Hioki SM7420 Instruction Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

SM7420

Instruction Manual

SUPER MEGOHM METER

Be sure to read this manual before

using the instrument.

When using the instrument for the

rst time

Names and Functions of Parts

Preparing for Measurement

Nov. 2018 Revised edition 2

SM7420A961-02 18-11H

p.16

p.27

Safety information

Operating Precautions

Troubleshooting

Maintenance and Service

Error display and solution

p.7

p.8

p.133

p.136

EN

Contents

Introduction .................................................. 1

Notati

........................................................... 1

Verifying Package Contents

Measurement Procedure

Safety Information

Operating Precautions

....................................... 7

........................ 3

............................. 6

................................. 8

1 Overview 15

1.1 Product Overview and Features ....... 15

1.2

Names and Functions of Parts ......... 16

1.3

Screen Conguration and Operation 21

Measurement screens ................................21

Settings screens

1.4 Basic Key Operation ........................ 23

Displaying measurement screen ................23

Displaying the various menu settings

screens

Selecting settings items

Methods for changing numerical values

................................................

.........................................22

.......23

..............................24

.....25

2 Preparing for

Measurement

2.1 Connecting Power Cord to

Instrument

2.2

Connecting Measurement Leads

to Instrument

2.3

Connecting Electrode ....................... 28

Connecting Humidity Sensor ............ 29

2.4

2.5

Outputting Measurement Current

Value Converted to Analog Signal

2.6

Turning On/Off Instrument ................ 31

Inspection Before Use ...................... 32

2.7

........................................ 27

.................................... 28

27

.... 30

3 Basic Measurement 33

3.1 Setting Measured Value Display

Mode ................................................ 33

Changing display notation ..........................34

Changing displayed digits ...........................34

3.2 Setting Voltage Value for

Resistance Calculation ..................... 35

3.3 Setting Measurement Speed ............ 36

3.4 Changing Current Range ................. 37

3.5 Connecting Measurement Leads

or Electrode to Object to Be

Measured ......................................... 38

3.6 Starting/Stopping Measurement ....... 39

3.7 Conrming Measurement Results .... 39

Detecting a measurement abnormality .......39

Temperature measurement indication ........39

Out-of-range indication ...............................39

3.8 Basic Measurement Examples ......... 40

4 Applied Measurement 43

4.1 Starting Measurement After

Measured Value Becomes Stable

(Delay Function)

4.2

Reducing Variation in Measured

alues (Average Function) ............... 44

V

4.3

Changing Measurement Starting

Conditions (Trigger Function)

Setting the trigger mode .............................46

Inputting an external trigger

4.4 Maintaining Measurement

Accuracy (Self-Calibration Function)

4.5

Contact Check (Various Settings) .... 49

Canceling Capacitance of

4.6

Measurement Fixture

(Fixture Capacitance Open

Correction Function) ......................... 52

Contact Check (Executing Contact

4.7

Check, Setting Reference Value)

4.8

Setting Resistivity Calculation

(Resistivity Measurement Function)

4.9

Further Accelerating

(Function of Updating Drawing

During Measurement)

............................... 43

........... 46

........................46

47

..... 53

. 55

Measurement

...................... 58

5 Measurement Methods

Suitable for Various

Objects to Be Measured 59

5.1 Measuring Components of Circuits .. 59

Measurement with use of a

measurement xture ...................................60

Measurement without use of a

measurement xture ...................................61

Automatic measurement .............................62

5.2 Measuring Flat Sample .................... 63

Measurement using pin type terminals .......63

Measurement using an electrode for

measuring surface resistance .....................63

Measurement using an electrode for a

at sample ..................................................64

Volume resistance measurement and

surface resistivity measurement

(the functional role of the guard electrode) .64

5.3 Measuring a Liquid Sample .............. 66

When using an electrode for liquid

samples ......................................................66

5.4 Measurement With Use of

Shielding Box ................................... 67

1

2

3

4

5

SM7420A961-02

i

Contents

5.5 Measuring Current ........................... 68

6 Judging Measured

Value (Comparator

Function) 69

6.1 Setting Judgment Sound .................. 71

6.2

Conrming Judgment Results .......... 72

7 Saving and Loading

Settings (Panel Saving

and Loading) 73

7.1 Saving Settings

(Panel Saving Function)

Loading Settings

7.2

(Panel Loading Function)

Changing Panel Name ..................... 76

7.3

7.4

Deleting Panel Contents .................. 77

................... 74

................. 75

8 System Setting 79

8.1 Setting Sound of Key Operation ....... 79

8.2

Disabling Key Operation

(Key Lock Function)

8.3

Browsing, Deleting, and Outputting

Internal Memory Data

Browsing and deleting data ........................82

8.4 Setting D/A Output ........................... 83

8.5

Adjusting Screen Contrast ............... 84

Adjusting Backlight Brightness ......... 84

8.6

8.7

Changing Power Frequency

Setting

(Power Frequency Setting Function)

8.8 Initializing Settings (Reset) ............... 86

Default setting list .......................................87

8.9 Checking Instrument Information ..... 88

9

External Control (EXT I/O)

......................... 80

....................... 81

... 85

89

Output signal status on start-up ..................97

Flowchart for acquiring a judgment

result or a measured value with the

external trigger setting

9.4 Internal Circuit Conguration ............ 98

Electrical Specications ..............................99

Examples of connection

9.5 Assembling Male Connector for

EXT I/O (Accessory)....................... 102

9.6

EXT I/O T

Testing

9.7 Settings for External Input and

Output

Trigger logic ..............................................104

Trigger lter

GO-signal outputting logic level

EOM signal output mode

erminal Input and Output

..........................................

............................................ 104

...............................................105

................................97

............................100

.. 103

................106

..........................107

10 Communications

(USB, RS-232C, GP-IB)

10.1 Summary and Features of Interface 109

USB Interface ..................................110

10.2

Installing the USB driver ........................... 110

Connecting the USB cable ........................ 110

Setting the instrument

10.3 RS-232C Interface ..........................112

Connecting the RS-232C cable ................ 112

Setting the instrument ............................... 11 3

Setting the controller (Computer or PLC)

10.4 GP-IB Interface ...............................114

Connecting the GP-IB cable ..................... 114

Setting the instrument ............................... 11 4

10.5 Settings Common to Interfaces .......116

Outputting measured values (data

output function)

(RS-232C and USB only)

Displaying communication commands

(communication monitor function)

10.6 Control by Using Commands ..........118

Remote state ............................................ 118

Local state ................................................ 118

............................... 111

.......................... 11

109

. 113

............. 117

6

9.1 Switching Current Sink (NPN) /

Current Source (PNP) ...................... 90

9.2 External Input/Output Terminals

and Signals

Instrument-side connector and mating

connectors ..................................................90

Instrument-side connector pin assignment .91

Functions of each of the signals .................93

9.3 Timing Chart ..................................... 94

From when measurement starts to

when judgment result is acquired ...............94

...................................... 90

ii

11 Specications 119

11.1 General Specications ....................119

11.2 Input/Output/Measurement

Specications ................................. 120

Basic specications ..................................120

Accuracy specications ............................121

11.3 Function specications ................... 124

11.4 Interface Specications .................. 130

11.5 External I/O Specications ............. 131

Contents

12 Maintenance and

Service 133

12.1 Troubleshooting .............................. 133

Q&A (Frequently Asked Questions) ..........133

Error display and solution

12.2 Inspection, Repair and Cleaning .... 138

Appendix Appx.1

Appx. 1 Internal Circuits ................... Appx.1

Appx. 2

Appx. 3

Appx. 4

App

Appx. 6 Modifying Measurement

Appx. 7

Appx. 8

Changes in Current

Running through Insulator

Countermeasures Against

................................... Appx.3

Noise

Using Instrument with

2000 V or Higher Voltage

Applied (With External

Power Supply) .................... Appx.6

x. 5

Assembling Switching

for Object to Be Measured

Connecting objects to be measured and

the switching unit to the instrument .....Appx.7

Selecting relays to be installed in the

switching unit

Circuit diagram of the switching unit ....Appx.9

Including current-limiting resistor

(protective resistance) and relay ..........Appx.9

Current-limiting resistor ......................Appx.10

Lead

Mounting Instrument in

Rack

Dimensional Diagram ....... Appx.15

.......................................Appx.8

.................................. Appx.11

.................................. Appx.13

.........................136

.. Appx.2

Unit

.. Appx.7

11

12

3

4

5

6

7

8

Index Ind.1

9

10

Appx. Ind.

iii

Contents

iv

Introduction

Thank you for purchasing the Hioki SM7420 Super Megohm Meter. To obtain maximum

performance from the instrument, please read this manual rst, and keep it handy for future

reference.

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so. It is assumed that the reader possesses basic electrical knowledge (equivalent to

that of someone who graduated from the electrical program at a technical high school).

Trademark

• Adobe and Adobe Reader are trademarks of Adobe Systems Incorporated.

• Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation

in the United States and other countries.

• TEFLON is a registered trademark or a trademark of The Chemours Company FC, LLC.

