Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Instruction Manual

SM7810

SM7810-20

SUPER MΩ HiTESTER

March 2012 Revised edition 1 SM7810A981-01 12-03H

Page 2

Contents

Introduction.................................................................................1

i

Contents

1

Confirming Package Contents....................................................1

Safety Information ......................................................................2

Operating Precautions................................................................4

Chapter 1

Overview ___________________________________ 7

1.1 Product Overview and Features ......................................... 7

Operating Principles and Block Diagram ............................................8

1.2 Names and Functions of Parts ............................................ 9

1.3 Screen Layout ................................................................... 10

Chapter 2

Measurement Preparations___________________ 11

2.1 Installation & Connection Procedures ...............................11

2.2 Connecting the Power Cord ..............................................12

2.3 Connecting the Measurement Cables ............................... 13

2

3

4

5

6

7

2.4 Connecting the Measurement Power Source ...................14

2.5 Turning the Power On and Off ..........................................15

Chapter 3

Setting Measurement Conditions ______________ 17

3.1 Pre-Operation Inspection .................................................. 17

3.2 Setting Measurement Conditions ......................................18

Chapter 4

Communication (GP-IB/RS-232C Interface)______ 19

4.1 Overview and Features ..................................................... 19

4.2 Specifications ....................................................................20

4.3 Connect a cable to the GP-IB connector

or RS-232C connector ...................................................... 21

4.4 Configuring the Communications Protocol ........................ 23

4.5 Communication Methods .................................................. 24

Status Byte Register .........................................................................27

Event Registers ................................................................................29

Error Registers ..................................................................................32

8

9

10

11

12

付

録

索

引

Page 3

ii

Contents

4.6 Message List ..................................................................... 33

4.7 Listener Specification Precautions .................................... 40

Input buffer size ................................................................................ 40

Reading from the output buffer ........................................................ 40

Chapter 5

External Control ____________________________41

5.1 External Input/Output Connector and Signals .................. 41

Connector Type and Signal Pinouts ................................................. 42

Signal Descriptions .......................................................................... 43

5.2 Timing Chart ..................................................................... 44

5.3 Internal Circuitry ................................................................ 47

Chapter 6

Specifications ______________________________ 49

6.1 General Specifications ...................................................... 49

6.2 Basic Specifications .......................................................... 50

6.3 Functions .......................................................................... 51

6.4 Measurement Specifications ............................................. 54

6.5 Input / Output Functions (Interface for External Control) .. 57

Chapter 7

Maintenance and Service ____________________ 59

7.1 Troubleshooting ................................................................ 59

Inspection and Repair ...................................................................... 59

7.2 Replacing the Power Fuse ................................................ 60

7.3 Error Displays ................................................................... 61

7.4 Cleaning ............................................................................ 61

Appendix _________________________________ A1

Appendix 1 Attaching Rubber Feet .............................................A1

Appendix 2 Rack Mounting .........................................................A2

Appendix 3 External Dimensions ................................................A4

Page 4

Introduction

Confirm that these contents are provided.

□ Model SM7810, SM7810-20 Super MΩ HiTester (1)

(Model SM7810 Rated supply voltage: 100 VAC, 110 VAC)

(Model SM7810-20 Rated supply voltage: 220 VAC)

□ Power cord (1)

□ Instruction manual (1)

□ Voltage input connector (1)

□ Spare fuse (1)

(built into inlet)

□ Rubber feet (4)

Thank you for purchasing the HIOKI Model SM7810, SM7810-20 Super MΩ HiTester. To obtain maximum performance from the instrument, please read this

manual first, and keep it handy for future reference.

Confirming Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

1

Introduction

Options

□ Model 9637 RS-232C Cable (9pin-9pin/Cross/1.8m)

□ Model 9638 RS-232C Cable (9pin-25pin/Cross/1.8m)

□ Model 9151-02 GP-IB Connector Cable (2 m)

Page 5

2

Safety Information

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards,

and has been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage to

the instrument. Using the instrument in a way not described in this manual

may negate the provided safety features.

Be certain that you understand the instructions and precautions in the

manual before use. We disclaim any responsibility for accidents or injuries

not resulting directly from instrument defects.

This manual contains information and warnings essential for safe operation of

the instrument and for maintaining it in safe operating condition. Before using it,

be sure to carefully read the following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important information that

the user should read before using the instrument.

The symbol printed on the instrument indicates that the user should refer

to a corresponding topic in the manual (marked with the symbol) before

using the relevant function.

Indicates that dangerous voltage may be present at this terminal.

Indicates a fuse.

Indicates a grounding terminal.

Indicates a ground terminal connected to the chassis of the system.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents an extreme hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that

could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the

user or damage to the instrument.

Indicates advisory items related to performance or correct operation

of the instrument.

Page 6

Other symbols

3

Safety Information

Indicates a prohibited action.

*

PAG E

UP

(Bold characters)

(p. #)

Indicates that descriptive information is provided below.

Bold characters within the text indicate operating key labels.

Indicates the location of reference information.

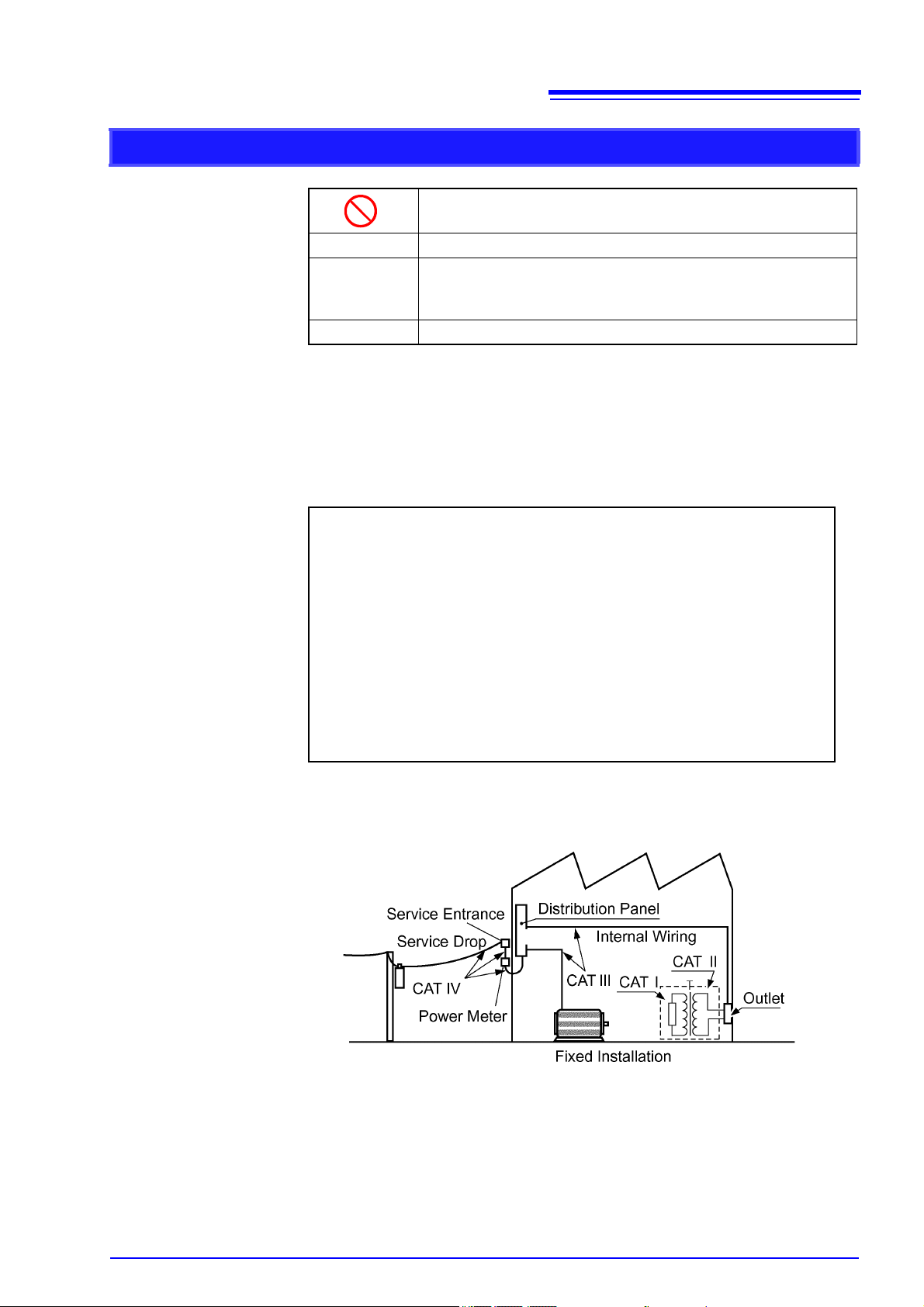

Measurement categories (Overvoltage categories)

To ensure safe operation of measurement instruments, IEC 61010 establishes

safety standards for various electrical environments, categorized as CAT I to

CAT IV, and called measurement categories.

CAT I

CAT II

CAT III

CAT IV

Secondary electrical circuits connected to an AC electrical

outlet through a transformer or similar device.

Primary electrical circuits in equipment connected to an AC

electrical outlet by a power cord (portable tools, household

appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

Primary electrical circuits of heavy equipment (fixed

installations) connected directly to the distribution panel, and

feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance, and

to the power meter and primary overcurrent protection device

(distribution panel).

Using a measurement instrument in an environment designated with a highernumbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

Page 7

4

Operating Precautions

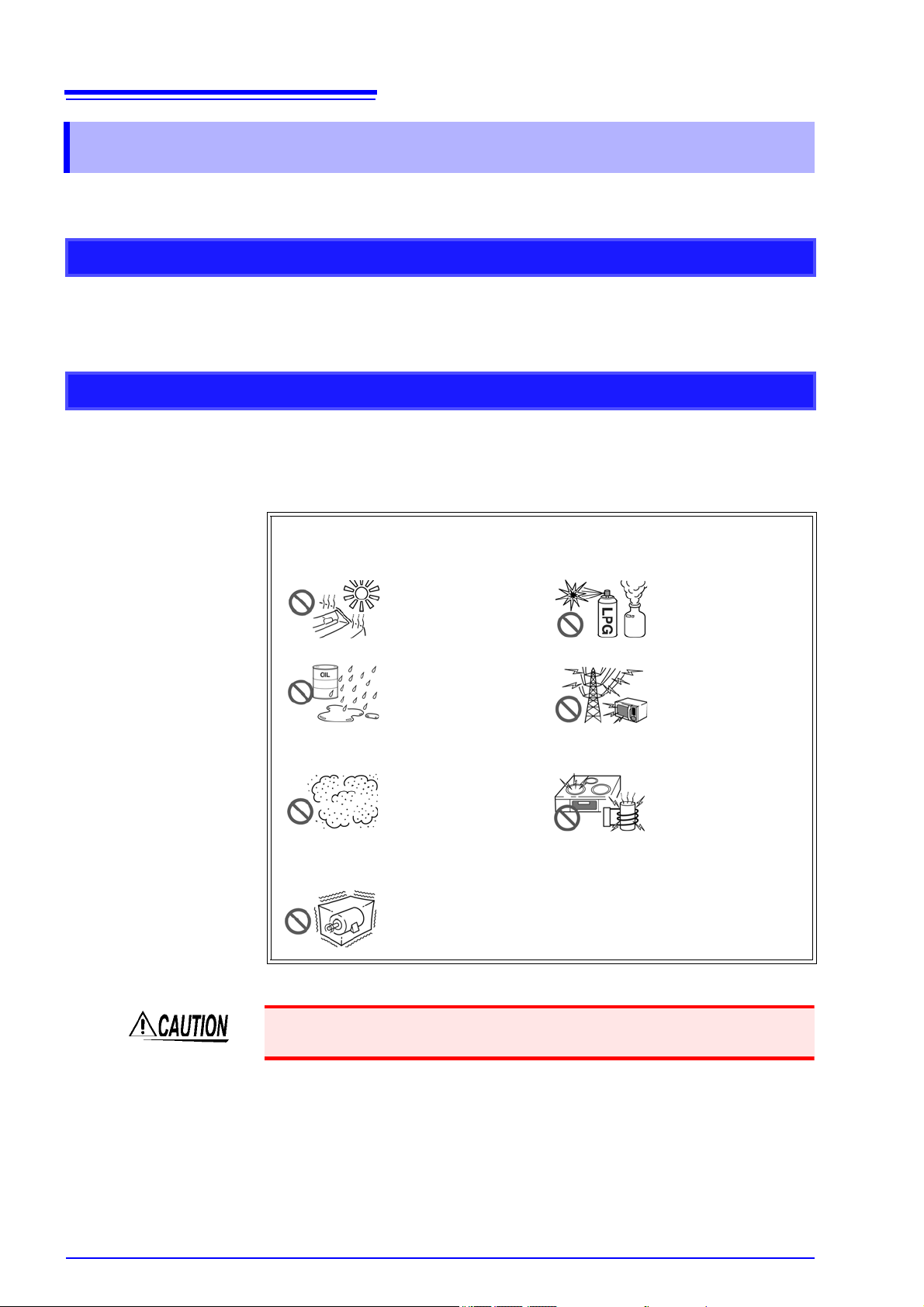

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits

of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Instrument Installation

Operating temperature and humidity:

0 to 40°C at 80%RH or less (non-condensing)

Temperature and humidity range for guaranteed accuracy:

23±5°C, 80%RH or less (non-condensing)

Avoid the following locations that could cause an accident or damage

to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals, or

solvents

Exposed to high humidity or condensation(

Exposed to high levels of particulate dust

Subject to vibration

In the presence of

corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Near electromagnetic radiators (e.g.,

high-frequency induction heating systems

and IH cooking utensils)

Do not slant the instrument or place it on top of an uneven surface. Dropping or

knocking down the instrument can cause injury or damage to the instrument.

