PW3390

HIOKI PW3390A961-06

PW3390-01

PW3390-02

PW3390-03

POWER ANALYZER

Instruction Manual

Be sure to read this manual before using the instrument.

When using the instrument for the

rst time

Names and Functions of Parts

Basic Operations

Measurement Preparations

Jan. 2023 Revised edition 6

PW3390A961-06

p.17 Troubleshooting

p.20 Error Indication

p.27

Troubleshooting

Video

Scan this code to watch the

instructional video(s).

Carrier charges may apply.

[600499396]

p.5

p.223

p.226

EN

Contents

HIOKI PW3390A961-06

Introduction.................................................................................1

Confirming Package Contents....................................................2

Safety Notes...............................................................................5

Usage Notes...............................................................................8

Chapter 1

Overview __________________________________ 13

1.1 Product Overview.............................................................. 13

1.2 Features............................................................................ 14

1.3 Operating Overview .......................................................... 16

i

Contents

Chapter 2

Names and Functions of Parts,

Basic Operations & Screens__________________ 17

2.1 Names and Functions of Parts.......................................... 17

2.2 Basic Operations............................................................... 20

2.3 Display Items and Screen Types ...................................... 21

2.3.1 Common Display Items .......................................................... 21

2.3.2 Measurement Screen ............................................................. 22

2.3.3 Screen Types ......................................................................... 23

Chapter 3

Measurement Preparations___________________ 27

3.1 Operations in general........................................................ 27

3.2 Initial Instrument Preparations .......................................... 28

3.3 Pre-Operation Inspection.................................................. 30

3.4 Connecting the Power Cord.............................................. 31

PW3390A961-06

3.5 Grounding the Instrument's Functional Earth

(when measuring in noisy environments) .........................31

3.6 Connecting the Voltage Measurement Cables ................. 32

3.7 Connecting the Current Sensors....................................... 33

3.8 Turning the Power On and Off.......................................... 36

3.9 Selecting the Wiring Mode ................................................ 37

3.10 Setting the Current Sensors.............................................. 41

ii

HIOKI PW3390A961-06

Contents

3.11 Attaching to the Lines to be Measured and

Zero Adjustment ...............................................................44

3.12 Verifying Correct Wiring (Connection Check) ................... 46

Chapter 4

Viewing Measurement Values _________________ 47

4.1 Measurement Value Display Procedure ........................... 47

4.2 Viewing Power Measurements,

and Changing the Measurement Configuration ................ 51

4.2.1 Displaying Power Measurements .......................................... 51

4.2.2 Selecting Ranges................................................................... 53

4.2.3 Selecting the Sync Source..................................................... 58

4.2.4 Frequency Measurement Settings......................................... 60

4.2.5 Selecting the Rectification Method......................................... 62

4.2.6 Setting Scaling (when using VT(PT) or CT)........................... 63

4.2.7 Setting the Low-Pass Filter.................................................... 64

4.3 Integration Value Observation .......................................... 65

4.3.1 Displaying Integration Values ................................................ 65

4.3.2 Setting the Integration Mode.................................................. 68

4.3.3 Manual Integration Method .................................................... 69

4.3.4 Integration Combined with Timing Control............................. 71

4.4 Viewing Harmonic Measurement Values.......................... 74

4.4.1 Displaying the Harmonic Bar Graph ...................................... 74

4.4.2 Displaying the Harmonic List ................................................. 76

4.4.3 Displaying Harmonic Vectors................................................. 77

4.4.4 Selecting the Harmonic Sync Source .................................... 79

4.4.5 Selecting the THD Calculation Method.................................. 80

4.5 Viewing Waveforms .......................................................... 81

4.5.1 Displaying Waveforms ........................................................... 81

4.5.2 Resizing Waveforms.............................................................. 84

4.6 Viewing Noise Measurement Values (FFT Function) ....... 85

4.6.1 Displaying Noise Voltage and Current................................... 85

4.6.2 Setting the Sampling Frequency and Points.......................... 87

4.6.3 Setting the Minimum Noise Frequency.................................. 88

4.6.4 Measurement Channel and Window Function Settings......... 90

4.7 Viewing Efficiency and Loss Measurement Values .......... 91

4.7.1 Displaying Efficiency and Loss .............................................. 91

4.7.2 Selecting the Calculation Formula ......................................... 92

4.7.3 Measurement Examples ........................................................ 93

4.8 Viewing Motor Measurement Values

(Model PW3390-03 only) .................................................. 96

4.8.1 Motor Input Settings ............................................................... 98

HIOKI PW3390A961-06

4.8.2 Measuring Motor Electrical Angle......................................... 104

4.8.3 Detecting the Motor Rotation Direction................................. 107

Chapter 5

Operating Functions _______________________ 109

5.1 Timing Control Functions ................................................ 109

5.2 Averaging Function......................................................... 112

5.3 Data Hold and Peak Hold Functions............................... 114

5.3.1 Data Hold Function............................................................... 114

5.3.2 Peak Hold Function .............................................................. 115

5.4 X-Y Plot Function............................................................ 117

iii

Contents

5.5 Delta Star (

∆-Y)Transform Function ................................ 118

5.6 Selecting the Calculation Method ................................... 120

5.7 Trend Function................................................................ 121

Chapter 6

Changing System Settings __________________ 129

6.1 Initializing the Instrument (System Reset) ...................... 132

6.2 Factory Default Settings.................................................. 133

Chapter 7

Data Saving and File Operations _____________ 135

7.1 Inserting and Removing Storage Media.......................... 136

7.2 The File Operation Screen.............................................. 138

7.3 Media Formatting............................................................ 139

7.4 Saving Operations .......................................................... 140

7.5 Measurement Data Saving ............................................. 141

7.5.1 Manually Saving Measurement Data.................................... 141

7.5.2 Auto-Saving Measurement Data .......................................... 143

7.5.3 Selecting Measurement Items to Save................................. 145

7.6 Saving Noise Data and Waveform Data ......................... 147

7.6.1 Saving Noise Data................................................................ 147

7.6.2 Saving Wave Data................................................................ 148

7.7 Saving Screen Capture Images...................................... 149

7.8 Loading Screenshots ...................................................... 150

7.9 Saving Setting Configurations......................................... 151

iv

HIOKI PW3390A961-06

Contents

7.10 Reloading Setting Configurations ................................... 152

7.11 File and Folder Operations ............................................. 153

7.11.1 Creating Folders .................................................................. 153

7.11.2 Copying Files and Folders ................................................... 154

7.11.3 Deleting Files and Folders ................................................... 156

7.11.4 Renaming Files and Folders................................................ 157

Chapter 8

Connecting External Devices ________________159

8.1 Connecting Multiple PW3390

(Synchronized Measurements) ....................................... 159

8.2 Controlling Integration with External Signals .................. 163

8.3 Using Analog and Waveform D/A Output ....................... 166

8.3.1 Connecting Application-Specific Devices to the Instrument. 166

8.3.2 Output Item Selection .......................................................... 168

8.3.3 Output Level ........................................................................ 171

8.3.4 D/A Output Examples .......................................................... 172

8.4 Connecting the Instrument to a LR8410 Link-compatible Logger .......... 174

8.4.1 Configuring and Connecting the Adapter............................. 175

8.5 Using the Motor Testing.................................................. 176

8.6 Connecting VT1005 ........................................................ 178

Chapter 9

Operation with a Computer __________________181

9.1 Control and Measurement via Ethernet

("LAN") Interface ............................................................. 182

