Hioki PW6001, PW6001-02, PW6001-03, PW6001-04, PW6001-05 Instruction Manual

...

Contents

Contents

Measurement Process .............................. 1

System Architecture .................................. 2

Example Measurement Setups................. 3

Introduction ................................................ 5

Verifying Package Contents ..................... 6

Options .........................................................7

Safety Information ..................................... 9

Operating Precautions .............................11

1 Overview 17

1.1 Product Overview ........................... 17

1.2 Features .......................................... 17

1.3 Part Names and Functions ............ 19

1.4 Basic Operation (Screen Display

and Layout) ..................................... 25

Screen Operation ........................................25

Common Screen Display ............................28

Measurement Screen Display .....................29

Screen Layouts ...........................................30

2 Preparing for

Measurement 33

2.1 After Purchase ................................ 33

Wrapping voltage cords in spiral tubes .......33

2.2 Inspecting the Instrument

before Use ....................................... 34

2.3 Connecting the Power Cord .......... 35

2.4 Connecting the Voltage Cords ...... 35

2.5 Connecting the Current Sensors .. 36

Connecting a current sensor to the

Probe1 terminal ..........................................37

Connecting a current sensor to the

Probe2 terminal ..........................................38

If the measurement range exceeds

(using a VT and CT) ...................................39

2.6 Turning the Instrument On/Off ...... 40

2.7 Setting the Connection Mode

and Current Sensors ...................... 41

2.8 Connecting the Instrument to

the Measurement Lines (Zero-

adjustment) ..................................... 43

Zero-adjustment and degaussing (DMAG) .43

Connecting the voltage cords to the

measurement lines .....................................44

Connecting the current sensor to the

measurement lines .....................................44

Using the quick conguration function ........45

2.9 Verifying Proper Connections

(Connection Check) ....................... 47

3 Viewing Measured

Values 49

3.1 Displaying Measured Values ......... 49

Selecting display parameters ......................49

3.2 Viewing Power Measured Values

and Changing Measurement

Conditions ...................................... 52

Displaying power measured values ............52

Displaying voltage and current ...................53

Setting the ranges .......................................53

Conguring zero-suppression .....................56

Setting the data update rate .......................57

Setting the synchronization source .............58

Setting the low-pass lter (LPF) ..................59

Conguring frequency measurement ..........60

Setting the frequency source ......................60

Setting the measurement upper limit

frequency and the lower limit frequency .....61

Setting the rectier ......................................62

Conguring scaling (when using a VT

[PT] or CT) ..................................................62

3.3 Viewing Integration Values ............ 63

Displaying integration values ......................63

Setting the integration mode .......................66

Using manual integration ............................67

Performing integration while using the

time control function ....................................68

3.4 Viewing Harmonic Measured

Values .............................................. 69

Displaying harmonics ..................................69

Setting the harmonic measurement mode ..72

Setting the THD calculation method ...........73

THD calculation order .................................73

Setting the grouping method .......................74

3.5 Viewing Measured Values for

Power Factor and Loss .................. 75

Displaying efciency and loss .....................75

Setting the calculation formulas for

efciency and loss ......................................76

Example measurements .............................77

3.6 Viewing Motor Measured

Values (Motor Analysis and D/

A-equipped Models) ....................... 80

Displaying motor measured values .............80

Performing zero-adjustment of motor input 81

Setting motor input ......................................82

Measuring a motor’s electrical angle ..........89

Detecting the motor’s direction of rotation ..91

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

PW6001A961-04

i

Contents

4 Viewing Waveforms 93

4.1 Displaying Waveforms ................... 93

Displaying waveforms on the WAVE

screen .........................................................93

Displaying waveforms and measured

values on the WAVE+VALUE screen ..........94

Initializing the display position ....................94

4.2 Changing the Waveform Display

and Conguring Recording ........... 96

Vertical axis zoom factor and display

position settings ..........................................96

Time axis setting .........................................97

Detailed display settings .............................99

Vertical axis scale display ...........................99

Trigger settings .........................................100

4.3 Recording Waveforms ................. 102

Recording a waveform continuously .........102

Recording a waveform once .....................102

Activating the trigger manually ..................102

4.4 Analyzing Displayed Waveforms 103

Viewing displayed waveform values

(Cursor measurement) ..............................103

Enlarging waveforms (zoom function) ......104

4.5 Viewing FFT Analysis Results .... 105

Displaying waveforms and FFT analysis

results .......................................................105

Changing the window size and position ....106

Displaying FFT analysis results as values 108

Turning the display of FFT analysis

results on and off ......................................108

Setting the lower limit frequency for the

FFT peak value display .............................109

Setting the window function ...................... 110

Changing the scale of the vertical axis

on the FFT analysis results display .......... 111

5 Using the Instrument’s

Functionality 113

5.1 Time Control Function ..................113

Interval time control .................................. 11 3

Timer time control .....................................113

Actual time control .................................... 113

5.2 Averaging Function .......................115

Simple average (ADD) .............................. 11 5

Exponential average (EXP) ...................... 11 5

5.3 Hold and Peak Hold Functions ....117

Hold function ............................................. 11 7

Peak hold function .................................... 119

5.4 Delta Conversion Function ......... 122

-Y conversion ..........................................122

∆

Y-∆ conversion ..........................................123

5.5 Selecting the Power Calculation

Formula ......................................... 124

5.6 Current Sensor Phase Shift

Function ........................................ 125

5.7 User-dened Calculations (UDF) 127

5.8 Simple Graph Function ................ 129

D/A monitor graph .....................................129

Detailed display settings ...........................130

Vertical axis scale display .........................130

X-Y plot function .......................................131

Vertical axis/horizontal axis scale

settings, integration full-scale setting ........133

6 Changing System

Settings 135

Checking and changing settings ...............135

Correcting the touch panel ........................136

6.1 Initializing the Instrument ............ 136

System reset .............................................136

Boot key reset ...........................................136

6.2 Default Settings ............................ 137

7 Saving Data and

Manipulating Files 139

7.1 Inserting and Removing USB

Flash Drives .................................. 139

7.2 File Operations Screen ................ 141

7.3 Saving Measurement Data .......... 142

Setting which measurement parameters

to save ......................................................142

Manually saving measurement data .........144

Automatically saving measurement data ..145

Automatic save operation using time

control .......................................................147

7.4 Saving Waveform Data ................ 148

7.5 Saving FFT Data ........................... 150

7.6 Saving Screenshots ..................... 152

7.7 Saving Settings Data ................... 153

7.8 Loading Screenshots ................... 154

7.9 Loading Settings Data ................. 154

7.10 File and Folder Operations .......... 155

Creating a folder .......................................155

Deleting les and folders ..........................155

Changing the name of a le or folder ........156

Copying les .............................................156

Formatting a USB ash drive ....................156

7.11 Measured Value Data Format ...... 157

Header structure .......................................157

Status data ................................................160

Measured value data format .....................162

7.12 Waveform Binary Data Format .... 163

ii

Contents

Data format ...............................................163

8 Connecting External

Devices 169

8.1 Synchronization Interface

(Two-instrument Synchronized

Measurement) ............................... 169

Connecting 2 instruments with the

L6000 Optical Connection Cable ..............170

8.2 Using D/A Output (Motor

Analysis and D/ A-equipped

Models Only) (Analog and

Waveform Output) ........................ 173

Connecting an application-specic

device to the instrument ............................173

Selecting output parameters .....................175

Output rates ..............................................178

Examples of D/A output ............................180

8.3 Using Motor Analysis (Motor

Analysis and D/ A-equipped

Models Only) ................................. 182

Connecting a torque meter and

tachometer ................................................182

8.4 Controlling Integration with

External Signals ........................... 185

8.5 Connecting an LR8410 Link-

compatible Logger ....................... 188

9 Connecting the

Instrument to a

Computer 189

9.1 Using the LAN Interface .............. 190

Conguring LAN settings and building a

network environment ................................190

Connecting the LAN cable ........................192

Controlling the instrument remotely with

an Internet browser ...................................193

9.2 Performing Instrument File

Operations from a Computer

(Using FTP) ................................... 195

Using FTP to connect to the instrument ...196

Performing le operations with FTP ..........197

9.3 Using GP-IB .................................. 198

Connecting the GP-IB cable .....................199

Setting the GP-IB address ........................199

9.4 Using RS-232C ............................. 200

Conguring the D-sub 9-pin connector .....201

Connecting the RS-232C cable ................202

9.5 Canceling the Remote State

(Reverting to the Local State) ..... 203

10 Specications 205

10.1 General Specications ................ 205

10.2 Basic Specications .................... 206

10.3 Functional Specications ............ 221

10.4 Measurement Parameter

Detailed Specications ................ 231

10.5 Calculation Formula

Specications ............................... 239

11 Maintenance and

Service 251

11.1 Repairs, Inspections, and

Cleaning ........................................ 251

11.2 Disposing of the Instrument ....... 253

Removing the lithium battery ....................253

11.3 Replacement Parts and Their

Service Lives ................................ 254

Replacing the fuse ....................................254

12 Troubleshooting 255

12.1 Frequently Asked Questions ....... 255

12.2 Error Displays ............................... 257

Startup errors and operating errors ..........257

Control errors ............................................257

USB ash drive and le operation errors ..259

Appendix Appx.1

Appx. 1 Rack-mounting the

Instrument ........................ Appx.1

Rack-mounting hardware .....................Appx.1

Installation instructions ........................Appx.4

Appx. 2 Outline Drawings ............. Appx.6

Index Ind.1

11

12

3

4

5

6

7

8

9

10

Appx.

