RM3543

HIOKI RM3543A981-04

RM3543-01

Instruction Manual

RESISTANCE HiTESTER

Be sure to read this manual before using the instrument.

When using the instrument for the

rst time

Names and Functions of

Measurement

Sept. 2020 Revised edition 4

RM3543A981-04 20-09H

Parts

Preparations

p.15

p.21

Troubleshooting

Maintenance and Service

Error Displays and

Remedies

p.183

p.185

p.5

EN

HIOKI RM3543A981-04

Contents

Contents

HIOKI RM3543A981-04

i

Task-Oriented Reference ............................... 1

Measurement Flow......................................... 2

Introduction..................................................... 3

Verifying Package Contents...........................3

Safety Information .......................................... 5

Operating Precautions.................................... 7

Chapter 1 Overview 11

1.1 Product Overview and Features ........11

Block Diagram ..........................................14

1.2 Names and Functions of Parts ........... 15

1.3 Screen Organization ..........................17

Chapter 2 Measurement

Preparations 21

2.1 Connecting the Power Cord............... 22

2.2 Connecting Measurement Cables and

Test Fixtures ...................................... 23

Making Your Own Measurement Cables ..24

2.3 Turning the Power On and Off ...........26

Chapter 3 Measurement

Settings (Basic

Measurements) 27

3.1 Pre-Operation Inspection ................... 27

3.2 Switching 100 m range Measurement

Currents ............................................. 28

3.3 Setting the Measurement Speed .......29

3.4 Setting Measurement Start Conditions

(Trigger Source) .................................30

3.5 Selecting the Measurement Range .... 31

3.6 Zero Adjustment ................................. 32

3.7 Judging Measured Values

(Comparator Function) .......................34

Enabling and Disabling the Comparator

Function ....................................................35

Decide According to Reference Value and

Tolerance (REF% Mode) ..........................35

Decide According to Upper/Lower Thresholds

(ABS Mode) ............................................. 37

3.8 Confirming Faulty Measurements ......38

Chapter 4 Customizing

Measurement

Settings 41

4.1 Making Range-Specific Measurement

Settings ..............................................41

4.2 Setting Pre-Measurement Delay ........42

4.3 Correcting Measured Values

(Scaling Function) ..............................44

4.4 Setting the Measurement Integration

Time Option ........................................46

4.5 Stabilizing Measured Values

(Averaging Function) ..........................48

4.6 Checking for Poor or Improper Contact

(Contact Check Function) ...................49

4.7 Improving Probe Contact

(Contact Improver Function) ...............50

4.8 Detecting Measurement Voltage Faults

(Voltage Level Monitor Function) .......52

4.9 Applying Current Only When Measuring

(Current Mode Setting) .......................53

4.10 Test for Short-Circuited Probe

(Probe Short-Circuit Detection Function)

............................................................54

4.11 Comparing the Measurement Settings of

Two Instruments

(Settings Monitor Function) ................ 56

4.12 Retrying Measurement After a Fault

(Retry Function) ..................................59

4.13 Maintaining Measurement Precision

(Self-Calibration) ................................60

4.14 Compensating for Thermal EMF Offset

(Offset Voltage Compensation - OVC) 61

Chapter 5 System Settings 63

5.1 Disabling and Enabling Key Operations

...........................................................63

Disabling Key Operations

(Key-Lock Function) ................................. 63

RM3543A981-04

ii

HIOKI RM3543A981-04

Contents

Re-Enabling Key Operations

(Key-Lock Cancel) ................................... 64

5.2 Setting the Comparator Decision and

Key Beepers .......................................65

Enabling or Disabling the Key Beeper ..... 65

Setting the Comparator Decision (“JUDGE”)

Beeper ..................................................... 66

5.3 Power Line Frequency Manual Setting

...........................................................67

5.4 Setting the Clock ................................68

5.5 Adjusting Screen Contrast ..................69

5.6 Adjusting the Backlight .......................70

5.7 Initializing (Reset) ...............................71

Default Settings ........................................ 72

Chapter 6 Storing and

Exporting Data 73

6.1 Storing Data at Specific Times

(Data Memory Function) .....................74

6.2 Store as soon as Measurement is Stable

(Auto-Memory Function) ....................75

6.3 Performing Statistical Calculations on

Measured Values ...............................78

Using Statistical Calculations ................... 79

Confirming, Printing, and Erasing Calculation

Results ..................................................... 80

6.4 Auto-Exporting Measured Values (at End

of Measurement) (Data Output Function)

............................................................81

Chapter 7 Printing 83

7.1 Connecting the Printer ........................83

Connecting the Printer to the Instrument . 84

7.2 Instrument Settings ............................85

7.3 Printing ...............................................86

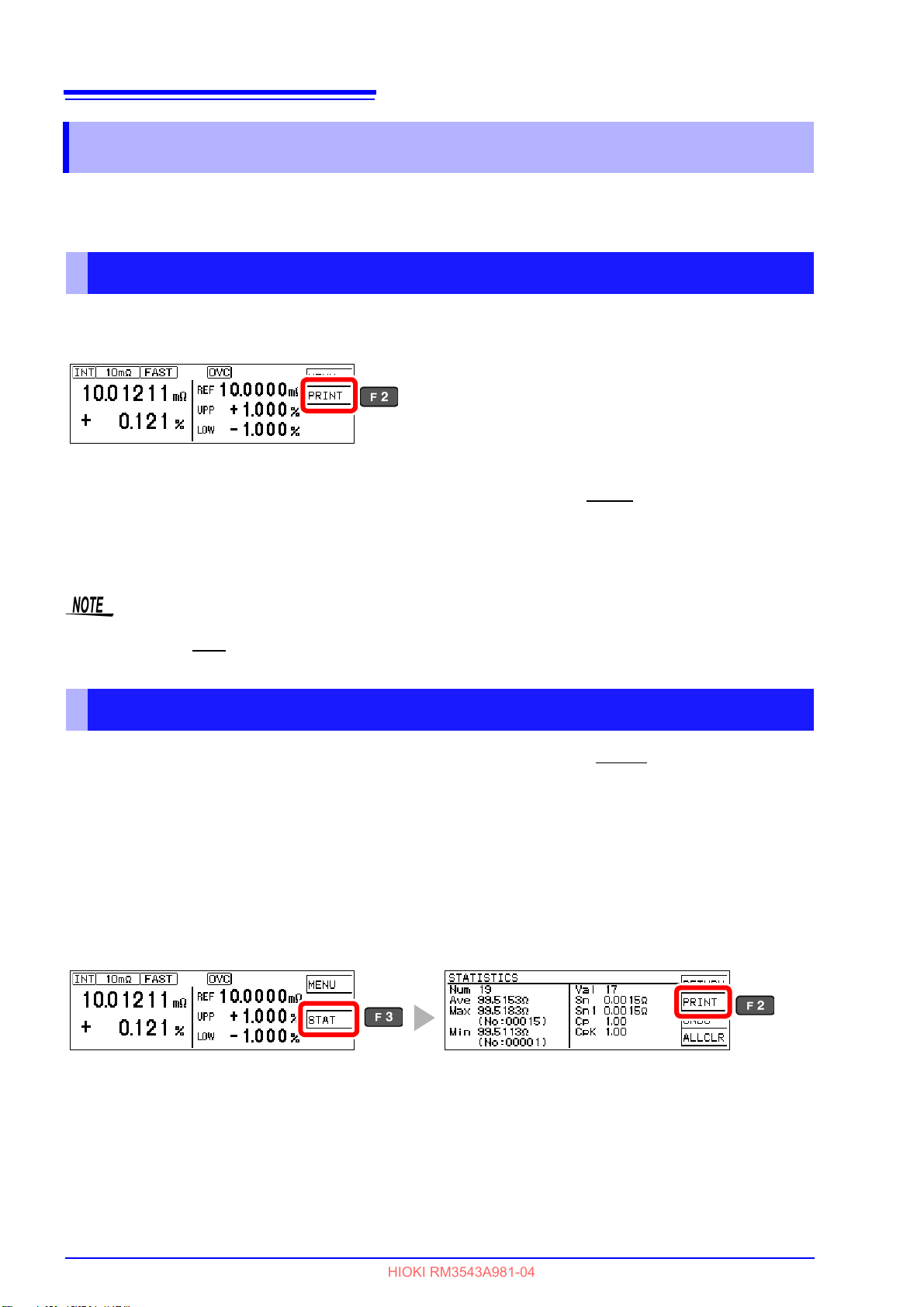

Printing Measured Values and Comparator

Decisions ................................................. 86

Printing Statistical Calculation Results ..... 86

Chapter 8 External Control 89

8.1 External Input/Output Connector

and Signals......................................... 89

Connector Type and Signal Pinouts ........ 90

Signal Descriptions .................................. 91

8.2 Timing Chart ...................................... 92

8.3 Internal Circuitry ................................. 94

Electrical Specifications ........................... 95

Connection Examples .............................. 96

8.4 External I/O Settings .......................... 97

Setting End-of-Measurement Signal Output

Signal Setting) ............................... 97

(EOM

Setting the Trigger (TRIG) Signal Logic ... 98

8.5 External Control Q&A ........................ 99

8.6 Supplied Connector Assembly ......... 100

Chapter 9 Communications

(RS-232C/ GP-IB

Interface) 101

9.1 Overview and Features .................... 101

9.2 Specifications ................................... 102

9.3 Connecting ....................................... 103

Using the RS-232C Interface ................. 103

Using the GP-IB Interface

(RM3543-01 only) .................................. 104

9.4 Configuring the Communications

Protocol ............................................ 105

Configuring RS-232C Interface

Communications .................................... 105

Configuring GP-IB Interface Communications

(RM3543-01 only) .................................. 106

Select the Measurement Data Transmission

Format (both RS-232C and GP-IB) ........ 107

9.5 Communication Methods ................. 108

To cancel the Remote state

(enter the local state) ............................. 108

Message Format .................................... 109

Output Queue and Input Buffer .............. 112

Status Byte Register .............................. 113

Event Registers ...................................... 115

Initialization Items ................................... 118

Command Execution Time ..................... 119

Errors During Communications .............. 119

9.6 Message List .................................... 120

Standard Commands ............................. 120

Device-Specific Commands ................... 121

9.7 Message Reference ......................... 126

Message Reference Interpretation ......... 126

Standard Commands ............................. 127

Device-Specific Commands ................... 131

9.8 Data Exporting Methods .................. 152

9.9 Sample Programs ............................ 154

HIOKI RM3543A981-04

Using Visual Basic 5.0 or 6.0 ..................154

Creation Procedure (Visual Basic 2005) .164

Sample Programs (Visual Basic 2005) ...166

9.10 Device Compliance Statement......... 168

Chapter 10 Specifications 171

Chapter 11 Maintenance and

Service 183

11.1 Troubleshooting ...............................183

Inspection and Repair .............................183

11.2 Cleaning ........................................... 184

11.3 Error Displays and Remedies .......... 185

11.4 Disposing of the Instrument ............. 187

Removing the Lithium Battery .................187

iii

Contents

Appendix A 1

Appendix 1 Four-Terminal (Voltage-Drop)