Introduction

Notati

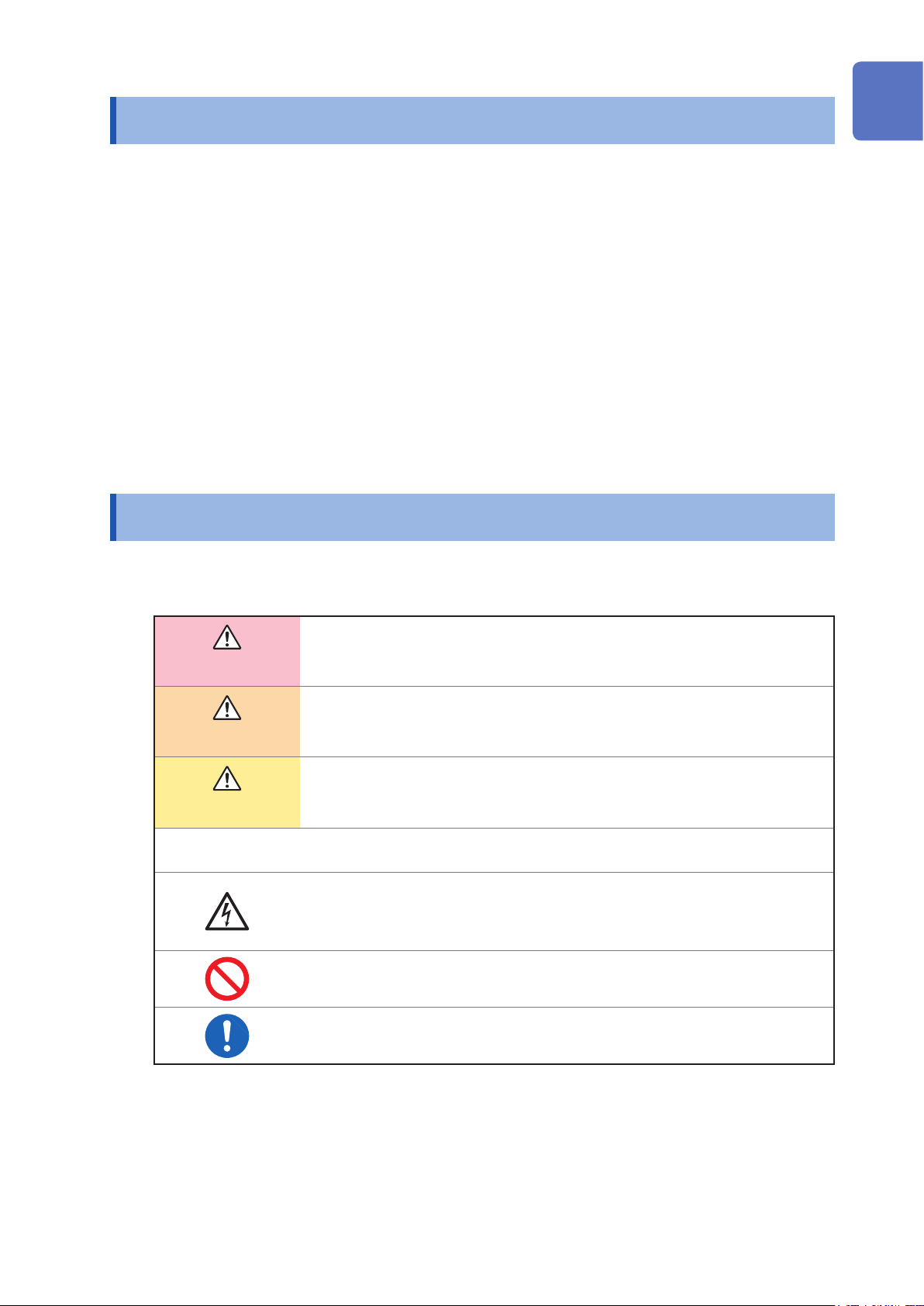

Concerning Safety

In this manual, the risk seriousness and the hazard levels are classied as follows.

Indicates an imminently hazardous situation that will result in death or serious injury

DANGER

WARNING

CAUTION

IMPORTANT

to the operator.

Indicates a potentially hazardous situation that may result in death or serious injury

to the operator.

Indicates a potentially hazardous situation that may result in minor or moderate

injury to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance tasks

with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled, this

may give rise to a hazardous situation; the operator may receive an electric shock,

may get burnt or may even be fatally injured.

Indicates prohibited actions.

Indicates the action which must be performed.

1

Notati

Symbols on the instrument

Indicates cautions and hazards. When the symbol is printed on the instrument, refer to a

corresponding topic in the Instruction Manual.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in EU

member states.

Indicates that the product conforms to regulations set out by the EU Directive.

Others

*

SET

(Bold character)

[ ]

Additional information is presented below.

Operation keys are displayed in bold.

Names on the screen are indicated with brackets [ ].

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading), and dgt. (digit) values

with the following meanings:

f.s.

rdg.

dgt.

(maximum display value or scale range)

The currently selected range.

(reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that

causes the digital display to show a “1” as the least-signicant digit.

2

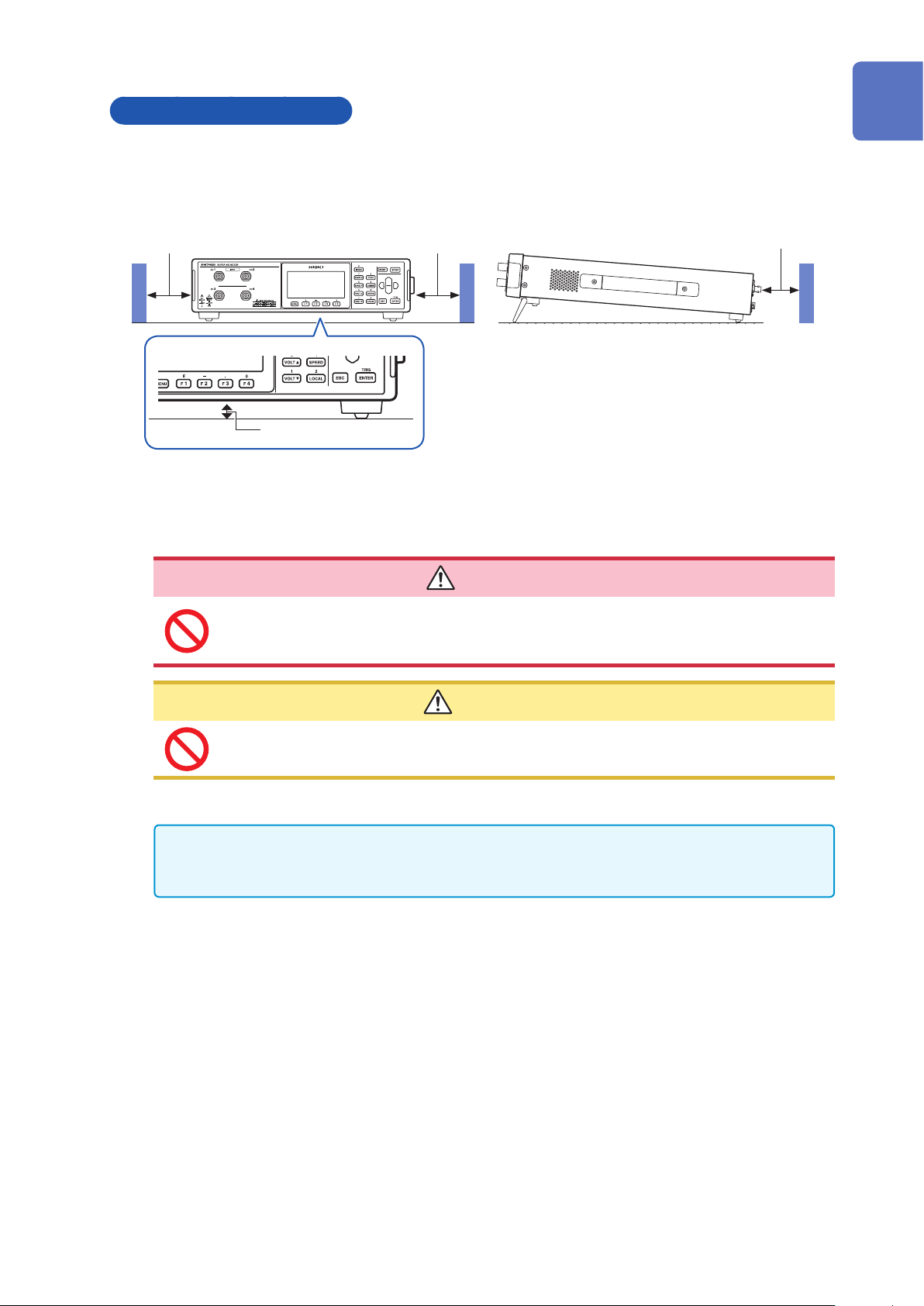

Verifying Package Contents

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories, panel switches, keys, and connectors. If damage

is evident, or if it fails to operate according to the specications, contact your authorized Hioki

distributor or reseller.

Main unit and accessories

Conrm that these contents are provided.

Model SM7420 Super Megohm Meter Instruction Manual

Male connector for EXT I/O Power cord

CD (Communications Command Instruction Manual,

USB driver)*

* The latest version can be downloaded from our

website.

