Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Instruction Manual

SM-8213

SM-8215

SM-8220

SUPER MEGOHMMETER

March 2013 Revised edition 5 SM8213A981-05 13-03H

Page 2

Page 3

The super megohmmeter is a unique resistance meter designed to measure highresistance in a wide range.

The meter outputs a high test voltage – 1000 V maximum for the SM-8220/8215, and 100 V

maximum for the SM-8213 – to apply across the sample circuit.

Operators are requested to read this operation manual thoroughly before trying to operate the

instrument for safety and to prevent electrical shock and damage to the measured circuit.

Keep this manual where all staff can access it any time.

i

Page 4

1. Safety Precautions

Operators of the SM-8200 Series super megohmmeter are requested to read this operation

manual thoroughly before operation for safety and to obtain best performance.

Operators are also requested to strictly observe all the DANGER, WARNING, and CAUTION

notices in this manual and on the instrument to prevent injury and damage.

1-1 Safety Warnings

This operation manual includes some DANGER!, WARNING!, and CAUTION! notice with a

symbol. These must be observed for safety of the operator and other persons, as well as for

protection of your super megohmmeter and samples from possible damage and destruction.

A “DANGER” CALLS ATTENTION TO A CONDITION OR POSSIBLE

SITUATION THAT CAN CAUSE DEATH OR INJURY TO THE

OPERATOR OR NEAR PESONS.

A “WARNING” CALLS ATTENTION TO A CONDITION OR POSSIBLE

SITUATION THAT COULD CAUSE DEATH OR INJURY TO THE

OPERATOR OR NEAR PESONS.

could cause injury to the operator or persons nearby and damage and

destroy the super megohmmeter and samples.

DANGER

WARNIN G

CAUTION

A “CAUTION” calls attention to a condition or possible situation that

ii

Page 5

This symbol is s how n a t p ats w h ose us age needs

This symbol is shown at the Rx

Measuring term inals which carry a high voltage

This symbol is shown at the GND

cannot be grounded, this terminal must be

connected to the ground.

2) DANGER and WARNING Labels on the Rear Panel

1.2 Symbols on the Super Megohmmeter

Symbol Meaning Description

WARNING

DANGER –

referen ce to t he op erati on ma nual.

HIGH VOLTAGE

HAZARD

to be applied across the circuit to be measured.

terminal on the rear of the unit. If the

ground prong of the power cord plug

Safety Warning Labels on the Super Megohmmeter

警告、危険シール

1) DANGER and WARNING Labels on the Housing and Front Panel

““/”+”

正面パネル

背面パネル

危険

DANGER

高電圧危険

端子より高電圧発生の為、

感電の恐れあり。

HIGHVOLTAGE

Terminals carry high voltage.

Elec tric shock hazard!

iii

Page 6

2. Op

s

t

8220/8215) or 100 V

(SM-8213) for measurement.

d

on the r ear of the in stru men t to a

ground. When the power cord plug is connected to the AC line socket via an

prong adapter, the green ground tab of the ad apter to the

t

may be present for several minutes after the

contact

s

n

Use the right size and amperage power fuse. If a fuse of incorrect amperage is inserted

is not level or

erating Environmental Precautions

D

DANGER

■Do not operate the super megohmmeters in the presence of flammable gas. There is

possibility of an explosion and/or fire.

■Do not touch the Rx “–”/“+” measuring terminals on the front panel of the instrumen

during measurement. They output a maximum of 1000 V (SM-

WARNING

■ Ground the ground prong of the power cord plug to avoid electrical shock. If the groun

prong cannot be grounded, connect the GND terminal

accessory 3-prong to 2ground.

■ Do not remove the housing cover of the instrument. Even after turning off the instrumen

powe

r switch, a dangerous residual voltage

power is turned off. If repair or internal readjustment is needed, contact your

your dealer or Hioki representative.

CAUTION

■Before turning on the power switch for the instrument, check that the VOLTAGE

SELECTOR switches are set for your local AC line voltage. If the wrong AC line voltage i

applied to the unit, it will be damaged (higher voltage supply) or will not functio

properly (lower voltage supply).

See 1.3 Setting VOLTAGE SELECTOR Switches for setting.

into the fuse holder, the unit will be damaged.

See 1.4 Checking the Fuse Amperage for a correct fuse amperage.

Do not insta ll or operate the supe r meg hommeter on a su rface w hich

■

not stable.

iv

Page 7

3. Inst

Do not install or place the super megohmmeter in a location which is not level, not

h

absorbing

r

f

5 to

allation Precaution

CAUTION

stable or not sturdy enough to hold the instrument and other related items.

4. Instrument Handling Precautions

WARNING

■ If the instrument generates smoke or smell, unplug the power cord.

If such an instrument is kept powered on, it may cause a fire.

contact y our d ealer or Hi oki rep res entati ve fo r repa ir.

■Do not o pera te th e ins trum ent wi th a w et han d. Thi s ma y caus e elec tri cal sho ck.

CAUTION

■When moving or transporting the super megohmmeter, avoid shock and vibration as muc

as possible. For long-distance transportation, put the instrume nt in a shock-

carton or use the original shipping carton.

■When not using the super megohmmeter for an extended period of time, unplug the powe

from the AC line socket. Put a dust cover on the instrument. Store it in a place free o

cord

corrosive gas and vibration, with a surrounding temperature within the range from –

45℃, and humidity 80% RH or less(non-condensating).

■Do not pl ace an ythi ng on th e inst rum ent.

v

Page 8

BRIEF DESCRIPTION

About the SM-8200 Series Super Megohmmeters

The SM-8200 Series super megohmmeters are insulation resistance meters consisting of a constant voltage

power supply and a high sensitive current measuring section. The super megohmmeters are designed to

measur e the el ect rical resi stan ce of i nsul atin g mat erial s with high insul atio n pro perti es.

The resistance measuring ranges of the SM-8200 S eries are as follows:

SM-8213: 2.5×104 to 2×1012Ω

SM-8215: 2.5×105 to 2×1013Ω

SM-8220: 5.0×104 to 2×10

16

Ω

Each model of the super megohmmeters is provided with an LCD 320×240 dot display for easy

observation of necessary information, including measuring voltage, measured resistance in both

digital and analog, timer, and resultant GO/NO judgment.

The following shows the main specifications for the super megohmmeters.

For detailed specifications, see 2. SPECIFICATIONS.

For optional accessories, see 9. OPTIONAL ACCESSORIES.

Main Specific ations –

For optional accessories, see 9. OPTIONAL ACCESSORIES.

For detailed spec ifications , see 2. SPEC IFICATIONS.

Measuring Voltage Ranges:

SM-8213 – 5, 10, 15, 25, 50 and 100 V

SM-8215 – 50, 100, 250, 500 and 10 00 V

SM-8220 – 10, 25, 50, 100, 250, 500 an d 1000 V

Measuring Resistance Range:

SM-8213: 2.5×104 to 2×1012Ω

SM-8215: 2.5×105 to 2×1013Ω

SM-8220: 5.0×104 to 2×10

16

Ω

Timer Function: Provided

Comparison and Judgme nt Function: Pro vided

HV-EN (High Voltage Enable) Interlocking Function: Provided

Voltage Charging Function: Provided

Voltage Discharging Function: Provided

RS-232C Interface Conn ector: Provided

Remote Measurement Function: Provided

vi

Page 9

Organization of This Operation Manual

This operation manual contains the following 10 sections.

1. PREPARATION BEFORE

This section describes precautions for unpacking and AC line voltage setting.

2. SPECIFICATIONS

This section describes the specifications for the SM-8200 Series super megohmmeters and

optional accessories.

3. OPERATING PRINCIPLE

This section describes the operating pri nciple with a block diagram of the SM-8200 Series.

4. FAMILIARIZATION WITH CONTROLS AND PARTS

This section describes the functions of the controls and parts on the front and rear panels.

5. PREPARATION FOR MEASUREMENT

This section describes the LCD display in detail for the measuring mode, setting mode and

operations. A variety of measured value display methods are also given.

OPERATION

6. MEASUREMENT

This section provides details for function setting, connection to the work to be measured, and

usage of a vari ety of opti onal measur ing jigs a nd el ectro des.

7. RS-232C INTERFACE

This section describes the application of the serial port interface.

8. REMOTELY CONTROLLED MEASUREMENT

This section describes the remote measuring function.

9. INTRODUCTION OF O PTIONALS

This section describes the optional accessories, including guard chips, DC signal outputs, and

others.

10. MAINTENANCE AND MISCELANEOUS

This section describes maintenance and calibration.

EXTERNAL APPEARANCE

11.

