Page 1

Instruction Manual

MR6000

MR6000-01

MEMORY HiCORDER

Feb. 2018 Edition 1

MR6000A966-00 18-02H

EN

Page 2

Page 3

Contents

Contents

Introduction ................................................ 1

HowtoRefertoThisManual .................... 2

1 MeasurementMethod 3

1.1 MeasurementProcedure ................. 3

1.2 ConguringMeasurement

Conditions ........................................ 5

Sampling rate setting guideline .....................7

Using the envelope .......................................9

1.3 Setting Input Channels ...................11

Analog channels .........................................13

Logic channels ............................................17

1.4 Setting the Sheets .......................... 18

Switching sheets on the waveform

screen .........................................................19

1.5 Starting/Stopping the

Measurement .................................. 20

2 Operating the

Waveform Screen and

Analyzing Data 21

2.1 ReadingMeasuredValues

(Trace Cursors) ............................... 22

2.2 Specifying the Waveform Range

(Section Cursor) ............................. 26

Changing the display magnication of

the waveforms while moving the section

cursor ..........................................................27

2.3 Displaying Vertical Scales

(Gauge Function) ........................... 28

2.4 Scrolling Waveforms ...................... 30

Scrolling waveforms ....................................30

Checking a position of waveforms with

the scroll bar ...............................................31

2.5 Changing the Display Position

andDisplayMagnicationofthe

Waveforms ...................................... 32

Differentiating the waveform display

position and display magnication for

each analog channel ...................................33

2.6 Operating the Rotary Knob ........... 36

2.7 Enlarging a Part of the

Waveform (Zoom Function) ........... 37

3 Advanced Functions 39

3.1 Overlaying New Waveforms

With Previously Acquired

Waveforms ...................................... 40

3.2 Converting Input Values

(Scaling Function) .......................... 42

When using Model U8969 Strain Unit .........47

3.3 Fine-Adjusting Input Values

(Vernier Function) .......................... 48

3.4 Inverting the Waveform

(Invert Function) ............................. 49

3.5 Copying Settings

(Copy Function) .............................. 50

3.6 ConguringModule-Specic

Settings ........................................... 51

Setting Model 8968 High Resolution

Unit .............................................................51

Setting Model 8967 Temp Unit ....................52

Setting Model U8969 Strain Unit ................54

Setting Model 8970 Freq Unit .....................56

Setting Model 8971 Current Unit ................59

Setting Model 8972 DC/RMS Unit ..............61

Setting Model MR8990 Digital Voltmeter

Unit .............................................................62

Setting Model U8974 High Voltage Unit .....64

4 Saving/Loading Data

andManagingFiles 65

4.1 Data That Can Be Saved and

Loaded ............................................ 66

4.2 Saving Data ..................................... 67

Save types and setting procedure ..............67

Saving waveform data automatically ..........68

Real-time save ............................................72

Freely selecting data items to be saved

and save les (SAVE key) ..........................74

4.3 Loading Data .................................. 77

Data loading procedure ..............................77

Loading the settings automatically

(Auto-setup function) ..................................78

4.4 ManagingFiles ............................... 79

5 Setting the Trigger 81

5.1 Trigger Setting Procedure ............. 82

5.2 Enabling the Trigger Function ...... 83

5.3 Setting the Trigger Timing ............. 84

5.4 Setting the Pre-trigger and

Post-trigger ..................................... 86

To observe the input waveforms while

the instrument is waiting for a trigger ..........90

5.5 Setting the Trigger Logical

Conditions (AND/OR) among

Trigger Sources .............................. 91

5.6 Triggering the Instrument Using

Analog Signals ............................... 93

5.7 Triggering the Instrument With

Logic Signals (Logic Trigger) ...... 102

1

2

3

4

5

6

7

8

9

10

Index

MR6000A966-00

i

Page 4

Contents

5.8 Triggering the Instrument at

Regular Intervals

(Interval Trigger) ........................... 104

5.9 Triggering the Instrument

Externally (External Trigger) ....... 106

5.10 Triggering the Instrument

Manually(ForcibleTrigger) ......... 106

6 Search Function 107

6.1 Searching For Peak Values ......... 108

6.2 Searching For the Positions

Where Trigger Condition Is

Satised .........................................110

6.3 Searching For Differences from

the Fundamental Wave

(MemoryHiConcierge) ..................114

6.4 Allowing the Display to Jump to

theSpeciedPosition ...................116

7 Numerical Calculation

Function 119

7.1 Numerical Calculation

Procedure ..................................... 120

7.2 Setting Numerical Calculation .... 122

Displaying the numerical calculation

results .......................................................131

7.3 Evaluating the Calculation

Results on a Pass/Fail Basis ....... 132

Displaying the evaluation results and

outputting signals externally .....................135

7.4 Numerical Calculation Types

and Descriptions .......................... 136

9.3 Sending Data to a PC With the

FTP Client Function ..................... 158

Setting up an FTP server on a PC ............159

Setting the FTP client with the

instrument .................................................163

9.4 Operating the Instrument with a

Browser Installed in a PC ............ 164

Connecting the PC to the instrument

with Internet browser ................................165

Operating the instrument remotely ...........166

Starting/Stopping the instrument ..............167

Setting the comment .................................168

Acquiring data from the instrument ...........169

Setting the clock .......................................170

Handling les ............................................170

9.5 Sending Emails ............................ 171

Conguring the basic setting for sending

email .........................................................172

Setting email contents ..............................173

Setting authentication, compression,

and encryption for emails to be sent .........174

9.6 Controlling the Instrument with

Command Communications

(LAN) ............................................. 176

10 Controlling the

Instrument Externally 179

10.1 External Input and Output ........... 180

External input (IN1), (IN2) .........................180

External output (OUT1), (OUT2) ...............181

Trigger output (TRIG.OUT) .......................183

External trigger terminal (EXT.TRIG) ........ 185

10.2 External Sampling

(EXT.SMPL) ................................... 187

8 Setting the System

Environment 143

9 Connecting the

Instrument to PCs 149

9.1 ConguringtheLANSettings

and Connecting to the

Network ......................................... 150

Conguring the LAN settings with the

instrument .................................................150

9.2 ManagingDataintheInstrument

With the FTP Server Function .... 155

Setting the FTP sever with the

instrument .................................................156

Operating the instrument with a PC

(FTP server function) ................................157

ii

11 Appendix 189

11.1 Information for Reference

Purposes ....................................... 189

Waveform le size (for reference) .............189

Maximum recording time when the

real-time save is on (reference) ................193

Scaling method for strain gauges .............199

Example of a waveform text le ................200

Index Ind.1

Page 5

Introduction

Introduction

Thank you for purchasing the HIOKI MR6000, MR6000-01 Memory HiCorder. To obtain maximum

performance from the instrument over the long term, be sure to read this manual carefully and keep

it handy for future reference.

Model MR6000-01 Memory HiCorder is a model of Model MR6000 equipped with the following

calculation functions (options):

• Digital lter calculation

• Real-time waveform calculation

Following manuals are provided along with these models. Refer to the relevant manual based on

the usage.

Type Contents Print PDF

Operating Precautions Information on the instrument for safe operation

Quick Start Manual Basic instructions and instrument specications

Instruction Manual

(this document)

Calculation Guide (Options)

Notations

(Bold-faced)

Functions and instructions for the instrument –

Method to use the calculation functions, etc. available

only with Model MR6000-01

*

(p. ) Indicates the location of reference information.

START

[ ]

Windows

Additional information is presented below.

Indicates the initial setting values of the items. Initialization sets the items to these

values.

Indicates the names and keys on the windows in boldface.

Menus, dialogs, buttons in a dialog, and other names on the screen are indicated in

brackets.

Unless otherwise specied, “Windows” represents Windows 7, Windows 8, and

Windows 10.

–

–

–

Current sensor Sensors measuring current are referred to as “current sensor.”

The number of times per second the analog input signals are digitized by the

S/s

instrument is expressed in terms of “samples per second (S/s).”

Example: “20 MS/s” (20 megasamples per second) indicates that the signal is digitized

20 × 10

6

times per second.

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), and rdg. (reading) with the following

meanings:

f.s.

rdg.

(maximum display value or scale length)

The maximum displayable value or scale length.

(displayed value)

The value presently being measured and indicated on the measuring instrument.

1

Page 6

How to Refer to This Manual

How to Refer to This Manual

How to open a screen

Indicates the order of tapping

the screens.

The button

setting key.

Sequence numbers

Numbered same as a

corresponding step-by-step

instruction.

Options and explanations

Describes selectable

settings when an item is

tapped.

The icon

default setting of the item.

represents the

indicates the

2

Page 7

1

Measurement Method

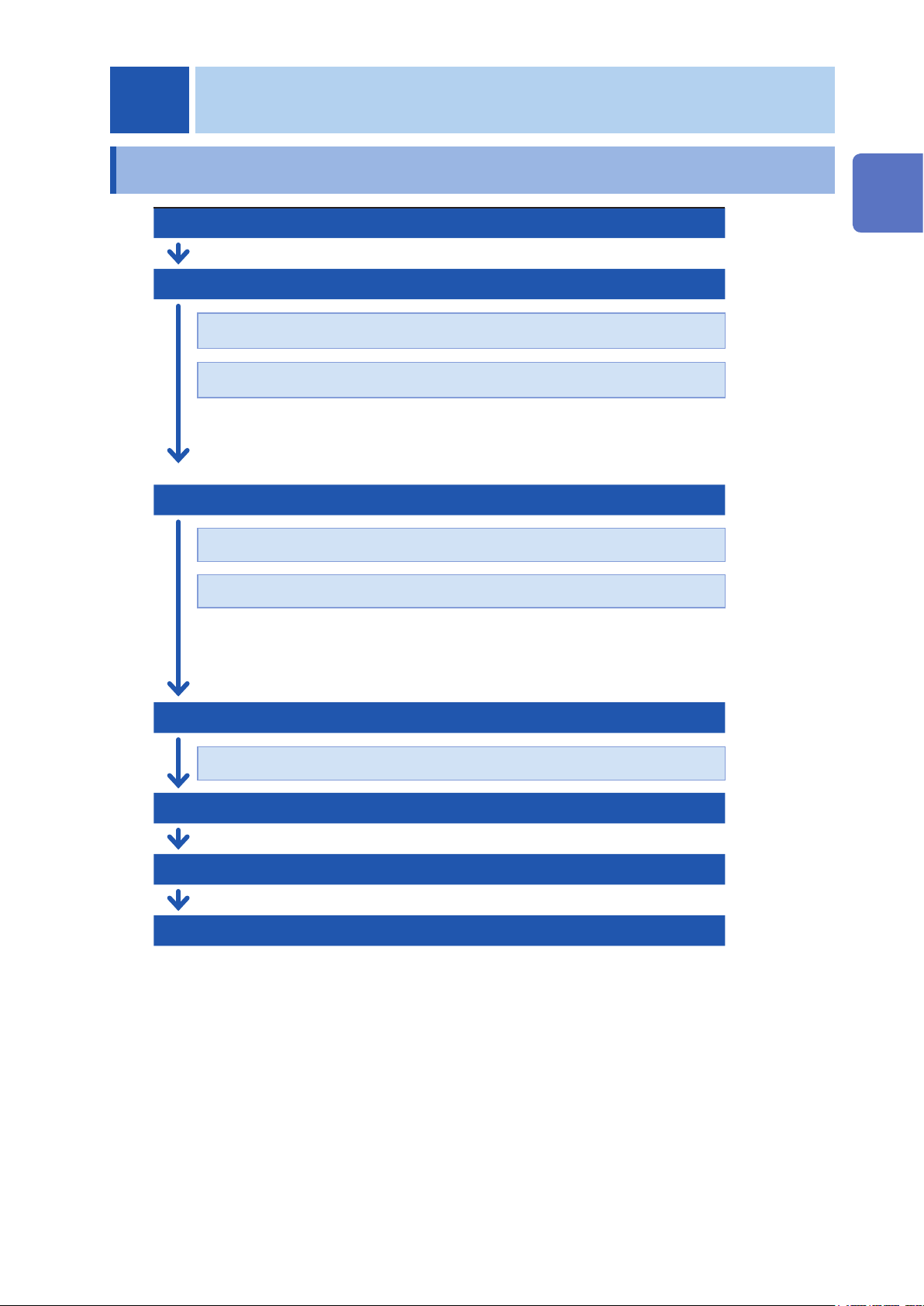

1.1 Measurement Procedure

Inspecting the instrument before measurement

Conguring the basic settings for measurement

1

Measurement Method

Set the sampling rate.

Set the recording length.

Advanced settings: “Using the envelope” (p. 9)

“3.1 Overlaying New Waveforms With Previously

Acquired Waveforms”

Setting the input channels

Set the analog channels.

Set the logic channels.

Advanced settings: “3.2 Converting Input Values (Scaling Function)” (p. 42)

“3.3 Fine-Adjusting Input Values (Vernier Function)” (p. 48)

“3.4 Inverting the Waveform (Invert Function)” (p. 49)

Setting the sheets

Set the display format of waveforms.

(p. 5)

(p. 6)

(p. 40)

(p. 11)

(p. 13)

(p. 17)

(p. 18)

Setting the triggers

Starting a measurement

Finishing the measurement

Advanced operation: “2.2 Specifying the Waveform Range (Section Cursor)” (p. 26)

“Scrolling waveforms” (p. 30)

“2.5 Changing the Display Position and Display

Magnication of the Waveforms”

“4 Saving/Loading Data and Managing Files” (p. 65)

“7 Numerical Calculation Function” (p. 119)

(p. 81)

(p. 20)

(p. 47)

3

Page 8

Measurement Procedure

To perform the automatic setup

On the waveform screen, tap [Auto range] to set the sampling rate, measurement range, and zero

position of input waveforms automatically, and then start a measurement.

Refer to “3.7 Measurement With the Auto-range Setting” in Quick Start Manual.

To load settings registered previously

Load the settings le on the le screen.

Refer to “4.3 Loading Data” (p. 77).

To load saved settings automatically at the time of startup

Congure the setting for the instrument so as to load the le containing the instrument settings at

the time of startup.

Refer to “Loading the settings automatically (Auto-setup function)” (p. 78)

To initialize the instrument (restoring the basic settings)

Restore the instrument settings to the factory default by tapping [Initialize], which is accessible by

proceeding in the following order:

> [System] > [Initialize]

The setting after the initialization is suitable for simple measurement.

If any unexpected or complicated behavior is observed, initialize the instrument.

Refer to “6.2 Initializing the Instrument” in Quick Start Manual.

