Hioki SW1001, SW1002 Instruction Manual

SW1001

SW1002

Instruction Manual

SWITCH MAINFRAME

Be sure to read this manual

before using the device

When using the device for the

rst time

Part Names and Functions

Measurement Flowchart

Preparation for Measurements

June 2018 Edition 1

SW1001A961-00 18-06H

Safety Information

Troubleshooting

p. 8 Troubleshooting

p. 12 Error display and troubleshooting p. 126

p. 13

p. 4

p. 125

EN

Contents

Introduction

ConrmingPackageContents

Safety Information

Usage Notes

........................................................1

........................2

............................................4

......................................................4

1 Overview 7

1.1 Overview of Product

1.2 Features

1.3 Parts Names and Functions

1.4 Block Diagram

1.5 Glossary

1.6 Measurement Flowchart

...................................................7

................................................. 11

...............................7

.................8

.......................................10

......................12

2 Preparation for

Measurements

2.1 Connecting Instruments and

Controlling the Device

2.2 Installing the Module

2.3 Removing the Module

2.4 Connecting the Measurement Cable

2.5 Connecting the Connection Cable

TERMINAL 1

TERMINAL 2

TERMINAL 3

2.6 Setting the Communication Setting

Mode

2.7 Connecting the Power Cord

2.8 Turning on/off the Power

2.9 When the Power is Turned on

............................................20

............................................20

............................................21

......................................................22

13

..........................13

............................15

..........................16

.18

.....19

................23

.....................23

............24

3 Channel Switching 25

3.1 Inspection before Measurement

Inspecting the device and peripheral

devices

Checking for relay contact welding

3.2 Overview of Channel Switching

3.3 Procedure for Switching the Channel

Selecting the connection method

Switching the shield

Selecting the channel

3.4 Channel Switching Operation

3.5 Measurement between Two

Instruments

3.6 Precautions for Measurement

3.7 Channel Delay Function

.....................................................25

..................................29

................................30

............................................32

......................37

.........25

............26

..........27

28

...............28

.............31

............35

4 Scan Function 39

4.1 Overview of the Scan Function

4.2 Setting the Scan Channel

4.3 Setting the Trigger Source for

Scan Operation

4.4 Scan Operation

4.5 Resetting Scan Operation

4.6 Scan Measurement Example

.....................................40

.....................................41

..........39

...................40

...................42

.............43

5 Other Functions 45

5.1 Checking the Device Status

................45

6 Initialization 47

6.1 Initialization Settings

............................47

7 External Control (EXT.

I/O)

49

7.1 External Control Flow

7.2 Switching between Sinking Current

(NPN) and Sourcing Current (PNP)

7.3 Connection

Device connector and compatible

connectors

Signal Functions

Connection to the instrument

7.4 Timing Chart

Channel switching operation and scan

operation reset

7.5 InternalCircuitConguration

Electricalspecications

Connection examples

............................................51

................................................51

.......................................52

..........................................53

..........................................53

..........................49

...50

.....................52

..............55

.............................56

...............................57

8 Communication

Function

8.1 Interface Overview and Features

8.2 Setting the Communication Setting

......................................................59

Mode

8.3 LAN Interface

Communication condition settings

Setting LAN communications

Connecting the LAN cable

8.4 USB Interface

Installing the USB driver

Connecting the USB cable

59

.......59

........................................60

.............61

....................62

.........................63

........................................64

............................64

........................65

1

2

3

4

5

6

7

8

9

9

10

10

Index

SW1001A961-00

i

Contents

8.5 RS-232C Interface

Connecting the RS-232C cable

Setting RS-232C communications

Setting the controller (PC, PLC, etc.)

................................66

.................66

.............68

.........68

8.6 Communication Command

Forwarding Function

8.7 Communication Method

Message format

Output queue and input buffer

Status Byte Register

Event Registers

Initialization items

Remote state

8.8 Message List

........................................71

........................................79

............................................86

.........................................87

8.9 Message Reference

Standard commands

Device-speciccommands

8.10 Sample Programs

Using Visual Basic® 5.0 or 6.0

Using Visual Basic® 2013

............................69

.......................71

...................76

.................................77

.....................................86

.............................90

.................................91

........................94

...............................107

.................107

........................ 111

9 Specications 119

9.1 SW1001, SW1002 General

Specications

9.2 SW1001, SW1002 Input

Specications/Output

Specications/Measurement

Specications

Basicspecications

9.3 SW1001, SW1002 Functional

Specications

9.4 SW1001, SW1002 Interface

Specications

LAN

........................................................123

USB

.......................................................123

RS-232C

EXT. I/O

..................................................124

...................................... 119

......................................120

................................120

......................................121

......................................123

................................................123

11 Multiplexer Module 129

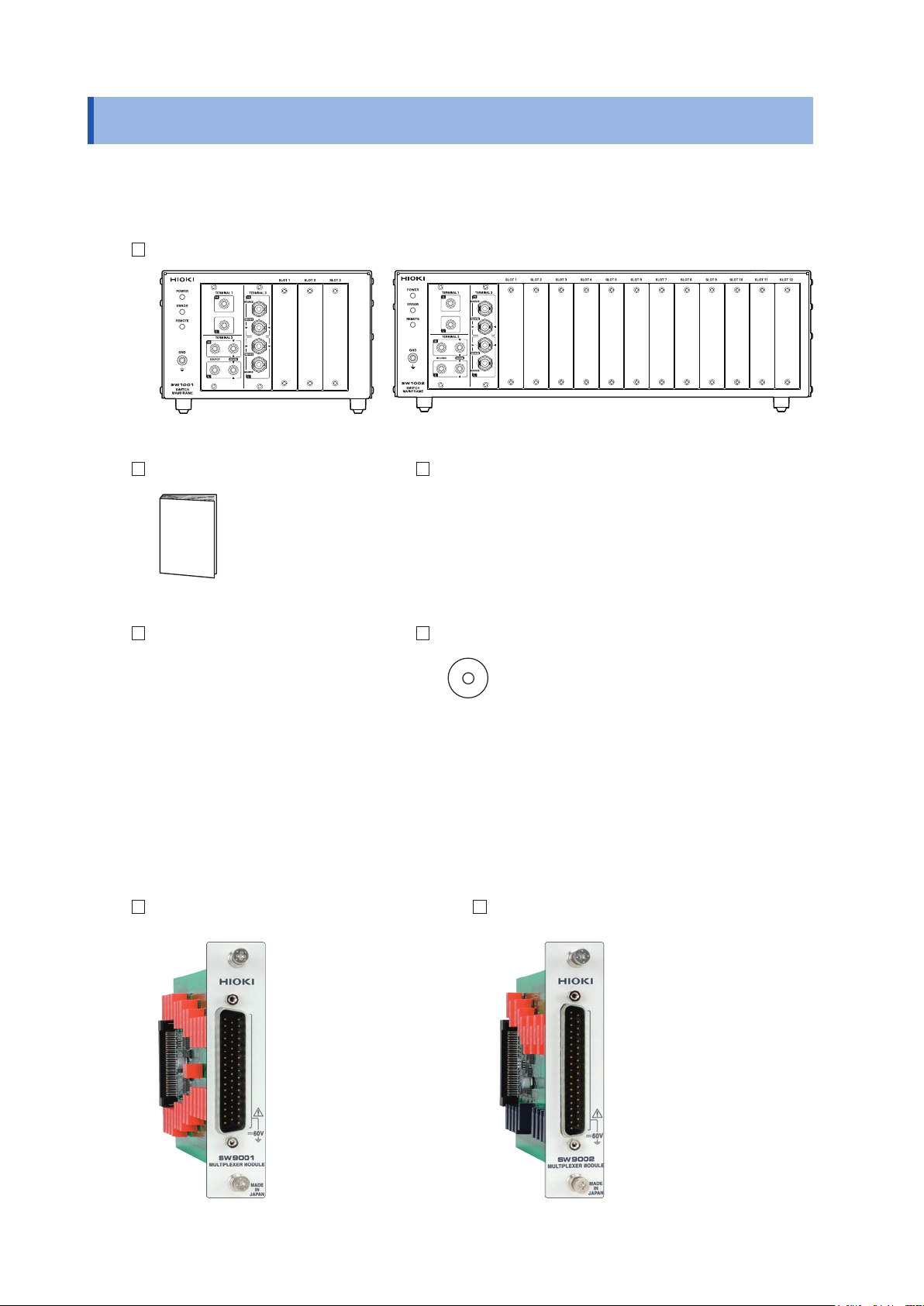

11.1 SW9001 Multiplexer Module

(2-wire/4-wire)

Features

Specications

Switching wiring diagram

Connector wiring diagram

Acquiring the number of relay on/off

cycles

.................................................129

.....................................................134

.....................................129

.........................................129

.........................132

.......................133

11.2 SW9002 Multiplexer Module

(4-terminal pair)

Features

Specications

Switching wiring diagram

Connector wiring diagram

Acquiring the number of relay on/off

cycles

.................................................135

.....................................................140

11.3 Accuracy Calculation Example

..................................135

.........................................135

.........................138

.......................139

.........141

12 Appendix 143

12.1 Measurement cable

12.2 Measuring Object Short Circuit

due to Relay Contact Welding

12.3 Rack Mount

Rack mount bracket

L-shape bracket (For installing the

module in automated equipment)

.........................................147

12.4 Outline Drawings

SW1001

SW1002

.................................................152

.................................................153

Index 155

Warranty Certicate

............................143

..........145

................................148

............151

................................152

10 Maintenance and

Service

10.1 Troubleshooting

Before sending the device for repair

Error display and troubleshooting

10.2 List of Device Error Numbers

10.3 Repair and Inspection

ii

125

..................................125

........................128

........125

............126

............127

Introduction

Introduction

Thank you for purchasing the Hioki SW1001, SW1002 Switch Mainframe. To obtain maximum

performance from the device over the long term, be sure to read this manual carefully and keep it

handy for future reference.

With the optional multiplexer module (hereafter referred to as “module”) installed on this device, the

input of multiple channels can be switched to one or two measuring instruments (hereafter referred

to as simply “instrument”).

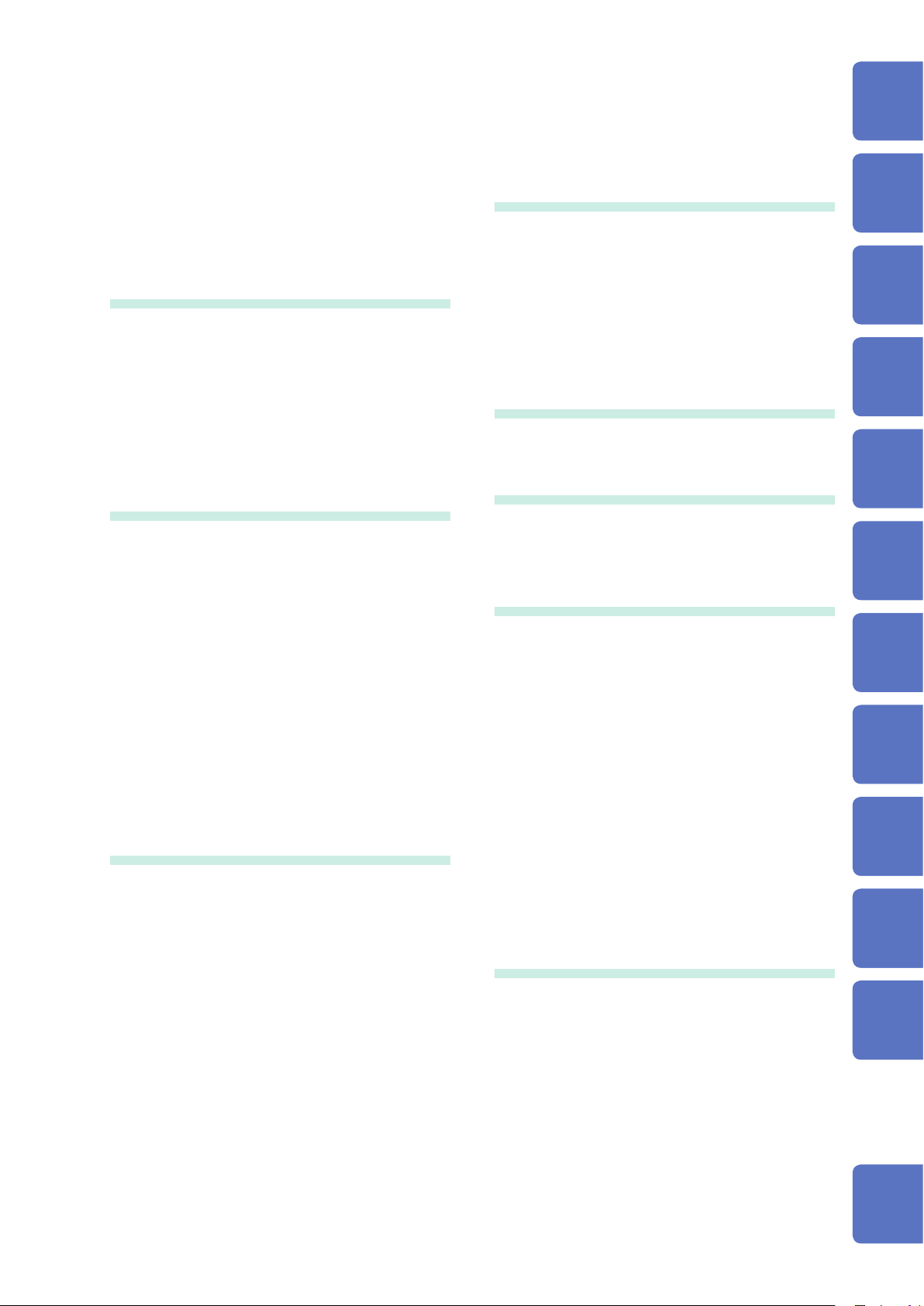

Modules can be installed in 3 slots for the SW1001 and 12 slots for the SW1002. Other functions

are common for all the models.

