Hioki IR3455 Instruction Manual

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

IR3455

Instruction Manual

HIGH VOLTAGE

INSULATION TESTER

Oct. 2016 Edition 1

IR3455A961-00 16-10H

EN

Contents

Introduction ......................................................1

Verifying Package Contents / Open the case ..1

Safety Information ...........................................5

Operating Precautions ..................................... 9

1 Overview 19

1.1 Product Overview ................................. 19

1.2 Features ...............................................21

1.3 Measurement Overview ....................... 23

1.4 Names and Functions of Parts ............. 29

1.5 Screen Setup ....................................... 33

2 Measurement Preparations 35

2.1 Supplying Power .................................. 35

2.1.1 Installing or Replacing the Battery...... 36

2.1.2 Installing the Battery Pack (Rechargeable

nickel-hydrogen battery) ..................... 39

2.1.3 Connecting the AC Adapter................ 45

2.1.4 Charging the Battery Pack ................. 47

2.2 Turning Power On and Off ................... 50

2.2.1 Auto Power Off ................................... 51

2.3 Setting and Checking Date and Time .. 52

2.3.1 Setting Date and Time........................ 52

2.3.2 Checking Date and Time.................... 55

2.4 Connecting Test Lead ..........................56

2.5 Connecting Temperature Sensor .........58

i

IR3455A961-00

ii

3 Measurement 59

3.1 Pre-Operation Inspection ..................... 59

3.2 Measuring Insulation Resistance ......... 62

3.2.1 Starting Measurement......................... 64

3.2.2 Ending Measurement.......................... 70

3.2.3 Checking and Deleting Held Data....... 72

3.2.4 Automatic Discharge Function ............ 73

3.2.5 Switching to Leakage Current Indication

.............................................................74

3.2.6 Insulation Resistance Measurement

Basis 75

3.2.7 Use of GUARD Terminal..................... 77

3.3 Measuring Voltage ............................... 79

3.4 Measuring Temperature ....................... 82

3.4.1 Measurement Procedure .................... 82

4 Advanced Measurement 85

4.1 Using Timer .......................................... 85

4.1.1 Setting Timer/Conducting Insulation

Resistance Measurement ...................85

4.2 Displaying PI and DAR .........................89

4.3 Temperature Compensation (TC) ........ 93

4.3.1 Performing Temperature Compensation

.............................................................93

4.3.2 Exiting Temperature Compensation

Mode ...................................................96

4.4 Step Voltage Test .................................97

4.4.1 Setting and Conducting a Step Voltage

Test .....................................................98

4.4.2 Viewing Detailed Data of Each Step after

Step Voltage Test .............................101

4.4.3 Exiting Step Voltage Test Mode........ 103

iii

5 Recording Measurement Data

(Memory Function) 105

5.1 Recording Measurement Data ........... 107

5.1.1 Manual Recording (Recording result of

one measurement session) 107

5.1.2 Logging Recording (Recording at regular

intervals) ........................................... 110

5.2 Checking Recorded Data ...................118

5.3 Deleting Recorded Data ..................... 123

5.3.1 Deleting Data of Chosen No............. 123

