LR8512

HIOKI LR8512B980-07

LR8513

LR8514

Instruction Manual

LR8515

WIRELESS PULSE LOGGER

WIRELESS CLAMP LOGGER

WIRELESS HUMIDITY LOGGER

WIRELESS VOLTAGE/TEMP LOGGER

Dec. 2020 Revised edition 7

LR8512B980-07 20-12H

EN

HIOKI LR8512B980-07

Contents

HIOKI LR8512B980-07

Introduction ........................................................................................1

Trademark ..........................................................................................1

Verifying Package Contents .............................................................2

Options ................................................................................................ 3

Safety Notes ....................................................................................... 5

Usage Notes ....................................................................................... 8

For customers who are using the LR8410 Wireless Logging

Station ..............................................................................................21

Instrument Version ..........................................................................22

1 Overview 23

1.1 Overview and Features .......................................................... 23

1.2 Parts Names and Functions .................................................. 24

1.3 DisplayCongurationExample ............................................26

2 Preparation for Measurements 29

2.1 Inspection Before Use ...........................................................29

2.2 Inserting/Replacing Batteries ...............................................30

Installation (Replacement)...............................................................31

Battery indicator display .................................................................32

Battery life indication ....................................................................... 33

2.3 Connecting the AC Adapter ...................................................35

ExternalPowerSupply ....................................................................35

2.4 Installing the Strap (optional) ...............................................36

2.5 Connecting Cables ................................................................. 37

Connecting the L1010 Connection Cable (LR8512) ...................... 37

Connecting the clamp sensor (LR8513) ......................................... 38

Connecting the temperature and humidity sensor (LR8514) ....... 48

LR8512B980-07

i

Contents

HIOKI LR8512B980-07

3 Using the LR8410 as a Unit 49

3.1 Real-time Measurement Using the LR8410 .......................... 49

®

3.2 Performing Real-time Measurement Using a Windows

PC ............................................................................................50

4 Collecting Measurement Data Using a

®

Windows

4.1 SoftwareSpecications ......................................................... 51

System requirements ....................................................................... 51

Functionspecications ................................................................... 52

4.2 MeasurementWorkow .........................................................53

4.3 Installing the Software ........................................................... 55

Installation ........................................................................................55

Startup procedure ............................................................................ 56

Termination procedure ....................................................................56

Uninstallation ....................................................................................57

4.4 DisplayConguration ............................................................ 58

4.5 Basic Operation Procedure ................................................... 59

Operationow .................................................................................. 59

Selecting multiple wireless loggers ...............................................60

4.6 Registering/Deleting a Wireless Logger ..............................61

Registering a wireless logger .........................................................61

Deleting a wireless logger ............................................................... 64

Grouping wireless loggers .............................................................. 65

4.7 Setting Measurement Conditions .........................................67

Setting measurement ....................................................................... 68

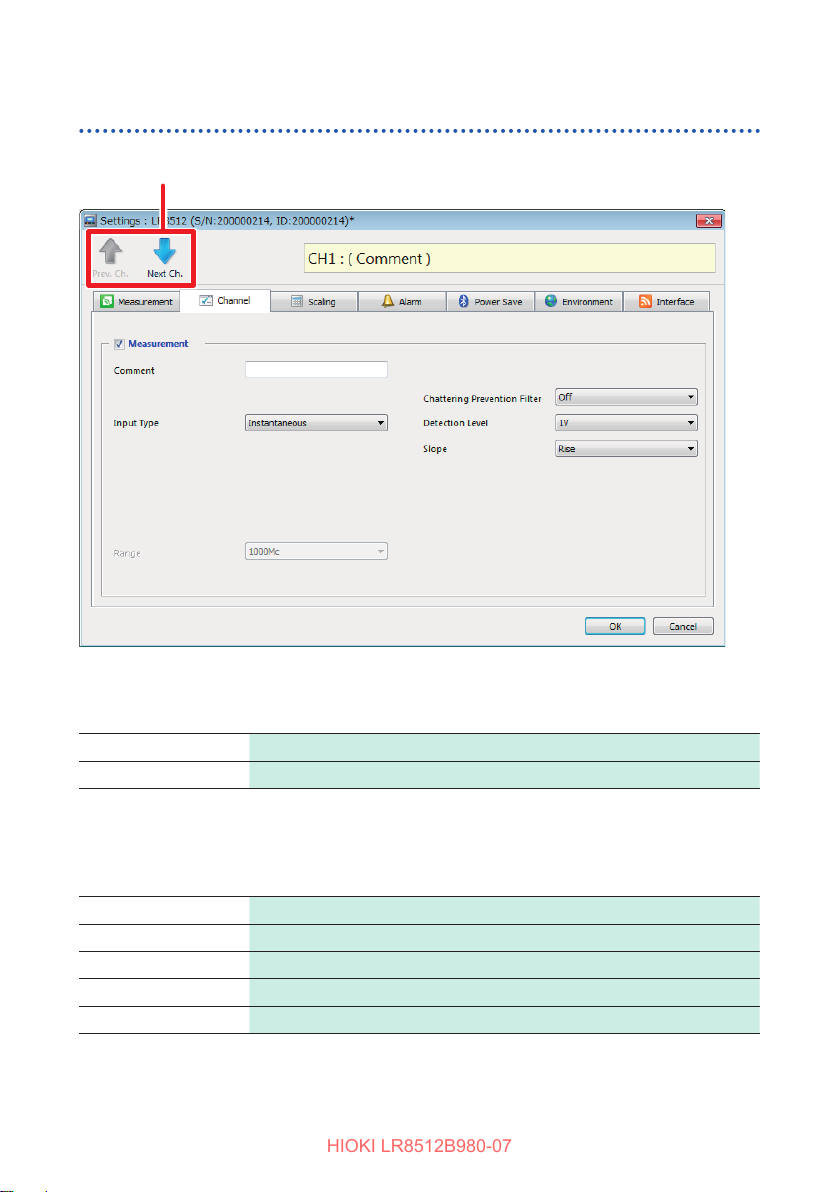

Setting the channel .......................................................................... 70

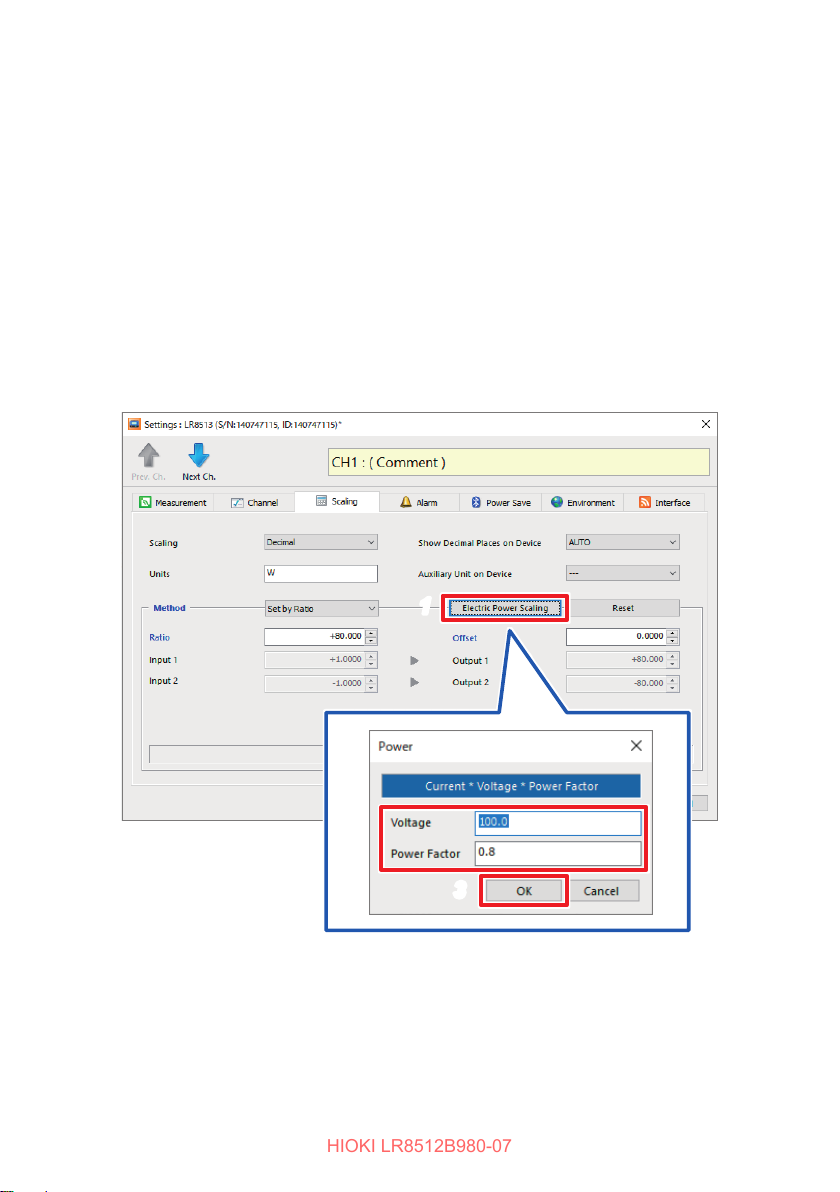

Setting scaling (as needed) ............................................................. 81

