Page 1

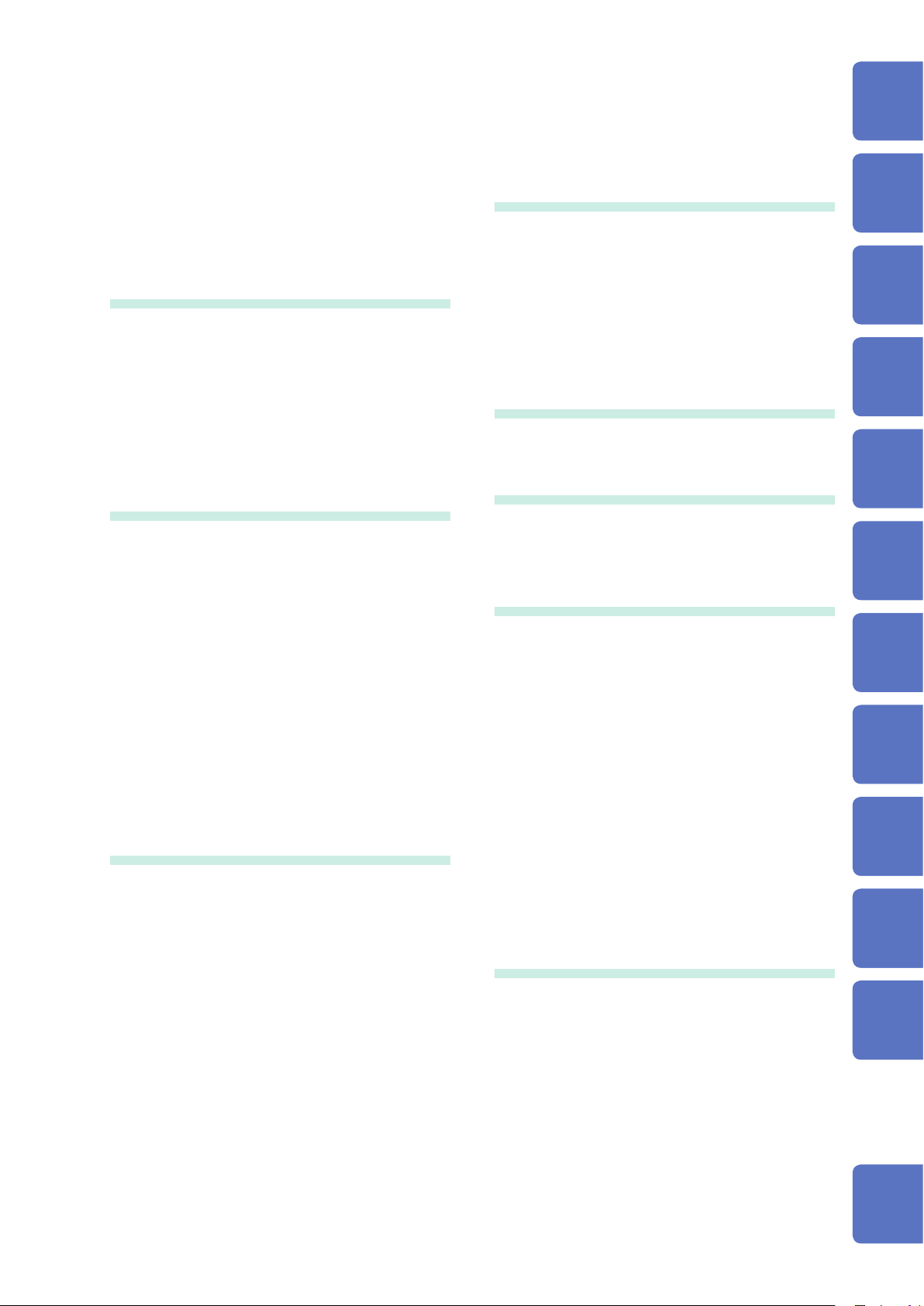

SW1001

SW1002

Instruction Manual

SWITCH MAINFRAME

Be sure to read this manual

before using the device

When using the device for the

rst time

Part Names and Functions

Measurement Flowchart

Preparation for Measurements

June 2018 Edition 1

SW1001A961-00 18-06H

Safety Information

Troubleshooting

p. 8 Troubleshooting

p. 12 Error display and troubleshooting p. 126

p. 13

p. 4

p. 125

EN

Page 2

Page 3

Contents

Introduction

ConrmingPackageContents

Safety Information

Usage Notes

........................................................1

........................2

............................................4

......................................................4

1 Overview 7

1.1 Overview of Product

1.2 Features

1.3 Parts Names and Functions

1.4 Block Diagram

1.5 Glossary

1.6 Measurement Flowchart

...................................................7

................................................. 11

...............................7

.................8

.......................................10

......................12

2 Preparation for

Measurements

2.1 Connecting Instruments and

Controlling the Device

2.2 Installing the Module

2.3 Removing the Module

2.4 Connecting the Measurement Cable

2.5 Connecting the Connection Cable

TERMINAL 1

TERMINAL 2

TERMINAL 3

2.6 Setting the Communication Setting

Mode

2.7 Connecting the Power Cord

2.8 Turning on/off the Power

2.9 When the Power is Turned on

............................................20

............................................20

............................................21

......................................................22

13

..........................13

............................15

..........................16

.18

.....19

................23

.....................23

............24

3 Channel Switching 25

3.1 Inspection before Measurement

Inspecting the device and peripheral

devices

Checking for relay contact welding

3.2 Overview of Channel Switching

3.3 Procedure for Switching the Channel

Selecting the connection method

Switching the shield

Selecting the channel

3.4 Channel Switching Operation

3.5 Measurement between Two

Instruments

3.6 Precautions for Measurement

3.7 Channel Delay Function

.....................................................25

..................................29

................................30

............................................32

......................37

.........25

............26

..........27

28

...............28

.............31

............35

4 Scan Function 39

4.1 Overview of the Scan Function

4.2 Setting the Scan Channel

4.3 Setting the Trigger Source for

Scan Operation

4.4 Scan Operation

4.5 Resetting Scan Operation

4.6 Scan Measurement Example

.....................................40

.....................................41

..........39

...................40

...................42

.............43

5 Other Functions 45

5.1 Checking the Device Status

................45

6 Initialization 47

6.1 Initialization Settings

............................47

7 External Control (EXT.

I/O)

49

7.1 External Control Flow

7.2 Switching between Sinking Current

(NPN) and Sourcing Current (PNP)

7.3 Connection

Device connector and compatible

connectors

Signal Functions

Connection to the instrument

7.4 Timing Chart

Channel switching operation and scan

operation reset

7.5 InternalCircuitConguration

Electricalspecications

Connection examples

............................................51

................................................51

.......................................52

..........................................53

..........................................53

..........................49

...50

.....................52

..............55

.............................56

...............................57

8 Communication

Function

8.1 Interface Overview and Features

8.2 Setting the Communication Setting

......................................................59

Mode

8.3 LAN Interface

Communication condition settings

Setting LAN communications

Connecting the LAN cable

8.4 USB Interface

Installing the USB driver

Connecting the USB cable

59

.......59

........................................60

.............61

....................62

.........................63

........................................64

............................64

........................65

1

2

3

4

5

6

7

8

9

9

10

10

Index

SW1001A961-00

i

Page 4

Contents

8.5 RS-232C Interface

Connecting the RS-232C cable

Setting RS-232C communications

Setting the controller (PC, PLC, etc.)

................................66

.................66

.............68

.........68

8.6 Communication Command

Forwarding Function

8.7 Communication Method

Message format

Output queue and input buffer

Status Byte Register

Event Registers

Initialization items

Remote state

8.8 Message List

........................................71

........................................79

............................................86

.........................................87

8.9 Message Reference

Standard commands

Device-speciccommands

8.10 Sample Programs

Using Visual Basic® 5.0 or 6.0

Using Visual Basic® 2013

............................69

.......................71

...................76

.................................77

.....................................86

.............................90

.................................91

........................94

...............................107

.................107

........................ 111

9 Specications 119

9.1 SW1001, SW1002 General

Specications

9.2 SW1001, SW1002 Input

Specications/Output

Specications/Measurement

Specications

Basicspecications

9.3 SW1001, SW1002 Functional

Specications

9.4 SW1001, SW1002 Interface

Specications

LAN

........................................................123

USB

.......................................................123

RS-232C

EXT. I/O

..................................................124

...................................... 119

......................................120

................................120

......................................121

......................................123

................................................123

11 Multiplexer Module 129

11.1 SW9001 Multiplexer Module

(2-wire/4-wire)

Features

Specications

Switching wiring diagram

Connector wiring diagram

Acquiring the number of relay on/off

cycles

.................................................129

.....................................................134

.....................................129

.........................................129

.........................132

.......................133

11.2 SW9002 Multiplexer Module

(4-terminal pair)

Features

Specications

Switching wiring diagram

Connector wiring diagram

Acquiring the number of relay on/off

cycles

.................................................135

.....................................................140

11.3 Accuracy Calculation Example

..................................135

.........................................135

.........................138

.......................139

.........141

12 Appendix 143

12.1 Measurement cable

12.2 Measuring Object Short Circuit

due to Relay Contact Welding

12.3 Rack Mount

Rack mount bracket

L-shape bracket (For installing the

module in automated equipment)

.........................................147

12.4 Outline Drawings

SW1001

SW1002

.................................................152

.................................................153

Index 155

Warranty Certicate

............................143

..........145

................................148

............151

................................152

10 Maintenance and

Service

10.1 Troubleshooting

Before sending the device for repair

Error display and troubleshooting

10.2 List of Device Error Numbers

10.3 Repair and Inspection

ii

125

..................................125

........................128

........125

............126

............127

Page 5

Introduction

Introduction

Thank you for purchasing the Hioki SW1001, SW1002 Switch Mainframe. To obtain maximum

performance from the device over the long term, be sure to read this manual carefully and keep it

handy for future reference.

With the optional multiplexer module (hereafter referred to as “module”) installed on this device, the

input of multiple channels can be switched to one or two measuring instruments (hereafter referred

to as simply “instrument”).

Modules can be installed in 3 slots for the SW1001 and 12 slots for the SW1002. Other functions

are common for all the models.

1

2

Be sure to also read the separate document “Operating Precautions” before use.

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so. It is assumed that the reader possesses basic electrical knowledge (equivalent to

that of someone who graduated from the electrical program at a technical high school).

Trademarks

Windows, Visual Studio and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

Notations

*

[ ]

POWER

(Bold)

(p. ) Indicates the location of reference information.

Additional information is presented below.

Menus, dialog boxes, buttons in a dialog box, and other names on the screen are

indicated in brackets.

Indicates the names and keys on the screen and the device in boldface.

3

4

5

6

7

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading), and dgt. (digit) with

the following meanings.

f.s.

rdg.

dgt.

(maximum display value or range)

The maximum display value.

(reading or displayed value)

The value currently being measured and indicated on the instrument.

(resolution)

The smallest displayable unit on a digital measuring device, i.e., the input value that

causes the digital display to show a “1” as the least-signicant digit.

8

9

10

Appx. Ind.

1

Page 6

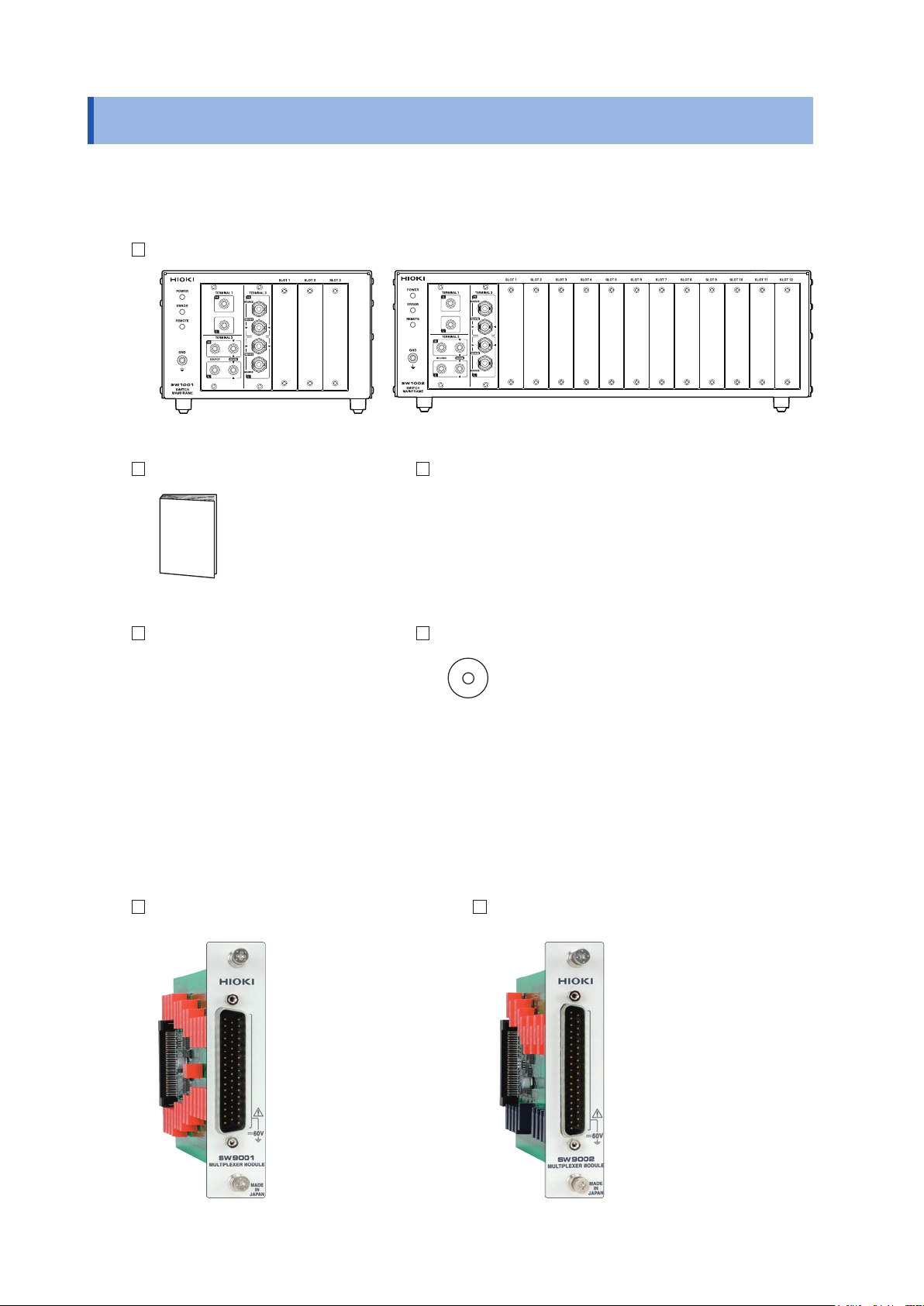

Conrming Package Contents

Conrming Package Contents

Main unit and accessories

Conrm that these contents are provided.

Model SW1001 or SW1002 Switch Mainframe

Instruction Manual (this document) Power cord

Operating Precautions (0990A905) CD (USB driver)*

* The latest version can be downloaded from our

web site.

Options

The following options are available for the device. Contact your authorized Hioki distributor or

reseller when ordering.

