Hioki ST5520-01, ST5520 Instruction Manual

ST5520

ST5520-01

Instruction Manual

INSULATION TESTER

Aug.2015 Revised edition 2

ST5520A981-02 15-08H

EN

Contents

Introduction ........................................................................................1

Verifying Package Contents .............................................................1

Safety Notes .......................................................................................3

Usage Notes .......................................................................................7

1 Overview 15

1.1 Product Overview and Features ...........................................15

■Overview ............................................................................................15

■Features .............................................................................................16

1.2 Parts Names and Functions ..................................................17

1.3 MeasurementWorkow .........................................................19

1.4 ScreenCongurationandOperationOverview ..................20

■Measurement screen..........................................................................20

■Settings screen...................................................................................21

2 Preparations 23

2.1 Connecting the Power Cord ..................................................23

2.2 Connecting the Measurement Leads ...................................24

■Removing and attaching the sleeves .................................................25

2.3 ConnectingtotheEquipmenttobeMeasured ....................26

2.4 Turning the Power On and Off ..............................................26

■Turning on the power .........................................................................26

■Turning off the power..........................................................................26

2.5 Pre-OperationInspection ......................................................27

■Checking the insulation resistance test ..............................................28

■Checking the contact check function ..................................................29

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

3 Basic Settings 33

3.1 Setting the Test Voltage .........................................................34

ST5520A981-02

i

Contents

3.2 Setting the Range ...................................................................36

3.3 SwitchingtheMeasurementSpeed(FAST/SLOW) .............38

3.4 SettingtheTestDurationandResponseTime ....................39

■Setting how long to apply the test voltage ..........................................39

■Setting the response time...................................................................41

3.5 JudgingMeasuredValues(Comparatorfunction) ..............44

3.6 Setting the Test Mode ............................................................46

3.7 AnnouncingtheJudgmentResultsUsingaBeepSound .47

4 Testing 49

4.1 Starting Measurements .........................................................49

4.2 During Measurement .............................................................51

4.3 MeasuredValueDisplay ........................................................52

4.4 CompletingMeasurement .....................................................53

4.5 AutomaticDischargeFunction .............................................54

5 Useful Functions 55

5.1 CheckingFaultyContactandContactStatus(Contact

checkfunction) .......................................................................56

■Connecting test leads .........................................................................58

■Example of connection to equipment to be measured .......................58

■2-terminal contact check function .......................................................59

5.2 CheckingShortCircuitbeforeApplyingtheSetVoltage

(Shortcircuitcheckfunction) ...............................................60

5.3 Enabling/DisablingtheKeyOperations ...............................65

5.4 SettingtheKeyOperationSound .........................................67

5.5 PreventingOperationErrorsattheStartofTesting

(Doubleactionfunction) ........................................................68

5.6 AdjustingtheScreenContrast .............................................69

5.7 AdjustingtheBacklight .........................................................70

5.8 SettingtheFrequencyofPowerSupplyManually ..............71

5.9 InitializingtheSystem(Reset) ..............................................72

ii

Contents

5.10 Default Setting List ................................................................73

6 Saving and Loading Measurement Conditions

(Memoryfunction) 75

6.1 Saving the Measurement Conditions

(Panelsavefunction) .............................................................76

6.2 Loading the Measurement Conditions

(Panelloadfunction) ..............................................................77

6.3 Changing the Panel Name .....................................................78

6.4 Deleting the Panel Data .........................................................79

7 ExternalControl(EXT.I/O) 81

7.1 ExternalInput/OutputTerminalandSignals........................82

■Switching between current sink (NPN) and current source (PNP) .....82

■Connector type and signal pinouts .....................................................83

■Signal descriptions .............................................................................86

7.2 Timing Chart ...........................................................................88

7.3 InternalCircuitConguration ...............................................96

■Electrical specications ......................................................................98

■Connection examples .........................................................................99

7.4 Setting the TEST Signal OFF Timing ..................................101

7.5 Checking External Control ..................................................103

■Performing an I/O test (EXT.I/O test function) ..................................103

7.6 UsingAnalogOutput ...........................................................104

■Connecting the output cord ..............................................................105

■Setting the analog output .................................................................105

7.7 Interlock Function ................................................................106

7.8 UsingtheSwitchedProbe ...................................................108

■Connecting the 9299 Switched Probe ..............................................109

7.9 AccessoryConnectorAssembly ........................................111

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

iii

Contents

8 Communications(RS-232Cinterface) 113

8.1 Interface Overview and Features ........................................113

8.2 Using the RS-232C Interface ...............................................114

■Setting communications conditions ..................................................114

■Connecting the RS-232C cable ........................................................115

8.3 AutomaticallyExportingMeasuredValuesattheEnds

ofTests(Dataoutputfunction) ...........................................117

8.4 ControllingtheInstrumentandAcquiringDatawith

Commands ............................................................................119

■Remote and local states ...................................................................119

■Displaying communications commands (Communications monitor

function)............................................................................................120

8.5 DataFormatTable ................................................................125

8.6 Command Reference ...........................................................126

9 Specications 151

■Environment and safety....................................................................151

■Output (output accuracy) ..................................................................151

■Resistance measurement ................................................................153

■Input .................................................................................................154

■Guaranteed accuracy .......................................................................154

■Test duration ....................................................................................155

■Response time .................................................................................156

■Functions ..........................................................................................156

■External interface .............................................................................159

■Other specications ..........................................................................162

■Accessories ......................................................................................164

■Options .............................................................................................164

10 Maintenance and Service 165

10.1 Maintenance .........................................................................165

10.2 Troubleshooting ...................................................................167

iv

Contents

■Error display and solutions ...............................................................171

Appendix Appx.1

Appx.1 BlockDiagram .......................................................Appx.1

Appx.2 ContactCheckFunction .......................................Appx.2

Appx.3 OutputVoltageandMeasurementResistance ...Appx.3

Appx.4 InuenceofCapacitiveLoad ...............................Appx.4

Appx.5 InuenceofCableLength ....................................Appx.6

Appx.6 InuenceofNoise .................................................Appx.7

Appx.7 RackMounting ....................................................Appx.10

Appx.8 DimensionalDiagram .........................................Appx.14

Index Ind.1

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

v

Contents

vi

Introduction

Introduction

Thank you for choosing the HIOKI ST5520/ST5520-01 Insulation Tester. To obtain

maximum performance from the product, please read this manual rst, and keep it

handy for future reference.

The ST5520-01 is equipped with the BCD output function of the ST5520. The artwork

of the ST5520 is used in this manual.

