Page 1

CAN EDITOR

HIOKI SF1002A961-00

Instruction Manual

Feb. 2022 Edition 1

SF1002A961-00 22

02H

-

EN

*600628910*

Page 2

HIOKI SF1002A961-00

Page 3

HIOKI SF1002A961-00

Contents

Introduction .......................................... 1

Trademarks .......................................... 1

Safety standards and notations ......... 1

Mouse operation .................................. 2

Precautions related to disc usage ...... 2

1 Overview 3

1.1 CAN Editor Overview .................. 3

1.2 Settings and Measurement

Procedure ..................................... 3

4.1 Main Screen Configuration ....... 15

4.2 Menu Bar .................................... 16

4.2.1 Opening the settings file .................... 16

4.2.2 Settings dialog box ............................. 17

4.2.3 Help .................................................... 17

4.3 Logger Information and

Send/Receive Information ......... 18

4.3.1 Search ................................................ 19

4.3.2 Manual register .................................. 19

4.3.3 Logger information ............................. 20

4.3.4 Unit configuration change .................. 20

5 Configuring CAN Unit

2 Installing CAN Editor 4

2.1 System Requirements for CAN

Editor ............................................ 5

2.2 Preparing the Installer ................ 5

2.2.1 Using the installer from the CD that

comes with the Logger ......................... 5

2.2.2 Using the installer from the HIOKI

website ................................................. 5

2.3 Installing CAN Editor .................. 6

2.4 Connecting the Logger and

PC Using a USB Cable ................ 8

2.4.1 Installing the USB driver ....................... 8

2.4.2 Connecting the Logger and PC

using a USB Cable ............................... 8

2.5 Uninstalling CAN Editor .............. 9

3 Starting Up CAN

Editor and Preparing

the Logger 10

3.1 Preparing for Measurement ...... 11

3.1.1 When connecting the Logger using

a USB cable ....................................... 11

3.1.2 When connecting the Logger using

a LAN cable ........................................ 11

3.1.3 When using the settings file ............... 11

3.2 Starting up CAN Editor ............. 12

3.3 CAN Editor Initial Selection

Screen ........................................ 13

3.3.1 Selecting the unit to be used .............. 14

Settings 21

5.1 Selecting the CAN Unit .............. 22

5.2 CAN Unit Setting Items ............. 23

5.3 Setting the Mode of the CAN

Unit .............................................. 23

5.4 Setting the Communication

Method of the CAN Unit ............ 24

5.5 CAN Unit Settings ...................... 26

5.6 Copying the CAN Unit

Settings ...................................... 26

6 Setting the Channels

(Receive Mode) 27

6.1 CAN Unit Channel Setting

Screen ......................................... 28

6.2 Display Selection Tab ................ 28

6.3 Receive CAN Data ...................... 29

6.3.1 Dialog box for editing CAN signal

receive channel .................................. 30

6.3.2 Import dialog box ............................... 33

6.3.3 Delete ................................................. 35

6.3.4 CAN data receive menu ..................... 36

6.3.5 Rearrange channels ........................... 37

6.3.6 Copy the selected channel settings ... 38

6.4 User Frame Transmission ......... 39

6.4.1 Dialog box for editing user frame

transmission ....................................... 40

6.4.2 Frame settings edit dialog box ........... 42

6.4.3 User frame menu ............................... 43

6.4.4 Frame settings menu ......................... 43

4 CAN Editor Main

SF1002A961-00

Screen 15

i

Page 4

HIOKI SF1002A961-00

7 Setting the Channels

(Measured Value

Output Mode) 44

7.1 Setting the CAN Unit Channels

(Measured Value Output

Mode) .......................................... 45

7.2 Loading the Measurement

Settings ...................................... 46

7.3 Assigning an ID Individually ..... 46

7.4 Assigning an ID All Together ... 47

7.5 Selecting the Channel to be

Output ........................................ 48

7.6 Selecting the Output Port ......... 48

7.7 Load Factor ................................ 48

7.8 Error ........................................... 49

7.9 Outputting the Measured

Value as a DBC File ................... 49

8 Updating the Logger

with CAN Settings 50

8.1 Sending the Settings from the

PC ............................................... 51

8.1.1 When there is a connected Logger .... 51

8.1.2 When there is no connected Logger .. 51

8.1.3 When the Logger is busy .................... 51

8.1.4 When the settings that do not allow

measurement to start are sent ........... 51

8.2 Loading the Settings File to

the Logger .................................. 52

8.2.1 Preparing media to be used ............... 52

8.2.2 Saving the settings file onto the

media .................................................. 52

8.2.3 Removing the media........................... 52

8.2.4 Loading the CES file to the Logger .... 52

9 Specifications 53

10 Knowledge and

Information 55

10.1 Load Factor of the Measured

Value Output Mode .................... 55

10.1.1 Number of frames that can be

transmitted on the CAN bus............... 55

10.1.2 Data volume to be transmitted on

the CAN bus ...................................... 55

10.2 Channel Type of the Receive

Mode ........................................... 56

10.2.1 When the channel type is set to

Data ................................................... 56

10.2.2 When the channel type is set to ID

count .................................................. 56

10.2.3 Examples of usage ............................ 57

10.3 User Frame Transmission

Operation .................................... 57

10.3.1 Relationship between user frame

No. and number of frames ................. 57

10.3.2 Relationship between scheduled

send ON and number of frames ........ 57

10.3.3 Output stop conditions ....................... 57

10.4 Counting the Bit Position .......... 58

10.5 Error and Warning Messages ... 60

10.5.1 Error message list .............................. 60

10.5.2 Warning message list ......................... 61

10.6 Setting the Logger on the PC ... 62

10.6.1 LAN connection (HTTP server

function) ............................................. 62

10.6.2 LAN/USB connection (Logger

Utility) ................................................. 62

10.7 No Communication with the

Logger ........................................ 62

10.7.1 When a USB connection is used ....... 62

10.7.2 When a LAN connection is used ........ 62

10.8 Open Source Software .............. 62

ii

Page 5

Model number

Model name

Supported CAN Unit

LR8450*1

Memory HiLogger

U8555 CAN Unit

LR8450-01*1

Memory HiLogger

U8555 CAN Unit

LR8535 Wireless CAN Unit

Safety notations

In this document, the severity levels of risk and hazard are classified as follows.

Indicates a potentially hazardous situation that, if not avoided,

damage to the supported product (or to other property).

from the standpoint of operating or maintaining the Logger.

Notation

(p. )

Indicates the page number to reference.

Indicates useful advice concerning instrument performance and

operation.

*

Indicates additional information is described below.

The names of user interface elements on the screen are enclosed

in brackets ([ ]).

Indicates the default setting. When initialized, the instrument will

revert to this value.

CURSOR

The bold alphanumeric characters in this manual indicate the

characters displayed on the PC keyboard.

Unless otherwise noted, the term “Windows” is used generically to

refer to Windows 10 or Windows 11.

Logger

Memory HiLoggers are referred to as “Logger” in this manual.

CAN Unit

U8555 and LR8535 are referred to as “CAN Unit” in this manual.

PC

Computers are referred to as “PC” in this manual.

HIOKI SF1002A961-00

Introduction

“CAN Editor” is an application software exclusively for the following instruments.

*1: Version 2.00 and later versions are supported.

For the Memory HiLoggers, refer to the instruction manuals that came with LR8450 and LR8450-01.

Trademarks

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in the

United States and other countries.

Safety standards and notations

CAUTION

IMPORTANT

could result in minor or moderate injury, or potential risks of

Indicates information or content that is particularly important

[ ]

☑

(Bold letters)

Windows

1

Page 6

Click

Press and quickly release the left button of the mouse.

Right-click

Press and quickly release the right button of the mouse.

Double-click

Quickly click the left mouse button twice.

Drag

While holding down the left button of the mouse, move the mouse and then

release the left button to deposit the chosen item in the desired position.

Active

Click on a window on the screen to activate that window.

Exercise care to keep the recording surface of the disc free of dirt and

with the use of this disc.

HIOKI SF1002A961-00

Mouse operation

Precautions related to disc usage

CAUTION

damage. If you need to label the disc, for example with text, use a marker

with a soft tip.

Store discs in protective cases. Avoid exposing the disc to direct sunlight,

high temperatures, or high humidity.

