Page 1

SS7012

Instruction Manual

DC SIGNAL SOURCE

Visit us at www.TestEquipmentDepot.com

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Mar. 2015 Revised edition 8

SS7012A981-08 15-03H

EN

* 6 0 0 2 8 7 5 1 8 *

Page 2

Contents

Introduction .......................................................................... 1

Confirming Package Contents ............................................. 2

Safety Information ................................................................ 3

Operating Precautions ......................................................... 7

Chapter 1 Overview 13

1.1 Product Overview .............................................. 13

1.2 Features ............................................................14

1.3 Names and Functions of Parts .......................... 15

1.4 Sourcing and Measurement Flowchart ............. 23

Chapter 2 Sourcing, Measurement and

Loop test Preparation 25

2.1 Supplying Power ............................................... 25

Installing or Replacing the Batteries .................. 25

Connecting the AC Adapter (Option) ................ 27

2.2 Connecting the Input Cord and the Test Lead .. 28

2.3 Turning the Power On and Off .......................... 33

2.4 Pre-Operation Inspection ..................................34

Chapter 3 Sourcing 37

3.1 Sourcing Example ............................................. 38

3.2 Sourcing Constant Voltage and

Constant Current ...............................................39

3.3 Sourcing Thermoelectromotive Force ............... 43

3.4 0°C Check of the

100 Ω Resistance Thermometer ....................... 50

3.5 Output Monitor Function .................................... 51

3.6 Memory Source Function .................................. 54

Saving setting value to memory ........................ 55

Recall sourcing .................................................. 59

SS7012A981-08

i

Page 3

ii

Scan sourcing ....................................................61

Initializing setting values ....................................63

3.7 When setting value is flashing ...........................65

Chapter 4 Measurement 67

4.1 Measurement Example ......................................67

4.2 Voltage Measurement and

Current Measurement ........................................68

4.3 Temperature Measurement ...............................71

Chapter 5 Loop Test 75

5.1 Loop Test Overview ...........................................75

5.2 Testing a Distributor (4-20 mA) .........................76

5.3 Testing a two-wire transmitter ...........................79

Chapter 6 Other Function 81

6.1 USB Communication Function ..........................81

Chapter 7 Specifications 83

7.1 General Specifications .......................................83

7.2 Accuracy ............................................................86

Chapter 8 Maintenance and Service 91

8.1 Troubleshooting .................................................91

8.2 Replacing the Circuit Protection Fuse ...............94

8.3 Cleaning ............................................................96

8.4 Error Indication ..................................................97

8.5 Other Indication .................................................97

8.6 When calibrating the instrument ........................98

Index Index 1

Page 4

Introduction

Introduction

Thank you for purchasing the HIOKI Model SS7012 DC Signal

Source. To obtain maximum performance from the instrument,

please read this manual first, and keep it handy for future reference.

1

Page 5

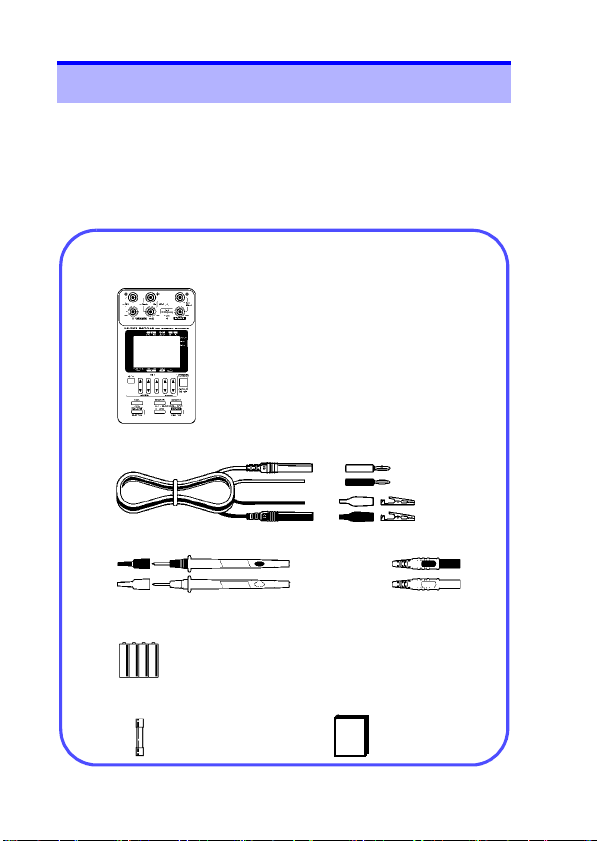

Confirming Package Contents

Confirm that these contents are provided.

SS7012 DC Signal Source (1)

Instruction Manual (1)

9168 Input Cord (1 set)

LR6 alkaline batteries (4)

L9170-10 Test lead (1 set)

Spare fuse (1)

2

Confirming Package Contents

When you receive the instrument, inspect it carefully to ensure

that no damage occurred during shipping. In particular, check

the accessories, panel switches, and connectors. If damage is

evident, or if it fails to operate according to the specifications,

contact your dealer or Hioki representative.

Page 6

Safety Information

Options

9184 Temperature Probe (reference junction compensation)

9380 Carrying Case (Holds main unit only, soft case)

9782 Carrying Case (Holds options, hard case)

9445-02 AC Adapter (For Japan, US, and Canada)

9445-03 AC Adapter (For EU)

SS9000 Communication Package

(Includes USB cable and USB driver software)

Safety Information

This instrument is designed to comply with IEC 61010

Safety Standards, and has been thoroughly tested for

safety prior to shipment. However, mishandling during use

could result in injury or death, as well as damage to the

instrument. Using the instrument in a way not described in

this manual may negate the provided safety features.

Be certain that you understand the instructions and precautions in the manual before use. We disclaim any

responsibility for accidents or injuries not resulting directly

from instrument defects.

3

Page 7

Safety Information

4

This manual contains information and warnings essential for

safe operation of the instrument and for maintaining it in safe

operating condition. Before using it, be sure to carefully read the

following safety precautions.

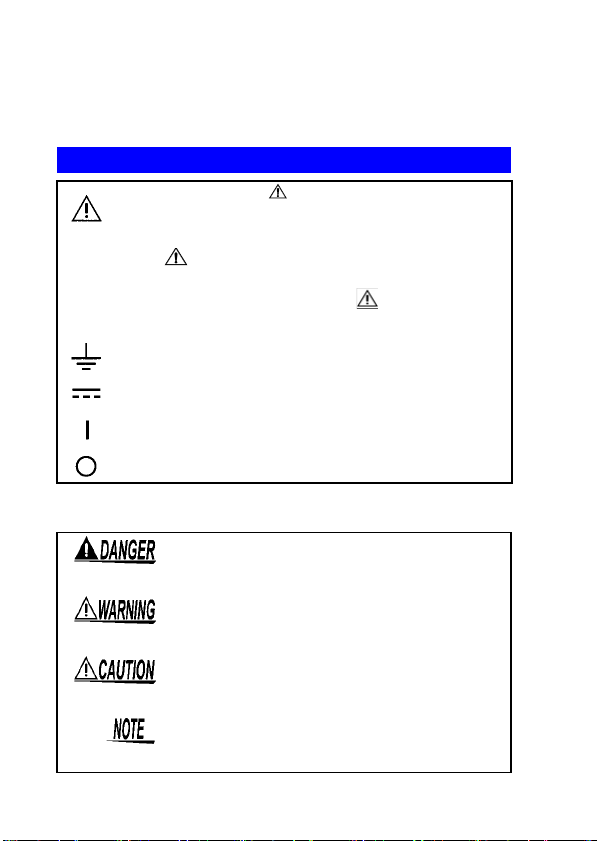

Safety Symbols

In the manual, the symbol indicates particularly

important information that the user should read

before using the instrument.

The symbol printed on the instrument indicates

that the user should refer to a corresponding topic in

the manual (marked with the symbol) before

using the relevant function.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents

an extreme hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious

injury or death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to

the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Page 8

Symbols for Various Standards

WEEE marking:

This symbol indicates that the electrical and

electronic appliance is put on the EU market

after August 13, 2005, and producers of the

Member States are required to display it on the

appliance under Article 11.2 of Directive 2002/

96/EC (WEEE).

This is a recycle mark established under the

Resource Recycling Promotion Law (only for

Ni-MH

Japan).

This symbol indicates that the product conforms

to regulations set out by the EC Directive.

Other Symbols

Indicates a prohibited action.

Safety Information

5

(p. #)

[ ] The names of setting objects are indicated by

OUTPUT

(Bold char-

acters)

The screen of this instrument displays characters in the following manner.

Indicates the location of reference information.

square brackets [ ].

Bold alphanumeric characters in this manual indicate key labels.

Page 9

Safety Information

6

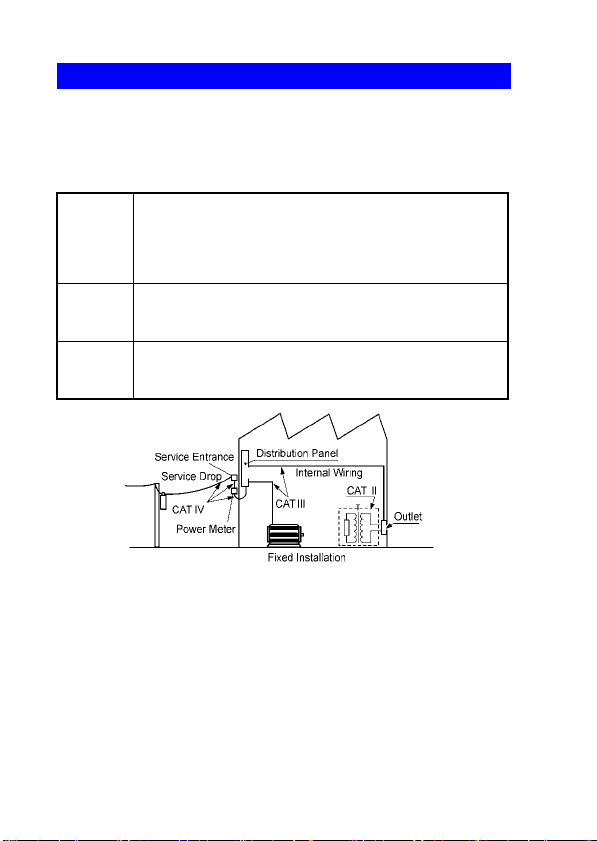

Measurement categories

To ensure safe operation of measurement instruments IEC

61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

Primary electrical circuits in equipment connected to an AC

CAT II

CAT III

CAT IV

Using a measurement instrument in an environment designated

with a higher-numbered category than that for which the instrument is rated could result in a severe accident, and must be

carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II

to CAT IV measurement applications could result in a severe

accident, and must be carefully avoided.

