Page 1

Page 2

Page 3

Contents

Contents

Introduction ................................................ 1

Verifying Package Contents ..................... 2

Safety Information ..................................... 4

Operating Precautions .............................. 7

1 Overview 15

1.1 Procedure for Investigating

Power Quality ................................. 15

Step 1: Clarifying the purpose ....................15

Step 2: Identifying the malfunctioning

component (measurement location) ...........15

Step 3: Checking investigation

(measurement) locations (collecting site

data) ............................................................16

Step 4: Making measurements with the

power quality analyzer (measurement

procedure) ..................................................16

Advice for identifying the cause of

abnormalities ..............................................18

1.2 Product Overview ........................... 19

1.3 Features .......................................... 20

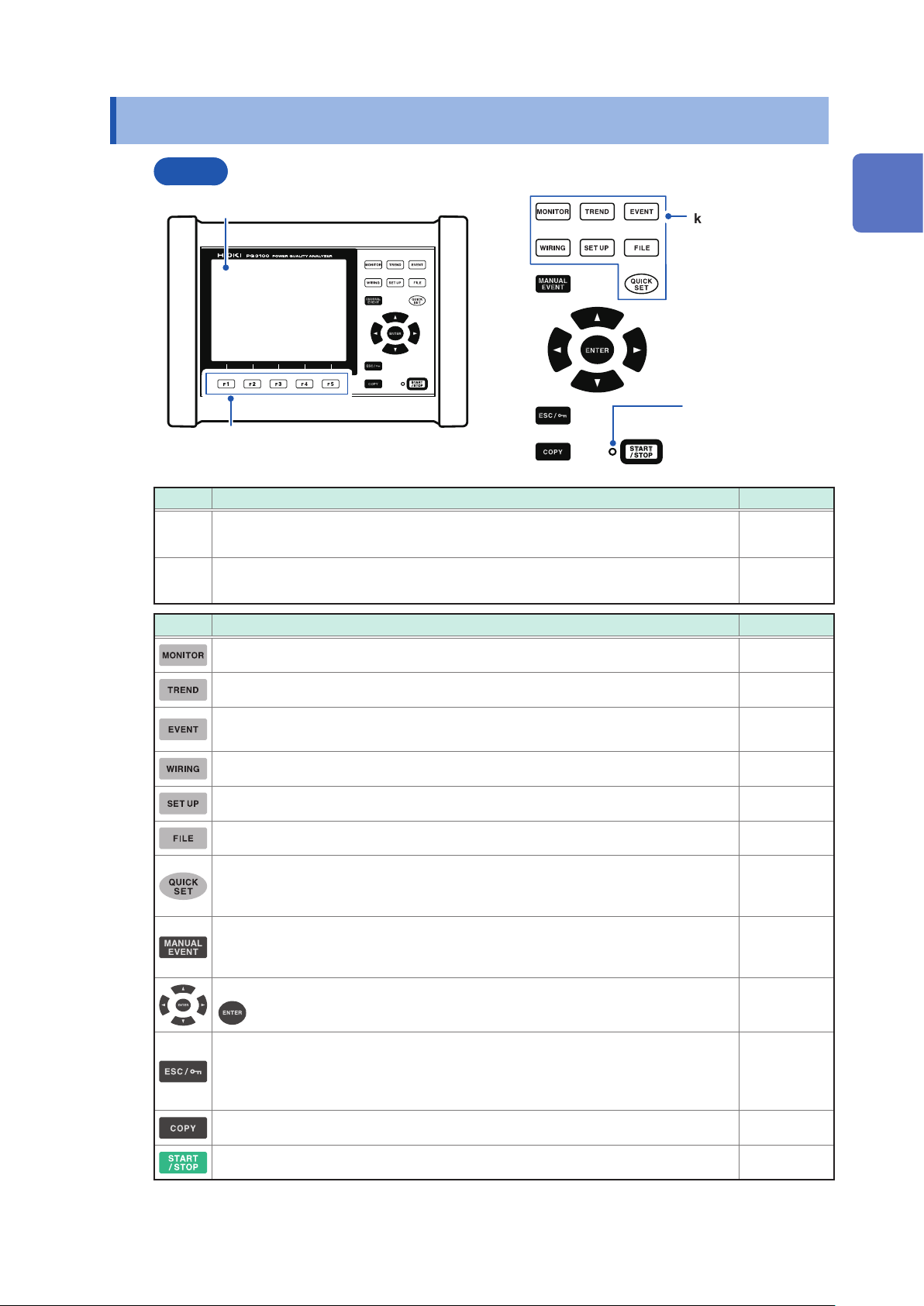

1.4 Names and Functions of Parts ..... 21

1.5 ScreenConguration ..................... 24

Displaying and switching screens ...............24

MONITOR screen .......................................25

TREND screen ............................................26

EVENT screen ............................................27

WIRING screen ...........................................27

SET UP screen ...........................................28

FILE screen ................................................29

QUICK SET screen .....................................29

1.6 Basic Key Operations .................... 30

Changing the required items .......................30

Entering characters .....................................31

1.7 Screen Display ............................... 32

1.8 Error Screen Display ...................... 34

2 Preparing for

Measurement 35

2.1 Preparation Flowchart ................... 35

2.2 Initial Measurement

Preparations ................................... 36

Color coding of current sensor (for

channel identication) .................................36

Bundling the voltage cords and current

sensors (If required) ....................................37

Installing the battery pack ...........................38

Attaching the strap (if required) ..................39

Setting the language, clock, and

measurement frequency .............................40

2.3 Pre-measurement Inspection ........ 41

2.4 Inserting the SD Memory Card ...... 42

2.5 Power Supply ................................. 43

2.6 Turning On/Off the Instrument ...... 44

2.7 Warm-up .......................................... 44

3 Quick Set 45

3.1 CongurableItems ......................... 45

3.2 Adding Settings .............................. 46

4 Wiring

(WIRING Screen) 47

4.1 Wiring Procedure ........................... 47

4.2 Wiring Method and Declared

Input Voltage Settings.................... 48

Wiring diagram ............................................50

4.3 Connecting Voltage Cords to

Instrument ....................................... 51

4.4 Connecting Current Sensors

andConguringCurrentSensor

Settings ........................................... 52

Connecting the optional current sensor ......52

Connecting current sensors other than

the optional sensors ....................................53

4.5 Zero Adjustment ............................. 54

4.6 Connecting Voltage Cords to

Objects ............................................ 55

4.7 Attaching Current Sensors to

Objects ............................................ 56

Load current measurement .........................56

Leakage current measurement ...................57

4.8 ConguringCurrentRange

Setting ............................................. 58

4.9 Checking Wiring ............................. 59

5 Setting Change (SET

UP Screen) 63

5.1 Measurement Settings ................... 64

SET UP, Measurement Settings 1

screen .........................................................64

SET UP, Measurement Settings 2

screen .........................................................66

5.2 Recording Settings ........................ 69

5.3 Event Settings ................................ 72

SET UP, Event Settings 1 screen .............72

SET UP, Event Settings 2 screen .............74

5.4 System Settings ............................. 75

System reset (Default) ................................76

Factory reset (Default) ................................77

Factory settings ..........................................78

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

PQ3100A961-00

i

Page 4

Contents

Contents

6 Verifying the Waveform,

Measured Values

(MONITOR Screen) 81

Fixing the waveform display and

measured values ........................................81

6.1 Verifying the Voltage Waveform

and Current Waveform ................... 82

Screen display ............................................82

Changing the zoom factor for the

vertical axis and horizontal axis (X and

Y axis) of the waveform ..............................83

Verifying the measured value and

time at the cursor position (cursor

measurement) .............................................83

Scrolling the waveform ...............................83

6.2 Verifying the Electric Power (List

of Numerical Values) ...................... 84

6.3 Verifying the Electric Energy ........ 85

6.4 Verifying the Voltage Details ......... 86

6.5 Verifying the Current Details ......... 87

6.6 Verifying the Vector ........................ 88

6.7 Verifying the Harmonics Graph

and Harmonics Numerical

Values .............................................. 89

7 Recording (Save) (SET

UP Screen) 91

7.1 Start and Stop of the

Recording ....................................... 91

7.2 Using the Instrument During an

Interruption ..................................... 94

8 Verifying the Trends

(Fluctuations) in

Measured Values

(TREND Screen) 95

8.5 Verifying the Harmonic Trend

(Availableafterthermware

update) .......................................... 103

8.6 VerifyingtheFlicker(Available

afterthermwareupdate) ........... 104

9 Checking Events

(EVENT Screen) 105

9.1 Checking Event List ..................... 108

Checking event details ..............................109

9.2 Checking Event Status .................110

Switching event monitor screen ................ 111

Checking trend data on event ................... 11 2

Checking transient waveforms during

an event (Available after the rmware

update) ...................................................... 11 3

10 File Saving and

Operations (FILE

Screen) 115

10.1 Viewing and Using FILE Mode

Screen ............................................116

10.2 Folder and File Structure ..............118

SD memory card ....................................... 11 8

Internal memory ........................................120

10.3 Screen Hard Copy ........................ 121

Checking images (Available after the

rmware update) .......................................121

10.4 Saving Setting Files ..................... 122

10.5 Loading Setting Files ................... 123

10.6 Loading Measured Data ............... 124

10.7 Copy from the Internal Memory

to SD Memory Card ...................... 125

10.8 Deleting Folders and Files .......... 125

10.9 Formatting SD Memory Card

(Deleting All Files) ........................ 126

10.10 Removing SD Memory Card

during Recording ......................... 127

Verifying the measured value and

time at the cursor position (cursor

measurement) .............................................96

Scrolling the graph ......................................96

Event search ...............................................97

8.1 Verifying the Basic Trend .............. 98

8.2 Verifying the Detail Trend ............ 100

8.3 Verifying the Electric Energy ...... 101

8.4 VerifyingtheDemand(Available

afterthermwareupdate) ........... 102

ii

ii

11 Analysis (with

Computer) 129

11.1 Copying Files ................................ 129

Use of SD Memory Cards .........................130

Use of USB Cable .....................................131

11.2 Use of Application Software PQ

One (Included) .............................. 133

What can be done with the application

software ....................................................133

Installation .................................................134

Page 5

Contents

Contents

12 Communications (USB/

LAN/RS-232C) 137

12.1 Preparing for LAN

Communications .......................... 138

Settings (SET UP Screen) ........................138

Example of establishing a network

environment ..............................................139

Connection ................................................140

12.2 Remote Control of the

Instrument through the Internet

Browser (LAN Communications

Only) .............................................. 142

Preparations .............................................142

Remote operation .....................................143

Restrict the access

(password settings) ...................................144

12.3 RS-232C Communication

Preparations ................................. 145

Settings (SET UP screen) .........................145

Connection ................................................145

13 External I/O 147

13.1 Event Input .................................... 148

13.2 Event Output ................................. 149

13.3 External Event Output Settings

(SET UP Screen) ........................... 150

13.4 Connection ................................... 151

14 Specications 153

15.2 Cleaning ........................................ 195

15.3 Error Indication ............................ 195

15.4 Disposing the Instrument ............ 199

Appendix Appx.1

Appx. 1 Fundamental

Measurement Items ......... Appx.1

Appx. 2 Event Item ......................... Appx.3

Appx. 3 Explanation of Power

Quality Parameters and

Events ............................... Appx.4

Appx. 4 Event Detection

Methods ............................ Appx.8

Appx. 5 Recording Trends and

Event Waveforms ........... Appx.15

Trend screen recording method .........Appx.15

Recording event waveforms ..............Appx.16

Method for verifying aggregation values

required by IEC61000-4-30 ...............Appx.17

Appx. 6 Detailed Explanation of

IEC Flicker and ∆V10

Flicker(availableafter

thermwareupdate) ..... Appx.18

IEC icker meter ................................Appx.18

V10 icker meter ..............................Appx.20

∆

Appx. 7 3-phase 3-wire

Measurement .................. Appx.21

Appx. 8 Method for Calculating

Active Power

Accuracy ......................... Appx.23

Appx. 9 Terminology ................... Appx.24

1

11

2

12

3

13

4

14

5

15

6

6

7

7

14.1 GeneralSpecications ................ 153

14.2 InputSpecications/Output

Specications/Measurement

Specications ............................... 155

14.3 Flagging Concept ......................... 169

14.4 QUICKSETSpecications .......... 170

14.5 EventSpecications .................... 172

14.6 InterfaceSpecications ............... 173

14.7 Calculation Formula ..................... 175

14.8 RangeCongurationand

CombinationAccuracy ................ 188

15 Maintenance and

Service 193

Calibrations ...............................................193

15.1 Troubleshooting ........................... 193

Before having the instrument repaired ......193

Replaceable parts and operating

lifetimes .....................................................194

Index Ind.1

iii

iii

8

8

9

9

10

10

Appx. Ind.

