4. OPC Signal Output Specications

4-1.OPC output signals

For the OPC signal output specications, refer to Table 1. For the timing chart of the OPC signal output.

*Do not use the device with any current exceeding the ratings of +30V and 10mA for each OPC signal output pin.

Table 1. OPC Signal Output Specications

Signal Name CN3 Connector Signal Output PIN Output Conditions Output Method

FOR signal PIN4 Screwdriver forward rotation

Open collector output

(Low active)

T-UP signal PIN2 Screwdriver torque up

REV signal PIN6 Screwdriver reverse rotation

4-2. D_ACT input signals

*Use devices rated at +50V, 20mA or more to open/close the D_ACT terminal and GND terminal.

Figure 3 Timing Chart of the OPC Signal Output

Signal Name

CN3 Connector Signal

Input PIN

Input signals Control of driver

D_ACT PIN3

ON (short-circuit between PIN3-GND) Driver starts up

OFF (open-circuit between PIN3-GND) Driver shuts down

4-3. OPC output signals and D_ACT input signals Timing Chart

OPC output signals and D_ACT input signals Timing Chart

1. Positive rotation movement of the driver controlled by external

devices and the clutch movement.

① Pull and tie the screwdriver’s

Switch Lever with a plastic belt.

② D_ACT input signal turns ON.

(D_ACT terminal – GND terminal

shorts out)

→ FOR output signal turns ON. (The

driver rotates clockwise.)

③ The screwdriver clutch activates.

• T-UP (nish) output signal turns

ON.

→ T-UP (nish) output signal turns

ON, the signal lasts for 50ms. (The

screwdriver stops)

* FOR signal does not turn OFF automatically in conjunction with T-UP (nish)

signal.

④

D_ACT input signal turns OFF (D_

ACT terminal – GND terminal opens)

2.

Reverse rotation movement of the driver controlled by external devices.

① Pull and tie the screwdriver’s

Switch Lever with a plastic belt.

→ REV signal output 0V.

(Screwdriver reverse rotation)

• Because there is no torque up during reverse rotation, the T-UP signal is

turned off and the output becomes

.

② D_ACT input signal turns ON.

(D_ACT terminal – GND terminal

shorts out)

→ REV output signal turns ON. (The

driver rotates counterclockwise.)

•

T-UP (nish) signal is OFF as there is no clutch activation during reverse rotation.

③ D_ACT input signal turns OFF. → REV output signal turns OFF.

(D_ACT terminal – GND terminal opens)

5. Accessories

(1) Instruction Manual (1 copy) (2) Brackets (2 pcs) (3) OPC signal plug (1 pc)

(4) 5P screwdriver cord [for power supply connection] <1.5m> ( 1pc)

BLOP-OST2 Relay Box

Instruction Manual

As of January 2017 Registration Number: No.ET-A060 17A

1. Overview of the Device

By connecting this interface box to a set of the BL-OPC or BLG-OPC and its power supply, these drivers

can start up / shut down by inputting D_ACT signals into the CN3 connector with external devices.

In addition, to facilitate the use of the OPC signal by external devices, the device converts the +30V,

which is the rated voltage of BL series screwdrivers, to +24V by using a regulator and outputs it to the

CN3 connector, the same output location as the OPC signal.

2. Precautions about Usage <<Please read the instructions below before use>>

Be aware that using the device without following these instructions may result in a malfunction of or breakdown with

the device and its power supply and screwdriver.

(1) Correctly connect the BL-OPC or BLG-OPC screwdriver and the power supply for BLor BLG to the specied

connectors of the device.Wrong connection may result in malfunction or breakdown.

(2) Do not directly connect the +24V pin of the CN3 connector or the external +24V power supply to the BL-OPC or

BLG-OPC signal pins of the CN3 connector.

(3) Set the speed selector switch of the power supply for BL or BLG to HI.If it is used at LOW, the output voltage of

the +24V pin of the CN3 connector decreases accordingly, resulting in a malfunction.

(4) Do not overload to the BL-OPC screwdriver. If the +30V voltage of the power supply for BL decreases to +25V

or lower due to overloading, the voltage at the +24V pin of the CN3 connector decreases accordingly, resulting

in a malfunction.

(5) If an external device requires a constant voltage of +24V without being affected by overloading, prepare a

separate external power supply for the external output circuit.

(6) Do not use the +24V output of the CN3 connector for any purpose other than for the OPC signal. Otherwise,

overcurrent will ow through the internal circuit of the BL-OPC screwdriver, resulting in a breakdown. Other

unspecied usage will affect the screwdriver’s tightening performance or result in a malfunction or breakdown.

(7) Avoid any usage in which the ratings of +30V and 10mA will be exceeded for each OPC signal pin of the CN3

connector. Overcurrent will result in a malfunction of or breakdown with the device and the screwdriver.

(8) Use devices rated at +50V, 20mA or more to open/close the D_ACT terminal and GND terminal.

