

routine.

How is the device

switched on?

The self-diagnosis takes approx. 3 seconds. During these tests the ‘Info’ LED additionally flashes

and the remaining LEDs light up in succession with a test pattern:

How long does the

self-diagnosis take?

LED key: off: lights: flashes slowly: flashes rapidly:

If no wireless sensors have been registered yet, only the ‘Power’ LED should be lit after completion

of the self-diagnosis:

How can I tell

whether the device is

working correctly?

If wireless sensors have already been registered, the ‘Online’ LED of the respective channel additionally lights up, indicating that the radio link has been established.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 17/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 18

Commissioning

If a ‘Low Battery’ LED lights up, this means that the battery set in the respective wireless sensor is

exhausted (remaining capacity < 6,5 %) and must be replaced as soon as possible.

Which does it mean

when the ‘Low Batt’

LED lights up?

If the ‘INFO’ LED lights up, this means that one of the connected wireless hoist limit switches has

reported ‘hoist limit’. At the same time, the relay contact opens and there is no voltage at the signal

output. The LED may also light up briefly after the iFLEX TRS 14 is switched on, until the radio link

to the registered hoist limit switches has been established. If the LED remains lit, this means that

the radio link to a registered wireless hoist limit switch is interrupted. In this case the ‘Online’ LED

assigned to the respective channel also flashes.

What does it mean

when the ‘Info’ LED

lights up?

The flashing of an ‘ONLINE’ LED after conclusion of the self-diagnosis means that either the radio

link with the registered wireless sensor on the indicated channel is interrupted, or, in conjunction

with the lighting up of the ‘INFO’ LED, that a wireless hoist limit switch on the indicated channel is in

‘sleep’ mode. This mode is activated automatically if the hoist limit switch remains in the hoist limit

condition for a lengthy period of time. This function serves to reduce the power requirement of the

hoist limit switch. The function is reset automatically upon the next switching of the hoist limit

switch.

What does it mean

when an ‘Online’

LED flashes?

NOTE

If the link to a wireless sensor is interrupted, rectify the fault first before putting the system

into operation.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 18/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 19

Commissioning

4.2 Status LEDs

There are 10 LEDs on the front panel of the device, which indicate the status of various operating

conditions.

The meaning of the signals can be taken from the table below. The signals apply only to normal

operation; deviating signals apply to programming mode:

off:

lights:

flashes:

No supply

voltage present

Supply voltage is

present

Hoist limit switch has

triggered

or

radio link to a wire-

less hoist limit switch

interrupted

During the system diagnosis

No sensor

registered to

this channel

Sensor registered to

this channel and

ready for operation

During the registration of new

wireless sensors

or

hoist limit switch on the indi-

cated channel is in ‘sleep’ mode

or

link with the sensor on the indi-

cated channel is interrupted

Batteries of the wire-

less sensor on this

channel are almost

exhausted!

(capacity < 6.5 %)

Replace the batter-

ies soon!

Table 2 Overview of status LED

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 19/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 20

Commissioning

4.3 Opening/closing the housing

It is necessary to open the housing of the iFLEX TRS 14 in order to configure the output signals

and the radio link by means of the programming button and jumpers as described below.

First of all, disconnect the device from the power supply by pulling out the central plug.

IMPORTANT

Damage to the equipment due to non-compliance with the regulations for the handling of

equipment containing electrostatically sensitive devices (ESDs):

Pay attention to the following instructions if the device has to be opened during commissioning:

• Discharge yourself (e.g. by touching an earthed object) before opening the device

• Hold the printed circuit board only by the edges

• Do not touch components or connector pins or tracks

Follow the procedure described below to open the housing:

Open the housing

HINT

A flat-blade screwdriver with a blade width of 4.5 - 5.5 mm is best suited for opening the

housing.

▲ 1. By means of a slight twisting movement of the

screwdriver, press the latches (on both sides of the

housing at the rear) carefully towards the housing

and in this way unlock the circuit board

▲ 2. The housing seal will be visible if the circuit

board has been unlocked correctly

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 20/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 21

Commissioning

▲ 3. Carefully pull the circuit board out of the

housing

▲ 4. View of the programming button and the

jumpers (in this case for channel 1) on the circuit

board

Follow the procedure described below to close the housing:

Close the housing

▲ 1. Carefully slide the circuit board into the guide

rails in the housing.