Appx. Ind.

iii

iv

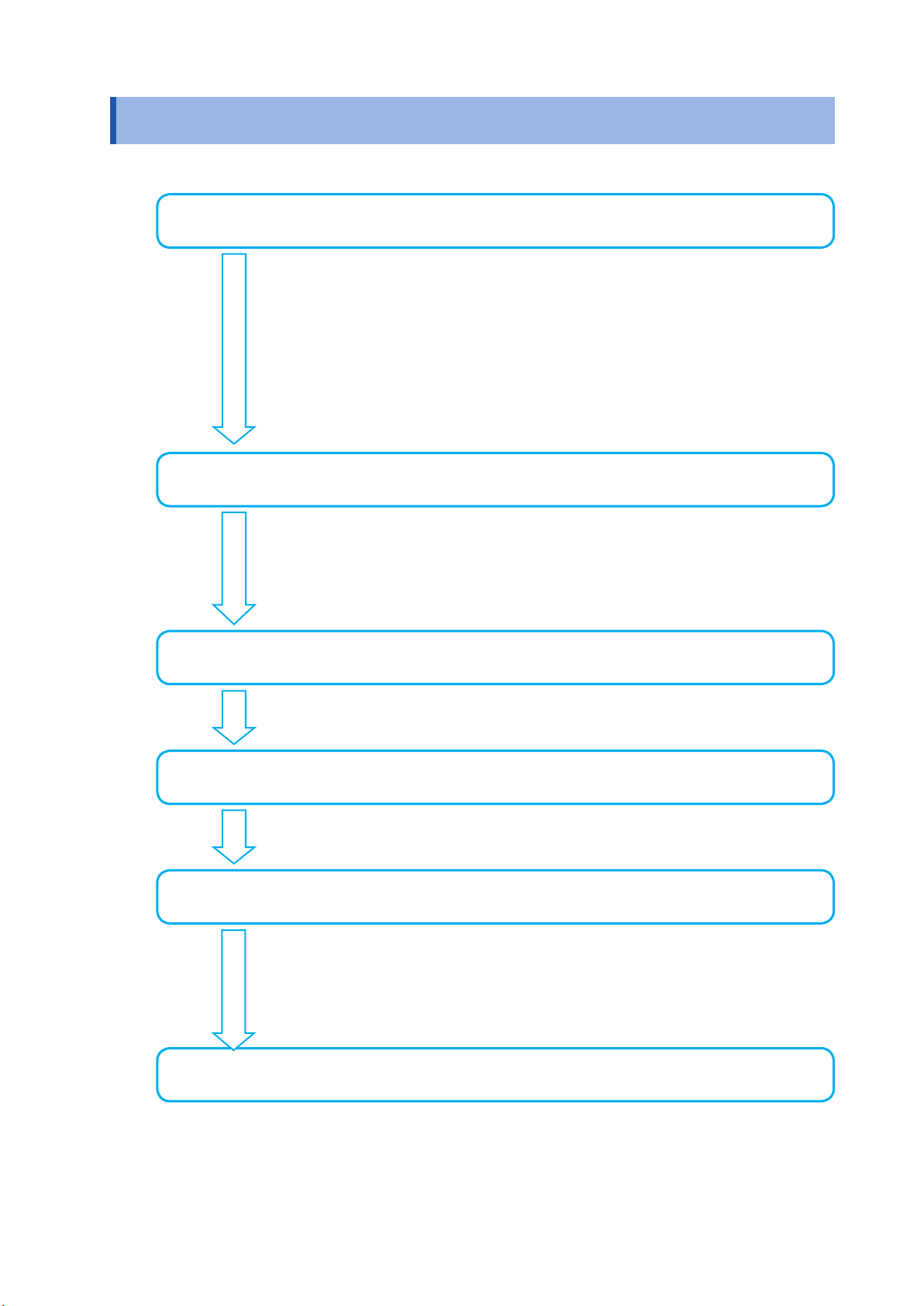

Measurement Process

Be sure to read “Operating Precautions” (p. 11) before use.

Setting up the instrument

• “Instrument placement” (p. 12)

• “2.1 After Purchase” (p. 33)

• “2.2 Inspecting the Instrument before Use” (p. 34)

• Be sure to inspect the instrument before connecting it or turning it on.

• “2.3 Connecting the Power Cord” (p. 35)

• “2.6 Turning the Instrument On/Off” (p. 40)

To ensure accurate measurement, allow a warm-up period of at least

30 minutes to elapse after turning on the instrument before performing

zero-adjustment.

Connecting the instrument

Measurement Process

• “2.7 Setting the Connection Mode and Current Sensors” (p. 41)

• Be sure to perform zero-adjustment before connecting the instrument.

• “2.8 Connecting the Instrument to the Measurement Lines (Zero-

adjustment)” (p. 43)

• “2.9 Verifying Proper Connections (Connection Check)” (p. 47)

Setting the measurement conditions

• “3 Viewing Measured Values”(p. 49)

• “4 Viewing Waveforms”(p. 93)

Viewing measured values

• “3 Viewing Measured Values”(p. 49)

• “4 Viewing Waveforms”(p. 93)

Saving data

• “Manually saving measurement data” (p. 144)

• Saving data with actual time control (p. 147)

Saving data with timer control (p. 147)

•

Saving data with interval control (p. 147)

•

• USB ash drive and the instrument’s internal memory (p. 139)

Analyzing data

• “8 Connecting External Devices”(p. 169)

• “9 Connecting the Instrument to a Computer”(p. 189)

1

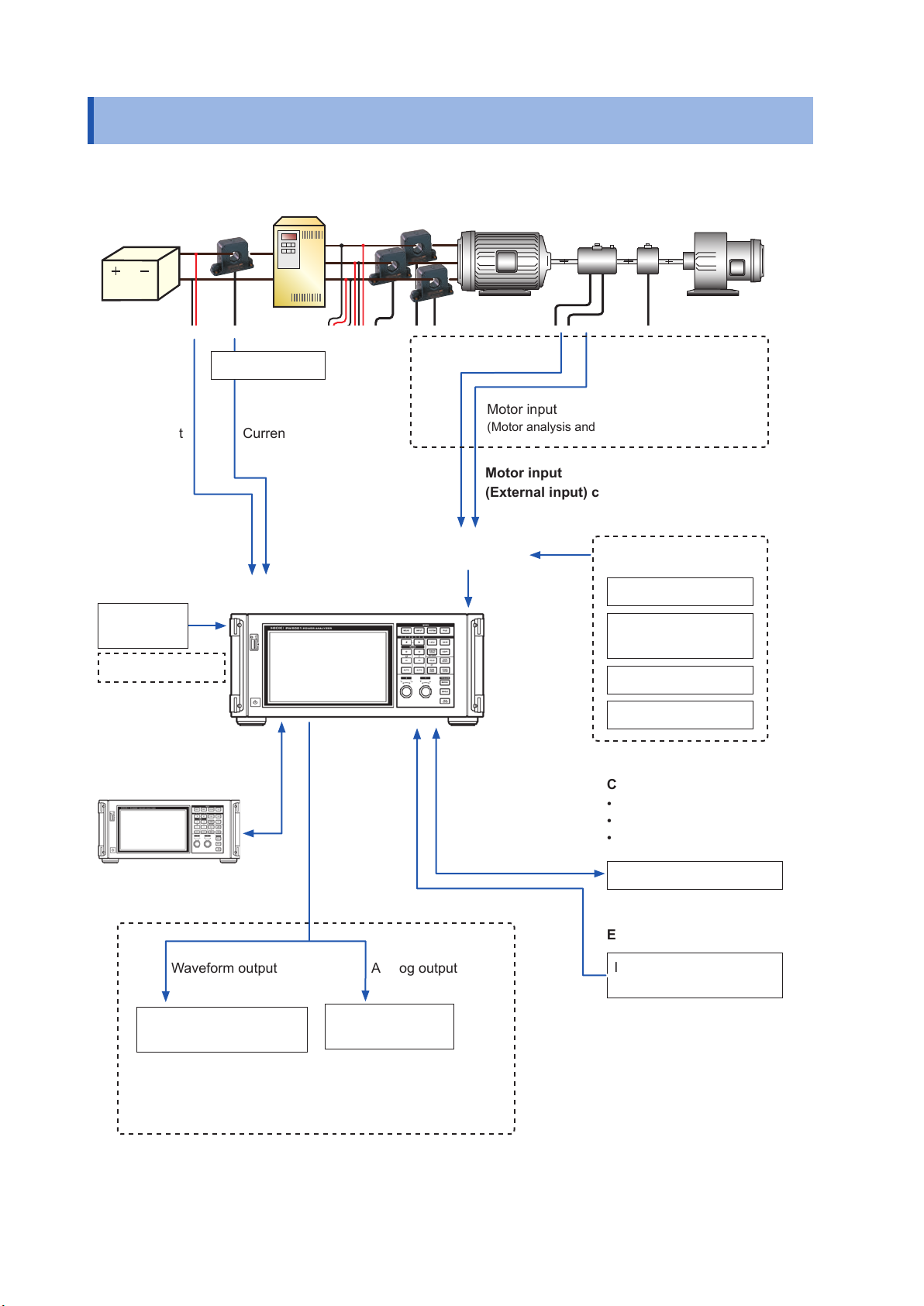

System Architecture

System Architecture

Inverter

Battery

sensor

EncoderTorque

Current sensor

Voltage input Current input

Input channels

USB ash

drive

Internal memory

Motor

Motor input

(Motor analysis and D/A-equipped models only)

Motor input

(External input) channels

Some combination

of inputs

Load

Encoder signalTorque sensor signal

External input

Pyranometer output

Thermometer analog

output

Pulse signal

Waveform trigger

Two-instrument

synchronization

Waveform output Analog output

Oscilloscope, memory

recorder, etc.

Communications interfaces

• LAN

• GP-IB

• RS-232C

Computer, controller, etc.

External control

Integration control

Start/stop/reset

Logger,

comparator, etc.

D/A output

Motor input

(Motor analysis and D/A-equipped models only)

2

Example Measurement Setups

Example Measurement Setups

Conversion efciency measurement of inverters with built-in SiC

3-phase

power

supply

Measuring the efciency of PV power conditioners

DC measurement

Converter

Power conditioner

Solar panel

Inverter

AC measurement

Motor

Power system

Load

EV/HEV motor analysis

Battery

Inverter Motor

Torque

sensor

Pulse

encoder

Load

3

Example Measurement Setups

4

Introduction

Thank you for purchasing the Hioki PW6001 Power Analyzer. To obtain maximum performance

from the product, please read the instruction manual rst, and keep it handy for future reference.

• One or more clamp-on sensors, AC/DC current sensors, or other sensors are required in order

to provide current input to the instrument. (These devices are referred to collectively as “current

sensor(s)” in this manual.) For more information, see the instruction manual for the current

sensor(s) you are using.

• One or more voltage cords (voltage measurement option) or other similar cords are required

in order to provide voltage input to the instrument. The instrument’s voltage input terminals

use standard φ 4 mm CAT II (1000 V) or CAT III (600 V) compatible safety banana connectors.

Provide voltage cords as appropriate for your application.

Trademarks

• Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation

in the United States and other countries.

• Adobe and Adobe Reader are trademarks of Adobe Systems Incorporated.

• Bluetooth® is a registered trademark of Bluetooth SIG, Inc.(USA). The trademark is used by

HIOKI E.E. CORPORATION under license.

• ParaniTM is a registered trademark of Sena Technologies, Inc.

