Hioki PW3198 Instruction Manual

Instruction Manual

PW3198

POWER QUALITY

ANALYZER

July 2012 Revised edition 2 PW3198A981-02 12-07H

Contents

Contents

i

1

Introduction ..................................................1

Confirming Package Contents....................2

Safety Notes..................................................4

Usage Notes..................................................6

Chapter 1 Overview 11

1.1 Product Overview ............................11

1.2 Features ............................................ 12

1.3 Measurement Flowchart ..................13

Starting and Stopping Recording .........14

Chapter 2 Names and Functions

of Parts

Basic Operations

& Screens 15

2.1 Names and Functions of Parts .......15

2.2 Basic Operations .............................19

2.3 Display Items and Screen Types ....20

Common Display Items........................ 20

Warning Indicators ...............................22

Screen Types.............................. ......... 23

3.7 Connecting the Clamp Sensors ......34

3.8 Turning the Power On and Off

(Setting the Default Language) .......36

Chapter 4 Configuring the

Instrument before

Measurement

(SYSTEM - SYSTEM

screen) and Wiring37

4.1 Warm-up and Zero-adjust

Operation ..........................................37

4.2 Setting the Clock ..............................38

4.3 Configuring the Connection Mode and

Clamp Sensors .................................39

Connection diagram ............................ 40

4.4 Setting the Vector Area

(Tolerance Level) ..............................45

4.5 Connecting to the Lines to be

Measured (Preparing for Current

Measurement) ...................................46

4.6 Verifying Correct Wiring

(Connection Check) .........................48

4.7 Quick setup .......................................50

2

3

4

5

Chapter 3 Measurement

Preparations 27

3.1 Preparation Flowchart .....................27

3.2 Initial Instrument Preparations .......28

Attaching input cable labels to the

voltage cords and clamp sensors ........28

Attaching the strap............................... 28

Bundle the voltage cord leads with the spi-

ral tubes............................................... 29

Installing the battery pack ....................30

3.3 Pre-Operation Inspection ................31

3.4 Connecting the AC Adapter ............32

3.5 Inserting (Removing) an SD Memory

Card ................................................... 32

3.6 Connecting the Voltage Cords .......34

4.8 Verifying Settings and Starting

Recording ..........................................53

4.9 Using the Instrument during a

Power Outage ...................................54

Chapter 5 Changing Settings

(as necessary) 55

5.1 Changing Measurement Conditions 55

5.2 Changing the Measurement Period 58

5.3 Changing the Recording Settings ..61

5.4 Changing Hardware Settings ..........64

5.5 Changing Event Settings .................66

ii

Contents

5.6 Initializing the Instrument

(System Reset) .................................73

5.7 Factory Settings ...............................74

Chapter 8 Checking Events

(EVENT screen) 119

8.1 Using the EVENT screen ............... 120

Chapter 6 Monitoring

Instantaneous Values

(VIEW Screen) 75

6.1 Using the VIEW screen ....................75

6.2 Displaying Instantaneous

Waveforms ........................................76

6.3 Displaying Phase Relationships

([VECTOR] Screen) ..........................80

6.4 Displaying Harmonics ......................83

Displaying harmonics as a bar graph.. 83

Displaying harmonics as a list ............. 86

6.5 Displaying Measured Values

Numerically (DMM Screen) ..............89

Chapter 7 Monitoring

Fluctuations in

Measured Values

(TIME PLOT

Screen) 91

8.2 Displaying the Event List .............. 121

8.3 Analyzing the Measurement Line

Status When Events Occur ........... 124

8.4 Analyzing Transient Waveforms .. 126

8.5 Viewing High-order Harmonic

Waveforms ..................................... 129

8.6 Checking Fluctuation Data ........... 132

Chapter 9 Data Saving and File

Operations

(SYSTEM-MEMORY

screen) 135

9.1 [MEMORY] Screen ......................... 135

9.2 Formatting SD Memory Cards ...... 138

9.3 Save Operation and File Structure 139

9.4 Saving, Display and Deleting

Measurement Data ......................... 141

9.5 Saving, Displaying, and Deleting

Screen Copies ................................ 144

7.1 Using the [TIMEPLOT] Screen ........93

7.2 Displaying Trends ............................94

7.3 Displaying detailed trends .............101

Displaying a detailed trend graph for

each TIMEPLOT interval.................. 101

7.4 Displaying Harmonic Trends .........107

7.5 Displaying Flicker Values in Graph

and List Form ..................................111

IEC flicker meters and V10 flicker

meters .............................................. 111

Displaying an IEC flicker fluctuation

graph .................................... ............. 111

Displaying an IEC flicker list.............. 114

Displaying a V10 flicker fluctuation

graph .................................... ............. 115

Displaying a V10 flicker list............. 118

9.6 Saving and Deleting Settings Files

(Settings Data) ...............................145

9.7 Loading Settings Files

(Settings Data) ...............................146

9.8 File and Folder Names .................. 146

Changing file and folder names ........ 146

Chapter 10 Analyzing Data

Using the Computer

Application

(9624-50) 147

10.1 Computer Application (9624-50) Capa-

bilities ............................................. 147

10.2 Downloading Data from the SD Memo-

ry Card ............................................ 148

Chapter 11 Connecting

External Devices149

11.1 Using the External Control

Terminal .......................................... 149

Connecting to the External Control

Terminal ..................................... ........150

Using the event input terminal

(EVENT IN) .......................................151

Using the event input terminal

(EVENT OUT) ............ ........................152

iii

Contents

13.8 GPS Time Synchronization

Function ..........................................197

13.9 Other Functions ..............................197

13.10Calculation Formula .......................198

13.11Clamp Sensors and Ranges ..........211

13.12Block Diagram ................................213

Chapter 14 Maintenance

and Service 215

13

14

3

Chapter 12 Operation with a

Computer 155

12.1 Downloading Measurement Data Using

the USB Interface ...........................156

12.2 Control and Measurement via Ethernet

("LAN") Interface ............................157

LAN Settings and Network Environment

Configuration ........... ... ... .... ... ... ... .... ... 158

Instrument Connection .......................160

12.3 Remote Control of the Instrument by

Internet Browser ............................162

Connecting to the Instrument .............162

Operating Procedure .........................163

12.4 Converting Binary Data to Text

Data .................................................164

Chapter 13 Specifications 165

13.1 Environmental Safety

Specifications ................................165

14.1 Cleaning ..........................................215

14.2 Trouble Shooting ............................216

14.3 Error Indication ...............................218

14.4 Disposing of the Instrument ..........221

Appendix A1

Appendix 1 Procedure for Investigating

Power Supply Quality ..........A1

Appendix 2 Explanation of Power Supply

Quality Parameters and

Events....................................A4

Appendix 3 Event Detection Methods ....A7

Appendix 4 Recording TIMEPLOT Data

and Event Waveforms........A14

Appendix 5 Detailed Explanation of IEC

Flicker and

Appendix 6 Making Effective Use of

Channel 4............................A21

Appendix 7 Terminology........................A24

V10 Flicker ....A18

4

5

6

7

8

9

10

13.2 General Specifications ..................165

13.3 Measurement Specifications ........169

13.4 Event Specifications ......................189

13.5 Operating Specifications ...............190

13.6 Measurement and Analysis

Function Specifications ................191

13.7 Configuration Function

Specifications ................................194

Index Index1

11

12

Appendix

Index

iv

Contents

Introduction

Introduction

Thank you for purchasing the HIOKI PW3198 Power Quality Analyzer. To obtain maximum performance from the product, please read this manual first, and keep it handy for future reference.

Clamp-on sensors (optional; see p.3) are required in order to input current to the instrument.

(Clamp-on sensors are called "clamp sensors" throughout this manual.) For more information,

see the instruction manual for the clamp sensors being used.

Registered trademarks

• Windows is a registered trademark of Microsoft Corporation in the United States and/or other countries.

• Sun, Sun Microsystems, Java, and any logos containing Sun or Java are trademarks or registered

trademarks of Sun Microsystems, Inc. in the United States and other countries.

• The SD logo is a trademark of SD-3C, LLC.

1

Symbols

Symbols in this manual

Indicates the prohibited action .

(p. )

*

[ ]

CURSOR

(Bold character)

Windows

Dialogue

Mouse action terminology

Click: Press and quickly release the left button of the mouse.

Indicates the location of reference information.

Indicates quick references for operation and remedies for troubleshooting.

Indicates that descriptive information is provided below.

Bold characters within the text indicate operating key labels.

Unless otherwise specified, "Windows" represents Windows 2000, Windows XP, Windows Vista,

or Windows 7.

Dialogue represents a Windows dialog box.

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with

the following meanings:

f.s.

(maximum display value

or scale length):

rdg.

(reading or displayed

value):

dgt.

(resolution):

The maximum displayable value or scale length. This is usually the name

of the currently selected range.

The value currently being measured and indicated on the measuring instrument.

The smallest displayable unit on a digital measuring instrument, i.e., the

input value that causes the digital display to show a "1" as the least-significant digit.

2

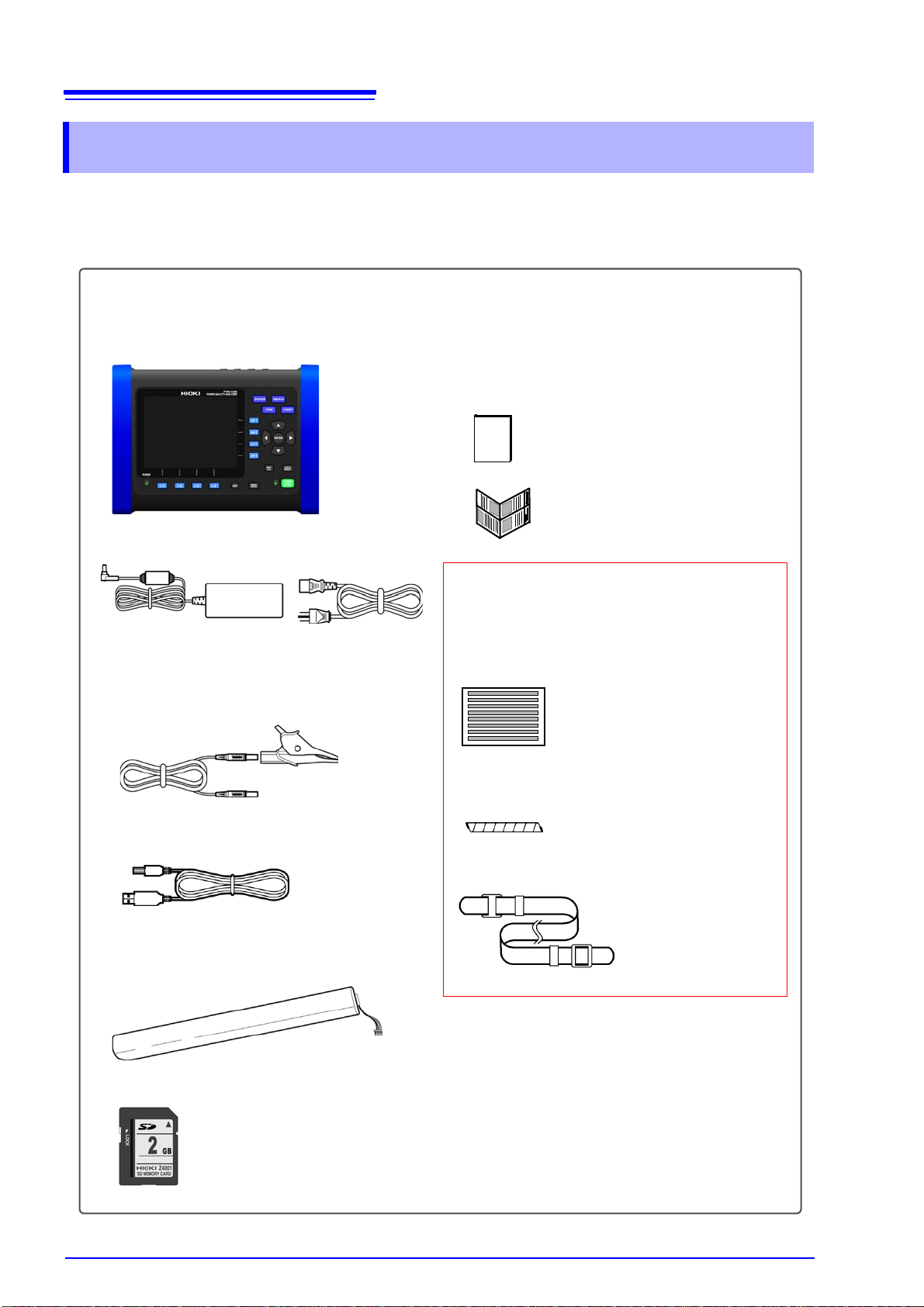

PW3198 Power Quality Analyzer....... 1

Confirm that these contents are provided.