Module

Model SW9001 Multiplexer Module

(2-wire/4-wire)

Model SW9002 Multiplexer Module

(4-terminal pair)

2

Page 7

Conrming Package Contents

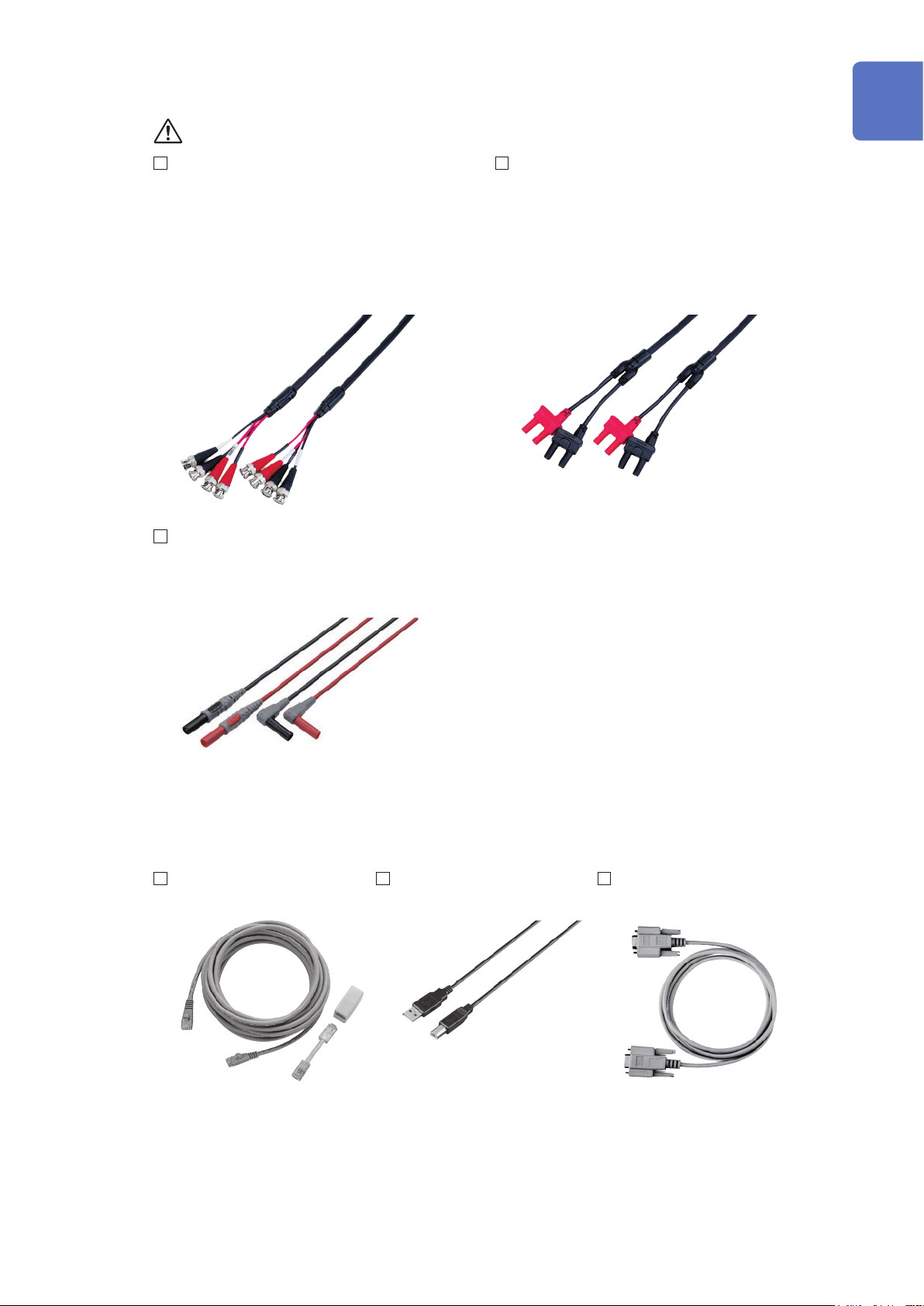

Connection cable

See: “Before measurement” (p. 5)

Model L2004 Connection Cable Model L2108 Connection Cable

Length: Approx. 910 mm Length: Approx. 840 mm

Maximum rated voltage: 30 V peak Maximum rated voltage: 60 V DC, 30 V AC rms,

42.4 V peak

Maximum rated voltage

to earth:

30 V DC or less, no

measurement category

Maximum rated voltage

to earth:

60 V DC or less, no

measurement category

1

Maximum rated current: 2.5 A peak Maximum rated current: 2 A peak

Model L4930 Connection Cable Set

Length: Approx. 1.2 m

Maximum rated voltage*: CAT III: 1000 V

CAT IV: 600 V

2

3

4

5

6

* Do not input voltage exceeding the rating of this device and the instrument.

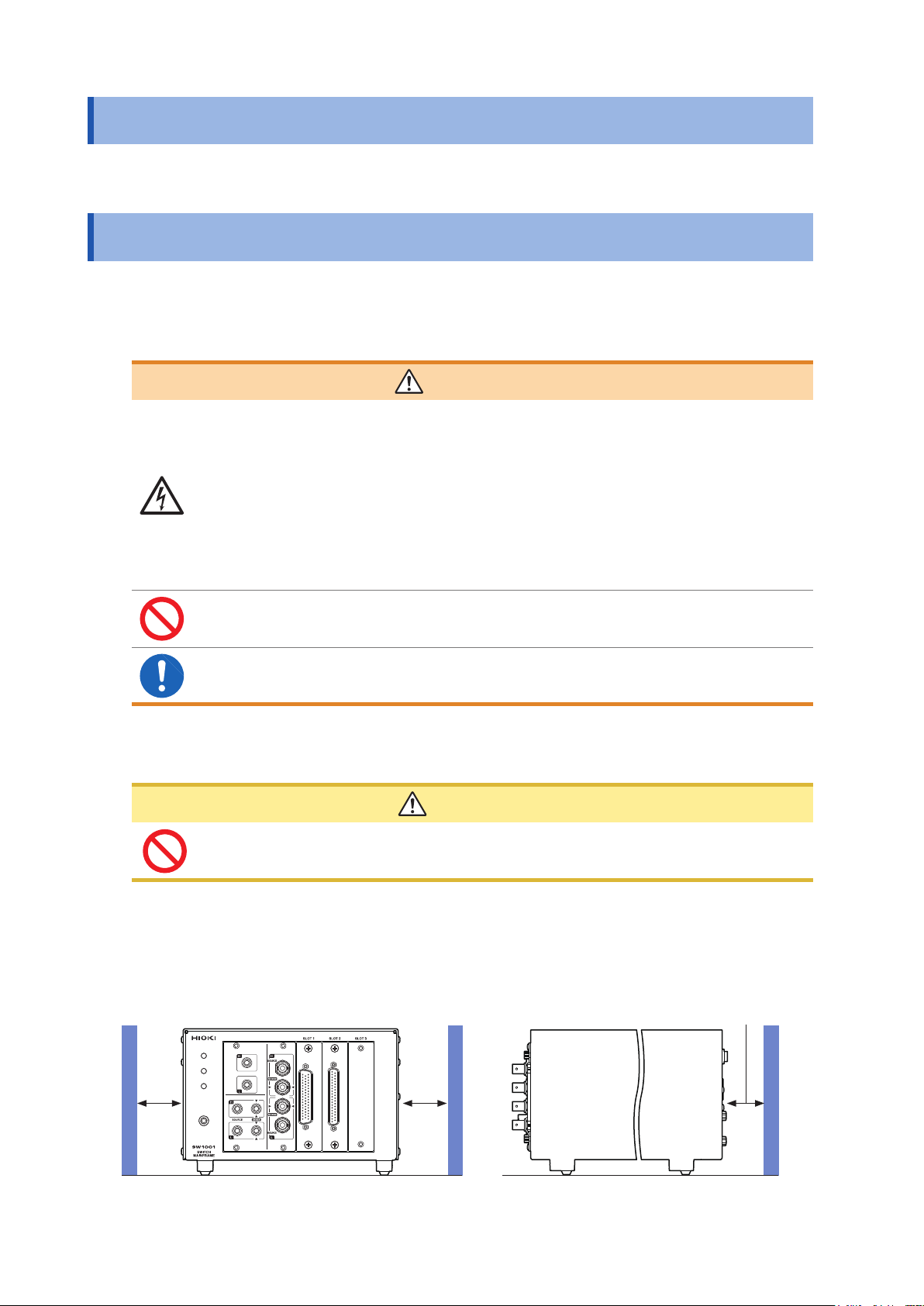

Communications cable

Model 9642

LAN Cable

Model L1002

USB Cable (A-B)

7

8

Model 9637

RS-232C Cable (9pin-9pin/1.8 m)

9

10

Appx. Ind.

3

Page 8

Safety Information

Safety Information

Be sure to also read the separate document “Operating Precautions” before use.

Usage Notes

Check before use

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

WARNING

If a connection cable or the device is damaged, there is a risk of an electric shock.

Perform the following inspection before using the device.

• Before using the device, check that the coating of the connection cables are

neither ripped nor torn and that no metal parts are exposed. Using the device

under such conditions could result in an electric shock. Replace any damaged

cable with a new one.

• Before using the device the rst time, verify that it operates normally to ensure

that no damage occurred during storage or shipping. If you nd any damage,

contact your authorized Hioki distributor or reseller.

This device is designed to measure voltages of 60 V or lower. Do not input

voltages over 60 V or measure locations exceeding 60 V from the ground potential.

If the relay of the device fails, the battery of the measuring object may be shorted

(p. 145).

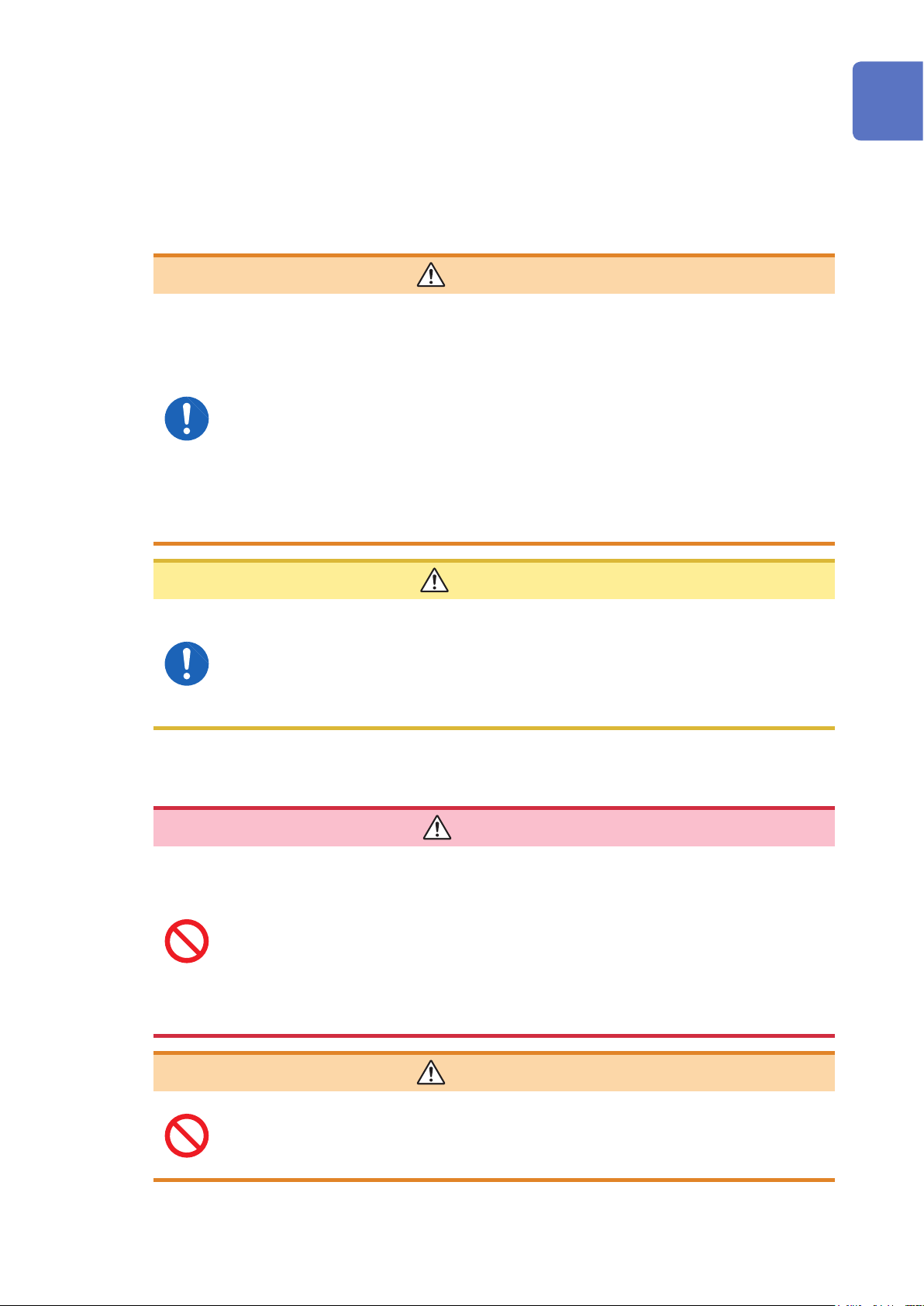

Installing the device and module

CAUTION

Do not position the device on an unstable table or inclined surface. Dropping or

knocking down the device can cause injury or damage to the device.

Installing

To prevent overheating, be sure to leave the specied clearances around the device.

• The device should be operated only with the bottom side downwards.

Rear: 10 mm or moreSide: 50 mm or more

4

Page 9

Handling the device

This device may cause interference if used in residential areas. Such use must be avoided unless

the user takes special measures to reduce electromagnetic emissions to prevent interference to the

reception of radio and television broadcasts.

Before installing the module

WARNING

• To prevent an electric shock, before removing or replacing a module, conrm

that the device is turned off and that all the measurement cables, connection

cables, and the power cord are disconnected.

• Installing a module while the device is turned on may prevent detection of

the contact state of relays on the module or result in short-circuiting of the

measuring object. Damage of the device or module may cause the measuring

object to be shorted or the instrument to fail.

• Be careful about short circuits when connecting a measuring object with

electromotive force (battery, power supply, etc.).

• The maximum voltage of the device contact is 30 V (rms value) and 42.4 V (peak

value) or 60 V (direct current). Do not directly connect a withstand voltage tester

or an insulation resistance tester.

Usage Notes

1

2

3

4

When installing or removing the module, be sure to observe the following precautions:

• Touch the GND terminal of the device with your hand to release static and then use

antistatic gloves to perform procedures.

• Hold the sheet metal area of the module. Directly touching the board with your hand may

damage the circuit board due to static. If the measurement target has high resistance, the

error component due to factors such as oil from your ngers may increase in magnitude.

Before measurement

•

Do not short-circuit between electrodes or terminals using a probe when

measuring the battery or capacitor. Doing so may cause an electric arc, resulting

in serious injury.

• Do not use the device or the connection cables that exceed its ratings or

specications. Doing so may damage the device or cause it to become hot,

resulting in a bodily injury.

• Do not use the instrument to be used in conjunction with the device outside of

its ratings or specications. Doing so may damage the instrument or cause it to

become hot, resulting in a physical injury.

CAUTION

5

6

7

DANGER

8

9

10

WARNING

The maximum rated voltage between the module and ground is 60 V DC. To avoid

an injury and damage to the device, ensure that voltage between channels never

exceeds this limit. Prevent the voltage potential difference of the entire system

from exceeding 60 V DC.

The measurement connector frame of the module is connected to the casing (metal) of the device

as well as the protective ground terminal of the power inlet (conductive).

Appx. Ind.

5

Page 10

Usage Notes

Before starting the external control

WARNING

To prevent an electric shock or damage to the device, always observe the

following precautions when connecting the cables to the EXT. I/O terminals.

• Always turn off the device and any devices to be connected before making

connections.

• Be careful to avoid exceeding the signal ratings of the EXT. I/O terminals.

• During operation, a wire becoming dislocated and contacting another

conductive object can be a serious hazard. Use screws to secure the external

connectors.

• Ensure that devices and systems to be connected to the EXT. I/O terminals are

properly isolated from one another.

Before connecting the communications cables

CAUTION

• Use a common ground for both the device and the PC. Using different ground circuits

will result in a potential difference between the device's ground and the computer's

ground. If the communications cable is connected while such a potential difference

exists, it may result in device malfunction or failure.

• Before connecting or disconnecting any communications cables, always turn off the

device and the PC. Failure to do so could result in equipment malfunction or damage.

• After connecting the communications cables, tighten the screws on the connector

securely. Failure to secure the connector could result in device malfunction or damage.

• To avoid device failure, do not disconnect the communications cables while

communications are in progress.

Precautions during shipment

Store the packaging in which the device was delivered, as you will need it when transporting the

device.

Disc precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on

a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

6

Page 11

1

Overview

1.1 Overview of Product

This device is a module type switching system that is ideal for multi-channel measurement of

batteries. You can choose a main frame from two choices according to the required number of

channels. You can also choose a module from two module types according to the instrument to be

used with the device (2-wire/4-wire module and 4-terminal pair module).

1.2 Features

Reduction of errors when measuring internal resistance

When AC low resistance measurement is performed using the BT4560 Battery Impedance Meter

or the BT3562 Battery HiTester, the inuence of electromagnetic induction (eddy current) on the

measured value can be minimized.

Ability to switch measurement between two instruments

For example, you can connect a BT3562 and DM7276 to the device and use it to switch between

internal resistance measurement and high-precision OCV measurement.

Protection against short circuit with fuses

To protect batteries to be measured if a short circuit occurs in a channel, a protective fuse is built

into each channel.

