Hioki RM3544, RM3544-01 Instruction Manual

Instruction Manual

RM3544

RM3544-01

RESISTANCE METER

June 2014 Revised edition 2 RM3544A981-02 14-06H

Using This Instruction Manual

To do this… Refer to these sections in t his m anual.

Review important

information

Start using the instrument right away

Learn more about

instrument functions

Learn more about

product specifications

Troubleshoot a problem

Learn more about

resist ance measure ment

Learn more about

communicat i o ns commands

Safety Informati o n (p.3)

Operating Precautions (p.5)

Overview (p.15)

Search for the function in question in the table

of contents (p.i) or the index (p.Index 1).

Specifications (p. 145)

Troubleshooting (p. 160)

Appendix (p . A1)

Communications Command Instruction Manual

(on the application di sc)

Contents

Introduction.....................................................1

Verifying Package Contents...........................1

Safety Information..........................................3

Operating Precautions......... ..... ...... ..... ...........5

Chapter 1 Overview 15

1.1 Product Overview and Features ........15

1.2 Names and Functions of Parts ...........17

1.3 Measurement Process .......................19

1.4 Screen Organization and

Operation Overview ...........................21

Contents

Chapter 4 Cu sto m iz ing Mea-

surement Conditions

43

4.1 Zero Adjustment .................................44

4.2 Stabilizing Measured Values

(Averaging Function) ..........................50

4.3 Correcting for the Effect s of Temper atur e

(Temperatu re Correction (TC)) ...........52

4.4 Correcting Meas ured Value s and D isplaying Physical Properties Other than Resis-

tance Values (Scaling Function) .........54

4.5 Changing the Number of Measured

Value Digits ........................................58

i

1

2

3

4

5

Chapter 2 Measurement

Preparations 25

2.1 Connecting the Power Cord............... 25

2.2 Connecting Measurement Leads .......26

2.3 Connecting Z2001 Temperature Sensor

(When using the TC) ..........................27

2.4 Turning the Power On and Off ...........28

Turning On the Instrument with the

Main Power Switch ...................................28

Turning Off the Instrument with the

Main Power Switch ...................................28

Canceling the Standby State ....................28

Placing the Instrument in the

Standby State ........................................ ...29

2.5 Pre-Operation Inspection ...................30

Chapter 3 Basic Measurements

31

3.1 Selecting the Measurement Range ....32

3.2 Setting the Measurement Speed .......33

3.3 Connecting Measurement Leads to the

Measurement Target ..........................34

3.4 Checking Measured Values ...............35

Switching the Display ................................35

Conf irm ing Me asu rem en t Faul ts ............... 3 8

Holding Measured Values .........................41

6

Chapter 5 J ud gm en t

Function 59

5.1 Judging Measured Values

(Comparator Function) .......................60

Enabling and Disabling the Comparator

Function ............... .................................... 61

Decide According to Upper/Lower Thresholds

(ABS Mode) ............................ ..... ..... ..... .. 62

Decide According to Reference Value and

Tolerance (REF% Mode) ......................... 64

Delaying the judge timing ......................... 66

Checking Judgments Using Sound

(Judgment Sound Setting Function) ........ 68

Checking Judgments with the L2105 LED

Comparator Attachment (Option) ............. 70

Chapter 6 Saving and Loading

Panels (Saving and

Loading Measurement Conditions) 71

6.1 Saving Measurement Conditions

(Panel Save Function) ........................72

6.2 Loading Measurement Conditions

(Panel Load Function) ........................73

Preventing Loading of Zero-adjustment

Values .................. .................................... 74

ii

Contents

6.3 Changing Panel Names .....................75

6.4 Deleting Panel Data ...........................76

Chapter 7 System Settings 77

7.1 Disabling and Enabling Key Operations

...........................................................78

Disabling Key Operations

(Key-Lock Function) ................................. 78

Re-Enabling Key Operations

(Key-Lock Cancel) ................................... 79

7.2 Power Line Frequency Manual Setting

...........................................................80

7.3 Enabling or Disabling the Key Beep er 82

7.4 Adjusting Screen Contrast ..................83

7.5 Adjusting the Backlight .......................84

7.6 Initializing (Reset) ...............................85

Default Settings ........................................ 87

Chapter 8 External Control

(EXT I/O) 89

8.1 External Input/Ou tput Connector

and Signals......................................... 90

Switching between Current Sink (NPN) and

Current Source (PNP) .............................. 90

Connector Type and Signal Pinouts ........ 91

Signal Descriptions .................................. 93

8.2 Timing Chart .......................................97

From Start of Measurement to Acquisition

of Judgment Results ................................ 97

Zero-adjustment timing ............................ 99

Panel Load Timing ................................. 100

BCD Signal Timing ................................. 100

Output Signal State at Power-On ........... 101

Acquisition Process When Using an

External Trigger ..................................... 102

8.3 Internal Circuitry ...............................104

Electrical Specifications ......................... 106

Connection Examples ............................ 107

8.4 External I/O Settings ........................108

Setting Measurement Start Conditions

(Trigger Source) ..................................... 108

Setting the TRIG Signal Logic ................ 110

Eliminating TRIG/PRINT Signal Chatter

(Filter Function) ...................................... 112

Setting EOM Signal ................................ 114

Switching Output Modes

(JUDGE Mode/ BCD Mode) ................... 116

8.5 Checking External Control ...............117

Performing an I/O Test

(EXT I/O Test Function) ......................... 117

8.6 Supplied Connector Assembly .........119

Chapter 9 Communications

(USB/ RS-232C

Interface) 121

9.1 Overview and Features ....................121

Specifications ............. ............................ 122

9.2 Preparations before Use

(Connections and Settings) .............123

Using the USB Interface .........................123

Using the RS-232C Interface ................. 126

9.3 Controlling the Instrument with

Commands and Acquiring Data ....... 130

Remote and Local States ....................... 130

Displaying Communications Commands

(Communications Monito r Function ) ...... 131

9.4 Auto-Exporting Measu red Va lues (at En d

of Measurement) (Data Output Function)

..........................................................133

Chapter 10Printing (Using an

RS-232C Printer) 137

10.1 Connecting the Printer to the Instrument

..........................................................137

10.2 Printing .............................................140

Printing Measured Values and Comparator

Judgments .................. ......... .......... .... ..... 140

Printing List of Measuremen t Cond it ions

and Settings ........................................... 140

Chapter 11Specifications 145

11.1 Instrument Specifications ........ ...... ...145

Measurement Ranges ................... .........145

Measurement Method ............................ 145

Measurement Specifications ..................1 46

About Instrument Accuracy .................... 148

Functions ............... ..... .... ..... ..... ..... .... ..... 149

Interface ................ ................................. 154

Environment and Safety Specifications ..158

Accessories ............................................158

Options ...................................................158

Chapter 12Maintenance and

Service 159

12.1 Troubleshooting ...............................160

Q&A (Frequently Asked Questions) ........160

Error Displays and Remedies .................169

12.2 Replacing the Measurement Circuit’s

Protective Fuse ................................171

12.3 Inspection and Repair ......................172

Appendix A 1

Appendix 1Block Diagram ..........................A 1

Appendix 2Four-Terminal (Voltage-Drop)

Method......................................A 2

Appendix 3 DC and AC Measurement.........A 3

Appendix 4Temperature Correction (TC)

Function....................... ..... ..... ...A 4

Appendix 5Effect of Thermal EMF..............A 6

Appendix 6Zero Adjustment .......................A 8

Appendix 7Unstable Measured Values.....A 13

Appendix 8Detecting the Location of a

Short on a Printed Circuit Board

................................................A 21

Appendix 9 JEC 2137 Induction Machine-com-

pliant Resistance Measurement

................................................A 22

Appendix 10Making Your Own Measurement

Leads......................................A 23

Appendix 11Checking Measurement Faults

................................................A 25

Appendix 12Using the I nstrument wi th a

Withstanding Voltage Tester...A 26

Appendix 13Measurement Leads (Options)

................................................A 27

Appendix 14Rack Mounting......................A 28

Appendix 15Dimensional Diagram............A 31

Appendix 16Calibration.............................A 32

Appendix 17Adjustment Procedure...........A 36

Appendix 18Instrument Settings (Memo)..A 37

iii

Contents

Index Index 1

6

7

8

9

10

11

12

12

Appendix

Index

iv

Contents

Introduction

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate according to the specifications, contact your authorized Hioki distributor or reseller.

