IM7580A-1

HIOKI IM7585A981-05

IM7580A

IM7581

IM7583

IM7585

IM7587

IM7580A-2

IM7581-01

IM7581-02

IM7583-01

IM7583-02

IM7585-01

IM7585-02

IM7587-01

IM7587-02

Instruction Manual

IMPEDANCE ANALYZER

Apr. 2020 Revised edition 5

IM7585A981-05 20-04H

EN

HIOKI IM7585A981-05

Contents

HIOKI IM7585A981-05

Introduction ................................................ 1

Verifying Package Contents ..................... 1

Options (Sold Separately) ......................... 2

Safety Information ..................................... 2

Operating Precautions .............................. 5

1 Overview 9

1.1 Overview and Features .................... 9

1.2 Names and Functions of Parts ......11

1.3 Screen Operations ......................... 14

2 Measurement

Preparations 17

2.1 Connecting the Test Head ............. 17

2.2 Pre-Operation Inspection .............. 19

2.3 Connecting the Power Cord .......... 20

2.4 Connecting a Measurement

Cable/Fixture .................................. 21

2.5 Connecting an Interface ................ 22

2.6 Turning the Power ON and OFF .... 24

2.7 Select the Measurement Mode ...... 25

3 LCR Function 27

3.1 LCR Function .................................. 27

3.1.1 Flowchart ..................................................... 27

3.1.2 Screen map ................................................. 28

3.1.3 Measurement screen ................................... 30

3.1.4 Status and error display of this instrument .... 31

3.2 Setting Basic Settings of

Measurement Conditions .............. 32

3.2.1 Setting Display Parameters .......................... 32

3.2.2 Starting Measurement at Any Arbitrary

Timing (Trigger) ...........................................33

3.2.3 Setting the Delay Time from Trigger to

Measurement Start (Trigger Delay) .............. 34

3.2.4 Applying the Signal to the Sample during

Measurement Only

(Trigger Synchronous Output) ...................... 35

3.2.5 Setting the Measurement Frequency ........... 37

3.2.6 Setting the Measurement Signal Level ......... 38

3.2.7 Setting the Measurement Speed ..................40

3.2.8 Display with Average Values (Average) ........ 41

3.3 Judging Measurement Results ..... 43

3.3.1 Setting the Judgment Mode ......................... 44

3.3.2 Judging with Upper and Lower Limit

Values (Comparator Judgment Mode) .......... 46

3.3.3 Classifying Measurement Results

(BIN Judgment) ............................................ 53

4 Analyzer Function 59

4.1 Analyzer Function .......................... 59

4.1.1 Flowchart ..................................................... 60

4.1.2 Screen map ................................................. 62

4.1.3 Measurement screen ................................... 64

4.1.4 Types of graph .............................................65

4.1.5 Status and error display of this instrument ....66

4.2 Setting Basic Settings of

Measurement .................................. 67

4.2.1 Setting the Measurement Parameters .......... 67

4.2.2 Starting Measurement at Any Arbitrary

Timing (Trigger) ...........................................68

4.2.3 Setting the Delay Time from Trigger to

Measurement Start (Trigger Delay) .............. 69

4.2.4 Applying the Signal to the Sample during

Measurement Only

(Trigger Synchronous Output) ...................... 70

4.2.5 Setting the Sweep Parameter ...................... 72

4.3 Sweep measurement ..................... 73

4.3.1 Setting the Sweep Method ........................... 74

4.3.2 Setting the Sweep Range ............................76

4.3.3 Normal Sweep ............................................. 81

4.3.4 Segment Sweep and Segment Interval

Sweep ......................................................... 84

4.4 Set Measurement Conditions for

Sweep Points .................................. 87

4.4.1 Setting the Measurement Signal Frequency . 87

4.4.2 Setting the Measurement Signal Level ......... 88

4.4.3 Setting the Measurement Speed ..................90

4.4.4 Displaying Average Values (Average) .......... 90

4.4.5 Setting the Delay Time for Each Sweep

Point (Point Delay) ....................................... 91

4.5 Setting the Graph Display Method 92

4.5.1 Setting the Horizontal Axis ........................... 92

4.5.2 Setting the Vertical Axis ...............................95

4.5.3 ConguringtheX-YDisplayVerticalAxis

Reversal Setting ..........................................98

4.5.4 SettingtheX-YDisplayScaleWidth ............ 99

4.5.5 Setting Grid Display ................................... 100

4.5.6 Setting Overlay .......................................... 101

4.6 Setting the Cursor ........................ 102

4.6.1 Selecting the Cursor to Display in the

Screen ....................................................... 102

4.6.2 Setting Cursor Move .................................. 103