Setting the alarm function (as needed) .......................................... 87

Setting the power saving function (as needed) .............................90

Setting the environment .................................................................. 91

Communications .............................................................................. 92

PC 51

ii

Contents

HIOKI LR8512B980-07

Copying the settings ........................................................................ 94

Initializing the settings .....................................................................95

4.8 Sending/Receiving the Setting Conditions .......................... 96

Sending the settings ........................................................................ 96

Receiving the settings ..................................................................... 97

4.9 Starting and Stopping Measurement and Monitoring ........98

Starting and stopping measurement .............................................. 98

Starting and stopping status monitoring ....................................... 99

Starting and stopping value monitoring ...................................... 100

4.10 Collecting Measurement Data ............................................. 101

Starting and stopping data collection .......................................... 101

4.11 Browsing/Analyzing Measurement Data ............................ 102

Browsing measurement data ........................................................ 102

Exportingmeasurementdata ........................................................ 103

Deleting measurement data ..........................................................105

4.12 Performing Wireless Logger Maintenance ........................106

Setting the clock.............................................................................106

Self-diagnosis ................................................................................. 107

Checking the version number ....................................................... 108

Updatingthermwareversion......................................................109

4.13 Convenient Functions ......................................................... 110

5 Collecting Measurement Data Using an

Android

5.1 SoftwareSpecications ....................................................... 113

System requirements ..................................................................... 113

Functionspecications ................................................................. 113

5.2 MeasurementWorkow ....................................................... 114

5.3 Installing the Software ......................................................... 117

Installation ...................................................................................... 117

Startup procedure .......................................................................... 118

Uninstallation .................................................................................. 118

5.4 DisplayConguration .......................................................... 119

TM

Terminal 113

iii

Contents

HIOKI LR8512B980-07

5.5 Registering/Deleting a Wireless Logger ............................124

Registering a wireless logger .......................................................124

Deleting a wireless logger ............................................................. 125

Grouping wireless loggers ............................................................ 126

5.6 Setting Measurement Conditions .......................................128

Setting measurement ..................................................................... 129

Setting the channel ........................................................................ 130

Advance settings............................................................................131

Initializing the settings ...................................................................132

5.7 Sending/Receiving the Setting Conditions ........................ 133

Sending the settings ...................................................................... 133

Receiving the settings ................................................................... 134

5.8 Starting and Stopping Measurement and Monitoring ......135

Starting and stopping measurement ............................................ 135

Starting and stopping monitoring ................................................136

5.9 Collecting Measurement Data ............................................. 138

Starting and stopping data collection .......................................... 138

5.10 Browsing/Analyzing Measurement Data ............................ 139

Browsing measurement data ........................................................ 139

Exportingmeasurementdata ........................................................ 141

Deleting measurement data ..........................................................144

5.11 Performing Wireless Logger Maintenance ........................145

Setting the clock.............................................................................146

Checking the version number ....................................................... 146

6 Specications 147

6.1 LR8512 Wireless Pulse Logger ........................................... 147

6.2 LR8513 Wireless Clamp Logger .........................................152

6.3 LR8514 Wireless Humidity Logger .....................................158

6.4 LR8515 Wireless Voltage/Temp Logger .............................163

6.5 Z2010, Z2011 Humidity Sensor ...........................................169

iv

Contents

HIOKI LR8512B980-07

7 Maintenance and Service 171

7.1 Repair, Inspection, and Cleaning ........................................171

7.2 Troubleshooting ...................................................................173

7.3 ErrorDisplay ......................................................................... 175

7.4 Disposal ................................................................................176

Removing lithium batteries ........................................................... 176

Appendix Appx.1

Measurement value recording ................................................Appx.1

Recording interval and recording time ..................................Appx.4

Target collection time ..............................................................Appx.4

Initial setting list ....................................................................... Appx.5

Handling Data ........................................................................... Appx.6

v

Contents

HIOKI LR8512B980-07

vi

Introduction

HIOKI LR8512B980-07

Introduction

Thank you for purchasing the HIOKI LR8512 Wireless Pulse Logger, LR8513 Wireless

Clamp Logger, LR8514 Wireless Humidity Logger, or LR8515 Wireless Voltage/Temp

Logger. To obtain maximum performance from the product, please read this manual

rst, and keep it handy for future reference.

In this manual, the name of each instrument is indicated as follows.

Product name Name indicated in the manual

LR8512 Wireless Pulse Logger

LR8513 Wireless Clamp Logger

LR8514 Wireless Humidity Logger

LR8515 Wireless Voltage/Temp Logger

There are the following instruction manuals available for this instrument. Please refer

to the appropriate manuals for the intended usage.

Model Manual contents

Measurement Guide For customers who use this instrument for

the rst time, this manual describes the basic

operation procedures.

Instruction Manual

(this manual)

Precautions Concerning

Use of Equipment That

Emits Radio Waves

Logger Utility*

User Manual

Describes details of the functions, operations,

and specications of this instrument.

Precautions relating to use of equipment that

emits radio waves, countries in which the

instrument has been certied, etc.

Describes how to operate the PC application

software.

Instrument

Printed

edition

–

–

CD

edition

–

–

*: To install the PC application software, Logger Utility, see “4.3 Installing the software” (p. 55).

For information about its operating procedure, see the Logger Utility User Manual contained in

the accompanying CD-R.

Trademark

• Microsoft, Windows, and Microsoft Excel are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• The Bluetooth

SIG, Inc. and any use of such marks by Hioki E.E. Corporation is under license.

Other trademarks and trade names are those of their respective owners.

• Adobe and Adobe Reader are either trademarks or registered trademarks of Adobe

Systems Incorporated in the United States and other countries.

• Android and Google Play are trademarks of Google, Inc.

®

word mark and logos are registered trademarks owned by Bluetooth

1

Verifying Package Contents

HIOKI LR8512B980-07

Verifying Package Contents

• When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel keys,

and connectors. If damage is evident, or if it fails to operate according to the

specications, contact your authorized Hioki distributor or reseller.

Check the package contents as follows.

Instrument

LR8512 × 1

LR8513 × 1

LR8514 × 1

LR8515 × 1

Common accessories

Logger Application Disc (CD-R)*

• Instruction Manual (PDF)

• Logger Utility

• Wireless Logger Collector

• Logger Utility Instruction Manual (PDF)

*: The latest version of the application software can be

downloaded from our website.

Measurement Guide

PrecautionsConcerningUseofEquipmentThatEmits

Radio Waves

LR6 Alkaline battery × 2

LR8512 Accessory

L1010ConnectionCable(lengthapprox.1.5m)×2

2

Verifying Package Contents

HIOKI LR8512B980-07

Options

The following options are available for the LR8512, LR8513, LR8514, and LR8515.

Contact your authorized Hioki distributor or reseller when ordering.

The options are subject to change. Visit our website for updated information.

Common options

Z2003 AC Adapter (power cord attached)

Z5004 Magnetic Strap

Z5020 Magnetic Strap

LR8512 Option

L1010 Connection Cable (length approx. 1.5 m)

LR8513 Option

9669 Clamp On Sensor

9695-02 Clamp On Sensor

CT6500 Clamp On Sensor

9657-10 Clamp On Leak Sensor

9675 Clamp On Leak Sensor

CT9691-90 Clamp On AC/DC Sensor

CT9692-90 Clamp On AC/DC Sensor

CT9693-90 Clamp On AC/DC Sensor

9219 Connection Cable (for 9695-02 connection)

CT7631 AC/DC Current Sensor

CT7636 AC/DC Current Sensor

CT7642 AC/DC Current Sensor

CT7731 AC/DC Auto-Zero Current Sensor

CT7736 AC/DC Auto-Zero Current Sensor

CT7742 AC/DC Auto-Zero Current Sensor

CT9667-01 AC Flexible Current Sensor

CT9667-02 AC Flexible Current Sensor

CT9667-03 AC Flexible Current Sensor

CT7044 AC Flexible Current Sensor

CT7045 AC Flexible Current Sensor

CT7046 AC Flexible Current Sensor

CM7290 Display Unit

For the CT7631,CT7636,CT7642,CT7731,CT7736,CT7742,CT7044,CT7045,CT7046

CM7291 Display Unit

For the CT7631,CT7636,CT7642,CT7731,CT7736,CT7742,CT7044,CT7045,CT7046

L9095 Output Cord (for CM7290/CM7291 connection)

3

Verifying Package Contents

HIOKI LR8512B980-07

LR8514 Option

Z2010 Humidity Sensor (Length including the sensor: Approx. 50 mm)

Z2011 Humidity Sensor (Cable length: Approx. 1.5 m)

Supported instrument

LR8410 Wireless Logging Station

(Supported for software version 1.30 and later)

4

Safety Notes

HIOKI LR8512B980-07

Safety Notes

This instrument is designed to conform to IEC 61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment. However, using the instrument in a way

not described in this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage

to the instrument. Be certain that you understand the instructions and

precautions in the manual before use.