Accessories

Instruction Manual... ... ... ... .... ... ... ... ... ...1

Measurement Guide............................1

Z1002 AC Adapter (includes power cord)1

L1000 Voltage Cord........ .... ... ... ... ... .... 1

(Cords: One each red, yellow, blue, and gray as well as

4 black; alligator clips: 1 each red, yellow, blue, and

gray as well as 4 black)

USB Cable.......................................... 1

Z1003 Battery Pack............................ 1

(Ni-MH, 7.2 V/4500 mAh)

Z4001 SD Memory Card 2GB............. 1

Input Cable Labels.............................. 1

(to identify voltage cable leads and input

channels)

Spiral Tubes........................................20

(to identify voltage cable leads and input

channels)

Strap...................................................1

(attach to instrument)

Please attach to the instrument before use.

(p.28)

Confirming Package Contents

Confirming Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to operate according to the spe cifications, cont act your d ealer or Hioki rep resentative.

Options

Contact your dealer or Hioki representative for details.

3

Confirming Package Contents

Clamp sensors (current measurement)

9660 Clamp-On Sensor

(100 A rms rated)

9661 Clamp-On Sensor

( 500 A rms rated)

9667 Flexible Clamp-On Sensor

(5000 A rms/500 A rms rated)

9669 Clamp-On Sensor

(1000 A rms rated)

9694 Clamp-On Sensor

(5 A rms rated)

9695-02 Clamp-On Sensor

(50 A rms rated)

9695-03 Clamp-On Sensor

(100 A rms rated)

9290-10 Clamp-On Adapter

9219 Connection Cable

(For use with Model 9695-02/9695-03)

9657-10 Clamp-On Leak Sensor

(10 A rms rated)

9675 Clamp-On Leak Sensor

(10 A rms rated)

CT9691 Clamp on AC/DC Sensor

(100 A/10 A rated)+CT6590 Sensor Unit

CT9692 Clamp on AC/DC Sensor

(200 A/20 A rated)+CT6590 Sensor Unit

CT9693 Clamp on AC/DC Sensor

(2000 A/200 A rated)+CT6590 Sensor Unit

CT9667 Flexible Clamp on Sensor

(5000 A rms/500 A rms rated)

Carrying cases

C1001 Carrying Case (Soft type)

C1002 Carrygin Case (Hard type)

Recording media

Z4001 SD Memory Card 2GB

Communications

9642 LAN Cable

9624-50 PQA-HiView Pro

(Computer application software)

Other

Z1002 AC Adapter

Z1003 Battery Pack

PW9000 Wiring Adapter

(For use with 3-phase

3-wire (3P3W3M) voltages)

PW9001 Wiring Adapter

(For use with 3-phase 4-wire

voltages)

PW9005 GPS Box

(Build-to-order)

Voltage measurement

9804-01 Magnetic Adapter

9804-02 Magnetic Adapter

9243 Grabber Clip

L1000 Voltage Cord

4

Ni-MH

Safety Notes

Safety Notes

This manual contains information and warnings essential for safe operation of the product and

for maintaining it in safe operating condition. Before using the product, be sure to carefully read

the following safety notes.

This instrument is designed to comply with IEC 61010 Safety Standards, and has

been thoroughly tested for safety prior to shipment. However, mishandling during use could result in injury or death, as well as damage to the instrument. However, using the instrument in a way not described in this manual may negate the

provided safety features.

Be certain that you understand the instructions and precautions in the manual

before use. We disclaim any responsibility for accidents or injuries not resulting

directly from instrument defects.

Safety Symbols

In the manual, the symbol indicates particularly important information that the user

should read before using the product.

The symbol printed on the product indicates that the user should refer to a corr esponding

topic in the manual (marked with the symbol) before using the relevant function.

Indicates a grounding terminal.

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates AC (Alternating Current).

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents a significant hazard that coul d result in serious injury

or death to the user.

Indicates that incorrect operation presents a significant hazard that coul d result in serious injury

or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage to the

product.

Advisory items related to performance or correct operation of the product.

Symbols for Various Standards

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU market after August

13, 2005, and producers of the Member States are required to display it on the appliance under Article

11.2 of Directive 2002/96/EC (WEEE).

This is a recycle mark established under the Resource Recycling Promotion Law (only for Japan).

This symbol indicates that the product conforms to safety regulations set out by the EC Directive.

5

Safety Notes

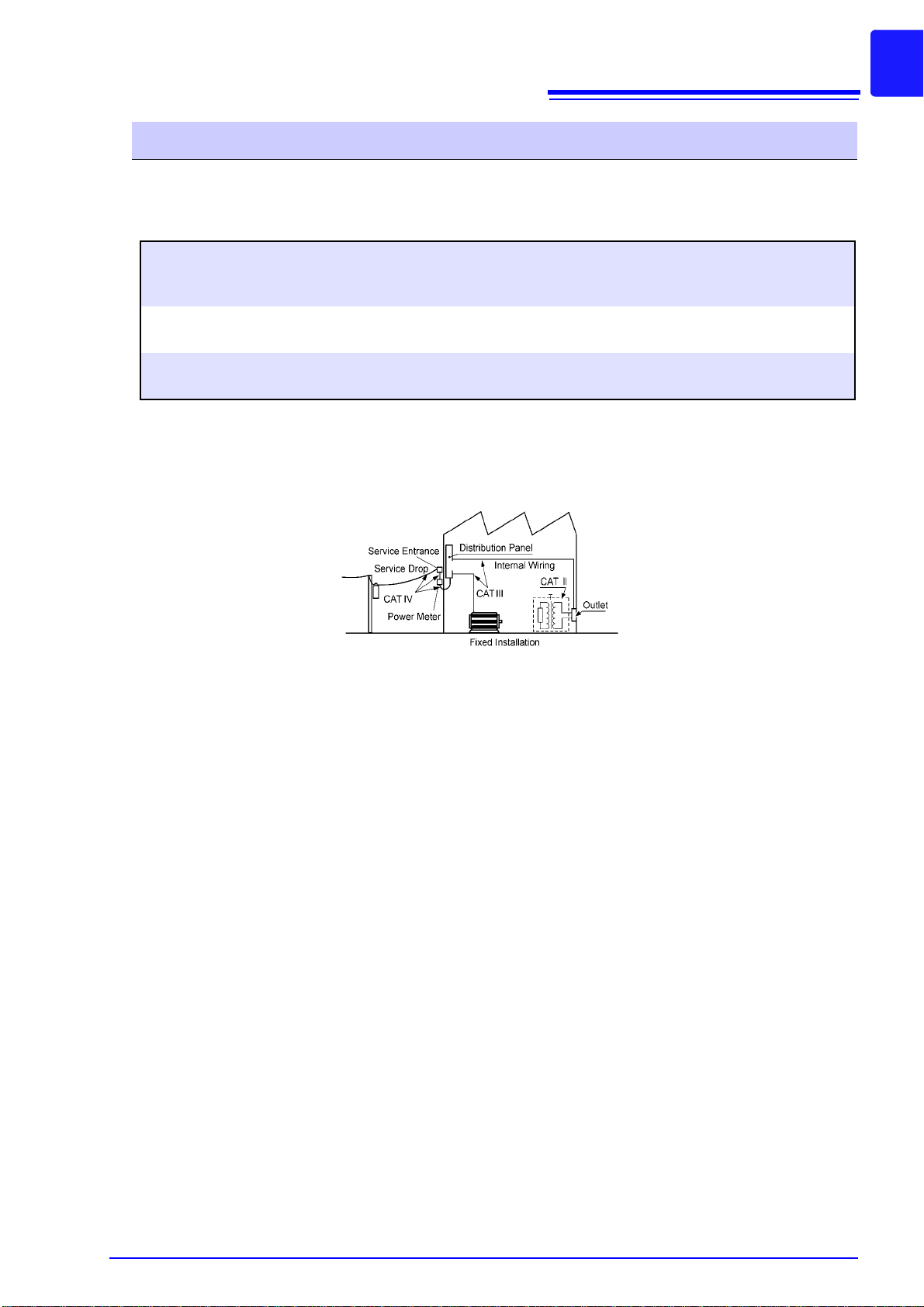

Measurement categories

This instrument complies with CAT IV (600 V) safety requirements.

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

CAT II: Primary electrical circuits in equipment connected to an AC electrical outlet by a power cord

(portable tools, household applianc es , etc .)

CAT II covers directly measuring electrical outlet receptacles.

CAT III: Primary electrical circuits of heavy equipment (fixed installations) connecte d directly to the

distribution panel, and feeders from the distribution panel to outlets.

CAT IV: The circuit from the service drop to the service entrance, and to the power meter and pri-

mary overcurrent protection device (distribution panel).

Using a measurement instrument in an environment designated with a higher-numbered category than

that for which the instrument is rated could result in a severe accident, and must be carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II to CAT IV measurement applications

could result in a severe accident, and must be carefully avoided.

6

50 mm or more

Usage Notes

Usage Notes

Follow these precautions to ensure safe operation and to obtain the full benefits of the various

functions.

Before Use

Before using the instrument the first time, verify that it operates normally to ensure that the no damage

occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the voltage cords

is undamaged and that no bare conductors are improperly exposed. Using the

instrument in such conditions could cause an electric shock, so contact your

dealer or Hioki representative for replacements.

Instrument Installation

Operating temperature and humidity: 0 to 50°C, 80%RH or less, Indoors only (non-condensating)

Storing temperature and humidity: -20 to 50° C, 80 %RH or less, Indo o rs only (non-condensating)

Avoid the following locations that co uld cause an accident or damage to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil, other

chemicals, or solvents

Exposed to high humidity or

condensation

Exposed to high humidity or

condensation

Exposed to high levels of particulate dust

Subject to vibration

Installing

• The instrument should be operated only with the bottom or rear side down wards.

• Vents (on the left and right side of the instrument) must not be obstructed.

In the presence of corrosive or

explosive gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction

heating systems and IH cooking utensils)

7

Usage Notes

Shipping precautions

Hioki disclaims responsibility for any direct or indirect damages that may occur when this instrument has

been combined with other devices by a systems integrator prior to sale, or when it is resold.

Handling the Instrument

To avoid electric shock, do not open the instrument's case. The internal components of the instrument carry high voltages and may become very hot during

operation.

• If the instr ument exhibits abnormal oper ation or display during use, review the information in "14.2 Trouble Shooting" (p.216) and "14.3 Error Indication" (p.218) before

contacting your dealer or Hioki representative.

• To avoid damage to the instrument, protect it from phys ical shock when tra nsporting

and handling. Be especially careful to avoid physical shock from dropping.

• The protection rating for the enclosure of this device (based on EN60529) is *IP30.

*IP30:

This indicates the degree of protection provided by the enclosure of the device against use in hazardous locations, entry of solid foreign objects, and the ingress of water.

3: Protected against access to hazardous parts with tools more than 2.5 mm in diameter. The

equipment inside the enclosure is protected against entry by solid foreign objects larger than

2.5 mm in diameter.

0: Not protected against use in hazardous locations. The enclosure does not protected against

entry by solid foreign objects.