9.1.1 LAN Settings and Network Environment

Configuration ....................................................................... 182

9.1.2 Instrument Connection......................................................... 184

9.2 Remote Control of the Instrument by Internet Browser .. 186

9.2.1 Connecting to the Instrument............................................... 186

9.2.2 Operating Procedure ........................................................... 187

9.3 Control and Measurement via USB Interface ................. 188

9.3.1 Connecting to the Instrument............................................... 188

9.3.2 After Connecting .................................................................. 188

9.4 Control and Measurement via RS-232C Interface.......... 189

9.4.1 Connecting to the Instrument............................................... 189

9.4.2 Setting the RS-232C Communications Speed..................... 190

Chapter 10

HIOKI PW3390A961-06

Specifications_____________________________ 193

10.1 General Specifications.................................................... 193

10.2 Basic Specifications........................................................ 194

10.3 Functions Specifications ................................................. 203

10.4 Setting Specifications...................................................... 208

10.5 Measurement Item Details .............................................. 211

10.6 Calculation Formula Specifications................................. 214

10.7 Wiring System Diagram Specifications ........................... 221

Chapter 11

Maintenance and Service ___________________ 223

v

Contents

11.1 Cleaning.......................................................................... 223

11.2 Troubleshooting .............................................................. 223

11.3 Error Indication................................................................ 226

11.4 Disposing of the Instrument ............................................ 230

Appendix__________________________________A1

Appendix 1Block Diagram ............................................................ A1

Appendix 2Measurement Data Saving Format............................. A2

Appendix 3Physical Illustration..................................................... A5

Appendix 4Rack Mounting............................................................ A6

Index ______________________________________ i

Appendix

Index

vi

HIOKI PW3390A961-06

Contents

Introduction

HIOKI PW3390A961-06

Introduction

Thank you for purchasing the Hioki PW3390 Power Analyzer. To obtain maximum performance from the

product, please read this manual first, and keep it handy for future reference.

To measure current, the power analyzer requires clamp-on current probes or AC/DC current probes

(Options, (p. 3), afterwards referred to generically as “current sensors”). See your current sensor’s

instruction manual for details.

Latest edition of intsruction manual

The contents of this manual are subject to change, for example as a result of product

improvements or changes to specifications.

The latest edition can be downloaded from Hioki’s website.

https://www.hioki.com/global/support/download

Product registration

Register this product in order to receive important product information.

https://www.hioki.com/global/support/myhioki/registration/

1

Trademarks

• CompactFlash is a registered trademark of Sandisk Corporation (USA).

• Microsoft and Excel are either registered trademarks or trademarks of Microsoft Corporation in the

United States and other countries.

• Adobe and Adobe Reader are either trademarks or registered trademarks of Adobe in the United

States and other countries.

• Bluetooth

E.E. CORPORATION under license.

is a registered trademark of Bluetooth SIG, Inc.(USA). The trademark is used by HIOKI

Product model numbers

Rear side

Product model number

The product model number is indicated as below depending on a manufacturing date.

Product model number

2

HIOKI PW3390A961-06

Confirming Package Contents

Product model number Feature

PW3390-01 Basic model (model without motor analysis and D/A output)

PW3390-02 Model with D/A output

PW3390-03 Model with motor analysis and D/A output

In this document, the terms “master” and “slave” used in the earlier editions have been replaced with “primary” and “secondary,” respectively.

Confirming Package Contents

When you receive the instrument, inspect it carefully to en

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to

operate according to the specifications, contact your authorized Hioki distributor or reseller.

Confirm that these contents are provided.

sure that no damage occurred during shipping.

Main instrument

PW3390 Power Analyzer ×1

Accessories

Grounded power cord ×1

Instruction manual (This document) ×1

USB cable

D-Sub connector

(used only with the D/A output function-equipped

PW3390-02 or PW3390-03)

×1

×1

Measurement guide

Input cable labels (to identify voltage cords and

current sensor channels)

Please attach to the instrument before use. (p. 28)

×1

×2

Confirming Package Contents

HIOKI PW3390A961-06

Options

The following options are available for the product. Contact your authorized Hioki distributor or reseller

when ordering. The options are subject to change. Visit our website for updated information.

Voltage measurement options

• L9438-50 Voltage Cord (banana/banana; 1 each red and black; with alligator clips/approx. 3 m)

CAT III 1000 V, 10 A / CAT IV 600 V, 10 A

• L1000 Voltage Cord (banana/banana; 1 each red, yellow, blue, and gray; 4 black; with alligator clips/

approx. 3 m) CAT III 1000 V, 10 A / CAT IV 600 V, 10 A

• L4931 Extension Cable Set (banana/banana; 1 each red and black/

L9438-50 or L1000) CAT III 1000 V, 10 A / CAT IV 600 V, 10 A

• L1021-01 Patch Cord (branched bananas/banana; 1 red/approx. 0.5 m, for branching the L9438-50 or L1000)

CAT III 1000 V, 10 A / CAT IV 600 V, 10 A

• L1021-02 Patch Cord (branched bananas/banana; 1 black/approx. 0.5 m, for branching the L9438-50 or L1000)

CAT III 1000 V, 10 A / CAT IV 600 V, 10 A

• L9243 Grabber Clip (1 each red and black

• PW9000 Wiring Adapter (for three-phase 3-wire) CAT III 1000 V, 1 A / CAT IV 600 V, 1 A (p. 32)

• PW9001 Wiring Adapter (for three-phase 4-wire) CAT III 1000 V, 1 A / CAT IV 600 V, 1 A (p. 32)

• VT1005 AC/DC High Voltage Divider

) CAT II 1000 V, 1 A

approx.