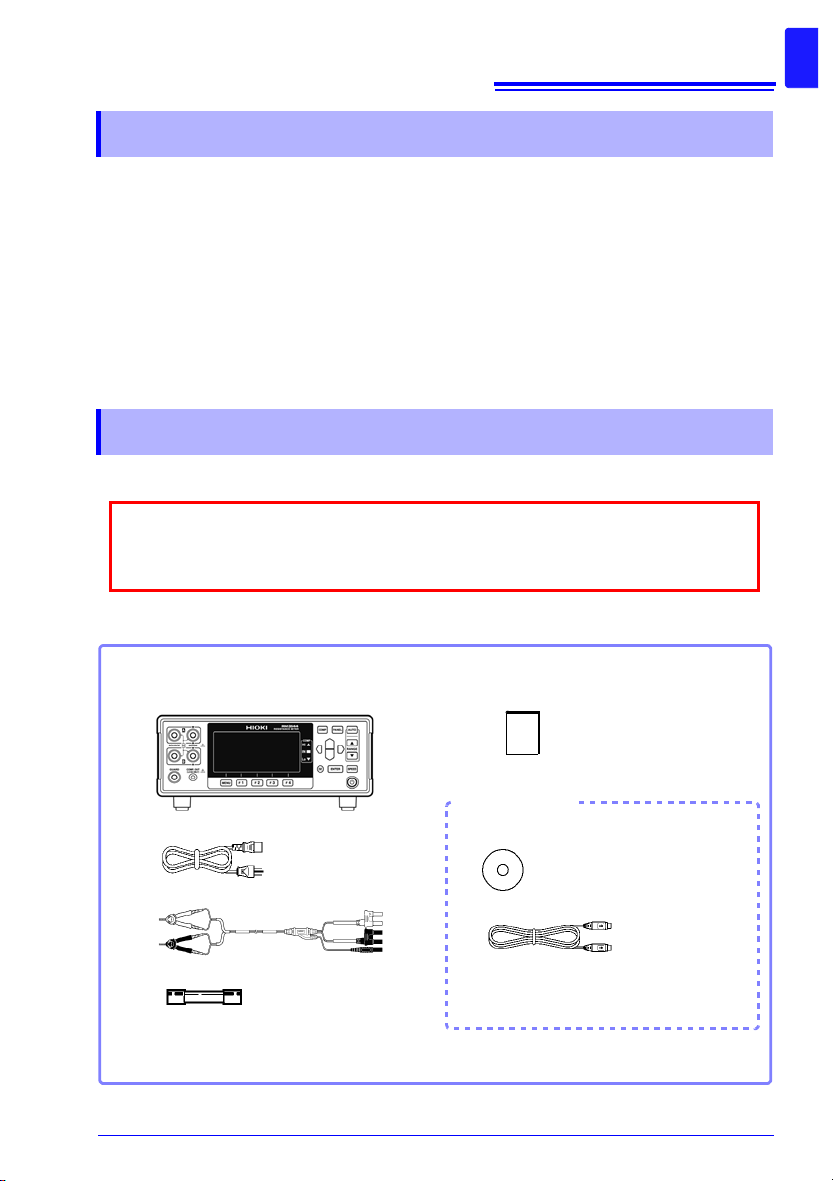

Confirm that these contents are provided.

Model RM3544 or RM3544-01..................1

Power Cord (2-line + ground) (p. 25) ........1

Model L2101 Clip Type Lead ................... .1

Spare Fuse (F500mAH/250V)...................1

Instruction Manual (This document)...1

* The latest version of the application disc can be downloaded from the Hioki web site.

Application disc (CD)*.........................1

(Communications Command

Instruction Manual , USB drive r)

USB cable (A-B type) .........................1

EXT I/O Male Connector (p. 119).......1

RM3544-01 only

Introduction

Thank you for purchasing the HIOKI Model RM3544/ RM3544-01 Resistance Meter.

To obtain maximum performance from the instrument, please read this manual first, and

keep it handy for future reference.

Model RM3544-01 is the same as the RM3544, but with USB, RS-232C, and EXT I/O

included.

Registered tradem ar ks

Windows is a registered trademark of Microsoft Corporation in the United States and/or

other countries.

Verifying Package Contents

Inspection

1

Content confirmation

2

Measurement

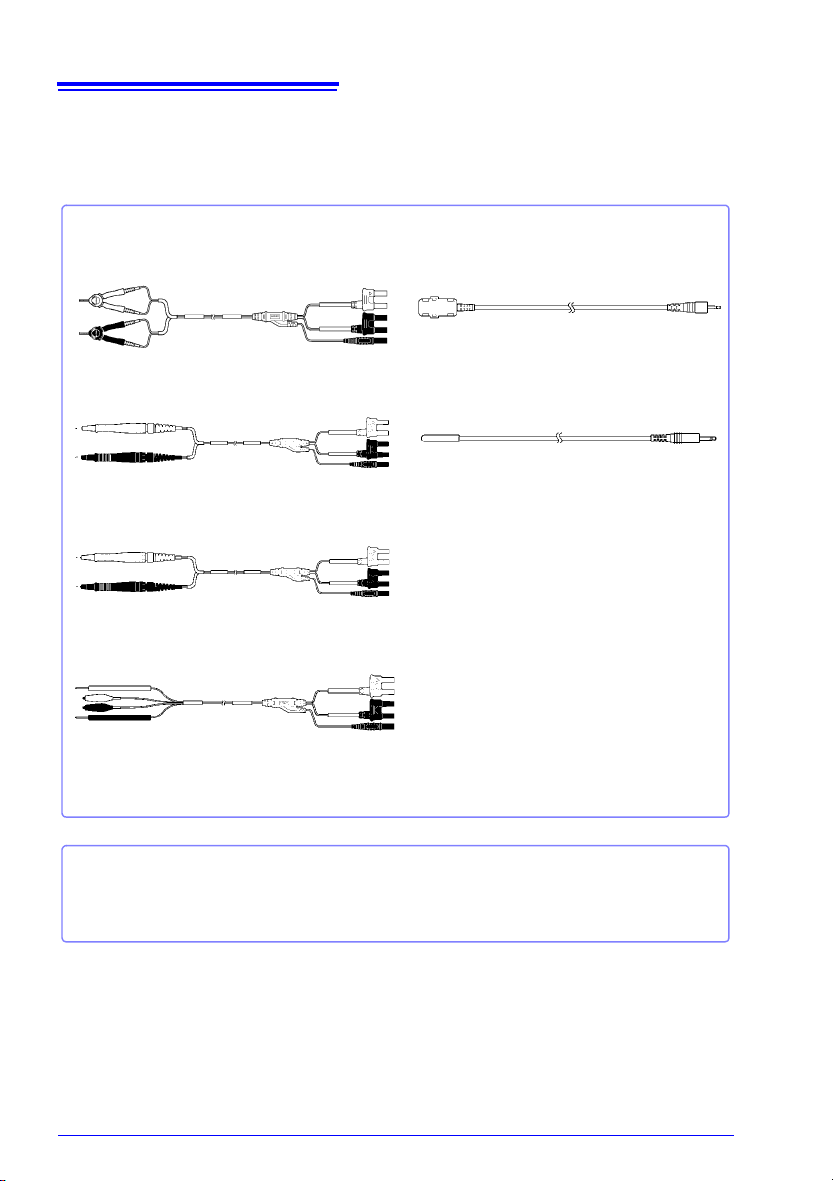

Model L2101 Clip Type Lead

Model L2102 Pin Type Lead

Model L2103 Pin Type Lead

Model L2104 4-Terminal Lead

Interface Cables

Model 9637 RS-232C Cable (9pin-9pin/ 1.8 m/ crossover cable)

