HIOS BLT-AY-71, BLT-AY-61 Instruction Manual

Power Supply for Automatic Brushless Screwdriver

BLT-AY-61 / BLT-AY-71

Instruction Manual

(April 2018)

No.ET-A048 18A

Table of Contents

03 Safety Instructions

04 What Can Be Done with This Unit:

05 Parts and Their Functions

Front

Rear

Conguration of I/O Circuit

Inside the Cover

Switching Between Reading Start and Pulse Start

09 Change the Operational Settings of the Automatic Screwdriver

Basic Setting Procedure

List of Setting Items and Setting Values

12 Relation Between the Rotation Number and Torque of the Automatic Screwdriver

BLF-2000/BLF-5000

BLF-7000/BLF-7000X/BLF-7025X

PGF-3000/PGF-5000/PGF-7000

15 Torque Up Settings

Clutch Mechanism

17 Timing Chart Table

36 Specications

External Dimensions

38 Terminology Related to This Unit

39 China RoHS2 Table

03

Installation

◦ Do not install this unit in a place with a lot of dust, dirt,

metal pieces, etc.

◦ Use this unit in the operating environment of

temperatures between 5 to 40 °C and humidity of 80%

or less (no dew condensation).

◦ Do not place heavy objects on top of this unit or stack

them.

◦ Choose a stable location with no vibrations. Especially,

when installing this unit in a high place, x it rmly.

◦ Do not install this unit near high-voltage equipment

or in a noisy environment.

Handling

◦ On any commercial power supply, be sure to install an

earth leakage breaker and a safety breaker.

◦ Connect the earth wire and use this unit with the

specied rated voltage.

◦ The load connected to the output terminal on the

back should not exceed the rated load. Exceeding the

rated load may cause a malfunction.

◦ If external devices connected to the I/O ports on the

back are aected by the electromagnetic induction

load from the relay, solenoid valve coil or others, take

measures against noises by using a diode to absorb

reverse voltage. Otherwise, it may cause a malfunction

and failure.

◦ When the automatic screwdriver is locked or

overloaded, the overload protection works. Please

note that if the overload protection works frequently,

that operation may impose a load larger than the

capability of this unit or the automatic screwdriver.

◦ Even if it is properly used, if the overload protection

works frequently with abnormal events including

heat-up, immediately stop using it, turn o the power,

unplug the power cord, and send it to our service

department for repair.

◦ When you tighten screws of workpieces such as resin

products that are charged with a lot of static

electricity, discharge them before screw tightening. If

the workpieces are not completely discharged, static

electricity may ow into the unit from the tip of the bit

causing malfunctions.

◦ When external equipment is to be used with an

external power supply using the function of this unit,

use the GND as the common terminal.

◦ Failure to do so may cause a malfunction and failure.

◦ Do not apply a voltage to the input side. It may cause

a malfunction.

◦ Do not make the wiring for input / output longer than

necessary.

◦ Note that bundling power cables together may cause

a malfunction.

◦ Do not connect parts other than specied ones to the

connection part of this unit. It may cause a

malfunction.

◦ Do not disassemble or remodel this unit. It may cause

a malfunction.

◦ In that case, we may not be able to accept your claim

for warranty or repair.

◦ Do not cause any strong impacts or vibrations against

this unit.

◦ Do not drag cords and do not allow them to touch oil

or sharp edges, or to be trapped under heavy objects.

◦ When connecting/disconnecting the power cord or

screwdriver cord, always hold the plug.

◦ If it is not used for a long time, turn o the power and

disconnect the power plug from the outlet for safety.

Illustrations

◦ Illustrations used in this manual are those for BLT-

AY-61 unless otherwise specied. However, if models

have dierences, multiple illustrations are also

displayed with the model names such as "BLT-AY-61 /

BLT-AY-71."

Safety Instructions

Please read this instruction manual carefully before use to ensure proper operations.

04

What Can Be Done with This Unit:

◦ Rotation speed can be switched between high and low, and each speed has 11 steps.

◦ The forward and reverse rotations as well as high speed and low speed rotations of the automatic screwdriver

can be externally controlled.

◦ The FOR input for forward rotation can be switched between pulse/reading (for details, see P.08).

◦Tightening check (impact number) can be set, and torque-up trigger in forward or reverse rotation can be

selected.

Note:

Torque-up for reverse rotation is not available for a standard automatic screwdriver because the one-way

clutch works.

◦ For tightening reverse screws, a special automatic screwdriver for reserve screws is required.

◦A special automatic screwdriver for reverse screws is available as an option. Please contact our distributor.

◦ When using the forward rotation screwdriver for reverse rotation, set the reverse torque-up to U0 or d0 (for

example, when engaging a screw with the bit).

◦ The mode of the signal input can be selected in coordination with the movement of the cam movement when

torque-up is set. Also, torque-up for reverse rotation can be set (in the case where the screwdriver for reverse

screw is used).

Example 1: set to U1 (torque-up trigger: once) to tighten a screw at high speed with one impact

Example 2: set to d3 (torque-down trigger: 3 times) to tighten a screw at low speed with three impacts

◦Overtime protection

This is to protect this unit and the automatic screwdriver. Even if the screwdriver happens to keep rotating, it

can stop automatically, and the buzzer noties it when the overtime protection is set on the controller.

◦Overload protection

This is to protect this unit and the automatic screwdriver. If the screwdriver happens to receive overload, it can

stop automatically and the buzzer or the display noties it.

Note:

If the overload protection works frequently, that operation may impose a load that exceeds the capability of this

unit or the automatic screwdriver.

◦ The built-in buzzer can be switched o. (For details, see P.08.).

◦ The terminal block on the rear panel is detachable, and it is easy to install or replace it.

