for Electric Screwdrivers

Power Pack

Operation Manual

(August 2017) No. ET-A018 17C

Please read carefully the operating instructions for the electric

screwdriver and take care to use it properly.

■

Warning

Read and understand the following cautions to use the HIOS electric

screwdriver, exclusive power supply, etc. safely and properly. Failure to

follow all the cautions listed below may result in electric shock, re and/

or serious personal injury.

1. Use the equipment with the indicated proper voltage and always connect the

equipment to ground while in use.

2. For safety, only use the equipment with a commercial power supply equipped

with a short-circuit breaker or safety breaker.

3. If a short-circuit breaker or other circuit breaker trips, stop operation

immediately, disconnect the power cord, and consult a HIOS representative

for repair.

4. Do not use the equipment with wet hands. This could cause an electric

shock.

5. Do not put the equipment near high-voltage/high-amperage machinery.

6. Do not use the equipment in or near a combustible gas, liquid or powder.

7. Do not use the equipment where static electricity (sparking) may occur.

8. Do not use the equipment with anything except a HIOS electric screwdriver.

HIOS can accept no responsibility for problems that occur if a power supply

not made by HIOS is used with a HIOS electric screwdriver.

9. Do not disassemble or modify the equipment.

10. When the equipment is not being used, turn off the power switch and

disconnect the power cord from the outlet.

11. If the equipment overheats or a circuit breaker trips, stop operation

immediately and consult a HIOS representative for repair.

12. Do not abuse the cord. Never drag the power supply by its screwdriver cord

or power cord. When disconnecting the power cord, hold and pull the plug.

13. Do not bring oil-based products or sharp edges near the cords.

14. Only use the equipment in locations with suitable humidity and temperature,

which have no smoke, dust, corrosive gases, etc.

15. Only use the equipment on a stable at surface. Do not stack the equipment

with other objects.

16. Do not put anything on the power supply. This could cause heating.

17. Do not drop or apply strong impacts to the equipment. This could damage the

structure and contents of the equipment. Always check that the equipment

has no damage before use.

18. Keep out of reach of children during use and during storage.

19. Store the equipment in a stable position in a location with suitable

temperature and humidity.