Method......................................A 1

Appendix 2 Effect of Thermal emf ...............A 2

Appendix 3 Unstable Measurement Values.A 3

Appendix 4 Effects of Probing .....................A 9

Appendix 5 Rack Mounting........................A 11

Appendix 6 Dimensional Diagram .............A 13

Appendix 7 Calibration...............................A 14

Appendix 8 Adjustment Procedure ............A 16

Appendix 9 Table of Commands Compatible

with the ADEX AX-1152D.......A 17

Appendix 10Zero Adjustment....................A 19

Index Index 1

iv

HIOKI RM3543A981-04

Contents

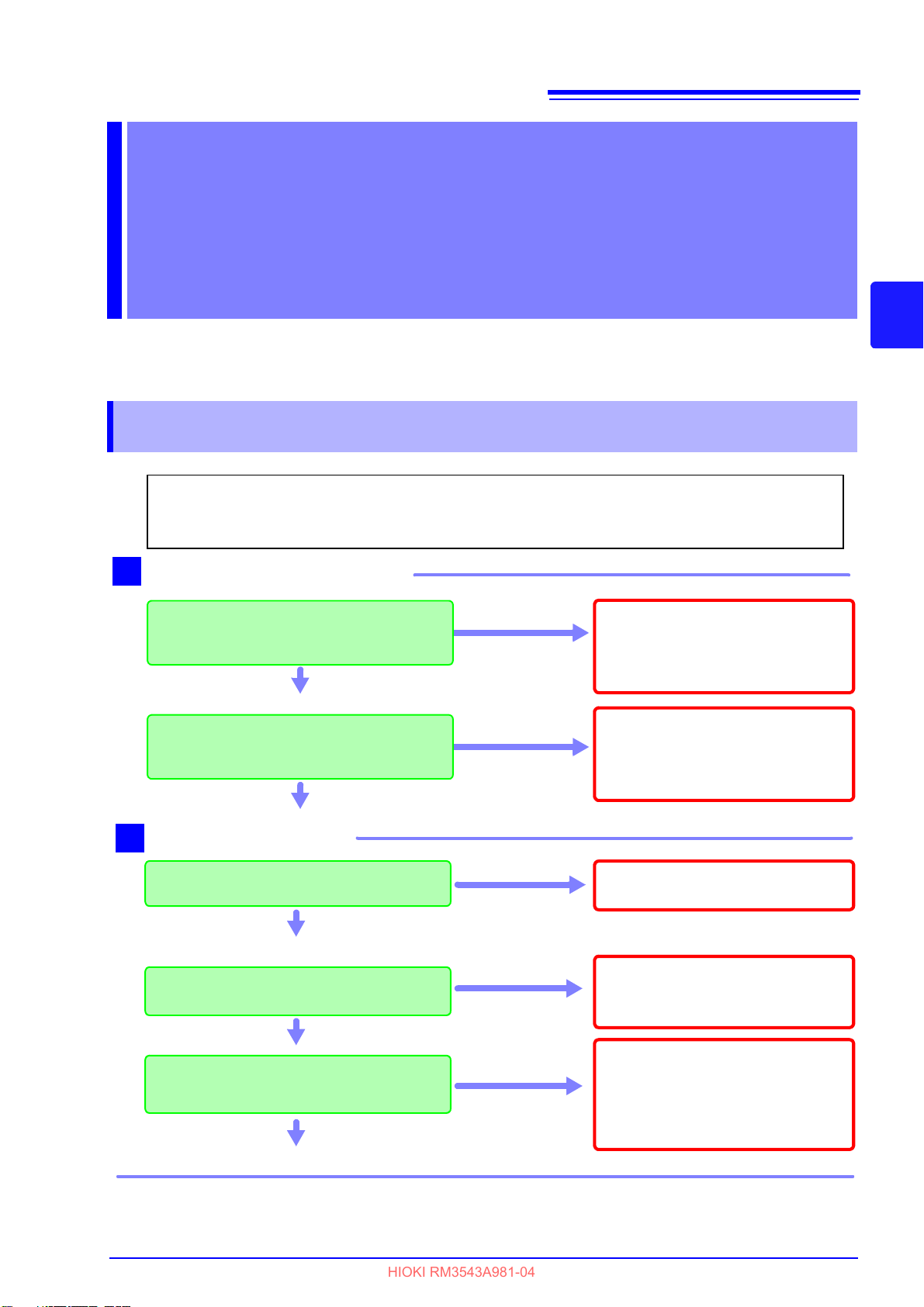

Task-Oriented Reference

HIOKI RM3543A981-04

Setting the measurement speed (p. 29)

Setting the averaging function (p. 48)

1

Task-Oriented Reference

To minimize measurement error

To judge measurement results

To correct faulty measurements

Setting the measurement speed integration time option (p. 46)

Correcting measured values (p. 44)

Zero-adjustment (p. 32)

Judge measured values (comparator function) (p. 34)

Compare the measurement settings of two instruments

(Settings Monitor function) (p. 56)

Confirm faulty measurement (p. 38)

Improve probe contact (Contact Improver function) (p. 50)

Test for short-circuited probe (probe short-circuit detection

function) (p. 54)

Compare the measurement settings of two instruments

(Settings Monitor function) (p. 56)

To automatically store measured

values

To print measurement results Printing (p. 83)

To measure by PLC connection

(PLC: Programmable Logic Controller)

To connect to a computer Communications (RS-232C/GP-IB interface) (p. 101)

To automatically send measurement data to a computer

(RS-232C interface only)

To check operation

Store as soon as measurement is stable

(Auto Memory function) (p. 75)

External control (p. 89)

Communications (RS-232C/GP-IB interface) (p. 101)

Export measurement values automatically

(when finished measuring) (p. 81)

Setting Measurement Start Conditions (Trigger Source) (p. 30)

Internal trigger (INT)

Calibration (p. A14)

2

Computer

communications

(p. 101)

Printing (p. 83)

External control

(p. 89)

EXT I/O

RS-232C

GP-IB

Compare the settings of two instruments

(p. 56)

SET MONITOR

Connecting the Power Cord (p. 22)

Turn the power on (p. 26)

Connect (p. 21)

Install (p. 7)

Connect the measurement cables (p. 23)

Set measurement

conditions (as needed)

Confirm the screen configuration

(p. 17)

Confirm the initial setup (p. 72)

• Basic Settings (p. 27)

• Configure settings for your

specific conditions (p. 41)

• System-related settings

(p. 63)

When changing settings

Change basic settings such

as measurement speed

Change to detailed settings

(measurement conditions

and system-related)

Set decision criteria

(p. 34)

Data transmission (p. 81) Printing (p. 83)

Computer communications

(p. 101)

External control (p. 89)

Statistical calculations

(p. 78)

Instrument interface settings must be

configured before printing or using

communications or remote control.

Turn the power off (p. 26)

HIOKI RM3543A981-04

Measurement Flow

Measurement Flow

Be sure to read the "Operating Precautions" (p. 7) before use.

Installing, Connecting and Turning On

Settings

Calculation, Printing, Communication, and External Control Settings

When Finished

Introduction

When you receive the instrument, inspect it carefully to ensure that no damage occurred during shipping. In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it

fails to operate according to the specifications, contact your dealer or Hioki representative.

Confirm that these contents are provided.

Model RM3543 or

RM3543-01 (with GP-IB included) ...............1

Power Cord (2-line + ground)(p. 22)

EXT I/O Male Connector (p. 100)

Instruction Manual (This document)............ 1

Operation Guide.......................................... 1

HIOKI RM3543A981-04

Thank you for purchasing the HIOKI Model RM3543/ RM3543-01 Resistance HiTester.

To obtain maximum performance from the instrument, please read this manual first, and keep

it handy for future reference.

Model RM3543-01 is the same as the RM3543, but with GP-IB included.

Registered trademarks

• Microsoft, Windows and Visual Basic are eitherregistered trademarks or trademarks of

Microsoft Corporation in the UnitedStates and other countries.

• Other products and company names are trade names, registered trademarks, or trademarks of their respective owners.

Verifying Package Contents

3

Introduction

Inspection

Content confirmation

4

Measurement Probes and Fixtures

(connect to measurement jacks)

Model 9140 4-terminal Probe

Model 9500 4-terminal Probe

Model 9262 Test Fixture

Model 9263 SMD Test Fixture

Alligator-clip-type measurement

probes. These general-purpose

dual-electrode clips fit a wide

range of conductor thicknesses.

Rubber-sheathed alligator-cliptype measurement probes. This

design is ideal for 4-terminalpair resistance measurement

applications, for example measuring standard resistors

This fixture is for measuring lead

components. (less than 10 m

residual resistance after zero

adjustment)

This fixture is for measuring chip

components. (less than 10 m

residual resistance after zero

adjustment)

Interface Cables

Model 9637 RS-232C Cable

(9-pin to 9-pin/ crossover cable)

Model 9638 RS-232C Cable

(9-pin to 25-pin/ crossover cable)

Model 9151-02 GP-IB Connector Cable (2m)

HIOKI RM3543A981-04

Verifying Package Contents

Options

The following options are available for the instrument. Contact your authorized Hioki distributor or reseller

when ordering.