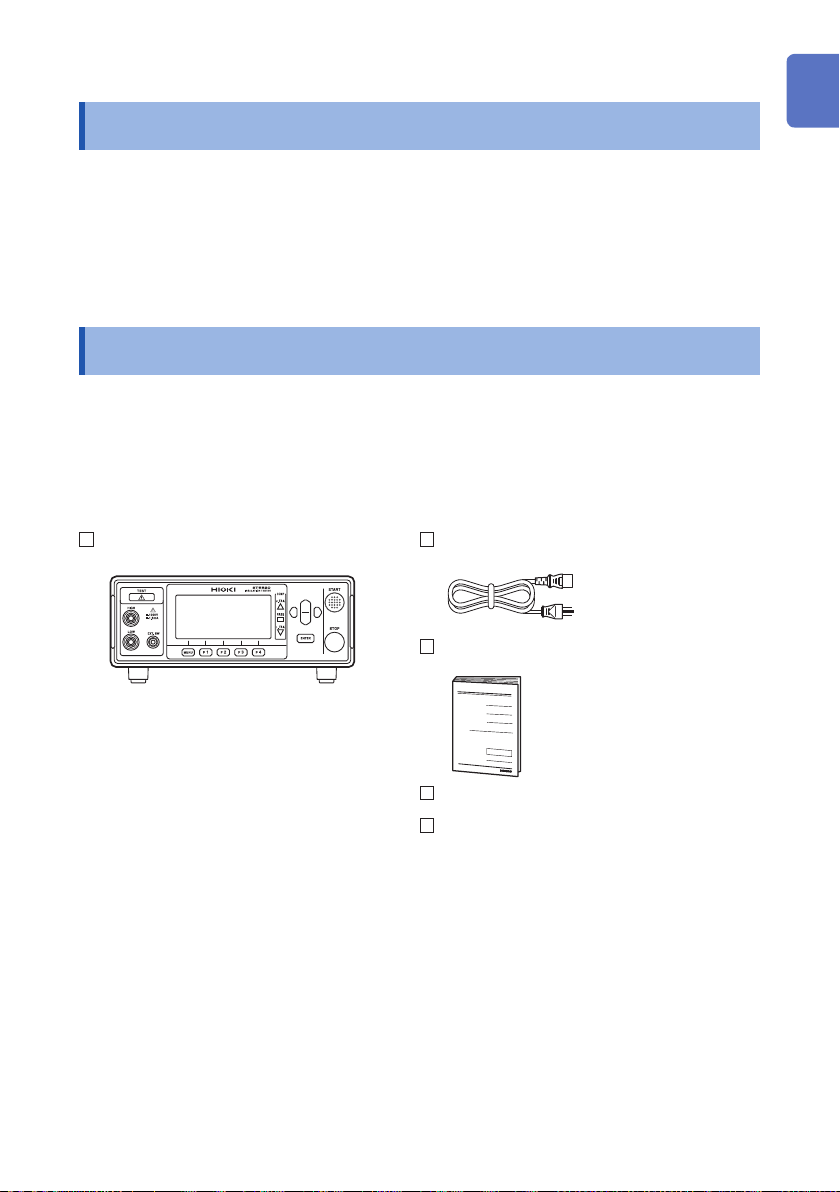

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specications, contact your authorized Hioki distributor or reseller.

Check the package contents as follows.

ST5520 or ST5520-01

Insulation Tester .........................................1

Power cord .................................................1

Instruction Manual ......................................1

1

2

3

4

5

6

7

EXT.I/O connector (pin contacts) ................1

EXT.I/O connector cover.......................1 set

8

9

10

Appx. Ind.

1

Verifying Package Contents

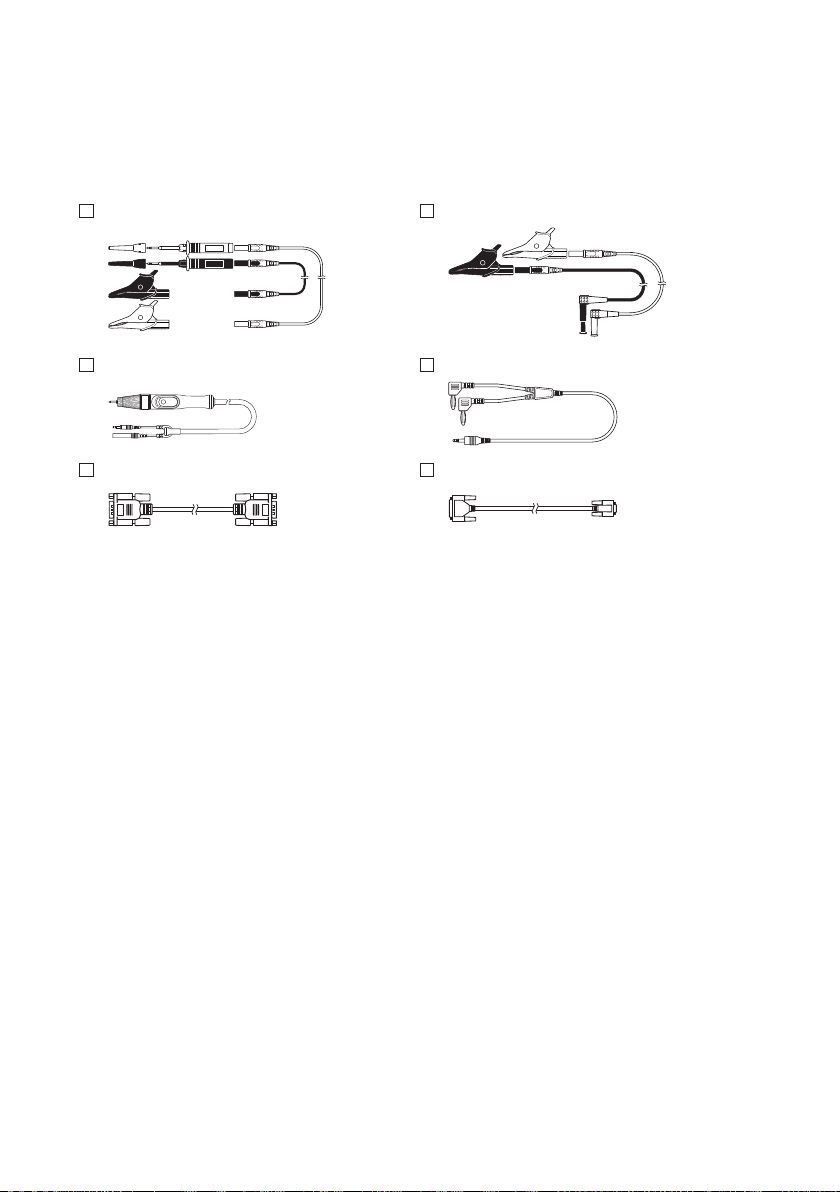

Options

The following options are available for ST5520/ST5520-01. Contact your authorized

Hioki distributor or reseller when ordering.

L2200 Test Lead L9257 Connection Cord

9299 Switched Probe 9094 Output Cord (analog output)

9637 RS-232C Cable (9pin-9pin/1.8 m) 9638 RS-232C Cable (9pin-25pin/1.8 m)

2

Safety Notes

Safety Notes

This instrument is designed to conform to IEC 61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment. However, using the instrument in a way

not described in this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well

as damage to the instrument. Be certain that you understand the

instructions and precautions in the manual before use.

WARNING

With regard to the electricity supply, there are risks of electric shock,

heat generation, re, and arc discharge due to short circuits. If

persons unfamiliar with electricity measuring instruments are to use

the instrument, another person familiar with such instruments must

supervise operations.