Note:

◦BLT-AY61 is only for BLF-2000/BLF-5000 and PGF-3000/PGF-5000.

◦BLT-AY71 is only for the BLF-7000 series and PGF-7000.

◦ Please do not connect the screwdriver to any power source other than specified one. Otherwise, it may cause a

malfunction or a problem.

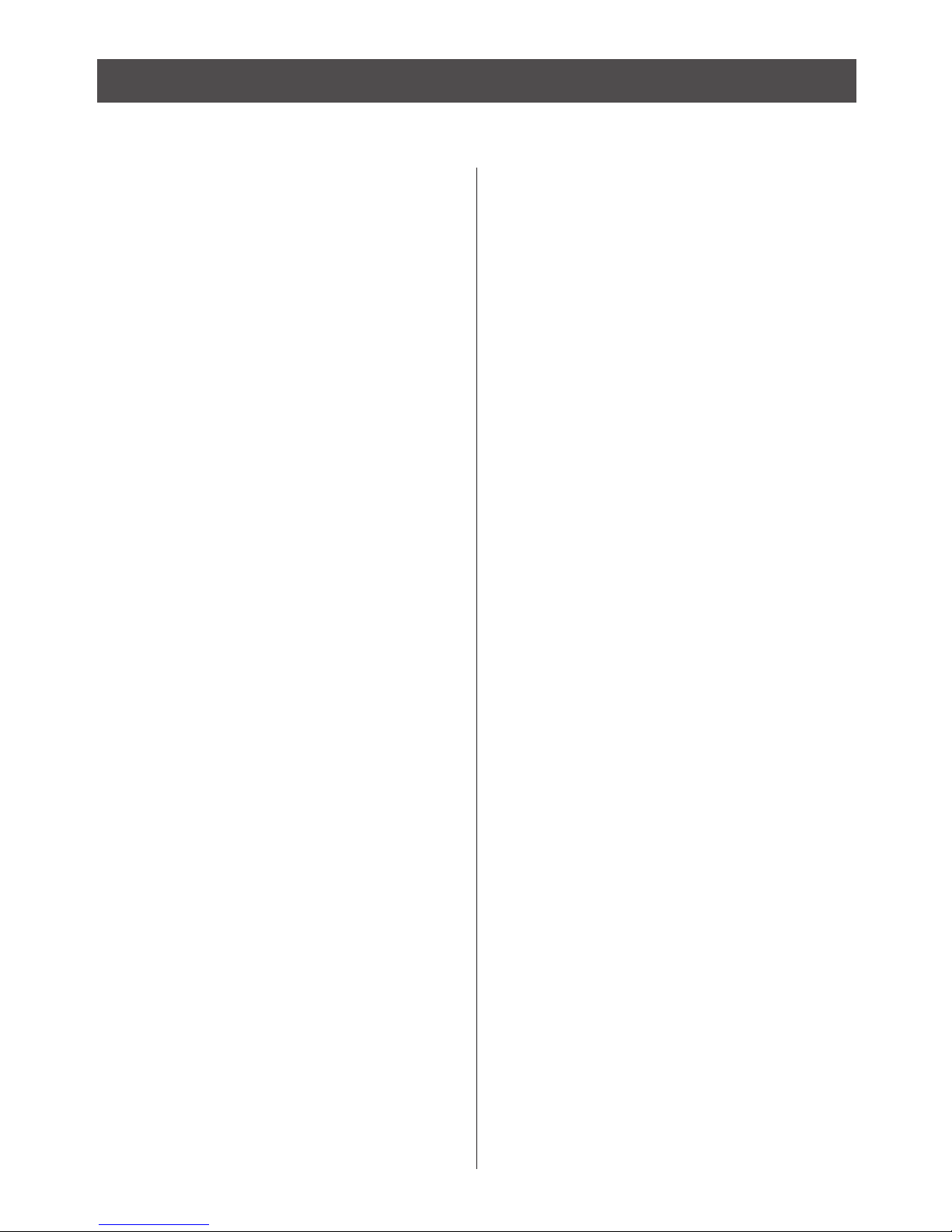

05

Parts and Their Functions

The functions on the front and rear are displayed commonly on BLT-AY-61 and BLT-AY-71.

■

Front

❶

❸

❹

❺

❷

❶

Power indicator

Lights up when the machine is power ON.

❷

Operation display LED

The external I/O and the operational conditions of the screwdriver can be checked by looking at LEDs’ on/o.

❸

Setting value display 7-segment

The number of torque-ups and the set rotation speed for the automatic screwdriver are displayed.

TUP FIN REV RES 2WS OVT

This is displayed when the overload protection works.

To release this, turn off the power of this unit and wait for one minute before turning it on again.

What does OL mean?

Note:

If the overload protection works frequently, that operation may have been imposing a load

that exceeds the capabilities of this unit or the automatic screwdriver.

Cases of overload

・The screwdriver is misaligned to the screw hole

・No device (such as a damper) to alleviate the shock to the screwdriver is attached

・The interval of screw tightening is too short

・ In case of screws with hexagonal socket holes or screws with hexalobular socket holes; they

are likely to be obliquely tightened

・

In case of tightening a tapping screw with a long neck on a sticky material such as resin material

❹

MODE button/ UP button/ DOWN button/ ENT button

The operational settings and the related values for the automatic screwdriver can be changed. For details, see

P.09.

❺

Connector for the brushless screwdriver

The screwdriver cord is connected here.

