Hioki LR8432-20 Instruction Manual

LR8432-20

Instruction Manual

HEAT FLOW LOGGER

Jan. 2016 Edition 1

LR8432B980-00 16-01H

EN

Contents

Introduction ..............................................................................1

Confirming Package Contents.................. ..............................2

Safety Information....................................................................4

Operating Precautions............................ .................................8

Chapter 1

Overview ____________________________________15

1.1 Product Overview and Features .............................15

1.2 Measurement Flow ................................... ... ............16

1.3 Names and Functions of Parts ...............................18

1.4 Screen Configurations ................... .........................20

1.5 Basic Operation .......................................................23

Screen Operations ...........................................................23

Starting and Stopping Recording .....................................24

Disabling Key Operations (Key-Lock Function) ...............25

Saving Data ................................................ ......................25

Verifying the Input Level (Level Monitor) ..........................26

i

Contents

1

2

Chapter 2

Measurement Preparations_________________ 27

2.1 Using the Battery Pack (Option) ............................28

Install the Battery Pack ....................................................32

Charge the Battery Pack ..................................................32

2.2 Connecting the AC Adapter ....................................33

2.3 Connecting Measurement Cables to the Instrument

....................................................................................34

Connecting Measurement Leads or Thermocouples

(for voltage or temperature, respectively) ........................36

Connect the Heat Flow Sensor (Heat flow measurement) 37

Connecting the Optional Model 9641 Connection Cable

(for Pulse Signal Input) .....................................................39

2.4 Turning the Power On and Off ...............................40

2.5 Zero Adjustment ......................................................41

LR8432B980-00

ii

Contents

Chapter 3

Setting before Measurement _______________ 43

3.1 Pre-Operation Inspection ....................................... 43

3.2 Operating Flow Overview .......................................44

3.3 Setting Configuration 1 – Recording Settings ..... 48

Specify the Recording Interval .........................................48

Setting the Display Time Base

(horizontal axis magnification, set as needed) .................49

Selecting the Recording Start/stop Method .....................51

Set the Recording Length for Repeated or

One-time Recording .........................................................52

Enable Digital Filtering (noise suppression) (as needed) 52

Automatic Saving .............................................................53

Replacing Removable Storage During Real-Time Saving 55

3.4 Setting Configuration 2 – Input Channel Settings 56

Voltage Measurement Settings ........................................58

Temperature Measurement Settings ...............................59

Heat Flow Measurement Settings ....................................61

Integration (Count) Measurement Settings ......................63

Revolution Measurement Settings ...................................64

3.5 Display Settings ...................................................... 66

Selecting Waveform Display Color ..................................66

Specifying Vertical Display Range by Magnification and

Zero Position (vertical axis expansion/compression) .......66

Specifying the Vertical Display Range by Upper and

Lower Limits (expansion/compression) ............................67

Converting Units (Scaling function) ..................................69

3.6 Entering Comments ................................................ 72

3.7 Viewing All Channel Settings in a List ..................74

Switching Channel Display Settings ................................75

Batch Copying Channel Settings .....................................76

Batch Setting Waveform Display/Hide and

Waveform Color Settings for All Channels .......................77

Initializing Settings (to factory defaults) ...........................77

Aligning Zero Positions on the Grid .................................78

Display Celsius (°C) temperature values as Fahrenheit (°F)

.......................................................................................... 79

Chapter 4

Specifying Criteria for Measurements

(Triggering, Alarm and Timer) ______________81

4.1 Setting Criteria to Start and Stop Recording ........82

Setting the Input Signal Trigger Threshold (Level Trigge r) 83

Setting Lower and Upper Trigger Thresholds

(Window Trigger) ...... ........................................................85

Selecting Trigger Sources and Combinations ..................86

Setting Criteria for Pre-Trigger Recording (Pre-Trig) .......87

4.2 Alarm Output ............................................................88

4.3 Confirming Trigger and Alarm Criteria Settings

(List) ..........................................................................91

4.4 Starting and Stopping Recording by Timer ..........92

4.5 About Recording Operation ...................................94

iii

Contents

3

4

5

Chapter 5

Waveform Analysis__________________________97

5.1 Viewing Waveforms .................................................98

Scrolling Waveforms ........................................................98

Verifying Waveform Display Position ...............................98

Magnifying and Compressing Horizontally .......................99

Viewing Any Waveform Location (Jump Function) ..........99

5.2 Selecting Display Options ....................................100

Displaying Gauges .........................................................100

Displaying Cursor Values ...............................................101

Specifying a Waveform Time Span ................................103

Viewing Input Signals as Numerical Values ...................104

5.3 Inserting Event Marks (Search Function) ............106

Inserting Event Marks While Viewing Waveforms ..........106

Inserting Event Marks Using External Input Signals ......107

Searching Event Marks ..................................................108

Chapter 6

Saving & Loading Data ___________________ 109

6.1 About Saving and Loading Data ..........................109

6.2 Using a CF Card/USB flash drive .........................111

CF Card Insertion & Removal ........................................112

6

iv

Contents

USB flash drive Insertion & Removal .............................112

Formatting a CF Card/USB flash drive ..........................113

6.3 Saving Data ........................................................... 114

Automatic Saving ...........................................................115

Selecting the Manual Saving Method

[Quick Save]/[Select & Save] .........................................116

Saving Waveform Data (with the SAVE Key) ................117

Capturing a Screen Image (With the SAVE Key) ...........118

Saving Numerical Calculation Results

(With the SAVE Key) ......................................................119

Saving Setting Configurations ........................................120

6.4 Loading Data on the Instrument .......................... 121

Loading a Setting Configuration .....................................121

Loading Waveform Data and Screen Images ................122

6.5 Data Management ................................................. 123

Switching removable storage .........................................123

Viewing Folder Contents and the Parent Folder ............124

Deleting Data .................................................................124

Renaming Files and Folders ..........................................125

Copying Data .................................................................126

Sorting Files ...................................................................127

6.6 Transferring Data to a Computer

(USB Drive Mode) .................................................128

Select the USB Drive Mode ........................................... 128

Connecting the USB Cable ............................................129

Chapter 7

Numerical/Waveform Calculations ________ 131

7.1 Performing Numerical Calculation ...................... 131

Key Operation During Setting ........................................133

Calculating values in real time during measurement

(Automatic calculation) ..... ..............................................134

Manual Calculation ........................................................137

Apply Calculations to a Specific Time Span

(Manual Calculation Only) ..............................................138

7.2 Numerical Value C al cu l ati o n Expressions ... ... ... 139

7.3 Performing Waveform Calculation ...................... 141

Key Operation During Setting ........................................141

Setting the Waveform Display Color ..............................144

Setting the Display Format .............................................144

Setting the Display Range in the Vertical Axis Direction

Using Upper/Lower Limit Values ....................................144

7.4 Waveform Calculation Formula ............................145

Chapter 8

System Environment Settings ____________ 147

8.1 Screen and Key Operation Settings ....................148

Using the Auto-Resume Function

(Resume After Power Restoration) ................................148

Adjust Backlight Brightness ............................................148

Enabling and Disabling the Backlight Saver ..................149

Setting the Screen Color Scheme ..................................149

Enabling or Disabling the Beeper ...................................149

Selecting the Horizontal (Time) Axis Display .................150

Selecting the Display Language .....................................150

8.2 CSV File Saving Settings ......................................151

CSV File Data Decimal and Separator Characters ........151

8.3 Making System Settings .......... .............................152

Setting the Date and Time .............................................152

Initializing the Instrument (System Reset) ......................153

Switching the USB mode ...............................................154

Self-Test ...................................................................... ... 155

Chapter 9

External Control __________________________ 157

9.1 Connecting to the External Control Terminals ...157

9.2 External Trigger Input ...........................................159

9.3 External Signal Output (Trigger Output) .............160

9.4 Alarm Signal Output (Alarm Output) ...................162

9.5 Synchronous Measurements with

Multiple Instruments .............................................163

v

Contents

6

7

8

9

10

11

Chapter 10

Specifications_____________________________ 165

Appendix

Index

vi

Contents

Chapter 11

Maintenance and Service _________________ 175

11.1 Troubleshooting ...................................................175

11.2 Cleaning ................................................................. 178

11.3 Disposing of the Instrument ........................ ........ 179

Appendix____________________________________ A1

Appendix 1 Error Messages and Remedial Actions.........A1

Appendix 2 File Naming ......................................................A7

Appendix 3 Text File (CSV) Internal Format......................A9

Appendix 4 Binary File Size Calculation ..........................A10

Appendix 5 List of Default Settings..................................A11

Appendix 6 Maximum Recordable Time ..........................A1 2

Appendix 7 Reference .......................................................A13

Appendix 8 Concerning Noise Countermeasures ..........A14

Appendix 9 Using the Application Program....................A20

Installing Logger Utility ....................................................A22

Installing the USB Driver .................................................A25

Connecting the Instrument to the Computer

with a USB Cable ............................................................A28

Starting and Ending Logger Utility ..................................A31

Uninstalling the Logger Utility .........................................A31

Appendix 10Frequently Asked Questions.......................A32

Installation and Settings ..................................................A32

Triggering ........................................................................ A 34

Measuring ....................................................................... A35

Data Saving .................................................................... A36

Logger Utility ...................................................................A40

Appendix 11Pulse Input Circuit Diagram.........................A41

Appendix 12Heat Flow.......................................................A42

Index ___________________________________ Index 1

Introduction

Thank you for purchasing the HIOKI “Model LR8432-20 Heat Flow

Logger.”