The options are subject to change. Visit our website for updated information.

5

HIOKI RM3543A981-04

Safety Information

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment. However, mishandling during use

could result in injury or death, as well as damage to the instrument. Using the instrument in a way not described in this manual may negate the provided safety features.

Be certain that you understand the instructions and precautions in the manual before

use. We disclaim any responsibility for accidents or injuries not resulting directly

from instrument defects.

This manual contains information and warnings essential for safe operation of the instrument and for maintaining it in safe operating condition. Before using it, be sure to carefully read the following safety precautions.

Safety Symbols

Indicates the need for caution or the presence of danger. For more information about locations where

this symbol appears on instrumen components, see the "Operating Precautions" (p. 7), warning messages listed at the beginning ofoperating instructions.

Indicates AC (Alternating Current).

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Symbols for Various Standards

This symbol indicates that the product conforms to regulations set out by the EC Directive.

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU market after August

13, 2005, and producers of the Member States are required to display it on the appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

6

HIOKI RM3543A981-04

Safety Information

Other Symbols

Indicates a prohibited action.

(p. )

*

[ ]

SET

(Bold characters)

Unless otherwise specified, “Windows” represents Windows 95, 98, Me, Widows NT4.0, Windows 2000,

Windows XP, or Windows Vista.

Click: Press and quickly release the left button of the mouse.

Double click: Quickly click the left button of the mouse twice.

Indicates the location of reference information.

Indicates that descriptive information is provided below.

Square brackets indicate instrument display labels (such as setting item names).

Bold characters within the text indicate operating key labels.

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with the following meanings.

f.s. (maximum display value)

The maximum displayable value. This is usually the name of the currently selected range.

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

dgt. (resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that causes the

digital display to show a “1” as the least-significant digit.

Operating Precautions

The instrument can be used with the stand (p. 16).

It can also be rack-mounted. (p. A11).

50 mm or more

10 mm or more

Rear

50 mm or more

Unplugging the power cord

kills power to the instrument.

Be sure to provide enough

unobstructed space to unplug

the power cord immediately

in an emergency.

HIOKI RM3543A981-04

Follow these precautions to ensure safe operation and to obtain the full benefits of the various

functions.

Preliminary Checks

• Before using the instrument for the first time, verify that it operates normally to ensure that

no damage occurred during storage or shipping. If you find any damage, contact your

dealer or Hioki representative.

• Before using the instrument make sure that the insulation on the power cord is undamaged

and that no bare conductors are improperly exposed. Using the instrument in such conditions could cause an electric shock, so contact your dealer or Hioki representative for

repair.

• Before using the instrument, make sure that the insulation on the measurement cables is

undamaged and that no bare metal is improperly exposed. If there is any damage, measured values may be unstable and measurement errors may occur.

7

Operating Precautions

Instrument Installation

Storage temperature and humidity : -10°C to 50°C at 80% RH or less (non-condensating)

Operating temperature and humidity : 0 to 40

Avoid the following locations that could cause an accident or damage to the instrument.

Installation Precautions

°C at 80% RH or less (non-condensating)

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil, other

chemicals, or solvents

Exposed to high humidity

or condensation

Exposed to high levels of

particulate dust

Subject to vibration

In the presence of corrosive or explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction

heating systems and IH cooking

utensils)

• The instrument should be operated only with the bottom downwards.

• Do not place the instrument on an unstable or slanted surface.

• Vents must not be obstructed.

8

HIOKI RM3543A981-04

Operating Precautions

Handling the Instrument

• Do not allow the instrument to get wet, and do not take measurements with wet

hands. This may cause an electric shock.

• Do not attempt to modify, disassemble or repair the instrument; as fire, electric

shock and injury could result.

To avoid damage to the instrument, protect it from physical shock when transporting and

handling. Be especially careful to avoid physical shock from dropping.

This instrument may cause interference if used in residential areas. Such use must be

avoided unless the user takes special measures to reduce electromagnetic emissions to prevent interference to the reception of radio and television broadcasts.

Handling the Cords and Probes

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from

the power outlet.

• When disconnecting the BNC connector, be sure to release the lock before pulling off the

connector. Forcibly pulling the connector without releasing the lock, or pulling on the cable,

can damage the connector (p. 23).

• Use only the specified connection cables. Using a non-specified cable may result in incorrect measurements due to poor connection or other reasons.

• Before using a test fixture, read the instructions provided with it.

Before Turning Power On

Before turning the instrument on, make sure the supply voltage matches that indicated on its power connector. Connection to an improper supply voltage may damage

the instrument and present an electrical hazard.

Before Connecting EXT I/O

HIOKI RM3543A981-04

To avoid electric shock or damage to the equipment, always observe the following

precautions when connecting to the EXT I/O connector.

• Always turn off the power to the instrument and to any devices to be connected

before making connections.

• Be careful to avoid exceeding the ratings of external terminals (p. 95).

• During operation, a wire becoming dislocated and contacting another conductive

object can be serious hazard. Use screws to secure the external connectors.

• Ensure that devices and systems to be connected to the EXT I/O terminals are prop-

erly isolated.

• The ISO_5V pin of the EXT I/O connector is a 5 V power output, and the ISO_12V pin

is a 12 V power output. Do not apply external power to this pin.

To avoid damage to the instrument, observe the following cautions:

• Do not apply voltage or current to the EXT I/O terminals that exceeds their ratings.

• When driving relays, be sure to install diodes to absorb counter-electromotive force.

• Be careful not to short-circuit ISO_5V to ISO_COM.

• Be careful not to short-circuit ISO_12V to ISO_COM.

• Do not draw loads from ISO_5V and ISO_12V at the same time.

See: "Connector Type and Signal Pinouts" (p. 90)

9

Operating Precautions

Before Measuring

• Do not apply any voltage to the measurement jacks. Doing so could damage the instrument.

• Never attempt to measure at a point where voltage is present. In particular, do not measure

a transformer or motor immediately after a temperature increase test or withstand-voltage

test, as the instrument could be damaged by induced voltage or residual charge.

• Battery internal resistance cannot be measured with this instrument. It will sustain damage.

To measure battery internal resistance, we recommend the HIOKI 3554, 3555, BT3562,

BT3563, and 3561 Battery HiTesters.

• To obtain the guaranteed measurement accuracy, allow at least 30 minutes warm-up.

• The instrument internally retains all settings (but not measured values), such as measurement range and comparator settings. However, measurement settings made through the

RS-232C or GP-IB interface are not memorized.

• The DC resistance of a power transformer cannot be measured. Do not measure objects

with a large L (100 H or higher in the 10 m to 100 range, or 10 H or higher in the

1,000 range), such as choke coils and other inductors. In such cases, contact your

dealer or Hioki representative.

• You may be unable to obtain accurate measured values when there is a capacitance component in parallel with the measurement target. For this instrument, any parallel capacitance component should be limited to a maximum of 1,000 pF.

• Carefully insulate all H

cannot be performed and an error will occur if core and shield wires touch.

• During measurement, a transient current equal to about 1.5 times the steady-state current

will flow for several microseconds (or about 10 mApk in the 1 k range). Exercise special

care when measuring targets whose characteristics are prone to vary.

CUR

, H

POT

, L

POT

, and L

wiring. Proper 4-terminal measurements

CUR

10

HIOKI RM3543A981-04

Operating Precautions

1.1 Product Overview and Features

The Hioki RM3543 Resistance HiTester employs the 4-terminal method to quickly and accurately measure

the DC resistance of components such as resistors and current sensing resistors. It includes advanced contact-check, comparator, and data output functions. The intuitive user interface and high noise immunity are

ideal for use with taping machines and separators.

Resistance Measurement

The factory defaults (initial settings)

are optimized for current sensing resistors measurements.

Interface

Communications

Connect the instrument to a

controller via the RS-232C

or GP-IB interface to control

measurement data acquisition (p. 101).

Send Measurement Data and

Calculation Results to a

Printer

Use a commercially available printer with a serial interface to print

measured values and calculation

results (p. 83).

Save and Output Measured

Values

Measured values can be stored in

internal memory (p. 73)

Statistical calculations can be performed on the stored data, which

can be transferred to a computer in

batch form (however, stored data

cannot be confirmed internally).

Judge Measured Values

Measured values are compared

with a pre-specified reference value

or thresholds, and the result is output externally and indicated by the

COMP indicators (comparator function, p. 34).

Connect a PLC or

I/O Board

To control from a PLC, connect to the EXT I/O connector. In addition to comparator

results, various measurement

anomaly signals can be output (p. 89).

Upper limit

Lower limit

Compare Two Instrument’s

Setting Conditions

When measuring with two interconnected instruments, settings

are compared, and an alarm is

output and measurement is inhibited if the settings differ (Settings

Monitor function, p. 56).

Optional Hioki probes and fixtures

are available to connect to the measurement jacks (BNC jacks, p. 4).

Alternatively,

commercially

available cables

such as 1.5D-2V

coax can be used

(p. 24).

HIOKI RM3543A981-04

Overview Chapter 1

1.1 Product Overview and Features

11

1

12

Ultra Fast and Accurate Measurements

Increase Productivity

The RM3543 is ideally suited for use in testing current

sensing resistors, where there has been remarkable

progress in lowering resistance values.

Measurement from which the effects of thermal EMF

are consistently eliminated (by the OVC function)

yields a resolution of 0.01

in the 10 m range.

Since measurement results are obtained by means of

a PASS/FAIL judgment process with a resolution of

0.001%, the instrument can test resistors of 1 m and

less at a high rate of speed. Thanks to proprietary ultra-fast, high-stability circuit technology, the RM3543

completes the sequence of contact improvement,

measurement and contact check, and judgment output in just 1.6 ms.

