Page 1

Instruction Manual

RM3545

RM3545-01

RM3545-02

RESISTANCE METER

October 2013 Revised edition 1 RM3545A981-01 13-10H

Page 2

Page 3

Using This Instruction Manual

To do this… Refer to these sections in t his m anual.

Review important

information

Start using the instrument right away

Learn more about

instrument functions

Learn more about

product specifications

Troubleshoot a problem

Learn more about

resist ance measure ment

Learn more about

communicat i o ns commands

Safety Informati o n (p.4)

Operating Precautions (p.6)

Overview (p.19)

Search for the function in question in the table

of contents (p.i) or the index (p.Index 1).

Specifications (p. 251)

Troubleshooting (p. 286)

Appendix (p . A1)

Communications Command Instruction Manual

(on the application di sc)

Page 4

Page 5

Contents

Introduction.....................................................1

Verifying Package Contents...........................2

Safety Information..........................................4

Operating Precautions......... ..... ...... ..... ...........6

Chapter 1 Overview 19

1.1 Product Overview and Features ........19

1.2 Names and Functions of Parts ...........22

1.3 Measurement Process .......................25

1.4 Screen Organization and

Operation Overview ...........................27

1.5 Checking the Measurement Target ....33

Chapter 2 Measurement

Preparations 35

2.1 Connecting the Power Cord............... 35

2.2 Connecting Measurement Leads .......36

2.3 Connecting Z2001 Temperature Sensor

or Thermometer with Analog Output

(When using the TC or T) ................37

Connecting the Z2001 Temperature Sensor

...................................................................37

Conn ect i ng an Anal o g Outp ut Th er mo meter

...................................................................39

2.4 Installing the Multiplexer Unit .............42

2.5 Turning the Power On and Off ...........43

Turning On the Instrument with the

Main Power Switch ...................................43

Turning Off the Instrument with the

Main Power Switch ...................................43

Canceling the Standby State ....................43

Placing the Instrument in the Standby State

......................... ....................... .................. 44

2.6 Pre-Operation Inspection ...................45

Chapter 3 Basic Measurements

47

3.1 Checking the Measurement Target ....48

3.2 Selecting the Measurement Range ....49

Contents

3.3 Setting the Measurement Speed ........50

3.4 Connecting Measurement Leads to the

Measurement Target ..........................51

3.5 Checking Measured Values ...............52

Switching the Display ............................... 52

Confirming Measurement Faults .............. 55

Holding Measured Values ........................ 60

Chapter 4 Cu stom iz ing

Measurement

Conditions 63

4.1 Switching to Low-power Resi stance

Measurement .....................................64

4.2 Switching Measurem en t Curre nts

(100 m to 100 ) ..............................66

4.3 Zero Adjustment .................................68

4.4 Stabilizing Measured Values

(Averaging Function) ..........................73

4.5 Correcting for the Effect s of Temper atur e

(Temperatu re Correction (TC)) ...........75

4.6 Correcting Measured Values and

Displaying Physical Properties Other

than Resistance Values

(Scaling Function) ..............................77

4.7 Changing the Number of Measured

Value Digits ........................................81

4.8 Compensating for Thermal EMF Of fset

(Offset Voltage Compensation - OVC)

...........................................................82

4.9 Setting Pre-Measurement Delay ........84

4.10 Checking for Poor or Improper Contact

(Contact Check Function) ...................88

4.11 Improving Probe Contact

(Contact Improver Function) ...............90

4.12 Maintaining Measurement Precision

(Self-Calibration) ................................92

4.13 Increasing the Precision of the 100 M

Range (100 M High-precision Mode)

...........................................................96

i

1

2

3

4

Page 6

ii

Contents

Chapter 5 Judgment, Statistics,

and Conversion

Functions 97

5.1 Judging Measured Valu es

(Comparator Function) .......................98

Enabling and Disabli ng the Compa ra t or

Function ................ ................................. 100

Decide According to Upper/Lower

Thresholds (ABS Mode) .................... ..... 101

Decide According to Reference Value and

Tolerance (REF% Mode) ....................... 103

Checking Judgments Using Sound

(Judgment Sound Setting Function) ...... 105

Checking Judgments with the L2105 LED

Comparator Attachment (Option) ........... 107

5.2 Classifying Measurement Results

(BIN Measurement Function) ...........108

5.3 Performing Statist ica l Calcu l ati on s on

Measured Values .............................111

Using Statistical Calculations ................. 112

Confirming, Printing, and Erasing

Calculation Results ................................ 114

5.4 Performing Temperature Rise Test

(Temperat ure Conversion Function (T))

..........................................................116

Chapter 6 Saving and Loading

Panels (Saving and

Loading Measurement Conditions)

119

6.1 Saving Measurement Conditions

(Panel Save Function) ......................120

6.2 Loading Measurement Conditions

(Panel Load Function) ......................121

Preventing Loading of Zero-adjustment

Values ........................ ............................ 122

6.3 Changing Panel Names ...................123

6.4 Deleting Panel Data .........................124

Disabling Key Operations

(Key-Lock Function) ... .... ..... ..... .............. 126

Re-Enabling Key Operations

(Key-Lock Cancel) .................................. 127

7.2 Ena bling or Disabling the Key Beeper

......................................................... 128

7.3 Power Line Frequency Manual Setting

......................................................... 129

7.4 Adjusting Screen Contrast ............... 131

7.5 Adjusting the Backlight ........... ...... ...132

7.6 Setting the Clock ..............................133

7.7 Initializing (Reset) ............................134

Default Settings ...................................... 136

Chapter 8 Multiplexer 139

8.1 About the Multiplexer .......................140

Connector Type and Pinouts .................. 143

About multiplexer wiring ......................... 145

8.2 Internal Circuitry ............................ ...146

Electrical Specifications ......................... 147

8.3 Multiplexer Settings ......................... 148

Configuring Multiplexer Settings ............148

Customizing Channel Pin Allocation ......152

Setting Basic Measurement Conditions and

Total Judgment Conditions for Individual

Channels ........................ ........................ 156

Customizing Measurement Conditions for

Individual Channels ................................ 160

8.4 Measuring with the Multiplexer ........ 161

Measuring While Switching Channels

Manually ................ ........................ ......... 161

Performing Scan Measurement ............. 162

8.5 Zero Adjustment

(When a Multiplexer Unit Has Been

Installed) .......................................... 163

Performing zero-adjustment ................... 163

Canceling zero-adjustment .................... 164

8.6 Performing the Multiplexer Unit

Test ..................................................166

8.7 Example Connections and Settings

......................................................... 168

Chapter 7 System Settings 125

7.1 Disabling and Enabling Key Operations

.........................................................126

Chapter 9 D/A Output 175

9.1 Connecting D/A Output ....................175

9.2 D/A Output Specifications ................176

Page 7

Chapter 10External Control

(EXT I/O) 177

10.1 External Input/Output Connecto r

and Signals...................................... 178

Switching between Current Sink (NPN) and

Current Source (PNP) .............................178

Conn ect or Typ e and Signal Pino ut s .......179

Signal Descriptions .................................181

10.2 Timing Chart .................................... 187

From Start of Measurement to Acquisition

of Judgment Results ...............................187

BCD Signal Timing .................................191

Zero-adjustment timing ...........................192

Self-calibration timing .............................193

Cont act imp rov er timin g .......... ..... ...........196

Panel Load Timing ..................................197

Mult iplex er Tim ing ........................ ..... ......198

Output Signal State at Power-On ...........201

Acquisition Process When Using an

External Trigger ..................................... .202

10.3 Internal Circuitry ...............................204

Electrical Specifications ..........................206

Connection Examples .................. ..... ..... .207

10.4 External I/O Settings ........................208

Setting Measurement Start Conditions

(Trigger Source) ......................................208

Setting the TRIG Signal Logic ................210

Eliminating TRIG/PRINT Signal Chatter

(Filter Function) .... ..... ..... ......................... 21 2

Setting EOM Signal ................................214

Switching Output Modes

(JUDGE Mode/ BCD Mode) ....................216

10.5 Checking External Control ...............217

Performing an I/O Test

(EXT I/O Test Function) .................... ..... .217

10.6 Supplied Connector Assembly .........219

Chapter 11Communications

(USB/ RS-232C/

GP-IB Interface) 221

11.1 Overview and Features ....................221

Specif ications ....... ............... .............. ...... 222

11.2 Preparations before Use

(Connections and Settings) ..............223

Using the USB Interface .........................223

Using the RS-232C Interface ..................226

iii

Contents

Using the GP-IB Interface

(RM3545-01 only) .................................. 230

11.3 Controlling the Instrument with

Commands and Acquiring Data .......232

Remo te and Local S tate s .... .... ............... 232

Displaying Communications Commands

(Communications Monitor Function) ...... 233

Acquiring Measured Values at Once

(Data Memory Function) ........................ 235

11.4 Auto-Exporting Measured Values

(at End of Measurement)

(Data Output Function) .....................236

Chapter 12Printing (Using an

RS-232C Printer) 239

12.1 Connecting the Printer to the Instrument

..........................................................239

12.2 Printing .............................................242

Printing Measured Values and Comparator

Judgments ............................................. 242

Printing List of Measurement Conditions

and Settings ........................................... 243

Printing Statistical Calculation Results ... 247

Chapter 13Specifications 251

13.1 Instrument Specifications .................251

Measurement Ranges ............................ 251

Measurement Method ............................ 251

Measurement Specifications .................. 252

About Instrument Accuracy .................... 259

Functions ............................................... 260

Inte rface .............................. ................... 271

Environment and Safety Specifications . 278

Acce sso ries . ..... ................................. ..... 278

O ptions ........ ......... ..... .......... ......... .......... 278

13.2 Z3003 Multiplexer Unit .....................279

General Specifications ........................... 279

Measurement Specifications .................. 281

About Instrument Accuracy .................... 282

Functions ............................................... 283

Environment and Safety Specifications . 283

Acce sso ries . ..... ................................. ..... 283

13

14

5

6

7

8

9

10

11

12

12

Appendix

Index

Page 8

iv

Contents

Chapter 14 Maintenance and

Service 285

14.1 Troubleshooting ................................286

Q&A (Frequently Asked Questions) ....... 286

Error Displays and Remedies ................ 298

14.2 Replacing the Measurement Circuit’s

Protective Fuse ................................302

14.3 Inspection and Repair ......................303

14.4 Disposing of the Instrument ..............304

Removing the Lithium Battery ................ 304

Appendix A 1

Appendix 1Block Diagram..........................A 1

Appendix 2Four-Terminal (Voltage-Drop)

Method..................................... A 2

Appendix 3DC and AC Measurement........A 3

Appendix 4 Temperature Correction (TC)

Function...................................A 4

Appendix 5Temperature Conversion (T)

Function...................................A 6

Appendix 6Zero Adjustment.......................A 7

Appendix 7Unstable Measured Values.... A 12

Appendix 8Mitigating Noise .....................A 19

Appendix 9Effect of Thermal EMF........... A 23

Appendix 10Detecting the Location of a Short

on a Printed Circuit Board......A 25

Appendix 11Measuring Contact Resistance

............................. ..................A 26

Appendix 12JEC 2137 Induction Machine-

compliant Resistance Measure-

ment.......................................A 28

Appendix 13Making Your Own Measurement

Leads, Making Connections to the

Multiplexer..............................A 29

Appendix 14Checking Measurement Faults

............................. ..................A 32

Appendix 15Using the Instrument with a

Withstanding Voltage Tester.. A 33

Appendix 16Measurement Leads (Options)

............................. ..................A 34

Appendix 17Rack Mounting......................A 35

Appendix 18Outline Drawing....................A 37

Appendix 19Calibration............................A 38

Appendix 20Adjustment Procedure..........A 43

Appendix 21Instrument Settings (Memo)..A 44

Index Index 1

Page 9

Introduction

Introduction

Thank you for purchasing the HIOKI Model RM3545/ RM3545-01/ RM3545-02 Resistance

Meter. To obtain maximum performance from the instrument, please read this manual first,

and keep it handy for future reference.

