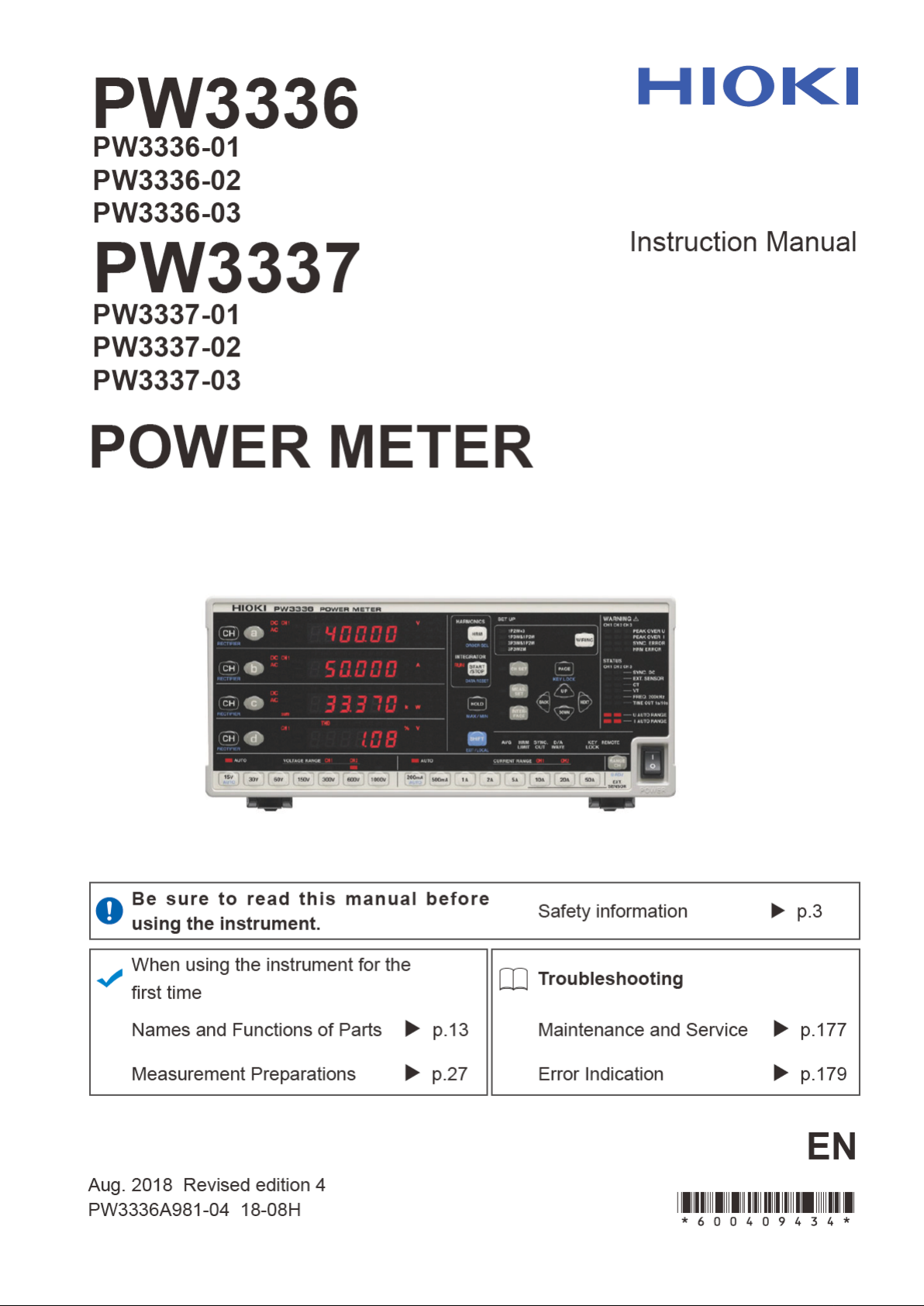

Page 1

Page 2

Page 3

Contents

Contents

i

1

Introduction.....................................................1

Confirming Package Contents........................2

Safety Information ..........................................3

Operating Precautions....................................5

Chapter 1 Overview 11

1.1 Product Overview ............................... 11

1.2 Features .............................................11

1.3 Names and Functions of Parts ........... 13

1.4 Measurement Workflow ..................... 22

Chapter 2 Measurement

Preparations 27

2.1 Installation and Connection Procedures

............................................................27

2.2 Connecting the Measurement Lines .. 28

2.3 Connecting the Power Cord ...............34

2.4 Turning On the Instrument ................. 35

2.5 Performing Zero-adjustment .............. 36

2.6 Activating Power to the Measurement

Lines ..................................................37

2.7 Turning Off the Instrument ................. 37

Chapter 3 Configuration and

Measurement 39

3.1 Pre-Measurement Inspection .............39

3.2 Configuring Settings ........................... 40

3.2.1 Selecting the Wiring Mode ................. 40

3.2.2 Selecting the Current Input Method ... 42

3.2.3 Selecting Display Content ..................44

Selecting display parameters ....................44

Selecting display channels .......................46

Selecting the rectifier ................................47

3.2.4 Selecting the Voltage and Current

Ranges ...............................................48

Selecting the desired range ......................48

PW3336A981-04

Automatically setting the range

(auto-range operation) ............................ 49

3.2.5 Setting the Synchronization Source

(SYNC) ...............................................51

3.2.6 Setting the Frequency Measurement

Range .................................................53

3.2.7 Setting the Timeout ............................55

3.2.8 Displaying Measured Values as an

Average (AVG: Averaging) .................57

3.2.9 Setting the VT and CT Ratio ..............59

Setting the VT ratio .................................. 60

Setting the CT ratio .................................. 61

3.3 Integration ..........................................62

Starting integration ................................... 64

Stopping integration ................................. 64

Starting integration while adding to previous

integrated values (additional integration) . 65

Canceling integration

(resetting integrated values) ................... 65

Performing integration after setting an

integration time (timer integration) .......... 66

Integration precautions ............................ 68

3.3.1 Integrated Value Display Format ........70

3.4 Viewing Harmonic Measured Values .71

3.4.1 Setting the Synchronization Source ...71

3.4.2 Method for Displaying Harmonic

Measurement Parameters ..................71

3.4.3 Setting the Analysis Order Upper Limit

............................................................76

3.4.4 About the HRM ERROR lamp ............77

3.5 Measuring Efficiency ..........................78

Examples of efficiency measurement ...... 79

3.6 Performing Synchronized Measurement

with Multiple Instruments (Multipleinstrument Synchronized Measurement)

81

Connecting 2 instruments (PW3336/PW3337)

with a synchronization cable ................... 82

Configuring synchronized measurement . 83

EXT SYNC terminal internal circuitry ....... 84

3.7 External Control ..................................85

3.7.1 External control terminal .....................85

Connecting wires to the external control

terminals ................................................. 87

3.8 Using D/A Output ................................................ 88

Connecting wires to D/A output terminals 90

3.8.1 Analog Level Output, Waveform Output,

and High-speed Active Power Level

Output .................................................91

2

3

4

5

6

7

8

9

10

11

12

付

録

索

引

Page 4

ii

Contents

Switching between analog output and

waveform output ...................................... 92

Setting the rectifier for analog output ....... 93

3.8.2 D/A Output ..........................................95

Setting D/A output parameters ................. 95

Example uses .......................................... 97

Examples of analog output ...................... 98

Example waveform output ..................... 101

3.9 Using a Current Sensor ....................102

Before connecting a current sensor ....... 103

Connecting a Type 1 current sensor ...... 104

Connecting a Type 2 current sensor ...... 104

Setting external current sensor input ..... 106

Using an external CT ............................. 107

3.10 Other Functions ................................108

3.10.1Fixing Display Values (Display Hold) 108

Activating display hold ........................... 108

Canceling the display hold state ............ 108

3.10.2Displaying Peak, Minimum, and Maximum Values (Maximum Value Hold) 109

Displaying maximum values .................. 109

Displaying minimum values ................... 109

Returning to the instantaneous value display

109

Clearing maximum and minimum values 109

3.10.3Disabling Control Keys (Key Lock) ..111

Enabling the key lock state .................... 111

Canceling the key lock state .................. 111

3.10.4Initializing the Instrument

(System Reset) .................................112

3.11 When PEAK OVER, o.r, or the Unit

Indicator Flashes ..............................114

3.11.1If the PEAK OVER U or PEAK OVER I

Lamp Lights Up ................................114

3.11.2When o.r (over-range) Is Displayed .115

3.11.3When the Unit Indicator Flashes .....116

Chapter 4 Connection to a PC

117

Setting the LAN’s default gateway ......... 125

Displaying the LAN’s MAC address ....... 126

Connecting the instrument to a computer

with a LAN cable .................................... 127

4.3 Operating the Instrument from a

PC's Browser ................................... 129

Operating the instrument remotely ......... 130

4.4 GP-IB Interface Settings and Connection

(Before Using Command

Communications) .............................................131

Connecting the cable to the GP-IB connector

................................................................................................... 132

Setting the GP-IB address ............................... 133

4.5 Canceling the Remote State

(Activating the Local State) .............. 134

Canceling the remote state .................... 134

Chapter 5 Specifications 135

5.1 Environmental and Safety Specifications

.......................................................... 135

5.2 General Specifications ..................... 136

5.3 Measurement specifications ............ 139

5.4 Functional Specifications ................. 156

5.5 Calculation Formulas Specifications 161

Voltage channel and sum value calculation

formula ................................................... 161

Current channel and sum value calculation

formulas ................................................. 163

Power channel and sum value calculation

formulas ................................................. 164

Power channel and sum value calculation

formulas ................................................. 167

5.6 Wiring Specifications ....................... 168

Wiring diagrams for direct input

(connections to instrument’s terminal block)

................................................................ 168

4.1 RS-232C Settings and Connection

(Before Using Command

Communications) .............................118

Setting the RS-232C communications speed

................................................................ 119

Connecting the RS-232C Cable ............. 120

4.2 LAN Settings and Connection

(Before Using Command

Communications) .............................122

Setting the LAN’s IP address ................. 123

Setting the LAN’s subnet mask .............. 124

Chapter 6 Maintenance and

Service 177

6.1 Trouble Shooting ............................. 177

6.2 Error Indication ................................ 179

Page 5

iii

Contents

Appendix A1

Appendix 1Detailed Specifications of

Measurement Items

(Display Items) ................................A1

Appendix 2Detailed Specifications

of Output..........................................A5

Appendix 2.1Detailed Specifications of Level

Output .............................................A5

Appendix 2.2Detailed Specifications of

Waveform Output ...........................A6

Appendix 2.3Detailed Specifications of

Selectable Items for D/A Output .....A7

Appendix 3Rack Mounting .........................A11

Appendix 4Dimensional Diagram...............A13

Index Index1

1

2

3

4

5

6

7

8

9

10

11

12

付

録

索

引

Page 6

iv

Contents

Page 7

1

Introduction

Introduction

Thank you for purchasing the Hioki Model PW3336, PW3336-01, PW3336-02, PW3336-03, PW3337,

PW3337-01, PW3337-02, PW3337-03 Power Meter. To obtain maximum performance from the instrument

software, please read this manual first, and keep it handy for future reference.

The following documents are provided with this instrument. Refer to them as appropriate for your application.

Measurement

1

Guide

Offers an introduction to the instrument's basic measuring method for first time users.

Instruction Manual

2

(This document)

The models are classified according to the number of the input channels and the factory-installed options as

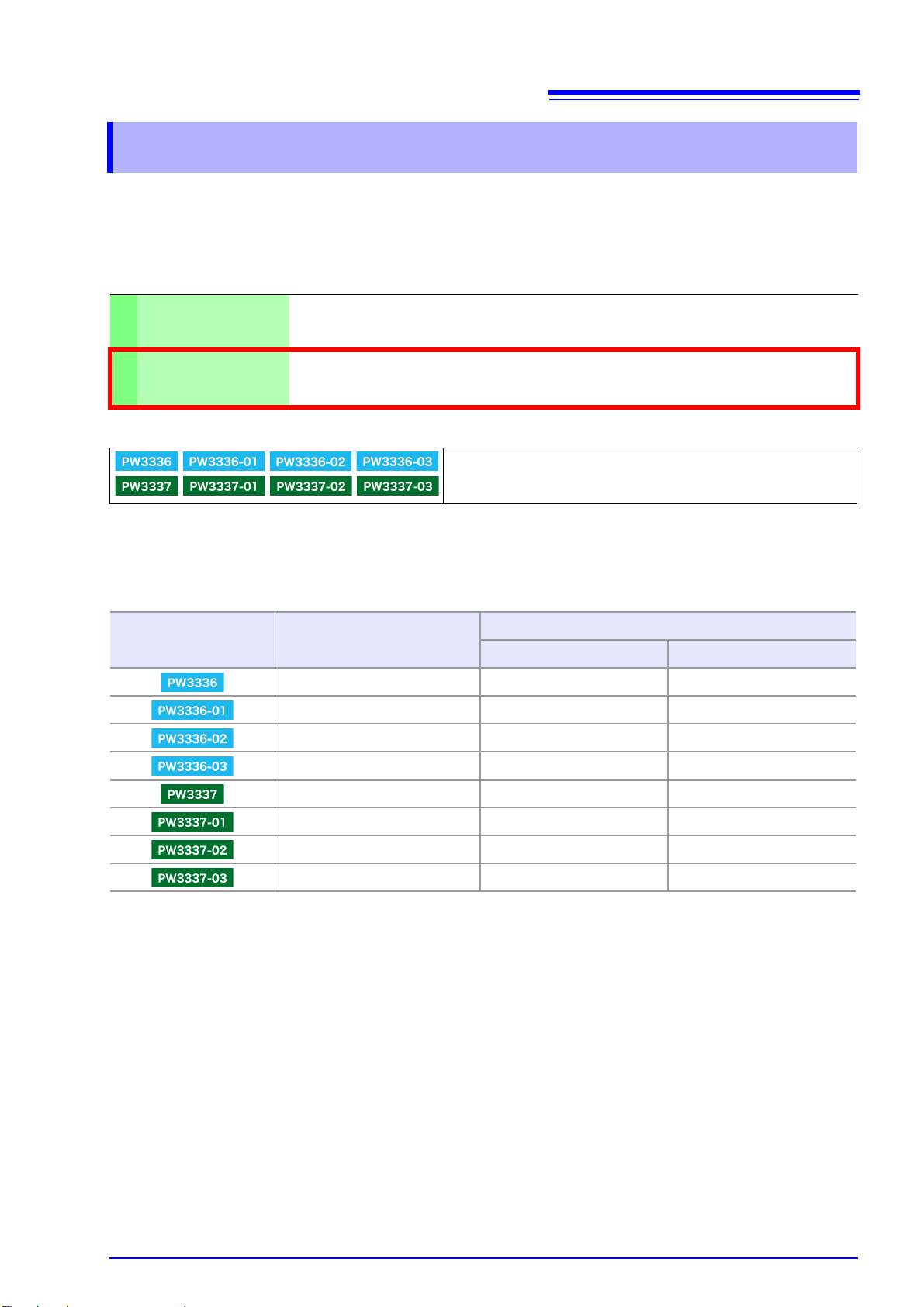

follows.

