Page 1

SP7001

SP7002

NON-CONTACT CAN SENSOR

NON-CONTACT CAN SENSOR

SP7100 CAN INTERFACE

SP9200 SIGNAL PROBE

Quick Start Manual

Dec. 2019 Edition 1

SP7001A971-00 19-12H

EN

Introduction

Thank you for choosing the Hioki SP7001/SP7002 Non-Contact

CAN Sensor, SP7100 CAN Interface, and SP9200 Signal Probe.

Keep this manual accessible so that you can take full advantage of

the product’s functionality throughout its service life.

Be sure to review the following documentation before using the

product:

–

Electronic

edition

–

–

Document Content

Quick Start

Manual

(this manual)

Instruction

Manual

Operating

Precautions

(0990A905)

The Quick Start Manual

provides a brief overview

of how to use the product.

The Instruction Manual

contains detailed

instructions about how to

use the product.

“Operating Precautions”

contains important

information about how to

use the product safely.

Paper

edition

Verifying Package Contents

SP7001/SP7002 Non-Contact CAN Sensor

SP7001 ×1 SP7002 ×1

Quick Start Manual

Japanese and English ×1 each

or

Operating Precautions (0990A905) ×1

SP7100 CAN Interface

SP7100 ×1

Quick Start Manual

Japanese and English

×1 each

Operating Precautions

(0990A905) ×1

L9500 Power Cable ×1

(For connecting an external battery;

terminates in wires; approx. 2 m long)

Alligator clip ×1

Operating Precautions

WARNING

Do not use the product in locations such as those listed

below. Doing so may result in product damage or cause

an accident.

• Locations where the product would be subject to

direct sunlight or high temperatures

• Locations where corrosive or explosive gases are

present

• Locations where there is powerful electromagnetic

radiation or that are close to electrically charged

objects

• Close to inductive heating equipment (high-frequency

inductive heating equipment, IH cooktops, etc.)

• Locations with an excessive amount of mechanical

vibration

• Locations where the product would be exposed to

water, oil, chemicals, solvents, or other liquids

• Locations with excessive humidity or condensation

• Locations with excessive dust

* The SP9200 Signal Probe is not covered by the warranty.

This is the Quick Start Manual. Be sure to download the most

recent version of the Instruction Manual from Hioki’s website.

https://www.hioki.com/en/products/detail/?product_key=6509

Communications standards

The Non-Contact CAN Sensor supports the following

communications standards:

Model Communications standards

SP7001

SP7002

–

Use of the product

Before using the product, review proper handling of the product, bus

systems, and related systems.

Only individuals who understand both safe product use and the

potential impacts arising from using the product should use the

product. Use of the product by others may cause bodily injury or

damage to the product or other devices.

Overview

The SP7001/SP7002 Non-Contact CAN Sensor can detect CAN

communications signals, which are used in control communications

in automobiles and in a variety of devices, from outside cables’

insulation.

Captured CAN signals can be connected to analyzers, loggers, and

other measuring instruments with a CAN interface.

Spiral tube ×1

(For securing the power

cable in place)

Ground connection cable (1.5 m) ×1

SP9200 Signal Probe

Signal Probe ×2

Specications

Operating

environment

Operating

temperature

and humidity

Storage

temperature

and humidity

Dustproofness

and

waterproofness

Power supply • Z1008 AC Adapter

For other specications, see “4 Specications” in the downloaded

Instruction Manual.

Indoors, Pollution Degree 2

altitude up to 2000 m (6562 ft.)

