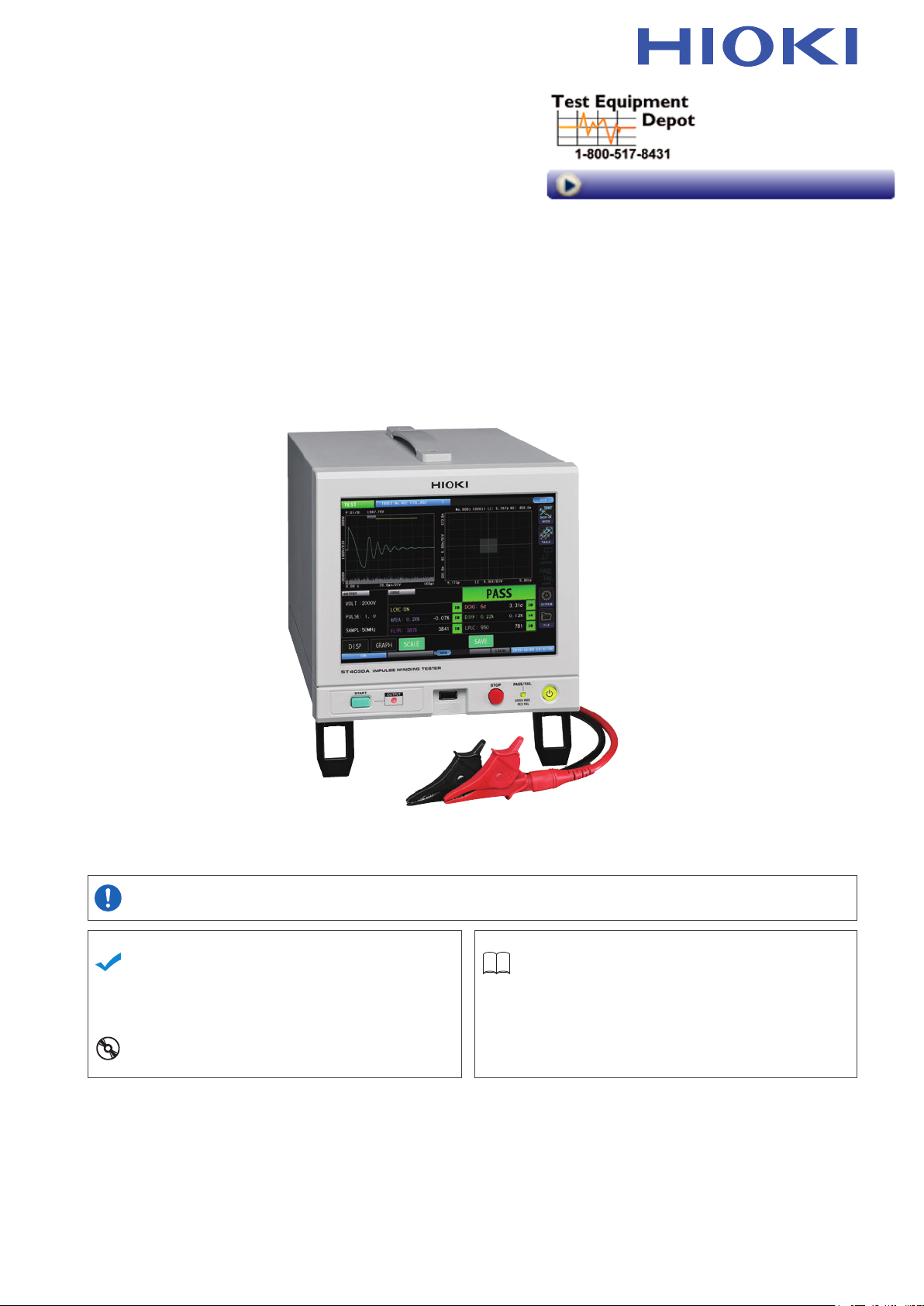

ST4030

Visit us at www.TestEquipmentDepot.com

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

ST4030A

Instruction Manual

IMPULSE WINDING TESTER

Be sure to read this manual before using the instrument.

When using the instrument for the

rst time

Parts Names and Functions

Communication Command

Instruction Manual

Dec. 2019 Revised edition 2

ST4030A961-02 19-12H

p.8 Maintenance and Service

CD Error Display and Solution

Troubleshooting

p.207

p.214

p.5

EN

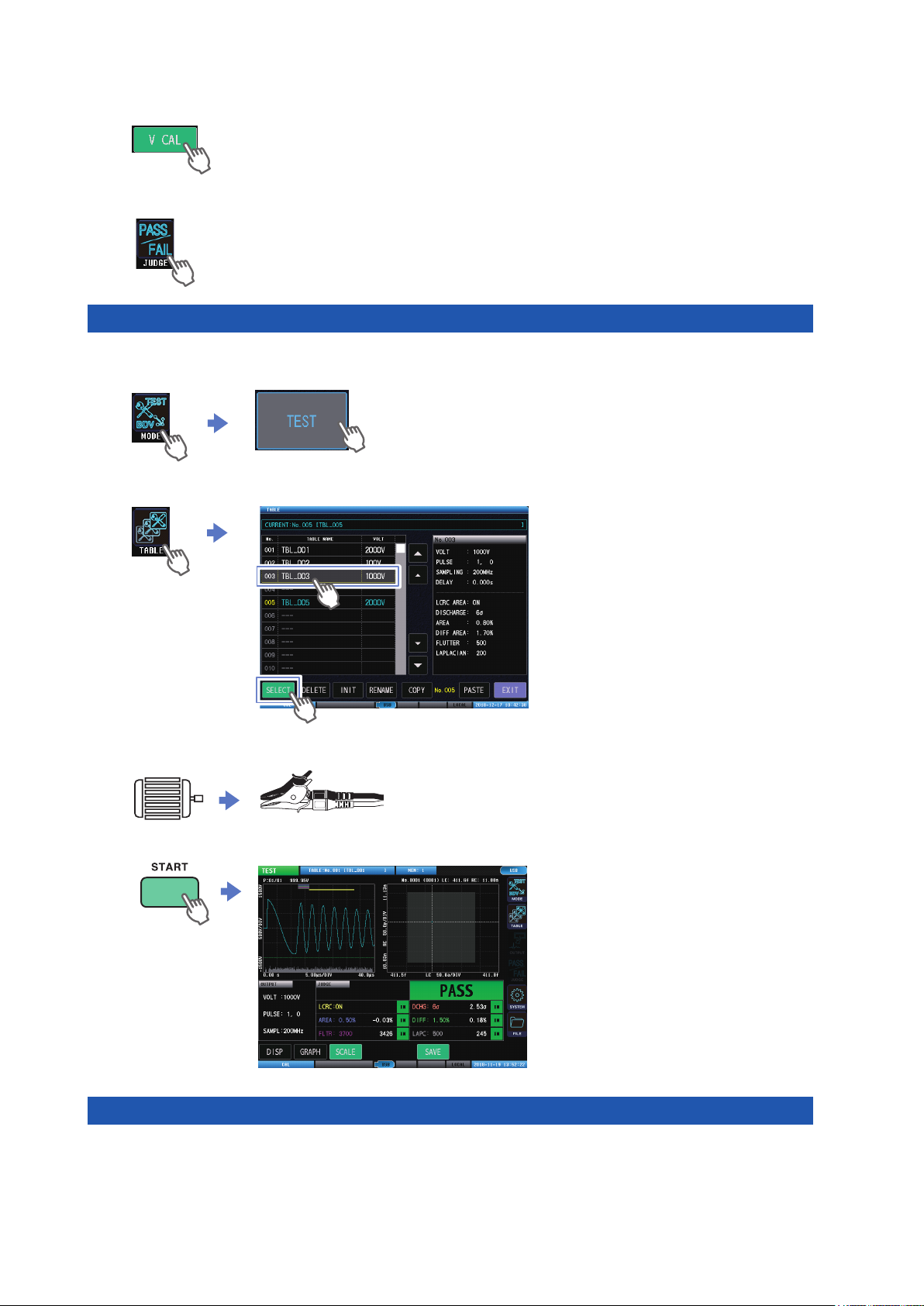

Measurement Flowchart

The basic measuring ow is as described below.

Preparation

See “2 Preparation for Measurements” (p. 13)

Master workpiece

(known-good winding)

Setting Test Conditions and Judgment Conditions

Select [SETTING] in test conditions settings mode. (p. 18)

1

Select the settings table that will acquire the master waveform. (p. 29)

2

Workpiece

under test

Set the output items such as applied voltage, applied number of pulses, sampling frequency,

3

etc. (p. 41)

Connect the master workpiece to the test lead.

4

ST4030A961-02

Calibrate the voltage and acquire the master waveform. (p. 49)

5

Set the judgment criteria. (p. 53)

6

Implementing tests

Select [TEST] in test mode. (p. 18)

1

Select the settings table that acquired the master waveform to be used in the test (p. 29)

2

Connect the workpiece under test to the test lead.

3

Start the test and check the test results. (p. 84)

4

Save the test results

Make the settings for saving the data. (p. 169)

1

Save the test results. (p. 176)

2

Contents

5

4

3

2

1

Introduction

Notations

Conrming Package Contents

Options (Sold separately)

Usage Notes

........................................................1

............................................................2

........................3

................................4

......................................................5

1 Overview 7

1.1 Overview

1.2 Features

1.3 Parts Names and Functions

1.4 Screen Operations

Measuring mode settings

Moving windows

Touch keyboard inputs

Screen conguration

..................................................7

...................................................7

.................8

...............................10

........................... 10

........................................ 11

............................... 11

..................................12

2 Preparation for

Measurements

2.1 Connecting the Test Lead (on the

ST4030)

2.2 Connecting the Power Cord

2.3 Power Supply ON/OFF

Main power supply ON

Main power supply OFF

Sleep mode

Startup mode

2.4 Select Measuring Mode

2.5 Inspecting before Measurement

and Verifying Operations

Inspection

Checking the voltage generated

Checking the impulse response waveforms

.................................................14

................15

........................16

..............................16

.............................16

............................................... 17

............................................17

.......................18

.....................19

.................................................19

................20

13

21

3 Switching Test

Conditions (Table

Functions)

3.1 Overview

Overview of test conditions switching

functions

Items that can be saved

Operations owchart in test conditions

settings mode and test mode

Screen conguration

3.2 Current Table Selection

3.3 Table Initialization

................................................25

...................................................25

.............................26

..................................28

.................................30

.....................27

.......................29

25

3.4 Table Deletion

3.5 Changing the Table Name

3.6 Table Copying

.......................................31

..................32

.......................................33

4 Setting the Test

Conditions

4.1 Overview

Operations owchart in test conditions

settings mode

Screen conguration

4.2 Applied Voltage

4.3 Number of Applied Pulses

4.4 Sampling Frequency/Number of

Sampling Data

Automatic settings for range of

waveform acquisition

4.5 Trigger Delay

4.6 Voltage Calibration

................................................35

............................................35

..................................36

.....................................41

...................42

......................................44

................................. 46

.........................................47

...............................49

5 Setting Judgment

Conditions

5.1 Overview

Judgment types

Settings operations procedure

5.2 LC and RC Values Area

Judgments [LCRC AREA]

Enabling the LC and RC values

judgments function

Importing LC and RC master values

Auto creation of the PASS judgment area

Manually creating the PASS judgment area

5.3 Waveform Judgments

Surface area comparison judgments

[AREA]

Differential surface area comparison

judgments [DIFF AREA]

Flutter detection judgments [FLUTTER]

Secondary differential detection

judgments [LAPLACIAN]

Waveform judgment area and judgment

threshold value automatic settings

functions

5.4 Discharge Judgments (When

Incorporating Model ST9000)

Discharge judgment methods

[DISCHARGE]

................................................51

.........................................51

...................52

..................53

....................................55

..........56

..........................62

..................................................... 62

............................ 64

.......................... 69

...................................................71

.............72

..........................................73

35

51

.. 58

60

..... 66

i

Contents

Threshold value of the test waveform

discharge amount over the master

waveform discharge amount

Deviation threshold value of the test

waveform discharge amount

Setting the discharge amount judgment

area

..........................................................76

......................74

......................75

6 Implementing Tests 77

6.1 Overview

Operations owchart in test mode

Screen conguration

6.2 Checking Test Start and Test Results

................................................77

..............77

..................................78

84

7 Break down voltage

test (BDV)

7.1 Overview

Operations owchart in break down

voltage test mode

Screen conguration

7.2 Checking Test Start and Test Results

7.3 Setting the Test Conditions

Applied voltage settings

Number of applied pulses settings

Setting the sampling frequency and

number of sampling data

Setting the waveform acquisition area

automatically

7.4 Setting Dielectric Break down

Judgment Conditions

LC and RC values judgments

Discharge judgment

Waveform surface area comparison

judgment

Peak voltage value uctuations

Vibration frequency uctuations

................................................85

...................................... 85

..................................86

.................90

.............................90

.............91

...........................93

............................................. 94

...........................95

.................... 95

..................................96

................................................... 97

.................. 98

.................99

85

89

8 Other Functions 101

8.1 Interlock Function

Unlocking the interlocks

8.2 Key Lock Function

Unlocking the key locks

8.3 Double Action Function

8.4 Memory Function

Memory function settings (ON/OFF)

Saving memory data

Deleting memory data

...............................101

...........................103

..............................104

...........................105

......................106

................................107

.........108

................................109

............................. 110

8.5 Displays

8.6 Graph Display Settings

Overlay settings

Waveform color settings

LC and RC graph scale settings

Implementing the LC and RC graph auto

scale

8.7 Judgment Beep

8.8 Key Beep

8.9 Test Time (EOM) Display

...............................................111

......................112

...................................... 112

..........................113

............... 115

....................................................... 116

...................................117

.............................................118

...................119

8.10 Communications Commands Long

Format Settings

..................................120

8.11 Initializing the Instrument (System

Reset)

8.12 Terminal Open Error Setting

8.13 Voltage Error Setting

...................................................121

.............122

..........................123

9 System Settings 125

9.1 Instrument System Information

9.2 Self-test Function

Touch panel test

Touch panel correction

Screen display test

ROM/RAM test

EXT. I/O test

............................................131

9.3 Date and Time Settings

................................126

...................................... 126

............................127

.................................. 128

........................................ 129

.....................132

........125

10 External Control

(EXT. I/O)

10.1 External Control Measurement

......................................................134

Flow

10.2 Sinking Current (NPN) / Sourcing

Current (PNP)

10.3 Connection (Instrument and

Control Devices)

Instrument connector and compatible

connectors

Signal functions

Internal circuit conguration

Electrical specications

Connection examples

10.4 Timing Chart

Explanation of timing chart times

Measurement timing example

Flow of starting measurements from

an external device, and reading the

judgment results

.....................................135

.................................136

..............................................136

.......................................138

..................... 139

............................140

.............................. 140

........................................142

.............142

.................. 143

......................................144

133

ii

Contents

Index

11

12

13

14

15

6

7

8

9

10

11 Communications

Interface

11.1 Overview

Screen display

11.2 Specications

RS-232C

GP-IB

USB

LAN

Total

11.3 Mounting and Removing an

Interface

11.4 Interface Settings

11.5 Connecting and Setting RS-232C

(Model Z3001)

11.6 Connecting and Setting GP-IB

(Model Z3000)

11.7 Connecting and Setting USB

11.8 Setting and Connecting LAN

Connection method

Setting procedure

11.9 Remote Mode

11.10 Communications Monitor

..............................................146

.........................................146

......................................147

................................................. 147

...................................................... 148

........................................................ 148

........................................................148

........................................................148

...............................................149

................................151

.....................................152

.....................................154

............155

............157

.................................157

.................................... 159

.....................................162

...................163

145

12 USB Host 165

12.1 Overview

12.2 Removing the USB Memory

12.3 File Window

12.4 Settings for Saving the Data

Setting auto save

Setting manual save

Text save items settings

Setting the text save format

Setting the image save format

Setting the name of the saved le and

its folder

12.5 Saving Test Results

Saving manually

Checking the test results that have been

saved

12.6 Saving and Importing Test

Conditions

Saving test conditions

Importing test conditions

12.7 Editing Files and Folders

Formatting USB memory

..............................................165

.............166

.........................................168

.............169

.....................................169

................................170

...........................171

.....................172

.................173

..................................................174

............................176

......................................176

......................................................178

............................................180

.............................. 180

..........................182

...................184

.........................184

Deleting les and folders

Creating folders

Changing the folder name and le name

Information display

.......................................187

.........................186

. . 188

..................................189

13 Specications 191

13.1 General Specications

13.2 Input Specications/Output

Specications/Measurement

Specications

Basic specications

Accuracy specications

13.3 Functional Specications

Test conditions settings

Set judgment conditions

Test conditions switching functions

Break down voltage test (BDV) mode

Safety protection function

Other functions

13.4 Interface Specications

External control terminal (EXT.I/O)

specications

Communications interface specications

USB host specications

Test time (Reference value)

