Page 1

TM6102

RGB LASER METER

Instruction Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

TM6103

RGB LASER LUMINANCE METER

TM6104

OPTICAL POWER METER

TM6102 TM6103 TM6104

Be sure to read this manual

before using the instrument.

When using the instrument

forthersttime

Parts Names and Functions

Measurement Condition Settings

Normal Measurement

Sept. 2018 Revised edition 1

TM6102A961-01 18-09H

p.13 to 21

p.35

p.45

Safety Notes

Troubleshooting

Maintenance and Service

Troubleshooting

Error Indication

p.4

p.93

p.94

p.79

EN

Page 2

Contents

Introduction

ConrmingPackageContents

Measurement Flowchart

Safety Notes

Usage Notes

........................................................1

........................2

..................................3

......................................................4

......................................................6

1 Overview 11

1.1 Overview and Features

1.2 Model TM6102 RGB Laser Meter

Parts Names and Functions

Dimensions

1.3 TM6103 RGB Laser Luminance

Meter

Parts Names and Functions

Dimensions

1.4 Model TM6104 Optical Power Meter

Parts Names and Functions

Dimensions

..............................................14

......................................................16

..............................................18

..............................................22

.......................11

......12

......................13

......................17

.20

......................21

2 Preparations 25

2.1 Inspection Before Measurement

2.2 Connecting the AC Adapter and

Power Cord

2.3 Setting the Communication Setting

Mode

2.4 Turning ON/OFF the Power

2.5 Installing the Application Software

Recommended computer operating

environment

Installation

Uninstallation

2.6 Using a LAN

Constructing the network environment

Connecting the LAN cable

Setting the LAN

...........................................26

......................................................26

..............................................28

................................................28

............................................28

..........................................29

.........................30

........................................31

........25

................27

.....28

.......29

3 Measurement

Condition Settings

3.1 Various Settings

Settings related to trigger

Measurement mode settings

Settings common to normal

measurement and dark measurement

Normal measurement settings

3.2 Correction Functions

Centroid wavelength input mode

Centroid wavelength offset correction

Radiometric quantity gain correction

Chromaticity xy offset correction

Photometric quantity gain correction

....................................35

..........................35

.....................36

...................37

............................38

...............39

................40

35

.......36

........39

..........40

..........40

3.3 Modulation Frequency Measurement

Modulation frequency measurement

settings

Modulation frequency measurement

execution and modulation frequency

settings

3.4 Dark Measurement

Dark measurement settings

Executing the dark measurement

.....................................................41

.....................................................41

...............................42

.......................42

..............43

41

4 Normal Measurement 45

4.1 Adjusting the White Balance of

the Light Source (White Balance

Adjustment Assistance Function)

4.2 Precaution

Measurement status

When a single color light enters or when

a light with large radiometric quantity of

only one color enters

.............................................48

.................................48

.................................49

.......46

5 External Control 51

5.1 External Input Terminals and Signals

5.2 InternalCircuitConguration

5.3 Frequently Asked Questions about

External Input

........................................54

..............53

51

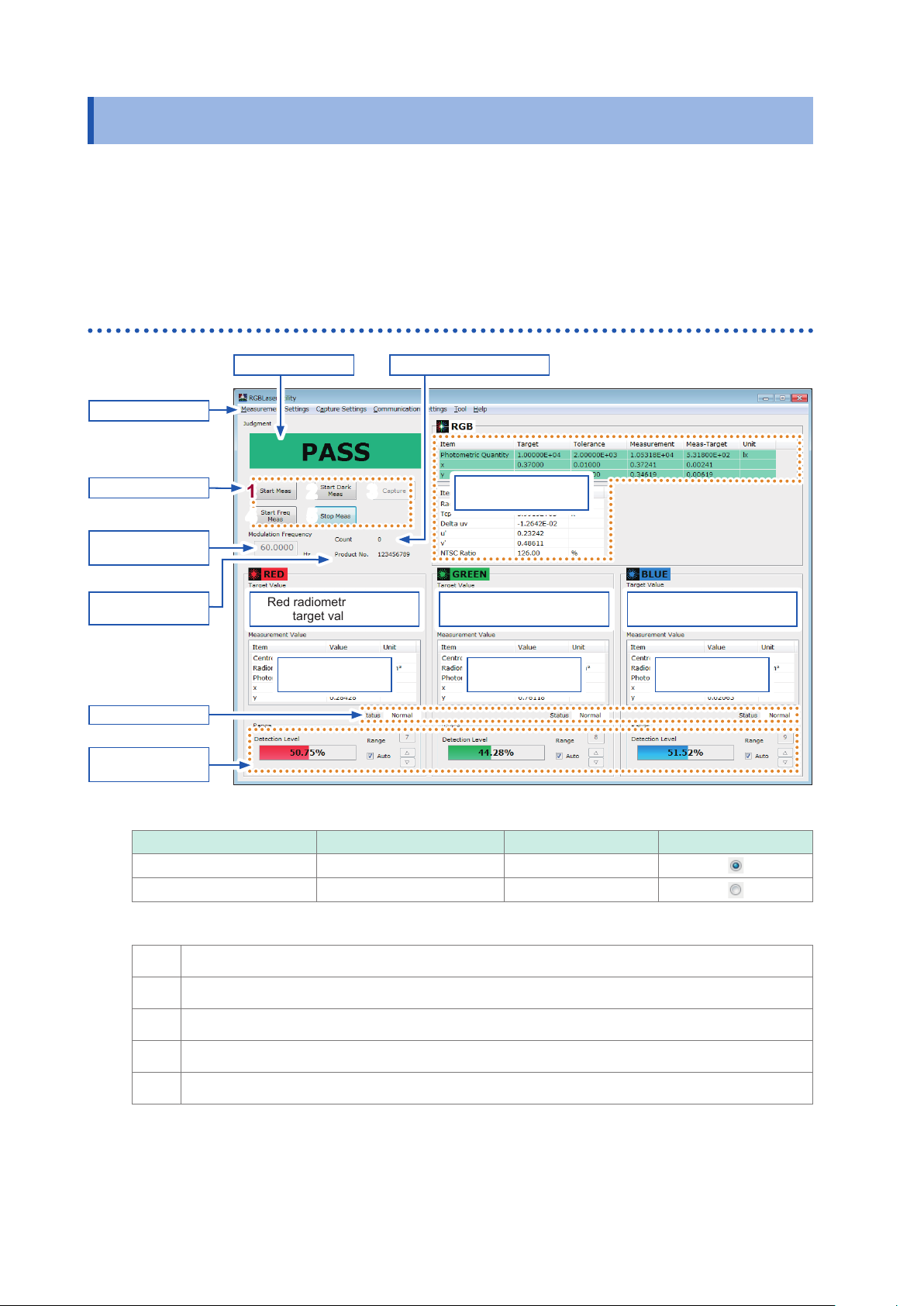

6 Application Software

(RGBLaserUtility)

6.1 Startup Procedure

Screenconguration(Maindialog)

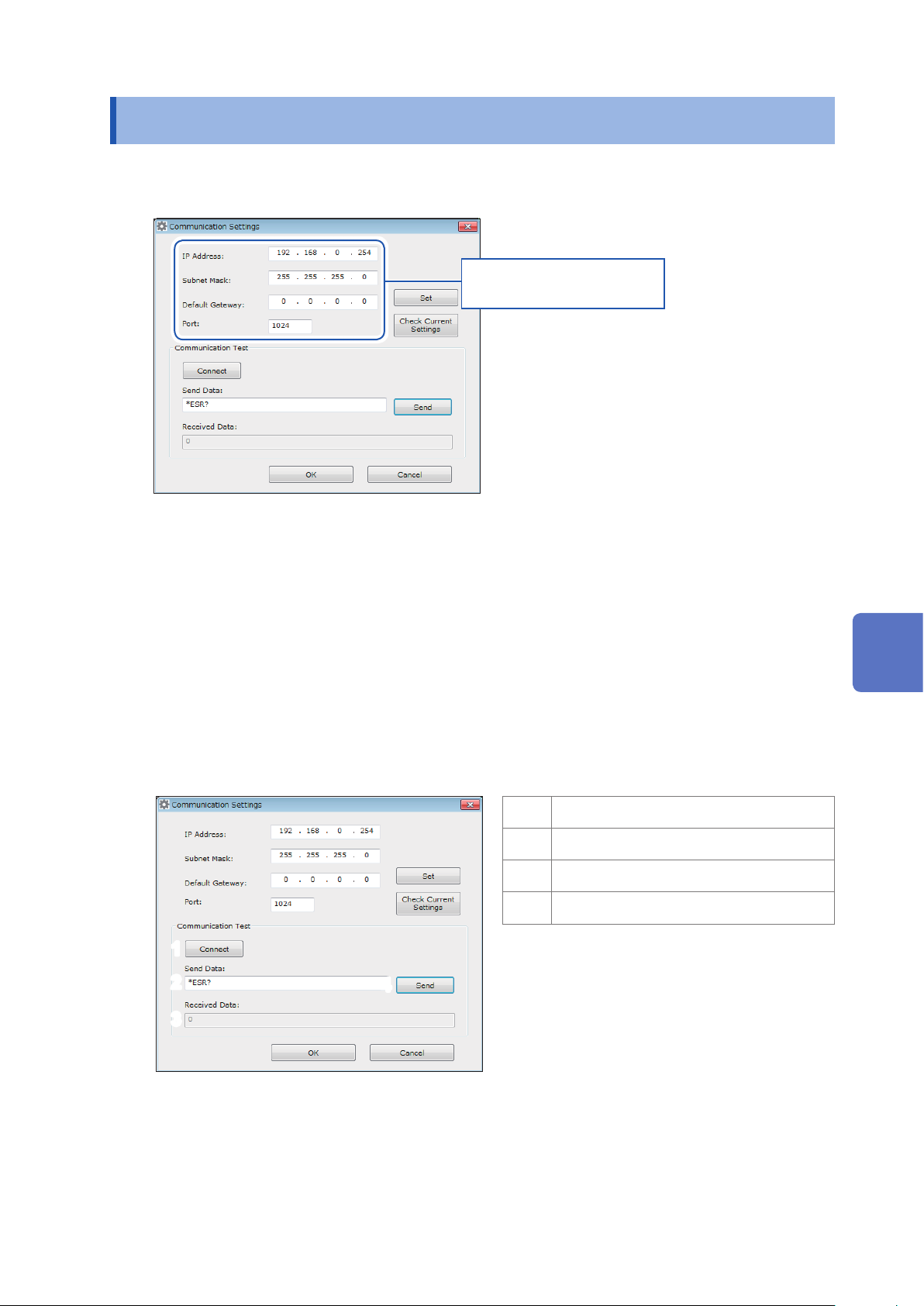

6.2 Setting the LAN

6.3 Measured Value Capture Settings

6.4 Measurement Settings

6.5 Chromaticity xy Chart Display

6.6 Modulation Frequency Measurement

6.7 Dark Measurement

6.8 Normal Measurement

Executing the normal measurement

Measurement range optimization

Capturing the measured values

Measured values of each color

Measured values of RGB mixed light

Overall judgment display

Modulation frequency display during

measurement

6.9 Exiting the Application Software

6.10 Others

Self-test

Starting RGBLaserUtility by specifying

themeasurementsettingle(.dcmle)

...........................................78

....................................................79

....................................................79

................................56

............56

.....................................57

.........................60

............67

...............................69

..........................70

..........70

...............71

.................72

..................76

...........................78

55

.....58

68

.........77

.........78

.....80

1

2

3

4

5

6

7

8

9

10

10

Appx.Index

TM6102A961-01

i

Page 3

Contents

Adjusting the width of the measured

value display list

Controlling multiple instruments

6.11 Menu List

6.12 Message List

.......................................81

.................81

...............................................82

.........................................82

7 Specications 85

7.1 GeneralSpecications

7.2 InputSpecications/Output

Specications/Measurement

Specications

7.3 Functionalspecications

7.4 Interfacespecications

7.5 List of default settings

........................................86

.........................85

.....................88

........................91

..........................92

8 Maintenance and

Service

8.1 Troubleshooting

....................................94

93

9 License Information 97

10 Appendix 99

10.1 Relationship between Radiometric

Quantity and Photometric Quantity

10.2 Prevention of External Noise Entry

Prevention measures against noise

entry from power supply line

10.3 LAN Settings on the Computer

....................100

....99

..100

.........101

Index Index1

Warranty

ii

Page 4

Introduction

Thank you for purchasing the Hioki TM6102 RGB Laser Meter, TM6103 RGB Laser Luminance

Meter, or TM6104 Optical Power Meter.

To obtain maximum performance from the instrument over the long term, be sure to read this

manual carefully and keep it handy for future reference.

1

Trademarks

• Adobe and Adobe Reader are trademarks of Adobe Systems Incorporated.

• Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation

in the United States and other countries.

• CORE i5 is a registered trademark of Intel Corporation.

License agreement

• The “RGBLaserUtility” application software is included with the instrument. This software requires

a license agreement. Please use it only after reading and accepting the license agreement inside

the CD.

Precautions during shipment

Store the packaging in which the instrument was delivered, as you will need it when transporting

the instrument. (p. 93)

2

3

4

5

6

7

8

9

10

Appx. Ind.

1

Page 5

Conrming Package Contents

Conrming Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories and connectors. If damage is evident, or if it fails to

operate according to the specications, contact your authorized Hioki distributor or reseller.

Main unit and accessories

Conrm that these contents are provided.

Model TM6102 RGB Laser Meter

Model TM6103 RGB Laser Luminance Meter

Model TM6104 Optical Power Meter

TM6102

TM6103

TM6104

Instruction Manual (this document) Light shielding cap (Expressed as “cap” in this document)

Instrument is shipped with the cap attached.

Be sure to attach the cap when the instrument is not in use.

For the TM6102 and the TM6104

Power cord LAN cable

Category 6A (CAT 6A)

Straight cable 3 m

Model Z1008 AC Adapter Application disc (CD)

• Application software

RGBLaserUtility

• Communication Command Instruction Manual

(PDF version)

(This manual describes the communication

commands.)

• Sample program

• Software license agreement

• The latest version can be downloaded from our

website.

For the TM6103

Option

The following options are available for the instrument. Contact your authorized Hioki istributor or

reseller when ordering.

Model Z1008 AC Adapter

2

Page 6

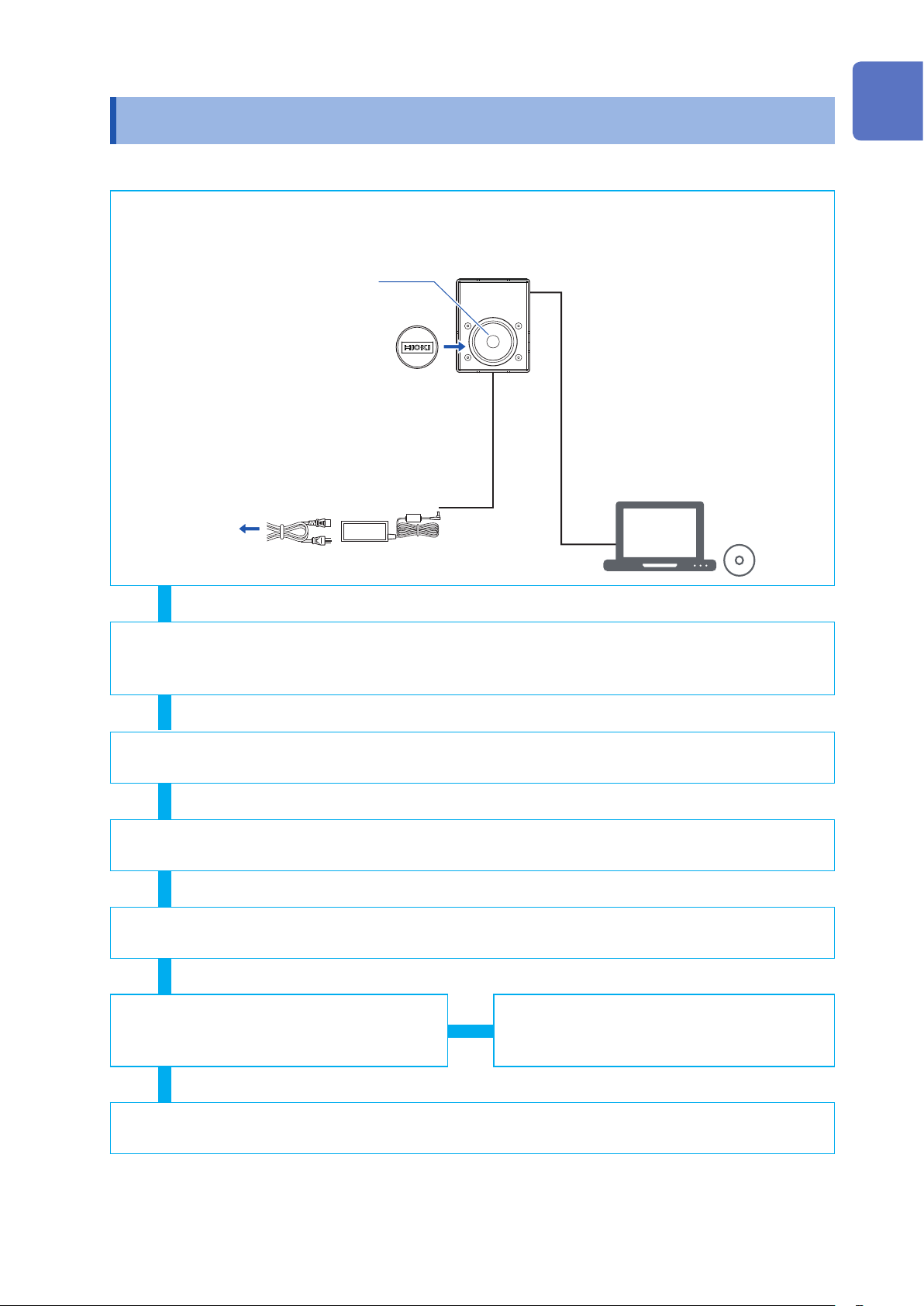

Measurement Flowchart

Measurement Flowchart

Installation

Check that no contaminant or

1

dust is adhered to the detector

window of the instrument.