4

Page 9

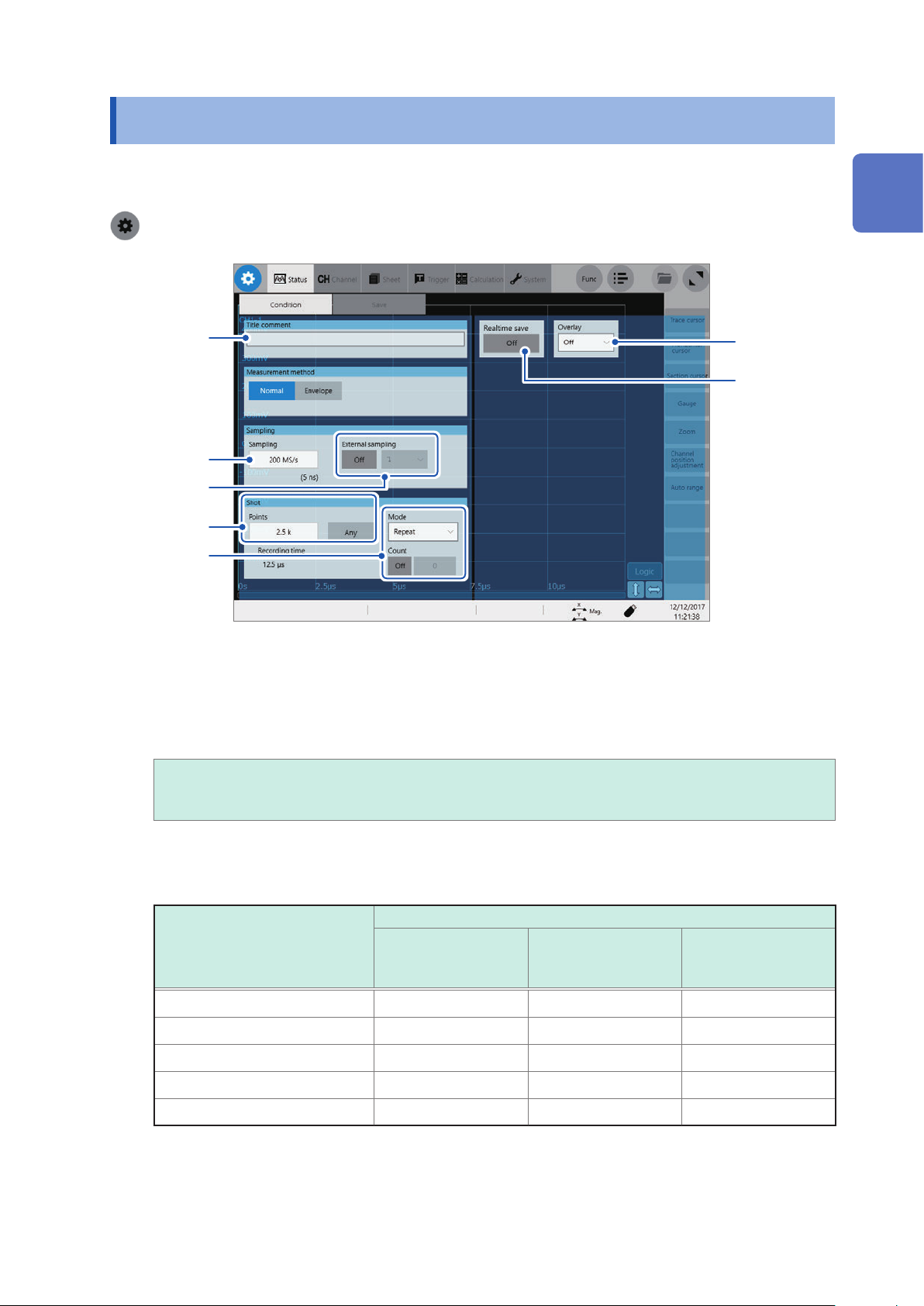

Conguring Measurement Conditions

1.2 Conguring Measurement Conditions

Congure conditions required for measurement including the sampling rate ([Sampling]) and

recording length ([Shot]).

> [Status] > [Condition]

1

Measurement Method

1

2

3

4

5

Type a comment in the [Title comment] box.

1

Number of characters: up to 40

Set [Sampling].

2

Refer to “Sampling rate setting guideline” (p. 7).

200 MS/s

500 kS/s, 200 kS/s, 100 kS/s, 50 kS/s, 20 kS/s, 10 kS/s, 5 kS/s, 2 kS/s, 1 kS/s,

500 S/s, 200 S/s, 100 S/s, 50 S/s, 20 S/s, 10 S/s, 5 S/s, 2 S/s, 1 S/s

, 100 MS/s, 50 MS/s, 20 MS/s, 10 MS/s, 5 MS/s, 2 MS/s, 1 MS/s,

6

7

When the real-time waveform calculation (Model MR6000-01 only) is set to [On], a sampling rate of 200 MS/s

cannot be selected.

When the real-time save is set to [On], due to the combination of the number of channels to be used and save

destinations, the maximum sampling rate that can be set varies as follows:

Maximum sampling rate that can be set

Number of channels to be used

1 channel to 2 channels 20 MS/s 10 MS/s 5 MS/s

3 channels to 4 channels 10 MS/s 5 MS/s 2 MS/s

5 channels to 8 channels 5 MS/s 2 MS/s 1 MS/s

9 channels to 16 channels 2 MS/s 1 MS/s 500 kS/s

17 channels to 32 channels 1 MS/s 500 kS/s 200 kS/s

Only if the following Hioki-designated options are used, the real-time save operation with the instrument is

guaranteed:

• Model U8332 SSD Unit

• Model U8333 HD Unit

• Model Z4006 USB Drive

• Model Z4001 and Model Z4003 SD Memory Card

SSD HDD

USB ash drive

SD card

FTP transmission

5

Page 10

Conguring Measurement Conditions

Set [External sampling].

3

The external sampling is disabled when the envelope is used.

Off

On Select this option to sample data at a sampling rate dened by a signal input into the

Set [Shot].

4

Tap [Points] to set the number of measurement points.

2.5 k

, 5 k, 10 k, 20 k, 50 k, 100 k, 200 k, 500 k, 1 M, 2 M, 5 M, 10 M, 20 M, 50 M, 100 M, 200 M,

500 M, 1 G

Enabling [Any] and tapping [Points] allows you to set the number of points in increments of 100.

When the real-time save is set to [On], [Shot] cannot be set in terms of [Points].

Set [Recording time] on the [Save] screen. (p. 73)

The maximum recording length that can be set varies depending on the number of channels to be measured.

Disables the external sampling function.

external sampling terminal (EXT.SMPL).

Samples data at rising edges of the input signal.

Samples data at falling edges of the input signal.

Set [Mode].

5

Single Measures waveforms only once. Pressing the START key starts recording waveforms,

and then stops when the specied recording length of the waveforms have been

acquired.

Repeat

When [Repeat] mode is set and [Count] is set to [On], the specied number of measurements are performed.

Only [Single] mode can be selected when [Realtime save] is set to [On].

Set [Overlay].

6

Refer to “3.1 Overlaying New Waveforms With Previously Acquired Waveforms” (p. 40).

Set [Realtime save] to [On].

7

Data can be recorded in the optional storage device while measuring waveforms.

Refer to “Real-time save” (p. 72).

Measures waveforms repeatedly. Pressing the STOP key stops the measurement in

progress.

6

Page 11

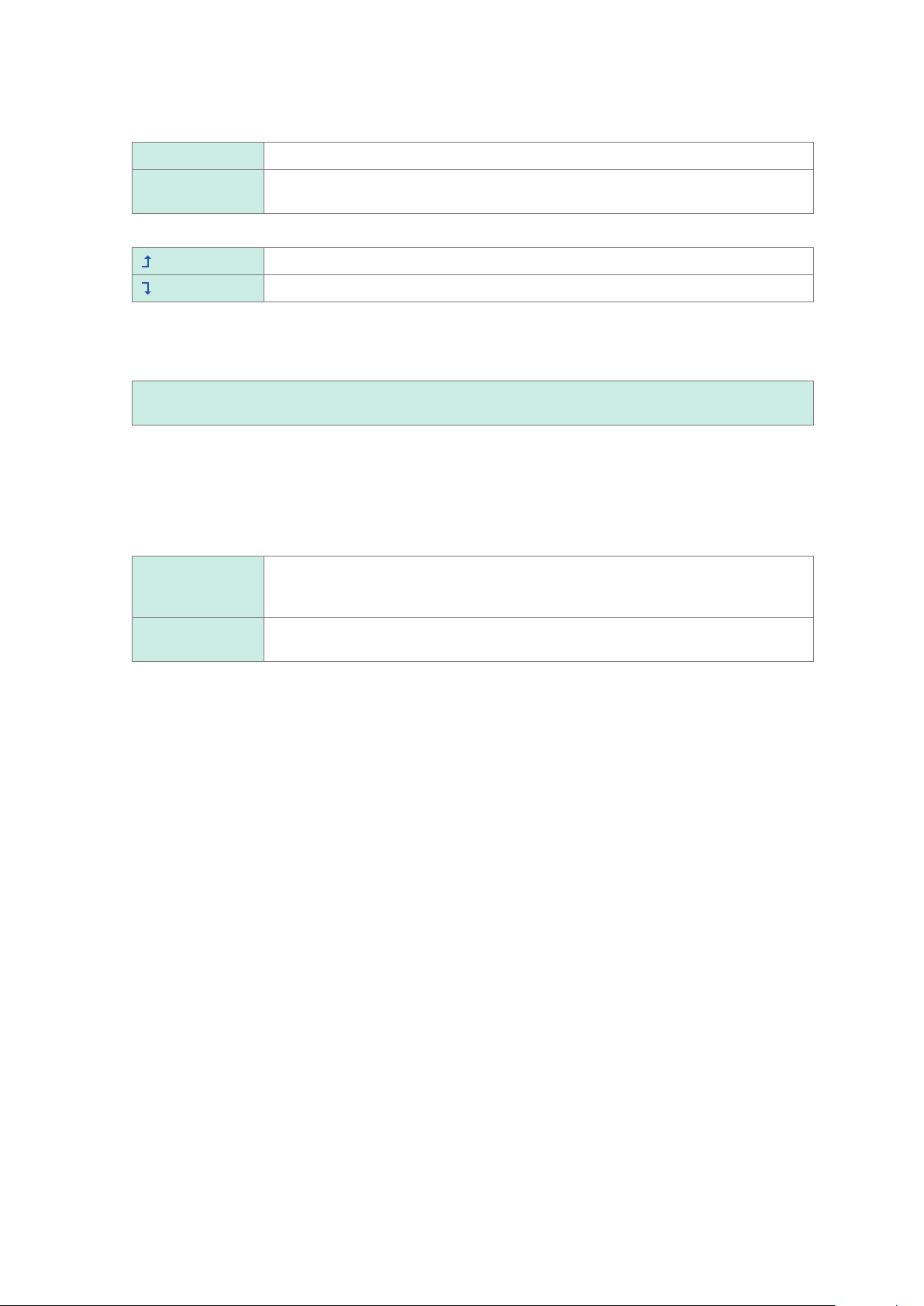

Sampling rate setting guideline

Select a sampling rate using the following table as a guideline.

Conguring Measurement Conditions

Maximum display

frequency

8 MHz 200 MS/s 400 Hz 10 kS/s

4 MHz 100 MS/s 200 Hz 5 kS/s

2 MHz 50 MS/s 80 Hz 2 kS/s

800 kHz 20 MS/s 40 Hz 1 kS/s

400 kHz 10 MS/s 20 Hz 500 S/s

200 kHz 5 MS/s 8 Hz 200 S/s

80 kHz 2 MS/s 4 Hz 100 S/s

40 kHz 1 MS/s 2 Hz 50 S/s

20 kHz 500 kS/s 0.8 Hz 20 S/s

8 kHz 200 kS/s 0.4 Hz 10 S/s

4 kHz 100 kS/s 0.2 Hz 5 S/s

2 kHz 50 kS/s 0.08 Hz 2 S/s

800 Hz 20 kS/s 0.04 Hz 1 S/s

Sampling rate

Maximum display

frequency

Sampling rate

If the instrument plots non-existent waveforms (aliasing)

If a measured signal oscillates at a higher frequency compared to the specied sampling rate, the

instrument may plot non-existent waveforms oscillating at a lower frequency than that of the actual

signal when the signal frequency reaches a certain level. This phenomenon is called aliasing.

1

Measurement Method

Actual input signal

A sampling interval longer than the cycle

of the input signal causes aliasing.

Sampling interval

To plot a sign wave that allows you to observe the peaks of the sine wave on the LCD without any

aliasing, the instrument needs to sample the waveform at a minimum of 25 points per cycle.

Observed waveform

: Sampled points

To set the sampling rate automatically

Refer to “3.7 Measurement With the Auto-range setting” in Quick Start Manual.

7

Page 12

Conguring Measurement Conditions

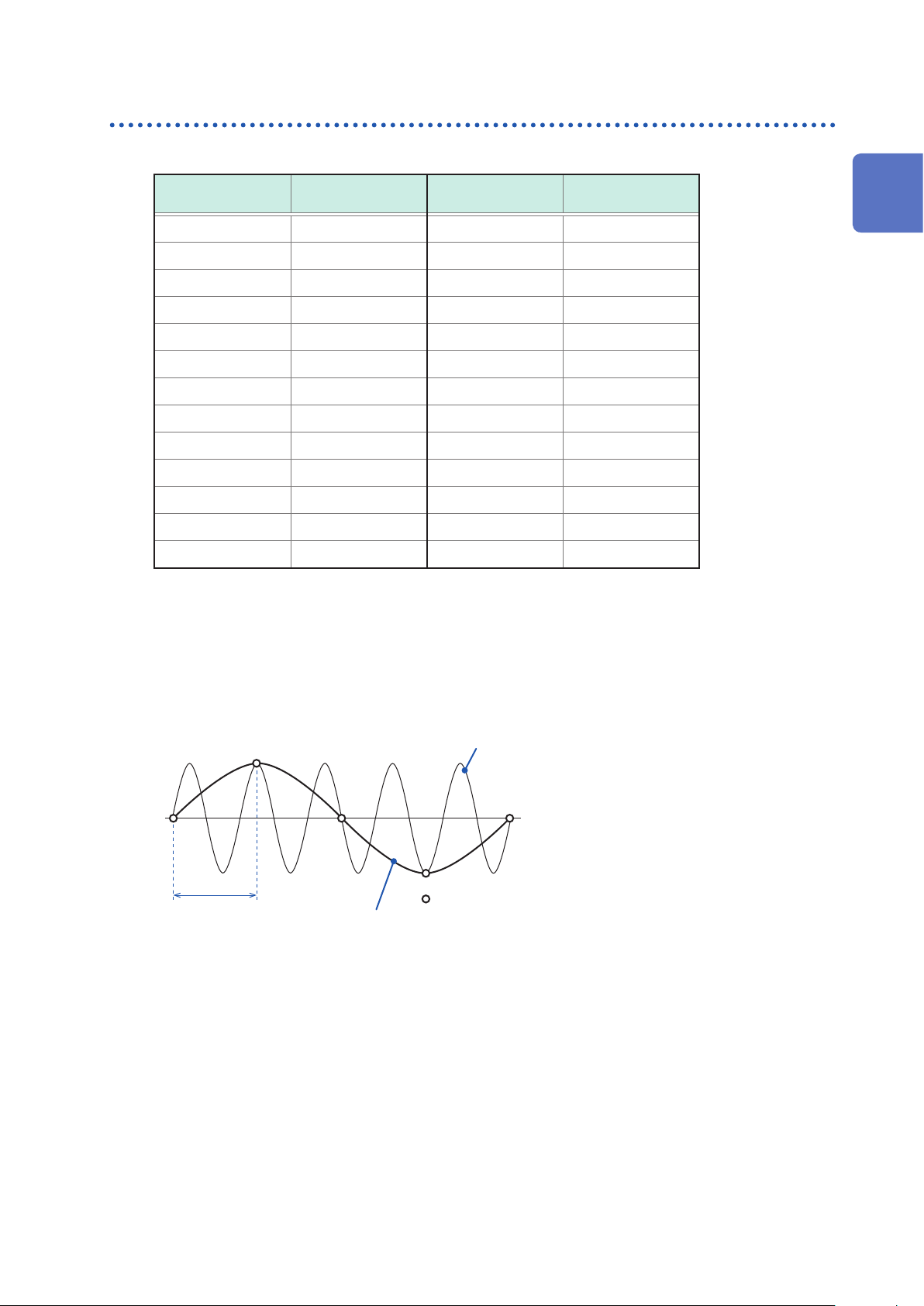

Update rate of each module

The data update rate is not allowed to exceed the maximum sampling rate of each module.

The same data are measured until they get updated, causing the instrument to plot a stair-step

waveform.

In addition, even though the same signal is measured simultaneously, values may vary due to

differences in the sampling rate, frequency range, and frequency characteristics of modules.

Module Sampling rate of module Reference

Model 8966 Analog Unit 20 MS/s (50 ns) –

Model 8967 Temp Unit

Model 8968 High Resolution Unit 1 MS/s (1 µs) –

Model U8969 Strain Unit 200 kS/s (5 µs) p. 54

Model 8970 Freq Unit Varies according to the setting. p. 56

Model 8971 Current Unit 1 MS/s (1 µs) p. 59

Model 8972 DC/RMS Unit Varies according to the response setting. p. 61

Model 8973 Logic Unit 20 MS/s (50 ns) –

MR8990

Digital Voltmeter Unit

Model U8974 High Voltage Unit 1 MS/s (1 µs) p. 64

Model U8975 4ch Analog Unit 5 MS/s (200 ns) –

Model U8976 High Speed Analog Unit 200 MS/s (5 ns) –

Varies according to the data refresh

setting.