WARNING

Ifyoudonothaveknowledgeorexperienceofelectricalmeasurements,

usethisinstrumentundersupervisionofexperiencedpersonnel.

Notation

In this manual, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Windows

Dialog Windows dialog boxes are referred to as dialogs.

[ ]

Indicates an imminently hazardous situation that will result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in minor

or moderate injury to the operator or damage to the instrument or

malfunction.

Indicates information related to the operation of the instrument or

maintenance tasks with which the operators must be fully familiar.

Indicates a strong magnetic-eld hazard.

The eects of the magnetic force can cause abnormal operation of

heart pacemakers and/or medical electronics.

Indicates prohibited actions.

Indicates an action that must be performed.

Additional information is presented below.

Windows 7, Windows 8 and Windows 10 are referred to as ″Windows″,

otherwise specied.

The names and keys on the screen including menus, commands,

dialogs, dialog button names, etc. are enclosed in brackets [ ].

5

Safety Notes

HIOKI LR8512B980-07

Symbolsaxedtotheinstrument

Indicates cautions and hazards. When the symbol is printed on the instrument,

refer to a corresponding topic in the Instruction Manual.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE

Directive) in EU member states.

Indicates that the product conforms to regulations set out by the EU Directive.

Indicates that the product incorporates Bluetooth® wireless technology.

FCC ID

Indicates the ID number of the wireless module certied by the U.S. Federal

Communications Commission (FCC).

Indicates the identication number of a wireless module approved by Industry

IC

Canada (IC).

Screen display

The instrument screen displays the alphanumeric characters as follows.

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

1 2 3 4 5 6 7 8 9 0

6

Safety Notes

HIOKI LR8512B980-07

Accuracy

We dene measurement tolerances in terms of rdg. (reading) and dgt. (digit) values,

with the following meanings:

(Maximum display value or scale length/range)

f.s.

rdg.

dgt.

The maximum displayable value or scale length. This is usually the name of

the currently selected range.

(Reading or displayed value)

The value currently being measured and indicated on the measuring

instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input

value that causes the digital display to show a “1” as the least-signicant digit.

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety

standards for various electrical environments, categorized as CAT II to CAT IV, and

called measurement categories.

DANGER

• Using a measuring instrument in an environment designated with

a higher-numbered category than that for which the instrument

is rated could result in a severe accident, and must be carefully

avoided.

• Using a measuring instrument without categories in an environment

designated with the CAT II to CAT IV category could result in a

severe accident, and must be carefully avoided.

CAT II: When directly measuring the electrical outlet receptacles of the primary

electrical circuits in equipment connected to an AC electrical outlet by a

power cord (portable tools, household appliances, etc.)

CAT III: When measuring the primary electrical circuits of heavy equipment (xed

installations) connected directly to the distribution panel, and feeders from

the distribution panel to outlets

CAT IV: When measuring the circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent protection device

(distribution panel)

Distribution panel

Service entrance

Service drop

CAT IV

CAT I V

Power meter

CAT III

CAT I I I

Fixed installation

Internal wiring

CAT II

CAT I I

T

Outlet

7

Usage Notes

HIOKI LR8512B980-07

Usage Notes

Follow these precautions to ensure safe operation and to obtain the full benets of

the various functions.

Bluetooth

This instrument and the LR8410 use radio waves of a band frequency of 2.4 GHz.

No radio station license is required to use this product, however, be aware of the

following.

®

WARNING

• Do not use this instrument in a system that requires high safety and

reliability.

• Do not use this instrument near any medical equipment, such as a

pacemaker, etc.

• Do not modify, disassemble, or repair the instrument.

CAUTION

• If this instrument is used near any equipment that uses the same

frequency band, such as wireless LAN equipment, etc., communications

may become unstable or other equipment may be aected.

• The line-of-sight distance between the instrument and the LR8410 is 30

m. If there is an obstacle (wall, metal screen, etc.), communications may

become unstable or the communications distance may become shorter.

In addition, even if multiple instruments are installed in the same

environment, each instrument may show a dierent radio-eld strength

(antenna-like indication).

• Communications between the instrument and the LR8410 are encrypted

by SSP, however, the condentiality of any information is not guaranteed.

We are not responsible for any leakage of measurement data by wireless

communications.

• This instrument and the LR8410 generate electric waves. Usage of

electric waves requires permission and authorization in each country.

Using electric waves in any country or region other than the ones listed

in the attached document “Precautions Concerning Use of Equipment

That Emits Radio Waves” is against the law and may be subject to

punishment.

• When the instrument is positioned on a stand instead of directly on the oor,

communications can become more stable.

• The Wireless Logger Collector may not correctly work according to the mobile

communication device.

8

Usage Notes

HIOKI LR8512B980-07

Check before use

Verify that it operates normally to ensure that no damage occurred during storage or

shipping. If you nd any damage, contact your authorized Hioki distributor or reseller.

Installation

WARNING

Installing the instrument in inappropriate locations may cause a

malfunction of the instrument or may give rise to an accident. Avoid

the following locations.

• Exposedtodirectsunlightorhightemperature

• Exposedtocorrosiveorcombustiblegases

• Exposedtowater,oil,chemicals,orsolvents

• Exposedtohighhumidityorcondensation

• Exposedtoastrongelectromagneticeldorelectrostaticcharge

• Exposedtohighquantitiesofdustparticles

• Near induction heating systems (such as high-frequency induction

heating systems and IH cooking equipment)

• Susceptible to vibration

For details on the operating temperature and humidity, see the

specications.

• This instrument is not drip-proof. Water that drips on the connector could

• Do not allow any condensation to form. Condensation can form

• Do not allow the instrument to become wet or take measurements with

• Do not position the instrument on an unstable table or inclined surface.

Install the LR8515 Wireless Voltage/Temp Logger with attention to the following:

• Take appropriate measures to prevent the ambient temperature near the terminal

block from changing. Install the instrument where it is not exposed to direct air

from a ventilation fan, air conditioner, etc. A measurement error can occur during

thermocouple input.

• When the instrument is moved to a location with a signicant temperature

change, wait for at least 60 minutes before starting measurement.

CAUTION

cause a malfunction.

particularly in an environment where the temperature changes drastically.

wet hands. Doing so may cause a malfunction.

When the instrument falls or tips, an injury or malfunction can occur.

9

Usage Notes

HIOKI LR8512B980-07

Handling of this instrument

CAUTION

Avoid any vibration or impact to prevent damage to the instrument during

transportation and handling. Be especially careful regarding the impact by

a fall.

This instrument may cause interference if used in residential areas. Such use must

be avoided unless the user takes special measures to reduce electromagnetic

emissions to prevent interference to the reception of radio and television broadcasts.

Handling of cords and cables

WARNING

Makesuretousethespeciedpowercordwhenusingtheinstrument.

Otherwise,aremaybecaused.

CAUTION

• Avoid stepping on or pinching the cables to prevent damage to the

cables. Do not bend or pull the cables.

• To prevent any wires from breaking, pull on the connector end, not the

• To prevent any wires from breaking, pull on the connector end, not the

• The cables become sti below 0°C. If the cables are bent or pulled in this

•

When using the instrument, make sure to use the connection cable specied by our

company. When any other cable is used, it may not be possible to perform accurate

measurement due to a contact failure, etc.

• When a measurement cable that is longer than 3 m is connected, measurement

may be aected by factors in the EMC environment, such as exogenous noise.

• Position the measurement cable away from the power line or ground cable.

• When the measurement cable is connected in parallel to other equipment,

measurement values may vary. If the measurement cable is to be connected in

parallel, make sure to check the operation before use.

10

cable, to disconnect the output connector.

cord, to disconnect the power cord from the outlet or the instrument.

condition, the cable insulation may be damaged or the wires may be cut.

Usage Notes

HIOKI LR8512B980-07

Before turning on the power

CAUTION

• When operating the instrument using a UPS (uninterruptible power

supply) or DC-AC inverter, do not use any square-wave and pseudo sinewave UPS or DC-AC inverter. Doing so may damage the instrument.

• Make sure that the power voltage connection is correct. Connection

errors could damage the internal circuit.

The instrument and measurement unit will not fail due to a momentary power

failure under 40 ms. If the power failure is longer than 40 ms, the power may be

shut o temporarily. Install the instrument in consideration of power conditions at

the installation location.

Magnet of the optional strap

DANGER

Those with medical electronics such as pacemakers should not use

the Z5004/Z5020 Magnetic Strap. Nor should such persons approach

theZ5004orZ5020.Itisextremelydangerous.Theelectronicsmay

not operate properly and the life of the operator may be put at great

risk.

