Page 1

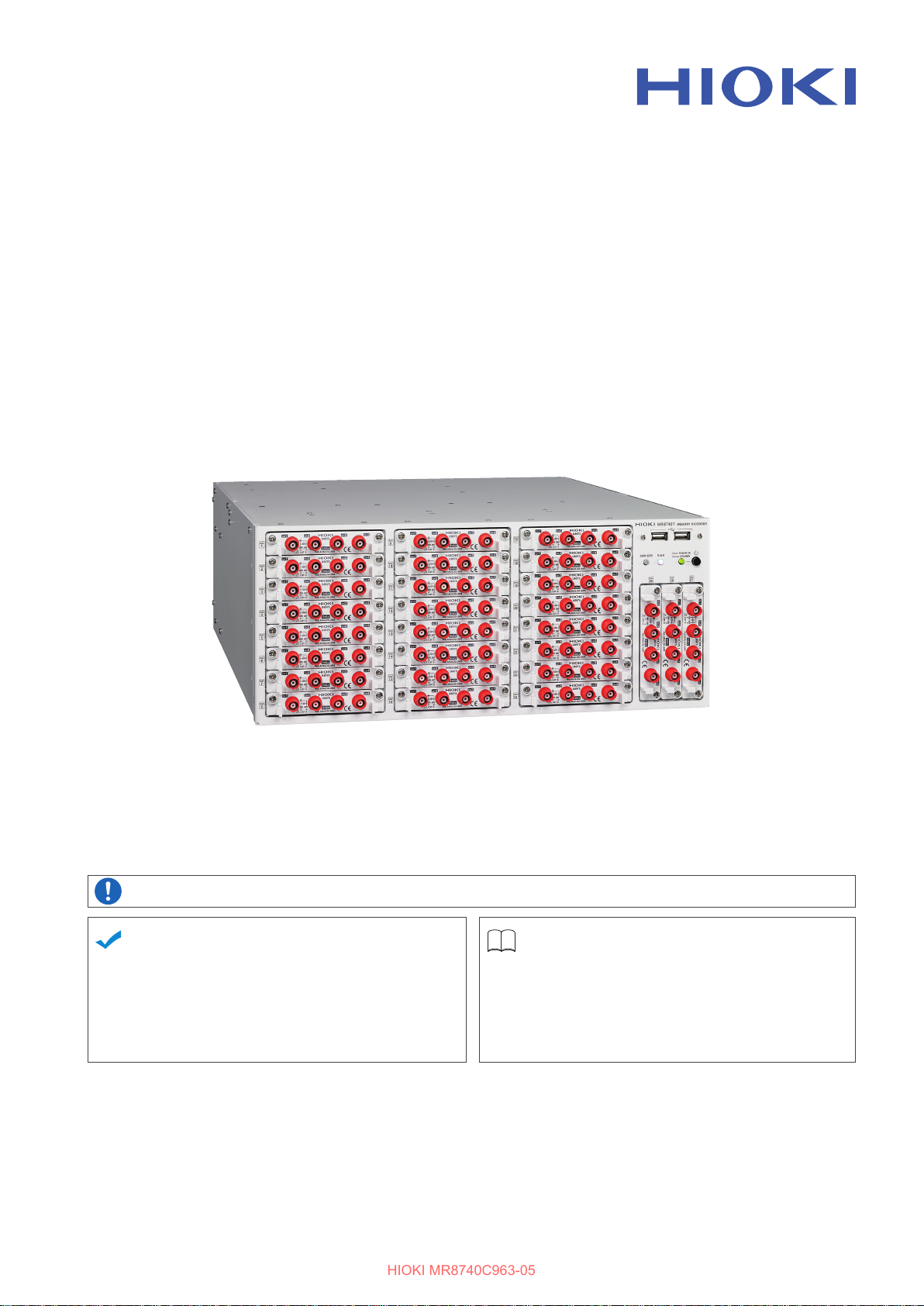

MR8740T

HIOKI MR8740C963-05

MR8740-50

Quick Start Manual

MEMORY HiCORDER

Be sure to read this manual before using the instrument.

When using the instrument for

the rst time

Name and Function of

Each Part

Measurement Method

Oct. 2021 Revised edition 5

MR8740C963-05 21-10H

Troubleshooting

Maintenance and Service

p. 24

Troubleshooting

p. 69 Message

p. 6

p. 149

p. 151

p. 154

EN

*600530255*

Page 2

HIOKI MR8740C963-05

Page 3

FAQs

HIOKI MR8740C963-05

To set the measurement range automatically

Refer to “3.7 Measuring Signals With the Auto-range Setting” (p. 80).

To change the measurement range

Refer to “Analog channel” (p. 73).

To add a comment to the data

Refer to “Analog channel” (p. 73).

To minimize inuence of noise (Low-pass lter, LPF)

Refer to “Analog channel” (p. 73).

To change the sampling rate

Refer to “3.2 Setting Measurement Conditions” (p. 70).

To congure the trigger settings

Refer to “3.4 Conguring the Level Trigger Settings” (p. 75).

To scroll through the waveform display

Refer to “4.2 Handling Waveforms” (p. 85).

To read measured values (cursor values) with cursors

Refer to “4.1 Reading Measured Values (Trace Cursors)” (p. 83).

To save data les

Refer to “3.6 Saving Data Consisting of Items Selected” (p. 78).

To estimate le size

Refer to “13.1 Information for Reference Purposes” of Instruction Manual.

To open data les with a computer

Refer to “4.3 Loading Data With Your Computer (Wave Viewer)” (p. 86).

MR8740C963-05

Page 4

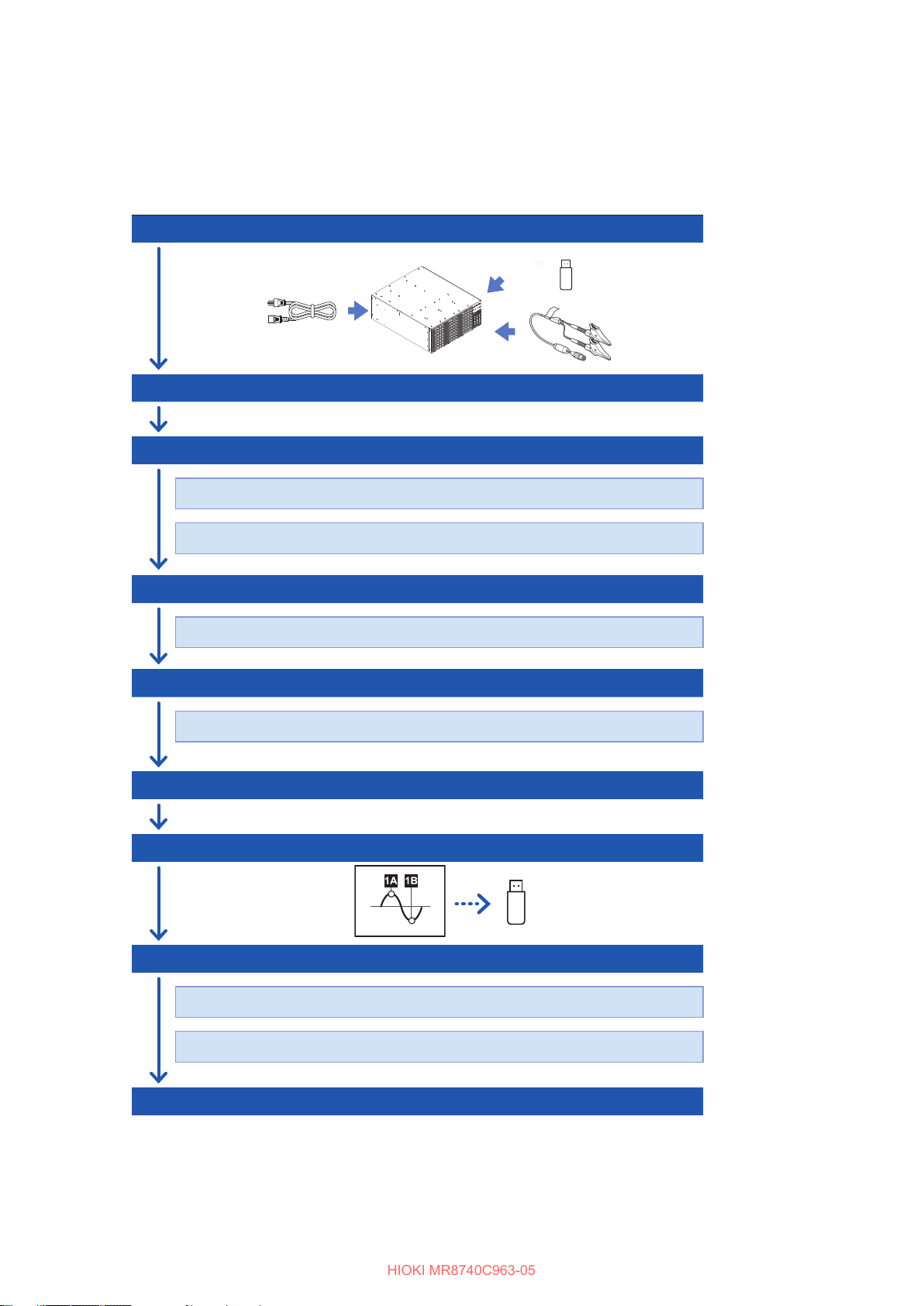

Measurement Procedure

HIOKI MR8740C963-05

The basic measurement procedure is as follows. For advanced use, refer to the Instruction Manual

(PDF) in the accompanying CD.

Preparing for measurement

Inspecting the instrument before measurement

Conguring the basic settings for measurement

Choose a sampling rate.

Choose a recording length (shot).

Conguring the input channel settings

Congure the analog channel settings.

(p. 35)

(p. 69)

(p. 70)

(p. 72)

Conguring the trigger settings

Congure the trigger settings.

Starting/Stopping measurement

Saving measured data les

Analyzing waveforms

Scroll through, zoom in, and zoom out waveforms.

Read measured values (with the trace cursors).

Finishing the measurement

(p. 75)

(p. 77)

(p. 78)

(p. 83)

