Page 1

SUPER MEGOHMMETER

INSTRUCTION MANUAL

SM-8213

SM-8215

SM-8220

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 2

i

The super megohmmeter is a unique resistance meter designed to measure highresistance in a wide range.

The meter outputs a high test voltage – 1000 V maximum for the SM-8220/8215, and 100 V

maximum for the SM-8213 – to apply across the sample circuit.

Operators are requested to read this operation manual thoroughly before trying to operate the

instrument for safety and to prevent electrical shock and damage to the measured circuit.

Keep this manual where all staff can access it any time.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 3

ii

DANGER

A “DANGER” CALLS ATTENTION TO A CONDITION OR POSSIBLE

SITUATION THAT CAN CAUSE DEATH OR INJURY TO THE

OPERATOR OR NEAR PESONS.

1. Safety Precautions

Operators of the SM-8200 Series super megohmmeter are requested to read this operation

manual thoroughly before operation for safety and to obtain best performance.

Operators are also requested to strictly observe all the DANGER, WARNING, and CAUTION

notices in this manual and on the instrument to prevent injury and damage.

1-1 Safety Warnings

This operation manual includes some DANGER!, WARNING!, and CAUTION! notice with a

symbol. These must be observed for safety of the operator and other persons, as well as for

protection of your super megohmmeter and samples from possible damage and destruction.

WARNIN G

A “WARNING” CALLS ATTENTION TO A CONDITION OR POSSIBLE

SITUATION TH AT COULD CAUSE DE ATH OR INJURY TO THE

OPERATOR OR NEAR PESONS.

CAUTION

A “CAUTION” calls attention to a condition or possible situation that

could cause injury to the operator or persons nearby and damage and

destroy the super megohmmeter and samples.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 4

iii

背面パネル

警告、危険シール

DANGER

端子より高電圧発生の為、

感電の恐れあり。

HIGH VOLTAGE

危険

高電圧危険

Electric shock hazard!

Terminals carry high voltage.

正面パネル

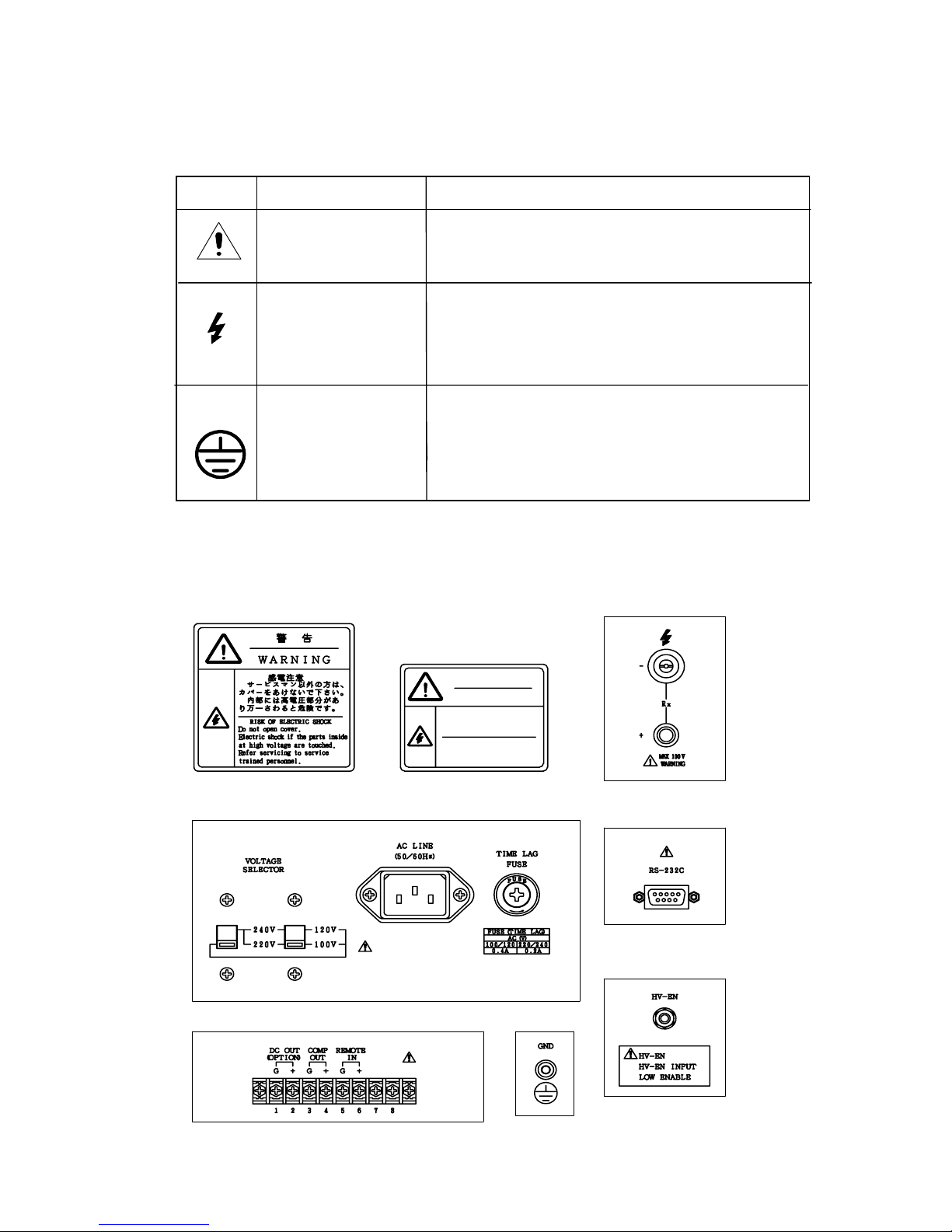

1.2 Symbols on the Super Megohmmeter

Safety Warning Labels on the Super Megohmmeter

Symbol Meaning Description

WARNING

This symbol is sh own at pats whose usage nee ds

referenc e to t he op erati on ma nual.

DANGER –

HIGH VOLTAGE

HAZARD

This symbol is shown at the Rx

“‑“/”+”

Measuring terminals which carry a high voltage

to be applied across the circuit to be measured.

This symbol is shown at the GND

terminal on the rear of the unit. If the

ground prong of the power cord plug

cannot be grounded, this terminal must be

connected to the ground.

1) DANGER and WARNING Labels on the Housing and Front Panel

2) DANGER and WARNING Labels on the Rear Panel

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 5

iv

2. Operating Environmental Precautions

D

DANGER

■Do not operate the super megohmmeters in the presence of flammable gas. There is s

possibility of an explosion and/or fire.

■D

o not touch the Rx “–”/“+” measuring terminals on the front panel of the instrument

during measurement. They output a maximum of 1000 V (

SM-8220/8215) or 100 V

(SM-8213) for measurement .

WARN ING

■Ground the ground prong of the power cord plug to avoid electrical shock. If the ground

prong cannot be grounded, connect the GND t

erminal on the r ear of t he in stru men t t o a

ground. When the power cord plug is connected to the AC line socket via an

accessory 3-prong to 2-prong adapter, the g reen ground tab of the adapter to the

ground.

■D

o not remove the housing cover of the instrument. Even after turning off the instrumen

t

p

ower switch, a dangerous residual voltage may be present for several minutes after t he

power is tur ned off. If r epair or in ternal readjus tment is neede d, contact your

dealer or Hioki representative

.

CAUTION

■Before turning on the power switch for the instrument, check that the VOLTAGE

SELECTOR switches are set for your local AC line voltage. If the wrong AC line voltage is

applied t

o the unit, it will be damaged (higher voltage supply) or will not function

properly (lower voltage supply).

See 1.3 Setting VOLTAGE SELECTOR Switches for setting.

Use the right size and amperage power fuse. If a fuse of incorrect amperage is inserted

into the fuse holder, the unit will be damaged.

See 1.4 Checking the Fuse Amperage for a correct fuse amperage.

■Do not insta ll or operate the supe r meg hommeter on a su rface w hich is not level or

not stable.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 6

v

3. Installation Precaution

4. Instrument Handling Precautions

CAUTION

Do not install or place the supe r me g oh mme te r i n a lo ca ti on which is not level, not

stable or not sturdy enough to hold the instrument and other related items.

WARNING

■If the instrument generates smoke or smell, unplug the power cord.

If such an instrument is kept powered on, it may cause a fire.

Contact your dealer or Hioki representative for repair.

■Do not operat e th e inst rumen t wi th a wet han d. Thi s may caus e elect ric al sho ck.

CAUTION

■When moving or transporting the super megohmmeter, avoid shock and vibration as much

as possible. For long-distance transportation,

put the instrume nt in a shock-absorbing

carton or use the original shipping carton.

■ Wh

en not using the super megohmmeter for an extended period of time, unplug the power

co

rd from the AC line socket. Put a dust cover on the instrument. Store it in a place free of

corrosive gas and vi

bration, with a surrounding temperature within the range from –5 to

45℃,

and humidity less than 85% RH.

■ Do not pl ace an ythi ng on t he inst rum ent.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 7

vi

BRIEF DESCRIPTION

About the SM-8200 Series Super Megohmmeters

The SM-8200 Series super megohmmeters are insulation resistance meters consisting of a constant voltage

power supply and a high sensitive current measuring section. The super megohmmeters are designed to

measur e the el ect rical resi stanc e of in sul ating mate rial s with high insul ation pro perti es.

The resistance measuring ranges of the SM-8200 Seri es are as follows:

SM-8213: 2.5×104 to 2×1012Ω

SM-8215: 2.5×105 to 2×1013Ω

SM-8220: 5.0×104 to 2×1016Ω

Each model of the super megohmmeters is provided with an LCD 320×240 dot display for easy

observation of necessary information, including measuring voltage, measured resistance in both

digital and analog, timer, and resultant GO/NO judgment.

The following shows the main specifications for the super megohmmeters.

For detailed specifications, see 2. SPECIFICATIONS.

For optional accessories, see 9. OPTIONAL ACCESSORIES.

Main Specific ations –

For detailed speci fications, see 2. SPEC IFICATIONS.

For optional accessories, see 9. OPTIONAL ACCESSORIES.

Measuring Voltage Ranges:

SM-8213 – 5, 10, 15, 25, 50 and 100 V

SM-8215 – 50, 100, 250, 500 and 1000 V

SM-8220 – 10, 25, 50, 100, 250, 500 and 1000 V

Measuring Resistance Range:

SM-8213: 2.5×104 to 2×1012Ω

SM-8215: 2.5×105 to 2×1013Ω

SM-8220: 5.0×104 to 2×1016Ω

Timer Function: Provided

Comparison and Judgment Function: Pro vided

HV-EN (High Voltage Enable) Interlocking Function: Provided

Voltage Charging Function: Provided

Voltage Discharging Function: Provided

RS-232C Interface Conn ector: Provided

Remote Measurement Function: Provided

DC Signal Output Function: Optional

1/R output or proportional to resistance value output

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 8

vii

Organization of This Operation Manual

This operation manual contains the following 10 sections.

1. PREPARATION BEFORE

OPERATION

This section describes precautions for unpacking and AC line voltage setting.

