Page 1

LOAD MOMENT INDICATOR

iFLEX5

vertical/horizontal console

HIRSCHMANN

OPERATOR’S MANUAL

P/N 031-300-190-147 REV E- 11/12/2008

Page 2

Page 3

NOTICE

PAT America, Inc. makes no warranty of any kind with regard to this material, including, but not limited

to, the implied warranties of merchantability and/or its fitness for a particular purpose.

PAT America, Inc. will not be liable for errors contained in this manual or for incidental or

consequential damages in connection with the furnishing, performance, or use of this manual. This

document contains proprietary information, which is protected by copyright, and all rights are reserved.

No part of this document may be photocopied, reproduced, or translated to another language without

the prior written consent of PAT America, Inc.

PAT America, Inc. reserves proprietary rights to all drawings, photos and the data contained therein.

The drawings, photos and data are confidential and cannot be used or reproduced without the written

consent of PAT America, Inc. The drawings and/or photos are subject to technical modification

without prior notice.

All information in this document is subject to change without notice.

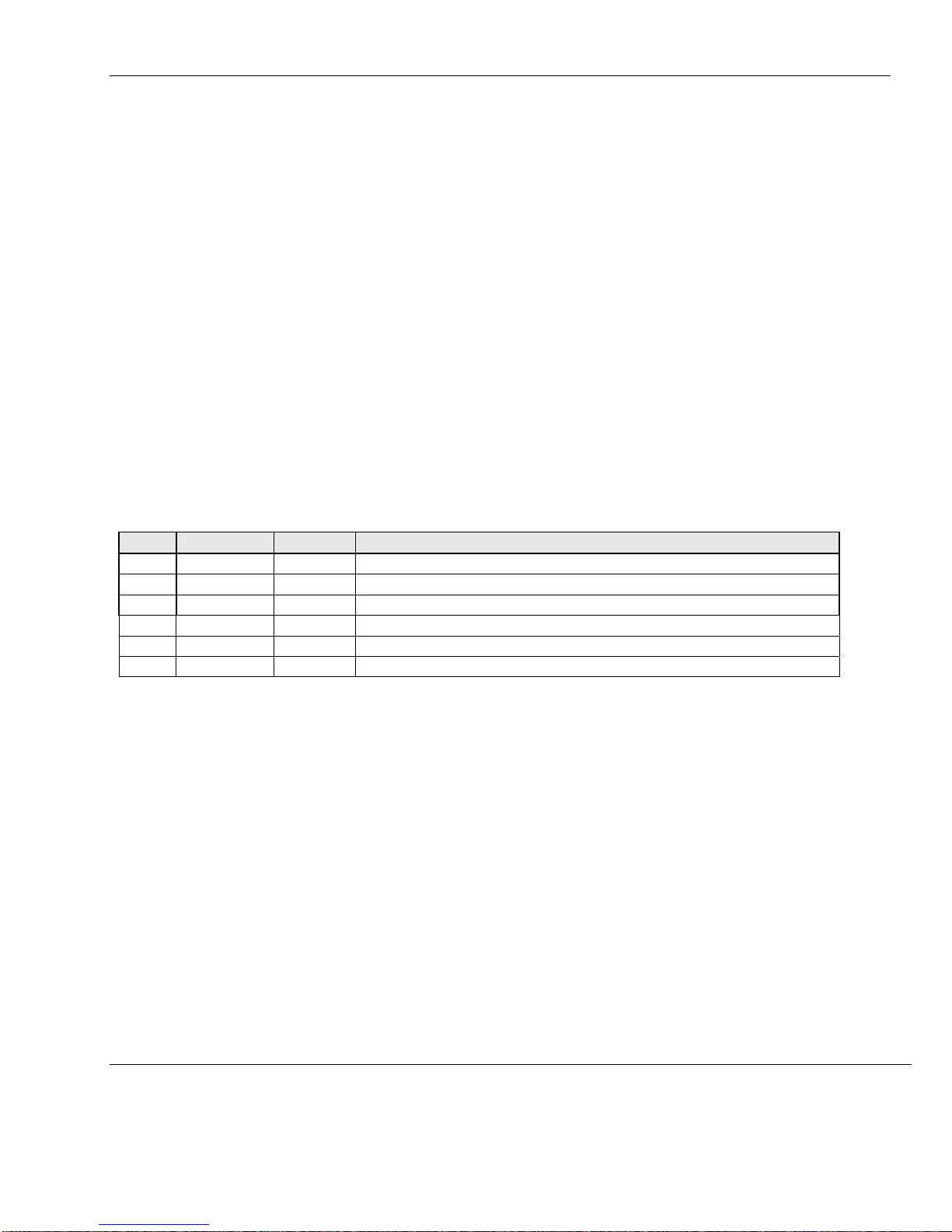

MANUAL REVISIONS

REV DATE NAME DESCRIPTION

- 2/22/02 MO ECN 02-64

A 11/11/02 CH ECN 02-278

B 05/19/03 SB ECN 03-065

C 02/22/05 MS ECN 05-041

D 01/06/06 SB ECN 05-217

E 11/12/08 WG ECN 08-179

© 2006 Hirschmann, Chambersburg, PA 17201, USA

© Hirschmann Rev. E 11/12/08 190147_E

Page 4

Page 5

Operator's Manual iFLEX5

TABLE OF CONTENTS

1 GENERAL INFORMATION.............................................................................................................1

2 WARNINGS.....................................................................................................................................1

3 SYSTEM DESCRIPTION ................................................................................................................2

3.1 SYSTEM FUNCTION ........................................................................................................................4

3.2 OPERATING CONSOLE ...................................................................................................................5

3.3 CONTROL IDENTIFICATION..............................................................................................................5

4 CONFIGURATION SETUP ...........................................................................................................11

4.1 LMI SETUP PROCEDURE..............................................................................................................11

4.2 QUICK SETTING OF THE REEVING .................................................................................................15

4.3 QUICK HOIST LINE SELECTION.....................................................................................................16

5 OPERATION ................................................................................................................................. 17

5.1 LIMIT SETTING .............................................................................................................................20

5.1.1 Slewing Angle Limitation / Work Area Definition...........................................................21

5.1.2 Tip Height Limitation ........................................................................................................26

5.1.3 Boom Angle Limitation.....................................................................................................27

5.1.4 Radius Limitation..............................................................................................................29

5.1.5 Wind Speed .......................................................................................................................30

5.2 INFO CRANE CONFIGURATION ......................................................................................................31

5.3 DISPLAY CONTRAST CONTROL.....................................................................................................32

6 PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION.....................................33

6.1 MACHINES WITH ONLY A MAIN HOIST............................................................................................33

6.2 MACHINES WITH MAIN AND AUXILIARY HOISTS .............................................................................33

6.3 INSTALLATION OF ANTI TWO-BLOCK RETAINER IN LOCKING POSITION..........................................34

6.4 REMOVAL AND STORAGE OF THE ANTI TWO-BLOCK RETAINER.....................................................34

6.5 PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION ....................................................35

7 SERVICE AND MAINTENANCE................................................................................................... 36

8 TROUBLESHOOTING ..................................................................................................................37

8.1 GENERAL ....................................................................................................................................37

8.2 MALFUNCTION TABLE ..................................................................................................................37

8.3 OPERATING ERRORS ...................................................................................................................38

9 APPENDIX A: DETAILED SYMBOL EXPLANATION OF BOOM EXTENSIONS ....................... 40

10 APPENDIX B:DETAILED SYMBOL EXPLANATION OF COUNTERWEIGHT OPTIONS....... 41

© Hirschmann Rev. E 11/12/08 190147_E

Page 6

Page 7

General Information

1 GENERAL INFORMATION

1

The PAT Load Moment Indicator

1

(LMI) has been designed to provide the crane operator with

the essential information required to operate the machine within its design parameters.

Using different sensing devices, the Load Moment Indicator monitors various crane functions

and provides the operator with a continuous reading of the crane’s capacity. The readings

continuously change as the crane moves through the motions needed to make the lift.

The LMI provides the operator with information regarding the length and angle of the boom,

working radius, rated load and the total calculated weight being lifted by the crane.