Temperature: −40°C to 85°C (−40°F to 185°F)

Humidity:

−40

C to 60°C (−40°F to 140°F), 80% RH or

°

less (no condensation)

60°C to 85°C (140°F to 185°F), 60% RH or

less (no condensation)

−40°C to 85°C (−40°F to 185°F)

80% RH or less (no condensation)

IP40 (EN 60529)

SP7001/SP7002: When 2 Signal Probes

connected

SP7100: When Non-Contact CAN Sensor

connected to both CH1 and CH2

Rated supply voltage: 100 V to 240 V AC

(accommodates to uctuations within a range

of ±10% of the rated supply voltage)

Rated power supply frequency: 50 Hz/60 Hz

Anticipated transient overvoltage: 2500 V

Maximum rated power: 8 VA (including AC

adapter), 3 VA (product only)

• External power supply

Rated supply voltage: 10 V to 30 V DC

Maximum rated power: 3 VA

• The Z1008 AC Adapter has a rated supply voltage

of 100 V to 240 V and a rated frequency of 50 Hz

or 60 Hz. To prevent damage to the product or an

electric accident, never use the adapter with any other

voltage.

• To prevent electric shock and ensure safety, connect

the included power cord to a grounded two-prong

outlet.

The Non-Contact Sensor is capable of extremely stable CAN frame

acquisition. However, the product is not guaranteed to achieve

an error rate of 0% under all conditions. Errors may be caused by

factors including the condition of the vehicle being tested and the

quality of the power supply being used. Please verify that the product

functions properly with the vehicle to be tested prior to use.

Maintenance and Service

WARNING

Do not attempt to modify, disassemble, or repair the

product.

Doing so may result in re, electric shock, or bodily

injury.

Troubleshooting

If you believe the product may be malfunctioning, contact your

authorized Hioki distributor or reseller after reviewing the contents of

downloaded Instruction Manual “Before sending the product to be

repaired.”

IMPORTANT

When shipping the product, do not disconnect the SP9200 Signal

Probes from the SP7001/SP7002 Non-Contact CAN Sensor.

Doing so may soil or degrade the connectors’ contacts, adversely

impacting signal detection.

When sending the product to be repaired, attach a description of the

issue.