This sec tio n incl ude s fro nt, r ear an d sid e view illu strat ion s of th e inst rum ent w ith di men sion s.

vii

Page 10

Page 11

CONTENTS

1. PRE PA RAT IO N BE FO RE O PER AT ION . . . . . . . . . . . . . . . . . . . . . . . 1

1. 1 Unpacking and Checking of the Contents . . . . . . . . . . . . . . . . . . . 1

1. 2 Operating AC Line V oltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. 3 Setting the VOLTAGE SELECTOR Switches . . . . . . . . . . . . . . . . . . 2

1. 4 Checking the Fuse Amperage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. 5 Grounding the Chas sis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1. 6 Wa rm-up Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Measuring Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Function Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Other Electrical and Physical Data . . . . . . . . . . . . . . . . . . . . 8

2.4 Optional Functions and Accessories . . . . . . . . . . . . . . . . . . . 8

2.5 List of Measurement Ranges and Guaranteed Accuracy

Ranges by Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3. OPERATING PRINCIPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. FAM IL IAR IZA TIO N W ITH CON TR OLS AN D PA RTS . . . . . . . . . . . . . 13

4.1 Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Measuring Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Measuring Condition Setting Display . . . . . . . . . . . . . . . . . . 18

4.5 Meanings of the Status and Mode Notices. . . . . . . . . . . . . . . . 19

5. PREPARATION FOR A MEASUREMENT . . . . . . . . . . . . . . . . . . . . . 20

5.1 Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 Self-calibration 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Self-calibration 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4 Check the Measuri ng Rods

. . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.5 Basic Procedures for a Measurement. . . . . . . . . . . . . . . . . . . 23

6. MEASUREMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 Measuring Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Discharging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3 Charging Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6. 4 In ter loc kin g F unc ti on – Usi ng the HV -EN Con ne cto r . . . . . . . . 26

6.5 Comparison and Judgment Function . . . . . . . . . . . . . . . . . . . 27

a

Page 12

6.6 Setting a Variety of Functions . . . . . . . . . . . . . . . . . . . . . . . 28

6.6.1 Setting the Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.6.2 Setting the Comparison GO/NO Judgment Level . . . . . . . . . 28

6.6.3 Setting Buzzer Sound ON/OFF . . . . . . . . . . . . . . . . . . . . . . 29

6.6.4 Setting the Charging Time, Measu ring Time, Comparison

GO/NO Judging Level and Buzzer Sound ON/OFF. . . . . . . . . 29

6.7 Changes in the Current Flowin g through Insulators. . . . . . . . . 31

6.8 Connectivity Precautions. . . . . . . . . . . . . . . . . . . . . . . 32

6.8.1 When the Screen Shows LOCK and Measurement Cannot Be Started . . .32

6.8.2 When Using an Optional Electrode for Plate Samples or Shield Box . .33

7. RS-232C INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1 RS-232C Communication Commands . . . . . . . . . . . . . . . . . . . 34

7.2 Applications of Commands . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.3 Connector Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.4 Printer Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8. REMOTELY CONTROLLED MEASUREMENT . . . . . . . . . . . . . . . . . 37

9. INTRODUCTION OF OPTI ONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.1 DC Signal Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.1.1 DC Output, RP-8000

– Directly proportional or linear to resistance . . . . . . . . . . 40

9.1.2 DC Output, RI-8000

– Inversely proportional or 1/R to resistance . . . . . . . . . . 42

10. MAINTENANCE AND MISCELANEOUS . . . . . . . . . . . . . . . . . . . . 45

10.1 Periodical Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.2 Storage, Transportation and Abando n . . . . . . . . . . . . . . . . . 45

11. EXTERNAL APPEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

b

Page 13

1. PREPARATION BEFORE OPERATION

When plugging the shorting plug, make sure that the power is turned off, otherwise,

1.1 Unpacking and Chec king of the Conten ts

When you have received the carton of the SM-8200 Series super megohmm eter, carefully unpack

it, and take out every thing from the carton.

Although the instrument and its accessories are severely inspected before shipment from factory,

visual ly ch eck t he it ems a nd th eir q uanti ties .

Keep t he shi ppi ng ca rton for r euse a t a lat er st age.

1) Visually check the external view of the instrument and its accessories.

2) Check the qu anti ties o f the l ist in acco rdan ce wit h the f ollow ing l ist:

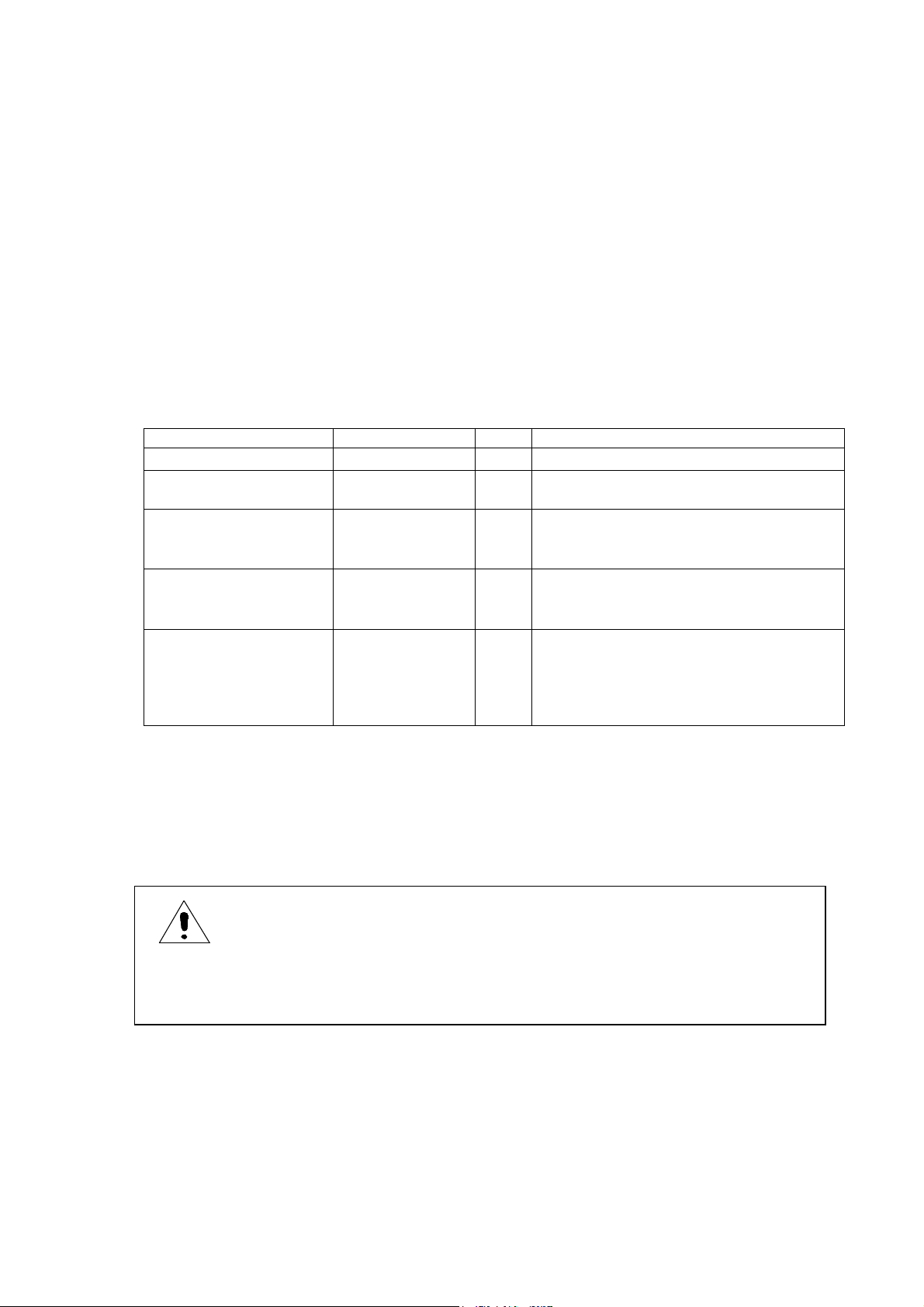

Table 1.1 List of Standard Accessories

Item Model No. Q’ty Remarks

Operation manual

Power cord

Measuring rod

(Red)

Measuring rod

(Black)

Shorting plug 0GZ00003 1

-

-

0GE00002 1

0GE00001 1

This item means this booklet.

1

Power cord with 3-prong plug with third

1

for grounding

A measuring rod with a 1meter cord to be connected to the Rx ‘’

socket.

A measuring rod with a 1meter cord to be connected to the Rx ‘+’

socket.

A plug to be plugged to the

HV-EN so cket of th e rear of

the inst rumen t. It i s plu gged

to the HV-EN socket when

shipping from factory.

Important!

When the accessory shorting plug is not plugged to the HV-EN socket on the rear of the

instrument, the measuring high voltage is not output.

Note: The shorting plug is plugged to the HV-EN socket when shipping from factory.

CAUTION

there i s an el ectr ic sh ock h azar d.

Upon checking the instrument and accessories, if any damage is found, immediately contact

your dealer or Hioki representative.

1

Page 14

1.2 Operating AC Line Voltage

confirm that the VOLTAGE

SELECTOR switches on the rear panel are set to the positions, accordingly (See 1.3

The sup er megohmemet er c a n b e o p e ra ted fro m o ne of the f o llowin g A C power so u r c e w hen the

VOLTAGE SELECTOR switches are set accordingly.

AC Line Voltage

100 V ±10% 50/60 Hz

120 V ±10% 50/60 Hz

220 V ±10% 50/60 Hz

240 V +10V, 10% 50/60 Hz

CAUTION

1.3 Setting VOLTAGE SELECTOR Switches

The super megohmmeter can be operated from one of the AC line voltages of 100 V, 120 V, 220 V

Before connecting the power cord to the AC outlet socket,

Setting the VOLTAGE SELECTOR Switches.).

If the switches are set to wrong positions, a fire or burn may occur.

and 240 V by setting the VOLTAGE S ELECTOR switch es to the specific positio ns, respectively.

Frequency

Confirm the switch setting to the specific positions in accordance with Fig. 1.1.

If they are not set properly, correct their positions, accordingly.