1.5 m, for extending the

3

Current measurement options

• CT6841 AC/DC Current Probe (20 A)

• CT6843 AC/DC Current Probe (200 A)

• CT6844 AC/DC Current Probe (500 A)

• CT6845 AC/DC Current Probe (500 A)

• CT6846 AC/DC Current Probe (1000 A)

• CT6841-05 AC/DC Current Probe (20 A)

• CT6843-05 AC/DC Current Probe (200 A)

• CT6844-05 AC/DC Current Probe (500 A)

• CT6845-05 AC/DC Current Probe (500 A)

• CT6846-05 AC/DC Current Probe (1000 A)

• CT6841A AC/DC Current Probe (20 A)

• CT6843A AC/DC Current Probe (200 A)

• CT6844A AC/DC Current Probe (500 A)

• CT6845A AC/DC Current Probe (500 A)

• CT6846A AC/DC Current Probe (1000 A)

• 9272-05 Clamp On Sensor (20 A/200 A AC)

• 9709-05 AC/DC Current Sensor (500 A)

• CT6862 AC/DC Current Sensor (50 A)

• CT6863 AC/DC Current Sensor (200 A)

• CT6865 AC/DC Current Sensor (1000 A)

• CT6872 AC/DC Current Sensor (50 A, cable length 3 m)

• CT6872-01 AC/DC Current Sensor (50 A, cable length 10 m)

• CT6873 AC/DC Current Sensor (200 A, cable length 3 m)

• CT6873-01 AC/DC Current Sensor (200 A, cable length 10 m)

• CT6862-05 AC/DC Current Sensor (50 A)

• CT6863-05 AC/DC Current Sensor (200 A)

• CT6865-05 AC/DC Current Sensor (1000 A)

• CT6875 AC/DC Current Sensor (500 A, cable length 3 m)

• CT6875-01 AC/DC Current Sensor (500 A, cable length 10 m)

• CT6876 AC/DC Current Sensor (1000 A, cable length 3 m)

• CT6876-01 AC/DC Current Sensor (1000 A, cable length 10 m)

• CT6877 AC/DC Current Sensor (2000 A, cable length 3 m)

4

HIOKI PW3390A961-06

Confirming Package Contents

• CT6877-01 AC/DC Current Sensor (2000 A, cable length 10 m)

• CT6904 AC/DC Current Sensor (500 A)

• CT6875A AC/DC Current Sensor (500 A, cable length 3 m)

• CT6875A-1 AC/DC Current Sensor (500 A, cable length 10 m)

• CT6876A AC/DC Current Sensor (1000 A, cable length 3 m)

• CT6876A-1 AC/DC Current Sensor (1000 A, cable length 10 m)

• CT6877A AC/DC Current Sensor (2000 A, cable length 3 m)

• CT6877A-1 AC/DC Current Sensor (2000 A, cable length 10 m)

• CT6904A AC/DC Current Sensor (500 A)

• PW9100-03 AC/DC Current Box (50 A, 3 channels)

• PW9100-04 AC/DC Current Box (50 A, 4 channels)

• PW9100A-3 AC/DC Current Box (50 A, 3 channels)

• PW9100A-4 AC/DC Current Box (50 A, 4 channels)

• CT9557 Sensor Unit (sensor power supply with 4-channel addition function)

• CT9904 Connection Cable (for connecting the CT9557)

• CT9900 Conversion Cable (PL23 receptacle-ME15W plug)

• CT9920 Conversion Cable (PL14 receptacle-ME15W plug)

• Special-order: 5 A rated version of the PW9100 AC/DC Current Box

• Special-order: High-accuracy version of the 9709-05 AC/DC Current Sensor

• Special-order: High-accuracy version of the CT6862-05 AC/DC Current Sensor

• Special-order: High-accuracy version of the CT6863-05 AC/DC Current Sensor

• Special-order: CT6904-01 AC/DC Current Sensor (500 A, cable length 10 m)

• Special-order: CT6904-60 AC/DC Current Sensor (800 A, cable length 3 m)

• Special-order: CT6904-61 AC/DC Current Sensor (800 A, cable length 10 m)

• Special-order: CT6904A-1 AC/DC Current Sensor (500 A, cable length 10 m)

• Special-order: CT6904A-2 AC/DC Current Sensor (800 A, cable length 3 m)

• Special-order: CT6904A-3 AC/DC Current Sensor (800 A, cable length 10 m)

• CT7742 AC/DC Auto-Zero Current Sensor (2000 A)

• CT7642 AC/DC Current Sensor (2000 A)

• CT7044 AC Flexible Current Sensor (6000 A, φ100 mm)

• CT7045 AC Flexible Current Sensor (6000 A, φ180 mm)

• CT7046 AC Flexible Current Sensor (6000 A, φ254 mm)

Connection options

• L9217 Connection Cord (isolated BNC/isolated BNC; 1.6 m; for motor analysis input)

CAT II 600 V, 0.2 A / CAT III 300 V, 0.2 A

See "8.5 Using the Motor Testing" (p. 176)

• Special-order: D/A Output Cable (25-pin D-sub/male BNC; 16-channel conversion/2.5 m)

• 9683 Connection Cable (for synchronization /1.5 m)

See "Connecting Multiple PW3390 (Synchronized Measurements)" (p. 159)

• 9642 LAN Cable (5 m, with straight/cross conversion connector)

• 9637 RS-232C Cable (9pin-9pin/1.8 m, crossing cable)

Other options

• 9728 PC Card 512M (512 MB CF Card + Adapter)

• 9729 PC Card 1G (1 GB CF Card + Adapter)

• 9830 PC Card 2G (2 GB CF Card + Adapter)

• 9794 Carrying Case (PW3390 dedicated hard type)

• Special-order: Rack mounting hardware (EIA/JIS)

Safety Notes

HIOKI PW3390A961-06

Safety Notes

This instrument is designed to comply with IEC 61010 Safety Standards, and has

been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage to the instrument. However, using the instrument in a way not described in this manual may negate the

rovided safety features.

p

Be certain that you understand the instructions and precautions in the manual

efore use. We disclaim any responsibility for accidents or injuries not resulting

b

directly from instrument defects.

This manual contains information and warnings essential for safe operation of the product and for maintaining it in safe operating condition. Before using the product, be sure to carefully read the following

safety notes.

5

Safety symbols

Indicates cautions and hazards. When the symbol is printed on the instrument, refer to

a corresponding topic in the Instruction Manual.

Indicates a grounding terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of th

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage

to the product.

Advisory items related to performance or correct operation of the product.

e power switch.

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in

EU member states.

Indicates that the product conforms to reg

ulations set out by the EU Directive.

