Hioki LR5051 Instruction Manual

Instruction Manual

LR5051

CLAMP LOGGER

July 2013 Revised edition 2 LR5051B980-02 13-07H

Contents

Introduction ..............................................................................1

Verifying Package Contents....................................................3

Safety Information....................................................................5

Operating Precautions.............................................................6

Measurement Preparation to Data Analysis ..........................8

i

Contents

1

2

3

Chapter 1

Overview__________________________________13

1.1 Product Overview and Features .............................13

1.2 Part Names/Functions and Display Indicators .....14

1.3 Display Organization ...............................................16

Chapter 2

Measurement Preparations___________________ 19

2.1 Installing (or Replacing) the Battery ......................19

2.2 Connecting a Clamp Sensor ...................................22

2.3 Installing the PC Application Program ..................29

Chapter 3

Settings___________________________________35

3.1 Settings List .............................................................35

3.2 Making Settings on the Logger ..............................37

3.3 Making Settings from the LR5000 Utility Program 43

Chapter 4

Measurement and Analysis___________________ 51

4.1 Pre-Measurement Inspection .................................51

4.2 Installing the Logger ...............................................52

4.3 Starting and Stopping Recording ..................... ... ..53

4.4 Confirming Currently Measured Values and Data

Recording .......................... .......................... ............. 55

4.5 Automatically Importing (Saving) Recorded Data

to a Computer, and Graph Display ........................55

4

ii

Contents

4.6 Manually Importing (Saving) Recorded Data to a

Computer, and Graph Display ............................... 65

4.7 Displaying a Graph of Saved Recording Data ..... 68

4.8 Printing Recorded Data .......................................... 70

Chapter 5

Processing Recorded Data ___________________71

5.1 Scaling ..................................................................... 73

5.2 Calculating Electric Power ..................................... 74

5.3 Calculating Energy Cost ....... .. ... .. ... ... .. .................. 75

5.4 Calculating Operating Rate ............. ... .. ... .. ... .......... 76

5.5 Integration ............................................................... 77

5.6 Calculating Dew-Point Temperature ..................... 78

5.7 Two-Data-Item Arithmetic Calculations ................ 79

5.8 Converting Over-Threshold Data Values .............. 80

Chapter 6

Organizing Data ____________________________81

6.1 Copying and Moving Data ...................................... 82

6.2 Deleting Data .................. ......................................... 83

6.3 Combining Data ...................................................... 84

6.4 Extracting Data ....................................................... 85

Chapter 7

Options Settings (LR5000 Utility Program) ______87

7.1 Changing the Saving Method for Imported Data . 88

7.2 Changing the Connection Monitoring Method,

and Logger Settings Displays ............................... 89

Chapter 8

Specifications______________________________91

8.1 Measurement Specifications ................................. 91

8.2 Functional Specifications ...................................... 92

8.3 Miscellaneous ......................................................... 93

8.4 LR5091 Communication Adapter Specifications . 94

Chapter 9

Maintenance and Service ____________________97

9.1 Cleaning ...................................................................97

9.2 Disposing of the Logger .........................................97

9.3 Troubleshooting ......................................................98

9.4 Error Displays . .......................................................100

Appendix_________________________________ A 1

iii

Contents

Appendix 1 About Recording Modes.............................. A 1

Appendix 2 Recording Intervals and Maximum

Recording Times.......................................... A 2

Appendix 3 Battery Life Approximation...................... ... A 2

Appendix 4 Measurement Method .................................. A 3

Index _________________________________Index 1

4

5

6

7

8

9

Appendix

Index

iv

Contents

1

Introduction

Introduction

Thank you for purchasing the HIOKI "Model LR5051 Clamp Logger." To obtain maximum performance from the instrument, please read this manual first, and keep it

handy for future reference.

Registered Trade Marks

Windows is a registered trademark of Microsoft Corporation in the United States and/

ther countries.

or o

Notation

Indicates a prohibited action.

(p. ) Indicates the location of reference information.

Indicates quick references for operation and remedies for

troubleshooting.

* Indicates that descriptive information is provided below.

Menus, commands, dialogs, buttons in a dialog, a nd other

[ ]

SET

(Bold charac-

ters)

Windows

Dialog Dialog box represents a Windows dialog box.

The screen of this instrument displays characters in the following manner.

names on the screen and the buttons are indicated in

brackets.

Bold characters within the text indicate operating button

labels.

Unless otherwise specified, “Windows” represents Windows XP, Windows Vista, or Windows 7.

2

Introduction

Accuracy

We define measurement tolerances in terms of rdg. (reading) and dgt.

(digit) values, with the following meanings:

rdg.

(reading or displayed

value)

dgt.

(resolution)

The value currently being measured and indicated

on the measuring instrument.

The smallest displayable unit on a digi tal measuring instrument, i.e., the input value that causes the

digital display to show a "1" as the least-significant

digit.

Mouse Operation

Click Press and quickly release the left button of the mouse.

Right-click

Double click Quickly click the left button of the mouse twice.

Drag

Activate Click on a window on the screen to activate that window.

Press and quickly release the right button of the mouse.

While holding down the left button of the mouse, move the

use and then release the left button to deposit the cho -

mo

sen item in the desired position.