Attach the cap.

2

Connect the AC adapter. (p. 26)

4

To a commercial

power supply

Illuminance measurement (p. 12), Luminance measurement (p. 16), Optical

power measurement (p. 20)

Before communicating

with the computer

Connect the LAN cable.

3

(p. 30)

Set the communication setting

5

mode. (p. 26)

Turn on the instrument. (p. 27)

6

Warm up for 30 minutes or

longer.

Turn on the computer.

7

• Installing the application software (p. 28)

• External control settings (p. 51)

1

2

3

4

5

6

Communication startup

Measurement condition settings

Dark measurement

(p. 42)

Normal measurement

(p. 45)

End of measurement

Attach the cap.

(p. 35)

White balance adjustment

(p. 46)

7

8

9

10

Appx. Ind.

3

Page 7

Safety Notes

Safety Notes

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly

tested for safety prior to shipment. However, using the instrument in a way not described in this

manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

WARNING

• Protective gears

Wear appropriate protective gear before measuring a strong laser light.

•

With regard to the electricity supply, there are risks of an electric shock, a heat

generation, a re, and an arc ash due to a short-circuit. Individuals using an

electrical measuring instrument for the rst time should be supervised by a

technician who has experience in electrical measurement.

CAUTION

Mishandling during use could damage to the instrument. Be certain that you understand

the instructions and precautions in the manual before use.

Notations

In this document, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will result in death or serious injury

to the operator.

Indicates a potentially hazardous situation that may result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in minor or moderate injury

to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance tasks

with which the operators must be fully familiar.

Indicates prohibited actions.

Indicates the action which must be performed.

*

p.

[ ]

Unless otherwise specied, “Windows” represents Windows 7, Windows 8, or Windows 10.

•

Additional information is presented below.

Reference

Menus, dialogs, buttons in a dialog, and other names on the screen and the keys are

indicated in brackets.

4

Page 8

Safety Notes

Symbols afxed to the instrument

Indicates cautions and hazards.

When the symbol is printed

on the instrument, refer to a

corresponding topic in the

Instruction Manual.

Indicates DC (Direct Current).

Accuracy

We dene measurement tolerances in terms of f.s. (full scale) and rdg. (reading) values, with the

following meanings:

f.s.

rdg.

f.s. (Maximum display value)

The maximum display value. Generally, this value indicates the range currently being used.

(Reading or displayed value)

The value currently being measured and displayed on the measuring instrument.

Symbols for various standards

Indicates the Waste Electrical and Electronic

Equipment Directive (WEEE Directive) in EU

member states.

Indicates that the product conforms to

regulations set out by the EU Directive.

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

5

Page 9

Usage Notes

Usage Notes

• Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

• Ensure that your use of the product falls within the specications not only of the instrument itself,

but also of any accessories, options and other equipment being used.

• Before using the instrument, verify that it operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized Hioki distributor or

reseller.

• This instrument may cause interference if used in residential areas. Such use must be avoided

unless the user takes special measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

• The instrument itself does not radiate any laser light. However, when a strong

laser light is irradiated to the detector window of the sensor, a strong reected

light is generated. In this case, do not look into the detector window directly.

Doing so may adversely affect your eyes or cause visual disturbance.

The instrument can measure lasers classied into classes I to IIIB. As required,

refer to the risks during measurement of the relevant class laser and cautions

on use stated in IEC60825-1 and FDA21CFR1040.10. When handling a laser

product, always follow the caution and warning labels adhered to the laser

product, and the contents described in the instruction manual.

• Refer to the description of safe use of the laser and laser system stated in

ANSI Z136.1. Only authorized operators who have trained in operation of the

laser and laser system are allowed to perform the measurement.

• Do not input a light exceeding the maximum input level. Otherwise, accurate

measurements cannot be performed or the sensor may be damaged by

excessive energy

• When an extremely focused beam is measured, the energy density on the

sensor is excessive, causing inaccurate measurements. In addition, the sensor

may deteriorate.

• To avoid the risk of re, do not irradiate a strong laser light to the instrument

or cap, nor focus a strong laser light on the instrument or cap. In particular, do

not place any combustible materials near the instrument in the unmanned state

such as automatic measurement.

• Use only the supplied Model Z1008

range is 100 V to 240 V AC at a frequency of 50 Hz/60 Hz. To avoid electrical

hazards and damage to the instrument, do not apply voltage outside of this

range.

• To prevent an electrical shock and to maintain the safety specications of this

instrument, connect only the power cord provided to an outlet.

WARNING

.

AC Adapter. The AC adapter input voltage

6

Page 10

CAUTION

• Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with rectangular

wave or pseudo-sine-wave output to power the supplied AC adapter. Doing so may

damage the instrument.

• The instrument consists of precision optical components. Dropping the instrument

or subjecting it to mechanical shock may damage it. Optical components inside the

instrument may fall out of alignment if the instrument is dropped or subjected to

mechanical shock, affecting measured values.

• To avoid damage to the instrument, protect it from physical shock when transporting

and handling it. Be especially careful to avoid physical shock due to dropping it.

• Do not connect the power supply improperly. Doing so may damage the instrument’s

internal circuitry.

• If a light outside the measurement wavelength range enters, this may cause the

sensor to deteriorate. Attach the cap when the instrument is not in use.

• Attach the cap when the instrument is not used for a long time.

Installing the instrument

Installing the instrument in inappropriate locations may cause a malfunction of instrument or may

give rise to an accident. Avoid the following locations.

Usage Notes

1

2

3

4

WARNING

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to a strong electromagnetic eld or electrostatic charge

• Exposed to high quantities of dust particles

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

CAUTION

• Do not place the instrument on an unstable table or an inclined place. Dropping or

knocking down the instrument can cause injury or damage to the instrument.

• The instrument consists of precision optical components. The instrument should be

securely mounted on a jig using the screw hole in its base. Dropping the instrument or

applying an impact to it can cause the accuracy to deviate from its specication. If an

impact is applied to the instrument, it needs to be inspected.

• When orienting the instrument so that a part other than its base is facing down, x it

in place so that it cannot fall. Failure to do so may cause a re or other malfunction in

the instrument.

• The instrument is housed in a metal case and emits heat. Be sure to leave adequate

space around the instrument. Failure to do so may cause the ambient temperature to

rise, affecting measured values and potentially damaging the instrument.

• Install the instrument so that no load is applied to the detector window.

5

6

7

8

9

10

Appx. Ind.

In an emergency, unplug the power cord to kill power to the instrument. Be sure to provide enough

unobstructed space to unplug the power cord immediately.

7

Page 11

Usage Notes

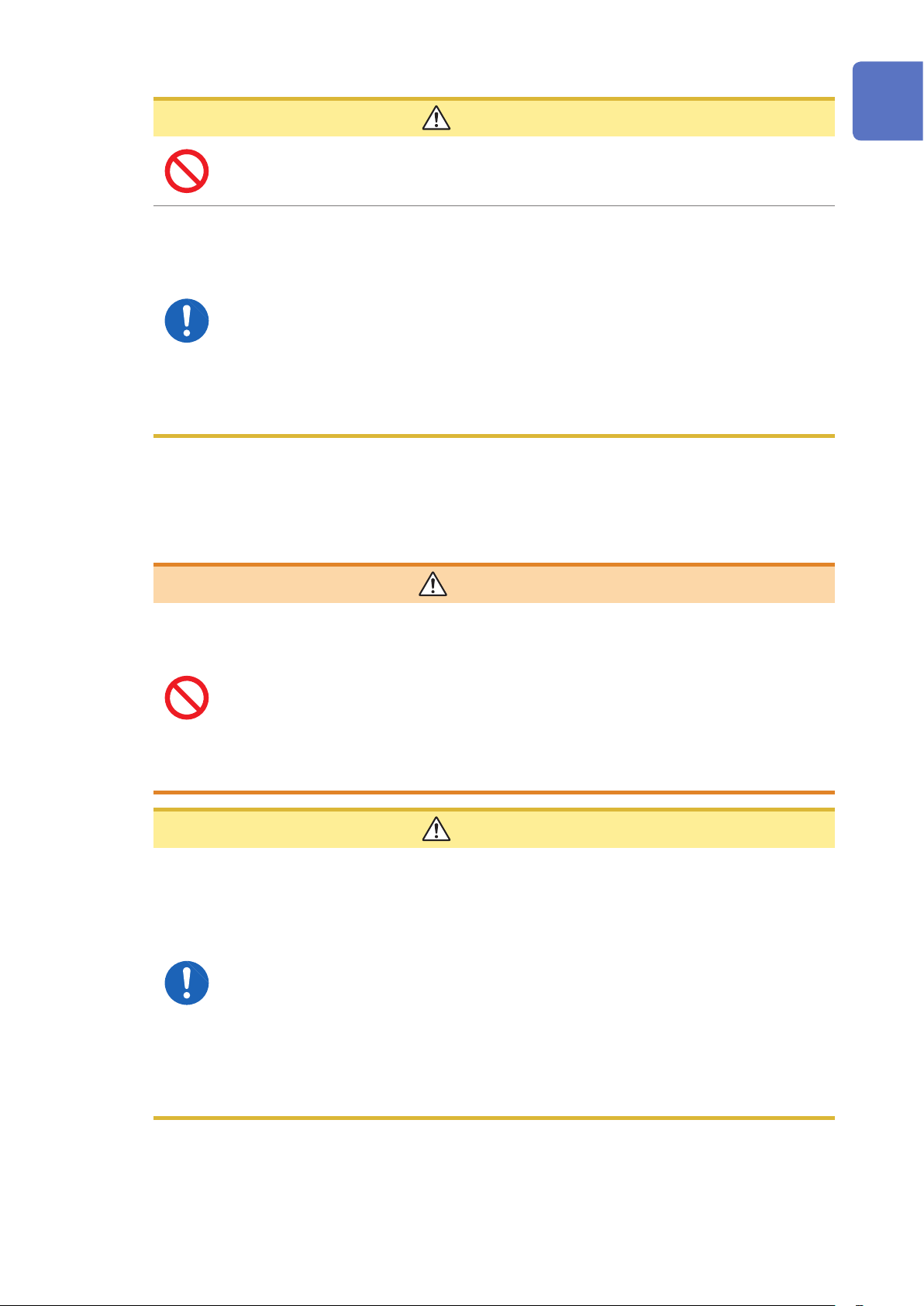

Securing the instrument

Securing the instrument using the tripod mounting screw holes in the rear

• Install the instrument using the tripod mounting screw holes in

the rear.

• Sufciently strengthen the surface on which the instrument is

installed so that the instrument is not unstable.

• For the TM6103, securing only the rear may cause an unstable

installation of the instrument. Therefore, be sure to secure the

instrument using the tripod mounting screws on the bottom.

Usable screw: 1/4-20UNC, hole depth 7.5 mm

Securing the instrument using the tripod mounting screw holes in the bottom

• Install the instrument using the tripod mounting screw holes in

the bottom.

Usable screw: 1/4-20UNC hole depth 7.5 mm

• A stand and others necessary for the installation work should be

prepared by the customer.

Detector window (face detecting the light)

CAUTION

• Do not touch the detector window. The instrument may fail to operate to its full level of

performance if the detector window is dirty.

• Avoid contacting the detector window with sharp objects (the tip of a pair of

tweezers, etc.) or hard surfaces. The instrument may fail to operate to its full level of

performance if the detector window is damaged.

• Never use solvents that contain benzene, alcohol, acetone, ether, ketones, thinners or

gasoline. They can deform and discolor the detector window. (p. 93)

Light shielding cylinder (TM6103)

CAUTION

When handling the TM6103, observe the following cautions to perform correct

measurement.

• Do not put any foreign object in the light shielding cylinder.

• Do not apply a large load to the light shielding cylinder.

• Do not touch the inside of the light shielding cylinder with bare hands.

• Do not damage the inside of the light shielding cylinder using a sharp object.

• Do not apply an impact to the light shielding cylinder.

• Never attempt to modify, disassemble, or repair the light shielding cylinder.

8

Page 12

AC Adapter

Usage Notes

WARNING

• Turn the instrument off before connecting the AC adapter to the instrument and

to AC power.

• Use only the supplied Model Z1008 AC Adapter.

1

Before starting the external control

To avoid damage to the instrument, do not apply a voltage exceeding the rated

maximum to the external input terminals.

• Always turn both devices OFF when connecting and disconnecting an interface

connector. Otherwise, an electric shock may occur.

• To avoid an electric shock or damage to the equipment, always observe the

following precautions when connecting to the external input terminals:

• Always turn off the power to the instrument and to any devices to be

connected before making connections.

• Be careful to avoid exceeding the ratings of the external input terminals.

• Connect cables securely to the external connector. During operation, a

wire becoming dislocated and contacting another conductive object can be

serious hazard.

• Use a common ground for both the instrument and the computer. Using different

ground circuits will result in a potential difference between the instrument’s ground

and the computer’s ground. If the communications cable is connected while such a

potential difference exists, it may result in equipment malfunction or failure.

• Before connecting or disconnecting any communications cables, always turn off the

instrument and the computer. Failure to do so could result in equipment malfunction

or damage.

• To prevent equipment failure, use the recommended wire type to connect to the

external input terminals.

Recommended wire

Single strand: φ0.65 mm (AWG #22)

Multi-strand: 0.32 mm

2

2

DANGER

3

WARNING

4

5

6

CAUTION

7

8

9

(AWG #22)

Acceptable limits

Single strand: φ0.32 mm to φ0.65 mm (AWG #28 to #22)

Multi-strand: 0.08 mm

Strand diameter: minimum φ0.12 mm (per strand)

Standard insulation stripping length: 9 mm to 10 mm

Button pressing tool: Blade screwdriver (shaft diameter: 3 mm, tip width 2.6 mm)

2

to 0.32 mm2 (AWG #28 to #22)

10

Appx. Ind.

9

Page 13

Usage Notes

CD precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on a

disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

10

Page 14

1

Overview

1.1 Overview and Features

The instrument measures the centroid wavelength and radiometric quantity of laser light sources

and calculates the chromaticity and photometric quantity.

In addition, the target value of the radiometric quantity (each of the red, green, and blue radiometric

quantities) and the tolerance of the radiometric quantity necessary to adjust the chromaticity and

photometric quantity to specied values are presented.

All of the control and display of the measurement are performed on the computer.

Highly accurate measurement dedicated for RGB lasers

The centroid wavelengths and radiometric quantities of the red, green, and blue lasers are

measured simultaneously by means of the discrete centroid wavelength method*.

Additionally, the highly accurate photometry and colorimetry are achieved.

*: A method to measure the red, green, and blue centroid wavelengths and radiometric quantities

of the RGB laser and calculate the chromaticity and photometric quantity from the color-matching

function.

The industry’s rst traceability to national standards in laser illuminance

The industry’s rst traceability to national standards in laser illuminance was achieved using a

monochromatic laser source. (As of May, 2017)

It is Hioki’s original compliant, which renovates the conventional traceability to the standard lamp.

1

Overview

Shortening of adjustment process

When the white balance is adjusted, the target value of the radiometric quantity and the tolerance

of the radiometric quantity are calculated from the measured result to contribute to shortening of

the adjustment process.

Stable high-speed measurement

Various modulation frequencies (screen refresh rates) are supported to ensure stable

measurement.

Measurement of centroid wavelength

In addition to the chromaticity and photometric quantity, the centroid wavelength, which is used to

control the RGB laser module product itself, can be measured.

In addition, the measured centroid wavelength is utilized for the quality control or production control

of the RGB laser module.

Sensors suitable for the measuring object

Three types of sensors, illuminance (TM6102), luminance (TM6103), and optical power (TM6104),

suitable for various measuring objects such as HMD, HUD, and projector or various measurement

scenes in the production process, are prepared.