Model Number of input channels

Contains explanation and instructions regarding the instrument's operating method and

functions.

Show the model that is equipped with each function as the icon.

z : Installed − : Not installed

Factory-installed options

GP-IB D/A output

2 −−

2 z −

2 − z

2 zz

3 −−

3 z −

3 − z

3 zz

The instrument can measure relatively high current with the use of HIOKI Clamp on Sensors (clamp sensors),

which are option, or current sensors. Hereafter, those sensors are collectively referred to as "current sensors". Please read the instruction manuals of each sensor for details before using.

The current sensors are classified as either "TYPE1" or "TYPE2" according to the output specifications.

Using a TYPE2 current sensor requires Model CT9555 series Sensor Unit, which is option. Please refer to

the instruction manual of Model CT9555 series for details.

Trademark

Microsoft and Internet Explorer are either registered trademarks or trademarks of Microsoft Corporation in the

United States and other countries.

Page 8

2

PW3336, PW3336-01, PW3336-02, PW3336-03,

PW3337, PW3337-01, PW3337-02, PW3337-03

Power Meter

Instruction manual

Measurement guide

Power cord

Voltage and current input terminal safety

cover

PW3336, -01, -02, -03..................... 4

PW3337, -01, -02, -03..................... 6

Safety

cover installation screws (M3 ×6 mm)

PW3336, -01, -02, -03..................... 8

PW3337, -01, -02, -03..................... 12

e.g.) PW3337

Confirming Package Contents

Confirming Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during shipping. In

particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to operate

according to the specifications, contact your dealer or Hioki representative.

Confirm that these contents are provided.

Options

Communications and control options

Model 9637 RS-232C Cable (1.8 m, 9pin-9pin, crossover cable)

Model 9638 RS-232C Cable (1.8 m, 25pin-9pin, crossover cable)

Model 9642 LAN Cable (5 m, Supplied with Cross-Over Adapter)

Model 9151-02 GP-IB Connector Cable (2 m)

Model 9165 Connection Cord (1.5 m, metal BNC to metal BNC, not CE marked, for the synchronized mea-

Current sensor options

Model 9661 Clamp on Sensor (500 A AC)

Model 9669 Clamp on Sensor (1000 A AC)

Model 9660 Clamp on Sensor (100 A AC)

Model CT9667 Flexible Clamp on Sensor (500 A/5000 A AC)

Model CT6862-05 AC/DC Current Sensor (50 A AC/DC)

Model CT6863-05 AC/DC Current Sensor (200 A AC/DC)

Model 9709-05 AC/DC Current Sensor (500 A AC/DC)

Model CT6865-05 AC/DC Current Sensor (1000 A AC/DC)

Model CT6841-05 AC/DC Current Probe (20 A AC/DC)

Model CT6843-05 AC/DC Current Probe (200 A AC/DC)

Model CT6844-05 AC/DC Current Probe (500 A AC/DC)

Model CT6845-05 AC/DC Current Probe (500 A AC/DC)

Model CT6846-05 AC/DC Current Probe (1000 A AC/DC)

Model 9272-05 Clamp on Sensor (20 A/200 A AC/DC)

Model CT9555 Sensor Unit

Model CT9556 Sensor Unit

Model CT9557 Sensor Unit

Model L9217 Connection Cord

surements)

Page 9

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment. However, mishandling during use

could result in injury or death, as well as damage to the instrument .

Using the instrument in a way not described in this manual may negate the provided

safety features.

• Be certain that you understand the instructions and precautions in the manual

before use. We disclaim any responsibility for accidents or injuries not resulting

directly from instrument defects.

• Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in the

manual before use.

With regard to the electricity supply, there are risks of electric shock, heat generation,

fire, and arc discharge due to short circuits. If persons unfamiliar with electricity measuring instruments are to use the instrument, another person familiar with such

instruments must supervise operations.

3

Safety Information

This manual contains information and warnings essential for safe operation of the instrument and for maintaining it in safe operating condition. Before using it, be sure to carefully read the following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly important information that the user should read before

using the instrument.

The symbol printed on the instrument indicates that the user should refer to a corresponding topic in the

manual (marked with the

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a grounding terminal.

Indicates AC (Alternating Current).

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard that could result in serious injury or

death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or

death to the user.

symbol) before using the relevant function.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the instrument.

Symbols for Various Standards

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU market after August 13,

2005, and producers of the Member States are required to display it on the appliance under Article 11.2 of

Directive 2002/96/EC (WEEE).

This symbol indicates that the product conforms to regulations set out by the EU Directive.

Page 10

4

Safety Information

Notation

Indicates the prohibited action.

(p. ) Indicates the location of reference information.

* Indicates that descriptive information is provided below.

SET

(Bold character)

The screen of this instrument displays characters in the following manner.

Names of settings, buttons, and other screen elements are enclosed in brackets.

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with the

following meanings:

f.s. (range) This is usually the name of the currently selected range.

rdg. (reading or displayed value) The value currently being measured and indicated on the measuring instrument.

dgt. (resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that causes the digital display to show a "1" as the least-significant digit.

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

• Using a measuring instrument in an environment designated with a higher-numbered

category than that for which the instrument is rated could result in a severe accident,

and must be carefully avoided.

• Using a measuring instrument without categories in an environment designated with

the CAT II to CAT IV category could result in a severe accident, and must be carefully

avoided.

This instrument conforms to the safety requirements for CAT II 1000 V, CAT III 600 V measuring instruments.

CAT II

CAT III

CAT IV

When directly measuring the electrical outlet receptacles of the primary electrical circuits in equipment connected to an AC electrical outlet by a power cord (portable tools, household appliances, etc.)

When measuring the primary electrical circuits of heavy equipment (fixed installations) connected directly to

the distribution panel, and feeders from the distribution panel to outlets.

When measuring the circuit from the service drop to the service entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Page 11

5

50 mm or more

50 mm or more

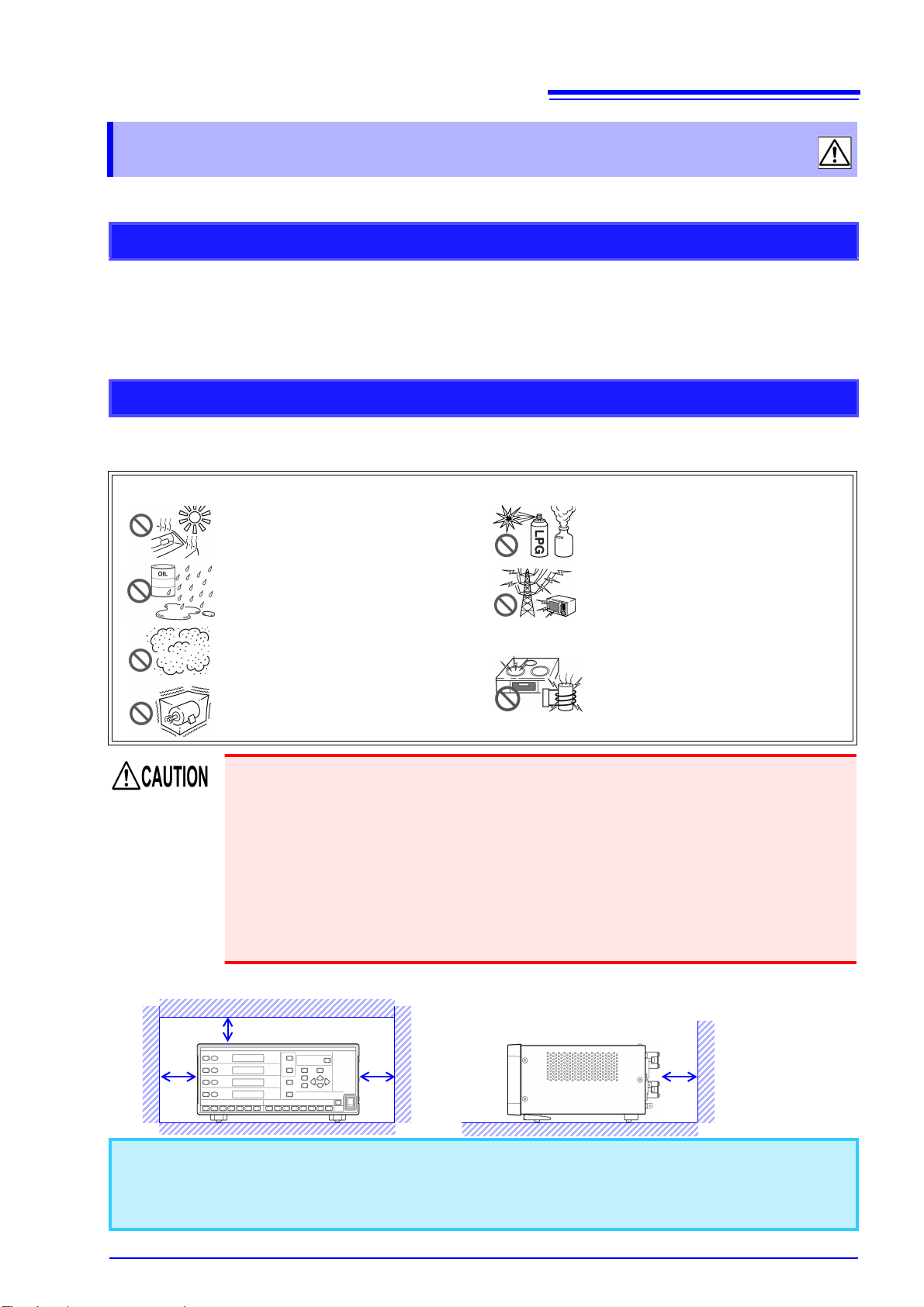

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Before Use

• Before using the instrument for the first time, verify that it operates normally to ensure that no damage

occurred during storage or shipping. If you find any damage, contact your dealeror Hioki representative.

• Before using the instrument, make sure that the insulation on the connection cable is undamaged and that

no bare conductors are improperly exposed. Using the instrument in such conditions could cause an electric shock, so contact your dealer or Hioki representative for replacements.

Instrument Installation

Operating temperature and humidity: 0°C to 40°C (32°F to 104°F) at 80% RH or less (non-condensating)

Temperature and humidity range for guaranteed accuracy: 23°C±5°C (73°F±9°F), 80%RH or less

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil, other chemicals,

or solvents

Exposed to high humidity or condensation

Exposed to high levels of particulate

dust

Subject to vibration

• Ventilation holes for heat radiation are provided on the side and rear panels of the

instrument. Leave sufficient space around the ventilation holes and install the

instrument with the holes unobstructed. Installation of the instrument with the ventilation holes obstructed may cause a malfunction or fire.

• Do not place another PW3336 or measuring instrument or other heat-generating

device underneath or on top of this instrument. Doing so may damage the instrument or cause burns or fire.

•

•

In the presence of corrosive or explosive

gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction heating

systems and IH cooking utensils)

To prevent overheating, be sure to leave the specified clearances around the unit.

• Unplugging the power cord kills power to the instrument. Be sure to provide enough unobstructed space to

unplug the power cord immediately in an emergency.

• The instrument can be used with the stands flipped out.(p.21)

• To mount the instrument in a rack, refer to "Appendix 3 Rack Mounting" (p. A11)

Page 12

6

Operating Precautions

Handling the Instrument

To avoid electric shock, do not remove the instrument's case.

The internal components of the instrument carry high voltages and may become very

hot during operation.

• Do not allow the instrument to get wet, and do not take measurements with wet

hands. This may cause an electric shock.

• Touching any of the high-voltage points inside the instrument is very dangerous.

Do not attempt to modify, disassemble or repair the instrument ; as fire, electric

shock and injury could result.

• To avoid damage to the instrument, protect it from physical shock when transporting and

handling. Be especially careful to avoid physical shock from dropping.

• After use, always turn OFF the power.

• Do not allow any conductive foreign objects to enter through the vents. Doing so may

cause damage to the instrument.

This instrument may cause interference if used in residential areas. Such use must be avoided unless the

user takes special measures to reduce electromagnetic emissions to prevent interference to the reception of

radio and television broadcasts.

Handling the Cables

• The maximum input voltage is 1000 V DC/AC and the maximum input current to the

current direct input terminals is 70 A DC/AC.

Attempting to measure a voltage or current in excess of each of the maximum inputs

could destroy the instrument and result in personal injury or death.

• The maximum rated voltage between input terminals and the ground is as follows;

(CAT II) 1000 V DC, 1000 V AC

(CAT III) 600 V DC, 600 V AC

Attempting to measure voltages exceeding this level with respect to ground could

damage the instrument and result in personalnjury.

• The external current sensor input terminals are not insulated. The terminals are

exclusive to the optional current sensors. Attempting to input a voltage or current

other than the output from the optional clamp sensors into the external current sensor terminals could destroy the instrument and result in personal injury or death.

• When using the optional current sensors, do not measure a current in excess of the

current rating. This could destroy the instrument, the current sensor, or both. Also

this coud result in personal injury or death.

