Page 1

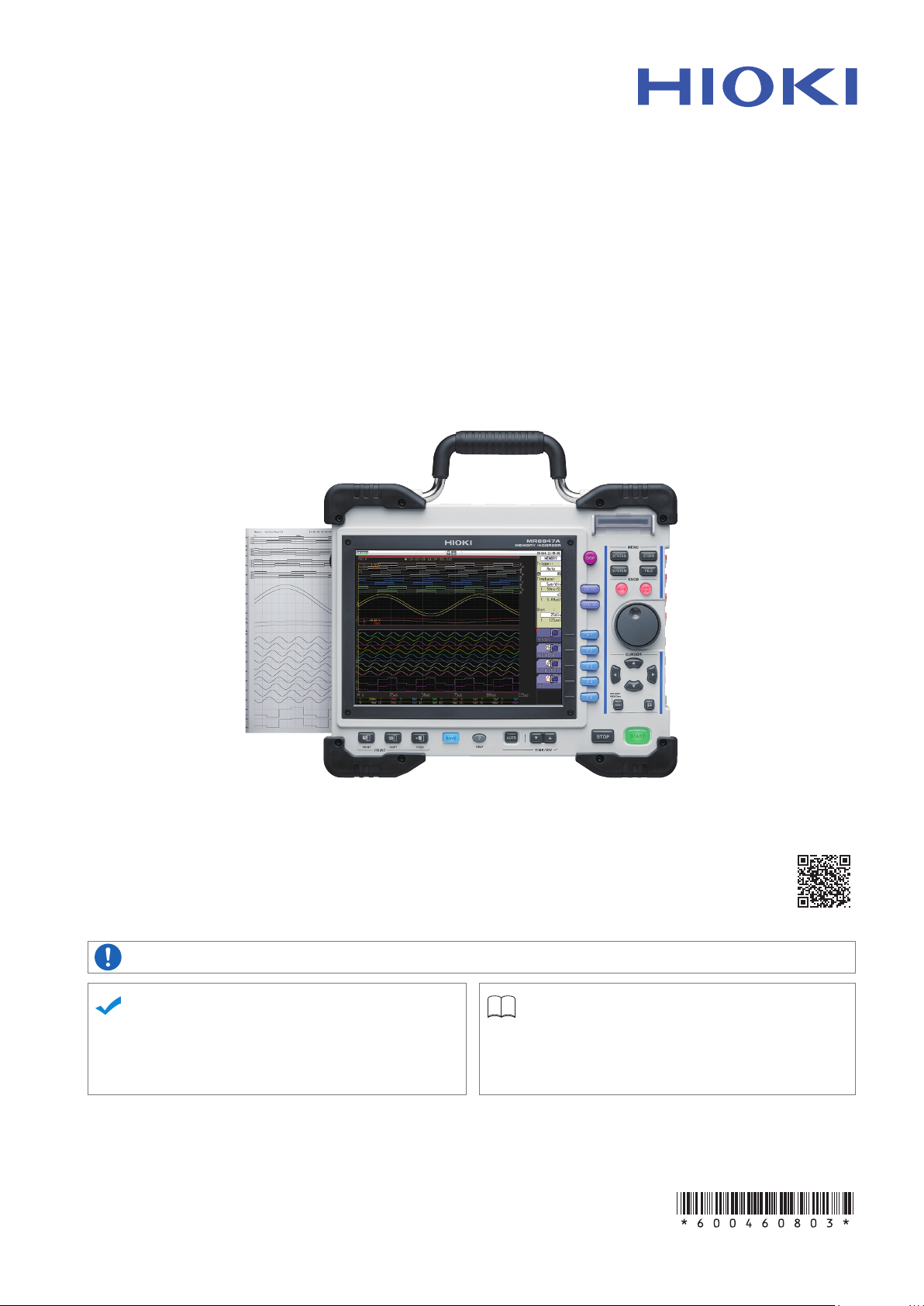

MR8847A

MR8847-51

MR8847-52

MR8847-53

Instruction Manual

MEMORY HiCORDER

Be sure to read this manual before using the instrument.

When using the instrument for the

rst time

Part Names and Functions

Preparing for Measurement p.25 Error Messages

Feb. 2019 Revised edition 3

MR8847G961-03 19-02H

p.16 Maintenance and Service p.415

Troubleshooting

Video

Scan this code to watch the

instructional video(s).

Carrier charges may apply.

p.4

p.422

EN

Page 2

Page 3

Contents

Contents

Usage Index ............................................... 1

Introduction ................................................ 2

Verifying Package Contents ..................... 3

Safety Information ..................................... 4

Operation Precautions .............................. 7

1 Overview 15

1.1 Product Overview ......................... 15

1.2 Part Names and Functions .......... 16

1.3 ScreensConguration ................. 19

Explanation of screen contents ................20

1.4 Basic Key Operation .................... 21

1.4.1 Using the HELP Key .................................. 22

1.4.2 Using Mouse to Enable Key Operation ...... 23

2 Preparing for

Measurement 25

2.1 Installing and Removing

Modules ......................................... 26

Channel conguration ...............................27

2.2 Attaching Connection Cables ..... 28

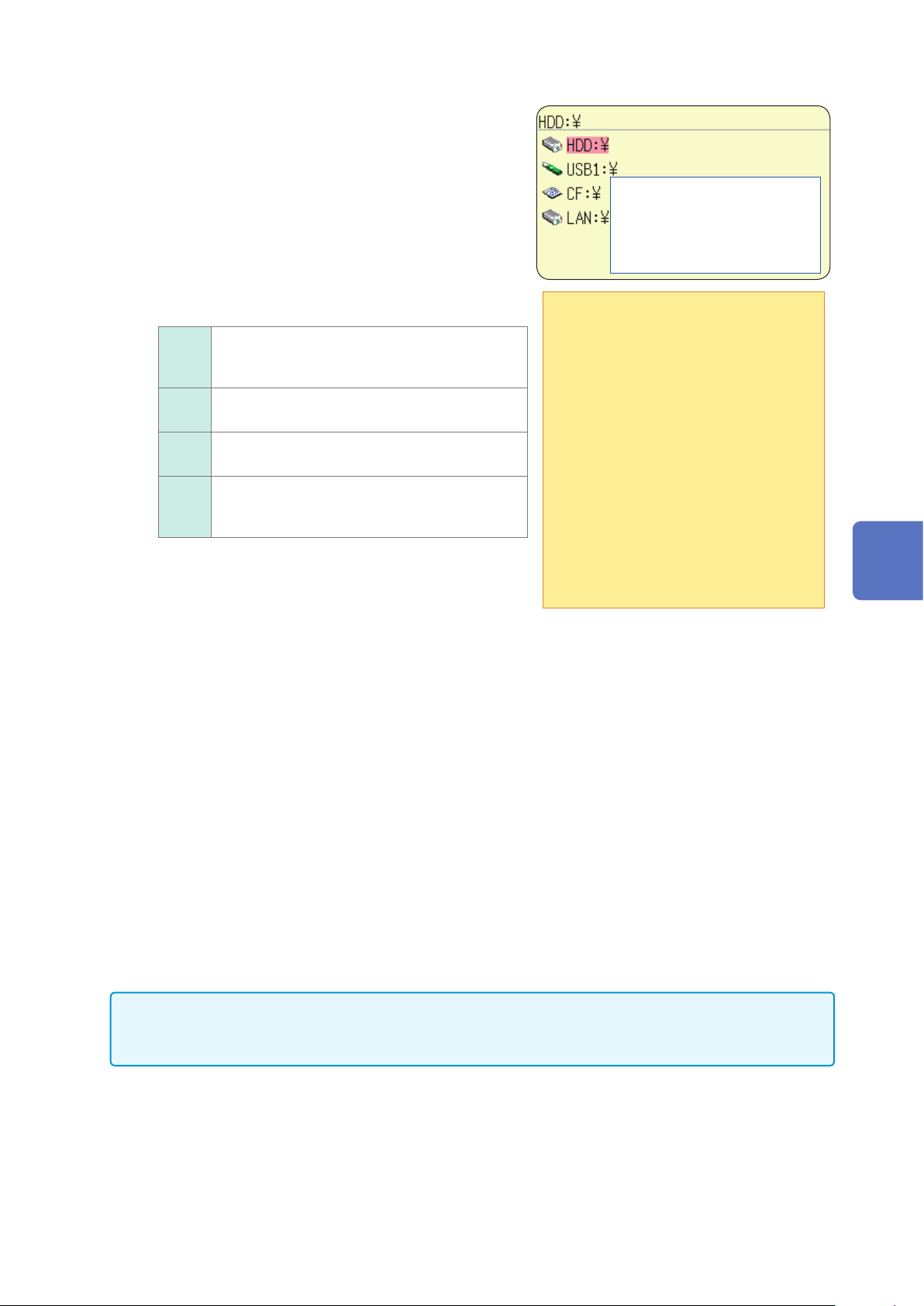

2.3 Preparing Storage Devices .......... 41

2.3.1 Available Storage Devices (Inserting a

CF Card and a USB Flash Drive) ............... 41

2.3.2 Formatting Storage Devices ......................43

2.4 Loading Recording Paper ............ 43

2.5 Supplying Power .......................... 45

2.5.1 Connecting the Power Cord ....................... 45

2.5.2 Connecting an Earthing Wire to the

GND Terminal (Functional Earth Terminal) ..45

2.5.3 Turning On and Off the Instrument ............. 46

2.6 Setting the Clock .......................... 47

2.7 Adjusting the Zero Position

(zero-adjustment) ......................... 48

2.8 Performing Calibration (When

Model MR8990 is Installed) .......... 49

3 Measurement 51

3.1 Measurement Procedure ............. 51

3.2 Inspecting the Instrument

Before Measurement .................... 53

3.3 Setting Measurement

Conditions ..................................... 54

3.3.1 Measurement Functions ............................ 54

3.3.2 Timebase and Sampling Rate .................... 56

3.3.3 Setting the Recording Length

(Number of Divisions) ................................ 60

3.3.4 Setting Screen Layout ............................... 63

3.4 ConguringInputChannels

Settings ......................................... 64

3.4.1 Channel Setting Procedure ........................ 65

3.4.2 Conguring Analog Channels Settings ....... 67

3.4.3 Conguring Logic Channel Settings ........... 70

3.4.4 Display Sheet ............................................ 71

3.5 Starting and Stopping

Measurement ................................ 73

3.6 Measurement in Automatic

Range Setting (Auto-Range

Function) ....................................... 76

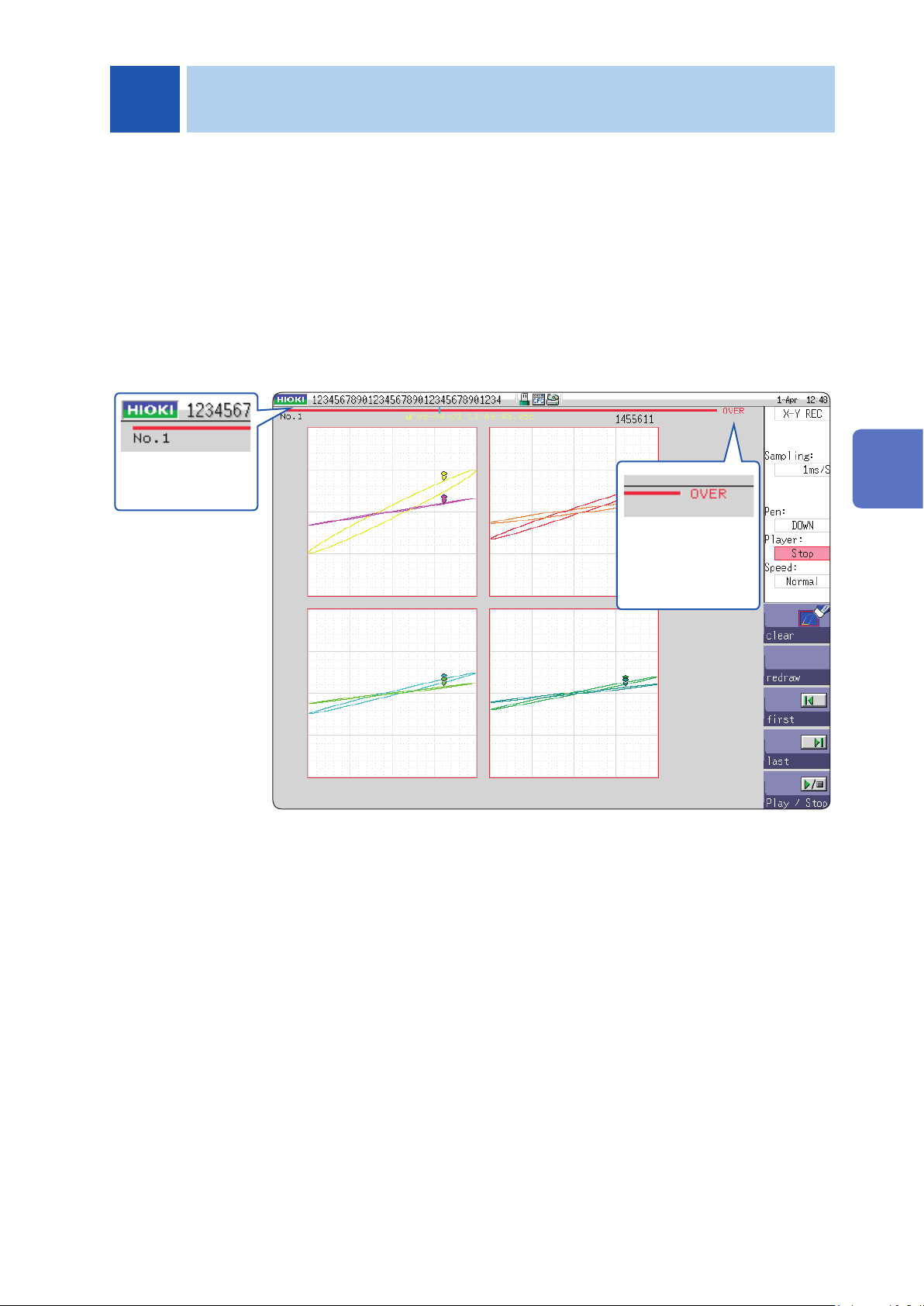

4 X-Y Recorder 79

4.1 Measurement procedure .............. 80

4.2 Setting Measurement

Conditions ..................................... 81

4.3 Starting and Stopping

Measurement ................................ 82

4.4 Observing X-Y Composite

Curves ........................................... 84

5 Saving/Loading Data

and Managing Files 85

5.1 Data That Can Be Saved and

Loaded ........................................... 87

5.2 Saving Data ................................... 89

5.2.1 Save Types and Setting Procedure ............ 89

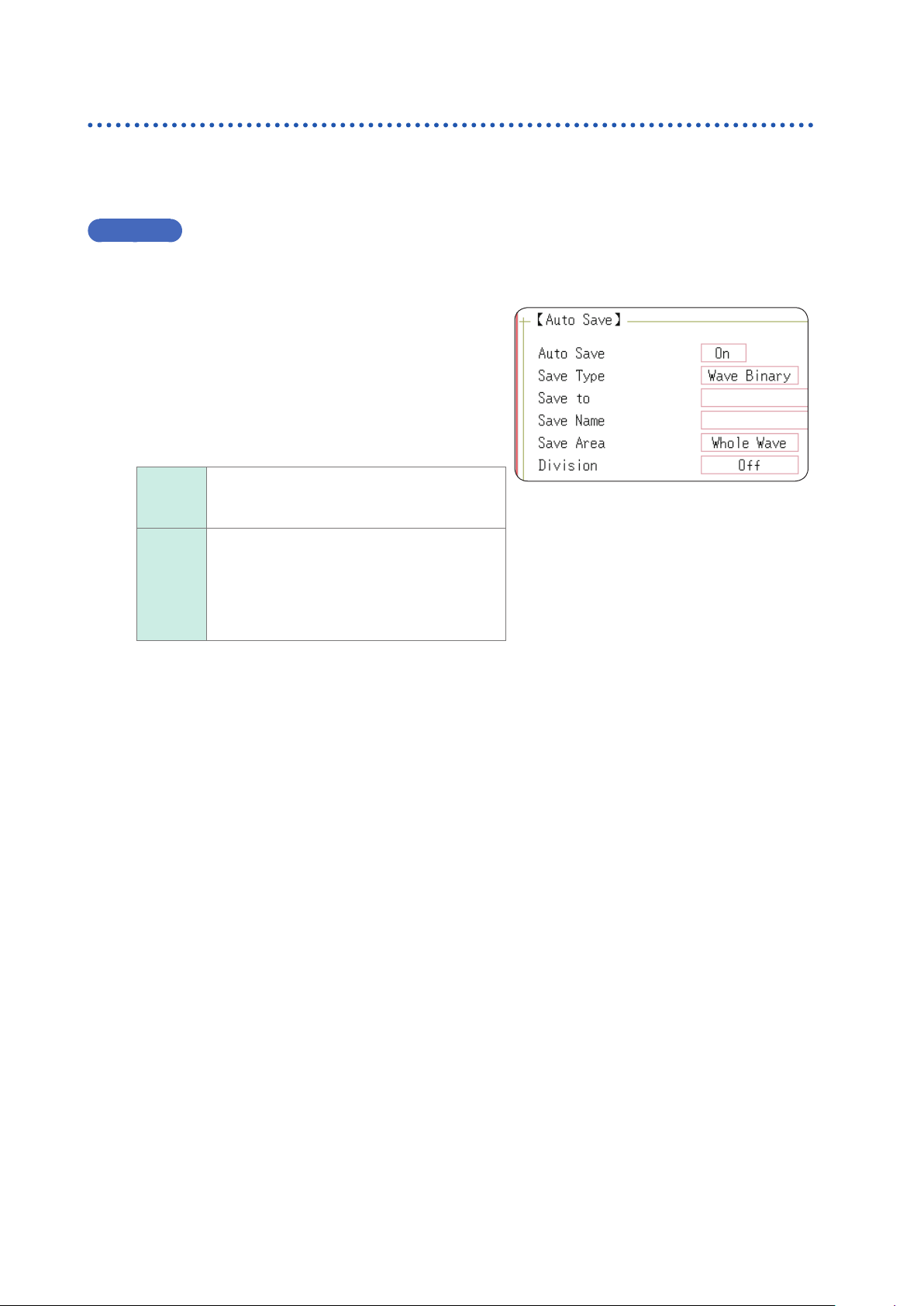

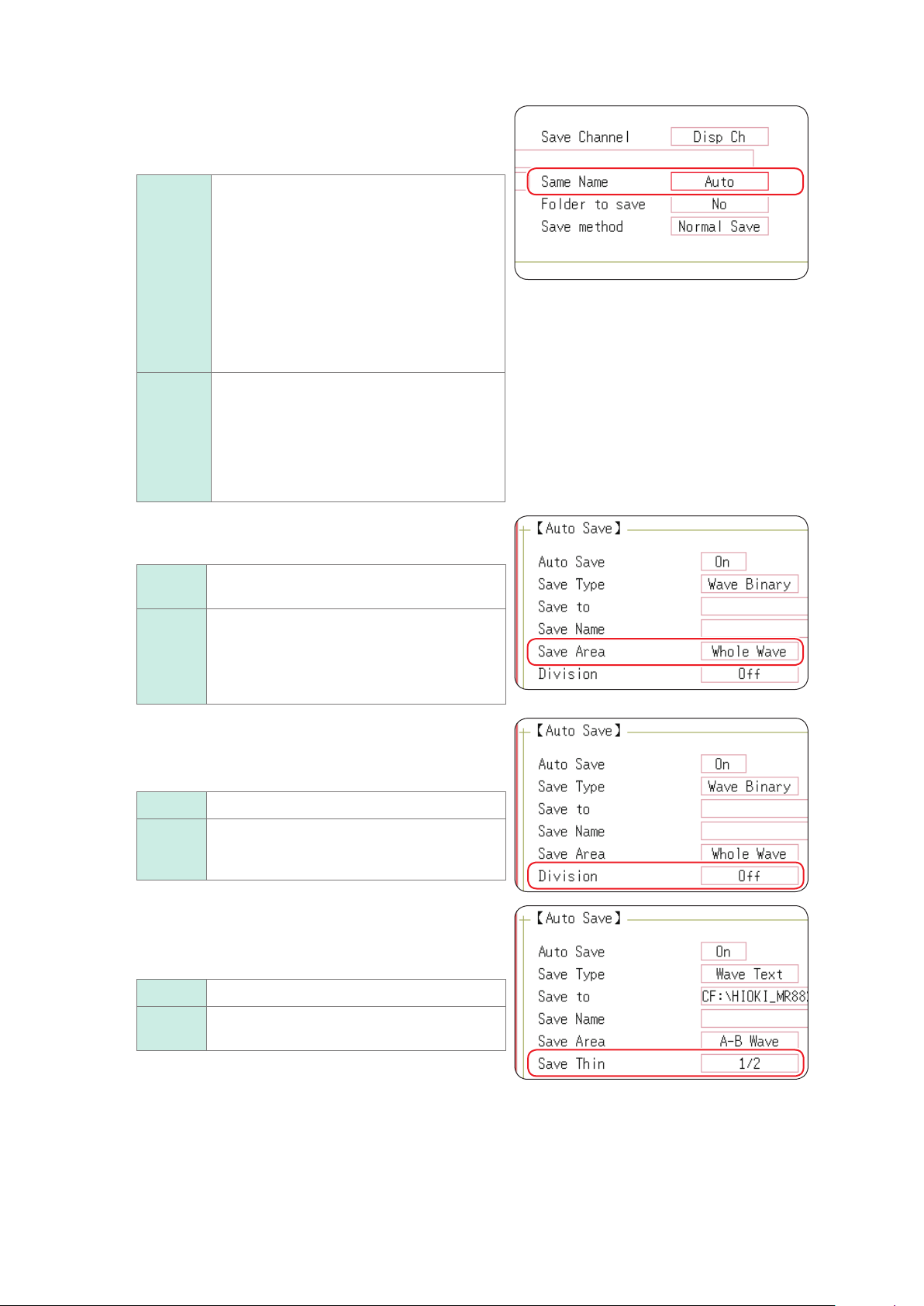

5.2.2 Automatically Saving Waveforms ............... 90

5.2.3 Saving Data Selectively (SAVE Key) .......... 97

5.2.4 Saving Waveform Outputting Data to a

Storage Device ........................................ 103

5.3 Loading Data ............................... 104

5.4 Automatically Loading Settings

(Auto-setup Function) ................ 107

5.5 Managing Files ........................... 108

5.5.1 Saving Data ............................................. 109

5.5.2 Checking the Contents in a Folder

(Opening a Folder) ....................................112

5.5.3 Creating New Folders ...............................112

5.5.4 Deleting Files and Folders.........................113

5.5.5 Sorting Files ............................................ 114

5.5.6 Renaming Files and Folders .....................115

5.5.7 Copying a File Into a Specied Folder .......11 6

5.5.8 Printing the File Table................................117

6 Printing Data 119

6.1 Print Type and Procedure .......... 120

6.2 Setting Auto-printing .................. 121

1

2

3

4

5

6

MR8847G961-03

i

Page 4

Contents

6.3 Manually Printing Data by

Pressing the PRINT Key

(Selection Print) .......................... 124

6.4 Setting the Print Density of the

Waveform .................................... 126

6.5 ConguringthePrinterSettings 127

6.6 Advanced Print Functions ......... 130

6.6.1 Printing the Screenshot ............................ 130

6.6.2 Printing Reports (A4-Sized Print) ............. 130

6.6.3 Printing a List ........................................... 132

6.6.4 Printing the Text Cooments ...................... 132

7 Monitoring and

Analyzing Waveforms

on the Waveform

Screen 133

7.1 Reading Measured Values

(Using Cursors A and B) ............ 134

7.2 Specifying the Waveform

Range (Cursors A and B) ........... 139

7.3 Moving the Waveform Display

Position ....................................... 141

7.3.1 Display Position ....................................... 141

7.3.2 Scrolling the Waveforms With the Jog

Dial and Shuttle Ring ............................... 141

7.3.3 Changing Position (Jump Function) .......... 143

7.4 Plotting X-Y Composite

Curves ......................................... 144

7.5 Magnifying and Demagnifying

Waveforms .................................. 146

7.5.1 Magnifying and Demagnifying Waveforms

Horizontally (in the Time Axis Direction)