13.5 L2250 Clip Type Lead (Option)

General Specications

Basic specications

13.6 L2252 Unprocessed Lead Cable

(Option)

General Specications

Basic specications

......................................192

........................................198

..........................................200

................................................205

.......................191

.................................192

...........................192

...................193

............................193

..........................193

...........195

......196

........................197

.....................200

. . 202

........................... 203

..................... 204

........205

............................. 205

.................................205

............................. 205

.................................205

14 Maintenance and

Service

14.1 Troubleshooting

Before sending the instrument for repair

FAQ regarding external control (EXT. I/O)

14.2 Initializing the Instrument (Full

Reset)

14.3 Error Display

14.4 Discarding the Instrument

(Removing the Lithium Battery)

...................................................213

..................................208

.......................................214

207

..208

212

........220

iii

Contents

15 Appendix 221

15.1 Block Diagram

15.2 Circuit Conguration

Circuit operations during tests

Effects of cable parasitic components

15.3 Rack Mount

Metal tting dimensions

Installation method

15.4 Dimensions Diagram

.....................................221

..........................222

..................222

......223

.........................................224

...........................225

..................................227

..........................229

15.5 Repeat Accuracy (Reference Value)

Reproducibility of the voltage generated

Oscillation waveform reproducibility

..230

.........231

15.6 Max. Applicable Voltage

(Reference Value) According to

the Workpiece Inductance

.................232

15.7 Voltage Switching Time (Reference

Value)

...................................................233

15.8 Waveform Differences (Typical

Values) Between Instruments

...........234

15.9 Affects on Measurements

According to the Length of the

Test Lead

.............................................236

15.10 Precautions when Processing Test

....................................................237

Leads

15.11 Ver. 1.01 Compatibility Function

.......239

230

Index 241

Warranty Certicate

iv

Introduction

Thank you for choosing the Hioki ST4030, ST4030A Impulse Winding Tester. Preserve this manual

carefully and keep it handy to make full use of this instrument for a long time. Read the separate

document “Operating Precautions” carefully before using the instrument.

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so.

It is assumed that the reader possesses basic electrical knowledge (equivalent to that of someone

who graduated from the electrical program at a technical high school).

Trademarks

• Windows is either registered trademarks or trademarks of Microsoft Corporation in the United

States and other countries.

• Any other products and company names are generally either trade names, registered trademarks

or trademarks of respective companies.

Introduction

1

Notations

Notations

Safety symbols

In this document, the risk seriousness and the hazard levels are classied as follows.

WARNING

CAUTION

IMPORTANT

Indicates a potentially hazardous situation that may result in death or serious

injury to the operator.

Indicates a potentially hazardous situation that may result in minor injury to the

operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance

tasks with which the operators must be fully familiar.

Indicates prohibited actions.

Indicates an action that must be performed.

Symbols afxed to the instrument

Indicates cautions and hazards. Refer to the “Usage Notes” (p. 5) and warning

messages presented at the beginning of each instruction for use of the Instruction

Manual, and included “Operating Precautions”.

Indicates that dangerous voltage may be present at this terminal.

Other Descriptions

(p. ) Indicates the location of reference information.

START

(Boldface)

[ ]

S/s

Indicates the names and keys on the windows in boldface.

Names of menus, dialog boxes, buttons in a dialog box, and other UI elements on the

screen are enclosed in brackets [ ].

The instrument describes the number per second of digitized analog input signals in

units of samples per second (S/s).

Example: “20 MS/s” (20 megasamples per second) means digitization of 20 × 10

times per second.

Accuracy descriptions

We dene measurement tolerances in terms of setting values with the following meanings.

Setting Indicates the value set as the output voltage, current, or other quantity.

6

2

Conrming Package Contents

Conrming Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories, panel switches, and connectors. If damage is evident,

or if it fails to operate according to the specications, contact your authorized Hioki distributor or

reseller.

Store the packaging materials even after unpacking, because you will need them when you

transport the instrument.

Conrm that these contents are provided.

Model ST4030 or ST4030A Impulse Winding Tester

Power cord

Instruction Manual (this document)

Operating Precautions (0990A903)

Application disc (CD)

• Communication Command Instruction Manual

Communication Command Reference

Default settings table

• USB driver

The latest version can be downloaded from our website.

3

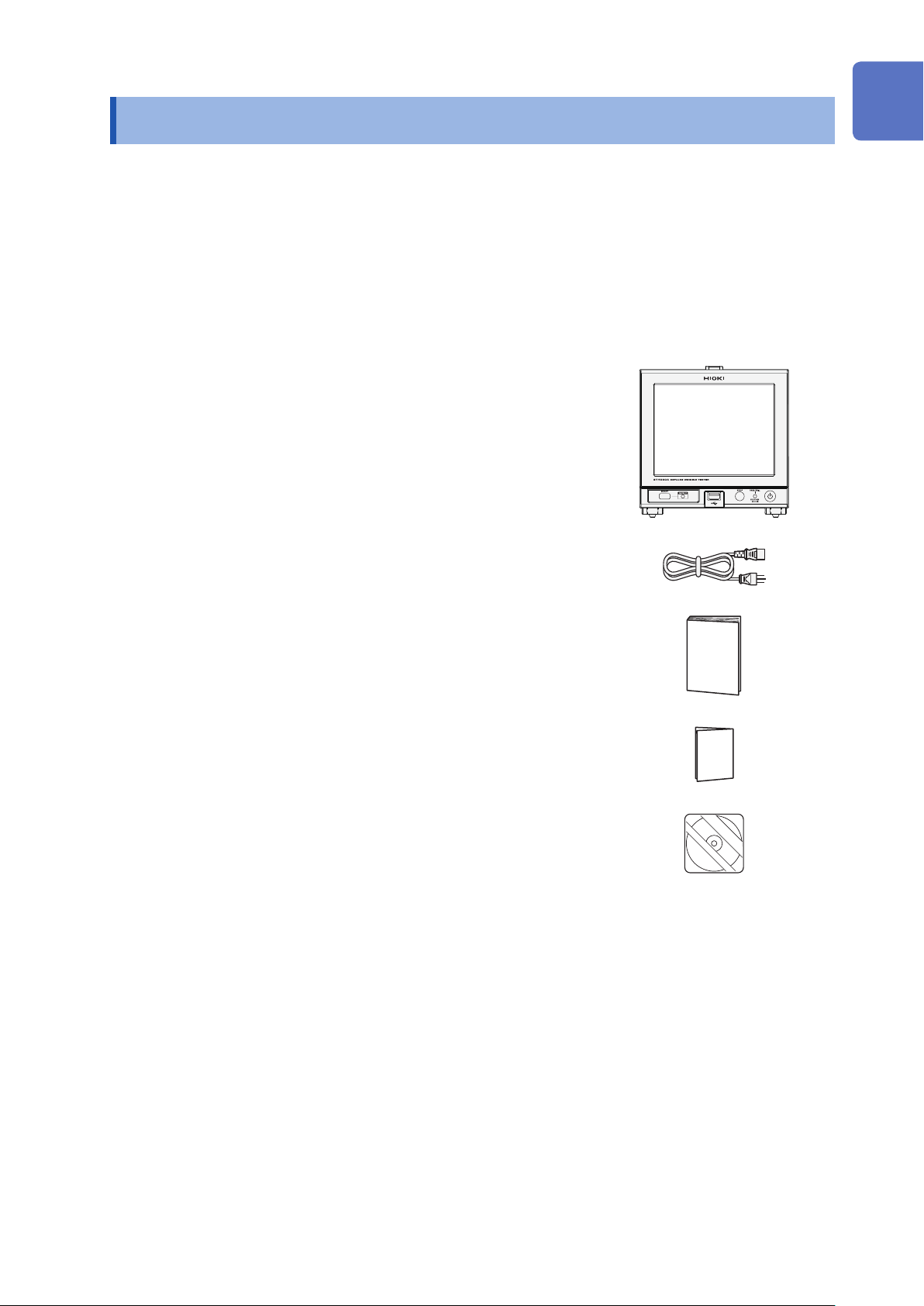

Options (Sold separately)

Options (Sold separately)

The following options are available for the instrument. To purchase an option, please contact your

authorized Hioki distributor or reseller. Options are subject to change. Please check Hioki’s website

for the latest information.

Model ST9000 Discharge Detection Upgrade

(Optional when shipped from factory)

Model L2250 Clip Type Lead

(Maximum rated voltage: 3300 V AC peak)

Model L2252 Unprocessed Lead Cable

(Maximum rated voltage: 4200 V AC peak)

Model Z3000 GP-IB Interface

Model 9151-02 GP-IB Connector Cable (2 m)

Model Z3001 RS-232C Interface

Model 9637 RS-232C Cable (9pin-9pin/1.8 m)

4

Usage Notes

Read the separate document “Operating Precautions” carefully before using the instrument. Follow

these precautions to ensure safe operation and to obtain the full benets of the various functions.

Installation

CAUTION

• Ventilation holes for heat radiation are provided on the rear of the instrument. Leave

sufcient space around the ventilation holes and install the instrument with the holes

unobstructed.

Installation of the instrument with the ventilation holes obstructed may cause a

malfunction of the instrument or a re.

• Do not place the instrument on an unstable surface or inclined place.Dropping or

knocking down the instrument could cause bodily injury or damage to the instrument.

Usage Notes

Open 5 cm or longer

This instrument may cause interference if used in residential areas. Such use must be avoided

unless the user takes special measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

Application disc

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on a

disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose them to direct sunlight, high temperature,

or high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

Test lead

CAUTION

• Do not make small bends or repeatedly bend the cable.

As a benchmark, bending to 6x or less the cable diameter will damage the cable core

and cover, causing deterioration.

• Do not hold the cable when removing the clip from the workpiece.

• Hold the clip in your hand, and open and close gently.

Repeatedly opening and closing so that the clip springs risks damaging and causing

deterioration to the opening and closing mechanism.

5

Usage Notes

6

1

Overview

1.1 Overview

Windings (workpieces) found in motors, coils, and other components are

covered with insulation, but the insulation resistance may fall and short

circuits occur between proximate layers for some reason. The condition is

called a “layer short circuit”.

The ST4030, ST4030A Impedance Winding Tester not only compares and

judges waveform conformance through comparisons with existing response

waveforms, but also detects layer short circuits using judgment methods

that employ the rendering of response waveforms as numerical values (LC

and RC values). Further, incorporating the ST9000 Discharge Detection Upgrade (optional) into

the instrument enables highly precise detection of partial discharges that occur in the stages in

advance of a layer short circuit.

1.2 Features

High-speed and high-resolution sampling

Sampling using 200 MHz, 12 bit resolution enables the detection of minute changes in the response

waveform that hitherto could not be seen. In this way, it is possible to detect layer short circuits with

a high level of accuracy compared to before.

Numerical rendering of impulse response waveforms (LC and RC values)

1

Overview

The equivalence circuits for the impulse test are viewed as LCR linear equivalent circuits, and the

response waveforms are rendered numerically into LC and RC values. Rendering the response

waveforms into numerical values enables the response waveforms to be judged quantitatively.

Further, the data can be managed more easily than the waveform data.

Impulse can be tested with the rotor mounted

With the rotor and motor stator mounted, the stray capacitance between the rotor and the stator

changes depending on the rotor angle.

Changes in the stray capacitance also change the impulse response waveform, so judgments are

difcult using existing waveform comparison methods.

Numerical judgment values using LC and RC values can create PASS judgment area from the LC

and RC values distribution, and so by creating PASS judgment area using a healthy phase, it is

possible to test the impulse with the rotor mounted.

High-precision Discharge Detection Upgrade

Extracting the high-frequency discharge components of the response waveform enables highly

precise detection of partial discharges, which have hitherto been difcult to detect using utter

operations and Laplacian operations.

High waveform reproducibility

The applied voltage variation is small, so it is possible to detect defective products accurately.

Further, the instrument differences when the same workpiece is tested are small, so it is possible to

use the master workpiece data as is even if the instrument is replaced.

Reference: “15.5 Repeat Accuracy (Reference Value)” (p. 230)

Easy-to-use interfaces and an abundance of interfaces

The screen uses 8.4-inch color TFT crystals with touch panel for easy viewing and intuitive

operability. Compatible with various usage scenarios using external control (EXT. I/O), USB

memory, USB devices, and LAN. Further, RS-232C or GP-IB can be added as options.