Model RM3545-01 is the same as the RM3545, but with GP-IB included.

Model RM3545-02 is the same as the RM3545, but Multiplexer Slot included.

Registered tradem ar ks

Windows is a registered trademark of Microsoft Corporation in the United States and/or

other countries.

1

Page 10

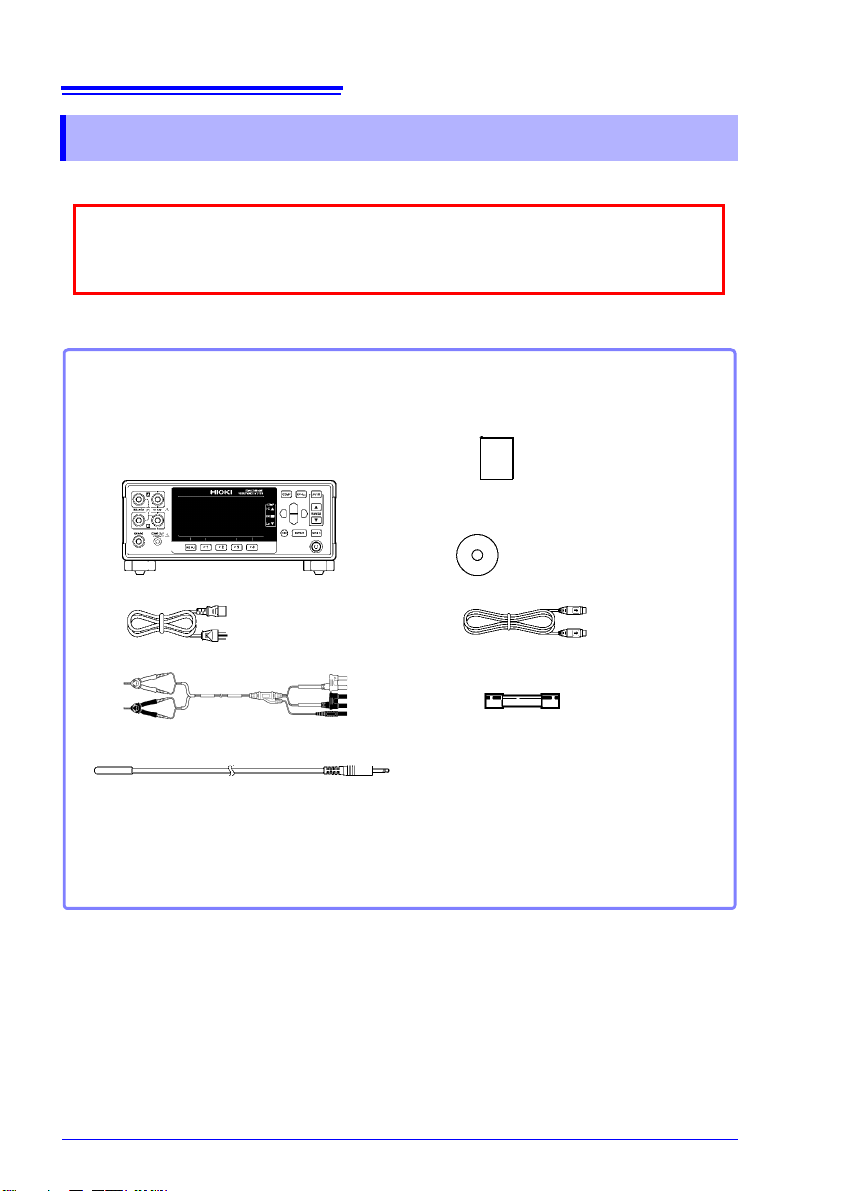

2

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate according to the specifications, contact your authorized Hioki distributor or reseller.

Confirm that these contents are provided.

Model RM3545 or

RM3545-01 (with GP-IB included) or

RM3545-02 (with Multiplexer

Slot included)..1

Power Cord (2-line + ground) (p. 35).............1

Model L2101 Clip Type Lead .........................1

Model Z2001 Temperature Sensor ................1

EXT I/O Male Connector (p. 219)...................1

Instruction Manual (This document)... 1

Application disc (CD)*........................1

(Communications Command

Instruction Ma nual, USB dr iver )

USB cable (A-B type).........................1

Spare Fuse (F1.6AH/250V) ...............1

* The latest version of the application disc can be downloaded from the Hioki web site.

Verifying Package Contents

Verifying Package Contents

Inspection

Content confirmation

Page 11

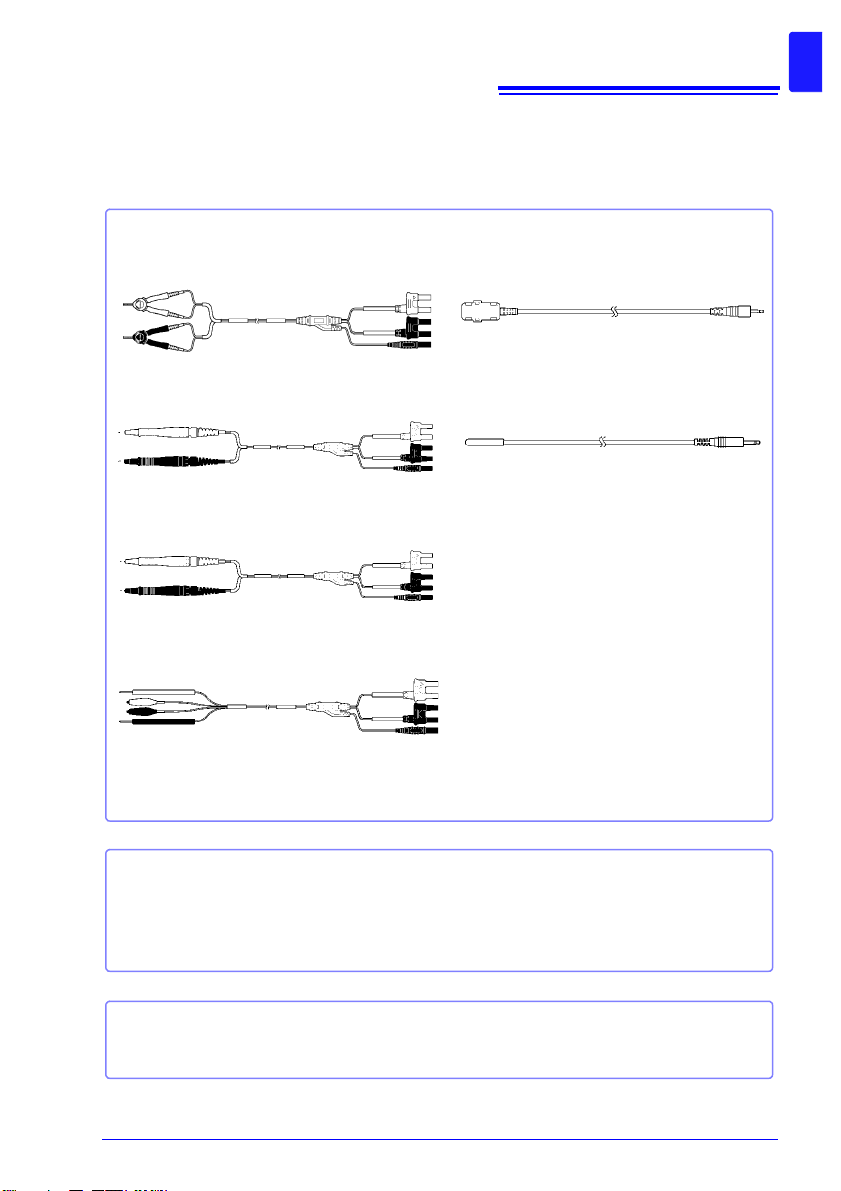

Options

Measurement

Model L2101 Clip Type Lead

Model L2102 Pin Type Lead

Model L2103 Pin Type Lead

Model L2104 4-Terminal Lead

Interface Cables

Model 9637 RS-232C Cable (9pin-9pin/ 1.8 m/ crossover cable)

Model 9638 RS-232C Cable (9pin-25pin/ 1.8 m/ crossover cable)

Model 9151-02 GP-IB Connector Cable (2 m)

Model L2105 LED Comparator Attachment

Model Z2001 Temperature Sensor

Multiplexer Unit

Model Z3003 Multi pl exer Unit

Contact your authorized Hioki distributor or reseller for details.

See: "Appendix 16 Measurement Leads (Options)" (p. A34)

3

Verifying Package Contents

Page 12

4

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested for safety prior to shipment.

However, using the instrument in a way not described in this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

Mishandling during use could result in injury or death, as well as damage to the product. Be certain that you understand the instructions and

precautions in the manual before use.

With regard to the electricity supply, there are risks of electric shock,

heat generation, fire, and arc discharge due to short circuits. If per sons

unfamiliar with electricity measuring instruments are to use the product, another person familiar with such instruments must supervise

operations.

This manual contains information and warnings essential for safe operation of the instrument and for maintaining it in safe operating condition. Before using it, be sure to carefully

read the following safety precautions.