1

2

Be sure to also read the separate document “Operating Precautions” before use.

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so. It is assumed that the reader possesses basic electrical knowledge (equivalent to

that of someone who graduated from the electrical program at a technical high school).

Trademarks

Windows, Visual Studio and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

Notations

*

[ ]

POWER

(Bold)

(p. ) Indicates the location of reference information.

Additional information is presented below.

Menus, dialog boxes, buttons in a dialog box, and other names on the screen are

indicated in brackets.

Indicates the names and keys on the screen and the device in boldface.

3

4

5

6

7

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading), and dgt. (digit) with

the following meanings.

f.s.

rdg.

dgt.

(maximum display value or range)

The maximum display value.

(reading or displayed value)

The value currently being measured and indicated on the instrument.

(resolution)

The smallest displayable unit on a digital measuring device, i.e., the input value that

causes the digital display to show a “1” as the least-signicant digit.

8

9

10

Appx. Ind.

1

Conrming Package Contents

Conrming Package Contents

Main unit and accessories

Conrm that these contents are provided.

Model SW1001 or SW1002 Switch Mainframe

Instruction Manual (this document) Power cord

Operating Precautions (0990A905) CD (USB driver)*

* The latest version can be downloaded from our

web site.

Options

The following options are available for the device. Contact your authorized Hioki distributor or

reseller when ordering.

Module

Model SW9001 Multiplexer Module

(2-wire/4-wire)

Model SW9002 Multiplexer Module

(4-terminal pair)

2

Conrming Package Contents

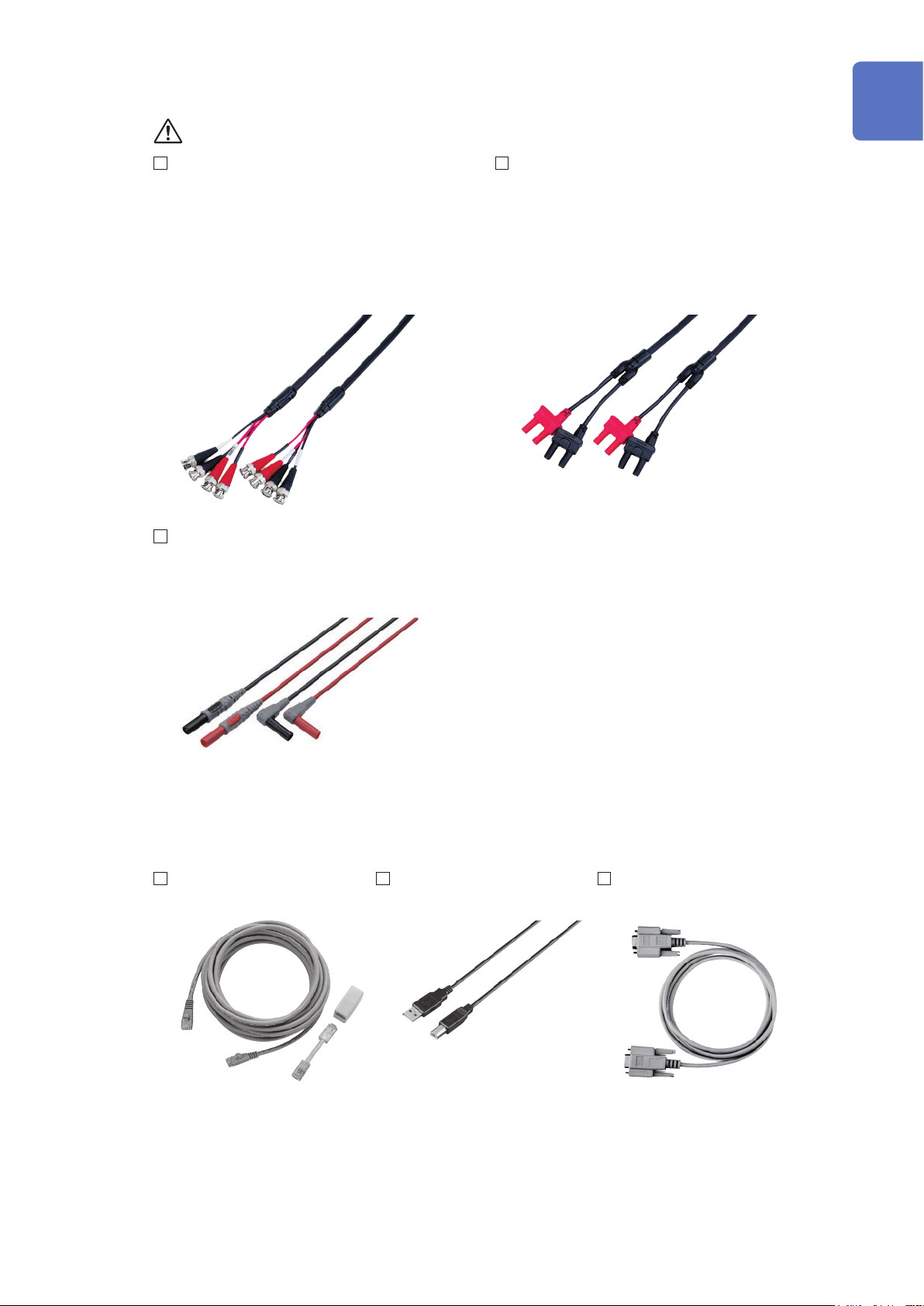

Connection cable

See: “Before measurement” (p. 5)

Model L2004 Connection Cable Model L2108 Connection Cable

Length: Approx. 910 mm Length: Approx. 840 mm

Maximum rated voltage: 30 V peak Maximum rated voltage: 60 V DC, 30 V AC rms,

42.4 V peak

Maximum rated voltage

to earth:

30 V DC or less, no

measurement category

Maximum rated voltage

to earth:

60 V DC or less, no

measurement category

1

Maximum rated current: 2.5 A peak Maximum rated current: 2 A peak

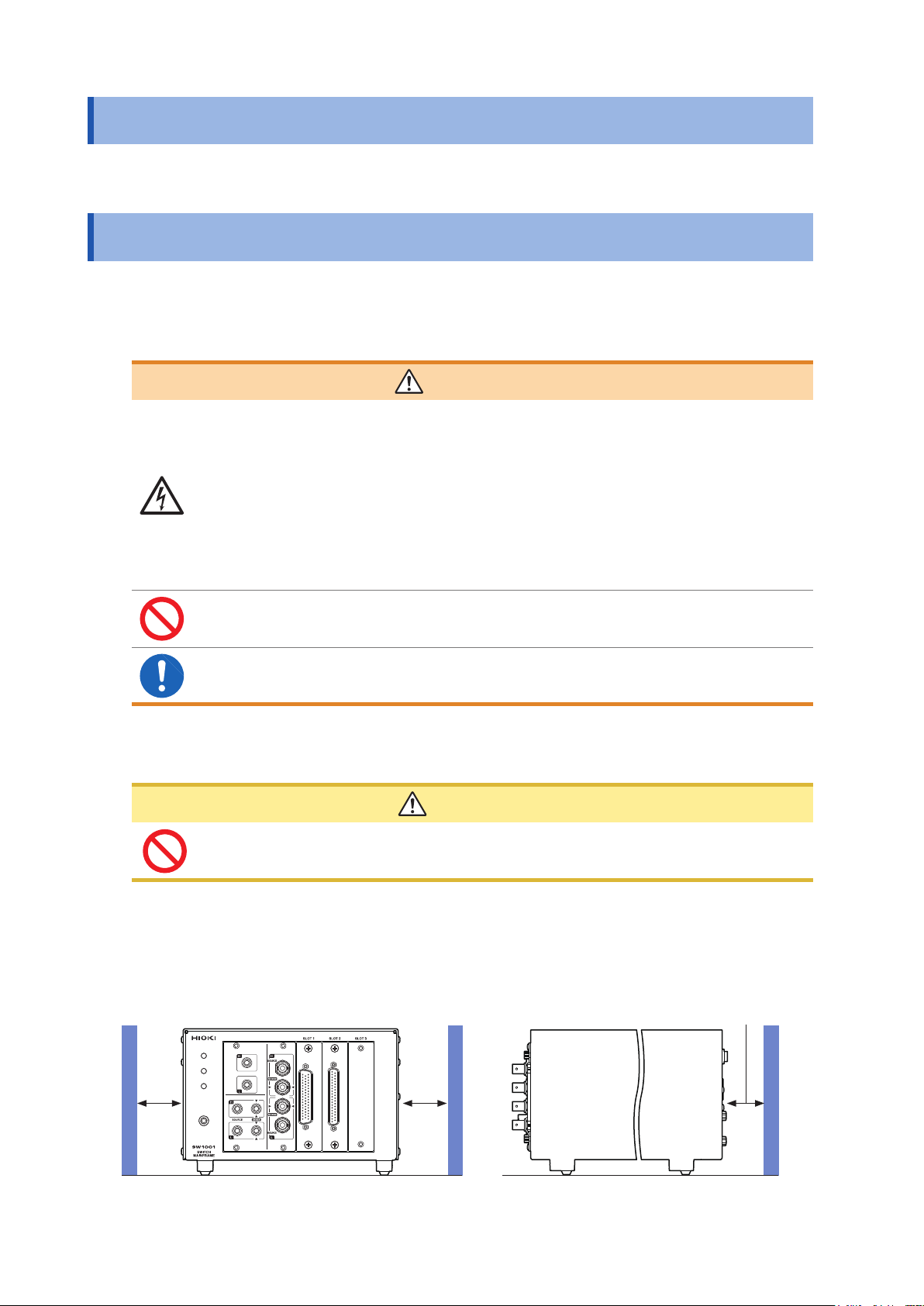

Model L4930 Connection Cable Set

Length: Approx. 1.2 m

Maximum rated voltage*: CAT III: 1000 V

CAT IV: 600 V

2

3

4

5

6

* Do not input voltage exceeding the rating of this device and the instrument.

Communications cable

Model 9642

LAN Cable

Model L1002

USB Cable (A-B)

7

8

Model 9637

RS-232C Cable (9pin-9pin/1.8 m)

9

10

Appx. Ind.

3

Safety Information

Safety Information

Be sure to also read the separate document “Operating Precautions” before use.

Usage Notes

Check before use

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

WARNING

If a connection cable or the device is damaged, there is a risk of an electric shock.

Perform the following inspection before using the device.

• Before using the device, check that the coating of the connection cables are

neither ripped nor torn and that no metal parts are exposed. Using the device

under such conditions could result in an electric shock. Replace any damaged

cable with a new one.

• Before using the device the rst time, verify that it operates normally to ensure

that no damage occurred during storage or shipping. If you nd any damage,

contact your authorized Hioki distributor or reseller.

This device is designed to measure voltages of 60 V or lower. Do not input

voltages over 60 V or measure locations exceeding 60 V from the ground potential.

If the relay of the device fails, the battery of the measuring object may be shorted

(p. 145).

Installing the device and module

CAUTION

Do not position the device on an unstable table or inclined surface. Dropping or

knocking down the device can cause injury or damage to the device.

Installing

To prevent overheating, be sure to leave the specied clearances around the device.

• The device should be operated only with the bottom side downwards.

Rear: 10 mm or moreSide: 50 mm or more

4

Handling the device

This device may cause interference if used in residential areas. Such use must be avoided unless

the user takes special measures to reduce electromagnetic emissions to prevent interference to the

reception of radio and television broadcasts.

Before installing the module

WARNING

• To prevent an electric shock, before removing or replacing a module, conrm

that the device is turned off and that all the measurement cables, connection

cables, and the power cord are disconnected.

• Installing a module while the device is turned on may prevent detection of

the contact state of relays on the module or result in short-circuiting of the

measuring object. Damage of the device or module may cause the measuring

object to be shorted or the instrument to fail.

• Be careful about short circuits when connecting a measuring object with

electromotive force (battery, power supply, etc.).

• The maximum voltage of the device contact is 30 V (rms value) and 42.4 V (peak

value) or 60 V (direct current). Do not directly connect a withstand voltage tester

or an insulation resistance tester.

Usage Notes

1

2

3

4

When installing or removing the module, be sure to observe the following precautions:

• Touch the GND terminal of the device with your hand to release static and then use

antistatic gloves to perform procedures.

• Hold the sheet metal area of the module. Directly touching the board with your hand may

damage the circuit board due to static. If the measurement target has high resistance, the

error component due to factors such as oil from your ngers may increase in magnitude.

Before measurement

•

Do not short-circuit between electrodes or terminals using a probe when

measuring the battery or capacitor. Doing so may cause an electric arc, resulting

in serious injury.

• Do not use the device or the connection cables that exceed its ratings or

specications. Doing so may damage the device or cause it to become hot,

resulting in a bodily injury.

• Do not use the instrument to be used in conjunction with the device outside of

its ratings or specications. Doing so may damage the instrument or cause it to

become hot, resulting in a physical injury.