7

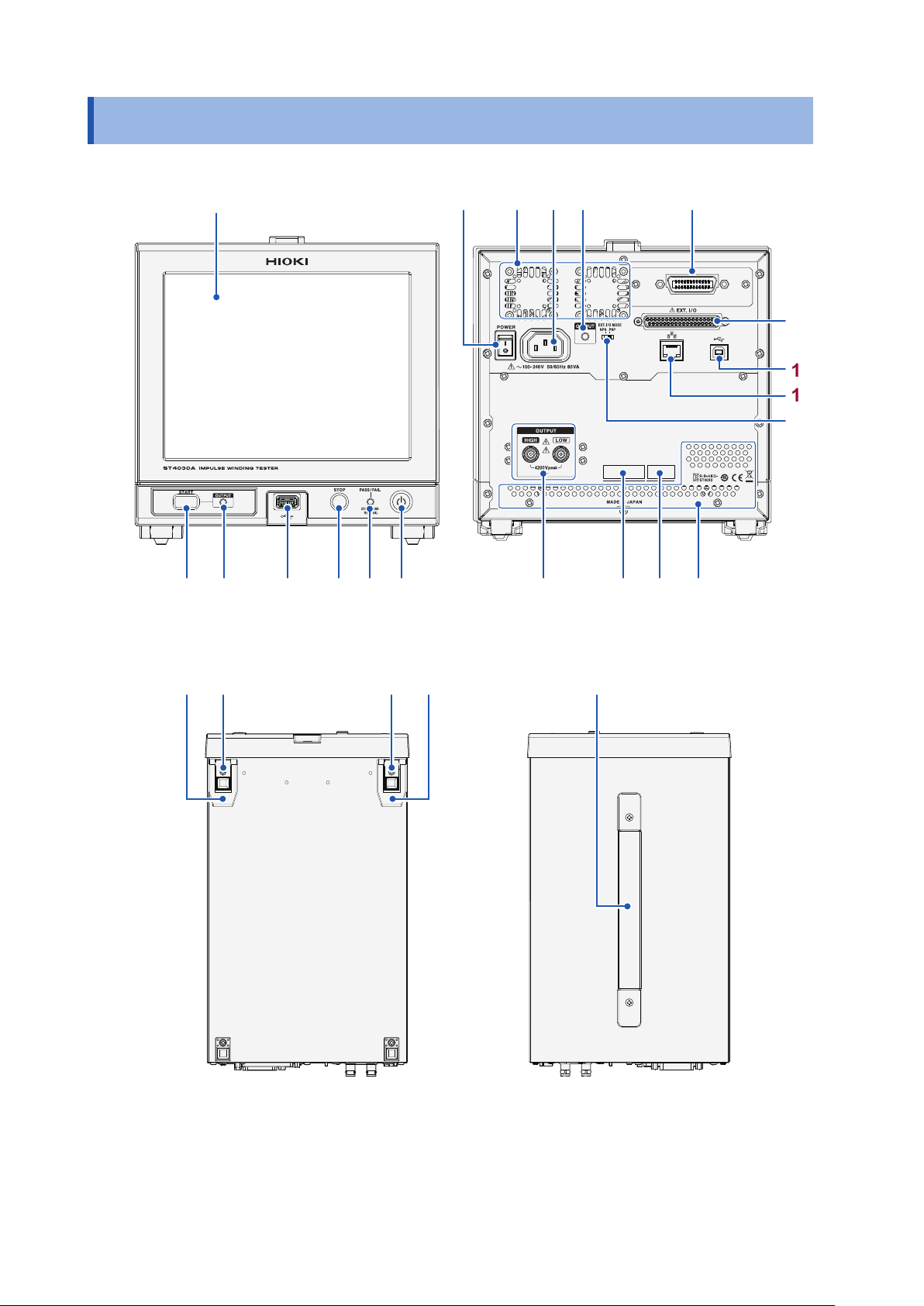

Parts Names and Functions

1.3 Parts Names and Functions

1

2 3 4 5 6 7

Front

18 17 16

11

8 11

9310

Rear

15

14

13

12

19 19

Bottom

212020

Top

8

Parts Names and Functions

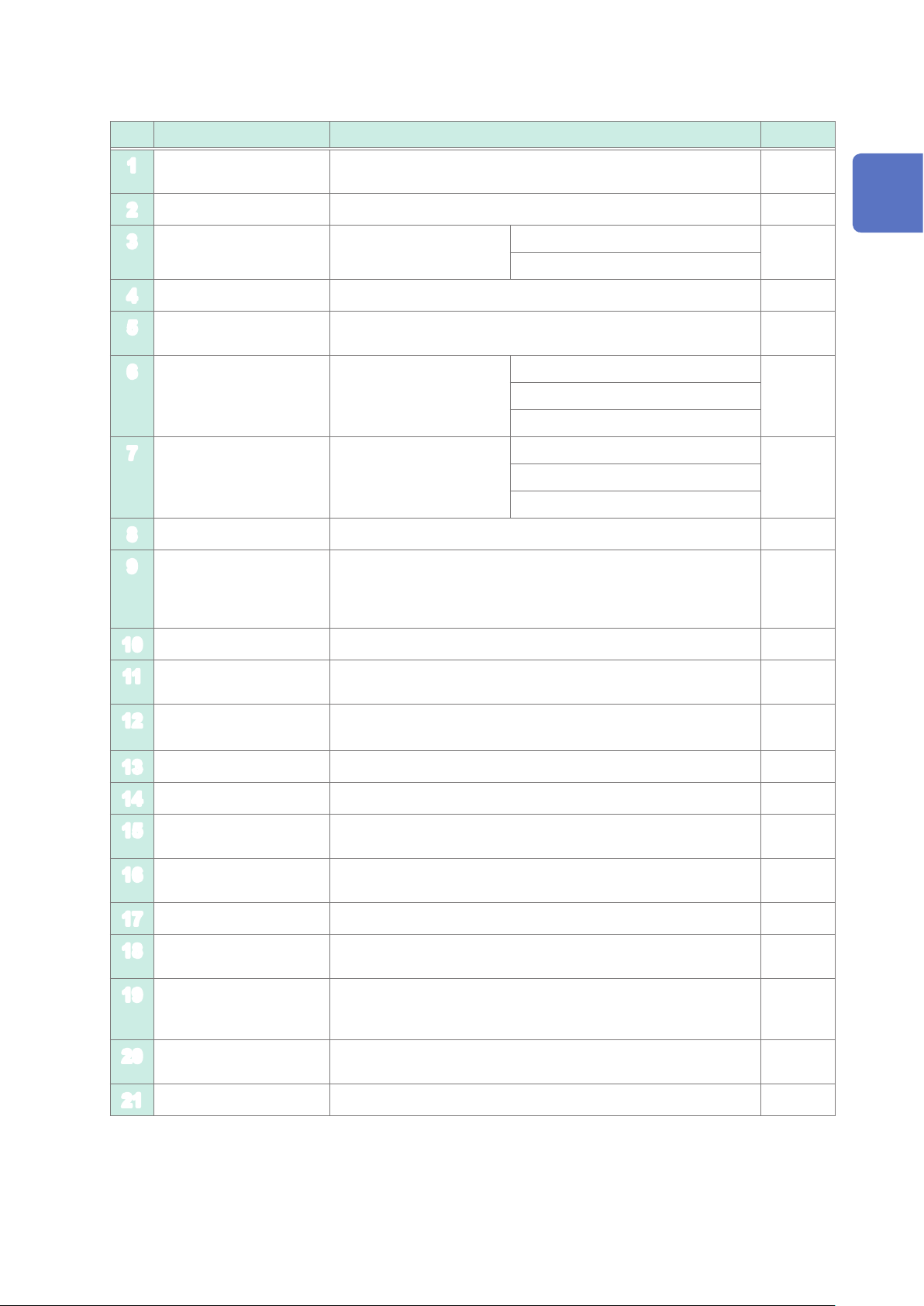

No. Name Function

Display 8.4-inch color TFT liquid crystal display.

1

START button Starts measurements. p. 77

2

OUTPUT lamp Shows the voltage

3

USB connector Connects a USB memory. p. 165

4

STOP button Stops the voltage application and suspends testing.

5

PASS/FAIL lamp Shows the total judgment

6

Startup button Switches the instrument

7

Voltage output terminal Connects a test lead (optional). p. 14

8

Serial number The serial number consists of 9 digits. The rst two (from the left)

9

Comes with a resistant lm touch panel.

Red: Voltage is being applied p. 84

application status.

Also used during double actions.

result.

ON and OFF.

indicate the year of manufacture, and the next two indicate the

month of manufacture.

Required for production control. Do not peel off the label.

OFF: Standby

Green: Total judgment result PASS p. 84

Red: Total judgment result FAIL

OFF: No judgments

OFF: Main power supply OFF p. 16

Red: Sleep mode

Green: ON mode

Reference

p. 10

p. 84,

106

p.

p.

125

1

Overview

MAC address MAC address of the instrument. p. 125

10

Vent holes For ventilation, and to prevent the interior of the instrument from

11

EXT.I/O

12

NPN/PNP switch

1

mount

1

1

LAN connector *

13

USB connector *

14

External control

15

terminal (EXT.I/O)

Communications

16

interface*

Power inlet Connects the provided power cord. p. 15

17

Main power supply

18

switch

Stand Tilts the instrument to enable the screen to be viewed easily.

19

20

Support legs

overheating. Install so that the vent holes are not blocked.

Switches the programmable type of the external control terminal.

Left: NPN (current sink)

Connects a LAN cable. p. 157

Connects a USB cable. p. 155

Enters signals from the programmable controller and I/O boards to

control the instrument.

Mount a Z3000 GP-IB Interface (optional) or Z3001 RS-232C

Interface (optional).

Turns ON and OFF the main power supply to the instrument. p. 16

Make sure to fully open both the left and right stands before

installation.

When mounting the instrument to a rack*

legs.

Right: PNP (current source)

2

, remove the support

–

133

p.

p. 133

152,

p.

p.

154

–

–

Handle Used to carry the instrument. –

21

*1: For how to use RS-232C, GP-IB, USB, and LAN, see the “Communications Commands Instruction

Manual” on the application disk.

*2: The instrument can be mounted to a rack. See “15.3 Rack Mount” (p. 224).

9

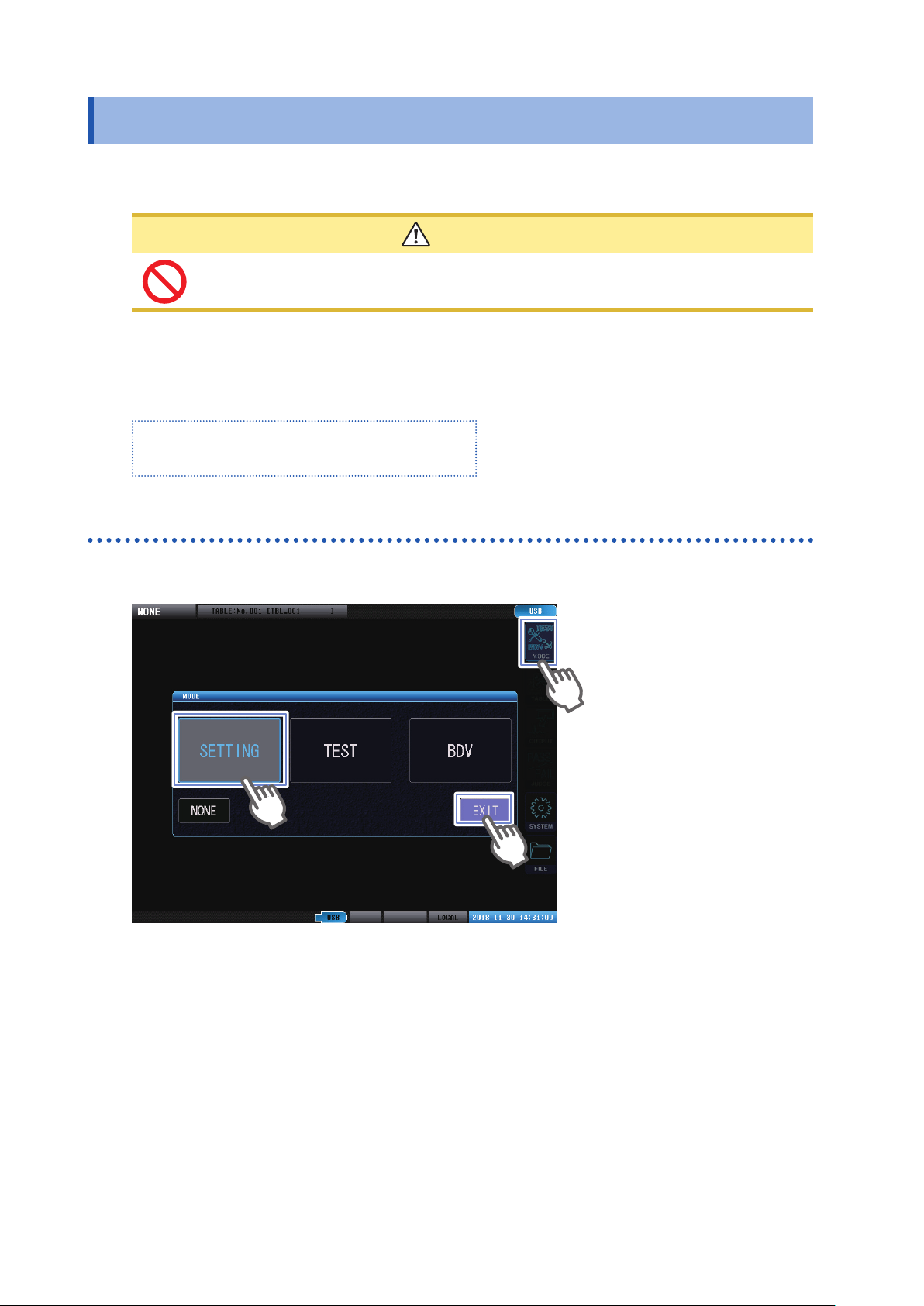

Screen Operations

1.4 Screen Operations

The instrument uses a touch panel for all settings and changes to the measuring conditions.

Gently touch the onscreen keys to select the items and values set for those keys.

CAUTION

Do not press the touch panel forcefully or jab it with the point of a hard object. Doing so

may cause a malfunction.

This document describes below the procedures up to displaying the various settings screens.

Example: When displaying the [SETTING] screen

Measurement screen

(

) [MODE] > [SETTING]

Measuring mode settings

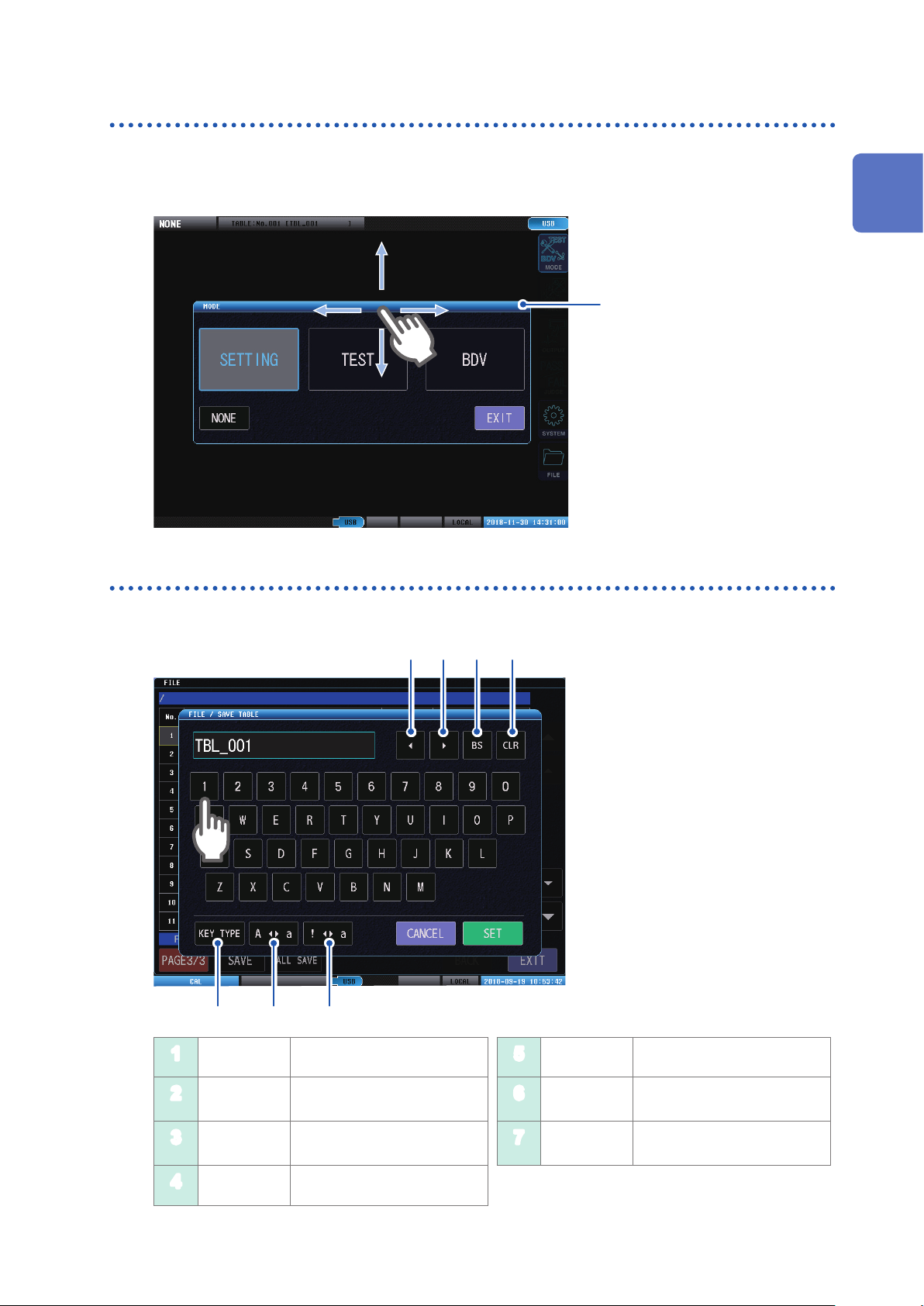

Example: Selecting the test conditions settings mode

2

Tap [MODE] to display the measuring mode selection window.

1

1

3

Select the measuring mode.

2

Here, tap [SETTING].

Tap [EXIT] to return to the measurement screen.

3

10

Moving windows

Press and hold the window title bar while dragging the window to move the window to a new

position.