To obtain maximum performance from the instrument, plea se read

this manual carefully, and keep it hand

Registered trademarks

• Windows® is a registered trademark of Microsoft Corporation in

the United States and other countries.

• CompactFlash® is a registered trademark of Sandisk Corporation (USA).

• Microsoft Excel

tion in the United States and other countries.

Introduction

y for future reference.

®

is a registered trademark of Microsoft Corpora-

1

2

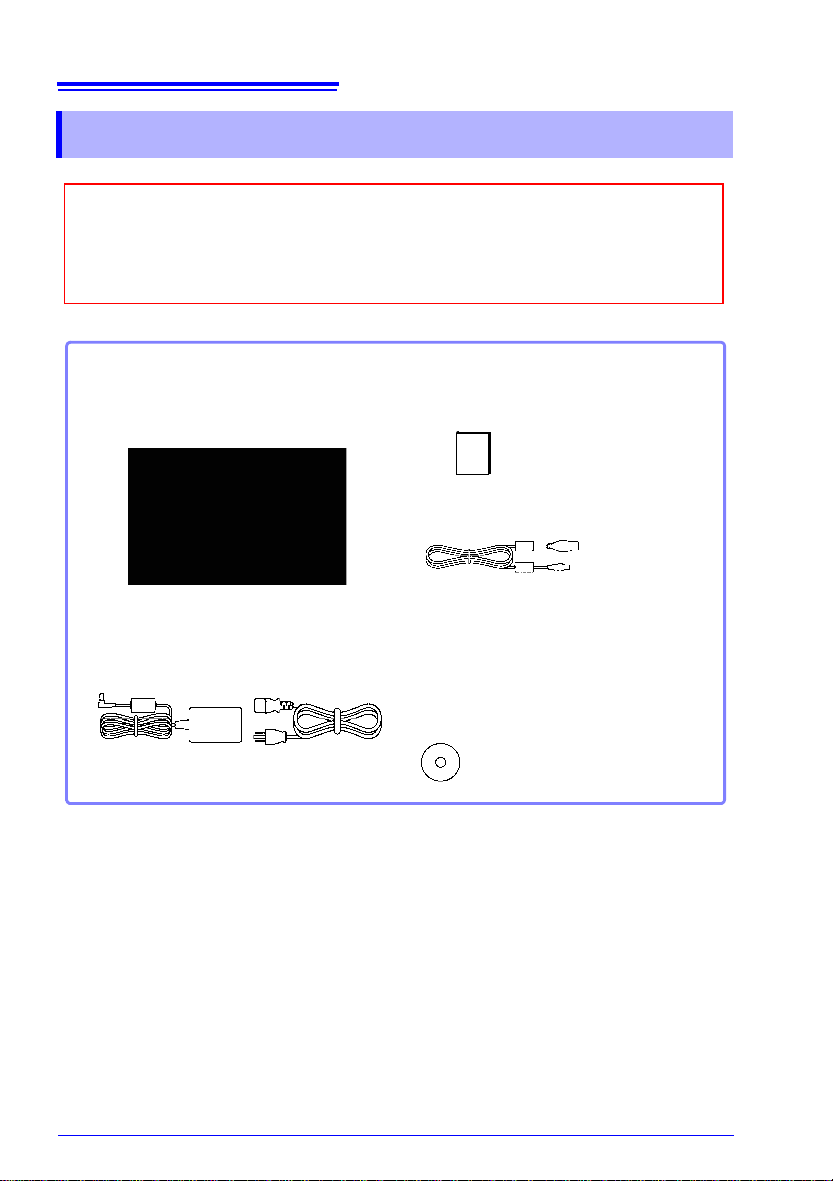

When you receive the instrument, inspect it carefully to ensure tha t no damage

occurred during shipping. In particular, check the accessories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specifications, contact your authorized Hioki distributor or reseller.

Confirm that these contents are provided.

Model LR8432-20 .........................1

Heat Flow Logger

Accessories:

Model Z1005 AC Adapter............ 1

with supplied power cord

(p. 33)

Measurement Guide....................1

USB Cable....................................1

CD.................................................1

• Instruction Manual (PDF)

(This document)

• Logger Utility Instruction Manual (PDF)

• Logger Utility (Data acquisition

application program)

(p. A28)

The latest version can be

downloaded from our web site.

Confirming Package Contents

Confirming Package Contents

About options:

Contact your authorized Hioki distributor or reseller for details.

Model 9780 Battery Pack

Model Z1005 AC Adapter

Model 9641 Connection Cable (for pulse inputs)

Model 9782 Carrying Case

Model 9812 Soft Case

Model 9728 PC Card 512M

Model 9729 PC Card 1G

Model 9830 PC Card 2G

Model 9809 Protection Sheet

Z2012 Heat Flow Sensor

Z2013 Heat Flow Sensor

Z2014 Heat Flow Sensor

Z2015 Heat Flow Sensor

Z2016 Heat Flow Sensor

Z2017 Heat Flow Sensor

Z5008 Thermally Conductive

Tape

3

Confirming Package Contents

Applying any excessive force to the Heat Flow Sensor can

damage the sensor. When transporting the Heat Flow Sensor

in a case, store the sensor in the pocket of the 9782 Carrying

Case. Do not store the Heat Flow Sensor in the 9812 Soft

Case.

4

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested for safety prior to shipment.

However, usi

ual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes:

Mishandling during use could result in injury or death, as well

as damage to the instrument. Be cer tain that you understand

the instructions and precaution s in the manual before use.

With regard to the electricity supply, there are risks of electric

shock, heat generation, fire, and arc flash due to short circuits. If persons unfamiliar with electricity measuring instrument are to use the instru ment, another person fa miliar with