1

Overview

7

Page 12

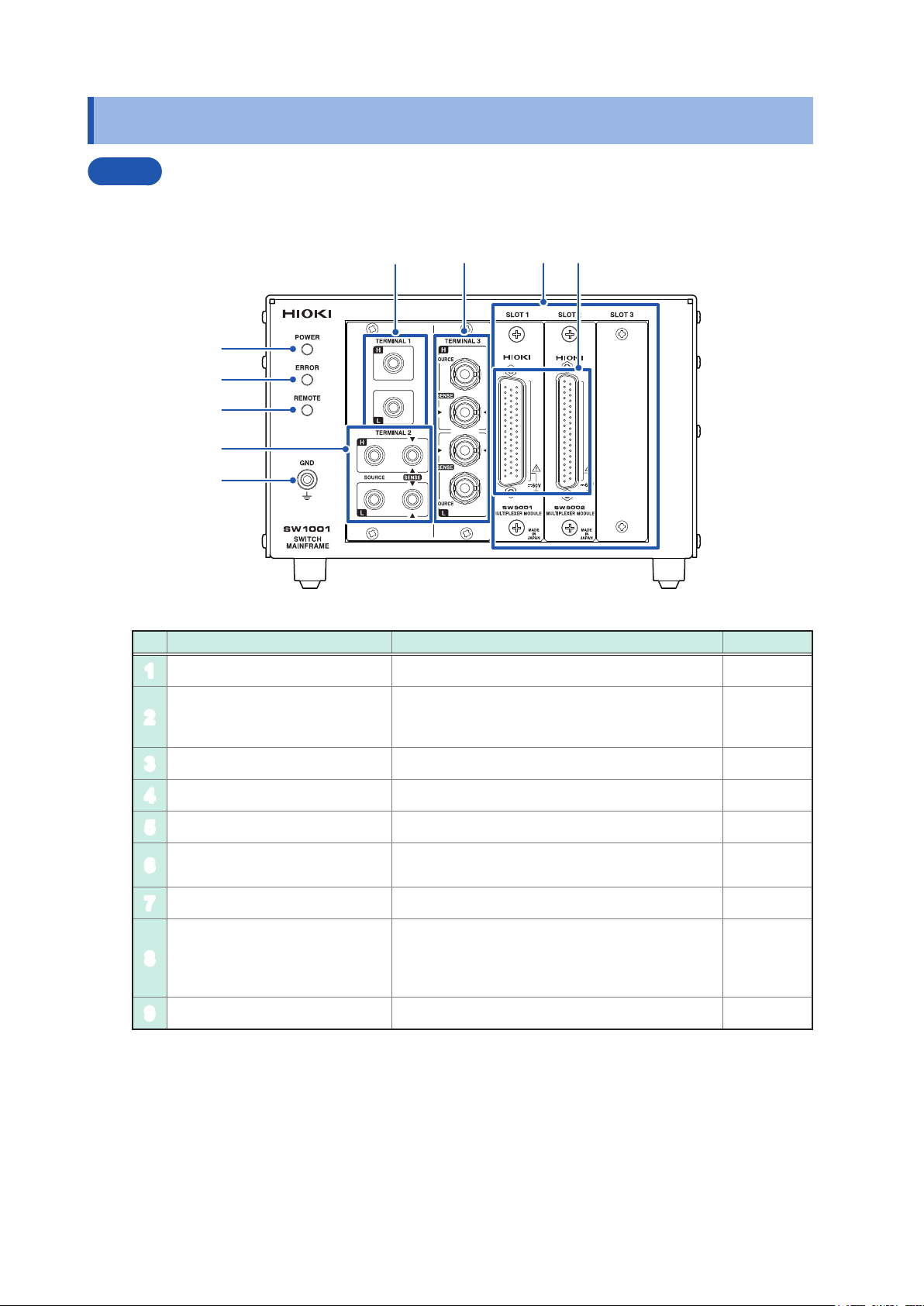

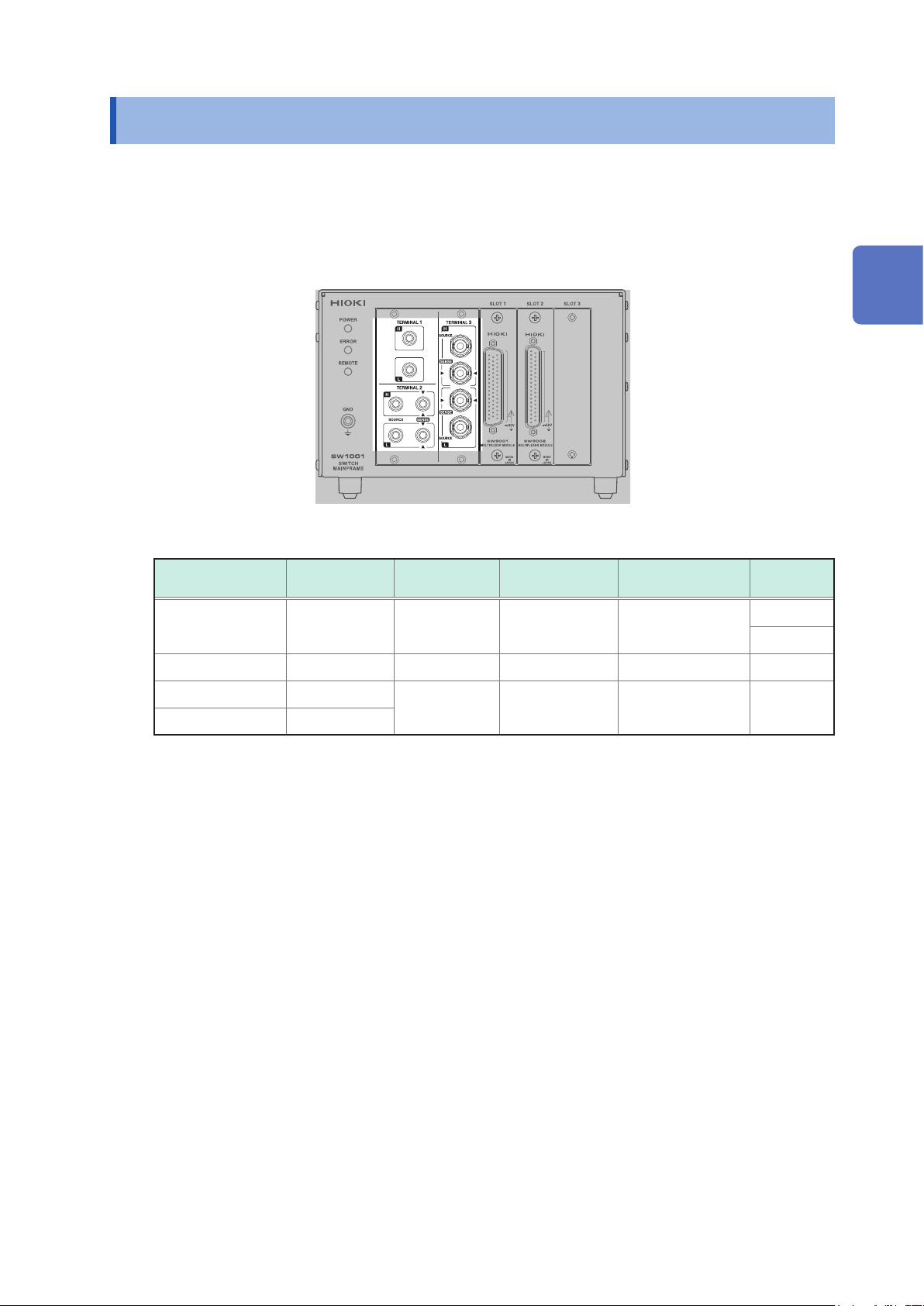

Parts Names and Functions

1.3 Parts Names and Functions

Front

The illustration shown here is for the SW1001.

4

6 7

8

1

2

3

5

9

No. Name Description Reference

POWER lamp Lights up when the main frame power is on. p. 23

1

Lights up for self-test at the time of startup and

ERROR lamp

2

REMOTE lamp Lights up when communications data is received. p. 86

3

TERMINAL 1 Used to connect a 2-wire instrument. p. 20

4

TERMINAL 2 Used to connect a 4-wire instrument. p. 20

5

TERMINAL 3

6

SLOT 1 to SLOT 3 Used to attach the module. p. 15

7

Measurement cable connector

8

GND terminal Ground for the device. Connected to the ground. p. 36

9

when an error, such as a communications error,

occurs.

Used to connect a 4-terminal pair (BNC terminal)

instrument.

Used to connect the measurement cable to each

module. For more details, see the chapter for the

multiplexer module.

p. 23

p. 126

p. 21

p. 5

p. 18

p. 133

p. 139

8

Page 13

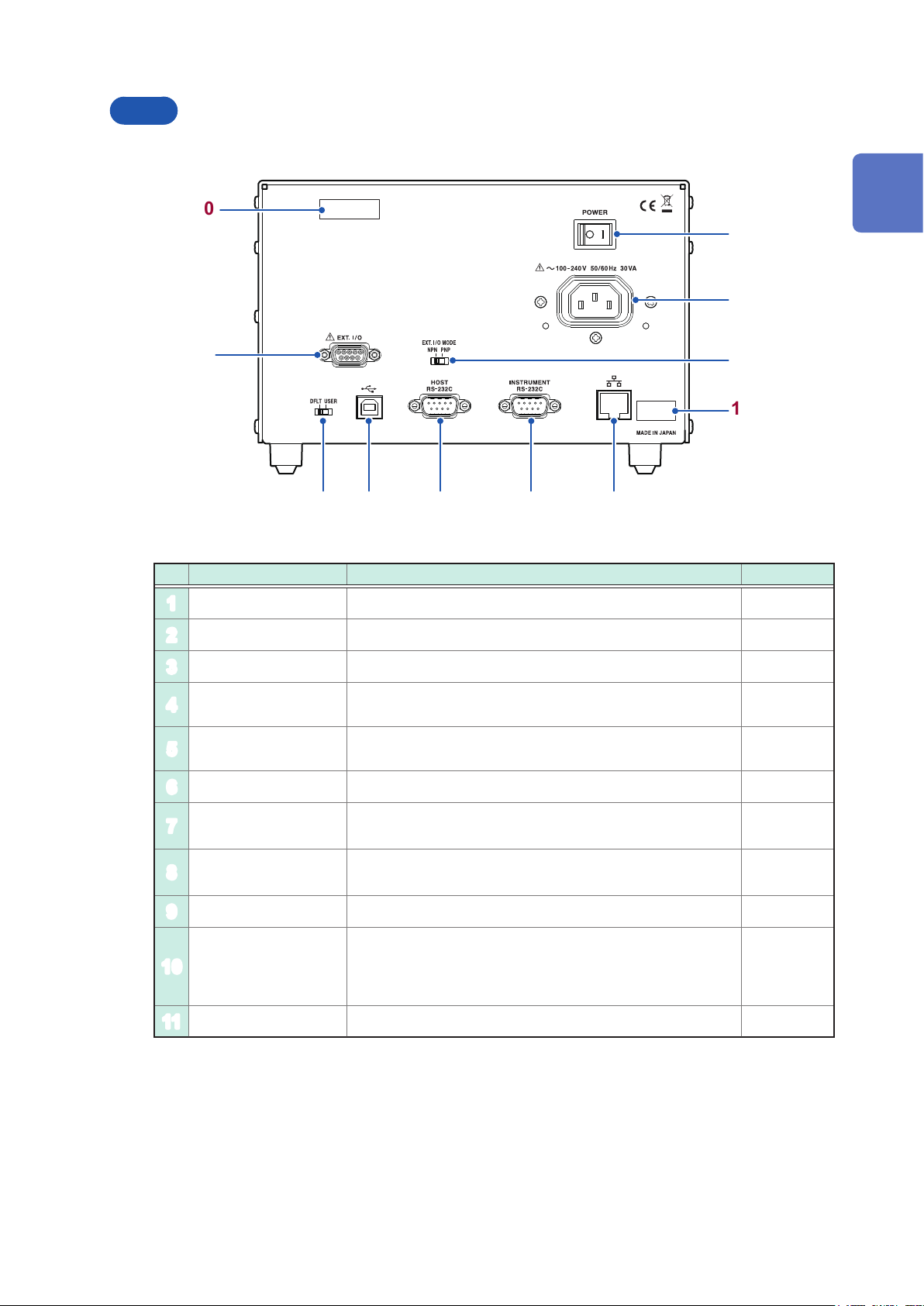

Rear

The illustration shown here is for the SW1001.

Parts Names and Functions

10

1

2

3

4

11

6 7 8 9

5

No. Name Description Reference

Power switch Turns on/off the power. p. 23

1

Power inlet Used to connect the provided power cord. p. 23

2

1

Overview

EXT. I/O terminal Used to connect the device to be externally controlled. p. 51

3

EXT. I/O MODE

4

change-over switch

Communication

5

setting mode switch

USB connector Used to connect the PC. p. 64

6

HOST

7

RS-232C connector

INSTRUMENT

8

RS-232C connector

LAN connector Used to connect the PC. p. 60

9

Serial number

10

MAC address MAC address of the LAN. p. 105

11

Left: Sinking current (NPN), Right: Sourcing current (PNP) p. 50

Perform communication using xed settings when the

communication settings are unknown.

Used to connect the PC. p. 66

Used to connect the RS-232C connector of the instrument for

scan measurement.

The serial number consists of 9 digits. The rst two (from

the left) indicate the year of manufacture, and the next two

indicate the month of manufacture.

Required for production control. Do not peel off the label.

p. 22

p. 70

–

9

Page 14

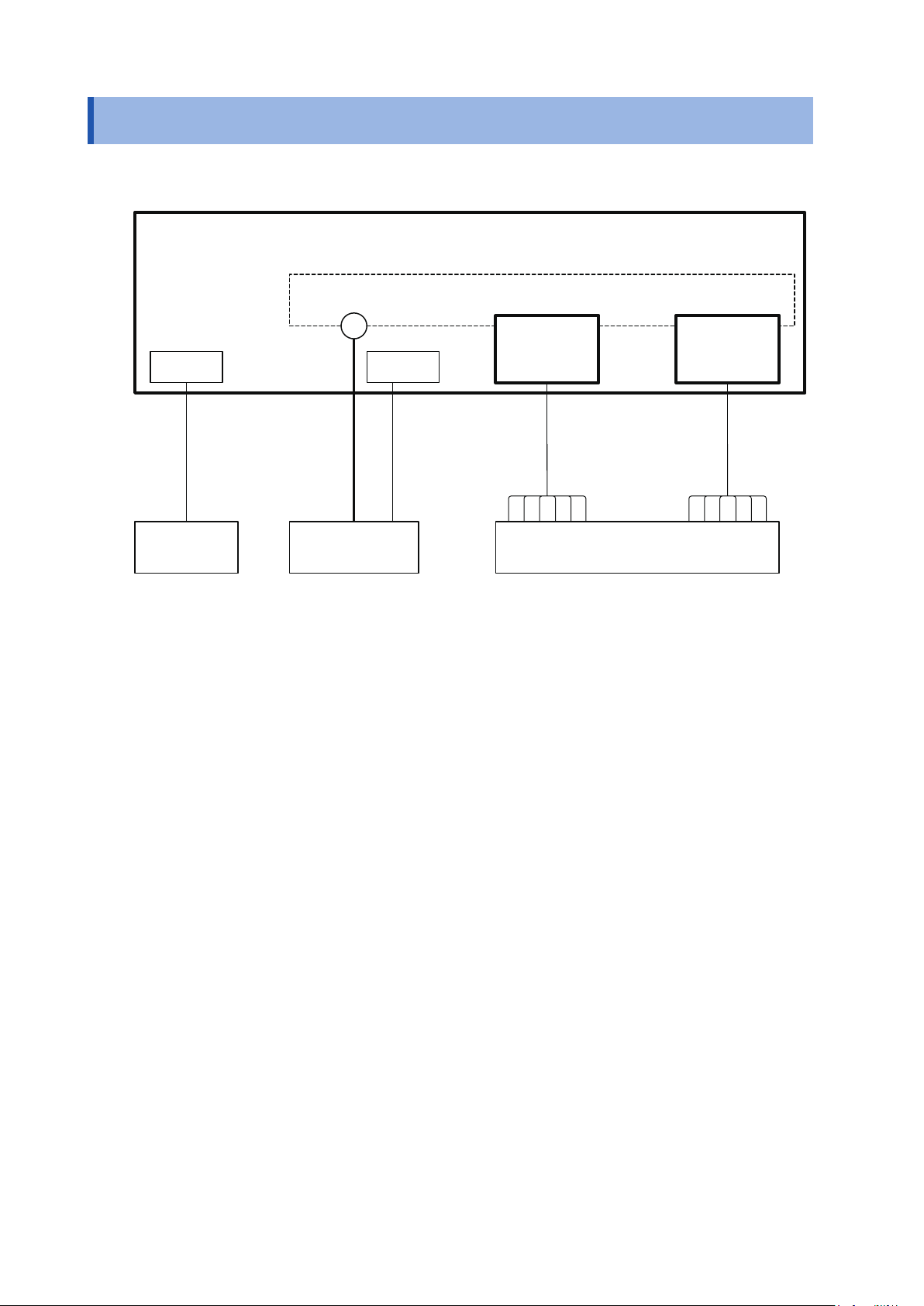

Block Diagram

1.4 Block Diagram

The conguration of this device is shown in the following block diagram.