Introduction

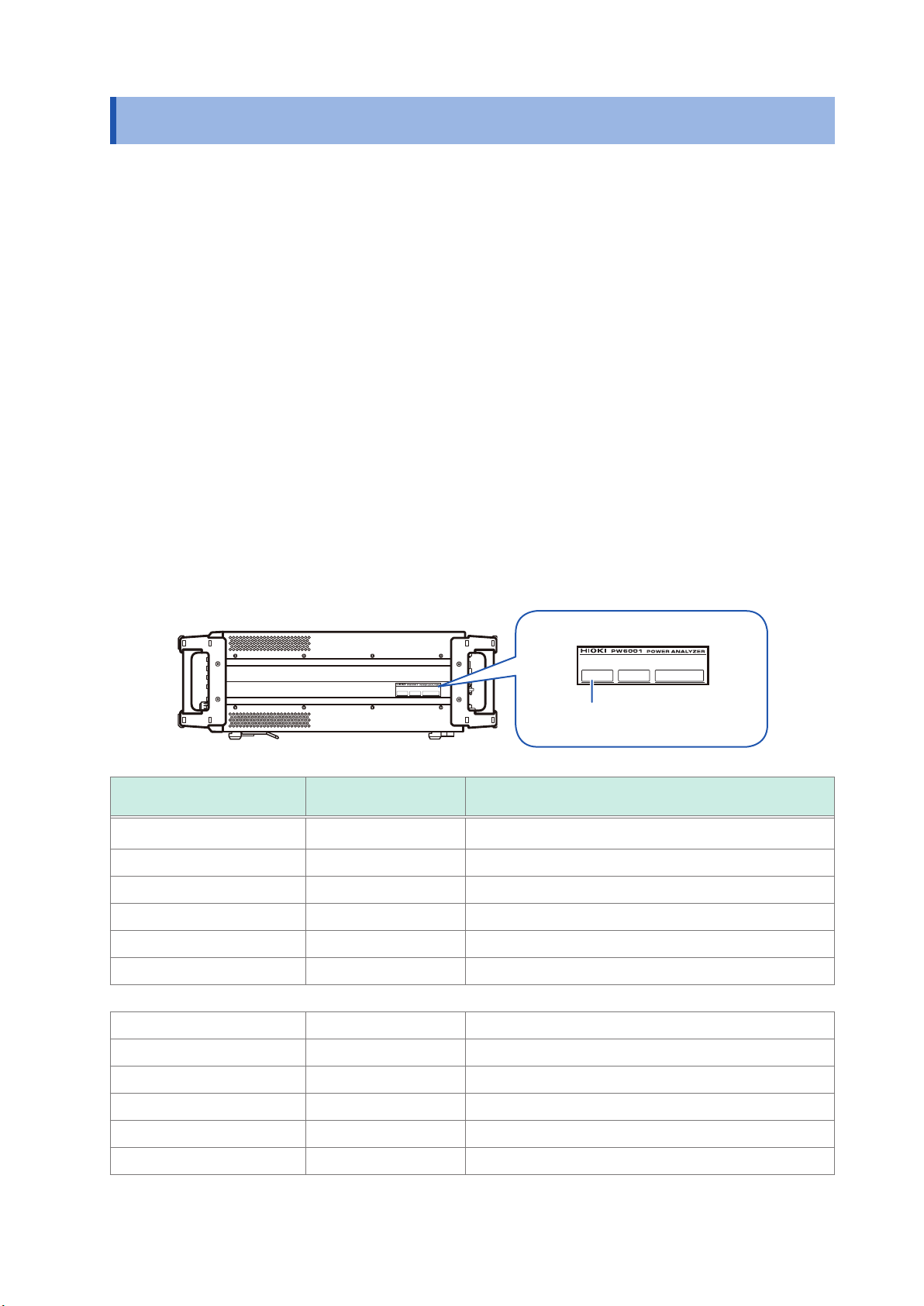

Product model numbers

Right side

Product model number

PW6001-01 1 n/a

PW6001-02 2 n/a

PW6001-03 3 n/a

PW6001-04 4 n/a

PW6001-05 5 n/a

PW6001-06 6 n/a

PW6001-11 1 Motor analysis and D/A output

Number of input

channels

Product model number

Additional functionality

PW6001-12 2 Motor analysis and D/A output

PW6001-13 3 Motor analysis and D/A output

PW6001-14 4 Motor analysis and D/A output

PW6001-15 5 Motor analysis and D/A output

PW6001-16 6 Motor analysis and D/A output

In this manual, models equipped with motor analysis and D/A output functionality are referred to as “motor

analysis and D/A-equipped models.”

5

Verifying Package Contents

Verifying Package Contents

Once you have received the instrument, verify that it has not suffered any damage during shipment

before using it. Pay particular attention to accessories, panel switches, and terminals. If you discover any

damage or nd that the instrument does not operate as stipulated in its specications, please contact your

authorized Hioki distributor or reseller. When transporting the instrument, use the original packaging.

Verify that the packaging includes all contents.

PW6001 Power Analyzer Instruction manual

Power cord

D-sub 25-pin connector

(Motor analysis and D/A-equipped models only)

6

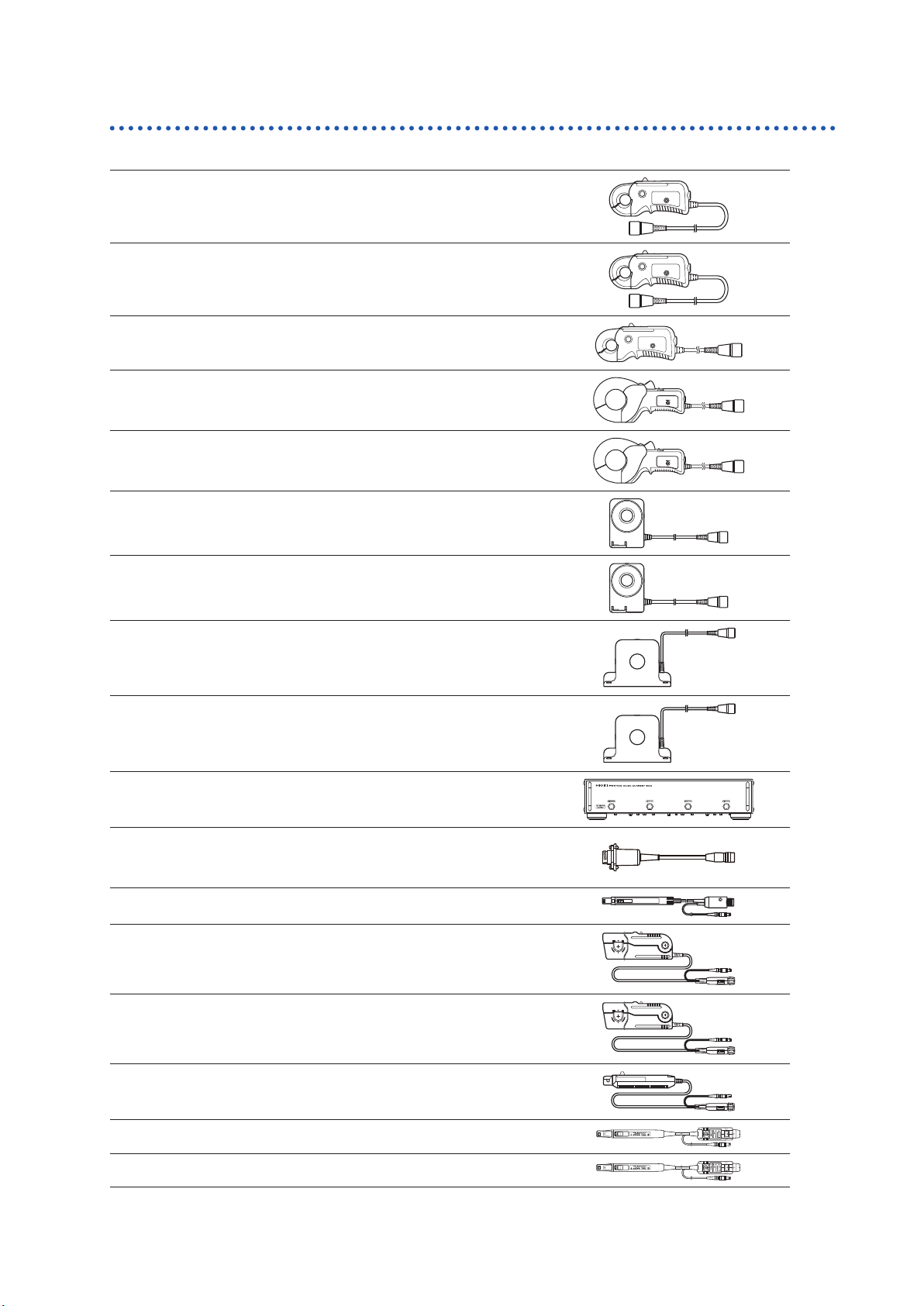

Options

Current measurement options

CT6841 AC/DC Current Probe (20 A)

CT6843 AC/DC Current Probe (200 A)

CT6844 AC/DC Current Probe (500 A)

CT6845 AC/DC Current Probe (500 A)

CT6846 AC/DC Current Probe (1000 A)

Verifying Package Contents

CT6862 AC/DC Current Sensor (50 A)

Cord length: 3m

CT6863 AC/DC Current Sensor (200 A)

Cord length: 3 m

9709 AC/DC Current Sensor (500 A)

Cord length: 3 m

CT6865 AC/DC Current Sensor (1000 A)

Cord length: 3 m

PW9100 AC/DC Current Box (50 A)

CT9900 Conversion Cable

(PL23 receptacle/ME15W plug)

3273-50 Clamp On Probe (30 A)

3274 Clamp On Probe (150 A)

3275 Clamp On Probe (500 A)

3276 Clamp On Probe (30 A)

CT6700 Current Probe (5 A)

CT6701 Current Probe (5 A)

7

Verifying Package Contents

Voltage measurement options

L9438-50 Voltage Cord

(Banana connector/banana connector; red and

black × 1 ea.; cord length: approx. 3 m)

L1000 Voltage Cord (banana connector/banana

connector; red, yellow, blue, and gray × 1 ea.;

black × 4; cord length: approx. 3 m with alligator

clips)

9243 Grabber Clip (red and black × 1 ea.)

Connection options

L6000 Optical Connection Cable (10 m)

L9217

9642

9637 RS-232C Cable (9-pin/9-pin; cross; 1.8 m)

9151-02 GP-IB Connector Cable (2 m)

9444

Connection Cord (isolated BNC; 1.7 m; for motor

input)

LAN Cable

(CAT 5e with cross conversion connector; 5 m)

Connection Cable

(For external control use; 9-pin/9-pin; straight;

1.5 m)

Other options

Specialorder

Specialorder

Rack mount hardware (for EIA or JIS)

Carrying case

(Rigid trunk type; with casters)

8

Safety Information

Safety Information

The PW6001 has been designed and tested in accordance with the IEC 61010 safety standard and

shipped in a safe state. However, failure to adhere to the precautionary information and follow the

instructions provided in this instruction manual may render safety-related functionality provided by

the instrument inoperable.

Before using the instrument, be sure to carefully review the following important safety information.

DANGER

Improper use of the instrument may result in bodily injury or equipment damage.

Read this instruction manual carefully and ensure that you understand its contents

before operating the instrument.

WARNING

Electricity poses a number of hazards, including electric shock, overheating, re,

and arc discharge (caused by a short). Individuals using an electrical measuring

instrument for the rst time should be supervised by a technician who has experience

in electrical measurement.