06

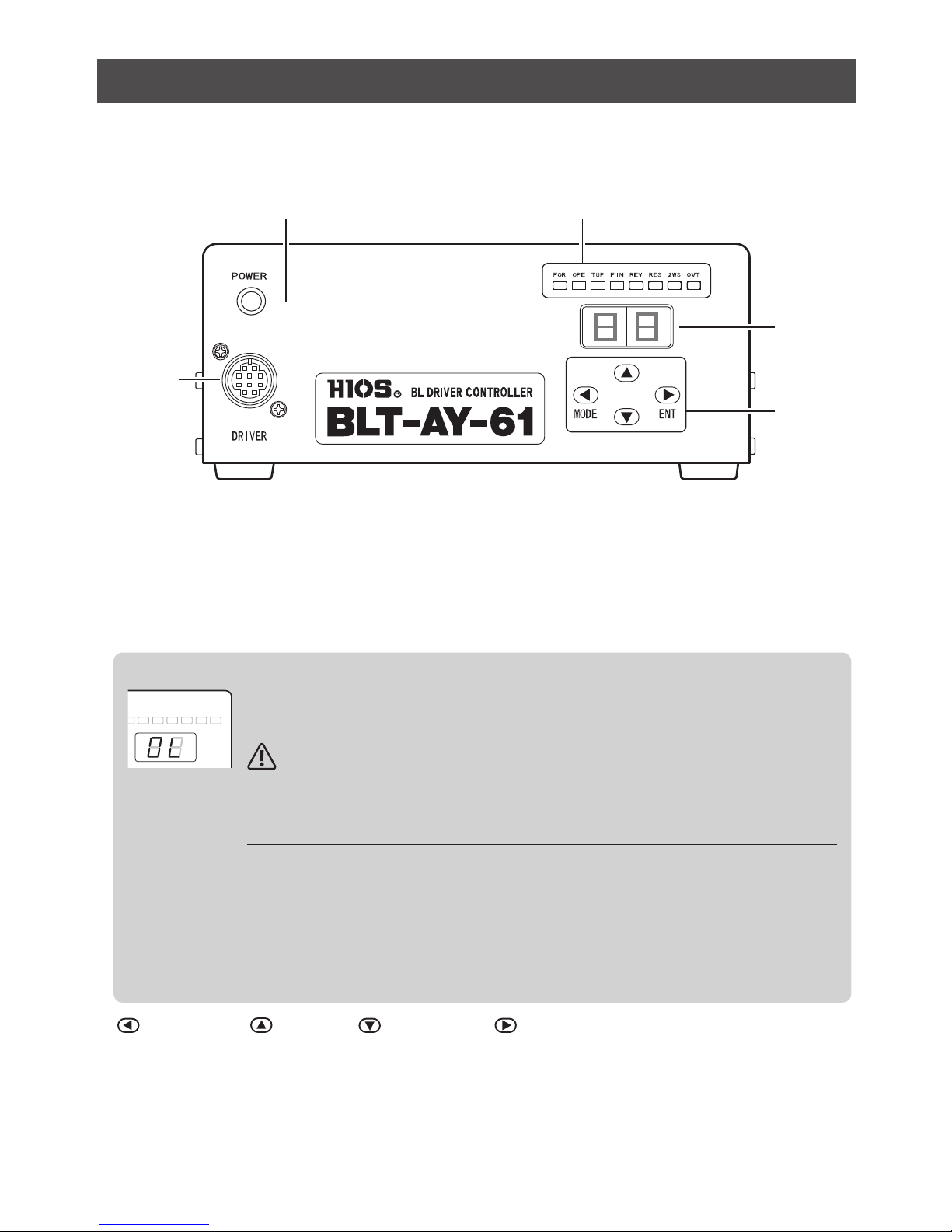

■

Rear

REV

2WS

RESET

FOR

NCNCNC

NC

FINISH

COM

1 2 3 4 5 6 7 8 9 10

❶

❸❷

❶

Inlet with a fuse holder

Connect the power cord here.

❷

Main SW

This switch turns power on and o. When turning on, the switch lamp is lit and the operation display LED and

the setting value display segment are lit for about 1 second.

❸

External I/O terminals/terminal block connector on the main unit side

Connect the terminal block connector here. The forward and reverse rotations as well as high speed and low

speed rotations of the automatic screwdriver can be externally controlled.

No. I/O Signal name Description

1 External output FINISH output

The signal is output when screw tightening is completed. It is canceled

when next FOR or REV input comes in or when there is a RESET input.

2 Common COM The signal is common for input and output.

3 External input REV input

The signal is input to make the screwdriver rotate reversely. Reverse

rotation continues as long as there is input.

4 External input 2WS input

The rotation speed of the automatic screwdriver can be switched

between two steps. The speed is LOW as long as there is input.

5 External input RESET input This is used to stop the automatic screwdriver.

6 External input FOR input

This is used to rotate the screwdriver forward.

The start type can be selected either pulse start or reading start.

The switching from one type to another can be done using the DIP SW

built in the board (SW6-2). (For details, see P.08.)

●

Pulse input

The forward rotation starts when a pulse (100mS or larger) is entered as

FOR input.

To stop the rotation, enter a RESET input.

●

Reading input

The forward rotation continues as long as there is a FOR input.

To stop the rotation, either turn o FOR input or enter a RESET input.

07

Con guration of I/O Circuit

−

+

No.6: FOR input terminal

The input circuit consists of

the photo coupler input.

Drop the input terminal to

the GND level with an open

collector or the like.

When importing the output, do so within the speci ed range.

(Maximum DC 24V 500mA. Be careful not to exceed this maximum

value due to a counter-electromotive force especially when connecting

inductive devices such as a relay. Also, for both input and output,

make the wiring to the connected device as short as possible and take

measures against noises.)

Dry contact is used for

the output circuit.

One side is shared with

GND.