CAUTION

5

6

7

DANGER

8

9

10

WARNING

The maximum rated voltage between the module and ground is 60 V DC. To avoid

an injury and damage to the device, ensure that voltage between channels never

exceeds this limit. Prevent the voltage potential difference of the entire system

from exceeding 60 V DC.

The measurement connector frame of the module is connected to the casing (metal) of the device

as well as the protective ground terminal of the power inlet (conductive).

Appx. Ind.

5

Usage Notes

Before starting the external control

WARNING

To prevent an electric shock or damage to the device, always observe the

following precautions when connecting the cables to the EXT. I/O terminals.

• Always turn off the device and any devices to be connected before making

connections.

• Be careful to avoid exceeding the signal ratings of the EXT. I/O terminals.

• During operation, a wire becoming dislocated and contacting another

conductive object can be a serious hazard. Use screws to secure the external

connectors.

• Ensure that devices and systems to be connected to the EXT. I/O terminals are

properly isolated from one another.

Before connecting the communications cables

CAUTION

• Use a common ground for both the device and the PC. Using different ground circuits

will result in a potential difference between the device's ground and the computer's

ground. If the communications cable is connected while such a potential difference

exists, it may result in device malfunction or failure.

• Before connecting or disconnecting any communications cables, always turn off the

device and the PC. Failure to do so could result in equipment malfunction or damage.

• After connecting the communications cables, tighten the screws on the connector

securely. Failure to secure the connector could result in device malfunction or damage.

• To avoid device failure, do not disconnect the communications cables while

communications are in progress.

Precautions during shipment

Store the packaging in which the device was delivered, as you will need it when transporting the

device.

Disc precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on

a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

6

1

Overview

1.1 Overview of Product

This device is a module type switching system that is ideal for multi-channel measurement of

batteries. You can choose a main frame from two choices according to the required number of

channels. You can also choose a module from two module types according to the instrument to be

used with the device (2-wire/4-wire module and 4-terminal pair module).

1.2 Features

Reduction of errors when measuring internal resistance

When AC low resistance measurement is performed using the BT4560 Battery Impedance Meter

or the BT3562 Battery HiTester, the inuence of electromagnetic induction (eddy current) on the

measured value can be minimized.

Ability to switch measurement between two instruments

For example, you can connect a BT3562 and DM7276 to the device and use it to switch between

internal resistance measurement and high-precision OCV measurement.

Protection against short circuit with fuses

To protect batteries to be measured if a short circuit occurs in a channel, a protective fuse is built

into each channel.

1

Overview

7

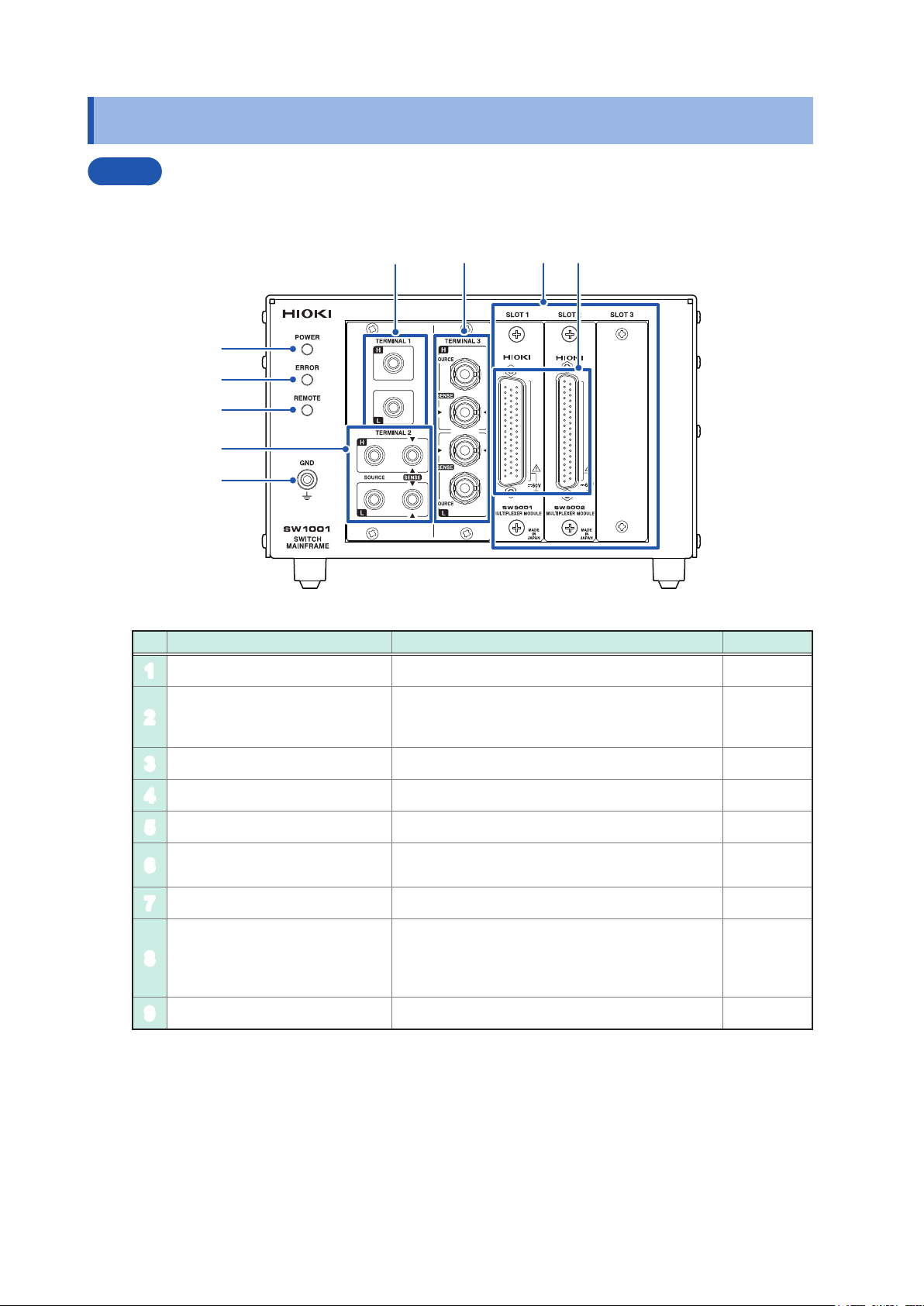

Parts Names and Functions

1.3 Parts Names and Functions

Front

The illustration shown here is for the SW1001.

4

6 7

8

1

2

3

5

9

No. Name Description Reference

POWER lamp Lights up when the main frame power is on. p. 23

1

Lights up for self-test at the time of startup and

ERROR lamp

2

REMOTE lamp Lights up when communications data is received. p. 86

3

TERMINAL 1 Used to connect a 2-wire instrument. p. 20

4

TERMINAL 2 Used to connect a 4-wire instrument. p. 20

5

TERMINAL 3

6

SLOT 1 to SLOT 3 Used to attach the module. p. 15

7

Measurement cable connector

8

GND terminal Ground for the device. Connected to the ground. p. 36

9

when an error, such as a communications error,

occurs.

Used to connect a 4-terminal pair (BNC terminal)

instrument.

Used to connect the measurement cable to each

module. For more details, see the chapter for the

multiplexer module.

p. 23

p. 126

p. 21

p. 5

p. 18

p. 133

p. 139

8

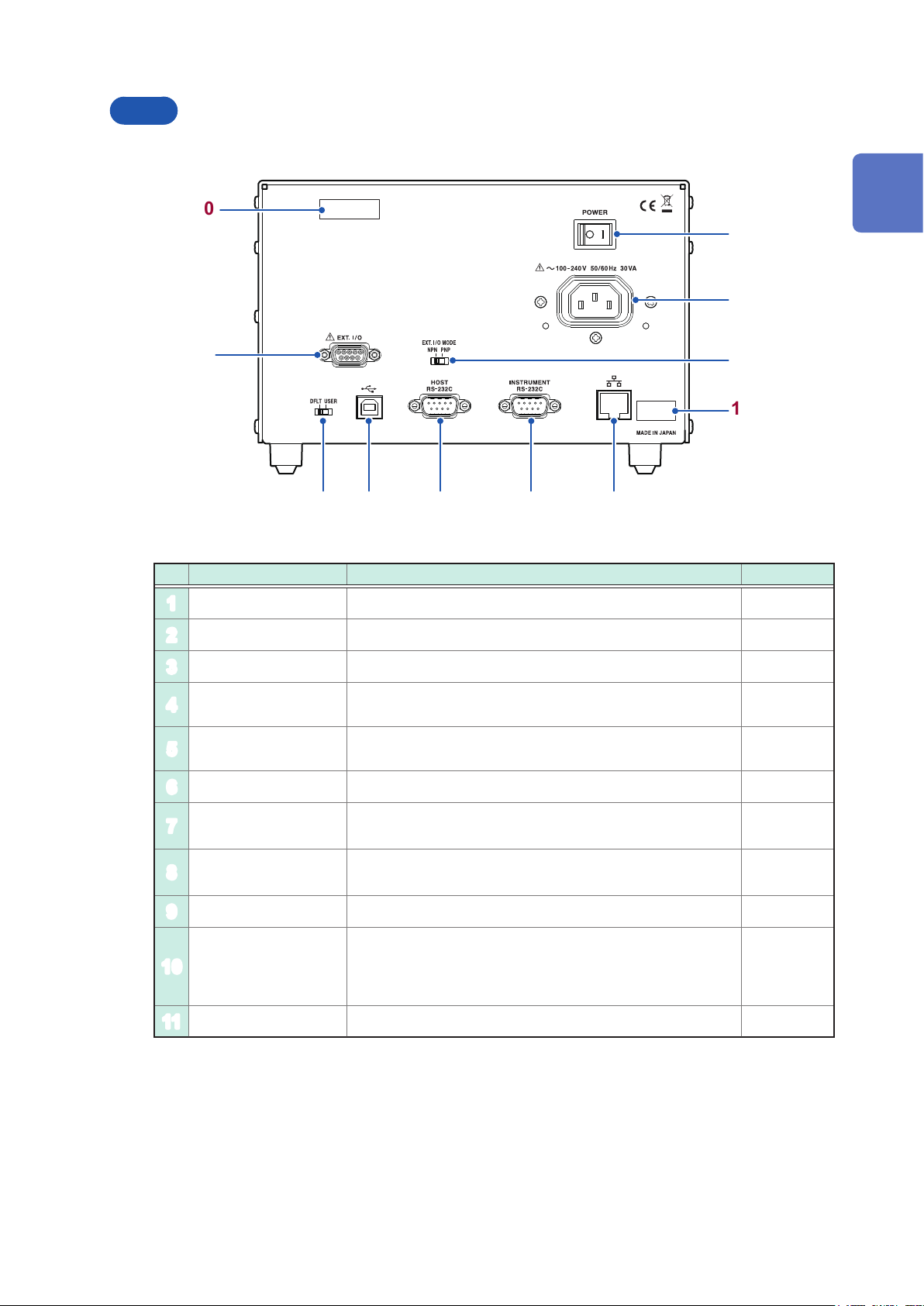

Rear

The illustration shown here is for the SW1001.

Parts Names and Functions

10

1

2

3

4

11

6 7 8 9

5

No. Name Description Reference

Power switch Turns on/off the power. p. 23

1

Power inlet Used to connect the provided power cord. p. 23

2

1

Overview

EXT. I/O terminal Used to connect the device to be externally controlled. p. 51

3

EXT. I/O MODE

4

change-over switch

Communication

5

setting mode switch

USB connector Used to connect the PC. p. 64

6

HOST

7

RS-232C connector

INSTRUMENT

8

RS-232C connector

LAN connector Used to connect the PC. p. 60

9

Serial number

10

MAC address MAC address of the LAN. p. 105

11

Left: Sinking current (NPN), Right: Sourcing current (PNP) p. 50

Perform communication using xed settings when the

communication settings are unknown.

Used to connect the PC. p. 66

Used to connect the RS-232C connector of the instrument for

scan measurement.

The serial number consists of 9 digits. The rst two (from

the left) indicate the year of manufacture, and the next two

indicate the month of manufacture.