Model 9638 RS-232C Cable (9pin-25pin/ 1.8 m/ crossover cable)

Model L2105 LED Comparator Attachment

Model Z2001 Temperature Sensor

Verifying Package Contents

Options

Contact your authorized Hioki distributor or reseller for details.

See: "Appendix 13 Measurement Leads (Options)" (p. A27)

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested for safety prior to shipment.

However, using the instrument in a way not described in this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

Mishandling during use could result in injury or death, as well as damage to the product. Be certain that you understand the instructions and

precautions in the manual before use.

With regard to the electricity supply, there are risks of electric shock,

heat generation, fire, and arc discharge due t o shor t circ ui ts. If persons

unfamiliar with electricity measuring instruments are to use the product, another person familiar with such instruments must supervise

operations.

This manual contains information and warnings essential for safe operation of the instrument and for maintaining it in safe operating condition. Before using it, be sure to carefully

read the following safety precautions.

Safety Symbols

3

In the manual, the symbol indicates particularly important information that the

user should read before using the instrument.

The symbol printed on the instrument indicates that the user should refer to a

corresponding topic in the manual (marked with the symbol) before using the

relevant function.

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a fuse.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in

serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in

serious injury or death to the user.

Indicates that inc o rr ect op er ati on pre s ents a po ss ib ili ty of i n jur y to th e use r or dam age to the instrument.

Indicates advisory ite ms relate d to perform ance or cor rect oper ation of th e instrument.

4

Safety Information

Symbols for Various Standards

This symbol indicates that the product conforms to regulations set out by the EC

Directive.

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU

market after August 13, 2005, and producers of the Member States are required to

display it on the appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

Other Symbols

Indicates the prohibited action.

(p. )

[ ]

SET

(Bold characters)

Unless otherwise specified, “Windows” represents Windows XP, Windows Vista, Windows 7, or

Windows 8.

Accuracy

We define measurement tol erances in terms of f.s. (full scale ), rdg. (read ing) and dgt. (di git) values, w ith the

following meanings.

f.s.

rdg.

dgt.

See: "Example accuracy calculations" (p. 148)

Indicates the location of reference information.

*

Indicates that descriptive information is provided below.

Square brackets indicate instrument display labels (such as setting item names).

Bold characters within the text indicate operating key labels.

(maximum display value)

This is usually the name of the maximum displayable value. For this instrument, it

indicates the currently selected range.

(reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value

that causes the digital display to show a “1” as the least-significant digit.

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to ensure that

no damage occurred during storage or shipping. If you find any damage, contact your

authorized Hioki distributor or reseller.

Before using the instrument, make sure that the insulation on the

power cord, leads or cables is undamaged and that no bare conductors

are improperly exposed. Using the instrument in such conditions could

cause an electric shock, so contact your authorized Hioki distributor or

reseller for replacements.

5

6

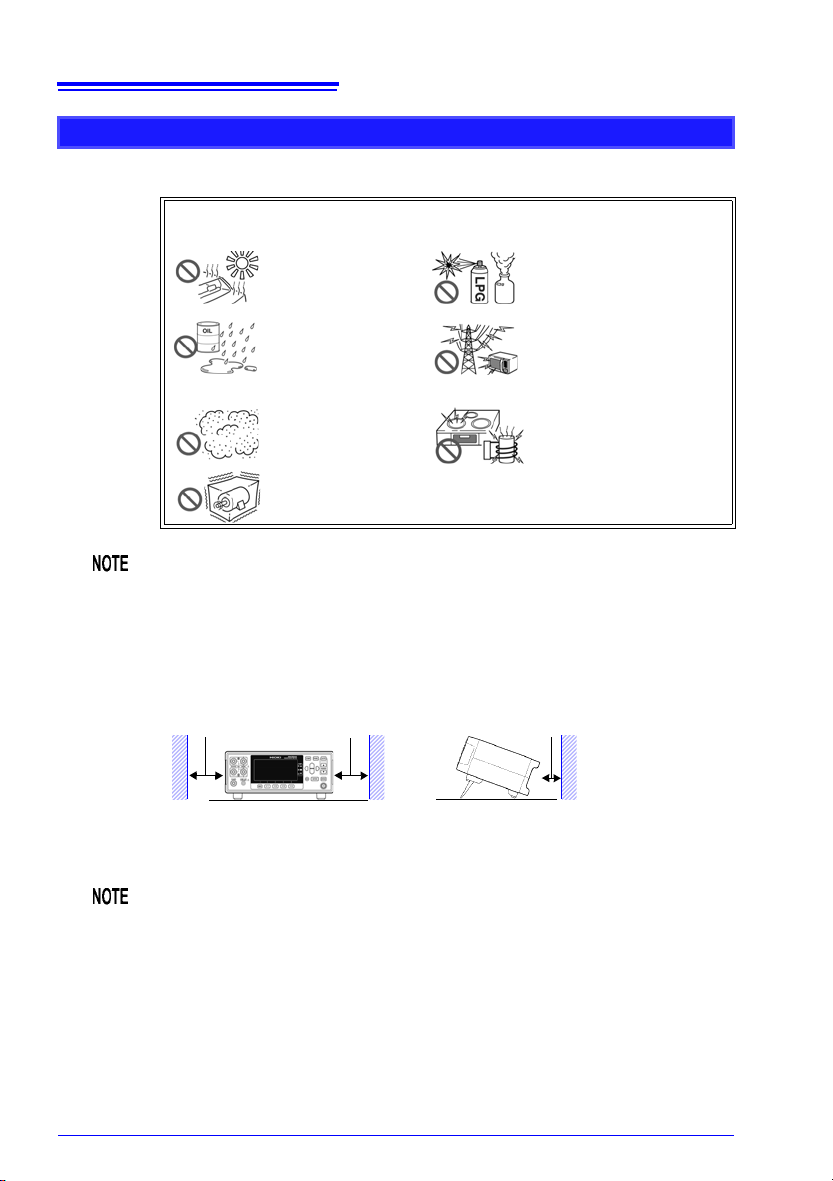

10 mm or more

Rear

50 mm or more 50 mm or more

The instrument can be used with the stan d (p. 18).

It can also be rack-mounted. (p. A28).

Operating Precautions

Instrument Installation

Operating temperature and humidity : 0 to 40°C at 80% RH or less (non-condensating)

Storage temperature and humidity : -10°C to 50°C at 80% RH or less (non-condensating)

Avoid the following locations that could cause an accident or damage to the

instrument.

Correct measurement may be impossible in the presence of strong magnetic

fields, such as near transformers and high-current conduct or s, or i n the presence of strong electromagnetic fields such as near radio transmitters.