• This instrument should only be connected to the secondary side of a breaker, so the

breaker can prevent an accident if a short circuit occurs. Connections should never

be made to the primary side of a breaker, because unrestricted current flow could

cause a serious accident if a short circuit occurs.

• To avoid electrical accidents, confirm that all terminals are secure. The increased

resistance of loose connections can lead to overheating and fire.

(Tightening torque of the input terminals: 3 N·m)

Page 13

7

Operating Precautions

Observe the following to avoid electric shock and short circuits.

• Turn off the power to lines to be measured before making connections to terminals

to be measured and turning on the instrument.

• Be sure to connect the voltage input and current input terminals correctly. An incorrect connection could damage or short circuit this instrument.

• When connecting wires to the voltage input terminals, be careful to avoid shorting

between one terminal and another with the wires.

• Since the screws of the terminals could be loosened, do not move the cables connected to the terminals more than neccessary.

• Do not tie the cables connected to the input terminals in a bundle with the power

supply cord, the communication cables, the external I/O cables, or the current sensor cables. This may cause damage.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• To avoid breaking the cables, do not bend or pull them.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from

the power outlet.

• Keep the cables well away from heat sources, as bare conductors could be exposed if the

insulation melts.

Before Connecting

• Before turning the instrument on, make sure the supply voltage matches that indicated on its power connector. Connection to an improper supply voltage may damage the instrument and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specifications of this instrument, connect the power cord provided only to a 3-contact (two-conductor + ground)

outlet.

See:Connection Methods : 2.3 Connecting the Power Cord (p.34)

• Use only the designated power cord with this instrument. Use of other power cords

may cause fire.

• Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with rectangular wave or pseudo-sine-wave output to power the instrument. Doing so may damage the instrument.

When connecting cables to the input terminals, the communication connectors, or the

external I/O terminals, observe the following to avoid electric shock and short circuits.

• Always turn off the power to the instrument and any device to be connected before

making connections.

• Be careful to avoid exceeding the ratings of the input terminals or external control

terminals.

• During operation, a wire becoming dislocated and contacting another conductive

object can be serious hazard. Use the screws to secure the communication connectors.

Page 14

8

Operating Precautions

Input and Measurement

• The maximum input voltage is 1000 V DC/AC and the maximum input current to the

current direct input terminals is 70 A DC/AC.

Attempting to measure a voltage or current in excess of each of the maximum inputs

could destroy the instrument and result in personal injury or death.

• The maximum rated voltage between input terminals and the ground is as follows;

(CAT II) 1000 V DC, 1000 V AC

(CAT III) 600 V DC, 600 V AC

Attempting to measure voltages exceeding this level with respect to ground could

damage the instrument and result in personal injury.

• The external current sensor input terminals are not insulated. The terminals are

exclusive to the optional current sensors. Attempting to input a voltage or current

other than the output from the optional clamp sensors into the terminals could

destroy the instrument and result in personal injury or death.

• To avoid the danger of electric shock, do not input a signal in excess of the ratings

to the external I/O terminals.

• This instrument should only be connected to the secondary side of a breaker, so the

breaker can prevent an accident if a short circuit occurs. Connections should never

be made to the primary side of a breaker, because unrestricted current flow could

cause a serious accident if a short circuit occurs.

When connecting

Observe the following to avoid electric shock and short circuits.

• Turn off the power to lines to be measured before making connections to input terminals and turning on the instrument.

• When making connections, do not mix up the voltage input terminals (U) and the

current input terminals (I). In particular, do not input a voltage into the current input

terminals (between I and ±). Using the instrument with a faulty wiring will damage

the instrument or cause injury.

• Be careful to avoid shorting between the voltage input terminals with the wires.

When abnormalities such as smoke, unusual noise, or unusual odor are observed

Stop the measurement immediately, and observe the following procedure. Using the

instrument in such a abnormal condition could cause death or injury.

1. Turn off the power switch of the instrument.

2. Disconnect the power cord from the outlet.

3. Turn off the power to the line to be measured.

Remove the measurement cables.

4. Contact your dealer or Hioki representative.

Page 15

9

Operating Precautions

• For safety reasons, disconnect the power cord when the instrument is not used and before

connecting it to a device to be tested.

• To avoid damage to the instrument, do not input the voltage to the output terminals. Also do

not short between any terminals.

• When the instrument is turned off, do not apply voltage or current to the instrument. Doing

so may damage the instrument.

• Do not connect or disconnect connection cords from the current sensor or CT9555 series

Sensor Unit while the instrument is turned on. Doing so may damage the instrument, current sensor, or CT9555 series Sensor Unit.

• Do not input current to the current sensor when it is not connected to the instrument or

when the instrument and CT9555 series Sensor Unit are turned off. Doing so may damage

the current sensor, instrument, or CT9555 series Sensor Unit.

• Correct measurement may be impossible in the presence of strong magnetic fields, such as near transformers and high-current conductors, or in the presence of strong electromagnetic fields such as near

radio transmitters.

To measure accurately

• Warm up the instrument for more than 30 minutes before use.

• To maintain sufficient measurement accuracy of the instrument, be sure to help heat radiation.

e.g.) Keeping away the instrument from a heat, leaving sufficient clearances around the instrument,

installing cooling fans to the rack in which the instrument is mounted, or other measures.

• The recommended calibration interval of the instrument is one year.

• The warranty period of the instrument is three years.

Page 16

10

Operating Precautions

Page 17

11

Support for all power lines

Guaranteed accuracy up to 65 A with direct input

High-accuracy, wide-band performance

Standard harmonic measurement function complying with

IEC 61000-4-7:2002 (p.71)

1.1 Product Overview

Overview Chapter 1

1.1 Product Overview

The PW3336/ PW3337 is a power meter with power measurement capabilities for the full range of electrical

equipment, from single-phase devices such as battery-driven devices and household electronics to industrialuse and three-phase electrical equipment.

The instrument provides coverage from DC to inverter frequencies with support for voltages up to 1000 V and

direct-input currents of up to 65 A. It can also measure currents of up to 5000 A using an optional current sensor.

1.2 Features

• : These instruments provide two channels each of voltage

input and current input.

• : These instruments provide three channels each of voltage

input and current input.

• Since all channels are isolated, the instrument can simultaneously measure multiple circuits.

• It supports measurement lines from single-phase to 3-phase/4-wire.

• With 3-phase/3-wire measurement lines, the instrument can measure either voltage between lines (3V3A)

or phase voltage (3P3W3M) using vector calculations simply by switching its line setting (input terminal

connections remain the same).

• Accuracy is guaranteed for currents of up to 65 A with direct input.

• (The maximum input current is 70 A, ±100 Apeak.)

• An optional current sensor can be used to measure currents in excess of 65 A. (p.102)

• The instrument delivers a high fundamental accuracy of ±0.15% rdg. (at less than 50% of range, ±0.1% rdg.

±0.05% f.s.).

• Over a wide band from DC and 0.1 Hz to 100 kHz, the instrument covers not only the fundamental frequency band for inverter-driven equipment, but also the carrier frequency band.

• Power factor effects are low at ±0.1% f.s. (with a internal circuit voltage/current phase difference of

±0.0573°), allowing high-accuracy measurement of active power during low power-factor operation, for

example during no-load testing of transformers and motors.

• The instrument can perform harmonic measurement in compliance with the IEC 61000-4-7:2002 international standard on harmonic measurement methods.

• You can set an upper limit for the analyzed order from the 1st to 50th order according to the harmonic measurement standard in use.

Page 18

12

Extensive measurement functionality, standard

High-speed D/A output to capture harsh load variations (p.88)

Building a system with 3 interfaces (p.117)

Synchronized control function with support for measurement of even

more channels (p.81)

1.2 Features

• Since processing for functions such as AC+DC (RMS), AC+DC Umn (voltage average value rectified RMS

equivalent), DC (DC component), AC (AC component), FND (fundamental wave component), and harmonic measurement as well as integration measurement can be performed internally and in parallel, it is

possible to obtain simultaneous measured values simply by switching the display.

• Since the measurement range and other parameters can be set independently for each channel, it is possible to measure input-output efficiency for inverters and other power supply devices. (p.78)

• The active power level can be output for each cycle for the voltage or current assigned to the synchronization source.

• Variations over extended periods of time can be recorded by using the instrument in conjunction with equipment such as a recorder or data logger using level output (updated every 200 ms) for each channel’s voltage, current, and active power as well as associated sum values and three user-selected parameters.

• Safe, insulated waveforms can be observed using waveform output (equivalent to a sampling rate of

approximately 87.5 kHz) for each channel’s instantaneous voltage, instantaneous current, and instantaneous power.

• You can control the instrument or capture data from it using a computer by using the standard RS-232C or

LAN interface. (You can also communicate with a computer over USB by using a commercially available

USB serial conversion cable.)

• The instrument also provides a GP-IB interface, an essential capability when building such systems.

( )

• Simultaneous measurement can be performed by connecting two instruments with an optional BNC cable.

• Calculations, display updates, data updates, integration control, display hold timing, zero-adjustment, and

key lock operation of the instrument set as the slave (IN setting) are matched to the master instrument

(OUT setting).

Page 19

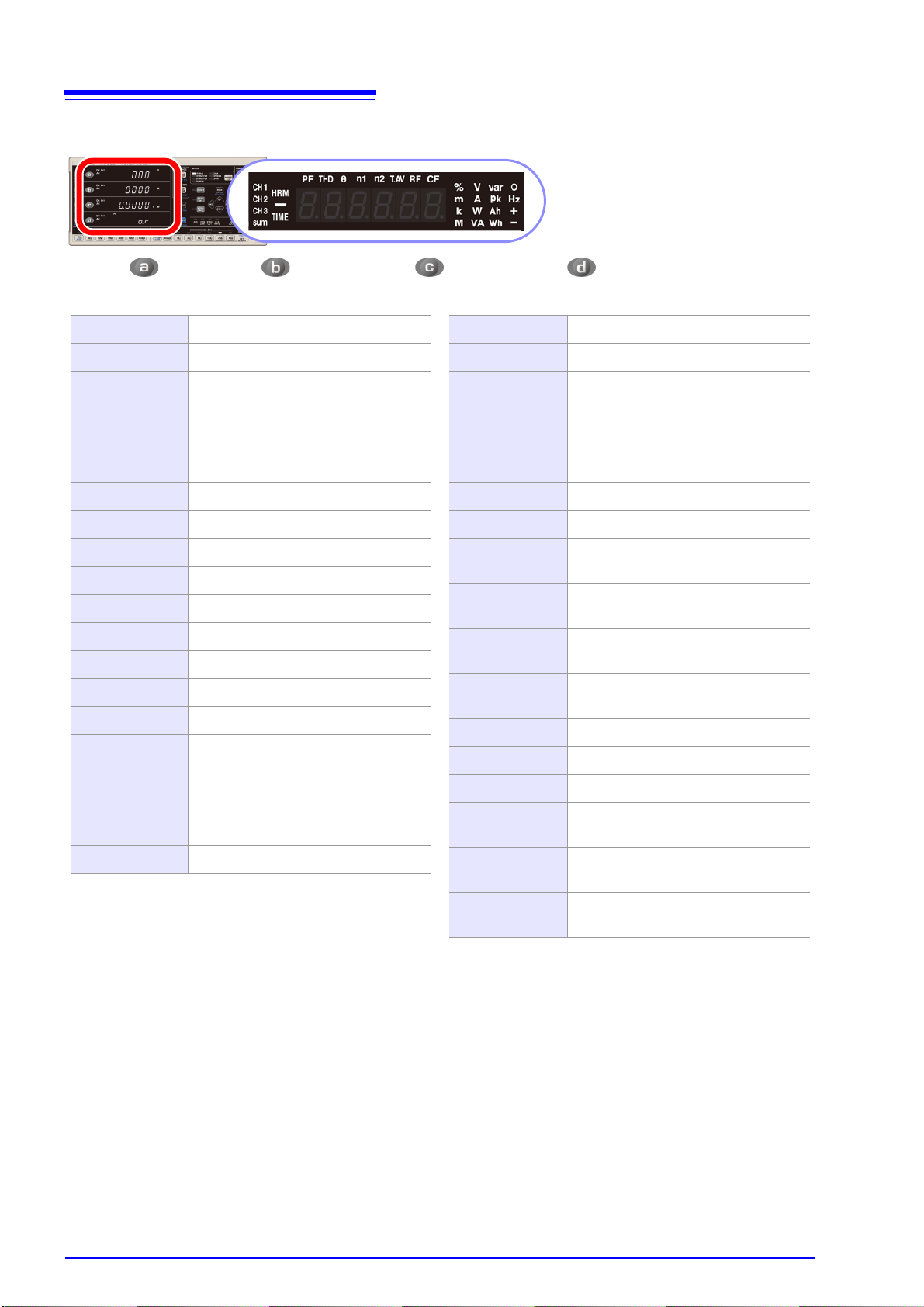

1.3 Names and Functions of Parts

Function setting status lamps

(for each channel) (p.18)

Light up to indicate when settings differ

from default settings.

CH/ RECTIFIER (p.46)

Switches the displayed channel and

rectifier (in the shift state).

Parameter keys (p.14)

Switch display parameters.

Warning lamps

(for each channel)

(p.19)

Current range (p.48)

(Pressing 200 mA in the

shift state selects autorange operation.)

CH

Switches the channel to configure.

(For both voltage

and current)

POWER switch (p.35)

Turns the instrument on and off.