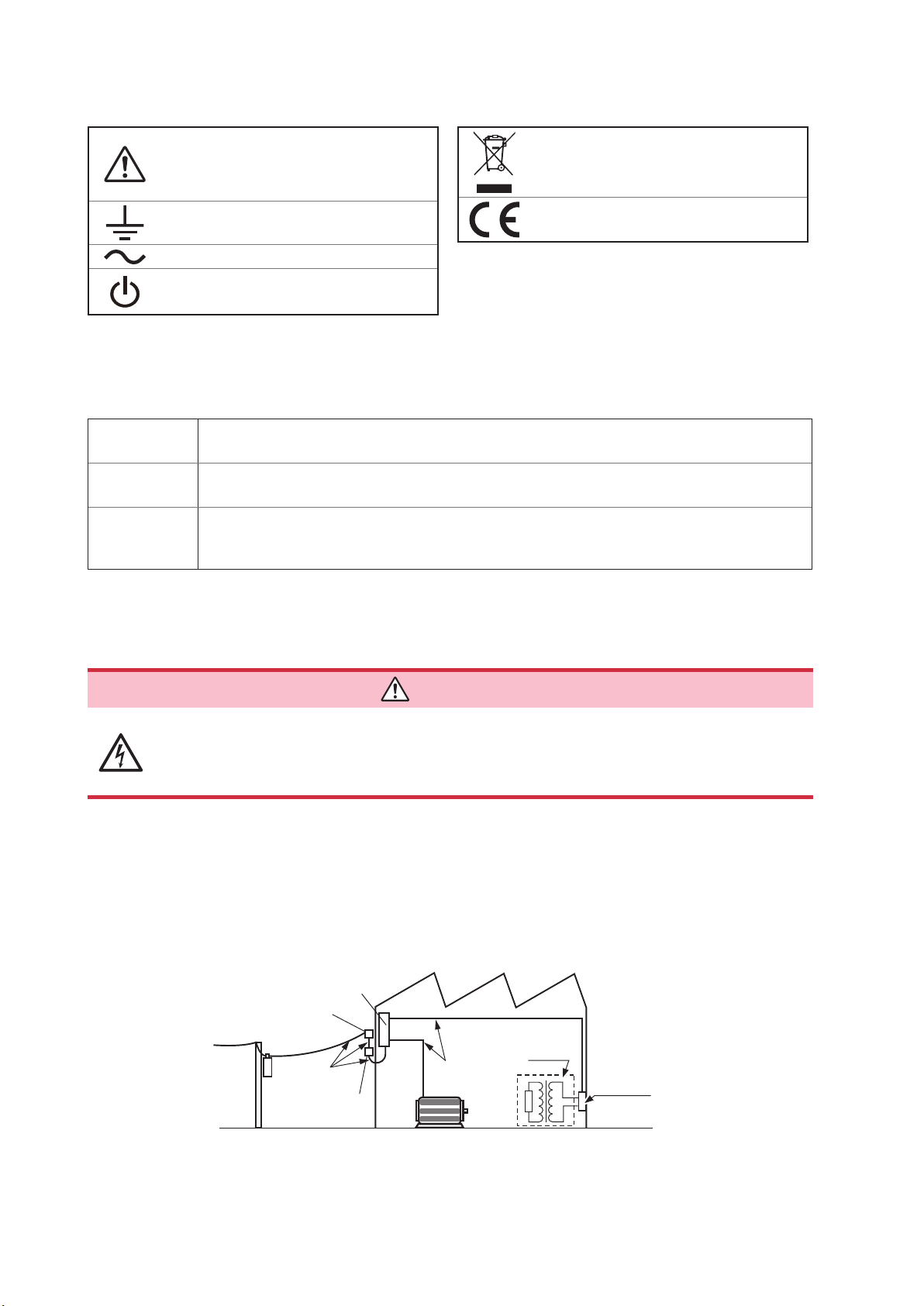

Safety-related notations

This manual classies safety information on the basis of the severity of the associated risk and

hazard level using the following categories.

DANGER

WARNING

CAUTION

IMPORTANT

*

Indicates an imminent hazard that could lead to serious injury or death.

Indicates a hazard that could lead to serious injury or death.

Indicates a hazard that could lead to minor injury or that could be expected to

result in equipment or other damage.

Indicates information or content that is especially important to keep in mind when

operating the instrument or performing maintenance work.

Indicates a high-voltage hazard.

Warns that failure to verify safety or improper use of the instrument could lead to

electric shock, burns, or death.

Indicates an action that you must refrain from performing.

Indicates an action that you must perform.

Indicates that there is additional information below.

p.

[ ]

ON

Unless otherwise noted, the term “Windows” is used in this manual to refer to Windows XP, Windows Vista,

and Windows 7.

Indicates a reference page number.

Key names are enclosed in parentheses.

Text shown on the instrument’s screen is formatted in bold.

9

Safety Information

Symbols displayed on the instrument

Indicates the need for caution or a hazard.

When this symbol is displayed on the

instrument, refer to the corresponding

section of the instruction manual.

Indicates the ground terminal.

Indicates AC (Alternating Current)

Indicates the power supply’s “on” and “off”

positions.

Symbols related to standards

Indicates the Waste Electrical and

Electronic Equipment Directive (WEEE

Directive) in EU member states.

Indicates that the product conforms to

regulations set out by the EC Directive.

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with

the following meanings:

f.s.

rdg.

dgt.

(Maximum display value)

The maximum displayable value. This is usually the name of the currently selected range.

(Reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that causes

the digital display to show a “1” as the least-signicant digit.

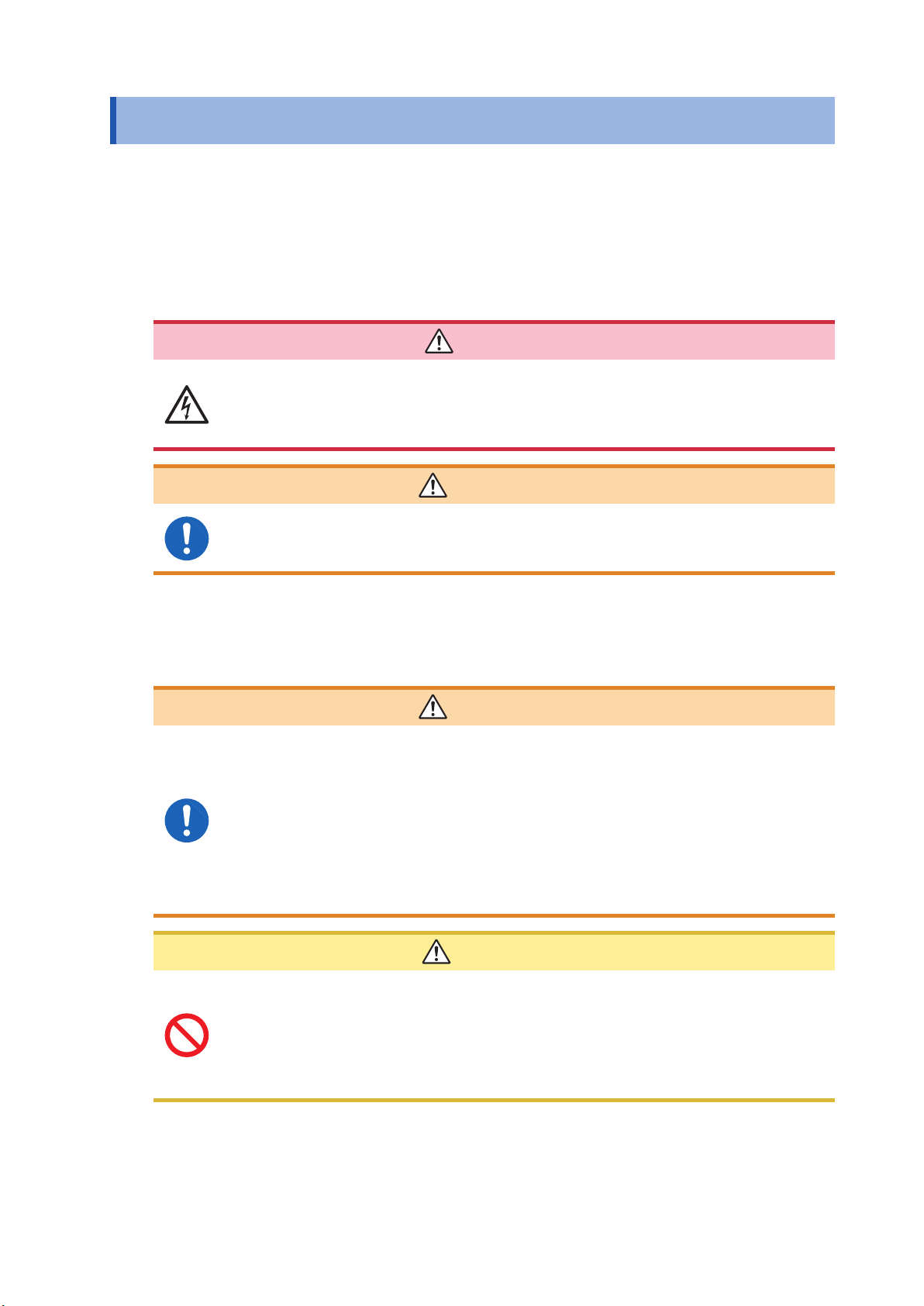

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

DANGER

• Never use a measuring instrument whose measurement category is lower than the

location in which it will be used. Doing so may result in a serious accident.

• Never use a measuring instrument with no category labeling in a CAT II to CAT IV

measurement category. Doing so may result in a serious accident.

The PW6001 conforms to the safety requirements for CAT II (1000 V) and CAT III (600 V) measuring instruments.

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical circuits in equipment

connected to an AC electrical outlet by a power cord (portable tools, household appliances, etc.)

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations) connected directly to

the distribution panel, and feeders from the distribution panel to outlets

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the power meter and

primary overcurrent protection device (distribution panel)

Distribution panel

Service entrance

Service drop

CAT IV

Power meter

Internal wiring

CAT III

CAT II

T

Outlet

10

Fixed installation

Operating Precautions

Operating Precautions

Please observe the following precautions to ensure that you can use the instrument safely and fully utilize

its functionality.

Checking the instrument before use

Before using the instrument, check the instrument for any damage that may have been sustained

while in storage or transit, inspect it, and verify that it is operating properly. If you discover any

malfunction or damage, contact your authorized Hioki distributor or reseller.

DANGER

Damage to voltage cords or the instrument may result in electric shock. Check

voltage cords for worm insulation and exposed metal before use. If you nd

damage, replace the cords with those specied by our company. Failure to do so

may result in electric shock.

WARNING

To prevent electric shock, verify that the white or red portion of the cable

(insulation layers) are not exposed. If any color is visible from the inside of the

cable, do not use the instrument.

Installation

Installing the instrument in inappropriate locations may cause a malfunction of instrument or may

give rise to an accident. Avoid the following locations.

WARNING

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to a strong electromagnetic eld or electrostatic charge

• Exposed to high quantities of dust particles

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

CAUTION

• Do not place the instrument on an unstable bench or inclined surface. Doing so may

cause the instrument to fall off the surface or to fall over, resulting in bodily injury or

equipment damage.