(9) Do not directly connect external devices in which noise may occur, such as relays, motors, buzzers, and lamps,

to the OPC signal pins of the CN3 connector. Drive noise or overcurrent from external devices will result in a

malfunction of or breakdown with the device and the BL-OPC screwdriver.If external devices in which noise may

occur need to be connected, mount noise suppression components such as photo couplers and diodes with

reference to Examples 5 and 6 in Figure 2, and carefully conrm the effectiveness before use.

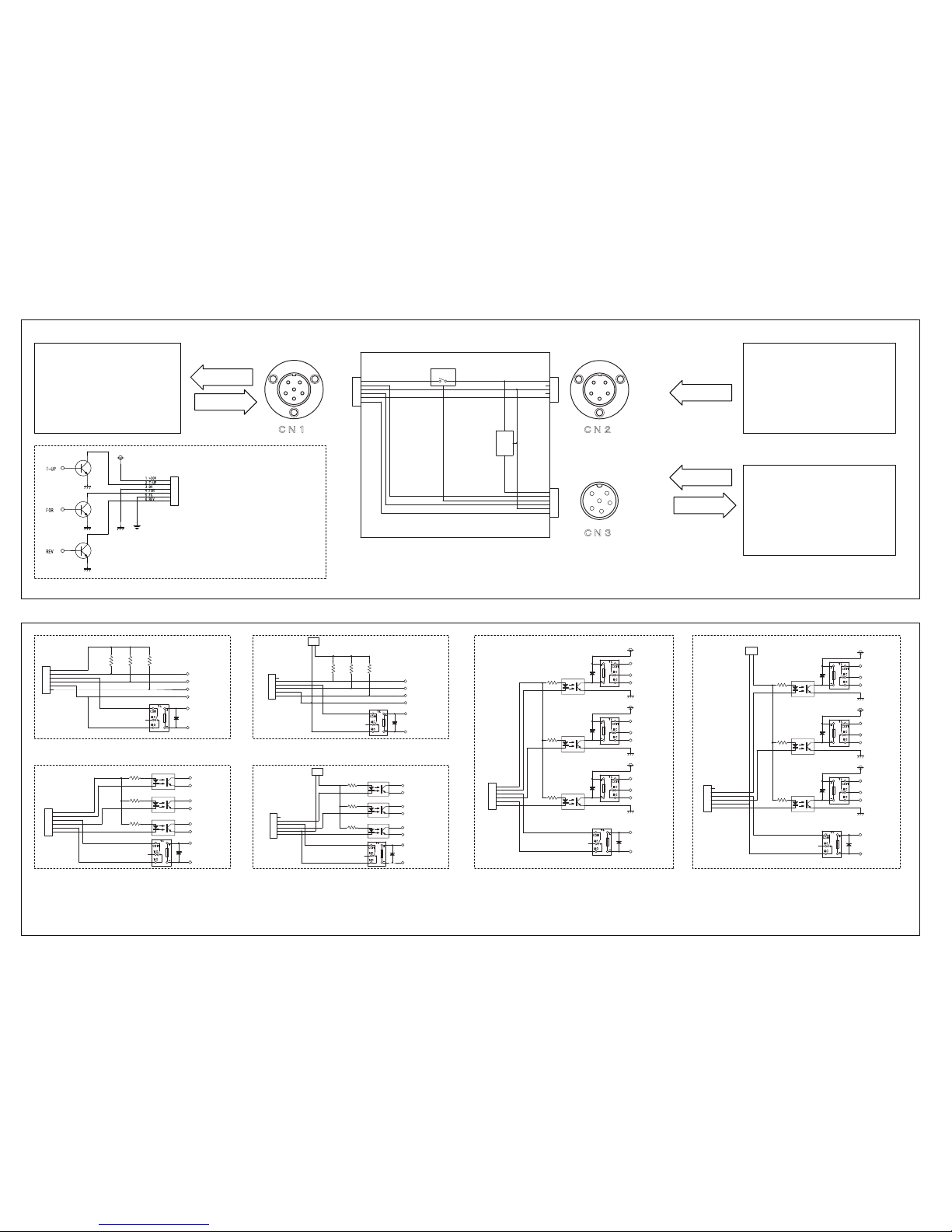

3. How to Use the Device

(1)

Connect the device with the BL-OPC or BLG-OPC screwdriver and the power supply for BL or BLG using a scre-

driver cord, as shown in Figure 1.

(2) Connect external devices to the CN3 connector of the device.

(3) Fix the Switch Lever of the driver to keep it on.

(4) Turn on the power of the power supply for the screwdriver.

(5) The OPC signal is output from the CN3 connector according to the operation of the screwdriver.

*For OPC signal output specications and timing, refer to 4. OPC Signal Output Specications.

(6) The driver starts up by connecting the D_ACT terminal and GND terminal of the CN3 connector with external

devices.

(7) The driver shuts down by disconnecting the D_ACT terminal and GND terminal of the CN3 connector.

(one-shotoutput)

LeverStart

LeverStart

1-16-5 Akiyama, Matsudo City, Chiba Pref., Japan

TEL: +81 (JAPAN) 47-392-2001

FAX: +81 (JAPAN) 47-392-7773

HIOS Inc.