Make sure that the foam strip is positioned as

shown.

▲ 2. Lock the circuit board by applying strong pres-

sure to the underside of the housing (clearly audible

click at both sides).

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 21/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 22

Commissioning

4.4 Preconfiguration of the output signals (current/voltage)

The analog signal outputs (channels 1 to 4) are commonly preconfigured in the factory as 4-20 mA

current outputs. If necessary the signal outputs can also be commonly configured as voltage outputs.

NOTE

The signal outputs (channels 1 to 4) can be commonly configured either as current outputs

or as voltage outputs. A mixed configuration is not possible!

The conversion is made by changing the jumpers on the circuit board and subsequently selecting

the signal range via the programming button. These elements are only accessible after opening

the device. (See chapter

4.3)

How can the outputs

be configured as

voltage outputs?

The jumpers for configuring the output signals are located above the LEDs for the corresponding

channels 1 - 4:

Jumper

Now set the jumpers identically for each channel according to the sketch below:

▲ Jumper setting

for current outputs

(standard)

▲ Jumper setting

for voltage outputs

NOTE

If you have configured the signal outputs as voltage outputs, it is also necessary to select

the signal range. (See chapter 5.4)

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 22/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 23

Configuration

5 Configuration

Wireless sensors are registered or deleted and further device configuration functions are performed

by pressing the programming button for a certain length of time whilst observing the visual confirmation via the LEDs.

The programming button is located inside the housing of the device and is only accessible after

opening the housing. (To open the housing, see chapter

4.3)

Programming

button

Figure 6: View of the programming button

When doing this, pay attention to the safety instructions for the handling of subassemblies containing electrostatically sensitive devices (ESDs). (See safety instructions in Chapter

1)

In order to select a certain function, press and hold the programming button until the desired function is signalled by the LEDs. Then release the programming button. Distinction must thereby be

made between flashing and steadily lit LEDs.

The programming cycle is circular and requires approx. 71 seconds for a complete circuit.

How are the func-

tions selected?

In order to exit from the programming cycle, you can either go through the cycle until the end or

briefly remove the central plug. Settings that have already been made will be retained.

How can I exit from

the programming

mode?

An overview of the functions that can be called via the programming button can be found below:

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 23/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 24

Configuration

5.1 Overview of functions

Function selection Display from to

Register wireless sensor

… to channel 1

LED 1, green, flashes

3 6

… to channel 2 LED 2, green, flashes 6 9

… to channel 3 LED 3, green, flashes 9 12

… to channel 4

LED 4, green, flashes 12 15

Delete wireless sensor

… from channel 1

LED 1, green, lights steadily

16 19

… to channel 2 LED 2, green, lights steadily 19 22

… to channel 3 LED 3, green, lights steadily 22 25

… to channel 4

LED 4, green, lights steadily 25 28

Set signal range A

(for all outputs)

All green LEDs flash

29 32

signal range B… all green LEDs light steadily 33 36

signal range C … All yellow LEDs flash 37 40

signal range D …

all yellow LEDs light steadily 40 43

Sensor calibration

(load/angle)

… on channel 1

LED 1, green and yellow, flash

43 46

… to channel 2 LED 2, green and yellow, flash 46 49

… to channel 3 LED 3, green and yellow, flash 50 53

… to channel 4

LED 4, green and yellow, flash 53 56

Erase EEPROM LED 1, yellow, flashes 56 59

Set angle range of angle

sensor

…to -15° to 15°(gSENS WGS)

LED 2, yellow, flashes

59 63

…to 0° to 90°(gSENS WGF) LED 3, yellow, flashes 63 66

- no function assigned -

LED 4, yellow, flashes 67 70

Menu end All LEDs off 71

A detailed description of the functions with which the device can be configured is provided below.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 24/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 25

Configuration

5.2 Registering a wireless sensor

Every wireless sensor to be used (maximum 4) must be registered once to the iFLEX TRS 14

for operation.

What needs to be

observed?

