Hioki PW3360-20, PW3360-21 Instruction Manual

Instruction Manual

PW3360-20

PW3360-21

CLAMP ON POWER LOGGER

May 2014 Revised edition 3 PW3360A981-03 14-05H

Contents

Contents

i

1

Introduction ..............................................................................1

Confirming Package Contents................................................2

Safety Information....................................................................4

Operating Precautions.............................................................7

Measurement Flowchart ..........................................................9

Chapter 1

Overview__________________________________11

1.1 Product Overview ....................................................11

1.2 Features ....................................................................12

1.3 Names and Functions of Parts ...............................14

1.4 Screen Configuration ..............................................17

1.5 On-Screen Indicators ..............................................19

Chapter 2

Measurement Preparations___________________ 21

2.1 Preparation Flowchart ................... ..........................21

2.2 Preparing to Use the Instrument after Purchase ..22

Bundle the Voltage Cord Leads with the Spiral Tubes .....22

Wrapping Color-coded Spiral Tubes around Clamp

Sensors and Grouping Together Cables ..........................23

Installing (replacing) the Battery Pack ..............................24

Storing the Instrument in the C1005 Carrying Case

(Option) ............................................................................27

Setting the Language and Measurement Line Frequency

(50/60 Hz) ........................................................................28

2.3 Pre-Operation Inspection ........................................29

2.4 Inserting (Removing) an SD Memory Card ...........30

2.5 Supplying the Power ...............................................33

Connecting the AC Adapter .............................................33

Supplying Power from Measurement Lines

(Using the PW9003 Voltage Line Power Adapter) ...........35

2.6 Turning the Power On/Off .......................................38

2

ii

Contents

Chapter 3

Connecting to Lines to be Measured ___________41

3.1 Connection Procedure .......... .. ............................... 42

3.2 Setting Measurement Conditions on the Wiring

Diagram Screen ...................................................... 43

3.3 Connecting the Voltage Cords ............ ... .. ... ... .. ..... 47

3.4 Connecting a Clamp Sensors ................................ 49

3.5 Connecting the Voltage Cords to Lines to be

Measured ................................................................. 51

3.6 Connecting Clamp Sensors to Lines to be

Measured ................................................................. 52

Load Current Measurement .............................................52

Leakage Current Measurement ................................... ....53

3.7 Setting the Current Range ..................................... 54

3.8 Verifying Correct Wiring (Wiring Check) .............. 56

Chapter 4

Changing Settings __________________________61

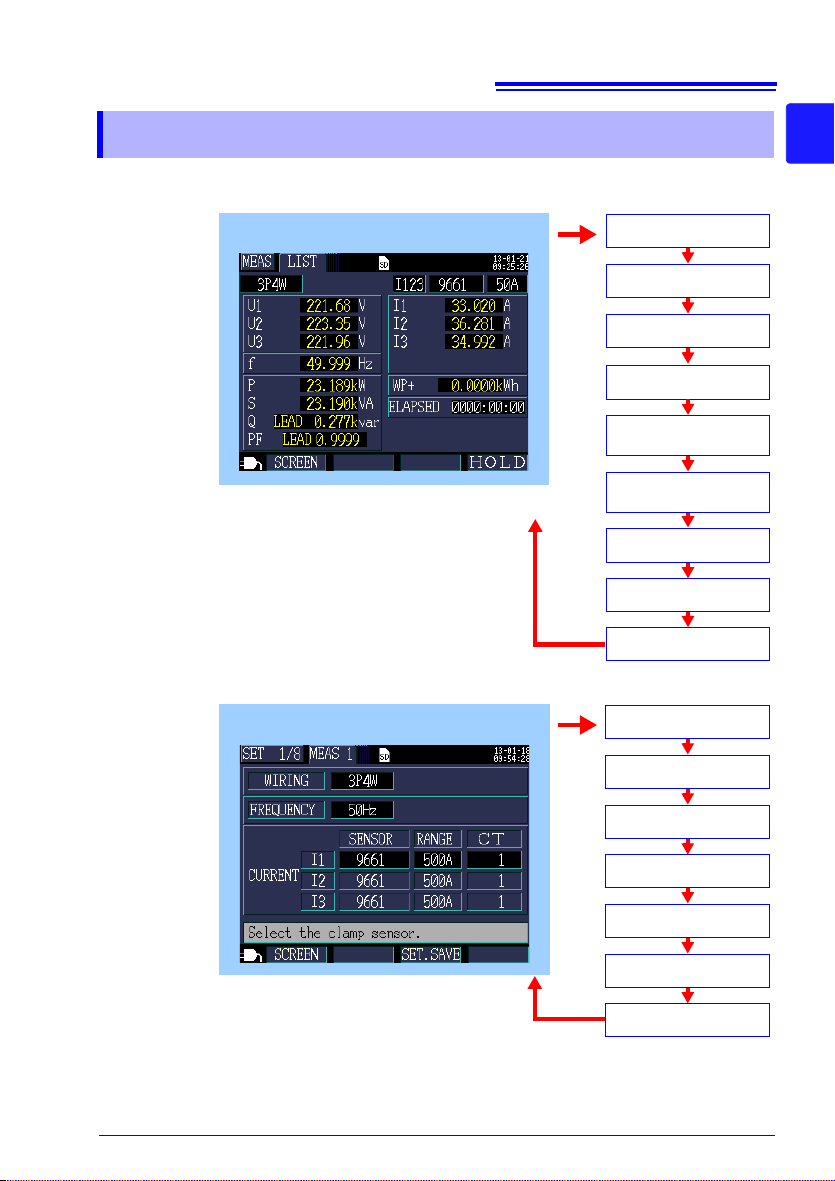

4.1 Viewing and Using the Settings Screen ............... 62

4.2 Changing Measurement Settings .......................... 63

Measurement 1 Setting Screen .......................................63

Measurement 2 Setting Screen .......................................65

4.3 Changing Recording (Save) Settings ................... 69

Recording 1 Setting Screen .............................................69

Recording 2 Setting Screen .............................................74

4.4 Changing System Settings (as Necessary) .......... 77

System 1 Setting Screen .................................................77

System 2 Setting Screen .................................................79

4.5 Initializing the Instrument (System Reset) ........... 80

Reverting the Instrument to Its Factory Settings

(Factory Reset) ................................................................81

4.6 Factory Settings ...................................................... 82

Chapter 5

Viewing Measurement Data __________________ 83

5.1 Viewing and Using the Measurement Screen .......83

1P2W x 2 or 1P2W x 3 Wiring ..........................................84

5.2 List of Measurement Screens .................................85

5.3 Viewing Data (Voltage, Current, Power, and Energy)

as a List ....................................................................86

5.4 Viewing Voltage and Current Value Details

(RMS Values, Fundamental Wave Values, Peak

Values, and Phase Angles) .....................................87

5.5 Viewing Power Details (Channel Power Values) ..88

5.6 Viewing Energy

(Active Energy and Reactive Energy) ....................89

5.7 Viewing a Demand Graph .......................................90

5.8 Viewing a Harmonic Graph (PW3360-21 only) ......91

5.9 Viewing a Harmonic List (PW3360-21 only) ..........93

5.10 Viewing Waveforms .................................................95

Changing the Zoom Factor for the Vertical Axis Used to

Display Voltage and Current Waveforms .........................96

5.11 Enlarging Measured Values on the Display ..........97

5.12 Viewing a Trend Graph ...........................................98

iii

Contents

3

4

5

6

Chapter 6

Starting and Stopping Recording and

Measurement _____________________________101

6.1 Starting Recording ................................................102

Starting Recording Manually ..........................................102

Staring Recording by Specifying a Time ........................103

Starting Recording at a Good Time Division

(Interval Time) ................................................................104

6.2 Stopping Recording ..............................................105

Stopping Recording Manually ........................................105

Stopping Recording by Specifying a Time .....................105

6.3 Using Repeat Recording .......................................106

6.4 Operation When a Power Outage Occurs While

Recording .......................... .......................... ........... 108

iv

Contents

Chapter 7

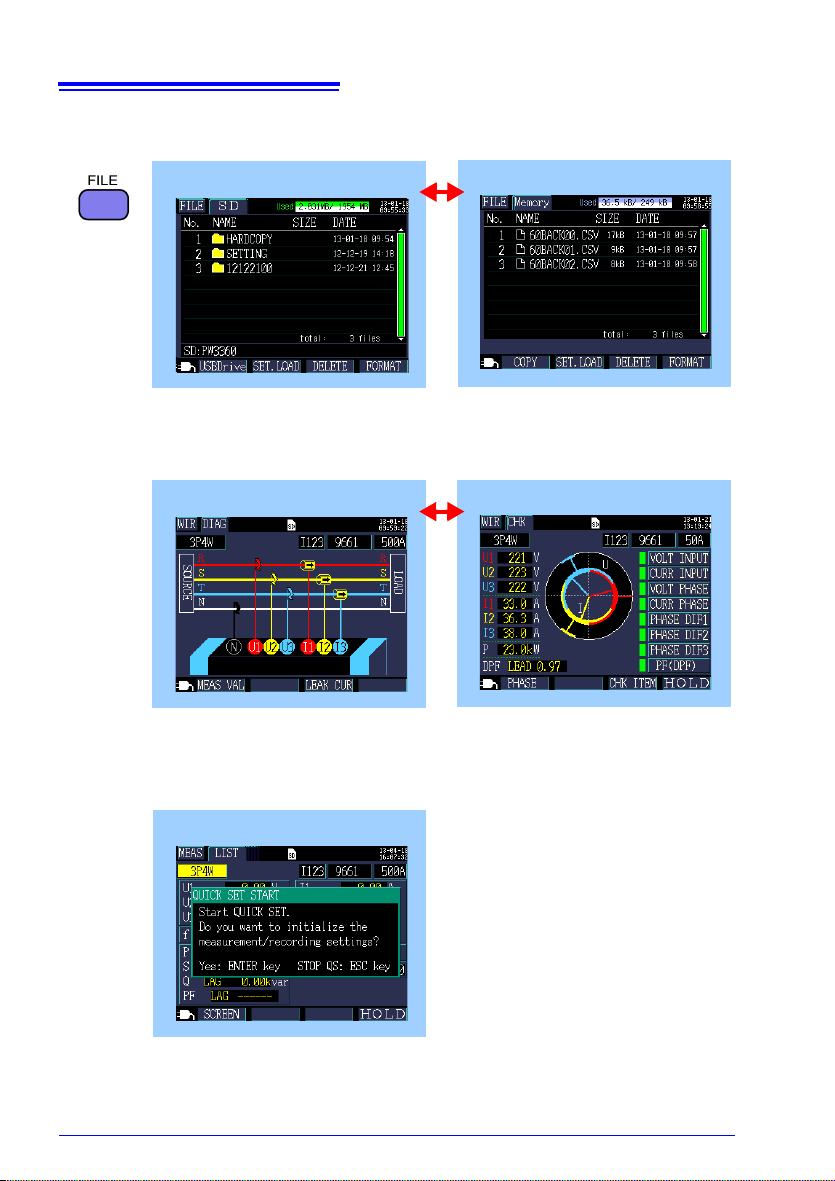

Quick Set_________________________________109

7.1 Settings Configured with the Quick Set ........ .. ... 109

7.2 Settings That Can Be Added to Quick Set

Settings ........................... ............. .......... ............. ... 110

