Page 1

ST5540

ST5541

Instruction Manual

LEAK CURRENT HiTESTER

July 2016 Revised edition 7

ST5540A981-07 16-07H

EN

Page 2

Page 3

Contents

Contents

i

1

Measurement Flowchart.................................1

Introduction.....................................................2

Inspection.......................................................2

Checking the contents of the package...........2

Safety Notes...................................................3

Usage Notes...................................................5

Chapter 1 Overview 7

1.1 Instrument Overview ..................7

1.2 Features .....................................8

1.3 What is Leakage Current? .......10

1.4 Leakage Current Measurement

Complying with Standards .......11

1.5 Types of Leakage Current .......12

1.6 Types of Leakage Current

Measurement ...........................13

Connect the terminal ................................. 36

3.4 Turning Power On and OFF .....38

Turning Power On ..................................... 38

Turning Power Off ..................................... 40

3.5 Pre-Test Inspection.................. 41

Checking measurement frequency ............ 43

Connection/VA check screen .................... 44

Chapter 4 Settings 47

4.1 Selecting a Network .................48

4.2 Selecting the Grounding Class of

Equipment Under Test .............49

Registering an Equipment Name/

Control Number........................................ 50

4.3 Selecting a Measurement Mode

(opens the measurement screen)

..................................................51

2

3

4

5

Chapter 2 Instrument Labels

and Screens 23

2.1 Instrument Labels and Functions

................................................. 24

2.2 Screen configuration outline ....27

2.3 About the Touch Panel ............30

Chapter 3 Setting

Preparations 31

3.1 Power switch, breaker ON/OFF 31

3.2 Connecting the Power Cord 3.....2

Connecting the instrument power cord ......32

Connecting the power cord of the

equipment under test ................................33

Making connections to terminals S10, S12

and S13 ....................................................35

3.3 Connecting equipment under

test to the instrument ...............36

4.4 Setting the Measurement Range

(Auto/Hold) ...............................54

4.5 Setting the Filter .......................59

4.6 Setting the Allowable Value .....61

Turning lower limit values on and off for

specific leakage current measurements .. 63

4.7 Selecting the Type of Target

Current .....................................64

4.8 Changing the Measurement

Method (Auto/Manual) ..............67

Setting automatic measurement items ...... 68

Setting the measurement delay

(delay time) .............................................. 70

Setting the measuring time ........................ 73

Chapter 5 Measurement

Preparations 75

5.1 Connecting the Test Lead ........75

Using L2200 Test Lead ............................. 77

Using the 9195 Enclosure Probe

(for measuring enclosure leakage current) 77

ST5540A981-07

Page 4

ii

Contents

Using Alligator Clips (when using two

or three test leads) .................................................78

Chapter 6 Measurements 79

6.1 Making manual measurements 79

6.2 Making automatic measurements

................................................. 82

6.3 Measurement examples ...........83

Earth leakage current measurement ......... 83

Touch current measurement ..................... 84

Patient leakage current measurement*

(Patient connection - Earth) ..................... 90

Patient leakage current measurement*

(external voltage on a SIP/SOP).............. 93

Patient leakage current measurement*

(external voltage on a specific F-type

applied part) ............................................. 95

Patient leakage current measurement*

(external voltage on metal accessible part

not protectively earthed) .......................... 97

Patient auxiliary current measurement* .... 99

Total patient leakage current measurement*

(Patient connection - Earth)................... 100

Free current measurement

(Enclosure - Enclosure) ......................... 101

6.4 Saving Measurement Data

(As required).......................... 102

Checking Saved Measurement Data ....... 104

Displaying Saved Measurement Data ..... 104

Selecting Saved Measurement Data ...... 105

Deleting Saved Data ............................... 105

6.5 Saving Measurement Conditions

7.2 Panel Load(Loading Saved

Measurement Conditions)...... 120

7.3 Initializing the Instrument .......121

7.4 Setting the Display Language 123

7.5 Checking Fuses(During Earth

leakage current and protective

conductor current measurements)

................................................123

7.6 Self-Test .................................124

7.7 Power On Polarity Switching

(to keep equipment under test

on during polarity switching) .. 126

Connect the isolation transformer............ 126

Setting Power On Polarity Switching ....... 127

Relay check 2 .......................................... 128

7.8 Auto Measure Setting

(set instrument status) ........... 129

7.9 Setting Lower Limit Values (factor)

............................................... 130

7.10 Setting Indication Unit ............131

7.11 Setting Date and Time ...........132

7.12 Interface Setting

(For Communication and Printing)

................................................133

7.13 Setting the Beep Sound .........135

7.14 Setting the Backlight .............. 136

(Panel Save Function)

(as required) ..........................106

6.6 Printing Measurement Data

(as required) ..........................108

Setting up and connecting a printer ......... 108

Chapter 7 Instrument System

Settings 115

System Screen Configuration .................. 116

7.1 Setting the Mode (To use the

instrument as a voltmeter) .....117

Chapter 8 Controlling the

Instrument From a

Computer

(RS-232C,

USB interface) 139

8.1 ST5540/ST5541 Remote Interface

Overview (USB connection) ...140

8.2 Connect and be sure to tighten

the screws on the connector.. 141

Installation and operation procedures ..... 143

Specifications of RS-232C....................... 144

Specifications of USB .......................... ... . 144

Page 5

iii

Contents

8.3 Setting Communication

Conditions on the HiTESTER 145

8.4 Command Message Description

................................................146

Message Format ......................................146

Output Queue and Input Buffer ................151

Event Registers ... ... .... ... ... ... .... ... ... ... .... ... .152

8.5 Initialization Items ..................153

8.6 Message Reference ...............154

Common Messages .................................154

Messages Specific to the HiTESTER....... 154

8.7 Command Message Description

............................................... 162

Common Messages .................................163

Specific commands ..................................165

8.8 To Transfer All Saved Data to

a Computer ............................243

8.9 Troubleshooting .....................244

Chapter 9 External Control

245

Network Section ...................................... 259

10.5 Other Functions ......................261

10.6 System-related Functions ......263

10.7 User interface .........................264

10.8 EXT I/O ..................................264

10.9 Relay output for medical equipment

(only ST5540) .........................264

10.10 PC Interfaces....................... 265

10.11Printer ...................................265

10.12General Specifications .......... 266

10.13Compliant standards............. 268

10.14Measurement Networks ........269

Network A (for Electrical Appliance

and Material Safety Law) ....................... 269

Network B1 (for JIS T 0601-1:1999) ........270

Network B2 (for IEC 60601-1:2005 3rd) .. 271

Network C (for IEC 60990) ...................... 272

Network D (for UL) .................................. 274

Network E (General-purpose 1) .............. 275

Network F (General-purpose 2) ............... 275

Network G (for IEC61010-1) .................... 276

11

5

6

7

9.1 Description of Signals............ 246

9.2 Connecting to the EXT I/O

Terminal................................. 247

9.3 Electrical Specifications .........249

9.4 Internal Circuit Configuration .250

9.5 Timing Chart ..........................251

Panel load function at EXT I/O start . .... ... .253

9.6 Example of Output Signal

Connection .............................254

Chapter 10 Specifications255

10.1 Basic Functions...................... 255

10.2 Auxiliary measurement functions*

............................................... 256

10.3 Measurement System ............256

Chapter 11 Maintenance

and Service 279

11.1 Cleaning and Storage ............279

11.2 Repair and Servicing...............280

11.3 Replacing Fuses ....................282

11.4 Instrument Disposal ...............283

Appendix A1

Appendix1Terminology.................... A1

Appendix2List of instrument status,

other test condition and special

test condition......................... A4

Appendix3List of default settings..... A7

Appendix4External Dimensions..... A29

8

9

10

Appendix

10.4 Accuracy ................................258

Current Measurement Section .................258

Index

Page 6

iv

Contents

Index i

Page 7

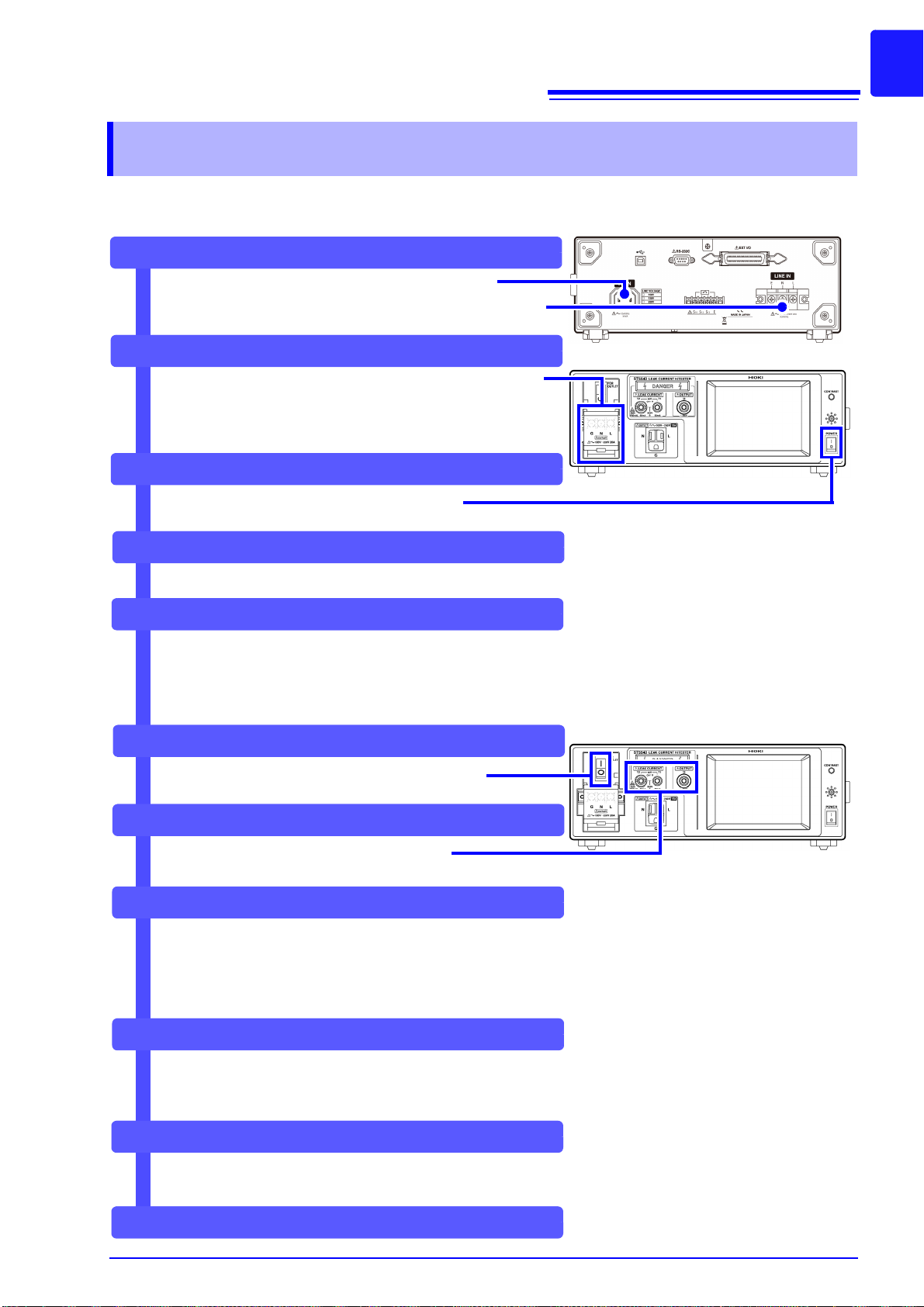

Measurement Flowchart

See "6.5 Saving Measurement Conditions (Panel Save Function) (as required)" (p. 106)

See "6.4 Saving Measurement Data (As required)" (p. 102)

See "3.5 Pre-Test Inspection" (p. 41)

See "Chapter 6 Measurements" (p. 79)

Manual : Free-run measurement

(Measurement conditions can be changed during ongoing measurements)

Automatic : Set measurement conditions and measuring time to perform automatic measurements.

See "6.6 Printing Measurement Data (as required)" (p. 108)

See "Connecting the power cord of the equipment under test"

(p. 33)

See "Connecting the instrument power cord" (p. 32)

See "5.1 Connecting the Test Lead" (p. 75)

See "3.1 Power switch, breaker ON/OFF" (p. 31)

See "3.4 Turning Power On and OFF" (p. 38)

See "3.1 Power switch, breaker ON/OFF" (p. 31)

See "3.4 Turning Power On and OFF" (p. 38)

Connect the power cord

Connect test leads

Pre-Operation Inspection

Measurements

After automatic measurement ends

See "Chapter 4 Settings" (p. 47)

Settings depend on measurement method (Manual or Automatic)

Manual measurement : Perform settings from (p. 48) to (p. 67)

Automatic measurement : Perform settings from (p. 48) to (p. 73)

Turn on the circuit breaker

Settings

Connecting equipment under test to the instrument

See "3.3 Connecting equipment under test to the instrument"

(p. 36)

Turn on the power switch of the HiTESTER

The actual connection procedure will vary with the power supply

of the equipment under test.

Disconnect test leads and equipment under test

Turn off breakers and instrument power

Be sure to read "Usage Notes" (p. 5) before measuring.

The flowchart does not show the detailed procedures but the rough workflow.