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

3

Safety Notes

Notation

In this manual, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

*

[ ]

SET

(Boldface)

Indicates an imminently hazardous situation that will result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in minor

or moderate injury to the operator or damage to the instrument or

malfunction.

Indicates information related to the operation of the instrument or

maintenance tasks with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is

mishandled, this may give rise to a hazardous situation; the operator

may receive an electric shock, may get burnt or may even be fatally

injured.

Indicates prohibited actions.

Indicates the action which must be performed.

Additional information is presented below.

Indicates set items and buttons on the display in [ ].

Bold-faced alphanumeric characters in the text indicate characters

shown on the operation keys.

4

Symbols afxed to the instrument

Indicates cautions and hazards. When the symbol is printed on the instrument,

refer to a corresponding topic in the Instruction Manual.

Indicates that dangerous voltage may be present at this terminal.

Safety Notes

1

Indicates the power “ON”.

Indicates the power “OFF”.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE

Directive) in EU member states.

Indicates that the instrument conforms to regulations set out by the EC Directive.

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading), and

dgt. (digit) values, with the following meanings:

(Maximum display value, scale length)

f.s.

rdg.

dgt.

The maximum display value or the full length of the scale. This is usually the

maximum value of the currently selected range.

(Reading or displayed value)

The value currently being measured and indicated on the measuring

instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input

value that causes the digital display to show a “1” as the least-signicant digit.

2

3

4

5

6

7

8

9

10

Appx. Ind.

5

Safety Notes

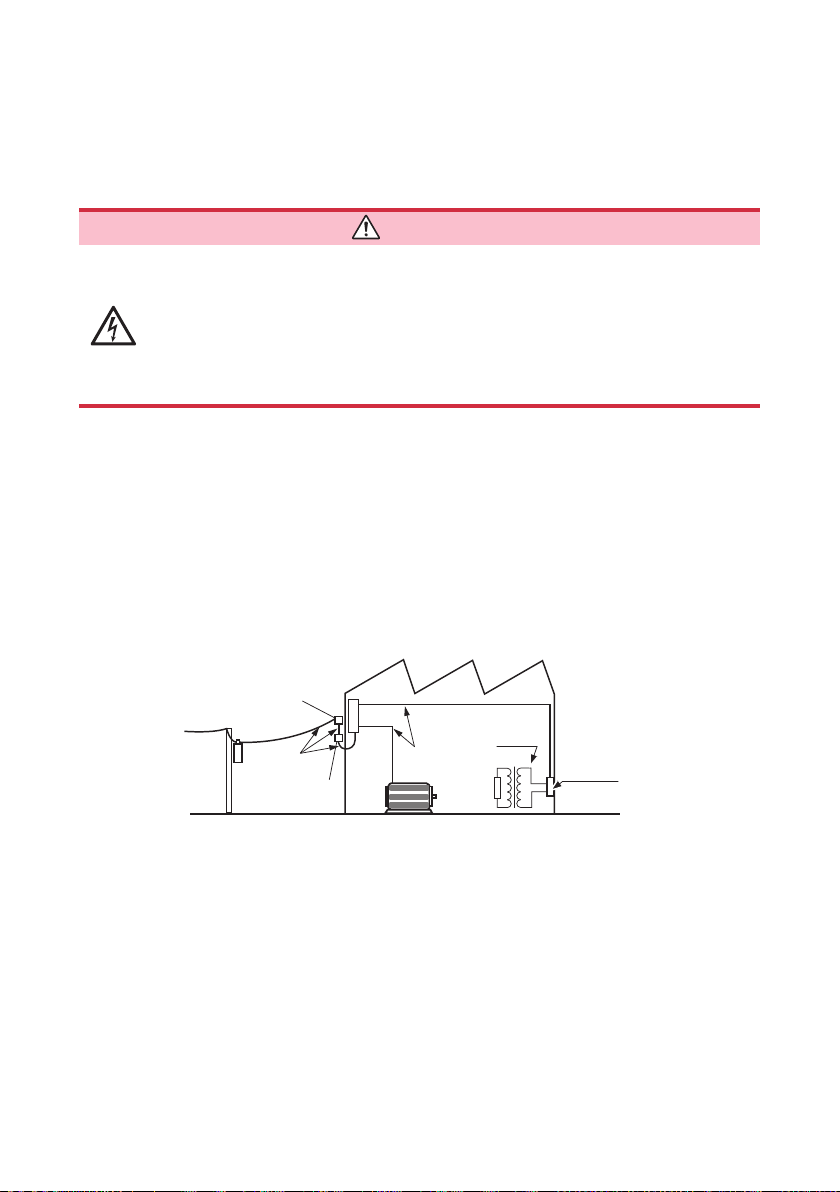

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety

standards for various electrical environments, categorized as CAT II to CAT IV, and

called measurement categories.

DANGER

• Using a measuring instrument in an environment designated with

a higher-numbered category than that for which the instrument

is rated could result in a severe accident, and must be carefully

avoided.

• Using a measuring instrument without categories in an environment

designated with the CAT II to CAT IV category could result in a

severe accident, and must be carefully avoided.

CAT II: When directly measuring the electrical outlet receptacles of the primary

electrical circuits in equipment connected to an AC electrical outlet by a

power cord (portable tools, household appliances, etc.)

CAT III: When measuring the primary electrical circuits of heavy equipment (xed

installations) connected directly to the distribution panel, and feeders from

the distribution panel to outlets

CAT IV: When measuring the circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent protection device

(distribution panel)

Service entrance

Service drop

CAT IV

Power meter

Distribution panel

Internal

wiring

CAT III

Fixed installation

CAT II

T

Outlet

6

Usage Notes

Usage Notes

Follow these precautions to ensure safe operation and to obtain the full benets of

the various functions.

Preliminary checks

DANGER

If the probe or the instrument is damaged, there is a risk of electric

shock. Before using the instrument, perform the following inspection.

• Before using the instrument, check that the coating of the probes

are neither ripped nor torn and that no metal parts are exposed.

Using the instrument under such conditions could result in electric

shock. Replace the probes with those specied by our company.

• Before using the instrument the rst time, verify that it operates

normally to ensure that no damage occurred during storage or

shipping. If you nd any damage, contact your authorized Hioki

distributor or reseller.

Installation

Installing the instrument in inappropriate locations may cause a malfunction of

instrument or may give rise to an accident. Avoid the following locations.

For details on the operating temperature and humidity, refer to the specications.