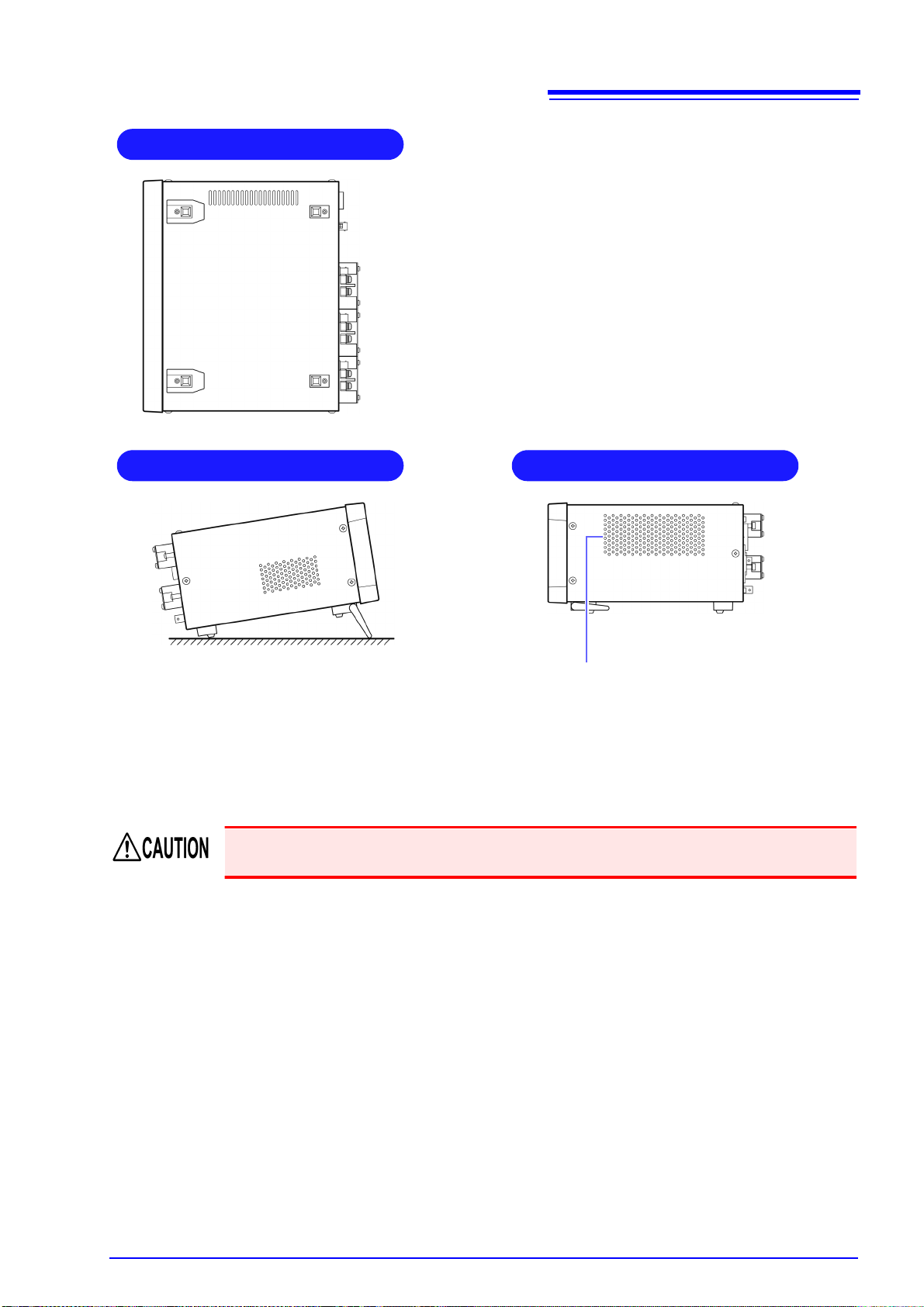

Front Panel

Display

Switches between measured

values and setting values.

Voltage range (p.48)

(Pressing 15 V in the

shift state selects autorange operation.)

e.g.) PW3337-03

HRM/ ORDER SEL

Harmonic display (switch among level, content percentage, and

normal display)

HOLD/ MAX/ MIN

Holds display values, switches between maximum and minimum

values (in the shift state).

SHIFT/ EXIT/ LOCAL

Activates/deactivates the shift state; exits settings mode or remote

mode.

START/STOP /DATA RESET

Starts/stops integration, resets integrated values (in the shift state).

Function setting

keys (p.40)

Configure functions.

Function setting status lamps

(p.18)

Light up to indicate activated functions.

1.3 Names and Functions of Parts

13

The shift state is automatically canceled after Approx. 10 seconds. When the RECTIFIER key or a parameter

key is pressed, the shift state is canceled after Approx. 2 seconds.

Page 20

14

Pressing on the first row, on the second row, on the third row, or on the fourth row of the measured

value display switches the display parameter, causing the selected display parameter to light up.

V Voltage (U)

A Current(I)

W Active power (P)

VA Apparent power (S)

Var Reactive power (Q)

PF Power factor (λ)

° Phase angle (φ)

V Hz Voltage frequency (f)

A Hz Current frequency (f)

Ah + Positive current integration

Ah - Negative current integration

Ah Current integration sum

Wh + Positive active power integration

Wh - Negative active power integration

Wh Active power integration sum

TIME Integration time

V pk Voltage waveform peak value (Upk)

A pk Current waveform peak value (Ipk)

η1 % Efficiency (η)

η2 % Efficiency (η)

CF V Voltage crest factor (Ucf)

CF A Current crest factor (Icf)

T.AV A Time average current (T.AV I)

T.AV W Time average active power (T.AV P)

RF V % Voltage ripple rate(Urf)

RF A % Current ripple rate(Irf)

THD V % Total harmonic voltage distortion (Uthd)

THD A % Total harmonic current distortion (Ithd)

θ V ° CH1 CH2

Inter-channel voltage fundamental

wave phase difference (θU2-1)

θ V ° CH1 CH3

Inter-channel voltage fundamental

wave phase difference (θU3-1)

θ A ° CH1 CH2

Inter-channel current fundamental

wave phase difference (θI2-1)

θ A ° CH1 CH3

Inter-channel current fundamental

wave phase difference (θI3-1)

HRM V LEVEL Harmonic voltage RMS value (Uk)

HRM A LEVEL Harmonic current RMS value (Ik)

HRM W LEVEL Harmonic active power (Pk)

HRM V % HD%

Harmonic voltage content percentage

(UHDk)

HRM A % HD%

Harmonic current content percentage

(IHDk)

HRM W % HD%

Harmonic active power content percentage (PHDk)

1.3 Names and Functions of Parts

Display parameters

Page 21

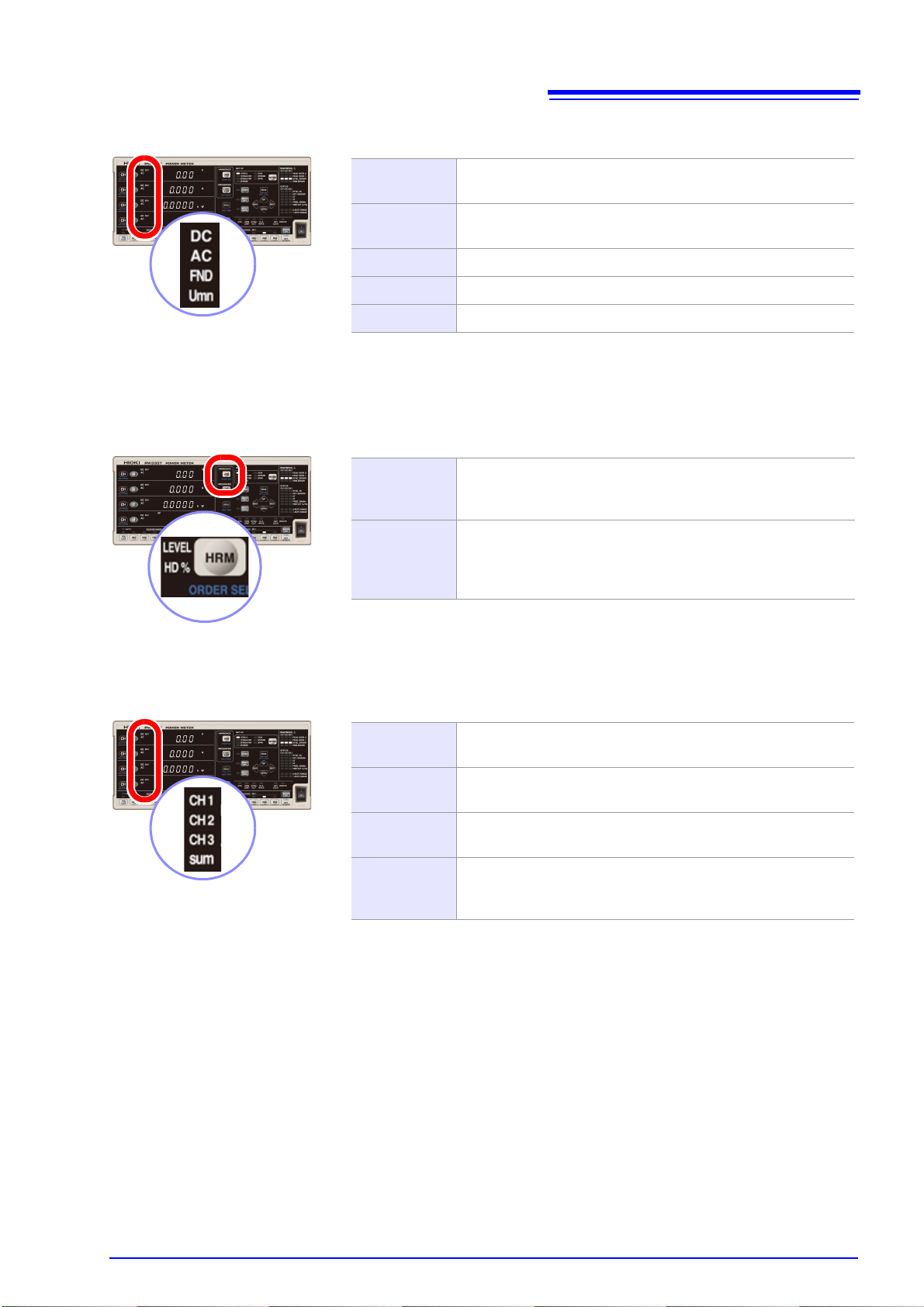

1.3 Names and Functions of Parts

DC AC

When using the AC+DC rectifier, both the DC and AC lamps light

up.

DC AC Umn

When using the AC+DC Umn rectifier, the DC, AC, and Umn

lamps light up.

DC Lights up when using the DC rectifier.

AC Lights up when using the AC rectifier.

FND Lights up when using the FND rectifier.

LEVEL

Lights up when the instrument is displaying a harmonic component level (harmonic voltage RMS value, harmonic current RMS

value, or harmonic active power).

HD%

Lights up when the instrument is displaying a harmonic content

percentage (harmonic voltage content percentage, harmonic

current content percentage, or harmonic active power content

percentage).

CH1

Lights up when the instrument is displaying the CH1 measured

value for the selected display parameter.

CH2

Lights up when the instrument is displaying the CH2 measured

value for the selected display parameter.

CH3

Lights up when the instrument is displaying the CH3 measured

value for the selected display parameter.

sum

Lights up when the instrument is displaying the measured value

for the sum of the selected display parameters when using a wiring mode other than 1P2W.

Rectifier indicator lamps (p.47)

Harmonic measurement (HARMONICS) lamps (p.71)

15

CH1, CH2, CH3, and sum lamps

Page 22

16

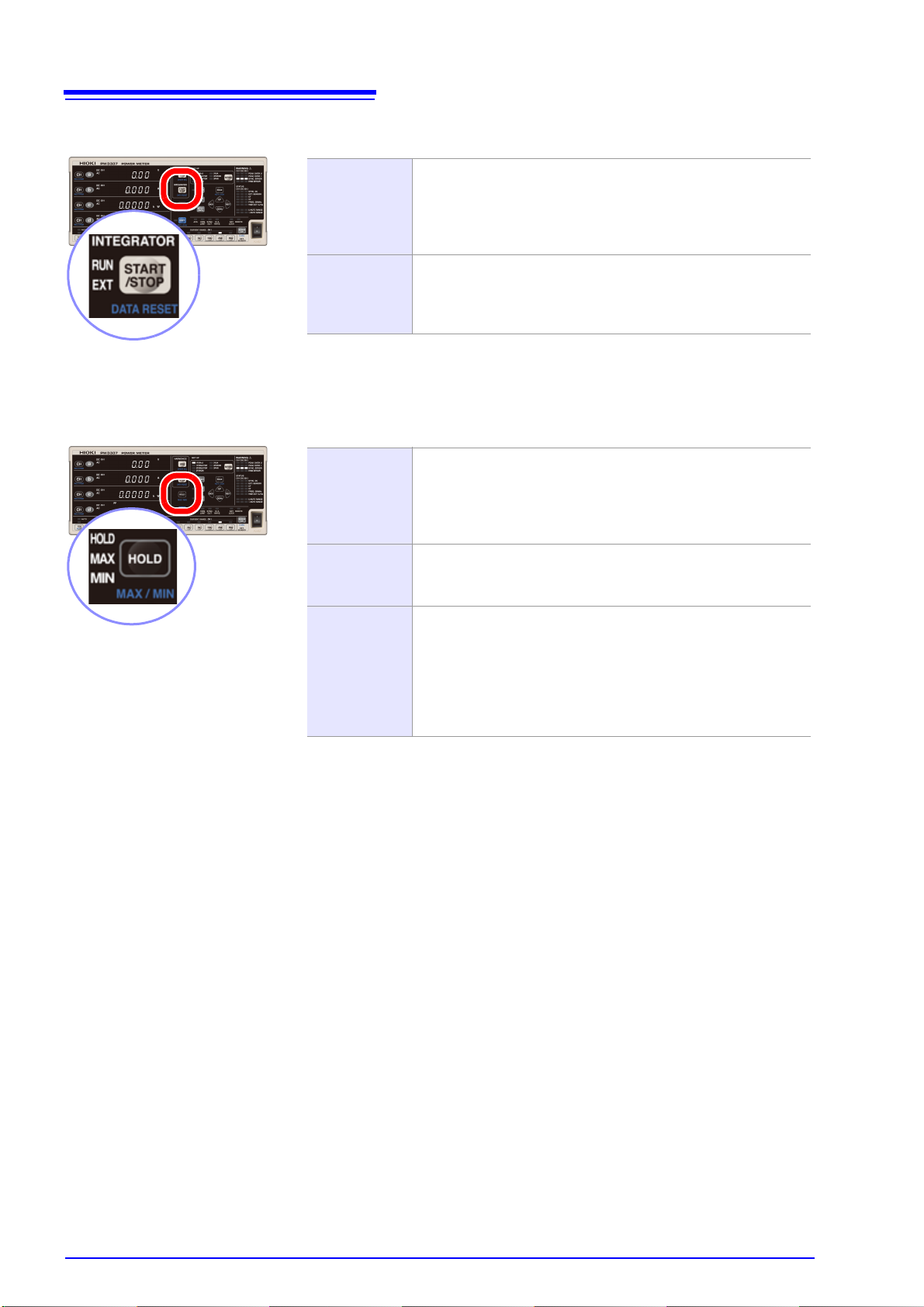

RUN

Indicates the status of integration based on START/STOP key

operation or communications.

