Hioki SM-8213, SM-8215, SM-8220 Instruction Manual

SUPER MEGOHMMETER

INSTRUCTION MANUAL

SM-8213

SM-8215

SM-8220

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

i

The super megohmmeter is a unique resistance meter designed to measure highresistance in a wide range.

The meter outputs a high test voltage – 1000 V maximum for the SM-8220/8215, and 100 V

maximum for the SM-8213 – to apply across the sample circuit.

Operators are requested to read this operation manual thoroughly before trying to operate the

instrument for safety and to prevent electrical shock and damage to the measured circuit.

Keep this manual where all staff can access it any time.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

ii

DANGER

A “DANGER” CALLS ATTENTION TO A CONDITION OR POSSIBLE

SITUATION THAT CAN CAUSE DEATH OR INJURY TO THE

OPERATOR OR NEAR PESONS.

1. Safety Precautions

Operators of the SM-8200 Series super megohmmeter are requested to read this operation

manual thoroughly before operation for safety and to obtain best performance.

Operators are also requested to strictly observe all the DANGER, WARNING, and CAUTION

notices in this manual and on the instrument to prevent injury and damage.

1-1 Safety Warnings

This operation manual includes some DANGER!, WARNING!, and CAUTION! notice with a

symbol. These must be observed for safety of the operator and other persons, as well as for

protection of your super megohmmeter and samples from possible damage and destruction.

WARNIN G

A “WARNING” CALLS ATTENTION TO A CONDITION OR POSSIBLE

SITUATION TH AT COULD CAUSE DE ATH OR INJURY TO THE

OPERATOR OR NEAR PESONS.

CAUTION

A “CAUTION” calls attention to a condition or possible situation that

could cause injury to the operator or persons nearby and damage and

destroy the super megohmmeter and samples.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

iii

背面パネル

警告、危険シール

DANGER

端子より高電圧発生の為、

感電の恐れあり。

HIGH VOLTAGE

危険

高電圧危険

Electric shock hazard!

Terminals carry high voltage.