7.5.2 Zoom Function (Horizontally Magnifying

a Part of Waveforms [in the time axis

direction]) ................................................. 147

7.5.3 Magnifying/demagnifying the

Waveforms Vertically (in the Voltage

Axis Direction) .........................................149

7.6 Monitoring Input Levels (Level

Monitor) ....................................... 150

7.6.1 Level Monitor ........................................... 150

7.6.2 Numerical Value Monitor .......................... 151

7.7 Switching the Waveform

Screen Display

(Display Menu) ............................ 152

7.7.1 Displaying Upper and Lower Limits on

the Waveform Screen .............................. 152

7.7.2 Displaying Comments on the Waveform

Screen ..................................................... 152

7.7.3 Switching the Waveform Display Width .... 152

7.7.4 Switching the Sheet to Be Displayed........ 153

.... 146

7.8 Viewing Waveforms Divided

Into Blocks .................................. 153

8 Advanced Functions 155

8.1 Adding Comments ..................... 156

8.1.1 Adding, Displaying, and Printing the Title

Comment................................................. 156

8.1.2 Adding, Displaying, and Printing the

Channel Comments ................................. 157

8.1.3 Entering Alphanumeric Characters ........... 159

8.2 Displaying Waveforms During

the Writing in the Memory

Simultaneously

(Roll Mode) .................................. 163

8.3 Overlaying New Waveforms

With Past Waveforms ................. 164

8.4 Setting Channels to Be Used

(Extending the Recording

Length) ........................................ 166

8.5 Converting Input Values

(Scaling Function) ...................... 167

8.5.1 Example of Scaling Settings .................... 169

8.6 Setting the Waveform Position

(Variable Function) ..................... 174

8.7 Fine-Adjusting Input Values

(Vernier Function) ....................... 177

8.8 Inverting the Waveform (Invert

Function) ..................................... 178

8.9 Copying Settings to Other

Channels (Copy Function) ......... 179

8.10 Setting Details of Modules ........ 180

8.10.1 Setting the Anti-aliasing Filter (A.A.F.)

(Model 8968 High Resolution Unit) ........... 181

8.10.2 Setting the Probe Voltage Dividing Ratio .. 181

8.10.3 Setting Model 8967 Temp Unit ................. 182

8.10.4 Setting Model 8969 and U8969 Strain

Unit .......................................................... 183

8.10.5 Setting Model 8970 Freq Unit .................. 184

8.10.6 Setting Model 8971 Current Unit ............. 187

8.10.7 Setting Model 8972 DC/RMS Unit ............ 187

8.10.8 Setting Model MR8990 Digital Voltmeter

Unit .......................................................... 188

8.10.9 Setting Model U8974 High Voltage Unit ... 189

8.10.10 Setting MR8790 Waveform Generator

Unit .......................................................... 190

8.10.11 Setting MR 8971 Pulse Generator Unit .... 192

8.10.12 Setting U8793 Arbitrary Waveform

Generator Unit ......................................... 194

8.11 Registering Waveforms in the

U8793 Arbitrary Waveform

Generator Unit ............................ 197

ii

Page 5

Contents

8.12 Saving Waveforms Registered

in Model U8793 onto a Storage

Device .......................................... 200

8.13 Setting Output Waveform

Parameters on the Waveform

Screen ......................................... 200

9 Setting the Trigger 201

9.1 Setting Procedure ...................... 202

9.2 Setting the Trigger Mode ........... 203

9.3 Triggering the Instrument

Using Analog Signals ................. 204

9.4 Triggering the Instrument

Using Logic Signals (Logic

Trigger) ........................................ 210

9.5 Triggering the Instrument

attheSpeciedTimeorat

Regular Intervals (Timer

Trigger) ........................................ 212

9.6 Triggering the Instrument

Externally (External Trigger) ..... 216

9.7 Triggering the Instrument

Manually (Manual Trigger) ......... 216

9.8 Setting the Pre-trigger ............... 217

9.8.1 Setting the Trigger Start Point (Pre-

trigger) ..................................................... 217

9.8.2 Setting the Trigger Acceptance (Trigger

Priority) .................................................... 219

9.9 Setting the Trigger Timing ......... 220

9.10 Setting the Trigger Logical

Connective (AND/OR) Among

the Trigger Sources .................... 222

9.11 Searching the Measured Data

Using the Trigger Settings ......... 223

10 Numerical Calculation

Functions 225

10.1 Numerical Calculation

Procedure .................................... 226

10.2 Setting the Numerical Value

Calculation .................................. 228

10.2.1 Displaying the Numerical Calculation

Results .................................................... 232

10.3 Judging the Calculation

Results ........................................ 233

10.3.1 Displaying the Judgment Results and

Outputting the Signals .............................. 235

10.4 Saving the Numerical

Calculation Results .................... 236

10.5 Printing the Numerical

Calculation Results .................... 238

10.6 Numerical Calculation Types

and Descriptions ........................ 239

11 Waveform Calculation

Function 243

11.1 Waveform Calculation

Workow ..................................... 244

11.2 Waveform Calculation Settings . 246

11.2.1 Displaying the Waveform Calculation

Results .................................................... 248

11.2.2 Setting Constants .................................... 250

11.2.3 Change the Display Method for

Calculated Waveforms ............................. 251

11.3 Waveform Calculation

Operators and Results ............... 254

12 Memory Division

Function 257

12.1 ConguringtheRecording

Settings ....................................... 259

12.2 ConguringtheDisplay

Settings ....................................... 260

13 FFT Function 263

13.1 Overview and Features .............. 263

13.2 OperationWorkow(Reference

Data) ............................................ 264

13.3 Setting the FFT Analysis

Conditions ................................... 265

13.3.1 Selecting the FFT Function ...................... 265

13.3.2 Setting the Data Source for Analysis

(Reference Data) ..................................... 266

13.3.3 Setting the Frequency Range and

Number of Analysis Points. ...................... 267

13.3.4 Decimating and Calculating Data ............. 269

13.3.5 Setting the Window Function ...................270

13.3.6 Conguring the Analysis Result Peak

Value Setting ........................................... 271

13.3.7 Averaging Analysis Results (Waveform

Averaging) ............................................... 272

13.3.8 Highlighting Analysis Results (Phase

Spectra Only) ..........................................275

13.3.9 Conguring the Analysis Mode Settings ... 276

13.3.10 Setting the Display Range of the

Vertical Axis (Scaling) .............................. 280

13.3.11 Setting and Changing Analysis

Conditions on the Waveform Screen ........ 281

11

12

13

7

8

9

10

Appx. Ind.

iii

Page 6

Contents

13.4 ConguringtheChannel

settings ........................................ 282

13.5 ConguringtheScreenDisplay

Settings ....................................... 283

13.5.1 Displaying the Running Spectrum ............ 285

13.6 Saving Analysis Results ............ 288

13.7 Printing Analysis Results .......... 289

13.8 Analyzing Waveforms on the

Waveform Screen ....................... 290

13.8.1 Calculating After Specifying the

Calculation Starting Point ......................... 290

13.9 FFT Analysis Modes ................... 292

13.9.1 Analysis Modes and Display Examples .... 292

13.9.2 Analysis Mode Functions ......................... 310

14 Waveform Evaluation

Function 311

14.1 Evaluating Waveforms and

Giving GO/NG Judgments

(MEM, FFT Function) ...................311

14.2 Setting the Evaluation Area ....... 314

14.3 ConguringtheWaveform

Evaluation Setting ...................... 316

14.4 Setting the Waveform

Evaluation Stopping

conditions ................................... 317

14.5 Creating the Evaluation Area .... 319

14.6 Details About the Editor

Commands .................................. 320

16.2.1 Setting HTTP With the Instrument ............ 338

16.2.2 Connecting the Computer to the

Instrument With the Internet Browser ....... 339

16.2.3 Operating the Instrument With the

Internet Browser ...................................... 340

16.3 Accessing Files on the

Instrument From the computer

(Using the FTP) ........................... 346

16.3.1 Setting the FTP With the Instrument ........347

16.3.2 Connecting the Computer to the

Instrument Using the FTP ........................ 348

16.3.3 Managing Files With the FTP ................... 349

16.4 Transferring Data to the

computer ..................................... 350

16.5 Wave Viewer (Wv) ....................... 351

16.6 ConguringtheUSBSettings

and Connecting the Instrument

to the Computer

Performing Command

Communications) ....................... 352

16.6.1 Conguring the USB Settings With the

Instrument ............................................... 352

16.6.2 Installing the USB Driver .......................... 352

16.7 Controlling the Instrument with

Command Communications

(LAN/USB) ................................... 357

16.7.1 Setting the Instrument .............................. 358

16.8 Operating the Instrument

Remotely and Acquiring Data

Using the Model 9333 LAN

Communicators .......................... 359

(Before

15 Setting the System

Environment 325

16 Connecting the

Instrument to a

Computer 331

16.1 Setting LAN and Connecting

the Instrument to the LAN

Network (Before Using FTP/

Internet Browser/Command

Communications) ....................... 332

16.1.1 Conguring the LAN Settings With the

Instrument ............................................... 332

16.1.2 Connecting the Instrument to the

Computer With the LAN Cable ................. 336

16.2 Controlling the Instrument

Remotely (Using an Internet

Browser). ..................................... 338

iv

17 Controlling the

Instrument Externally 361

17.1 Connection of the External

Control Terminals ....................... 362

17.2 External I/O ................................. 363

17.2.1 External Input (START/EXT.IN1) (STOP/

EXT.IN2) (PRINT/EXT.IN3) ....................... 363

17.2.2 External Output (GO/EXT.OUT1) (NG/

E X T.OU T 2) .............................................. 365

17.2.3 External Sampling (EXT.SMPL)................367

17.2.4 Trigger Output (TRIG OUT) .....................369

17.2.5 External Trigger Terminal (EXT.TRIG) ...... 370

18 Specications 371

18.1 GeneralSpecicationsofthe

Instrument ................................... 371

18.2 Common Functions .................... 374

18.3 Measurement Functions ............ 376

18.3.1 Memory Function ..................................... 376

Page 7

Contents

18.3.2 Recorder Function ................................... 377

18.3.3 X-Y Recorder Function ............................378

18.3.4 FFT Function ........................................... 379

18.4 Other Functions .......................... 380

18.5 File ............................................... 385

18.6 SpecicationsofModules ......... 387

18.6.1 Model 8966 Analog Unit ........................... 387

18.6.2 Model 8967 Temp Unit ............................. 388

18.6.3 Model 8968 High Resolution Unit ............. 391

18.6.4 Model 8969 Strain Unit,

U8969 Strain Unit ....................................393

18.6.5 Model 8970 Freq Unit .............................. 395

18.6.6 Model 8971 Current Unit .......................... 397

18.6.7 Model 8972 DC/RMS Unit ........................ 399

18.6.8 Model 8973 Logic Unit ............................. 401

18.6.9 Model MR8990 Digital Voltmeter Unit .......402

18.6.10 Model U8974 High Voltage Unit ............... 404

18.6.11 Model U8793 Arbitrary Waveform

Generator Unit ......................................... 406

18.6.12 Model MR8790 Waveform Generator

Unit .......................................................... 409

18.6.13 Model MR8791 Pulse Generator Unit ....... 4 11

Specications of output connector ..........413

Index Ind.1

14

15

19 Maintenance and

Service 415

19.1 Trouble Shooting ........................ 417

19.2 Resetting the Instrument ........... 420

19.2.1 Resetting System Settings ....................... 420

19.2.2 Resetting Waveform Data ........................ 421

19.3 Error Messages .......................... 422

19.4 Self-Test (Self-Diagnostics) ....... 427

19.4.1 ROM/RAM Check .................................... 427

19.4.2 Printer Check ...........................................428

19.4.3 Display Check ......................................... 428

19.4.4 Key Check ............................................... 429

19.4.5 System Conguration Check ................... 429

19.5 Cleaning the instrument ............ 431

19.6 Disposing of the Instrument

(Removing Lithium Battery) ...... 433

Appendix Appx.1

Appx. 1 Default Values for Major

Settings ............................. Appx.1

Appx. 2 For Reference ................... Appx.2

Appx. 3 About Options ................ Appx.13

Appx.4 FFTDenitions ............... Appx.20

16

17

18

19

Appx. Ind.

v

Page 8

Contents

vi

Page 9

Usage Index

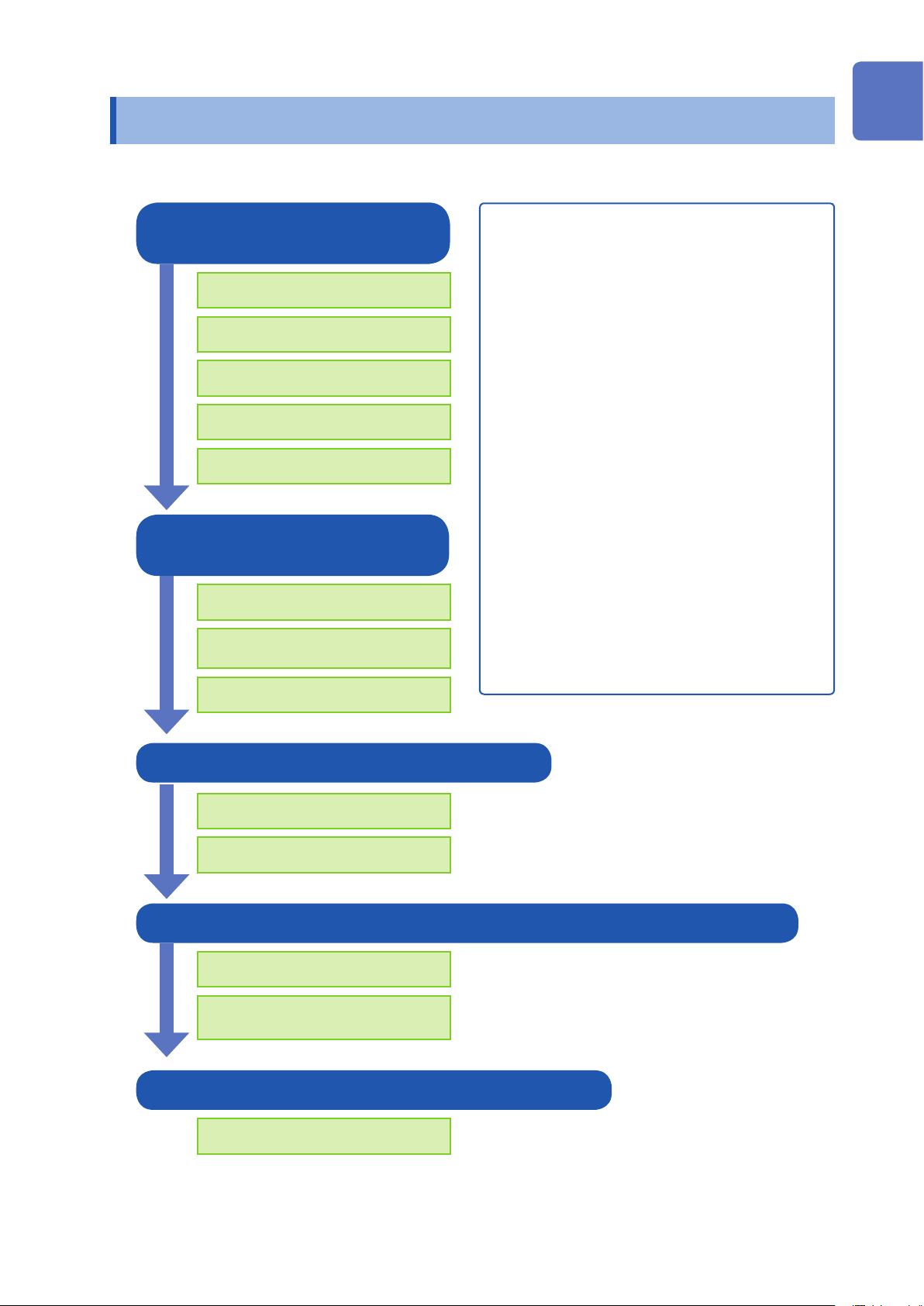

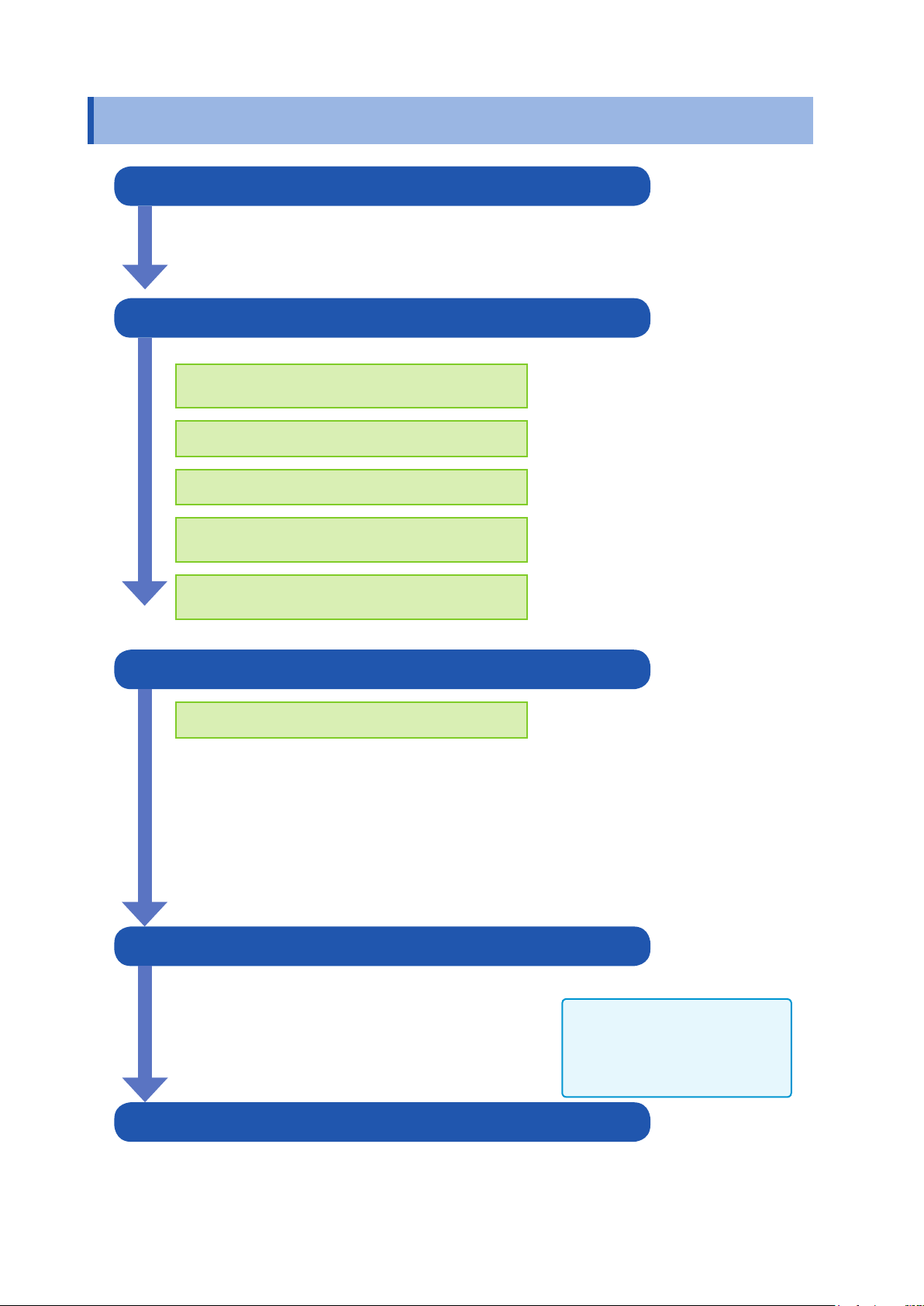

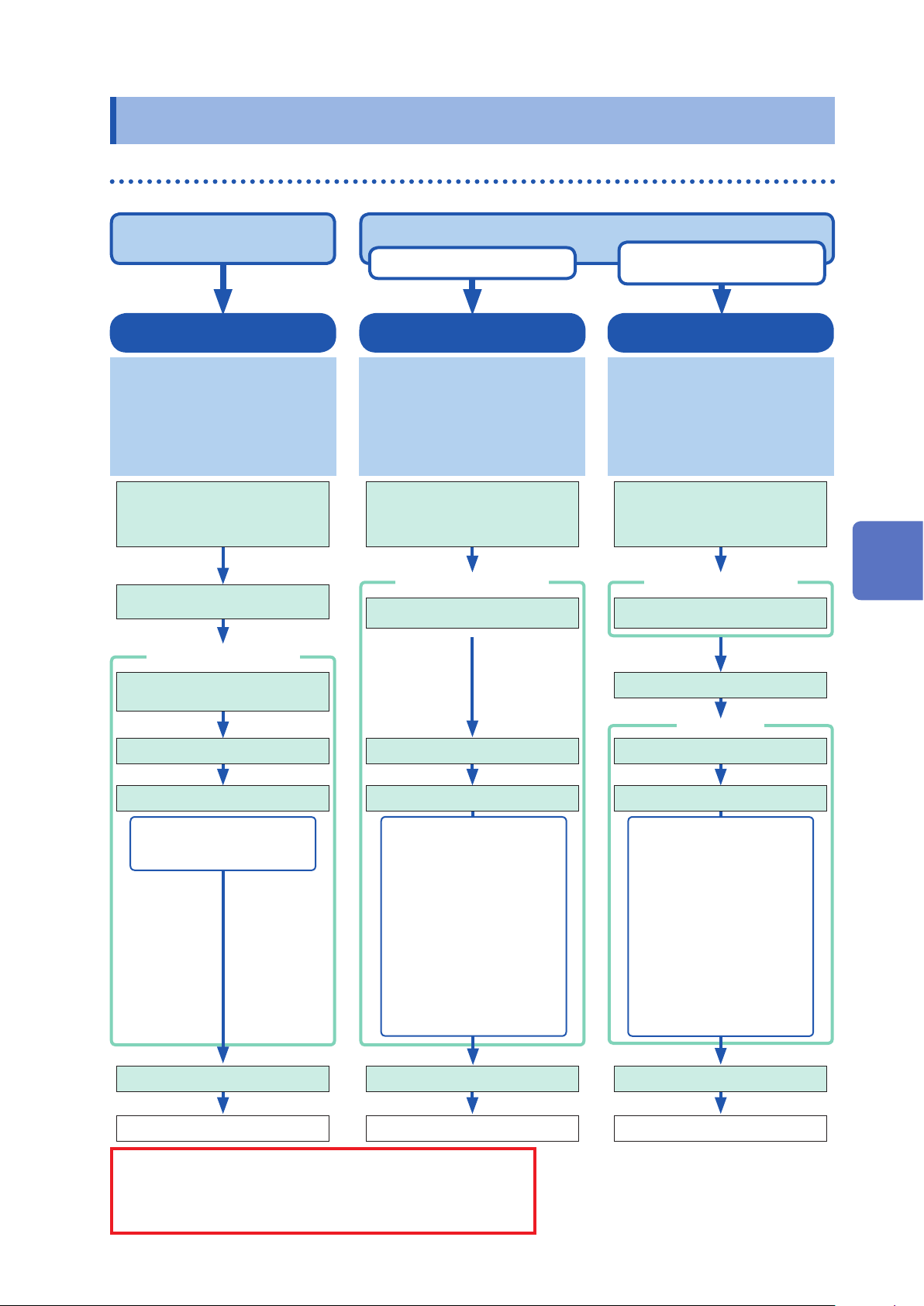

Basic measurement procedure

1 Installing the instrument

(p. 25)

Installing the instrument

Installing modules

Usage Index

Performing measurement in the automatic

range setting (

Monitoring changes in input signals (p. 201)

Manually triggering the instrument (p. 216)

Entering comments (p. 156)

p. 76

)

1

2

Connecting cables

Loading the recording paper

Turning on the instrument

2 Setting the instrument

(p. 51)

Selecting a function

Selecting measurement settings

Selecting input channels

3 Measuring input signals (p. 73)

Starting measuring input signals

Freely setting the waveform display (p. 64)

Converting input values (p. 167)

Copying settings to other channels (p. 179)

Eliminating noise (Low-pass lter) (p. 70)

Plotting X-Y composite curves (p. 144)

Locking the operation keys (p. 17)

Formatting a CF Card (p. 43)

Scaling measured values obtained with current

clamp sensors (p. 169)

3

4

5

6

7

Completing the measurement

4 Analyzing (

Saving/printing results

5 Completing the measurement (p. 46)

Turning off the instrument

p. 133

Performing analysis

(optionally)

), saving (

p. 85

), and printing data (

p. 119

8

)

9

10

Appx. Ind.

1

Page 10

Introduction

Introduction

Thank you for purchasing the Hioki MR8847A Memory HiCorder (MR8847-51, MR8847-52, MR8847-53).

To obtain maximum performance from the instrument, please read this manual rst, and keep it handy for

future reference.

The optional clamps (p. Appx.13) collectively mean “clamp sensors.”

The following instruction manuals are available for this instrument. Refer to the relevant manual as usage.