Hioki is not liable for any computer system issues that arise in connection

2

Page 7

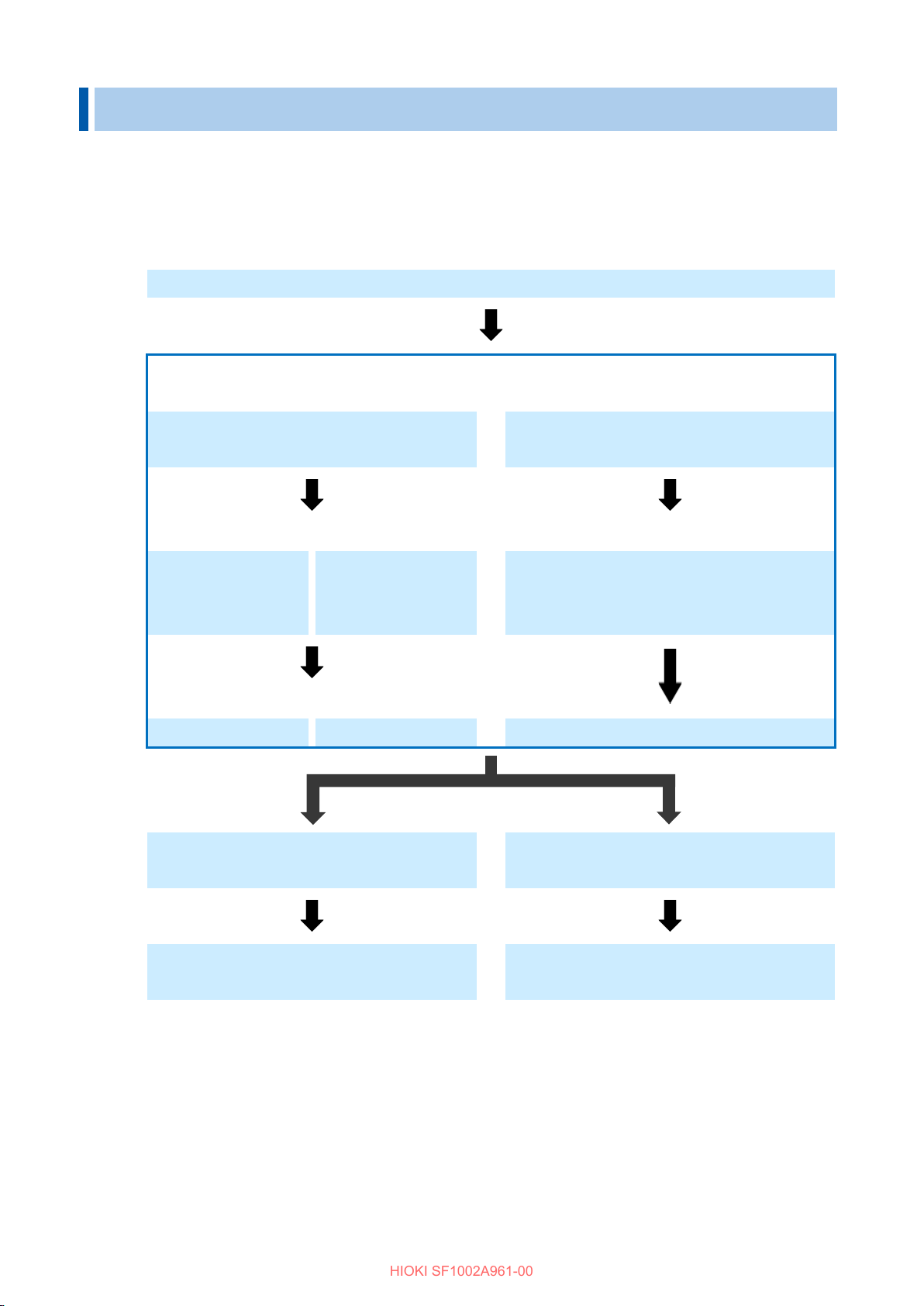

1. Installing CAN Editor on the PC (Chapter 2)

2. Starting up CAN Editor and preparing the Logger (Chapter 3)

3. Setting the CAN Unit (Chapter 5)

4. Setting the channels based on the CAN Unit mode

(1) Receive mode (Chapter 6)

(2) Measured value output mode

(Chapter 7)

5. Updating the Logger with the CAN settings (Chapter 8)

6. Starting and ending measurement (See the Logger operation procedure.)

(2) Finish the measurement

HIOKI SF1002A961-00

1 Overview

1.1 CAN Editor Overview

CAN Editor is application software for setting CAN signal measurements and output of the Logger to

which the CAN Unit is connected. The following operations can be performed when the CAN Unit is

set.

• Measures the CAN signals using the Logger.

• Sends a signal to the CAN bus from the Logger.

• Sends data measured using the Logger to the CAN bus (data measured with a plug-in module).

1.2 Settings and Measurement Procedure

The settings and measurement procedure are shown below.

(1) Check the CAN settings on the Logger and start measurement.

3

Page 8

1. Checking the operation environment for CAN Editor (2.1)

2. Preparing the installer (2.2)

3. Installing CAN Editor (2.3)

4. When connecting the Logger

When not connecting the Logger using

Installing the USB driver (2.4.1)

Connecting the Logger using a USB cable

(2.4.2)

5. Completing the installation

Uninstalling CAN Editor if necessary (2.5)

HIOKI SF1002A961-00

2 Installing CAN Editor

Install CAN Editor on the PC according to the following instructions.

The installation procedure described in this chapter is shown below.

using a USB cable

a USB cable

4

Page 9

OS

Windows 10 (32 bits/64 bits) / Windows 11 (64 bits)

CPU

1 GHz or faster 32 bit (x86) or 64 bit (x64) processor

Display

1280 × 1024 dots or more

65,536 colors or more

Memory

2 GB or more

Hard disk

3 GB or more of available space

Interface

With an Ethernet or USB terminal

Required framework

Microsoft .NET Framework 4.6 and a language pack applicable for the

execution environment must be installed.

HIOKI SF1002A961-00

2.1 System Requirements for CAN Editor

Before installing CAN Editor, check the system requirements of the PC.

2.2 Preparing the Installer

CAN Editor can be installed in the following two methods.

2.2.1 Using the installer from the CD that comes with the Logger

Install CAN Editor using the installer from the CD that comes with the Logger.

2.2.2 Using the installer from the HIOKI website

Install CAN Editor using the installer downloaded from Hioki’s website.

The latest installer for CAN Editor can be downloaded.

https://www.hioki.com/global

5

Page 10

IMPORTANT

Click

Click

HIOKI SF1002A961-00

2.3 Installing CAN Editor

The procedure for installing CAN Editor is described in this section.

Displayed messages and operations may be different depending on the operating system or settings.

If any anti-virus software is running, make sure to close it before starting the installation. If anti-virus

software is running, the software may not be installed properly.

1. Start up Windows

Close all the software that is running.

®

.

2. Set the supplied CD in the CD-ROM

drive.

The Logger Application Disc page is

displayed.

Select a language and select [CAN

Editor] → [Install].

3. Select the language to use for the

installation and click [OK].

The procedure for when English is

selected is described in this manual.

4. Click [Next]. Accept the license

agreement and then click [Next].

Check

Click

When the Logger Application Disc

page is not displayed

Execute [index.htm] on the CD. If a dialog

box asking for permission for application

installation is displayed, click [Allow] and

proceed.

6

Page 11

Click

HIOKI SF1002A961-00

5. Click [Next].

Installation starts.

How to change the installation

destination

Click [Change] and change the folder to

which CAN Editor is to be installed. Normally

this setting does not need to be changed.

The installation is now complete.

Click

7

Page 12

CAUTION

Click

Click

HIOKI SF1002A961-00

2.4 Connecting the Logger and PC Using a USB Cable

2.4.1 Installing the USB driver

When connecting the Logger using a USB cable, install the USB driver.

1. Install the USB driver.

Execute [DriverSetupWin10.msi] in the

USB Driver folder on the CD.

If CAN Editor has already been installed,

execute the program at the following

location.

[C:¥Program Files (x86)¥HIOKI¥ CAN

Editor for MEMORY HiLOGGER¥

Driver¥DriverSetupWin10.msi]

Please wait as it may take time for a dialog

box to be displayed depending on the PC.

If the installation destination has been

changed, refer to the location.

2. Click [Continue].

When a dialog box asking for permission

for application installation is displayed,

click [Continue] and proceed.

3. Click [Install].

If a dialog box asking for permission for

application installation is displayed, check

the [Always trust software from “HIOKI

E.E. CORPORATION”] check box and

click [Install] to proceed.