Window title bar

Screen Operations

1

Overview

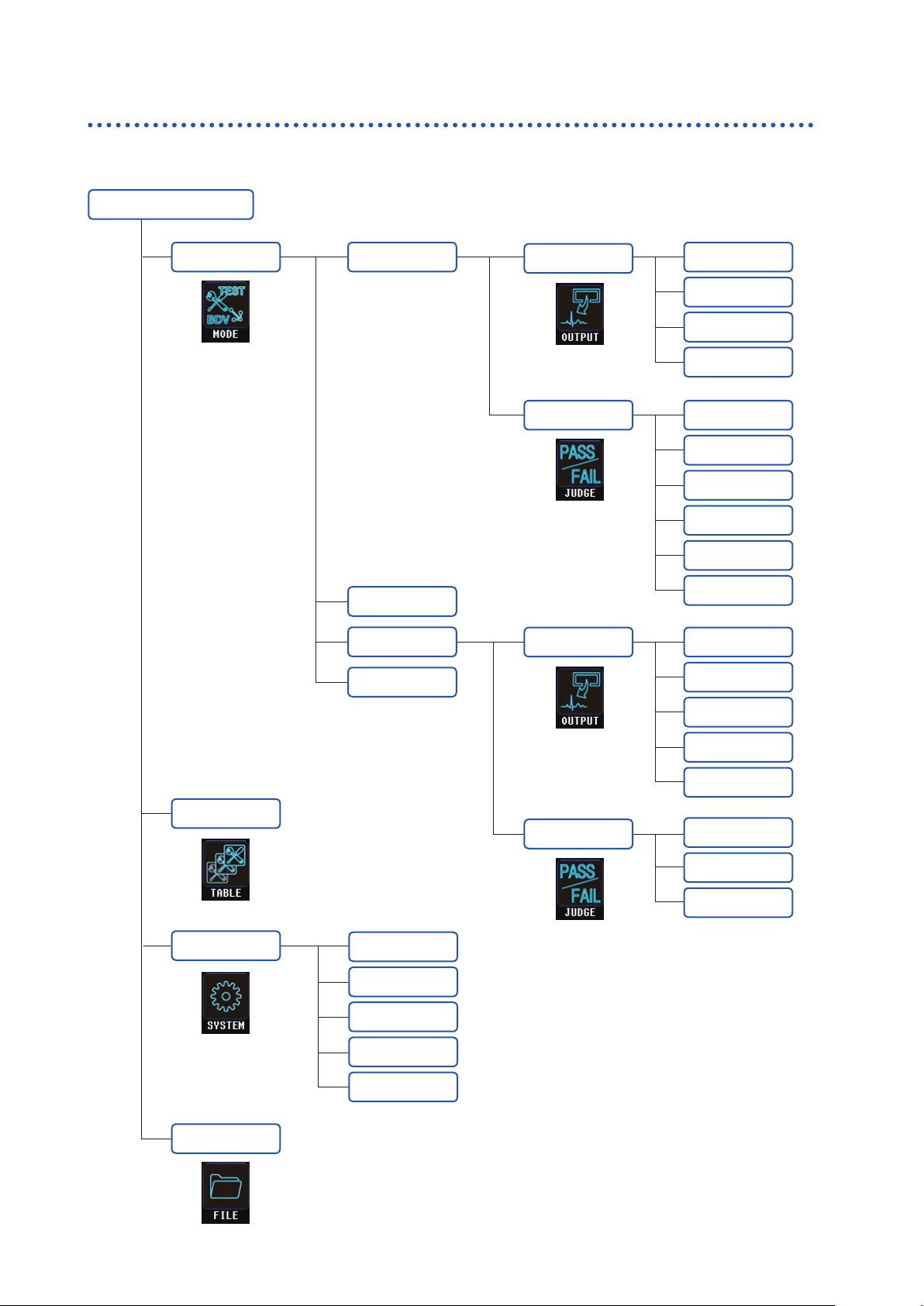

Touch keyboard inputs

Enter text and then tap [SET] to conrm. To cancel, tap [CANCEL].

1 3 4

2

5 6 7

1

2

3

4

BS Deletes 1 character.

CLR Deletes all.

Moves the cursor to the left.

Moves the cursor to the right.

KEY TYPE Switches the keyboard type.

5

6

7

A a Switches between upper and

lower case.

! A Switches between symbols/

numbers, and the alphabet.

11

Screen Operations

Screen conguration

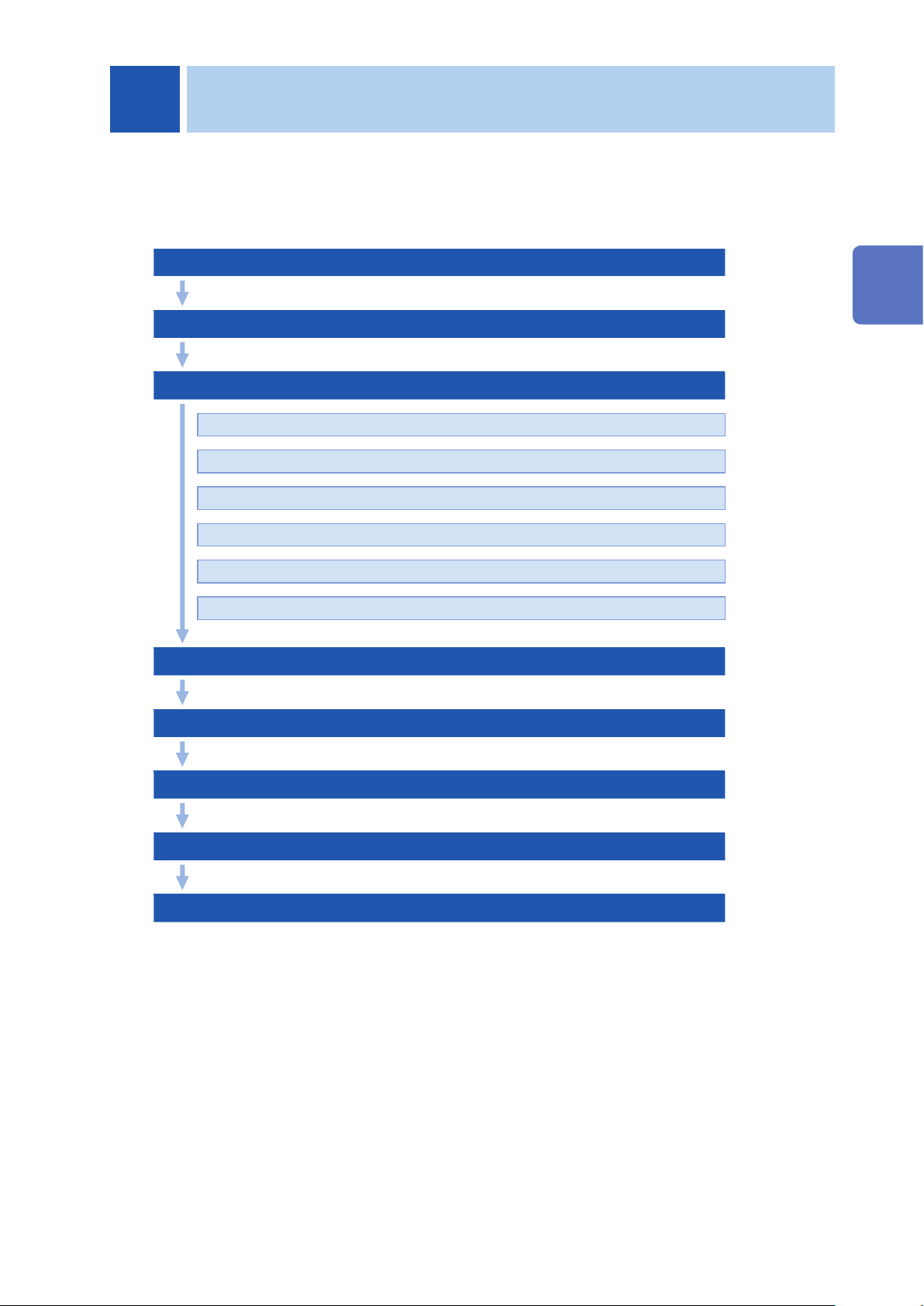

The instrument settings windows are congured using the following stages.

Measurement screen

MODE VOLT

SETTING

TEST

BDV

NONE

OUTPUT

PULSE

SAMPLING

DELAY

JUDGE

OUTPUT START

LCRC AREA

DISCHARGE

AREA

DIFF AREA

FLUTTER

LAPLACIAN

END

TABLE

SYSTEM

FILE

SYSTEM

I/F

INFO

TEST

CLOCK

JUDGE

STEP

PULSE

SAMPLING

LCRC AREA

DISCHARGE

AREA

12

2

Preparation for Measurements

Make sure to read through both “Usage Notes” (p. 5) in this manual and the separate “Operating

Precautions” before starting the preparations that precede measuring.

For rack mounts, see “15.3 Rack Mount” (p. 224).

Installing the device.

Connecting the test lead.

p. 5

p. 14

Connecting and setting the external interface (as necessary).

EXT. I/O p. 136

RS-232C p.

GP-IB p.

USB p.

152

154

155

2

Preparation for Measurements

LAN p.

USB memory p.

Connecting the power cord.

Turning on the instrument power supply.

Setting the date and time (as necessary).

Setting the measuring mode.

Inspecting before measurement and verifying operations.

157

169

p. 15

p. 16

p. 132

p. 18

p. 19

13

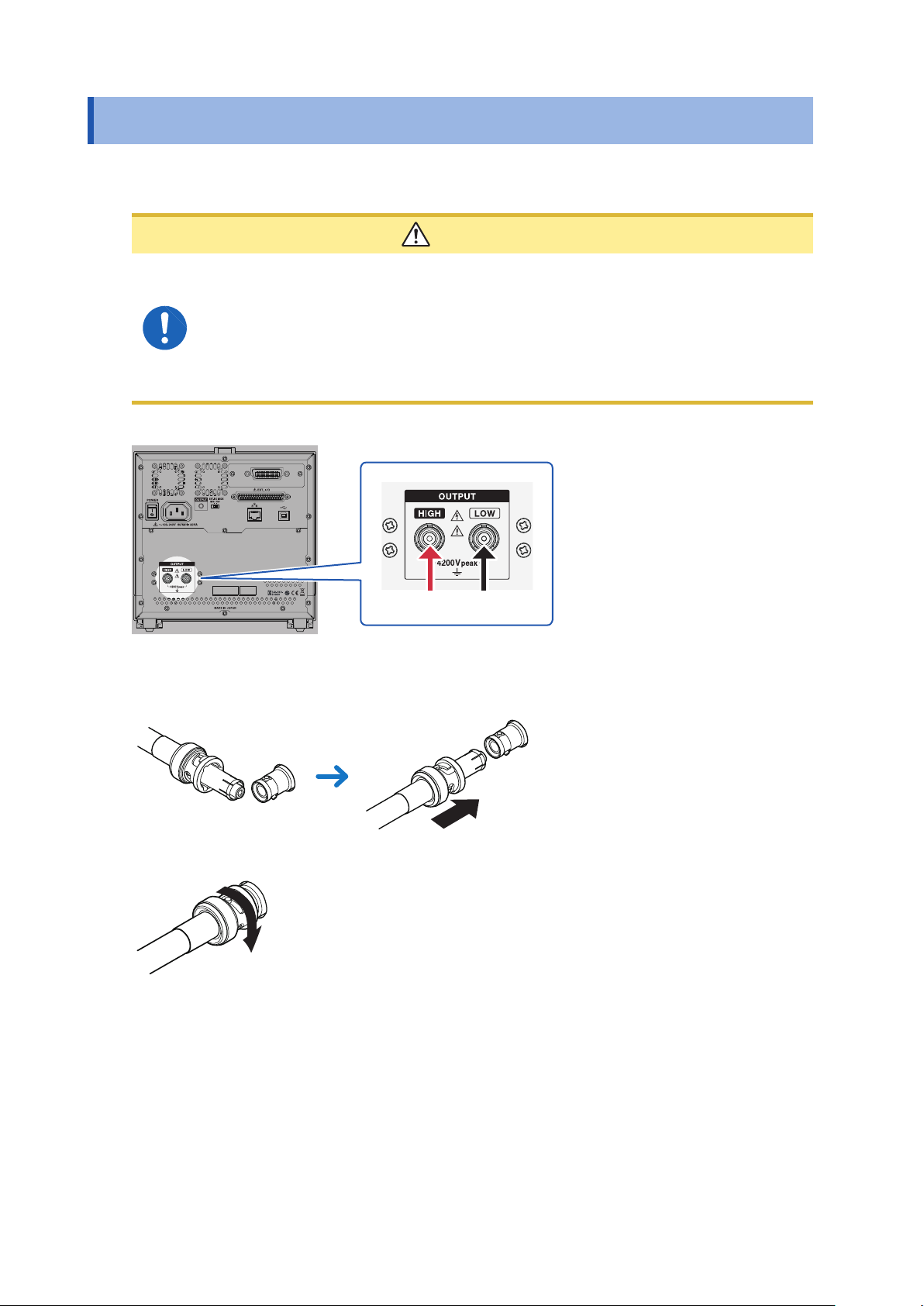

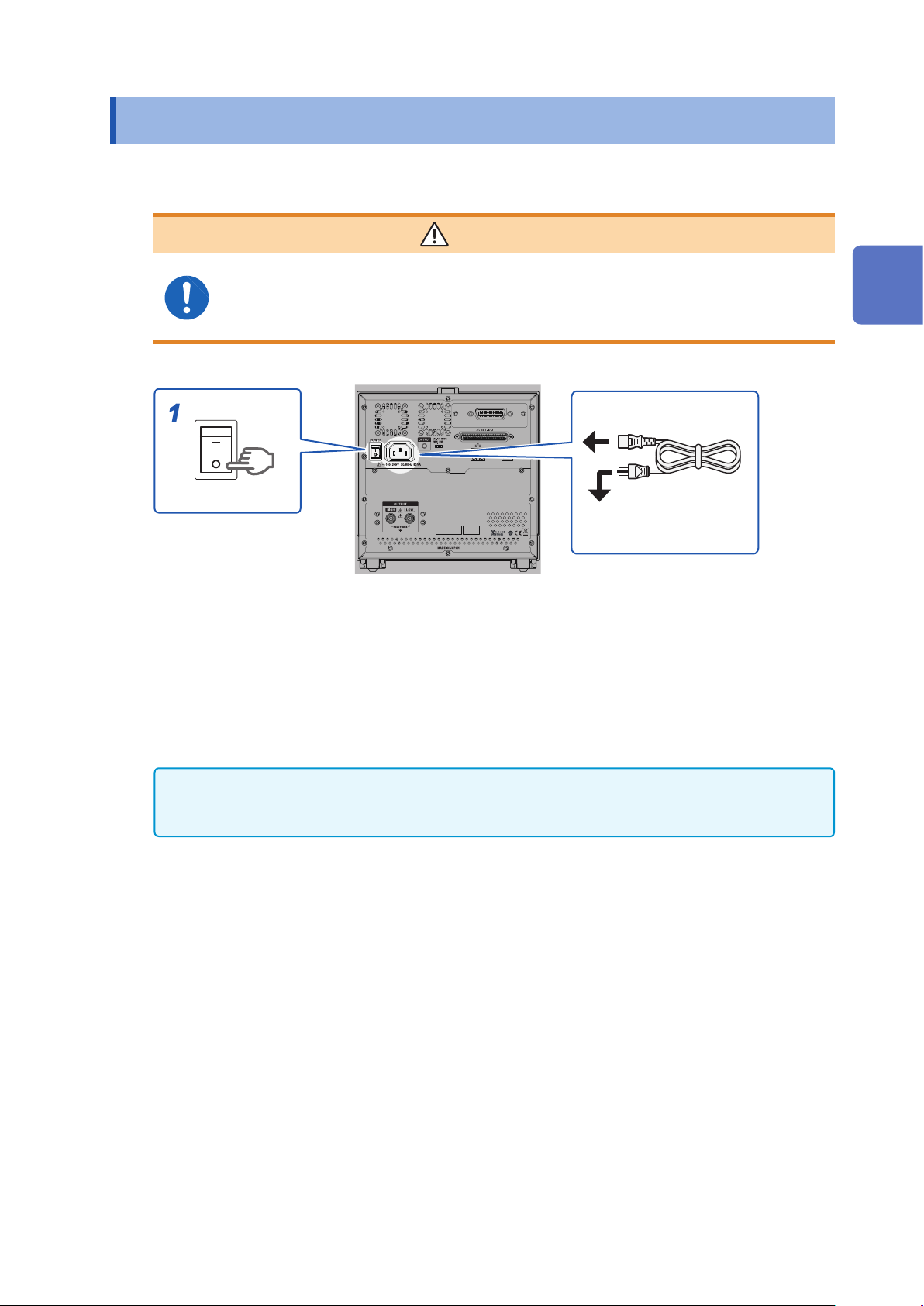

Connecting the Test Lead (on the ST4030)

2.1 Connecting the Test Lead (on the ST4030)

Connect the test lead to the voltage output terminal on the instrument.

