Page 1

RM3544

RM3544-01

Instruction Manual

RESISTANCE METER

Be sure to read this manual before using the instrument.

When using the instrument for the

rst time

Names and Functions of Parts

Measurement Preparations

p.17 Troubleshooting

p.25 Error Displays and

Troubleshooting

Mar. 2019 Revised edition 4

RM3544A981-04 19-03H

Remedies

p.3

p.160

p.169

EN

Page 2

Page 3

Using This Instruction Manual

To do this… Refer to these sections in this manual.

Review important

information

Start using the instrument right away

Learn more about

instrument functions

Learn more about

product specifications

Troubleshoot a problem

Learn more about

resistance measurement

Learn more about

communications commands

Safety Information (p.3)

Operating Precautions (p.5)

Overview (p.15)

Search for the function in question in the table

of contents (p.i) or the index (p.Index 1).

Specifications (p. 145)

Troubleshooting (p. 160)

Appendix (p. A1)

Communications Command Instruction Manual

(on the application disc)

RM3544A981-04

Page 4

Page 5

Contents

Introduction.....................................................1

Verifying Package Contents...........................1

Safety Information ..........................................3

Operating Precautions.................................... 5

Chapter 1 Overview 15

1.1 Product Overview and Features ........ 15

1.2 Names and Functions of Parts ........... 17

1.3 Measurement Process .......................19

1.4 Screen Organization and Operation

Overview ............................................21

Contents

Chapter 4 Customizing

Measurement

Conditions 43

4.1 Zero Adjustment .................................44

4.2 Stabilizing Measured Values

(Averaging Function) ..........................50

4.3 Correcting for the Effects of Temperature

(Temperature Correction (TC)) ...........52

4.4 Correcting Measured Values and

Displaying Physical Properties Other than

Resistance Values (Scaling Function) 54

4.5 Changing the Number of Measured

Value Digits ........................................58

i

1

2

3

4

5

Chapter 2 Measurement

Preparations 25

2.1 Connecting the Power Cord............... 25

2.2 Connecting Measurement Leads .......26

2.3 Connecting Z2001 Temperature Sensor

(When using the TC) .........................27

2.4 Turning the Power On and Off ........... 28

Turning On the Instrument with the Main

Power Switch ............................................28

Turning Off the Instrument with the Main

Power Switch ............................................28

Canceling the Standby State ....................28

Placing the Instrument in the Standby

State .........................................................29

2.5 Pre-Operation Inspection ...................30

Chapter 3 Basic Measurements

31

3.1 Selecting the Measurement Range .... 32

3.2 Setting the Measurement Speed ....... 33

3.3 Connecting Measurement Leads to the

Measurement Target .........................34

3.4 Checking Measured Values ............... 35

Switching the Display ................................35

Confirming Measurement Faults ...............38

Holding Measured Values ......................... 41

6

Chapter 5 Judgment

Function 59

5.1 Judging Measured Values

(Comparator Function) .......................60

Enabling and Disabling the Comparator

Function ................................................... 61

Decide According to Upper/Lower Thresholds

(ABS Mode) ............................................. 62

Decide According to Reference Value and

Tolerance (REF% Mode) ......................... 64

Delaying the judge timing ......................... 66

Checking Judgments Using Sound

(Judgment Sound Setting Function) ........ 68

Checking Judgments with the L2105 LED

Comparator Attachment (Option) ............. 70

Chapter 6 Saving and Loading

Panels (Saving and

Loading Measurement Conditions) 71

6.1 Saving Measurement Conditions

(Panel Save Function) ........................72

6.2 Loading Measurement Conditions

(Panel Load Function) ........................73

Preventing Loading of Zero-adjustment

Values ...................................................... 74

Page 6

ii

Contents

6.3 Changing Panel Names .....................75

6.4 Deleting Panel Data ...........................76

Chapter 7 System Settings 77

7.1 Disabling and Enabling Key Operations

............................................................78

Disabling Key Operations

(Key-Lock Function) ................................. 78

Re-Enabling Key Operations

(Key-Lock Cancel) ................................... 79

7.2 Power Line Frequency Manual Setting

............................................................80

7.3 Enabling or Disabling the Key Beeper 82

7.4 Adjusting Screen Contrast ..................83

7.5 Adjusting the Backlight .......................84

7.6 Initializing (Reset) ...............................85

Default Settings ........................................ 87

Chapter 8 External Control

(EXT I/O) 89

8.1 External Input/Output Connector

and Signals......................................... 90

Switching between Current Sink (NPN) and

Current Source (PNP) 90

Connector Type and Signal Pinouts ........ 91

Signal Descriptions .................................. 93

8.2 Timing Chart .......................................97

From Start of Measurement to Acquisition

of Judgment Results ................................ 97

Zero-adjustment timing ............................ 99

Panel Load Timing ................................. 100

BCD Signal Timing ................................. 100

Output Signal State at Power-On ........... 101

Acquisition Process When Using an

External Trigger ..................................... 102

8.3 Internal Circuitry ...............................104

Electrical Specifications ......................... 106

Connection Examples ............................ 107

8.4 External I/O Settings ........................109

Setting Measurement Start Conditions

(Trigger Source) ..................................... 109

Setting the TRIG Signal Logic ................ 111

Eliminating TRIG/PRINT Signal Chatter

(Filter Function) ...................................... 113

Setting EOM Signal ................................ 115

Switching Output Modes

(JUDGE Mode/ BCD Mode) ................... 117

8.5 Checking External Control ............... 118

Performing an I/O Test

(EXT I/O Test Function) ......................... 118

8.6 Supplied Connector Assembly ......... 120

Chapter 9 Communications

(USB/ RS-232C

Interface) 121

9.1 Overview and Features .................... 121

Specifications ......................................... 122

9.2 Preparations before Use

(Connections and Settings) ............. 123

Using the USB Interface ......................... 123

Using the RS-232C Interface ................. 126

9.3 Controlling the Instrument with

Commands and Acquiring Data ....... 130

Remote and Local States ....................... 130

Displaying Communications Commands

(Communications Monitor Function) 131

9.4 Auto-Exporting Measured Values (at End

of Measurement)

(Data Output Function) .................... 133

Chapter 10 Printing

(Using an RS-232C

Printer) 137

10.1 Connecting the Printer to the Instrument

.......................................................... 137

10.2 Printing ............................................. 140

Printing Measured Values and Comparator

Judgments ..............................................140

Printing List of Measurement Conditions and

Settings .................................................. 140

Page 7

iii

Contents

Chapter 11 Specifications 145

11.1 Instrument Specifications ................. 145

Measurement Ranges ............................145

Measurement Method .............................145

Measurement Specifications ...................146

About Instrument Accuracy .....................148

Functions ................................................149

Interface ..................................................154

Environment and Safety Specifications ..158

Accessories ............................................ 158

Options ...................................................158

Chapter 12Maintenance and

Service 159

12.1 Troubleshooting ............................... 160

Q&A (Frequently Asked Questions) ........160

Error Displays and Remedies .................169

12.2 Replacing the Measurement Circuit’s

Protective Fuse ................................171

12.3 Inspection and Repair ......................172

Appendix A 1

Appendix 1 Block Diagram .......................... A 1

Appendix 2 Four-Terminal

(Voltage-Drop) Method............. A 2

Appendix 3 DC and AC Measurement ........A 3

Appendix 4 Temperature Correction

(TC) Function ........................... A 4

Appendix 5 Effect of Thermal EMF ............. A 6

Appendix 6 Zero Adjustment ....................... A 8

Appendix 7 Unstable Measured Values .... A 13

Appendix 8 Using Multiple RM3544s ........ A 21

Appendix 9 Detecting the Location of a

Short on a Printed Circuit

Board...................................... A 22

Appendix 10JEC 2137 Induction Machine-

compliant Resistance

Measurement ......................... A 23

Appendix 11Making Your Own Measurement

Leads ..................................... A 24

Appendix 12Checking Measurement Faults

............................................... A 26

Appendix 13Using the Instrument with a

Withstanding Voltage TesterA ...27

Appendix 14Measurement Leads (Options)

............................................... A 28

Appendix 15Rack Mounting...................... A 29

Appendix 16Dimensional Diagram ........... A 33

Appendix 17Calibration............................. A 34

Appendix 18Adjustment Procedure .......... A 38

Appendix 19Instrument Settings (Memo) . A 39

6

7

8

9

Index Index 1

10

11

12

12

Appendix

Index

Page 8

iv

Contents

Page 9

Introduction

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate according to the specifications, contact your authorized Hioki distributor or reseller.

Confirm that these contents are provided.

Model RM3544 or RM3544-01 .................. 1

Power Cord (2-line + ground) (p. 25) ........ 1

Model L2101 Clip Type Lead .................... 1

Spare Fuse (F500mAH/250V) ................... 1

Instruction Manual (This document) ...1

* The latest version of the application disc can be downloaded from the Hioki web site.

Application disc (CD)*.........................1

(Communications Command

Instruction Manual, USB driver)

USB cable (A-B type) .........................1

EXT I/O Male Connector (p. 120).......1

RM3544-01 only

Introduction

Thank you for purchasing the HIOKI Model RM3544/ RM3544-01 Resistance Meter.

To obtain maximum performance from the instrument, please read this manual first, and

keep it handy for future reference.

Model RM3544-01 is the same as the RM3544, but with USB, RS-232C, and EXT I/O

included.

Trademarks

• Microsoft and Windows are either registered trademarks or trademarks of Microsoft Cor-

poration in the United States and other countries.

• TEFLON is a registered trademark or trademark of The Chemours Company FC, LLC

Verifying Package Contents

Inspection

1

Content confirmation

Page 10

2

Measurement

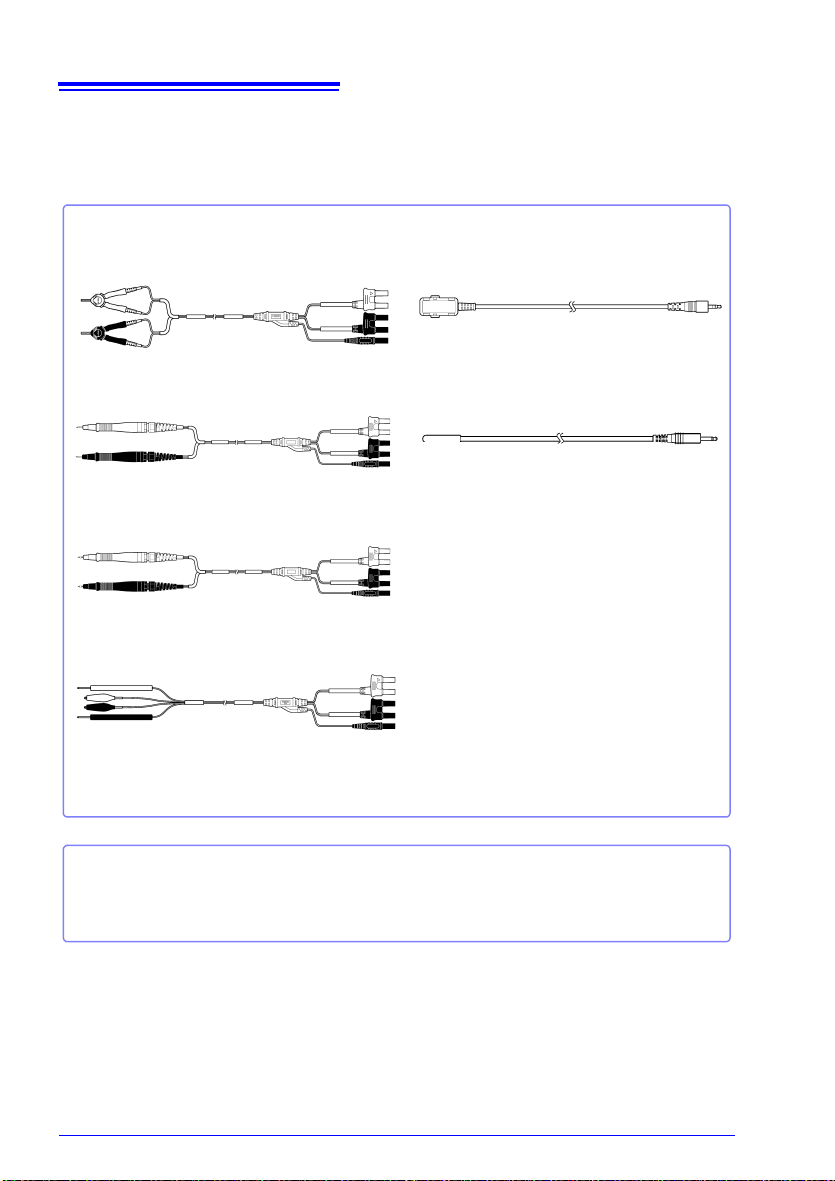

Model L2101 Clip Type Lead

Model L2102 Pin Type Lead

Model L2103 Pin Type Lead

Model L2104 4-Terminal Lead

Interface Cables

Model 9637 RS-232C Cable (9pin-9pin/ 1.8 m/ crossover cable)

Model 9638 RS-232C Cable (9pin-25pin/ 1.8 m/ crossover cable)

Model L2105 LED Comparator Attachment

Model Z2001 Temperature Sensor

Verifying Package Contents

Options

Contact your authorized Hioki distributor or reseller for details.

See: "Appendix 14 Measurement Leads (Options)" (p. A28)

Page 11

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested for safety prior to shipment.

However, using the instrument in a way not described in this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

Mishandling during use could result in injury or death, as well as damage to the product. Be certain that you understand the instructions and

precautions in the manual before use.

With regard to the electricity supply, there are risks of electric shock,

heat generation, fire, and arc discharge due to short circuits. If persons

unfamiliar with electricity measuring instruments are to use the product, another person familiar with such instruments must supervise

operations.

This manual contains information and warnings essential for safe operation of the instrument and for maintaining it in safe operating condition. Before using it, be sure to carefully

read the following safety precautions.

Safety Symbols

3

In the manual, the symbol indicates particularly important information that the

user should read before using the instrument.

The symbol printed on the instrument indicates that the user should refer to a

corresponding topic in the manual (marked with the symbol) before using the

relevant function.

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a fuse.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in

serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in

serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Page 12

4

Safety Information

Symbols for Various Standards

Indicates that the product conforms to regulations set out by the EU Directive.

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU

market after August 13, 2005, and producers of the Member States are required to

display it on the appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

Other Symbols

Indicates the prohibited action.

(p. )

[ ]

SET

(Bold characters)

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with the

following meanings.

f.s.

rdg.

dgt.

See: "Example accuracy calculations" (p. 148)

Indicates the location of reference information.

*

Indicates that descriptive information is provided below.

Square brackets indicate instrument display labels (such as setting item names).

Bold characters within the text indicate operating key labels.

(maximum display value)

This is usually the name of the maximum displayable value. For this instrument, it

indicates the currently selected range.

(reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value

that causes the digital display to show a “1” as the least-significant digit.

Page 13

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to ensure that

no damage occurred during storage or shipping. If you find any damage, contact your

authorized Hioki distributor or reseller.

Before using the instrument, make sure that the insulation on the

power cord, leads or cables is undamaged and that no bare conductors

are improperly exposed. Using the instrument in such conditions could

cause an electric shock, so contact your authorized Hioki distributor or

reseller for replacements.