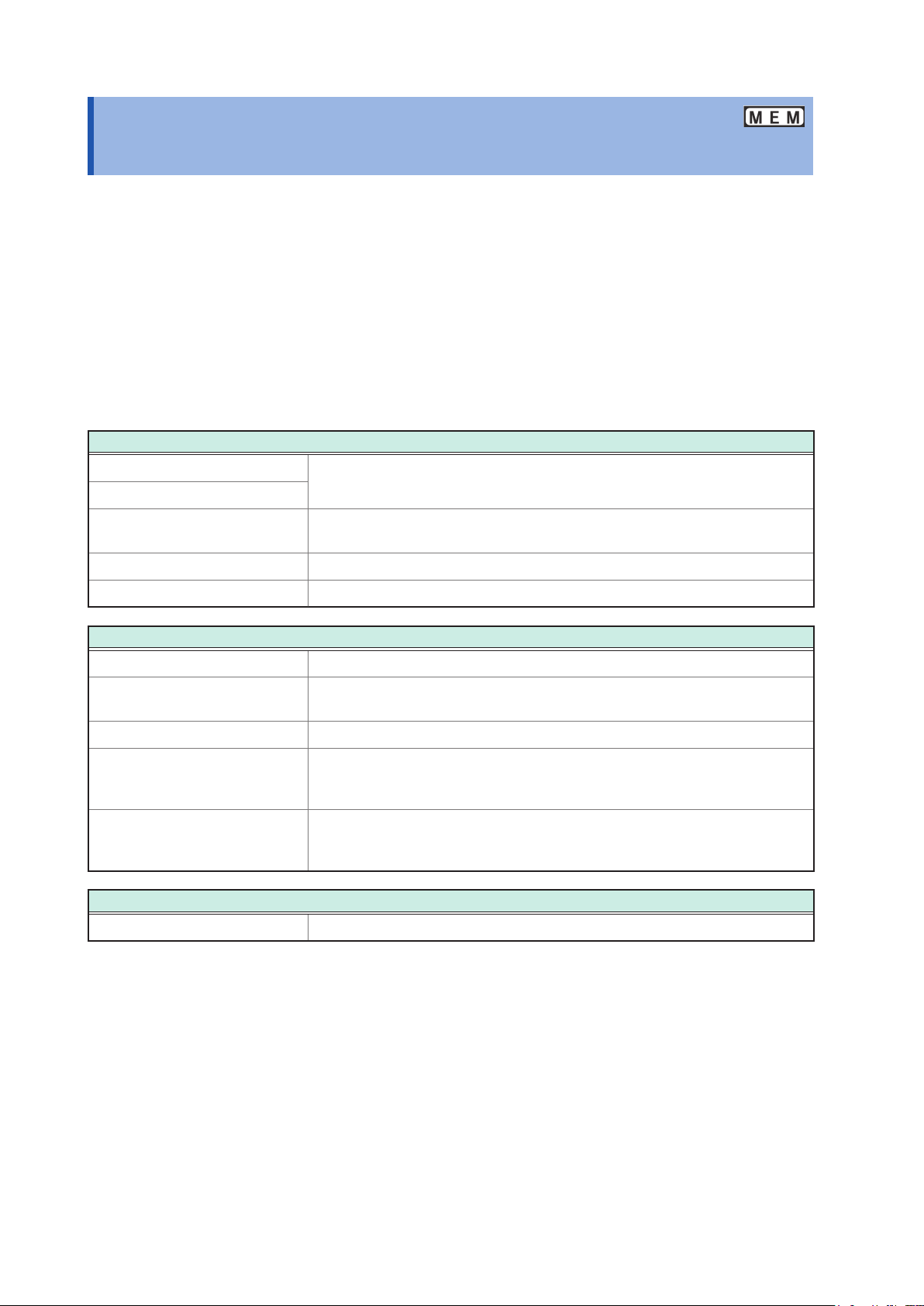

Instruction Manual Description

1 Measurement Guide

(booklet)

2

(This

document)

3 Communication

4 U8793, MR8790,

Instruction Manual

(booklet)

Command

Instruction Manual

(PDF)

MR8791 Instruction

Manual

(PDF)

Read this booklet rst.

Contains basic operating procedures for those who use this instrument

for the rst time.

Contains details and specifications regarding the functions and

operations of this instrument.

Contains a list of the communication commands and their explanations

to control the instrument with a computer.

Contains specications and explanations of functions/operations of

Models U8793 Arbitrary Waveform Generator Unit, MR8790 Waveform

Generator Unit, MR8791 Pulse Generator Unit, and SF8000 Waveform

Maker.

Trademarks

• Microsoft Windows, Excel and Internet Explorer are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• CompactFlash is a registered trademark of SanDisk Corporation (USA).

• Sun, Sun Microsystems, Java, and any logos containing Sun or Java are trademarks or registered

trademarks of Oracle Corporation in the United States and other countries.

2

Page 11

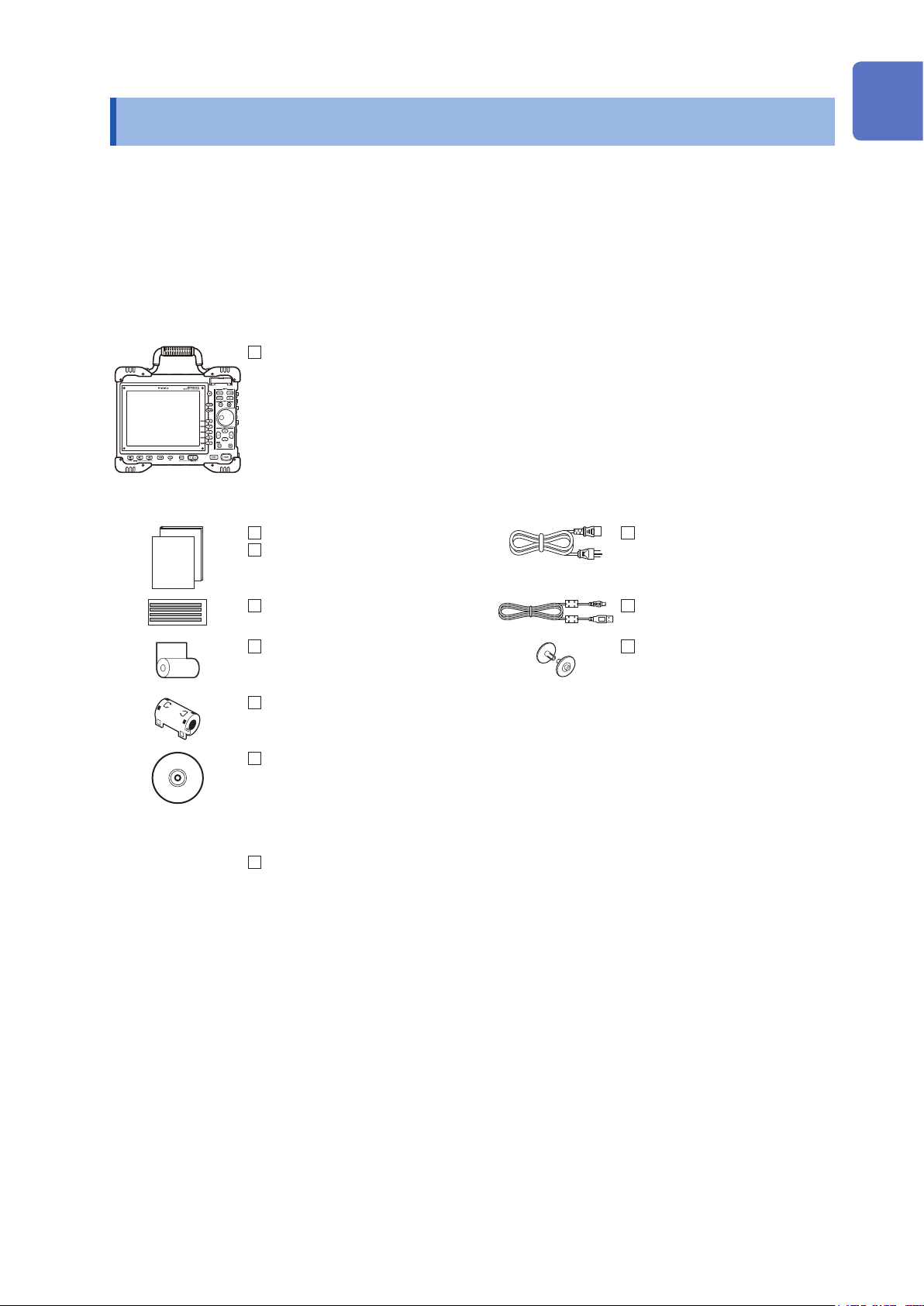

Verifying Package Contents

Verifying Package Contents

When you receive your instrument, inspect it carefully to ensure that no damage occurred during shipping.

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to

operate according to the specications, contact your authorized Hioki distributor or reseller.

Store the packaging in which the instrument was delivered, as you will need it when transporting the

instrument.

1

Instrument and accessories

Conrm that you received the following items: (One each)

MR8847A Memory HiCorder

(MR8847-51, MR8847-52, MR8847-53)

Accessories

Measurement Guide

Instruction Manual (this document)

Input cable label USB cable

Model 9231 Recording Paper Paper Roll Axle ×2

Ferrite clamp-on choke

(for LAN/USB cable)

*1

2

3

4

Power cord

5

6

Application disc*2 (CD) (p. 351)

• Model SF8000 Waveform Maker

• Wave Viewer (WV)

• Communication Command Instruction Manual

• U8793, MR8790, MR8791 Instruction Manual

Other options as specied in your order “Appx. 3.1 Options” (p. Appx.13)

*1: When one or more pieces of Model 8967 Temp Unit are installed in the instrument, two ferrite clamp-

on chokes (small) are supplied per module.

*2: The latest version can be downloaded from our website.

7

8

9

10

Appx. Ind.

3

Page 12

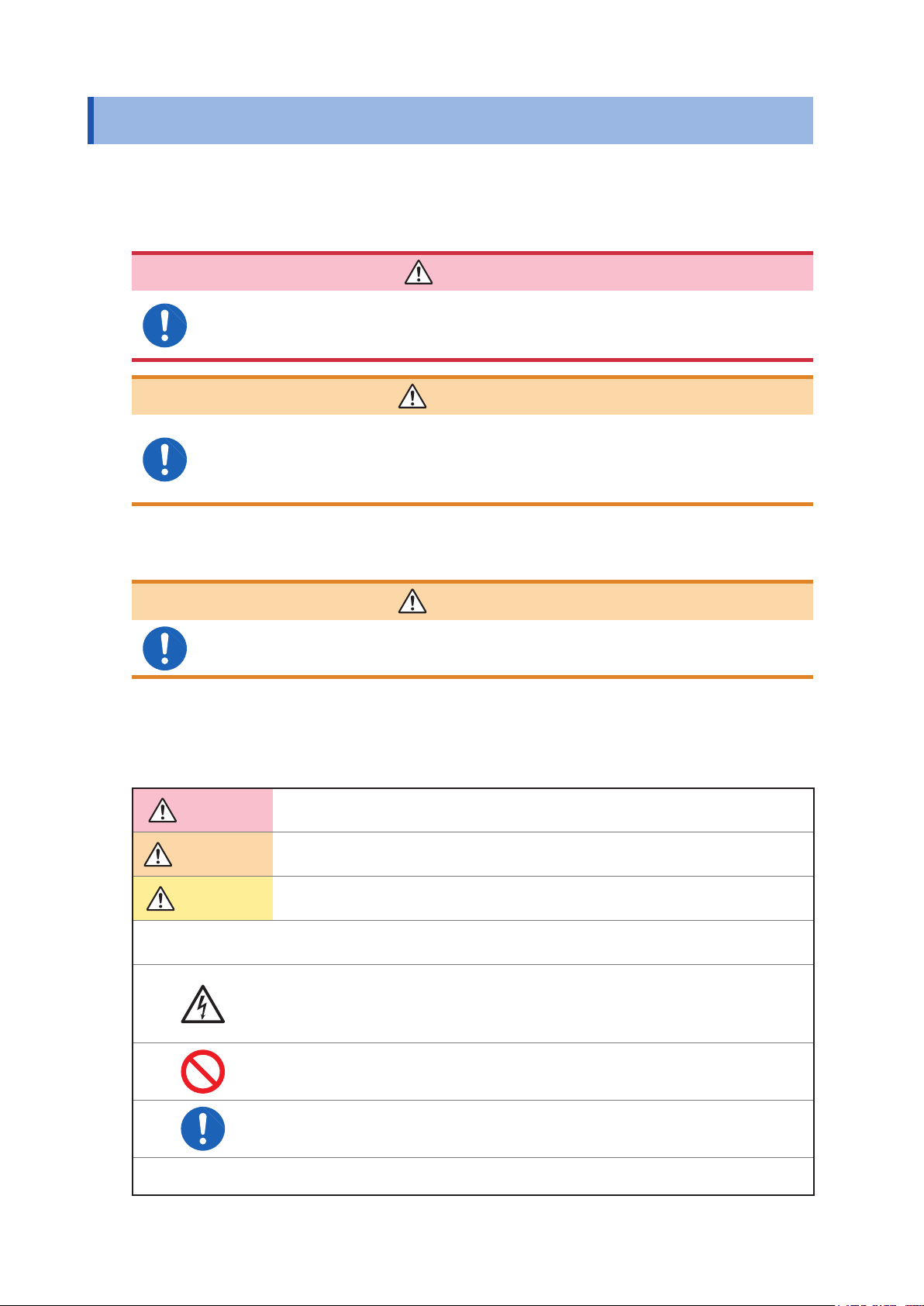

Safety Information

Safety Information

This instrument and modules are designed to conform to IEC 61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment. However, using the instrument in a way not described in

this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes:

DANGER

Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in

the manual before use.

WARNING

With regard to the electricity supply, there are risks of electric shock, heat

generation, re, and arc discharge due to short circuits. Individuals using an

electrical measuring instrument for the rst time should be supervised by a

technician who has experience in electrical measurement.

Protective Gear

WARNING

This instrument measures live lines. To prevent electric shock, use appropriate

protective insulation and adhere to applicable laws and regulations.

Notation

In this document, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will result in death or serious injury

to the operator.

Indicates a potentially hazardous situation that may result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in minor or moderate injury

to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance tasks

with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled, this may

give rise to a hazardous situation; the operator may receive an electric shock, may

get burnt or may even be fatally injured.

Indicates prohibited actions.

Indicates the action which must be performed.

*

Additional information is presented below.

4

Page 13

Symbols Afxed to the Instrument

Indicates cautions and hazards. When the symbol is printed on the instrument, refer to the

corresponding topic in the Instruction Manual.

Safety Information

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Indicates a fuse.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates a burn hazard if touched directly.

Standards Symbols

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in EU

member states.

Indicates that the product conforms to regulations set out by the EU Directive.

1

2

3

4

5

6

Other Symbols

This manual uses the following symbols to indicate specic information for operating the instrument.

(p. ) Indicates the location of reference information.

CURSOR

(Bold-faced)

[ ]

Names of settings, buttons, and other screen elements are written in bold blue text.

Unless otherwise specied, “Windows” represents Windows Vista, Windows 7, and Windows 8.

IE is an acronym for Internet Explorer.

Menus, commands, dialogs, buttons in a dialog, and other names on the screen and keys

are indicated in brackets.

Indicates that the memory function supports the function.

Indicates that the recorder function supports the function.

Indicates that the X-Y recorder function supports the function.

Indicates that the FFT recorder function supports the function.

Click: Press and quickly release the left button of the mouse.

Right-click: Press and quickly release the right button of the mouse.

Double-click: Quickly click the left button of the mouse twice.

7

8

9

10

Appx. Ind.

5

Page 14

Safety Information

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading), and setting values

with the following meanings:

f.s. (maximum display value

or scale length)

rdg. (reading or displayed

value)

Setting Indicates the value set as the output voltage, current, or other quantity.

The maximum displayable value or scale length.

For this instrument, the maximum displayable value equals the numerical

number of a presently set range (unit: V/div) multiplied by the number of divisions (20) on the vertical axis.

Example: When the range is set to 1 V/div, f.s. = 20 V

The value currently being measured and indicated on the measuring

instrument.

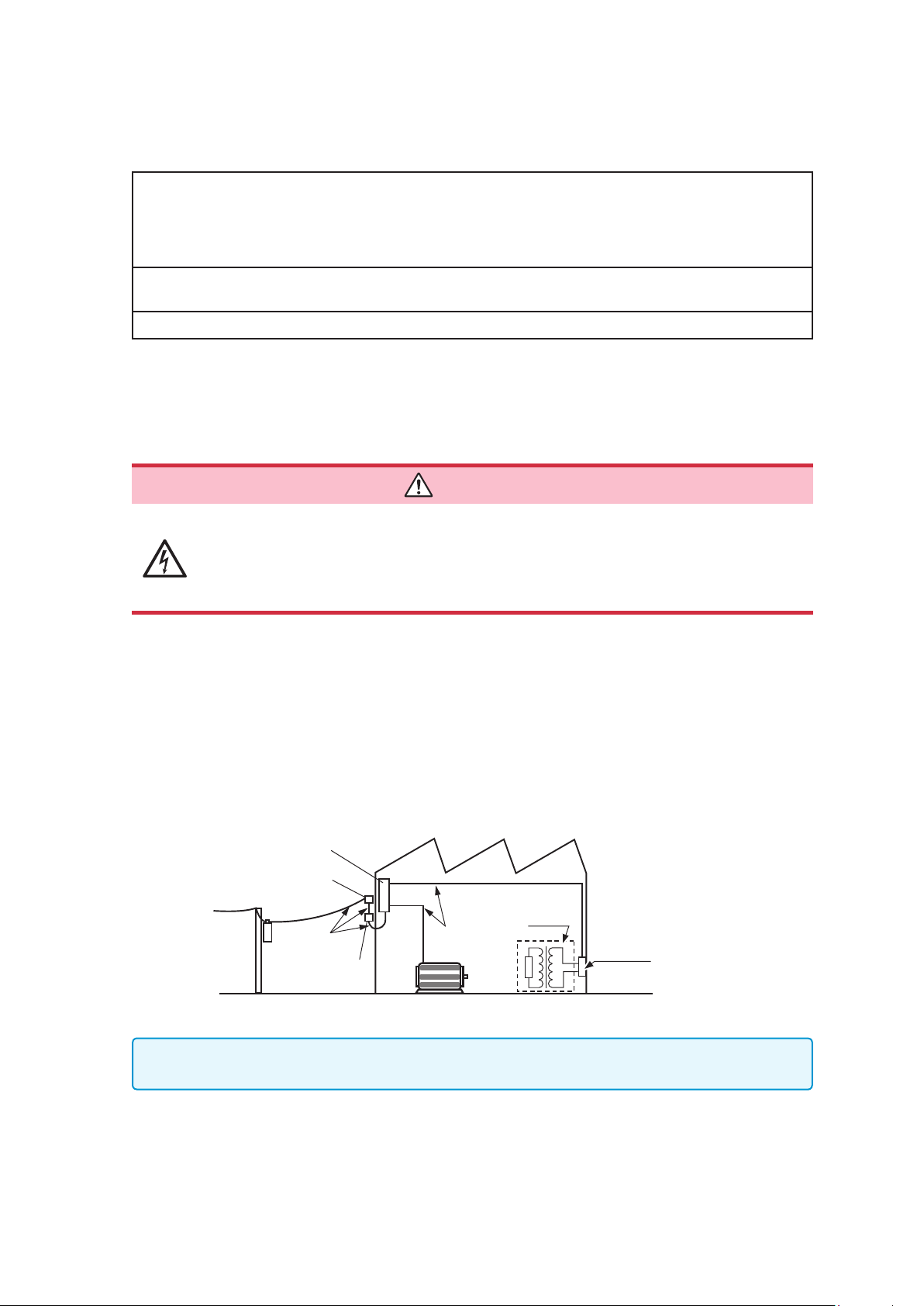

Measurement Categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement

categories.

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

• Never use a measuring instrument that lacks category labeling in a CAT II to

CAT IV measurement environment. Doing so could result in a serious accident.

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical

circuits in equipment connected to an AC electrical outlet with a power cord (portable

tools, household appliances, etc.)

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to

outlets

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel)

Distribution Panel

Service Entrance

Service Drop

CAT IV

Power Meter

Fixed Installation

Internal Wiring

CAT III

CAT II

T

Outlet

The applicable measurement category is determined based on the module being used.

Refer to “18.6 Specications of Modules” (p. 387).

6

Page 15

Operation Precautions

Before Use

Operation Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

DANGER

If the connection cables or the instrument are damaged, there is a risk of an

electric shock. Perform the following inspection before using the instrument:

• Before using the instrument, check that the coatings of the connection cables

are neither ripped nor torn and that no metal parts are exposed. Using the

instrument under such conditions could result in an electric shock. Replace the

connection cables with those specied by our company.

• Verify that it operates normally to ensure that no damage occurred during

storage or shipping. If you nd any damage, contact your authorized Hioki

distributor or reseller.

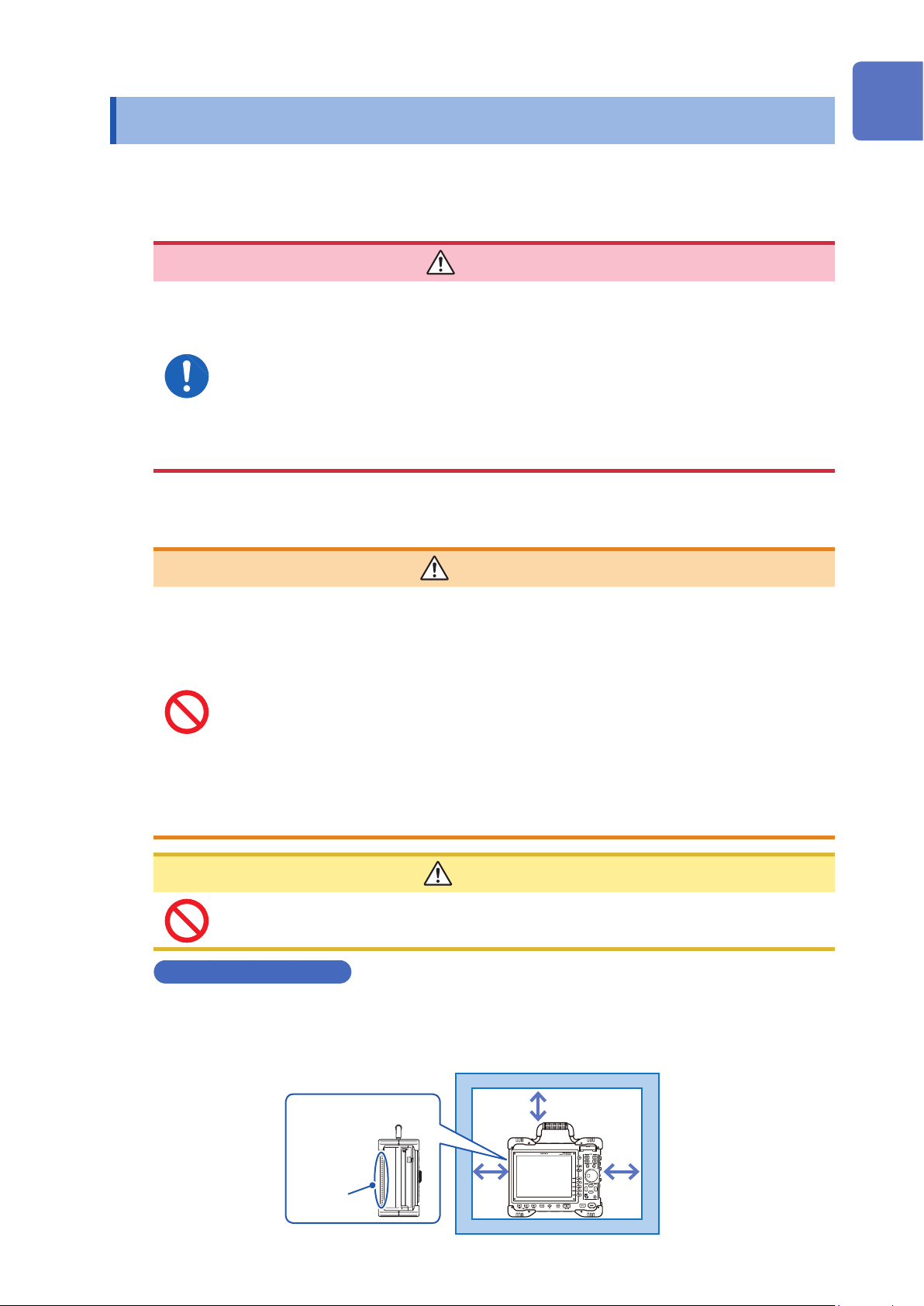

Installing the instrument and modules

WARNING

Installing the instrument and modules in inappropriate locations may cause a

malfunction of the instrument or may give rise to an accident. Avoid the following

locations:

• Exposed to direct sunlight or high temperatures

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

1

2

3

4

5

6

7

8

CAUTION

Do not place the instrument on an unstable table or an inclined place. Dropping

or knocking down the instrument can cause injury or damage to the instrument.

Installing the instrument

To prevent overheating, be sure to leave the specied clearances around the instrument.

• The instrument should be operated only with the bottom or rear side downwards.

• Vents must not be obstructed.

• Do not install the instrument at an angle.

Left side

Vents

At least 5 cm

on all sides

9

10

Appx. Ind.

7

Page 16

Operation Precautions

Handling the Instrument and Modules

• Do not use the modules or the cables with circuits that exceed those ratings or

specications.

Doing so may damage the instrument or cause it to become hot, resulting in

bodily injury.

Even including any devices, such as an attenuator, in the input terminal will

never increase the maximum rated voltage to earth. Take care of the connection

not to allow any input voltage to exceed the maximum rated voltage to earth.

• To avoid an electric shock, do not remove the instrument’s cover and the

modules’ cases.

The internal components of the instrument carry high voltages and may

become very hot during operation.

• To avoid an electric shock, before removing or replacing an input module,

conrm that the instrument is turned off and that the connection cords are

disconnected.