CAUTION

• To prevent damage to the coaxial connectors or joint, make sure to unlock rst, and

grasp the coaxial connector and pull it out.

• Model L2250 Clip Type Lead’s maximum rated voltage is 3300 V AC peak. To test

higher voltages, use the L2252 Unprocessed Lead Cable.

• Model L2252 requires customer modication. To prevent electric shock and equipment

damage when modifying the lead, see “15.10 Precautions when Processing Test

Leads” (p. 237).

Red Black

Rear

Align the groove on the test lead’s coaxial cable to the lock pin on the voltage output

1

terminal on the ST4030 side and insert.

Rotate the coaxial connector on the test lead to the right to lock it.

2

When removing, rotate the coaxial connector on the connection cable to the left and then pull out.

14

Connecting the Power Cord

2.2 Connecting the Power Cord

To supply power to the instrument, connect the power cord to the power supply inlet on the rear of

the instrument.

WARNING

Before turning on the power supply, check that the power supply voltage described on

the power supply connector on the instrument and the power supply voltage to be used

match each other. Using outside the range of the designated power supply voltage may

cause damage and electrical malfunction to the instrument.

2

Preparation for Measurements

1

OFF

Rear

Turn OFF the main power supply switch on the rear of the instrument.

1

Connect the power cord to the power inlet.

2

Connect the plug of the power cord to the grounded outlet.

3

IMPORTANT

If the power supply is cut off while the main power supply is ON (by a breaker tripping, etc.), the instrument

will start automatically when the power is supplied again.

2

To grounded outlet

3

15

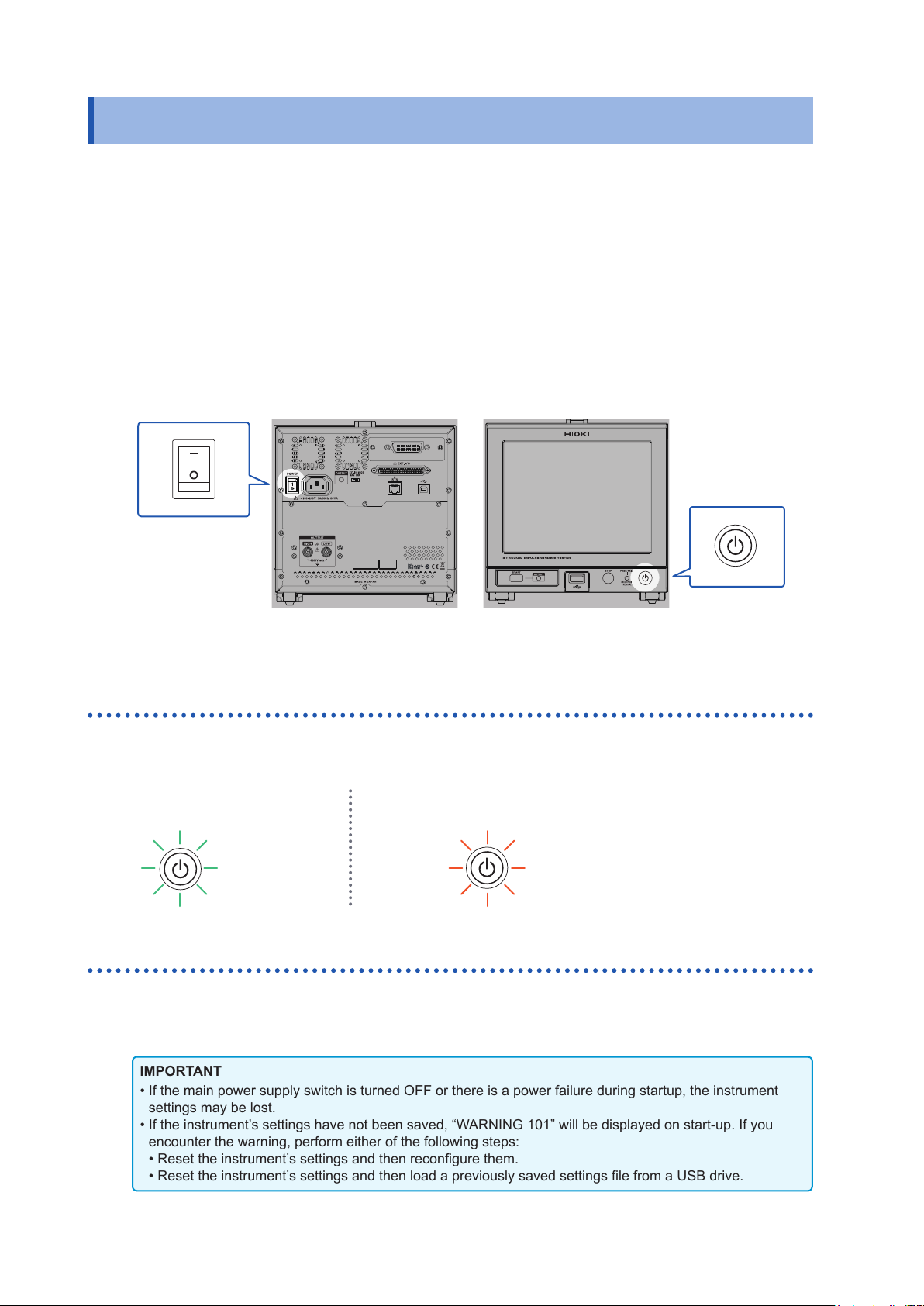

Power Supply ON/OFF

IMPORTANT

• If the main power supply switch is turned OFF or there is a power failure during startup, the instrument

settings may be lost.

• If the instrument’s settings have not been saved, “WARNING 101” will be displayed on start-up. If you

encounter the warning, perform either of the following steps:

• Reset the instrument’s settings and then recongure them.

• Reset the instrument’s settings and then load a previously saved settings le from a USB drive.

2.3 Power Supply ON/OFF

Turn ON the main power supply on the rear of the instrument beforehand to enable turning ON and

OFF the power supply using the startup button on the front. This is convenient if incorporating the

instrument into an automated machine or assembly line.

If the main power supply is turned OFF while the instrument is in sleep mode and then turned ON

again, the instrument will start in sleep mode.

• Using the startup button in sleep mode will hold the instrument settings even if the main power

supply switch is turned OFF (backup).

• If the instrument was not used for a long time, it is necessary to charge the internal backup

battery. Turning ON the instrument’s main power supply will charge the internal battery. Charge

for a minimum of 3 hours, although 24 hours is recommended.

Main power supply

switch

Main power supply ON

Turn ON the main power supply switch.

The startup button lamp will turn on.

Startup mode

Lit green

Main power supply OFF

Startup button

Rear Front

Sleep mode

Lit red

Turn OFF the main power supply switch.

The startup button lamp will turn off.

16

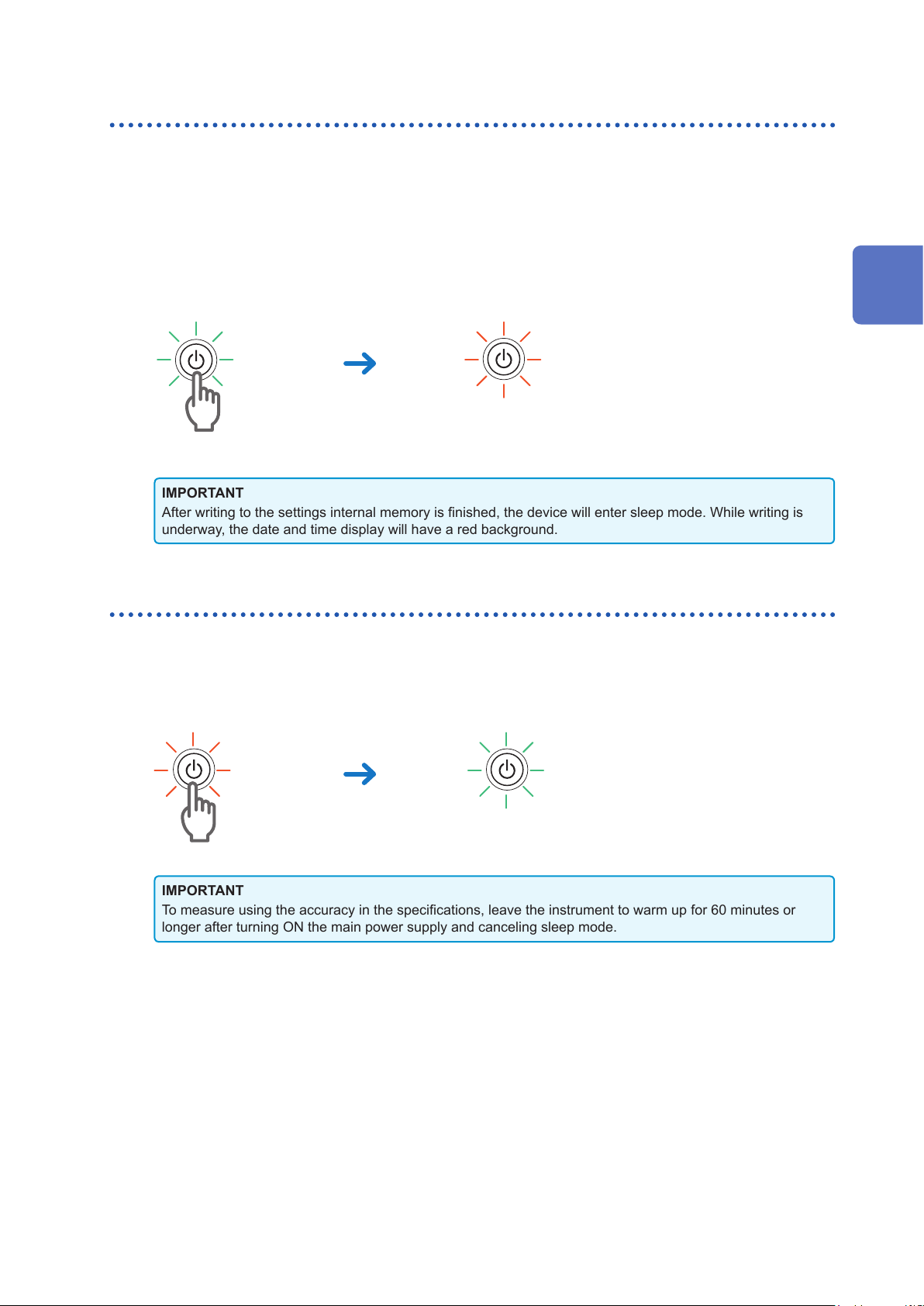

Power Supply ON/OFF

IMPORTANT

After writing to the settings internal memory is nished, the device will enter sleep mode. While writing is

underway, the date and time display will have a red background.

IMPORTANT

To measure using the accuracy in the specications, leave the instrument to warm up for 60 minutes or

longer after turning ON the main power supply and canceling sleep mode.

Sleep mode

This is the mode in which the device power supply is OFF.

Only the circuit that turns on the startup button lamp is operating.

With the main power supply switch turned ON, press and hold the startup button for approx.

2 sec.

The startup button lamp will turn red and the instrument will enter sleep mode.

Startup mode Sleep mode

Lit green Lit red

Approx. 2 sec.

Startup mode

Press the startup button when the instrument is in sleep mode.

The startup button lamp will turn green and the instrument will enter startup mode.

Sleep mode

Startup mode

2

Preparation for Measurements

Lit red

Lit green

17

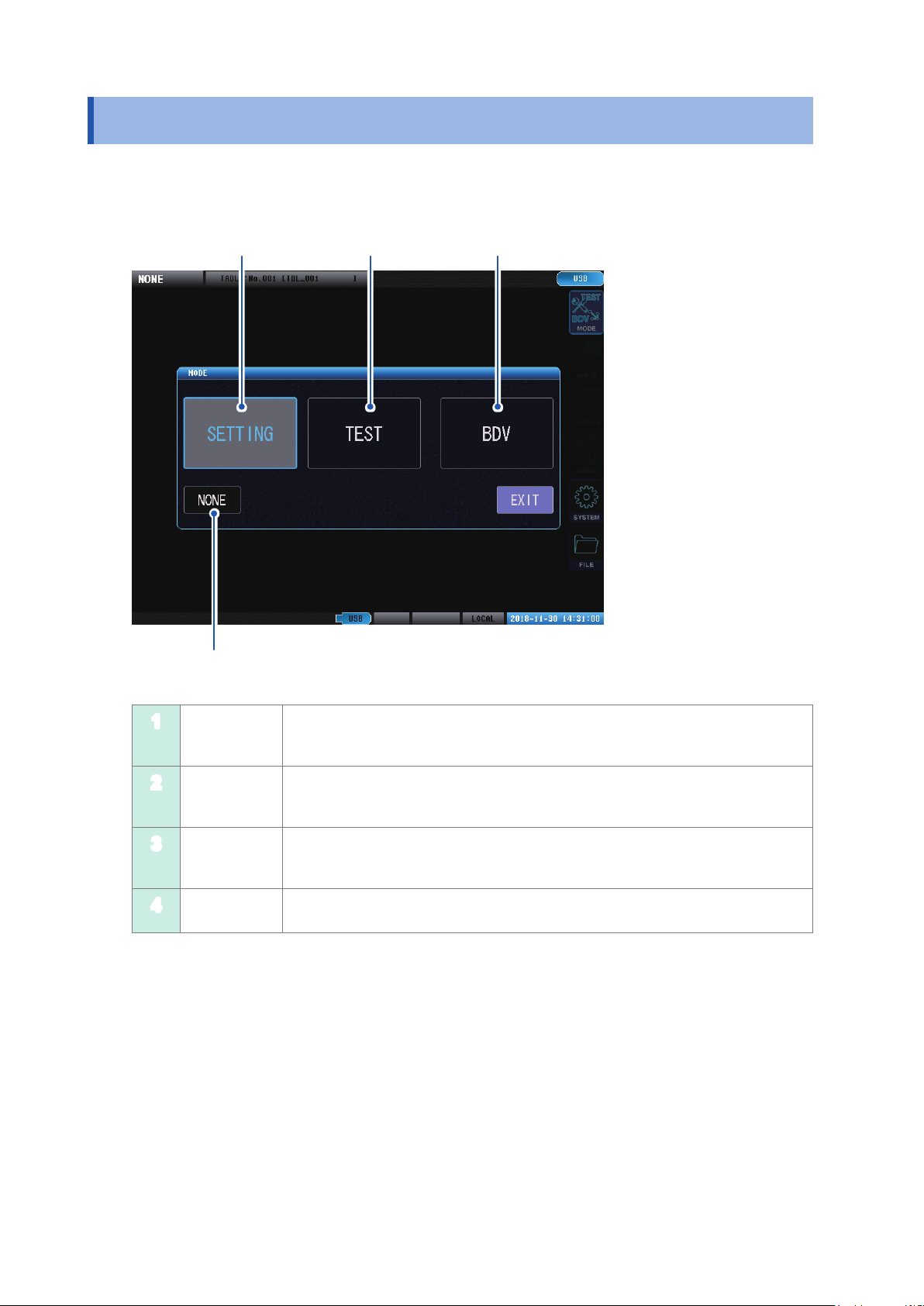

Select Measuring Mode

2.4 Select Measuring Mode

Tap [MODE] in the measurement screen to display the measuring mode selection window. Choose

from 4 types of measuring mode.

1 2 3

4

[SETTING] Test conditions settings mode

1

2

3

4

[TEST] Test mode

[BDV] Break down voltage test (BDV) mode

[NONE] Voltage application disabled mode

Sets the test conditions, sets the judgment conditions, and acquire the master

waveforms.

Calls the test conditions that have been set using test conditions settings mode, and

to test objects.

Tests the impedance while gradually increasing the voltage applied to the workpiece

to determine the break down voltage.

It is not possible to output from the instrument for safety reasons.