■

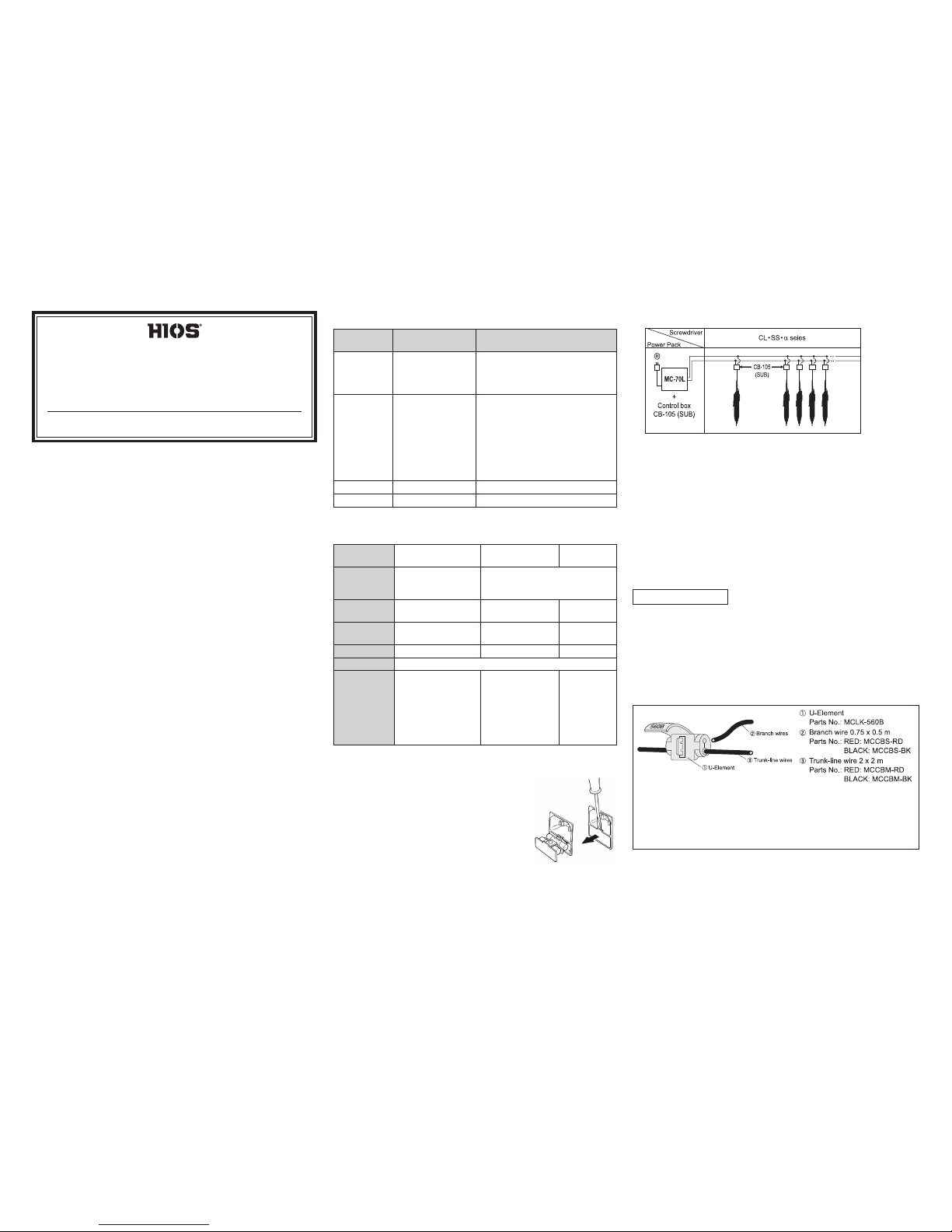

HIOS Screwdrivers Run from Power Packs

Power pack

model

Number

HIOS electric screwdrivers for use with

HIOS power packs

CLT-100 For two drivers

CL-2000, CL-3000, CL-4000,

CL-6000, CL-6500

SS-2000, SS-3000, SS-4000, SS-6500

α

-4500, α-5000

MC-70L For many drivers

Up to 20

CL-2000, CL-3000, CL-4000,

SS-2000, SS-3000, SS-4000

Up to 10

CL-6000, CL-6500, CL-7000,

SS-6500, SS-7000, α-4500, α-5000

Up to 5

α-6500

CLT-75 For one drivers For CL-9000

CLT-75AF For one drivers For CL-9000

■

Specications

Model Name CLT-100 MC-70L

CLT-75

CLT-75AF

Primary Input

Power Source

AC100V/120V/220-240V

±5%

(50/60 Hz)

AC100V ±5% (50/60 Hz)

Secondary

Output Voltage

HI, LOW HI, LOW HI only

Dimensions (mm)

(W) × (D) × (H)

182×145×132

320×220×153

182×220×133

Weight 4 kg 12 kg 6 kg

Cord Length 1.8 m (inlet cord with ground wire)

Accessories –

Trunk-line wire 20 m 1

piece (Black & Red)

Branch wire 0.5 m 10

pieces

(Black & Red)

U-Element 20 pieces

(see reverse side)

–

■

Replacing a Fuse

The LED will not light when the fuse burns

out. If the LED doesn't go on after the fuse is

replaced, the power cord may be damaged.

In this case, discontinue use immediately and

notify a HIOS service agent.

spare fuse

1-16-5 Akiyama, Matsudo City, Chiba Pref., Japan

TEL: 81-47-392-2001 FAX: 81-47-392-7773

HIOS Inc.

■

MC-70L and Control Box Combinations

●

Only one driver can be connected to the model CB-105 control box.

●

Connect the control box between the power pack and the screwdriver.

■

How to Wire the MC-70L Power Pack

There are two plus-minus pairs of terminals on the back of the power

pack's case for connection of the trunk-line wires.

Caution

1. When connecting the trunk-line wire, be sure the red wire goes to

the plus terminal and the black wire to the minus terminal.

2. Use no more than the 20 meters of trunk-line wiring provided. A

longer lead would result in delivery of insufcient voltage that can

cause driver malfunction.

Connecting procedure

1. Use U-Element to connect the trunk-line wire to the control box.

Allow a suitable amount of trunk-line wire, then connect a female

terminals of branch wire to a male terminals of CB-105, making sure

both wires are the same color.

2. Connect the driver's power cord to the control box output connector.

It is recommended that the U-Element (included with the power unit) be

used to attach a branch wire to the main wire.

1. Holding the slot at the bottom of the element open, push the trunk-line wire into the

groove.

2. Insert the cut area of the branch wire through the upper hole from the right and push it

in all the way to the opposite end.

