HIRED-HAND SUPER-SAVER XL, HH-SS-200-XL, HH-SS-175-XL, HH-SS-120-XL, SS-75-XL Instruction Manual

...

♦

MODEL BTUH kW

HH-SS-225-XL 225,000 65.9

HH-SS-200-XL 200,000 58.6

HH-SS-175-XL 175,000 36.6

HH-SS-120-XL 120,000 35.2

SS-75-XL 75,000 21.9

SS-40-XL 40,000 11.7

SUPER-SAVER XLTMHEATER

Agricultural Building Heater – 120 Volt

Hot Surface Ignition ♦ Wash Down Design ♦ 120 Volt (only)

FOR YOUR SAFETY

If you smell gas:

1. Open windows

2. Don’t touch electrical switches

3. Extinguish any open flames

4. Immediately call your gas supplier

CONSIGNES DE SECURITE

Si vous sentez une odeur de gaz:

1. Ouvrez les fenetres

2. Ne touchez pas aux interrupteurs electriques

3. Etegnex toute flamme hue

4. Contactez immediatement votre compangie

de gaz

Retain Instructions for Future Reference

FOR YOUR SAFETY

Do not store or use gasoline or any

flammable vapors and liquids in the

vicinity of this or any other appliance.

CONSIGNES DE SECURITE

II es interdit d′utiliser des liquides

inflammables ou degageant des

vapeurs inflammables, a proximite

de tout appareil fonctionnant au gaz

Part No. 4801-1015 Rev 6-09 Owners Manual Super-Saver XL Heater – 120 Volt

!

!

GENERAL HAZARD WARNING

Failure to comply with precautions and instructions provided with this heater can result

in death, serious bodily injury and property loss or damage from hazards of fire,

explosion, burn, asphyxiation, carbon monoxide poisoning, and/or electrical shock. If

you need assistance or heater information such as an instruction manual, labels, etc.

contact the manufacturer.

!

Keep solid combustibles, such as building materials, paper, cardboard, feathers, straw

and dust a safe distance away from the heater as recommended by the instructions.

Never use the heater in spaces which contain or may contain volatile or airborne

combustibles, or products such as gasoline, solvents, paint thinner, dust particles, or

unknown chemicals. Failure to follow these instructions may result in a fire or

explosion, property damage, personal injury or loss of life.

WARNING

WARNING

Not for home or recreational vehicle use. Installation of this heater in a home or

recreational vehicle may result in a fire or explosion, property damage, personal injury

or loss of life.

!

Proper gas supply pressure must be provided to the inlet of the appliance. Refer to

rating plate for proper gas supply pressure. Gas pressure in excess of the maximum

inlet pressure specified at the appliance inlet can cause fires or explosions, leading to

serious injury, death, building damage or loss of livestock.

WARNING

Likewise, gas pressure below the minimum inlet pressure specified at the appliance

inlet may cause improper combustion, leading to asphyxiation, carbon monoxide

poisoning and therefore serious injury or death to humans and livestock.

The intended use of this appliance is the heating of agricultural animal confinement

The electrical connections and grounding of the appliance shall be in compliance with

the National Electrical Code ANSI/NFPA 70.

Part No. 4801-1015 Rev 6-09 Super-Saver XL Heater – 120 Volt Page 2 of 25

USE OF EQUIPMENT

buildings

.