such instr

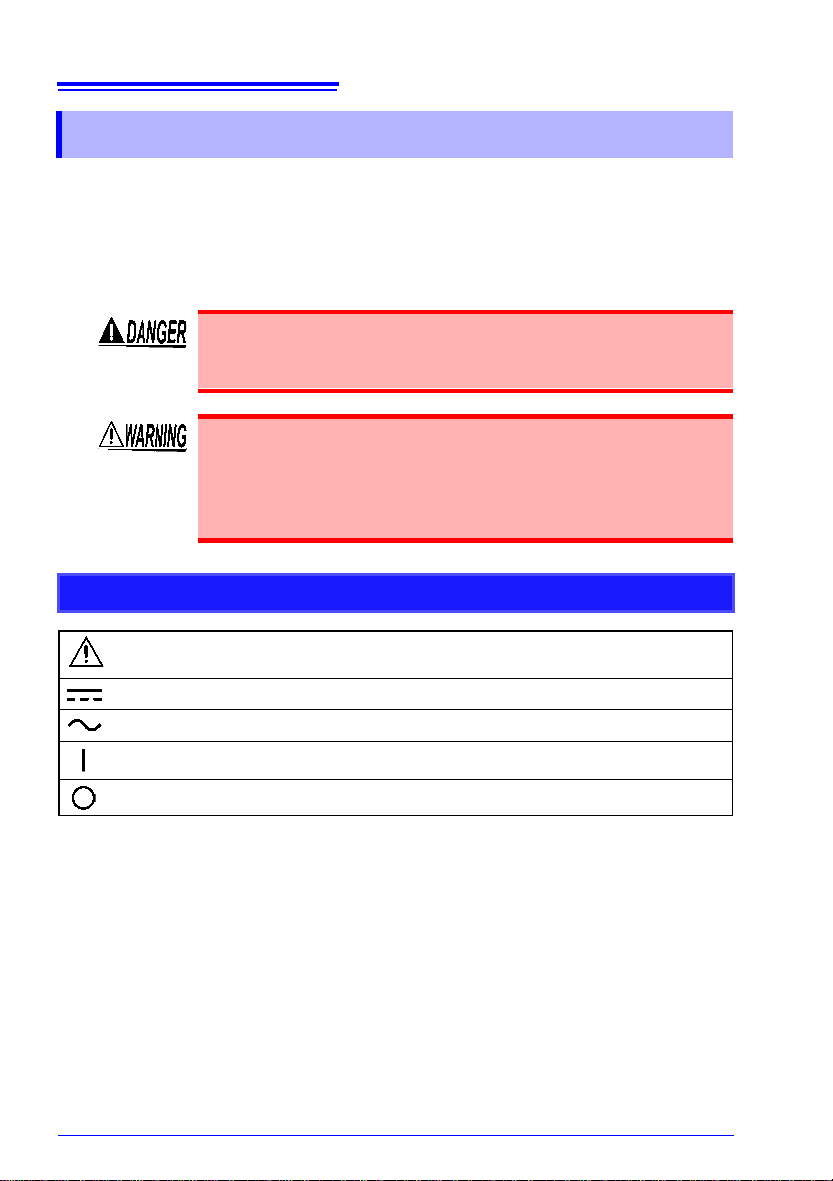

Safety Symbols

ng the instrument in a way not described in this man-

uments must supervise operations.

Indicates cautions and hazards. When the symbol is printed on the instrument,

refer to a corresponding topic in the Instruction Manual.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Safety Information

Ni-MH

Notation

In this document, the risk seriousness and the hazard levels are classified as follows.

Indicates an imminently hazardous situation that will result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in minor or

moderate injury to the operator or damage to the instrument or malfunction.

Indicates advisory items related to performance or correct operation of

the instr

ument.

IMPORTANT

Indicates information related to the operation of the instrument or

maintenance tasks with which the operators must be fully familiar.

Symbols for Various Standards

This symbol indicates that the product conforms to regulations set out by the

EC Directive.

This is a recycle mark established under the Resource Recycling Promotion

Law

(only f

or Japan).

5

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the

EU

mark

required to display it on the appliance under Article 11.2 of Directive 2002/96/

EC (WEEE).

et after August 13, 2005, and producers of the Member States are

Other Symbols

Indicates the prohibited action.

(p. #)

∗

[ ]

SET

(Bold characters)

Unless otherwise specified, “Windows

Windows

Click: Press and quickly release the left button of the mouse.

Double click: Quickly click the left button of the mouse twice.

®

7, Windows® 8, or Windows® 10.

Indicates the location of reference information.

Indicates that descriptive information is provided below.

The names of setting objects and buttons on the screen are indicated

by square brackets [ ].

Bold characters within the text indicate operating key labels.

®

” represents Windows® XP, Windows Vist a®,

6

Safety Information

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and

dgt. (digit) values, with the following meanings:

f.s. (maximum display value or scale length)

The maximum displayable value or scale length. This is usually the name of the currently selected range.

Example: For the 1 V range, f.s. = 1 V

rdg. (reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

dgt. (resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value

that causes the digital display to show a “1” as the least-significant digit.

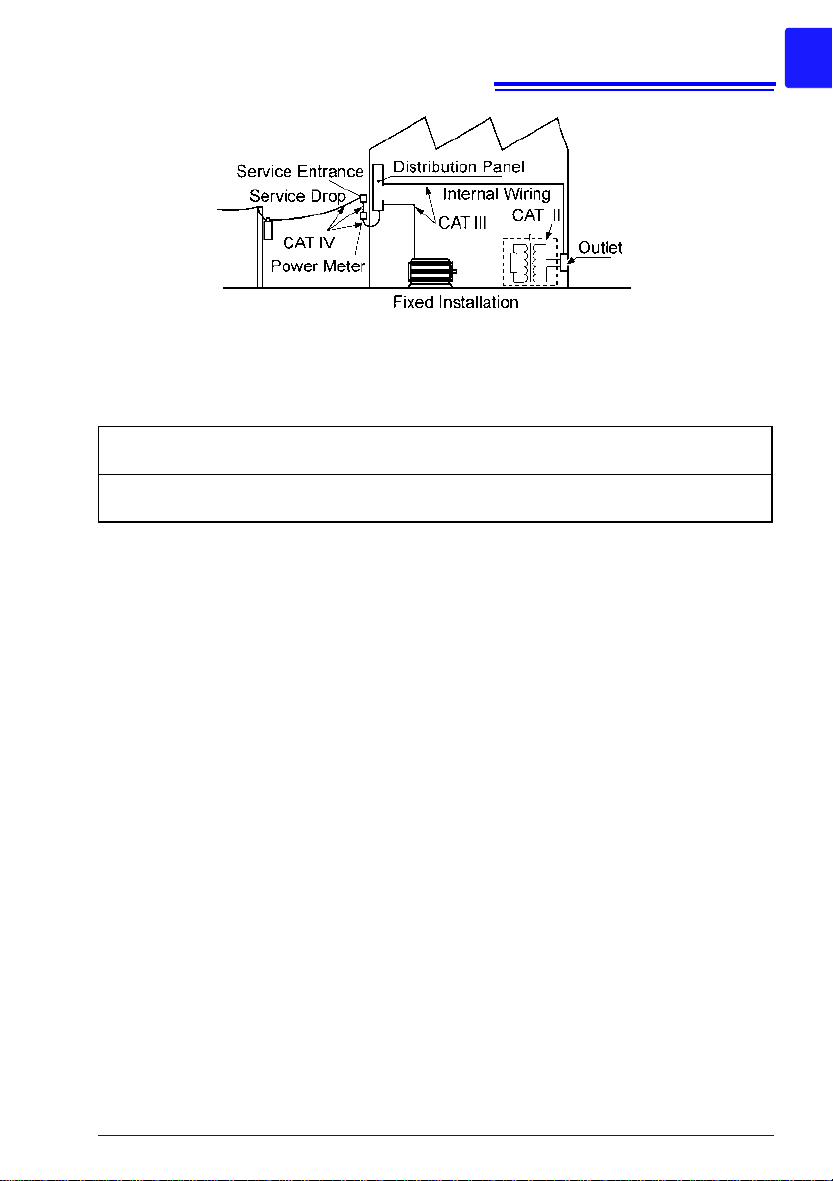

Measurement categ o ries

To ensure safe operation of measurement instruments, IEC 61010

establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

• Using a measuring instrument in an environment designated with a higher-n umbered category tha n that for which

the instrume

and must be carefully avoided.

• Never use a measuring instrument that lacks category labeling in a CAT II to CAT IV measurement environment. Doing

so could result in a serious accident.

nt is rated could result in a severe accident,

CAT II

CAT III

CAT IV

When directly measuring the electrical outlet receptacl es of the prim ary electrical circuits in equipment connected to an AC electrical outlet by a power

cord (por

When measuring the primary electrical circuits of heavy equipment (fixed

install

the distribution panel to outlets

When measuring the circuit from the service drop to the service entrance,

and to the power meter and primary overcurrent protection device (distribution panel)

table tools, household appliances, etc.)

ations) connected directly to the distribution panel, and feeders from

Safety Information

Difference between “Measurement” and “Recording”

The measurement and recording processes are distinguished as follows for the purposes of

these instructions.

7

Measurement:

Recording:

Measured data (data acquired in internal memory) is erased whenever a new measurement

start

s. To retain data, always record (save) it.

The acquisition of input values into the instrument’s internal memory or to

a PC vi

a communications.

Storing measurement data on a CF card, USB flash drive or on a PC via

dat

a commu

nication.

8

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of

the various functions.

Before Use

• Before using the instrument for the first time, verify that it operates normal

ensure that no damage occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributor or reseller.

• Before using the instrument, make sure that the insulation on the cables is undamaged and that no bare conductors are improperly exposed. Using the instrument in

such c

onditions could cause an electric shock, so contact your authorized Hioki

distributor or reseller for replacements.

ly to

Instrument Installation

Installation environment

• This instrument is not drip-proof. Install the instrument with the

measurement cables hanging lower than the instrument to prevent water or other fluid from entering the instrument through the

measurement cables and terminal block.

• The maximum operating (ambient) temperature for the LR843220 is 40°C. D

ments.

• Correct measurement may be impossible in the presence of

strong magnetic fields, such as near transformers and high-current conductors, or in the presence of strong electromagneti

fields such as near radio transmitters.