Appx. Ind.

Page 6

Contents

iv

Page 7

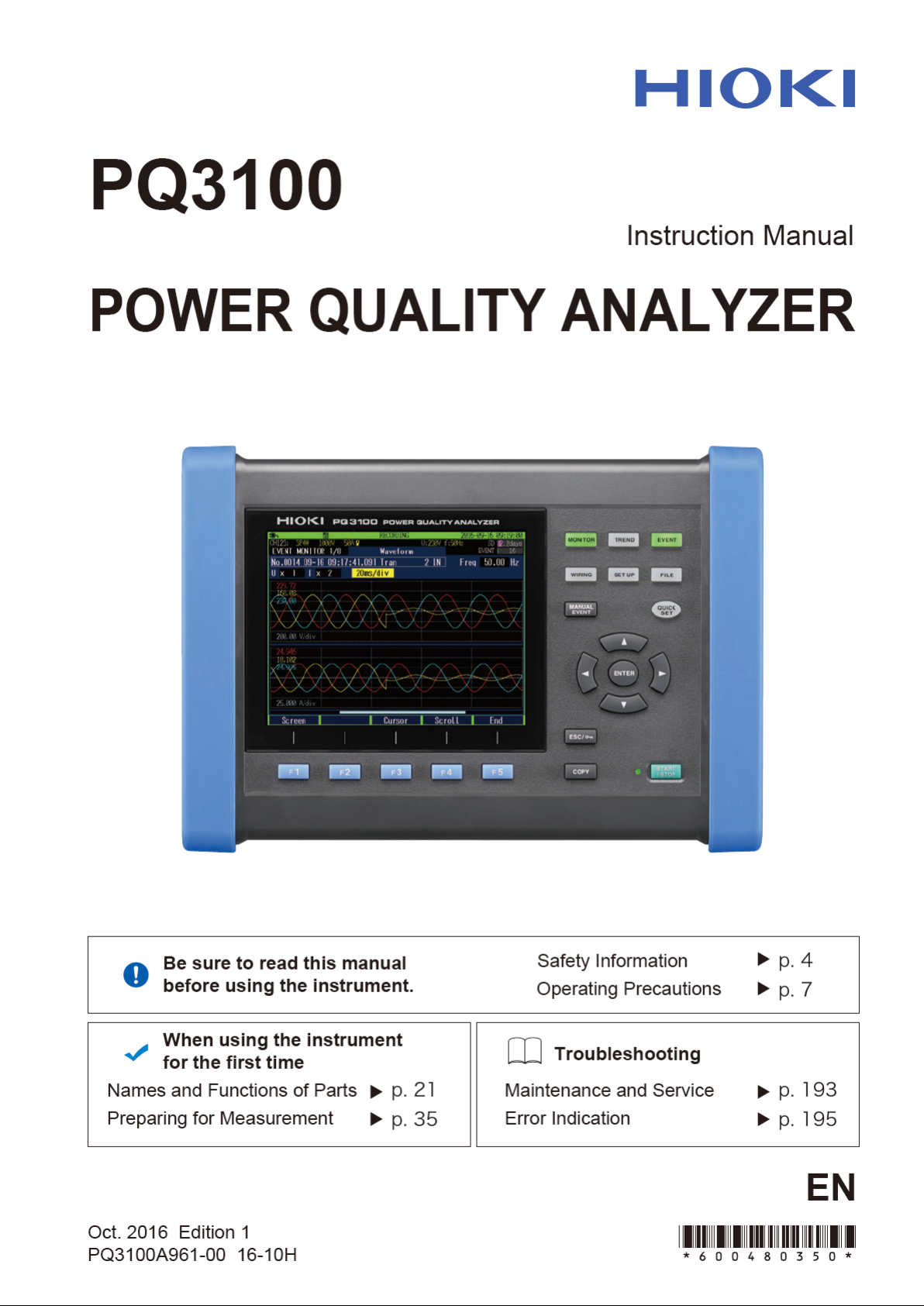

Introduction

Thank you for purchasing the Hioki PQ3100 Power Quality Analyzer. To obtain maximum

performance from the instrument, please read this manual rst, and keep it handy for future

reference.

Registered trademarks

• Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation

in the United States and other countries.

• Microsoft and Windows 7, Windows 10 are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• The SD logo is a trademark of SD-3C, LLC.

• Microsoft and Excel are either registered trademarks or trademarks of Microsoft Corporation in

the United States and other countries.

• Any other products and company names are generally either trade names, registered trademarks

or trademarks of respective companies.

Introduction

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

1

Page 8

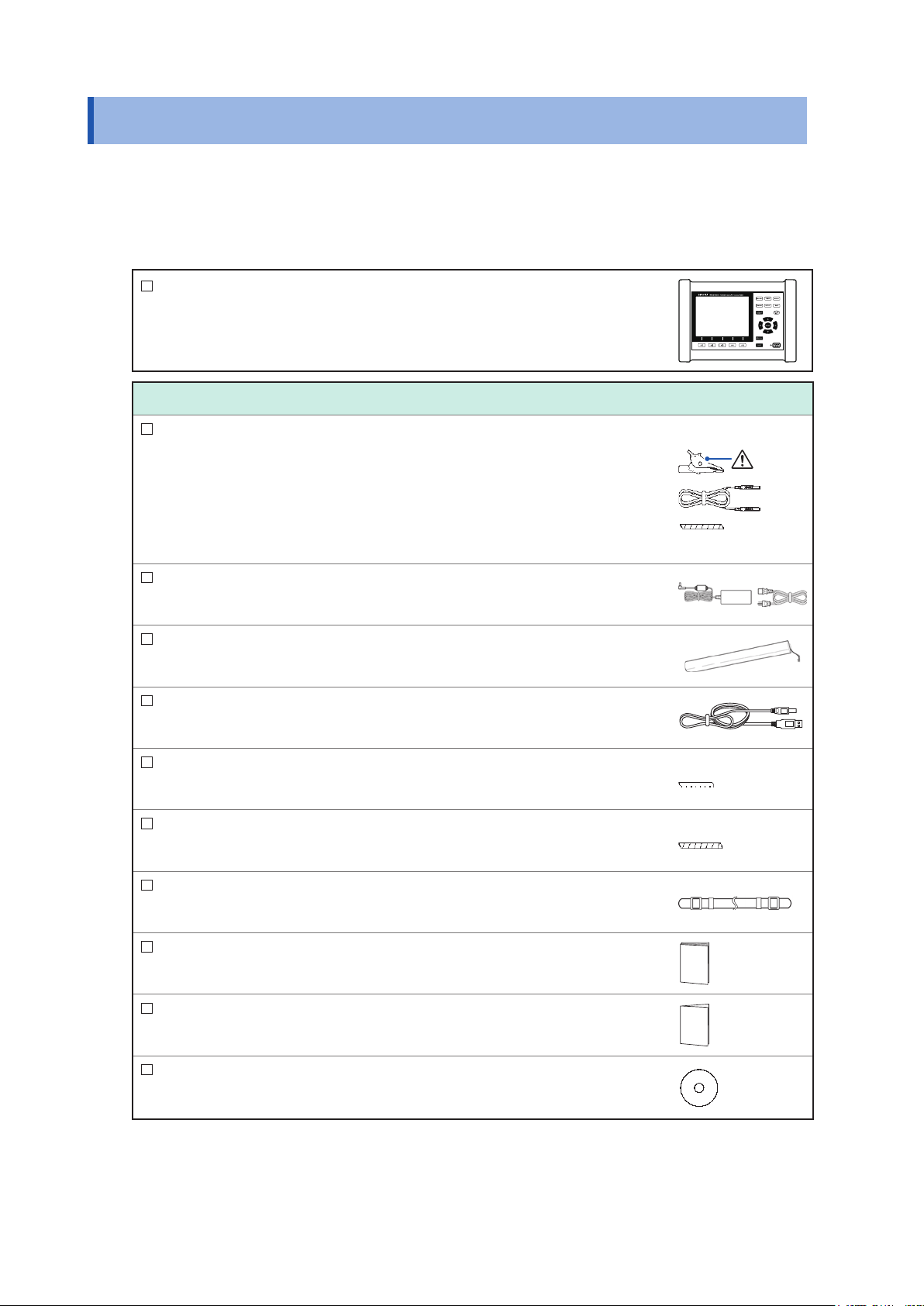

Verifying Package Contents

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories, keys, switch, and connectors. If damage is evident,

or if it fails to operate according to the specications, contact your authorized Hioki distributor or

reseller.

Check that the package contents are correct.

PQ3100 Power Quality Analyzer

Accessories

L1000-05 Voltage Cord

Maximum rated voltage: 1000 V, maximum rated current: 10 A

Alligator clips (black, red, yellow, blue, gray)

3 m banana plug leads (black, red, yellow, blue, gray)

Spiral Tubes (Cord bundling)

See “Bundling the voltage cords and current sensors (If required)”

(p. 37), “Connecting Voltage Cords to Instrument” (p. 51), and

“Connecting Voltage Cords to Objects” (p. 55).

Z1002 AC Adapter (with power cord)

Z1003 Battery Pack

USB cable

× 1

×1 each

×1 each

×5

×1

×1

×1

Colored spiral tubes in red, yellow, and blue (color coding for

current sensors)

Spiral tubes in black (cord bundling for current sensors)

Strap

See “Attaching the strap (if required)” (p. 39).

Instruction Manual*

Measurement Guide*

CD (computer application software)

See “11.2 Use of Application Software PQ One (Included)” (p. 133).

The latest version can be downloaded from our website.

*: See Hioki website for other languages.

Precautions when transporting the instrument

Handle the instrument carefully so that it is not damaged due to a vibration or shock.

×2 each

×5

×1

×1

×1

×1

2

Page 9

Verifying Package Contents

Options

The following options are provided for the PQ3100. Contact your authorized Hioki distributor or

reseller when ordering.