3

Verifying Package Contents

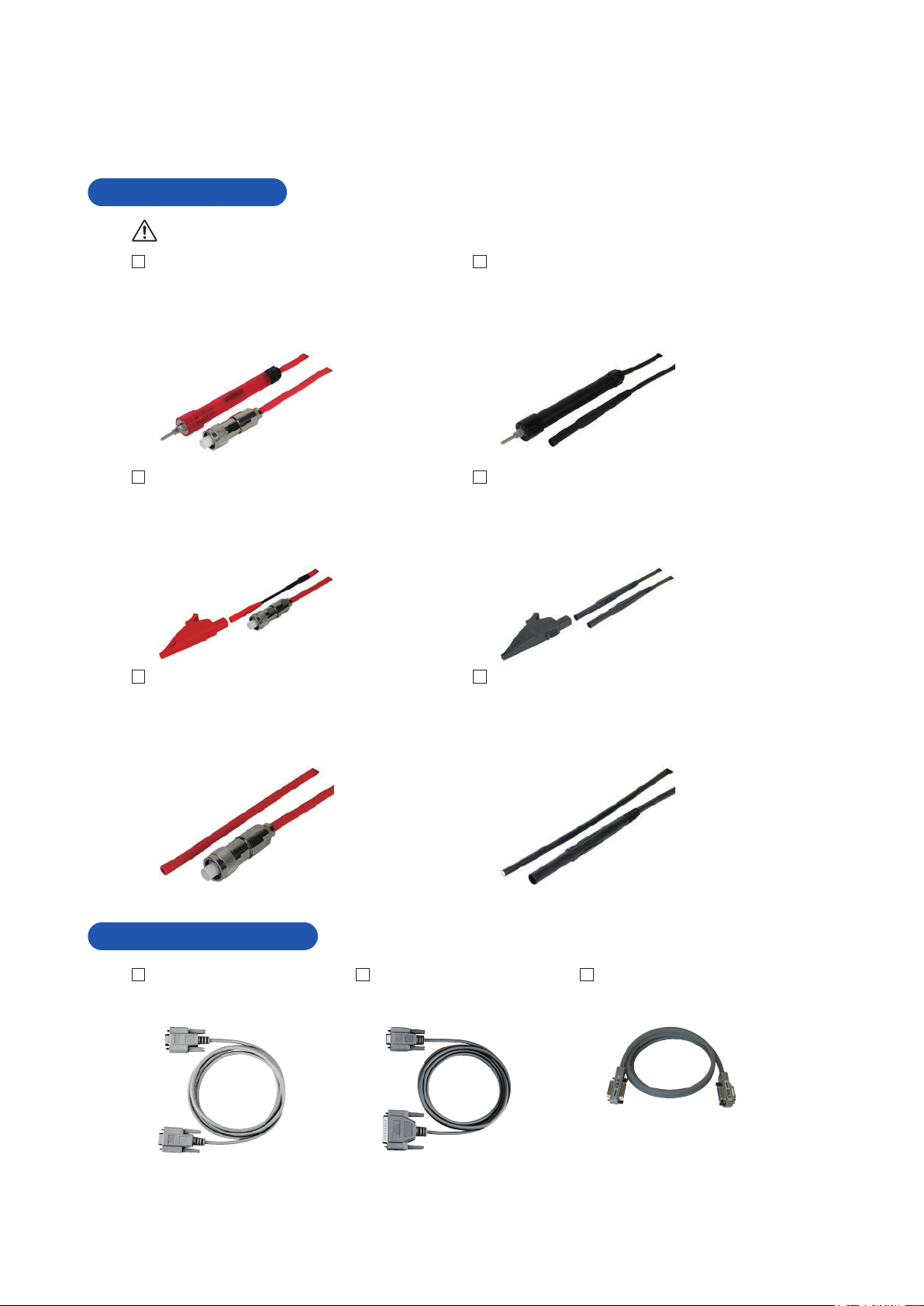

Options

The following options are available for the instrument. Contact your authorized Hioki distributor or

reseller when ordering.

Measurement leads

See p. 10.

Model L2230 Pin Type Lead (Red) Model L2231 Pin Type Lead (Black)

Length: 1 m Length: 1 m

Terminal shape: Triaxial BNC Terminal shape: Banana

Maximum rated voltage: 2000 V Maximum rated voltage: 2000 V

Maximum rated current: 1 A Maximum rated current: 1 A

Model L2232 Clip Type Lead (Red) Model L2233 Clip Type Lead (Black)

Length: 1 m Length: 1 m

Terminal shape: Triaxial BNC Terminal shape: Banana

Maximum rated voltage: 2000 V Maximum rated voltage: 2000 V

Maximum rated current: 1 A Maximum rated current: 1 A

Model L2234 Open Lead (Red) Model L2235 Open Lead (Black)

Length: 3 m Length: 3 m

Terminal shape: Triaxial BNC Terminal shape: Banana

Maximum rated voltage: 2000 V Maximum rated voltage: 2000 V

Maximum rated current: 1 A Maximum rated current: 1 A

Communication cables

Model 9637 RS-232C Cable

(9pin-9pin/1.8 m)

Model 9638 RS-232C Cable

(9pin-25pin/1.8 m)

Model 9151-02 GP-IB

Connector Cable

(2 m)

4

Verifying Package Contents

Electrodes

Conversion of the connectors is required to connect these electrodes. Contact your authorized

Hioki distributor or reseller.

Model SME-8301 Surface Resistance

Measurement Electrode

Model SME-8310 Plate Sample Electrode SME-8311 Electrode for Flat Sample

Model SME-8320 Weight Electrode Model SME-8330 Liquid Sample Electrode

Model SME-8302 Electrode for Surface

Resistance

Model SME-8350 Shielding Box Model SME-8360 Electrode for Chip Capacitor

Model SM9001 Surface/Volume Resistance

Measurement Electrode

Temperature and humidity sensor

Model Z2011 Humidity Sensor

Model SR-2 Standard Resistor

5

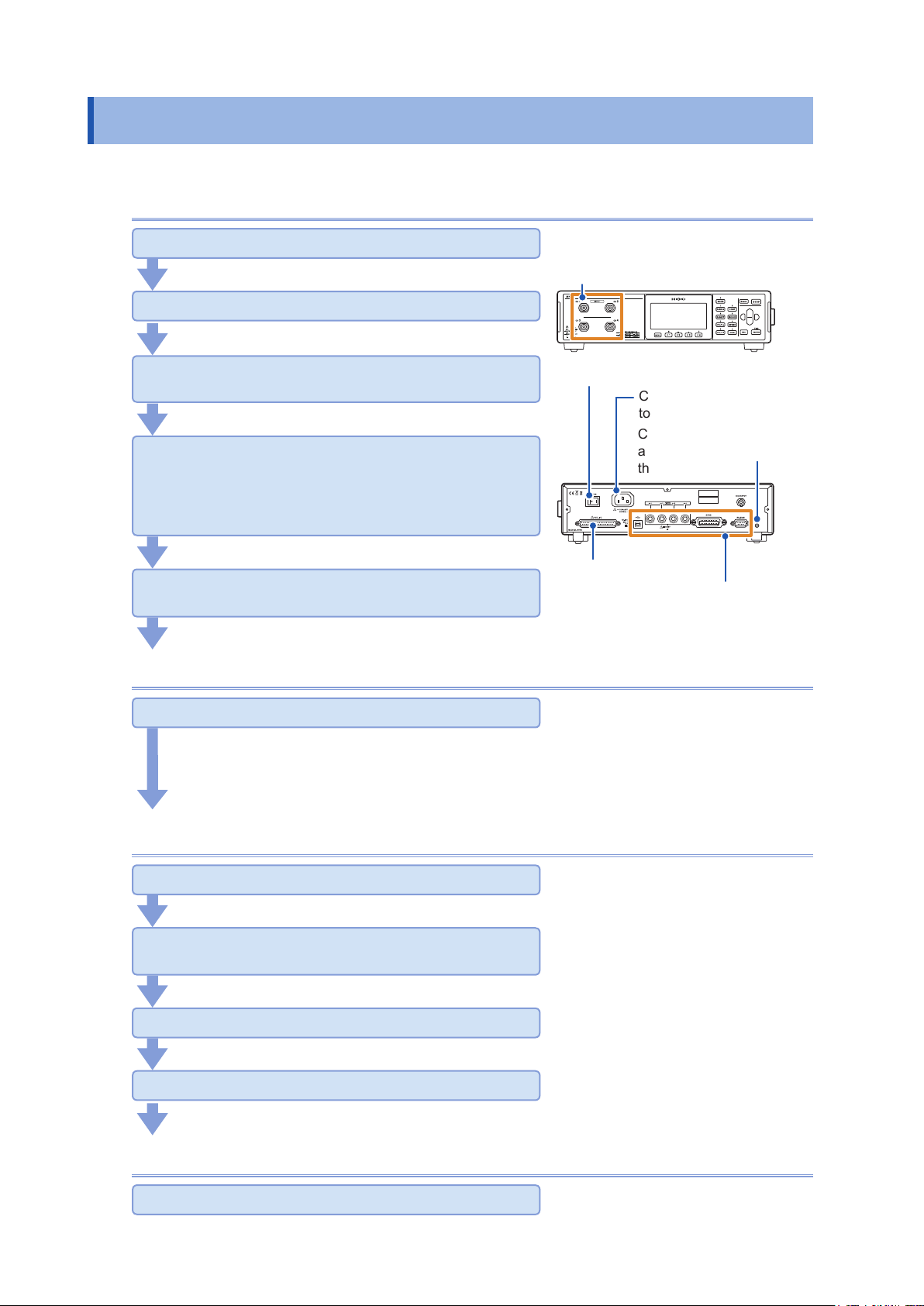

Measurement Procedure

Measurement Procedure

Be sure to read “Operating Precautions” (p. 8) beforehand.