5.3.2 Deleting all Data ............................... 124

6 Other Functions 125

6.1 Changing and Checking Interval Setting

for PI Calculation ................................ 125

6.1.1 Changing Interval Setting ................. 125

6.1.2 Checking Interval Setting ................. 127

6.2 Changing and Checking Voltage

Application Time for Step Voltage Test

............................................................128

6.2.1 Changing Time Setting..................... 128

6.2.2 Checking Time Setting ..................... 130

6.3 Entering Temperature and Humidity

Measured with External Thermometer and

Hygrometer ........................................131

6.3.1 Entering and Saving ......................... 132

6.3.2 Clearing Indications of Temperature and

Humidity Stored Data ....................... 135

6.4 Communicating with PC ..................... 136

6.4.1 Installing Data Analysis Software

for 3455 ............................................. 137

6.4.2 Installing Driver................................. 138

6.4.3 Downloading Data to Save to PC/ Setting

up Instrument on PC 139

iv

7 Specifications 141

7.1 General Specifications ....................... 141

7.2 Measurement Specifications ..............146

7.2.1 Insulation Resistance Measurement. 146

7.2.2 Leakage Current Measurement ........ 149

7.2.3 Voltage Measurement....................... 150

7.2.4 Temperature Measurement .............. 151

7.3 9750-01/-02/-03/-11/-12/-13 and

9751-01/-02/-03 ALLIGATOR CLIPs

Specifications .....................................152

8 Maintenance and Service 153

8.1 Troubleshooting .................................154

8.2 Cleaning .............................................156

8.3 Error Display ......................................156

8.4 Performing System Reset .................. 158

8.5 Discarding the Instrument .................. 159

Appendix 163

Appendix 1 Test Voltage

Characteristic Graph .................163

Appendix 2 Example of Insulation Resistance

Criteria ......................................164

Appendix 3 Example of PI Criteria

(Polarization Index) ...................164

Appendix 4 Temperature Compensation Table

..................................................165

Introduction

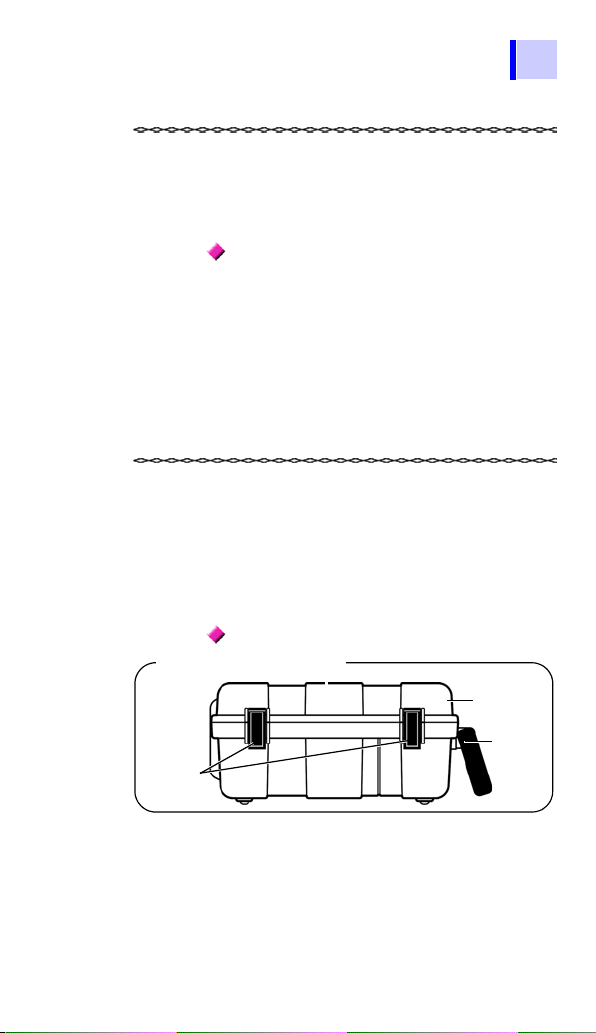

Appearance of Case

Cover

Latches

Handle

Introduction

1

Thank you for purchasing the Hioki IR3455

High Voltage Insulation Tester. To obtain

maximum performance from the instrument, please read this manual first, and

keep it handy for future reference.

Registered trade mark

• Microsoft and Windows are either registered trademarks or trademarks of

Microsoft Corporation in the United States

and other countries.

• Adobe and Adobe Reader are trademarks

of Adobe Systems Incorporated.

Verifying Package Contents / Open the case

When you receive the instrument, inspect it

carefully to ensure that no damage

occurred during shipping. In particular,

check the accessories, panel switches, and

connectors. If damage is evident, or if it fails

to operate according to the specifications,

contact your authorized Hioki distributor or

reseller.

Open the case

Open the case by releasing the two latches.

(See next page.)

2

Verifying Package Contents / Open the case

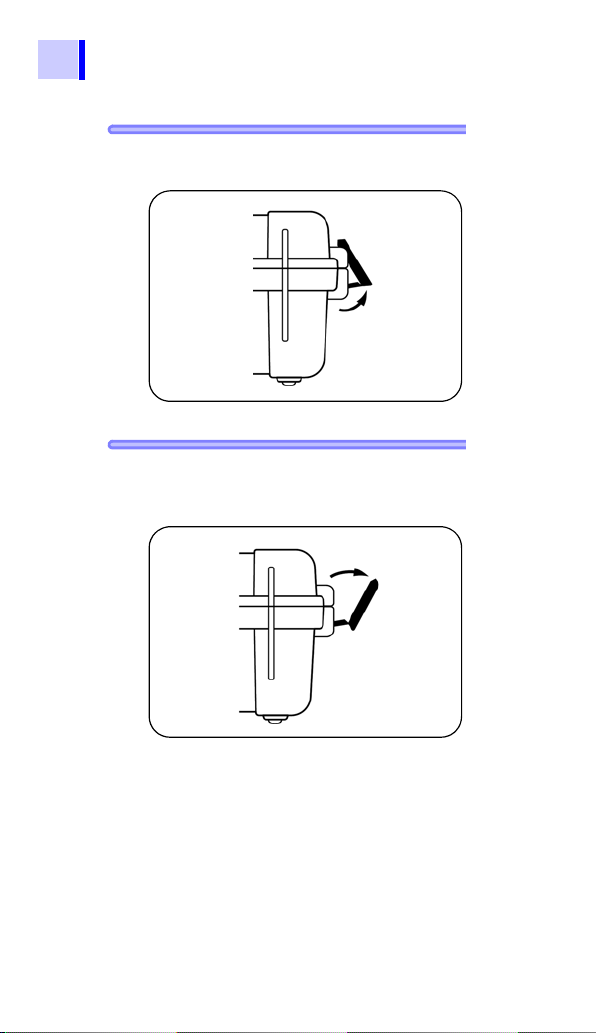

Procedure

1. Draw the latch outwards with your fin-

ger.

2. While raising the entire latch, place a

finger on the top of the latch and pull

it out.