To change the position of the switch, insert the tip of a flat blade screwdriver into the slot of the

switch lever, and slide the lever upward or downward.

CAUTION

To chan ge the V OLTA SGE SELE CTOR swit ch posi tio ns, be s ure t o

Unplug the po wer co rd pl ug fr om the A C li ne soc ket to preven t a

possible damage.

When th e swit ch po siti on is chan ged whi le t he vol tag e is on, the

Switch contacts will be damaged.

2

Page 15

up and down. Slide the

Do not leave the lever at a neutral position. If the lever is set at a neutral position, a

When the VOLTAGE SELECTOR switch position is changed, fuse amperage must be

Time Lag Fuse

CAUTION

The VOLTAGE SELECTOR switches have two positions –

switch lever to either position until it stops.

normal function cannot be obtained, and it will cause a failure.

G

A

T

L

O

V

100V

120V

220V

240V

E

R

O

T

C

E

L

E

S

Fig. 1.1 VOLTAGE SELECTOR Switch Setting

CAUTION

changed to m eet th e requ irem ents of th e new AC lin e volt age.

Incorr ect fu se am pera ge wi ll ca use a f ailu re of t he in strum ent .

1.4 Checking the Fuse Amperage

The fuse holder of the instrument contains a time lag fuse of the following amperage:

AC Line Voltage

100 V/120 V 0.4 A

220 V/240 V 0.2 A

Fuse Amperage

3

Page 16

To replace or check the fuse, make sure to disconnect the power cord from the AC line

To prevent an accident, connect the ground prong of the power cord

sure to connect

p

Fuse Replacement

The fuse is inserted in the FUSE holder (Fig. 1.2) on the rear of the unit.

Remove the cap, and replace the fuse with a new one with a correct amperage.

To remove the cap of the fuse holder, use a 4 mm Phillips screwdriver, and turn the cap

counterclockwise.

To set the cap in position, insert the cap, holding the fuse into the holder, and turn it with the

screwdriver.

Fuse

Fig. 1.2 Fuse Holder and Fuse Replacement

WARNING

socket. If not , ther e is a f ear of el ect rical shoc k.

Ca

1.5 Grounding the Chassis

To avoid an electr ical shock accid ent, connect the GND terminal on the rear of the unit to the

ground prong of the power cord to the ground post of the AC line system.

The round prong of the 3-prong plug o f the power cord is the grou nd prong.

It is recommended to use an AC line socket with its third contact grounded for connection of the

accessory 3-prong power cord.

To use the accessory 3-prong to 2-prong adapt er to connect the power cord to a 2-cont act AC line

socket, make sure to ground the green tab of the adapter.

WARNING

Plug to the ground post of the AC line system. If it is impossible to

ground the ground prong of the power cord plug, be

the GND terminal on the rear of the unit.

4

Page 17

1.6 Warm-up Period

To obtain the performance of published specifications, allow the SM-8200 Series super

megohmmeter to warm for a minimum of 30 minutes.

5

Page 18

2. SPECIFICATIONS

2.1 Measuring Performance

1) Electrical Resistance Measurement

SM-8213(RANGE : ×1 , ×10 , ×10

Measur em ent Ra nge (MΩ) [RANGE=×10

0.5 × 10R to 20 × 10R

0.25 × 10R to 10 × 10R

0.125 × 10R to 5 × 10R

0.075 × 10R to 3 × 10R

0.05 × 10R to 2 × 10R

0.025 × 10R to 1 × 10R

Accuracy of target voltage: ±3% of set value

Measuring output current: 50 mA maximum (Note: 1)

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range) (Note: 2)

SM-8215(RANGE : ×1 , ×10 , ×10

Measur em ent Ra nge (MΩ) [RANGE=×10

5 × 10R to 200 × 10R

2.5 × 10R to 100 × 10R

1.25 × 10R to 50 × 10R

0.5 × 10R to 20 × 10R

0.25 × 10R to 10 × 10R

Accuracy of target voltage: ±3% of set value

2

, ×103 , ×104 , or ×105)

R

]

Target Voltage

100 V

50 V

25 V

15 V

10 V

5 V

2

, ×103 , ×104 , or ×105)

R

]

Target Voltage

1000 V

500 V

250 V

100 V

50 V

Measuring output current: 2 mA maximum (Note: 1)

Accuracy of measurement: ±10% (A range of 10 times of the minimum

value of each range) (Note: 2)

2

SM-8220(RANGE : ×1 , ×10 , ×10

Measur em ent Ra nge (MΩ) [RANGE=×10

5 × 10R to 200 × 10R

2.5 × 10R to 100 × 10R

1.25 × 10R to 50 × 10R

0.5 × 10R to 20 × 10R

0.25 × 10R to 10 × 10R

0.125 × 10R to 5 × 10R

0.05 × 10R to 2 × 10R

, ×103 , ×104 , ×105 , ×106 , ×107 , or ×108)

R

]

Target Voltage

1000 V

500 V

250 V

100 V

50 V

25 V

10 V

Accuracy of target voltage: ±3% of set value

Measuring output current: 2 mA maximum (Note: 1)

Accuracy of measurement: ±10% (A range of 10 times of the minimum

8

value of each range) except for×10

±20% for×10

8

range

range. (N ote: 2)

6

Page 19

Note 1: The measurement output current may reach as high as approximately 1.4 times th e

maximum value. When a current in excess of the measurement output current’s

maximu m val ue is output , the s et m easur ement volt age m ay dro p.

Note 2: The measurement accuracy is defined as ±10% of the indicated measured value

displayed on the screen.

2) Measuring Time (Sampling Cycle)

Approx. 200 ms

2.2 Function Specifications

1) CHARGE Function

This function charges the sample to be measured by applying the Selected measuring

voltage when the CHARGE switch is pushed.

Internal Resistance

SM-8213: Approx. 0Ω

SM-8215: Approx. 30kΩ

SM-8220: Approx. 30kΩ

2) DISCHARGE Function

This function discharges a residual voltage on the sample after measurement when the

DISCHARGE switch is pushed.

Internal Resistance

All models: Approx. 100kΩ

3) HV-EN (High Voltage Enable) – Interlocking Function

This function externally controls to make the o utput of mea suri ng vo ltag e on or off.

This function is used in combination with an interlock switch on the measuring jig so as to

preven t an el ectr ical shoc k dur ing m easur em ent.

4) TIMER Function

This function determines the voltage charging time and the measuring time, respectively,

within a range from 1 to 999 s econds. Aft er the set ti me is up, the measur ed value is sho wn

held.

5) COMPARISON and JUDGMENT F unction

This function makes a comparison of the measured value with the preset judgment value,

and if the measured value is less than the judgment level, it makes the alert buzzer sound,

closing the incorporated relay contacts.

6) RS-232C Interface Functi on

This function allows a control of an optional print er via RS-232C interfac e.

The optional printer prints measured da ta.

7) REMOTE MEASUREMENT Function

This function allows a remotely controlled measurement by means of a remote switch.

7

Page 20

2.3 Other Electrical and Physical Data

1) Envi ronm ent al te mpera tur e and Hum idit y

Operation: 0 to 40℃ (SM-8213/8215),80% RH or l ess (non-condensat ing)

Storage: 5 to 45℃,80% RH or l ess(non-condensating)

5 to 35℃ (SM-8220),80% RH or less (non-condensating)

2) Power Requirements

AC 100 V, 120 V, 220 V, ±10%, 240 V +10 V, 10% 50/60 Hz

3) Power Consumption

Approx. 25 VA

4) Dimensions

Approx. 284 (W) × 139 (H) × 215 (D) mm

Also, see 11. EXTERNAL VIEW for external appearance.

5) Weight

Approx. 4.3 kg

2.4 Optional Functions and Accessories

In addition to the standard accessories shown in 1.1 Unpacki ng and Chec king of th e Content s

and Table 1.1 List of Standard Accessories, the following two groups of optiona l acce ssories are

available to expand the applic ations of the SM-820 0 Series super megohmm eters.

1) Options – designed exclusive for the SM-8200 Series

Name Model

Printer 9442

2) Options – designed for common to SM- 8200 Series, SM-8216, and

SM-8000 Series super megohmmeters.

Name Model Description

With surface/volumetric

selector, interlock function

Selector. Needs shield box.

resistance measurement

resistance measurement

Electrode constant: Appro x. 500 cm

measurement of antistatic flooring,

etc.