For current measurement

CT7126 AC Current Sensor (60 A, φ15 mm)

CT7131 AC Current Sensor (100 A, φ15 mm)

CT7136 AC Current Sensor (600 A, φ46 mm)

CT7044 AC Flexible Current Sensor (6000 A, φ100 mm)

CT7045 AC Flexible Current Sensor (6000 A, φ180 mm)

CT7046 AC Flexible Current Sensor (6000 A, φ254 mm)

CT7731 AC/DC Auto-Zero Current Sensor (100 A, φ33 mm)

CT7736 AC/DC Auto-Zero Current Sensor (600 A, φ33 mm)

CT7742 AC/DC Auto-Zero Current Sensor (2000 A, φ55 mm)

CT7116 AC Leakage Current Sensor (6 A, φ40 mm)

L9910 Conversion Cable (BNC-PL14)

For voltage measurement

L1000-05 Voltage Cord (accessory)

Maximum rated voltage: 1000 V, maximum rated current: 10 A

9804-01 Magnetic Adapter (Red: 1, for changing the voltage cord tips)

Maximum rated voltage: 1000 V, maximum rated current: 2 A

9804-02 Magnetic Adapter (Black: 1, for changing the voltage cord tips)

Maximum rated voltage: 1000 V, maximum rated current: 2 A

9243 Grabber Clip (Red/Black: 1 each, for changing the voltage cord tips)

Maximum rated voltage: 1000 V, maximum rated current: 1 A

Power supply

Z1002 AC Adapter (accessory)

Z1003 Battery Pack (accessory)

Media for recording

Z4001 SD Memory Card 2GB

Z4003 SD Memory Card 8GB

1

2

3

4

5

6

Communication

9637 RS-232C Cable (9 pin-9 pin/1.8 m, cross cable)

9642 LAN Cable

Carrying Case

C1009 Carrying Case (Bag)

C1001 Carrying Case (Soft)

C1002 Carrying Case (Hard)

7

8

9

10

Appx. Ind.

3

Page 10

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly

tested for safety prior to shipment. However, using the instrument in a way not described in this

manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in the

manual before use.

WARNING

With regard to the electricity supply, there are risks of electric shock, heat

generation, re, and arc discharge due to short circuits. Individuals using an

electrical measuring instrument for the rst time should be supervised by a

technician who has experience in electrical measurement.

Notation

In this document, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will result in death or serious injury

to the operator.

Indicates a potentially hazardous situation that may result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in minor or moderate injury

to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance tasks

with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled, this may

give rise to a hazardous situation; the operator may receive an electric shock, may

get burnt or may even be fatally injured.

Indicates a strong magnetic-eld hazard.

The effects of the magnetic force can cause abnormal operation of heart pacemakers

and/or medical electronics.

Indicates a prohibited action.

Indicates the action which must be performed.

MONITOR

(Bold character)

[ ] Operation keys are displayed in brackets ([ ]).

*

(Available after the

rmware update)

Names on the screen are displayed in bold characters.

Additional information is presented below.

This function is not available with the present rmware. This function will be available

after the rmware version update scheduled in May, 2017.

4

Page 11

Symbols on the instrument

Indicates cautions and hazards. When the symbol is printed on the instrument, refer to a

corresponding topic in the Instruction Manual.

Safety Information

Indicates DC (Direct Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a grounding terminal.

Indicates an instrument that has been protected throughout by double insulation or reinforced

insulation.

(9243 Grabber Clip)

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in EU

member states.

Indicates that the product conforms to regulations set out by the EC Directive.

This is a recycle mark established under the Resource Recycling Promotion Law (only for Japan).

Ni-MH

1

2

3

4

5

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values,

with the following meanings:

(maximum display value, range)

f.s.

rdg.

dgt.

Protective gear

The maximum value that can be displayed. This is usually the name of the currently selected

range.

(reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that

causes the digital display to show a “1” as the least-signicant digit.

WARNING

This instrument measures live lines. To prevent electric shock, use appropriate

protective insulation and adhere to applicable laws and regulations.

6

7

8

9

10

Appx. Ind.

5

Page 12

Safety Information

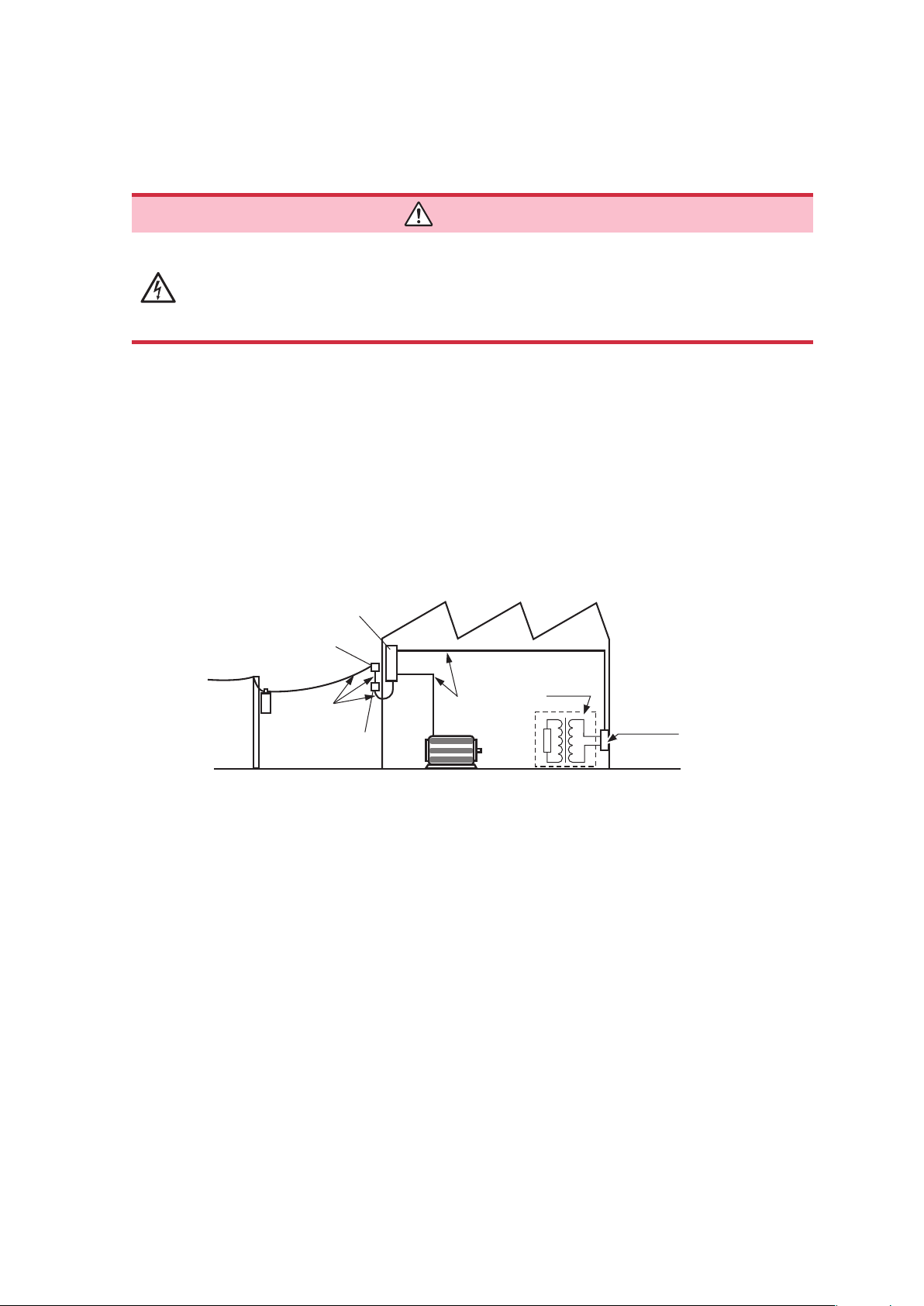

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement

categories.

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

• Never use a measuring instrument that lacks category labeling in a CAT II to CAT

IV measurement environment. Doing so could result in a serious accident.

The instrument conforms to the safety requirements for CAT III 1000 V, CAT IV 600 V measuring

instruments.

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical circuits

in equipment connected to an AC electrical outlet by a power cord (portable tools,

household appliances, etc.).

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to

outlets.

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel).

Distribution Panel

Service Entrance

Service Drop

CAT IV

Power Meter

Internal Wiring

CAT III

Fixed Installation

CAT II

T

Outlet

6

Page 13

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

Preliminary Checks

Before using the instrument, verify that it operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized Hioki distributor or

reseller.

DANGER

1

2

To prevent an electric shock, conrm that the white portion (insulation layer) inside

the cable is not exposed. If a color inside the cable is exposed, do not use the

cable.

Installation Environment

Installing the instrument in inappropriate locations may cause a malfunction of

instrument or may give rise to an accident. Avoid the following locations:

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

3

4

WARNING

5

6

7

CAUTION

Do not place the instrument on an unstable table or an inclined place. Dropping or

knocking down the instrument can cause injury or damage to the instrument.

Handling the Instrument

CAUTION

To avoid damage to the instrument, protect it from physical shock when transporting and

handling. Be especially careful to avoid physical shock from dropping.

This instrument may cause interference if used in residential areas.

Such use must be avoided unless the use takes special measures to reduce electromagnetic emissions to

prevent interference to the reception of radio and television broadcasts.

8

9

10

Appx. Ind.

7

Page 14

Operating Precautions

Handling Cords and Cables

If the insulation on a cord or cable melts, the metal conductor may be exposed. Do

not use any cord or cable whose metal conductor is exposed. Doing so could result

in electric shock, or other hazard.

The cord and cable are hardened under the 0 degree or colder environment. Do not bend

or pull them to avoid tearing their shield or cutting them.

Using Voltage Cords

To prevent an electric shock, conrm that the white portion (insulation layer) inside

the cable is not exposed. If a color inside the cable is exposed, do not use the

cable.

DANGER

CAUTION

DANGER

WARNING

• Use only the specied voltage cords. Using a non-specied cord may result in

electric shock or short circuits.

• Avoid contact between the cord and the measured line in order to protect the

cord from damage. Any contact can cause the instrument to malfunction and lead

to short-circuits or electric shock.

8

Page 15

Using Battery Pack

• To avoid the possibility of explosion, do not short circuit, disassemble or

incinerate battery pack. Battery may explode if mistreated. Handle and dispose of

batteries in accordance with local regulations.

• Be sure to observe the following precautions. Incorrect handling may result in

liquid leaks, heat generation, ignition, bursting and other hazards.

• The battery pack contains lye, which may cause blindness if it comes into

contact with the eyes. Should battery liquid get into your eyes, avoid rubbing

them. Flush them with water and seek immediate medical attention.

• When storing the instrument, make sure no objects that could short-circuit the

connectors are placed near them.

• For battery operation, use only the HIOKI Model Z1003 Battery Pack. We do not

take any responsibility for accidents or damage related to the use of any other

batteries.

• To avoid electric shock, turn off the power switch, disconnect all the power and

voltage cords and current sensor from the device to be measured, and replace

the battery pack.

• To prevent the instrument damage or electric shock, use only the screws

(M6×12 mm) for securing the battery cover in place that are originally installed.

If you have lost any screws or nd that any screws are damaged, please contact

your Hioki distributor for a replacement.

Operating Precautions

WARNING

1

2

3

4

5

CAUTION

• Observe the following to avoid damage to the instrument.

• Use the battery pack in an ambient temperature range of 0°C to 50°C and charge it in

an ambient temperature range of 10°C to 35°C.