• To avoid the danger of an electric shock, never operate the instrument with an

input module removed. To use the instrument with a module removed, install a

blank panel over the opening of the removed module.

• To prevent the instrument damage or an electric shock, use only the screws

that are originally installed for securing the module in place.

If you have lost any screws or nd that any screws are damaged, please contact

your Hioki distributor for a replacement.

DANGER

WARNING

CAUTION

• To avoid damage to the instrument, protect it from physical shock when

transporting and handling it. Be especially careful to avoid physical shock due

to dropping it.

• The mounting screws must be rmly tightened or the module may not perform

to specications, or may even fail.

• To avoid damaging modules, do not touch the connectors, installed in the

instrument, to which the modules are connected.

• Before carrying the instrument, disconnect all cables and remove the CF card, USB

ash drive, and the recording paper.

• Displayed waveforms can frequently uctuate due to induction potential even when no

voltage is applied. This, however, is not a malfunction.

• This instrument may cause interference if used in residential areas. Such use must be

avoided unless the user takes special measures to reduce electromagnetic emissions to

prevent interference to the reception of radio and television broadcasts.

Handling the printer and the recording paper

WARNING

The print head and surrounding metal parts can become hot. Be careful to avoid

touching these parts.

8

Page 17

Operation Precautions

CAUTION

Be careful not to cut yourself with the paper cutter.

• Please use only the specied recording paper. Using non-specied paper may not only

result in faulty printing, but printing may become impossible.

• If the recording paper is skewed on the roller, paper jams may result.

• Always use the paper cutter to cut the printed paper. Excessive paper dust can

accumulate on the roller if the paper is cut with the print head, which may result in paper

jams or white streaks in the printing.

1

2

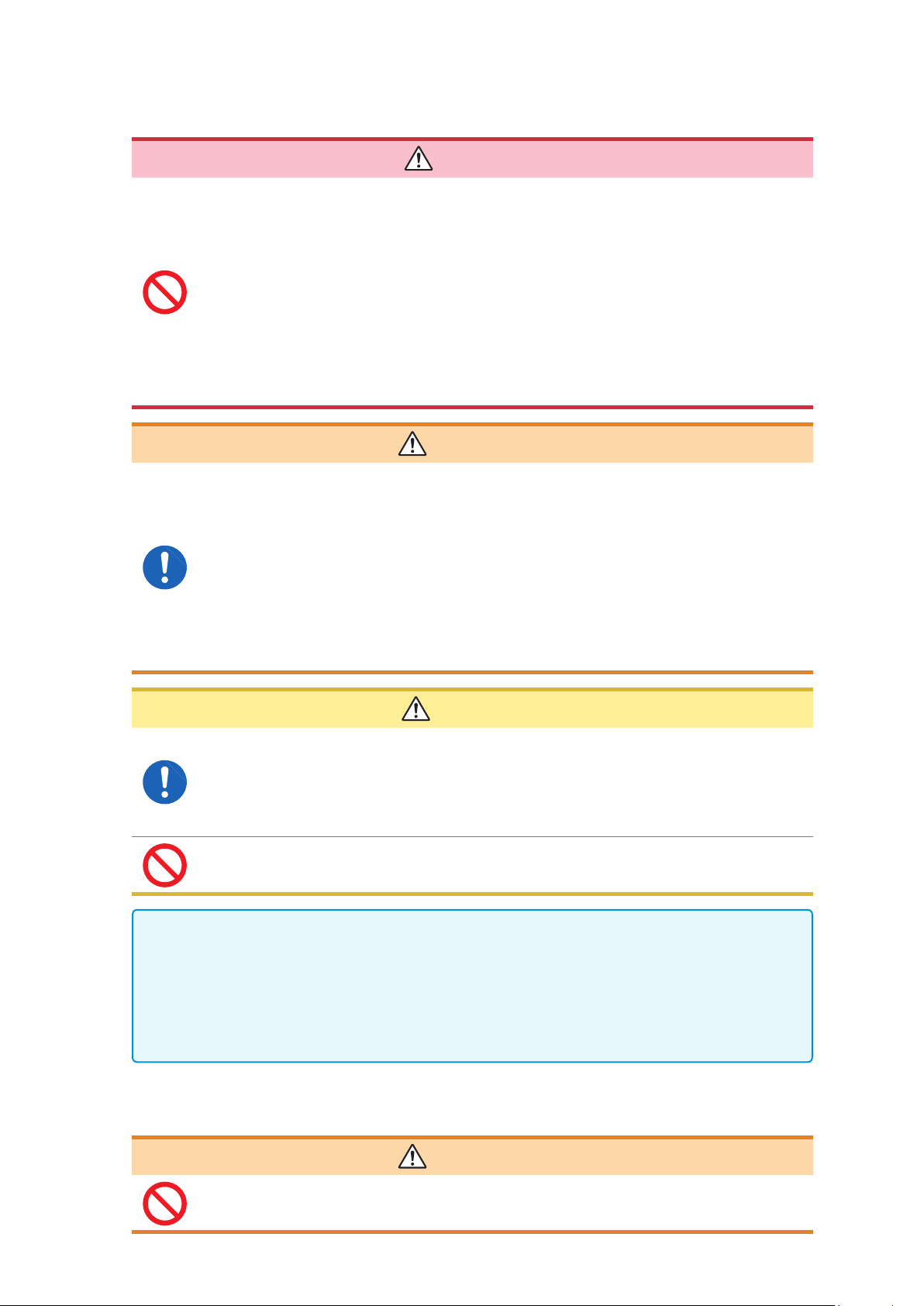

Storing data recordings

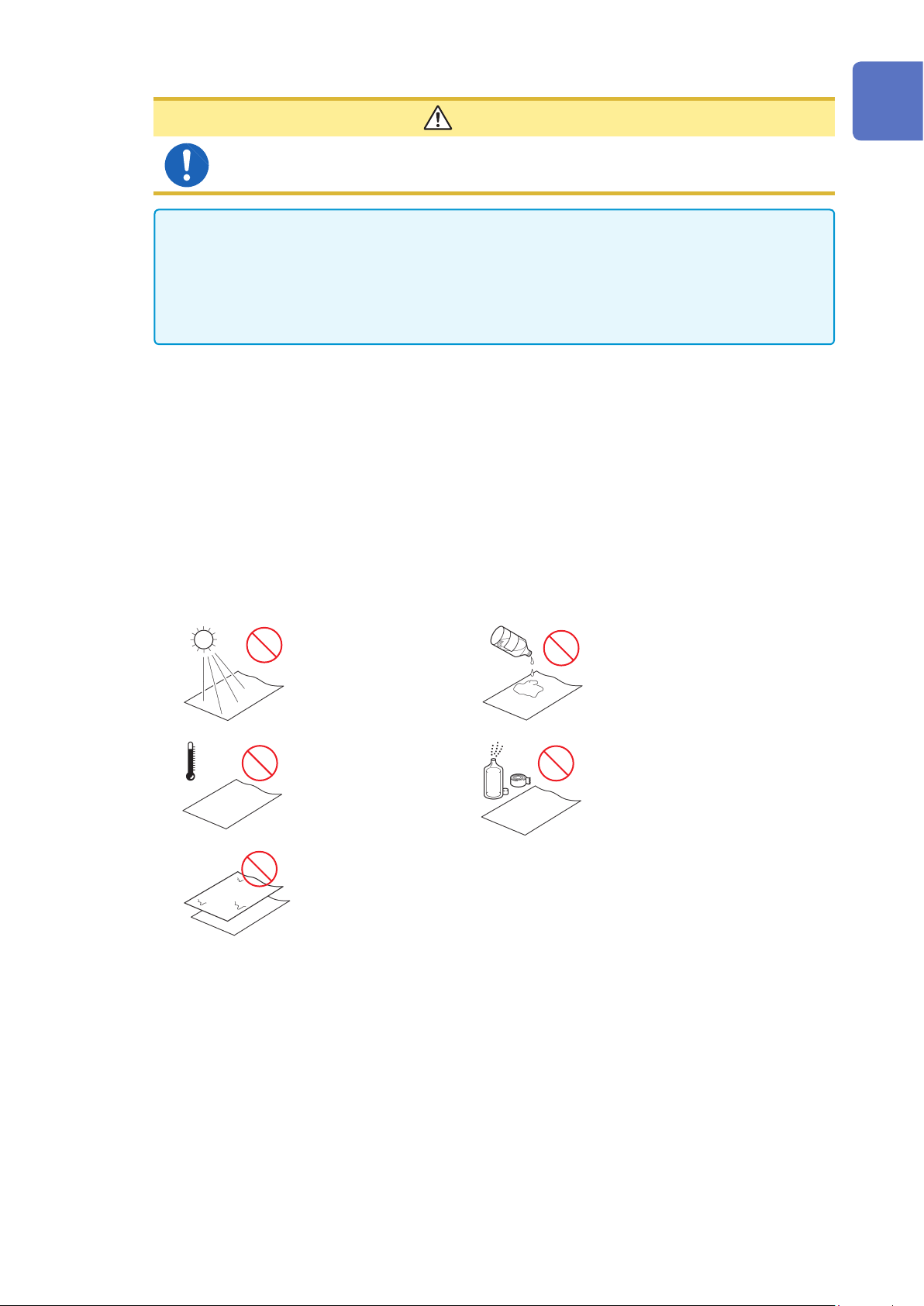

The recording paper is thermally sensitive. Observe the following precautions to avoid paper discoloration

and fading.

• To avoid paper discoloration, do not expose it to direct sunlight. Store the paper at no more than 40°C

and 90% RH.

• Store the paper away from dew and damp places.

• Make photocopies of recording printouts that are to be handled or stored for legal purposes.

• If the thermal paper is exposed to an organic solvent such as alcohol or ketone, it may no longer

develop properly, and recorded data may fade. Keep the printer papers away from exible PVC lms

and pressure sensitive tapes including scotch tapes because they contain organic solvents.

• Also, the thermal recording paper is ruined by contact with wet diazo copy paper.

Avoid exposure to direct

sunlight.

Do not store the paper at

more than

40°C (104°F) and 90%

RH.

Avoid exposure to volatile

organic solvents like

alcohol, ethers, and

ketones.

Avoid contact with exible

PVC lms or adhesive

tapes such as scotch

tapes.

3

4

5

6

7

Avoid stacking with wet

Diazo copy paper.

Storing recording paper

• Store thermal paper where its temperature will not exceed 40°C.

• The paper will deteriorate if exposed to light for a long time; thus, do not remove the wrapping paper

from the roll until it is ready to be used.

8

9

10

Appx. Ind.

9

Page 18

Operation Precautions

Handling storage devices

CAUTION

• Do not remove the storage device while it is being accessed by the instrument (

SAVE

key is lit in blue). Data saved on the device could be lost.

• Do not turn off the instrument while it is accessing the storage device (

key is lit up in blue). Data saved on the device could be lost.

• Do not carry the instrument with a USB ash drive left connected. Damage could result.

• Exercise care when using such products because static electricity could damage the

storage device or cause a malfunction of the instrument.

•

Do not subject the SSD to extreme shock or vibration. Shock can cause it to be

damaged.

IMPORTANT

• No compensation is available for loss of data stored on the built-in drive (SSD) or a removable

storage device, regardless of the content or cause of damage or loss. Be sure to back up any

important data saved on the built-in drive (SSD) or the removable storage device.

• Use only CF cards sold by Hioki. (No adapter is required to insert a CF card into the

instrument.)

• Compatibility and performance are not guaranteed for PC cards made by other manufacturers.

You may be unable to read from or save data to such cards.

■Hioki optional CF cards (with an adapter accompanying)

Model 9728 PC Card 512M, Model 9729 PC Card 1G, Model 9830 PC Card 2G

• With some external storage device, the instrument may not start up if it is turned on while the

external storage device is inserted. In such a case, turn on the instrument rst, and then insert

the external media. Prior testing is recommended.

• The instrument does not support particular kind of USB ash drives, such as those that require

ngerprint authentication or a password.

• When saving or loading data, insert the storage device before selecting data to be saved.

When the storage device is not inserted, no devices are not displayed in the le list.

• All storage devices (built-in drive [SSD], USB ash drive, and CF card) have a limited service

life. After extensive use for a long period, saving and loading data may be disabled. In that

case, replace the device with a new one.

• The built-in drive (SSD) is a consumable part. When the saved data reaches the capacity (about

60 TB), no further data can be recorded. In such a case, the SSD should be replaced with a

new one.

• When the instrument is left powered off for a one year or more, the data saved on the built-in

drive (SSD) may be lost. Be sure to back up the data if the instrument is left powered off for a

long time.

• Devices the automatic data saving supports are the built-in drive (SSD), a USB ash drive, and

a CF card.

• Data can also be automatically saved on a USB ash drive; however, we recommend using

Hioki optional CF card instead for data protection.

while the

while the

SAVE

10

Page 19

Before connecting cables

Operation Precautions

DANGER

When measuring power line voltage

• Connect the connecting cables to only the secondary side of a breaker. Even

if a short-circuit occurs on the secondary side of the breaker, the breaker will

interrupt a short-circuit current. Do not connect them to the primary side of the

breaker because an unrestricted current ow could damage the instrument and

facilities if a short circuit occurs.

• To prevent an electrical shock and a bodily injury, do not touch any input

terminals on the VT (PT), CT or the instrument when they are in operation.

• Do not leave the measurement cables connected to the instrument in an

environment where voltage surges exceeding the maximum input voltage may

occur. Subjecting the instrument to such a voltage may result in damage to the

instrument or a serious accident.

• Do not short-circuit two wires to be measured by bringing the connection

cables into contact with them. Arcs or such grave accidents are likely to occur.

• To avoid a short-circuit or an electric shock, do not touch the metal parts of the

connecting cable clips.

• To avoid electrical shock, be careful to avoid shorting live lines with the

connection cable chips.

WARNING

To avoid an electric shock and a short-circuit accident, use only the specied test

leads to connect the instrument input terminals to the circuit to be tested.

• To avoid an electric shock, do not exceed the lower of the ratings shown on the

instrument and connection cords.

1

2

3

4

5

6

To prevent an electric shock, conrm that the white or red portion (insulation

layer) inside the cable is not exposed. If a color inside the cable is exposed, do

not use the cable.

CAUTION

• The cable is hardened in the freezing temperatures. Do not bend or pull it to avoid

tearing its shield or cutting cable.

• Connecting cables to the BNC jacks on modules

Do not use any cable terminated with a metal BNC connector. If you connect a metal

BNC cable to an insulated BNC connector, the insulated BNC connector and the

instrument may be damaged.

To prevent cable damage, do not step on cables or pinch them between other objects.

Do not bend or pull on cables at their base.

IMPORTANT

• Use only the specied connection cables. Use of any cable not specied by our company does

not allow safe measurements due to poor connection or other reasons.

• For detailed precautions and instructions regarding connections, refer to the instruction

manuals for your modules, connection cables, etc.

7

8

9

10

Appx. Ind.

11

Page 20

Operation Precautions

Measurement

Functional Earth

Before connecting a logic probe to the measurement object

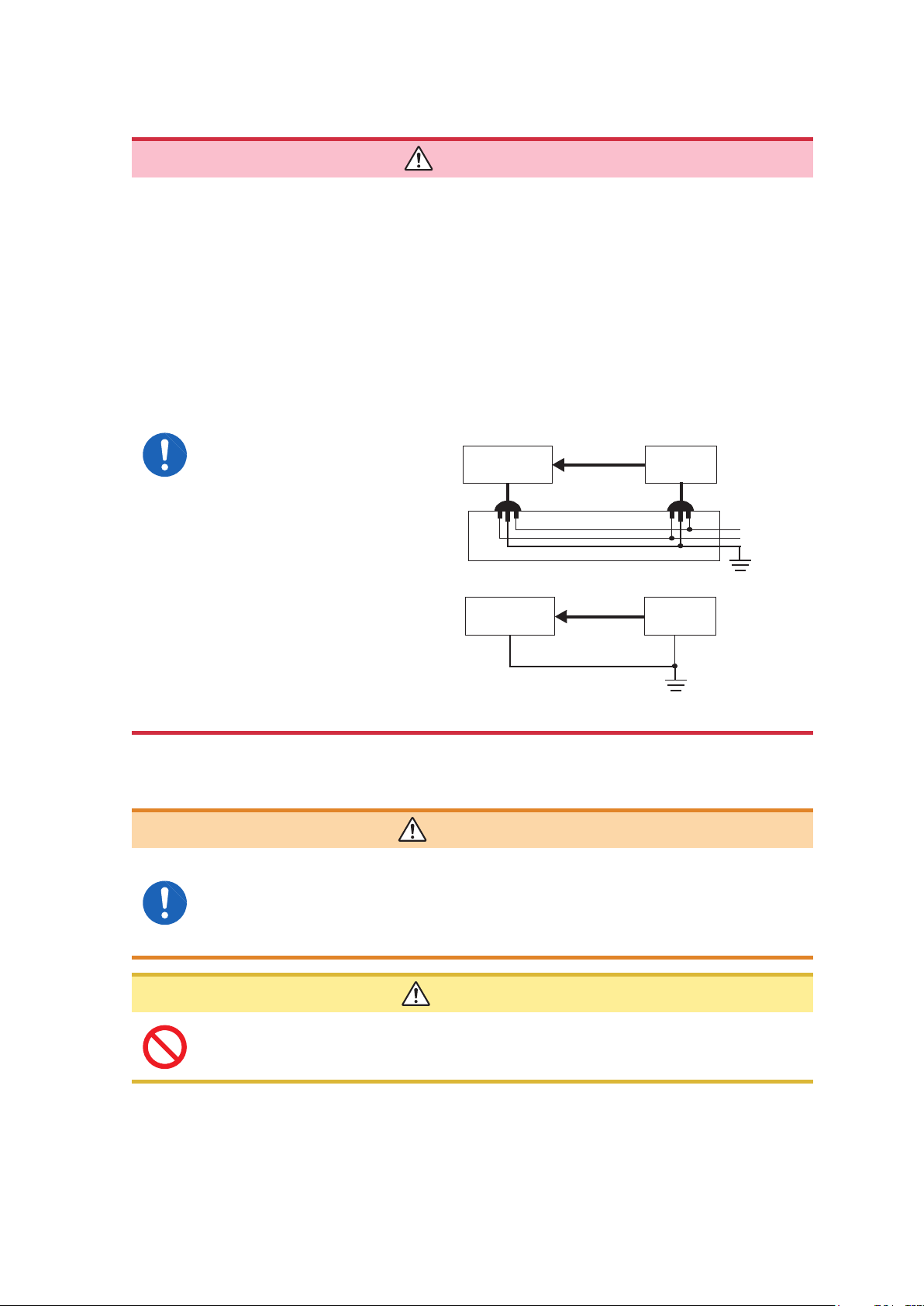

DANGER

To avoid an electric shock, a short-circuit, and damage to the instrument, observe

the following precautions:

• The ground pin in the logic connector (plug) of Model 9320-01 Logic Probe and

Model 9327 Logic Probe are not isolated from the instrument’s ground (common

ground).

Supply power to the instrument with the provided power cord and measurement

objects from a single mains circuit.

Connecting the instrument and a measurement object to different mains circuits

from one another or using a non-grounding power cord may cause damage to

the measurement object or the instrument because of current owing through

the logic probes resulting from the potential difference between the grounds of

the different wiring systems.

To avoid that, we recommend the following connection procedure:

Connect the provided power cord

to the instrument and supply

power from the same outlet as the

measurement object.

Object

Logic probe

Memory

HiCorder

Connect the measurement object’s

ground to the GND terminal

(functional earth terminal) of the

instrument.

(Always supply power from the

single mains circuit.)

Refer to

Wire to the GND Terminal (Functional

Earth Terminal)” (p. 45).

“2.5.2 Connecting an Earthing

Before turning on the instrument

• To avoid electrical accidents and to maintain the safety specications of this

instrument, connect the power cord provided only to an outlet.

• Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage

may damage the instrument and present an electrical hazard.

Avoid using an uninterruptible power supply (UPS), DC/AC inverter with rectangular-

wave or pseudo-sine-wave output to power the instrument. Doing so may damage the

instrument.

Measurement

Object

GND

WARNING

CAUTION

Logic probe

Memory

HiCorder

Terminals

12

Page 21

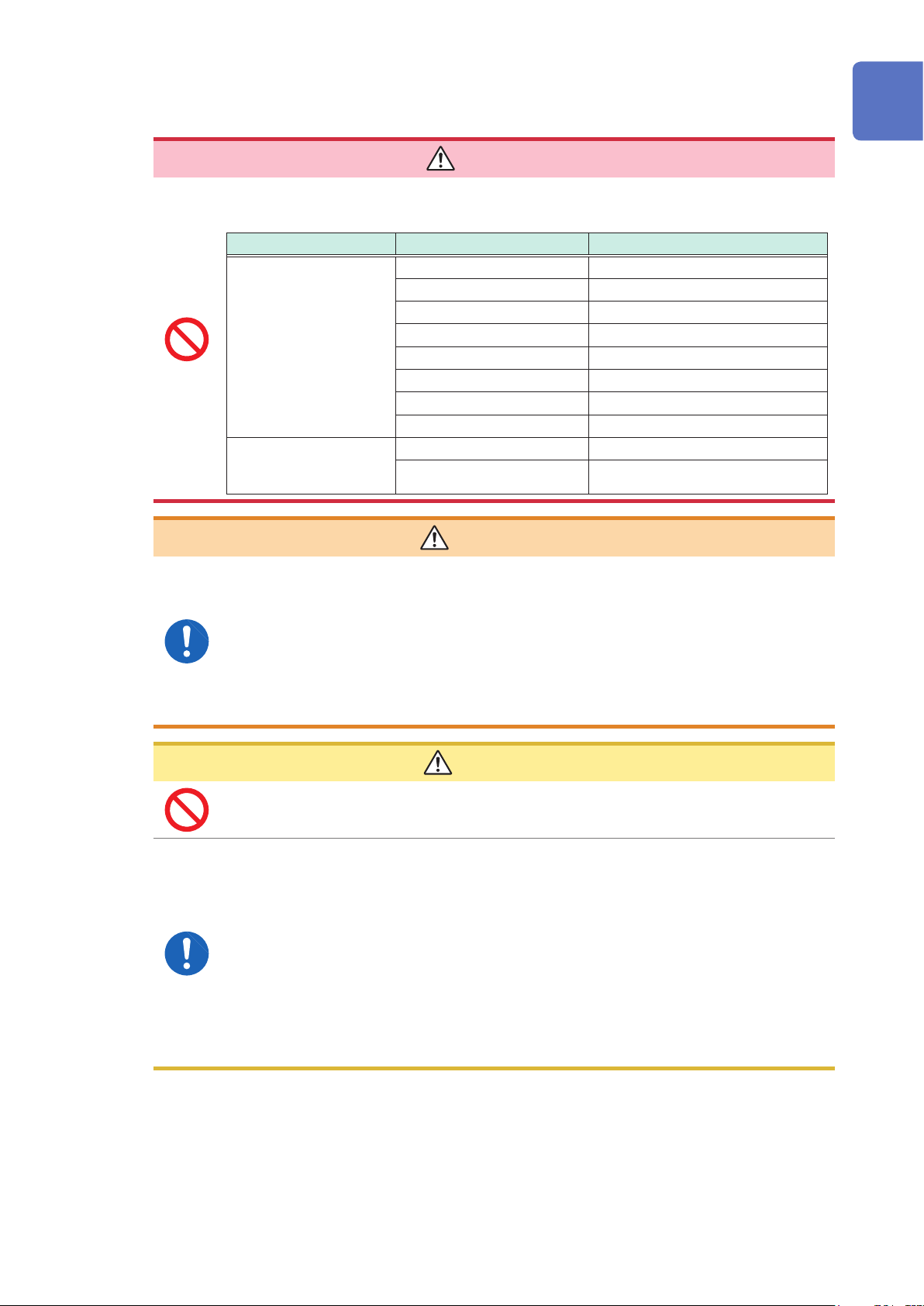

Before connecting the instrument to an external device

DANGER

Operation Precautions

To avoid electrical hazards and damage to the instrument, do not apply voltage

exceeding the rated maximum to the external control terminals.

I/O terminals Maximum input voltage

Instrument START/EXT.IN1 −0.5 V to 7 V DC

STOP/EXT.IN2 −0.5 V to 7 V DC

PRINT/EXT.IN3 −0.5 V to 7 V DC

GO/EXT.OUT1 50 V DC, 50 mA DC, 200 mW

NG/EXT.OUT2 50 V DC, 50 mA DC, 200 mW

EXT.SMPL −0.5 V to 7 V DC

TRIG OUT 50 V DC, 50 mA DC, 200 mW

EXT.TRIG −0.5 V to 7 V DC

U8793

Arbitrary Waveform

Generator Unit

IN −0.5 V to 7 V DC

OUT 30 V DC, 50 mA DC

WARNING

To avoid an electric shock or damage to the equipment, always observe the

following precautions when connecting the cables to external control terminals.

• Always turn off the instrument and any devices to be connected before making

connections.

• Be careful to avoid exceeding the ratings of the external control terminals and

the external connectors.

• Ensure that devices and systems to be connected to the external control

terminals are properly isolated from one another.