Electrode for plate sampl es SME-8310

Electrode for plate sampl es SME-8311

Weight electrode SME-8320 With surface/volumetric

Shield box SME-8350 Electromagnetic shieldin g

Electro de fo r surf ace

resistance measurement

Electro de fo r surf ace

resistance measurement

Electrodes for liquid sample

measur em ent

Surface/Volume

Resistance Measurement

Electr od e

Electro des fo r chi p

capacitors

SME-8301 Simplified electrode for surfa ce

SME-8302 Simplified electrode for curved surface

SME-8330 Capacity, approx. 25 mL

SM9001 Surface/volume resistance

SME-8360 Chip capacitor measurement

8

Page 21

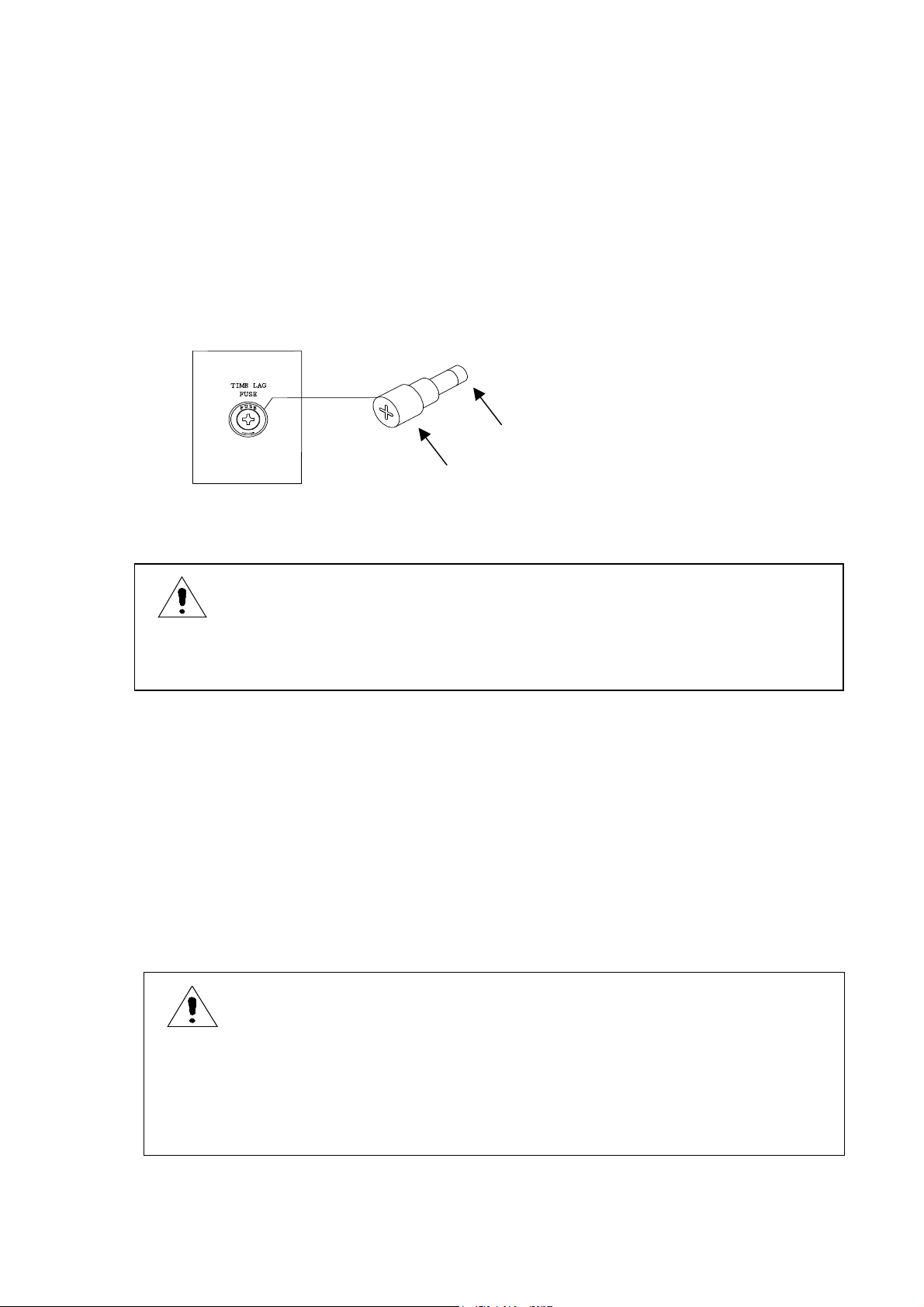

2.5 List of Measurement Ranges and Guaranteed Accuracy Ranges by Model

SM-8213

Voltage

5V

10V

15V

25V

50V

100V

*All resistance values are expressed in MΩ.

Range/measurement range (with guaranteed accuracy range in parentheses)[MΩ]

×1 ×10 ×10

:

:

:

:

:

:

1

1

)

1

1

)

1

1

)

1

1

)

1

1

)

1

1

)

0.025×100

:

1.00×100

(0.250×10

0.050×100

:

2.00×100

(0.500×10

0.075×100

:

3.00×100

(0.750×10

0.125×100

:

5.00×100

(1.25×10

0.250×100

:

10.0×100

(2.50×10

0.500×100

:

20.0×100

(5.00×10

0.025×10

1.00×101

0

)

(0.250×10

0.050×10

2.00×101

0

)

(0.500×10

0.075×10

3.00×101

0

)

(0.750×10

0.125×10

5.00×101

0

)

(1.25×10

0.250×10

10.0×101

0

)

(2.50×10

0.500×10

20.0×101

0

)

(5.00×10

(0.250×10

(0.500×10

(0.750×10

2

0.025×10

:

1.00×102

0.050×10

:

2.00×102

0.075×10

:

3.00×102

0.125×10

:

5.00×102

(1.25×10

0.250×10

:

10.0×102

(2.50×10

0.500×10

:

20.0×102

(5.00×10

×103 ×104 ×105

2

0.025×10

1.00×103

2

)

(0.250×10

0.050×10

2

2.00×103

2

)

(0.500×10

0.075×10

2

3.00×103

2

)

(0.750×10

0.125×10

2

5.00×103

2

)

2

(1.25×10

0.250×10

10.0×103

2

)

2

(2.50×10

0.500×10

20.0×103

2

)

(5.00×10

:

:

:

:

:

:

3

0.025×10

:

1.00×104

3

)

(0.250×10

0.050×10

3

:

2.00×104

3

)

(0.500×10

0.075×10

3

:

3.00×104

3

)

(0.750×10

0.125×10

3

:

5.00×104

3

)

3

(1.25×10

0.250×10

:

10.0×104

3

)

3

(2.50×10

0.500×10

:

20.0×104

3

)

(5.00×10

4

0.025×10

5

:

1.00×105

4

)

(0.250×10

0.050×10

4

5

)

5

:

2.00×105

4

)

(0.500×10

0.075×10

4

5

)

5

:

3.00×105

4

)

(0.750×10

0.125×10

4

5

)

5

:

5.00×105

4

)

4

(1.25×10

0.250×10

5

)

5

:

10.0×105

4

)

4

(2.50×10

0.500×10

5

)

5

:

20.0×105

4

)

(5.00×10

5

)

9

Page 22

SM-8215

Voltage

50V

100V

250V

500V

1000V

*All resistance values are expressed in MΩ.

Range/measurement range (with guaranteed accuracy range in parentheses) [MΩ]

×1 ×10 ×10

1

:

:

:

:

:

1

1

)

1

1

1

)

1

1

1

)

1

1

)

1

1

)

0.250×100

:

10.0×100

(2.50×10

0

0.500×10

:

20.0×10

(5.00×10

1.25×10

0

0

0

:

50.0×10

(12.5×10

0

0

2.50×100

:

100×100

(25.0×10

0

5.00×100

:

200×100

(50.0×10

0

0.250×10

10.0×10

)

0

)

)

(2.50×10

0.500×10

20.0×10

(5.00×10

1.25×10

50.0×10

(12.5×10

2.50×10

100×101

)

(25.0×10

5.00×10

200×101

)

(50.0×10

2

0.250×10

:

10.0×10

(2.50×10

0.500×10

:

20.0×10

(5.00×10

1.25×10

:

50.0×10

(12.5×10

2.50×10

:

100×102

(25.0×10

5.00×10

:

200×102

(50.0×10

×103 ×104 ×105

2

2

2

)

2

2

2

)

2

2

2

)

2

0.250×10

10.0×10

(2.50×10

0.500×10

20.0×103

(5.00×10

1.25×10

50.0×10

(12.5×10

2.50×10

100×103

2

)

2

(25.0×10

5.00×10

200×103

2

)

(50.0×10

:

:

:

:

:

3

3

3

)

3

0.250×10

10.0×104

(2.50×10

0.500×10

20.0×10

3

)

3

3

3

)

3

(5.00×10

1.25×10

50.0×10

(12.5×10

2.50×10

100×104

3

)

3

(25.0×10

5.00×10

200×104

3

)

(50.0×10

:

:

:

:

:

4

0.250×10

:

10.0×10

4

)

4

(2.50×10

0.500×10

:

4

4

)

4

20.0×10

(5.00×10

1.25×10

:

4

4

)

4

50.0×10

(12.5×10

2.50×10

:

100×105

4

)

4

(25.0×10

5.00×10

:

200×105

4

)

(50.0×10

5

5

5

)

5

5

5

)

5

5

5

)

5

5

)

5

5

)

10

Page 23

SM-8220

Voltage

10V

25V

50V

100V

250V

500V

1000V

*All resistance values are expressed in MΩ.