4. When the installation is completed and

the following dialog box is displayed,

click [Close].

The driver installation is now complete.

2.4.2 Connecting the Logger and PC using a USB Cable

After installing the USB driver, connect the Logger and PC using a USB cable.

Do not plug in or unplug the USB cable while the instrument is operating.

1. Connect the AC adapter to the Logger and turn on the power.

2. Connect the PC and Logger using the provided USB cable.

The Logger is automatically recognized and the preparation to use the Logger is completed.

8

Page 13

The settings files, etc. remain unchanged. Delete them manually if they are not needed.

The uninstallation is

now complete.

(1) Right-click.

(2) Click.

Click

Click

Click

HIOKI SF1002A961-00

2.5 Uninstalling CAN Editor

The procedure for uninstalling CAN Editor is described in this section.

Right-click the Start button of Windows® and then click [Apps and Features].

1.

From the displayed application list, select and click [CAN Editor].

2.

Click this button to display [Uninstall].

Click [Uninstall].

3.

The installer starts automatically.

Click this button to display the confirmation dialog box.

The [Apps and Features] dialog box is displayed again.

9

Page 14

When connecting the Logger and PC

When not connecting the Logger and PC

Preparing for measurement (3.1)

When using a

(3.1.1)

When using a

(3.1.2)

When using the

(3.1.3)

When setting

When using

settings

Connecting the

Connecting

LAN

Preparing the

Starting up CAN Editor (3.2)

Initial selection screen (3.3)

When setting CAN Editor online

When setting CAN Editor offline

Selecting the

continue

Communicating with LR8450 to

Opening the

Selecting the

To the CAN Editor main screen (Chapter 4)

HIOKI SF1002A961-00

3 Starting Up CAN Editor and Preparing

the Logger

The procedure from starting up CAN Editor to starting Logger settings is shown below.

USB cable

cable

LAN cable

the cable

Setting the

settings file

settings file

manually

the previous

previous

settings to

receive the unit configuration

settings file

unit to be used

10

Page 15

Settings file that can be loaded

File extension

Settings file that has been saved in the Logger

.SET

Settings file that has been saved in CAN Editor

.CES

HIOKI SF1002A961-00

3.1 Preparing for Measurement

Make all the settings except for the CAN Unit on the Logger in advance.

3.1.1 When connecting the Logger using a USB cable

Prepare a USB cable and connect the Logger and PC with CAN Editor installed.

The USB driver needs to be installed.

See “2.4.1 Installing the USB driver”

3.1.2 When connecting the Logger using a LAN cable

Prepare a LAN cable and connect the Logger and PC with CAN Editor installed.

The LAN communication needs to be set.

See “9.3 Configuring and Establishing a LAN Connection” in Logger Instruction Manual

3.1.3 When using the settings file

Prepare the settings files that can be loaded to CAN Editor.

11

Page 16

Click

HIOKI SF1002A961-00

3.2 Starting up CAN Editor

From the Windows® Start menu, click [HIOKI] - [CAN Editor].

The initial selection screen is displayed when CAN Editor starts up.

See “3.3 CAN Editor Initial Selection Screen”

1.

Click

2.

Click

3.

Starting up CAN Editor while holding down the Shift key starts up the application at the initial position

and in the initial size.

12

Page 17

1 Communicate with LR8450

Connects the Logger using a USB or LAN cable and receives

See “4.3.1 Search”

2 Open the settings file

Loads the settings file.

See “3.1.3 When using the settings file”

3 Select the unit to be used

Registers the CAN Unit.

See “3.3.1 Selecting the unit to be used”

4 Continue previous settings

Continues from the previous setting of CAN Editor.

5 Do not show this screen

When this check box is checked, this dialog box is not displayed

See “4.1 Main Screen Configuration”

1 2 3 4 5

HIOKI SF1002A961-00

3.3 CAN Editor Initial Selection Screen

The initial selection screen is displayed when CAN Editor starts up.

If the [Do not show this screen again] check box (5 shown below) was checked when CAN Editor

was used the last time, the main screen is displayed.

Select how to set CAN Editor.

to receive settings

again

the Logger settings.

at the time of startup and the main screen is displayed.

Continues from the previous setting of CAN Editor.

13

Page 18

HIOKI SF1002A961-00

3.3.1 Selecting the unit to be used

Clicking [Select the unit to be used] displays the unit selection screen.

Up to four units for which CAN settings are to be configured can be selected.

The unit configuration can be changed later on.

See “4.3.4 Unit configuration change”

14

Page 19

1 Display change, close

Changes the CAN Editor display or ends CAN Editor.

is clicked.

2 Menu bar

Displays the menu bar (list) of CAN Editor.

See “4.2 Menu Bar”

3 Logger information and

Displays the information of the units connected to the Logger.

See “4.3 Logger Information and Send/Receive Information”

4 Setting-title information

Allows you to enter a setting title.

5 CAN Unit information

Displays the information of the unit to be set.

See “5 Configuring CAN Unit Settings”

6 CAN channel information

Displays the information of the channel to be set.

Channels (Measured Value Output Mode)”

2 3 4 6 5

1

HIOKI SF1002A961-00

4 CAN Editor Main Screen

4.1 Main Screen Configuration

The configuration of the main screen is shown below.

buttons

send/receive information

If the dialog box is displayed, it is closed when [×] of the dialog box

Select the units that send/receive the settings to/from the Logger.

See “6 Setting the Channels (Receive Mode)”, “7 Setting the

15

Page 20

1 New

Discards the information that is being set and sets new information.

Registered Logger information is also discarded.

2 Open

Loads the settings file.

See “4.2.1 Opening the settings file”

3 Save

Saves the CAN Editor settings as a settings file (CES file).

4 Settings

Opens the CAN Editor settings dialog box.

See “4.2.2 Settings dialog box”

5 Help

Opens the Help information.

See “4.2.3 Help”

5

1

3

4

2

HIOKI SF1002A961-00

4.2 Menu Bar

The configuration of the main bar is shown below.

See “3.1.3 When using the settings file”

4.2.1 Opening the settings file

If the unit configuration of the settings file is the same as that of CAN Editor, clicking [Open] displays

the following dialog box.

Select the settings to be loaded and click [Confirm] to load the settings.

If the unit configuration of the settings file is different from that of CAN Editor, the following dialog box

is displayed. Clicking [OK] initializes the settings of the measured value output mode after the settings

are loaded.

16

Page 21

1 Open the instruction manual

Opens the CAN Editor instruction manual.

2 CAN editor version information

Opens the CAN Editor version information.

1

2

1

2

HIOKI SF1002A961-00

4.2.2 Settings dialog box

Clicking [Settings] displays the following dialog box.

1. Parameter

Clicking an item displays the setting details at the right side of the dialog box.

2. Setting details display

Configures various settings.

4.2.3 Help

Clicking [Help] displays the following items.

17

Page 22

1 Search

Searches for the Logger to be set. (USB connection, LAN connection)

See “4.3.1 Search”

2 Logger information

Displays the information of the Logger to be set.

See “4.3.3 Logger information”

3 Receive

Receives the unit configuration and CAN settings from the Logger to be

set.

4 Unit configuration

Displays the information of the unit connected to the Logger.

Select the units that send/receive the settings to/from the Logger.

5 Send

Transfers the information set by CAN Editor to the Logger to be set.

1

2

3

4

5

HIOKI SF1002A961-00

4.3 Logger Information and Send/Receive Information

The Logger information and send/receive information configuration are shown below.

18

Page 23

1 Search

Performs a search again.

2 Register

Registers the selected Logger.

3 Cancel

Closes the dialog box without registering the Logger.

4 Manual

Registers a Logger manually when no Logger is found.

See “4.3.2 Manual register”

1 2 4

3

HIOKI SF1002A961-00

4.3.1 Search

The Logger connected using a USB or LAN cable is searched.

The search result list is displayed.

4.3.2 Manual register

Clicking [Manual] displays the following dialog box.

• LAN: Enter the IP address and port number set in the Logger. For the port number, enter the first

three digits out of four digits or five digits.

The last digit cannot be specified.

• USB: Select the COM port.

Click [Register] to start connection.

19

Page 24

1 Logger name

Registered Logger name

2 Serial number

Serial number of the registered Logger

3 Communication interface

Type of communication interface of the registered Logger

When a LAN cable is used, the port number is also displayed.

4 Port or IP address

Displays the following depending on the communication interface.