2. SPECIFICATIONS

This section describes the specifications for the SM-8200 Series super megohmmeters and

optional accessories.

3. OPERATING PRINCIPLE

This section describes the operating principle with a block diagram of the SM-8200 S eries.

4. FAMILIARIZATION WITH CONTROLS AND PARTS

This section describes the functions of the controls and parts on the front and rear panels.

5. PREPARATION FOR MEASUREMENT

This section describes the LCD display in detail for the measuring mode, setting mode and

operations. A variety of measured value display methods are also given.

6. MEASUREMENT

This section provides details for function setting, connection to the work to be measured, and

usage of a vari ety of optio nal m easur ing j igs a nd elec tro des.

7. RS-232C INTERFACE

This section describes the application of the serial port interface.

8. REMOTELY CONTROLLED MEASUREMENT

This section describes the remote measuring function.

9. INTRODUCTION OF OPTION ALS

This section describes the optional accessories, including guard chips, DC signal outputs, and

others.

10. MAINTENANCE AND MISCELANEOUS

This section describes maintenance and calibration.

11.

EXTERNAL APPEARANCE

This section inclu des front , rea r and side v iew illust rat ions of th e inst rumen t wit h di mens ions .

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 9

a

CONTENTS

1. PRE PA RAT ION BE FO RE O PER AT ION . . . . . . . . . . . . . . . . . . . . . . . 1

1. 1 Unpacking and Checking of the Contents . . . . . . . . . . . . . . . . . . . 1

1. 2 Operating AC Line Volta ge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. 3 Setting the VOLTAGE SELECTOR Switches . . . . . . . . . . . . . . . . . . 2

1. 4 Checking the Fuse Amperage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. 5 G rounding the Chas sis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1. 6 Warm-u p Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Measuring Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Other Electrical and Physical Data . . . . . . . . . . . . . . . . . . . . 7

2.4 Optional Functions and Accessories . . . . . . . . . . . . . . . . . . . 8

3. OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. FAM ILI AR IZA TIO N WI TH CON TR OLS AND PA RTS . . . . . . . . . . . . . 11

4.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Measuring Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Measuring Condition Setting Display . . . . . . . . . . . . . . . . . . 16

4.5 Meanings of the Status and Mode Notices. . . . . . . . . . . . . . . . 17

5. PREPARATION FOR A MEASUREMENT . . . . . . . . . . . . . . . . . . . . . 18

5.1 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Calibration . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Basic Procedures for a Measurement. . . . . . . . . . . . . . . . . . . 20

6. MEASUREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Measuring Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Discharging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Charging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6. 4 Int erl oc kin g F unc tio n – Usi ng the HV -EN Con ne cto r . . . . . . . . 23

6

.5 Comparison and Judgment Function . . . . . . . . . . . . . . . . . . . 24

6.6 Setting a Variety of Functions . . . . . . . . . . . . . . . . . . . . . . . 25

6.6.1 Setting the Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.6.2 Setting the Comparison GO/NO Judgment Level . . . . . . . . . 25

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 10

b

6.6.3 Settin g Buzzer Sound ON/OFF . . . . . . . . . . . . . . . . . . . . . . 26

6.6.4 S etting the Charging Time, Measu ring Time, Comparison

GO/NO Judging Level and Buzzer Sound ON/OFF. . . . . . . . . 26

6.7 Changes in the Current Flowing th rough Insulators. . . . . . . . . 28

7. RS-232C INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.1 RS-232C Communication Commands . . . . . . . . . . . . . . . . . . . 30

7.2 Applications of Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.3 Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.4 Printer Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8. REMOTELY CONTROLLED MEASUREMENT . . . . . . . . . . . . . . . . . 33

9. INTRODUCTION OF OPTI ONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.1 Guard Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.2 DC Signal Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.2.1 DC Output, RP-8000

– Directly proportional or linear to resistance . . . . . . . . . . 38

9.2.2 DC Output, RI-8000

– Inversely proportional or 1/R to resistance . . . . . . . . . . 40

10. MAINTENANCE AND MISCELANEOUS . . . . . . . . . . . . . . . . . . . . 41

10.1 Periodical Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.2 Storage, Transportation and Abando n . . . . . . . . . . . . . . . . . 41

11. EXTERNAL APPEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 11

1

1. PREPARATION BEFORE OPERATION

1.1 Unpacking and Ch ecking of the Conte nts

When you have received the carton of the SM-8200 Series super megohmmeter, carefull y unpack

it, and take out every thing from the carton.

Although the instrument and its accessories are severely inspected before shipment from factory,

visuall y ch eck th e it ems a nd th eir q uanti ties .

Keep the ship ping cart on fo r reus e at a later sta ge.

1) Visually check the external view of the instrument and its accessories.

2) Check the qua ntiti es of the li st in a ccor danc e with the fo llowi ng li st:

Table 1.1 List of Standard Accessories

Item Reference No. Q’ty Remarks

Operation manual 0PA00007 1 This item means this booklet.

Power cord 0AC00001 1 Power cord with 3-prong plug with third

for grounding

Power cord plug

adapter

0AA00002 1 This adapter makes it possible to use

the 3-prong plug power cord with

2-prong AC output.

Attached to the power cord 3-

prong plug when shipping

from factory

Measuring rod

(Red)

0GE00002 1 A measuring rod with a 1-

meter cord to be connected to the Rx ‘‑’

socket.

Measuring rod

(Black)

0GE00001 1 A measuring rod with a 1-

meter cord to be connected to the Rx ‘+’

socket.

Shorting plug 0GZ00003 1 A plug to be plugged to the

HV-EN so cket of the r ear of

the instr umen t. It i s plug ged

to the HV-EN socket when

shipping from factory.

Important!

When the accessory shorting plug is not plugged to the HV-EN socket on the rear of the

instrument, the measuring high voltage is not output.

Note: The shorting plug is plugged to the HV-EN socket when shipping from factory.

CAUTION

When plugging the shorting plug, make sure that the power is turned off, otherwise,

there is an el ectr ic sh ock h azar d.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 12

2

Upon checking the instrument and accessories, if any damage is found, immediate ly contact

your dealer or Hioki representative.

1.2 Operating AC Line Voltage

The super meg o h memeter c a n b e o p er a ted from on e o f th e following AC power s o u r c e w hen the

VOLTAGE SELECTOR switches are set accordingly.

AC Line Voltage

Frequency

100 V ±10% 50/60 Hz

120 V ±10% 50/60 Hz

220 V ±10% 50/60 Hz

240 V +10V,‑10% 50/60 Hz

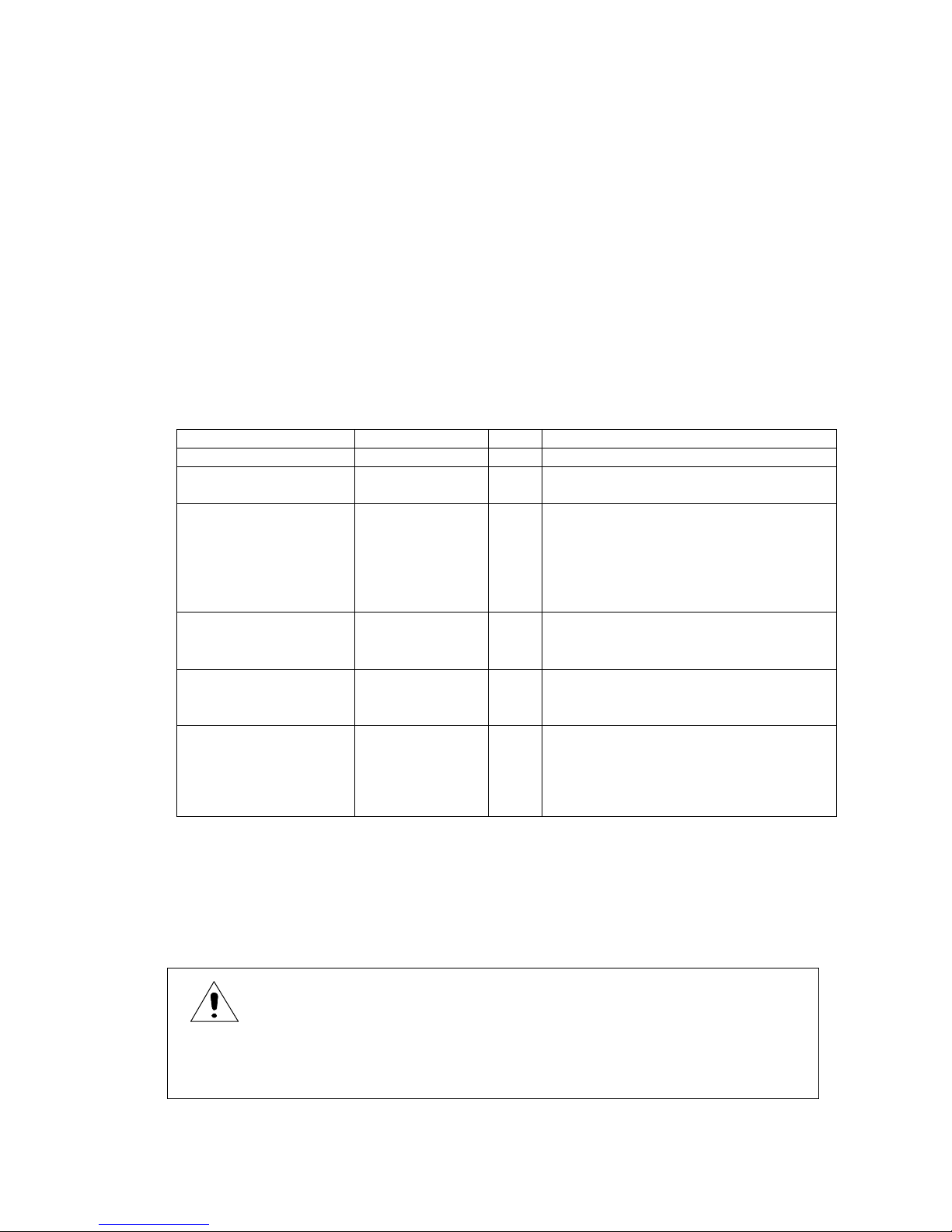

1.3 Setting VOLTAGE SELECTOR Switches

The super megohmmeter can be operated fro m one of the AC lin e voltages of 100 V, 120 V, 220 V

and 240 V by setting the VOLTAGE SE LECTOR switch es to the specific position s, respectively.

Confirm the switch setting to the specific positions in accordance with Fig. 1.1.

If they are not set properly, correct their positions, accordingly.

To change the position of the switch, insert the tip of a flat blade screwdriver into the slot of the

switch lever, and slide the lever upward or downward.

CAUTION

Before connecting the power cord to the AC outlet socket, confirm tha

t the VOLTAGE

SELECTOR switches on the rear panel are set to the positions, accordingly (See 1.3

Setting the VOLTAGE SELECTOR Switches.).

If the switches are set to wrong positions, a fire or burn may occur.

CAUTION

To chan ge th e VOLT ASGE SELE CTOR swit ch po sitio ns, b e sur e to

Unplu g the po wer co rd p lug fr om th e AC li ne soc ket to prev ent a

possible damage.