11

Page 15

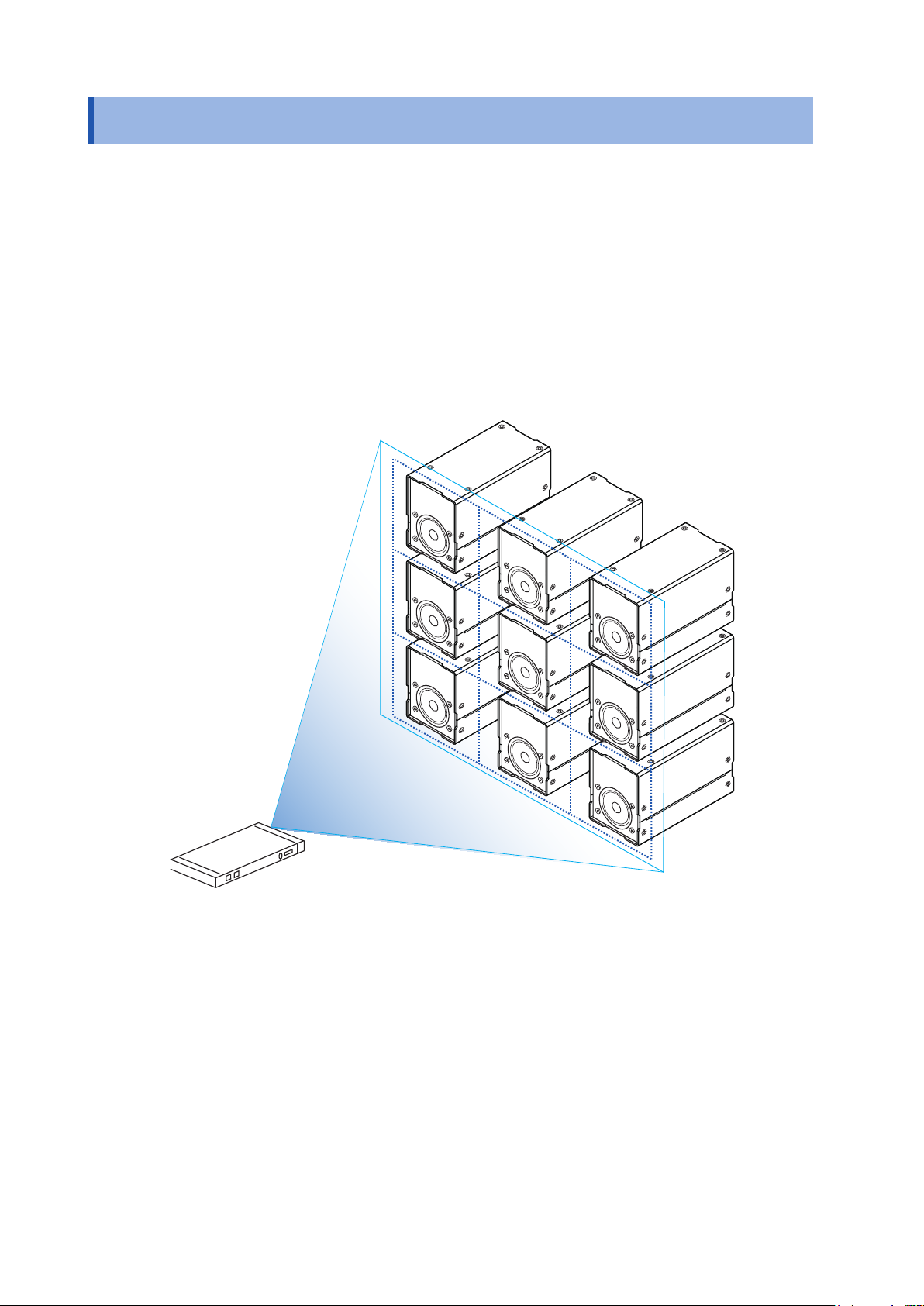

Model TM6102 RGB Laser Meter

1.2 Model TM6102 RGB Laser Meter

The TM6102 RGB Laser Meter measures the light that is irradiated uniformly to the entire detector

window from the RGB laser module of the projector or HUD (head up display).

The reference surface of the illuminance measurement is REF.LEVEL shown in the drawings of the

dimensions. (p. 15)

The measurement settings and measurement items except for the following points are the same as

the TM6103 and TM6104.

• Radiometric quantity → Irradiance

• Photometric quantity → Illuminance

Measurement example

12

Example: Laser projector

Page 16

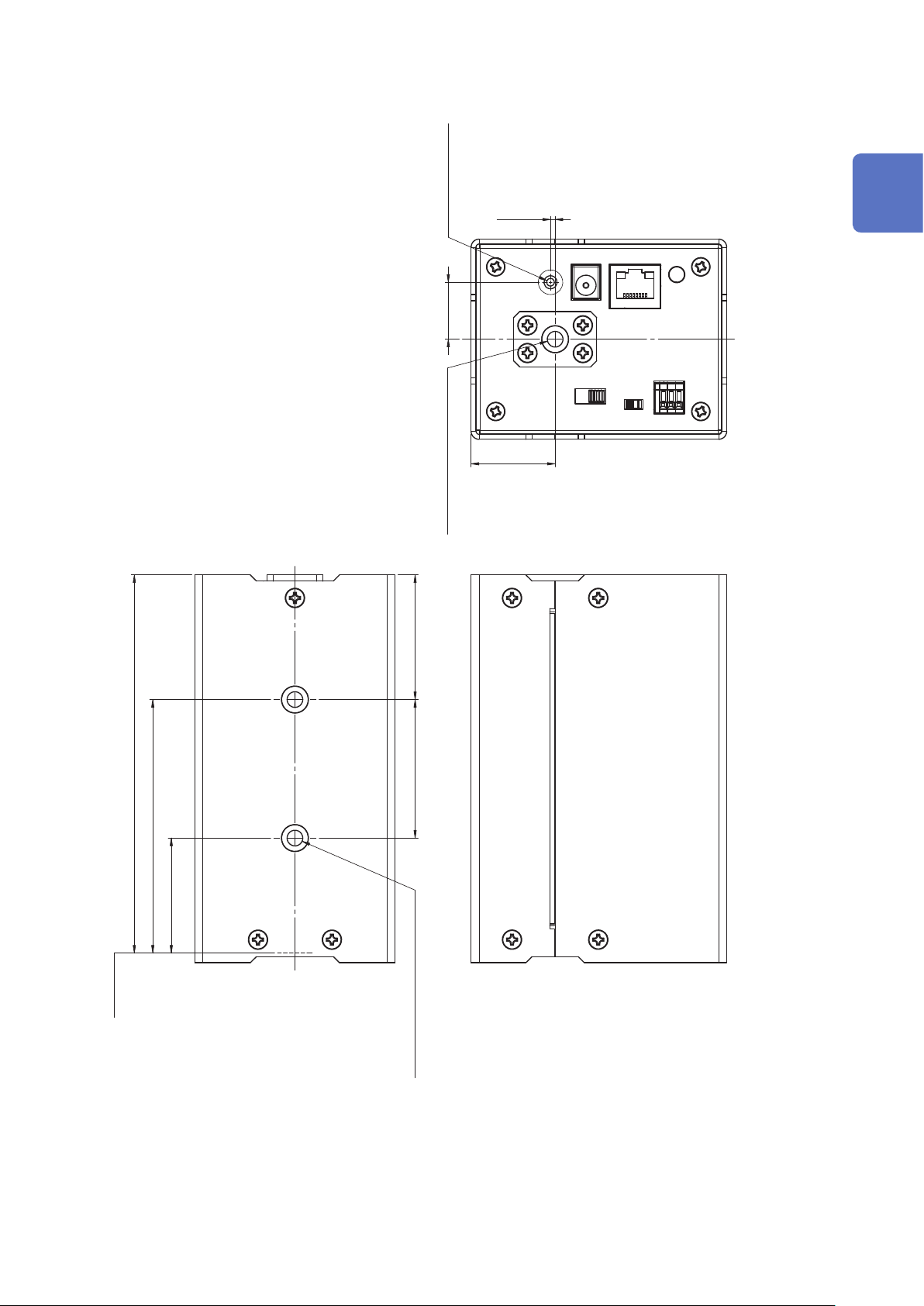

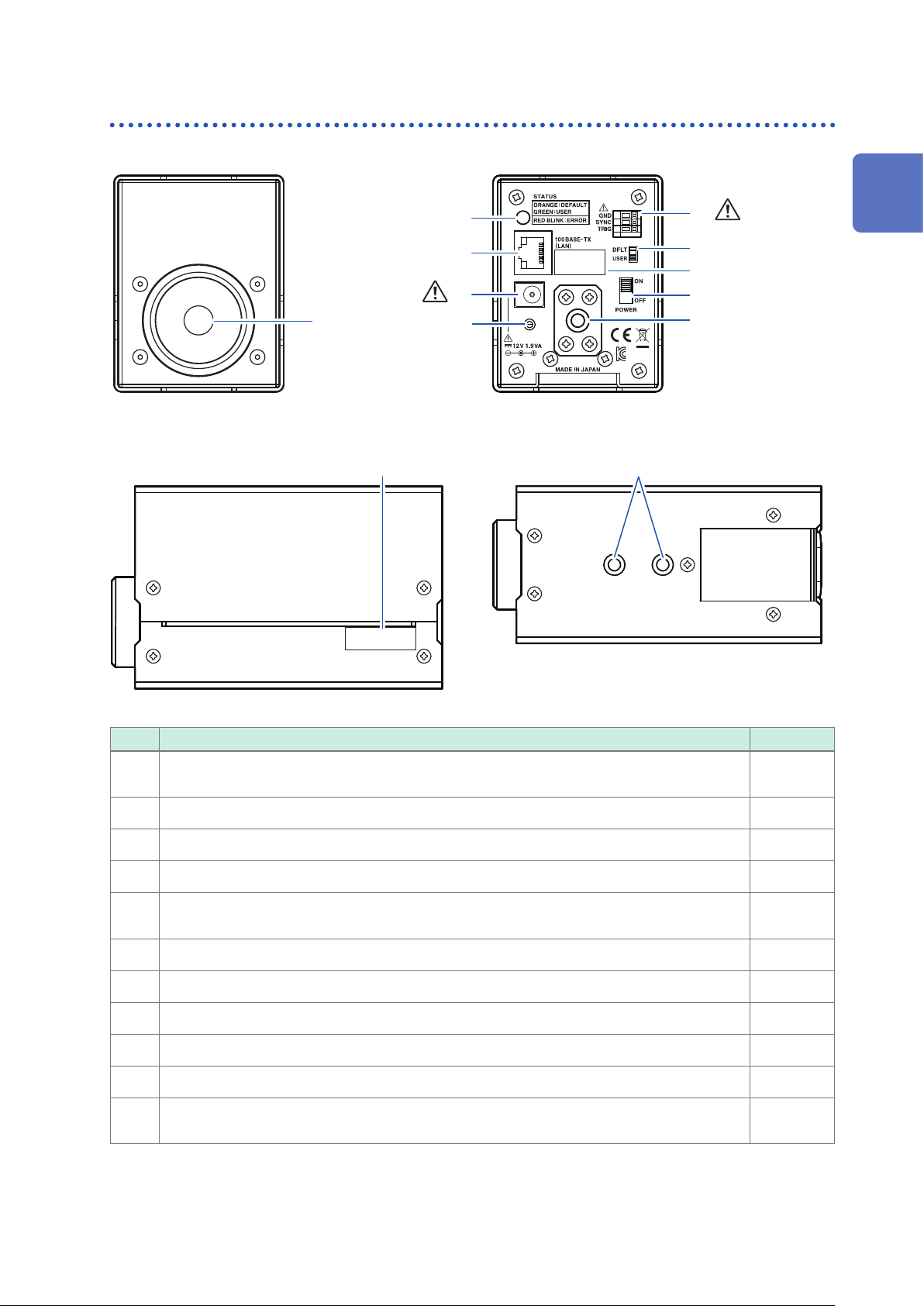

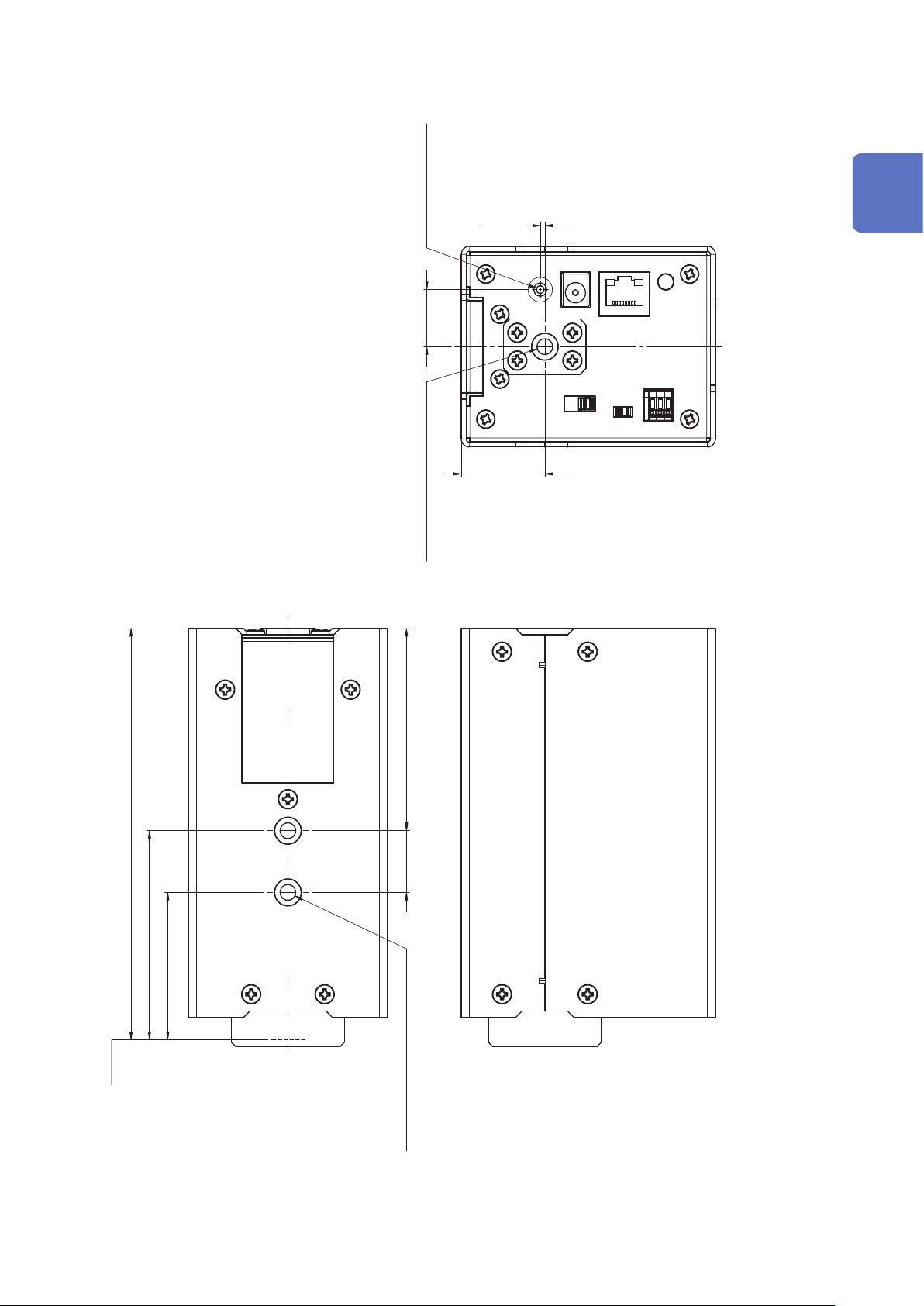

Parts Names and Functions

Model TM6102 RGB Laser Meter

Front

Right side

Rear

2

3

6

7

(p. 9)

1

Overview

8

(p. 6)

1

11

4

5

Bottom

9

10

10

No. Description Reference

Detector window

1

(φ11.3 mm ±0.1 mm)

Power LED p. 27

2

LAN connector p. 29

3

AC adapter connector p. 26

4

General purpose screw hole

5

(Used to secure the power cord.)

External input terminals p. 51

6

Communication mode switch p. 26

7

MAC address

8

Power switch p. 27

9

Tripod mounting screw holes p. 8

10

Serial No.