Verifying Package Contents / Open the case

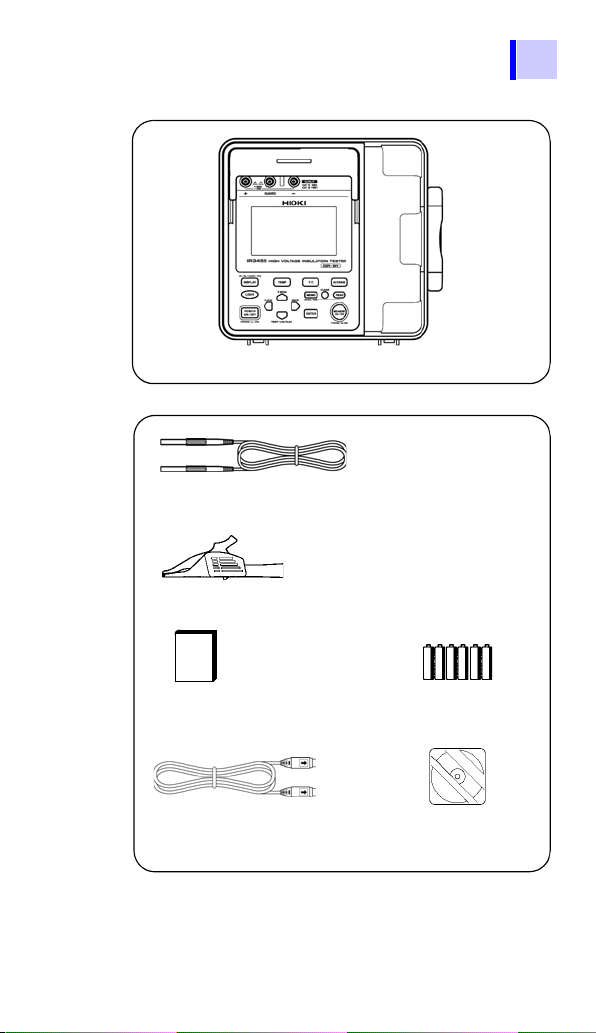

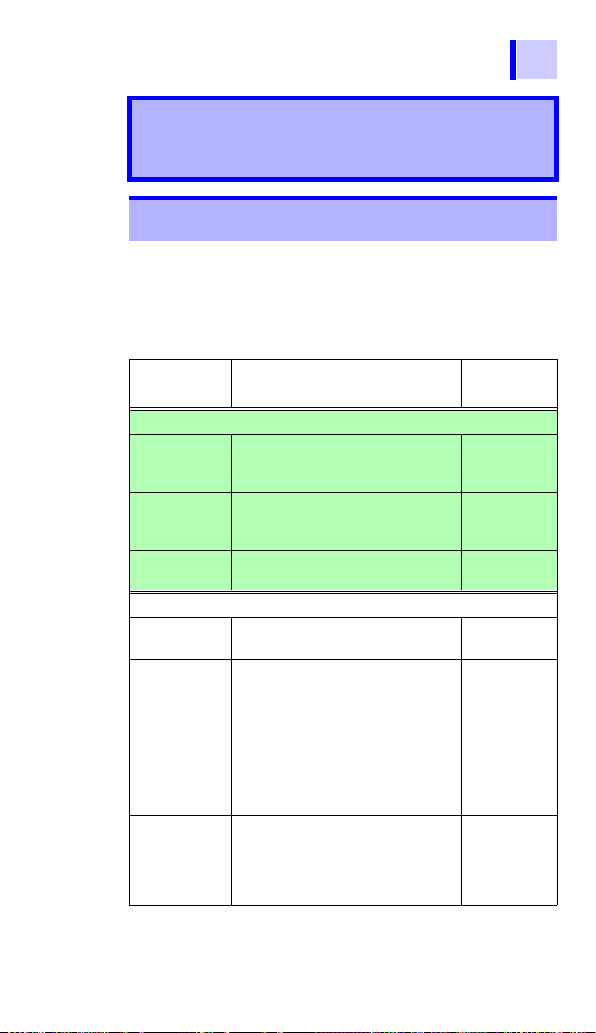

IR3455 HIGH VOLTAGE INSULATION TESTER × 1

9750-01,-02,-03 TEST LEAD (Red, Black, Blue)

Lead length Approx. 3 m

×

1 each

LR6 alkaline battery × 6Instruction Manual

(This book)

×

1

USB Cable

×

1

9751-01,-02,-03 ALLIGATOR CLIP (Red, Black, Blue)

×

1 each

CD (Data Analysis

Software for 3455)*

×

1

Main Unit

Accessories

3

*The latest version can be downloaded

from our web site.

4

Verifying Package Contents / Open the case

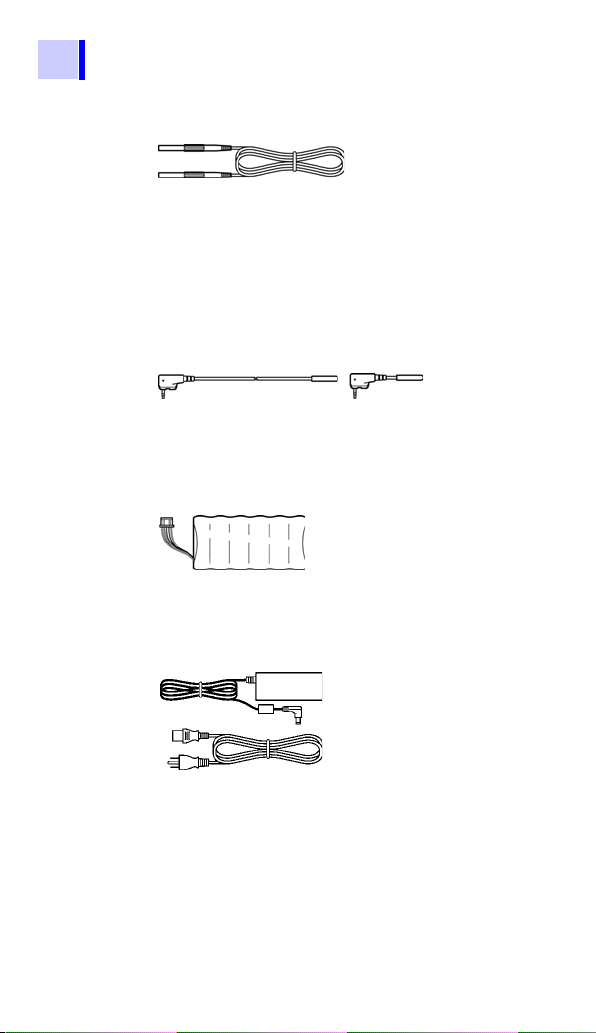

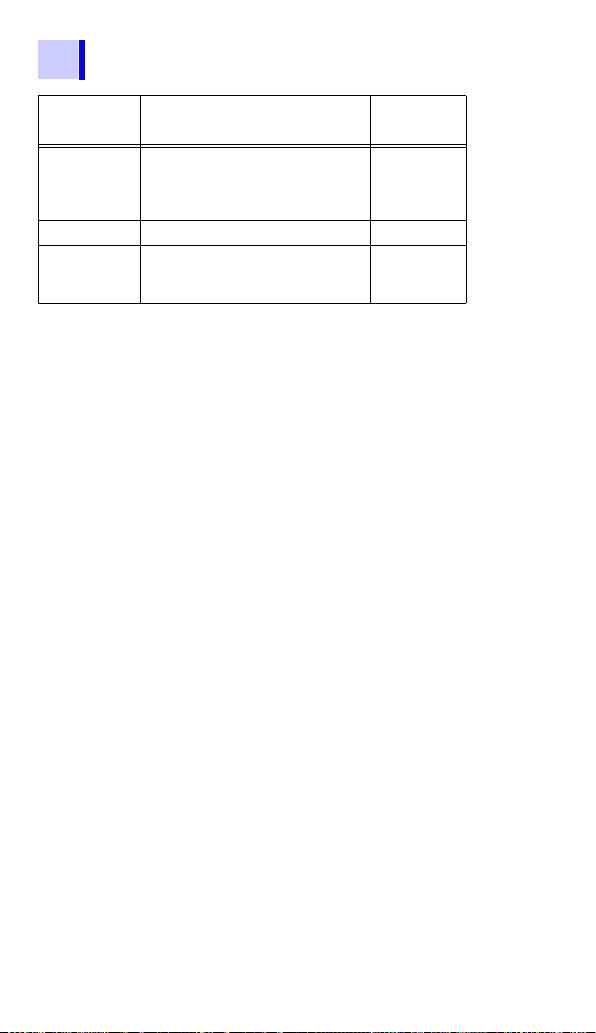

Options

9750-11,-12,-13 TEST LEAD

(Red, Black, Blue Lead length Approx. 10 m)

The specifications for the 9750-11 and

9750-12 models differ from the standard

specifications in regards to temperature

characteristics.