Range/measurement range (with guaranteed accuracy range in parentheses) Voltage [MΩ]

2

×1 ×10 ×10

0.050×10

:

2.00×10

(0.500×10

0.125×10

:

5.00×10

(1.25×10

0.250×10

:

10.0×100

(2.50×10

0.500×10

:

20.0×100

(5.00×10

1.25×10

:

50.0×100

(12.5×10

2.50×10

:

100×100

(25.0×10

5.00×10

:

200×100

(50.0×10

0

0

0

)

0

0

0

)

0

0

)

0

0

)

0

0

)

0

0

)

0

0

)

0.050×10

:

2.00×10

(0.500×10

0.125×10

:

5.00×10

(1.25×10

0.250×10

:

10.0×10

(2.50×10

0.500×10

:

20.0×10

(5.00×10

1.25×10

:

50.0×101

(12.5×10

2.50×10

:

100×101

(25.0×10

5.00×10

:

200×101

(50.0×10

1

1

1

)

1

1

1

)

1

1

1

)

1

1

1

)

1

1

)

1

1

)

1

1

)

0.050×10

:

2.00×10

(0.500×10

0.125×10

:

(1.25×10

0.250×10

:

(2.50×10

0.500×10

:

(5.00×10

1.25×10

:

(12.5×10

2.50×10

:

100×102

(25.0×10

5.00×10

:

200×102

(50.0×10

×103 ×104 ×105 ×106 ×107 ×108

2

2

2

)

2

2

5.00×10

2

)

2

10.0×102

2

)

2

20.0×102

2

)

2

50.0×102

2

)

2

2

)

2

2

)

0.050×10

:

2.00×10

(0.500×103)

0.125×10

:

5.00×103

3

(1.25×10

0.250×10

:

10.0×103

3

(2.50×10

0.500×10

:

20.0×103

3

(5.00×10

3

1.25×10

:

50.0×103

3

(12.5×10

3

2.50×10

:

100×103

3

(25.0×10

3

5.00×10

:

200×103

3

(50.0×10

3

3

3

)

3

)

3

)

)

)

)

0.050×10

:

2.00×104

(0.500×10

0.125×10

:

5.00×10

(1.25×10

0.250×10

:

10.0×104

(2.50×10

0.500×10

:

20.0×104

(5.00×10

1.25×10

:

50.0×104

(12.5×10

2.50×10

:

100×104

(25.0×10

5.00×10

:

200×104

(50.0×10

4

4

)

4

4

4

)

4

4

)

4

4

)

4

4

)

4

4

)

4

4

)

0.050×10

:

2.00×10

(0.500×10

0.125×10

:

5.00×10

(1.25×10

0.250×10

:

10.0×105

(2.50×10

0.500×10

:

20.0×105

(5.00×10

1.25×10

:

50.0×105

(12.5×10

2.50×10

:

100×105

(25.0×10

5.00×10

:

200×105

(50.0×10

5

5

5

)

5

5

5

)

5

5

)

5

5

)

5

5

)

5

5

)

5

5

)

0.050×10

:

2.00×106

(0.500×10

0.125×10

:

5.00×10

(1.25×10

0.250×10

:

10.0×106

(2.50×10

0.500×10

:

20.0×106

(5.00×10

1.25×10

:

50.0×106

(12.5×10

2.50×10

:

100×106

(25.0×10

5.00×10

:

200×106

(50.0×10

6

6

)

6

6

6

)

6

6

)

6

6

)

6

6

)

6

6

)

6

6

)

0.050×10

:

2.00×10

(0.500×10

0.125×10

:

5.00×107

(1.25×10

0.250×10

:

10.0×107

(2.50×10

0.500×10

:

20.0×107

(5.00×10

1.25×10

:

50.0×107

(12.5×10

2.50×10

:

100×107

(25.0×10

5.00×10

:

200×107

(50.0×10

7

7

7

)

7

7

)

7

7

)

7

7

)

7

7

)

7

7

)

7

7

)

0.050×10

:

2.00×108

(0.500×10

0.125×10

:

5.00×10

(1.25×10

0.250×10

:

10.0×10

(2.50×10

0.500×10

:

20.0×108

(5.00×10

1.25×10

:

50.0×108

(12.5×10

2.50×10

:

100×108

(25.0×10

5.00×10

:

200×108

(50.0×10

8

8

)

8

8

8

)

8

8

8

)

8

8

)

8

8

)

8

8

)

8

8

)

11

Page 24

3. OPEARATING PRINCIPLE

The SM-8200 Series super megohmmeters consist of a constant voltage power supply and a high

sensitive current measuring section to be combined to compose a resistance measuring circuit.

The current measuring section is composed of a current detective resistor, low drift voltage

amplifier and an integrator-type A/D converter.

A measured resistance value is computation-processed by a CPU to display the result on a liquid

crystal display (LCD).

Fig. 3.1 shows a circuit composition of the SM-8200 Series.

(Option)

DC

(-)

Rx

RANGESele ctor

Currentto Voltager

MEAS

CHARGE

DISCHARGE

e

g

r

a

h

c

s

i

D

t

i

u

c

r

i

C

Converte

DC

Amplifier

Discharge

Controller

Signal Output

Control Keys

A/D

Converte r

CPU

RS-232C

LCD

VOLTAGE SELECTOR

Switches

(+)

MEAS

CHARGE

DISCHARGE

-

High Volta ge

Power Supply

+

Fig. 3.1 Circuit Composition

AC Li ne Source

Power

Supply

12

Page 25

4. FAMILIARIZATION WITH CONTROLS AND PARTS

4.1 Front Panel

The figure below shows the front panel of the SM-8200 Series. However, note that the values for

the two knobs on the right are represent ed by those of the SM- 8213.

②

①

Fig. 4.1 Front Panel

③

④

⑥⑤

⑨⑧⑦

① LCD Display: This is a 320×240 dot liqu id crystal display modul e.

This shows measured results, measuring conditions and a variety of

data settings.

② POWER Switch: T his i s a po wer s witch to t urn o n or o ff th e ins trument s.

A press of this switch in the released position turns ON the unit.

A press of this switch in the pushed position turns OFF the unit.

⑪

⑩

③ V. OUT Indicator: This indicato r lights when the Rx /+ measuring

terminals carry a measuring voltage across them.

④

voltage across them to measure the insulation resistance of a sample

via a pair of measuring rods or electrodes.

Note: Each of the terminals is incorporated with a plug insertion

detector switch. Unless otherwise this switch is turned on by a

full insertion of the plug of the measuring rod or electrode, the

output voltage circuit cannot be completed – no output.

Pease be careful when inserting or removing the plug so as not

to cause any impact on the detection switch inside the terminal.

Rx /+ Measuring Terminals: These terminals carry a selected measuring

13

Page 26

⑤ SELECT Switch: This switch moves the curso r in th e LCD d ispl ay to the

desired item set it.

This switch also acts as a STOP switch; this switch makes the voltage

on the Rx /+

the measuring voltage is being applied.

⑥

pressed.

⑦

⑧

measuring terminals to charge the sample to be measured when it is

pressed. During the chargi ng period, th e V. OUT indicator light s.

the next press of this switch discharges the sample, turning off the

V. OUT indicator.

Note: When the timer function is used to determine the charging

period, the measurement automatically starts when the set

time is up.

⑨

sample in connection, when it is pressed, turning on the

incorporated indicator and the V. OUT indicator.

The next press of this switch discharges the sample, turning off the

DOWN Switch: This switch decreases the value to set each time it is

UP Switch: This switch increases the value to set each time it is pressed.

CHARGE Switch: This switch applies the measuring voltage across the Rx

MEASUR E/D ISCH ARGE Swit ch: Th is swit ch st arts a measu rem ent of the

measuring terminals OFF when it is pressed while

two indicators.

⑩

across the Rx +/

a voltage to output.

VOLTAGE Selector Switch: This switch selects the voltage to be applied

measuring terminals. The arrow on the knob shows

⑪ RANGE Selector Switch: This switch selects a factor for the measur ed

value.

The selected factor is also shown at the ×10 multiplier area.

14

Page 27

4.2 Rear Panel

The figure below shows the rear pan el of the SM-8200 Series. However, not e

that the VOLTAGE SELECTO R switches are set for the op eration from 100 V

AC line.

⑱⑰ ⑯ ⑮

Fig. 4.2 Rear Panel

⑭⑬⑫

⑫

accordance with the local AC line voltage (50 or 60 Hz) fo r the

instrument.

For a proper setting, see 1.3 Setting VOLTAGE SELECTOR Switches.

For line voltage change betw een 100 V/120 V and 220 V/24 0 V, the

power fuse amperage must be also changed accordingly.

⑬

⑭

tube. T he am perag e of t he fus e must agr ee wit h the l ocal AC lin e

voltage from which the unit is powered.

AC Line Voltage

100 V/120 V (50/60 Hz) 0.4 A

220 V/240 V (50/60 Hz) 0.2 A

Note: When the AC line voltage for the unit is changed after receipt of

your super megohmmeter, check the fuse amperage.

VOLTAG E SEL ECTO R Swi tch es: Th ese tw o swi tches are t o be s et in

AC LINE Receptacle: This connects the accessory power cord.

TIME LAG FUSE Holder: This holder contains a time lag fuse in a glass

Fuse Amperage

⑮ GND Terminal: This is a ground terminal connected to the chassis of the

unit.

15

Page 28

⑯

signals measured result judgment outputs, optional DC output, and

remote signal input.

For details, see the following sections;

6.5 Comparison and Judgment Function

8. MEMORY CONTROLLED MEASUREMENT

9.2 DC Signal Output

⑰

provided for connection of an external interlocking switch on the

measuring jig designed to block the applicatio n of a high voltage

across the Rx +/

when the switch is in the off position.

If such a switch is not provided, keep this connector plugged with

the accessory shorting plug, instead.

⑱

interfacing. For details, see 7. RS-232C INTERFACE CONNECTIONS.

External Input/Output Termin al Block: This terminal bloc k carries

HV-EN (High Voltage Enable) Interlocking Connector: This connector is

measuring terminals ④ for safety of the operator

RS-232C Interface Co nnector: This conn ector is provided fo r RS-232C

16

Page 29

4.3 Measuring Display

In the measuring mode, the LCD display shows the resultant measured

resistance value and its NO/GO judgment, as well as the measuring voltage

and time.