1

2

3

4

5

6

6P

CN1

GND

GND

GND

FG

GND

VCC

1:+30V

2:T-UP

3:OV

4:FOR

5:FG

6:REV

1:+24V

2:T-UP (finish)

3:D_ACT

4:FOR

5:OV

6:REV

1:+30V

2:NC

3:OV

4:NC

5:FG

OPC Screwdriver

BL-OPC Screwdriver

BLG-OPC Screwdriver

BLOP-OST2

Power supply for BL

External device

Reference: Internal Circuit for the OPC Signal Output of the BL-OPC or BLG-OPC Screwdriver

• Be sure to use an external output circuit.

(Refer to Figure 2)

• Do not connect screwdrivers other than the OPC

Series. Wrong connection may result in

breakdown.

T-30BL (Discontinued model)*

1

T-45BL

T-70BL

*1 Only for BL-2000-OPC Series

• Use the speed selector switch of the power

supply for BL at HI.

•If it is used at LOW, the output voltage of the +24V

pin of the CN3 connector decreases accordingly.

Please be careful about this.

• If the external device has no internal

resistance, connect a current-limiting

resistance to ensure that the following

specifications will not be exceeded during use.

REV signal pin: O.C. output, MAX +30V / 10mA

T-UP (finish) signal pin:O.C. output, MAX +30V / 10mA

FOR signal pin: O.C. output, MAX +30V / 10mA

*Connected using a

6P screwdriver cord

*Connected using 5P

screwdriver cord

(An accessory of the

main unit)

DRIVER 6P Metal

Connector Front View

POWER IN 5P Metal

Connector Front View

OPC Signal Receptacle

Front View

Power Output

OPC Signal Input

Power input

D_ACT signal input

OPC Signal Output

Figure 2 External Output Circuit Example

Figure 1 Connection drawing

Example 1

Voltage output circuit (with an internal power supply)

Example 2

Voltage output circuit (with an external power supply)

Example 3

Current output circuit (with an internal power supply)

Example 4

Current output circuit (with an external power supply)

Example 5

Relay output circuit (with an internal power supply)

Example 6

Relay output circuit (with an external power supply)

Note 1: Do not directly connect the +24V pin of the CN3 connector or the external + power source to the OPC signal pins of the CN3

connector.Otherwise, overcurrent will flow through the internal circuit of the BL-OPC or BLG-OPC screwdriver, resulting in a breakdown.

Please be careful about this.

Note 2: Select the resistance value for each OPC signal pin such that the ratings of +30V and 10mA will not be exceeded.

Note 3: If an external device in which noise may occur needs to be connected, mount noise suppression components such as photo couplers

and diodes, and carefully confirm the effectiveness before use.

Note 4. Use the device rated at and over +50V, 20mA that opens and closes between D_ACT terminal and GND terminal.

+30V

0V

FG

+30V

0V

FG

1

2

3

4

5

5P

CN2

1

2

3

4

5

6

6P

CN1

1

2

3

4

5

6

6P

CN3

FET

IN +30VOUT +24V

D_ACT

Regulator

D_ACT

0V

REV

FOR

T-UP

+24V

T-UP

FOR

REV

Note 2 Note 2Note 2

Note 3

D_ACT

Note 1

0V

0V

T-UP signal

FOR signal

REV signal

D_ACT signal

1

2

3

4

5

6

6P

CN3

Note 4

REV

FOR

T-UP

+24V

Note 2

Note 2

Note 2

+24V

T-UP

FOR

REV

D_ACT

D_ACT

Note 1

Note 3

0V

0V

Note 4

T-UP signal

FOR signal

REV signal

D_ACT signal

1

2

3

4

5

6

6P

CN3

D_ACT

Note 3

0V

T-UP

REV

Note 2 Note 2 Note 2

FOR

T-UP

FOR

REV

+24V

D_ACT

Note 1

0V

0V

0V

Note 4

T-UP signal

FOR signal

REV signal

D_ACT signal

1

2

3

4

5

6

6P

CN3

T-UP

FOR

REV

Note 2

Note 2

Note 2

T-UP

REV

FOR

+24V

D_ACT

D_ACT

Note 1

Note 3

0V

0V

0V

Note 4

T-UP signal

FOR signal

REV signal

D_ACT signal

1

2

3

4

5

6

6P

CN3

REV

FOR

T-UP

+24V

Note 2

Note 2

Note 2

+24V

T-UP

FOR

REV

D_ACT

D_ACT

Note 1

Note 3

Note 3

Note 3

Note 4

Note 3

Note 3

Note 3

0V

0V

Note 4

T-UP signal

FOR signal

REV signal

D_ACT signal

1

2

3

4

5

6

6P

CN3

REV

FOR

T-UP

Note 2

Note 2

Note 2

+24V

REV

FOR

T-UP

+24V

D_ACT

D_ACT

Note 1

Note 3

Note 3

Note 3

Note 3

Note 3

Note 3

Note 3

0V

0V

0V

Note 4

T-UP signal

FOR signal

REV signal

D_ACT signal

1

2

3

4

5

6

6P

CN3

CN3

Front View

165

4

3

2

CN

1

SCK Front view

1

6

5

3

2

4

CN2

SCK Front view

1

5

3

2

4

Loading...

Loading...