5

Page 14

6

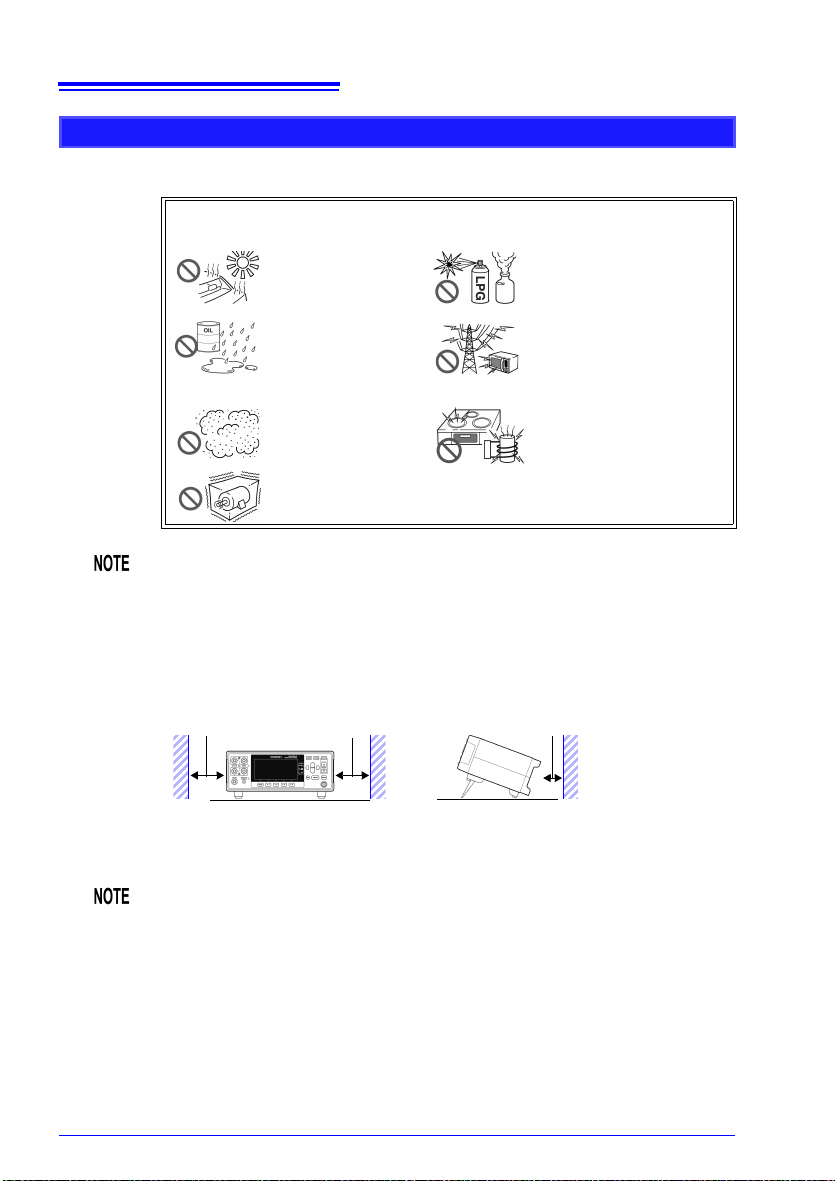

10 mm or more

Rear

50 mm or more 50 mm or more

The instrument can be used with the stand (p. 18).

It can also be rack-mounted. (p. A29).

Operating Precautions

Instrument Installation

Operating temperature and humidity : 0 to 40°C at 80% RH or less (non-condensating)

Storage temperature and humidity : -10°C to 50°C at 80% RH or less (non-condensating)

Avoid the following locations that could cause an accident or damage to the

instrument.

Correct measurement may be impossible in the presence of strong magnetic

fields, such as near transformers and high-current conductors, or in the presence of strong electromagnetic fields such as near radio transmitters.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals, or solvents

Exposed to high humidity or condensation

Exposed to high levels

of particulate dust

Subject to vibration

In the presence of corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction heating systems and IH

cooking utensils)

Installation Precautions

• The instrument should be operated only with the bottom downwards.

• Do not place the instrument on an unstable or slanted surface.

Unplugging the power cord kills power to the instrument. Be sure to provide

enough unobstructed space to unplug the power cord immediately in an

emergency.

Page 15

Handling the Instrument

• Do not allow the instrument to get wet, and do not take measurements

with wet hands. This may cause an electric shock.

• Do not attempt to modify, disassemble or repair the instrument; as

fire, electric shock and injury could result.

• To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock

from dropping.

• To avoid damage to the instrument, do not apply voltage or current to mea-

surement terminals, TEMP.SENSOR jack, or COMP.OUT jack.

• This instrument may cause interference if used in residential areas. Such

use must be avoided unless the user takes special measures to reduce

electromagnetic emissions to prevent interference to the reception of radio

and television broadcasts.

• Use the original packing materials when transporting the instrument, if pos-

sible.

Handling the Cords and Leads

7

Operating Precautions

To avoid electrical shock, be careful to avoid shorting live lines with the

test leads.

• Avoid stepping on or pinching cables, which could damage the cable insula-

tion.

• To avoid breaking cables or lead wires, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

• To avoid damaging the cable, grasp the connector, not the cable, when

unplugging the cable.

• The ends of the pin type lead are sharp. Be careful to avoid injury.

• Keep the cables well away from heat sources, as bare conductors could be

exposed if the insulation melts.

• Temperature sensors are precision devices. Be aware that excessive volt-

age pulses or static discharges can destroy the film.

• Avoid subjecting the temperature sensor tip to physical shock, and avoid

sharp bends in the leads. These may damage the probe or break a wire.

• To avoid electric shock, do not exceed the lower of the ratings shown on the

instrument and test leads.

Page 16

8

Operating Precautions

• Use only the specified cords and leads. Using a non-specified cord or lead

may result in incorrect measurements due to poor connection or other reasons.

• If the part of the temperature sensor that connects to the instrument

becomes dirty, wipe it clean. The presence of dirt may affect temperature

measured values by increasing the contact resistance.

• Exercise care so that the temperature sensor connector does not become

disconnected. (If the sensor is disconnected, it will not be possible to perform temperature correction.)

CD-R disc precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches.

When writing text on a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight,

high temperature, or high humidity.

• Hioki is not liable for any issues your computer system experiences in the

course of using this disc.

Before Connecting the Power Cord

• To avoid electrical accidents and to maintain the safety specifications

of this instrument, connect the power cord provided only to a 3-contact (two-conductor + ground) outlet.

• Use only the designated power cord with this instrument. Use of other

power cords may cause fire.

• Before using the instrument, make sure that the insulation on the

power cord is undamaged and that no bare conductors are improperly

exposed. Any damage could cause electric shock, so contact your

authorized Hioki distributor or reseller.

To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

Before Connecting Measurement Leads

To avoid shock and short circuits, turn off all power before connecting

measurement leads.

Page 17

Before Connecting the LED Comparator Attachment

• To keep from damaging the instrument or LED Comparator Attachment,

turn off the instrument before connecting the attachment.

• The COMP.OUT jack is provided exclusively for use with the L2105. Do not

connect any device other than the L2105.

• The attachment may not fulfill the specifications if the connector is not

attached securely.

• Do not over-tighten the cable tie around the measurement leads. Doing so

may damage the measurement leads.

• Avoid the following as damage to the cable conductor or insulation may

result:

Twisting or pulling on cables

Bending cables near the lamp excessively in order to connect them

Before Connecting the Temperature Sensor

Failure to fasten the connectors properly may result in sub-specification performance or damage to the equipment.

Note the following precautions to avoid damaging the instrument:

• To keep from damaging the instrument or temperature sensor, turn off the

instrument’s main power switch before connecting the sensor.

• Connect the temperature sensor by inserting the plug all the way into the

TEMP.SENSOR jack. A loose connection can cause a large error component in measured values.

9

Operating Precautions

If the temperature sensor jack becomes dirty, wipe it clean. The presence of

dirt will cause an error in temperature measured values.

Page 18

10

Operating Precautions

Before Connecting Data Cables (USB, RS-232C)

Observe the following precautions when connecting the instrument and a

controller:

• To avoid faults, do not disconnect or reconnect the USB cable during instru-

ment operation.

• The USB and RS-232C interfaces are not isolated from the ground circuit.

Connect the instrument and the controller to a common earth ground.

Using different grounds could result in potential difference between the

instrument and the controller. Potential difference on the data cable can

result in malfunctions and faults.

• Before connecting or disconnecting the RS-232C Cable, always turn off the

instrument and the controller. Failure to do so could result in equipment

malfunction or damage.

• After connecting the RS-232C Cable, tighten the screws on the connector

securely. Failure to secure the connector could result in equipment malfunction or damage.

Before Connecting the Printer

Because electric shock and instrument damage hazards are present,

always follow the steps below when connecting the printer.

• Always turn off the instrument and the printer before connecting.

• A serious hazard can occur if a wire becomes dislocated and contacts

another conductor during operation. Make certain connections are

secure.

Page 19

Operating Precautions

Before Switching between Current Sink (NPN) and Current Source (PNP)

• Configure the NPN/PNP setting to accommodate externally connected

equipment.

• Do not operate the NPN/PNP switch while the instrument is on.

Before Connecting EXT I/O

To avoid electric shock or damage to the equipment, always observe

the following precautions when connecting to the EXT I/O connector.

• Always turn off the main power switch on the instrument and on any

devices to be connected before making connections.

• Be careful to avoid exceeding the ratings of external terminals (p.

106).

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Use screws to secure the

external connectors.

• The ISO_5V pin of the EXT I/O connector is a 5V (NPN)/ -5V (PNP)

power output. Do not apply external power to this pin. (External power

cannot be supplied to the instrument’s EXT I/O connector.)

11

To avoid damage to the instrument, observe the following cautions:

• Do not apply voltage or current to the EXT I/O terminals that exceeds their

ratings.

• When driving relays, be sure to install diodes to absorb counter-electromo-

tive force.

• Be careful not to short-circuit ISO_5V to ISO_COM.

• Configure the NPN/PNP setting to accommodate externally connected

equipment.

• Do not operate the NPN/PNP switch while the instrument is on.

See: "Connector Type and Signal Pinouts" (p. 91)

Before Turning Power On

Before turning the instrument on, make sure the supply voltage

matches that indicated on its power connector. Connection to an

improper supply voltage may damage the instrument and present an

electrical hazard.

Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with

rectangular wave or pseudo-sine-wave output to power the instrument. Doing

so may damage the instrument.

Page 20

12

The measurement target is

connected to a power supply.

• Never attempt to measure at a point where volt-

age is present. Even if the power supply to the

motor is turned off, while the motor is rotating

inertially, high electromotive power is generated

in terminals. When attempting to measure a

transformer or motor immediately after voltage

withstanding test, induced voltage or residual

charge may damage the instrument.

Rotating inertially

• When the RM3544 is used in a way that connects to a withstanding voltage

tester via switching relays, construct a testing line bearing the following in

mind.

See: "Appendix 13 Using the Instrument with a Withstanding Voltage Tester" (p.

A27)

(1) The voltage withstanding specification of switching relays should

include a safe margin over the withstanding testing voltage.

(2) To protect against damage due to arc discharge in relay contacts, all

RM3544 measurement terminals should be grounded during voltage

withstanding testing.

(3) To protect against damage due to residual charge, measure resistance

first, and voltage withstanding last.

3158 AC Withstanding Voltage HiTester

Withstand voltage of relay switch is not high enough.

Residual charge from voltage

withstanding test is present.

RM3544

Operating Precautions

Before Measuring

• To avoid electric shock or damage to the

instrument, do not apply voltage to the

measurement terminals. Also, to avoid

electrical accidents, only take measurements after turning off the power to the

measurement targets being measured.

• Sparks may result at the moment the instrument is connected to, or

disconnected from, the measurement target. To avoid fire or bodily

injury, avoid use in the presence of explosive gases.

• Battery internal resistance cannot be measured with this instrument. It will

sustain damage. To measure battery internal resistance, we recommend the

HIOKI 3554, 3555, BT3562, BT3563 and 3561 Battery HiTesters.

Page 21

• When measuring devices such as power supply transformers with high

inductance or open-type solenoid coils, measured value may be unstable.

In such cases, connect a film capacitor of about 1 F between SOURCE A

and SOURCE B.

• Carefully insulate all SOURCE A, SENSE A, SENSE B, and SOURCE B

wiring. Proper 4-terminal measurements cannot be performed and an error

will occur if core and shield wires touch.

• The SOURCE terminal is protected by a fuse. If the fuse is tripped, the

instrument will display “

Blown Fuse.” and you will not be able to measure

resistance values. If the fuse is tripped, replace the fuse.

See: "12.2 Replacing the Measurement Circuit’s Protective Fuse" (p. 171)

When using the temperature sensor

The temperature sensor is not waterproof. Do not submerse it in water or

other liquid.

• Allow the measurement target for which temperature correction is being

performed and the temperature sensor to adjust to the ambient temperature

prior to measurement. Failure to do so will result in a large error component.

• Handling of the temperature sensor with bare hands may cause the sensor

to pick up inductive noise, resulting in unstable measured values.

• The temperature sensor is designed for use in applications in which ambi-

ent temperature is measured. It is not possible to accurately measure the

temperature of the measurement target itself by placing the sensor in contact with the surface of the target.

• Connect the temperature sensor by inserting the plug all the way into the

TEMP.SENSOR jack. A loose connection may cause a large error component in measured values.

13

Operating Precautions

Page 22

14

Operating Precautions

Page 23

15

• Installed footprint: 215 mm × 166 mm

Compact footprint and limited depth leave plenty of work space in front of the instrument.

• Measurement range: 30.000 m to 3.0000 M with a basic accuracy of 0.02%

rdg.

• Maximum measurement current: 300 mA

Ensures stable measurement, even when there is a significant amount of external noise.

• No need for warm-up operation or zero-adjustment

Since wasteful wait times are not required, you can start making measurements as soon as

the instrument is turned on.

• Choice of interfaces

RM3544 (no interface), RM3544-01 (USB, RS-232C, EXT I/O)

Compact yet reliable specifications

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

The RM3544 is capable of performing high-speed, high-precision measurement of the

winding resistance of components such as motors and transformers, the contact resistance

of relays and switches, the pattern resistance of printed circuit boards, and the DC resistance of fuses, resistors, and materials such as conductive rubber using four-terminal measurement. Since the instrument incorporates a temperature correction function, it is

particularly well suited to the measurement of targets whose resistance values vary with

temperature.

1

Page 24

16

LED Comparator Attachment (option)

Streamlines work by eliminating the need to look at the screen.

Graphical LCD

Operation is intuitive and easy to learn.

Easy configuration of comparator and panel

load operation

Facilitates smooth setup changes on production lines.

Simple basic settings

Range and measurement

speed can be set directly.

Guard terminal

You can reduce the

effects of external

noise by connecting the guard terminal.

Free power supply (100 to 240 V) with

automatic frequency switching

Allows the instrument to be easily moved to

overseas production lines.

Judgment sounds with user-selectable patterns

Keeps you from mistaking audio from a

nearby operator’s instrument as your own.

Easy-to-use functions in research and development,

on production lines, or in acceptance inspections

Monitor and test functions

Provides robust support for line development by allowing you to check

communications and EXT I/O on the

screen.

