SM7860

SM7860-51

SM7860-52

SM7860-53

SM7860-54

SM7860-55

SM7860-56

SM7860-57

SM7860-58

SM7860-61

SM7860-62

SM7860-63

SM7860-64

SM7860-65

SM7860-66

SM7860-67

SM7860-68

Instruction Manual

POWER SOURCE UNIT

Be sure to read this manual

before using the device

When using the device for the rst time Troubleshooting

Part Names and Functions

Screen Conguration

Installation and Connection Procedures

July 2018 Revised edition 1

SM7860J961-01 18-07H

p.

p.

p.

10

13

15

Safety Information

Troubleshooting

Error Display

p.

p.

p.

4

53

55

EN

Contents

Introduction

Notation

Verifying Package Contents

Safety Information

Operating Precautions

........................................................1

..............................................................2

............................3

............................................4

.....................................4

1 Overview 9

1.1 Product Overview and Features

1.2 Part Names and Functions

1.3 ScreenConguration

...........................13

...........9

.................10

2 Preparation and Supply

Power

2.1 Installation and Connection

Procedures

2.2 Connecting the Power Cord

2.3 Connecting the Device to the

Measuring Instrument

2.4 Inspection Before Operation

2.5 Turn ON/OFF the power

2.6 Operating Conditions Setting

2.7 Output Setting for the Device

Interlocked

15

............................................15

................16

..........................17

...............18

......................19

..............20

.............................................21

4 External Control 37

4.1 EXT I/O Connector and Signals

Connector Type and Signal Pinouts

Signal Functions

4.2 Timing Chart

4.3 Internal Circuitry

.......................................39

..........................................40

....................................44

.........37

...........38

5 Specications 45

5.1 GeneralSpecications

5.2 BasicSpecications

Graph description and operating

precautions

...............................................50

5.3 Input / Output Functions

.........................45

.............................46

......................52

6 Maintenance and Service 53

6.1 Troubleshooting

6.2 Error Display

6.3 Repairs, Inspections, and Cleaning

6.4 Replacing the Power Fuse

Warranty Certicate

....................................53

.........................................55

...55

..................56

3 Changing the Interface 23

3.1 Overview and Features of the

Interfaces

3.2 InterfaceSpecications

3.3 Connecting the Interface

Using the GP-IB Interface

Using the RS-232C Interface

3.4 ConguringtheCommunications

Protocol

ConguringGP-IBInterface

Communications

ConguringRS-232CInterface

Communications

3.5 Communication Method

Status Byte Register

Event Register

Error Register

3.6 Message List

3.7 ListenerSpecicationPrecautions

Input buffer size

Reading from the output buffer

...............................................23

.......................24

.....................26

GP-IB

..................................................27

GP-IB

...........................27

RS-232C

.................................30

..........................................31

...........................................33

.........................................34

........................................36

..............26

RS-232C

.......................28

.......................28

..................36

.....26

.....36

SM7860J961-01

i

Contents

ii

Introduction

Introduction

Thank you for purchasing the Hioki Model SM7860 series Power Source Unit.

To obtain maximum performance from the device over the long term, be sure to read this manual carefully

and keep it handy for future reference.

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so. It is assumed that the reader possesses basic electrical knowledge (equivalent to that of

someone who graduated from the electrical program at a technical high school).

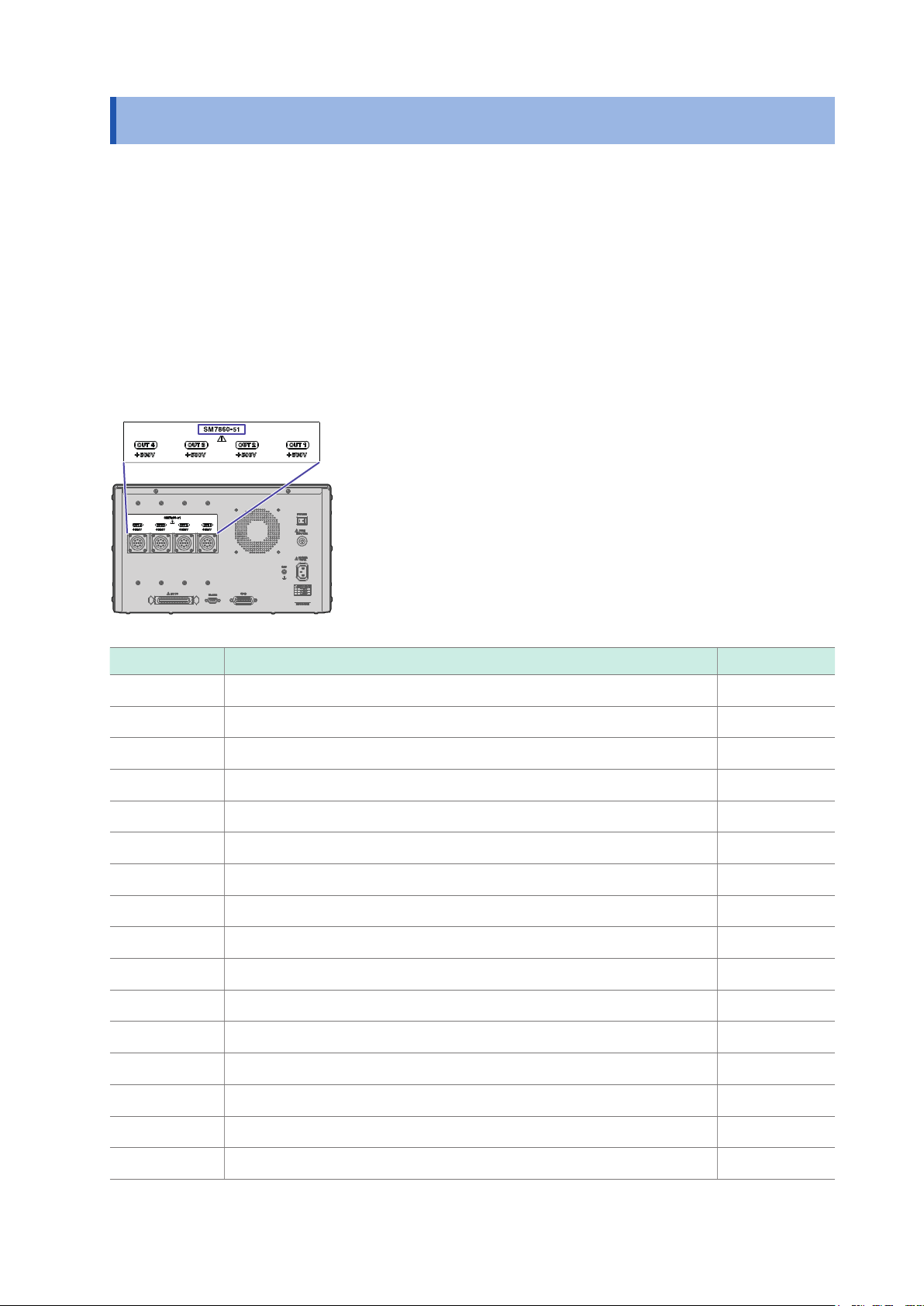

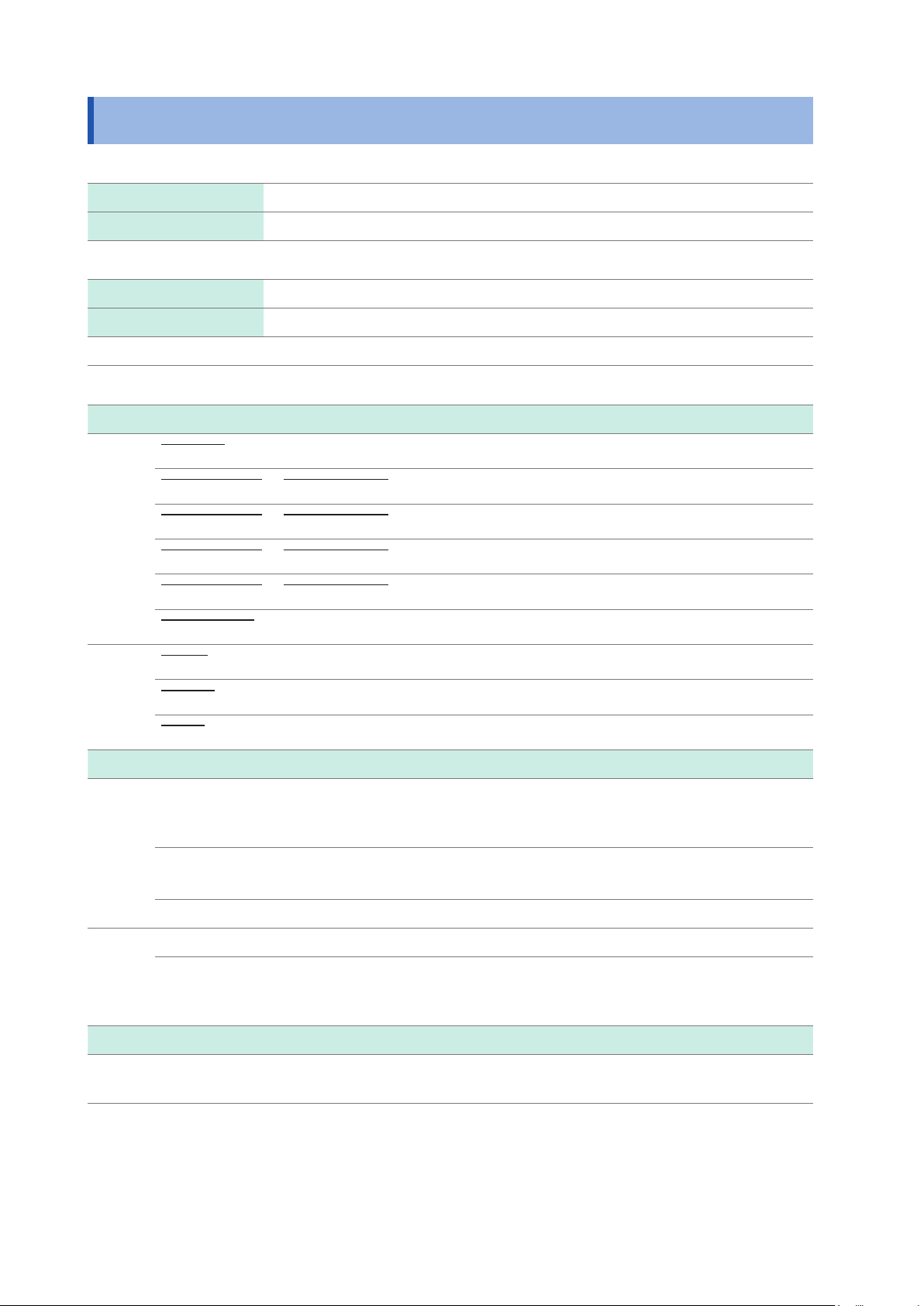

Finding the product’s model number

You can nd the model number on the rear of the device.

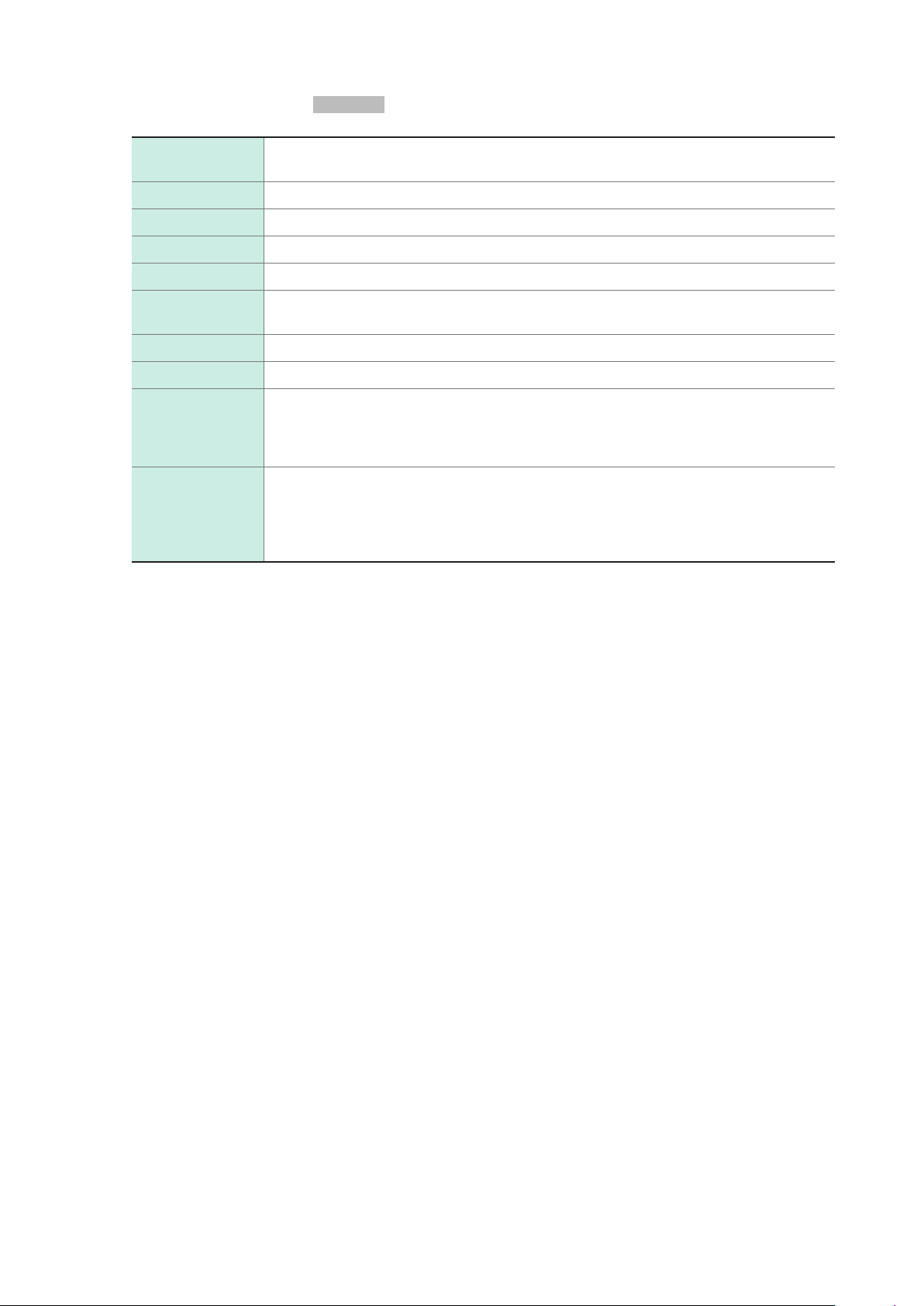

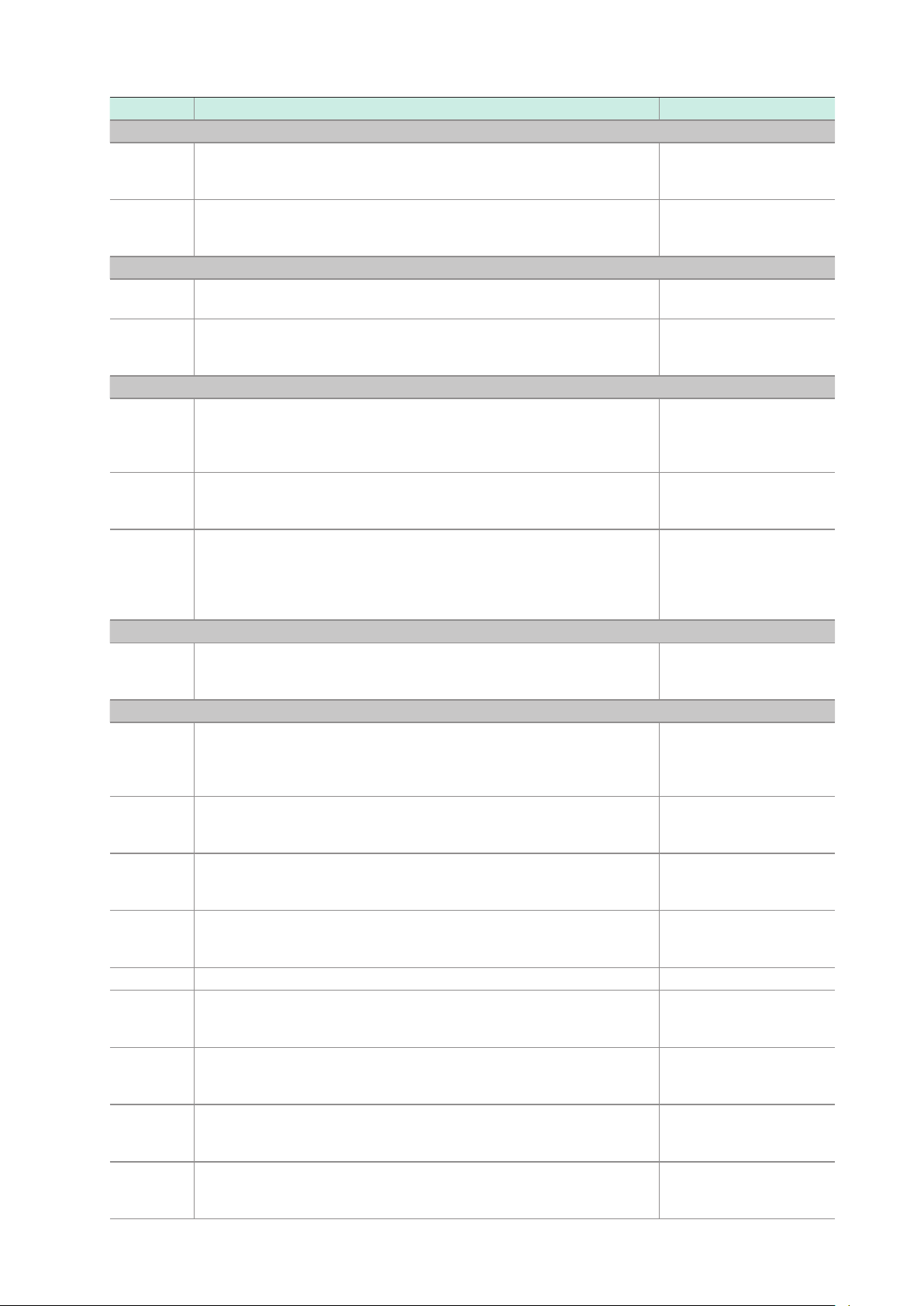

Model Overview Supply voltage

SM7860-51 500 V × 32 channels 100 V to 110 V

SM7860-52 1000 V × 32 channels 100 V to 110 V

SM7860-53 500 V × 16 channels, −500 V × 16 channels 100 V to 110 V

SM7860-54 1000 V × 16 channels, −1000 V × 16 channels 100 V to 110 V

SM7860-55 500 V × 8 channels, −500 V × 8 channels, discharge × 16 channels 100 V to 110 V