Required for production control. Do not peel off the label.

p. 22

p. 70

–

9

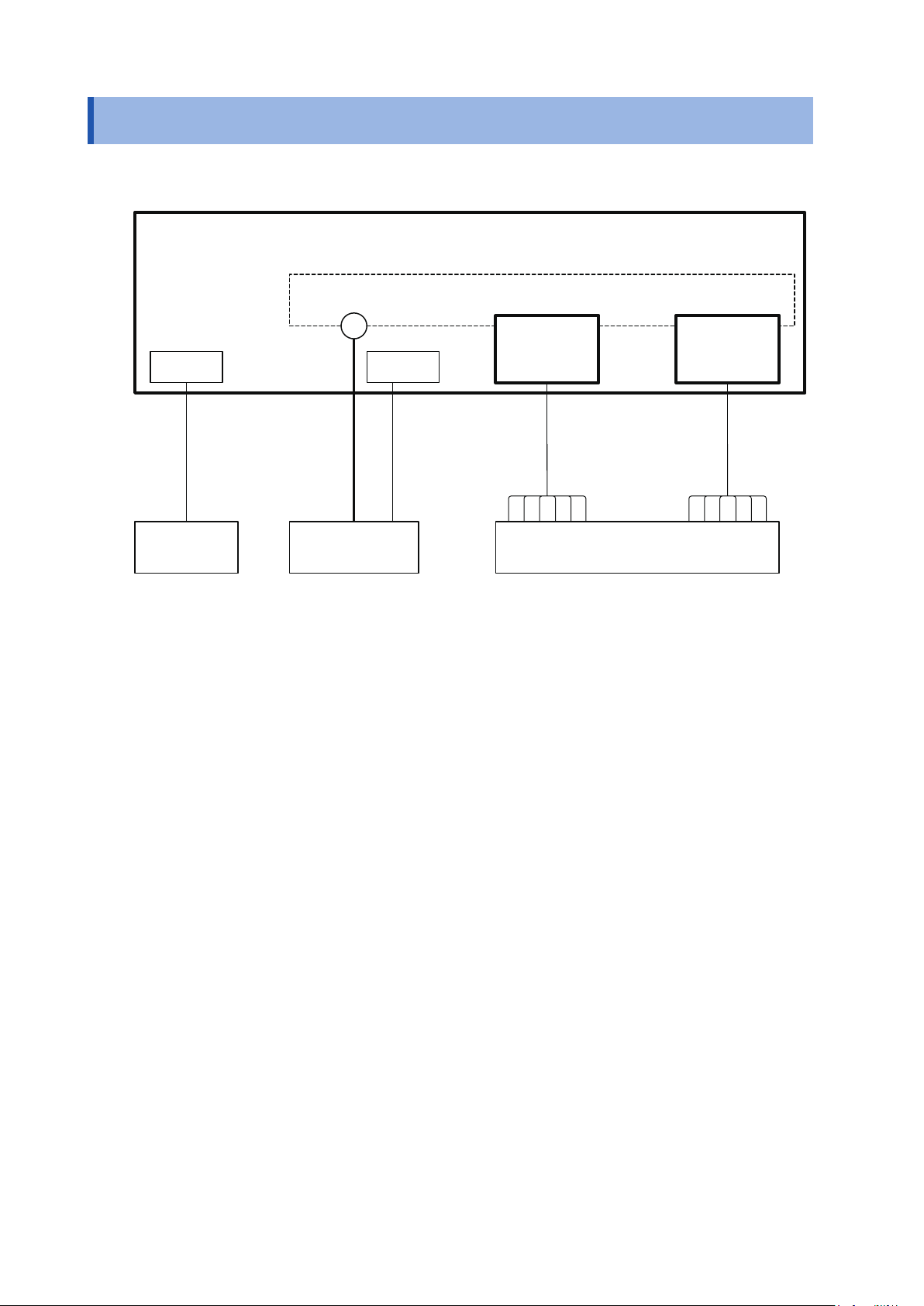

Block Diagram

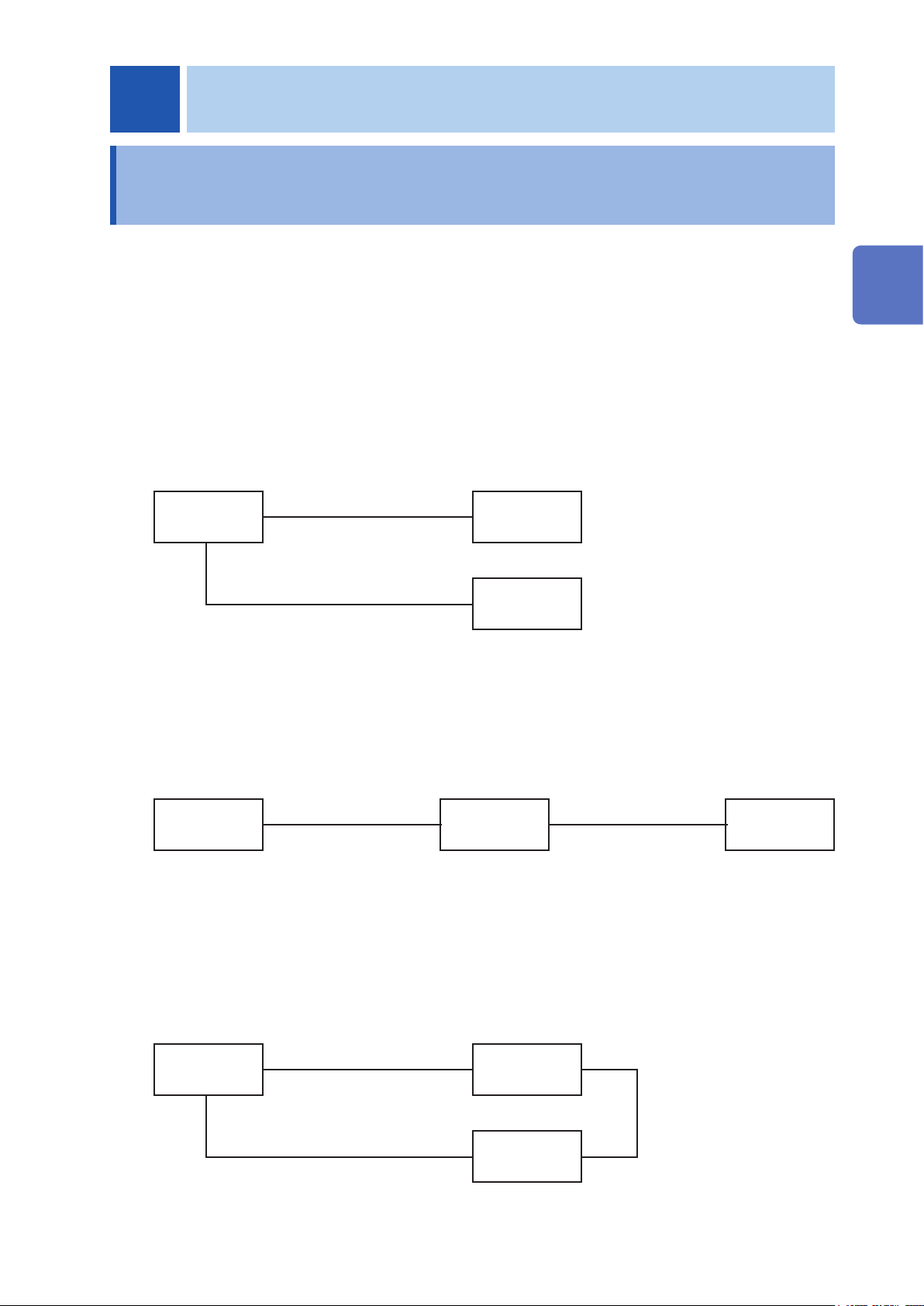

1.4 Block Diagram

The conguration of this device is shown in the following block diagram.

Switch Mainframe

Internal analog bus

Terminal Module

I/F EXT. I/O

Connection cable Measurement cable

PC/PLC

Instrument Measuring object

...

Module

10

1.5 Glossary

Terms Description Reference

Measurement cable Connects the measuring object and the module.

It is prepared by the customer.

Connection cable Connects the switch mainframe and instrument.

Prepare the optional cable.

Glossary

p. 143

p. 19

1

Overview

Terminal Connects the instrument.

The terminal to be used varies depending on the connection method

(2-wire/4-wire/4-terminal pair)

Module For the switching circuit.

The connection method varies depending on the module type.

Slot Used to attach the module.

The number of slots varies depending on the switch mainframe type.

Channel Channel inside the module.

Specify the slot and channel and select the measuring object.

Analog bus Common analog signal inside the switch mainframe.

The analog buses for 4 systems are built in.

The analog bus to be used is determined based on the connection

method.

Channel relay Switches the channel inside the module. p. 27

Bus relay Connects the measurement signal selected for the channel relay to

the analog bus.

It is built into the module.

Switching the bus relay allows you to select the connection method.

Connection method You can select the measurement connection from 2-wire, 4-wire, or

4-terminal pair.

Selecting a connection method determines the connection terminal for

the instrument.

p. 28

p. 129

p. 30

p. 30

p. 27

p. 27

p. 28

Shield For the measurement cable (cable for the measuring object).

The destination to which the shield is connected inside the module

can be switched.

Switching the connection destination can reduce the inuence of

noise depending on the instrument to be used or the measurement

environment.

Scan Switches the pre-registered channel (scan list) in sequence.

Connecting the instrument and this device using EXT. I/O enables

the channel to be switched and trigger measurement to be performed

automatically.

p. 29

p. 39

11

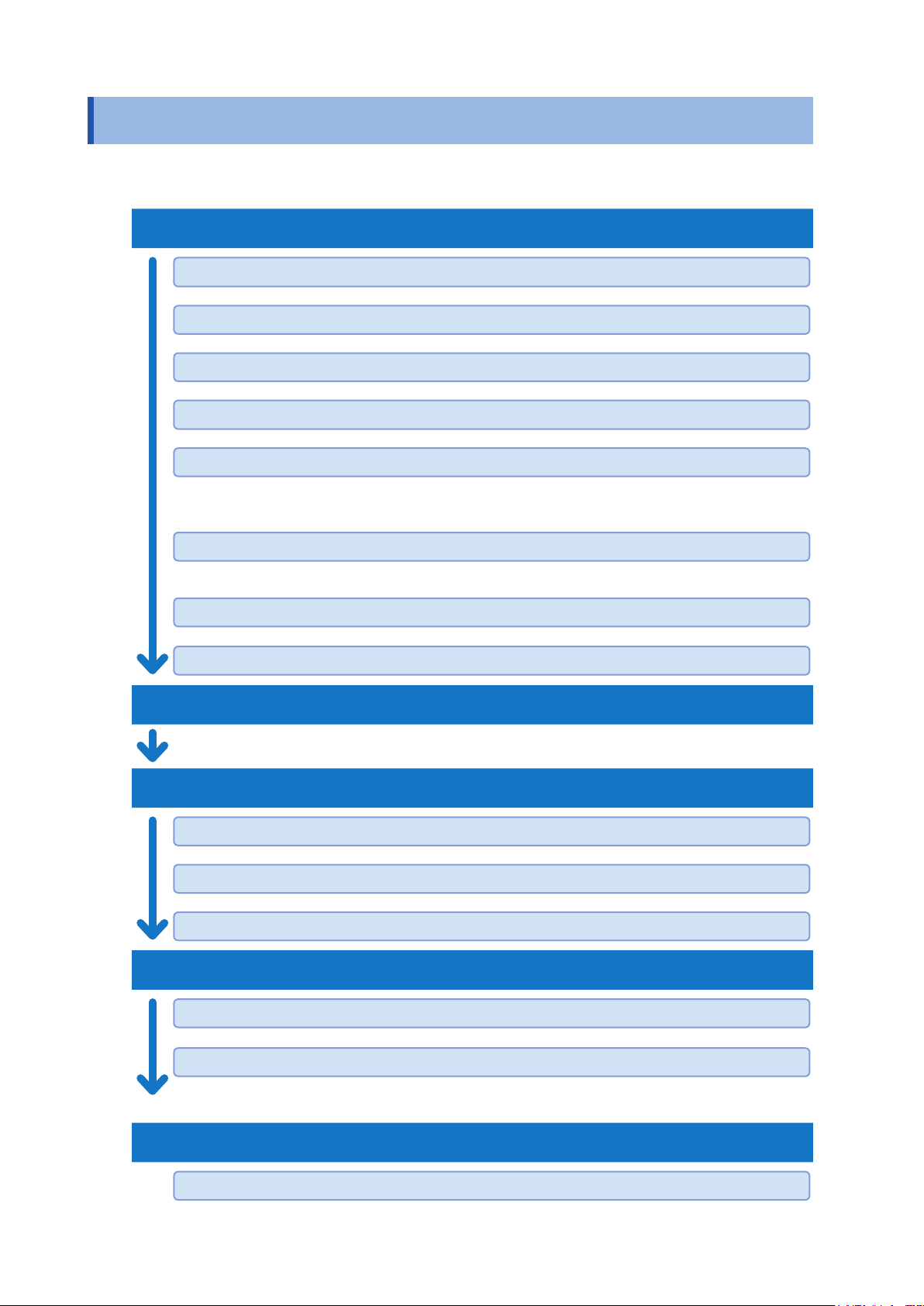

Measurement Flowchart

1.6 Measurement Flowchart

Thoroughly read “Usage Notes” (p. 4) beforehand.

Installation, connection, and turning on of power

Installing the device. (p. 4)

Attaching the module to the device. (p. 15)

Connecting the measurement cable to the module. (p. 18)

Connecting the device and the instrument using the connection cable. (p. 19)

Connecting the communications cable and making settings.

• Set the communication setting mode (p. 22).

• Connect the LAN, USB, or RS-232C cable to the PC (p. 59).

Connecting the device and the external control device. (for scan measurement)

• Connect the device to an external device such as a PLC using EXT. I/O (p. 49).

Connecting the power cord. (p. 23)

Turning on the power. (p. 23)

Inspection before measurement (p. 25)

Setting before measurement

Selecting the module connection method. (p. 28)

Switching the shield. (p. 29)

Selecting the channel to be measured. (p. 30)

Starting the measurement

12

Sending a measurement command to the instrument.

Receiving measurement results.

• For information on the measurement processing and receiving measurement results, see the

instruction manual of the instruments to be used.