ELECTRICAL

Table Of Contents

1. Specifications And Requirements..................4

2. Warnings And Cautions.................................5

3. Maintenance And Warranty...........................6

4. Installation......................................................7

5. User Instructions............................................8

6. Outside Mount (Optional)...............................9

7. Component And Wiring Diagram.................10

8. Ladder Type Schematic Diagram................11

9. Servicing Instructions...................................12

10. Pipe Sizing Guidelines.................................17

11. Parts & Assemblies......................................19

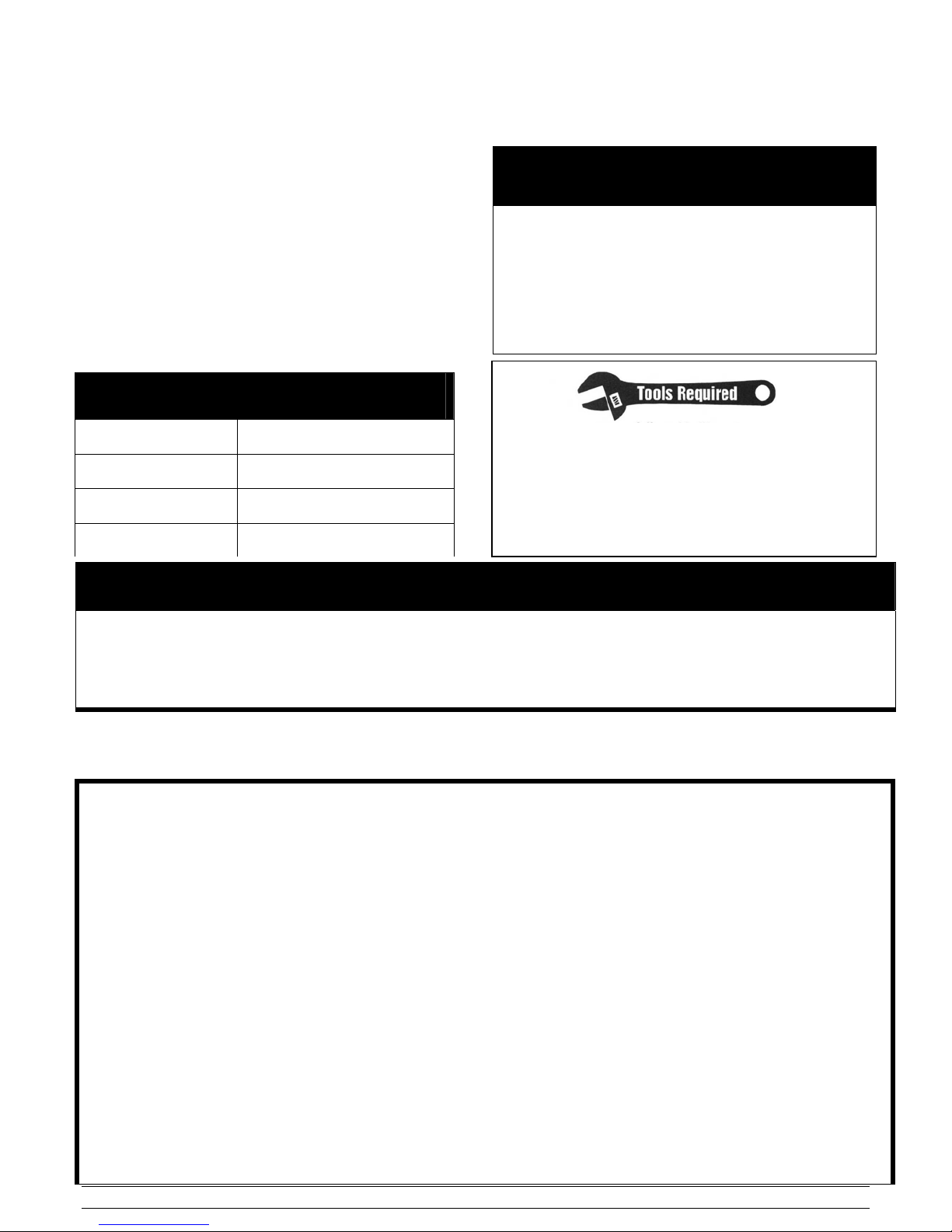

HEATER DIMENSIONS

WEIGHT 130 lb. (60 kg)

HEIGHT 30 in. (76.2 cm)

WIDTH 24-1/2 in. (62.2 cm)

DEPTH 19-1/4 in. (48.9 cm)

Be Sure To Check Delivery!

Locate packing slip and make sure

all of the listed parts are enclosed.

If not, call your Hired-Hand

Distributor immediately.

Adjustable Wrench

Pipe Glue

Install screw hooks with hammer or drill.