Installing, connecting, and turning on the instrument

Install the instrument. (p. 9)

Connect the power cord to the instrument. (p. 27)

Connect the measurement lead, electrode, and the

Humidity Sensor to the instrument. (p. 28)

Connect other devices to the instrument via the

external interface (as needed).

• Use the EXT I/O. (p. 90)

• Connect a computer to the instrument for communications

through USB, RS-232C, or GP-IB. (p.

Turn on the instrument. (p. 31)

(It takes at least 30 minutes to complete a warm-up.)

109)

Setting the instrument (p. 33)

Connect the measurement lead

and electrode to the instrument.

Turn on the instrument.

Connect the power cord

to the instrument.

Connect the temperature

and humidity sensor to

the instrument.

Use the EXT I/O.

Communicate with the computer

through USB, RS-232C, or GP-IB.

Set the measurement conditions (as needed).

• Basic setting (p. 33)

• Customized setting for measurement conditions (p. 43)

• Setting related to the system (p. 79)

• Default setting table (p. 87)

Starting the measurement

Execute the open correction. (p. 52)

If contact check is set to ON, execute the open correction.

Connect the measurement lead to an object to be

measured. (p. 38)

Start the measurement. (p. 39)

Check the measured values. (p. 39)

Press the STOP key to end the measurement. (p. 39)

If the trigger source setting is set to [EXTERNAL], the measurement automatically stops on completion

of each measurement.

Ending

Turn off the instrument. (p. 31)

6

Safety Information

Safety Information

This instrument is designed to conform to IEC61010 Safety Standards, and has been thoroughly

tested for safety prior to shipment. However, using the instrument in a way not described in this

manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes:

DANGER

Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in

the manual before use.

WARNING

With regard to the electricity supply, there are risks of electric shock, heat

generation, re, and arc ash due to short circuits. If persons unfamiliar with

electricity measuring instrument are to use the instrument, another person

familiar with such instruments must supervise operations.

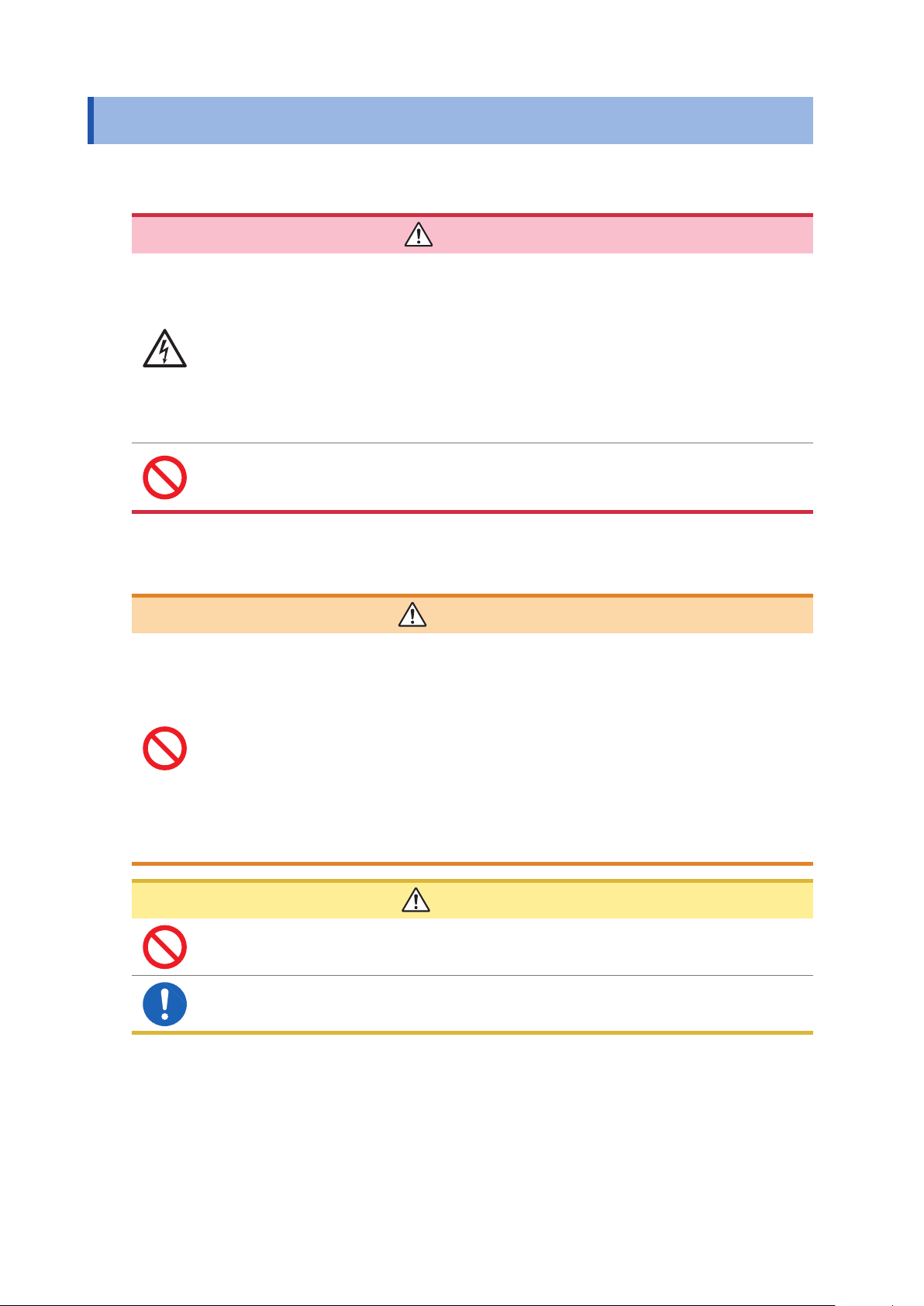

Measurement categories

To ensure safe operation of measuring instruments, IEC61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement

categories.

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

• Never use a measuring instrument that lacks category labeling in a CAT II to

CAT IV measurement environment. Doing so could result in a serious accident.

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical

circuits in equipment connected to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to

outlets

CAT IV:

When measuring the circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel)

Distribution Panel

Service Entrance

Service Drop

CAT IV

Power Meter

Internal Wiring

CAT III

Fixed Installation

CAT II

T

Outlet

7

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

DANGER

If the measurement lead or the instrument is damaged, there is a risk of electric

shock. Before using the instrument, perform the following inspection:

• Before using the instrument check that the coating of the measurement leads

are neither ripped nor torn and that no metal parts are exposed. Using the

instrument under such conditions could result in electric shock. Replace the

measurement leads with those specied by our company.

• Verify that the instrument operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized

Hioki distributor or reseller.

To prevent an electric shock, conrm that the braided conductor for shielding

wire is not exposed. If a braided conductor for shielding wire is exposed, do not

use the cable.

Instrument installation

Installing the instrument in inappropriate locations may cause a malfunction of

instrument or may give rise to an accident. Avoid the following locations:

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

• Do not place the instrument on an unstable table or an inclined place. Dropping or

knocking down the instrument can cause injury or damage to the instrument.

• This instrument is not drip-proof. Water droplets on the connector may result in

malfunctions.

WARNING

CAUTION

8

Installing the instrument

To prevent overheating, be sure to leave the specied clearances around the instrument.

• Install with the bottom surface facing downward.

• Vents must not be obstructed.

50 mm or more50 mm or more

15 mm or more

“Unfolding and retracting the stands” (p. 18)

Operating Precautions

10 mm or more

Rear

Handling the instrument

To avoid electric shock, do not remove the instrument’s case. The internal

components of the instrument carry high voltages and may become very hot

during operation.

To avoid damage to the instrument, protect it from physical shock when transporting

and handling. Be especially careful to avoid physical shock from dropping.

This instrument may cause interference if used in residential areas. Such use must be avoided

unless the user takes special measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

DANGER

CAUTION

9

Operating Precautions

Before connecting the power cord to the instrument

DANGER

Use only the designated power cord with this instrument. Use of other power

cords may cause re.

WARNING

• Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage

may damage the instrument and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specications of this

instrument, connect the power cord provided only to an outlet.

CAUTION

• Do not connect the supply voltage improperly. Doing so may damage the instrument’s

internal circuitry.

• To avoid damaging the cords, unplug it by grasping the connector, not the cord.

Before connecting the measurement leads and electrode to the instrument

WARNING

• Do not use the instrument with circuits that exceed its ratings or specications.

Doing so may damage the instrument or cause it to become hot, resulting in

electric shock.

• The maximum rated to-ground voltage of the input terminal is 2000 V DC. Do

not apply any higher voltage input to the input terminal.

• Use only the specied measurement lead. If using a measurement lead other

than the one specied, you cannot perform measurement safely.

• To avoid electric shock, do not exceed the lower of the ratings shown on the

instrument and measurement leads.

Before connecting the Humidity Sensor to the instrument

CAUTION

• The sensor used in the Humidity Sensor is a thin, precision platinum lm. Be aware

that excessive voltage pulses or static discharges can destroy the lm.