This instrument may cause interference if used in residential areas. Such use must be

avoided unless the user takes special measures to reduce electromagnetic emissions

to prevent interference to the reception of radio and television broadcasts.

Handling the cords and clamp sensors

• To prevent damage to the instrument and clamp sensors, never connect or disconnect a sensor while the clamp sensor is clamped around a conductor.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

from the power outlet.

• To avoid breaking the cables, do not bend or pull them.

• For safety reasons, when taking measurements, only use the L1000 Voltage Cord.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• Keep the cables well away from heat sources, as bare conductors could be exposed

if the insulation melts.

• When disconnecting the BNC connector, be sure to release the lock before pulling off

the connector. Forcibly pulling the connector without releasing the lock, or pulling on

the cable, can damage the connector.

• To avoid damaging the output cable, grasp the connector, not the cable, when

unplugging the cable.

• When disconnecting the clamp sensor from the instrument, be sure to grip the part of

the connector with the arrows and pull it straight out. Gripping the connector elsewhere or pulling with excessive force may damage the connector.

8

Usage Notes

• Use the 9217 Connection Cord (resin) when connecting to insulated BNC connector

(resin), and the 9165 Connection Cord (metal) when connecting to metallic BNC connector (metal). If you connect metal BNC cable to insulated BNC connector, the insulated BNC connector can be damaged and the connection equipment may be

damaged.

• Be careful to avoid dropping the clamp sensors or otherwise subjecting them to

mechanical shock, which could damage the mating surfaces of the core and

adversely affect measurement.

• Keep the clamp jaws and core slits free from foreign objects, which could interfere

with clamping action.

• Keep the clamp closed when not in use, to avoid accumulating dust or dirt on the

mating core surfaces, which could interfere with clamp performance.

Use only the specified voltage cords and inpu t cables. Usin g a non-sp ecified cable may

result in incorrect measurements due to poor connection or other reasons.

Before Connecting Measurement Cables

• To avoid electric shock, turn off the power to all devices before plugging or

unplugging any cables or peripherals.

• Be sure to connect the voltage input and current input terminals correctly. An

incorrect connection could damage or short circuit this instrument.

• In order to prevent electric shock or device damage, observe the following precautions when making connections to the external control terminals and other

interface connectors.

• Turn off the instrument and any equipment being connected before connecting

the measurement cables.

• Exercise care not to exceed the ratings of external control terminal and interface connector signals.

• Make connections securely to avoid the risk of connections coming loose during instrument operation and bringing wires into contact with other electrically

conductive parts.

• Ensure that devices and systems to be connected to the exte rnal control ter minals are properly isolated.

• To avoid electric shock and short-circuit accidents, use only the supplied voltage

cords to connect the instrument input terminals to the circuit to be tested.

Always turn both devices OFF when connecti ng and disconnecting an interfac e

connector.

About the AC adapter

• To avoid electrical accidents and to maintain the safety specifications of this

instrument, connect the power cord only to a 3-contact (two-conductor +

ground) outlet.

• Turn the instrument off bef ore connecting the AC adapter t o the instrument an d

to AC power.

• Use only the supplied Model Z1002 AC Adapter. AC adapter input voltage range

is 100 to 240 VAC (with ±10% stability) at 50/60 Hz. To avoid electrical hazards

and damage to the instrument, do not apply volt age outside of this range.

9

Usage Notes

About the battery pack

For battery operation, use only the HIOKI Model Z1003 Battery Pack. We do not

take any responsibility for accidents or damage related to the use of any other

batteries.

• The battery pack is subject to self-discharge. Be sure to charge the battery pack

before initial use. If the battery capacity remains very low after correct recharging , the

useful battery life is at an end.

• To avoid problems with battery operation, remove the batteries from the instrument if

it is to be stored several week or more.

Others

Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with rectangular

wave or pseudo-sine-wave output to power the instrument. Doing so may damage the

instrument.

Before Connecting to the Lines to be Measured

• To avoid short circuit s a nd potentially life-thre atening hazards, never att ach the

clamp sensor to a circuit that operates at more than the maximum rated voltage to earth

(See your clamp sensor's instruction manual for its maximum ratings.)

• The maximum input voltage is 1000 VAC, ±600 VDC. Attempting to measure

voltage in excess of the maximum input could destroy the instrument and

result in personal injury or death.

• To avoid electrical hazards and damage to the ins trume nt , do not a pply voltage

exceeding the rated maximum to the input terminals.

• The maximum rated voltage between input terminals and ground is 600 VDC/

AC. Attempting to measure voltages exceeding 600 V with respect to ground

could damage the instrument and result in personal injury.

• Connect the clamp sensors or voltage cords to the instrument first, and then to

the active lines to be measured. Observe the following to avoid electric shock

and short circuits.

• Do not allow the voltage cord clips to touch two wires at the same time.

• Never touch the edge of the metal clips.

• When the clamp sensor is opened, do not allow the metal part of the clamp to

touch any exposed metal, or to short between two lines, and do not use over

bare conductors.

• When connecting a clip-type input cord, you will need to clip the line to the terminal while it is hot. Bringing two wires into contact with each other while connecting the clips will cause a short-circuit.

• To prevent electrical shock and personnel injury, do not touch any input terminals on the VT (PT), CT or the instrument when they are in operation.

10

Usage Notes

While Measuring

• To avoid electrical accidents, confirm that all connections are secure. The

increased resistance of loose connections can lead to overheating and fire.

• Ensure that the input does not exceed the maximum input volt age or cu rren t to

avoid instrument damage, short-circuiting and electric shock resulting from

heat building.

• To avoid electric shock when measuring live lines, wear appropriate protective

gear, such as insulated rubber gloves, boots and a safety helmet.

When the instrument's power is turned off, do not apply voltage to the instrument.

Doing so may damage the instrument.

If an abnormality such as smoke, strange sound or offensive smell occurs, stop

measuring immediately, disconnect from the measurement lines, turn off the

instrument, unplug the power cord from the outlet, and undo any changes to the

wiring. Contact your dealer or Hioki repr esen tative as soon as possible. Continuing to use the instrument may result in fire or electric shock.

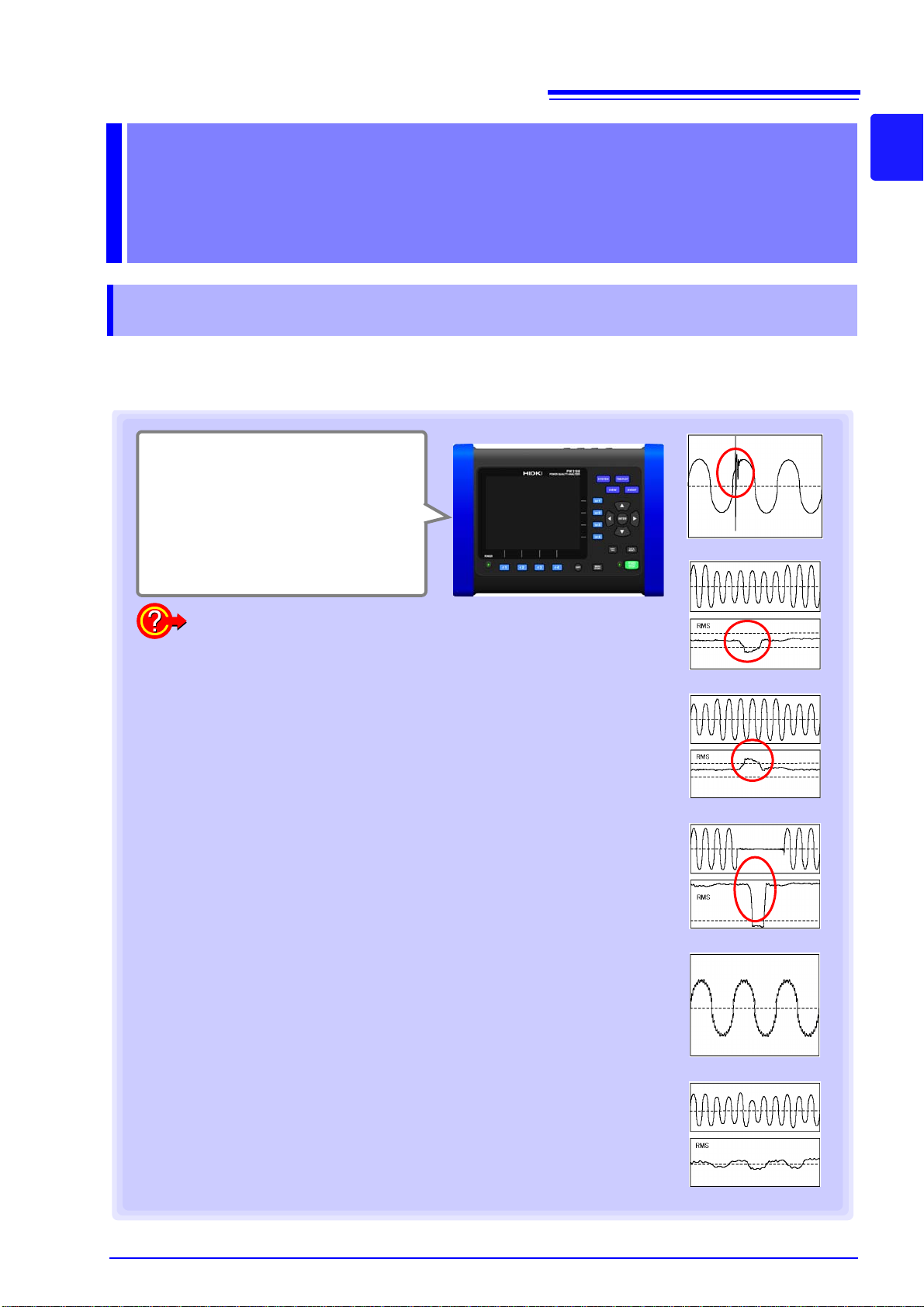

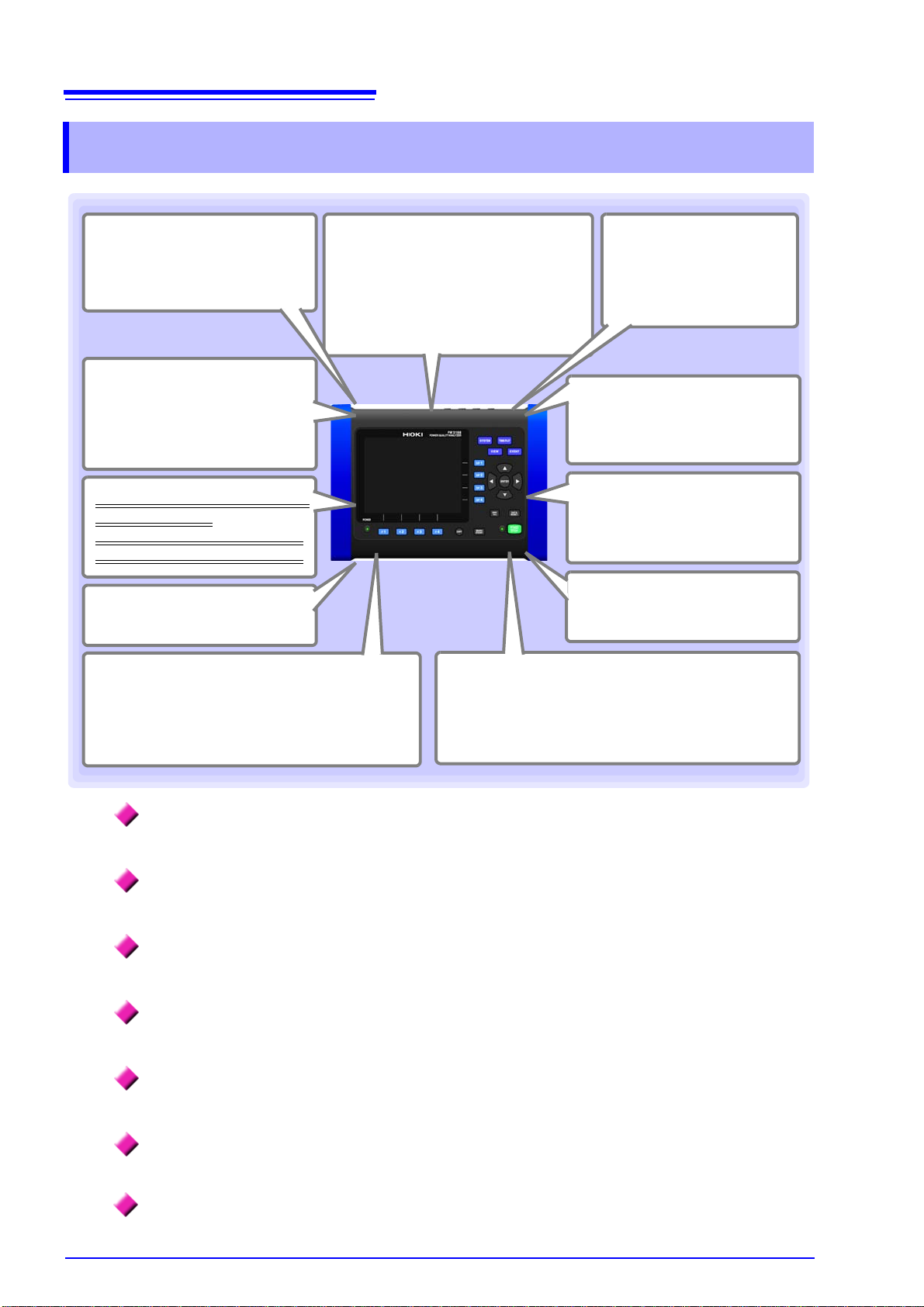

1.1 Product Overview

Record abnormal waveforms

Record voltage fluctuations

Observe power supply waveforms

Measure harmonics

Measure flicker

Measure power

One instrument does it all!