Gas Leak Testing Solution

1/4″ (7 mm)

Nut Driver

MINIMUM CLEARANCES

The heater must be located a minimum of 12 inches (305 mm) from the ceiling, a minimum of 12 inches (305 mm)

from the wall on the sides and back, a minimum of 20 inches (305 mm) from the ground, and positioned such that

livestock and combustible materials are unable to come in contact with the heater or within 10 feet (3 meters) of the

hot air discharge. (See Figure 1 - Installation Instructions).

1. Specifications and Requirements

(air required to support combustion)

LP/Propane

Gas

Natural

Gas

Part No. 4801-1015 Rev 6-09 Super-Saver XL Heater – 120 Volt Page 3 of 25

Model No. Maximum Input Ventilation

SS-40-XL 40,000 BTUH (11.7 kW) 500 CFM (849.5 m3/hr)

SS-75-XL 75,000 BTUH (21.9 kW) 500 CFM (849.5 m3/hr)

HH-SS-120-XL 120,000 BTUH (35.2 kW) 1000 CFM (1699 m3/hr)

HH-SS-175-XL 175,000 BTUH (36.6 kW) 1000 CFM (1699 m3/hr)

HH-SS-200-XL 200,000 BTUH (58.6 kW) 1000 CFM (1699 m3/hr)

HH-SS-225-XL 225,000 BTUH (65.9 kW) 1000 CFM (1699 m3/hr)

Maximum 14 in. W.C. (34.8 mbar) and minimum 12.5 in. W.C. (31.1 mbar) inlet gas supply

pressure acceptable at gas regulator connection. Burner manifold pressure 11 in. W. C. (27.4

mbar) at maximum input. Gas pressure should be checked by a certified gas technician while

heater is in operation.

Maximum 14 in. W.C. (34.8 mbar) and minimum 5 in. W.C. (12.5 mbar) inlet gas supply pressure

acceptable at gas regulator connection. Burner manifold pressure of 3.5 in. W. C. (8.7 mbar) at

maximum input. Gas pressure should be checked by a certified gas technician while heater is in

operation.

Refer to heater ratings plate for unit voltage, amperage, and frequency ratings.

2. Warnings and Cautions

!

This appliance is equipped with a three prong (grounding) plug for your

protection against electrical shock and should be plugged directly into a

properly grounded three-prong receptacle. Failure to use a properly grounded

When Heater Is Connected To Remote Thermostat

Heater May Start At Any Time!

ELECTRICAL GROUNDING INSTRUCTIONS

receptacle can result in electrical shock, personal injury or death.

WARNING

CAUTION!

1. Installation must conform with local, state, and national codes, or in the absence of local codes, with the

Standard for the Storage and Handling of Liquefied Petroleum Gases, in accordance with ANSI/NFPA 58

and/or the National Fuel Gas Code, ANSI Z223.1, as applicable.

2. Follow safety, maintenance, and test firing instructions packaged with Heater.

3. Refer to model specifications label for gas type (LP or Natural Gas).

4. Check all connections for gas leaks.

5. Gas supply and regulator must be installed outside building.

6. The hose assembly should be protected from traffic, building materials, and any contact with hot surfaces

both during and while in storage.

7. Do not open heater doors, or remove a heater panel, or move or handle the heater while it is operating,

hot, or connected to power supply.

8. Turn power off before servicing. (Heater may start at any time if power is connected).

9. Heater is not recommended for heating human living quarters.

10. Not to be used for heating where flammable liquids and vapors are stored or used.

11. Inadequate gas volume and (or) pressure will directly influence the combustion efficiency of the heater.

Adequate gas volume and (or) pressure is the responsibility of the installer.

12. Adequate ventilation is required.

13. Combustion and ventilation air must not be obstructed.

14. Not for use with duct work other than types provided by manufacturer.

15. Position heater properly before us e. Heater must be level and in ac cordance with minimum clearances.

16. For safety, this heater is equipped with air flow proving switch and manual-reset high limit switch.

17. Keep temperature of fuel containers below 100° F (37.8°C). Containers must be installed outside

building.