3

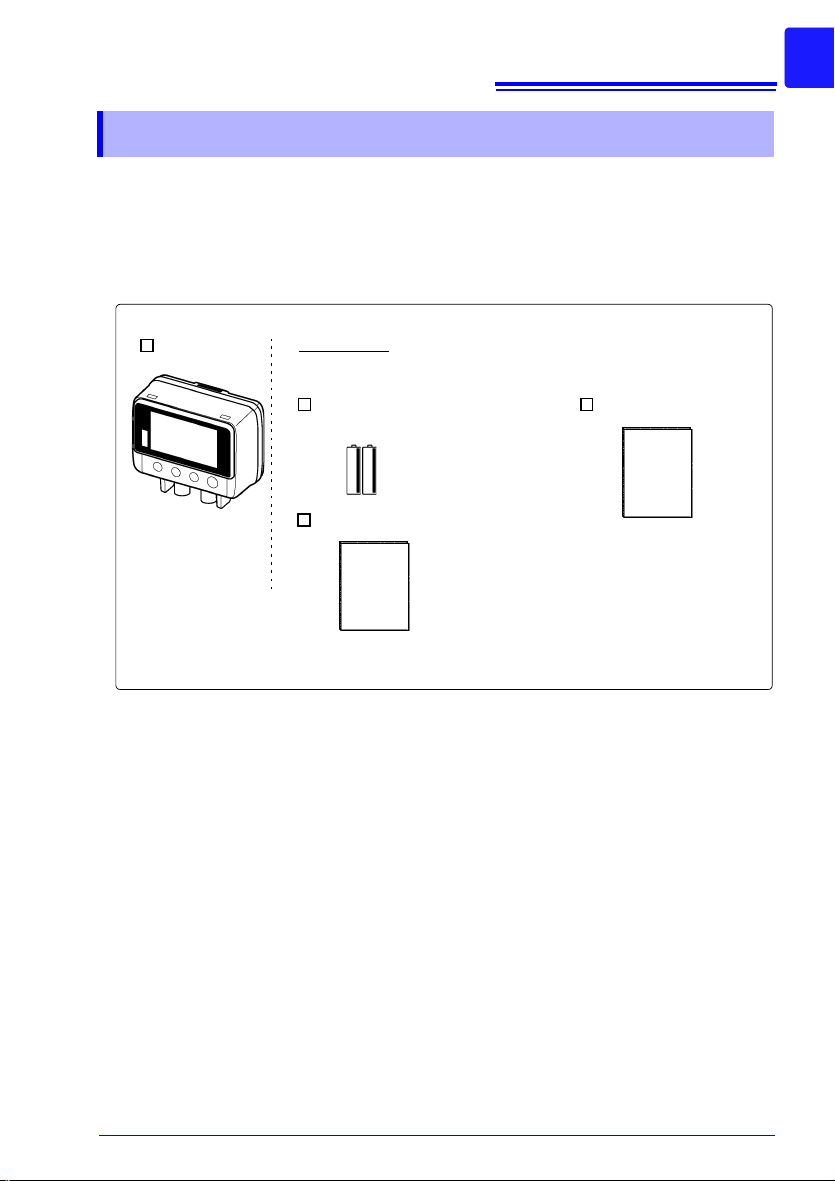

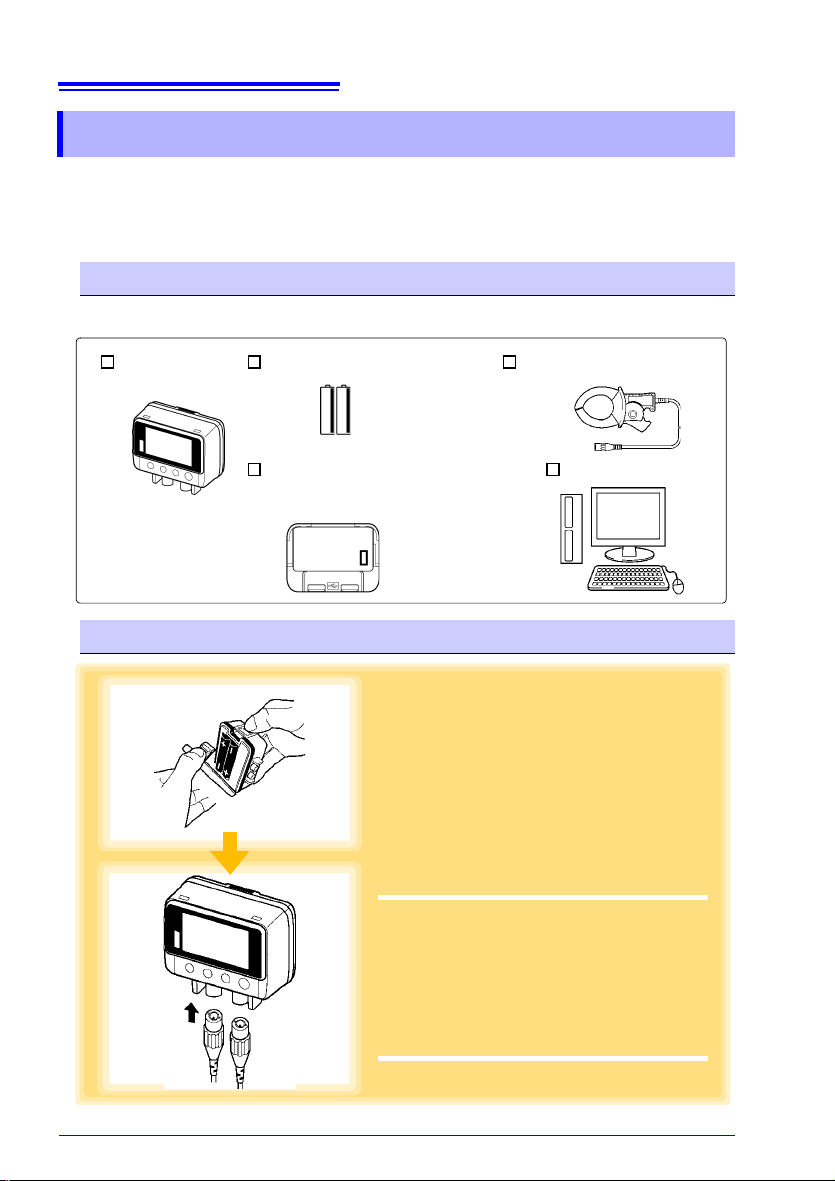

LR5051(1)

LR6 alkaline battery (2)

(Pre-installed in the logger.)

Accessories

See: Other specified option s: " O ptions" (p.4)

Instruction Manual (1)

Operation Manual (1)

Verifying Package Contents

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate according to the specifications, contact your dealer or Hioki representative.

Quantities in parentheses ( ).

4

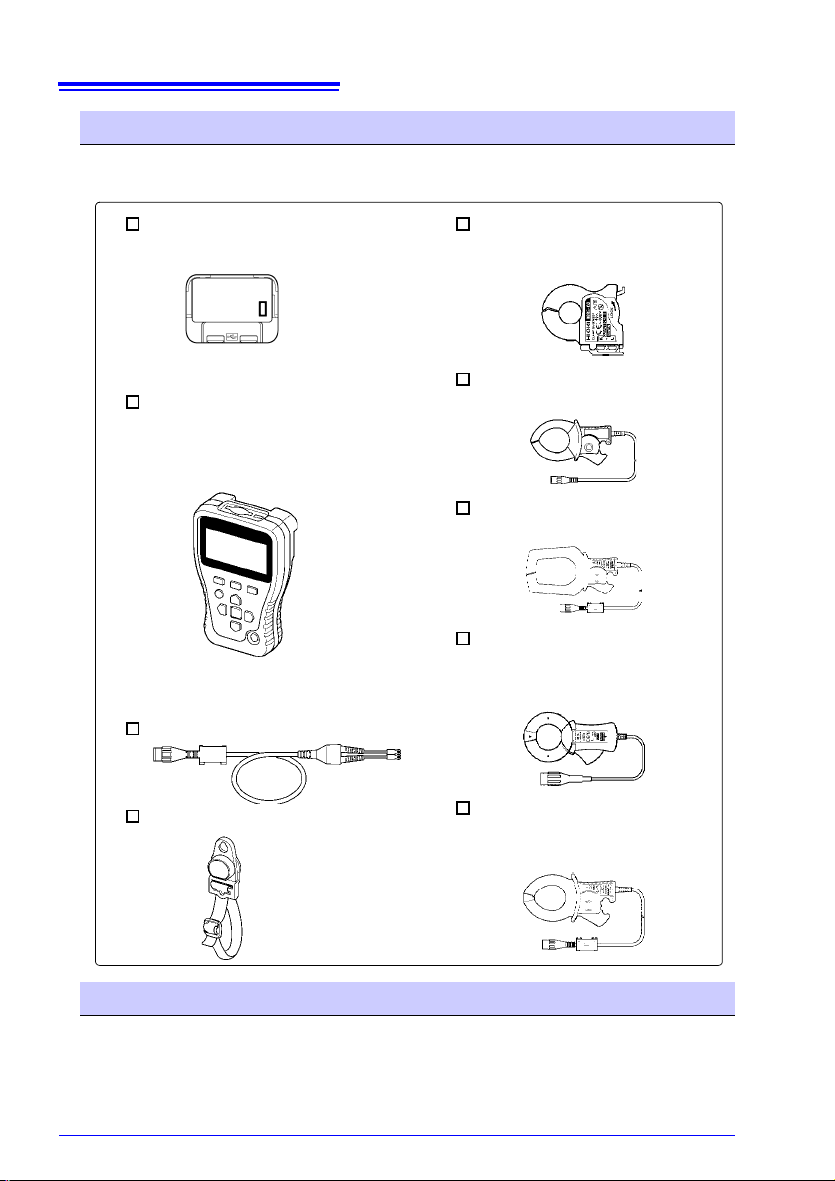

LR5092-20 Data Collector

(Includes LR5000 Utility Program* CD [PC application software], LR6 alkaline battery x2, I nstruction manual, Operation manual, and USB

Cable)

9695-02 Clamp On Sensor

50 A AC load current

Note: Requires 9219 Connection

Cable

LR5091 Communication Adapter(1)

(Includes LR5000 Utility Program* CD [PC application software] and USB Cable)

*:The latest version can be download-

ed from our web site.

CT6500 Clamp On Sensor

AC500 A AC load current

9669 Clamp On Sensor

1000 A AC load current

9675 Clamp On Leak Sensor

10A AC leakage current

Note: Displays up to 5.000 A with

the LR5051

See: LR5091 specification:(p.94)

Z5004 Magnetic Strap

9219 Connection Cable

9657-10 Clamp On Leak Sensor

10A AC leakage current

Note: Displays up to 5.000 A with

the LR5051

See: Method of mounting:

(p.52)

Verifying Package Contents

Options

The following logger options are available separately. Even if purchased previously,

you may want to confirm that you have them at hand.

Transporting Precautions

Use the original packing materials when transporting the instrument, if possible.

Pack the instrument so that it will not sustain damage during shipping, and include a

description of existing damage. We do not take any responsibility for damage incurred

during shipping.

5

Safety Information

Safety Information

This manual contains information and warnings essential for safe operation of the

instrument and for maintaining it in safe operating condition. Before using it, be

sure to carefully read the following safety precautions.

This instrument is designed to comply with IEC 61010 Safety Standards, and has been thoroughly te

ment. However, mishandling during use could re

death, as well a s damage to the instrument. However, using the

instrument in a way not described in this manual may negate the

provided safety features.

Be certain that you understand the instruc

the manual before use. We disclaim any responsibility for accidents or injuries not resulting directly from instrument defects.

Safety Symbols

Markings on the logger have the following meanings.

In the manual, the symbol indicates particularly important information that the user should read before using the instrument.

The symbol printed on the instrument

should refer to a corresponding topic in the manual (marked w ith the

symbol) before using the re

Indicates DC (Direct Current).

Symbols for Various Standards

Markings on the logger have the following meanings.

WEEE marking:

This symbol indicates that the electrica

put on the EU market after August 13, 2005, and producers of the

Member States are required to display it on the appliance under Article 11.2 of Directive 2002/96/EC (WEEE).

This symbol indicates that the product conforms to safety r egulations set out by the EC Directive.

sted for safety prior to ship-

sult i n injury or

tions and precautions in

indicates that the user

levant function.

l and electronic appliance is

Danger Levels

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an extreme hazard

that could result in serious injury or death to the user.

Indicates that incorrect operation

that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of

in

jury to the user or damage to the instrument.