⑦⑥

⑧

⑨

000

s

2010521.5

⑤

100V

10

3

MΩ

④

③②①

Fig. 4.3

① Test Voltage Indication: This shows the test voltage set with the VOLTAGE

selector switch.

②

Measured Resistance Indication: This shows the measured resistance in

real time. When the measuring time is up, the final value is held

until the next measurement will start.

③

RANGE selector switch.

④

Measuring Range Indication: This shows the measuring range set with the

Analog Indicator: This shows the measured resistance value in analog

referred to the analog resistance scale.

⑤

Analog Resistance Scale: This shows the scale for the analog indicator

reading. When the measuring voltage is changed, the scale and

values are changed, accordingly.

⑥ NO/GO Comparison Judgment Indication: When the NO/GO comparison

judgment function is set on, a judgment of resultant resistance can

be done r efer red to preset hi gh/lo w limi ts. W hen th e com pari son

judgment value is set to 000, the function becomes off.

⑦ Timer Count Indication: This is a count-down timer shown in seconds.

When the timer is set to 000 sec., th e function becomes invali d.

⑧

Comparison Judgment Value Mark: When the comparison judgment

function is set on, a heart mark appears at a position showing the

set value on the measured resistance bar graph.

⑨

Measured Resistance Bar Graph: This shows the measured resistance as

a length of the bar.

17

Page 30

4.4 Measuring Condition Setting Display

The LCD display showing the measuring condition setting.

⑬

000

s

2010521.5

⑫

100V

LOCK

M.S ET

10

3

MΩ

⑭

⑪⑩

Fig. 4.4

⑩ Status and Mode Notice: When the MEASURE/DISCHARGE selector

switch is set to the DISCHARGE position, press the SELECT switch to

enter the setting mode, and the selected mode is shown in this box.

Each time the SELECT switch is pressed, the mode is changed in

the order; C. SET (voltage charging time setting mode) → M. SET

(measuring time setting mode) → COMP (measured value comparison

level setting mode) → BUZZ (buzzer sound level setting mode) →

(blank – measuring display).

When the RANGE selector is set to the CAL position, CAL1 is shown.

With the CAL1 status shown, the press of the SELECT switch changes

the status to CAL2 .

⑪ Highlighted Comparison and Judgment Val ue: When the COMP (co mparison

and judging level setting mode) is selected, the value is shown high lighted, and the it can be changed with the UP and DOWN switches.

⑫ Comparison and Judgment Value Mark: This heart mark is shown when the

comparison and judgment function is set to on, showing the position

of the comparison and judgment level.

⑬ Highlighted Judgment value: This shows the judgment level which can be

changed with the UP/DOWN switches.

⑭ LOCK (Interlocking) Notice: This shows that preparation for the measure ment is not ready, yet. This notice is shown when the interlocking

function is used to show that the HV-EN connector is free, and/or the

Rx /+ measuring terminals are free.

When the LOCK notice is shown, the MEASURE and CHARGE switches

become inoperative.

18

Page 31

4.5 Meanings of the Status and Mode Notices

This describes the meanings of the status and mode notice in the lower left

corner o f th e LCD disp lay.

1) LOCK (Interlocking): The test voltage applyi ng circuit is interlo cked, an

measurement is not ready, yet. This notice is shown when the

interlocking function is in use, but the HV-EN plug or measuring rod

plug is not plugged into the connector.

When the LOCK is shown, the MEASURE and CHARGE switches become

inoperative.

2) CAL1 (Calibration-1): This is shown when the RANGE selector switch is set

to the CAL position.

3) CAL2 (Calibration-2): This is shown when the SELECT switch is pushed

while the CAL1 notice is shown.

4) C. SET (Measuring voltage charging time setting mode): The time can be

adjusted within a range from 0 to 999 seconds.

5) M. SET (Measuring time setting mode): The time can be adjusted within a

range from 0 to 999 seconds.

6) COMP (Comparison judgment value setting mode): The value can be set

within a range from the minimum value for the range to 10 times the

value.

7) BUZZ (Buzzer ON/OFF setting mode): The buzzer can be set ON or OFF when

the resultant comparison judgment is NO.

19

Page 32

5. PREPARA TION FOR A MEASUR EMENT

WARNING

Make sure, before turning the instrument on, that the VOLTAGE

SELECTOR switches on the rear of the unit are properly set to the

positions in agreement with the local AC line voltage. If the agree ment is failed, the unit may bre ak a fire or burning.

WARNING

Be sure to connect the ground prong of the power cord plug to

prevent danger. If grounding of the ground prong is impossible,

connect GND terminal to the ground post of the power line system.

Note: For safety, the measuring voltage cannot be output unless otherwise

the accessory shorting plug is plugged into the HV-EN connector on

the rear of the unit. During measurement, the shorting plug must

be kept plugged in

WARNING

Before trying to plug the shorting plug into the HV-EN connector,

be sure to turn the POWER switch OFF.

.

5.1 Preparation

Confirm the setting of the instrument in the order shown below.

1) Confirm that the VOLTAGE SELECTOR switches on the rear of the unit

are set to the positions in accordance with the local AC line voltage from

which the unit is p owered (Se e 1.3 Set ting the V OLTAGE SELECT OR

Switches.).

2) Confirm that the POWER switch of the unit is positioned at the OFF

(released) position. Note that if the switch is in the ON position, it is

depressed.

3) Plug the accessory power cord into the AC LINE receptacle on the rear of

the unit. Also, plug the plug on the other end of the cord into the

commercial AC line socket.

20

Page 33

4) Confirm that the accessory shorting plug is inserted into HV-EN

connector on the rear the unit.

5) Leave the Rx /+ measuring terminals free at this stage – do not connect

the measuring rods and the sample to be measured to the terminals.

6) Set the RANGE selector switch to the ×1 position – the minimum

Multiplier.

7) Set the VOLTAGE SELECTOR switches to the lowest voltage available.

8) Turn the POWER switch ON.

Allow the unit to warm for a minimum of 30 seconds to obtain the

specified performance. However, a measurement can be done after a

warm-up of several seconds.

5.2 Self-calibration 1

1) Set the RANGE switch to the CAL position. (The display will show CAL1 .)

The calibration will be verified by the internal calibration circuit. Verify

that the measured data display indicates a value within the range of .970

to 1.03.

2) If the value f alls within the no rmal range, the self-calibratio n is complete.

Set the RANGE switch to a position other than

CAL. (If self-calibration 1

yields a result within the normal range, there is no need to perform

self-calibration 2.)

5.3 Self-calibration 2

1) Press the SELECT switch while CAL1 is being displayed. (The display will

show CAL2 ; see “4-4 Measurement Condition Setting Display” for more

information.)

2) Increase the RANGE switch to the

×10

range.

2

3) Verify that the screen is displaying values with 5 digits and press the

SELECT switch.

4) This completes self-calibration 2. Repeat self-calibration 1 and verify

that the v alue falls within the pro per range.

21

Page 34

5.4 Check the Measuring Rods

1) Confirm that V.OUT indicator turns off and that the Rx /+ measu ring

terminals don’t carry a measuring voltage across them.

2) Plug the accessory measuring rods to the Rx +/ measuring terminals

until they are stopped. (Red measuring rod to the Rx measuring

terminal / Bla ck measuring rod to the Rx + measuring terminal)

3) Set the RANGE selector switch to the ×1 position – the minimum Multiplier.

4) Set the VOLTAGE SELECTOR switches to the lowest voltage available.

5) Connect the measuring rods each other. Do not place the measuring rods

4) anywh ere.

6) Push MEASURE / DISCHARGE Switch.

7) Confirm that the analog indicating needle is shown leftward and that the

6 ) indicated value is shown blinking.

8) Push MEASURE / DISCHARGE Switch. Con firm that the Rx /+ measuring

7) terminals don’t carry a measuring voltage across them.

9) Separa te the mea suring rod s

.

22

Page 35

HV-EN shorting plug inserti

on

HV-EN shorting plug insertion

Timer Setting

5.5 Basic Procedures for a Measurement

End

<Preparation>

<Measurement>

VOLTAGE SELCT OR Switch Se tting

VOLTAGE SELCTOR switch setting

Power ON

30-minute warm-up

Calibrat ion

Measuring Rods che cks

Sample Connection

VOLTAGE SELCTOR switch setting

Control Set ting

Measuring Vo ltage Setting

Range Sett ing

-- (See 6.6.1)

Comparison and Judgment V alue Setting

-- (See 6.6.2)

Preparatory Voltage Charging

-- See 6.3.

Measurement -- See 6.1.

Residual Voltage Discharge

-- See 6.2.

<End>

23

Page 36

6. MEASUR EMENT

Red

Black

Measuring

Red Measur

ing

Bar (

“–“)

Black Measuring

6.1 Measuring Method

1) Plug the accessory measuring rods to the Rx +/ measuring terminals

until they are stopped.

■ Red measuring rod to the Rx measuring termina l

■ Black measur ing rod to the Rx + measur ing terminal

N ote that eac h terminal ha s an incomple te plugging detection sw itch.

If the rod is incompletely plugged, the switch is left open, and the

measuring voltage cannot be output.

2) Connect the measuring rods to the sample to measure.

Note 1: When one end of the sample is grounded, connect the black

measuring rod to the grounded end. (See Fig. 6.1.1.)