Chapter 8

Saving Data and Manipulating Files __________113

8.1 Viewing and Using the File Screen ..................... 114

8.2 Folder and File Structure ..................................... 116

SD Memory Card ...........................................................116

Internal Memory .............................................................120

8.3 Saving Copies of the Screen

(SD Memory Card Only) ....................................... 121

8.4 Saving Settings Files ............................................ 122

8.5 Loading Settings Files .................................... ..... 123

SD Memory Card ...........................................................123

Internal Memory .............................................................124

8.6 Copying Internal Memory Files to the SD

Memory Card .......................... ............................... 125

8.7 Deleting Folders and Files ................................... 126

8.8 Formatting the SD Memory Card or Internal

Memory ............................. ..................................... 127

Chapter 9

Analyzing Data on a Computer_______________129

9.1 Copying Data to a Computer (SD) ....................... 130

9.2 SF1001 Power Logger Viewer (Optional) ............ 132

9.3 Checking Recording and Measurement Data

with Excel .............................................................. 134

Opening recording and measurement data ...................134

Saving Data as an Excel File .........................................135

Example of Data from a Measurement File ...................136

Measurement File Contents ...........................................136

Converting Measured Value Exponential Data ..............144

Contents

Appendix

v

9.4 Using the PW3360/PW3365 Auto Excel Graph

Creation Application ..................................... .. ... ...145

Chapter 10Using Communications (USB/LAN)__ 147

10.1 Copying Data to a Computer (USB) .....................148

10.2 Installing the USB Driver on a Computer ............150

10.3 Installing the PW3360/PW3365 Settings and

Download Application (USB/LAN) .......................150

10.4 Using the PW3360/PW3365 Settings and

Download Application (USB) ................................151

Initiating USB Communications between the PW3360

and a Computer .............................................................151

Disconnecting the USB connection from the Computer .154

10.5 LAN Communications ...........................................155

Configure the Instruments LAN Settings ........................156

Connecting the Instrument and Computer with a

LAN Cable ......................................................................158

10.6 Using the PW3360/PW3365 Settings and

Download Application (LAN) ................................161

Initiating LAN Communications between the PW3360

and a Computer .............................................................161

Disconnecting the LAN connection from the Computer .16 2

10.7 Remote Control of the Instrument by Internet

Browser ..................................................................163

Operating the Instrument Remotely ...............................165

Setting a Password ........................................................166

If You Forget Your Password .........................................166

Chapter 11

Using Pulse Input and Output _______________ 167

11.1 Connecting Wires to the Pulse I/O Terminals .....168

11.2 Configuring Pulse Settings ..................................169

11.3 Inputting a Pulse Signal ........................... .. ...........170

Signal Input Method .......................................................170

11.4 Outputting a Pulse Signal .......................... ... .. ......172

Index

7

8

9

10

11

12

13

vi

Contents

Chapter 12

Specifications_____________________________175

12.1 General Specifications ......................................... 175

12.2 Basic Specifications ............................................. 178

12.3 Detailed Measurement Specifications ................ 182

12.4 Functional Specifications .................................... 190

12.5 Calculation Formulas . ... ....................................... 201

12.6 Range Configuration and Accuracy by Clamp

Sensor ............................. .......... ........... ....... ........... 210

When the 9660, 9661, or 9695-03 is Used ....................211

When the 9669 is Used ..................................................211

When the 9694 or 9695-02 is used (CAT III, 300 V) ......212

When the CT9667 is Used .............................................212

12.7 Model PW9003 Voltage Line Power Adapter ...... 213

Chapter 13

Maintenance and Service ___________________215

13.1 Trouble Shooting .................................................. 215

Before Having the Instrument Repaired .........................217

13.2 Cleaning .......................... .......... ........... .......... ........ 219

13.3 Error Indication ................................ ... .................. 219

13.4 Disposing of the Instrument ................................ 224

Appendix____________________________________A1

Appendix1 How the Instrument Samples Data.................A1

Appendix2 Three-phase 3-wire Measurement..................A2

Appendix3 Method for Calculating Active Power

Accuracy...........................................................A5

Appendix4 Terminology .....................................................A6

Index___________________________________Index 1

Introduction

Thank you for purchasing the HIOKI Model PW3360 Clamp on

Power Logger.To obtain maximum performance from the instrument, please read this manual first, and keep it handy for future reference.

Registered trademarks

• Microsoft and Windows are either registered trademarks or

trademarks of Microsoft Corporation in the United States and

other countries.

• Microsoft and Excel are either regi

marks of Microsoft Corporation in the United States and other

countries.

•

The SD logo is a trademark of SD-3C, LLC.

Model Numbers

In this Instruction Manual, “PW3360” is used as the instrument

model.

1

Introduction

stered trademarks or trade-

Model No.

PW3360-10 Not available

PW3360-11 Available

PW3360-20 Not available

PW3360-21 Available

PW3360-30 Not available

PW3360-31 Available

Harmonic measurement

function

Operation panel

Japanese

English

Chinese

2

Confirming Package Contents

Confirming Package Contents

• When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel keys, and

connectors. If damage is evident, or if it fails to operate according to the specifications, contact your authorized Hioki dist

ributor or re

• Use the original packing materials when transporting the instrument, if possible.

Check that the package contents are correct.

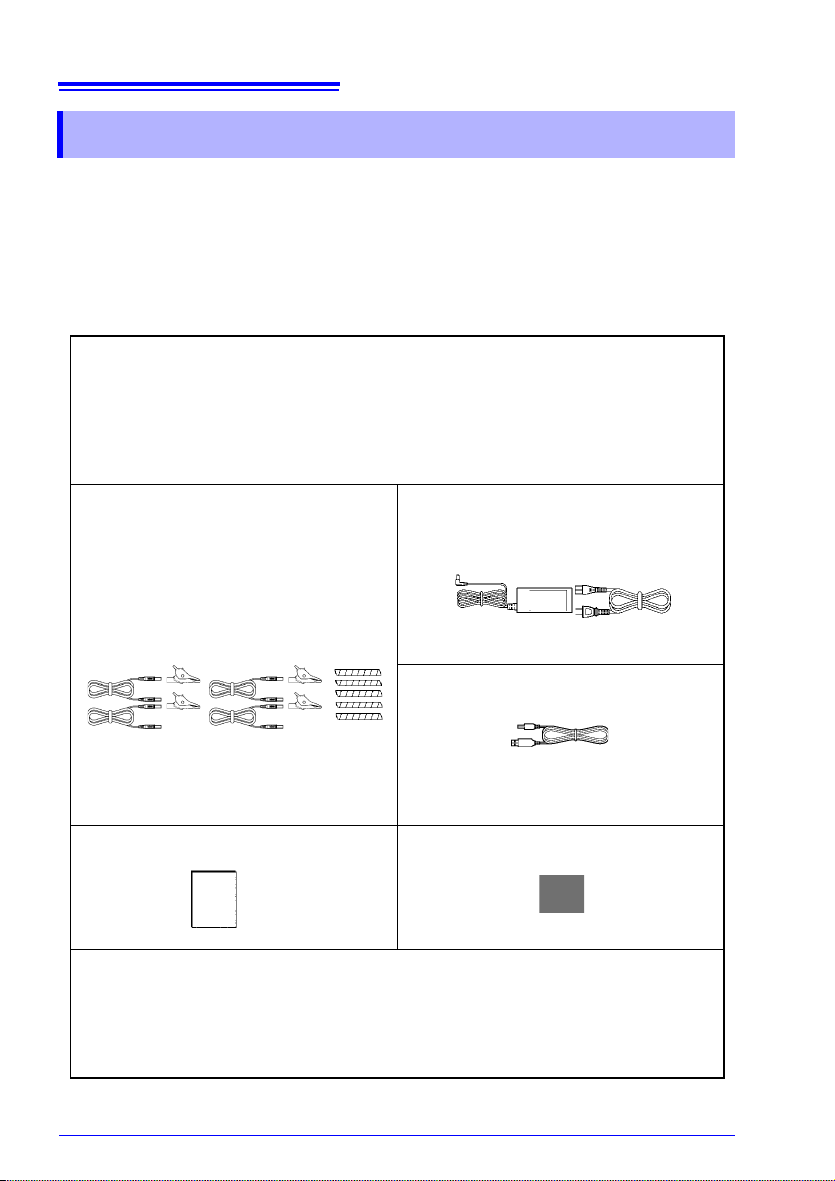

Model PW3360 Clamp on Power Logger ................1

seller.

Model L9438-53 Voltage Cord

..............................................1 Set

Alligator Clip.........................4

(red, yellow, blue, and black /one each)

Banana - banana leads........ 4

(red, yellow, blue, and black /one each)

Spiral tubes..........................

(for band

See: "Bundle the Voltage Cord Leads with

ing the cords)

the S

piral Tubes" (p. 22)

3.3, "Connecting the Voltage Cords" (p.

47)

Instruction Manual

5

.......... 1 Measurement Guide....... 1

Model Z1006 AC Adapter

(includes power cord)......1

USB Cable

......................1

Spiral Tubes for the clamp sensors ......................................... 1 set

For color-coding purposes (red, yellow, and blue/2 each)

For banding the cords (Black)

See: "Wrapping Color-coded Spiral Tubes around Clamp Sensors and Grouping Together

Cables" (p. 23)

........................................................5

.............6

3

Confirming Package Contents

Options

The following options are provided for the PW3360. For purchase, contact your

authorized Hioki distributor or reseller.