Page 8

Handling the Instrument

• Do not allow the instrument to get wet, and do not take measurements

with wet hands. This may cause an electric shock.

• Touching any of the high-voltage points inside the instrument is very

dangerous. Do not attempt to modify, disassemble or repair the instrument; as fire, electric shock and injury could result.

To avoid damage to the instrument, protect it from physical shock when transporting and handling. Be especially careful to avoid physical shock from dropping.

Handling the Cords

5

Operating Precautions

Before Connecting

Before using the instrument, make sure that the insulation on the Connection Cable is undamaged and that no bare conductors are improperly

exposed. Using the instrument in such conditions could cause an electric

shock, so contact your dealer or Hioki representative for replacements.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the power outlet.

• Keep the cables well away from heat sources, as bare conductors could be

exposed if the insulation melts.

Use only the specified connection cables. Using a non-specified cable may

result in incorrect measurements due to poor connection or other reasons.

• Before turning the instrument on, make sure the supply voltage matches

that indicated on its power connector. Connection to an improper supply

voltage may damage the instrument and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specifications of

this instrument, connect the power cord only to a 3-contact (two-conductor + ground) outlet.

Page 9

6

Operating Precautions

Input and Measurement Precautions

• The maximum input voltage and maximum rated voltage to earth are 1000

VDC. If their voltages are exceeded, this instrument will be damaged and

personal injury will result. Therefore, do not input signals in excess of

these values.

• To avoid electrical hazards and damage to the instrument, do not apply

voltage exceeding the rated maximum to the voltage input terminal.

To ensure measurements are accurate,

• Warm up the instrument 60 minutes or more before use.

• The instrument should be calibrated once a year.

Page 10

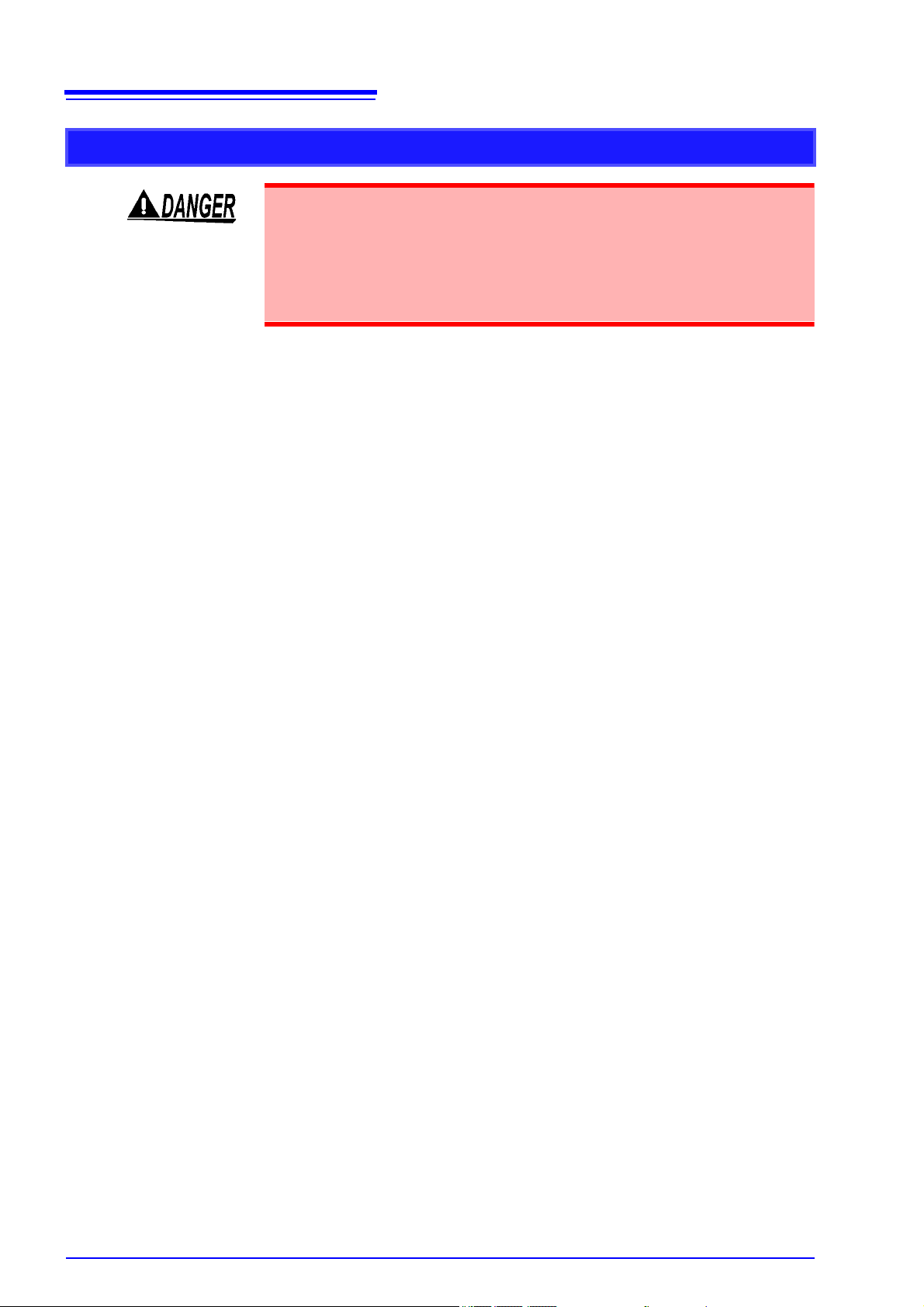

1.1 Product Overview and Features

Easy integration into automated testing systems

The instrument features a standard external I/O interface, allowing contact check results and comparison

judgment results to be downloaded to other devices.

Additionally, external I/O can be used to easily change

target objects, making it easy to integrate the instrument into an automated testing system.

High-speed insulation resistance measurement

The instrument is a high-sensitivity ammeter for use in insulation resistance measurement applications. The time

from trigger activation to index output is as little as 7 ms.

TRIG

INDEX

Judgment

7 ms (min)

C.C.

Measu

rement

Machine cycl e

8-channel simultaneous measurement

The instrument can measure 8 channels simultaneously, boosting production volume. This capability improves on previous HIOKI instruments,

which offered 4 channels.

充電3

充電1

充電2

充電n

測定1

測定2

1列

8列

Charge 2

Charge 1

Charge 3

Charge n

Measure 1

Measure 2

Row 1

Row 8

Compatibility with highcapacity capacitors

Range: 100 pA to 1 mA

The instrument features an expanded current measurement

range to accommodate increasingly high-capacity MLCCs, making possible more accurate pass/

fail judgments.

Interface communications

The instrument can be connected to a control device and controlled via either its GP-IB or RS232C interface. Measurement

data can also be downloaded.

Contact check for improved reliability

The instrument can check for poor contact with the object under measurement using the capacitance detection method, and the results of this check can be

output from the instrument.

Overview Chapter 1

1.1 Product Overview and Features

The instrument is an 8-channel, high-sensitivity ammeter for use in measuring

insulation resistance. It can perform insulation measurement of target objects

such as electrical insulators with high resistance values, measuring all 8 channels simultaneously at high speed. The instrument is designed for use in applications such as automatic insulation testing, particularly of capacitors.

This insulation measuring instrument requires an external measurement power

source to be provided by the operator. HIOKI offers a recommended power

source (Model SM7860 series Power Source Unit).

7

Page 11

8

Current-

voltage

converter

A/D

converter

Measuring

interface

Control

unit

EXT I/O

(isolation)

GP-IB

interface

LCD

module

Current-

voltage

converter

A/D

converter

Current-

voltage

converter

A/D

converter

Current-

voltage

converter

A/D

converter

Current-

voltage

converter

A/D

converter

Current-

voltage

converter

A/D

converter

Current-

voltage

converter

A/D

converter

Current-

voltage

converter

A/D

converter

Measuring

interface

INPUT

CH1

CH2

CH3

CH4

INPUT

CH5

CH6

CH7

CH8

OUTPUT

CH1

CH2

CH3

CH4

GUARD

VOLTAGE

INPUT

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

COM

CH5

CH6

CH7

CH8

OUTPUT

Measurement block

Measurement block

A

BC

D

RS-232C

interface

1.1 Product Overview and Features

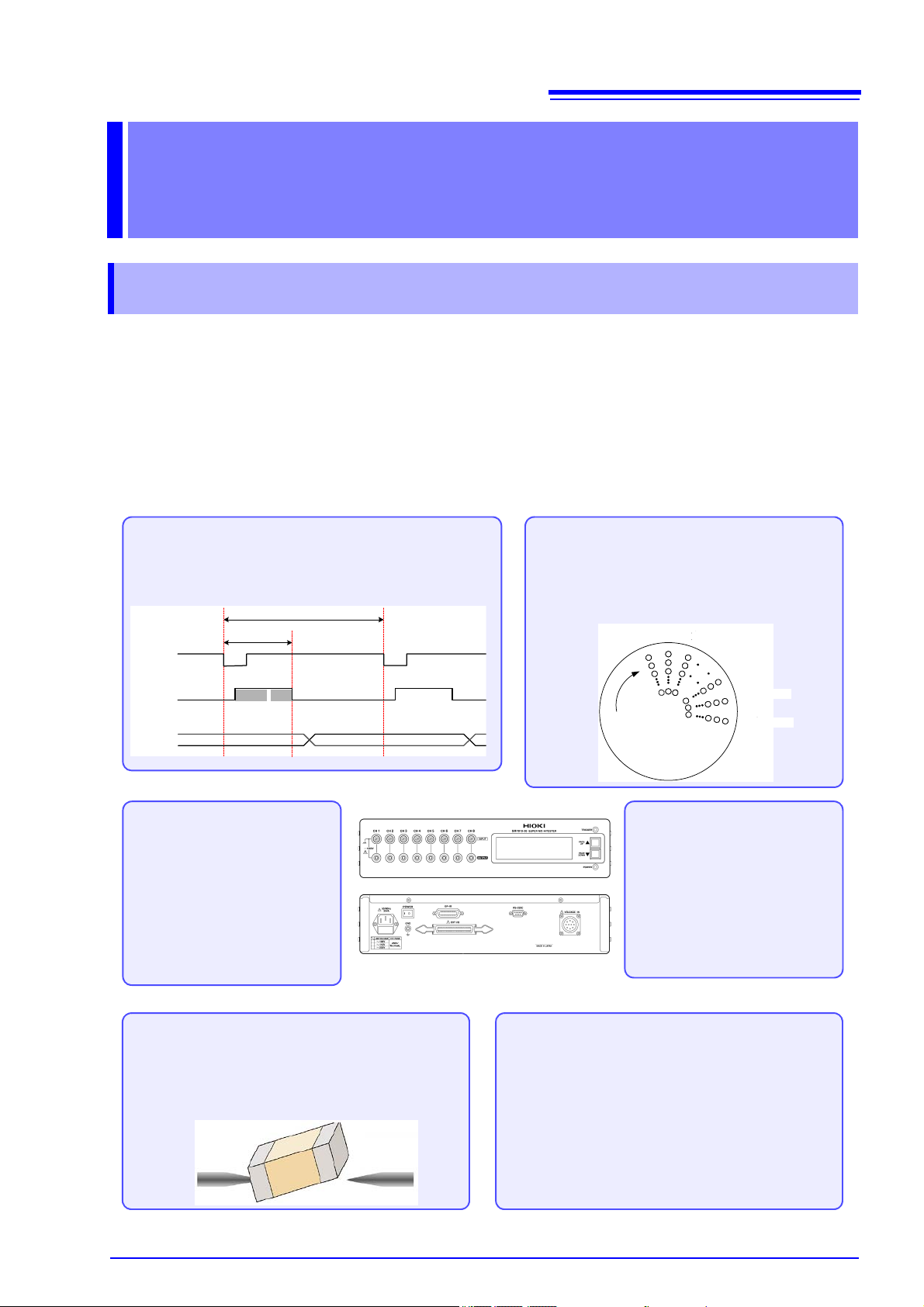

Operating Principles and Block Diagram

The instrument is an 8-channel, high-sensitivity ammeter for use in measuring insulation resistance. After

connecting the dedicated external power source to the voltage input terminal (A) and applying voltage to the

object under measurement from the voltage output terminals (OUTPUT), current is measured at the current

input terminals (INPUT). The resistance value is then calculated from the measured current values and the

set measurement voltage values.

The measurement block performs current/voltage conversion using charge measurement type current-voltage

converters (B) that integrate input current values and A/D converters (C). This method allows precise measurement of minute currents by using long integration times.

Having been converted into digital data, measurement block output is sent to the control block (D) memory.

The control block (D) performs arithmetic processing on measurement data that has been input to its memory

and sends output to the instrument’s LCD screen and interfaces.