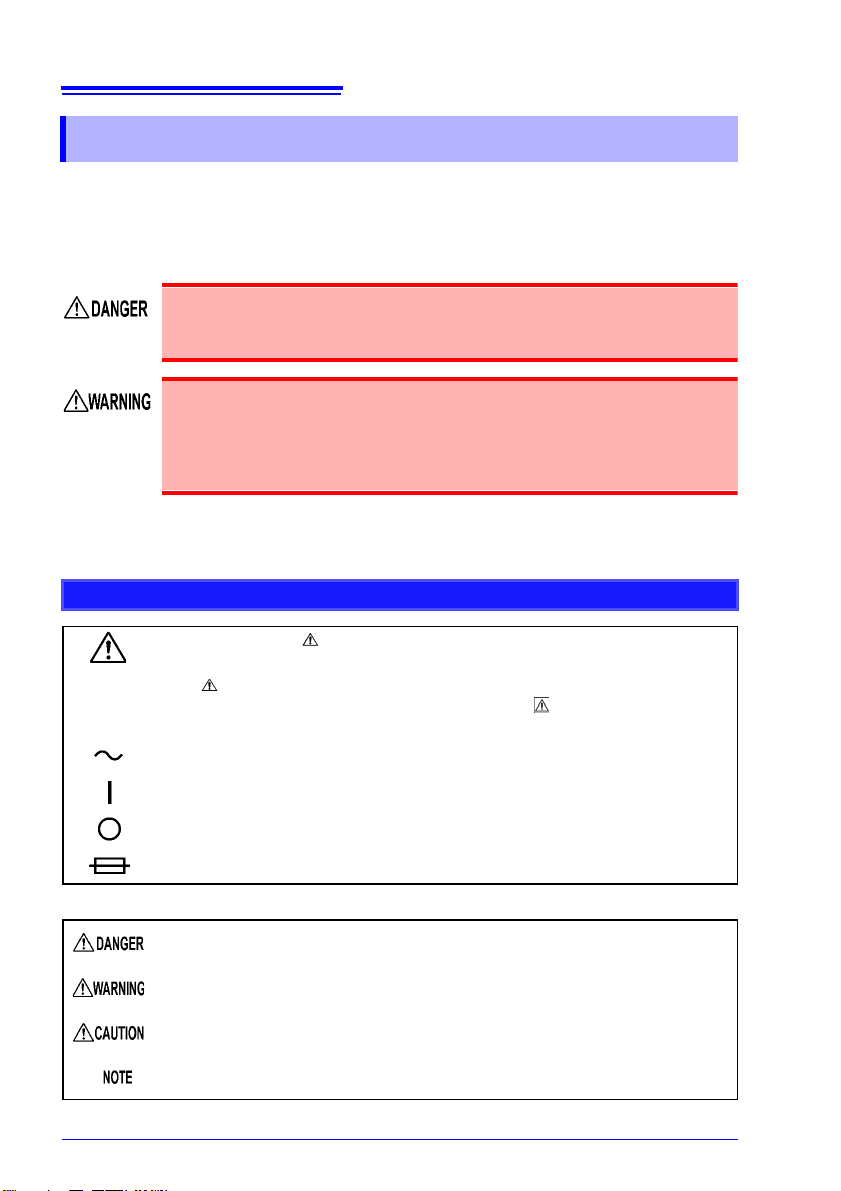

Safety Symbols

In the manual, the symbol indicates particularly important information that the

user should read before using the instrument.

The symbol printed on the instrument indicates that the user should refer to a

corresponding topic in the manual (marked with the symbol) before using the

relevant function.

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a fuse.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in

serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in

serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Page 13

Safety Information

Symbols for Various Standards

This symbol indicates that the product conforms to regulations set out by the EC

Directive.

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU

market after August 13, 2005, and producers of the Member States are required to

display it on the appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

Other Symbols

Indicates the prohibited action.

(p. )

[ ]

SET

(Bold characters)

Unless otherwise specified, “Windows” represents Windows XP, Windows Vista, Windows 7, or

Windows 8.

Indicates the location of reference information.

*

Indicates that descriptive information is provided below.

Square brackets indicate instrument display labels (such as setting item names).

Bold characters within the text indicate operating key labels.

Accuracy

We define measur ement tol erance s in te rms o f f. s. (fu ll scal e), rd g. (r eading ) and dgt. (di git) va lues , wit h the

following meanings.

f.s.

rdg.

dgt.

See: "Example accuracy calculations" (p. 259)

(maximum display value)

This is usually the name of the maximum displayable value. For this instrument , it

indicates the currently selected range.

(reading or displayed value)

The value currently being me as ur ed and ind ica ted on the measuring instrument .

(resolution)

The smallest displaya bl e un it on a di gi tal measuring instrument, i.e., the input val ue

that causes the digital display to show a “1” as the least-significant digit.

5

Page 14

6

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to ensure that

no damage occurred during storage or shipping. If you find any damage, contact your

authorized Hioki distributor or reseller.

Before using the instrument, make sure that the insulation on the

power cord, leads or cabl es i s undamaged and that no bare conductors

are improperly exposed. Using the instrument in such condi tions could

cause an electric shock, so contact your authorized Hioki distributor or

reseller for replacements.

Page 15

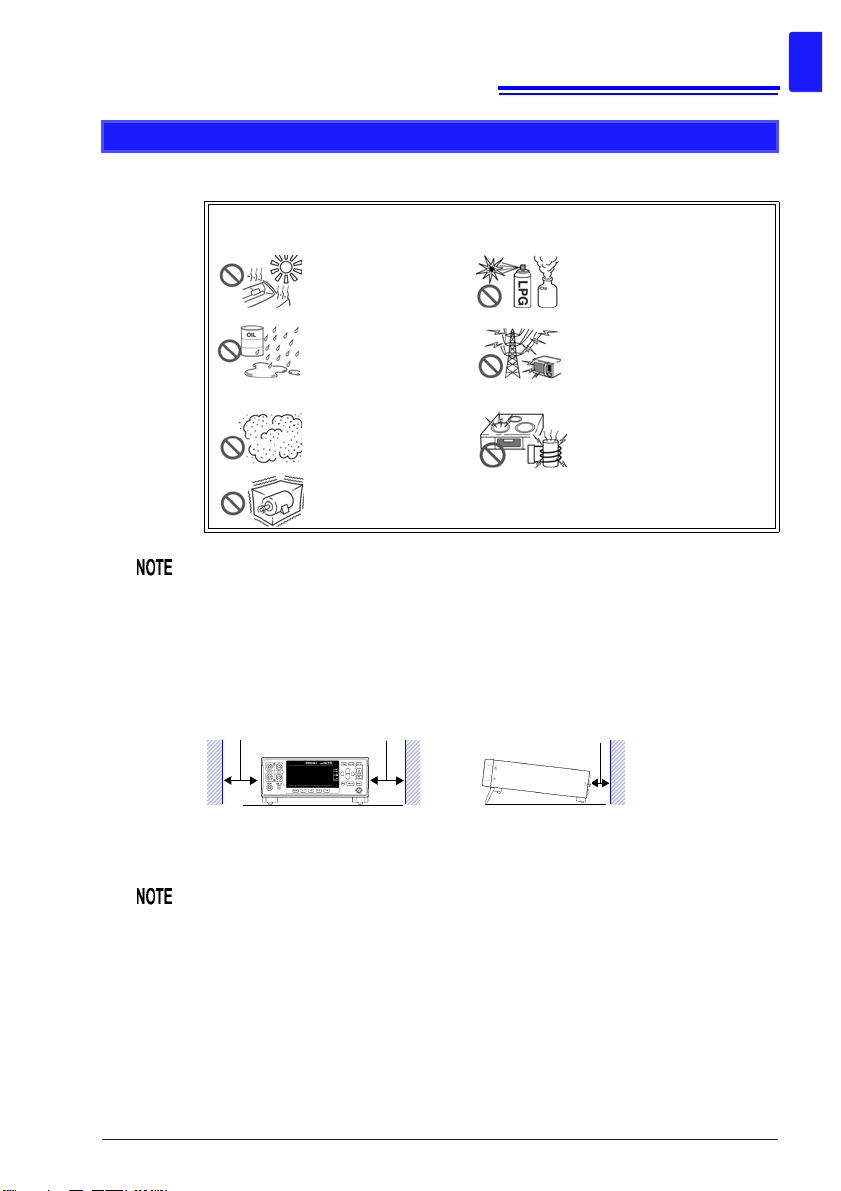

Instrument Installation

The instrument can be used with the stand (p. 24).

It can also be rack-mounted. (p. A35).

50 mm or more

10 mm or more

Rear

50 mm or more

Operating temperature and humidity: 0 to 40°C at 80% RH or less (non-condensating)

Storage temperature and humidity : -10°C to 50°C at 80% RH or less (non-condensating)

Avoid the following locations that could cause an accident or damage to the

instrument.

Correct measurement may be impossible in the presence of strong magnetic

fields, such as near transformers and high-current conductors, or in the pre sence of strong electromagnetic fields such as near radio transmitters.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals , or solvents

Exposed to high humidity or condensation

Exposed to high levels

of particulate dust

Subject to vibration

7

Operating Precautions

In the presence of corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction heating systems and IH

cooking utensils)

Installation Precautions

• The instrumen t should be operated only with the bottom downwards.

• Do not place the instrument on an unstable or slanted surface.

Unplugging the power cord kills power to the instrument. Be sure to provide

enough unobstructed space to unplug the power cord immediately in an

emergency.

Page 16

8

Operating Precautions

Handling the Instrument

• Do not allow the instrument t o get w et , a nd do not take measurements

with wet hands. This may cause an electric shock.

• Do not attempt to modify, disassemble or repair the instrument; as

fire, electric shock and injury could result.

• To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock

from dropping.

• To avoid damage to the instrument, do not apply voltage or current to mea-

surement terminals, TEMP.SENSOR jack, TEMP.ANALOG INPUT terminal

block, COMP.OUT jack, or D/A OUTPUT terminal block.

• This instrument may cause interference if used in residential areas. Such

use must be avoided unless the user takes special measures to reduce

electromagnetic emissions to prevent interference to the reception of radio

and television broadcasts.

• Use the original packing materials when transporting the instrument, if pos-

sible.

Page 17

Handling the Cords and Leads

To avoid electrical shock, be careful t o avoid shorting live lines with the

test leads.

• Avoid stepping o n or pinching cables, which could damage t he cable insul a-

tion.