18

Inspecting before Measurement and Verifying Operations

2.5 Inspecting before Measurement and Verifying

Operations

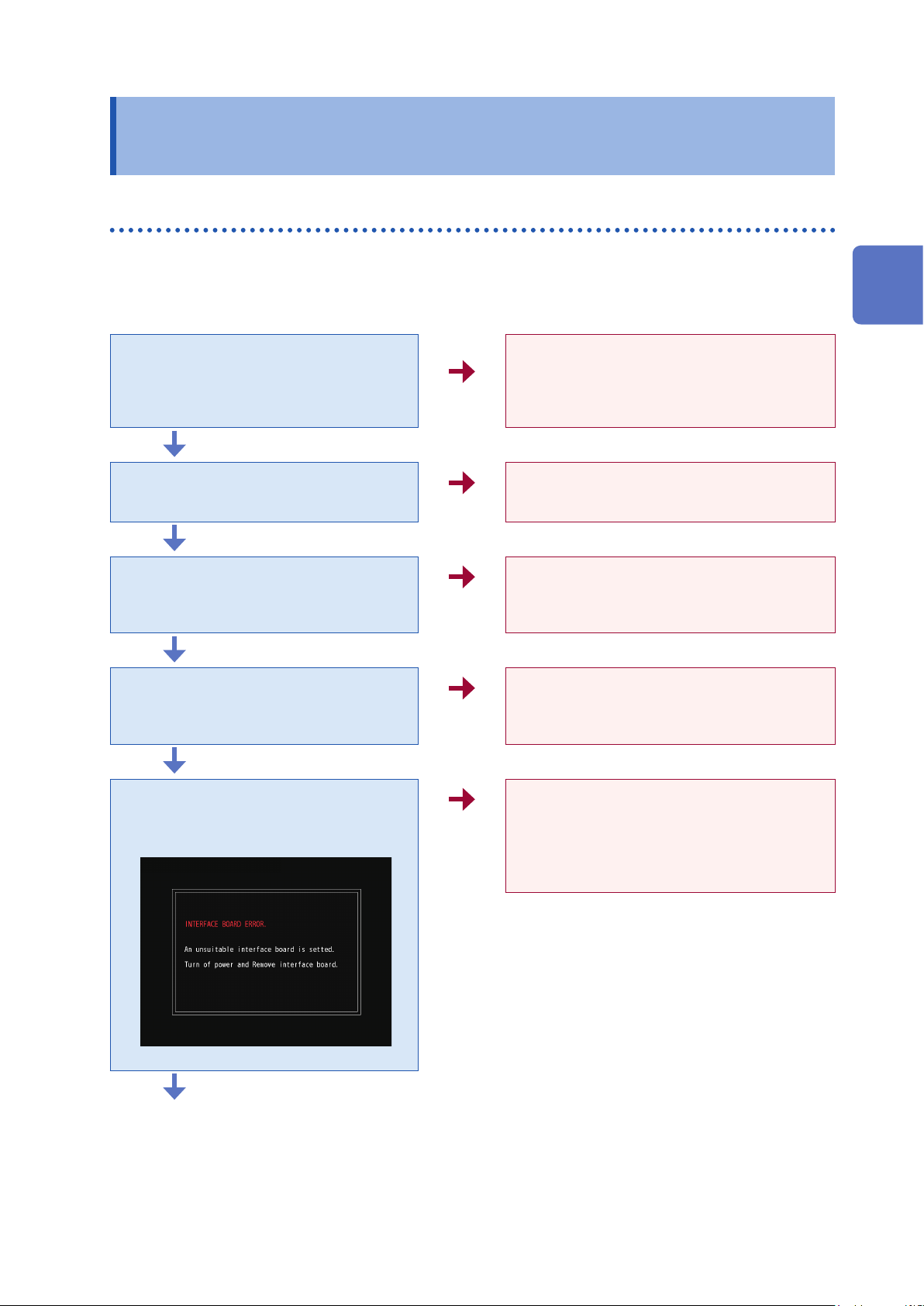

Inspection

Before using the instrument for the rst time, verify that it operates normally to ensure that no

damage occurred during storage or shipping. If you nd any damage, contact your authorized Hioki

distributor or reseller.

Is the sheath of the cable

1

normal without any damage or

exposed metal part?

Not exposed

Is the instrument normal

2

without any damage?

Exposed

Damaged

This may cause electric shock or short circuit,

so replace with an undamaged cable.

Contact your authorized Hioki distributor or

reseller.

Send for repairs.

2

Preparation for Measurements

Not damaged

When the main power supply

3

is ON, is the startup button

lamp either green or red?

Lamp is ON

When the startup button is ON,

4

is the opening screen (model

name and version) displayed?

Displayed

After the opening screen is

5

displayed, is the interface

board error screen displayed?

Lamp is

OFF

Not

displayed

Displayed

Send for repairs.

There is a risk of a broken wire in the power

cord, or of a malfunction in the instrument.

Send for repairs.

There is a risk of a malfunction in the device.

Turn OFF the power supply, remove the

interface board, and turn ON the power

supply again.

Z3002 LAN Interface boards cannot be used

with this instrument.

Not displayed

Inspection is complete.

19

Inspecting before Measurement and Verifying Operations

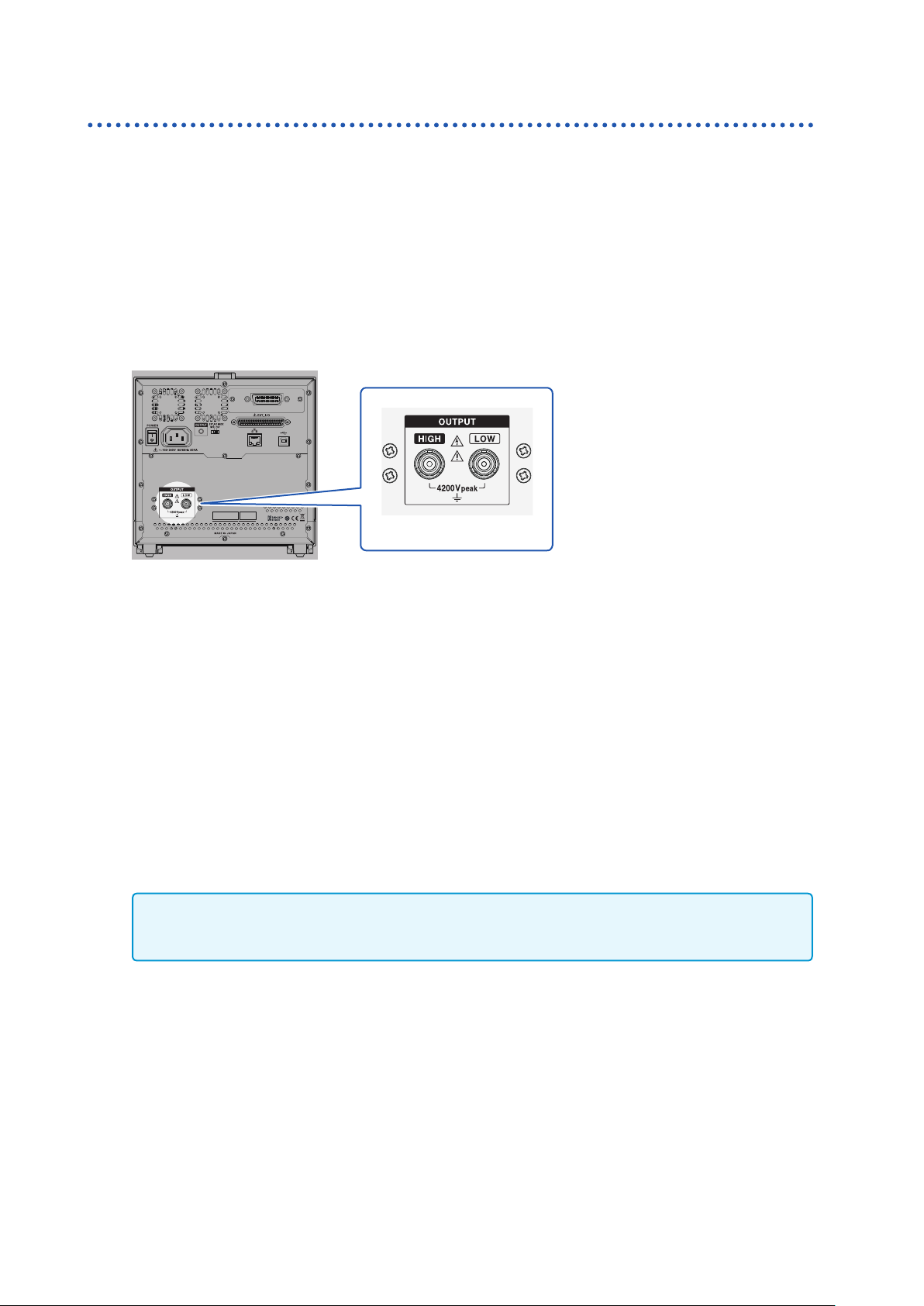

Checking the voltage generated

Check that operations are at an environmental temperature of 23C±5C, and that the humidity is

80% RH or less.

Select an empty table to which nothing has been saved in the test conditions settings mode.

1

Set the applied voltage to 100 V, the sampling frequency to 200 MHz, the number of sampling

2

data to 1001, and the number of pulses to be applied to 1.

Implement the tests with nothing connected to the voltage output terminal.

3

(Illustration below is ST4030A)

(Nothing is connected)

Rear

Check that the peak voltage (value displayed on the instrument) is 100 V ±2%.

4

Change the voltage setting.

5

ST4030: 3300 V

ST4030A: 4200 V

Implement the test with nothing connected to the voltage output terminal.

6

Check that the peak voltage (value displayed on the instrument) is below.

7

ST4030: 3300 V±2%

ST4030A: 4200 V±2%

IMPORTANT

Contact your authorized Hioki distributor or reseller if the peak voltage differs from the set voltage by 2% or

greater.

20

Inspecting before Measurement and Verifying Operations

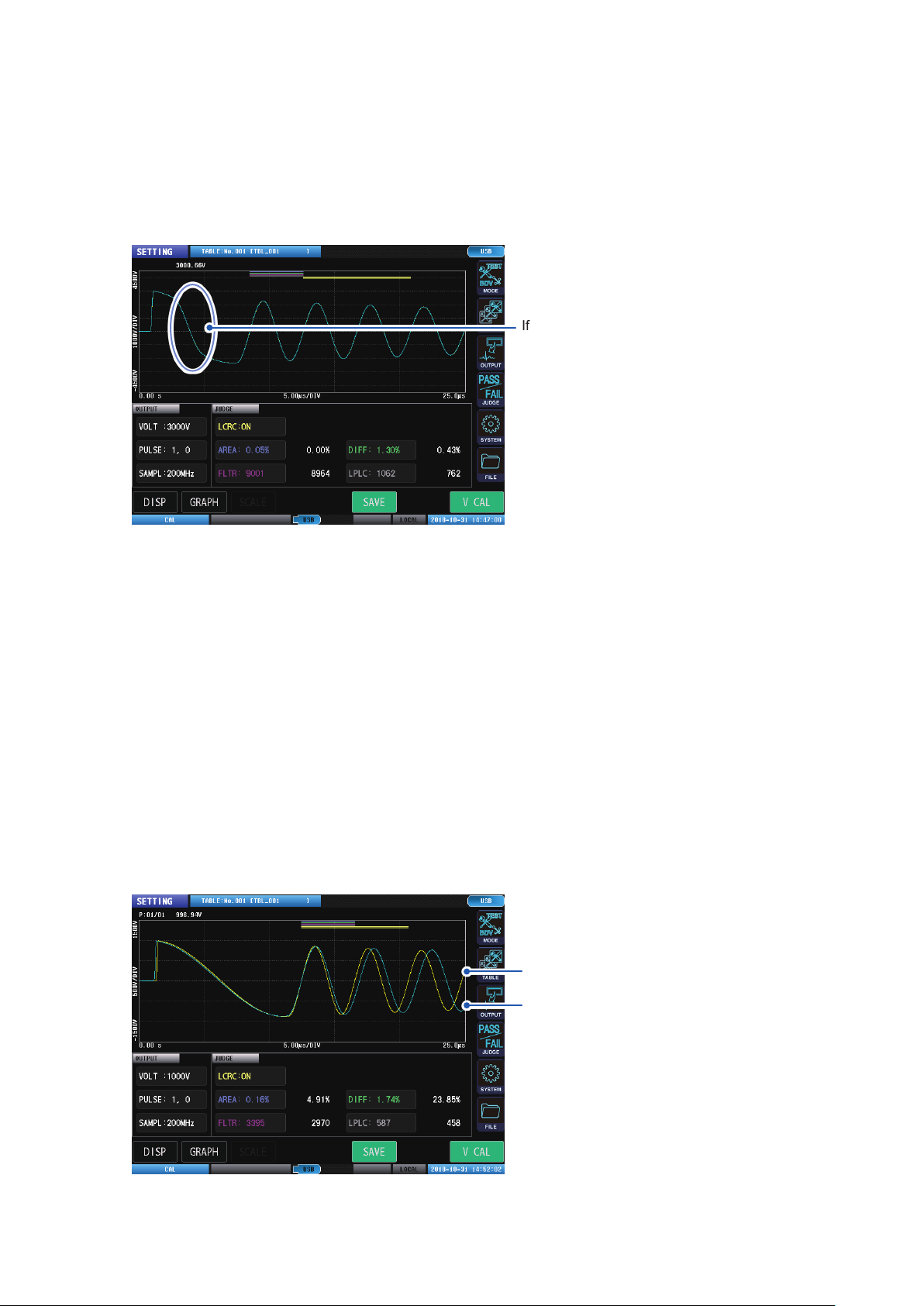

Checking the impulse response waveforms

Implement impulse testing on the inspection master workpiece to check that there are no

abnormalities in the instrument or equipment. Set the test conditions according to the workpiece.

Tools to be prepared

Master workpiece (a workpiece close to the mass production master workpiece, or a coil of approx.

1 mH created using reinforced insulation wire)

Calibrate the voltage of the master workpiece beforehand and record the master waveform.

Connect the master workpiece to the test lead.

1

Select the table to which the master waveform was saved in test mode.

2

Implement the test.

3

If the waveform shape (peak voltage, zero‑cross point, etc.) changes greatly

(1) Being affected by residual magnetization from the workpiece core.

2

Preparation for Measurements

Apply a degaussing impulse to the workpiece until the waveform stops changing.

You can see how waveforms diverge by turning

on waveform superposition and repeating the

test multiple times.

Reference: “Overlay settings” (p.

112)

21

Inspecting before Measurement and Verifying Operations

(2) Waveform reproducibility is poor.

Periods of magnetic saturation reduces the workpiece inductance, so the vibration frequency of the

response waveform increases (i.e., inclination is more sudden).

The waveform may experience major variation when multiple impulse tests are performed on the

same workpiece because of the magnetic characteristics of the core.

If the core is magnetically saturated, the

waveform will tilt rapidly.

(3) Being affected by the magnetic anisotropy of the workpiece core.

The characteristics of the magnetic materials may depend on its orientation. Implement the tests

using the same layout as during the voltage calibration.

(4) The master workpiece has been changed.

Recalibrate the voltages.

Even if the coil and motor have the same model number, if they have different magnetic core

characteristics (varied by lot), there is a risk that the waveform will change due to differences in the

stray capacitance of the workpiece.

(5) The equipment cable or device connected in parallel to the instrument has changed.

The cable capacitance and the parasitic capacitance of the equipment connected in parallel affects

the vibration frequency. Recalibrate the voltages.

Example:

Waveform difference due to cable length when implementing impulse tests on coils with

the same inductance values (1 mH).