11

(Do not peel off the label because it is necessary for production control.)

p. 8

–

–

–

13

Page 17

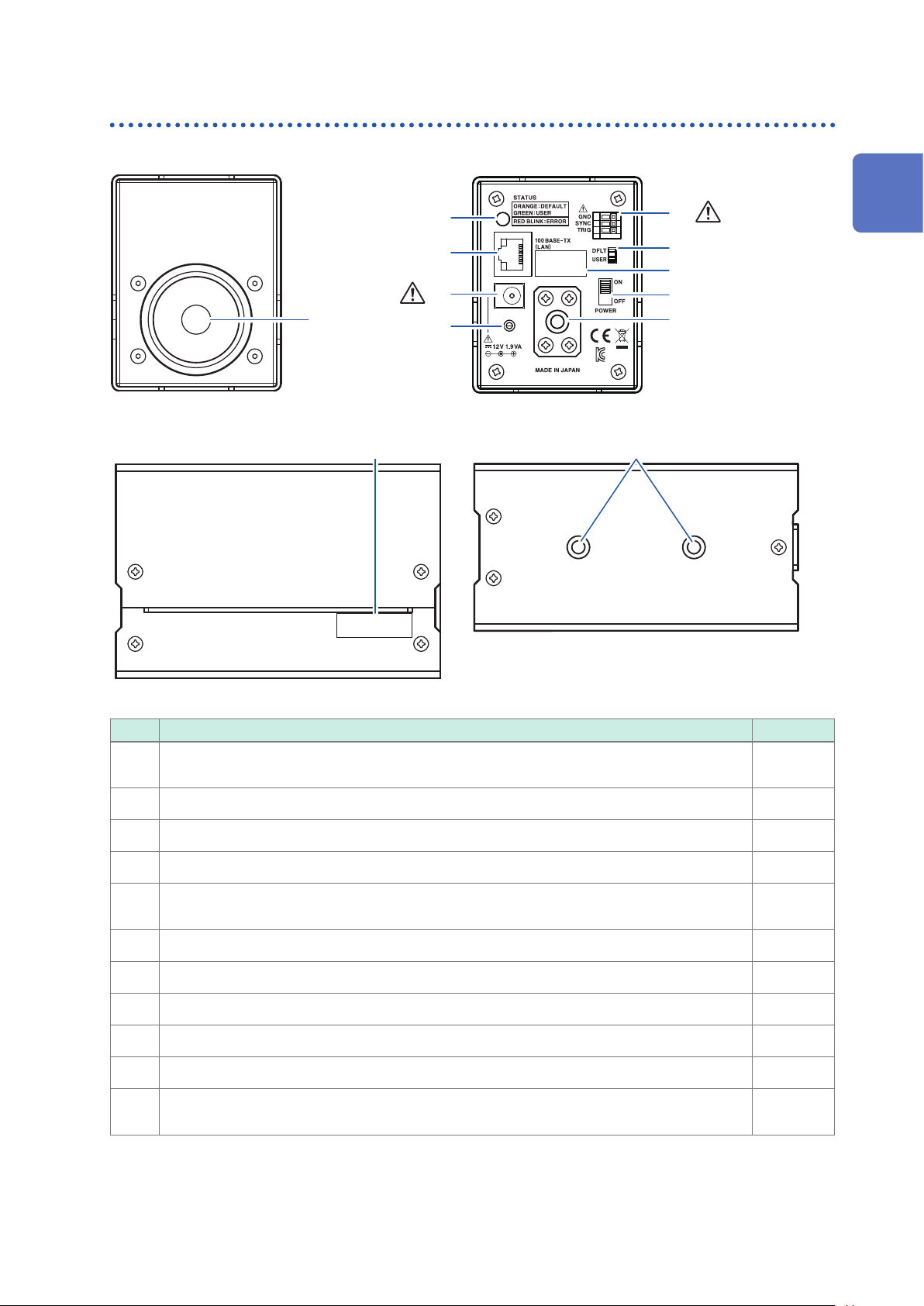

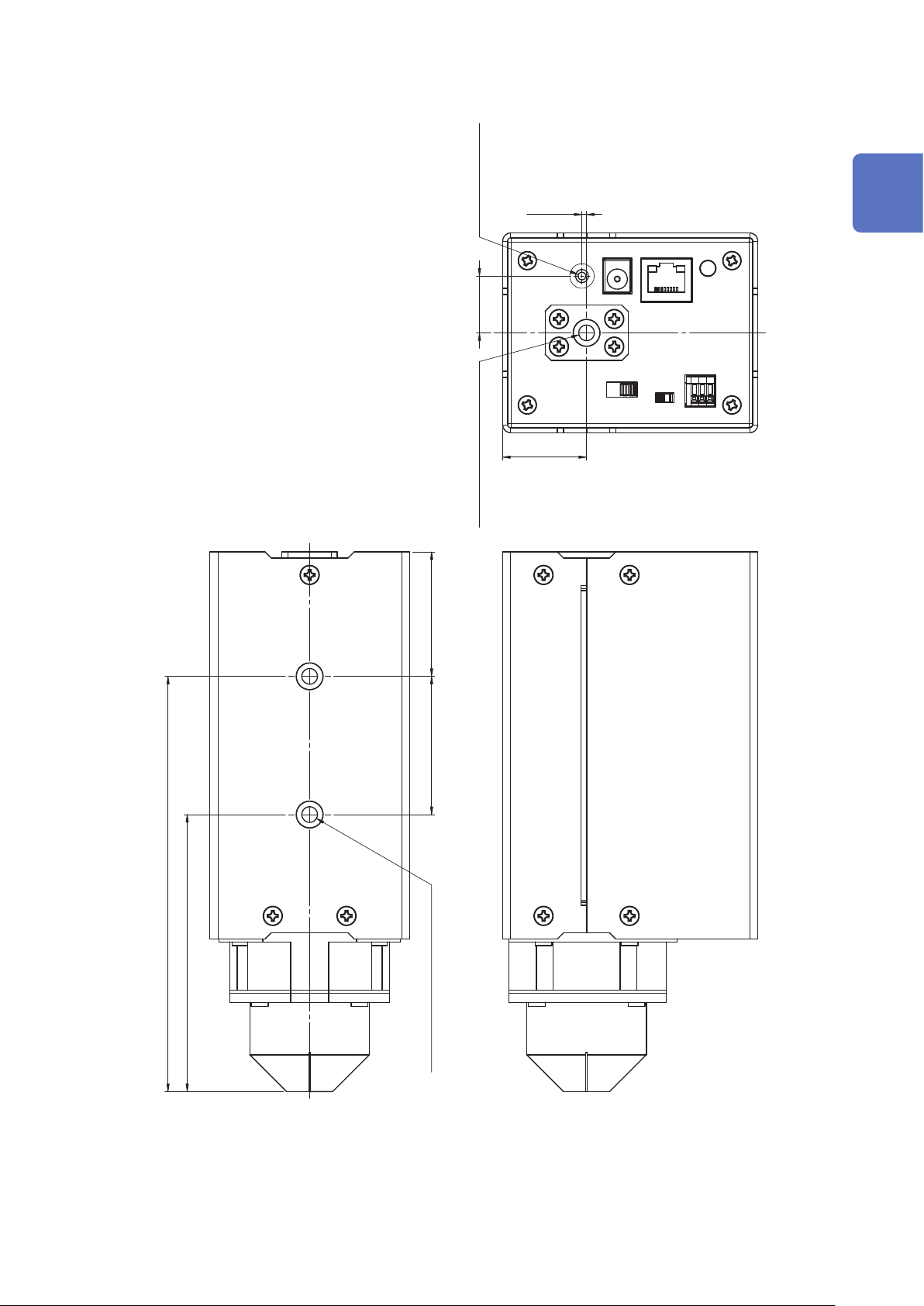

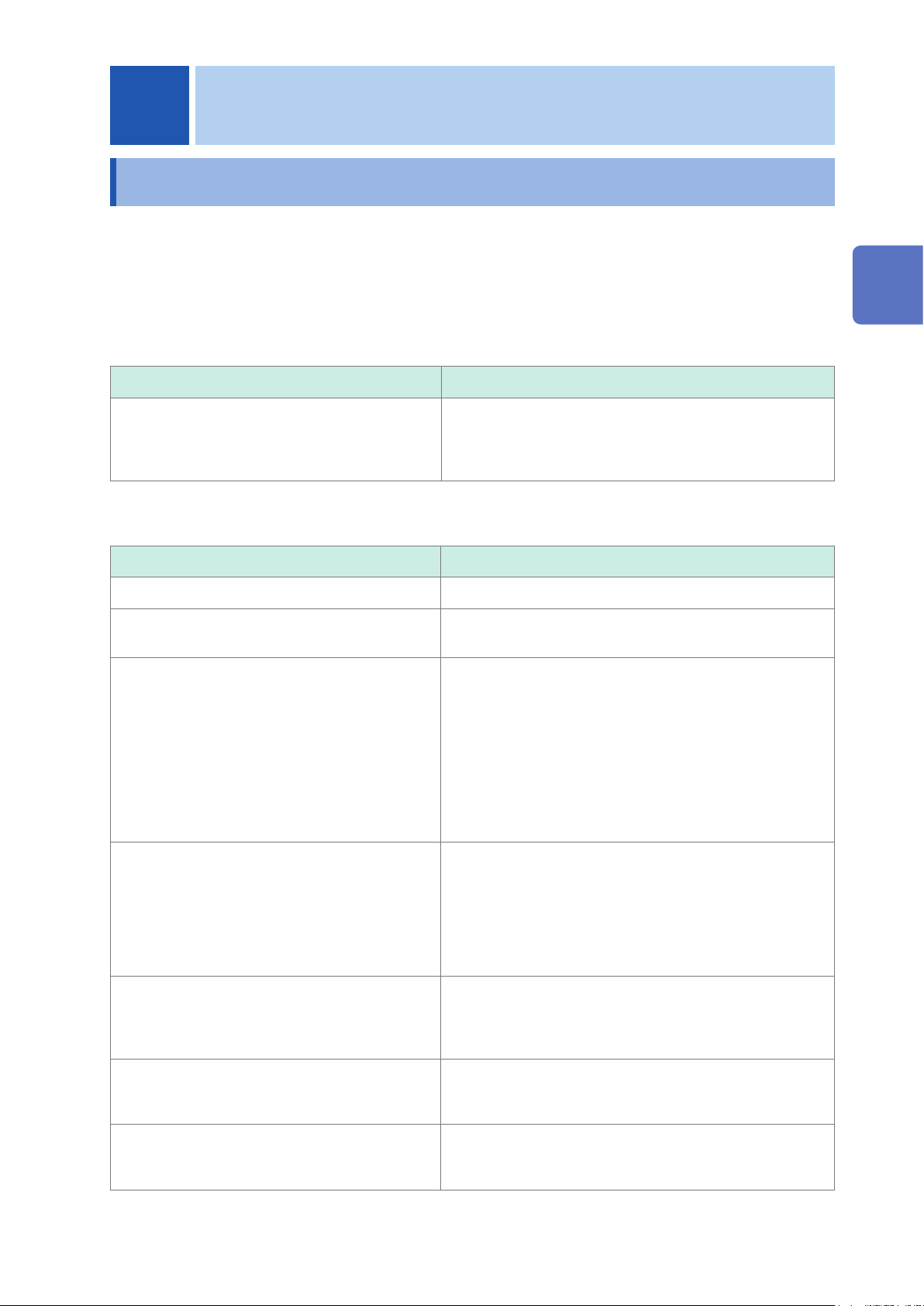

Model TM6102 RGB Laser Meter

C

L

±1

65

83 ±1

±0.5

27.3

11.3

±0.1

126

±1

Dimensions

65±1

83 ±1

27.3 ±0.5

11.3 ±0.1

φ

(Unit : mm)

14

Page 18

Model TM6102 RGB Laser Meter

M3 Effective Depth 5

1.5 ±0.3

1

Overview

18.5

±0.5

C

L

1/4-20UNC Effective Depth 7.5

27.3

±0.5

C

L

122.85

±1

±0.5 82.35

37.35

±0.5

REF.LEVEL

(Measurement reference surface)

(45) 5.7 htpeD evitceffE CNU02-4/1 ×2 )5.04(

(Unit : mm)

15

Page 19

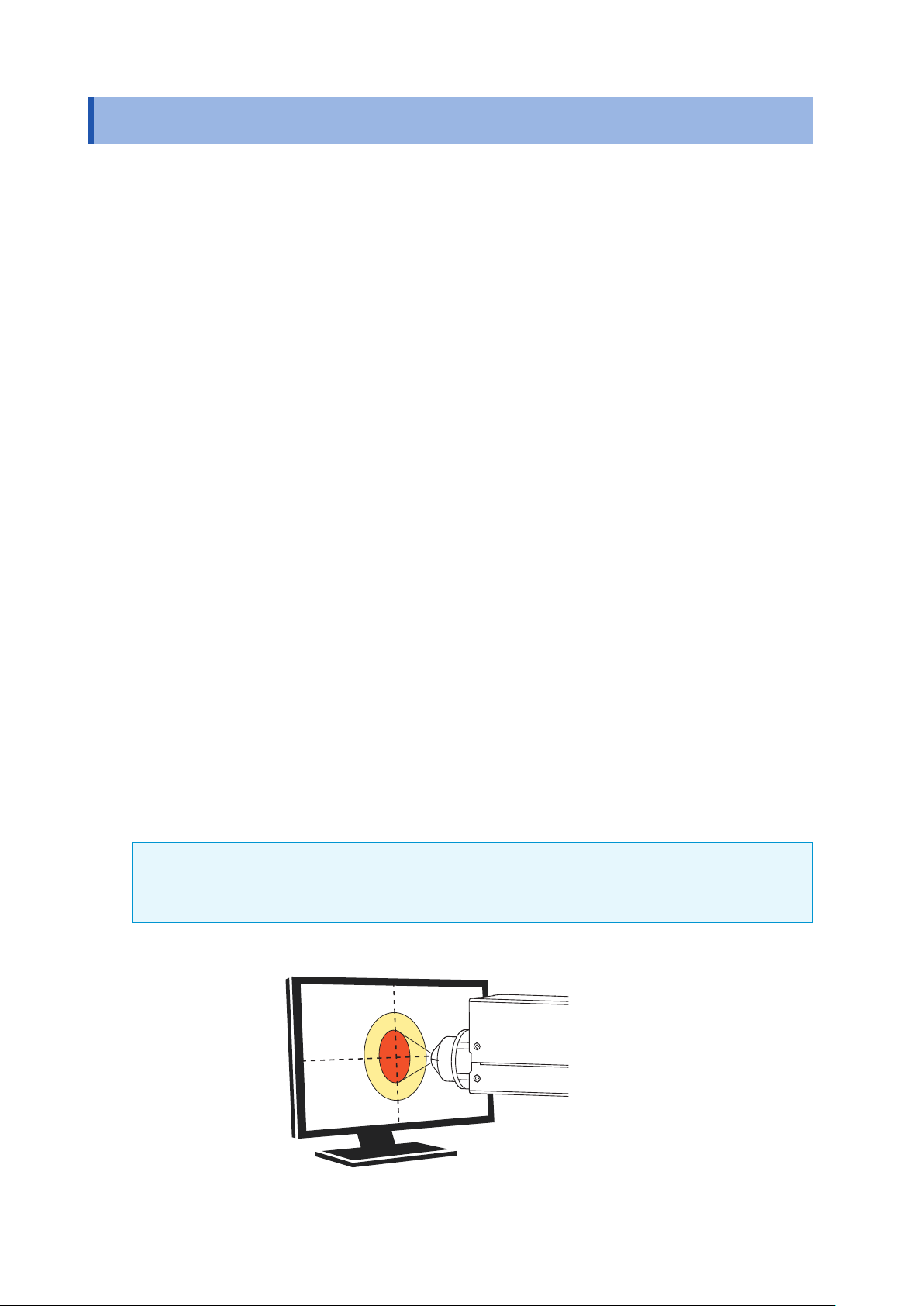

TM6103 RGB Laser Luminance Meter

1.3 TM6103 RGB Laser Luminance Meter

The TM6103 RGB Laser Luminance Meter is a light shielding cylinder type luminance meter.

The TM6103 measures the luminance at a close range of the display (example: the distance from

the top end of the light shielding cylinder to the display is 10 mm).

Before starting the measurement, install the TM6103 so that it is perpendicular to the display. (To

measure the luminance more accurately, align the light axis of the light emitted from the display and

the light axis of the TM6103.)

The light source that becomes the measuring object needs to be larger than the measurement eld

diameter of the TM6103.

To perform accurate measurements, it is recommended to measure the light source that is

sufciently larger than the measurement eld diameter.

The TM6103 measures the average luminance within the measurement eld diameter in the same

way as the conventional luminance meter.

When a directional light source (light source with an inconstant luminance) is measured using

luminance meters with different angle-of-visibilities, the measured value that differs among them.

This phenomenon occurs because the calibration light source of the luminance meter has a

constant luminance area, but the measuring object does not have one.

• When the light source of the measuring object has a constant luminance area, differences in the

angle-of-visibility do not affect the measured luminance value.

• The measured luminance is a value for which the angle dependency of the light source luminance

is averaged by the angle-of-visibility. Therefore, when the light source of the measuring object

does not have a constant luminance area, the angle-of-visibility of the luminance meter affects

the measured luminance value, in principle.

To perform the measurement with excellent reproducibility, it is necessary to align the light axis

of the light emitted from the display and the light axis of the luminance meter. In this case, it is

recommended to use an optical bench.

The measurement settings and measurement items except for the following points are the same as

the TM6102 and TM6104. (p. 12)

• Radiometric quantity → Radiance

• Photometric quantity → Luminance

CAUTION

Removing or disassembling the light shielding cylinder may cause inaccurate measurements. (p. 8)

Never attempt to remove or disassemble the light shielding cylinder.

Measurement example

16

Light source (Target)

Page 20

Parts Names and Functions

Front Rear

TM6103 RGB Laser Luminance Meter

Right side

(p. 6)

10

1

2

3

4

Bottom

5

(p. 9)

1

Overview

6

7

8

9

9

No. Description Reference

Power LED p. 27

1

LAN connector p. 29

2

AC adapter connector p. 26

3

General purpose screw hole

4

(Used to secure the power cord.)

External input terminals p. 51

5

Communication mode switch p. 26

6

MAC address –

7

Power switch p. 27

8

Tripod mounting screw holes p. 8

9

Serial No.

10

(Do not peel off the label because it is necessary for production control.)