• To avoid breaking cables or lead wires, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

• To avoid damaging the cable, grasp the connector, not the cable, when

unplugging the cable.

• The ends of the pin type lead are sharp. Be careful to avoid injury.

• Keep the cables well away from heat sources, as bare conductors could be

exposed if the insulation melts.

• Temperature sensors are precision devices. Be aware that excessive volt-

age pulses or static discharges can destroy the film.

• Avoid subjecting the temperature sensor tip to physical shock, and avoid

sharp bends in the leads. These may damage the probe or break a wire.

• Use only the specified cords and leads. Using a non-specified cord or lead

may result in incorrect measurements due to poor connection or other reasons.

• If the part of the temperature sensor that connects to the instrument

becomes dirty, wipe it clean. The presence of dirt may affect temperature

measured values by increasing the contact resistance.

• Exercise care so that the temperature sensor connector does not become

disconnected. (If the sensor is disconnected, it will not be possible to perform temperature correction or temperature conversion.)

9

Operating Precautions

CD-R disc precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches.

When writing text on a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight,

high temperature, or high humidity.

• Hioki is not liable for any issues your computer system experiences in the

course of using this disc.

Page 18

10

Operating Precautions

Before Connecting the Power Cord

• To avoid electrical accidents and to maintain the safety specifications

of this instrument, connect the power cord provided only to a 3-contact (two-conductor + ground) ou tl et .

• Use only the design ate d power cord with this instrument. Use of other

power cords may cause fire.

• Before using the instrument, make sure that the insulation on the

power cord is undamaged and that no bare conduct ors are impr operly

exposed. Any damage could cause electric shock, so contact your

authorized Hioki distributor or reseller.

To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

Before Connecting Measuremen t Leads

To avoid shock and short circuits, turn off all power before connecting

measurement leads.

Before Connecting the LED Comparator Attachment

• To keep from damaging the instrument or LED Comparator Attachment,

turn off the instrument before connecting the attachment.

• The COMP.OUT jack is provided exclusively for use with the L2105. Do not

connect any device other than the L2105.

• The attachment may not fulfill the specifications if the connector is not

attached securely.

• Do not over-tighten the cable tie around the measurement leads. Doing so

may damage the measurement leads.

• Avoid the following as damage to the cable conductor or insulation may

result:

Twisting or pulling on cables

Bending cables near the lamp excessively in order to connect them

Page 19

Before Connecting the Temperature Sensor

Failure to fasten the connectors properly may result in sub-specification performance or damage to the equipment.

Note the following precautions to avoid damaging the instrument:

• To keep from damaging the instrument or temperature sensor, turn off the

instrument’s main power switch before connecting the sensor.

• Connect the temperature sensor by inserting the plug all the way into the

TEMP.SENSOR jack. A loose connection can cause a large error component in measured values.

• If the temperature sensor jack becomes di rty, wipe it clean. The pr esence of

dirt will cause an error in temperature measured values.

• When connecting the temperature sensor, do not connect anything to the

TEMP.ANALOG INPUT terminal block. Doing so may cause erroneous

measured values to be displayed.

Before Connecting the Thermometer

• Note that thermometer circuit is grounded. To avoid electric shock

accidents or damage to the instrument, do not connect an analog output thermometer to the TEMP.ANALOG INPUT terminal block that ha s

any potential offset from ground.

• Failure to fasten the connectors properly may result in sub-specifica-

tion performance or damage to the equipment.

11

Operating Precautions

Note the following precautions to avoid damaging the instrument:

• Before connecting a thermometer t o t he instrument, confirm that any power

to the instrument and thermometer is turned OFF.

• Allowable input voltage from an analog thermometer is 0 to 2 V (between

terminal contacts). Do not apply voltage exceeding this range.

• With thermometers providing 4 to 20 mA output, connect a shunt resistance

of about 50 before connecting, and convert the resulting voltage.

• When connecting the thermometer, do not connect anything to the

TEMP.SENSOR jack. Doing so may cause erroneous measured values to

be displayed.

Page 20

12

Operating Precautions

Before Connecting Data Cables (US B, RS-232C, GP-IB)

• Failure to fasten the connectors properly may result in sub-specifica-

tion performance or damage to the equipment.

• Always turn both devices OFF when connecting and di sconnecting an

interface (except USB) connector. Otherwise, an electric shock accident may occur.

Observe the following precautions when connecting the instrument and a

controller:

• To avoid faults, do not disconnect or reconnect the USB cable d uring instru-

ment operation.

• The USB, RS-232C, and GP-IB interfaces are not isolated from the ground

circuit. Connect the instrument and the controller to a common earth

ground. Using different grounds could result in potential difference between

the instrument and the controller. Potential difference on the data cable can

result in malfunctions and faults.

Before Connecting the Printer

Because electric shock and instrument damage hazards are present,

always follow the steps below when connecting the printer.

• Always turn off the instrument and the printer before connecting.

• A serious hazard can occur if a wire becomes dislocated and contacts

another conductor during operation. Make certain connections are

secure.

Before Switching between Current Sink (NPN) and Current Source (PNP)

• Configure the NPN/PNP setting to accommodate externally connected

equipment.

• Do not operate the NPN/PNP switch while the instrument is on.

Page 21

Before Connecting EXT I/O

To avoid electric shock or damage to the equipment, always observe

the following precautions when connecting to the EXT I/O connect or.

• Always turn off the main power switch on the instrument and on any

devices to be connected before making connec tions.

• Be careful to avoid exceeding the ratings of external terminals (p.

206).

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Use screws to secure the

external connectors.

• The ISO_5V pin of the EXT I/O connector is a 5V (NPN)/ -5V (PNP)

power output. Do n ot apply ext ernal power t o thi s pin. (Exte rnal p owe r

cannot be supplied to the instrument’s EXT I/O connector.)

To avoid damage to the instrument, observe the following cautions:

• Do not apply voltage or current to the EXT I/O terminals that exceeds their

ratings.

• When driving relays, be sure to install diodes to absorb counter-electromo-

tive force.

• Be careful not to short-circuit ISO_5V to ISO_COM.

• Configure the NPN/PNP setting to accommodate externally connected

equipment.

• Do not operate the NPN/PNP switch while the instrument is on.

See: "Connector Type and Signal Pinouts" (p. 179)

13

Operating Precautions

Page 22

14

Operating Precautions

Before Attaching a Multiplexer Unit

Before Connecting the Multiplexer’s Connector

• To avoid electric shock, before removing or replacing a Multiplexer

Unit, confirm that the instrument’s main power switch is off and that

the measurement leads, power cord, and all connectors have been

disconnected.

• The mounting screws must be firmly tightened or the Multiplexer Unit

may not perform to specifications, or may even fail.

• Failure to fasten the connectors properly may result in sub-specifica-

tion performance or damage to the equipment.

• When connecting a measurement target with electromotive force (a

battery or power supply), take steps to protect against short-circu its.

• The Z3003 Multiplexer Unit’s maximum allowable voltage for contacts

is 33 V RMS/46.7 V peak, or 70 V DC. Do not connect directly to a

dielectric strength tester or insulation resistance tester.

• To avoid the danger of electric shock, never operate the instrument

with a multiplexer unit removed. To use the instrument after removing

a multiplexer unit, install a blank panel over the opening of the

removed unit.

• When inserting in the unit, hold the metal plate. Directly touching the board

may cause damage of the unit or accuracy deteriorations in the higher

resistance ranges due to the influence of static electricity. Taking countermeasures against static electricity (using antistatic devices such as a wrist

strap) as well as wearing antistatic gloves are recommended.

• To prevent malfunctions when not using the Multiplexer Unit, store it using

the packaging materials in which it was delivered.

Before Using D/A Output

• To avoid electric shock and instrument damage when connecting a device

to the instrument’s D/A output terminal, turn off main power switch on the

instrument and the device being connected and ensure that the measurement leads have been disconnected from the measurement target.

• The maximum output voltage that can be generated from the D/A output is

5 V . If the rated vol tage of the device being conne cted is less than 5.5 V, the

connected device could be damaged.

• D/A output is not isolated from the gro und circuit. If the device connected to

D/A output is not isolated from the ground circuit, the error component in

measured values will increase.

Page 23

Before Turning Power On

Before turning the instrument on, make sure the supply voltage

matches that indicated on its power connector. Connection to an

improper supply voltage may damage the instrument and present an

electrical hazard.

Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with

rectangular wave or pseudo-sin e-wave output t o power t he instru ment. Doing

so may damage the instrument.

15

Operating Precautions

Page 24

16

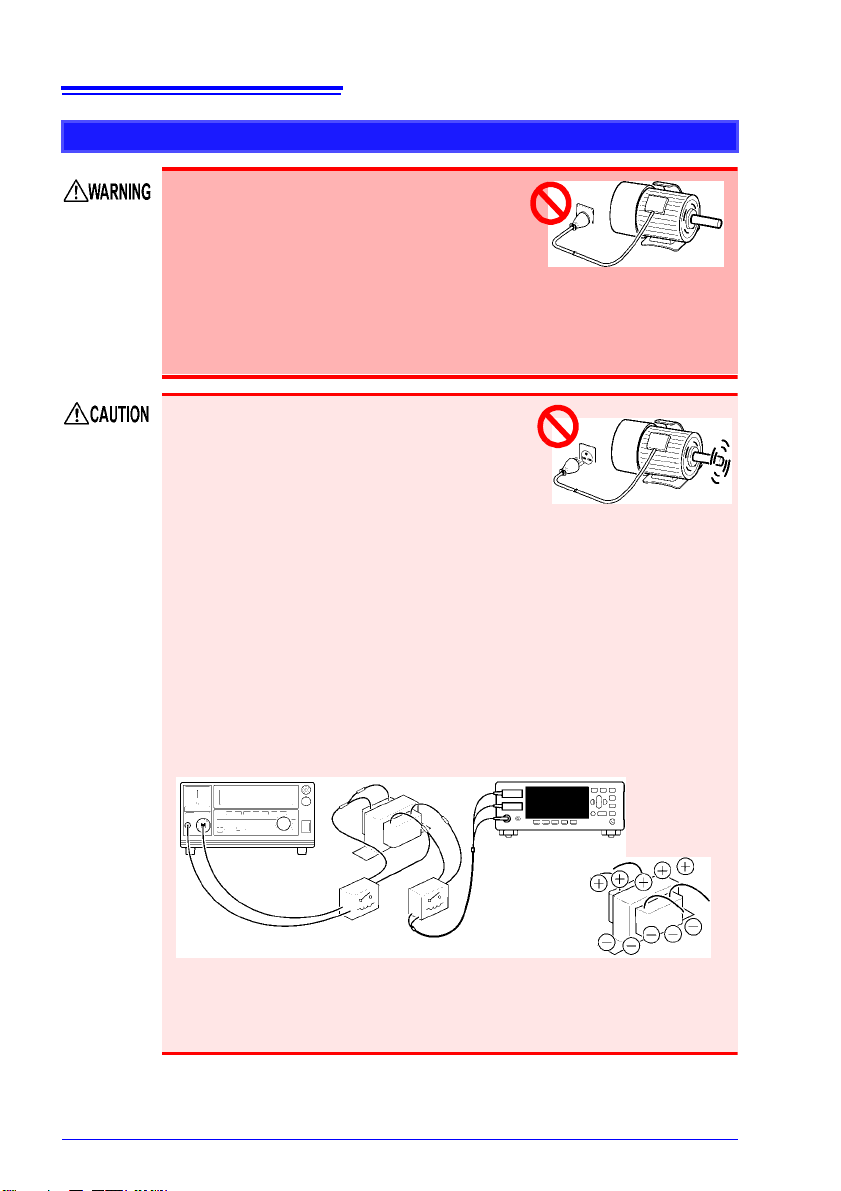

The measurement target is

connected to a power supply.