4.7 Performing Measurement Value

Search ........................................... 104

4.7.1 Setting the Search Target Parameter ......... 104

4.7.2 Setting the Search Type .............................105

4.7.3 Using the Automatic Search Function ......... 106

4.7.4 Executing Search....................................... 107

4.8 Judging Measurement Results

(Comparator Function) ................ 108

4.8.1 Setting the Judgment Mode ....................... 108

1

1

2

2

3

3

44

4

5

6

7

8

9

10

Appx. Index

IM7585A981-05

i

i

Contents

HIOKI IM7585A981-05

4.8.2 Setting the Parameter to be Judged

(Spot Judgment Excluded) ..........................110

4.8.3 Setting the Judgment Area to Display in

the Measurement Screen

(Spot Judgment Excluded) .......................... 111

4.8.4 Area Judgment ...........................................112

4.8.5 PeakJudgment ...........................................116

4.8.6 Spot Judgment .......................................... 120

4.9 Equivalent Circuit Analysis

Function ........................................ 125

4.9.1 Equivalent Circuit Analysis Function ........... 125

4.9.2 ConguringBasicSettingsforAnalysis ...... 126

4.9.3 Performing Equivalent Circuit Analysis ....... 133

4.9.4 Simulating Frequency Characteristics ........ 136

4.9.5 Settings to Judge Analysis Results ............. 138

5 Calibration and

Compensation 141

5.1 Calibration and Compensation

Function Overview ....................... 141

5.2 Calibration .................................... 145

5.2.1 Setting Calibration Conditions and

Executing Calibration [CAL] .......................145

5.3 Error Compensation .................... 154

5.3.1 Setting the Electric Length Compensation

[LENGTH] .................................................. 154

5.3.2 Setting Compensation Conditions and

Executing Compensation [COMPEN] ......... 155

5.4 Calculating Values (Scaling) ....... 160

5.5 Troubleshooting of

Compensation .............................. 162

6 Continuous

Measurement Function 163

6.1 Continuous Measurement

Function ........................................ 163

6.1.1 Operationow ........................................... 164

6.1.2 Measurement screen ................................. 165

6.2 ConguringContinuous

Measurement Basic Settings ...... 166

6.3 Executing and Stopping

Continuous Measurement ........... 167

6.4 Checking Continuous

Measurement Results .................. 168

6.5 Cancels the Measurement if an

Error is Detected .......................... 169

7 Application function 171

7.1 Checking Contact Defects and

the Contact State

(Contact Check Function) ........... 171

7.1.1 Setting the DC Measurement ..................... 171

7.1.2 Setting the Judgment ................................. 174

7.1.3 DetectingOPENduring2-terminal

Measurement (Hi Z Reject Function) .......... 176

7.1.4 Monitoring the Detection Level

(Detection Level Monitoring Function) ........ 177

7.2 Other Functions ........................... 179

7.2.1 Set the number of display digits ................. 179

7.2.2 Setting Absolute Value Display (LCR only) . 180

7.2.3 Setting the Communication Measurement

Data Type .................................................. 181

7.3 Common Functions

(LCR Mode, ANALYZER Mode) .... 182

7.3.1 Saving Measurement Results

(Memory Function) ..................................... 182

7.3.2 Setting the Screen Display ......................... 184

7.3.3 Setting the Beep Sound ............................. 188

7.3.4 DisplaytheWarm-upMessage .................. 189

7.3.5 Disabling Key Operation

(Key-lockFunction) .................................... 190

7.3.6 Setting the Communication Measurement

Data Type .................................................. 194

7.3.7 Initializing the Instrument (System Reset) ... 196

8 External Control 199

8.1 External Input/Output Connector

and Signals ................................... 199

8.2 Timing Chart ................................. 209

8.2.1 LCR mode ................................................. 209

8.2.2 ANALYZERMode .......................................211

8.2.3 CONTINUOUS measurement mode .......... 213

8.3 Internal Circuit .............................. 215

8.4 External Control Q&A .................. 218

8.5 Measurement Using a Computer 218

8.6 External Control I/O Settings ...... 219

8.6.1 Enabling Trigger Input During

Measurement (Trigger Enabled) ................. 219

8.6.2 Setting Valid Edge of Trigger Input

(Trigger Edge) ............................................ 220

8.6.3 Setting Reset of Judgment Results

(Judgment Result Signal Reset) ................. 221

8.6.4 Setting the EOM Output Method

(EOM mode) .............................................. 222

8.6.5 Setting Delay Time from Judgment

Results Output until Output of EOM