When th e swi tch po siti on is chan ged wh ile t he vo ltag e is on , the

Switch contacts will be damaged.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 13

3

V

O

L

T

A

G

E

S

E

L

E

C

T

O

R

100V

120V

220V

240V

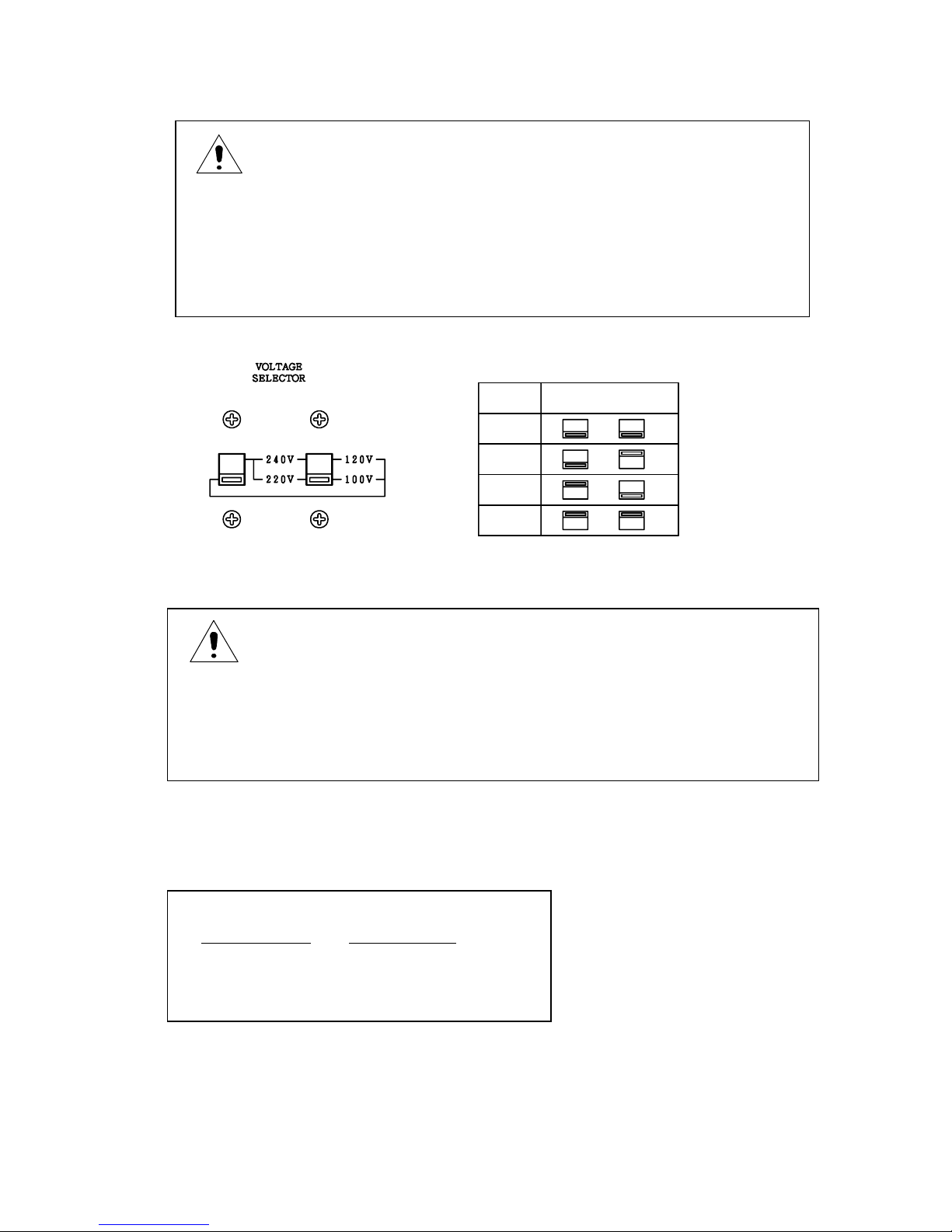

Fig. 1.1 VOLTAGE SELECTOR Switch Setting

1.4 Checking the Fuse Amperage

The fuse holder of the instrument contains a time lag fuse of the following amperage:

CAUTION

The VOLTAGE SELECTOR switches have two positions –

up and down. Slide the

switch lever to either position until it stops.

Do not leave the lever at a neutral position. If the lever is set at a neutral position, a

normal function cannot be obtained, and it will cause a failure.

CAUTION

When the VOLTAGE SELECTOR switch position is changed, fuse amperage must be

changed t o me et the r equ irem ents of the n ew AC line v olt age.

Incorr ect fu se am perag e wil l cau se a f ailur e of th e inst rum ent.

Time Lag Fuse

AC Line Voltage

Fuse Amperage

100 V/120 V 0.4 A

220 V/240 V 0.2 A

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 14

4

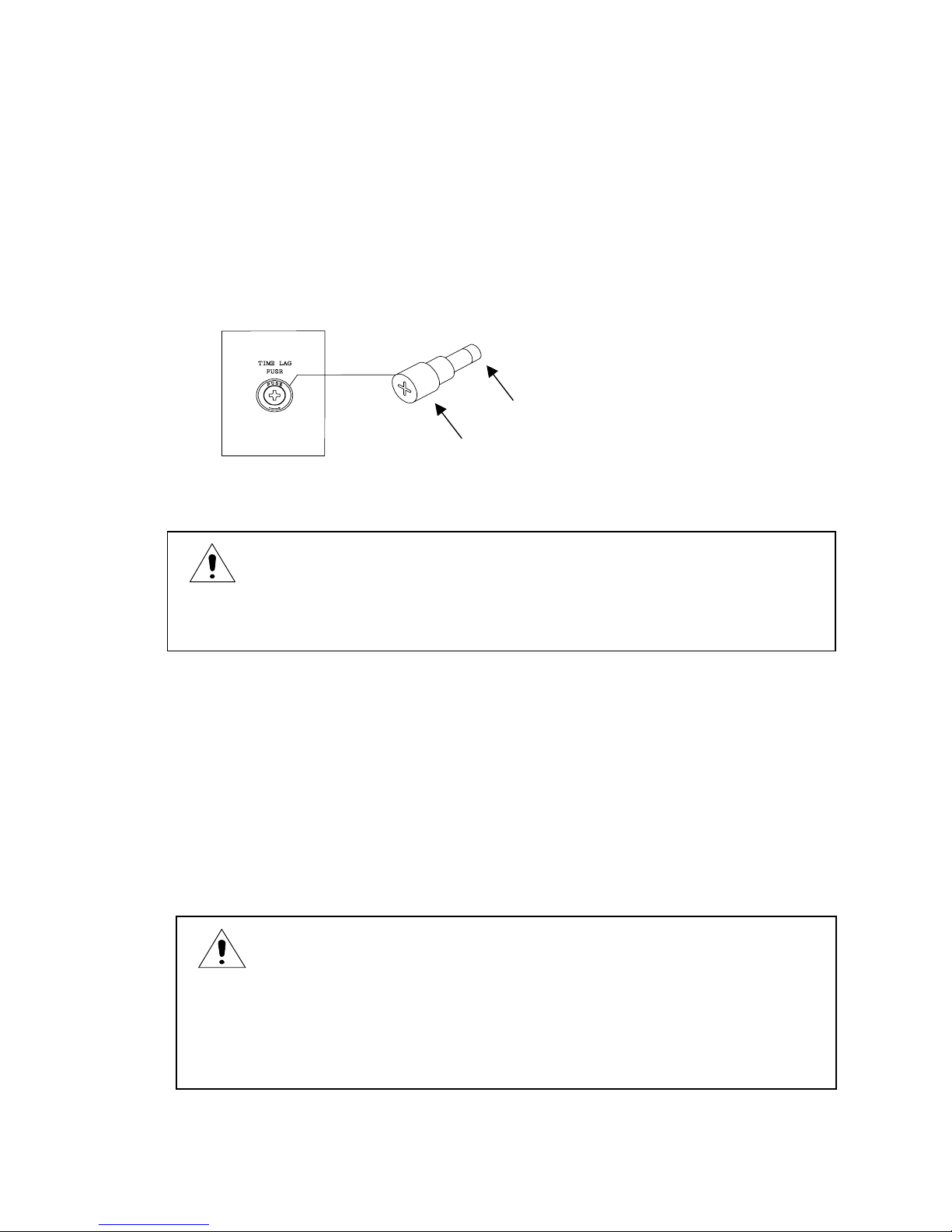

Fuse Replacement

The fuse is inserted in the FUSE holder (Fig. 1.2) on the rear of the unit.

Remove the cap, and replace the fuse with a new one with a correct amperage.

To remove the cap of the fuse holder, use a 4 mm Phillips screwdriver, and turn the cap

counterclockwise.

To set the cap in position, insert the cap, holding the fuse in to the holder , and turn it wi th the

screwdriver.

Fig. 1.2 Fuse Holder and Fuse Replacement

1.5 Grounding the Chassis

To avoid an electr ical shock accide nt, connect the GND terminal on the rear of the u nit to the

ground prong of the power cord to the ground post of the AC line system.

The round prong of the 3-pron g plug of the power cord is th e ground prong.

It is recommended to use an AC line socket with its third contact grounded for connection of the

accessory 3-prong power cord.

To use the accessory 3-prong to 2-prong a dapter to connect the power cord to a 2-co ntact AC line

socket, make sure to ground the green tab of the adapter.

WARNING

To replace or check the fuse, make sure to disconnect the power cord from the AC line

socket. If not, ther e is a fe ar of el ect rical shoc k.

WARNING

To prevent an accident, connect the ground prong of the power cord

Plug to the ground post of the AC line system. If it is impossible to

ground the ground prong of the power cord plug, be sure to connect

the GND terminal on the rear of the unit.