How does the PW3198 record abnormal waveforms?

The instrument automatically judges and records a range of problems:

Transient voltages

Transient voltages are caused by lightning strikes, circuit-breaker and relay

contact obstructions and tripping, and other phenomena. They are often characterized by precipitous voltage variations and a high peak voltage.

Flicker (V10, IEC)

Flicker is caused by blast furnace, arc welding, and thyristor control loads. The

resulting voltage fluctuations cause flicker in light bulbs and similar phenomena.

Voltage dips (falling voltage)

Short-lived voltage drops are caused by the occurrence of a inrush current with

a large load, such as when a motor starts.

Interruptions

In an interruption, the supply of power stops momentarily or for a short or long

period of time due to factors such as a circu it breaker tripping as a result of a

power company accident or power supply short-circuit.

Voltage swells (rising voltage)

In a voltage swell, the voltage rises momentarily due to a lightning strike or the

switching of a high-load power line.

Harmonic and high-order harmonic elements

Harmonics are caused by distortions in the voltage and current caused by the

semiconductor control devices that are frequently used in equipment power

supplies.

Transient voltages

Voltage dips

Voltage swells

Interruptions

Harmonic

Flicker

Overview Chapter 1

1.1 Product Overview

The PW3198 Power Quality Analyzer is an analytical instrument for monitoring and recording

power supply anomalies, allowing their causes to be quickly investigated. The instrument can

also be used to assess power supply problems (voltage drops, flicker, harmonics, etc.).

11

1

1

Chapter 1 Overview

12

Extensive selection

of clamp sensors

(Available rated for use with signals ranging from leak currents

to a maximum of 5,000 A.)

High precision

Voltage measurement

accuracy of ±0.1%rdg.

Complies with the new IEC610004-30 Class A international power

quality standard.

Safety

Cat IV 600 V compliant.

Capable of measuring lead-in

wires on their primary side.

Measurement of

transient voltages of

up to 6,000 V from

5 kHz to 700 kHz

SD memory card data storage

By allowing the PW3198 to record data continuously for up to one year, the ability to use highcapacity 2 GB memory cards inspires peace of

mind.

Easy downloading of data to a

computer via USB or LAN

Separately available software simplifies analysis.

Support for 400 Hz

lines

Simultaneous

3-channel measurement of V10 flicker

Ability to measure all

parameters

necessary for power

quality measurement

Measurement of

high-order harmonic

components from

2 kHz to 80 kHz

Reliable

Quick setup functionality

ensures you won't miss

the occurrence of any

abnormal phenomena.

Capable of accommodating 1-phase 2-wire, 1-phase 3-wire, 3-phase 3-wire,

and 3-phase 4-wire power supplies.

Features isolated channels for equipment analysis, neutral line ground fault

measurement, and measurement of power supply lines from separate systems.

Lets you select line voltage or phase voltage. Includes -Y conversion and Y-

conversion functionality.

Features a TFT color LCD that is easily visible in both bright and dark settings.

Capable of true simultaneous measurement with gap-less continuous operation, assuring your ability to reliably capture target phenomena.

Capable of accurately assessing the time at which phenomena occur. A GPS

option allows time correction.

Can be operated with peace of mind during an extended power outage thanks

to a generous battery drive time of 180 minutes.

1.2 Features

1.2 Features

13

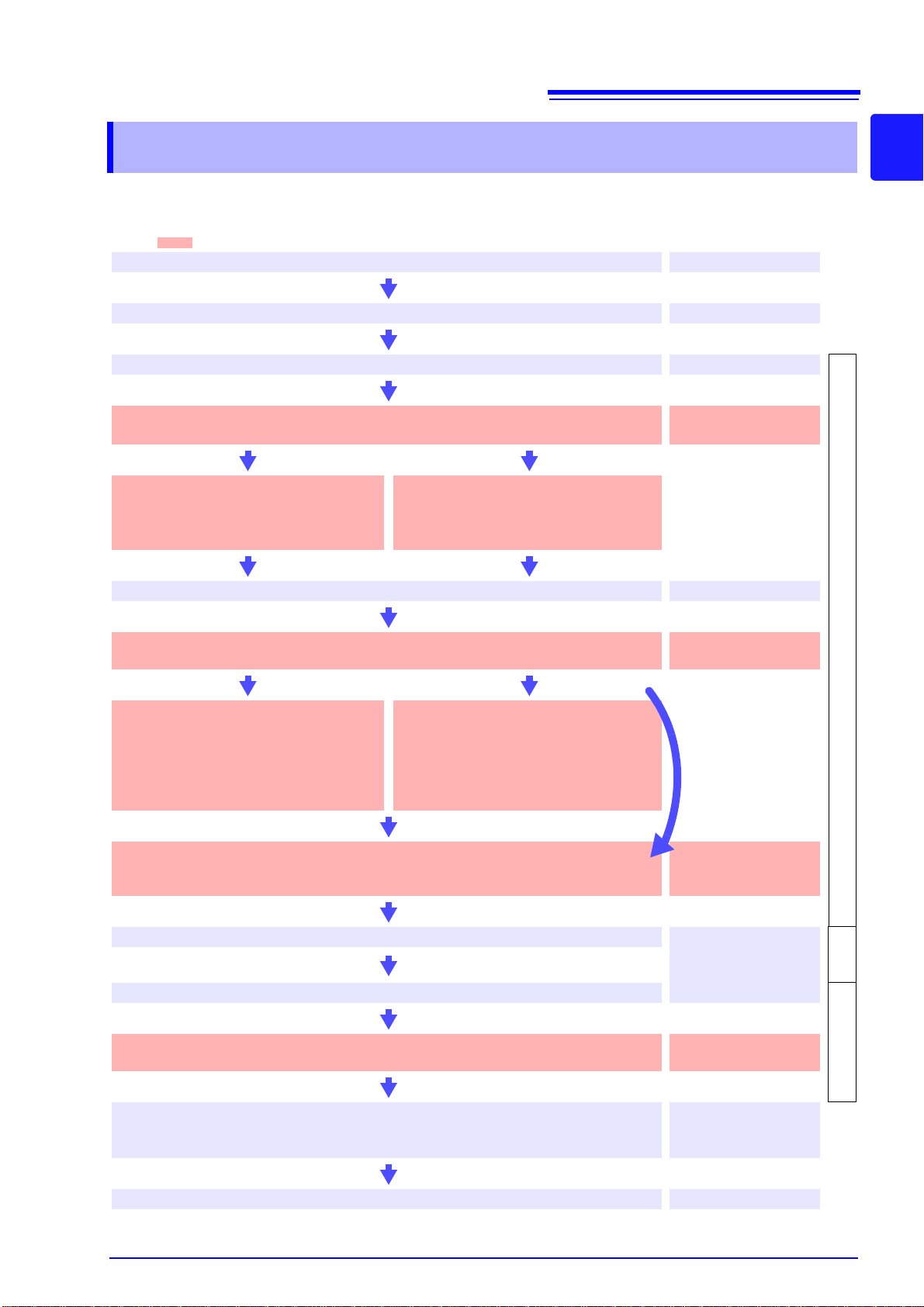

Note: shaded areas indicate settings configured on the instrument's screen.

Perform the pre-measurement inspection.

3.3 (p.31)

PW3198

operating state

Connect the AC adapter, voltage cords, and current clamps.

3.4 (p.32) to 3.7 (p.34)

Turn on th e in st rum en t.

3.8 (p.36)

[SETTING]

Perform zero adjustment after allowing the instrument to warm up for 30

minutes.

4.1 (p.37)

Configure initial settings.

Configure connection and clamp sensor

settings.

See: 4.3 (p.39)

Load a settings file (setting s data).

Load a settings file from the SD memory

card.

See: 9.7 (p.146)

Connect to the measurement line.

4.5 (p.46)

Verify connections.

Note: If waveforms, measured values, or vector diagrams appear incorrect, reconnect the lines.

4.6 (p.48)

9.7 (p.146)

Configure settings using quick

setup.

Select quick setup and configure the con-

nection, clamp sensor, VT and CT, and

TIMEPLOT interval settings.

See: 4.7 (p.50)

Configure the settings as desired.

Set thresholds and other values as desired.

Settings can be configured as desired even

after using quick setup functionality.

See: Chapter 5 (p.55)

Verify settings, event count, and memory capacity.

Note: If waveforms or settings appear incorrect, or if the event count is unusually high,

change the settings.

4.8 (p.53)

Start recording.

"Starting and Stopping

Recording" (p.14)

[RECOR

DING]

Stop recording.

[ANALYZING]

Check and analyze measurement data.

(Data can also be checked while recording is in progress.)

Chapter 6 (p.75) to

Chapter 8 (p.119)

Disconnect the voltage cords and clamp sensors from the measurement

line and turn off the instrument.

(The display data will be erased. It cannot be redisplayed.)

3.8 (p.36)

Analyze the data on a computer using the computer applica tion.

Chapter 12 (p.155)

See:

If you have loaded a

settings file

(settings data)

1.3 Measurement Flowchart

1.3 Measurement Flowchart

Be sure to read "Usage Notes" (p.6) before measuring.