Exposed to direct sunlight

Exposed to h igh temp erature

Exposed to water, oil,

other chemicals, or s olvents

Exposed to high humidity or condensation

Exposed to high levels

of particulate dust

Subject to vibration

In the presence of corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction heating systems and IH

cooking utensils)

Installation Precautions

• The instrument should be operated only with the bottom downwards.

• Do not place the instrument on an unstable or slanted surface.

Unplugging the power cord kills power to the instrument. Be sure to provide

enough unobstructed space to unplug the power cord immediately in an

emergency.

Handling the Instrument

• Do not allow the inst ru men t to get w e t, and do not take measurements

with wet hands. This may cause an electric shock.

• Do not attempt to modify, disassemble or repair the instrument; as

fire, electric shock and injury could result.

• To avoid damage to the instrument, protect it from physical shock when

transporting and handling. Be especially careful to avoid physical shock

from dropping.

• To avoid damage to the instrument, do not apply voltage or current to mea-

surement terminals, TEMP.SENSOR jack, or COMP.OUT jack.

• This instrument may cause interference if used in residential areas. Such

use must be avoided unless the user takes special measures to reduce

electromagnetic emissions to prevent interference to the reception of radio

and television broadcasts.

• Use the original packing materials when transporting the instrument, if pos-

sible.

Handling the Cords and Leads

7

Operating Precautions

To avoid electrical shock, be careful t o avoid shorting live lines with the

test leads.

• Avoid stepping o n or pinching cables, which could damage t he cable insul a-

tion.

• To avoid breaking cables or lead wires, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

• To avoid damaging the cable, grasp the connector, not the cable, when

unplugging the cable.

• The ends of the pin type lead are sharp. Be careful to avoid injury.

• Keep the cables well away from heat sources, as bare conductors could be

exposed if the insulation melts.

• Temperature sensors are precision devices. Be aware that excessive volt-

age pulses or static discharges can destroy the film.

• Avoid subjecting the temperature sensor tip to physical shock, and avoid

sharp bends in the leads. These may damage the probe or break a wire.

8

Operating Precautions

• Use only the specified cords and leads. Using a non-specified cord or lead

may result in incorrect measurements due to poor connection or other reasons.

• If the part of the temperature sensor that connects to the instrument

becomes dirty, wipe it clean. The presence of dirt may affect temperature

measured values by increasing the contact resistance.

• Exercise care so that the temperature sensor connector does not become

disconnected. (If the sensor is disconnected, it will not be possible to perform temperature correction.)

CD-R disc precautions

• Exercise care to keep the recorded side of discs free of dirt and s cratches.

When writing text on a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight,

high temperature, or high humidity.

• Hioki is not liable for any issues your computer system experiences in the

course of using this disc.

Before Connecting the Power Cord

• To avoid electrical accidents and to maintain the safety specifications

of this instrument, connect the power cord provided only to a 3-contact (two-conductor + ground) ou tl et .

• Use only the design ate d power cord with this instrument. Use of other

power cords may cause fire.

• Before using the instrument, make sure that the insulation on the

power cord is undamaged and that no bare conduct ors are impr operly

exposed. Any damage could cause electric shock, so contact your

authorized Hioki distributor or reseller.

To avoid damaging the power cord, grasp the plug, not the cord, when

unplugging it from the power outlet.

Before Connecting Measuremen t Leads

To avoid shock and short circuits, turn off all power before connecting

measurement leads.

Before Connecting the LED Comparator Attachment

• To keep from damaging the instrument or LED Comparator Attachment,

turn off the instrument before connecting the attachment.

• The COMP.OUT jack is provided exclusively for use with the L2105. Do not

connect any device other than the L2105.

• The attachment may not fulfill the specifications if the connector is not

attached securely.

• Do not over-tighten the cable tie around the measurement leads. Doing so

may damage the measurement leads.

• Avoid the following as damage to the cable conductor or insulation may

result:

Twisting or pulling on cables

Bending cables near the lamp excessively in order to connect them

Before Connecting the Temperature Sensor

Failure to fasten the connectors properly may result in sub-specification performance or damage to the equipment.

Note the following precautions to avoid damaging the instrument:

• To keep from damaging the instrument or temperature sensor, turn off the

instrument’s main power switch before connecting the sensor.

• Connect the temperature sensor by inserting the plug all the way into the

TEMP.SENSOR jack. A loose connection can cause a large error component in measured values.

9

Operating Precautions

If the temperature sensor jack becomes dirty, wipe it clean. The presence of

dirt will cause an error in temperature measured values.

10

Operating Precautions

Before Connecting Data Cables (US B, RS-232C)

Observe the following precautions when connecting the instrument and a

controller:

• To avoid faults, do not disconnect or reconnect the USB cable during instru-

ment operation.

• The USB and RS-232C interfaces are not isolated from the ground circuit.

Connect the instrument and the controller to a common earth ground.

Using different grounds could result in potential difference between the

instrument and the controller. Potential difference on the data cable can

result in malfunctions and faults.

• Before connecting or disconnect ing the RS- 232C Cabl e, always tu rn off the

instrument and the controller. Failure to do so could result in equipment

malfunction or damage.

• After connecting the RS-232C Cable, tighten the screws on the connector

securely. Failure to secure the connector could result in equipment malfunction or damage.

Before Connecting the Printer

Because electric shock and instrument damage hazards are present,

always follow the steps below when connecting the printer.

• Always turn off the instrument and the printer before connecting.

• A serious hazard can occur if a wire becomes dislocated and contacts

another conductor during operation. Make certain connections are

secure.

Operating Precautions

Before Switching between Current Sink (NPN) and Current Source (PNP)

• Configure the NPN/PNP setting to accommodate externally connected

equipment.

• Do not operate the NPN/PNP switch while the instrument is on.

Before Connecting EXT I/O

To avoid electric shock or damage to the equipment, always observe

the following precautions when connecting to the EXT I/O connect or.

• Always turn off the main power switch on the instrument and on any

devices to be connected before making connec tions.

• Be careful to avoid exceeding the ratings of external terminals (p.

106).

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Use screws to secure the

external connectors.

• The ISO_5V pin of the EXT I/O connector is a 5V (NPN)/ -5V (PNP)

power output. Do n ot apply ext ernal power t o thi s pin. (Exte rnal p owe r

cannot be supplied to the instrument’s EXT I/O connector.)

11

To avoid damage to the instrument, observe the following cautions:

• Do not apply voltage or current to the EXT I/O terminals that exceeds their

ratings.

• When driving relays, be sure to install diodes to absorb counter-electromo-

tive force.

• Be careful not to short-circuit ISO_5V to ISO_COM.

• Configure the NPN/PNP setting to accommodate externally connected

equipment.

• Do not operate the NPN/PNP switch while the instrument is on.

See: "Connector Type and Signal Pinouts" (p. 91)

Before Turning Power On

Before turning the instrument on, make sure the supply voltage

matches that indicated on its power connector. Connection to an

improper supply voltage may damage the instrument and present an

electrical hazard.

Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with

rectangular wave or pseudo-sin e-wave output t o power t he instru ment. Doing

so may damage the instrument.

12

The measurement target is

connected to a power supply.

• Never attempt to measure at a point where volt-

age is present. Even if the power supply to the

motor is turned off, while the motor is rotating

inertially, high electromotive power is generated

in terminals. When attempting to measure a

transformer or motor immediately after voltage

withstanding test, induced voltage or residual

charge may damage the instrument.

Rotating inertially

• When the RM3544 is used in a way that connects to a withstanding voltage

tester via switching relays, construct a testing line bearing the following in

mind.

See: "Appendix 12 Using the Instrument with a Withstanding Voltage Tester" (p.

