HIOS HDP-50, HDP-5, HDP-100 Operation Manual

17A

HIOS Digital Torque Meters

HDP-50

HDP-5

HDP-100

Option

Operation manual

(May 2017)

Operation manual No. ET−C007

Utilizing 100% post-consumer

recycled paper pulp

( )

Contents

•

Applications and features of

HIOS Digital Torque Meters ............................1

•

Safety Precautions ............................................ 2

•

HIOS Digital Torque Meter controls and

List of items.................................................... 3

•

Functions............................................................4

•

Operating procedure .........................................5

•

Explanations of functions .............................. 6−8

DIP switch .......................................................6

Torque settings ...............................................6

Memory ..........................................................7

Average torque measurement ........................8

•

Battery charger...................................................8

•

Types of data output...........................................9

•

Customer service ...............................................9

•

Inspection and calibration ..................................9

•

Troubleshooting ...............................................10

•

Specications ...................................................10

•

External features diagram ................................ 11

•

Analog and serial data

output specications .....................................11

•

China RoHS2 Table ..........................................12

However high the quality of your screwdriver, you cannot make full use of its potential unless you know

the right amount of torque for each job and make sure that is the torque being delivered. This instrument

monitors tightening and loosening torque of screws. With an optional attachment, it is also possible to

transfer measurement data to a computer for use in integrated production management systems.

Easy to use, accurate and low in cost, HIOS digital torque meters are used by manufacturers of electronic

goods, cameras, watches and other kinds of precision instruments, as well as by makers of automobiles

and aircraft.

■

Applications

•

Measurement of tightening and loosening torque

(torque increase and slack torque).

•

Torque measurement of other kinds of rotation

tools (may require adapter)

Examples of uses of torque measurement data

•

Reference for preparation of tap screw coun-

terbore diameters

•

Sorting screws by required torque values

•

Classifying jars by screw cap tightness

•

Destructive testing of small parts

•

Quality control of plastic screw threads and

plastic parts

■

Features

•

Up to 100 data measurements can be stored in

memory at a time.

•

Checks maximum, minimum and average torque

measurements.

•

Torque value display can be automatically reset

to zero.

•

Torque value display are automatically recali-

brated.

•

First peak mode (F.PEAK*) measurement

makes it possible to determine slip torque.

*This function may not be available due to fas-

tening condition.

Please inquire to HIOS for the condition.

•

Values are displayed digitally for ease and ac-

curacy in reading out data.

•

The display captures torque peak measurements

until the reset button is pressed to assure accuracy of records.

•

Can be set for rotation in either direction, for easy

measurement of both tightening and loosening

torque.

•

Counterclockwise torque measurement is indi-

cated by a minus sign in front of displayed values.

•

The strain meter is directly attached to the

torque sensor, as part of the instrument's simple,

rugged design.

•

Can be integrated into a statistical process con-

trol system.

•

Small, light and operated by rechargeable bat-

tery, this instrument is highly portable.

•

Data can be output analogically, as waveforms

or numerical printouts, for a wide range of uses.

(Requires optional analog cord.)

•

An input tool is available to make possible trans-

fer of measurement data to a computer. (See page

9 for details.)

•

Comes with an AC adapter that can be used with

100 − 240 volt power sources. Runs on an environment-friendly nickel-hydrogen battery.

- 1 -

Safety Precautions

■

Before using

•

Before you begin using the instrument, read the

operating instructions and also the precautions

given on the seal afxed to the instrument.

•

The torque meter's display unit and sensor unit

come with the same serial number. These two

parts of the instrument are calibrated together;

do not use any different combination.

•

HIOS cannot assume responsibility for ac-

cidents or difculties when the instrument has

been remodeled or disassembled, or when it has

been used in a way other than that explained in

the operating instructions.

■

During operation

•

Be sure to attach the bit securely into the sensor

unit chuck.

•

For safety, make sure the bit never points at

anything other than the tool to be measured.

•

When using the support arm that comes with

Model HDP-50, be sure to attach it securely to

prevent it from coming loose under high torque

loads.

•

To avoid damaging the sensor unit, do not sub-

ject it to rough handling.

•

If the torque meter shows any functioning ab-

normality, cease operation immediately and

contact HIOS Corporation or your HIOS dealer.

•

Operators of power tools should always button

cuffs and shirt fronts and fasten zippers on apparel when conducting operations.

•

Operators of power tools should not wear gloves,

as this interferes dangerously with having a

proper grip on the tools.

■

Precautions in operating a digital

torque meter

•

Never exceed the maximum torque levels indi-

cated in the specications on page 10. Exceeding capacity load levels by 120% will result in

internal damage to the meter.

•

The battery charger is for NiMH batteries only. Nev-

er use any other kind of battery, even from HIOS.