• Never attempt to measure at a point where volt-

age is present. Even if the power supply to the

motor is turned off, while the motor is rotating

inertially, high electromotive power is generated

in terminals. When attempting to measure a

transformer or motor immediately after voltage

withstanding test, induced voltage or residual

charge may damage the instrument.

Rotating inertially

• When the RM3545 is used in a way that connects to a withstanding voltage

tester via switching relays, construct a testing line bearing the following in

mind.

See: "Appendix 15 Using the Instrument with a Withstanding Voltage Tester" (p. A33)

(1) The voltage withstanding specification of switching relays should

include a safe margin over the withstanding testing voltage.

(2) To protect against damage due to arc discharge in relay contacts, all

RM3545 measurement terminals should be grounded during voltage

withstanding testing.

(3) To protect against damage due to residual charge, measure resistance

first, and voltage withstanding last.

3158 AC Withstanding Voltage HiTester RM3545

Withstand voltage of relay switch is not high enough.

Residual charge from voltage

withstanding test is present.

Operating Precautions

Before Measuring

• To avoid electric shock or damage to the

instrument, do not apply voltage to the

measurement terminals. Also, to avoid

electrical accidents, only take measurements after turning off the power to the

measurement targets being measured.

• Sparks may result at the moment the instrument is connected to, or

disconnected from, the measurement target. To avoid fire or bodily

injury, avoid use in the presence of explosive gases.

• Battery internal resistance cannot be measured with this instrument. It will

sustain damage. To measure battery internal resistance, we recommend the

HIOKI 3554, 3555, BT3562, BT3563 and 3561 Battery HiTesters.

Page 25

• To obtain the guaranteed measurement accuracy, allow at least 60 minutes

warm-up.

• When measuring devices such as power supply transformers with high

inductance or open-type solenoid coils, measured value may be unstable.

In such cases, connect a film capacitor of about 1 F between SOURCE A

and SOURCE B.

• Carefully insulate all SOURCE A, SENSE A, SENSE B, and SOURCE B

wiring. Proper 4-terminal measurements cannot be performed and an error

will occur if core and shield wires touch.

• The SOURCE terminal is protected by a fuse. If the fuse is tripped, the

instrument will display “

Blown Fuse.” and you will not be able to measure

resistance values. If the fuse is tripped, replace the fuse.

See: "14.2 Replacing the Measurement Circuit’s Protective Fuse" (p. 302)

• Since the instrument uses DC current for measurement, it may be affected

by thermal EMF, resulting in a measurement error . If so, use the Offset V o ltage Compensation function (OVC).

See: "4.8 Compensating for Thermal EMF Offset (Offset Voltage Compensation -

OVC)" (p. 82)

See: "Appendix 9 Effect of Thermal EMF" (p. A23)

When using the temperature sensor

The temperature sensor is not waterproof. Do not submerse it in water or

other liquid.

17

Operating Precautions

• Allow the measurement target for which temperature correction is being

performed and the temperature sensor to adjust to the am bient temper ature

prior to measurement. Failure to do so will result in a large error component.

• Handling of the temperature sensor with bare hands may cause the sensor

to pick up inductive noise, resulting in unstable measured values.

• The temperature sensor is designed for use in applications in which ambi-

ent temperature is measured. It is not possible to accurately measure the

temperature of the measurement target itself by placing the sensor in contact with the surface of the target. Use of an infrared thermometer to perform correction is appropriate when there is a large temperature difference

between the ambient environment and the measurement target.

• Connect the temperature sensor by inserting the plug all the way into the

TEMP.SENSOR jack. A loose connection may cause a large error component in measured values.

Page 26

18

Operating Precautions

Page 27

19

• Measurement range: 10 m to 1000 M/ Basic accuracy: 0.006%rdg.

• Maximum resolution: 10 n

Supports low-resistance measurement of current detection resistors, reactors, welds, etc.

• Up t o 1 G range

Can be used in open testing of contacts.

• Discharge vol tage of 20 mV or less

Low-power measurement can be used in testing under IEC 60512-2 and other contact

standards.

• Accuracy defined without zero-adjustmen t

Conduct measurement with peace of mind, even without performing zero-adjustment.

• Wiring resistance tolerance in low-resistance range: 1.5

Measurement cables can be extended easily, even when using the 1 A measurement current range.

High-performance specifications to meet advanced development

and production needs

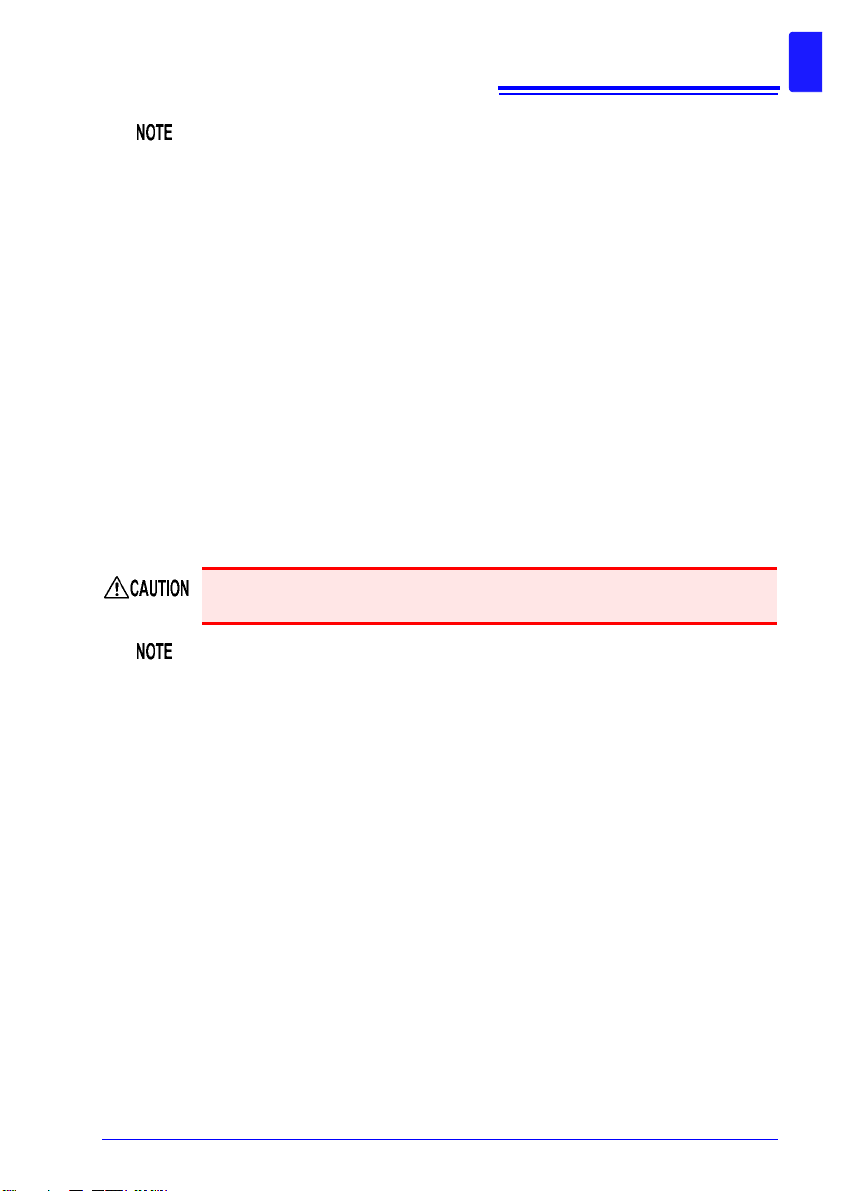

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

The RM3545 is capable of performing high-speed, high-precision measurement of the

winding resistance of components such as motors and transformers, the contact resistance

of relays and switches, the pattern resistance of printed circuit boards, and the DC resistance of fuses, resistors, and materials such as conductive rubber using four-terminal measurement. Since the instrument incorporates a temperature correction function, it is

particularly well suited to the measurement of targets whose resistance values vary with

temperature. It also provides features such as a comparator function, communications,

external control, and a multiplexer*, allowing it to be used in a wide range of applications,

including in development work and on production lines.

* The multiplexer can be used with the RM3545-02.

1

Page 28

20

LED Comparator Attachment (option)

Streamlines work by eliminating the need to look at the screen.

Graphical LCD

Operation is intuit ive and easy to l earn.

Easy configuration of comparator and panel

load operation

Facilitates smooth se tup changes o n production lines.

Simple basic settings

Range and measurement

speed can be set directly.

Guard terminal

You can reduce the

effects of external

noise by connecting the guard terminal.

Free power supply (100 to 240 V) with

automatic frequency switching

Allows the instrument to be easily moved to

overseas production lines.

Judgment sounds with user-selectable patterns

Keeps you from mistaking audio from a

nearby operator ’s instrument as your own.

Easy-to-use functions in research and development,

on production lines, or in acceptance inspections

Monitor and test functions

Provides robust support for line development by allowing you to check

communications and E XT I/ O on th e

screen.

Example communic ations

monitor screen

Example EXT I/O test

screen

Support for a variety of temperature sensors

You can connect a radiation thermometer with

analog output in addition to the included sensor.