Fuse

Ca

p

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 15

5

1.6 Warm-up Period

To obtain the performance of published specifications, allow the SM-8200 Series super

megohmmeter to warm for a minimum of 30 minutes.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 16

6

2. SPECIFICATIONS

2.1 Measuring Performance

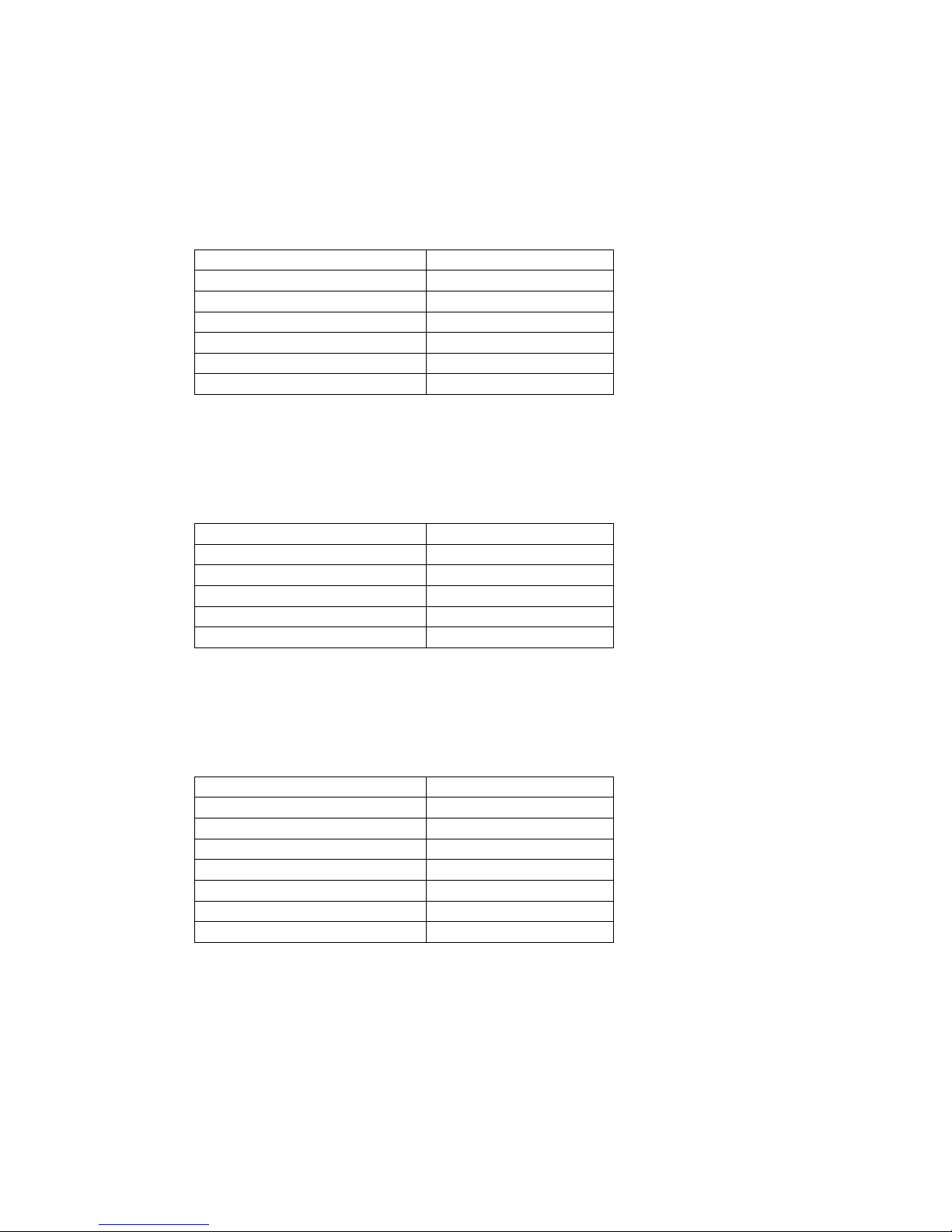

1) Electrical Resistance Measurement

SM-8213

Measuring Range (Ω)

Measuring Voltage

5.0 × 105 to 2 × 1012

100 V

2.5 × 105 to 1 × 1012

50 V

1.25 × 105 to 5 × 1011

25 V

7.5 × 104 to 3 × 1011

15 V

5.0 × 104 to 2 × 1011

10 V

2.5 × 104 to 1 × 1011

5 V

Accuracy of measuring voltage: ±3% of set value

Measuring output current: 50 mA maximum

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range)

SM-8215

Measuring Range (Ω)

Measuring Voltage

5.0 × 106 to 2 × 1013

1000 V

2.5 × 106 to 1 × 1013

500 V

1.25 × 106 to 5 × 1012

250 V

5.0 × 105 to 2 × 1012

100 V

2.5 × 105 to 1 × 1012

50 V

Accuracy of measuring voltage: ±3% of set value

Measuring output current: 2 mA maximum

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range)

SM-8220

Measuring Range (Ω)

Measuring Voltage

5.0 × 106 to 2 × 1016

1000 V

2.5 × 106 to 1 × 1016

500 V

1.25 × 106 to 5 × 1015

250 V

5.0 × 105 to 2 × 1015

100 V

2.5 × 105 to 1 × 1015

50 V

1.25 × 105 to 5 × 1014

25 V

5.0 × 104 to 2 × 1014

10 V

Accuracy of measuring voltage: ±3% of set value

Measuring output current: 2 mA maximum

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range) except for×10

8

range.

±20% for×10

8

range

2) Measuring Time (Sampling Cycle)

Approx. 200 ms

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 17

7

2.2 Function Specifications

1) CHARGE Function

This function charges the sample to be measured by applying the Selected measuring

voltage when the CHARGE switch is pushed.

Internal Resistance

SM-8213: Approx. 0Ω

SM-8215: Approx. 30kΩ

SM-8220: Approx. 30kΩ

2) DISCHARGE Function

This function discharges a residual voltage on the sample after measurement when the

DISCHARGE switch is pushed.

Internal Resistance

All models: Approx. 100kΩ

3) HV-EN (High Voltage Enable) – Interlocking Function

This function externally controls to make the output of mea suri ng vo lta ge on or off.

This function is used in combination with an interlock switch on the measuring jig so as to

preven t an el ectr ical s hoc k duri ng m easur em ent.

4) TIMER Function

This function determines the voltage charging time and the measuring time, respectively,

within a range from 1 to 999 s econds. Aft er the set time is up, the measur ed value is shown

held.

5) COMPARISON and JUDGMEN T Function

This function makes a comparison of the measured value with the preset judgment value,

and if the measured value is less than the judgment level, it makes the alert buzzer sound,

closing the incorporated relay contacts.

6) RS-232C Interface Func tion

This function allows a control of an optional prin ter via RS-232C interfac e.

The optional printer prints measured da ta.

7) REMOTE MEASUREMENT Function

This function allows a remotely controlled measurement by means of a remote switch.

2.3 Other Electrical and Physical Data

1) Envi ronm ent al te mper atu re and Hum idit y

Operation: 0 to 40℃ (SM-8213/8215), less than 85% RH

0 to 35℃ (SM-8220), less than 85% RH

Storage: ‑5 to, less than 85% RH

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 18

8

2) Power Requirements

AC 100 V, 120 V, 220 V, ±10%, 240 V +10 V,‑10% 50/60 Hz

3) Power Consumption

Approx. 25 VA

4) Dimensions

Approx. 284 (W) × 139 (H)×215 (D) mm

Also, see 11. EXTERNAL VIEW for external appearance.

5) Weight

Approx. 4.3 kg

2.4 Optional Functions and Accessories

In addition to the standard accessories shown in 1.1 Unpacki ng and Ch ecking of t he Conten ts

and Table 1.1 List of Standard Accessories, the following two groups of optiona l acces sories are

available to expand the applica tions of the SM-8200 S eries super megohmm eters.

1) Options – designed exclusive for the SM-8200 Series

Name Model Remarks

DC signa l out put ( resis tan ce val ue

proportional or linear signal)

RP-8000*

Factory installed

DC signal output (1/R sign al) RI-8000*

Factory installed

Guard chips 0GZ00001

See 9.1.

Printer 0KC00001

Printer cable 0GC00004

Printer roll chart P000119

Printer ribbon cassette P000124

RS-232C cable (DOS/V) 0GC00002

HV-EN connection plug wit h cord 0GZ00002

Time lag fuse, 0.4 A, 5 pcs./pack 0AE00001

100 V/120 V line

Time lag fuse, 0.2 A, 5 pcs./pack 0AE00002

220 V/240 V line

*Either one of the RP-8000 or RI-8000 optional function can be installed in a single

SM-8200 Series unit.

2) Options – designed for common to SM- 8200 Series, SM-8216, and

SM-8000 Series super megohmmeters.

Name Model Description

Electrode for plate samples SME-8310

Electrode for plate sampl es SME-8311

With surface/volumetric

selector, interlock function

Weight electrode SME-8320 With surfac e/volumetric

Selector. Needs shield box.

Shield box SME-8350 Electro magnetic shieldin g

Mercury electrodes SME-8322 Stai nless steel rin g electro des designed

to put mercury

between them.

-- continu ed --

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 19

9

Name Model Description

Electro de for surf ace

resistance measurement

SME-8301 Simplifi ed electrode for surf ace

resistance measurement

Electro de for surf ace

resistance measurement

SME-8302 Simplified electrode for curved surface

resistance

measurement

Electrodes for liquid sample

measur em ent

SME-8330 Capacit y, approx. 25 mL

Electro de con stant : Appro x.

500 cm

Electro des for conti nuou s

liquid sample

measurement

SME-8335 Capacit y, approx. 30 mL

Electro de con stant : Appro x.

75 cm

Electro des fo r chip

capacitors

SME-8360 Chip capacito r measurement

Other types o f opt iona l el ectro des a nd dev ic es ar e avai labl e upon req uest .

Contact your dealer or Hioki representative.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 20

10

3. OPEARATING PRINCIPLE

The SM-8200 Series super megohmmeters consist of a constant voltage power supply and a high

sensitive current measuring section to be combined to compose a resistance measuring circuit.

The current measuring section is composed of a current detective resistor, low drift voltage

amplifier and an integrator-type A/D converter.

A measured resistance value is computation-processed by a CPU to display the result on a liquid

crystal display (LCD).

Fig. 3.1 shows a circuit composition of the SM-8200 Series.

Fig. 3.1 Circuit Composition

Amplifier

+

−

C

i

r

c

u

i

t

D

i

s

c

h

a

r

g

e

Supply

Power

High Voltage

Power Supply

Switches

VOLTAGE SELECTOR

Control Keys

Signal Output

DC

A/D

Converter

DC

Current‑to Voltager

AC Line Source

(Option)

Discharge

Controller

Converte

RANGE Selector

RS−232C

(−)

(+)

DISCHARGE

DISCHARGE

CHARGE

CHARGE

MEAS

MEAS

LCD

CPU

Rx

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 21

11

4. FAMILIARIZATION WITH CONTROLS AND PARTS

4.1 Front Panel

The figure below shows the front panel of the SM-8200 Series. However, note that the values for

the two knobs on the right are represent ed by those of the SM-8213.

Fig. 4.1 Front Panel

① LCD Display: This is a 320×240 dot liqui d crystal display module.

This shows measured results, measuring conditions and a variety of

data settings.

②POWER Sw itch: This is a power switc h to turn on or off the in stru ments.

A press of this switch in the released position turns ON the unit.

A press of this switch in the pushed position turns OFF the unit.

③ V. OUT Indicator: This indicator lights when t he Rx ‑/+measuring

terminals carry a measuring voltage across them.

④

Rx ‑/+Measuring Terminals: These terminals carry a selected measuring

voltage across them to measure the insulation resistance of a sample

via a pair of measuring rods or electrodes.

Note: Each of the terminals is incorporated with a plug insertion

detector switch. Unless otherwise this switch is turned on by a

full insertion of the plug of the measuring rod or electrode, the

output voltage circuit cannot be completed – no output.

⑤

SELECT Switch: This switch moves the curs or in t he LCD dis play to the

desired item set it.

This switch also acts as a STOP switch; this switch makes the voltage

①

⑪

⑩

⑨⑧⑦

⑥⑤

④

③

②

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 22

12

on the Rx ‑/+

measuring terminals OFF when it is pressed while

the measuring voltage is being applied.

⑥

DOWN Switch: This switch decreases the value to set each time it is

pressed.