• Do not use an uninterruptible power supply (UPS) or a DC-AC inverter that produces

rectangular waves or pseudo-sine-wave output to power the instrument. Doing so

may damage the instrument.

11

Operating Precautions

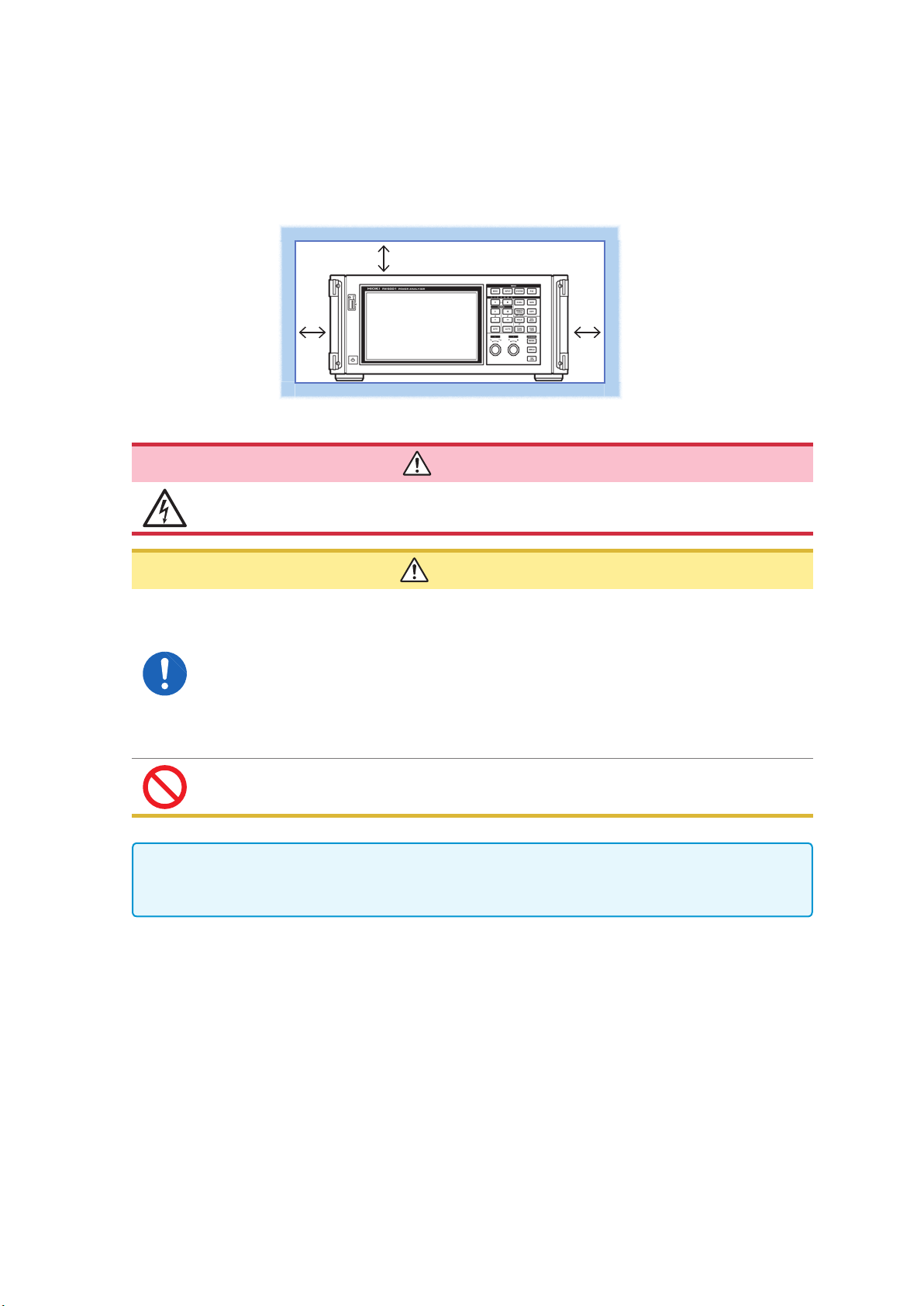

Instrument placement

• Place the instrument right-side up.

• Do not block the instrument’s air vents.

• Leave at least 20 mm between the instrument’s air vents and surrounding surfaces.

See “1.3 Part Names and Functions” (p. 19).

Handling of the instrument

At least 20 mm on all sides

DANGER

To prevent electric shock, never remove the instrument’s enclosure. There are

high-voltage and high-temperature parts inside the instrument.

CAUTION

• To prevent damage to the instrument, avoid exposing it to vibration or mechanical

shock when transporting or otherwise handling it. Exercise particular care not to drop

the instrument.

• If the instrument malfunctions or displays an error during use, consult

“12 Troubleshooting” (p. 255) and then contact your authorized Hioki distributor or

reseller.

• Carry the instrument using its handle after disconnecting all cords and removing the

USB ash drive.

• Do not press down on the touch panel with excessive force or use hard or sharp

objects to press down on the touch panel. Doing so may result in equipment damage.

This instrument may cause interference if used in residential areas. Such use must be avoided

unless the user takes special measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

12

Cord and current sensor handling

• Always connect voltage cords and current sensors to the secondary side of a

circuit breaker. The secondary side will be protected by the breaker in the event

of a short. Do not measure the primary side of a circuit breaker as it will carry a

larger current, increasing the amount of damage in the event of a short-circuit.

• When using the instrument, always use the designated power cord. Use of a

power cord other than the designated cord may result in re.

• Connect current sensors and voltage cords to the instrument before connecting

them to a live measurement line. Observe the following precautions to prevent

short-circuits and electric shock:

• Do not place the metal part of the tips of voltage cord clips across two

measurement lines at the same time. Never touch the metal part of the tips of

voltage cord clips.

• When a current sensor is in the open position, do not place the metal part

of its clamp tip across two measurement lines at the same time or use the

sensor on a bare conductor.

• Do not connect voltage cords unnecessarily.

Operating Precautions

DANGER

• To prevent short-circuit or bodily injury, use current sensors with circuits

whose voltage is less than or equal to the sensor’s maximum rated input-toground voltage. Do not use current sensors with bare conductors. (For more

information about a current sensor’s maximum rated input-to-ground voltage,

refer to its instruction manual.)

WARNING

• When using an AC/DC Current Sensor such as the CT6862, it is necessary to

cut the measurement line in order to route it through the sensor. To prevent

an electric shock or short-circuit, turn off all equipment before connecting the

sensor.

• To prevent an electric shock or short-circuit, use the designated voltage cords

to connect the measurement lines to the instrument’s voltage input terminals.

CAUTION

• To ensure safety, use only voltage cords designated by our company.

• To prevent a break in instrument wiring, grip the plug (not the cord) when unplugging

the power cord from an outlet or disconnecting it from the instrument.

• Exercise caution as conductors being measured may become hot.

• To avoid damaging cord insulation, do not step on cords or allow them to be pinched

between other objects.

• If a voltage cord melts, its metal conductor may be exposed. Do not use a cord whose

metal conductor is exposed. Doing so may result in electric shock, burns, or other

injury.

• Do not drop current sensors or subject them to mechanical shock. Doing so may

damage the core joint and adversely impact measurement. When disconnecting a

connector, always release the lock and then grip the connector to pull it out. Pulling

on connectors with excessive force before releasing the lock or pulling on cables will

cause damage to connectors. (p. 36)

• Do not connect or disconnect connectors while the instrument is on or while a sensor

is clamped to the conductor being measured. Doing so may damage the instrument or

current sensor.

13

Operating Precautions

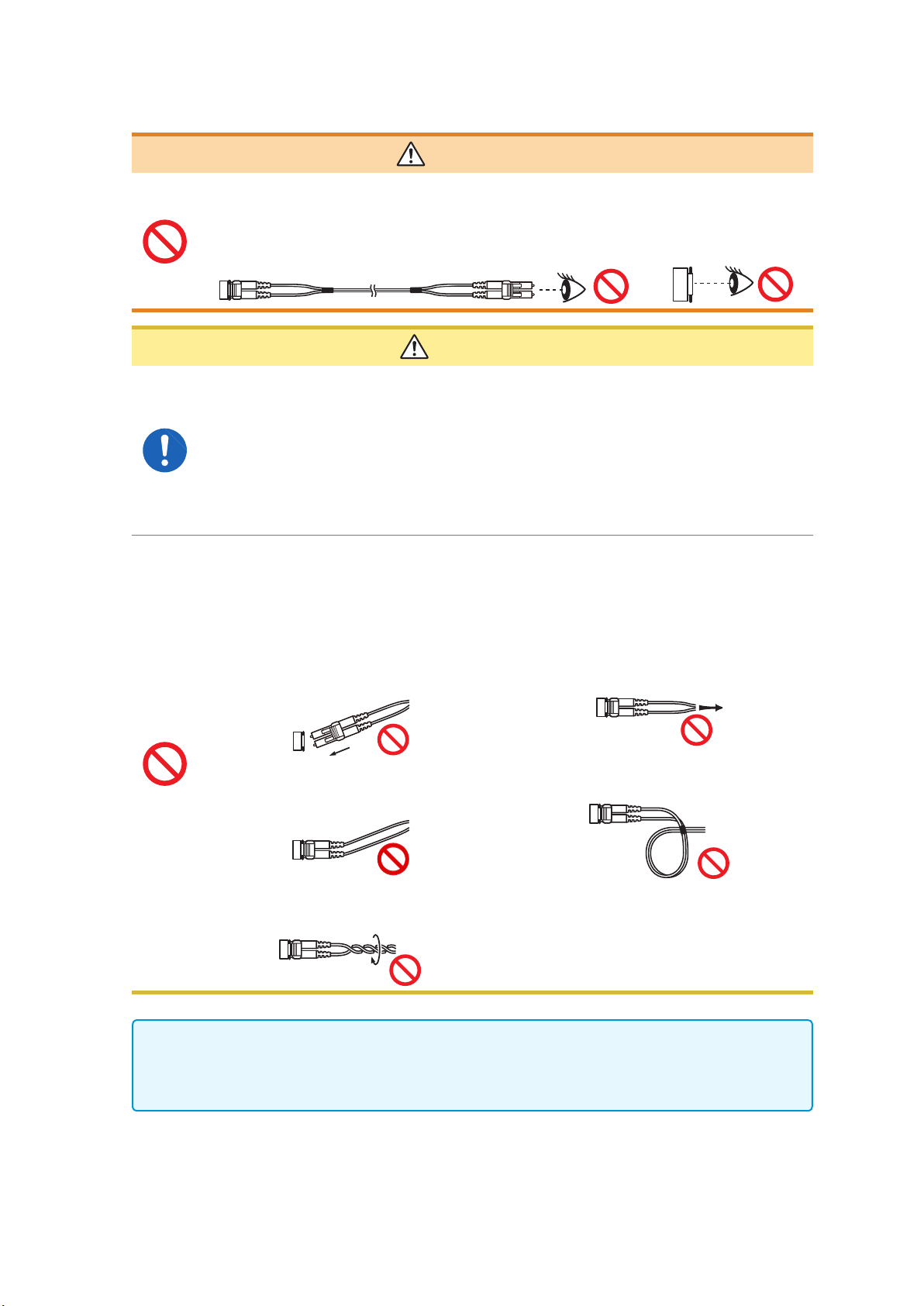

Handling of the L6000 Optical Connection Cable

WARNING

When connecting an L6000 Optical Connection Cable that is already connected

to an operating optical output to the instrument, never look directly at the tip of

the cable or observe it with a device such as a magnifying glass. Doing so may

adversely affect your eyes or damage your vision.