• If liquid enters the enclosure through an air vent or other opening, it

may damage the instrument’s internal circuitry . Exercise caution concerning the surrounding environment when installing the instrument.

o not attempt to use in higher temperature environ-

c

Do not place the instrument on an unstable table or an inclined

place. Dropping or knocking down the instrument can cause injury

or damage to the instrument.

Installation Precautions

Horizontal placement Upright placement

• If the instrument is used in any state other than the following, the

measurement accuracy may not satisfy the device specifications.

• Leave sufficient space around the ventilation holes and install the

instrument with the holes unobstructed.

• Avoid temperature changes around the terminal block. Especially

avoid di

vent. Thermocoup le inp ut s are pr one to me asure ment error s.

• When the instrument is moved to a location with significantly different ambient temperature, allow at least 30 minutes for thermal

equalization be

rected airflow such as from an electric fan or air conditioner

Handling the Instrument

9

Operating Precautions

fore measuring.

• Do not allow the in strum ent to g et we t, and do no t take measurements with wet hands. This may cause an electric shock.

• Do not attempt to modify, disassemble or repair the instrument; as fire, electric shock and injury could result.

To avoid damage to the instrument, protect it from physical shock

when transporting and handling. Be especially careful to avoid

physical shock from dropping.

This instrument may cause interference if used in residential

areas. Such use must be avoided unless the user takes special

measures to reduce electromagnetic emissions to prevent interfer

ence to the reception of radio and television broadcasts.

-

10

Operating Precautions

Handling the Cords and Cables

The cable is hardened under the 0°C or colder environment. Do

not bend or pull it to avoid tearing its shield or cutting cable.

Before Turning Power On

Using the Battery Pack

• For battery operation, use only the HIOKI Model 9780 Battery

Pack. We do not take any responsibility for accidents or

damage related to the use of any other batteries.

Refer to “2.1 Using the Battery Pack (Option)” (p. 28).

Using the AC Adapter

• Use only the supplied Model Z1005 AC Adapter. AC adapter

input voltage range is 100 V to 240 VAC at 50 Hz/60 Hz. To

avoid electrical hazards and dam age to the instrument, do

not apply voltage outside of this range.

• Tur n the instrument off bef ore connec ting the AC adapter to

th

e instrum

• T o avoid electrical accidents and to maintain the safety specifications of this instrument, connect the power cord provided only to a 3-contact (two-conductor + ground) outlet.

• Use only the designated power cord with this instrument.

Use of othe

• Before turning the instrument on, make sure the supply voltage matches that indicated on its power connector. Connection to an improper supply voltage may damage the

instrument and present an electr ical hazard.

ent and to AC power.

r power cords may cause fire.

• Do not connect the supply voltage improperly. Doing so may

damage the instrument’s internal circuitry.

• Avoid using an uninterruptible power supply (UPS) or DC/AC

inverter with rectangular wave or pseudo-sine-wave output to

power the instrument. Doing so may damage the instrument.

• When the power is turned off, do not apply voltage or current to

the terminals.

Doing so may damage the instrument.

• After use, always turn OFF the power.

IMPORTANT

Select Hioki 9641 Connection Cable for use as a cable for the

pulse input connector.

• Brief power interruptions of 40 ms or less will not cause this

instrument to malfunction. However, Longer interruptions may

cause the instrument to shut itself off, so consider local power

conditions before installing, as appropriate.

• To ensure that recording is not interrupted by power outages, you

can use the Z1005 AC Adapter and 9780 Battery Pack tog ether.

About Inputs and Measurement

• Do not use the instrument with circui ts that exceed its ratings or specifications. Doing so may cause it to become

hot, resulting in bodily injury.

• To av oid electrical hazards and damage to the instrument ,

do not apply voltage exceeding the rated maxim um to the

input terminals.

• The maximum input voltage (and the maximum r ated voltage to earth) for the analog input terminals is 30 V AC rms

(or 60 V

may be damaged and perso nal injury or death co uld occur,

so do not attempt measurement.

• Do not leave the instrument connected to test objects in environments where a voltage surge m ight exceed the dielec tric

wi

instrument, bodily injury or fatal accident.

• Channels are insulated by semiconductor relays. When a

voltage beyond the

channels, the semiconductor relay may short circuit. Please

ensure that a voltage beyond specification, especially a

surge such as a lightning, is never applied. When an abn ormal measurement value is observed, please contact your

authorized Hioki distributor or reseller for inspection.

DC). If these limits are exceeded, the instrument

nd voltage. Doing so could result in damage to the

thsta

11

Operating Precautions

specification is applied between the

The waveform for an open channel may sometimes appear to b e

influenced by the signals of the other channels being measured. If

you do not like this, please set the waveform display of the open

channel to OFF or short-circuit the input terminals of the open

channel by connecting the positive and negative terminal.

12

Operating Precautions

CD Handling

CD precautions

• Exercise care to keep the recorded side of discs free of dirt and

scratches. When writing text on a disc’s label, use a pen or

marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct

sunlight, high temperature, or h

• Hioki is not liable for any issues your computer system experiences in the course of using this disc.”

Using a CF Card/USB flash drive

• Inserting a CF card/USB flas h drive upside down, backwards or i n the

wrong direction may damage the CF card, USB flash drive, or instrument.

• Never eject a CF card /USB flash drive while measuring or when the

instrum

ent is or accessing the card. Data on the CF card/USB flash

drive may be destroyed. (The CF icon/USB flash drive icon at the

lower right is red while the card is being accessed.)

• Do not transport the instrument while a USB flash drive is connected.

D

amage cou

• As the CF card/USB flash drive is sensitive to static elect ricity, damage

to the CF card/USB flash drive or wrong operations by the instrument

may occur due to static electricity. Please be careful when handling it.

• With some USB flash drives, the instrument may not start up if power

is tur

power on first, and then insert the USB flash drive. It is recommended

to try out operation with a USB flash drive before starting to use it for

actual measurements.

ld result.

ned on while the USB flash drive is inserted. In such a case, turn

igh humidity.

13

USB method of use

Connector

used

[System] screen USB

mode setting

Use a USB flash drive. Type A USB Memory (Default)

Communicate with the LR8432-20

and initiate measurem ent using the

Logger Utility software from a computer (using a USB ca bl e).

Type B USB Communication

Read files o n a CF card that is connected to the LR8432-20 from a

computer (using a USB cable) .

Type B USB Drive

Operating Precautions

• The Flash memory in a CF card/USB flash drive has a limited operating life. After long-term usage, data storage and retrieval beco me difficult. In this case, replace the CF card/USB flash drive with a new one.

• We cannot provide compensation for data loss in a CF card/USB flash

drive,

regardless of content or cause of the damage. Data is also cleared

from memory if a long time passes after measuring. Always maintain a

backup of important data stored on a CF card/USB flash drive.

• Although real-time saving to USB flash drive is supported, a CF card is

r

ecommend

when using storage media other than a Hioki-sp ecified C F card optio n.

• Use a USB flash drive whose continuous current consumption does not

exceed 300 m

Power” under the USB flash drive self -test on the [System] screen.)

• Depending on how USB is used, the USB connector and i nst r um ent settings may vary as shown in the chart below.

• The three USB methods of use described in the chart below involve

exclusive set

ed for data preservat ion. Perf ormance can not be gu aranteed

A (peak 500 mA). (The peak value is displayed as “Max

tings and cannot be used simultaneou sly.

Heat Flow Sensor (Models Z2012, Z2013, Z2014, Z2015, Z2016,

Z2017)

Do not subject the Heat Flow Sensor to excessive force.

Refer to the instruction manual included with the Heat Flow Sensor

for details.

Thermally Conductive Tape Z5008

Stop using double-sided Thermally Conductive Tape immediately

if it touches the human body and causes an abnormality.