1

2

3

4

5

6

CAUTION

To avoid equipment failure, do not disconnect the USB cable while communications are

in progress.

• Use a common ground for both the instrument and the connection equipment. Using

different ground circuits will result in a potential difference between the instrument’s

ground and the connected equipment’s ground. If the communications cable is

connected while such a potential difference exists, it may result in equipment

malfunction or failure.

• Before connecting or disconnecting any communication cable, always turn off the

instrument and the device to be connected. Failure to do so may result in equipment

malfunction or damage.

• After connecting the communications cable, tighten the screws on the connector

securely. Failure to secure the connector could result in equipment malfunction or

damage.

7

8

9

10

Appx. Ind.

13

Page 22

Operation Precautions

CD precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on a

disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperatures, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

When the instrument is not used for a long period

• To avoid straining some parts of the printer, and to prevent dirt adhering to the print head, close

the printer cover.

• Perform test prints (printer check) three or four times before using the printer that has been in

storage and has left unused for a long period.

Precautions during shipment

Store the packaging in which the instrument was delivered, as you will need it when transporting

the instrument.

14

Page 23

1

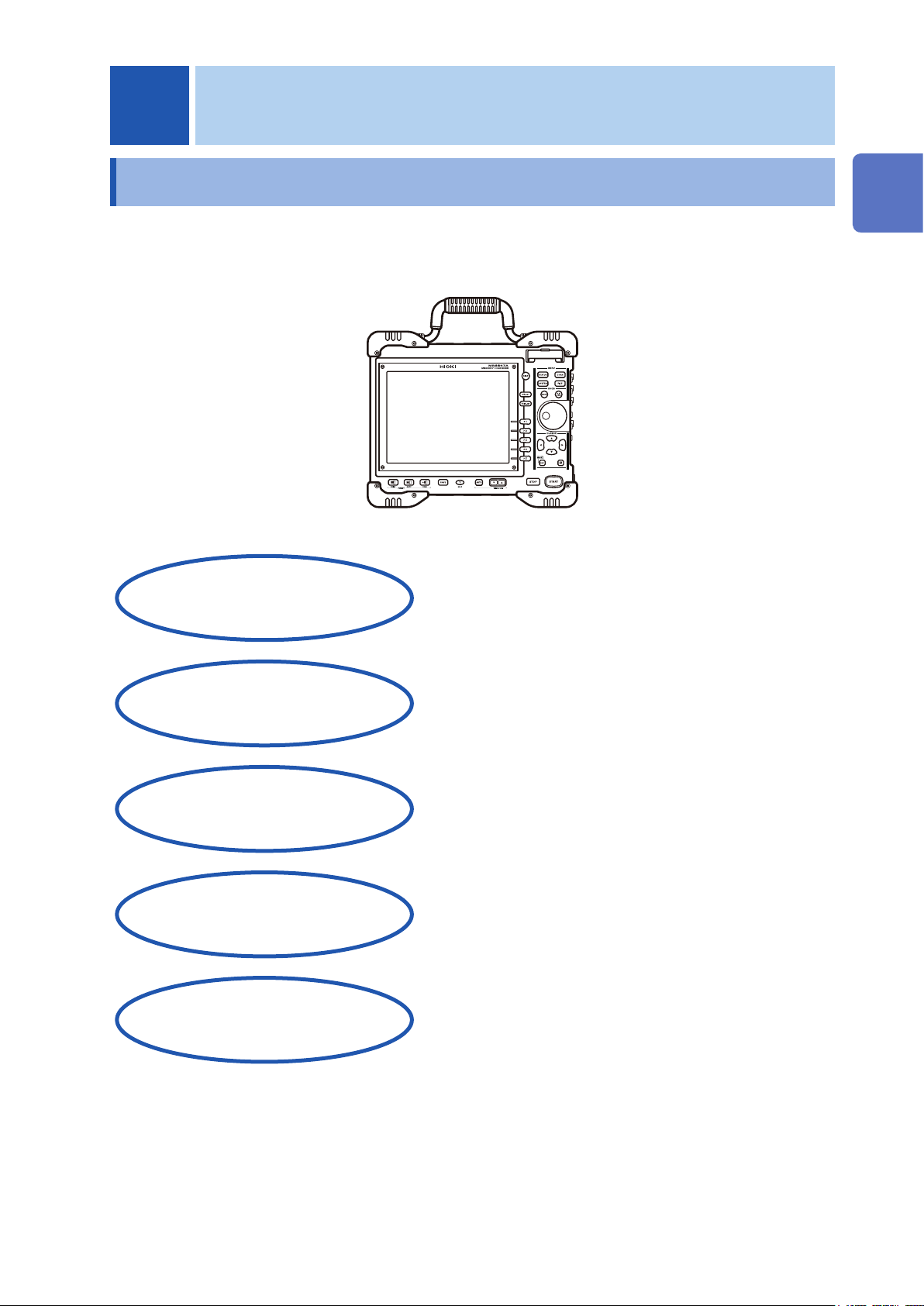

Overview

1.1 Product Overview

This instrument enables you to measure and analyze various waveforms with simple methods.

You can use this instrument mainly for facility diagnosis, preventive maintenance, and troubleshooting.

Sturdy body with easy-to-grasp

handle installed

You can install this portable instrument anywhere.

1

Overview

Logic modules can measure

signals input on 64 channels

Easy loading of recording paper

High-speed printing

High-speed sampling

at 20 MS/s

Arbitrary Waveform Generator Unit

can output waveforms simulating

measured signals

You can take multiple measurements simultaneously.

You can load the recording paper through one-touch

operation.

You can conduct reliable response evaluation.

You can have the instrument output realistically simulated

waveforms.

15

Page 24

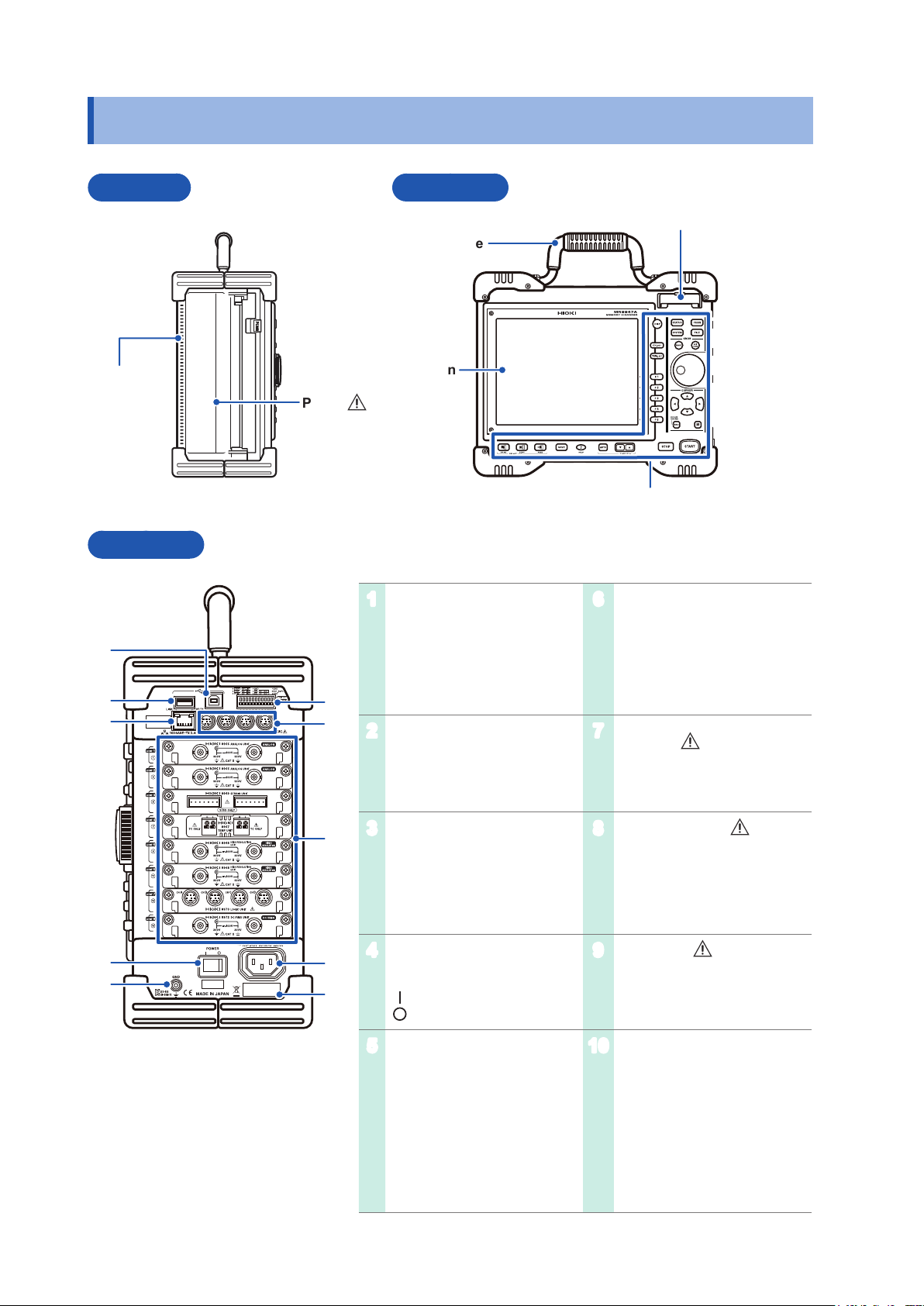

Part Names and Functions

1.2 Part Names and Functions

Left side

Vents

Right side

1

2

3

Printer

(p. 9)

6

7

Front side

Handle

Screen

USB connector (Type B)

1

Connect the USB cable to

operate the instrument with a

computer.

(p. 352)

USB connector (Type A)

2

Connect a USB ash drive or

a mouse. (p. 41)

CF card slot

Operation keys (p. 17)

External control terminals

6

Input an external sampling

signal.

(p. 361)

Connect signal cables to

operate the instrument

externally.

Standard LOGIC

7

terminals

Connect optional Hioki logic

probes.

(p. 28)

4

5

16

8

9

10

100BASE-TX connector

3

Connect a LAN cable.

(p. 331)

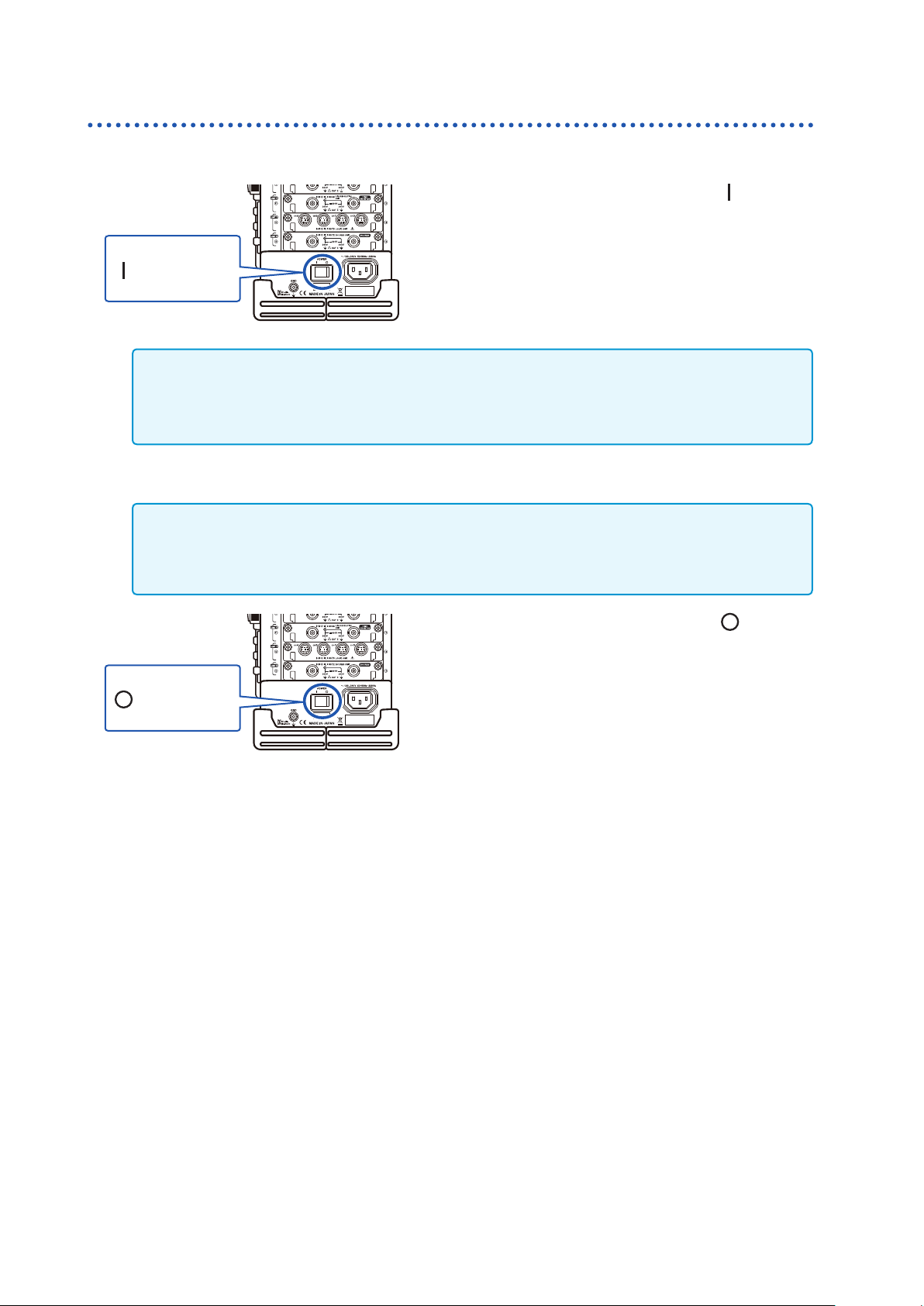

Power switch (p. 46)

4

Flip the switch to turn on and

off the instrument.

: Power-on

: Power-off

GND terminal (Functional

5

earth terminal)

Connect a grounded

conductor.

(p. 45)

Various modules

8

(p. 26), (p. 28)

For details, refer to “8.10

Setting Details of Modules” (p.

180) or “18.6 Specications

of Modules” (p. 387).

Power inlet

9

Connect the provided power

cord. (p. 45)

Serial number

10

The serial number consists

of 9 digits. The rst two (from

the left) indicate the year of

manufacture, and the next

two indicate the month of

manufacture.

Required for production

control. Do not peel off the

label.

Page 25

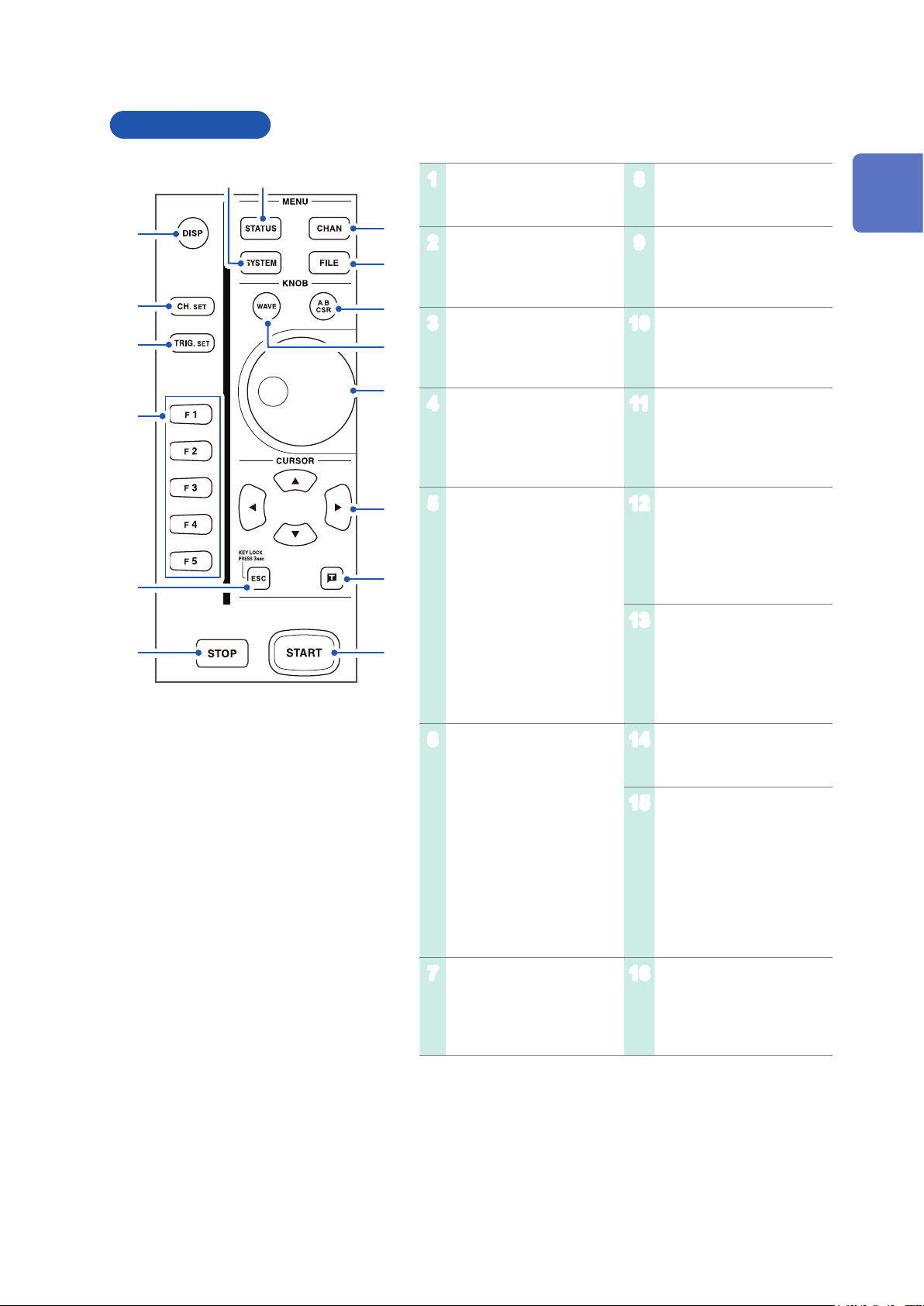

Operation keys

Part Names and Functions

87

1

9

10

2

3

11

12

13

4

14

5

6

15

16

DISP key

1

Displays the waveform

screen.

CH.SET key

2

Displays the channel

settings window on the

waveform screen (p. 64).

TRIG.SET key

3

Displays the trigger settings

window on the waveform

screen (p. 201).

F key

4

Selects setting items.

ESC key

5

Cancels the last action.

Closes the displayed dialog

and window.

KEY LOCK:

Press and hold the ESC

key for 3 seconds to

engage the key lock

function, which prevents

accidental operation.

Press and hold this key for

3 seconds to disengage

the key lock function.

STATUS key

8

Displays the status screen.

CHAN key

9

Displays the channel

screen.

FILE key

10

Displays the File screen.

(p. 108)

AB CSR key

11

(Lights up in red when

selected.)

Sets Cursors A and B. (p.

134)

WAVE key

12

(Lights up in red when

selected.)

Assigns waveform scrolling

to the jog dial and shuttle

ring. (p. 141)

Inner: Jog dial

13

Outer: Shuttle ring

Scrolls waveforms display.

(p. 141)

Increases and decreases a

setting value.

(p. 21)

1

Overview

STOP key

6

Stops the measurement in

progress.

Press the key once:

Stops the measurement

in progress after the

instrument records the

specied recording length

of waveforms.

Press the key twice:

Immediately stops the

measurement in progress.

(p. 328)

SYSTEM key

7

Displays the system

screen.

(p. 325)

CURSOR key

14

Moves the cursor up, down,

left, and right on the screen.

Manual trigger key

15

Manually trigger the

instrument.

(p. 216)

START key

16

Starts measurement.

(Lights up in green during

measurement.)

(p. 328)

17

Page 26

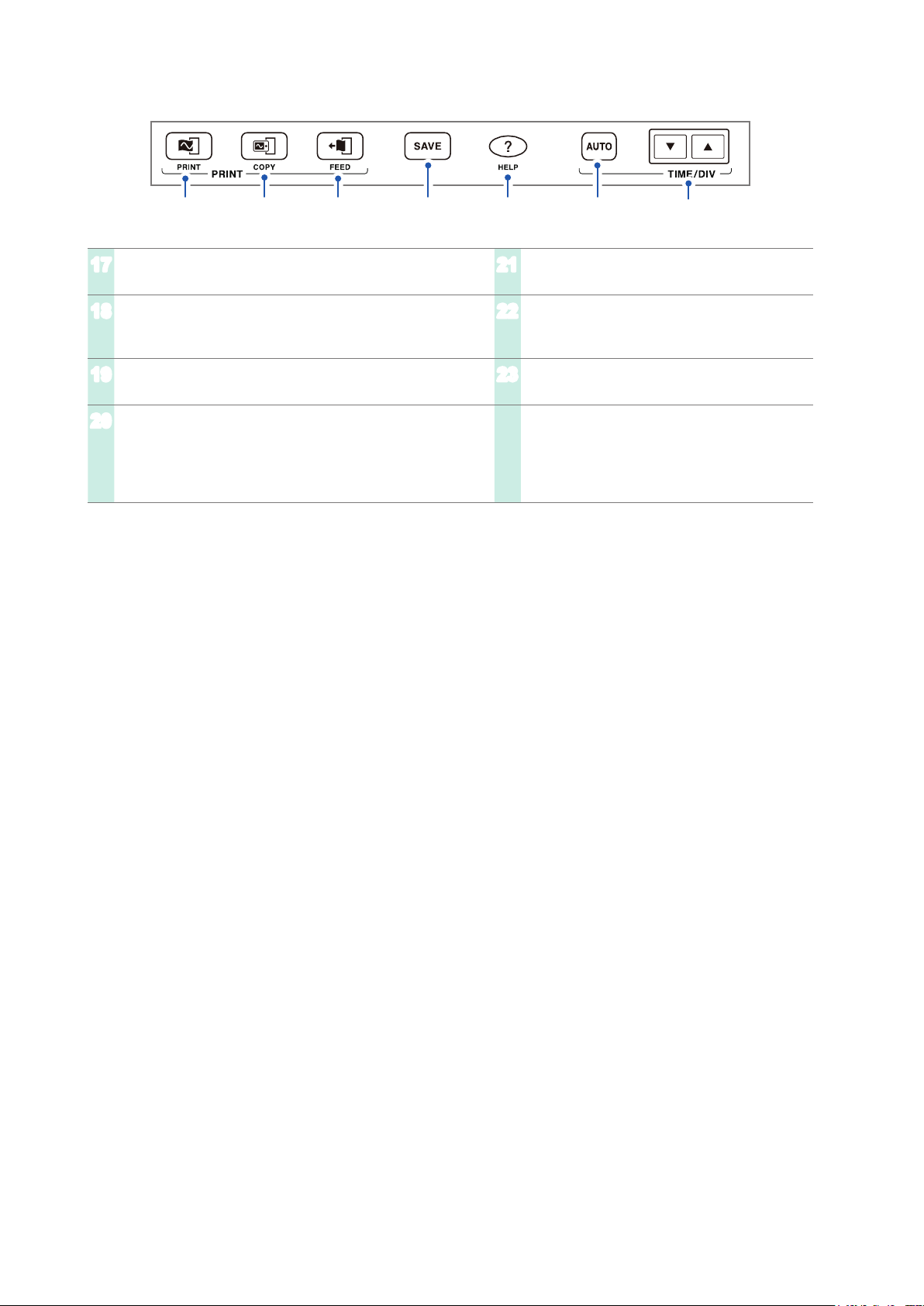

Part Names and Functions

17 18 19 20 21 22 23

PRINT key

17

Prints waveforms and lists. (p. 119)

COPY key

18

Prints a screenshot. (p. 130)

FEED key

19

Feeds paper.

SAVE key (Lights up in blue while the instrument is

20

accessing a storage device.)

Saves data to a storage device. (p. 85)

The dialog box can be switched between visible and

invisible during auto-saving.

HELP key

21

Displays help information. (p. 22)

AUTO key

22

Starts measurement in the auto-range setting.

(p. 76)

TIME/DIV key

23

Sets the timebase.