(LOW)(JUDGE-EOM) ............................... 224

8.6.6 SetaDelayforINDEXSignalOutput

(INDEXDelay) ........................................... 225

ii

Contents

HIOKI IM7585A981-05

9 Saving and Loading

Panel Information 227

9.1 Saving Measurement Conditions

(Panel Save Function) .................. 228

Loading Measurement Conditions

9.2

(Panel Load Function) ................. 231

9.3 Changing a Panel Name .............. 232

9.4 Deleting a Panel ........................... 233

10 Setting the SYSTEM 235

10.1 Setting the Interface ..................... 235

Checking the Instrument Version

10.2

10.3 Self Checks (Self Diagnosis) ....... 237

10.3.1 Panel Test .................................................. 237

10.3.2 Panel Compensation .................................. 238

10.3.3 Screen Display Test ................................... 239

10.3.4 ROM/RAM Test .........................................240

10.3.5 I/O Test ...................................................... 241

10.4 Setting the Date and Time ........... 242

. 236

11.7.5 CheckingtheContentsofFiles .................. 274

12 Specications 275

12.1 GeneralSpecications ................ 275

12.2 MeasurementSpecications ....... 276

12.3 Functionalspecication .............. 285

12.4 InterfaceSpecications ............... 291

12.5 Measurement Accuracy ............... 292

12.5.1 Example: Calculation of Accuracy .............. 292

12.5.2 Measurable Range .................................... 299

13 Maintenance and

Service 301

13.1 Inspection, Repair and Cleaning 301

13.2 Disposal ........................................ 303

13.3 Troubleshooting ........................... 305

13.4 Error Display ................................. 310

Appendix A1

1

11

2

12

3

13

44

5

11 Using USB Flash Drive 243

11.1 Overview ....................................... 243

11.2 Inserting and Removing USB

Flash Drive .................................... 245

11.3 Screen Display When Using USB 246

11.4 Saving Data to USB Flash Drive . 247

11.4.1 Saving Measurement Result as Text .......... 247

11.4.2 Saving Measurement Screen

(Screen Copy) ........................................... 258

11.4.3 Setting Save Folder ................................... 260

11.4.4 Saving Memory Data ................................. 262

11.5 Saving Instrument Settings to

USB Flash Drive ........................... 263

11.5.1 Saving Instrument Settings ........................ 263

11.5.2 Saving All Settings of Instrument

(ALL SAVE Function) ................................. 264

11.6 Loading Binary Data from USB

Flash Drive .................................... 265

11.6.1 Loading Measurement Data

(ANALYZERFunction) ............................... 265

11.6.2 Loading Instrument Settings ....................... 266

11.6.3 Loading All Settings (ALL LOAD Function) .268

11.7 Editing Data Saved in USB

Flash Drive .................................... 269

11.7.1 Formatting a USB Flash Drive .................... 269

11.7.2 Creating a Folder in USB Flash Drive ......... 270

11.7.3 Changing Folder Name or File Name in

USB Flash Drive ........................................ 271

11.7.4 Deleting a File or Folder in USB Flash

Drive .......................................................... 273

Appx. 1

Appx. 2

Appx. 3 Series Equivalent Circuit

Appx. 4 Selecting the Equivalent

Appx. 5 Maintenance of Coaxial

Appx. 6 Rack Mounting .........................A7

Appx. 7 Dimensional Diagram ............A15

Measurement Parameters

and Calculation Formula

Countermeasures to

Prevent Entry of External Noise

Countermeasures to prevent entry of

noise from the power supply line ............... A3

Countermeasures to prevent entry noise

from the measurement cables ................... A3

Mode and Parallel

Equivalent Circuit Mode .......... A4

Circuit Model ............................ A5

Connector ................................. A6

Plate dimension ......................................... A8

Installation procedure .............................. A12

..........A1

A3

Index Ind.1

6

7

8

9

10

Appx. Index

iii

Contents

HIOKI IM7585A981-05

iv

Measurement Process

HIOKI IM7585A981-05

Read “Operating Precautions” (p. 5) before installing and connecting this instrument.

Refer to “Appx. 6 Rack Mounting” (p. A7) for rack mounting.

Install the instrument (p. 5)

Connect the test head (p. 17)

Connect the power cord (p. 20)

Connect measurement cables, optional Hioki probes, or test xture (p. 21)

Connect external interfaces (as required) (p. 235)

Inspect all the connections (p. 19)

Turn ON the power supply (p. 24)

Perform calibration / compensation (p. 141)

Set measurement conditions

Connect to the test sample

Make measurements

Turn OFF the power supply (p. 24)

After using the instrument, remove the test sample and turn OFF the power supply.