1

2

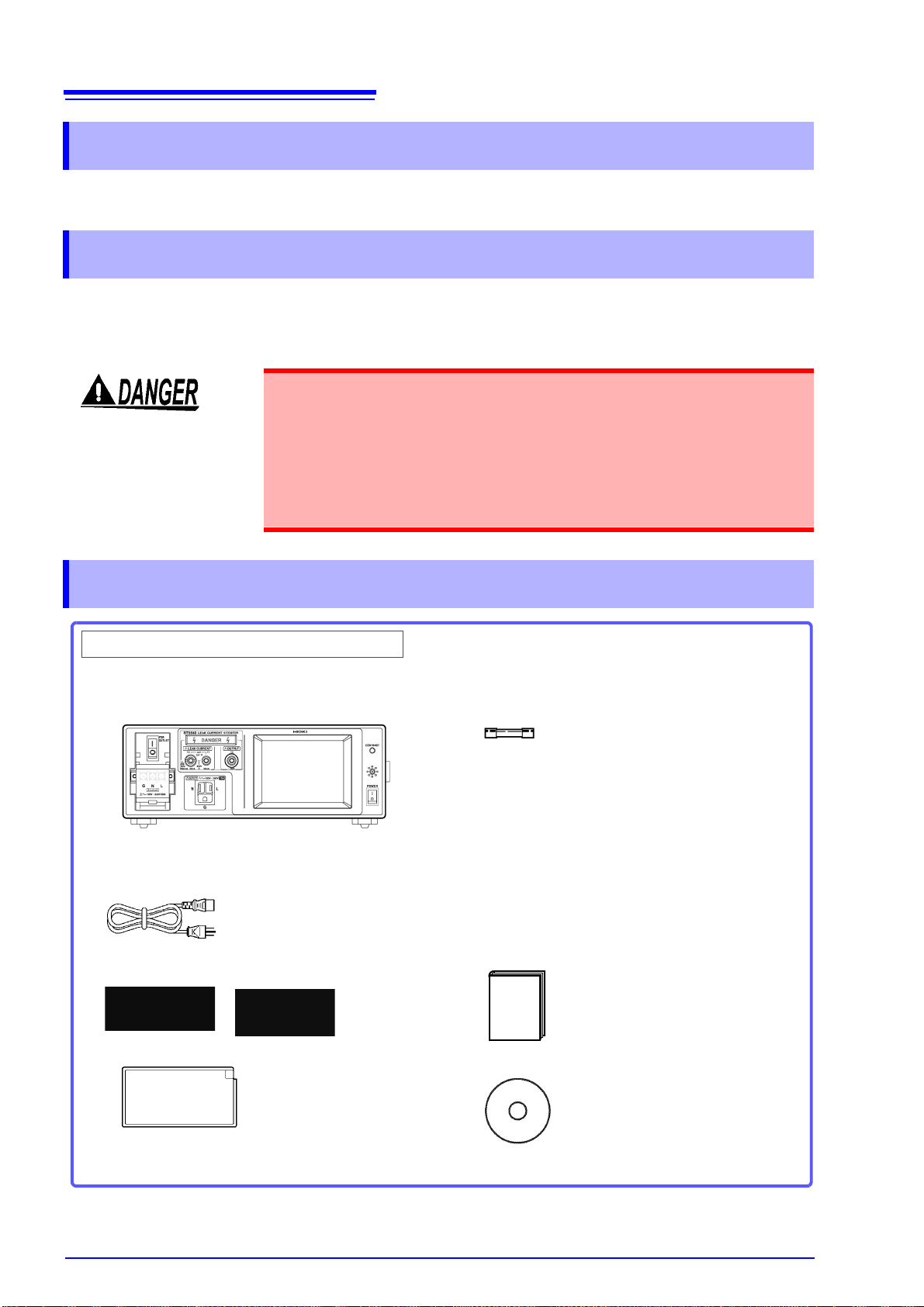

Page 8

2

"ST5540/ST5541 Leak Current HiTester".........1

Power cord (for main instrument)..................... 1

Power cord for equipment under test............... 2

(

for [LINE IN])

Enclosure Probe............ ... ................................ 1

Spare fuse for main instrument........................ 1

(250 V F50 mAL)

L2200 Test Lead...........................................1set

(1 red, 1 black)

Test lead(red)................................................... 1

(only ST5540)

Instruction manual............................................ 1

CD-ROM .......................................................... 1

Confirm that these contents are provided.

Introduction

Thank you for purchasing the HIOKI Model "ST5540/ST5541 Leak Current HiTester". To obtain maximum

performance from the instrument, please read this manual first, and keep it handy for future reference.

Inspection

When you receive the instrument, inspect it carefully to ensure that no damage oc curr ed du rin g shippin g.

In particular, check the accessories and connector s. If damage is evi dent, or if it fails to operate according

to the specifications, contact your dealer or Hioki representative.

• Before using the instrumen t, make sure that the insulation on the test leads is

undamaged and that no bare conductors are improperly exposed. Using the

Model L2200 Test Lead in such conditions could cause an electric shock, so contact your dealer or Hioki representative for replacements.

• Before using th e in stru ment, m ake sur e that the insu lation on the po wer co rd s is

undamaged and that no bare conductors are improperly exposed. Using the

instrument in such conditions could cause an electric shock, so contact your

dealer or Hioki representative for replacements.

• Use the original packing materials when transporting the instrument, if possible.

Checking the contents of the package

Page 9

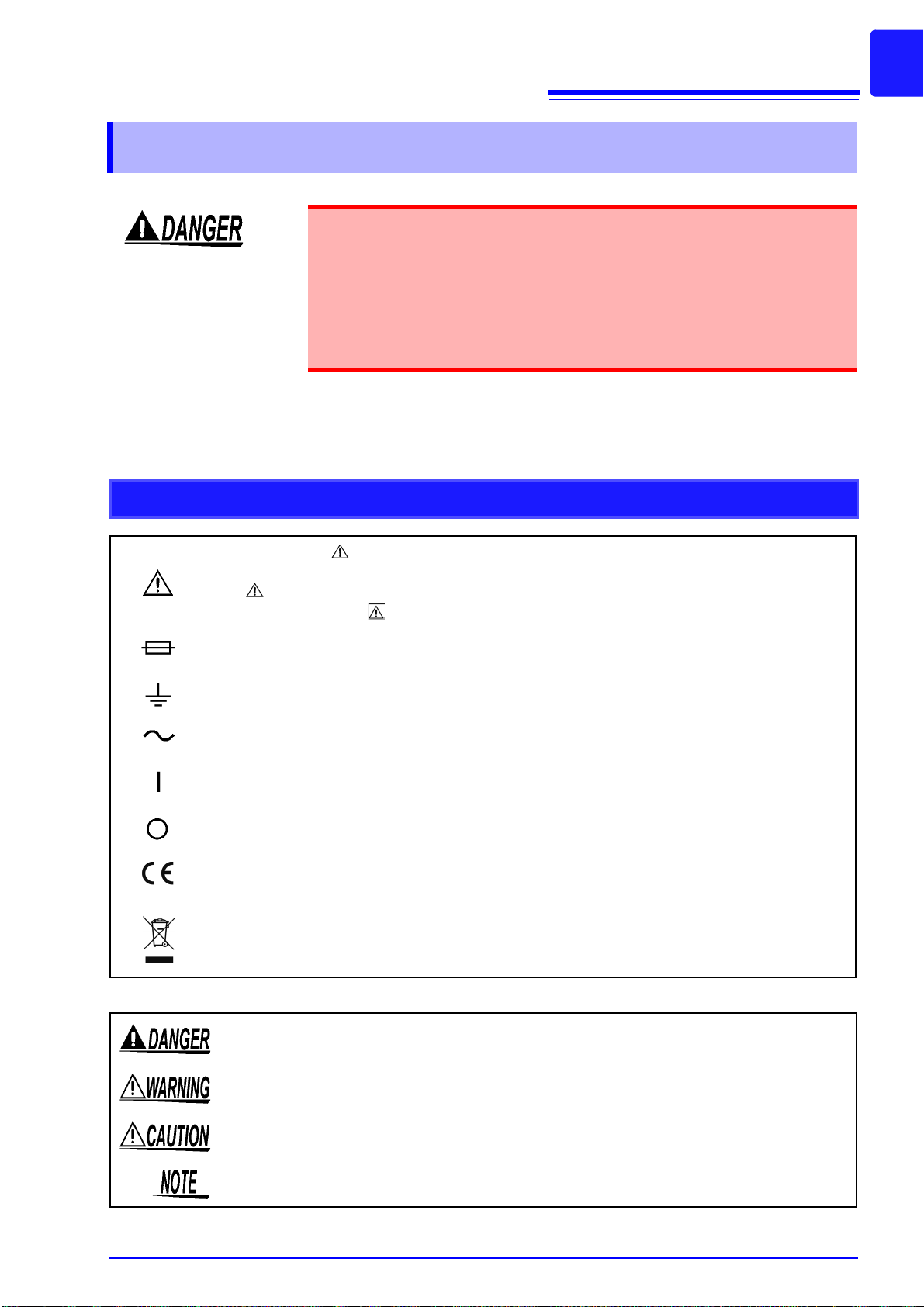

Safety Notes

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior t o shipment. However, mishandling during use could result in injury or death, as well as damage to

the instrument. Using the instrument in a way not described in this manual

may negate the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or injuries

not resulting directly from instrument defects.

This manual contains information and warnings essential for safe operation of the instrument and for

maintaining it in safe operating condition. Before using it, be sure to carefully read the following safety

precautions.

3

2

Safety Symbols

In the manual, the symbol indicates particularly important information th at the user should read befo re

using the instrument.

The symbol printed on the instrument indicates that the user should refer to a corresponding topic in the

manual (marked with the symbol) before using the relevant function.

Indicates a fuse.

Indicates a grounding terminal.

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates that the product conforms to regulations set out by the EC Directive.

WEEE marking:

This symbol indicates that the electrical and electronic appliance is pu t on the EU market after August 13,

2005, and producers of the Member States are requ ired to display i t on the applia nce u nder Articl e 11 .2 of

Directive 2002/96/EC (WEEE).

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in serious injury or death

to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death

to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Page 10

4

USB

Other Symbols

Indicates a prohibited action.

See Indicates the location of reference information.

*

(Example)

Leakage current

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with

the following meanings:

Indicates that descriptive information is provided below.

For information on text in italics, refer to "Appendix1 Terminology" (p. A1).

Indicates descriptions relating to the RS-232C only.

Indicates descriptions relating to the USB only.

f.s. (maximum display

value):

rdg. (reading or

displayed value):

dgt. (resolution):

The maximum displayable value. This is usually the name of the currently selected range.

The value currently being measured and indicated on the measuring instrument.

The smallest displayable unit on a digital measuring instrument , i.e., the input value that

causes the digital display to show a "1" as the least-significant digit.

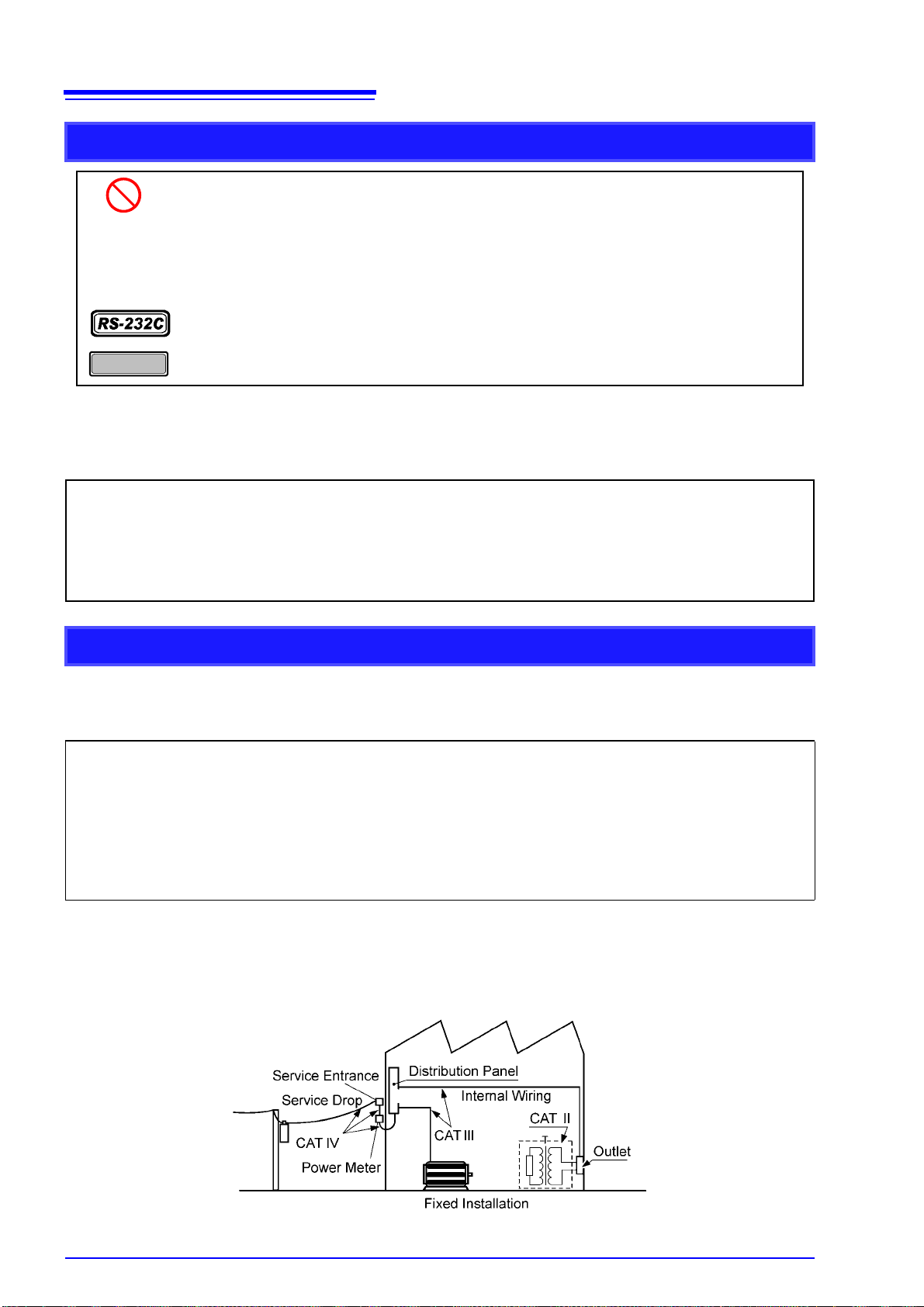

Measurement categories

This instrument complies with CAT II (300 V) safety requirements.

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

CAT II :

CAT III : Prima ry electrical circuits o f heavy equipment (fixed installations) connected directly to th e distrib ution panel,

CAT IV : The circuit from the service drop to the service entrance, and to the power meter and primary overcurrent pro-

Using a measurement instrument in an environment designated with a higher-numbered category than

that for which the instrument is rated could result in a severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV measurement applications

could result in a severe accident, and must be carefully avoided.

Primary electrical circuits in equipment connected to an AC electrical outlet by a power cord (portable tools,

household appliances, etc.)

CAT II covers directly measurin g ele ctrical outlet recept acles.

and feeders from the distribution panel to outlets.

tection device (distribution panel).

Page 11

Usage Notes

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Avoid the following locations that could cause an accident or damage to the instru-

ment.