Varies according to the NPLC setting. p. 62

p. 52

8

Page 13

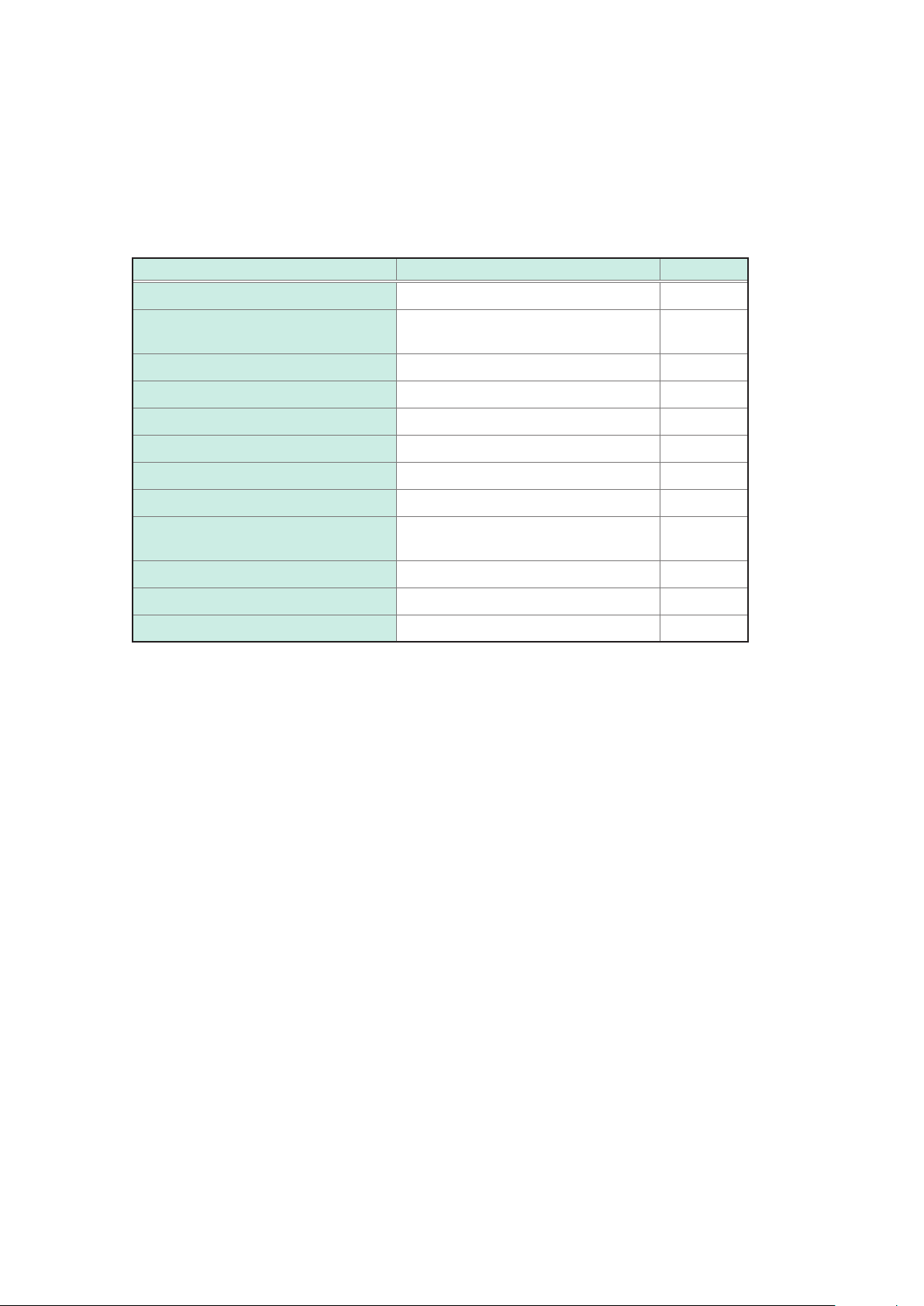

Using the envelope

> [Status] > [Condition]

1

2

3

Conguring Measurement Conditions

1

Measurement Method

Set [Measurement method] to [Envelope].

1

Normal

Envelope Uses the envelope.

• Normal:

• Envelope:

• Values to be acquired using the envelope

A set of sampled data acquired using the envelope consists of two values: the maximum value and the

minimum value. These values are taken from the measured values acquired at an over-sampling rate during

the recording interval set in [Sampling]. When shown on the screen, they are displayed as if they range in

amplitude. When saved in an external storage device, the data of the maximum and minimum values are

stored for a single instance of measurement.

The instrument records data at the specied sampling rate.

At the specied recording interval, the instrument records the maximum and minimum values among data

sampled within each specied recording interval at an over-sampling rate* of 100 MS/s. Hence, even though

a relatively longer recording interval is set, peaks of uctuations can be recorded without being missed.

*: Over-sampled data (indicated by blue dots

Recording

interval

Oversampling interval (10 ns)

Does not use the envelope.

Maximum

Minimum

in the gure) are not saved.

: Over-sampled data

: Stored data (data of the maximum and minimum

values)

: Waveform shown on the screen

9

Page 14

Conguring Measurement Conditions

Set [Sampling].

2

The following are the sampling rates that can be selected when the envelope is used.

10 MS/s

5 kS/s, 2 kS/s, 1 kS/s, 500 S/s, 200 S/s, 100 S/s, 50 S/s, 20 S/s, 10 S/s, 5 S/s, 2 S/s, 1 S/s,

30 S/min, 12 S/min, 6 S/min, 2 S/min, 1 S/min

Set [Shot].

3

Tap [Points] to set the number of measurement points.

2.5 k

500 M, 1 G

Enabling [Any] and tapping [Points] allows you to enter [Points] in increments of 100 points.

When the real-time save is set to [On], [Shot] cannot be set in terms of [Points].

Set [Recording time] on the [Save] screen. (p. 73)

The maximum recording length that can be set varies depending on the number of channels to be measured.

, 5 MS/s, 2 MS/s, 1 MS/s, 500 kS/s, 200 kS/s, 100 kS/s, 50 kS/s, 20 kS/s, 10 kS/s,

, 5 k, 10 k, 20 k, 50 k, 100 k, 200 k, 500 k, 1 M, 2 M, 5 M, 10 M, 20 M, 50 M, 100 M, 200 M,

10

Page 15

1.3 Setting Input Channels

Congure the settings of the analog and logic channels.

Setting Input Channels

> [Channel]

Operation available on the [Channel] screen

• Adding a comment to a channel

• Setting measurement conditions for a channel

• Setting the display method of waveforms

• Converting measured values into physical quantities and displaying them

1

Measurement Method

11

Page 16

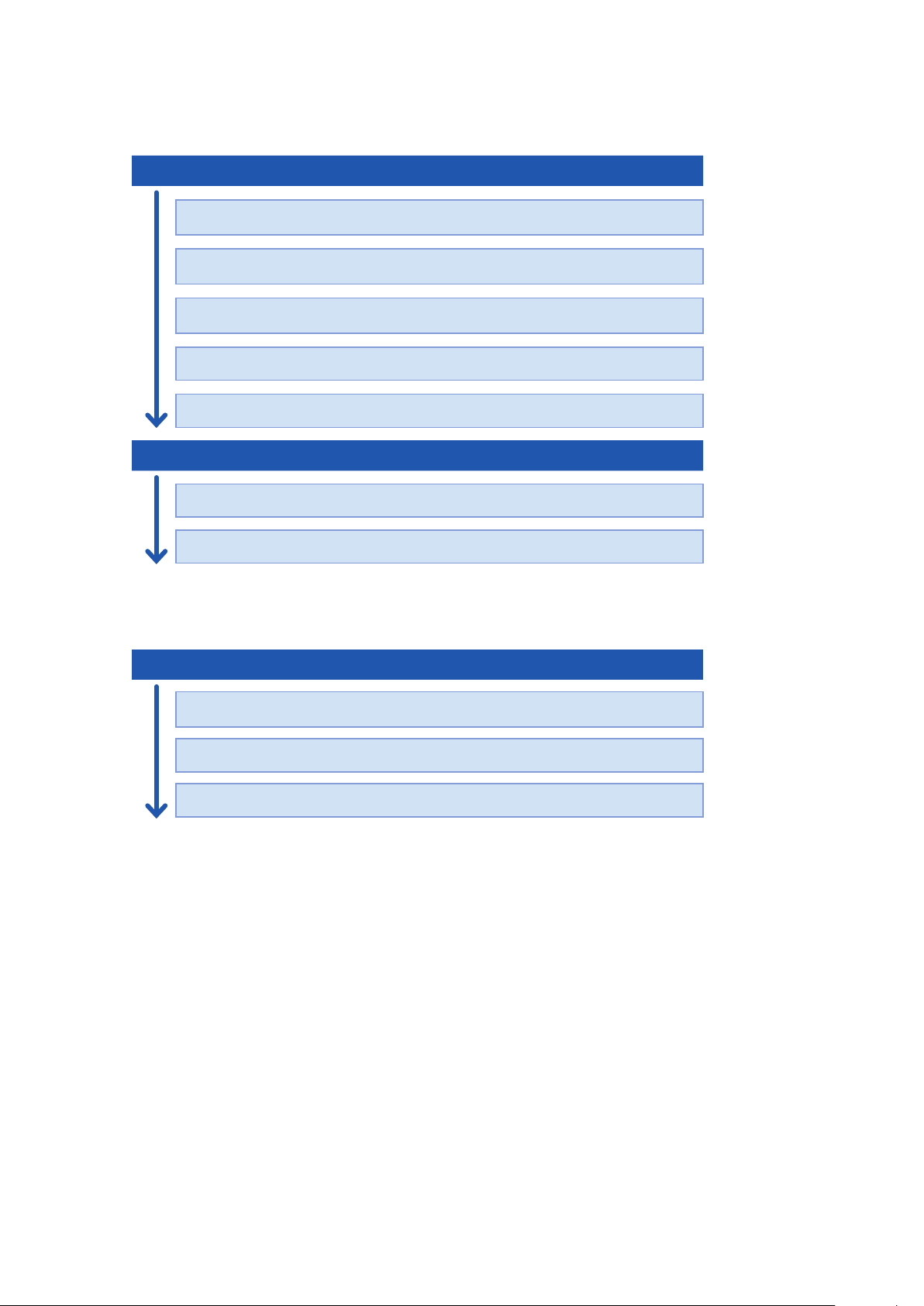

Setting Input Channels

Channel setting procedure

Analog channels (CH1 through CH32) setting procedure

Conguring input settings

Set the measurement mode.

Select an appropriate range for measurement.

Convert input values. (Scaling function)

Set the input coupling.

Set the low-pass lter (if noise is observed).

Conguring the display settings

Set the display color of waveforms.

Convert input values. (Scaling function)

Logic channels (Model 8973 Logic Unit) setting procedure

(p. 13)

(p. 14)

(p. 16)

(p. 15)

(p. 15)

(p. 16)

(p. 16)

Conguring the display settings

Set the logic recording width.

Set the display positions of waveforms.

Set the display colors of waveforms.

(p. 17)

(p. 17)

(p. 17)