For current measurement

Model 9660 Clamp on Sensor (100 Arms rated)

Model 9661 Clamp on Sensor (500 Arms rated)

Model 9669 Clamp on Sensor (1000 Arms rated)

Model 9694 Clamp on Sensor (5 Arms rated)

Model 9695-02 Clamp on Sensor (50 Arms rated)

Model 9695-03 Clamp on Sensor (100 Arms rated)

Model 9219 Connection Cable (For use with Model 9695-02/9695-03)

Model CT9667 Flexible Clamp on Sensor (5000 A rms rated)

Model 9657-10 Clamp on Leak Sensor

Model 9675 Clamp on Leak Sensor

Model 9290-10 Clamp on Adapter

For voltage measurement

Model 9804-01 Magnet Adapter (Red 1, for changing the voltage cord tips)

Model 9804-02 Magnet Adapter (Black 1, for changing the voltage cord tips)

Power supply

Model PW9003 Voltage Line Power Adapter

(for supplying power from measurement lines)

Model PW9002 Battery Set (The 9459 Battery Pack and battery case set)

Model 9459 Battery Pack

(for replacing the 9459 Battery Pack that comes with PW9002)

Model Z1006 AC Adapter

Media for recording

Model Z4001 SD Memory Card 2GB

For communications

Model 9642 LAN Cable

Software

Model SF1001 Power Logger Viewer

Carrying case

Model C1005 Carrying Case

4

Safety Information

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards, and has

been thoroughly tested for safety prior to shipment. However, mishand ling during

use could result in injury or death, as well as damage to the instrument. Using the

instrument in a way not described in this manual may negate the provided safety

features.

Before using the instrument, be certain to carefully read the following safety notes.

Mishandling during use could result in injury or death, as well

as damage to the instrument. Be certain that you understand

the instructions and precautions in the manual before use.

With regard to the electricity supply, there are risks of electric

shock, heat generation, fire, and arc discharge due to short

circuits. If persons unfamiliar with electricity measuring

instruments are to use the product, another person familiar

with such instruments must supervise operations.

This manual contains information and warnings essential for saf

instrument and for maintaining it in safe operating condition. Before using the instrument, be certain to carefully read the following safety notes.

e operation of the

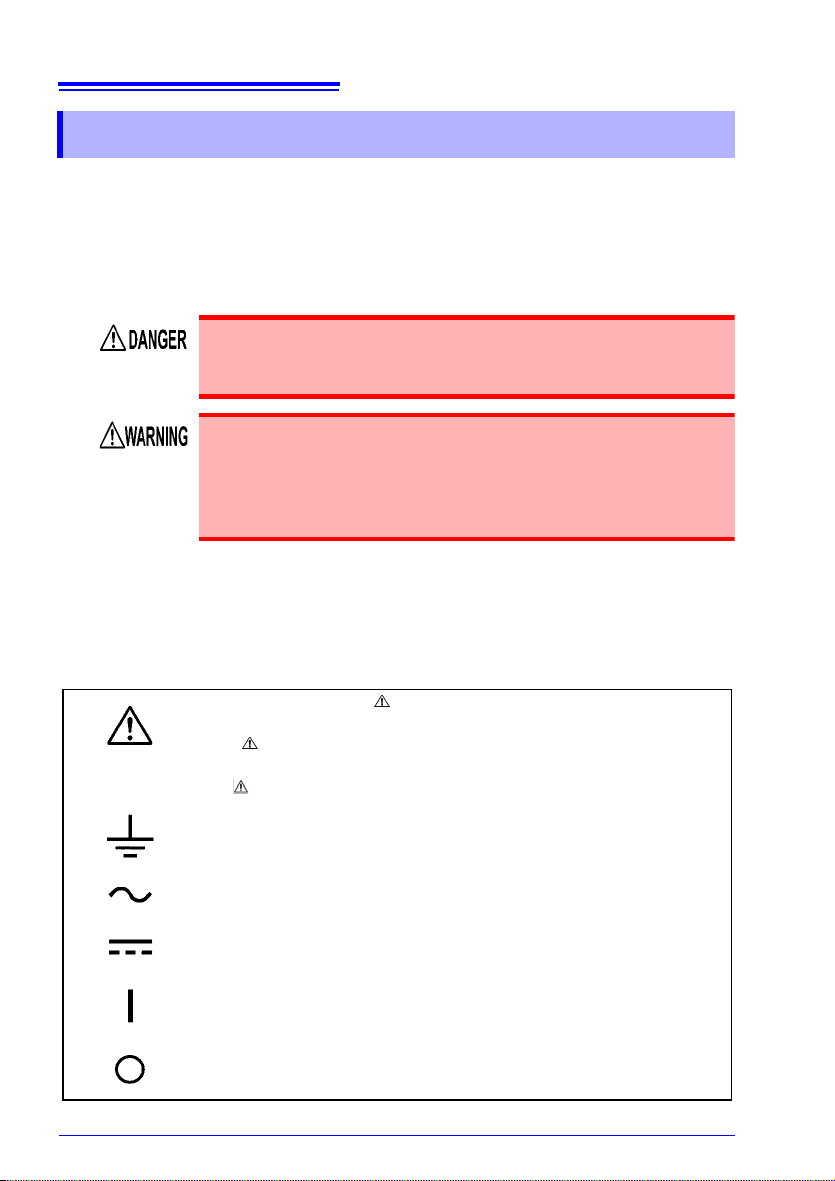

Symbols on the instrument

In the manual, the symbol indicates particularly important

information that the user should read before using the instrument.

The symbol printed on the instrument indicates that the user

should refer to a corresponding topic in the manual

the symbol) before using the relevant function.

Indicates a grounding terminal.

Indicates AC (Alternating Current).

Indicates DC (Direct Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

(marked with

5

Ni-MH

Safety Information

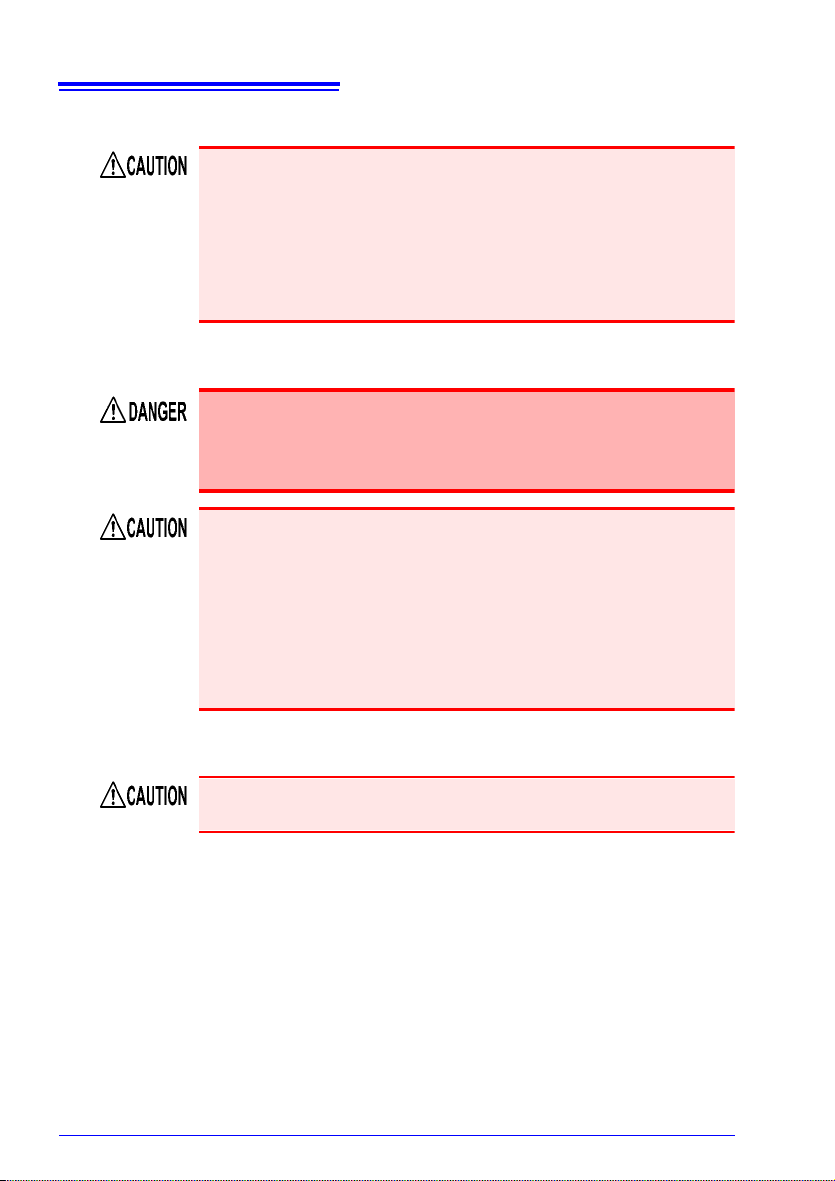

Notation

The following symbols in this manual indicate the relative importance of cautions

and warnings.

Indicates that incorrect operation presents an extreme hazard

that could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard

that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury

to the user or damage to the instrument.

Indicates advisory items related to performance or correct operation of the instrument.

(p.)

*

Windows

[ ]

Dialog

Indicates the location of reference information.

Indicates the prohibited action.

Indicates that descriptive information is provided below.

Unless otherwise specified, “Windows” represents Windows XP,

Windows Vista (32bit), or Windows 7 (32bit/64bit).

Names of settings, buttons, and other screen elements are

enclosed in brackets.

Dialog box represents a Windows dialog box.

Symbols for various standards

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU market after August 13, 2005, and producers of the Member States are requ

appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

This is a recycle mark establis

cling Promotion Law (only for Japan).

ired to display it on the

hed under the Resource Recy-

This symbol indicates that the product conforms to regulatio ns

t by the EC Directive.

set ou

6

Safety Information

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and

dgt. (digit) values, with the following meanings:

f.s.

rdg.

dgt.