–

–

17

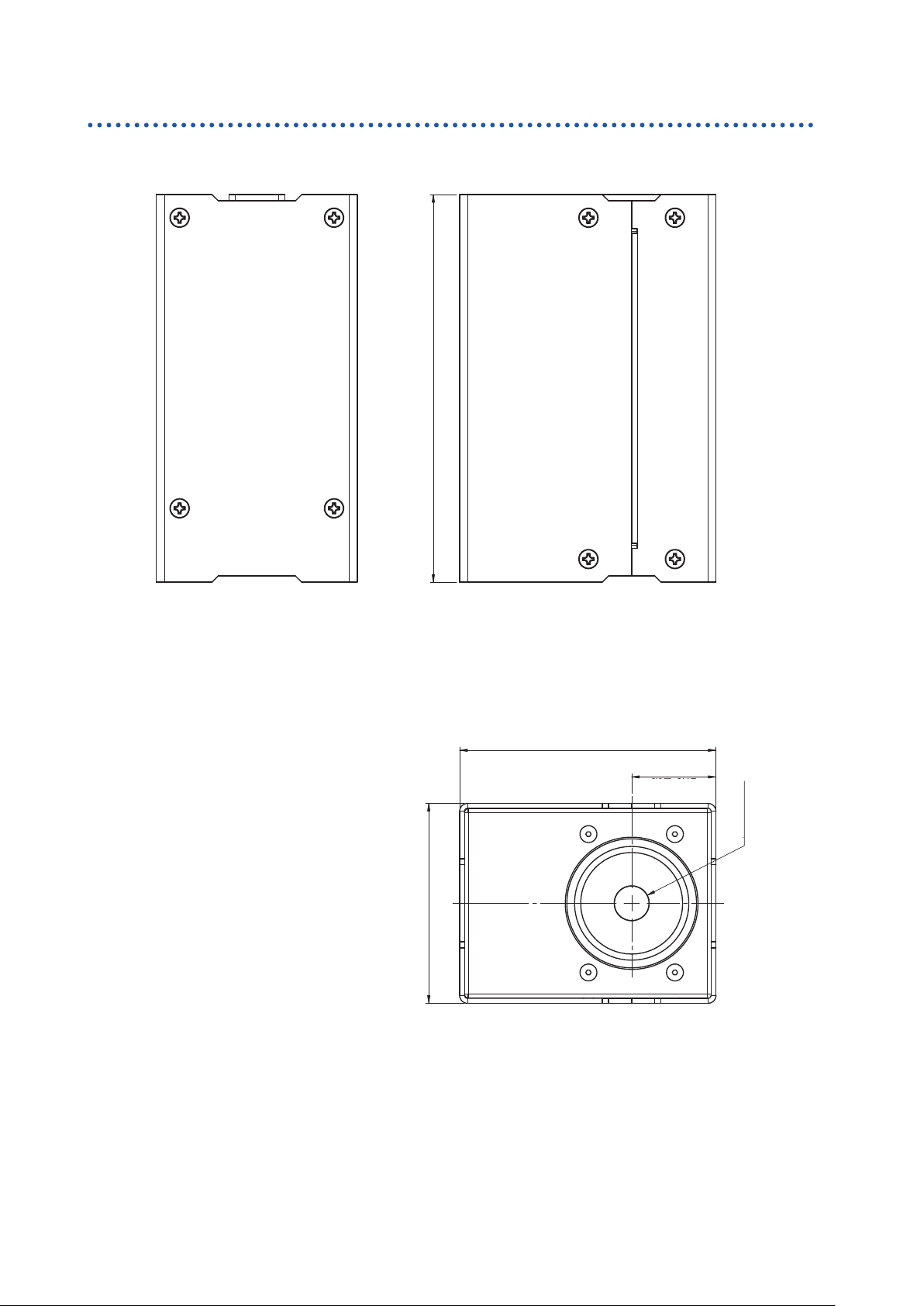

Page 21

TM6103 RGB Laser Luminance Meter

Dimensions

126 ±0.5

175.7 ±1

175.7 ±1

126 (49.7) ±0.5

39 ±0.5

φ

52 ±0.5

φ

L

C

L

C

±0.5

39

52 ±0.5

±1

L

C

65 ±1

65

83 ±1

83 ±1

27.3 ±0.5

±0.5 27.3

(Unit : mm)

18

Page 22

TM6103 RGB Laser Luminance Meter

1.5

±0.3

1

Overview

18.5 ±0.5

C

L

5 htpeD evitceffE 3M 1/4-20UNC Effective Depth 7.5

27.3 ±0.5

C

L

(40.5)

(45)

135.2

±0.5

90.2

±0.5

2× 1/4-20UNC Effective Depth 7.5

(Unit : mm)

19

Page 23

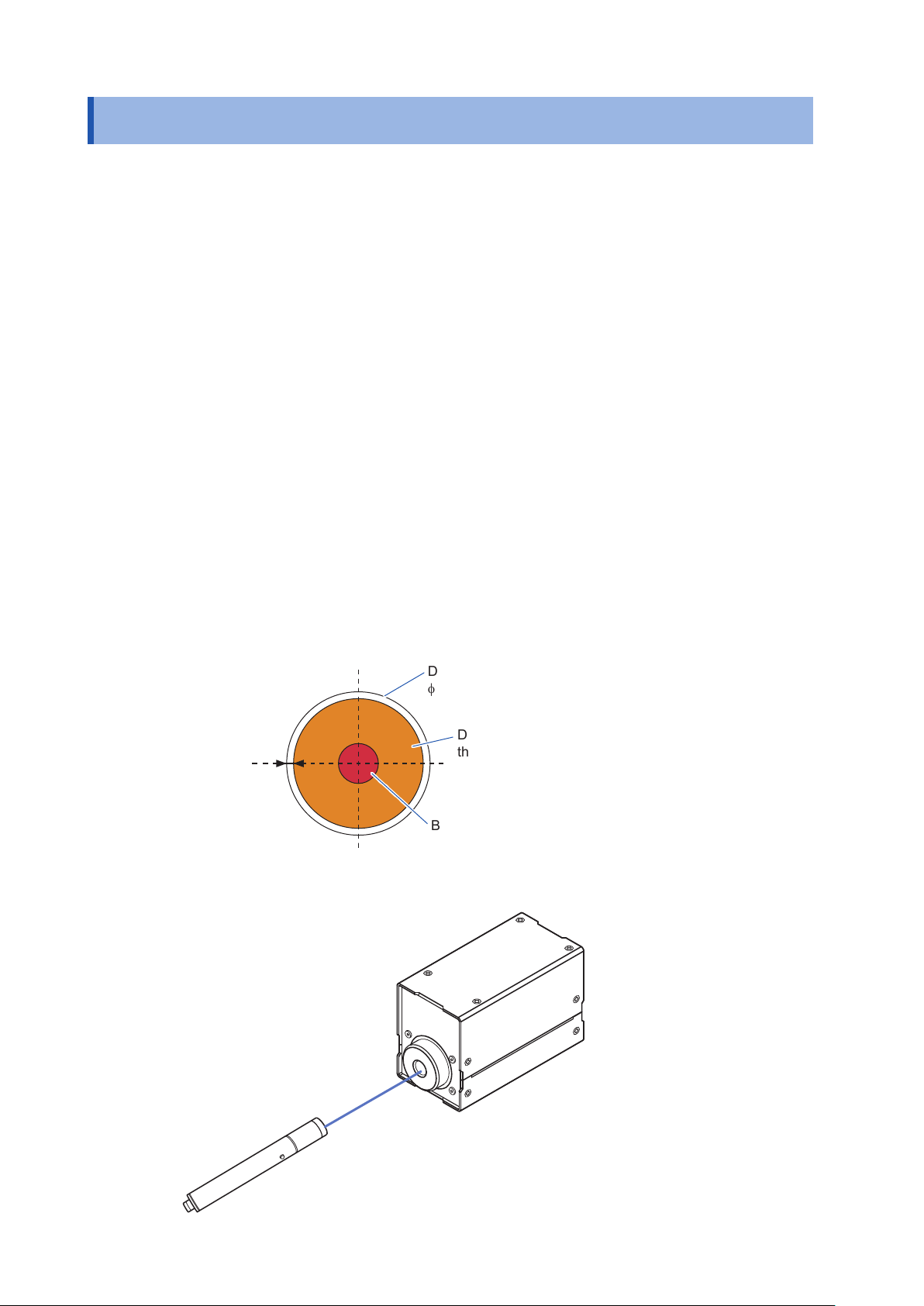

Model TM6104 Optical Power Meter

1.4 Model TM6104 Optical Power Meter

The TM6104 Optical Power Meter measures the power and centroid wavelength of the laser beam

irradiated at the center of the detector window.

When performing the measurement, you have to consider the beam diameter.

The beam diameter is dened as a maximum distance between the points in the cross section

of the beam where the optical power density is e

(JIS C6182).

Although IEC1040 adopts e

−1

as the denition of a beam diameter instead of e−2, this instrument

uses the denition of JIS C6182.

To perform accurate measurements, it is necessary to make all powers of the beam enter the

detector window.

In addition, it is recommended to use a laser with a beam diameter of 3.1 mm or less so as to

perform accurate measurements.

This makes the diameter that is 3 times larger than the beam diameter smaller than the diameter of

the detector window (= φ11.3 mm) as a guide since the beam usually has a spread.

Example: When the beam diameter is 1 mm, make the beam enter an area within 6 mm dia. from

the center of the detector window.

−2

(= 0.1353) to the maximum value in the beam

However, this does not apply when the beam has no spread.

The measurement settings and measurement items except for the following points are the same as

the TM6102 and TM6103. (p. 12)

• Radiometric quantity → Radiant ux (Optical power)

• Photometric quantity → Luminous ux

Detector window

11.3 mm

φ

1 mm

Diameter 3 times larger than

the beam diameter

9.3 mm (Maximum value)

φ

Beam diameter

3.1 mm (Maximum value)

φ

Measurement example

Layout of optical system

20

Laser light source

Page 24

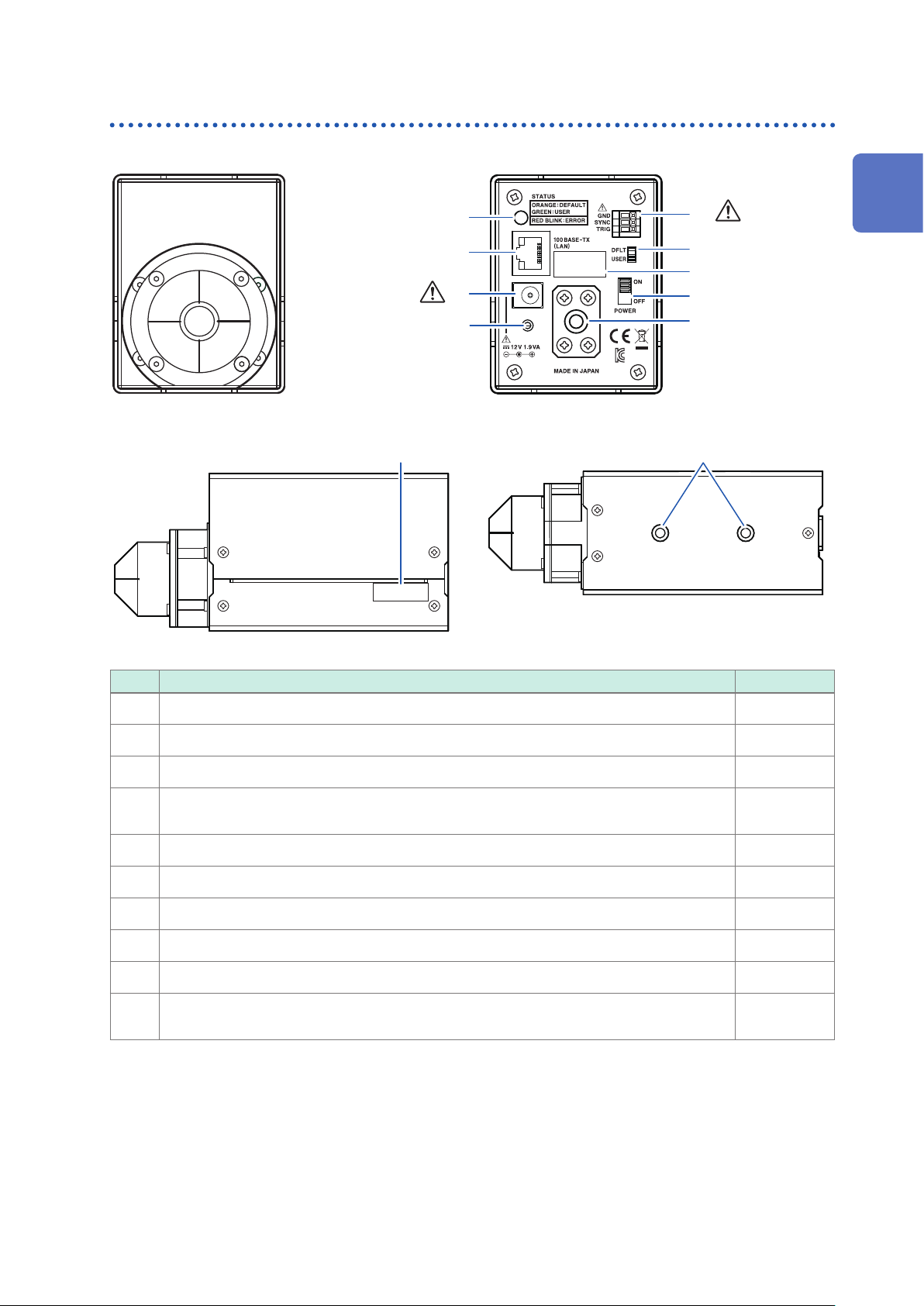

Parts Names and Functions

Model TM6104 Optical Power Meter

Front

Right side

Rear

2

3

6

7

(p. 9)

1

Overview

8

(p. 6)

1

11

4

5

Bottom

9

10

10

No. Description Reference

Detector window

1

(φ11.3 mm ±0.1 mm)

Power LED p. 27

2

LAN connector p. 29

3

AC adapter connector p. 26

4

General purpose screw hole

5

(Used to secure the power cord.)

External input terminals p. 51

6

Communication mode switch p. 26

7

MAC address –

8

Power switch p. 27

9

Tripod mounting screw holes p. 8

10

Serial No.

11

(Do not peel off the label because it is necessary for production control.)