12

Page 17

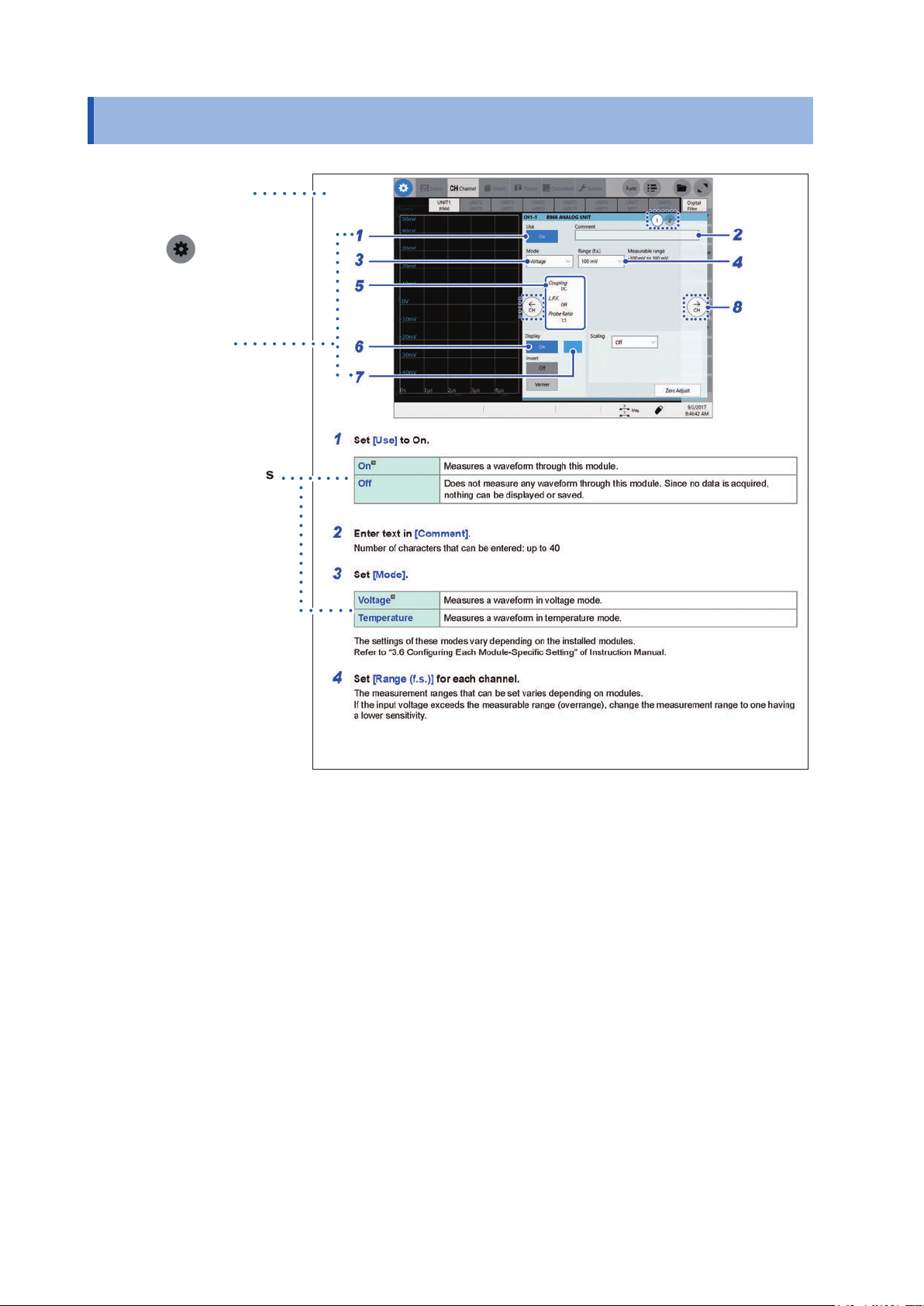

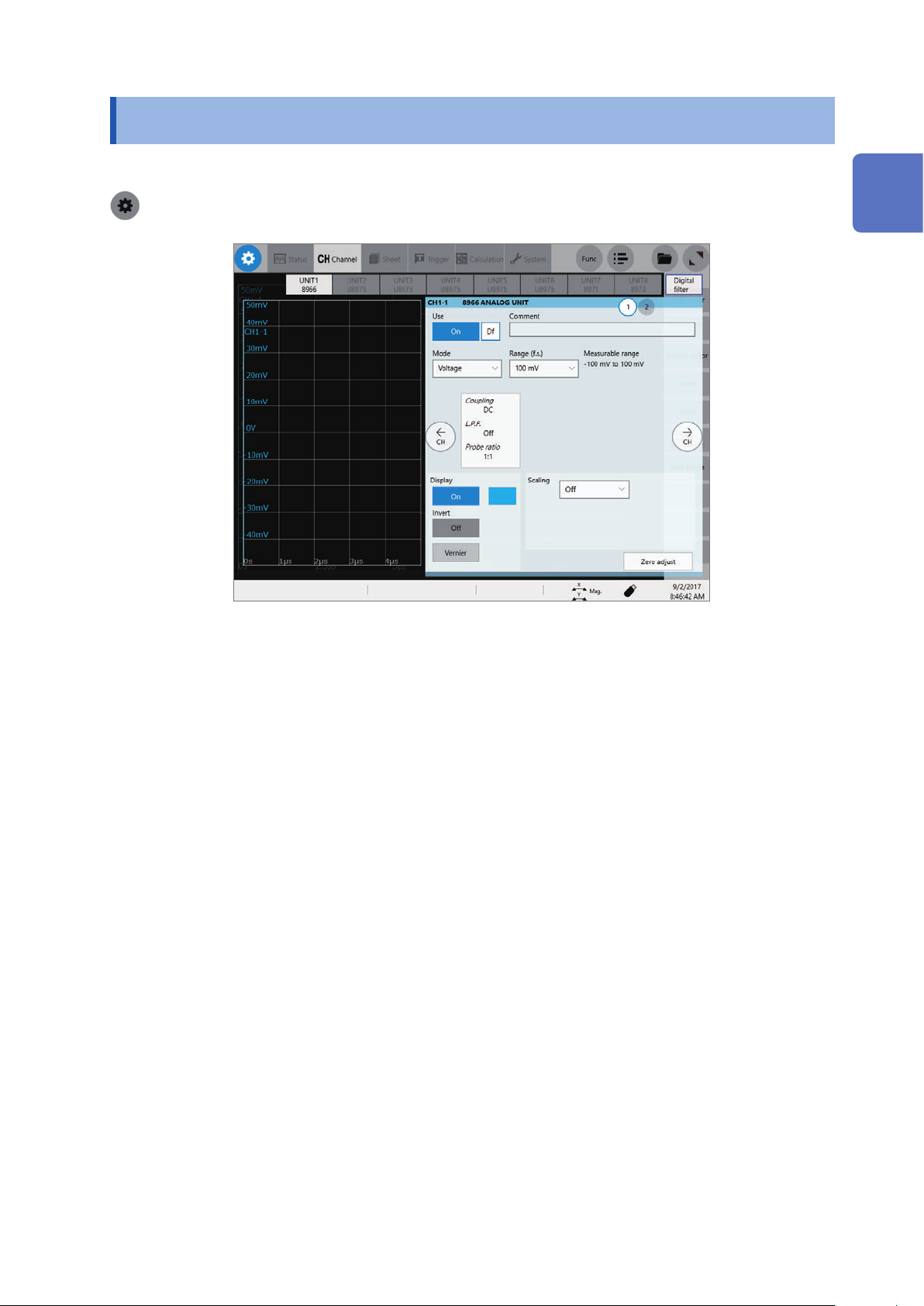

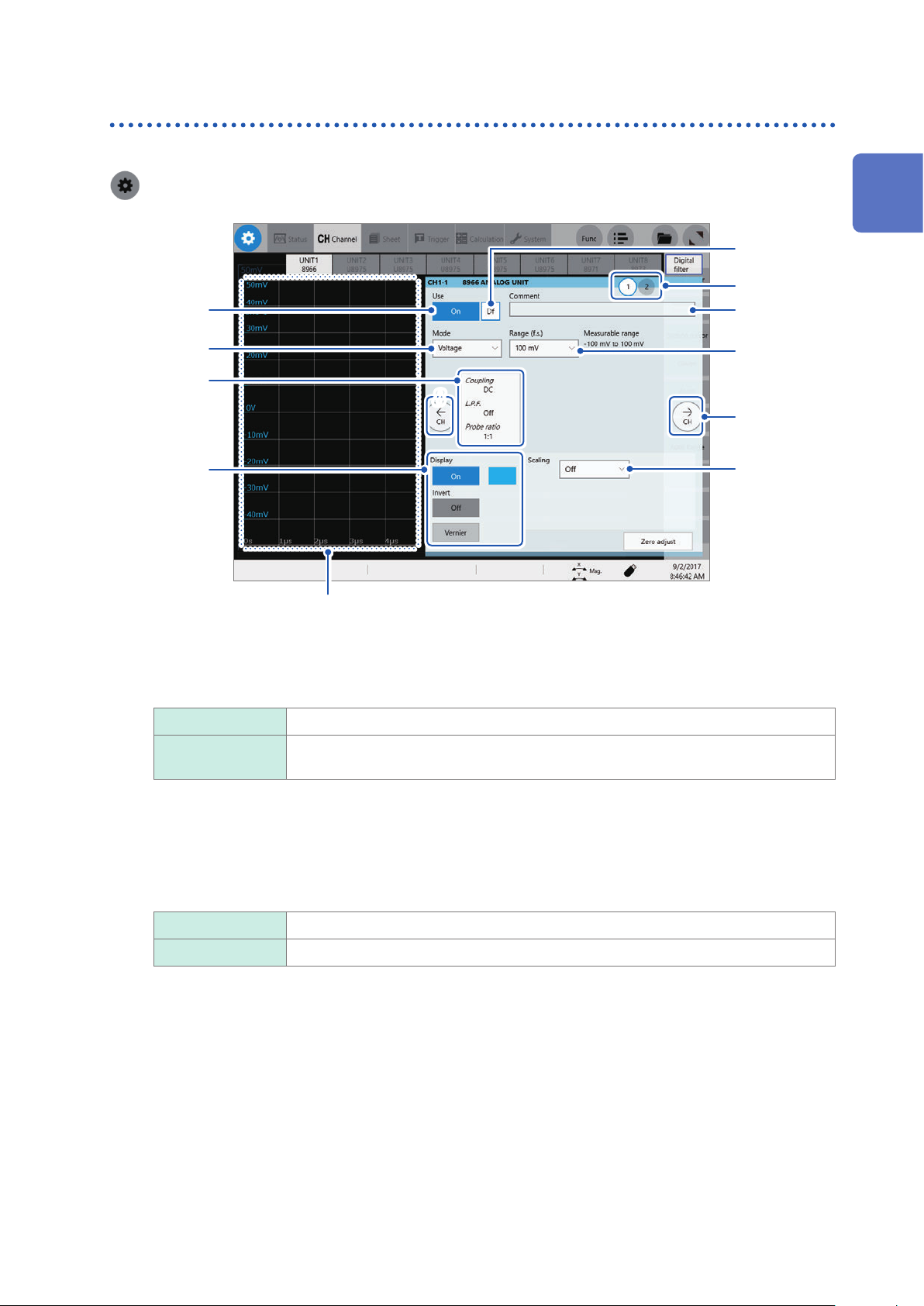

Setting Input Channels

Analog channels

For details on setting each module, refer to “3.6 Conguring Module-Specic Settings” (p. 51).

> [Channel] > [UNIT]

1

1

Measurement Method

9

8

2

3

5

8

6

The waveform screen is displayed during measurement.

When no measurement is not performed, the presently

input waveforms are displayed on the monitor.

Set [Use] to [On] or [Off].

1

On

Off Does not set the module as the measurement device.

Sets the module as the measurement device.

Since no data is acquired, nothing can be displayed or saved.

4

8

7

Type a comment in the [Comment] box.

2

Number of characters: up to 40

Set [Mode].

3

Voltage

Temperature Measures a waveform in temperature mode.

Settings vary depending on the installed modules.

Refer to “3.6 Conguring Module-Specic Settings” (p. 51).

Measures a waveform in voltage mode.

13

Page 18

Setting Input Channels

Set [Range (f.s.)].

4

Set the measurement range for each channel. The value of the range represents its maximum displayable

value (f.s.).

See the following table for the full-scale resolution of each module.

If the input voltage exceeds the measurable range (overrange occurs), change the measurement range to one

having a lower sensitivity.

After changing [Range (f.s.)], check the [Level], [Upper], [Lower], and other values of the trigger, search,

and numerical calculation functions.

Module Resolution [LSB]

Model 8966 Analog Unit, Model 8971 Current Unit, Model 8972 DC/RMS Unit 2,000

Model 8967 Temp Unit 20,000

Model 8968 High Resolution Unit, Model U8974 High Voltage Unit,

Model U8975 4ch Analog Unit

Model U8976 High Speed Analog Unit 1,600

Model U8969 Strain Unit 25,000

Model 8970 Freq Unit (Power frequency mode) 2,000

Model 8970 Freq Unit (Count mode) 40,000

Model 8970 Freq Unit

(Frequency mode, rotation speed mode, duty ratio mode, pulse width mode)

Model MR8990 Digital Voltmeter Unit 1,000,000

*: For the Model 8967 Temp Unit, the valid range varies depending on the thermocouples. For more

information about resolution, refer to “Model 8967 Temp Unit” in “5.2 Specications for Options” in Quick

Start Manual.

32,000

10,000

14

Page 19

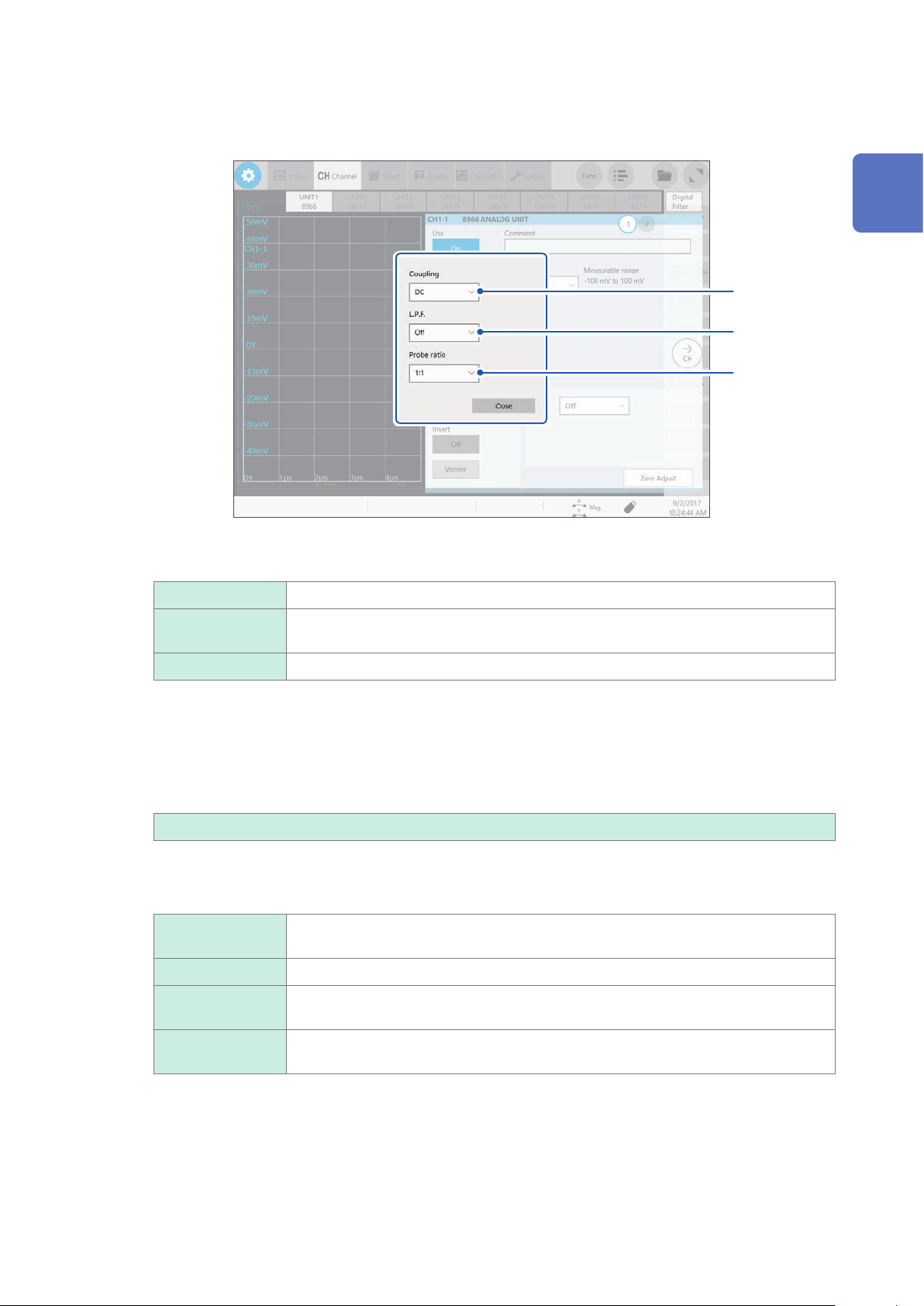

Set [Coupling], [L.P.F.], and [Probe ratio].

5

Tap the screen to open the settings dialog box.

Setting Input Channels

1

Measurement Method

(1)

(2)

(3)

(1) Set [Coupling].

The input signal coupling method can be specied. In general, use the DC coupling.

DC

AC Measures an AC component only of an input signal. A DC component can be

GND Connect the input terminal to the ground (Enables you to check the zero position).

Measures both DC and AC components of an input signal.

eliminated.

(2) Set [L.P.F.] (low-pass lter).

Enabling the low-pass lter installed in the module allows elimination of unwanted high-frequency components.

The lters that can be set varies depending on the type of modules. Select a lter according to the

characteristics of the input signals.

Example: For Model 8966 Analog Unit

Off

, 5 Hz, 50 Hz, 500 Hz, 5 kHz, 50 kHz, 500 kHz

(3) Set [Probe ratio].

Select this setting when the measurement is to be performed with a connection cable or probe.

1:1

1:10 Select this option when using Model 9665 10:1 Probe.

Select this option when using Model L9197, Model L9198, Model L9790, or Model

L9217 Connection Cord.

1:100 Select this option when using Model 9666 100:1 Probe, Model P9000-01 Differential

Probe, or Model P9000-02 Differential Probe.

1:1000 Select this option when using Model 9322 Differential Probe, Model P9000-01

Differential Probe, or Model P9000-02 Differential Probe.

15

Page 20

Setting Input Channels

Set [Display].

6

On

Displays the waveforms on the waveform screen.

Color Allows you to select display colors of the waveforms. You can also select the

same color as the lines acquired through other channels.

Invert

, On)

(Off

Vernier Allows you to ne-adjust the input voltage freely on the waveform screen

Off Displays no waveforms.

Set [Scaling].

7

Refer to “3.2 Converting Input Values (Scaling Function)” (p. 42).

Switch the channels.

8

Tap the corresponding location to switch the channels.

Set [Digital lter] for each channel. (Model MR6000-01 only)

9

The [Df] setting is displayed for only channels with [Digital lter] set to [On], allowing you to set the digital

lter for each channel.

For more information, refer to “Setting the Digital Filter Calculation” in Calculation Guide.

When the signs of displayed waveforms are reversed, the waveforms can be

inverted.

Refer to “3.4 Inverting the Waveform (Invert Function)” (p. 49).

(display adjustment only). When recording physical values such as noise,

temperature, and acceleration with sensors, you can adjust those amplitudes,

facilitating calibration.

Refer to “3.3 Fine-Adjusting Input Values (Vernier Function)” (p. 48).

16

Page 21

Setting Input Channels

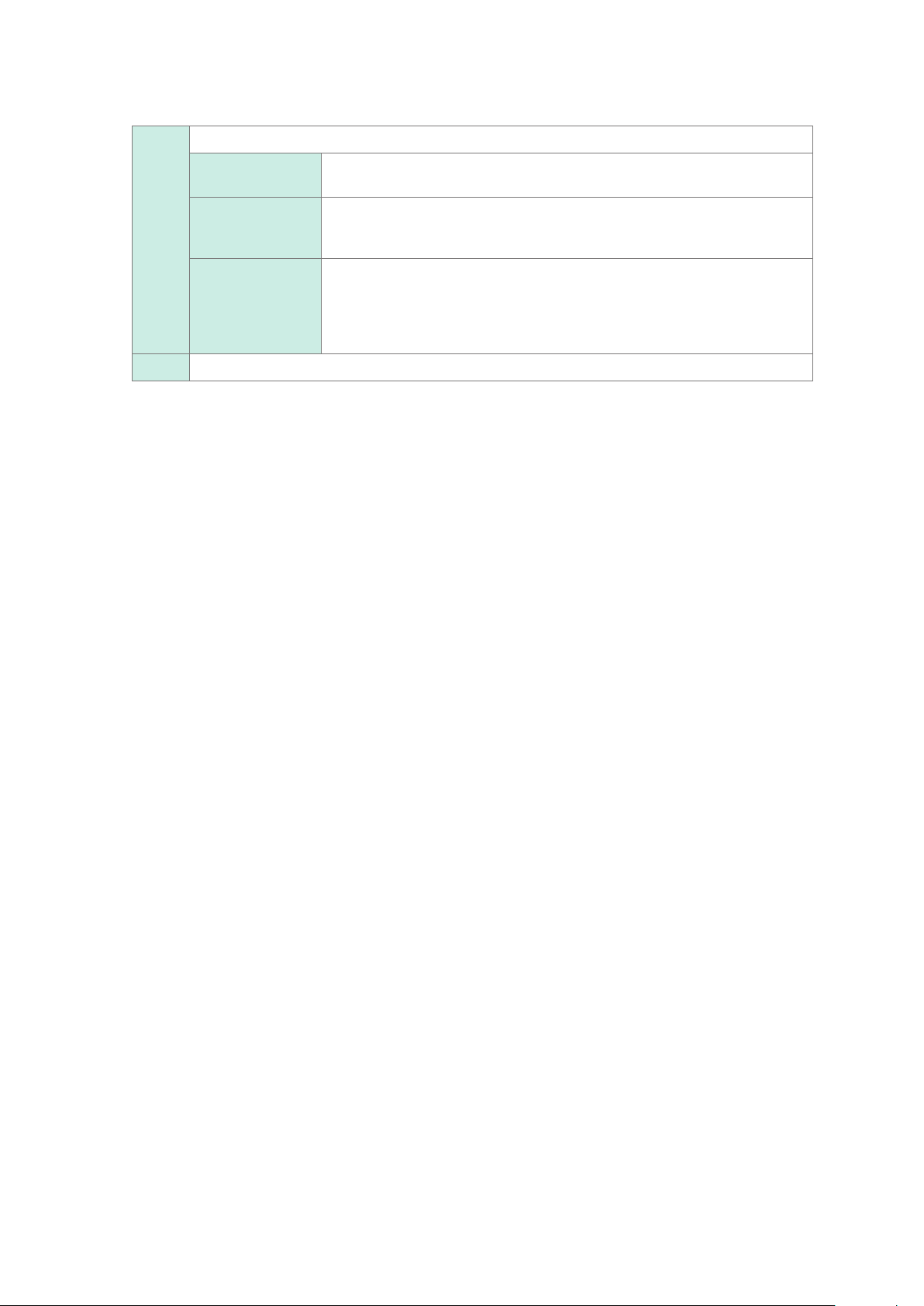

Logic channels

The logic sheet is displayed when the screen is in Single, Dual, Quad, Octa, or Hexadeca mode.