Ending the measurement

Turning off the power. (p. 23)

2

Preparation for Measurements

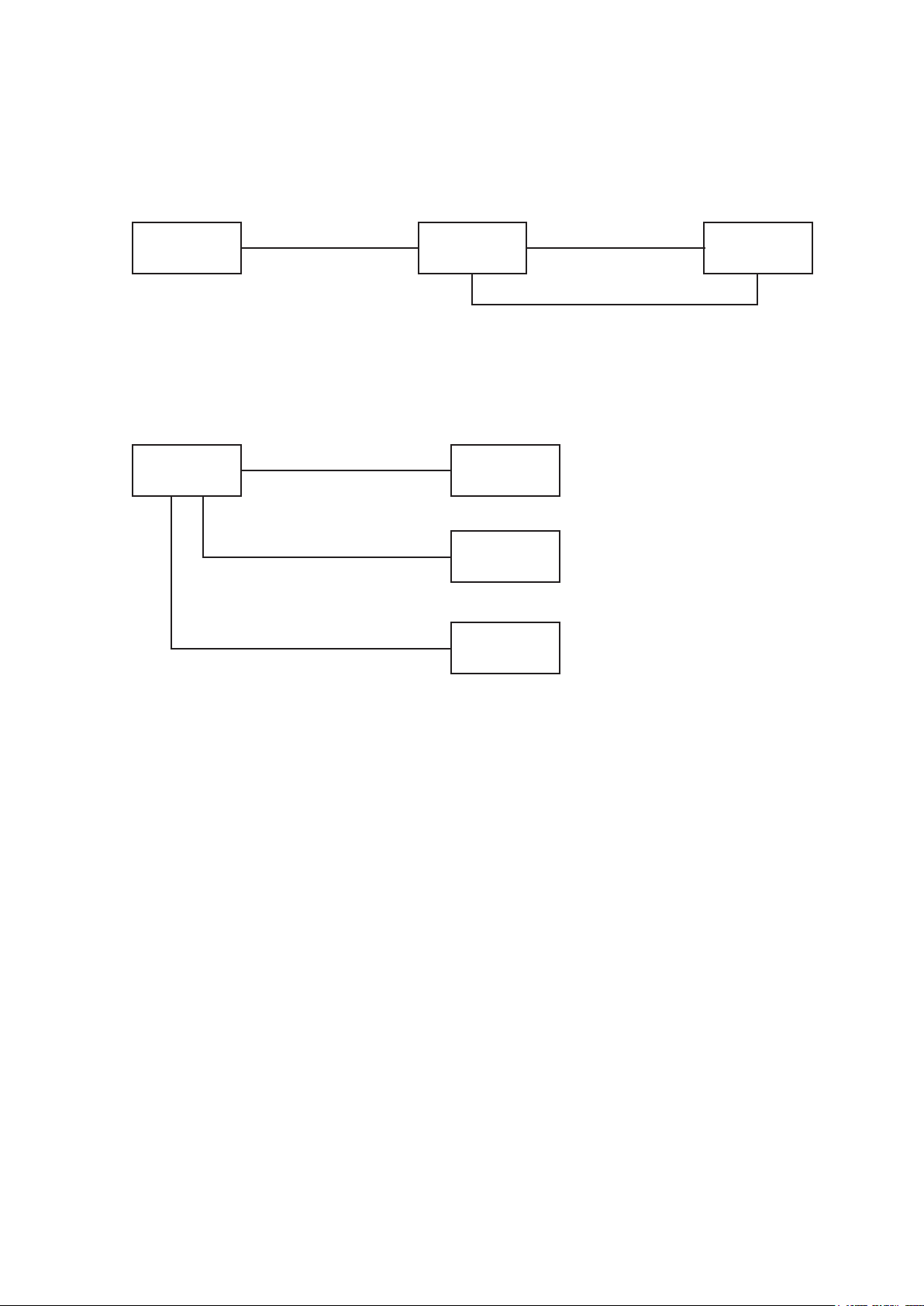

2.1 Connecting Instruments and Controlling the Device

This section describes how to connect one or more measuring instruments and control the device.

A PC or PLC must be connected in order to control the device. A PC or PLC connection is also

required in order to control instruments and acquire measured values.

The device utilizes the connection and control methods described below.

Basic control

Connect the PC to the device and instrument via separate communications interfaces.

Control the device to switch channels and control the instrument to congure settings, perform

measurement, and acquire measured values.

See: “3.2 Overview of Channel Switching” (p. 27)

2

Preparation for Measurements

PC

LAN/USB/RS-232C

LAN/USB/RS-232C

SW1001

Instrument

Controlling an instrument via the device

You can also use the device’s functionality for forwarding communication commands to control

instruments simply by sending commands to the device.

See: “8.6 Communication Command Forwarding Function” (p. 69)

INSTRUMENT

PC

LAN/USB/RS-232C

SW1001

connector

RS-232C only

Performing automatic scan measurement using EXT. I/O

You can switch channels and perform a series of measurements in accordance with a previously

created scan list by connecting the device and an instrument via the EXT. I/O interface. You can

also acquire measured values by using the instrument’s data output function (to automatically send

measured values) or memory function.

See: “4 Scan Function” (p. 39)

Instrument

PC

LAN/USB/RS-232C

SW1001

EXT. I/O

Instrument

LAN/USB/RS-232C

13

Connecting Instruments and Controlling the Device

Performing automatic scan measurement using EXT. I/O

(using the communication command forwarding function)

Furthermore, you can perform automatic scan measurement over a single communications

interface by using the device’s communication command forwarding function.

INSTRUMENT

PC

LAN/USB/RS-232C

SW1001

connector

RS-232C only

EXT. I/O

Connecting two instruments

You can perform measurement by connecting two instruments to the device.

See: “3.5 Measurement between Two Instruments” (p. 32)

Instrument

PC

LAN/USB/RS-232C

SW1001

Instrument 1

LAN/USB/RS-232C

Instrument 2

LAN/USB/RS-232C

14

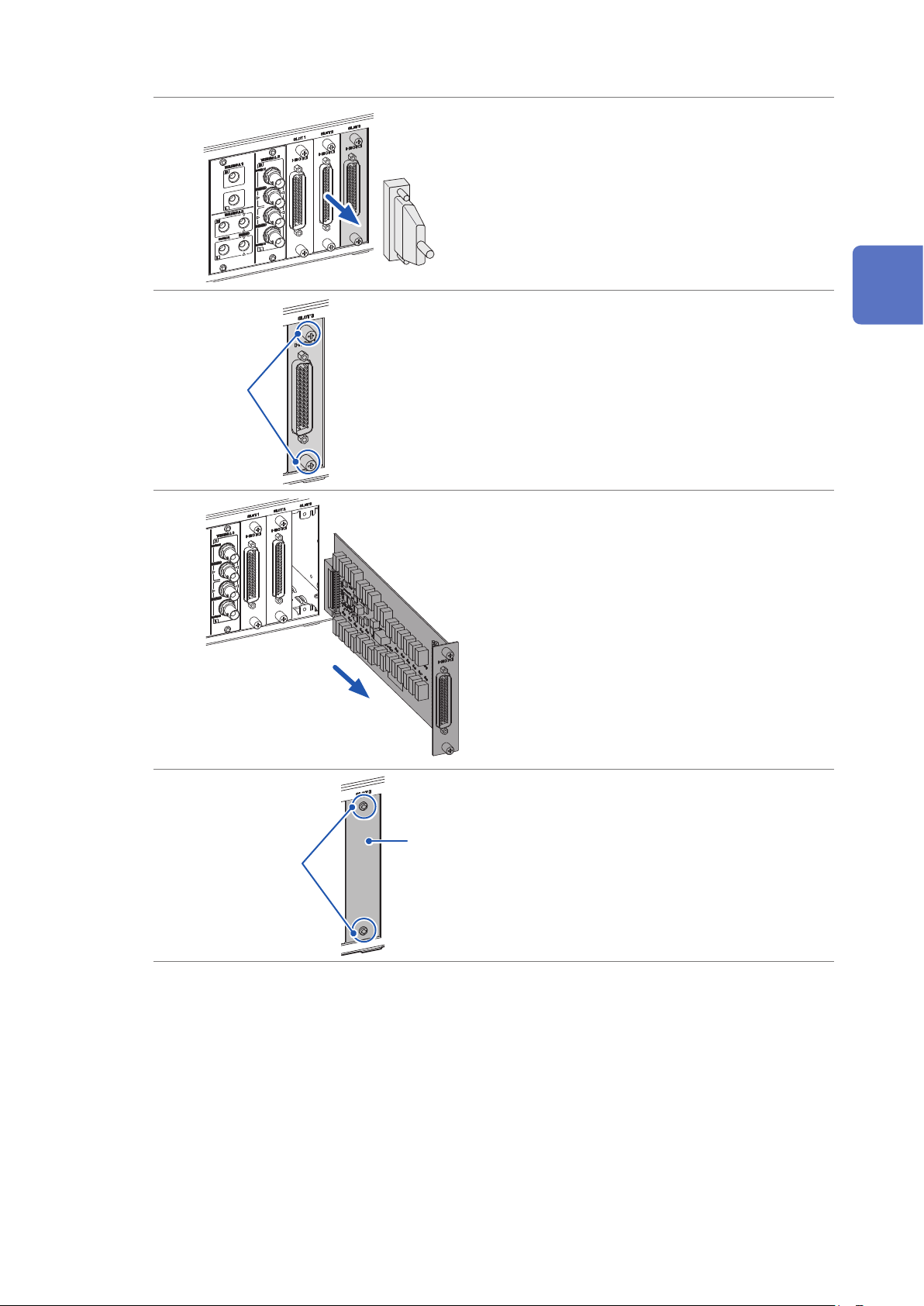

Installing the Module

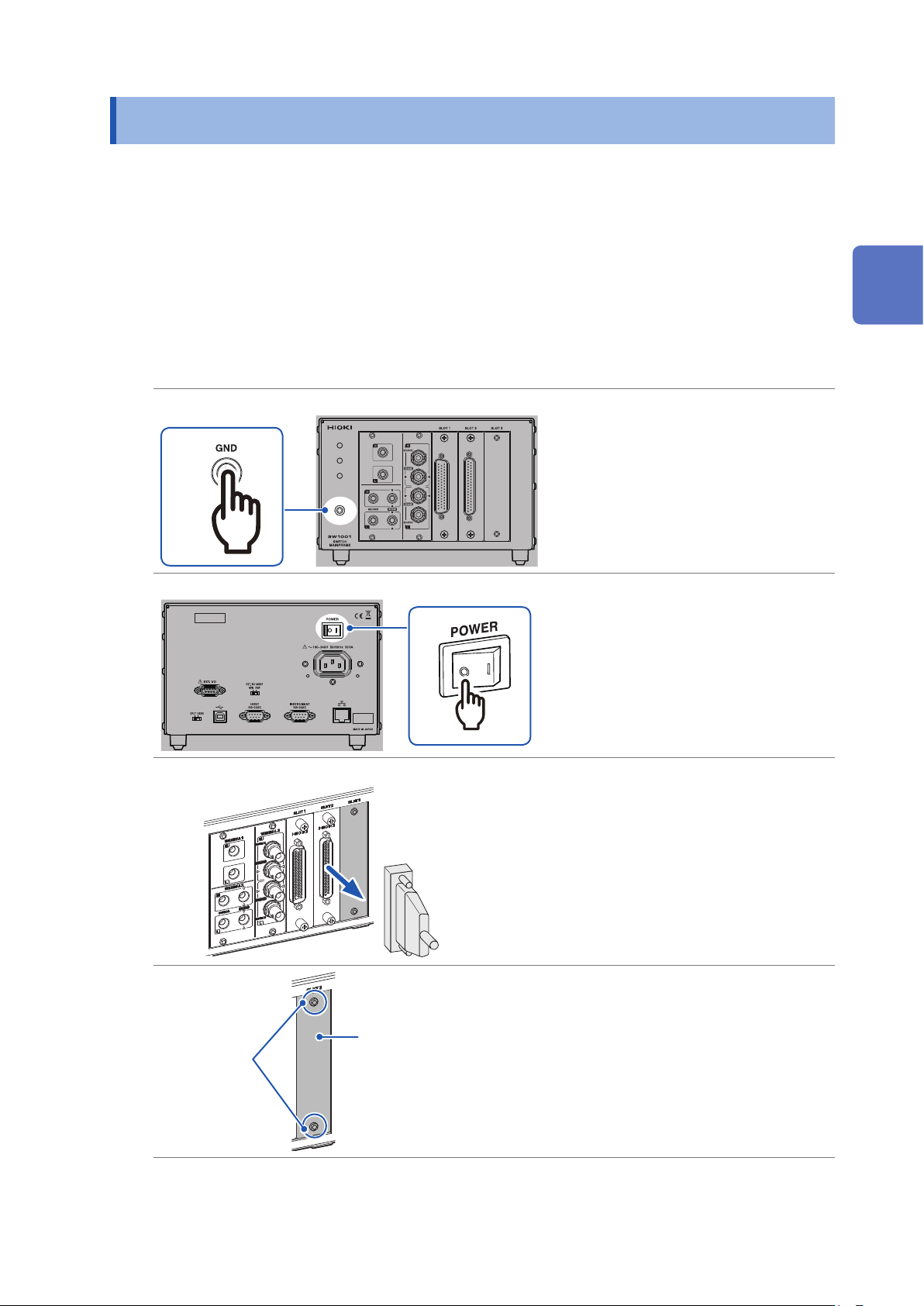

2.2 Installing the Module

Thoroughly read “Before installing the module” (p. 5) beforehand.