18

Page 27

Screens Conguration

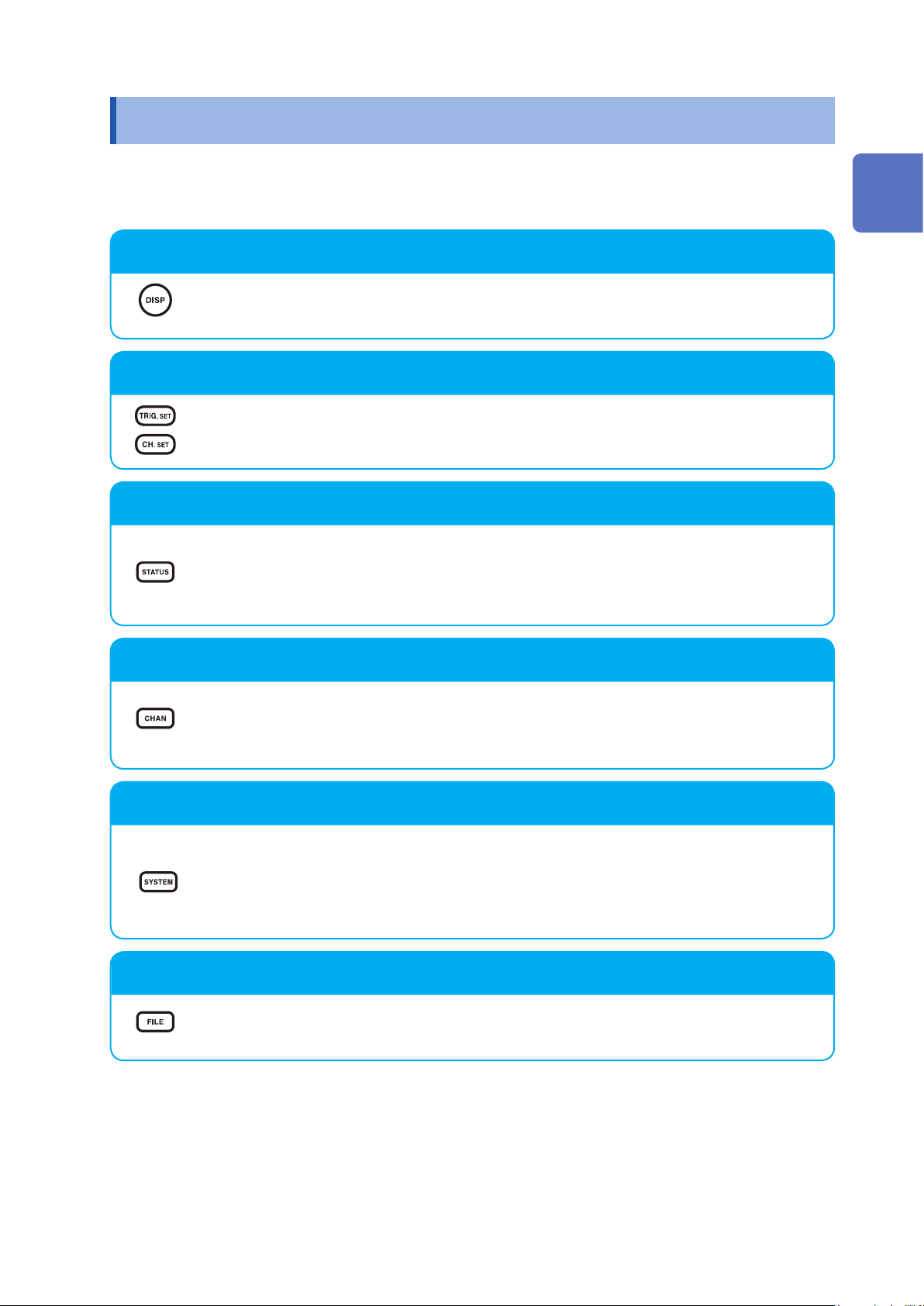

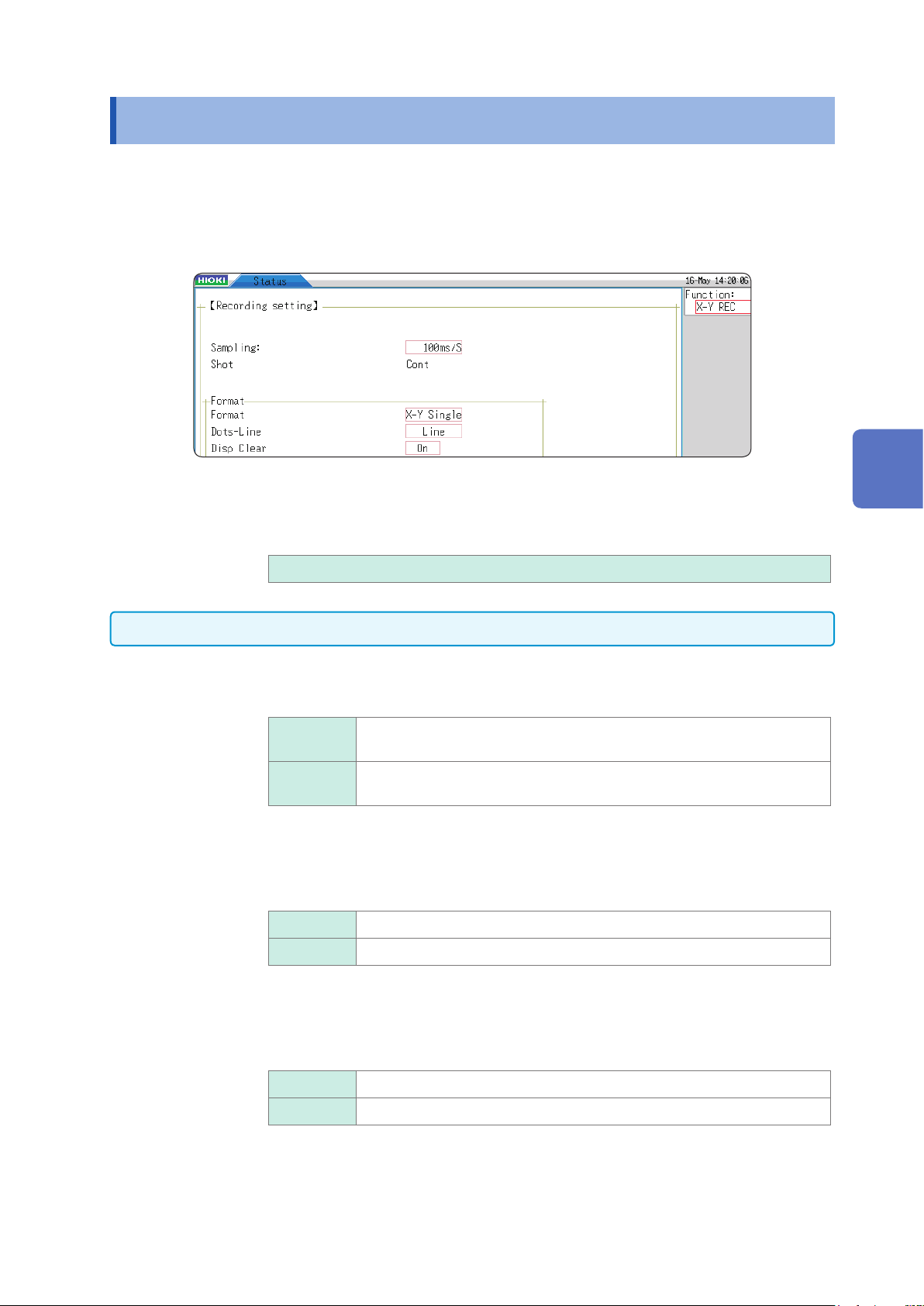

1.3 Screens Conguration

The screens are congured as listed below. Pressing each of the keys listed below displays a

corresponding screen or window.

The waveform screen can display the trigger settings window, and the channel settings window.

Waveform screen

The display used to observe waveforms.

Congure measurement conditions using the settings window on the right.

Trigger settings window, channel settings window

The display used to congure the trigger settings

The display used to congure the settings of analog channels and logic channels

1

Overview

Status screen

The window used to congure the measurement methods and numerical calculation

settings.

Pressing the STATUS key switches the sheets to be displayed in the following order:

[Status] sheet, [Num Calc] sheet, [Memory Div] sheet, and [Wave Calc] sheet.

Channel screen

The screen used to congure the channel, the scaling, and the comment settings

Pressing the CHAN key switches the sheets to be displayed in the following order:

[Unit List] sheet, [Each Ch] sheet, [Scaling] sheet, and [Comment] sheet.

System screen

The screen used to congure the environment, the le saving, the le printing, and the

interface settings, and to initialize data.

Pressing the SYSTEM key switches sheets to be displayed in the following order:

[Environment] sheet, [File Save] sheet, [Printer] sheet, [Interface] sheet, and [Init]

sheet.

File screen

The screen used to view saved data les in storage devices (a CompactFlash card, the

built-in drive, a USB ash drive, the internal memory).

19

Page 28

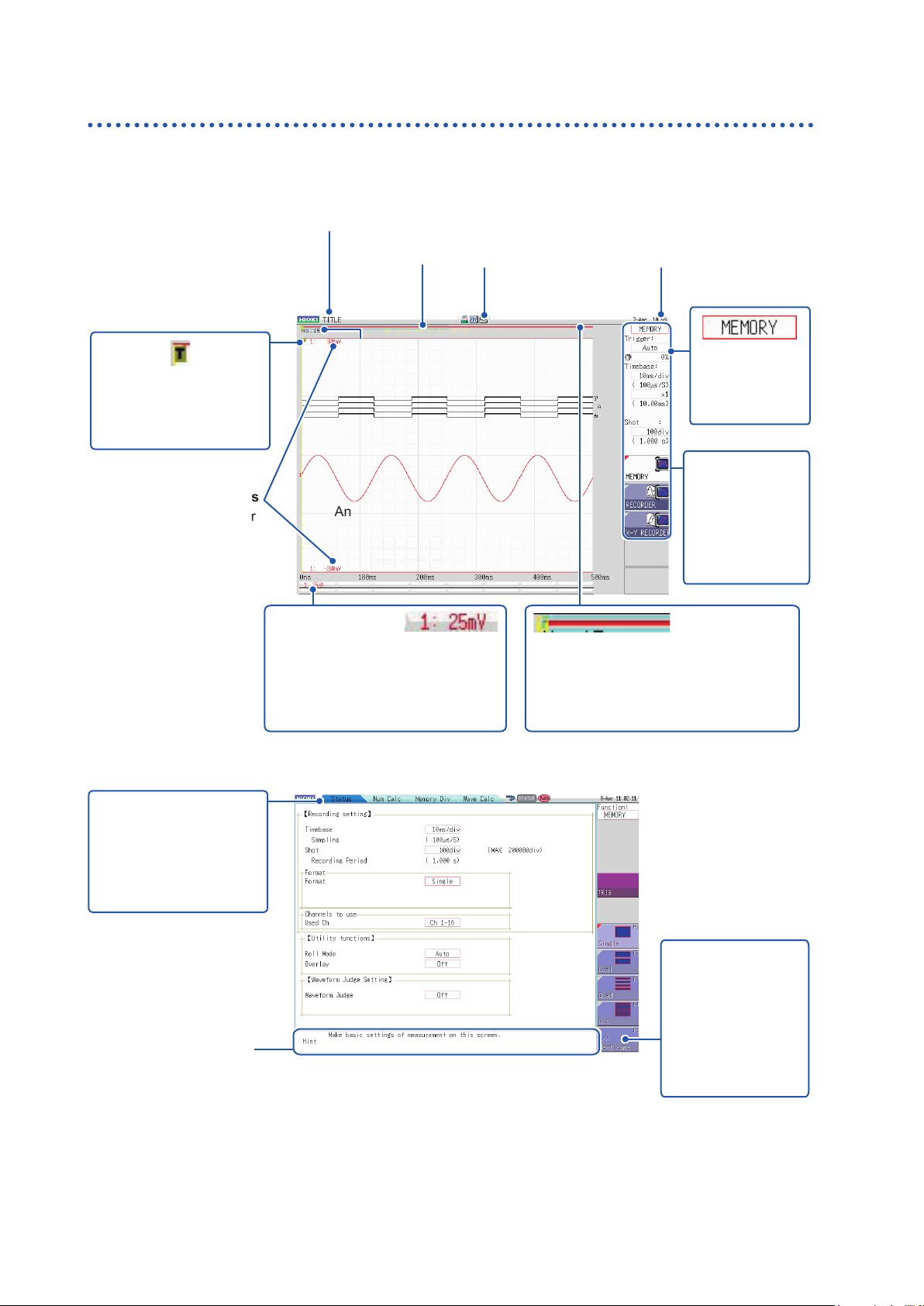

Screens Conguration

Explanation of screen contents

Waveform screen

Title comment

Shows a previously

entered title

comment.

(p. 156)

Trigger marker

Indicates the point when

the instrument triggered.

(p. 201)

Upper and lower limits

Shows upper and lower

limit values for each

channel. (p. 152)

Trigger time

Shows the date

and time when

the instrument

triggered.

(p. 201)

Storage counter

Shows the number of times the

instrument triggered. (p. 74)

Logic waveform (p. 70)

Analog waveform (p. 67)

Vertical axis display

Shows a value per division for each

channel linked to the range settings

of the vertical axis (voltage axis).

(p. 67)

Storage device icon

Displays the status of

storage devices.

(p. 41)

Current date and time

Shows the current date

and time in the manner

previously congured.

(p. 47)

Settings cursor

The present

cursor position

ashes.

Settings window

The window

used to congure

measurement

conditions.

(p. 54)

Scroll bar

The red bar indicates the waveform range

written in the memory. The blue frame

indicates the displayed waveform range.

(p. 141)

Items common to the Status, Channel, System, and File screens

Sheet tabs

Shows names of sheets

that can be selected.

Pressing each of the

MENU keys switches a

sheet to another.

Hint

Shows details about the item at the present settings cursor

position.

Messages such as “Online,” “Key Lock active.,” and error

messages also appear here.

Next Page button

Appears when more

than ve setting

items are available.

Pressing this button

switches other

groups of items to be

displayed.

20

Page 29

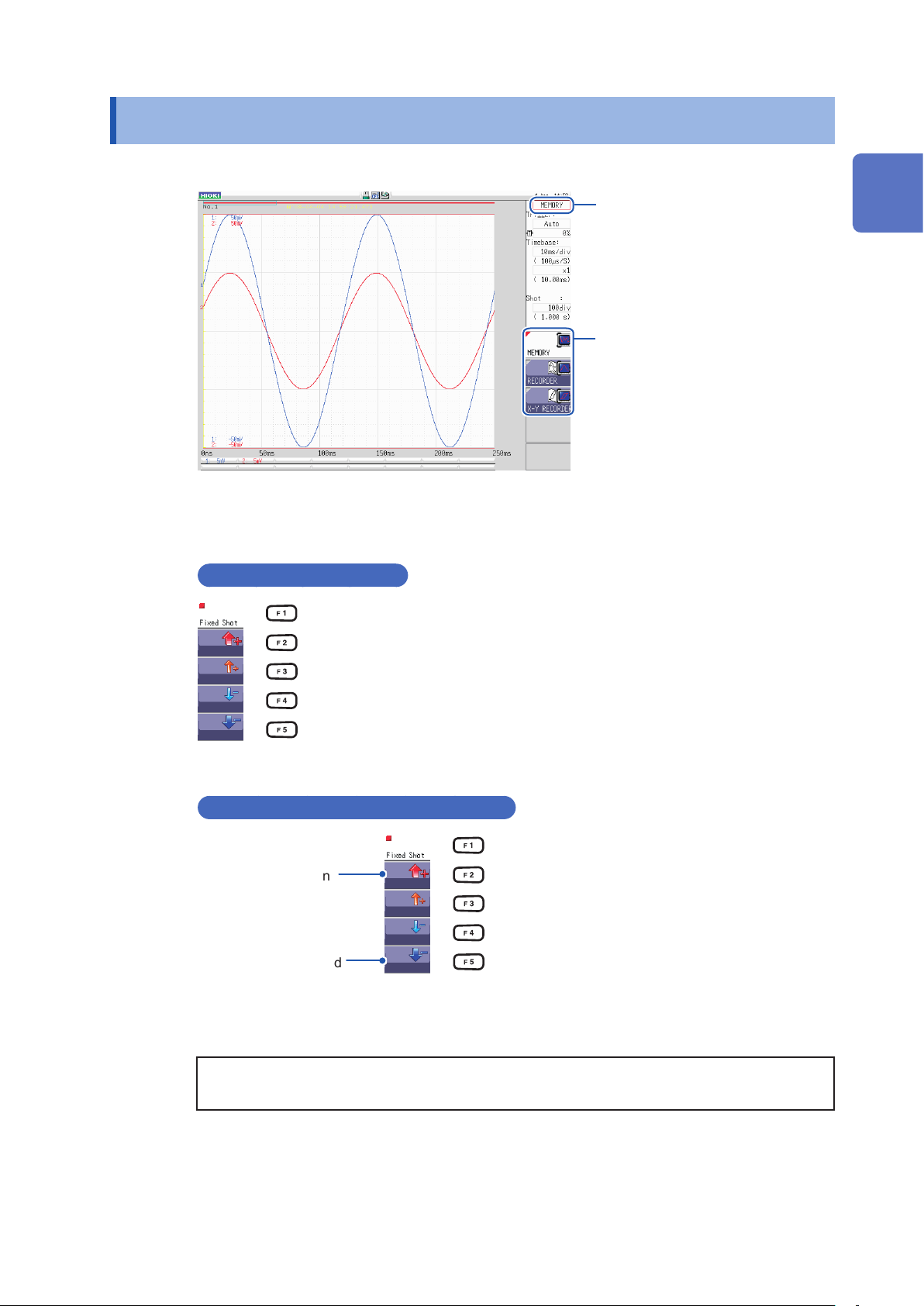

1.4 Basic Key Operation

Press the CURSOR key and move the cursor to an item to be changed.

1

Cursor

GUI

Basic Key Operation

1

Overview

2

Check the illustrations on the GUI and press the function key (F key) to change the

settings.

The function assigned to the F key varies depending on the setting items.

To select an item to be set

Press the F key to change settings.

When there are more than six setting items, press the

F5 [Next Page] key to switch to the next page.

To increase and decrease a setting value

Increases a

numerical value at an

accelerated rate.

Decreases a numerical

value at an accelerated

rate.

Press the F key to change the setting value.

(Turning the jog dial or shuttle ring enables you

to change values.)

3

For some settings, press the CH.SET key to select [Exec], and press the TRIG.SET key

to select [Cancel].

To enter characters and numbers

See “8.1.3 Entering Alphanumeric Characters” (p. 159).

21

Page 30

Basic Key Operation

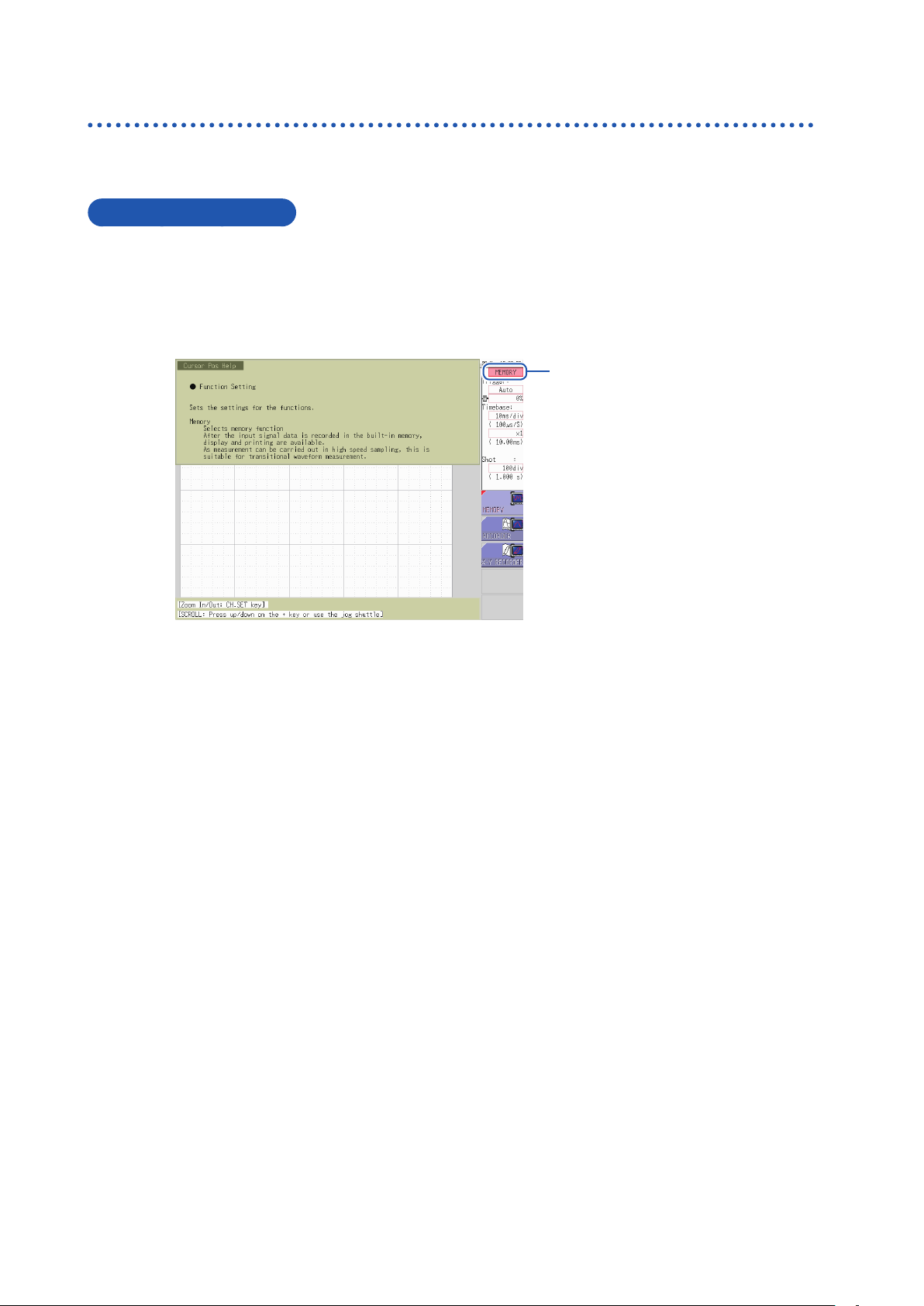

1.4.1 Using the HELP Key

Pressing the HELP key displays a simple explanation of the item at the cursor position. You can also

search the help messages for the information for which you are looking.

Cursor position help

Move the cursor to the item for which you want to display a help message.

1

Press the HELP key. The [Cursor Pos Help] sheet that contains the help message of

2

the cursor position appears.

Pressing the CURSOR up and down keys or turning the Jog dial scrolls the information.

Cursor

• Pressing the CH.SET key switches the display mode of the [Cursor Pos Help] sheet between the

following modes: The full-screen display, the upper-half display, and the lower-half display. The gure

above illustrates the upper-half display mode.

• Pressing the HELP key closes the [Cursor Pos Help] sheet.

22

Page 31

Basic Key Operation

1.4.2 Using Mouse to Enable Key Operation

Using a commercially available USB mouse enables you to operate the instrument in the manner similar

to that with the keys on the instrument.

• The instrument may not support some types of mouses.

• Do not connect any type of device other than a mouse or a USB ash drive to the USB connector of

the instrument.

• Operating the instrument with a mouse may cause temporary operating delay or abnormal screen

display.

• While operating the instrument with a mouse, do not change the interface on the system screen

to anything other than “LAN.” Operating the instrument with a mouse is disabled while USB

communications are in progress.

• External noise may cause the instrument to malfunction while it is operated with a mouse. Keep the

mouse and mouse cable as far away as possible from sources of noise.

The gure below illustrates the basic operation of the instrument with a mouse.

Clicking the right button (rightclick)

Displays a menu with a list of

screens.

Dimmed screen items are

unavailable.

1

Overview

Clicking the left button (click)

Selects a menu or executes the

selected menu. During measurement

with the memory division engaged,

you can change blocks to be

displayed by double-clicking the left

button.

Click the current path shown on the

File screen to move to the upper

folder in the folder hierarchy.

Clicking the center wheel

Changes an item to be

selected.

On the File screen, clicking

the center wheel changes

a le to be selected. During

measurement with the

memory division engaged,

you can change blocks to be

displayed.

Move the mouse forward/

backward/leftward/

rightward

Moves the mouse cursor

on the screen.

23

Page 32

Basic Key Operation

The operation keys of the instrument and the shortcut menu relate to each other as follows.

To operate the functions assigned to the CH.SET, WAV E, and AB CSR keys and to congure those

settings, click the icons displayed while a mouse is connected to the instrument.

Icon Operation key

CH.SET key

WAVE key

WAVE key

Useful functionality

Dragging the right button of the mouse (hold down the button, moving the mouse rightward, leftward, or

forward, and then release the button) performs the same function as when pressing the following keys:

Rightward: START

Leftward: STOP

Upward: ESC

24

Page 33

2

Procedure

Preparing for Measurement

Install the instrument.

1

Install or remove modules.

2

(When adding or replacing modules)

Connect logic probes to the LOGIC

3

terminals.

(When measuring logic signals)

Connect connection cables to the

4

modules.

(When measuring analog signals)

Probes and cables differ depending on the type of

measurement to be performed.

Insert a storage device (CF card, USB

5

ash drive).

Load a roll of recording paper.

6

Connect the power cord.

7

Connect an earthing wire to the GND

8

terminal (functional earth terminal).

(When performing measurement in noisy

environments)

Turn on the instrument.