LAN: IP address

Configuration change

check box

Specifies the unit with the check box checked as a CAN unit. Only

units that are not yet registered can be selected.

1

2 3 4

HIOKI SF1002A961-00

4.3.3 Logger information

Registered Logger information is displayed.

USB: Port number

4.3.4 Unit configuration change

The information of the unit to be set is displayed.

20

Page 25

Selecting the CAN Unit to be set (5.1)

Setting the mode of the CAN Unit (5.3)

Receive mode

Measured value output mode

Setting the communication method of the CAN Unit (5.4)

Setting the update interval of the CAN Unit (5.5)

To Chapter 6

To Chapter 7

HIOKI SF1002A961-00

5 Configuring CAN Unit Settings

The procedure for configuring CAN Unit settings is shown below.

21

Page 26

1 Unit selection

Clicking the CAN Unit opens the CAN Unit setting screen.

Only the CAN Unit can be selected.

2 CAN Unit setting items

Displays the settings of the selected CAN Unit.

See “5.2 CAN Unit Setting Items”

3 CAN channel setting

items

Displays the channel settings of the selected CAN Unit.

1

2

3

HIOKI SF1002A961-00

5.1 Selecting the CAN Unit

Specify various settings of the CAN Unit in the CAN Unit setting screen.

22

Page 27

1 Mode setting

Allows you to select the CAN Unit mode.

See “5.3 Setting the Mode of the CAN Unit”

2 CAN bus settings

Specifies the CAN bus.

See “5.4 Setting the Communication Method of the CAN Unit”

3 CAN Unit setting

Specifies the data refresh interval of the CAN Unit.

See “5.5 CAN Unit Settings”

1 Receive mode☑

Measures a signal flowing in the CAN bus.

See Chapter 6 for setting the channels after setting the CAN Unit.

2 Measured value

Outputs the measured value of the Logger (plug-in module) to the CAN

See Chapter 7 for setting the channels after setting the CAN Unit.

2

2 3 1

1

HIOKI SF1002A961-00

5.2 CAN Unit Setting Items

The configuration of the CAN Unit setting screen is shown below.

5.3 Setting the Mode of the CAN Unit

Select whether to set the CAN Unit in the receive mode or measured value output mode.

The mode can be selected for each CAN Unit. Only the plug-in CAN Unit can be selected in the

measured value output mode. (Wireless units can be set only in the receive mode.)

A signal is output to the CAN bus. The signal can be output while the

CAN signal is measured.

output mode

bus.

23

Page 28

CAN

Sets the CAN mode.

CAN FD☑

Sets the CAN FD mode. (ISO 11898-1:2015 compliant)

CAN FD(non-ISO)

Sets the CAN FD (non-ISO) mode. (not ISO compliant)

The ACK is fixed to ON in this mode.

ON

Sends ACK frame from the CAN controller.

OFF☑

Does not send ACK frame from the CAN controller.

measured value output mode.

ON

Terminates the CAN bus using a 120 Ω resister between CAN_H and

CAN_L.

OFF☑

Opens the CAN bus between CAN_H and CAN_L.

50 k, 62.5 k, 83.3 k, 100 k, 125 k, 250 k, 500 k☑, 800 k, 1000 k (Baud)

50.0% to 95.0%, 80.0%☑

1 2 3 4 5 9 8 6 7

HIOKI SF1002A961-00

5.4 Setting the Communication Method of the CAN Unit

Clicking [Edit] opens the communication settings edit screen.

The settings edit screen is shown below. The ports to be used are set on this screen.

1. Select the interface.

2. Select the ACK.

3. Select the terminator.

4. Select the baud rate.

5. Set the sampling point.

The instrument will not be able to send user frames or operate in

24

Page 29

0.5 M, 1.0 M, 2.0 M☑, 2.5 M, 4.0 M, 5.0 M (Baud)

50.0% to 95.0%, 80.0%☑

HIOKI SF1002A961-00

6. Select the data rate (when the interface is not CAN).

7. Set the data sampling point (only when the interface is not CAN).

8. Sampling point value to be set

For the sampling point, a value that can be set varies depending on the baud rate.

The sampling point that can be set and is the closest to the value input on the edit screen is

displayed.

This value is displayed in 5 “Sampling point”.

9. Data sampling point value to be set

For the data sampling point, a value that can be set varies depending on the data rate.

The data sampling point that can be set and is the closest to the value input on the edit screen is

displayed.

This value is displayed in 7 “Data sampling point”.

25

Page 30

8 double-byte characters, 16 single-byte characters

10 ms, 20 ms, 50 ms, 100 ms☑, 200 ms, 500 ms, 1 s, 2 s, 5 s, 10 s

Data refresh interval

Number of channels that can be measured

10 ms

Up to 50 channels

20 ms

Up to 100 channels

50 ms

Up to 250 channels

100 ms or greater

Up to 500 channels

1

2

HIOKI SF1002A961-00

5.5 CAN Unit Settings

Specifies the data refresh interval of the CAN Unit.

1. The unit identifier set in the Logger is displayed.

2. Select the data refresh interval.

The number of channels that can be measured varies depending on the selected data refresh

interval.

5.6 Copying the CAN Unit Settings

Right-clicking the CAN Unit opens the menu. Clicking [Copy CAN Unit settings] allows you to

copy the CAN Unit settings.

Right-clicking the CAN Unit with the CAN Unit settings copied opens the menu with the settings of

[Paste copied settings] added. Clicking [Paste copied settings] reflects the CAN Unit settings

and receive mode settings. Only the CAN Unit with the check box checked can be copied.

26

Page 31

Switching the display tabs (6.2)

HIOKI SF1002A961-00

6 Setting the Channels (Receive Mode)

The channels of the CAN Unit set in the receive mode are set here.

The CAN Unit in the receive mode can receive CAN signals and sends user frames to the CAN bus.

The procedure for setting the receive mode is shown below.

Checking the entire channel setting screen (6.1)

CAN signal receive settings display

Checking the CAN signal receive screen

(6.3)

Adding a channel

Manually adding a

channel (6.3.1)

As needed

Edit (6.3.1) Delete (6.3.3)

When there are other CAN Unit settings

Importing the

definition from the

file (6.3.2)

User frame output settings display

Checking the user frame output screen

(6.4)

Adding frame output

Add (6.4.1)

Frame settings edit (6.4.2)

When there are no other CAN Unit

Configuring other CAN Unit settings as

well

27

settings

Updating the Logger with the CAN Unit

settings (Chapter 8)

Page 32

1 Display selection tab

Switches the displayed items between CAN data receive and user

See “6.2 Display Selection Tab”

2 Channel settings

Displays the channel settings and processing.

tab.

3 Channel settings list

Displays the list of channel settings.

tab.

1 Receive CAN data

Displays the information required for the CAN data receive settings.

See “6.3 Receive CAN Data”

2 User frame

Displays the information required for the user frame transmission

See “6.4 User Frame Transmission”

1 1 2

2

3

HIOKI SF1002A961-00

6.1 CAN Unit Channel Setting Screen

The configuration of the channel setting screen is shown below.

frame transmission.

The information varies depending on the selected display selection

The information varies depending on the selected display selection

6.2 Display Selection Tab

Receive CAN data and user frame transmission display are switched.

transmission

settings.

28

Page 33

1 Add

Assigns the CAN data receive channels to the CAN Unit.

See “6.3.1 Dialog box for editing CAN signal receive channel”

2 Import

Assign the CAN signal receive channels from the CAN data definition

See “6.3.2 Import dialog box”

3 Receiving size

Displays the total receiving size and maximum receiving size that can be

The receiving size for each channel varies depending on the setting.

4 Delete

Deletes the information of the channels registered in the selected

See “6.3.3 Delete”

5 Channel list

Displays a list of registered channel settings.

See “6.3.4 CAN data receive menu”

6 Use

Measures the registered channels with the check box checked.

7 Ch

For the channels with the [Use] check box checked, the button of the

See “6.3.1 Dialog box for editing CAN signal receive channel”

7

6

1 4 2 3 5

HIOKI SF1002A961-00

6.3 Receive CAN Data

When the “Receive CAN data” tab is selected, the following items are displayed.

See “6.2 Display Selection Tab”

file.

registered of all the channels of the selected CAN Unit.

Channels can be registered up to the maximum receiving size.

The maximum receiving size varies depending on the CAN Unit update

interval.

CAN Unit.

The menu is displayed when the right button of the mouse is clicked.

target channels can be clicked. The settings of the target channels

can be edited.