Indicates advisory items related to performance or correct

ope

ration of the

instrument.

presents a significant hazard

6

Operating Precautions

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

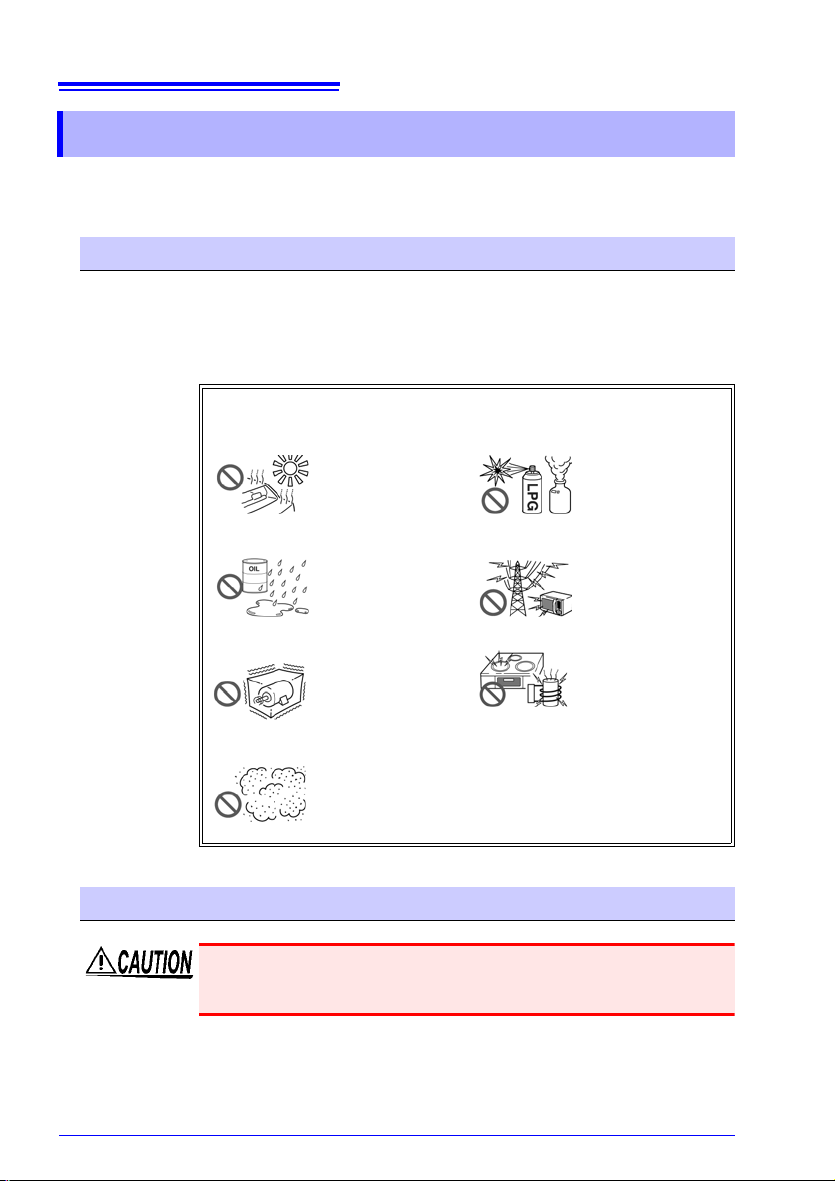

Installation Precautions

• Operating temperature and humidity: 0 to 50C (32 to 122F), 80%RH or less

• Storage temperature and humidity: -10 to 60C (14F to 140F),

80%RH or less (non-condensating)

• Operating environment: indoors

Avoid the following locations that could cause an accident or damage to the instrument.

Transporting and Handling

To avoid damage to the instrument and sensors, protect it from physical

shock when transporting and handling. Be especially careful to avoid

physical shock from dropping.

Exposed to direct

sunlight

Exposed to high temperature

Exposed to liquids

Exposed to high

y or condensa-

humidit

tion

Subject to vibration

Exposed to high levels of particulate dust

In the presence of

corrosive or explosive

gases

Exposed to strong

romagnetic

elect

fields

Near electromagnetic

radiators

Near induction heating systems

(e.g., high-frequency

ction heating sys-

indu

tems and IH cooking

ensils)

ut

CD Handling

7

Operating Precautions

• Always hold the disc by the edges, so as not to make fingerprints on

the disc or scratch the printing. Never touch the recorded side of the

disc. Do not place the disc directly on anything hard.

• Do not wet the disc with volatile alcohol or water, as there is a possibility of the label printing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not

u

se a ball-point pen or hard-tipped pen, because there is a danger of

scratching the surface and corrupting the data. Do not use adhesive

labels.

• Do not expose the disc directly to the sun's rays, or keep it in conditions of high temperature or humidity, as there is a danger of warping,

with

consequent loss of data.

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry

cloth, or use a CD cleaner. Alway s wipe from the insid e to the o utside,

and do no wipe with circular movements. Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer system

th

at arises from the use of this CD, or for any problem related to the

purchase of a Hioki product.

Preliminary Checks

Before using the instrument the first time, verify that it operates normally to ensure

that the no damage occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the

sensor cables is undamaged and that no bare conductors are

improperly exposed. Using the instrument in such conditions

could cause an electric shock, so contact your dealer or Hioki representative for replacements.

8

LR5051 (1) LR6 alkaline battery (2) CT6500 Clamp On Sensor (1)

LR5091 Communication Adapter (1)

(CD [PC application software] and

USB Cable)

Computer (1)

1

Install the battery in the logger.

See: "Installing (or Replacing) the Bat-

tery" (p.19)

2

Connect the CT6500 Clamp On Sensor to

the logger.

See: "Connecting a Clamp Sensor"

(p.22)

1

2

Measurement Preparation to Data Analysis

Measurement Preparation to Data Analysis

The steps from measurement preparation to data analysis are illustrated with a typical measurement example.

Example case: Record factory current consumption at one-minute intervals for one

month, and store the data on a computer.

Required Items:

Quantities in parentheses ( ).

Procedure:

Measurement Preparation to Data Analysis

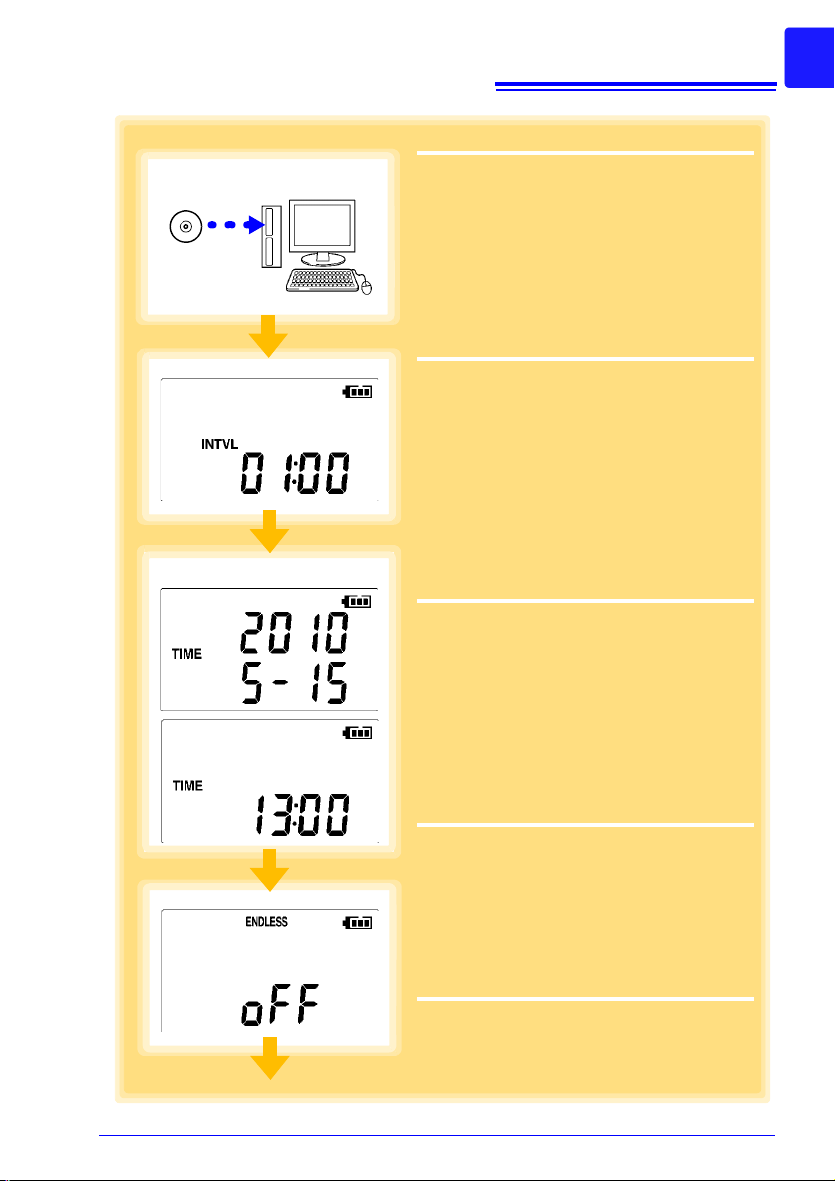

3

Install the LR5000 Utility Program on the

computer.