If non permitted conditions are approached, the Load Moment Indicator will warn the operator

by sounding an audible alarm, lighting a warning light and locking out those functions that may

aggravate the crane’s condition.

2 WARNINGS

The LMI is an operational aid that warns a crane operator of approaching overload conditions

and of overhoist conditions that could cause damage to equipment and personnel.

The device is not, and shall not, be a substitute for good operator judgment, experience and use

of accepted safe crane operating procedures.

The responsibility for the safe crane operation shall remain with the crane operator who shall

ensure that all warnings and instructions supplied are fully understood and observed.

Prior to operating the crane, the operator must carefully and thoroughly read and understand

the information in this manual to ensure that he knows the operation and limitations of indicator

and crane.

Proper functioning depends upon proper daily inspection and observance of the operating

instructions set forth in this manual. Refer to Section 6. Pre-Operation Inspection and

Calibration Verification of this handbook.

The LMI can only work correctly, if all adjustments have been properly set. For correct

adjustment, the operator has to answer thoroughly and correctly all questions asked

during the setup procedure in accordance with the real rigging state of the crane. To

prevent material damage and serious or even fatal accidents, the correct adjustment

of the LMI has to be ensured before starting the crane operation.

1

LOAD MOMENT: generally the product of a force and its moment arm; specifically, the product of the load and the load-radius. Used in the

determination of the lifting capacity of a crane

© Hirschmann Rev. E 11/12/08 190147_E

Page 8

2

Operator's Manual iFLEX5

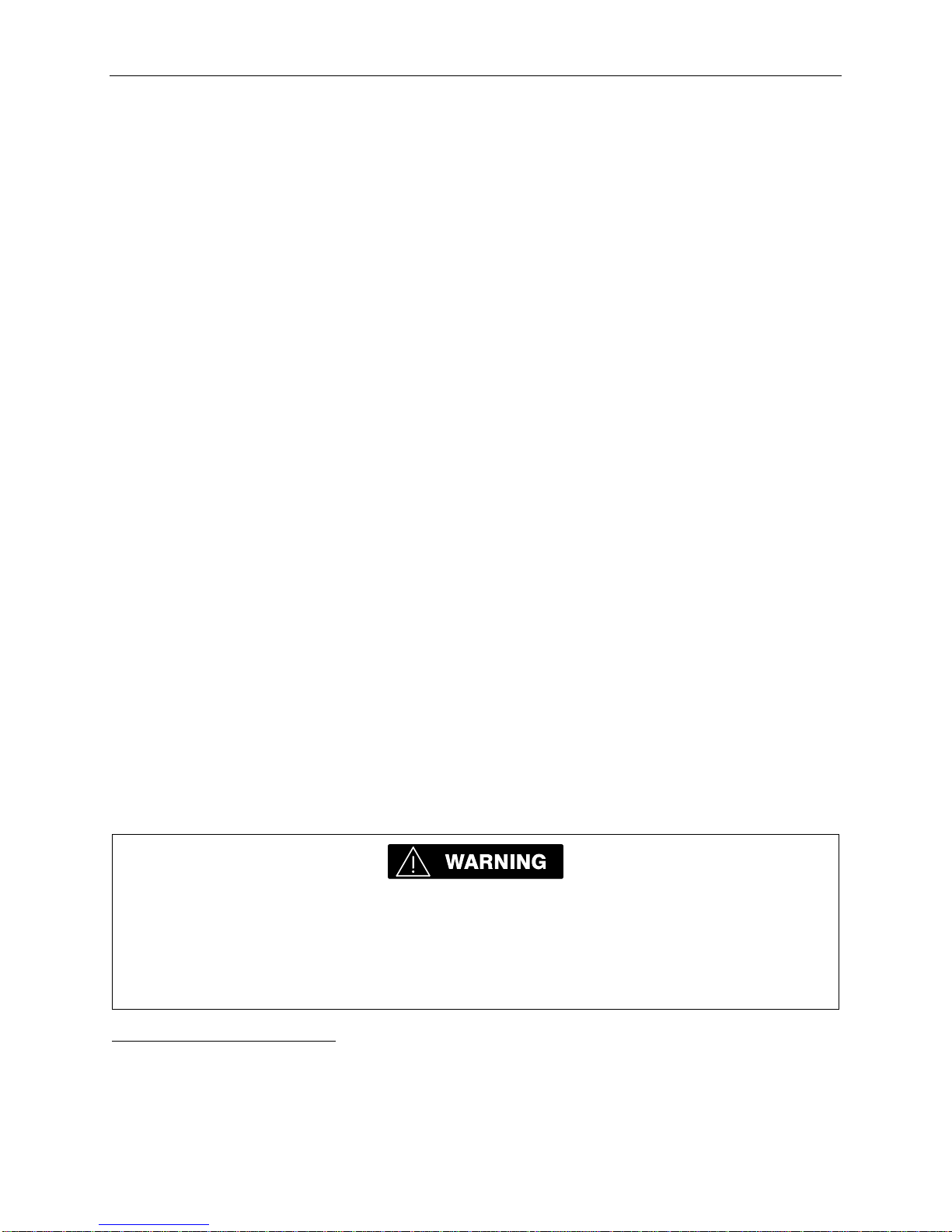

3 SYSTEM DESCRIPTION

The PAT Load Moment Indicator consists of a central micro processor unit, operating console,

length/angle sensor, pressure transducers, and anti-two block switches.

The system operates on the principle of reference/real comparison. The real value, resulting

from the pressure measurement is compared with the reference data, stored in the central

processor memory and evaluated in the micro processor. When limits are reached, an overload

warning signal is generated at the operator’s console. At the same time, the aggravating crane

movements, such as hoist up, telescope out and boom down, will be stopped.

The fixed data regarding the crane, such as capacity charts, boom weights, centers of gravity

and dimensions are stored in memory chips in the central processor unit. This data is the

reference information used to calculate the operating conditions.

Boom length and boom angle are registered by the length/angle sensor, mounted inside the

cable reel which is mounted on the boom. The boom length is measured by the cable reel cable

which also serves as an electrical conductor for the anti two-block switches.

The crane load is measured by pressure transducers attached to the piston and rod side of the

hoist cylinders.

The interactive user guidance considerably simplifies the input of operating modes as well as

the setting of geometry limit values.