SM7860-56 1000 V × 16 channels, −1000 V × 16 channels, discharge × 16 channels 100 V to 110 V

SM7860-57 10 V × 24 channels, discharge × 8 channels 100 V to 110 V

SM7860-58 500 V × 24 channels, discharge × 8 channels 100 V to 110 V

SM7860-61 500 V × 32 channels 220 V

SM7860-62 1000 V × 32 channels 220 V

SM7860-63 500 V × 16 channels, −500 V × 16 channels 220 V

SM7860-64 1000 V × 16 channels, −1000 V × 16 channels 220 V

SM7860-65 500 V × 8 channels, −500 V × 8 channels, discharge × 16 channels 220 V

SM7860-66 1000 V × 16 channels, −1000 V × 16 channels, discharge × 16 channels 220 V

SM7860-67 10 V × 24 channels, discharge × 8 channels 220 V

SM7860-68 500 V × 24 channels, discharge × 8 channels 220 V

1

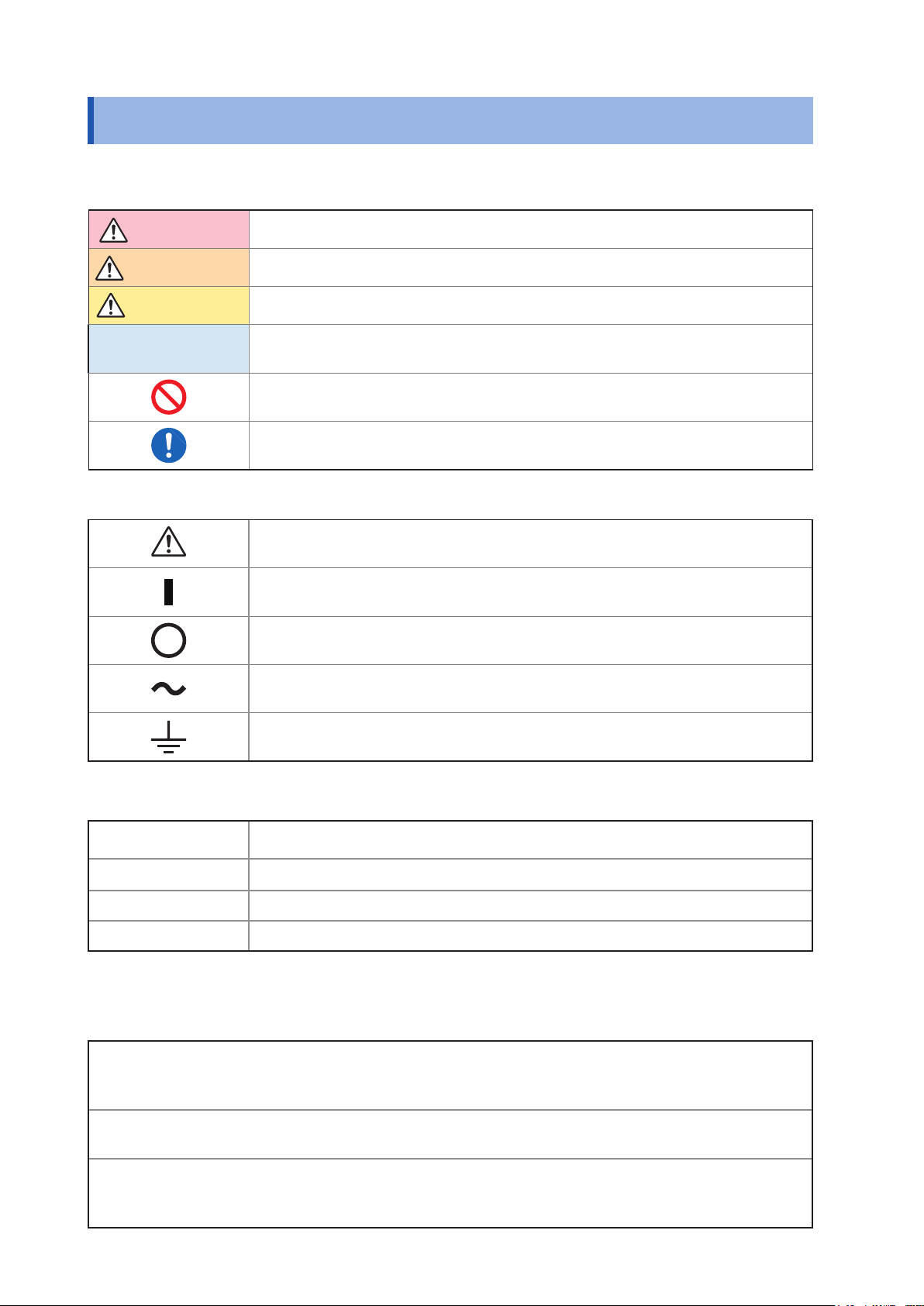

Notation

Notation

Concerning Safety

In this document, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Imminent risk of operator death or serious injury

Potential for operator death or serious injury

Potential for minor operator injury or device damage or malfunction

Indicates information related to the operation of the device or maintenance tasks

with which the operators must be fully familiar.

Prohibited actions

Actions that must be performed

Symbols Afxed to the Device

Precaution or hazard (See “Operating Precautions”.)

ON side of the power switch

OFF side of the power switch

AC (alternating current)

Grounding terminal

Others

*

p.

[ ]

ON

Additional information is presented below.

Indicates the location of reference information.

Key names are indicated in brackets.

Names and keys on the screen are shown in boldface.

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading), and dgt. (digit) values, with

the following meanings:

f.s. (maximum display value)

f.s.

rdg.

The maximum displayable value. This is usually the name of the currently

selected range.

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring device.

dgt. (resolution)

dgt.

The smallest displayable unit on a digital measuring device, i.e., the input value

that causes the digital display to show a “1” as the least-signicant digit.

2

Verifying Package Contents

Verifying Package Contents

When you receive the device, inspect it carefully to ensure that no damage occurred during shipping.

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to

operate according to the specications, contact your authorized Hioki distributor or reseller.

Device and Accessories

Conrm that you have received the following items:

Model SM7860 series Power Source Unit

Power cord

Instruction Manual (This document)

Options

The following options are available for the device. Contact your authorized Hioki distributor or reseller

when ordering.

Model 9637 RS-232C Cable (9pin-9pin/1.8 m) Cross

Model 9151-02 GP-IB Connector Cable 2 m

Model L2221 Connector Voltage output

3

Safety Information

Safety Information

Before using the device, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage to the

device. Be certain that you understand the instructions and precautions in the

manual before use.

WARNING

• With regard to the electricity supply, there are risks of an electric shock,

heat generation, re, and arc ash due to a short-circuit. Individuals using

an electrical measuring device for the rst time should be supervised by a

technician who has experience in electrical measurement.

• Protective gear

This device is measured on a live line. To prevent an electric shock, use

appropriate protective insulation and adhere to applicable laws and regulations.

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various functions.

Checks before use

DANGER

If the connection cord or the device is damaged, there is a risk of an electric

shock. Perform the following inspection before using the device:

• Check that the coatings of the connection cords are neither ripped nor torn and

that no metal parts are exposed. Using the device under such conditions could

result in an electric shock. Replace the connection cords with those specied

by our company.

• Verify that the device operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized

Hioki distributor or reseller.

WARNING

To prevent an electric shock, conrm that the white or red portion (insulation

layer) inside the cable is not exposed. If a color inside the cable is exposed, do

not use the cable.

4

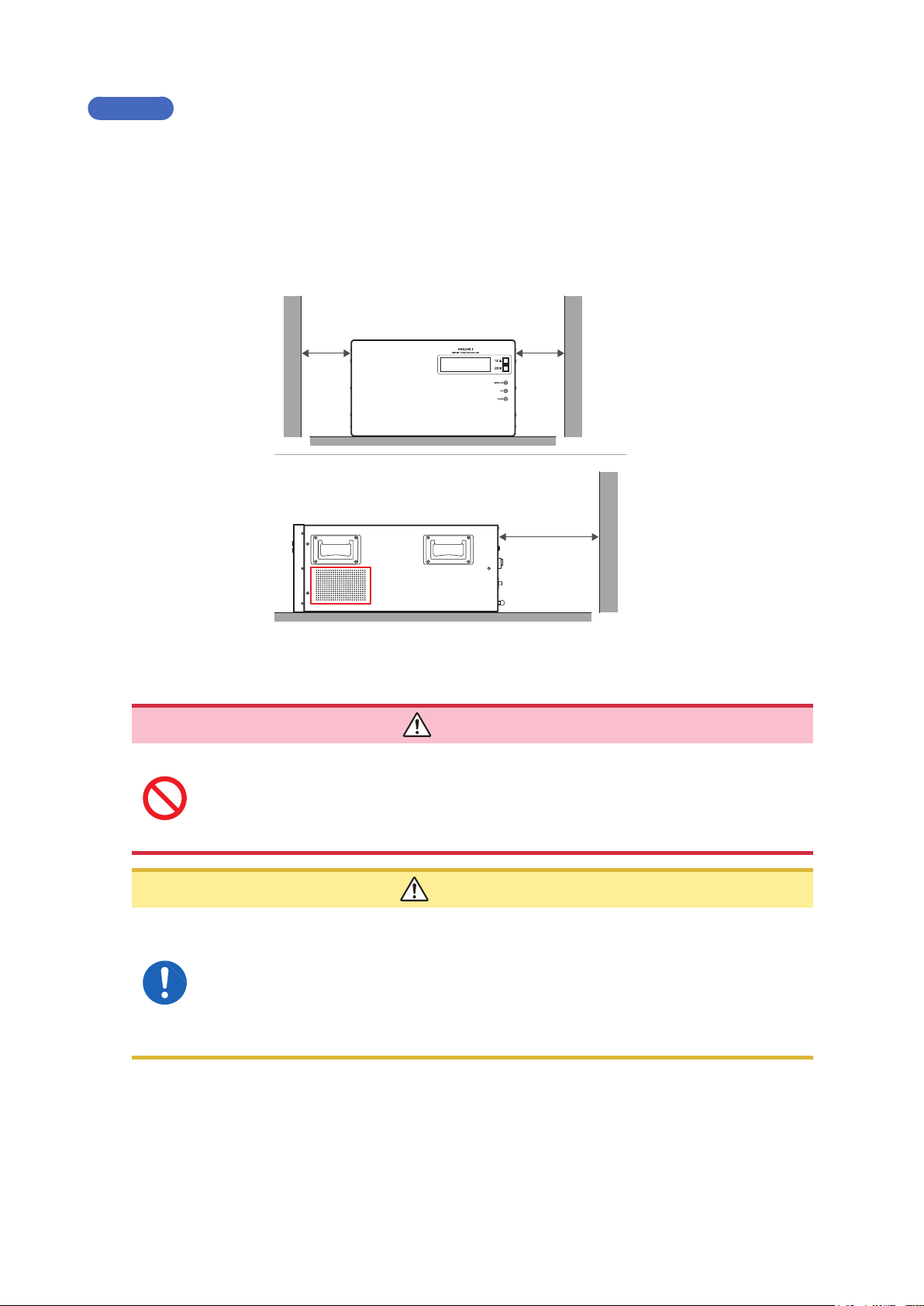

Installing the device

• Ventilation holes for heat radiation are provided on the side and rear panels of

the device. Leave sufcient space around the ventilation holes and install the

device with the holes unobstructed. Installation of the device with the ventilation

holes obstructed may cause a malfunction or a re.

• Unplugging the power cord kills power to the device. Be sure to provide enough

unobstructed space to unplug the power cord immediately in an emergency.

Installing the device in inappropriate locations may cause a malfunction of device

or may give rise to an accident. Avoid the following locations:

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

Operating Precautions

WARNING

CAUTION

Failure to observe the following precaution may result in bodily injury.

• The device weighs approx. 47 kg (Model SM7860-57 and SM7860-67: approx. 34 kg).

It should be moved by at least two people, who should grip it using the handles on the

left and right sides. The center of gravity is located on the front side of the device.

• The device is heavy. When transporting it, follow your company’s workplace safety

standards to assure safety (for example, by wearing non-slip gloves and protective

footwear).

Do not place the device on an unstable table or inclined place. Dropping or knocking

down the device can cause injury or damage to the device.

5

Operating Precautions

Installing

Prolonged operation in hot temperatures will shorten the device’s service life. Keep the ambient temperature

as low as possible.

• Avoid obstructing the ventilation holes.

• To prevent overheating, be sure to leave the specied clearances around the device.

• When rack-mounting the device, fans must be installed above or on top of the rack to ensure proper

ventilation. Be sure that the rack is adequately ventilated so that the internal temperature remains at or

below 40°C.

Handling the Device

• Do not use the device with circuits that exceed its ratings or specications.

Doing so may damage the device or cause it to become hot, resulting in a bodily

injury.

• Do not short-circuit two wires to be measured by bringing the cable into contact

with them. Arcs or such grave accidents are likely to occur.

50 mm or more

Prevent from

blocking

50 mm or more

100 mm or more

DANGER

CAUTION

Failure to observe the following precaution may result in bodily injury.

• The device weighs approx. 47 kg (Model SM7860-57 and SM7860-67: approx. 34 kg).

It should be moved by at least two people, who should grip it using the handles on the

left and right sides. The center of gravity is located on the front side of the device.

• The device is heavy. When transporting it, follow your company’s workplace safety

standards to assure safety (for example, by wearing non-slip gloves and protective

footwear).

6

Handling the Cords

If the insulation on a cord melts, the metal conductor may be exposed. Do not use

any cord whose metal conductor is exposed. Doing so could result in an electric

shock, burn, or other hazards.

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

from the outlet or device.

To prevent cord damage, do not step on cords or pinch them between other objects. Do

not bend or pull on cables at their base.

IMPORTANT

Use only the specied connection cords. Use of any cable not specied by our company may

result in incorrect measurements due to poor connection or other reasons.

Operating Precautions

WARNING

CAUTION

To ensure accurate measurements

• Warm up the device an hour or more before use.

• The device should be calibrated once a year.

Transporting Precautions

• To ensure safe handling, when transporting the device, please use the original box and packing

materials, but do not use if the box is damaged or warped, or if the packing materials are in poor

condition or incomplete.

• When packing the device, make sure to disconnect power supply cords from the main device.

• When transporting, avoid dropping or other excessive impacts.