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

Primary electrical circuits of heavy equipment (fixed installations) connected directly to the distribution panel, and

feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent protection

device (distribution panel).

Page 10

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to ensure that no damage occurred during storage

or shipping. If you find any damage, contact your dealer or Hioki

representative.

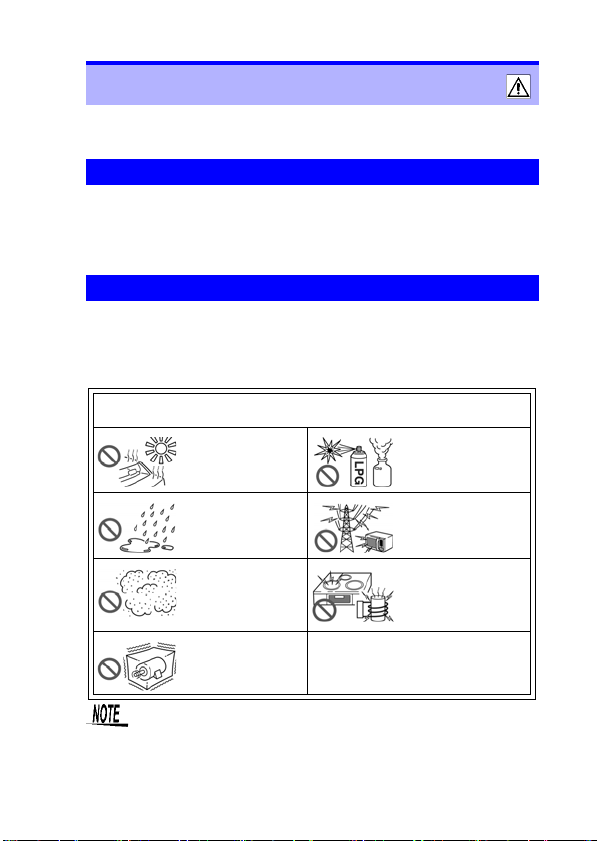

Instrument Installation

Operating temperature and humidity: 0 to 40°C at 80%RH or

less (non-condensating)

Temperature and humidity range for guaranteed accuracy:

23±5°C, 80%RH or less (non-condensating)

Avoid the following locations that could cause an accident or damage

to the instrument.

Exposed to direct

sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or condensation

Exposed to high levels of particulate dust

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Near electromagnetic

radiators (e.g., highfrequency induction

heating systems and

IH cooking utensils)

7

Subject to vibration

Correct measurement may be impossible in the presence of strong magnetic fields, such as near transformers and high-current conductors, or in the presence of

strong electromagnetic fields such as near radio transmitters.

Page 11

Operating Precautions

8

Handling the Instrument

The maximum rated voltage between input terminals and

ground is 30 VAC/ 60 VDC. Attempting to measure voltages

exceeding 30 VAC/ 60 VDC with respect to ground could

damage the instrument and result in personal injury.

• This instrument is designed for safe operation only at low

voltage. Ensure that no more than 60 V is present

between any terminal and ground, and that the potential

difference between any two terminals does not exceed 60

V. The instrument cannot be guaranteed in an overrange

situation, such as due to an inadvertent electric shock or

faulty insulation, and we cannot accept responsibility for

any consequences that might occur from misuse.

• The output terminals and the voltage and current input

terminals (terminals for the standard resistor) are all isolated. Before connecting the terminals, ensure that the

target device will not provide excessive output to, or

require excessive input from, the terminals. The instrument cannot be guaranteed in an overrange situation,

such as due to an inadvertent electric shock or faulty

insulation, and we cannot accept responsibility for any

consequences that might occur from misuse.

• Ensure that the input does not exceed the maximum input

voltage or current to avoid instrument damage, short-circuiting and electric shock resulting from heat building.

• Do not allow the instrument to get wet, and do not take

measurements with wet hands. This may cause an electric shock.

• The case is not hermetically sealed for protection against

explosion, so do not use in a flammable atmosphere.

Page 12

Operating Precautions

• When the power is turned off, do not apply voltage to the voltage input terminals. Doing so may damage the instrument.

• To avoid damage to the instrument, protect it from physical

shock when transporting and handling. Be especially careful

to avoid physical shock from dropping.

• If this instrument has been vibrated or impacted, restart it

before use.

• Before sourcing or measurement, make sure of the function

position. If current or voltage in excess of sourcing or measurement range is input, the instrument may be damaged.

• Note that the instrument may be damaged if the applied voltage or current exceeds the measurement range.

• If output is impossible when is displayed which indicates

outputting, set to with OUTPUT ON/OFF key and set

output to ON again.

• To avoid corrosion and damage to this instrument from battery

leakage, remove the batteries from the instrument if it is to be

stored for a long time.

To avoid problems with battery operation, remove the

batteries from the instrument if it is to be stored for a

long time.

9

Page 13

Operating Precautions

10

Handling the Cords

• Before using the instrument, make sure that the insulation on the test lead and input cord is undamaged and

that no bare conductors are improperly exposed. Using

the instrument in such conditions could cause an electric

shock, so contact your dealer or Hioki representative for

repair.

• Use the 9168 Input Cord with DC 28 V or less.

If this level is exceeded, electric shock may occur.

• Always turn both devices OFF when connecting and disconnecting an interface connector. Otherwise, an electric

shock accident may occur.

• To avoid breaking the test lead and input cord, do not bend or

pull them.

• For safety reasons, when taking measurements, only use the

L9170-10 Test lead provided with the instrument.

Page 14

Operating Precautions

11

Handling the AC Adapter and the Nickel Hydride

Batteries

• Turn the instrument off before connecting the AC adapter

to the instrument and to AC power.

• Use only the supplied Model 9445-02 AC Adapter or

Model 9445-03 AC Adapter. AC adapter input voltage

range is 100 to 240 VAC (with ±10% stability) at 50/60 Hz.

To avoid electrical hazards and damage to the instrument,

do not apply voltage outside of this range.

• To avoid damaging the power cord, grasp the plug, not the

cord, when unplugging it from the power outlet.

The nickel hydride battery is subject to self-discharge.

Be sure to charge the nickel hydride batteries before initial use. If the battery capacity remains very low after

correct recharging, the useful battery life is at an end.

Page 15

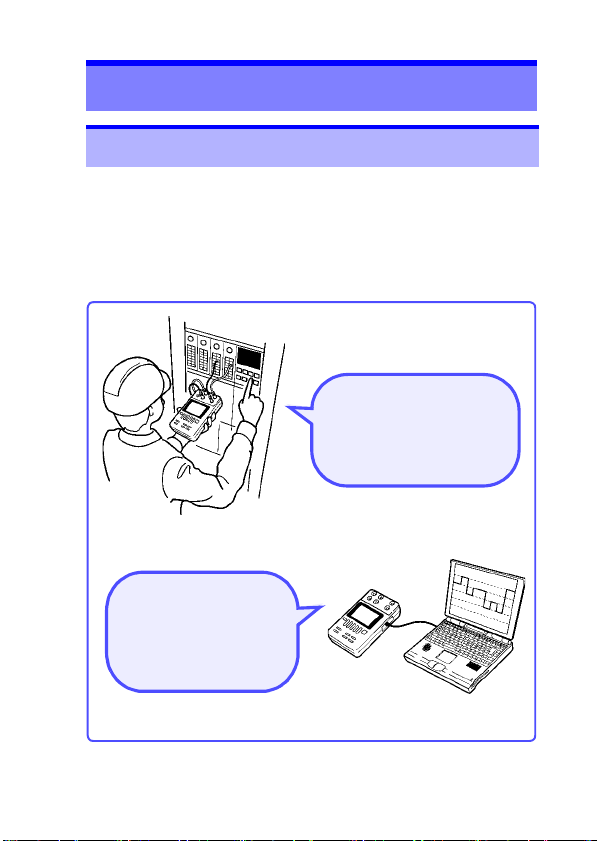

1.1 Product Overview

Two-wire transmitter and

distributor tests (4-20mA)

can be easily performed.

(Loop tests)

Source waveforms can

be freely programmed

through communication with a computer.

13

Overview Chapter 1

1.1 Product Overview

This instrument is a compact DC signal source (calibrator).

It can perform maintenance or loop tests of instrumentation systems and can be operated from a computer via a USB cable.

Furthermore, it can calibrate thermometers and measure DC

voltage and DC current.

Page 16

1.2 Features

14

1.2 Features

Source function (p.39) (p.43)

Sourcing DC voltage from -25.000 V to +25.000 V (minimum

resolution 100 μV), and DC current from -25.000 mA to

25.000 mA (minimum resolution 1 μA). Sourcing thermoelectromotive force by setting temperature (thermocouples: K, E,

J, T, R, S, B, N; JIS C1602-1995, IEC 584).

Measure function (p.68) (p.71)

Measurement of DC voltage from -28.000 V to +28.000 V

(minimum resolution 100 μV), and of DC current from -

28.000 mA to 28.000 mA (minimum resolution 1 μA). Temperature measurement from -25°C to 80°C with the optional

Model 9184 Temperature Probe.

Loop test (p.75)

The output of this instrument is bipolar and it can sink current. Therefore, loop test in the instrumentation system is

possible.

Output monitor function (p.51)

This function monitors the applied current of the constant

voltage source.

This function monitors the applied voltage of the constant

current source.

This function monitors the reference junction temperature of

the thermoelectromotive force source.

Memory source function (p.54)

Up to 20 units of source data (settings) for each function can

be saved to memory. Settings saved to memory can be

sourced in recall source mode or scan source mode.

AC power is not required for operation

Common LR6 alkaline batteries or nickel hydride batteries

support use in situations where AC power is not available.

Continuous long-term operation

The optional Model 9445-02 AC Adapter or 9445-03 AC

Adapter allows continuous long-term operation.