Page 12

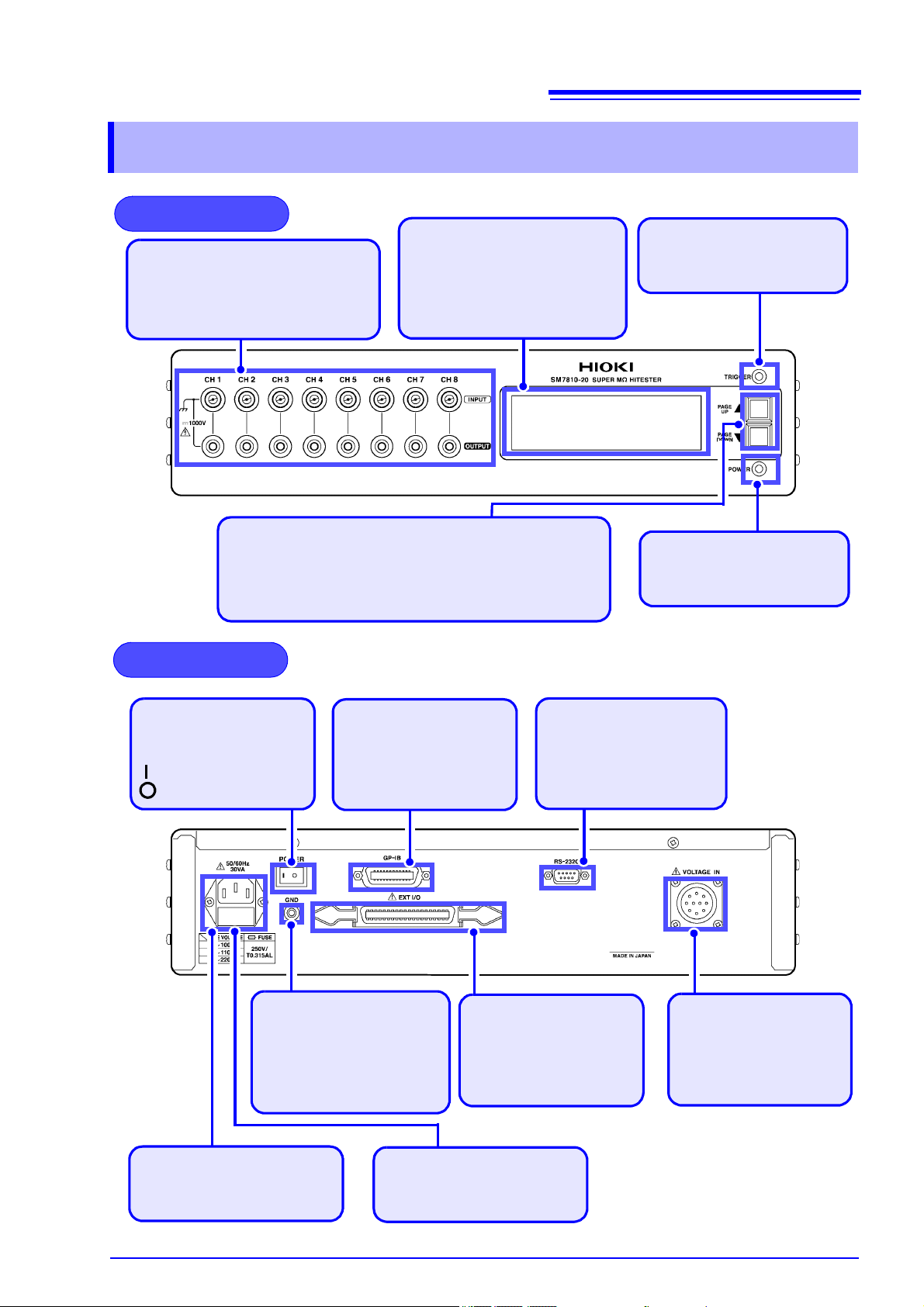

1.2 Names and Functions of Parts

Power indicator

Lights up when the instrument is

on.

Trigger indicator

Lights up when the trigger signal is on.

LCD screen

The instrument’s interface consists

of three display pages, including

measured values, contact check

results, and operating conditions.

"1.3 Screen Layout" (p.10).

Front Panel

Measurement terminals

•

INPUT: Current input terminals

• OUTPUT: Voltage output terminals

The instrument’s 8 channels can be

measured simultaneously.

Scroll keys (PAGE U P ▲/ PA GE DOWN▼)

Used to scroll through the display pages.

"1.3 Screen Layout" (p.10)

The scroll keys are also used to set the GP-IB address.

(p.23)

Rear Panel

GND terminal

Serves as the ground terminal.

The GND terminal is connected to the instrument’s enclosure. It is used when shielding

measurement cables.

Power inlet

Connect the supplied power cord

here. (p.12)

POWER switch

Turns the instrument on and

off. (p.15)

: Power On

: Power Off

GP-IB connector

Connect to a computer

when using the GP-IB interface.

(p.21)

RS-232C connector

Connect to a computer when

using the RS-232C interface.

(p.21)

EXT I/O connector

The external I/O connector

can be used to control the

instrument.

(p.41)

Voltage input terminal

Supplies the measurement

power source. Connect the

included voltage input connector.

Fuse holder

Allows the fuse to be replaced.

(p.60)

1.2 Names and Functions of Parts

9

Page 13

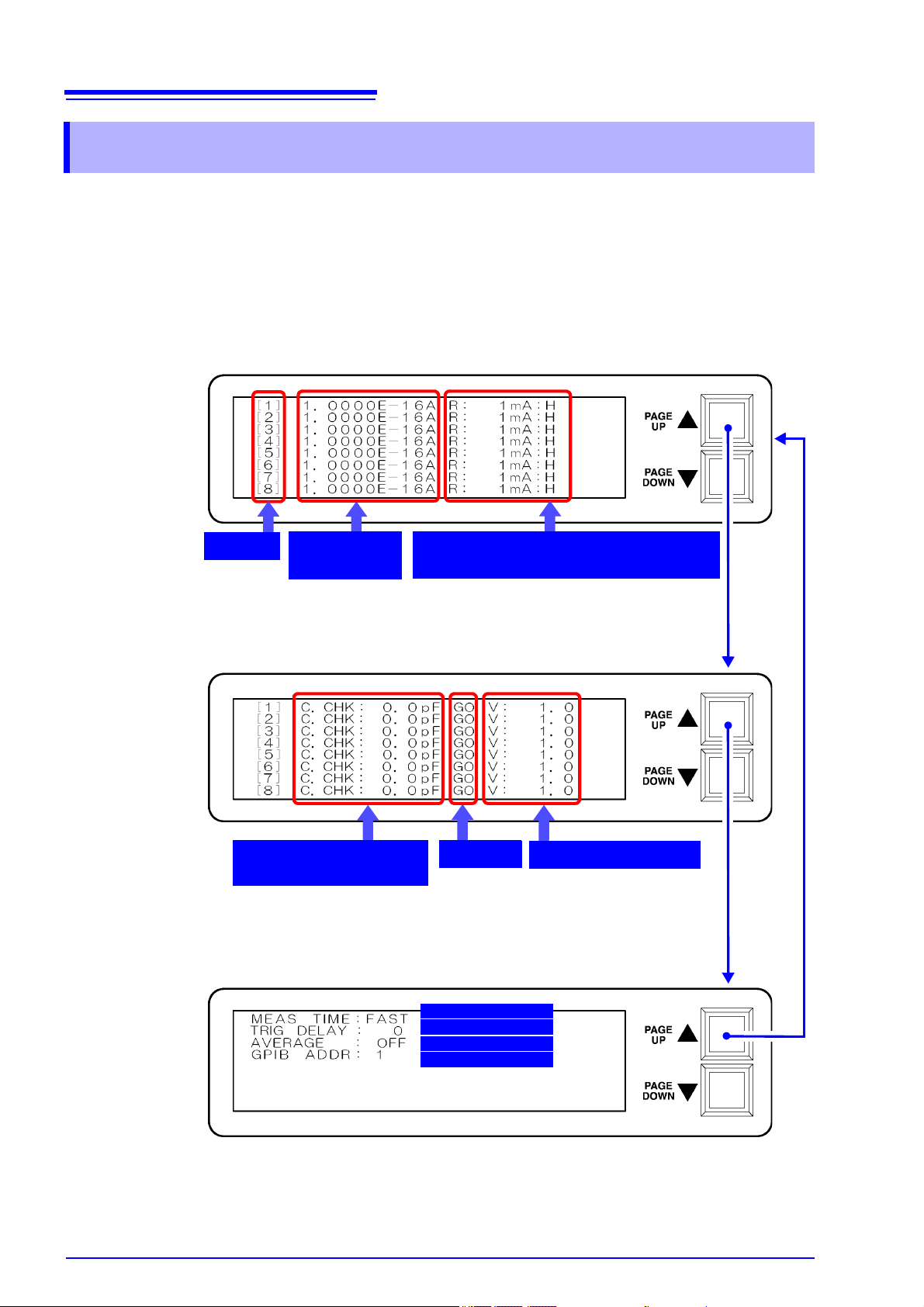

10

■ Screen P1: Measured value display

■ Screen P2: Contact check results display

■ Screen P3: Operating condition display

Measurement speed

Trigger delay time

Averaging settings

Contact-check

measurement values

Judgment

Measurement voltage

Measurement

values

GP-IB address

Channel

Measurement range: A (Auto range)

: H (Fixed range)

1.3 Screen Layout

1.3 Screen Layout

The LCD screen consists of three display pages. When the instrument is turned

on, page 1 is shown. The scroll keys on the front of the instrument (PAGE U P ▲/

PAG E DOWN▼) are used to scroll among the display pages, which can also be

selected directly by sending the “

interface.

See: Message List "PAG" (p.38)