7

Operating Precautions

8

1

Overview

1.1 Product Overview and Features

The SM7860 series Power Source Unit is a power source designed for use with the SM7420 Super

Megohm Meter and SM7810‑20 Super MΩ HiTester. When used in conjunction with the SM7420 or

SM7810‑20, the SM7860 serves as an ideal power source for automatic testing and measurement of

capacitors.

Positive- and negative-polarity output / Multi-channel output

• The device supports multichannel systems with up to 32 channels.

• The output voltage can be set separately for two circuits, each consisting of 8 or 16 channels.

• The device provides both positive‑ and negative‑polarity power sources.

• It can be used to create an optimal testing line with the minimum necessary number of power sources.

Independent on/off output switching and current limitations for all channels

• Since each channel has its own output on/off switch, it is possible to control voltage application

without an external circuit (allowing charging and discharging).

• Use of semiconductor switches eliminates the need for maintenance.

• Ability to limit current for individual channels means the measurement of other channels won’t be

affected when a target workpiece has a short.

Variable output current limit value

• 500 V output model: The output current limit can be set as desired from 2 mA per channel to 50 mA

per channel.

• 1000 V output model: The output current limit can be set as desired from 2 mA per channel to 10 mA

per channel.

1000 V output voltage model

• The line includes a model that can generate output of up to ±1000 V.

High-current output at 50 mA/channel*

• The device can quickly charge high‑capacity MLCC (multi‑layer ceramic capacitor). Number of

charges can be reduced.

* For the 1000 V model, limited to 10 mA/channel.

Standard interfaces

• Devices ship standard with EXT. I/O, GP‑IB, and RS‑232C interfaces for sequencing. Interfaces are

used to congure and power the device.

Interlock function

• Since the device outputs measurement and charging voltages when measurement starts, erroneous

operation poses the risk of electric shock. An interlock function is used to ensure safe measurement.

Settings can be congured by sending signals via the device’s external I/O interface.

9

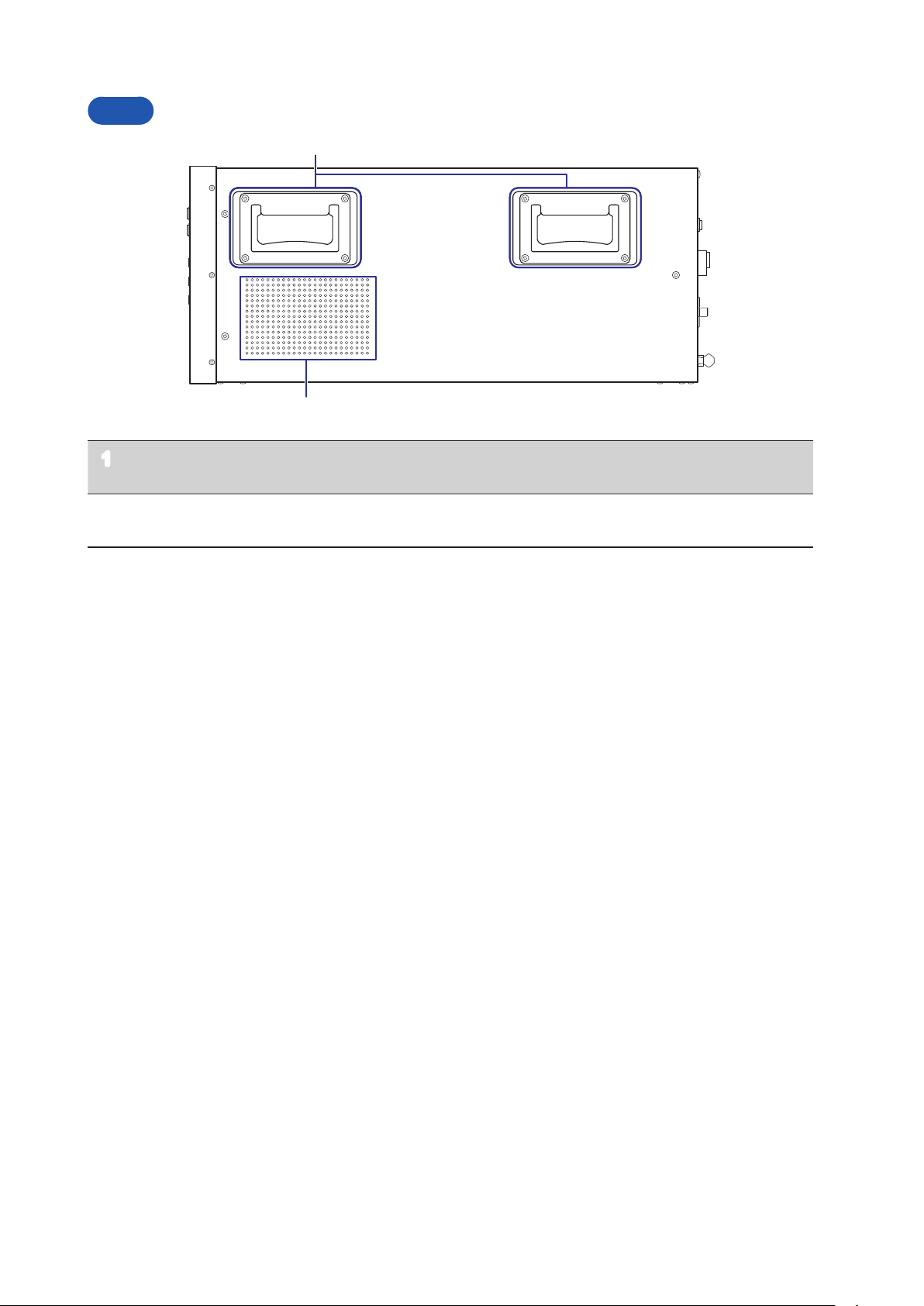

Part Names and Functions

1 2

3

4

5

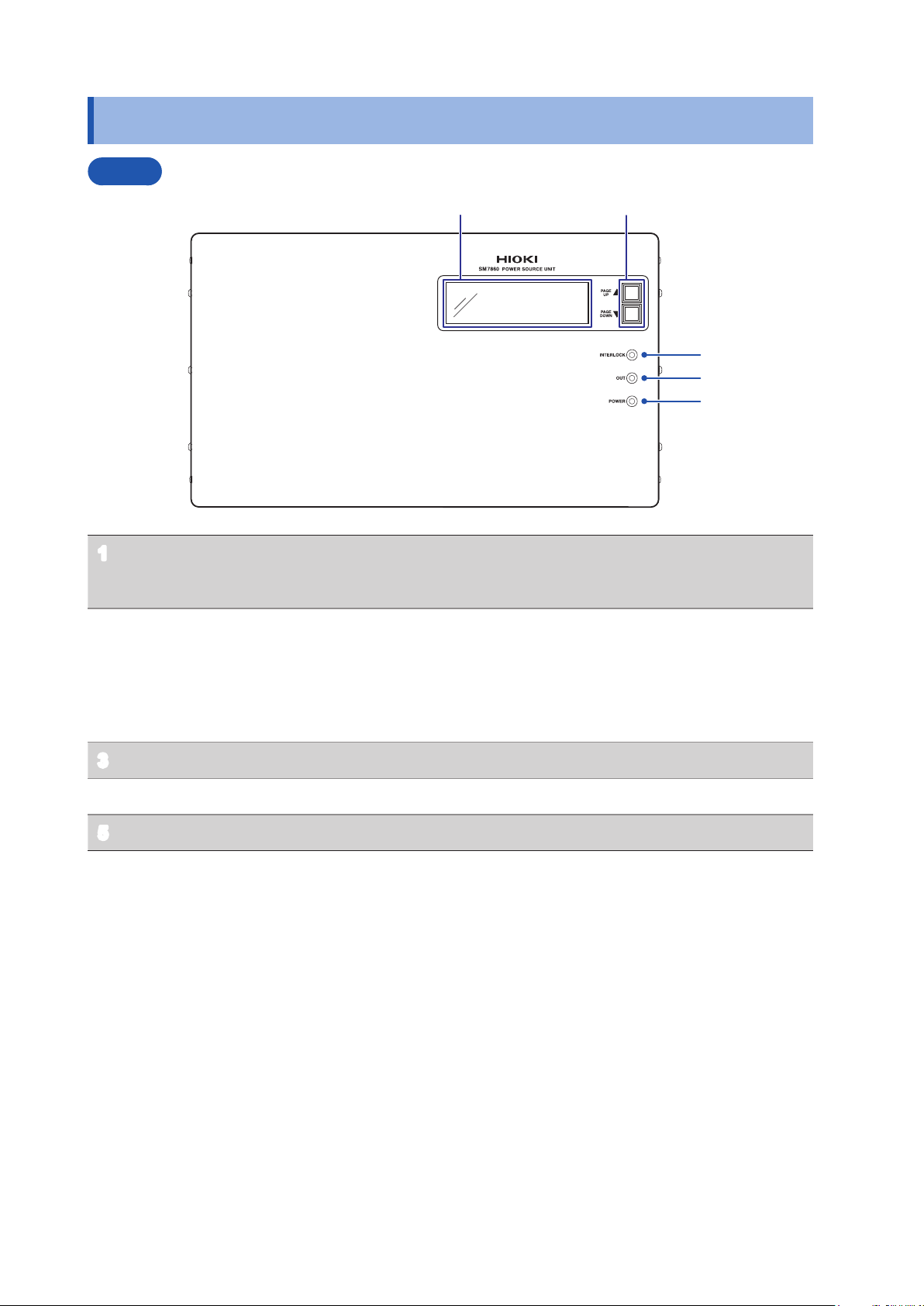

1.2 Part Names and Functions

Front

Display (LCD) The screen uses a 2‑page layout to display setting values

1

and setting status information.

Refer to “1.3 Screen Conguration” (p. 13)

Scroll keys

2

[PAGE UP▲], [PAGE DOWN▼]

Interlock indicator (INTERLOCK) Lights up when the interlock is on.

3

Voltage output indicator (OUT) Lights up when a voltage is being output.

4

Power indicator (POWER) Lights up when the device is on.

5

• Use to scroll the display (LCD).

Refer to “1.3 Screen Conguration” (p. 13)

• Used to assign the GP-IP address and to congure the

output setting for the device interlocked.

Refer to “Conguring GP-IB Interface Communications

GP-IB” (p. 27)

10

Rear

1 32

4

5

6 789

10

Part Names and Functions

Voltage output terminal Voltage is output. Connect the optional Model L2221 Connector.

1

Ventilation holes Keep clear of obstructions.

2

Power switch (POWER) Turns the device on and off.

3

Fuse holder (FUSE) Fuse can be replaced.

4

Power inlet Connect the supplied power cord.

5

GND terminal Serves as the ground terminal. Connects to the device’s enclosure.

6

GP‑IB connector Connect to a PC when using the GP‑IB interface.

7

RS‑232C connector Connect to a PC when using the RS‑232C interface.

8

Refer to “2.3 Connecting the Device to the Measuring Instrument”

(p. 17)

Refer to “Installing” (p. 6)

: Power ON

: Power OFF

Refer to “2.5 Turn ON/OFF the power” (p. 19)

Refer to “6.4 Replacing the Power Fuse” (p. 56)

Refer to “2.2 Connecting the Power Cord” (p. 16)

Refer to “Using the GP-IB Interface GP-IB” (p. 26)

Refer to “Using the RS-232C Interface RS-232C” (p. 26)

EXT I/O connector The EXT I/O connector can be used to control the device.

9

Refer to “4 External Control” (p. 37)

Serial number The serial number consists of 9 digits. The rst two (from the left)

10

indicate the year of manufacture, and the next two indicate the

month of manufacture.

Required for production control. Do not peel off the label.

11

Part Names and Functions

1

2

Side

Handle (total of 4, located on the

1

left and right sides of the device)

Ventilation holes Keep clear of obstructions.

2

It should be moved by at least two people, who should grip

it using the handles on the left and right sides.

Refer to “Installing” (p. 6)

12

Screen Conguration

1

3 4 5 6

27

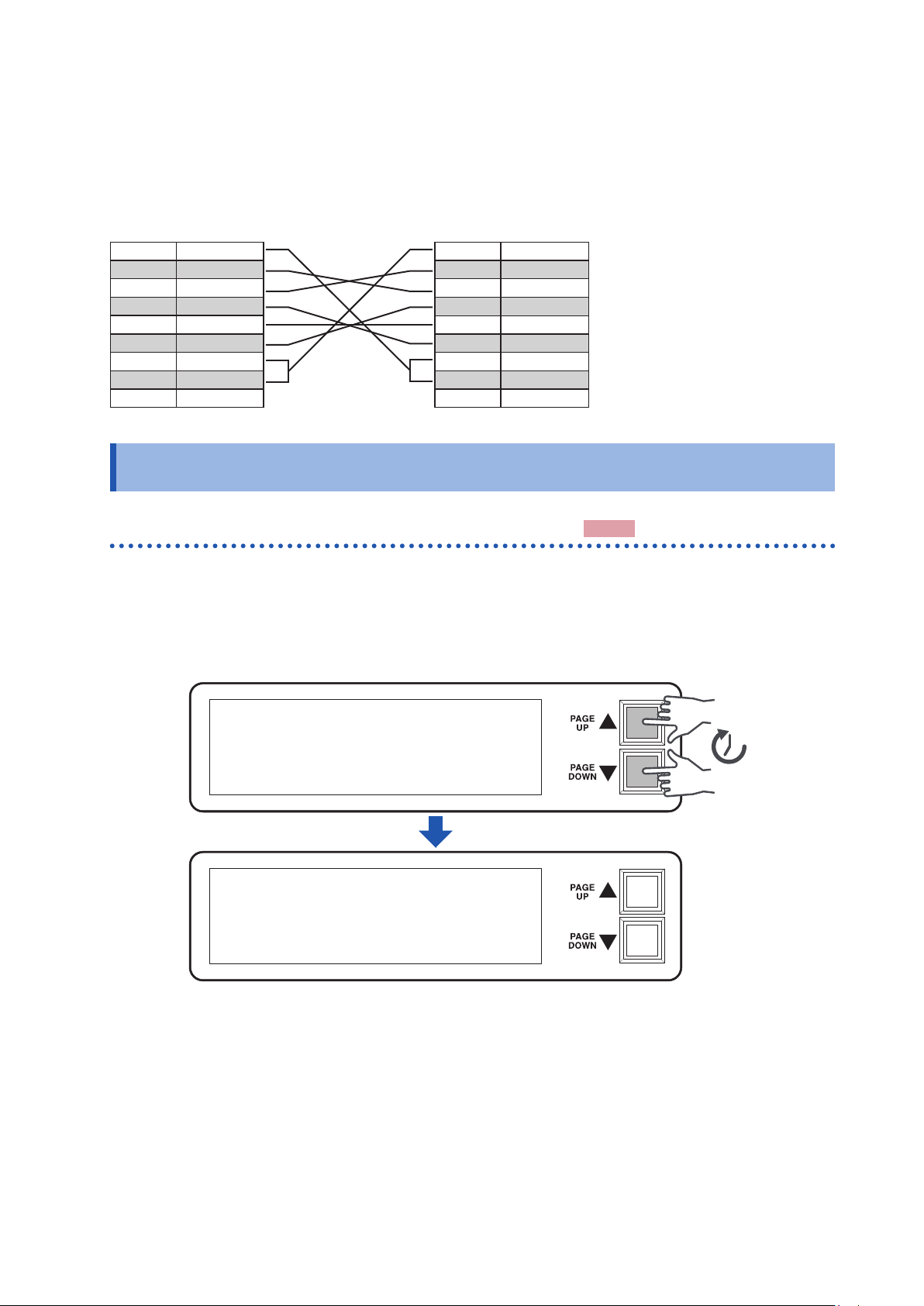

1.3 Screen Conguration

The display (LCD) consists of two display pages (Screen P1, Screen P2).

• Screen P1 is displayed when the device is turned on.

• The display pages can be scrolled using the scroll keys ([PAGE UP▲], [PAGE DOWN▼]) to the right of

the screen.

• You can select a display page directly by sending a “

interface. Refer to “3.6 Message List” (p. 34)

Screen P1: Displays output voltage settings

P1

PAG

” command from the GP-IB or RS-232C

VA (+) IR:1000.0

VB (+) IR: 250.0

TERMINAL:

OUT1:11100000

OUT2:11100000

OUT3:11100000

OUT4:11100000

L

Output voltage setting VA : Displays the power supply A circuit voltage setting.

1

VB : Displays the power supply B circuit voltage setting.

( Display example: VA (+) IR: 1000.0

Indicates that the power source’s A circuit is set to 1000.0 V.)

Temperature error display When a temperature error is detected, TEMP blinks.

2

Key lock display When the keys are locked, L is displayed.