Specially designed for current sensing resistors

Thanks to its scaling function, the RM3543 can compensate for the difference between resistance values

obtained at the time of mounting on the board and

during testing. By using the averaging function during

super-low-resistance measurement with a small detection voltage, it is possible to achieve even higher

levels of accuracy.

Multiple Interfaces

EXT I/O is isolated from the measurement and control

circuits to provide noise immunity (p. 89).

All data can be acquired in real time using the built-in

38.4-kbps high-speed RS-232C interface. Connect

the commercially available printer with a serial interface to print measured values and statistical calculation results (p. 83).

The GP-IB interface is available for Model RM3543-01

(specified when ordering, p. 101).

Clearly Visible Display and Intuitive Operation

High-contrast LCD provides clear visibility, helping

avoid setting mistakes. The optimum range is selected

automatically when comparator thresholds are entered.

Auto Memory Function Convenient for Sampling Tests (p. 75)

The auto memory function is convenient for sampling

tests after screen-printing. Measured values are automatically acquired as soon as they stabilize, and statistical calculations proceed until the specified quantity is

obtained, upon which an alert notification (alarm) occurs. Selecting [PRINT] (screen display) prints measured values and statistical calculation results (p. 86).

Fixtures for Component Measurements (p. 4)

The BNC-type measurement jacks exhibit good noise

immunity. Ready availability and easy assembly ensure smooth system setup. Various test fixtures are

available for Hioki LCR HiTesters.

Features

High-Speed Data Output and Ample Memory

The Data Output function transfers measured data at

5 ms/sample, even via RS-232C. Up to 30,000 measurements can be stored, and all data can be exported

at the end of measuring each reel. This function is ideal for system setup, debugging and process management.

HIOKI RM3543A981-04

1.1 Product Overview and Features

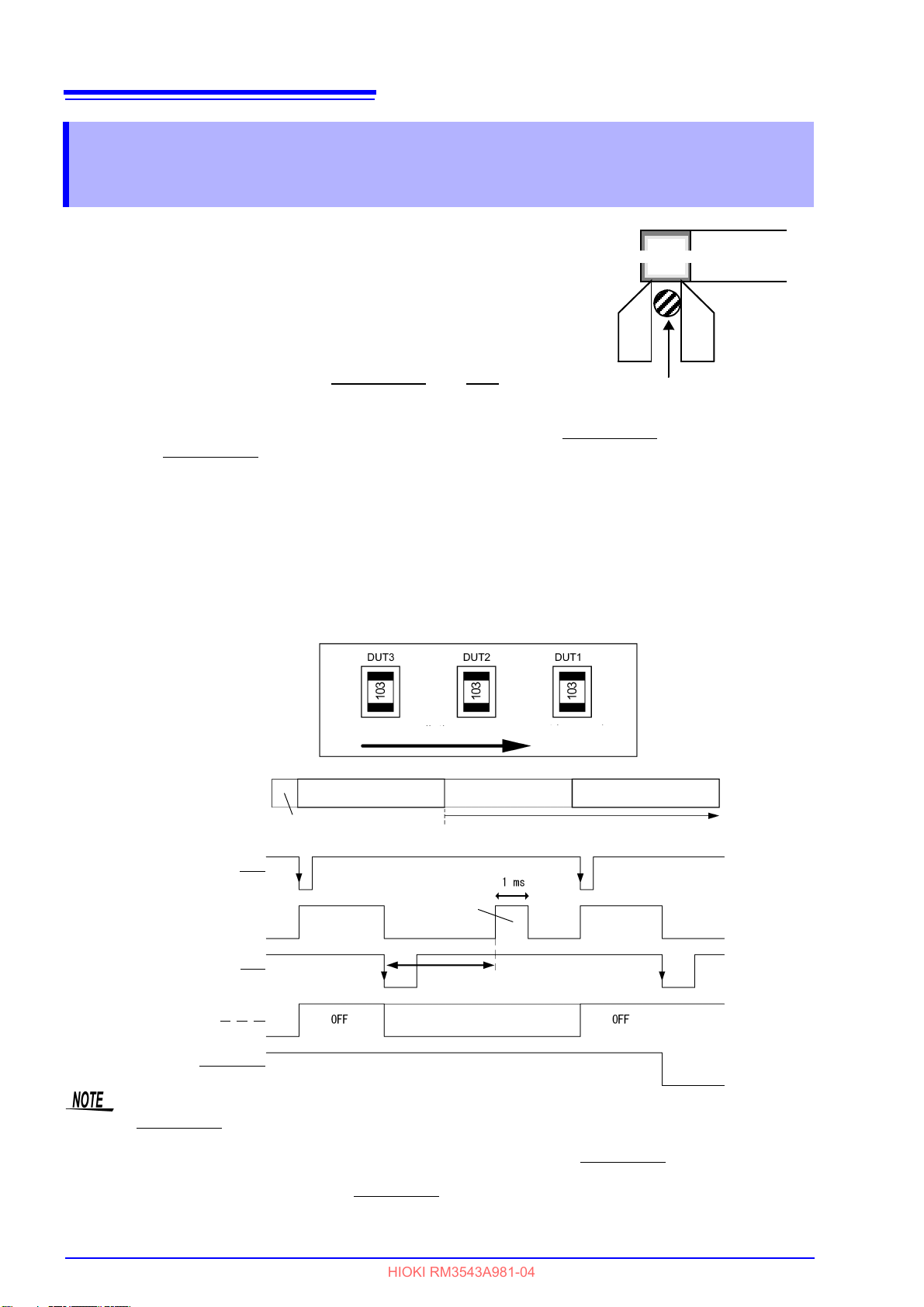

Reliable Contact Checking (p. 49)

Contact checking (that was previously performed before and after measuring) is now performed during measurement, so probe bounce and contact resistance

fluctuations can be detected. Contact checking time can

be shortened, improving tact times.

Features

Measurement Circuit Strongly Immune to

Contact Resistance Fluctuations

The effects of contact resistance fluctuations are reduced even when scattering occurs near the end of

probe life. Such effects are minimized by the fast response of the measurement circuit.

Contact Improver Function (p. 50)

The Contact Improver function improves bad contacts

between probes and test samples. Contacts errors are

reduced by penetrating oxidation and impurities between probes and samples. Reducing contact errors

can increase productivity and quality. The intensity of

the contact improver function can be adjusted according to probe type.

Reject Faulty Data –

Voltage Level Monitor Function (p. 52)

When the contact resistance of the H

CUR

and L

CUR

leads fluctuates, the measurement current changes

momentarily. Such momentary changes are not detectable by typical contact checking. The Voltage Level

Monitor function detects a contact error if the detection

voltage changes significantly, which can increase the

reliability of measured values.

Minimize Human Error and Risk –

the Settings Monitor Function (p. 56)

If the settings of two instruments are different, triggering is inhibited and an alarm notification is generated

to avoid setting mistakes due to human error.

Reliable Four-Terminal Measurement –

Probe Short-Circuit Detection Function

(p. 54)

Four-terminal measurements are inhibited when a

conductive foreign object is present between the

POT and CUR probe tips. Short-circuit probe anomalies are detected by checking the resistance between

these tips when not measuring.

Strong Electrical Noise Immunity

The specified measurement accuracy is achieved

even with ±1.5 kV mixed pulse noise. The floating

measurement section design is highly impervious to

electrical noise, minimizing the effect on measured

values even when turning large-induction motors on

and off. The free-range power supply input (90 to 264

V) is practically unaffected by voltage fluctuations, so

stable measurements are possible even in under

poor power conditions.

Previously

Model

RM3543

Contact Condition

Contact Check

Measuring

Probe Bounce

Contact

Condition

Detection

Voltage

Error

Good Contact

Poor Contact

Excessive detection

voltage fluctuation error

Good Contact

ERROR

Measurement

Status

Contact Check

Contact Condition

Contact Improver

Function

Contact Improvement

Measuring

Checking

ONON

DUT

Foreign object

POT

CUR

DUT electrode

HIOKI RM3543A981-04

13

1.1 Product Overview and Features

1

14

AB

C

D

E

F

G

H

I

E

D

HIOKI RM3543A981-04

1.1 Product Overview and Features

Block Diagram

• Constant current (determined by the measurement range) is applied between the H

age is measured between the H

voltage (B) by the constant current flow (A).

POT

and L

terminals. The resistance value is obtained by dividing the measured

POT

CUR

and L

terminals while volt-

CUR

• The effects of large offset voltage such as from thermal emf are reduced by current flowing in the positive and negative

directions (A).

• The constant current source (A) and voltmeter (B) circuit designs are largely unaffected by contact resistance.

• Faulty measurement values caused by unstable or chattering contact conditions can be eliminated by monitoring (C)

the detection voltage (B) waveform (Voltage Level Monitor function).

• Before measuring, the Contact Improver circuit (D) optimizes contact when the probes touch the DUT.

• By also performing contact checking (E), short circuits between CUR and POT terminals caused by a clogged probe tip

can be detected (probe short-circuit detection function).

• When measurement starts, the contact check circuit (E) and constant current monitor (F) are activated to monitor for

fault conditions while measuring. The dual-CPU (C and G) design provides ultra-high-speed measurements and fast

system response.

• Immunity from electrical noise is provided by isolation between the Measurement and Control blocks (H).

• The auto-ranging 100-to-240 V switching power supply (I) can provide stable measurements even in poor power quality

environments.

15

Display Screen

Monochrome graphical LCD

There are three general screen

types: Measurement, Basic Settings and Detailed Settings.

Screen Configurations (p. 17)

Judging measured values (p. 34)

(Comparator function)

Set a reference value and range for judging

measurements, which can be confirmed by

the COMP indicators.

Select this to judge measured values relative to a reference value

and tolerance (%). The REF% setting display appears.

Press to judge measured values

relative to upper/lower thresholds.

The ABS setting display appears.

Setting

POWER Button

Turns the instrument on and

off (p. 26).

• Unlit: power off

(when no power supplied)

• Red light: power off

(while power is supplied)

• Green light: power on

Power On/Off

Entering numerical values

Enter a numerical value.

(we call these the “tenkeys”)

Switches the sign of a numerical value.