5

2

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil, other

chemicals, or solvents

Exposed to high humidity or

condensation

Exposed to high levels of particulate dust

Subject to vibration

Avoid obstructing the ventilation holes on the sides of the instrument, as it could

overheat and be damaged, or cause a fire.

If the instrument operates abnormally or displays a n abno rma l indication, tur n off

the power switch immediately, and contact your dealer or Hioki representative.

Precautions before measurement

In the presence of corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction heating systems and IH

cooking utensils)

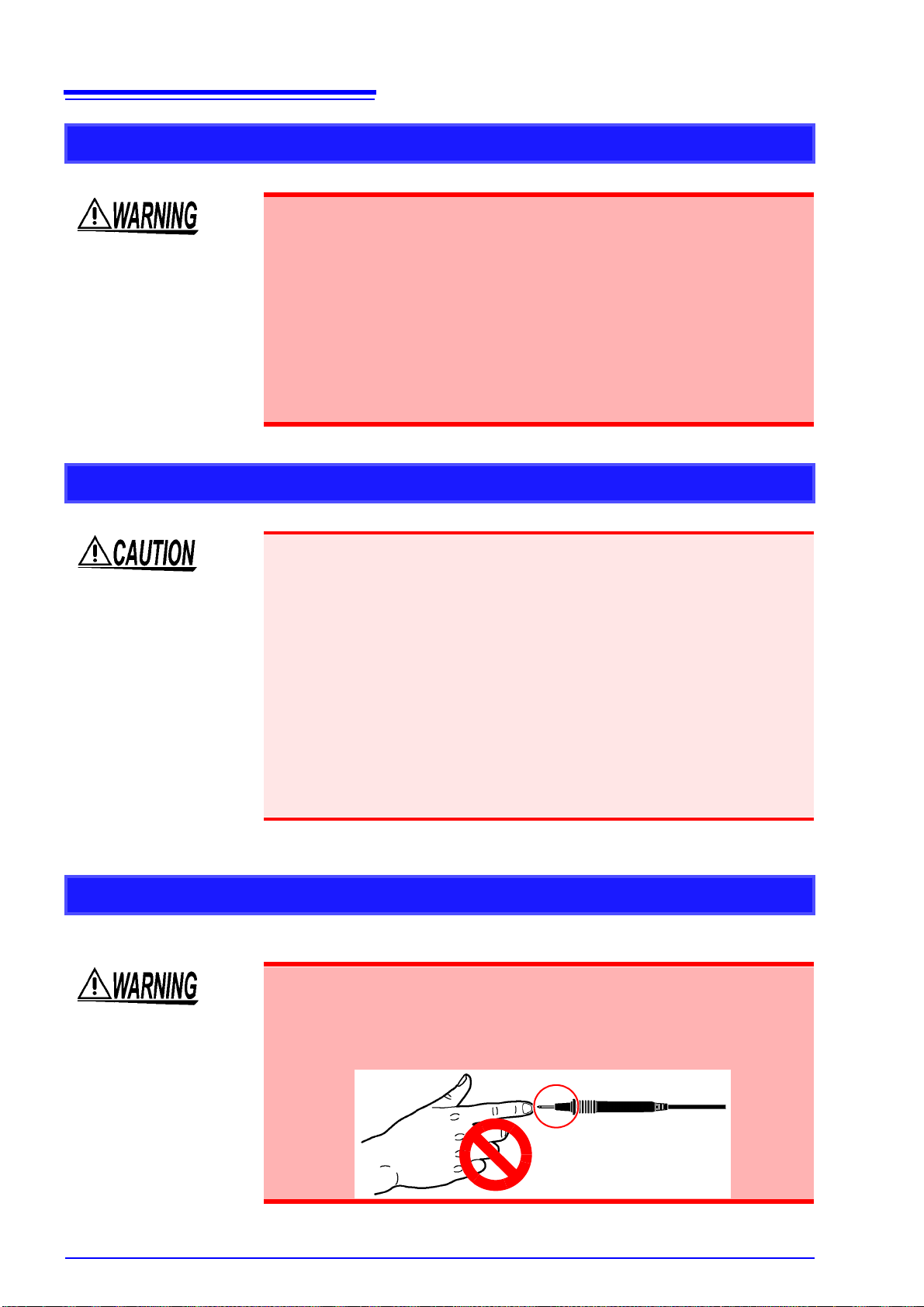

• Before turning on the instrument, confirm that the voltage of the power

source matches the voltage specification indicated on the instrument's

power connector ([AC IN]). (The voltage specification (100, 120, 220 or

240 V) ordered by the customer is marked with a black dot in the line

voltage column on the rear panel.)

Note that using the power supply with improper voltage may damage the

instrument and result in electrical hazards.

• To avoid electrical accidents and to maintain the safety specifications of

this instrument, connect the power cord provided only to a 3-contact

(two-conductor + ground) outlet.

Do not use excessive force on the touch pane l, and do not use sharp object s that

could damage the touch screen.

Page 12

6

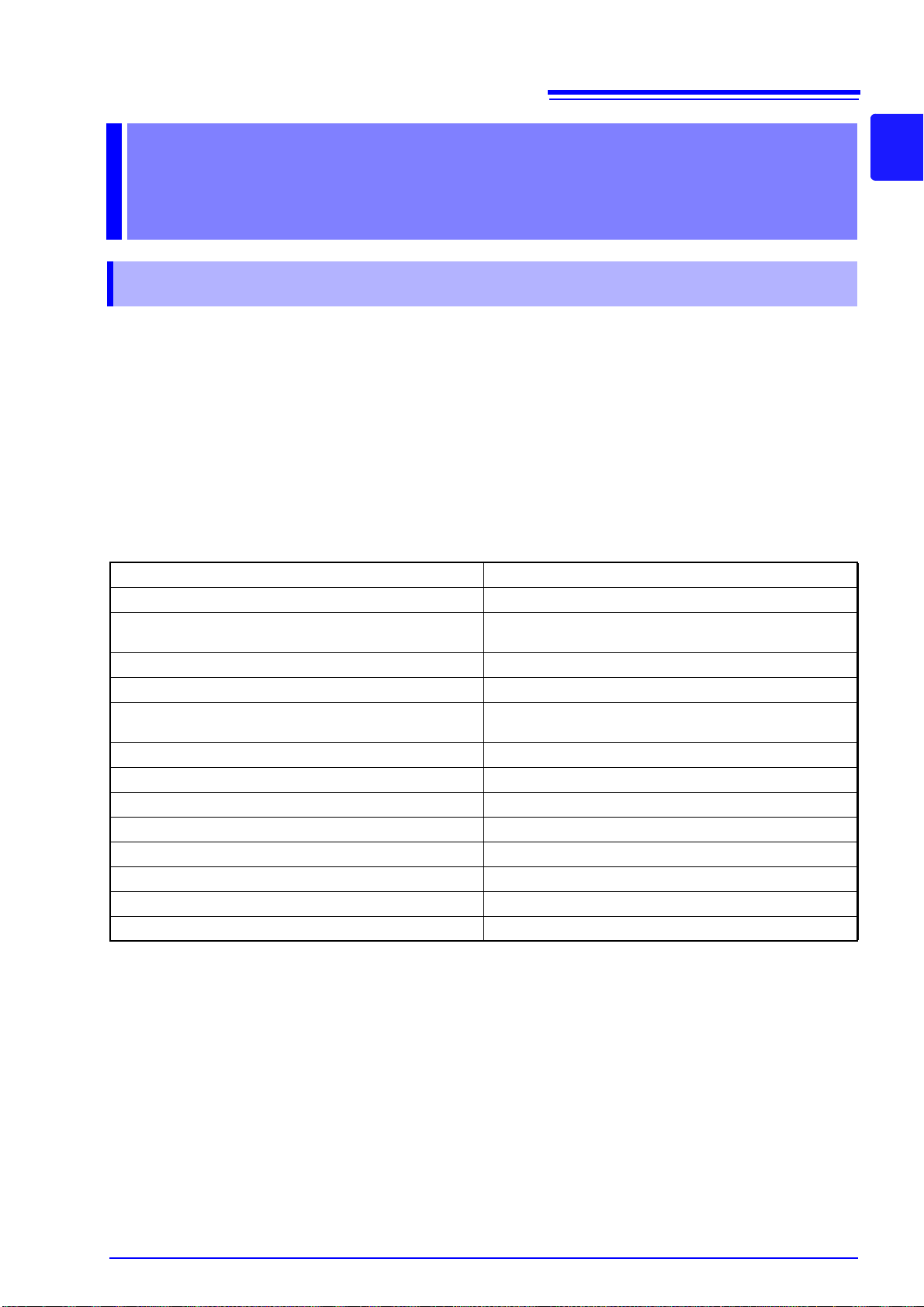

Do not touch any part of

the test lead beyond the

finger barrier

Fuse

Connection

• Replace the fuse only with one of the specified chara cteristics and

voltage and current ratings. Us ing a non-specified fuse or shorti ng

the fuse holder may cause a life-threatening hazard.

Measurement terminal section : 250 V F50 mAL

• To avoid electric shock, turn off the power switch and disconnect

the power cord and test leads before replacing the fuse.

• Since a blown fuse cannot be repaired or replaced by the customer, contact your dealer or nearest Hioki sales office.

Use the VA check function for power supply fuse and blown fuse

check function for measurement circuit fuse to check for blown

fuses.

Measurement

• Always turn both devices OFF when connecting and disconnecting an interface connector and test lead. Otherwise, an electric shock accident may

occur.

• To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

• To avoid breaking the test lead or enclosure probe, do not bend or pull them.

• When the power is turned off, do not apply voltage or current to the measurement terminals. Doing so may damage the instrument.

• L (Line), N (Neutral) and G (Ground) are indicated on the te rminal bl ock of th e

instrument, and the contacts of the power cord of the device to be measured

are denoted L, N and E (Earth). If the power cord does not include an earth

(E) line, connect only the L and N terminals.

For details regarding the terminal block, refer to "3.3 Connecting equipment

under test to the instrument" (p. 36).

To avoid the risk of electric shock when test leads are connected to

the T1 - T3 terminals, do not touch the part of the test lead that is

beyond the finger barrier.

The terminals output high voltages in some measurement modes.

Page 13

7

1.1 Instrument Overview

1

Overview Chapter 1

1.1 Instrument Overview

To ensure the safe use of electrical products, it is necessary to conduct electrical safety tests such as

insulation resistance, withstand voltage, ground resistance, and leakage current.

Complying with laws and standards regarding medical electrical equipment as well as non-medical electrical equipment, this instrument can be used to measure leakage current in all types of electrical products from computers to medical equipment. It consists of measu rement networ ks that simulate the human

body and a high-frequency volt meter.

It is also capable of switching power supply polarities and making measurements under simulated singlefault conditions in equipment under test.

To simplify leakage current testing, all test operations can be selected and run from a touch panel on the

display screen.

Applicable lines of business and product applications

Manufacturers of medical electrical equipment Type approval testing, shipment inspection

Dealers of medical electrical equipment Maintenance, inspection

Service technicians for medical electric al equipment

(authorized service technicians)

Clinical engineers, hospitals Maintenance, inspection

Clinical engineering schools For educational purposes

Authorized electricians for operating rooms, ICUs,

and CCUs

Public organizations Type inspection

Manufacturers of general electrical equipment Type inspection , shipment inspection

Users of general electrical equipment Maintenance, inspection

General electrical equipment installers Maintenance, inspection

Service technicians for general electrical equipment Maintenance, inspection

Manufacturers of general electrical equipment pa rts Type inspection, shipment inspection

Manufacturers of power supply equipment Type inspection, shipment inspection

Manufacturers of electrical automobiles Type inspection, shipment inspection

Maintenance, inspection

Isolation transformer inspection

Chapter 1 Overview

Page 14

8

Wide range of measurement networks in compliance with standards

and laws

1. Network A :For compliance with Electrical

Appliance and MaterialSafety Law

2. Network B1 :For JIS T0601-1:1999

3. Network B2 :IEC 60601-1:2005 3rd

Complies with JIS T 0601-1:2012

4. Network C :For IEC60990

5. Network D :For UL

6. Network E :For general-purpose 1

7. Network F :For general-purpose 2

8. Network G :For IEC 61010-1

Leakage current measurement mode

1. Earth leakage current

2. Touch current (Enclosure - Earth)

3. Touch current (Enclosure - Enclosure)

4. Touch current (Enclosure - Line)

5. Patient auxiliary current

6. Patient leakage current (Patient connection - Earth)

7. Patient leakage current (external voltage on a SIP/SOP

*

)

8. Patient leakage current (external voltage on a specific F-type applied part)

9. Patient leakage current

(external voltage on metal accessible part not protectively earthed)

10. Total patient leakage current (Patient connection - Earth)

11. Total patient leakage current (external voltage on a SIP/SOP

*

)

12. Total patient leakage current (external voltage on a specific F-type applied part)

13. Total patient leakage current

(external voltage on metal accessible part not protectively earthed)

14. Free current (Enclosure - Enclosure)

15. Enclosure - Earth leakage current

16. Enclosure - Enclosure leakage current

17. Enclosure - Line leakage current

18. Patient leakage current I

19. Patient leakage current II

20. Patient leakage current III

*

SIP(Signal Input Part)/SOP(Signal Output Part)

Power on polarity switching function

Rated current 20 A

1.2 Features

1.2 Features

To test electrical equipment for leakage current, it is necessary to use a measurement network that simulates the human body in compliance with applicable standards or laws.

The instrument includes the 8 measurement networks below.

The use of these networks enables instrument compliance with other standards.

Once a measurement network is selected, the instrument displays a leakage current measurement mode

corresponding to the applicable standard or law.

This function makes it possible to contin ue testing without shutting down the equipment under test when

polarities are changed, which shortens the duration of the test.

(Be sure to use an isolation transformer when using power on polarity switching.)

The instrument provides a rated current of 20 A and a rated voltage of 250 V.

Page 15

9

Function for checking for blown fuses

Ease of operation

Interfaces

Printing (with optional printer)

Monitor function

1.2 Features

The insutrument allows you to check for unintended blown fuses in networks.

Check for blown fuses before and after measurements to enable high-reliability measurements.

All operations are performed using the touch panel. The display shows operable keys and the interactive

system guides you through measurement procedures.

The RS-232C, EXT I/O and USB interfaces are provided as standard equipment to enable the easy

transfer of measurement data with a computer. The EXT I/O connector allows external control.