Page 2

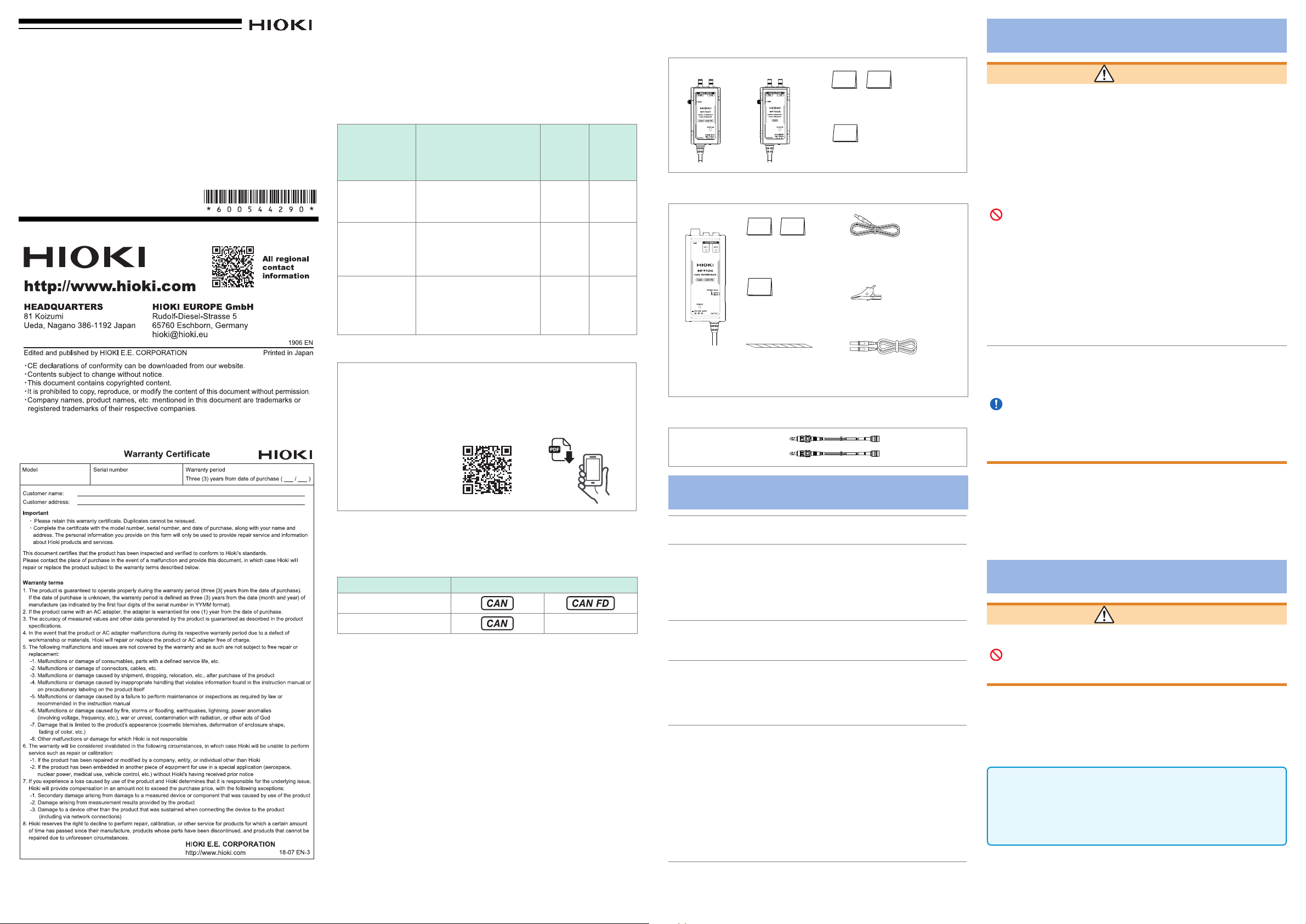

Preparations

For details, see “2 Preparing Before Use” in the downloaded

Instruction Manual.

6

“2.7 Connecting

the Signal Probes

to the CAN bus”

“2.2 Connecting

the SP9200

Signal Probes”

“2.4

Connecting

the Ground

Terminal”

3

“2.3 Connecting the

SP7001/SP7002

Non-Contact CAN

Sensor”

2

1

3

“2.4 Connecting

the Ground

Terminal”

5

“2.6 Supplying

Power”

4

“2.5 Connecting the

SP7100 CAN Interface”

LED lighting/ashing specications

SP7001/SP7002 Non-Contact CAN Sensor

Product status STATUS LED

Self-test error (failure)

Signal not detected

Signal detected

Probe high/low reverse connection

warning

SP7100 CAN Interface

Product status POWER LED CH1, CH2 LED

Self-test error (failure)

CAN sensor not

connected

CAN sensor connected

Output bus error

detection

Flashing green Steady red

Steady green Unlit

Steady green

Steady green

Steady red

Steady green

Flashing green

Flashing red

Reects CAN

Sensor’s STATUS

LED.

Quickly

alternating red/

green

Detection Procedure

CAUTION

Do not connect the probes to bare conductors with

exposed metal or cables with damaged insulation. Do

not allow the tips of the probes to come into contact with

any energized part.

Doing so may damage the equipment you are using (the

vehicle) or cause it to malfunction.

IMPORTANT

• The Signal Probe’s connector incorporates a locking mechanism.

Always use the probe with the connector in the locked state to

ensure signals can be properly detected and to prevent damage

to the connector.

• Leave the Signal Probe connected to prevent deterioration of

the Signal Probe and Non-Contact CAN Sensor’s connector’s

contacts and to keep out dirt.

• Any dirt on the cable under test could aect signal detection.

Remove any dirt before axing (connecting) the Signal Probe.

Connect the SP9200 to the SP7001 or SP7002 Non-

1

Contact CAN Sensor’s signal probe connector.

SP9200 Signal Probe

SP7001 or SP7002

Signal Probe connector

Insert until you hear a clicking

sound to lock the connector.

SP7001/SP7002 Non-Contact CAN Sensor

Connect the SP7001 or SP7002 Non-Contact CAN

2

Sensor’s to the SP7100 CAN Interface.

SP7001 or SP7002 output connector

Align slits

SP7100 CAN Interface

Connect the SP7100 CAN Interface’s ground

3

terminal to the vehicle’s ground.