See 7.2"Measurement Specifications" (page

146).

9631-01,-05 TEMPERATURE SENSOR

Used for temperature measurement.

9631-01: Lead length Approx. 1 m

9631-05: Lead length Approx. 5 cm

9459 BATTERY PACK

(Rechargeable nickel-hydrogen battery)

The 9753 AC ADAPTER is required for

charging.

9753 AC ADAPTER

Input: 100 to 240 VAC

Output: 12 V DC, 3.33 A

Safety Information

Safety Information

This instrument is designed to conform to IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior

to shipment. However, using the instrument in a way not

described in this manual may negate the provided safety

features.

Before using the instrument, be certain to carefully read the

following safety notes:

Mishandling during use could result in

injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in

the manual before use.

• Protective gear

This instrument measures live lines. To

prevent electric shock, use appropriate

protective insulation and adhere to

applicable laws and regulations.

• With regard to the electricity supply,

there are risks of electric shock, heat

generation, fire, and arc flash due to

short circuits. Individuals using an electrical measuring instrument for the first

time should be supervised by a technician who has experience in electrical

measurement.

5

6

Safety Information

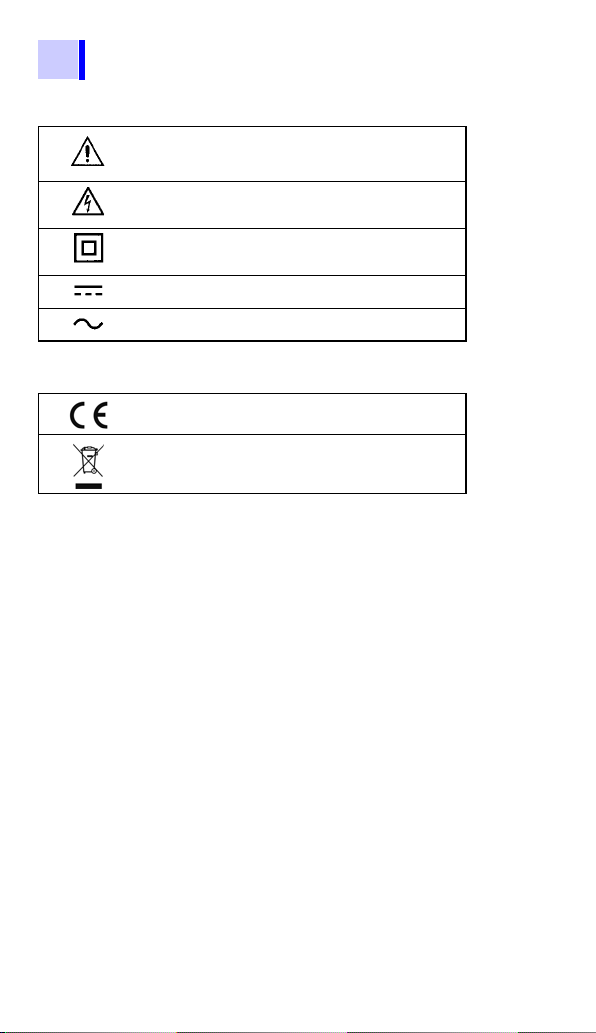

Symbols on the instrument

Indicates cautions and hazards. When the symbol is

printed on the instrument, refer to a corresponding

topic in the Instruction Manual.

Indicates that dangerous voltage may be present at

this terminal.

Indicates a double-insulated device.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Symbols for standards

Indicates that the product conforms to regulations

set out by the EC Directive.

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in EU member

states.