If 1.5 m

22

If 3.0 m

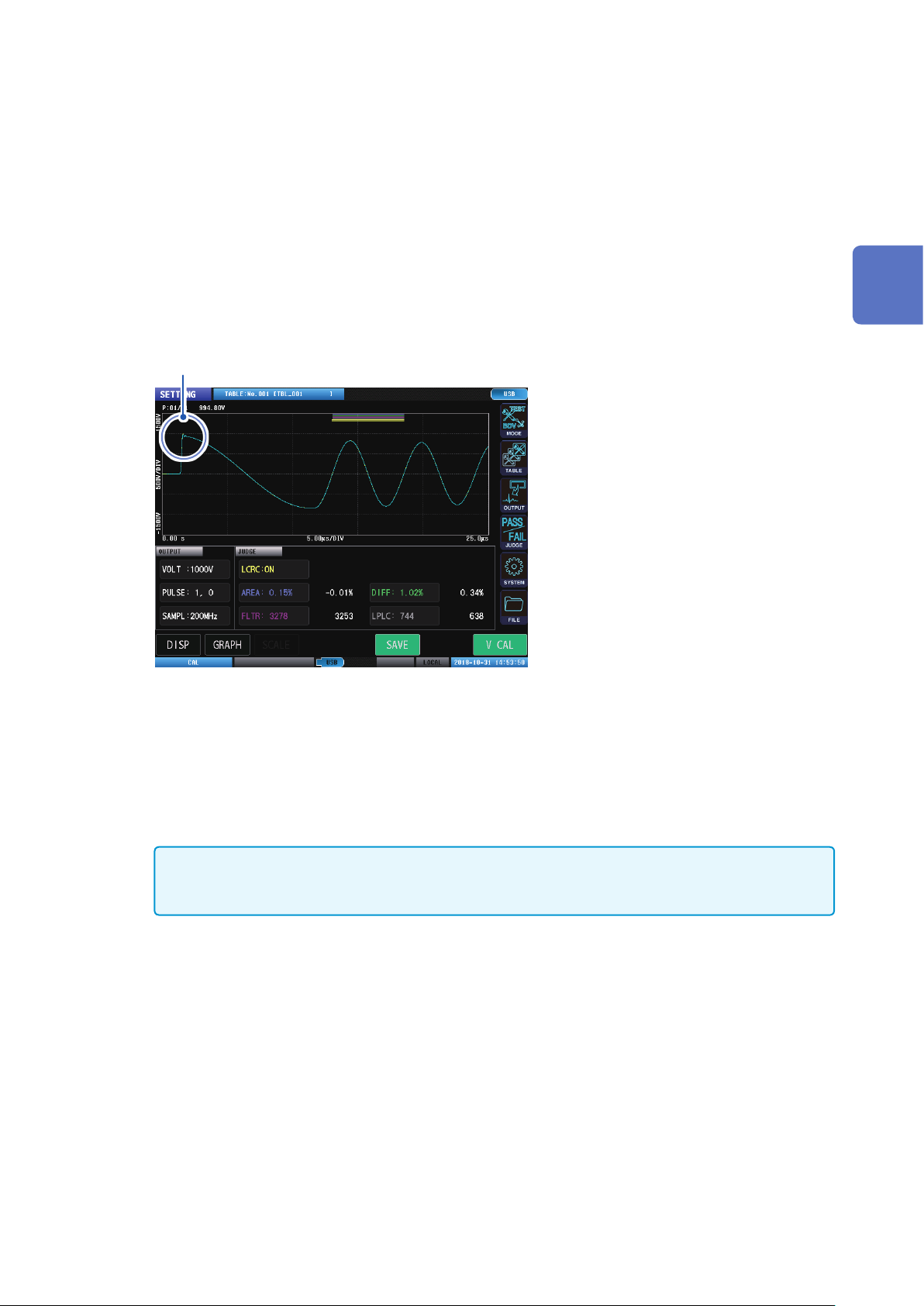

Inspecting before Measurement and Verifying Operations

If ringing occurs that did not occur during voltage calibration

(1) Master workpiece is grounded.

When the master workpiece is grounded, ringing may occur due to parasitic components of the

power cord or test lead.

Do not ground the master workpiece.

Th

(2)

e test lead has been extended.

The longer the test lead the more the parasitic capacitance and parasitic inductance increase,

making it easy for ringing to occur.

If the user is processing the test lead themselves, make the lead as short as possible.

If replacing the test lead, recalibrate the voltages.

Ringing

2

Preparation for Measurements

(3) Master workpiece insulation is worn.

Prepare a new master workpiece, and implement voltage calibration.

(4) Test lead insulation is worn.

Prepare a new test lead, and implement voltage calibration.

IMPORTANT

If none of these apply, there is a risk that the instrument is damaged. Contact your authorized Hioki

distributor or reseller.

23

Inspecting before Measurement and Verifying Operations

24

Switching Test Conditions (Table

3

Functions)

3.1 Overview

• The test conditions, judgment conditions, and master waveform are saved to the instrument’s

internal memory as settings tables.

A maximum of 255 settings tables (No. 001 to No. 255) can be created.

• Select a table that creates the master waveform in test conditions settings mode to acquire the

master waveform.

• Select the table to which the master waveform to be used in the test was saved in test mode, and

implement the test.

• Even if the instrument’s power supply is turned OFF, the settings table details will be retained.

Overview of test conditions switching functions

You can save multiple test conditions, judgment conditions, and master waveforms as settings

tables and switch between them as desired.

3

Switching Test Conditions (Table Functions)

Number of settings saved

Retained settings

Switching between settings

tables

Settings table settings

initialization

Settings table name settings

IMPORTANT

Select the table to be used, and change the test conditions and acquire the waveform. Changing the test

conditions and acquiring the waveform will overwrite the previous settings.

255

Test conditions, judgment conditions, and master waveforms

Switch using screen operations, communications, and signal inputs

to external control terminal (EXT.

Restores the settings such as the master waveforms in the settings

tables to their default settings.

Add a user-selected name to each settings table (127 characters

max.)

Default value: TBL_XX (XX is the table number)

I/O).

25

Overview

Items that can be saved

The following items can be saved to settings tables.

Test conditions settings

VOLT Applied voltage

PULSE No. of applied pulses, No. of degaussing pulses, min. interval between pulse outputs

SAMPLING Sampling frequency, No. of sampling data

DELAY Trigger delay

Judgment conditions settings

LCRC AREA LC and RC values judgments

DISCHARGE*

AREA Waveform surface area comparison judgment

DIFF-AREA Waveform difference surface area comparison judgments

1

Discharge judgment*

1

FLUTTER Waveform utter detection judgments

LAPLACIAN Waveform secondary differential detection judgments

*1: When incorporating Model ST9000

Master waveform

Master waveform data

26

Overview

Operations owchart in test conditions settings mode and test mode

In test conditions settings mode and test mode, select the table to be used before you move on to

the next operation, by using the operations procedure as shown in the diagram.

Test conditions

settings mode

[SETTING]

Select the table to which to save

the master waveform.

[TABLE]

Set the test conditions.

[OUTPUT]

Enable the judgment conditions to be

used.

[JUDGE]

Calibrate the voltage and import the

master waveform.

[V CAL]

Test mode

[TEST]

Select the table to which the

master waveform to be used

in the tests was saved.

[TABLE]

Implement the test.

Check the test results.

Finish

3

Switching Test Conditions (Table Functions)

Import the master data for the LC and

RC values (When using LC and RC

values judgments).

Set the judgment conditions.

[JUDGE]

Finish

27

Overview

Screen conguration

(Measurement screen) [MODE] > [SETTING] or [TEST] > [TABLE]

1 2 5

3 4

6 7 8 9 10

Current table number

1

Table name

Tables list List of the tables that have been saved.

2

Scroll bar Drag to scroll the table.

3

UP/DOWN buttons Moves up or down the table that is displayed.

4

Table setting description Settings descriptions for the table selected onscreen.

5

[SELECT] Sets the selected table as the current table.

6

[DELETE] Deletes the selected table.

7

[INIT] Initializes the selected table.

8

[RENAME] Changes the name of the selected table.

9

[COPY] [No.xxx] [PASTE] Copies the table that has been created and pastes it to a table

10

4

Number and name of the (current) table that is presently set.

The table in which the characters are light blue is the present table.

Reference: “3.2 Current Table Selection” (p. 29)

Reference: “3.4 Table Deletion” (p. 31)

Reference: “3.3 Table Initialization” (p. 30)

Reference: “3.5 Changing the Table Name” (p. 32)

chosen by the user.

The table selected for copying is displayed as [No. xxx] (with the

characters in yellow).

Reference: “3.6 Table Copying” (p. 33)

28

Current Table Selection

3.2 Current Table Selection

Sets the table used as the test conditions as the current table (i.e., the table to be used from now

on).

(Measurement screen) [MODE] > [SETTING] or [TEST] > [TABLE]

1

2

Tap the table that is to be set as the current table.

1

The table selected will be surrounded by a yellow frame.

Tap [SELECT].

2

The characters in the table selected as the current table will turn light blue.

Test conditions settings mode: Saves the settings and the master waveform to the selected current table.

Test mode: Implements tests using the master waveform in the selected current table.

3

Switching Test Conditions (Table Functions)

29

Table Initialization

3.3 Table Initialization

Restores the settings details of the selected table to their default values. Also deletes the master

waveform.

Reference: “Default settings table” on the application disc

(Measurement screen) [MODE] > [SETTING] > [TABLE]

1

2

Tap the table.

1

Tap [INIT].

2

The conrmation window will be displayed.

Tap [OK].

3

3

30

3.4 Table Deletion

Deletes the settings details from unnecessary tables. After deletion, the [TABLE NAME] is

displayed as [– – –].

(Measurement screen) [MODE] > [SETTING] > [TABLE]

Table Deletion

1

2

Tap the table to be deleted.

1

Tap [DELETE].

2

The conrmation window will be displayed.

Tap [OK].

3

3

Switching Test Conditions (Table Functions)

3

31

Changing the Table Name

3.5 Changing the Table Name

Changes the name of the table saved to the instrument.

(Measurement screen) [MODE] > [SETTING] > [TABLE]

1

2

Tap the table whose name you want to change.

1

Tap [RENAME].

2

Enter the new name of the table.

3

Reference: “Touch keyboard inputs” (p. 11)

32

3.6 Table Copying

You can copy the table that has been created and paste it to your chosen table.

(Measurement screen) [MODE] > [SETTING] > [TABLE]

Table Copying

3

1

3

2

Tap the table to be copied.

1

Tap [COPY].

2

Tap the table to be pasted.

3

Tap [PASTE].

4

The conrmation window will be displayed.

Tap [OK].

5

Switching Test Conditions (Table Functions)

5

4

IMPORTANT

If there is already data in the target table, the source data will be overwritten.

33

Table Copying

34

4

Setting the Test Conditions

4.1 Overview

Use the master workpiece to set the test conditions in order to judge whether or not the workpiece

to be tested is defective.

In test conditions settings mode, set the output conditions and the judgment conditions such as the

pulse to be applied, etc., and acquire the master waveform. You can save up to 255 test conditions

settings in a table.

Operations owchart in test conditions settings mode

In test conditions settings mode, set the output conditions and judgment conditions, and acquire the

master waveform using the operations procedure as shown in the diagram.

Test conditions settings mode

[SETTING]

Select the table to which to save the master waveform.

[TABLE]

4

Setting the Test Conditions

Set the test conditions.

[OUTPUT]

Enable the judgment conditions to be used.

[JUDGE]

Calibrate the voltage and import the master waveform.

[V CAL]

Import the master data for the LC and RC values.

(When using LC and RC values judgments)

Set the judgment conditions.

[JUDGE]

Finish

35

Overview

Screen conguration

Measurement screen

1 2

3 5 6 8 9

4 7

Graph display Displays the waveform graph and the LC and RC graph.

1

Menu icons [MODE]: See “2.4 Select Measuring Mode” (p. 18)

2

[DISP] Switches the graph displayed onscreen.

3

Test conditions settings

4

display

[GRAPH] Sets the graph display.

5

[SCALE] Auto-scales the LC and RC graph.

6

Judgment conditions settings

7

display

[SAVE] Saves the test results to USB memory.

8

Reference: “Graph display (display graph switching)” (p.

[TABLE]: See “3.2 Current Table Selection” (p.

[OUTPUT]: See “4 Setting the T

[JUDGE]: See “5 Setting Judgment Conditions” (p.

[SYSTEM]: See “9 System Settings” (p.

[FILE]: See “12 USB Host” (p.

[WAVE]: Waveform graph

[LCRC]: LC and RC graph

[WAVE&LCRC]: Waveform graph + LC and RC graph

Displays the setting for the applied voltage, number of pulses, and

sampling frequency.

Reference: “8.6 Graph Display Settings” (p. 112)

Reference: “LC and RC graph scale settings” (p.

Displays the judgment conditions settings.

Reference: “12 USB Host” (p. 165)

est Conditions” (p. 35)

125)

165)

37)

29)

51)

115)

36

[V CAL] Calibrates the voltages.

9

IMPORTANT

Tap items such as the output conditions settings and the judgment conditions settings to display each

settings window directly.

Reference: “4.6 Voltage Calibration” (p. 49)

Graph display (display graph switching)

Waveform graph display

Displays the waveform graph only.

21 3 54

Overview

4

Number of applied pulses and

1

peak voltage display

Waveform judgment area and

2

LC and RC values operation

range bar

Response waveform Yellow: Master waveform

3

Discharge judgment threshold

4

value bar

Discharge waveform Green dotted line: Discharge judgment threshold value

5

[P:XX/XX]: Number of pulses that have been applied/Total number of

pulses

[xxxV]: Max. peak voltage value of the response waveform

Blue: AREA judgment area

Green: DIFF judgment area

Purple FLUTTER judgment area

Gray: LAPLACIAN judgment area

Yellow (×2): LC and RC value operation areas

Blue: Test waveform

Note: You can change the color of the waveform.

Reference: “8.6 Graph Display Settings” (p.

Displays the discharge judgment threshold value.

Gray: Discharge amount graph (Parts where the discharge amount

exceeds the threshold value are displayed in red)

Note: Displayed only if the Discharge Detection Upgrade is ON.

Reference: “5.4 Discharge Judgments (When Incorporating Model

ST9000)” (p.

72)

Setting the Test Conditions

112)

37

Overview

LC and RC graph display

Displays only the LC and RC graph.

1 2

3

4

5

LC and RC graph Blue (dots): Latest LC and RC values

1

LC and RC cursor values [No.XXX, (XXX)]: Master data number of the cursor values (Total

2

[DELETE] Deletes the master data for the LC and RC values shown by the

3

[DELETE ALL] Deletes the master data for all LC and RC values.

4

[CREATE] Creates the PASS judgment area automatically.

5

IMPORTANT

Tap the LC and RC values on the graph to move the cursor and check each LC and RC value.

Yellow (dots): Imported LC and RC values master data

Gray (solid): LC and RC values PASS judgment area

Note: Dotted colors operate in tandem with the waveform colors.

Also, you can change the color of the waveform.

Reference: “8.6 Graph Display Settings” (p.

number of master data that have been imported)

[LC/RC: xxx]: LC and RC values selected using the cursor

cursor.

Reference: “Importing LC and RC master values” (p. 56)

Reference: “Importing LC and RC master values” (p.

Reference: “Auto creation of the PASS judgment area” (p. 58)

112)

56)

38

Display the waveform graph and the LC and RC graph

Displays the waveform graph and the LC and RC graph simultaneously.

Overview

4

Setting the Test Conditions

39

Overview

Instrument status display and error display

1 2 3

4

Current measurement

1

mode display

Current table display Displays the number and table name of the table presently being used.

2

Communications

3

interface settings display

Voltage calibration status

4

display

Test status display Displays the test status.

5

USB memory status

6

display

Double action status

7

display

Interlock status display

8

Communications status

9

display

Date and time display Displays the date and time that has been set in the instrument.

10

5 6 8 9 10

Displays the settings for the communications interface presently being

used.

Reference: “14.3 Error Display” (p.

Note: The background is displayed in red while writing to the settings

internal memory.

7

(Gray)

(Blue)

(Red)

(No display)

(Green)

(Gray)

(No display)

(Red)

(Gray)

Voltage application disabled mode

Test conditions settings mode

Test mode

BDV mode

Voltage calibration not implemented

(Master waveform not acquired)

Voltage calibration implemented

(Master waveform acquired)

214)

USB memory not connected

USB memory connecting

Accessing USB

Double action function OFF

START button enabled

START button disabled

Interlock function OFF

Interlock engaged

Interlock canceled

Remote status

Local status

40

4.2 Applied Voltage

Sets the peak voltage value of the pulse applied to the workpiece. Inputs can be set either by using

the up and down keys, or be entered using the numeric keypad.