A26)

(1) The voltage withstanding specification of switching relays should

include a safe margin over the withstanding testing voltage.

(2) To protect against damage due to arc discharge in relay contacts, all

RM3544 measurement terminals should be grounded during voltage

withstanding testing.

(3) To protect against damage due to residual charge, measure resistance

first, and voltage withstanding last.

3158 AC Withstanding Voltage HiTester

Withstand voltage of relay switch is not high enough.

Residual charge from voltage

withstanding test is present.

RM3544

Operating Precautions

Before Measuring

• To avoid electric shock or damage to the

instrument, do not apply voltage to the

measurement terminals. Also, to avoid

electrical accidents, only take measurements after turning off the power to the

measurement targets being measured.

• Sparks may result at the moment the instrument is connected to, or

disconnected from, the measurement target. To avoid fire or bodily

injury, avoid use in the presence of explosive gases.

• Battery internal resistance cannot be measured with this instrument. It will

sustain damage. To measure battery internal resistance, we recommend the

HIOKI 3554, 3555, BT3562, BT3563 and 3561 Battery HiTesters.

• When measuring devices such as power supply transformers with high

inductance or open-type solenoid coils, measured value may be unstable.

In such cases, connect a film capacitor of about 1 F between SOURCE A

and SOURCE B.

• Carefully insulate all SOURCE A, SENSE A, SENSE B, and SOURCE B

wiring. Proper 4-terminal measurements cannot be performed and an error

will occur if core and shield wires touch.

• The SOURCE terminal is protected by a fuse. If the fuse is tripped, the

instrument will display “

Blown Fuse.” and you will not be able to measure

resistance values. If the fuse is tripped, replace the fuse.

See: "12.2 Replacing the Measurement Circuit’s Protective Fuse" (p. 171)

When using the temperature sensor

The temperature sensor is not waterproof. Do not submerse it in water or

other liquid.

• Allow the measurement target for which temperature correction is being

performed and the temperature sensor to adjust to the am bient temper ature

prior to measurement. Failure to do so will result in a large error component.

• Handling of the temperature sensor with bare hands may cause the sensor

to pick up inductive noise, resulting in unstable measured values.

• The temperature sensor is designed for use in applications in which ambi-

ent temperature is measured. It is not possible to accurately measure the

temperature of the measurement target itself by placing the sensor in contact with the surface of the target.

• Connect the temperature sensor by inserting the plug all the way into the

TEMP.SENSOR jack. A loose connection may cause a large error component in measured values.

13

Operating Precautions

14

Operating Precautions

15

• Installed footprint: 215 mm × 166 mm

Compact footprint and limited depth leave plenty of work space in front of the instrument.

• Measurement range: 30.000 m to 3.0000 M with a basic accuracy of 0.02%

rdg.

• Maximum measurement current: 300 mA

Ensures stable measurem ent, even when there is a significant amount of exter na l noise.

• No need for warm-up operation or zero-adjustment

Since wasteful wait t im es a re not required, you can s t ar t m aki ng measurements as soon as

the instrument is turned on.

• Choice of interfaces

RM3544 (no interface), RM3544-01 (USB, RS-232C, EXT I/O)

Compact yet reliable specifications

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

The RM3544 is capable of performing high-speed, high-precision measurement of the

winding resistance of components such as motors and transformers, the contact resistance

of relays and switches, the pattern resistance of printed circuit boards, and the DC resistance of fuses, resistors, and materials such as conductive rubber using four-terminal measurement. Since the instrument incorporates a temperature correction function, it is

particularly well suited to the measurement of targets whose resistance values vary with

temperature.

1

16

LED Comparator Attachment (option)

Streamlines work by eliminating the need to look at the screen.

Graphical LCD

Operation is intuit ive and easy to l earn.

Easy configuration of comparator and panel

load operation

Facilitates smooth se tup changes o n production lines.

Simple basic settings

Range and measurement

speed can be set directly.

Guard terminal

You can reduce the

effects of external

noise by connecting the guard terminal.

Free power supply (100 to 240 V) with

automatic frequency switching

Allows the instrument to be easily moved to

overseas production lines.

Judgment sounds with user-selectable patterns

Keeps you from mistaking audio from a

nearby operator ’s instrument as your own.

Easy-to-use functions in research and development,

on production lines, or in acceptance inspections

Monitor and test functions

Provides robust support for line development by allowing you to check

communications and E XT I/ O on th e

screen.