Switch Mainframe

Internal analog bus

Terminal Module

I/F EXT. I/O

Connection cable Measurement cable

PC/PLC

Instrument Measuring object

...

Module

10

Page 15

1.5 Glossary

Terms Description Reference

Measurement cable Connects the measuring object and the module.

It is prepared by the customer.

Connection cable Connects the switch mainframe and instrument.

Prepare the optional cable.

Glossary

p. 143

p. 19

1

Overview

Terminal Connects the instrument.

The terminal to be used varies depending on the connection method

(2-wire/4-wire/4-terminal pair)

Module For the switching circuit.

The connection method varies depending on the module type.

Slot Used to attach the module.

The number of slots varies depending on the switch mainframe type.

Channel Channel inside the module.

Specify the slot and channel and select the measuring object.

Analog bus Common analog signal inside the switch mainframe.

The analog buses for 4 systems are built in.

The analog bus to be used is determined based on the connection

method.

Channel relay Switches the channel inside the module. p. 27

Bus relay Connects the measurement signal selected for the channel relay to

the analog bus.

It is built into the module.

Switching the bus relay allows you to select the connection method.

Connection method You can select the measurement connection from 2-wire, 4-wire, or

4-terminal pair.

Selecting a connection method determines the connection terminal for

the instrument.

p. 28

p. 129

p. 30

p. 30

p. 27

p. 27

p. 28

Shield For the measurement cable (cable for the measuring object).

The destination to which the shield is connected inside the module

can be switched.

Switching the connection destination can reduce the inuence of

noise depending on the instrument to be used or the measurement

environment.

Scan Switches the pre-registered channel (scan list) in sequence.

Connecting the instrument and this device using EXT. I/O enables

the channel to be switched and trigger measurement to be performed

automatically.

p. 29

p. 39

11

Page 16

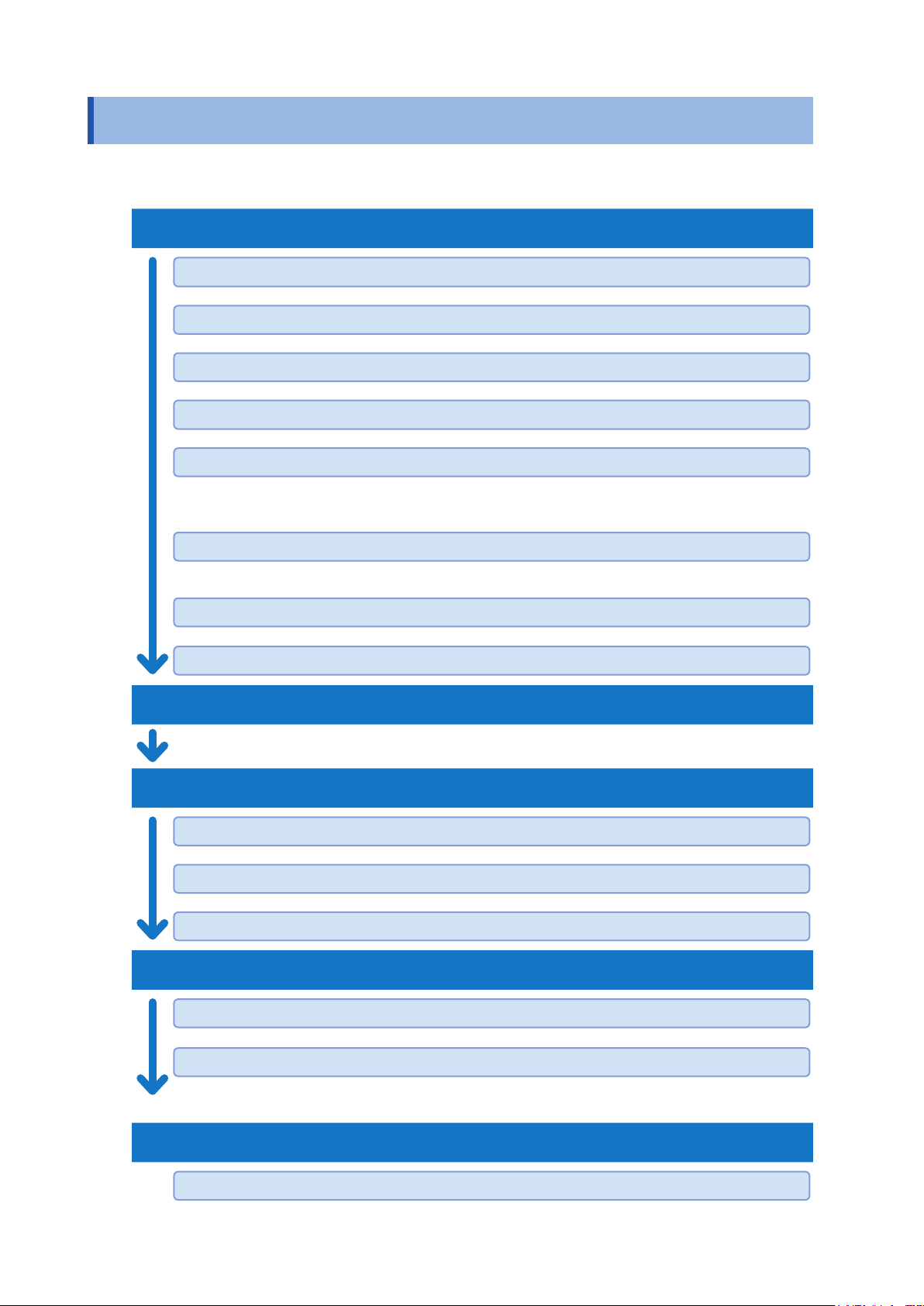

Measurement Flowchart

1.6 Measurement Flowchart

Thoroughly read “Usage Notes” (p. 4) beforehand.

Installation, connection, and turning on of power

Installing the device. (p. 4)

Attaching the module to the device. (p. 15)

Connecting the measurement cable to the module. (p. 18)

Connecting the device and the instrument using the connection cable. (p. 19)

Connecting the communications cable and making settings.

• Set the communication setting mode (p. 22).

• Connect the LAN, USB, or RS-232C cable to the PC (p. 59).

Connecting the device and the external control device. (for scan measurement)

• Connect the device to an external device such as a PLC using EXT. I/O (p. 49).

Connecting the power cord. (p. 23)

Turning on the power. (p. 23)

Inspection before measurement (p. 25)

Setting before measurement

Selecting the module connection method. (p. 28)

Switching the shield. (p. 29)

Selecting the channel to be measured. (p. 30)

Starting the measurement

12

Sending a measurement command to the instrument.

Receiving measurement results.

• For information on the measurement processing and receiving measurement results, see the

instruction manual of the instruments to be used.

Ending the measurement

Turning off the power. (p. 23)

Page 17

2

Preparation for Measurements

2.1 Connecting Instruments and Controlling the Device

This section describes how to connect one or more measuring instruments and control the device.

A PC or PLC must be connected in order to control the device. A PC or PLC connection is also

required in order to control instruments and acquire measured values.

The device utilizes the connection and control methods described below.

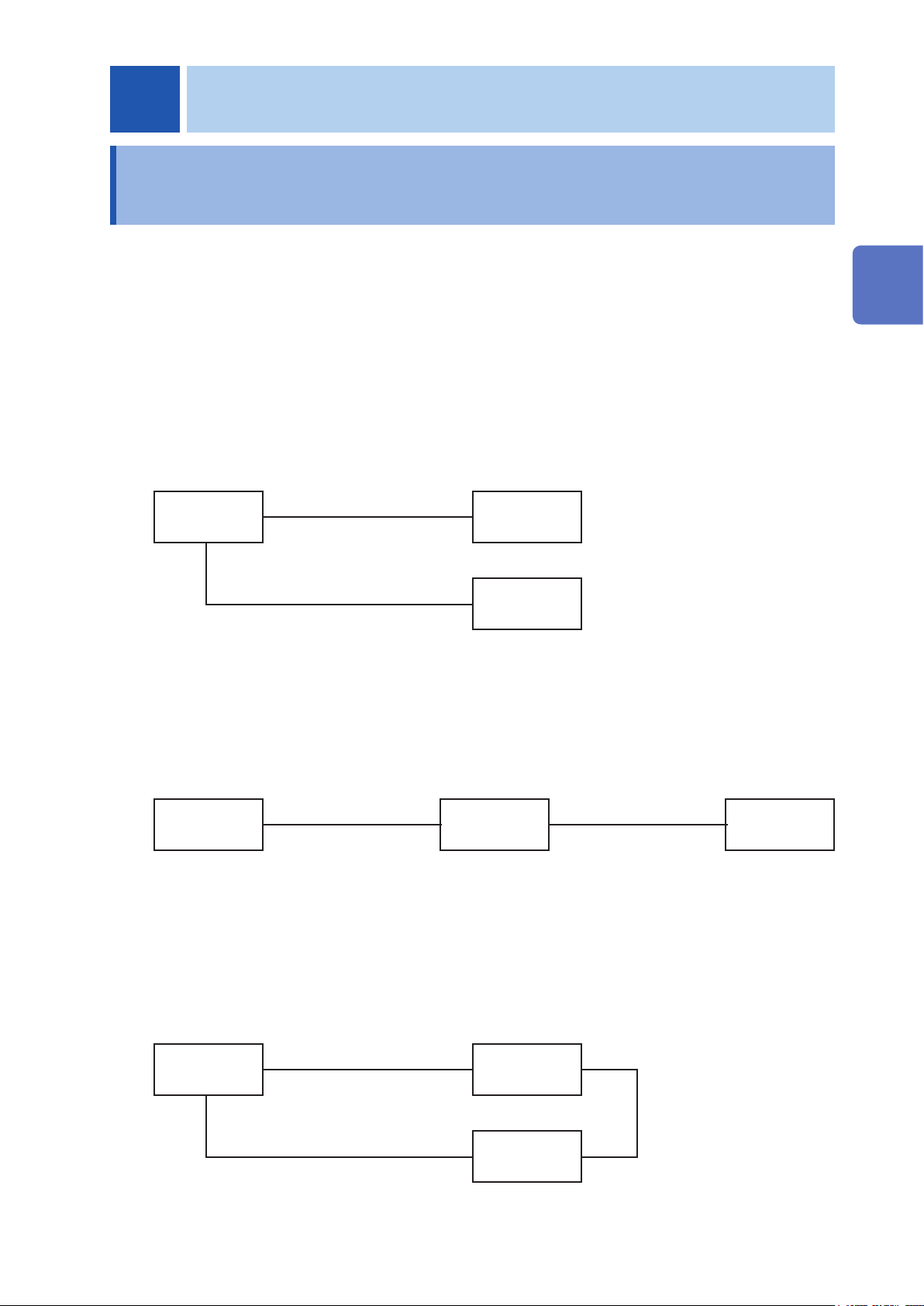

Basic control

Connect the PC to the device and instrument via separate communications interfaces.

Control the device to switch channels and control the instrument to congure settings, perform

measurement, and acquire measured values.

See: “3.2 Overview of Channel Switching” (p. 27)

2

Preparation for Measurements

PC

LAN/USB/RS-232C

LAN/USB/RS-232C

SW1001

Instrument

Controlling an instrument via the device

You can also use the device’s functionality for forwarding communication commands to control

instruments simply by sending commands to the device.

See: “8.6 Communication Command Forwarding Function” (p. 69)

INSTRUMENT

PC

LAN/USB/RS-232C

SW1001

connector

RS-232C only

Performing automatic scan measurement using EXT. I/O

You can switch channels and perform a series of measurements in accordance with a previously

created scan list by connecting the device and an instrument via the EXT. I/O interface. You can

also acquire measured values by using the instrument’s data output function (to automatically send

measured values) or memory function.

See: “4 Scan Function” (p. 39)

Instrument

PC

LAN/USB/RS-232C

SW1001

EXT. I/O

Instrument

LAN/USB/RS-232C

13

Page 18

Connecting Instruments and Controlling the Device

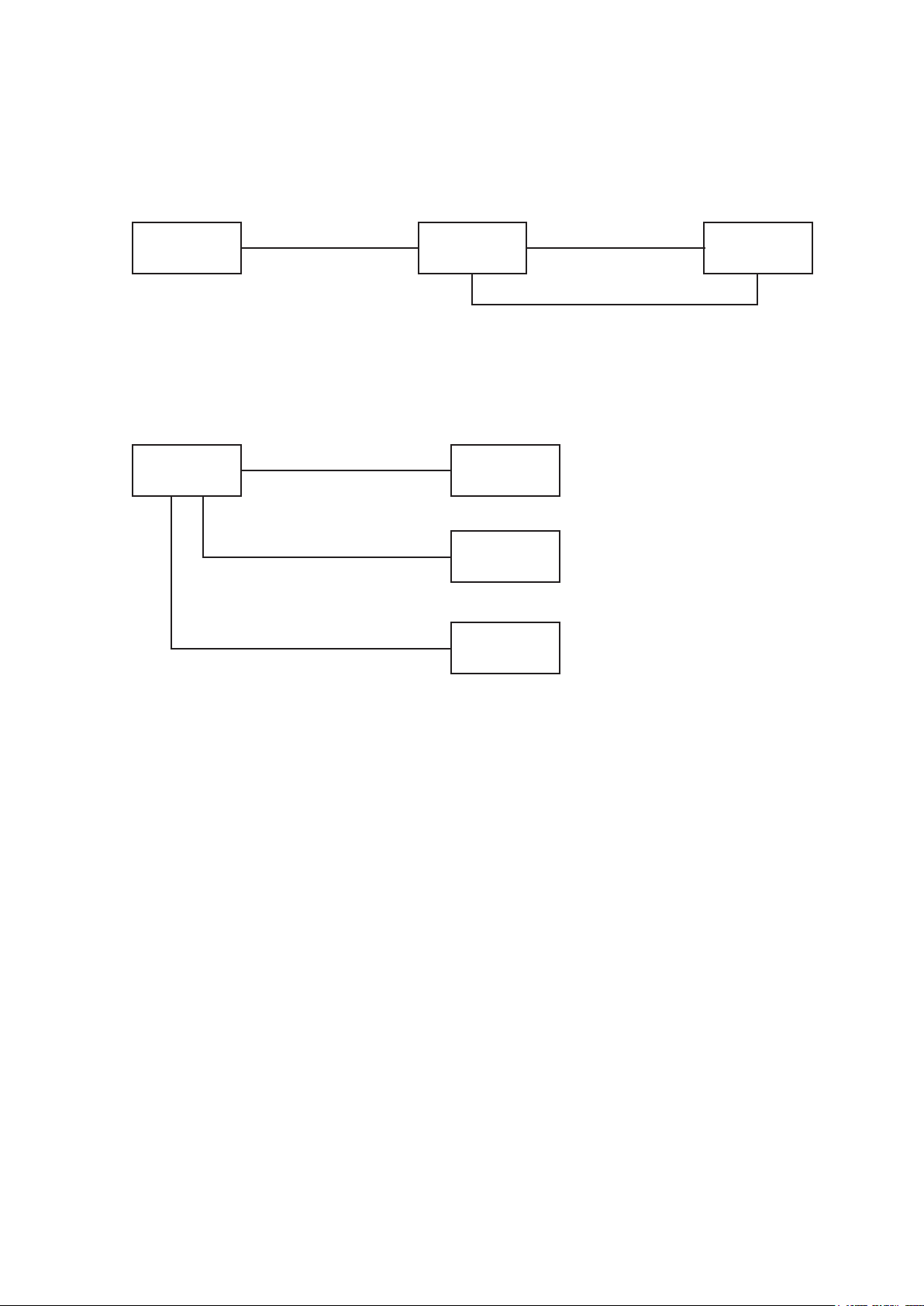

Performing automatic scan measurement using EXT. I/O

(using the communication command forwarding function)

Furthermore, you can perform automatic scan measurement over a single communications

interface by using the device’s communication command forwarding function.