The following settings are initialized when you install a new module into a slot or change the type of

module installed in a given slot.

• Connection method

• Shield switching

• Channel delay

• Scan list

Required items: Phillips screwdriver (No. 2), antistatic gloves

2

Preparation for Measurements

1

Rear

Front

Front

3

Touch the GND terminal with

1

bare hands.

Wear antistatic gloves.

2

Turn off the device.

3

Remove all the measurement

4

cables connected to the device

and module.

(To prevent electric shock and short

circuit of the measuring object.)

Screw

(M3 × 6 mm)

Blank panel

Loosen the two screws

5

(M3 × 6 mm) and then remove

the blank panel.

Store the blank panel and screws.

You need the screws when using the

device after removing the module.

15

Removing the Module

Align with the guide rail

Insert the module to the back.

6

Tighten the two screws to

7

secure the module in place.

Screw

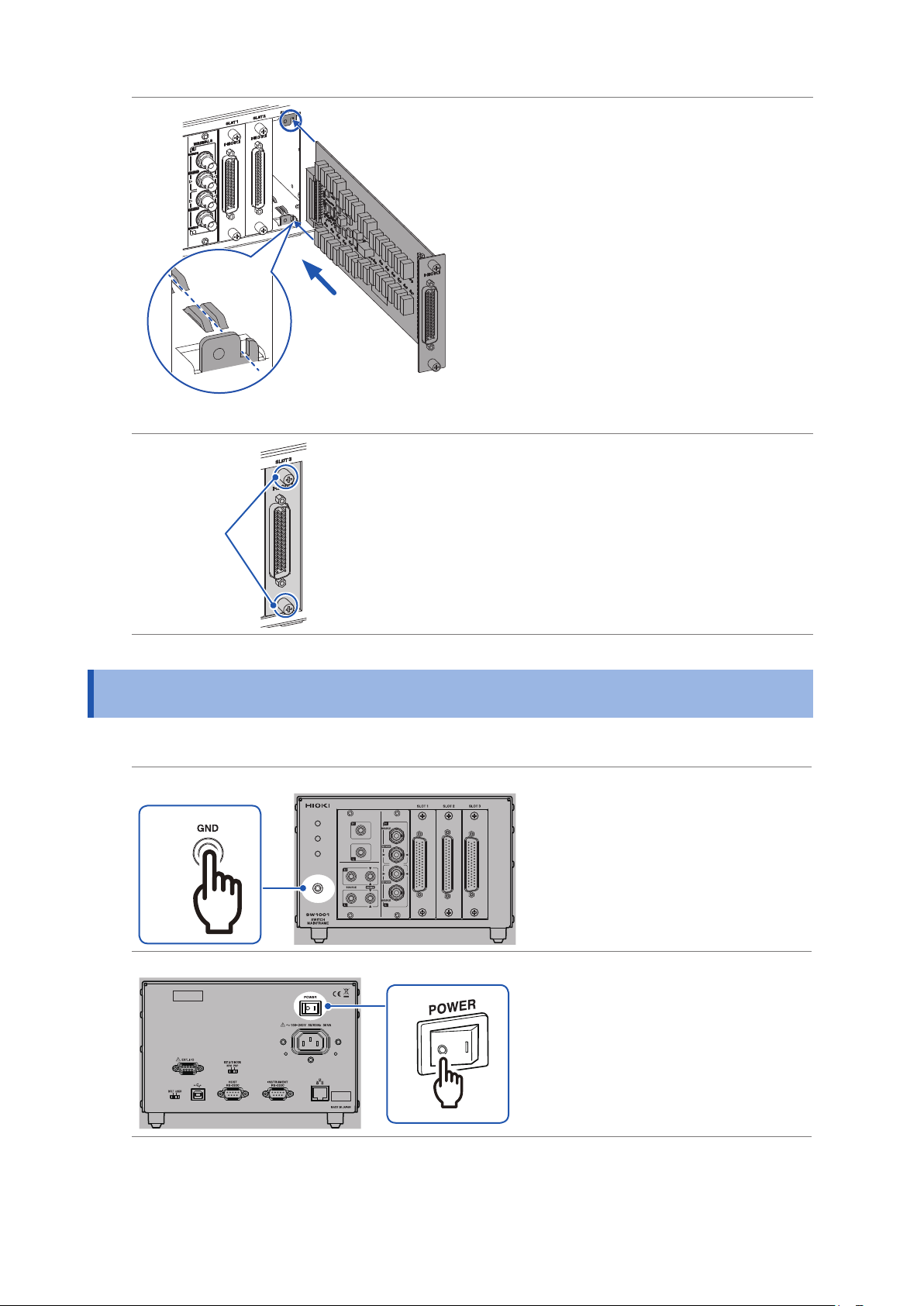

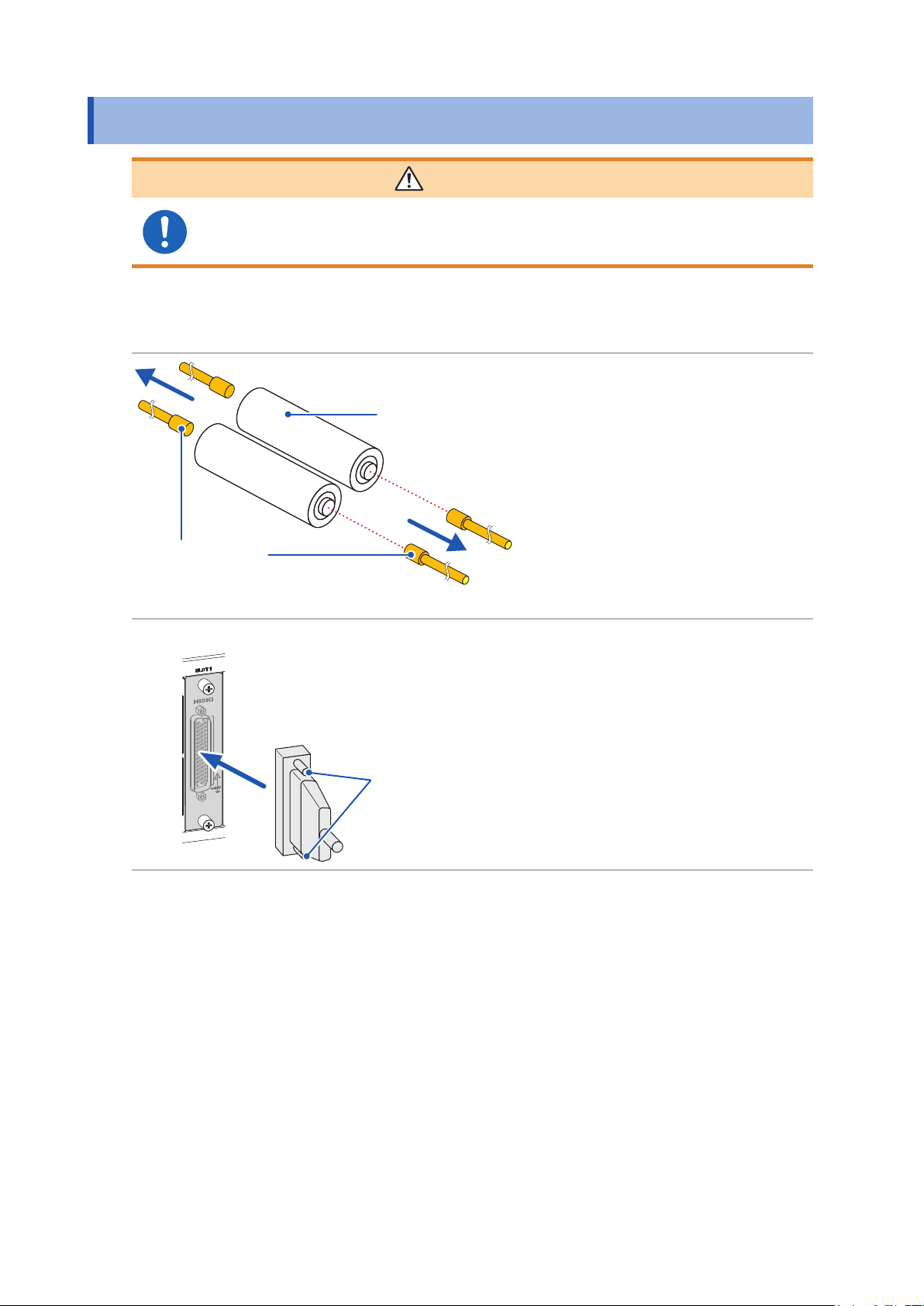

2.3 Removing the Module

Required items: Phillips screwdriver (No. 2), antistatic gloves

Front

1

Rear

Touch the GND terminal with

1

bare hands.

Wear antistatic gloves.

2

Turn off the device.

3

16

3

Removing the Module

Front

Screw

Remove all the measurement

4

cables connected to the

device and module.

(To prevent electric shock and short

circuit of the measuring object.)

Loosen the two screws.

5

Pull out the module.

6

2

Preparation for Measurements

Screw

(M3 × 6 mm)

Blank panel

Attach the blank panel and

7

tighten the two screws

(M3 × 6 mm) to secure the

panel.

17

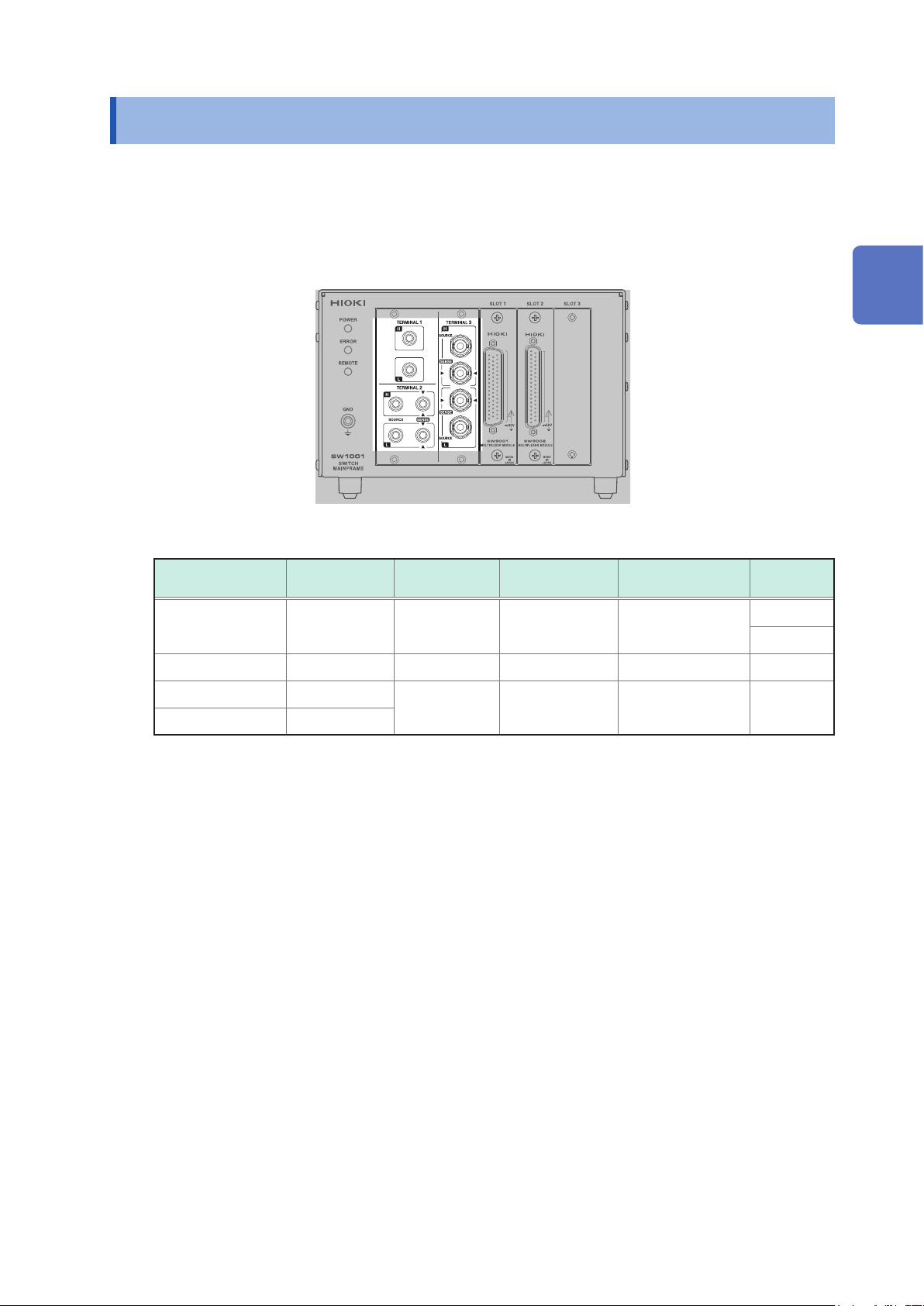

Connecting the Measurement Cable

2.4 Connecting the Measurement Cable

WARNING

Connect the measurement cable with the measuring object disconnected from

the measurement cable. The measuring object may be shorted depending on the

condition of the module switching circuit.

Please provide a suitable measurement cable.

See: “12.1 Measurement cable” (p. 143)

Turn off the device.

1

Disconnect the probe from the

Disconnect

Measuring object

2

measuring object.