Calibration/compensation execution timing

• Before measurements

• After the length of measurement cable is changed

• After the type of measurement sample is changed

• After the xture is changed

HIOKI IM7585A981-05

Introduction

HIOKI IM7585A981-05

Introduction

Thank you for purchasing the HIOKI IM7580A, IM7581, IM7583, IM7585, IM7587 Impedance Analyzer.

To obtain maximum performance from the instrument, please read this manual rst, and keep it handy for

future reference.

The screen display has been explained using Model IM7585 as an example.

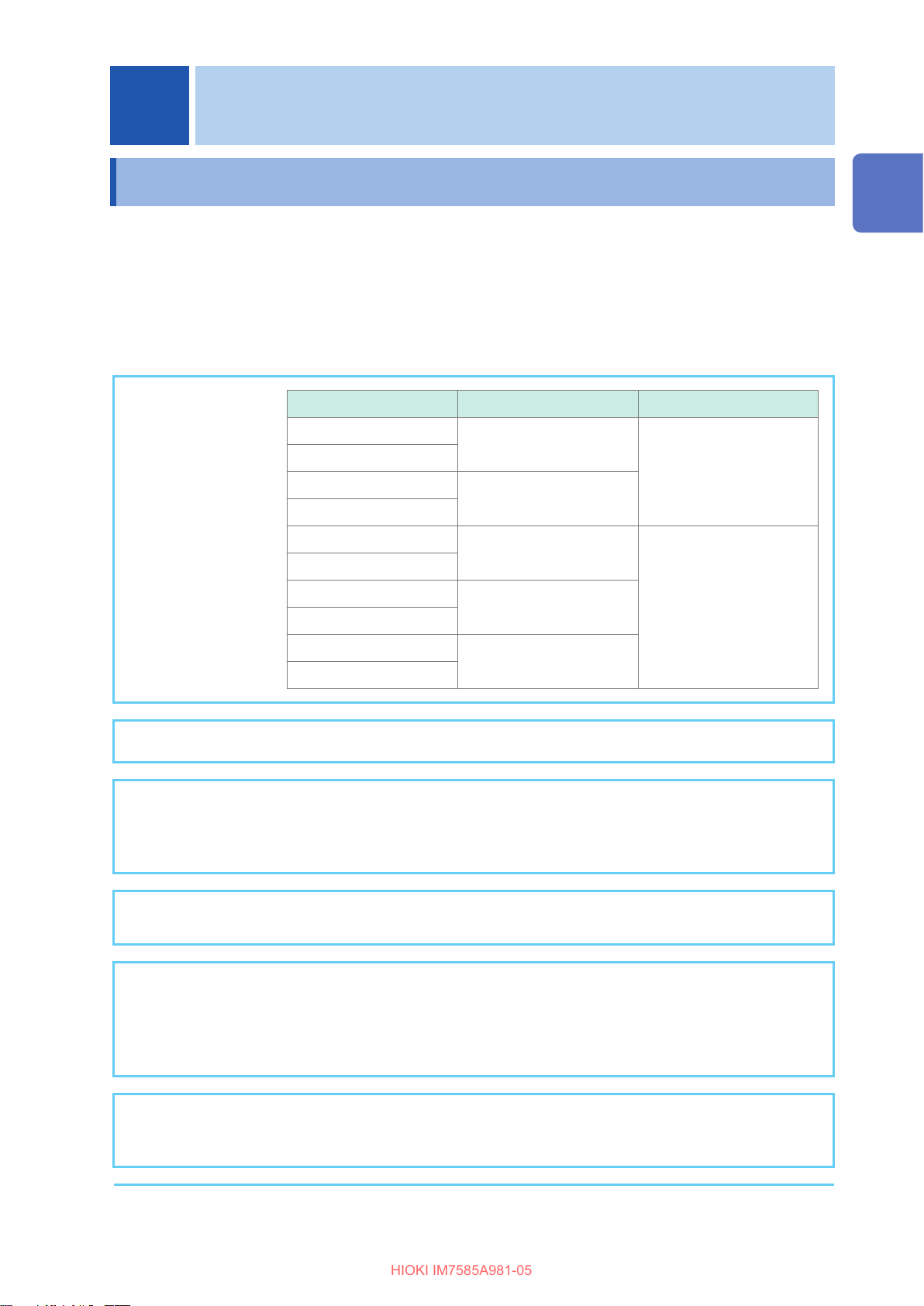

Model Information

Model Measurement frequency Cable length

1

2

Rear

(Example: IM7585)

IM7580A-1

1 MHz to 300 MHz

IM7580A-2 2 m

IM7581-01

100 kHz to 300 MHz

IM7581-02 2 m

IM7583-01

1 MHz to 600 MHz

IM7583-02 2 m

IM7585-01

1 MHz to 1.3 GHz

IM7585-02 2 m

IM7587-01

1 MHz to 1.3 GHz

IM7587-02 2 m

1 m

1 m

1 m

1 m

1 m

Verifying Package Contents

• When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping.