© Hirschmann Rev. E 11/12/08 190147_E

Page 9

System Description

Fig. 1: Components of the LMI system PAT iFLEX5

3

PAT

1 Central-Micro-Processor U nit

2 Operating Console

3 Pressure Transducers

4 Length/Angle Sensor

5 Anti Two-Block Switch(es)

POWER

LOCKOUT

OTHER

© Hirschmann Rev. E 11/12/08 190147_E

Page 10

4

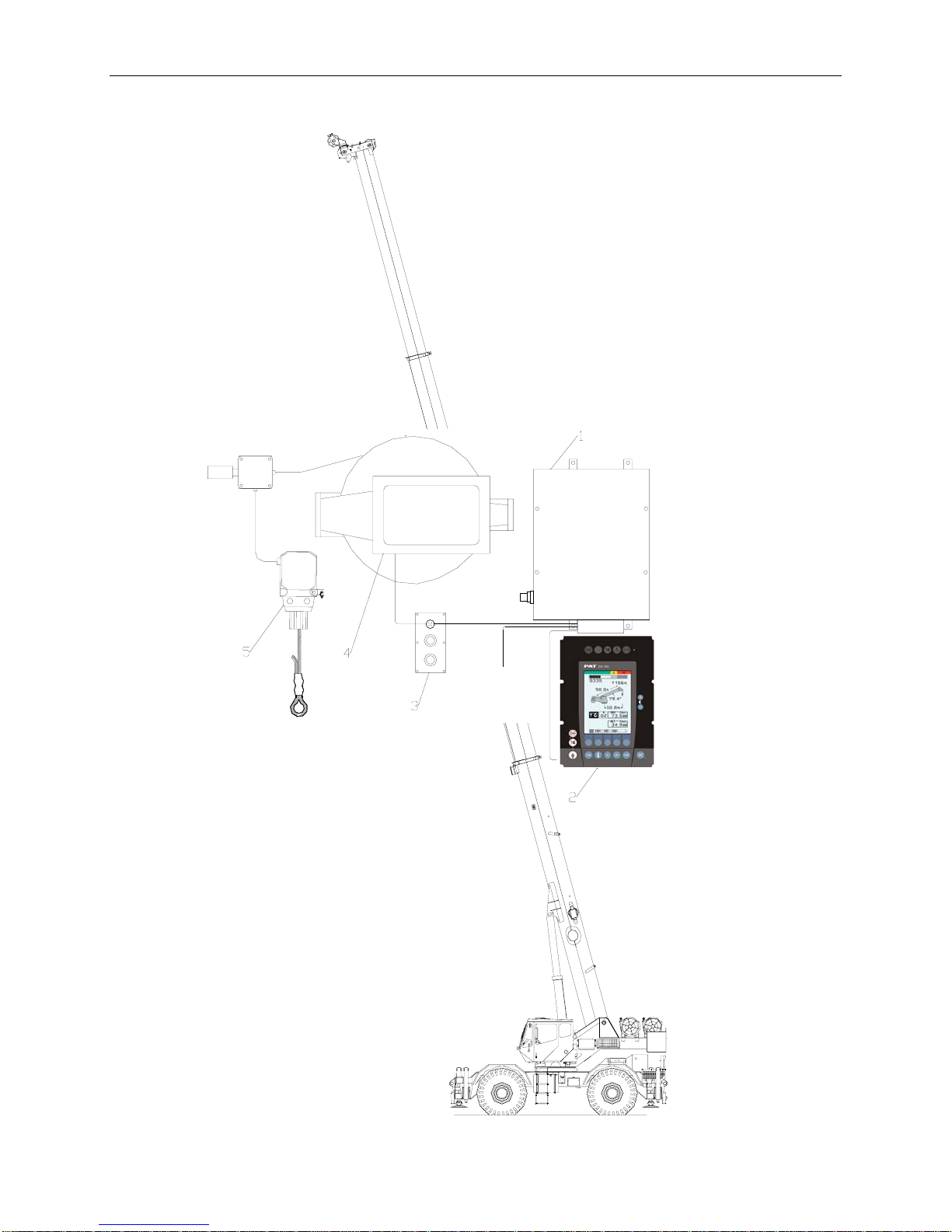

3.1 SYSTEM FUNCTION

Upon switching on, the system starts with an

automatic test of the LMI system, of lamps

and audible alarm. During the test, the LC

display shows the initial logo.

If the system was turned off for more than

two hours, the setup configuration has to be

entered after the system test. (⇒ chapter 4)

Operator's Manual iFLEX5

First, the operating mode is determined by

an interactive step-by-step interrogation of

the rigging states.

Next is the interactive input of the reeving.

Now the LC display shows in symbols all

inputs and awaits acknowledgment or

canceling.

Upon acknowledgment of the inputs the

system is ready for operation.

© Hirschmann Rev. E 11/12/08 190147_E

Page 11

System Description

5

3.2 OPERATING CONSOLE

The console has 3 functions:

• inputs by the crane operator (operating mode, reeving)

• input of geometry limit values and signalization of exceeded limit values

• display of important data and information

The operator’s console is mounted in the crane’s cab in the operator’s field of vision. For a

better identification of displays and operating elements, they are continuously backlit during

operation.

3.3 CONTROL IDENTIFICATION

This unit contains a display and different controls which are described as follows:

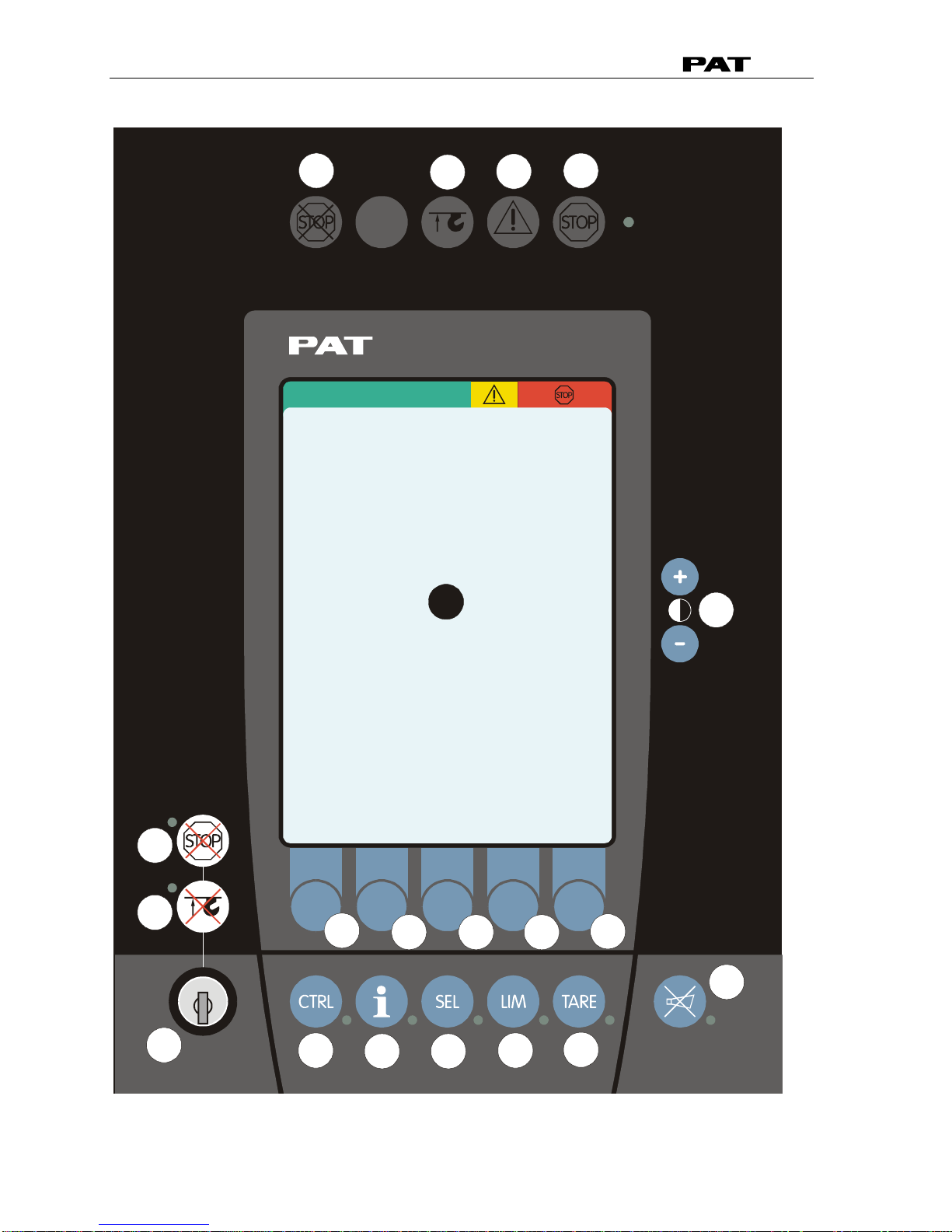

Legend to Fig 2:

1 LC Display Area 10 Button and Control Light "INFO"

2 Load Moment Limit Light 11 Button and Control Light "CONTROL"

3 Load Moment Prewarning Light 12 By-Pass Key Switch

4 Alarm Light “Anti-Two-Block” 13 Button and Control Light "By-Pass Anti-Two-Block"

5 Override Key Warning Light 14 Button and Control Light "By-Pass LMI shut-off

function"

6 Button “Alarm Stop” 15 Contrast Control

7 Button and Control Light “TARE” F1 Button "Function 1"

8 Button and Control Light “LIMITS” F2 Button "Function 2"

9 Button and Control Light “SELECT F3 Button "Function 3"

OPERATING MODE” F4 Button "Function 4"

F5 Button "Function 5"

© Hirschmann Rev. E 11/12/08 190147_E

Page 12

6

Fig. 2a: Operating Console (vertical)

Operator's Manual iFLEX5

5

4

1

3

2

15

14

13

12

© Hirschmann Rev. E 11/12/08 190147_E

11

F5

10

F4

9

8

F2F3

F1

6

7

Page 13

System Description

Fig. 2b: Operating Console (horizontal)