Selects the unit of measure.

Sets the tolerance values.

Deletes the value in the selected field.

Accepts the displayed comparator threshold values.

Aborts comparator setting

and returns to the previous

display.

Measurement Terminals

Connect measurement cables or a fixture (p. 23).

• H

CUR

jack: Current source terminal

• H

POT

jack: Detected voltage high

terminal

• L

POT

jack: Detected voltage low ter-

minal

• L

CUR

jack: Measurement current

detected terminal

• GUARD jack: Shield (measurement

ground) terminal

Connecting Probes

COMP indicator

LEDs

Indicate the decision result of the measured

value (p. 34).

Hi Measured value is

above upper limit

IN Pass (meets crite-

ria)

Lo Measured value is

below lower limit

Viewing

Comparator

Results

Viewing Measured

Values and Settings

Audible Alarm

(beeper)

Selecting the setting contents

(“the F keys”) F1 to F4 keys

Selects the corresponding

item on the right side of the

display.

Cursor keys

Move among the displayed

setting items.

The cursor location is indicated by reverse characters.

HIOKI RM3543A981-04

1.2 Names and Functions of Parts

1.2 Names and Functions of Parts

Front Panel

1

16

Manufacturer's Serial Number

Shows the serial number. The 9-digit serial number indicates

the year (first two digits) and themonth of manufacture (next

two digits).

Do not remove this label, as it is required for product support.

Connect the supplied power cord (p. 22).

Connecting the Power Cord

RS-232C Connector

The RS-232C interface can be used to connect to

a PLC or computer (p. 101).

It is also used by the commercially available printer

with a serial interface (p. 83).

RS-232C Communications

Printer Output

GP-IB Connector (RM3543-01 only)

The GP-IB interface can be used to connect to a computer

(p. 101).

GP-IB Communications

SET MONITOR Connector

Connect another RM3543 here to compare instrument settings (p. 56).

Compare Two Instruments’

Settings

EXT I/O Connector

Connect to a PLC or I/O board to control

measurement start, and to acquire comparator results (p. 89).

External Control

Bottom Panel

Stand

When using the stand

Extend the stand until it clicks into place.

Make sure to extend both legs of the stand.

Collapsing the stand

Fold in the stand until it clicks into place.

This instrument can be rack mounted.

See: "Appendix 5 Rack Mounting" (p. A11)

Parts removed from this instrument should be stored in

a safe place to enable future reuse.

Do not apply heavy downward pressure with the

stand extended. The stand could be damaged.

HIOKI RM3543A981-04

1.2 Names and Functions of Parts

Rear Panel

17

Detailed Settings Screens (p. 19)

Measurement Settings Screens

[MEAS SETTINGS]

Data Settings Screens

[DATA SETTINGS]

System Screens

[SYSTEM]

Measurement Screen (p. 18)

Basic Settings Screen (p. 18)

Return to Previous Screen

Indicates a Continued Screen

Return to Previous Screen

HIOKI RM3543A981-04

1.3 Screen Organization

1.3 Screen Organization

The instrument has three general display screen types: Measurement, Basic Settings and Detailed

Settings.

Refer to "11.3 Error Displays and Remedies" (p. 185) for error displays.

The screen examples in this guide appear reversed (black on white) for best visibility on the printed page.

However, the instrument screens can actually be displayed only as white characters on black background.

1

18

Measurement Screen

This screen normally appears while measuring. View currently measured values and measurement conditions.

Some parts of the display depend on the comparator

mode and other settings.

Measured Value

Settings Menu (corresponding to F keys)

Displayed contents depend on the current function settings.

Parentheses ( ) indicate the corresponding F-key

MENU (F1) Displays the Basic Settings screen

PRINT (F2) Print (p. 85)

Appears only when the interface is

set for the printer

STAT (F3) Statistical calculation results (p. 78)

Appears only when statistical calculation is enabled

NUMBER (F4) Set Auto-Memory number (quantity)

(p. 75)

Displays the number of stored data

items and the number of passed and

failed products at the lower left.

UNDO (F3) Deletes the previously stored mea-

surement and calculation result (only

one can be deleted) (p. 80)

Appears only when calculation results are displayed

ALLCLR (F4) Clears all memory and calculation

(p. 80)

Appears only when calculation re-

sults are displayed

LOCAL (F1) Enables local control (p. 108)

UNLOCK (F1) Cancels the key-lock state (hold 1s)

(p. 64)

Criteria Setting Values (p. 34)

Displayed contents depend on the

selected comparator mode.

(Ex.: REF% mode)

To display the Basic Settings screen

Measurement Conditions

Shows current setting contents. Displayed contents depend on the current settings.

INT/ EXT Trigger source type (p. 30)

Measurement range (p. 31)

FAST/ MED/ SLOW Measurement speed (p. 29)

0ADJ/

OFF (not shown)

Appears only when zero-adjust is

enabled (p. 32)

OVC/

OFF (not shown)

(OVC: Offset Voltage Compensation)

Appears only when OVC is enabled (p. 61)

SC/

OFF (not shown)

Appears only when the scaling

function is enabled (p. 44)

NUM Appears only when tenkey input is

enabled

RMT Remote control (p. 108)

M.LOCK Disables all operations except

comparator settings (p. 63)

F. LO CK Disables all operations including

comparator settings (p. 63)

Basic Settings Screen

Make basic measurement condition settings on this

screen. Measurement speed and range can be changed

while viewing measured values. (Trigger source: INT)

TRG

Change trigger source (measurement start

control method) (p. 30)

When EXT triggering is enabled, [MANU] ap-

pears beside the F4 key (press to trigger

measurement manually).

RANGE Change range (p. 31)

SPEED Change measurement speed (p. 29)

0ADJ Turn zero-adjust on/off (p. 32)

COMP Turn comparator on/off (p. 34)

LOCK Enable/disable key lock (p. 63)

Select measurement

condition settings

Move with cursor keys.

Measurement condition

setting selections

Return to previous screen

To display the [MEAS SETTINGS] screen

To display the [DATA SETTINGS] screen

To display the [SYSTEM] screen

MISC To display the Detailed Settings screen

HIOKI RM3543A981-04

1.3 Screen Organization

19

Measurement Settings Screen

[MEAS SETTINGS]

Shows detailed settings for measurements.

Adjust the measurement speed, stability and measurement fault

detection functions.

DELAY1 Adjust the delay from probing to trigger

input (p. 42)

DELAY2 Adjust measurement object electrical re-

sponse (p. 42)

SCALING(A*R+B) Correct measured values with the scal-

ing function (p. 44)

INT (FAST/ MED/

SLOW)

Make fine adjustment to integration time

(p. 46)

AVERAGE Stabilize measured values with the aver-

aging function (p. 48)

CONT CHECK Contact check threshold setting (p. 49)

CONT IMP Contact Improver function setting (p. 50)

VOLT MONITOR Voltage level monitor function setting

(p. 52)

CURRENT MODE Current mode setting (p. 53)

Data Settings Screen

(Save, Analysis, and Output)

[DATA SETTINGS]

These are settings for memory and statistical calculation functions.

AUTO MEMORY Turn Auto-Memory on/off (p. 75)

STATISTICS Statistical calculation on/off (p. 78)

DATA OUT Automatically output measured values

(communications) (p. 81)

Detailed Settings Screens

HIOKI RM3543A981-04

1.3 Screen Organization

1

20

Set instrument system-related settings on this screen.

SET MONITOR Turn two-instrument setting comparison

on/off (p. 56)

PROBE CHECK Turn probe short-circuit detection on/off

(p. 54)

RETRY Retry function setting (p. 59)

TRIG EDGE (External I/O) Set trigger rising/falling

edge (p. 98)

EOM (External I/O) Set EOM

(end-of-mea-

surement) signal (p. 97)

INTERFACE Communications interface settings

(p. 105)

100m CURR 100 m range measurement current set-

tings

100 mA/1 A (p. 28)

CALIBRATION Self-calibration operation settings (p. 60)

JUDGE BEEP Comparator beeper settings (p. 66)

KEY BEEP Key beeper on/off (p. 65)

CLOCK (Y-M-D) Set internal clock (p. 68)

LINE FREQ Set power source frequency (p. 67)

CONTRAST Adjust screen contrast (p. 69)

BACKLIGHT Adjust screen backlight (p. 70)

RESET Initialize (p. 71)

ADJUST Instrument Adjustment (p. A16)

System Screen

[SYSTEM]

HIOKI RM3543A981-04

1.3 Screen Organization

21

Install this instrument (p. 7)

1

Rear PaneFront Panel

Connect measurement cables

(p. 23)

Turn the power on (p. 26)

5

Connect to the test sample

When finished measuring, turn the

power off (p. 26).

Connect the external interface

(as needed)

4

• Using the printer (p. 83)

• Using the RS-232C or GP-IB interface

(p. 101)

• Connecting to a PLC or I/O board

(p. 89)

• Automatically comparing the settings

of two instruments (Settings Monitor

function) (p. 56)

Connect the power cord (p. 22)

2

3

2

3

4

5

Make instrument settings (p. 27)

6

HIOKI RM3543A981-04

Measurement Preparations Chapter 2

Be sure to read the "Operating Precautions" (p.7) before installing and connecting this instrument.

Refer to "Appendix 5 Rack Mounting" (p. A11) for rack mounting.

2

22

Rear Panel

1 Confirm that the mains supply voltage matches the

instrument, and connect the power cord to the power

inlet on the instrument.

2 Plug the power cord into the mains outlet.

The POWER button on the front panel lights red.

In event of a power outage, operation resumes with the same

settings when power is restored (breaker reset, etc.).

Power inlet

HIOKI RM3543A981-04

2.1 Connecting the Power Cord

2.1 Connecting the Power Cord

• Before turning the instrument on, make sure the supply voltage matches that indi-

cated on its power connector. Connection to an improper supply voltage may damage the instrument and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specifications of this instru-

ment, connect the power cord only to a 3-contact (two-conductor + ground) outlet.