RUN lamp on: Integration active

RUN lamp flashing: Integration stopped

RUN lamp off: Integration reset

RUN EXT

Indicates the status of integration based on external control.

RUN lamp on, EXT lamp on: Integration active

RUN lamp flashing, EXT lamp on: Integration stopped

RUN lamp and EXT lamp off: Integration reset

HOLD

Lights up when display hold is activated by pressing the HOLD

key.

To cancel display hold: Pressing the HOLD key once more

causes the display hold state to be canceled and the HOLD lamp

to be turned off.

MAX

When the HOLD, MAX, and MIN lamps are all off, pressing the

SHIFT key and then the HOLD key causes the maximum value

to be held and the MAX lamp to light up.

MIN

Pressing the HOLD key while the MAX lamp is lit up (indicating

that the maximum value is being held) causes the minimum value to be held and the MIN lamp to light up.

Pressing the HOLD key while the MIN lamp is lit up (indicating

that the minimum value is being held) causes the minimum value

hold to be canceled, returning to the normal measured value display.

1.3 Names and Functions of Parts

Integration (INTEGRATOR) status indicator lamps (p.62)

Hold (HOLD) status indicator lamp (p.108)

Page 23

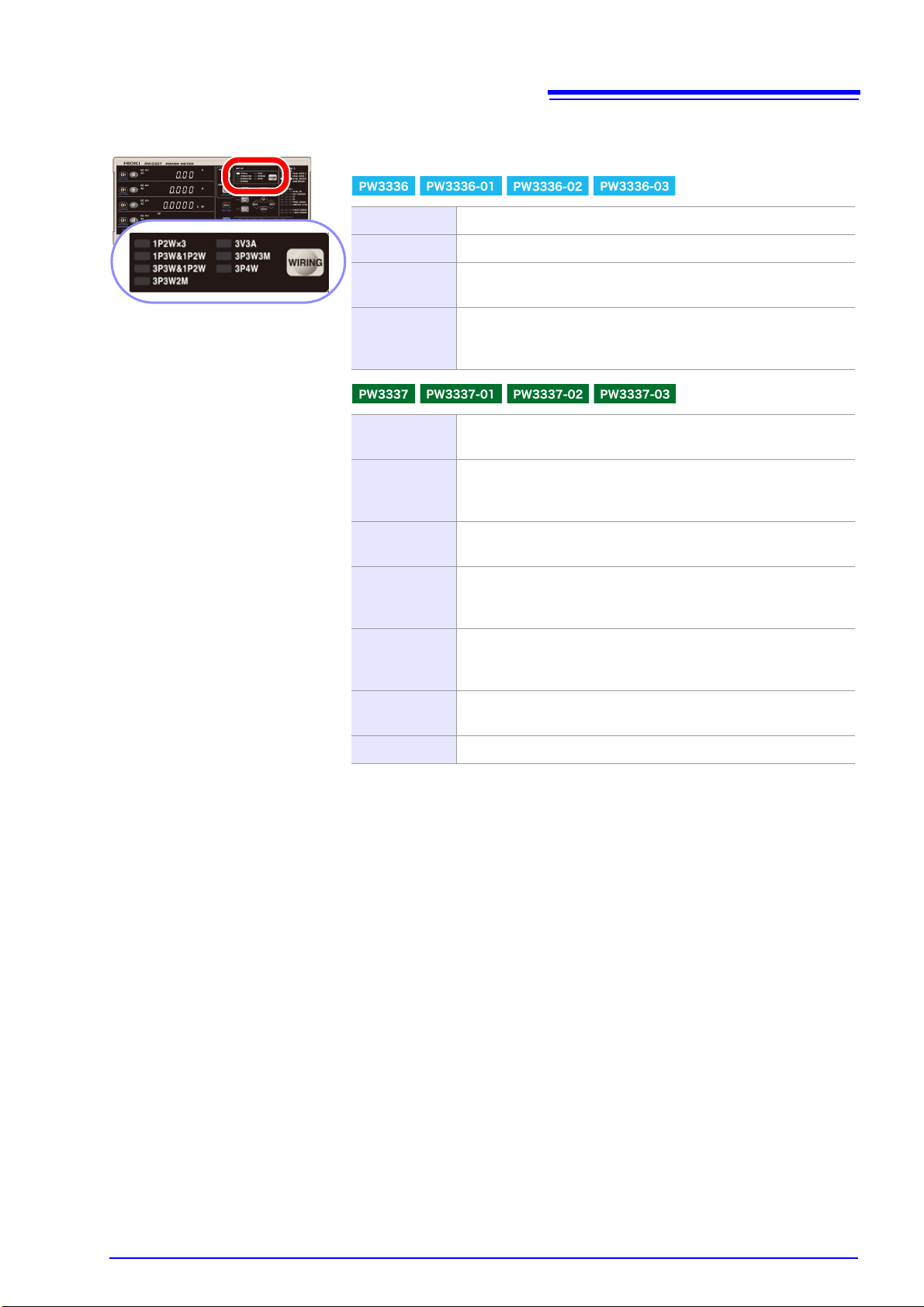

Wiring (WIRING) mode indicator lamps (p.40)

These lamps light up when the following wiring modes are selected:

1P2W×2 1-phase/2-wire × 2 circuits (CH1 and CH2 are 1-phase/2-wire.)

1P3W 1-phase/3-wire

3P3W

3-phase/3-wire, active power measurement using the two-power-meter method

3P3W2M

3-phase/3-wire, active power measurement using the two-power-meter method (Displays line voltage and phase current, which

are not measured, using vector calculations.)

1P2W×3

1-phase/2-wire × 3 circuits (CH1, CH2, and CH3 are 1-phase/2wire)

1P3W&1P2W

1-phase/3-wire & 1-phase/2-wire (CH1 and CH2 are 1-phase/3wire, Active power is measured by 2-power measurement method, and CH3 is 1-phase/2-wire.)

3P3W&1P2W

3-phase/3-wire & 1-phase/2-wire (CH1 and CH2 are 3-phase/3wire, and CH3 is 1-phase/2-wire.)

3P3W2M

3-phase/3-wire, active power measurement using the two-power-meter method (Displays wire voltage and phase current,

which are not measured, using vector calculations.)

3V3A

3-phase/3-wire, active power measurement using the two-power-meter method (Actually measures and displays all wire voltages and phase currents.)

3P3W3M

3-phase/3-wire (Converts and displays wire voltages and phase

voltages using vector calculations with 3V3A wiring.)

3P4W 3-phase/4-wire

17

1.3 Names and Functions of Parts

Page 24

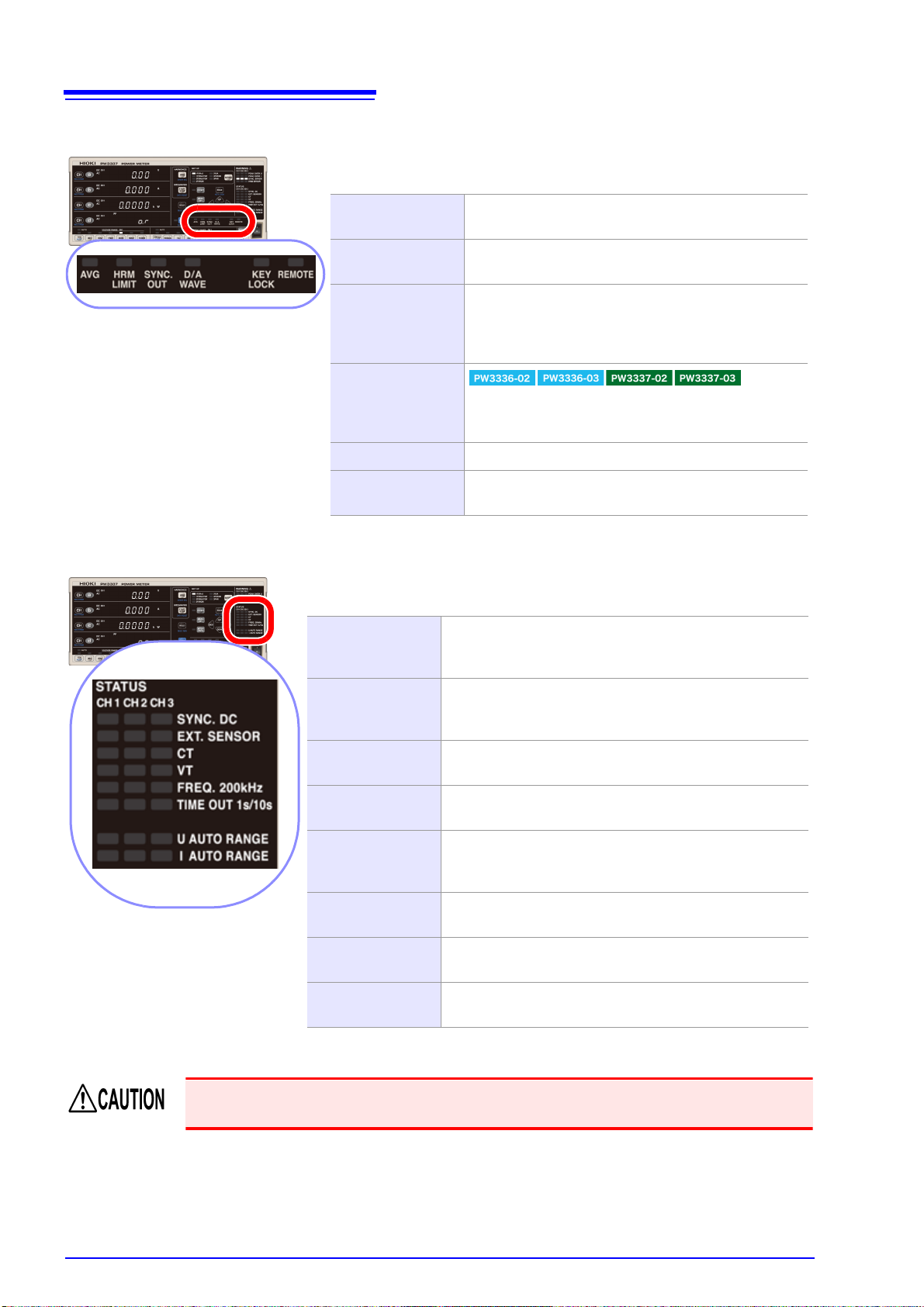

18

These lamps indicate the instrument’s overall setting status. They light up

when the corresponding function is ON.

AVG

Lights up when the number of averaging iterations is

set to a value other than the default value of 1.(p.57)

HRM LIMIT

Lights up when the harmonic analysis order upper limit

is set to a value other than the default value of 50.(p.71)

SYNC. OUT

Lights up when the synchronized measurement I/O setting is set to OUT (Master). Flashes with external synchronized signal input when set to IN (Slave). Turns off

when set to OFF.(p.81)

D/A WAVE

Lights up when the D/A output setting is set to waveform/high-speed active power level output (the default

setting is level output). (p.88)

KEY LOCK Lights up when key operation is disabled. (p.111)

REMOTE

Lights up when the instrument is in remote operation

mode. (p.134)

These lamps indicate the setting status for each channel. Function lamps light up

when set to a value other than the default setting.

SYNC. DC

Lights up when the synchronization source is set to DC (the

default setting is each channel’s voltage: U1, U2, and U3).

(p.51)

EXT. SENSOR

Lights up when the current input method setting is set to

TYPE1 or TYPE2 (current sensor input) (the default setting

is OFF [current value direct input]). (p.42)

CT

Lights up when the CT ratio setting is set to a value other

than the default setting of 1. (p.59)

VT

Lights up when the VT ratio setting is set to a value other

than the default setting of 1. (p.59)

FREQ. 200kHz

Lights up when the zero-cross and frequency measurement

filter setting is set to 100 Hz, 5 kHz, or 200 kHz (the default

setting is 500 Hz). (p.53)

TIME OUT 1s/10s

Lights up when the synchronization detection timeout is set

to 1 sec. or 10 sec. (the default setting is 0.1 sec.). (p.55)

U AUTO RANGE

Lights up when the voltage measurement range is set to

auto range (the default setting is auto range OFF). (p.48)

I AUTO RANGE

Lights up when the current measurement range is set to

auto range (the default setting is auto range OFF). (p.48)

1.3 Names and Functions of Parts

Setting status indicator lamps

When the VT and CT lamps are lit up, note that voltage and current inputs differ from the

displayed measured values.

