Page 1

HTI

_CW

CW

5

HIGH

TECHNOLOGY

IN

REFRIGERATION

DEVICES

H T I - CW

Packaged Air Conditioning Unit

Chilled water unit

Users Manual

HF61G00269SB HTI-0-UM-GB_

GB

Rev. 20-05-201

Page 2

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

2

HF61G00269SB HTI-0-UM-GB_CW

Page 3

3

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

Index

1 General Description.................................................................................................................. 4

1.1 Structure ...........................................................................................................................................4

1.2 Field of application ...........................................................................................................................4

1.3 Cooling circuit ...................................................................................................................................4

1.4 Hydraulic section ..............................................................................................................................6

1.5 Installation warnings .........................................................................................................................7

2 Inspection / Transport .............................................................................................................. 8

2.1 Inspection on receipt ........................................................................................................................8

2.2 Lifting and transport .........................................................................................................................8

2.3 Unpacking ........................................................................................................................................8

3 Installation ................................................................................................................................ 9

3.1 HTI - Indoor unit positioning .............................................................................................................9

3.2 Free-cooling duct connections (optional) ......................................................................................... 10

4 Electrical Connections ........................................................................................................... 11

4.1 Generalities ................................................................................................................................... 11

4.2 Starting up for the first time ........................................................................................................... 12

4.3 Starting operation .......................................................................................................................... 12

5 Operating Parameters Setting ............................................................................................... 12

5.1 Generalities ................................................................................................................................... 12

6 Maintenance ............................................................................................................................ 13

6.1 Warnings ....................................................................................................................................... 13

6.2 Periodical checks .......................................................................................................................... 13

7 Troubleshooting ..................................................................................................................... 15

HF61G00269SA HTI-0-UM-GB_CW

Page 4

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

1 General Description

HTS “HiRef Telecom Split” units composed by an evaporating indoor unit HTI for ceiling or wall installation, mainly

for electronic equipped shelters, process centers, telecommunications sites from 4.5 to 38 kW of nominal cooling

capacity.

The system provides air filtration, indoor ventilation, cooling, heating, free cooling with outdoor fresh air to assure

the useful climate in the site.

1.1 Structure

All HTS units have a galvanized sheet steel supporting base and enclosing panels are painted with epoxy polyester

powder coating cured at 180°C, or, on request, painted galvanized sheet steel (RALxxxx).

1.2 Field of application

All HTS units are to be used within the operating limits stated in this manual (see Tab. 1); failure to comply with said

limits will invalidate the warranties provided in the contract of sale.