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to

operate according to the specications, contact your authorized Hioki distributor or reseller.

• Store the packaging in which the instrument was delivered, as you will need it when transporting the

instrument.

3

4

5

6

7

Conrm that the following items have been provided:

IM7580A, IM7581, IM7583, IM7585, IM7587 Impedance Analyzer ×1

• Test head ×1

• Measurement cable ×1

(IM7580A-1: 1 m, IM7580A-2: 2 m,

IM7581-01: 1 m, IM7581-02: 2 m,

IM7583-01: 1 m, IM7583-02: 2 m,

IM7585-01: 1 m, IM7585-02: 2 m,

IM7587-01: 1 m, IM7587-02: 2 m)

IM7580A, IM7581 IM7583, IM7585, IM7587

Instruction Manual ×1 Power cord ×1

Impedance Analyzer Application Disc ×1

(Communications user manual [PDF],

communications commands manual,

USB driver, sample application, and initial

settings table)

• The latest version can be downloaded

from our website.

8

9

10

Appx. Ind.

1

Options (Sold Separately)

HIOKI IM7585A981-05

Options (Sold Separately)

Contact your authorized Hioki distributor or reseller when ordering.

The options are subject to change. Visit our website for updated information.

Test xtures

IM9200 Test Fixture Stand

IM9201 SMD Test Fixture (for SMDs)

IM9202 Test Fixture (for through-hole components and SMDs)

IM9906 Adapter (3.5mm/7mm)

IM9905 Calibration Kit

Interfaces

Z3000 GP-IB Interface

Z3001 RS-232C Interface

Connection cables

9151-02 GP-IB Connector Cable (2 m)

9637 RS-232C Cable (9pin-9pin/1.8m)

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly tested

for safety prior to shipment. However, using the instrument in a way not described in this manual may

negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in

the manual before use.

2

WARNING

With regard to the electricity supply, there are risks of electric shock, heat

generation, re, and arc discharge due to short circuits. If persons unfamiliar

with electricity measuring instrument are to use the instrument, another person

familiar with such instruments must supervise operations.

Notation

HIOKI IM7585A981-05

In this manual, the risk seriousness and the hazard levels are classied as follows.

Safety Information

DANGER

WARNING

CAUTION

IMPORTANT

*

Symbols on the instrument

Indicates an imminently hazardous situation that will result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in death or serious injury to

the operator.

Indicates a potentially hazardous situation that may result in minor or moderate injury

to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance tasks

with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled, this may

give rise to a hazardous situation; the operator may receive an electric shock, may get

burnt or may even be fatally injured.

Indicates prohibited actions.

Indicates the action which must be performed.

Additional information is presented below.

1

2

3

4

5

Indicates cautions and hazards. When the symbol is printed on the instrument, refer to a

corresponding topic in the Instruction Manual.

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

Symbols for standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE Directive) in EU

member states.

Indicates that the product conforms to regulations set out by the EU Directive.

6

7

8

9

10

Appx. Ind.

3

Safety Information

HIOKI IM7585A981-05

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values,

with the following meanings:

(maximum display value or scale length)

f.s.

The maximum displayable value or scale length. This is usually the name of the currently

selected range.

rdg.

dgt.

(reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input value that

causes the digital display to show a “1” as the least-signicant digit.