> [Channel]

1

Measurement Method

1

2

3

The waveform screen is displayed when a logic channel is

selected. Positions of the logic display can be checked.

Set [Use] to [On] or [Off].

1

On

Off Does not set the module as the measurement device.

Set [Logic width].

2

You can change the display width of the logic waveforms. Making waveforms narrower can enhance the

readability of a display that contains a large number of waveforms.

This setting is shared by all installed logic modules.

Wide Increases the width of the waveforms.

Normal

Narrow Reduces the width of the waveforms.

Select a display method for each probe (LA through LD).

3

Position Allows you to set the position of the logic waveforms within the display range. The

Sets the module as the measurement device.

Since no data is acquired, nothing can be displayed or saved.

Displays the waveforms in normal width.

position of the waveforms can be set in increments of one percent point.

This setting is shared by all probes (LA through LD).

You can move the logic position freely within the screen limits.

Display Sets whether to display each logic waveform.

Color Allows you to select a display waveform of each waveform. You can also select the

same color as the lines acquired through other channels.

Comment Allows you to type a comment for each channel.

Number of characters: up to 40

17

Page 22

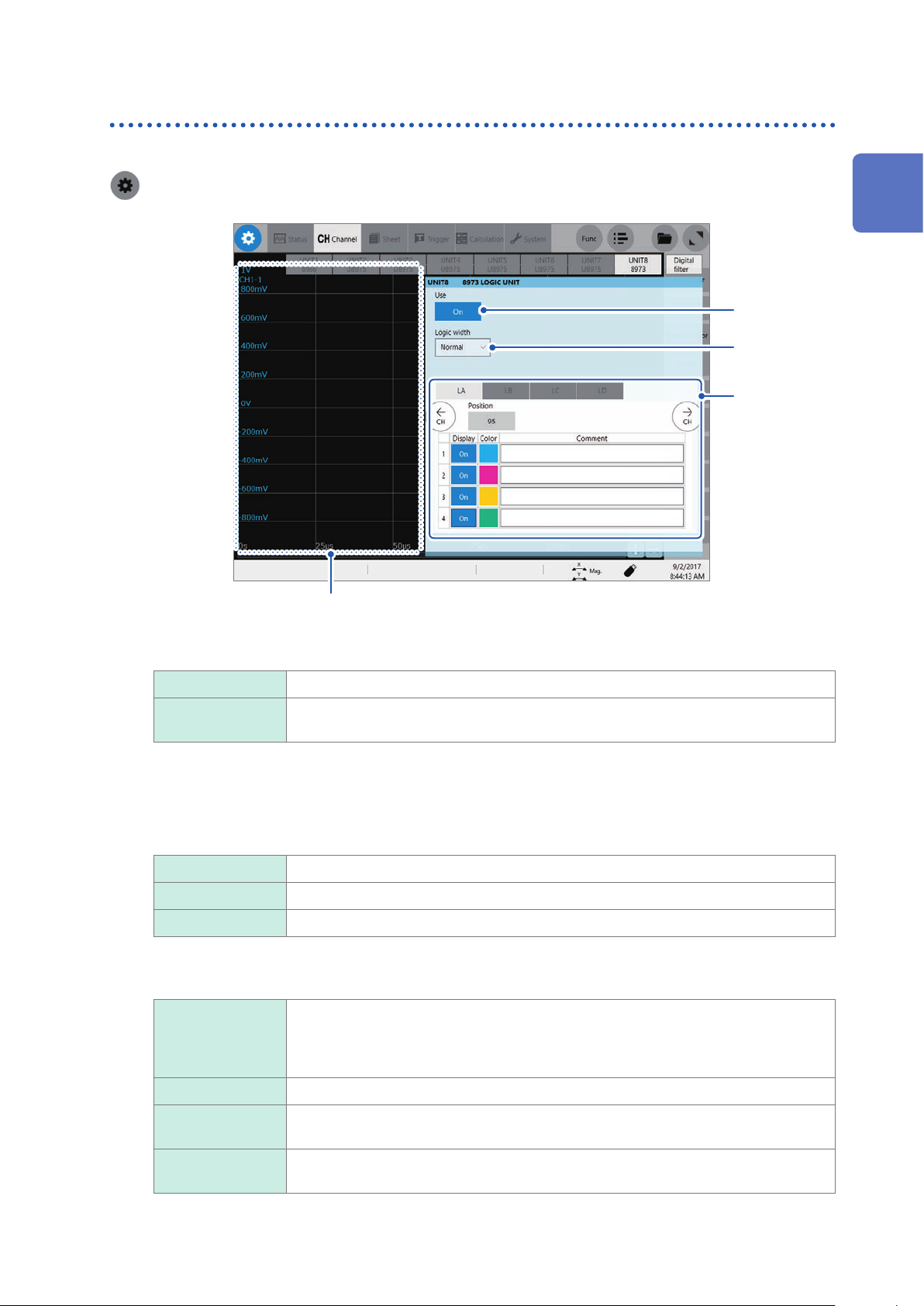

Setting the Sheets

1.4 Setting the Sheets

You can dene the display format of waveforms on the sheet. You can dene different display

formats for each of the 16 sheets. You can also switch the sheets to be displayed on the waveform

screen.

> [Sheet]

1

Select a sheet.

1

Set [Type].

2

Time sequence

waveform

2

3

4

Displays time-sequence waveforms.

Set [Divide].

3

You can divide the screen into multiple screens (graphs).

The options when [Type] is set to [Time sequence waveform] are as follows:

Single

Assign channels to the graph.

4

Tap the display panel of each graph to open the [Select the channel] dialog box.

, Dual, Quad, Octa, Hexadeca

18

Page 23

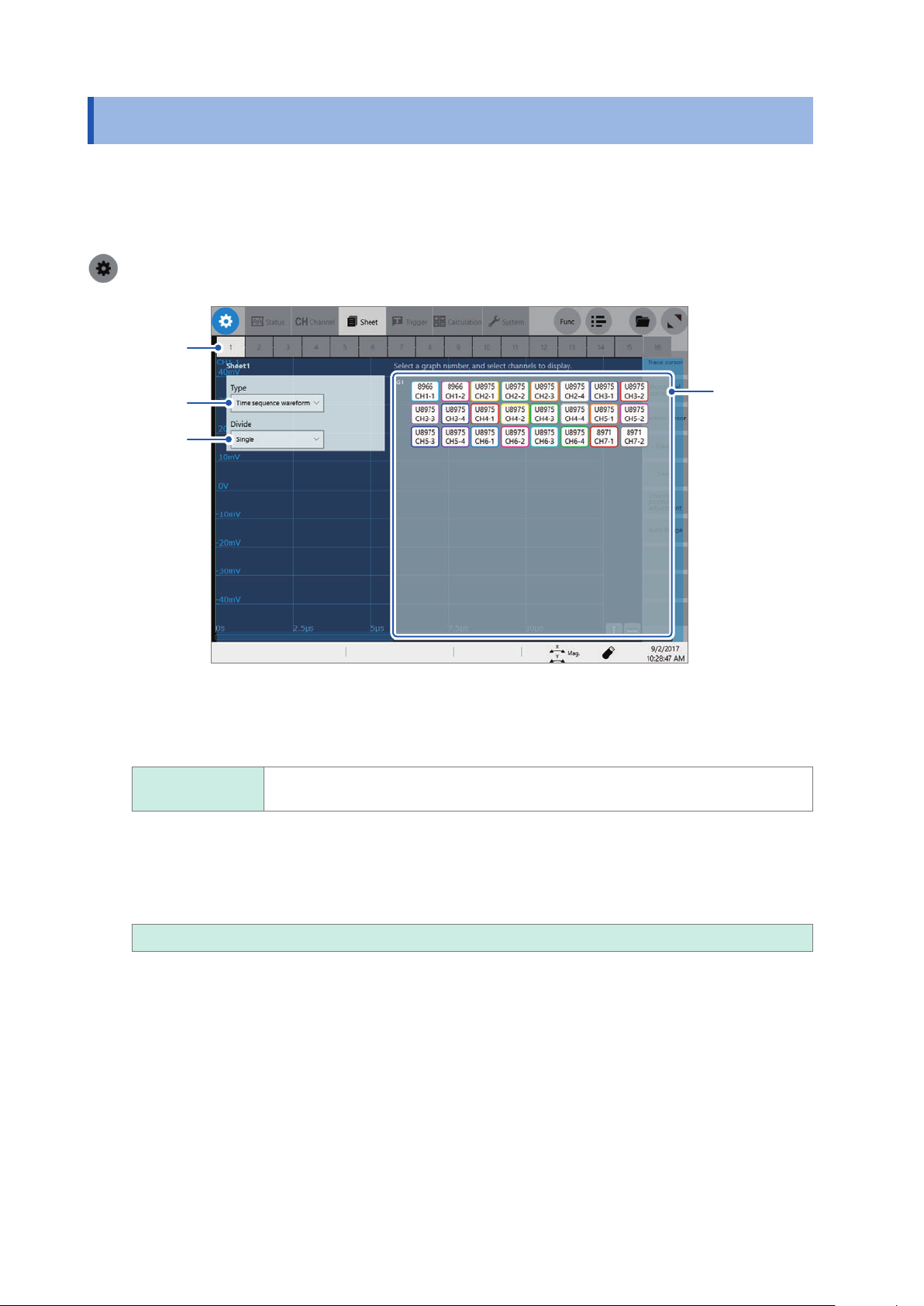

Setting the Sheets

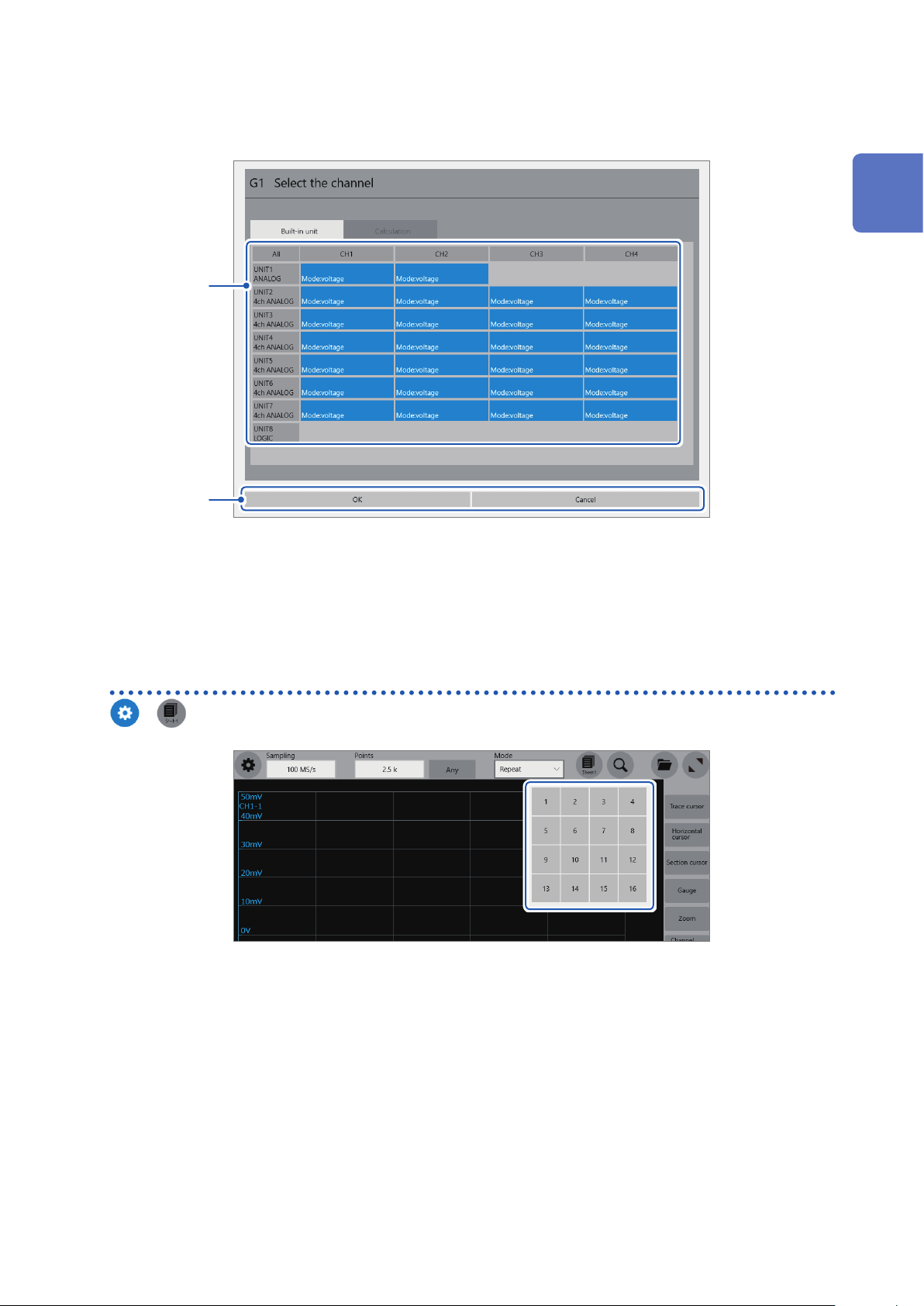

Select the channels to be displayed on the graph.

5

All channels are selected in the default setting. Tap a button to deselect a channel (Tap it again to select it).

5

1

Measurement Method

6

Tap [OK].

6

The selection is conrmed.

Tapping [Cancel] closes the dialog box without your selection conrmed.

Switching sheets on the waveform screen

>

Select the sheet numbers to be displayed.

19

Page 24

Starting/Stopping the Measurement

1.5 Starting/Stopping the Measurement

Starting a measurement

Pressing the START key starts a measurement.

• Waveform data displayed on the screen is cleared once the measurement starts.

• You can also start the measurement by inputting signal into the external control terminal.

Refer to “10 Controlling the Instrument Externally” (p. 179).

Waveform display during measurement

In general, the waveforms are displayed after the specied recording length of data has been

acquired. When the measurement is performed at a relatively slow speed, the waveforms are

displayed while the data is being acquired.

However, even if a slow-speed range is set, the waveforms are displayed after the data of the

whole waveform has been acquired, depending on the overlay or magnication setting.

To save data automatically during measurement

Refer to “Saving waveform data automatically” (p. 68).

Stopping the measurement

Pressing the STOP key once stops the measurement after the waveforms of the specied recording

length have been acquired.

Pressing the STOP key twice stops the measurement immediately.

20

Page 25

Operating the Waveform Screen

2

and Analyzing Data

You can analyze measured data with various functions including trace cursor measurement and

search of input waveforms on the waveform screen. You can also change measurement conditions

or other conguration on this screen.