The common use of angle sensors gSENS WGF-W1 and gSENS WGF-W1 is not possible.

The wireless sensor does not need to be registered again following a battery change.

Re-registration is necessary after exchanging a wireless sensor.

Wireless sensors that are not to be used any longer must be deleted and deactivated by re-

moving the batteries.

CAUTION

Danger due to the inadvertent registration of a nearby wireless sensor.

Make sure that the batteries of other wireless sensors are not changed during a registration

procedure on an iFLEX TRS 14.

Follow the procedure described below to register a wireless sensor.

The wireless sensor should be no more than 1 metre away from the iFLEX TRS 14 during the

registration phase.

Connect the iFLEX TRS 14 to the power supply again. (See also Chapter 4.1)

HINT

Keep a fresh set of batteries at the ready for the registration.

▲ 1. First of all, open the battery compartment of

the wireless sensor to be registered by undoing the

cover screws and removing the cover of the battery

compartment.

▲ 2. Remove the batteries

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 25/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 26

Configuration

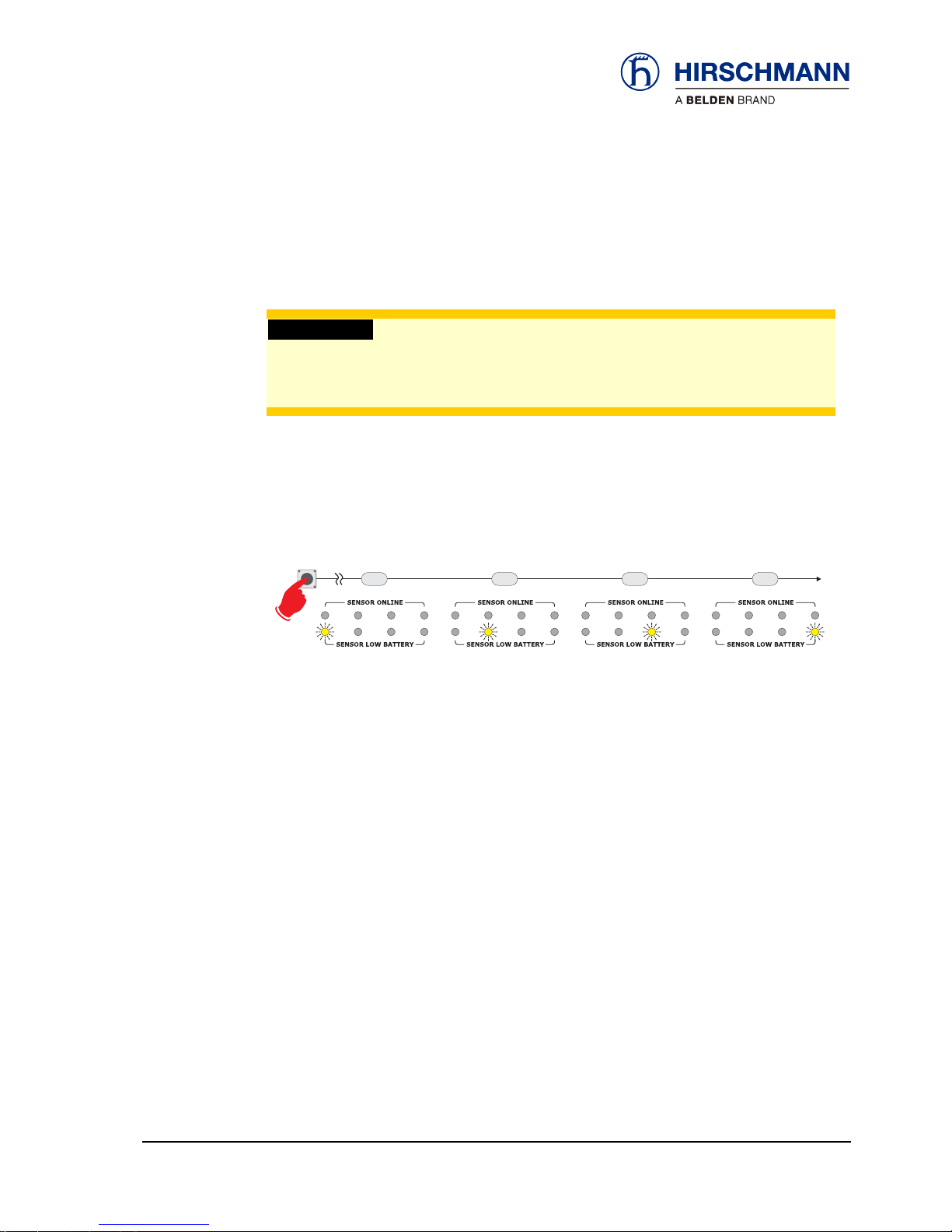

3s 6s 9s 12s

anmelden an Kanal 1 anmelden an Kanal 2 anmelden an Kanal 3 anmelden an Kanal 4

▲ 3. Press and hold the programming button of the iFLEX TRS14 until:

- Online LED1 flashes (for the registration of a wireless sensor to channel 1)

- Online LED2 flashes (for the registration of a wireless sensor to channel 2)

- Online LED3 flashes (for the registration of a wireless sensor to channel 3)

- Online LED4 flashes (for the registration of a wireless sensor to channel 4)

and then release the button.

▲ 4. Now insert the batteries into the battery com-

partment of the wireless sensor to be registered,

observing the correct polarity.

▲ 5. Observe the LED on the underside of the

housing. This should light up with short pulses. Now

fit the cover of the battery compartment.

▲ 6. The wireless sensor is registered correctly if

the respective Online LED lights steadily (in this

case e.g. channel 1).

If a wireless hoist limit switch has been registered:

Now pull on the rope of the wireless hoist limit switch

for 5 secs. The system is working perfectly if the

‘INFO’ LED extinguishes within this time. The wireless sensor is now ready to be mounted.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 26/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 27

Configuration

5.3 Deleting wireless sensors