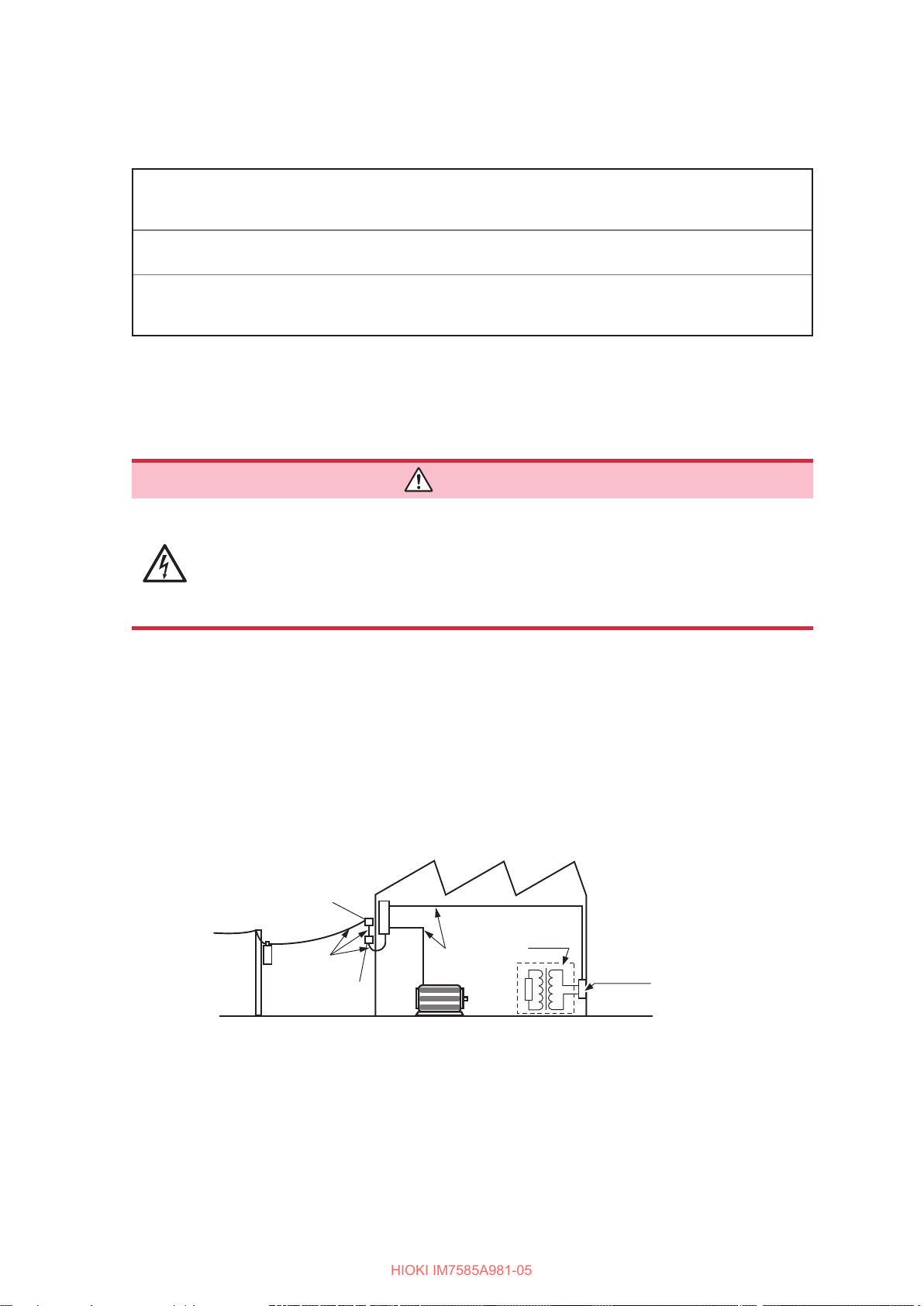

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement

categories.

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

• Using a measuring instrument without categories in an environment designated

with the CAT II to CAT IV category could result in a severe accident, and must

be carefully avoided.

CAT II: When directly measuring the electrical outlet receptacles of primary electrical circuits

in equipment connected to an AC electrical outlet by a power cord (portable tools,

household appliances, etc.).

CAT III: When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to

outlets.

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution panel).

4

Service entrance

Service drop

CAT IV

Power meter

Distribution panel

Internal wiring

CAT III

Fixed installations

CAT II

T

Outlet

Operating Precautions

HIOKI IM7585A981-05

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various functions.

WARNING

If the measurement cable or the instrument is damaged, there is a risk of electric

shock. Perform the following inspection before using the instrument:

• Before using the instrument, make sure that the insulation on the measurement

cables are undamaged and that no bare conductors are improperly exposed. If

the instrument is damaged, contact your authorized Hioki distributor or reseller.

• Before using the instrument for the rst time, verify that it operates normally

to ensure that no damage occurred during storage or shipping. If you nd any

damage, contact your authorized Hioki distributor or reseller.

CAUTION

Avoid using an uninterruptible power supply (UPS) or DC/AC inverter with rectangular

wave or pseudo-sine-wave output to power the instrument. Doing so may damage the

instrument.