6

HIOKI PW3390A961-06

Safety Notes

Other symbols

Symbols in this manual

Indicates the prohibited action.

(p. ) Indicates the location of reference information.

Indicates quick references for operation and remedies for troubleshooting.

* Indicates that descriptive information is provided below.

[ ] Menus, commands, dialogs, buttons in a dialog, and other names on the screen

and the keys are indicated in brackets.

CURSOR

(Bold character)

Windows Unless otherwise specified, “Windows” represents Windows 7, Windows 8, or Win-

Dialog Dialog box represents a Windows dialog box.

Bold characters within the text indicate operating key labels.

dows 10.

Mouse action terminology

Click: Press and quickly release the left button of the mouse.

Right-click: Press and quickly release the right button of the mouse.

Double click: Quickly click the left button of the mouse twice.

Drag: While holding down the left button of the mouse, move the mouse and then release

the left button to deposit the chosen item in the desired position.

Activate: Click on a window on the screen to activate that window.

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with

the following meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or scale length. This is usually the name of the

currently selected range.

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

dgt. (resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value

that causes the digital display to show a "1" as the least-significant digit.

Safety Notes

HIOKI PW3390A961-06

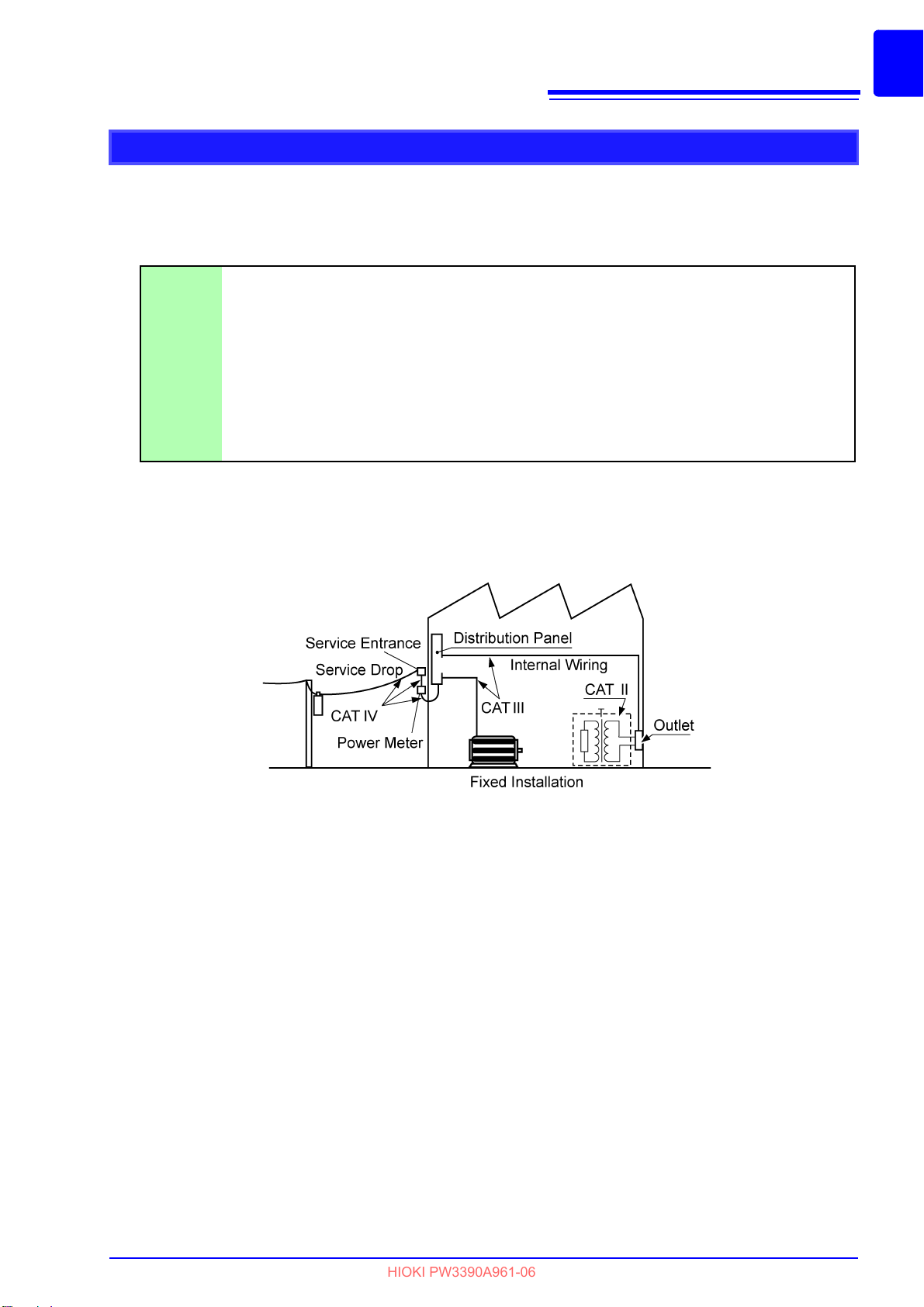

Measurement categories

This instrument complies with CAT II (1000 V) and CAT III (600 V) safety requirements.

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

CAT II Primary electrical circuits in equipment connected to an AC electrical outlet by a power

cord (portable tools, household appliances, etc.) CAT II covers directly measuring electrical outlet receptacles.

CAT II covers directly measuring electrical outlet receptacles.

CAT III Primary electrical circuits of heavy equipment (fixed installations) connected directly to the

distribution panel, and feeders from the distribution panel to outlets.

CAT IV The circuit from the service drop to the service entrance, and to the power meter and pri-

mary overcurrent protection device (distribution panel).

Using a measurement instrument in an environment designated with a higher-numbered category than that for

which the instrument is rated could result in a severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV measurement applications

could result in a severe accident, and must be carefully avoided.

7

8

HIOKI PW3390A961-06

Usage Notes

Usage Notes

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Before use

Before using the instrument the first time, verify that

occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributor or

reseller.

Before using the instrument, make sure that the insulation on the voltage cords

is undamaged and that no bare conductors are improperly exposed. Using the

instrument in such conditions could cause an electric shock, so contact your

authorized Hioki distributor or reseller for replacements.

it operates normally to ensure that the no damage

Instrument installation

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high humidity or

condensation

Exposed to high levels of particulate dust

In the presence of corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction

heating systems and IH cooking

utensils)

Subject to vibration

Installing

• The instrument should be operated only with the bottom or rear side downwards.

• Vents (on the right side of the instrument) must not be obstructed.