正面パネル

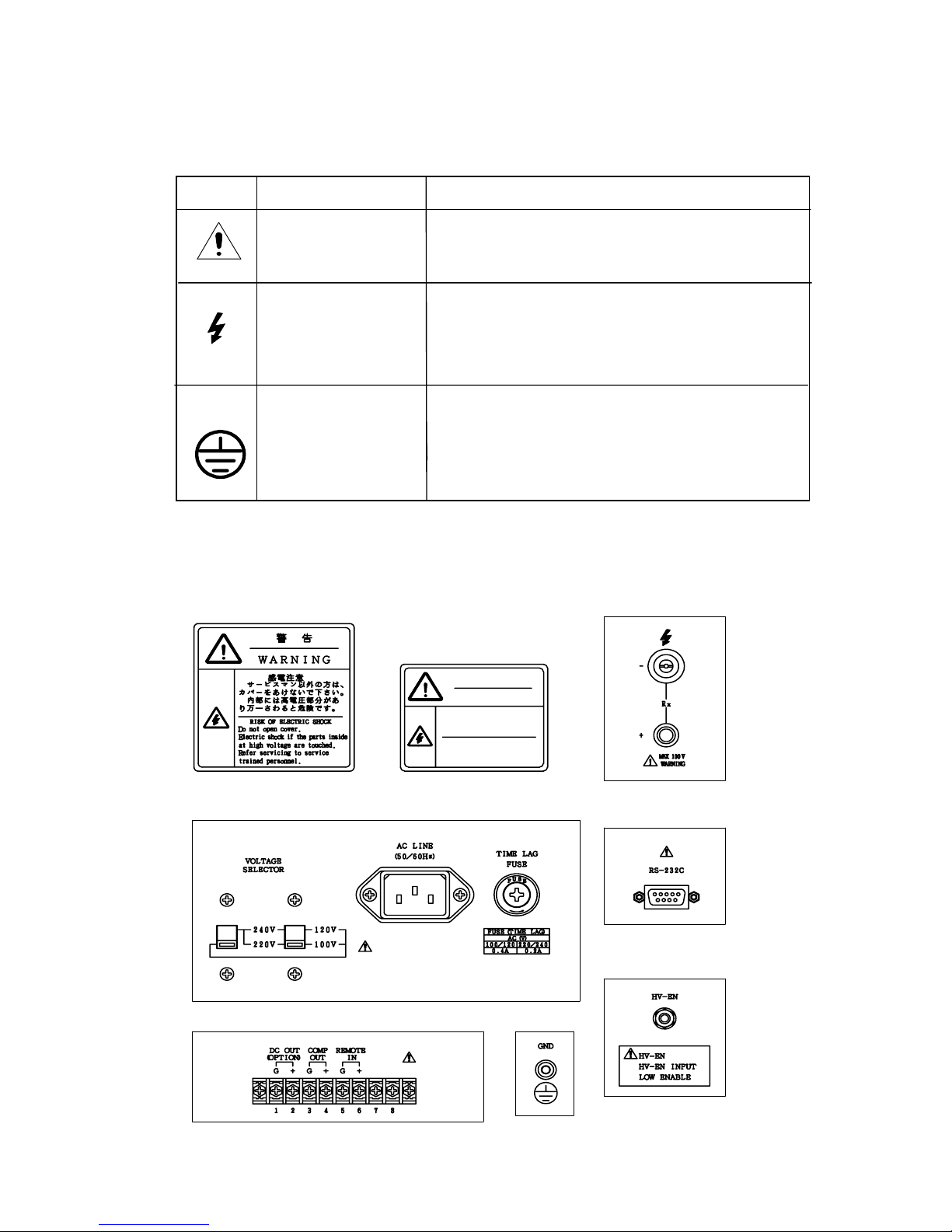

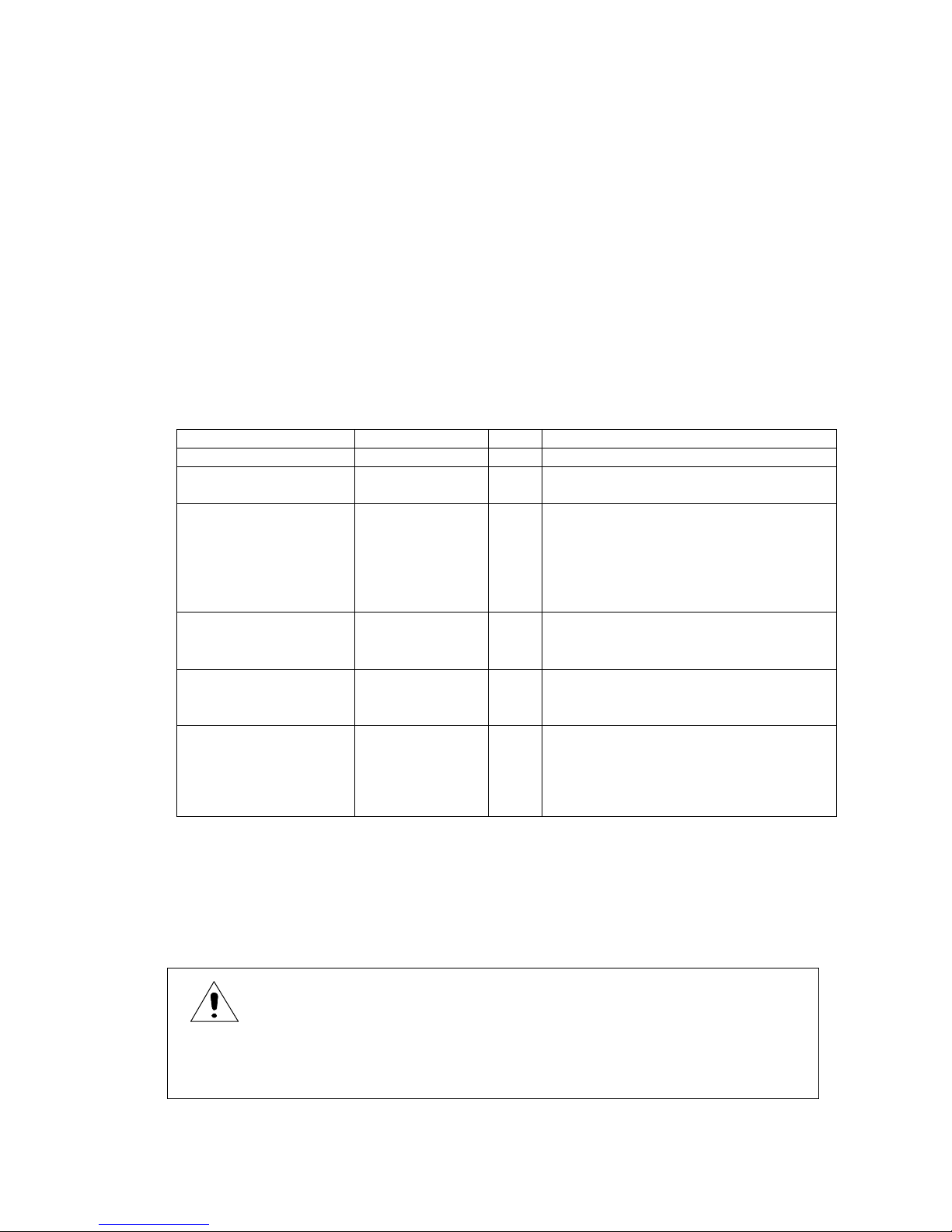

1.2 Symbols on the Super Megohmmeter

Safety Warning Labels on the Super Megohmmeter

Symbol Meaning Description

WARNING

This symbol is sh own at pats whose usage nee ds

referenc e to t he op erati on ma nual.