Connect the optional 9442 Printer to print out measurement data and saved measurement data.

1

Chapter 1 Overview

The instrument is equipped with a function to monitor the power supply voltage and current of equipment

under test.

Page 16

10

1.3 What is Leakage Current?

1.3 What is Leakage Current?

High voltage is present in an electrical ap plia n ce t ha t uses a commercial power supply as its main power

source. Touching such equipment may expose a person to an electrical shock when current passes

through the body to ground. This electrical shock is the result of "le akage curr ent" or "touch curren t." Normally, electrical equipment is grounded to protect against electrical shocks. Current regularly flows

through the grounding wire, but should an abnormality (due to faulty design or fault) occur in equipment,

the resulting electrical shock may cause serious personal injury and sometimes lead to the death of the

*1

victim. For this reason, leakage current measurements including single-fault conditi ons

lated.

Leakage current measurements perfor med acco rd ing to the applicable standard makes it possible to verify the safety of equipment.

*1

What is a single-fault condition?

This refers to when equipment has a fault in a safety protection measure, or a fault that may result in a

hazardous condition.

Leakage current testing includes the following three single-fault conditions.

are strictly regu-

1. Disconnected grounding wire (not applicable in current tests of leakage current)

2. One wire in the power cord is disconnected (neutral power supply wire)

*2

3. External equipment damage

(patient leakage current II and patient leakage current III)

*2

In JIS T0601-1:1999 classified as a single-fault condition.

Not a single-fault condition, the instrument is capable of switching polarity during measurements and

retaining a recording of the phase with the highest leakage current.

Page 17

11

1.4 Leakage Current Measurement Complying with Standards

1.4 Leakage Current Measurement

Complying with Standards

Electrical safety standards and laws are enacted for electrical products according to fields of application.

Each standard and law specifies a circuit network for simulating the human body, and prescribes network

performance, as well as measuring locations, type (e.g., AC, DC) of current to be measured, allowable

values, and other characteristics.

Listed below are various standards that requir e leakage current measurement.

Standards requiring leakage current measurement

(Refer to the User's Guide for information on other standards.)

Electrical equipment

IEC 60065:2001 +A1:2005

IEC60335-1:2010

IEC 60950-1:2005 Safety of information technology equipment

IEC 60990:1999

UL2231-1, UL2231-2 Personnel Protection Systems for EV

Electric measuring instruments

IEC 61010-1:2010

Medical electrical equipment

JIS T 0601-1:1999

JIS T 0601-1:2012

IEC 60601-1:2005 3rd

Audio, video, and similar electronic apparatus - Safety

requirements

Safety of household and similar electrical appliances.

- Part 1: General requirements

Methods of measuring touch current and protective conductor current

Safety requirements for electrical equipment used in measurements, control and laboratories

Current measurement circuits for testing in damp co nditions

Medical electrical equipment-Part1:General requirements

for basic safety and essential performace

Medical electrical equipment

Part 1: General requirements for safety

1

Chapter 1 Overview

Page 18

12

1.5 Types of Leakage Current

1.5 Types of Leakage Current

Leakage current can largely be classified as shown in the table below.

Types of

Leakage Current

Earth leakage

current

Touch current

Enclosure

leakage current

Patient leakage

current

Patient auxiliary

current

Total patient

leakage current

Protective

conductor current

Overview

This refers to electric current that flows through a protective earth conductor to

the ground.

Touch current is electric current that flows through a p erson who touches an

ungrounded enclosed section of equipment. It does not include current that

flows to the human body in contact with an applied part.

Patient leakage current flows through the body of someone connected to the

applied part.

Test items vary based on the type of applied part.

Electric current that flows between applied parts and through a patient during

normal operation of medical equipment that is not intended to have any physiological effect.

When multiple applied parts are attached to a patient, the total leakage current

must be measured.

The sum of patient leakage current of applied part s is tot a l p atient leakage current.

Electric current that flows through a protective earth conductor (grounding

wire) during normal operating conditions

Refer-

ence

Page

P.13

P.14

P.15

P.15

P.19

P.20

Page 19

13

1.6 Types of Leakage Current Measurement

1.6 Types of Leakage Current Measurement

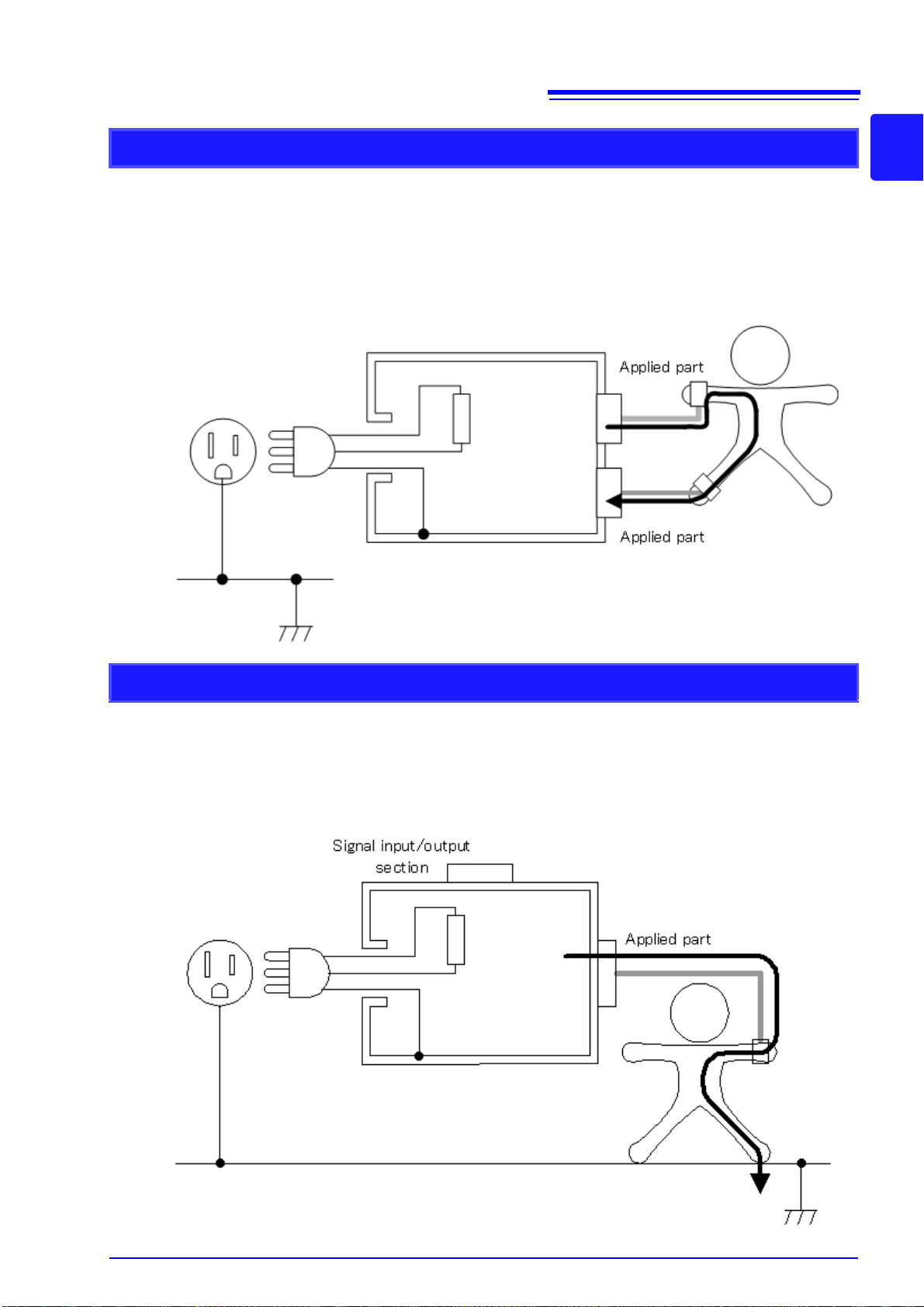

Earth leakage current measurement

Class-II equipment does not require the measurement of Earth leakage current since it has no protective

earth conductor.

Earth leakage current is measured by inserting a resistance equivalent to the human body in the protec-

tive earth conductor. Using a clamp (Clamp On HiTester) for measuring current does not satisfy the standard.

1

Chapter 1 Overview

Page 20

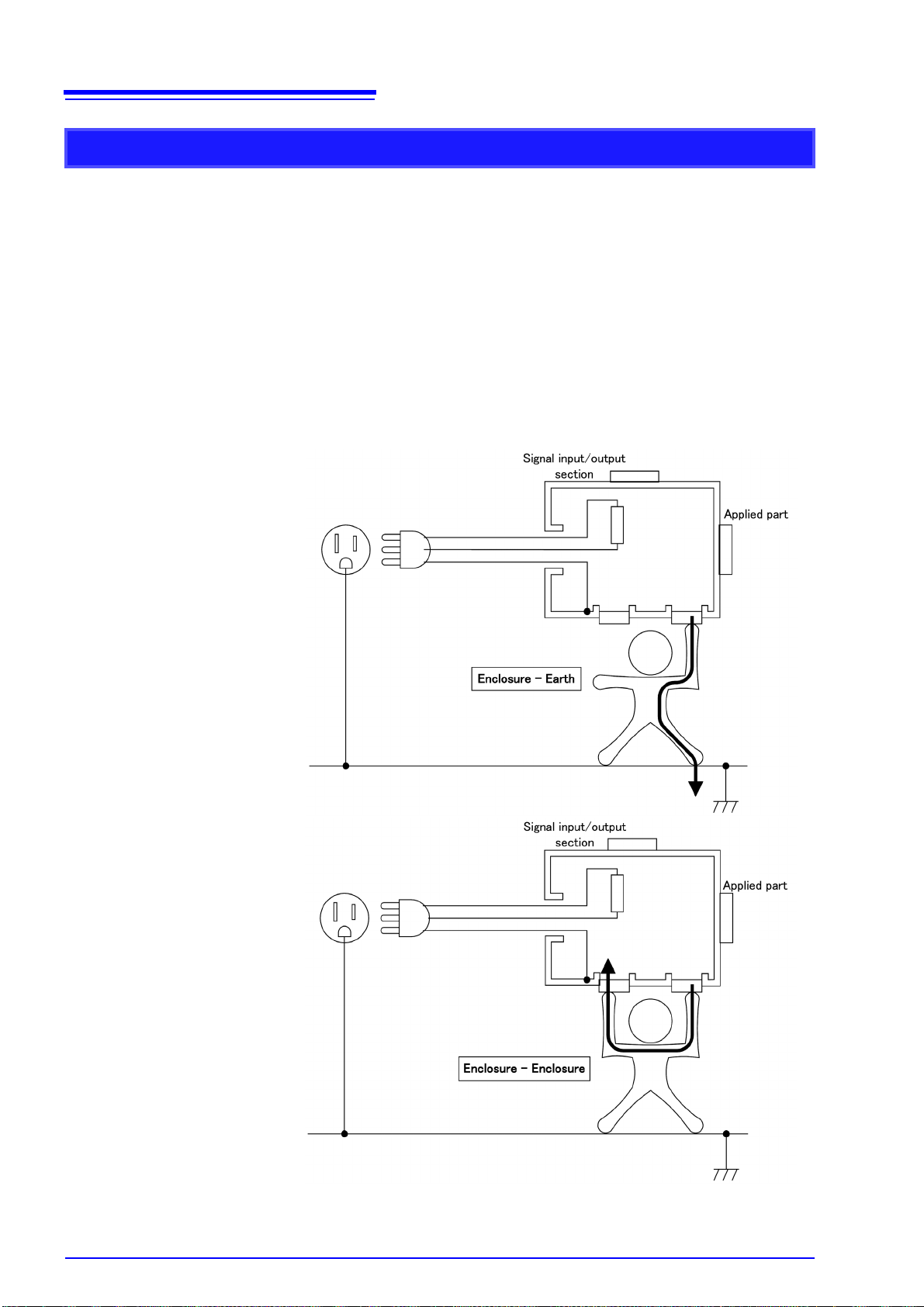

14

1.6 Types of Leakage Current Measurement

Touch current measurement

Class-I equipment does not require the measurement of enclosure leakage current since metal enclosures must be grounded for electrical protectio n.

disconnected (single fault), the enclosure is no longer grounded for protection and must be measured.

For Class-II equipment, all enclosures are ungrounded for electrical protection and must be tested.

Ungrounded equipment are often made of plastics and other insulated materials. Since leakage current

flows through the human body, the standard stipulates that a probe is applied to metal foil the size of a

hand pressed against the insulated material. Use the 9195 enclosure probe supplied with the instrument

for measurements involving this instrument.

There are two paths for touch current to flow: "enclosure

human body enclosure." Note that for "enclosure human body enclosure" to occur a person

must touch two electrically isolated (separate) enclosure sections not two sections on the same enclosure.