• Avoid subjecting the tip of the Humidity Sensor to physical shock, and avoid sharp

bends in the leads. These may damage the probe or break a wire.

• Note that the ambient temperature does not exceed the temperature range specied

in “Specications of Model Z2011 Humidity Sensor” (p. 123).

10

Before performing a measurement

• While measuring insulation resistance, dangerous voltage is applied to the

measurement terminals. To avoid electric shock, do not touch the tip of the

measurement leads.

• Even after the STOP key is pressed, the measurement voltage may remain in

the measured object. Because there is a risk of an electric shock, take care

to not touch metallic parts to which the voltage is applied until they are fully

discharged.

To avoid malfunctions of the instrument, insert an adequate protective resistor between

the external power supply and the object to be measured. A short-circuit of the terminals

of the object causes the instrument to be subject to a voltage output from the external

power supply.

• To avoid malfunctions of the instrument, limit the input current at up to 1.8 mA during

the testing using a measurement voltage of between 1000 V and 2000 V.

Operating Precautions

WARNING

CAUTION

See “Appx. 4 Using Instrument with 2000 V or Higher Voltage Applied (With External Power

Supply)” (p.

Appx.6).

Before performing an automatic measurement

CAUTION

To protect the relay contacts, switching the measurement terminals with relays leaving

a measurement voltage output requires a protective resistor* inserted in series in the

circuit.

Protective resistance value ≥ (Measurement voltage) / (Maximum allowable current)

* Implements resistance to prevent the current owing through the contact from

exceeding the maximum allowable current of the contact

Before using the shielding box

WARNING

Be sure to connect the external case of the shielding box to the ground.

In addition, take sufcient precautions to avoid an electric shock.

Before removing the measured object

If a high-voltage is used to measure resistance, because measurement voltage

may remain in the measured object even after the measurement has ended,

there is the risk of an electric shock if you try to immediately remove the object.

Remove the measured object after the dangerous voltage has been discharged.

WARNING

11

Operating Precautions

Before controlling the instrument externally

WARNING

To avoid electric shock or damage to the equipment, always observe the following

precautions when connecting to connectors:

• Be careful to avoid exceeding the ratings of connectors.

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Use screws to secure the RS-232C

connector, GP-IB connector, and EXT I/O terminal.

• Ensure that devices and systems to be connected to the RS-232C connector,

GP-IB connector, or EXT I/O terminal are properly isolated.

CAUTION

You must not operate the EXT I/O MODE switch (NPN/PNP) while the instrument is

turned on.

Select the external I/O mode between NPN and PNP based on devices that are

externally connected (p. 90).

Before connecting the communication cable to the instrument

DANGER

To avoid electrical hazards and damage to the instrument, do not apply voltage

exceeding the rated maximum to the EXT I/O terminal.

CAUTION

• Use a common ground for both the instrument and the computer. Use of different

ground circuits will result in a potential difference between the instrument’s ground

and the computer’s ground. If the communications cable is connected while such a

potential difference exists, it may result in equipment malfunction or failure.

• Before connecting any communications cable to the instrument or disconnecting any

communications cable from the instrument, always turn off the instrument and the

computer. Failure to do so could result in equipment malfunction or damage.

• After connecting the communications cable, tighten the screws on the connector

securely. Failure to secure the connector could result in equipment malfunction or

damage.

Before performing the open correction

12

WARNING

If an open correction is carried out, a measurement voltage is instantly output

from the measurement terminal.

Before carrying out an open correction (pressing the F2 key [EXEC]), check that

no human body is in contact with any jigs or measurement circuits.

Operating Precautions

Precautions during shipment

Store the packaging in which the instrument was delivered, as you will need it when transporting

the instrument.

CD precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text

on a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

13

Operating Precautions

14

1

Overview

1.1 Product Overview and Features

This instrument is an insulation resistance meter containing a highly sensitive ammeter.

Employing the triaxial BNC connector enables the instrument to measure high resistance such as

resistance of insulators with no inuence of exogenous noise. The maximum measurement voltage

is 2000 V.

Stable measurements for a variety of items

• The triaxial BNC connector is used to have external noise resistant structures.

• The maximum measurement voltage is 2000 V, so various objects can be simply measured with

a single instrument.

• The instrument has a wide measuring range. (Depends on applied voltage)

• Resistance measuring range: 50 Ω to 2 ×1019 Ω; Current measuring range: 0.1 fA to 2 mA

• Because temperature and humidity can be measured simultaneously, change in resistance can

be checked with the change in temperature and humidity.

• The contact check function enables you to perform stable measurements.

Suitable for production lines

• High-speed measurement; it takes only 6.4 ms from input of a trigger to output of the INDEX

signal.

• The frequency change function of contact check reduces interference with other devices in the

production line.

• It is not necessary to correct cable length even when changing production line construction

because the instrument automatically corrects the cable length of contact check.

• Because you can check the control status with the command monitor function and the external

I/O monitor function, you can quickly construct a production line.

• Because the external I/O is compatible with both NPN and PNP types, you can immediately use it

on your production line.

1

Overview

What can be measured

• Insulation resistance between capacitor terminals

• Insulation resistance between a battery terminal and a case

• Insulation resistance between coils of common mode lters

• Checking breakdown voltage

• Surface resistivity and volume resistivity of lm, etc.

• Insulation resistance of liquid sample

15

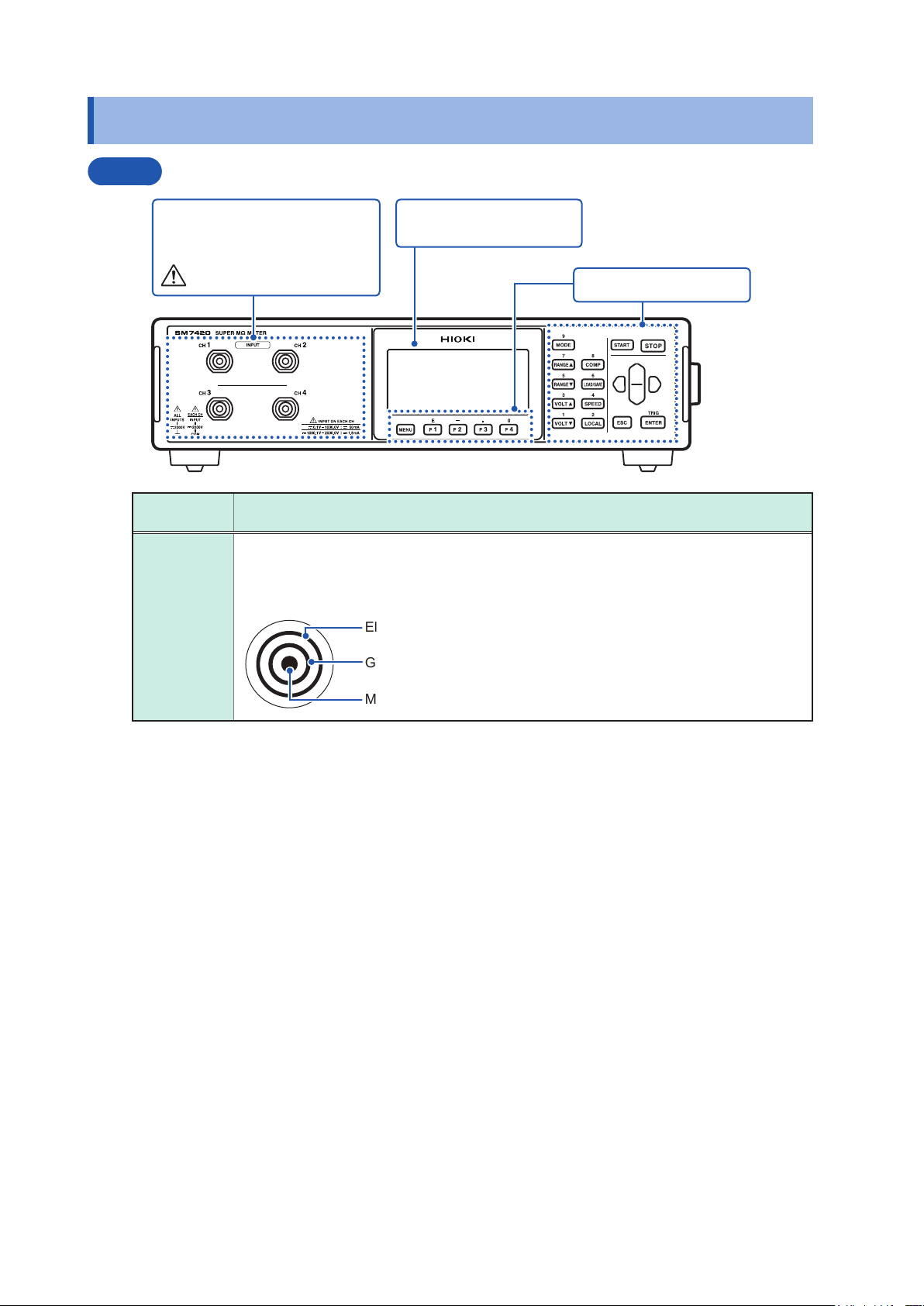

Names and Functions of Parts

1.2 Names and Functions of Parts

Front

Measurement terminals (INPUT)

Connect measurement leads to

these terminals.