DANGER –

HIGH VOLTAGE

HAZARD

This symbol is shown at the Rx

“‑“/”+”

Measuring terminals which carry a high voltage

to be applied across the circuit to be measured.

This symbol is shown at the GND

terminal on the rear of the unit. If the

ground prong of the power cord plug

cannot be grounded, this terminal must be

connected to the ground.

1) DANGER and WARNING Labels on the Housing and Front Panel

2) DANGER and WARNING Labels on the Rear Panel

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

iv

2. Operating Environmental Precautions

D

DANGER

■Do not operate the super megohmmeters in the presence of flammable gas. There is s

possibility of an explosion and/or fire.

■D

o not touch the Rx “–”/“+” measuring terminals on the front panel of the instrument

during measurement. They output a maximum of 1000 V (

SM-8220/8215) or 100 V

(SM-8213) for measurement .

WARN ING

■Ground the ground prong of the power cord plug to avoid electrical shock. If the ground

prong cannot be grounded, connect the GND t

erminal on the r ear of t he in stru men t t o a

ground. When the power cord plug is connected to the AC line socket via an

accessory 3-prong to 2-prong adapter, the g reen ground tab of the adapter to the

ground.

■D

o not remove the housing cover of the instrument. Even after turning off the instrumen

t

p

ower switch, a dangerous residual voltage may be present for several minutes after t he

power is tur ned off. If r epair or in ternal readjus tment is neede d, contact your

dealer or Hioki representative

.

CAUTION

■Before turning on the power switch for the instrument, check that the VOLTAGE

SELECTOR switches are set for your local AC line voltage. If the wrong AC line voltage is

applied t

o the unit, it will be damaged (higher voltage supply) or will not function

properly (lower voltage supply).

See 1.3 Setting VOLTAGE SELECTOR Switches for setting.

Use the right size and amperage power fuse. If a fuse of incorrect amperage is inserted

into the fuse holder, the unit will be damaged.

See 1.4 Checking the Fuse Amperage for a correct fuse amperage.

■Do not insta ll or operate the supe r meg hommeter on a su rface w hich is not level or

not stable.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

v

3. Installation Precaution

4. Instrument Handling Precautions

CAUTION

Do not install or place the supe r me g oh mme te r i n a lo ca ti on which is not level, not

stable or not sturdy enough to hold the instrument and other related items.

WARNING

■If the instrument generates smoke or smell, unplug the power cord.

If such an instrument is kept powered on, it may cause a fire.

Contact your dealer or Hioki representative for repair.

■Do not operat e th e inst rumen t wi th a wet han d. Thi s may caus e elect ric al sho ck.

CAUTION

■When moving or transporting the super megohmmeter, avoid shock and vibration as much

as possible. For long-distance transportation,

put the instrume nt in a shock-absorbing

carton or use the original shipping carton.

■ Wh

en not using the super megohmmeter for an extended period of time, unplug the power

co

rd from the AC line socket. Put a dust cover on the instrument. Store it in a place free of

corrosive gas and vi

bration, with a surrounding temperature within the range from –5 to

45℃,

and humidity less than 85% RH.

■ Do not pl ace an ythi ng on t he inst rum ent.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

vi

BRIEF DESCRIPTION

About the SM-8200 Series Super Megohmmeters

The SM-8200 Series super megohmmeters are insulation resistance meters consisting of a constant voltage

power supply and a high sensitive current measuring section. The super megohmmeters are designed to

measur e the el ect rical resi stanc e of in sul ating mate rial s with high insul ation pro perti es.

The resistance measuring ranges of the SM-8200 Seri es are as follows:

SM-8213: 2.5×104 to 2×1012Ω

SM-8215: 2.5×105 to 2×1013Ω

SM-8220: 5.0×104 to 2×1016Ω

Each model of the super megohmmeters is provided with an LCD 320×240 dot display for easy

observation of necessary information, including measuring voltage, measured resistance in both

digital and analog, timer, and resultant GO/NO judgment.

The following shows the main specifications for the super megohmmeters.

For detailed specifications, see 2. SPECIFICATIONS.

For optional accessories, see 9. OPTIONAL ACCESSORIES.

Main Specific ations –

For detailed speci fications, see 2. SPEC IFICATIONS.

For optional accessories, see 9. OPTIONAL ACCESSORIES.