Example communications

monitor screen

Example EXT I/O test

screen

1.1 Product Overview and Features

Page 25

17

Display Screen (Monochrome graphical LCD)

Display of measurements and

settings (p. 21)

Viewing Measured

Values and Settings

COMP indicator LEDs

Indicate the judgment result of the measured value (p.60).

Hi Measured value is above upper limit

IN Pass (meets criteria)

Lo Measured value is below lower limit

Viewing Comparator Results

MENU key

Switching of F key pages

F keys

Selection of settings displayed

on the screen

COMP.OUT jack

Connect the L2105 LED Comparator Attachment to

view judgment results without needing to refer to the

instrument display. (p.70)

Connecting the LED Comparator Attachment

PANEL key

Saving and loading of panels

(p.72)

COMP key

Configuration of comparator

settings (p.60)

AUTO, RANGE key

Range switching (p.32)

SPEED key

Measurement speed switching

(p.33)

Cursor keys

Selection of settings and digits

ENTER key

Acceptance of settings and

manual trigger input

ESC key

Cancellation of operation

Settings

Measurement Terminals

Connect measurement leads (p. 26).

• SOURCE A : Current detection terminal

• SOURCE B : Current source terminal

• SENSE A : Voltage detection terminal

• SENSE B : Voltage detection terminal

• GUARD : Guard terminal

Connecting Measurement Leads

STANDBY Key: Initiates or cancels the

standby state. (p. 28).

• Unlit: power off (when no power supplied)

• Red light: Standby State (while power is supplied)

• Green light: power on

Initiating and Canceling the Standby State

1.2 Names and Functions of Parts

1.2 Names and Functions of Parts

Front Panel

1

Page 26

18

TEMP.SENSOR jack

Connect the Z2001 Temperature Sensor

when using temperature correction (p.27).

Correcting Temperature

RS-232C connector

• Connect to a computer, PLC, or other

device (p.126).

• Connect to a printer (p.137).

RS-232C Communications

Printer Output

Fuse holder (p.171)

Replacing the Fuse

Main power switch

(p.28)

: Main power off

: Main power on

Turning the Main

Power On and Off

EXT I/O connector

Connect when controlling the instrument with a PLC, I/O board, or other equipment to allow measurement to be started and measured values and comparator results to be acquired (p. 89).

External Control

Manufacturer's Serial No.

Do not remove this label, as it is

required for product support.

Power Inlet

Connect the supplied

power cord (p.25).

Connecting the

Power Cord

EXT I/O NPN/PNP switch

Left : Current sink (NPN)

Right : Current source (PNP)

Switching between NPN and PNP

USB jack

Connect to a computer (p.123).

Sending and Receiving

Data via USB

Maintenance

terminal

Do not use.

Bottom Panel

Stand

When using the stand

Extend the legs all the way. Do not extend partially.

Make sure to extend both legs of the stand.

Collapsing the stand

Do not collapse the stand partway. Be sure to collapse it

all the way.

This instrument can be rack mounted.

See: "Appendix 15 Rack Mounting" (p. A29)

Parts removed from this instrument should be stored

in a safe place to enable future reuse.

Do not apply heavy downward pressure with the

stand extended. The stand could be damaged.

1.2 Names and Functions of Parts

Rear Panel

Page 27

19

Install this instrument (p. 5)

1

Rear Panel

Turn on the instrument and cancel

the standby state

(p.28)

6

When finished measuring, turn the

power off (p.28).

Connect the temperature sensor

(p.27)

(When using the temperature correction function)

4

2

3

Make instrument settings

*1

Connect measurement leads (p.26)

7

Connect to the test sample (p.34)

8

Connect the power

cord (p.25)

Connect the external interface

(RM3544-01; as necessary)

5

• Using the printer (p.137)

• Using the USB or RS-232C inter-

face (p.121)

• Using the EXT I/O (p.89)

When clipping a small-gauge

wire

(Clip with the tip of the alligator

clips.)

When clipping a large-gauge

wire

(Clip with the back of the alligator

clips, where there are no teeth.)

6

3

4

2

5

Front Panel

Rear Front

1.3 Measurement Process

1.3 Measurement Process

1

Page 28

20

1.3 Measurement Process

*1 About zero-adjustment

Perform zero-adjustment in the following circumstances:

• The measured value is not cleared due to thermal EMF or other factors.

The measured value will be adjusted to zero. (Accuracy is not affected by whether or

not the zero adjustment is performed.)

• Four-terminal connection (called Kelvin connection) is difficult.

The residual resistance of the two-terminal connection wires will be canceled.

See: "4.1 Zero Adjustment" (p.44)

"Appendix 6 Zero Adjustment" (p.8)

Page 29

21

Trigger source (INT/EXT)

Measurement range

TC (ON)

0ADJ (ON)

Auto range

Key lock state or remote state

Cancel the key lock state or remote

state by pressing and holding the

MENU key.

F.LOCK : All operations prohibited.

M.LOCK: Menu operations prohibited.

RMT : Remote state

Judgment value

Switched with the VIEW key

(No display / temperature /

pre-calculation resistance

value)

Page switching

Measurement screen layout

Hold state

Scaling (ON)

Measurement speed

Number and name

of loaded panel

Measured value

1.4 Screen Organization and Operation Overview

1.4 Screen Organization and

Operation Overview

The instrument’s screen interface consists of a Measurement screen and various Settings

screens.

The screen examples in this guide appear reversed (black on white) for best visibility on the

printed page. However, the instrument screens can actually be displayed only as white

characters on black background.

1

Display of information other than measured values

(For more information, see "Confirming Measurement Faults" (p.38).)

* To treat current faults (when the source wiring is open) as over-range events, change the

Display Description

+OvrRng

-OvrRng

- - - - -

current fault output mode setting. (p.40)

Over-range

Not measured, or broken connection in measurement target *

Page 30

22

Overview of screen operation

Menu switching

(4) To Settings screens

(1) Measurement screen

(2) Comparator Settings screen

Upper limit

value

Lower limit

value

(3) Panel Save/Load screen

Select a panel number.

3

Change

values.

Move among

digits.

Accept the setting with the

key or cancel with the key.

4

Change the range with the

and keys.

2

1

2

Perform action with an F key.

1

Select the mode with an F key.

(4) Settings screen

< Setting values >

Make the value editable with the

key.

2

Change values.

1

Move among

digits.

Accept the setting with the key

or cancel with the key.

3

Return to the Measurement screen

with the key.

Move to the [MEAS], [SYS], [I/O],

or [IF] tab.

([I/O] and [IF] tabs: RM3544-01 only.

Not shown on RM3544.)

1

2

Select a

setting.

Move among

settings.

Switch functions with an F key or set

values.

3

4

1.4 Screen Organization and Operation Overview

Page 31

23

1.4 Screen Organization and Operation Overview

List of settings

Measurement screen COMP Comparator function (p.61)

Measurement screen

(P.1/2)

Measurement screen

(P.2/2)

Settings

screen

(SETTING)

*1 RM3544-01 only.

Screen Setting and key Overview See

PANEL Save/load panel (p.71)

Measurement

Settings screen

(MEAS)

System Settings

screen

(SYS)

EXT I/O Settings

screen

*1

(I/O)

Communication

Interface

Settings screen

*1

(IF)

AUTO

(RANGE)

SPEED Measurement speed (p.33)

INFO (F1) Display setting conditions

VIEW (F2)

PRINT (F4) Print

0 ADJ (F1) Zero-adjustment

LOCK (F2) Key lock

SETTING (F4) Switch to Settings screen

0 ADJUST Clear zero-adjustment (p.48)

TC SET Temperature correction (p.52)

AVERAGE Averaging (p.50)

AUTO HOLD Hold measured value (p.41)

COMP DELAY Judge delay (p.66)

SCALING(A∗R+B)

A:

B:

UNIT:

DIGITS Set the display digits (p.58)

CURR ERROR

MODE

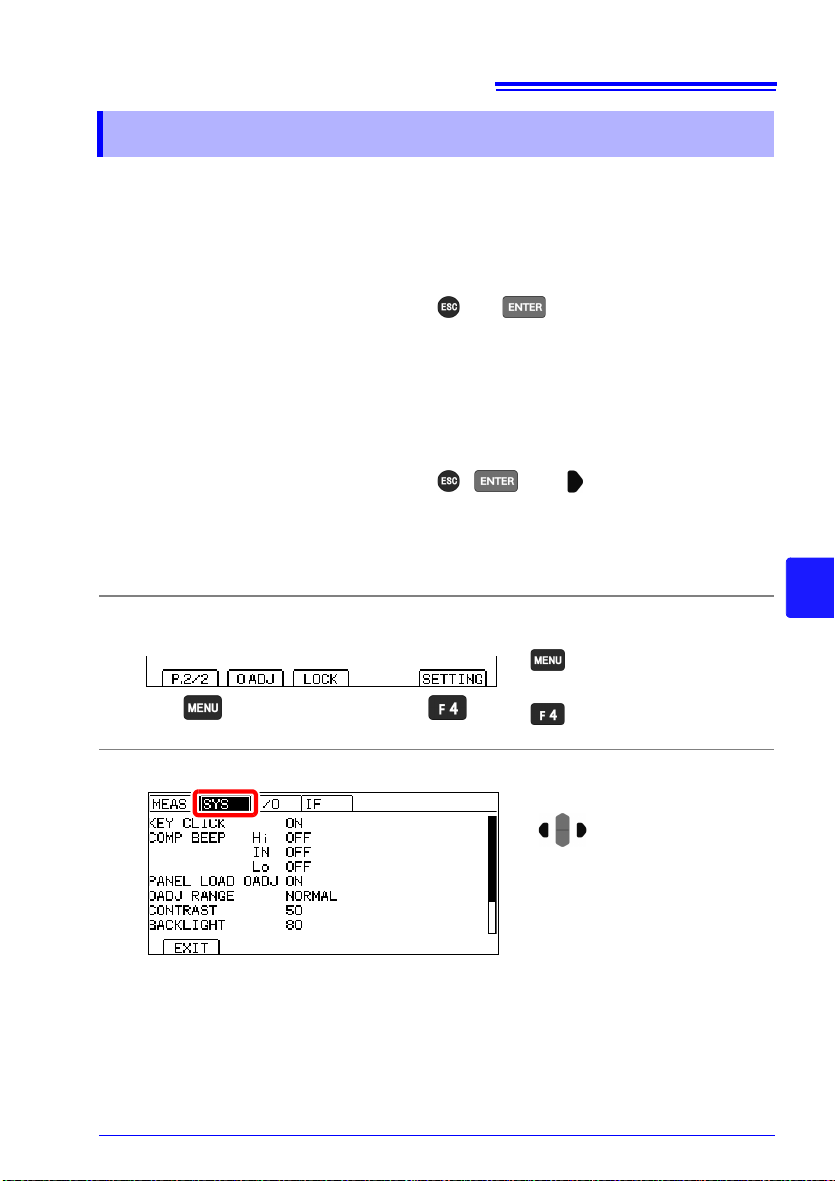

KEY CLICK Set the operation sound (p.82)

COMP BEEP Hi

Lo

PANEL LOAD 0ADJ Load zero-adjustment values (p.74)

0ADJ RANGE Zero-adjustment range (p.47)

CONTRAST Set the contrast (p.83)

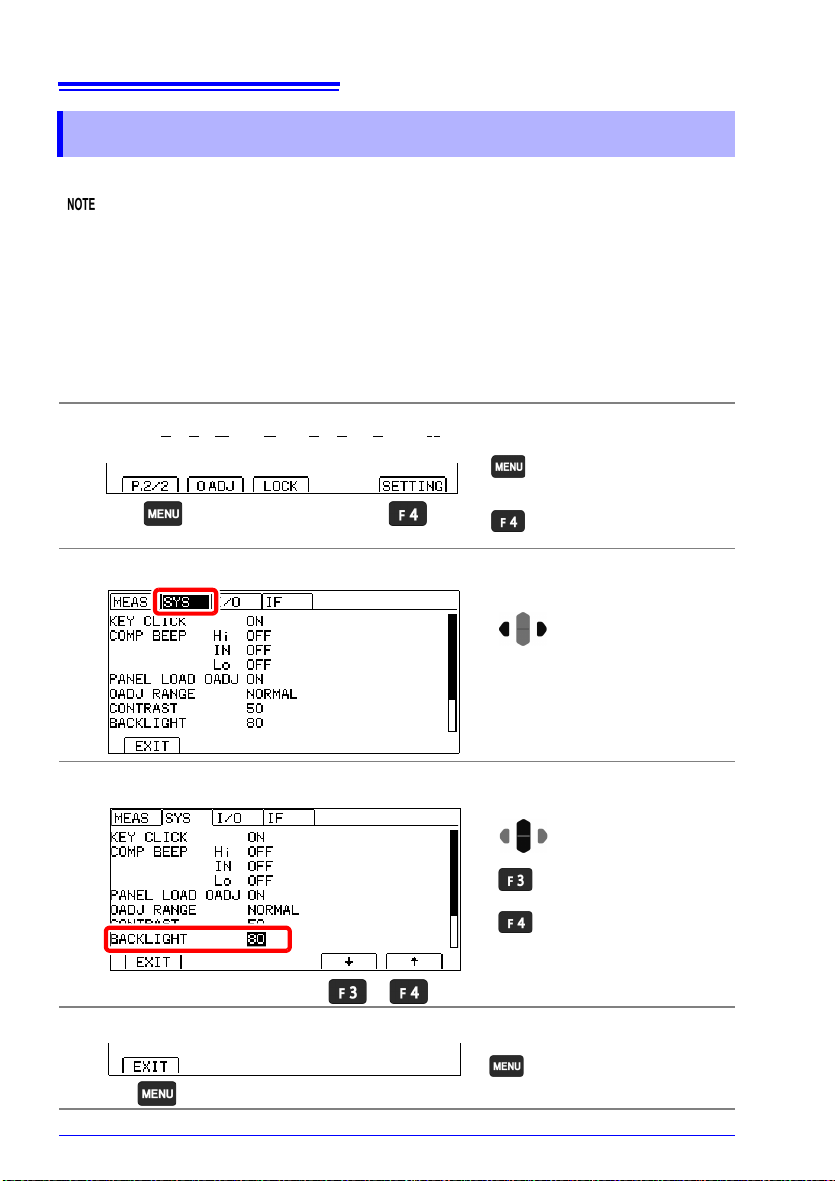

BACKLIGHT Set the contrast brightness (p.84)

POWER FREQ Set the power frequency (p.80)

RESET Reset the instrument (p.85)

ADJUST Adjust the instrument (p.A38)

TRIG SOURCE Set the trigger source (p.109)

TRIG EDGE Set the trigger signal logic (p.111)

TRIG/PRINT FILT Trigger/print filter function (p.113)

EOM MODE EOM signal setting (p.115)

JUDGE/BCD MODE EXT I/O output mode (p.117)

EXT I/O TEST Test EXT I/O (p.118)

INTERFACE Configure interface settings (p.123)

SPEED

CMD MONITOR

PRINT INTRVL

PRINT COLUMN

Measurement range

Switch measurement screen

display

Scaling (p.54)

Set the current fault output

mode

Set the judgment sound (p.68)IN

Communications (p.121)DATA OUT

Printing (p.137)

(p.32) (RANGE)

(p.139)

(p.44)