29

Page 34

Port 1☑

Measures the CAN signals received by Port 1.

Port 2

Measures the CAN signals received by Port 2.

Up to 20 double-byte characters or 40 single-byte characters

Up to 3 double-byte characters or 7 single-byte characters

Data☑

Converts the CAN data to a physical quantity and records the data.

ID count

Counts the number of times the specified ID is received.

The counter is reset to 0 at the data refresh interval.

1 2 3 4 5 6 7 8 9

10

11

12

13

14

15

16

17

20

18

19

HIOKI SF1002A961-00

6.3.1 Dialog box for editing CAN signal receive channel

Clicking [Add] or the [Ch] button for the channel to be edited displays the following dialog box.

The settings that were determined previously after CAN Editor started up are displayed as default

settings.

When there are no previously determined settings, the default value of each item is displayed.

1. Select the port to be measured.

2. Set the comment (as needed).

3. Set the unit.

4. Select the channel type.

30

Page 35

Standard☑

Expresses the ID by 11 bits.

Extended

Expresses the ID by 29 bits.

[Standard] format: 0h☑ to 7FFh, [Extended] format: 0h☑ to 1FFFFFFFh

Motorola☑

Format sending the upper byte first (big endian)

Intel

Format sending the lower byte first (little endian)

Unsigned☑

Unsigned integer type

Signed

Signed integer type

IEEE Float

Single-precision floating-point format

IEEE Double

Double-precision floating-point format

1 to 64, 2☑

0☑ to 511

Factor

Allows you to enter the factor and offset for converting data to a physical

(Default value: Factor 1.0, offset 0.0)

Offset

HIOKI SF1002A961-00

5. Select the ID format.

6. Set the ID.

Set the ID using a hexadecimal number.

7. The value of the set ID is expressed as a decimal number.

8. Select the byte order.

9. Set the data type.

10. Set the length.

When the data type is IEEE Float, the length is fixed to 32.

When the data type is IEEE Double, the length is fixed to 64.

11. Set the start bit.

The setting range varies depending on the byte order and length settings.

12. Set the factor and offset.

quantity.

A physical quantity can be calculated using the following formula.

(Physical quantity) = (Factor) × (Data) + (Offset)

13. Auto (Factor and Offset)

The factor and offset are automatically set so that the measured value can change in the range

from the upper limit to the lower limit.

This is enabled only when the data type is signed and unsigned.

31

Page 36

Upper

Specifies the upper limit of the waveform displayed on the Logger screen.

Default: 1.0

Lower

Specifies the lower limit of the waveform displayed on the Logger screen.

Default: -1.0

0 to 10, 3

Decimal☑

Specifies the number display format of the Logger to a decimal.

Exponent

Specifies the number display format of the Logger to an exponent.

OFF, 24 colors

Confirm

Reflects the settings in the dialog box and closes the dialog box.

Cancel

Discards the settings in the dialog box and closes the dialog box.

HIOKI SF1002A961-00

14. Set the upper and lower limits.

15. Auto (Upper and Lower)

The minimum value is automatically set as the lower limit and the maximum value is automatically

set as the upper limit within the range of the measured value.

16. Select the number of digits.

☑

The number of decimal places for the measured value displayed in the Logger is set.

The default value is 0 when the channel type is ID count.

17. Select the format.

18. Select the display color.

19. Set the threshold value.

The threshold value for numerical calculation is set.

20. Confirm the settings in the dialog box.

32

Page 37

Open

Allows you to select a file.

File available for import

File extension

DBC file*1

.DBC

Logger settings file

.SET

CAN Editor settings file

.CES

Definition file created by MR8904 CAN Editor

.CDF

Port 1

Adds definitions with Port 1 to be used.

Port 2

Adds definitions with Port 2 to be used.

1 2 4 5 9 6 11

10 3 7

8

HIOKI SF1002A961-00

6.3.2 Import dialog box

Clicking [Import] displays the following dialog box.

1. Select the file to be imported.

*1: The Chinese characters code is only available for Shift_JIS.

2. List of import file definitions

A list of definitions existing for the import file is displayed.

Select the definition to be added to the measurement channel.

Clicking the definition while holding down the Ctrl key on the keyboard allows you to select multiple

channels.

3. Import file information

Clicking the item other than No. sorts the definition list of that item.

4. Select the port to be added.

5. Comment

Check the check box to add a definition in the form of “Signal name + Comment” as an import file

definition to the channel comment.

Default: Check box checked

33

Page 38

Data>>

Registers the channel type as data.

ID count>>

Registers the channel type as ID count.

Confirm

Reflects the settings in the dialog box and closes the dialog box.

Cancel

Discards the settings in the dialog box and closes the dialog box.

HIOKI SF1002A961-00

6. Add

Definitions can be dragged from the definition list and dropped to the registered channel list to be

registered as data.

Up to 500 definitions can be registered for one unit.

7. Receiving size

The status of the receiving size registered in the CAN Unit is displayed.

8. Delete

Deletes the information of the channels registered in the selected CAN Unit.

See “6.3.3 Delete”

9. Registered channel list

The information of the imported channels is displayed as a preview.

10. Number of signals

The number of the imported signals is displayed.

11. Confirm the settings in the dialog box.

34

Page 39

Confirm

Deletes the settings in the dialog box and closes the dialog box.

Cancel

Closes the dialog box without deleting the settings.

1 2 3

HIOKI SF1002A961-00

6.3.3 Delete

Selecting this menu displays the following dialog box.

1. Delete selected channels in the unit.

Deletes the selected channels.

2. Delete all channels in the unit.

Deletes all of the channels registered in the unit.

3. Confirm the settings in the dialog box.

35

Page 40

2

3

1

4 5 6

HIOKI SF1002A961-00

6.3.4 CAN data receive menu

The following menu is displayed when the right button of the mouse is clicked in the channel list area.

1 Add

Assigns the CAN data receive channels to the CAN Unit.

See “6.3.1 Dialog box for editing CAN signal receive channel”

2 Replace the selected channel with one above

Replaces the selected channel with one above.

It is enabled when only one channel is selected.

3 Replace the selected channel with one below

Replaces the selected channel with one below.

It is enabled when only one channel is selected.

4 Rearrange channels

Clicking this menu displays a dialog box for rearranging the channels.

See “6.3.5 Rearrange channels”

5 Copy the selected channel settings

Clicking this menu displays a dialog box for copying the selected channel settings.

See “6.3.6 Copy the selected channel settings”

6 Set the display color to standard

Specifies the display color to the standard setting.

Set the display color of the channels with the “Use” check box checked that are registered in the

unit in order of color 1 to 24.

36

Page 41

Ascending order

Rearranges the channels in the ascending order.

Descending

order

Rearranges the channels in the descending order.

Confirm

Rearrange the channels based on the settings in the dialog box

Cancel

Closes the dialog box without rearranging the channels.

1

2

3

4

HIOKI SF1002A961-00

6.3.5 Rearrange channels

The order of the channels registered in the unit is rearranged.

1. Rearrangement condition

Use, Comment, Unit, Port, Ch type, ID, Format, Start bit, Length, Byte order, Value

type, Factor, Offset, Upper, Lower, Digit, Format, Display color, Threshold

Select the conditions for rearrangement.

2. Order

3. Set the display color to standard

Specifies the display color to the standard setting after the order of the channels with the check box

checked is rearranged. Set the display color of the channels with the “Use” check box checked that

are registered in the unit in order of color 1 to 24.

4. Confirm the settings in the dialog box.

37

Page 42

Copy the selected settings to other channels in the same unit.*1

Copy all settings to other channels in the same unit.

Port

Copies the settings to a channel with the same port as that of the channel to

be copied.

Ch type

Copies the settings to a channel with the same channel type as that of the

channel to be copied.

Confirm

Copies the settings in the dialog box and closes the dialog box.

Cancel

Closes the dialog box without copying the settings.

1

2 3 4

5

HIOKI SF1002A961-00

6.3.6 Copy the selected channel settings

The settings of the selected channels are copied to other channels in the unit.

1. Select the settings to be copied.

*1: Any condition settings that cause an error in other channels are not copied.

2. Original

Displays the channel to be copied.

3. Conditions

The condition can be set when [Copy the selected settings to other channels in the same unit]

is selected.

4. Copy items

Copies the settings of the items with the check box checked.

The condition can be set when [Copy the selected settings to other channels in the same unit]

is selected.