Example communic ations

monitor screen

Example EXT I/O test

screen

1.1 Product Overview and Features

17

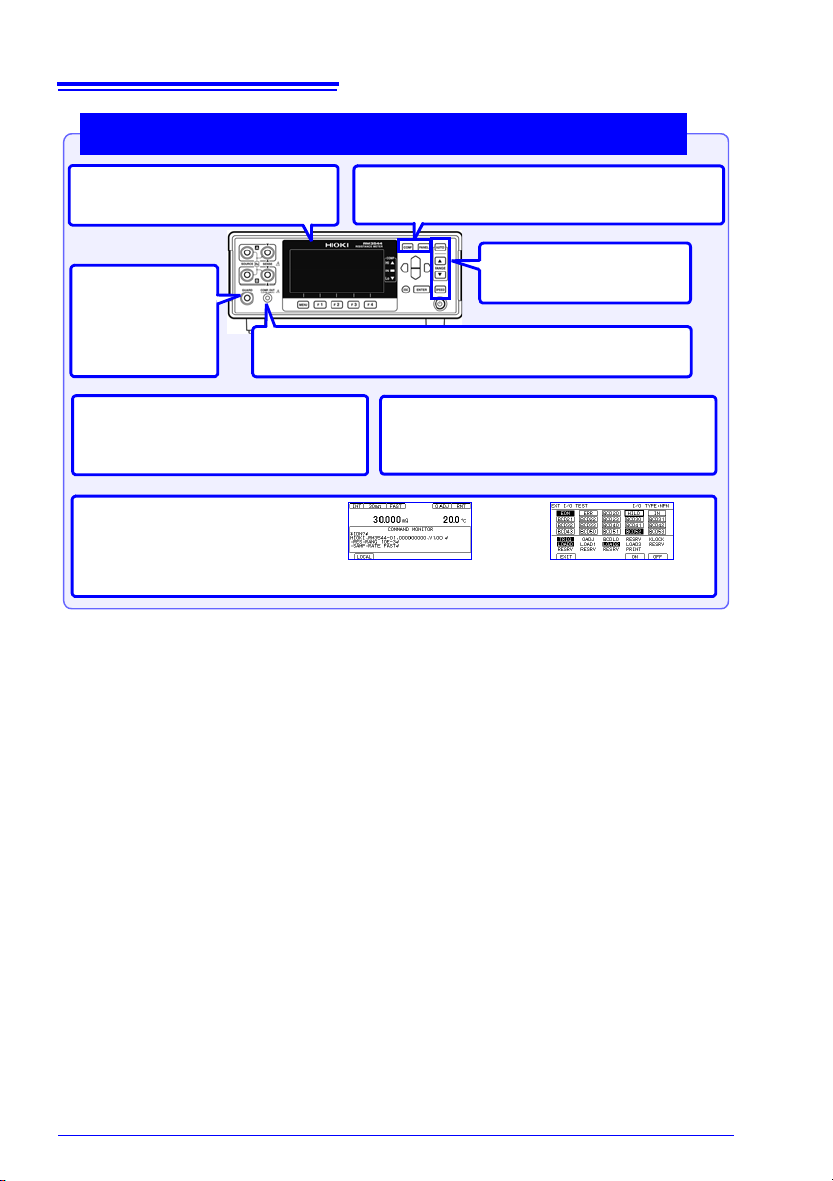

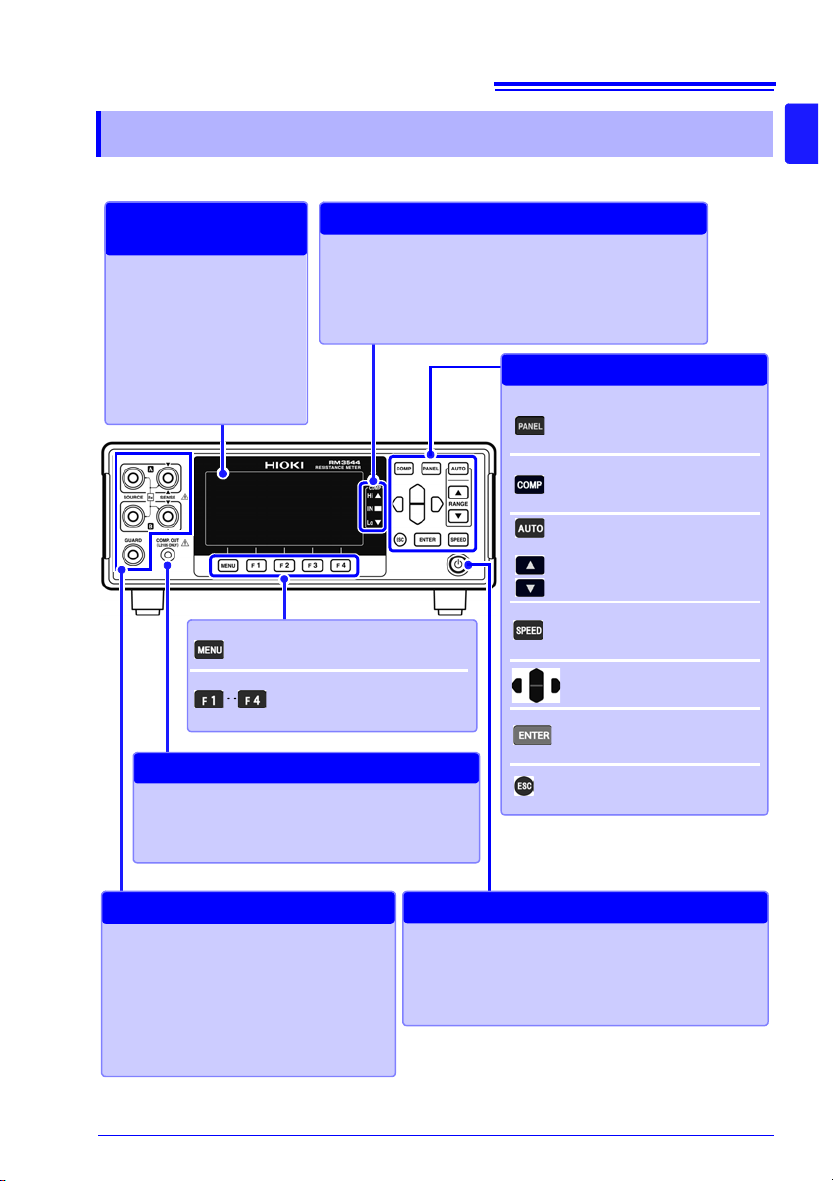

Display Screen (Monochrome graphical LCD)

Display of measuremen ts and

settings (p. 21)

Viewing Measured

Values and Settings

COMP indicator LEDs

Indicate the judgment result of the measured value (p.60).

Hi Measured value is above upper limit

IN Pass (meets criteria)

Lo Measured value is below lower limit

Viewing Comparator Results

MENU key

Switching of F key pages

F keys

Selection of settings displayed

on the screen

COMP.OUT jack

Connect the L2105 LED Comparator Attachment to

view judgment re sults without needing to refe r to the

instrument display. (p.70)

Connecting the LED Compa rator Att achment

PANEL key

Saving and loading of panels

(p.72)

COMP key

Configuration of comparator

settings (p.60)

AUTO, RANGE key

Range switching (p.32)

SPEED key

Measurement speed switch ing

(p.33)

Cursor keys

Selection of settings and digits

ENTER key

Acceptance of settings and

manual trigger input

ESC key

Cancellation of operation

Settings

Measurement T erminals

Connect measurement leads (p. 26).

• SOURCE A : Current detection terminal

• SOURCE B : Current source terminal

• SENSE A : Voltage detection terminal

• SENSE B : Voltage detection terminal

• GUARD : Guard terminal

Connecting Measurement Leads

STANDBY Key: Initiates or cancels the

standby stat e. (p . 28) .

• Unlit: power off (when no power supplied)

• Red light: Standby State (while power is supplied)

• Green light: power on

Initiating and Canceli ng the Standby State

1.2 Names and Functions of Parts

1.2 Names and Functions of Parts

Front Panel

1

18

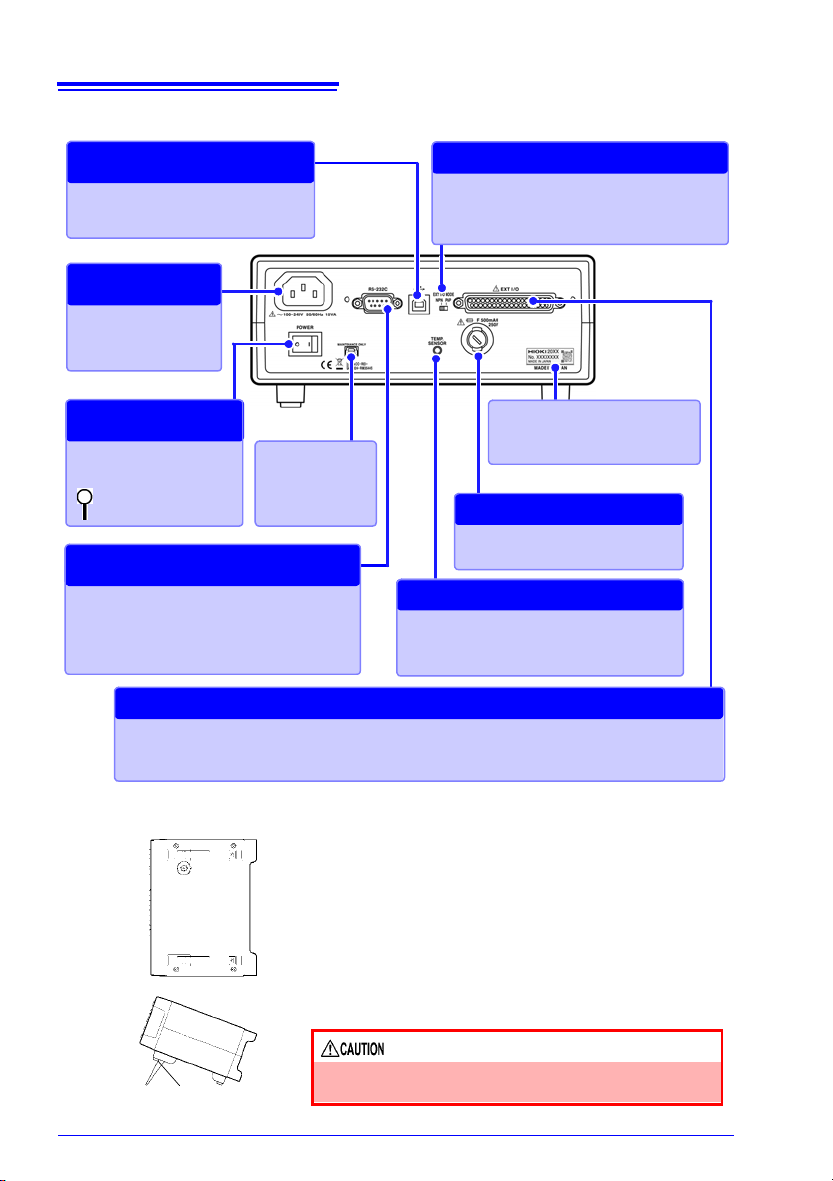

TEMP.SENSOR jack

Connect the Z2001 Temperature Sensor

when using temperature correction (p.27).