3

Terminal output setting

4

state

Displays rows 1 through 8 of OUTn (where n indicates a value from 1

to 4), from left to right.

The setting is 0 or 1.

0 : High‑impedance

1 : ON

CLM1: 10mA

CLM2: 10mA

CLM3: 10mA

CLM4: 10mA

VMA: 1000.0

VMB: 250.0

TEMP

TEMP

OK

OK

Monitor voltage value VMA : Voltage monitor value for the power supply A circuit.

5

VMB : Voltage monitor value for the power supply B circuit.

The zero decimal point’s position is xed using zero suppression.

Voltage error alarm results

6

OK: The monitor voltage (5) error relative to the output voltage setting

(1) falls within the normal range relative to the voltage error alarm

setting (8, p. 14).

NG: The monitor voltage (5) error relative to the output voltage setting

(1) indicates an error relative to the voltage error alarm setting (8,

p. 14).

13

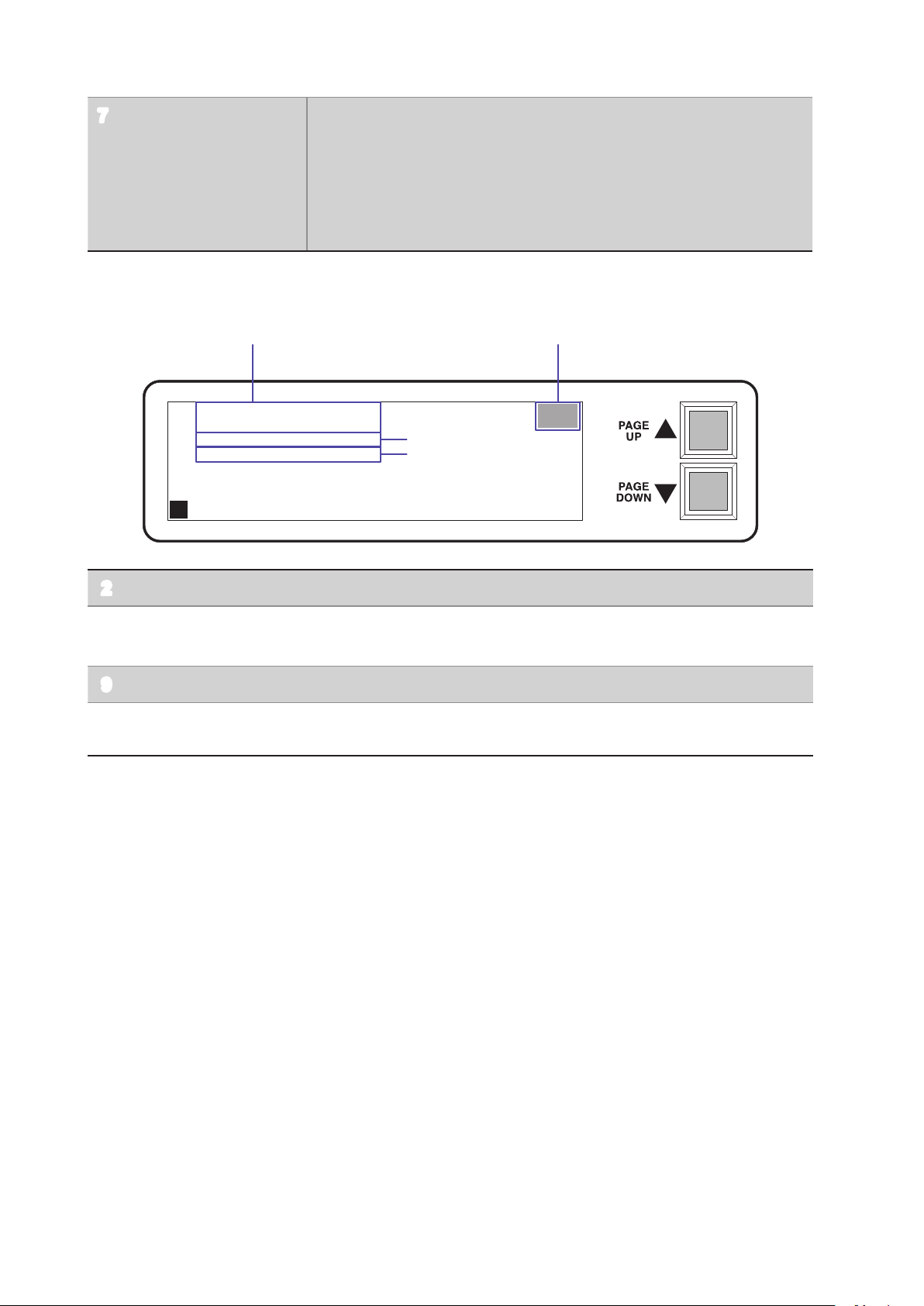

Screen Conguration

8

2

P2

Output current limit value CLM1 : OUT1 output current limit value setting display

7

CLM2 : OUT2 output current limit value setting display

CLM3 : OUT3 output current limit value setting display

CLM4 : OUT4 output current limit value setting display

The digit following CLM corresponds to OUT1 to 4.

( Display example: CLM1: 10mA

Indicates that the current output from OUT1 is limited to 10 mA.)

Screen P2: Displays alarms, the GP-IP address, and output setting for the device interlocked.

VA ALARM : 19

VB ALARM : 19

GPIB ADDR: 1

ILOCK DCHG: OFF

9

10

TEMP

TEMP

L

Temperature error display When a temperature error is detected, TEMP blinks.

2

Voltage error alarm setting VA ALARM : Power supply A circuit voltage error alarm setting ± (%)

8

VB ALARM : Power supply B circuit voltage error alarm setting ± (%)

GP‑IB address Refer to “Using the GP-IB Interface GP-IB” (p. 26)

9

Output setting for the

10

device interlocked

Refer to “2.7 Output Setting for the Device Interlocked” (p. 21)

14

2

Preparation and Supply Power

2.1 Installation and Connection Procedures

Be sure to read the “Operating Precautions” (p. 4) before installing and connecting the device.

3

4

6

Front Rear

Install the device. (p. 5)

1

Connect the power cord. (p. 16)

2

Connect the device to the measuring instrument. (p. 17)

3

Connect the external interface.

4

• Using the GP-IB or RS-232C interface (p. 23)

• Using the EXT I/O (p. 37)

Complete the pre-use inspection. (p. 18)

5

Be sure to inspect the device prior to use.

2

Turn the power on. (p. 19)

6

Make device settings. (p. 20)

7

(via the external interface)

Activate the power source.

8

15

Connecting the Power Cord

2.2 Connecting the Power Cord

WARNING

• Before turning the device on, make sure the supply voltage matches that indicated

on its power connector. Connection to an improper supply voltage may damage the

device and present an electrical hazard.

• To prevent an electric shock and to maintain the safety specications of this device,

connect the power cord provided only to an outlet.

• Before using the device, make sure that the insulation on the power cord is

undamaged and that no bare conductors are improperly exposed. Using the device in

such conditions could cause an electric shock, so replace the power cord with those

specied by our company.

CAUTION

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the

outlet or device.

Turn off the power before disconnecting the power cord.

Connection Method

1

Power inlet

2

Conrm that the device is turned off.

1

Conrm that the supply voltage

2

matches the device, and connect the

power cord to the power inlet on the

device.

Plug the power cord into the outlet.

3

This completes the process of

connecting the power cord.

16

Connecting the Device to the Measuring Instrument

2.3 Connecting the Device to the Measuring Instrument

WARNING

To prevent an electric shock or damage to the equipment, always observe the following

precautions when connecting to voltage output terminal:

• Always turn off the device and any devices to be connected before connecting the

voltage output connectors.

CAUTION

To avoid damage to the device, be sure to observe the following precautions:

• Do not connect the device to a load with a charge in excess of the output voltage range.

• Do not connect the device to a load with a charge that has the opposite polarity of the output

voltage range.

• Do not connect the device to a load that has a charge when the device is turned off.

Connection Method

Conrm that the device is turned off.

1

Connect model L2221 Connector*1

OUT1

2

(optional) to the voltage output

terminal on the rear of the device.

This completes the process of

connecting the device to the

measuring instrument.

1

OUT2*

Circuit A

OUT3

Circuit B

OUT4*

Circuit B

1

2

*1: Refer to “Voltage output pin assignment specications” described below to modify the L2221 to

connect measurement targets.

Voltage output pin assignment

specications

3

2

1

Pin No.

1 CH1 CH1 CH1 CH1

2 CH2 CH2 CH2 CH2

3 CH3 CH3 CH3 CH3

Circuit A

2

7

10 8

9

456

4 CH4 CH4 CH4 CH4

5 CH5 CH5 CH5 CH5

6 CH6 CH6 CH6 CH6

7 CH7 CH7 CH7 CH7

8 CH8 CH8 CH8 CH8

9 NC NC NC NC

10 COM COM COM COM

*1: On the SM7860-55, -56, -65, and -66, serves as the discharging terminal.

*2: On the SM7860-55, -56, -57, -58, -65, -66, -67, and -68, serves as the

discharging terminal.

17

Inspection Before Operation

2.4 Inspection Before Operation

Verify that the device operates normally to ensure that no damage occurred during storage or shipping. If

you nd any damage, contact your authorized Hioki distributor or reseller.

Inspection of peripheral devices

• Is the power cord insulation torn, or

is any metal exposed?

• Is the connection cord insulation

torn, or is any metal exposed?

Not exposed

Inspection of device

Is there any damage on the device?

No

Does the supply voltage of your

power source match the supply

voltage indicated on the power

source inlet on the rear of the

device?

Exposed

Do not use them if they are damaged

because it may cause an electric shock.

(Replace with a new cord.)

Yes

If any, request repair.

No

Use of a supply voltage outside the

specied range may damage the device

or cause an electric shock.

Yes

The inspection is complete.

Please read the “Operating Precautions” (p. 4) before use.

18

2.5 Turn ON/OFF the power

WARNING

Before turning the device on, make sure the supply voltage matches that indicated on

its power connector. Connection to an improper supply voltage may damage the device

and present an electrical hazard.

When turning the device on and off, do not touch the voltage output terminals. Doing so

may cause an electric shock.

CAUTION

When turning the device on and off, do not connect a load to the voltage output terminals.

Turning the device on or off with a load connected may damage the load.

Turn on the power

Turn ON/OFF the power

Turn on the power switch.

The power indicator and display (LCD) on

the front of the device will light up.

Turn off the power

Before Starting Measurement

To obtain precise measurements, provide

about an hour warm-up after turning on the

power.

Turn off the power switch.

19

Operating Conditions Setting

2.6 Operating Conditions Setting

This section describes how to set the operating conditions according to the manner in which the device is

to be used. Settings are congured via either of the device’s external interfaces:

Refer to “3 Changing the Interface” (p. 23)

The device cannot be congured directly in a standalone manner.

Setting function Description of operation and settings Reference

Output voltage

Voltage error alarm

LCD display mode

Sets the output voltage.

Setup ranges: 1.0 V to 1000.0 V (0.1 V resolution)

Generates an alarm when the monitor voltage error relative to the output

voltage setting falls outside the set value range.

Setup ranges: ±2 to ±19% (1% resolution)

Turns the LCD display on and off.

OFF/ ON

p. 34

p. 34

p. 35

20

Output Setting for the Device Interlocked

3 s

2.7 Output Setting for the Device Interlocked

This section describes how to choose between an impedance state and a discharging state for the output

with the device interlocked.

This setting remains the same even after the device is initialized.

ILOCK DCHG: OFF High-impedance state (Default)

ILOCK DCHG: ON Discharging state

Press and hold both of the scroll keys ([PAGE UP▲] and [PAGE DOWN▼]) on the right of

1

the screen simultaneously for approx. 3 s.

(The address can be set from the P1 or P2 screen.)

The GP-IB-address assigning screen is displayed.

VA (+) IR:1000.0

VB (+) IR: 250.0

TERMINAL:

OUT1:11100000

OUT2:11100000

OUT3:11100000

OUT4:11100000

GPIB ADDR: 1

Press and hold both the scroll keys ([PAGE UP▲] and [PAGE DOWN▼]) again

2

CLM1: 10mA

CLM2: 10mA

CLM3: 10mA

CLM4: 10mA

VMA: 1000.0 OK

VMB: 250.0 OK

simultaneously for 3 s.

The setting screen for the output setting for the device interlocked is displayed.

Press either of the scroll keys ([PAGE UP▲] or [PAGE DOWN▼]).

3

The output state is switched.

ILOCK DCHG: OFF

ILOCK DCHG: ON

Turn off the device once you have nished conguring the settings.

4

21

Output Setting for the Device Interlocked

22

3

The mark shown below indicates that the following instructions are specic to the RS-232C or the GP-IB

interface. Instructions without these symbols are for both the RS-232C and the GP-IB interface.

Changing the Interface

GP-IB

RS-232C

Before communicating

When connecting a GP-IB or RS-232 cable, be sure to secure the connector in place with screws or other

appropriate hardware.

When issuing commands that contain data, make sure that the data is provided in the specied format.

1

2

3

: GP-IB interface only

: RS-232C interface only

Connect the cable. (p. 26)

Connect the device and controller (PC etc.) with a GP-IB connection cable or RS-232C interface

cable.

Set the communications protocol.

GP-IB

RS-232C

(p. 28)

Set the transmission format.

Enter a GP-IB address. (p. 27)

Set the device to the same communications protocol as the controller (PC etc.).

3.1 Overview and Features of the Interfaces

The device provides standard communication functionality in the form of GP-IB and RS-232C interfaces,

both of which can be used to control the device remotely and to transfer data.

GP-IB

This device is designed with reference to the following standard:

Reference standard IEEE 488.1-1987

23

Interface Specications

3.2 Interface Specications

Precautions

RS-232C and GP-IB communications cannot be used simultaneously.

(1) GP-IB Specications

• Electrical machinery specications: IEEE std. 488.1-1987 compliant

• Address setting: Can be set to talker/listener addresses 1 to 30.

Interface Functions

SH1 Source handshake functions (all)

AH1 Acceptor handshake functions (all)

T6 Basic talker functions

L4 Basic listener functions

SR1 Service request functions (all)

RL1 Remote/Local functions (all)

GP-IB

Serial poll function

Talk-only mode

The talker cancel function with MLA (My Listen Address)

Listen-only mode

The listener cancel function with MTA (My Talk Address)

: Available,

–

: Unavailable

–

–

PP0 Parallel poll function –

DC1 Device clear functions (all)

DT1 Device trigger functions (all)

C0 Controller function –

E2 Tri-state output

Operating code: ASCII codes

24

Interface Specications

(2) RS-232C Specications

Transfer method Communication method: Full duplex

Transmission rate 38400 bps xed

Data bit length 8 bits

Stop bit 1 bit

Parity bit None

Delimiter Transmit: CR+LF

Flow control No X ow control, no hardware ow control

Protocol TTY

Electrical

specication

Connector Male 9-pin D-sub, with #4-40 attachment screws,

RS-232C

Synchronization method: Asynchronous

Receive: CR, CR+LF

Input voltage level 5 V to 15 V: ON

−15 V to −5 V: OFF

Output voltage level +5 V or more: ON

−5 V or less: OFF

The I/O connector is a DTE (Data Terminal Equipment) conguration

Recommended cable: Model 9637 RS-232C Cable (9 pin-9 pin/1.8 m)

Refer to “3.3 Connecting the Interface” (p. 26)

Operating code: ASCII codes

25

Connecting the Interface

6 7 8 9

3.3 Connecting the Interface

WARNING

• To avoid equipment failure, do not disconnect the communications cable while

communications are in progress.

• Use a common ground for both the device and the PC. Using different ground circuits

will result in a potential difference between the device’s ground and the PC’s ground.

If the communications cable is connected while such a potential difference exists, it

may result in equipment malfunction or failure.

• Before connecting or disconnecting any communications cable, always turn off the

device and the PC. Failure to do so could result in equipment malfunction or damage.

• After connecting the communications cable, tighten the screws on the connector securely.

Failure to secure the connector could result in equipment malfunction or damage.

CAUTION

To avoid damage to the device, do not short-circuit the terminal and do not input voltage to the

terminal.

Using the GP-IB Interface

Connect the GP-IB cable to the GP-IB connector.

Recommended cable: Model 9151-02 GP-IB Connector Cable (2 m)

Using the RS-232C Interface

Connect the RS-232C cable to the RS-232C connector.

Recommended cable: Model 9637 RS-232C Cable (9 pin-9 pin/1.8 m)

GP-IB

RS-232C

1 2 3 4 5

Pin No.