50 mm or more

50 mm or more

Handling the instrument

HIOKI PW3390A961-06

To avoid electric shock, do not remove the instrument's case. The internal components of the instrument carry high voltages and may become very hot during

operation.

• If the instrument exhibits abnormal operation or display during use, review the information in Troubleshooting section "11.2 Troubleshooting" (p. 223) and Error Indications section "11.3 Error Indication" (p. 226) before contacting your authorized Hioki

distributor or reseller.

• To avoid damage to the instrument, protect it from physical shock when transporting

d handling. Be especially careful to avoid physical shock from dropping.

an

• To move the instrument, first disconnect a

memory, and carry it by the handle.

• Do not apply heavy downward pressure with the stand extended. The stand could

b

e damaged.

See "Using the Handle as a Stand" (p. 17)

• Use a common ground for both the instrument and any devices to be connected.

Using different ground circuits will result in a potential difference between the instrument's ground and the computer's ground. If th

while such a potential difference exists, it may result in equipment malfunction or

failure.

• Before connecting or disconnecting the comm

instrument and any devices to be connected. Failure to do so could result in equipment malfunction or damage.

• After connecting the communications cable, tigh

securely. Failure to secure the connector could result in equipment malfunction or

damage.

9

Usage Notes

ll cables, remove any CF card and USB

e communications cable is connected

unications cable, always turn off the

ten the screws on the connector

This instrument may cause interference if used in residential areas. Such use must be

avoided unless the user takes special measures to reduce electromagnetic emissions

to prevent interference to the reception of radio and television broadcasts.

10

HIOKI PW3390A961-06

Usage Notes

Handling the cords and current sensors

Connect the current sensors or voltage cords to the instrument first, and then to

the active lines to be measured. Observe the following to avoid electric shock

and short circuits.

• Do not allow the voltage cord clips to touch two wires at the same time. Never

ouch the edge of the metal clips.

t

• When the current sensor is opened, do not allow the metal part of the clamp to

ouch any exposed metal, or to short between two lines, and do not use over

t

bare conductors.

• To avoid short circuits and potentially life-threatening hazards, never attach the

urrent sensor to a circuit that operates at more than the maximum rated volt-

c

age to earth (See your current sensor's instruction

ings.)

• Current sensor and voltage cables should only be connected to the secondary

ide of a breaker, so the breaker can prevent an accident if a short circuit

s

occurs. Connections should never be made to the primary side of a breaker,

because unrestricted current flow could cause a serious accident if a short circuit occurs.

• Connect only those voltage cables necessary for measurement.

• To prevent an electric shock accident, confirm that the white or red portion

(insulation layer) inside the cable is not exposed. If a color inside the cable is

exposed, do not use the cable.

manual for its maximum rat-

• In order to use the CT6862 AC/DC Current Sensor, the line to be measured

must be temporarily disconnected.

To avoid shock and short circuits, turn of

before making connections to terminals to be measured and turning on the

instrument.

• To avoid electric shock, do not exceed the lower of the ratings shown on the

trument and test leads.

ins

• To avoid electric shock and short-circuit accidents, use only the specified voltage

cord to connect the instrument input terminals to the circuit to be tested.

• For safety reasons, when taking measurement

Avoid stepping on or pinching cables, which could damage the cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

from

the power outlet.

• Keep the cables well away from heat sources, as

if the insulation melts.

• Be careful to avoid dropping the current sensors or otherwise subjecting them to

m

echanical shock, which could damage the mating surfaces of the core and

adversely affect measurement.

• Be careful when handling the cords, since the conductor being measured may

come very hot.

be

• When disconnecting the connector, be sure to release the

connector. Forcibly pulling the connector without releasing the lock, or pulling on the

cable, can damage the connector.

• To prevent damage to the instrument and current sensors, never connect or disconnect a sensor while the power is on, or wh

ductor.

f the power to lines to be measured

s, only use the optional voltage cord.

bare conductors could be exposed

lock before pulling off the

ile the sensor is clamped around a con-

Before connecting measurement cables

HIOKI PW3390A961-06

• Do not use the instrument with circuits that exceed its ratings or specifications. Doing so may damage the instrument or cause it to become hot, resulting in bodily injury.

• Never exceed a current sensor’s input current rating. Doing so could destroy

e instrument and cause personal injury.

th

• Before turning the instrument on, make sure the source voltage matches that

indicated on the instrument's power connector. Connection to an improper

supply voltage may damage the product and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specifications of this

strument, connect the power cord provided only to an outlet.

in

For safety reasons, disconnect the power cord when the instrument is not used.

11

Usage Notes

Before connecting to the lines to be measured

To avoid electrical hazards and damage to the instrument, do not apply voltage

exceeding the rated maximum to the external input terminals.

• To avoid electrical accidents, confirm that all connections are secure. The

increased resistance of loose connections can lead to overheating and fire.

• Ensure that the input does not exceed the maximum input voltage or current to

oid instrument damage, short-circuiting and electric shock resulting from

av

heat building.

• When the power is turned off, do not apply voltage or current to the voltage input terminals, current input terminals, or current sensors. Doing so may damage the instrument.

• Note that the instrument may be damaged if the applied voltage or current exceeds

th

e measurement range.

While measuring

If an abnormality such as smoke, strange sound or offensive smell occurs, stop

measuring immediately, disconnect from the measurement lines, turn off the

instrument, unplug the power cord from the outlet, and undo any changes to the

wiring. Contact your authorized Hioki distributor or reseller as soon as possible.

Continuing to use the instrument may result in fire or electric shock.

12

HIOKI PW3390A961-06

Usage Notes

13

HIOKI PW3390A961-06

1.1 Product Overview

1

Overview Chapter 1

1.1 Product Overview

The Hioki PW3390 Power Analyzer is a high-precision, broad-range instrument for measuring electrical

power from DC to inverter frequencies. Four input channels are provided to support single- and threephase inverter motor system measurements.

For developing and evaluating high efficiency inverter motors

• High precision and stability ensure highly reproducible power measurements

• Electrical phase angle measurements necessary for motor analysis

• Measure motor efficiency by connecting with

For developing and evaluating alternative energy sources such as solar,

wind power, and fuel cells

a high precision torque meter or encoder.

Chapter 1 Overview

• Simultaneously measure AC and DC power.

• Separately measure power input, sold, consumed, and regenerated using the DC mode and the current and integrated power (electrical energy) in RMS mode.

• Save long-term measurement data t

o high-capacity storage media.

For inverter motor maintenance

• Easily measure inverter secondary power on site.

• Simultaneously measure primary and secondary inverter power.

• Measure inverter noise.