Page 17

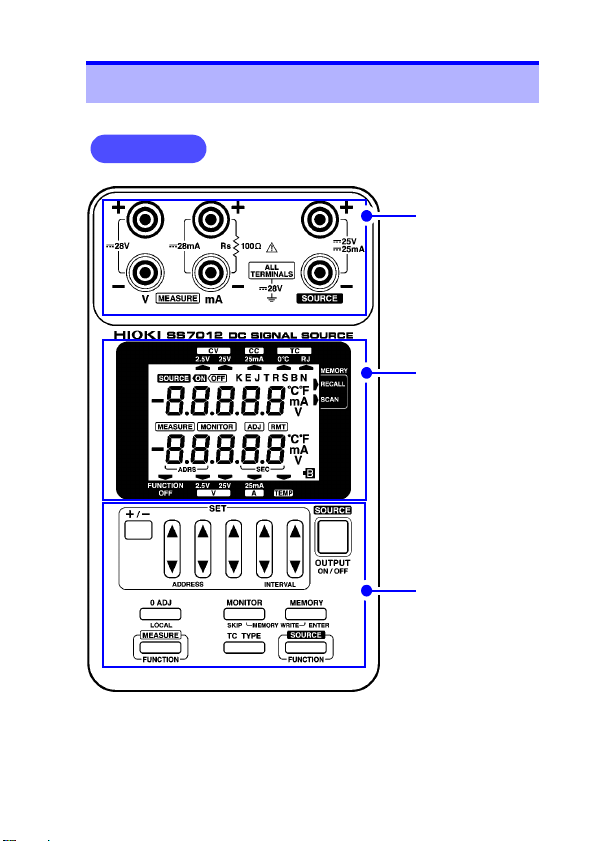

1.3 Names and Functions of Parts

Front panel

Display

(p.19)

Operation Keys

(p.21)

Ter m ina ls

(p.18)

1.3 Names and Functions of Parts

15

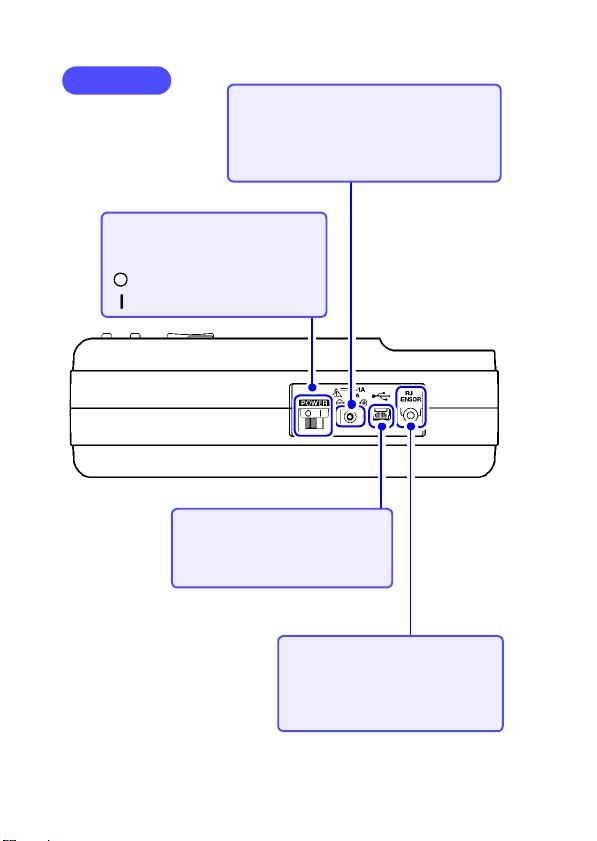

Page 18

1.3 Names and Functions of Parts

Right side

RJ sensor terminal

Connect the optional Model 9184

Temperature Probe (reference

junction compensation).

(p.30) (p.71)

USB port

The SS7012 can communicate

with a computer via a USB cable.

(p.81)

AC adapter terminal

Connect the optional Model 9445-02 AC

Adapter or 9445-03 AC Adapter.The input

voltage range is 9 V DC±10% and the

adapter has a positive center pin. (p.27)

Power switch

Turns the power for the instrument on or off. (p.33)

: Power switch OFF

: Power switch ON

16

Page 19

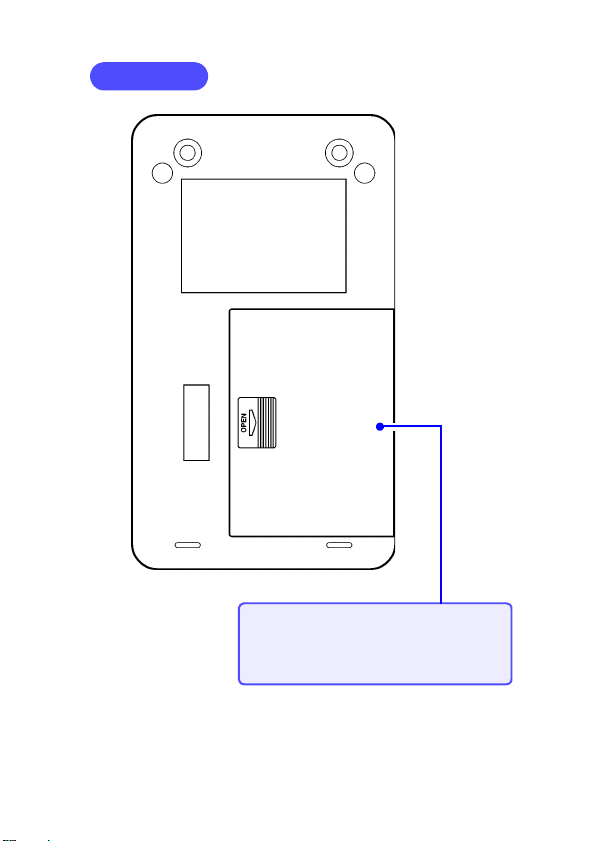

Rear panel

Battery cover

Open this battery cover to install the LR6

alkaline batteries or the nickel hydride batteries. (p.25)

1.3 Names and Functions of Parts

17

Page 20

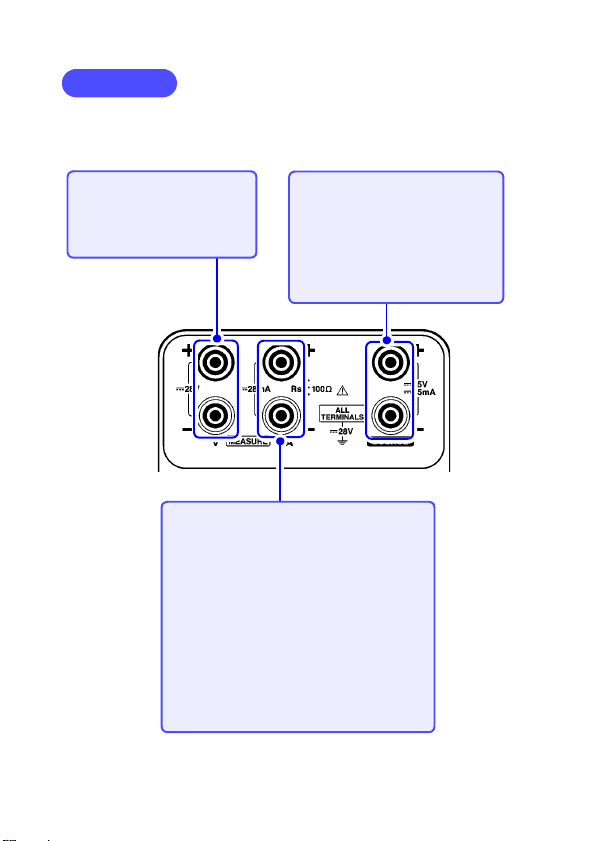

18

Termi nals

Voltage input terminal

Inputs voltage for voltage

measurement. Input resistance is about 1 MΩ.

Current input terminal/

Terminal for the standard resistor

Current input

Inputs current for current measurement

function. The SS7012 has built-in input

protection fuse. The input resistance of

current detection and input protection fuse

is about 30 Ω.

Standard resistor

When current measurement function is

off, a 100 Ω standard resistor is connected

for the 0°C check of the 100 Ω standard

resistance thermometer.

Output terminal

When output is on, the setting

value will be output. This terminal is shorted with about 50 kΩ

resistance when output is off.

The SS7012 has built-in output

protection fuse.

1.3 Names and Functions of Parts

Page 21

1.3 Names and Functions of Parts

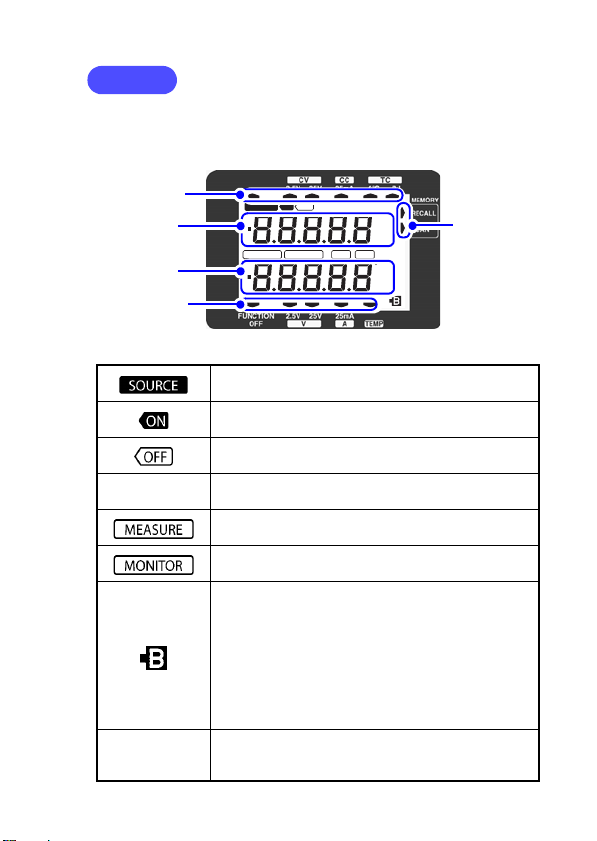

Display

Various values are displayed, including functions, source values, measurement values, monitor values, thermocouples, polarity, units, output

status and warnings.

Upper values

Lower values

Upper triangles

Lower triangles

Right side

triangles

19

SOURCE ON OFF

MEASURE

K

EJTRSBN

MONITOR ADJ RMT

C

mA

C

mA

V

V

Indicates values and settings related to source functions.