18. Heater must not be operated for one hour following wash-down.

Part No. 4801-1015 Rev 6-09 Super-Saver XL Heater – 120 Volt Page 4 of 25

3. Maintenance and Warranty

MAINTENANCE

1. The appliance area should be kept clear & free from combustible materials, gasoline and other flammable

vapors, and liquids.

2 The flow of combustion and ventilation air must not be ob structed.

3. Your Super Saver XL Heater should be inspected before each use, and at least annually by a qu alified

service person.

4. The hose should be visually inspected prior to each use of the heater. If it is evident there is excessive

abrasion or wear or the hose is cut, it must be replaced prio r to the heater being put into operation. The

replacement hose assembly shall be that specifi ed by the manufacturer. (See parts list).

5. Inspect heater and gas connections periodically for gas leaks with an approved gas leak testing sol ution;

applying a soapy water mixture to gas connections works well. Bubble formation indicates a leak.

6. Keep heater clean at all times.

A. Open doors and blow out dust with high pressure air hose. Be sure interior of burner and flared

end are kept clean.

B. Burner orifice and hot surface ignition assembly must be kept clean and free of carbon build-up.

C. Check blower wheel regularly for dust accumulation and clean periodically for maximum airflow.

D. Thermostat coils must be kept clean to assure proper temperature control.

E. Igniter must be cool before wash down. Do not operate heater for one hour following wash-down.

WARRANTY

Your Super-Saver XL Heater has been manufactured with the finest materials and components

available, and is backed by a one-year warranty against electrical and mechanical defects in

material and workmanship. If this heater fails to operate during this period, return it intact and

prepaid to Hired-Hand, Inc., 1733 Co Rd 68, Bremen, AL 35033 for repair or replacement without

charge at the manufacturer’s option.

Damage by accident or abuse is not covered by this warranty.

This warranty gives you specific legal rights.

You may also have other rights which vary by location.

Warrantor: Hired-Hand, Inc. Bremen, AL 35033 USA

This appliance rating is based on the use of ANSI LC-2 test gases including LP (2500 BTU/ft3,

93.15 MJ/m

regarding the proper operation of this appliance when these conditions a re not met.

3

) and natural gas (1075 BTU/ft3, 40 MJ/m3). Hired-Hand, Inc. makes no guarantees

DISCLAIMER

Part No. 4801-1015 Rev 6-09 Super-Saver XL Heater – 120 Volt Page 5 of 25

4. Installation

r

4.1 Hanging The Heater

Chain Suspension Cable Suspension

Mount the heater with screw hooks and chains so that

the back of the heater is at least 12 inches (305 mm)

from the ceiling and wall. The heater must be a

minimum of 20 inches (500 mm) from floor, and

located so that livestock and combustible materials

are unable to come in contact with heater or within 10

ft (3 meters) of the hot air discharge.

4.2 Directions for Leveling

Adjust cables or chains as required

to level the heater. Use a

carpenter's level to check that the

heater is level.

4.3 Installing Dual-Flare Duct

Fold Dual-Flare duct to shape as

shown in Fig. 1. Install Dual-Flare

duct to heater exhaust (Fig. 1) as

shown with sheet metal screws

provided. This provides a multidirectional heat flow that may be set

by bending flaps.