5. Confirm the settings in the dialog box.

38

Page 43

1 User frame list

Displays the user frame transmission settings.

See “6.4.3 User frame menu”

2 Use

Outputs the selected frames.

3 User frame No.

[No.] is available when the user frame transmission is enabled.

See “6.4.1 Dialog box for editing user frame transmission”

1

2

3

HIOKI SF1002A961-00

6.4 User Frame Transmission

When the [User frame transmission] tab is selected, the following items are displayed.

See “6.2 Display Selection Tab”

The menu is displayed when the right button of the mouse is clicked.

The user frame settings are configured.

39

Page 44

Port 1☑

Sends a user frame from Port 1.

Port 2

Sends a user frame from Port 2.

Start☑

Starts transmission at the start of measurement.

Stop

Sends only one frame for every condition when measurement is stopped.

Periodic and two or more frames cannot be set.

Start trigger

Starts transmission when a start trigger is set.

Alarm

Starts transmission when an alarm is set.

Manual

Starts transmission when the operation in the Logger CAN frame transmission

See “1.5 Configuring CAN Settings” in Logger Instruction Manual

All ALM☑, ALM1, ALM2, ALM3, ALM4, ALM5, ALM6, ALM7, ALM8

1☑ to 9999

1☑, 2, 3, 4, 5, 6, 7, 8

1 2 4

6 7 9 8 5

3

HIOKI SF1002A961-00

6.4.1 Dialog box for editing user frame transmission

Clicking [No.] displays the following dialog box.

1. Select the port to be used.

2. Timing

dialog box is performed.

3. Target alarm

4. Periodic

Checking the check box repeats transmission periodically after all frames are sent. If the check box

is not checked, all frames are sent only once.

Default: Check box not checked

5. Send interval

This setting is available only when Periodic is ON. The send interval is the set value × 10 ms.

6. Frame

40

Page 45

Confirm

Reflects the settings in the dialog box and closes the dialog box.

Cancel

Discards the settings in the dialog box and closes the dialog box.

HIOKI SF1002A961-00

7. Frame setting list

Only frames for the number of frames set in Frame are displayed.

The menu is displayed when the right button of the mouse is clicked.

See “6.4.4 Frame settings menu”

8. Frame number

Clicking the frame number button opens the frame settings edit dialog box.

See “6.4.2 Frame settings edit dialog box”

9. Confirm the settings in the dialog box.

41

Page 46

CAN Standard☑

Standard ID (0h to 7FFh) CAN frame

CAN Extended

Extended ID (0h to 1FFFFFFFh) CAN frame

CAN FD Standard

Standard ID (0h to 7FFh) CAN FD frame

CAN FD Extended

Extended ID (0h to 1FFFFFFFh) CAN FD frame

[CAN Standard] or [CAN FD Standard] type: 0h☑ to 7FFh

[CAN Extended] or [CAN FD Extended] type: 0h☑ to 1FFFFFFFh

Frame 1: 0☑ to 9999, Frame 2 and subsequent frames: 1☑ to 9999

1 8 9 2 3 4 5 6 7

HIOKI SF1002A961-00

6.4.2 Frame settings edit dialog box

Clicking the frame number in the User frame transmission settings dialog box displays the following

dialog box.

1. Select the type.

2. Set the ID.

Set the ID using a hexadecimal number.

3. The value of the set ID is expressed as a decimal number.

4. Set the delay time.

The delay time is the set value × 10 ms.

42

Page 47

0, 1☑, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15

0h☑ to FFh

Confirm

Reflects the settings in the dialog box and closes the dialog box.

Cancel

Discards the settings in the dialog box and closes the dialog box.

HIOKI SF1002A961-00

5. Select the DLC.

6. The byte size of the data corresponding to the specified DLC is displayed.

7. The data list is displayed. The data can be edited up to the byte length specified in DLC.

8. Set the data.

Set the data using a hexadecimal number one byte at a time.

9. Confirm the settings in the dialog box.

6.4.3 User frame menu

The following menu is displayed when the right button of the mouse is clicked in the user frame list

area.

All settings of the selected condition are copied to other conditions within the same unit.

6.4.4 Frame settings menu

The following menu is displayed when the right button of the mouse is clicked in the frame settings list

area.

All settings of the selected frame are copied to other frames within the same condition.

43

Page 48

Checking the entire CAN Unit channel setting screen (7.1)

Loading the measurement settings (7.2)

Assigning an ID

Assigning an ID individually (7.3)

Assigning an ID all together (7.4)

Load factor (7.7)

As needed

Setting the output

channel (7.5)

Setting the output

port (7.6)

Outputting the measured value as a DBC file (7.9)

HIOKI SF1002A961-00

7 Setting the Channels (Measured Value

Output Mode)

The channel settings of the CAN Unit in the measured value output mode are described.

The CAN Unit in the measured value output mode outputs the measured value of the Logger to the

CAN bus.

The definitions of the specified CAN output can be output as a DBC file.

The procedure for setting the measured value output mode is shown below.

Error (7.8)

44

Page 49

1 Assign ID

Assigns the channel ID.

See “7.4 Assigning an ID All Together”

2 Load factor

Displays the load factor for each port.

See “10.1 Load Factor of the Measured Value Output Mode”

3 Create DBC file

Creates a DBC file.

See “7.9 Outputting the Measured Value as a DBC File”

4 Status message

Displays whether transmission and DBC file output can be

performed.

5 Channel settings list

Displays a list of currently set information.

5 1 2 3 4

HIOKI SF1002A961-00

7.1 Setting the CAN Unit Channels (Measured Value Output Mode)

The configuration of the measured value output mode screen is shown below.

45

Page 50

[Standard] format: 0h☑ to 7FFh, [Extended] format: 0h☑ to 1FFFFFFFh

1 2 3

4

HIOKI SF1002A961-00

7.2 Loading the Measurement Settings

The measurement settings can be loaded in two ways: Selecting the settings file by clicking 2 [Open]

in 4.2 and receiving the settings file by communicating with the Logger by clicking 3 [Receive] in 4.3.

When the loading has been completed, the measurement channel list is displayed as shown below.

7.3 Assigning an ID Individually

Clicking [Edit] in the channel settings list displays a dialog box for editing channels.

1. Change the output status.

2. Change the output port.

3. Change the format.

4. Set the ID.

Set the ID using a hexadecimal number.

46

Page 51

[Standard] format: 0h☑ to 7FFh, [Extended] format: 0h☑ to 1FFFFFFFh

1 2 3 4 5 6 7

HIOKI SF1002A961-00

7.4 Assigning an ID All Together

Clicking [Assign ID] displays a dialog box for assigning an ID all together.

1. Select the unit to which an ID is to be assigned.

An ID is assigned to the units with the check box checked. An ID may not be assigned to some

channels depending on the anticipated load factor. Start assigning the ID with Unit 1.

2. Assign an ID to only channels in the output status only.

An ID is assigned only to the channels in the output status before the dialog box opens. For the

output status, see 7.3 and 7.5. An ID may not be assigned to some channels depending on the

anticipated load factor. Start assigning the ID with Unit 1.

3. Select the output port.

Select the port to be used for output. After [Confirm] is clicked, the channels to which an ID is to

be assigned are set to the selected port.

4. Select the format.

Select the format. The selected format is applied to all IDs to assign.

5. Set the start ID.

Set the ID using a hexadecimal number. The ID specified here is assigned by sequence.

6. Select grouping.

Checking the [Enabled] check box assigns multiple output channels to one ID.

Unchecking the [Enabled] check box assigns one output channel to one ID.

47

Page 52

HIOKI SF1002A961-00

7. Display the preview.

According to the settings from 1 to 6, the number of channels to which an ID is to be assigned for

each unit is displayed. The anticipated load factor is also displayed. Clicking [Confirm] actually

assigns an ID.

7.5 Selecting the Channel to be Output

Checking the [Output] check box can output the channel. The channels with the check box checked

are to be output.

In addition to selecting the check box, select channels for which the output status is to be changed

and right-click to display the menu to change the output status.

7.6 Selecting the Output Port

Checking the [Port 1] and/or [Port 2] check box allows you to select which port to be used for output.

In addition to selecting the check box, select channels for which the output status is to be changed

and right-click to display the menu to change the output status.

7.7 Load Factor

When the ID is set, the load factor of the CAN bus is displayed for each port.

Set the output channel so that the load factor does not exceed 90% for each port.

See “10.1 Load Factor of the Measured Value Output Mode”

48

Page 53

HIOKI SF1002A961-00

7.8 Error

In the following conditions, a DBC file cannot be created or settings cannot be sent to the Logger unit.