1 LC Display Area 10 Button and Control Light "INFO"

2 Load Moment Limit Light 11 Button and Control Light "CONTROL"

3 Load Moment Prewarning Light 12 By-Pass Key Switch

4 Alarm Light “Anti-Two-Block” 13 Button and Control Light "By-Pass Anti-Two-Block"

5 Override Key Warning Light 14 Button and Control Light "By-Pass LMI shut-off

function"

6 Button “Alarm Stop” 15 Contrast Control

7 Button and Control Light “TARE” F1 Button "Function 1"

8 Button and Control Light “LIMITS” F2 Button "Function 2"

9 Button and Control Light “SELECT F3 Button "Function 3"

OPERATING MODE” F4 Button "Function 4"

F5 Button "Function 5"

7

F1

2

3

F2

F3

4

1

F4

F5

15

5

12

13

14

11

10

9

8

7

6

© Hirschmann Rev. E 11/12/08 190147_E

Page 14

8

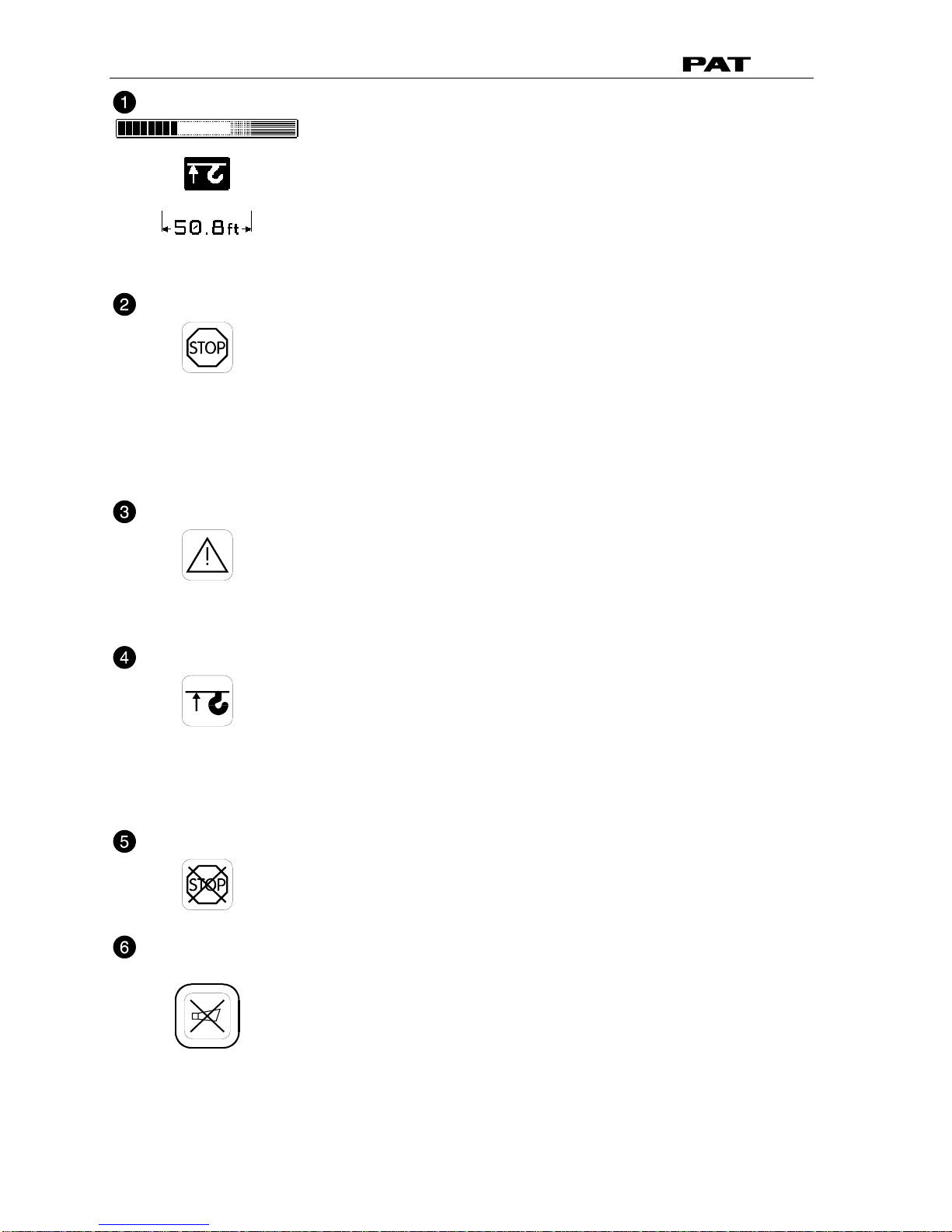

LC-Display

Load Moment Limit Light

Operator's Manual iFLEX5

The LC display visualizes graphical symbols, texts and numerical

values. Depending on the selected operating mode (setup, limit mode

or LMI representation), the corresponding information is indicated on

the display.

Please refer to the description of the different operating modes for the

signification of the individual elements.

The red LOAD MOMENT LIMIT LIGHT (2) warns the operator that a

rated load condition has been reached. It lights up when the load on

the crane reaches the crane load capacity. The audible alarm also

sounds when this condition has been reached.

The following crane movements will be stopped concurrently:

− hoist up

− telescope out

− boom down

Load Moment Prewarning Light

The yellow LOAD MOMENT PRE-WARNING LIGHT (3) will light up

when the load on the crane reaches the defined prewarning area,

thus indicating that an overload condition is approaching.

This means for the operator to continue his crane operation with

extreme caution.

Alarm Light “Anti-2-Block”

The red “Anti Two-Block Alarm Light” (4) lights up when the anti-twoblock limit switch contacts open, indicating that a two-blocking

condition is approaching. At the same time the audible alarm will

sound.

The following crane movements will be stopped subsequently: hoist

up, telescope out, boom down.

Override Key Warning Light

The red OVERRIDE KEY WARNING LIGHT (5) flashes to indicate

that the cut-off function of the A2B / LMI system is deactivated.

Button and Control Light “Alarm Stop”

This ALARM STOP BUTTON (6) allows the audible alarm to be

silenced for approximately 15 seconds by pressing this button.

Reference ⇒ “Audible Alarm” (12).

© Hirschmann Rev. E 11/12/08 190147_E

Page 15

System Description

Button and Control Light “TARE”

The button “TARE” (7) is used to indicate the “Net load” on the LC

Display (1). Net load is the present load, less lifting tackle and hook

block. The Tare Button (7) has to be activated before lifting.

After pushing the “Tare Button” (7) the load display is set to zero

(taring) and the control light lights up. After lifting a load the display

shows the net load (pay load).

The net load display will change to the actual load display when the

boom radius is changed (either by angle or length).

Button "LIMITS"

Button to start the function "program limit values".

For the proceeding please refer to ⇒ chapter 5.1.

Button "SELECT"

Button to start the function "set operating mode".

For the proceeding please refer to ⇒ chapter 4.1.

9

The correct setting is of utmost importance for the proper function of the system and

the crane. Therefore only operators who are thoroughly familiar with use and

operation of the system shall set this button.

Button "INFO"

Button to start the function "information crane configuration"

Please refer to ⇒ chapter 5.2.

Button "CONTROL"

Button to start additional functions.

Please refer to ⇒ chapter 5.3.

© Hirschmann Rev. E 11/12/08 190147_E

Page 16

10

Key Switch

Button "By-pass A2B"

Operator's Manual iFLEX5

The anti-two-block switch cut-off function is deactivated when

the KEY SWITCH (12) is turned to position "B" and the “By-pass

A2B” button (13) is pushed.

OR

The LMI cut-off function is deactivated when the KEY SWITCH

(12) is turned to position "B" and the “By-pass LMI” button (14) is

pushed.

KEY SWITCH (12) can be operated only by using the matching key.

This button can be operated only if key switch (12) is turned to

position B.

After pushing this button, the cut-off function of the anti-two-block

switch is deactivated.

The Override Key Warning Light (5) flashes to indicate that the cut-off

function is deactivated.