2

Operating the Waveform Screen and Analyzing Data

Operation available on the waveform screen

Use the trace cursors

• Reading measured values (p. 22)

Moving the waveform display position

• Moving waveforms by dragging them

• Moving waveforms with the scroll bar

Use the section cursors

• Specifying the waveform range (p. 26)

Changing the display magnication of

waveforms

• Magnifying/demagnifying waveforms (p. 32)

• Magnifying a part of waveforms horizontally

(p. 37)

21

Page 26

Reading Measured Values (Trace Cursors)

2.1

1

Reading Measured Values (Trace Cursors)

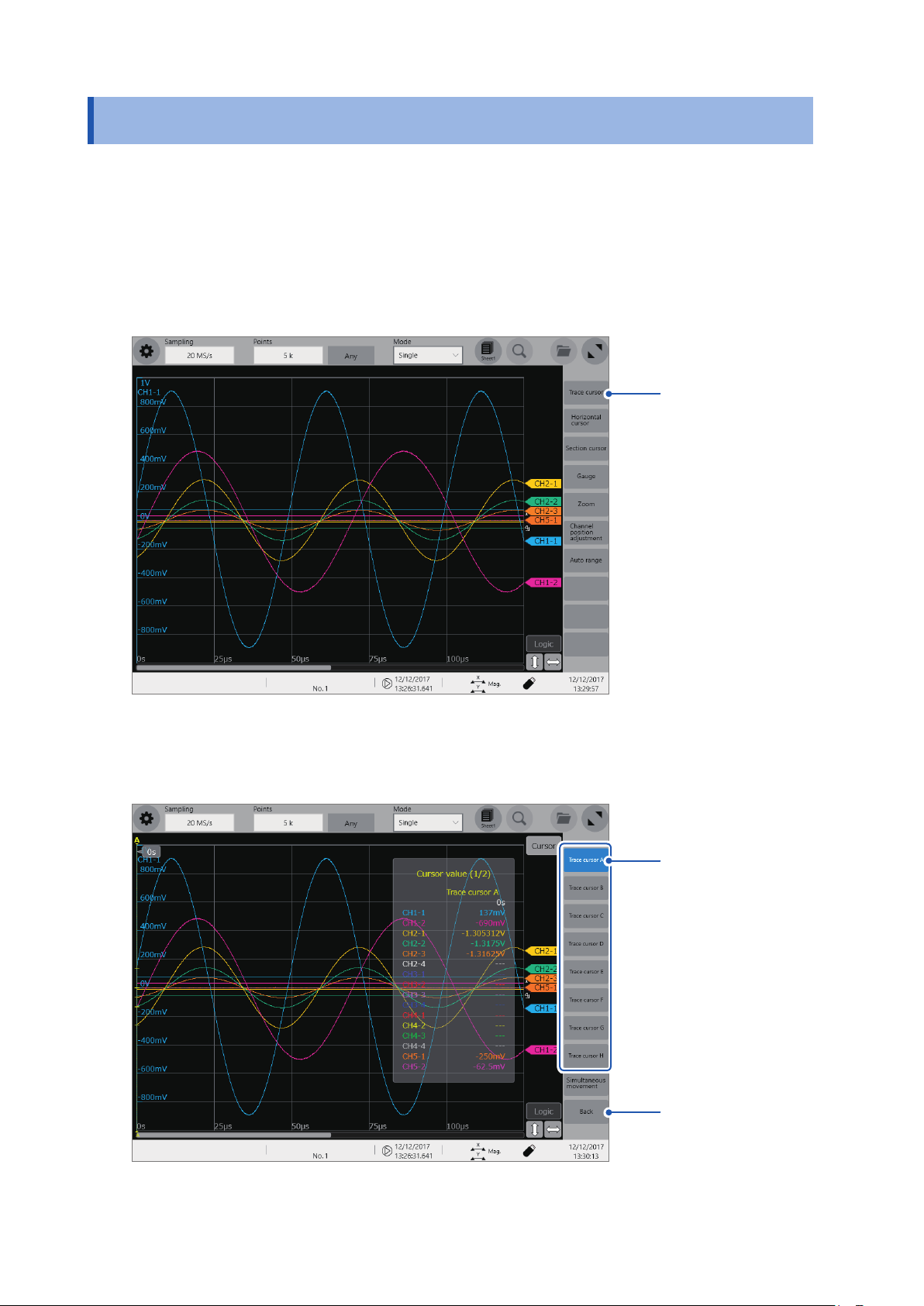

Using trace cursors on the waveform screen allows you to read measured values (scaled

value when the scaling is used). Up to eight trace cursors can be displayed simultaneously.

You can read differences in times and measured values at any two selected among them.

The time lag, for example, shows the difference in time between Trace cursor A and Trace

cursor B when they are enabled.

Tap [Trace cursor].

1

Select one or more cursors from [Trace cursor A] through [Trace cursor H] by tapping them.

2

The selected trace cursors are displayed on the waveform screen.

Move the trace cursors by dragging them on the waveform screen.

2

3

3

22

Tap [Back].

Page 27

Reading Measured Values (Trace Cursors)

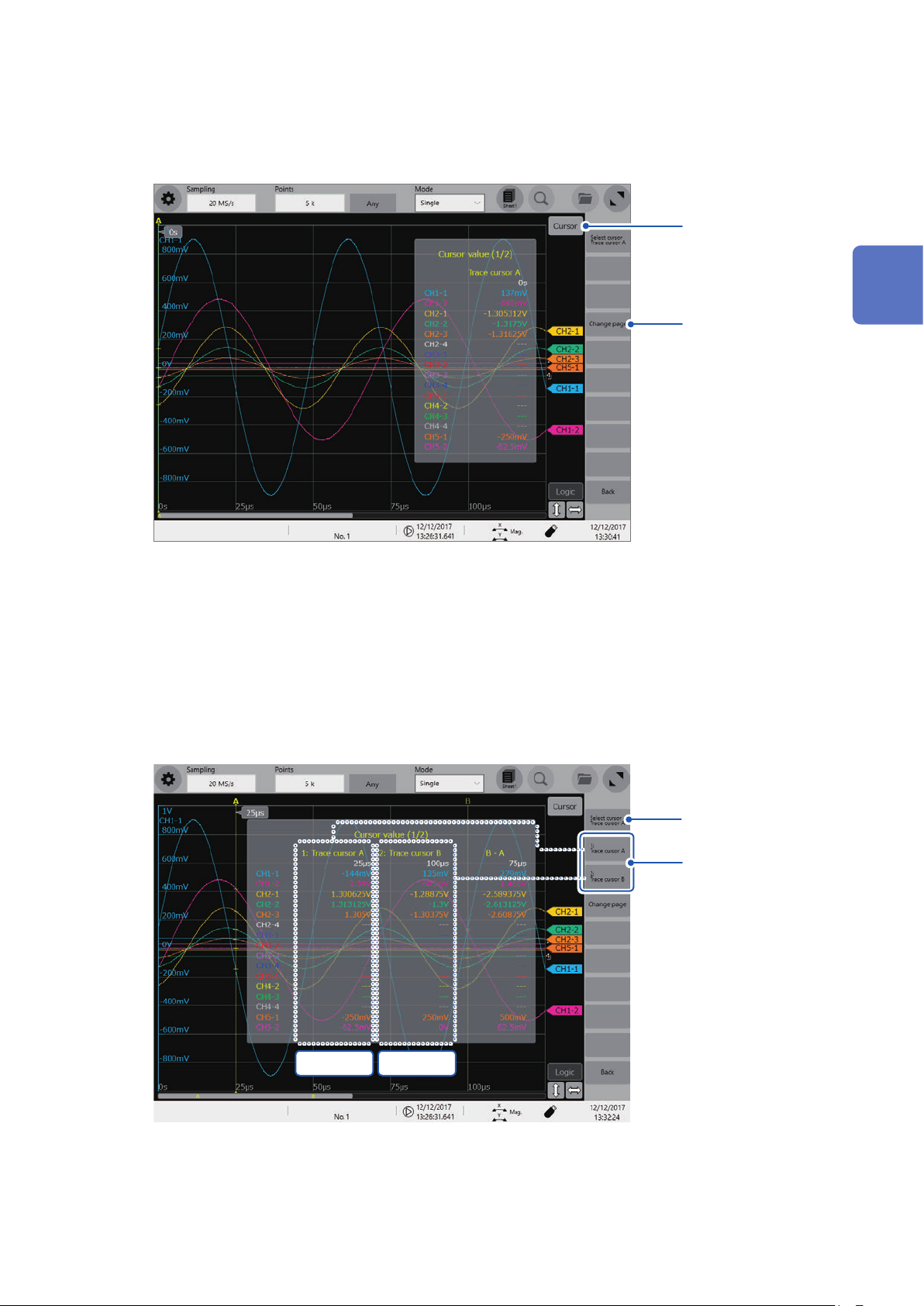

Tap [Cursor].

4

The cursor value display can be switched between on and off every time

tapped.

[Cursor]

4

is

2

5

Tap [Change page].

5

If multiple channels are displayed, switch the pages to check the cursor values of each channel.

Every time it is tapped, the pages are switched.

Tap [1: Trace cursor] or [2: Trace cursor].

6

When the multiple trace cursors are displayed, the cursor values acquired at the two trace cursors are

displayed on the waveform screen (Cursor values 1 and 2).

Every time you tap [1: Trace cursor] (or [2: Trace cursor]), the values of Cursor values 1 (or Cursor values 2)

switches from one to another.

Operating the Waveform Screen and Analyzing Data

Cursor values 1 Cursor values 2

7

6

23

Page 28

Reading Measured Values (Trace Cursors)

Tap [Select cursor].

7

Every time you tap

by one in sequence. In addition, you can activate any one of the cursors displayed on the screen by tapping it.

[Select cursor]

when the multiple trace cursors are displayed, a cursor is activated one

Changing the magnication of the waveform display while moving the trace

cursor

Sliding your nger upward on the screen while dragging the trace cursor enlarges the waveform

display centered around the trace cursor in proportion to the dragging distance. Sliding your nger

downward compresses the waveform display.

Once you have adjusted the display to a suitable size, move the trace cursor along the horizontal

axis to change the display position.

Releasing your nger from the screen reverts the display to the original magnication.

To move the trace cursor using the rotary knob X

When [Cursor] is assigned to the rotary knob, you can move the active trace cursor with the rotary

knob X.

If the trace cursor is not displayed on the screen even though it is enabled

Check the position of the trace cursor on the scroll bar. (p. 31)

24

Page 29

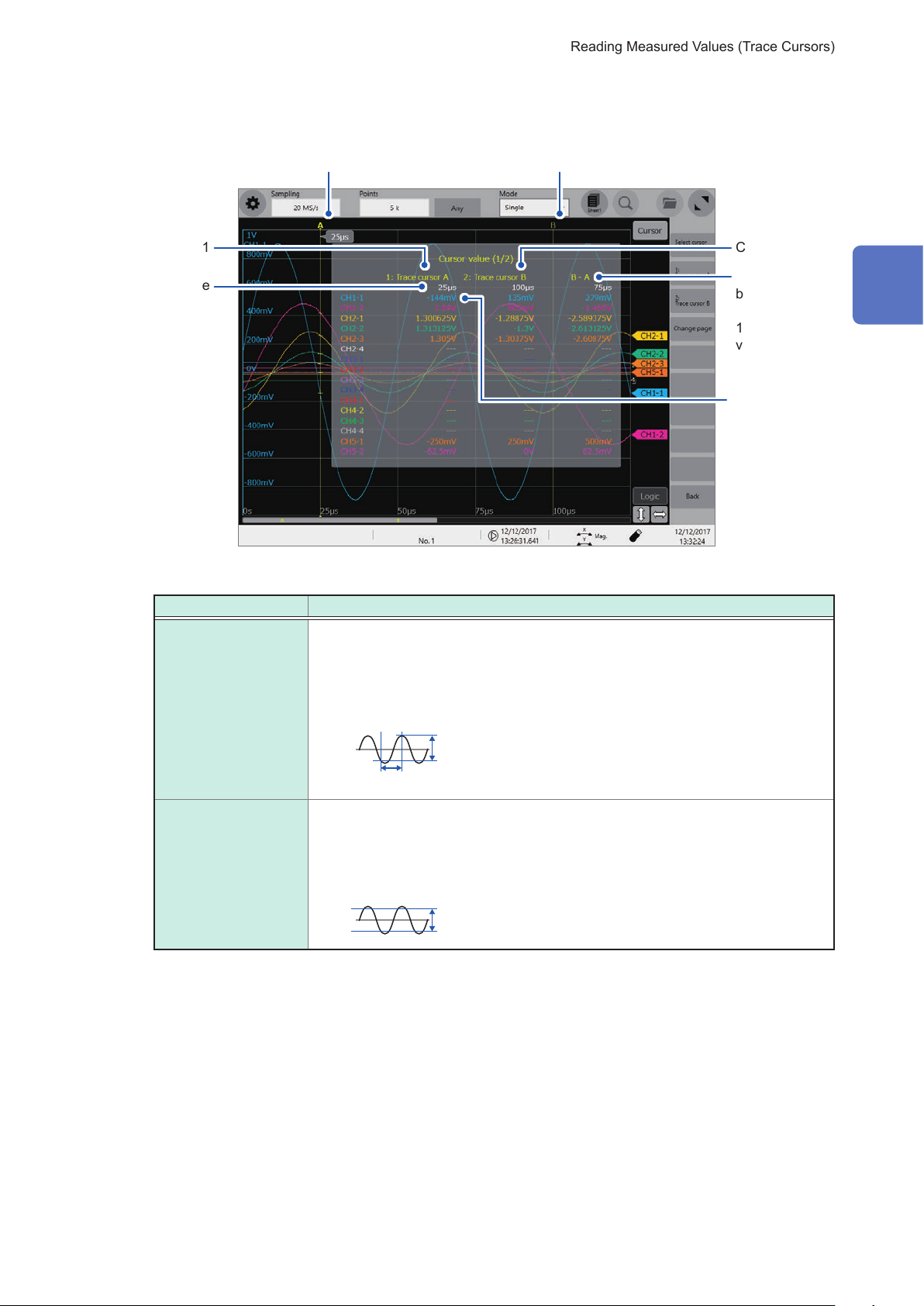

Reading measured values on the waveform screen

A B

When the trace cursor is selected

Reading Measured Values (Trace Cursors)

Trace cursor A

Cursor value 1 Cursor value 2

Time

Trace cursor B

Difference

between

Cursor value

1 and Cursor

value 2

The values

of the points

at which

each cursor

crosses the

waveforms

are displayed.

The display of the cursor values vary depending on the selected cursor type.

Cursor type Cursor value

Trace cursor

When Trace cursor A is assigned to Cursor value 1; and Trace cursor B, to Cursor

value 2.

Time: A period of time from the trigger point or starting point of recording until the

trace cursor selected for Cursor value 1 or Cursor value 2

B − A: Difference in measured values between Trace cursor A and Trace cursor B

2

Operating the Waveform Screen and Analyzing Data

B − A (Difference between measured values)

B − A (Time lag)

Horizontal cursor

When Horizontal cursor A is assigned to Cursor value 1; and Horizontal cursor B,

to Cursor value 2

Cursor value 1 or Cursor value 2: Measured value of the specied cursor

B − A: Difference in measured values between Horizontal cursor A and Horizontal

cursor B

A

B

B − A

When the external sampling is used, the time is replaced with the number of samples.