• If the battery pack fails to nish charging within the stipulated time, disconnect the AC

adapter to stop charging and contact your dealer or Hioki representative.

• Consult your dealer or nearest service station should liquid leaks, strange odor, heat,

discoloration, deformation and other abnormal conditions occur during use, charging

or storage. Should these conditions occur during use or charging, turn off and

disconnect the instrument immediately.

• Do not expose the instrument to water and do not use it in excessively humid

locations or locations exposed to rain.

• Do not expose the instrument to strong impact and do not throw it around.

• Heed the following instructions to avoid battery pack performance drop or leakage.

• The battery pack is a consumable. If you are able to use the instrument for only a limited period of time

despite the battery pack being properly charged, the battery pack’s service life is at an end, and it should be

replaced.

• When a battery pack that has not been used for a long time is used, charging may end before the battery

pack is fully charged. In such a case, repeat charging and discharging a number of time before use. (A

battery pack may also be in such a state immediately after purchase.)

• The life of the battery pack (when capacity is 60% or more of initial capacity) is approximately 500 chargedischarge cycles. (The life differs depending on the conditions of use.)

• To prevent battery pack deterioration when the battery will not be used for 1 month or longer, remove it and

store it in a dry location with an ambient temperature range of between −20°C to 30°C.

• When a battery pack is used, the instrument turns off automatically when the capacity drops. Leaving the

instrument in this state for a long time may lead to over discharge so be sure to turn off the power switch on

the instrument.

• The charging efciency of the battery pack deteriorates at high and low temperatures.

• The battery pack is subject to self-discharge. Be sure to charge the battery pack before initial use. If the

battery capacity remains very low after correct recharging, the useful battery life is at an end.

6

7

8

9

10

Appx. Ind.

9

Page 16

Operating Precautions

Attaching the Strap

Attach the strap securely at 2 locations of the instrument. If insecurely attached, the

instrument may fall and be damaged when carrying.

Using SD Memory Cards

• Do not remove a card while data is being written to it. Doing so may damage the card.

See “10.10 Removing SD Memory Card during Recording” (p. 127).

• Exercise care when using such products because static electricity could damage the SD

card or cause malfunction of the instrument.

IMPORTANT

•

Format the card with the instrument. Using a computer to format the card may reduce the

card’s performance.

See “10.9 Formatting SD Memory Card (Deleting All Files)” (p. 126).

• No compensation is available for loss of data stored on the SD memory card, regardless of the

content or cause of damage or loss. Be sure to back up any important data stored on an SD

memory card.

• Observe the following to avoid corruption or loss of stored data:

• Do not touch the electrical contacts on the card or inside the insertion slot with your skin or

metallic objects.

• While writing or reading data, avoid vibration or shock, and do not turn the power off or

remove the card from the instrument.

• Before formatting (initializing) a card, conrm that it contains no important information (les).

• Do not bend or drop the card, or otherwise subject it to intense shock.

CAUTION

CAUTION

• The operating lifetime of the SD memory card is limited by its ash memory. After long-term or frequent

usage, data reading and writing capabilities will be degraded. In that case, replace the card with a new one.

• If you are unable to write data to an SD memory card, manipulate folders and les, or format the card, check

the position of the write-protect lock and disengage it if necessary.

The connector of the SD memory card is used to judge whether the card is write-protected.

If the write-protected lock is in an intermediate position, the determination of whether the card is writeprotected will depend on the connector. For example, even if the instrument determines that the card is

not write-protected and allows data to be written to it, a computer may determine that it is write-protected,

preventing data from being written to it.

10

Page 17

Using AC Adapter

• Use only the supplied Model Z1002 AC ADAPTER. AC adapter rated input voltage

range is 100 to 240 V AC at 50/60 Hz. To avoid electrical hazards and damage to

the instrument, do not apply voltage outside of this range.

• Turn the instrument off before connecting the AC adapter to the instrument and

to AC power.

• To avoid electrical accidents and to maintain the safety specications of this

instrument, connect the power cord provided only to an outlet.

Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with rectangular

wave or pseudo-sine-wave output to power the instrument. Doing so may damage the

instrument.

Operating Precautions

WARNING

1

2

CAUTION

3

Turning On the Instrument

Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage may

damage the instrument and present an electrical hazard.

• Do not connect the supply voltage improperly. Doing so may damage the instrument’s

internal circuitry.

• If the power does not turn on, the AC adapter or the instrument may be malfunctioning

or the power cord may be disconnected. Contact your authorized Hioki distributor or

reseller.

• If an error during the self-test, the instrument is damaged. Contact your authorized Hioki

distributor or reseller.

Using Magnetic Adapter

Persons wearing electronic medical devices such as a pacemaker should not use

the Magnet Adapter. Such persons should avoid even proximity to the Magnet

Adapter, as it may be dangerous. Medical device operation could be compromised,

presenting a hazard to human life.

WARNING

CAUTION

DANGER

4

5

6

7

8

9

10

CAUTION

Do not bring the Magnet Adapter near magnetic media such as oppy disks, magnetic

cards, pre-paid cards, or magnetized tickets. Doing so may corrupt and may render

them unusable. Furthermore, if the Magnet Adapter is brought near precision electronic

equipment such as computers, TV screens, or electronic wrist watches, they may fail.

Appx. Ind.

11

Page 18

Operating Precautions

Wiring

• Do not short-circuit two wires to be measured by bringing the metal part of the

voltage cord clips or current sensor tips into contact with them. Doing so could

result in a severe accident such as arcing.

• To prevent electrical shock and personal injury, do not touch any input terminals

on the VT (PT), CT or the instrument when they are in operation.

• Do not use the instrument with circuits that exceed its ratings or specications.

Doing so may damage the instrument or cause it to become hot, resulting in

bodily injury.

• To avoid electric shock, be careful to avoid shorting live lines with the voltage

cords.

• We recommend measurements at the secondary side of the distribution

panel. Measurements at the primary side cause unrestricted current ow. The

instrument and equipment could be damaged if a short circuit occurs.

• To avoid short circuit or electric shock, do not touch the metal parts of the

voltage cords or current sensor tips.

DANGER

CAUTION

• To avoid damaging the instrument, do not short the voltage cord input terminals or

current sensor input terminals or input any voltage to them.

• To ensure safe operation, use only the voltage cord and current sensor specied by

Hioki.

Displayed values can frequently uctuate due to induction potential even when no voltage is applied. This,

however, is not a malfunction.

Using USB Connector (USB Cable)

CAUTION

• To avoid equipment failure, do not disconnect the USB cable while communications are

in progress.

• Use a common ground for both the instrument and the computer. Using different ground

circuits will result in a potential difference between the instrument’s ground and the

computer’s ground. If the USB cable is connected while such a potential difference

exists, it may result in equipment malfunction or failure.

• If the instrument and computer are both off and connected with the USB cable, turn on the computer and

then the instrument. Powering up the devices in a different order may prevent the instrument and computer

from communicating.

• Copying large data les from the SD memory card to a computer via the instrument’s USB interface can be

time-consuming. When you need to copy a large data le to a computer, it is recommended to use an SD

memory card reader.

12

Page 19

Connecting the Instrument to an External Device

CAUTION

• Use a common ground for both the instrument and the computer. Using different ground

circuits will result in a potential difference between the instrument’s ground and the

computer’s ground. If the communications cable is connected while such a potential

difference exists, it may result in equipment malfunction or failure.

• Before connecting or disconnecting any communications cable, always turn off the

instrument and the computer. Failure to do so could result in equipment malfunction or

damage.

• After connecting the RS-232C cable, tighten the screws on the connector securely.

Failure to secure the connector could result in equipment malfunction or damage.

Using External I/O Terminals

WARNING

To avoid electric shock or damage to the equipment, always observe the following

precautions when connecting to external terminals or connectors.

• Always turn off the power to the instrument and to any devices to be connected

before making connections.

• Be careful to avoid exceeding the ratings of external terminals and connectors.

• During operation, a wire becoming dislocated and contacting another conductive

object can be serious hazard. Use screws to secure the external connectors.

Operating Precautions

1

2

3

4

5

CD precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on a disc’s

label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this disc.

6

7

8

9

10

Appx. Ind.

13

Page 20

Operating Precautions

14

Page 21

1

Overview

1.1 Procedure for Investigating Power Quality

By measuring power quality parameters, you can assess the power quality and identify the causes

of various power supply malfunctions. The ability of the instrument to measure all power quality

parameters simultaneously makes this process a quick and simple one.

The following is the description of the investigation process for the power quality.

Step 1: Clarifying the purpose

To nd the cause for the power supply malfunction

A power supply malfunction such as an equipment failure or malfunction has occurred and

you wish to address it quickly.

Go to Step 2 (p. 16).

To assess power supply quality (power quality)

There is no known problem with the power supply, and you just want to assess the power

quality.

• Periodic power quality statistical investigation

• Testing after the installation of electric or electronic equipment

• Load investigation

• Preventive maintenance

1

Overview

Go to Step 3 (p. 16).

Step 2: Identifying the malfunctioning component (measurement

location)

Check the following:

(1) Where is the issue occurring?

• Principal electrical system

Large copier, uninterruptible power supply, elevator, air compressor, air conditioning compressor,

battery charger, cooling system, air handler, time-controlled lighting, variable-speed drive, etc.

• Electric distribution system

Conduit [electrical conduit] damage or corrosion, transformer heating or noise, oil leak, circuit

breaker operation or overheating

(2) When does the issue occur?

• Does it occur continuously, regularly, or intermittently?

• Does it occur at a specic time of the day or on a specic day of the week?

(3) What type of investigation (measurement) should be performed to nd the cause?

• Measure the voltage, current (power) continuously to analyze voltage and current trends when

the issue occurs.

• Concurrent measurements at more than one location

Examples:

• Dedicated systems lines in the electrical substation (can be measured only by the power

companies)

• High-voltage and low-voltage lines of the service entrance

• Distribution panels and switchboards

• Power feeder and outlets of power supply for electric and electronic equipment

15

Page 22

Procedure for Investigating Power Quality

(4) What is the expected cause?

• Abnormal voltage

RMS value trends, waveform distortion, transient overvoltage

• Abnormal current

Leakage current, inrush current

Step 3: Checking investigation (measurement) locations (collecting

site data)

Collect information (site data) from as many locations as possible to prepare for the investigation.

Check the following:

(1) Wiring

1P2W / 1P3W /

3P3W2M / 3P3W3M / 3P4W

3P4W2.5E (available after the

rmware update)

(3) Frequency

50 Hz/60 Hz

(5) Current capacity

Current capacity is required to

select current sensors used for

the measurements.

(2) Declared input voltage

100 V to 800 V

(4) Is the voltage between the neutral line and ground,

and neutral line current required to be measured?

If the measurements are required, CH4 of the wiring settings

should be set to ON. See p. 48, and p. 64.

(6) Other items related to the whole facility

• Other systems causing power supply malfunctions

• Principal electrical system operating cycle

• Any additions or changes to facility equipment

• Check of the power distribution system in the

facilities

Step 4: Making measurements with the power quality analyzer (measurement procedure)

Measurements are performed using the following procedure:

16

Preparations

Attach accessories and optional equipment required for the measurements to the Power

Quality Analyzer.

See “2 Preparing for Measurement” (p. 35).

Measurement settings/Connections/Wiring*

Congure the conditions required for the measurements and connect voltage cord and

current sensors to the instrument.