14

Operating Precautions

15

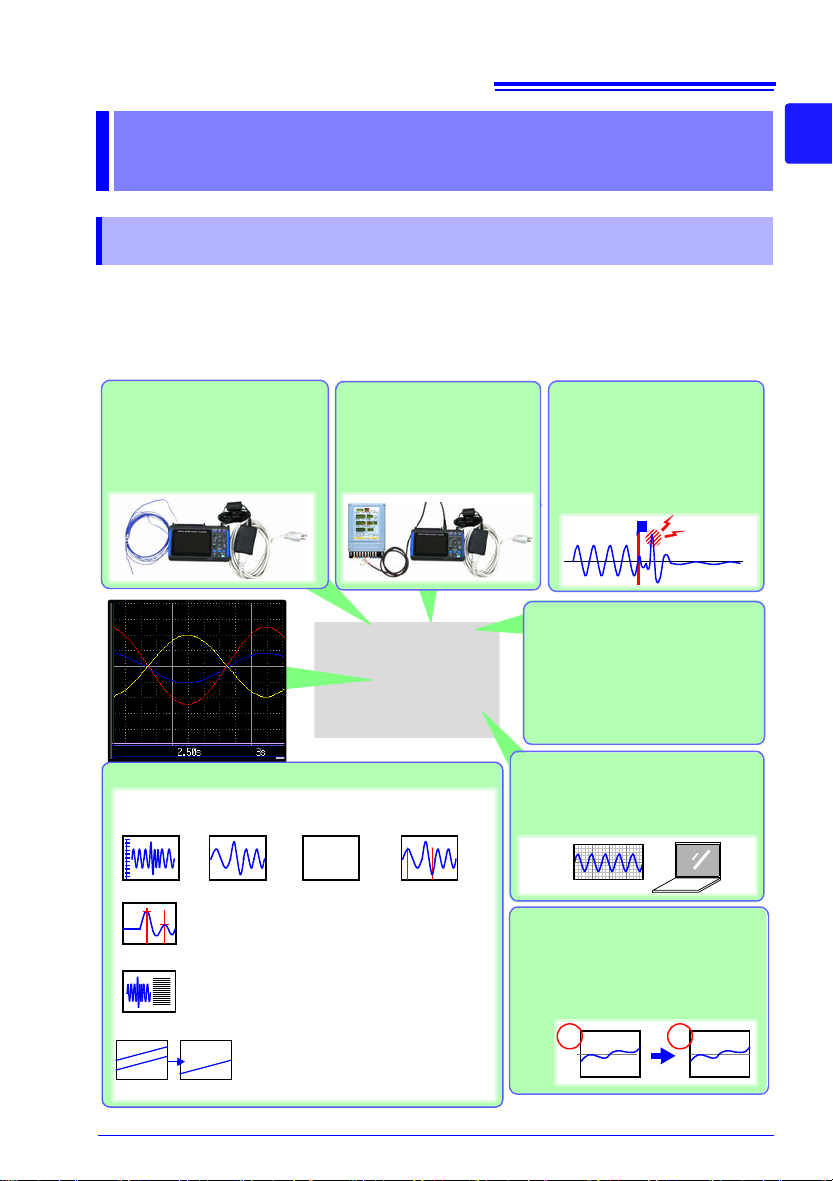

Record anomalies

Abnormal events ca n be analyzed by recording with the

trigger function (p. 81)

Use the alarm function to ou tput signals when anomalies

occur (p. 88).

Measurement data and

setting configurations are

stored, read and managed

as data files

Measuremen t d ata c a n be s to re d

to and read from a CF card or

USB flash drive (p. 109).

Waveform analysis

mV A

Cursor Measurements (p. 101)

Using the A/B cursors, values at cursor locations

on waveforms and the tim e at trigger positions

can be displayed.

Performs seven calculation types, including maximum and average values.

Numerical Calculations (p. 131)

Acquire pulse signals

Measure integrated pulses

or revolutions from sensors

and pulse output devices

such as watt-hour meters.

Gauge display (p. 100)

Zoom in/out

(p. 99)

Numerical display

(p. 104)

Analysis on a PC

Monitor and anal yze m easu re me nt

data with the supplied application

program (p. A20).

Event search

(p. 106)

T

Display in converted units

Using the scaling function, in put values can be displayed in units of the

actual physical quantity being measured, such as current or flow volume (p. 69).

Observe voltage fluctuations,

temperature, and heat flow

Just connect measurement leads,

thermocouples, or heat flow sensors to perform measurement as

needed.

Waveform Calculations (p. 101)

Performs five types of calculations, including four arit hm etic operations and a

moving average, a nd disp lays results in

a waveform format.

CH1

CH2

W1

123.4V

1 2

A

B

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

The Hioki LR8432-20 Heat Flow Logger is a compact, lightweight, easy-tooperate waveform recorder. It can run on batteries, and can be quickly

deployed when a power anomaly occurs.

Measurement data can be m onitored, subjected t o calculations and ana lyzed

o

n a perso

nal computer using the sup plied application program.

1

Chapter 1 Overview

3

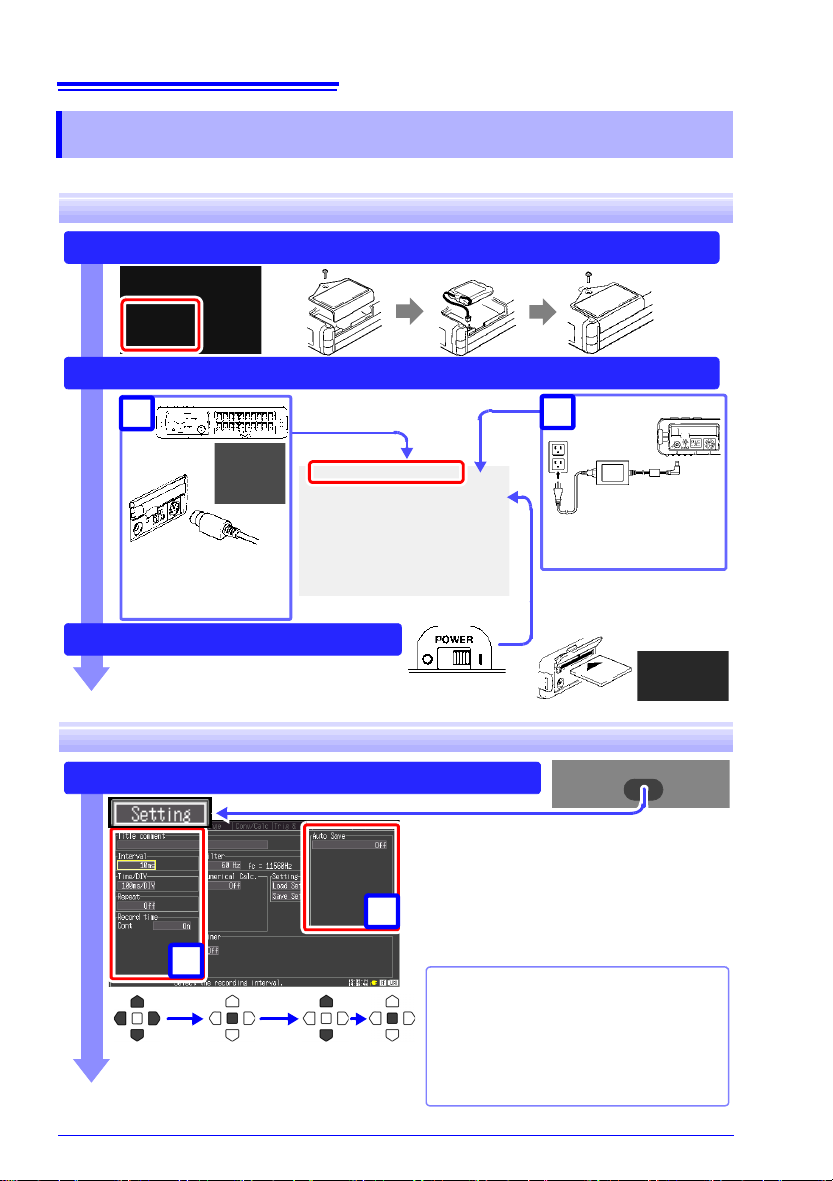

16

To save data, insert a

CF card or USB flash

drive. (p. 112)

AC adapter

connection (p. 33)

Install the Battery Pack (option) (p. 28)

Connect to the Model LR8432-20 (p. 27), and Set Up (p. 9)

Turn the Power On (p. 40)

Measurement

cables connections

(p. 34)

1

2

Configure Recording Settings (p. 44)

Using a previously saved

setting configuration

Reload a previously stored setting con figuration from Model LR8432-20

memory or a CF card or USB flash

drive, and measure (p. 121)

Set the data acquisition (recording) interval, and recording length (time span).

Select the type of measurement data to

save when automatically saving to a CF

card or USB flash drive.

Remaining data stored in the instrument

can be saved when finished measuring.