25

Page 30

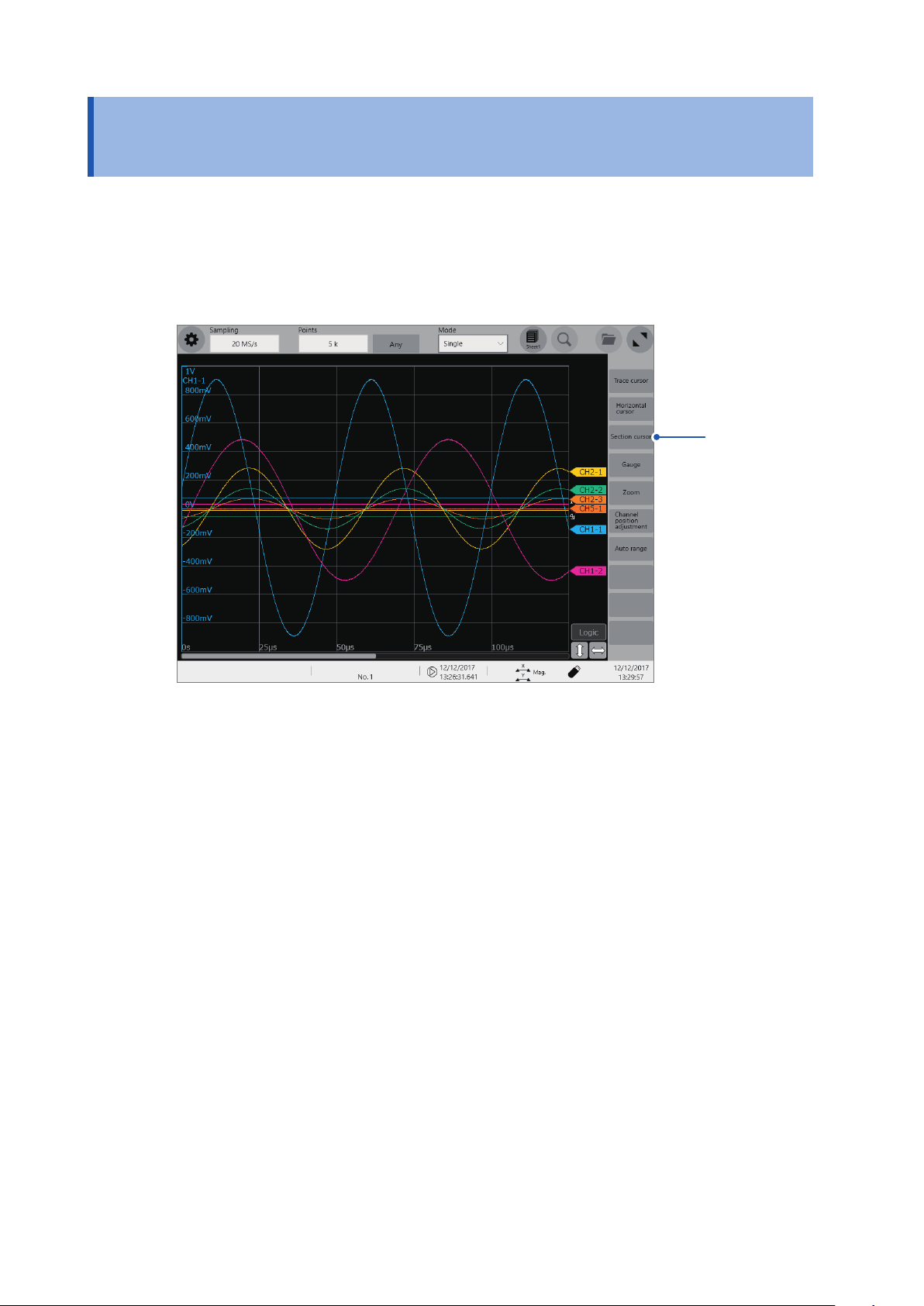

Specifying the Waveform Range (Section Cursor)

2.2 Specifying the Waveform Range (Section Cursor)

The range can be specied with section cursors.

The specied range is applicable for le saving, the numerical calculation, and search. The range

selection remains to be common even when the waveform display format is changed.

Tap [Section cursor].

1

1

26

Page 31

Specifying the Waveform Range (Section Cursor)

Tap [Section cursor 1] or [Section cursor 2].

2

The cursor is displayed on the left side of the screen.

You can move the section cursors or each cursor on the waveform screen by dragging one of them.

Section cursor 1 Species the section with Cursor 1A and Cursor 1B.

Section cursor 2 Species the section with Cursor 2A and Cursor 2B.

Cursor 1A Cursor 2B

2

Operating the Waveform Screen and Analyzing Data

2

Changing the display magnication of the waveforms while moving

the section cursor

Sliding your nger upward on the screen while dragging the section cursor enlarges the waveform

display centered around the section cursor in proportion to the dragging distance (Sliding your

nger downward compresses the waveform display.).

Once you have adjusted the display to a suitable size, move the section cursor along the horizontal

axis to change the display position.

Releasing your nger from the screen reverts the display to the original magnication.

27

Page 32

Displaying Vertical Scales (Gauge Function)

2.3 Displaying Vertical Scales (Gauge Function)

Using the gauge function enable the vertical scales (for convenience, hereafter referred to as

“gauges”) to be displayed overlapping waveforms.

Tap [Gauge].

1

1

Select gauges to be displayed from [Gauge A] through [Gauge H].

2

Gauges are displayed at the left of the screen.

To move a gauge, tap the gauge, thereby it is selected, and drag it.

2

Tapping [Left-justied] aligns the gauges to the left.

28

Page 33

Tap [CH ] or [CH ].

3

You can switch channels to be displayed along with the guage.

Displaying Vertical Scales (Gauge Function)

3

4

2

Operating the Waveform Screen and Analyzing Data

Tapping [Hide] hides the gauges.

Tap [Upper and lower limit value].

4

The setting dialog box is displayed, which allow you to set the channel display range numerically. Type the

upper and lower values in the [Upper] and [Lower] boxes, respectively, and then tap [OK].

29

Page 34

Scrolling Waveforms

2.4 Scrolling Waveforms

Scrolling waveforms

Dragging the waveform screen scroll the waveforms that are being measured or existing

waveforms.

Scrolling direction

Screen display

Previous Latest

Dragging the waveform

rightward:

Scrolls the waveform

backward from the present.

To anchor the waveforms vertically

Tap the button to deselect

it as the scroll direction.

To anchor the waveforms horizontally

Dragging the waveform

leftward:

Scrolls the waveform

forward from the present.

Tap the button to deselect

it as the scroll direction.

To observe waveforms obtained previously during slow-speed measurement

When the waveform is being displayed during a slow-speed measurement, dragging the waveform

screen allows you to observe waveforms obtained previously. To observe the waveform being

measured presently again, tap [

] on the screen.

30

Page 35

Scrolling Waveforms

Checking a position of waveforms with the scroll bar

The scroll bar provides the position and size of the displayed part of the waveforms relative to

the entire recording length of the waveforms. It also shows the positions of the trigger point, trace

cursors, and section cursors.

2

Operating the Waveform Screen and Analyzing Data

Scroll bar

Verifying the position of the trigger point and cursors on the scroll bar

Trigger point

Section cursor position

Screen display range

With the display zoomed in, the scroll bars are displayed at both the top and bottom.

Trace cursor A

Recorded range

31

Page 36

Changing the Display Position and Display Magnication of the Waveforms

2.5 Changing the Display Position and Display

Magnication of the Waveforms

Pinch in or out waveforms on the waveform screen to change the display magnication.

Pinch out

Pinch in

Magnies the waveforms.

Demagnies the waveforms.

To change the display position of logic channels in a batch

Select [Logic] and drag waveforms on the waveform screen to move logic channels only.

When [Logic] is not selected, only analog channels can be moved.

Tap the button to select or deselect it.

32

Page 37

Changing the Display Position and Display Magnication of the Waveforms

Differentiating the waveform display position and display

magnication for each analog channel

Tap [Channel position adjustment].

1

2

Operating the Waveform Screen and Analyzing Data

1

The channel position adjustment screen is displayed.

The yellow area shows the display range of the waveform screen.

33

Page 38

Changing the Display Position and Display Magnication of the Waveforms

Tap a channel number the display position of which is to be changed.

2

Dragging and thereby moving the selected area changes the display position.

2

Tap a channel number the display magnication of which is to be changed.

3

Pinching in or out the selected area changes the display magnication.

3

34

Page 39

Changing the Display Position and Display Magnication of the Waveforms

Adjust the display position and magnication.

4

The display can be adjusted as follows depending on the selected state.

Initialize the

position of all

channels.

Initialize the

position of select

channels.

Align the position

of all channels

equidistantly.

Multiple selection Allows you to select the channels the displays of which are to be adjusted.

Restores all the channels to the initial positions and displays them at the default

magnication.

Restores only selected channels to the initial positions and displays them at the default

magnication.

Adjusts the display positions and magnications of all channels such that they are

aligned at the same intervals.

4

2

Operating the Waveform Screen and Analyzing Data

35

Page 40

Operating the Rotary Knob

2.6 Operating the Rotary Knob

Push the rotary knob to select an action and turn the knob to perform the action.

Operation of the rotary knob X

Rotate

Push

Pushing the rotary knob X selects one of the following actions in turn:

Magnication/

demagnication ratio

Position Changes the display position of all channels in the

Cursor Moves the selected cursor.

Setting Changes the sampling rate. This operation can be

Operation of the rotary knob Y

Rotate

Push

Pushing the rotary knob Y selects one of the following actions in turn:

Magnication/

demagnication ratio

Position Changes the display position of the selected channel

Cursor Moves the selected cursor.

Setting Changes the measurement range. This operation

Changes the magnication/demagnication ratio of

all channels in the horizontal axis direction.

horizontal axis direction.

used on the waveform screen only.

Changes the display magnication of the selected

channel in the vertical axis direction.

in the vertical axis direction.

can be used on the waveform screen only.

When a rotary knob is operated, the channel-selecting panel is displayed in some cases, which

allows you to select an operational channel by tapping the [←] or [→] button. In addition, you can

directly select an operational channel by tapping a channel marker.

Tap a channel

marker.

Select a channel.

36

Page 41

Enlarging a Part of the Waveform (Zoom Function)

2.7 Enlarging a Part of the Waveform (Zoom Function)

Using the zoom function allows you to enlarge a part of the waveform.

Normal display Zoomed display

Normal

waveform

2

2

2

Zoomed

waveform

Operating the Waveform Screen and Analyzing Data

1

Set [Zoom].

1

When the zoom function is enabled, the screen is horizontally split into two: the upper and lower screens.

Upper screen: Displays the waveforms in the magnication specied before the zoom function was applied.

The part of the waveforms enclosed by the yellow frame represents the zoomed display range

shown in the lower screen.

Lower screen: Displays the zoomed-in waveform

Change the display magnication.

2

Pinch in or out each screen to change the display magnication of waveforms on each screen.

Scroll the waveform to be observed.

3

Drag and scroll waveforms on each screen.

To cancel the zoomed display

Tap [Zoom] on the screen to cancel the zoomed display. When you cancel the zoomed display, the

display (the upper screen) restores that with the normal magnication.

37

Page 42

Operating the Rotary Knob

38

Page 43

3

Converting input values (scaling) (p. 42)

Fine-adjusting input values (p. 48)

Inverting waveforms (p. 49)

Copying a setting to another channel

(p. 50)

Advanced Functions

Advanced measurements and settings

• Overlaying new waveforms with previously

acquired waveforms (p. 40)

Detailed module settings (p. 51)

• Anti-aliasing lters

• Thermocouple types

• Reference junction compensation

• Detecting a burnout

• Updating data

• Executing the auto-balance

• Probe division ratio

• Response time

• Measurement mode

3

Advanced Functions

39

Page 44

Overlaying New Waveforms With Previously Acquired Waveforms

3.1 Overlaying New Waveforms With Previously Acquired Waveforms

The new waveform can be overlaid with the presently displayed waveforms.

• You can compare the new waveforms with those recorded before. (When [Mode] is set to

[Repeat]) (p. 6)

• There are two methods for overlaying waveforms: the automatic overlaying during measurement

and the manual overlaying.

> [Status] > [Condition]

1

Set [Overlay].

1

Off

Auto Overlays the newly acquired waveforms with the presently displayed waveforms every

Manual Overlays the new waveforms manually with the presently displayed waveforms.

Refer to “When the overlay function is enabled (When [Overlay] is set to [Auto] or [Manual])” (p. 41).

Does not overlay the waveforms.

time the new ones are acquired.

When [Mode] is set to [Repeat], the instrument overlays the new waveforms with

the presently displayed waveforms beginning from the start until the stop of the

measurement.

Refer to Step 3 “Overlay the waveforms manually (leaving any waveform to be

displayed on the screen).” (p. 41).

40

Page 45

Overlaying New Waveforms With Previously Acquired Waveforms

Tap the button to display the waveform screen.

2

3

3

Overlay the waveforms manually (leaving any waveform to be displayed on the screen).

3

Tap the button on the right side of the waveform screen.

Overlay Leaves the acquired waveforms to be displayed on the screen.

The overlay setting continues to be available until the waveforms are cleared.

Clear Clears all the overlaid waveforms displayed on the screen.

No cleared waveforms can be displayed again.

When the overlay function is enabled (When [Overlay] is set to [Auto] or [Manual])

• The waveforms are always displayed after the data has been acquired.

• The trace cursors show the measured values of the waveforms acquired most recently.

• The following operation is not available on the waveform screen:

Scrolling waveforms, switching the zoom function between on and off, changing the magnication,

and changing the zero position.

• The instrument leaves only the waveforms most recently to be displayed and clears the others in

the following cases:

Advanced Functions

• After changing the [Sheet] setting, which is accessible by proceeding the following order:

> [Sheet]

• After changing the waveform display settings (switching the display between on and off,

changing waveform color) in the [Channel] screen, which is accessible by proceeding in the

following order:

> [Channel]

• After executing the search.

41

Page 46

Converting Input Values (Scaling Function)

3.2 Converting Input Values (Scaling Function)

About the scaling function

The scaling function enables you to convert the measured voltage output from measuring devices

such as sensors into physical quantities of measurement targets.

Hereafter, the term “scale” refers to converting numerical values using the scaling function.

Gauge scales, scaled values (upper and lower limits of the vertical axis or voltage axis), and

measured values at trace cursors are expressed as scaled values in terms of the specied units.

You can scale the input values for each channel.

Before scaled After scaled

0.2

[V]

0.1

0

Scaling methods

The following six methods are available:

• Specifying a conversion ratio and offset

• Specifying two points

• Selecting a model name of a connected current sensor or differential probe

• Selecting an output rate

• Specifying an input value in decibels and value after scaled

• Specifying a rated capacity and rated output according to an inspection record of a strain gauge

converter (for Model U8969 Strain Unit only)

10

[A]

5.0

0

42

Page 47

> [Channel]

Converting Input Values (Scaling Function)

3

Set [Scaling].

1

Off

On (ENG) Displays values in decimal notation with a unit prex (such as m and k).

On (SCI) Displays values in scientic notation (as a power of 10).

Tap the setting item.

2

The settings dialog box is displayed.

Does not scale any values.

4

1

2

3

Advanced Functions

43

Page 48

Converting Input Values (Scaling Function)

Set [Method].

3

Ratio

Allows you to specify a conversion ratio and offset.

2-Point Allows you to specify two scaling-reference points.

Sensor Allows you to select a model name and measurement range of a connected current

sensor or differential probe.

Output rate Allows you to select an output rate (ratio) of a current sensor or a division ratio of a

voltage dividing probe.

dB Allows you to specify an input value in decibels and value after scaled.

Rating Allows you to specify a rated capacity and rated output according to an inspection

record of a strain gauge converter to be used. (For Model U8969 Strain Unit only)

When using [Ratio]: Specify [Ratio] and [Offset].

Type a numerical value in the [Ratio] box.

−9.9999E+9 to 9.9999E+9

Type a numerical value in the [Offset] box.

−9.9999E+19 to 9.9999E+19

When converting the values in volts into those in amperes

Specify a physical quantity per volt (conversion ratio: [eu/

V]), an offset value, and a measurement unit to be used. The

instrument converts (scales) measured values acquired in

terms of volts into values in the specied measurement unit.

(eu: engineering unit)

Example:

Ratio: Change in terms of amperes per change in terms of

volts; Offset value: B

Unit: A

Scaling using slope (conversion

ratio) and offset value

[A]

B

When using [2-Point]: Specify two input values and those after scaling.

Type a value in each of the following elds: [Input1], [Input2], [Scale1], [Scale2].

−9.9999E+29 to 9.9999E+29

Set two points of the input signal in terms of volts, those after

scaled, and a measurement unit to be used. The instrument

converts (scales) measured values acquired in terms of volts

into values in the specied measurement unit.

Example:

2 points of values in

Values after scaled

terms of volts

Scaling using conversion ratio

and offset value, both of which

are calculated using two points

[A]

A

H

A

L

[V]

44

V

: Higher potential point AH: Value for higher potential

H

point

V

: Lower potential point AL: Value for lower potential

L

point

V

V

L

H

Actual measured values

Values after scaled

[V]

Unit: A

When the [Ratio] setting is changed, VL and VH set as two points do not change, whereas the values

for A

and AH change.

L

Page 49

Converting Input Values (Scaling Function)

When using [Sensor]: Select a connected current sensor or differential probe from the list.

Set a measurement range according to the current sensor.