CAUTION

• When connecting an L6000 Optical Connection Cable to the instrument, exercise care

to ensure that there is no dirt or dust in the optical connector. In particular, exercise

caution concerning the end face (ferrule). Accurate measurement may be impossible

if the cable is connected while there is dirt or other foreign matter on the face, or if the

face is scratched or otherwise damaged.

• The instrument’s two-instrument synchronization connector and the L6000 Optical

Connection Cable’s optical connector are precisely machined parts. When not in use,

always attach the included dust cap to each.

• When cleaning the center of an optical connector, do not apply excessive force to the

cleaning cloth. Doing so may damage the connector, preventing it from performing to

specications.

• To prevent damage to the L6000 Optical Connection Cable, observe the following

precautions:

• Do not insert the optical connector at an

angle.

• Do not bend the cable at the neck of the

optical connector.

• Do not bend or twist the cable. • Do not touch the end face (ferrule).

• Do not pull on the cable with excessive

force.

• Do not allow the cable to become kinked.

14

• Clean the optical connector end face (ferrule) of the L6000 Optical Connection Cable each time

it is connected.

• To clean the L6000 Optical Connection Cable’s optical connectors, use the 9738 Optical

Connector Cleaner.

Before connecting the instrument

• Do not measure voltages that exceed the rating indicated on the instrument

labeling or the measurement range listed in the specications. Doing so may

result in damage to the instrument or bodily injury.

• The maximum rated input-to-ground voltages for the instrument’s voltage

inputs are as follows:

CAT II: 1000 V DC, 1000 V AC rms

CAT III: 600 V DC, 600 V AC rms

Do not measure a voltage in excess of these limits. Doing so may result in

damage to the instrument or bodily injury.

• The Probe1 and Probe2 terminals are not isolated. These input terminals are

provided for use with optional current sensors only. Connections of input other

than output from an optional current sensor may damage the instrument or

result in bodily injury.

• To avoid electric shock and instrument damage, do not input a voltage in

excess of the maximum input voltage to the instrument’s external input

terminals.

Operating Precautions

DANGER

• Before turning on the instrument, verify that the supply voltage being used is

the same as that noted on the instrument’s power inlet. Use of a voltage outside

the specied supply voltage range may result in damage to the instrument or

an electrical accident.

• To avoid an electric shock or short-circuit, verify that all connections have been

made securely. Loose terminals may result in increased contact resistance,

causing overheating, equipment burnout, or re.

• Connect voltage cords to input terminals securely. Loose terminals may result

in increased contact resistance, causing overheating, equipment burnout, or

re.

To ensure safety, always disconnect the power cord from the instrument and isolate the

instrument from the power supply completely when not in use.

Measurement precautions

WARNING

CAUTION

WARNING

If you notice smoke, an unusual sound, an unusual odor, or other anomaly,

halt measurement immediately, disconnect measurement lines, turn off the

instrument, unplug the power cord from the outlet, and disconnect the instrument

from the measurement target. Then contact your authorized Hioki distributor or

reseller. Continued use may result in re or electric shock.

15

Operating Precautions

Precautions when transporting the instrument

CAUTION

• To transport the instrument safely, use the packing box and cushioning material in

which the product was shipped from Hioki. However, do not use the packing box if it is

torn or deformed, and do not use the cushioning material if it has been crushed. If you

are unable to use the packing box and cushioning materials in which the product was

shipped from Hioki, consult your authorized Hioki distributor or reseller.

• Be sure to disconnect any voltage cords and current sensors as well as power cords

from the instrument before packing it. When transporting, avoid dropping or other

excessive impact.

• Pack the instrument so that it will not be damaged during shipment and note the

nature of the malfunction. Damage occurred during transportation is not covered by

warranty.

16

Product Overview

1

Overview

1.1 Product Overview

The PW6001 series of power analyzers comprises models with simultaneous measurement capabilities

for targets ranging from one 1-phase/2-wire circuit to two 3-phase/4-wire circuits, enabling them to

accommodate a variety of measurement lines. Variants offer from one to six channels.

For use in the development and evaluation of increasingly efcient inverter motors

• The PW6001 can perform high-precision, high-stability, wideband inverter power measurement that is highly

reproducible.

• The instrument can perform electrical angle measurement, which is a necessary part of motor analysis.

• When connected to a high-precision torque meter and encoder, the instrument can measure motor efciency.

For use in the development and evaluation of alternative energy technologies,

including solar power, wind power, and fuel cells

• The PW6001 can simultaneously measure AC power and DC power at a high level of precision and calculate

efciency.

• The instrument can measure power drawn from the grid, power sold to the grid, and power by consumption/

generation by means of DC mode and RMS mode current and power integration.

1

Overview

For use in the measurement of high-frequency power in wireless power feeds

and DC/DC converters

• The PW6001 can measure power at frequencies of up to 1 MHz.

• The instrument can measure and analyze harmonic distortion of switching waveforms at frequencies of up to

300 kHz.

1.2 Features

Simultaneous measurement of multiple circuits incorporating various types

of power lines (p. 41)

• For 3-phase/3-wire circuits, users can select a Hioki model 3193-compatible 3V3A connection or a Hioki

model 3390-compatible 3P3W3M connection in addition to the two-wattmeter method. The 3P3W3M

connection is particularly well suited to measuring power with inverter motors that have high-frequency leak current.

High accuracy and highly stable circuitry for high measurement reproducibility (p. 75)

The instrument delivers best-in-class basic accuracy and DC accuracy for active power and therefore provides

support for DC/AC conversion efciency with high-accuracy measurement performance.

High-bandwidth, high-speed opto-isolated sampling

• The PW6001 can measure increasingly high-speed switching waveforms accurately thanks to wideband

voltage and current input circuits (DC, 0.1 Hz to 2 MHz) and 5 MS/s, 18-bit high-speed, high-resolution

sampling capability.

• Thanks to its use of voltage inputs that use new optical devices to implement isolation with a high dielectric

strength, the instrument delivers a CMRR of 80 dB (at 100 kHz), enabling it to aggressively reject highfrequency common-mode noise when measuring inverters.

Support for a variety of current sensors (p. 36)

• In addition to conventional power measurement sensors, the PW6001 supports wideband current probes

designed for use with megahertz-order frequencies.

• The instrument ships standard with a power supply for 3270 series clamp-on probes.

17

Features

New functionality to take full advantage of current sensor performance (p. 125)

The instrument’s phase compensation calculations can correct current sensor’s high-frequency phase

characteristics.

Complete six-channel + dual mode harmonic analysis function (p. 69)

The PW6001 supports simultaneous harmonic analysis for all channels. By performing simultaneous harmonic

analysis for multiple circuits with different frequencies, the instrument can perform simultaneous harmonic

analysis for both the primary and secondary sides of an inverter.

Waveform observation functionality on par with that of an oscilloscope (p. 93)

The PW6001 can record waveforms of up to 100 sec. in duration (10 kS/s sampling) or 10 sec. in duration (at

100 kS/S sampling) thanks to its large waveform storage memory (1 Mword × 6 voltage/current channels).

Standard USB ash drive support and large internal memory (p. 139)

• Thanks to its large, 64 MB internal memory capacity, the PW6001 can continuously record data for numerous

parameters even when using a high-speed interval.

• Data can be saved directly on a USB ash drive, screens can be copied to a USB ash drive, and data can

be copied from the internal memory to a USB ash drive.

Easy-to-understand touch panel and key operation (p. 19)

• The PW6001 can be controlled using either dedicated hardware keys or an easy-to-understand touch panel.

• Comments can be entered on the touch panel when saving screen copies and measurement data.

Robust motor analysis functionality (option) (p. 182)

• When fed output from a torque meter and tachometer, the PW6001 can measure motor power and motor

efciency.

• The instrument supports A-phase/B-phase pulse output from a rotary encoder as rotation input and can

detect the direction of rotation.

• It also supports Z-phase output from the encoder and can measure the motor’s electrical angle.

• A single PW6001 can simultaneously accept two sets of torque and RPM input, leveraging its six channels of

input to allow simultaneous analysis of two motors.

• The instrument can simultaneously display either the torque waveform or the encoder pulse waveform along

with voltage and current waveforms.

• Since all inputs are functionally isolated, they can be used for two-channel voltage measurement at up to

±10 V or pulse waveform measurement across four channels at up to 1 MHz.

High-speed D/A output with waveform capability (option) (p. 173)

The PW6001 incorporates 20 channels of D/A output, enabling it to generate analog output for 20 userselected measurement parameters.

• When using waveform output mode, voltage and current waveforms for the number of channels with which

the instrument is equipped are output in order at 1 MS/s and 16 bits. Safe, isolated voltage and current

waveforms can be input to another waveform measuring instrument for analysis.

High-performance remote synchronization function using optical ber (p. 169)

• Optical ber can be connected to the synchronization interface to enable synchronized measurement at

multiple locations with different instrument power supply potentials.

• Up to two instruments separated by up to 500 m can be synchronized to perform measurement.

Dedicated communications application software (downloadable from Hioki’s

website) (p. 189)

• A dedicated PC application that can control the instrument remotely, acquire data in real time, and display it

on the screen can be downloaded free of charge from our website.

• The following communications interfaces are supported: LAN, GP-IB, RS-232C.