However, when the protective earth conductor becomes

human body earth" and "enclosure

Page 21

15

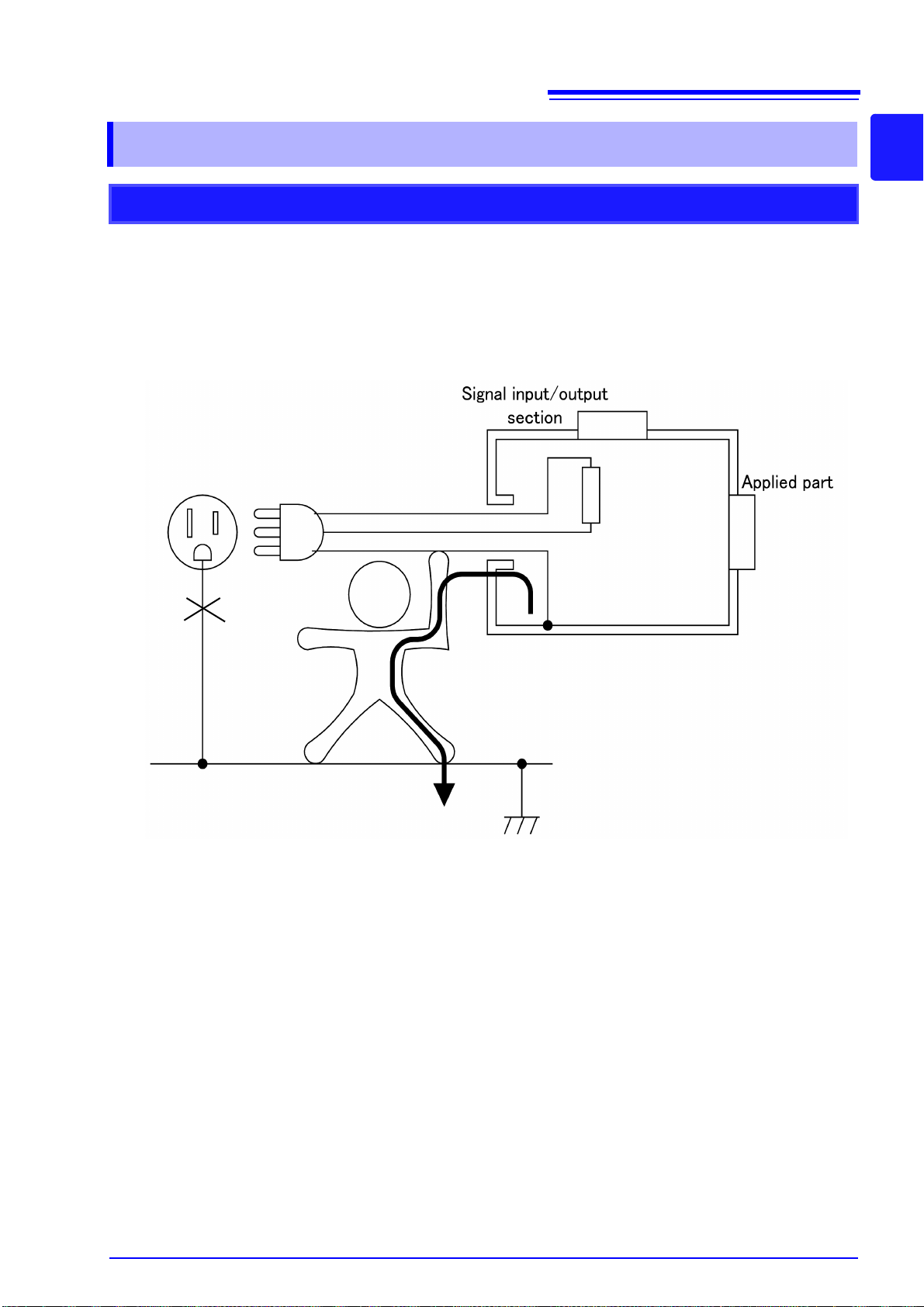

1.6 Types of Leakage Current Measurement

Patient auxiliary current

Patient auxiliary current is current that flows through an "applied part human body applied part" path.

Regardless of the medical equipment class, type of applied parts, and signal input/output selection, all

medical equipment with multiple applied part s must undergo this measurement.

Make both AC and DC measurements for this type of leakage current.

1

Chapter 1 Overview

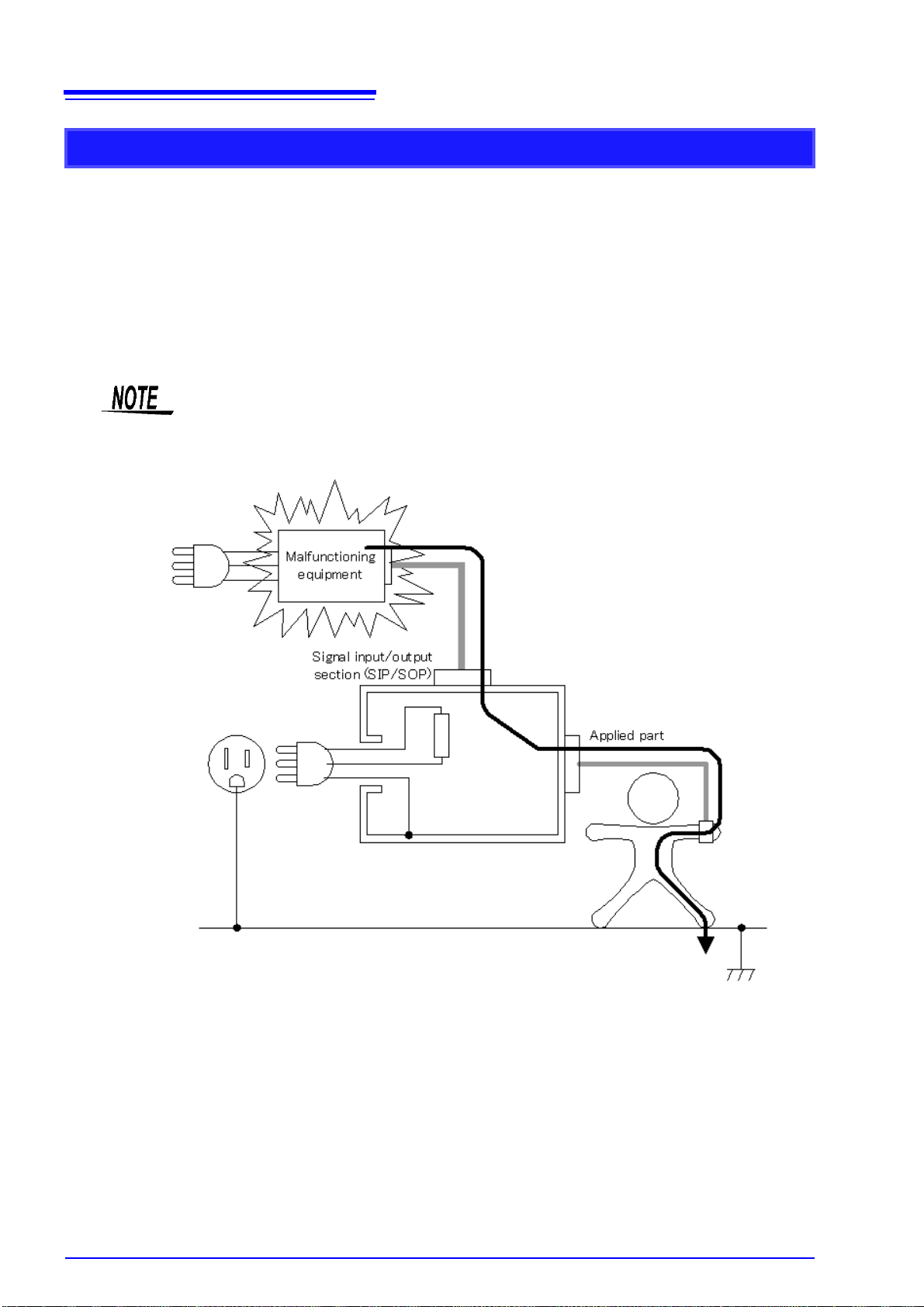

Patient leakage current measurement (Patient connection - Earth)

This is electric current that flows through an "applied part

Regardless of medical equipment class, type of applied parts and signal input/output section, all medical

equipment with patient connections must undergo this measurement.

Make both AC and DC measurements for this type of leakage current.

human body ground" path.

Page 22

16

1.6 Types of Leakage Current Measurement

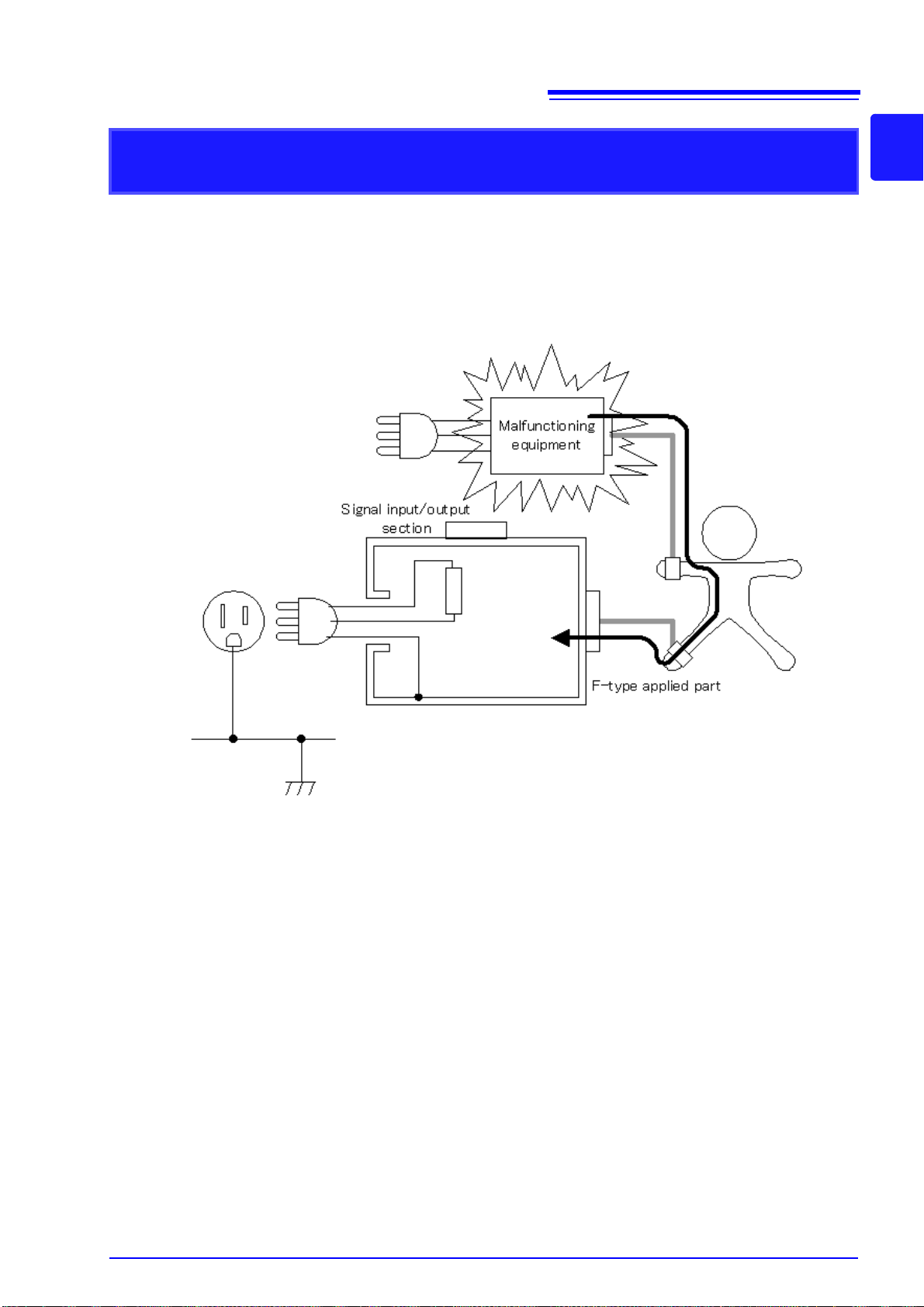

Patient leakage current measurement (external voltage on a SIP/SOP)

This is electric current that flows through an "applied part human body ground" path.

Measure medical instruments with a signal input/output section and applied parts other than F-type. Measure assuming that medical equipm ent with a broken signal input/output section is connected. Instead of

connecting damaged medical equipment to generate a single-fault condition, input a voltage that is 110%

of the rated voltage.

(Use the T3 terminal on the instrument)

IEC 60601-1:2005 3rd Edition stipulates that the connection of damaged medical equipment does not

constitute a single-fault condition, but handles it as a normal condition.

JIS T0601-1:1999 treats patient leakage current II as patient leakage current I plus a

single fault condition.

Page 23

17

1.6 Types of Leakage Current Measurement

Patient leakage current measurement

(external voltage on a specific F-type applied part)

This is electric current that flows through an "applied part of malfunctioning medical equipment human

body

F-type applied part" path.

The measurement of this leakage current is required only for medical devices with an F-type applied part.

Instead of connecting damaged medical equipment to generate a single-fault condition, input a voltage

that is 110% of the rated voltage.

1

Chapter 1 Overview

Page 24

18

1.6 Types of Leakage Current Measurement

Patient leakage current measurement

(external voltage on metal accessible part not protectively earthed)

Additions to IEC 60601-1:2005 3rd Edition

Patient leakage current is current that takes the following route: "metal accessible part not protectively

earthed

patient connection of applied parts that are not protectively earthed (B-type or BF-type) and with metal

accessible parts that are not protectively earthed.

Instead of connecting damaged medical equipment to generate a single-fault condition, input a voltage

that is 110% of the rated voltage to metal accessible parts not protectively earthed. (Use the T3 terminal

on the instrument)

This test is not required for CF-type applied parts.

applied part human body Earth." Use this standard to measure medical equipment wit h

Page 25

19

1.6 Types of Leakage Current Measurement

Total patient leakage current measurement

To tal patient leakage current is the total of all leakage current to or from patient connections of all the

same type of applied parts (B-Type, BF-Type and CF-Type applied parts) simultaneously connected.

When there are two or more patient connections that go to different functions and are not electr ically connected together, the total patient leakage current for B-Type applied parts must be measured.

If required, measure all patient leakage current components (patient connection - earth, external voltage

on an SIP/SOP, external voltage on an F-type applied part, external voltage on a metal accessible part

that is not protectively earthed.)

(The figure shows patient - earth.)

1

Chapter 1 Overview

Page 26

20

1.6 Types of Leakage Current Measurement

Protective conductor current measurement

A protective conductor current measurement measures the electric current that flows thro ugh a protective

earth conductor (grounding wire) during normal operating cond itions.

Like Earth leakage current, class II equipment does not have a protective earth wire and therefore does

not require measurement of protective conductor current.

To measure the protective conductor current, place a resistor with a resistance so small as to be negligible in the protective earth wire circuit.