⑦

UP Switch: This switch increases the value to set each time it is pressed.

⑧

CHARGE Switch: This switch applies the measuring voltage across the Rx

measuring terminals to charge the sample to be measured when it is

pressed. During the charging perio d, the V. OUT indi cator lights.

the next press of this switch discharges the sample, turning off the

V. OUT indicator.

Note: When the timer function is used to determine the charging

period, the measurement automatically starts when the set

time is up.

⑨

MEASUR E/D ISCH ARGE Swit ch: Th is swit ch st arts a measu rem ent of the

sample in connection, when it is pressed, turning on the

incorporated indicator and the V. OUT indicator.

The next press of this switch discharges the sample, turning off the

two indicators.

⑩

VOLTAGE Selector Switch: This switch selects the voltage to be applied

across the Rx +/‑

measuring terminals. The arrow on the knob shows

a voltage to output.

⑪RANGE Selector Switch: This switch selects a factor for the m easured

value.

The selected factor is also shown at the ×10 multiplier area.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 23

13

⑱⑰ ⑯ ⑮

⑭⑬⑫

4.2 Rear Panel

The figure below shows the rear pan el of the SM-8200 Series. However, not e

that the VOLTAGE SE LECTOR switches are set fo r the operation from 100 V

AC line.

Fig. 4.2 Rear Panel

⑫

VOLTAGE SELE CTO R Swi tches : Thes e tw o swit ches are t o be s et in

accordance with the local AC line voltage (50 o r 60 Hz) for the

instrument.

For a proper setting, see 1.3 Setting VOLTAGE SELECTOR Switches.

For line voltage change between 100 V/120 V an d 220 V/240 V, the

power fuse amperage must be also changed accordingly.

⑬

AC LINE Receptacle:This connects the accessory power cord.

⑭

TIME LAG FUSE Holder: This holder contains a time lag fuse in a glass

tube. The a mper age o f the f use mu st a gree w ith t he lo cal AC l ine

voltage from which the unit is powered.

AC Line Voltage

Fuse Amperage

100 V/120 V (50/60 Hz) 0.4 A

220 V/240 V (50/60 Hz) 0.2 A

Note: When the AC line voltage for the unit is changed after receipt of

your super megohmmeter, check the fuse amperage.

⑮GND Terminal: This is a ground terminal connected to the chassis of the

unit.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 24

14

⑯

External Input/Output Terminal Block: This terminal block ca rries

signals measured result judgment outputs, optional DC output, and

remote signal input.

For details, see the following sections;

6.5 Comparison and Judgment Function

8. MEMORY CONTROLLED MEASUREMENT

9.2 DC Signal Output

⑰

HV-EN (High Voltage Enable) Interlocking Connector: This connector is

provided for connection of an external interlocking switch on the

measuring jig designed to block the ap plication of a hi gh voltage

across the Rx +/‑

measuring terminals ④for safety of the operator

when the switch is in the off position.

If such a switch is not provided, keep this connector plugged with

the accessory shorting plug, instead.

⑱

RS-232C Interface Con nector: This conn ector is provided fo r RS-232C

interfacing. For details, see 7. RS-232C INTERFACE CONNECTIONS.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 25

15

4.3 Measuring Display

In the measuring mode, the LCD display shows the resultant measured

resistance value and its NO/GO judgment, as well as the measuring voltage

and time.

Fig. 4.3

① Test Voltage Indication: This shows the test voltage set with the VOLTAGE

selector switch.

②

Measured Resistance Indication: This shows the measured resistance in

real time. When the measuring time is up, the final value is held

until the next measurement will start.

③

Measuring Range Indication: This shows the measuring range set with the

RANGE selector switch.

④

Analog Indicator: This shows the measured resistance value in analog

referred to the analog resistance scale.

⑤

Analog Resistance Scale: This shows the scale for the analog indicator

reading. When the measuring voltage is changed, the scale and

values are changed, accordingly.

⑥NO/GO Comparison Judgment Indication: When the NO/GO comparison

judgment function is set on, a judgment of resultant resistance can

be done ref erre d to pr eset h igh /low li mits . When the c ompar ison

judgment value is set to 000, the function becomes off.

⑦Timer Count Indication: This is a count-down timer shown in seconds.

When the timer is set to 000 sec., the function becomes invalid.

⑧

Comparison Judgment Value Mark: When the comparison judgment

function is set on, a heart mark appears at a position showing the

set value on the measured resistance bar graph.

⑨

Measured Resistance Bar Graph: This shows the measured resistance as

a length of the bar.

100V

⑦⑥

⑨

⑧

⑤

④

③②①

3

s

MΩ

10

2010521.5

000

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 26

16

4.4 Measuring Condition Setting Display

The LCD display showing the measuring condition setting.

Fig. 4.4

⑩Status and Mode Notice:When the MEASURE/DISCHARGE selector

switch is set to the DISCHARGE position, press the SELECT switch to

enter the setting mode, and the selected mode is shown in this box.

Each time the SELECT switch is pressed, the mode is changed in

the order; C. SET (voltage charging time setting mode) →M. SET

(measuring time setting mode) →COMP (measured value comparison

level setting mode) → BUZZ (buzzer sound level setting mode) →

(blank – measuring display).

When the RANGE selector is set to the CAL position, CAL1is shown.

With the CAL1 status shown, the press of the SELECT switch changes

the status to CAL2 .

⑪Highlighted Compa rison and Judgment Val ue: When the COMP (co mparison

and judging level setting mode) is selected, the value is shown high lighted, and the it can be changed with the UP and DOWN switches.

⑫Comparison and Judgment Value Mark: This heart mark is shown when the

comparison and judgment function is set to on, showing the position

of the comparison and judgment level.

⑬Highlighted Judgment value: This shows the judgment level which can be

changed with the UP/DOWN switches.

⑭LOCK (Interlocking) Notice: This shows that preparation for the measure ment is not ready, yet. This notice is shown when the interlocking

function is used to show that the HV-EN connector is free, and/or the

Rx ‑/+measuring terminals are free.

When the LOCK notice is shown, the MEASURE and CHARGE switches

become inoperative.

LOCK

100V

⑭

⑬

⑫

⑪⑩

3

M.SET

s

MΩ

10

2010521.5

000

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 27

17

4.5 Meanings of the Status and Mode Notices

This describes the meanings of the status and mode notice in the lower left

corner of the LC D di spla y.

1) LOCK (Interlocking): The test voltag e applying circuit is int erlocked, an

measurement is not ready, yet. This notice is shown when the

interlocking function is in use, but the HV-EN plug or measuring rod

plug is not plugged into the connector.

When the LOCK is shown, the MEASURE and CHARGE switches become

inoperative.

2) CAL1 (Calibration-1): This is shown when the RANGE selector switch is set

to the CAL position.

3) CAL2 (Calibration-2): This is shown when the SELECT switch is pushed

while the CAL1 notice is shown.

4) C. SET (Measuring voltage charging time setting mode): The time can be

adjusted within a range from 0 to 999 seconds.

5) M. SET (Measuring time setting mode): The time can be adjusted within a

range from 0 to 999 seconds.

6) COMP (Comparison judgment value setting mode): The value can be set

within a range from the minimum value for the range to 10 times the

value.

7) BUZZ (Buzzer ON/OFF setting mode): The buzzer can be set ON or OFF when

the resultant comparison judgment is NO.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 28

18

5. PREPARA TION FOR A MEASUR EMENT

WARNING

Make sure, before turning the instrument on, that the VOLTAGE

SELECTOR switches on the rear of the unit are properly set to the

positions in agreement with the local AC line voltage. If the agree ment is failed, the unit may br eak a fire or burning.

WARNING

Be sure to connect the ground prong of the power cord plug to

prevent danger. If grounding of the ground prong is impossible,

connect GND terminal to the ground post of the power line system.

Note: For safety, the measuring voltage cannot be output unless otherwise

the accessory shorting plug is plugged into the HV-EN connector on

the rear of the unit. During measurement, the shorting plug must

be kept plugged in

.

WARNING

Before trying to plug the shorting plug into the HV-EN connector,

be sure to turn the POWER switch OFF.

5.1 Preparation

Confirm the setting of the instrument in the order shown below.

1) Confirm that the VOLTAGE SELECTOR switches on the rear of the unit

are set to the positions in accordance with the local AC line voltage from

whic h the un it is powere d (See 1.3 Setting the VOLTAGE SELECTOR

Switches.).

2) Confirm that the POWER switch of the unit is positioned at the OFF

(released) position. Note that if the switch is in the ON position, it is

depressed.

3) Plug the accessory power cord into the AC LINE receptacle on the rear of

the unit. Also, plug the plug on the other end of the cord into the

commercial AC line socket.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 29

19

77

8802500

000

CAL2

100V

.5 1 2 5 1020

10

MΩ

CAL

SELECT MEASURE/DISCHARGECHARGE

s

UPDOWN

RANGE

VOLTAGE

4) Confirm that the accessory shorting plug is inserted into HV-EN

connector on the rear the unit.

5) Leave the Rx ‑/+ measuring terminals free at this stage – do not connect

the measuring rods and the sample to be measured to the terminals.

6) Set the RANGE selector switch to the ×1 p osition – the minimum

Multiplier.

7) Set the VOLTAGE SELECTOR switches to the voltage to be applied to

the sample.

8) Turn the POWER switch ON.

Allow the unit to warm for a minimum of 30 seconds to obtain the

specified performance. However, a measurement can be done after a

warm-up of several seconds.

5.2 Calibration

1) CAL1 Calibration*1

Set the RANGE selector switch to the CAL position.

The LCD display shows the CAL1 message in the lower left area of the

screen. When the unit is normal, the measured value indication area

should show a value wi thin a range from .970 (-3%)to 1.03 (+3%).

If the CAL2 calibration is not needed, set the RANGE switch to a position

other than the CAL .

2) CAL2 Calibration*2

To perform the CAL2 calibration, press the SELECT switch to start the

CAL2, replacing the CAL1 message with the CAL2 .

Set the RANGE switch to the ×102 position .

When the 5-digit value indication on the LCD display is stabilized with its

5 th place within a value of 4 peak to peak, the unit is normal.

To finish the CAL2 calibration, press the SELECT switch.

Example:The CAL2 calibration Note:

*1

This function is intended to check

the accuracy of the measuring voltage

and the integrity of the current

measuring circuit.

*2

This function is intended to measure

the offset. An offset value is stored in

E

2

PROM and is subtracted from

subsequent the measured value.

Fig.5.2.1

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 30

20

VOLTAGE SELCTOR switch setting

HV-EN shorting plug insertion

VOLTAGE SELCTOR switch setting

HV-EN shorting plug insertion

Measuring Vo ltage Setting

Range Sett ing

Timer Set

ting -- (See 6.6.1)

Comparison and Judgment Va lue Setting

-- (See 6.6.2)

-- See 6.3.

-- See 6.2.

5.3 Basic Procedures for a Measurement

<Preparation>

<Measurement>

<End>

Power ON

VOLTAGE SELCTO R Switch Set ting

30-minute warm-up

Calibratio n

Sample Connection

Control Set ting

Preparatory Voltage Charging

Measurement -- See 6.1.