Connect the wires to the measuring object and check if there is any mistake.

See “Installation Environment” (p. 7) and “4 Wiring (WIRING Screen)” (p. 47).

Recording settings/Event settings*

Page 23

Congure the conditions and events required for recording.

If the EVENT indicator on the screen (p. 32) frequently changes to red, too many events

have occurred.

When the number of events reaches 9999 during recording/measurement, subsequent

events will not be recorded (trend recording continues). Adjust the event settings as

required.

See “5 Setting Change (SET UP Screen)” (p. 63).

Measured value check

Press the [MONITOR] key, and use the MONITOR screen to check if there is any problem

with the values measured.

See “6 Verifying the Waveform, Measured Values (MONITOR Screen)” (p. 81).

Recording start*

Press the [START/STOP] key to start recording.

See “7 Recording (Save) (SET UP Screen)” (p. 91).

Analysis/Actions

Procedure for Investigating Power Quality

1

Overview

Continue recording for the period necessary for the analysis, check the state of the power

supply malfunction based on the detected events.

Check while recording

Check after recording is

stopped

Next, take the preventive measures for the power supply malfunction.

(The instrument is effective not only for the power supply investigation but also to check

after taking the measures for the power supply malfunction.)

“8 Verifying the Trends (Fluctuations) in Measured

Values (TREND Screen)” (p. 95), and “9 Checking

Events (EVENT Screen)” (p. 105).

“11 Analysis (with Computer)” (p. 129)

*: Use “Quick Set” for easy and secure setting, and recording start!

The Quick Set allows easy and secure procedure for setting and recording start by following the

navigation of the instrument.

The event settings also allows typical setting by only selecting the menu.

(Menu: Voltage events, Inrush current, Trend record only, EN50160)

See “3 Quick Set” (p. 45), supplied Measurement Guide.

17

Page 24

Procedure for Investigating Power Quality

Advice for identifying the cause of abnormalities

Record voltage and current trends at the power circuit inlet.

If the voltage drops while the building’s current consumption rises, the likely cause for power

abnormality lies inside the building. If the voltage and current are both low, the cause is likely to lie

outside the building.

It’s extremely important to select the right measurement locations and measure current for

troubleshooting.

Check power trends.

Overloaded equipment can cause problems. By understanding power trends, you can more easily

identify problematic equipment and locations.

See “8 Verifying the Trends (Fluctuations) in Measured Values (TREND Screen)” (p. 95).

Check when the problem occurs.

Equipment that is operating or turning on or off when events (abnormalities) are recorded may be

the cause of malfunction. By understanding the precise times at which events start and stop, you

can more easily identify problematic equipment and locations.

See “9 Checking Events (EVENT Screen)” (p. 105).

Check for heat and unusual sounds.

Motors, transformers, and wiring may produce heat or unusual sounds due to causes such as

overloading or harmonics.

18

Page 25

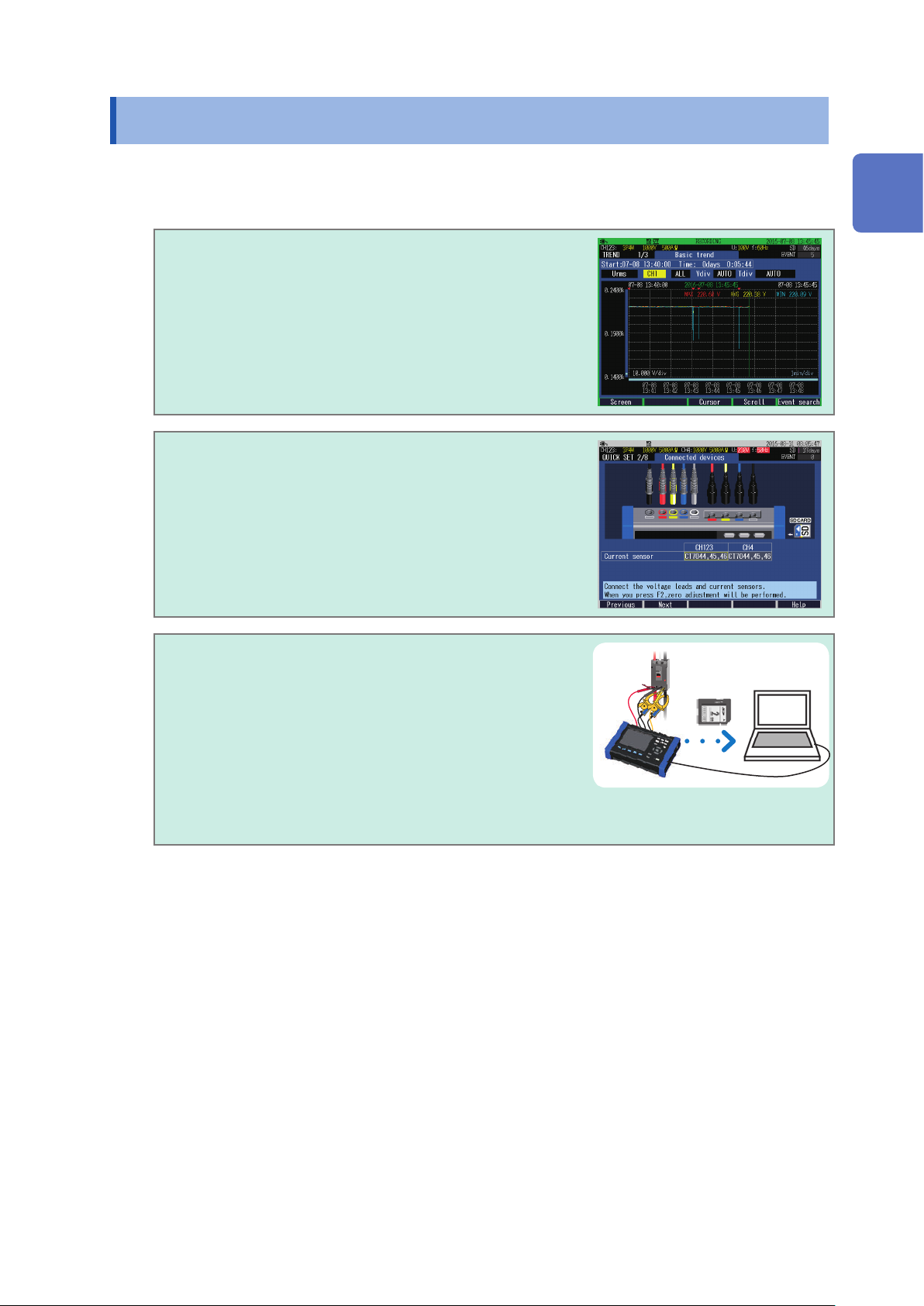

Product Overview

1.2 Product Overview

The PQ3100 Power Quality Analyzer is a measuring instrument used to manage power quality and

identify abnormalities of the power line to analyze the cause of the trouble.

All parameters can be recorded

simultaneously.

Trends and power abnormalities (events) of all parameters

can be recorded simultaneously.

The instrument guides the procedures.

The Quick Set function allows proper and easy item

settings and connections required for measurements by

following the steps.

1

Overview

See “3 Quick Set” (p. 45), Measurement Guide (provided

separately).

Data can be easily analyzed and reported.

The data loaded to a computer can be easily analyzed and

reported with the supplied software.

See “11 Analysis (with Computer)” (p. 129) and “12 Communications (USB/LAN/RS-232C)”

(p. 137).

19

Page 26

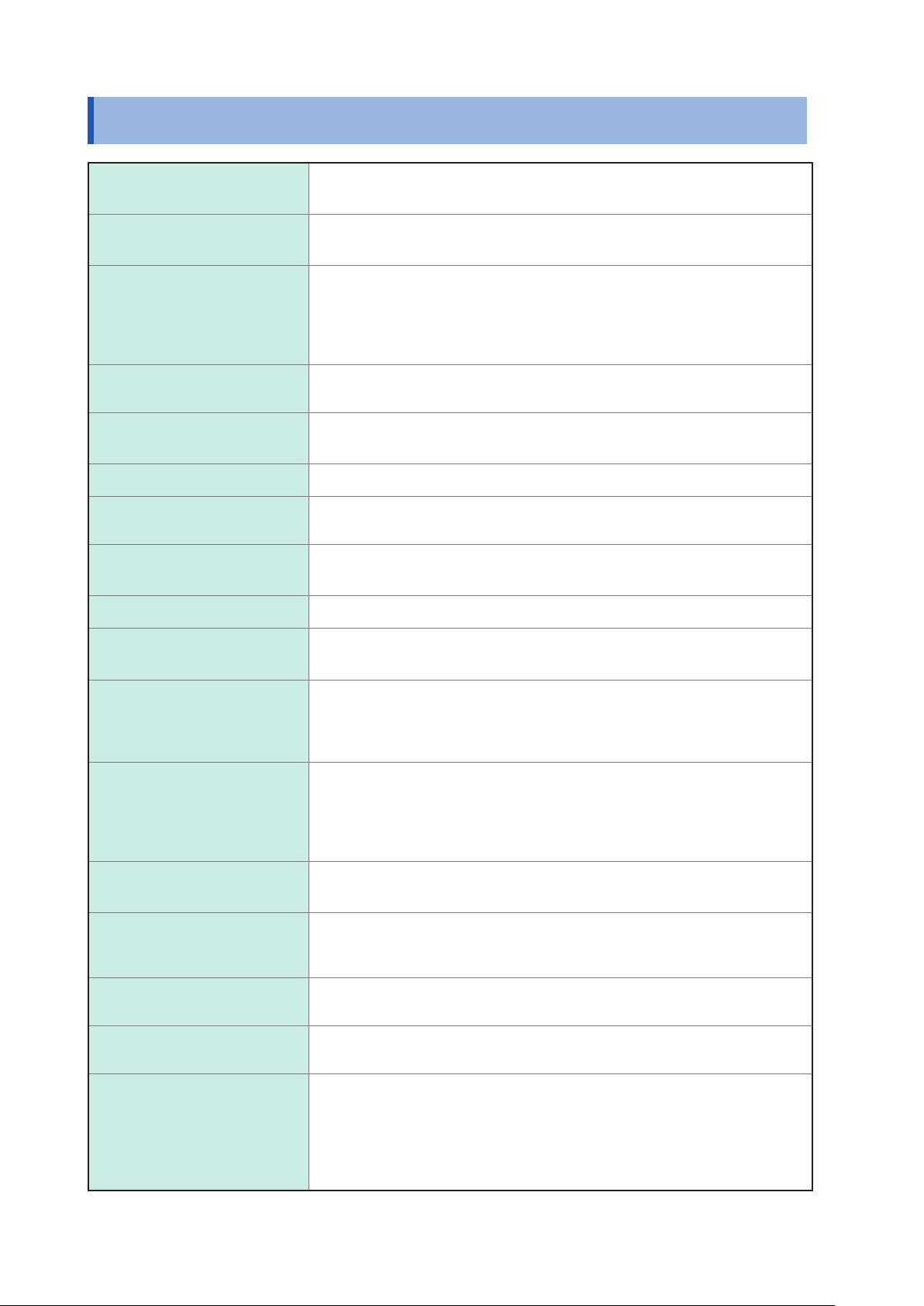

Features

1.3 Features

Long-term event waveform

recording

DC (Direct Current)

measurements

Easy and secure

Wiring check

Easy analysis and reporting

of data

Safety

High accuracy

4 voltage channels

4 current channels

Transient measurements

Waveforms for up to 11.2 s when event occurs (1 s before event, 0.2 s on

event, 10 s after event) can be saved for power abnormality analysis.