Swallowing magnets could be life-threatening. Keep any magnets

out of reach, especially of small children. If you accidentally swallow

magnets, immediately seek medical attention.

• Do not use the Z5004 or Z5020 in locations where it may be exposed to

• Do not bring the Z5004 or Z5020 near magnetic media such as oppy

• Keep magnets away from any impact by a fall. The magnets may chip or

WARNING

CAUTION

rainwater, dust, or condensation. In those conditions, the magnet may be

decomposed or deteriorated. The magnet adhesion may be diminished.

In such case, the instrument may not be hung in place and may fall.

disks, magnetic cards, pre-paid cards, or magnetized tickets. Doing so

may corrupt and may render them unusable. Furthermore, if the Z5004

or Z5020 is brought near precision electronic equipment such as PCs, TV

screens, or electronic wrist watches, they may fail.

crack due to impact.

11

Usage Notes

HIOKI LR8512B980-07

AC adapter

• Make sure to use the optional Z2003 AC Adapter. The rated power

voltage for the AC adapter is 100 V to 240 V AC and the rated

power frequency is 50 Hz/60 Hz. Do not use the AC adapter at any

voltage other than the above to avoid damage to the instrument and

electrical accidents.

• Before turning on the power, make sure that the power voltage

indicated on the AC adapter matches the power voltage to be used.

UsingtheACadapteroutsidethespeciedpowervoltagerange

could cause damage to the instrument or AC adapter or electrical

accidents.

• Connect the output plug to the instrument and then connect the plug to

an outlet. Connecting the energized output plug to the instrument may

damage the instrument.

• When connecting an external power supply, connect the output plug to

the instrument and then supply external power.

Handling of batteries

WARNING

CAUTION

• Do not short circuit, disassemble, or incinerate batteries. Do not

• In order to prevent electric shocks, remove measurement cables

• After battery replacement, reattach and screw down the battery

• To prevent damage to the instrument or electric shocks, make sure

12

WARNING

chargealkalinebatteries.Doingsomaycauseanexplosion.Handle

and dispose of batteries in accordance with local regulations.

and then replace the batteries.

cover before use.

to use the battery cover screw (screw with a spring) that is attached

atthetimeofshipment.Ifyoulosethescreworspringorndany

damage, contact your authorized Hioki distributor or reseller.

Usage Notes

HIOKI LR8512B980-07

CAUTION

Poor performance or damage from battery leakage could result. Observe

the cautions listed below.

• Do not mix new and old batteries, or dierent types of batteries.

• Be careful to observe the battery polarity during installation. Poor

performance or damage from battery leakage could result.

• Do not use batteries after their recommended expiry date.

• Do not allow used batteries to remain in the instrument.

• To avoid corrosion from battery leakage and/or damage to the instrument,

remove the batteries from the instrument if it is to be kept in storage for

an extended period.

IMPORTANT

The displayed remaining battery level may be dierent from the actual remaining

battery level due to the battery characteristics, settings during use, temperature or

consumption level. When a battery is used in a low temperature environment or

a weak and deteriorated battery is used, the power may shut o regardless of the

battery indicator display.

Batteries

The battery indicator display and battery life are based on the use of a new alkaline

battery.

Use of nickel-metal hydride batteries

When nickel-metal hydride batteries are used, the battery indicator display does

not operate correctly.

The battery life varies depending on the capacity, charging condition, deterioration

due to repeated use, etc. Use batteries in consideration of the factors above.

Useofmanganesedioxidebatteries

Do not use manganese dioxide batteries as the instrument may not be able to

measure or communicate.

13

Usage Notes

HIOKI LR8512B980-07

Wire connection

Do not permanently connect the instrument in an environment where

thereisapossibilityofsurgesexceedingthedielectricwithstandvoltage.

Doing so may damage the instrument and result in personal injury.

• Donotallowinputthatexceedsthemaximumrating.Doingsomay

cause heat to generate, which can cause damage to the instrument,

short circuits or electric shocks.

• Donotconnectanyequipmentotherthanthespeciedclamp

sensor to the LR8513 Wireless Clamp Logger. Doing so may cause

electric shocks or damage to the instrument.

• Donotconnectanyequipmentotherthanthespeciedtemperature

and humidity sensor to the LR8514 Wireless Humidity Logger.

Doing so may cause electric shocks or damage to the instrument.

• A semiconductor relay is used to isolate between the input

terminals and channel of the LR8515 Wireless Voltage/Temp Logger.

Whenanyvoltagethatexceedsthespeciedratingisapplied,the

semiconductor relay can fail with a short-circuit. Never input any

voltagethatexceedsthespeciedrating.Especiallybeawareof

lightning surges. If there is an error in measurement values, send

the instrument for repair.

• Do not connect the measurement cable to the instrument while it

is connected to the object to be measured. Doing so may cause

electric shocks.

• Theanaloginputterminalmaximuminputvoltage,maximumrated

voltagetoearth,andmaximumratedvoltagebetweentheinput

terminals and channel of each logger is shown in the following

table. To avoid electric shocks and damage to the instrument, do

not input any voltage over the voltages shown below.

DANGER

WARNING

14

Model

LR8512 0 to 50 V DC

LR8515 ±50 V DC

Maximum

input voltage

Maximumratedvoltage

to earth

30 V AC rms or 60 V DC

(between each analog

input channel and chassis)

30 V AC rms or 60 V DC

(between each analog

input channel and chassis)

Maximumrated

voltage between

input terminals

and channel

Non-isolated

(GND common)

60 V DC

Usage Notes

HIOKI LR8512B980-07

WARNING

The power supply ground and input terminals (-) are common and

notisolated.Whenusinganexternalpowersupply,useanisolated

externalpowersupplyorconnectthewiressothatthereisno

potentialdierencebetweenthegroundoftheexternalpowersupply

and the object to be measured to prevent damage to the instrument or

electric shocks.

Handling of CD

• Do not allow any dirt or scratches on the disk recording surface. When writing on

the label face, use a pen with a soft tip.

• Store the disk in a protective case and do not expose the disk to direct sunlight

or high temperatures and humidity.

• We are not responsible for any trouble in the Windows

this disk is used.

®

computer system when

15

Usage Notes

HIOKI LR8512B980-07

Handling of clamp sensor

Connect the clamp sensor to the LR8513 and then to the live

measurement wire. Observe the following to avoid short circuits and

electric shocks.

• When the clamp sensor is opened, do not allow the metal part of

the clamp to short between the 2 wires, and do not use it over bare

conductors.

• Use the clamp sensor in a circuit below the following voltage values.

Do not use over bare conductors.

Model name Clamp sensor Clamp sensor

9669

9695-02 CAT III 300 V AC

CT6500 CAT III 600 V AC

9657-10

9675

CT9691-90

CT9693-90

CT7631

CT7636

CT7642

CT7731

CT7736

CT7742

CT9667-01

CT9667-02

CT9667-03

CT7044

CT7045

CT7046

DANGER

CAT III 600 V AC

Clamp On Sensor

Clamp On Leak Sensor CAT III 300 V AC

Clamp On AC/DC Sensor

AC/DC Current Sensor

AC/DC Auto-Zero

Current Sensor

AC Flexible Current Sensor

CAT III 600 V AC/DCCT9692-90

CAT IV 600 V AC/DC

CAT IV 600 V AC/DC

CAT III 1000 V AC/DC

CAT IV 600 V AC/DC

CAT IV 600 V AC/DC

CAT III 1000 V AC/DC

CAT IV 600 V AC/DC

CAT III 1000 V AC/DC

16

Usage Notes

HIOKI LR8512B980-07

DANGER

• Do not allow the clamp sensor to touch beyond a barrier.

• Themaximuminputcurrentoftheclampsensorisasfollows.(At45

to 66 Hz)

Model name Clamp sensor Maximuminputcurrent

9669

9695-02 60 A

CT6500 600 A

9657-10

9675 10 A

CT9691-90

CT9692-90 200 A

CT9693-90 2000 A

CT7631

CT7636 600 A

CT7642 2000 A

CT7731

CT7736 600 A

CT7742 2000 A

CT9667-01

CT9667-02 10000 A

CT9667-03 10000 A

CT7044

CT7045

CT7046

Clamp On Sensor

Clamp On Leak Sensor

Clamp On AC/DC Sensor

AC/DC Current Sensor

AC/DC Auto-Zero

Current Sensor

AC Flexible Current Sensor

10000 A(6000 A range)*

1000 A

30 A

100 A

100 A

100 A

10000 A

1000 A(600 A range)

• Make sure to connect the clamp sensor to the secondary side of

Supplyingacurrentinexcessofthemaximuminputmaydamage

the instrument and result in personal injury.

*: Range changes are controlled from the CM7290/CM7291

the breaker. The secondary side of the breaker is protected by

the breaker even if a short-circuit occurs. Do not measure on the

primarysideasithasalargecurrentcapacity,andsignicant

damage is caused when a short-circuit occurs.