Page 25

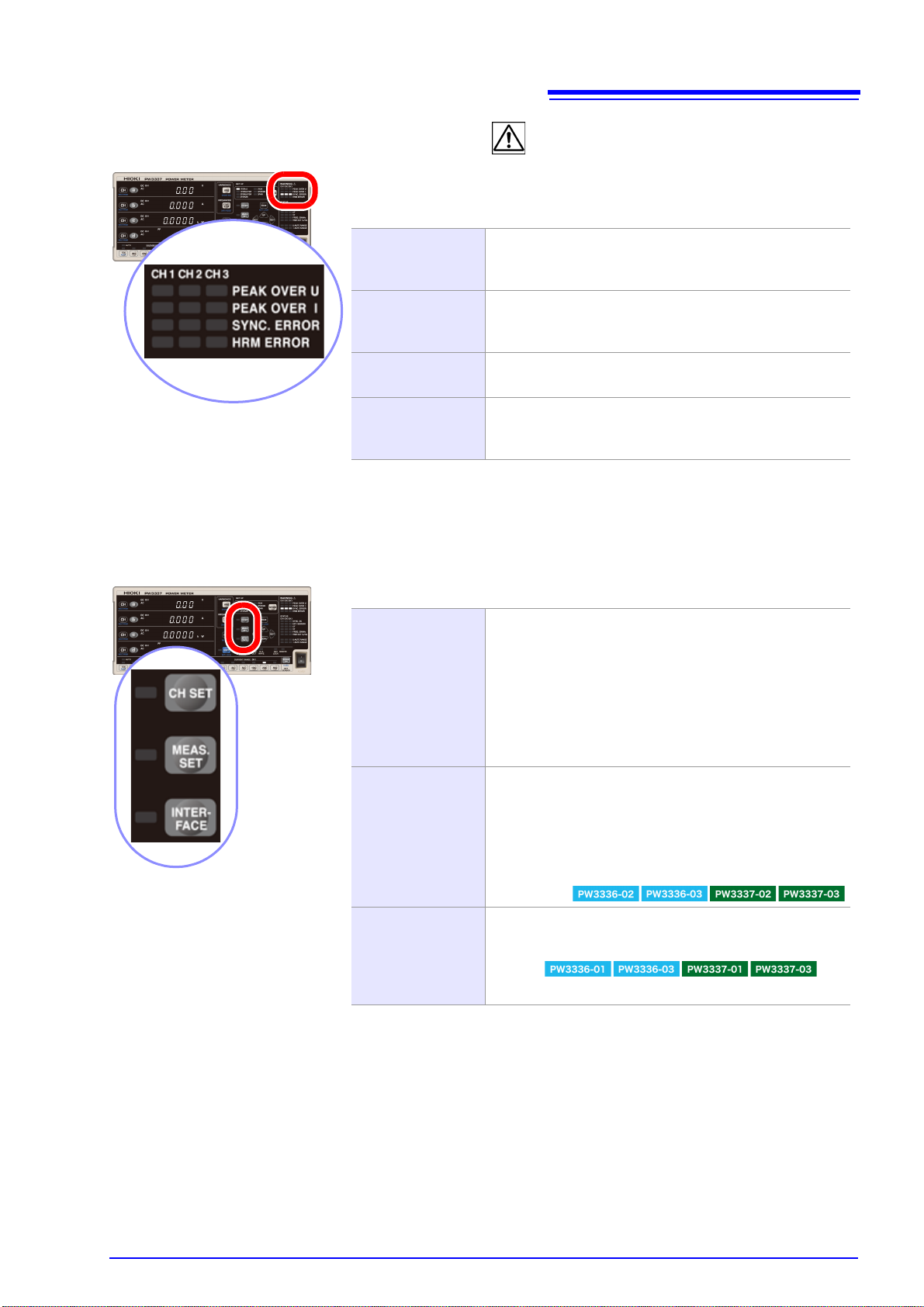

Warning (WARNING) indicator lamps

These lamps indicate channel warnings. When the following warning lamps and error lamps are lit up, they indicate a hazardous state or inability to perform measurement accurately:

PEAK OVER U

Lights up when an overvoltage input warning occurs, indicating that the input voltage peak value has exceeded

±1500 V or ±600% of the voltage measurement range.

PEAK OVER I

Lights up when an overcurrent input warning occurs, indicating that the input current peak value has exceeded ±100

A or ±600% of the current measurement range.

SYNC. ERROR

Lights up when a synchronization error occurs, indicating

that synchronization cannot be detected.

HRM ERROR

Lights up when a harmonic measurement synchronization

error occurs, indicating that the harmonic measurement

synchronization frequency range was exceeded.

These lamps light up in response to settings on the following setting screens:

CH SET

Channel settings

• Synchronization source

• Current input method

•CT ratio

•VT ratio

• Zero-cross and frequency measurement filter

• Synchronization detection timeout

MEAS. SET

Shared settings that apply to all channels

• Integration time

• Number of averaging iterations

• Harmonic analysis upper limit order

• Synchronized measurement I/O (master, slave)

• D/A output

INTERFACE

Interface settings

• RS-232C

•GP-IB

•LAN

19

1.3 Names and Functions of Parts

Setting screen indicator lamps

Page 26

20

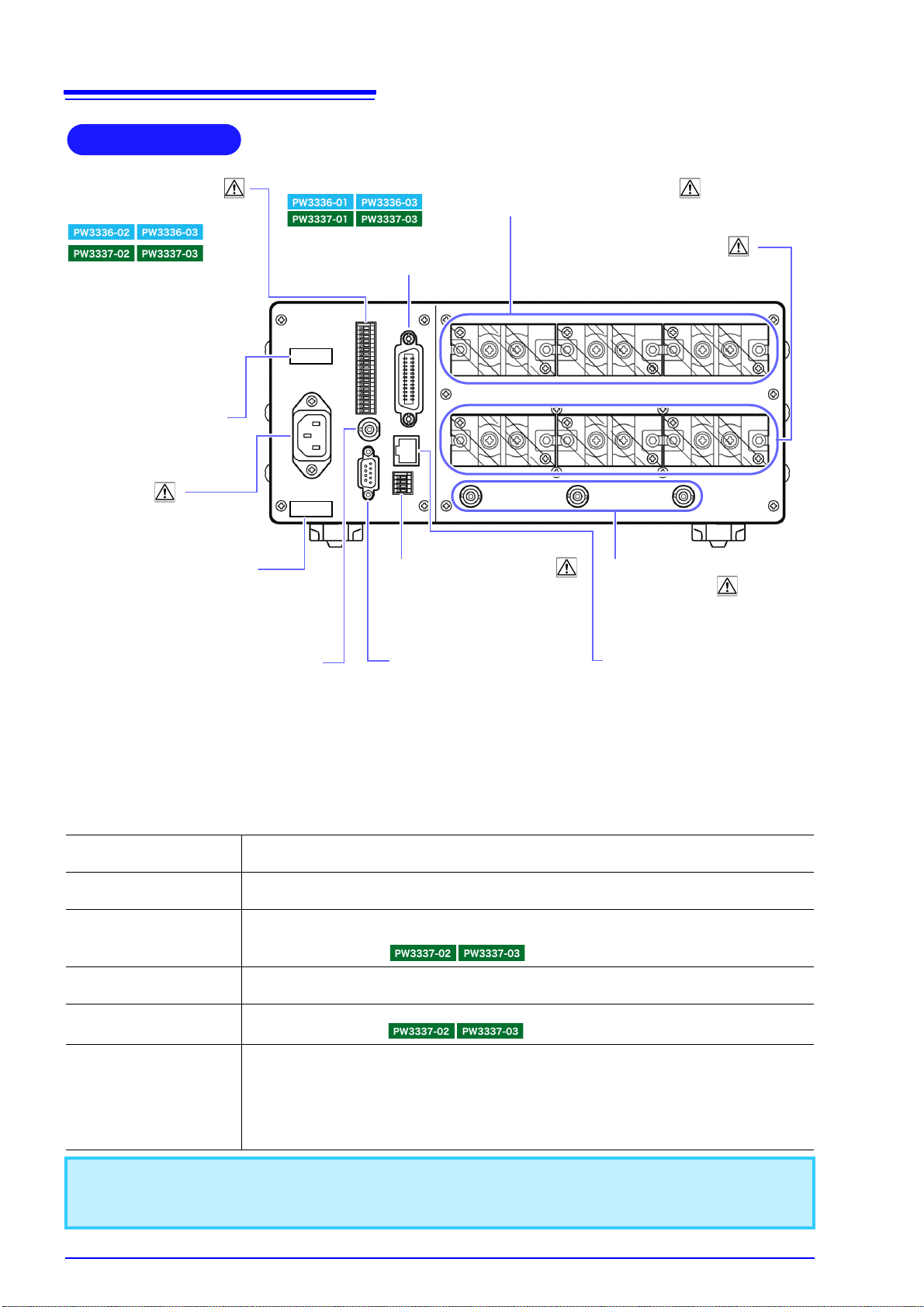

Manufacturer's Serial No.

Model name number

Shows the serial number.

Do not remove this label, as it is

required for product support.

Voltage input terminal (U )

Input voltage signals. (p.28)

Rear

MAC address of the

LAN

e.g.) PW3337-03

GP-IB connector

Connect a communications cable when using the

GP-IB interface. (p.131)

External synchronization terminal

Connect a cable for synchronized

measurement. (p.81)

Power Inlet

(p.34)

D/A Output terminal

*

(D/A OUTPUT)

The voltages listed below

are output from each

terminal. (p.88)

RS-232C connector

Connect a communications

cable when using the RS232C interface. (p.118)

External current sensor

input terminal

(CURRENT SENSOR)

Connect current sensors. (p.102)

LAN connector

Connect a communications cable when using the LAN interface. (p.122)

External control terminal

(EXT. CONTROL)

Input signals from an integration

external control function. (p.85)

Current input terminal ( I )

Input current signals. (p.28)

1.3 Names and Functions of Parts

*D/A OUTPUT terminals

The following voltages are output from each terminal.

Level output: Level (analog) output is updated at an interval of approximately 200 ms.

Instantaneous waveform output: The input waveform as sampled at a frequency of approximately 87.5 kHz is output.

High-speed active power level output: The active power for every cycle for the voltage or current set as the synchronization

source is output.

U1/u1, U2/u2, U3/u3

I1/i1, I2/i2, I3/i3

P1/p1, P2/p2, P3/p3

Psum/Hi-Psum

Hi-P1, Hi-P2, Hi-P3

DA1, DA2, DA3

Key processing is embedded in the instrument for production and verification purposes. For example, this

processing includes transitioning to an adjustment mode. If key operation causes a message or indication

that is not described in this manual to be displayed, immediately cycle the instrument’s power.

Generates voltage level output or instantaneous voltage waveform output (set to one or the

other) for each channel.

Generates current level output or instantaneous current waveform output (set to one or the

other) for each channel.

Generates active power level output or instantaneous power waveform output (set to one or

the other) for each channel.

(P3/p3 is generated by only.)

Generates active power sum level output or high-speed level output (set to one or the other)

for wiring modes other than 1P2W.

Generates active power high-speed level output for each channel.

(Hi-P3 is generated by only.)

Generates level output for three of the following parameters for each channel and as a sum

(sum value) as selected by the user:

Voltage, current, active power, apparent power, reactive power, power factor, phase angle,

voltage total distortion, current total distortion, voltage crest factor, current crest factor, voltage ripple rate, current ripple rate, voltage frequency, current frequency, efficiency, current

integration, and active power integration

Page 27

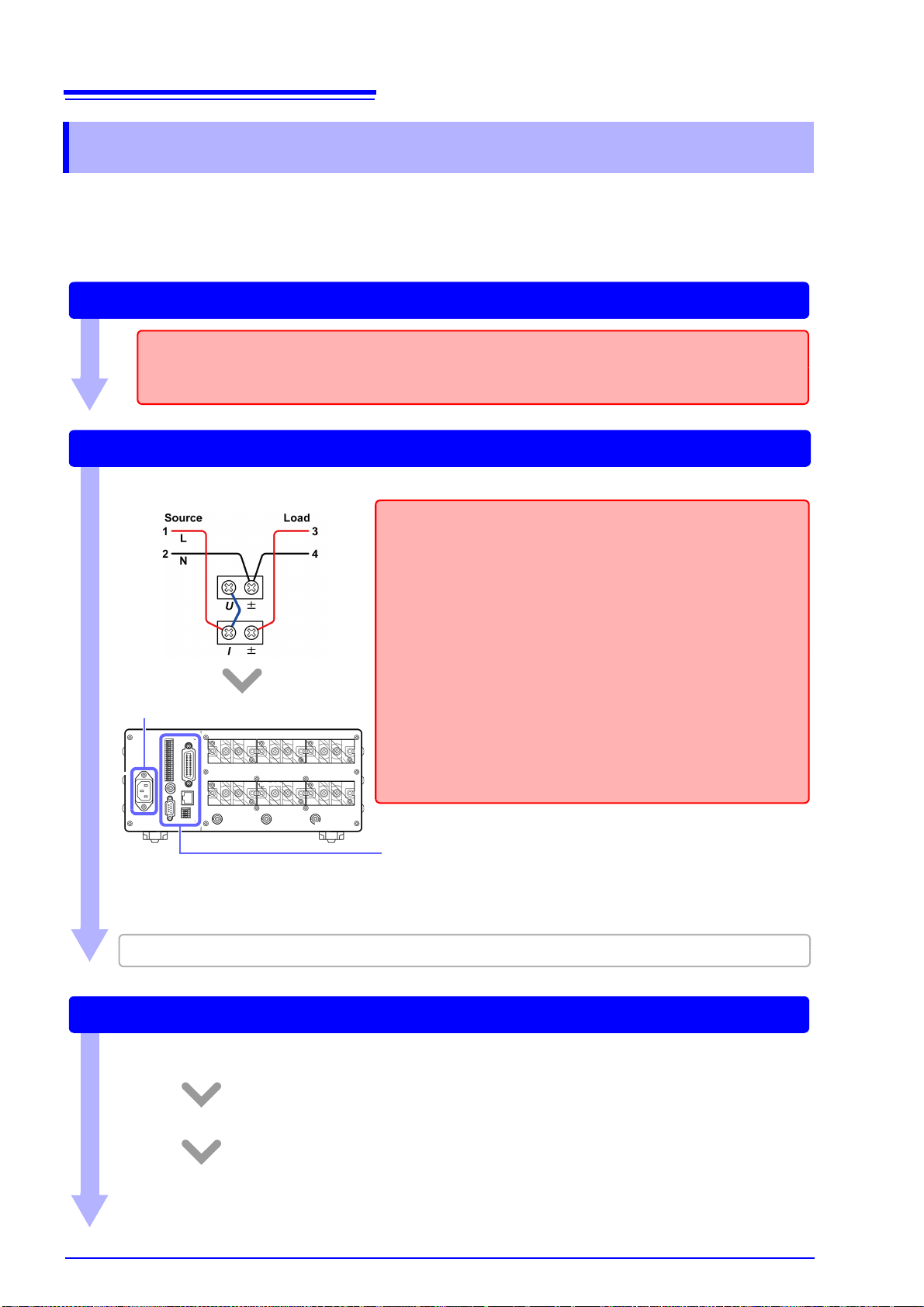

21

Bottom panel

This instrument can be rack mounted.