Safety Information

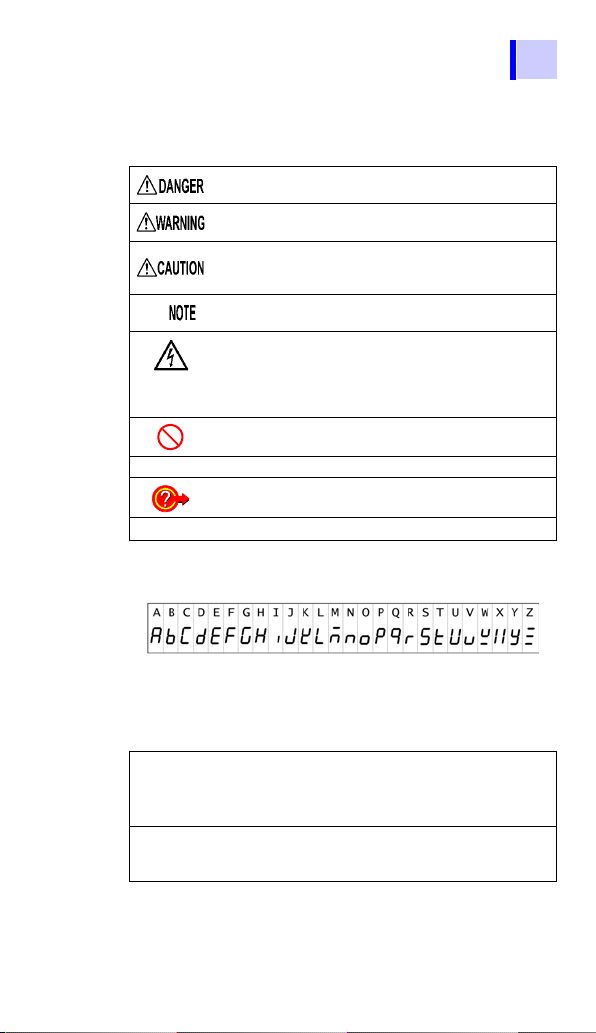

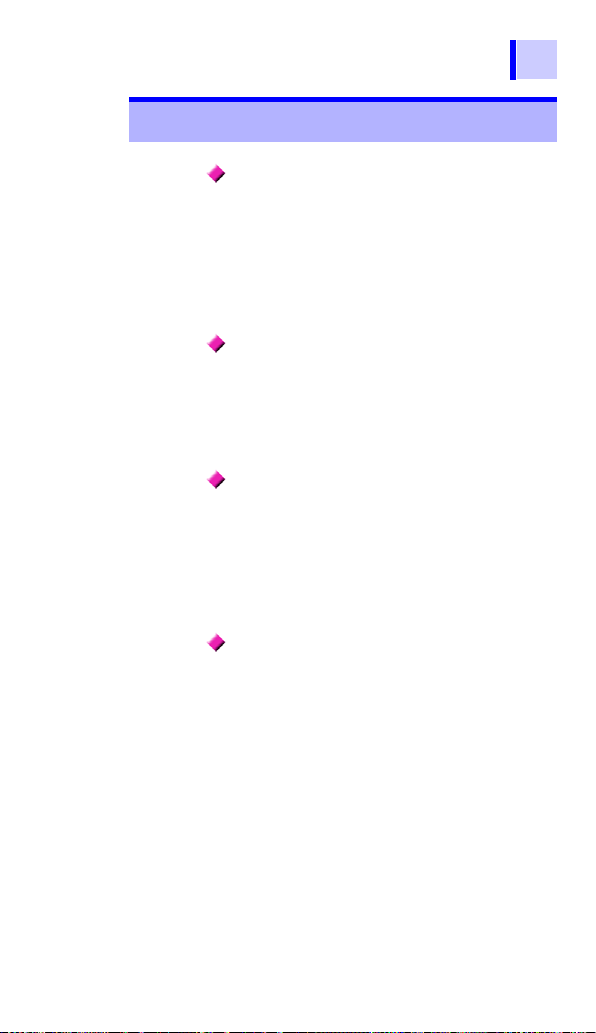

Notation

In this document, the risk seriousness and the hazard levels

are classified as follows.

Indicates an imminently hazardous situation that will

result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may result in minor or moderate injury to the operator or damage to the instrument or malfunction.

Indicates advisory items related to performance or correct operation of the instrument.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled, this may give rise to a hazardous situation; the operator may receive an electric

shock, may get burnt or may even be fatally injured.

Indicates prohibited actions.

Indicates the location of reference information.

Indicates quick references for operation and remedies

for troubleshooting.

Additional information is presented below.

*

The instrument screen displays the alphanumeric characters as follows.

7

Accuracy

We define measurement tolerances in terms of rdg. (reading) and dgt. (digit) values, with the following meanings:

dgt.

(resolution)

rdg.

(reading or

displayed value)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that

causes the digital display to show a "1" as the

least-significant digit.

The value currently being measured and indicated on the measuring instrument.

8

Safety Information

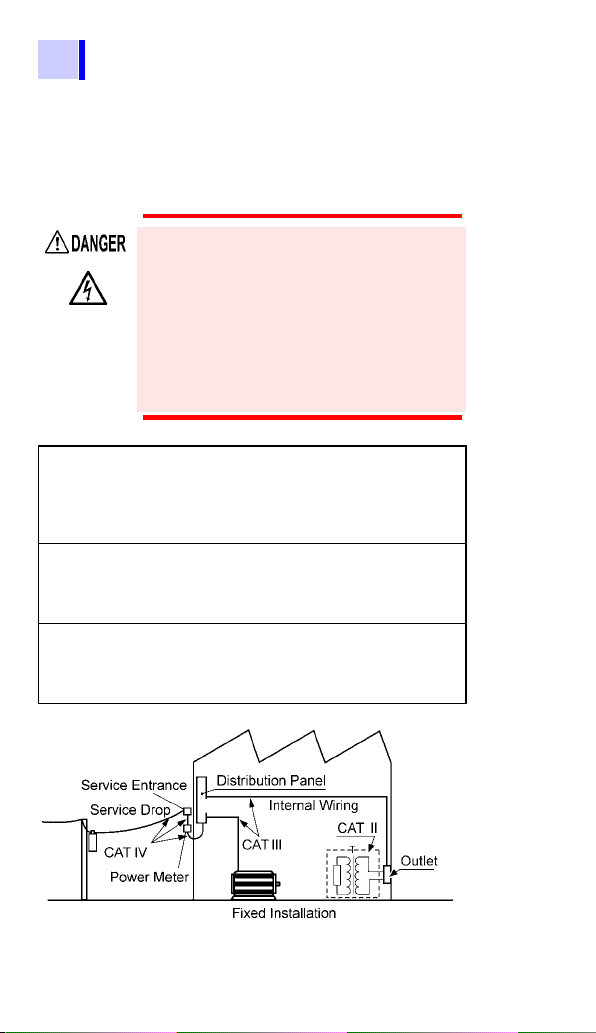

Measurement categories

To ensure safe operation of measuring instruments, IEC

61010 establishes safety standards for various electrical

environments, categorized as CAT II to CAT IV, and called

measurement categories.

• Using a measuring instrument in an

environment designated with a highernumbered category than that for which

the instrument is rated could result in a

severe accident, and must be carefully

avoided.

• Never use a measuring instrument that

lacks category labeling in a CAT II to

CAT IV measurement environment.

Doing so could result in a serious accident.

CAT II Primary electrical circuits in equipment con-

CAT III Primary electrical circuits of heavy equip-

CAT IV The circuit from the service drop to the ser-

nected to an AC electrical outlet by a power

cord (portable tools, household appliances,

etc.) CAT II covers directly measuring electrical outlet receptacles.

ment (fixed installations) connected directly

to the distribution panel, and feeders from

the distribution panel to outlets.

vice entrance, and to the power meter and

primary overcurrent protection device (distribution panel).

Operating Precautions

Preliminary Checks

Precautions during shipment

Operating Precautions

Follow these precautions to ensure safe operation and to

obtain the full benefits of the various functions.

Before using the instrument, verify that it

operates normally to ensure that no damage occurred during storage or shipping. If

you find any damage, contact your authorized Hioki distributor or reseller.

If the test lead or the instrument is damaged, there is a risk of electric shock.

Perform the following inspection before

using the instrument:

• Before using the instrument check that

the coating of the test leads are neither

ripped nor torn and that no metal parts

are exposed. Using the instrument

under such conditions could result in

electric shock. Replace the test leads

with those specified by our company.

• Verify that the instrument operates normally to ensure that no damage

occurred during storage or shipping. If

you find any damage, contact your

authorized Hioki distributor or reseller.

• To prevent an electric shock, confirm

that the white or red portion (insulation

layer) inside the cable is not exposed. If

a color inside the cable is exposed, do

not use the cable.

9

During shipment of the instrument, handle it

carefully so that it is not damaged due to a

vibration or shock.