Since button (14) and (15) deactivate the cut-off function of the LMI system / the anti twoblock system, the following instructions must be obeyed:

• The by-pass function shall be used with discretion, as unwarranted use of it to override

the control lever lockout system can result in harm to the crane and danger to property

and persons.

• Never use the by-pass function to either overload or operate the crane in a nonpermissible range.

Button "By-pass LMI"

This button can be operated only if the key switch (12) is turned to

position B.

After pushing this button, the control lever lockout function of the LMI

is deactivated.

The Override Key Warning Light (5) flashes to indicate that the cut-off

function is deactivated.

Contrast Control

This function serves for the contrast adjustment of the LC display.

The last adjustment is stored and does not have to be repeated at

every system start.

During normal LMI operation the display contrast can be adjusted by

pressing the “+” or “-“ button.

© Hirschmann Rev. E 11/12/08 190147_E

Page 17

Configuration Setup

4 CONFIGURATION SETUP

The LMI setup procedure allows the operator to input the crane configuration using interactive

displays. The operator must complete the setup procedure for the Load Moment Indicator

system if the system has been turned off for more than two hours or the crane operation

configuration has been changed.

4.1 LMI SETUP PROCEDURE

...starts:

automatically, if the system was turned off for more than

two hours.

manually at each modification of the crane configuration

by pressing key (9) "SEL"

9

...is operated:

...is cancelled:

If the system is turned off, for example during short breaks (less than 2 hours), all adjustments

remain stored. When turning on again the system these adjustments can be acknowledged by

merely pressing one key (provided that the crane configuration has not been modified!).

During the programming procedure the Load Moment Prewarning Light (3) and the Load

Moment Limit Light (2) will light up and the aggravating crane movements will be interrupted.

Note: If a configuration is selected which is not available, the display will indicate error code

E04. In this case, the procedure has to be repeated with valid values!

by answering the different questions using functional keys

F1...F5 in accordance with the actual configuration of the

crane.

any time by pressing again key (9) "SEL". The system,

however, is only ready for operation, if the procedure has

been completed and the inputs have been confirmed.

11

The correct setting is of utmost importance for the proper functioning of the system

and the crane. Therefore, only operators who are thoroughly familiar with the crane

and the operation of the system should execute the setting of the system according

the operating configuration of the crane.

© Hirschmann Rev. E 11/12/08 190147_E

Page 18

12

Operator's Manual iFLEX5

The LMI programming procedure consists of the following steps:

• setting the boom configuration

• setting the counterweight configuration (where applicable)

• setting the hoist configuration

• setting the outrigger configuration

• setting the reevings

• confirmation of the programming procedure

For easy operation, the computer guides the operator through the procedure step by step

(interactive operation.)

Definition of the Displayed Symbols:

The following illustrations define the symbols appearing on the display during the setup

procedure. Not all symbols will be shown, depending on the crane type and the answers to the

questions.

• Select interactive configuration setup / special mode setup

interactive configuration setup

special mode setup

Note: Refer to manufacturer load

chart for special LMI operating code

• (if selected special mode setup only)

increase selected numeral

decrease selected numeral

select next numeral

confirm selected operating code

• Setting the boom configuration

main boom / aux. boom nose operation

operation with boom extensions, includes luffing jib operation

rigging mode operation*

*

for cranes with rigging mode for outrigger box installation only

or

© Hirschmann Rev. E 11/12/08 190147_E

main boom

operation with boom extensions

Page 19

Configuration Setup

• Setting the luffer configuration

extension retracted

extension extended

13

main

boom

aux.

boom

nose

Aframe

boom

ext.

fixed

ext.

fixed,

offsettable

extension

tele-offsettable

extension

fixed jib Luffing jib

For detailed symbol explanation of extensions, please refer to Appendix A in this manual.

• Setting the counterweight configuration

If your crane is equipped with counterweight options, please

refer to Appendix B in this manual for detailed symbol

explanation of counterweight.

• Setting the hoist configuration

Front Hoist

Rear Hoist

• Setting the outrigger configuration (If no outrigger configuration is skipped,

configuration can only be used with 100% outrigger position).

© Hirschmann Rev. E 11/12/08 190147_E

on rubber

outrigger position 0%

outrigger position 50%

outrigger position 100%

Page 20

14

• (if selected on rubber mode only)

static

pick & carry

• Setting the reeving (parts of line)

increase reeving

decrease reeving

confirm reeving

• Confirmation of the programming procedure

Operator's Manual iFLEX5

counterweight

configuration

(optional)

hoist

selection

boom

configuration

reeving

(parts of line)

At the end of the procedure all selections are shown once again in symbolic forms. If selections have

been made, the corresponding symbols are filled black.

outrigger

configuration

quick setting the reeving

(⇒ chapter 4.3)

quick hoist line selection

cancel procedure

confirm inputs

(⇒ chapter 4.2)

© Hirschmann Rev. E 11/12/08 190147_E

Page 21

Configuration Setup

4.2 QUICK SETTING OF THE REEVING

If, during the crane operation, the number of reeving is modified, the LMI system has to be

adjusted to this modification. The input of the reeving can be carried out directly without having

to go through the whole LMI programming procedure again:

Call LMI Programming

9

Procedure.

15

Directly call function "Quick

Setting of the Reevings".

Note:

The direct call is impossible, if

the system has been turned off

for more than 2 hours.

input of reeving:

increase reeving

decrease reeving

confirm reeving

Confirm modification.

(select again the function upon

faulty input)

Note:

If a configuration is selected which is not available on the present crane, the system will not accept the

selection and the display will indicate the error code E04.

© Hirschmann Rev. E 11/12/08 190147_E

Page 22

16

Operator's Manual iFLEX5

4.3 QUICK HOIST LINE SELECTION

If, during the crane operation, the crane is switched over from front to rear hoist, the LMI system has to

be adjusted to this modification. This modification can be entered without having to go through the whole

LMI setup procedure again:

9

Call LMI setup procedure.

Directly call function "Hoist Line

Selection".

Note:

The direct call is not possible, if the

system has been turned off for

more than 2 hours.

Select hoist:

Front Hoist

Rear Hoist

Confirm modification.

(call up the function again if you

have selected the wrong whinch by

mistake)

Note:

If a configuration is selected which is not available on the crane, the system will not accept the

selection and the display will indicate the error code E04.

© Hirschmann Rev. E 11/12/08 190147_E

Page 23

Operation

17

5 OPERATION

Upon correct inspection the LMI is operational (see chapter 6. Pre-Operation Inspection and

Calibration Verification.) The operator shall be thoroughly familiar with all controls of the LMI

before operating the crane. The proper function of the system shall be checked by lifting a load

of known weight and comparing the load to the information displayed on the LMI.

Rated loads include the weight of the hook block, slings, and auxiliary load handling devices.

Their combined weights shall be subtracted from the listed load capacities as stated on the load

capacity chart to obtain the net load to be lifted.

If any of the displays reflects a deviation between displayed and actual values, an

authorized PAT service representative shall be called for repair of the system or

reverification of the crane’s LMI calibration.

Any structural modifications or changes to the crane shall require reverification of the

crane’s LMI calibration.

© Hirschmann Rev. E 11/12/08 190147_E

Page 24

18

r

Operator's Manual iFLEX5

After having set the LMI to the actual crane configuration, the system is ready for operation. The

display shows the LMI screen (example for value representation).

utilization bargraph

operation code

numbe

boom length

reeving

(parts of line)

only for cranes

with boom control

system

tip height

boom angle

radius

max.

load

actual load

(The elements are the same on the horizontal display – but in a different order.)

© Hirschmann Rev. E 11/12/08 190147_E

Page 25

Operation

19

Upon request, further symbols can be shown on the display:

Symbol Anti-Two-Block Alarm

• visible when the anti-two-block limit

switch contacts open, indicating that

a two-blocking condition is

approaching.