Correcting Temperature

RS-232C connector

• Connect to a computer, PLC, or other

device (p.126).

• Connect to a printer (p.137).

RS-232C Communications

Printer Output

Fuse holder (p.171)

Replacing the Fuse

Main power switch

(p.28)

: Main power off

: Main power on

Turning the Main

Power On and Off

EXT I/O connector

Connect when controlling the instrument with a PLC, I/O board, or other equipment to allow measurement to be started and measured values and comparator results to be acquired (p. 89).

External Control

Manufacturer's Serial No.

Do not remove this label, as it is

required for product support.

Power Inlet

Connect the supplied

power cord (p.25).

Connecting the

Power Cord

EXT I/O NPN/PNP switch

Left : Current sink (NPN)

Right : Current source (PNP)

Switching between NPN and PNP

USB jack

Connect to a computer (p.123).

Sending and Receiving

Data via USB

Maintenance

terminal

Do not use.

Bottom Panel

Stand

When using the stand

Extend the legs all the way. Do not extend partially.

Make sure to extend both legs of the stand.

Collapsing the stand

Do not collapse the sta nd partway. Be sur e to collapse it

all the way.

This instrument can be rack mounted.

See: "Appendix 14 Rack Mounting" (p. A28)

Parts removed f rom th is inst rumen t sh ould be sto red

in a safe place to enable future reuse.

Do not apply heavy downward pressure with the

stand extended. The stand could be damaged.

1.2 Names and Functions of Parts

Rear Panel

19

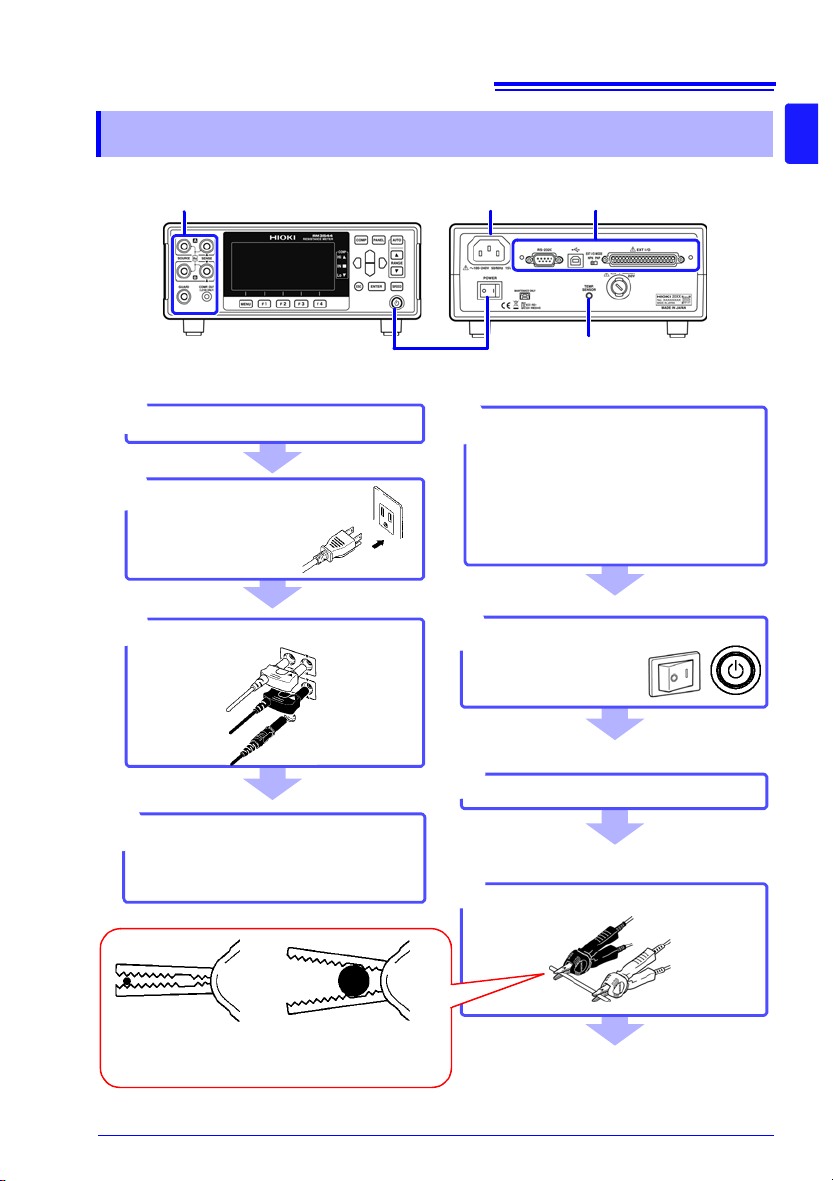

Install this instrum e nt (p. 5)

1

Rear Panel

Tu rn on the instrument and cancel

the standby state

(p.28)

6

When finished measuring, turn the

power off (p.28).

Connect the temperature sensor

(p.27)

(When using the temperature correction function)

4

2

3

Make instrument settings

*1

Connect measurement leads (p.26)

7

Connect to the test sample (p.34)

8

Connect the power

cord (p.25)

Connect the external interface

(RM3544-01; as necessar y)

5

• Using the printer (p.137)

• Using the USB or RS-232C inter-

face (p.121)

• Using the EXT I/O (p.89)

When clipping a small-gauge

wire

(Clip with the tip of the alligator

clips.)

When clipping a large-gauge

wire

(Clip with the back of the alligator

clips, where there are no teeth.)

6

3

4

2

5

Front Pane l

Rear Front

1.3 Measurement Process

1.3 Measurement Process

1

20

1.3 Measurement Proces s

*1 About zero-adjustment

Perform zero-adjustment in the following circumstances:

• The measured value is not cleared due to thermal EMF or other factors.

The measured value will be adjusted to zero. (Accuracy is not affected by whether or

not the zero adjustment is performed.)

• Four-terminal connection (called Kelvin connection) is difficult.

The residual resistance of the two-terminal connection wires will be canceled.