(p. 151)

CAUTION

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

• Susceptible to vibration

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

7

Usage Notes

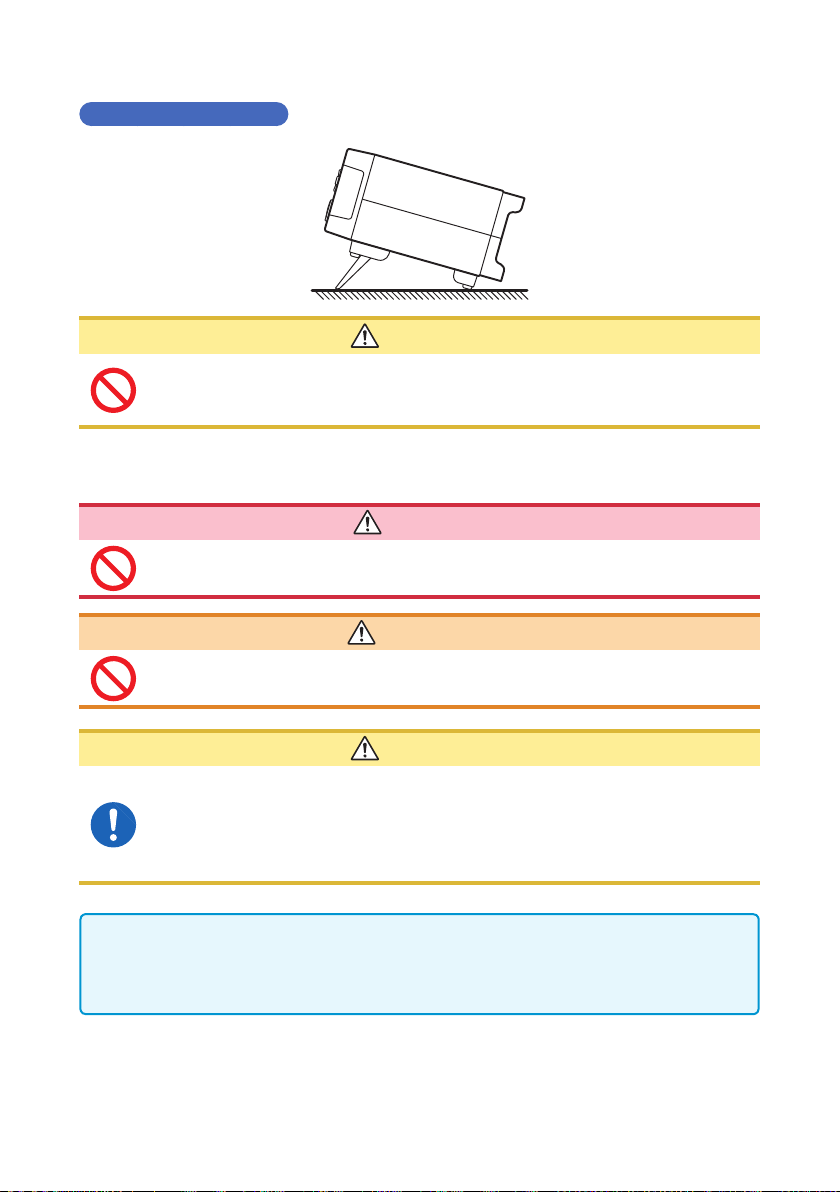

Installation precaution

Do not position the instrument on an unstable table or inclined surface. If

the instrument falls or tips, a malfunction of the instrument or injury may be

caused.

Handling the instrument

To avoid electric shock, do not remove the instrument's case. The

internal components carry high voltage and high temperature.

CAUTION

DANGER

WARNING

Customers are not allowed to modify, disassemble, or repair the

instrument. Doing so may cause re, electric shock, or injury.

CAUTION

• To avoid damage to the instrument, protect it from vibrations and physical

shock when transporting and handling. Be especially careful to avoid

physical shock from dropping.

• To avoid damage to the instrument, do not apply voltage or current to

EXT.SW terminal, analog output terminal, or maintenance terminal.

This instrument may cause interference if used in residential areas. Such use must

be avoided unless the user takes special measures to reduce electromagnetic

emissions to prevent interference to the reception of radio and television

broadcasts.

8

Handling the cords and leads

Usage Notes

DANGER

To avoid electric shock, be careful to avoid shorting live lines with the

test leads.

WARNING

Before using the instrument, check that the coating of the cords are

not either ripped or torn and that no metal parts are exposed. If any

damage is found, contact your authorized Hioki distributor or reseller

to prevent electric shock.

CAUTION

• To avoid damage to the instrument, do not short connectors or output

components or input voltage.

• To avoid damage to the instrument, do not apply voltage or current to the

analog output terminal or EXT.SW terminal.

• Avoid stepping on or pinching the cables, which could damage the cable

insulation.

• To avoid breaking cables or lead wires, do not bend or pull them at the

base.

• Bare conductors could be exposed if the insulation melts. Do not touch

the heat sources.

To avoid electric shock and damage to the instrument, observe the cautions

listed below when connecting the analog output terminal, RS-232C

connector, and EXT.I/O terminal.

• Always turn off the power on the instrument and on any devices to be

connected before making connections.

• Be careful to avoid exceeding the rating of the analog output terminal,

RS-232C connector, or EXT.I/O terminal signal.

• During operation, a wire becoming dislocated and contacting another

conductive object can cause serious hazard. Use screws to secure the

external connectors.

• Properly isolate the devices and equipment to which the analog output

terminal, RS-232C connector, and EXT.I/O terminal are connected.

• To avoid damaging the cord, grasp the plug, not the cord, when

unplugging the output connector.

• The cables can become hard in the environment at a temperature of 0°C

or lower. When the cables are bent or pulled, the coating of the cables

may become damaged or may break.

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

9

Usage Notes

IMPORTANT

When using the instrument, be sure to use the connecting lead wires, etc.

specied by our company. When other cords and lead wires are used, accurate

measurement may not be possible because the connection becomes poor, etc.

Before connecting the power cord

WARNING

• To avoid electric shock and to maintain the safety specications

of this instrument, connect the power cord provided only to a

3-contact (two-conductor + ground) outlet.

• Use only the designated power cord with this instrument. Use of

other power cords may cause re.

CAUTION

To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

IMPORTANT

Turn off the power before disconnecting the power cord.

Before connecting measurement leads

DANGER

To avoid electric shock and short circuit accidents, turn off all power

of the measurement target before connecting measurement leads.

WARNING

To avoid electrical accidents, use the designated wires or ones with more

than enough dielectric strength and current capacity.

UL1032 AWG18

Twisted wires 75 wires × φ0.12 mm

10

Before connecting switched probes

Usage Notes

To avoid damage to the probes, do not bend or pull the probe base.

To ensure safe operation, use only the probes specied by our company.

Residual risk

The test leads generate high voltage. To avoid electric shock, do not

touch the metal ends of the test leads.

The ends of the probes are sharp. Be careful to avoid injury.

Before connecting data cables

• Failure to fasten the connectors properly may result in sub-

specication performance or damage to the equipment.

• Always turn off both devices when connecting and disconnecting

an interface connector. Otherwise, an electric shock accident may

occur.

CAUTION

WARNING

CAUTION

WARNING

1

2

3

4

5

6

7

8

Before switching between current sink (NPN) and current source (PNP)

CAUTION

Do not operate the EXT.I/O mode switch (NPN/PNP) while the instrument is

on.

Congure the NPN/PNP setting to accommodate externally connected

equipment.

11

9

10

Appx. Ind.

Usage Notes

Before connecting EXT.I/O

• External power cannot be supplied to the instrument’s EXT.I/O

connector. Do not apply external power. (The ISO_5V pin of the EXT.