Measuring Voltage Ranges:

SM-8213 – 5, 10, 15, 25, 50 and 100 V

SM-8215 – 50, 100, 250, 500 and 1000 V

SM-8220 – 10, 25, 50, 100, 250, 500 and 1000 V

Measuring Resistance Range:

SM-8213: 2.5×104 to 2×1012Ω

SM-8215: 2.5×105 to 2×1013Ω

SM-8220: 5.0×104 to 2×1016Ω

Timer Function: Provided

Comparison and Judgment Function: Pro vided

HV-EN (High Voltage Enable) Interlocking Function: Provided

Voltage Charging Function: Provided

Voltage Discharging Function: Provided

RS-232C Interface Conn ector: Provided

Remote Measurement Function: Provided

DC Signal Output Function: Optional

1/R output or proportional to resistance value output

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

vii

Organization of This Operation Manual

This operation manual contains the following 10 sections.

1. PREPARATION BEFORE

OPERATION

This section describes precautions for unpacking and AC line voltage setting.

2. SPECIFICATIONS

This section describes the specifications for the SM-8200 Series super megohmmeters and

optional accessories.

3. OPERATING PRINCIPLE

This section describes the operating principle with a block diagram of the SM-8200 S eries.

4. FAMILIARIZATION WITH CONTROLS AND PARTS

This section describes the functions of the controls and parts on the front and rear panels.

5. PREPARATION FOR MEASUREMENT

This section describes the LCD display in detail for the measuring mode, setting mode and

operations. A variety of measured value display methods are also given.

6. MEASUREMENT

This section provides details for function setting, connection to the work to be measured, and

usage of a vari ety of optio nal m easur ing j igs a nd elec tro des.

7. RS-232C INTERFACE

This section describes the application of the serial port interface.

8. REMOTELY CONTROLLED MEASUREMENT

This section describes the remote measuring function.

9. INTRODUCTION OF OPTION ALS

This section describes the optional accessories, including guard chips, DC signal outputs, and

others.

10. MAINTENANCE AND MISCELANEOUS

This section describes maintenance and calibration.

11.

EXTERNAL APPEARANCE

This section inclu des front , rea r and side v iew illust rat ions of th e inst rumen t wit h di mens ions .

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

a

CONTENTS

1. PRE PA RAT ION BE FO RE O PER AT ION . . . . . . . . . . . . . . . . . . . . . . . 1

1. 1 Unpacking and Checking of the Contents . . . . . . . . . . . . . . . . . . . 1

1. 2 Operating AC Line Volta ge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. 3 Setting the VOLTAGE SELECTOR Switches . . . . . . . . . . . . . . . . . . 2

1. 4 Checking the Fuse Amperage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. 5 G rounding the Chas sis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1. 6 Warm-u p Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Measuring Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Other Electrical and Physical Data . . . . . . . . . . . . . . . . . . . . 7

2.4 Optional Functions and Accessories . . . . . . . . . . . . . . . . . . . 8

3. OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. FAM ILI AR IZA TIO N WI TH CON TR OLS AND PA RTS . . . . . . . . . . . . . 11

4.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Measuring Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Measuring Condition Setting Display . . . . . . . . . . . . . . . . . . 16

4.5 Meanings of the Status and Mode Notices. . . . . . . . . . . . . . . . 17

5. PREPARATION FOR A MEASUREMENT . . . . . . . . . . . . . . . . . . . . . 18

5.1 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Calibration . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Basic Procedures for a Measurement. . . . . . . . . . . . . . . . . . . 20

6. MEASUREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Measuring Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Discharging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Charging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6. 4 Int erl oc kin g F unc tio n – Usi ng the HV -EN Con ne cto r . . . . . . . . 23

6

.5 Comparison and Judgment Function . . . . . . . . . . . . . . . . . . . 24

6.6 Setting a Variety of Functions . . . . . . . . . . . . . . . . . . . . . . . 25

6.6.1 Setting the Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.6.2 Setting the Comparison GO/NO Judgment Level . . . . . . . . . 25

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

b

6.6.3 Settin g Buzzer Sound ON/OFF . . . . . . . . . . . . . . . . . . . . . . 26

6.6.4 S etting the Charging Time, Measu ring Time, Comparison

GO/NO Judging Level and Buzzer Sound ON/OFF. . . . . . . . . 26

6.7 Changes in the Current Flowing th rough Insulators. . . . . . . . . 28

7. RS-232C INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 RS-232C Communication Commands . . . . . . . . . . . . . . . . . . . 30

7.2 Applications of Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3 Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.4 Printer Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8. REMOTELY CONTROLLED MEASUREMENT . . . . . . . . . . . . . . . . . 33

9. INTRODUCTION OF OPTI ONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.1 Guard Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.2 DC Signal Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.2.1 DC Output, RP-8000

– Directly proportional or linear to resistance . . . . . . . . . . 38

9.2.2 DC Output, RI-8000

– Inversely proportional or 1/R to resistance . . . . . . . . . . 40

10. MAINTENANCE AND MISCELANEOUS . . . . . . . . . . . . . . . . . . . . 41

10.1 Periodical Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.2 Storage, Transportation and Abando n . . . . . . . . . . . . . . . . . 41

11. EXTERNAL APPEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

1

1. PREPARATION BEFORE OPERATION

1.1 Unpacking and Ch ecking of the Conte nts

When you have received the carton of the SM-8200 Series super megohmmeter, carefull y unpack

it, and take out every thing from the carton.