9

Set the clock

10

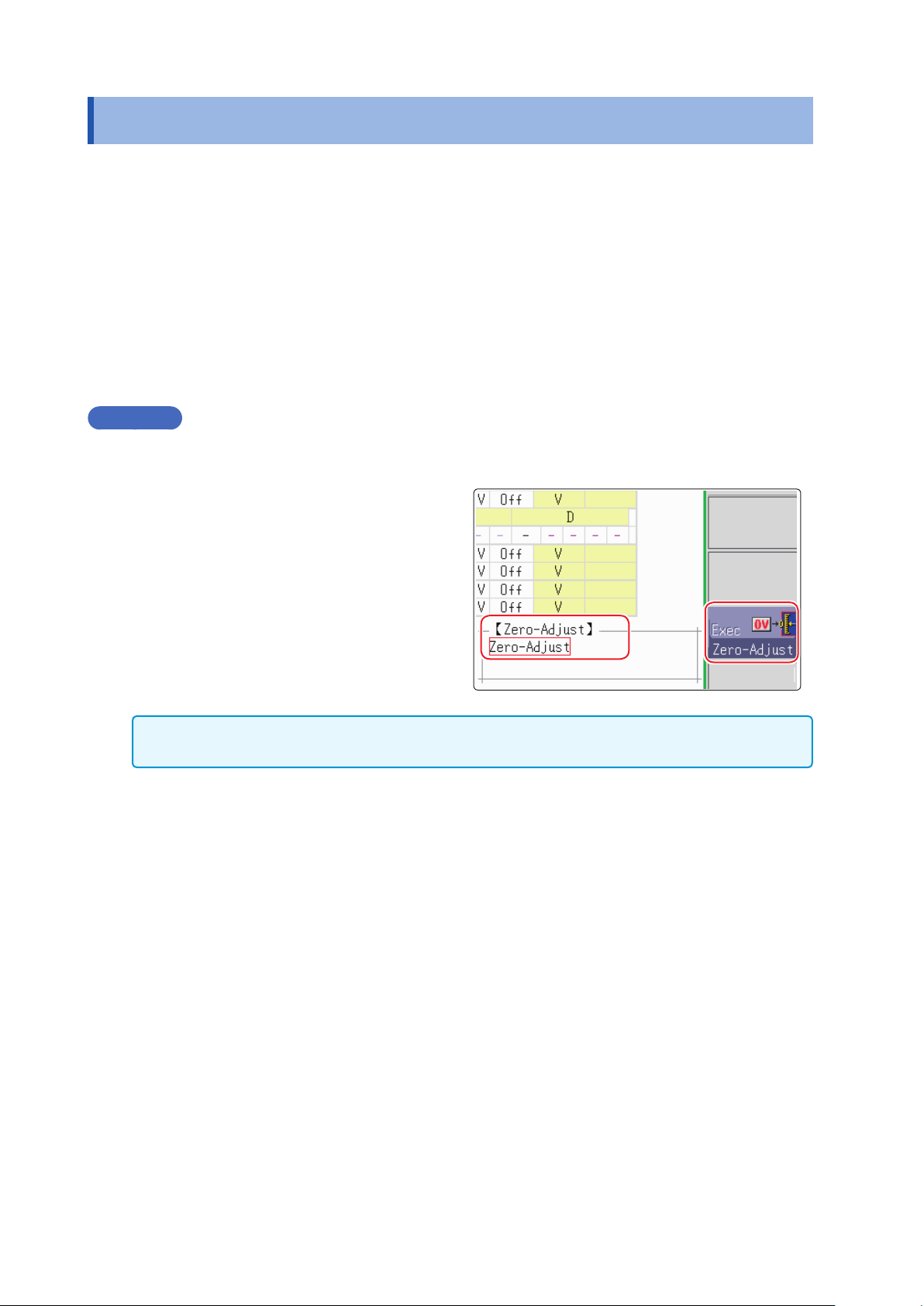

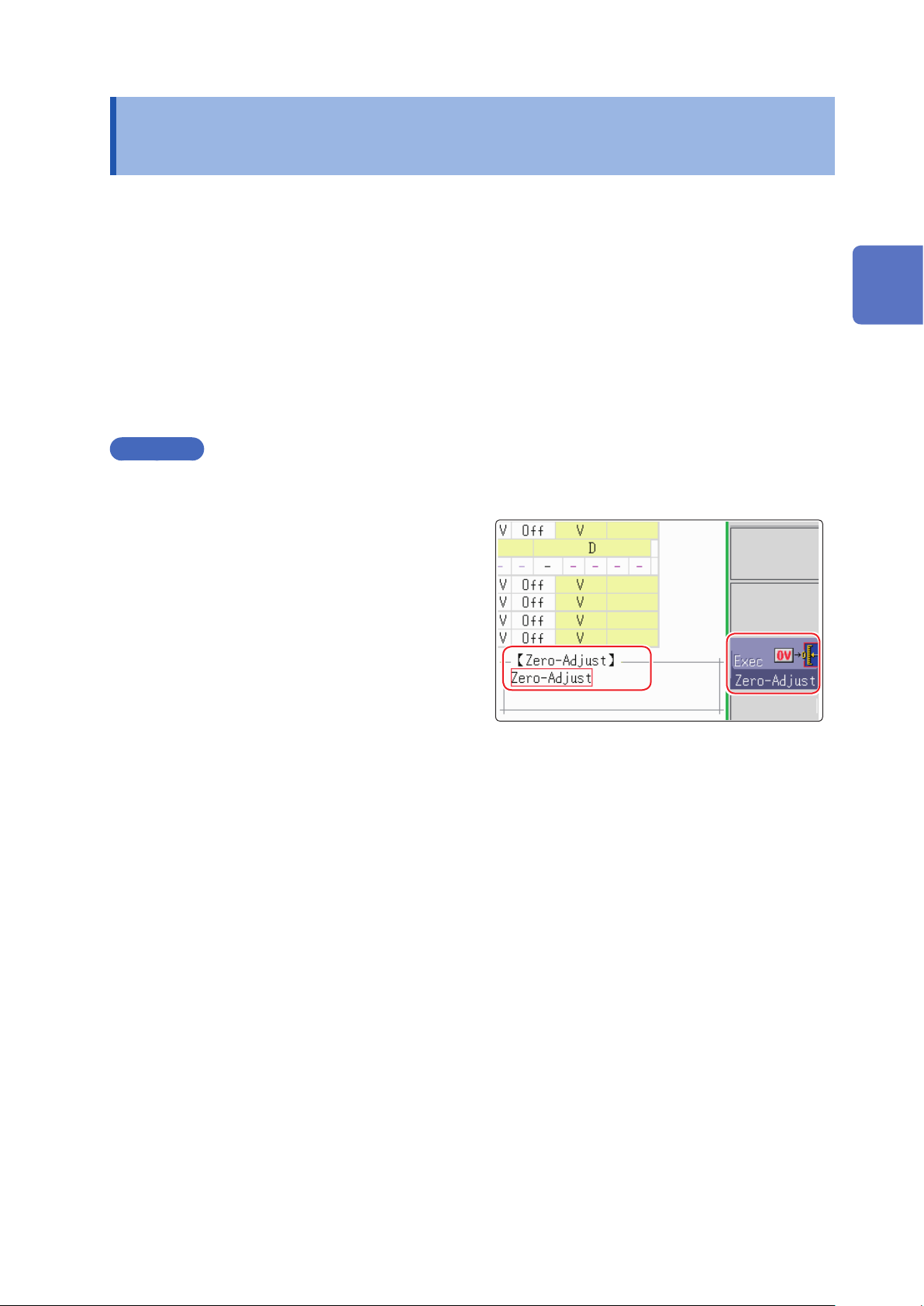

Perform zero-adjustment

11

Perform calibration

(For the instrument with Model MR8990

installed)

(p. 7)

(p. 26)

(p. 28)

(p. 28)

(p. 41)

(p. 43)

(p. 45)

(p. 45)

(p. 46)

(p. 47)

(p. 48)

(p. 49)

2

Preparing for Measurement

After preparation terminates, start

measurement. (p. 51)

To operate the instrument with a computer

Refer to “16 Connecting the Instrument to a Computer” (p. 331).

To control the instrument externally

Refer to “17 Controlling the Instrument Externally” (p. 361).

25

Page 34

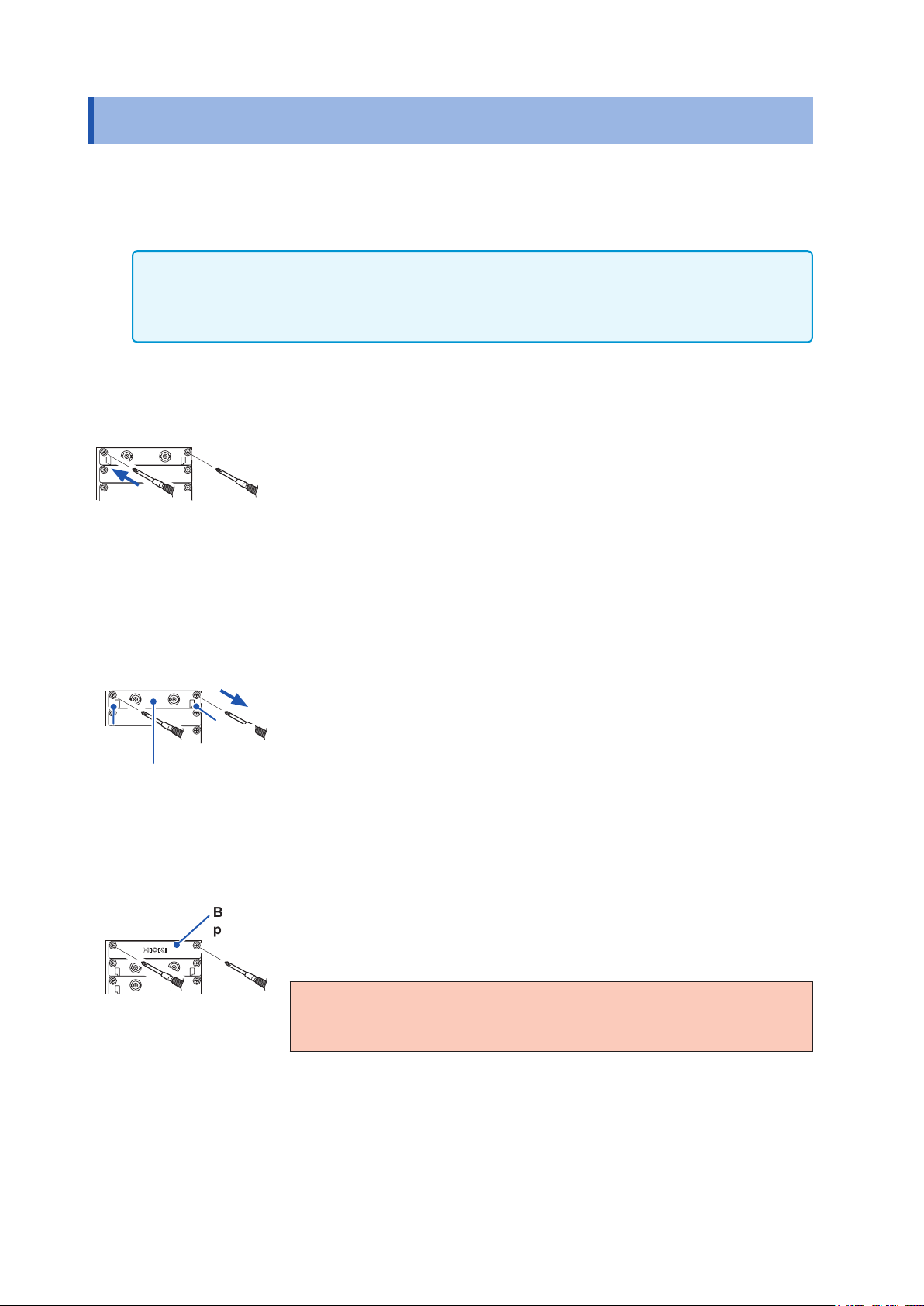

Installing and Removing Modules

2.1 Installing and Removing Modules

Read “Handling the Instrument and Modules” (p. 8) carefully.

Modules ordered with the instrument has already been installed in the instrument. Follow the procedures

below to add, replace, or remove modules from the instrument.

• Up to three logic units can be installed. The instrument ignores the fourth logic module and

later modules that are installed in the instrument.

• For information on the analog channel resolution when logic channels are used, refer to “8.10

Setting Details of Modules” (p. 180).

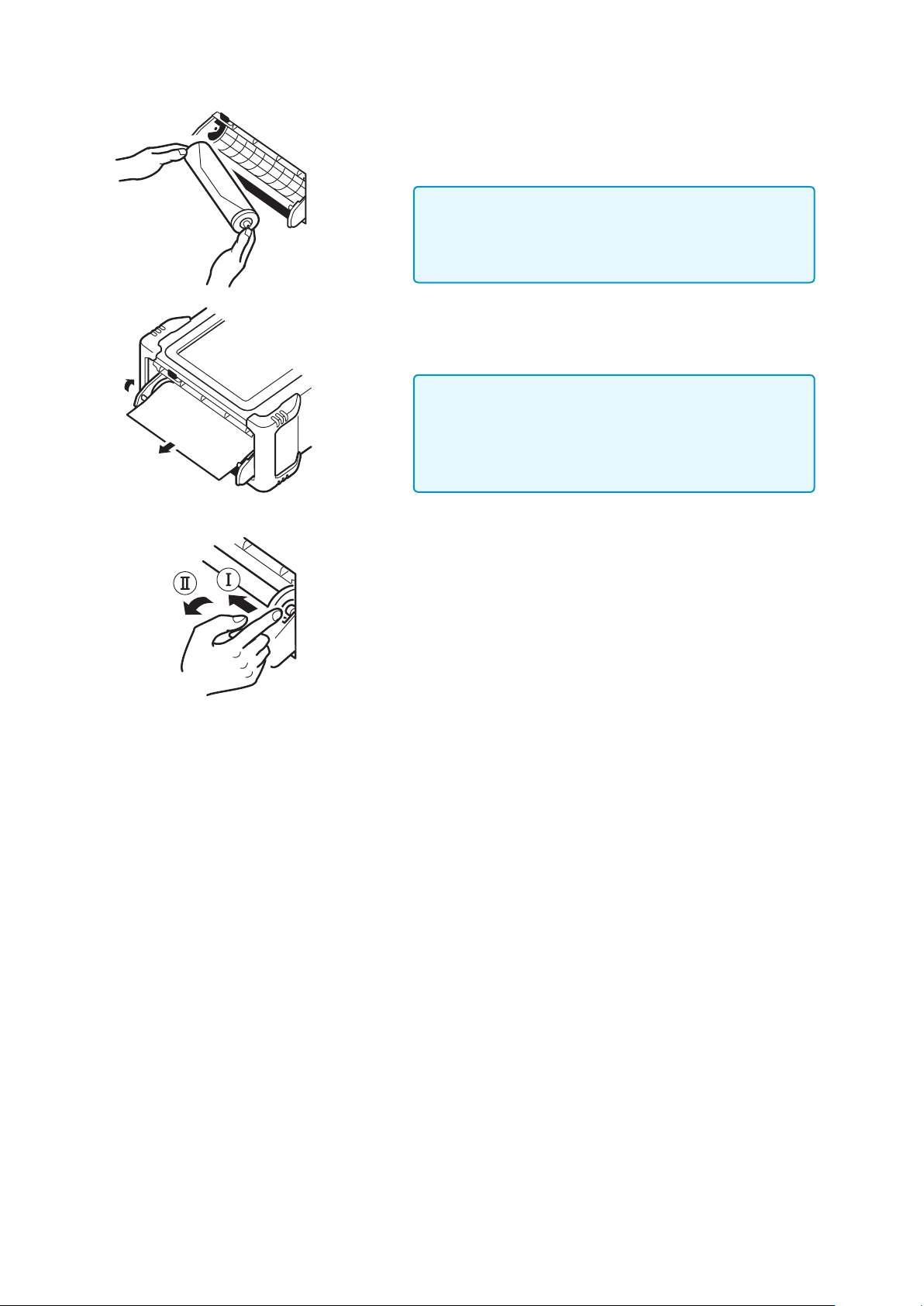

Installing a module

Right side

Removing a module

Right side

Knob

(Example: Model 8966)

Knob

Required items: Phillips-head screwdriver (No. 2)

Turn off the instrument.

1

Orient the module and insert it all the way into the instrument.

2

Make certain that the module is installed in such a way that the

characters printed on the module’s panel are right side up about

those printed on the instrument.

Tighten the two module mounting screws with a Phillips

3

screwdriver.

Required items: Phillips-head screwdriver (No. 2)

Turn off the instrument.

1

Remove all connection cables and thermocouples connected to

2

the module.

Remove the power cord.

3

Loosen the two module mounting screws with a Phillips

4

screwdriver.

Pinch the knobs and pull out the module.

5

When not installing another module after removal

Right side

Blank

panel

Place a blank panel.

1

Tighten two screws with a Phillips screwdriver.

2

If measurement is performed with the instrument without a blank

panel installed, the instrument may fail to meet specications

because of temperature instability within modules.

26

Page 35

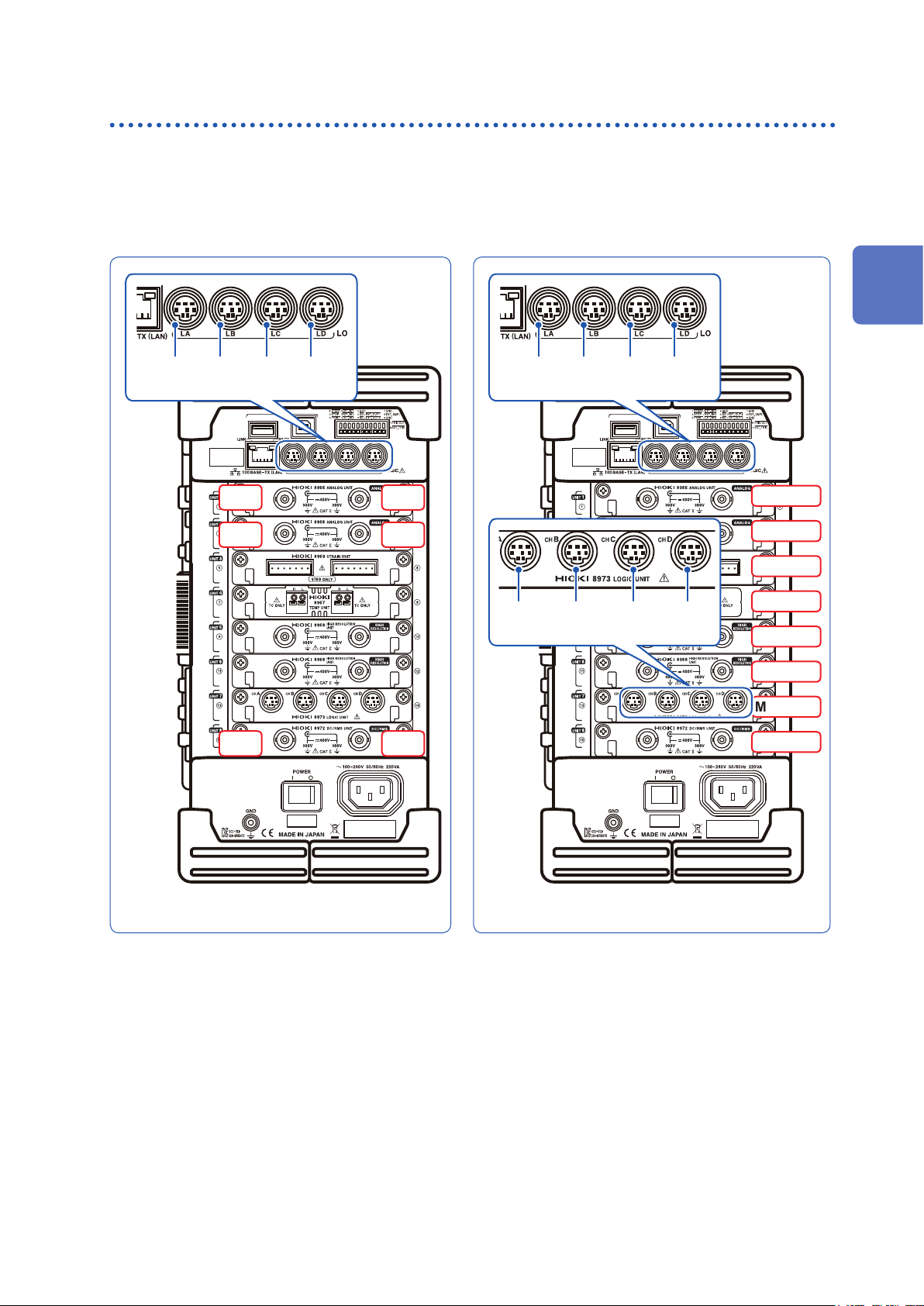

Installing and Removing Modules

Channel conguration

Modules are numbered beginning at the top, and channels are numbered beginning at the left of the

module installed at the top.

You can nd out information about the modules installed in the instrument in the System Information (p.

429).

2

Preparing for Measurement

LA

[1:4]LB[1:4]LC[1:4]LD[1:4]

CH1

CH3

CH15

CH2

CH4

CH16

LA

[1:4]LB[1:4]LC[1:4]LD[1:4]

L7A

[1:4]

L7B

[1:4]

L7C

[1:4]

L7D

[1:4]

Module 1

Module 2

Module 3

Module 4

Module 5

Module 6

Module 7

Module 8

Analog channels only

Both analog and logic modules are installed.

27

Page 36

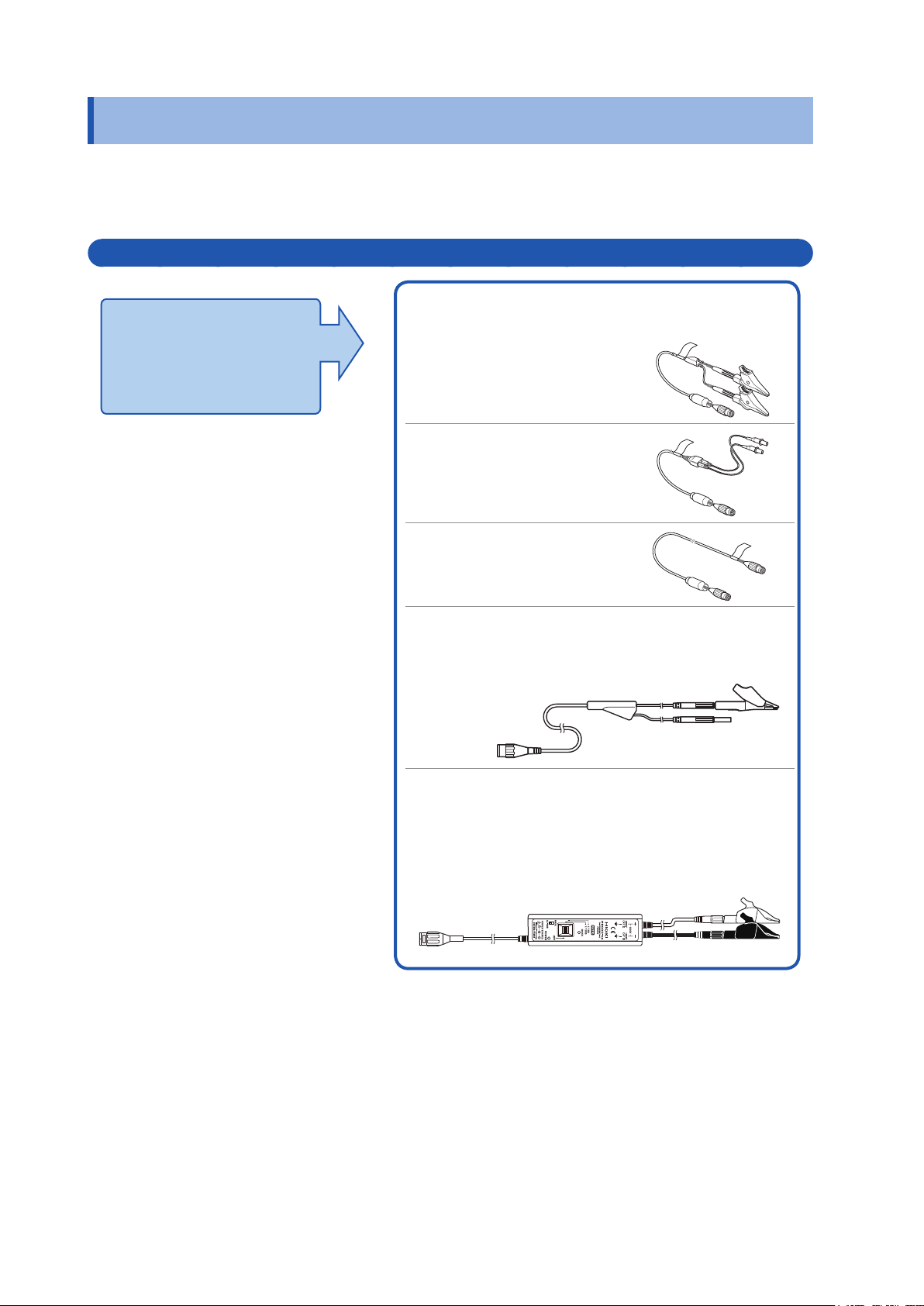

Attaching Connection Cables

2.2 Attaching Connection Cables

Read “Before connecting cables” (p. 11) carefully.

For detailed precautions and instructions regarding connections, refer to the instruction manuals for your

modules, connection cables, etc.