No.5: RESET input terminal

Circuit con guration same as above

Circuit con guration same as above

Circuit con guration same as above

No.4: 2WS input terminal

No.3: REV input terminal

No.2: COM input terminal

No.1: FINISH output terminal

Internal circuit

Internal

circuit

Internal power source

+12V

12V 10mA max

Transistor, photo-coupler,

etc.

Example of external circuit

Load

resistor

Load

resistor

GND

08

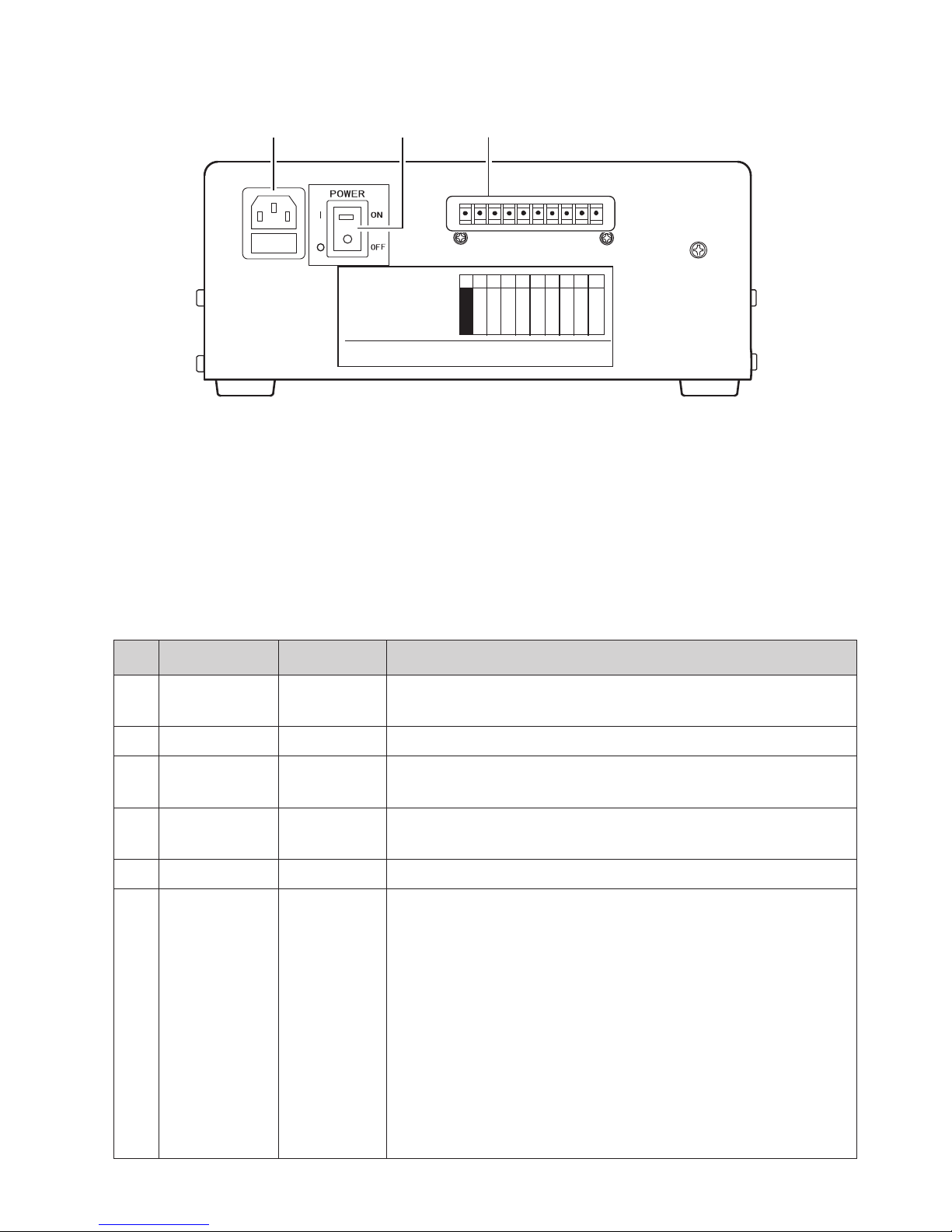

■

Inside the Cover

❶❷

DIP SW

Screws on the side

❶

SW of the buzzer

This can sound or mute the buzzer.

・

ON: sound

・

OFF: mute

❷

SW for reading/pulse start

This can switch the start mode.

・

ON: pulse start (factory setting)

・

OFF: reading start

Switching Between Reading Start and Pulse Start

1. Turn o the power of this unit and unplug the power cable from the outlet.

2. Remove the screwdriver cord from the connector.

3. Unscrew eight screws on the side and remove the cover of the unit.

4. Change the SW6-NO.2 on the board on the front side inside the unit.

Be careful that nothing is left inside of BLT-AY-61/BLT-AY-71.

5. After completion, attach the cover.

09

Change the Operational Settings of the Automatic Screwdriver

To change the settings of the automatic screwdriver, input RESET and turn o all the operation display LEDs by

cancelling the inputs such as 2WS.