PAG” command from the GP-IB or RS-232C

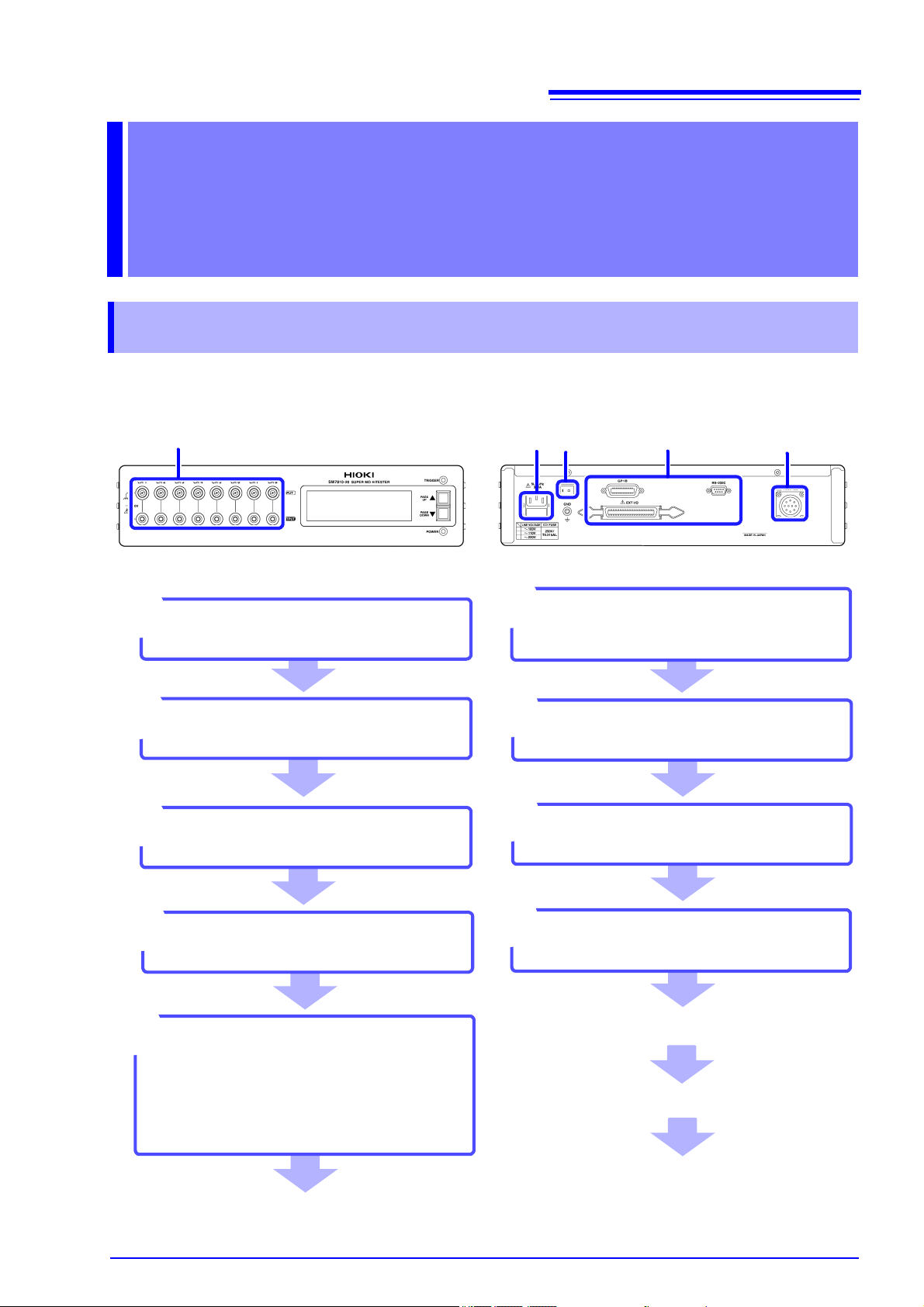

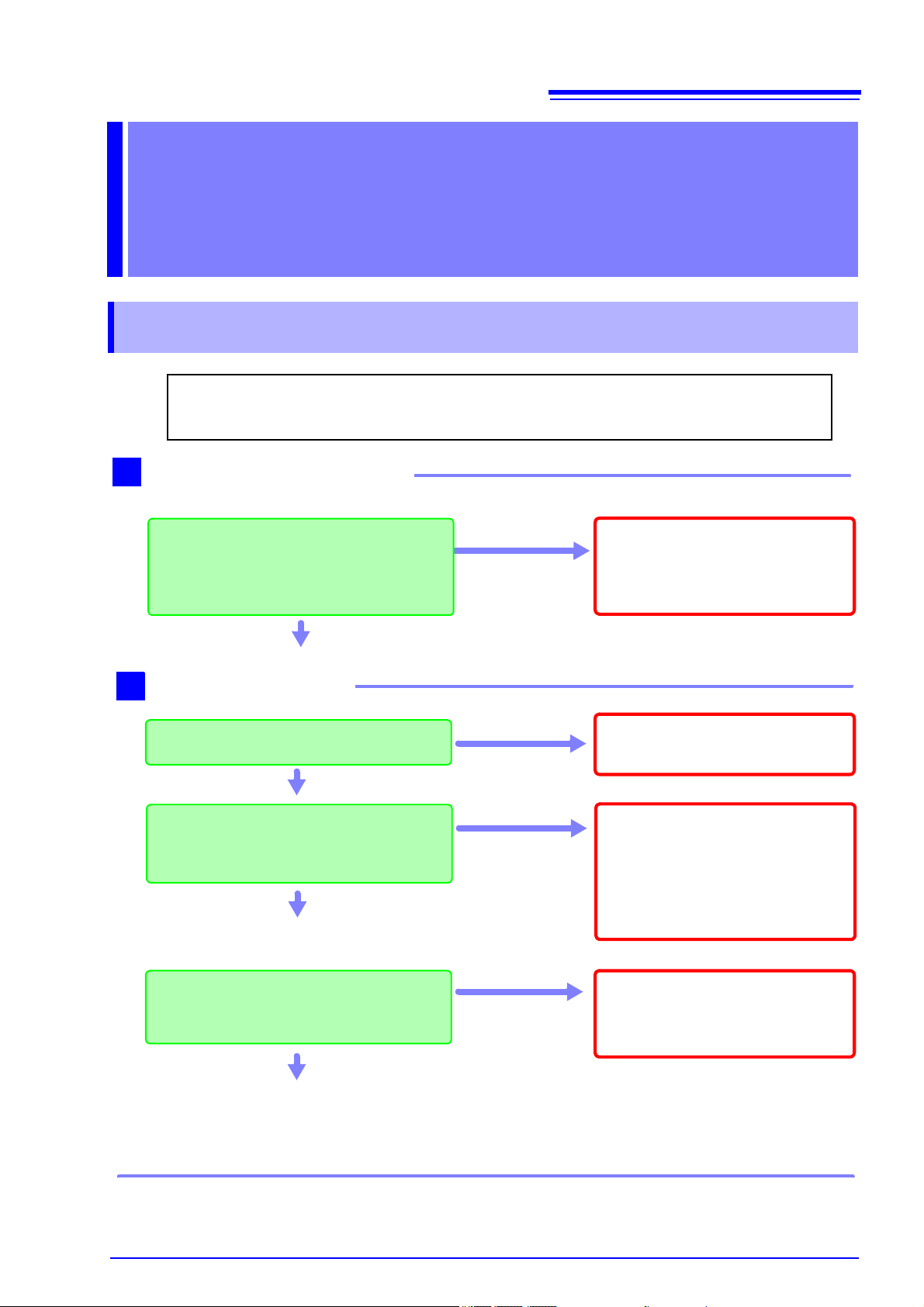

Page 14

11

Connect to the test sample

9

Install this instrument (p.4)

1

Rear PanelFront Panel

Connect measurement cables

(p.13)

Turn the power on (p.15)

7

Connect the external interface

(as needed)

5

• Using the GP-IB or RS-232C interface

(p.19)

• Using the EXT I/O (p.41)

Connect the power cord (p.12)

2

3

2

3

5

Make instrument settings (p.18)

(via the external interface)

8

Connect the instrument to the

measurement line (p.14)

4

Be sure to complete the pre-operation inspection (p.17) before

starting measurement

6

When finished measuring,

turn the power off (p.15)

4

Activate the measurement

power source

Make measurements

7

2.1 Installation & Connection Procedures

Measurement

Preparations Chapter 2

2.1 Installation & Connection Procedures

Be sure to read the "Operating Precautions" (p.4) before installing and connecting

this instrument.

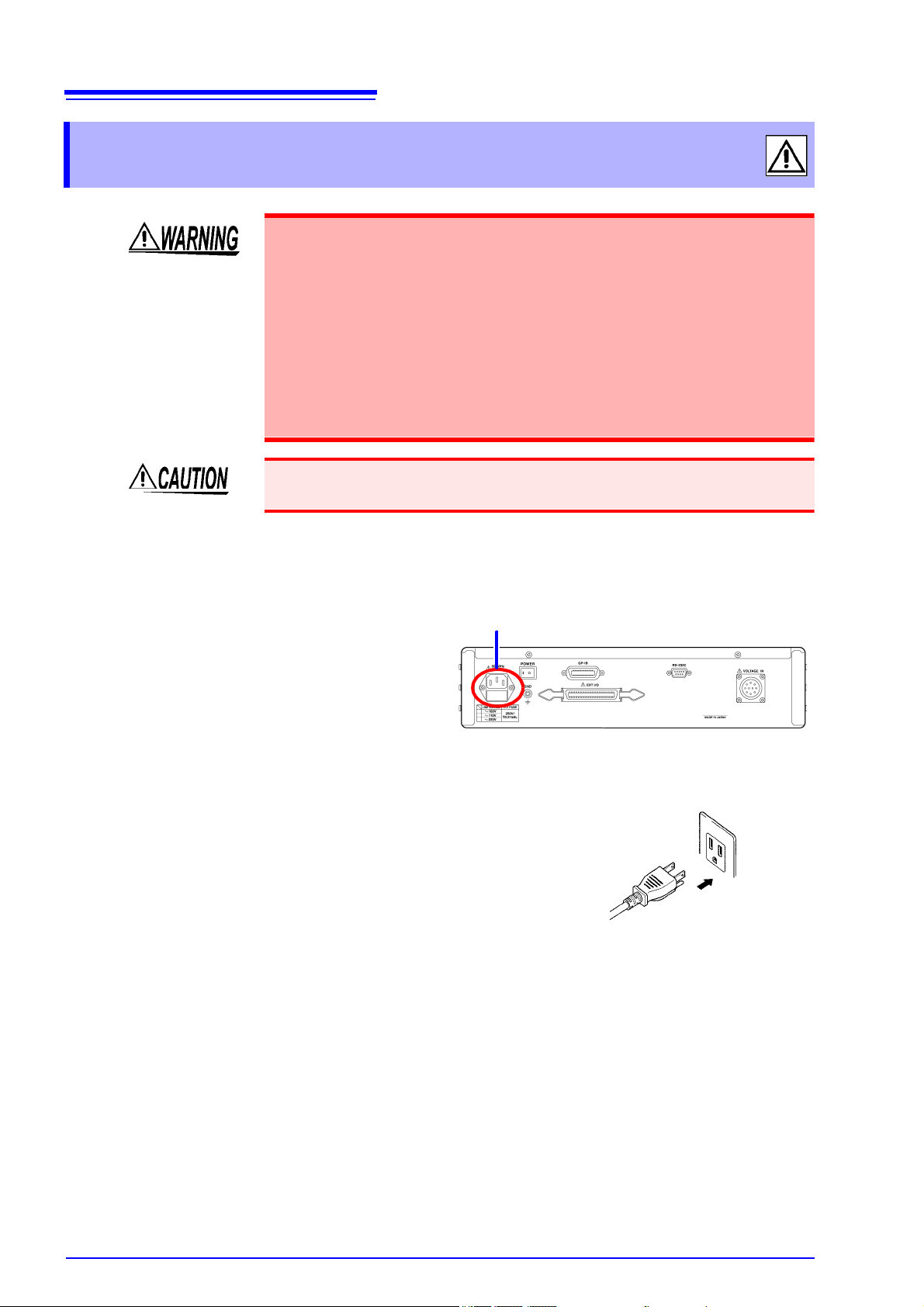

Page 15

12

Rear Panel

1 Confirm that the instrument is turned

off.

2 Confirm that the mains supply volt-

age matches the instrument, and

connect the power cord to the power

inlet on the instrument.

3 Plug the power cord into the mains

outlet.

Power inlet

2.2 Connecting the Power Cord

2.2 Connecting the Power Cord

• Before turning the instrument on, make sure the supply voltage matches

that indicated on its power connector. Connection to an improper supply

voltage may damage the instrument and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specifications of

this instrument, connect the power cord only to a 3-contact (two-conductor + ground) outlet.

• Before using the instrument, make sure that the insulation on the power

cord is undamaged and that no bare conductors are improperly exposed.

Using the instrument in such conditions could cause an electric shock,

so contact your dealer or Hioki representative for replacements.

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the power outlet.

Turn off the power before disconnecting the power cord.

Connection Methods

Page 16

2.3 Connecting the Measurement Cables

Front panel

1 Connect the measurement cables to

each channel’s current input terminal.

2 Connect the voltage output cables to

each channel’s voltage output terminal.

Current input terminals

Voltage output terminals

For more information about measurement cables and voltage output cables,

please contact your dealer or HIOKI representative.

2.3 Connecting the Measurement Cables

To avoid damage to the instrument, do not apply voltage to measurement terminals.

Connection Methods

13

• The current input terminals incorporate a two-tiered design with both center

and outer conductors. The center conductors are connected to measurement

input, while the outer conductors are connected to guard signals.

• Because the instrument performs high-sensitivity current measurement, noise

occurring on the measurement cables may prevent measured values from stabilizing. Use low-noise shielded measurement cables that meet HIOKI’s specifications.

Page 17

14

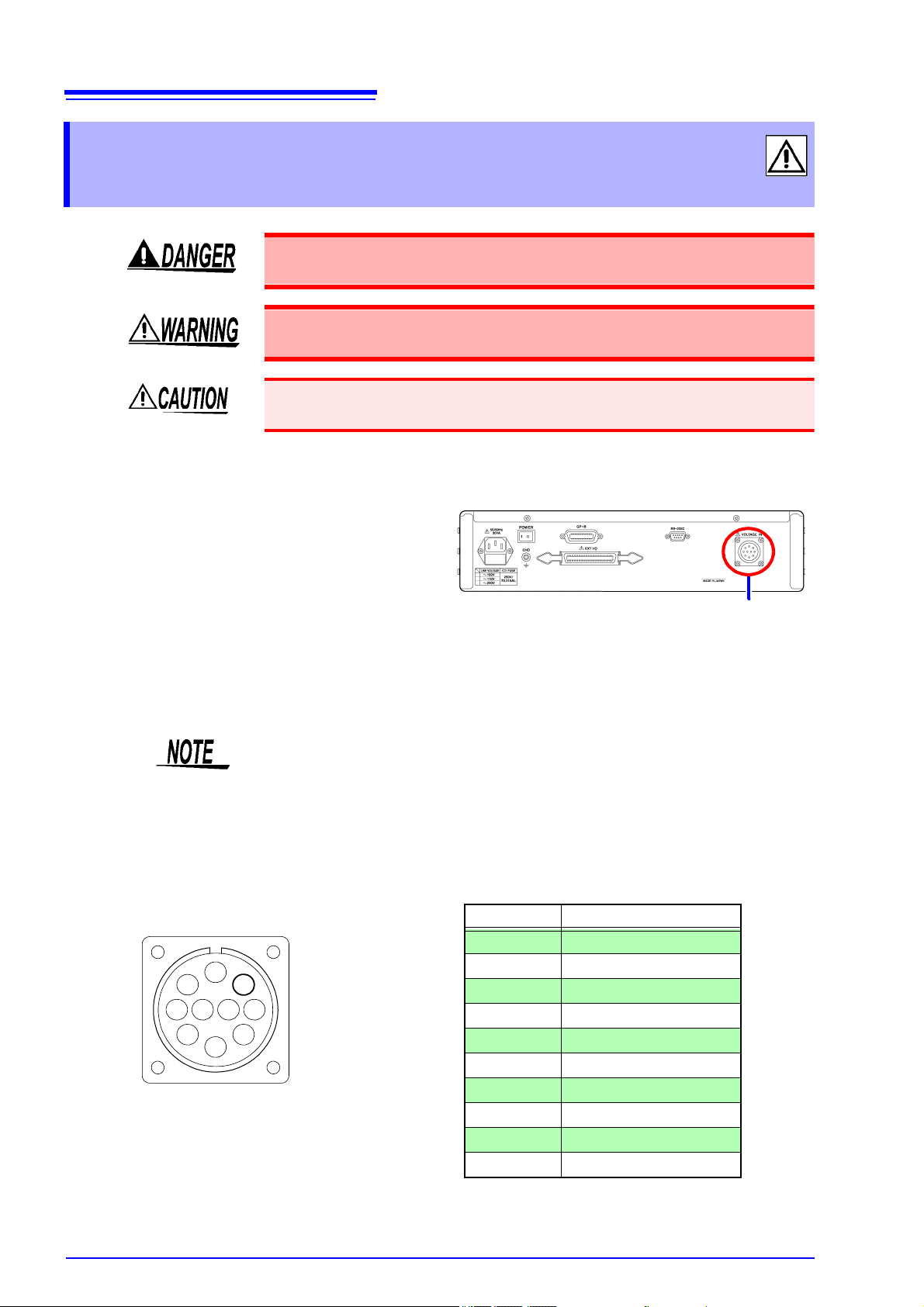

Rear Panel

1 Confirm that the instrument is turned

off.