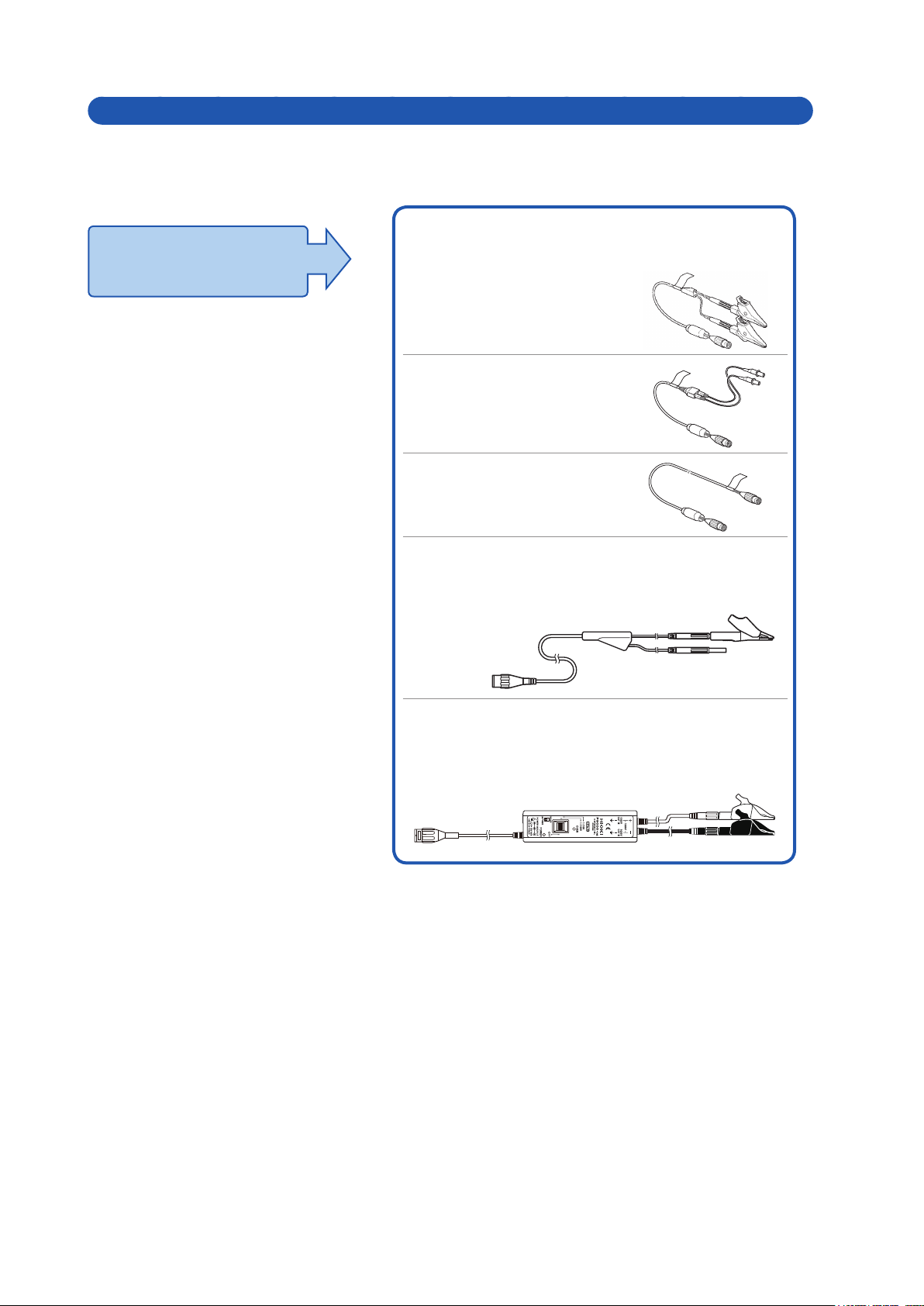

Measuring voltage

Applicable modules

• Model 8966 Analog Unit

• Model 8968 High

Resolution Unit

• Model 8972 DC/RMS Unit

Connect connection cables to the

BNC female connectors on modules.

The following connection cables can be connected

to the modules:

• Model L9197 Connection Cord

(Maximum input voltage: 600 V)

Large alligator clip type

• Model L9198 Connection Cord

(Maximum input voltage: 300 V)

Small alligator clip type

• Model L9217 Connection Cord

(Maximum input voltage: 300 V)

For measuring output signal

from a BNC connector

• Model L9790 Connection Cord

(Maximum input voltage: 600 V)

Terminal type: Alligator, contact, grabber

Example: Terminal type: Alligator

*1 An optional power cord or AC

adapter is required.

*2 An optional AC adapter or a

commercially available USB cable

is required.

When a voltage to be measured exceeds a maximum input

rating of a module being used

• Model 9322 Differential Probe*

• Model 9665 10:1 Probe

• Model 9666 100:1 Probe

• Model P9000-01/-02 Differential Probe*

Example: Model P9000-02 Differential Probe

1

2

28

Page 37

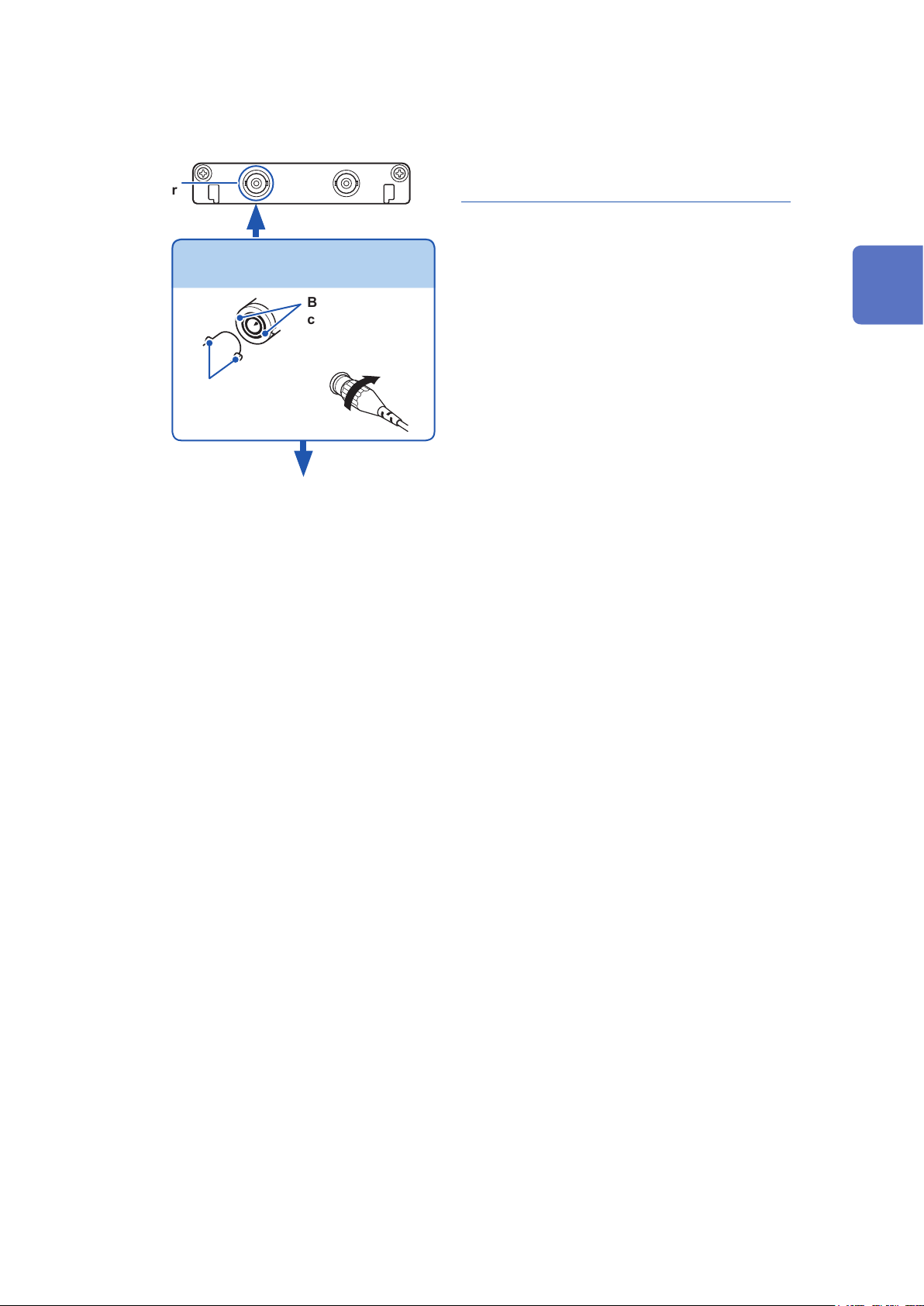

Connecting cables to the BNC female terminals on modules

Example: Model 8966 Analog Unit

BNC

female

connector

Connecting the cable

BNC male

connector slots

Lock

Bayonet rugs on

the module

Required item: Connection cables

Connect the BNC male connector of

1

the cable to a BNC female connector

on the module.

Align the slots in the BNC male

2

connector with the bayonet lugs

on the BNC female connector on

the module, then attach the male

connector while turning it clockwise

until it locks.

Connect the cable clips to a

3

measurement object.

Attaching Connection Cables

2

Preparing for Measurement

Connect the logic probe to a

measurement object.

To disconnect the connection cable from

the BNC female connector

Turn the BNC male connector

counterclockwise, then pull it out.

29

Page 38

Attaching Connection Cables

Measuring Frequency, Number of Rotations, and Count

Refer to (p. 29) for details about connecting a cable to the BNC female terminal.

Applicable Module

• Model 8970 Freq Unit

Connect cables to BNC female

connectors on modules.

The following connection cables can be connected

to the modules:

• Model L9197 Connection Cord

(Maximum input voltage: 600 V)

Large alligator clip type

• Model L9198 Connection Cable

(Maximum input voltage: 300 V)

Small alligator clip type

• Model L9217 Connection Cord

(Maximum input voltage: 300 V)

For measuring output signal

from a BNC connector

• Model L9790 Connection Cable

(Maximum input voltage: 600 V)

Terminal type: Alligator, contact, grabber

Example: Terminal type: Alligator

*1 An optional power cord or AC

adapter is required.

*2 An optional AC adapter or a

commercially available USB cable

is required.

When a voltage to be measured exceeds a maximum input

rating of a module being used

• Model 9322 Differential Probe*

• Model P9000-01/-02 Differential Probe*

Example: Model P9000-02 Differential Probe

1

2

30

Page 39

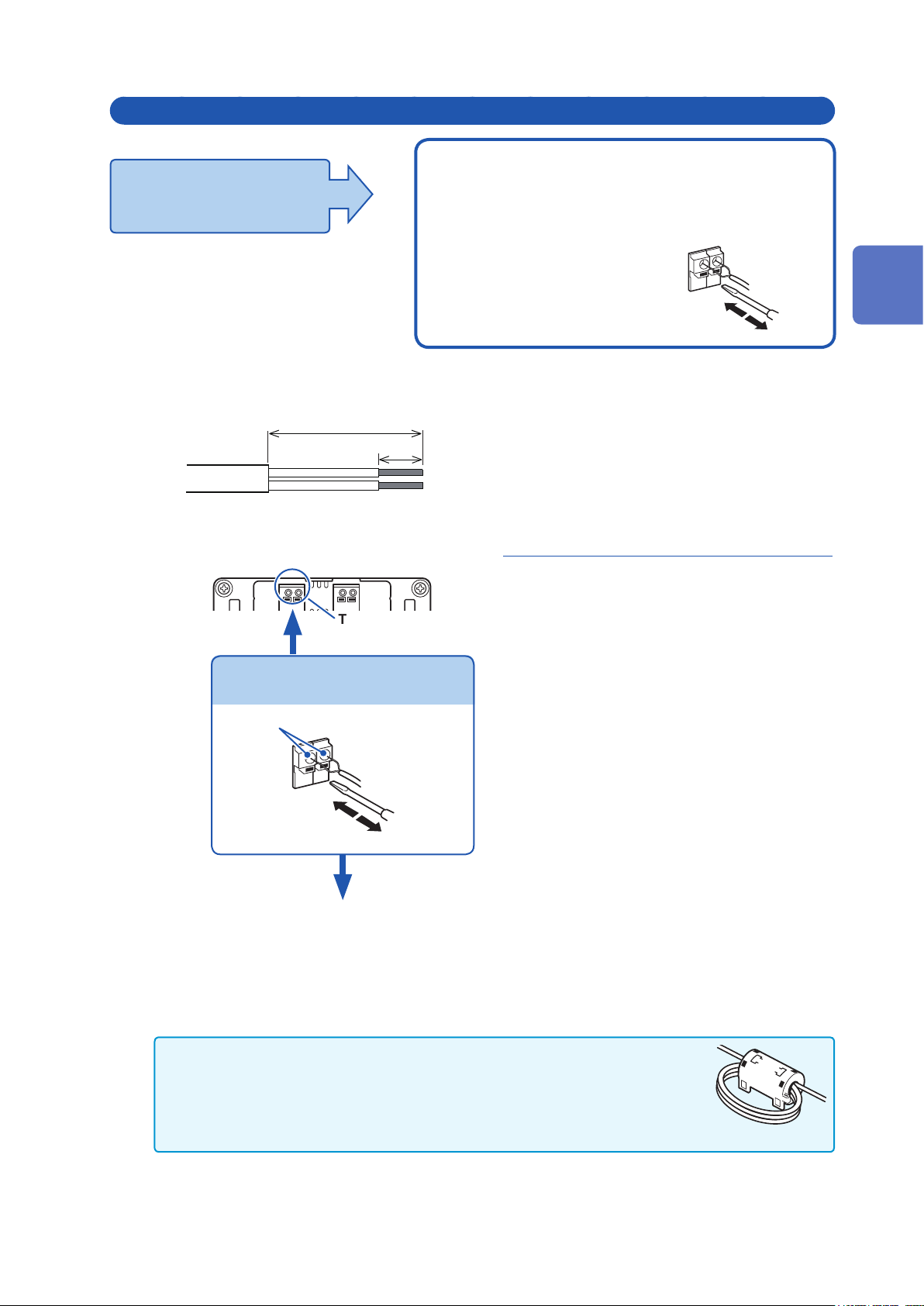

Measuring temperature

Attaching Connection Cables

Applicable Module

• Model 8967 Temp Unit

Connect a thermocouple to the

terminal block on the module.

The following thermocouple can be connected to the

module.

Thermocouple

(Compatible wire: from 0.4 mm

to 1.2 mm in diameter)

Connecting thermocouples to the terminal blocks

Required items:

Thermocouple, at-blade screwdriver (2.6-mm

blade)

Recommended wire:

Compatible wire: Thermocouple element

wires from 0.4 mm to 1.2 mm in diameter

Strip length: 10 mm

Outer insulation

25 mm

Inner

insulation

10 mm

1

Thermocouple

element wire

1

Terminal block

Connect thermocouple to

terminal block

2

Preparing for Measurement

Strip the insulation of the

thermocouple wires as shown on the

left.

Strip length: approx. 10 mm

Depress the button on the terminal

Connecting a thermocouple

Connection holes

3

2

block on the module with the at-

blade screwdriver.

Insert each thermocouple wire into

3

the appropriate terminal hole while

depressing the button.

Conrm proper polarity.

2

Release the button.

4

Connect the thermocouple to a

5

measurement object

• If noise inuences surrounding equipment, turn the thermocouple around the

accessory ferrite clamp-on choke several times (as seen in the right diagram).

• When connecting the thermocouple that is more than 3 meters long, the

measurement may be affected by EMC environments including external

noise.

4

The thermocouple is connected.

Connect to the measurement object.

5

To remove the thermocouple

Pull the thermocouple wire while depressing

the button.

31

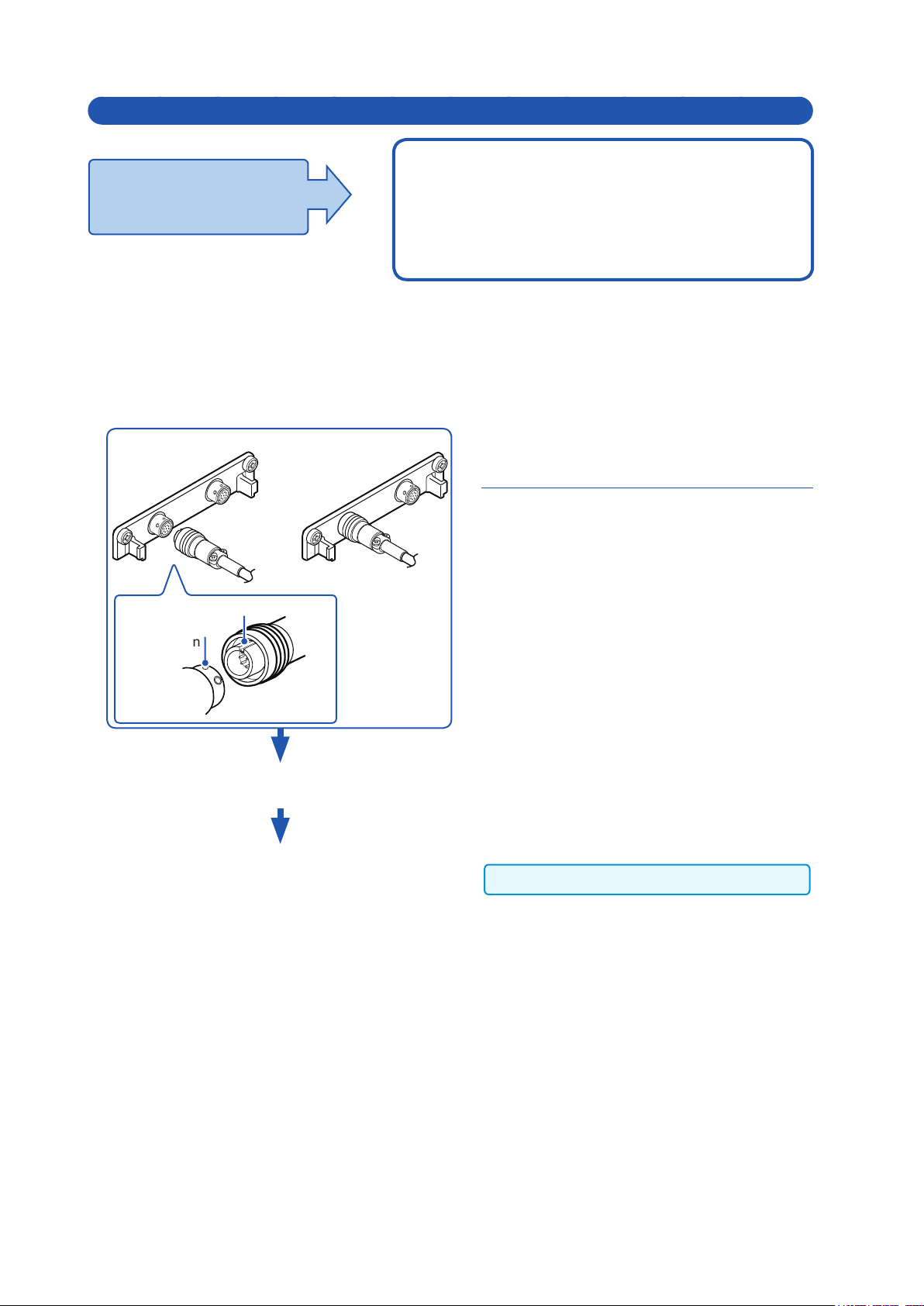

Page 40

Attaching Connection Cables

Measuring vibration or displacement with a strain gauge transducer

Applicable Module

• Model U8969 Strain Unit

• Model 8969 Strain Unit

Connect a strain gauge transducer to a connector on Model U8969 Strain Unit via Model L9769

Conversion Cable; Model 8969 Strain Unit via Model 9769 Conversion Cable.

The following device can be connected to the

module.

• Strain gauge transducer (Not available from Hioki)

Connect L9769 or 9769 Conversion Cable to the strain gauge

transducer.

Connecting the strain gauge transducer to a module’s connector

Example: Connecting the strain gauge transducer to Model U8969 Strain Unit via Model L9769

Conversion Cable

Required items:

Model L9769 Conversion Cable, strain gauge

transducer

Insert Model L9769 into a connector

1

of Model U8969 with the slot of

the plug aligned with the outward

indentation of the connector.

Insert the plug into the connector

2

until they are locked together.

Connect Model L9769 to the strain

3

gauge transducer.

Connector’s

indentation

U8969 Strain Unit

1

Connect the L9769.

Plug’s slot

2

Connect Model L9769 to the strain

3

gauge transducer.

Connect the strain gauge transducer to

4

a measurement object.

Connect the strain gauge transducer

4

to a measurement object.

How to disconnect Model L9769

Pull the sleeve of the plug gently,

releasing the plug, and disconnect the

cable.

The instrument describes Model U8969 as “8969.”

32

Page 41

Connector pin-out

Attaching Connection Cables

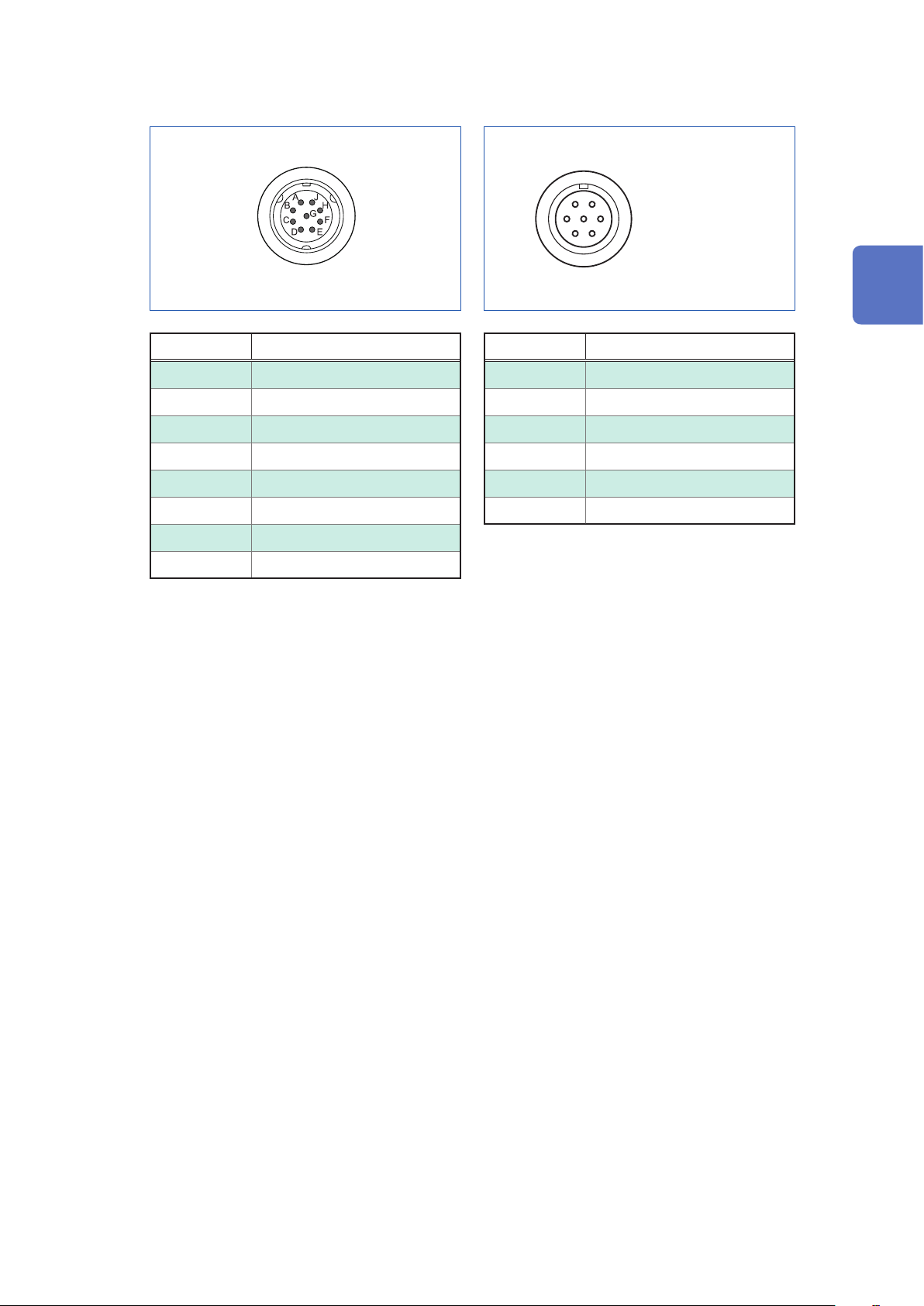

Model U8969 Strain Unit

The metal shell is connected to

the GND of the instrument.

Pin mark Description

A BRIDGE+

B INPUT−

C BRIDGE−

D INPUT+

E

F SENSE+

G SENSE−

H, J N.C.

FLOATING COMMON

Model L9769 Conversion Cable

(Strain gauge transducer end)

A F

G

B

C D

The metal shell is connected to

the GND of the instrument.

Pin mark Description

A BRIDGE+, SENSE+

B INPUT−