Indicates that the setting for the source function is

being output.

Indicates that the setting for the source function is

not being output.

K/ E/ J/ T/ R/

S/ B/ N

Indicates the specified thermocouple type.

Indicates values and settings related to measure

functions.

Indicates that the output monitor function has been

set. (p.51)

This is the battery indicator (Battery low warning).

When this indicator starts flashing, either exchange

the batteries or connect the AC adapter.

When this indicator is flashing, output cannot be set

to ON. (If the SS7012 is outputting when the indica-

Flashing of

setting value

tor starts flashing, output continues until the output

is set to OFF.

Furthermore, the accuracy of measurement values

cannot be guaranteed.

The setting value flash when it is not being output.

(p.65) If a setting value is flashing, press the

OUTPUT key to set the output to OFF.

Page 22

1.3 Names and Functions of Parts

Upper triangles

Lower triangles

Right side

triangles

20

Indicates that the SS7012 is in remote control

mode. The instrument cannot be operated by the

keys. Use the LOCAL key to enable key operation.

If the USB cable is removed when the is displayed, the indicator does not turn off.

Indicates the specified source function.

Upper values Displays setting value for the source functions.

Lower values

Displays the measurement values of the measure

function and the address and sourcing time interval

of the memory source function.

Indicates the specified measure function.

Indicates the specified source mode.

Off : Normal source mode

RECALL : Recall source mode

SCAN : Scan source mode

Page 23

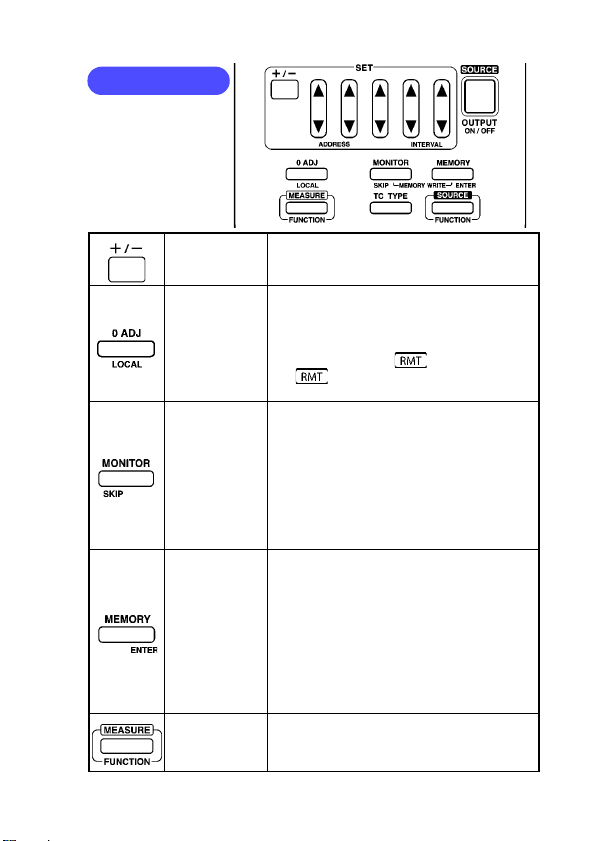

1.3 Names and Functions of Parts

Operation Keys

21

+/- key

0 ADJ/

LOCAL key

MONITOR/

SKIP key

MEMORY/

ENTER key

MEASURE

FUNCTION

key

Selects the polarity of the output setting

value.

1. Possible to return the display to

"00000" in voltage measurement function ([V:2.5V], [V:25V]), or current mea-

surement function ([A: 25mA]).

2. If pushed while is displayed, the

indicator goes out and local con-

trol is possible.

1. Toggles the measure function and output monitor function. (p.51)

2. When writing to memory in the memory

source function, this key sets a skip

setting. (p.55)

3. When pushed simultaneously with the

MEMORY/ENTER key, toggles the

source function and the memory write

mode of the source function. (p.55)

1. Toggles between the normal source,

recall source, and scan source. (p.59)

(p.61)

2. When writing to memory in the memory

source function, this key confirms the

setting value. (p.55)

3. When pushed simultaneously with the

MONITOR/SKIP key, toggles the

source function and the memory write

mode of the source function. (p.55)

Sets the measure function for the instrument.

Page 24

1.3 Names and Functions of Parts

22

TC TYPE key

SOURCE

FUNCTION

key

Sets the thermocouple type in the thermoelectromotive force source function

([TC:0°C], [TC:RJ]).

Sets the source function for the instrument.

OUTPUT

ON/OFF key

/ key

ADDRESS

key

INTERVAL

key

Switches the output on or off in the source

function.

This key can be used as the start/stop for

memory source function.

The digit increases or decreases by one

count each time the key is pressed. Press

and hold the key to change the digit continuously.

These are the two / keys on the left

of the arrow key group.

In the memory source function, these keys

specify the address.

These are the two / keys on the right

of the arrow key group.

In the memory source function, these keys

specify the sourcing time interval.

Page 25

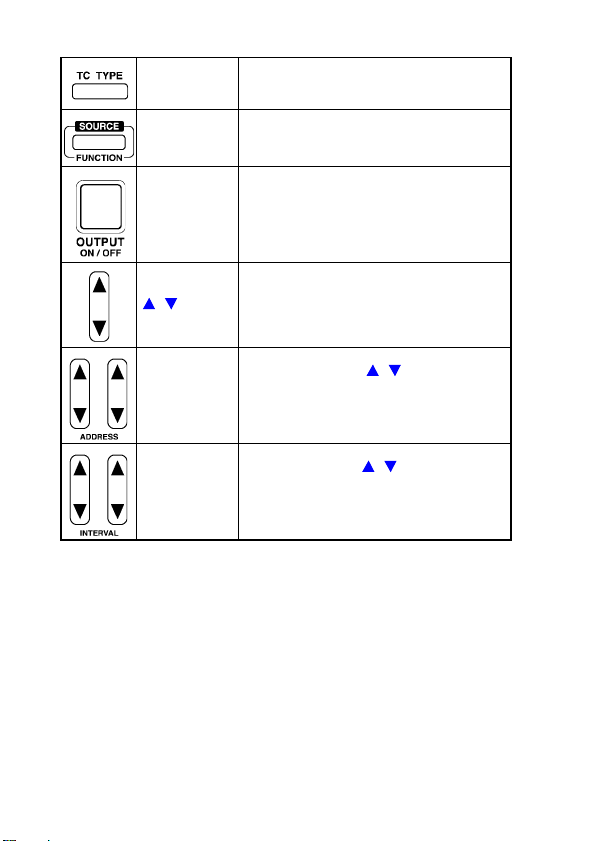

1.4 Sourcing and Measurement Flowchart

1. Inspections before switching on the power and

using the instrument

Connecting the AC Adapter (p.27)

Installing the Batteries (p.25)

Turning the Power On (p.33)

Pre-Operation Inspection (p.34)

2. Sourcing

Constant voltage (p.39)

Constant current (p.39)

Thermoelectromotive force (p.43)

Standard register (100 Ω) (p.50)

Output monitor function (p.51)

Memory source function (p.54)

2. Measurement

Voltage (p.68)

Current (p.68)

Temperature (p.71)

3. Turning the Power Off (p.33)

2. Loop test (p.75)

or

or

1.4 Sourcing and Measurement Flowchart

23

Page 26

2.1 Supplying Power

25

Sourcing, Measurement and Loop test Preparation Chapter 2

2.1 Supplying Power

Installing or Replacing the Batteries

• Use the common LR6 alkaline batteries or the common

nickel hydride batteries.

• To avoid electric shock, turn off the power switch and disconnect the test leads or input cords from the target

device before replacing the batteries.

• After replacing the batteries, replace the cover before

using the instrument.

• Do not mix old and new batteries, or different types of

batteries. Also, be careful to observe battery polarity during installation. Otherwise, poor performance or damage

from battery leakage could result.

• Battery may explode if mistreated. Do not short-circuit,

disassemble or dispose of in fire. Do not recharge alkaline batteries. Handle and dispose of batteries in accordance with local regulations.

Page 27

2.1 Supplying Power

26

• Do not use the LR6 alkaline batteries together with the nickel

hydride batteries.

• To avoid corrosion and damage to this instrument from battery

leakage, remove the batteries from the instrument if it is to be

stored for a long time.

• The indicator flashes when the remaining battery

capacity is low. In this case, the instrument's reliability

is not guaranteed. Replace the battery immediately.

• When the nickel hydride batteries have not been used

for a long time and are not repeat charge and discharge, the device may not operate normally. (This

may also occur immediately after purchase.)

• Please use only LR6 alkaline batteries or nickel

hydride (HR6) batteries. Please do not use manganese, oxyride batteries, etc.

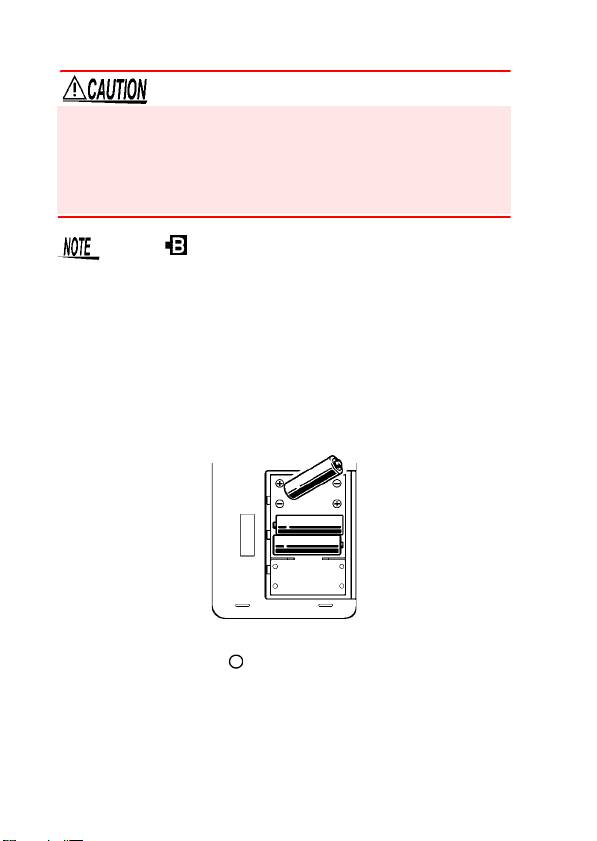

Before installing or exchanging batteries, turn the

1.

power switch off ( ).