■

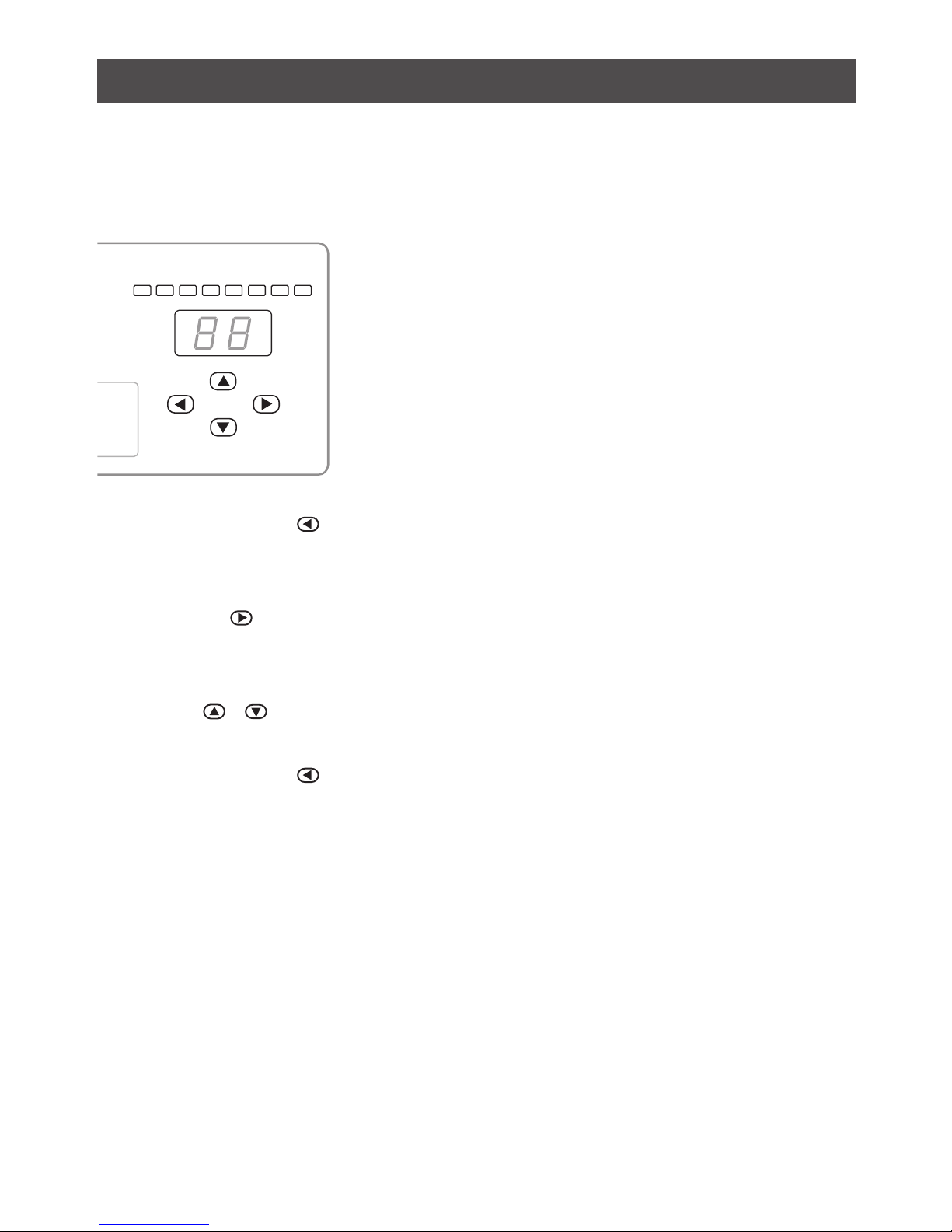

Basic Setting Procedure

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

1 Press and hold the button.

◦ The buzzer sounds twice in 2 seconds and the setting mode starts.

◦The operation display LED and the setting display segments are lit.

2 Press the to select a target item.

◦The operation display LED and the setting display 7-segment will change.

◦For the setting items, see P.10.

3 Press / to change the setting value.

◦For the setting value, see P.10.

4 Press and hold the button.

◦ The buzzer sounds twice after 2 seconds and the setting mode ends.

◦The operation display LED and the setting display segments turn o.