17

Usage Notes

HIOKI LR8512B980-07

WARNING

• This instrument measures live wires. To avoid electric shocks when

measuring live wires, wear appropriate protective gear, such as

insulated rubber gloves, boots and a safety helmet.

• To avoid electric shocks, disconnect the clamp from the object to be

measured, open the cover, and then replace the batteries.

• After battery replacement, reattach and screw down the battery

cover before use.

• To avoid electric shocks, do not approach high-voltage equipment

or wiring when measuring the Class B ground cable for a

transformer. When the ground cable is close to a high-voltage live

partanditisdiculttomeasure,changetherouteoftheground

cable before measurement. (When the 9657-10, 9675 Clamp On Leak

Sensor is used)

CAUTION

• To prevent damage to the BNC connector, make

sure to release the lock and then pull on the

connector end of the BNC connector.

• Close the clamp core when it is not used. When the clamp core remains

open, dust collects on the butt joint of the core, which can cause a

malfunction.

• If the screw of the output terminal for the 9695-02 Clamp On Sensor is

lost, purchase the “M3 screw with spring washer × 5”. Using any screw

other than the above can cause damage to the clamp sensor.

18

Usage Notes

HIOKI LR8512B980-07

CAUTION

• Do not excessively tighten the screw of the output terminal for the 969502 Clamp On Sensor. The appropriate torque is 0.5 N•m.

• Do not input current exceeding the specied measurement range. Doing

so may damage the instrument.

• Avoid stepping on or pinching the cords to prevent damage to them. Do

not bend or pull the cord bases.

• Do not drop or hit the clamp sensor. Doing so can damage the core butt

joint and negatively aect measurement.

• Do not tuck foreign material into the joint of the clamp core tip and

instrument or insert an object into the gap of the core. Doing so may

deteriorate the sensor characteristics or cause an open/close operation

failure.

• To avoid damaging the instrument, do not connect any equipment other

than the clamp sensor to the BNC terminal.

• To avoid damaging the instrument, do not short the connector or input

voltage.

• When dust is attached to the clamp core tip butt joint, gently wipe it with a soft

cloth to prevent adverse eects on measurement.

• When connecting a cable to the output terminal of the 9695-02 Clamp On

Sensor, bring the cable as close to the terminal as possible to avoid the inuence

of an external magnetic eld.

• When connecting the 9695-02 Clamp On Sensor to the instrument, use the 9219

Connection Cable. (The 9219 connection is “Crimped terminal-BNC”.)

19

Usage Notes

HIOKI LR8512B980-07

Handling of temperature and humidity sensor

CAUTION

• The temperature and humidity sensor is not dustproof or waterproof. Do

not use the sensor in locations where it may be exposed to dust or water.

It may cause a malfunction of the instrument.

• The temperature and humidity sensor is not drip-proof. Water that drips

onto the connector could cause a malfunction.

• Sensor sensitivity and precision will degrade over time, even under normal

operating conditions. To maintain the instrument’s ability to make measurements

that conform to the accuracy specications, it is recommended to replace the

temperature and humidity sensor with a new unit once it has been used for one

year after being opened.

• When the sensor is used outside the specied operating (storage) environment,

the sensor accuracy may deteriorate even within the 1 year accuracy warranty

period and accurate measurement cannot be performed.

• In principle, the surface of the instrument’s temperature and humidity sensor

may become contaminated if exposed to an environment containing organic

gases (ketone, acetone, ethanol, toluene, etc.), increasing the error component

of humidity measurement.

• Do not expose the temperature and humidity sensor to any concentrated

chemical solvent for an extended period of time while it is used or stored.

• The sensor may become contaminated by organic gases released from some

types of vinyl chloride and packaging material.

• When the temperature and humidity sensor is not used, place it with a drying

agent in a plastic bag, seal the bag completely, and store it in a cool, dark place.

• Do not allow any condensation to form. Condensation can form particularly in

any environment where the temperature changes drastically.

• This instrument does not come with a guarantee against any problem when the

sensor is used outside the specied operating (storage) environment.

• Due to a humidity change (from low to high humidity or high to low humidity),

up to ±1% RH of change (hysteresis) occurs in the measured humidity value.

Precautions during shipment

• To avoid damaging the instrument, remove accessories and options from

• Avoid any vibration or impact to prevent damage to the instrument,

20

CAUTION

the instrument.

humidity sensor, and clamp sensor during transportation and handling.

Be careful especially with impact by a fall.

For customers who are using the LR8410 Wireless Logging Station

HIOKI LR8512B980-07

For customers who are using the LR8410

Wireless Logging Station

This instrument can be used on the LR8410 rmware version 1.30 or later.

The rmware version for the LR8410 is displayed on the system screen.

The latest version can be downloaded from our website.

For details on how to upgrade the software, see our website or check with your authorized Hioki

distributor or reseller.

21

Instrument Version

HIOKI LR8512B980-07

Instrument Version

The Wireless Logger Collector can be used on the instrument software version 1.20

or later.

A version older than 1.20 needs to be updated. The software can be updated in

Wireless Logger Collector (Windows

If the software version is older than 1.20, a communication error (protocol error)

occurs in any communications attempted between the instrument and Wireless

Logger Collector.

®

PC version). (p. 109)

22

1

HIOKI LR8512B980-07

Overview

1.1 Overview and Features

This is a compact wireless logger that is capable of measurement, display, and recording.

Model Description

LR8512 Wireless Pulse Logger • Counts pulses and records an integrated value.

• Measures the rotation and logic ON/OFF signal.

LR8513 Wireless Clamp Logger • Measures AC/DC current with the optional (sold

separately) clamp sensors installed.

• Sets the voltage and power factor and measures

the power easily.

LR8514 Wireless Humidity Logger • Measures temperature and humidity precisely.

LR8515 Wireless Voltage/Temp Logger • Measures the voltage of ±50 mV to ±50 V and

temperature (thermocouple K, T).

Real-time measurement and manual data collection functions

*1

Real-time measurement (used as a unit)

LAN/USB

communications

LR8410

*2

Windows® PC

(Logger Utility)

Manual data collection (used as stand-alone)

• Android tablet

• Android smartphone

(Wireless Logger Collector)

Windows® PC

0.1 sec. high-speed sampling

The data update of the LR8513 and LR8514 is every 0.5 sec.

The memory capacity for each channel is 500,000 data

3-way power supply

You can choose a power supply from LR6 alkaline batteries, AC adapter, and external power

supply (5 V to 13.5 V).

Average/Maximumrecordingmodeinstalled

An average/maximum recording mode is installed on the LR8513 Wireless Clamp Logger. An

average/maximum of the eective values measured at intervals of 0.5 seconds is recorded for

each recording interval.

*1 For a single-phase/2-wire, the power value can be directly read on the instrument using the

scaling setting.

For a single-phase/3-wire and three-phase/3-wire, a value can be displayed on the LR8410 with

the waveform calculations function of the LR8410.

*2 For the procedure for connecting to the LR8410, refer to the LR8410 instruction manual.

23

Parts Names and Functions

HIOKI LR8512B980-07

1.2 Parts Names and Functions

Front Rear

(Common areas of each model are described.)

Display

Battery cover

1 2 3

Operation keys Pressbriey Hold down (for at least 2 seconds)

Power

1

Display

2

Measurement

3

Left side

Right side

LR8512, LR8514

(Common to all models)

Serial number label

The serial number consists of 9

digits. The rst two (from the left)

indicate the year of manufacture,

and the next two indicate the month

of manufacture.

It is necessary for production control

requirements such as the product

warranty. Do not peel o the label.

AC adapter connection terminal

Bluetooth ON/OFF Power ON/OFF

Display change

YES (During operation

verication)

NO (During operation

verication)

Measurement start/stop

Bottom side

LR8513

Connection terminal

Connect the clamp sensor.

(p. 35)

(p. 38)

Bottom side

LR8515

―

(p. 30)

24

Connection terminal

For LR8512, connect the L1010

Connection Cable.

For LR8514, connect the

temperature and humidity sensor.

(p. 37)

Connection terminal

Connect the input cable or thermocouple.

(p. 48)

Display

HIOKI LR8512B980-07

Parts Names and Functions

Display Description

1

2

Channel (CH)

Blinking: During monitoring

Maximum value

MAX

MIN

Minimum value

AVG

Average value

Data number

Unit number

Date and time

Operation verication

Measurement

Lit: Performing measurement

Blinking: Waiting for a

measurement start to be

preset

Alarm

Lit: The current measurement

value is outside the range.

Blinking: There was a value

that was outside the range

but the current value is in the

range. (Alarm hold)

2

3

41

Display Description

2

3

4

Lit: Average recording mode

Blinking: Maximum recording

AVG

MODE

mode (LR8513 Wireless Clamp

Logger only)

Lit: Bluetooth ON

Blinking: Bluetooth OFF

(The power saving function is

enabled.)