Extensive selection of interfaces

Standard USB, RS-2 32C, EXT I/O , and D/

A output interfaces

(The RM3545-01 also provides a GPIB interface.)

1.1 Product Overview and Features

Page 29

1.1 Product Overview and Features

• Measure up to 20 locations with 4-terminal measurement or 42 locations with

2-terminal measurement (when using two Z3003 units).

• Multipoint measurement

Allows measurement of network resistors, steering switches, 3-phase motors, etc.

• Total judgments

Outputs total judgment based on measurement results for tested locations.

• Comparator judgments based on measurement results

Allows judgments to be based on comparisons with standard elements for measurement

targets such as thermistors that are susceptible to the effects of temperature.

• External instrument connectivity

Allows multipoint measurement, including for external measuring instruments such as LCR

meters.

Multiplexer support to allow multipoint measurement and total

judgments (RM3545-02)

Z3003 Multiplexer Unit

21

1

Page 30

22

Display Screen (Monochrome graphical LCD)

Display of measuremen ts and

settings (p. 27)

Viewing Measured

Values and Settings

COMP indicator LEDs

Indicate the judgment result of the measured value (p.98).

Hi Measured value is above upper limit

IN Pass (meets criteria)

Lo Measured value is below lower limit

Viewing Comparator Results

MENU key

Switching of F key pages

F keys

Selection of settings displayed

on the screen

COMP.OUT jack

Connect the L2105 LED Comparator Attachment to

view judgment re sults without needing to refe r to the

instrument display. (p.107)

Connecting the LED Compa rator Att achment

PANEL key

Saving and loading of panels

(p.120)

COMP key

Configuration of comparator

settings (p.98)

AUTO, RANGE key

Range switching (p.49)

SPEED key

Measurement speed switch ing

(p.50)

Cursor keys

Selection of settings and digits

ENTER key

Acceptance of settings and

manual trigger input

ESC key

Cancellation of operation

Settings

Measurement T erminals

Connect measurement leads (p. 36).

• SOURCE A : Current detection terminal

• SOURCE B : Current source terminal

• SENSE A : Voltage detection terminal

• SENSE B : Voltage detection terminal

• GUARD : Guard terminal

Connecting Measurement Leads

STANDBY Key: Initiates or cancels the

standby stat e. (p . 43) .

• Unlit: power off (when no power supplied)

• Red light: Standby State (while power is supplied)

• Green light: power on

Initiating and Canceli ng the Standby St a te

1.2 Names and Functions of Parts

1.2 Names and Functions of Parts

Front Panel

Page 31

Rear Panel

RS-232C connector

• Connect to a computer, PLC, or other

device (p.226).

• Connect to a printer (p.239).

RS-232C Communications

Printer Output

Power Inlet

Connect the supplied power cord

(p. 35).

Connecting

the Power

Cord

Manufacturer's Serial Number

Do not remove this label, as it is required

for product support.

Fuse holder (p.302)

Replacing the

Measurement Fuse

Main power switch (p.43)

: Main power off

: Main power on

Turning the Main Power

On and Off

EXT I/O connector

Connect when controlling the instrument with

a PLC, I/O board, or other equipment to allow

measurement to be started and measured

values and comparator results to be acquired

(p.177).

External Control

USB jack

Connect to a computer

(p. 223).

Sending and

Receiving Data

via USB

EXT I/O NPN/PNP switch

Left : Current sink (NPN)

Right: Current source (PNP)

Switching between

NPN and PNP

TEMP.SENSOR jack/

TEMP.ANALOG INPUT terminal block

Connect the Z2001 Temperature Sensor or thermometer with analog outpu t when using t emper ature

correction or temperature conversion. (p.37)

Connect the Z20 01 to the TEMP.S ENSOR jack on

the right. Connect analog voltage output from a radiation thermometer or a shunt resistor for analog current output from a radiation thermometer to the

TEMP.ANALOG INPUT terminal block.

Correcting Temperature

Converting Temperature

D/A OUTPUT terminal block

The D/A OUTPUT terminal block outp uts r esistance values as a voltag e signal . (Conne ct a device that can acce pt vo ltag e inpu t, for exam ple

a Memory HiCorder.) (p.175)

D/A Output

RM3545-01

GP-IB Connector

(RM3545-01 only)

Connect to a compute r, or other device

(p.230)

GP-IB Communications

23

1.2 Names and Functions of Parts

1

Page 32

24

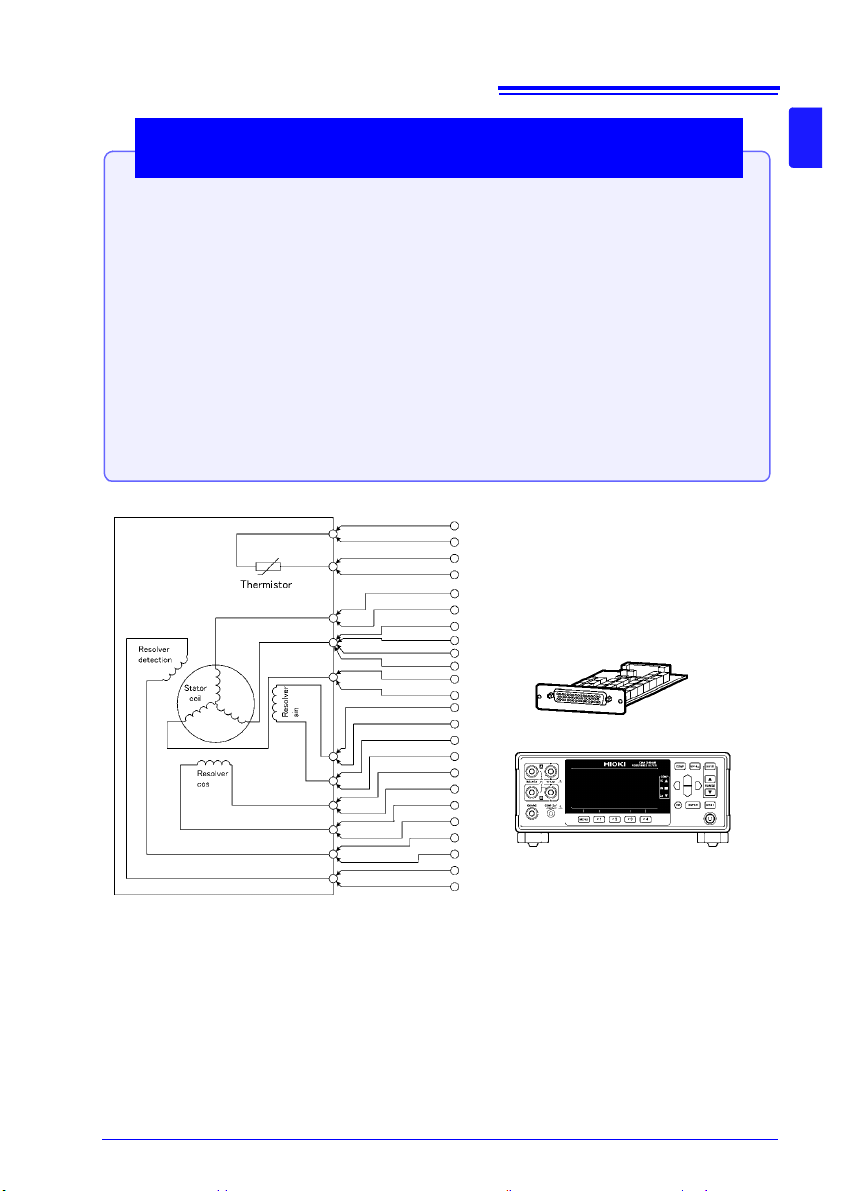

Multiplexer Unit Slot

(RM3545-02 only)

Installing the Z3003 Multiplexer Unit

(up to 2 units) (p.42)

Using the Multiplexer Unit

RM3545-02

Bottom Panel

Stand

When using the stand

Extend the legs all the way. Do not extend partially.

Make sure to extend both legs of the stand.

Collapsing the stan d

Do not collapse the stand partw a y. Be sure to col lap se

it all the way.

This instrument can be rack mounted.

See: "Appendix 17 Rack Mounting" (p. A35)

Parts removed f r om this instrument should be

stored in a safe place to enable future reuse.

Do not apply heavy downward pressure

with the stand extended. The stand coul d

be damaged.

1.2 Names and Functions of Parts

Page 33

25

2

6

5

3

Install the Multiplexer Unit

(RM3545-02; as necessary)

4

Install this instrum e nt (p. 6)

1

Rear Panel

Front Panel

Tu rn on the instrument and cancel

the standby state

(p.43)

6

When finished measuring, turn the

power off (p.43).

Connect the temperature sensor

or infrared thermometer (p.37)

(When using the temperature correction function or T)

4

2

3

Make instrument settings

*1

7

Connect measurement leads (p.36)

Check the measurement target

(p.48)

8

Connect to the test sample (p.51)

9

Connect the power

cord (p.35)

Connect the external interface

(as needed)

5

• Using the printer (p.239)

• Using the USB, RS-232C or GP-IB

interface (p. 221)

• Using the EXT I/O (p. 177)

• Using D/A Output (p. 175)

Rear Front

(Connect connectors

to the Multiplexer

Unit as necessary.)

When clipping a small-gauge

wire

(Clip with the tip of the alligator

clips.)

When clipping a large-gauge

wire

(Clip with the back of the alligator

clips, where there are no teeth.)

1.3 Measurement Process

1.3 Measurement Process

1

Page 34

26

1.3 Measurement Proces s

*1 About zero-adjustment

Perform zero-adjustment in the following circumstances:

• The measured value is not cleared due to thermal EMF or other factors.

The measured value will be adjusted to zero. (*2)

• Four-terminal connection (called Kelvin connection) is difficult.

The residual resistance of the two-terminal connection wires will be canceled.

See: "4.3 Zero Adjustment" (p.68)

"Appendix 6 Zero Adjustment" (p.7)

*2 Accuracy specifications vary when zero-adjustment has not been performed.

For more information, see "Chapter 13 Specifications" (p.251).

Thermal EMF can also be canceled by using OVC.

See: "4.8 Compensating for Thermal EMF Offset (Offset Voltage Compensation - OVC)" (p.82 )

Page 35

27

Trigger source (INT/EXT)

Measurement range

TC (ON)

0ADJ (ON)

Auto range

Key lock state or remote state

Cancel the key lock state or remote

state by pressing and ho lding the

MENU key.

F.LOCK : All operations prohibited .

M.LOCK: Menu operations prohibited.