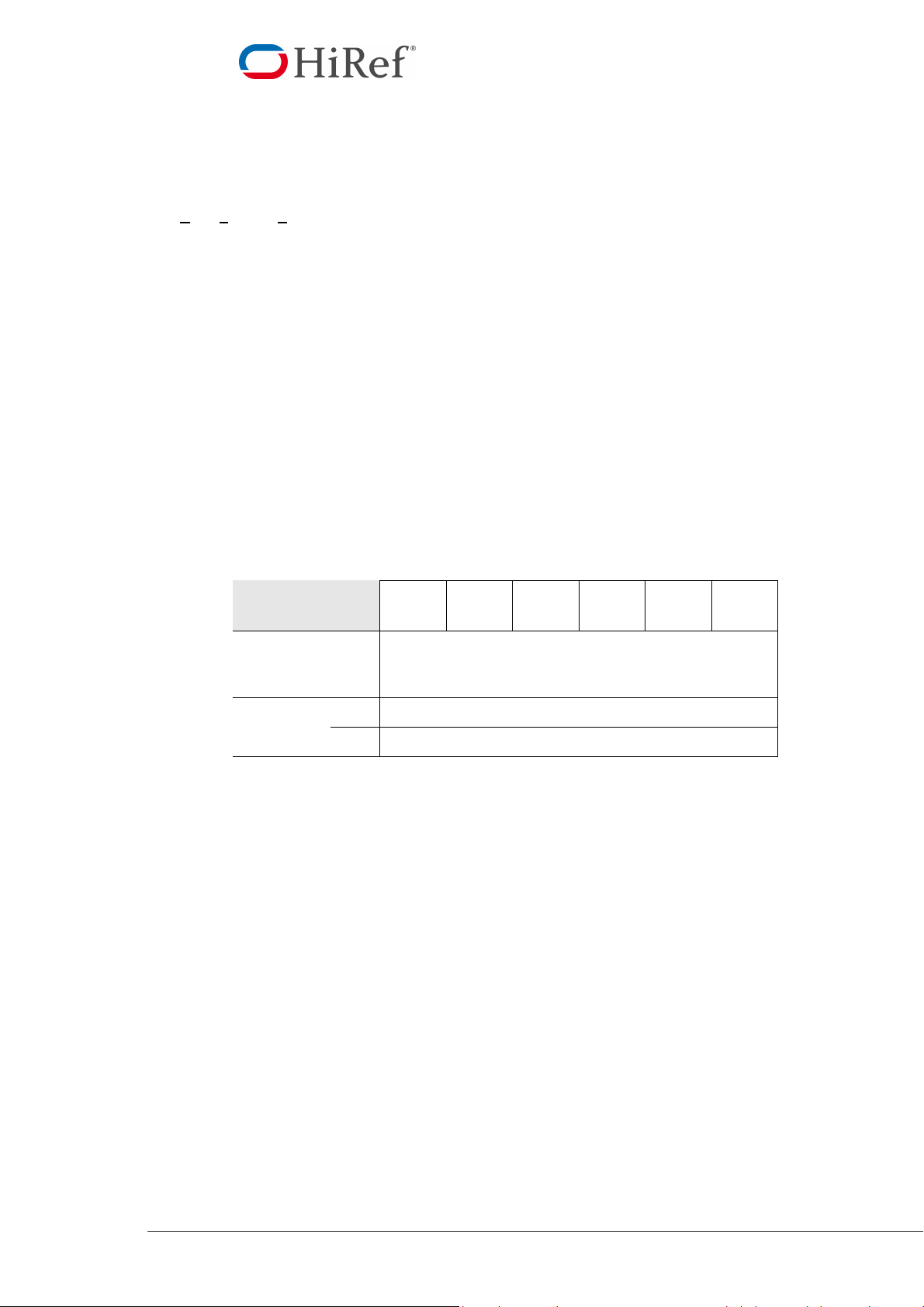

Tab. 1 Operating limits

Model: HTI

073

105

120

145

310

380

Power supply

400Vac ±10% / 3Ph+N+PE / 50Hz

Storage

conditions

Min

Max

-10 °C / 90% R.H.

55 °C / 90% R.H.

1.3 Cooling circuit

The entire cooling circuit is built in the HiRef factory using only components of the finest quality brands and

processes conforming to the specifications of “Directive 97/23” for brazing and testing.

Cooling components

• Water valves

• Airflow switch

• Filter

Electric control board

The electric control board is constructed and wired in accordance with Directives 73/23/EEC and 89/336/EEC and

related standards. All the remote controls use 24V signals powered by an insulating transformer.

Note: The mechanical safety devices such as the high pressure switch are of the kind that trigger directly; their

efficiency will not be affected by any faults occurring in the microprocessor control circuit, in compliance with

97/23 PED.

Microprocessor control

The microprocessor built into the unit allows the different operating parameters to be controlled from a set of

pushbuttons situated on the electric control board:

• Alarm management: -

- Dirty filters alarm;

- Air flow alarm.