Symbol slewing angle limitation:

• continuously visible:

slewing angle limitation active

blinking:

•

slewing angle limits exceeded

(⇒ see chapter 5.1.1.a)

Symbol work area definition:

• continuously visible:

work area definition active

blinking:

•

work area limits exceeded

(⇒ see chapter 5.1.1.b)

Symbol height limitation:

• continuously visible:

height limitation active

blinking:

•

height limit exceeded

(⇒ see chapter 5.1.2)

Symbol boom angle limitation:

• continuously visible:

boom angle limitation active

blinking:

•

angle limits exceeded

(⇒ see chapter 5.1.3)

Symbol radius limitation:

• continuously visible:

radius limitation active

blinking:

•

range limits exceeded

(⇒ see chapter 5.1.4)

Symbol wind speed:

• Continuously visible:

E####

Wind speed value

(⇒ see chapter 5.1.5

Error code No. ####

(⇒ see chapter 8 "Troubleshooting")

© Hirschmann Rev. E 11/12/08 190147_E

Page 26

20

Operator's Manual iFLEX5

5.1 LIMIT SETTING

The LMI system has been equipped with programmable limits for the crane's operation range.

• Easy programming due to interactive, step-by-step user guidance

• Functions can be used individually or in combinations.

• Exceeding a programmed limit triggers an audible and visual alarm.

• Depending on the crane type not all functions listed below are available.

Overview limits:

Slewing Angle Limitation /

Work Area Definition

(⇒ chapter 5.1.1)

Tip Height Limitation

(⇒ chapter 5.1.2)

Boom Angle Limitation

(⇒ chapter 5.1.3)

Radius Limitation

(⇒ chapter 5.1.4)

© Hirschmann Rev. E 11/12/08 190147_E

Page 27

Operation

21

5.1.1 Slewing Angle Limitation / Work Area Definition

Programmable function for the limitation of the left and/or right slewing angle or working area

definition.

• Call function:

Call LIMIT Setting.

8

Enter the corresponding figure to call the function:

Slewing angle limitation

(maximum/minimum

slewing angle)

(⇒ chapter 5.1.1.A)

Work Area Definition

(Virtual wall setup. A wall is

defined by a straight line between

two set points.)

(⇒ chapter 5.1.1.B)

5.1.1.A Slewing Angle Limitation

• set / delete left slewing angle:

Select limit:

© Hirschmann Rev. E 11/12/08 190147_E

Select left limit

set:

Position boom to

required left limit

value.

program

present slewing

angle as left limit

quit

function

angle limit

delete:

delete left

Page 28

22

• set / delete right slewing angle

Select limit:

select right limit

set:

Position boom to

the required right

limit value.

set

present slewing

angle as right

limit

Display shows

symbols and

angle values of

the programmed

slewing angle

limit

Operator's Manual iFLEX5

delete:

delete right

angle limit

Display shows

symbols without

angle values

quit function

© Hirschmann Rev. E 11/12/08 190147_E

Page 29

Operation

23

5.1.1.B Work Area Definition

The work area definition system helps the operator to define the crane’s working area. This is

done by creating vertical wall(s) that can represent obstacles (i.e. buildings, towers, poles, etc.)

in the crane’s working range. The wall(s) are set by defining points with the boom tip along the

outer limits of the operator’s work area, see setup procedure below. Because these walls are

defined by the operator and are not “actual real” walls, we refer to them as “virtual” walls. When

setting the walls, always keep a safe working distance to any obstacles. Never work

outside a safe working area as outlined by common practice, standards, and manuals.

A virtual wall is set by defining two points. To prevent inaccuracies when defining the two points

for the virtual wall, use the following to rules:

1. The two points should be the same distance form the obstacle.

2. Set the two points at the maximum distance apart, which can be safely reached by the boom tip.

The operator can setup up to 5 virtual walls, the first wall is defined by a straight line between

two set points. The second through fifth walls are created by one new point and the previously

selected point. After the walls have been set, the system alerts the operator when the boom

approaches them. This is done both visual and audible. The console will warn the operator by

an audible, beeping alarm which increases in frequency as the boom approaches the wall. At

the same times, the control light “Alarm Stop” (refer to no. 6, chapter 3.3 of the operator’s

manual) will come on and the button “LIM” (refer to no. 8, chapter 3.3 of the operator’s manual)

will be lit. Similarly, the “virtual wall” symbol in the main screen blinks. If the boom crosses the

wall the audible alarm becomes continuous. See the Pre-warning System Section for

information on how the pre-warning system is defined.

THERE ARE NO CUTOUTS ASSOCIATED WITH THE WORK AREA DEFINITION

FEATURE.

• set / delete work area:

On entering the work area definition

function, the crane working area is

displayed. A blinking X indicates that

a point may be set to define a wall.

Move the boom tip to one end of the

virtual wall you want to set.

Sets a point in the working

area to start a wall

Exits the screen

© Hirschmann Rev. E 11/12/08 190147_E

Page 30

24

Operator's Manual iFLEX5

Having pressed SET, the X is

displayed (without blinking) at this

point.

A blinking X at the boom tip indicates

that the second point may be set to

define the wall.

Move the boom tip to other end of the

virtual wall you want to set.

Sets the second point to

create a wall

Exits the screen and deletes

all virtual wall settings

After pressing SET, an infinite virtual

wall is defined. Now, three soft keys

are available:

Accepts the defined wall and

exits

Allows for further walls to be

added

Exits the screen and deletes

all virtual wall settings

After pressing SET, an X appears

where the last point had been set,

and a new wall may thus be added.

Move the boom tip to the other end of

the additional virtual wall you want to

set.

© Hirschmann Rev. E 11/12/08 190147_E

Sets the third point to create

a second wall

Exits the screen and deletes

all virtual wall settings

Page 31

Operation

25

Upon pressing SET, the second wall

is created.

Accepts the defined walls

and exits

Allows for further walls to be

added

Exits the screen and deletes

all virtual wall settings

© Hirschmann Rev. E 11/12/08 190147_E

Page 32

26

5.1.2 Tip Height Limitation

Programmable function for the limitation of the tip height

• Set tip height / delete height limitation:

Call LIMIT Setting.

8

Operator's Manual iFLEX5

Press the corresponding

figure to select function "tip

height limitation".

Press key

set:

Move the tip to

the required

upper limit.

height limitation

delete:

delete tip

set

present tip height

as upper limit

Display shows

symbol and value

of the

programmed

height limit

© Hirschmann Rev. E 11/12/08 190147_E

quit function

Display shows

symbol without

values

Page 33

Operation

27

5.1.3 Boom Angle Limitation

Programmable function for the limitation of the upper and/or lower boom angle.

• Call function:

Call LIMIT Setting.

8

Enter the corresponding figure to call

function "boom angle limitation".

• set / delete upper limit value:

Select limit:

selection upper boom angle

limit

Luff up the boom

the requested

limit value.

set:

delete:

delete

upper angle limit

© Hirschmann Rev. E 11/12/08 190147_E

set present

boom angle as

upper limit

Display shows

symbol with value

of the upper angle

limit

quit

function

Display shows

symbol without

value of the upper

angle limit

Page 34

28

• set / delete lower limit angle

Select limit:

limit

Operator's Manual iFLEX5

selection lower boom angle

set:

Luff down boom

to the required

limit value.

delete:

delete

lower angle limit

set present

boom angle as

lower limit

Display shows

symbol with lower

angle limit

Display shows

symbol without

value of lower

limit angle

quit

function

© Hirschmann Rev. E 11/12/08 190147_E

Page 35

Operation

29

5.1.4 Radius Limitation

Programmable function for the limitation of the minimum and/or maximum working radius.

• Call function:

Call LIMIT Setting

8

Select the corresponding figure to call

the function "radius limitation".

• set / delete minimum radius:

Select limits:

select minimum radius limit

set:

position boom at

the required

minimum radius

value.

delete:

delete

minimum radius

limit

© Hirschmann Rev. E 11/12/08 190147_E

set present

boom radius as

minimum radius

display shows

symbol with

radius value of

minimum limit

quit

function

display shows

symbol without

value of minimum

radius

Page 36

30

• set / delete maximum radius

Select limit:

Operator's Manual iFLEX5

selection maximum radius limit

set:

position boom to

the required

maximum radius

value.

set present

boom radius as

maximum radius

display shows

symbol with

radius value of

max. limit

delete:

delete

maximum radius

limit

display shows

symbol without

value of max.

radius

quit

function

5.1.5 Wind Speed

This function serves to display the current wind speed.