Residual Voltage Discharge

End

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 31

21

6. MEASUR EMENT

6.1 Measuring Method

1) Plug the accessory measuring rods to the Rx +/‑ measuring terminals

until they are stopped.

■Red measu ring rod to the Rx ‑ measuring terminal

■Black measuri ng rod to the Rx + measur ing terminal

Note tha t each termin al has an incomp lete plugg ing detect ion switch.

If the rod is incompletely plugged, the switch is left open, and the

measuring voltage cannot be output.

2) Connect the measuring rods to the sample to measure.

Note 1: When one end of the sample is grounded, connect the black

measuring rod to the grounded end. (See Fig. 6.1.1.)

Note 2: When one end of the sample has a larger surface area which is

exposed to atmosphere than the other end, connect the black

measuring rod to such an end. (See Fig. 6.1.2.)

Fig. 6.1.1 Fig. 6.1.2

3) Set the VOLTAGE selector switch to the voltage to be used for the

measurement.

4) Set the RANGE selector switch to the range to be expected. If there is no

idea about the approximate insulation value of the sample, set the

selector to the × 1 range. Press the MEASURE switch to start a

measurement. Change the position of the RANGE selector switch to find

the most appropriate position to read the measured value. If the selector

is set to a position out of the measured value, the indicated value is

shown blinking.

Note 1: When the analog indicating needle is shown leftward, select a

larger range, while if the needle is shown rightward, select a

smaller range.

Note 2: To measure a capacitive sa mple within a possible s hortest time,

press the CHARGE switch to change the sample as much as

possible. Then, press the MEASURE switch to start a measurement.

During the measurement, the measured value will be changed with

time. In such a state, the elapsed time after voltage charging

試料

黒色測定棒

赤色測定棒

赤色測定棒

黒色測定棒

試料

Red

Measuring

Bar (“– “)

Black

Measuring

Bar (“+”)

Sample

Red Measuring

Bar (

“–“)

Black Measuring

Bar (“+“)

Sample

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 32

22

becomes a significant parameter for the measuring conditions. In

most cases, the value of 1 minute after voltage charging is read as

a 1 minute rate value. The integrated timer can determine the

value at 1 minute after voltage charging. For details, see 6.6.

Note 3: When a measuring jig is used, it is recommend

ed to provide an

interlocking switch with it for safety. For the interlocking, utilize

the HV-EN (high voltage enable) socket on the rear of the unit.

This makes it possible to disarm the jig when the cover of the jig is

opened. For details, see 6.4.

6.2 Discharge Function

This function is intended to discharge the change on the sample connected

to the Rx ‑/+ measuring termina ls. Discharging is automatically performed

each time the super megohmmeter is turned on, and the measurement

is ended. The sample after measurement must be disconnected from the

terminals after the discharging func tion is performed.

Status of the MEASURE/DISCHARGE switch can be known by the

indicator.

Indicator

ON ------ MEASURE

OFF ------ DISCHARGE

In the DISCHARGE status, a resistor of approx. 100 kΩ is internally

inserted to discharge the charge of the sample.

A time required to discharge the charge of the sample depends on the

capacitance of the sample. When the capacitance of the sample is 1μF, it

takes approx. 5 seconds to reduce the residual voltage down to 5% of the

charged value.

Note: The discharge function does not work if the POWER switch is kept

OFF.

6.3 Charge Function

To measure a capacitive sample, charge it with the measuring voltage by

pressing the CHARGE switch. Then, the charge of the sample is completed

within several seconds.

There is no rule to determ ine the charging time, it is necessary to set it to

a fixed time to make the measur ing conditions unchanged among samples.

WARNING

When the super megohmmeter is in the charge status do not touch

the Rx ‑/+ measuring terminals a nd the sample being cha rged.

The measuring voltage selected with the VOLTAGE switch is directly

applied to these parts because there is a fear of electrical shock.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 33

23

6.4 Interlocking Function – Using the HV-EN Connector

The super megohmmeter generates a high voltage to be used as a testing

power source. It is dangerous if this measuring voltage is output to the

sample not ready for measurement, yet. To protect the operator from a

hazard of electric al shock, the HV-EN (high voltage enable ) connector is

prov ided on the rear of the unit to p rovide an inte rlocking fu nction in

combination with a measuring jig.

If a measurement does not use a jig with an interlocking mechanism, keep

the HV-EN connector plugged with the accessory shorting plug.

Usage of the HV-EN Connector for Interlocking

Connect the HV-EN connector to a switch to be actuated by the

interlocking mechanism of a measuring jig via an optionally available

HV-EN plug connected with a cord. Fig. 6.4.1 shows an example

interlocking circuit.

The optional accessories shown below have a safety interlocking switch.

SME-8310 – Electrode for plate samples

SME-8311 – Electrode for plate samples

SME-8350 – Shield box

Connect the plug at the end of the measuring cord of the optional

accessory to the HV-EN connector on the rear of the unit.

For connection of a customer designed measuring jig to the HV-EN

connector, use an optional HV-EN plug.

Fig. 6.4.1

Optional HV-EN Plug

(User should solder a

proper cord to the plug.)

Interlocking

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 34

24

6.5 Comparison and Judgment Function

This function is provided to sound a built-in buzzer, and turn on the

COMP OUT G/+ terminals when the measured insulation resistance is

lower than the preset judgment value and make the COMP OUT G/+

terminals are of open collector as shown as an equivalent circuit in Fig.

6.5.3. Use this circuit within the conditions shown below:

Voltage: 50 V or less

Current: 50 mA or less

Fig. 6.5.1 shows a circuit diagram for connection with the COMP OUT

terminals.

Fig. 6.5.2 shows the externa l input/outpu t termina l block, includ ing the

COMP OUT G/+ terminals.

Fig. 6.5.1

Fig. 6.5.2 Fig. 6.5.3

G

+

COMP OUT

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 35

25

6.6 Setting a Variety of Functions

A variety of useful functions can be set when the RANGE selector switch is

set to any position other than the CAL , and by using the SELECT, UP and

DOWN switches.

Each time the SELECT switch is pushed, the LCD display is changed in the

order of the Me asuring Display →C. SET → M. SET → COMP.→ BU ZZ

→ Measuring Display .

C. SET : Charging timer setting

M. SET : Measuring time setting

COMP. : GO/NO ju dgment leve l setting

BUZZ : Buzzer sound ON/OFF setting

6.6.1 Setting the Timer

Example: Setting a measuring time to 50 seconds

Fig. 6.6.1

1) Press the SELECT switch twice to show the M. SET indication in the

lower left area of the LCD for the measuring timer setting mode.

2) Using the UP and DOWN switches, set the time indication in the upper

center area of the display to 050 seconds.

3) Press the SELECT switch 3 times to return to the measuring display.

To accelerate the change of a value, keep the corresponding UP or DOWN

switch pushed.

6.6.2 Setting the Comparison GO/NO Judging Level

Example: Setting a judgment of NO<100MΩ≦GO for 100 V test voltage

Fig. 6.6.2

VOLTAGE

RANGE

050

DOWN UP

2

100

2

×10

M.SET

s

CHARGE MEASURE/DISCHARGESELECT

MΩ

10

2010521.5

100V

VOLTAGE

RANGE

DOWN UP

100

2

2

×10

COMP

s

CHARGE MEASURE/DISCHARGESELECT

MΩ

10

2010521.5

000

100V

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 36

26

1) Set the VOLTAGE selector switch to 100 V.

2) Set the RANGE selector switch to×10

2

.

3) Press the SELECT switch 3 times to show the COMP indication in the

lower lef t area of the LCD for the compar ison GO/NO jud gment level .

4) Using the UP and DOWN switches, set the GO/NO judgment level to

100×10

2

MΩ.

5) Press the SELECT switch twice to return to the measuring display.

To accelerate the change of a value, keep the corresponding UP or DOWN

switch pushed.

Note : The comparis on GO/NO judg ment level set ting can be e ffective for

the currently set RANGE and VOLTAGE values, only. If setting is

required for other RANGE and VOLTAGE values , set desired RANGE

and VOLTAGE, first.

6.6.3 Setting Buzzer Sound ON/OFF

Fig. 6.6.3

1) Press the SELECT switch 4 times to show the BUZZ indication in the

lower left area of the LCD for the buzzer sound ON/OFF setting.

2) Using the UP and DOWN switches, set ON or OFF .

3) Press the SELECT switch once to return to the measuring display.

6.6.4 Setting Charging Time, Measuring Time, Comparison GO/NO

Judging Level and Buzzer Sound ON/OFF

Example: Setting for measuring co nditions below:

Charging Time: 10 seconds

Measuring Time: 50 seconds

Comparison Level: NO<100MΩ≦GO ju dgment

Buzzer Sound: Buzzer sounds when NO judgment is resulted.

RANGE Position: ×10

2

VOLTAGE Position: 100 V

VOLTAGE

RANGE

DOWN UP

100

2

×10

2

ONBUZZ

CHARGE MEASURE/DISCHARGESELECT

s

MΩ

10

2010521.5

000

100V

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 37

27

Fig. 6.6.4

1) Set the VOLTAGE selector switch to 100 V .

2) Set the RANGE selector switch to ×102 .

3) Press the SELECT switch to show the C. SET indication for charging

time setting mode.

4) Using the UP or DOWN switch, set the charging time to 010 seconds.

(Fig. 6.6.4)

5) Press the SELECT switch to enter the value of 010. This action provides

the measuring time setting mode, showing the M. SET indication.

6) Using the UP and/or DOWN switches, set the measuring time to 050

seconds.

7) When this value is OK, press the SELECT switch to enter it. This action

provides the judgment level setting mode, showing the COMP indication.

8) Using the UP and/or DOWN switches, set the judgment level to

100×102 MΩ.(Fig. 6.6.2)

9) When this level is OK, press the SELECT switch to enter it. This action

provides the buzzer sound on/off setting mode, showing the BUZZ

indication.

10) Using the UP and/or DOWN switches, set ON or OFF for the buzzer.

(Fig. 6.6.3)

11) Press the SELECT switch to end the measuring condition setting mode,

and go back to the measurement screen.

After setting the measuring conditions as shown in the example, press

the CHARGE switch. Then, the measurement starts after a charging

period of 10 seconds.

VOLTAGE

RANGE

DOWN U P

2

100

2

×10

010

C.SET

s

CHARGE MEASURE/DISCHA RGESELECT

MΩ

10

2010521.5

100V

Note 1: The set measuring cond

itions are stored in the memory, and

the contents are kept backed up even if the power is turned

off.

Note 2: The c omparison jud gment leve l settings ar e valid only f or the

range and test voltage used for setting. For other ranges and

test voltages, change the settings, accordingly.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 38

28

Cn

Rn

C3C2C1

R3R2R1

C0

R0

6.7 C hanges in the Cu rrent Flow ing th rough an Insulator

In insulation resistance measurements, a large amount of current flows

upon the application of the test voltage to the insulator. The current

gradually reduces its value with time, but it takes a time until the value

becomes stable and fixed. This phenomena is due to the combination of the

charging current, absorption current, and leakage current, and it is

generally called dielectric absorption phenomena. The equivalent circuit of

an insulator is considered as shown in Fig. 6.7.1.