14

-

HIOKI PW3390A961-06

1.2 Features

1.2 Features

Supports multiple power system configurations

• Four isolated voltage and current input channels are provided to support simultaneous multisystem measurements such as inverter primary and secondary power.

• Measure power system wiring configurations from sing

le-phase to three-phase, four-wire.

• Broad frequency range (0.5 Hz to 5 kHz fundament

al) supports DC to inverter frequencies.

High accuracy over a broad range

• Basic accuracy is ±0.04% rdg. ±0.05% f.s.

• Precise measurements over a broad range of inverter

at 10 kHz, and ±1.5% rdg. ±0.5% f.s. at 100 kHz.

at DC and from 0.5 Hz to 200 kHz.

carrier frequencies: ±0.2% rdg. ±0.1% f.s.

Current sensor phase correction function (standard feature)

• This function utilizes virtual oversampling, a new

errors at a resolution of 0.01

power-factor power components contained in inverter output switching frequencies.

°, allowing accurate measurement of the high-frequency, low-

technology, to correct current sensor phase

Provides both fast data processing and high accuracy

• While maintaining high accuracy, power measurements and harmonic analysis updates every

50

ms.

• During low-frequency measurements, data is automatically updated in sync with frequency, so

o refresh (data update rate) switching is needed when changing from low to high rotation

n

rates.

Extensive data analysis functions are included as standard features

• Simultaneously measure RMS, MEAN, AC and DC components, and fundamental waveforms.

th

• Perform harmonic analysis up to the 100

• Display high-speed waveforms samp

• Perform multifaceted analysis with X-Y gr

order and inverter noise (FFT) analysis up to 200 kHz.

led at up to 500 kS/s.

aph functions.

Simultaneous analysis of all parameters

• Simultaneously analyzes harmonics, noise while

and trend graph.

performing integration, displaying waveforms

Supports measurements with both easy-to-use clamp probes and high

precision penetrating probes

• Select from various AC and AC/DC clamp-on current probes with ranges from 20 A to 1000 A.

• Measure high currents with high precision using clamp-on current sensor probes.

• Clamp-on current probes eliminate the need for problematic direct contact with wiring.

• In-phase effects on inverter measurements are g

from the measurement objects.

reatly reduced by isolating current sensors

15

HIOKI PW3390A961-06

1.2 Features

Single-unit instrument ideal for portable as well as rack-mount applications

1

• Small and light weight (approx. 4.6 kg), with a convenient carrying handle (p. 17).

• Rack mountable in 170 mm (EIA 4U) vertical space.

Variety of interfaces are equipped in standard

• Includes 100 Mbps Ethernet and USB 2.0 Hi

• Supports high-speed data communication systems.

• Provides a dedicated front-panel USB port and CF car

• Supports high-capacity media for high-speed data storage.

gh Speed communications interfaces.

d slot for removable storage devices.

PC application program provides remote control and data acquisition (p. 181)

• With the instrument connected to a computer by

application program to acquire data on the computer and control the instrument remotely.

Download the PC application program from Hioki's website. (https://www.hioki.com)

• Even without the PC application p

browser to access the HTTP server function.

rogram, the same operations can be performed using a

LAN, USB cable, or RS-232C, use the PC

Wiring confirmation function avoids wiring mistakes (p. 46)

• The vector display avoids wiring mistakes by con

firming even complicated three-phase wiring.

Chapter 1 Overview

Multi-instrument synchronization capability supports additional

measurement channels (p. 159)

• Measure with up to 8 instruments simultaneously.

• Secondary (slave) instruments measure and record data in synchronization with the primary

ster) instrument.

(ma

• Using the PC application program, synchronously acquire and record data on up to 8 instruments.

Prepared for motor evaluation options (p. 176)

• Motor power can be determined by measuring torque meter output and rotation rate.

• Supports both analog DC and frequency-output-type torque measurement inputs.

• Supports both analog DC and rotation pulse outputs for measurement inputs.

• Supports encoder Z-phase signals for phase me

asurements with standard encoder pulses.

D/A output option for waveform output (p. 166)

• Outputs up to 16 analog measurement parameters on 16 D/A output channels.

• Voltage and current waveforms sampled at 500 kHz in the waveform output mode provide

sa

fely isolated voltage and current waveforms for other waveform measuring instruments.

Easy-to-see color LCD (p. 17)

• Includes a 9-inch color TFT LCD.

• Easily view waveforms and graphs on the wide-screen 800 ×

480 dot display.

16

HIOKI PW3390A961-06

1.3 Operating Overview

1.3 Operating Overview

Be sure to read "Usage Notes" (p. 8) before measuring.

Follow the procedures below to perform measurements. Data saving and analysis on the computer can

be performed as necessary.

Initial Instrument Preparations

See 3.2 ( p.28)

Pre-Operation Inspection

See 3.3 ( p.30)

Installing the Instrument

See "Instrument installation" (p. 8)

Connecting Cables and Probes, and

Turning Power On

See 3.4 ( p.31) to 3.8 ( p.36)

Configuring wiring settings and sensor

settings, and checking the wiring

See 3.9 ( p.37) to 3.12 ( p.46)

Viewing Measurement Values

See Chapter 4 ( p.47)

Saving

Always perform these checks before connecting, and when turning the power on.

For high-precision measurements, allow at least

30 minutes warm-up after power-on before executing zero adjustment.

Configure current sensor phase correction to

facilitate more precise measurement.

Always execute zero adjustment before connecting to measurement objects.

Press the key, and select display contents

with the and F keys.

See "2.2 Basic Operations" (p. 20)

Manual saving

Press the .

See Chapter 7 ( p.135)

Save in realtimecontrol

After pressing

saving starts at the specified start time.

Stops automatically at the

specified stop time.

Press the key to

force stop.

Analyzing Saved Data on a Computer

See Chapter 9 ( p.181)

Turning Power Off

See 3.8 ( p.36)

Save timer control

Press to save

for a specified time

span.

Stops automatically

when the specified time

has elapsed.

Press the key to

force stop.

Connect the instrument to a computer with the supplied USB cable or an Ethernet cable and use the

dedicated PC application program to transfer data to

the computer for analysis. This also enables remote

operation and control of the instrument.

Save interval control

Press to start.

Save the specified time span.

Press to stop.

When the timer and real-time

control are set, stops at the

specified time.

2.1 Names and Functions of Parts

HIOKI PW3390A961-06

Names and Functions of Parts,

Basic Operations

& Screens Chapter 2

2.1 Names and Functions of Parts

17

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

Front

USB memory interface

Connect a USB flash drive storage device.

See p. 135

Display

Displays the Measurement,

Setting, or File Operation

screen.