• Before using the instrument, make sure that the insulation on the power cord is

undamaged and that no bare conductors are improperly exposed. Any damage

could cause electric shock, so contact your dealer or Hioki representative.

To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from the

power outlet.

2.2 Connecting Measurement Cables and Test Fixtures

Example of defeated guard measurement

Connecting measurement cables

Connecting a fixture

Connect directly to the measurement

jacks with the label side up, and affix

with the levers on the left and right.

Connect the red plugs to the

H

CUR

and H

POT

jacks, and the

black plugs to the L

CUR

and

L

POT

jacks.

Black plugs

Red plugs

BNC Jack Guide Pins

(on the instrument)

Lock

BNC plug slots

2

1

Align the slots in the BNC plug with the

guide pins on the jack on the instrument,

then push and twist the plug clockwise

until it locks.

Disconnecting BNC connectors

Push the BNC plug, twist it counterclockwise, and pull it out.

Making your own probes and extenders (p. 24)

Connection Methods

HIOKI RM3543A981-04

2.2 Connecting Measurement Cables and

Test Fixtures

23

Connect your measurement cables, optional Hioki probes or test fixture to the measurement jacks.

Refer to "Options" (p.4) for details. See the instructions provided with the fixture for operating

details.

• Do not apply a voltage to the measurement terminals. Doing so may damage the unit.

• When disconnecting the BNC connector, be sure to release the lock before pulling off the

connector. Forcibly pulling the connector without releasing the lock, or pulling on the cable,

can damage the connector.

• We recommend using optional Hioki fixtures.

• Use the GUARD jack only for Faraday

shield, and avoid more than 10 mA current flow. This jack is not for guarding

network resistance measurements.

2

24

Wiring Diagram

Before Wiring

See: "Appendix 3 Unstable Measurement Values" (p. A3)

• Twist together the H

POT

and L

POT

wires, and the H

CUR

and L

CUR

wires. If not twisted together, measured

values may be unstable, and errors may occur, when measuring with low resistance values.

• The phenomenon of induction becomes pronounced in the 10 m and 100 m ranges (when the mea-

surement current is set to 1 A). Changes in the cable position and configuration may cause measured values to vary. Exercise particular care so that the cable position and configuration do not change.

Additionally, measurement cables and measurement targets should be kept as far as possible from metallic objects.

• When using two or more RM3543 units, do not group the wires from multiple instruments together. The

"C.E. Volt" error display may be triggered by the phenomenon of induction.

• Refer to the block diagram (p. 14) for internal circuit details.

• Probes and measurement objects should be shielded at BNC or GUARD jack potential.

• Wiring resistance in excess of the following values may cause a current monitor error, making measurement impossible. When using measurement current 1 A ranges, keep the wiring resistance as well as the

contact resistance between the DUT and probe low.

Range

10m 100m 100m 1000m 10 100 1000

Measurement Current

1 A 1 A 100 mA 100 mA 10 mA 10 mA 1 mA

Between H

CUR

and DUT

1 1 18 18 180 180 1.8 k

Between L

CUR

and DUT

1 1 8 8 80 80 800

HIOKI RM3543A981-04

2.2 Connecting Measurement Cables and Test Fixtures

Making Your Own Measurement Cables

Recommended Measurement Cable Specifications

Conductor resistance

Capacitance 150 pF/m or less

Cable dielectric material

Connector insulating material

Length 2 m or less

Example: JIS standard 3C-2V, 1.5D-2V MIL standard RG-58A/U

* Teflon is a registered trademark of E. I. du Pont de Nemours and Company.

500 m/m or less

Polyethylene (PE), Teflon* (TFE), polyethylene foam (PEF)

Insulation resistance at least 10 G

Teflon* (TFE), polybutylene terephtalate (PBT)

Insulation resistance at least 10 G

25

• Measurement cable length should not exceed 2 m (with conductor resistance 500 m/m or less). Long

cables are more susceptible to noise, and measured values may be unstable.

• Extensions should maintain the four-terminal structure. If converted to a two-terminal circuit in the wir-

ing, correct measurement may not be possible due to the effects of wiring and contact resistance.

• Cables and measurement objects should be shielded.

• After extending measurement cables, confirm operation and accuracy ("Measurement Specifications"

(p.180)).

• If cutting the ends off of optional measurement cables, make sure that the shield does not touch the

center conductor of the H

CUR

, H

POT

, L

POT

and L

CUR

cables. Correct measurement is not possible with

a shorted cable.

• Do not twist wires from multiple units together.

Extending Measurement Cables

Observe the following when extending measurement cables:

HIOKI RM3543A981-04

2.2 Connecting Measurement Cables and Test Fixtures

2

26

Press the POWER button (it lights green).

Self-test

Indicates an error (p. 185).

After Power-On

A self-test (instrument diagnostic routine) is performed.

During the self-test, the following information is displayed while the hardware is verified.

Error

No Errors

Normal display (measurement screen)

The following information is displayed during self-testing:

• Manufacturer and model name

• Firmware versions (main, and measurement)

• Communication setting

• Line frequency setting

HIOKI RM3543A981-04

2.3 Turning the Power On and Off

2.3 Turning the Power On and Off

Turning Power On

Turning Power Off

When the power is turned on, the same setting as when the power was last turned off

appears (backup function).

When powered up for the first time, the default settings appear.

See: "Default Settings" (p.72)

Before Starting Measurement

To obtain precise measurements, provide about 30 minutes warm-up after turning power on.

Measurement settings are recalled from when the power was previously turned off (settings

backup).

However, measurement settings made through the RS-232C or GP-IB interface are not

retained, although they can be stored using the

Press the POWER button (it lights red when the instrument is off).

Disconnect the power cord from the outlet to extinguish the POWER button light.

When power is turned on again, operation resumes with the same settings as when last

turned off.

If a power outage (e.g., breaker trip) occurs when the instrument is on, it will automatically

turn on again when power is restored (without pressing the POWER button).

:SYSTem:BACKup command (p. 139).

27

Do not use the instrument if damage is

found, as electric shock or short-circuit

accidents could result. Contact your

dealer or Hioki representative.

Metal Exposed

Is the power cord insulation torn, or is

any metal exposed?

1

Before using the instrument for the first time, verify that it operates normally to ensure that no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Peripheral Device Inspection

Is the insulation on a measurement

cable torn, or is any metal exposed?

No Metal Exposed

If there is any damage, measured values may be unstable and measurement errors may occur. Replace the

cable with an undamaged one.

Metal Exposed

No Metal Exposed

If damage is evident, request repairs.

Yes

Is damage to the instrument evident?

Instrument Inspection

When turning power on

Does the self-test screen appear

(model no., version no.)? (p. 26)

No

2

The power cord may be damaged, or

the instrument may be damaged internally. Request repairs.

Does the Measurement screen appear

after self-test?

No

Yes

The instrument may be damaged internally. Request repairs.

See: "11.1 Troubleshooting" (p. 183)

"11.3 Error Displays and Remedies" (p. 185)

An error indication

occurs (ERR)

Yes

Inspection complete

Please read the "Operating Precautions" (p. 7) before use.

HIOKI RM3543A981-04

3.1 Pre-Operation Inspection

Measurement Settings (Basic Measurements)

Chapter 3

See "Measurement Flow" (p. 2) for an outline of the measurement process from preparation to endof-measurement.

3.1 Pre-Operation Inspection

3

28

Measurement Current: 100 mA

To achieve more precise measurement

Measurement Current: 1 A

To limit the effects of external noise

The Basic Settings screen appears.

1

The System screen appears.

[SYSTEM]

Selection

2

Selection

1

2

100 mA (default)

1 A

Return to the setting screen.

Save setting and return to

previous screen.

Discard setting and return to

previous screen.

The confirmation screen appears.

HIOKI RM3543A981-04

3.2 Switching 100 m range Measurement Currents

3.2 Switching 100 m range Measurement

Currents

The 100 m range measurement current can be switched between 100 mA and 1 A. The 100 mA

setting (which is the factory default) allows measurement at a high level of precision. The 1 A setting

can be used to provide better resistance to external noise.

See: "(5) DUT Becomes Warm" (p. A6)

(Example)If the resistance to be measured is 100 m

(Measurement Current)

100 mA 100 m × 0.12 = 1 mW

1 A 100 m

× 1

2

= 100 mW

Open the Basic Settings screen.

1

Open the System screen.

2

Select the 100 m range measurement current.

3

Return to the Measurement screen.

4

• The 100 m range measurement condition settings are configured separately for each measurement current. Consequently, the 100 m range measurement condition settings should be configured after first setting the measurement current.

• During measurement, a transient current equal to about 1.5 times the steady-state current will flow for several microseconds (or about 10 mApk in the 1 k range). Exercise special care when measuring targets

whose characteristics are prone to vary.

29

The Basic Settings screen appears.

1

Selection

2

See table below

(default)

Press the up/down cursor keys to change the

setting.

HIOKI RM3543A981-04

3.3 Setting the Measurement Speed

3.3 Setting the Measurement Speed

The measurement speed can be set to FAST, MED (medium), or SLOW. A slower measurement

speed provides greater measurement precision, and a faster measurement speed results in greater

susceptibility to environmental noise. Ensure that measurement cables and the sample are sufficiently shielded.

The averaging function can be used to further stabilize measured values. (p. 48)

Open the Basic Settings screen.

1

Select the measurement speed.

2

3

Return to the Measurement screen.

3

Relationship Between Measurement Range and Speed

(factory defaults)

Measurement Range

10m

Average: 16 times

11 ms 17 ms

10m

100m

(1A)

100m

(100mA)

2.0 ms 6.4 ms

1000m

1.6 ms 6.0 ms

10

100 1.6 ms 4.0 ms

1.6 ms 4.0 ms

1000

FAST MED SLOW

176 ms 272 ms

*1

5.0 ms 13 ms

3.8 ms 13 ms

752 ms

640 ms

47 ms

40 ms

43 ms

36 ms

43 ms

36 ms

41 ms

35 ms

41 ms

34 ms

41 ms

34 ms

41 ms

34 ms

Integration time can be optionally set for each range (p. 46).