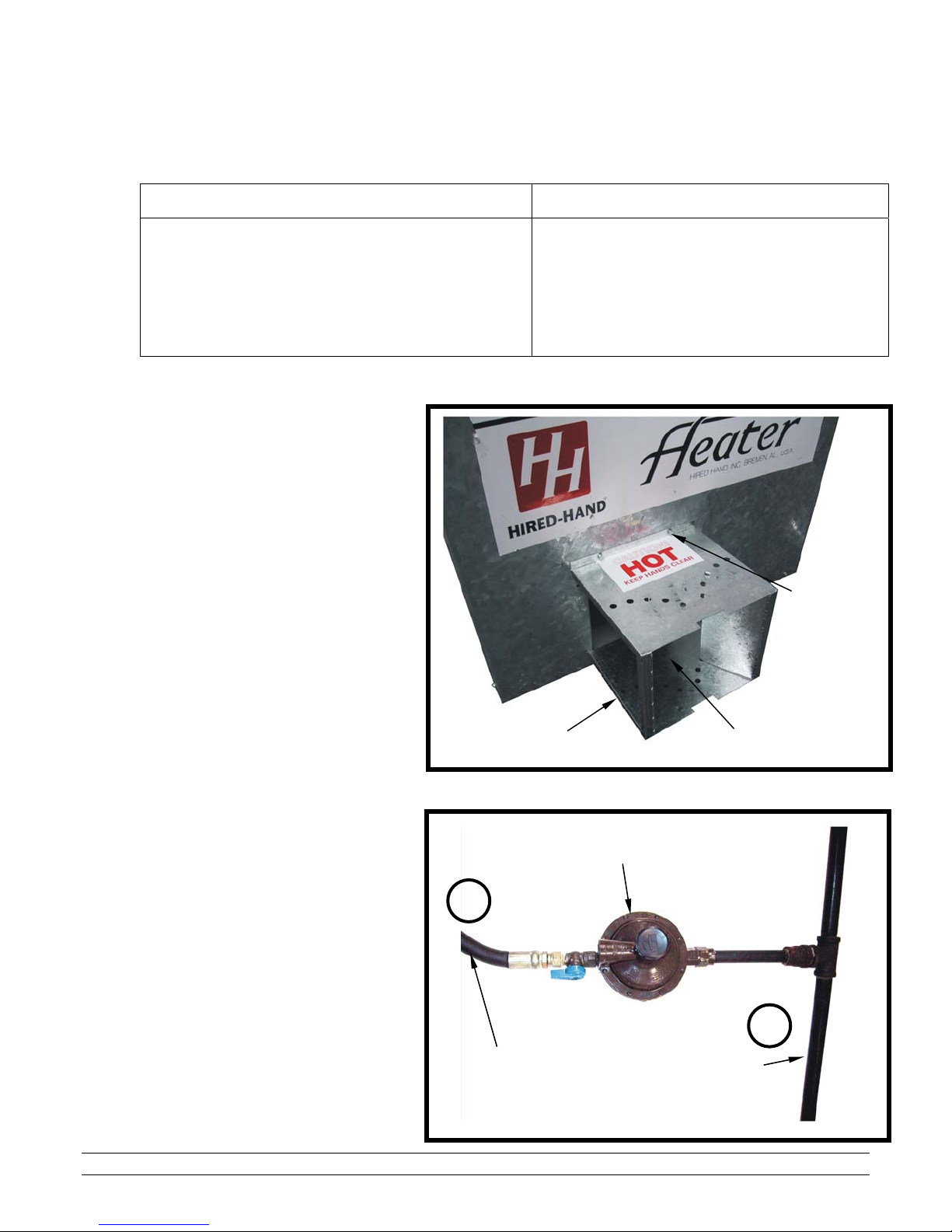

4.4 Connecting the Gas Supply

For gas connection (Fig. 2) attach

regulator to the Hi-Pressure Line (A)

at outside of building. Connect

flexible hose (B) to low pressure end

of regulator with special brass

coupling. See page 1 for LP, and

natural gas requirements.

Fig. 1

Fig. 2

B

If frequent height adjustment is required, use

cables and pulleys. Main line cable would be

connected to a winch.