2 Connect the included voltage input

connector to the voltage input terminal on the rear of the instrument.

Voltage input terminal

6 5 47

3

2

10

8

9

1

Voltage input pin assignments

(View of terminal on instrument)

Pin No. Channel

1 CH1

2 CH2

3 CH3

4 CH4

5 CH5

6 CH6

7 CH7

8 CH8

9 NC

10 COM

2.4 Connecting the Measurement Power Source

2.4 Connecting the Measurement Power

Source

To avoid electrical hazards and damage to the instrument, do not apply

voltage exceeding the rated maximum to the voltage input terminal.

Do not input voltage to the voltage input terminal before connecting measurement cables and voltage output cables. Doing so may result in injury.

When the power is turned off, do not apply voltage to the voltage input terminals.

Doing so may damage the instrument.

Connection Methods

This insulation measuring instrument requires an external measurement power

source provided by the operator. HIOKI offers a recommended power source

(Model SM7860 series Power Source Unit).

Specifications

Page 18

2.5 Turning the Power On and Off

Rear Panel

POWER switch

Turn the POWER switch on ( ).

The power indicator and LCD screen on the front of the instrument will light up.

When the power is turned on, the same setting as when the power was last turned off appears

(backup function).

When powered up for the first time, the instrument will be configured with its default settings.

However, the LCD screen is not backed up.

Before Starting Measurement

To obtain precise measurements, provide about 60 minutes warm-up after turning power on.

Before turning the instrument off, turn off measurement power source output.

Turn the POWER switch off ( ).

2.5 Turning the Power On and Off

Before turning the instrument on, make sure the supply voltage matches

that indicated on its power connector. Connection to an improper supply

voltage may damage the instrument and present an electrical hazard.

15

Turning Power On

Turning Power Off

If a power outage (e.g., breaker trip) occurs when the instrument is on, it will

automatically turn on again when power is restored.

Page 19

16

2.5 Turning the Power On and Off

Page 20

3.1 Pre-Operation Inspection

Do not use a damaged cord because

doing so may result in electric

shock. (Replace the cord with a new

one.)

Metal Exposed

• Is the power cord insulation torn, or is

any metal exposed?

• Is the connection cord insulation torn, or

is any metal exposed?

1

No Metal Exposed

Before using the instrument the first time, verify that it operates normally to ensure that the

no damage occurred during storage or shipping. If you find any damage, contact your dealer

or Hioki representative.

Peripheral Device Inspection

If damage is evident, request repairs.

Yes

Is damage to the instrument evident?

When turning power on

Do the “HIOKI”, “SM7810” and version number indications appear on the display area?

No

2

The power cord may be damaged, or

the instrument may be damaged internally.

Request repairs.

No

Yes

Inspection complete

Please read the "Operating Precautions" (p.4) before use.

Use of a supply voltage outside the

specified range may damage the instrument or cause electric shock.

Before turning the instrument on,

make sure the supply voltage

matches that indicated on its power

connector.

No

Does the supply voltage of your power

source match the supply voltage indicated

above the power source inlet on the rear of

the instrument?

Yes

Instrument Inspection

Setting Measurement

Conditions Chapter 3

3.1 Pre-Operation Inspection

17

Page 21

18

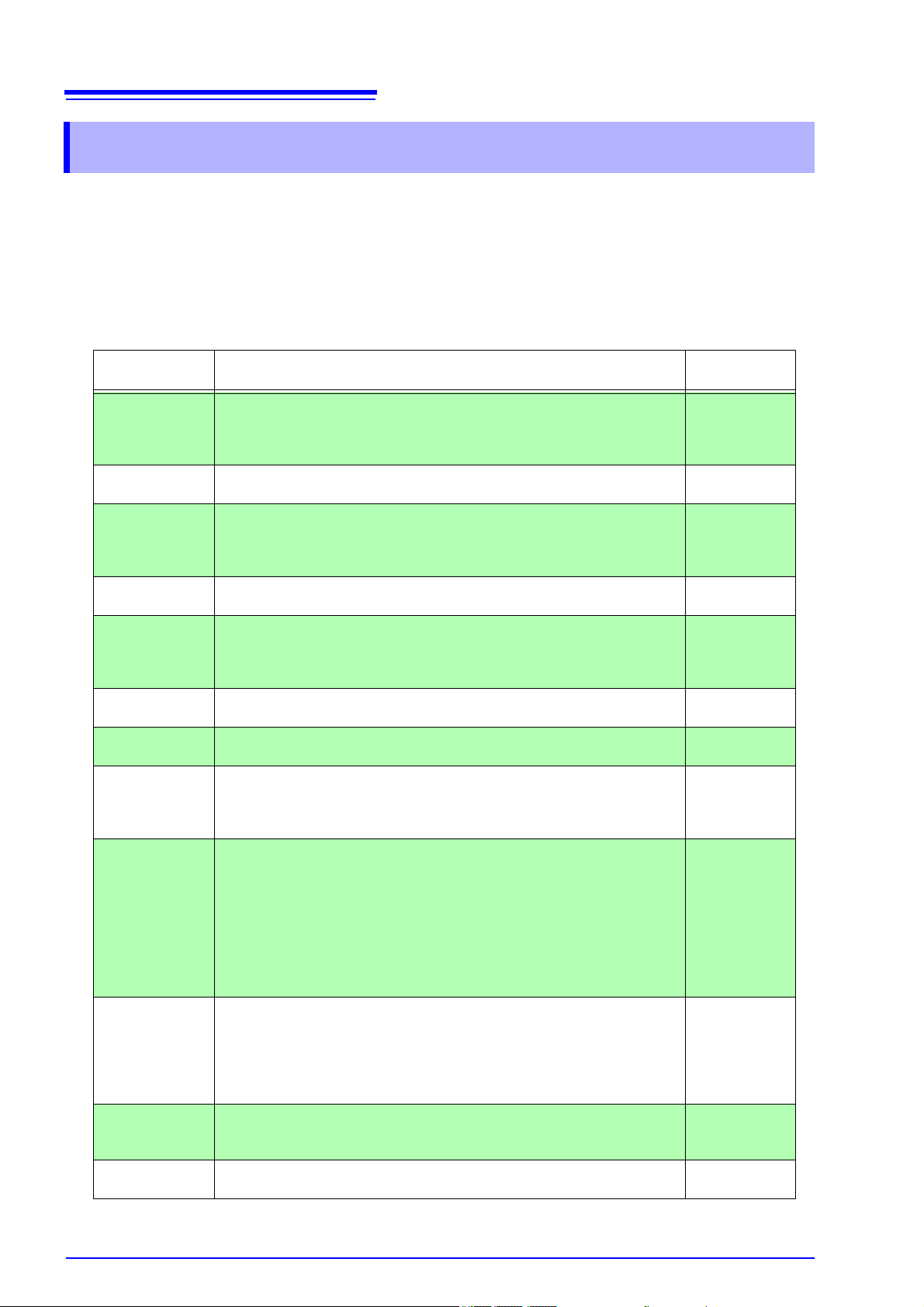

3.2 Setting Measurement Conditions

3.2 Setting Measurement Conditions

This section describes how to set measurement conditions according to the

manner in which the instrument is to be used. Settings are configured via either

of the instrument’s external interfaces:

See: GP-IB/RS-232C Interface (p.19)

The instrument cannot be configured directly in a standalone manner. For more

detailed setting specifications, see "6.3 Functions" (p.51).

Setting

function

Measurement

value indication

Measurement

speed

Current

measurement

range

Trigger delay

time

Averaging

Power source

frequency

Measurement

voltage

Fixture capacitance open correction function

Contact-check

Measured value

comparison/

judgment function

Fixture resistance open correction function

LCD display

mode

Description of operation and settings For more

Selects the displayed value.

[Resistance * / Current]

* Resistance is calculated from the set measurement voltage and current

value.

Selects the measurement speed.

[FAST / MED (medium) / SLOW / SLOW2]

Switches the current measurement range.

[HOLD/ AUTO]

Selects the current measurement range.

[100 pA/ 1 nA/ 10 nA/ 100 nA/ 1 μA/ 10 μA/ 100 μA/ 1 mA]

Fix time between inputting trigger signal and starting measurement.

0 ms to 9999 ms (1 ms resolution)

Configures averaging of measured values.

OFF (No averaging) / ON (Required setting number of times for averaging) / AUTO (Number of times for averaging is automatically determined)]

Number of times (in case “ON” setting): 1 to 255

Selects the power source frequency.

[50/60 Hz]

Sets the measurement voltage.

Setup ranges: 0.1 to 1000.0 V (0.1 V resolution)

Measures the capacitance value with the fixture in the open state.

The fixture capacitance open correction function can be used to increase

measurement precision by decreasing the effects of residual inductance of

the fixture (including probes) and other components.

Judges whether the object under measurement is connected by performing capacitance measurement with a high-frequency signal and evaluating

the difference between that reading and the reading obtained when the

system is in the open state.

[OFF/ ON]

Judgment GO: Capacitance measured value > judgment reference value *

NG: Judgment reference value * ≥ capacitance measured value

* Judgment reference value = Fixture capacitance + (object under mea-

surement capacitance setting / 2)

Compares the measured value and reference value to make a PASS/FAIL

judgment.

[OFF/ ON]

Judgment HI : Measured value > upper limit setting

IN : Upper limit setting ≥ measured value ≥ lower limit setting

LO: Lower limit setting > measured value

Measures the current of the fixture in the open state and corrects measured values.

[OFF/ ON]

Turns the LCD display on and off.

[OFF/ ON]

information

(p.33)

(p.33)

(p.34)

(p.34)

(p.34)

(p.34)

(p.35)

(p.37)

(p.43)

(p.36)

(p.43)

(p.37)

(p.46)

(p.37)

(p.43)

(p.38)

Page 22

19

Wiring Diagram (p.21)

Connect the Instrument and

Controller with a GP-IB or RS232C Interface Cable

Communications Protocol Settings

Enter a GP-IB address. (p.23)

Set the instrument to the same

communications protocol as the

controller

Send the “

RMT” command. (p.23)

4.1 Overview and Features

Communication

(GP-IB/RS-232C Interface) Chapter 4

The symbol shown below indicates that the following instructions are specific to

the RS-232C or the GP-IB interface. Instructions without these symbols are for

both the RS-232C and the GP-IB interface.

: GP-IB only

: RS-232C only

Before Use • Always make use of the connector screws to affix the GP-IB or RS-232C con-

nectors.

• When issuing commands that contain data, make certain that the data is provided in the specified format.

4.1 Overview and Features

The instrument provides standard communication functionality in the form of GPIB and RS-232C interfaces, both of which can be used to control the instrument

remotely and to transfer data.

• This instrument is designed with reference to the following standard:

Reference standard IEEE 488.1-1987

Page 23

20

4.2 Specifications

4.2 Specifications

Precautions

RS-232C and GP-IB communications cannot be used simultaneously.

GP-IB Specifica-

tions

Electrical machinery specifications: IEEE std. 488.1-1987 compliant

Address setting : Can be set to talker/listener addresses 1 to 30.

Interface Functions

SH1 All Source Handshake functions ●

AH1 All Acceptor Handshake functions ●

T6 Basic talker functions

Serial poll function

Talk-only mode

The talker cancel function with MLA (My Listen Address)

L4 Basic listener functions

Listen-only mode

The listener cancel function with MTA (My Talk Address)

SR1 All Service Request functions ●

RL1 All Remote/Local functions ●

PP0 Parallel Poll function −

DC1 All Device Clear functions ●

DT1 All Device Trigger functions ●

C0 Controller functions −

E2 Tri-state output

Operating Code: ASCII codes

●

●

−

●

●

−

●

RS-232C Specifica-

tions

Transfer method Communications: Full duplex

Synchronization: Start-stop synchronization

Baud rate 38400 bps

Data length 8 bits

Parity none

Stop bit 1 bit

Flow control none

Electrical specification Input voltage levels 5 to 15 V : ON

-15 to -5 V : OFF

Output voltage levels +5 V or more : ON

-5 V or less : OFF

Connector RS-232C Interface Connector Pinout

(Male 9-pin D-sub, with #4-40 attachment screws)

The I/O connector is a DTE (Data Terminal Equipment)

configuration

Recommended cables:

• Model 9637 RS-232C Cable

• Model 9638 RS-232C Cable

See: "4.3 Connect a cable to the GP-IB connector or

RS-232C connector" (p.21)

Operating Code: ASCII codes

Page 24

4.3 Connect a cable to the GP-IB connector or RS-232C connector

Rear Panel

Recommended cable:

HIOKI Model 9151-02 GP-IB Connector Cable (2 m)

6 7 8 9

1 2 3 4 5

Rear Panel

Male 9-pin D-sub

#4-40 attaching screws

4.3 Connect a cable to the GP-IB

connector or RS-232C connector

• Always turn both devices OFF when connecting and disconnecting an

interface connector. Otherwise, an electric shock accident may occur.