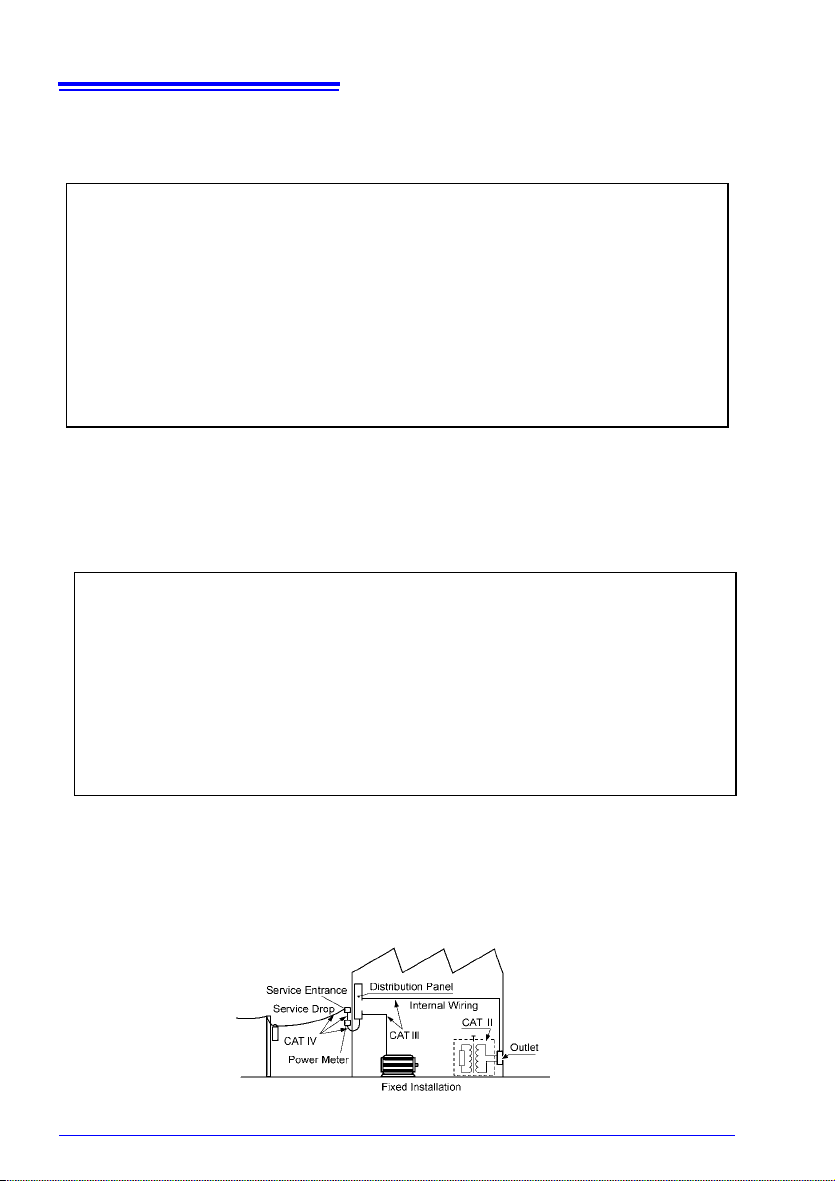

Measurement categories

This device complies with CAT III (600 V)/ IV (300 V) safety requirements.

To ensure safe operation of measuremen t roducts, IEC 61010 establishes safety

standards for various electrical environments, categorized as CAT II to CAT IV, and

called measurement categories.

CAT II

CAT III

CAT IV

(maximum display value or scale length)

The maximum displayable value or scal

name of the currently selected range.

(reading or displayed value)

The value currently being measured and indicated on the me asuring

instrument.

(resolution)

The smallest displayable unit on a digi

the input value that causes the digital display to show a "1" as the

least-significant digit.

Primary electrical circuits in equipment connected to an AC electrical

outlet by a power cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

Primary electrical circuits of heavy equipment (fixed installations)

connected directly to the distribution panel, and feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution

panel).

e length. This is usually the

tal measuring instrument, i.e.,

Using a measurement device in an environment designated with a higher-numbered

category than that for which the device is rated could result in a severe accident, and

must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV measurement applications could result in a severe accident, and must be carefully

avoided.

7

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of

the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to

ensure that no damage occurred during storage or shipping. If you find any damage,

contact your authorized Hioki distributor or reseller.

Before using the instrument, verify that damage to any of the

voltage cords’ insulation has not revealed the white (insulator) part of the cord or its metallic conductor. Cord damage

may result in electric shock. Replace with part number L9438-

53.

Instrument Installation

Storage temperature and humidity range

-20°C to 60°C (-4°F to 140°F), 80%RH or less (non-condensating)

If the instrument will not be used for an extended period, remove the battery pack

and store at a temperature from -20°C to 30°C (-4°F to 86°F).

Operating temperature and humidity range

-10°C to 50°C (14°F to 122°F), 80%RH or less (non-condensating)

When operating on battery power: 0°C to 40°C (32°F to 104°F)

When charging the battery: 10°C to 40°C (50°F to 104°F)

When sending or receiving data over a LAN: 0°C to 50°C (32°F to 122°F)

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil,

other chemica

ventsExposed to high

humidity or con

Exposed to high levels of

rticulate dust

pa

Subject to vibration

ls, or sol-

densation

In the presence of corrosive or explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic

iators

rad

Near induction heating

syste

ms

(e.g., high-frequency

indu

ction heating systems

and IH cooking utensils)

8

Operating Precautions

Handling the Instrument

• To avoid damage to the instrument, protect it from physical

shock when transporting and handling. Be especially careful to

avoid physical shock from dropping.

• This instrument may cause interference if used in residential

areas. Such use m

measures to reduce electromagnetic emissions to prevent interference to the reception of radio an

Handling the Clamp Sensor

To avoid short circuits and potentially life-threatening hazards, never attach the clamp to a circuit that

than maximum rated voltage to earth, or over bare conduc tors.

• Be careful to avoid dropping the clamps or otherwise subjecting

them to mechanical shock, which could damage the mating sur faces of the core and adversely affect measurement.

• Keep the clamp jaws and core slits free from foreign objects,

which cou

• Keep the clamp closed when not in use, to avoid accumulating

dust or dirt on

with clamp performance.

ld interfere with clamping action.

ust be avoided unless the user takes special

broadcasts.

operates at more

the ma

d television

ting core surfaces, which could interfere

Handling the Cables

To prevent cable damage, do not step on cables or pinch them

between other objects. Do not bend or pull on cables at their base.