INSTRUMENT

PC

LAN/USB/RS-232C

SW1001

connector

RS-232C only

EXT. I/O

Connecting two instruments

You can perform measurement by connecting two instruments to the device.

See: “3.5 Measurement between Two Instruments” (p. 32)

Instrument

PC

LAN/USB/RS-232C

SW1001

Instrument 1

LAN/USB/RS-232C

Instrument 2

LAN/USB/RS-232C

14

Page 19

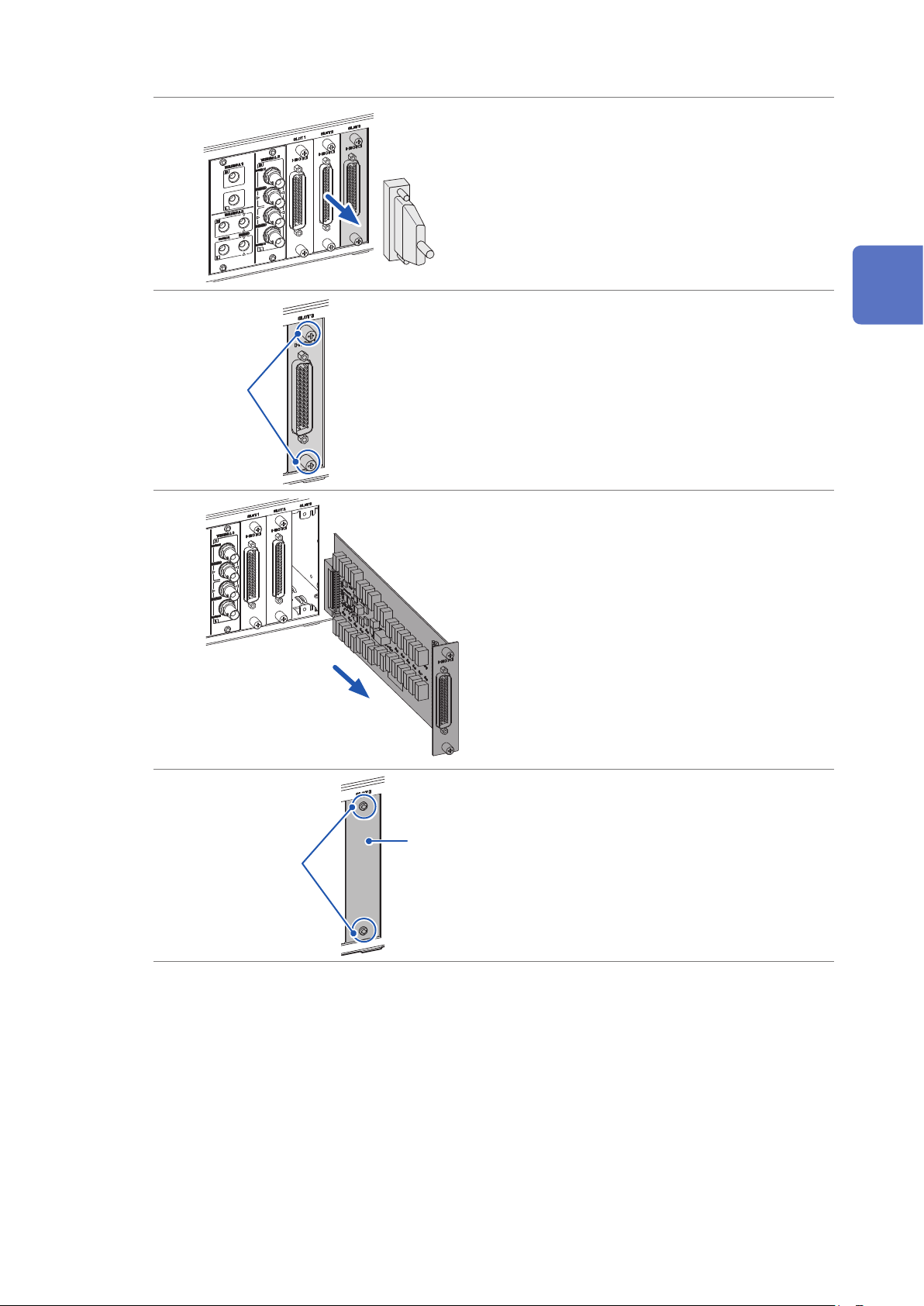

Installing the Module

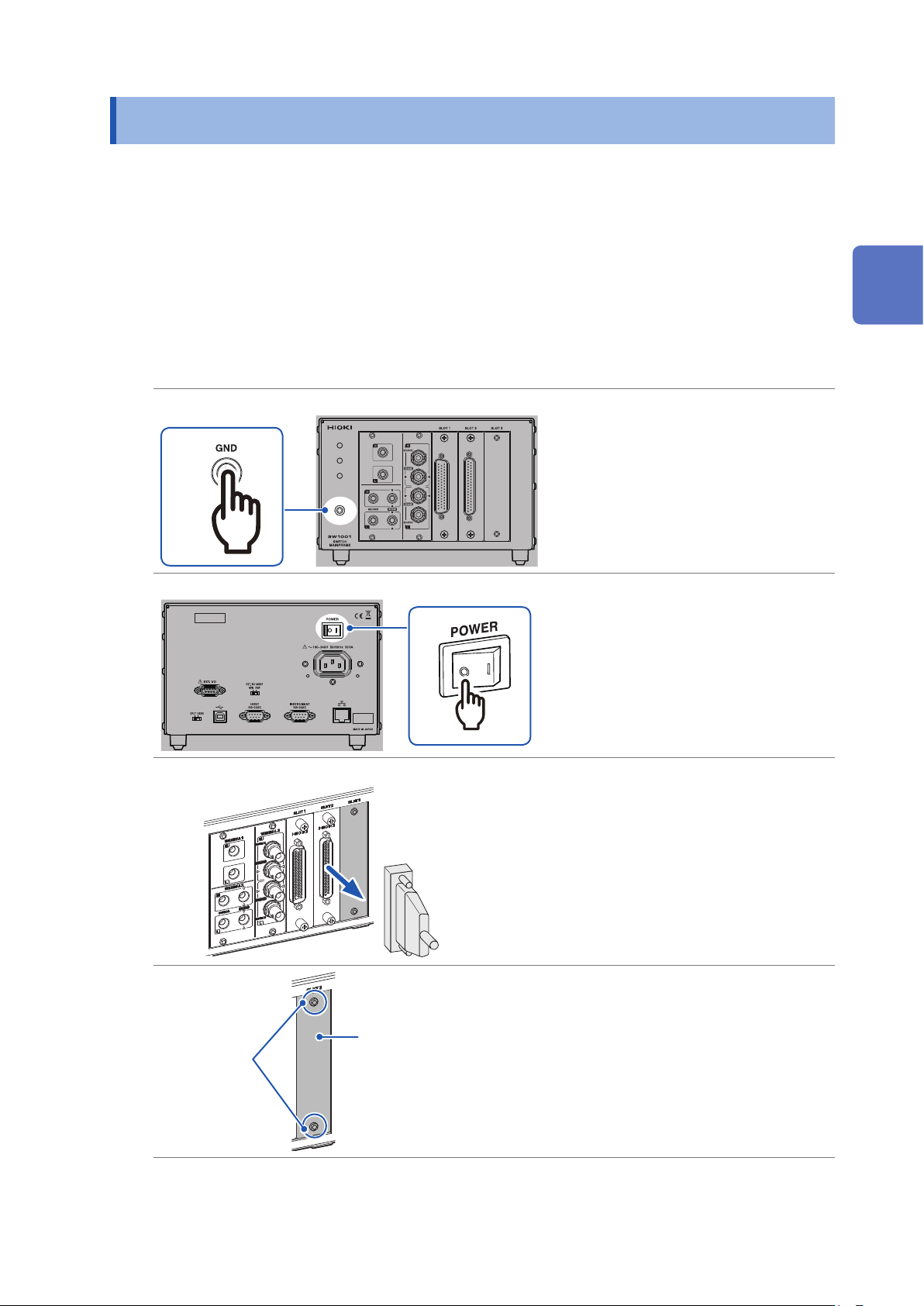

2.2 Installing the Module

Thoroughly read “Before installing the module” (p. 5) beforehand.

The following settings are initialized when you install a new module into a slot or change the type of

module installed in a given slot.

• Connection method

• Shield switching

• Channel delay

• Scan list

Required items: Phillips screwdriver (No. 2), antistatic gloves

2

Preparation for Measurements

1

Rear

Front

Front

3

Touch the GND terminal with

1

bare hands.

Wear antistatic gloves.

2

Turn off the device.

3

Remove all the measurement

4

cables connected to the device

and module.

(To prevent electric shock and short

circuit of the measuring object.)

Screw

(M3 × 6 mm)

Blank panel

Loosen the two screws

5

(M3 × 6 mm) and then remove

the blank panel.

Store the blank panel and screws.

You need the screws when using the

device after removing the module.

15

Page 20

Removing the Module

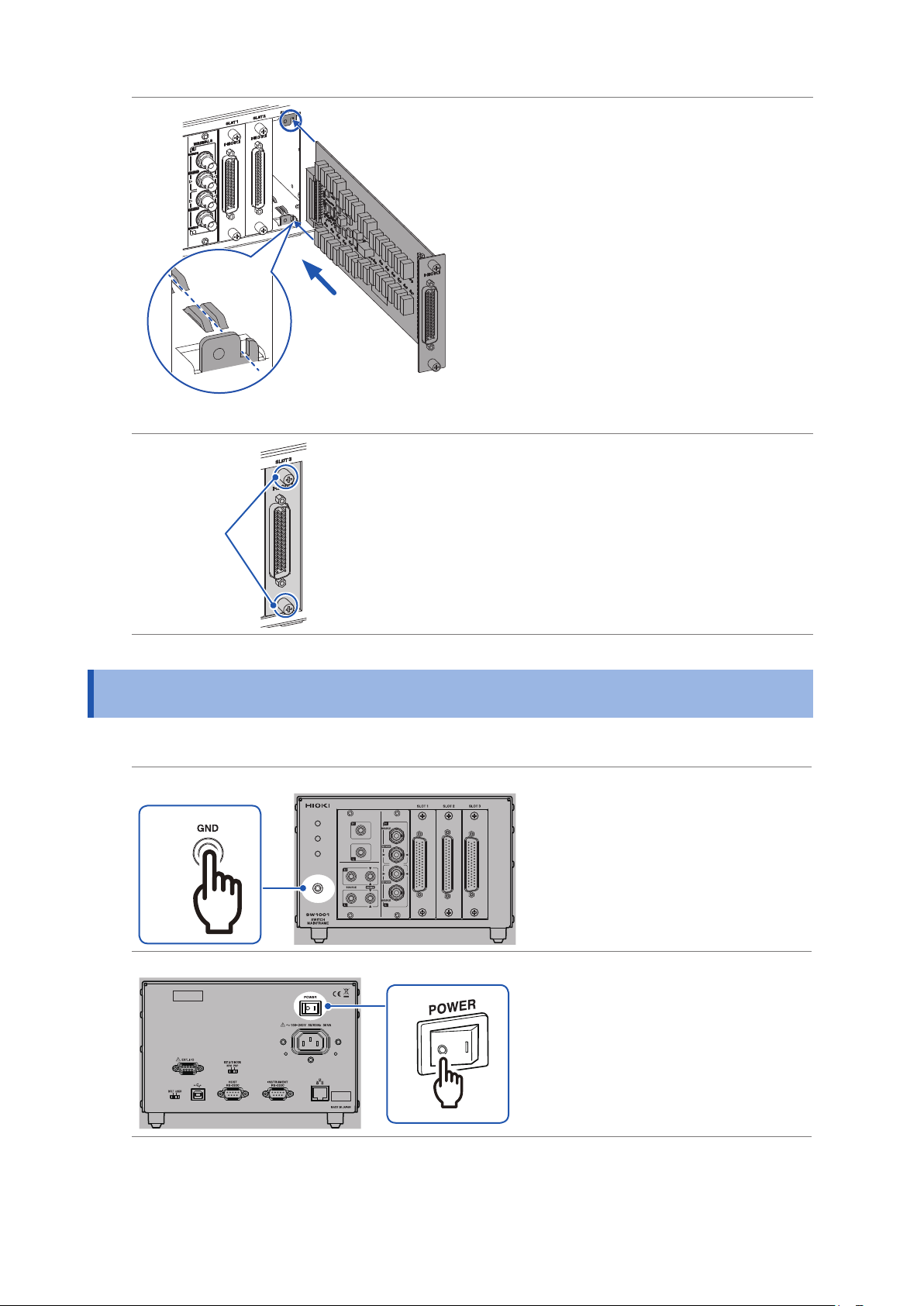

Align with the guide rail

Insert the module to the back.

6

Tighten the two screws to

7

secure the module in place.

Screw

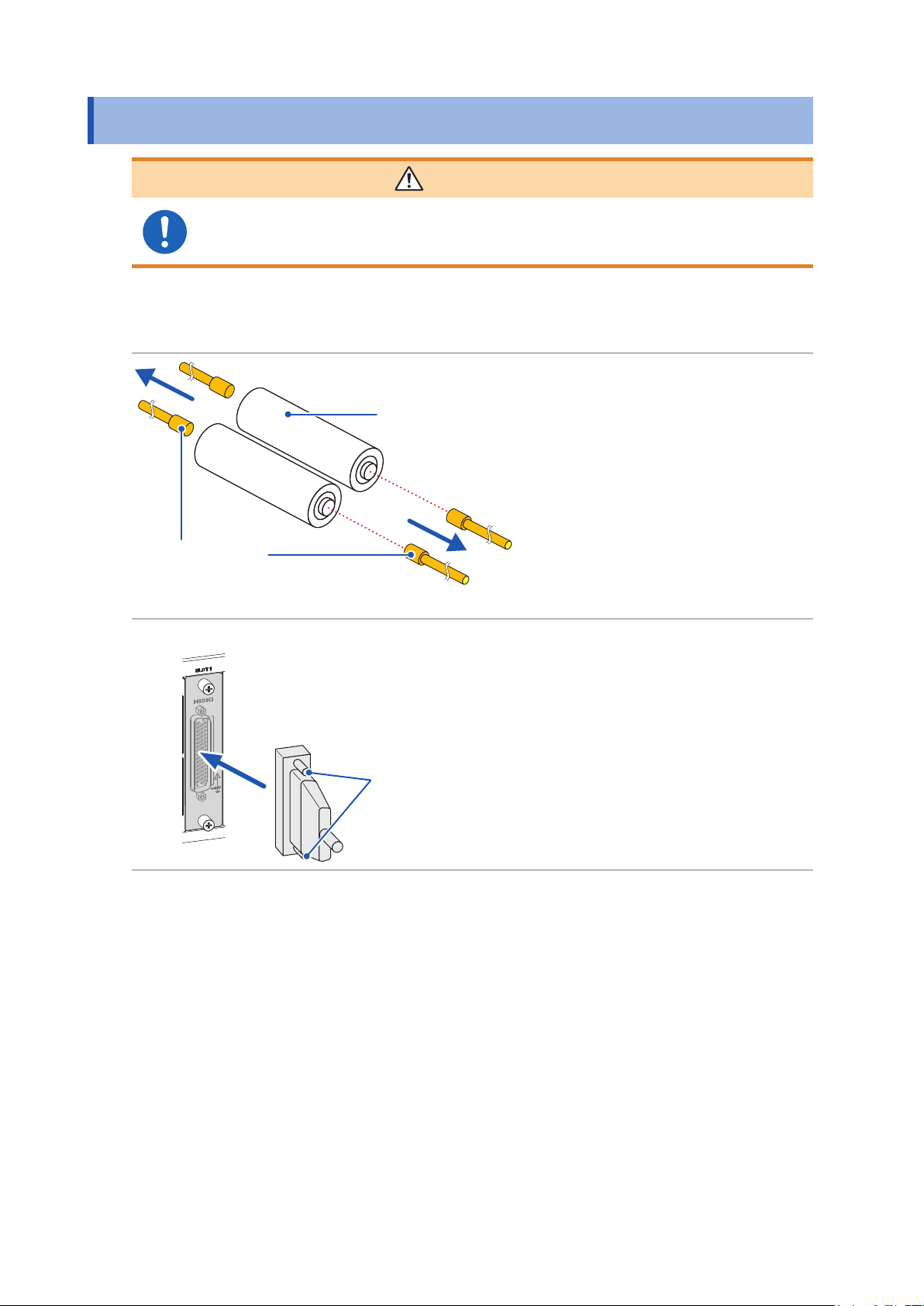

2.3 Removing the Module

Required items: Phillips screwdriver (No. 2), antistatic gloves

Front

1

Rear

Touch the GND terminal with

1

bare hands.