Although the instrument and its accessories are severely inspected before shipment from factory,

visuall y ch eck th e it ems a nd th eir q uanti ties .

Keep the ship ping cart on fo r reus e at a later sta ge.

1) Visually check the external view of the instrument and its accessories.

2) Check the qua ntiti es of the li st in a ccor danc e with the fo llowi ng li st:

Table 1.1 List of Standard Accessories

Item Reference No. Q’ty Remarks

Operation manual 0PA00007 1 This item means this booklet.

Power cord 0AC00001 1 Power cord with 3-prong plug with third

for grounding

Power cord plug

adapter

0AA00002 1 This adapter makes it possible to use

the 3-prong plug power cord with

2-prong AC output.

Attached to the power cord 3-

prong plug when shipping

from factory

Measuring rod

(Red)

0GE00002 1 A measuring rod with a 1-

meter cord to be connected to the Rx ‘‑’

socket.

Measuring rod

(Black)

0GE00001 1 A measuring rod with a 1-

meter cord to be connected to the Rx ‘+’

socket.

Shorting plug 0GZ00003 1 A plug to be plugged to the

HV-EN so cket of the r ear of

the instr umen t. It i s plug ged

to the HV-EN socket when

shipping from factory.

Important!

When the accessory shorting plug is not plugged to the HV-EN socket on the rear of the

instrument, the measuring high voltage is not output.

Note: The shorting plug is plugged to the HV-EN socket when shipping from factory.

CAUTION

When plugging the shorting plug, make sure that the power is turned off, otherwise,

there is an el ectr ic sh ock h azar d.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

2

Upon checking the instrument and accessories, if any damage is found, immediate ly contact

your dealer or Hioki representative.

1.2 Operating AC Line Voltage

The super meg o h memeter c a n b e o p er a ted from on e o f th e following AC power s o u r c e w hen the

VOLTAGE SELECTOR switches are set accordingly.