Disconnect

Tip of the probe

Front

Connect the measurement

3

cable connector to the module’s

connector.

Secure the measurement cable

4

connector using the screws.

3

4

For information on connecting the measuring object, see the instruction manual of each instrument.

18

Connecting the Connection Cable

2.5 Connecting the Connection Cable

The connection cable is optional (p. 2).

Connect the device to the instrument.

For information on connecting the instrument, see the instruction manual of each instrument.

Front

2

Preparation for Measurements

Select the terminal and connection cable to be connected based on the instrument to be connected.

Instrument

example

Voltmeter DM7276 TERMINAL 1 L4930 2-wire

Battery tester BT3562 TERMINAL 2 L2108 4-wire SW9001

Battery tester BT4560

LCR meter IM3590

Model Terminal

TERMINAL 3 L2004 4-terminal pair SW9002

Connection

cable

Connection

method

Module

SW9001

SW9002

19

Connecting the Connection Cable

TERMINAL 2 and TERMINAL 3 are internally conducted. Do not connect the instrument

to TERMINAL 2 and TERMINAL 3 at the same time. Doing so may damage the

instrument.

TERMINAL 1

Turn off the device.

1

Connect the connection cable to TERMINAL 1.

2

CAUTION

Front

Connect the other end of the connection cable to the instrument.

3

TERMINAL 2

Turn off the device.

1

Connect the connection cable to TERMINAL 2.

2

Connect the connection cable so that the red

lead wire match and the black

match.

Red

Black

H

L

mark of the device and the

mark of the device and the

Front

mark of the black lead wire

mark of the red

20

H

Red

L

Black

Connect the other end of the connection cable to the instrument.

3

TERMINAL 3

Turn off the device.

1

Connect the connection cable to TERMINAL 3.

2

Connecting the Connection Cable

Match the cable and the connection

terminal signal.

SOURCE-H (red)

SENSE-H (red)

SENSE-L (black)

SOURCE-L (black)

1. Check the direction of

the grooves of the BNC

connector. The grooves

should t into the connector

guide of the device.

Device side

Connector guide

Front

2. Align the grooves of the

BNC connector with the

connector guide of the

device and insert the BNC

connector.

2

Preparation for Measurements

3. Turn the BNC connector to

the right to lock it.

BNC connector grooves of

the connection cord

Connect the other end of the connection cable to the instrument.

3

Connection cable terminal

SOURCE-H (red) SOURCE-H (red) Hcur

SENSE-H (red) SENSE-H (red) Hpot

SENSE-L (black) SENSE-L (black) Lpot

SOURCE-L (black) SOURCE-L (black) Lcur

BT4560 IM3590

Instrument terminal

21

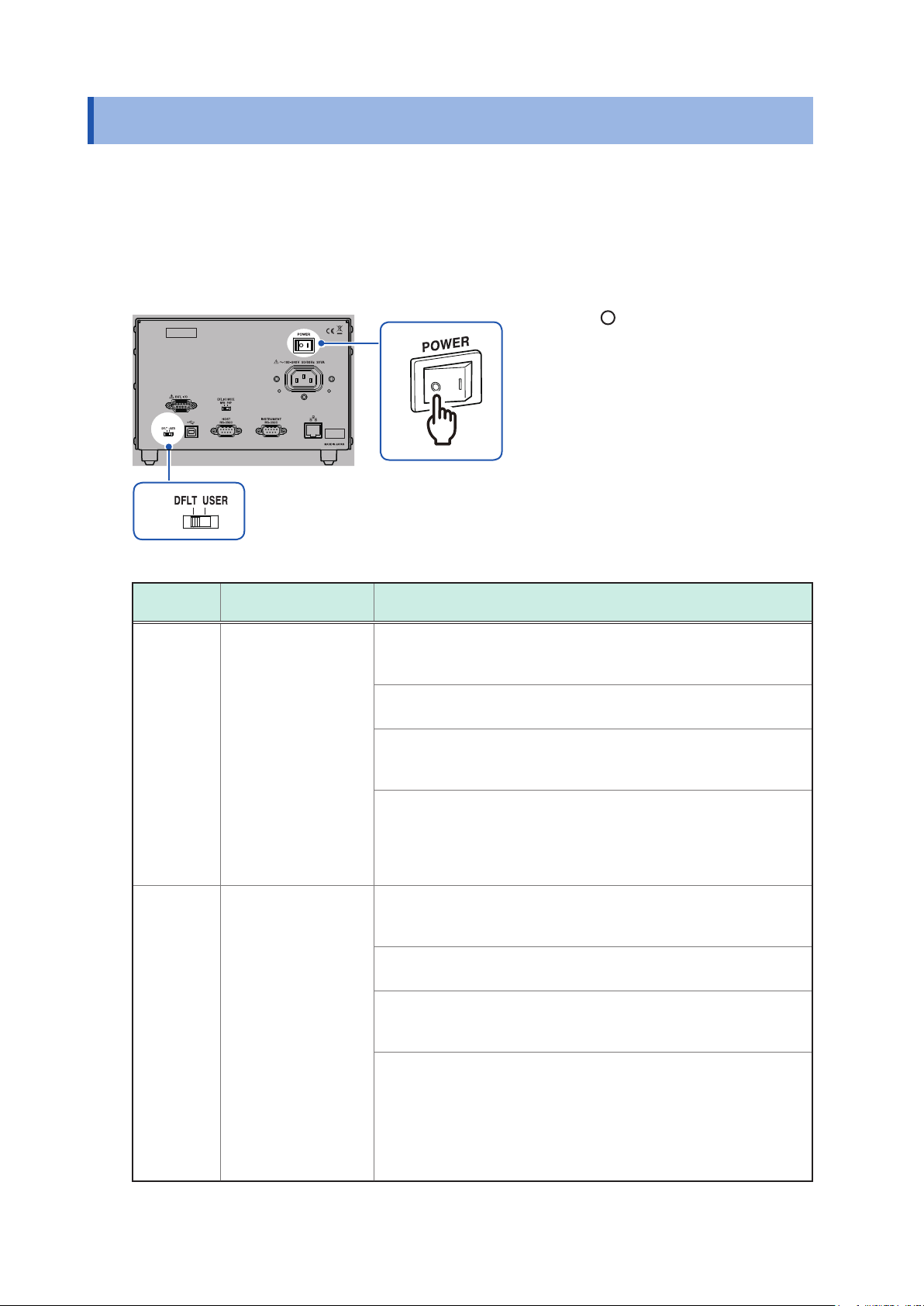

Setting the Communication Setting Mode

2.6 Setting the Communication Setting Mode

The device uses the communications interface for control.

You can select the xed setting mode for initial communication settings or the user setting mode for

user settings using the switch on the rear of the device.

Specify the communication settings according to the interface to be used in the user setting mode.

Reference: “8.1 Interface Overview and Features” (p. 59)

Rear

Check that the power switch is

1

off ( ).

Change the communication

1

2

setting mode using the

communication setting mode

switch.

2

Switch

DFLT Fixed setting mode All of USB, RS-232C, and LAN can be used.

Communication

setting mode

Device setting description

Communications are performed using the specied communication

settings.

• USB

No setting item

• RS-232C

Transmission speed: 9600 bps, data bits: 8; stop bit: 1; parity

check: none; ow control: none

• LAN

IP address: 192.168.0.254

Subnet mask: 255.255.255.0

Default gateway: 0.0.0.0 (None)

Communication command port number: 23

USER User setting mode All of USB, RS-232C, and LAN can be used.

Use the communication settings that are specied using the following

communication commands.

• USB

No setting item

• RS-232C

:SYSTem:COMMunicate:RS232C:SPEED <

Reference: “(8) RS-232C settings” (p. 103)

• LAN

:SYSTem:COMMunicate:LAN:IPADdress <

:SYSTem:COMMunicate:LAN:SMASk <

:SYSTem:COMMunicate:LAN:GATeway <

:SYSTem:COMMunicate:LAN:CONTrol <

:SYSTem:COMMunicate:LAN:UPDate

Reference: “(9) LAN settings” (p. 103)

Subnet mask

Transmission speed

IP address

Gateway address

Port No.

>

>

>

>

>

22

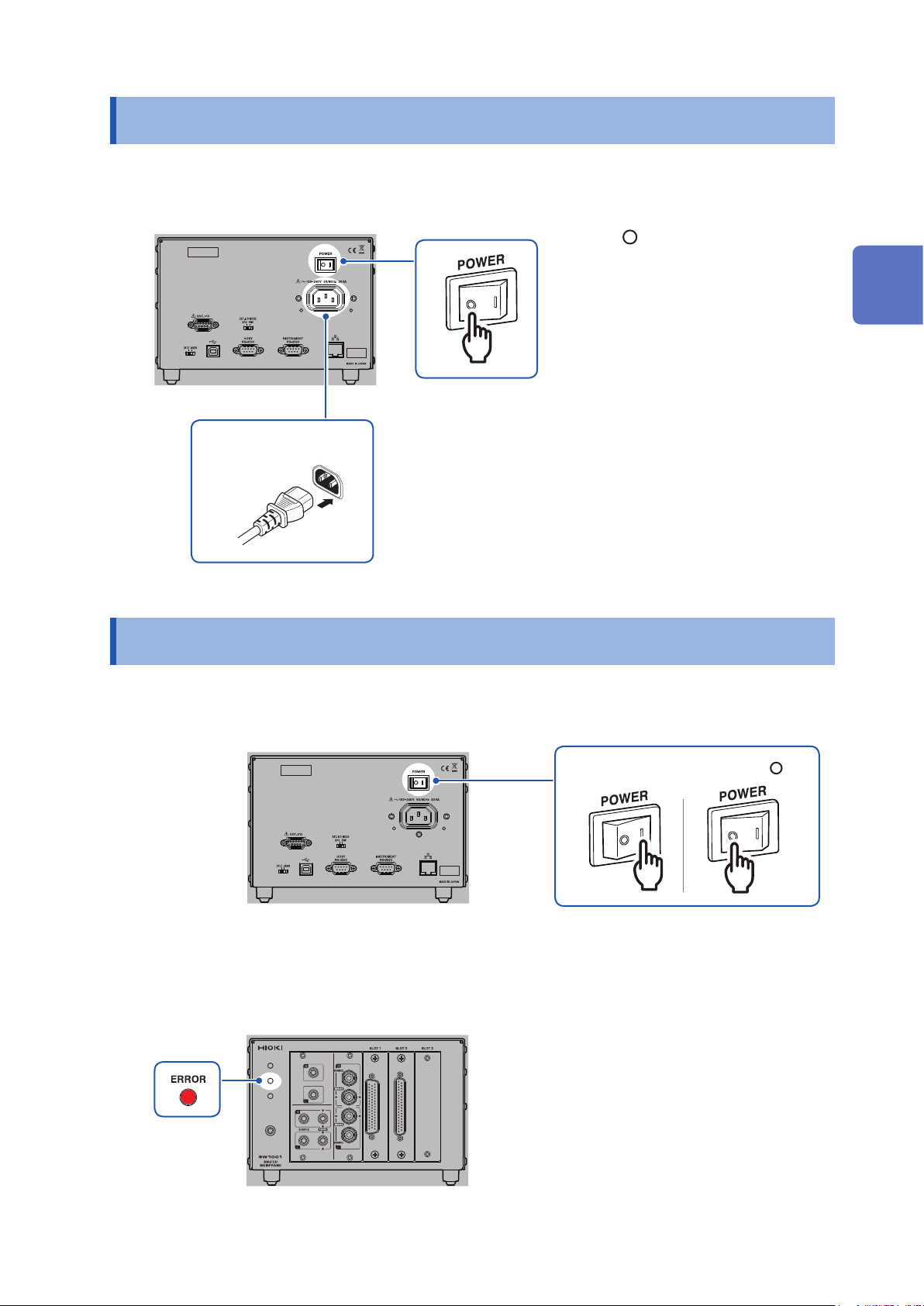

Connecting the Power Cord

2.7 Connecting the Power Cord

Be sure to thoroughly read the separate document “Operating Precautions” before use.

Rear

1

Power inlet

2

2.8 Turning on/off the Power

Check that the power switch is

1

off ( ).

Check that the power voltage is

2

within the range indicated on the

rear of the device and connect

the power cord to the power

inlet.

Connect the plug of the power

3

cord to the outlet.

2

Preparation for Measurements

Use the power switch on the rear of the device to turn on/off the power.