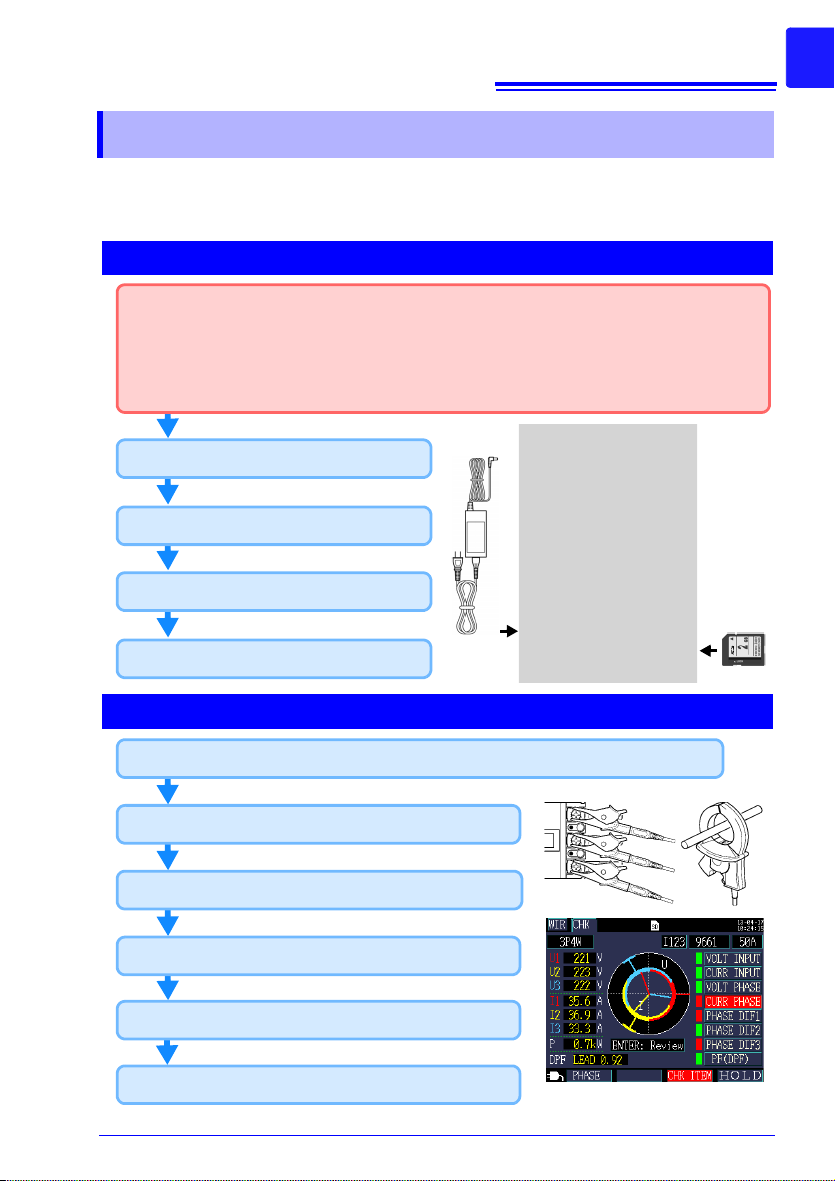

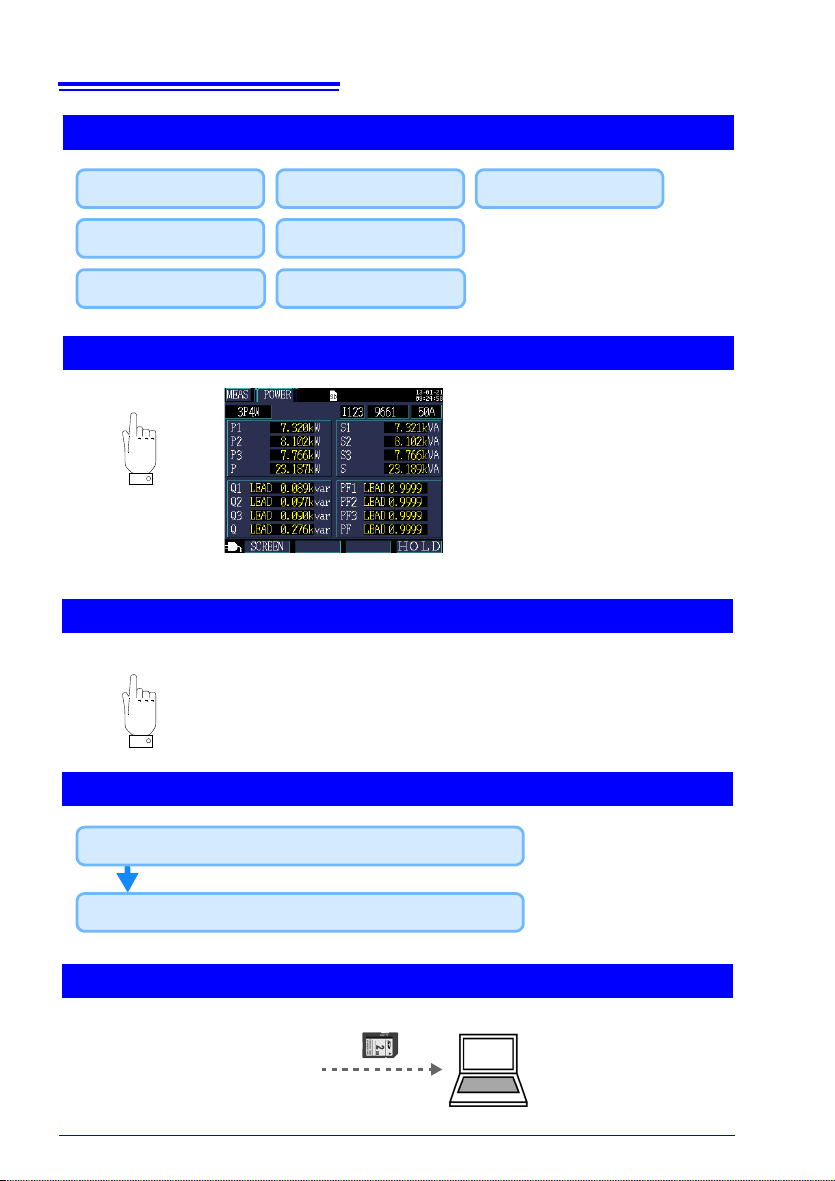

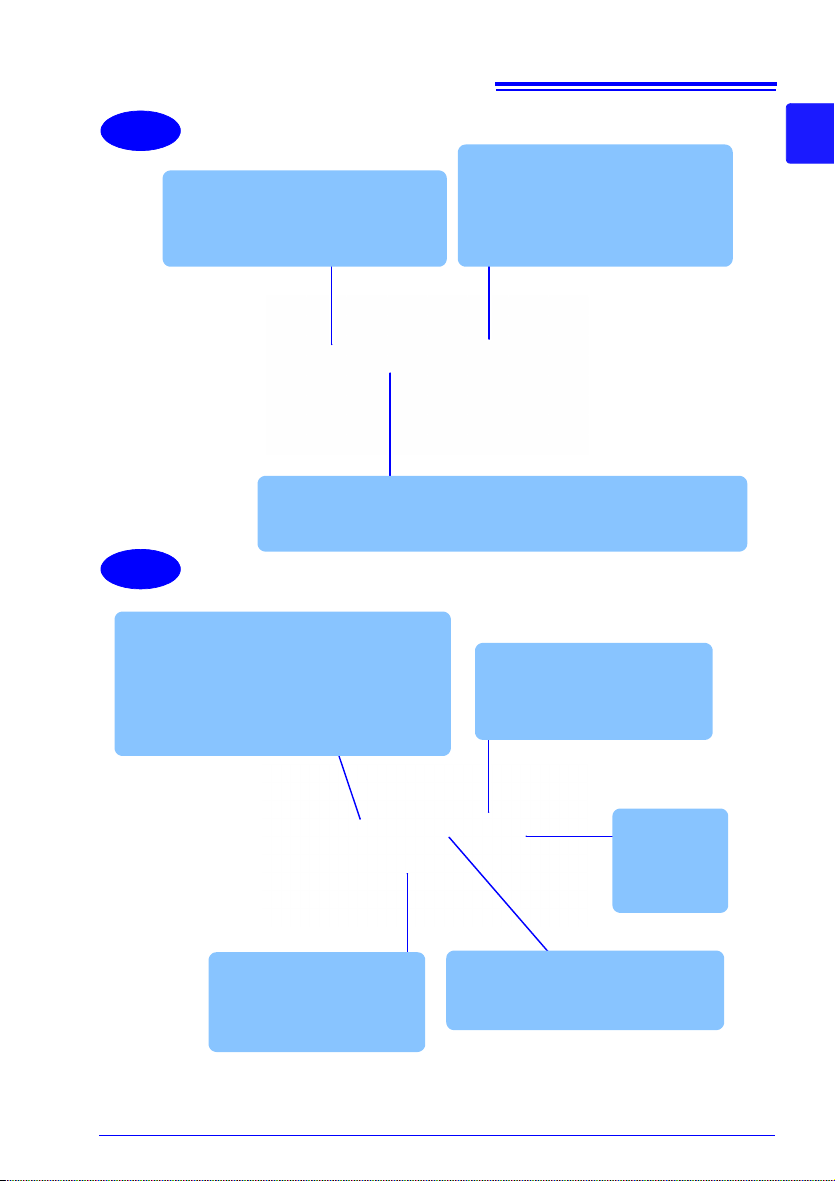

Measurement Flowchart

Wiring check (p. 56)

Setting the current range (p. 54)

Turning the power on (p. 38)

(At purchase)

• Secure the voltage cords together with a spiral tube. (p. 22)

• Wrap the color spiral tubes around the clamp sensor cables. (p. 23)

• Grouping together clamp cables (p. 23)

• Install the battery pack. (p. 24)

• Setting the language and measurement line frequency (p. 28)

Pre-Operation Inspection (p. 29)

Inserting an SD memory card (p. 30)

Supplying power (p. 33)

Connecting to measurement lines (p. 51)(p. 52)

Setting measurement conditions on the Wiring Diagram Screen (p. 43)

Attach voltage cords (p. 47)

Connecting clamp sensors (p. 49)

Wiring Check screen

Measurement preparations

Connecting to lines to be measured and check

This section presents a series of instrument operations without using the Quick Set

function. For more information about the Quick Set function, see the Measurement

Guide (published separately in color).

9

Measurement Flowchart

10

Turn off the instrument.

Starting recording (p . 102) / Stopping recording (p. 105)

Disconnect the cables from the measurement lines.

Save destination

Save interval

Save items

Change the settings of measurement (calculation selection, energy cost), system, and interface

when required.

[MEAS, LIST] screen

Folder/ File name

Recording start

Recording stop

Clock

Measurement is complete

Analyzing data on a computer (p. 129)

Viewing measurement data (p. 83)

Recording settings (p. 69)

Measurement Flowchart

11

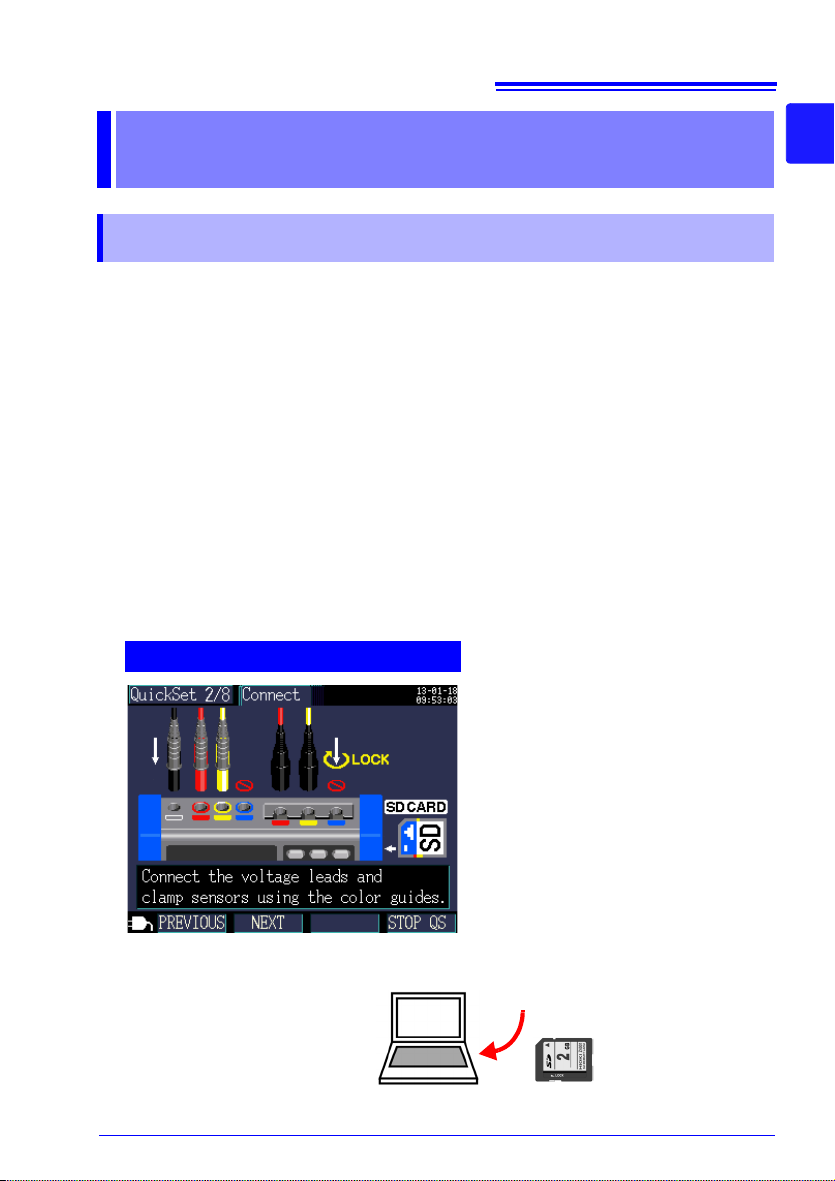

Quick Set

1.1 Product Overview

Overview Chapter 1

1.1 Product Overview

The PW3360 Clamp on Power Logger is a clamp-type power meter capable of measuring lines with from single-phase to three-phase four-wire.