AC Line Voltage

Frequency

100 V ±10% 50/60 Hz

120 V ±10% 50/60 Hz

220 V ±10% 50/60 Hz

240 V +10V,‑10% 50/60 Hz

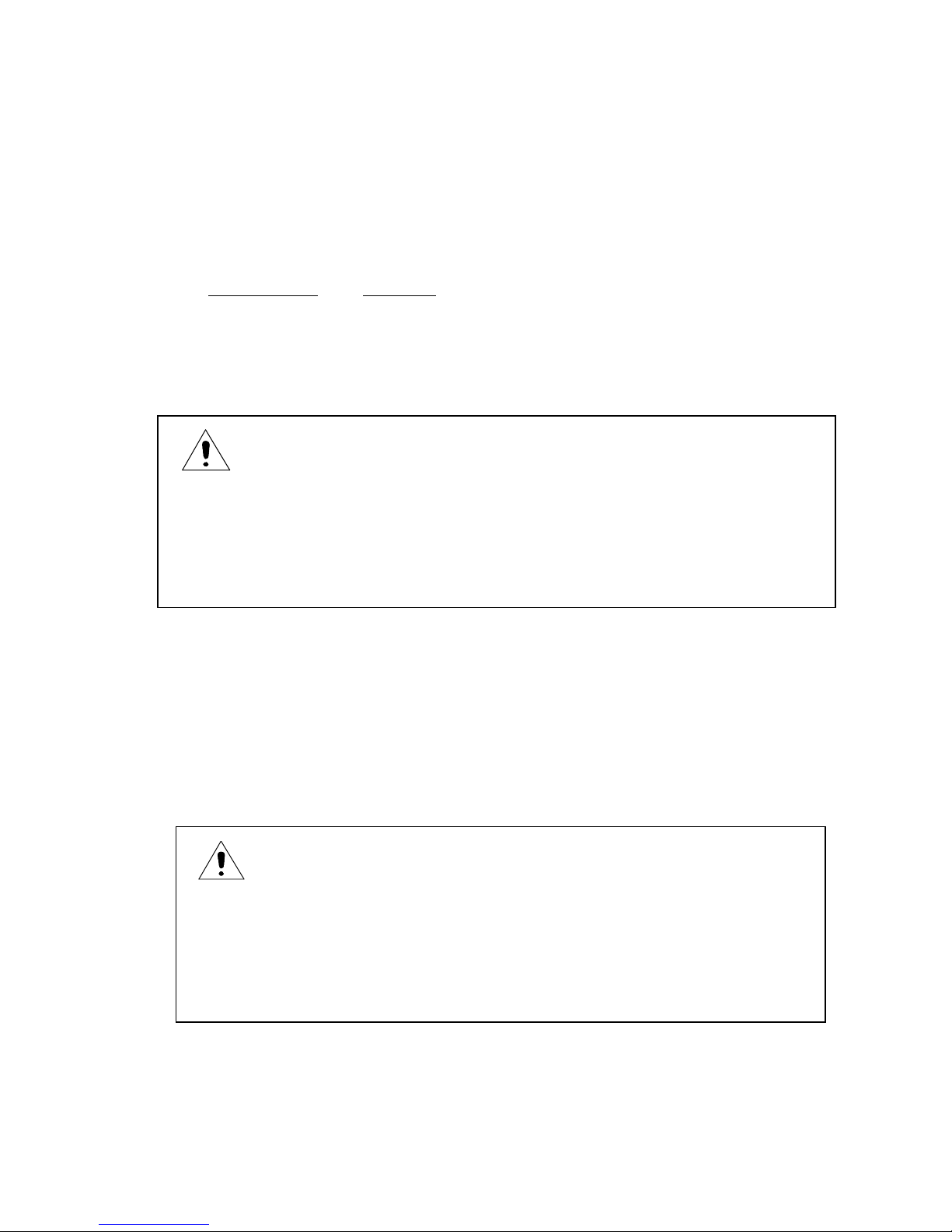

1.3 Setting VOLTAGE SELECTOR Switches

The super megohmmeter can be operated fro m one of the AC lin e voltages of 100 V, 120 V, 220 V

and 240 V by setting the VOLTAGE SE LECTOR switch es to the specific position s, respectively.

Confirm the switch setting to the specific positions in accordance with Fig. 1.1.

If they are not set properly, correct their positions, accordingly.

To change the position of the switch, insert the tip of a flat blade screwdriver into the slot of the

switch lever, and slide the lever upward or downward.

CAUTION

Before connecting the power cord to the AC outlet socket, confirm tha

t the VOLTAGE

SELECTOR switches on the rear panel are set to the positions, accordingly (See 1.3

Setting the VOLTAGE SELECTOR Switches.).

If the switches are set to wrong positions, a fire or burn may occur.

CAUTION

To chan ge th e VOLT ASGE SELE CTOR swit ch po sitio ns, b e sur e to

Unplu g the po wer co rd p lug fr om th e AC li ne soc ket to prev ent a

possible damage.

When th e swi tch po siti on is chan ged wh ile t he vo ltag e is on , the

Switch contacts will be damaged.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

3

V

O

L

T

A

G

E

S

E

L

E

C

T

O

R

100V

120V

220V

240V

Fig. 1.1 VOLTAGE SELECTOR Switch Setting

1.4 Checking the Fuse Amperage

The fuse holder of the instrument contains a time lag fuse of the following amperage:

CAUTION

The VOLTAGE SELECTOR switches have two positions –

up and down. Slide the

switch lever to either position until it stops.

Do not leave the lever at a neutral position. If the lever is set at a neutral position, a

normal function cannot be obtained, and it will cause a failure.

CAUTION

When the VOLTAGE SELECTOR switch position is changed, fuse amperage must be

changed t o me et the r equ irem ents of the n ew AC line v olt age.

Incorr ect fu se am perag e wil l cau se a f ailur e of th e inst rum ent.