See: Appendix 3 Rack Mounting(p. A11)

Parts removed from this instrument should be stored in a

safe place to enable future reuse.

Left side

When using the stands

Open the stands until they clicks into place. Be sure

to use both stands.

When folding up the stands

Fold up the stands until they click into place.

Right side

Vents

Keep clear of obstructions.

1.3 Names and Functions of Parts

Do not apply heavy downward pressure with the stand extended. The stand could be damaged.

Page 28

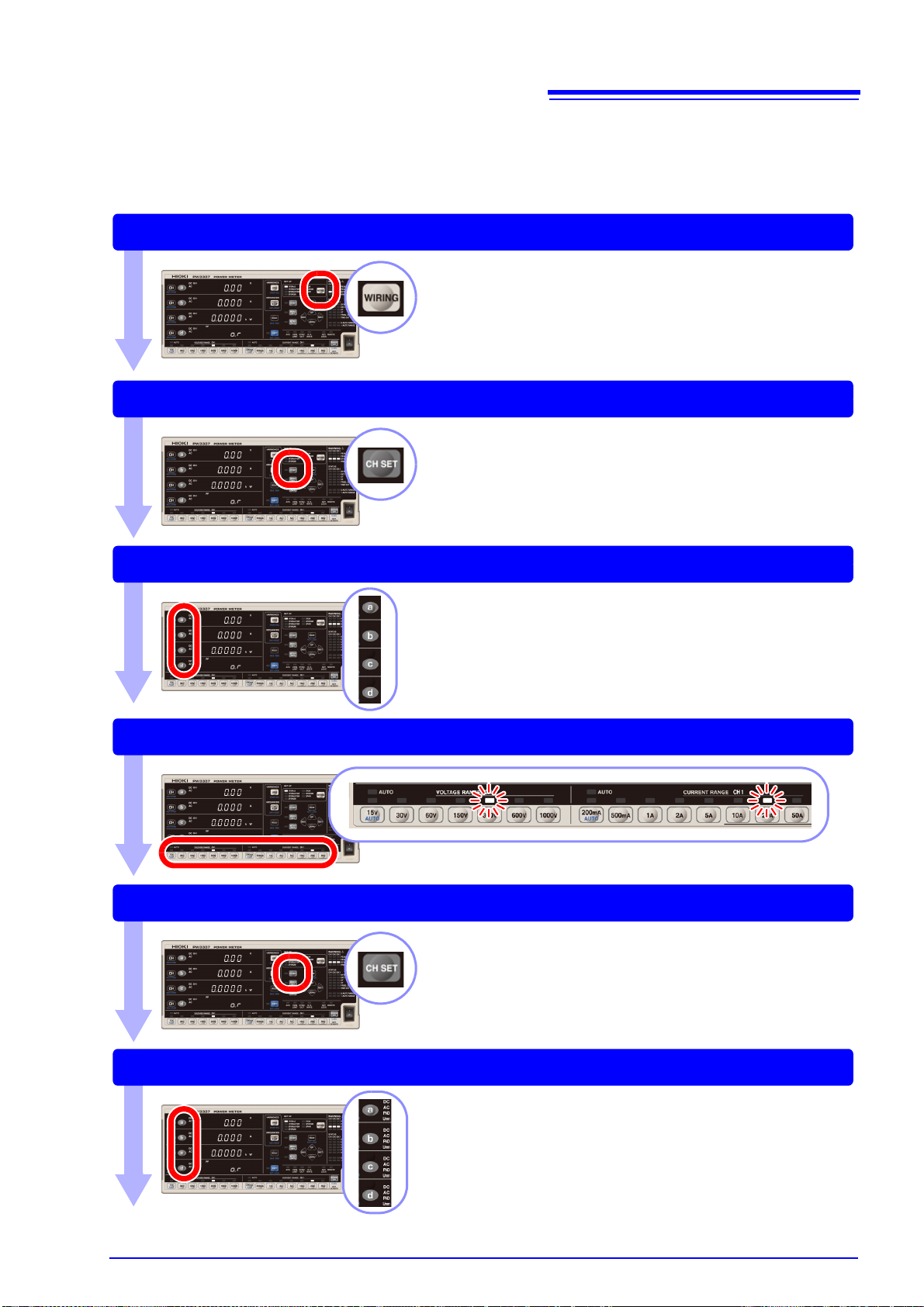

22

Installing the Instrument (p.5)

CHECKS

• Are the wires from the measurement targets shut off?

• Is the instrument turned off, and has the power cord been disconnected?

• Using D/A output (p.88)

• Using synchronized control to conduct measurements with 2

instruments simultaneously (p.81)

• Using external control to control integration (p.62)

• Sending and receiving data with the RS-232C, LAN, and GP-IB

interfaces (p.117)

Connecting Wires and Cords

Connect the measurement lines to the instrument and then connect the power cord to the instrument.

CHECKS

• Is the instrument connected on the secondary side of the circuit

breaker?

• Does the circuit being used exceed 1000 V?

• Does the voltage or current being measured exceed 1000 V or 70

A, respectively?

If so, use VT and CT.

• Are appropriate types of wire being used to connect to the voltage

and current input terminals?

Use solderless terminals that cover wiring with insulation. When

using solderless terminals with exposed metallic parts, use wire

with adequate dielectric strength and current capacity.

• Has the wiring been shorted?

• Are the input terminals loose?

• Have wires been connected properly?

Connect wires. (p.28)

e.g.)

Connect the power cord. (p.34)

When using one or more current sensors, see "3.9 Using a Current Sensor" (p.102).

Turning on the instrument (p.35)

Before turning on the instrument, verify that the wires have been connected properly one more time.

After displaying the initial screen, the instrument will display input values under the current settings.

Allow the instrument to warm up for at least 30 minutes.

Perform zero-adjustment.

To fulfill the instrument’s accuracy specifications, be sure to perform zero-adjustment for the voltage

and current measured values.

1.4 Measurement Workflow

1.4 Measurement Workflow

1 Install the instrument, connect wires and cords, and

turn on the instrument.

Page 29

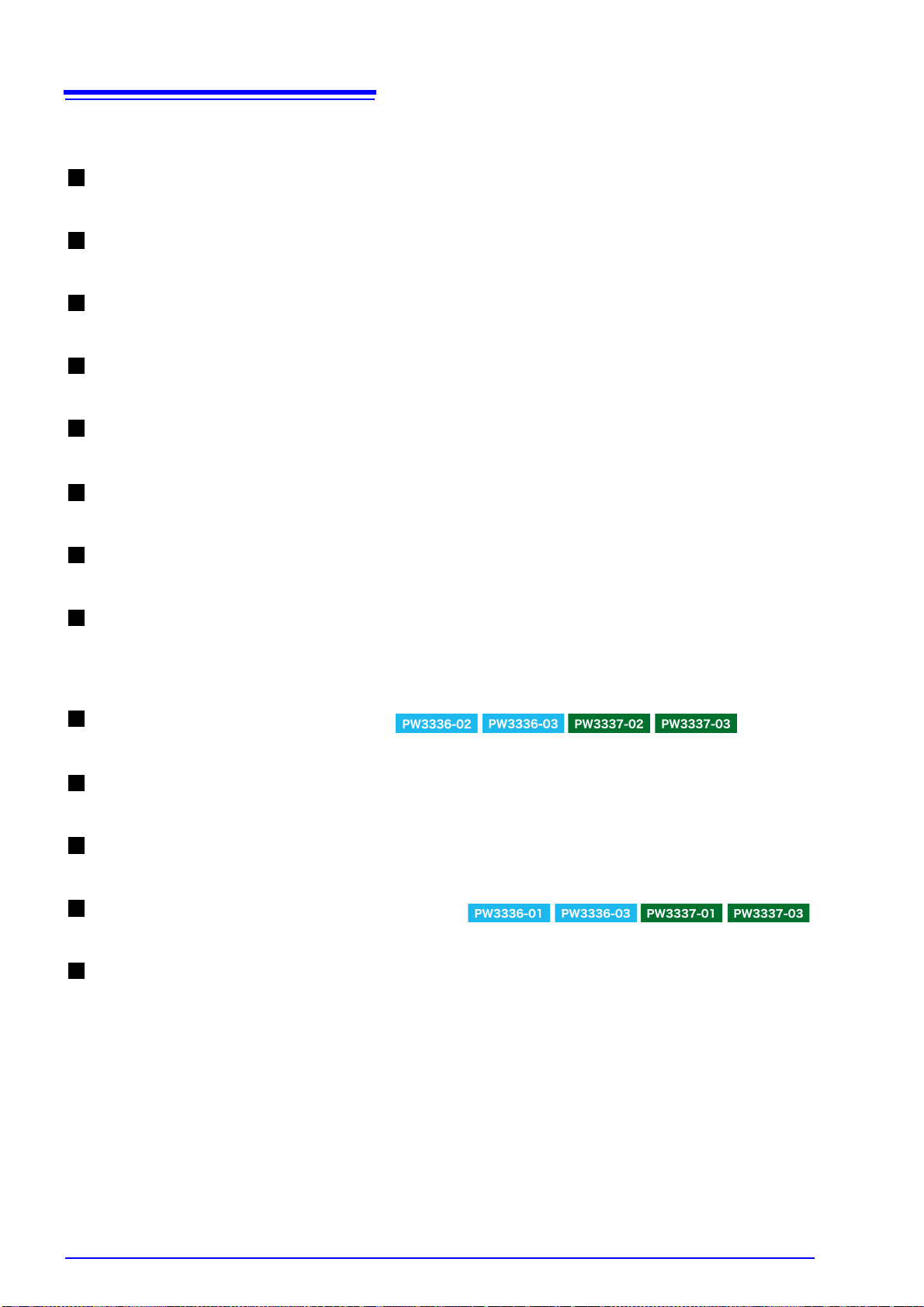

23

Selecting the wiring mode (p.40)

Setting the current input method (p.42)

Selecting display parameters (p.44)

Selecting voltage and current ranges (p.48)

Setting the synchronization source (p.51)

Selecting rectifiers (p.47)

1.4 Measurement Workflow

2 Configure instrument settings. (These settings can

also be changed during measurement.)

Page 30

24

Configure the following settings as necessary:

Setting the frequency measurement range

See: "3.2.6 Setting the Frequency Measurement Range" (p.53)

Addressing display value variation: Displaying average measured values

See: "3.2.8 Displaying Measured Values as an Average (AVG: Averaging)" (p.57)

Measuring voltages in excess of 1000 V: Using VT (PT) to make measurements

See: "3.2.9 Setting the VT and CT Ratio" (p.59)

Measuring currents in excess of 65 A: Using CT to make measurements

See: "3.2.9 Setting the VT and CT Ratio" (p.59)

When you wish to perform integration

See: "3.3 Integration" (p.62)

When you wish to measure harmonics

See: "3.4 Viewing Harmonic Measured Values" (p.71)

When you wish to measure efficiency

See: "3.5 Measuring Efficiency" (p.78)

When you wish to use the display hold, maximum value hold, and minimum value

hold functions

See: "3.10.1 Fixing Display Values (Display Hold)" (p.108)

"3.10.2 Displaying Peak, Minimum, and Maximum Values (Maximum Value Hold)" (p.109)

When you wish to use D/A output

See: "Examples of analog output"(p.98)

When you wish to use the RS-232C interface

See: "Setting the RS-232C communications speed"(p.119)

When you wish to use the LAN interface

See: "Setting the LAN’s IP address"(p.123)

When you wish to use the GP-IB interface

See: "Setting the GP-IB address"(p.133)

When you wish to perform synchronized measurement with multiple instruments

See: "3.6 Performing Synchronized Measurement with Multiple Instruments (Multiple-instrument Syn-

chronized Measurement)" (p.81)

1.4 Measurement Workflow

Page 31

3 Start measurement.

Activating power to the measurement lines

Measuring and outputting data

The instrument will display the measured values.

You can change the voltage and current range as well as display parameters during measurement.

Example:

When you wish to hold display

values (p.108)

Press .

Displaying maximum and minimum

values (p.109)

Press while holding down .

Voltage

Current

Active power

Power factor

Turning off the instrument

After disconnecting the cords from the object under measurement, turn off the instrument.

See: "2.4 Turning On the Instrument" (p.35)

25

1.4 Measurement Workflow

4 Stop measurement.

About measured values

• The instrument’s apparent power (S), reactive power (Q), power factor (λ), and phase angle (φ) are calculated based on the measured voltage (U), current (I), and active power (P). For the actual equations used,

see "5.5 Calculation Formulas Specifications" (p.161). Values displayed by the instrument may differ from

values displayed by measuring instruments that use different operating principles or equations.

• Display values are forcibly set to zero for voltage and current when the input is less than 0.5% of the measurement range and for the voltage peak value and current peak value when the input is less than 0.3% of

the peak range (this is known as zero-suppression).

• Measured values may include an error component in measurements in which a terminal-to-ground voltage

with a high frequency is input.

• Display values may exhibit variation in applications in which the frequencies of the voltage and current

being measured differ.

• Measured values may include an error component when the instrument is used near a strong magnetic

field such as that generated by a transformer or high-current path, a strong electric field generated by a

radio or similar device, or a high-frequency magnetic field generated by a high-frequency current.

Page 32

26

1.4 Measurement Workflow

Page 33

27

Install the instrument

(p.5)

1

After use, deactivate power

to the measurement lines,

disconnect cables, and

turn off the instrument.

Connect the connection

cables to the voltage input

terminals and current input

terminals. (p.28)

3

Connect the power cord.

(p.34)

5

Turn the power on

(p.35)

6

Activate power to the

measurement lines.

7

Remove the safety

covers.

2

Reattach the safety

covers.