RMT : Remote state

Judgment value

Switched with the VIEW key

(No display / temperature /

pre-calculation resistance

value)

Page switching

Measurement scre en la yo u t

Hold state

Scaling (ON)

Measurement speed

Number and name

of loaded panel

Measured value

OVC (ON)

1.4 Screen Organization and Operation Overview

1.4 Screen Organization and

Operation Overview

The instrument’s screen interface consists of a Measurement screen and various Settings

screens.

The screen examples in this guide appear reversed (black on white) for best visibility on the

printed page. However, the instrument screens can actually be displayed only as white

characters on black background.

1

Display of information other than measured values

(For more information, see "Confirming Measurement Faults" (p.55).)

Display Description

+OvrRng

-OvrRng

CONTACT TERM.A

CONTACT TERM.B

- - - - - - -

* To treat current faults (when the source wiring is open) as over-range events, change the

current fault output mode setting. (p.59)

Over-range

Contact error

Not measured, or broken connection in measurement target *

Page 36

28

Channel number

Total judgment result

Individual channels’ measured value

Individual channels ’ com par ato r re sul t

(If a measured va lue fa ult occu rs, a des cript ion of the er ror i s dis play ed.)

Individual channels’

PASS/FAIL judgment result (If a measured value

fault occurs, ”---” is dis-

played.)

Overview of screen operation

Menu switching

(4) To Settings screens

(1) Measurement screen

(2) Comparator Settings screen

Upper limit

value

Lower limit

value

(3) Panel Save/Load screen

Select a panel number.

3

Change

values.

Move among

digits.

Accept the setting with the

key or cancel with the key.

4

Change the range with the

and keys.

2

1

2

Perform action with an F key.

1

Select the mode with an F key.

When the measurement te rminal setting

is MUX (multiplexer): Select a channel.

P.3/3 is only displayed on

the RM3545-02.

1.4 Screen Organization and Operation Overview

When the scan function is set to auto or step (RM3545-02 only)

Page 37

(4) Settings screen

< Setting values >

Make the value editable with the

key.

2

Change values.

1

Move among

digits.

Accept the setting with the key

or cancel with the key.

3

Return to the Measurement screen

with the key.

Move to the [MEAS], [SYS], [I/O],

[IF], [BIN], [MUX1], or [MUX2] tab.*

* MUX1/MUX2 is only di splayed on the

RM3545-02.

1

2

Select a

setting.

Move among

settings.

Switch functions with an F key or set

values.

3

4

When the measurement terminal setting is MUX (multiplexer)

[CH−]: Changes (decreases) the

channel.

Set the measurement conditions by

channel.

[CH+]: Changes (increases) the

channel.

29

1.4 Screen Organization and Operation Overview

1

Page 38

30

1.4 Screen Organization and Operation Overview

List of settings

Screen Setting and key Overview See

Measurement screen COMP Comparator function (p.100)

PAN EL Save/load panel (p.119)

Measurement screen

(P.1/2) (For the RM3545-02, P.1/3)

Measurement screen

(P.2/2) (For the RM3545-02, P.2/3)

Measurement screen

*2

(P.3/3)

Settings

screen

(SETTING)

Multiplexer Channel

Settings screen

*2

(MUX1)

Multiplexer Basic

Measurement screen

*2

(MUX2)

AUTO

(RANGE)

SPEED Measurement speed (p.50)

INFO (F1) Display setting conditions

VIEW (F2)

STAT (F3)

STOP (F3)

PRINT (F4) Print (p.241)

0 ADJ (F2) Zero-adjustment

LOCK (F3) Key lock (p.126)

SETTING (F4) Switch to Settings screen

FRONT (F1) Use of the multiplexer

SCANSET (F3) Scan function

CH Use of channels

TERM Channel terminals

INST

0ALL

0ADJ

SPD

RANGE Individual channels’ range

UPP/REF

LOW%

PASS

*2

Measurement range (p.49)

(p.54)

Switch measur ement scre en

display

Display statistical calculation results

Stop scan

Use the front measurement

terminals

Measuring instruments for

each channel

Scan channels

Zero-adjustment settings

Individual channels’ zeroadjustment s tatus

Individual channels’ measurement speed

Individual channels’ comparator settings

Individual channels’ PASS

conditions

(p.52)

(p.111)

(p.68)

(p.151)MUX (F2)

(p.153)

(p.163)

(p.157)

Page 39

Settings

screen

(SETTING)

1.4 Screen Organization and Operation Overview

Screen Setting and key Overview See

Measurement

Setting screen

*3

(MEAS)

0 ADJUST Clear zero-adjustment (p.71)

TC SET Temperature correction (p.75)

T

Temperature conversion (p.116) R0, T0

k

DELAY Delay (p.84)

AVERAGE Averaging (p.73)

AUTO HOLD Hold measured value (p.60)

SCALING(A∗R+B)

A:

B:

UNIT :

OVC

LOW POWER

MEAS CURRENT

DIGITS Set the display digits (p.81)

CURR ERROR

MODE

CONTACT CHECK Contact check function (p.88)

CONTACT IMPRV Contact improver function (p.90)

100M PRECISION 100 M high-prec is io n m ode (p.96)

Scaling (p.77)

Offset voltage compensa-

tion function (OVC)

Low-power resistance mea-

surement (LP)

Switching me asur ement c ur-

rents

Current fault output format (p.59)

(p.82)

(p.64)

(p.66)

31

1

Page 40

32

1.4 Screen Organization and Operation Overview

Screen Setting and key Overview See

Settings

screen

(SETTING)

System Setting

screen

(SYS)

TERMINAL

*2

WIRE

*2

SCAN MODE

FAIL STOP

UNIT TEST

*2

*2

STATISTICS Statistical calculations function (p.11 1)

TEMP INPUT

ANALOG SET2

CALIBRATION Self-calibration (p.92)

KEY CLICK Set the operation sound (p.128)

COMP BEEP Hi

IN

Lo

PASS

FAIL

PANEL LOAD 0ADJ Load zero-adjustment values (p.122)

CONTRAST Set the contrast (p.131)

BACK LIGHT Set the contrast brightness (p.132)

POWER FREQ Set the power frequency (p.129)

CLOCK Clock settings (p.133)

RESET Reset the instrument (p.134)

ADJUST Adjust the instrument (p.A43)

EXT I/O Setting

screen

(I/O)

TRIG SOURCE Set the trigger source (p.208)

TRIG EDGE Set the trigger signal logic (p.210)

TRIG/PRINT FILT Trigger/print filter function (p.212)

EOM MODE EOM signal setting (p.214)

JUDGE/BCD MODE EXT I/O output mode (p.216)

EXT I/O TEST EXT I/O test (p.217)

Communication

Interface

Setting screen

(IF)

INTERFACE Configure interface settings (p.223)

SPEED

*1

GP-IB

DATA OUT

CMD MONITOR

PRINT INTRVL

STAT CLEAR

BIN Setting screen

(BIN)

*1 RM3545-01 only

*2 RM3545-02 only

*3 When using the multiplexer, the selecte d chan nel number will be displayed next to “MEAS.”

BIN BIN measurement settings (p.108)

Measurement terminal settings

Multiplexer measurement

*2

method

Scan function

Stop at FAIL during scan

Z3003 unit test (p.166)

Temperature sensor settings (p.37) ANALOG SET1

Set the judgment sound

(PASS/FAIL: RM3545-02

only)

Communications (p.221)

Printing (p.239)PRINT COLUMN

(p.148)

(p.105)

Page 41

33

1.5 Checking the Measurement Target

1.5 Checking the Measurement Target

To carry out proper resistance measurement, change the measurement conditions appropriately according to the measurement target. Before starting measurement, use the examples recommended in the following table to configure the instrument.

Recommended settings

Measure-

ment Current

(p.66)

TC/ T

(p. 75)

(p.116)

TC

TC ON

Low *1 − ON

−

OVC

(p.82)

OFF ON

OFF

Contact

check

(p.88)

OFF *3

OFF

ON

ON

Measurement target

Motors, solenoids, choke coils,

transformers

Signal contact

Wire harnesses, connectors,

relay contacts, switches

Power contact

Wire harnesses, connectors,

relay contacts, switches

Fuses, resistors

Conductive paint, Conduct ive rubber

(Bold indicates a change from the factory default.)

Low-Power

(p.64)

OFF High

ON − TC −

OFF High

OFF

OFF High

1

Other, Standard resistance measurement

Heaters, Electrical wires, Welds

Temperature-rise test

Motors, choke coils, transformers

OFF High *2

OFF High

T

ON

OFF ON

ON

*1: When there is sufficient margin with regard to the rated power, select High.

*2: When the measurement target significantly depends on temperature, use the tempera-

ture correction function.

*3: When there is sufficient margin with regard to the allowable applied voltage, select ON.

When measuring a commercial power supply transformer using an external trigger, mea-

surement cannot be performed using the delay setting preset. Either make the delay adequately long or measure using the internal trigger (p.84).

Page 42

34

1.5 Checking the Measurement Target

Page 43

Measurement

Rear Panel

1 Confirm that the instrument's Main power

switch (rear panel) is OFF( ).

2 Confirm that the mains supply voltage matches

the instrument, and connect the power cord to

the power inlet on the instrument.

3 Plug the power cord into the mains outlet.

If power to the instrument is cut off with the power switch

in the ON position (by a circuit breaker, etc.), the instrument will start up when power is restored, without any

need to press the STANDBY key.

Power inlet

Main power switch

35

2.1 Connecting the Power Cord

Preparations

Be sure to read the "Operating Precautions" (p.6) before installing and connecting this

instrument.

Refer to "Appendix 17 Rack Mounting" (p. A35) for rack mounting.

Chapter 2

2.1 Connecting the Power Cord

Turn off the power before disconnecting the power cord.

2

Page 44

36

Connection Methods

Connecting measurement leads

Connect the red plugs to the SOURCE A and

SENSE A terminals, the black plugs to the

SOURCE B and SENSE B terminals, and the

guard plug to the GUARD terminal.

When clipping a small-gauge wire

(Clip with the tip of the alligator clips.)

When clipping a large-g aug e wi re

(Clip with the back of the alligator clip s, where

there are no teeth.)

Measurement leads

(Example: When using the L2101 Clip Type Lead)

SENSE

SOURCE

The “V” mark indicates

the SENSE side.

SENSE

SOURCE

Red

Black

SENSE

SOURCE

SENSE

SOURCE

Red

Black

Red plugs

Black plugs

Guard plug

2.2 Connecting Measurement Leads

2.2 Connecting Measurement Leads

Connect the included or optional Hioki measurement leads to the measurement terminals.