O: Bluetooth OFF

Bluetooth connection status

(3 levels)

(Signal strength

1: Weak to 3: Strong)

Blinking: Security lock

O: Bluetooth not connected

Operating with the AC adapter

Battery indicator display

(p. 31)

Displays the unit of

measurement values.

• While the Bluetooth is being connected (the antenna symbol ( ) is lit), it cannot

be turned o.

• The power cannot be turned o during measurement.

• During real-time measurement using the LR8410 Wireless Logging Station, the

measurement cannot be stopped with key operation on the instrument.

25

Display Conguration Example

HIOKI LR8512B980-07

1.3 DisplayCongurationExample

CH1/CH2 Measurement value

*9

(Top: Hour and minute/Bottom: Second)

(Top: Year/Bottom: Month and day)

Time

Date

*9

*1, *2, *4, *7, *8, *10

Screen

change

CH1 Statistical value (MAX/MIN)

CH2 Statistical value (MAX/MIN)

CH1/CH2 Statistical value (Average)

*1, *2, *5, *7, *8, *10

*1, *2, *5, *7, *8, *10

*1, *2, *4, *6, *7, *8, *10

Unit number (1 to 7)

*1 Update for each sample during measurement.

*2 The unit of the channel for which the scaling setting is ON is not displayed. If it matches the

unit for which a segment is prepared, however, the unit is displayed.

*3 It is displayed only when connected to the LR8410.

*4 For pulse measurement (instant/integrating mode, scaling OFF) or temperature and humidity

measurement, separate screens are displayed for CH1 and CH2.

*5 For pulse measurement (instant/integrating mode, scaling OFF) or temperature and humidity

measurement,separate screens are displayed for MAX and MIN.

*6 In case of pulse measurement (integrating/logic mode), an average value is not displayed.

26

*3

Number of measurement data

*1, *11

Display Conguration Example

HIOKI LR8512B980-07

*7 If the measurement value (pulse value) of pulse measurement (instant/integrating mode,

scaling OFF) is over 10,000, it is displayed at the top and bottom. If the measurement value

is over 10,000,000, any value less than 1,000 is not displayed.

*8 The screen for the channel for which the temperature and humidity measurement is set to

OFF is not displayed.

*9 The current time is set from the wireless logger collector. (p. 106) It can also be set from

the LR8410 . For more details, refer to the LR8410 instruction manual.

*10 When scaling is set to ON, the allowable display range is indicated in the following table.

Scaling

displayed

digit setting

Automatic -10,000 or less ±0.001 to ±9,999 +10,000 or more Less than ±0.001

0 digit -10,000 or less ±1 to ±9,999 +10,000 or more Less than ±1

1 digit -1,000.0 or less ±0.1 to ±999.9 +1,000.0 or more Less than ±0.1

2 digits -100.00 or less ±0.01 to ±99.99 +100.00 or more Less than ±0.01

3 digits -10.000 or less ±0.001 to ±9.999 +10.000 or more Less than ±0.001

*11 If the value is 10,000 or more, it is displayed at the top and bottom.

U.F display

(Underow)

Allowable

display range

O.F. display

(Overow)

0 display

(Zero)

27

Display Conguration Example

HIOKI LR8512B980-07

28

2

HIOKI LR8512B980-07

Before using the instrument, make sure to refer to “Usage Notes” (p.8).

Preparation for Measurements

2.1 Inspection Before Use

Before using the instrument for the rst time, verify that it operates normally to ensure

that no damage occurred during storage or shipping. If you nd any damage, contact

your authorized Hioki distributor or reseller.

“Before sending the instrument for repair” (p.173)

Checking the instrument appearance and operation

Check item Action

Is there any damage to the

instrument and clamp sensor

connection cable?

Does the display turn on when

the power is turned on/batteries

are inserted?

Does the battery indicator

display

Is the temperature and humidity

value displayed?

?

If it is damaged, there is a risk of electric shocks. Do not

use the instrument but instead send it for repair.

If the display does not turn on, send the instrument for

repair.

When is displayed, replace the current batteries with

new batteries.

If the temperature and humidity values are not displayed,

completely insert the Z2010 or Z2011 Temperature and

Humidity Sensor.

29

Inserting/Replacing Batteries

HIOKI LR8512B980-07

2.2 Inserting/Replacing Batteries

Insert two LR6 Alkaline batteries. Before measurements, check that the battery level

is sucient. When the battery charge is low, replace the batteries.

CAUTION

Stop measurement and then replace the batteries. Replacing the

batteries during measurement may damage the data.

IMPORTANT

Batteries

The battery indicator display and battery life are based on the use of a new

alkaline battery.

Use of nickel-metal hydride batteries

When nickel-metal hydride batteries are used, the battery indicator display does

not operate correctly.

The battery life varies depending on the capacity, charging condition, deterioration

due to repeated use, etc. Use batteries in consideration of the factors above.

Useofmanganesedioxidebatteries

Do not use manganese dioxide batteries as the instrument may not be able to

measure or communicate.

• Even when the batteries are low in charge or replaced, the data and

measurement conditions saved in the instrument are not deleted.

• When the battery voltage drops to the point where the

instrument cannot operate properly, the screen on the

right is displayed. Measurement or communications

cannot be made in this condition. When the Z2003 AC

Adapter is connected or the batteries are replaced, the

instrument returns to the normal operation.

30

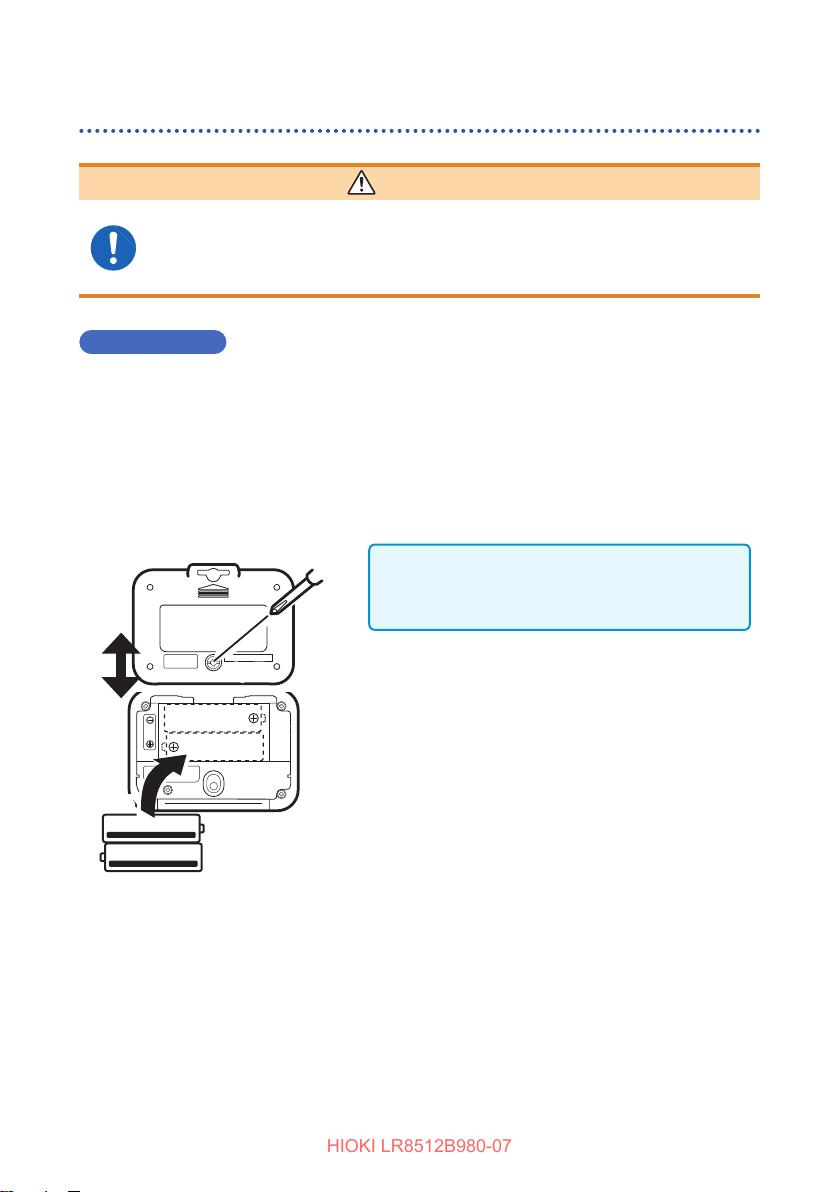

Installation (Replacement)

HIOKI LR8512B980-07

WARNING

To prevent damage to the instrument or electric shocks, make sure

to use the battery cover screw (screw with a spring) that is attached

atthetimeofshipment.Ifyoulosethescreworspringorndany

damage, contact your authorized Hioki distributor or reseller.

Required items

LR6 Alkaline battery × 2, Phillips screwdriver (No. 2)

Remove the connection cables.