Sensor Range

3273-50 30 A

3274 150 A

3275 500 A

3276 30 A

3283

3284 20 A

3285 200 A

9010-50 10 A

9018-50 10 A

9132-50 20 A

9322 –

9657-10 10 A

10 mA, 100 mA, 1 A, 10 A, 200 A

, 200 A

, 2000 A

, 20 A, 50 A, 100 A, 200 A, 500 A

, 20 A, 50 A, 100 A, 200 A, 500 A

, 50 A, 100 A, 200 A, 500 A, 1000 A

3

Advanced Functions

9675 10 A

CT6700 1 A

CT6701 1 A

Example of setting:

To display values measured with Model 9018-50 Clamp on Probe using the 10 A range as values in

terms of amperes (A)

Sensor: 9018-50

Range: 10 A

When using [Output rate]: Select an output rate of a current sensor (ratio) or division ratio of

a voltage dividing probe.

Select a scaled value for one volt.

10 mA

2500 A, 5000 A, 1000 V

, 100 mA, 1 A, 10 A, 20 A, 50 A, 100 A, 200 A, 250 A, 500 A, 1000 A, 2000 A,

When using [dB]: Specify a physical quantity per input signal (ratio) in terms of decibels.

−200 to +200

A ve-digit gures or less can be specied.

Setting example:

Converting (scaling) an input value of 40 dB into 60 dB

Input dB: 40

Output dB: 60

The conversion ratio corresponding to values entered in decibels is specied (The offset becomes

zero.).

45

Page 50

Converting Input Values (Scaling Function)

When using [Rating]: Specify a rated capacity and rated output of a strain gauge converter

to be used.

(for Model U8969 Strain Unit only)

+1.0000E-9 to +9.9999E+9

A ve-digit gures or less can be specied.

Set the parameters such that the rated capacity divided by two times the rated output is less than or

equal to 9.9999E+9.

For the rated capacity and rated output, see an inspection record of a strain gauge converter to be

used.

Setting example: To display the data measured with the strain gauge converter having a rated capacity

of 20 G and rated output of 1000

Unit: G

Rated capacity: 20

Rated output: 1000

μV/V as values in terms of gees (G)

The upper and lower values of the waveforms also change automatically according to the changes

made in the scaling settings.

Type a unit in the [Units] box.

4

Specify the unit into which you wish to convert the values. (Number of characters: up to 7)

To copy the scaling setting to another channel

Refer to “3.5 Copying Settings (Copy Function)” (p. 50).

46

Page 51

Converting Input Values (Scaling Function)

When using Model U8969 Strain Unit

When an inspection record of a strain gauge converter provides a calibration

factor

Example: To display data measured with the strain gauge converter having a calibration

factor of 0.001442 G/1 × 10−6 strain* as values in terms of gees (G)

(*: 10−6 strain = me)

Scaling On (ENG)

Method Ratio

Units G

Ratio 0.001442 [G] (Displayed as “1.4420 m”)

When an inspection record of a strain gauge converter provides the rated

capacity and rated output

Refer to “When using [Rating]” in “3.2 Converting Input Values (Scaling Function)” (p. 46).

When using a strain gauge having a gauge factor of other than 2.0

Model U8969 Strain Unit measures outputs of the gauge supposing that the gauge factor stands at

2.0.

When a strain gauge having a gauge factor of other than 2.0 is used, the gauge factor needs to be

set as the conversion ratio.

For example, if the gauge factor stands at 2.1, the conversion ratio will be 0.952 (≈ 2 / 2.1).

Example: To display data measured with a strain gauge (gauge factor: 2.1) as values in terms

of gees (G)

This conversion requires calculations based on both a gauge factor and a conversion ratio that

converts data into physical quantities. In this case, specify the product of the conversion ratios of

the gauge factor and the scaling ratio as the conversion ratio.

Where the conversion ratio of the gauge factor is 0.952, and the conversion ratio to convert data

into physical quantities is 0.001442*.

Conversion ratio = 0.952 × 0.001442 = 0.0013728

3

Advanced Functions

Type [0.0013728] as the conversion ratio.

*: To convert values measured with the strain gauge into physical quantities, calculate the conversion ratio

based on Young’s modulus or Poisson’s ratio of a measurement object. The conversion method varies

depending on the conditions in which the strain gauge is used.

Refer to “Scaling method for strain gauges” (p. 199).

47

Page 52

Fine-Adjusting Input Values (Vernier Function)

3.3 Fine-Adjusting Input Values (Vernier Function)

You can ne-adjust the input voltage freely on the waveform screen. When recording physical

quantities such as noise, temperature, and acceleration with sensors, you can adjust those

amplitudes, facilitating calibration.

Waveform processed by

Normal waveform

the vernier function

> [Channel]

1.2 V

1.0 V

When an input voltage of 1.2 V is

displayed as a voltage of 1.0 V

Adjust the set value in [Vernier].

• The adjustable range is from 50% to 200% of an original waveform.

• You cannot check if waveforms are adjusted by the vernier function only by observing waveforms.

• The waveform data (data saved as les) is that adjusted by the vernier function.

48

Page 53

Inverting the Waveform (Invert Function)

3.4 Inverting the Waveform (Invert Function)

This function can be used for analog channels only. The positive and negative sides of the

waveform get reversed.

The waveform data (saved as les) is that inverted by the invert function.

Example

• When the signal is input with spring-pulling force being negative and spring-compressing force

being positive; however, you would like the results to be displayed with spring-pulling force being

positive and spring-compressing force being negative

• If the current sensor is attached around the wire with its current direction mark mistakenly in the

direction opposite to the current ow

> [Channel]

Set [Invert] to [On].

3

Advanced Functions

This setting is not available for Model 8967 Temp Unit, Model 8970 Freq Unit, and Model 8973

Logic Unit.

49

Page 54

Copying Settings (Copy Function)

3.5 Copying Settings (Copy Function)

You can copy settings of other channels, as well as the trigger settings and the real-time waveform

calculation settings (Model MR6000-01 only).

The following procedure explains how to copy settings of another channel.

> [Func] > [Copy] > [Channel]

1

4

Set [Contents].

1

Depending on the type of module, some items may not be able to be copied.

Basic Copies the following settings: mode, measurement range, coupling, L.P.F., division

ratio, and module-specic settings.

Display Copies the display setting (excluding comments).

Comment Copies a comment.

Scaling Copies the scaling setting.

2

3

Set [Source].

2

Select the source channel to be copied.

Set [Destination].

3

CH1-1

(Channel selection)

All Copies settings to UNIT 1 through UNIT 8.

Tap [Copy].

4

After copying the settings, check that the [Range (f.s.)] setting as well as values in the [Level], [Upper],

[Lower] boxes of the numerical calculation function, the trigger function, and the search function are

appropriate.

Tap this option when you would like to copy the settings to any one of channels.

Select a destination channel from the list.

50

Page 55

Conguring Module-Specic Settings

3.6 Conguring Module-Specic Settings

The advanced settings can be congured for each module.

Setting Model 8968 High Resolution Unit

> [Channel] > [8968]

3

Advanced Functions

Set [A.A.F.] (anti-aliasing lter).

The anti-aliasing lter can prevent aliasing distortion when FFT calculations are performed. The cutoff

frequency changes automatically according to the sampling rate setting.

Off

On Enables the anti-aliasing lter.

Disables the anti-aliasing lter.

(Disabled when the external sampling is used or the sampling rate is set at a rate of

100 kS/s or faster)

51

Page 56

Conguring Module-Specic Settings

Setting Model 8967 Temp Unit

> [Channel] > [8967]

1

2

3

4

Set [Mode].

1

Choose an option depending on the type of thermocouple to be used.

Mode Measurable range Mode Measurable range

K

J −200°C to 1100°C S 0°C to 1700°C

E −200°C to 800°C B 400°C to 1800°C

T −200°C to 400°C W 0°C to 2000°C

N −200°C to 1300°C

Set [RJC].

2

Int.

Ext. Does not execute the reference junction compensation inside the module.

When connecting a thermocouple directly to the module, select [Int.].

When connecting a thermocouple via a reference junction device (e.g., zero-point bath), select [Ext.].

Set [Burn out].

3

You can detect a broken thermocouple wire during temperature measurement. If a thermocouple wire breaks,

measured values will uctuate.

Off

−200°C to 1350°C R 0°C to 1700°C

Execute the reference junction compensation inside the module.

(Measurement accuracy: The sum of the accuracy of the temperature measurement

and that of the reference junction compensation)

(Measurement accuracy: The accuracy of the temperature measurement only)

Does not check wires for breaks.

On Check wires for breaks by owing approximately 100 nA of minuscule current through

the thermocouple.

If the thermocouple wires are long or have a relatively high resistance, set [Burn out] to [Off] to avoid

measurement errors.

52

Page 57

Set [Data update].

4

The data update rate has 3 options:

Fast Updates data approximately every 1.2 ms.

Select this option for a quicker response; however, selecting this option caused some

increase in noise superimposed on input signals.

Normal

Slow Updates data approximately every 500 ms.

Updates data approximately every 100 ms.

Selecting this option eliminates noise, leading to stable measurement.

Selecting this option leads to stabler measurement.

Conguring Module-Specic Settings

3

Advanced Functions

53

Page 58

Conguring Module-Specic Settings

Setting Model U8969 Strain Unit

For Model U8969 Strain Unit, the auto-balance can be executed.

Executing the auto-balance regulates the reference output level of a transducer at the specied

zero position. This function is available for Model U8969 Strain Unit only.

You can use Model 8969 Strain Unit you own with this instrument. The instrument displays the

model name of Model 8969 Strain Unit as [U8969].

Before executing the auto-balance

• Turn on the instrument and leave it for 30 minutes to allow the internal temperature of the module

to stabilize.

• After connecting a strain gauge converter to the module, execute the auto-balance without any

input including distortion.

• The auto-balance cannot be executed during measurement.

• No key operation is accepted during the execution of the auto-balance.

To execute the auto-balance on the channel screen of each channel

> [Channel] > [U8969]

Tap [Auto balance].

54

One channel only Executes the auto-balance for only the channel displayed on the channel screen.

All channel Executes the auto-balance for all of the channels in which Model U8969 is installed.

Page 59

Conguring Module-Specic Settings

To execute the auto-balance on the list screen

> [Channel] > > [Operate] > [Auto balance]

Executes the auto-balance for all of the channels in which Model Strain Unit is installed.

In the following cases, execute the auto-balance again.

• After changing the vertical axis (strain axis) range

• After replacing any of modules

• After replacing the strain gauge converter

• After cycling the instrument

• After initializing the instrument

• When the ambient temperature has changed signicantly (The zero position may drift.)

If the auto-balance fails

Verify the following, and execute the auto-balance again.

• Is the strain gauge converter not subject to any load?

(Make sure that the strain gauge converter is not subject to vibration, etc.)

• Is the strain gauge converter connected properly?

3

Advanced Functions

55

Page 60

Conguring Module-Specic Settings

Setting Model 8970 Freq Unit

> [Channel] > [8970]

1

2

to

10

Set [Mode].

1

Freq

RPM Measures the number of rotations of a measurement target (in rotations per minute

P-Freq Measures power frequency uctuation (in hertz [Hz]).

Count Accumulates the number of input pulses.

Duty Measures duty ratios of a measurement waveform (in percent [%]).

Pulse width Measures pulse widths (in second [s]).

A pulse (having a frequency of 25 kHz or higher) that rises during the dead time (calculating period) cannot be

measured.

Set [Input voltage].

2

Set the maximum level of an input signal.

±10 V

, ±20 V, ±50 V, ±100 V, ±200 V, ±400 V

Measures the frequency of a waveform (in hertz [Hz]).

[r/min]).

Ignored

Calculation (40 μs)Acquisition of the waveform Acquisition of the waveform

56

Page 61

Conguring Module-Specic Settings

Specify [Threshold].

3

• Measured values are acquired based on the following: the interval between the times when measured

waveform exceeds or falls below the threshold value, and the number of times when the waveform exceeds

or falls below the threshold value.

• The upper and lower limits of the threshold value and the increment in the threshold value vary depending

on the input voltage setting.

To prevent measurement errors due to noise, the hysteresis width that is approximately 3% of the input voltage

is tolerated for the threshold.

(When [Input voltage] is set to [±10 V], it stands at approximately ±0.3 V.)

Specify a threshold allowing for tolerance exceeding the hysteresis width relative to a peak voltage.

Set [Slope].

4

The instrument detects the waveform when the waveform crosses the specied threshold in the direction

specied here, which is used in each measurement mode.

Detects the waveform when it exceeds the specied threshold value (in the positive

direction).

Detects the waveform when it falls below the specied threshold value (in the negative

direction).

3

Advanced Functions

Specify [Division].

5

The instrument determines the frequency every time the specied number of pulses has been counted.

1

to 4,096

Example: For the encoder that outputs 360 pulses per rotation, set [Division] to [360] to measure the

frequency of each rotation. When [Division] is not used, set [Division] to [1].

Set [Timing].

6

Only when [Mode] is set to [Count], this setting is available.

You can set when to start accumulating the number of pulses.

Start

Trigger Starts the accumulation when the instrument is triggered.

• When [Timing] is set to [Start], some internal processing time is required between the pressing of the

START key and the start of measurement. Thus, the count value is not zero at the start point.

• When [Timing] is set to [Start], the instrument does not trigger even when the input signal exceeds the

specied trigger level while the pre-trigger length of data is being acquired. Furthermore, the time for internal

processing at the start and the trigger priority setting may cause the instrument not to trigger even when the

input signal exceeds the specied trigger level.

Set [Count over].

7

Only when [Mode] is set to [Count], this setting is available.

Hold

Starts the accumulation when the START key is pressed.

Counts pulses and stops counting when the number of pulses reaches the upper limit

(65535 for the 40 k range).

Back Starts counting pulses and brings the count back to zero when the number of pulses

reaches 25 times of the range (50000 for the 40 k range).

Set [Level].

8

Only when [Mode] is set to [Pulse width] or [Duty ratio], this setting is available.

For the pulse width measurement and duty ratio measurement, you can select whether to detect the parts

above the threshold level or those below the level.

HIGH

LOW Measures the parts of waveforms below the threshold value.

Measures the parts of waveforms above the threshold value.

57

Page 62

Conguring Module-Specic Settings

Set [Smoothing].

9

Only when [Mode] is set to [Freq] or [Revolution], this setting is available.

Off

On Interpolates the measured data to smooth the waveforms and outputs the waveforms.

Set [Hold].

10

Only when [Mode] is set to [Freq] or [Revolution], this setting is available.

The hold for frequencies and number of rotations can be set.

Records the measured data without smoothing (resulting in a stair-step waveform).

(Upper limit: 10 kHz, outputting data with this setting set to On lags behind than with

this setting set to Off)

Off (1 Hz),

Off (0.5 Hz),

Off (0.2 Hz),

Off (0.1 Hz)

On

When the instrument does not determine the measured value even when the

frequency reaches one of the values in the brackets, the measurement is dened to

stop and regards the measured value to be 0 Hz (0 rpm).

Retains the value settled last time.

58

Page 63

Setting Model 8971 Current Unit

> [Channel] > [8971]

Conguring Module-Specic Settings

21

3

Advanced Functions

Set [Mode].

1

The instrument automatically recognizes the current sensor connected to Model 8971 Current Unit and

displays it as follows:

20A/2V When one of the following current sensors is connected: Model 9272-10 (20 A range) and

Model CT6841.

200A/2V When one of the following current sensors is connected: Model 9272-10 (200 A range), Model

CT6843, and CT6863.

50A/2V When the current sensor Model CT6862 is connected.

500A/2V When one of the following current sensors is connected: Model 9709, Model CT6844, Model

CT6845, Model CT6846*, and Model CT6865*.

None When no current sensor is connected.

IMPORTANT

*: When Model CT6846 or Model CT6865 is connected to Model 8971 Current Unit via Model

9318 Conversion Cable, the instrument recognizes the sensor as a 500 A AC/DC sensor. Set

the conversion ratio to 2.00 in the scaling setting.

Make sure to execute the zero adjustment after you change the setting. Execute the zero adjustment without any

input.

DC

Current measurement

RMS RMS measurement

Set [Range (f.s.)].

2

Select a measurement range from the scaled set values for the automatically recognized current sensor.

59

Page 64

Conguring Module-Specic Settings

IMPORTANT

The values displayed under [Range (f.s.)] represent the maximum displayable values (f.s. or

full-scale) of Model 8971. Currents that exceed the rated current of the connected current sensor

cannot be measured. Check the specications of the current sensor.

60

Page 65

Setting Model 8972 DC/RMS Unit

> [Channel] > [8972]

1

Conguring Module-Specic Settings

2

3

Advanced Functions

Set [Mode].

1

Make sure to execute the zero adjustment after you change the setting. Execute the zero adjustment without