4

HF61G00269SB HTI-0-UM-GB_CW

Page 5

5

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

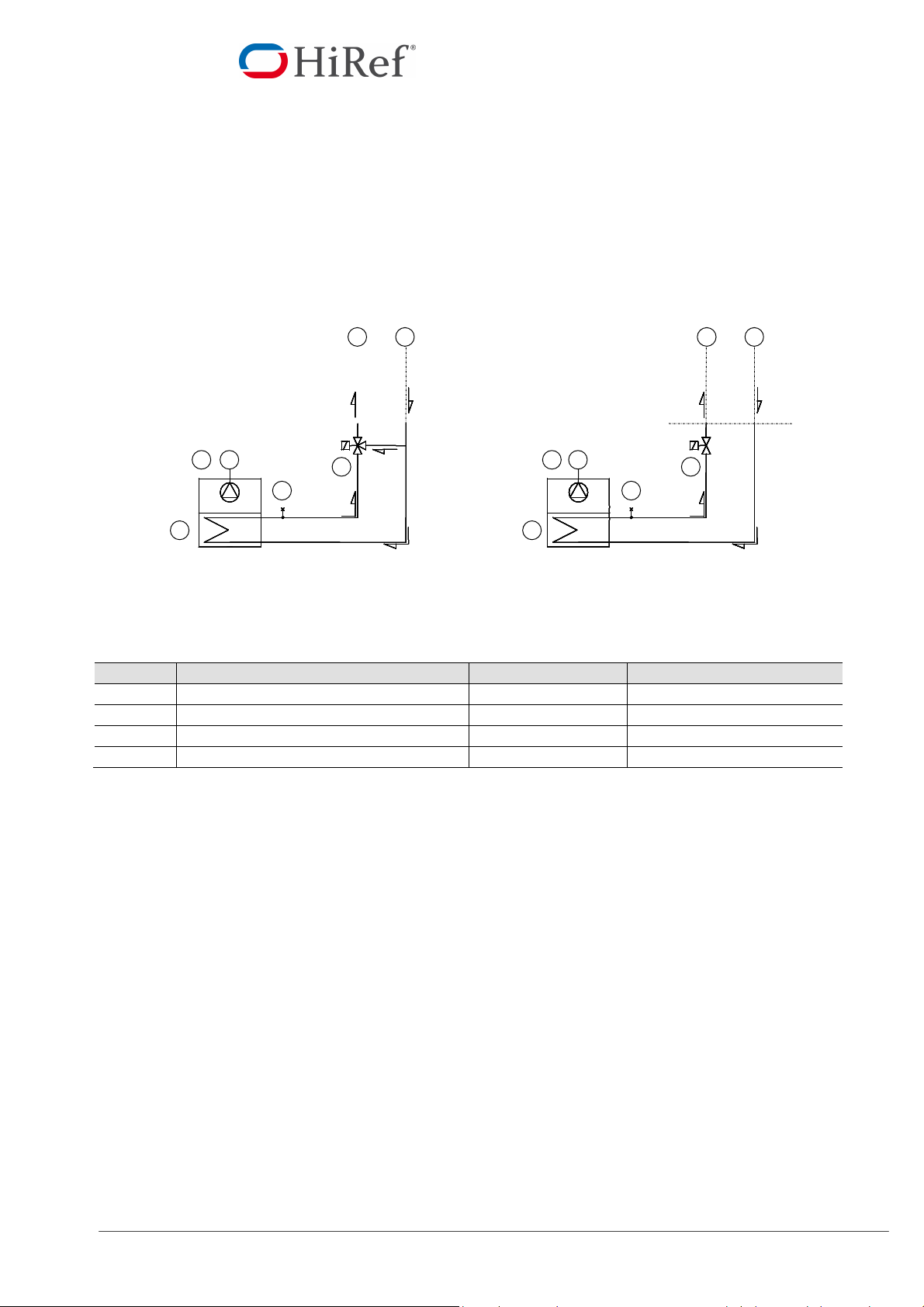

3 –

way valve

2-way valve

• Alarm signalling.

• Display of operating parameters.

• RS232, RS485 serial output management (optional).

• Phase sequence error (Not displayed by the mP, but prevents the compressor from starting up).

See microprocessor control manual for further details, also in relation to particular customer

specifications.

Fig. 1 Basic cooling circuits DX

2

1

2 1

5

M

4 M4

6

3

5

7

6

Pos Description Pos. Description

1 Chilled water inlet 5 Coil heat exchanger

2 Chilled water outlet 6 Breather valve

3 3-way valve 7 2-way valve (Opt.)

4 Plug fan

-

HF61G00269SA HTI-0-UM-GB_CW

Page 6

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

1.4 Hydraulic section

Three-way valve

The 3-way valve used on HTI0105 version unit for inlet water flow regulation allowing a foundamentally maximum

precision’s regulation on CCAC applications.

Tab. 3 Technical characteristics

HTI 0073-0105

Kvs valve (m3/h)

PN valve

P max. (kPa)

Connections (inch)

6.3 6.3 16,0

200 200 200

3/4” 3/4” 1 1/4”

16 16 16

120-145 310-380

Air presence in hydraulic circuit

It is necessary to leak air from the hydraulic circuit of unit after the connection to the external circuit. To do this,

open the below panel to valve access and use adapted tools for the manual valve’s setting.