See p. 21

Handle

Use to carry the instrument, and fold it down to serve as a stand.

See Bottom part of this page

Operation keys

See p. 18

CF card interface

Insert a CF card.

See p. 136

Using the Handle as a Stand

12

F key (Function key)

Select and change display contents and settings.

See p. 20

Press Press

Power switch

Turns the instrument on

and off.

See p. 36

Rotate the handle

to the click point.

Keep on

pressing

18

HIOKI PW3390A961-06

2.1 Names and Functions of Parts

Operation keys

MENU keys (Screen selection)

Press a key to select a screen (the lit key indicates the current selection).

Displays the Measurement screen for viewing measurement values. Voltage and current ranges can be selected, and low-pass filter settings can be changed.

Displays the Setting screen for setting measurement criteria, wiring mode (phase systems), wiring check and system environment configuration.

Displays the File Operation screen for performing file operations on data saved to

storage media, and selecting data file formats.

(p. 25)

(p. 23)

(p. 24)

PAGE keys

• Changes the screen page.

• Allows you to configure

averaging (p. 112).

RANGE keys

•The U + and – keys change

the voltage measurement

range, and the I + and –

keys change the current

measurement range.

• Pressing the AUTO key

activates Auto Ranging (p.

54).

• These keys also set the low-

pass filter (p. 64) and the

lower measurement limit setting (p. 60).

ENTER key

Accepts selections and

changes to settings.

CURSOR keys

Move the cursors.

SHIFT key

(Lit when running)

Activates alternate key functions.

0 ADJ key

Performs zero adjustment and

current sensor degaussing.

See 3.11 (p.44)

SAVE key

Saves data to the storage

media.

See 7.5.2 (p.143)

(Screen Capture)

Press the SAVE key while

holding the SHIFT key to capture a screen image to the

specified storage media.

(p. 149)

HOLD key

(Lit when running)

Toggles the peak-hold function.

See 5.3 (p.114)

ESC key

Cancels the last change to a

setting, and returns it to its

original state.

(Key-lock)

Hold for three seconds to

toggle the key lock. The key

lock state is indicated at the

top of the screen (p. 21).

DATA RESET key

Resets the integration values.

See 4.3.1 (p.65)

START/STOP key

(Lit when running)

Starts and stops integration and saving operations.

To restart integration and saving: Press the DATA

RESET key to reset integration values, then press

this key. (Press the START/STOP key without reset-

ting the integrated value if you wish to add the integration result to the previous one.)

• When the key lock function is enabled, all other key operations are disabled.

• The key lock state is retained even when power is off.

Right side

HIOKI PW3390A961-06

Ethernet interface jack

For LAN connection with an

Ethernet cable.

See p. 184

Sync interface

For synchronizing cables, as

needed.

See p. 159

19

2.1 Names and Functions of Parts

Vent

Keep clear of obstructions.

See p. 8

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

USB port

For the supplied USB cable,

as needed.

See p. 188

Rear side

Power inlet

Connect the supplied power

cord.

See p. 31,

"Usage Notes" (p. 8)

Voltage input terminals

Connect Hioki-specified voltage

measurement cables.

See p. 32,

"Usage Notes" (p. 8)

RS-232C interface

For RS-232C cable connection, as needed.

See p. 189

CH A torque signal input BNC jack

Connect the Hioki L9217 BNC connection cable to

this terminal (PW3390-03 [model with motor analysis and D/A output] only).

See p. 176,

"Usage Notes" (p. 8)

Functional ground terminal

Connect this terminal to a clean

common ground to suppress electrical noise when measuring in an

electrically noisy environment.

See p. 31

* The serial number consists of 9 digits. The first two (from the left) indicate the year of manufacture, and the next two

Output terminal

Connect the supplied D-sub plug (PW3390-02

Serial No.

This is the instrument’s serial

number.

*

[model with D/A output] and PW3390-03 [model with motor analysis and D/A output] only).

See p. 166

CH B and CH Z rotation signal

input BNC jacks

Current input terminals

Connect an Hioki-specified current sensor.

See p. 32,

"Usage Notes" (p. 8)

indicate the month of manufacture. Required for product control. Do not peel off the label.

Connect the Hioki L9217 Connection

Cord to these terminals (PW3390-03 [model with motor analysis and D/A output] only).

See p. 176,

"Usage Notes" (p. 8)

20

HIOKI PW3390A961-06

2.2 Basic Operations

2.2 Basic Operations

To select a display screen

Press , , or to display the corresponding screen.

See p. 23 to p. 25

To select the displayed screen page

Press the keys to change.

See p. 23, p. 25

Help comment

Describes the object at the current

cursor position (only on Setting and

File Operations screens).

To select and change display contents and settings

Press one of the F keys to select and change display contents and settings. The displayed function labels depend on

the currently displayed screen.

Special Setting Items

All CH Set Select to apply the same setting to all channels.

This appears when more than six setting

Next

items are available. Press F6 to display the

function labels of the additional items.

Using [All CH Set]

(For example, to enable auto-ranging on all channels.)

CH1 CH2 CH3 CH4

All channels are set to

Set any channel to

1

[AUTO].

3

[AUTO].

Select [All CH Set]