• Battery replacement

Please use TRS05 manual 031-300-190-176 for battery replacement.

© Hirschmann Rev. E 11/12/08 190147_E

Page 37

Operation

31

5.2 INFO CRANE CONFIGURATION

With the system being ready for operation, this function serves to display the system

configuration

• Call function

Press key "INFO".

10

• End function

10

The display shows the crane

symbol representing the

adjusted configuration

(marked black), the extended

operating code number and

the reeving number (parts of

line).

Press again key "INFO".

© Hirschmann Rev. E 11/12/08 190147_E

Page 38

32

Operator's Manual iFLEX5

5.3 DISPLAY CONTRAST CONTROL

This function serves for the contrast adjustment of the LC display. The last adjustment is stored

and does not have to be repeated at every system start.

• Contrast adjustment

Press "CTRL".

11

A pattern is shown by means

of which the display can be

adjusted to the optimum

contrast. Use the functional

keys to modify the contrast

upon request:

darken display

brighten display

confirm setting

Press key "OK" to store the

momentarily adjusted contrast

value and to quit the function.

During normal LMI operation

the display contrast can be

adjusted too by pressing the

“+” or “-“ button.

© Hirschmann Rev. E 11/12/08 190147_E

Page 39

Pre-Operation Inspection and Calibration Verification

33

6 PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION

Before operating the crane, the following electrical connections must be checked to ensure that

the system is properly connected for the crane configuration.

6.1 MACHINES WITH ONLY A MAIN HOIST

If the crane works only with the boom and without boom extension, no additional connections

are necessary. However, be sure the weight of the anti two-block switch is properly installed on

the main hoist load line. With even parts of hoisting line, the weight shall be attached to the

dead-end line. With odd parts of hoisting line, the weight shall be attached to the line of lowest

speed.

If the crane works with boom extension, the connecting cable shall be installed between the

junction box on the boom extension and the boom junction box. The weight attached to the main

hoist anti two-block switch shall be removed. In that case the anti two-block switch has to be

locked with the red Anti Two-Block Retainer, which is fixed with a red lanyard at the anti twoblock switch (described in the following pages). Then the weight shall be reattached to the

boom extension anti two-block switch.

Failure to re-position the anti two-block switch weight will prevent the overhoist

system from functioning properly. No weight shall be on the main hoist anti two-block

switch when the boom extension is being used.

6.2 MACHINES WITH MAIN AND AUXILIARY HOISTS

If the boom extension is not in the operating position, the by-pass plug shall be installed in the

main boom junction box. The weight of the main hoist anti two-block switch shall be installed.

If the boom extension is in the operating position, the connecting cable shall be installed

between the junction boxes on the boom extension and the main boom. Weights shall also be

attached to the anti two-block switches on both the main boom and boom extension.

If the boom extension is in the operating position and no load line is being used on main boom,

to prevent injury or damage to equipment, the weight shall be removed from main boom switch.

In that case the anti two-block switch has to be locked with the red Anti Two-Block Retainer,

which is fixed with a red lanyard (not shown) at the anti two-block switch.

© Hirschmann Rev. E 11/12/08 190147_E

Page 40

34

Operator's Manual iFLEX5

6.3 INSTALLATION OF ANTI TWO-BLOCK RETAINER IN LOCKING POSITION

Procedure (see Fig. 1 and 2):

1. Pull the cable out of the switch and bend back parallel to the boom and hold (1).

2. Slide the retainer from left side with its slot over the cable between the crimped stop and the

switch (2). Push it firmly straight onto the cable guide of the Anti Two-Block switch (3).

Fig. 1: Setting of Anti Two-Block

Retainer in Locking Position

Fig. 2: Retainer in Locking Position

3. Straighten the cable completely into the slot and release the cable (4).

4. Turn the flag of the retainer for best visibility for the operator (5).

6.4 REMOVAL AND STORAGE OF THE ANTI TWO-BLOCK RETAINER

Procedure (see Fig. 3 and 4):

1. Pull the cable out of the switch (1) and bend back parallel to the boom and hold (2).

2. Move the retainer down (3) and then left (4) to remove it from the Anti Two-Block switch.

Release the cable.

3. For storage slide the retainer from right side (5) over the Anti Two-Block switch until the clips

(A) lock into the holes (B).

Fig. 3: Removal of the Anti Two-

Block Retainer

© Hirschmann Rev. E 11/12/08 190147_E

Fig. 4: Retainer in Storage Position

Page 41

Pre-Operation Inspection and Calibration Verification

35

6.5 PRE-OPERATION INSPECTION AND CALIBRATION VERIFICATION

After the electrical connections have been checked to insure that the system is properly

connected for the crane configuration, the following checks shall be made:

1. Check the electrical wiring connecting the various parts of the system for physical damage.

2. Check the anti two-block switches and weights for free movement.

3. Check the spring-loaded cable reel to be sure it is free to rotate, has tension and the cable is

reeled properly.

The following tests shall be performed with care to prevent damage to the machine or

injury to personnel. Proper functioning of the system requires successful completion

of these tests before operating the machine.

If the light and audible alarm do not function as described and the crane movements

are not stopped, the system is not working properly. The malfunction shall be

corrected before operating the crane.

If the operator cannot see the load handling device approaching the boom nose, he shall have

an assistant (signal person) watch the load handling device. The operator shall be prepared to

stop the machine immediately should the LMI system not function properly as indicated by

lighting the red warning light (4), sounding the audible alarm and locking the crane movements,

hoist up, telescope out and boom down.

1. Check the anti two-block alarm light (4) and the audible alarm by performing one of the

following tests:

a) By manually lifting the weight attached to the anti two-block switches. When the weight

is lifted, the audible alarm should sound, the anti two-block alarm light (4) should light.

b) Slowly raise the main boom load handling device to create a potential two-block

condition. When the load handling device lifts the weight, the audible alarm should

sound, the anti two- block alarm light (4) should light and the motion of the load handling

device should be stopped. Lower the load handling device slightly to eliminate this

condition.

c) Slowly lower the boom to create a potential two-block condition. When the load handling

device lifts the weight, the audible alarm should sound, the anti two-block alarm light (4)

should light and the boom lowering function should be stopped. Lower the load handling

device slightly to eliminate this condition.

d) Slowly extend (telescope) the boom to create a potential two-block condition. When the

load handling device lifts the weight, the audible alarm should sound, the anti two-block

alarm light (4) should light and the boom telescope out function should be stopped.

Lower the load handling device slightly to eliminate this condition.

2. If the crane is equipped with a boom extension, repeat the test procedure for the boom

extension anti two-block switch. Check that the display of the main boom length agrees with

the actual boom length.

3. Check that the display of the main boom angle agrees with the actual boom angles.

4. Check that the display of the operating radius of the crane agrees with the actual radius.

5. Check the load display by lifting a load of known weight.

© Hirschmann Rev. E 11/12/08 190147_E

Page 42

36

Operator's Manual iFLEX5

7 SERVICE AND MAINTENANCE

Daily maintenance of the load moment indicator consists of inspecting:

1. The electrical wiring connecting the various parts of the system.

If electrical wiring is damaged, it shall be replaced immediately.

2. If the insulation is worn on the length sensor cable or cable guides are damaged, these

parts shall be replaced.

3. Check the anti two-block limit switches for freedom of movement.

4. The cable reel shall be under tension to operate properly.

5. Check the pressure transducers at the hoist cylinder(s) and the connecting hoses for oil

leakage.

Other than correcting the problems identified in the Malfunctions Table and replacing faulty

mechanical parts and cables, no other repairs shall be performed by non expert personnel.

© Hirschmann Rev. E 11/12/08 190147_E

Page 43

Troubleshooting

37

8 TROUBLESHOOTING

8.1 GENERAL

In case of a malfunction of the system, the display (1) will indicate a code that identifies the

system malfunction.

The error codes listed in the Malfunction Table will identify various faults that can occur with the

LMI. Following the Malfunction Table are pages which explain each fault and describe the

action which shall be taken to correct the fault.

Faults within the electronic microprocessor shall be repaired by factory trained service

personnel. When these faults occur, the competent service organization shall be contacted.