Page 5

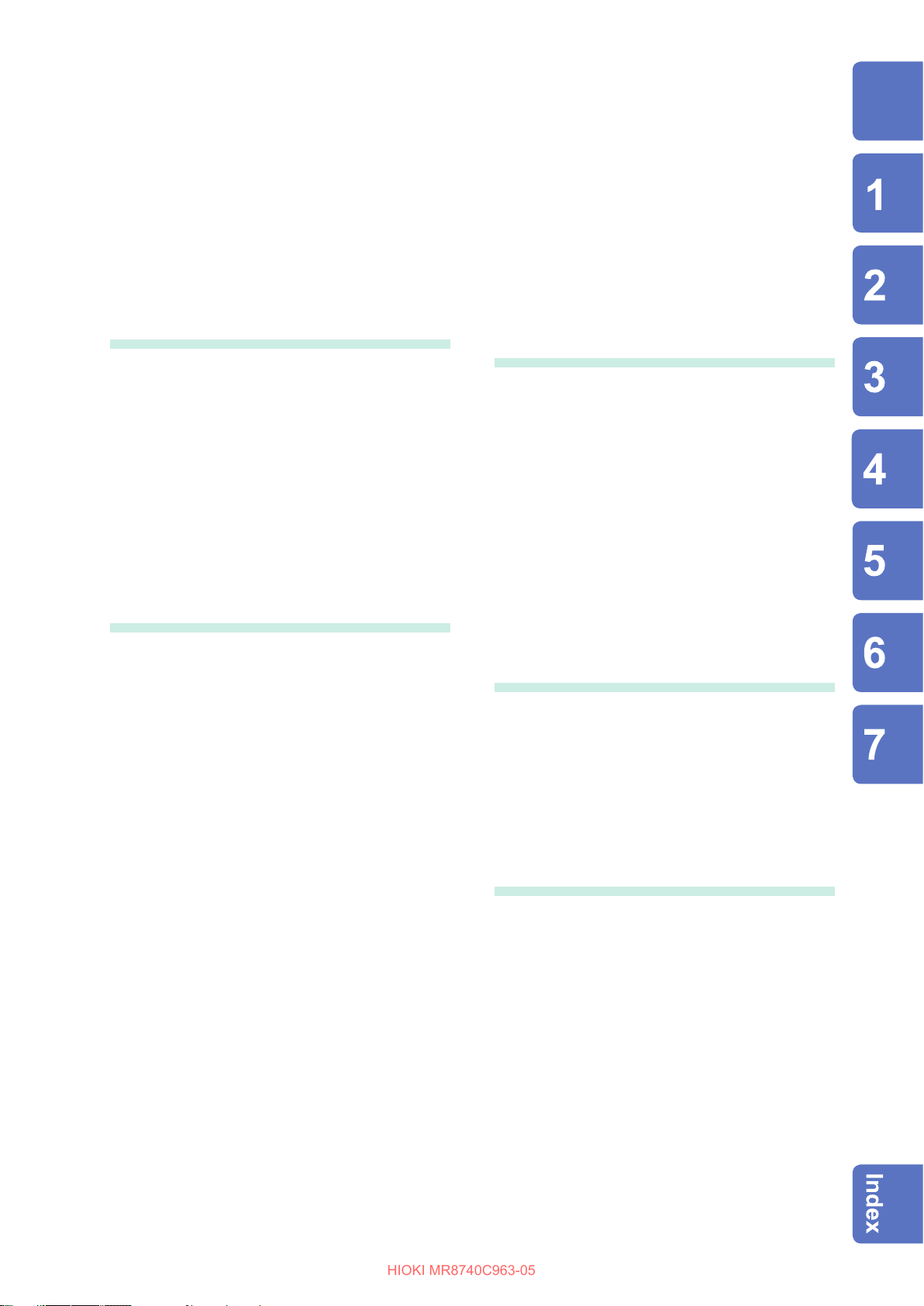

Contents

HIOKI MR8740C963-05

Introduction

Symbols and abbreviations

Conrming Package Contents

Safety Information

Operation Precautions

How to Refer to This Document

........................................................1

.............................2

........................4

............................................6

.....................................8

...................21

1 Overview 23

1.1 Product Overview and Features

1.2 Name and Function of Each Part

1.3 Screen

Screen conguration

Explanation of each screen

1.4 Basic Operation

Mouse operation

Changing screens and settings

Help Function

(Displaying Instruction Manual)

....................................................28

.................................28

.......................29

....................................31

.......................................31

.........23

.......24

.................32

.................34

2 Preparing for

Measurement

35

Turning o the instrument

2.7 Setting the Clock

..........................64

..................................65

2.8 Regulating the Zero Position

(Zero-Adjustment)

................................66

2.9 Executing Calibration

(For the Instrument With Model

MR8990 Installed)

................................68

3 Measurement Method 69

3.1 Inspection Before Measurement

3.2 Setting Measurement Conditions

Sampling rate setting guideline

3.3 Conguring the Input Channel

Settings

Analog channel

..................................................72

.........................................73

3.4 Conguring the Level Trigger

Settings

..................................................75

3.5 Starting/Stopping Measurement

3.6 Saving Data Consisting of Items

Selected

.................................................78

3.7 Measuring Signals With the Autorange Setting

.........................................80

........69

.......70

..................71

.........77

2.1 Installing and Removing Modules

Allocation of modules and channels

2.2 Attaching Connection Cords

Connection cables

(For measuring voltage, frequency,

or rotation speed, and obtaining

accumulations)

Thermocouple (Temperature)

Strain gauge transducer

Current sensor

Acceleration sensor

Logic probe (Measuring logic signals)

Connection cable

(For precisely measuring voltage)

Outputting waveforms

Outputting pulse waveforms

Outputting voltage, current, and

resistance

Connection cable (high voltage)

.........................................40

............................43

..........................................45

..................................49

...............................52

......................53

.................................................54

...........37

...............38

....................42

........51

..............51

................55

2.3 Connecting the External Control

Terminals

...............................................56

2.4 Connecting the Instrument with

computers

..............................................58

2.5 Preparing Storage Devices

(Recording Media)

USB ash drive

Built-in drive

Removing storage devices

Formatting storage devices

..............................................60

................................60

.........................................60

........................61

.......................62

2.6 Supplying Power to the Instrument

Turning on the instrument

.........................63

......36

....63

4 Analysis Method 83

4.1 Reading Measured Values

(Trace Cursors)

4.2 Handling Waveforms

Scrolling through waveforms

Zooming in and out waveforms

.....................................83

............................85

.....................85

..................85

4.3 Loading Data With Your Computer

(Wave Viewer)

.......................................86

5 Specications 89

5.1 Specications of Model MR8740T

General specications

Trigger

......................................................94

Waveform screen

Setting screen

File

...........................................................99

Performing calculation

Memory division

Waveform search

Others

....................................................101

..........................................97

...............................89

......................................96

.............................100

......................................101

....................................101

5.2 Specications of the Options

Model 8966 Analog Unit

Model 8967 Temp Unit

Model 8968 High Resolution Unit

Model U8969 Strain Unit

Model 8970 Freq Unit

Model 8971 Current Unit

..........................103

............................105

.........................109

............................. 111

......................... 113

.....89

............103

............107

i

Page 6

Contents

HIOKI MR8740C963-05

Model 8972 DC/RMS Unit

Model 8973 Logic Unit

Model MR8990 Digital Voltmeter Unit

Model U8974 High Voltage Unit

Model U8975 4ch Analog Unit

Model U8977 3CH Current Unit

Model U8978 4CH Analog Unit

Model U8979 Charge Unit

Model U8991 Digital Voltmeter Unit

Model MR8790 Waveform Generator

Unit

........................................................134

Model MR8791 Pulse Generator Unit

Model U8793 Arbitrary Waveform

Generator Unit

Model U8794 VIR Generator Unit

........................................139

....................... 115

............................117

.................122

................127

.......................129

6 Maintenance and

Service

6.1 Troubleshooting

Before sending the instrument for repair

6.2 Initializing the Instrument

6.3 Message

Error messages

Warning messages

6.4 Self-check

Memory check

LAN check

Media check

System conguration check

6.5 Cleaning the Instrument

6.6 Disposing of the Instrument

(Removing the lithium battery)

149

..................................151

...................153

..............................................154

......................................155

.................................156

............................................160

........................................160

..............................................161

...........................................163

.....................164

....................165

......118

...............120

...............124

.........132

......136

............143

..151

..........165

7 Appendix 167

7.1 Mounting the instrument in a rack

Rack-mount brackets

How to secure the rack-mount brackets

Index 169

Warranty Certicate

ii

....167

..............................167

...168

Page 7

Introduction

HIOKI MR8740C963-05

Thank you for choosing the Hioki MR8740T Memory HiCorder (Model MR8740-50). Preserve this

manual carefully and keep it handy to make full use of this instrument for a long time.

Following manuals are provided along with these models. Refer to manuals relevant to your

purpose.

Type Contents Printed PDF

Operating Precautions Information on the instrument for safe operation

Introduction

–

Quick Start Manual

(This document)

Instruction Manual Functions and instructions for the instrument –

Instruction Manual

U8793, MR8790, MR8791

Basic instructions and specications of the instrument

Functions, specications, and instructions for the

U8793, MR8790, and MR8791

–

Latest instruction manual

The contents of this manual are subject to change, for example as a result of

product improvements or changes to specications.

The latest edition can be downloaded from Hioki’s website.

https://www.hioki.com/global/support/download

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so.

It is assumed that the reader possesses basic electrical knowledge (equivalent to that of someone

who graduated from the electrical program at a technical high school).

Trademarks

• Microsoft and Internet Explorer are either registered trademarks or trademarks of Microsoft

Corporation in the United States and other countries.

• Other products and company names are trade names, registered trademarks, or trademarks of

their respective owners.

–

1

Page 8

Symbols and abbreviations

HIOKI MR8740C963-05

Symbols and abbreviations

Safety notations

In this document, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will result in death or serious

injury to the operator.

Indicates a potentially hazardous situation that may result in death or serious

injury to the operator.

Indicates a potentially hazardous situation that may result in minor or moderate

injury to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance

tasks with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled,

this may give rise to a hazardous situation; the operator may receive an electric

shock, may get burnt or may even be fatally injured.

Indicates prohibited action.

Indicates the action which must be performed.

Symbols axed to the instrument

Indicates cautions and hazards. When the symbol appears on the instrument, read the

corresponding topic in the Instruction Manual.

Indicates the power button that switches the instrument between on and o states.

Indicates a grounding terminal.

Indicates DC (direct current).

Indicates AC (alternating current).

Symbols for Standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in EU

member states.

Indicates that the product conforms to regulations set out by the EU Directive.

2

Page 9

Others

HIOKI MR8740C963-05

Symbols and abbreviations

*

(p. ) Indicates the location of reference information.

START

(Bold-faced)

[ ]

Windows

Current sensor Sensors measuring current are referred to as “current sensor.”

S/s

Additional information is presented below.

Indicates the initial setting values of the items. Initializing the instrument restores

settings to each of these values.

Names and keys on the screen are indicated in boldface.

Menus, dialog boxes, buttons in a dialog box, and other names on the screen are

indicated in brackets ([ ]).

Unless otherwise specied, “Windows” represents Windows 7, Windows 8, and

Windows 10.

The number of times per second the analog input signals are digitized by the

instrument is represented in “samples per second (S/s).”

Example: “20 MS/s” (20 megasamples per second) indicates that the signal is digitized

20 × 106 times per second.

Notations

We dene measurement tolerances in terms of f.s. (full scale) and rdg. (reading) values, with the

following meanings:

f.s.

rdg.

setting

(maximum display value or scale length)

The maximum displayable value or scale length.

(displayed value)

The value currently being measured and displayed on the measuring instrument.

(setting value)

Indicates the value set as the output voltage, current, or other quantity.