Move to a

setting item

Open the

setting options

Select Apply

1

2

1.2 Measurement Flow

1.2 Measurement Flow

Installing, Connecting and Turning On

Settings

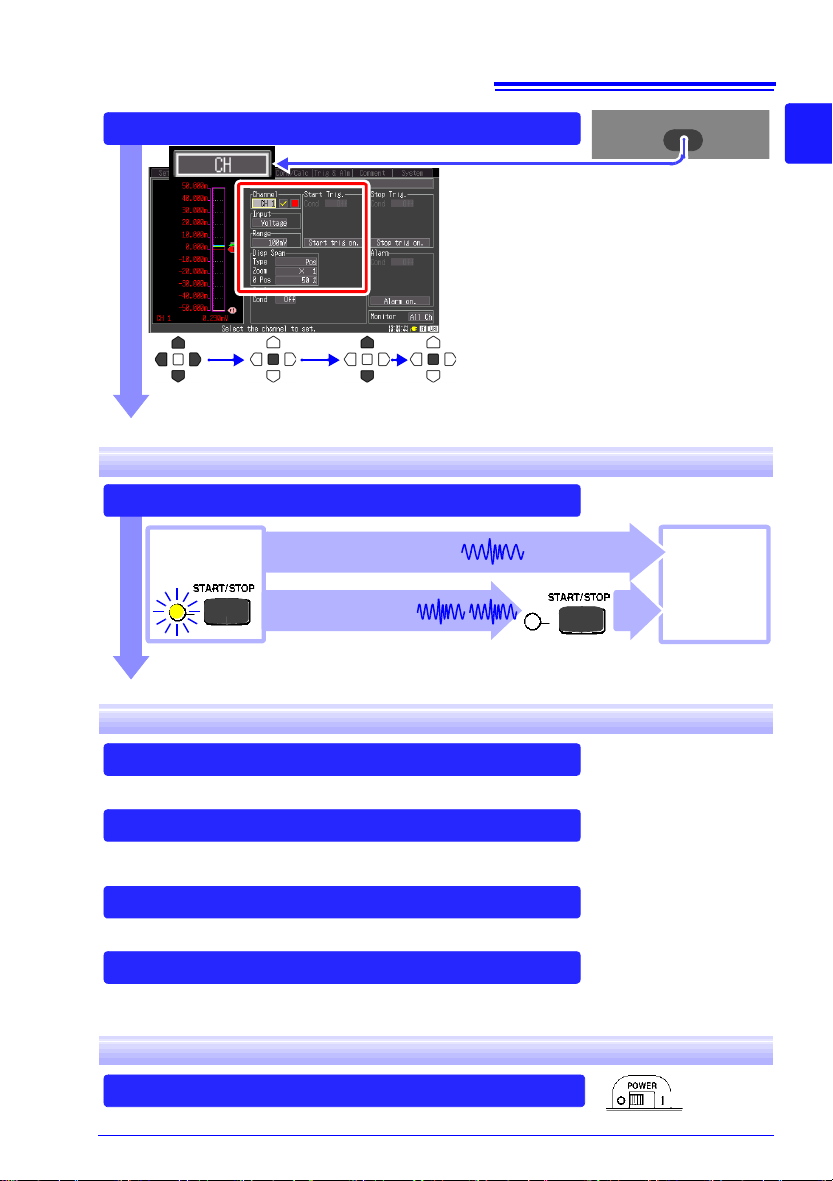

1.2 Measurement Flow

Configure Input Channe ls (p. 44)

Select input channels, and set input types

and measurement ranges.

Make other settings as desired.

Move to a

setting item

Open the

setting options

Select Apply

Press the START/STOP Key (p. 24)

Record once, and stop.

[Repeat]: Off

Stop

Measurement

Start

Measurement

When recording using the trigger function, recording occurs only

when the input waveform satisfies specified trigger criteria.

Record repeatedly.

[Repeat]: On

(default setting)

View Measurement Data (p. 97)

Waveforms can be zoomed and numerical values confirmed.

Save Data (p. 109)

Measurement data, waveform data, screen images and numerical calculation

results can be saved.

Calculate (p. 131)

Numerical measurement data can be applied to calculations.

View on a Computer (p. A20)

Analyze recorded data using the supplied application program.

Turn the Instrument O ff (p. 40)

Sta rting and Stopping Measurement

17

1

Chapter 1 Overview

3

Data Analysis

When Finished

18

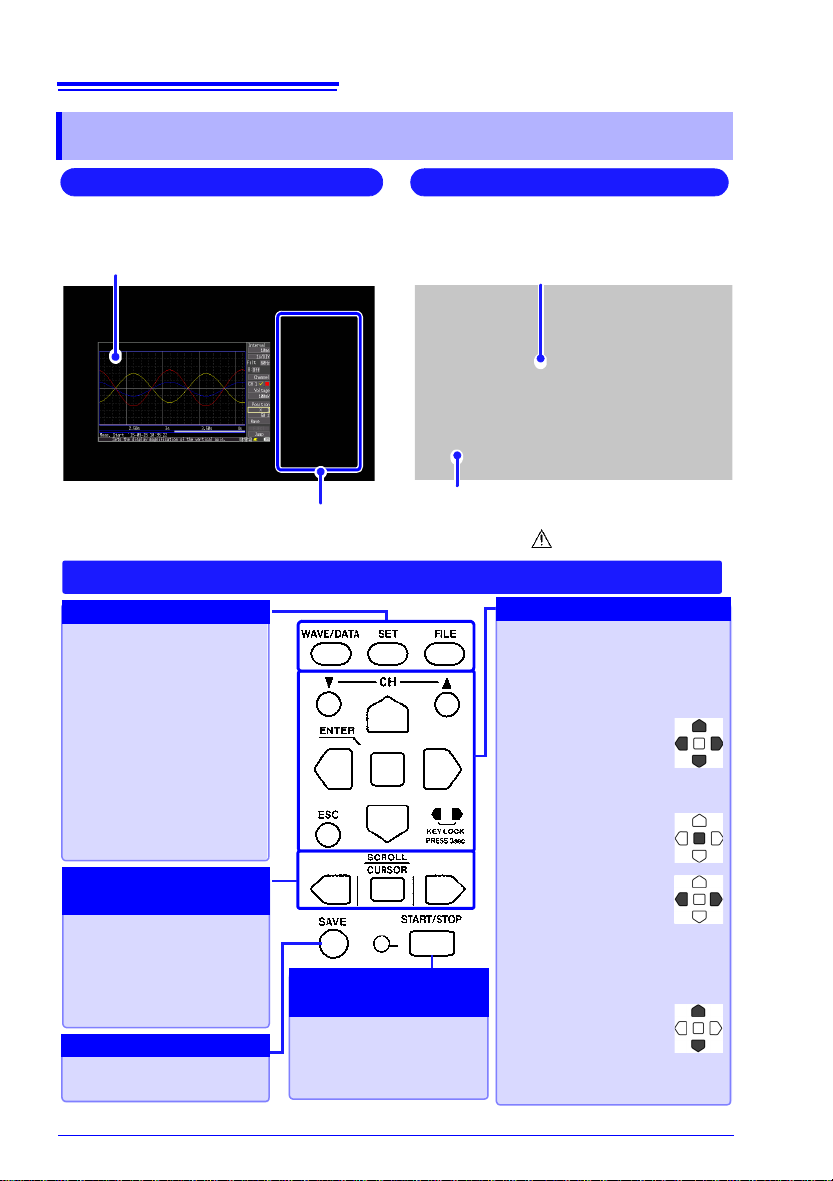

Front Panel

Operating Keys

Rear Panel

Battery Compartment (p. 28)

The optional Model 9780 Battery Pack is

installed here.[ :(p. 10)]

Manufacturer’s Serial No.

Shows the serial number.

Do not remove this label, as it is required

for product support.

Display Screen (p. 97)

4.3-inch TFT color LCD

Screen Configurations (p. 20)

WAVE/DATA

Selects among waveform

screen displays (p. 20).

SET

Displays the Settings

screens, and switches

among the screen tabs

with each press (p. 22).

FILE

Displays file information

(p. 21).

CH/

Select channels.

ESC

Cancels changes to settings.

Cursor Keys

Moves the position of

the cursor (blinking

selection) on the

screen.

ENTER

Accepts displayed

settings.

KEY LOCK

Disables keypad operations. Press and

hold the left and right

cursor keys simultaneously for

three seconds to lock and unlock the keys.

(Zero Adjust )

Performs zero adjustment. Press the up

and down keys simultaneously to execute (p. 41).

Press to save data manually (p. 114).

Press the center key to

select waveform scrolling

or A/B cursor movement,

then press the left and

right cursor keys to scroll

or move (p. 23).

Setup and display

Saving operations

Scroll waveforms and

read cursor values

Choose a screen

Start and stop measurement. The LED at the left

lights green while measuring (p. 24).