See: "Installing the PC Application Pro-

gram" (p.29)

4

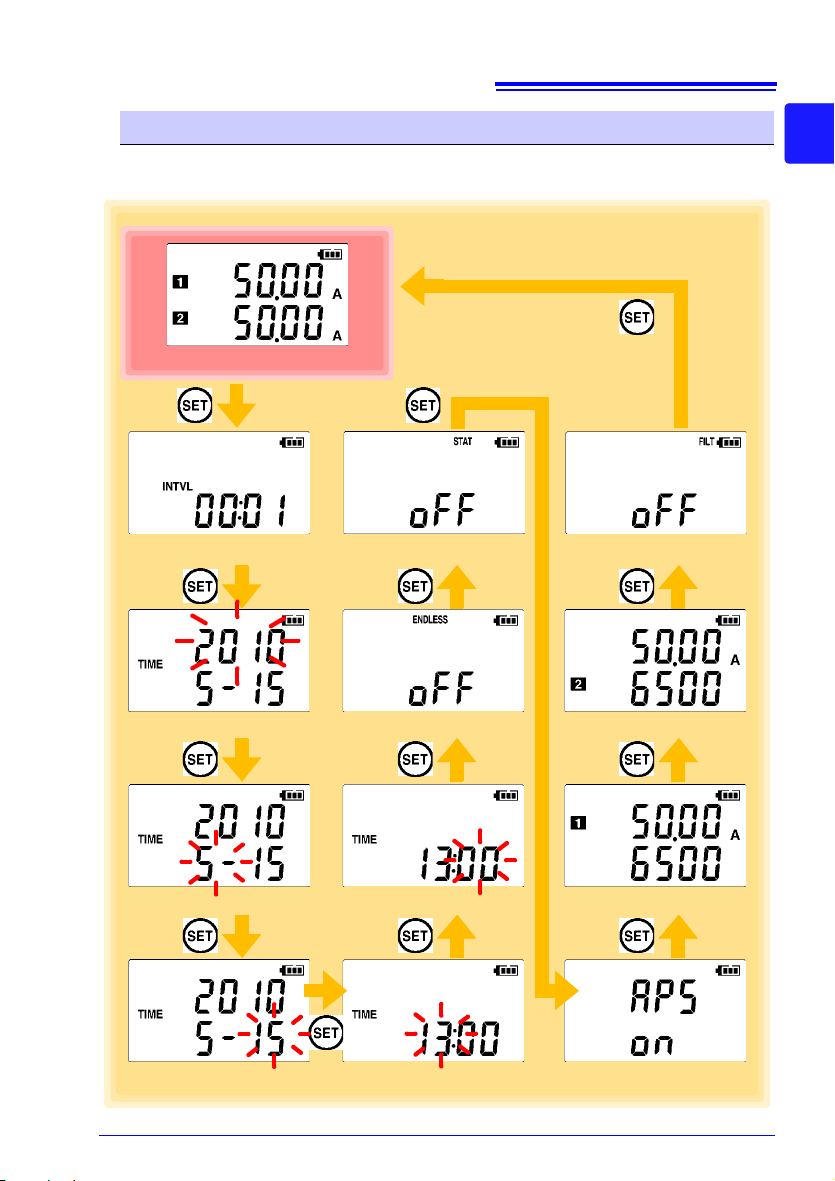

Select the recording interval for the logger

(in this case, 1 minute).

See: "Recording In terval Setting" (p.37)

(The setting can be made also from the

LR5000 Utility Program.) (p.46)

5

Set the logger to the correct date and time

(in this case, 15 May 2010, 13:00).

See: "Real-Time Clock Setting" (p.38)

(With the LR5000 Utility Program, the logger can be set to the computer time.)

(p.49)

6

Set the stop method to [OFF].

(This setting provides one-time measurement:

recording stops when memory becomes full.)

See:

"Stop Method Setting (for when

memory becomes full)" (p.39)

(The setting can be made also from the

LR5000 Utility Program.) (p.46)

5

4

3

6

9

10

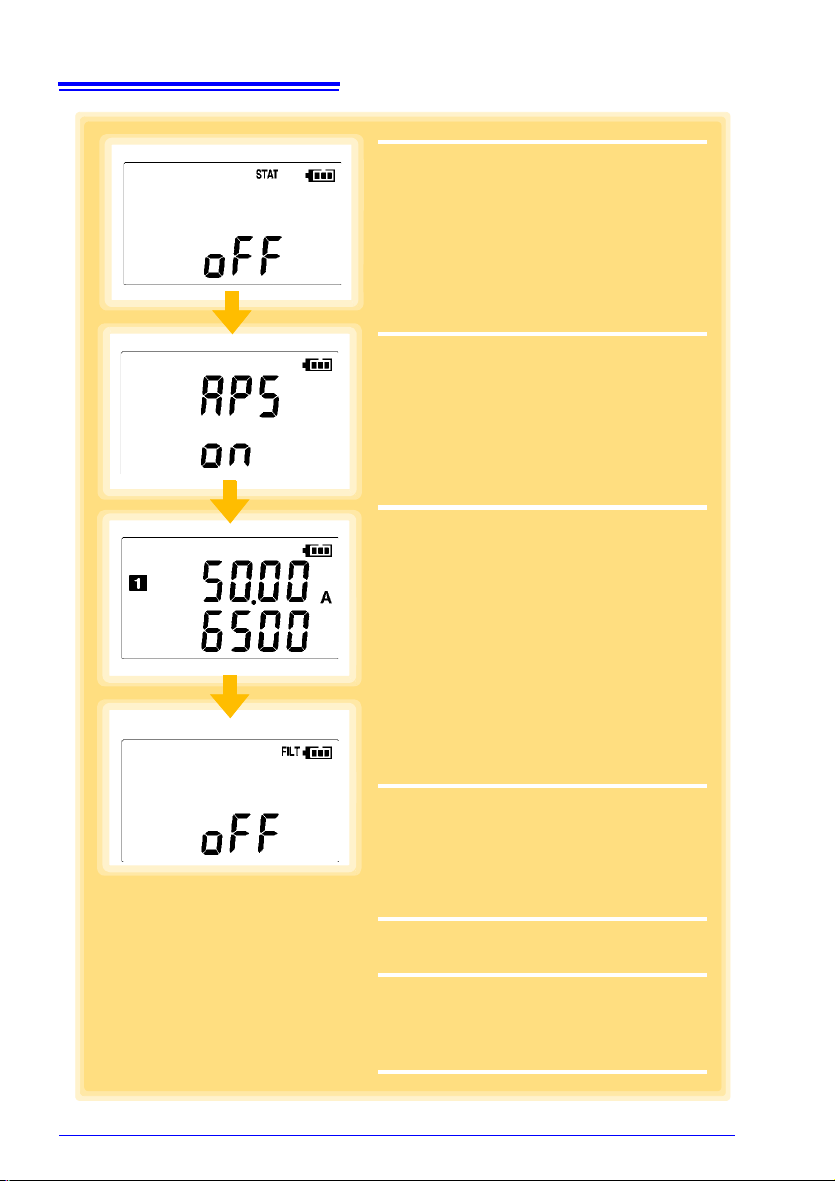

7

Set the recording mode to [OFF].

(This setting provides instantaneous measurement.)

See:

"Recording Mode Setting" (p.40)

(The setting can be made also from the

LR5000 Utility Program.) (p.46)

8

Set the power save setting to [ON].

(The on (enabled) setting is recommended

for long-term recording.)

See:

"Power Save Setting" (p.40)

(The setting can be made also from the

LR5000 Utility Program.) (p.45)

9

Set the CH1 measurement range to

[6500 50.00 A].

See: "Selecting the Clamp Sensor

Model and Measurement Range"

(p.41)

(The model name of the clamp sensor is

displayed above the current range.)

Note: The CT6500 Clamp On Sensor is

displayed as [6500] on the screen.

10

Set the filter to [OFF].

See: "Filter Setting" (p.42)

11

Pre-measurement inspection (p.51)

12

Install the logger at the measurement

site in the factory.

See: "4.2" (p.52)

It can be wall-mounted.)