3

Page 10

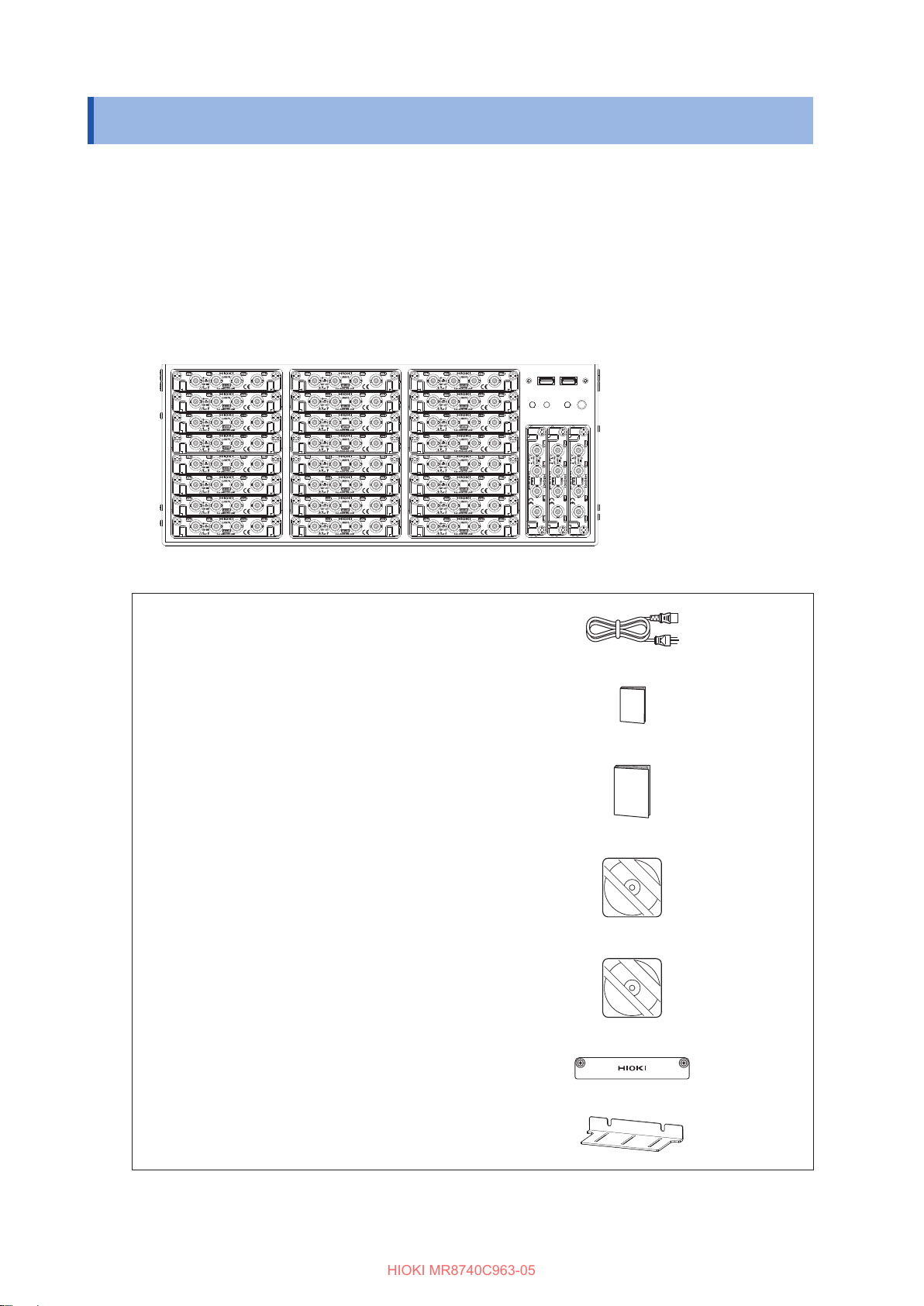

Conrming Package Contents

HIOKI MR8740C963-05

Conrming Package Contents

When you open the package, inspect the instrument carefully to ensure that everything is in good

condition, and that no damage occurred during shipping. Carefully check the accessories, panel

keys and switches, and connectors. If the instrument seems to have been damaged or does not

work as specied, contact your authorized Hioki distributor or reseller.

Check that the package contents are correct.

Instrument

Model MR8740T Memory HiCorder

Accessories

Power cord

Operating Precautions (0990A903)

Quick Start Manual (This document)

Instruction Manual CD*

• Instruction Manual

MR8740C964-xx.pdf

Application disc*

(p. 63)

1

(p. 34)

1

(p. 86)

*1: The latest version can be downloaded from our website.

4

Blank panel (for slots with no module installed)

Rack-mount brackets

(p. 36)

(p. 167)

Page 11

Conrming Package Contents

HIOKI MR8740C963-05

Options (sold separately)

The options listed below are available for the instrument. To order an option, please contact your

authorized Hioki distributor or reseller. Options are subject to change. Please check Hioki’s website for the

latest information.

For information about products, including cables, probes, and sensors, that can be connected to optional

modules, see the “Options” row of each module’s specications in “5.2 Specications of the Options”

(p. 103).

Input modules

Model 8966 Analog Unit

Model 8967 Temp Unit

Model 8968 High Resolution Unit

Model U8969 Strain Unit

Model 8970 Freq Unit

Model 8971 Current Unit

Model 8972 DC/RMS Unit

Model 8973 Logic Unit

Model U8974 High Voltage Unit

Model U8975 4ch Analog Unit

Model U8977 3CH Current Unit

Model U8978 4CH Analog Unit

Model U8979 Charge Unit

Model MR8990 Digital Voltmeter Unit

Model U8991 Digital Voltmeter Unit

Output modules

Model MR8790 Waveform Generator Unit

Model MR8791 Pulse Generator Unit

Model U8793 Arbitrary Waveform Generator Unit

Model U8794 VIR Generator Unit

USB ash drive

Model Z4006 USB Drive (16 GB)

LAN cable

Model 9642 LAN Cable

Other

Model 9335 Wave Processor

5

Page 12

Safety Information

HIOKI MR8740C963-05

Safety Information

This instrument and modules are designed to conform to IEC 61010 Safety Standards, and has

been thoroughly tested for safety prior to shipment. However, using the instrument in a way not

described in this manual may negate the provided safety features.

Read the following safety notes carefully before using the instrument.

DANGER

Mishandling the instrument could result in bodily injury or even death, as well

as damage to the instrument. Familiarize yourself with the instructions and

precautions in this manual before using the instrument.

WARNING

Electricity can cause potentially serious events such as an electric shock,

heat generation, re, and an arc ash due to a short-circuit. If you have not

used electrical measuring instruments before, you should be supervised by a

technician who has experience in electrical measurement.

Protective gear

Performing measurement using this instrument involves live-line work. To

prevent an electric shock, use appropriate protective insulation and adhere to

applicable laws and regulations.

WARNING

6

Page 13

Safety Information

HIOKI MR8740C963-05

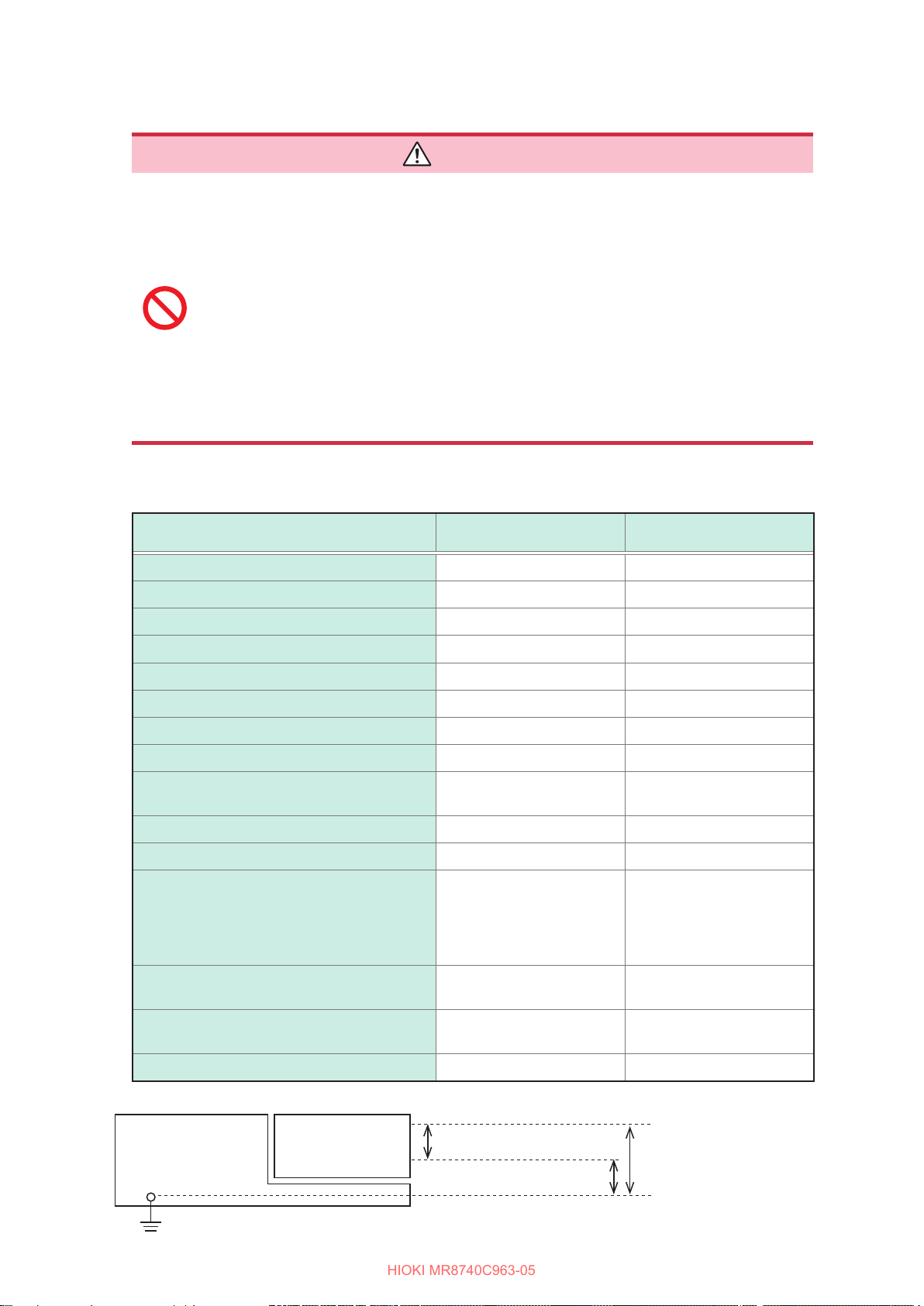

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement

categories.

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

• Never use a measuring instrument that lacks category labeling in a CAT II to

CAT IV measurement environment. Doing so could result in a serious accident.

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical

circuits in equipment connected to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.).

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to

outlets.

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel).

Distribution Panel

Service Entrance

Service Drop

CAT IV

Power Meter

Fixed Installation

Internal Wiring

CAT III

CAT II

T

Outlet

The applicable measurement category is determined based on the module being used.

Refer to “Handling the instrument and modules” (p. 10).

7

Page 14

Operation Precautions

HIOKI MR8740C963-05

Operation Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various

functions.

Checks before Use

DANGER

If the connection cords or the instrument is damaged, there is a risk of an electric

shock. Perform the following inspection before using the instrument:

• Check that the insulation of the connection cords are neither ripped nor torn

and that no metal parts are exposed before using the instrument. Using the

instrument under such conditions could result in an electric shock. Replace the

connection cords with those specied by our company.

• Check if there is any damage to the instrument occurred during storage or

shipping and verify that it operates normally before using the instrument. If you

nd any damage, contact your authorized Hioki distributor or reseller.

Installing the instrument and modules

Installing the instrument in inappropriate locations could cause a malfunction of

the instrument an accident, or re. Avoid the locations that are:

• Exposed to direct sunlight or high temperatures

• Exposed to corrosive or combustible gases

• Exposed to strong electromagnetic elds or electrostatic charges

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

• Unplugging the power cord kills power to the instrument. Be sure to provide

enough unobstructed space to unplug the power cord immediately in an

emergency.

• Use M4 × 8 mm screws to x the rack-mount brackets on the MR8740-50.

Using a screw longer than 8 mm can cause damage to the inside of the instrument

or an electric shock.

WARNING

8

Page 15

Operation Precautions

HIOKI MR8740C963-05

CAUTION

Failure to observe the following precaution may result in bodily injury.

• The instrument weighs about 14 kg (20.8 kg with modules installed in all slots). It

should be moved by at least two people.

• The instrument is heavy. When transporting it, follow your company’s workplace safety

standards to assure safety (for example, by wearing non-slip gloves and protective

footwear).

5 cm or wider

• Do not place the instrument on an unstable table.

• Do not place the instrument on an inclined

surface.

• Do not stack the multiple instruments.

• Vents must not be blocked.

• To prevent overheating, be sure to leave 5 cm

(2 inches) around the instrument.

• The instrument should be operated only with the

bottom side downwards.

9

Page 16

Operation Precautions

HIOKI MR8740C963-05

Handling the instrument and modules

• Do not use the modules or the cables to measure circuits that exceed those

ratings or specications. Damage to the instrument or overheating can cause

bodily injury.