(Measurement screen) [MODE] > [SETTING] > [OUTPUT] > [VOLT]

Applied Voltage

4

1

Set the applied voltage value.

1

Settings range: ST4030: 100 V to 3300 V (resolution: 10 V)

ST4030A: 100 V to 4200 V (resolution:10 V)

C Sets to the default values.

‑KEY Displays the numeric keypad.

10

Increases by 1.

Decreases by 1.

Setting the Test Conditions

41

Number of Applied Pulses

4.3 Number of Applied Pulses

Sets the number of test pulses to be used in the tests and the number of degaussing pulse

applications to eliminate magnetic elds from the workpiece.

Both the test pulses and degaussing pulses continue to be applied until their set number is

reached.

PULSE NUM

(Number of test pulses applied)

DEGAUSS NUM

(Number of degaussing pulses

applied)

PULSE PERIOD

(Pulse application interval)

Sets the number of test pulses to be applied.

When multiple test pulses are applied, each test pulse is judged

individually.

Sets the number of degaussing pulses to be applied.

A degaussing pulse is a pulse that is applied before the test pulses

to remove any residual magnetization from the workpiece.

Degaussing pulse waveforms are not sampled or judged.

Sets the pulse application interval if multiple degaussing pulses and

test pulses are to be applied.

When multiple pulses are applied, the pulse application interval

operates at or above the set time.

Overview of application pulse settings

TRIG EOM

Degaussing pulse

*1

Test pulse

*2

Pulse application interval

*1: Sampling and judgment not implemented

Each pulse is sampled and judged

*2:

*3: If the single pulse test time setting is shorter than the application interval time setting, the set time will wait

before applying the next pulse. If the single pulse test time is longer than the set time, the next pulse is

applied after the previous pulse test has nished.

*3

42

(Measurement screen) [MODE] > [SETTING] > [OUTPUT] > [PULSE]

Number of Applied Pulses

3

1

Set the number of test pulses.

1

Setting range: 1 to 32

C Sets to the default values.

Set the number of degaussing pulses.

2

Setting range: 0 to 10

C Sets to the default values.

Increases by 1.

Decreases by 1.

Increases by 1.

Decreases by 1.

2

4

Setting the Test Conditions

Set the pulse application interval.

3

Setting range: 0.050 s to 1.000 s (resolution 0.001 s)

C Sets to the default values.

10‑KEY Displays the numeric keypad.

Increases by 1.

Decreases by 1.

43

Sampling Frequency/Number of Sampling Data

4.4 Sampling Frequency/Number of Sampling Data

Sets the voltage sampling frequency and the number of sampling data to be imported to the

instrument.

Sets the voltage sampling frequency.

SAMPLING

(Sampling frequency)

RECORD LENGTH

(No. of sampling data)

If a sufciently long response waveform cannot be imported because

the response waveform vibration period is long, you can extend the

length of the waveform being imported by extending the sampling

frequency.

Sets the number of sampling data to be imported to the instrument.

Sets the length of the waveform to be imported, and sets the

sampling frequency. Adjust the number of sampling data so that a

suitable waveform length can be imported for judgment.

AUTO SET

(Automatic settings function for

range of waveform acquisition)

Sampling waveform lengths

Pulse application

area

Imported waveform length when the number of sampling data is 8001 points

Imported waveform length when the number of sampling data is

6001 points

This function automatically adjusts and sets the sampling frequency

and number of sampling data during voltage calibration so that the

waveform acquisition range is optimal.

Self-resonant area

44

Important: Recommended import length of the sampling waveform

Adjust the sampling wavelength so that the vibration waveform of the self-resonant area imports for 4 or

more periods to enable sufcient waveform data to be used by the LC and RC values operations and the

waveform judgment function. Slow the sampling frequency to lengthen the waveform to be imported.

Sampling Frequency/Number of Sampling Data

(Measurement screen) [MODE] > [SETTING] > [OUTPUT] > [SAMPLING]

1

2

4

Set the sampling frequency.

1

Setting range: 10 MHz, 20 MHz, 50 MHz, 100 MHz, 200 MHz

Set the number of sampling data.

2

Setting range: 1001 points to 8001 points (resolution: 1000 points)

Slows the sampling frequency.

Accelerates the sampling frequency.

Decreases by 1000.

Increases by 1000.

Setting the Test Conditions

45

Sampling Frequency/Number of Sampling Data

Automatic settings for range of waveform acquisition

You can automatically adjust and set the sampling frequency and number of sampling data during

voltage calibration so that the waveform acquisition range is optimal.

(Measurement screen) [MODE] > [SETTING] > [OUTPUT] > [SAMPLING]

1

Tap [AUTO SET].

1

46

Trigger Delay

4.5 Trigger Delay

Sets the delay time (trigger delay) from the start of measuring to the application of the rst pulse.

If using this function, you can start measuring after the workpiece connection status has stabilized

even if trigger timing and probing timing are the same when combined in the equipment.

Trigger delay

4

Trigger

(Measurement start)

IMPORTANT

The OUTPUT lamp is synced to the EOM signals and so turns on even if the trigger is delayed.

Pulse application

Setting the Test Conditions

47

Trigger Delay

(Measurement screen) [MODE] > [SETTING] > [OUTPUT] > [DELAY]

1

Set the trigger delay.

1

Setting range: 0.000 s to 9.999 s (resolution: 0.001 s)

C Sets to the default values.

‑KEY Displays the numeric keypad.

10

Increases by 1.

Decreases by 1.

48

4.6 Voltage Calibration

Calibrates the voltages after the test conditions settings are nished.

Voltage calibration adjusts the output voltage so that the set voltage is applied to the workpiece,

and then imports the master waveform using the output voltage after making the adjustments.

Items implemented using voltage calibration

Gradually raise and adjust the output voltage so that the max. peak

Output voltage calibration

voltage of the response waveform is the same as the set voltage

value.

Voltage Calibration

Automatically sets the

sampling frequency and

number of sampling data

LC and RC values operation

range settings

Importing basic data for

discharge judgments

Auto settings for the judgment

range and judgment standards

for each waveform judgment

Importing master waveform

Implemented when the auto setting for the waveform acquisition

range is ON.

Implemented when the ST9000 Discharge Detection Upgrade is

enabled.

Implemented when the auto settings for waveform judgment areas

and judgment threshold values are ON.

Calibrating output voltages

The max. peak voltage of the response waveform is repeatedly compared to the pulse application,

max. peak voltage, and set voltage values while gradually increasing the set voltage value and the

output voltage.

4

Setting the Test Conditions

Max. peak voltage

Even if the response waveform max. peak voltage is outside the primary peak, adjust so that the

max. peak voltage value is the same as the set voltage value.

49

Voltage Calibration

(Measurement screen) [MODE] > [SETTING] > [OUTPUT]

2

3

1

Tap [V CAL].

1

The settings window will open.

Select the calibration type.

2

TYPE1 If the instrument determines that the entire workpiece response waveform can be measured

using more appropriate settings by adjusting the sampling frequency and sampling data count,

either “INFORMATION 1021” or “INFORMATION 1022” will be displayed.

If the set voltage is not applied, “WARNING 104” will be displayed.

TYPE2 The above information will not be displayed.

Tap [YES].

3

Voltage calibration starts.

When importing the master waveform has nished after the voltage calibration has nished, the icon at the

bottom left of the screen will change from [UNCAL] (red) to [CAL] (blue).

Reference: See “14.3 Error Display” (p. 214).

50

5

Setting Judgment Conditions

5.1 Overview

Applies a set impulse voltage using voltage calibration to the workpiece to be tested, and compares

the response waveform, LC and RC values, and discharge composition amount to the master

workpiece data to judge whether or not the workpiece being tested conforms to quality.

LC and RC values judgments

Judgment types

The following three types of judgment are available.

LC and RC values judgments

Waveform judgments

Waveform judgments

“LC and RC Values Area Judgments [LCRC AREA]” (p. 53)

“Surface area comparison judgments [AREA]” (p. 62)

“Differential surface area comparison judgments [DIFF AREA]”

(p. 64)

“Flutter detection judgments [FLUTTER]” (p. 66)

“Secondary differential detection judgments [LAPLACIAN]”

(p.

69)

Discharge judgments

5

Setting Judgment Conditions

Discharge judgments (When

incorporating ST9000)

“Discharge judgment methods [DISCHARGE]” (p. 73)

51

Overview

Settings operations procedure

Imports the master workpiece waveform as the master waveform, and sets the threshold values for

each judgment function from the master waveform.

Turns ON the [ENABLE] settings for the

Test conditions

settings mode

[SETTING]

Select the table to which to save

the master waveform.

[TABLE]

Set the test conditions.

[OUTPUT]

Enable the judgment conditions

to be used.

[JUDGE]

Calibrate the voltage and import the

master waveform.

[V CAL]

Imports the master data for the LC

and RC values and creates the PASS

judgment area.

(When using LC and RC values

judgments)

Set the judgment conditions.

[JUDGE]

Finish

1

judgment functions to be used. (p. 55)

• [JUDGE] > Use the judgment functions tab to turn ON

the [ENABLE] setting for the judgment functions to be

used, and to turn OFF the [ENABLE] setting for the

judgment functions that will not be used.

• Turning OFF the judgment functions that will not be

used shortens the test times.

Press START button to implement the impulse

2

tests and import the LC and RC master values

(Implemented multiple times). (p. 56)

• Up to 1024 LC and RC master values max. can be

imported.

• Tap

[SCALE] at the bottom of the screen to

automatically set the LC and RC graph scale values.

• Tap the master values on the LC and RC graph to

move the cursor.

• Tap

[DELETE] alongside the LC and RC graph to

delete the LC and RC master values selected by the

cursor.

• Tap [DELETE ALL] alongside the LC and RC graph

to delete all the imported LC and RC master values.

The PASS judgment area is created

3

automatically from the imported LC and RC

master values. (p. 58)

• Tap [CREATE] alongside the LC and RC graph>

Set the margin for the master values in the

PASS judgment area, and then tap [CREATE] to

automatically create the PASS judgment area.

• The PASS judgment area that has been created is

displayed in a gray square on the LC and RC graph.

Adjust the PASS judgment area manually.

4

(p. 60)

• You can set the PASS judgment area manually using

the [JUDGE] > [LCRC AREA] tab.

You can set the PASS judgment area using the upper

and lower limit values of the LC and RC values when

[HI-LO] is ON.

You can set the PASS judgment area using the LC

and RC values of the rectangle’s zenith when [HI-LO]

is OFF.

• Tap the LC and RC values graph when the [LCRC

AREA] tab is selected to edit the PASS judgment

area directly.

Setting judgment conditions other than LC

5

and RC values judgments.

• [JUDGE] > Set the judgment threshold values in the

judgment functions tab.

52

LC and RC Values Area Judgments [LCRC AREA]

5.2

LC and RC Values Area Judgments [LCRC AREA]

What are LC and RC values?

The equivalence circuit for the impulse tests is viewed as a LCR linear equivalence circuit as shown

in the diagram below, and is the value that was quantied as the 2 parameters of “L*C” value and

“R*C” value using the equivalence circuit and impulse response waveform data.

Impulse response waveforms

: R*C value

R

C

Power

supply

L

: L*C value

5

Setting Judgment Conditions

Impulse Winding Tester Motor

IMPORTANT

The LC and RC values are values approximated from the impulse response waveform. Accurate

equivalence circuit parameter values may be different.

53

LC and RC Values Area Judgments [LCRC AREA]

LC and RC values judgments

Test conditions settings mode

The PASS judgment area is created based on multiple LC and RC values imported from the master

workpiece after voltage calibration has been implemented.

LC and RC graph (Test conditions settings mode)

Yellow dots: Imported LC and RC master

values

Gray: The PASS judgment area that has

been created

Test mode

Judged by whether the LC and RC values of the workpiece being tested are inside the PASS

judgment area that has been created.

LC and RC graph (Test mode)

Blue dots: LC and RC values of workpiece

under test

Gray: PASS judgment area

IMPORTANT

• The LC and RC values judgments function calculates the internal coefcients such as the waveform

operation area of the LC and RC values during voltage calibration. Consequently, make sure to enable the

LC and RC values judgments function before implementing voltage calibration.

• The PASS judgment area created during voltage calibration is set based on the LC and RC values

variation for the conforming workpiece during voltage calibration. If the settings include LC and RC values

variation for the workpiece under test, it is necessary to import the LC and RC master values and create a

P

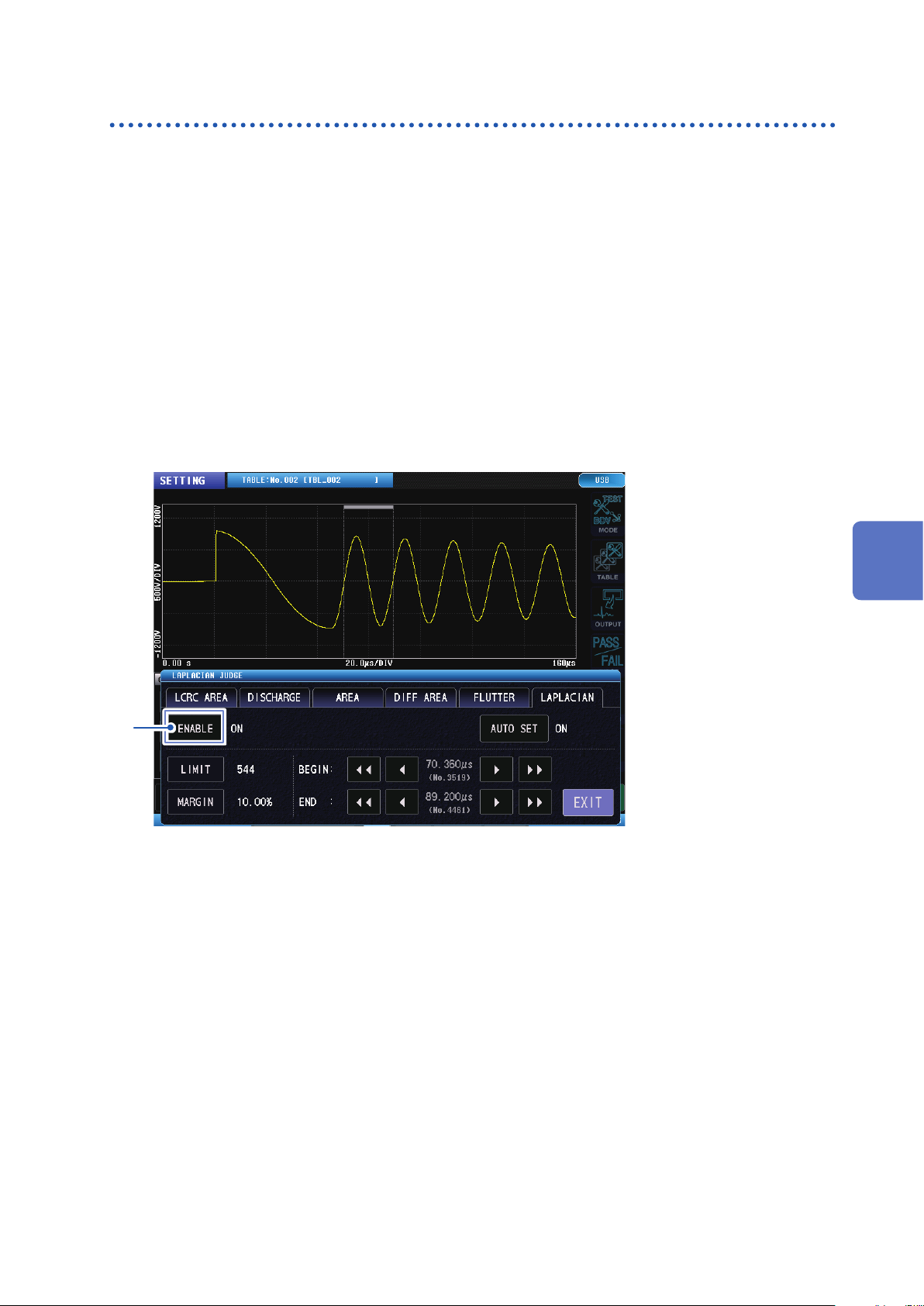

ASS judgment area, or to adjust the judgment area manually.