In addition to basic measurements including voltage, current, power, power factor,

and energy, the instrument can perform demand measurement and harmonic measurement (PW3360-21 harmonic model only), which are important parameters in

power management.

The Quick Set makes the instrument simple enough to be used even by beginners

by enabling them to configure basic settings, wirings, recording settings, and the

start of recording through a series of steps.

The PW3360 Clamp on Power Logger supports extended data acquisition and automated measurement, thanks to the use of the SD memory card and USB/LAN interface. This makes the PW3360 Clamp on Power Logger suitable for power

measurement at commercial frequencies involved in the power maintenance and

management of a building or factory.

1

Chapter 1 Overview

3

12

1.2 Features

1.2 Features

Quick Set function

The Quick Set function simplifies instrument operation by walking users

through a series of steps to configure basic settings, wirings, wiring check

(wiring confirmation), recording settings, and the start of recording in order to

prevent mistakes.

See: Chapter 7, "Quick Set" (p. 109), Measurement Guide (published separately in color)

Wiring Check (wiring confirmation)

When wirings have been set up improperly, a help function displays hints to

help users establish proper wirings.

See: 3.8, "Verifying Correct Wiring (Wiring Check)" (p. 56)

Ability to make measurements even when power is not available

from a wall outlet

The PW9003 Voltage Line Power Adapter (option) can be used to supply

power from measurement lines.

See: "Supplying Powe r from Measurement Lines (Using the PW9003 Voltage Line Power

Adapter)" (p. 35)

Ability to operate for about 8 hours on battery power

Even when AC power is unavailable, the optional battery pack can be used to

enable about eight hours of measurement.

See: "Installing (replacing) the Battery Pack" (p. 24)

Corresponding to the various power line

The instrument can perform single-phase/2-wire (up to three circuits), singlephase/3-wire, 3-phase/3-wire (2-power measurement/3-power measurement),

and 3-phase/4-wire measurement. When performing single-phase/3-wire, or

3-phase/3-wire 2-power measurement, the instrument can perform power and

leakage current measurement simultaneously.

See: 4.2, "Changing Measurement Settings" (p. 63)

Broad operating temperature range

The instrument can be used at temperatures ranging from -10°C to 50°C.

However, the operating temperature range is limited to 0°C to 40°C when

operating on battery power and from 0°C to 50°C when using the LAN.

TFT color LCD

The instrument uses an LCD that is easy to see in both dim and bright conditions.

13

1.2 Features

Safe design

Despite its compact footprint, the instrument features a safe design that is

CAT IV (300V) and CAT III (600 V) compliant.

Extensive line of clamp sensors

Choose the clamp sensor that’s right for your application, with models

designed for targets ranging from leakage currents to a maximum ranting of

5,000 A.

Ability to store data on SD memory cards

Used with a high-capacity, 2 GB SD memory card, the instrument can record

data continuously for up to one year.

Communications functionality

Instrument settings and data can be downloaded via the instrument’s USB

and LAN interfaces.

See: Chapter 10, "Using Communications (USB/LAN)" (p. 147)

Pulse I/O

Pulse input counts a pulse signal from an external source and saves the result

at a constant interval. Unit consumption management can be performed

based on power data and pulse counts (production volume). During recording

and measurement, pulse output is proportional to active energy.

See: Chapter 11, "Using Pulse Input and Output" (p. 167)

1

Chapter 1 Overview

3

14

Front

Display

3.5" TFT color LCD

(p. 17)

POWER LED

Lights up when the

POWER switch is

turned on and power is

supplied to the instrument. (p. 38)

Flashes if the backlight

has been turned off

due to the AUTO OFF

setting. (p. 77)

Recording LED

Flashing green: When in the

recording standby state

Solid green: When recording

Function key (F1 to F4 key)

Select and change display contents

and settings.

KEY LOCK

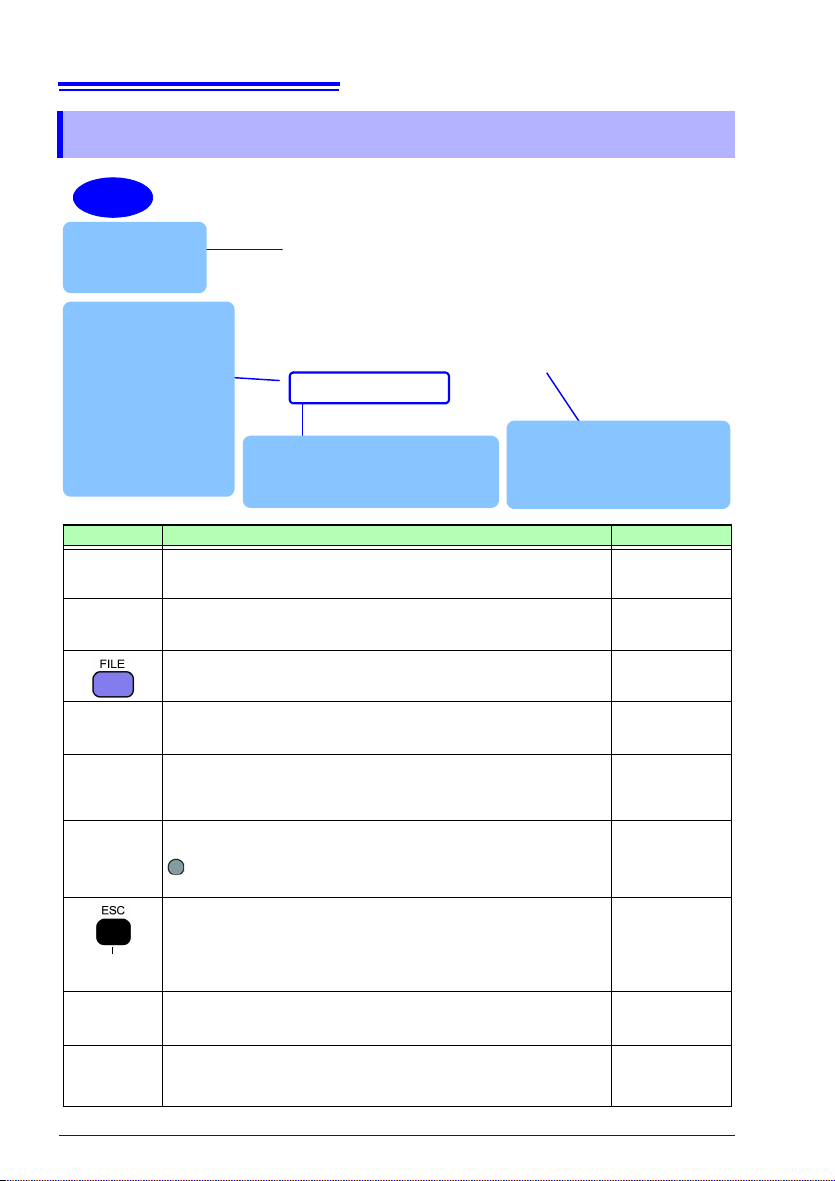

Press 3 sec

1.3 Names and Functions of Parts

1.3 Names and Functions of Parts

Key Description Reference

Measurement key. Displays the Measurement screen and

switches to the ne

xt screen.

(p. 83)

Settings key. Displays the Settings screen and switches to

the next scree

n.

File key. Displays the File (SD memory card/internal memory) screen and switches screens.

Wiring key. Displays the Wiring Diagram/Wiring Check

screen and switc

hes screens.

Quick Set key. Displays the Quick Set screen and switches

to the next scr

een.

(p. 61)

(p. 113)

(p. 41)

(p. 109),

Measurement

gui

de

Cursor keys. Moves the cursor on the screen. The cursor

keys are also used to scroll graphs and waveforms.

: Enter key. Selects items on the screen and accepts

changes.

Cancel key. Cancels selections and changes, reverting set-

tings to their previous values. Switches to the previous

screen. Pressin

g and holding the Cancel key for 3 or more

seconds activates the key lock (which is canceled by pressing and holding the key again).

Screen Copy key. Outputs an image of the currently displayed screen to the SD memory card.

(p. 121)

Start/Stop key. Starts and stops recording. (p. 101)

Right

Left

LAN interface

Connect a computer here using the optional LAN cable.

See: (p. 155)

SD memory card slot

Insert an SD memory card here.

Be sure to close the cover when

recording.

See: (p. 30)

USB interface

Connect a computer here using

the included USB cable.

See: (p. 148)

AC adapter hook

Loop the AC adapter cord

through this hook.

See: (p. 33)

Power switch

Turns the instrument on and off.

See: (p. 38)

AC adapter

connection

jack

See: (p. 33)

Pulse I/O terminal

Pulse input: Counts pulse input from an

external source.

Pulse output: Generates pulse output

based on integrated energy values.

See: (p. 167)

Charge LED

Lights up while the 9459

Battery Pack is charging.

See: (p. 24)

15

1.3 Names and Functions of Parts

1

Chapter 1 Overview

3

16

Back

Upper

Voltage input terminals

Connect the included L9438-53

Voltage Cord here.

See: (p. 51)

Current input terminals

Connect optional clamp sensors here.

See: (p. 52)

MAC address label

Displays the instrument's unique

MAC address, which is used when

configuring a LAN connection. Do

not remove the label as the information it contains is necessary in

order to manage the device.

Serial number

Displays the instrument's serial number. Do not remove the label as the

information is contains is necessary

in order to manage the device.

Protector

Remove when using the battery. Connect the

PW9002 Battery Set (including the 9459 Battery Pack

and a battery case).

See: (p. 24)

Indicates the CE

mark, KC mark,

WEEE Directive

mark, and country of

manufacture.