DC voltages can be measured. AC/DC Auto Zero Sensor allows DC current

measurements.

The Quick Set allows easy operations by following the steps for secure

measurements.

Continuous calculation without a gap also allows simultaneous measurements

of all the parameters required for the power quality measurements to securely

identify the phenomenon.

Checks the wiring state. If the instrument has been connected improperly, tips

for correct connections will be displayed by the help function.

The supplied software PQ One allows easy analysis and reporting of the data.

Compatible with CAT III 1000 V and CAT IV 600 V

Voltage measurement accuracy of ±0.2% rdg.

Complies with the IEC61000-4-30 Class S international power quality standard

Measurements for voltage between neutral line and ground, and neutral line

current are available for 3-phase 4-wire wiring.

Transient measurements for 5 kHz to 40 kHz, up to 2200 V

3-channel simultaneous

∆V10 icker measurement

Simultaneous measurement

of line voltage and phase

voltage for 3-phase

Extensive lineup of current

sensors

Ability to operate for about

8 hours on battery power

Broad operating

temperature range

Saving to SD memory cards

TFT color LCD

Communications

functionality

(Available after the rmware update)

3-channel simultaneous ∆V10 icker measurement is available.

For 3-phase 3-wire 3-watt meter measurement (3P3W3M) and 3-phase 4-wire

measurement (3P4W), both line voltage and phase voltage are measured and

output.

Line voltage or phase voltage, whichever is selected, is displayed.

You can choose the best current sensors for your measurement application

ranging from leakage currents to a maximum rating of 6,000 A.

The instrument can feed the power to both Flexible Current Sensor and AC/

DC Auto-Zero Sensor enabling you to make long-term measurements without

worrying about the power supply.

Even when AC power is not available, the supplied battery pack can be used

for about 8 hours of measurement.

Operating temperature range is from −20°C to 50°C.

However, the operating temperature range is from 0°C to 50°C when Battery

Pack is used.

Data can be continuously recorded to an optional 2 GB or an 8 GB memory

card for up to one year.

The instrument uses an LCD that is easy to see in both dim and bright

conditions.

The instrument includes standard USB and Ethernet interfaces to connect a

computer for the following operations.

• To congure the instrument using a computer.

• To download data from the instrument to the computer.

• To operate the instrument remotely.

See “12 Communications (USB/LAN/RS-232C)” (p. 137).

20

Page 27

1.4 Names and Functions of Parts

Names and Functions of Parts

Front

1

2

No. Name and description Reference

Display

1

6.5″ TFT color LCD

Function key ([F1] to [F5] key)

2

Select and change display contents and settings.

Operation keys

Screen switching

key

START/STOP LED

Flashing green: When

in the recording

standby state

Solid green: When

recording

p. 24

—

1

Overview

Keys Description Reference

Displays and changes the MONITOR screen (waveform and measured values). p. 81

Displays and changes the TREND screen (time series trend graphs). p. 95

Displays and changes the EVENT screen (event status).

(Version upgrade supported for switching)

Displays and changes the WIRING screen (wiring settings, wiring check). p. 47

Displays and changes the SET UP screen (settings). p. 63

Displays and changes the FILE screen (SD memory card/internal memory). p. 115

Displays and changes the QUICK SET screen.

Pressing this key during recording allows checking the current main settings.

An event occurs at the timing when this key is pressed during recording.

The voltage and current waveforms and measured values when an event occurs

are recorded.

Moves the cursor on the screen. Scrolls through graphs or waveforms.

: Selects items on the screen and accepts changes.

Cancels any selections or changes made and reverts to the previous settings.

Switches to the previous screen.

Pressing and holding this key for at least 3 s activates the key lock function. (Same

operation for unlock)

p. 105

p. 45

Measure-

ment Guide

—

—

—

Outputs the image of the currently displayed screen to the SD memory card. p. 121

Starts and stops recording. p. 91

21

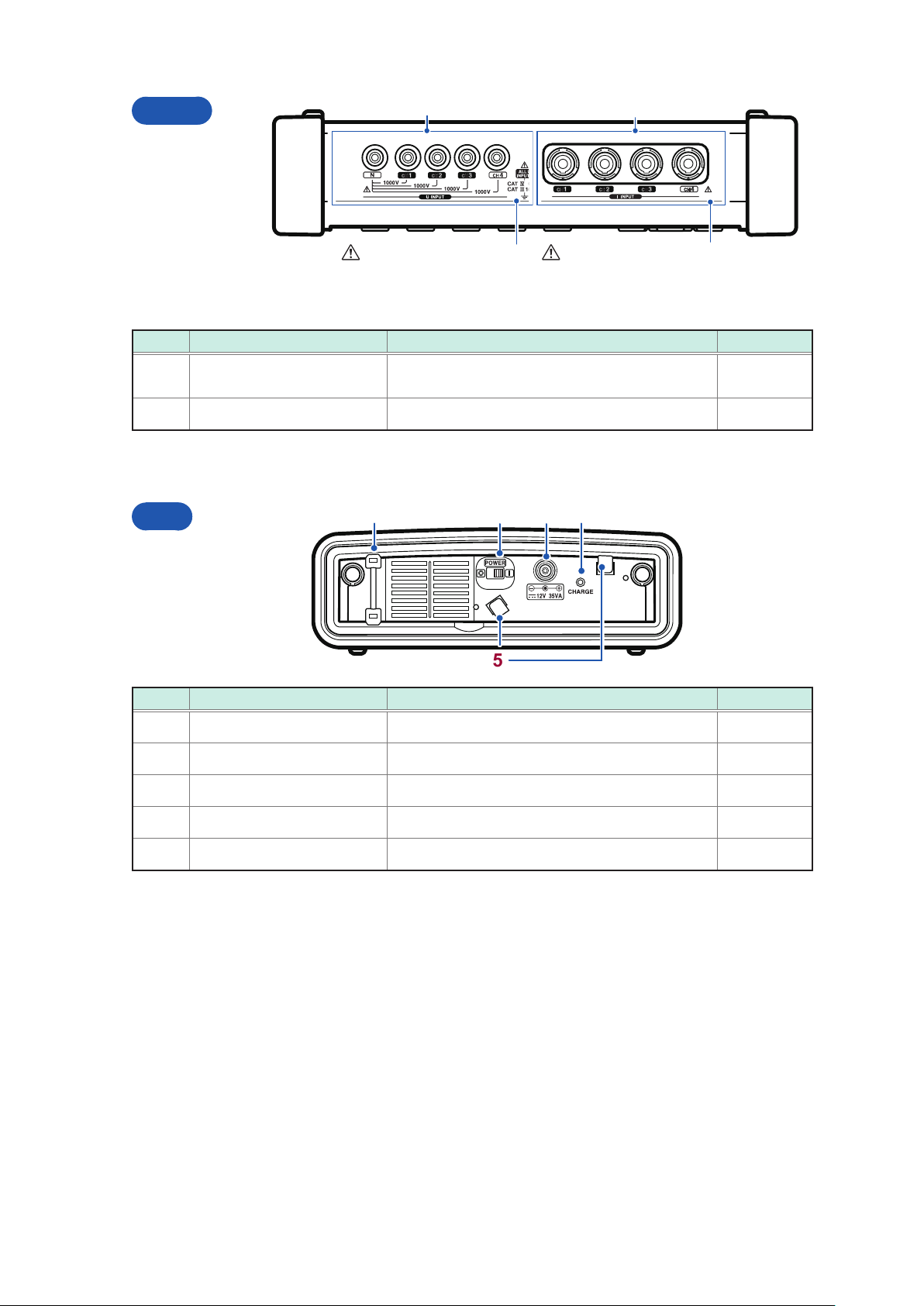

Page 28

Names and Functions of Parts

Upper

“4.3 Connecting Voltage

Cords to Instrument”

(p. 51)

No. Name Description Reference

Voltage input terminal

1

Current input terminal Connects optional current sensors. p. 52

2

Left

1

“4.4 Connecting Current

Sensors and Conguring

Current Sensor Settings”

(p. 52)

Connects supplied L1000-05 voltage cord to one of

the jacks.

3 4

21

2

p. 51

5

No. Name Description Reference

Strap eyelet Attaches the strap. p. 39

1

POWER Switch Turns the instrument on and off. p. 44

2

AC adapter connection jack Connects the AC adapter. p. 43

3

CHARGE LED Lights up when the Z1003 Battery Pack is charging. p. 38

4

Hook for AC adapter Loops the AC adapter cord through these hooks. p. 43

5

22

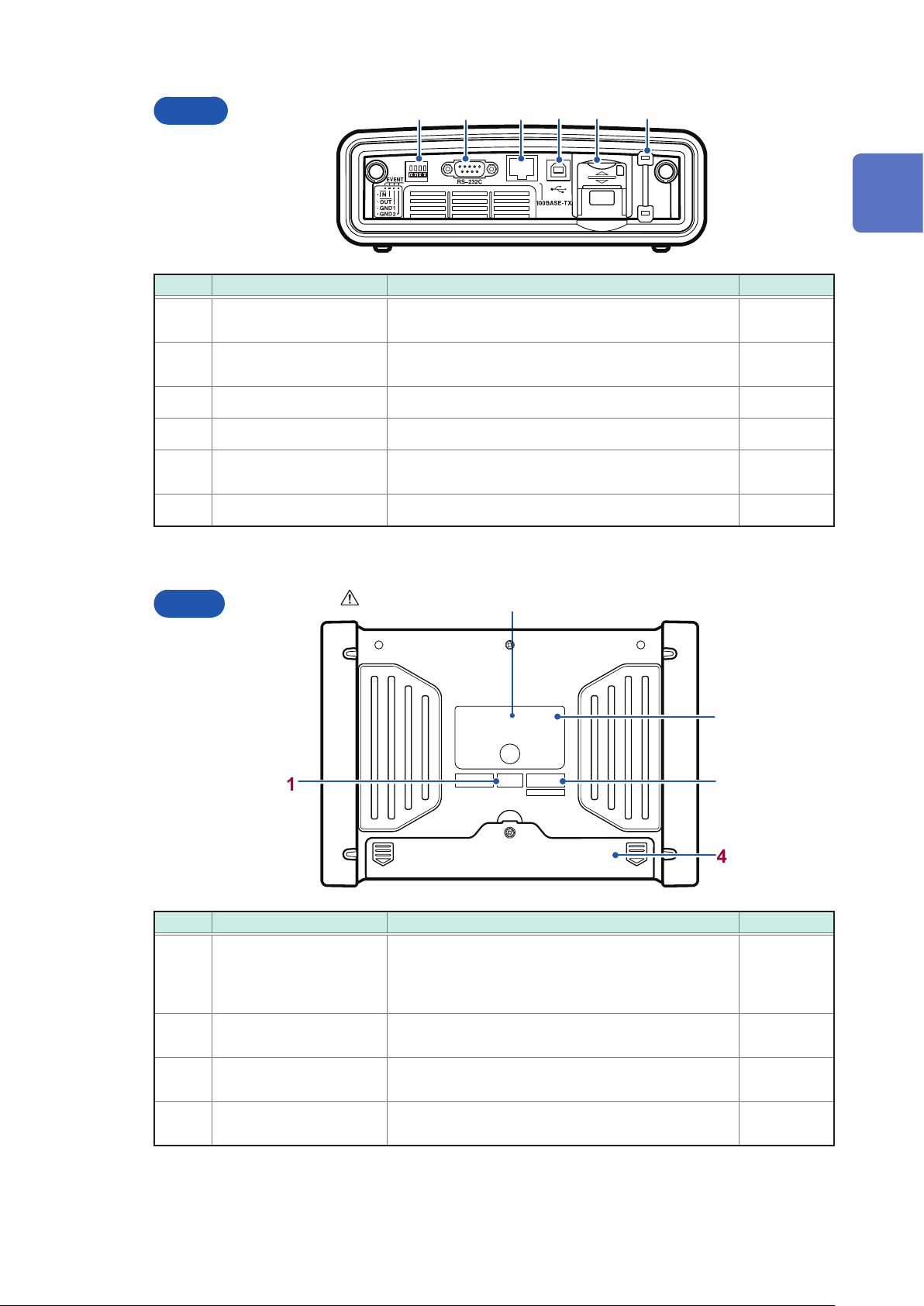

Page 29

Names and Functions of Parts

5 6

Right

No. Name Description Reference

External I/O terminals

1

1 2 3

Uses commercially available wires to connect with

external devices.