Instrument installation

For details on the operating temperature and humidity, refer to the specications (p. 275).

1

2

3

4

5

Installing the instrument in inappropriate locations may cause a malfunction of

instrument or may give rise to an accident. Avoid the following locations.

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

Installation method

Example: IM7585

50 mm or more

WARNING

To prevent overheating, be sure to leave the specied

clearances around the instrument.

• Install the instrument with the bottom facing down.

• Vents must not be obstructed.

• A distance of 50 mm or more must be maintained between the

rear and the surroundings.

6

7

8

9

10

Appx. Ind.

5

Operating Precautions

HIOKI IM7585A981-05

Warranty

Hioki disclaims responsibility for any direct or indirect damages that may occur if this instrument has been

combined with other devices by a systems integrator prior to sale or during resale. Please note.

Handling the instrument

DANGER

• To avoid electric shock, do not remove the instrument’s case. The internal

components of the instrument carry high voltages and may become very hot

during operation.

• Do not allow the instrument to get wet, and do not take measurements with wet

hands. This may cause an electric shock.

CAUTION

• If the instrument exhibits abnormal operation or display during use, review the

information given in “13.3 Troubleshooting” (p. 305) and “13.4 Error Display” (p. 310)

before contacting your authorized Hioki distributor or reseller. Do not connect charged

capacitors, input voltage or current to the measuring terminals. The instrument will get

damaged.

• To avoid damage to the instrument, protect it from physical shock when transporting

and handling. Be especially careful to avoid physical shock from dropping.

• This instrument is not designed to be entirely water- or dust-proof. Do not use it in an

especially dusty environment, nor where it might be splashed with liquid. This may

cause damage.

• Do not use excessive force on the touch panel, and do not use hard or sharp objects

that could damage the touch screen.

• Do not apply heavy downward pressure with the stand extended. The stand could be

damaged.

• To avoid damage to the instrument, do not short-circuit the terminal/output terminal

and do not input voltage to the terminal/output terminal.

• After use, always turn OFF the power.

IMPORTANT

This instrument may cause interference if used in residential areas. Such use must be avoided

unless the user takes special measures to reduce electromagnetic emissions to prevent

interference to the reception of radio and television broadcasts.

Before turning ON the power

• Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage

may damage the instrument and present an electrical hazard. Be careful to

avoid connecting the supply voltage improperly. Doing so may damage the

instrument’s internal circuitry. To avoid electrical accidents and to maintain the

safety specications of this instrument, connect the power cord provided only

to an outlet.

6

WARNING

Handling of cords and xtures

HIOKI IM7585A981-05

Use only the designated power cord with this instrument. Using other power cords may

cause re.

Operating Precautions

WARNING

1

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

• To avoid breaking the cables or probes, do not bend or pull them.

• Bare conductors may get exposed if the insulation melts. Keep the cables well away

• Keep in mind that, in some cases, conductors to be measured may be hot.

• Use only the specied measurement cables. Using a non-specied measurement cable

may result in incorrect measurements due to poor connection or other reasons.

• Read the instruction manual supplied with the product to be used before using a xture.

CD precautions

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing

text on a disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high

temperature, or high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of

using this disc.

CAUTION

2

from the power outlet.

3

from heat sources.

4

5

6

7

Before connecting to the EXT I/O terminals

WARNING

To avoid electric shock or damage to the equipment, always observe the following

precautions when connecting to the EXT I/O connector.

• Always turn OFF the power to the instrument and to any devices to be

connected before making connections.

• Be careful to avoid exceeding the ratings of EXT I/O connector (p. 216).

• During operation, a wire becoming dislocated and contacting another

conductive object can be a serious hazard. Use screws to secure the EXT I/O

connectors.

• Ensure that devices and systems to be connected to the EXT I/O terminals are

properly isolated.

• The ISO_5V pin of the EXT I/O connector is a 5V power output. Do not apply

external power to this pin.

8

9

10

Appx. Ind.

7

Operating Precautions

HIOKI IM7585A981-05

USB ash drives

• Hioki cannot recover or analyze data from damaged or faulty storage media. We

cannot compensate for such data loss, irrespective of the contents or cause for the

failure or damage. We recommend you to make a backup of all important data in a

computer or other devices.

• Avoid inserting the USB ash drive with the wrong orientation. This can damage the

USB ash drive or instrument.

• When a USB ash drive is being accessed, the color of the USB icon changes from

blue to red. Do not turn off the power of the instrument while the USB ash drive is

being accessed. Also, do not remove the USB ash drive from the instrument while it

is being accessed. This may result in the loss of data stored in the USB ash drive.