Wireless sensors that are not to be used any longer must be deleted and deactivated by removing

the batteries.

Follow the procedure described below to delete a wireless sensor.

1. Open the housing of the iFLEX TRS 14 as described in chapter 4.3.

16s 19s 22s 25s

abmelden von Kanal 1 abmelden von Kanal 2 abmelden von Kanal 3 abmelden von Kanal 4

▲ 2. Press and hold the programming button of the iFLEX TRS14 until:

- Online LED1 lights steadily (for the deletion of a wireless sensor from channel 1)

- Online LED2 lights steadily (for the deletion of a wireless sensor from channel 2)

- Online LED3 lights steadily (for the deletion of a wireless sensor from channel 3)

- Online LED4 lights steadily (for the deletion of a wireless sensor from channel 4)

and then release the button.

The wireless sensor is deleted as soon as the respective ‘Online’ LED has extinguished.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 27/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 28

Configuration

5.4 Setting the signal range

After preselecting the signal outputs (current/voltage) via the jumpers (see chapter 4.4), it is then

also necessary to select the signal range.

An overview of the possible signal outputs for the different types of sensor can be found in the table

below. The signal outputs are all preconfigured in the factory to signal range B (current 4 to 20mA).

Select a desired signal range and note the assigned letter A to D

Signal range Type of sensor Output signal Error from

fSENS KMD-xxx-W1 load cell 0…2,5V [0…45000 lb] 5V

gSENS WGF-W1 angle sensor -3,125…-1,875V [0…90°] -3,14V

gSENS WGS-W1 inclination sensor 0,5…4,5V [-15…+15°] 5V

A

(voltage)

iSENS WSS-W1 anemometer 1,8…9,0V [0…50 mph] 9V

fSENS KMD-xxx-W1 load cell 4…20mA [0…45000 lb] 24mA

gSENS WGF-W1 angle sensor 20…4mA [0…90°] 24mA

gSENS WGS-W1 inclination sensor 4…20mA [-15…+15°] 24mA

B

(current)

standard

iSENS WSS-W1 anemometer 4…20 mA [0…50 mph] 24mA

fSENS KMD-xxx-W1 load cell 1,8…9,0V [0…45000 lb] 9V

gSENS WGF-W1 angle sensor 1,8…9,0V [0…90°] 9V

gSENS WGS-W1 inclination sensor (not defined) -

C

(voltage)

iSENS WSS-W1 anemometer 1,8…9,0V [0…50 mph] 9V

fSENS KMD-xxx-W1 load cell 0…2,5V [0…45000 lb] 5V

gSENS WGF-W1 angle sensor +3,125…+1,875V [0…90°] 3,14V

gSENS WGS-W1 inclination sensor (not defined) -

D

(voltage)

iSENS WSS-W1 anemometer 1,8…9,0V [0…50 mph] 9V

Table 3 Overview of signal ranges

Conversion: 1 lb(US) = 0,453kg 1 mph = 1,61 km/h

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 28/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 29