2

2.3 Display Items and Screen Types

HIOKI PW3390A961-06

2.3 Display Items and Screen Types

21

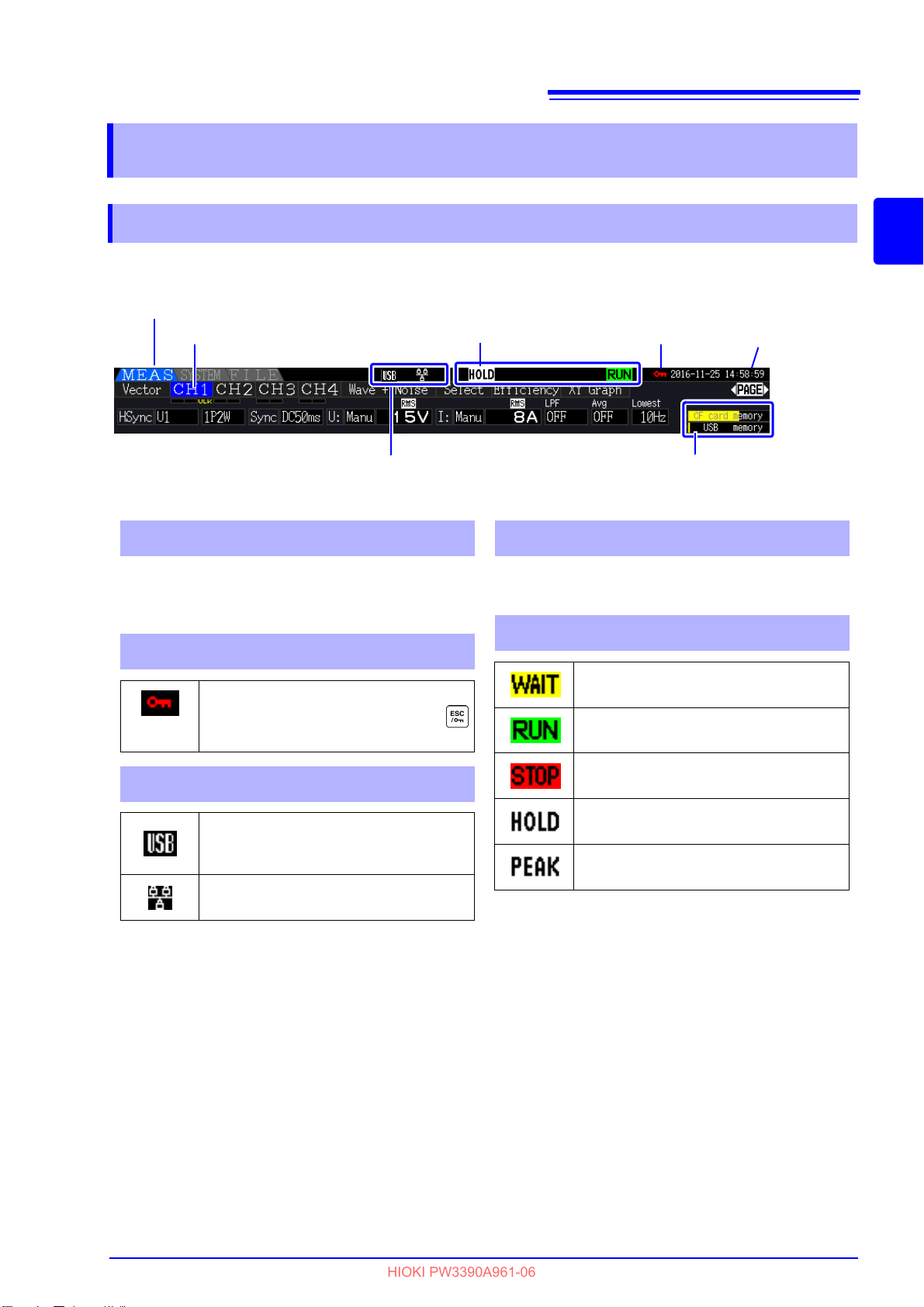

2.3.1 Common Display Items

These items are displayed on every screen.

Displayed Screen

Displayed Page

Operating State Indicators

Interface Indicators

3

1 Storage Media Indicators

Level indicators for the CF card and USB memory

stick. The used storage space is indicated in yellow, and it turns to red when the media is 95% full.

2 Key-Lock Indicator

Lights to indicate Key Lock is active

(keys are locked), after holding the

key for three seconds.

Key-Lock Indicator

2

1

45

Storage Media

Indicators

4 Time Display

Displays the current date and time.

To set the Clock: (p. 131)

5 Operating State Indicators

Indicates that the instrument is in the

integration standby state.

Indicates integration is in progress.

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

Time Display

3 Interface Indicators

Lights when the instrument is connected to a computer by USB cable

(and the computer is on).

Lights when the instrument is connected to a LAN.

Indicates integration is stopped.

Indicates Data Hold is active.

Indicates Peak Hold is active.

22

HIOKI PW3390A961-06

2.3 Display Items and Screen Types

2.3.2 Measurement Screen

These display items appear only on the Measurement screen.

∆-Y Transform

9

Harmonic sync

8

source

Sync source

7

Low-pass filter

4

Wiring mode

2

Peak Over display indicators

1

Sync Unlocked

Current peak over range

Voltage peak over range

Voltage range

3

1 Peak Over display indicators

These indicators appear in red at the bottom of

each channel page tab (CH1 to CH4). These indicate (from the left) when voltage and current peaks

ranges are exceeded (p. 50), and when synchronization is unlocked (p. 59).

2 Wiring mode

Indicates the selected wiring mode (p. 37). The wiring mode (phase system selection) must be set to

match actual measurement connections.

3 Voltage range/Current range

• Indicate the voltage and current range settings.

• The settings are made by the RANGE keys (p. 54).

• When the range has been set manually, [MANU]

appears.

• When the auto-ranging is enabled, [AUTO]

appears (p. 53).

4 Low-pass filter

Indicates the low-pass filter setting (p. 64).

To change the setting, hold the key while

pressing an

LPF key (one of the left-most or

RANGE keys).

Current range

3

5

Average

Lower

6

measurement limit

5

Average

Indicates the averaging setting state (p. 112).

To change the setting, hold the key while

pressing the

PAGE key.

AVG key either or of the

6 Lower measurement limit

Displays the lower measurement limit setting (p. 60).

To change the setting, hold the key while

pressing a

LOW FREQ key (one of the right-most

or

RANGE keys).

7 Sync source

Indicates the synchronization source signal that

determines the period (between zero crossings)

used as the basis for all calculations (p. 58). The setting is made on the Input Settings page of the Settings screen.

8 Harmonic sync source

Indicates the synchronization signal source used for

harmonic measurements (p. 79). The setting is made

on the Input Settings page of the Settings screen.

9 ∆-Y Transform

Indicates whether ∆-Y transform is enabled or disabled (ON/OFF)(p. 118). The setting is made on the

Input Settings page of the Settings screen.

2.3.3 Screen Types

HIOKI PW3390A961-06

23

2.3 Display Items and Screen Types

Measurement Screen (Press the key to display)

Press the keys to change the screen page as follows.

[Vector]

This page displays measured harmonic voltage,

harmonic current, and harmonic power on channels

1 to 4 as numerical values and as vectors.

[Motor]

Displayed only on

the PW3390-03

(model with motor

analysis and D/A

output).

This page displays measured power, voltage and current

values, integration values, and provides access to

harmonic graphs and lists for each channel.

This screen displays measurement values.

[CH1 to CH4]

[Wave + Noise]

2

Chapter 2 Names and Functions of Parts, Basic Operations & Screens

This page displays measured values for the

motor analysis.

[Trend]

This page displays measurement item fluctuations.

[XY Graph]

This page displays voltage, current, and noise

waveforms. The data can be saved.

[Select]

Select any parameter on this page for display.

[Efficiency]

This page displays an X-Y graph of measurement

parameters selected for horizontal and vertical axes.

This page displays the numerical values of efficiency

and loss determined by calculation formulas.

Loading...

Loading...