1 DCD CF CD Carrier detect Unused

2 RxD BB RD Receive data

3 TxD BA SD Transmit data

4 DTR CD ER Data terminal ready Unused

5 GND AB SG Signal ground

6 DSR CC DR Data set ready Unused

7 RTS CA RS Request to send Unused

8 CTS CB CS Clear to send Unused

9 RI CE CI Ring indicator Unused

Common name EIA JIS

Signal Name

Signal Remarks

26

Conguring the Communications Protocol

3 s

When connecting the device to a PC

Use a crossover cable with female 9-pin D-sub connectors.

Crossover Wiring

Female 9-pin D-sub Female 9-pin D-sub Recommended cable:

SM7860 side

Pin No. Pin No.

DCD 1

RxD 2 2 RxD

TxD 3 3 TxD

DTR 4 4 DTR

GND 5 5 GND

DSR 6 6 DSR

RTS 7 7 RTS

CTS 8 8 CTS

RI 9 9 RI

PC/AT Enhanced

Graphics Adapter

1 DCD

Model 9637 RS-232C Cable (9 pin9 pin/1.8 m)

3.4 Conguring the Communications Protocol

Conguring GP-IB Interface Communications

GP-IB

Setting the GP-IB address

Press and hold both of the scroll keys ([PAGE UP▲] and [PAGE DOWN▼]) on the right of

1

the screen simultaneously for approx. 3 s.

(The address can be set from the P1 or P2 screen.)

The setting screen is displayed.

VA (+) IR:1000.0

VB (+) IR: 250.0

TERMINAL:

OUT1:11100000

OUT2:11100000

OUT3:11100000

OUT4:11100000

GPIB ADDR: 1

CLM1: 10mA

CLM2: 10mA

CLM3: 10mA

CLM4: 10mA

VMA: 1000.0 OK

VMB: 250.0 OK

Press either of the scroll keys ([PAGE UP▲] or [PAGE DOWN▼]), set the desired address.

2

(Valid setting range: 1 to 30)

Turn off the device once you have nished conguring the settings.

3

27

Communication Method

Conguring RS-232C Interface Communications

Set the communications protocol on the controller (PC, etc.) to the same communications settings. For

more information about how to congure these settings, refer to the controller’s instruction manual or

other documentation.

Communication conditions

Baud rate 38400 bps

Parity none

Stop bit 1 bit

Data 8 bits

Flow control none

Remote switching requests

Send the

RS-232C interface communications will not be available until the

RMT

command from the RS-232C interface.

RMT

RS-232C

command is sent.

3.5 Communication Method

Various messages are supported for controlling the device through the interfaces.

Messages can be either program messages, sent from the controller such as PC to the device, or

response messages, sent from the device to the controller.

Program message

Controller

Response message

Message types are further categorized as follows.

Messages

When issuing commands that contain data, make certain that the data is provided in the specied format.

Program messages

Response message

Device (SM7860)

Command message

Query message

28

Program Messages

1. Command Messages and Query Messages

Command Messages

Commands that control the device, for example to congure settings or reset the device.

Query Messages

Requests for responses relating to results of operation or measurement, or the state of device settings.

Query commands end with a question (?) mark.

2. Message delimiter (terminator)

This device recognizes the following input message delimiters:

LF with CR+EOI

LF with EOI

CR with EOI

EOI

CR+LF

LF

Response Messages

1. Response Messages

When a query message is received, its syntax is checked and a response message is generated.

2. Message delimiter (terminator)

The following three response message delimiters can be specied with the “

LF (initial setting)

CR+LF

EOI

DLM

” command:

Communication Method

Separators

1. Message Unit Separator

Multiple message can be written in one line by separating them with semicolons “ ; ”.

2. Header Separator

In a message consisting of both a header and data, the header is separated from the data by a space (ASCII

code 20H).

3. Data Separator

In a message containing multiple data items, commas “,” are required to separate the data items from one

another.

Data Formats

Query messages use the formats outlined in the table below. The format is selected according to the command.

Response Messages and Parameter Data Types

Data type Description Example Remarks

NR1 Integer 0, 1, 2, 3 etc. Setting items, etc.

NR2 Fixed-point decimal number +12.345, 400.0 etc. Primarily setting values

NR3 Floating-point decimal number +1.234±50 etc. Primarily settings and measured values

ASCII ASCII string XXXXXXXXXXXXXXXX Primarily device IDs

29

Communication Method

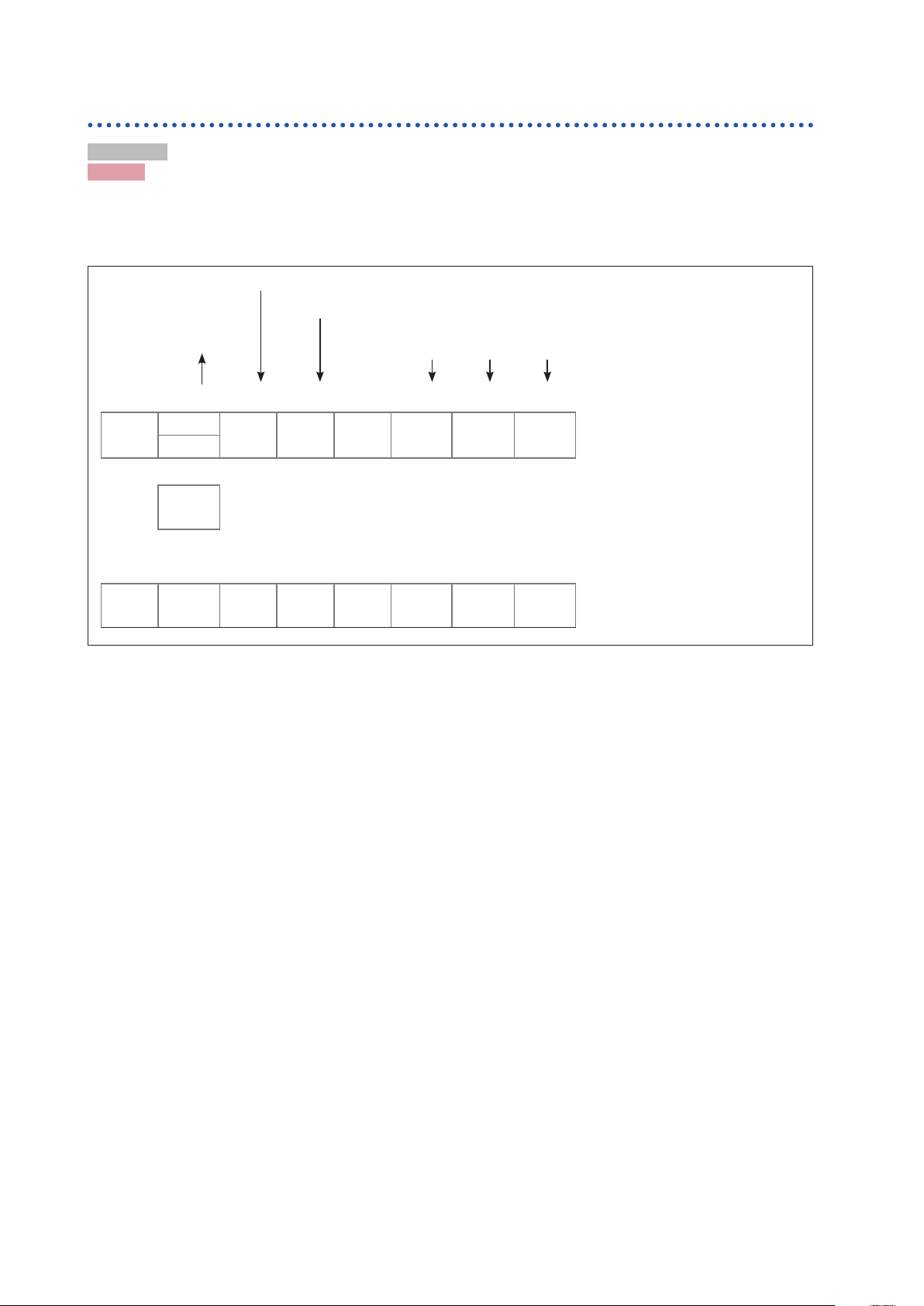

Status Byte Register

RS-232C

GP-IB

: RS-232C reads the status bytes to nd out the status of the device.

: The device adopts the IEEE488.1-1987 dened status model for parts related to the serial

polling performed by the service request function. A trigger for generating a service request is

called an event.

Overview of Service Request Occurrence

Standard event register information

Output queue data information

Service request

occurrence

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

ERR

↓ ↑ ↓ ↓ ↓ ↓ ↓ ↓

& → Logical

↑ ↑ ↑ ↑ ↑ ↑ ↑ ↑

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

ERR × ESB MAV DSB unused unused unused

RQS

MSS

sum

ESB M AV DSB unused unused unused Status Byte Register (STB)

← & & & & & &

Each of these bits corresponds

to a specic event register

Service Request Enable Register

(SRER)

The Status Byte Register contains information about the event registers and the output queue. Required

items are selected from this information by masking with the Service Request Enable Register. When any

bit selected by the mask is set, bit 6 (MSS; the Master Summary Status) of the Status Byte Register is

also set, which generates an SRQ (Service Request) message and dispatches a service request.

For RS-232C, bit 4 (MAV message available) of the status byte register is not set.

30

Communication Method

Status Byte Register (STB)

A status byte register is an 8-bit register output from the unit to the controller during serial polling. If even

one of the status byte register bits enabled by the service request enable register changes from “0” to

“1” the MSS bit becomes 1. At the same time, the RQS bit also becomes “1” and a service request is

generated.

The RQS bit is always synchronized with the service request and only read and simultaneously cleared

upon being serial polled. The MSS bit is only read by an “

is cleared by a command such as a “

Bit 7 ERR Unrecoverable error

CLS

” command.

∗

STB?

” query and is not cleared until the event

∗

Bit 6 RQS

MSS

Bit 5 ESB Standard Event Status (logical sum) bit

Bit 4 M AV Message available

Bit 3 DSB Event Status (logical sum) bit

Bit 2 – Unused

Bit 1 – Unused

Bit 0 – Unused

Set to “1” when a service request is dispatched.

This is the logical sum of the other bits of the Status Byte Register.

This is logical sum of the Standard Event Status Register.

Indicates that a message is present in the output queue.

This is the logical sum of Event Status Register.

Service Request Enable Register (SRER)

This register masks the Status Byte Register. Setting a bit of this register to “1” enables the corresponding

bit of the Status Byte Register to be used.

Event Register

Standard Event Status Register (SESR)

A standard event status register is an 8-bit register.

If any bit in the Standard Event Status Register is set to “1” (after masking by the Standard Event Status

Enable Register), bit 5 (ESB) of the Status Byte Register is set to “1”.

Refer to “Standard Event Status Enable Register (SESER)” (p. 32)

The standard event status register is cleared at the following times:

• When a “

• When a “

CLS

” command is executed

∗

ERR?

” command is executed

• When the device power is cycled

31

Communication Method

Bit 7 PON Power-On Flag

Set to “1” when the power is turned on, or upon recovery from an outage.

Bit 6 URQ User Request

Unused

Bit 5 CME Command error (The command to the message terminator is ignored.)

This bit is set to “1” when a received command contains a syntactic or semantic error:

• Program header error

• Incorrect number of data parameters

• Invalid parameter format

• Received a command not supported by the device

Bit 4 EXE Execution Error

This bit is set to “1” when a received command cannot be executed for some reason.

• The specied data value is outside of the set range

• The specied setting data cannot be set

• Execution is prevented by some other operation being performed

Bit 3 DDE Device-Dependent Error

This bit is set to “1” when a command cannot be executed due to some reason

other than a command error, a query error or an execution error.

• When the command cannot be executed because there is an internal anomaly

Bit 2 QYE Query Error (the output queue is cleared)

This bit is set to “1” when a query error is detected by the controller of the output queue.

• When an attempt has been made to read an empty output queue (GP-IB only)

• When the data overows the output queue

• When data in the output queue has been lost

Bit 1 RQC Request Control

Unused

Bit 0 OPC Operation Complete

This bit is set to “1” in response to an “

• It indicates the completion of operations of all messages up to the “

∗

OPC

” command.

∗

OPC

” command

Standard Event Status Enable Register (SESER)

Setting any bit of the Standard Event Status Enable Register to “1” enables access to the corresponding

bit of the Standard Event Status Register.

Standard Event Status Register (SESR) and Standard Event Status Enable Register (SESER)

bit 6 bit 5 bit 4

SRQ

MSS Standard Event Status Register (SESR)

ESB MAV

↑

Logical

sum

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

PON URQ CME EXE DDE QYE RQC OPC

↓ ↓ ↓ ↓ ↓ ↓ ↓ ↓

← & & & & & & & &

↑ ↑ ↑ ↑ ↑ ↑ ↑ ↑

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

PON URQ CME EXE DDE QYE RQC OPC

Standard Event Status Enable Register (SESER)

32

Communication Method

Error Register

The Error Register, which consists of 8 bits, manages error information. The contents of this register

are aggregated in the CME, EXE, DDE, and QYE bits of the Standard Event Status Register (no mask

processing is performed).

Error register-related message are listed below.

CLS

∗

ERR?

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

– MLE HDE DFE DRE CNE ISE BDE Error Register

PON URQ CME EXE DDE QYE RQC OPC Standard Event Status Register

bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

MLE: Message Length Error HDE: Header Error

DFE: Data Format Error DRE: Data Range Error

CNE: Can Not Execute ISE: Internal communication Error

BDE: Environment Backup was Damaged (RAM)

Clears the following registers:

• Status Byte Register

• Standard Event Status Register

• Error Register

Queries and clears the Error Register.

Error Register structure

Bit No. Name Event/status indicated by set bit

Bit 7 – Unused

Bit 6 MLE Message Length Error

Set when the message length exceeds the allowable range.

The bit is reset after the register is read.

Bit 5 HDE Message Header Error

Set when an unrecognizable message header is received.

The bit is reset after the register is read.

Bit 4 DFE Data Format Error

Set when the number of parameters exceeds the stipulated number or when there is an

unrecognizable parameter.

The bit is reset after the register is read.

Bit 3 DRE Data Range Error

Set when a parameter falls outside the stipulated range.

The bit is reset after the register is read.

Bit 2 CNE Unexecutable command

Set when an unexecutable command is received.

The bit is reset after the register is read.

Bit 1 ISE Internal communication error

Set when an internal communication error occurs.

The bit is reset after the register is read.

Bit 0 BDE Environment backup was damaged

Set when data stored in the device’s backup RAM is corrupted.

The bit is reset after the register is read.

33

Message List

3.6 Message List

RS-232C-only commands are indicated by

RS-232C

. When using the RS-232C interface to send

commands, include a uniform wait time of 100 ms (excluding the following exceptions).

Command Description Format

Communication condition

RMT

Delimiter

DLM

DLM?

Output voltage setting

VAI

VAI?

VBI

VBI?

Remote switching request

Talker delimiter specication

d1 (delimiter specication: 0 to 2)

0: LF<EOI> Default

1: CRLF<EOI>

2: <EOI>

Note: This setting reverts to its default when the device is powered on.

A combination CR+LF is used as the RS-232C delimiter for both

data transmission and reception.

Delimiter query

The contents of responses are the same as the settings.

Circuit A output voltage setting

d1: 1.0 V to 1000.0 V

Note: Set as an absolute value.

The valid setting range varies with the model.

Circuit A output voltage setting query

The contents of responses are the same as the settings.

Circuit B output voltage setting

d1: 1.0 V to 1000.0 V

Note: Set as an absolute value.

The valid setting range varies with the model.

Circuit B output voltage setting query

The contents of responses are the same as the settings.

Output voltage setting range by model

RS-232C

[Format] RMT

[Format] DLM d1

[Format]

[Response]

[Format] VAI d1

[Format]

[Response]

[Format] VBI d1

[Format]

[Response]

d1: NR1

format

DLM?

d1

d1: NR2

format

VAI?

d1

d1: NR2

format

VBI?

d1

Alarm setting

ARM

ARM?

Model Lower limit (V) Upper limit (V)

SM7860-51, -61 1.0 500.0

SM7860-52, -62 250.0 1000.0

SM7860-53, -63 1.0 500.0

SM7860-54, -64 250.0 1000.0

SM7860-55, -65 1.0 500.0

SM7860-56, -66 250.0 1000.0

SM7860-57, -67 1.0 10.0

SM7860-58, -68 1.0 500.0

Voltage error alarm setting

d1: 2% to 19%, Circuit A voltage error alarm setting

d2: 2% to 19%, Circuit B voltage error alarm setting

Note: d1 or d2 can be omitted.

Voltage error alarm setting query

The contents of responses are the same as the settings.