1.3 Names and Functions of Parts

17

POWER

INTEGRATE

WAVEFORM

ZOOM

VOLT/CURR(U/I)

DEMAND

TREND

HARMONIC GRAFT

(PW3360-21 only)

HARMONIC LIST

(PW3360-21 only)

Measurement screen

LIST

Setting screen

MEAS 1

REC 1

REC 2

SYS 1

SYS 2

PULSE

MEAS 2

LAN

See: Chapter 5, "Viewing Measurement Data" (p. 83)

See: Chapter 4, "Changing Settin gs" (p. 61)

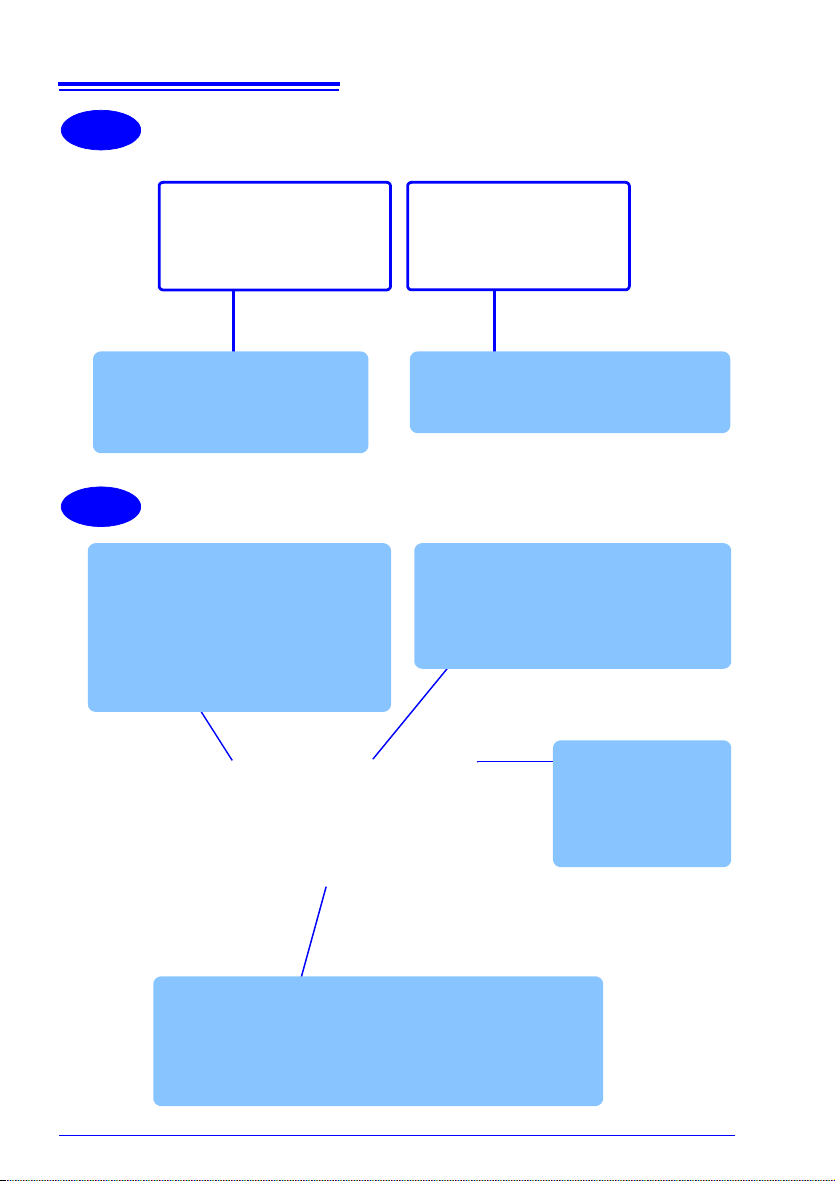

1.4 Screen Configuration

1.4 Screen Configuration

1

Chapter 1 Overview

3

18

Wiring Screen

Wiring Diagram

Wiring Check

See: Chapter 3, "Connecting to Lines to be Measured" (p. 41)

File Screen

SD card

Memory

See: Chapter 8, "Saving Data and Manipulating Files" (p. 113)

Quick Set Screen

Quick Set Start

See: Chapter 7, "Quick Set" (p. 109)

Measurement Guide (published separately in color)

1.4 Screen Configuration

19

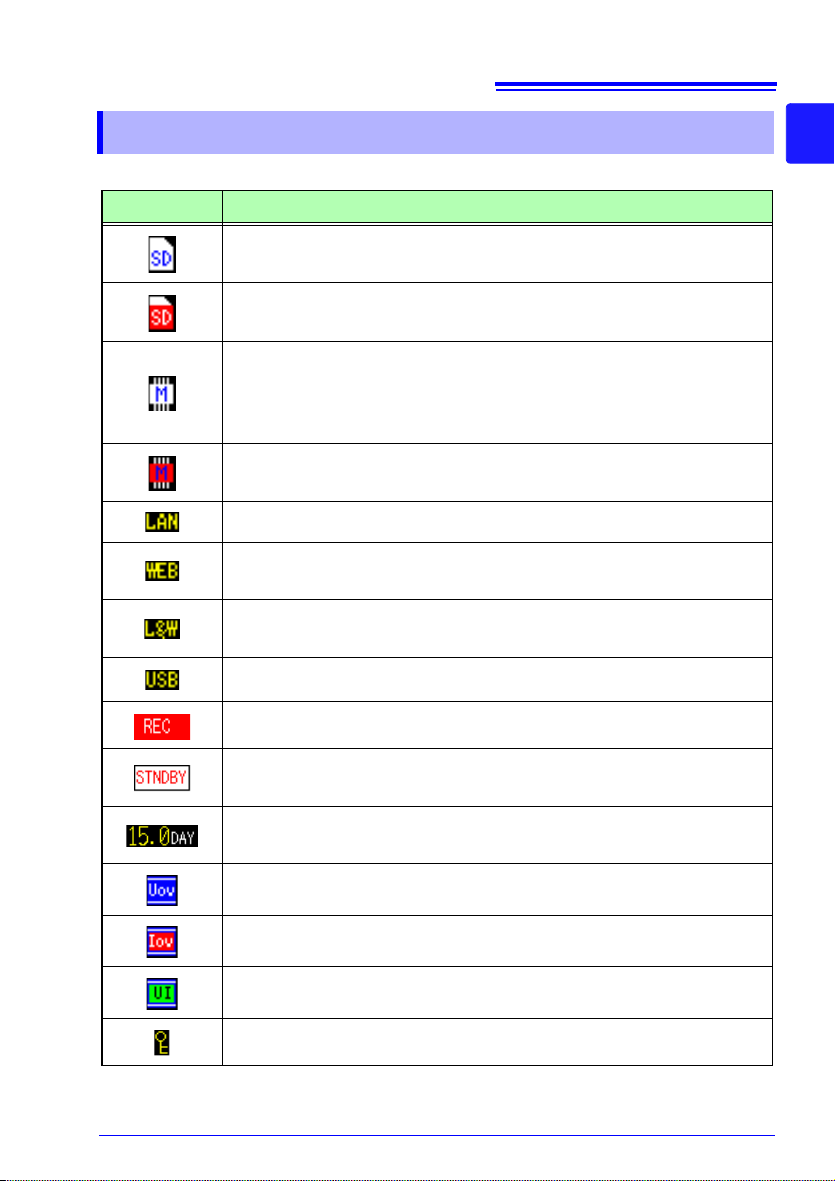

1.5 On-Screen Indicators

1.5 On-Screen Indicators

Marks Description

Lights up when the save destination is [SD CARD] and an SD

memory card is loaded in the instrument.

Lights red when the SD memory card is being accessed.

Lights up when the save destination is the instrument’s internal

memory

tion set to [SD CA

saved to the instrument’s internal memory).

Lights red when the instrument’s internal memory is being

accessed.

Indicates that data is being sent or received over the LAN. (p. 161)

Indicates that data is being sent or received by the HTTP server

functio

Indicates that data is being sent or received both over and LAN and

by th

Indicates that data is being sent or received by the USB interface.

. Lights up when recording is started with the save destina-

RD] but no card inserted (in this case, data will be

n. (p. 163)

e HTTP se

rver.

1

Chapter 1 Overview

3

Indicates that recording and measurement are in progress.

Indicates that the instrument is standing by for recording and mea-

surement to start.

Indicates how much recording time remains on the SD memory

card or in

Lights up when the voltage exceeds the peak.

Lights up when the current exceeds the peak.

Lights up when both the voltage and current exceed the peak.

Lights up when the key lock has been activated. (p. 14)

the

instrument’s internal memory.

20

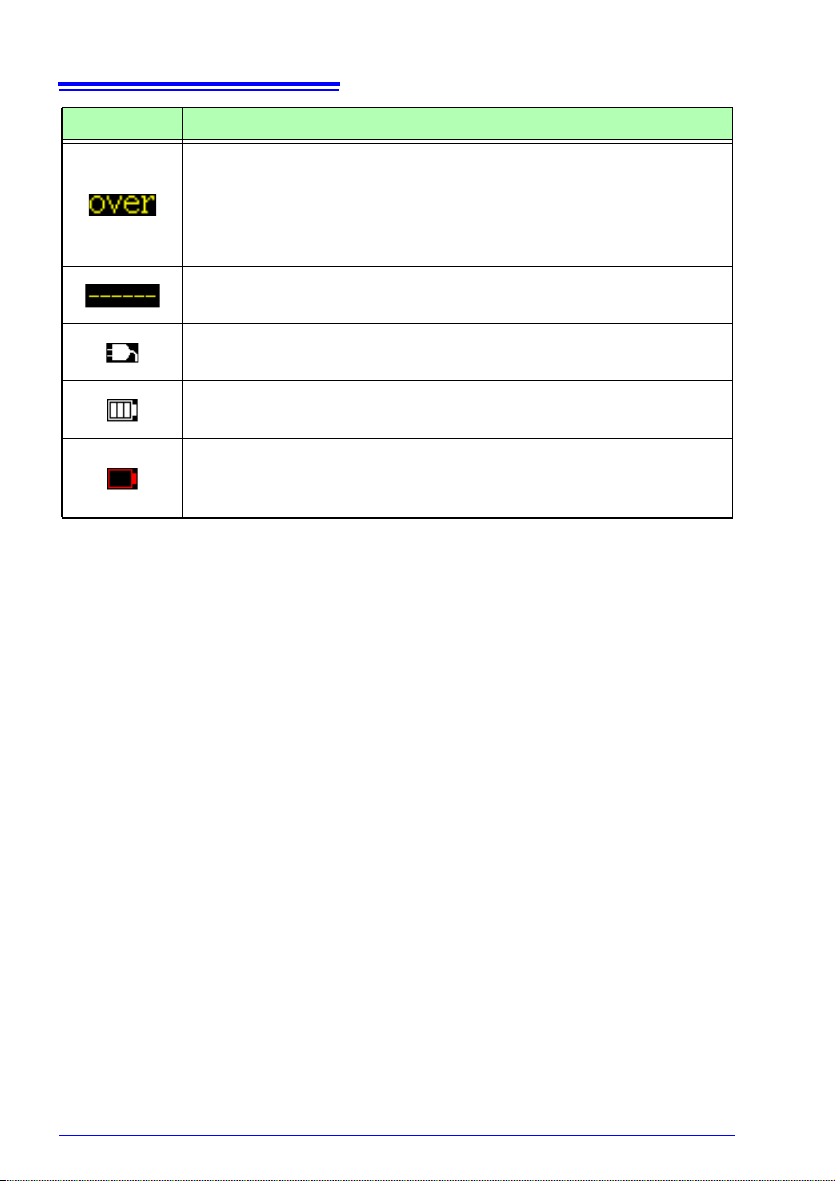

1.5 On-Screen Indicators

Marks Description

Indicates that the display range upper limit has been exceeded,

causing an over-range event. (p. 180)

If the voltage is over-range, the voltage that the instrument is capable of measuring is being exceeded

instrument. If the current is over-range, increase the current range.