10

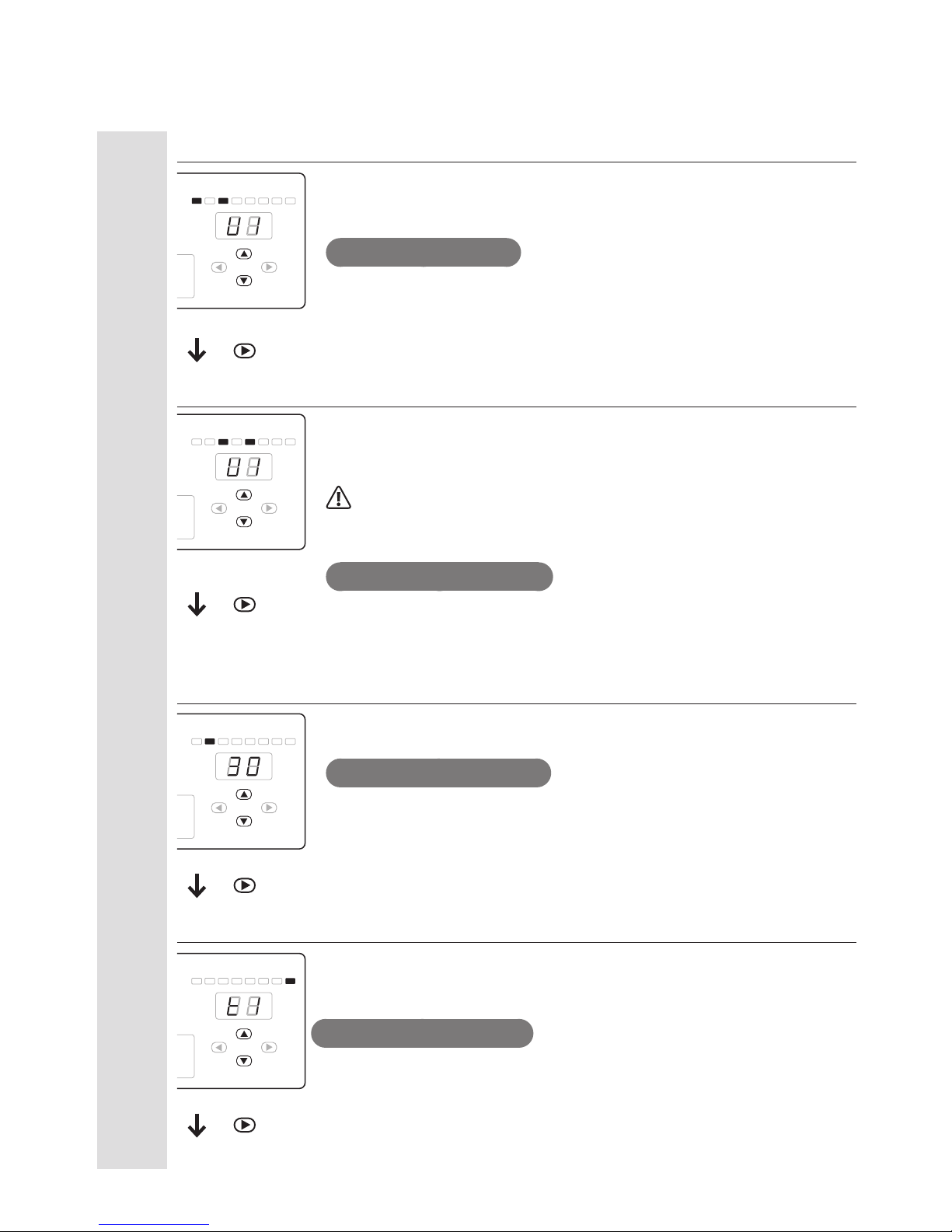

Setting of the number of impacts for forward rotation and torque-up trigger

This is to set the number of impacts in forward rotation and the type of torque-up

trigger.

When U0/d0 is set, impacts continued to be applied without torque up.

Setting value (initially U1)

U: Up trigger

d: DOWN trigger

0 to 4: the number of impacts

Setting of the number of impacts for reverse rotation and torque-up trigger

This is to set the number of impacts in reverse rotation and the type of torque-up

trigger.

When U0/d0 is set, impacts continued to be applied without torque up.

Note:

When reverse rotation is used for the screwdriver specied with the forward

rotation, never fail to set this U0 or d0.

Setting value (initial value: U0)

U: UP trigger

d: DOWN trigger

0 to 4: the number of impacts

Setting of rotation speed

This sets the high rotation speed among 11 steps. For details of setting value and

rotation speed, see P.12.

Setting value (initial value: 30)

20 to 30

Overtime setting

If the automatic screwdriver keeps rotating, this stops it automatically to protect this

unit and the screwdriver.

Usually, set this in the program on the system including PLC.

Setting value (initial value: t0)

t0 to t9 (t1: about 10 sec. to t9: about 90 sec., t0: about 42 minutes)