Flare Duct

Gas Regulato

Fig. 2

Flexible

hose

Adjust Flap To

Direct Heat Flow

High Pressure

Line

Attach Flare

Duct To

Heater With

Sheet Metal

Screws

A

Part No. 4801-1015 Rev 6-09 Super-Saver XL Heater – 120 Volt Page 6 of 25

5. User Instructions

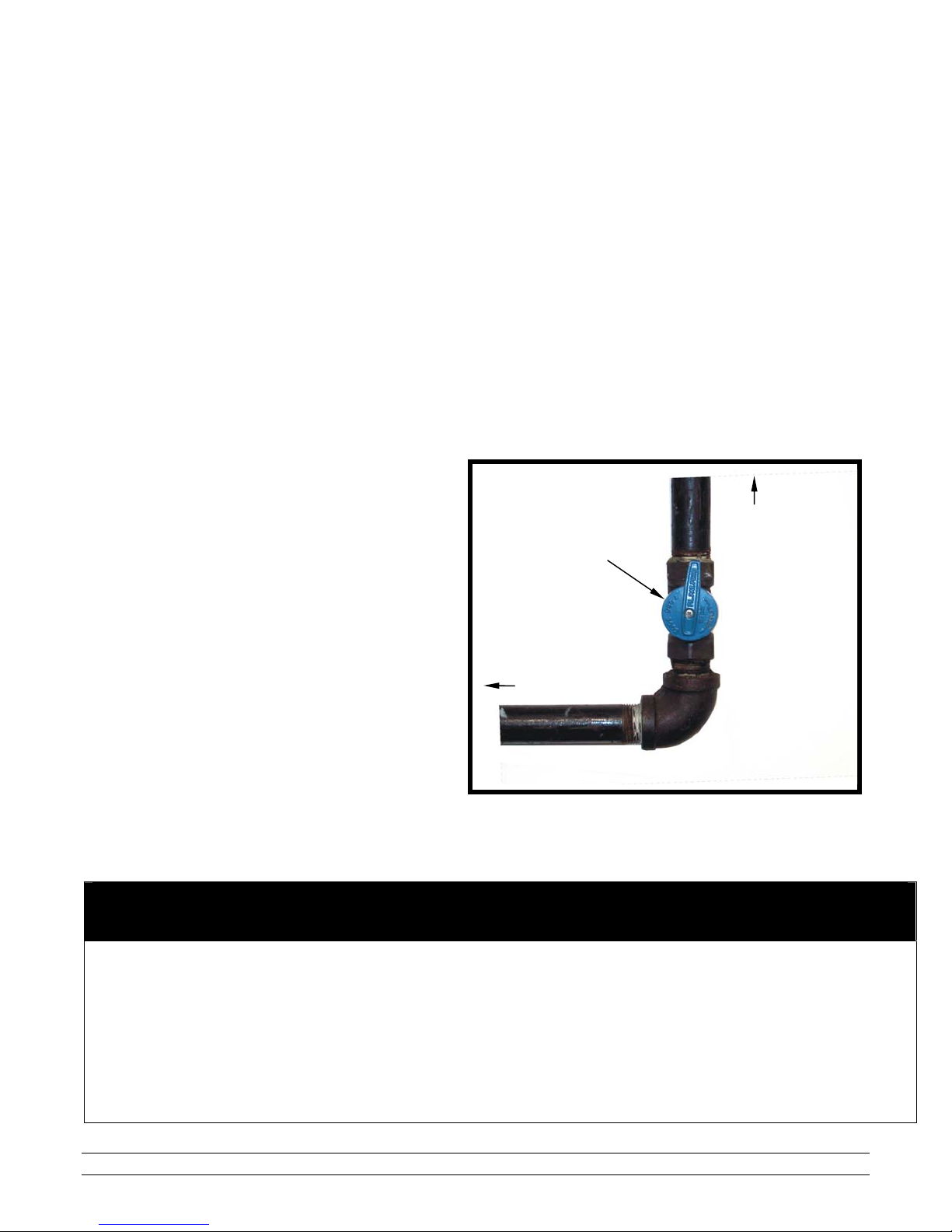

Before turning on gas, check main supply valve to be sure it is open (Fig. 3). Be sure to check all

connections for leaks with a Gas Leak Testing solution, (soap and water work well). Check to see if gas

valve knob is in the ON position. If not, turn counter-clockwise until knob “clicks” into the ON position.

(This may not apply to all units). Turn on gas by turning ball valve handle into vertical position.

5.1 Connecting Electrical Power

Make sure a circuit breaker or similar cutoff device is provided to permit disconnection of

electrical power to heater for service and cleaning. This heater is designed to be wired directly,

with no plugs and outlets necessary. All electrical work should be performed by a certified electrician.

The wiring diagrams on pages 7-8 show how to wire a line power supply directly to the heater’s

terminal block. If no adjustments are made, the heater will operate every time power is supplied and

the on/off switch is activated. If an external thermostat is to be used (See Component & Wiring

Diagram), the heater will operate only when power is supplied, the on/off switch is activated, and the

thermostat indicates a call for heat.