Measurement is performed using the following process:

1

1

Chapter 1 Overview

14

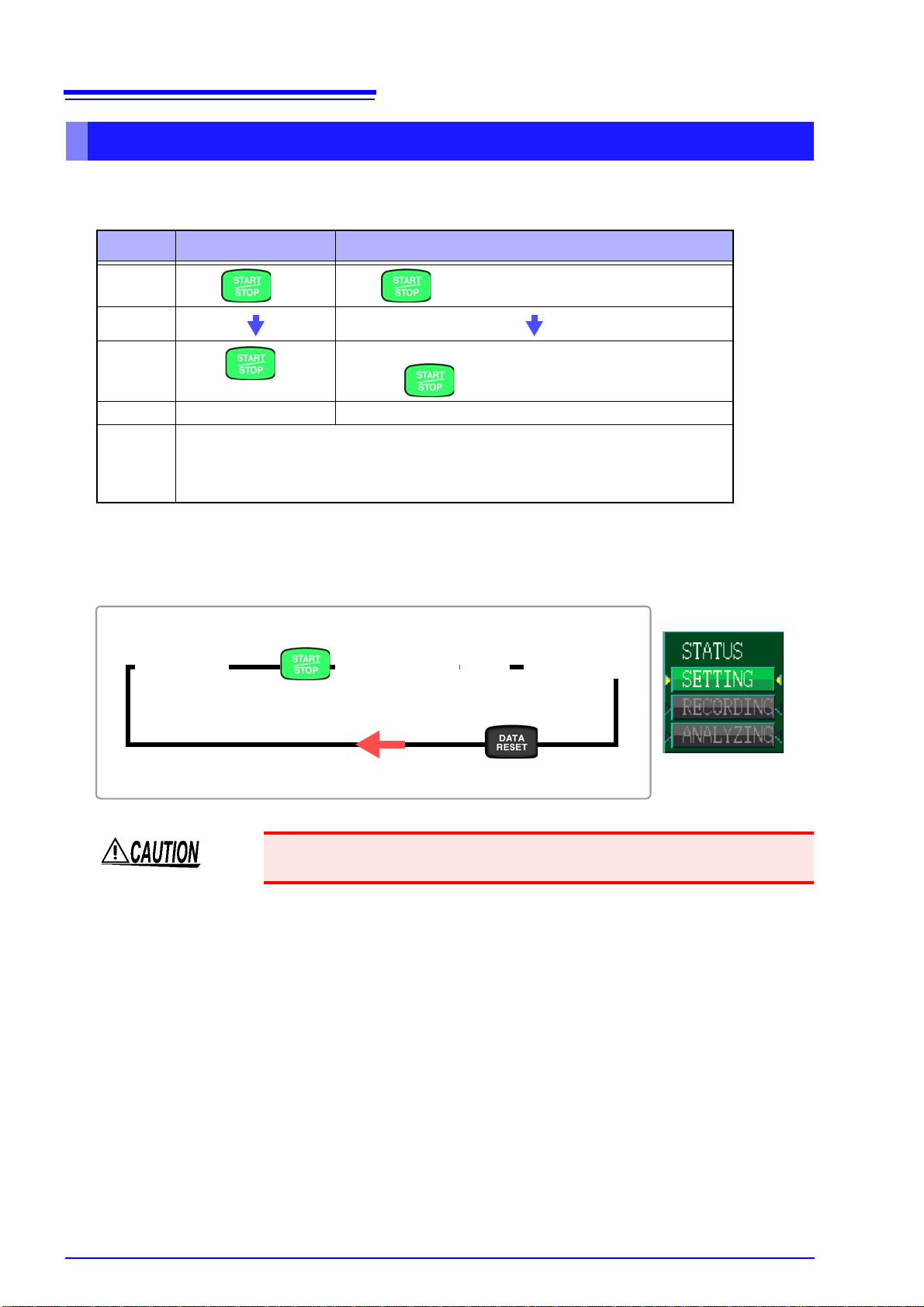

Relationship between the operation status and key operations

[SETTING] [RECORDING]

[ANALYZING]

Start

recording

Stop

recording

Revert to [SETTING] mode

Set

1.3 Measurement Flowchart

Starting and Stopping Recording

You can start and stop recording either manually or using real-time control. In either case, repeat recording can be used.

Manual Real-time control

Start

Stop

Notes See: "Time Start" (p.58)

Repeated

recording

Press . Press to start recording at the set time and date.

Press to stop

recording.

Recording is performed at the specified interval (once a week or once a day), and files

containing measurement data are created at the specified interval. Repeated recording

can be used to record for up to 55 weeks (approx. 1 year).

See: "Repeat Record" (p.59)

Stops automatically at the specified stop time.

Press the to force stop.

To start a new recording session after recording has ended, press the DATA RESET key, set the instru-

ment to [SETTING] mode, and then press the START/STOP key. (Note that pressing the DATA RESET

key will erase the displayed measurement data.)

Do not remove the SD memory card while recording or analyzing data. Doing so

may cause data on the card to be corrupted.

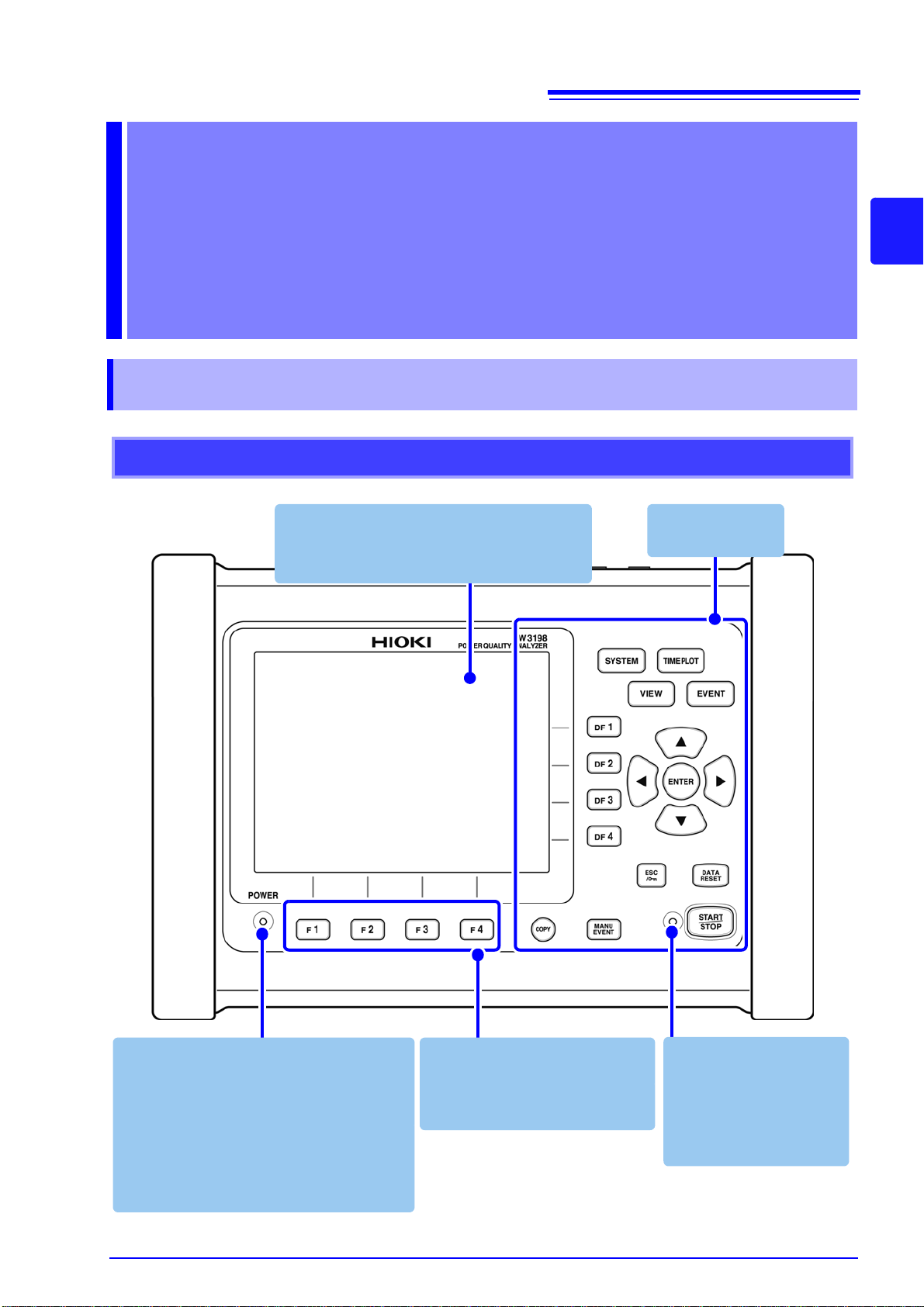

2.1 Names and Functions of Parts

Display

6.5" TFT color LCD display

See: "Display Items and Screen Types" (p.20)

Front

F key (Function key)

Select and change display contents and settings.

See:"2.2 Basic Operations" (p.19)

Operation keys

See:(p.16)

POWER LED

Lights up when the

POWER switch is

turned on and power is supplied to the instrument.

Normal operation: Solid green

When using battery pack: Solid red

See: "3.8 Turning the Power On and Off (Set-

ting the Default Language)" (p.36)

START/STOP LED

When in the recording

standby state:

Flashing green

When recording:

Solid green

Names and Functions of Parts

Basic Operations

15

2

& Screens Chapter 2

2.1 Names and Functions of Parts

Chapter 2 Names and Functions of Parts Basic Operations & Screens

16

START/STOP key

Starts and stops recording. To resume recording, press the DA T A RESET key to reset the data followed by the START/STOP

key.

Operation keys

Menu keys (Screen selection)

Press a key to select a screen (the lit key indicates the current selection).

Displays the [SYSTEM] screen (which provides a list of system settings, event

settings, recording condition settings, and memory [file] options [settings data,

screen copy, measurement data]). (p.23)

Displays the [VIEW] screen (which displays waveform and measured values).

(p.24)

Displays the [TIMEPLOT] screen (which displays time series graphs). (p.25)

Displays the [EVENT] screen (which displays an event list). (p.26)

Cursor keys

Move the cursor on the

screen. The cursor keys

are also used to scroll

through graphs or waveforms.

ENTER key

Finalizes the selected or

changed item.

DF keys (display function keys)

Selects which screen to

display from the selected

[SYSTEM], [VIEW],

[TIMEPLOT], or

[EVENT] screen.

MANU EVENT key

Generates an event, initiating recording of measured values and event

waveforms.

COPY key

Outputs data from the

currently displayed

screen to the SD memory card or printer.

ESC key

Cancels any selections or

changes made and reverts

to the previous settings.

Pressing and holding this

key for at least 3 seconds

activates the key lock function. (To cancel the key

lock, press and hold for at

least 3 seconds again.)

DATA RESET key

Erases all currently displayed measurement data .

(Data that has been recorded to the SD memory card

is not erased.) To start a

new recording session,

press this key to reset the

data.

2.1 Names and Functions of Parts

17

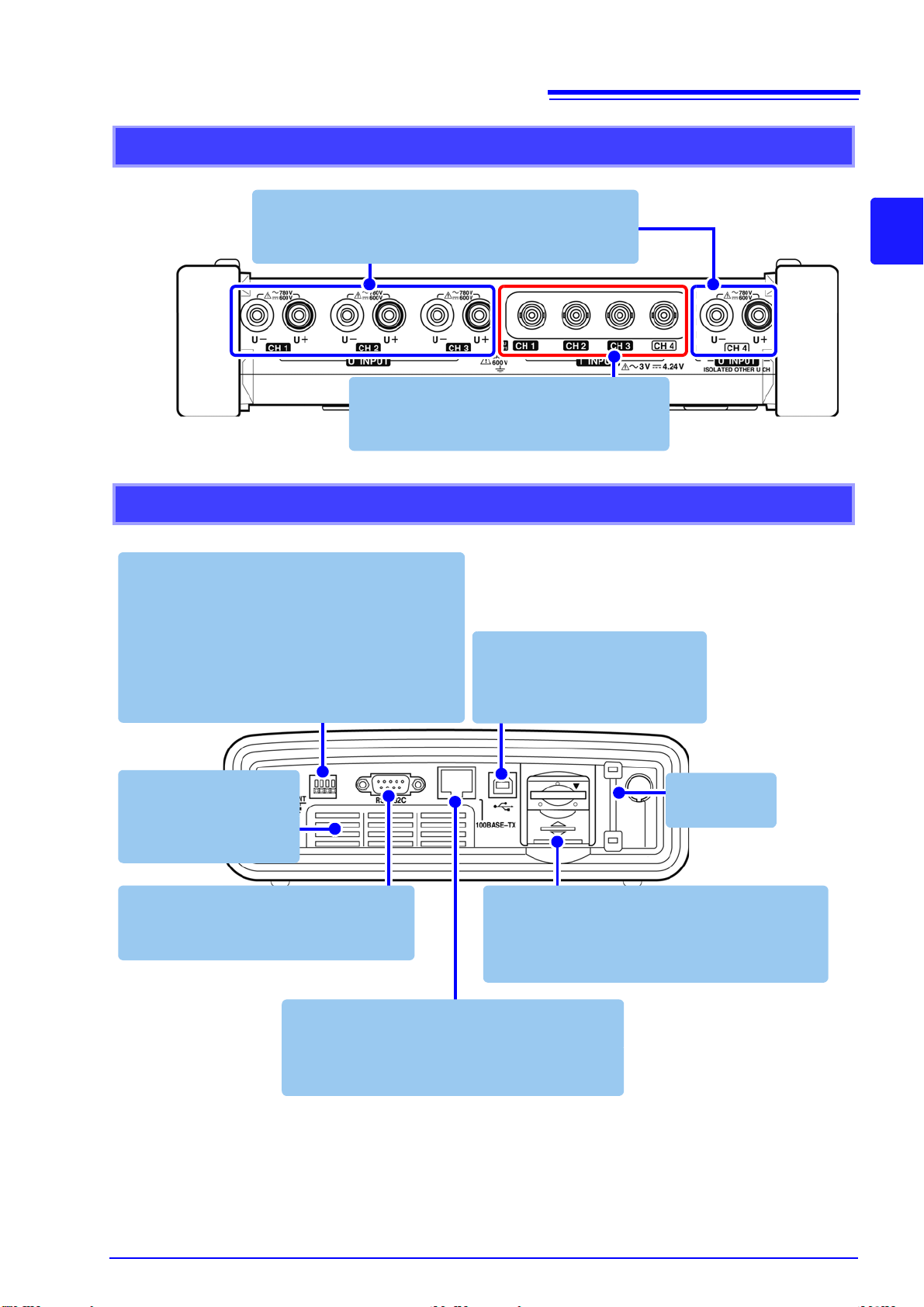

Upper side

Current input jacks

Connect optional clamp sensors here.