•

Do not disassemble the instrument or loosen the

screws on its body, as this could cause inaccuracy in measurement.

•

Protect the display and sensor units from shocks

or impacts.

•

Always detach the bit from the sensor unit after

use.

•

Use of the battery charger

See page 8 for instructions on battery charging.

•

Use only the products specied in these operat-

ing instructions for connection to the data output ports.

•

When disconnecting cables, grasp the cable plug

and take care not to damage connector pins.

•

Always turn the power switch off after complet-

ing measurement operations.

•

Do not strike the acrylic display panel or place

heavy objects on it.

•

Avoid excessive internal adjustments for calibrat-

ing or other purposes.

•

Handle the instrument with care and take care

not to drop it.

•

This instrument is sensitive to ambient condi-

tions. Avoid using it in the following kinds of

places:

•

Places where water, oil or other liquids could

fall onto or get inside the instrument.

•

Places subject to vibration, dust or hot air.

•

Outdoors, or places where electrical discharges

may occur.

•

Places of high temperature or humidity. (Operat-

ing humidity and temperature ranges for digital

torque meters are 25% − 65% and 15℃ − 35℃).

•

Any other place where there is a danger of the

instrument being damaged or its functioning

impaired.

•

Please do not store the instrument in places of

high temperature or high humidity. This could

result in condensation forming inside, which

could endanger functioning.

Please read the following safety precautions

to ensure safe and correct operation.

- 2 -

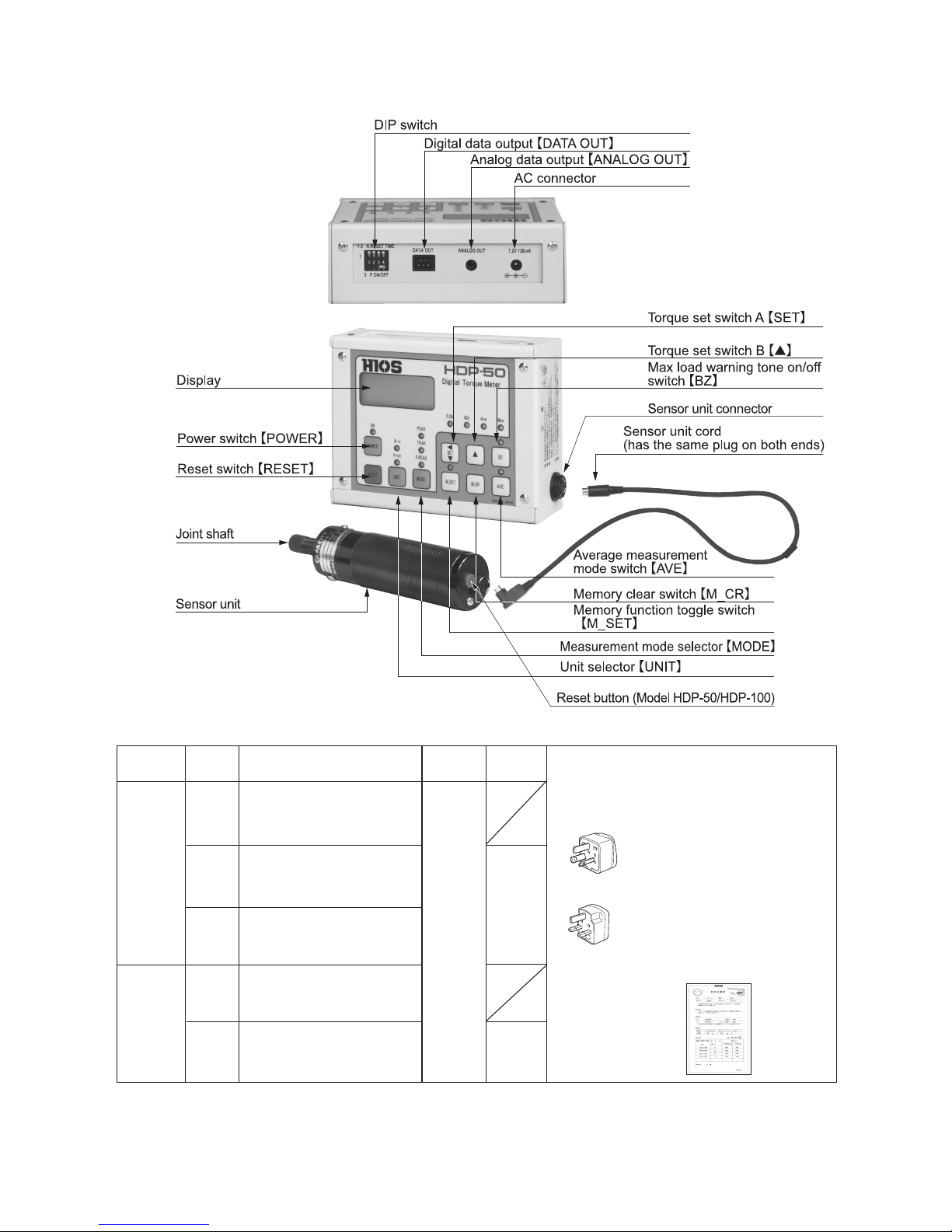

■

Items included with torque meter

Bit

Support

Arm

HDP-50

HIOS shank ∅4

+Bit #0 × 40 mm

#1 × 40 mm

#2 × 40 mm 1 piece each

HDP-5

1 pc.