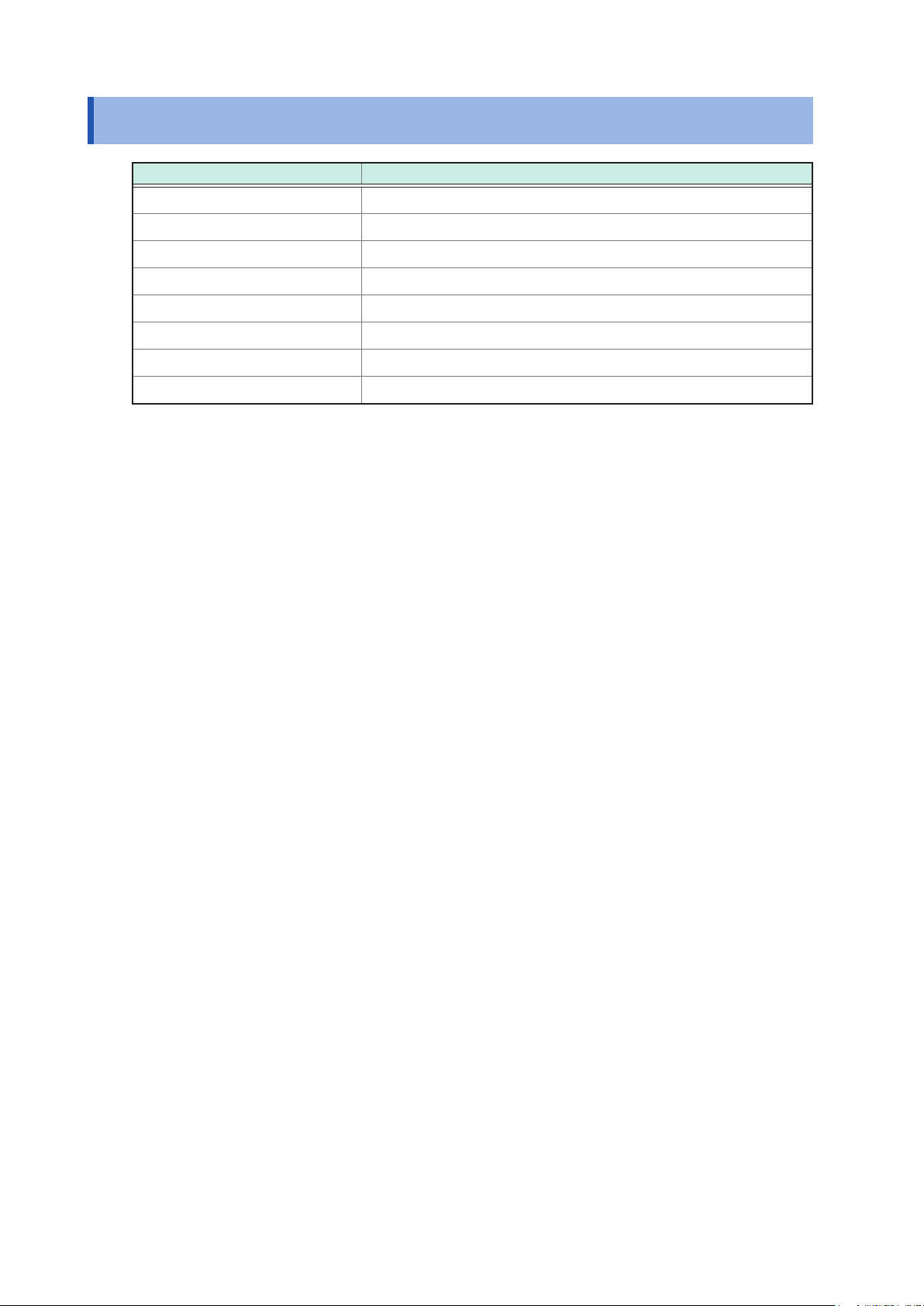

Rear

Power off ( )Power on (I)

The front POWER lamp lights up when the device is turned on, and a self-test is executed.

When an error occurs, the ERROR lamp on the front lights up. If an error occurs during self-test,

communications and control using EXT. I/O become disabled.

Front

23

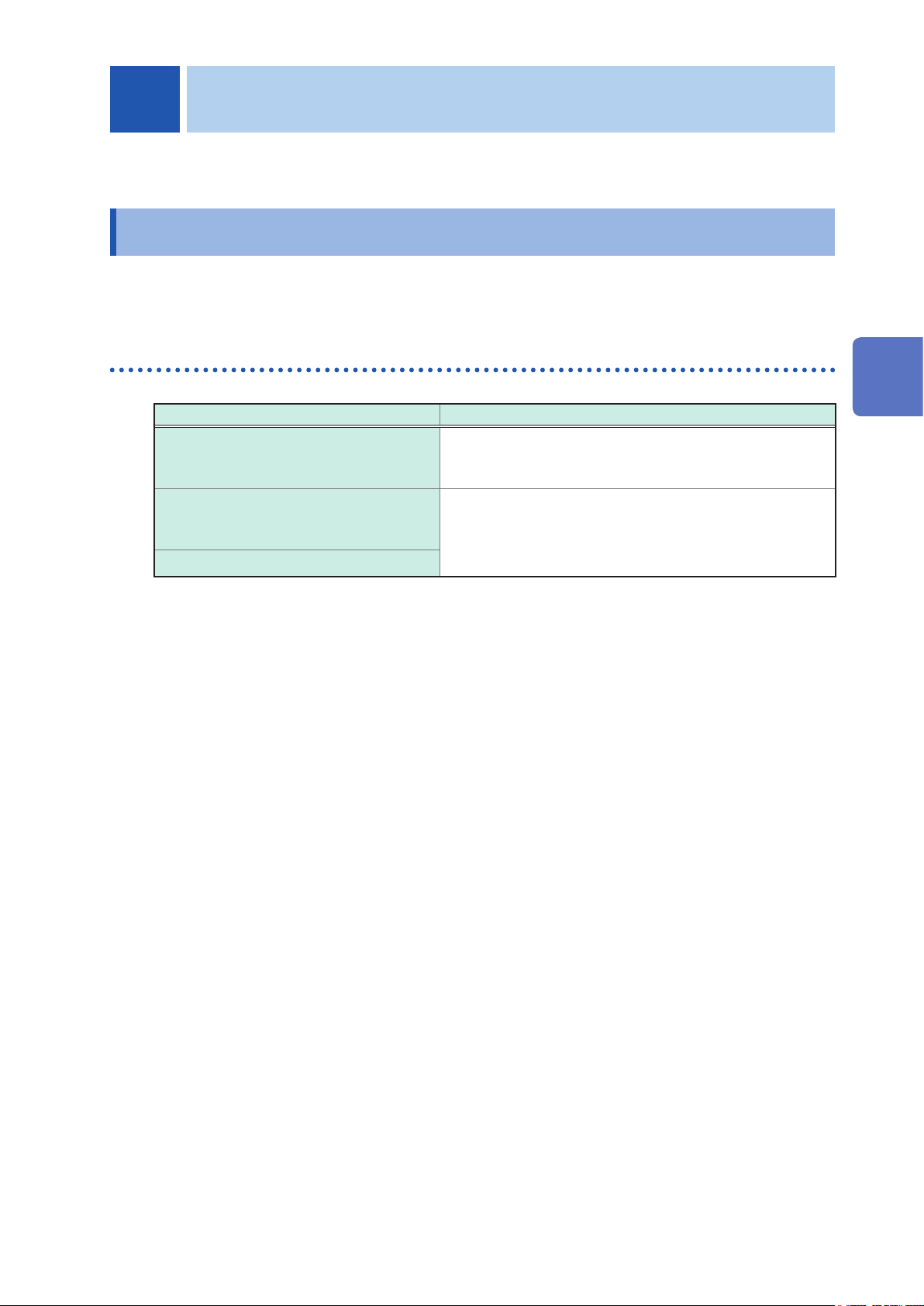

When the Power is Turned on

2.9 When the Power is Turned on

Item Initialization description

Channel relay All relays open

Bus relay All relays open

EXT. I/O CLOSE output signal Off

Connection method Settings (for each slot) are saved with the settings backup command.

Shield switching Settings (for each slot) are saved with the settings backup command.

Scan settings Settings are saved with the settings backup command.

Channel delay settings Settings are saved with the settings backup command.

Communication settings Settings are saved with the settings backup command.

See: “Backing up settings” (p. 105)

24

3

Channel Switching

Thoroughly read "Usage Notes" (p. 4) beforehand.

3.1 Inspection before Measurement

Verify that it operates normally to ensure that no damage occurred during storage or shipping.

If you nd any damage, contact your authorized Hioki distributor or reseller.

Inspecting the device and peripheral devices

3

Check item Action

Is the sheath of the power cord normal

without any damage or exposed metal part?

Are the sheaths of the measurement cables

or connection cables to be used normal

without any damage or exposed metal part?

Is the device normal without any damage?

Channel Switching

Damage may cause an electric shock or a short circuit

accident. Do not use it.

Contact your authorized Hioki distributor or reseller.

Damage may cause an electric shock. Stop using it and

replace it with a specied one.

25

Inspection before Measurement

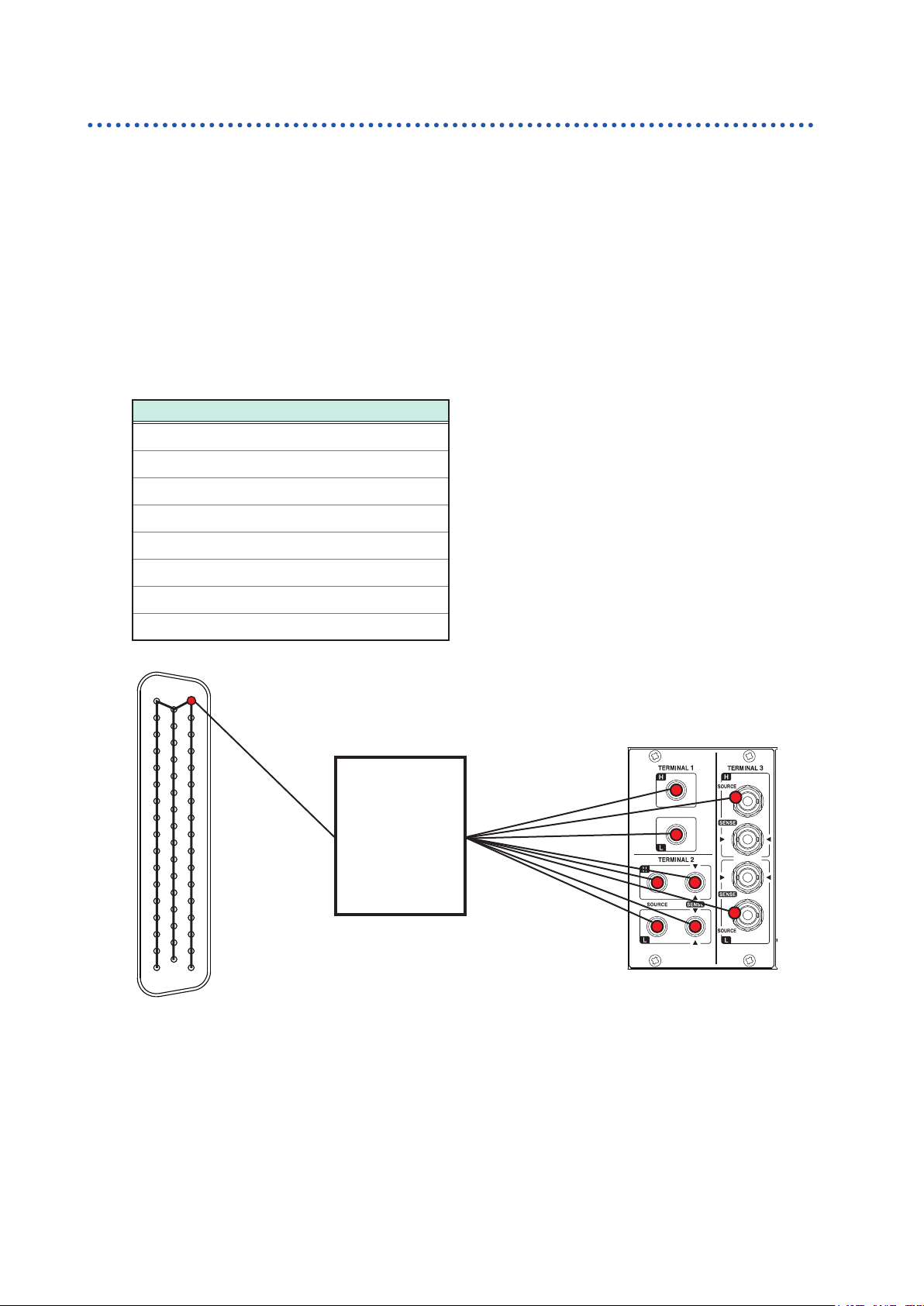

Checking for relay contact welding

If a relay contact welds, the battery of the measuring object may short or the channels may be

connected in parallel, resulting in improper measurement.

You can check that the relays are not welded according to the following procedure.

Short all the module terminals.

1

Send inspection command: TEST:RELAYSHORT <No. of slot to be inspected>,CH, and set the

2

test state of the channel relay.

Example: Inspect the channel relay of SLOT 1.

:TEST:RELAYSHORT 1,CH

Check that the terminals of the shorted modules and the following points of the terminals on

3

the main frame are not electrically connected.

Continuity inspection points

TERMINAL 1, H

TERMINAL 1, L

TERMINAL 2, SENSE H

TERMINAL 2, SENSE L

TERMINAL 2, SOURCE H

TERMINAL 2, SOURCE L

TERMINAL 3, SOURCE H shield

TERMINAL 3, SOURCE L shield

17

1

33

18

The connector is for the SW9001.

50

Check that the terminal of the shorted

module and the above points of the

34

terminal on the main frame are not

electrically connected.

Tester

Send inspection command: TEST:RELAYSHORT <No. of slot to be inspected>,BUS, and set the

4

test state of the bus relay, then conrm step 3.

Send inspection command: TEST:RELAYSHORT <No. of slot to be inspected>,OPEN, and end the

5

inspection for this slot.

Perform steps 1 to 5 for all the slots.

6

Module relay contact may be weld if it was conducted during inspection. Stop the use and contact

your authorized Hioki distributor or reseller.

26

Loading...

Loading...