(p.78)

(p.40)

1

Page 32

24

1.4 Screen Organization and Operation Overview

Page 33

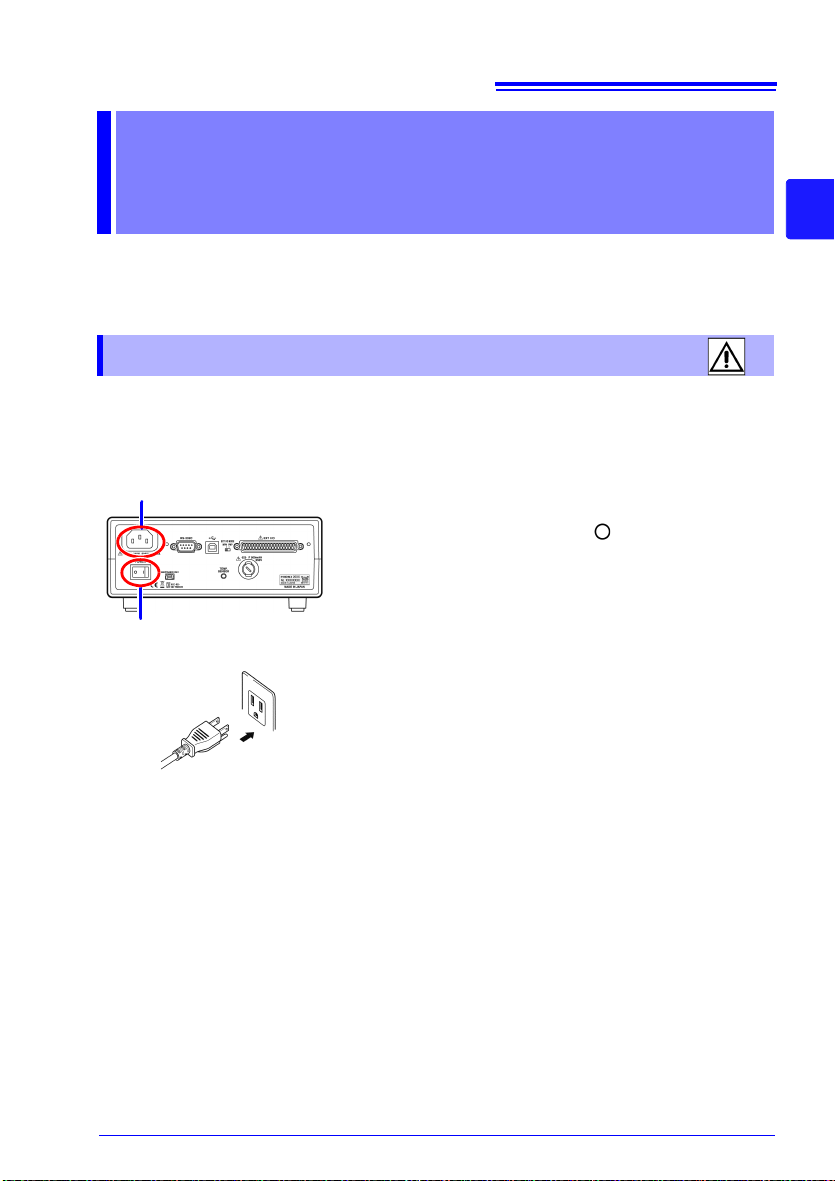

Measurement

Rear Panel

1 Confirm that the instrument's Main power

switch (rear panel) is OFF( ).

2 Confirm that the mains supply voltage matches

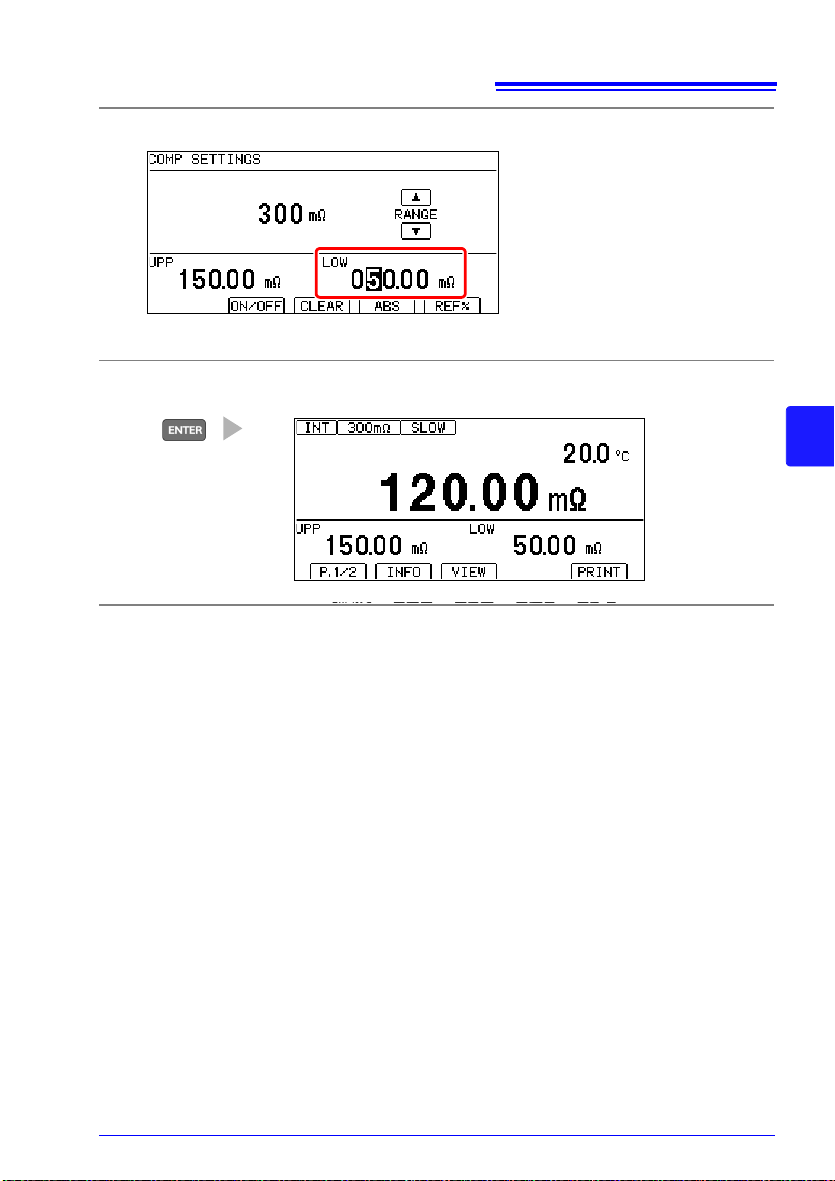

the instrument, and connect the power cord to

the power inlet on the instrument.

3 Plug the power cord into the mains outlet.

If power to the instrument is cut off with the power switch

in the ON position (by a circuit breaker, etc.), the instrument will start up when power is restored, without any

need to press the STANDBY key.

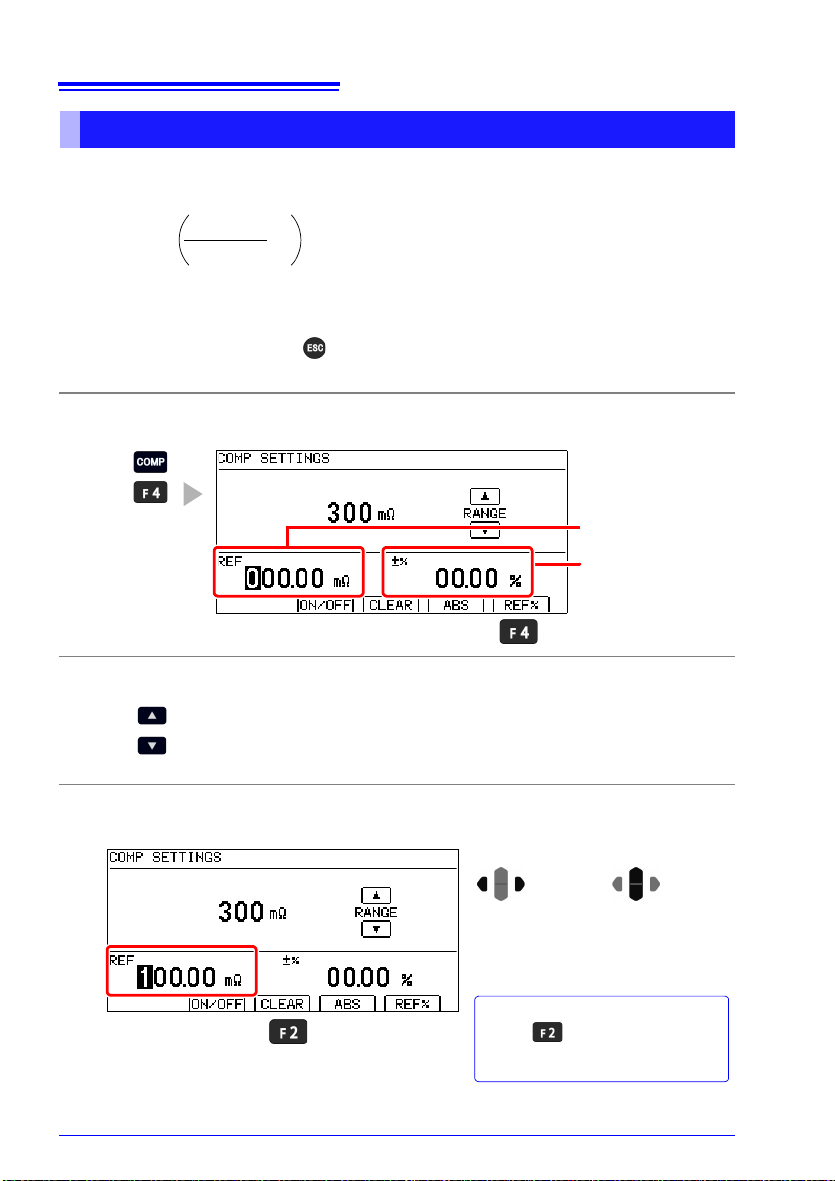

Power inlet

Main power switch

25

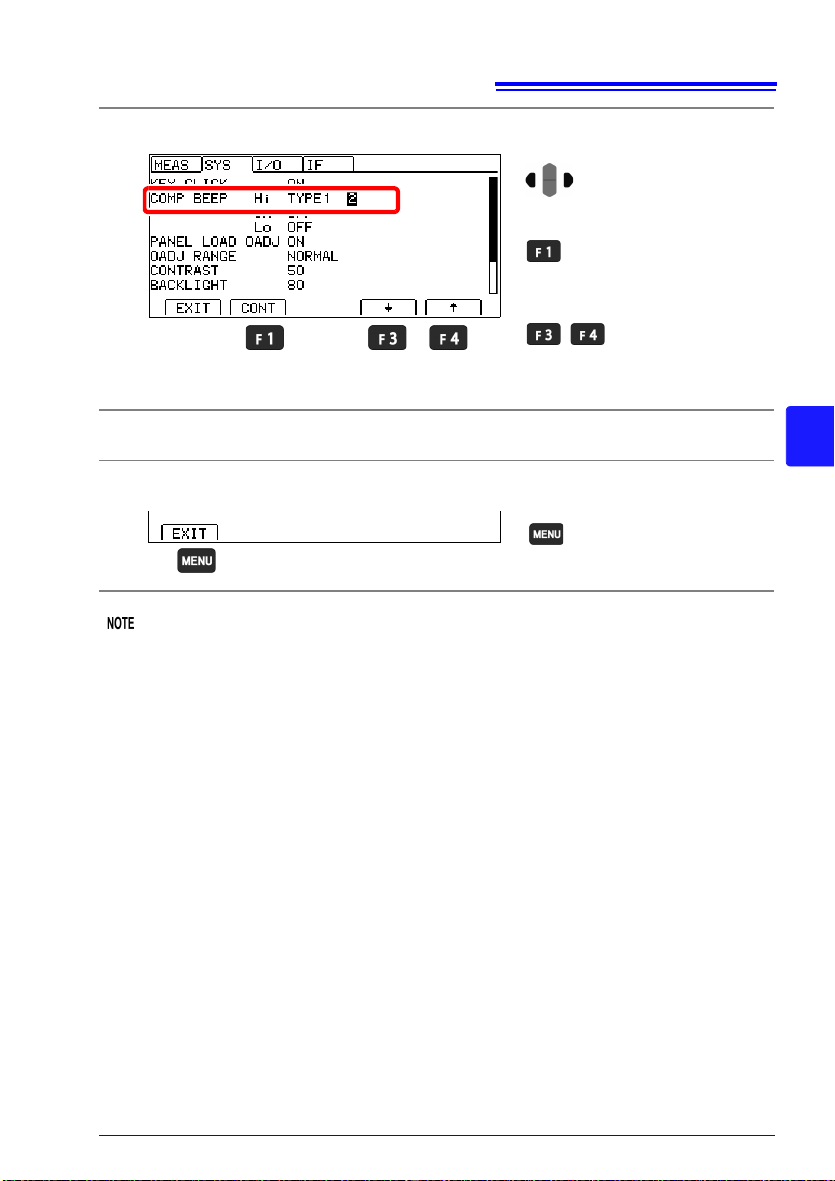

2.1 Connecting the Power Cord

Preparations

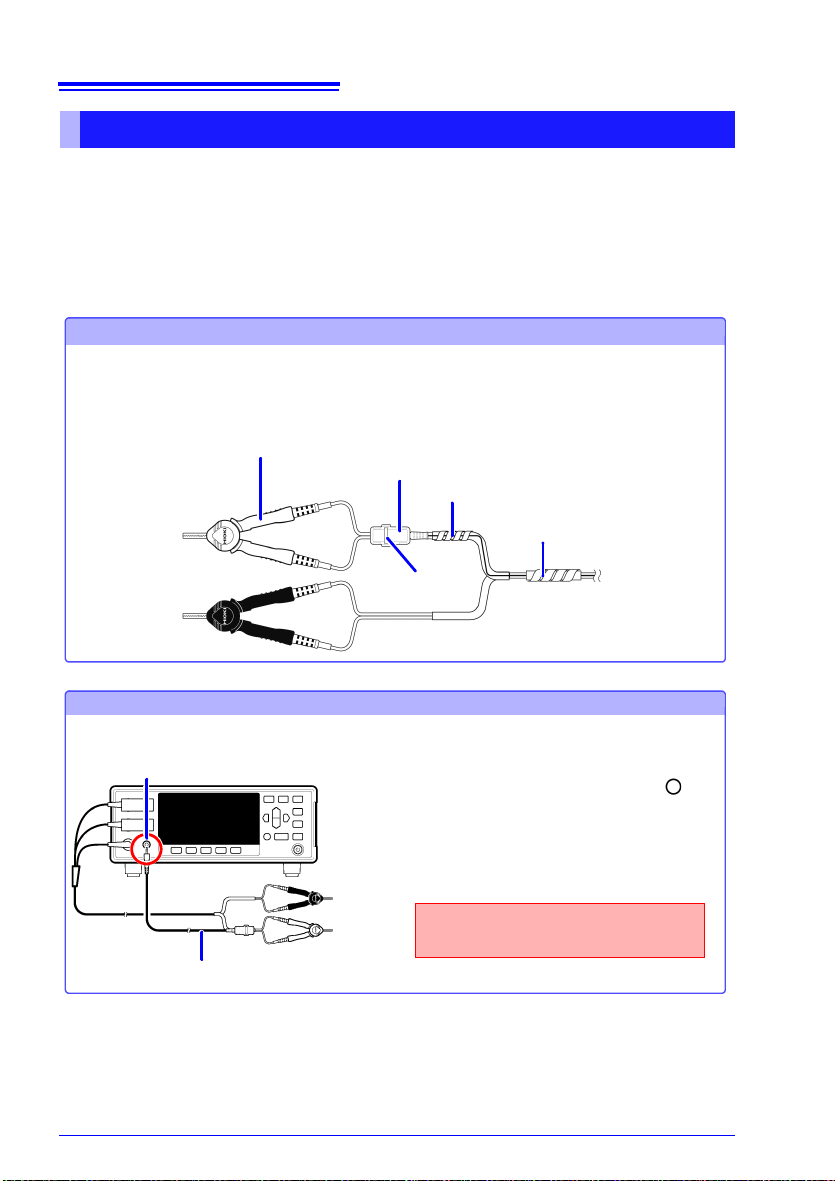

Be sure to read the "Operating Precautions" (p.5) before installing and connecting this

instrument.