I/O connector is a 5 V (NPN)/-5 V (PNP) power output.)

To avoid electric shock or damage to the equipment, always observe

the following precautions when connecting to the EXT.I/O connector.

• Always turn off the main power switch on the instrument and on any

devices to be connected before making connections.

• Be careful to avoid exceeding the ratings of external terminals.

(p. 159) During operation, a wire becoming dislocated and

contacting another conductive object can cause serious hazard.

Use screws to secure the external connectors.

To avoid damage to the instrument, observe the following cautions:

• Do not short circuit ISO_5V and ISO_COM.

• When connecting the relay coil to the EXT.I/O output terminal, be sure to

install diodes to absorb current-electromotive force.

WARNING

CAUTION

Before turning the power on

• While insulation resistance is being measured or the START key is

pressed, hazardous voltage may be generated in the measurement

terminal. To avoid electric shock, do not touch the measurement

leads.

• Before turning the instrument on, make sure that the supply voltage

matches that indicated on its power connector. Connection to an

improper supply voltage may damage the instrument and present

electrical hazard.

• Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with

rectangular wave or pseudo-sine-wave output to power the instrument.

Doing so may damage the instrument.

12

WARNING

CAUTION

Usage Notes

CAUTION

• When connecting to the measurement object or not using the instrument,

be sure to unplug the power cord from the instrument and completely

disconnect it from the power supply for safety.

• Do not connect a wrong power voltage. Doing so may damage the

internal circuit.

IMPORTANT

• Turn off the power before disconnecting the power cord.

• To suppress noise, it is necessary to switch the power frequency setting on the

instrument. Set the frequency to the frequency of the commercial power supply to

be used before starting the measurement.

In the manual setting, a measured value does not stabilize unless the power

frequency setting is switched properly.

1

2

3

4

Precautions during shipment

Observe the following during shipment.

Hioki cannot be responsible for damage that occurs during shipment.

CAUTION

When shipping the instrument, use the packaging materials used when the

instrument is delivered.

5

6

7

8

9

10

Appx. Ind.

13

Usage Notes

14

1

Overview

1.1 Product Overview and Features

Overview

The HIOKI ST5520/ST5520-01 Insulation Tester is an insulation resistance tester that

performs insulation resistance testing on components and equipment using direct

current voltage.

The test duration is 50 ms at the fastest and high speed testing can be performed.

Because this Insulation Tester is equipped with selectable test voltages and EXT.I/

O, RS-232C interface, and analog output terminal, it can be used in various elds

including production and inspection lines as well as laboratories.

1

2

3

4

5

6

7

15

8

9

10

Appx. Ind.

Product Overview and Features

Features

Test duration

50 ms (fastest)

Selectable test voltage

Easy-to-read display

Saved setting

conditions

External interface

Equipped with

RS-232C interface

Judgment results can be displayed in 50 ms at the fastest.

The test voltage can be selected from 25 V to 1000 V in

increments of a resolution of 1 V. The comparator function

(p. 44) and test duration function (p. 39) support a wide

variety of insulation resistance testing according to safety

standards.

High denition LCD display for a high level of visibility

Up to ten patterns of test conditions can be saved. When the

power is turned on again after it is turned off, the settings

before the power is turned off are replicated. (p. 76)

EXT.I/O outputs a signal according to the ST5520/ST552001 status. The start/stop signal input and test conditions can

be selected. Extended insulation resistance uctuation can

be recorded when analog output is used. (p. 81)

A personal computer (PC) can be connected for automated

testing and recording test results. (p. 119)

Switched probe

Automatic

discharge function

16

The optional 9299 Switched Probe enables efcient manual

testing.

Any charge remaining in pieces of equipment to be

measured is released inside the instrument after tests. As

the TEST lamp blinks during discharge, the discharge status

can be checked.

Equipment can be protected from possible damage during

successive insulation resistance testing.

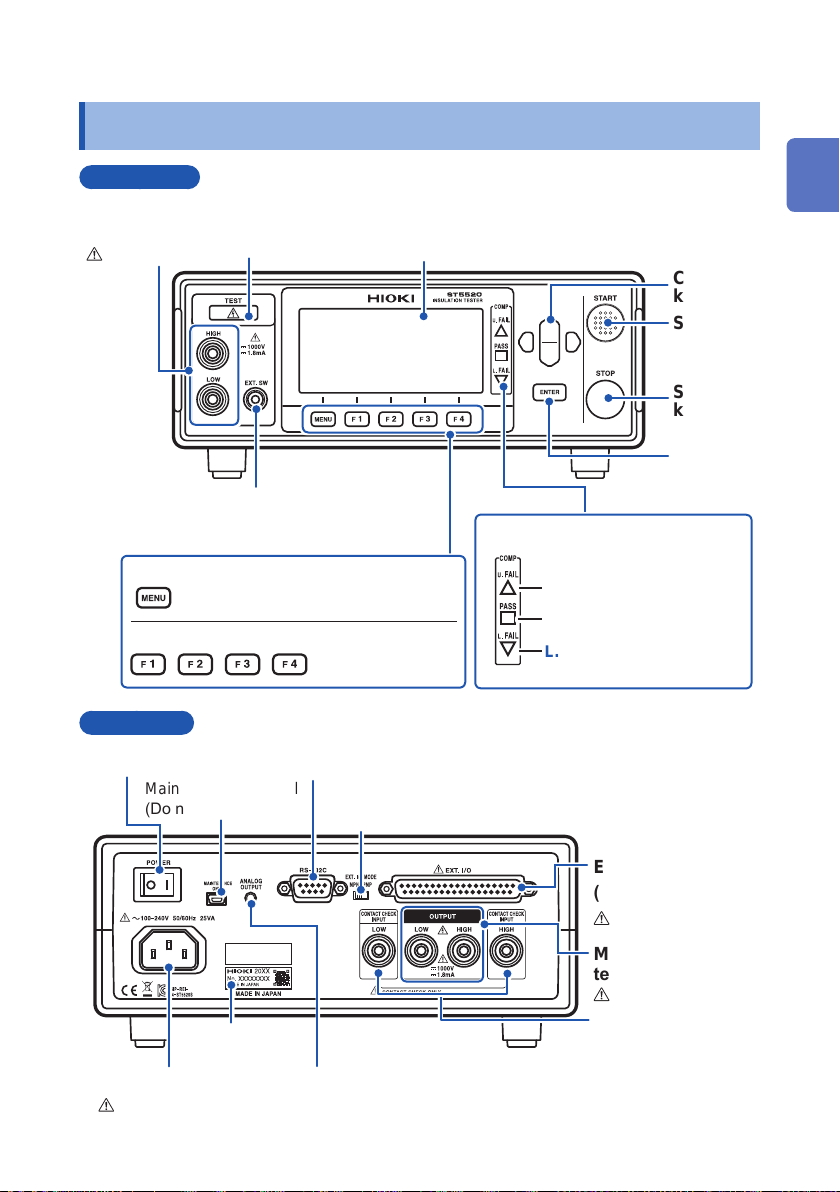

1.2 Parts Names and Functions

Parts Names and Functions

Front panel

Measurement

terminals (p. 24)

Refer to p. 10.