10

Placement

Operating Precautions

Operating temperature and humidity range: P.141

Temperature and humidity range for guaranteed accuracy:

P. 1 48 to P.150

Installing the instrument in inappropriate

locations may cause a malfunction of

instrument or may give rise to an accident. Avoid the following locations:

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible

gases

• Exposed to a strong electromagnetic

field or electrostatic charge

• Near induction heating systems (such

as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

Operating Precautions

Shutter

11

Observe the following to avoid electric

shock and short circuits.

• Before connecting or disconnecting the

test leads to/from the instrument, be

sure to disconnect the test leads from

the object under test and turn off power.

• Do not perform measurement with the

battery cover removed.

• Do not use the shutter if it is broken.

• To avoid electric

shock, do not

remove the instrument's case. The internal components of the instrument carry

high voltages and may become very hot

during operation.

• Do not use the instrument in environments containing ignitable gases,

explosive powders, etc. (Risk of explosion)

• Do not place the instrument on an

unstable table or an inclined place.

Dropping or knocking down the instrument can cause injury or damage to the

instrument.

• Do not use the instrument with circuits

that exceed its ratings or specifications.

Doing so may damage the instrument or

cause it to become hot, resulting in

bodily injury/electric shock.

• Before using the instrument, inform

those around you of your intention to

do so.

• To prevent instrument damage or

electric shock, use only the screw for

securing the battery cover in place that

are originally installed. If you have lost

a screw or find that a screw is damaged,

please contact your Hioki distributor for

a replacement.

12

Operating Precautions

• This instrument is designed for use indoors.

It can be operated at temperatures

between -10 to 50°C (14 to 122

°F

) without

degrading safety.

• To avoid damage to the instrument, protect

it from physical shock when transporting

and handling. Be especially careful to avoid

physical shock from dropping.

• If the protective functions of the instrument

are damaged, either remove it from service

or mark it clearly so that others do not use it

inadvertently.

• Touching any of the high-voltage points

inside the instrument is very dangerous.

Customers are not allowed to modify, disassemble, or repair the instrument. Doing so

may cause fire, electric shock, or injury.

• Place the cover on the instrument when not in

use.

• To avoid damage to the instrument, do not

connect an external device to the USB terminal or the temperature sensor terminal.

• The cable is hardened under the 0 degree

or colder environment. Do not bend or pull

it to avoid tearing its shield or cutting cable.

• This instrument is not drip-proof. Water

droplets on the grip or connector may result

in malfunctions.

• The protection rating for the enclosure of

this device (based on EN60529) is *IP40.

This indicates the degree of protection provided by

the enclosure of the device against use in hazardous locations, entry of solid foreign objects, and the

ingress of water.

4: Protected against access to hazardous parts with

wire measuring 1.0 mm in diameter. The equipment

inside the enclosure is protected against entry by

solid foreign objects larger than 1.0 mm in diameter.

0: The equipment inside the enclosure is not protected against the harmful effects of water.

Operating Precautions

13

• After use, always turn off the power.

• Standby State

The use of "standby state" in this manual

means that measurement is not being

performed and that no parameters are

set. This includes the state in which

is on.

• If the instrument is exposed to an abrupt

large variation in temperature,

condensation may occur, resulting in

measurement errors.

Leave the instrument in a new

environment for a while before starting

measurement.

14

Measurement

Operating Precautions

• It is recommend to make measurements

on the secondary side of distribution

panels. Measuring the primary side,

where the current capacity is much

larger, could cause damage to the

instrument or panel in the event of a

short-circuit.

• Do not short the two measurement lines

with the metal portion of the tips of the

test leads. Doing so may cause arcing

or otherwise result in a serious

accident.

• To avoid short circuit or electric shock,

do not touch the metal parts of the

connecting cable clips.

• To prevent electric shock, when measuring the voltage of a power line use

only the specified test lead.

• The optional test leads provided with

this instrument conform to the safety

standard EN61010. Use a test lead in

accordance with its defined measurement category and rated voltage.

To avoid damage to the instrument, do not

apply voltage or current to temperature

probe.

Operating Precautions

Electrical Units

CD precautions

Handling the Battery Pack

15

1 T (Tera ohm) =1000 G =1012

1 G (Giga ohm) =1000 M =10

1 M(Mega ohm) =1000 k =10

1 mA (Milliampere) =0.001 A =10

1 A (Micro ampere) =0.001 mA =10

1 nA (Nano ampere) =0.001 A=10

9

6

-3

A

-6

A

-9

A

• Exercise care to keep the recorded side

of discs free of dirt and scratches. When

writing text on a disc's label, use a pen or

marker with a soft tip.

• Keep discs inside a protective case and

do not expose to direct sunlight, high temperature, or high humidity.

• Hioki is not liable for any issues your

computer system experiences in the

course of using this disc.

Be sure to observe the following precautions. Incorrect handling may result in

liquid leaks, heat generation, ignition,

bursting and other hazards:

• The battery pack contains lye, which

may cause blindness if it comes into

contact with the eyes. Should battery

liquid get into your eyes, avoid rubbing

them. Flush them with water and seek

immediate medical attention.

• When storing the instrument, make sure

no objects that could short-circuit the

connectors are placed near them.

16

Operating Precautions

Observe the following to avoid damage to

the instrument:

• Use the battery pack in an ambient temperature range of 0 to 40°C and charge it in an

ambient temperature range of 0 to 40°C.

• If the battery pack fails to finish charging

within the stipulated time, disconnect the

AC adapter to stop charging and contact

your dealer or Hioki representative.

• Consult your dealer or nearest service station should liquid leaks, strange odor, heat,

discoloration, deformation and other abnormal conditions occur during use, charging

or storage. Should these conditions occur

during use or charging, turn off and disconnect the instrument immediately.

• Do not expose the instrument to water and

do not use it in excessively humid locations

or locations exposed to rain.

• Do not expose the instrument to strong

impacts and do not throw it around.

Heed the following instructions to avoid battery performance drop or leakage.

• Do no mix old and new batteries, or different types of batteries.

• Pay attention to the polarity markings "+-",

so that you do not insert the batteries the

wrong way around.

• Do not use batteries after their recommended expiry date.

• Do not leave a depleted batteries inside the

instrument.

• Replace batteries only with the specified

type.

• Remove the batteries or battery pack from

the instrument if it is to be stored for a long

time.