[Format] ARM d1,d2

ARM d1

ARM ,d2

[Format]

[Response]

ARM?

d1,d2

34

Command Description Format

Voltage monitor

VMA?

VMB?

Output current limit

CLM

CLM?

LCD display mode

LCD

LCD?

PAG

Error information

ERR?

Others

RST

∗

IDN?

∗

SAV

∗

RCL

∗

CLS

∗

SRE

∗

SRE?

∗

STB?

∗

ESE

∗

Circuit A power supply voltage monitor value query [Format]

[Response]

Circuit B power supply voltage monitor value query [Format]

[Response]

OUT1 to OUT4[mA]: 2 to 50 mA

Note: The valid setting range varies by model.

Current limit setting value query [Format]

LCD display mode setting

d1 (Display mode: 0 to 1)

0: OFF (Display off)

1: ON (Display on)

LCD display mode query

The contents of responses are the same as the settings.

LCD display page specication

d1 (Page number: 0 to 1)

0: Output voltage setting, monitor voltage value, channel-specic output

setting state

1: Alarm setting, GP-IB address

Error information query

d1 (Error information: 0 to 127)

Note: Error information is cleared when the response is output.

Resets the device

Restore all the settings to the factory default (except for the output setting

for the device interlocked).

Device operation will be stopped.

Hardware ID query

Returns the device’s hardware ID as the response.

d1 (HIOKI, SM7860-5x, 0, 01.00) or d1 (HIOKI, SM7860-6x, 0, 01.00)

Save environmental data (output voltage setting, current limit value, and

alarm setting)

d1 (Environmental data no.: 0 to 3)

Recall environmental data

(output voltage setting, current limit value, and alarm setting)

d1 (Environmental data no.: 0 to 3)

Clear status register [Format]∗CLS

Sets the service request enable register.

d1 (0 to 255)

Service request enable register query

d1 (0 to 63, 128 to 191)

Note: Bit 6 is not set by

Status byte register query

d1 (0 to 255)

Sets the standard event status enable register.

d1 (0 to 255)

∗

SRE

.

[Format] CLM

[Response]

[Format] LCD d1

[Format]

[Response]

[Format] PAG d1

[Format]

[Response]

[Format]∗RST

[Format]

[Response]

[Format]∗SAV d1

[Format]∗RCL d1

[Format]∗SRE d1

[Format]

[Response]

[Format]

[Response]

[Format]∗ESE d1

VMA?

d1: NR2

format

VMB?

d1: NR2

format

d1,d2,d3,d4

CLM?

d1 to d4:

NR1 format

d1: NR1

format

LCD?

d1: NR1

format

d1: NR1

format

ERR?

d1: NR1

format

∗

d1: String

d1: NR1

format

d1: NR1

format

d1: NR1

format

∗

d1: NR1

format

∗

d1: NR1

format

d1: NR1

format

Message List

IDN?

SRE?

STB?

35

Listener Specication Precautions

Command Description Format

ESE?

∗

ESR?

∗

OPC

∗

OPC?

∗

CNF

CNF?

KLC

KLC?

Standard event status enable register query

The contents of responses are the same as the settings.

Standard event status register query

d1 (0 to 255)

Sets the standard event status register’s OPC bit after all ongoing

operations have completed.

This command is used to detect the completion of commands that involve

time-consuming processing.

Returns the value “1” when all ongoing operations have completed.

d1: 1

Operating environment setting

d1 (Interlock control enable/disable: 0 to 1)

0: CONNECT (Enables interlock)

1: CUTOFF (Disables interlock) Default

Operating environment query

The contents of responses are the same as the settings.

Key lock setting

d1 (0 to 1)

0: Key lock off

1: Key lock on

Key lock query

d1 (0 to 1)

The contents of responses are the same as the settings.

[Format]

[Response]

[Format]

[Response]

[Format]∗OPC

[Format]

[Response]

[Format] CNF d1

[Format]

[Response]

[Format] KLC d1

[Format]

[Response]

ESE?

∗

d1: NR1

format

ESR?

∗

d1: NR1

format

OPC?

∗

d1: NR1

format

d1: NR1

format

CNF?

d1

d1: NR1

format

KLC?

d1: NR1

format

3.7 Listener Specication Precautions

Input buffer size

Multiple command messages can be transferred at once by joining them with message separators. Since

the device provides an 128-byte input buffer, the device is unable to receive message strings in excess

of 127 characters in length. In this case, the entire command will be ignored (discarded), and the Error

Register’s MLE (Message Length Error) bit will be set.

Reading from the output buffer

The output buffer uses a FIFO design, with older data being read rst. Consequently, the read value may

differ from the expected value under certain circumstances, for example if no response is acquired after

issuing a query. Additionally, the output buffer is 511 bytes in size. If data in excess of 511 bytes is written

to the buffer, it will be discarded, and the Error Register’s QYE (Query Error) bit will be set.

36

4

This chapter describes how to use the EXT I/O connector on the rear of the device to control the device.

External Control

4.1 EXT I/O Connector and Signals

WARNING

To prevent an electric shock or damage to the equipment, always observe the

following precautions when connecting the cables to EXT I/O connector:

• Always turn off the device and any devices to be connected before making

connections.

• During operation, a wire becoming dislocated and contacting another conductive

object can be serious hazard. Use bail locks to secure the EXT I/O connector.

• Ensure that devices and systems to be connected to the EXT I/O connector are

properly isolated from one another.

CAUTION

To avoid damage to the device, observe the following cautions:

• Do not apply voltage or current to the EXT I/O connector that exceeds their ratings.

• When driving relays, be sure to install diodes to absorb counter-electromotive force.

Refer to “Connector Type and Signal Pinouts” (p. 38)

37

EXT I/O Connector and Signals

Connector Type and Signal Pinouts

Connector: 57RE-40500-730B (50 pin: DDK)

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

EXT I/O connector

Pin No. Signal name I/O Pin No. Signal name I/O

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

COM

EXT_DCV2 (+24V)

OUTPUT

OUT1 (1)_ON

OUT1 (3)_ON

OUT1 (5)_ON

OUT1 (7)_ON

OUT2 (1)_ON

OUT2 (3)_ON

OUT2 (5)_ON

OUT2 (7)_ON

OUT3 (1)_ON

OUT3 (3)_ON

OUT3 (5)_ON

OUT3 (7)_ON

– 26

Input 27

Input 28

Input 29

Input 30

Input 31

Input 32

Input 33

Input 34

Input 35

Input 36

Input 37

Input 38

Input 39

Input 40

COM

EXT_DCV2 (+24V)

INTERLOCK

OUT1 (2)_ON

OUT1 (4)_ON

OUT1 (6)_ON

OUT1 (8)_ON

OUT2 (2)_ON

OUT2 (4)_ON

OUT2 (6)_ON

OUT2 (8)_ON

OUT3 (2)_ON

OUT3 (4)_ON

OUT3 (6)_ON

OUT3 (8)_ON

–

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

Input

16

17

18

19

20

21

22

23

24

25

OUT4 (1)_ON

OUT4 (3)_ON

OUT4 (5)_ON

OUT4 (7)_ON

(Reserved)

(Reserved)

(Reserved)

(Reserved)

ALARM

TEMP

Do not connect to reserved pins.

38

Input 41

Input 42

Input 43

Input 44

– 45

– 46

– 47

– 48

Output 49

– 50

OUT4 (2)_ON

OUT4 (4)_ON

OUT4 (6)_ON

OUT4 (8)_ON

(Reserved)

(Reserved)

(Reserved)

(Reserved)

BUSY

(Reserved)

Input

Input

Input

Input

–

–

–

–

Output

–

EXT I/O Connector and Signals

Signal Functions

Input Signals

EXT_DCV2 (+24V) External power source input

OUTPUT Output on/off setting

OUT1 (1)_ON to OUT1 (8)_ON Specic-channel on/off setting

OUT2 (1)_ON to OUT2 (8)_ON Specic-channel on/off setting

OUT3 (1)_ON to OUT3 (8)_ON Specic-channel on/off setting

OUT4 (1)_ON to OUT4 (8)_ON Specic-channel on/off setting

INTERLOCK When on, no voltage can be generated.

• The INTERLOCK signal cannot be used unless it has been enabled with the operating environment

setting (CNF=0).

• The device ships with this setting disabled (CNF=1).

Refer to “CNF” (p. 36)

• The output voltage cannot be changed while the OUTPUT signal is enabled.

Output Signals

ALARM Generated voltage alarm

BUSY Voltage being output

TEMP Temperature alarm

39

Timing Chart

Discharge *

O

O

O

O

e

e

e

t1 t2

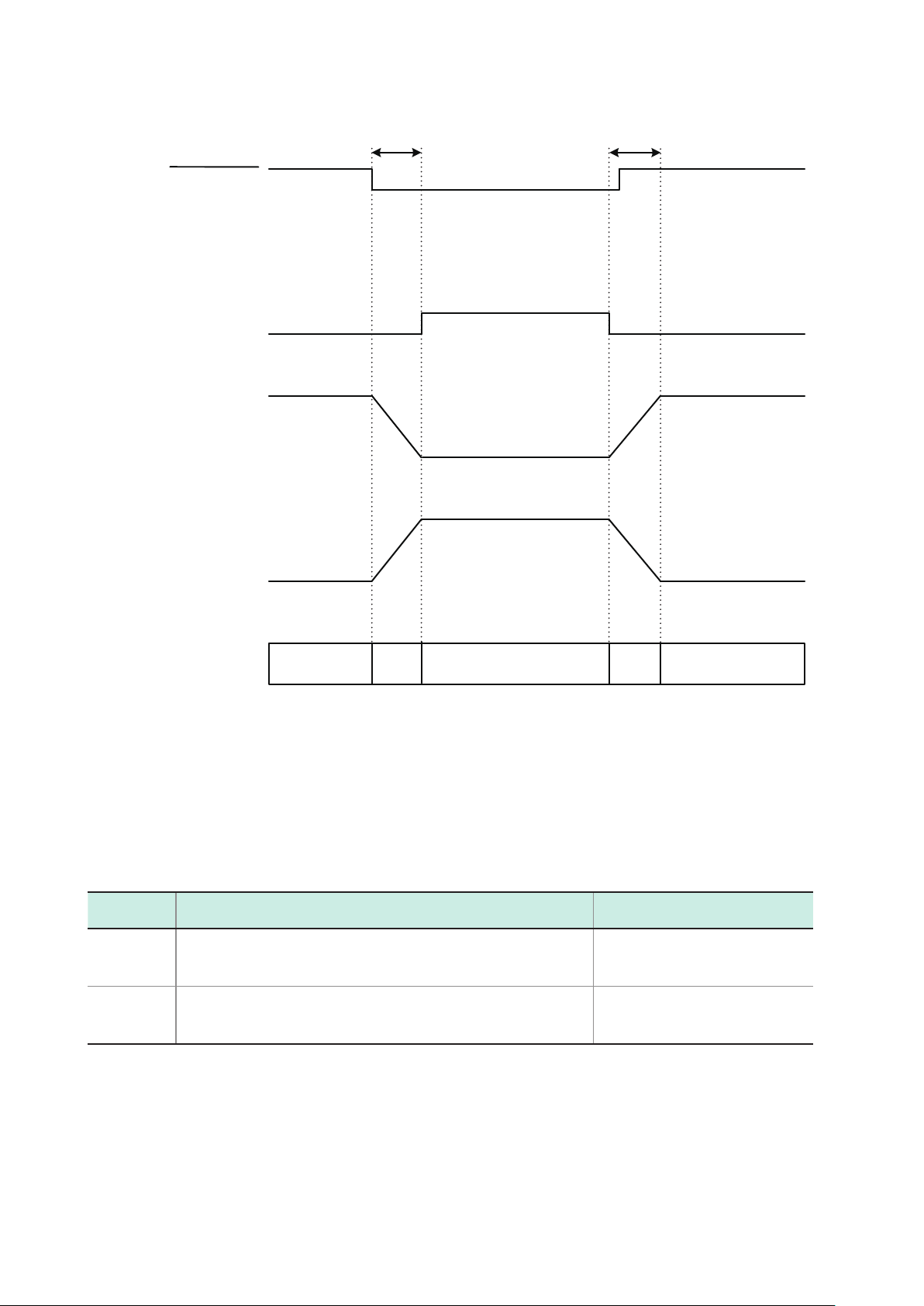

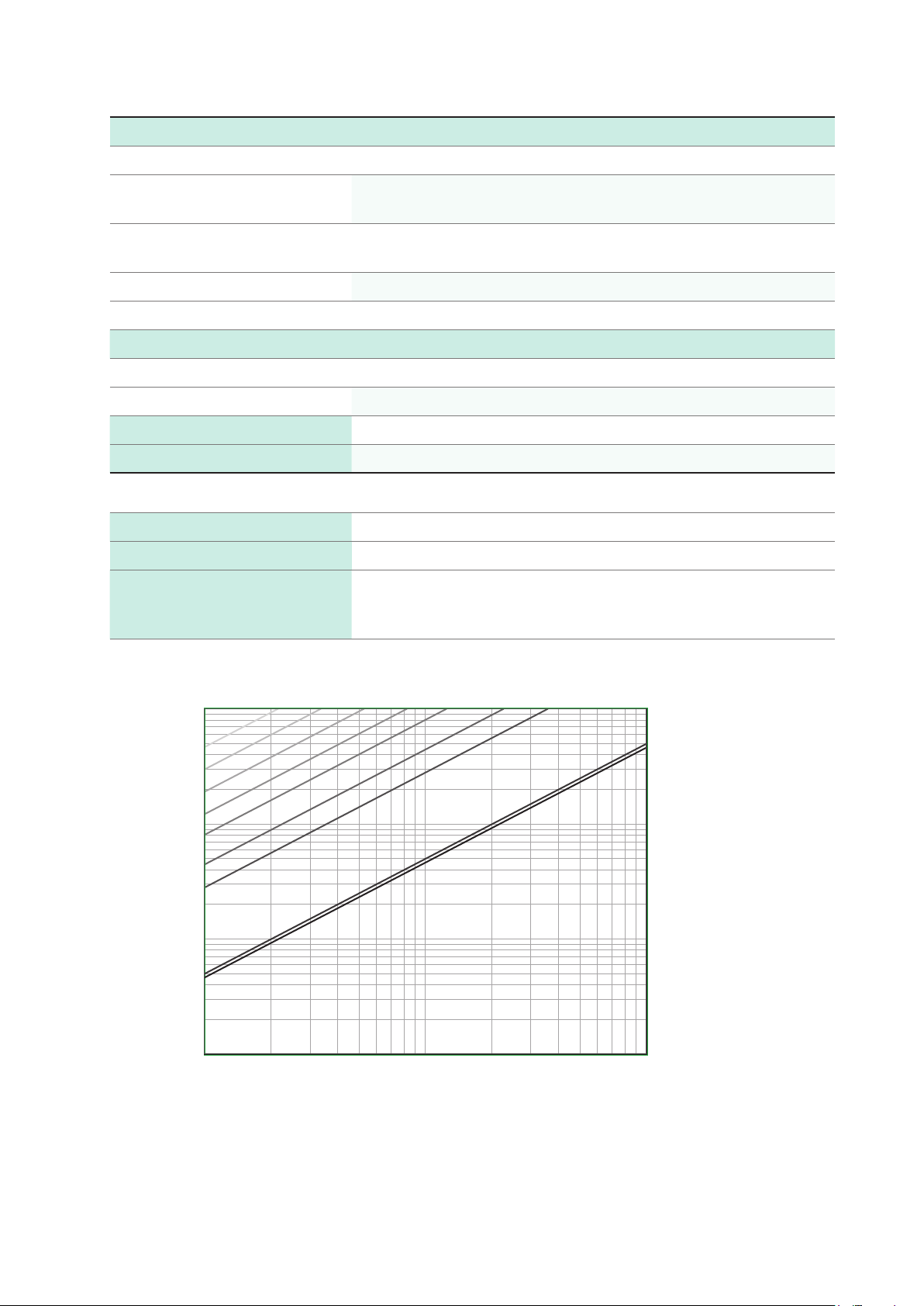

4.2 Timing Chart

Each signal level indicates a corresponding voltage level.

EXT I/O connector

UT1 (1)_ON to (8)_ON

UT2 (1)_ON to (8)_ON

UT3 (1)_ON to (8)_ON

UT4 (1)_ON to (8)_ON

OUTPUT

t3 t7

BUSY

t5

t6 t9

ALARM

Previous ALARM result

New ALARM result

Voltage output terminal

OUT1 (CH1) to (CH8)

OUT2 (CH1) to (CH8)

OUT3 (CH1) to (CH8)

OUT4 (CH1) to (CH8)

Voltage output *

1

High-impedance High-impedanc

OUT3 (CH1) to (CH8)

OUT4 (CH1) to (CH8)

Voltage output *

2

High-impedance

OUT2 (CH1) to (CH8)

OUT4 (CH1) to (CH8)

3

High-impedance

t4 t8

t10

Discharge

High-impedanc

t11

High-impedanc

States of the voltage output terminals follow any one of the patterns with *1 through *3 depending on

models.