Refer to "Appendix 15 Rack Mounting" (p. A29) for rack mounting.

Chapter 2

2.1 Connecting the Power Cord

Turn off the power before disconnecting the power cord.

2

Page 34

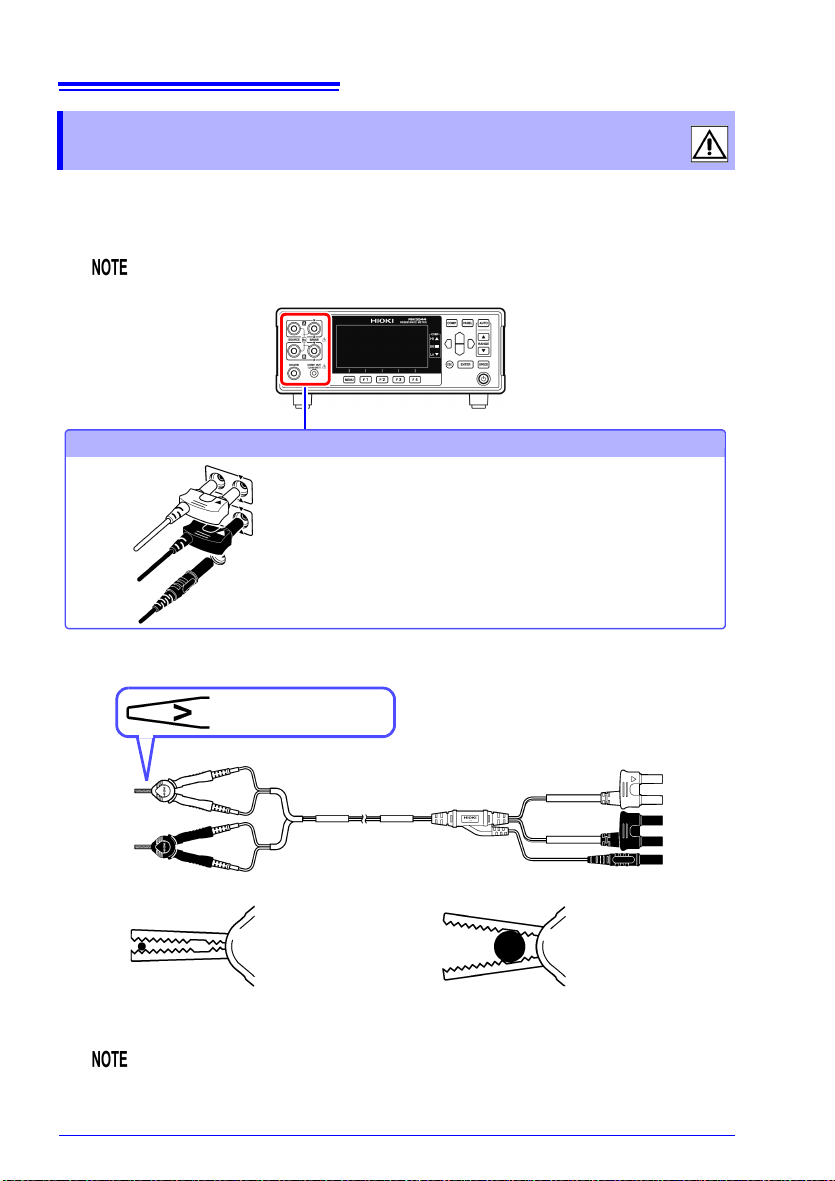

26

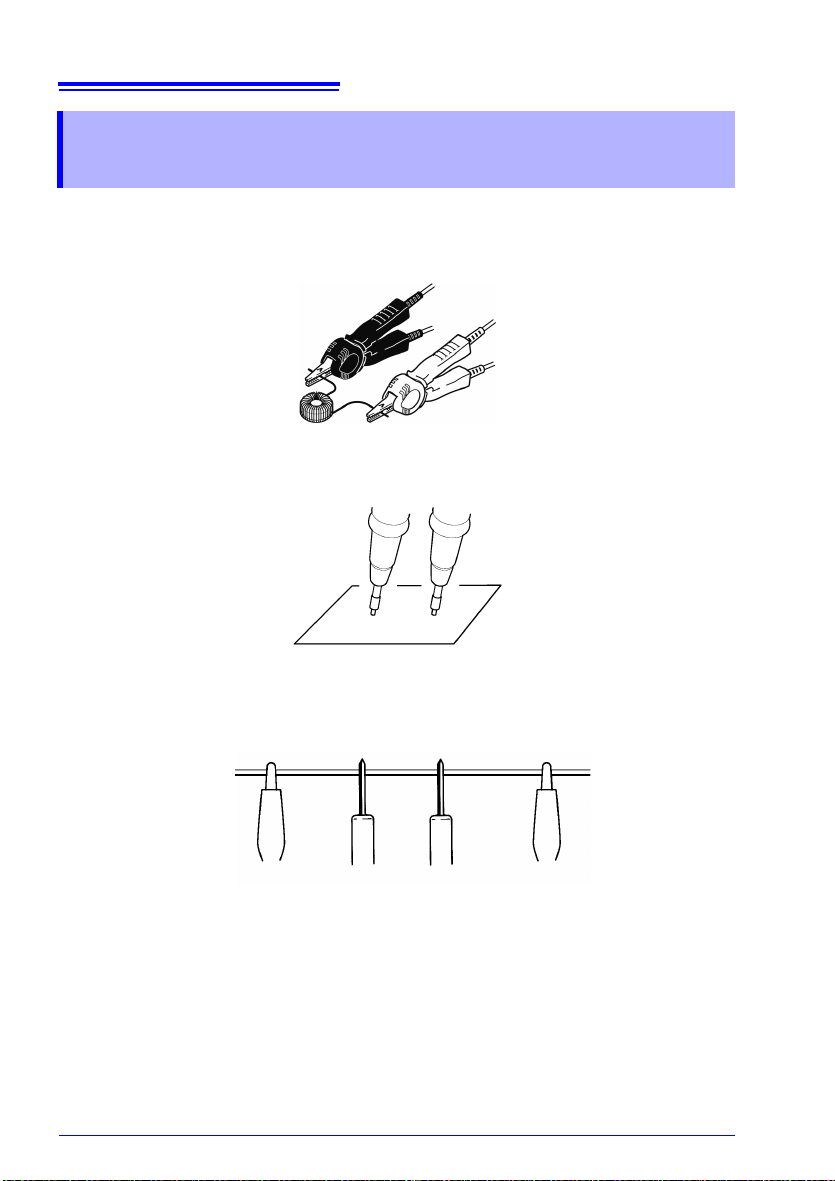

Connection Methods

Connecting measurement leads

Connect the red plugs to the SOURCE A and

SENSE A terminals, the black plugs to the

SOURCE B and SENSE B terminals, and the

guard plug to the GUARD terminal.

When clipping a small-gauge wire

(Clip with the tip of the alligator clips.)

When clipping a large-gauge wire

(Clip with the back of the alligator clips, where

there are no teeth.)

Measurement leads

(Example: When using the L2101 Clip Type Lead)

SENSE

SOURCE

The “V” mark indicates

the SENSE side.

SENSE

SOURCE

Red

Black

SENSE

SOURCE

SENSE

SOURCE

Red

Black

Red plugs

Black plugs

Guard plug

2.2 Connecting Measurement Leads

2.2 Connecting Measurement Leads

Connect the included or optional Hioki measurement leads to the measurement terminals.

Before connecting the measurement leads, read "Operating Precautions" (p.5) carefully.

Refer to "Options" (p.2) for details.

We recommend using optional Hioki measurement leads.

When making your own measurement leads or extending a measurement

lead, see "Appendix 11 Making Your Own Measurement Leads" (p. A24).

Page 35

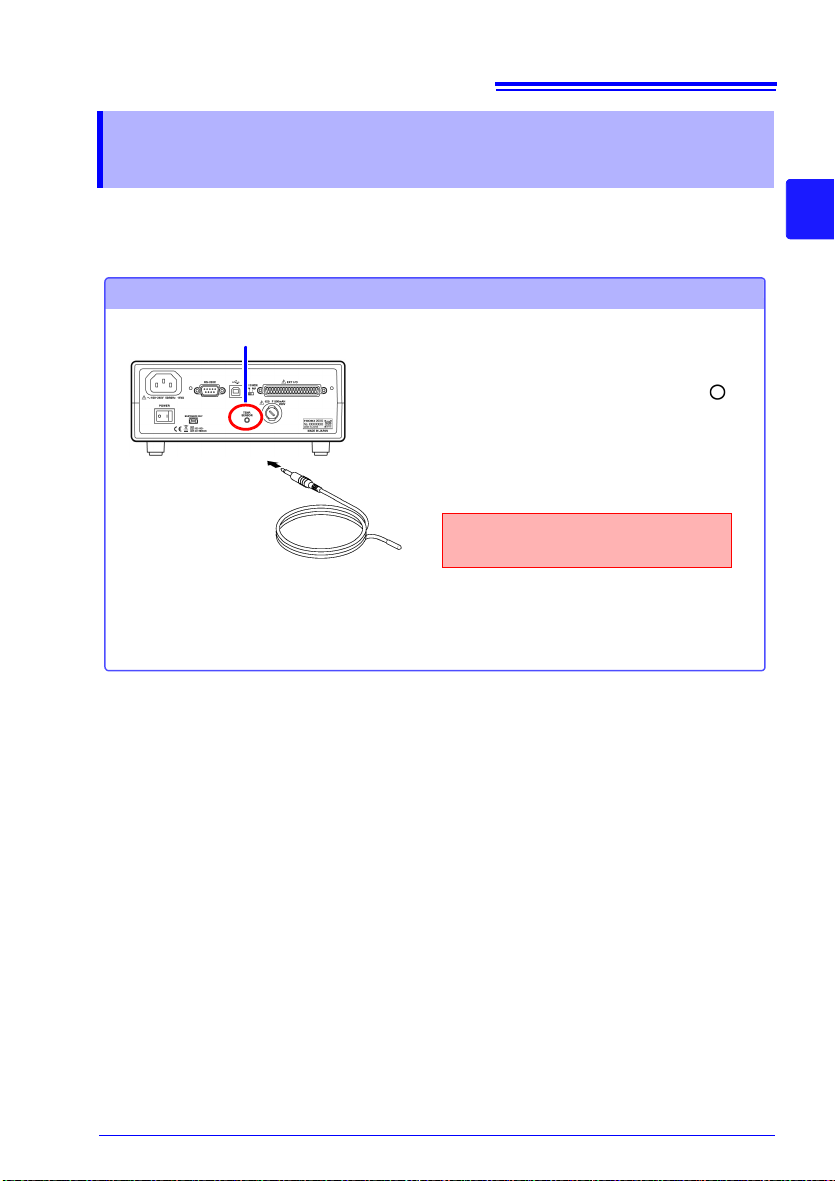

2.3 Connecting Z2001 Temperature Sensor (When using the TC)

Connection Methods

Connecting the Z2001 Temperature Sensor

Rear Panel

Z2001 Temperature Sensor

TEMP.SENSOR jack

Insert the plug securely all the way

into the jack.

1 Confirm that the instrument's Main

power switch (rear panel) is OFF( ).

2 Plug the Z2001 Temperature Sensor

into the TEMP.SENSOR jack on the rear

panel.

3 Place the tip of the temperature sensor

near the measurement target.

2.3 Connecting Z2001 Temperature Sensor

(When using the TC)

27

Before connecting the temperature sensor, read "Operating Precautions" (p.5) carefully.

2

Page 36

28

Turn on ( ) the main power switch on the rear of the

instrument.

If the main power switch was turned off while the

instrument was not in the standby state, the standby

state will be automatically canceled when the main

power switch is turned on.

Power ON

Turn off ( ) the main power switch on the rear of the

instrument.

Power OFF

Press the STANDBY key (the STANDBY

key will change from red to green).

2.4 Turning the Power On and Off

2.4 Turning the Power On and Off

Turning On the Instrument with the Main Power Switch

Turning Off the Instrument with the Main Power Switch

Canceling the Standby State

Page 37

2.4 Turning the Power On and Off

Self-test

Indicates an error (p. 169).

After the standby state is canceled, a self-test (instrument diagnostic routine) is performed.

During the self-test, the following information is displayed while the hardware is verified.

Error

No Errors

Normal display (measurement screen)

The following information is displayed during self-testing:

• Manufacturer and model name

• Firmware versions

• Communication interface setting

• Detected line frequency

• EXT I/O (NPN/PNP) setting

When powered up for the first time, the default settings appear.

See: "Default Settings" (p.87)

29

2

Before Starting Measurement

The SOURCE terminal is protected by a fuse. If the fuse is tripped, the instrument will display “Blown FUSE.” and you will not be able to measure resistance values. In this case,

replace the fuse.

See: "12.2 Replacing the Measurement Circuit’s Protective Fuse" (p.171)

Measurement settings are recalled from when the power was previously turned off (settings

backup).

Placing the Instrument in the Standby State

Press the Standby key (the Standby key will change from green to red).

Disconnect the power cord from the outlet to extinguish the standby key light.

When power is turned on again, operation resumes with the same state as when last turned

off.

If a power outage (e.g., breaker trip) occurs when the instrument is on, it will automatically

turn on again when power is restored (without pressing the standby key).

Page 38

30

Do not use the instrument if

damage is found, as electric

shock or short-circuit accidents

could result. Contact your authorized Hioki distributor or reseller.

Metal Exposed

Is the power cord insulation torn, or

is any metal exposed?

1

Before using the instrument for the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributor or reseller.

Peripheral Device Inspection

Is the insulation on a measurement

lead torn, or is any metal exposed?

No Metal Exposed

If there is any damage, measured

values may be unstable and

measurement errors may occur.

Replace the cable with an undamaged one.

Metal Exposed

No Metal Exposed

If damage is evident, request repairs.

Yes

Is damage to the instrument evident?

Instrument Inspection

When turning power on

Is the STANDBY key red or green?

No

2

The power cord may be damaged, or the instrument may be

damaged internally. Request repairs.

After the completion of the self-test

(when the model number is shown

on the screen), is the Measurement screen displayed?