8

9

7

10

Measurement Preparation to Data Analysis

11

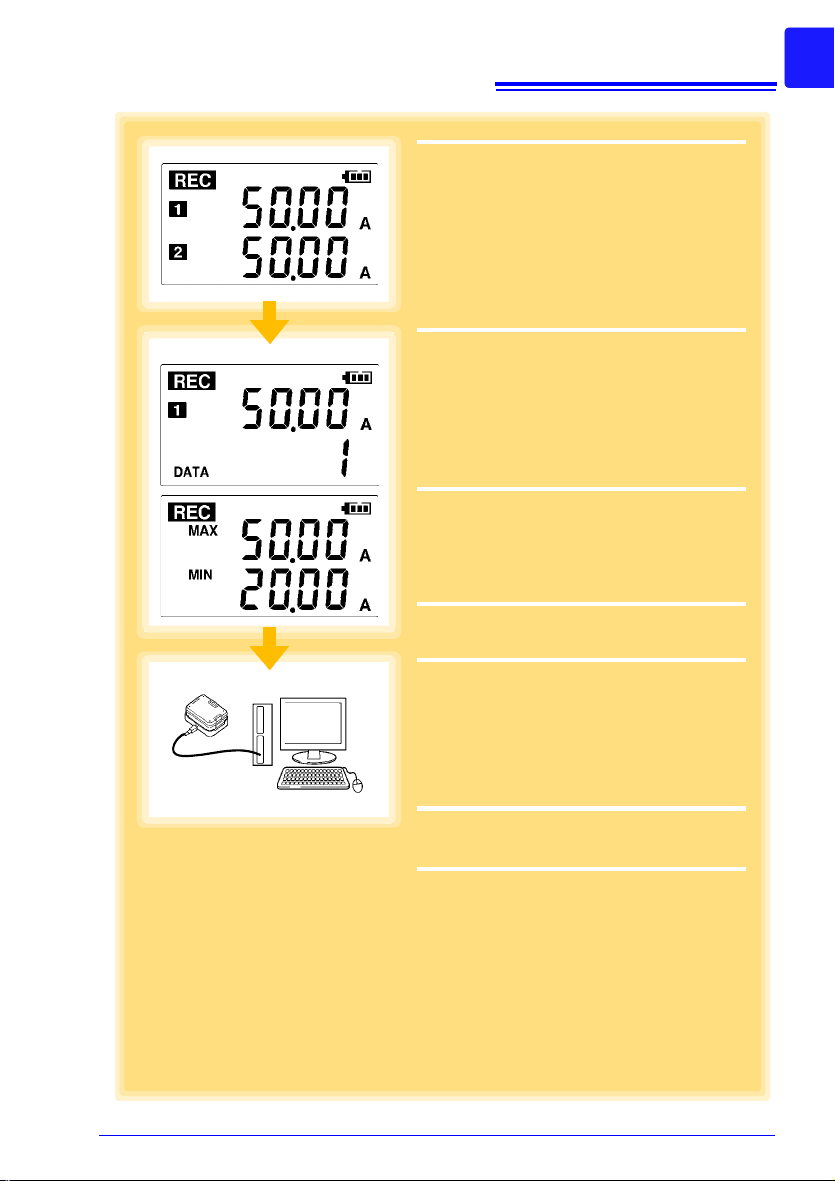

13

Hold REC/STOP on the logger for two

seconds to start recording.

See: "4.3" (p.53)

14

Press (+) and (-) on the logger to confirm

that the recording count is incrementing,

and that recording data (maximum and

minimum values) are displayed.

(Confirm that recording is actually occurring.)

See:

"4.4" (p.55)

15

After a month, hold REC/STOP on the

logger again for two seconds to stop

recording.

See: "4.3" (p.53)

16

Retrieve the logger from the factory.

17

Import recorded data from the logger to

a connected computer. For analysis, display the data in a graph.

See: "4.5" (p.55)

The data is automatically saved when

imported to the computer. By default, it is

also automatically displayed in a graph.)

18

Print recorded data as needed.

See: "4.8" (p.70)

13

17

14

Measurement Preparation to Data Analysis

12

Measurement Preparation to Data Analysis

13

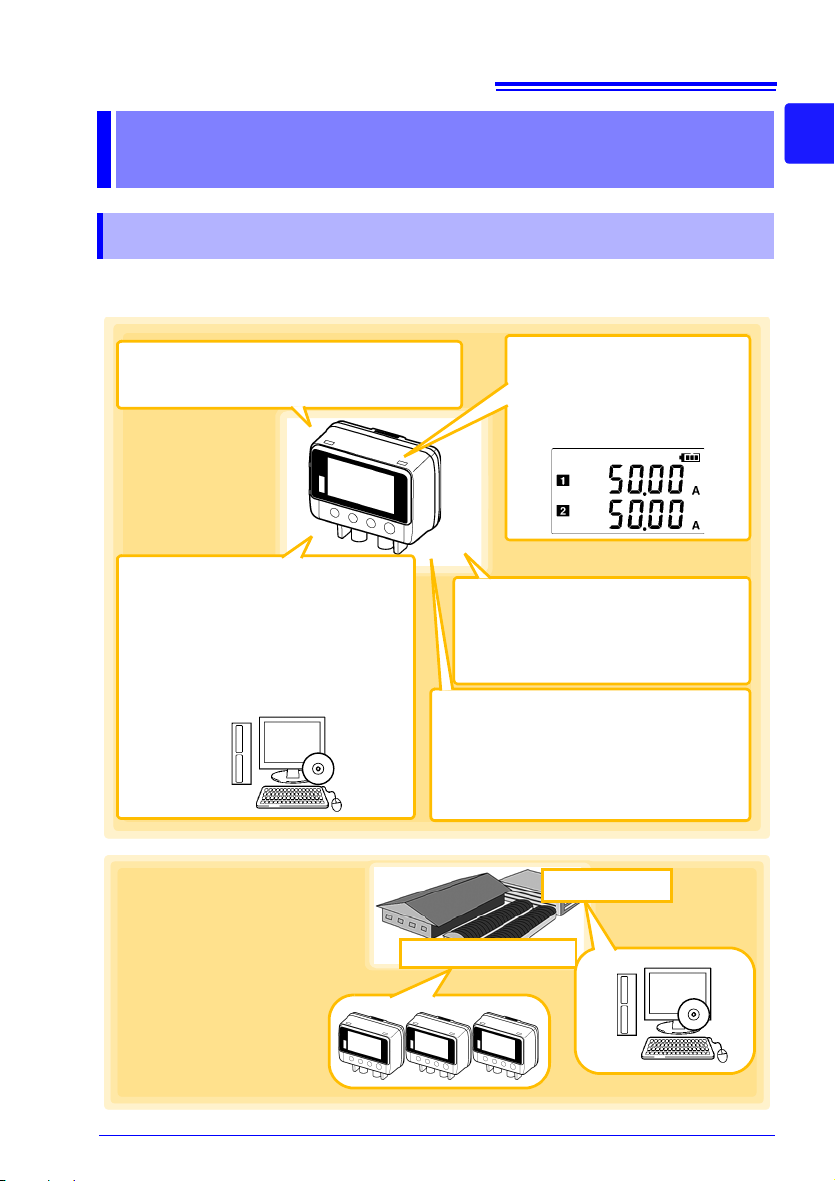

Browse and manage data with

LR5000 Utility Program on a PC.

The LR5000 Utility Program PC application is very easy to install.

After installation, data management and

browsing is easy with auto-start, data display and saving.

Large display shows two

channels' data simultaneously

Measures AC current on two

channels.

• Data can be imported while recording.

• Records up to 60,000 measurements

• Data is preserved independently

of battery state.

• Recording continues (for approx.

30 s) during battery replacement

Advanced functions included

• Record statistical values (p .3 9), (p.46)

• Scaling (p.47), (p.73)

• Alarm display (p.48)

Measurement Sites

Analysis Site

Energy saving measurements in

houses, offices, factories, warehouses, etc.

Suitable for ESCO environmental

measurements.

1.1 Product Overview and Features

Overview Chapter 1

1.1 Product Overview and Features

This instrument is a compact portable data logger for measuring, displaying, and

recording AC current.

1

Chapter 1 Overview

3

14

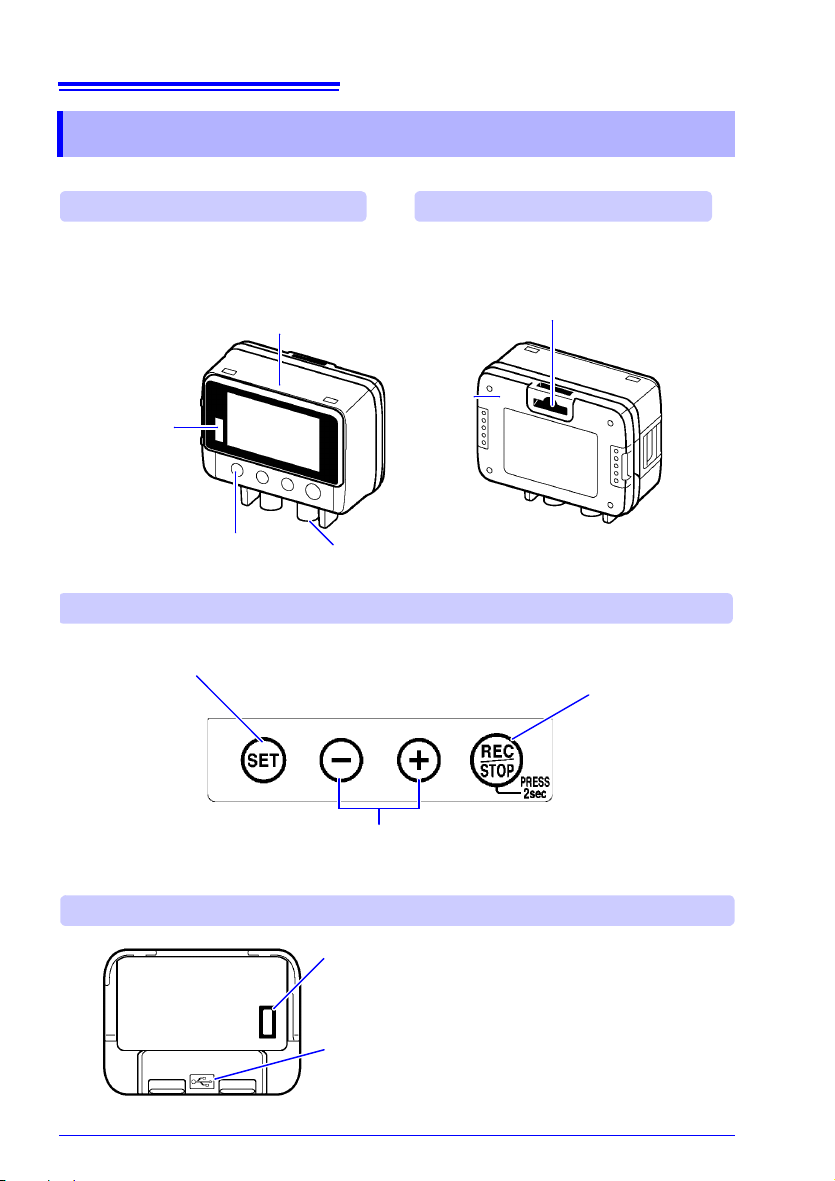

IR Port (p.55)

Communicates

with the LR5091

Communication

Adapter or

LR5092-20 Data

Collector.