5.2 Starting Up

Adjust thermostat higher than house

temperature. Allow 20 seconds for

heater to ignite. On initial start up or

when heater has not been in service

for some time, heater may require

more than one attempt to purge air

and ignite heater. (IF HEATER

FAILS TO IGNITE. REFER TO

TROUBLE SHOOTING GUIDE).

Adjust thermostat to desired house

temperature.

5.3 Shutting OFF Heater

Shut off main gas supply valve, close

ball valve, and disconnect electrical

power.

Fig. 3

Gas Valve

Shown in

"ON" Position

To Heater

To Gas

Supply

In order to prevent hazardous accumulation of CO2 gases, the heater must

Ventilation requirements are given in 'Specifications and Requirements' on page 1.

Both installer and operator must ensure that the building’s ventilation rate never drops

Part No. 4801-1015 Rev 6-09 Super-Saver XL Heater – 120 Volt Page 7 of 25

CAUTION!

LIMITING EXCESS CARBON DIOXIDE (CO2 )

operate ONLY in a properly ventilated room.

below the noted limits.

6. Outside Mount (Optional)

″

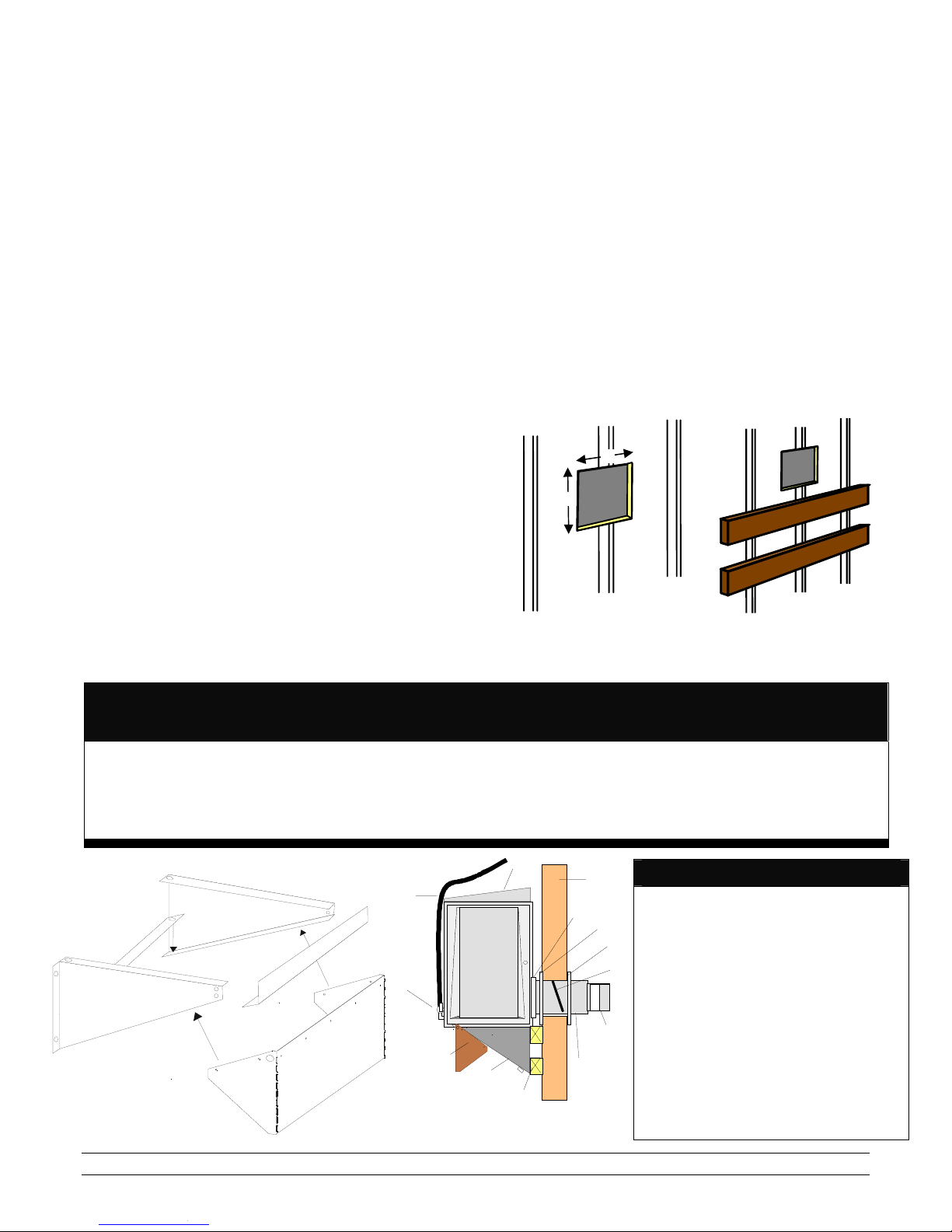

Hired-Hand heaters are available in Outs ide Mount (OSM) models. These heaters are designed to be mounted to

the outside wall of a building. This saves valuable space inside the building and ensures fresh air intake for the

heater. If you have purchased one of our OSM heaters, please read the following before install ing your new heater.

1. Before disposing of the box, cut the installation template

from the side.

2. Position template on outside of building where heater is

to be mounted. Be sure the template is level.

3. Drill 6.3 mm (1/4″) holes through all 8 X’s shown on

template. NOTE: Opening for duct measures 254 mm

(10″) width (W) x 254mm (10″) height (H). See Detail A.

4. Locate 4 X’s for thru-wall extension duct and cut from

one hole to the next until opening is removed. See Detail

A.

5. If additional support is needed, add support by fastening

two 2' x 4' boards on outside of wall where heater

support brackets are to be positioned. The two 2' x 4'

boards are to be fastened to studs inside the wall. See

Detail B.

6. Assemble heater support bracket as shown in Detail C.