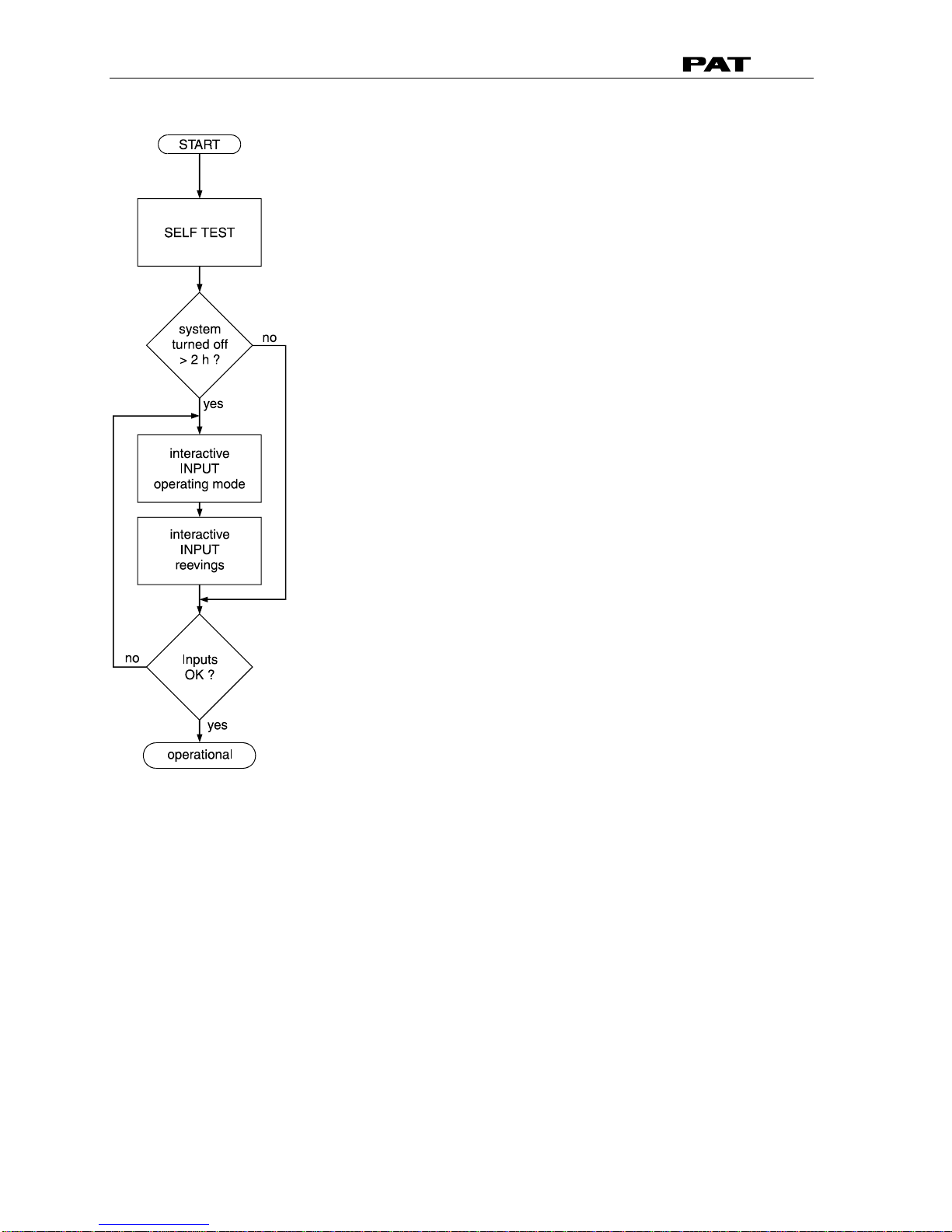

8.2 MALFUNCTION TABLE

Error

Code

E01

E02

E03

E04

E05

E18

E83

flashing

…% (tele.)

NOTE:

If there is any Error Code displayed on the console which is not listed in the Malfunctions

Table you shall call the Local Distributor.

Error

Fallen below the radius or above angle range

Radius range exceeded or fallen below angle range

Boom position is out of the permissible working area

Operating mode not existing

Prohibited length range

Front outrigger overloaded

Center Mid not fully extended

Telescope out of permissible sequence

© Hirschmann Rev. E 11/12/08 190147_E

Page 44

38

Operator's Manual iFLEX5

8.3 OPERATING ERRORS

Malfunctions in the system which are caused by range exceeding or operating errors by the

crane operator himself are indicated on the display together with an explanation. These error

codes are E01, E02, E03, E04, E05, E18 and E83 and they can normally be eliminated by the

crane operator himself.

Error

Code

E01

E02

E03

E04

E05

E18

E83

flashing

…% (tele.)

ECO

EC1

Cause Elimination

Fallen below the minimum radius or

above the angle given in the load

Boom down to a radius or angle given in

the load capacity chart.

capacity chart due to luffing up the

boom too far.

The maximum radius or minimum

angle given in the load capacity chart

Boom up to a radius or angle given in the

load capacity chart.

was exceeded due to luffing down

the boom too far.

Boom position is out of the

permissible working area

(over front).

Move boom back to the permissible

working area.

See lifting diagram in the load capacity

charts.

Operating mode switch in the

console incorrectly set.

Correctly set operating mode switch to the

code assigned to the operating mode of the

crane.

Operating mode is not permissible

with the actual crane configuration,

Be sure crane is set up according to proper

operating configurations.

boom position or area definition.

Boom was telescoped too far or not

far enough, you may only operate up

Telescope boom to correct length, given in

the load capacity chart.

to a certain maximum or minimum

boom length or with load curves for

boom extension where you have to

telescope the main boom to a certain

length.

Length sensor adjustment changed

For elimination refer to service manual.

i.e. length sensor cable slid off the

length sensor drum.

Front outrigger overloaded

The Center Mid is not on its fully

extended position while the OM/Fly

is not completely retracted.

Telescope is out of the permissible

Refer to load capacity charts.

Extend the Center Mid

Retract the OM/Fly

Check the OM/Fly switch (dig. input 4)

Fully retract telescope

sequence.

Prohibited area

Boom is about to collide with the

engine hood, switch off

Approaching prohibited area

Boom is about to collide with the

engine hood, prewarning

Move boom to permitted area

Move boom to permitted area

© Hirschmann Rev. E 11/12/08 190147_E

Page 45

Appendix A: Detailed symbol explanation of boom extensions

9 APPENDIX A: DETAILED SYMBOL EXPLANATION OF BOOM

EXTENSIONS

Main boom

auxiliary

boom nose

39

A-frame boom

extension

Fixed

extension

Fixed,

offsettable

extension

Swingaway/

bifold with fly

stowed on

main boom

Swingaway/

bifold without

fly stowed on

main boom

fly stowed on

main boom

offsetable

A-frame

teleoffsettable

extension

fixed jib

swingaway

with fly/tele

swingaway/

bifold without

fly

bifold with fly

stowed on

main boom

© Hirschmann Rev. E 11/12/08 190147_E

Page 46

40

Operator's Manual iFLEX5

10 APPENDIX B:DETAILED SYMBOL EXPLANATION OF

COUNTERWEIGHT OPTIONS

without auxiliary hoist structure

with mounted auxiliary hoist

structure

with counterweight A

with counterweight B

only for cranes with auxiliary

counterweight:

without auxiliary counterweight

with auxiliary counterweight

without counterweight

with counterweight A

with counterweight B

with counterweight A + B

only for cranes with auxiliary

counterweight:

without auxiliary counterweight

with auxiliary counterweight

© Hirschmann Rev. E 11/12/08 190147_E

for cranes with pre-programmed counterweight:

scroll up to the next pre-programmed counterweight configuration

scroll down to the next pre-programmed

counterweight configuration

press the O.K. button to confirm and to proceed with console

programming

only for cranes with superstructure counterweight and front bumper

counterweight configuration:

scroll up to the next pre-programmed counterweight configuration

scroll down to the next pre-programmedcounterweight

configuration

press the O.K. button to confirm and to proceed with console

programming

Loading...

Loading...