Open the battery cover and install four batteries with

2.

the correct polarity.

Be sure to close the battery cover.

3.

Page 28

2.1 Supplying Power

27

Connecting the AC Adapter (Option)

• Turn the instrument off before connecting the AC adapter

to the instrument and to AC power.

• Use only the supplied Model 9445-02 AC Adapter or

Model 9445-03 AC Adapter. AC adapter input voltage

range is 100 to 240 VAC (with ±10% stability) at 50/60 Hz.

To avoid electrical hazards and damage to the instrument,

do not apply voltage outside of this range.

Turn the power switch off ( ).

1.

Connect the 9445-02 AC Adapter or the 9445-03 AC

2.

Adapter output plug to the AC adapter terminal for the

instrument. (The input voltage range is 9 VDC±10%

and the adapter has a positive center pin)

After making sure that the voltage of the power supply

3.

being used matches the supply voltage of the AC

adapter, put the plug in the outlet.

Page 29

2.2 Connecting the Input Cord and the Test Lead

28

2.2 Connecting the Input Cord and

the Test Lead

The SS7012 has voltage input terminal, current input terminal

(terminal for the standard resistor) and output terminal.

In addition, RJ sensor terminal is provided for temperature measurement.

To prevent an electric shock accident, confirm that the white or

red portion (insulation layer) inside the cable is not exposed. If a

color inside the cable is exposed, do not use the cable.

Removable sleeves are attached to the metal pins at

the ends of the test leads. The test leads can also be

used with the sleeves removed.

Removing and attaching the sleeves

The tips of the metal pins are sharp, so take care not to injure

yourself.

Removing the sleeves

Gently hold the bottom of the sleeves and pull the sleeves off.

Safely store the removed sleeves so as not to lose them.

Attaching the sleeves

Insert the metal pins of the test leads into the holes of the

sleeves, and firmly push them all the way in.

Page 30

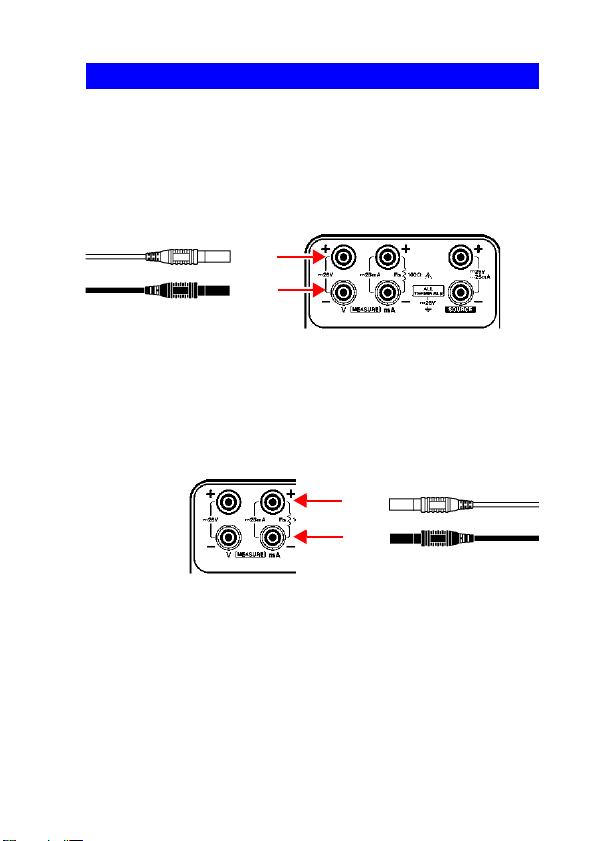

2.2 Connecting the Input Cord and the Test Lead

Voltage measurement

Connect the L9170-10 Test lead to the voltage input terminal.

Connect the red and black connectors to the + and - input terminals,

respectively.

Input only voltage to the voltage input terminal.

L9170-10 Test lead

Current measurement

Connect the L9170-10 Test lead to the current input terminal.

Connect the red and black connectors to the + and - input terminals,

respectively.

Input only current to the current input terminal.

L9170-10 Test lead

(red)

(black)

(red)

(black)

Connecting Method

29

Page 31

2.2 Connecting the Input Cord and the Test Lead

[TC:RJ] sourcing, Temperature measurement

Connect the optional 9184 Temperature Probe to the

RJ sensor terminal.

9184 Temperature Probe

Sourcing

With the output off, connect the 9168 Input Cord to the

output terminal.

Connect the red and black connectors to the + and - output terminals,

respectively.

9168 Input Cord

(red)

(black)

0°C check for the 100 Ω resistance thermometers

Connect the 100 Ω standard resistance thermometer to

the terminal for the standard resistor.

(red)

(black)

30

Page 32

2.2 Connecting the Input Cord and the Test Lead

• This instrument is designed for safe operation only at low

voltage. Ensure that no more than 60 V is present

between any terminal and ground, and that the potential

difference between any two terminals does not exceed 60

V. The instrument cannot be guaranteed in an overrange

situation, such as due to an inadvertent electric shock or

faulty insulation, and we cannot accept responsibility for

any consequences that might occur from misuse.

• The output terminals and the voltage and current input

terminals (terminals for the standard resistor) are all isolated. Before connecting the terminals, ensure that the

target device will not provide excessive output to, or

require excessive input from, the terminals. The instrument cannot be guaranteed in an overrange situation,

such as due to an inadvertent electric shock or faulty

insulation, and we cannot accept responsibility for any

consequences that might occur from misuse. (For the

maximum value of the output voltage/current and voltage/

current input, refer to the specifications)

• To avoid electrical accidents, confirm that all connections

are secure. The increased resistance of loose connections can lead to overheating and fire.

• Be sure to connect the voltage input and current input terminals correctly. An incorrect connection could damage

or short circuit this instrument.

31

Page 33

2.2 Connecting the Input Cord and the Test Lead

32

• When switching the power on and off, remove the target

device from all terminals. Furthermore, always set the output

to OFF when connecting or disconnecting the output terminal

and target device. In either of these cases, failure to heed this

caution may result in damage to the instrument or to the target

device.

• Do not input current more than 25 mA DC to the terminal for

the standard resistor. Doing so may damage the resistor of the

instrument.

• Output terminal and current input terminal have circuit protection fuses. If the fuse is blown, output or current measurement

is impossible. Exchange the fuses before operation.

See: "8.2 Replacing the Circuit Protection Fuse" (p.94)

• When output is off, the output terminals are shorted

with a resistance of about 50 kΩ.

• Input resistance of the voltage input terminal is

approx. 1 MΩ and that of the current input terminal is

approx. 30 Ω.

Page 34

2.3 Turning the Power On and Off

33

2.3 Turning the Power On and Off

Before turning the instrument on, make sure the supply

voltage matches that indicated on the AC adapter. Connection to an improper supply voltage may damage the instrument or AC adapter and present an electrical hazard.

When switching the power on and off, remove the target device

from all terminals. Furthermore, always set the output to OFF

when connecting or disconnecting the output terminal and target device. In either of these cases, failure to heed this caution

may result in damage to the instrument or to the target device.

• If power switch is set to on ( ) for the instrument,

even when sourcing or measurement is not executed

current is still consumed. The lifetime of battery therefore shortens. The power switch should be turned off

( ) when unused.

• Because turning the power on or off places a load on

the instrument, wait at least 5 seconds before turning

the power off or on again.

• If the power doesn’t turn on when turning on the

power again, turn the power off and leave for more

than 5 seconds.

• The warm-up time of this instrument is 5 minutes.

Source values and measurement values can be

unstable within 5 minutes after turning the power on.

Page 35

2.4 Pre-Operation Inspection

Set the power switch to the " " position.

When the power switch is on, all settings

except memory are initialized to appear initial

screen after LCD display indications are all lit.

(ON)

Set the power switch to the " " position. Turn

off the power switch to go off the LCD display

indications.

(OFF)

Is the insulation of the test

lead or input cord to be used

damaged, or is bare metal exposed?

Is damage to the AC adapter

evident?

Is damage to the instrument

evident?

Do not use the instrument

if even one point of damage is found, as it can

cause electric shock.

If damage is evident, request repairs.

Yes

Yes

Yes

34

Turning Power On

Turning Power Off

2.4 Pre-Operation Inspection

Before using the instrument, verify that it operates normally to

ensure that no damage occurred during storage or shipping.

Instrument inspection

1.

Check the following points.

Page 36

Inspection at power on

The batteries may have

run out. Replace the batteries with new ones and

then check again.

No

Inspection

complete

Yes

The instrument may be damaged internally.

Request repairs.

No

An error is displayed

When the power is

switched on, does the

screen come on?

An error is

displayed

Yes

Use a powered outlet

and then check again.

Yes

The power cord may be

disconnected or the AC

adapter or instrument internals may be malfunctioning.

Request repairs.

Is a power failure

or another cause

preventing power

from reaching the

outlet?

No

Yes

Inspection

complete

The instrument may be damaged internally.

Request repairs.

No

When the power is

switched on, does the

screen come on?

An error is

displayed

2.

< When using batteries >

< When using AC adapter >

2.4 Pre-Operation Inspection

35

Page 37

37

Sourcing Chapter 3

Always inspect the instrument before sourcing.

See: "2.4 Pre-Operation Inspection" (p.34)

Always set the output to OFF when connecting or disconnecting

the output terminal and target device.

• If the display shows all zeros or is out of the setting

range while using the

disabled.

• Settings can be changed consecutively using the

/ keys. However, this operation cannot be used in

the following cases.

• When the changed setting exceeds the permitted

range

• When the changed setting exceeds “00000” and the

polarity changes (For example, when the setting is

“00001”, all keys and the right-most key can

be used.)

+/- keys, polarity changing is

Page 38

3.1 Sourcing Example

38

3.1 Sourcing Example

The SS7012 can source constant voltage, constant current, and

standard register.

Instead of the thermocouple, a voltage corresponding to a specified temperature can be sourced.

Constant voltage (CV) (p.39)

In [CV:2.5V], constant voltage can be sourced from -2.5 to +2.5 V with

the resolution of 100 µV.

In [CV:25V], constant voltage can be sourced from -25 to +25 V with

the resolution of 1 mV.