See p. 10.

Measurement

terminals

These are measurement input terminals.

Have triaxial structure. The central conductor is for measurement input. The outermost

electrode is connected to the GROUND potential of the measurement circuit. The secondoutermost electrode is connected to the ground (case metal part).

INPUT

Screen

Monochrome graphic LCD

Description

Electromagnetic shielding wire

Guard wire for measurement

Measurement input wire

Operation keys (p. 19)

Additionally installing the shield wires

in the measurement line enables

the instrument to perform stable

measurement with no inuence of

exogenous noise.

16

Names and Functions of Parts

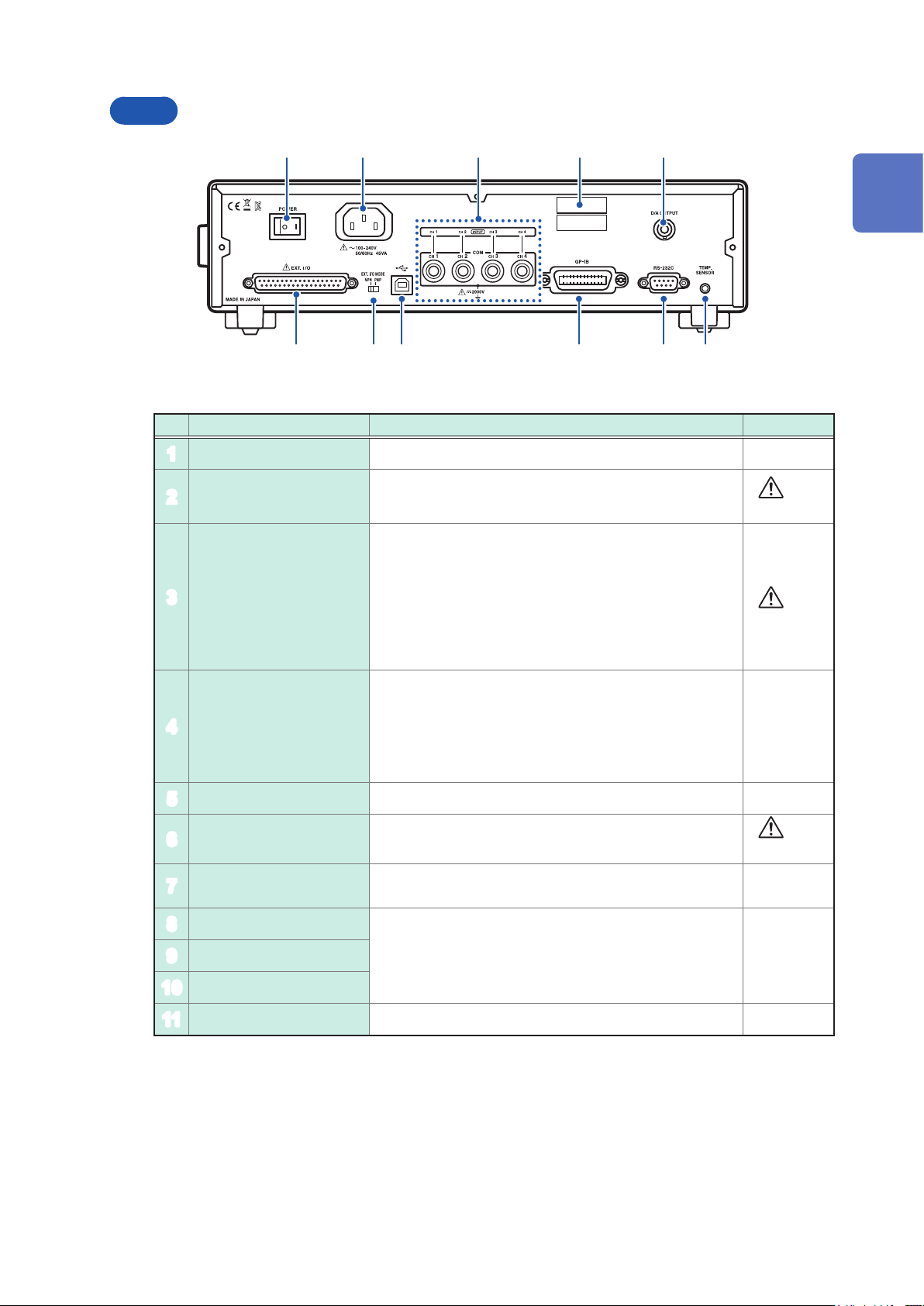

Rear

1 2 3 4 5

6 7 8 9 10 11

No. Name Description Reference

Power switch Turn on and off the instrument, ipping this switch. p. 31

1

1

Overview

Power inlet Connects the accessory power cord to this inlet.

2

These terminals are used to share the GROUND potential

of the measurement circuit of the instrument and the

external power supply.

COM terminals

3

Serial number

4

D/A OUTPUT terminal Outputs a voltage proportional to the measured value. p. 30

5

EXT I/O terminal Connects an external controller to this connector.

6

EXT I/O MODE

7

switch

USB connector

8

Connect these terminals to the COM or the GND terminal

of the external power supply.

If the GND terminal of the external power supply is shared

by 4 channels, connect the COM1 terminal of instrument

to the GND terminal of the external power supply.

Indicates the serial number.

The serial number consists of 9 digits. The rst two (from

the left) indicate the year of manufacture, and the next two

indicate the month of manufacture.

Do not remove this label because it is required for product

support.

Left: Current sink (NPN), Right: Current source (PNP) p.

p. 10

27

p.

p. 10

–

p. 12

p. 89

90

GP-IB connector

9

RS-232C connector

10

TEMP. SENSOR terminal Connects Model Z2011 Humidity Sensor to this terminal. p. 29

11

Connects a computer to one of these connectors. p. 109

17

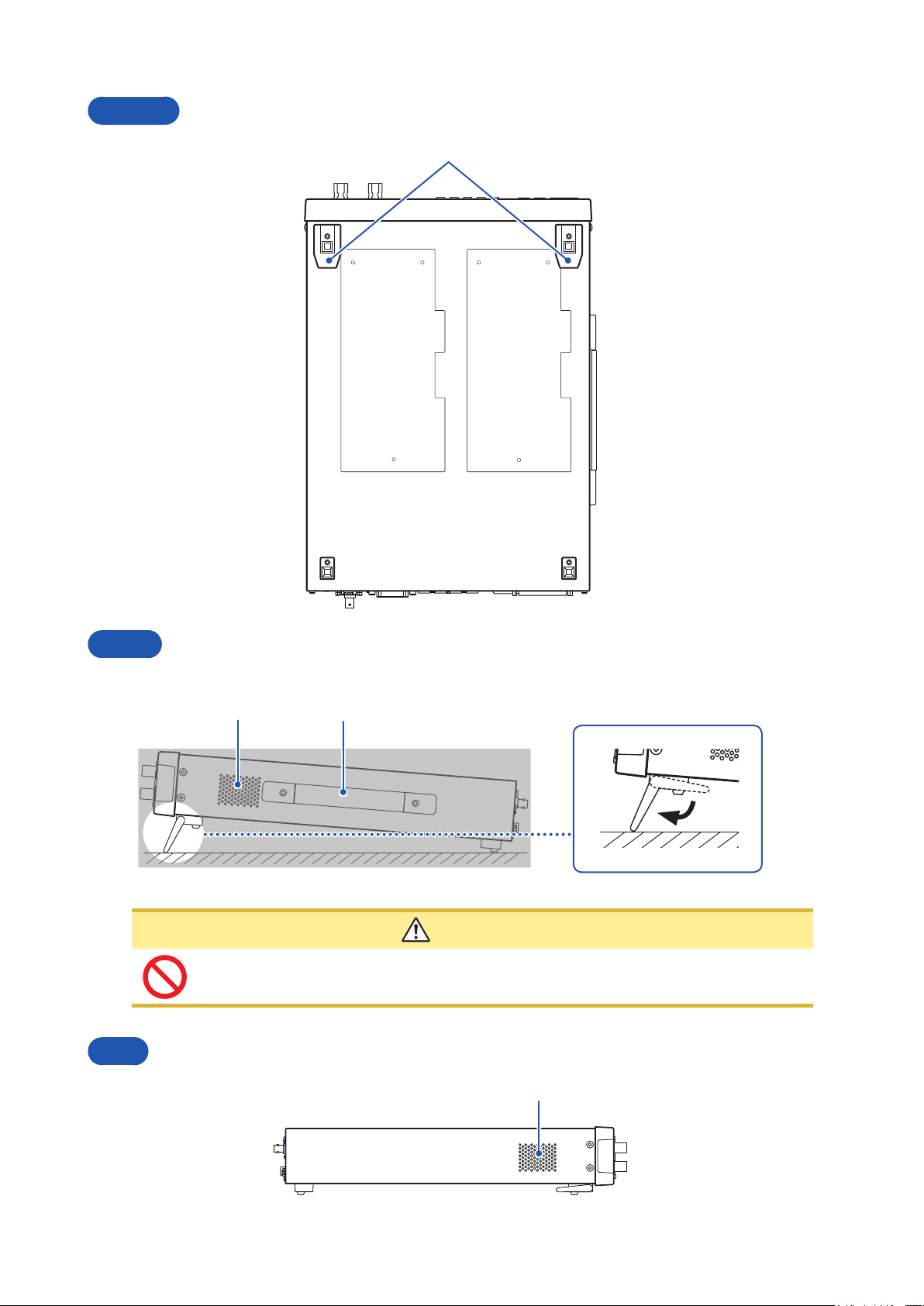

Names and Functions of Parts

Bottom

Stands

Right

Unfolding and retracting the stands

Vent Handle

Do not apply heavy downward pressure with the stand extended. The stand could be

damaged.