• The maximum input voltage and maximum rated voltage to earth of the modules

and connection cords are shown in the following table. To avoid an electric

shock and damage to the instrument, ensure that input voltage never exceeds

these limits. The lower maximum input voltage of the module or connection

cord must be used. Measuring a voltage exceeding this value can cause

damage to the instrument, resulting in bodily injury. The same applies to the

maximum rated voltage to earth using an input attenuator for the measurement.

Ensure that the connection does not allow the input voltage to exceed the

maximum rated voltage to earth.

Refer to

Rating of input modules

“5.2 Specications of the Options” (p. 103).

DANGER

Modules Maximum input voltage

Model 8966 Analog Unit

Model 8967 Temp Unit – 300 V AC/DC (CAT II)

Model 8968 High Resolution Unit

Model U8969 Strain Unit – 30 V rms / 60 V DC

Model 8970 Freq Unit

Model 8971 Current Unit – Non-isolated

Model 8972 DC/RMS Unit

Model 8973 Logic Unit – Non-isolated

Model U8974 High Voltage Unit

Model U8975 4ch Analog Unit

Model U8977 3CH Current Unit – Non-isolated

Model U8978 4CH Analog Unit

400 V DC 300 V AC/DC (CAT II)

400 V DC 300 V AC/DC (CAT II)

400 V DC 300 V AC/DC (CAT II)

400 V DC 300 V AC/DC (CAT II)

1000 V DC

700 V AC

200 V DC 300 V AC/DC (CAT II)

40 V DC (Direct input)

400 V DC (with Model 9665

10:1 Probe used)

Maximum rated voltage to

earth

1000 V AC/DC (CAT III)

600 V AC/DC (CAT IV)

30 V AC, 60 V DC

(Direct input)

300 V AC/DC (CAT II)

(with Model 9665 10:1

Probe used)

10

Model U8979 Charge Unit

Model

MR8990

Model U8991 Digital Voltmeter Unit

Digital Voltmeter Unit

ModulesModel MR8740T

High

Low

40 V DC

500 V DC 300 V AC/DC (CAT II)

100 V DC 100 V AC/DC

Maximum input voltage

30 V AC

60 V DC

Maximum rated voltage

to earth

Page 17

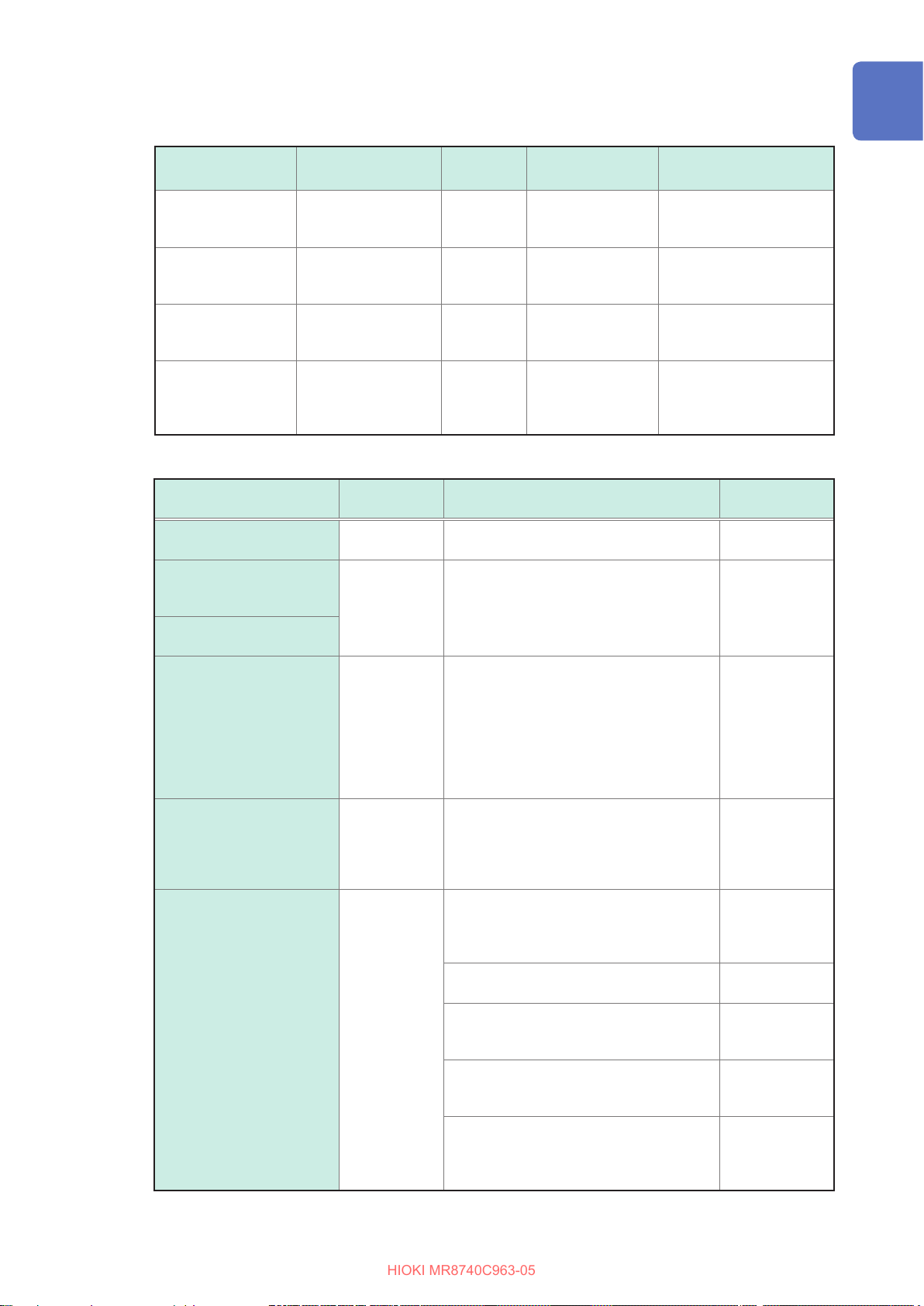

Rating of generator modules

HIOKI MR8740C963-05

You can mixedly install generator modules and measurement modules in the instrument.

Operation Precautions

Intended use Model name Number of

For generating sine

wave and DC

For generating pulse

For generating

arbitrary waveforms

For generating DC

voltage, DC current,

and resistance

generation

Model MR8790

Waveform Generator

Unit

Model MR8791

Pulse Generator Unit

Model U8793

Arbitrary Waveform

Generator Unit

Model U8794

VIR Generator Unit

Ratings of connection cords

Connection Cord

Model L9197

Connection Cord

Model L9198

Connection Cord

(for measuring low-voltage)

Model L9217

Connection Cord

Model L9790

Connection Cord

Model 9322

Dierential Probe

Model L4940

Connection Cord

*: When Model U8974 High Voltage Unit is used

Maximum

input voltage

600 V AC/DC

300 V AC/DC

600 V AC/DC

2000 V DC

1000 V AC

1000 V DC*

Maximum output

channels

4 20 kHz −10 V to 10 V

8 20 kHz

2 100 kHz −10 V to 15 V

8

Maximum rated voltage to earth

600 V AC/DC (CAT III)

300 V AC/DC (CAT IV)

600 V AC/DC (CAT II)

300 V AC/DC (CAT III)

• With Model L9790-01 Alligator Clip or

Model 9790-03 Contact Pin attached

600 V AC/DC (CAT II)

300 V AC/DC (CAT III)

• With Model 9790-02 Grabber Clip

attached

300 V AC/DC (CAT II)

150 V AC/DC (CAT III)

• With grabber clips attached

1000 V AC/DC (CAT II)

• With alligator clips attached

1000 V AC/DC (CAT II)

600 V AC/DC (CAT III)

• With Model L4935 Alligator Clip Set or

Model L4932 Test Pin Set attached

600 V AC/DC (CAT IV)

1000 V AC/DC (CAT III, CAT II)

• With Model L9243 Grabber Clip attached

1000 V AC (CAT II)

• With Model L4936 Bus Bar Clip Set

attached

600 V AC/DC (CAT III)

• With Model L4937 Magnetic Adapter Set

attached

1000 V AC/DC (CAT III)

• With Model L4934 Small Alligator Clip

Set attached

300 V AC/DC (CAT III)

600 V AC/DC (CAT II)

frequency

Output voltage

TTL level

(amplitude: 0 to 5 V)

Open-collector output

Voltage: −0.1 V to 5.3 V

Current: −5 mA to 5 mA

Resistance: 10 Ω to 1 M

Maximum rated

1 A

0.2 A

1 A

10 A

1 A

5 A

2 A

3 A

Ω

current

–

11

Page 18

Operation Precautions

HIOKI MR8740C963-05

Connection Cord

Model P9000-01

Dierential Probe

Model P9000-02

Dierential Probe

Model 9166

Connection Cord

Model L9795-01

Connection Cable

(for generating)

Model L9795-02

Connection Cable

(for generating)

It is recommended to measure the secondary side of a distribution panel with

the U8974 High Voltage Unit. Do not measure the primary side of the distribution

panel because an unrestricted current ow could damage the instrument and

facilities if a short circuit occurs.

• Each channel of Model U8979 Charge Unit has the BNC terminal and miniature

connector terminal with the common ground. Do not connect cables with each

of the terminals simultaneously to avoid a short-circuit.

Maximum

input voltage

1000 V AC/DC 1000 V AC/DC (CAT III) –

30 V AC

60 V DC

±30 V 30 V rms AC, 42.4 V peak AC, or 60 V DC –

Maximum rated voltage to earth

For inputting voltage into Model U8979 –

Maximum rated

current

DANGER

WARNING

• To avoid an electric shock and damage to the module and the instrument,

conrm that the instrument is turned o and that the connection cords are

disconnected before removing or replacing a module.

• To avoid an electric shock, install a blank panel over any slot with a module

removed.

• To prevent the instrument damage or an electric shock, use only the screws that

are originally installed for securing the module in place. If you have lost any

screws or nd that any screws are damaged, please contact your authorized

Hioki distributor or reseller.

12

Page 19

Operation Precautions

HIOKI MR8740C963-05

CAUTION

• Do not touch module connectors inserted to the instrument to avoid damaging a

module.

• To avoid damage to the instrument, do not unplug the power cable from the

instrument when operations are in progress. Be sure to use the power key to turn o

the instrument.

• The U8794 permits a load resistance of 1 kΩ or more while outputting a voltage. Do

not connect a load resistance lower than the permissible value or short-circuit an

output terminal. Damage to the instrument could result.

• Do not set the OUTPUT terminal status of the U8794 to SHORT when a power supply

unit connects with the OUTPUT terminal. A short-circuit current will ow, resulting in

damage to the instrument or power supply device.

• Do not connect anything with the U8794 OUTPUT terminal during a general test

of the self-diagnosis function and an oset measurement of the oset canceling

function. When the connected target is a power supply device, the instrument and the

connected target can be damaged because the OUTPUT terminals of each channel

are momently short-circuited.

• The mounting screws must be rmly tightened or the module may not work as

specied, or may even fail.

• When you use the U8794 resistance generation function to presume a characteristic

of a connected target with an output resistance of less than 1 kΩ, a current that

exceeds the specication will ow, resulting in damage to the instrument and the

connected target.

• Model U8979 Charge Unit has two miniature connectors with the maximum input

charge of ±500 pC (for six higher-sensitivity range) or ±50,000 pC (for six lowersensitivity range). Inputting a charge that exceeds these value causes damage to the

instrument.

• Use an acceleration sensor with a built-in pre-amplier that conforms to the

specication of Model U8979 (3.5 mA, 22 V). Using a inapplicable sensor may cause

damaging itself.

IMPORTANT

• Install a blank panel over the slot with no module installed. If the measurement is performed

without the blank panel installed, the instrument may not work as specied because of

temperature instability within the modules.

• If any unexpected waveform is observed or a module is not recognized, send the instrument for

repair.

• Disconnect all cables and remove a USB ash drive before carrying the instrument.