7. Attach Insert thru-wall extension duct assembly through

opening in wall. The ‘varmint’ flap, located inside the

thru-wall extension duct, should be positioned as shown

in Detail D.

8. Bend extension duct mounting flange into a rectangle

and fasten around exhaust outlet on front of heater with

sheet metal screws provided.

9. Place heater on support bracket. Support bracket must

be level before heater is set in place.

10. Slide thru-wall extension duct assembly into flange,

and secure with sheet metal screws.

11. Place outer flashing seal around thru-wall extension

duct and secure with sheet metal screws to inside

of wall.

12. Fasten directional duct to extension duct mounting

flange, then bend deflectors until they force heated

air in the desired direction.

13. To continue with installation of your heater, see

‘User Instructions’ section on the next page.

Detail A

Detail B

W

H

W = 254 mm (10

H = 254 mm (10″)

)

CAUTION!

The minimum side clearance to combustible walls must be 305 mm (12 inches).

The minimum clearance between the appliance and rear wall must be 305 mm (12 inches).

Weeds, snow, or other materials must not be allowed to accumulate on heater or adjacent to heater. Heat er and thru-

Part No. 4801-1015 Rev 6-09 Super-Saver XL Heater – 120 Volt Page 8 of 25

wall extension duct must be a minimum of 500 mm (20 inches) above ground and out of reach of livestock.

Detail C

Detail D

9

5

2

3

14

4

10

1

8

6

1. Wall (By others)

2. Rain shield, included with OSM heater.

3. Door, included with OSM heater.

13

4. Mounting brace, included with OSM kit.

12

5. Gas shutoff valve, included with heater.

11

6. Thru-wall extension duct, included with OSM kit.

7. Dual flare duct. Use T-duct included with heater

or use optional OSM Y-duct ordered separately.

8. Extension flange, included with OSM kit.

7

9. Gas hose, optional ordered separately.

10. 2 x 4 Framing for Brace, not included

11. ‘Varmint’ flap, included with OSM kit.

12. Inner flashing seal, included with OSM kit.

13. Outer flashing, included with OSM kit.

14. Wind Guard, included with OSM kit.

Legend

Loading...

Loading...