Wear antistatic gloves.

2

Turn off the device.

3

16

3

Page 21

Removing the Module

Front

Screw

Remove all the measurement

4

cables connected to the

device and module.

(To prevent electric shock and short

circuit of the measuring object.)

Loosen the two screws.

5

Pull out the module.

6

2

Preparation for Measurements

Screw

(M3 × 6 mm)

Blank panel

Attach the blank panel and

7

tighten the two screws

(M3 × 6 mm) to secure the

panel.

17

Page 22

Connecting the Measurement Cable

2.4 Connecting the Measurement Cable

WARNING

Connect the measurement cable with the measuring object disconnected from

the measurement cable. The measuring object may be shorted depending on the

condition of the module switching circuit.

Please provide a suitable measurement cable.

See: “12.1 Measurement cable” (p. 143)

Turn off the device.

1

Disconnect the probe from the

Disconnect

Measuring object

2

measuring object.

Disconnect

Tip of the probe

Front

Connect the measurement

3

cable connector to the module’s

connector.

Secure the measurement cable

4

connector using the screws.

3

4

For information on connecting the measuring object, see the instruction manual of each instrument.

18

Page 23

Connecting the Connection Cable

2.5 Connecting the Connection Cable

The connection cable is optional (p. 2).

Connect the device to the instrument.

For information on connecting the instrument, see the instruction manual of each instrument.

Front

2

Preparation for Measurements

Select the terminal and connection cable to be connected based on the instrument to be connected.

Instrument

example

Voltmeter DM7276 TERMINAL 1 L4930 2-wire

Battery tester BT3562 TERMINAL 2 L2108 4-wire SW9001

Battery tester BT4560

LCR meter IM3590

Model Terminal

TERMINAL 3 L2004 4-terminal pair SW9002

Connection

cable

Connection

method

Module

SW9001

SW9002

19

Page 24

Connecting the Connection Cable

TERMINAL 2 and TERMINAL 3 are internally conducted. Do not connect the instrument

to TERMINAL 2 and TERMINAL 3 at the same time. Doing so may damage the

instrument.

TERMINAL 1

Turn off the device.

1

Connect the connection cable to TERMINAL 1.

2

CAUTION

Front

Connect the other end of the connection cable to the instrument.

3

TERMINAL 2

Turn off the device.

1

Connect the connection cable to TERMINAL 2.

2

Connect the connection cable so that the red

lead wire match and the black

match.

Red

Black

H

L

mark of the device and the

mark of the device and the

Front

mark of the black lead wire

mark of the red

20

H

Red

L

Black

Connect the other end of the connection cable to the instrument.

3

Page 25

TERMINAL 3

Turn off the device.

1

Connect the connection cable to TERMINAL 3.

2

Connecting the Connection Cable

Match the cable and the connection

terminal signal.

SOURCE-H (red)

SENSE-H (red)

SENSE-L (black)

SOURCE-L (black)

1. Check the direction of

the grooves of the BNC

connector. The grooves

should t into the connector

guide of the device.

Device side

Connector guide

Front

2. Align the grooves of the

BNC connector with the

connector guide of the

device and insert the BNC

connector.

2

Preparation for Measurements

3. Turn the BNC connector to

the right to lock it.

BNC connector grooves of

the connection cord

Connect the other end of the connection cable to the instrument.

3

Connection cable terminal

SOURCE-H (red) SOURCE-H (red) Hcur

SENSE-H (red) SENSE-H (red) Hpot

SENSE-L (black) SENSE-L (black) Lpot

SOURCE-L (black) SOURCE-L (black) Lcur

BT4560 IM3590

Instrument terminal

21

Page 26

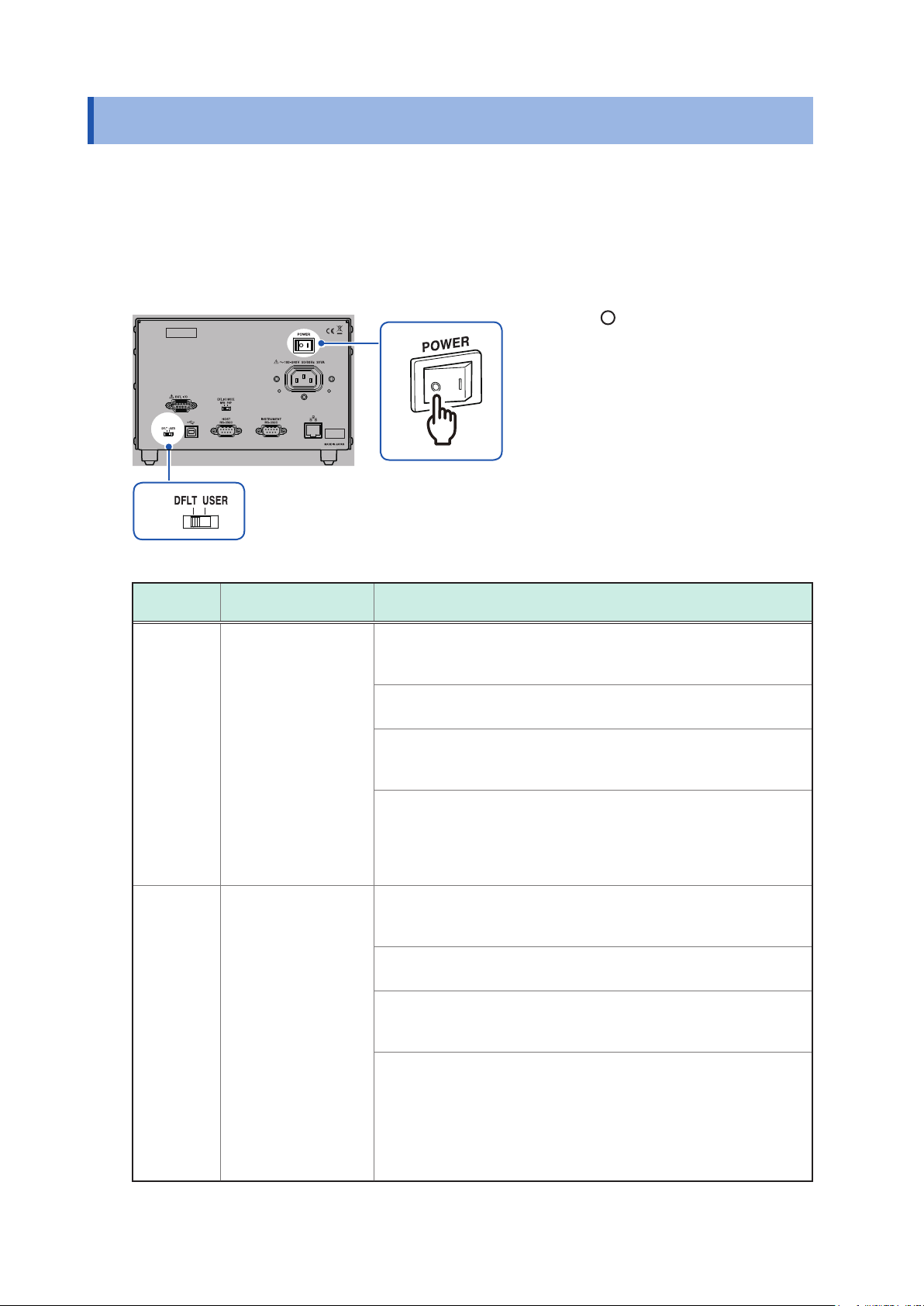

Setting the Communication Setting Mode

2.6 Setting the Communication Setting Mode

The device uses the communications interface for control.

You can select the xed setting mode for initial communication settings or the user setting mode for

user settings using the switch on the rear of the device.

Specify the communication settings according to the interface to be used in the user setting mode.

Reference: “8.1 Interface Overview and Features” (p. 59)

Rear

Check that the power switch is

1

off ( ).

Change the communication

1

2

setting mode using the

communication setting mode

switch.

2

Switch

DFLT Fixed setting mode All of USB, RS-232C, and LAN can be used.

Communication

setting mode

Device setting description

Communications are performed using the specied communication

settings.

• USB

No setting item

• RS-232C

Transmission speed: 9600 bps, data bits: 8; stop bit: 1; parity

check: none; ow control: none

• LAN

IP address: 192.168.0.254

Subnet mask: 255.255.255.0

Default gateway: 0.0.0.0 (None)

Communication command port number: 23

USER User setting mode All of USB, RS-232C, and LAN can be used.

Use the communication settings that are specied using the following

communication commands.

• USB

No setting item

• RS-232C

:SYSTem:COMMunicate:RS232C:SPEED <

Reference: “(8) RS-232C settings” (p. 103)

• LAN

:SYSTem:COMMunicate:LAN:IPADdress <

:SYSTem:COMMunicate:LAN:SMASk <

:SYSTem:COMMunicate:LAN:GATeway <

:SYSTem:COMMunicate:LAN:CONTrol <

:SYSTem:COMMunicate:LAN:UPDate

Reference: “(9) LAN settings” (p. 103)

Subnet mask

Transmission speed

IP address

Gateway address

Port No.

>

>

>

>

>

22

Page 27

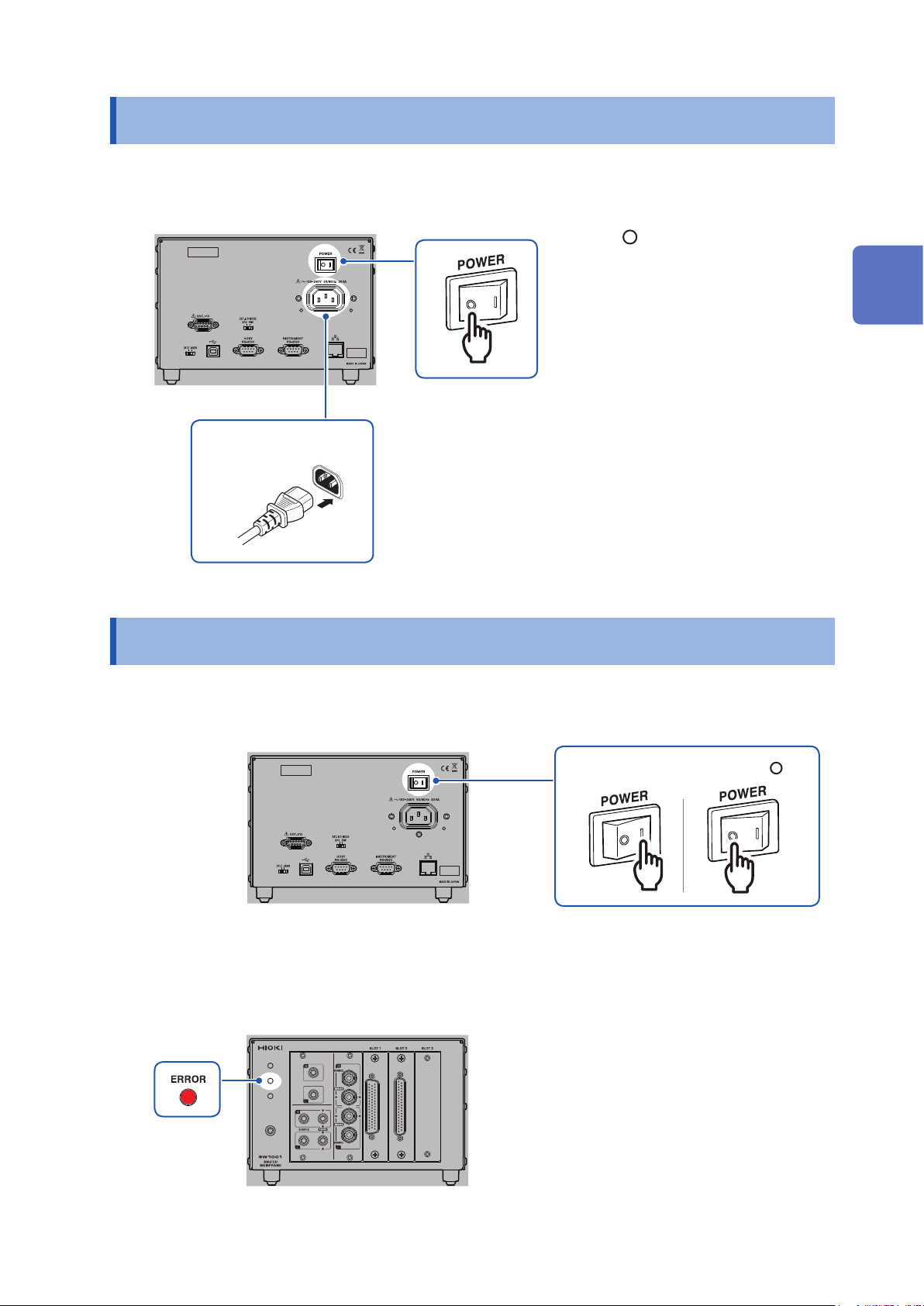

Connecting the Power Cord

2.7 Connecting the Power Cord

Be sure to thoroughly read the separate document “Operating Precautions” before use.

Rear

1

Power inlet

2

2.8 Turning on/off the Power

Check that the power switch is

1

off ( ).

Check that the power voltage is

2

within the range indicated on the

rear of the device and connect

the power cord to the power

inlet.

Connect the plug of the power

3

cord to the outlet.

2

Preparation for Measurements

Use the power switch on the rear of the device to turn on/off the power.

Rear

Power off ( )Power on (I)

The front POWER lamp lights up when the device is turned on, and a self-test is executed.

When an error occurs, the ERROR lamp on the front lights up. If an error occurs during self-test,

communications and control using EXT. I/O become disabled.

Front

23

Page 28

When the Power is Turned on

2.9 When the Power is Turned on

Item Initialization description

Channel relay All relays open

Bus relay All relays open

EXT. I/O CLOSE output signal Off

Connection method Settings (for each slot) are saved with the settings backup command.

Shield switching Settings (for each slot) are saved with the settings backup command.

Scan settings Settings are saved with the settings backup command.

Channel delay settings Settings are saved with the settings backup command.

Communication settings Settings are saved with the settings backup command.

See: “Backing up settings” (p. 105)

24

Page 29

3

Channel Switching

Thoroughly read "Usage Notes" (p. 4) beforehand.

3.1 Inspection before Measurement

Verify that it operates normally to ensure that no damage occurred during storage or shipping.

If you nd any damage, contact your authorized Hioki distributor or reseller.

Inspecting the device and peripheral devices

3

Check item Action

Is the sheath of the power cord normal

without any damage or exposed metal part?

Are the sheaths of the measurement cables

or connection cables to be used normal

without any damage or exposed metal part?

Is the device normal without any damage?

Channel Switching

Damage may cause an electric shock or a short circuit

accident. Do not use it.

Contact your authorized Hioki distributor or reseller.

Damage may cause an electric shock. Stop using it and

replace it with a specied one.

25

Page 30

Inspection before Measurement

Checking for relay contact welding

If a relay contact welds, the battery of the measuring object may short or the channels may be

connected in parallel, resulting in improper measurement.

You can check that the relays are not welded according to the following procedure.

Short all the module terminals.

1

Send inspection command: TEST:RELAYSHORT <No. of slot to be inspected>,CH, and set the

2

test state of the channel relay.

Example: Inspect the channel relay of SLOT 1.