1. When the interface is set to CAN, five or more of the same ID are used in the same unit or

port.

When the interface is set to CAN, an error occurs under this condition since up to four sets of

measured value information can be included in one frame.

2. The same ID is used in multiple units and the same port.

3. The load factor is over 90%.

7.9 Outputting the Measured Value as a DBC File

Clicking [Create DBC] can output the measured value output settings as a DBC file. Clicking [Create

DBC] displays a dialog box.

Enter a name under the folder to be saved and click [Save] to create a DBC file. When any of the

errors in 7.8 occurs, a DBC file cannot be output.

49

Page 54

Sending the settings from the PC (8.1)

Loading the settings file to the Logger (8.2)

When a connected

(8.1.1)

When no connected

Preparing media to save the settings

Saving the CES file to the media (8.2.2)

Removing the media (8.2.3)

Connecting the media to the Logger

Logger side

Loading the CES file

Starting measurement

HIOKI SF1002A961-00

8 Updating the Logger with CAN

Settings

The Logger is updated with the information set using CAN Editor.

The operating procedure is shown below.

Logger already exists

Logger exists (8.1.2)

(8.2.1)

50

Page 55

1

2

HIOKI SF1002A961-00

8.1 Sending the Settings from the PC

8.1.1 When there is a connected Logger

1 Check the connected Logger.

2 Click [Send].

The procedure is complete when the [Success] message is displayed. When the location within the

application at which the CAN Unit is registered is different from the location of the Logger at which the

CAN Unit is connected, the settings cannot be sent. If there are units that are set in the measured

value output mode, the settings are sent only when information of all the units is consistent.

8.1.2 When there is no connected Logger

Prepare a Logger according to 3.1.2 and register the Logger according to 4.3.1.

Refer to 8.1.1 to send the settings after registering the Logger.

8.1.3 When the Logger is busy

When the Logger is busy during measurement, file processing, or monitoring, the settings cannot be

sent.

The busy state needs to be resolved.

8.1.4 When the settings that do not allow measurement to start are sent

Measurement may not be performed depending on the combination of the recording interval, save

format, and number of channels to be measured.

When the settings that do not allow measurement are sent, a warning dialog box is displayed. The

settings need to be sent again after they are optimized.

51

Page 56

3 1 1

2

HIOKI SF1002A961-00

8.2 Loading the Settings File to the Logger

8.2.1 Preparing media to be used

Prepare media (SD memory card, USB flash drive, etc.) to be used to save the settings file (CES file).

Using Hioki genuine media compatible with the Logger is recommended.

8.2.2 Saving the settings file onto the media

1 Click [Save] in the CAN Editor main screen.

In the dialog box, set the prepared media as a saving destination and name and save the file.

8.2.3 Removing the media

1 Display the indicator on the Windows® screen.

2 Right-click the target media.

The list is displayed.

Select [Eject].

3

8.2.4 Loading the CES file to the Logger

Connect the media to the Logger.

Setting the CAN is completed only by loading the settings file (CES file).

See “3.4 Loading Data” in Logger Instruction Manual

52

Page 57

Operating environment

OS: Windows 10 (32 bits/64 bits) / Windows 11 (64 bits)

the execution environment must be installed.

Interface

LAN / USB

Applicable language

Japanese / English / Simplified Chinese

Applicable measuring

instrument

HIOKI LR8450 / LR8450-01 Memory HiLogger

Unit position

Unit 1 to Unit 4

Wireless Unit 1 to Wireless Unit 7

CAN interface setting

Interface

ACK

Unit operating mode

The receive mode and measured value output mode can be changed for each unit.

Update interval

10 ms, 20 ms, 50 ms, 100 ms, 200 ms, 500 ms, 1 s, 2 s, 5 s, 10 s

Receiving channel

CAN input port setting

Port 1 / Port 2

Ch type

Data / ID count

Common settings

1. Format: Standard / Extended

5. Factor, Offset

Ch type:

1. Start bit: 0 to 511

4. Value type: Unsigned / Signed/ IEEE Float/ IEEE Double

LR8450 display

1. Display upper limit / Display lower limit

4. Color

User frame

Send condition number

No. 1 to No. 8

CAN output port

setting

Port 1 / Port 2

Frame

1 to 8 frames

Scheduled send

setting

ON / OFF

Scheduled send

interval

1 to 9999 (× 10 [ms])

Timing

Start

Manual

Frame type

CAN Standard / CAN Extended / CAN FD Standard / CAN

FD Extended

Send ID

0 h to 1FFFFFFF h

DLC (byte)

0 to 15 (0 to 8/12/16/20/24/32/48/64)

Sent data

Set send data using a hexadecimal number.

Delay

0 to 9999 (× 10 [ms])

HIOKI SF1002A961-00

9 Specifications

1. Basic Specifications

CPU: 1.0 GHz or faster 32 bit (x86) or 64 bit (x64) processor

Memory: 2 GB or more

Display: 1280 × 1024 dots or more, 65,536 colors or more

Hard disk: 3.0 GB or more of available space

.NET Framework: Microsoft .NET Framework 4.6 and a language pack applicable for

Terminator

Baud rate

Data rate

Sampling point

Data sampling point

2. Receive mode

definition settings

transmission settings

Data

settings

2. ID: 0 h to 1FFFFFFF h

3. Comment

4. Unit

2. Length: 1 to 64 [bit]

3. Byte order: Motorola / Intel

2. Number of display digits, display format

3. Numerical calculation threshold

Stop

Start trigger

Alarm

53

Page 58

Measured value output

CAN output port setting

Port 1 / Port 2

Frame type

Standard / Extended

Send ID

0 h to 1FFFFFFF h

Sent data

The measured values of the following units can be set as

U8550, U8551, U8552, U8553, U8554

CAN bus load factor

estimate function

Displays the CAN bus load factor when the measured value is output in the current

send settings.

Save function

1. CANdb file (.dbc) for send data defined in the measured value output mode settings

2. Entire settings data (.CES) of CAN Editor

Read function

1. Reads the CANdb file (.dbc) and MR8904 definition file (.CDF) to be used for

the entire settings of CAN Editor.

Title

Up to 50 single-byte characters or 25 double-byte characters can be used to set the

title in the settings data (.CES).

HIOKI SF1002A961-00

3. Measured value output mode settings

settings

4. File specifications

setting receiving channels.

2. Reads the LR8450 settings (.SET)/CAN Editor settings (.CES) to be reflected on

data to be output.

54

Page 59

Parameter

Example/Recommended parameter

Interface

CAN FD

Baud rate

1M baud

Data rate

5M baud

ID

Standard

Parameter

Setting example

Update interval of the output source unit

1 ms

Number of output channels of the output source unit

15 channels (U8553 × 3 units)

Correlation between output channels of the output

source unit and IDs

HIOKI SF1002A961-00

10 Knowledge and Information

10.1 Load Factor of the Measured Value Output Mode

The load factor is a ratio of the current number of frames of CAN Editor to the number of frames that

can be transmitted on the CAN bus.

It is expressed by “Number of frames to be transmitted on the CAN bus / Number of frames that can

be transmitted on the CAN bus × 100”.

Set the load factor to be approximately 50%.

The load factor indicates a value for when only CAN frames that are output from the CAN Unit exist on

the CAN bus. The load factor may drop if there is CAN output from other equipment or an error occurs

in the CAN bus.

10.1.1 Number of frames that can be transmitted on the CAN bus

It is calculated from the interface, baud rate, data rate, and ID (standard/extended).

Example:

The number of frames that can be transmitted on the CAN bus in the above example is approximately

24,000 [frame/s].

10.1.2 Data volume to be transmitted on the CAN bus

The data volume is affected by the update interval of the output source unit, number of output

channels, and correlation between the output channels and IDs.

Example:

One output channel assigned to one ID

The number of frames to be transmitted on the CAN bus in the above example is approximately

15,000 [frame/s].

The load factor is approximately 62.5% (15,000/24,000).

55

Page 60

Signal on the CAN bus

CAN Unit data refresh interval

Signal on the CAN bus

CAN Unit data refresh interval

HIOKI SF1002A961-00

10.2 Channel Type of the Receive Mode

10.2.1 When the channel type is set to Data

When Data is selected as the channel type for the receive mode, the data of the specified

requirements is collected upon the start of CAN Unit recording and the received data is recorded until

the sampling time is expired. If data is not received at all, 0 is recorded. Unlike ID count, the data

value is not received at the data refresh interval. If data of the same conditions is received twice or

more within the single data refresh interval, the most recent data is reflected on the recorded value.