Fig. 6.7.1

When a voltage is applied to the circuit, a charging current flows through a

bank of capacitors, C

0

, C1, C2,....Cn. Firstly, C0 is charged, and

other capac itors follow. As the charging progresses the curre nt through R

0

constantly flows as shown in Fig. 6.7.2.

Fig. 6.7.2

R

0

is an insulation resistance to be measured, but, C0, C1, C2,....C

n

0

Charge current

Absorption current

Leakage current

Time

(Charge)

Voltage

application

Current

(Discharge)

Current

short

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 39

29

Have series resistors R

0

, R1, R2,....Rn. Therefore, a measurement

of R

0

only is very difficult. It is said that, with some insulation resistance

measurements, it takes several hours to a few days for the leakage current

to stabilize. This is not practical.

To avoid this problem, a method is customarily used in the insulation

resistance measurement for convenience to read the resistance value one

minute after charging the test voltage to the sample. This value is called

minute rate value for the resistance value of an insulator, and is widely

employed among a variety of electrical standards.

In the 1-minute rate insulation resistance measurement, the measured

values may vary when a measurement is repeated once or twice with the

same sample. To minimize such a deviation, it is important to completely

discharge the sample before the start of each measurement. The required

discharge time mainly depends upon the charging voltage and the size of

C

0

in Fig. 6.7.1, but, generally it can be said to be 5 to 6 times longer than

the time of test voltage charging.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 40

30

7. RS-232C INTERFACE

7.1 RS-232C Communication Commands

Mnemonic

Contents Format

R Measuring Da ta Output Format : R

C

R

L

F

Response: ****E*,

Judgment [GO] 0 or [NO] 1

Example: 10.0E4, 0

C

R

L

F

M Starting a Me asurement Format: M

C

R

L

F

Response: 0 (valid) or 1 (invalid)

C Starting a Charg ing Format : C

C

R

L

F

Response:

0 (valid) or 1 (invalid)

S Stopping Forcedly Format: S

C

R

L

F

Response:

0 (valid) or 1 (invalid)

T Measuring Time Setting Format: T *** (000 to 999)

C

R

L

F

Example: T 60

C

R

L

F

Response:

0 (valid) or 1 (in valid)

G Charging Time Setting Format: G *** (000 to 999)

C

R

L

F

Example: G 120

C

R

L

F

Response:

0 (valid) or 1 (in valid)

P Judgment Level Setting Format: P *** (000 to 999)

C

R

L

F

Example: P . 100

C

R

L

F

Response:

0 (valid) or 1 (in valid)

B

Judgment Buzzer

Setting

Format: B [OFF] 0 or [ON) 1

C

R

L

F

Example: B 1

Response:

0 (valid ) or status

U Measuring Condition

Output

Format: U

C

R

L

F

Response: Range, Voltage, inter locking, Status

Example: 4, 1000, 0, 2

C

R

L

F

Range: 0 to 8

Voltage: 5 to 1000

Interlocking: 0[OFF]/1[ON]

Status:

Stand-by – 2

Under measurement – 3

Charging – 4

On setting – 5

Under calibration – 6

Timer in operation – 7

I Instrument ID Format: I

C

R

L

F

Response: Model, Version

Example:SM-8215V1.00

C

R

L

F

Baud Rate 9600 bps

Data Bit 8 bit

Parity Bi t None

Stop Bit 1 bit

Flow Contro l RTS/CTS possib le

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 41

31

7.2 Applications of Commands

1) After each command transmission, make sure to receive the re sponse.

2) For R command, a state only response will be received, depending upon

the conditions at such a time.

Even during me asurement, a state 7 only response will be received when

the timer is functioning.

During stand-by, measured data are transmitted once. A command invalid

will be transmitted except for after re-measurement.

3) If a charging time is set upon receipt of a C command, a me asurement is

started as soon as the charging is completed.

4) For a P command, if a value out of the specified measuring range is

received without an actual setting.

7.3 Connector Specifications

Type of Connector: HDBE-9PF (05) [Hirose]

Type of Lock Fitting – HD-LNA (4-40), inch type

Pin Arrangement:

Direction of Signal Flow

Pin

No.

Signal

Line

Megohmmeter External Unit

Application

1 NC

No connectio n

2 TD

Transmission data

3 RD

Receiving data

4 NC

No connectio n

5 SG

Signal ground

6 ER

Data peri pheral re ady

7 CS

Send ready signal

8 RS

Send request signal

9 NC

No connectio n

Example of Connections

1) For connection with a DOS/V personal computer, use a straight 9-pin to

9-pin cable.

《 9-pin》 《 9-pin》

2 2

3 3

5 5

6 6

7 7

8 8

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 42

32

2) For connection with an NEC PC-9801 Series personal computer, use a

straight 9-pin to 25-pin cable.

《9-pin》 《 25-pin》

2 2

3 3

4

5 5

6 6

7 7

8 8

7.4 Printer Output

Via the RS -232C interfac e, measured data can be outp ut to an optiona l

printer, 0KC00001.

[Printer Output Procedures]

1) Connect the RS-232C interface connector on the rear of the unit, to the

optional p rinter v ia the ded icated conne ction cord .

2) Set the measuring intervals as needed. (See Fig. 6.6.1.)

3) Press the MEASURE switch.

4) When the measurement is completed, the measured data are output to

the prin ter.

Example:

Measured Data – 10.0×10

4

MΩ, GO judgment

Printing – 10.0E4, 0

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 43

33

Start of

Measurement

End of

Measurement

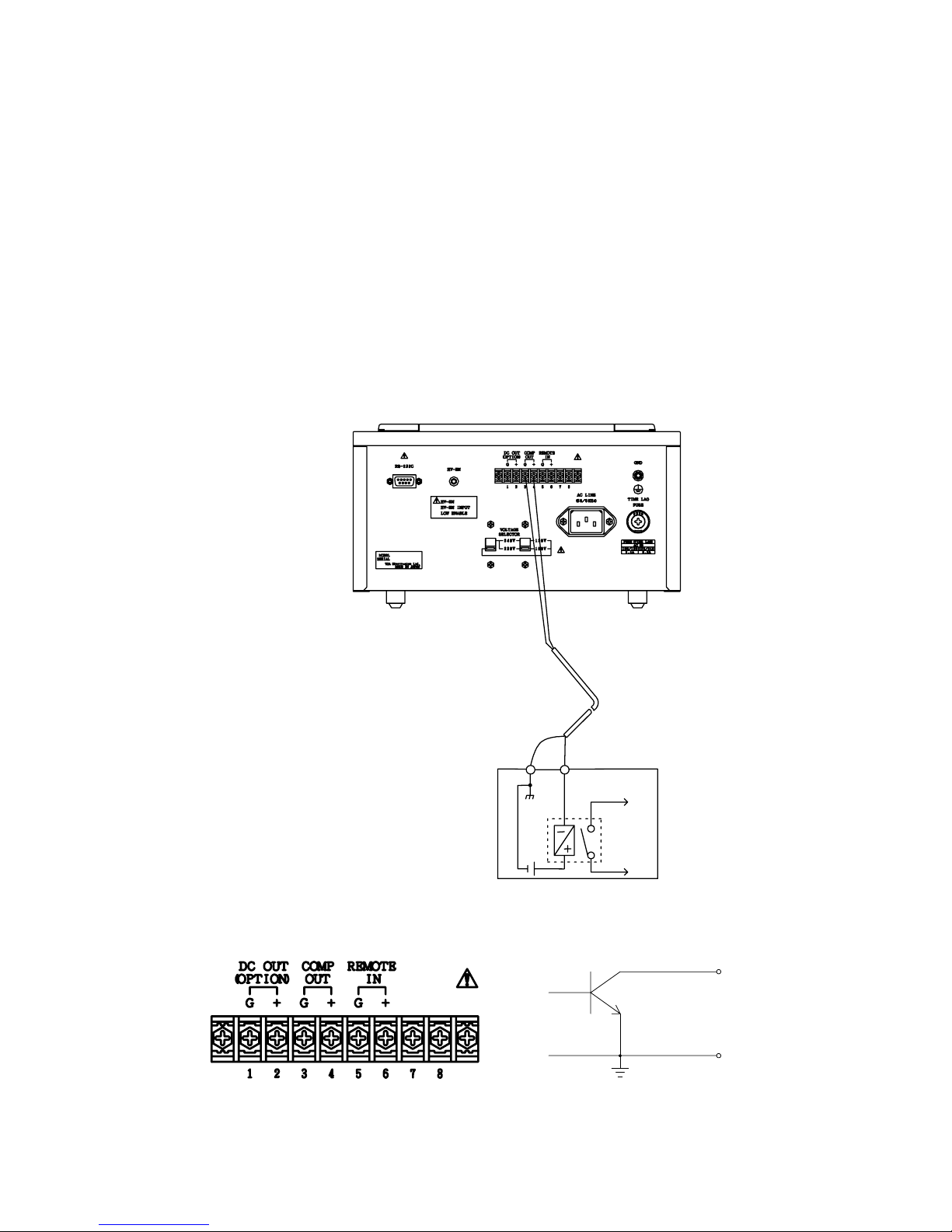

8. REMOT ELY CONTROL LED MEASU REMENT

A measurement can be remotely controlled by shorting the “G” and “+”

terminals of the REMOTE IN o f the External Input/Outpu t terminal bloc k on

the rear of the unit. When the terminals are shorted by a remote switch, a

measurement will start, and when opened the measure ment is ended.

Fig. 8.1.1 shows an example wiring and the signal timing.

Fig. 8.1.2 shows the external input/output terminal block.

■ Signal Timing

REMOTE IN OFF OFF

ON

Fig. 8.1.2

Fig. 8.1.1

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 44

34

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 45

35

Note 1: When the measuring time is set with the incorporated timer,

the timer has a priority over a remotely controlled switch

actuation.

When the REMOTE IN “G” and “+”

terminals are closed, a

measurement will start. The measurement will automatically end

when the time set with the timer is up.

Note that when the closed “G” and “+” terminals are opened

before the time-up of the timer, the opening of the “G” and “+”

terminals has a priority over the time set with the timer.

Note 2: When the charging time is set with the incorporated timer, the

timer has a priority over a remotely controlled switch

actuation.

When the REMOTE IN “G” and “+” terminals are closed, a

charging will start. The measurement will automatically start

when the charging time set with the timer is up.

Note that when the closed “G” and “+” terminals are opened

before the time-up of the timer, the opening of the “G” and “+”

terminals has a priority over the time set with the timer.

Note 3: When both the charging time and measuring time

are set with

the incorporated timer, the timer has a priority over a re mote

control.

When the REMOTE IN “G” and “+”

terminals are closed, a

charging wil l start.

When the set charging time is up, a measurement

automatically starts. However, note that when the “G” and “+”

terminals are opened before the set measuring time is up ,

the

remote control has a priority over the time set with the timer.

When the set measuring time is up, a measurement

automatically ends. However, note that when the “G” and “+”

terminals are opened before the set measuring time is up , the

remote control has a priority over the time set with the timer.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 46

36

9. INTRODUNTION OF OPTIONS

With the SM-8200 Series super megohmmeters, any of the following options

can be provided as needed. However, note that some of them can be installed

at factory.