No

Yes

The instrument may be damaged

internally. Request repairs.

See: "12.1 Troubleshooting" (p. 160)

"Error Displays and Remedies"

(p.169)

An error indication

occurs

Yes

Inspection complete

2.5 Pre-Operation Inspection

2.5 Pre-Operation Inspection

Page 39

Basic Measurements

Chapter 3

31

Before making measurements, read "Operating Precautions" (p. 12) carefully.

This chapter explains basic operating procedures for the instrument.

"3.1 Selecting the Measurement Range" (p.32)

"3.2 Setting the Measurement Speed" (p.33)

"3.3 Connecting Measurement Leads to the Measurement Target" (p.34)

"3.4 Checking Measured Values" (p.35)

To customize measurement conditions, see "Chapter 4 Customizing Measurement Conditions" (p.43).

3

Page 40

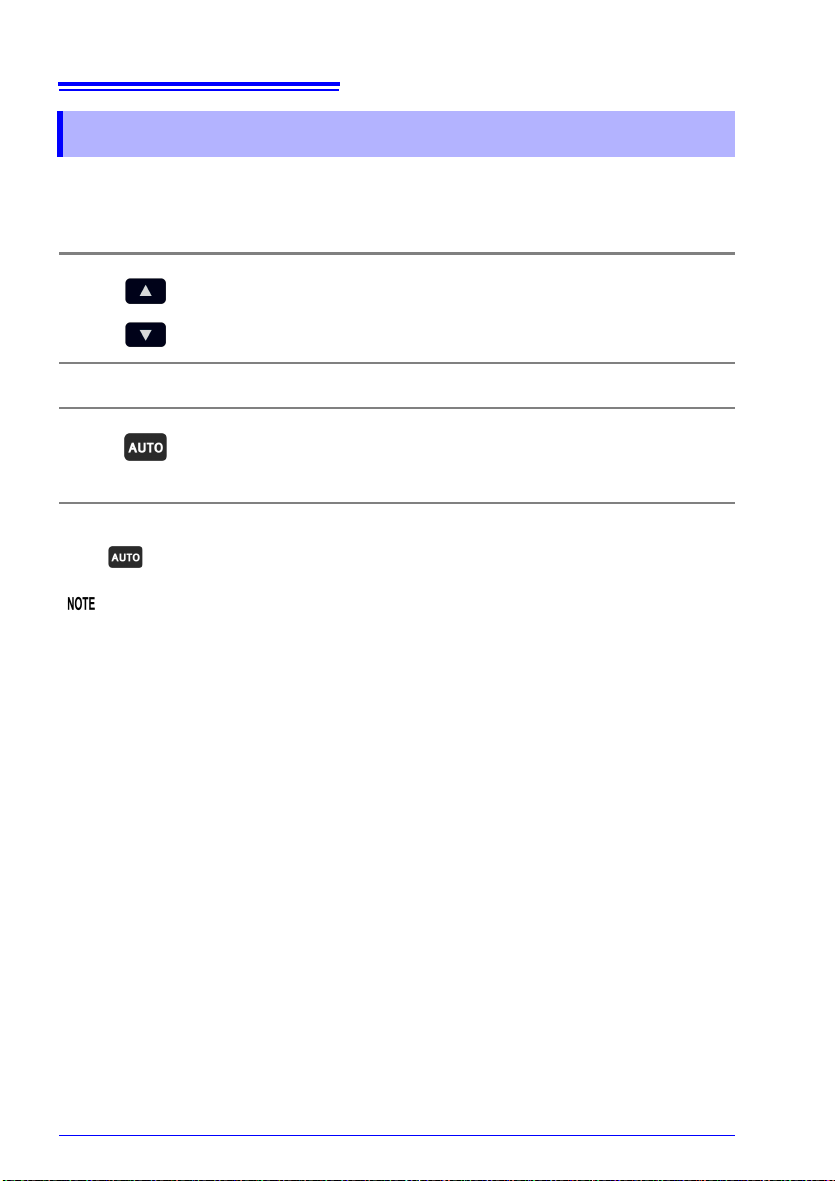

32

Select the range to use. (AUTO off)

The decimal point location and unit indicator change with each

key press.

Press this while a manual range is selected. (AUTO lights)

The optimum measurement range is automatically selected.

3.1 Selecting the Measurement Range

3.1 Selecting the Measurement Range

The measurement range can be set as follows. Auto-ranging (the AUTO range) can also be

selected.

Manual Range Setting

Auto-Ranging

Switching from Autoranging back to Manual range selection

Press again. The range can now be changed manually.

• When the comparator function is turned ON, the range cannot be changed from fixed (it

cannot be switched to auto-ranging). To change the range, turn OFF the comparator

function or change the range from within the comparator settings.

• When measuring certain motor, transformer or coil components, the auto range setting

may not stabilize. In such cases, use manual range selection.

• The measurement target power is given by (resistance value × (measurement current)

if the measured value is within the measurement range. If the measurement range is

exceeded, the power may reach a maximum value that is given by (open voltage × measurement current). Check the measurement range before connecting the measurement

target.

A rush current of up to 500 mA will flow at the moment the instrument is connected to the

measurement target.

(Convergence time: For pure resistance, approximately 1 ms)

• Refer to "Resistance Measurement Accuracy" (p. 146) for information on each range

measurement accuracy.

2

)

Page 41

33

Press this to change the measurement speed.

Measurement speed

FAST

MEDIUM SLOW

50 Hz 60 Hz

Measurement time 21 ms 18 ms 101 ms 401 ms

With TC ON, comparator ON, and error of ±10%±2 ms

Integration time (detected voltage data acquisition time) reference values

FAST (50 Hz): 20.0 ms, FAST (60 Hz): 16.7 ms, MEDIUM: 100 ms, SLOW: 400 ms

3.2 Setting the Measurement Speed

3.2 Setting the Measurement Speed

The measurement speed can be set to FAST, MED (medium), or SLOW.

The MED (medium) and SLOW settings offer increased measurement precision compared

to the FAST setting as well as greater resistance to the effects of the external environment.

If the setup is excessively susceptible to the effects of the external environment, shield the

measurement target and measurement leads adequately and twist the cables together.

See: "Appendix 7 Unstable Measured Values" (p.13)

Relationship Between Measurement Range and Speed

3

Page 42

34

(Place leads in contact with target.)

SOURCE A SENSE A SENSE B SOURCE B

The SENSE terminals are placed to the inside of the SOURCE terminals.

3.3 Connecting Measurement Leads to the Measurement Target

3.3 Connecting Measurement Leads to the Measurement Target

Before making measurements, read "Operating Precautions" (p.5) carefully.

Example with L2101

Example with L2102

Example with L2104

Page 43

35

The resistance value will be displayed.

• If the display does not indicate the mea-

sured value, see "Confirming Measurement Faults" (p. 38).

• To convert the value into a parameter

other than resistance, see below.

See: "4.4 Correcting Measured Values and

Displaying Physical Properties Other than

Resistance Values (Scaling Function)"

(p.54)

[VIEW]

Switch the Measurement

screen.

Switch the function menu

to P.1/2.

1

2

You can switch this part of the display to

show nothing, the temperature, or the precalculation measured value.

See: "Example displays" (p.36)

3.4 Checking Measured Values

3.4 Checking Measured Values

When measuring close to 0 , measured values may turn negative. If measured values turn

negative otherwise, check the following:

• Are the SOURCE or SENSE wires connected backwards?

Rewire correctly.

• Has the contact resistance decreased since you performed zero-adjustment?

Repeat the zero-adjustment process.

• Is the scaling calculation result negative?

Change the scaling settings.

3

Switching the Display

You can change what information is shown on the Measurement screen.

Displaying temperature and pre-calculation measured values

Page 44

36

(No display) (Temperature display)

Rt: Resistance measured value

before TC calculation

R: Resistance measured value

before scaling

(Value before REF% calculation

: With REF% comparator setting and

scaling OFF)

(Value before REF% calculation

: With REF% comparator setting and

scaling ON)

(Value before TC calculation

: With TC ON)

(Value before scaling calculation

: With scaling ON)

R: Resistance measured value

(before relative calculation)

RS: Resistance measured value

after scaling (before relative calculation)

3.4 Checking Measured Values

Example displays

Display of pre-calculation measured values varies with the settings.

Page 45

3.4 Checking Measured Values

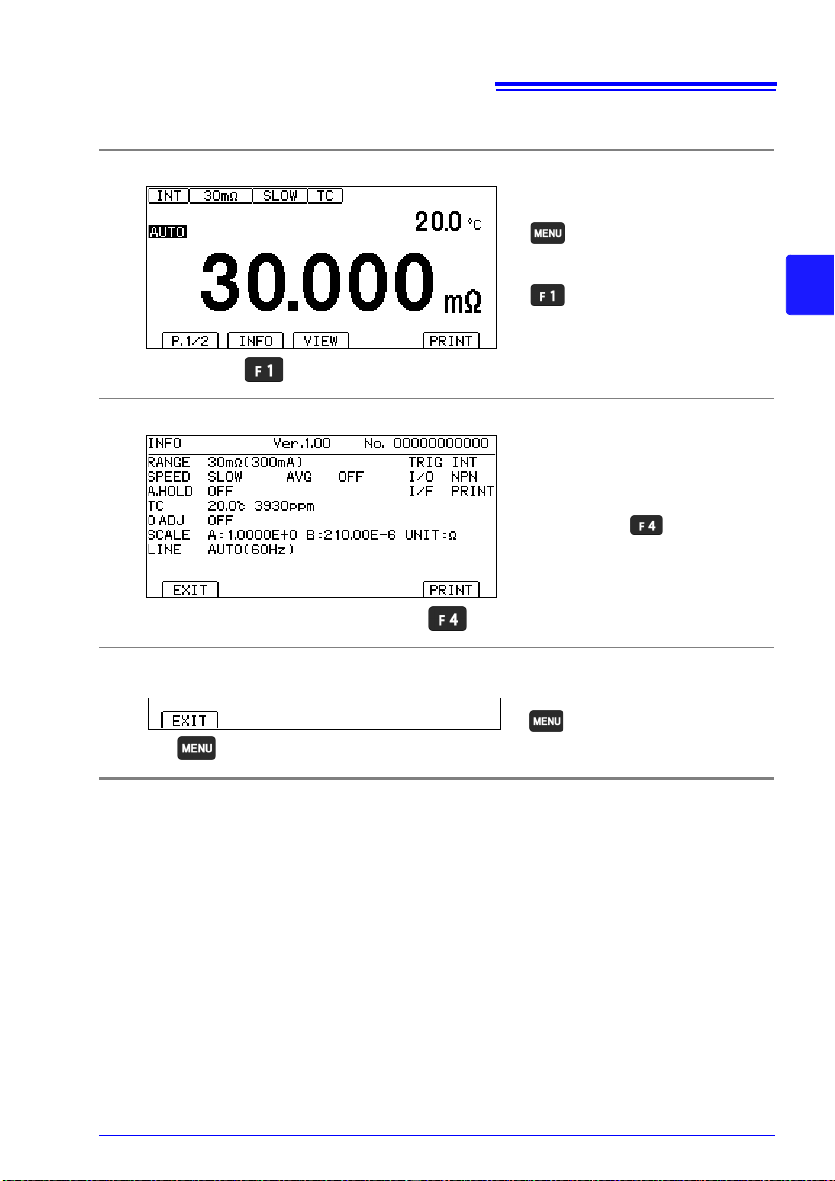

[INFO]

Display measurement

conditions.

Switch the function menu

to P.1/2.

1

2

If the interface type has been

set to "printer," you can print

settings with .

Return to the

Measurement screen.

Displaying a list of measurement conditions and settings

Display the measurement conditions.

1

Check the measurement conditions.

2

37

3

Return to the Measurement screen.

3

Page 46

38

This fault is displayed in the following two instances.

(1) Appears when the measured value is outside of the measurement or display range. (*1)

(2) Appears when a measurement fault(*2) occurs (when the current fault mode setting is

“Over-range”).

When no measurement current flows from the SOURCE A terminal to the SOURCE B

terminal

Similarly, if the measurement range is exceeded in temperature measurement, OvrRng is

displayed.

The comparator result is Hi when +OvrRng is displayed, and Lo when -OvrRng is displayed. No ERR signal is output.

Over-range

+OvrRng

-OvrRng

Display

- - - - -

Current Fault or measurement not performed

This fault is displayed in the following instances. If “- - - - -” is displayed, a comparator judgment will not be made.

(1) Appears when a measurement fault(*2) occurs (when the current fault mode setting is

“Current fault”).

When no measurement current flows from the SOURCE A terminal to the SOURCE B

terminal

(2) This fault is displayed when no measurement has been performed since the measure-

ment conditions were changed.

Display

Temperature measurement cannot be performed because the temperature sensor has not

been connected. There is no need to connect the temperature sensor when not using temperature correction. Switch the display if you do not wish to display the temperature.

See: "Switching the Display" (p.35)

- - . - °C

Temperature sensor not connected

Display

Current fault mode setting (p. 40)

Current fault Over-range

Display: - - - - COMP indicator: No judgment

EXT I/O: ERR signal output, no HI signal output

Display: +OvrRng

COMP indicator: Hi

EXT I/O: No ERR signal output, HI signal output

3.4 Checking Measured Values

Confirming Measurement Faults

When a measurement is not performed correctly, a measurement fault indicator appears

and a ERR signal of the EXT I/O is output (no ERR signal is output for over-range or

unmeasured events). Operation when a current fault occurs can be changed with the settings.

An unstable measured value may be displayed if the SOURCE terminal is connected to the

measurement target but the SENSE terminal has poor contact.

Example displays: Display and output when the probes are open or when the measurement target is open

Page 47

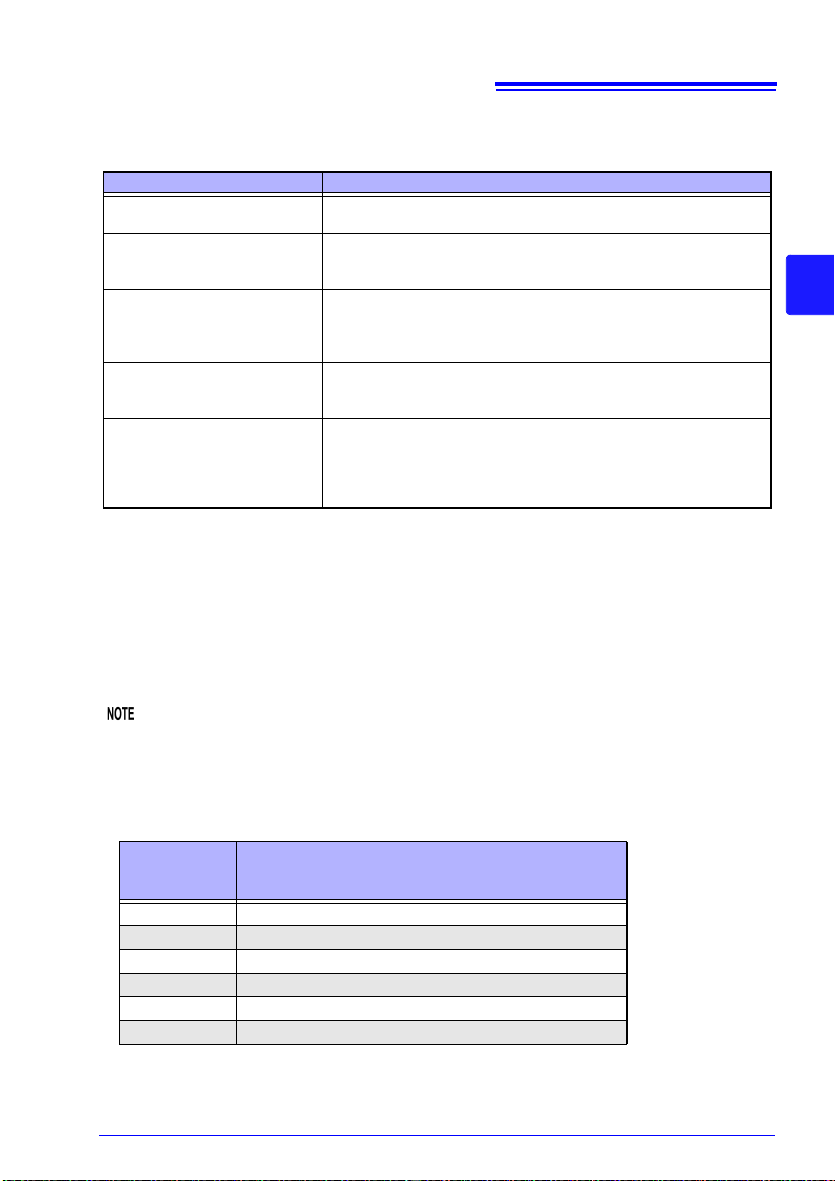

*1 Over-range Detection Function

Examples of Over-range Faults

Over-range Detection Measurement Example

The measured value is outside of

the measurement range.