Operating Precautions

17

• The battery pack is a consumable. If you

are able to use the instrument for only a

limited period of time despite the battery

pack being properly charged, the battery

pack's service life is at an end, and it

should be replaced.

• When a battery pack that has not been

used for a long time is used, charging may

end before the battery pack is fully

charged. In such a case, repeat charging

and discharging a number of time before

use. (A battery pack may also be in such a

state immediately after purchase.)

• The life of the battery pack (when capacity

is 60% or more of initial capacity) is

approximately 500 charge-discharge

cycles. (The life differs depending on the

conditions of use.)

• To prevent battery pack deterioration

when the battery will not be used for 1

month or longer, remove it and store it in a

dry location with an ambient temperature

range of between -20°C to 30°C. Be sure

to discharge and charge it every two

months. Long-term storage at low battery

capacity will reduce performance.

• When a battery pack is used, the

instrument turns off automatically when

the capacity drops. Leaving the

instrument in this state for a long time may

lead to over discharge so be sure to turn

off the power switch on the instrument.

• The charging efficiency of the battery pack

deteriorates at high and low

temperatures.

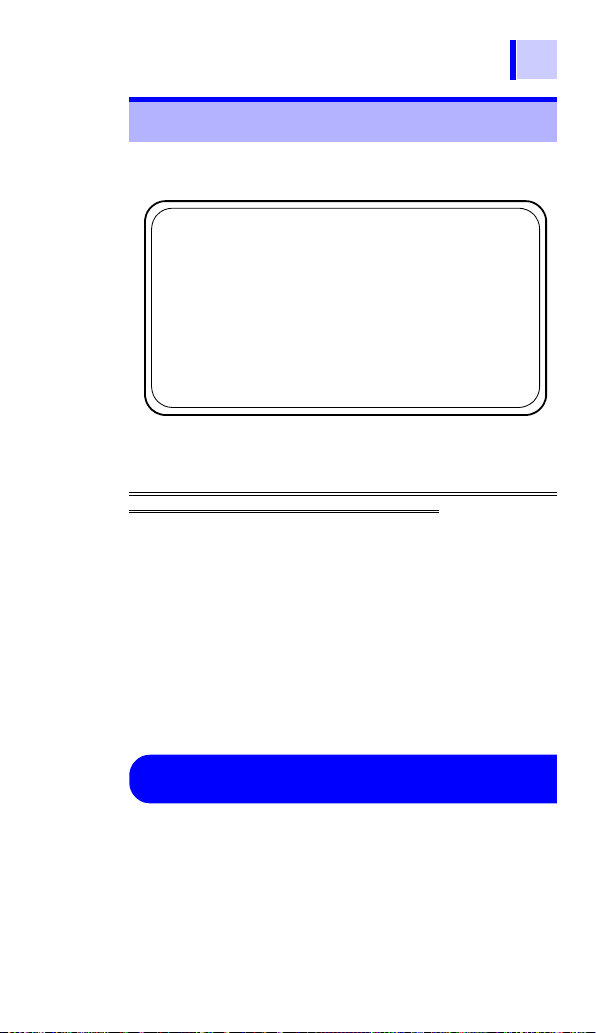

1.1 Product Overview

19

Overview

1

1.1 Product Overview

The IR3455 is an insulation resistance tester with a wide

measurement range, for use in such environments involving

low to high voltage.

The instrument has the functions and purposes given

below.

Function Purpose

(Basic)

Insulation

resistance

measurement

Voltage

measurement

Temperature

measurement

(Applied)

Timer To automatically end measurement

Display

PI and DAR

values

Temperature

compensation (TC)

To test the insulation resistance of

an electrical facility.

To measure the voltage of an external circuit, e.g., commercial power

supply.

To measure a temperature

after a predetermined time.

To check whether the insulation resistance increases with time after a

voltage is applied.

[When the PI (polarization index)

value or the DAR (dielectric absorption ratio) value is close to 1, the instrument determines that the

insulation of the object to be measured has deteriorated.]

To obtain the insulation resistance

at various temperatures varied from

the actual environmental temperature at which measurement is performed.

Reference

page

3.2 (P.62)

3.3 (P.79)

3.4 (P.82)

4.1 (P.85)

4.2 (P.89)

4.3 (P.93)

20

1.1 Product Overview

Function Purpose

Step voltage

test

Memory

PC

Communication

To determine whether the insulation resistance of an object changes according to test voltage

applied.

To save the measurement data.

To create tables or graphs of the

data saved in the memory for reports, etc.

Reference

page

4.4 (P.97)

5 (P.105)

6.4 (P.136)

1.2 Features

Wide test voltage range

Generates a wide range of test voltages, from

250 V to 5 kV

The voltage may be chosen from the commonly used presets of 250 V, 500 V, 1 kV, 2.5

kV, and 5 kV; or set to a desired level by

increments or decrements of 25 V or 100 V.

3.2 "Measuring Insulation Resistance" (page 62)

Insulation diagnoses

For automatic calculation and indication of

PI (polarization index) and DAR (dielectric

absorption ratio), step voltage testing, and

temperature compensation.

4 "Advanced Measurement" (page 85)

Large memory

Stores up to 100 manual records and 10

logging records. The stored data may be

displayed on the LCD or downloaded to a

PC.

5 "Recording Measurement Data (Memory Function)" (page 105)

6.4 "Communicating with PC" (page 136)

1.2 Features

21

Large, clear display

The large display provides easy viewing.

Measurements may also be displayed

using a logarithmic bar graph, offering the

feel of an analog meter.

The LCD is backlit, enabling measurement

in poor lighting conditions.

22

1.2 Features

PC software with report creation/

printing feature

The instrument has a USB interface. Data

stored in the memory may be downloaded

to PC using the data download software.

The same software also enables reports to

be created and printed with ease.

6.4 "Communicating with PC" (page 136)

Compact hard case

The case is durable-designed to withstand

the toughest of working conditions, compact, and highly portable.

Dual battery power supply

The instrument can be powered by either

alkaline or rechargeable nickel-hydrogen

batteries. (Selectable via switch)

2.1.1 "Installing or Replacing the Battery" (page

36)

2.1.2 "Installing the Battery Pack (Rechargeable

nickel-hydrogen battery)" (page 39)

1.3 Measurement Overview

Purpose : Inspection of high-voltage electrical

facilities

Location : High-voltage receiving station or trans-

forming station

Test object : Large motors, transformers, cables,

etc.