Start and stop

measurement

Operating Keys

1.3 Names and Functions of Parts

1.3 Names and Functions of Parts

19

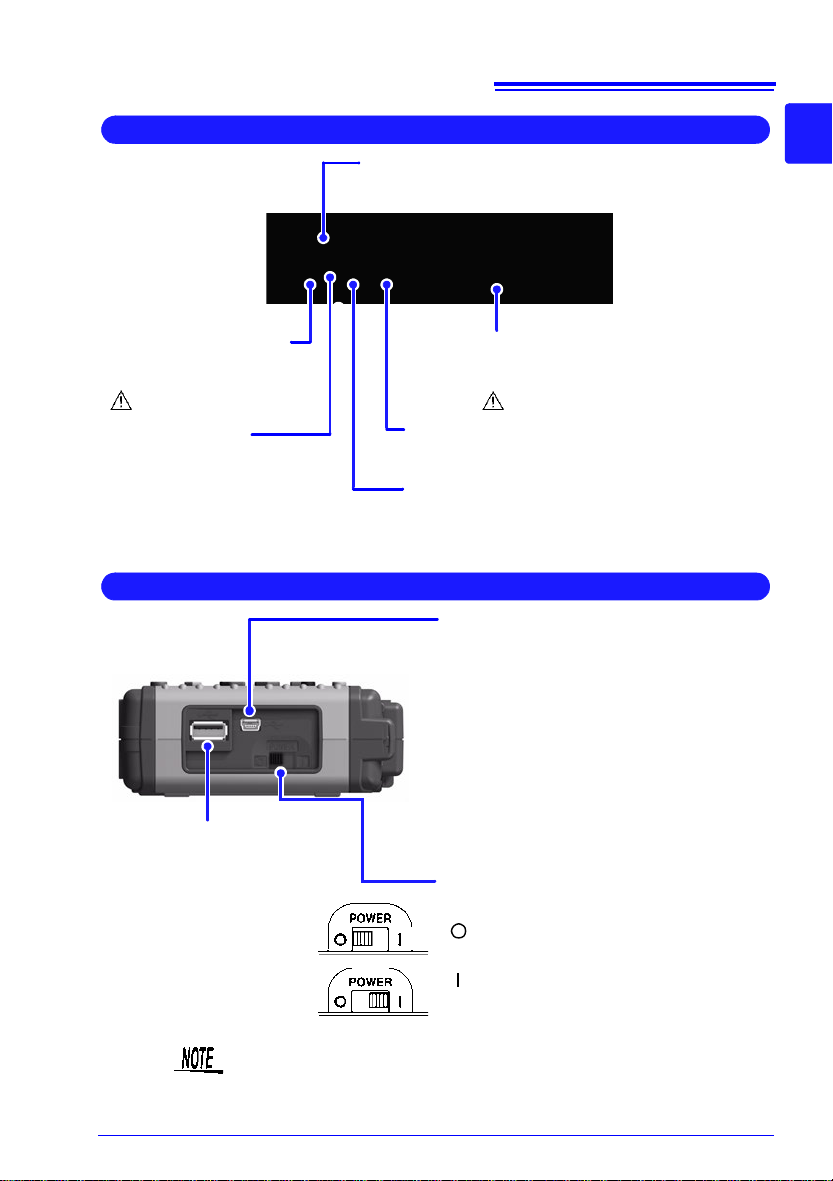

Top Panel

AC Adapter Socket

Connect the supplied Model

Z1005 AC Adapter (p. 33).

[ :(p. 10)]

CF Card Slot

Insert an optional CF card. (p. 111)

Analog Input Terminals

Connect measurement leads for voltage measurement, and thermocouples for temperature

(p. 34).[ :(p. 11)]

CHARGE LED

This LED lights when the

battery is charging (p. 32).

Pulse Input Connector

Connect an optional 9641 cable (p. 39) .

External Control Terminals

Control signals can be received from and

output to external devices (p. 157).

Right Side

POWER Switch

Turns the instrument on and off (p. 40)

Power Off

Power On

USB Port

(USB 2.0 mini-B receptacle)

• Using the included Logger Utility application software, you can monitor measurement data on the computer and transfer

settings to the instrument. (p. A28) (To

use, set the USB mode on the [System]

screen to [USB Comm.].)

• You can transfer data on the instrument’s

CF card to a computer. (p. 128) (To use,

set the USB mode on the [System]

screen to [USB Drive].)

USB flash drive Slot

(Type A USB 2.0

receptacle)

Used to save data to a USB

flash drive. (p. 112) (To

use, set the USB mode on

the [System] screen to

[USB Memory].)

1.3 Names and Functions o f Parts

1

Chapter 1 Overview

3

The [USB Memory ], [USB Comm.], and [USB Drive] US B mo d e

settings are exclusive and cannot be used simultaneously.

20

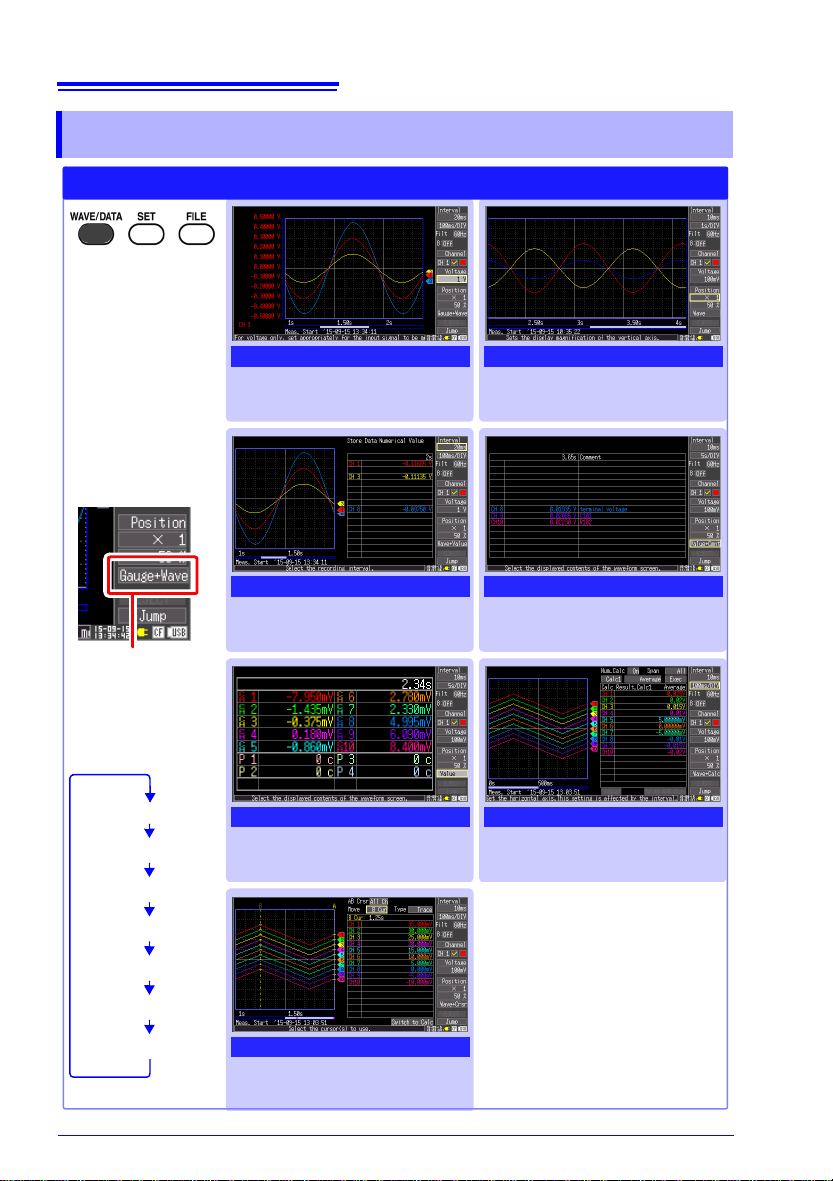

Selects between

seven display

types.

The screen switches

each time you press

the key.

Operational information is displayed

along the bottom of

the screen.

[Wave] Screen

Measurement data is displayed

as waveforms (p. 97).

[Value+Cmnt] Screen

Measurement data is displayed

as numerical values with comments (p. 104).

[Wave+Calc] Screen

Measurement data is displayed

as waveforms with calculation

results (p. 137).

[Gauge+Wave] Screen

Measurement data is displayed

as waveforms with gauges (p.

100).