• Failure to fasten the connectors properly may result is sub-specification

performance or damage to the equipment.

To avoid damage to the instrument, do not short-circuit the terminal and do not

input voltage to the terminal.

Using the GP-IB Interface

21

Connect the GP-IB cable to the GP-IB connector.

Using the RS-232C Interface

Connect the RS-232C cable to the RS-232C connector.

Pin No.

1 DCD CF CD

2 RXD BB RD

3 TXD BA SD

4DTRCD ER

5 GND AB SG

6DSRCC DR

7 RTS CA RS

8 CTS CB CS

9 RI CE CI

Signal

Name

Code Addr.

EIA JIS

Mutual connection

circuit name

Carrier Detect Not used

Receive Data

Transmit Data

Data Terminal Ready Not used

Signal Ground

Data Set Ready Not used

Request to Send Not used

Clear to Send Not used

Ring Indicator Not used

Remarks

Page 25

22

Recommended cable:

HIOKI

Model 9637 RS-232C

Cable (1.8 m)

Crossover Wiring

Female 9-pin

D-sub

Model SM7810,

SM7810-20 end

Female 9-pin

D-sub

PC/AT-end

Pin No. Pin No.

DCD 1 1 DCD

RxD 2 2 RxD

TxD 3 3 TxD

DTR 4 4 DTR

GND 5 5 GND

DSR 6 6 DSR

RTS 7 7 RTS

CTS 8 8 CTS

RI 9 9 RI

4.3 Connect a cable to the GP-IB connector or RS-232C connector

When connecting the instrument to a computer

Use a crossover cable with female 9-pin D-sub connectors.

Page 26

4.4 Configuring the Communications Protocol

1 Press and hold the scroll keys (PAG E U P▲/PA GE D OW N ▼) on the front of the instru-

ment for about 7 seconds. (The address can be set from the P1, P2, or P3 screen.)

■ Screen P1: Measured value display

3 When finished making the setting, turn off the instrument.

4 Turn on the instrument.

The instrument will revert to the initial screen, and the GP-IB address will be set to

the selected address.

2 Using the scroll keys (PAGE UP▲/PAGE DOWN▼), set the desired address.

(Valid setting range: 1 to 30)

4.4 Configuring the Communications Protocol

Configuring GP-IB Interface Communications

Setting the address

23

Configuring RS-232C Interface Communications

Communication conditions

Baud rate 38400 bps

Parity none

Stop bit 1 bit

Data 8 bits

Flow control none

Remote switching requests

Send the “RMT” command from the RS-232C interface.

RS-232C interface communications will not be available until the “RMT” command is sent.

Page 27

24

Program Messages

Response Messages

SM7810

SM7810-20

Program Messages

Messages

Command Message

Query Message

Response Message

Controller

Message types are further categorized as follows

When issuing commands that contain data, make certain that the data is provided in the specified format.

4.5 Communication Methods

4.5 Communication Methods

Various messages are supported for controlling the instrument through the interfaces.

Messages can be either program messages, sent from the controller such as PC to the

instrument, or response messages, sent from the instrument to the controller.

Program Messages

1. Command Messages and Query Messages

(1) Command Messages

Commands that control the instrument, for example to configure settings or reset

the device.

(2) Query Messages

Requests for responses relating to results of operation or measurement, or the

state of instrument settings.

Query commands end with a question (

2. Message delimiter (terminator)

This instrument recognizes the following input message delimiters:

CR+LR with EOI

LF with EOI

CR with EOI

EOI

CR+LF

LF

?) mark.

Response Messages

1. Response Messages

When a query message is received, its syntax is checked and a response message is generated.

2. Message delimiter (terminator)

The following three response message delimiters can be specified with the

“

DLM” command:

LF (initial setting)

CR+LF

EOI

Page 28

3. Measurement data format

1,±d.ddddE±dd,d,d,2,±d.ddddE±dd,d,d,

abcdab cd

3,±d.ddddE±dd,d,d,4,±d.ddddE±dd,d,d,

abcdab cd

5,±d.ddddE±dd,d,d,6,±d.ddddE±dd,d,d,

abcdab cd

7,±d.ddddE±dd,d,d,8,±d.ddddE±dd,d,d

abcdab cd

LF <EOI>

e

±d.ddddE±dd

d: Number

When the range is exceeded, all numbers in the output data are set to 9 (for resistance

measurements) or 0 (for current measurements).

9.9999E+99

+0.0000E+00

Resistance measurement

Current measurement

A status of 0 indicates normal operation.

When comparative measurement is off, comparison results (d) are not added to the

output data.

The data format returned by the “MTG” and “RDT?” commands can be set to

any of the following three types by command:

(1) Basic format

Data is returned in channel order.

Fields are separated by a data separator (

25

4.5 Communication Methods

,).

a. Channel number

The channel number is set as a 1-byte number from 1 to 8.

b. Measured value

The measured value is set as an 11-byte exponent.

c. Status

The contact check and range exceeded results are set as numbers from 0 to 4. The results are allocated to bits 0 to 2 of the status, and their logical sum is output.

Bit 0: 0 (fixed)

Bit 1: Contact check error (automatic execution result)

Bit 2: Range exceeded

d. Comparison result

When comparative measurement is on, this field is set to the result (0 to 2).

0: High (The measured value was greater than the upper limit reference value.)

1: IN (The measured value fell within the range defined by the upper and lower limits.)

2: LOW (The measured value was less than the lower limit reference value.)

e. Delimiter

The output message delimiter can be specified with the “

DLM” command.

Page 29

26

4.5 Communication Methods

(2) Measured value only

The status (c) and comparison results (d) are not added to the output data.

Otherwise, this format is the same as the basic format.

(3) Comparison results only

The measured value (b) and status data (d) are not added to the output data.

Otherwise, this format is the same as the basic format.

Separators

1. Message Unit Separator

Multiple message can be written in one line by separating them with semicolons

“

; ”

2. Header Separator

3. Data Separator

Data Formats

In a message consisting of both a header and data, the header is separated from

the data by a space “ ” (ASCII code 20H).

In a message containing multiple data items, commas are required to separate

the data items from one another.

Query messages use the formats outlined in Table 1. The format is selected

according to the command.

Table 1: Response Messages and Parameter Data Types

Data

type

NR1 Integer 0, 1, 2, 3, etc. Parameter settings, etc.

NR2

NR3

ASCII ASCII string XXXXXXXXXXXXXXXX Primarily hardware IDs

Description Example Notes

Fixed-point decimal number

Floating-point decimal number

+12.345, 400.0, etc. Primarily settings

+1.234±50, etc.

Primarily settings and measured values

Page 30

Status Byte Register

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

ERR

RQS

ESB MAV DSB

unused unused

unused

MSS

& &&&&&&

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

ERR x ESB MAV DSB

unused unused

unused

Logical

sum

Status Byte

Register (STB)

Service Request Enable

Register (SRER)

Service Request

occurrence

Output Queue data information

Standard Event Register Information

Each of these bits corresponds to a specific event register

Overview of Service Request Occurrence

RS-232C reads the status bytes to find out the status of the instrument.

The instrument adopts the IEEE488.1-1987 defined status model for parts

related to the serial polling performed by the service request function. A trigger

for generating a service request is called an event.

27

4.5 Communication Methods

The Status Byte Register contains information about the event registers and the

output queue. Required items are selected from this information by masking with

the Service Request Enable Register. When any bit selected by the mask is set,

bit 6 (MSS; the Master Summary Status) of the Status Byte Register is also set,

which generates an SRQ (Service Request) message and dispatches a service

request.

For RS-232C, bit 4 (MAV message available) of the status byte register is not

set.

Page 31

28

4.5 Communication Methods

Status Byte Register (STB) ______________________________________

A status byte register is an 8-bit register output from the unit to the controller during serial polling. If even one of the status byte register bits enabled by the service request enable register changes from "0" to "1" the MSS bit becomes 1. At

the same time, the RQS bit also becomes "1" and a service request is generated.

The RQS bit is always synchronized with the service request and only read and

simultaneously cleared upon being serial polled. The MSS bit is only read by an

"*

STB?" query and is not cleared until the event is cleared by a command such

as a "*

CLS" command.

Bit 7 ERR

Bit 6 RQS

MSS

Bit 5 ESB

Bit 4 MAV

Bit 3 DSB

Bit 2 −

Bit 1 −

Bit 0 −

Unrecoverable error

Set to 1 when a service request is dispatched.

This is the logical sum of the other bits of the Status Byte Register.

Standard Event Status (logical sum) bit

This is logical sum of the Standard Event Status Register.

Message available

Indicates that a message is present in the output queue.

Event Status (logical sum) bit

This is the logical sum of Event Status Register.

unused

unused

unused

Service Request Enable Register (SRER) __________________________

This register masks the Status Byte Register. Setting a bit of this register to 1

enables the corresponding bit of the Status Byte Register to be used.

Page 32

29

4.5 Communication Methods

Event Registers

Standard Event Status Register (SESR) ____________________________

A standard event status register is an 8-bit register.

If any bit in the Standard Event Status Register is set to 1 (after masking by the

Standard Event Status Enable Register), bit 5 (ESB) of the Status Byte Register

is set to 1.

See: "Standard Event Status Enable Register (SESER)" (p.30)

The standard event register is cleared at the following times:

• When a "

• When an event register query (

• When the instrument is powered on

*CLS" command is executed

*ESR?) is executed

Bit 7 PON

Bit 6 URQ

Bit 5 CME

Bit 4 EXE

Bit 3 DDE

Bit 2 QYE

Bit 1 RQC

Bit 0 OPC

Power-On Flag

Set to 1 when the power is turned on, or upon recovery from an outage.

User Request

unused

Command error (The command to the message terminator is ignored.)

This bit is set to 1 when a received command contains a syntactic or semantic

error:

• Program header error

• Incorrect number of data parameters

• Invalid parameter format

• Received a command not supported by the instrument

Execution Error

This bit is set to 1 when a received command cannot be executed for some

reason.

• The specified data value is outside of the set range

• The specified setting data cannot be set

• Execution is prevented by some other operation being performed

Device-Dependent Error

This bit is set to 1 when a command cannot be executed due to some reason

other than a command error, a query error or an execution error.

• When the command cannot be executed because there is an internal

anomaly

Query Error (the output queue is cleared)

This bit is set to 1 when a query error is detected by the controller of the output

queue.

• When an attempt has been made to read an empty output queue (GP-IB

only)

• When the data overflows the output queue

• When data in the output queue has been lost

Request Control

unused

Operation Complete

This bit is set to 1 in response to an "

• It indicates the completion of operations of all messages up to the "*OPC"

command

*OPC" command.

Page 33

30

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

PON URQ CME EXE DDE QYE RQC OPC

&&&&&&&&

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

PON URQ CME EXE DDE QYE RQC OPC

Standard Event Status Register (SESR)

Standard Event Status Enable Register (SESER)

bit 6bit 5bit 4

SRQ

MSS

ESB MAV

Logical

sum

4.5 Communication Methods

Standard Event Status Enable Register (SESER) ____________________

Setting any bit of the Standard Event Status Enable Register to 1 enables

access to the corresponding bit of the Standard Event Status Register.

Standard Event Status Register (SESR) and Standard Event Status Enable

Register (SESER)

Device Event Status Registers (DESR)_____________________________

This instrument provides specific event status registers for controlling events.

Each event register is an 8-bit register.

When any bit in one of these event status registers enabled by its corresponding

event status enable register is set to 1, bit (DSB) of the Status Byte Register is

set to 1.

Device Event Status Registers are cleared in the following situations:

• When a "

• When an Event Status Register query (

• When the instrument is powered on

Bit 7 − Unused

Bit 6 − Unused

Bit 5 BOV Reserved bit

Bit 4 BFL Reserved bit

Bit 3 STP Measured stop event

Bit 2 ITL Reserved bit

Bit 1 LM2 Reserved bit

Bit 0 LM1 Reserved bit

*CLS" command is executed

DSR?) is executed

Page 34

31

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

−−

BOV BFL STP ITL LM2 LM1

&&&&&&&&

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

−−

BOV BFL STP ITL LM2 LM1

Device Event Status Enable Register (DESER)

bit 3

DSB

Status Byte Register (STB)

Logical

sum

Device Event Status Register (DESR)

4.5 Communication Methods

Device Event Status Register (DESR) and Device Event Status Enable Register (DESER)

Page 35

32

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

− MLE

HDE DFE DRE CNE ISE BDE

Error Register

PON URQ CME EXE DDE QYE RQC OPC

Standard Event Status Register

bit 7bit 6bit 5bit 4bit 3bit 2bit 1bit 0

MLE: Message Length Error HDE: Header Error

DFE: Data Format Error DRE: Data Range Error

CNE: Can Not Execute ISE: Internal communication Error

BDE: Environment Backup was Damaged (RAM)

Error Register structure

4.5 Communication Methods

Error Registers

The Error Register, which consists of 8 bits, manages error information. The

contents of this register are aggregated in the CME, EXE, DDE, and QYE bits of

the Standard Event Status Register (no mask processing is performed).

Error register-related message are listed below.

*CLS

ERR?