See: "4.1 Zero Adjustment" (p.44)

"Appendix 6 Zero Adjustment" (p.8)

21

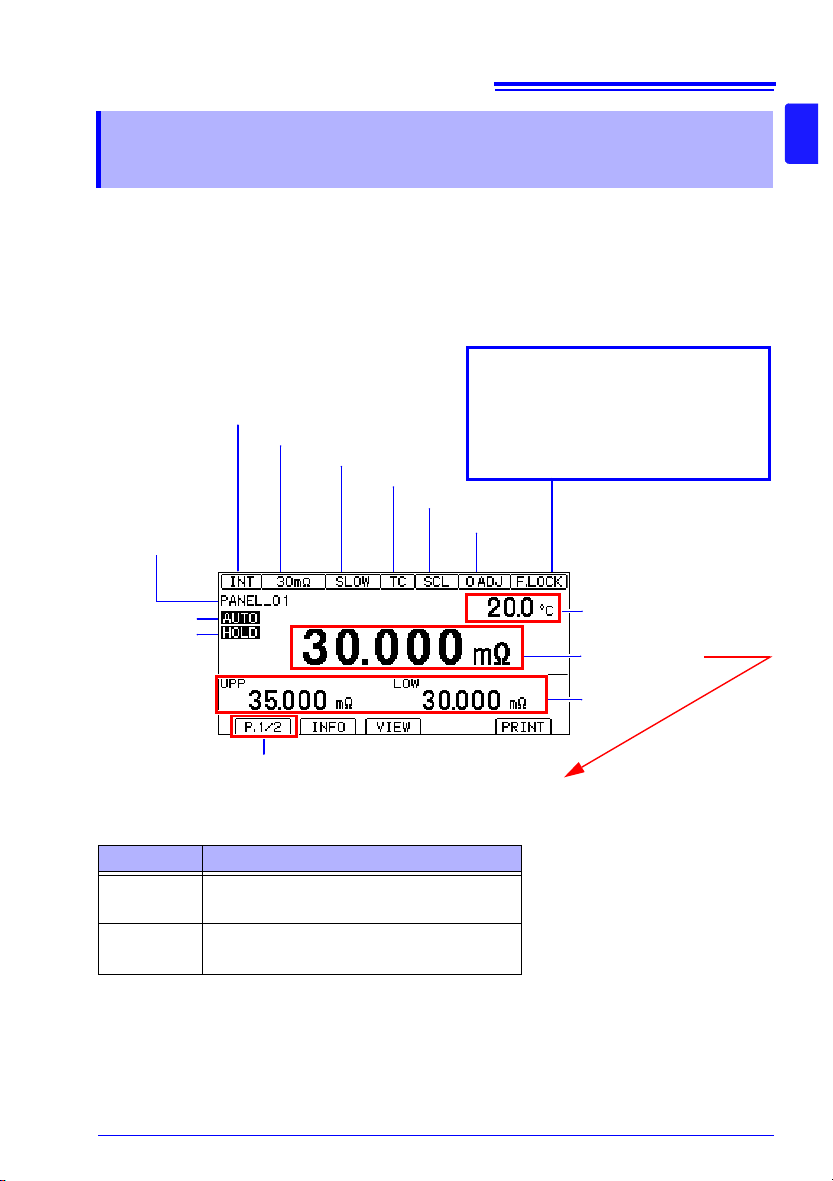

Trigger source (INT/EXT)

Measurement range

TC (ON)

0ADJ (ON)

Auto range

Key lock state or remote state

Cancel the key lock state or remote

state by pressing and ho lding the

MENU key.

F.LOCK : All operations prohibited .

M.LOCK: Menu operations prohibited.

RMT : Remote state

Judgment value

Switched with the VIEW key

(No display / temperature /

pre-calculation resistance

value)

Page switching

Measurement scre en la yo u t

Hold state

Scaling (ON)

Measurement speed

Number and name

of loaded panel

Measured value

1.4 Screen Organization and Operation Overview

1.4 Screen Organization and

Operation Overview

The instrument’s screen interface consists of a Measurement screen and various Settings

screens.

The screen examples in this guide appear reversed (black on white) for best visibility on the

printed page. However, the instrument screens can actually be displayed only as white

characters on black background.

1

Display of information other than measured values

(For more information, see "Confirming Measurement Faults" (p.38).)

* To treat current faults (when the source wiring is open) as over-range events, change the

Display Description

+OvrRng

-OvrRng

- - - - -

current fault output mode setting. (p.40)

Over-range

Not measured, or broken conn ection in measurement target *

22

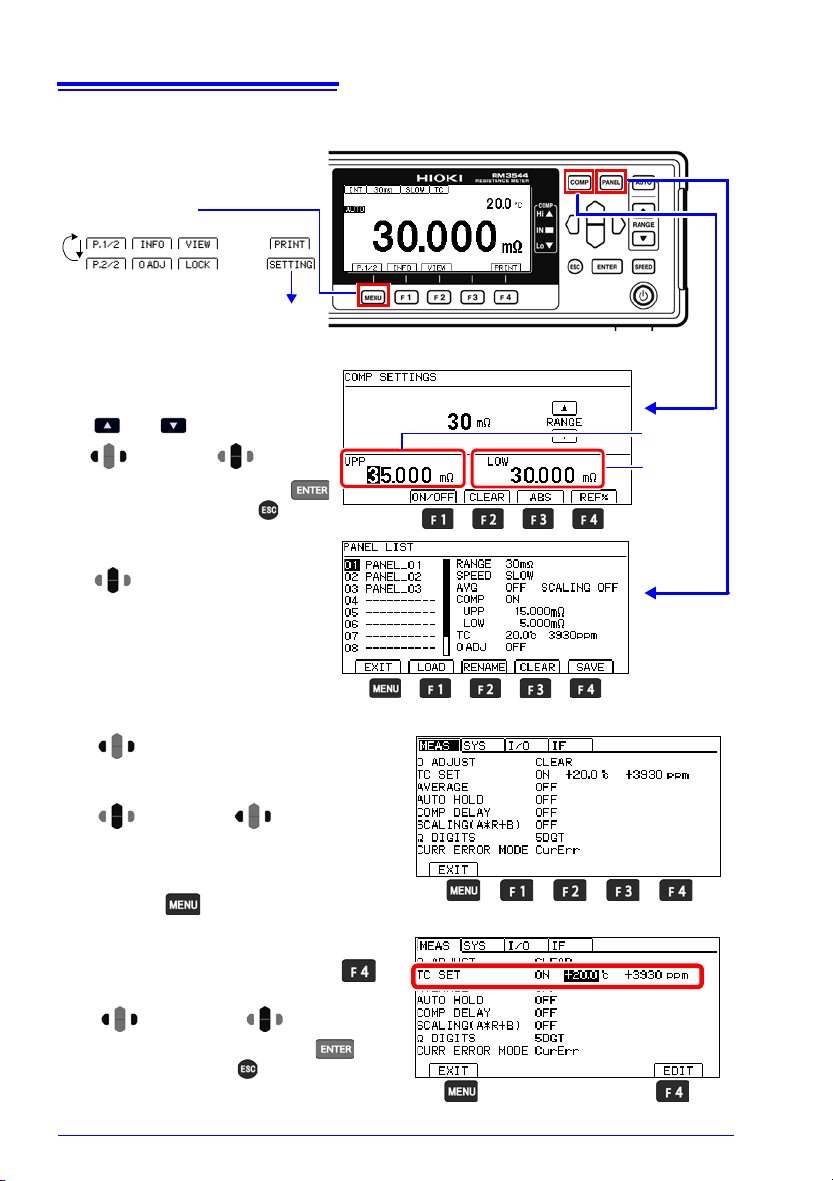

Overview of screen operation

Menu switching

(4) To Settings screens

(1) Measurement screen

(2) Comparator Settings screen

Upper limit

value

Lower limit

value

(3) Panel Save/Load screen

Select a panel number.

3

Change

values.

Move among

digits.

Accept the setting with the

key or cancel with the key.

4

Change the range with the

and keys.

2

1

2

Perform action with an F key.

1

Select the mode with an F key.

(4) Settings screen

< Setting values >

Make the value editable with the

key.

2

Change values.

1

Move among

digits.

Accept the setting with the key

or cancel with the key.

3

Return to the Measurement screen

with the key.

Move to the [M EAS], [SYS], [I/ O],

or [IF] tab.

([I/O] and [IF] tabs: RM3544-01 only.

Not shown on RM3544.)

1

2

Select a

setting.

Move among

settings.

Switch functions with an F key or set

values.

3

4

1.4 Screen Organization and Operation Overview

Loading...

Loading...