18

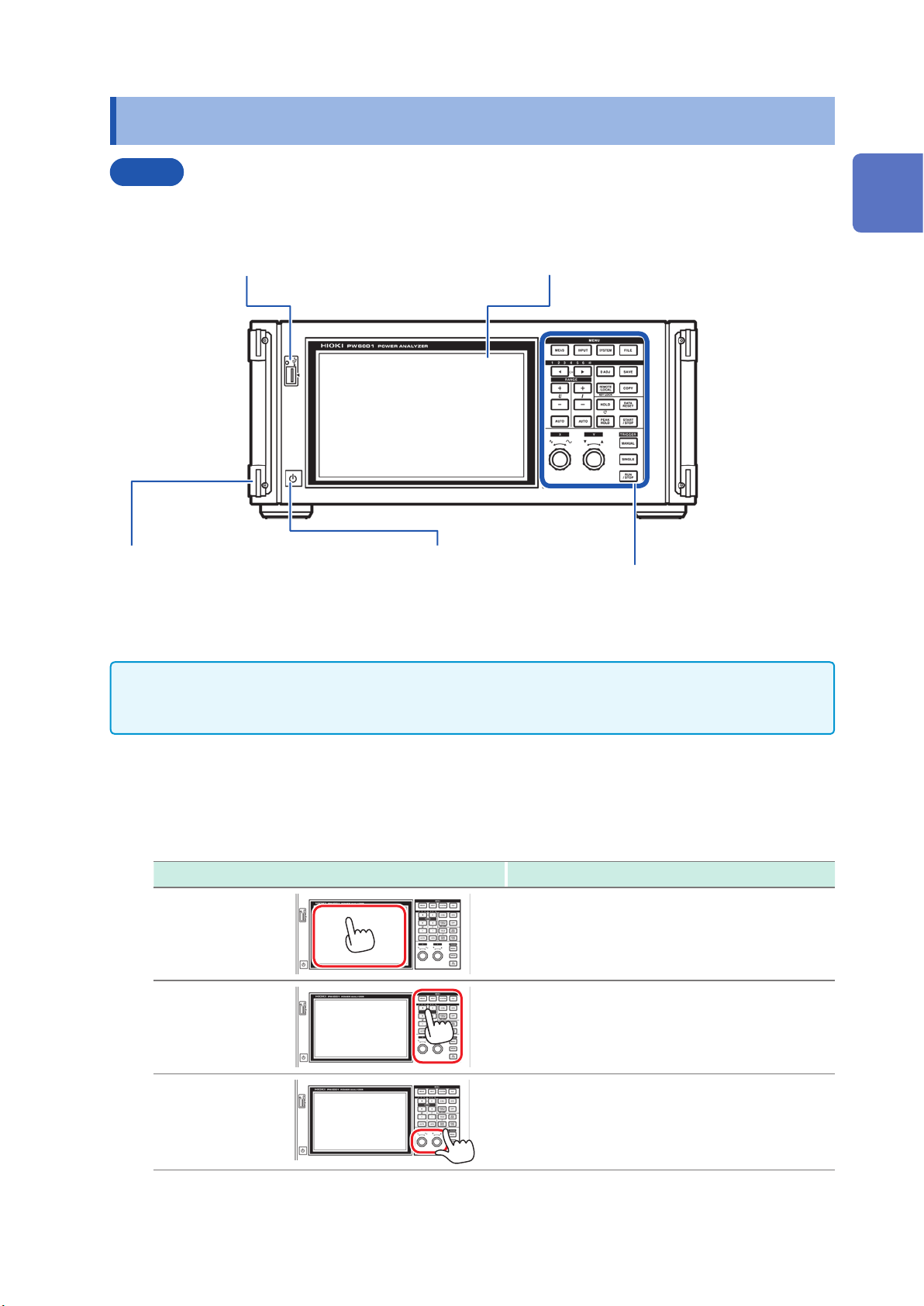

1.3 Part Names and Functions

Front

Part Names and Functions

USB ash drive interface (p. 139)

Connect a USB ash drive to save measurement data,

settings, screenshots, and other data. This interface does

not support use of a mouse, keyboard, or other device.

Handle

Use the handle to carry the

instrument.

Power switch (p. 40)

Turn the instrument on and off.

Display

Touch the touch panel to display measured values and

change settings.

Control area (p. 20)

1

Overview

• Both key operation and touch panel operation are completely disabled while the key lock function is

active, with the exception of key operation used to cancel the key lock state (p. 21).

• The key lock state will persist even if the instrument’s power is cycled.

Instrument operation

The instrument is controlled by means of the MENU keys and rotary knobs in the control area and

the display’s touch panel.

Operation Description

Touch

Press

Turn

Touch the touch panel.

Press a control key.

Turn a rotary knob.

19

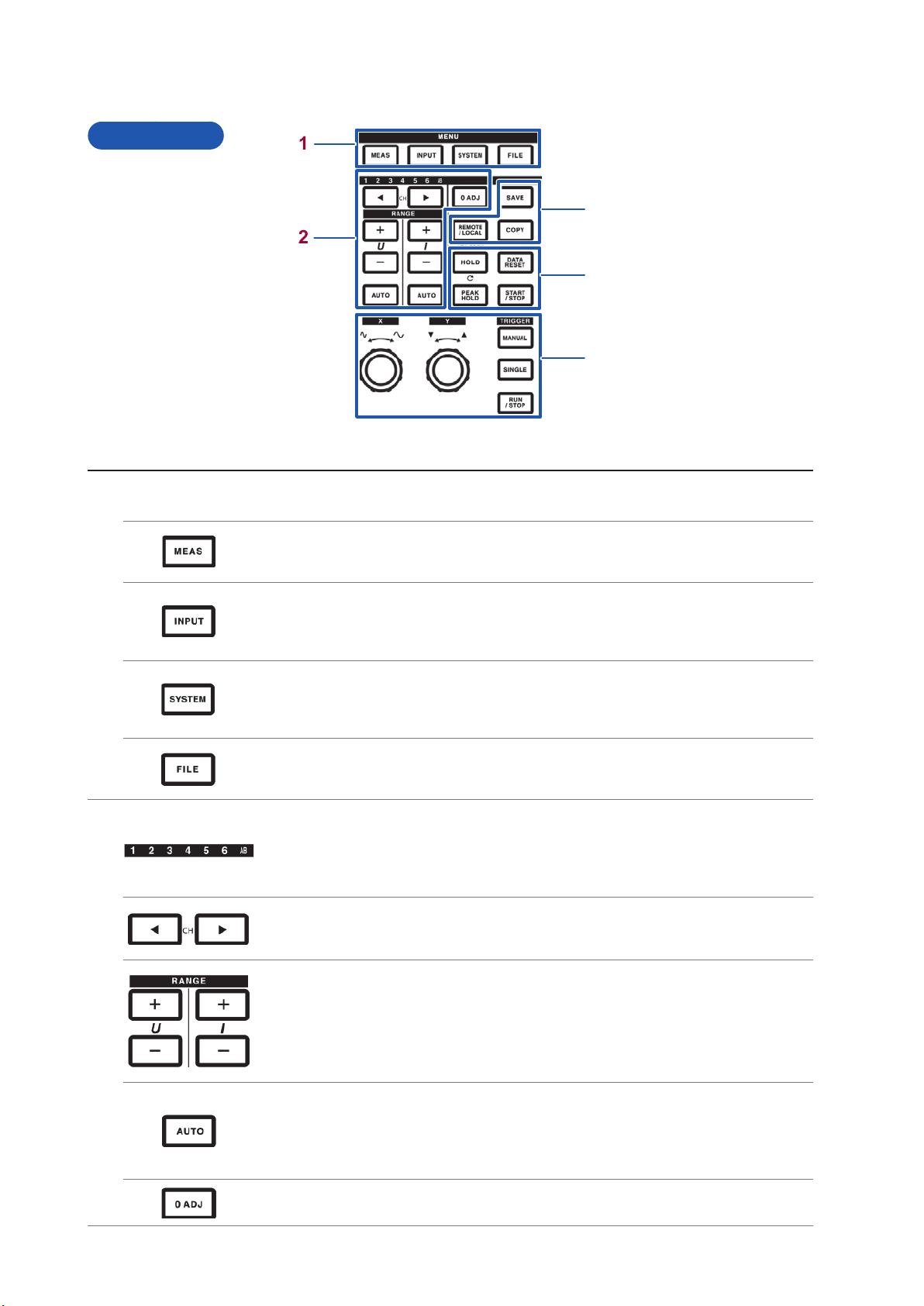

Part Names and Functions

Control area

1

3

2

4

5

MENU keys (switching screens)

1

Pressing a key causes the selected key to light up and the screen to change to the selected screen.

[MEAS] key (p. 30)

Displays the Measurement screen.

The Measurement screen is used to display measured values and waveforms.

[INPUT] key (p. 31)

Displays the Input Settings screen.

The Input Settings screen is used to congure settings related to input, connections, measurement,

and calculations.

[SYSTEM] key (p. 135)

Displays the System Settings screen.

The System Settings screen is used to congure settings related to time control, interfaces, and

overall instrument parameters.

[FILE] key (p. 139)

Displays the File Operations screen.

The File Operations screen is used to manipulate les.

2

Channel indicator LED

• Lights up to indicate the input channel to which the [RANGE] key and setting indicators apply.

• Channels that have been grouped into a connection based on connection settings will light up at

the same time.

• The AB LED corresponds to CH A and CH B on motor analysis and D/A-equipped models.

[CH] keys

• Used to switch the channel whose channel indicator LED is lit up.

• Used to switch the channel on the Basic Settings screen and Harmonic screen.

[RANGE] keys

• The U [+/-] keys change the voltage range, while the I [+/-] keys change the current range.

• Changes apply to the channel whose channel indicator LED is lit up.

• When the AB LED is lit up, the U buttons apply to CH A analog input, while the I buttons apply to

CH B analog input.

• When the [AUTO] key is lit up, AUTO range operation is canceled when the range is changed.

20

[AUTO] keys

• The U [AUTO] key enables the AUTO range function for voltage, while the I [AUTO] key enables

the AUTO range function for current. The key will light up. It will go out if pressed again, and the

range will be xed to the current setting at that time.

• Changes apply to the channel whose channel indicator LED is lit up.

[0ADJ] key (p. 43)

Performs zero adjustment for the input channel.

Part Names and Functions

3

Measurement control keys

4

The measurement control keys function primarily to control power measurement functions. They do not affect the waveform

display.

[SAVE] key

Saves the measurement data at the time the key is pressed to the USB ash drive.

[COPY] key

Saves a screenshot of the screen at the time the key is pressed to the USB ash drive.

[REMOTE/LOCAL] key (key lock)

• Lights up when in the remote state for GP-IB communications. Pressing the key again will return

to the local state, causing the light to turn off.

• Pressing and holding the key for 3 sec. or more will enable the key lock function, causing the key

lock icon to be displayed on the screen. Pressing and holding the key again for 3 sec. or more will

cancel the key lock, causing the light to turn off.

[HOLD] key

• Toggles the hold function on and off. The key lights up when the hold function is on.

• Pressing the [HOLD] key while the peak hold function is on will clear the peak hold data.

[PEAK HOLD] key

• Toggles the peak hold function on and off. The key lights up when the peak hold function is on.

• Pressing the [PEAK HOLD] key while the hold function is on will update the hold data.

[DATA RESET] key

• Resets integration data.

• The key functions while the [START/STOP] key is lit up (red).

1

Overview

[START/STOP] key

• Controls starting and stopping of the integration and automatic save functions.

• It lights up when operation starts (green) and when operation stops (red).

• It turns off when the [DATA RESET] key is pressed.

21

Part Names and Functions

Waveform control keys (rotary knobs)

5

The waveform control keys function primarily to control waveform capture. They operate independently of the instrument’s

power measurement functionality.