Time Lag Fuse

AC Line Voltage

Fuse Amperage

100 V/120 V 0.4 A

220 V/240 V 0.2 A

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

4

Fuse Replacement

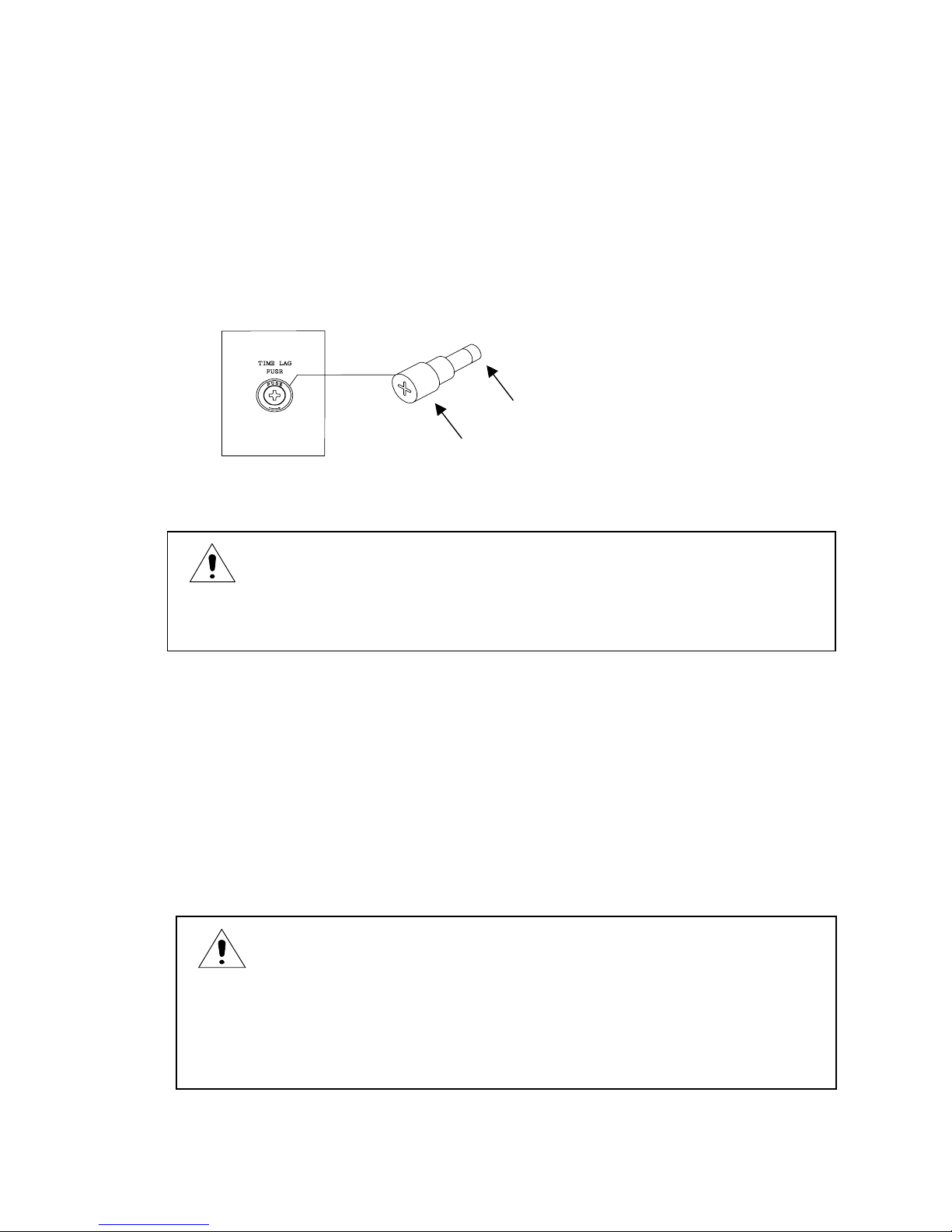

The fuse is inserted in the FUSE holder (Fig. 1.2) on the rear of the unit.

Remove the cap, and replace the fuse with a new one with a correct amperage.

To remove the cap of the fuse holder, use a 4 mm Phillips screwdriver, and turn the cap

counterclockwise.

To set the cap in position, insert the cap, holding the fuse in to the holder , and turn it wi th the

screwdriver.

Fig. 1.2 Fuse Holder and Fuse Replacement

1.5 Grounding the Chassis

To avoid an electr ical shock accide nt, connect the GND terminal on the rear of the u nit to the

ground prong of the power cord to the ground post of the AC line system.

The round prong of the 3-pron g plug of the power cord is th e ground prong.

It is recommended to use an AC line socket with its third contact grounded for connection of the

accessory 3-prong power cord.

To use the accessory 3-prong to 2-prong a dapter to connect the power cord to a 2-co ntact AC line

socket, make sure to ground the green tab of the adapter.

WARNING

To replace or check the fuse, make sure to disconnect the power cord from the AC line

socket. If not, ther e is a fe ar of el ect rical shoc k.

WARNING

To prevent an accident, connect the ground prong of the power cord

Plug to the ground post of the AC line system. If it is impossible to

ground the ground prong of the power cord plug, be sure to connect

the GND terminal on the rear of the unit.

Fuse

Ca

p

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

5

1.6 Warm-up Period

To obtain the performance of published specifications, allow the SM-8200 Series super

megohmmeter to warm for a minimum of 30 minutes.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