Upper value: for 50-Hz power line frequency

Lower value: for 60-Hz power line frequency

Tolerance: ±10%±0.2 ms

(Without retry)

*1 When performing external trigger measurement.

When performing internal trigger measurement, same as

when averaging is off.

30

Trigger signals are automatically generated internally for continuous

measurement.

Measure with internal (INT) triggering

To measure automatically

Measurements are triggered by an external signal.

Manual measurement triggering is also available.

• Apply a trigger signal at the EXT I/O connector (p. 89)

• Send the TRG command by communications interface (p. 130)

• Press F4 [MANU] (only appears when EXT is selected)

Measure with external (EXT) triggering

To measure at specific times

To retain measured values

• When internal triggering is enabled, the EXT I/O TRIG signal and the “TRG” command are ignored

(except for memory storage and statistical calculations).

• When using the internal trigger, the delay time (DELAY1) is obtained by adding 100 ms to the setting (to

prevent heat generation).

• To measure samples such as inductors that require time to settle, adjust delay time DELAY2. Start with

a long delay, and gradually shorten it while watching for the measured value to settle.

See: "4.2 Setting Pre-Measurement Delay" (p. 42)

• When external triggering is enabled, the Auto-Memory function is disabled by force.

The Basic Settings screen appears.

1

Selection

2

Internal trigger

External trigger

(default)

Press F3 [EXT] to display the F4 [MANU] indicator.

Press to trigger a measurement manually.

Press the up/down

cursor keys to

change the setting.

HIOKI RM3543A981-04

3.4 Setting Measurement Start Conditions (Trigger Source)

3.4 Setting Measurement Start Conditions

(Trigger Source)

Measurements can be started in two ways.

Open the Basic Settings screen.

1

Select internal (INT) or external (EXT) triggering.

2

Continuous measurement (:INITIATE:CONTINUOUS ON) is the normal trigger state when operating from

the front panel. Selecting the internal (INT) trigger source activates continuous triggering ("free-run"). When

external (EXT) triggering is selected, each external trigger event initiates one measurement. Continuous measurement can be disabled by sending the

IB. When continuous measurement is disabled, trigger acceptance is controlled only by the host (computer or

PLC).

See: for trigger command: "Triggering" (p. 142), "9.8 Data Exporting Methods" (p. 152)

Return to the Measurement screen.

3

:INITIATE:CONTINUOUS OFF command via RS-232C or GP-

31

The Basic Settings screen appears.

1

Selection

2

Press the up/down

cursor keys to

change the setting.

Increments the

range

Decrements the

range

HIOKI RM3543A981-04

3.5 Selecting the Measurement Range

3.5 Selecting the Measurement Range

The measurement range can be set as follows. When making comparator settings with the panel

keys, the measurement range is selected automatically according to the settings (reference/tolerance or upper/lower thresholds, see the following table). When the comparator settings are made by

remote control commands, the measurement range is unaffected.

Changing the Range

Measurement error is larger when measuring values nearer the bottom of a measurement range.

Auto-Ranging (when making comparator settings)

Reference (REF%) and

Upper/Lower Threshold (ABS) Ranges

0 to 10.009 m 10 m

10.01 to 100.09 m 100 m

100.1 to 1000.9 m 1000 m

1.001 to 10.009 10

10.01 to 100.09 100

100.1 to 1200.0 1000

Selected Range

3

Manual Range Selection

Open the Basic Settings screen.

1

Select the range.

2

• 10m, 100m, 1000m, 10, 100, 1000 (default)

Return to the Measurement screen.

3

• The measurement range is automatically selected when using the comparator function, but an OvrRng

error may occur when the scaling function is on. If this occurs, set an appropriate range manually.

For example, the 1,000 m range will be selected under the following conditions, but the measurement target of 2 will result in an OvrRng error:

• During measurement, a transient current equal to about 1.5 times the steady-state current will flow for several microseconds (or about 10 mApk in the 1 k range). Exercise special care when measuring targets

whose characteristics are prone to vary.

Measurement target: 2

Scaling compensation coefficient: 0.5

Displayed measured value: 1

Comparator reference value: 1

32

The Basic Settings screen appears.

1

Selection

2

Internal trigger

Press the up/down cursor keys to change the

setting.

1

Selection

2

Disable zero adjustment (cancel)

Execute zero adjustment

HIOKI RM3543A981-04

3.6 Zero Adjustment

3.6 Zero Adjustment

When four-terminal measurement (Kelvin connection) is impractical such as when measuring very

small samples, the additional inherent resistance of the two-terminal wiring should be canceled out.

The zero-adjustment function can cancel out up to 10 additional resistance.

Before Zero Adjustment

• The guaranteed accuracy of the instrument applies to four-terminal connections without zero adjustment.

When using four-terminal connections, do not execute zero adjustment. Executing zero adjustment with

incorrect wiring may amplify measurement error. However, zero adjustment may be needed even with fourterminal measurements if they are affected by a large offset voltage, such as due to thermal emf.

• Execute zero adjustment when the ambient temperature has changed, or when a probe is replaced.

Execute zero adjustment after the warm-up period following power on.

Open the Basic Settings screen.

1

Select the internal (INT) trigger mode.

2

Short the probes together.

3

Confirm that the measured value does not exceed 10 .

4

If no measured value is displayed, increment the measurement range (p. 31).

Select whether to enable or disable zero adjustment.

5

After confirming that the measured value does not exceed 10 , execute zero adjustment.

Return to the Measurement screen.

6

Zero Adjustment Faults

HIOKI RM3543A981-04

If zero adjustment fails, the following error message appears.

33

3.6 Zero Adjustment

Before attempting zero adjustment again, confirm the following:

• With the 10 range selected, confirm that the displayed value does not exceed 10 .

• Confirm that the probe connections are correct.

When the scaling calculation function is on, you may be unable to zero out the measured value, even if you

perform zero adjustment (because the zero-adjusted measured value is still subject to scaling calculation).

3

34

Measured value is above

upper limit

Pass (meets criteria)

Measured value is below

lower limit

Select the REF% (relative values) decision

mode

Decide whether a measured value is

within specified tolerance limits relative to a specified reference value

(p. 35)

Select the ABS (absolute values) decision

mode

Decide whether a measured value is

between specified upper and lower

threshold values (absolute values)

(p. 37)

12.000 m .... reference value

+0.080%........ positive tolerance

-0.080%......... negative tolerance

example

100.00 m.... upper threshold

80.00 m...... lower threshold

example

Hi

IN

IN

Lo

Hi

IN

Lo

Positive

tolerance [%]

Reference value [

]

Negative

tolerance [%]

Upper

threshold [

]

Lower

threshold [

]

HIOKI RM3543A981-04

3.7 Judging Measured Values (Comparator Function)

3.7 Judging Measured Values

(Comparator Function)

Comparator results are available as external output (at the

EXT I/O connector) when the comparator reference/tolerance

or upper/lower threshold values have been set.

See: "Chapter 8 External Control" (p. 89)

Comparator results are also indicated by the COMP Hi/IN/Lo

panel lamps, and by audible beeper (disabled by default).

See: "Setting the Comparator Decision (“JUDGE”) Beeper" (p. 66)

The comparator decision mode can be set as one of the following:

Before Using the Comparator Function

• When the measured value is out of the selected measurement range, comparator decision indicators

appear as follows. In the event of a measurement fault, no decision is made.

See:"3.8 Confirming Faulty Measurements" (p. 38)

Out-of-Range Display Comparator Decision Indicator

• If power is turned off during comparator setting, changes to settings are lost as they revert to their previous

values. To accept the settings, press the ENTER key.

• When setting comparator criteria, the appropriate range is selected automatically. Refer to "Auto-Ranging

(when making comparator settings)" (p. 31) for range settings.

+OvrRng Hi

-OvrRng Lo

3.7 Judging Measured Values (Comparator Function)

The Basic Settings screen appears.

1

Selection

2

Disable the function

Enable the function

Press the up/down

cursor keys to

change the setting.

(When the function is disabled)

Comparator decisions are indicated only when the function is enabled.

Relative Value =

(tolerance)

Reference

Value

Measured

Value

- 1

X 100 [%]

Setting range:

-9.999% to +9.999% (When 10% or less)

-99.99% to +99.99% (When more than 10%)

Reference value

Positive tolerance (upper decision threshold)

Negative tolerance (lower decision threshold)

HIOKI RM3543A981-04

Enabling and Disabling the Comparator Function

The comparator function is enabled by default.

When the function is disabled, comparator settings are ignored.

Open the Basic Settings screen.

1

Enable or disable the comparator function.

2

35

3

Return to the Measurement screen.

3

Decide According to Reference Value and Tolerance (REF% Mode)

Example: Set a reference value of 10.5

To abort the setting process, press . Settings are abandoned and the display returns to the previous

screen.

with ±4.5% decision tolerance.

1

Open the relative tolerance setting screen.

36

Selection

1

To Reset Numerical Values

Deletes entered digits.

This key is enabled only when entering numerical values.

To change the value after selecting the

units, use the cursor keys to select

the item to change, then enter the new value with the tenkeys.

1_ 10_ 10._ 10.5_ 10.500

m

(Example: 10.5m)

2

Selection

To Reset Numerical Values

Deletes entered digits.

This key is enabled only when entering numerical values.

To change the value after selecting the

units, use the cursor keys to select

the item to change, then enter the new value with the tenkeys.

To Set a Negative Value

Press this key to change the sign,

as needed.

1

+4_ +4._ +4.5_ +4.500%

(Example: 4.5%)

2

Selection

• Internal calculations are performed on floating-point values, and decisions round up any fraction of the

least-significant digit.

• Displayed values of the reference and tolerances are rounded according to the selected range. Internal

calculations use unrounded data, so decisions are based on the entered (setting) values.

• An error message appears if you press ENTER with the positive tolerance set lower than the negative

tolerance.

See: "11.3 Error Displays and Remedies" (p. 185) (ERR:001)

HIOKI RM3543A981-04

3.7 Judging Measured Values (Comparator Function)

Set the reference value.