6

HF61G00269SB HTI-0-UM-GB_CW

Page 7

7

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

1.5 Installation warnings

General rules

• When installing or servicing the unit, you must strictly follow the rules provided in this manual, comply with

the directions on the units themselves and take all such precautions as are necessary.

• The fluids under pressure in the cooling circuit and the presence of electrical components may cause

hazardous situations during installation and maintenance work.

All work on the unit must be carried out by qualified personnel only, trained to do their job

in accordance with current laws and regulations.

• Failure to comply with the rules provided in this manual or any modification made to the unit without prior

authorisation will result in the immediate invalidation of the warranty.

Warning: Before performing any kind of work on the unit, make sure it has been

disconnected from the power supply.

HF61G00269SA HTI-0-UM-GB_CW

Page 8

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

2 Inspection / Transport

2.1 Inspection on receipt

On receiving the unit, check that it is perfectly intact: the unit left the factory in perfect conditions; immediately report

any signs of damage to the carrier and note them on the Delivery Slip before signing it. HiRef S.p.A. or its Agent

must be promptly notified of the entity of the damage. The Customer must submit a written report describing every

significant sign of damage.

2.2 Lifting and transport

While the unit is being unloaded and positioned, utmost care must be taken to avoid abrupt or violent maneuvers.

The unit must be handled carefully and gently; avoid using machine components as anchorages or holds and

always keep it in an upright position.

The unit should be lifted using the pallet it is packed on; a trans pallet or similar conveyance means should be used.

Warning: In all lifting operations make sure that the unit is securely anchored in order

to prevent accidental falls or overturning.

2.3 Unpacking

The packing must be carefully removed to avoid the risk of damaging the unit. Different packing materials are used:

wood, cardboard, nylon etc.

It is recommended to keep them separately and deliver them to suitable waste disposal or recycling facilities in

order to minimize their environmental impact.

8

HF61G00269SB HTI-0-UM-GB_CW

Page 9

9

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

A

3 Installation

The HTS package air-conditioning unit is suitable for all environments except aggressive ones. Do not place any

obstacles near the units and make sure that the air flow is not impeded by obstacles and/or situations causing back

suction.

3.1 HTI - Indoor unit positioning

Bear in mind the following aspects when choosing the best site for installing the unit and the relative connections:

• position of the indoor unit next to the main heat source;

• location of power supply;

• solidity of the supporting ceiling / wall.

It is recommended to first prepare holes in the ceiling / wall for the screw anchors.

The dimensions and the positions of the holes for the screw anchors are shown below.

14.2

14.2

170

B

200

Model: HTI

073-0105

120-145

Model: HTI

310 - 380

ONLY FOR CEILING MOUNTING

A

(mm) B (mm)

1021.6 560

1121.6 650

A

(mm) B (mm)

1475 445

HF61G00269SA HTI-0-UM-GB_CW

Page 10

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

D

B

A

C

Fig. 2 Service area

HTI

unit

HTI unit

DX VERSION

Model A

HTI -073-105-120-310-380

(mm)

0 200 200 200

B

(mm)

C

(mm)

D

(mm)

3.2 Free-cooling duct connections (optional)

The air conditioner may be supplied with an integrated free-cooling device (optional), which uses fresh air from

outside to cool the ambient without starting up the compressor.

The device supplies the correct cooling capacity required, through a modulating motor damper.

In this case, the back side of the unit is equipped with connections collect the outside air, as follows:

10

HF61G00269SB HTI-0-UM-GB_CW

Page 11

11

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

4 Electrical Connections

4.1 Generalities

Before carrying out any job on electrical parts, make sure the power supply is disconnected.

Check that the mains electricity supply is compatible with the specifications (voltage, number of phases, frequency)

shown on the unit rating plate.

The power connection for single-phase loads is to be made with a three-pole cable and “N” wire at the centre of the

star (optional: power supply w/o neutral).

The size of the cable and line protections must conform to the specifications provided in the

wiring diagram.

The supply voltage may not undergo fluctuations exceeding ±5% and the unbalance between phases must always

be below 2%.