Front

LCD (p.15)

The display blanks after 30 seconds of operator inactivity (auto power save). The display

reappears by pressing a button.

When the display is visible, it refreshes about

once per second.

Battery

Cover

(p.19)

SET button

Displays settings.

Back

Operating Buttons

Sensor Jacks (p.22)

Connect a clamp sensor.

Operating

Buttons

LR5091 Communication Adapter

IR Port (p.55)

Communicates with the logger.

USB Port (p.43)

Connect a USB cable here to communicate with a

computer. (Mini-B receptacle)

Stand/Strap Attachment Hole (p.52)

Attach the logger to a wall or other surface by

hanging it on a screw. (Supported screw head

dimensions: up to approx. 6.8 mm in diameter

and approx. 2.5 mm in thickness)

REC/STOP button

Hold for two seconds to start/stop recording.

From a setting display, switches to measurement display.

(-) button, (+) button

Changes Measurement display contents.

Changes setting values on the Settings display.

1.2 Part Names/Functions and Display Indicators

1.2 Part Names/Functions and Display Indicators

15

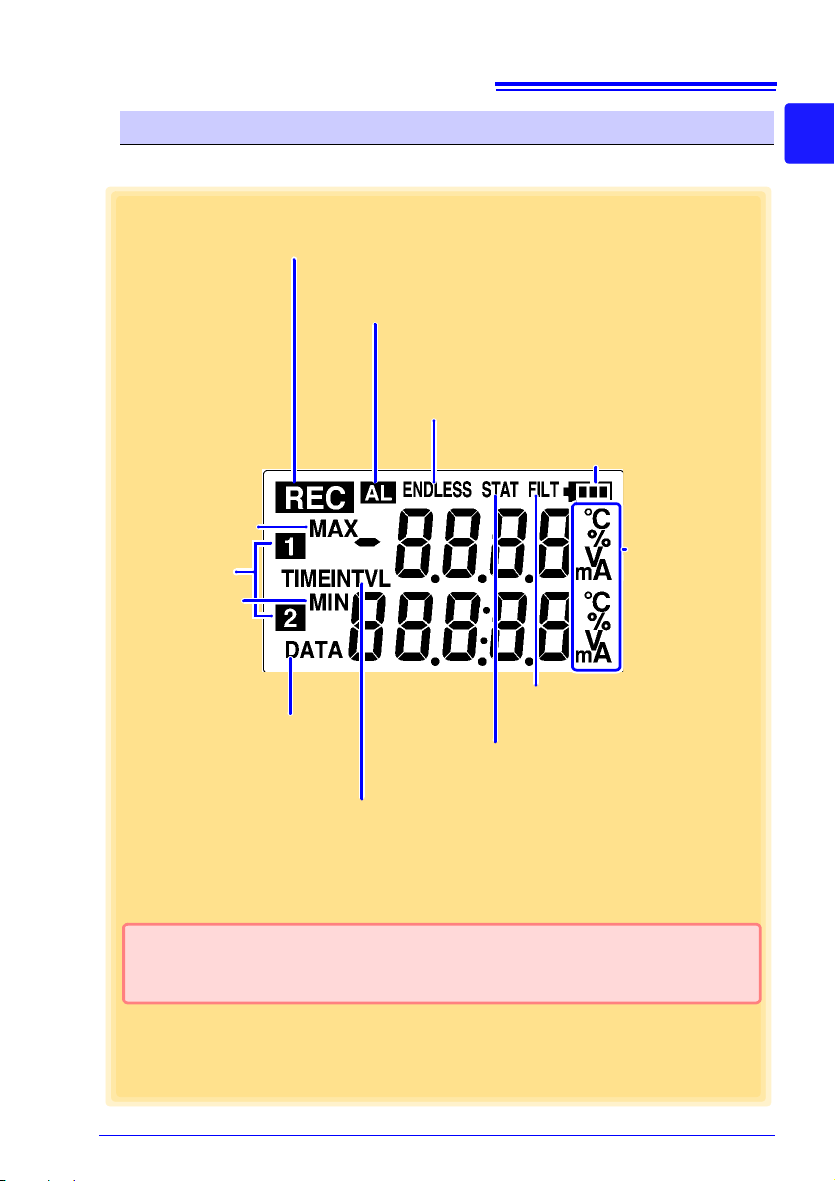

REC Indicator

Indicates recording in progress. (Blinks when waiting to record.)

ENDLESS indicator

Indicates the Stop Method Setting display.

Also appears on the Measurement display to indicate

endless recording (p. 29) is enabled.

STAT indicator

Indicates the Recording Mode Setting display.

Also appears on the Measurement display to

indicate statistic recording (p. 29) is enabled.

Battery Status Indicator

Indicates the battery charge status. (p.20)

Units

Indicates the unit of

measurement on

each channel.

Measurement

Channel

MAX indicator

Indicates that the

value displayed at

the right is the maximum.

MIN indicator

Indicates that the

value displayed at

the right is the minimum.

DATA indicator

Indicates that the value displayed

at the right is the data count.

Setting is available from the LR5000 Utility Program or via the LR5092-20 Data Collector.

See: "3.3 Making Settings from the LR5000 Utility Program" (p.43), LR5092-20 Data Col-

lector Instruction Manual

TIME indicator

Indicates the Date-Time Setting display.

INTVL indicator

Indicates the Recording Interval Setting

display.

AL indicator

When the alarm* function is enabled, this indicates when a measured value is outside of the specified (upper/lower value*) range.

FILT ind icat or

Indicates filter setting display.

1.2 Part Names/Functions and Display Indicators

Display Indicators

The display indicators provide the following information.