■

List of Setting Items and Setting Values

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

Rotation

setting

HIGH

To LOW

11

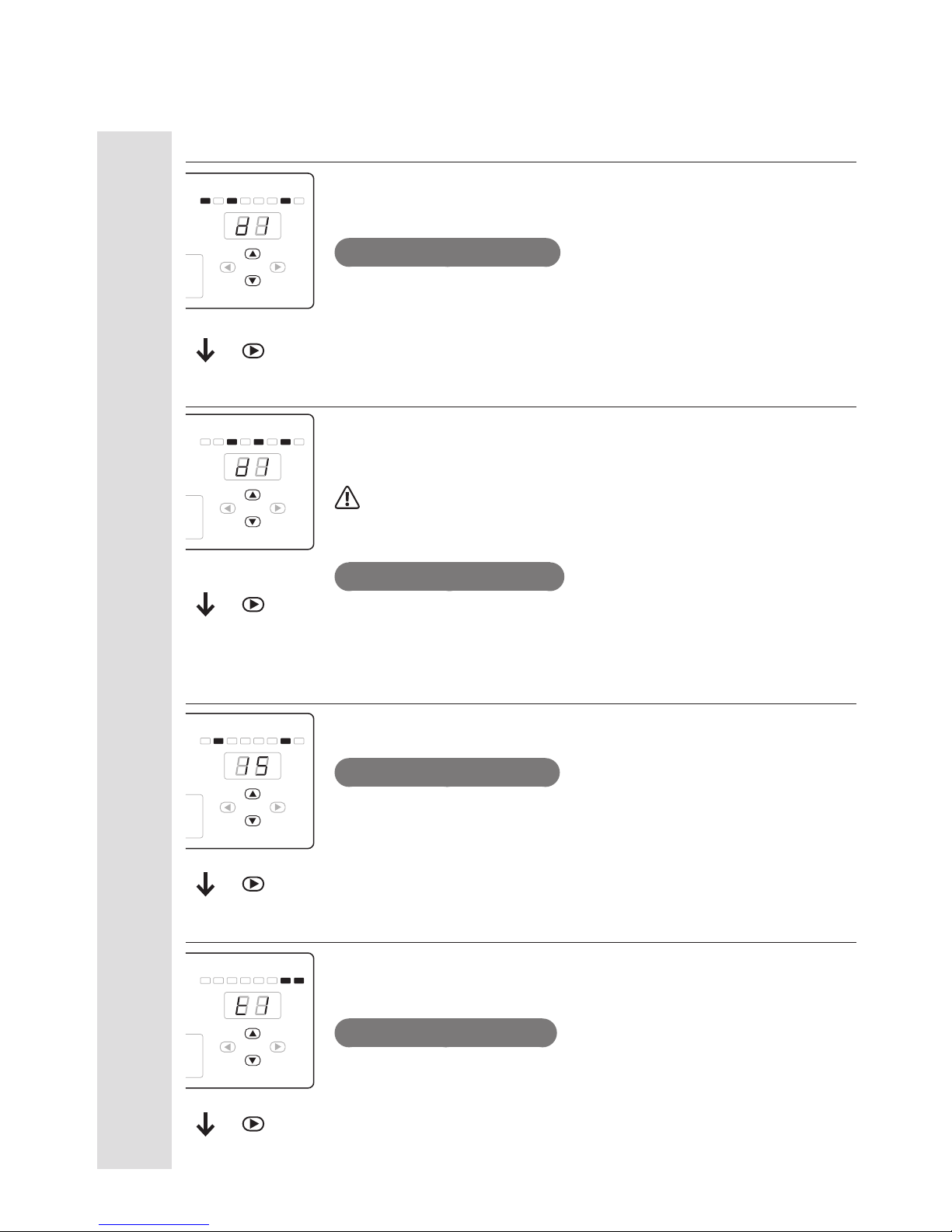

Setting of the number of impacts for forward rotation and torque-up trigger

This sets the number of impacts in forward rotation and the type of torque-up

trigger.

When U0/d0 is set, impacts continued to be applied without torque up.

Setting value (initial value: d1)

U: UP trigger

d: DOWN trigger

0 to 4: the number of impacts

Setting of the number of impacts for reverse rotation and torque-up trigger

This is to set the number of impacts in reverse rotation and the type of torque-up

trigger.

When U0/d0 is set, impacts continued to be applied without torque up.

Note:

When reverse rotation is used for the screwdriver specied with the forward rotation,

never fail to set this U0 or d0.

Setting value (initial: value: d0)

U: UP trigger

d: DOWN trigger

0 to 4: the number of impacts

Setting of rotation speed

This sets the low rotation speed among 11 steps. For details of setting values and

rotation speeds, see P.12.

Setting value (initial value: 15)

05 to 15

Setting of overtime

If the automatic screwdriver keeps rotating, this stops it automatically to protect

this unit and the screwdriver.

Usually, set this in the program on the system including PLC.

Setting value (initial value: t0)

t0 to t9 (t1: about 10 sec. to t9: about 90 sec., t0: about 42 minutes)