The example of data of ID 1 and ID 2 is shown below.

For ID 1, data “C” is received within the data refresh interval after data “A”, however, only data “C” is

recorded in the LR8450 unit.

Data

(ID:1)

Data

(ID:2)

10.2.2 When the channel type is set to ID count

When ID count is selected as the channel type for the receive mode, the number of times the

specified ID is received at every data refresh interval for the CAN Unit is recorded. When the data

refresh interval is set to 2 seconds or more, the ID count may become 0 since the time period over the

specified data refresh interval cannot be secured before the first sample after the start of

measurement.

The example of ID count of ID 1 and ID 2 is shown below.

The number of times the specified ID is received within a certain time period can be checked and

recorded depending on the ID count value.

The counter is reset to 0 at every data refresh interval for the CAN Unit.

ID count

(ID:1)

ID count

(ID:2)

56

Page 61

HIOKI SF1002A961-00

10.2.3 Examples of usage

(1) Using the specific ID received as a trigger or warning

The measured value of the measurement channel for which a channel type ID count has been

performed can be set as a trigger/warning source like normal measurement channels. The measured

value can be used to output signals to external equipment as a trigger for measurement start or

warning when the specific ID is received.

(2) Checking the data update on the CAN bus

When the channel type is set to Data, the final data received after recording starts is retained until the

measurement is stopped. Therefore, it is difficult to distinguish a case in which CAN data is

continuously received when CAN communication is stopped in the middle. When ID count is also

used, the above case can be distinguished based on the ID count receiving count.

10.3 User Frame Transmission Operation

10.3.1 Relationship between user frame No. and number of frames

For user frame transmission, CAN frames of up to 64 conditions by combinations of the user frame

No. and the number of frames can be output. The transmission order of each frame is as follows.

(1) When 8 frames are set for user frame No. 1

After frame 1 is sent, frame 2 and other frames up to frame 8 are sent in the same manner.

At least a 10 ms delay is required between the frames.

(2) When 1 frame is set for user frames No. 1 to No. 8

After user frame No. 1 is sent, user frame No. 2 and other frames up to user frame No. 8 are sent in

the same manner.

When the delay is set to 0 ms, the user frames are sent without any delay.

10.3.2 Relationship between scheduled send ON and number of frames

When the scheduled send setting is ON, all frames set in the user frame No. are sent and then the

frames are repeatedly sent at the same condition according to the send interval setting.

(1) When schedule send is ON and 1 frame is set

One set frame is sent periodically at the send interval.

(2) When schedule send is ON and 8 frame is set

After frame 1 is sent, frame 2 and other frames up to frame 8 are sent in the same manner.

After the time set for the send interval has elapsed, the frames are sent starting with frame 1.

10.3.3 Output stop conditions

When the timing is not set to Stop, transmission of user frames of all conditions is stopped when

measurement of LR8450 (-01) is stopped.

When the timing is set to Stop, one frame is sent for each user frame No. and transmission of user

frames is stopped.

57

Page 62

MSB LSB

End

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

7 6 5 4 3 2 1

0

Byte 1

15

14

13

12

11

10 9 8

Byte 2

23

22

21

20

19

18

17

16

Byte 3

31

30

29

28

27

26

25

24

Byte 4

39

38

37

36

35

34

33

32

Byte 5

47

46

45

44

43

42

41

40

Byte 6

55

54

53

52

51

50

49

48

Byte 7

63

62

61

60

59

58

57

56

Data frame top Data frame end

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 ……

HIOKI SF1002A961-00

10.4 Counting the Bit Position

In the data frame, the position of the lowest bit (LSB) of the start byte data is 0. The value increases

one by one towards the highest bit (MSB) position.

When the bit position reaches MSB, it moves onto the next byte data and the value increases one by

one from the LSB position to the MSB position like the first byte (bite 0).

The data frame size is a maximum of 64 bytes (512 bits).

Top

How to calculate the data start position ([Start bit])

When 8 bit data of the second byte (byte 1) is to be captured, the LSB value is 8.

LSB at this position The value is

8 based on the above table.

Byte 0

(First byte)

Byte 1

(Second byte)

Byte 2

(Fourth byte)

Byte 3

(Second byte)

58

Page 63

MSB: 9

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

7 6 5 4 3 2 1 0 Byte 1

15

14

13

12

11

10 9 8

Byte 2

23

22

21

20

19

18

17

16

Byte 3

31

30

29

28

27

26

25

24

MSB: 25

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

Byte 0

7 6 5 4 3 2 1 0 Byte 1

15

14

13

12

11

10 9 8

Byte 2

23

22

21

20

19

18

17

16

Byte 3

31

30

29

28

27

26

25

24

Data frame top Data frame end

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0 7 6 5 4 ……

HIOKI SF1002A961-00

Data arrangement ([Byte order])

Even when the data start position ([Start bit]) is the same as the bit length ([Length]), the data

position (eject) varies depending on the data arrangement set by Motorola or Intel.

When the bit length is set to 10 bits and the data start position (LSB position) is set to bit 16, the data

in the blue colored cells of the following tables is captured.

Motorola

Intel

For the following 16 bit data, when the value of byte 0 is FF and the value of byte 1 is 00, the 16 bit

data is as follows.

Motorola: FF00 (Data start position: 8)

Intel: 00FF (Data start position: 0)

Byte 0

(First byte)

Byte 1

(Second byte)

Byte 2

(Fourth byte)

Byte 3

(Second byte)

59

Page 64

No.

Message

Troubleshooting

HIOKI SF1002A961-00

10.5 Error and Warning Messages

This section describes troubleshooting for when error and warning messages are displayed.

10.5.1 Error message list

100 Connection cannot be established. Check that the PC and Logger are properly

connected and the IP address and port No. are

correct.

200 Data cannot be sent. The unit configuration is not

the same for the Logger and PC.

201 Data cannot be sent. There is an error in the unit

in the measured value output mode.

202 Sending has failed. Check that the PC and Logger are properly

206 COM port error Check that the PC and Logger are properly

211 Receiving has failed. Check that the PC and Logger are properly

212 The Logger version needs to be updated. Check that the Logger has been updated to the

301 Invalid file Select the DBC file.

302 The application cannot be found. Uninstall CAN Editor and then install it again.

303 No more channels can be added. Delete existing channels to add a new channel.

Check that the unit configuration is the same for

the PC application and Logger.

Dissolve the error in the unit in the measured

value output mode.

connected.

connected.

connected.

latest version.

The file may be corrupted.

305 The definition cannot be imported. There are

settings with the factor value being 0.

500 A DBC file cannot be created due to an error. Dissolve the error in the unit in the measured

601 CAN Editor is already running. CAN Editor cannot be started if it is already

701 There is no access right to the specified location. Specify an accessible location.

702 The specified file location is invalid. Set the file save and load locations correctly.

703 The file cannot be loaded. The file format is not

supported.

704 File access has failed. If the specified file is opened on another

Specify a definition with the factor that is not 0.

value output mode.

running.

Check that the Logger and CAN Editor have

been updated to the latest version.

The file may be corrupted.

application, close the file.

Check that the file is not write-protected.

60

Page 65

No.

Message

Troubleshooting

HIOKI SF1002A961-00

705 The available storage capacity is low. Delete unnecessary files or use new media.

706 File processing has failed. Check that the storage media of the saving

destination is not damaged or the file is not

corrupted.

707 An unexpected error occurred. The settings may

be corrupt.

10.5.2 Warning message list

101 The port number is invalid. The effective range is as follows.

102 No Logger is selected. Select the Logger to be connected and then click

203 Sending may have failed. Resend.

208 When the Logger is busy during measurement,

file processing, or monitoring, the settings data

cannot be transmitted.

209 The recording interval, save format, and

The settings may be corrupt.

Perform an initialization, and then reconfigure

the settings.

LAN: 1020 to 65535

USB: 1 to 999

[Register].

Send the settings when the Logger is not busy.

Lower the recording interval, change the save

measurement ON count need to be optimized.

210 The registration information of the CAN Unit is

incorrect.

304 It is enabled when the selection target is 1. Set the number of selection targets to 1

501 A DBC file is not created when the number of

output channels is 0.

600 Another unit is set in the measured value output

mode. Only one CAN Unit be set in the

measured value output mode.