The above operating conditions must always be complied with: failure to ensure said

conditions will result in the immediate invalidation of the warranty.

The electrical connections must be made in accordance with the information shown in the wiring diagram provided

with the unit and with current and local regulations. An earth connection is mandatory. The installer must connect

the earthing wire using the earthing terminal situated on the electric control board (yellow and green wire).

The power supply to the control circuit is taken from the power line through an insulating transformer situated on the

electric control board.

The control circuit is protected by suitable fuses or automatic breakers depending on the unit size.

HF61G00269SA HTI-0-UM-GB_CW

Page 12

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

4.2 Starting up for the first time

Electrical connection

• Open the frontal panel of the units

• Turn HTI unit QS main switch OFF.

• Insert the power supply cable using one of the special holes you can find on HTI unit sides and connect it to

QS main switch.

• Connect user interface to microprocessor J10 connector (you can find it in HTS wiring diagram) using a

telephone cable.

• Turn HTI unit QS main switch ON.

4.3 Starting operation

Before starting the unit, turn the main switch on, select the operating mode desired from the control panel and press

the ”ON” button on the control panel.

If the unit fails to start-up, check if the service thermostat has been set according to the nominal values

provided.

You should not disconnect the unit from the power supply during periods when it is

inoperative but only when it is to be taken out of service for a prolonged period (e.g. at the end

of the season).

5 Operating Parameters Setting

5.1 Generalities

All the control devices are set and tested in the factory before the unit is dispatched. However, after the unit has

been in service for a reasonable period of time you can perform a check on the operating and safety devices.

The settings are shown in Tab. 4 and Tab. 5.

All servicing of the equipment is to be considered extraordinary maintenance and may be carried

out BY QUALIFIED TECHNICIANS ONLY: incorrect settings may cause serious damage

to the unit and injuries to persons.

The operating parameters and control system settings configurable by means of the microprocessor control are

password protected if they have a potential impact on the integrity of the unit.

Tab. 4 Setting of control devices

Control device Set point Differential

Differential air pressure switch (outlet air flow) Pa 50 30

Values to be calibrated depending on the application.

Differential air pressure switch (dirty filter) Pa 50 20

12

HF61G00269SB HTI-0-UM-GB_CW

Page 13

13

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

6 Maintenance

The only operations to be performed by the user are to switch the unit On and Off.

All other operations are to be considered maintenance work and must thus be carried out by qualified personnel

trained to do their job in accordance with current laws and regulations.

6.1 Warnings

All the operations described in this chapter MUST ALWAYS BE PERFORMED BY QUALIFIED

PERSONNEL ONLY.

Before carrying out any work on the unit or accessing internal parts, make sure you have

disconnected it from the mains electricity supply.

The upper part and the outlet pipe of the compressor reach high temperatures. Be especially

careful when working in the surrounding area with the panels off.

Be especially careful when working in proximity to finned coils since the 0.11 mm thick

aluminium fins can cause superficial injuries due to cuts.

After completing maintenance jobs, always replace the panels enclosing the units and secure

them with the fastening screws provided.

6.2 Periodical checks

To guarantee a constantly satisfactory performance over time, it is advisable to carry out routine maintenance and

checks as described below. The indications below are related to standard tear and wear.

Tab. 6 Periodical checks

Operation Frequency

Check the efficiency of all the control and safety devices. Once a year

Check the terminals on the electric control board and compressor terminal boards to ensure that they are

securely tightened. The movable and fixed contacts of the circuit breakers must be periodically cleaned and

replaced whenever they show signs of deterioration.

Check the efficiency of the differential air pressure switch and dirty filter differential pressure switch. Every 6 mos.

Check the condition of the air filter and replace it if necessary. Every 6 mos.

Once a year

HF61G00269SA HTI-0-UM-GB_CW

Page 14

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

Remove the grilled panel to access the damper and air filter compartment.

Servomotor

Remove the grilled panel to access the damper and air filter compartment.

Air filter

Fig. 7 Inspecting the air filter

Pull out the air filter.

Check the condition of the filter and replace it if necessary.

Grilled panel

Fig. 8 Inspecting the damper servomotor

Remove the damper fastening screws placed at the side.

Pull out the entire damper section to access the servomotor.