4

p. 147

1

Overview

2

3

4

5

6

Back

RS-232C interface

LAN interface Connects to a computer using the LAN cable. p. 138

USB port Connects to a computer using the supplied USB cable. p. 131

SD memory card slot

Strap eyelet Attaches the strap. p. 39

Connects to a computer using the optional RS-232C

cable.

Inserts an SD memory card. Be sure to close the cover

when recording.

“Installing the battery pack” (p. 38)

p. 145

p. 42

2

1

3

4

No. Name Description Reference

Displays the instrument’s unique MAC address. This

MAC address label

1

Label

2

Serial No.

3

Battery compartment

4

address is used when conguring a LAN connection.

Do not remove the label as the information is

necessary for managing the device.

Indicates the warning, CE mark, KC mark, WEEE

Directive mark, and manufacturer.

Do not remove the label as the information is

necessary for managing the device.

Installs the supplied Z1003 Battery Pack within the

compartment.

p. 138

—

—

p. 38

23

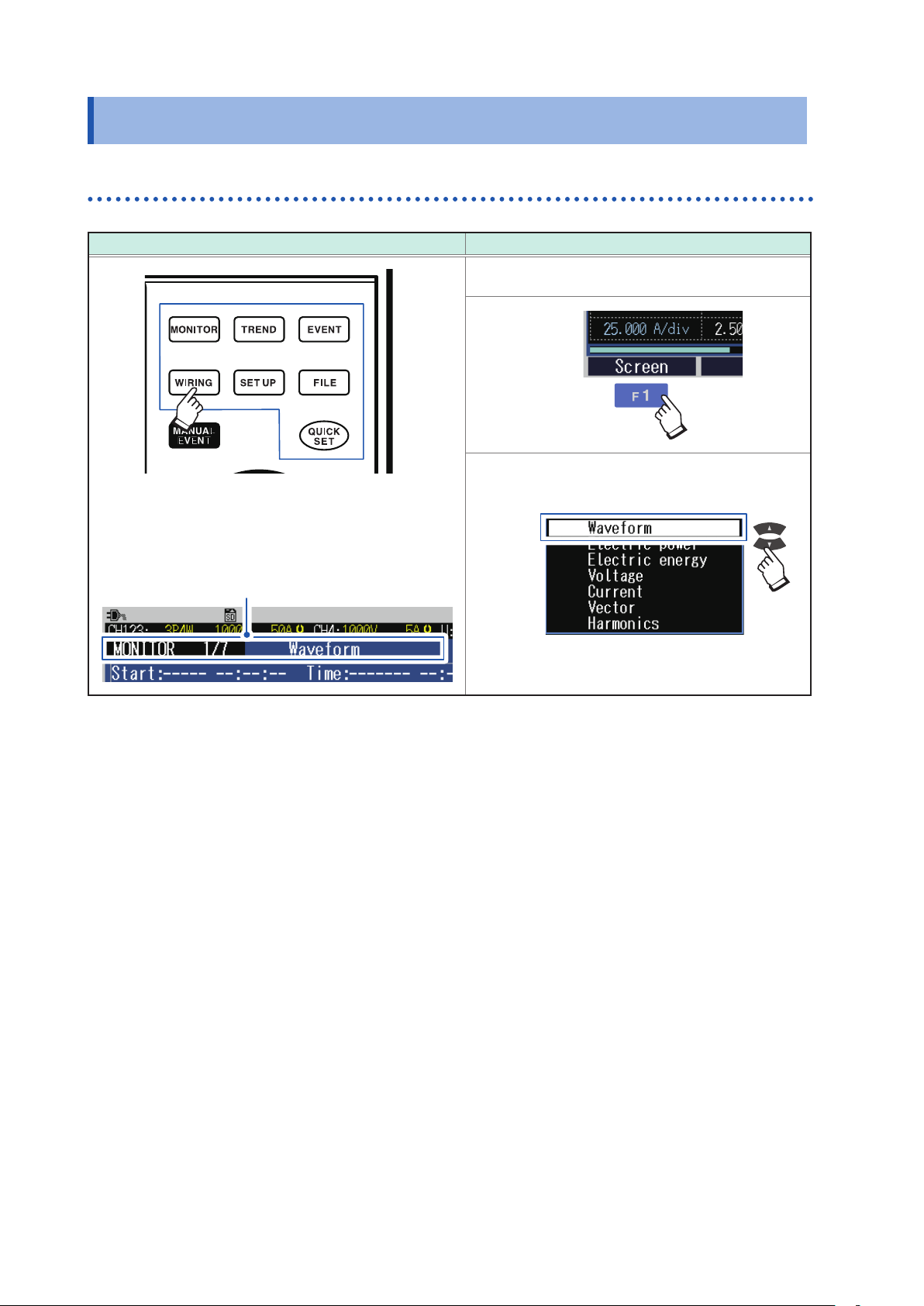

Page 30

Screen Conguration

1.5 Screen Conguration

Displaying and switching screens

Use operation keys (screen switching key) Use [F1] (SCREEN) key to switch screens

Screen example: MONITOR screen

1

The screens consist of seven screens each of which

corresponds to the operation keys.

The screen corresponding to the key pressed is displayed.

The screen can be switched by pressing the key

repeatedly.

Screen name

2

24

Page 31

MONITOR screen

A screen that is used to monitor instantaneous values. This screen is used to view voltage and

current instantaneous waveforms, and the measured values.

Screen Conguration

Display/switch screen: [MONITOR] key

See “6 Verifying the Waveform, Measured Values (MONITOR Screen)” (p. 81).

Waveform screen

Voltage and current waveforms of CH1 to

CH4 are displayed.

Electric power screen

RMS voltage, RMS current, frequency, power, power

factor, active energy (consumption) and elapsed time are

displayed.

Electric energy screen

Electric energy, energy cost, start time, stop time,

elapsed time, power and power factor are displayed.

Voltage screen

Measured values related to voltage are displayed.

Current screen

Measured values related to current are displayed.

Vector screen

Phase relationship between voltage and current is

displayed in a vector diagram.

1

Overview

Harmonics screen

Harmonic current, harmonic voltage, and harmonic

power from 0 to 50th order are displayed.

Zoom screen (available after the rmware

update)

Enlarged view of 6 user-selected parameters are

available.

25

Page 32

Screen Conguration

TREND screen

A screen used to check the trend (uctuations) of the measured values.

Display/switch screen: [TREND] key

See “8 Verifying the Trends (Fluctuations) in Measured Values (TREND Screen)” (p. 95).

Basic trend screen

This screen is used to check uctuation

width of maximum, minimum and average

values between recording intervals.

Detail trend screen

This screen is used to check uctuation width of

maximum and minimum values between recording

intervals for the following parameters.

• RMS voltage refreshed each half-cycle

• RMS current refreshed each half-cycle

• Inrush current

• Frequency (1 wave)

Electric energy screen

This screen is used to check electric energy trends for

each recording interval.

Demand screen (available after the rmware

update)

This screen is used to check demand trends.

Harmonics trend screen (available after the

rmware update)

This screen is used to check trends of harmonics and

interharmonics.

Flicker screen (available after the rmware

update)

This screen is used to check trends of IEC icker or

∆V10 icker.

26

Page 33

EVENT screen

A screen used to check the event status.

Screen Conguration

Display/switch screen: [EVENT] key

See “9 Checking Events (EVENT Screen)” (p. 105).

Event list screen

Events can be checked on the list.

The events are sorted in the order of

occurrence.

EVENT MONITOR screen: See p. 111.

1

Overview

Event statistics screen

(available after the rmware update)

This screen is used to check the statistical

results for each event type.

WIRING screen

A screen used to check the wiring settings.

Display/switch screen: [WIRING] key

See “4 Wiring (WIRING Screen)” (p. 47).

Wiring settings screen

This screen is used to congure the wiring.

Make wiring by checking the wiring diagram.

Wiring check screen

This screen is used to check whether the

instrument has been connected properly.

27

Page 34

Screen Conguration

SET UP screen

A screen used to congure settings.

Display/switch screen: [SET UP] key

See “5 Setting Change (SET UP Screen)” (p. 63).

Measurement settings 1 screen

This screen is used to congure the wiring.

Measurement settings 2 screen

This screen is used to congure settings for calculation

method, energy cost, and icker (available after the

rmware update).

Recording settings screen

This screen is used to congure the settings for

recording.

Event settings 1 screen

This screen is used to congure the event threshold

value and hysteresis for voltage and current.

Event settings 2 screen

This screen is used to congure the timer event, external

event, and event waveform recording time.

System settings screen

This screen is used to congure the clock, beep sound,

language, display color, and phase name.

Interface settings screen

This screen is used to congure the settings for LAN,

RS-232C, and external output.

28

Page 35

FILE screen

A screen used for le operations.

This screen allows listing and operations for les of the SD memory card and internal memory.

Display/switch screen: [FILE] key

See “10 File Saving and Operations (FILE Screen)” (p. 115).

Screen Conguration

1

Overview

SD card screen

This screen shows lists of folders and les in the

SD memory card.

This screen shows lists of folders and les in the

internal memory.

Internal memory screen

QUICK SET screen

Minimum conditions required for recording can be set by following the Quick Set instructions.

Quick Set start: [QUICK SET] key

See “3 Quick Set” (p. 45) and refer to Measurement Guide (provided separately).

Quick Set start dialog

Press the

[ENTER]

key.

29

Page 36

Basic Key Operations

1.6 Basic Key Operations

See “1 Displaying and switching screens” (p. 24).

Changing the required items

1

2

3

4

On the MONITOR screen and the TREND screen, the items can be changed by pressing

the keys

Move the cursor to the item.

The drop down list will be

displayed.

Select an item.

Accept the setting.

without the drop-down list box displayed.

30

Page 37

Entering characters

Basic Key Operations

1

2

3

4

Move the cursor to the item.

A dialog box will be displayed.

: Character selection

: Input

: Delete a character

OK

:

The setting will be accepted.

1

Overview

Cancel

:

The entry will be canceled.

31

Page 38

Screen Display

1.7 Screen Display

18

9

17

8

2

3

4 5 6

7

1 1110 12 13

Actual time

14

16

15

No. Display Description

Gray (no character):

(START/STOP LED: Off)

• Recording is stopped.