:TEST:RELAYSHORT 1,CH

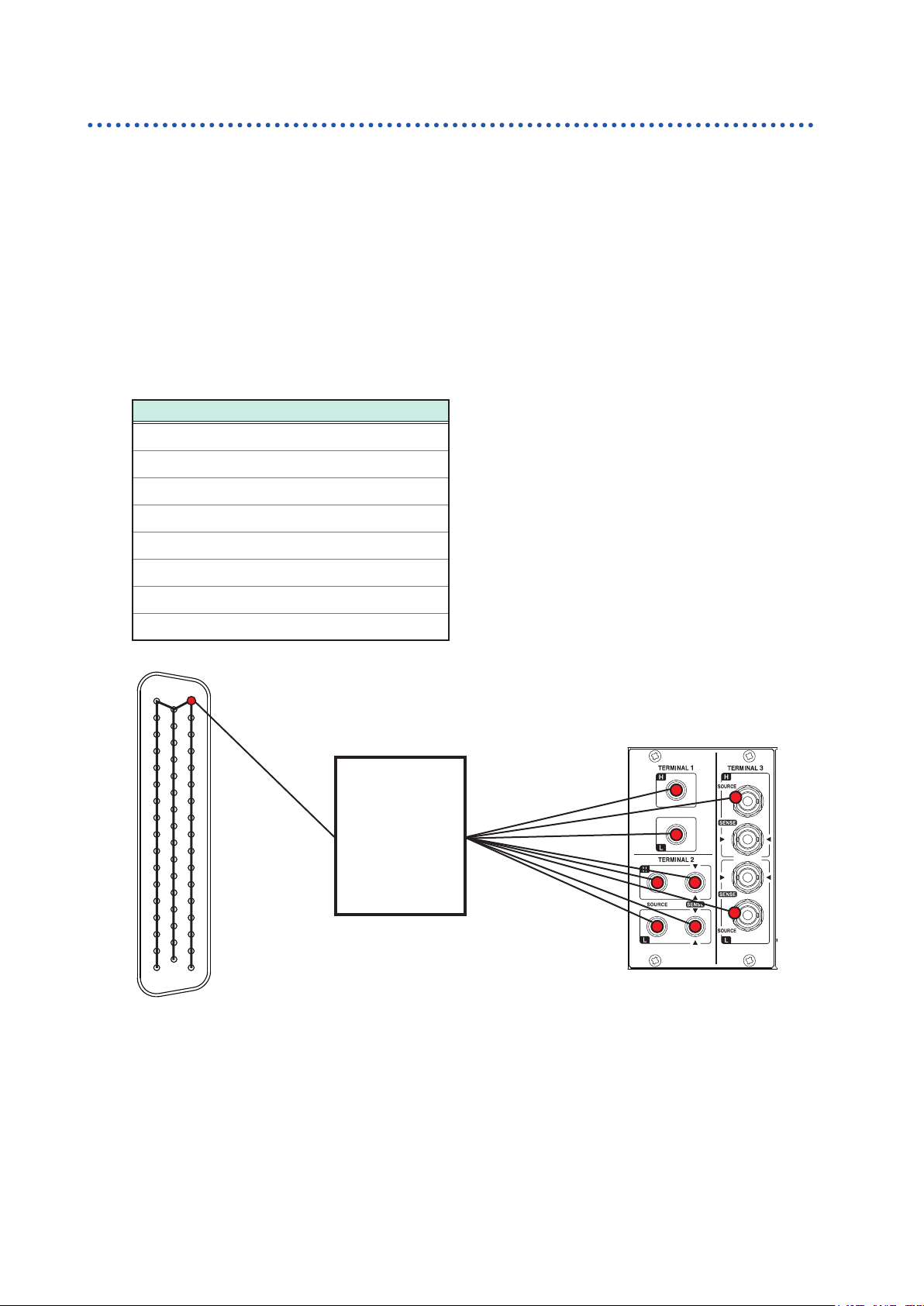

Check that the terminals of the shorted modules and the following points of the terminals on

3

the main frame are not electrically connected.

Continuity inspection points

TERMINAL 1, H

TERMINAL 1, L

TERMINAL 2, SENSE H

TERMINAL 2, SENSE L

TERMINAL 2, SOURCE H

TERMINAL 2, SOURCE L

TERMINAL 3, SOURCE H shield

TERMINAL 3, SOURCE L shield

17

1

33

18

The connector is for the SW9001.

50

Check that the terminal of the shorted

module and the above points of the

34

terminal on the main frame are not

electrically connected.

Tester

Send inspection command: TEST:RELAYSHORT <No. of slot to be inspected>,BUS, and set the

4

test state of the bus relay, then conrm step 3.

Send inspection command: TEST:RELAYSHORT <No. of slot to be inspected>,OPEN, and end the

5

inspection for this slot.

Perform steps 1 to 5 for all the slots.

6

Module relay contact may be weld if it was conducted during inspection. Stop the use and contact

your authorized Hioki distributor or reseller.

26

Page 31

Overview of Channel Switching

3.2 Overview of Channel Switching

This device connects to the internal analog bus by switching the relay of each module channel. The

internal analog bus is connected to the terminal for connecting the instrument.

The device is all controlled by communication commands. For details about the command, refer to

the description of each item.

TERMINAL 1

2-terminal banana

Sense

H

L

GND

terminal

TERMINAL 2

4-terminal banana

Sense

H

L

H

L

TERMINAL 3

BNC

Sense

Sense shield

SourceSource

H

L

Source shield

Bus relay

Internal analog bus

3

Channel Switching

Channel relay

Sense

channel

Source

channel

Return

channel

Shield wire

Module

• The sense shield for TERMINAL 3 (BNC terminal) is common (short circuit) for H and L.

• The diagram for wire connection inside the module is conceptual and differs from the actual

module connection. See the wiring diagram for each module.

Reference: Switching wiring diagram (p. 132, p. 138)

Select the channel to be measured using the channel relay and specify the terminal to which

the channel is to be connected (select the connection method) using the bus relay. The selected

channel can be measured using an instrument.

The sense and source for TERMINAL 2 (4-terminal banana terminal) and TERMINAL 3 (BNC

terminal) use a common analog bus (electrically connected).

CAUTION

Do not connect TERMINAL 2 and TERMINAL 3 to the instrument at the same time.

Doing so may damage the instrument.

27

Page 32

Procedure for Switching the Channel

3.3 Procedure for Switching the Channel

Switch the channel according to the following setting and procedure.

• Selecting the connection method

• Switching the shield

• Selecting the channel

Selecting the connection method

The connection method can be selected for each slot. Selecting the connection method determines

the terminal of the connection destination (instrument).

Module

SW9001

SW9002

SW9001 4-wire Battery tester BT3562 TERMINAL 2 L2108

SW9002 4-terminal pair

Connection

method

2-wire Voltmeter DM7276 TERMINAL 1 L4930

Instrument

example

Battery tester BT4560

LCR meter IM3590

Model Terminal

Connection

cable

TERMINAL 3 L2004

Once the connection method is specied, it is retained. You do not have to specify the connection

method every time the channel is switched.

Once the connection method is specied, all the channels become open. The shield wire is

connected to the specied connection destination for each connection method. If you wish to switch

a channel to another terminal, specify the connection method and then close the channel.

The number of channels that can be used varies depending on the module type and connection

method as shown below.

Module

SW9001

Connection

method

2-wire 22 Sense CH1 to CH22 TERMINAL 1

4-wire 11

Number of

channels

Signal type Signal to be used

Source CH1 to CH11

Sense CH12 to CH22

Terminal to be

used

TERMINAL 2

2-wire 6 Sense Sense: CH1 to CH6 TERMINAL 1

SW9002

4-terminal pair 6

If the SW9001 is set to 4-wire and the 4-

in pairs.

Source: CH n

Sense: CH (n+11)

Item Communication command

Setting

procedure

Setting

example

:SYSTem:MODule:WIRE:MODE <

Set SLOT 1 to 2-wire.

:SYST:MOD:WIRE:MODE 1,WIRE2

Set SLOT 5 to 4-terminal pair.

:SYST:MOD:WIRE:MODE 5,TP4

28

Source Source: CH1 to CH6

TERMINAL 3Return Return: CH1 to CH6

Sense Sense: CH1 to CH6

wire

selection channel is “n”, the following signals are used

slot number

>,<WIRE2/WIRE4/TP4>

Page 33

Procedure for Switching the Channel

Switching the shield

When the connection method is selected, the shield wire is connected to the specied connection

destination.

Specied shield switching setting (shielding connection destination)

Module Connection method Shield connection destination

SW9001

2-wire TERMINAL 1, LOW terminal

4-wire GND

SW9002

2-wire TERMINAL 1, LOW terminal

4-terminal pair TERMINAL 3, sense shield terminal

The destination for shielding connection can be switched as necessary (for each slot).

Any time the connection method for a slot is changed, the switching shield will be reset to the

specied value. To set the switching shield to a value other than the specied value, be sure to set

the switching shield after setting the connection method.

Destination for shield wire connection to be selected

Module Connection destination terminal

Not connected

GND

TERMINAL 1, LOW terminal

SW9001

TERMINAL 2,TERMINAL 3, source LOW terminal

TERMINAL 3, sense shield terminal

TERMINAL 1, LOW terminal + TERMINAL 3, sense shield terminal

Not connected

GND

SW9002

TERMINAL 1, LOW terminal

3

Channel Switching

TERMINAL 3, sense shield terminal

For the SW9001, the [TERMINAL 1, LOW terminal + TERMINAL 3, sense shield terminal] shielding

connection destination terminal should only be used when connecting a BT3562 and DM7275/DM7276

at the same time when the DM7275/DM7276 contact check function is not operating properly.

Once the connection destination is specied, it is retained until the connection method is changed.

You do not have to specify the connection destination every time the channel is switched.

When the switching shield is set, all channels are set to open.

The source terminal for TERMINAL 2 and sense terminal are common for TERMINAL 3.

Item Communication command

Setting

procedure

Setting

example

:SYSTem:MODule:SHIeld <

TERMinal3/T1T3>

Set the shield wire connection destination for SLOT 1 to GND.

:SYST:MOD:SHI 1,GND

Set the shield wire connection destination for SLOT 5 to “not connected”.

:SYST:MOD:SHI 5,OFF

slot No.

>,<OFF/GND/TERMinal1/TERMinal2/

29

Page 34

Procedure for Switching the Channel

Selecting the channel

Select the slot and channel No.

When the channel is selected, the specied slot of channel relay is closed, as well as the bus relay

is also closed due to the connection method.

Item Communication command

Setting

procedure

[ROUTe]: CLOSe <

<

Slot and channel No.

Slot and channel No.

> =

Slot No. × 100 + CH No.

>

Setting

example

Item Communication command

Setting

procedure

Setting

example

Select CH7 of SLOT 1.

:CLOS 107

Select CH22 of SLOT 12.

:CLOS 1222

[:ROUTe]:OPEN

Open all channels.

:OPEN

Restriction

Multiple channels cannot be closed simultaneously.

Waiting for channel selection (switching) to complete

Switching operation is triggered by the channel selection command.

You can verify whether channel switching operation has completed by receiving the next query

response. The switching operation time is included in the channel delay time.

See: "3.7 Channel Delay Function" (p. 37)

Waiting for channel switching operation to complete

Item Communication command

Conrming

procedure

Conrming

example

OPC

∗

Response:

Waits for the present operation to complete and returns the value 1.

The subsequent command will be made to wait until this command completes.

Select CH7 of SLOT 1 and wait for switching operation to complete.

:CLOS 107

OPC?

∗

1

(receive a response = switching operation complete)

1

30

Page 35

Channel Switching Operation

3.4 Channel Switching Operation

When the channel is selected (closed), channel switching is performed according to the following

ow.

Channel switching

Enabled channel Previous channel Selected channel

Relay operation Close Open Close

Operation

standby time

EXT. I/O CLOSE ON OFF ON

If the next channel is closed before the CLOSE signal pulse reaches the set pulse width, CLOSE

signal pulse will automatically turn off.

After the previous channel relay is opened, the selected channel relay is closed (break before

make).

Channel switching cannot be overlapped (make before break).

In channel switching within the same slot, the bus relay is not opened and only the channel relay is

switched.

If the channel for a different slot is selected, the bus relay and channel relay of the previous slot are

opened and the bus relay and channel relay of the selected slot are closed.

After the channel relay is closed and then the settling time that is automatically set and the channel

delay time that is specied by the customer elapse, channel switching operation is complete and

the CLOSE output signal of EXT. I/O is turned on (pulse output at the set pulse width).

Settling time

Channel

delay

Set pulse

width

3

Channel Switching

31

Page 36

Measurement between Two Instruments

3.5 Measurement between Two Instruments

Changing the connection method enables measurement to be performed by switching between two

instruments according to the application.

Example: Measure the internal resistance of 8 batteries using BT3562 and measure the OCV using

DM7276. (Use SLOT 1, 4-wire, CH1 to CH8.)

Connect BT3562 to TERMINAL 2 and DM7276 to TERMINAL 1.

1

Instrument

BT3562

DM7276 OCV SW9001 2-wire

Set the connection method of SLOT 1 to 4-wire.

2

The signal is connected to TERMINAL 2.

Repeat channel selection and measurement using BT3562 for 8 channels (internal resistance

3

measurement).

Measurement

item

Internal

resistance

Module

SW9001 4-wire

Connection

method

Channel selection Terminal to be used

SLOT 1, CH1

SLOT 1, CH2

SLOT 1, CH3

⁞

SLOT 1, CH8

SLOT 1, CH12

SLOT 1, CH13

SLOT 1, CH14

⁞

SLOT 1, CH19

TERMINAL 2

TERMINAL 1

Set the connection method to 2-wire.

4

The signal is connected to TERMINAL 1.

Repeat channel selection and measurement using DM7276 in the same way as for internal

5

resistance measurement (OCV measurement).

The sense wire for 4-wire CH1 to CH8 corresponds to 2-wire CH12 to CH19.

32

Page 37

Control example using communication command

[SW1001] :SYST:MOD:WIRE:MODE 1,WIRE4

[SW1001] :CLOSE 101

[SW1001] ∗OPC?

[SW1001] 1

[BT3562] :READ?

[BT3562] 1.0258E-3

[SW1001] :CLOSE 102

...

[SW1001] :SYST:MOD:WIRE:MODE 1,WIRE2

[SW1001] :CLOSE 112

[SW1001] ∗OPC?

[SW1001] 1

[DM7276] :READ?

[DM7276] +03.764987E+00

[SW1001] :CLOSE 113

...

Measurement between Two Instruments

Set the SLOT 1 connection method to 4-wire (connect to

TERMINAL 2).

Select SLOT 1, CH1.

Check that the channel relay has been closed.

OPC?

Receive a response “1” to the

Execute single measurement using BT3562.

Receive measured values.

Select the next CH2.

(Repeat until CH8.)

Set the SLOT 1 connection method to 2-wire (connect to

TERMINAL 1).

Select SLOT1, CH12 (4-wire CH1 sense).

Check that the channel relay has been closed.

Receive a response “1” to the

Execute single measurement using DM7276.

Receive measured values.

Select the next CH13 (4-wire CH2 sense).

(Repeat until CH19.)

∗

OPC?

∗

query.

query.

3

Channel Switching

Example: Measure the internal resistance of 8 batteries using BT3562 and measure the OCV using

DM7276. Then measure the external potential for batteries using the DM7276.

(Use SLOT 1, 4-wire, CH1 to CH8 for internal resistance and OCV measurement.

Use SLOT 2, 2-wire, CH1 to CH8 for external potential measurement for batteries.)

Connect BT3562 to TERMINAL 2 and DM7276 to TERMINAL 1.

1

Instrument Measurement item Module

BT3562 Internal resistance SW9001 4-wire

DM7276 OCV SW9001 2-wire

Connection

method

Channel selection Terminal to be used

SLOT 1, CH1

SLOT 1, CH2

SLOT 1, CH3

⁞

SLOT 1, CH8

SLOT 1, CH12

SLOT 1, CH13

SLOT 1, CH14

⁞

SLOT 1, CH19

TERMINAL 2

TERMINAL 1

External potential

DM7276

Set the connection method of SLOT 1 to 4-wire.

2

The signal is connected to TERMINAL 2.

measurement for

batteries

SW9001 2-wire

SLOT 2, CH1

SLOT 2, CH2

SLOT 2, CH3

⁞

SLOT 2, CH8

TERMINAL 1

33

Page 38

Measurement between Two Instruments

Repeat channel selection and measurement using BT3562 for 8 channels (internal resistance

3

measurement).

Set the connection method to 2-wire.

4

The signal is connected to TERMINAL 1.

Repeat channel selection and measurement using DM7276 in the same way as for internal

5

resistance measurement (OCV measurement).

The sense wire for 4-wire CH1 to CH8 corresponds to 2-wire CH12 to CH19.

Set the connection method of SLOT 2 to 2-wire.

6

Use SLOT 2 for external potential for batteries since the measurement points are different.

The signal is connected to TERMINAL 1.

Repeat channel selection and measurement using DM7276 (external potential measurement

7

for batteries).

Control example using communication command

[SW1001] :SYST:MOD:WIRE:MODE 1,WIRE4

[SW1001] :CLOSE 101

[SW1001] ∗OPC?