If connecting the SP7100 CAN interface’s ground terminal to

the ground cannot reduce the noise, connect the SP7001’s or

SP7002’s ground terminal to the vehicle’s ground.

SP9200 connector

with lock

SP7001 or SP7002SP7100

Connect the SP7100 CAN Interface’s CAN signal

4

output connector to the CAN interface-equipped

device with which you wish to use it.

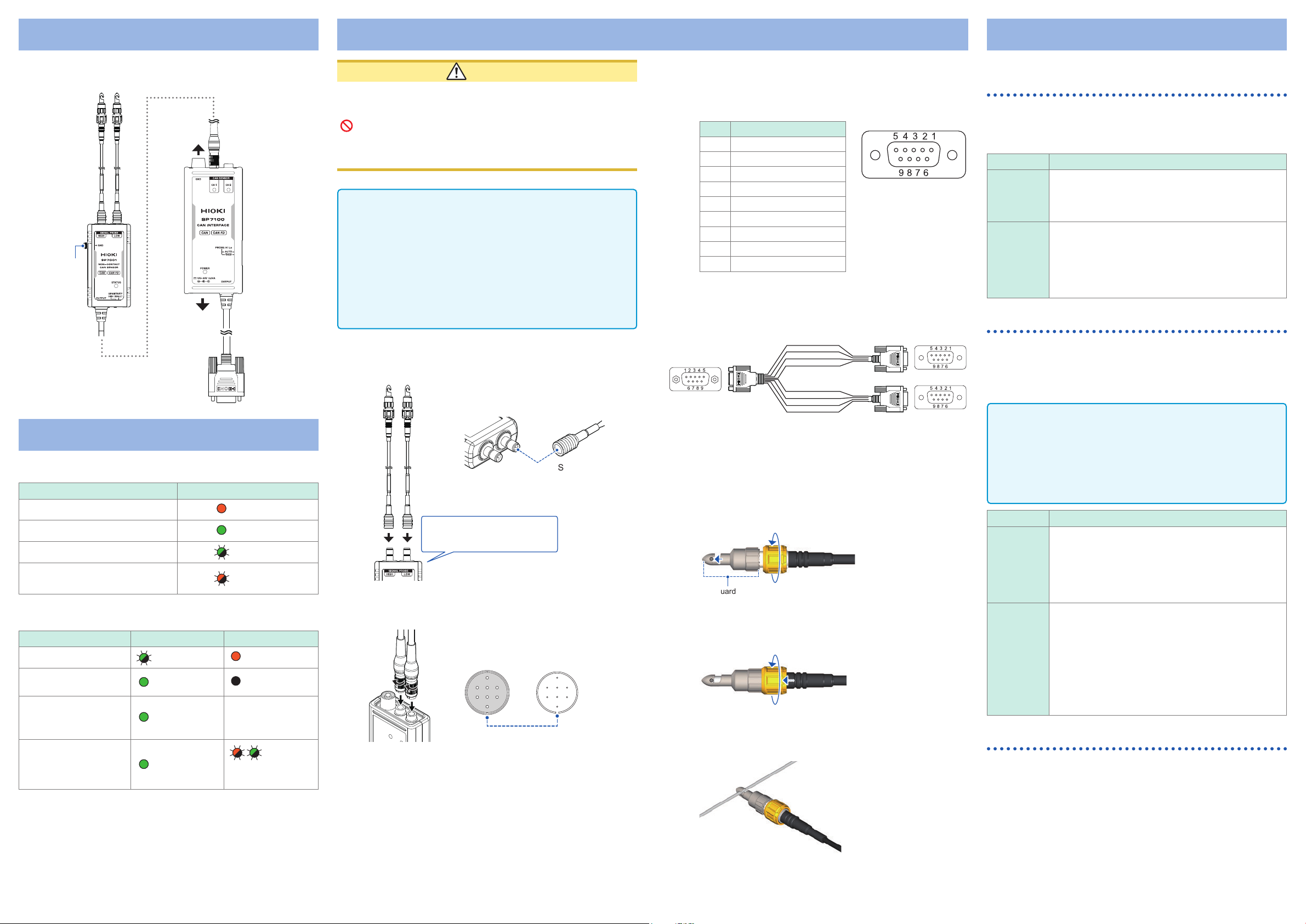

Pin assignment of CAN signal output connector

Pin Assignment

1 CH2 CAN Low

2 CH1 CAN Low

3 CH1 GND

4 N.C.

5 Shield

6 CH2 GND

7 CH1 CAN High

8 CH2 CAN High

9 N.C.

SP9900 Split Cable

If the input interface provided by the device you plan to use does not

support 2-channel input, use the SP9900 Split Cable.

CH1 CAN Low

2 2

CH1 GND

MALE

CH1/CH2

Supply power to the SP7100 CAN Interface

5

Rotate the grip of SP9200 Signal Probe to press the

6

3 3

CH1 CAN High

7 7

Shield

5 5

CH2 CAN Low

1

6

CH2 GND

CH2 CAN High

8

Shield

5

2

3

7

5

FEMALE

CH1

CH2

cable under test against the detection electrode.

Connect the tips of the SP9200 Signal Probes to the CAN

bus. Connect the Signal Probe connected to the terminal

labeled

to the CAN_L line.

Tighten the grip until it no longer rotates.

7

The probe contains a built-in spring that supports the cable

under test.

HIGH

to the CAN_H line and the other Signal Probe

Guard hook

• Position the probe so that the cable under test is in contact

with the back of the detection electrode.

• Proper detection will be impossible if the cable under test is

positioned too shallowly or angled in the guard hook.

Functionality

Switching the Non-Contact CAN Sensor’s Signal

Detection Sensitivity

This section describes how to switch the Non-Contact CAN Sensor’s

signal detection sensitivity

for most applications. Select

CAN signal level and cable eects.

Setting Description

The DEFAULT setting represents the normal mode.

DEFAULT

HIGH

It is recommended to use DEFAULT mode since

it delivers the optimal level of vibration and noise

resistance.

The HIGH setting represents high-sensitivity mode.

Use this mode when you encounter detection errors