Model

Sensor

Unit Cord

1.7 m

1 pc.

Part No.

DPC-0506

•

The main unit and accessories come all together in a dedicated aluminum attache case.

■

HIOS Digital Torque Meter controls

Exclusive Battery Charger 1 pc. ( See p4)

Calibration Sheet

(quantity: 3)

●

Please ask your distributor if you

want to know the plug type for the country not described in the list(page.4).

●

The conversion plugs (attached with

TCH-MULTI-CE area) will be no longer

available as soon as the current stock

has run out.

We would like to ask those, who use BF

and S plug, to get them locally.

220 Volt Adaptor Plug

Market

Areas

China

Japan

Korea

Taiwan

Hong Kong

Singapore

Europe

U.S.A.

Canada

U.K.

Australia

HDP-50

HDP-5

HIOS shank ∅5

+Bit #0 × 60 mm

#1 × 60 mm

#2 × 60 mm 1 piece each

6.35 mm hex shank

+Bit #1 × 50 mm

#2 × 50 mm 1 piece each

6.35 mm hex shank

+Bit #1 × 50 mm

#2 × 50 mm 1 piece each

1 pc.

6.35 mm hex shank

+Bit #1 × 50 mm

#2 × 50 mm 1 piece each

HDP-100

(option)

HDP-100

(option)

Type BF

Type S

- 3 -

■

Functions

Control Function

Power switch【POWER】 Button switch. The LED lights when the power is on. *

1

The power is automatically turned off when the instrument is not operated (or torque

load is less than 10) for a period of 10 minutes.

Reset switch【RESET】 Used to return the display to zero or print out data.

Display Measuring unit display

Unit selector【UNIT】 Switches between one of the following combinations of torque measurement units,

depending on which combination the purchaser ordered: N

•

m↔lbf•in, N•m↔N•cm,

N

•

m↔kgf•cm

Measuring mode selector PEAK: Freezes display at peak torque value. (Press reset to cancel)

【

MODE】 TRACK: Displays current torque value.

F.PEAK: Freezes display at rst peak torque value.

AC connector For battery charger.

Analog data output Port for analog voltage data output.

【

ANALOG OUT】

Digital data output Press reset to output measurement data. This functions makes it possible to use the

【

DATA OUT】 instrument in statistical process control systems.*

2

DIP switch For setting auto reset timer and turning data output on ("P.ON" LED indicates "on"

setting).

Torque set switch A【SET】 Sets maximum torque load at which warning tone will sound.

Memory function toggle switch The LED lights when the memory function is on.

【

M_SET

】

Torque set switch B

【▲】

Sets the torque level at which the warning tone sounds.

Max load warning tone The LED lights when this function is on.

on/off switch【BZ

】

Memory clear switch【M_CR】 Deletes data in memory.

Average measurement When average measurement mode is on, the LED lights and the torque measure-

mode switch【AVE】 ment average values are displayed.

Support arm (comes with Model HDP-50/HDP-100)

Use the support arm when measured torque is too high for the operator to control

without assistance. It makes stable measurement possible with merely a light touch.

*1 Please push the power switch and detach it immediately until a buzzersounds.

*2 Statistical Process Control (SPC) uses statistical techniques to monitor variations in manufacturing processes for use in quality control.

Support arm

Model N•m N•cm

HDP-5 0.000 0.0

HDP-50 0.00 0

HDP-100 0.00 0

Part No.

TCH-MULTI 1 pc

(for AC100-240V, A plug)

PSE, cUL, UL

JAPAN, U.S.A, Canada,

Mexico, Taiwan, Thailand,

Philippines

Part No.

TCH-MULTI-CN 1 pc

(for AC100-240V, A plug)

CCC

China

Part No.

TCH-MULTI-CE 1 pc

(for AC100-240V, A plug)

CE

Vietnam, Indonesia, India,

Singapore, Malaysia, Korea,

Hong Kong, U.K., Ireland,

South America, The Middle

East, New Zealand

Part No. TCH-EU 1 pc

(for AC100-240V, C plug)

CE

Europe (except U.K.,

Ireland)

• Battery Charger

- 4 -

Loading...

Loading...