Constant current (CC) (p.39)

In [CC:25mA], constant current can be sourced from -25 to +25 mA

with the resolution of 1 µA.

Thermocouple (TC) (p.43)

In [TC], voltage can be sourced according to the setting temperature

instead of thermocouples.

Eight types of thermocouples are supported: K, E, J, T, R, S, B, and N.

Thermometers using thermocouples can be calibrated.

Standard register (Rs) (p.50)

100 Ω standard resistor is connected to the terminal for the standard

resistor (current input terminal).

The resister can be used for the 0°C check of the 100 Ω standard resistance thermometer.

Output monitor function (p.51)

When a constant voltage is sourced, the current flowing in the target

device can be monitored. (this function is used when testing the twowire transmitter in a loop test.)

When a constant current is sourced, the voltage between the output

terminals can be monitored.

When a thermoelectromotive force is sourced, the reference junction

temperature can be monitored. ("0°C" is displayed in [TC:0°C], the

temperature measured with the optional 9184 Temperature Probe is

displayed in [TC:RJ])

Memory source function (p.54)

Values to be sourced can be recorded ahead of time.

The recorded value can be switched using a single key operation or

automatically. (When testing a distributor in the loop test, 4-20 mA can

be easily sourced.)

For each source function, up to 20 values can be recorded.

Page 39

3.2 Sourcing Constant Voltage and Constant Current

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

3.2 Sourcing Constant Voltage and

Constant Current

Source DC voltage and DC current.

Turn the power switch on.

1.

Press the SOURCE FUNCTION key

2.

the required number of times to set

the constant voltage source function

([CV:2.5V], [CV:25V]) or constant current source function ([CC:25mA]).

At power on, [CV:2.5V] is set. Pressing the

SOURCE FUNCTION key changes the setting

in the lower shown sequence.

[CV:25V] → [CC:25mA] → [TC:0°C]

↑ ↓

[CV:2.5V] ← [TC:RJ]

In the upper part of the screen, the

moves to the specified function.

39

Page 40

40

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

3.2 Sourcing Constant Voltage and Constant Current

Use the / keys and +/- key to set

3.

the value to be sourced.

The five / keys correspond to the five

columns of the setting.

The ranges within which the values can be set

are as follows:

[CV:2.5V] :

[CV:25V] : -25.000 V to 25.000 V

[CC:25mA] : -25.000 mA to 25.000 mA

If the target device has a power

4.

source, switch it off and then con-

-2.5000 V to 2.5000 V

nect the target device to the output

terminal of the SS7012. If necessary,

switch the power of the target device

back on.

If the target device doesn’t have a

power source, simply connect the

target device to the output terminal

of the instrument.

Page 41

3.2 Sourcing Constant Voltage and Constant Current

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

Press the OUTPUT ON/OFF key.

5.

is displayed on the screen and the setting value is output.

However, if the load gets excessive and the

setting value cannot be output, the setting value flashes. If the setting value starts flashing,

press the OUTPUT ON/OFF key to set the

output to OFF.

See: "3.7 When setting value is flashing" (p.65)

41

If you want to change the value to be

6.

sourced during sourcing, use the

/ keys and +/- key.

The new set value is output.

Page 42

3.2 Sourcing Constant Voltage and Constant Current

42

Press the OUTPUT ON/OFF key.

7.

is displayed on the screen and the out-

put changes to OFF.

Never connect this instrument to any voltage sources when

sourcing constant voltage. Furthermore, never connect

this instrument to an electric current source when sourcing

constant current. Doing so may damage the instrument and

the target device.

• In constant voltage source function ([CV:2.5V], [CV:25V]), do

not set the output to exceed ±25 mA. Furthermore, in constant

current source function ([CC:25mA]), do not set the output to

exceed ±25 V. Doing so may damage the instrument and the

target device.

• When using constant current source function, if the target

device is connected incorrectly, overvoltage can be applied to

the target device, which may result in damage to this instrument or to the target device.

If the indicator is flashing, output cannot be set to

ON. (If it flashes during output, output continues until

output is set to OFF.) Replace the batteries or connect

the AC adapter.

Page 43

3.3 Sourcing Thermoelectromotive Force

Thermocouple

Copper

conductor

Reference junction (0°C)

Container filled with ice water, etc.

Thermometer

+

-

43

3.3 Sourcing Thermoelectromotive

Force

Outputs voltage according to the setting temperature instead of

thermocouples.

Thermometers using thermocouples can be calibrated.

There are 2 types of thermoelectromotive force source functions.

The temperature of voltage input terminal (reference junction) of

the thermometer can be set to either 0°C or room temperature.

[TC:0°C] : Use when sourcing thermoelectromotive force with

the temperature of voltage input terminal (reference

junction) of the thermometer at 0°C. As shown in the

diagram below, use the [TC:0°C] setting when the

calibrating the thermometer measuring the thermoelectromotive force using 0°C as a reference. When

using this function, create 0°C by putting ice water in

a thermos flask or other means and make the reference junction to 0°C.

.

Page 44

3.3 Sourcing Thermoelectromotive Force

Compensation

thermometer

-

Thermocouple

Thermocouple or

compensated

conductors

+

Thermometer

44

[TC:RJ] : Use when calibrating a thermometer that can com-

pensate the temperature of voltage input terminal

(reference junction) of the thermometer. As shown in

the diagram below, use the [TC:RJ] setting when

calibrating a thermometer that compensates the

thermoelectromotive force of thermocouples at the

reference junction temperature. However, the

optional 9184 Temperature Probe is required to

measure the temperature to compensate when

using this function.

.

1.

Turn the power switch on.

Press the SOURCE FUNCTION key

2.

the required number of times to set

the thermoelectromotive force

source function ([TC:0°C], [TC:RJ]).

At power on, [CV:2.5V] is set. Pressing the

SOURCE FUNCTION key changes the setting

in the lower shown sequence.

[CV:25V] → [CC:25mA] → [TC:0°C]

↑ ↓

[CV:2.5V] ← [TC:RJ]

In the upper part of the screen, the

moves to the specified function.

Page 45

3.3 Sourcing Thermoelectromotive Force

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

Press the TC TYPE key to set ther-

3.

mocouple ([K], [E], [J], [T], [R], [S], [B]

or [N]).

Use the / keys and +/- key to set

4.

the value.

The ranges within which the values can be set

are as follows:

[K] :

-174.0°C to 1372.0°C

[E] : -220.0°C to 839.0 °C

[J] : -208.0°C to 1108.0 °C

[T] : -169.0°C to 400.0°C

[R] : -50 °C to 1768 °C

[S] : -50 °C to 1768 °C

[B] : 300 °C to 1820 °C

[N] : -113 °C to 1300.0 °C

45

Page 46

3.3 Sourcing Thermoelectromotive Force

< Figure 1 >

46

Connect the thermometer to the out-

5.

put terminal.

The connection methods for [TC:0°C] and

[TC:RJ] differ.

[TC:0°C]: Connect it as indicated in Figure 1.

The optional 9184 Temperature

Probe may be connected to the RJ

sensor terminal or not, without effect. Create 0°C by putting ice water

in a thermos flask or other means

and make the reference junction to

0°C.

Page 47

< Figure 2: When using a copper conductor >

The temperature probe

close to the thermometer.

Copper conductors

< Figure 3: when using a thermocouple the same

type as the thermometer or compensated conductors >

The temperature probe close

to the output terminal of the

SS7012.

Thermocouple or compensated

conductors

3.3 Sourcing Thermoelectromotive Force

[TC:RJ]: Connect the optional 9184 Tempera-

ture Probe to the RJ sensor terminal. As indicated in Figure 2,

connect the temperature probe

close to the thermometer when using a copper conductor, or close to

the output terminal of the SS7012

as indicated Figure 3, when using a

thermocouple the same type as the

thermometer or compensated conductors.

47

Page 48

3.3 Sourcing Thermoelectromotive Force

48

Press the OUTPUT ON/OFF key.

6.

is displayed on the screen and the setting value is output.

However, if the load gets excessive and the

setting value cannot be output, the setting value flashes. If the setting value starts flashing,

press the OUTPUT ON/OFF key to set the

output to OFF.

See: "3.7 When setting value is flashing" (p.65)

The output value will change if the

7.

setting value is changed with the

/ keys and

Press the OUTPUT ON/OFF key.

8.

is displayed on the screen and the out-

put changes to OFF.

To avoid damage to the instrument and the target device, in the

thermoelectromotive force source function ([TC:0°C], [TC:RJ]),

never apply an external voltage or current to the output terminal.

• The reference junction compensation temperature

ranges are as follows:

[K], [E], [J], [T], [R], [S], [N]: -25.0 to 80.0°C

[B]: 0 to 80°C

• In the thermoelectromotive force source function

([TC:0°C], [TC:RJ]), use a thermocouples thermometer

with an input resistance of at least 100 kΩ. If the input

resistance is under 100 kΩ, the following error will be

added to the specification precision: 100 × (1-Rin/

(2.2+Rin))% (where Rin is the thermocouples thermometer input resistance.)

+/- key.

Page 49

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

3.3 Sourcing Thermoelectromotive Force

• When output in the thermoelectromotive force source

function ([TC:RJ]) is on, reference junction compensation will be performed about every 5 seconds, and the

output value compensated.

• In the thermoelectromotive force source function

([TC:RJ]), when the detected temperature of the

optional 9184 Temperature Probe is outside the -25°C

to 80°C range, or if connection is incorrect, the messages "rJErr" will be displayed even when the output

on switch is pressed, and output will remain off.

•

• To perform reference junction compensation at a temperature out of the operating temperature range of the

main instrument, be careful that the ambient temperature of the main instrument.

• If the instrument is moved to a new location, or the

thermometer being compensated for is changed,

errors may result due to changes in the timetemperature constants. Do not attempt to perform measurements until the instrument has had sufficient time to

reach thermal stability.

• If the indicator is flashing, output cannot be set to

ON. (If it flashes during output, output continues until

output is set to OFF.) Replace the batteries or connect

the AC adapter.

49

Page 50

3.4 0°C Check of the 100 Ω Resistance Thermometer

50

3.4 0°C Check of the 100 Ω Resistance

Thermometer

100 Ω reference resistor is connected between reference resistor terminals, which are the same terminals as the current input

terminals. This resistor is for 0°C check of the 100 Ω standard

resistance thermometer. Usable except for current measurement

function ([A:25mA]). Make sure measurement function is never

set to current measurement function before connecting the

instrument to the 100 Ω standard resistance thermometer.