The relative tolerance (%) display

of the measured value exceeds

the display range (999.99%).

The zero-adjusted value is outside of the display range.

While measuring, input voltage

exceed the A/D converter input

range.

Current did not flow normally to

the measurement target.

(When the current fault mode setting is set to “Over-range output”

only)

Attempting to measure 40 m with the 30 m range selected

Measuring 500 (+2400%) with a reference value of 20

Performing zero-adjustment after connecting 50 m with the 300 m

range

Measuring 10 m yields a -40 m reading, exceeding the display

range.

Measuring a large resistance value in an electrically noisy environment

When the measurement target yields an open FAIL result

When either the SOURCE A or SOURCE B terminal suffers from poor

contact.

*To display “- - - - -” when a current fault occurs, set the current fault

mode setting to “Current fault.”(p.40)

*2 Current Fault Detection Function

Example of Current Fault

• SOURCE A or SOURCE B probe open

• Broken measurement target (open work)

• SOURCE A or SOURCE B cable break, poor connection

39

3.4 Checking Measured Values

3

• SOURCE wiring resistance in excess of the following values may cause a current fault,

making measurement impossible. When using measurement current 300 mA ranges,

keep the wiring resistance as well as the contact resistance between the measurement

target and measurement lead low.

(Reference value)

Range

30 m, 300 m 2

3 70

30 100

300 2 k

3 k 700

30 k to 3 M 2 k

• If a measurement is performed using a high-resistance range, it will take time after the

Wiring resistance and contact resistance

(Resistance value between SOURCE B and SOURCE A,

excluding measurement target)

probes are actually open until a constant current error occurs.

Example:300 k range 20 ms

3 M range 250 ms

Page 48

40

The Settings screen

appears.

Switch the function menu

to P.2/2.

1

2

Move the cursor to the

[MEAS] tab with the left and

right cursor keys.

2

Current fault (default)

Over-range

Selection

1

Return to the

Measurement screen.

3.4 Checking Measured Values

Setting the measurement method for an open target (current fault mode

setting)

This section describes how to configure instrument operation when current fault output is

detected.

When set to current fault, a break in the measurement target wiring is determined to be an

error, and no comparator judgment is made. When set to over-range, a break in the measurement lead or other open state is determined to be an over-range event, and a comparator judgment of Hi results. Choose the setting that best suits your application.

Open the Settings Screen.

1

Open the Measurement Settings Screen.

2

Select the desired current fault mode.

3

Return to the Measurement screen.

4

Page 49

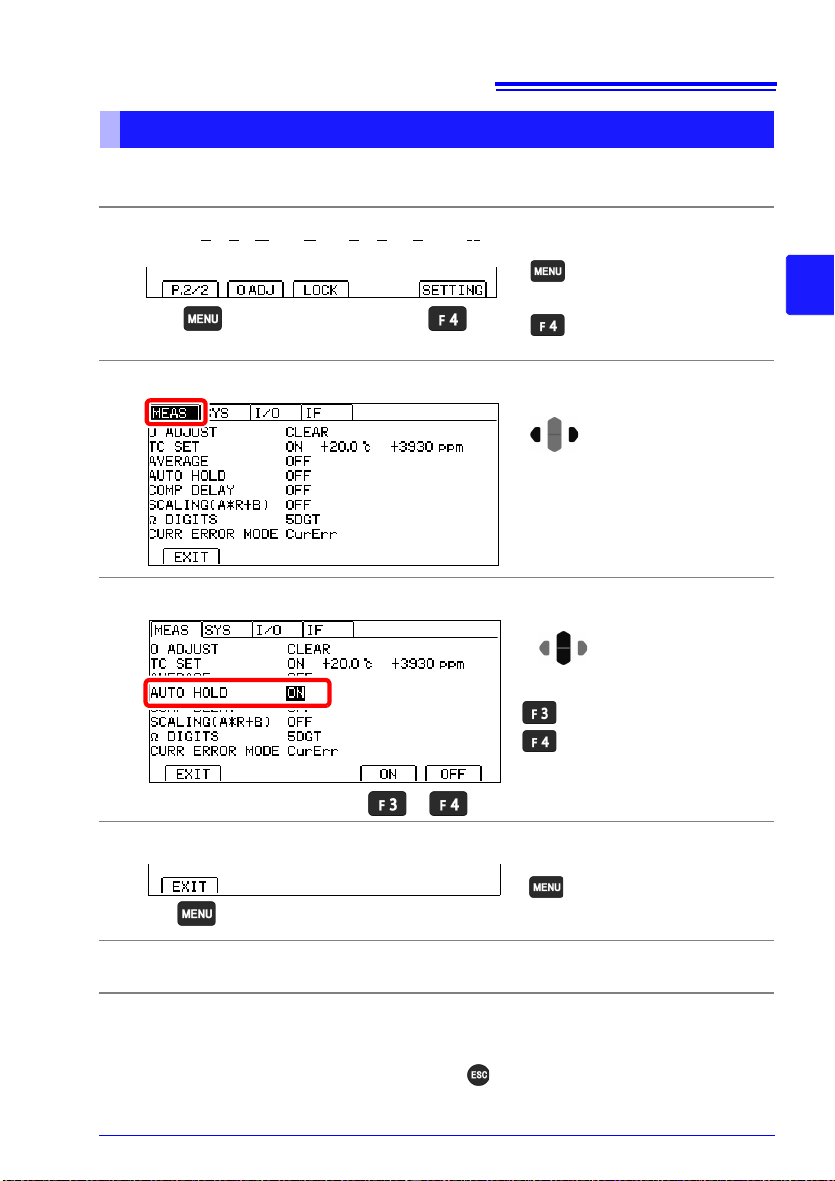

41

The Settings screen

appears.

Switch the function menu

to P.2/2.

1

2

Move the cursor to the

[MEAS] tab with the left and

right cursor keys.

2

ON

OFF (default)

Selection

1

Return to the

Measurement screen.

3.4 Checking Measured Values

Holding Measured Values

The auto-hold function provides a convenient way to check measured values. Once the

measured value stabilizes, the beeper will sound, and the value will be automatically held.

Open the Settings Screen.

1

Open the Measurement Settings Screen.

2

Enable the auto-hold function.

3

3

Return to the Measurement screen.

4

While the measured value is being held, the HOLD indicator will light up.

5

Canceling auto-hold operation

Hold operation is automatically canceled when the measurement leads are removed from

the measurement target and then brought into contact with the measurement target again.

You can also cancel hold operation by pressing or changing the range and measurement speed. When hold operation is canceled, the HOLD indicator will go out.

Page 50

42

3.4 Checking Measured Values

Page 51

Customizing Measurement

43

Conditions

Before making measurements, read "Operating Precautions" (p. 12) carefully.

This chapter explains functionality employed to make more advanced, more accurate measurements.

"4.1 Zero Adjustment" (p. 44)

"4.2 Stabilizing Measured Values (Averaging Function)" (p. 50)

"4.3 Correcting for the Effects of Temperature (Temperature Correction

(TC))" (p. 52)

"4.4 Correcting Measured Values and Displaying Physical Properties Other

than Resistance Values (Scaling Function)" (p. 54)

"4.5 Changing the Number of Measured Value Digits" (p. 58)

Chapter 4

4

Page 52

44

4.1 Zero Adjustment

4.1 Zero Adjustment

Perform zero-adjustment in the following circumstances:

• The measured value is not cleared due to thermal EMF or other factors.

The measured value will be adjusted to zero. (Accuracy is not affected by whether or

not the zero adjustment is performed.)

• Four-terminal connection (called Kelvin connection) is difficult.

The residual resistance of the two-terminal connection wires will be canceled.

For more information about how to perform zero-adjustment properly, see "Appendix 6 Zero

Adjustment" (p. A8).

Before Zero Adjustment

• Execute zero adjustment when the ambient temperature has changed, or when a mea-

surement lead is replaced after zero adjustment was performed. However, when performing zero-adjustment is difficult, for example when using the L2102 or L2103 Pin Type

Lead, perform zero-adjustment using the standard included L2101 Clip Type Lead or similar lead and then switch to the pin type lead to perform measurement.

• Zero adjustment should be executed in each range to be used. Perform zero-adjustment

for the current range only when setting the range manually or for all ranges when using

auto-ranging.

• Zero adjustment values are retained internally even when the instrument is turned off.

They are also saved with panels. You can also elect not to load zero-adjustment values

from panels.

See: "6.1 Saving Measurement Conditions (Panel Save Function)"(p.72)

"6.2 Loading Measurement Conditions (Panel Load Function)"(p.73)

• Zero-adjustment can be performed even when the EXT I/O 0ADJ signal is ON (when

shorted with the EXT I/O connector’s ISO_COM pin).

• Although resistance of -3%f.s. to 50%f.s. can be canceled in each range, try to keep the

canceled resistance to 3%f.s. (f.s.=30,000dgt.) The zero-adjustment range can be

changed to TIGHT (-3%f.s. to 3%f.s.).

See: "Changing the zero-adjustment range" (p. 47)

• If a resistance that is smaller than the resistance value when zero-adjustment was per-

formed is measured, the measured value will be negative.

Example: If you set an offset of 20 m for the 300 m range

If you measure 10 m, -10 m will be displayed.

Page 53

Performing zero-adjustment

Red

SOURCE

SOURCE

SOURCE

SENSE

SENSE

SENSE

Red

Black

Black

SOURCE

SENSE

Bring the "V" marks together

at the same position.

Connection

Connection

SENSE A SENSE B

SOURCE A SOURCE B

L2104 (option)

L2101

L2102, L2103 (options)

Since zero-adjustment cannot be performed with the L2102 or L2103,

use the L2101 Clip Type Lead or other lead type to perform zero-adjustment.

Place the alligator clips on the outside

and the lead rods on the inside when

performing zero-adjustment.

Correct

Incorrect

Short the measurement leads together.

1

45

4.1 Zero Adjustment

4

Page 54

46

Proper wiring Improper wiring

[0ADJ]

Perform zero-adjustment.

Switch the function menu

to P.2/2.

1

2

Perform zero-adjustment

and return to the Measurement screen.

Cancel the operation and

return to the previous

screen.

4.1 Zero Adjustment

Verify that the measured value is within ±3%f.s. If the zero-adjustment range

2

is set to NORMAL (-3%f.s. to 50%f.s.), zero-adjustment can be performed

when the measured value is 50%f.s. or less in each range, but a warning will

be issued when it is greater than 3%f.s.

If no measured value is displayed, verify whether the measurement leads

have been wired properly.

Perform zero-adjustment.

3

A confirmation message will be displayed. Confirm and return to the Mea-

4

surement screen.

Page 55

Zero Adjustment Faults

The Settings screen

appears.

Switch the function menu

to P.2/2.

1

2

Move the cursor to the [SYS]

tab with the left and right cursor keys.

If zero adjustment fails, the following error message appears.

47

4.1 Zero Adjustment

Before attempting zero adjustment again, confirm the following:

• Verify that the measured value is within each range (NORMAL: -3%f.s. to 50%f.s.,

TIGHT: -3%f.s. to 3%f.s.).

• When using measurement leads that you made, reduce the wiring resistance.

• Confirm that the measurement leads connections are correct.

See: "*2 Current Fault Detection Function" (p. 39)

• If zero-adjustment fails for auto-ranging, zero-adjustment will be canceled for all ranges.

• If zero-adjustment fails for a manually set range, zero-adjustment will be canceled for the

current range.

Changing the zero-adjustment range

Although the default setting of the zero-adjustment range is -3%f.s. to 50%f.s. (the warning

will be issued when the value is more than 3%f.s.), the zero-adjustment range can be

changed to the setting that a value exceeding 3%f.s. results in an error without issuing any

warning.

Open the Settings Screen.

1

Open the System Setting Screen.

2

4

Page 56

48

2

Range: -3%f.s. to 3%f.s.

Range: -3%f.s. to 50%f.s.

(default)

Selection

1

Return to the

Measurement screen.

The Settings screen

appears.

Switch the function menu

to P.2/2.

1

2

Move the cursor to the

[MEAS] tab with the left and

right cursor keys.

4.1 Zero Adjustment

Select the zero-adjustment range setting function to be TIGHT.

3

Return to the Measurement screen.

4

The changed setting will be applied to the zero-adjustment that will be performed after the

setting is changed. The zero-adjustment that has been already performed and panel-saved

remains effective. Perform zero-adjustment again as necessary.

Canceling zero-adjustment

Cancels zero-adjustment for all ranges.

Open the Settings Screen.

1

Open the Measurement Settings Screen.

2

Page 57

Select 0 ADJUST.

2

Cancel zero-adjustment.

Selection

1

Clear zero-adjustment and

return to the Settings

screen.

Cancel the operation and

return to the previous

screen.

Return to the

Measurement screen.

3

49

4.1 Zero Adjustment

A confirmation message will be displayed. Confirm and return to the Mea-

4

surement screen.

Return to the Measurement screen.

5

4

Page 58

50

The Settings screen

appears.

Switch the function menu

to P.2/2.

1

2

Move the cursor to the

[MEAS] tab with the left and

right cursor keys.

Enables the averaging

function

Disables the averaging

function (default) (go to

step 5)

Selection

2

1

4.2 Stabilizing Measured Values (Averaging Function)

4.2 Stabilizing Measured Values

(Averaging Function)

The averaging function averages multiple measured values and displays the results. It can

be used to reduce variation in measured values.

For internal trigger measurement (Free-Run), a moving average is calculated.

For external trigger measurement (and :READ? command operation) (Non-Free-Run), a

mean average is used.

For more information about communications commands, see the included application disc.

Average (of measurements D1 to D6) with Averaging Samples set to 2.