1

Chapter 1 Overview

3

16

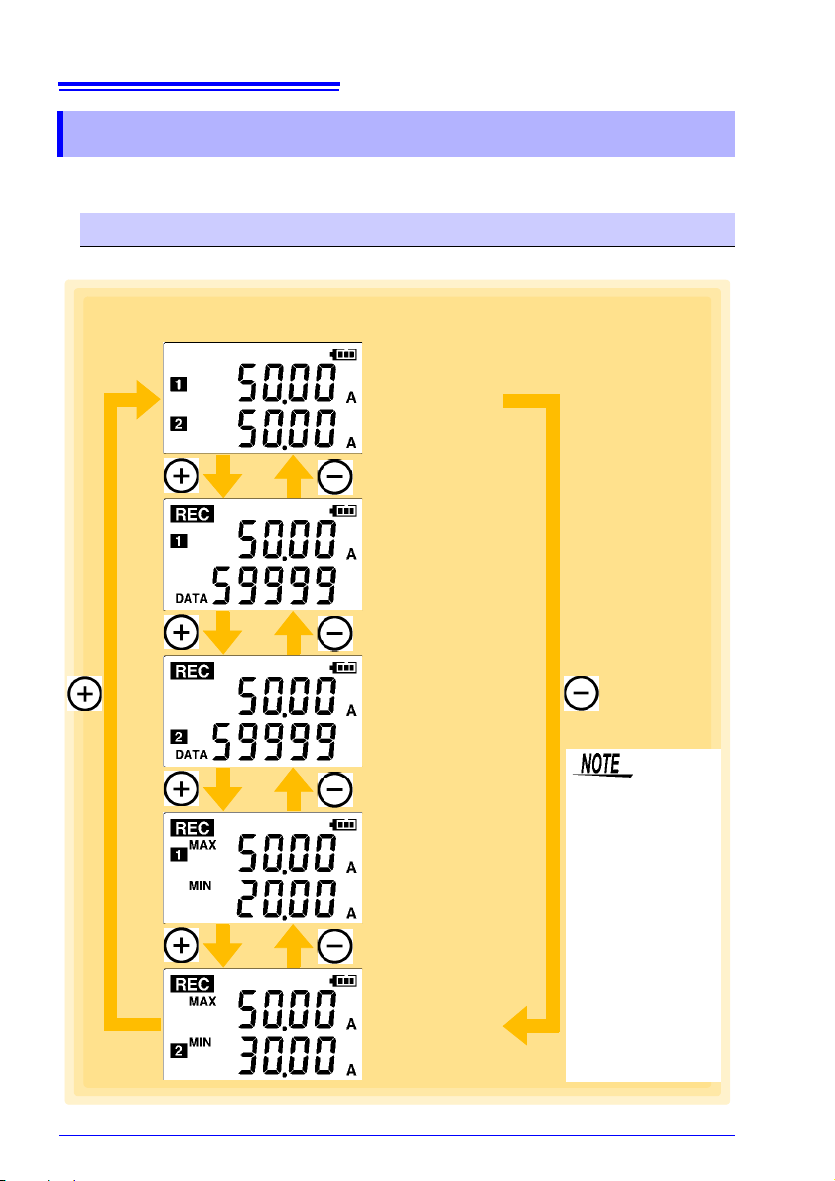

Channel 1

measured value

Channel 2

measured value

Channel 1

maximum value

Channel 1

minimum value

Channel 2

maximum value

Channel 2

minimum value

Example: Two-channel measurement in

the 50 A range

Channel 1

measured value

Recorded data count

Channel 2

measured value

Recorded data count

• For instantaneous

recording, the maximum and minimum

values are obtained

from all the data

measured at each

recording interval.

• For statistical r ecor ding, the maximum

and minimum values are obtained

from all the data

measured every second.

• The maximum and

minimum values are

not displayed when

the recorded data

count is 0.

1.3 Display Organization

1.3 Display Organization

The logger has two general display types: Measurement and Settings.

Measuring display

The (+) and (-) buttons switch the display type.

17

Recording Interval Setting

(p.37)

Year Setting (p.38)

Month Setting (p.38)

Day Setting (p.38)

Stop Method Setting

*1

(p.39)

Minute Setting (p.38)

Hour Setting (p.38)

Measuring display

See: Footnotes *1 to *3 are on the next page.

Filter Setting (p.42)

Power Save Setting

*3

(p.40)

Recording Mode Setting

*

2

(p.40)

Channel 1 Range Setting

(p.41)

Channel 2 Range Setting

(p.41)

Example: Two-channel measurement with the

CT6500 in the 50 A range

1.3 Display Organization

Setting Display

Select the display with the SET button. Press (+) and (-) to change a setting.

Press the REC/STOP button to switch to the Measurement display from any other.

1

Chapter 1 Overview

3

18

1.3 Display Organization

1: Select what happens when memory becomes full. When on, the oldest data is

overwritten, and when off, recording stops. (Default is on.)

2: When on (statistical recording), instantaneous, maximum, minimum, and average

values are recorded at each interval. Battery life is shorter. (Default is off.) (R ecord

instantaneous values)

3: Battery life is extended when on (enabled). (Default is on.)

See:"Appendix 3 Battery Life Approximation" (p.A2)

• When no operation occurs for 30 seconds with the Settings display,

automatically switches to Measurement display.

• When the battery indicator appears, settings cannot be changed

(although they can still be displayed).

• Settings cannot be changed while recording. However, settings can

still be displayed by pressing the SET button from the Measurement

display.

19

1. All segments

2. Model name 3. Firmware version

4. Year Setting display

2.1 Installing (or Replacing) the Battery

Measurement

Preparations Chapter 2

2

2.1 Installing (or Replacing) the Battery

•

After replacing the battery, replace the cover before using the logger .

• Battery may explode if mistreated. Do not short-circuit, recharge,

disassemble or dispose of in fire.

•

Handle and dispose of batteries in accordance with local regulations.

Do not mix old and new batteries, or different types of batteries. Also,

be careful to observe battery polarity during installation. Otherwise,

poor performance or damage from battery leakage could result.

• Data and settings stored in the logger are retained even when the battery is depleted, and during battery replacement.

• Once the battery indicator appears, operation can still continue for

about 30 seconds when the battery is removed during recording.

• Testing monitor batteries installed in the unit may possibly be weak.

Rep

lace batteries before extended measurement usage.

• Use only LR6 Alkaline batteries. Using manganese batteries may not

result in accurate measurements or proper communication with the

LR5091 Communication Adapter and LR5092-20 Data Collector.

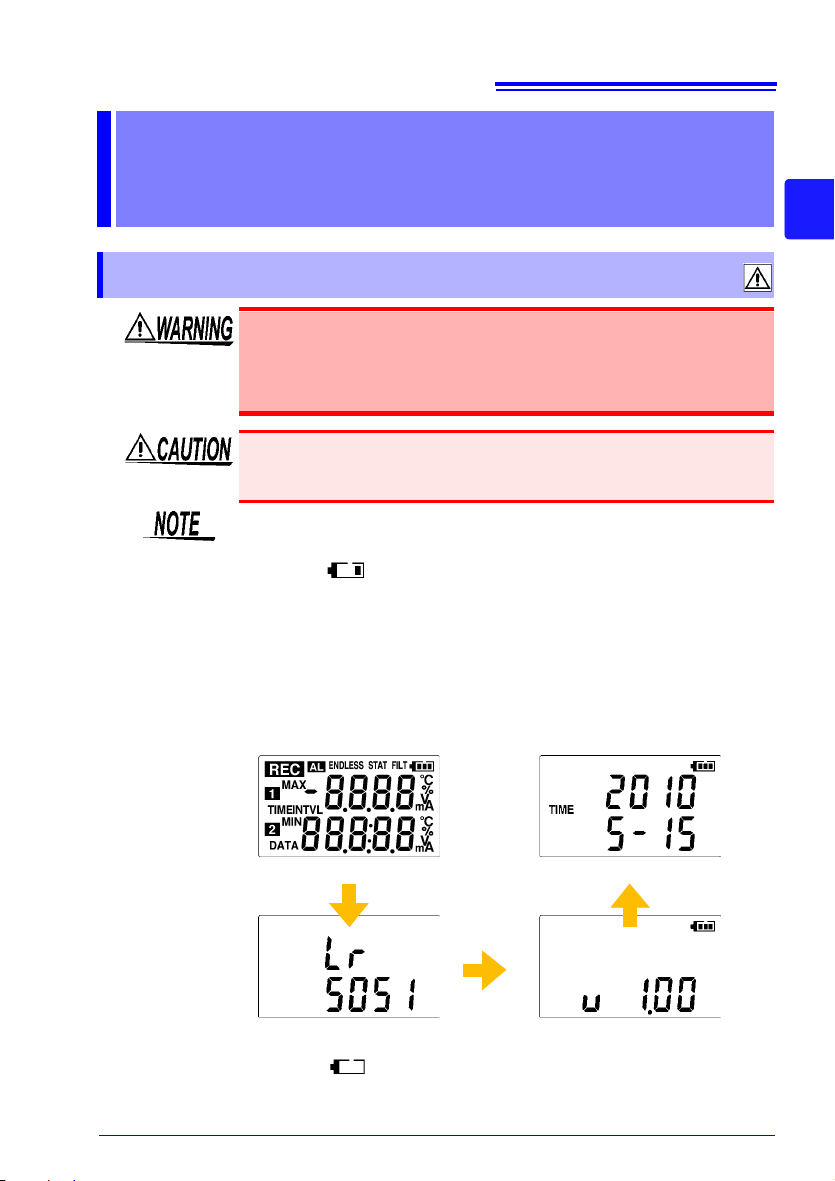

• After installing the batteries, the following displays appear, and the

d

ate and time need to be set.

(p.38)

Chapter 2 Measurement Preparations

3

• When the battery indicator appears, settings cannot be changed

(although they can still be displayed).

20

2.1 Installing (or Replacing) the Battery

• When battery voltage is too low to operate the logger, the following

appears. Replace the battery to restore normal operation.

Battery Status Indicator

This indicator is displayed at the top right corner.

Battery charge remains. Fewer blocks within the indicator signify weaker battery charge.

Replace the discharged battery as soon as possible. (Even when the battery is removed

during recording, operation can continue for about 30 seconds.)

The battery is exhausted. In this state, recording and communication with the LR5091

Communication Adapterr and LR5092-20 Data Collector are not possible.

Using a NiMH Battery

The battery status indicator does not accurately show the remaining battery capacity

wh

en using a NiMH battery. Moreover, the battery life will vary greatly with the capacity, charging conditions and repeated uses. Please take note of these points when

using it.

The device's battery status display and battery life are based on the usage of a brandnew alkaline battery.

When the logger will not be used for long time

To avoid corrosion and damage to this instrument from battery leakage,

remove the batteries from the instrument if it is to be stored for a long

time (1 week).

1

3

The cover will not close correctly if

there are any gaps.

Never attempt to force the battery

cover closed when not aligned

properly. Doing so could cause

damage.