• Waveforms can frequently uctuate even when no voltage is applied due to an induction voltage.

This, however, is not a malfunction.

• This instrument may cause interference if used in residential areas. Such use must be avoided

unless the user takes special measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

Precautions during shipment

To avoid damage to the instrument, protect it from physical shock when transporting

and handling. Be especially careful to avoid physical shock due to dropping it.

• Store the packaging materials even after unpacking, because you will need them when you

transport the instrument.

CAUTION

13

Page 20

Operation Precautions

HIOKI MR8740C963-05

• To ensure safe handling, when transporting the instrument, please use the original box and

packing materials,

but do not use if the box is damaged or warped, or if the packing materials are in poor condition

or incomplete.

If you nd any damage, contact your authorized Hioki distributor or reseller.

• When packing the instrument, make sure to disconnect the test leads and power supply cords

from the main device.

• When transporting, avoid dropping or other excessive impact.

CD precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on a

disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

14

Page 21

Handling storage devices

HIOKI MR8740C963-05

• Do not carry the instrument with a USB ash drive inserted. Damage could result.

•

Do not subject the instrument to extreme shock or vibration. Shock can cause damage to

the built-in SSD unit.

• Do not insert a storage device upside down, backward, or in the wrong direction.

Doing so may damage the storage device or instrument.

Exercise care when using such products because static electricity could damage the

external storage device or cause a malfunction of the instrument.

IMPORTANT

• Do not extract any external storage device or turn o the instrument while the instrument is

accessing the storage device (while the green DIAG LED is lighting up). Data stored in the

device could be lost.

• No compensation is available for loss of data stored on the external storage device (USB ash

drive) or the built-in SSD unit of the instrument, regardless of the content or cause of damage

or loss. Be sure to back up any important data stored on the device (USB ash drive) and the

built-in SSD unit of the instrument.

• When the instrument is left powered o for a long period of time (about 1 year or more), the

data saved to the built-in SSD may be lost. Be sure to back up the data if the instrument is to

be left powered o for a long time.

Operation Precautions

CAUTION

• With some external storage device, the instrument may not start up if power is turned on while

the device is inserted. In such a case, turn o and cycle the instrument.

• The instrument supports not all commercially available USB ash drives.

• The number of times data can be written on external storage devices (USB ash drive) and the

built-in SSD unit of the instrument is limited by their ash memory. If data has been rewritten

many times, data reading and writing capabilities will be degraded. In that case, replace the

device.

• Model Z4006 USB Drive can be used to save data. Use the product available as Hioki’s option

only. (p. 5)

15

Page 22

Operation Precautions

HIOKI MR8740C963-05

Built-in battery

The instrument contains a battery (sealed lead acid battery) to shut down Windows® in case power

is cut (power outrage or turning o a breaker). Since the battery has a limited life expectancy,

it must regularly be replaced. When replacing batteries, please contact your authorized Hioki

distributor or reseller.

Expected lifetime: About 2 years (Operated at an ambient temperature of

25°, when the instrument is turned o once a day)

About 4 years (Operated at an ambient temperature of

25°, when the instrument is turned o ve times a year)

CAUTION

• You have to charge the battery periodically even if you do not use the instrument.

Periodically charge the battery every three months at a storage temperature of 35°C;

every six months at a storage temperature of 25°C. Failure to do so may reduce the

battery life expectancy.

• Do not install the instrument in a sealed space or near a re. Doing so may cause an

explosion or re.

• Do not use the instrument at high ambient temperature. Do not use the instrument

with the end-of-life battery. Doing so may cause electrolyte leakage, resulting in a bad

inuence that includes a re at a worst. Make sure that you use the instrument within

the operating temperature range and inspect and replace the battery periodically.

16

Page 23

Operation Precautions

HIOKI MR8740C963-05

Before connecting cords

For detailed precautions and instructions on connections, refer to the instruction manuals of your

connection cords.

DANGER

• If the insulation on a connecting cable melts, the metal conductor may be

exposed. Do not use any cable whose metal conductor is exposed. Doing so

could result in an electric shock, burn, or other hazards.

When measuring power line voltage

• Only connect connection cords on the secondary side of a distribution panel. If

a short-circuit occurs on the secondary side of the distribution panel, the panel

will interrupt the short-circuit current. Do not connect the connection cords on

the primary side of the distribution panel because an unrestricted current ow

can damage the connection cords and facilities if a short-circuit occurs.

• To prevent an electrical shock and bodily injury, do not touch any input

terminals on the VT (PT), CT or the instrument when they are in operation.

• Do not leave the measurement cables connected to the instrument in an

environment where voltage may surge beyond the maximum input voltage.

Applying voltage may result in damage to the instrument, or serious accidents.

• Do not cause a short-circuit between another wire and the wire to be measured

with the metal tip of the connection cord. Arcs or such grave accidents are

likely to occur.

• To avoid a short-circuit or electric shock, do not touch the metal tip of the

connection cord.

WARNING

• To prevent an electric shock, conrm that the white or red portion (insulation

layer) inside the cable is not exposed. If a color inside the cable is exposed, do

not use the cable.

• Do not place a cable in contact with the lines to be measured. Any contact

can cause the instrument to malfunction and lead to a short-circuit or electric

shock, resulting in bodily injury.

• Be sure to connect the voltage input and current input terminals correctly.

incorrect connection could damage or a short-circuit.

• Use only the specied connection cords. Using a non-specied cable may

result in unsafe measurements. Using a non-specied cable may also result in

incorrect measurements due to poor connection or other reasons.

• To avoid electric shock, do not exceed the lower of the ratings shown on the

modules and connection cords.

An

17

Page 24

Operation Precautions

HIOKI MR8740C963-05

• To prevent cord damage, do not step on cords or pinch them between other objects.

• The cable is hardened in freezing temperatures. Do not bend or pull it to avoid tearing

• Do not use any cable terminated with a metal BNC connector for connecting cables

CAUTION

Do not bend or pull on cords at their base.

its shield or cutting the cable.

to the BNC jacks on modules. If you connect a metal BNC cable to insulated BNC

connector, the insulated BNC connector and instrument may be damaged.

• To prevent damage to the BNC connector, be sure to release the

locking mechanism, grip the head of the connector (not the cord),

and pull it out.

Before connecting a logic probe to a measuring object

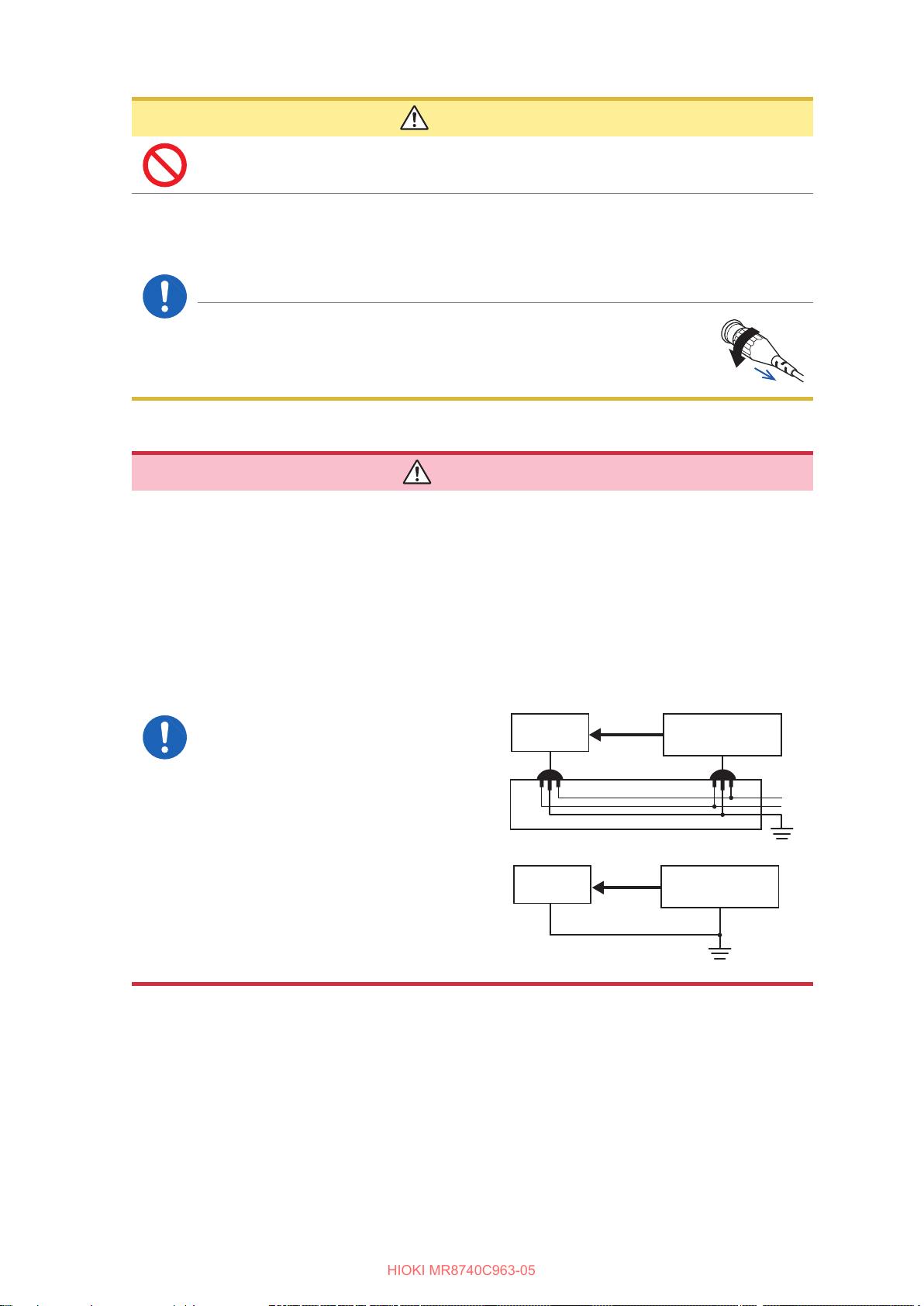

DANGER

To avoid an electric shock, a short-circuit and damage to the instrument, supply

power from a single main to the instrument and a measuring object with the

accompanying power cord.

The ground pin of logic terminal of Model 9320-01 Logic Probe (or Model 9327

Logic Probe) is not isolated from the instrument ground. The ground is shared.

If each of the terminals are supplied with power from separate mains or power

is supplied through a non-grounded power cord, the measuring object and the

instrument may be damaged because a current may ow through the logic probe

due to the resulting ground potential dierence between the terminals. The

following connection procedure is recommended to avoid this problem:

• Connect the power cord provided

to the instrument and supply

power from the same outlet as the

measuring object.

• Connect the ground of the

measuring object to the GND

terminal (functional earth terminal)

of the instrument.

(Always supply power from a single

main.)

Refer to “2.6 Supplying Power to

the Instrument” (p. 63).

Measuring

object

Measuring

object

GND

1

2

Model MR8740T

Logic

Probe

Model MR8740T

Logic

probe

18

Functional ground terminal

Page 25

Before turning on the instrument

HIOKI MR8740C963-05

• To prevent electrical shock and to maintain the safety specications of this

instrument, connect the accompanying power cord only to an inlet.

• Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage

may damage the instrument and present an electrical hazard.

Do not operate the instrument on any of the power sources (UPS or uninterruptible

power supply, DC/AC inverter) that provide rectangular-wave or pseudo-sine-wave

power. Doing so may damage the instrument.

Operation Precautions

WARNING

CAUTION

19

Page 26

Operation Precautions

HIOKI MR8740C963-05

Before connecting the instrument to external equipment

DANGER

To avoid electrical hazards and damage to the instrument, do not apply voltage

exceeding the rated maximum to the external control terminals.