1st Sample 2nd Sample 3rd Sample

Free-Run (Moving Avg.) (D1+D2)/2 (D2+D3)/2 (D3+D4)/2

Non-Free-Run (Mean Avg.) (D1+D2)/2 (D3+D4)/2 (D5+D6)/2

Open the Settings Screen.

1

Open the Measurement Settings Screen.

2

Enable the averaging function.

3

Page 59

Set the number of averaging iterations.

Move the cursor to the setting you

wish to configure. Make the value

editable with the key.

2

Move the cursor to the digit you

wish to set with the left and right

cursor keys. Change the value

with the up and down cursor keys.

Change

values.

1

Move among

digits.

Setting range: 2 to 100 times (default: 2 times)

3

Accept

( Cancel)

Return to the

Measurement screen.

4

Return to the Measurement screen.

5

51

4.2 Stabilizing Measured Values (Averaging Function)

4

Page 60

52

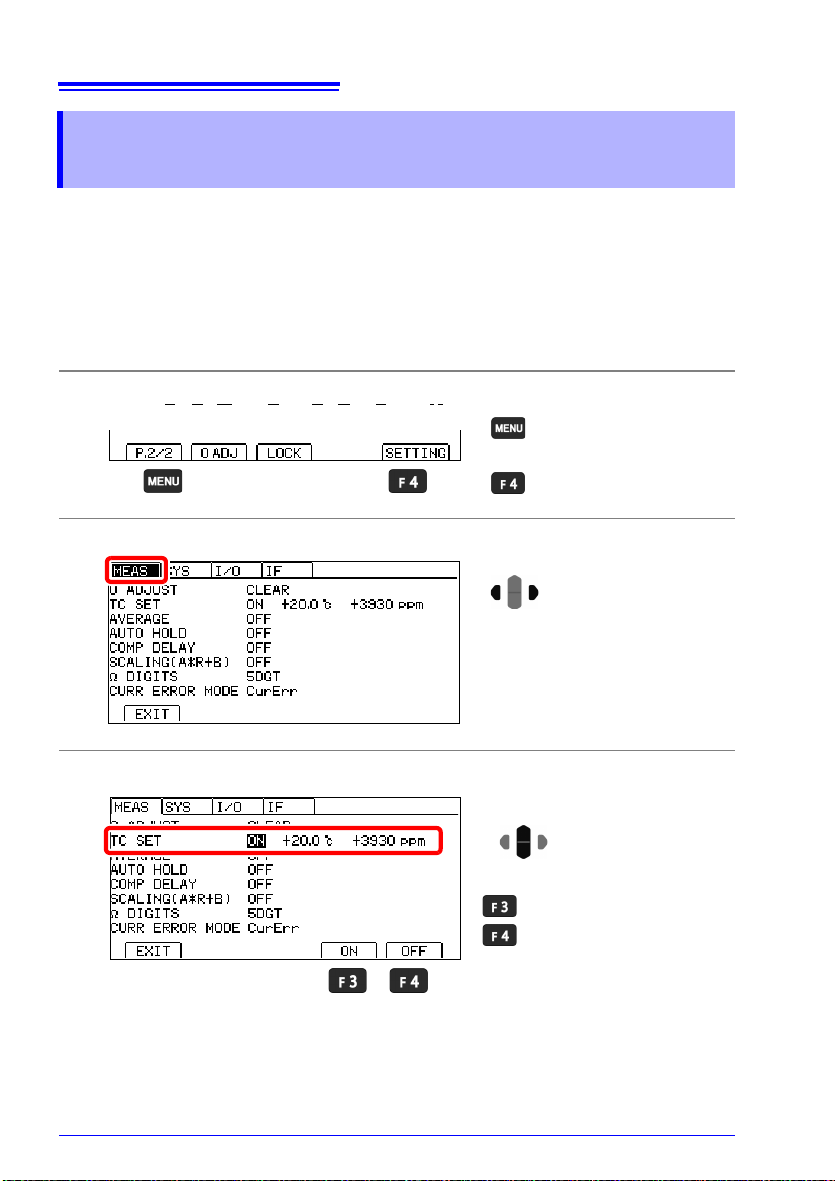

The Settings screen

appears.

Switch the function menu

to P.2/2.

1

2

Move the cursor to the

[MEAS] tab with the left and

right cursor keys.

2

Enables the TC function

Disables the TC function

(default) (go to step 5)

Selection

1

4.3 Correcting for the Effects of Temperature (Temperature Correction (TC))

4.3 Correcting for the Effects of Temperature

(Temperature Correction (TC))

Temperature correction converts resistance values to resistance values at standard temperature and displays the result.

For more information about the principle of temperature correction, see "Appendix 4 Tem-

perature Correction (TC) Function" (p. A4).

To perform temperature correction, connect the temperature sensor to the TEMP.SENSOR

jack on the back of the instrument.

See: "2.3 Connecting Z2001 Temperature Sensor (When using the TC)" (p. 27)

Open the Settings Screen.

1

Open the Measurement Settings Screen.

2

Enable the temperature correction function. (TC)

3

Page 61

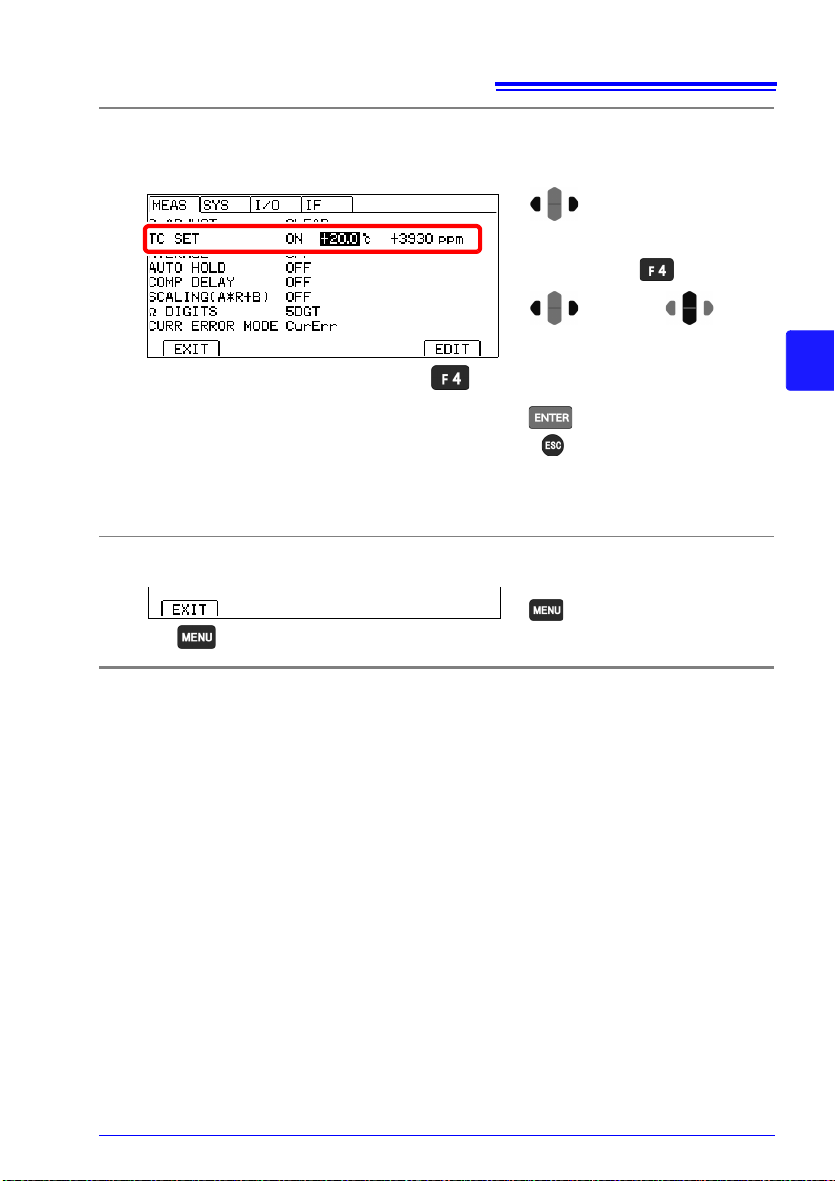

4.3 Correcting for the Effects of Temperature (Temperature Correction (TC))

Setting range

reference temperature : -10.0 to 99.9°C (default: 20°C)

temperature coefficient : -9999 to 9999ppm/°C (default: 3930ppm/°C)

Move the cursor to the setting you

wish to configure. Make the value

editable with the key.

2

Move the cursor to the digit you

wish to set with the left and right

cursor keys. Change the value

with the up and down cursor keys.

Change

values.

1

Move among

digits.

3

Accept

( Cancel)

Return to the

Measurement screen.

Set the reference temperature and temperature coefficient.

4

(Set the reference temperature and temperature coefficient by following steps 1

through 3 for each.)

Return to the Measurement screen.

5

53

4

Page 62

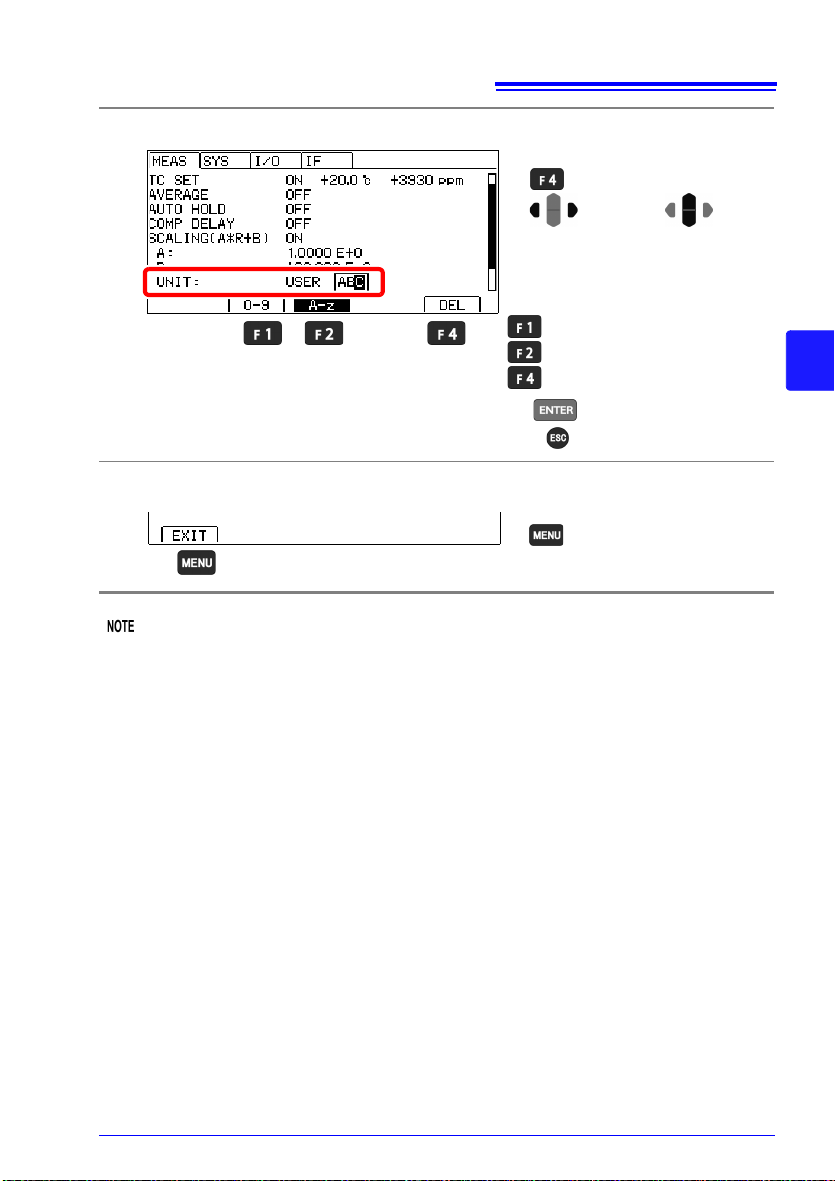

54

Range

Gain coefficient

(0.2000 to

1.9999)

×10

-3

(0.2000 to

1.9999)

×10

-2

(0.2000 to

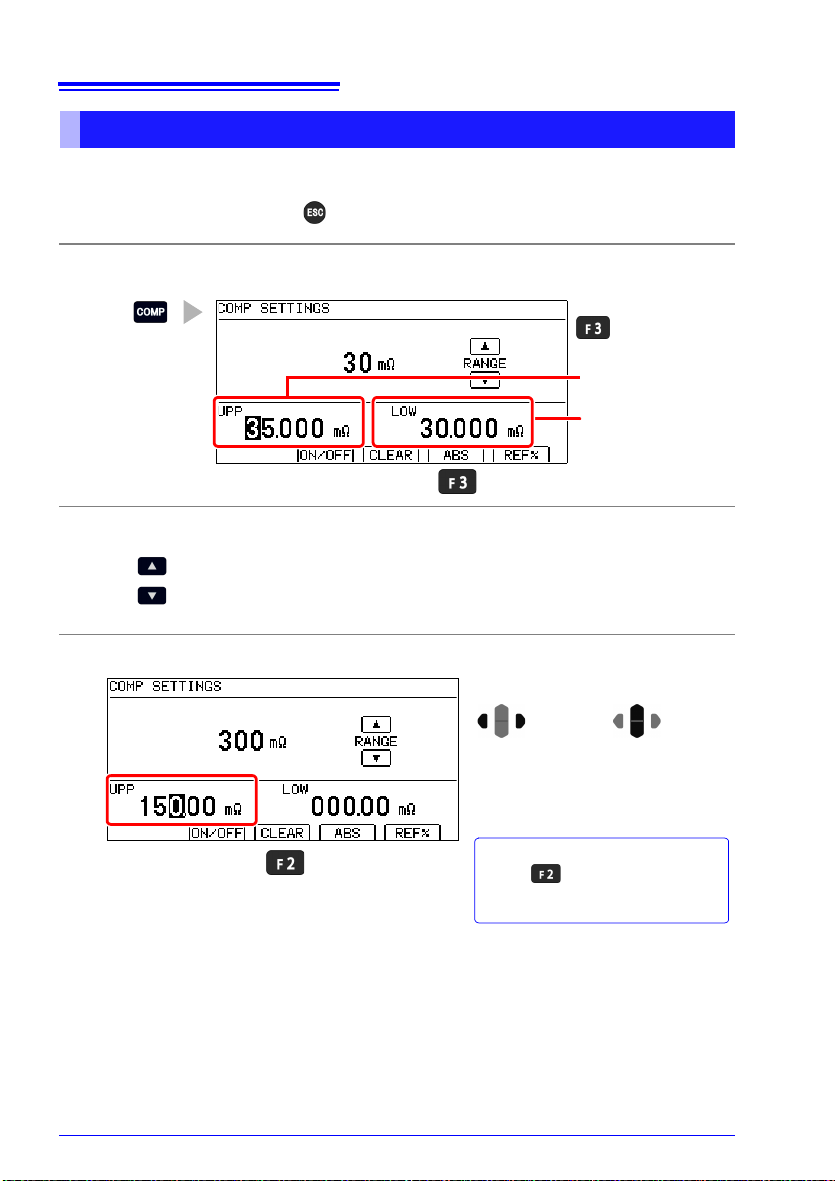

1.9999)