[MANUAL] key (manual trigger function)

• Forcibly applies a trigger while waiting for a trigger.

• The trigger is applied when the key is pressed, causing recording to start.

[SINGLE] key

• Performs one waveform capture.

• The key lights up (green) when pressed. Once the trigger is applied and the waveform captured, it

turns off.

Lit up (green)

Off

The instrument is waiting for a trigger.

Recording will start when the trigger is applied.

Recording will stop once data has been recorded for the

[RUN/STOP]:

Lit up (red)

recording length.

Pressing [RUN/STOP] while the instrument is waiting for a trigger

will cause recording to stop.

[RUN/STOP] key

• Causes waveform to be recorded continuously.

• The key lights up (turns green) when pressed and then turns red when pressed again.

Lit up

(green)

Lit up

(red)

The instrument enters the trigger standby state.

Recording will start when the trigger is applied.

The instrument will repeatedly wait for a trigger.

Recording will stop.

Rotary knobs

• The rotary knobs function primarily to zoom waveforms in or out and to change the position or

cursor.

• They are also used with certain settings to vary (increase/decrease) values.

• Each knob operates as appropriate when turned or pressed while lit up but does nothing if the

light is off.

22

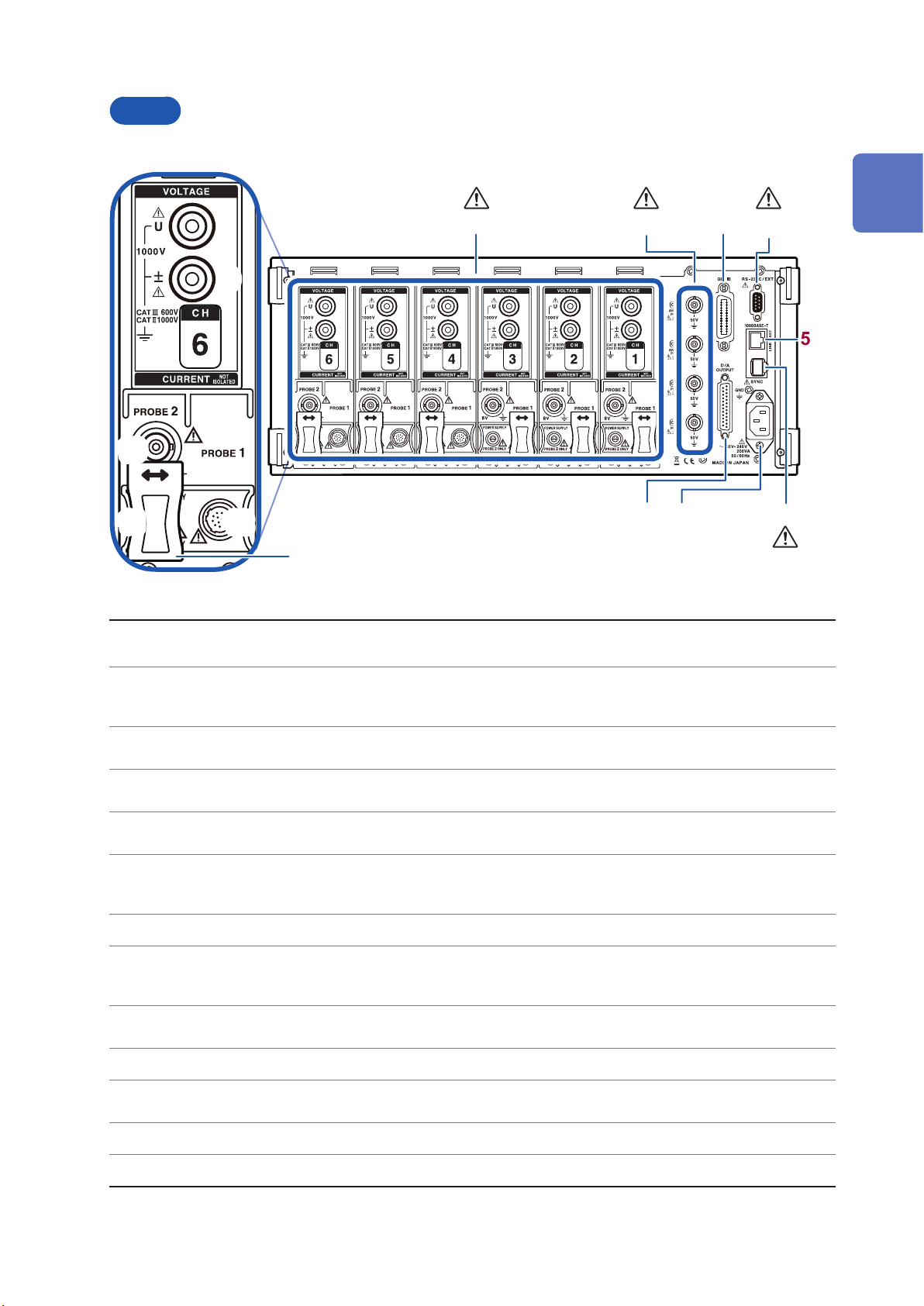

Back

10

Part Names and Functions

(p. 13) ,

(p. 15)

(p. 201)(p. 13)

1

1 2

9

3 4

Overview

5

11

12

13

Input channels 1 through 6

1

Motor input (external

2

input) channels (p. 80)

GP-IB connector (p. 198)

3

D-sub 9-pin connector

4

(p. 201)

LAN connector (p. 190)

5

Two-instrument

synchronization connector

6

(p. 169)

Power inlet (p. 35) Connect the included power cord.

7

D/A output connector

8

(p. 173)

Voltage input terminal

9

(p. 35)

Insert up to six channels in the form of units that accept input of voltage and current for one

phase of power.

(Motor analysis and D/A-equipped models only)

• Measure motor efciency.

• Input torque sensor and tachometer output to measure motor output.

• Control the instrument remotely using GP-IB.

• Transfer data to a computer.

• Control the instrument remotely from a computer or controller via serial RS-232C communications.

• Control starting and stopping of integration with a contact switch.

• Control the instrument remotely over a LAN.

• Acquire data.

Perform measurements using two synchronized instruments.

(Motor analysis and D/A-equipped models only)

• Input the instrument’s output into a recorder to record data over an extended period of time.

• Input to an oscilloscope to observe the waveform.

Connect a Hioki-designated voltage cord.

8

7

6

p.14

Probe2 terminal (p. 38) Connect a Hioki 3270 series current probe for wideband current measurement.

10

Probe2 power supply

11

terminal (p. 38)

Probe1 terminal (p. 37) Connect a CT6800 series current sensor for high-precision current measurement.

12

Sliding cover Slide open the cover to select the current sensor being used.

13

Connect a 3270 series current probe.

23

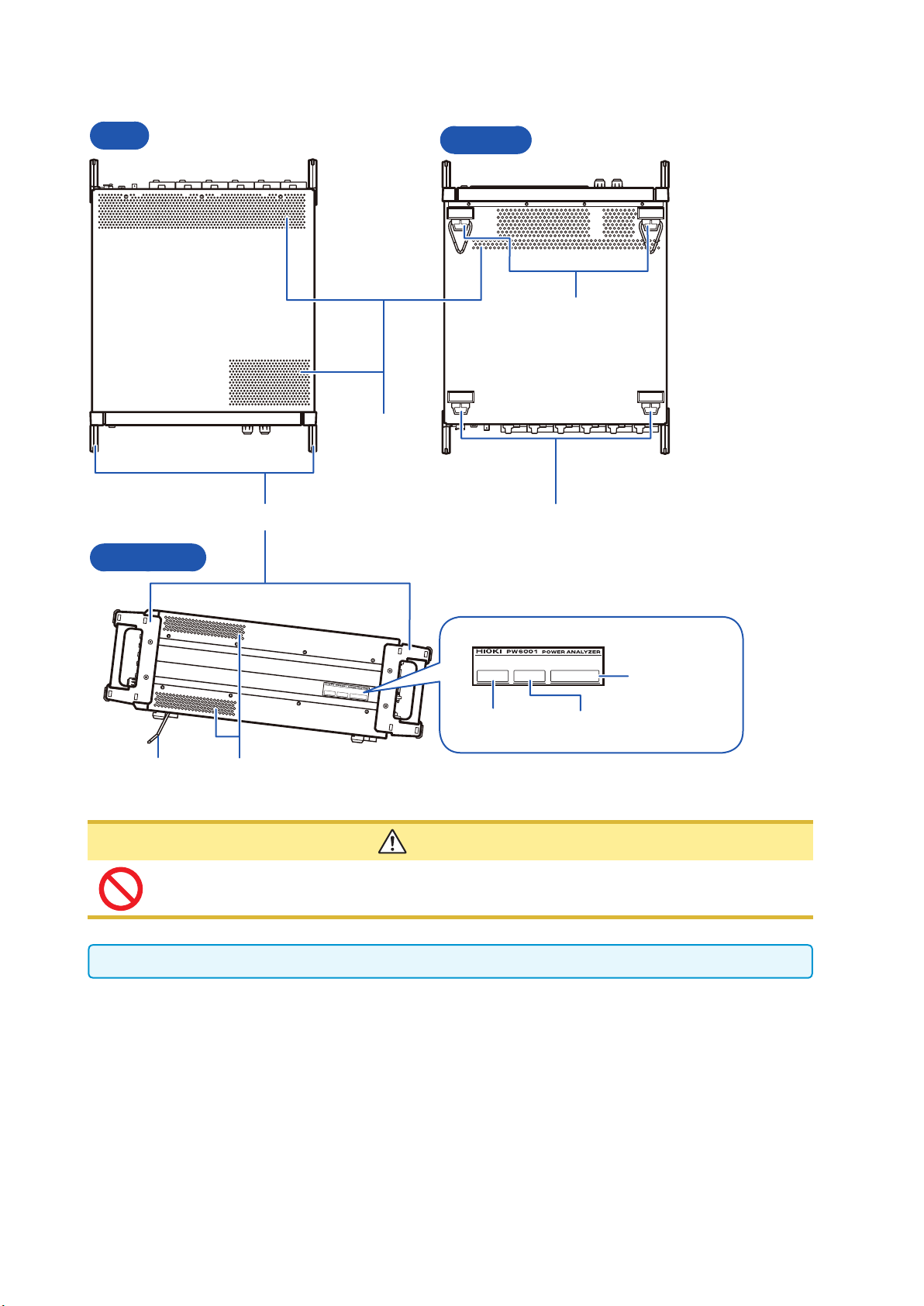

Part Names and Functions

Top

Right side

Handles

Bottom

Support legs

(With stand)

Air vents

Support legs

Serial number

Model number MAC address

Stand

Air vents

CAUTION

Do not subject the instrument to excessive force from above while using the stand. Doing so

may damage the stand.

Leave at least 20 mm between the instrument’s air vents and surrounding surfaces.

24

Loading...

Loading...