Note 2: When one end of the sample has a larger surface area which is

exposed to atmosphere than the other end, connect the black

measuring rod to such an end. (See Fig. 6.1.2.)

Sample

試料

赤色測定棒

Measuring

Bar (“– “)

黒色測定棒

Bar (“+”)

試料

Sample

赤色測定棒

黒色測定棒

Bar (“+ “)

Fig. 6.1.1 Fig. 6.1.2

3) Set the VOLTAGE selector switch to the voltage to be used for the

measurement.

4) Set the RANGE selector switch to the range to be expected. If there is no

idea about the approximate insulation value of the sample, set the

selector to the × 1 range. Press the MEASURE switch to start a

measurement. Change the position of the RANGE selector switch to find

the most appropriate position to read the measured value. If the selector

is set to a position out of the measured value, the indicated value is

shown blinking.

Note 1: When the analog indicating needle is shown leftward, select a

smaller range, while if the needle is shown rightward, select a

larger range.

Note 2: To measure a capac itive sample w ithin a poss ible shorte st time,

press the CHARGE switch to change the sample as much as

possible. Then, press the MEASURE switch to start a measurement.

During the measurement, the measured value will be changed with

time. In such a state, the elapsed time after voltage charging

24

Page 37

becomes a significant parameter for the measuring conditions. In

Note 3: When a measuring jig is used, it is recommended to provide an

most cases, the value of 1 minute after voltage charging is read as

a 1 minute rate value. The integrated timer can determine the

value at 1 minute after voltage charging. For details, see 6.6.

interlocking switch with it for safety. For the interlocking, utilize

the HV-EN (high voltage enable) socket on the rear of the unit.

This makes it possible to disarm the jig when the cover of the jig is

opened. For details, see 6.4.

6.2 Discharge Function

This function is intended to discharge the change on the sample connected

to the Rx /+ measuring terminals. Discharg ing is automatically performed

each time the super megohmmeter is turned on, and the measurement

is ended. The sample after measurement must be disconnected from the

terminals after the discharging fun ction is performed.

Status of the MEASURE/DISCHARGE switch can be known by the

indicator.

Indicator

OFF ------ DISCHARGE

In the DISCHARGE status, a resistor of approx. 100 kΩ is internally

inserted to discharge the charge of the sample.

A time required to discharge the charge of the sample depends on the

capacitance of the sample. When the capacitance of the sample is 1μ F, it

takes approx. 1 seconds to reduce the residual voltage down to 5% of the

charged value.

Note: The discharge function does not work if the POWER switch is kept

OFF.

ON ------ MEASURE

6.3 Charge Function

To measure a capacitive sample, charge it with the measuring voltage by

pressing the CHARGE switch. Then, the charge of the sample is completed

within several seconds.

There is no rule to determine the charging time, it is nece ssary to set it to

a fixed time to make the measuring conditions unchanged among samples.

WARNING

When the super megohmmeter is in the charge status do not touch

the Rx /+ me asuring terminals and the s ample being charged.

The measuring voltage selected with the VOLTAGE switch is directly

applied to these parts because there is a fear of electrical shock.

25

Page 38

6.4 Interlocking Function – Using the HV-EN Connector

proper cord to the plug.)

The super megohmmeter generates a high voltage to be used as a testing

power source. It is dangerous if this measuring voltage is output to the

sample not ready for measurement, yet. To protect the operator from a

hazard of ele ctrical sh ock, the HV-EN (h igh voltage enable) conne ctor is

provided on the rear of the unit to provide an interlock ing function in

combination with a measuring jig.

If a measurement does not use a jig with an interlocking mechanism, keep

the HV-EN connector plugged with the accessory shorting plug.

Usage of the HV-EN Connector for Interlocking

Connect the HV-EN connector to a switch to be actuated by the

interlocking mechanism of a measuring jig via an optionally available

HV-EN plug connected with a cord. Fig. 6.4.1 shows an example

interlocking circuit.

The optional accessories shown below have a safety interlocking switch.

SME-8310 – Electrode for plate samples

SME-8311 – Electrode for plate samples

SME-8350 – Shield box

Connect the plug at the end of the measuring cord of the optional

accessory to the HV-EN connector on the rear of the unit.

For connection of a customer designed measuring jig to the HV-EN

connector, use an optional HV-EN plug.

Optional HV-EN Plug

(User should solder a

Interlocking

Fig. 6.4.1

26

Page 39

6.5 Comparison and Judgment Function

This function is provided to sound a built-in buzzer, and turn on the

COMP OUT G/+ terminals when the measured insulation resistance is

lower than the preset judgment value and make the COMP OUT G/+

terminals are of open collector as shown as an equivalent circuit in Fig.

6.5.3. Use this circuit within the conditions shown below:

Voltage: 50 V or less

Current: 50 mA or less

Fig. 6.5.1 shows a circuit diagram for connection with the COMP OUT

terminals.

Fig. 6.5.2 shows the exte rnal input /output term inal block , including the

COMP OUT G/+ terminals.

Fig. 6.5.2 Fig. 6.5.3

Fig. 6.5.1

27

COMPOUT

+

G

Page 40

6.6 Setting a Variety of Functions

A variety of useful functions can be set when the RANGE selector switch is

set to any position other than the CAL , and by us ing the SELECT, UP and

DOWN switches.

Each time the SELECT switch is pushed, the LCD display is changed in the

order of the Measuring Display → C. SET → M. SET → COMP. → BUZZ

→ Measuring Display .

C. SET : Charging timer setting

M. SET : Measuring time setting

COMP. : GO/NO judg ment leve l setting

BUZZ : Buzzer sound ON/OFF setting

6.6.1 Setting the Timer

Example: Setting a measuring time to 50 seconds

Fig. 6.6.1

100V

M.SET

050

DOWN UP

s

10

CHARGE MEASURE/DISCHARGESELECT

RANGE

2

×10

2010521.5

VOLTAGE

100

2

MΩ

1) Press the SELECT switch twice to show the M. SET indication in the

lower left area of the LCD for the measuring timer setting mode.

2) Using the UP and DOWN switches, set the time indication in the upper

ce nter area of the display to 050 seconds.

3) Press the SELECT switch 3 times to return to the measuring display.

To accelerate the change of a value, keep the corresponding UP or DOWN

switch pushed.

6.6.2 Setting the Comparison GO/NO Judging Level

Example: Setting a judgment of NO<100MΩ≦GO for 100 V test voltage

Fig. 6.6.2

100V

COMP

000

DOWN UP

RANGE

2

×10

s

2010521.5

VOLTAGE

100

2

10

MΩ

CHARGE MEASURE/DISCHARGESELECT

28

Page 41

1) Set the VOLTAGE selector switch to 100 V .

2) Set the RANGE selector switch to×102.

3) Press the SELECT switch 3 times to show the COMP indication in the

lower lef t area of the LCD for the compar ison GO/NO jud gment leve l.

4) Using the UP and DOWN switches, set the GO/NO judgment level to

1.00×102 MΩ.

5) Press the SELECT switch twice to return to the measuring display.

To accelerate the change of a value, keep the corresponding UP or DOWN

switch pushed.

Note: The comp arison GO/N O judgment lev el setting c an be effectiv e for

the currently set RANGE and VOLTAGE values, only. If setting is

required for other RANGE and VOLTAGE values , set desired RANGE

and VOLTAGE, first.

6.6.3 Setting Buzzer Sound ON/OFF

000

s

100V

ONBUZZ

10

RANGE

2

×10

2010521.5

VOLTAGE

100

2

MΩ

Fig. 6.6.3

DOWN UP

CHARGE MEASURE/DISCHARGESELECT

1) Press the SELECT switch 4 times to show the BUZZ indication in the

lower left area of the LCD for the buzzer sound ON/OFF setting.

2) Using the UP and DOWN switches, set ON or OFF .

3) Press the SELECT switch once to return to the measuring display.

6.6.4 Setting Charging Time, Measuring Time, Comparison GO/NO

Judging Level and Buzzer Sound ON/OFF

Examp le: Setting for measuri ng conditions below:

Charging Time: 10 seconds

Measuring Time: 50 seconds

Comparison Level: NO<100MΩ≦GO judg ment

Buzzer Sound: Buzzer sounds when NO judgment is resulted.

2

RANGE Position: ×10

VOLTAGE Position: 100 V

29

Page 42

e 1: The set measuring conditions are stored in the memory, and

the contents are kept backed up even if the power is turned

off.

er ranges and

2010521.5

RANGE

×10

VOLTAGE

100

2

s

010

Fig. 6.6.4

100V

C. SET

DOWN UP

10

CHARGE MEASURE/DISCHARGESELECT

2

MΩ

1) Set the VOLTAGE selector switch to 100 V .

2) Set the RANGE selector switch to ×102 .

3) Press the SELECT switch to show the C. SET indication for charging

time setting mode.

4) Using the UP or DOWN switch, set the charging time to 010 seconds.

(Fig. 6.6.4)

5) Press the SELECT switch to enter the value of 010. This action provides

the measuring time setting mode, showing the M. SET indication.

6) Using the UP and/or DOWN switches, set the measuring time to 050

seconds.

7) When this value is OK, press the SELECT switch to enter it. This action

provides the judgment level setting mode, showing the COMP indication.

8) Using the UP and/or DOWN switches, set the judgment level to

1.00×102 MΩ. (Fig. 6.6.2)

9) When this level is OK, press the SELECT switch to enter it. This action

provides the buzzer sound on/off setting mode, showing the BUZZ

indication.