Do not input current more than 25 mA DC to the terminal for the

standard resistor. Doing so may damage the resistor of the

instrument.

Page 51

3.5 Output Monitor Function

51

3.5 Output Monitor Function

• In the constant voltage source function ([CV:2.5V], [CV:25V]),

the current that flows into the target device is displayed on the

LCD display.

• In the constant current source function ([CC:25mA]), the voltage between the output terminals is displayed on the LCD display.

• In the thermoelectromotive force source function, the reference

junction temperature is displayed on the LCD display ("0°C" is

displayed in [TC:0°C], the temperature measured with the

optional 9184 Temperature Probe is displayed in [TC:RJ]).

Turn the power switch on.

1.

Press the SOURCE FUNCTION key

2.

the required number of times.

Set the source function.

Use the / keys and +/- key to set

3.

the value to be sourced.

If the target device has a power

4.

source, switch it off and then connect the target device to the output

terminal of the SS7012. If necessary,

switch the power of the target device

back on.

Page 52

52

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

3.5 Output Monitor Function

Press the OUTPUT ON/OFF key.

5.

is displayed on the screen and the setting value is output.

However, if the load gets excessive and the

setting value cannot be output, the setting value flashes. If the setting value starts flashing,

press the OUTPUT ON/OFF key to set the

output to OFF.

See: "3.7 When setting value is flashing" (p.65)

Press the MONITOR key.

6.

The instrument switches from the measure

function to the output monitor function.

Read the monitor value at the lower

7.

portion of the display.

Press the MONITOR key again.

8.

The instrument switches from the output monitor function to the measure function.

Press the OUTPUT ON/OFF key.

9.

put changes to OFF.

is displayed.

is displayed.

is displayed on the screen and the out-

Page 53

3.5 Output Monitor Function

Monitor ranges are shown below:

[CV:2.5V] Load current : -28.00 mA to 28.00 mA

[CV:25V] Load current : -28.00 mA to 28.00 mA

[CC:25mA] Load voltage : -28.00 V to 28.00 V

[TC:0°C] Reference junction temperature: 0°C

[TC:RJ] Reference junction temperature

: -25.0°C to 80.0°C

If the output is outside this range, the display will indicate "oF" in

the constant voltage source function ([CV:2.5V], [CV:25V]) and

constant current source function ([CC:25mA]), and "rJErr" in the

thermocouple power function ([TC:RJ]). In this case, turn off the

output and confirm the target device. If output is continued, the

unit and the target device may be damaged.

• If the output is OFF, the display will indicate " - - - - - ".

• If the indicator is flashing, output cannot be set to

ON. (If it flashes during output, output continues until

output is set to OFF.) Replace the batteries or connect

the AC adapter.

53

Page 54

3.6 Memory Source Function

54

3.6 Memory Source Function

This function records sourcing values and then later recalls them

for sourcing.

For each source function, up to 20 values can be recorded. In

[TC:0°C] and [TC:RJ], the thermocouple type can also be

recorded.

There are 2 sourcing methods.

Recall sourcing (p.59): Single key operation for changing the setting.

•

• Scan sourcing (p.61) : Automatically changes the setting value at

In Chapter 5, a loop test method is introduced as a practical

example of using the memory source function.

See: "Chapter 5 Loop Test" (p.75)

In [CV:25V] and [CC:25mA], setting values are already saved as

a default.

Address 1 2 3 4 5

CV:25V

CC:25mA

a set time interval.

1 V2 V3 V4 V5 V

-4 mA -8 mA -12 mA -16 mA -20 mA

Page 55

3.6 Memory Source Function

Confirm that a does not appear near [MEMORY] at

the upper right of the screen (normal source mode).

If a is displayed, press the MEMORY key the

required number of times until it is no longer displayed.

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

Saving setting value to memory

Turn the power switch on.

1.

Press the SOURCE FUNCTION key to

2.

set the source function.

Press the MONITOR key and the

3.

MEMORY key together.

The system will shift to the memory write

mode.

"01" is displayed in the memory address and

output setting value of the address is displayed. At this time, if the address "01" has

been skipped before, "- - - - -" is displayed and

numerical value is not displayed.

55

Page 56

3.6 Memory Source Function

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

MEASURE MONITOR ADJ RMT

V

C

mA

V

C

mA

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

56

Use the / keys and +/- key to set

4.

the value to be sourced.

The five / keys correspond to the five

columns of the setting.

Press the ENTER key.

5.

After flashing, the setting value is set. Next,

the instrument advances automatically to the

next address.

Page 57

3.6 Memory Source Function

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

57

If you do not want to save a setting

value to the address, press the SKIP

key. (Skip setting)

"- - - - -" flashes and then the instrument advances automatically to the next address.

Repeat steps 4. and 5. to save setting

values to memory. A maximum of 20

items can be saved.

Press the MONITOR key and the

6.

MEMORY key together.

Exit memory write mode.

Page 58

3.6 Memory Source Function

58

Never switch off the power in memory write mode. It may damage the SS7012.

• Addresses with skip settings cannot be called by the

memory source function.

• If the setting value or "

value or skip setting is being written to memory.

• The sourcing time interval is set using scan source

mode ([SCAN]).

• In memory write mode, measurements and output

monitoring cannot be performed.

• Memory data is shared in the thermoelectromotive

force source functions ([TC:0°C], [TC:RJ]).

- - - - -" is flashing, the setting

Page 59

3.6 Memory Source Function

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

12

3

Recall sourcing

Press the SOURCE FUNCTION key to

1.

set the memory sourcing function.

Press the MEMORY key once to set

2.

to the recall source mode ([RECALL]).

Use the ADDRESS keys (the 2 left-

3.

side / keys) to set the address to

be sourced.

The output setting value in memory is displayed at the sourcing screen.

Connect the target device.

4.

Press the OUTPUT ON/OFF key.

5.

59

is displayed on the screen and the set-

ting value is output.

Page 60

3.6 Memory Source Function

Normal source mode

Recall source mode

Scan source mode

60

Press the OUTPUT ON/OFF key.

6.

is displayed on the screen and the out-

put changes to OFF.

Repeat steps 3. to 6.

7.

Press the MEMORY key twice.

8.

Exit recall source mode.

• In recall source mode, the output setting value cannot

be changed. The / keys only set addresses. To

change the setting value, see "Saving setting value to

memory" (p.55).

• When output is ON, press the MONITOR key to enable

the output monitor function and monitor output. When

output is OFF, measurement and monitoring cannot be

performed.

• Every time the MEMORY key is pressed, the source

mode changes in the following sequence.

• Addresses that can be set for recall sourcing are only

those set between 1 and 20. (Those with no skip setting.)

• If the indicator is flashing, output cannot be set to

ON. (If it flashes during output, output continues until

output is set to OFF.) Replace the batteries or connect

the AC adapter.

Page 61

Scan sourcing

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

1

2

3

Start address for sourcing

4 Sourcing time

interval

1.

2.

3.

4.

3.6 Memory Source Function

61

Press the SOURCE FUNCTION key to

set the memory sourcing function.

Press the MEMORY key twice to set

to the scan source mode ([SCAN]).

Use the ADDRESS keys (the 2 leftside / keys) to set the address to

be sourced.

The output setting value in memory is displayed at the sourcing screen.

Use the INTERVAL keys (the 2 rightside / keys) to set the sourcing

time interval.

The sourcing time interval is from 1 to 99 seconds. A sourcing time interval cannot be set

for each address.

Connect the target device.

5.

Page 62

3.6 Memory Source Function

Normal source mode

Recall source mode

Scan source mode

62

Press the OUTPUT ON/OFF key.

6.

is displayed on the screen and output

starts.

The setting switches by the specified time interval.

Press the OUTPUT ON/OFF key.

7.

is displayed on the screen and the output changes to OFF. Scan sourcing also

stops.

Press the MEMORY key once.

8.

Exit scan source mode.

• In scan source mode, the output setting value cannot

be changed. The / keys only set addresses. To

change the setting value, see "Saving setting value to

memory" (p.55).

• When output is ON, press the MONITOR key to enable

the output monitor function and monitor output. When

output is OFF, measurement and monitoring cannot be

performed.

• Every time the MEMORY key is pressed, the source

mode changes in the following sequence.

• Addresses that can be set for scan sourcing are only

those set between 1 and 20. (Those with no skip setting.)

• If the indicator is flashing, output cannot be set to

ON. (If it flashes during output, output continues until

output is set to OFF.) Replace the batteries or connect

the AC adapter.

Page 63

3.6 Memory Source Function

63

Initializing setting values

• Initialize setting values saved to memory. Initialization by

source function is possible. Furthermore, all functions can be

initialized at same time.

• This feature is useful when re-saving settings to memory or

when batch initializing the contents of functions that are no

longer used.

• After initialization, the memory contents are as follows.

Address 1 2 3 4 5

CV:25V

CC:25mA

Those not listed above are as follows.

Setting count : 00000

Source setting : Skip (Not used)

Sourcing time interval : 1 s

Thermocouple : [K] ([TC:0°C], [TC:RJ] source function)

1 V2 V3 V4 V5 V

-4 mA -8 mA -12 mA -16 mA -20 mA

Turn the power switch on while hold-

1.

ing both the 0 ADJ and the MEMORY

keys.

The display shows "CLr" when the Memory

Clear mode is activated.

If it does not, repeat step 1.

Page 64

3.6 Memory Source Function

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

64

Press the SOURCE FUNCTION key to

2.

select the function for which settings

are to be initialized.

After selecting the thermoelectromotive force

source function, all functions will be selected:

([CV:2.5V] → [CV:25V] → [CC:25mA] →

[TC:0°C], [TC:RJ] → All functions)

Press the MONITOR key.

3.

The settings of selected functions are initialized and “CLr” flashes on the screen.

Turn the power off.

4.

To avoid damaging the instrument, do not turn the power off in

the middle of the Memory Clear procedure. The "CLr" display

should be blinking before turning the power off.

Page 65

3.7 When setting value is flashing

65

3.7 When setting value is flashing

When the OUTPUT key is pressed and output is set to ON, setting value may flash.

When setting value is flashing, the value being output may be

lower than the setting value. (Overload) Press the OUTPUT key

to set the output to OFF.