See: (p.34)

Voltage input jacks

Connect the included L1000 Voltage Cord here.

See: (p.34)

Right side

LAN interface

Connect a computer here using the optional

9642 LAN Cable.

See: (p.160)

RS-232C interface

Connect a GPS box or printer using an

RS-232C cable.

External control terminal

IN : Allows use of external input as an event

trigger.

OUT : Outputs a signal when an internal event

occurs.

GND : Serves as the ground terminal for the

external event input and output terminals.

See: (p.149)

Air vents

Do not block these

vents.

See: (p.6)

USB interface

Connect a computer here using

the included USB cable.

See: (p.156)

Strap eyelet

See: (p.28)

SD memory card slot

Insert an SD memory card here. Be sure to close

the cover when recording.

See: (p.32)

2.1 Names and Functions of Parts

2

Chapter 2 Names and Functions of Parts Basic Operations & Screens

18

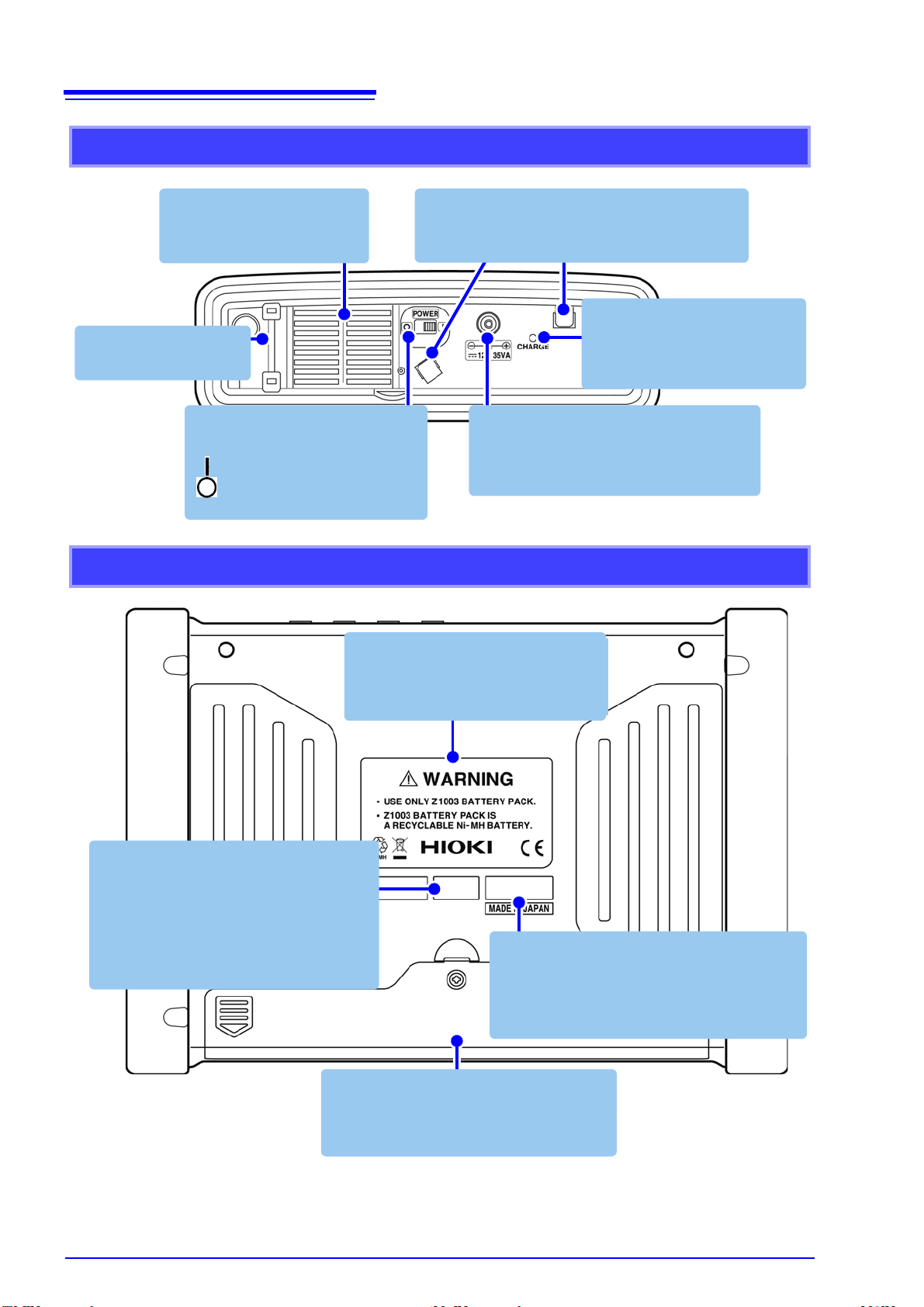

Left side

AC adapter connection jack

Connect the included Z1002 AC Adapter

here.

See: (p.32)

Power switch

Turns the instrument on and off.

See: (p.36)

Power ON

Power OFF

CHARGE LED

Lights up while the Z1003 Battery Pack is charging.

See: (p.30)

Strap eyelet

See: (p.28)

AC adapter hook

Loop the AC adapter cord through this hook.

See: (p.32)

Air vents

Do not block these vents.

See: (p.6)

Back

Label

Contains important warnings as well

as the CE mark, country of manufacture, and manufacturer.

Serial No.

Displays the instrument's serial number. Do

not remove the label as the information is

contains is necessary in order to manage the

device.

MAC address label

Displays the instrument's unique MAC

address, which is used when configuring

a LAN connection. Do not remove the label as the information it contains is necessary in order to manage the devic e.

Battery compartment

Install the included Z1003 Battery Pack

here.

See: (p.30)

2.1 Names and Functions of Parts

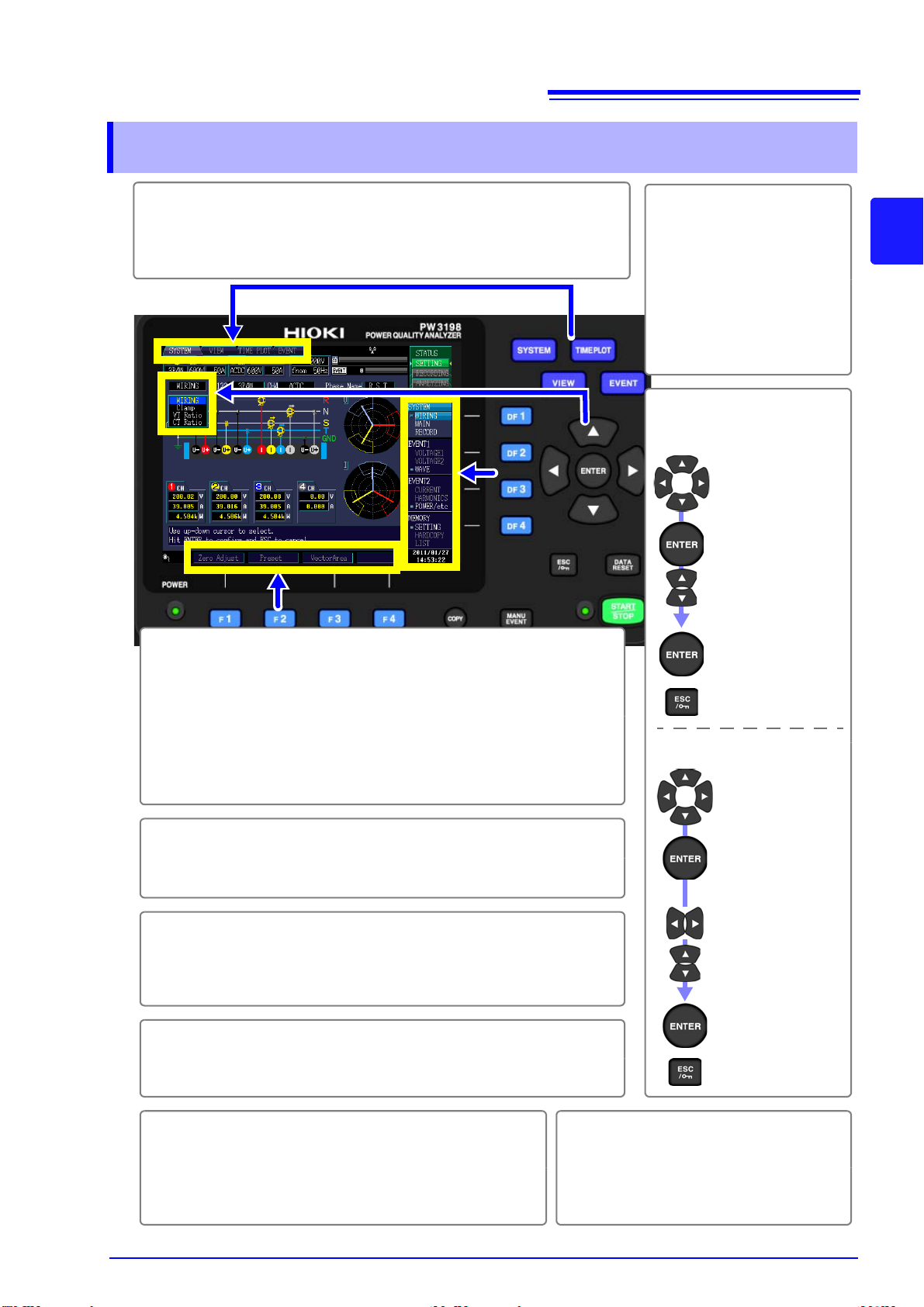

2.2 Basic Operations

2

3

4

5

67

89

1

4 Select and finalize

the desired settings.

Display a pulldown menu

Select the

desired setting

Accept setting

Move the

cursor to the

desired setting

1 To select a display screen

Press SYSTEM, VIEW,TIME PLOT, or EVENT to display the correspo nd ing screen.

See: "2.3 Display Items and Screen Types" (p.20)

To chan g e a va lu e

Select the

value so that it

can be

changed

Select a digit

Select a value

Accept setting

Move the

cursor to the

desired setting

5 Start/stop recording.

Press the START/STOP key to start/stop recording.

See: "Starting and Stopping Recording" (p.14)

6 Revert to [SETTING] mode after stopping recording.

Press the DATA RESET key to reset the measurement data.