p. 8

–

–

21

Page 25

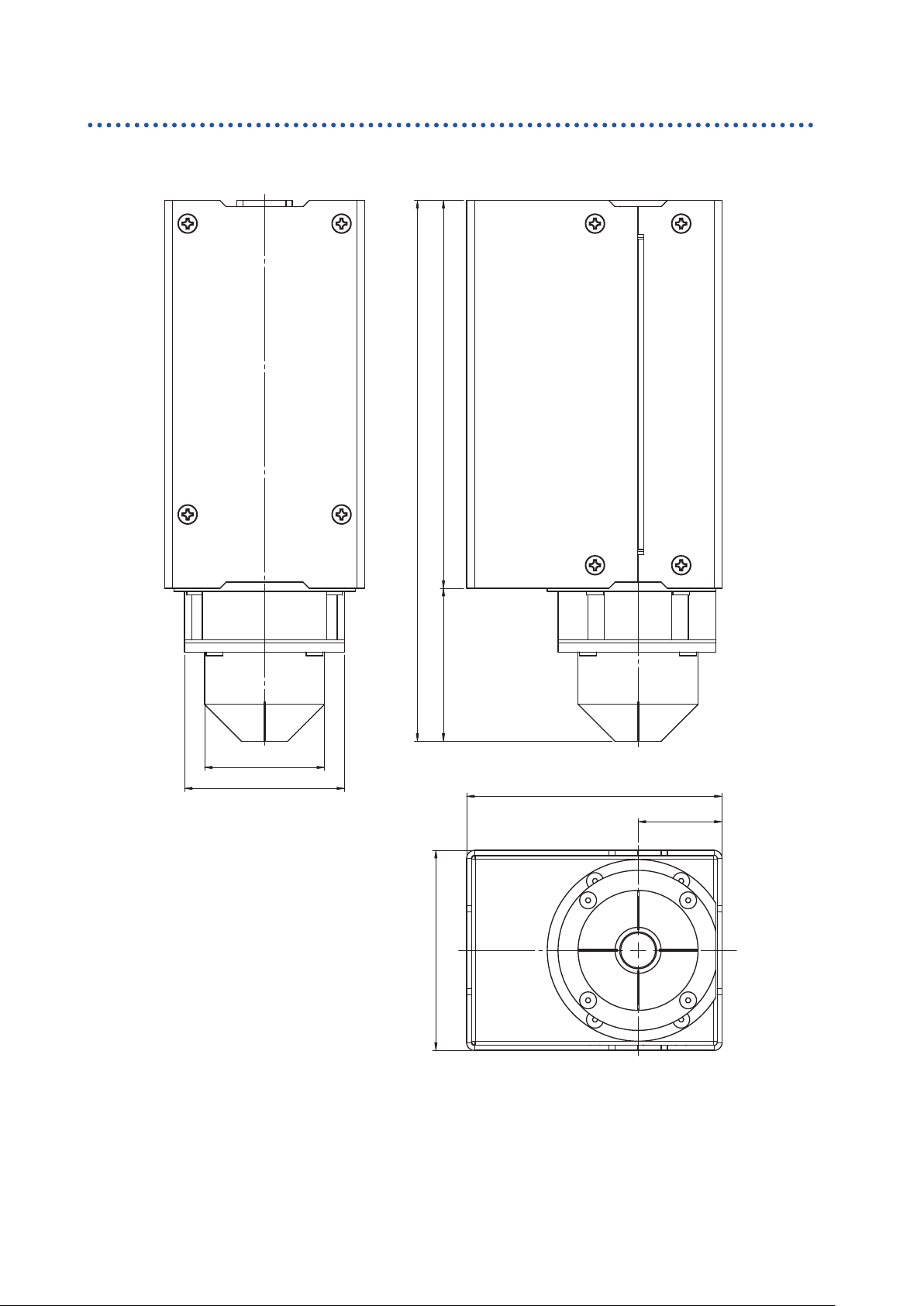

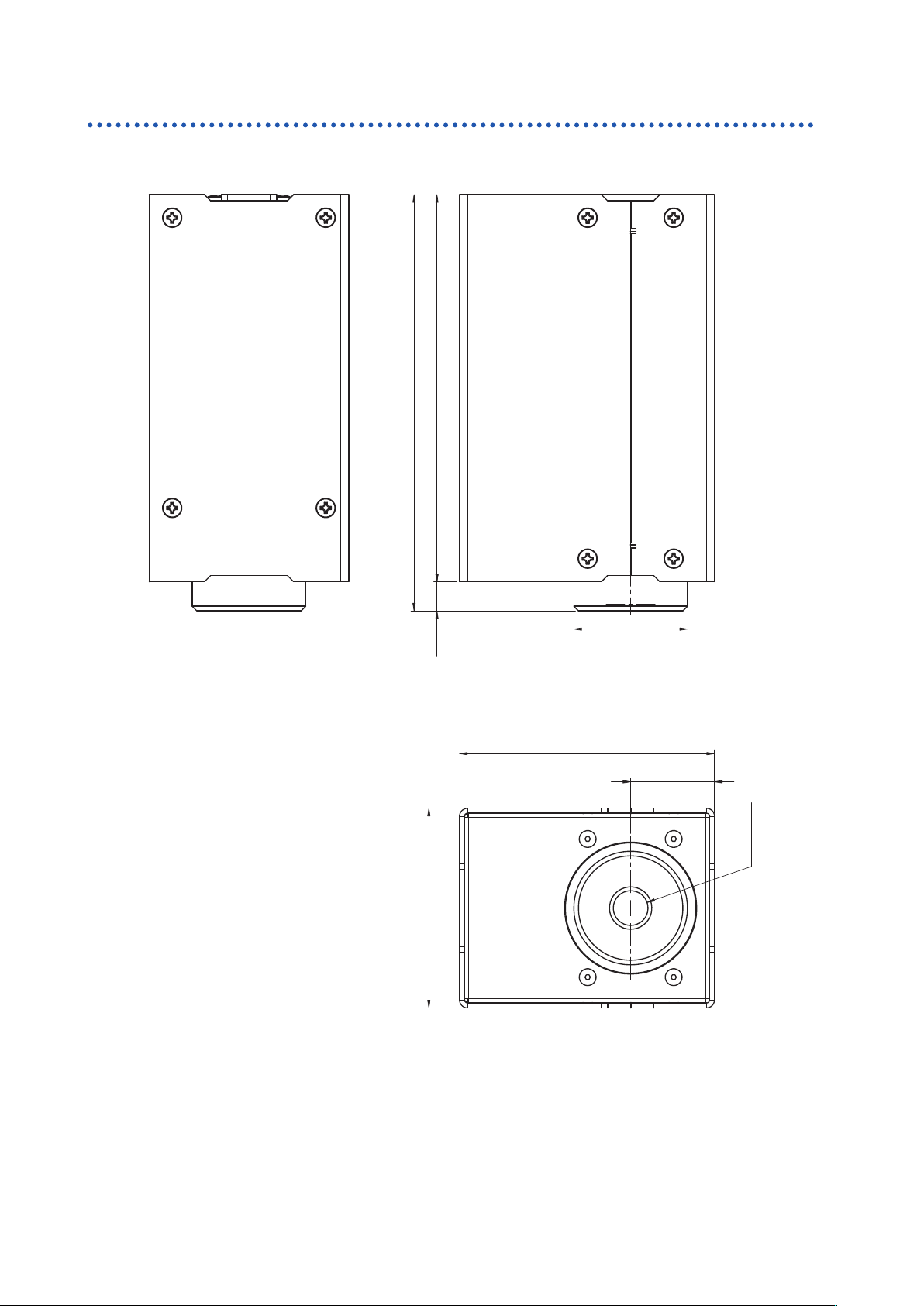

Model TM6104 Optical Power Meter

Dimensions

±1

±0.5

621 )5.9(

135.5 ±1

126 ±0.5

135.5

±1

65 ±1

65

37 ±0.5

φ

37

±0.5

83 ±1

83 ±1

27.3 ±0.5

L

C

27.3 ±0.5

11.3 ±0.1

Detector window

11.3 ±0.1

受光面

φ

(Unit : mm)

22

Page 26

±0.5

67.75

47.75

±0.5

133.25

±1

受光面

C

L

2× 1/4-20UNC Effective Depth 7.5

(20)

(65.5)

C

L

±0.5

M3 Effective Depth 5 1/4-20UNC Effective Depth 7.5

27.3

±0.5

18.5

1.5

±0.3

Model TM6104 Optical Power Meter

1

Overview

Detector window

(Unit : mm)

23

Page 27

Model TM6104 Optical Power Meter

24

Page 28

2

Preparations

2.1 Inspection Before Measurement

Check before use

Before using the instrument, verify that it operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized Hioki distributor or

reseller.

Inspecting peripheral devices

Check item Action

Using a damaged connection cable may cause an electrical

Is the sheath of any connection cable damaged or

any metal part exposed?

Inspecting the instrument

Check item Action

shock or a short circuit accident. Do not use any damaged

connection cable.

Replace the damaged connection cable with a new one.

2

Preparations

Is the instrument damaged? If the instrument is damaged, send the instrument for repair.

Is any dust or contaminant adhered to the detector

window?

Does the power LED light up?

Execute the self-test to check if an error occurs.

(Use the

When no error occurs,

When an error occurs,

Input the modulation frequency signal to the SYNC

terminal and execute the modulation frequency

measurement. Is the measured result of the

modulation frequency within the assumed range?

TST?

command to execute the self-test.

*

PASS

is returned.

FAIL

is returned.)

If the detector window is contaminated, clean it. (p. 93)

• If the power LED does not light up, the power cord contains

a broken wire or the inside of the instrument malfunctions. If

the instrument malfunctions, send it for repair. (p. 27)

• If the power LED blinks in red, an error occurred inside the

instrument. After connecting the instrument via TCP/IP, use

ESR?,:SYSTem:ERRor?

the

*

of the error, and then take appropriate corrective actions

corresponding to the error.

Details of error: Communication Command Instruction

Manual (CD)

• When an error occurs, use the

to check the details of the error, and then take appropriate

corrective actions corresponding to the error.

• For details about the error, see the Communication Command

Instruction Manual (CD).

• When executing the self-test using the application software,

see “Self-test” (p. 79).

If the measured result of the modulation frequency is not

within the assumed range, the inside of the instrument may

malfunction. Send the instrument for repair.

command to check the details

:SYSTem:ERRor?

command

Is the measured value of the photometric quantity

changed by changing the brightness of the

irradiation light?

Is the measured result of the centroid wavelength

within the assumed range when the laser light

source with the known wavelength is measured?

If the measured value of the photometric quantity is not

changed, the inside of the instrument may malfunction. Send

the instrument for repair.

If the measured result of the centroid wavelength is not

within the assumed range, the inside of the instrument may

malfunction. Send the instrument for repair.

25

Page 29

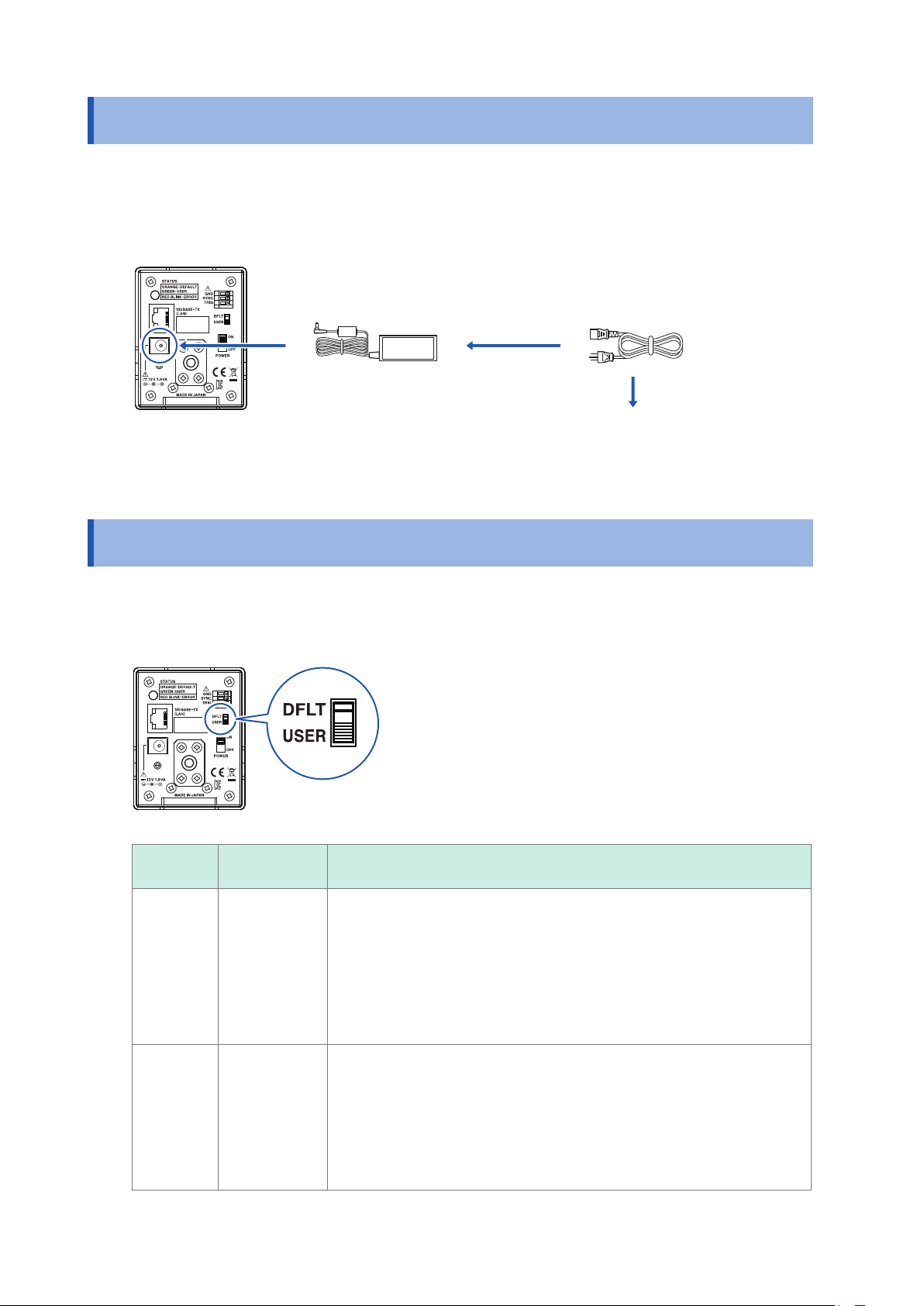

Connecting the AC Adapter and Power Cord

2.2 Connecting the AC Adapter and Power Cord

Check the following points before starting the connection work.

• Check that the cap is attached to the detector window.

• Thoroughly read “AC Adapter” (p. 9).

Rear

Connect the AC adapter to

1

the AC adapter connection

terminal of the instrument.

Connect the power cord to

2

the AC adapter.

Connect the power cord

3

to a commercial power

supply.

2.3 Setting the Communication Setting Mode

Change the LAN communication setting mode using the communication setting mode switch. (p. 31)

The LAN communication setting mode cannot be changed when the power is ON.

Rear

26

Switch

DFLT

USER

Communication

setting mode

Fixed setting

mode

User setting

mode

Settings

• The LAN settings are as follows.

IP address: 192.168.0.254

Subnet mask: 255.255.255.0

Default gateway: 0.0.0.0 (None)

Communication command port: 1024

• The xed setting mode is used to make the LAN settings.

• The xed setting mode can also be used when one-to-one communication

with the computer is performed.

Use the LAN settings that are set using the following communication

commands.

:SYSTem:COMMunicate:LAN:IPADdress <IP

:SYSTem:COMMunicate:LAN:SMASk <

:SYSTem:COMMunicate:LAN:GATeway <

:SYSTem:COMMunicate:LAN:CONTrol <

:SYSTem:COMMunicate:LAN:UPDate

Subnet mask

Address

Port No.