[SW1001] 1

[BT3562] :READ?

[BT3562] 1.0258E-3

[SW1001] :CLOSE 102

...

[SW1001] :SYST:MOD:WIRE:MODE 1,WIRE2

[SW1001] :CLOSE 112

[SW1001] ∗OPC?

[SW1001] 1

[DM7276] :READ?

[DM7276] +03.764987E+00

[SW1001] :CLOSE 113

...

[SW1001] :SYST:MOD:WIRE:MODE 2,WIRE2

[SW1001] :CLOSE 201

[SW1001] ∗OPC?

[SW1001] 1

[DM7276] :READ?

[DM7276] +00.257139E+00

[SW1001] :CLOSE 202

...

Set SLOT 1 to 4-wire (connect to TERMINAL 2).

Select SLOT 1, CH1.

Check that the channel relay has been closed.

OPC?

Receive a response “1” to the

Execute single measurement using BT3562.

Receive measured values.

Select the next CH2.

(Repeat until CH8.)

Set SLOT 1 to 2-wire (connect to TERMINAL 1).

Select SLOT 1, CH12 (4-wire CH1 sense).

Check that the channel relay has been closed.

Receive a response “1” to the

Execute single measurement using DM7276.

Receive measured values.

Select the next CH13 (4-wire CH2 sense).

(Repeat until CH19.)

Set SLOT 2 to 2-wire (connect to TERMINAL 1).

Select SLOT 2, CH1.

Check that the channel relay has been closed.

Receive a response “1” to the

Execute single measurement using DM7276.

Receive measured values.

Select the next CH2.

(Repeat until CH8.)

∗

OPC?

∗

OPC?

∗

query.

query.

query.

34

Page 39

Precautions for Measurement

3.6 Precautions for Measurement

Use in combination with BT3562 or BT3563

Contact check does not operate properly at 3000 Ω range. Also be aware that contact check cannot

be performed properly in the voltage function, either.

Use in combination with BT4560

Use the device with BT4560 for external trigger measurement or single measurement using the

:READ?

When using the device for internal trigger (free running), the life time of the relay is shortened as

the channel is switched during measurement (hot switching).

As the measurement current for BT4560 is 1.5 A (3 mΩ range), heat generation at the relay contact

becomes high. With heat generation, the thermoelectric power may become high.

command.

3

Use in combination with DM7275 or DM7276

If a measurement accuracy of a few µV is required, there is an effect by the thermoelectric power

due to coil heating of the channel relay. Minimize the close time of each channel to reduce this

effect as much as possible. Use single measurement using the

trigger and open the channel immediately after the measurement (heating from the relay coil is

controlled).

Measured value variation may be signicant when connected at the same time as the IM3590.

If you encounter this issue, enable the IM3590’s trigger synchronous output function.

:READ?

command or external

Use in combination with IM3590

Execute open correction and short correction to each channel you will use.

Error might occur to open correction and short correction due to high frequency. (Set the frequency

range you will correct when executing.)

Threshold value of the contact check might be larger than the setting.

Also, the inspection result of the contact state (the resistance value near the threshold) might vary.

Relay operation time and stability time

The relay open/close operation waits for a contact operation time (settling time). The settling time is

as follows.

Channel switching time

Channel Switching

Relay open settling time Relay close settling time

Settling time

Relay open Relay close Channel switching

5 ms 5 ms 11 ms

The relay contact operation is completed within the settling time, however, it may take some time

for the relay to be stabilized depending on the instrument to be used or measuring object. Set the

channel delay time or perform measurement after a sufcient delay time on the instrument.

Preventing relay contact welding

The relay contact may weld when relay switching is repeated with a large current owing (also

when the measuring object or instrument to be connected is capacitive). When relay contact

welding occurs, the measuring object may be shorted. Periodic inspection is recommended.

Reference: "Checking for relay contact welding" (p. 26)

35

Page 40

Precautions for Measurement

Inuence of thermoelectric power

Be aware of the thermoelectric power when a voltage accuracy of a few µV is required.

Install the device and instrument in a constant temperature environment and fully adjust them to the

ambient temperature before use.

Especially prevent uneven temperatures at the terminal.

When creating a measurement cable, use a connector and terminal of a material with low

thermoelectric voltage, such as brass (nickel plate), pure copper (+ gold plate), etc.

Exercise care to keep the contact surface clean.

High resistance and minute current measurement

In a high humidity environment, high resistance or minute current measurement may be affected by

leak current.

Do not touch the module board with your bare hand. Grease can cause leak current, which may

affect high resistance and minute current measurement.

Do not bundle the measurement cables when measuring minute current. Doing so may cause leak

current due to the capacity of the cables, resulting in an error in the measured value.

Caution regarding noise

Do not bundle the measurement cables or connection cables for the instrument and the power line.

Noise on the power line may cause malfunction of channel switching or an error in the measured

value.

When the measured value cannot be stabilized due to noise, connecting the ground (GND terminal)

of the device and the ground of the instrument may improve the condition.

Caution regarding load

When a load is applied to the measurement cable, the contact area of the connector becomes

unstable and the contact resistance is increased, which can cause the measured value to be

unstable.

When attaching the module to the main frame, be sure to secure the panel using screws. If the

panel cannot support the load when a vertical load is applied to the main frame, the module board

is stressed and may malfunction.

36

Page 41

Channel Delay Function

3.7 Channel Delay Function

The delay time after channel switching can be specied. When the specied delay time elapses

after the channel relay is closed, a CLOSE signal of EXT. I/O is output.

If the measurement response time for the instrument needs to be ensured, set the delay time.

The required delay time depends on the instrument to be used and the measuring object.

Channel delay time setting example

Model Delay time

BT4560 1 ms

BT3562 10 ms

3561 3 ms

DM7276 0 ms

The channel delay time can be specied for each slot. The same delay time is used for all channels

within the slot.

For the switching sequence, see "3.4 Channel Switching Operation" (p. 31)

Item Communication command

Setting

procedure

Setting

example

:SYSTem:MODule:DELay <

Set the channel delay time for SLOT 1 to 0.01 sec. and for SLOT 2 to 0 sec.

:SYST:MOD:DEL 1,0.01

:SYST:MOD:DEL 2,0

slot No.

>,<

delay time 0 to

9.999[s]>

3

Channel Switching

37

Page 42

Precautions for Measurement

38

Page 43

4

Scan Function

Thoroughly read "Usage Notes" (p. 4) beforehand.

4.1 Overview of the Scan Function

For scanning, specify the channel range (scan list) in advance and switch the channel in order.

Channel switching (scan channel moving forward) can be performed using EXT. I/O or

communications. Connecting the switch mainframe and the instrument EXT. I/O can switch the

channel and perform measurement in synchronization with the instrument.

This device

CH 1

↓

CH 2

↓

⁞

The channel is switched every time the signal is input.

Scanning in combination with the instrument

This device

CH 1

↓

CH 2

↓

⁞

Channel switching and external trigger measurement

synchronized for automatic execution

CLOSE output signal

SCAN input signal

EXT. I/O SCAN signal

or

TRG

command

*

TRIG input

Instrument

External trigger

measurement executed

EOM output

EOM = Measurement completion signal

Set the instrument to the external trigger

mode.

4

Scan Function

Precautions when performing a scan when the device and instrument are connected via EXT. I/O

• Only one instrument can be used.

• Use either the instrument’s data output function or its memory function to acquire measured

values from the scan. For more information, please see the instrument’s instruction manual.

• The EOM signal from the instrument may cause scan measurement to resume even if it has been

stopped using the SCAN_RESET signal or the

For the EXT. I/O signal, see "Signal Functions" (p. 52).

:ABORt

command.

39

Page 44

Setting the Scan Channel

4.2 Setting the Scan Channel

The channels to be scanned need to be registered as a scan list.

Specify the start and end channels. An individual channel list can also be specied.

Item Communication command

Setting

procedure

[:ROUTe]:SCAN<(@

<(@

Channel list

Channel list format

<CH>,<CH>,...,<CH>

<CHm>:<CHn>

Channel list

)>

)>

Specify the channels to be measured individually.

Specify from CHm to CHn consecutively.

Setting

example

Scan CH1 of SLOT 1 to CH22 of SLOT 3.

:SCAN 101:322

Scan CH1 and CH2 of SLOT 1 and CH1, CH2, and CH5 of SLOT 2.

:SCAN (@101,102,201,202,205)

4.3 Setting the Trigger Source for Scan Operation

A trigger source for scan operation is set for STEP only.

Trigger source Scan operation

STEP Scanning is started by the SCAN input signal or

closed). Then the next scan channel is scanned every time the SCAN input signal or

TRG

command is sent.

*

STEP is set as the default setting. Normally select STEP and execute scanning while

synchronizing with control of the instrument.

The commands to be set are as follows.

Item Communication command

Setting

procedure

:TRIGger:SOURce <STEP>

<STEP>

TRG

command (the rst channel is

*

40

Setting

example

STEP:

External trigger. Scanning is performed with the SCAN input signal of EXT. I/O or the

command. Scan operation moves along the steps every time the trigger is input.

Set to proceed with the next step every time the external trigger is input.

:TRIG:SOUR STEP

*

TRG

Page 45

4.4 Scan Operation

Scan Operation

Scanning is started by the SCAN signal of EXT. I/O or the communication

channel is moved forward by the SCAN signal or the

*

TRG

command.

When the channel is the nal channel, scanning is completed by the SCAN signal or the

TRG

command. The scan

*

*

TRG

command,

and all relay is opened and goes back to the beginning of the scan list. Note that scan operation will not

complete until another SCAN signal or

TRG

command is input in the nal channel state.

*

Scan operation when the trigger source is set to STEP

SCAN signal or

TRG

command

*

Channel Open

CLOSE signal OFF ON

Start

channel

Open

Next

channel

…

Open

The CLOSE signal is output in pulses. The pulse width can be set using the following command

IO:PULSe:TIME <0.001

0.100/MIN/MAX/DEF>

to

. (See p. 102.)

If the next channel is closed before the CLOSE signal pulse reaches the set pulse width, CLOSE

signal pulse will automatically turn off.

Item Communication command

Setting

procedure

Setting

example

TRG

*

:ABORt

Executes scanning twice from CH1 of SLOT 1 to CH22 of SLOT 3.

:SCAN 101:322

:TRIG:SOUR STEP

TRG

*

TRG

*

Scanning is performed again after completion.

TRG

*

TRG

*

Starts scanning and proceeds along the scan channels.

Aborts scan operation and returns to the beginning of the scan

channel.

Advances the scan channel one step at a time using the

command (or SCAN signal).

(Repeats for the number of channels.)

Scan operation complete by nal channel state.

(Repeats for the number of channels.)

Scan operation complete by nal channel state.

Final

channel

Scan complete

Open

TRG

*

:

4

Scan Function

Aborts scan operation and restarts from the beginning.

:SCAN 101:322

:TRIG:SOUR STEP

TRG

*

:ABOR

TRG

*

Advances the scan channel one step at a time using the

command (or SCAN signal).

(Repeats.)

(Aborts scan operation and returns to the beginning of the scan

channel.)

(Repeats for the number of channels from the rst channel.)

All channels are open after scanning is stopped.

The following commands are disabled during scanning.

• Setting the connection method

• Setting the shield switching

• Channel switching

• Setting the channel delay

• Setting the scan list

• Setting concerning the EXT. I/O

• Channel control due to CLOSE command

TRG

*

41

Page 46

Resetting Scan Operation

4.5 Resetting Scan Operation

Scanning is reset and stopped by the SCAN_RESET signal of EXT. I/O or the communication

:ABORt

command. All channel relays are opened and goes back to the beginning of the scan list.

42

Page 47

Scan Measurement Example

4.6 Scan Measurement Example

The following example shows scan measurement with the SW1001 and BT3562 connected using

EXT. I/O.

For acquiring measured values, the BT3562 data output function is used.

Scan measurement start

BT3562 setting

External trigger

Set data output to on

SW1001 setting

Connection method: 4-wire

Scan list registration

SW1001

Start scanning

Scan input signal or

command

*

TRG

PC

USB

SW1001

CLOSE

SCAN

TRIG

EOM

RS-232C

BT3562

4

Scan Function

Wiring diagram

No

BT3562

Receive measured values.

Measured value

received for all

channels

Yes

Scan measurement

complete

43

Page 48

Resetting Scan Operation

44

Page 49

5

Other Functions

5.1 Checking the Device Status

The following items can be checked using the free software for the SW1001 series (downloaded

from our website).

• Module information of each slot

Slot position, model, serial number, and opening/closing frequency of each relay

Use the information as a reference for the relay lifetime.

5

Other Functions

45

Page 50

Checking the Device Status

46

Page 51

6

Initialization

6.1 Initialization Settings

The device is in the initial state at the time of shipment and at the time of initialization using

commands. However, communications settings will not be initialized if the initialization is triggered

by command.

Settings that are backed up can be stored so that they persist even when the power is turned off by

executing the

See: “Backing up settings” (p. 105)

Communications settings are backed up even if the

Channel relay All relays open –

Bus relay All relays open –

EXT. I/O CLOSE output signal OFF –

:SYSTem:BACKup

Item Initialization description Backup

command.

:SYSTem:BACKup

command is not executed.

: Yes, –: No

Connection method

Shield switching

Channel delay settings 0.0 s

Scan list None

Scan operation trigger source STEP

Query forwarding timeout 10 s

EXT. I/O lter function OFF, 0.05 s

Pulse width of CLOSE output

signal

Communication settings (USB) (No setting item) –

Communication settings

(RS-232C)

Communication settings (LAN)

SW9001: 2-wire

SW9002: 4-terminal pair

SW9001: TERMINAL 1, LOW terminal

SW9002: TERMINAL 3, sense shield terminal

0.005 s

9600 bps

User setting mode (setting switch: USER)

IP address: 192.168.0.254

Subnet mask: 255.255.255.0

Default gateway: 0.0.0.0 (None)

Communication command port number: 23

Fixed setting mode (setting switch: DFLT)

6

Initialization

IP address: 192.168.0.254

Subnet mask: 255.255.255.0

Default gateway: 0.0.0.0 (None)

Communication command port number: 23

–

47

Page 52

Initialization Settings

48

Page 53

7

External Control (EXT. I/O)

Thoroughly read “Before starting the external control” (p. 6) beforehand.

Connecting the instrument and the EXT. I/O terminal allows you to perform measurement in

synchronization with channel switching when using the scan function. Also scan control can be

performed from the PLC and other devices.

All signals are isolated from the switching circuit, communication circuit, and ground (earth) (the

common terminal for I/O is shared).

The input circuit can be switched so that it can support sinking current output (NPN) or sourcing

current output (PNP).

Check the input/output rating and internal circuit conguration, and then understand the safety

precautions. After that, connect the instrument or control system and use it in a correct manner.

Rear

Signal output or input

7.1 External Control Flow

Check the I/O specications of the instrument and external device to be connected.

Setting NPN/PNP in the device (p. 50).

Connecting the device and the external device (p. 51).

7

External Control (EXT. I/O)

49

Page 54

Switching between Sinking Current (NPN) and Sourcing Current (PNP)

7.2 Switching between Sinking Current (NPN) and Sourcing Current (PNP)

Thoroughly read “Before starting the external control” (p. 6) beforehand.

The applicable PLC type can be changed using the EXT. I/O MODE change-over switch. It is set to

NPN at the time of shipment.

EXT. I/O MODE change-over switch settings

NPN PNP

Device input circuit Supports sinking output. Supports sourcing output.

Device output circuit Non-polar Non-polar

Rear

ISO_5 V output +5 V output

Left: Sinking current (NPN)

Right: Sourcing current (PNP)

-

5 V output

50

Page 55

7.3 Connection

Device connector and compatible connectors

Thoroughly read “Before starting the external control” (p. 6) beforehand.

Rear

5 4 3 2 1

9 8 7 6

Connectors used (device unit side)

• D-SUB 9-pin

Female #4-40 inch screw

Connection

Compatible connectors

• DE-9P-ULR (solder type)

• DESP-JB9PR (crimping type)

Manufactured by Japan Aviation Electronics Industry, Limited

The connector frame is connected to the casing (metal) of the device as well as the protective

ground terminal of the power inlet (conductive). Be aware that it is not isolated from the ground.

Pin Signal name I/O Function Logic

1 SCAN IN Scan start/advance Edge

2 (Reserved) IN – –

3 ISO_5V – Isolated power supply +5 V (−5 V) output –

4 CLOSE OUT Channel closing complete Pulse

5 (Reserved) OUT – –