Rotation

setting

LOW

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

FOR OPE TUP FIN REV RES 2WS OVT

MODE

ENT

To HIGH

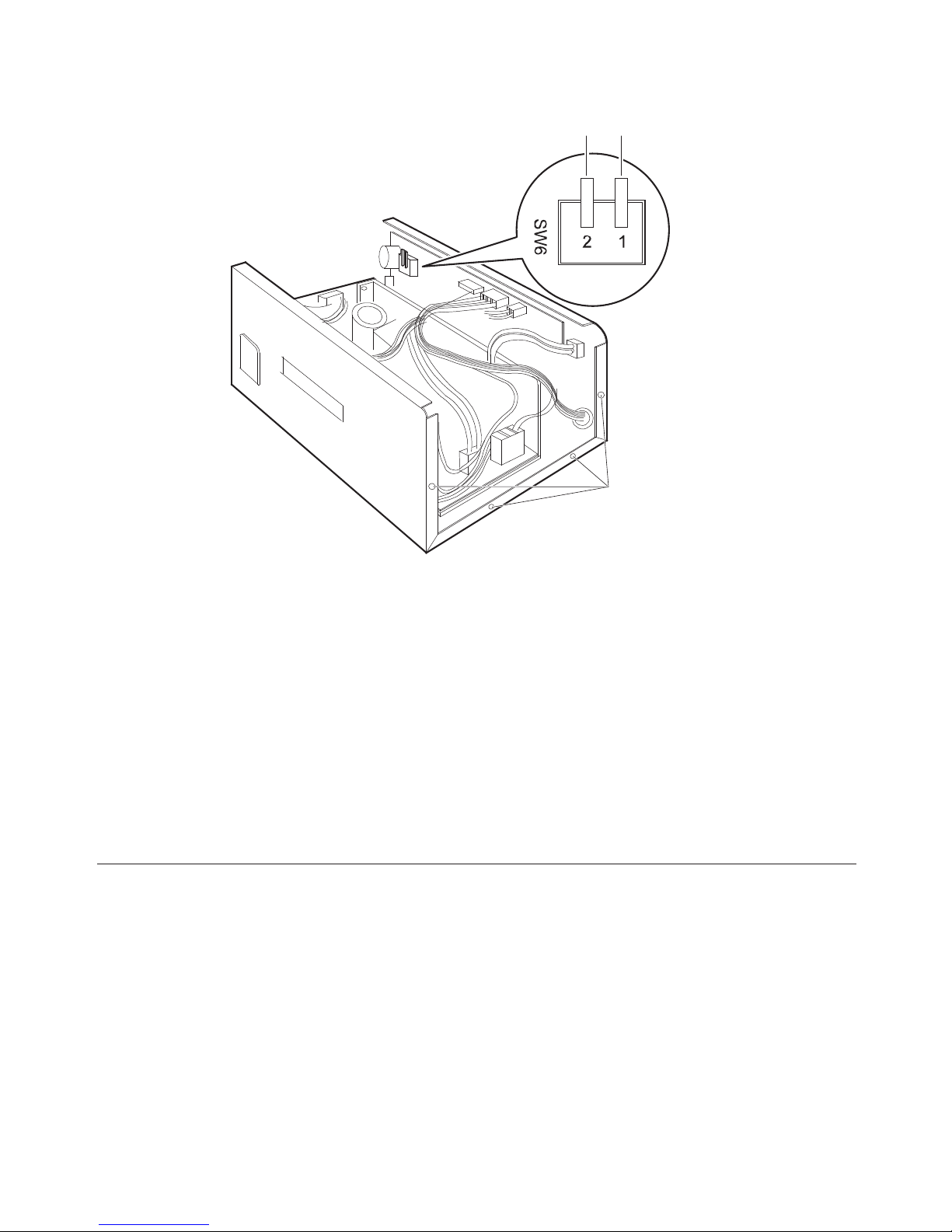

12

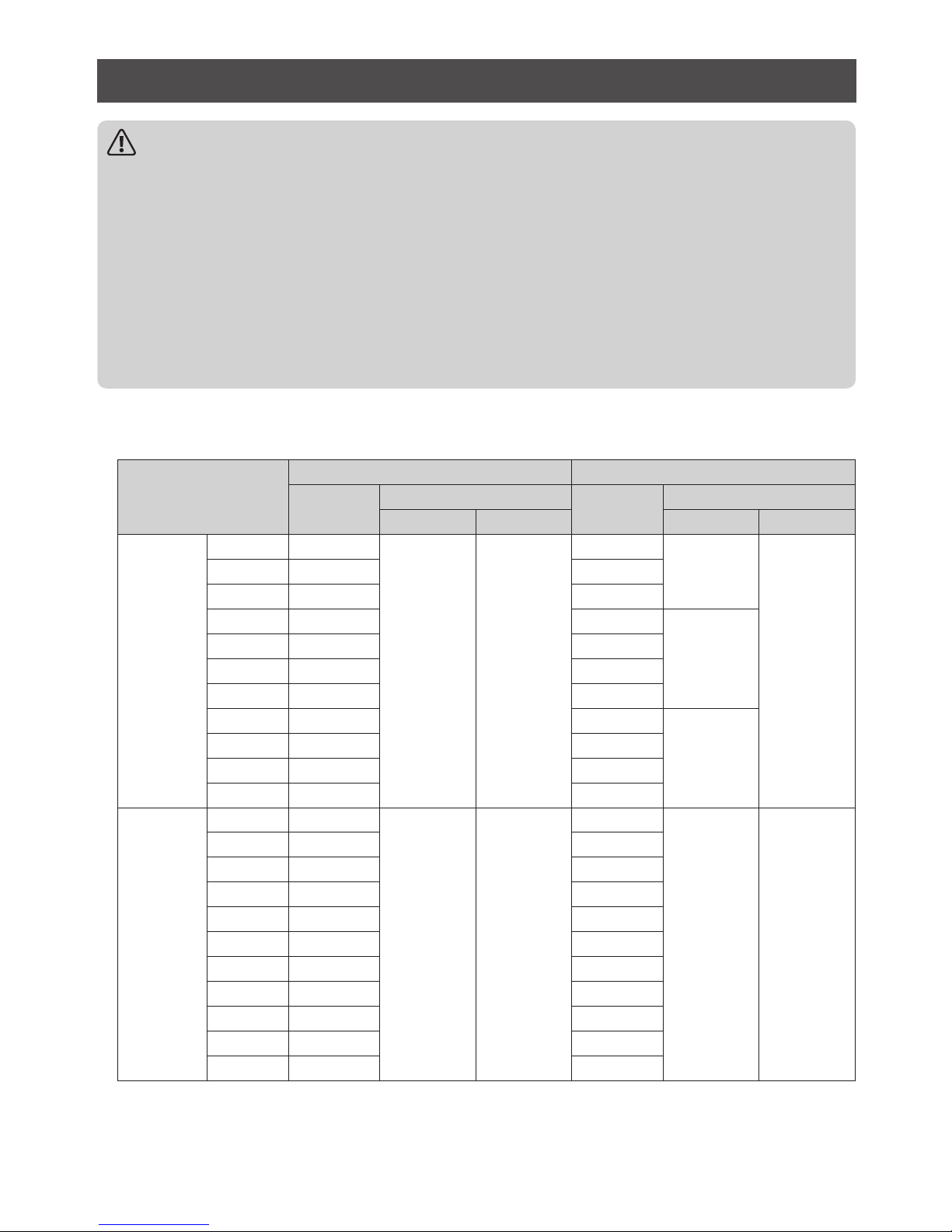

Relation Between the Rotation Number and Torque of the Automatic Screwdriver

Note:

These values are only for reference, and they do not guarantee actual performances.

◦Set the number of rotations to ±10% of a specified value.

◦The number of rotations was measured as free run. The number of rotations varies depending on the load over 27.

◦The number of rotations may fluctuate between forward and reverse rotations.

◦The torque was measured by a combination of our torque meter and Fidaptor.

◦The reference table of output torque is listed in the instruction manual of the automatic screwdriver. Refer to them

at the same time.

◦If the overload protection works, change the rotation setting.

■

BLF-2000/BLF-5000

Rotation setting

BLF-2000*

1

BLF-5000

r.p.m

Torque (N・m)

r.p.m

Torque (N・m)

max. min. max. min.

LOW

05 120

0.35 0.03

115

0.6

0.3

06 150 135

07 165 150

08 187 180

0.8

09 210 195

10 232 210

11 270 240

12 285 255

1

13 300 285

14 315 300

15 345 320

HI

20 690

0.35 0.03

660

1 0.3

21 720 690

22 750 720

23 780 750

24 810 780

25 825 810

26 870 840

27 975 940

28 975 940

29 975 940

30 975 940

*1 For the torque adjustment spring for BLF-2000, two types are available. The silver spring for high torque (accessory), the black

spring for low torque (installed inside of screwdriver). Please select a suitable one for your work.

Loading...

Loading...