4

1

2

3

4

5

6

7

Configure the following settings as desired:

1: When you wish to use D/A output (p.88)

2: When you wish to perform synchronized measurement (p.81)

3: When you wish to use the RS-232C interface (p.118)

4: When you wish to use the GP-IB interface (p.131)

5: When you wish to use the LAN interface (p.122)

6: When you wish to use external control (p.85)

7: When you wish to use an external current sensor (p.102)

2.1 Installation and Connection Procedures

Measurement Preparations Chapter 2

2.1 Installation and Connection Procedures

Please read "Operating Precautions" (p.5) carefully before installing or connecting

the instrument.

Page 34

28

e.g.) 1P2W

Corresponding with Method 1 (1)

Corresponding with Method 2 (1)

• Phase differences between an

external VT (PT) and CT can introduce a large error component into

power measurements.

To ensure accurate power measurement, use a VT (PT) and CT

with a small phase error in the frequency band of the circuit being

used.

• To ensure safe operation, always

ground the secondary side of the

VT (PT) and CT (see figure below)

2.2 Connecting the Measurement Lines

2.2 Connecting the Measurement Lines

Please read "Handling the Cables" (p.6) carefully before installing, connecting the

instrument, or connecting the measurement LINES.

Verify that power to the measurement lines has been cut off before connecting the

instrument to them.

To ensure accurate measurement

• When measuring power, the polarity of the voltage and current affects readings, so it is essential to connect the instrument to the measurement lines properly. Accurate measurement will not be possible if these

connections are not made properly.

• Keep power supply wiring away from the instrument so that it is not affected by external magnetic fields.

If the object under measurement’s voltage and current levels exceed the instrument’s measurement range

You can then read primary-side input values directly by setting the VT ratio and CT ratio on the instrument.

See: "3.2.9 Setting the VT and CT Ratio"(p.59)

• To prevent electrical shock and personnel injury, do not touch any input terminals

on the VT (PT), CT or the instrument when they are in operation.

• When using an external VT (PT): Do not short the secondary side.

Applying a voltage to the primary side while the secondary side is shorted will cause

a large current to flow to the secondary side, causing it to burn up and resulting in a

fire.

• When using an external CT: Do not leave the secondary side open.

Allowing a current to flow to the primary side while the secondary side is open will

cause a high voltage to occur on the secondary side, which is extremely dangerous.

Page 35

2.2 Connecting the Measurement Lines

Wire materials (Voltage input terminal, Current input terminal)

To avoid electric shock or a short-circuit at the input terminals, use solderless terminals that cover wiring with insulation.

(Screws for voltage input terminals and current input terminals: M6)

To avoid electric shock, use wiring with adequate dielectric strength and current capacity.

29

Page 36

30

Remove the safety cover.

2

Remove the screws. (M3 × 6 mm)

1

Input terminal tightening torque: 3 N

•m

1 Remove the screws with the Phillips head screwdriver.

2 Position each wire as shown in the figure and secure in

place with the screw. (M6 × 12 mm)

Screw

(M6 × 12 mm)

Wire

• Use solderless terminals with a width of 13 mm or less.

• Tighten screws securely.

e.g.) Voltage input terminal

e.g.) Current input terminal

Solderless terminal

(Width 13 mm or less and

capable of accommodat-

ing an M6 screw)

Attach each cover securely.

2.2 Connecting the Measurement Lines

Connecting the measurement lines

Please read "Handling the Instrument" (p.6) carefully before connecting the instrument to the measurement lines.

• Verify that power to the measurement lines has been cut off before connecting the

instrument to them.

• To avoid electric shock or a short-circuit at the input terminals, use solderless terminals that cover wiring with insulation.

• To prevent instrument damage or electric shock, use only the screws (M6

for securing the voltage input terminals and current input terminals in place and the

screws (M3

uct. If you loose any screw or find that any screws are damaged, please contact your

Hioki distributor for a replacement.

×6 mm) for securing the safety cover in place that shipped with the prod-

Safety covers

• The safety covers play a protective role by preventing contact with the terminals. Always attach the covers

before using the instrument.

• Verify that no voltage is being applied to the measurement lines before attaching or removing the safety

covers.

×12 mm)

Connect cables to the instrument’s voltage and current input terminals.

You will need: A Phillips head screwdriver with a No. 3 tip

Remove the safety covers from the voltage input terminals and current input terminals.

1

Connect the cables to the voltage input terminals and current input terminals.

2

Attach the safety covers.

3

Page 37

2.2 Connecting the Measurement Lines

When measuring measurement lines that are within the maximum input range,

connect the instrument to the measurement lines directly.

(For wiring modes other than 1P2W, see "Wiring diagrams for direct input (connections

to instrument’s terminal block)" (p.168) in "5.6 Wiring Specifications".)

Referring to "Selecting the connection method (Example: 1P2W connection)" (p.33), select the

connection method with the lower power meter loss.

Method 1: Connect the voltage input terminals to the load side.

(1) (2)

1

Voltage input

terminal

Current direct

input terminal

Current direct

input terminal

Voltage input

terminal

Method 2: Connect the current input terminals to the load side.

• When the instrument is affected by common-mode voltage, the error can be reduced by connecting the ammeter as shown in (2) under Method 1 and (2) under Method 2.

• If leaving the connections in place after measurement is complete, be sure to conduct a pre-measurement inspection (p.39) before making the next measurement. Such an inspection will enable

you to prevent electric shock and measurement errors caused by breaks in cables, short-circuits,

instrument failures, and other issues.

Voltage input

terminal

Current direct

input terminal

Voltage input

terminal

Current direct

input terminal

(1) (2)

Connect the instrument to the measurement lines. (Example: 1P2W connection)

4

There are three types of connection methods:

31

Page 38

32

2

When measuring measurement lines that exceed the maximum input current

Connect the instrument using a current sensor.

(For wiring modes other than 1P2W, see "Wiring diagrams when using an external current sensor" (p.173) in "5.6 Wiring Specifications".)

2

(1) (2)

2

When measuring measurement lines that exceed the maximum input, connect

the instrument using a VT (PT) and CT.

3

Corresponding with Method 1 (1) Corresponding with Method 2 (1)

2.2 Connecting the Measurement Lines

Page 39

33

Method 1

Connect the voltage input terminals to the

load side.

Method 2

Connect the current input terminal to the

load side.

Loss = (Input voltage [V])

2

÷ 2 [MΩ]

Loss = (Input current [A])

2

x 1 [mΩ]

Power measurement includes loss from the

voltage input terminals’ input resistance.

Power measurement includes loss from the current input terminals’ input resistance.

Power

supply

Load

Current input resistance

Voltage input resistance

Load

Power

supply

Current input resistance

Voltage input resistance

1 mΩ 1 mΩ

2 MΩ

2 MΩ

Power

supply

Load

Current input resistance

Voltage input resistance

Load

Power

supply

Current input resistance

Voltage input resistance

1 mΩ 1 mΩ

2 MΩ2 MΩ

U

L

N

±

±

I

±U

±

I

L

N

U

U

±

±

±

I

±

I

±

LL

NN

2.2 Connecting the Measurement Lines

Selecting the connection method (Example: 1P2W connection)

Depending on the input level, the power meter’s instrument loss may affect measured values. Select the connection method below with the lower loss.

2

/ 2 [MΩ] = 0.000072 [W]

2

× 1 [mΩ] = 4.225 [W]

2

2

/ 2 [MΩ] = 0.5 [W]

× 1 [mΩ] = 0.0000001 [W]

Example:

When measuring 12 V, 65 A

Method 1: Loss = (12 [V])

Method 2: Loss = (65 [A])

Method 1 is characterized by lower loss and therefore allows more accurate measurement.

When measuring 1000 V, 10 mA

Method 1: Loss = (1000 [V])

Method 2: Loss = (10 [mA])

Method 2 is characterized by lower loss and therefore allows more accurate measurement.

Page 40

34

Rear

1 Check that the instrument’s power switch is turned off.

2 Connect a power cord that matches the line voltage to

the power inlet on the instrument.

3 Plug the other end of the power cord into an outlet.

Turn off the power before disconnecting the power cord.

2.3 Connecting the Power Cord

2.3 Connecting the Power Cord

• Before turning the instrument on, make sure the supply voltage matches that indicated on the its power connector. Connection to an improper supply voltage may

damage the instrument and present an electrical hazard.

(Voltage fluctuations of ±10% from the rated supply voltage are taken into account.)

• To avoid electrical accidents and to maintain the safety specifications of this instrument, connect the power cord provided only to a 3-contact (two- conductor +

ground) outlet.

Page 41

35

: Power ON

The product model and version number

are displayed.

Self-test (example: PW3337-03)

Any errors are displayed.

See: "6.2 Error Indication"(p.179)

Error(s)No errors

Normal display (Measurement

screen)

Do not press any keys during the self-test.

Display during zero-adjustment

2.4 Turning On the Instrument

2.4 Turning On the Instrument

Check the following once more before turning on the instrument:

• Are the instrument and peripheral equipment connected properly?

• Are any wires shorted between the voltage input terminals?

If so, an electric shock or short-circuit may result.

Turn the POWER switch on ( | ).

When the instrument is turned on, it will start a self-test. During the self-test, all indicators will light up, and

then the model and version number will be displayed. Finally, hardware and saved data will be checked.

• The current settings when the instrument was last turned off will be restored when it is turned on (backup

function).

• If you’re using the instrument for the first time, the default settings will be used. (p.112)

• To ensure high-precision measurement, allow the instrument to warm up for at least 30 minutes after turning it on.

Page 42

36

1 Deactivate power to measurement

lines and ensure that no input is

being supplied to the instrument.

2 Press to place the instrument in

the shift state and then press .

3 Zero-adjustment will be performed,

and the display will show [

- - - - -] for

approximately 40 sec.

Once zero-adjustment is complete, the instrument will change to the normal measured value display and be ready for

measurement.

2.5 Performing Zero-adjustment

2.5 Performing Zero-adjustment

Zero-adjustment (offset adjustment) is performed for voltage and current measured values after the instrument has warmed up for approximately 30 minutes in order to ensure that its measurement accuracy specifications are satisfied. Zero-adjustment consists of degaussing (DEMAG) its internal current input unit and

performing offset adjustment for the voltage and current internal circuitry.

Although the zero-adjustment function operates automatically when the instrument is turned on, it should

always be performed before starting measurement after the instrument has warmed up.

• Perform zero adjustment when there is no input to the instrument, for example after deactivating power to

measurement lines. If zero-adjustment is performed while there is input to the instrument, the process will

not complete normally, and you will be unable to make accurate measurements.

• Optional current sensors are not degaussed. Degauss current sensors as described in the instruction

manual that came with each current sensor before performing the instrument’s zero-adjustment process.

Zero-adjustment adjusts offsets within the following ranges:

Voltage circuitry: ±10% of the measurement range

Current direct input circuitry: ±10% of the measurement range

External current sensor input circuitry: ±10% of the measurement range

Operating time: Approx. 40 sec. (No measured values are displayed during zero-adjustment.)

• Zero-adjustment is performed for all channels, regardless of wiring mode or current input method.

• Settings cannot be changed, and integration cannot be started, during zero-adjustment.

• Zero-adjustment cannot be performed while integration is being performed or during display hold or maximum value/minimum value hold operation.

• To enable high-precision measurement, it is recommended to perform zero-adjustment at an ambient temperature that falls within the range specified in the specifications.

• Perform the zero-adjustment process with no input. The instrument will display [Err.18] if input is present

when performing zero-adjustment. If this occurs, remove the input and then repeat the zero-adjustment

process.

• It may be impossible to completely degauss the instrument’s current input unit if current input in excess of

the maximum input current is flowing to its current direct input terminals. In this case, perform zero-adjustment multiple times or cycle the instrument’s power.

Page 43

2.6 Activating Power to the Measurement Lines

: Power OFF

Once measurement is complete, turn

off the instrument and disconnect any

connection cables and other wiring.

2.6 Activating Power to the Measurement Lines

Before activating power to the measurement lines

Before activating power to the measurement lines, turn on the instrument and verify

that no errors are displayed.

If any measurement target lines are live before the instrument is turned on, the instrument may be damaged, or an error may be displayed when it is turned on.

See: "2.4 Turning On the Instrument"(p.35), "6.2 Error Indication"(p.179)

2.7 Turning Off the Instrument

37

Turn the POWER switch off ( ).

Disconnect any connection cables and other wiring.

When power is turned on again, the display appears with the settings that existed when power was last turned

off.

If leaving the connections in place after measurement is complete, be sure to conduct a pre-measurement

inspection (p.39) before making the next measurement. Such an inspection will enable you to prevent electric shock and measurement errors caused by breaks in cables, short-circuits, instrument failures, and other

issues.

Page 44

38

2.7 Turning Off the Instrument

Page 45

3.1 Pre-Measurement Inspection

Before using the instrument the first time, verify that it operates normally to ensure that the no damage

occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

If there is any damage or the screws

are loose, there is a risk of electric

shock or short-circuit. Do not use the

instrument. Replace the probe or cable

with an undamaged equivalent. Securely retighten screws.

Metal Exposed?

Screws are loose.

Is the insulation of the probe or connection

cable to be used damaged, or is bare metal

exposed?

Are any of the input terminal screws loose?

When using connection cables

1

No Metal Exposed

Screws are tight.

Peripheral Device Inspection

If damage is evident, request repairs.

Yes

Is there any damage to the instrument?

Instrument Inspection

Turn on the instrument.

Is self-test information (model, version number)

displayed?

No

2

There may be a break in the power

cord, or there may be internal damage

to the instrument. If the instrument is

damaged, have it repaired.

Is the Measurement screen displayed after the

self-test completes?

No

Yes

The instrument may be damaged internally. Request repairs.

See: "6.2 Error Indication" (p.179)

An error indication

occurs (ERR)

Yes

Inspection complete

Allow the instrument to warm up for at

least 30 minutes after turning it on.

Supply power to the measurement target.

There may be a break in a connection

cable or internal damage to the instrument, or the instrument may have

been connected improperly. Stop supplying power to the measurement target immediately and repeat the

inspection. If there is no problem with

the wiring, have the instrument repaired.

No measured value

is displayed.

Measured value error

Perform zero-adjustment.

Configuration and Measurement Chapter 3

Please read Operating Precautions (p.5) carefully before using the instrument.