Indicates that measurement is not possible. Power factor cannot be

measured w

Lights up when the PW3360 is being operated using the AC

adapt

Lights up when the PW3360 is being operated on battery power. (p.

24)

Lights up when the PW3360 is being operated on battery power

a

nd th

adapter and charge the battery. (p. 24)

hen there is no input.

er. (p. 33)

ere is inadequate battery life remaining. Connect the AC

diately disconnect the

. Imme

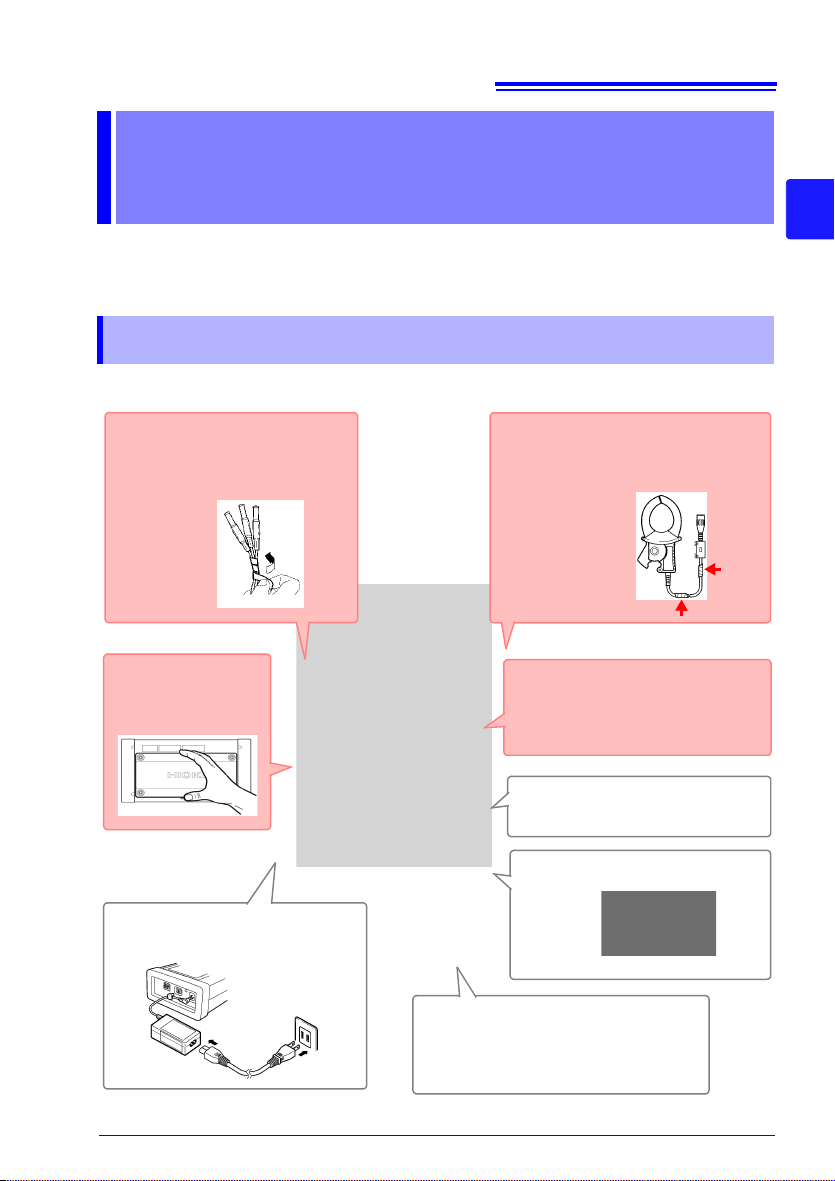

Measurement

(At purchase)

(At purchase)

Wrap the color spiral tubes

around the clamp sensor cables.

(p. 23)

2

Connect the AC adapter.

(p. 33)

Insert an SD memory card.

(p. 30)

6

7

3

8

Secure the voltage cords together with a spiral tube.

(p. 22)

1

(At purchase)

Install the battery

pack. (p. 24)

Turn on the instrument. (p. 38)

Perform the pre-measurement

inspection. (p. 29)

5

Set the language and measurement line frequency

(p. 28)

4

(At purchase)

21

2.1 Preparation Flowchart

Preparations

Before starting measurement, connect accessories and options to the instrument.

Before performing measurement, be sure to inspect the instrument as well as any

accessories and options for possible malfunctions.

2.1 Preparation Flowchart

Follow the procedure described below to prepare for measurement.

Chapter 2

2

Chapter 2 Measurement Preparations

3

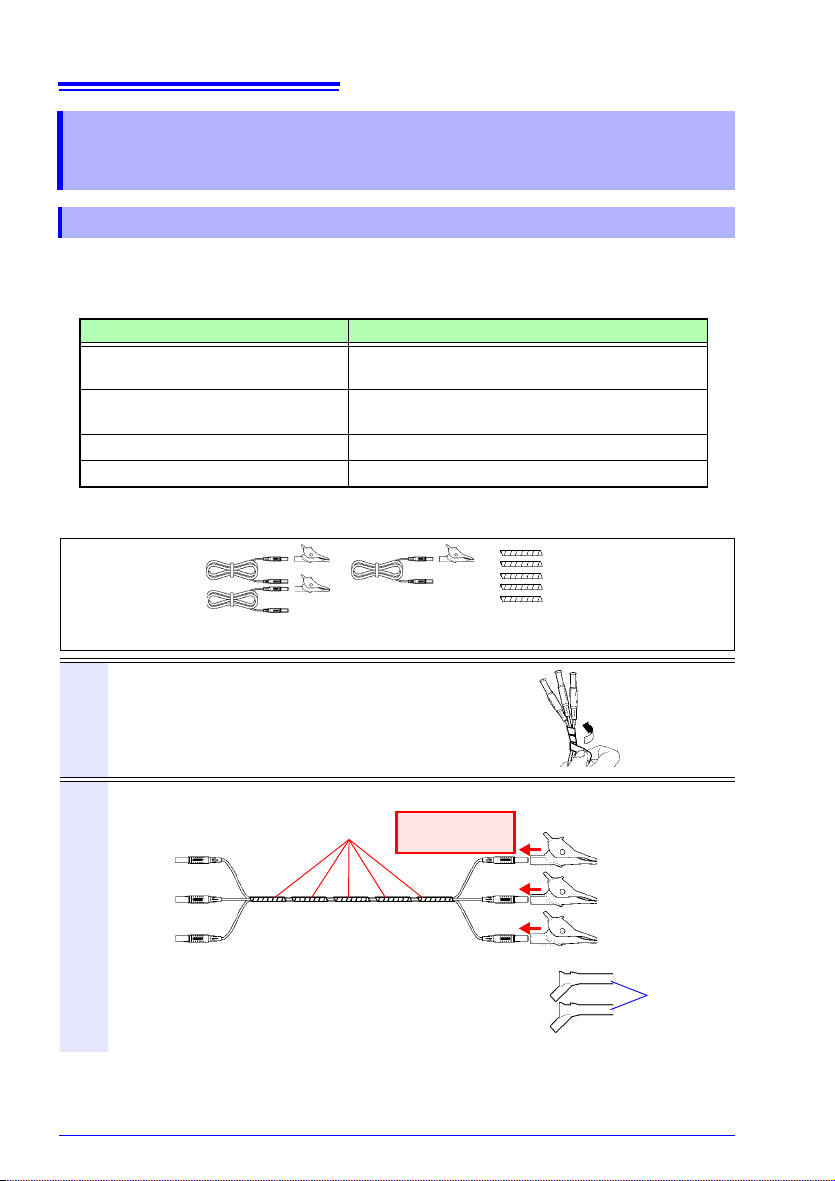

22

Model L9438-53

Voltage Cord

Banana Plug Leads three, one each black, red, and yellow

Alligator Clips three, one each black, red, and yellow

Five Spiral Tubes

(for cable bundling)

Spiral Tubes

Yellow

Black

Red

Yellow

Black

Red

Insert securely

all the way.

• Model 9804-01 Magnet Adapter

(optional, red, standard screws: M6 pan-head screw)

• Model 9804-02 Magnet Adapter

(optional, black, standard screws: M6 pan-head screw)

φ11 mm

2.2 Preparing to Use the Instrument after Purchase

2.2 Preparing to Use the Instrument after

Purchase

Bundle the Voltage Cord Leads with the Spiral Tubes

5 Spiral Tubes provided with Model L9438-53 Voltage Cord. Use the Spiral Tubes as

and when required. The number of voltage cords that will be bound together

depends on the measurement target.

Measurement target Voltage cord to use (color)

Single-phase/2-wire (1P2W),

Single-phase/3-wire (1P3W1U)

Single-phase/3-wire (1P3W),

3-phase/3-wire (3P3W2M)

3-phase/3-wire (3P3W3M)

3-phase/4-wire (3P4W)

Preparation items:

single-phase/3-wire (1P3W) and 3-phase/3-wire (3P3W2M)

Two cords (black and red)

Three cords (black, red, and yellow)

Three cords (red, yellow, and blue)

Four cords (black, red, yellow, and blue)

Line up the ends of the voltage cords and

1

wrap the spiral tube around them.

Wind a Spiral Tube round the multiple cords.

Five Spiral Tubes are provided. Please wind the

tubes at appropriate intervals.

Insert the same color alligator clip into each lead.

2

You can also use magnet adapters instead of alligator clips.

Loading...

Loading...