Clears the following registers:

• Status Byte Register

• Standard Event Status Register

• Device Event Status Register

• Error Register

Queries and clears the Error Register.

Bit No. Name Event/status indicated by set bit

Bit 7 −

Bit 6 MLE

Bit 5 HDE

Bit 4 DFE

Bit 3 DRE

Bit 2 CNE

Bit 1 ISE

Bit 0 BDE

Unused

Message Length Error

Set when the message length exceeds the allowable range.

The bit is reset after the register is read.

Message Header Error

Set when an unrecognizable message header is received.

The bit is reset after the register is read.

Data Format Error

Set when the number of parameters exceeds the stipulated number or

when there is an unrecognizable parameter.

The bit is reset after the register is read.

Data Range Error

Set when a parameter falls outside the stipulated range.

The bit is reset after the register is read.

Unexecutable command

Set when an unexecutable command is received.

The bit is reset after the register is read.

Internal communication Error

Set when an internal communication error occurs.

The bit is reset after the register is read.

Environment Backup was Damaged

Set when data stored in the instrument's backup RAM is corrupted.

The bit is reset after the register is read.

Page 36

4.6 Message List

Measurement speed setting

FAST MED SLOW SLOW2

Wait time 10 ms 30 ms 100 ms 400 ms

4.6 Message List

RS-232C-only commands are indicated by .

When using the RS-232C interface to send commands, include a uniform wait

time of 100 ms (excluding the following exceptions).

<Exceptions>

OCL command: Requires a wait time of 8 s.

MTG command: Although the instrument can respond to the next command in

2.7 ms, the following wait times are required depending on the

measurement speed in order to allow the instrument to wait for

the measurement results and obtain measured values:

Command Description Formats

Communication conditions

RMT

Remote switching request

[Format] RMT

33

Delimiter

DLM

DLM?

Talker delimiter specification

d1 (delimiter specification: 0 to 2)

0: LF<EOI> Default

1: CRLF<EOI>

2: <EOI>

Note: This setting reverts to its default value when the instrument

is powered on. A combination CR+LF is used as the RS232C delimiter for both data transmission and reception.

Delimiter query

The contents of responses are the same as the settings.

Measurement value indication

MOD

MOD?

Measurement mode setting

d1 (Mode: 0 to 1)

0: Resistance measurement mode

1: Current measurement mode

Measurement mode query

The contents of responses are the same as the settings.

Measurement speed

SPL

SPL?

Measurement speed setting

d1 (Speed: FAST, MED, SLOW, SLOW2)

Note: The current measurement ranges available for selection vary

with the measurement speed. If the selected current range is

no longer valid when the measurement speed changes, it

will be automatically changed to the optimal current range.

RNG command (p.34)

See:

Measurement speed query (setting)

The contents of responses are the same as the settings.

Current channel

CCH

Current channel setting

CH (d1: 1 to 8)

Note: Sets which channel to enable. This setting is only valid for

the following commands:

RNG RNG? CMP CMP? OIR?

CCH?

Current channel query

The contents of responses are the same as the settings.

[Format] DLM d1

d1: NR1 format

[Format] DLM?

[Response] d1

[Format] MOD d1

d1: NR1 format

[Format] MOD?

[Response] d1

[Format] SPL d1

d1: String

[Format] SPL?

[Response] d1

[Format] CCH d1

d1: NR1 format

[Format] CCH?

[Response] d1

Page 37

34

Measurement speed setting

FAST MED SLOW SLOW2

1 mA

100 uA 100 uA 100 uA

10 uA 10 uA 10 uA 10 uA

1 uA 1 uA 1 uA 1 uA

100 nA 100 nA 100 nA 100 nA

10 nA 10 nA 10 nA 10 nA

1 nA 1 nA 1 nA 1 nA

100 pA 100 pA 100 pA

Available ranges

4.6 Message List

Command Description Formats

Measurement ranges

RNG

Current measurement range setting

AUTO/HOLD selection and HOLD range setting

d1 (Selection: 0 to 1)

0: HOLD

1: AUTO

d2 (HOLD range: string)

Sets the current measurement range as a string. The current

measurement ranges available for selection vary with the measurement speed setting. When using the AUTO range setting, d2

can be omitted.

[Format] RNG d1,d2

d1: NR1 format

d2: String

Note: Attempting to select an unavailable range will result in an

execution error.

Note: In communications, use "u" (small letter "u") to refer to "μ"

(microns) in settings.

Example: Input "10 uA" for the setting "10 μA."

RNG?

Current measurement range query

The contents of responses are the same as the settings.

Trigger delay time

DLY

DLY?

Trigger delay time (ms) setting

d1 (time: 0 to 9999)

Trigger delay time (ms) query

The contents of responses are the same as the settings.

Averaging

AVE

AVE?

Averaging setting

d1 (Selection: 0 to 2)

0: OFF (Disables averaging.)

1: ON (Enables count averaging.)

2: AUTO (Enables automatic averaging.)

d2 (Measurement count: 1 to 256; default value: 1)

Averaging query

The contents of responses are the same as the settings.

Power source frequency

FRQ

FRQ?

Power source frequency selection

d1 (Selection: 0 to 1)

0: 50 Hz

1: 60 Hz

Power line frequency query

The contents of responses are the same as the settings.

[Format] RNG?

[Response] d1,d2

[Format] DLY d1

d1: NR1 format

[Format] DLY?

[Response] d1

[Format] AVE d1,d2

d1: NR1 format

d2: NR1 format

[Format] AVE?

[Response] d1,d2

[Format] FRQ d1

d1: NR1 format

[Format] FRQ?

[Response] d1

Page 38

4.6 Message List

Command Description Formats

Measurement voltage

VM1

VM1?

VM2

VM2?

VM3

VM3?

VM4

VM4?

VM5

VM5?

VM6

VM6?

VM7

VM7?

VM8

VM8?

CH1 measurement voltage setting

d1: 0.1 to 1000.0 V

CH1 measurement voltage query

The contents of responses are the same as the settings.

CH2 measurement voltage setting

d1: 0.1 to 1000.0 V

CH2 measurement voltage query

The contents of responses are the same as the settings.

CH3 measurement voltage setting

d1: 0.1 to 1000.0 V

CH3 measurement voltage query

The contents of responses are the same as the settings.

CH4 measurement voltage setting

d1: 0.1 to 1000.0 V

CH4 measurement voltage query

The contents of responses are the same as the settings.

CH5 measurement voltage setting

d1: 0.1 to 1000.0 V

CH5 measurement voltage query

The contents of responses are the same as the settings.

CH6 measurement voltage setting

d1: 0.1 to 1000.0 V

CH6 measurement voltage query

The contents of responses are the same as the settings.

CH7 measurement voltage setting

d1: 0.1 to 1000.0 V

CH7 measurement voltage query

The contents of responses are the same as the settings.

CH8 measurement voltage setting

d1: 0.1 to 1000.0 V

CH8 measurement voltage query

The contents of responses are the same as the settings.

[Format] VM1 d1

[Format] VM1?

[Response] d1

[Format] VM2 d1

[Format] VM2?

[Response] d1

[Format] VM3 d1

[Format] VM3?

[Response] d1

[Format] VM4 d1

[Format] VM4?

[Response] d1

[Format] VM5 d1

[Format] VM5?

[Response] d1

[Format] VM6 d1

[Format] VM6?

[Response] d1

[Format] VM7 d1

[Format] VM7?

[Response] d1

[Format] VM8 d1

[Format] VM8?

[Response] d1

35

d1: NR2 format

d1: NR2 format

d1: NR2 format

d1: NR2 format

d1: NR2 format

d1: NR2 format

d1: NR2 format

d1: NR2 format

Page 39

36

4.6 Message List

Command Description Formats

Contact-check

CCM

CCM?

WCP

WCP?

CCK?

Contact check automatic execution mode selection

d1 (Selection: 0 to 1)

0: OFF

1: ON

Contact check automatic execution mode query

The contents of responses are the same as the settings.

Target object capacitance setting

Target object capacitance used to perform contact checks and

calculate the judgment reference value

d1: CH1 (0.5 to 99.9) pF

d2: CH2 (0.5 to 99.9) pF

d3: CH3 (0.5 to 99.9) pF

d4: CH4 (0.5 to 99.9) pF

d5: CH5 (0.5 to 99.9) pF

d6: CH6 (0.5 to 99.9) pF

d7: CH7 (0.5 to 99.9) pF

d8: CH8 (0.5 to 99.9) pF

Target object capacitance query

The contents of responses are the same as the settings.

Returns the contact check results and capacitance as a response.

[Format]

d1 (Operation specification)

0: Returns the most recent contact check execution results

and capacitance value without performing a contact check.

1: Performs a contact check and returns the results and capac-

itance.

[Response]

d1 (CH1 results: 0 to 1)

d2 (CH1 capacitance: 0 to 99.9)

d3 (CH2 results: 0 to 1)

d4 (CH2 capacitance: 0 to 99.9)

d5 (CH3 results: 0 to 1)

d6 (CH3 capacitance: 0 to 99.9)

d7 (CH4 results: 0 to 1)

d8 (CH4 capacitance: 0 to 99.9)

d9 (CH5 results: 0 to 1)

d10 (CH5 capacitance: 0 to 99.9)

d11 (CH6 results: 0 to 1)

d12 (CH6 capacitance: 0 to 99.9)

d13 (CH7 results: 0 to 1)

d14 (CH7 capacitance: 0 to 99.9)

d15 (CH8 results: 0 to 1)

d16 (CH8 capacitance: 0 to 99.9)

Results 0: NO1: GO

Note: Omitted parameters are treated as 0.

[Format] CCM d1

[Format] CCM?

[Response] d1

[Format] WCP d1,d2,d3,d4,

[Format] WCP?

[Response] d1,d2,d3,d4,

[Format] CCK? d1

[Response] d1,d2,d3,d4,d5,

d1: NR1 format

d5,d6,d7,d8

d1: NR2 format

d2: NR2 format

d3: NR2 format

d4: NR2 format

d5: NR2 format

d6: NR2 format

d7: NR2 format

d8: NR2 format

d5,d6,d7,d8

d6,d7,d8,d9,d10,

d11,d12,d13,d14,

d15,d16

d1: NR1 format

d2: NR2 format

d3: NR1 format

d4: NR2 format

d5: NR1 format

d6: NR2 format

d7: NR1 format

d8: NR2 format

d9: NR1 format

d10: NR2 format

d11: NR1 format

d12: NR2 format

d13: NR1 format

d14: NR2 format

d15: NR1 format

d16: NR2 format

Page 40

4.6 Message List

Command Description Formats

OST?

Returns the fixture capacitance open correction value (fixture

capacitance) as a response.

[Format] OST? d1

37

d1: NR1 format

[Format]

d1 (operation specification)

0: Returns the capacitance without performing open correction.

1: Performs open correction and then returns the capacitance.

If an error occurs, this command will return the value 999.9.

[Response]

d1 (CH1 fixture capacitance: 0 to 99.9)

d2 (CH2 fixture capacitance: 0 to 99.9)

d3 (CH3 fixture capacitance: 0 to 99.9)

d4 (CH4 fixture capacitance: 0 to 99.9)

d5 (CH5 fixture capacitance: 0 to 99.9)

d6 (CH6 fixture capacitance: 0 to 99.9)

d7 (CH7 fixture capacitance: 0 to 99.9)

d8 (CH8 fixture capacitance: 0 to 99.9)

Error: 999.9

Note: Open correction must be performed once before a contact

check can be performed.

Note: Omitted parameters are treated as 0.

Measured value comparison and judgment function

CMP

CMP?

Comparative measurement mode setting

d1 (Execute comparison: 0 to 1)

0: OFF 1: ON

d1 (Mode: 0 to 2)

0: HI 1: IN 2: LO

d3 (Upper limit comparison value)

(-9.9999E+30 to 9.9999E+30)

d4 (Lower limit comparison value)

(-9.9999E+30 to 9.9999E+30)

Note: Always set parameters so that d3 ≥ d4. Failure to do so will

cause the current settings to be applied.

Note: The d2, d3, and d4 parameters are valid even when compar-

ison execution is set to OFF.

(They will be saved as the current settings.)

Comparative measurement mode query

The contents of responses are the same as the settings.

Fixture resistance open correction function

OCM

OCM?

OCL

OIR?

Fixture resistance open correction mode selection

d1 (Selection: 0 to 1)

0: OFF (Disables use of correction value in measured value

calculations.)

1: ON (Enables use of correction value in measured value cal-

culations.)

Fixture resistance open correction mode query

The contents of responses are the same as the settings.

Performs fixture resistance open correction once and saves the

correction value.

d1 (Channel specification)

1 to 255: Specifies the channel for which to perform correction as

the weight of bits 0 (channel 1) to 7 (channel 8).

Fixture resistance open value query

The contents of responses are the same as the settings.

Note: The value for the current channel is returned as a query.

Note: The AD converted values for the instrument's internal

ammeter's seven ranges are used as the return values.

Note: A return value of 32768 indicates that correction was not

performed due to an error.

[Response] d1,d2,d3,d4,

d5,d6,d7,d8

d1: NR2 format

d2: NR2 format

d3: NR2 format

d4: NR2 format

d5: NR2 format

d6: NR2 format

d7: NR2 format

d8: NR2 format

[Format] CMP d1,d2,d3,d4

d1: NR1 format

d2: NR1 format

d3: NR3 format

d4: NR3 format

[Format] CMP?