Model MR8740T

I/O terminal Maximum input voltage

IN1

IN2 10 V DC

OUT1 50 V DC, 50 mA, 200 mW

OUT2 50 V DC, 50 mA, 200 mW

TRIG.OUT 50 V DC, 50 mA, 200 mW

Model U8793 Arbitrary Waveform Generator Unit

I/O terminal Maximum input voltage

IN −0.5 V to 7 V DC

OUT 30 V DC, 50 mA

10 V DC

WARNING

To avoid an electric shock or damage to the equipment, always observe the

following precautions when connecting your external equipment to external

control terminals.

• Always turn o the instrument and any equipment to be connected before

making connections.

• Be careful to avoid exceeding the ratings of the external control terminals.

• The external control terminal shares the ground with the chassis. As required,

isolate the devices and systems to be connected to the external control

terminals from one another.

Always turn both devices o before connecting and disconnecting an interface

connector. This may cause an electric shock.

I/O terminals Maximum input voltage

EXT.TRIG

EXT.SMPL 10 V DC

10 V DC

20

CAUTION

• Use a common ground to both the instrument and the connected equipment. Using

dierent ground circuits will result in a ground potential dierence between the

instrument and the connected equipment. If the cable is connected while such a

potential dierence exists, it may result in equipment malfunction or failure.

• Before connecting or disconnecting any cable, always turn o the instrument and your

device to be connected. Failure to do so could result in an equipment malfunction or

damage to the equipment.

• After inserting the connector, securely tighten the screws of the connector. Failure to

do so could result in an equipment malfunction or damage to the equipment.

• To prevent damage to the equipment, use the recommended type of wires to connect

your external equipment to the external control terminal, or otherwise ensure that the

wires have sucient withstand voltage and current capacity.

Refer to “2.3 Connecting the External Control Terminals” (p. 56).

Page 27

How to Refer to This Document

HIOKI MR8740C963-05

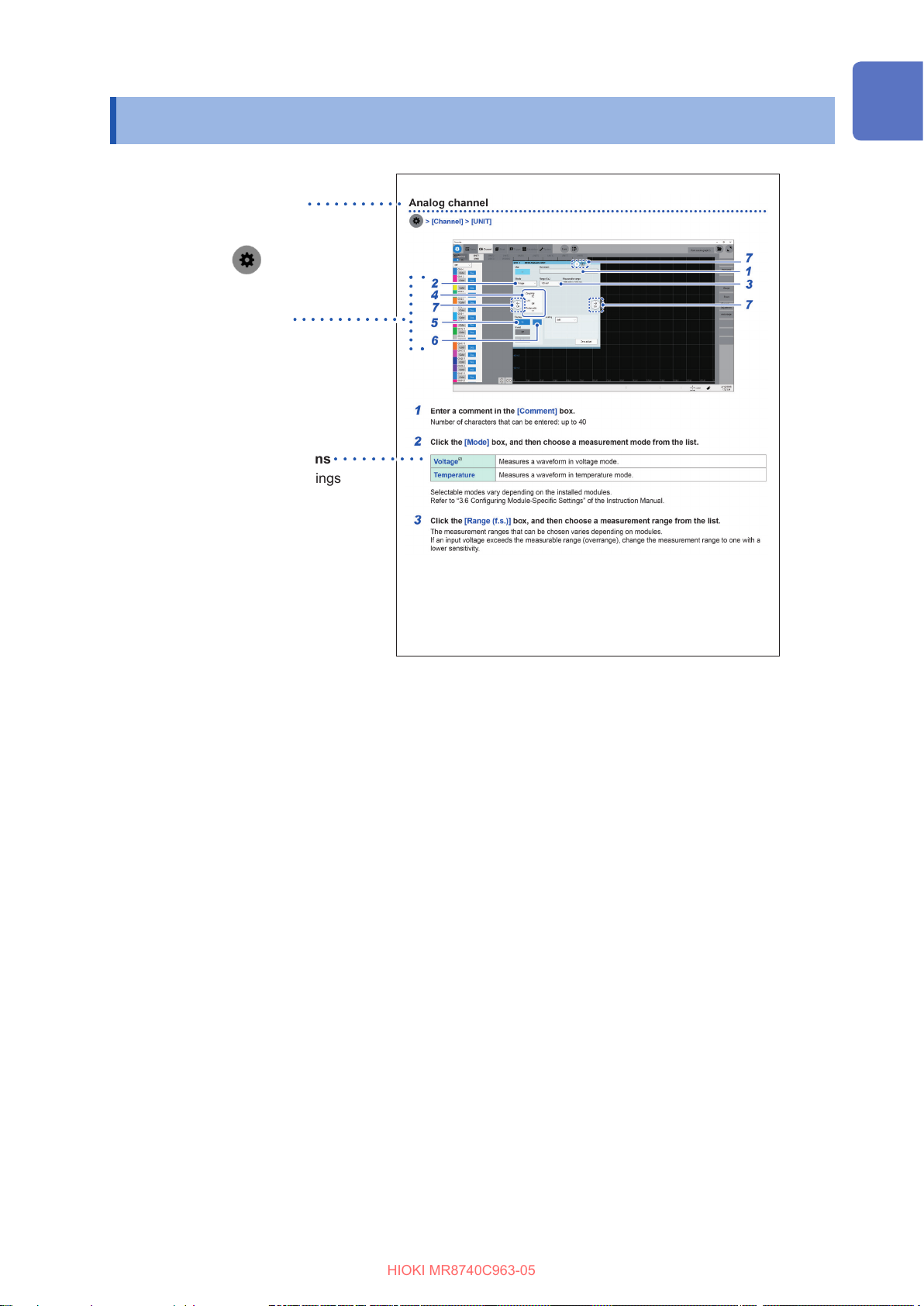

How to open a screen

Indicates the order of clicking the

screens.

The button

setting key.

Procedure numbers

Numbered same as a

corresponding step-by-step

instruction.

Options and explanations

Describes selectable settings

when an item is clicked.

The icon indicates the default

setting of the item.

represents the

How to Refer to This Document

21

Page 28

How to Refer to This Document

HIOKI MR8740C963-05

22

Page 29

1

HIOKI MR8740C963-05

Overview

1.1 Product Overview and Features

This recorder allows you to observe a wide range of waveforms from low-speed signals to highspeed waveforms.

You can mainly use this instrument for analyzing test and evaluation results of various products and

troubleshooting those products.

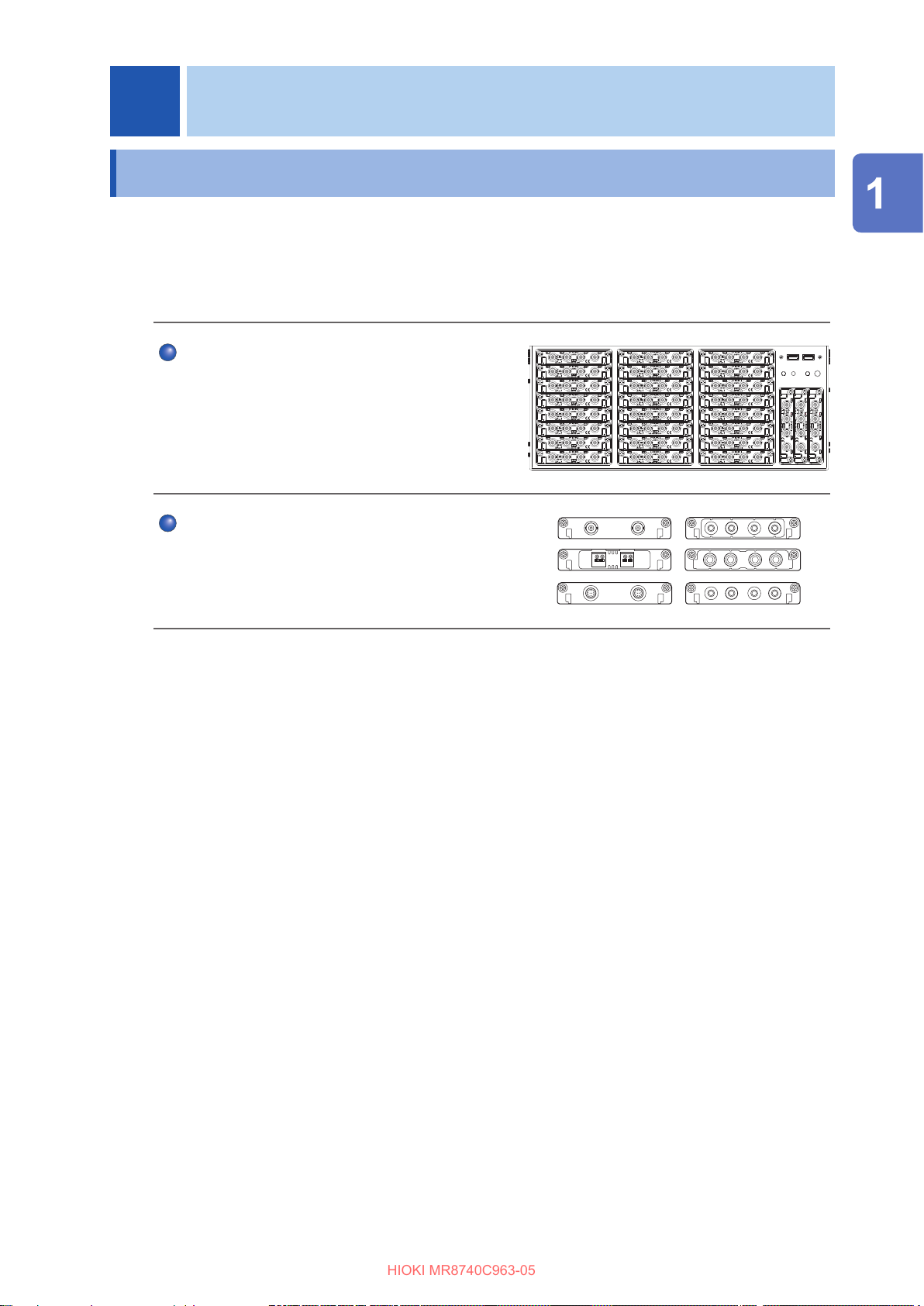

Multichannel simultaneous sampling

This instrument can simultaneously measure signals

across up to 108 channels.

Extensive line of measurement modules

Many types of measurement modules let the

instrument measure a variety of signals that include

voltage, current, temperature, and frequency.

Overview

23

Page 30

Name and Function of Each Part

HIOKI MR8740C963-05

1.2 Name and Function of Each Part

Front side

1

No. Name Function

Up to 27 modules can be installed in the instrument.

You can install as many modules of Model 8971 Current

Unit and Model U8977 3CH Current Unit as possible in any

Module embedding part

1

slots unless the total number of connectable current sensors

reaches nine. Model 8973 Logic Unit can be installed in slots

to which UNIT 25, UNIT 26, or UNIT 27 is assigned only.

Refer to an instruction manual that comes with each input

module.

2

3

4

5

6

Reference

page

p. 10

p. 36

USB2.0 connector Connect a USB ash drive, USB mouse, or USB keyboard.

2

Start button. Activates the instrument or puts it into standby when pressed.

3

POWER lamp

4

DIAG lamp Indicates instrument status.

5

Command error lamp Lights up if a command error occurs.

6

Indicates whether the instrument is powered on or in standby

mode.

p. 60

p. 26

24

Page 31

Rear side

HIOKI MR8740C963-05

Name and Function of Each Part

5

1

4

Overview

6

No. Name Function

Vents (fan motors) Do not block the vents. –

1

Windows® license The Windows

2

The rst four digits of the 9-digit number indicate the year (the

rst two digits omitted) and the month of manufacture. Do not

Serial number

3

Main power switch Turns the instrument on and o. –

4

Power inlet Connects the power cord provided.

5

Interface terminals Connect an LCD, LAN cable, and USB cable.

6

External control

7

terminals

remove this sticker as the number is important.