• Measures insulation resistance, voltage and temperature.

• Stores measurement data in the internal memory.

• Downloads data to a PC for table, graph, or report

creation.

Prepare for measurement

2 "Measurement Preparations" (page 35)

1.3 Measurement Overview

This instrument is designed for measurement of the following:

Measurement condition

When measuring insulation resistance, ensure that power

supply to the object under test is turned off.

You will need:

• IR3455 HIGH VOLTAGE INSULATION TESTER

• AA alkaline batteries (LR6), or

9459 BATTERY PACK

• 9750-01,-02,-03 TEST LEAD

• 9751-01,-02,-03 ALLIGATOR CLIP

• 9631-01,-05 TEMPERATURE SENSOR (for temperature

measurement)

23

Flow of measurement

Before starting measurement, check the following:

• The power supply method.

• The power ON/OFF method.

• That date and time are set.

• Connection of test leads, temperature sensor, and USB

cable.

24

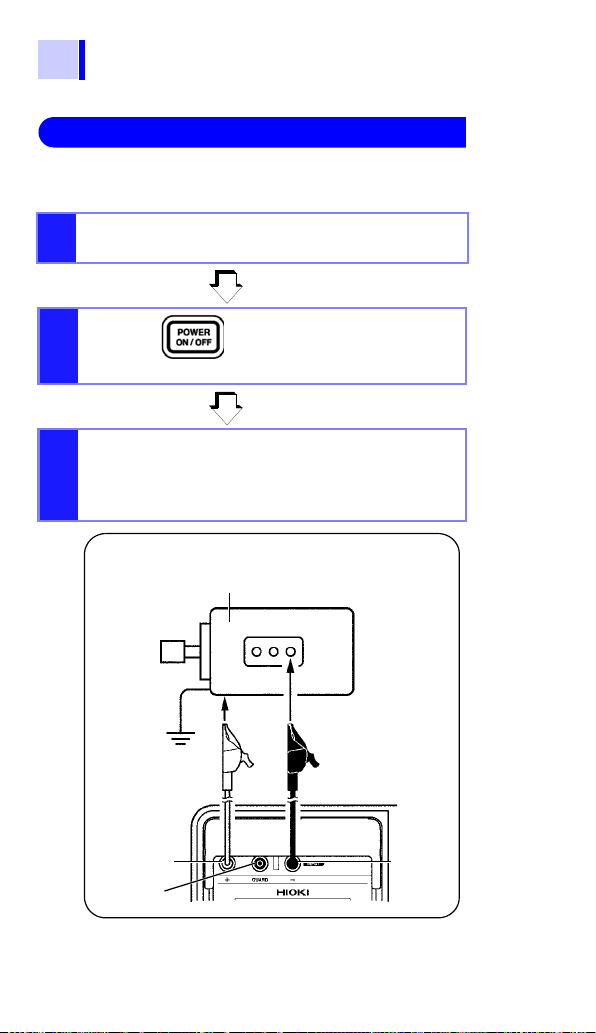

Start measurement.

GUARD

terminal

Warning: Confirm that the power supply to the

object under test has been turned off.

Object to be measured (Ex.: Motor)

+ terminal

- terminal

Test lead (Red)

Attach to a metal

chassis or a ground

terminal.

Test lead (Black)

Attach to a metal part

of the power supply

terminal.

1.3 Measurement Overview

Insulation Resistance Measurement

3.2 "Measuring Insulation Resistance" (page 62)

Make sure that power supply to the object under

1.

test is turned off.

2.

Press the key to turn on

the instrument.

Connect the test leads into the

3.

"+" and "-" terminals of the instrument and to the object to be

tested.

2.2 (page 50)

2.4 (page 56)

3.2.1 (page 64)

1.3 Measurement Overview

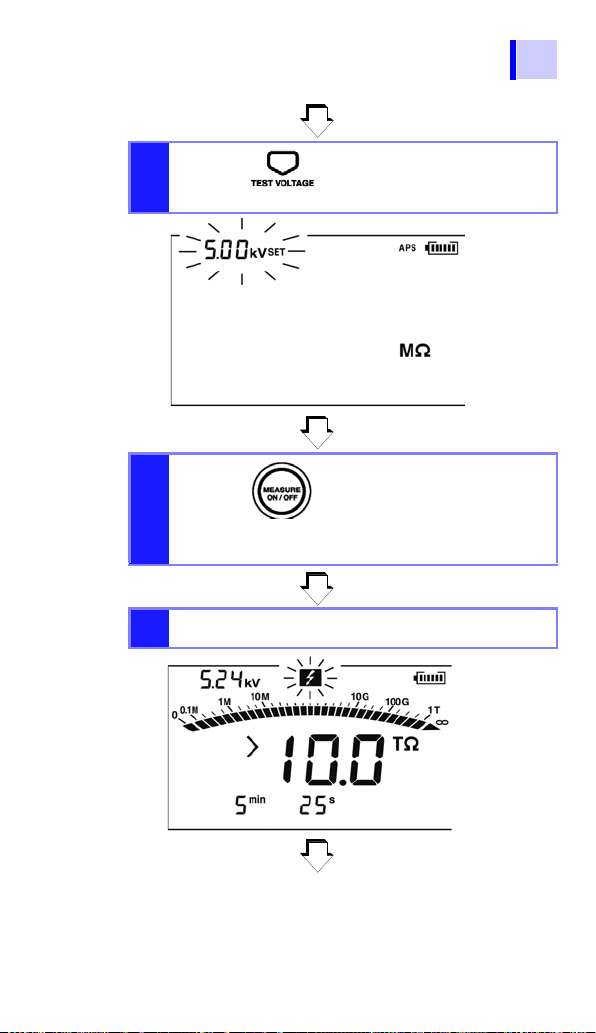

4.

Press the key and set

the test voltage.

5.

Press the key to gener-

ate a voltage and start measurement.

Read the indication.

6.

3.2.1 (page 64)

3.2.1 (page 64)

3.2.1 (page 64)

25

26

1.3 Measurement Overview

7.

Press the key to stop

voltage generation and measurement.

3.2.2 (page 70)

The automatic discharge function

8.

is activated.

Measurement is terminated when

9.

the voltage falls below 10 V.

3.2.4 (page 73)

Loading...

Loading...