address

>

>

>

>

Page 30

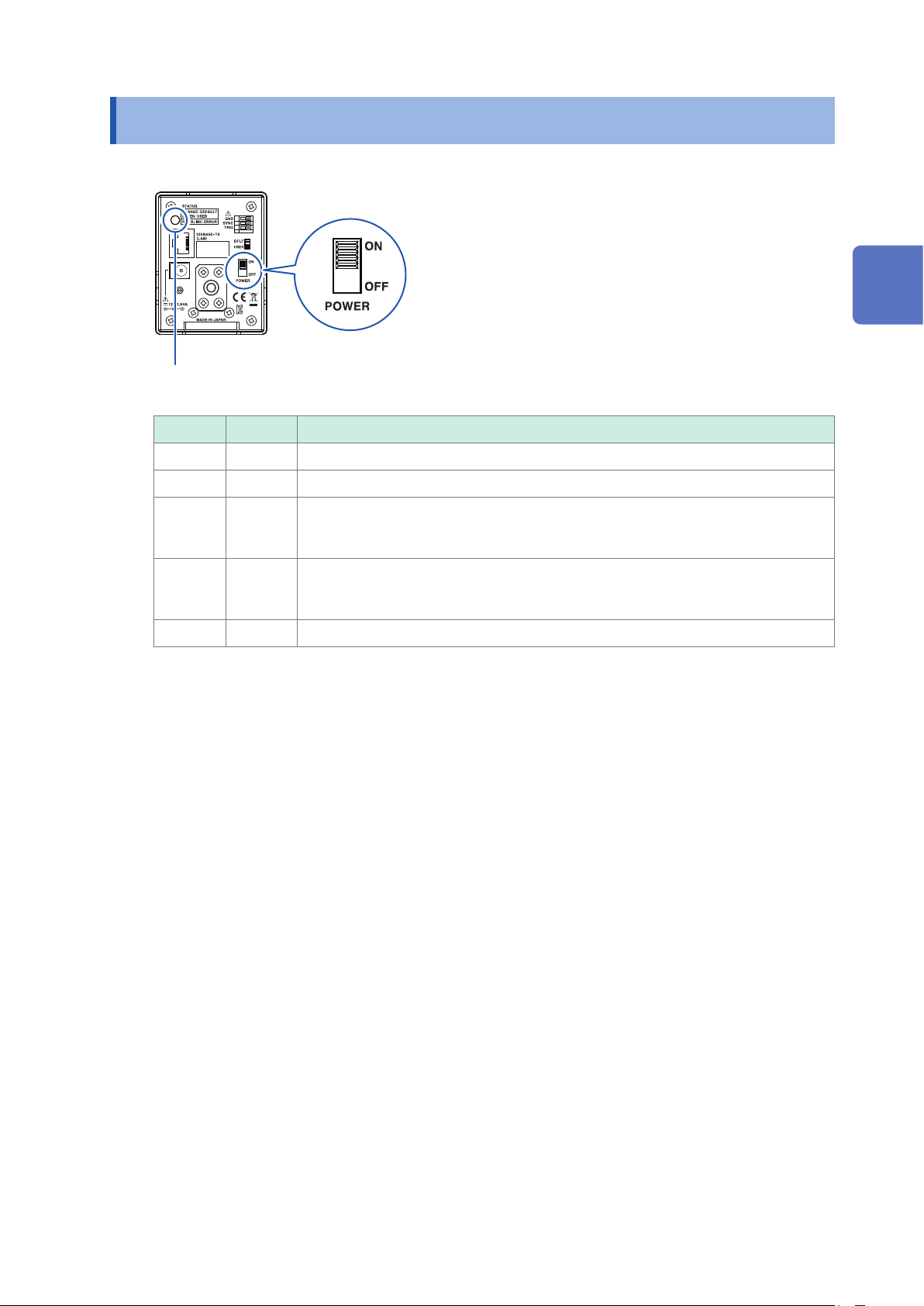

Turning ON/OFF the Power

2.4 Turning ON/OFF the Power

Rear

Power LED

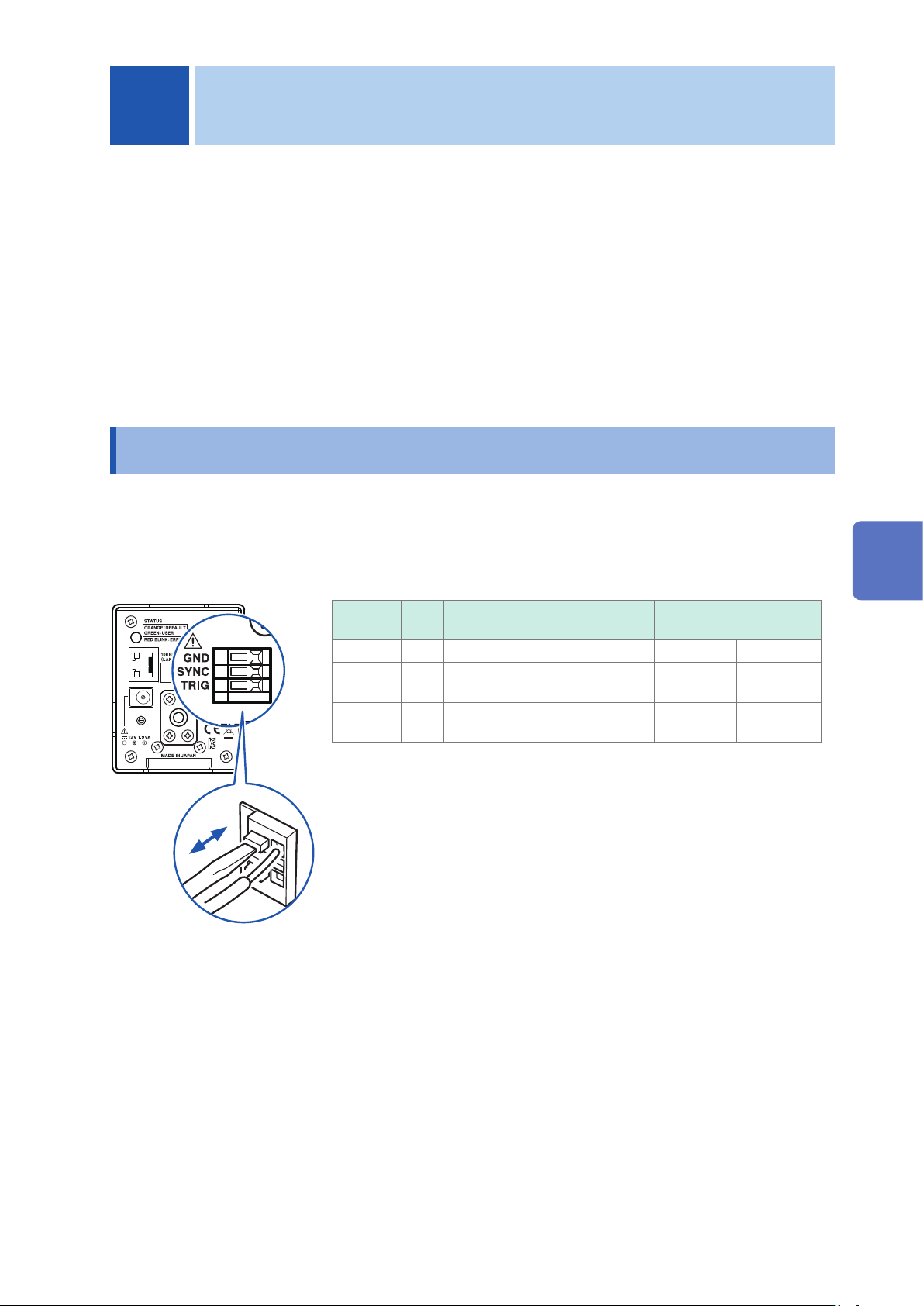

Color Status Description

Green Lit Running when the communication setting mode is set to the user setting mode.

Orange Lit Running when the communication setting mode is set to the xed setting mode.

2

Preparations

An internal error is occuring.

Red Blink

Orange Blink

‒ Off The power is off.

Use the communication command (

See: Communication Command Instruction Manual (CD)

Running in the version up mode (boot mode).

The communication setting mode becomes the xed setting mode regardless of the

communication setting mode switch state.

ESR?, :SYSTem:ERRor?

*

) to check the details.

27

Page 31

Installing the Application Software

2.5 Installing the Application Software

Recommended computer operating environment

CPU Core i5, 2.7 GHz or faster

OS Windows 7/ Windows 8/ Windows 10

Memory 8 GB or more

Screen display Resolution 1024

Hard disk Free capacity 100 MB or more

Interface LAN 100BASE-TX (TCP/IPv4 connection)

CD-ROM drive For software installation

The application software supplied with the instrument may run slowly depending on the computer

operating environment and the type of other application software that is used at the same time. It is

recommended to run the application software in the recommended operating environment.

768 dots, 64,000 colors or more

×

Installation

Before starting the installation, exit all applications running on the computer.

Log into the computer using an account with administrative privileges such as

1

“administrator”.

Execute X:\RGBLaserUtility\Setup.msi contained in the TM6102/TM6103/TM6104

2

Application Disc (CD).

(X: is a CD-ROM drive.)

After executing setup.msi, follow the instructions that appear on the screen to proceed the installation.

After the installation has been completed and all connections have been performed,

3

start the program in one of the following ways.

• Double-click the [RGBLaserUtility] icon on the desktop.

• From the [Start] menu of Windows, click [All Programs] > [HIOKI] > [RGBLaserUtility].

Uninstallation

When the application software is no longer needed, delete it in one of the following ways.

28

• Click

[Control Panel] > [Uninstall a program], and then delete [HIOKI RGBLaserUtility].

• Click [Control Panel] > [Programs and Features], and then delete [HIOKI RGBLaserUtility].

Page 32

Using a LAN

2.6 Using a LAN

The instrument is equipped with an Ethernet 100BASE-TX interface as a standard.

The instrument is connected to the network using the recommended LAN cable (p. 30), and then

the instrument can be controlled using the computer.

When a program is created and the instrument is connected to the communication command port

via TCP/IP, the instrument can be controlled using communication commands. (For details, see the

Communication Command Instruction Manual (CD).)

Network multiple instruments and computer.

Hub

Flow of preparations

Connect the LAN cable (p. 30).

1

Set the communication conditions of the instrument (p. 31).

2

Perform one-to-one connection

between the instrument and computer.

Constructing the network environment

For LAN settings on the computer, see “LAN Settings on the Computer” (p. 101).

2

Preparations

• Do not connect the instrument to the existing network.

When the instrument is started in the xed setting mode or version up mode, it uses

the xed IP address (192.168.0.254). Therefore, when there is the same IP address in

the existing network, the IP addresses are overlapped.

• Do not send more commands than necessary. Doing so may lower the communication

speed when multiple instruments are controlled.

• Accessing using a wireless LAN or router is not recommended.

Description of setting items

An address to identify individual instruments that are connected on the network.

IP address

Subnet mask

Default gateway

Communication

command port

number

Set a unique IP address that does not overlap with other instrument.

The instrument uses IP version 4. The IP address is expressed by four decimal numbers separated

by a dot (.) like “192.168.0.1”.

This setting separates the IP address into the address part showing the network and the address

part showing the instrument.

Normally, the subnet mask is expressed by four decimal numbers separated by a dot (.) like

“255.255.255.0”.

When the communicating computer and the instrument are in different networks, specify the IP

address of the device that becomes a gateway.

When performing one-to-one connection or when using no gateway, set “0.0.0.0” for the instrument.

Specify the connected TCP/IP port number for communication commands.

CAUTION

29

Page 33

Using a LAN

Example of network environment construction

Example 1: Connect one computer and multiple instruments using a hub.

When a local network that is not connected externally is constructed, it is recommended to use a

private IP address shown in an example for the IP address.

IP address

Subnet mask 255.255.255.0

Default gateway

Computer: 192.168.0.1

Instrument: Specify 192.168.0.2, 192.168.0.3, 192.168.0.4, ...in order.

Computer: No entry

Instrument: 0.0.0.0

Example 2: Perform one-to-one connection between the computer and instrument using the

LAN cable.

When performing one-to-one connection between the computer and instrument, you can set a

desired IP address. However, it is recommended to use a private IP address.

Computer: 192.168.0.1

IP address

Subnet mask 255.255.255.0

Default gateway

Instrument: 192.168.0.2 (Set an IP address different from the computer

setting.)

Computer: No entry

Instrument: 0.0.0.0

Connecting the LAN cable

Connect the instrument and computer using the LAN cable.

If the green LED on the LAN connector is not lit even after the instrument has been connected to

the LAN, the instrument or connection device may malfunction or the LAN cable may have a broken

wire.

Rear

Recommended cable

Category 6A (CAT 6A) cable (Maximum 100 m)

• Since the instrument supports only 100BASE-TX,

the communication can be performed using at least

category 5 (CAT 5) cable. However, to ensure the high

quality communication, it is recommended to use the

Green LED

Lit: Linking

Blink: Communicating

Orange LED

Lit: 100BASE-TX

category 6A cable.

• The instrument incorporates a cable automatic

recognition function. Either the straight cable or cross

cable can be used.

30

Page 34

Setting the LAN

To set the LAN of the instrument, follow the settings and steps below.

• Be sure to perform one-to-one connection with the computer.

• Set the communication setting mode to the xed setting mode.

Using a LAN

Perform one-to-one connection

between the instrument and computer.

Turn OFF the instrument.

1

Disconnect the LAN cable from the instrument and computer.

2

Start the instrument in the xed setting mode.

3

Rear

Set the communication mode switch to the xed setting mode

1

(DFLT).

Turn ON the power switch.

2

Instrument settings (xed setting mode)

IP address: 192.168.0.254

Subnet mask: 255.255.255.0

Default gateway: None

Port: 1024

2

Preparations

When the power is ON, check that the power LED is lit in

3

orange.

If the power LED is not lit in orange, the setting of the communication mode switch may be

incorrect or the instrument may malfunction. If the instrument malfunctions, stop the setting

and send the instrument for repair.

Turn OFF the instrument.

4

Make the network settings of the computer.

5

Make the TCP/IPv4 settings of the computer to be connected to the instrument as follows.

IP address: 192.168.0.1

Subnet mask: 255.255.255.0

Default gateway: None

Connect the instrument and computer using the LAN cable in the power OFF state.

6

Check again that the communication mode switch of the instrument is set to the xed

7

setting mode (DFLT), and then turn ON the instrument.

Check again that the power LED is lit in orange.

31

Page 35

Using a LAN

8

Make the settings of the LAN you want to use.

Using the application software (RGBLaserUtility.exe) supplied with the instrument

Installation procedure: Communication Command Instruction Manual (CD)

From the [Start] menu of Windows, click [All Programs] > [HIOKI] > [RGBLaserUtility] to start

1

the program.

Click this tab to start the Communication

2

settings screen.

Enter the parameters to be set for the

3

instrument.

Click.

4

(Dialog [Cancel] will be invalid.)

Click this button to exit the

5

Communication settings screen.

Using communication commands (The customer creates a program.)

Connect the instrument to the following port via TCP/IP.

1

IP address: 192.168.0.254

Port: 1024

Set the commands shown below.

2

See: Communication Command Instruction Manual (CD)

:SYSTem:COMMunicate:LAN:IPADdress <IP

:SYSTem:COMMunicate:LAN:SMASk <

:SYSTem:COMMunicate:LAN:GATeway <

:SYSTem:COMMunicate:LAN:CONTrol <

:SYSTem:COMMunicate:LAN:UPDate

Subnet mask

Address

Port No.

address

>

>

>

>

32

Cancel the connection.

3

Page 36

Acquiring the communication settings you have set

Acquiring the communication settings using RGBLaserUtility

Click.

Displays the contents set on the instrument.

Acquiring the communication settings using communication commands

• IP address

:SYSTem:COMMunicate:LAN:IPADdress?

• Subnet mask

:SYSTem:COMMunicate:LAN:SMASk?

• Default gateway

:SYSTem:COMMunicate:LAN:GATeway?

• Port

:SYSTem:COMMunicate:LAN:CONTrol?

Using a LAN

2

Preparations

Turn OFF the instrument.

9

Disconnect the LAN cable from the instrument.

10

Change the communication mode switch to the user setting mode, and then start the

11

instrument.

Rear

Set the communication mode switch to the user setting mode

1

(USER).

Turn ON the power switch.

2

Turn OFF the power switch.

4

When the power is ON, check that the power LED is lit in

3

green.

If the power LED is not lit in green, the setting of the communication mode switch may be

incorrect or the instrument may malfunction. If the instrument malfunctions, stop the settings

and send the instrument for repair.

Connect the instrument to the network to be used using the LAN cable.

12

33

Page 37

Using a LAN

13

14

CAUTION

When the connection to the instrument is performed multiple times, the existing connection is

canceled and the last connection is enabled.

Check that the communication mode switch is set to the user setting mode (USER), and

then turn the instrument power ON.

Check again that the power LED is lit in green.

Perform the TCP/IP connection using the IP address and port settings you have set.

34

Page 38

Measurement Condition

3

Settings

You can set the measurement conditions in one of the following ways.

Setting using the

application software

supplied with the

instrument.

Setting using

communication

commands.

See:

“6 Application Software

(RGBLaserUtility)” (p. 55),

“6.4 Measurement Settings” (p. 60)

An example of communication commands is described in the following document.

For details about the communication commands, see the Communication

Command Instruction Manual (CD).

3.1 Various Settings

Precaution

• If you turn OFF the power during measurement or setting change, the settings might not be

saved. In this case, the backup error occurs when the instrument is started next time, and then

the settings are reset.

Before turning OFF the power, execute the following items.

1. Check that the response of

2. After checking, turn OFF the power without triggering or changing the settings.

• When using the application software supplied with the instrument, exit the application software,

and then turn OFF the instrument. If you turn OFF the power during measurement or setting

change, the backup error may occur when the instrument is started next time.

OPC?

*

is 1.

3

Measurement Condition Settings

Settings related to trigger

Trigger source (p. 60)

Bus trigger: Triggering is enabled by the communication command (

External trigger: Triggering is enabled from the TRIG terminal.

Communication command

:TRIGger:SOURce <BUS/EXTernal>

Trigger edge (p. 60)

Set to detect the rising edge of the external trigger signal, or to detect the falling edge of the

external trigger signal.

Communication command

:TRIGger:EDGE <RISE/FALL>

Trigger delay (p. 60)

Set the delay time from the trigger signal to the measurement start.

The trigger delay function does not apply to the modulation frequency measurement.

Communication command

:TRIGger:DELay <

Delay time

[sec]>

*TRG

).

35

Page 39

Various Settings

Measurement mode settings

Normal measurement mode (p. 68) to (p. 78)

The RGB laser light is measured in this mode.

Dark measurement mode (p. 69)

The dark is measured in this mode.

Modulation frequency measurement mode (p. 68)

The modulation frequency is measured in this mode.

Input the modulation frequency signal to the external input terminal (SYNC terminal) to measure its

period.

Set the result of the modulation frequency measurement to the modulation frequency.

Communication command

:MODE <NORMal/DARK/PULSe>

Settings common to normal measurement and dark measurement

Modulation frequency settings (p. 61)

CAUTION

If the modulation frequency is set incorrectly, accurate measurements cannot be

performed. Set the modulation frequency that matches the blinking period of the

measuring object.

For the light source that is lit continuously, set the modulated light function to OFF.

The set value of the modulation frequency is not reected in the parameter settings inside the

instrument while the modulated light function is OFF.

When setting the modulation frequency, set the modulated light function to ON, and then set the

modulation frequency result or known modulation frequency.

The parameters such as the measurement time based on the set modulation frequency are set

inside the instrument.

Communication command

:PULSe <1/0/ON/OFF>

:PULSe:FREQuency <

Frequency

[Hz]>

36

Page 40

Auto range settings (p. 71)

Set the auto range to ON or OFF for each of three sensors that are the R, G, and B sensors.

The auto range may not operate properly depending on input light conditions.

In that case, turn off the auto range and set the range properly.

Communication command

:RANGe:AUTO:R <1/0/ON/OFF>

:RANGe:AUTO:G <1/0/ON/OFF>

:RANGe:AUTO:B <1/0/ON/OFF>

Range settings (p. 61)

Set an arbitrary range (1 to 16) for each of three sensors that are the R, G, and B sensors.

When the range is set in the auto range ON state, the auto range setting is OFF.

A larger range number increases the measurement sensitivity and a weaker light can be measured.

Various Settings

3

Communication command

:RANGe:R <

:RANGe:G <

:RANGe:B <

Range number (1 to

Range number (1 to

Range number (1 to

16)>

16)>

16)>

Normal measurement settings

Color-matching function (p. 61)

Select the color-matching function from 2° or 10°.

The chromaticity is calculated using the set color-matching function.

However, the photometric quantity is always calculated using the color-matching function with a

eld-of-view of 2° regardless of the color-matching function settings.

In addition, when a eld-of-view of 10° is set, the following measurement items are not measured.

• Correlated color temperature

• Delta uv

• NTSC ratio

Communication command

:ANGLe <2/10>

Measurement Condition Settings

Averaging (p. 63)

The averaging is performed the specied number of times.

When the number of averaging is increased, the measurement may take some time.

Number of averaging = 1 to 100 times

Communication command

:AVERaging <1

to

100>

37

Page 41

Correction Functions

3.2 Correction Functions

Centroid wavelength input

mode (p. 39)

Centroid wavelength

offset correction (p. 39)

Radiometric quantity gain

correction (p. 40)

Chromaticity xy offset

correction (p. 40)

Photometric quantity gain

correction (p. 40)

The photometry is performed using the centroid wavelength set for each of R, G,

and B.

The centroid wavelength is corrected using the centroid wavelength offset value

set for each of R, G, and B.

The radiometric quantity is corrected using the radiometric quantity gain value set

for each of R, G, and B.

xy of the RGB mixed light (lights with R, G, and B wavelengths are mixed) are

corrected.

The photometric quantity of the RGB mixed light (lights with R, G, and B

wavelengths are mixed) is corrected.

The corrections of the centroid wavelength and radiometric quantity may affect the calculations of the

chromaticity and photometric quantity.