1

Using a Phillips screwdriver, remove the

2

screw (1 location) from the battery cover.

The screw cannot be removed from the

battery cover. Do not try to remove the screw

forcefully.

3

2, 7

6

Slide up and remove the cover.

3

Inserting/Replacing Batteries

5

4

Remove the old batteries (for battery

4

replacement).

Insert new batteries, being careful with the

5

battery polarity.

Slide down and reattach the battery cover.

6

Secure the cover with the screw.

7

31

Inserting/Replacing Batteries

HIOKI LR8512B980-07

When batteries are installed, the following screen is displayed.

1. All indicators on 2. Model

(Example: When the

LR8512 is used)

3. Version number

(Example: Version 1.00)

Battery indicator display

Displayed at the upper right corner of the display.

Fully charged.

As the battery charge diminishes, black charge bars disappear, one by one, from

the left of the battery indicator.

The battery voltage is low. Replace the batteries as soon as possible.

(Blinks) The battery is drained. Recording or communications cannot be made in

this condition.

O

IMPORTANT

Thedisplayedremainingbatterylevelmaybedierentfromtheactual

remaining battery level due to the battery characteristics, settings during

use, temperature or consumption level. When a battery is used in a low

temperature environment or a weak and deteriorated battery is used, the

powermayshutoregardlessofthebatteryindicatordisplay.

The battery indicator display turns o when the AC adapter or an external power

supply is connected.

32

Inserting/Replacing Batteries

HIOKI LR8512B980-07

Battery life indication

The battery life varies depending on the recording interval. In case of the free run

function, the battery life is the same as for 1 second regardless of the recording

interval setting. (when recording interval setting is more than 2 seconds)

LR8512 Wireless Pulse Logger

Recording interval

0.1 sec. 1 sec. 10 sec. 1 min.

Real-time measurement

Bluetooth ON

Manual data collection

Bluetooth ON

Manual data collection

Bluetooth OFF

LR8513 Wireless Clamp Logger

Real-time measurement

Bluetooth ON

Manual data collection

Bluetooth ON

Manual data collection

Bluetooth OFF

The values indicated in the table are for instant value recording. For average/maximum value

recording, the battery life is the same as for 0.5 sec. regardless of the recording interval.

Approx. 5 days Approx. 7 days Approx. 10 days Approx. 10 days

Approx. 14 days Approx. 14 days Approx. 14 days Approx. 14 days

Approx. 1.5

months

0.5 sec. 1 sec. 10 sec. 1 min.

Approx. 5 days Approx. 7 days Approx. 10 days Approx. 14 days

Approx. 10 days Approx. 10 days Approx. 20 days Approx. 20 days

Approx. 14 days Approx. 1 month

Approx. 2

months

Recording interval

Approx. 2

months

Approx. 2.5

months

Approx. 2

months

Approx. 3

months

LR8514 Wireless Humidity Logger

Real-time measurement

Bluetooth ON

Manual data collection

Bluetooth ON

Manual data collection

Bluetooth OFF

Recording interval

0.5 sec. 1 sec. 10 sec. 1 min.

Approx. 5 days Approx. 7 days Approx. 10 days Approx. 14 days

Approx. 20 days Approx. 20 days Approx. 20 days Approx. 20 days

Approx. 2.5

months

Approx. 3

months

Approx. 3.5

months

Approx. 3.5

months

33

Inserting/Replacing Batteries

HIOKI LR8512B980-07

LR8515 Wireless Voltage/Temp Logger

0.1 sec. 1 sec. 10 sec. 1 min.

Real-time measurement

Bluetooth ON

Manual data collection

Bluetooth ON

Manual data collection

Bluetooth OFF

Approx. 2 days Approx. 4 days Approx. 7 days Approx. 14 days

Approx. 3 days Approx. 7 days Approx. 14 days Approx. 20 days

Approx. 3 days Approx. 10 days

Recording interval

Approx. 1.5

months

Approx. 2.5

months

34

Connecting the AC Adapter

HIOKI LR8512B980-07

2.3 Connecting the AC Adapter

Connect the instrument, the optional Z2003 AC adapter, and power cord, and then

connect to an outlet.

When using the AC Adapter with a batteries, the AC Adapter has priority in powering

the instrument. When power from the AC Adapter is interrupted, the instrument or

module will switch to battery power.

Before connecting, make sure to read “AC adapter” (p.12) and “Handling of cords

and cables” (p.10).

Rated supply voltage: 100 V to 240 V AC

Rated supply frequency: 50 Hz/60 Hz

Connect the power

1

cord and AC adapter.

Connect the outlet

2

3

1

Power cord

AC adapter

2

plug to the instrument

AC adapter connection

terminal (left side).

Connect the output

3

plug to an outlet.

When the AC adapter is connected, the following screen is displayed.

1. All indicators on 2. Model

When the AC adapter is used, is lit at the upper right of the display.

ExternalPowerSupply

The instrument can work either on a DC power supply unit (5 V to 13.5 V DC) or the

USB bus power (5 V DC).

If you need a conversion cord to connect the instrument and an external power

supply unit, contact your authorized Hioki distributor or retailer.

(Example: When the

LR8512 is used)

3. Version number

(Example: Version 1.00)

35

Installing the Strap (optional)

HIOKI LR8512B980-07

2.4 Installing the Strap (optional)

When the optional Z5004/Z5020 Magnetic Strap is attached to the instrument, the

magnet can be attached to the wall surface (metal plate).

Attach the Z5004 or Z5020 through the strap hole.

1

In order of (1) → (2) → (3)

(1)

(2)

(3)

36

Magnet

Attach it to the wall surface (with a metal plate

2

axed).

Connecting Cables

HIOKI LR8512B980-07

2.5 Connecting Cables

Connecting the L1010 Connection Cable (LR8512)

Connect the connection cable to the LR8512 connection terminal.

Not

−

used

+

L1010 Connection Cable (length approx. 1.5 m)

Red wire: Voltage input (+)

+

−

Black wire: Voltage input (-)

• If a wrong input on the instrument side or connection destination is made or the

L1010 is not completely inserted, a correct value is not displayed.

• If a correct value is not displayed even when the L1010 is completely inserted,

the instrument or connection cable may have a problem. Send the instrument

for repair.

37

Connecting Cables

HIOKI LR8512B980-07

Connecting the clamp sensor (LR8513)

Connect the clamp sensor to the LR8513 connection terminal. Use the specied

clamp sensor. For more details, see the instruction manual supplied with the clamp

sensor.

Align the BNC connector groove of

1

the clamp sensor with the instrument

connector guide and insert it.

Turn it to the right to lock it.

2

When removing the connector, turn it to the

left and pull it out.

Clamp the object to be measured.

3

(p. 42)

• If it is not completely inserted, a correct

value is not displayed. If a correct value is

not displayed even when it is completely

inserted, the instrument or sensor may have

a problem. Send the instrument for repair.

• Do not connect any clamp sensor other than

the specied sensor.

1

BNC connector groove

Connector guide

CH2CH1

Clamp

sensor

2

Lock

Supported clamp sensor

Model Clamp sensor

9669

CT6500

9657-10

9675

CT9691-90

CT9692-90

CT9693-90

38

3

(The gure is for the

CT6500.)

*1

Clamp On Sensor9695-02

Clamp On Leak Sensor

Clamp On AC/DC Sensor

Connecting Cables

HIOKI LR8512B980-07

Model Clamp sensor

*2

CT7631

CT7642

CT7731

CT7736

CT7742

*2

*2

*2

*2

*2

AC/DC Current SensorCT7636

AC/DC Auto-Zero

Current Sensor

CT9667-01

CT9667-02

CT9667-03

*2

CT7044

*2

CT7045

*2

CT7046

*1

: The 9219 Connection Cord is required in order to connect a compatible clamp sensor.

*2:

The CM7290 or CM7291 Display Unit and L9095 Output Cord are required in order to connect

AC Flexible Current Sensor

a compatible clamp sensor.

39

Connecting Cables

HIOKI LR8512B980-07

Using the CT9691-90, CT9692-90 or CT9693-90

The CT9691-90, CT9692-90, and CT9693-90 are each composed of the CT9691,

CT9692, or CT9693 Clamp Sensor and CT6590 Sensor Unit.

CT6590 Sensor Unit overview and parts names

The CT6590 Sensor Unit is a unit to connect the CT9691, CT9692, and CT9693

Clamp ON AC/DC Sensor to the measuring instrument. The clamp sensor measures

current and the instrument converts and outputs the voltage signal. After connecting

the sensor to the measuring instrument, correct any deviation in the output using the

zero adjustment knob before starting measurement.

POWERLED

Green lamp lit:

Power ON

Red lamp lit:

Low battery

Lamp o: Power OFF

Zero adjustment knob

Turn the knob to the left or

right to adjust the zero point

of the connection sensor

.

Selector switch

H: High range

L: Low range

OFF: Power OFF

The range level varies

depending on the clamp

sensor.