Check the connection of the SS7012 and the target device. If

there are unexpected shorts or contact failures, eliminate them.

If the setting value is still flashing even after setting output to

ON, the performance level of the SS7012 is being exceeded.

(See below.)

In the constant voltage source function of this instrument, the

possible electrical current that can flow is ±25 mA. (Current must

flow to source the specified constant voltage.) If a current

exceeding ±25 mA flows, the source voltage may become lower

than the setting value. In other words, the set voltage cannot be

sourced in this condition.

Furthermore, in the constant current source function, the applied

voltage is ±25 V. (Voltage must be applied for the specified constant current to flow.) If a voltage exceeding ±25 V is applied, the

source current may become lower than the setting value. In

other words, the set current cannot be sourced in this condition.

Page 66

4.1 Measurement Example

67

Measurement Chapter 4

Always inspect the instrument before measurement.

See: "2.4 Pre-Operation Inspection" (p.34)

4.1 Measurement Example

The following are the voltages, currents, and temperatures that

the SS7012 can measure.

Voltage (V) (p.68)

In [V:2.5V], measurement is possible from -2.8 to +2.8 V with the resolution of 100 µV.

In [V:25V], measurement is possible from -28 to +28 V with the resolution of 1 mV.

In all cases, DC voltage can be measured.

Current (A) (p.68)

In [A:25mA], measurement is possible from -28 to +28 mA with the resolution of 1 µA.

DC current can be measured.

Temperature (TEMP) (p.71)

In [TEMP], measurement is possible from -25 to +80°C with the resolution of 0.1°C.

The optional 9184 Temperature Probe is required.

Page 67

4.2 Voltage Measurement and Current Measurement

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

68

4.2 Voltage Measurement and Current

Measurement

Measure DC voltage or DC current as following procedure.

Turn the power switch on.

1.

Press the MEASURE FUNCTION key

2.

the required number of times to set

the voltage measure function

([V:2.5V], [V:25V]) or current measure

function ([A:25mA]).

At power on, [FUNCTION OFF] is set. Pressing the MEASURE FUNCTION key changes

the setting in the lower shown sequence.

[V:2.5V] → [V:25V] → [A:25mA]

↑ ↓

[FUNCTION OFF] ← [TEMP]

In the lower part of the screen, the moves

to the specified function.

Page 68

4.2 Voltage Measurement and Current Measurement

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

3.

<For voltage measurement>

Connect the test leads to the voltage

input terminals for the instrument and

short out the ends of the test leads.

<For current measurement>

Connect the test leads to the current

input terminals for the instrument and

open the ends of the test leads.

Press the 0 ADJ key to execute the

4.

zero adjustment.

Connect the end of the test lead to

5.

the target device and read the displayed value.

69

In order to prevent damage to the instrument or the target

device, do not input voltage in excess of ±28 V to the voltage

input terminal and do not input current in excess of ±28 mA to

the current input terminal. Do not input voltage to the current

input terminal.

Page 69

4.2 Voltage Measurement and Current Measurement

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

70

• If the input is outside the measurement range, the dis-

play will indicate "oF".

• The zero adjustment function works only when the

measurement value is within ±100 counts. When the

measurement value is within ±100 counts, press the

0 ADJ key to revert the display to “00000”.

• Every time pressing the 0 ADJ key, the input value is

memorized. The LCD shows the difference between

the memorized value and the input value.

• In the following cases, the zero adjustment function

does not work and “AdJEr” is displayed, even if the

0 ADJ key is pressed.

• In [V:2.5V], the input value exceeds ±0.0100 V

• In [V:25V], the input value exceeds ±0.100 V

• In [A:25mA], the input value exceeds ±0.100 mA

Page 70

4.3 Temperature Measurement

9184 Temperature Probe

71

4.3 Temperature Measurement

Temperature measurement is possible with the optional 9184

Temperature Probe.

Connect the optional 9184 Tempera-

1.

ture Probe to the instrument.

Turn the power switch on.

2.

Page 71

4.3 Temperature Measurement

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

72

3.

4.

Press the MEASURE FUNCTION key

4 times to set the temperature measure function ([TEMP]).

At power on, [FUNCTION OFF] is set. Pressing the MEASURE FUNCTION key changes

the setting in the lower shown sequence.

[V:2.5V] → [V:25V] → [A:25mA]

↑ ↓

[FUNCTION OFF] ← [TEMP]

In the lower part of the screen, the moves

to the specified function.

Read the displayed value.

Page 72

4.3 Temperature Measurement

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

73

• If the temperature measurement function is selected

without the optional 9184 Temperature Probe being

connected, the message "rJErr" will be displayed.

When a Temperature Probe is connected, the error

disappears and temperature measurement starts.

• The optional 9184 Temperature Probe cannot be used

out of the temperature measurement range between

-25 and 80°C. If measurement exceeds this temperature range, the lead insulation of the temperature

probe being used is damaged. In addition, if the input

is outside measurement range, the display will indicate

"rJErr".

Page 73

Loop Test Chapter 5

The connections for the two-wire transmitter, etc.

Sensor

Two-wire

transmitter

Distributor

Output signal

4-20 mA

24 V

5.1 Loop Test Overview

Loop tests can be performed with the SS7012.

The loop tests are for systems that include two-wire transmitters

and distributors. (See the diagram below).

Two-wire transmitters and distributors can be tested using the

SS7012.

The two-wire transmitter receives the sensor output and converts it to a 4-20 mA current signal.

In addition to supplying the power to the two-wire transmitter, the

distributor outputs a signal corresponding to the current signal to

a later stage.

5.1 Loop Test Overview

75

Page 74

5.2 Testing a Distributor (4-20 mA)

Distributor test

Current source

SS7012

Distributor

4-20 mA

Output signal

76

5.2 Testing a Distributor (4-20 mA)

The 4-20 mA current flow of the distributor can be tested by

using the SS7012 to sink the 4-20 mA current (a two-wire transmitter simulation).

For the distributor test, setting values of the source current are

minus because the SS7012 sinks current.

It is assumed that the memory source function setting of the

SS7012 is default. When the setting is not at the default, initialize the memory settings or set -4 mA/ -8 mA/ -12 mA/

-16 mA/ -20 mA.

See: "Initializing setting values" (p.63)

"Saving setting value to memory" (p.55)

Note that when you make the setting yourself, they may not

match with the [ADRS] values of the following procedure.

Page 75

5.2 Testing a Distributor (4-20 mA)

77

Test procedure

1. Check which distributor input terminal has the higher potential.

Power on the SS7012 and perform the pre-operation

1.

inspection.

See: "2.4 Pre-Operation Inspection" (p.34)

Press the MEASURE FUNCTION key to set the mea-

2.

sure function to [V:25V].

Connect the voltage input terminal of the SS7012 and

3.

the input terminal of the instrumentation.

Read the voltage of the distributor input terminals

4.

and check which terminal has the higher potential.

Release the connection with the distributor of the

5.

SS7012.

2. Checking the memory source function setting

Press the SOURCE FUNCTION key to set the source

1.

function to [CC:25mA].

Press the MEMORY key to switch from normal source

2.

to recall source. (The selected memory source function is displayed at the upper right display area.)

Check that [ADRS] is “01” and the setting is -4.000

3.

mA.

Press the right ADDRESS key (the ADDRESS keys

4.

are the 2 / keys on the left) and switch [ADRS]

from “01” to “02”.

Check that the setting is -8.000 mA.

5.

Press the ADDRESS key. Check that, as [ADRS]

6.

increases from “03” to “04” to “05”, the setting

changes to -12.000 mA to -16.000 mA to -20.000 mA.

Press the ADDRESS key to set [ADRS] to “01”.

7.

Page 76

5.2 Testing a Distributor (4-20 mA)

78

3. Connect the SS7012 and the distributor and then test.

Connect the output terminal of the SS7012 and the

1.

input terminal of the distributor as shown in the figure. Be careful of the connection direction. Connect

the positive side of the output terminal of the SS7012

with the input terminal of the distributor with the

higher potential. Connect the negative side of the

output terminal of the SS7012 with the input terminal

of the distributor with the lower potential.

Press the OUTPUT ON/OFF key to set the output to

2.

ON. (During output, is displayed in the display

area.) A current of 4.000 mA is now flowing. (The setting is -4.000 mA.)

Check the indicated value of the meter.

3.

In this state, press the ADDRESS key to set [ADRS] to

4.

“02”. A current of 8.000 mA is now flowing. (The setting is -8.000 mA.)

Check the indicated value of the meter.

5.

Similarly to below, increase [ADRS] to “03”, “04”, and

6.

“05". (The current flow increases to 12.000 mA,

16.000 mA, and 20.000 mA). Check that the indicated

value of the meter accordingly.

Press the OUTPUT ON/OFF key to set the output to

7.

OFF.

Release the connection with the distributor of the

8.

SS7012.

Turn off the power of the SS7012.

9.

Page 77

5.3 Testing a two-wire transmitter

Two-wire transmitter test

4-20 mA

Voltage source 24 V

(Using the monitor function)

SS7012

Sensor

Two-wire

transmitter

5.3 Testing a two-wire transmitter

The two-wire transmitter can be tested by sourcing voltage (voltage of the power for the transmitter of the distributor) from the

SS7012 and monitoring the output current. In this case, it is

assumed that the power voltage of the two-wire transmitter is 24

V. (24 V loop power)

Power on the SS7012 and perform the pre-operation

1.

inspection.

See: "2.4 Pre-Operation Inspection" (p.34)

Press the SOURCE FUNCTION key to set the source

2.

function to [CV:25V].

Press the / keys to set the source setting to

3.

24.000 V (the voltage of the distributor).

Connect the two-wire transmitter and the SS7012 as

4.

shown in diagram “Two-wire transmitter

Press the OUTPUT ON/OFF key to set the output to

5.

6.

ON. (During output, is displayed in the display

area.)

Press the MONITOR key to set the output monitor

function to ON.

79

test”.

Page 78

5.3 Testing a two-wire transmitter

SOURCE ON OFF

MEASURE

MONITOR ADJ RMT

K

V

C

mA

V

C

mA

EJTRSBN

80

Insert a suitable input into the two-wire transmitter

7.

(pressure, temperature, etc.). Read and check the

current value from the SS7012 at this time. (Do this

for all the inputs that required for testing. The display

example is as follows.)