9-1 Guar d Tip

1) Applications

1)-1 In a measurement of the insulation resi

stance of a capacitive sample,

the optional guard tip is used as a charging tip.

1)-2 In a measurement of the high insulation resistance, the optional

guard tip is used to guard the sample from the surface current of the

sample support made of insulation materials to obtain more reliable

data.

2) Usage

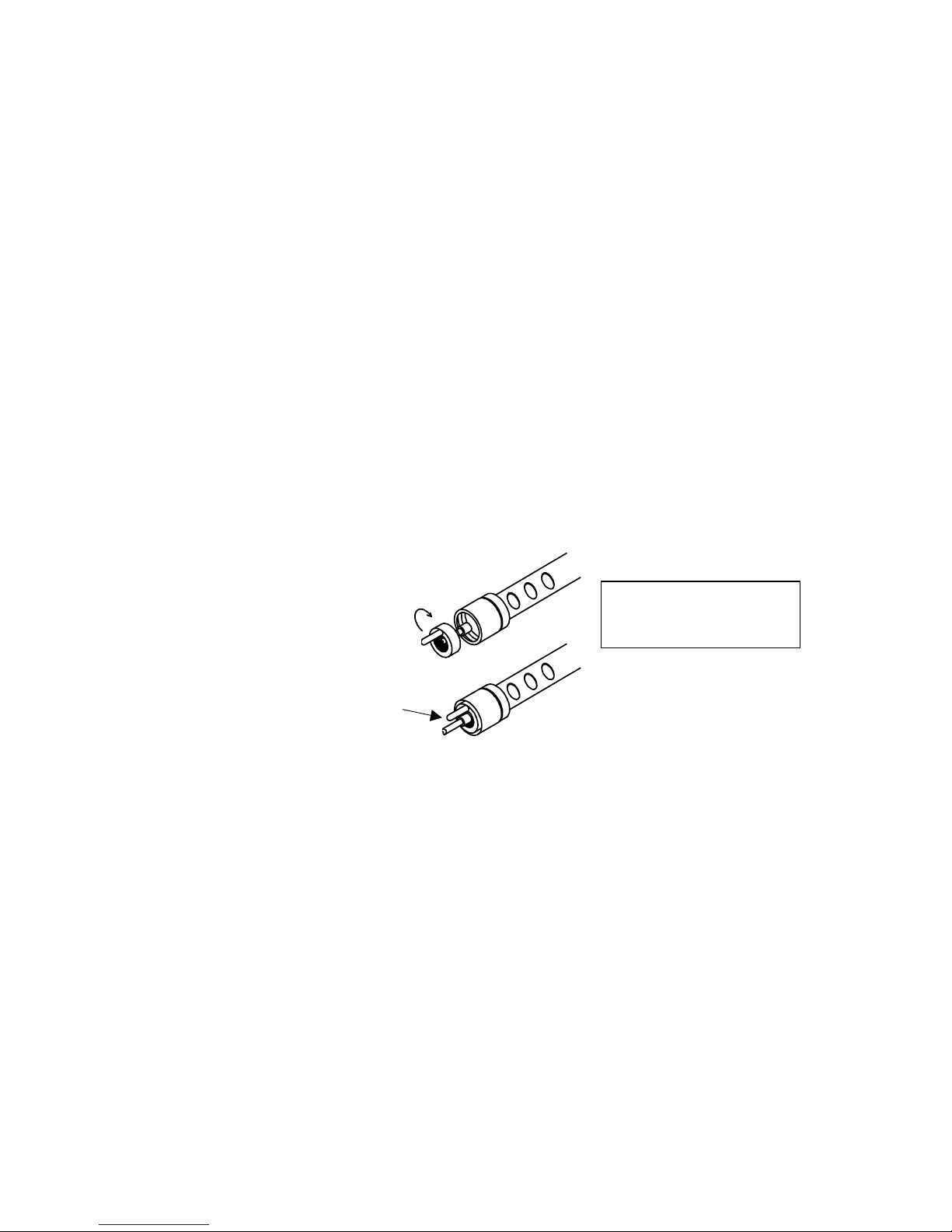

2)-1 Charging Tip

(1) Before connecting the measur ing plug of the red me asuring rod to

the Rx “‑“ terminals, mount the guard tip on the measuring plug as

shown in Fig. 9.1.1.

Fig. 9.1.1

(2) After mounting the guard tip, connect the measuring rod to the Rx

“‑“me asuringterm inals.

(3) Connect the black measuring rod to the sample to measure.

(4) Press the MEASURE switch.

(5) Connect the guard tip of the red measuring rod to the sample to

charge.

(6) When an appropriate period (See Note.) of charging time has passed,

connect the measuring tip of the rod to the sample in place of the

guard tip.

Note 1: When changing the guard tip connection to the measuring

tip connection, a spark may occur, depending upon the

capacitance of the sample.

1)

2)

Turn clockwise

to fit

Sample end of the

red measuring rod

Guard Tip

Measuring Tip

Guard Tip

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 47

37

Note 2: There is no technical standards available to specify the

charging time for samples, but a constant time should be

always applied to a specific type of samples, and such a time

should be recorded for later reference.

2)-2 Leakage Guard

(1) Before connecting the measuring rods to the Rx ‑/+measu ring

terminals, mount the guar d tip onto the red measuring rod as shown

in Fig. 9.1.1 on the previous page.

(2) Connect the measuring rods to the Rx ‑/+me asuring terminals.

(3) Connect the samp le as shown in Fig. 9.1.2 bel ow.

Fig. 9.1.2

(4) Press the MEASURE switch to start the measurement.

DANGER

Do not touch the Rx ‑/+ measuring terminals and the connected

sample when the unit is in the MEASURE or CHARGE mode

because they carry the voltage set with the VOLTAGE selector

switch. It is electric shock hazardous.

CAUTION

For safety, unplug the measuring rod from the Rx ‑/+ measuring

terminals before disconnecting the guard tip from the sample.

Sample

Metal Plate

Sample Support

(Insulator)

Black

Measuring Rod

Red

Measuring Rod

Measuring Tip

Guard Tip

-- to be continued --

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 48

38

DANGER

Use utmost care when handling a capacitive sample connected

to the Rx ‑/+ measuring terminals because the a capacitive

s ample’s inte rnal impedan ce is low, and a t ouch of the vol tage

applied parts of the sample may discharge the charge of the

sample at a time, giving a strong shock to the operator.

This is especially dangerous when the test voltage is high and

the capacitance of the sample is large.

This suggests, after measurement, to discharge the charge of

the sample without a fail.

9. 2 DC Signal Outputs

Either one of two different types of DC signal outputs can be optionally

installed with the unit at factory. The output can be used to make a

permanent record of measured data by connecting a chart recorder such as

the HIOKI EPR-3000 Series.

One of the outputs provides a linear DC signal directly proportional to the

measured resistance (RP-8000), and the othe r outputs a 1/R DC signal which

is inversely proportional to the measured resistance (RI-8000).

9 .2.1 DC Output, RP-8000 – Directly prop ortional or l inear to resis tance

An insulation resistance can be obtained when the measuring voltage is

divided by the current flowing through the circuit. When the measuring

voltage is constant, if the insulation resistance is doubled, the current

flowing through the circuit is halved. The RP-8000 DC output is designed

to convert the measured insulation resistance into a DC signal directly

proportional to the resistance.

1) Specifications

Output Range: From fu ll scale of the super me gohmmeter to 10 times

full scale

Output Voltage: 1V/full scale, 10 V/10 times full scale

Output Accuracy: Within ±10 % full scale

2) Usage

Measure the insulation resistance of a sample with the method

designed in 6.1 Measuring Method. There is no limitation in the

applications in relation with the provision of the RP-8000 DC output.

Fig. 9.2.1 on the next page illustrates an example connection with

the HIOKI EPR-3000 Series chart recorder.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 49

39

Recorder scale(Linear)

100 V scale

graduation

Fig. 9.2.1

Fig. 9.2.2

Fig. 9.2.2 shows the DC OUT (OPTI ON) “G”/”+” te rminals on the external

inpu t/output te rminal block on the rear of the unit.

A DC measuring instrument like a HIOKI chart recorder can be connected

to these terminals. For permanent data recording, a HIOKI chart recorder

is recommended for better technical follow-up, including a supply of a

variety of recording charts and technical service.

Fig. 9.2.3 shows the chart for the HIOKI EPR-3000 Series chart recorder (0

to 10 V full span) whose measuring range is set to ±5 V, and the –5 V

point is set to the zero (left most) line of the chart.

Fig. 9.2.3

SM‑8200シリーズ

EPR‑3000シリーズ

背面

正面

SM-8200 Series

Super Megohmmeter

HIOKI EPR-3000 Series Chart Recorder

Front

Rear

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 50

40

graduation

100 V scale

Voltage

Output

Recorder scale(Linear)

9.2.2 DC O utput, RI-8000 – 1/R or inversely proportional to resistance

In insulation resistance, as described in 9.2.1 DC Output, RP-8000, if the

measuring voltage is constant, the current flowing through the sample is

halved, and the output voltage is also halved when the insulation

resistan ce -- R -- is do ubled. This relation ca n be expressed as “1 /R.”

The RI-8000 provides this type of DC signal output.

1) Specifications

Output Range: Full range of the measuring range of the SM-8200

Series super megohmmeter

Output Voltage: 10 V/full scale, 1 V/10 times full scale

Output Accuracy: Within 10% of displayed value in the range from full

scale to 10 times full scale

2) Usage

Measure the insulation resistance of a sample with the method

designed in 6.1 Measuring Method. There is no limitation in the

applications in relation with the provision of the RP-8000 DC output.

Fig. 9.2.1 on the previous page illustrates an example connection with

the HIOKI EPR-3000 Series chart recorder.

Fig. 9.2.2 on the previous page shows the DC OUT (OPTION) “G”/”+”

terminals on the extern al input/outp ut termina l block on the re ar of

the unit.

A DC measuring instrument like a HIOKI chart recorder whose input

impedance is greater than 10 MΩcan be connected to these terminals.

For permanent data recording, a HIOKI chart recorder is recommended for

better technical follow-up, including a supply of a variety of recording charts

and technical service.

Fig. 9.2.3 shows the chart for the HIOKI EPR-3000 Series chart recorder (0

to 10 V full span) whose measuring range is set to ±5 V, and the –5 V point

is set to the zero (left most) line of the chart.

Fig. 9.2.4

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Page 51

41

10. MAINTENANCE AND MISCELANEOUS

Periodical maintenance, including checking and calibration is required for

the MS-8200 super megohmmeter to pe rform reliable measurements and

prevent a trouble and accident.

If necessary, ask your dealer or Hioki representative

to do such a

s

ervice as periodical checking, calibration and routine maintenance.

10.1 Periodical Checking

To keep your instrument its at best condition, the following checking is

required at monthly periods.

1) Check the Rx measuring term inals and input/output terminal block for

integrity.

As the Rx measuring terminals carry a high voltage (100 V to 1000 V,