Therefore, when the chromaticity or photometric quantity is corrected in the state where the centroid

wavelength or radiometric quantity is corrected, this is double-correction.

It is recommended to apply the correction in accordance with the combinations shown in the table below.

: Recommended. – : Not recommended.

Centroid

wavelength

input mode

Centroid wavelength input

mode

Centroid wavelength offset

correction

Radiometric quantity gain

correction

Chromaticity xy offset

correction

Photometric quantity gain

correction

*: When the double-correction of the centroid wavelength input mode and centroid wavelength offset is set, the centroid

wavelength offset correction is disabled.

– –

*

–

– – – –

– – –

Centroid

wavelength

offset correction

*

–

Radiometric

quantity gain

correction

Chromaticity

xy offset

correction

– –

– –

– – –

Photometric

quantity gain

correction

–

38

Page 42

Correction Functions

Centroid wavelength input mode

See: “Centroid wavelength input mode settings” (p. 63)

When the detection level is less than 10%, the measurement accuracy of the centroid wavelength

becomes worse. This affects the measured value of the radiometric quantity. In this case, set the

centroid wavelength beforehand when a strong laser light is measured, and then measure the

radiometric quantity.

• The settable centroid wavelength value must be only in the measurable wavelength range.

• When the centroid wavelength input mode is used, the centroid wavelength offset correction does

not reect to the measurement result.

• When the centroid wavelength input mode is set to ON, the auto range operation is not

performed. After setting the range, execute the measurement.

• Be sure to specify an appropriate range, and then perform the measurement.

3

Measured value

Measured value of centroid wavelength = Set centroid wavelength value

Communication command

:SCALe:WAVelength:R <1/0/ON/OFF>

:SCALe:WAVelength:DATA:R <

:SCALe:WAVelength:G <1/0/ON/OFF>

:SCALe:WAVelength:DATA:G <

:SCALe:WAVelength:B <1/0/ON/OFF>

:SCALe:WAVelength:DATA:B <

Centroid Wavelength

Centroid Wavelength

Centroid Wavelength

(615.00

(505.00

(435.00

665.00) [nm]>

to

550.00) [nm]>

to

477.00) [nm]>

to

Centroid wavelength offset correction

See: “Centroid wavelength offset correction settings” (p. 63)

Set the centroid wavelength offset correction when you want to correct the measured value of the

centroid wavelength.

When the centroid wavelength offset correction is enabled, the measurement may not be performed

near the upper and lower limits of the centroid wavelength measurement range.

In this case, the centroid wavelength measurement is treated as an underow, and other measured

values are also treated as underows.

When the centroid wavelength input mode is used, the centroid wavelength offset correction does

not reect to the measurement result.

Measurement Condition Settings

Measured value

Measured value of centroid wavelength = Centroid wavelength obtained from measurement +

Offset value

Communication command

:SCALe:WAVelength:OFFSet <1/0/ON/OFF>

:SCALe:WAVelength:OFFSet:DATA:R <

:SCALe:WAVelength:OFFSet:DATA:G <

:SCALe:WAVelength:OFFSet:DATA:B <

Offset

Offset

Offset

(-2.00

(-2.00

(-2.00

2.00) [nm]>

to

2.00) [nm]>

to

2.00) [nm]>

to

39

Page 43

Correction Functions

Radiometric quantity gain correction

See: “Radiometric quantity gain correction settings” (p. 63)

Set the radiometric quantity gain correction when you want to correct the measured value of the

radiometric quantity.

Measured value

Measured value of radiometric quantity = Gain value × Radiometric quantity obtained from

measurement

Communication command

:SCALe:RADiometry:GAIN <1/0/ON/OFF>

:SCALe:RADiometry:GAIN:DATA:R <

:SCALe:RADiometry:GAIN:DATA:G <

:SCALe:RADiometry:GAIN:DATA:B <

Gain value

Gain value

Gain value

(1.00000E-3

(1.00000E-3

(1.00000E-3

1.00000E+3)>

to

1.00000E+3)>

to

1.00000E+3)>

to

Chromaticity xy offset correction

See: “Chromaticity xy offset correction settings” (p. 63)

Set the chromaticity xy offset correction when you want to correct the measured values of the

chromaticity xy of the RGB mixed light (lights with R, G, and B wavelengths are mixed).

The measured value may become a non-existent value depending on the offset correction value.

Measured value

Measured value of chromaticity x = Chromaticity x obtained from measurement + Chromaticity x

offset value

Measured value of chromaticity y = Chromaticity y obtained from measurement + Chromaticity y

offset value

Communication command

:SCALe:XY:OFFSet <1/0/ON/OFF>

:SCALe:XY:OFFSet:DATA:X <

:SCALe:XY:OFFSet:DATA:Y <

Chromaticity x Offset value

Chromaticity y Offset value

(-1.0000E+00

(-1.0000E+00

1.0000E+00)>

to

1.0000E+00)>

to

Photometric quantity gain correction

See: “Photometric quantity gain correction” (p. 63)

Set the photometric quantity gain correction when you want to correct the measured values of the

photometric quantity of the RGB mixed light (lights with R, G, and B wavelengths are mixed).

correction is applied to the photometric quantity of the RGB mixed light and the tristimulus values

XYZ of the RGB mixed light.

The gain

Measured value

Measured value of photometric quantity = Gain value × Photometric quantity obtained from

measurement

Measured value of tristimulus value = Gain value × Tristimulus value obtained from measurement

Communication command

:SCALe:PHOTometry:GAIN <1/0/ON/OFF>

:SCALe:PHOTometry:GAIN:DATA <

Gain value

(1.00000E-3

1.00000E+3)>

to

40

Page 44

Modulation Frequency Measurement

3.3 Modulation Frequency Measurement

Input the modulation frequency signal to the external input terminal (SYNC terminal) to measure its

period.

Set the result of the modulation frequency measurement to the modulation frequency.

Modulation frequency measurement settings

Averaging (p. 64)

The averaging is performed the specied number of times.

Number of averaging = 1 to 10 times

Communication command

:PULSe:AVERaging <1

Measurement edge (p. 64)

Set to count the rising edge of the modulation frequency, or to detect the falling edge of the

modulation frequency.

to

10>

3

Measurement Condition Settings

Communication command

:PULSe:EDGE <RISE/FALL>

Modulation frequency measurement execution and modulation

frequency settings

See: “Modulation Frequency Measurement” (p. 68)

Set the measurement mode to the modulation frequency measurement.

1

:MODE PULSe

Make the modulation frequency measurement settings.

2

:PULSe:AVERaging <1

:PULSe:EDGE <RISE/FALL>

Input the modulation frequency signal between the SYNC terminal and the ground

3

terminal.

Execute the modulation frequency measurement (apply triggering).

4

:READ?

TRG

*

Set the dark estimation.

5

:DARK:ESTimate <ON/OFF>

Set the modulation frequency.

6

:PULSe <ON/OFF>

:PULSe:FREQuency <

When the dark estimation is ON, acquire the estimation result.

7

:DARK:ESTimate:RESult?

Set the measurement mode to the dark measurement mode or normal measurement

8

mode.

:MODE <NORMal/DARK>

10>

to

Modulation frequency

[Hz]>

41

Page 45

Dark Measurement

3.4 Dark Measurement

Before starting the measurement (after warming up for 30 minutes or longer), attach the cap, and

then be sure to execute the dark measurement.

When the dark measurement is performed, the sensor offset can be canceled and the correct

measured value can be acquired.

Additionally, it is recommended to perform the dark measurement every time the set value of the

modulation frequency is changed.

• After the dark measurement has been executed, the value that is corrected using the acquired

dark value is reected in the measured result. This dark value is valid until the power is turned off.

• To perform more highly accurate measurements, if the atmospheric temperature changes after

the dark measurement has been executed, execute the dark measurement again.

• When the dark measurement is not performed after the power has been turned on, the dark

measurement value at shipment (default dark value) is reected in the measurement result.

To measure a weak light, the following dark measurements are recommended.

• Increase the number of averaging of the dark measurement.

• Execute the dark measurement frequently.

Dark measurement settings

Range in which the dark measurement is performed (p. 64)

Set the measurement to be performed in all ranges or only in the xed range.

When all ranges are selected, the dark measurement is performed in all ranges.

When the xed range is selected, the dark measurement is performed only in the range selected at

this time.

However, when the auto range setting is ON, the dark measurement is performed forcibly in all

ranges regardless of the settings.

Communication command

:DARK:TYPE <ALL/FIX>

Averaging (p. 64)

The averaging is performed the specied number of times.

To measure a weak light, it is recommended to increase the number of averaging.

When the number of averaging is increased, the measurement may take some time.

Number of averaging = 1 to 100 times

Communication command

:DARK:AVERaging <1

to

100>

Dark measurement result judgment (p. 64)

Whether the dark value is correct can be judged.

When the dark measurement is performed with the judgment set to OFF, the dark measurement

succeeds in any dark measurement state. However, when the dark measurement is executed in the

light incidence state, subsequent normal measurement may not be performed correctly.

Therefore, it is recommended to set the dark measurement judgment to ON and check the

judgment after the dark measurement has been executed.

Communication command

:DARK:JUDGment <1/0/ON/OFF>

42

Page 46

Dark Measurement

Dark estimation

The dark estimation is used when the modulation frequency setting is changed.

When the modulation frequency setting is changed in the dark estimation ON state, the dark value

at the new modulation frequency is calculated.

• When the modulation frequency is changed in the dark estimation ON state, be sure to check

that the dark estimation is performed correctly.

• To execute the dark estimation correctly, set the modulated light function to ON beforehand.

After that, perform the dark measurement in all ranges of all colors. (p. 64)

It is recommended to set the number of averaging of the dark measurement to 10 or more.

• The dark estimation is performed in all ranges regardless of the setting of the range in which

the dark measurement is performed.

• When the modulation frequency is changed in the modulated light function OFF state, the dark

estimation is not executed.

• The dark estimation is used only in a range of the modulation frequency ±5 Hz or less after

the dark measurement has been performed. The dark value obtained by the dark estimation

is an estimate value. Basically, it is recommended to execute the dark measurement when the

modulation frequency setting is changed.

3

Measurement Condition Settings

Communication command

:DARK:ESTimate <1/0/ON/OFF>

:DARK:ESTimate:RESult?

Executing the dark measurement

See: “Dark Measurement” (p. 69)

Attach the cap.

1

Set the modulation frequency.

2

Communication command

:PULSe:FREQuency <10.0000

Set the measurement mode to the dark measurement.

3

Communication command

:MODE DARK

Make the dark measurement settings.

4

Set the range in which the dark measurement is performed, the number of averaging, and the

measurement result judgment.

Communication command

:DARK:TYPE <ALL/FIX>

:DARK:AVERaging <1

:DARK:JUDGment <ON/OFF>

Execute the dark measurement (apply triggering).

5

Communication command

:READ?

TRG

*

Acquire the measurement result of the dark measurement, and then check that the dark

6

value is appropriate.

to

to

100>

300.0000>

Set the measurement mode to the normal measurement mode.

7

43

Page 47

Dark Measurement

44

Page 48

4

The centroid wavelength, radiometric quantity, tristimulus value, chromaticity, photometric quantity,

correlated color temperature, NTSC ratio, and dominant wavelength of the laser light source that is

a measuring object are measured.

The measurement can be performed in two ways shown below.

Normal Measurement

Measurement using the

application software

supplied with the

instrument.

Measurement using

communication

commands.

Measurement item Command

Centroid Wavelength

1. Make preparations for measurement.

See: “2 Preparations” (p. 25)

2. Execute the measurement in accordance with the application software

RGBLaserUtility.

See: “6 Application Software (RGBLaserUtility)” (p. 55)

The instrument can be controlled using commands.

An example of communication commands is described in the following.

For details about the communication commands, see the Communication

Command Instruction Manual (CD).

:FETCh:WAVelength:CENTroid:R?

:FETCh:WAVelength:CENTroid:G?

:FETCh:WAVelength:CENTroid:B?

4

Normal Measurement

Radiometric Quantity

Tristimulus Values XYZ

Chromaticity xy

Chromaticity u’v’

Photometric Quantity

Correlated Color Temperature, Delta uv

NTSC Ratio

Dominant Wavelength

:FETCh:RADiometry:R?

:FETCh:RADiometry:G?

:FETCh:RADiometry:B?

:FETCh:RADiometry:RGB?

:FETCh:XYZ:R?

:FETCh:XYZ:G?

:FETCh:XYZ:B?

:FETCh:XYZ:RGB?

:FETCh:XY:R?

:FETCh:XY:G?

:FETCh:XY:B?

:FETCh:XY:RGB?

:FETCh:UDVD:R?

:FETCh:UDVD:G?

:FETCh:UDVD:B?

:FETCh:UDVD:RGB?

:FETCh:PHOTometry:R?

:FETCh:PHOTometry:G?

:FETCh:PHOTometry:B?

:FETCh:PHOTometry:RGB?

:FETCh:TCP?

:FETCh:DELUv?

:FETCh:NTSCratio?

:FETCh:WAVelength:DOMinant:R?

:FETCh:WAVelength:DOMinant:G?

:FETCh:WAVelength:DOMinant:B?

45

Page 49

Adjusting the White Balance of the Light Source (White Balance Adjustment Assistance Function)

4.1 Adjusting the White Balance of the Light

Source (White Balance Adjustment Assistance

Function)

The instrument provides a function that assists the work to adjust the white balance of the RGB

laser light source, which is a measuring object, to the target chromaticity and photometric quantity.

Acquiring the target value of the radiometric quantity

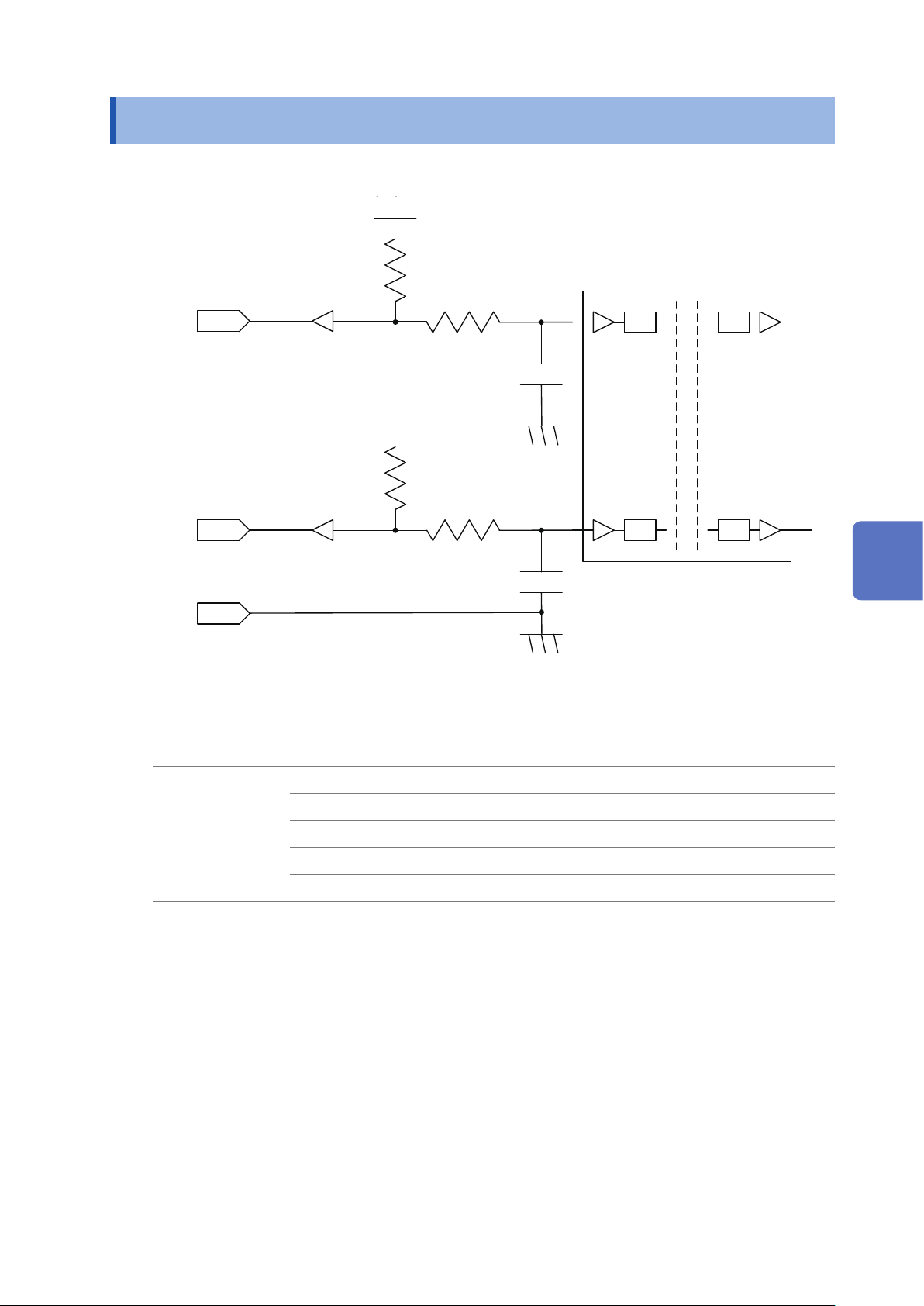

When inputting the target chromaticity and photometric quantity for the white balance before