Inform your authorized Hioki distributor or reseller of this

number if required.

Connect an external device.

7

®

license label is axed. –

2

3

CAUTION

Reference

page

–

p. 19

p. 63

p. 27

p. 56

If you set the main power switch to o while the instrument is powered on, the power

from the built-in battery is lost, resulting in incorrect Windows® shutdown. Be sure to use

the front start button to set the instrument in the standby state, and then set the main

power switch to o.

25

Page 32

Name and Function of Each Part

HIOKI MR8740C963-05

Instrument status indicator

The LEDs indicate the instrument status.

Basic LED indicator

LED name Color Lighting up /

blinking

POWER

STANDBY

DIAG Refer to the

CMD ERR Red Lighting up A command received contained a

Orange Lighting up Stand-by status Set the rear switch

Green Lighting up Power-on status Shut the power o.

Green Blinking Power-on status (warm-up) Shut the power o.

table below.

Refer to the

table below.

Refer to the table below.

syntax error.

When lights up How to turn o

Details of DIAG LED

DIAG LED mode table

Indicator

priority order

1 The inside temperature is high

(ambient temperature > 35°C).

2 The inside temperature is low

(ambient temperature < 10°C).

Status Color Note

Red

Purple

the LED

to o.

–

Send the

command to turn

o the LED.

–

–

*CLS

3 CPU load rate ≥ 80% Yellow Updated every 0.5 seconds, based

on average load rates calculated

over the period.

4 Waiting for a trigger. Blue –

4 The recording is in progress. Green –

4 The recording is complete. Pink Switches to the normal operation

indication when a new command is

received.

5 During normal operation (under

suspension)

White

–

26

Page 33

Name and Function of Each Part

HIOKI MR8740C963-05

1

6

No. Name Function

PS2 connector Not available –

1

COM terminal Not available –

2

VGA terminal

3

4

1000BASE-T connector

LINK ACT

5

2

7 8

Connect a display with an RGB cable.

Maximum resolution: 2560 × 1600

Attach a LAN cable to connect the instrument to your

network.

ACT LED

Blinking: Communicating data

LINK LED

Yellow light: 1000BASE

Green light: 100BASE

O: 10BASE

3

4

9

5

Overview

10

Reference

page

–

p. 58

USB2.0 connector

6

HDMI terminal

7

DisplayPort* terminal

8

USB3.0 connector

9

Audio terminal Not available –

10

• A resolution of 1920 × 1080 dots or more is recommended. Using a display with a lower

resolution can cause poor visibility of waveforms.

• Using a 4K-resolution monitor connected to the HDMI or DisplayPort terminal with the

maximum resolution set may require longer time for processing command communication and

displaying screens.

*: Trademark of another company

Connect a USB ash drive, USB mouse, or USB

keyboard.

Connect a display with an HDMI cable.

Maximum resolution: 3840 × 2160

Connect a display with a DisplayPort cable.

Maximum resolution: 4096 × 2160

Connect a USB ash drive, USB mouse, or USB

keyboard.

p. 60

–

–

p. 60

27

Page 34

Screen

HIOKI MR8740C963-05

1.3 Screen

A commercially-available monitor is required to display information. Use a monitor that supports a VGA

input, HDMI input, or DisplayPort input. (Full HD with a resolution of 1920 × 1080 dots is recommended)

Screen conguration

Waveform screen (p. 29)

List screen

Setting screen

Status

This screen is used to set the measurement conditions such as the sampling rate,

recording length (shot), and saving data.

Refer to

Channel

This screen is used to congure the input channel settings such as the measurement

range and low-pass lter.

Refer to

Sheet screen

This screen is used to congure a display settings for each sheet.

Choose channels to be displayed on each sheet.

Refer to “1.4 Conguring the Sheet Settings” of the Instruction Manual.

Trigger

This screen is used to congure the trigger settings.

Refer to

Calculation screen

This screen is used to congure the numerical and waveform calculation settings.

Refer to “7 Numerical Calculation Functions” and “8 Waveform Calculation”in Instruction

Manual.

“3.2 Setting Measurement Conditions” (p. 70).

“3.3 Conguring the Input Channel Settings” (p. 72).

“3.4 Conguring the Level Trigger Settings” (p. 75).

28

System screen

This screen is used to congure the system environment, communications, and external

control terminal settings, and to initialize the instrument. You can also check the

instrument conguration on this screen.

Refer to

“6.2 Initializing the Instrument” (p. 153).

Page 35

Explanation of each screen

HIOKI MR8740C963-05

Screen

Waveform screen

2

43 5 6 7

8 9

1

10

1213

14

No. Item Description Reference page

1

Switches between the setting and waveform screens. p. 70, p. 83

11

Overview

Measurement condition

2

setting

Sheet selection Switches among preset sheets. *

3

Search setting screen Allows you to set search conditions. *

4

5

6

7

8

9

10

11

12

13

14

(Start icon)

(Stop icon)

(Save icon)

File screen Opens the le screen. *

Waveform area zoom-in Zooms in the waveform area. –

Function buttons

Current date and time Displays the current date and time.

Eject button Ejects a USB ash drive.

Trigger time Displays the trigger time. –

Number of measurement

times

Allows you to choose a sampling rate, recording length

(the number of points and user-dened length), and

recording mode (single or repeat).

Starts a measurement.

Stops the measurement.

Saves data.

Allows you to choose functions available on the

waveform screen.

Displays the processing state of the instrument.

Displays the number of measurement times.

p. 70

1

2

p. 77

3

p. 83

p. 65

p. 61

–

*1: Refer to “1.4 Specifying the Sheet Settings” of Instruction Manual.

*2: Refer to “6 Search Function” of Instruction Manual.

*3: Refer to “4 Saving/Loading Data and Managing Files” of Instruction Manual.

29

Page 36

Screen

HIOKI MR8740C963-05

Cross-screen functions

1

2

No. Name Description

Menu tab Click a tab to choose a menu to open.

1

Sub-menu tab Click a tab to choose a sub-menu to open.

2

30

Page 37

1.4 Basic Operation

HIOKI MR8740C963-05

Mouse operation

Basic Operation

Using a commercially available USB mouse enables you to operate the instrument.

Basic mouse operation for the instrument is as follows:

Mouse operation Description

Click Allows you to choose a menu or execute an action.

Wheel button Changes options to be selected.

Up/down/left/right Moves the mouse cursor around.

External noise may cause the mouse to malfunction. Keep the mouse and mouse cable as far away

as possible from sources of noise.

Use the mouse on an insulated table. Some commercially available mouse devices are susceptible

to noise and using such a mouse on a metal table may cause the instrument to malfunction.

Overview

31

Page 38

Basic Operation

HIOKI MR8740C963-05

Changing screens and settings

Switching between the waveform and setting screens

Click the button to switch between the waveform and setting screens.

Waveform screen

Switching the setting screens

Click a tab to switch the setting screens.

Setting screen

32

Page 39

Choosing an option from a list

HIOKI MR8740C963-05

Example: Choosing a sampling rate Example: Choosing a measurement range of Model

Entering numerical values

Example: Entering a user-dened recording length Example: Entering a scaling ratio

Basic Operation

8966

Overview

33

Page 40

Basic Operation

HIOKI MR8740C963-05

Help Function (Displaying Instruction Manual)

The HTML le of a selected manual appears.

> [Func] > [Help]

34

Page 41

2

HIOKI MR8740C963-05

Preparing for Measurement

Carefully read “Operation Precautions” (p. 8) before starting preparation.

Keyboard, mouse

(p. 31)

External control

terminals

(p. 56)

Zero-adjustment

(p. 66)

Modules

(p. 36)

Computer

(p. 58, p. 86)

Setting the clock

(p. 65)

Connection cords

Preparing for Measurement

(p. 38)

Storage devices

(p. 60)

Power cord

(p. 63)

35

Page 42

Installing and Removing Modules

HIOKI MR8740C963-05

2.1 Installing and Removing Modules

If you order the instrument with modules specied, the instrument will be delivered with the modules

pre-installed. Follow the procedures below to install a module additionally, replace modules, or

remove a module. Up to four modules of Model 8971 Current Unit and up to three modules of

Model 8973 Logic Unit can be installed to the instrument.

Refer to “Handling the instrument and modules” (p. 10).

Required items: Phillips-head screwdriver (No. 2)

How to install a module

Orient and insert the module all the way into the

1

instrument.

Tighten the two screws with the Phillips-head

Right side

2

screwdriver to secure the module.

How to remove the module

Knob

When not installing any module after removal

Install a blank panel. To order additional blank panels, contact your authorized Hioki distributor or

reseller.

Blank panel

Loosen the two module mounting screws with the

1

Phillips-head screwdriver.

Pinch the two knobs and pull out the module.

2

Place a blank panel.

1

Tighten the two screws with the Phillips screwdriver

2

to secure the blank panel.

36

Page 43

Allocation of modules and channels

HIOKI MR8740C963-05

Module numbers

Modules are numbered beginning at the top.

Installing and Removing Modules

Channel numbers

The channels are numbered

beginning from the top left.

Units 1 through 8

Units 9 through 16 Units 17 through 24

Units 25 through 27 (L to R)

Model 8973 Logic Unit can be installed in slots to which Unit 25, 26, or 27 is assigned only.

You can nd out information about the modules installed in the instrument in

Refer to

“System conguration check” (p. 164).

[System information].

Preparing for Measurement

> [System] > [System information]

37

Page 44

Attaching Connection Cords

HIOKI MR8740C963-05

2.2 Attaching Connection Cords

Refer to the manuals of the modules and connection cables if provided.

Measurement Applicable module Cable to be connected

Voltage

Frequency

Rotation

speed

Count

Temperature

Vibration

Load

Pressure

Acceleration

Torque

Displacement

Model 8966 Analog Unit

Model 8968 High Resolution Unit

Model 8972 DC/RMS Unit

Model U8975 4ch Analog Unit

Model U8978 4CH Analog Unit

Model U8979 Charge Unit*

Model 8970 Freq Unit

Model 8967 Temp Unit Thermocouple p. 42

Model U8969 Strain Unit Strain gauge transducer p. 43

Model U8979 Charge Unit Acceleration sensor p. 49

Model L9197 Connection Cord

Model L9198 Connection Cord

(For measuring low-voltage)

Model L9217 Connection Cord

Model L9790 Connection Cord

Model 9665 10:1 Probe

Model 9666 100:1 Probe

Model 9322 Dierential Probe

Model P9000-01 Dierential Probe

Model P9000-02 Dierential Probe

Model 9166 Connection Cord*

(For inputting voltage

into Model U8979)

Reference

page

p. 18

p. 40

Model 8971 Current Unit

Current

Logic signal

Voltage

(precision)

High voltage

Model U8977 3CH Current Unit

(Up to nine current sensors)

Model 8973 Logic Unit

(Up to 3 modules)

Model MR8990 Digital Voltmeter Unit Model L2200 Test Lead p. 51

Model U8991 Digital Voltmeter Unit

Model U8974 High Voltage Unit

Current sensor

Model 9320-01 Logic Probe

Model MR9321-01 Logic Probe

Model 9327 Logic Probe

Model L9197 Connection Cord

Model L9198 Connection Cord

(for measuring low-voltage)

Model L9217 Connection Cord

Model L9790 Connection Cord

Model L4940 Connection Cable

Set

*: Model 9166 Connection Cord can be used for Model U8979 Charge Unit only.

p. 45

p. 51

p. 40

p. 55

38

Page 45

Attaching Connection Cords

HIOKI MR8740C963-05

Output Applicable module Cable to be connected

Waveform

Pulse

DC voltage

DC current

Resistance

(simulated)

Model MR8790 Waveform Generator

Unit

Model U8793 Arbitrary Waveform

Generator Unit

Model MR8791 Pulse Generator Unit

Model U8794 VIR Generator Unit

Model L9795-01 Connection

Cable

Model L9795-02 Connection

Cable

Commercially available cable

(Half-pitch 50 pins)

Commercially available cable

(D-sub 25 pins)

Reference

page

p. 52

p. 53

p. 54

Preparing for Measurement

39

Page 46

Attaching Connection Cords

HIOKI MR8740C963-05

Connection cables (For measuring voltage, frequency, or rotation speed, and obtaining accumulations)

Insert connection cords to modules. Choose an appropriate connection cord based on the

maximum input voltage and tips of cables.