Grilled panel

14

HF61G00269SB HTI-0-UM-GB_CW

Page 15

15

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

7 Troubleshooting

On this pages you will find a list of the most common reasons that may cause the package unit to fail or any

malfunction. This causes are broken down according to easily identifiable symptoms.

You should be extremely careful when attempting to implement any of the possible remedies

suggested: overconfidence can result in injuries, even serious ones, to inexpert individuals.

Therefore, once the cause has been identified, you are advised to contact the manufacturer or

a qualified technician for help.

Tab. 7 Fault-Causes-Corrections

FAULT POSSIBLE CAUSES CORRECTIVE ACTIONS

Check if power is being supplied both to the primary and

auxiliary circuits.

Check whether any alarms are signalled on the

microprocessor control panel, eliminate the causes and

restart the unit.

Invert two phases in the primary power line after

disconnecting them upstream from the unit.

Check the phase sequence relay. Invert the phases on the

terminal board after disconnecting the unit and contact the

manufacturer.

Check for the presence of obstructions in the condenser

section ventilation circuit.

Check whether the condenser coil surface is obstructed.

Check the condensation control device (optional).

Drain and pressurise the circuit and check for leaks.

Evacuate slowly (for more than 3 hours) until reaching a

pressure of 0.1 Pa and then recharge in the liquid phase.

Drain the circuit.

Check the temperatures upstream and downstream from

the valve and filter and replace them if necessary.

Check the efficiency of the condensation control device

(optional).

Warming the bulb with your hand, check whether the valve

opens and adjust it if necessary. If it does not respond,

replace it.

Pressure drops upstream and downstream from the filter

should not exceed 2°C. If they do, replace the filt er.

Check the efficiency of the condensation control device

(where present).

Check the refrigerant level by measuring the degree of

Sub-cooling; if it is below 2°C replenish the charg e.

Pinpoint the cause by measuring the resistance of the

individual windings and the insulation from the casing

before restoring power.

Check the phase sequence relay.

Open the front panels, remove the sheet metal just below

the e-panel (down flow units) and clean it.

The unit does

not start

The compressor

is noisy

Presence of

abnormally

high pressure

Low

condensation

pressure

Low evaporation

pressure

The compressor

does not start

Water out from

the unit

No power supply.

The electronic card is cut off from the power supply. Check the fuses.

Alarms have been released.

The phase sequence is wrong.

The compressor is rotating in the wrong direction.

Insufficient airflow through the condenser.

Presence of air in the refrigerant circuit, as revealed

by the presence of bubbles in the flow indicator

also with sub-cooling values exceeding 5 °C.

Unit overcharged, as revealed by a Sub-cooling of

more than 8 °C.

Thermostatic valve and/or filter obstructed. These

symptoms may also occur in the presence of an

abnormally low pressure.

Transducer fault.

Malfunctioning of thermostatic valve.

Filter dryer clogged.

Low condensation temperature.

Low level of refrigerant.

The circuit breakers or line fuses have been tripped

by a short circuit.

One of the HP or LP pressure switches has tripped. Check on the microprocessor, eliminate the causes.

The phases have been inverted in the distribution

compartment.

The drain pan hole is closed.

The siphon is missing. Check for the presence and provide for a new one.

Unit is not perfectly level Place correctly the unit.

HF61G00269SA HTI-0-UM-GB_CW

Page 16

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

HIGH TECHNOLOGY IN REFRIGERATION DEVICES

Wolf (Schweiz) AG

Dorfstrasse 147

CH-8802 Kilchberg

Telefon +41 43 500 48 00

Fax +41 43 500 48 19

info@wolf-klimatechnik.ch

www.wolf-klimatechnik.ch

All rights reserved. No part of this publication may be reproduced without prior written permission from HiRef S.p.A. HiRef

S.p.A. reserves the right to make changes in specifications and other information contained in this manual without prior

notice. In no event shall HiRef S.p.A be liable for any incidental, special, indirect, or consequential damages whatsoever,

including but no limited to lost profits, arising out of or related to this manual or the information contained herein, even if

Hiref S.p.A. has been advised of, known, or should have known, the possibility of such damages.

16

HF61G00269SB HTI-0-UM-GB_CW

Loading...

Loading...