Configuration

Follow the procedure described below to set the signal range.

1. Open the housing of the iFLEX TRS 14 as described in chapter 4.3.

29s 33s 37s 40s

Auswahl Signalbereich A Auswahl Signalbereich B Auswahl Signalbereich C Auswahl Signalbereich D

▲ 2. Press and hold the programming button of the iFLEX TRS14 until:

- all green LEDs flash (for signal range A)

- all green LEDs light steadily (for signal range B)

- all yellow LEDs flash (for signal range C)

- all yellow LEDs light steadily (for signal range D)

and then release the button.

The selected signal range is set as soon as the button is released.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 29/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 30

Configuration

5.5 Adjusting the zero point (load/angle sensor only)

If load and angle sensors are connected, this function can be used to make subsequent small corrections to the zero point.

Follow the procedure described below in order to adjust the zero point.

1. Open the housing of the iFLEX TRS 14 as described in chapter 4.3.

43s 46s 50s 53s

abgleichen Sensor an Kanal 1 abgleichen Sensor an Kanal 2 abgleichen Sensor an Kanal 3 abgleichen Sensor an Kanal 4

▲ 2. Press and hold the programming button of the iFLEX TRS14 until:

- green and yellow LED1 flash (for adjustment of a sensor on channel 1)

- green and yellow LED2 flash (for adjustment of a sensor on channel 2)

- green and yellow LED3 flash (for adjustment of a sensor on channel 3)

- green and yellow LED4 flash (for adjustment of a sensor on channel 4)

and then release the button. The previously flashing LEDs are now lit steadily.

The device remains in the ‘zero point adjustment’ mode.

3. Now press the programming button of the iFLEX TRS14 again, several times if necessary, until:

- the INFO LED lights up (for adjustment in the positive direction)

- the INFO LED extinguishes (for adjustment in the negative direction)

and keep the button depressed until the desired zero point is reached.

The ‘zero point adjustment’ mode can only be terminated by disconnecting the central plug.

The previously set values thereby remain stored.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 30/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 31

Configuration

5.6 Erasing the EEPROM

Using this function, all stored registration and configuration data can be deleted and the factory

settings restored.

IMPORTANT

Danger due to inadvertent deletion of all registration and configuration data!

Only use this function if you really want to delete all configuration data!

Follow the procedure described below in order to erase the EEPROM:

1.

Open the housing of the iFLEX TRS 14 as described in chapter 4.3.

56s 59s 63s 67s

EEProm löschen Winkelbereich -15...+15° Winkelbereich 0...90° (keine Bedeutung)

▲ 2. Press and hold the programming button of the iFLEX TRS14 until:

- the yellow LED 1 flashes

and then release the button.

The EEPROM is erased as soon as the button is released.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 31/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 32

Configuration

5.7 Setting the angle range (angle sensor only)

If an angle sensor is connected, this function is used to define the type of sensor being used.

Follow the procedure described below in order to adjust the angle range.

1. Open the housing of the iFLEX TRS 14 as described in chapter 4.3.

56s 59s 63s 67s

EEProm löschen Winkelbereich -15...+15° Winkelbereich 0...90° (keine Bedeutung)

▲ 2. Press and hold the programming button of the iFLEX TRS14 until:

- the yellow LED 2 flashes (for selection of angle range -15 to +15°, gSENS WGS-W1)

- the yellow LED 3 flashes (for selection of angle range 0 to +90°, gSENS WGF-W1)

and then release the button.