RATING

BATTERY

2

LR6

2

Battery cover

Remove the screw and insert

batteries.

Sensor

connection

terminal

Connect the clamp

sensor.

Output rate and range of the CT9691-90, CT9692-90, and CT9693-90 Sensor

H Range (f.s.) 100 A 200 A 2000 A

Output rate 1 mV/A 1 mV/A 0.1 mV/A

L Range (f.s.) 10 A 20 A 200 A

Output rate 10 mV/A 10 mV/A 1 mV/A

Output (f.s.) 100 mV 200 mV 200 mV

40

AC adapter

connection

terminal

BNC connector

Connect the connector to

the LR8513.

CT9691 sensor CT9692 sensor CT9693 sensor

Measurement procedure

HIOKI LR8512B980-07

Connecting Cables

5

67

Zero adjustment

4

LR8513

0.00 A

2

CT6590 Sensor Unit

3

Supply power to the CT6590 Sensor Unit (battery or AC adapter).

1

There are two power supplies, batteries (accessory) and AC adapter (optional).

Use the AC adapter when operating the instrument continuously for a long period of time.

Connect the clamp sensor to the CT6590.

2

Connect the CT6590 to the LR8513.

3

Select the range with the selector switch.

4

Refer to “Output rate and range of the CT9691-90, CT9692-90, and CT9693-90 Sensor”

(p.40) and select the range appropriate for the measuring instrument.

The voltage corresponding to the input current is output.

For example, 100 mV is output for 10 A when the L range is selected on the CT9691.

The voltage corresponding to the input current is output.

For example, 100 mV is output for 10 A when the L range is selected on the CT9691.

Turn the zero adjustment knob and perform zero adjustment so that the

5

measured value indicates around 0 A in the instrument screen.

Before starting measurement, turn the zero adjustment knob on the CT6590 and correct

any deviation in the output.

• The zero adjustment knob has a design that is not easy to turn so it is not turned

accidentally after zero adjustment.

• If the measured value does not indicate around 0 A after zero adjustment, send

the CT6590 and clamp sensor for repair.

Wire the clamp sensor to the object to be measured.

6

After the measurement, remove the clamp sensor.

7

41

Connecting Cables

HIOKI LR8512B980-07

Using the CM7290 or CM7291

The CM7290/CM7291 Display Unit provides a Hioki PL14 output connector and is

used by connecting it to a current sensor.

Measurement procedure

5

6 -1

Select the

measurement mode

1

4

Perform zero-

adjustment

Press and hold

6 -2 6 -3

Select the

output mode

L9095 Output Cord

Connect the current sensor to the CM7290/CM7291.

1

Supply power to the CM7290/CM7291.

2

The CM7290/CM7291 can operate on AC adapter or battery power.

Connect output from the CM7290/CM7291 to the LR8513 with the L9095

3

Output Cord.

Perform zero-adjustment for the current sensor.

4

The CT7044, CT7045, and CT7046 do not require zero-adjustment

Connect the current sensor to the conductor being measured.

5

Select the

output rate

LR8513

0.00 A

3

42

Connecting Cables

HIOKI LR8512B980-07

Congurethecurrentsensor.

6

-1. Select the measurement mode. AC. DC. AC/DC

-2. Select the output mode.

-3. Select the output rate.

Refer to “The table of output rates and corresponding measurement ranges”.

StartmeasurementafterconguringtheLR8513.

7

To congure the LR8513 settings, see"LR8513 Wireless Clamp Logger" (p. 75)

Once measurement is complete, disconnect the current sensor from the

8

conductorbeingmeasuredandturnotheLR8513.

The values displayed by the CM7290/CM7291 and the LR8513 may dier due to dierences

in the devices’ accuracy.

When measuring a negative DC current in AC/DC measurement mode, the CM7290/CM7291

and LR8513 may indicate dierent polarity readings.

The table of output rates and corresponding measurement ranges

Model CM7290/CM7291

output rates

CT7631/CT7731 10mV/A 10A

1mV/A 100A

CT7636/CT7736 10mV/A 20A

1mV/A 200A

CT7642/CT7742 1mV/A 200A

0.1mV/A 2000A

CT7044/CT7045/CT7046 10mV/A 50A

1mV/A 500A

0.1mV/A 5000A

Disable the CM7290/CM7291’s 10× output function.

LR8513

measurement ranges

43

Connecting Cables

NO

NO

NO

HIOKI LR8512B980-07

Connecting to a conductor

Clamp only one conductor with the clamp sensor for measurement.

NOOK

9669, 9695-02, CT6500 Clamp On Sensor

CT9691-90, CT9692-90, CT9693-90 Clamp On AC/DC Sensor

(The gure is for the CT6500.)

OK

9675, 9657-10 Clamp On Leak Sensor

(The gure is for the 9675.)

• For details, refer to the instruction manual for the clamp sensor to be used.

• A wrong measurement procedure could result in injury or death, as well as damage

to the instrument.

OK

NO

NO

44

Connecting Cables

HIOKI LR8512B980-07

For leak current measurement

The 9675, 9657-10 Clamp On Leak Sensor can be used.

Clamp the conductor at the center of the clamp core.

When the measurement current level is unknown, set the range level to the 5 A range before

starting measurement.

Measurement with a ground cable

Single-phase/3-wire circuit

Transformer

Leak

Class B ground

cable

current lg

Batch measurement

Single-phase/3-wire circuit Three-phase/3-wire circuit

Transformer

Leak

current lg

• For a single-phase/2-wire circuit, clamp 2-wires.

• For a three-phase/4-wire circuit, clamp 4-wires. When the wires cannot be clamped, you

can still measure using the equipment ground cable.

• If a wire close to the instrument carries a large current, correct measurement may not be

performed. Ensure enough distance for measurement.

• Do not input current exceeding the continuous maximum input in the measurement range.

• When the clamp is opened or the current range is changed, tens of counts may be

displayed, however, this is not a problem. It takes time but the display gradually drops to

0. If measurement is performed before the display returns to 0, the measurement is not

aected.

• The accuracy of AC voltage overlapped with a DC component cannot be guaranteed.

Clamp 3-wires at a time.

Class B

ground cable

Loading

equipment

Clamp all the wires at the center.

Loading

equipment

Clamp only one conductor.

Three-phase/3-wire circuit

Leak current

Class B

ground cable

Leak

current lg

lg

Clamp 3-wires at a time.

Class B ground

cable

Loading

equipment

Class D ground cable

Loading

equipment

Class D ground cable

45

Connecting Cables

HIOKI LR8512B980-07

Inspection for areas with insulation deterioration

1. Measure the leak current in the entire circuit and determine whether there is

any short-circuit based on a change in the current. Normally leak current is

measured with the Class B ground cable of the transformer.

Single-phase/3-wire circuit

Load

Class B

Leak

current lg

2. If any short-circuit is found, inspect from the power supply to the load using batch

measurement (circuit clamped all at a time).

ground

cable

a

’a

equipment

b

Leak

current lg

• If wire insulation deterioration is found at A in the gure, batch measurement a can

detect a leak current but not ’a.

• If loading equipment insulation deterioration is found at B in the gure, batch

measurement b can detect a leak current but not ’b.

Class B

ground

cable

Insulation

deteriorated

area A

Load

equipment

Insulation

deteriorated area B

’b

46

Connecting Cables

HIOKI LR8512B980-07

For load current measurement

Tuck in the conductor at the center of the clamp core.

• Any special waveforms like the secondary side of an inverter cannot be measured.

• When the measurement current level is unknown, set the range level to the following before

starting measurement.

Model Clamp sensor Range

9695-02

CT6500

9669

9675

9657-10

CT9691-90

CT9692-90

CT9693-90

CT7631

CT7636

CT7642

CT7731

CT7736

CT7742

CT9667-01

CT9667-02

CT9667-03

CT7044

CT7045

CT7046

Clamp On Sensor

Clamp On Leak Sensor

Clamp On AC/DC Sensor

AC/DC Current Sensor

AC/DC Auto-Zero

Current Sensor

AC Flexible Current

Sensor

50 A range

500 A range

1000 A range

5 A range

5 A range

100 A range

200 A range

2000 A range

100 A range

200 A range

2000 A range

100 A range

200 A range

2000 A range

5000 A range

5000 A range

5000 A range

5000 A range

5000 A range

5000 A range

47

Connecting Cables

HIOKI LR8512B980-07

Connecting the temperature and humidity sensor (LR8514)

Attach one or two pieces of Humidity Sensor to the connection terminals of the

LR8514 Wireless Humidity Logger.

Supported sensors

Z2010 Humidity Sensor Length including the sensor: Approx. 50 mm

Z2011 Humidity Sensor Cable length: Approx. 1.5 m

Right side of

instrument

Z2010 or Z2011 Humidity Sensor

CH1

CH2

• When the temperature and humidity sensor is not completely inserted, [BURN

OUT] is displayed for the measurement value and [BURN] is displayed on the