NG

Battery

4

Projections

Holes

OK

Push the tab

Battery cover

2

5

1

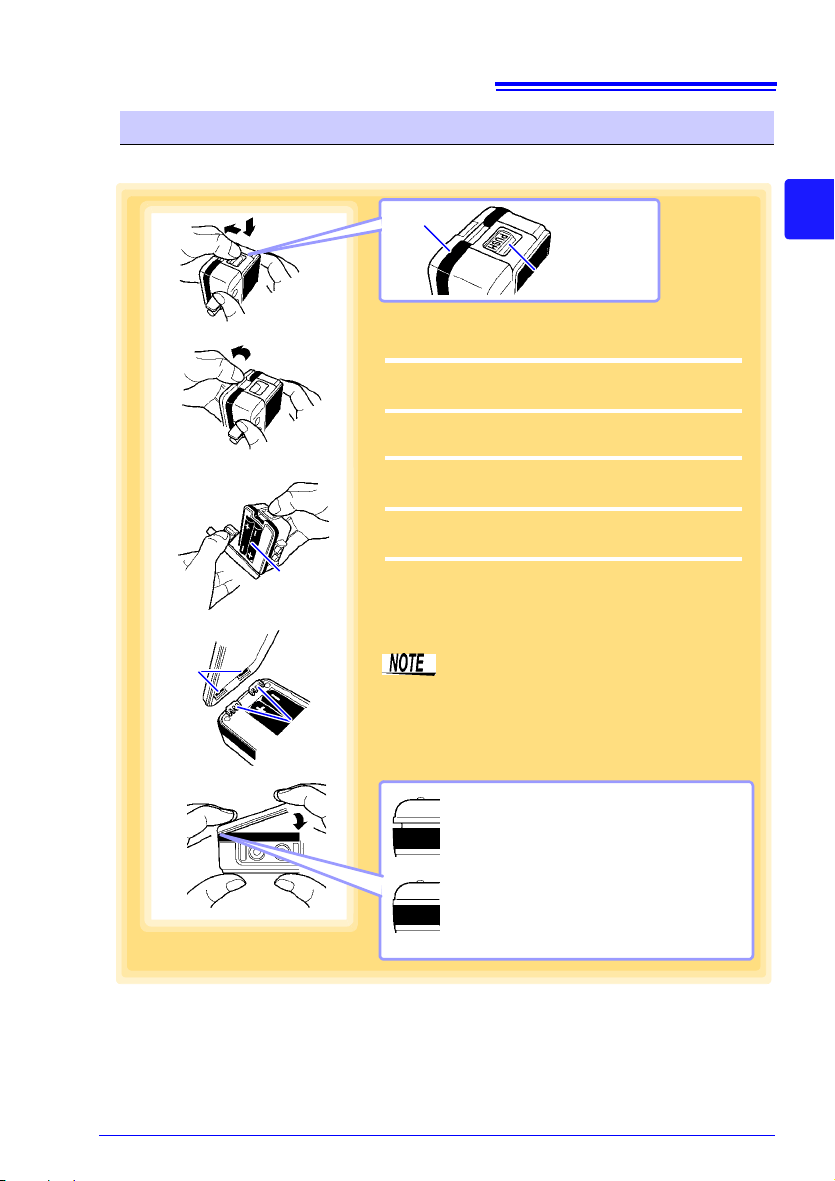

Press the PUSH tab as shown, and pull the

battery cover back.

2

Hold the battery cover while separating it from

the logger

3

Install the battery as shown.

4

Align the holes in the battery cover with the

projections on the back of the logger.

5

While confirming that there are no gaps, press

with your fingers to close the battery cover.

When the battery is installed, the logger turns

on.

(there is no power switch)

Note that the battery cover is designed

to seal tightly to preserve dust- and dripresistance.

When the holes in the battery cover are

properly aligned with the projections,

the battery cover should close smoothly.

Battery Replacement

Required Items: LR6 alkaline battery (1)

21

2.1 Installing (or Replacing) the Battery

2

Chapter 2 Measurement Preparations

3

22

Clamp Sensor Maximum input current

9695-02 Clamp On Sensor 60 A

CT6500 Clamp On Sensor 600 A

9669 Clamp On Sensor 1000 A

9675 Clamp On Leak Sensor 10 A

9657-10 Clamp On Leak Sensor

10 A

2.2 Connecting a Clam p Sensor

2.2 Connecting a Clamp Sensor

Connect a clamp sensor to the logger's sensor jacks.

• Connect the clamp sensors to the instrument first, and then to

the active lines to be measured.

Observe the following to avoid electric shock

• When the clamp sensor is opened, do not allow the metal part of

the cl

amp to touch any exposed metal, or to short between two

lines, and do not use over bare conductors.

• Use the appropriate cla

the maximum voltage shown:

9695-02 Clamp On Sensor: CAT

CT6500 Clamp On Sensor: CAT

9669 Clamp On Sensor: CAT

9675 Clamp On Leak Sensor: CAT

9657-10 Clamp On Leak Sensor: CAT

Or over bare conductors.

• Clamp sensor should only be connect

a breaker, so the breaker can prevent an accident if a short circuit occurs. Connections should never be made t

side of a breaker, because unrestricted current flow could cause

a serious accident if a short circuit occurs.

• During use, do not touch the end of the sensor beyond the protective barrier.

• Maximum clamp sensor input current is as follows: (At 45 to 66 Hz)

mp sensor for electrical circuits with

III AC300 V

III AC600 V

III AC600 V

and short circuits.

III AC300 V

III AC300 V

ed to the secondary side of

o the primary

Never exceed this limit, as doing so could result in destruction of

the instrument and personal injury or death.

• To avoid electric shock when measuring live lines, wear appropriate protective gear, such as in

and a safety helmet.

• To avoid electric shock when measuring using the

wire for transformer class B grounding work, ensure that the

grounding wire is not near high-voltage devices and wires. In a

location in which measurement is difficult because the grounding wire is near high-voltage live p

grounding wire and then perform measurement. (when using the

9657-10, 9675 Clamp On Leak Sensor)

sulated rubber gloves, boots

grounding

arts, change the routing of the

23

2.2 Connecting a Clamp Sensor

• When disconnecting the BNC connector, be sure to release the lock

before pulling off the connector. Forcibly pulling the connector without

releasing the lock, or pulling on the cable, can damage the connector.

• Do not connect or disconnect when the logger is on, or when clamped

a

round a conductor. Otherwise, the logger or clamp sensor could be

damaged.

• To avoid breaking the cables, do not bend or pull them.

• Avoid stepping on or pinching cables, which could damage the cable

lation.

insu

• To avoid damage to the instrument, protect it from physical shock

when transporting and handling. Be especially careful to avoid physical shock from dropping.

• Be careful to avoid dropping the clamp sensor or otherwise subjecting

th

em to mechanical shock, which could damage the mating surfaces

of the core and adversely affect measurement.

• Keep the clamp jaws and core slits free from foreign objects, which

co

uld interfere with clamping action.

• Keep the clamp closed when not in use, to avoid accumulating dust or

dirt on the mating core surfaces, which could interfere with clamp performance.

• Do not over-tighten the output terminal screws on the 9695-02 Clamp

On

Sensor Proper torque is about 0.5 Nm.

• To replace the output terminal screws of the 9695-02 Clamp On Sensor, use M3x5 screws with captive spring washers. Using other

scr

ews may damage the clamp sensor.

• To avoid damage to t he instrument, do not short- circuit the sensor jack

and do not input voltage to the sensor jack.

• Note that the instrument may be damaged if the applied current

exceeds the measurement range.

• When the power is turned off, do not apply current to the sensor jack.

Doing so may damage the instrument and clamp sensor.

• Note that the instrument and clamp sensor may be damaged if current

exceeding the selected measurement range is applied for a long time

• Measurements are degraded by dirt on the mating surfaces of the

clamp-on sensor, so keep the surfaces clean by gently wiping with a

soft cloth.

2

Chapter 2 Measurement Preparations

3

• When connecting the cable to the output terminals of the 9695-02

Clamp On Sensor, keep the twist as close to the terminals as possible, to minimize the effects of external magnetic fields.

• Use only the special-purpose 9219 Connection Cable to connect the

9695-02 Clamp On Sensor to the logger. (The connectors on the 9219

re solderless terminals and a BNC plug.)

a

24

1

Align the slots in the BNC plug on the sensor

cable with the pins in the jack on the logger.

2

Push and turn clockwise to lock.

To disconnect, push and turn the plug counterclockwise, then pull out.

Values are not displayed correctly if the sensor

plug is not inserted far enough.(See the 50 A range

example below.)

If values are not displayed correctly even when the

plug is inserted properly, the logger or sensor may

be damaged. Repair may be necessary.

See: "Requesting repairs" (p.97)

Lock

Pins in the

jack

Slots in the

BNC plug

1

2

2.2 Connecting a Clam p Sensor

Connecting to the Logger

Required Items: Hioki Clamp sensors (See: "Options" (p.4))

Compatible Clamp Sensors

9695-02 Clamp On Sensor,CT6500 Clamp On Sensor,

9669 Clamp On Sensor,9675 Clamp On Leak Sensor,

9657-10 Clamp On Leak Sensor

Note: The 9219 Connection Cable is required to connect the 9695-02 Clamp On Sensor.

Loading...

Loading...