The maximum input voltage of the instrument or connection cord, whichever is lower, is applicable.

Refer to “Before connecting cords” (p. 17).

Required items: Connection cords

Connection cord

Model L9197 Connection Cord

Model L9198 Connection Cord

Model L9217 Connection Cord

Model L9790 Connection Cord

Example: with the alligator clip attached.

Maximum input

voltage

600 V Large alligator clip

300 V Small alligator clip

300 V BNC output

600 V Alligator clip

Grabber clip

Contact pin

Type

When the voltage to be measured exceeds the maximum input rating of the module

being used

(excluding Model U8991 Digital Voltmeter Unit)

Model 9665 10:1 Probe*

Model 9666 100:1 Probe*

Model 9322 Dierential Probe*

Model P9000-01 Dierential Probe*

Model P9000-02 Dierential Probe*

*1: The maximum rated voltage to earth depends on a module to be used.

*2: An optional power cord or AC adapter is required.

*3: An optional AC adapter or a commercially available USB cable is required.

1

1

2

3

3

Example: Model P9000-02 Dierential Probe

Alligator clip

40

Page 47

How to connect a cord

HIOKI MR8740C963-05

Attaching Connection Cords

Example: Model 8966 Analog Unit

1

Locking studs of

module connector

Locking studs

BNC connector slots

2

3

Lock

Align the slots in the BNC connector of a

1

connection cord with the locking studs of a

BNC connector on the module, and insert the

connector.

Turn the BNC connector of the connection cord

2

clockwise until it locks.

Connect the connection cord clips to a

3

measuring object.

How to disconnect the cord

Turn the BNC male connector of the connection cable

counterclockwise, and then pull out the connector.

Preparing for Measurement

41

Page 48

Attaching Connection Cords

HIOKI MR8740C963-05

Thermocouple (Temperature)

Connect thermocouples to Model 8967 Temp Unit.

Required items: Thermocouple and at-blade screwdriver (2.6-mm-width blade)

25 mm

Outer

insulation

Inner insulation

10 mm

Thermocouple

element wires

How to connect the thermocouple

Model 8967 Temp Unit

2

Thermocouple

4

1

3

Recommended cable

Compatible wire: Thermocouple element wires with a diameter

of 0.4 mm to 1.2 mm

Standard insulation stripping length: About 10 mm

Strip the insulation of the thermocouple wires as shown on the

left.

Depress a button on the terminal block on the

1

module with the at-blade screwdriver.

While depressing the button with the at-blade

2

screwdriver, insert each thermocouple wire into

the appropriate terminal hole

Release the button.

3

The thermocouple is connected.

Attach the thermocouple on a measuring

4

object.

How to disconnect the thermocouple

While depressing the button, pull the thermocouple wire.

• If noise inuences surrounding equipment, pass the thermocouple element

wires through the center hole of the ferrite clamp-on choke (comes with

Model 8967 Temp Unit) several times successively from the same end.

• If a thermocouple three meters long or longer is connected, the measurement

may be inuenced by the EMC environment that includes external noise.

• For K type and E type thermocouples, the physical phenomenon, short-range ordering can

probably cause incorrect temperature measurement in the range of 250°C to 600°C. Contact a

thermocouple manufacturer to choose proper thermocouples.

42

Page 49

Attaching Connection Cords

HIOKI MR8740C963-05

Strain gauge transducer

Connect a strain gauge transducer*1 to Model U8969 Strain Unit via Model L9769 Conversion

Cable*2.

*1: Hioki does not oer any strain gauge transducers.

*2: Model L9769 Conversion Cable is an accessory of Model U8969 Strain Unit.

CAUTION

To prevent damage due to in a break in a conversion cable, do not excessively bend,

pull, or twist the cables and joints between the cables and connectors.

Required items: Strain gauge transducer and Model L9769 Conversion Cable

How to connect the transducer

Preparing for Measurement

Model U8969 Strain Unit

1 2

Model L9769 Conversion Cable

Slot of the plug

Indentation of

the connector

Align the plug slot of Model L9769

1

with the outward indentation of Model

U8969, and then insert the plug into the

connector on Model U8969.

Insert the plug until it locks.

2

Connect Model L9769 to the strain gauge

3

transducer.

Connect the strain gauge transducer to a

4

measuring object.

How to disconnect the conversion cable

Gently pull the collar of the plug, which releases

the lock, and disconnect the cable.

43

Page 50

Attaching Connection Cords

HIOKI MR8740C963-05

Connector pin-out

Model U8969 Strain Unit

The metal shell is connected to the GND terminal of

the instrument.

Pin mark Description

A BRIDGE+

B INPUT−

C BRIDGE−

D INPUT+

E FLOATING COMMON

F SENSE+

G SENSE−

Model L9769 Conversion Cable

(Strain gauge converter)

Applied voltage:

A bridge voltage of 2 V

The metal shell is connected to the GND terminal of

the instrument.

Pin mark Description

A BRIDGE+, SENSE+

B INPUT−

C BRIDGE−, SENSE−

D INPUT+

E FLOATING COMMON

F N.C.

G N.C.

H N.C.

J N.C.

Model L9769 connection

• Pin F of the conversion cable (module end) is connected to pin A of the conversion cable

(transducer end).

• Pin G of the conversion cable (module end) is connected with pin C of the conversion cable

(transducer end).

IMPORTANT

• A bridge box is required to measure strain using a strain gauge. Use a commercially available

strain gauge and a bridge box.

• Some bridge boxes may be susceptible to noise. In that case, grounding the bridge box allows

the box to be less susceptible to noise. For information on how to ground the bridge box, refer

to the manual of your bridge box or contact its manufacturer.

You can use your Model 8969 Strain Unit with the instrument. The instrument with Model 8969

Strain Unit installed refers to Model 8969 as [U8969] on the display.

44

Page 51

Attaching Connection Cords

HIOKI MR8740C963-05

Current sensor

Familiarize yourself with “Operation Precautions” (p. 8) before connecting a current sensor.

Refer to the instruction manual that comes with each current sensor for details on specications

and directions for use.

CAUTION

Do not connect and remove a current sensor while the instrument remains on.

Doing so will cause damage to the current sensor.

Up to nine sensors can connect to Model 8971 Current Unit and Model U8977 3CH Current Unit all

together.

Preparing for Measurement

45

Page 52

Attaching Connection Cords

HIOKI MR8740C963-05

Current sensors that can be connected to current modules

The following current sensors can be connected to the Model U8977 3CH Current Unit and Model

8971 Current Unit. Use of conversion cables may be required depending on sensors and modules.

: Directly connectible

Model

number

9709

9709-05

9272-05

9272-10 CT9900 9318 Plastic

CT6841

CT6841-05

CT6843

CT6843-05

CT6844

CT6844-05

CT6845

CT6845-05

Model name

AC/DC Current Sensor

Clamp on Sensor

AC/DC Current Probe

AC/DC Current Probe

AC/DC Current Probe

AC/DC Current Probe

Maximum

input current /

Frequency

500 A

DC to 100 kHz

20 A / 200 A

1 Hz to 100 kHz

20 A

DC to 1 MHz

200 A

DC to 500 kHz

500 A

DC to 200 kHz

500 A

DC to 100 kHz

Conversion

cable for

U8977

CT9900 9318 Plastic

CT9900 9318 Plastic

CT9900 9318 Plastic

CT9900 9318 Plastic

CT9900 9318 Plastic

Conversion

cable for 8971

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

Connector*

Metal

Metal

Metal

Metal

Metal

Metal

1

CT6846

AC/DC Current Probe

CT6846-05

CT6862

AC/DC Current Sensor

CT6862-05

CT6863

AC/DC Current Sensor

CT6863-05

CT6865

AC/DC Current Sensor

CT6865-05

CT6875 AC/DC Current Sensor

CT6876 AC/DC Current Sensor

CT6877 AC/DC Current Sensor

*1: Metal connector (ME15W), plastic connector (PL23)

1000 A

DC to 20 kHz

50 A

DC to 1 MHz

200 A

DC to 500 kHz

1000 A

DC to 20 kHz

500 A

DC to 2 MHz

1000 A

DC to 1.5 MHz

1000 A

DC to 1 MHz

CT9900 9318 Plastic

CT9900 9318 Plastic

CT9900 9318 Plastic

CT9900 9318 Plastic

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

CT9900

+ 9318

Cannot

connect

Metal

Metal

Metal

Metal

Metal

Metal

Metal

46

Page 53

Attaching Connection Cords

HIOKI MR8740C963-05

Connecting a current sensor with Model U8977 3CH Current Unit

You can directly connect a current sensor with the sub model-number “-05,” which has a metal

connector (ME15W).

Point the widest key upward.

Hold the metal

sleeve.

Using Model CT9900 Conversion Cable, you can connect a current sensor without the sub modelnumber “-05,” which has a plastic connector (PL23), with Model U8977 3CH Current Unit.

Align the connector guides of the cable with

1

those of the module connector.

Straightly insert the connector until it locks.

2

Hold the part other than metal to insert the

connector.

The instrument automatically recognizes the

model of the current sensor.

How to disconnect the current sensor

Hold and pull the metal collar, which releases

1

the lock.

Pull the connector.

2

Model CT9900

Conversion Cable

Preparing for Measurement

When Model CT9900 Conversion Cable is used, the instrument recognizes Model CT6846 or

CT6865 (1000 A rating) as a 500-A AC/DC sensor. Set the conversion ratio to 2.00.

47

Page 54

Attaching Connection Cords

HIOKI MR8740C963-05

By using Model CT9920 Conversion Cable (optional), you can connect a current sensor of Model

CT7000 series with Model U8977 3CH Current Unit. The instrument cannot recognize any sensor

with Model CT9920 connected.

Select a mode in the setting screen.

Supported models Model CT7631, Model CT7636, Model CT7642, Model CT7731, Model CT7736,

Model CT7742, Model CT7044, Model CT7045,

Model CT7046

Model CT9920

Conversion Cable

For current sensor

Connecting a current sensor with Model 8971 Current Unit

Current sensors whose model number is without the sux -05, which have a plastic connector

(PL23), can be connected with Model 8971 Current Unit in combination with Model 9318

Conversion Cable*.

Those whose model number is with the sux -05, which have a metallic connector, can be

connected to Model 8971 Current Unit in combination with both the 9318 Conversion Cable* and

the CT9901 Conversion Cable.

*: Model 9318 Conversion Cable is an accessory of Model 8971 Current Unit.

Model 8971 Current Unit

Model 9318

Conversion Cable

1

2

Align the guides of the conversion cable with

1

those of the sensor connector on the module,

and straightly insert the plug until it locks.

Align the guides of the current sensor to

2

be used with those of the conversion cable

connector, and straightly insert the plug until it

locks.

The instrument automatically recognizes the

model of the current sensor.

Clamp the current sensor around a line of a

3

measuring object.

How to connect the cable and a sensor

When measuring currents with a voltage module

Using Model 9018-50 Clamp on Probe, you can measure a current using a voltage measurement

module such as Model 8966 Analog Unit.

Conguring the scaling settings allows measured waveforms to be displayed as current values. For

the setup procedure, refer to “Converting Input Values (Scaling Function)” of the Instruction Manual.

48

Hold and pull the plastic collar of the

1

conversion cable, which releases the lock, and

the remove the connector.

Hold and pull the plastic collar of the current

2