[Response] d1,d2,d3,d4

[Format] OCM d1

d1: NR1 format

[Format] OCM?

[Response] d1

[Format] OCL d1

d1: NR1 format

[Format] OIR?

[Response] d1,d2,d3,d4,d5,

d6,d7

d1 to d7:

NR1 format

Page 41

38

4.6 Message List

Command Description Formats

LCD display

LCD

LCD?

PAG

LCD display mode setting

d1 (Display mode: 0 to 1)

LCD display mode query

The contents of responses are the same as the settings.

LCD display page specification

d1 (Page number: 0 to 2)

Measurement data

RDT?

MTG

Measurement data query

d1 (Format specification: 0 to 2)

Note: When the comparative measurement function is OFF, no

Manual trigger

d1 (Format specification: 0 to 2 [may be omitted])

0: OFF Display OFF

1: ON Display ON

0: Displays measured value.

1: Displays contact check results.

2: Displays operation conditions.

0: Fundamental waveform

1: Measured value only

2: Comparison results only

query is returned even if the RTD? 2 command is executed.

For more information about the response, see "Measurement data format" (p.25).

If omitted: No automatic data return

0: Fundamental waveform

1: Measured value only

2: Comparison results only

For more information about the response, see "Measurement

data format" (p.25).

[Format] LCD d1

[Format] LCD?

[Response] d1

[Format] PAG d1

[Format] RDT? d1

[Response] d1: NR1 format

[Format] MTG d1

d1: NR1 format

d1: NR1 format

d1: NR1 format

Page 42

4.6 Message List

Command Description Formats

Others

*RST

*IDN?

*TRG

*SAV

*RCL

*CLS

*SRE

*SRE?

Instrument initialization

Initializes all settings to their factory values. Instrument operation

will be stopped.

Hardware ID query

Returns the instrument’s hardware ID as the response.

d1 (HIOKI E.E. CORPORATION, SM7810, 0, 01.00)

Provides the same functionality as the GET message.

Save environmental data

d1 (Environmental data no.: 0 to 3)

Recall environmental data

d1 (Environmental data no.: 0 to 3)

Clear status register

Sets the service request enable register.

d1 (0 to 255)

Service request enable register query

d1 (0 to 63, 128 to 191)

[Format] *RST

[Format] *IDN?

[Response] d1: String

[Format] *TRG

[Format] *SAV d1

[Format] *RCL d1

[Format] *CLS

[Format] *SRE d1

[Format] *SRE?

[Response] d1: NR1 format

39

d1: NR1 format

d1: NR1 format

d1: NR1 format

*STB?

*ESE

*ESE?

*ESR?

*OPC

*OPC?

ERR?

DSE

DSE?

DSR?

Note: Bit 6 is not set by *SRE.

Status byte register query

d1 (0 to 255)

Sets the standard event status enable register.

d1 (0 to 255)

Standard event status enable register query

The contents of responses are the same as the settings.

Standard event status register query

d1 (0 to 255)

Note: Register contents are cleared when the response is output.

Sets the standard event status register’s OPC bit after all ongoing

operations have completed.

This command is used to detect the completion of commands that

involve time-consuming processing.

Returns the value 1 when all ongoing operations have completed.

d1: 1

Error information query

d1 (Error information: 0 to 255)

Note: Error information is cleared when the response is output.

Sets the device event status enable register.

Device event status enable register query

The contents of responses are the same as the settings.

Device event status register query

d1 (0 to 255)

[Format] *STB?

[Response] d1: NR1 format

[Format] *ESE d1

d1: NR1 format

[Format] *ESE?

[Response] d1: NR1 format

[Format] *ESR?

[Response] d1: NR1 format

[Format] *OPC

[Format] *OPC?

[Response] d1: NR1 format

[Format] ERR?

[Response] d1: NR1 format

[Format] DSE d1

d1: NR1 format

[Format] DSE?

[Response] d1

[Format] DSR?

[Response] d1: NR1 format

Note: Register contents are cleared when the response is output.

Page 43

40

4.7 Listener Specification Precautions

4.7 Listener Specification Precautions

Input buffer size

Multiple command messages can be transferred at once by joining them with

message separators. Since the instrument provides an 128-byte input buffer, the

instrument is unable to receive message strings in excess of 127 characters in

length. In this case, the entire command will be ignored (discarded), and the

Error Register's MLE (Message Length Error) bit will be set.

Reading from the output buffer

The output buffer uses a FIFO design, with older data being read first. Consequently, the read value may differ from the expected value under certain circumstances, for example if no response is acquired after issuing a query.

Additionally, the output buffer is 511 bytes in size. If data in excess of 511 bytes

is written to the buffer, it will be discarded, and the Error Register's QYE (Query

Error) bit will be set.

Page 44

41

Connect the instrument’s EXT I/

O connector to the signal output

or input device.

Rear Panel

5.1 External Input/Output Connector and Signals

External Control Chapter 5

This chapter describes how to use the EXT I/O connector on the rear of the

instrument to control the device.

5.1 External Input/Output Connector

and Signals

To avoid electric shock or damage to the equipment, always observe the

following precautions when connecting to the EXT I/O connector.

• Always turn off the power to the instrument and to any devices to be con-

nected before making connections.

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Ensure that the cable is

securely attached to the EXT I/O connector.

• Ensure that devices and systems to be connected to the EXT I/O connec-

tor are properly isolated.

To avoid damage to the instrument, observe the following cautions:

• Do not apply voltage or current to the EXT I/O connector that exceeds their ratings.

• When driving relays, be sure to install diodes to absorb counter-electromotive

force.

See: "Connector Type and Signal Pinouts" (p.42)

Page 45

42

EXT I/O connector

Connector

• 57RE-40500-730B (50-pin: DDK)

12345678910111213141516171819

262728293031323334353637

Rear Panel

202122232425

383940414243444546474849

50

5.1 External Input/Output Connector and Signals

Connector Type and Signal Pinouts

Pin Signal name I/O Pin Signal name I/O

COM -

1

EXT_DCV2(+24V) IN

2

TRIG IN

3

C.CHECK IN

4

(Reserved)

5

(Reserved)

6

(Reserved)

7

ALARM OUT

8

EOM OUT

9

NO CONTACT1 OUT

10

NO CONTACT3 OUT

11

NO CONTACT5 OUT

12

NO CONTACT7 OUT

13

LO1 OUT

14

LO3 OUT

15

LO5 OUT

16

LO7 OUT

17

IN1 OUT

18

IN3 OUT

19

IN5 OUT

20

IN7 OUT

21

IN1 OUT

22

HI3 OUT

23

HI5 OUT

24

HI7 OUT

25

-

-

-

COM -

26

EXT_DCV2(+24V) IN

27

OPEN_IR IN

28

OPEN_CX IN

29

(Reserved)

30

(Reserved)

31

(Reserved)

32

(Reserved)

33

INDEX OUT

34

NO CONTACT2 OUT

35

NO CONTACT4 OUT

36

NO CONTACT6 OUT

37

NO CONTACT8 OUT

38

LO2 OUT

39

LO4 OUT

40

LO6 OUT

41

LO8 OUT

42

IN2 OUT

43

IN4 OUT

44

IN6 OUT

45

IN8 OUT

46

HI2 OUT

47

HI4 OUT

48

HI6 OUT

49

HI8 OUT

50

-

-

-

-

Reserved pins are not connected inside the instrument.

Do not connect to reserved pins.

Page 46

Signal Descriptions

Input Signals

EXT_DCV2(+24V) External power source input

TRIG External trigger input signal

43

5.1 External Input/Output Connector and Signals

C.CHECK Contact check input signal

OPEN_IR Fixture resistance open correction execution signal

OPEN_CX Fixture capacitance open correction execution signal

Output Signals

EOM This signal indicates the end of a measurement.

Output data is acquired when this signal changes to low.

INDEX This signal indicates that A/D conversion in the measurement circuit is com-

plete. Sample switching is performed when this signal changes to low.

NO CONTACT Contact check judgment results

LO Comparative measurement results (LOW)

IN Comparative measurement results (IN)

HI Comparative measurement results (HIGH)

ALARM Instrument malfunction

(p.52)

(p.53)

(p.52)

(p.52)

(p.52)

Page 47

44

TRIG

INDEX

EOM

NO CONTACT

1 to 8

HI 1 to 8

IN 1 to 8

LO1 to 8

t1

t2

t3 t4

t5 t6

t7

Contact-

check

T delay

Measur

ement

Previous measurement results New measurement results

Normal measurement

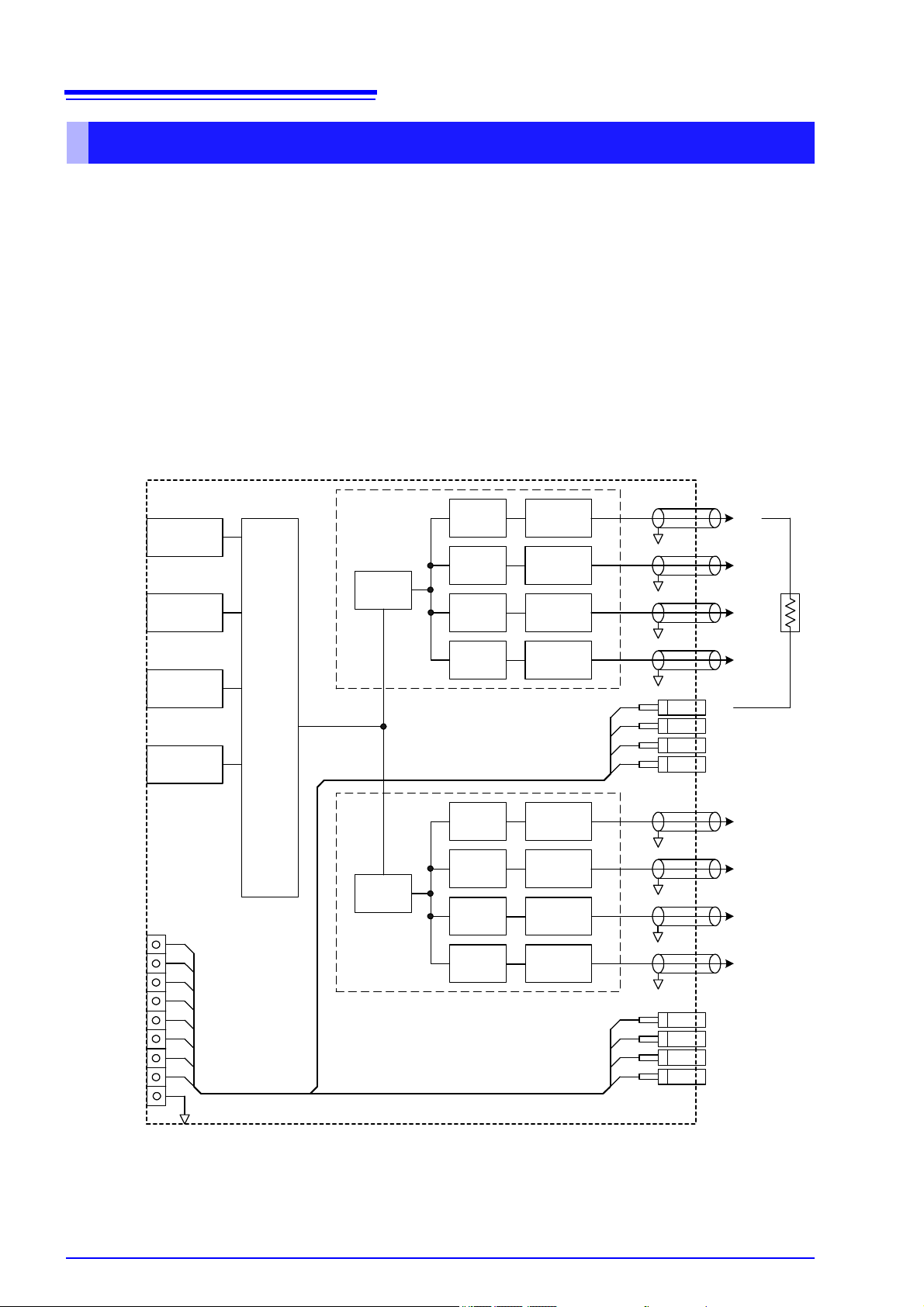

5.2 Timing Chart

5.2 Timing Chart

Each signal level indicates a corresponding voltage level.

Timing Chart Interval Descriptions

Interval Description Duration

Trigger pulse width (Low time) 100 μs or more

t1

Trigger OFF (Hi time) 100 μs or more

t2

INDEX, EOM delay time 200 μs or less

t3

T index (Measurement time) Within (set measurement time + T delay)

t4

T eom Within (T index + 500 μs)

t5

t6

Trigger setup time

NO CONTACT delay time 3 ms or less

t7

Display ON : 30 ms or more

Display OFF: 1 ms or more

Page 48

Fixture capacitance or fixture resistance open correction

OPEN CX

or

OPEN IR

INDEX

t1

t2 t3

t4 t5

EOM

Timing Chart Interval Descriptions

45

5.2 Timing Chart

Interval Description Duration

Pulse width (Low time) 100 μs or more

t1

INDEX, EOM delay time 400 μs or less

t2

t3

T index (Measurement time)

t4

T eom

Trigger setup time 2 s or more

t5

OPEN CX : 8 ms typ

OPEN IR

OPEN CX

OPEN IR