3. Use pliers to forcefully push U-Element at with plastic body.

4. Snap on the insulation cover.

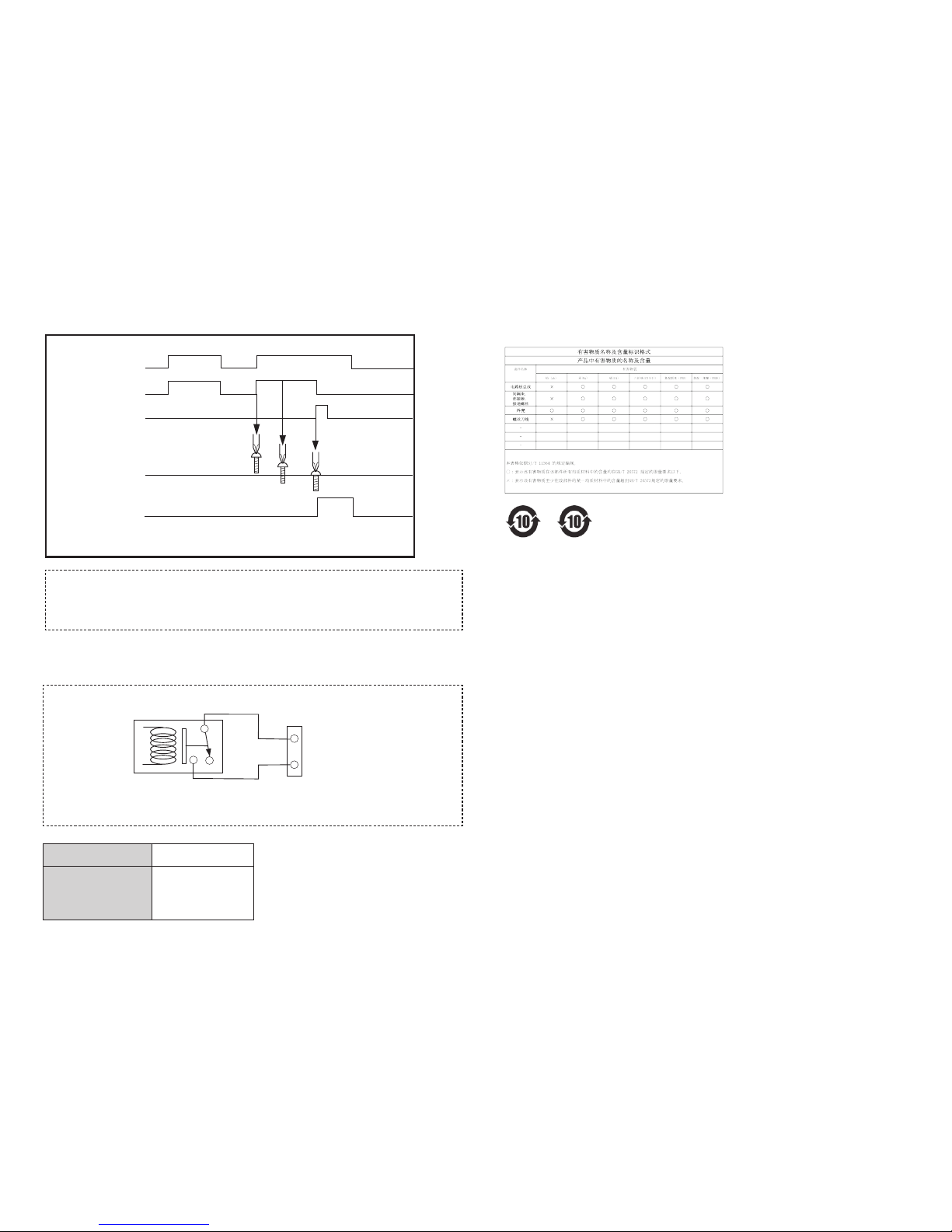

■

Time Chart

■

Finish Output (Relay contact)

On/OFF Time: 20 ms or less / 20 ms or less

Terminal

Contact resistance 100mΩ or less

Max.current 2A 125V AC

1A 250V AC

(1A 30V DC)

Driver start signal

Driver running

Torque up signal

Finish signal*

*Finish signal is not output during reverse-rotaion.

●

When the screwdriver “Torque up” then the screwdriver stop turning.

“Finish signal” is active after “Torque up” of screwdriver until “Lever Off” of screwdriver.

No “Finish signal” for Reversing.

■

China RoHS2 Table

If you export to China by yourselves, below is the table of China RoHS2.

* In addition, if the following mark cannot be found at the rear side of the

product and/or Product box, cut off a mark and stick a mark to the product

and/or product box.

Note: minimum size of China RoHS mark is 5mm at outer diameter

Loading...

Loading...