The angle range is set as soon as the button is released.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 32/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 33

Service and maintenance

6 Service and maintenance

The iFLEX TRS 14 transceiver does not contain any serviceable parts. The micro-fuse inside the

device is self-resetting and therefore does not need to be exchanged. If you notice malfunctions,

you should switch the device off and have it checked and, if necessary, repaired immediately by an

authorised Hirschmann service partner.

Clean the surface of the equipment occasionally with a damp cloth using a mild cleaning agent.

However, you should never use abrasive or alcohol-based cleaning agents, as these can damage

the housing or the front foil!

IMPORTANT

Damage to the front foil can lead to the penetration of moisture and dirt into the interior of

the device.

Never clean the device with a high pressure cleaner! Have damage to th e fro nt foil rep aired

professionally without delay!

Keep the contact area of the device plug and the antenna connector clean and occasionally check

that the connections are tight.

Occasionally check the connecting cable and antenna cable as well as the antenna itself. If parts

are damaged, these must be repaired properly or replaced immediately.

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 33/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 34

Technical data

7 Technical data

Article designation iFLEX TRS 14

Article number 608177 (complete with accessories, see scope of supply)

Operating voltage 10 - 30 V DC

Fuse Self-resetting internal fuse, 500 mA

Transmission frequency 2.45 GHz, ISM band, licence-free and exempt from duty

IEEE 802.15.4 standard, DSSS /OQPSK modulated

Class1 radio system in accordance with FTEG and 1999/5/EC

(R&TTE)

Antenna 2.4 GHz, with magnetic base and screwed on antenna radiator,

4m connecting cable, RP-SMA plug

Range approx. 300 m (depending upon environmental conditions)

CE conformity ETSI EN 300 328

ETSI EN 301 489-1

ETSI EN 300 489-17

EN 60950-1

FCC conformity FCC 47 CFR Part 15, Radio Frequency Devices, Subpart B

Control elements 1 programming button (inside the device),

jumpers for the configuration of the signal outputs

Displays 10 Status LEDs for signalling various operating conditions

Electrical connection Central connector (German) 12-pole (on underside of device)

Signal outputs 4 analog outputs,

commonly configurable for current/voltage,

signal range commonly adjustable

1 relay contact,

switches to +U

b

when hoist limit is triggered

Antenna connection RP-SMA, coaxial (on the underside of the device)

Dimensions H 134 mm x W 118,2 mm x D 36,3 mm

Weight 0,258 kg (device only)

Distance between mounting holes 102,1 mm

Operating temperature range -40 ºC to +85 ºC

Storage temperature range -50 ºC to +85 ºC

Protection class IP 65

Scope of supply iFLEX TRS 14 with accessories:

- Magnetic base antenna with 4 m connecting cable

- Antenna radiator 2.4 GHz band

- Connecting cable, 4.5 m, partly prefabricated

- User manual on CD

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 34/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 35

Feedback

Feedback

What is your opinion about this manual? We always try to describe the products fully in our manuals, as well as providing important background knowledge to ensure trouble-free operation.

We take the task of continuous improvement and reduction of errors very seriously. Your comments

and suggestions help us to increase the quality and level of information for this document.

Your assessment of this manual:

excellent good satisfactory so-so poor

Accuracy O O O O O

Readability O O O O O

Ccomprehensibility O O O O O

Examples O O O O O

Structure / Layout O O O O O

Completeness O O O O O

Illustrations / Images O O O O O

Drawings, Diagrams O O O O O

Tables O O O O O

Did you discover errors in this manual?

If so, on which side?

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 35/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 36

Feedback

Suggestions for improvement and additional information:

General comments:

Sender:

Company / Department

Name / Phone

Street

Zip code / City

Date / Signature

Dear user,

please complete and return both pages of this feedback:

via fax to: +49 (0)7243 709 3222

via mail to: Hirschmann Automation and Control GmbH

Documentation

Hertzstr. 32-34

76275 Ettlingen / Germany

Thank you !

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 36/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Page 37

Notes

© 2010 Hirschmann Automation and Control GmbH · Branch Office Ettlingen · E-mail: info.ecs@hirschmann.de 37/37

21-810-19-0003_421830_en (Rev A).doc / 2010-08-31 / Issue A / rk.

Loading...

Loading...