EXT.SW terminal (p. 109)

For 9299 Switched Probe

MENU key

Switching of pages

F keys

Rear panel

TEST lamp

(p. 49)

Selection of settings

displayed on the

screen

Display screen

(Monochrome graphical LCD)

COMP lamps (p. 44)

U.FAIL

Upper limit value ≤ Measured value

PASS

Within judgment standard

L.FAIL

Lower limit value ≥ Measured value

Cursor

keys

START

key

STOP

key

ENTER

key

1

2

3

4

5

6

7

Power switch (p. 26)

Maintenance terminal

(Do not use.)

Manufacturer’s

serial No.

Power inlet (p. 23)

Refer to p. 10.

RS-232C connector (p. 115)

EXT.I/O mode switch (NPN/PNP) (p. 82)

Left: Current sink (NPN), Right: Current source (PNP)

EXT.I/O terminal

(p. 82)

Measurement

terminals (p. 24)

Contact check

terminals (p. 58)

Analog output terminal (p. 105)

For 9094 Output Cord

Refer to p. 11.

Refer to p. 11.

8

9

10

Appx. Ind.

17

Parts Names and Functions

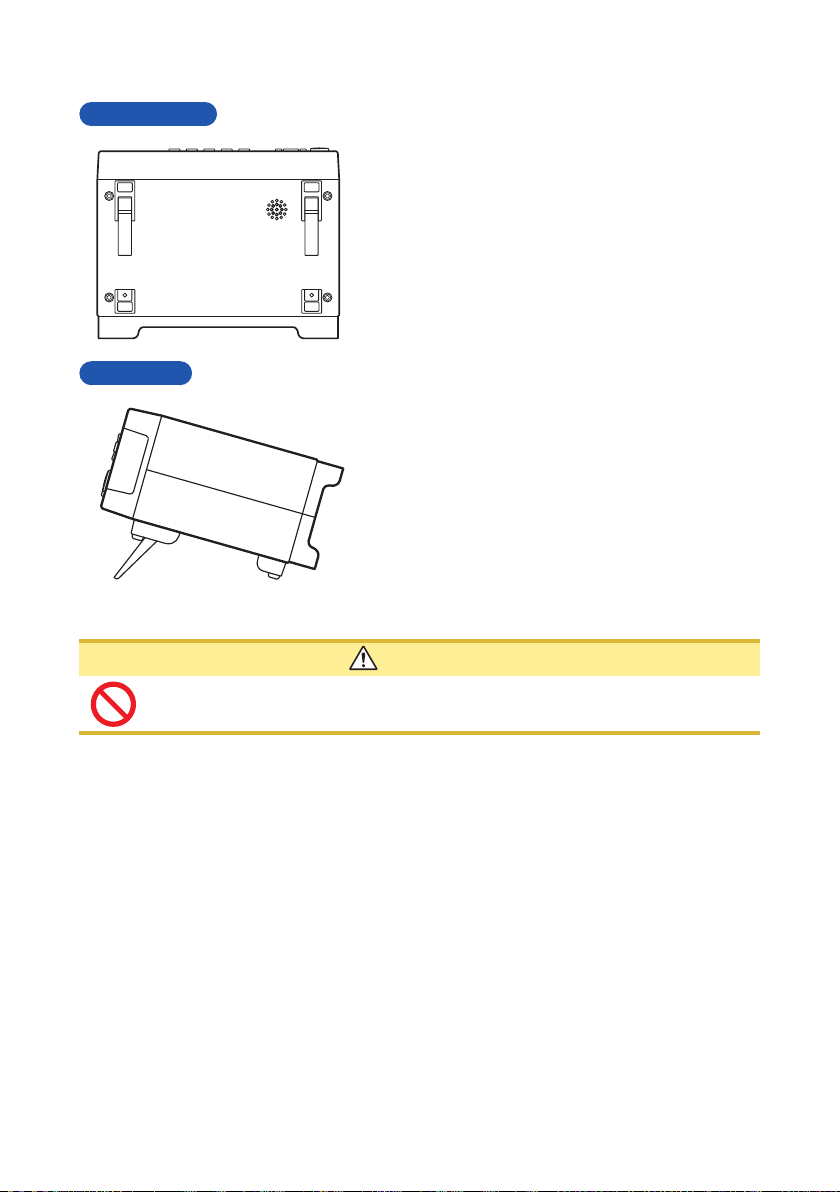

Bottom panel

Side panel

This instrument can be rack-mounted.

Refer to “Appx. 7 Rack Mounting” (p. Appx.10).

The parts removed from this instrument

should be stored in a safe place for future

reuse.

When using the stand

Extend the legs all the way.

Make sure to extend both legs of the stand.

When collapsing the stand

Do not collapse the stand partway. Be sure to

collapse it all the way.

18

CAUTION

When the instrument is set on the stand, do not apply a strong force from

above. Doing so may damage the stand.