*1 SM7860-51, -52, -61, -62: OUT1 to OUT4

SM7860-53, -54, -63, -64: OUT1 to OUT2

SM7860-55, -56, -65, -66: OUT1

SM7860-57, -58, -67, -68: OUT1 to OUT3

*2 SM7860-53, -54, -63, -64: OUT3 to OUT4

SM7860-55, -56, -65, -66: OUT3

*3 SM7860-55, -56, -65, -66: OUT2, OUT4

SM7860-57, -58, -67, -68: OUT4

40

Timing Chart Interval Descriptions

Interval Description Duration

t1 Channel setup time 100 μs or more

t2 Channel hold time 200 μs or more

t3 Output on → Busy delay time 200 μs or less

t4 Output on → Voltage output delay time 600 μs or less

t5 Alarm delay time 3.5 ms or less

t6 Output pulse width 8 ms or more

t7 Output off → Busy delay time 800 μs or less

t8 Output off → Voltage output delay time 2.5 ms or less

t9 Output off time 4 ms or more

Timing Chart

t10 Output on → Discharging start delay time 1.2 ms or less

t11 Output off → Discharging complete delay time 1.1 ms or less

41

Timing Chart

When the output setting for the device interlocked is set to the discharging state

EXT I/O connector

INTERLOCK

Voltage output terminal

OUT1 (CH1) to (CH8)

OUT2 (CH1) to (CH8)

OUT3 (CH1) to (CH8)

OUT4 (CH1) to (CH8)

Internal voltage

Circuit A, B *

Circuit B *

1

2

OFF

Setting voltage

Setting voltage

t1

t2

ON

OFF

Setting voltage

0 V

0 V

Setting voltage

High-

impedance

Change

voltage

Discharge

Change

voltage

High-

impedance

The internal voltage follows either the pattern with *1 or that with *2 depending on models.

*1 SM7860-51, -52, -61, -62: OUT1 to OUT4

SM7860-53, -54, -63, -64: OUT1 to OUT2

SM7860-55, -56, -65, -66: OUT1

SM7860-57, -58, -67, -68: OUT1 to OUT3

*2 SM7860-53, -54, -63, -64: OUT3 to OUT4

SM7860-55, -56, -65, -66: OUT3

Interval Description Duration

t1 Time taken for the internal voltage to decrease from the

Not specied

specied voltage to 0 V

t2 Time taken for the internal voltage to increase from 0 V to

7 s or less*

3

the specied voltage

*3 The device does not accept any signals inputted into the EXT I/O connector during this period.

42

Timing Chart

When the output setting for the device interlocked is set to the high-impedance

state

EXT I/O connector

INTERLOCK

OUT1 (CH1) to (CH8)

OUT2 (CH1) to (CH8)

OUT3 (CH1) to (CH8)

OUT4 (CH1) to (CH8)

OFF

High-impedance

43

Internal Circuitry

4.3 Internal Circuitry

Input Circuit

24 V DC

EXT_DC2

Input signals

Input Signals

Output Circuit

Input method Photocoupler-isolated input

Input voltage Input voltage LOW: 0 V to 0.5 V, HIGH: 24 V±10%

SM7860 side

SM7860 side

External device side

5 V DC to 24 V DC

Output signals

COM

External device side

Output Signals

44

Output method Photocoupler-open collector output

Output voltage/

current

LOW < 0.5 V, HIGH > 5 V to 24 V (depends on external

voltage), Max. 5 mA

5

Specications

5.1 General Specications

Operating

environment

Operating

temperature and

humidity

Storage

temperature and

humidity

Power supply Rated supply voltage

Maximum rated

power

Interface RS-232C, GP-IB

Indoors, Pollution degree 2, up to 2000 m (6562 ft.)

0°C to 60°C (32°F to 140°F), 80% RH or less (no condensation)

−10°C to 55°C (14°F to 131°F), 80% RH or less (no condensation)

SM7860-51, -52, -53, -54, -55, -56, -57, -58: 100 V AC to 110 V AC

SM7860-61, -62, -63, -64, -65, -66, -67, -68: 220 V AC

(Voltage uctuations of ±10% from the rated supply voltage are taken into

account.)

Rated supply frequency: 50 Hz, 60 Hz

Anticipated transient overvoltage: 2500 V

860 VA

Dimensions Approx. 425W × 249H × 581D mm (16.73″W × 9.80″H × 22.87″D)

Mass Approx. 47 kg (1657.8 oz.) ( SM7860-51, -52, -53, -54, -55, -56, -58, -61, -62, -63,

-64, -65, -66, -68)

Approx. 34 kg (1199.3 oz.) (SM7860-57, -67)

Accessories See “Device and Accessories” (p. 3)

Options See “Options” (p. 3)

Replacement part Fuse: MF60NRF-8A (250V M 8.0A φ6.4×30 mm)

Product warranty

period

3 years

45

Basic Specications

5.2 Basic Specications

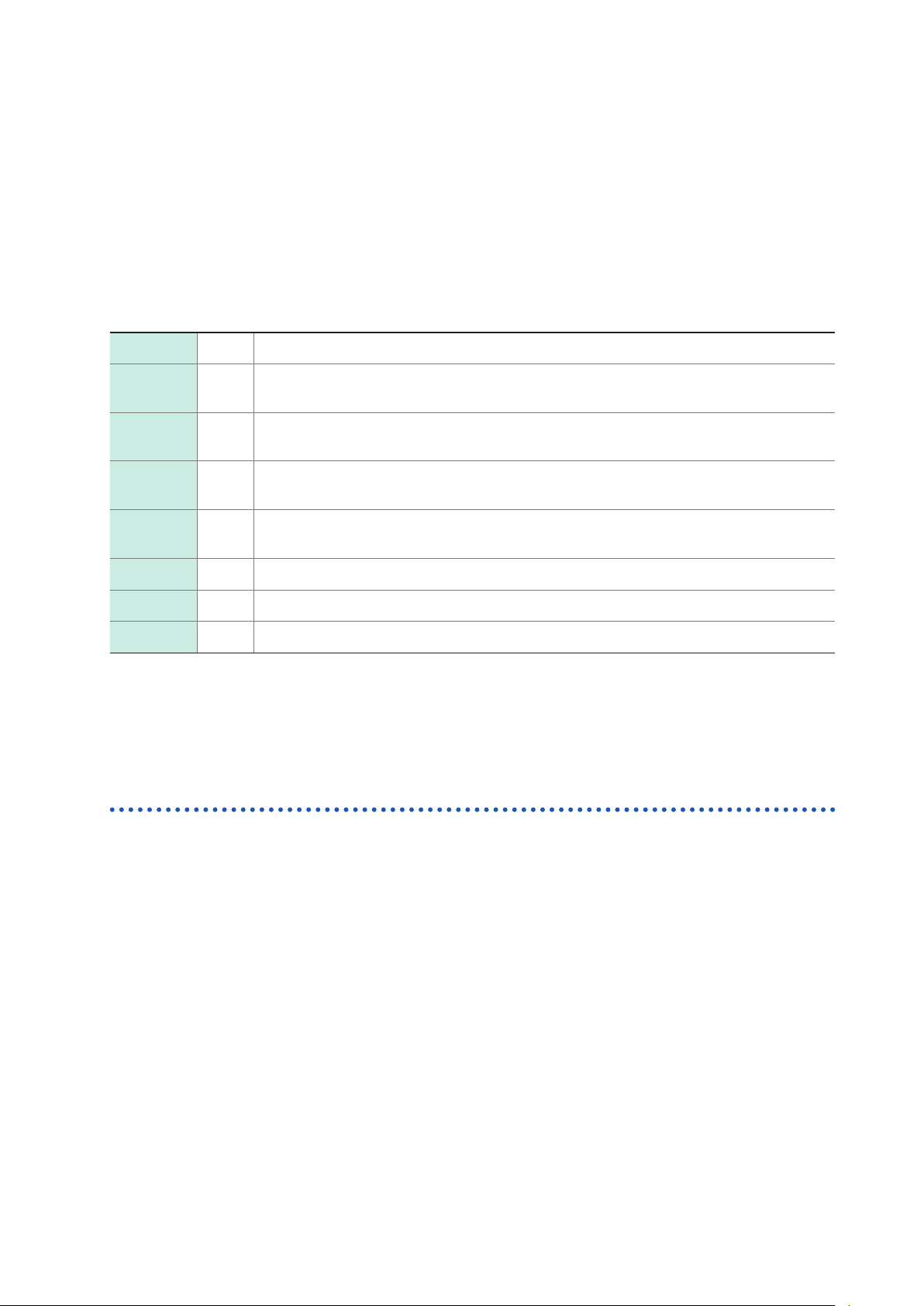

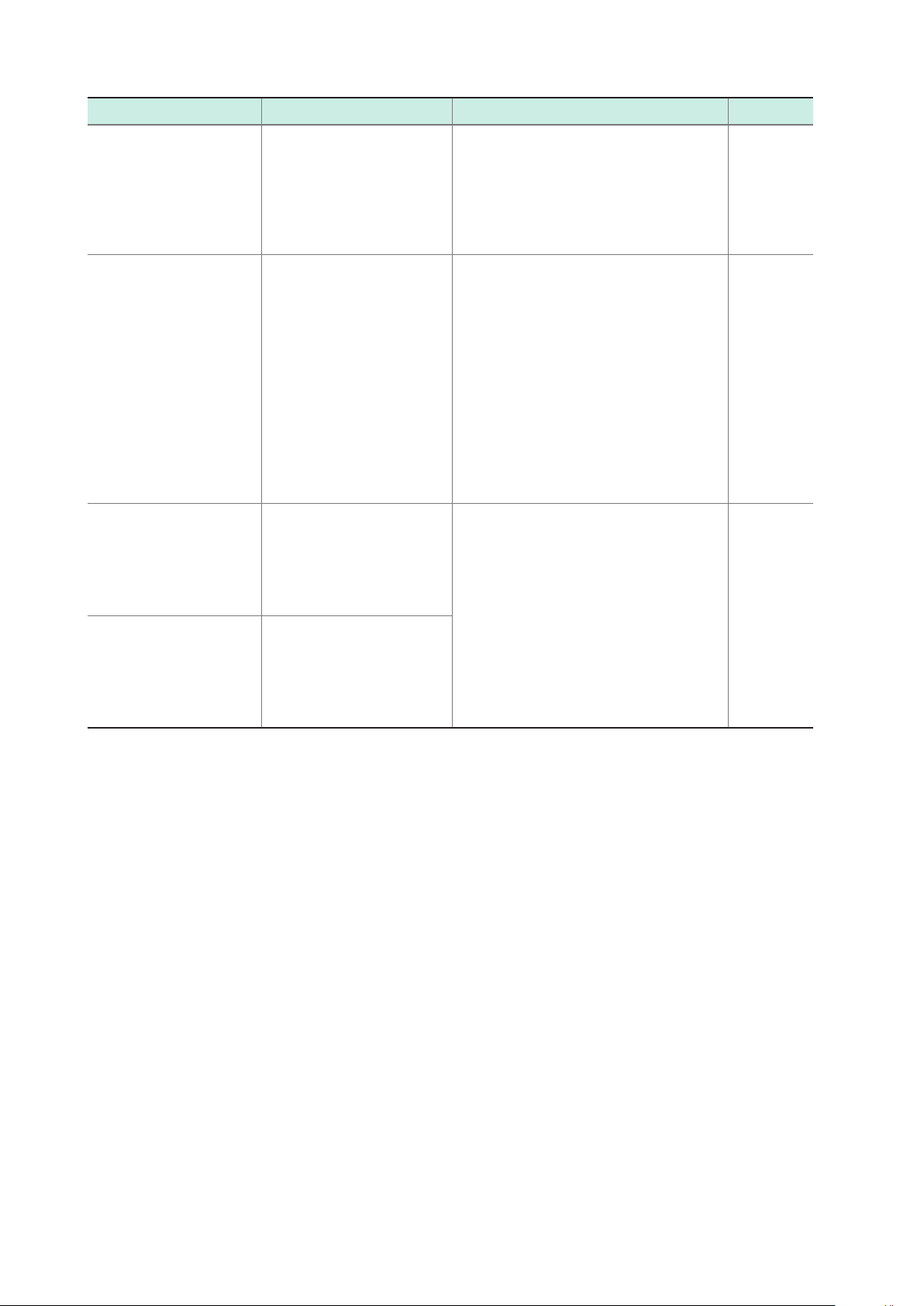

Conguration

Model Item Circuit A Circuit B

SM7860-51

SM7860-61

SM7860-52

SM7860-62

SM7860-53

SM7860-63

Maximum

output current

Output voltage

range

Channels OUT 1 (1) to (8) : Voltage output

Current limit ±(2 mA to 50 mA) /CH ±(2 mA to 50 mA) /CH

Maximum

output current

Output voltage

range

Channels OUT 1 (1) to (8) : Voltage output

Current limit ±(2 mA to 10 mA) /CH ±(2 mA to 10 mA) /CH

Maximum

output current

Output voltage

range

430 mA (200 VA) 430 mA (200 VA)

1.0 V to 500.0 V

(0.1 V resolution)

OUT 2 (1) to (8) : Voltage output

100 mA (100 VA) 100 mA (100 VA)

250.0 V to 1000.0 V

(0.1 V resolution)

OUT 2 (1) to (8) : Voltage output

430 mA (200 VA) 430 mA (200 VA)

1.0 V to 500.0 V

(0.1 V resolution)

1.0 V to 500.0 V

(0.1 V resolution)

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Voltage output

250.0 V to 1000.0 V

(0.1 V resolution)

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Voltage output

−1.0 V to −500.0 V

(0.1 V resolution)

SM7860-54

SM7860-64

SM7860-55

SM7860-65

Channels OUT 1 (1) to (8) : Voltage output

OUT 2 (1) to (8) : Voltage output

Current limit ±(2 mA to 50 mA) /CH ±(2 mA to 50 mA) /CH

Maximum

output current

Output voltage

range

Channels OUT 1 (1) to (8) : Voltage output

Current limit ±(2 mA to 10 mA) /CH ±(2 mA to 10 mA) /CH

Maximum

output current

Output voltage

range

Channels OUT 1 (1) to (8) : Voltage output

Current limit ±(2 mA to 50 mA) /CH ±(2 mA to 50 mA) /CH

100 mA (100 VA) 100 mA (100 VA)

250.0 V to 1000.0 V

(0.1 V resolution)

OUT 2 (1) to (8) : Voltage output

430 mA (200 VA) 430 mA (200 VA)

1.0 V to 500.0 V

(0.1 V resolution)

OUT 2 (1) to (8) : Discharge

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Voltage output

−250.0 V to −1000.0 V

(0.1 V resolution)

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Voltage output

−1.0 V to −500.0 V

(0.1 V resolution)

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Discharge

46

Basic Specications

Model Item Circuit A Circuit B

SM7860-56

SM7860-66

SM7860-57

SM7860-67

SM7860-58

SM7860-68

Maximum

output current

Output voltage

range

Channels OUT 1 (1) to (8) : Voltage output

Current limit ±(2 mA to 10 mA) /CH ±(2 mA to 10 mA) /CH

Maximum

output current

Output voltage

range

Channels OUT 1 (1) to (8) : Voltage output

Current limit ±(2 mA to 50 mA) /CH ±(2 mA to 50 mA) /CH

Maximum

output current

Output voltage

range

100 mA (100 VA) 100 mA (100 VA)

250.0 V to 1000.0 V

(0.1 V resolution)

OUT 2 (1) to (8) : Discharge

430 mA (4 VA) 430 mA (4 VA)

1.0 V tp 10.0 V

(0.1 V resolution)

OUT 2 (1) to (8) : Voltage output

430 mA (200 VA) 430 mA (200 VA)

1.0 V to 500.0 V

(0.1 V resolution)

−250.0 V to −1000.0 V

(0.1 V resolution)

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Discharge

1.0 V to 10.0 V

(0.1 V resolution)

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Discharge

1.0 V to 500.0 V

(0.1 V resolution)

Channels OUT 1 (1) to (8) : Voltage output

OUT 2 (1) to (8) : Voltage output

Current limit ±(2 mA to 50 mA) /CH ±(2 mA to 50 mA) /CH

Maximum rated

voltage to earth

Output terminals Special round connector (support for 8 channels), withstand voltage of 1000 V,

LED indicator POWER, voltage output indicator, inter-lock

LCD screen P1: Output voltage setting, monitor voltage value, channel-specic output

Key

1000 V DC, maximum generated internal voltage of 1320 V DC

isolated channels

setting state

P2: Alarm setting, GP-IB address, output setting for the device interlocked

(for toggling display)

OUT 3 (1) to (8) : Voltage output

OUT 4 (1) to (8) : Discharge

47

Basic Specications

Functions Specication

Voltage output function

Operating method Sink/source (support for charging and discharging)

Output voltage setting

value

Generation control

Output on/off Can be set independently for each channel.