[Wave+Value] Screen

Measurement data is displayed

as waveforms and numerical

values (p. 104).

[Value] Screen

Measurement data is displayed

as numerical values (p. 104).

[Wave+Crsr] Screen

Measurement data is displayed

as waveforms with cursor values (p. 101).

Waveform/Numerical Screens

Selection is also

available from the

name of the current

screen displayed

near the bottom right

[Gauge+Wave]

[Wave]

[Wave+Value]

[Value+Cmnt]

[Value]

[Wave+Calc]

[Wave+Crsr]

1.4 Screen Configurations

1.4 Screen Configurations

21

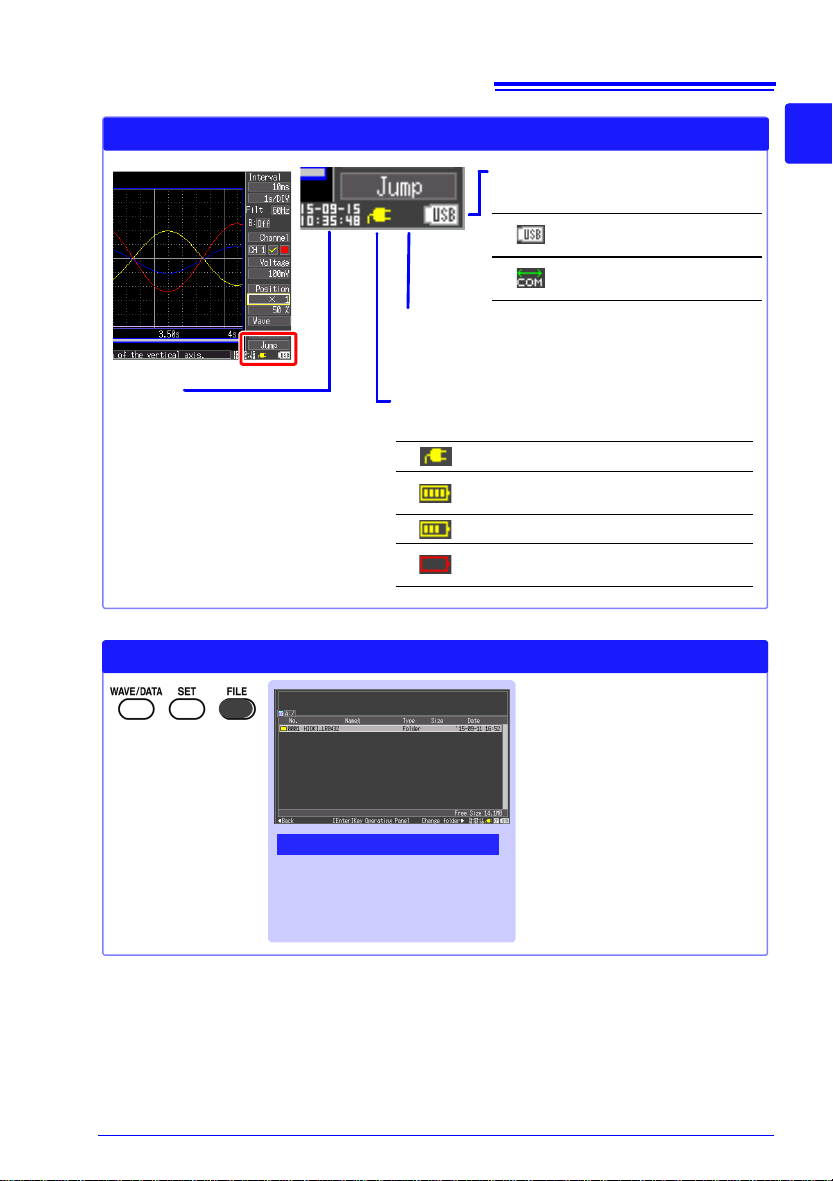

Icons (Commonly used on all of the screens)

Clock

“Setting the Date and Time”

(p. 152).

Power source indicator

Indicates the instrument’s power source.

AC adapter operation

Battery pack operation

(

Fully charged battery pack)

Battery pack operation

Battery pack operation

(Low battery indicator)

CF card

Displayed when a CF card is inserted.

The icon appears red when accessing the card.

USB source indicator

Indicates the USB status.

USB flash drive inserted

in USB Memory mode.

Operating in USB

Communication mode.

File Screen

View and manage files on the

CF card or USB flash drive

(p. 109).

File Screen

Operational information is displayed

along the bottom of

the screen.

1.4 Screen Configurations

1

Chapter 1 Overview

3

22

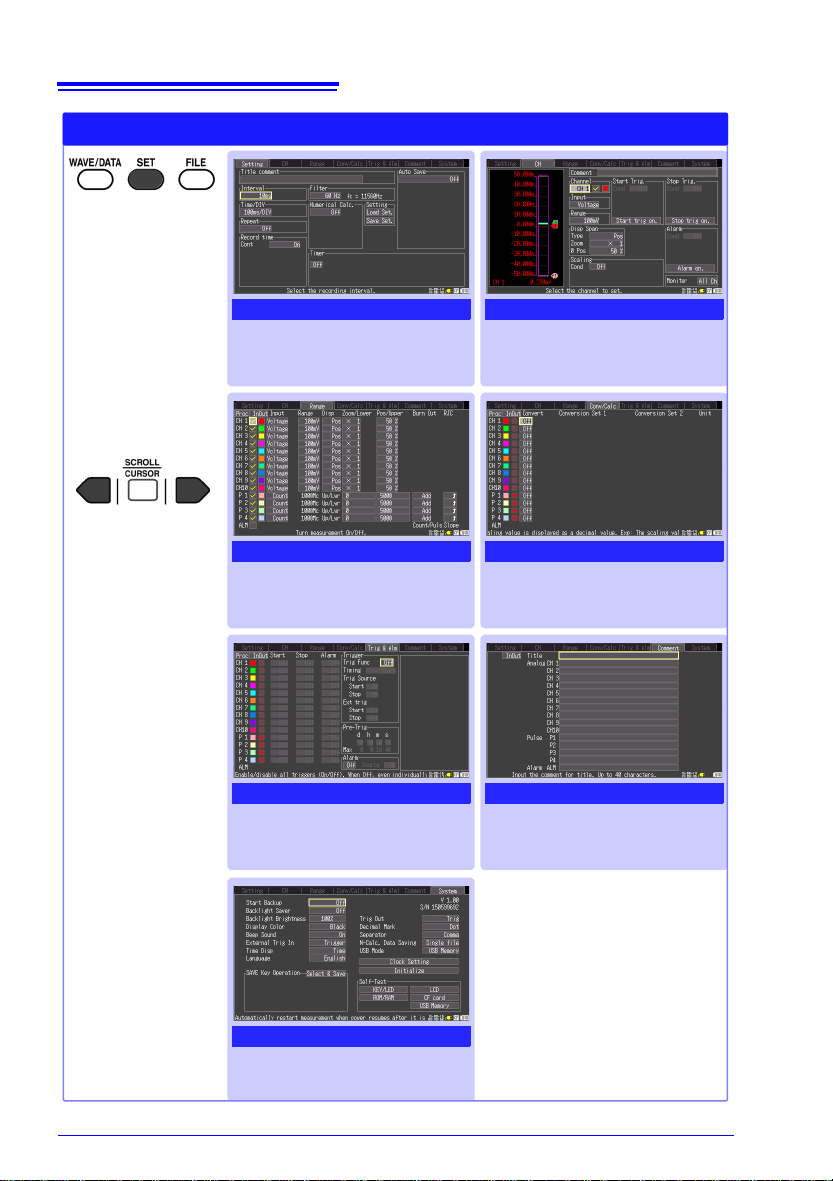

[CH] Screen

Make input channel settings

while viewing the monitor display (p. 56).

[Conv/Calc] Screen

Make these settings to convert

measured values to arbitrary

units for display (p. 69).

[Comment] Screen

Enter channel comments

(p. 72)

[Setting] Screen

[Range] Screen

Make settings while viewing all

channel settings (p. 74).

[Trig & Alm] Screen

Recording criteria (triggering)

and warning sounds can be set

for each channel (p. 81).

[System] Screen

Configure the system environment (p. 147).

Settings Screens

Press the left/right

cursor keys to select between the

Settings screens.

Selects between

seven display

types.

The screen switches each time you

press the key.

Operational information is displayed

along the bottom of

the screen.

Make settings for recording (p .

48). Set numerical calculation,

auto-saving and timers.

1.4 Screen Configurations

Loading...

Loading...