Page 27

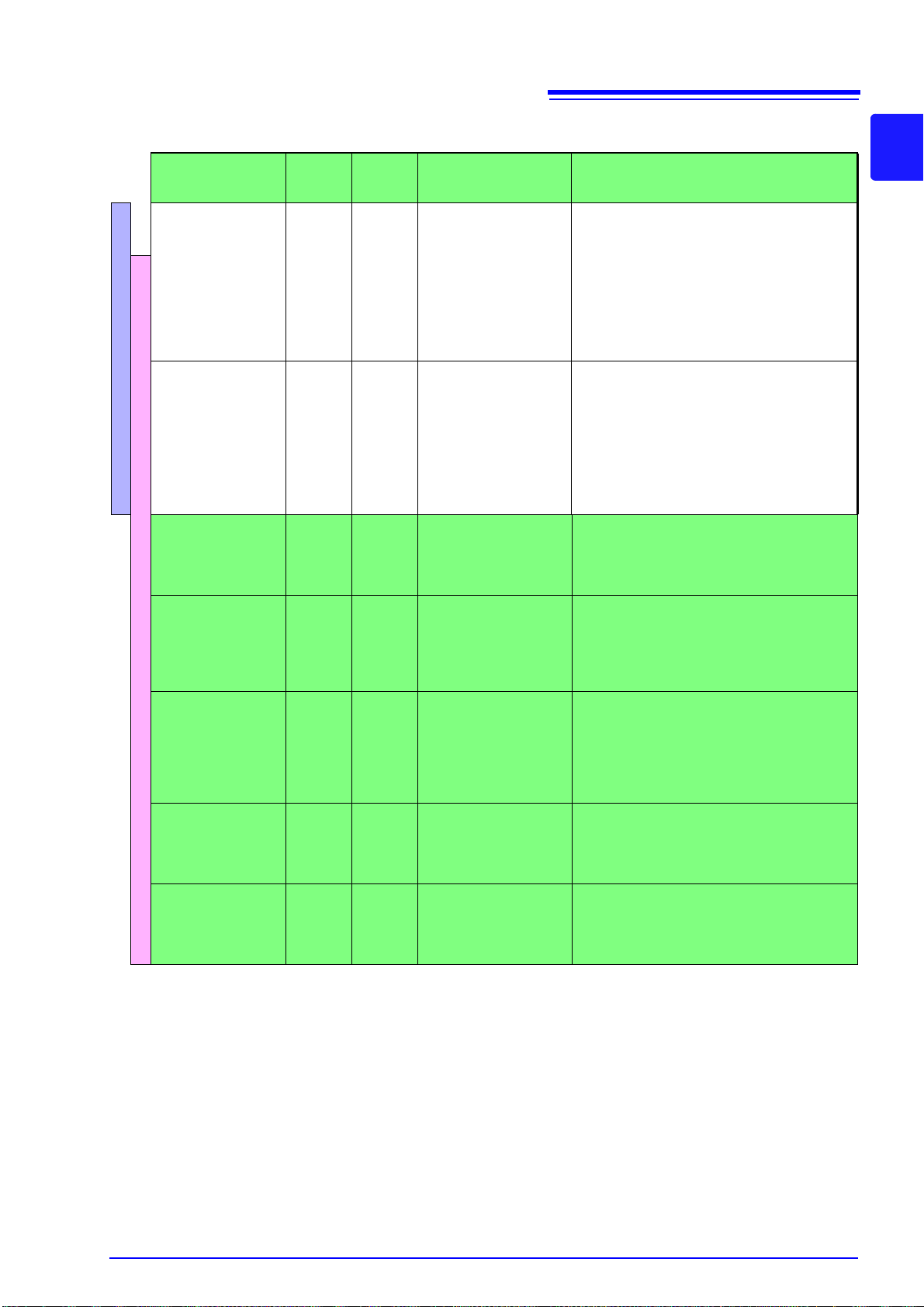

Measurement

General electrical equipment

Medical electrical equipment

Touch current

Enclosure - Line

1.6 Types of Leakage Current Measurement

List of Leakage-Current Measurement Items

Normal

condition

Single-

fault

condition

(Description of fault) (Other conditions)

Situation other than touch current

(Enclosure - Line) is applicable

21

1

Chapter 1 Overview

1. One wire in the power

cord is disconnected.

2. protective earth conductor is disconnected

Touch current

•Enclosure - Earth

•Enclosure - Enclosure

Earth leakage current

Patient leakage cur-

rent (Patient connec-

tion - Earth)/

(Patient leakage

current I)

Patient leakage

current

(external voltage on a

SIP/SOP)/

(Patient leakage

current II)

Patient leakage cur-

rent (external voltage

on a specific F-type

applied part)/

(Patient leakage

current III)

Patient leakage cur-

rent (external voltage

on metal accessible

part not protectively

earthed)

Patient auxiliary

current

*

Measurement with a disconnected protective earth conductor is applicable only to Class-I equipment.

1. One wire in the power

cord is disconnected.

1. One wire in the power

cord is disconnected.

2. The protective earth

conductor is disconnected.

1. One wire in the power

cord is disconnected.

2. The protective earth

conductor is disconnected.

1. The protective earth

conductor is disconnected.

1. One wire in the power

cord is disconnected.

2. The protective earth

conductor is disconnected.

1. Functional grounding wire is disconnected

2. Grounding wire for patient connection and power

*

supply circuit for measurement are disconnected

3. A voltage that is 110% of the rated voltage is applied between an isolated signal input/output

section and earth (Not medical equipment)

1. Functional grounding wire is disconnected

(Class I only)

2. Grounding wire for patient connection and power

supply circuit for measurement are disconnected (Class I only)

1 Functional grounding wire is disconnected

2. Grounding wire for patient connection and power

supply circuit for measurement are disconnected

1. Functional grounding wire is disconnected

2. Metal accessible part not protectively earthed

and grounding wire is disconnected

3. A voltage that is 110% of the rated voltage is applied between an isolated signal input/output

section and earth

1. A voltage that is 110% of the rated voltage is applied between an F-applied part and earth.

(Does not qualify as a single fault condition under IEC 60601-1: 2005 3rd Edition.)

2. Metal accessible part not protectively earthed

and grounding wire is disconnected

3. Functional grounding wire is disconnected

1. Applied to metal accessible part not protectively

earthed

2. Functional grounding wire is disconnected

Functional grounding wire is disconnected

Page 28

22

1.6 Types of Leakage Current Measurement

ST5540/ST5541 List of functions

item ST5540 ST5541

Network A

Network B1

Network B2

Network

Testing leakage current mode

Major functions

Total patient leakage current

Enclosure - Earth leakage current

Enclosure - Enclosure leakage current

Enclosure - Line leakage current

Patient leakage current I

Patient leakage current II

Patient leakage current III

Power on polarity switching function

Function for checking for blown fuses

Frequency band switching

110% voltage output terminal (T3 terminal)

S10, S12, S13, E terminal

Network C

Network D

Network E

Network F

Network G

Earth leakage current

Touch current

Patient auxiliary current

Patient leakage current

Free current

Rated current 20 A

–

–

–

–

–

–

–

–

–

–

–

Page 29

Instrument Labels

23

and Screens Chapter 2

2

Chapter 2 Instrument Labels and Screens

Page 30

24

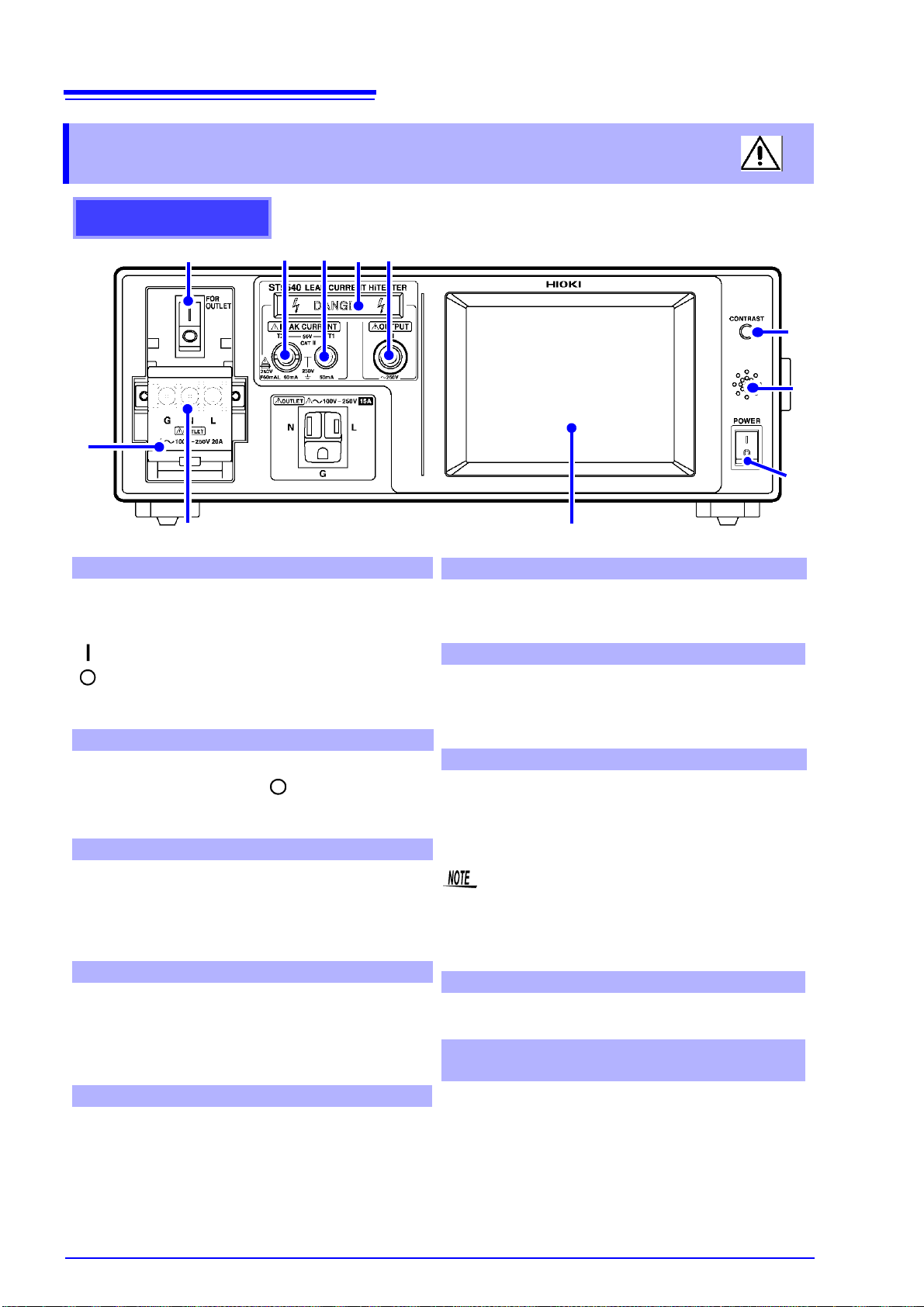

Front Panel

Detects overcurrent in the power line for equipment

under test and activates a protective device.

(Rated current : 20 A)

: ON (for normal measuring operation)

: OFF (idle condition or when overcurrent

protection device has been triggered)

See (p. 31)

Covers the terminal block to prevent electric shock.

Turn the circuit breaker off ( ) before opening the

cover.

See (p. 37)

Outputs voltage based on the power supplied to

[LINE IN] (p. 25).

Also used to connect the power cord of equipment

under test.

See (p. 36)

Five-inch liquid crystal display unit with a touch

panel function.

Also provided with input key functions.

The backlight (p. 136) can be set to turn OFF automatically.

Turns the main instrument ON and OFF.

See (p. 38)

1. Circuit breaker

2. Terminal block cover

3. Terminal block

4. Liquid crystal display unit (LCD)

5. Power switch

Generates a beep sound when a key is pressed, and

activates a warning buzzer.

See (p. 135)

Used to adjust screen contrast.

Turning the dial to the right darkens the display; turning to the left lightens the display.

Use this dial when the display requires adjustment.

Insulates the voltage supplied to [LINE IN] (p. 25)

using the built-in transformer and outputs a 1:1 voltage from terminal T3. Effective only when B1 or B2

network is selected. (only ST5540)

See (p. 75)

Input 110% of the rated voltage to [LINE IN] (p.

25) using the isolation transformer to use the T3

terminal. The T3 terminal will only output a 110% of

the rated voltage when the same voltage is input to

[LINE IN].

Lights when high volltage is generated at the T1 - T3

terminals.

Used to measure leakage current other than Earth

leakage current. The T2 terminal is provided with a

protective fuse.

(fuse rating : 250 V, F50 mAL)

See (p. 75), (p. 282)

6. Buzzer

7. Contrast adjustment dial

8. 110% voltage output terminal (terminal T3)

9. Warning lamp

10. Measuring terminals (terminals T1)

11. Measuring terminals (terminals T2)

1

2

3

4

5

6

7

8

9

11

10

2.1 Instrument Labels and Functions

2.1 Instrument Labels and Functions

Page 31

Rear Panel

Used for input of the power supply to operate the

instrument.

Used to connect the power cord provided.

Marked with a black dot (

) in the power line voltage

specification section.

Used for input of the power supply for equipment

under test.

Used to connect the power cord provided.

(Maximum rating: 250 V/20 A)

Correct measurements are not made whe n no

voltage is input to [LINE IN].

See (p. 33)

Input/output terminal for external control.

(The proper connector is required for connection.)

See (p. 245)

Used to connect an RS-232C cable or 9444 Connection Cable (for the 9442 Printer).

(The 9442 Printer, 9444 Connection Cable,

and other accessories are optional products.)

See (p. 139)

Used to connect a USB cable.

(The USB terminal provides communication functions but no storage capacity.)

See (p. 139)

1. Power inlet [AC IN]

2. Power source rating

3. Inlet for p ower line of equipme nt under test

[LINE IN]

4. EXT I/O connector

5. RS-232C connector

6. USB connector

Terminal for connecting function ground terminal

and power supply system for measurement. Connect to E (earth) for [LINE IN].

Enables connection to earth during leakage current

measurements. (only ST5540)

See (p. 35)

Terminal for connecting patient connection to

ground for power supply circuit for measurement.

Connect to E (earth) for [LINE IN].

Enables connection to earth during leakage current

measurements. (only ST5540)

See (p. 35)

Terminal providing ground connection for metal

accessible part not protectively earthed. Connect to

E (earth) for [LINE IN]. Enables ground connection

during leakage current measurements. (only

ST5540)

See (p. 35)

Connected to E (earth) of [LINE IN].

This is a permanent connection that cannot be

changed.

*

Setting enabled only when B1 or B2 network

is selected.

7. S10 terminal*

8. S12 terminal*

9. S13 terminal*

10. E terminal

1

2

3

4

5

6

7

8

9

10

25

2.1 Instrument Labels and Functions

2

Chapter 2 Instrument Labels and Screens

Page 32

26

Side Panel

1

2

Used to carry the instrument.

1. Handle

Used to tilt the instrument.

2. Stand

2.1 Instrument Labels and Functions

Take the following precautions to prevent electric shock accidents and damage

to the instrument.

• Use M3 screws to attach rack mount brackets after removing the feet.