Left

CAUTION

Vent

18

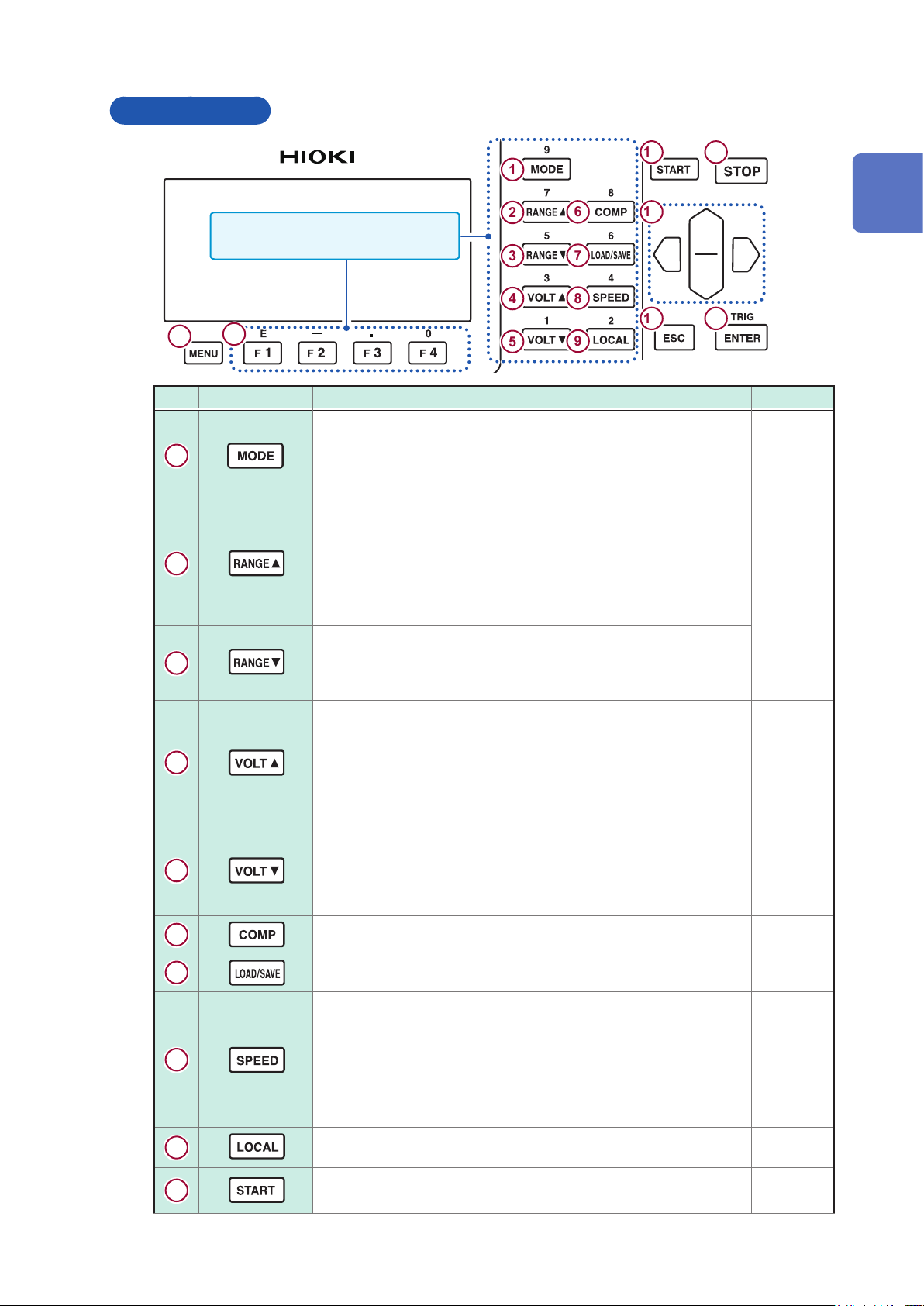

Operation keys

Names and Functions of Parts

10 11

1

These keys also serve as the numeric

keypad to enter the numerical values.

15

No. Key Description Reference

1

2

3

4

5

16

Switches the measurement mode.

The mode changes every time the key is pressed in the following

order:

Resistance, Current, Surface resistance, Volume resistance, Liquid

volume resistance, and returns back to Resistance.

Switches the present current range to the next upper one. You can

change settings on the measurement screen.

The mode changes every time the key is pressed in the following

order:

20 p, 200 p, 2 n, 20 n, 200 n, 2 u, 20 u, 200 u, and 2 m.

Some ranges are not available depending on the measurement

speed setting.

Switches the present current range to the next lower one. You can

change settings on the measurement screen.

The range changes every time the key is pressed in the reverse

order of the above.

Switches the present voltage value for resistance calculation to

the next upper one. You can change settings on the measurement

screen.

The value changes every time the key is pressed in the following

order:

0.1, 0.5, 1, 2.5, 5, 10, 25, 50, 100, 250, 500, 1000, 1500, 2000, 2500,

3000, 3500, 4000, 4500, and 5000

Switches the present voltage value for resistance calculation to

the next upper one. You can change settings on the measurement

screen.

The value changes every time the key is pressed in the reverse

order of the above.

2

3

4

5

6

7

8

9

12

13 14

33

p.

p.

37

p.

35

1

Overview

10

6

7

8

Displays the comparator settings screen. p. 69

Displays the panel load / panel save screen. p. 73

Switches the measurement speed. You can change settings on the

measurement screen.

The speed changes every time the key is pressed in the following

order:

FAST, FAST2, MED, SLOW, SLOW2, and returns back to FAST.

p. 36

Some measurement speeds are not available depending on

the current range setting.

9

Disables the remote control (communicating with an external device)

and enables the key operation.

Starts measurement. –

p. 118

19

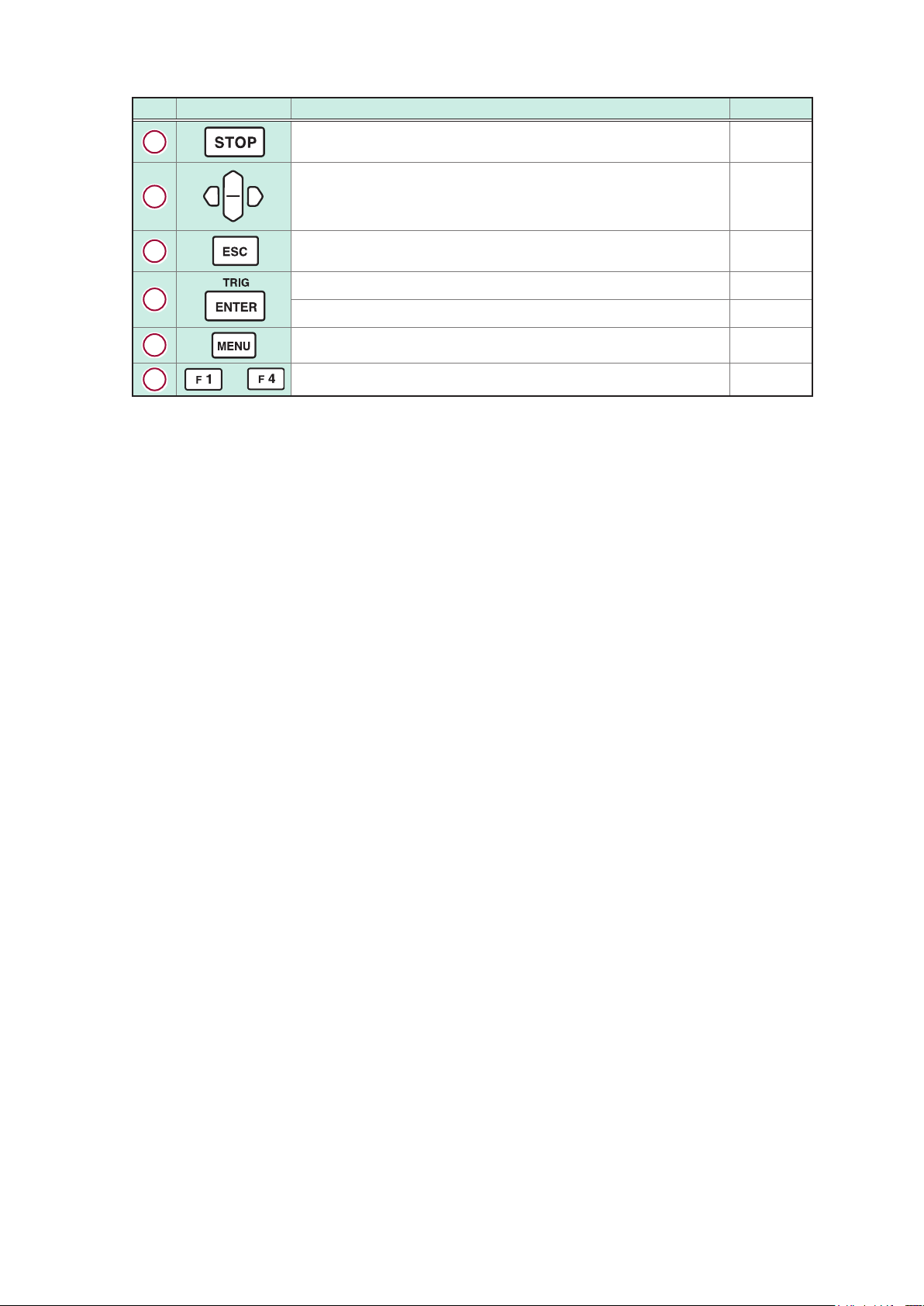

Names and Functions of Parts

No. Key Description Reference

11

12

13

14

15

16

to

Stops measurement. –

• Moves the cursor to another setting item or digit.