2

Pressing an inoperative key during setting sounds a low-pitch beep (when the key beeper is enabled).

Press the units key to accept the setting and move the cursor to the positive tolerance.

Set the positive tolerance.

3

Press the % key to accept the setting and move the cursor to the negative tolerance value.

The negative tolerance is initially set to the same amplitude as the positive tolerance (change as needed).

Set the negative tolerance in the same way (as needed).

4

Accept the settings and return to the Measurement screen.

5

37

Upper threshold

Lower threshold

1_ 15_ 150_ 150.0m

(Example: 150 m)

Selection

To Reset Numerical Values

Deletes entered digits.

This key is enabled only when entering numerical values.

To change the value after selecting the

units, use the cursor keys to select

the item to change, then enter the new value with the tenkeys.

1

2

1

2

Selection

(Example: 50 m)

5_ 50_ 50.0m

• Internal calculations are performed on floating-point values, and decisions round up any fraction of the

least-significant digit.

• Displayed values of the reference and tolerances are rounded according to the selected range. Internal

calculations use unrounded data, so decisions are based on the entered (setting) values.

• An error message appears if you press ENTER with the positive tolerance set lower than the negative

tolerance.

See: "11.3 Error Displays and Remedies" (p. 185) (ERR:001)

HIOKI RM3543A981-04

3.7 Judging Measured Values (Comparator Function)

Decide According to Upper/Lower Thresholds (ABS Mode)

Setting example: Upper threshold 150 m, lower threshold 50 m

To abort the setting process, press . Settings are abandoned and the display returns to the

previous screen.

Open the absolute value threshold setting screen.

1

Set the positive tolerance.

2

Pressing an inoperative key during setting sounds a low-pitch beep (when the key beeper is enabled).

No error message is displayed.

3

Press the units key to accept the setting and move the cursor to the lower threshold value.

Set the negative tolerance in the same way.

3

Press the units key to accept the setting and move the cursor to the upper threshold.

Accept the settings and return to the Measurement screen.

4

38

Appears when the measured value is outside of the measurement or display range.

Check for a broken sample component.

The comparator result is Hi when +OvrRng is displayed, and Lo when -OvrRng is displayed.

No external measurement fault signal (ERR

) is output.

Out-of-Range

The resistance between the H

POT

and H

CUR

probe contacts, and between the L

POT

and L

CUR

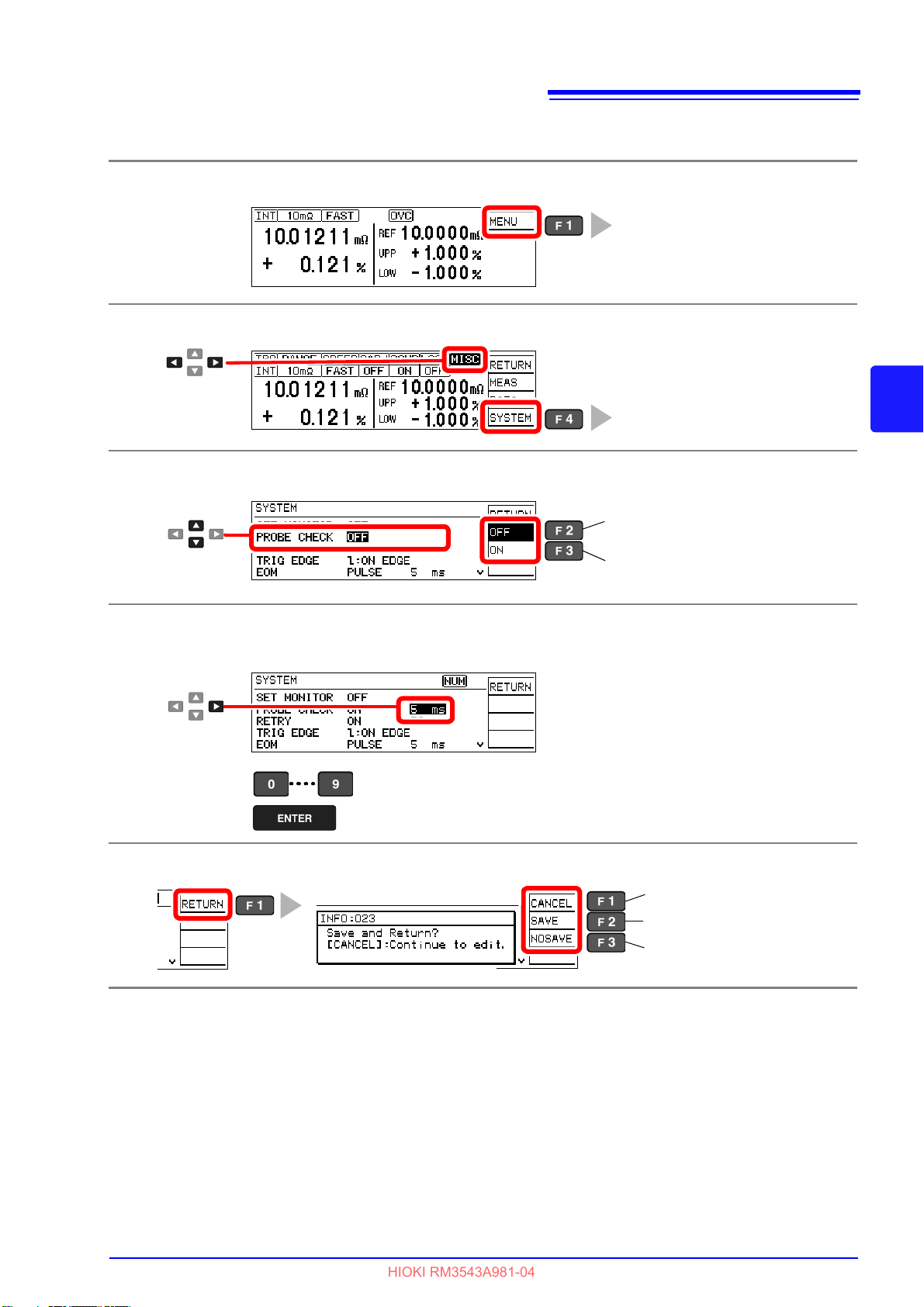

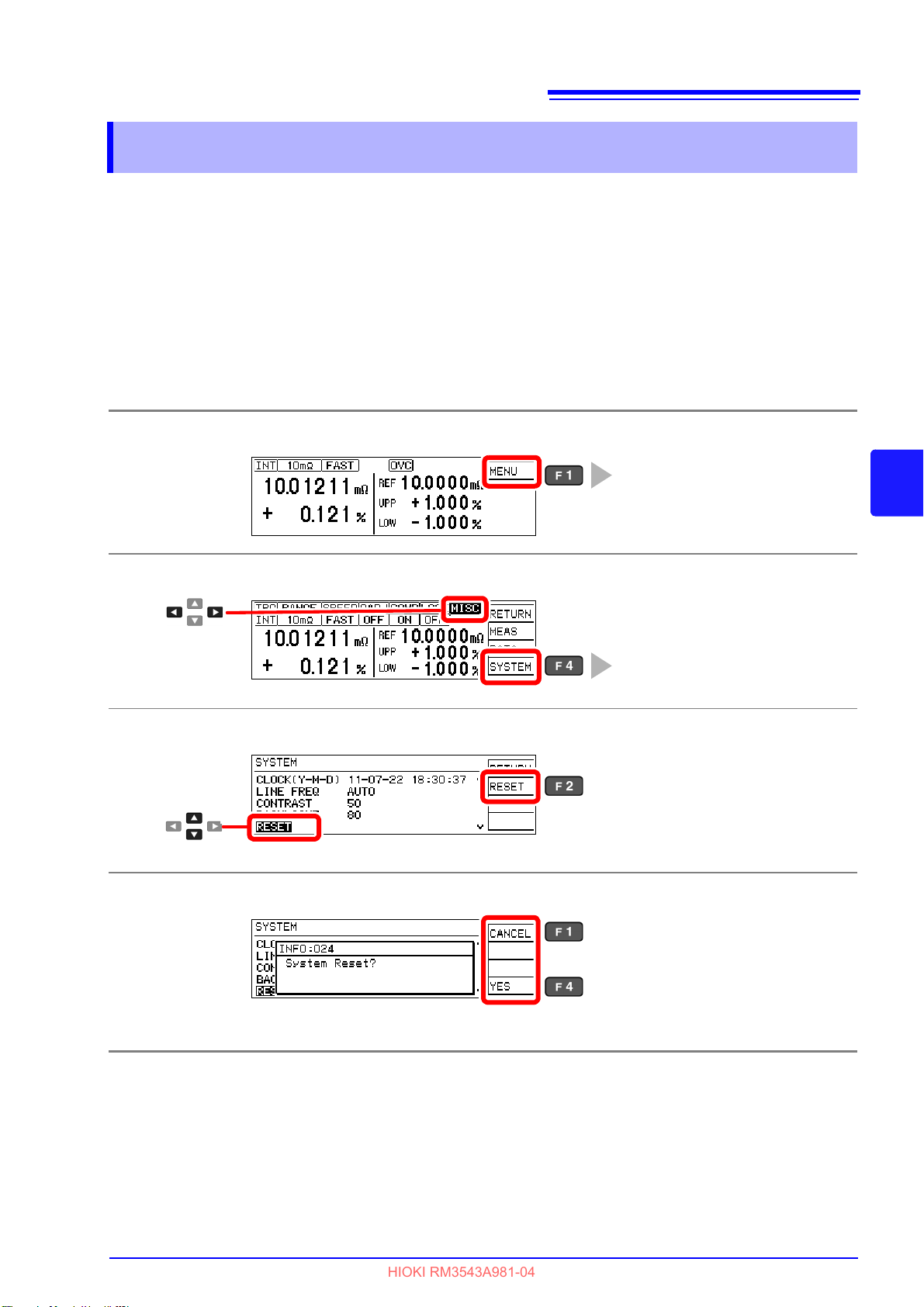

probe contacts, are measured and compared with specified contact fault values.