• When the rack mount brackets are removed to restore the instrument to its

original condition, be sure to use the original screw s.

• The screws used must not penetrate more than 5 mm below the metal pane ls.

• Do not apply heavy downward pressure with the stand extended. The stand

could be damaged.

Page 33

2.2 Screen configuration outline

Measurement screen

System screen

Setting screen of

equipment under test

Network select screen

Initial screen 1

Initial screen 2

Select network to use. (p. 48)

Press to set up the system. (p. 115)

Set measurement conditions for the

selected measurement mode. (p. 51)

Set up equipment under test.(p. 49)

Return to initial screen 1.

Go between pages.

Network

key

measurement

mode keys

Go between pages.

Return to initial

screen 1.

Return to initial screen 1.

Return to initial screen 1.

Network select screen 1

Network select

screen 2

2.2 Screen configuration outline

The following example shows screens that appear after selecting network A. (Screens for networks C to

G look the same as the screen for ne twork A only the network keys differ. Due to the larger number of

measurement mode keys, selecting network B1 opens three initial screens and selecting B2 opens four

initial screens.)

27

2

Chapter 2 Instrument Labels and Screens

Page 34

28

Result of comparison between current measurement

value and allowable value.

PASS

: Current measurement value is equal to or

less than the Upper limit value.

FAIL

: Current measurement value is greater than

the Upper limit value.

LOW

: Current measurement value is equal to or

less than the Lower limit value.

Range Up

:

Measurements exceed the guaranteed accuracy range.

(PASS or FAIL is not determined)

Range Down:

Measurements drop below the guaranteed accuracy range.

(PASS or FAIL is not determined)

Currently set

allowable value

Measurement conditions

at maximum value

acquisition

Maximum measurement

value in same

measurement item

Current measurement

mode

Result of comparison between maximum value and

allowable value.

PASS

: Maximum value is equal to or less than

the Upper limit value.

FAIL

: Maximum value is greater than the Upper

limit value.

LOW

: Maximum value is equal to or less than

the Lower limit value.

Range Up

:

Measurements exceed the guaranteed accuracy range.

(PASS or FAIL is not determined)

Range Down:

Measurements drop below the gua ra nteed accuracy

range. (PASS or FAIL is not determined)

Current measurement value

Selected network

Grounding class

Equipment name

Control number

Date

Current measurement conditions

Measurement screen (manual measurement)

Current measurement value is

minus

2.2 Screen configuration outline

Shared measurement screen displays

The following describes shared measurement screen displays.

(Screen example : Earth leakage current measurement screen)

Page 35

Key description

Shared keys

Clears the maximum value.

Unless this key is pressed, the maximum value is not cleared even if measurement conditions are changed in the same measurement mode.

Changing the measurement mode clears the maximum value.

Displays the allowable value setting screen.

See "4.6 Setting the Allowable Value" (p. 61)

The measurement condition setup screen ap p ea rs .

See "4.8 Changing the Measurement Method (Auto/Manual)" (p. 67)

Displays the filter setting screen. (When a filter selection is available)

Used to turn the filter ON and OFF, or change the setting of the filter.

See "4.5 Setting the Filter" (p. 59)

Displays the screen for setting the target current.

(When an target current selection is available)

See "4.7 Selecting the Type of Target Current" (p. 64)

Displays the screen for setting the measurement range.

Switches the range between Auto and Hold.

See "4.4 Setting the Measurement Range (Auto/Hold)" (p. 54)

29

2.2 Screen configuration outline

2

Chapter 2 Instrument Labels and Screens

Displays the screen for selecting data to be saved.

See "6.4 Saving Measurement Data (As required)" (p. 102)

Starts transmitting data to the 9442 Printer (option).

This key is displayed only when the interface setting is set to "Printer".

See "6.6 Printing Measurement Data (as required)" (p. 108)

Exits the currently selected measurement mode, and returns to th e system screen.

Specific keys (not displayed for some measurement method)

Applies a high voltage to a test lead connected to the T3 terminal.

See "6.3 Measurement examples" (p. 83)

Starts automatic measurements.

See "6.2 Making automatic measurements" (p. 82)

During automatic measurement: Stops automatic measurements.

During application : Stops output of high voltage.

During printing : Terminates printing.

See "6.2 Making automatic measurements" (p. 82)

See "6.3 Measurement examples" (p. 83)

See "Printing" (p. 111)

Displayed only when the frequency range is set from 0.1 Hz.

Press this key to adjust the measurement value.

(Measurement values are automatically adjusted when set from 15 Hz.)

Displayed when patient leakage current (patient - eart h) and internally powered equipment

are selected.

See "Measuring the internally powered equipment 1" (p. 91)

See "Measuring the internally powered equipment 2" (p. 92)

Page 36

30

Non-selectable keys

(indicated in white and

protruding)

Selectable keys

(Black)

Selected keys

(indicated in white

and pushed in)

2.3 About the Touch Panel

2.3 About the Touch Panel

The HiTESTER uses a touch panel for setting and changing all of the measurement conditions.

Gently touch the black keys on the screen to make settings and selections. A key turns white and has a

concave look when selected. In this manual, lightly touching a soft key area on the screen is termed

"pressing" a key.

Do not use excessive force on the touch panel, and do not use sharp o bjects that

could damage the touch screen.

Keys on screen

Keys whose key captions appear as dotted lines are keys for measurement

modes not required for the selected grounding class.

Page 37

31

ON

OFF

Circuit breaker

Power switch

ON

OFF

3.1 Power switch, breaker ON/OFF

Setting

Preparations Chapter 3

3.1 Power switch, breaker ON/OFF

3

Chapter 3 Setting Preparations

Page 38

32

1. Confirm that the main power switch on the front panel of the main instrument and the circuit

breaker are turned off.

2. Connect the power cord to the [AC IN] power inlet on the rear panel of the main instrument, and

insert the power cord plug into a power outlet that supplies the voltage specified for the instrument.

[AC IN]

Preparation items : Power cord for main instrument

3.2 Connecting the Power Cord

3.2 Connecting the Power Cord

Connecting the instrument power cord

• Before turning on the instrument, confirm that the voltage of the

power source matches the voltage specification indicated on the

instrument's power connector ([AC IN]). (The voltage specification

(100, 120, 220 or 240 V) ordered by the customer is marked with a

black dot in the line voltage column on the rear panel.)

Note that using the power supply with improper voltage may damage the instrument and result in electrical hazards

.

• To avoid electrical accidents and to maintain the safety specifica-

tions of this instrument, connect the power cord provided only to

a 3-contact (two-conductor + ground) outlet.

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the power outlet.

The ground (G) for the power inlet [AC IN] is a protective earth conductor and is

connected to the enclosure of the instrument.

Page 39

33

Preparation items : Power cord for equipment under test

Isolation transformer (separately purchased)

Isolation

transformer

[LINE IN]

[AC IN]

3

4

Use the screws

to secure

the connection

LNE

L

N

E

2

Secondary side of the

Isolation transformer

3.2 Connecting the Power Cord

Connecting the power cord of the equipment under test

1. Confirm that the main power switch on the front panel of the main instrument and the circuit breaker

are turned off.

2. Connect the supplied power cord of the equipment under test to the [LINE IN] line power terminal

block for equipment under test on the rear panel of the instrument.

3

Chapter 3 Setting Preparations

3. Connect the plug of the power cord to the isolation transformer.

4. Connect the isolation transformer p lug to a power supply with the voltage specified by the equip-

ment under test.

• When the power on polarity switching function is used, be sure not to

connect the neutral wire on the secondary side of the isolation transformer to ground. If it is connected to ground, a ground fault will occur.

• Use a voltmeter or voltage detec tor to make su re that terminal E [ LINE IN]

is at ground potential (approx. 0 V). Failure to make this confirmation

could lead to electric shock or damage the instrument or the equipment

under test.

• When connecting the power cord of the equipment under test to the

[LINE IN] terminal, use a cord suitable for the capacity of the equipment

under test. Using a power cord with another rating may result in fire.

Page 40

34

3.2 Connecting the Power Cord

• Use of network B1 or B2 requires the connection of an isolation transformer

capable of outputting a voltage equivalent to 110% of the rated power supply

voltage of the equipment under test.

• When network C is selected, an isolation transformer is required.

However, when the power on polarity switching function is not used, connect

the neutral wire on the secondary side to ground. When the function is used,

not to connect the neutral wire to ground.

• The [LINE IN] and [AC IN] power supplies are isolated from each other.

• Use the cable supplied with the ST5540 and ST5541 instruments to connect

the equipment under test [LINE IN]. Do not connect any other electrical appliance to this inlet.

• The [LINE IN] terminal cannot be used to connect a single-phase three-wire

or center-grounded power supply (for example, a stabilized power supply).

• Nor will the input of 110% of a rated 250 V power supply voltage be a problem.

Description of isolation transformer

The standard requires that an isolation transformer is used for performing leakage current measurements.

Should the equipment under test break down during measurements, unforeseen current could be generated resulting in tripping the earth leakage breaker. Such an event could shut down other electrical equ ipment used in the same facility, which could cause a serious accident. Since an isolation transformer

isolates equipment under test from the earth leakage breaker, equipment breakdown will not have an

impact on the earth leakage breaker or on any other equip m en t.

Voltage fluctuations of ±10% from the rated supply voltage are taken into

account. Nor will the input of 110% of a rated 250 V power supply voltage be a

problem.

Page 41

3.2 Connecting the Power Cord

Use the screws

to secure

the connection

LN

E

L

N

E

S10 terminal and

functional earth terminal

Making connections to terminals S10, S12 and S13

1. Make sure that the connection to [LINE IN] is correct.

If the wrong connection has been made to [LINE IN], the E terminal may

output the power supply voltage. Since there is then a risk of electric

shock, make sure that the [LINE IN] connection is correct before making

connections to the S10, S12 and S13 terminals.

35

3

Chapter 3 Setting Preparations

2. Make connections to S10, S12 and S13 to prepare for a leakage current test.

S10 terminal

S12 terminal

S13 terminal For testing connection of metal accessible part not protectively earthed to ground

Example: Connecting S10 terminal to functional earth terminal

For testing connection of function ground terminal to gro und of power supply system for measurement

For testing connection of patient connections to ground of power supply system

for measurement

• S10, S12 and S13 are internally connected to the [LINE IN] E terminal (E terminal is permanently connected to the [LINE IN] E terminal) and correct measurements are not possible unless a power supply is connec te d to [L INE IN].

• When you do not know whether the S10, S12 or S13 termina l should be used,

refer to the documentation supplied with the equipment under test.

Page 42

36

LNG

N

E

L

HiTESTER

Terminal block

Power cord (cable case)

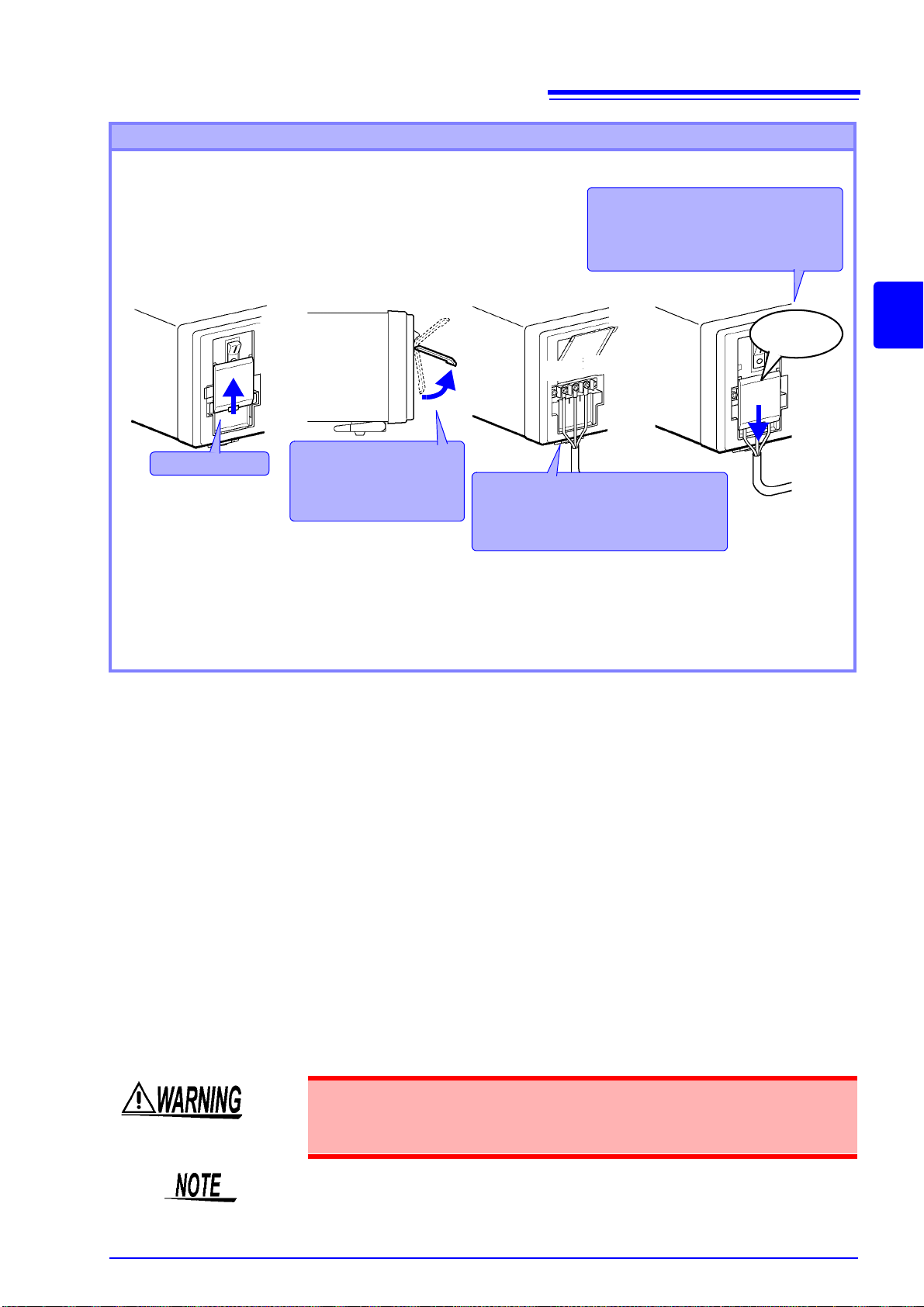

3.3 Connecting equipment under test to the instrument

3.3 Connecting equipment under test to

the instrument

The actual connection procedure will vary with the power supply of the equipment under test. A cord to

connect the instrument and the equipment under test is not supplied. Use a power cord that suits the

power supply of the equipment under test.