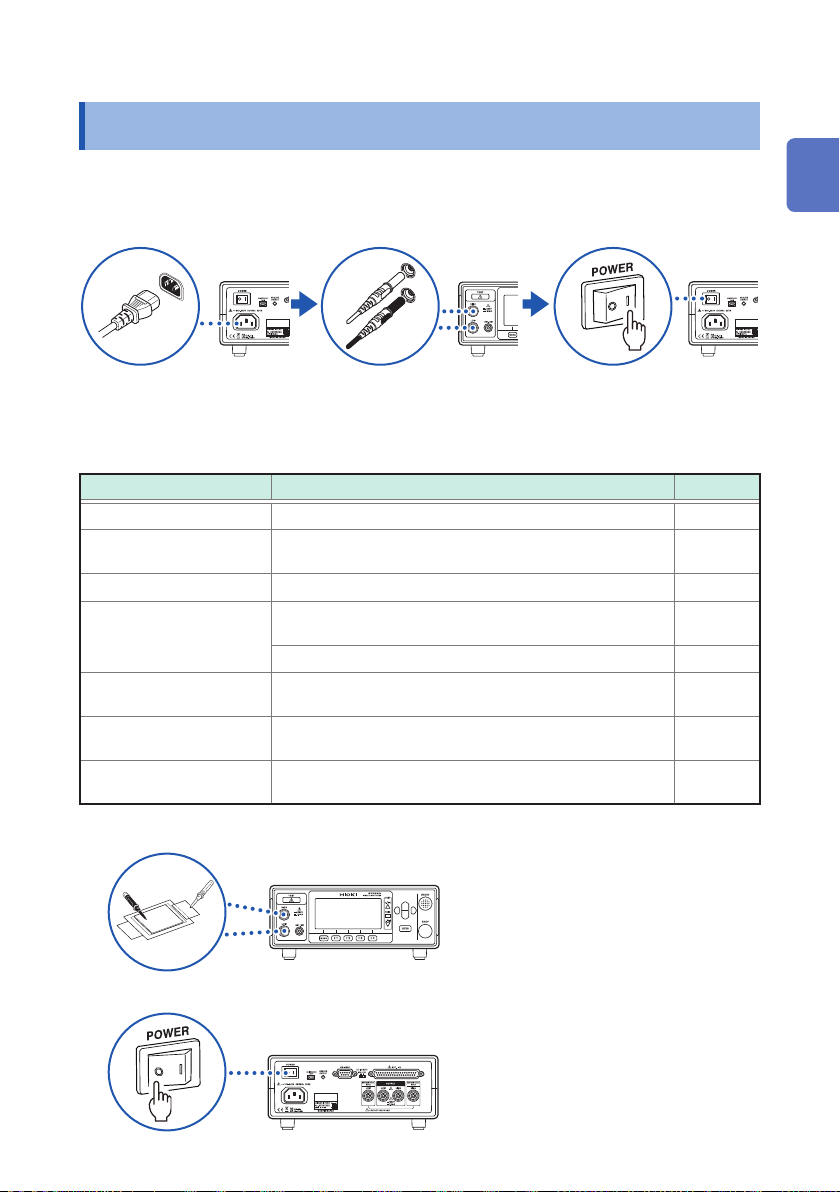

1.3 Measurement Workow

Measurement Workow

Be sure to refer to “Usage Notes” (p. 7) before use.

Preparing for measurement (p. 23)

1

(Use the measurement terminals on the rear

panel in case of 4-terminal measurements.)

Checking before measurement (p. 27)

2

Setting measurement conditions (p. 33)

3

Item Description Reference

Test voltage

Resistance range

Measurement speed

Test duration

Comparator

(upper/lower limit values)

Test mode

Beep sound

Select from 25 V to 1000 V.

Select either manual range (2 M

2000 M

Select either FAST or SLOW.

Set how long to apply the test voltage (test duration

function).

Set the response time.

Set the upper/lower resistance values.

Select from continuous mode, FAIL STOP mode, PASS

STOP mode, or forced termination judgment mode.

Set the conditions to announce the judgment result

with a beep sound.

, 4000 MΩ) or auto range.

Ω

, 20 MΩ, 200 MΩ,

Ω

p. 34

p. 36

p. 38

p. 39

p. 41

p. 44

p. 46

p. 47

1

2

3

4

5

6

7

8

Performing measurement

4

Turning off the power after use

5

9

10

Appx. Ind.

19

Screen Conguration and Operation Overview

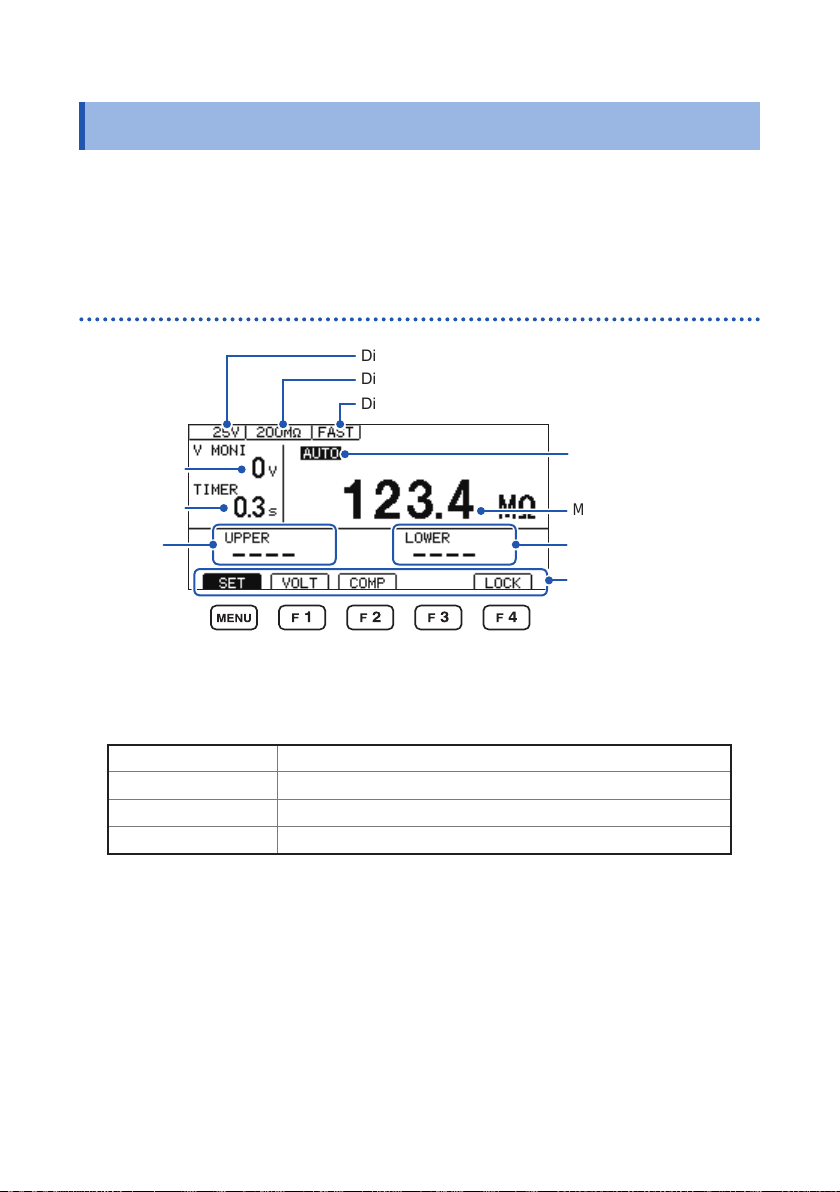

1.4 Screen Conguration and Operation Overview

This instrument consists of a measurement screen and various settings screens.

The screen examples in this manual appear reversed (black on white) for best

visibility. The instrument screens, however, can actually be displayed only as white

characters on a black background.

Measurement screen

Displays the test voltage setting.

Displays the resistance range setting.

Displays the measurement speed setting.

Voltage

monitor value

Test duration

Upper limit

value

F key set items

SET Moves to the Settings screen. (p. 33)

VOLT Moves to the Test Voltage Settings screen. (p. 34)

COMP Moves to the Comparator Settings screen. (p. 44)

LOCK Executes the key lock function. (p. 65)

The auto range is set.

(Nothing is displayed in

the manual range.)

Measured value

Lower limit value

Moves to various settings

screens.

Use the F keys at the

bottom of the screen to

select a screen.