Before connecting the measurement leads, read "Operating Precautions" (p.6) carefully.

Refer to "Options" (p.3) for details.

We recommend using optional Hioki measurement leads.

When making your own measurement leads or extending a measurement

lead, see "Appendix 13 Making Your Own Measurement Leads, Making

Connections to the Multiplexer" (p. A29).

Page 45

37

1 Confirm that the instrument's Main

power switch (rear panel) is OFF( ).

2 C onnect the Z2001 Temperature Sensor

into the TEMP.SENSOR jack on the rear

panel.

3 Place the tip of the temperature sensor

near the measurement target.

4 Configure temperature measurement.

Connection Methods

Connecting the Z2001 Temperature Sensor

Rear Panel

Z2001 Temperature Sensor

TEMP.SENSOR jack

Insert the Z2001 securely all the way into

the jack.

Do not connect anything to the

TEMP.ANALOG INPUT terminal block.

2.3 Connecting Z2001 Temperature Sensor or Thermometer with Analog Output (When using

2.3 Connecting Z2001 Temperature Sensor or

Thermometer with Analog Output

(When using the TC or T)

Connecting the Z2001 Temperature Sensor

Before connecting the temperature sensor, read "Operating Precautions" (p.6) carefully.

2

Page 46

38

The Settings screen

appears.

Switch the function menu

to P.2/3.

1

2

Move the cursor to the [SYS]

tab with the left and right cursor keys.

2

Thermistor sensor (Z2001)

Selection

1

Return to the

Measurement screen.

2.3 Connecting Z2001 Temperature Sensor or Thermometer with Analog Output (When using

After turning on the instrument, check whether the temperature measurement settings are

correct. Change if necessary.

Open the Settings Screen.

1

Open the System Setting Screen.

2

Select TEMP INPUT and press (SENSOR).

3

Return to the Measurement screen.

4

Page 47

2.3 Connecting Z2001 Temperature Sensor or Thermometer with Analog Output (When using

1 Confirm that the instrument's Main

power switch (rear panel) is OFF( ).

2 Connect the thermometer's analog output

connector to the TEMP.ANALOG INPUT terminal block on the rear panel, using a

cable.

3 Configure temperature measurement.

Connection Methods

Connecting an Analog Output Ther m o m et e r

Rear Panel

TEMP.ANALOG INPUT terminal block

Recommended

wire type

: Single line: AWG22 (0.65 mm diameter)

Twisted wire: AWG22 (0.32 mm

2

)

Diameter of search wire: 0.12 mm or more

Compatible wire

types

: Single line: AWG28 (0.32 mm diameter) to AWG22 (0.65 mm diameter)

Twisted wire: AWG28 ( 0.08 mm

2

) to AWG22 (0.32 mm2) stranded condu ctor

Diameter of search wire: 0.12 mm or more

Standard bare

wire length

:8 mm

Insert the thermometer's analog output

connector securely all the way into the

terminal block.

Do not connect anything to the

TEMP.SENSOR jack.

Connecting an Analog Output Thermometer

To measure temperature, connect the analog output thermometer to the instrument.

Before connecting the thermometer, read "Operating Precautions" (p.6) carefully.

39

2

When using a thermometer that generates 4 to 20 mA output, connect a shunt resistor of

about 50 between the positive and negative term ina ls an d conver t th e output to a voltage

prior to input. With a 50 resistor connected, the reference voltage (V

0.20 V (V

) and 1.00 V (V2).

1

, V2) settings are

1

Page 48

40

The Settings screen

appears.

Switch the function menu

to P.2/3.

1

2

Move the cursor to the [SYS]

tab with the left and right cursor keys.

2

Analog input

Selection

1

2.3 Connecting Z2001 Temperature Sensor or Thermometer with Analog Output (When using

After turning on the instrument, check whether the temperature measurement settings are

correct. Change if necessary.

Open the Settings Screen.

1

Open the System Setting Screen.

2

Select TEMP INPUT and press (ANLG-V).

3

Page 49

41

Move the cursor to the setting you

wish to configure. Make the value

editable with the key.

2

Move the cursor to the digit you

wish to set with the left and right

cursor keys. Change the value

with the up and down cursor keys.

Change

values.

1

Move among

digits.

3

Accept

( Cancel)

Setting range

reference voltage (V

1

, V2): 00.00 to 02.00 V (default V1: 0 V, V2: 1 V)

reference temperature (T

1

, T2): -99.9 to 999.9°C (default T1: 0°C, T2: 100°C)

Return to the

Measurement screen.

V1 V20

T1

T2

アナログ入力電圧

温度

T

2

−

T

1

V

2

−

V

1

⋅ (Inp ut V oltage) +

T1V

2

−

T2V

1

V

2

−

V

1

T

2

T

1

V

1

V

2

Temperature

Analog Input Voltage

2.3 Connecting Z2001 Temperature Sensor or Thermometer with Analog Output (When using

Set two reference voltages and the corresponding reference temperatures.

4

Set reference voltages V

Steps

1 through 3 for each.

Return to the Measurement screen.

5

and V2 and reference temperatures T1 and T2 by following

1

2

The displayed value is calculated by the following expression.

Page 50

42

Required item: One Phillips-head screwdriver

Installing a Multiplexer Unit

Rear panel

Blank panel

UNIT 1 UNIT 2

1 Turn off the instrument’s main power

switch and disconnect the cords and

leads.

2 Remove the two screws with a Phillips

head screwdriver and remove the blank

panel.

3 With attention to the orientation of the Mul-

tiplexer Unit, insert it firmly all the way in.

Insert the unit after aligning it with the

guide rail.

Taking countermeasures against static electricity

(using antistatic devices such as a wrist strap) as well

as wearing antistatic gloves are recommended.

4 Using the Phillips screwdriver, tighten the

two Multiplexer Unit mounting screws.

Configure the settings so that they match

the unit number used.

See: "Customizing Channel Pin Allocation" (p.152)

When using only one Multiplexer Unit, it can be installed as either UNIT 1 or UNIT 2.

Guide rail

Model Z3003

Do not directly touch the board

2.4 Installing the Multiplexer Unit

2.4 Installing the Multiplexer Unit

To use multiplexing capability, you must first install the Z3003 Multiplexer Unit.

Before connecting the Multiplexer Unit, read "Operating Precautions" (p.6) carefully.

Removing a Multiple xer U nit

After turning off t he instrument ’s main power switch and disconne cting all co rds and

leads, remove the Multiplexer Unit by reversing the above procedure and then att ach

the blank panel.

Page 51

2.5 Turning the Power On and Off

Turn on ( ) the main power switch on the rear of the

instrument.

If the main power switch was turned off while the

instrument was not in the standby state, the standby

state will be automatically canceled when the main

power switch is turned on.

Power ON

Turn off ( ) the main power switch on the rear of the

instrument.

Power OFF

Press the STANDBY key (the STANDBY

key will change from red to green).

2.5 Turning the Power On and Off

Turning On the Instrument with the Main Power Switch

Turning Off the Instrument with the Main Power Switch

43

2

Canceling the Standby State

Page 52

44

Self-test

Indicates an error (p. 298).

After the standby state is canceled, a self-test (instrument diagnostic routine) is performed.

During the self-test, the following information is displayed while the hardware is verified.

Error

No Errors

Normal display (measurement screen)

The following informatio n is dis playe d du r ing self -t est in g:

• Manufacturer and model name

• Firmware versions

• Communication interface setting

• Detected line frequency

• EXT I/O (NPN/PNP) setting

• Self-Calibration setting

• Inserted unit information (RM3545-02 only)

2.5 Turning the Power On and Off

The Z3003 Multiplexer Unit test is not performed during the self-test on startup.

See: "8.6 Performing the Multiplexer Unit Test" (p.166)

Before Starting Measurement

To obtain precise measurements, provide about 60 minutes warm-up after turning power

on.

The SOURCE terminal is protected by a fuse. If the fuse is tripped, the instrument will display “

Blown FUSE.” and you will not be able to measure resistance values. In this case,

replace the fuse.

See: "14.2 Replacing the Measurement Circuit’s Protective Fuse" (p.302)

Measurement settings are recalled from when the power was previously turned off (settings

backup).

Placing the Instrument in the Standby State

Press the Standby key (the Standby key will change from green to red).

Disconnect the power cord from the outlet to extinguish the standby key light.

When power is turned on again, operation resumes with the sa me state as w hen last turned

off.

If a power outage (e.g., breaker trip) occurs when the instrument is on, it will automatically

turn on again when power is restored (without pressing the standby key).

Page 53

2.6 Pre-Operation Inspection

Do not use the instrument if

damage is found, as electric

shock or short-circuit accidents

could resul t. Cont act yo ur auth orized Hioki distributor or reseller.

Metal Exposed

Is the power cord insulation torn, or

is any metal exposed?

1

Before using the instrument for the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributor or reseller.

Peripheral Device Inspection

Is the insulation on a measurement

lead torn, or is any metal exposed?

No Metal Exposed

If there is any damage, measured

values may be unstable and

measurement errors may occur.

Replace the cable with an undamaged one.

Metal Exposed

No Metal Exposed

If damage is evident, req uest repairs.

Yes

Is damage to the instrument evident?

Instrument Inspection

When turning power on

Is the STANDBY key red or green?

No

2

The power cord may be damaged, or the inst rument may be

damaged internally. Request repairs.

After the completion of the self-test

(when the model number is shown

on the screen), is the Measurement screen displayed?

No

Yes

The instrument may be damaged

internally. Request repairs.

See: "14.1 Troubleshooting" (p. 286)

"Error Displays and Remedies"

(p.298)

An error indication

occurs

Yes

Inspection complete

45

2.6 Pre-Operation Inspection

2

Page 54

46

2.6 Pre-Operation Inspection

Page 55

Basic Measuremen ts

Chapter 3

47

Before making measurements, read "Operating Precautions" (p. 16) carefully.

This chapter explains basic operating procedures for the instrument.

"3.1 Checking the Measurem ent Target" (p.48)

"3.2 Selecting the Measu rem ent Range" (p.49)

"3.3 Setting the Measurem ent Speed" (p.50)

"3.4 Connect i ng Measuremen t Leads to the Measurement Target" (p.51)

"3.5 Checking Measured Values" (p.52)

To customize measurement conditions, see "Chapter 4 Customizing Measurement Conditions" (p.63).

3

Page 56

48

3.1 Checking the Measurement Target

3.1 Checking the Measurement Target