6

2. SPECIFICATIONS

2.1 Measuring Performance

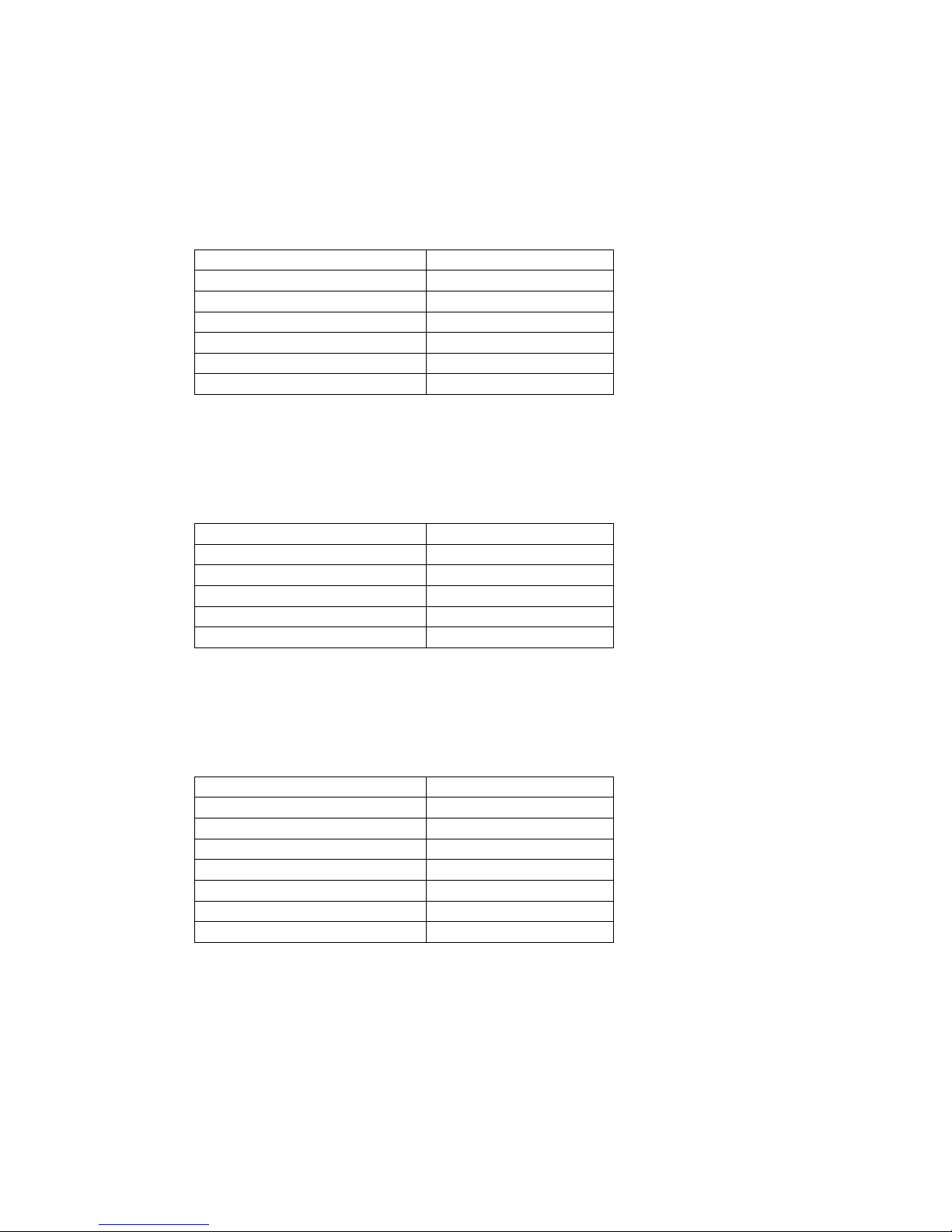

1) Electrical Resistance Measurement

SM-8213

Measuring Range (Ω)

Measuring Voltage

5.0 × 105 to 2 × 1012

100 V

2.5 × 105 to 1 × 1012

50 V

1.25 × 105 to 5 × 1011

25 V

7.5 × 104 to 3 × 1011

15 V

5.0 × 104 to 2 × 1011

10 V

2.5 × 104 to 1 × 1011

5 V

Accuracy of measuring voltage: ±3% of set value

Measuring output current: 50 mA maximum

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range)

SM-8215

Measuring Range (Ω)

Measuring Voltage

5.0 × 106 to 2 × 1013

1000 V

2.5 × 106 to 1 × 1013

500 V

1.25 × 106 to 5 × 1012

250 V

5.0 × 105 to 2 × 1012

100 V

2.5 × 105 to 1 × 1012

50 V

Accuracy of measuring voltage: ±3% of set value

Measuring output current: 2 mA maximum

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range)

SM-8220

Measuring Range (Ω)

Measuring Voltage

5.0 × 106 to 2 × 1016

1000 V

2.5 × 106 to 1 × 1016

500 V

1.25 × 106 to 5 × 1015

250 V

5.0 × 105 to 2 × 1015

100 V

2.5 × 105 to 1 × 1015

50 V

1.25 × 105 to 5 × 1014

25 V

5.0 × 104 to 2 × 1014

10 V

Accuracy of measuring voltage: ±3% of set value

Measuring output current: 2 mA maximum

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range) except for×10

8

range.

±20% for×10

8

range

2) Measuring Time (Sampling Cycle)

Approx. 200 ms

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Loading...

Loading...