20

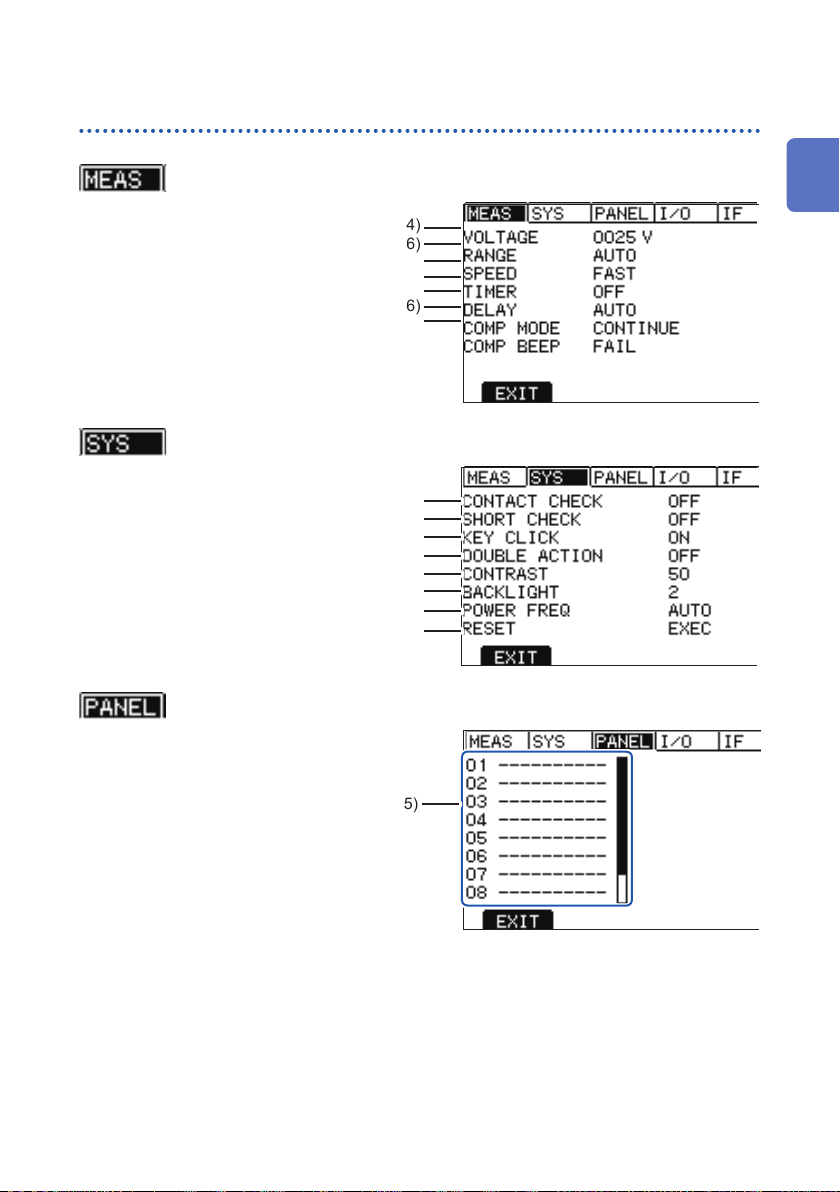

Settings screen

Screen Conguration and Operation Overview

(MEAS screen)

Setting the test voltage (p. 34)

Setting the measurement speed (p. 38)

(SYS screen)

Setting the contact check function (p. 56)

Setting the short circuit check function (p. 60)

Setting the double action function (p. 68)

Setting the screen contrast (p. 69)

Setting the power frequency (p. 71)

(PANEL screen)

Setting the range (p. 36)

Setting the test duration (p. 39)

Setting the response time (p. 41)

Setting the test mode (p. 46)

Setting the beep sound (p. 47)

Setting the key beeper (p. 67)

Setting the backlight (p. 70)

Initializing the system (p. 72)

1

2

3

4

5

6

7

Setting the panel save/panel load (p. 75)

8

9

10

Appx. Ind.

21

Screen Conguration and Operation Overview

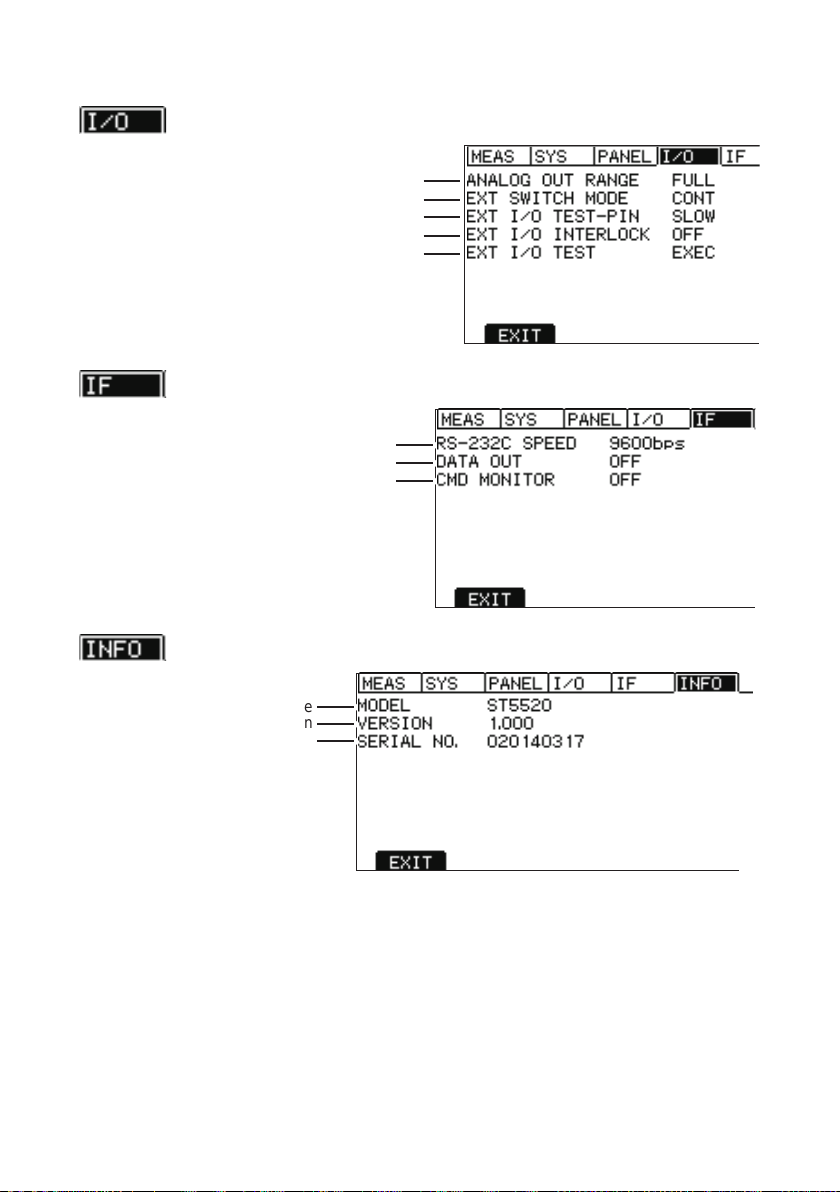

(I/O screen)

Setting the analog output range (p. 104)

Setting the Switched Probe operation (p. 108)

Setting the test signal OFF timing (p. 101)

Setting the INTERLOC test function (p. 108)

Setting the EXT.I/O test function (p. 103)

(IF screen)

Setting the RS-232C interface (p. 114)

Setting the data output function (p. 117)

Setting the communications monitor function

(p. 120)

(INFO screen)

Manufacturer's serial No.

22

Model name

Version

Loading...

Loading...