10) Using the UP and/or DOWN switches, set ON or OFF for the buzzer.

(Fig. 6.6.3)

11) Press the SELECT switch to end the measuring condition setting mode,

and go back to the measurement screen.

After setting the measuring conditions as shown in the example, press

the CHARGE switch. Then, the measurement starts after a charging

period of 10 seconds.

Not

Note 2: The comparison jud gment leve l settings ar e valid only for the

range and test voltage used for setting. For oth

test voltages, change the settings, accordingly.

30

Page 43

6.7 Changes in the C urrent F lowing th rough an Insulato r

In insulation resistance measurements, a large amount of current flows

upon the application of the test voltage to the insulator. The current

gradually reduces its value with time, but it takes a time until the value

becomes stable and fixed. This phenomena is due to the combination of the

charging current, absorption current, and leakage current, and it is

generally called dielectric absorption phenomena. The equivalent circuit of

an insulator is considered as shown in Fig. 6.7.1.

R0

C0

R3R2R1

C3C2C1

Rn

Cn

Fig. 6.7.1

When a voltage is applied to the circuit, a charging current flows through a

bank of capacitors, C

other capacitors follow. As the charging progresses the current through R

, C1, C2,….Cn. Firstly, C0 is charged, and

0

0

constantly flows as shown in Fig. 6.7.2.

Curr ent

Charge curr ent

Absorpti on current

0

Volt age

appl ic at io n

(Charge)

Fig. 6.7.2

R

is an insulation resistance to be measured, but, C0, C1, C2,….C

0

Leakage current

Curr ent

short

(Dis charge)

31

Time

n

Page 44

Have series resistors R

, R1, R2,…Rn. Therefore, a measurement of R0 only

0

is very difficult. It is said that, with some insulation resistance

measurements, it takes several hours to a few days for the leakage current

to stabilize. This is not practical.

To avoid this problem, a method is customarily used in the insulation

resistance measurement for convenience to read the resistance value one

minute after charging the test voltage to the sample. This value is called

minute rate value for the resistance value of an insulator, and is widely

employed among a variety of electrical standards.

In the 1-minute rate insulation resistance measurement, the measured

values may vary when a measurement is repeated once or twice with the

same sample. To minimize such a deviation, it is important to completely

discharge the sample before the start of each measurement. The required

discharge time mainly depends upon the charging voltage and the size of

C

in Fig. 6.7.1, but, generally it can be said to be 5 to 6 times longer than

0

the time of test voltage charging.

6.8 Connectivity Precautions

6.8.1 When the Screen Shows LOCK and Measurement Cannot Be Started

The super megohmmeter can output measurement voltages of up to 1,000 V.

Consequently, failure to wire the instrument correctly may pose hazards such

as electric shock. The instrument provides an interlock function in order to

prevent these risks. An HV-EN (high-voltage enable) connector is provided for

interlock function use on the rear of the instrument.

When using the measuring rods (red/black) that come with the instrument,

insert the shorting plug into the HV-EN connector on the rear of the

instrument. If LOCK is displayed at the bottom left of the instrument’s screen,

check the following:

(1) Has the measuring rod (black) been properly inserted into the Rx+

terminal?

(2) Has the shorting plug been properly inserted into the HV-EN connector

on the rear o f the instrume nt?

Display of the LOCK indicator at the bottom left of the screen indicates that

the instrument has detected an issue with the measuring rod or shorting plug

wiring.

32

Page 45

6.8.2 When Using an Optional Electrode for Plate Samples or Shield Box

When using an electrode for plate samples (for e xample the SME-8310; or the

SME-8350 shield box, etc.), which is an option designed specifically for use

with the megohmmeter, the following guidelines should be observed when

wiring the instrument and performi ng measurements:

1) To prevent the hazard of electric shock, be sure to ground either the

ground pin of the 3-pin power cable or the ground terminal on the rear

of the instrument before use. When using a power plug conversion

adapter (3-pin to 2-pin conversion adapter), be sure to ground the

ground lead from the adapter.

2) Connect the option’s red cable to the instrument’s Rx- terminal and the

option’s black cable to the instrument’s Rx+ terminal.

3) Remove the shorting plug from the HV-EN connector on the rear of the

instrument.

4) Connect the interlock (HV-EN) plug from the electrode for plate samples

or the shield box to the HV-EN connector on the rear of the instrument.

5) When using the SME-8350 shield box, directly ground the shield box’s

ground terminal or connect it to the ground terminal on the

megohmmeter.

*When using a shield box, failure to ground the ground terminal may

cause measured values to oscillate.

6) Completely close the electrode for plate samples and shield box lid.

(Starting measurement without first closing the lid completely will

trigger the hazard prevention interlock.)

33

Page 46

7. RS-232C INTERFAC E

7.1 RS-232C Communication Commands

Mnemonic

R Measuring Data Output Format: R

Contents Format

C

L

R

F

Response: ****E*,

Judgment [GO] 0 or [NO] 1

Example: 10.0E4, 0

C

M Starting a Measurement Format: M

L

R

F

Response: 0 (valid) or 1 (invalid)

C

C Starting a Charg ing Format: C

Response:

S Stopping Forcedly Format: S

Response:

L

R

F

0 (valid) or 1 (invalid)

C

L

R

F

0 (valid) or 1 (invalid)

T Measuring Time Setting Format: T *** (000 to 999)

Example: T 60

Response:

C

0 (valid) or 1 (in valid)

G Charging Time Setting Format: G *** (000 to 999)

Example: G 120

Response:

0 (valid) or 1 (in valid)

P Judgment Level Setting Format: P *** (000 to 999)

Example: P . 100

Response:

B

U Measuring Condition

Judgment Buzzer

Setting

Format: B [OFF] 0 or [ON) 1

Example: B 1

Response:

Format: U

Output

Response: Range, Voltage, inter -

0 (valid) or 1 (in valid)

0 (valid ) or status

C

L

R

F

locking, Status

Example: 4, 1000, 0, 2

Range: 0 to 8

Voltage: 5 to 1000

Interlocking: 0[OFF]/1[ON]

Status:

Stand-by – 2

Under measurement – 3

Charging – 4

On setting – 5

Under calibration – 6

Timer in operation – 7

C

I Instrument ID Format: I

L

R

F

Response: Model, Version

Example:SM-8215V1.00

C

L

R

F

C

L

R

L

R

F

C

L

R

F

C

L

R

F

C

R

C

F

C

L

R

F

C

L

R

F

C

L

R

F

L

F

L

R

F

Baud Rate 9600 bps

Data Bit 8 b it

Parity Bi t None

Stop Bit 1 bit

Flow Contr ol RTS/CTS possib le

34

Page 47

7.2 Applications of Commands

1) After each command transmission, make sure to receive the re sponse.

2) For R command, a state only response will be received, depending upon

the conditions at such a time.

Even during measurement, a state 7 only response will be received when

the timer is functioning.

During stand-by, measured data are transmitted once. A command invalid

will be transmitted except for after re-measurement.

3) If a charging time is set upon receipt of a C command, a me asurement is

started as soon as the charging is completed.

4) For a P command, if a value out of the specified measuring range is

received without an actual setting.

7.3 Connector Specifications

Type of Connector: HDBE-9PF (05) [Hirose]

Type of Lock Fitting – HD-LNA (4-40), inch type

Pin Arrangement:

Pin

No.

1 NC

2 TD

3 RD

4 NC

5 SG

6 ER

7 CS

8 RS

9 NC

Example of Connections

1) For connection with a DOS/V personal computer, use a straight 9-pin to

9-pin cable.

《 9-pin》 《9-pin》

5 5

Signal

Line

2 2

3 3

Direction of Signal Flow

Megohmmeter External Unit

Application

No connectio n

Transmission dat a

Receiving data

No connectio n

Signal ground

Data pe ripheral re ady

Send ready signal

Send request signal

No connectio n

6 6

7 7

8 8

35

Page 48

2) For connection with an NEC PC-9801 Series personal computer, use a

straight 9-pin to 25-pin cable.

《 9-pin》 《25-pin》

2 2

3 3

4

5 5

6 6

7 7

8 8

7.4 Printer Output

Via the RS -232C inter face, measure d data can be outp ut to an option al

printer, 9442.

[Printer Output Procedures]

1) Connect the RS-232C interface connector on the rear of the unit, to the

optional p rinter v ia the ded icated co nnection cord .

2) Set the measuring intervals as needed. (See Fig. 6.6.1.)

3) Press the MEASURE switch.

4) When the measurement is completed, the measured data are output to

the prin ter.

Example:

Measured Data – 10.0×10

4

MΩ , GO judgment

Printing – 10.0E4, 0

36

Page 49

8. REMOT ELY CONTROL LED MEAS UREMENT

A measurement can be remotely controlled by shorting the “G” and “+”

terminals of the REMOTE IN of the External Input/Outpu t terminal bl ock on

the rear of the unit. When the terminals are shorted by a remote switch, a

measurement will start, and when opened the measure ment is ended.

Fig. 8.1.1 shows an example wiring and the signal timing.

Fig. 8.1.2 shows the external input/output terminal block.

■ Signal Timing

REMOTE IN OFF OFF

ON

Start of

Measurement

End of

Measurement

Fig. 8.1.1

Fig. 8.1.2

37

Page 50

38 39

Page 51