• The setting can be changed.

Yellow (WAITING):

(START/STOP LED: Blinking)

• Recording is in standby.

• This screen is shown from the time the

1

Operation

status

[START/STOP] key is pressed until the

recording actually starts.

• During repeated recording, this screen

is also displayed when recording is

stopped.

• The setting cannot be changed.

Green (RECORDING):

(START/STOP LED: On)

• Recording is in progress.

• The setting cannot be changed.

32

Page 39

Screen Display

No. Display Description Reference

The instrument is operating with the AC adapter. p. 43

2

3

4

5

6

7

8

9

The instrument is running on the battery. p. 38

The instrument is running on the battery, which is almost out of charge.

(Blinking)

(Black)

(Blue)

(Black) The SD memory card is inserted and identied.

(Red) The SD memory card is locked. Unlock it.

Connect the AC adapter and charge the battery.

The LAN is connected. p. 138

The HTTP server is connected. p. 143

The key lock is engaged. p. 21

Holding the screen display.

The VT ratio has been set.

The CT ratio has been set.

Wiring, voltage range, and current range for CH1 to CH3.

(Red): No current sensors are connected. Otherwise, the sensors

are erroneously congured. (p. 52)

(Yellow): The current sensors are correctly congured.

p. 38

p. 58

p. 81

p. 42

p. 64

1

Overview

10

11

12

(Black background)

(Green background)

13

MEM

(Black background)

MEM

(Green background)

14

Voltage range and current range for CH4. When CH4 is OFF, no icon is

displayed.

(Red): No current sensor is connected. Otherwise, the sensor is

erroneously congured. (p. 52)

(Yellow): The current sensor is correctly congured.

Declared input voltage.

Measuring frequency (nominal frequency). p. 64

The SD memory card has been inserted in the instrument. p. 42

The SD memory card is being accessed.

As no SD memory card is inserted to the instrument, measured data will

be saved in the instrument’s internal memory.

The shortest recording interval of the internal memory is 2 s. If the

interval is set to 1 s or less, measured data cannot be saved in the

internal memory.

The internal memory is being accessed.

Indicates how much recording time or days remains on the SD memory

card or in the instrument’s internal memory. If the event data is recorded

as well, the actual recording time will become shorter than the displayed

recording time.

The utilization status is indicated with a level meter.

p. 48

p. 64

33

Page 40

Error Screen Display

No. Display Description Reference

(Black background)

No event has been detected.

15

(Red background)

16

Screen name

17

18

F key text Texts of function keys assigned for each screen.

Event IN (detection) state.

Number of events recorded. Up to 9999 events.

The event detection status is indicated with a level meter.

This is the screen name. Select with the key.

[(Present screen number) / (number of screens)] is displayed within the

screen. (See “1.5 Screen Conguration” (p. 24) for details.)

1.8 Error Screen Display

Display Description

If a voltage peak over, i.e., that the peak of the voltage exceeds 2200 V or falls below

−2200V, occurs, the background of the voltage range turns red.

If a voltage overrange, i.e., that the voltage exceeds 1300 V, occurs, the background of

the voltage range turns yellow.

If a current peak over, i.e., that the peak of the current exceeds 400% of the present

range or falls below −400% of it, occurs, the background of the current range turns red.

If a current overrange, i.e., that the current exceeds 130% of the present range, occurs,

the background of the current range turns yellow.

When a voltage value exceeds a certain ratio based on the declared input voltage, the

background color turns any of the following colors:

110% < Yellow

90% ≤ (Regular background color) ≤ 110%

80% ≤ Yellow < 90%

Red < 80%

When the measured value is different from the declared frequency, the background of

the declared frequency turns red.

Measured value became overrange (the measurement is out of measuring range).

The voltage that the instrument is capable of measuring is being exceeded. Immediately

disconnect the instrument.

If the current is overrange, increase the current range.

Measurement is not possible. Shown instead of the measured value.

If there is no input, the power factor cannot be measured.

34

Page 41

2

Preparing for Measurement

Before starting measurement, connect accessories and options to this instrument. Before

performing measurement, be sure to read “Operating Precautions” (p. 7) and to inspect the

instrument, accessories, and options to ensure that there is no damage.

2.1 Preparation Flowchart

2

Follow the procedure for preparation described below. (The items preceded by † need to be

performed only during the rst use.)

†

Initial Measurement Preparations

• Color coding of current sensor (for channel identication) (p. 36)

• Bundling the voltage cords and current sensors (If required) (p. 37)

• Installing the battery pack. (p. 38)

• Attaching the strap (if required) (p. 39)

• Setting the language, clock, and measurement frequency (p. 40)

Pre-Measurement Inspection (p. 41)

Inserting the SD Memory Card (p. 42)

Power Supply (p. 43)

Turning On the Instrument (p. 44)

Preparing for Measurement

Warm-up (p. 44)

• At least 30 min

35

Page 42

Initial Measurement Preparations

2.2 Initial Measurement Preparations

Color coding of current sensor (for channel identication)

Be sure to read “Handling Cords and Cables” (p. 8).

At both the ends of the current sensor cable, connect the spiral tube of the same color as the

channel which is to be connected to the current sensor, to avoid wiring mistakes.

Example: In the case of using 2 current sensors

Required items

Color Spiral tubes

(for color-coding the current sensor)

Current sensor in use × 2

Red (thin) × 2

Yellow (thin) × 2

Connector side

Sensor side

Color Spiral tubes for CH1 (red) Color Spiral tubes for CH2 (yellow)

Measuring object

Single-phase 2-wire (1P2W) 1 (CH1 red)

(Diagram of Model CT7136)

Number of current sensors in use

(Colors of the CH and color spiral tubes)

36

Single-phase 3-wire (1P3W)

2 (CH1 red, CH2 yellow)

3-phase 3-wire (3P3W2M)

3-phase 3-wire (3P3W3M)

3 (CH1 red, CH2 yellow, CH3 blue)

3-phase 4-wire (3P4W)

Page 43

Initial Measurement Preparations

Bundling the voltage cords and current sensors (If required)

Be sure to read “Handling Cords and Cables” (p. 8), “Using Voltage Cords” (p. 8).

If required, group the cables together by using the spiral tubes (black).

Example: In the case of using 3 voltage cords and 2 current sensors

Required items

Spiral tubes (for grouping the cables together)

Black (thick) ×10

Model L1000-05 Voltage Cord ×3

Black

Red

Yellow

CH1 Red

N Black

CH2 Yellow

Model L1000-05 Voltage Cord Current sensor

Red

Black

Yellow

Current sensor in use ×2

CH1 Red

CH2 Yellow

2

Preparing for Measurement

(The model illustrated above is

Model CT7136)

Red

Yellow

37

Page 44

Initial Measurement Preparations

Installing the battery pack

Be sure to read “Using Battery Pack” (p. 9).

The battery pack is subject to self-discharge. Be sure to charge the battery pack before initial use

(See Step 7).

If the battery can only be used for a considerably short time even after correct charging, replace it

with a new battery pack.

Required items

Phillips screwdriver (No. 2)

Turn off the instrument. (p. 44)

1

Turn the instrument over, remove

3

the screws on the primary battery

compartment and remove the cover.

Insert the battery pack in the direction

5

that is indicated by the labeling on the

battery pack.

Be careful not to pinch the wires of the battery

pack.

Model Z1003 battery pack

Remove all cords.

2

Connect the plug of the Model Z1003

4

battery pack to the connector of the

instrument. (Turn the 2 projection

surfaces of the plug to the left and

connect.)

Put the cover and tighten the screws.

6

Projection

7

38

Connect the AC adapter (p. 43) to the

instrument and charge the battery pack.

The battery pack will be charged regardless of

whether the power is ON or OFF.

• The battery pack is used as a backup power supply for the instrument during interruption. When fully

charged, it can provide backup power for approximately 8 hours in the event of an interruption.

• Note that if an interruption occurs while the battery pack is not being used, the displayed time series data will

be erased. (Data that has been recorded on the SD memory card and instrument’s internal memory will be

retained.)

• For more information about the operating temperature and humidity and the storage temperature and

humidity, see “14.1 General Specications” (p. 153).

(Left side surface of the instrument)

CHARGE LED

Solid red During charging

Off Fully charged or when the

battery is not attached

Page 45

Initial Measurement Preparations

Attaching the strap (if required)

Be sure to read “Attaching the Strap” (p. 10).

If required, attach the strap when carrying the instrument or hanging it on a hook at the installed

location.

Pass through the strap eyelet.

1

Pass through the loop.

Pass through the

2

buckle.

3

2

Preparing for Measurement

Tighten the straps securely to avoid loosening or twisting.

39

Page 46

Initial Measurement Preparations

Setting the language, clock, and measurement frequency

When you turn on the instrument for the rst time after purchase, the language setting screen, clock

setting screen, and frequency setting screen will be displayed. Congure these settings.

Similarly, these settings must be congured if a factory reset (p. 77) is performed to reset the

instrument to its default settings.

Turn on the instrument. (p. 44)

1

Select the display language.

2

Move the cursor

Japanese

English

Chinese Simple

Chinese Trad

Korean

German

French

Italian

Spanish

Turkish

Set the date and time.

3

Move the cursor

The seconds cannot be set. If you press the

[Enter] key after changing value, the seconds

will be set to 00.

Once you have set the display language, time, and measurement frequency, this settings screen will not be

shown again when the instrument is turned on.

You can change these settings on the setting screen.

See Display language, time“System Settings” (p. 75), and measurement frequency“SET UP, Measurement

Settings 1 screen” (p. 64).

Change the value

Select the frequency for the measuring

4

object using the function keys.

Move the cursor

The WIRING, wiring setting screen will be

displayed.

40

Page 47

Pre-measurement Inspection

2.3 Pre-measurement Inspection

Before using the instrument, verify that it operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized Hioki distributor or

reseller.

(1) Inspect the voltage cords

Is the insulation of the voltage cord damaged,

or is bare metal exposed?

No

(2) Inspect the current sensor

• Is there any crack or damage in the jaw part?

• Is the insulation on the cables torn?

No

(3) Inspect the AC adapter

• Is damage to the AC adapter evident?

• Is the power cord’s insulation damaged?

Yes

Yes

Yes

Do not use if damage is present,

as you could receive an electric

shock.

Contact your authorized Hioki

distributor or reseller.

2

Preparing for Measurement

No

(4) Inspect the instrument

Is the device damaged?

No

Inspection complete

Yes

41

Page 48

Inserting the SD Memory Card

2.4 Inserting the SD Memory Card

Be sure to read “Using SD Memory Cards” (p. 10).

Turn off the instrument. (p. 44)

1

Disengage the lock.

3

Lock key

Open the cover.

2

Insert the SD memory card inside.

4

Arrow

Insert the card horizontally. Inserting the SD

memory card at an angle may cause the writeprotect lock to engage, preventing data from

being written to the card.

Close the cover. How to remove:

5

When storing the data to the SD memory card, congure the recording settings.

See “5.2 Recording Settings” (p. 69).

Open the cover, push in the SD memory

card and then pull it out.

42

Page 49

2.5 Power Supply

Be sure to read “Using AC Adapter” (p. 11).

Required items

Model Z1002 AC adapter

Power Supply

Power OFF

1

2

Connect

(AC adapter + power cord)

Connect

3

Hook

4

AC adapter

Power cord

5

2

Preparing for Measurement

Connect

43

Page 50