due to the low signal levels detected by the Signal

Probes.

The product is more susceptible to vibrations and

various types of noise when used in this mode.

SENSITIVITY

(

HIGH

as necessary depending on the

). Use the

Probe Setting Function (Automatic Polarity Selection)

The probe setting function automatically selects the Signal Probe’s

polarity.

It is a convenient function that automatically switches the sensor

input when the SP9200 signal probes have been connected in

reverse to the Non-Contact CAN Sensor input label (HIGH/LOW).

IMPORTANT

When performing rigorous evaluations, for example in bus testing

that includes verication of wiring consistency, connect the high

and low Signal Probes to the CAN bus’s high and low lines and

use xed input polarity (

In automatic input polarity mode (

guaranteed under all conditions.

Setting Description

The FIXED setting represents xed input polarity

mode.

FIXED

AUTO

If the Non-Contact CAN Sensor detects that the

Signal Probes are connected to the CAN bus in

reverse, it will indicate this state with the

LED, which will ash red.

The AUTO setting represents automatic input

polarity mode.

If the Non-Contact CAN Sensor detects that the

Signal Probes are connected to the CAN bus in

reverse, it will switch the high and low detected

signals via its internal circuitry.

This function will operate in approximately 2

seconds as long as the CAN bus load factor is

approximately 5% or greater.

FIXED

) mode.

AUTO

), correct detection is not

Output Bus Error Detection Function

This function determines that an output error has occurred when the

SP7100 CAN Interface is unable to output a proper CAN signal to

the bus connected to the CAN signal output connector.

The SP7100 CAN interface output does not have CAN signal

arbitration functionality. CAN communications signals detected by

the Non-Contact CAN Sensor are output without modication.

The output bus error detection function operates when the NonContact CAN Sensor is connected properly to the CAN_H and

CAN_L lines (as per the labels on the Non-Contact CAN Sensor

inputs).

DEFAULT

STATUS

setting

Loading...

Loading...