Voltage error alarm Operation: Alarm is generated when the monitor voltage falls outside the set

Current limit function

Limit method Current can be limited independently for each channel.

Limit value setting 2 mA to 50 mA (set in 1 mA increments; valid setting range varies by model)

Current limit direction Current can be limited in both directions.

Backup Function

Backup items Output voltage setting, alarm setting, GP-IB address

Voltage monitor function

Voltage monitor Measures and displays output voltage for each circuit.

Interlock function

1.0 V to 1000.0 V (set in 0.1 V increments; valid setting range varies by model)

Refer to “Conguration” (p. 46) in “5.2 Basic Specications”)

Output only when EXT I/O interface’s OUTPUT signal is on.

range.

Valid setting range : ±2% to ±19% (1% resolution)

Refer to “Conguration” (p. 46) in “5.2 Basic Specications”)

Operation Interlock is enabled when set to “on,” with low input, or when terminals are

shorted.

Measurement is disabled, including by device keys and communications

commands, when interlock is enabled.

Output setting function for the device interlocked

Operation The output setting with the device interlocked can be chosen between an

impedance state and a discharging state.

Setting procedure Cannot be set by sending commands.

Press and hold both the scroll keys ([PAGE UP▲] and [PAGE DOWN▼])

on the right of the screen simultaneously for 3 s.

The GP-IB-address assigning screen is displayed.

Press and hold both the scroll keys ([PAGE UP▲] and [PAGE DOWN▼])

again simultaneously for 3 s.

The setting screen is displayed.

Press either of the scroll keys ([PAGE UP▲] or [PAGE DOWN▼]) to set the

GP-IB-address and turn off the device to conrm the address you entered.

Supported model Hioki Model SM7420 Super Megohm Meter,

Hioki Model SM7810-20 Super M

HiTester

Ω

48

Accuracy Specications

10 100 1000

6.3 V 10 V 16 V 25 V 50 V 100 V4 V

Conditions of guaranteed accuracy

Guaranteed accuracy period 1 year

Basic Specications

Guaranteed accuracy period

1 year

after adjustment made by Hioki

Temperature and humidity for

23°C±5°C (73°F±9°F), 80% RH or less

guaranteed accuracy

Warm-up time at least an hour

Power supply frequency 50 Hz/60 Hz ±2 Hz

Voltage generation accuracy

Output voltage accuracy ±2% of setting ±0.5 V (no load)

Error between channels ±0.01 V or less (no load, between outputs from same circuit)

Voltage monitor accuracy ±2% of output voltage ±0.5 V

Current limit accuracy ±10% of setting ±1 mA

Limitations

Voltage application target Multi-layer ceramic capacitor

Number of charging channels Up to 8 channels/circuit

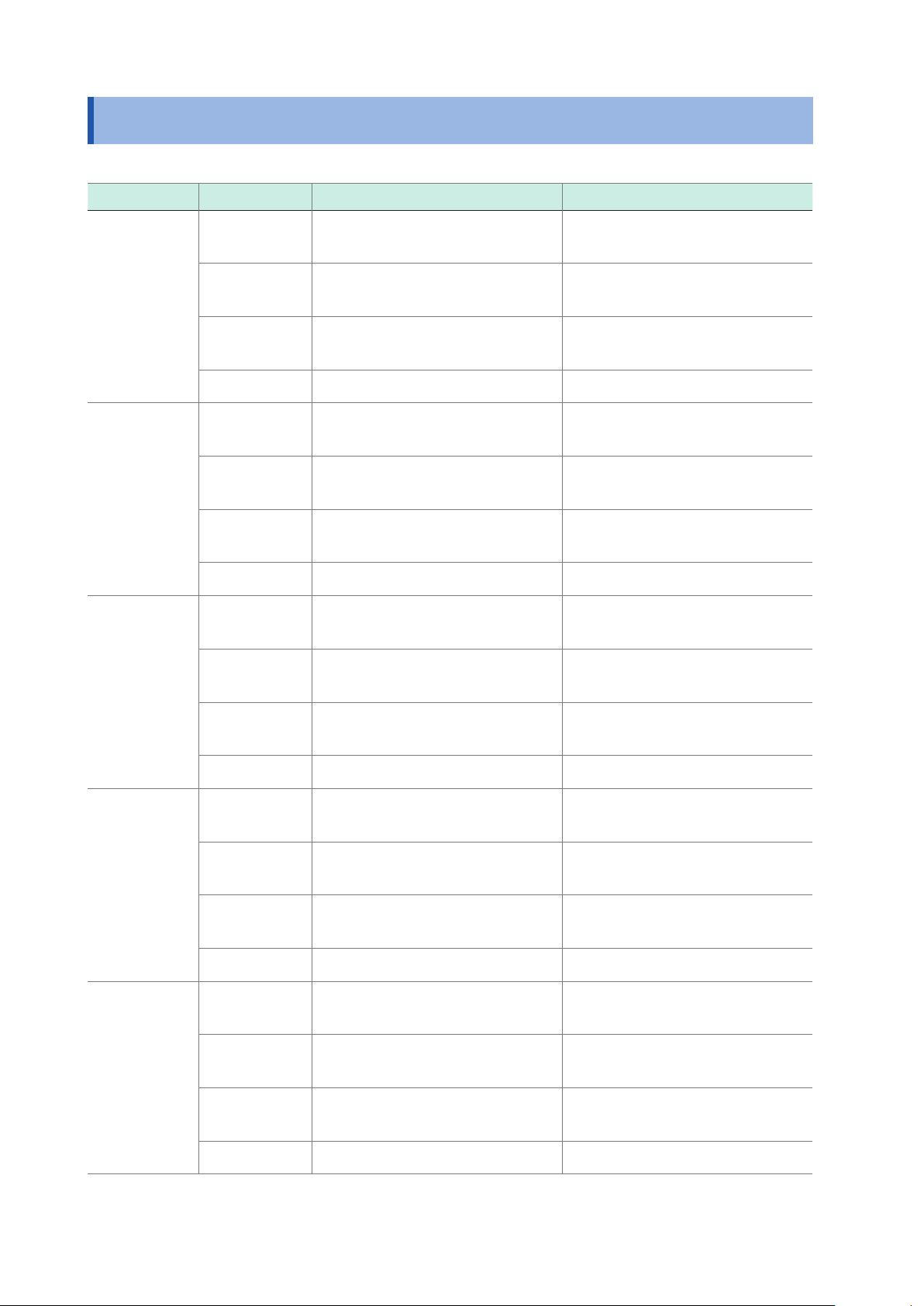

Operating conditions Charging interval must be greater than or equal to the time

calculated from the graphs shown in Figure 1 and Figure 2 below.

(Continuous charging is not supported.)

100.0

10.0

1.0

Capacitance [µF]

0.1

Applied voltage

Applied voltage 500 V

Applied voltage 250 V

Charging interval [ms]

Figure 1: Charging Interval by Applied Voltage and Capacitance

(SM7860-51, -53, -55, -57, -58, -61, -63, -65, -67, -68)

49

Basic Specications

100.0

Applied voltage 250 V

Applied voltage 500 V

10.0

Capacitance [µF]

1.0

0.1

10 100 1000

Charging interval [ms]

Applied voltage 1000 V

Figure 2: Charging Interval by Applied Voltage and Capacitance

(SM7860-52, -54, -56, -62, -64, -66)

Graph description and operating precautions

Since the SM7860 is designed to be embedded in an automated system in applications in which it

charges capacitors, it cannot be used with a continuous load.

Figures 1 and 2 dene the minimum cycle times at which this automated system can operate based on

the output voltage and capacitor capacitance.

For example, when charging a 25 V, 30 μF capacitor, a charge interval of approximately 37 ms can be

read from the point at which a line extending from the 30 μF position on the vertical axis intersects the

25 V line. This gure (37 ms) denes the minimum cycle for the automated system.

The time (T) representing the interval during the 37 ms for which the SM7860 charges the capacitor at the

full power of 50 mA or 10 mA can be calculated as follows:

T = C × V / I

C : Capacitor capacitance (μF)

V : Voltage (V)

I : Current (50 mA)

Using values of 25 V, 30 μF, and 50 mA yields:

T = 30 μF × 25 V / 50 mA

= 15 ms

50

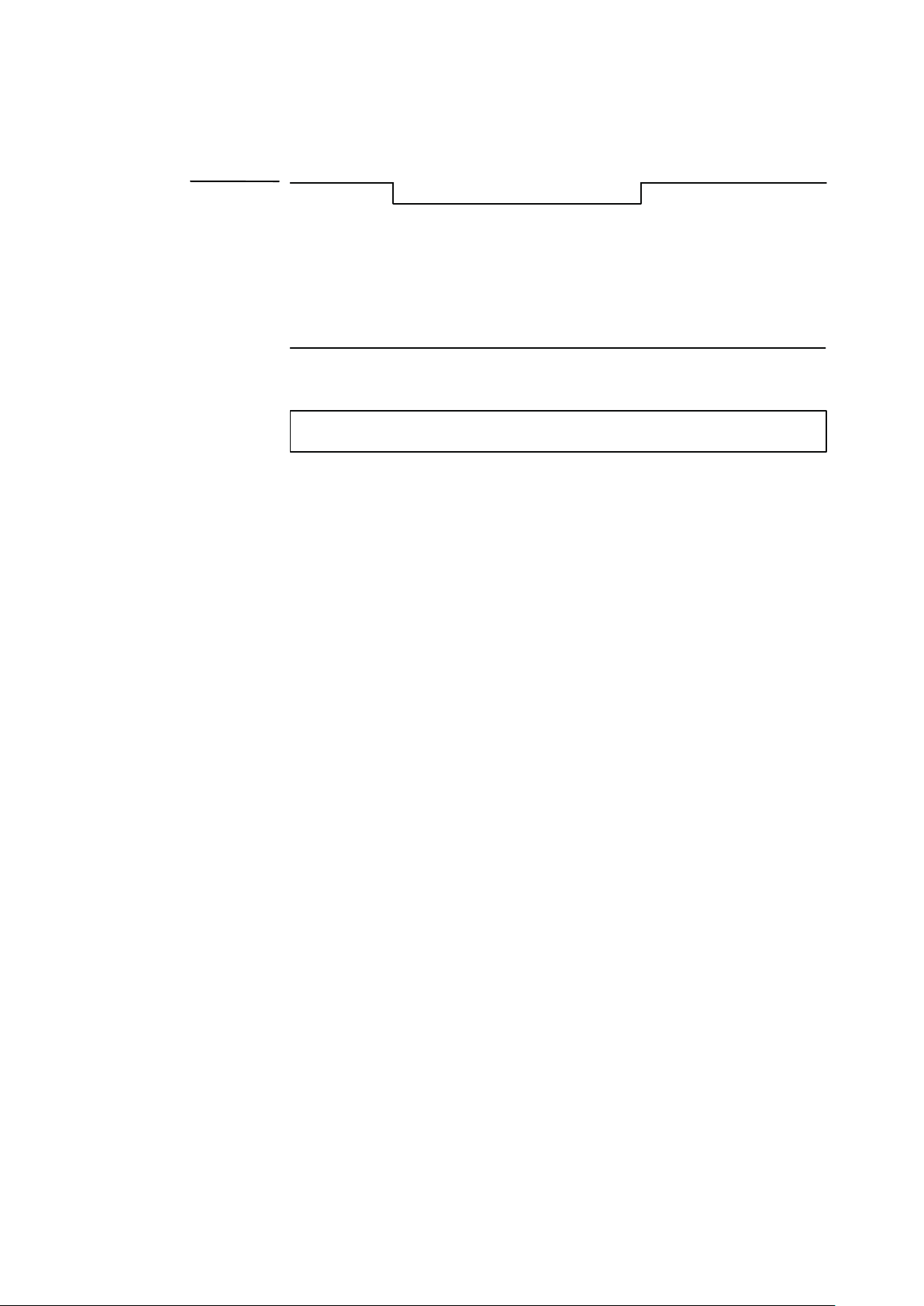

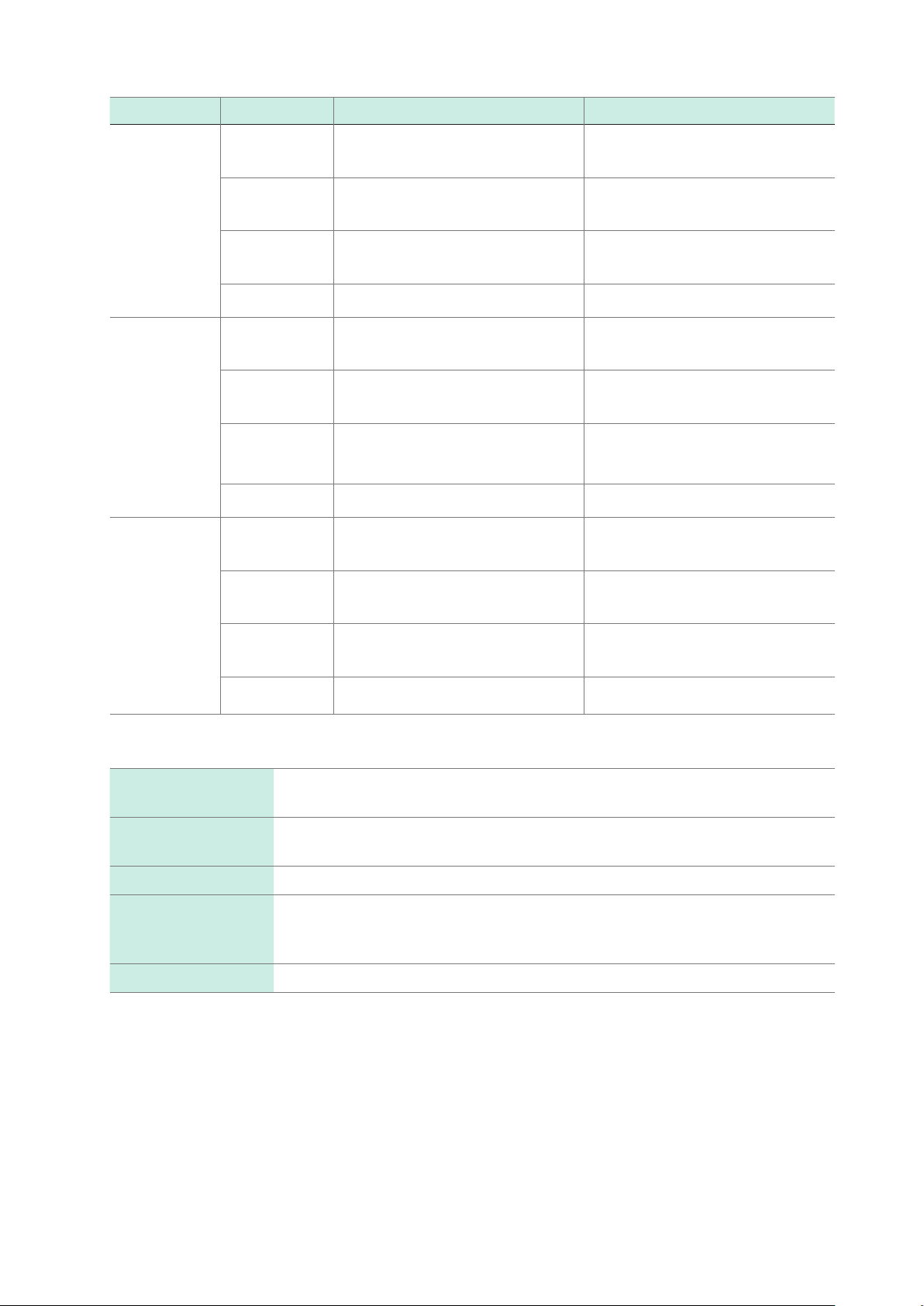

The following diagram expresses this as a timing chart:

37 ms

Basic Specications

Automated system operation

Contact Contact

15 ms

Movement Movement

Charging current

Almost no current during this interval

During the 37 ms interval, the charging current ows for 15 ms, and almost no current ows for the