The instrument will return to [SETTING] mode from [ANALYZ-

ING] mode.

3 To select and change display contents and

settings

Press one of the F keys to select and change display contents

and settings. The displayed function labels depend on the currently displayed screen.

Freeze the waveform or value display.

On the [VIEW] screen, you can freeze the waveform or value

display by pressing the F4 [HOLD] key.

Cancel

Cancel

the setting

7 Engage the key lock.

Press and hold the ESC key for at least 3 seconds. To cancel

the key lock, press and hold the key for at least 3 seconds.

8 Save screen data (output it to a printer).

Press the COPY key. Data will be saved to the SD

card (or output to the printer).

See: "9.5 Saving, Displaying, and Deleting Screen Copies"

(p.144)

9 Generate an event manually.

Press the MANU EVENT key. Measured values and event waveforms

at that time will be recorded.

See: "Manual Events" (p.13)

2 Select the screen to

display.

Press one of the DF keys

to select and change display contents and settings. The displayed

function labels depend

on the currently displayed screen.

19

2.2 Basic Operations

2

Chapter 2 Names and Functions of Parts Basic Operations & Screens

20

5

Screen T ypes

The tab for the currently displayed screen is shown brighter than the rest.

2

1

2, 3

4

1SD memory card operation and

usage status display

Lights up when no SD card is inserted.

(White)

Lights up when an SD memory card is

inserted.

(Red)

Lights up when the SD memory card is

being accessed.

2Operating State Indicators

Indicates Data Hold is active.

Lights to indicate Key Lock is active

(keys are locked), after holding the

ESC key for three seconds.

Lights up when settings can be configured.

The [SETTING] indicator shows

[WAITING] from the time that the

START/STOP key is pressed until

recording actually starts. During

repeated recording, [WAITING] is also

displayed when recording is stopped.

Lights up when data is being recorded.

Lights up when the instrument is in

[ANALYZING] mode after recording

stops.

Current CH1 to CH4 connection state, voltage range, current range settings

Nominal input voltage and

measurement frequency

(nominal frequency) settings

TIMEPLOT data capacity

Once the memory is full, no additional data can be

recorded.

Help comment

Displays an explanation for the item

highlighted by the cursor.

6

2.3 Display Items and Screen Types

2.3 Display Items and Screen Types

Common Display Items

These items are displayed on every screen.

21

Displays the current year, month, day, hour, minute,

and second.

See: Setting the Clock: (p.65)

3 Interface status display

Lights up during normal operation.

Lights up when the instrument is b oth

connected to an HTTP server and

downloading data.

Lights up when the instrument is

downloading data.

Lights up when the instrument is connected to an HTTP server.

Lights up when a printer is conne cted

to the RS-232C terminal.

(Blue)

Lights up when GPS positioning is

active while connected to the PW9005

GPS Box.

(Red)

Lights up when the RS connected

device is set to GPS but the PW9005

GPS Box is not yet connected.

(Yellow)

Lights up when the PW9005 GPS Box

is connected but GPS positioning is

not yet active.

4Real-time clock display

5 Power supply status display

(White)

Lights up when the instrument is being

powered by the AC adapter.

The POWER LED will turn green.

(Orange)

Lights up when the instrument is being

powered by the AC adapter and the

battery is charging. The POWER LED

will turn green.

(White)

Lights up when the instrument is being

powered by the battery. The POWER

LED will turn red.

(Red)

Lights up when the instrument is being

powered by the battery and the

remaining battery life is limited. The

POWER LED will turn red.

No display

No display indicates that the instrument is off or charging.

The CHARGE LED will light up.

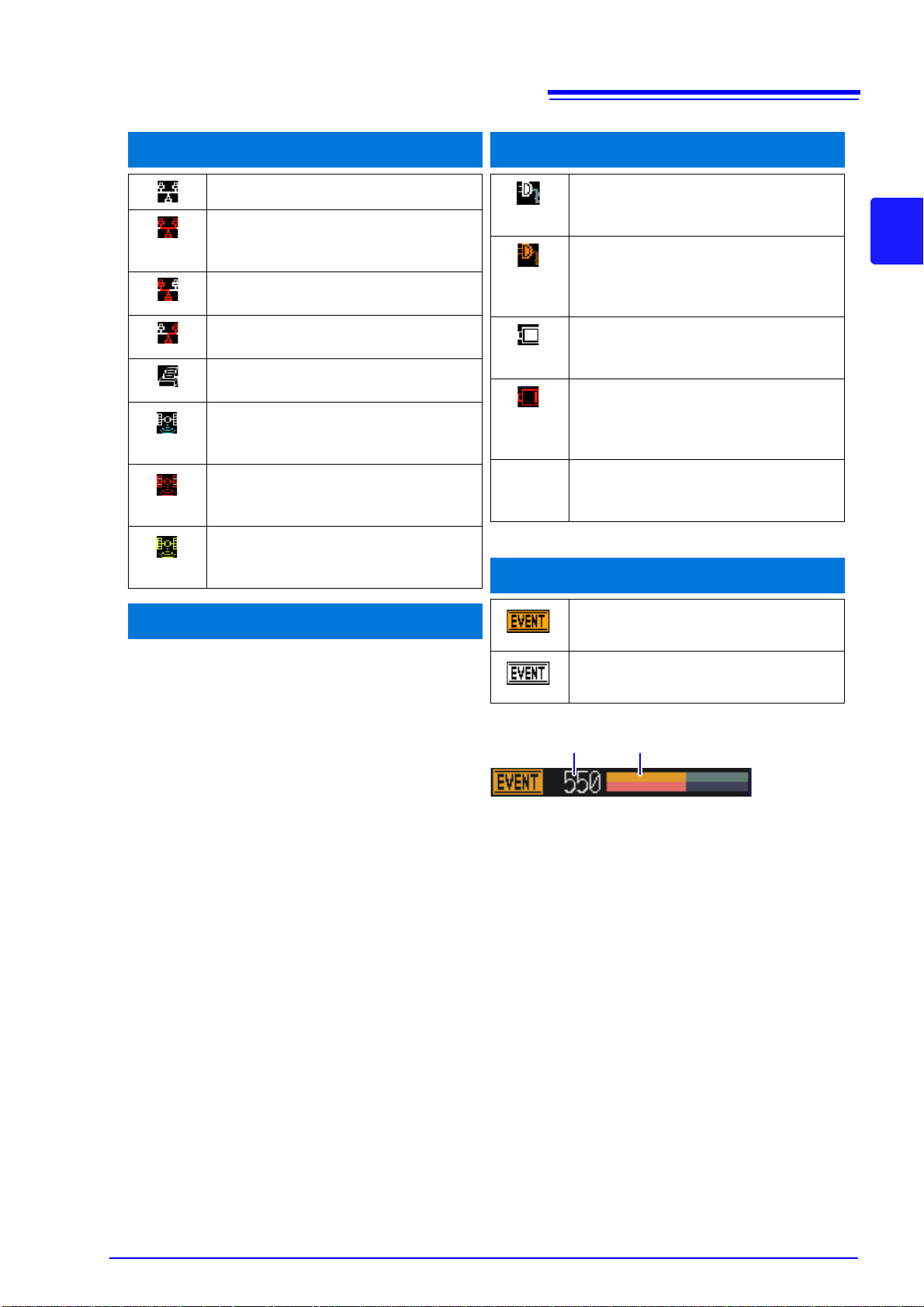

6 Event generation status display

(Orange)

An event has been detected.

(White)

No event has been detected.

Event indicator

Full bar indicates 1,000 events.

No. of events recorded

(Max. 1,000)

2.3 Display Items and Screen Types

2

Chapter 2 Names and Functions of Parts Basic Operations & Screens

22

1

2

1

1

2.3 Display Items and Screen Types

Warning Indicators

The instrument may display the following warnings:

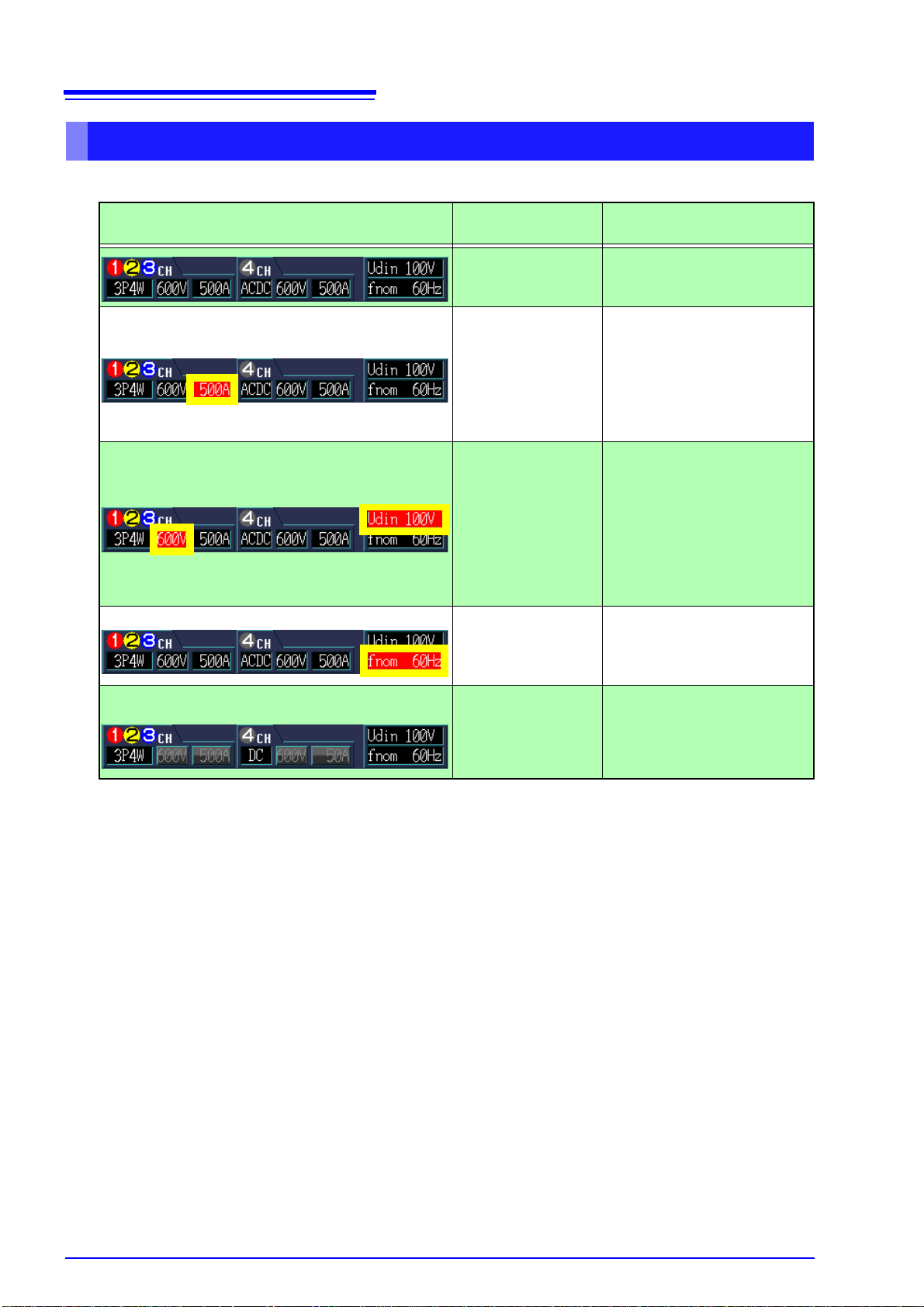

Display Cause

(Current range indicator turns red.)

(Volt a ge indi cator turns red.) ([Udin] indicator turns red.)

([fnorm] indicator turns red.)

(The voltage range indicator and current range indicator

are grayed out.)

Solution and page number for

more information

Normal screen display -

Switch to an appropriate clamp

sensor.

Range or crest factor

exceeded (current).

1. Range or crest factor exceeded (voltage).

2. The measured value

and nominal input

voltage ([Udin])* differ.