• Changes numerical values.

• Cancels the setting.

• Returns to the measurement screen from other screens.

Conrms the setting. –

Inputs the trigger if the external trigger setting is used. p.

Moves the screen to another menu settings screen. p. 21

Function keys. Selects item on each settings screen. –

25

p.

–

46

20

Screen Conguration and Operation

1.3 Screen Conguration and Operation

The screens of the instrument consists of the measurement screens and the settings screens.

For information about the settings screen, see “Displaying the various menu settings screens”

(p. 23).

Measurement screens

Press the F3 key [MONI] to switch between the 1-channel display and the 4-channel display.

1-channel display

1

Overview

7

8

9

10

4-channel display

7

1 2 3 4 6

13 1514 16 17

1 2 3 4 6

5

5

11

12

8

9

10

11

12

13 1514 16 17

21

Screen Conguration and Operation

Displayed items

No. Content Description Reference

Trigger setting

1

Sampling data Appears during the sampling data. –

2

Self-calibration Appears during the self-calibration. p. 47

3

Contact check

4

Open correction

5

execution result

Key lock [K.LOCK] Appears while the key lock function is activated. p. 80

6

Remote [RMT]

Measurement judgments

7

Channel numbers

8

Temperature

9

Humidity

10

Measured values

11

Measurement conditions

12

MENU key [SET] Pressing the MENU key displays the menu settings display. p. 24

13

F1 key [CH1234]

14

F2 key [C.CHK]

15

F3 key [MONI]

16

F4 key [MODIFY]

17

Displays the presently set trigger.

p. 46[INT] Internal trigger

[EXT] External trigger

Appears when the contact check function is enabled.

Highlighted in reverse video if a contact error occures.

Displays the result when the open correction is executed

once.

Appears while the instrument is placed in the

remote status (communicating with an external

device).

Pressing the LOCAL key disables the remote

control.

Displays the judgment results if the measurement judgment

function is enabled.

Displays the presently selected channel number when using

the 1-channel display.

Displays temperature and humidity if the Humidity Sensor is

connected.

Displays an error message if the Humidity Sensor is not

connected to the instrument.

Displays the measured values corresponding to the

measured value display mode.

[EXT.V] Voltage value for resistance calculation p. 35

[SPEED] Measurement speed p.

[RANGE] Current range p.

[DELAY] Delay function p.

[AVG] A

The presently selected channel number is highlighted in

reverse video.

The channel is switched in the order from CH1 through CH4

every time the F1 key is pressed.

Pressing the F2 key executes the contact check (only with

the contact check set to [ON]).

Pressing F3 key switches between the 1-channel display

and the 4-channel display.

Pressing the F4 key enables the measurement conditions to

be changed.

verage function p. 44

p. 53

p.

p.

118

p. 69

p. 29

p.

137

p. 33

p. 53

52

–

36

37

43

–

–

–

Settings screens

For information about the settings display, see “Displaying the various menu settings screens”

(p. 23).

22

1.4 Basic Key Operation

Displaying measurement screen

Basic Key Operation

1

Overview

You can also press the ESC key to return to the measurement screen.

Displaying the various menu settings screens

This section shows an example of switching the measurement screen to the [SYS] screen.

1

2

Select

Select

(left or right)

(left or right)

In this manual, the procedure to display the settings screen is described as follows:

Procedure to display the settings screen: (Measurement screen) MENU key >

(That is to say, to display the settings screen, on the measurement screen, press the MENU key,

and then press the keys

and to select the [SYS] tab.)

[SYS] tab

23

Basic Key Operation

List of menu settings screens

[MEAS] screen

Conguring settings for measurement

[COMP] screen

Conguring settings for measured value judgment

[SYS] screen

Conguring system settings

[C.CHK] screen

Conguring settings for open correction and contact

check

[ELEC] screen

Conguring settings for calculating resistivity

[I/O] screen

Conguring settings for external control

[IF] screen

Conguring settings for interface.

Selecting settings items

Move

[INFO] screen

Displays the information of this instrument.

24

Select

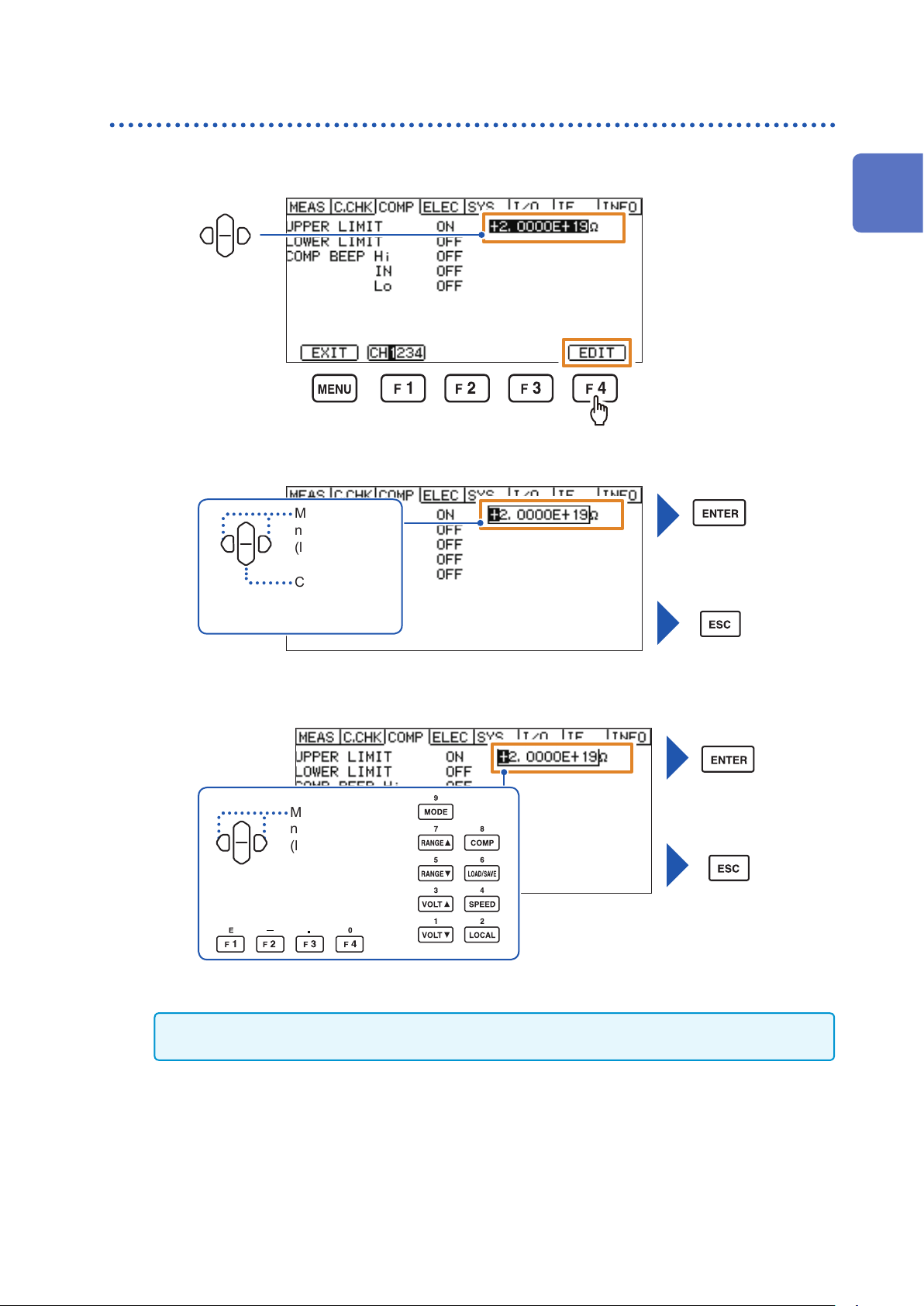

Methods for changing numerical values

The two options available are: using the cursor keys and using the numeric keypad.

Basic Key Operation

1

Move

(If using the cursor keys)

2

Move to the

next digit

(left or right)

Change the

numerical value

(up or down)

1

Overview

Conrm

Cancel

(If using the numeric keypad)

Conrm

Move to the

next digit

(left or right)

Cancel

If you press the ESC key while changing the numerical value, the numerical value change will be canceled.

If you press the ENTER key, the changed content is conrmed.

25

Loading...

Loading...