• To avoid electrical accidents, confirm that all connections are secure.

The increased resistance of loose connections can lead to overheating

and fire.

• To avoid electric shock or damage to the equipment, always observe the

following precautions when connecting to external terminals.

Always turn off the power to the instrument and to any devic es to be connected before making connections.

Be careful to avoid exceeding the ratings of external terminals and connectors.

During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Make sure that c onnections are

secure and use screws to secure the external connectors.

• The permissible current for the terminal block is 20 A. Current exceeding

this limit will trip the breaker and shut down the power supply of the

equipment under test.

Connect the terminal

When connecting the HiTESTER to equipment under test with a power cord, use the terminal

block.

• L (Line), N (Neutral) and G (Ground) are indicated on the terminal b lock of the

instrument, and the contacts of the power cord of the device to be measured

are denoted L, N and G. Connect the wires as shown below. Other wirin g configurations may cause electric shock or damage.

• If the power cord does not include an Ground (G) line, connect only the L and

N terminals.

• When reinstalling the terminal block cover, hang the connected wires straight

down to prevent the wires from being pinched by the cover. Otherwise, the

wires may be disconnected when pinched by the cover.

• To avoid the risk of electric shock and short-circuiting, use the supplied power

cord to connect the measurement line and voltage input terminal.

Page 43

3.3 Connecting equipment under test to the instrument

G

N

L

Check that the G, N and L terminals

are correctly connected and make

sure the wires are properly secured

Turn on the instrument.

Fit the right and left projecting portions of the terminal block cover

into the panel slit. Slide the cover

downwards until it clicks into place

Slide upwards

Raise the cover.

(The cover will stay in

place when raised to a

certain height)

G : For grounding wire connection

(Class-I equipment only)

N : For neutral wire connection

L : For live wire connection

Turn off the instrument and set the breaker to Off.

See "Turning Power Off" (p. 40)

See "3.1 Power switch, breaker ON/OFF" (p. 31)

1

2

3

4

5

Turn on the HiTESTER.

See "3.4 Turning Power On and OFF" (p. 38)

6

Clicking

sound

Multi-connection adapter, etc.

Connecting wires to the terminal block

37

3

Chapter 3 Setting Preparations

Using a wiring adapter

Obtain and use a wiring adapter as shown below.

Leakage current will increase with the use of multi-connection adapters, etc.

• Turn off the circuit breaker connecting a wiring adapter or equipment.

• The terminal block continuously ou tput the voltage based on the power sup plied to [LINE IN].

Page 44

38

3.4 Turning Power On and OFF

3.4 Turning Power On and OFF

Turning Power On

• Before turning on the instrument, confirm that the voltage of the power

source matches the voltage specification indicated on the instrument's

power connector ([AC IN]). (The voltage specification (100, 120, 220 or

240 V) ordered by the customer is marked with a black dot in the line

voltage column on the rear panel.)

Note that using the power supply with improper voltage may damage the

instrument and result in electrical hazards.

• To avoid electrical accidents and to maintain the safety specifications of

this instrument, connect the power cord provided only to a 3-contact

(two-conductor + ground) outlet.

• Before turning on the power switch, confirm that the circuit breaker is turned

off. Even if the instrument was turned off in fault mode (i.e., disconnection of

one wire in the power line) at last use, the instrument will be initialized to normal condition when the power switch is turned on. Therefore, the terminal

block outputs voltage.

• The instrument can operate continuously for 30 minutes at maximum load.

Measurements that continue for longer than 30 minutes may raise internal

temperature and thereby trip the circui t brea ke r.

Page 45

39

1. Confirm that the circuit breaker is turned off.

(If the instrument is turned on when the circuit br eaker i s

On, the circuit breaker may be triggered.)

2. Turn on the power switch (ON: ) on the fr ont panel.

3. The LCD shows the opening message.Then the wiring

check screen appears.

4. Use the contrast adjustment dial to set the LCD for easy

viewing.

5. Turn the circuit breaker On and press to check

wires connected to LINE IN.( appears only when

wiring is incorrect. Press for advice.)

6. Press to open the fuse check screen.

See "7.5 Checking Fuses(During Earth leakage current and

protective conductor current measurements)" (p. 123)

7. Pressing in the fuse check screen opens the

relay check screen.

See "Relay Check" (p. 41)

8. Pressing in the relay check screen,The network

select screen appears by default.

If the instrument was turned off with th e LCD showing

the measurement screen at last u se, that m easurem ent

screen appears.

If the instrument was turned off with the LCD showing a

screen other than the measurement screen, the initial

screen appears.

9. After turning the power on, let the instrument warm up

for about 20 minutes before starting measurement op eration.

1

2

Wiring check screen

Check again.

4

Fuse check screen

Relay check screen

5

6

7

8

3.4 Turning Power On and OFF

3

Chapter 3 Setting Preparations

When "Check at each power ON operation" is enabled on the connection/VA

check screen, the connection/VA check screen appears after th e p ower switch is

turned on.

See ."Inspecting line power supply for the equipment under test" (p. 42)

(If the power on polarity switching func tion was on wh en the in strument was last

turned off, a message to check isolation transformer con nection and pre c autions

appear before the wiring check screen.)

When the grounding class of the equipment under test is set to internally pow-

ered equipment, is displayed, and after the initial measurement, the voltage value will not be renewed as long as "Renew" is not pressed.

Page 46

40

NO:Normally open

Condition of power line for equipment under test with the main

instrument power switch turned OFF (schematic diagram)

1. Turn off the power switch of equipment under test connected to the terminal block.

2. Turn off the circuit breaker.

3. Turn off the power switch (OFF: ) on the front panel.

When the power switch is turned o ff, the measurement conditions are saved. In case of power

supply failure (e.g., power outage), the instrument restores the conditions held immediately

before power failure occurred.

2

3

3.4 Turning Power On and OFF

Turning Power Off

Always turn off the power switch of equipment under test before turning off

power of the instrument to avoid damaging the equipment under test. The instrument uses an internal relay for switching the power line to equipment under test

and turning off the power switch of the instrument opens all lines and turns off

the equipment under test.

Page 47

3.5 Pre-Test Inspection

Before using the instrument the first time, verify that it operates normally to ensure that no damage occurr ed

during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Enables the user to check whether the measurement network and internal circuit relays work normally.

(1) Press on the initial screen to display the system screen.

(2) Press to open the relay check screen.

(3) Press to start a relay check.

(4) An "OK" appears when the check ends without error.

(5) Press to return to the system screen.

Supply power via [LINE IN] and turn the circuit breaker

On as a relay check will otherwise not operate normally.

Always confirm this before performing a relay check.

Do not connect a device under test during a relay check.

Relay Check

1

See next page.

A "NG" indication indicates that the measurement network or an internal relay does not work

normally. As the instrument is not in normal

working order, contact your dealer or nearest

Hioki sales office.

Relay check screen

Press or to select whether the check

is to be conducted each time power is turned.

An "OK" is displayed

A "NG" is displayed

3

4

The internal configuration of the instrument makes it possible that a device

under test connected during a relay check may be exposed to unexpected

voltage that could damage it.

Pre-connection inspection

Does any cable insulation appear damaged,

or is bare metal exposed?

Is damage to the instrument evident?

Does the power supply use single-side-

grounded wiring?

Power-on confirmation

Do not use if damage is present, as you could receive an electric shock. Contact your dealer or Hioki representative if you

find any damage.

When using a center-grounded wiring type power supply (for

example, a stabilized power supply), you may not be able to

perform all checks accurately.

41

3.5 Pre-Test Inspection

3

Chapter 3 Setting Preparations

Page 48

42

Fuse inspection (when using modes other than Earth leakage current

and protective conductor current modes)

2

The current detection circuit in the instrument contains a fuse. Should the fuse blow due to incorrect wiring

or an over-current condition, the instrument may no longer be able to detect current. Before use, make sure

that the fuse is not blown.

Required items

• A device for measuring impedance

(for example, a tester)

(1) Select network E in the Network Select screen and select

Enclosure - Enclosure leakage current.

(2) Use a tester to measure the impedance between

the T1 and T2 terminals on the front panel.

(Or place the tip of test leads connected to the T1 and T2

terminals on the tester to measure.)

(3) Check that an impedance value of 1015

10 is obtained.

When the tester is connected to the T1 and T2 termina l s,

the instrument measures the leakage current going through the tester.

The impedance is not

1015

10 .

The fuse at the T2 terminal on the front of the

instrument may be blown, or a non-specified

fuse may be inserted. Replace the fuse.

See "11.3 Replacing Fuses" (p. 282)

Network E : Enclosure-Enclosure

leakage current measurement screen

Check the line power supply of the equipment under test.

(1) Press in the initial screen.

(2) Turn on the circuit breake r of the instrument. (p. 31)

(3) Press to display the connection/VA check

screen.

(4) The check is made automatically.

(5) Press to return to the system screen.

Supply power via LINE IN and turn the circuit breaker On as a

connection / VA check will not otherwise operate normally. Always

confirm this before performing a connection / VA check.

Inspection complete

(When network B2 is selected(p. 43))

Inspecting line power supply for the equipment under test

3

An "NG" appears

Press to display the screen that shows advice

concerning the present condition. According to the

displayed advice, check the current consumption,

power cord connection, and other aspects of the

equipment under test.

See "About the NG Indication" (p. 44)

Press or to select

whether the check is to be conducted

each time power is turned.

The impedance is an

overflow

The impedance is about 15 .

(The fuse is not blown.)

Remove the fuse from the T2 terminal, and directly measure the

fuse resistance.

The impedance is

not about 15 .

3.5 Pre-Test Inspection

Page 49

3.5 Pre-Test Inspection

(1) Press in the initial screen.

(2) Press .

(3) Press and set a frequency range setting of 0.1 Hz.

(Press to confirm and return to the system screen.)

(4) The appears when 0.1 Hz frequency range is set.

Press and adjust the value

(5) Measure the leakage current of the equipment under test

and record the measured value.

(Perform this measurement for 1 or 2 minutes.)

(6) When recording ends, perform operations in step (1) and (2)

again and press and set a frequency range setting of

15 Hz.

(7) Measure the leakage current of the equipment under test

and compare this value with the value obtained in the 0.1 Hz

- 1 MHz setting.

Unless the two values differ substantially, the customer's

equipment under test does not produce any leakage current

and the 15 Hz - 1 MHz setting is enough for any subsequent

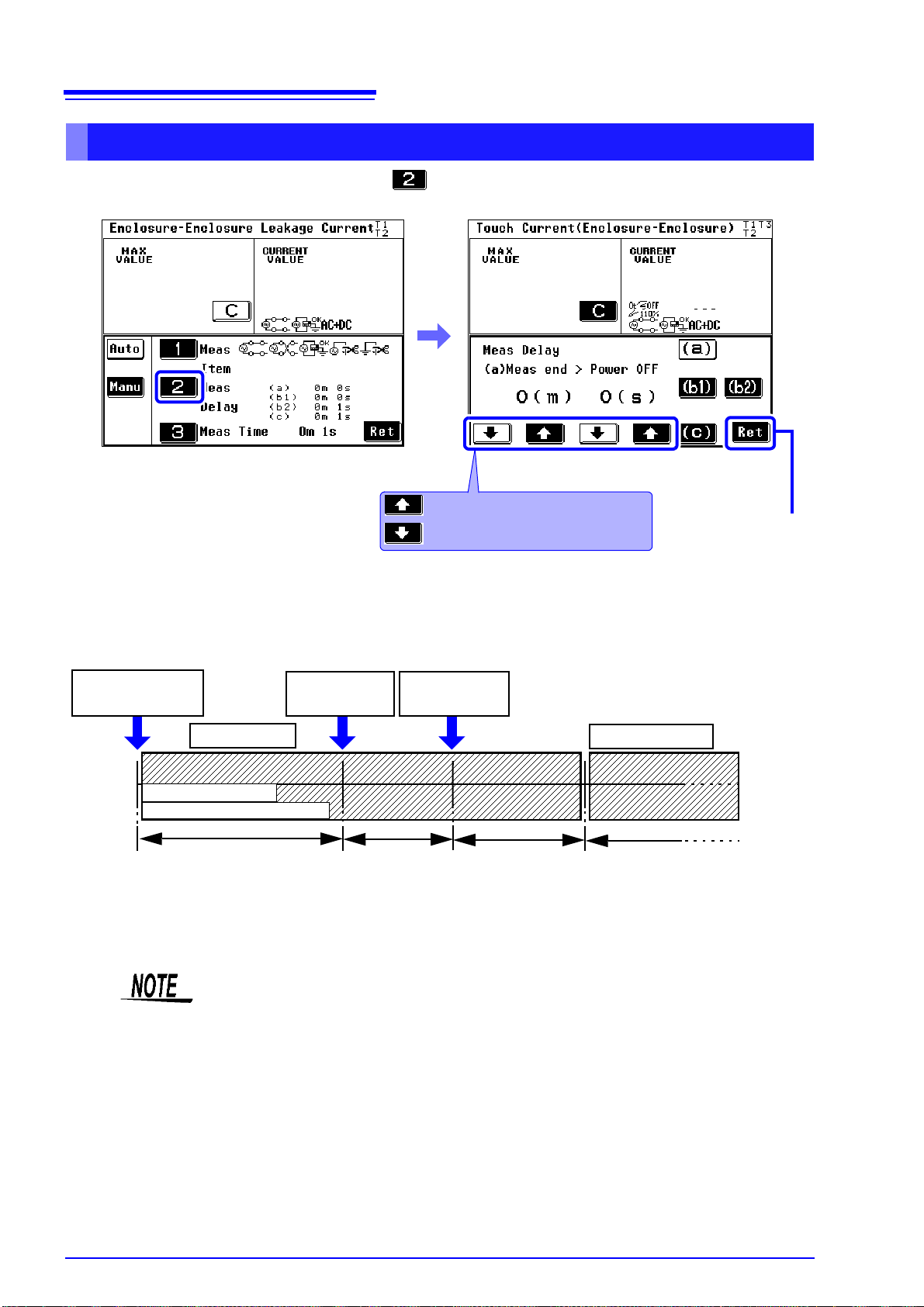

measurement.