The measurement frequency (nominal frequency [fnom]) and

measured value differ.

VT (PT) and CT have

been set.

See: "Options" (p.3)

Change the settings to an appropriate range.

See: "5.1 Changing Measure-

ment Conditions" (p.55)

For (1), the measured value has

exceeded the voltage value that

the instrument is capable of measuring. Use VT (PT) to make the

measurement. If only (2) applies,

change the nominal input voltage

to an appropriate value.

See: "5.1 Changing Measure-

ment Conditions" (p.55)

Change the measurement frequency to an appropriate value.

See: "5.1 Changing Measure-

ment Conditions" (p.55)

-

*: The nominal input voltage (Udin), which is calculated from the nominal supply voltage using the trans-

former ratio, indicates the voltage that is actually input to the instrument.

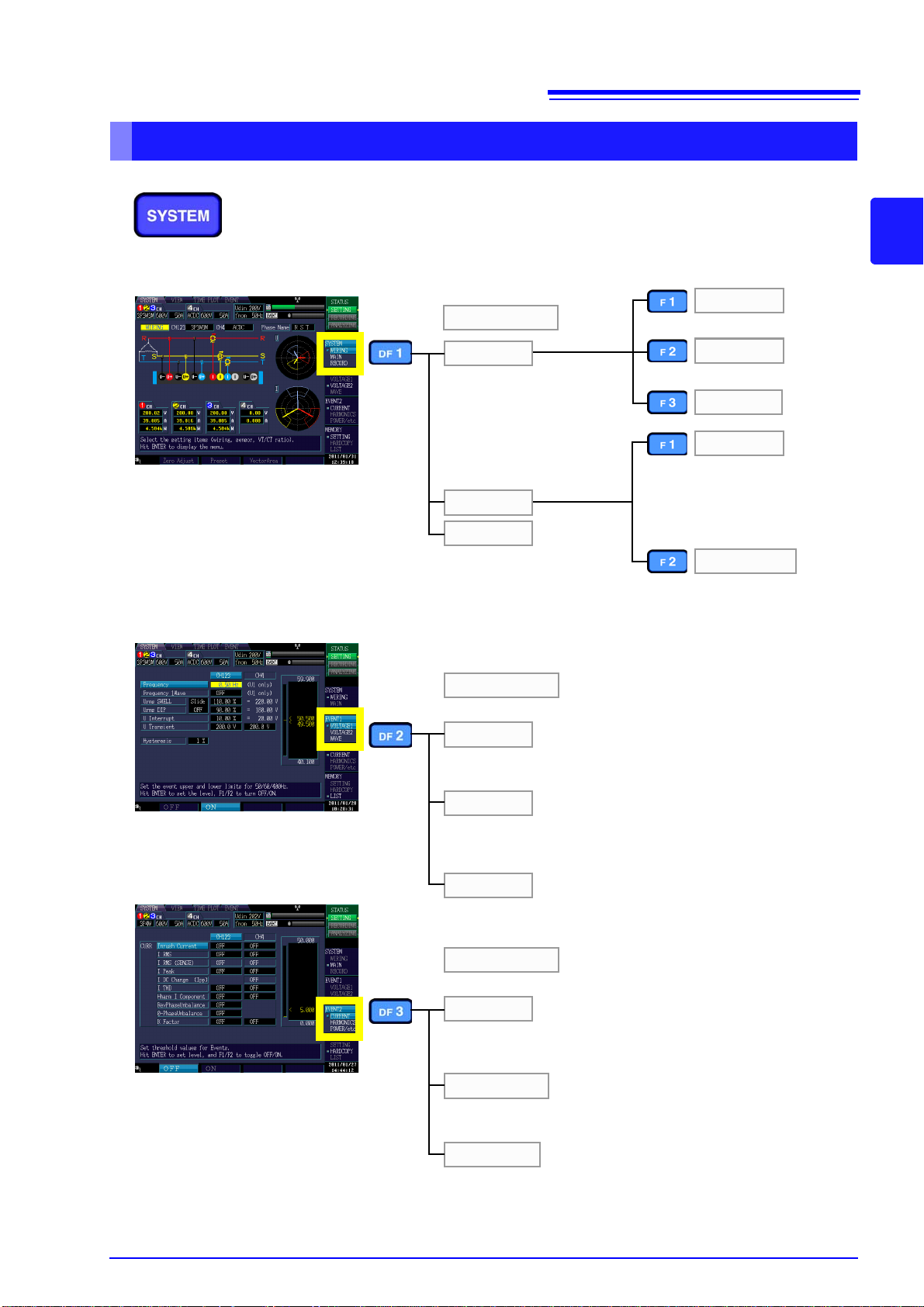

Screen Types

Configure settings

(SYSTEM screen)

The [SYSTEM] screen is used to configure var ious instrument

settings.

Press the SYSTEM key to display the [SYSTEM] screen. The

screen can be changed with the DF keys.

Configures the connection,

clamp sensor, VT ratio, and

CT ratio settings. (This

screen is always displayed

after the instrument is turned

on.)

See: Chapter 4 (p.37)

VOLTAGE1

VOLTAGE2

WAVE

WIRING

MAIN

RECORD

SYSTEM

MEASURE

HARDWARE

Zero Adjust

Preset

VectorArea

Configures the recording,

TIMEPLOT interval, realtime control, and repeated

recording settings.

See: 5.2 (p.58) to 5.3 (p.61)

Configures the connection,

clamp sensor, VT ratio, CT ratio,

current range, event, and TIMEPLOT settings.

See: 5.1 (p.55)

Configures the display language, screen color, clock, external output, RS-connected

device, beep, LCD backlight,

and LAN settings. Resets the

system.

See: 5.4 (p.64)

EVENT1

Configures the frequency, swell, dip, interruption, transient

threshold, and hysteresis settings.

Configures the RMS voltage, waveform peak, DC fluctuation,

harmonic distortion factor, high-order harmonic component, and

unbalance factor threshold settings.

See: 5.5 (p.66)

Configures the threshold settings for generating events with the

voltage waveform.

CURRENT

HARMONICS

POWER/etc

EVENT2

Configures the inrush current, RMS current, waveform peak, DC

fluctuation, harmonic distortion factor, high-order harmonic component, unbalance factor, and K factor threshold settings.

Configures the threshold settings for 0- to 50-order harmonics

(voltage, current, power, phase).

See: 5.5 (p.66)

Configures the active power, reactive power, apparent power,

power factor threshold, timer event, external event, and continuous event settings.

See: 4.7 (p.50)

See: 4.1 (p.37)

23

2.3 Display Items and Screen Types

2

Chapter 2 Names and Functions of Parts Basic Operations & Screens

24

SETTING

HARDCOPY

LIST

MEMORY

Displays a list of settings data.

Displays a list of screenshot

data.

See: Chapter 9 (p.135)

Displays a list of the files

stored on the SD memory

card.

LOAD

SAVE

VIEW

DELETE

DELETE

FORMAT

DELETE

LOAD*

*The List's F1 (LOAD) will appear when the cursor is in the stored data folder. (B*******).

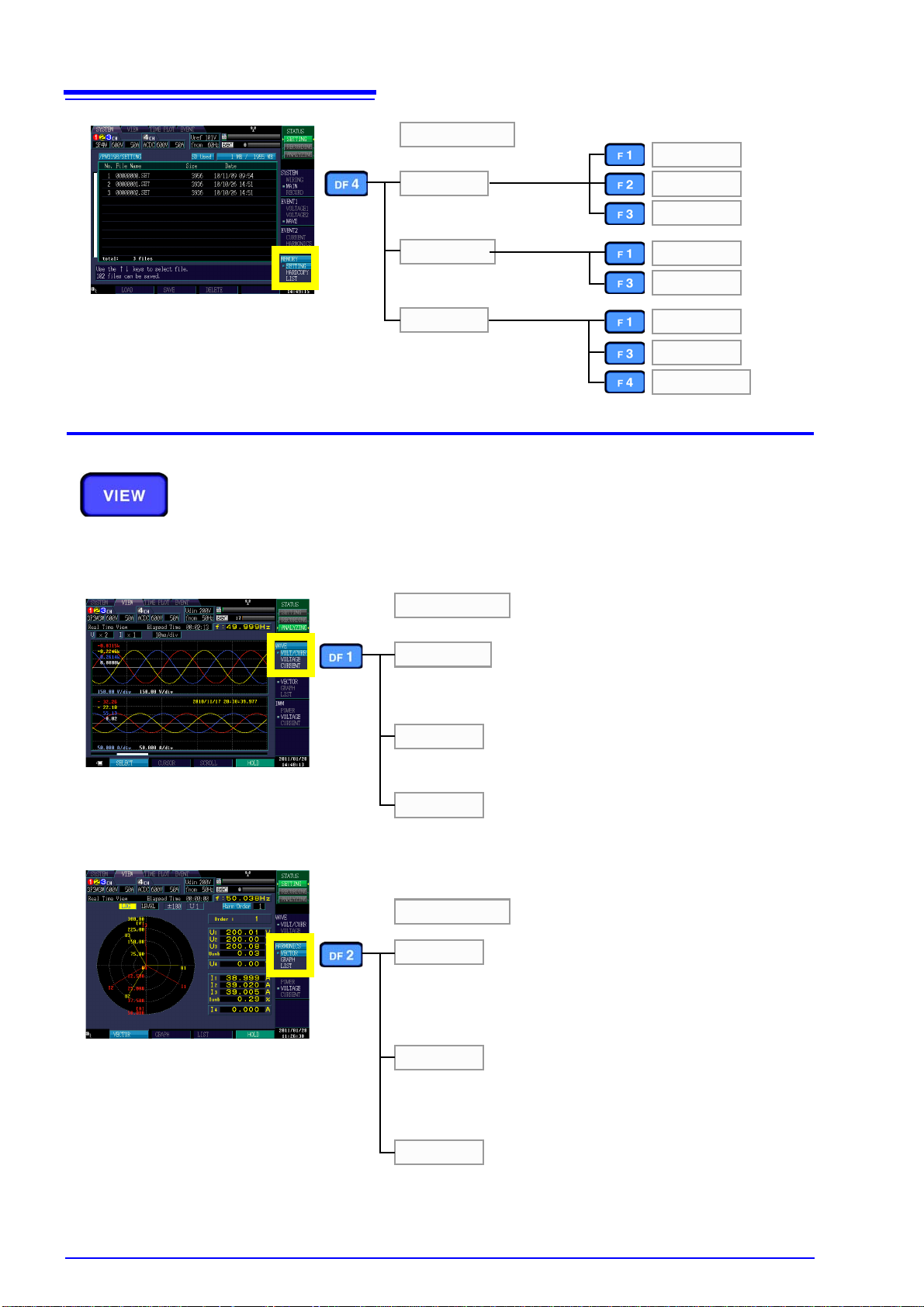

Monitor

instantaneous values

(VIEW screen)

The [VIEW] screen is used to view voltage and current

instantaneous waveforms, phase relationships, values, and

harmonics.

Press the VIEW key to display the [VIEW] screen. The

screen can be changed with the DF keys.

VOLT/CURR

VOLTAGE

CURRENT

WAVE

Displays voltage waveforms for channels 1 to 4 on one screen

and current waveforms for channels 1 to 4 on another screen (for

a total of two screens).

Displays separate voltage waveforms for channels 1 to 4.

See: 6.2 (p.76)

Displays separate current waveforms for channels 1 to 4.

VECTOR

GRAPH

LIST

HARMONICS

Displays the phase relationship between voltage and current for

channels 1 to 3 as a vector diagram. The RMS value and phase

instantaneous value is also shown for each order.

See: 6.3 (p.80)

Displays the sum voltage, current, and 0- to 50-order power measured values for channels 1 to 4 as a graph.

See: 6.4 (p.83)

Displays the sum voltage, current, power measured values (orders 0 to 50) for channels 1 to 4 as a graph.

See: 6.4 (p.83)

2.3 Display Items and Screen Types

Loading...

Loading...