• Do not transport the instrument while a USB ash drive is connected. Damage could

result.

• Some USB ash drive are susceptible to static electricity. Exercise care when using

such products because static electricity could damage the USB ash drive or cause

malfunction of the instrument.

• With some USB ash drives, the instrument may not start up if power is turned on

while the USB ash drive is inserted. In such a case, turn the power on rst, and then

insert the USB ash drive. We recommend that various operations such as copy and

save be carried out with the USB ash drive before using it for actual measurements.

CAUTION

USB ash drives have a limited usable lifetime. Data reading and writing will fail after long-term

use. Replace the USB ash drive in this case.

Input modules (optional)

Always turn both devices OFF when connecting and disconnecting an interface

connector. This may cause an electric shock.

• To connect or disconnect optional interfaces, hold the metal part. Touching the PCB

with bare hands could damage the instrument due to static electricity. (Antistatic wrist

strap is recommended when disconnecting the interface.)

• To avoid equipment failure, do not disconnect the communications cable while

communications arein progress.

• Use a common ground for both the instrument and the computer. Using different

ground circuits will resultin a potential difference between the instrument’s ground and

the computer’sground. If the communications cable is connectedwhile such a potential

difference exists, it may result inequipment malfunction or failure.

• Before connecting or disconnecting any communications cable, always turn off the

instrument and the computer. Failure to do so could result in equipmentmalfunction or

damage.

• After connecting the communications cable, tightenthe screws on the connector

securely. Failure to secure theconnector could result in equipment malfunction or

damage.

WARNING

CAUTION

8

1

HIOKI IM7585A981-05

Overview

1.1 Overview and Features

The HIOKI IM7580A, IM7581, IM7583, IM7585, IM7587 Impedance Analyzer is an impedance measuring

instrument that has achieved high speed and high accuracy.

The IM7585 combines the functionality of two devices: an impedance analyzer that can perform

measurement while sweeping the measurement frequency and signal level, and an LCR meter that can

simultaneously display up to four parameters under a single set of measurement conditions.

A wide range of measurement conditions can be set, and the instrument can be used for a wide range of

applications such as measurement of high frequency inductors.

Model Measurement frequency Signal level

Wide range of

measurement

conditions

IM7580A-1

IM7580A-2

IM7581-01

IM7581-02

IM7583-01

IM7583-02

IM7585-01

IM7585-02

1 MHz to 300 MHz

100 kHz to 300 MHz

1 MHz to 600 MHz

1 MHz to 1.3 GHz

-40.0 dBm to +7.0 dBm

-40.0 dBm to +1.0 dBm

1

Overview

IM7587-01

IM7587-02

Fast measurement The measurement speed is 0.6 ms (typical value) at the fastest.

The measurement frequency and sweep function of measurement level

Graph display

Equivalent circuit

analysis

CONTINUOUS

measurement mode

measures and displays the frequency characteristics and level characteristics

as a graph on the color LCD display of the instrument.

A Cole-Cole plot and admittance pie graph can also be easily displayed.

It provides ve types of equivalent circuit models for circuit element

components.

It is capable of continuous measurements using measurement conditions

stored in the instrument memory. This function enables making pass/fail

judgments with different measurement conditions.

(Example: Performs C-D measurement with 1 MHz and Ls measurement with

100 MHz in succession.)

1 MHz to 3 GHz

Various interfaces are

supported

It supports EXT I/O (handler interface), which is the most suitable for

production lines, USB, GP-IB, RS-232C, and LAN.

* GP-IB and RS-232C are optional.

9

Overview and Features

HIOKI IM7585A981-05

Comparator function

• LCR mode: (p. 46) It is capable of making pass/fail judgements by

determining whether measurement values qualify as higher, within a range,

or lower (hereafter referred to as HI, IN, and LO, respectively) regarding four

parameters.

• ANALYZER mode: (p. 108) It is capable of making pass/fail judgments for

sweep measurement results.

BIN function

LCR mode can divide the rank up to 10 classications based on the

measurement values.

10

1.2 Names and Functions of Parts

HIOKI IM7585A981-05

Front panel of the instrument

Names and Functions of Parts

Example: IM7585

Coaxial connectors

(p. 17)

• CONTROL

• RF OUT

• PORT 1

• PORT 2

IM7580A and IM7581 only

Connector for USB

ash drive (p. 243)

Connect a USB ash

drive storage device.

Coaxial connectors (p. 17)

• RF OUT

• PORT 1

• PORT 2

LCD display

This is a touch panel display.

Press the keys displayed on the screen to

operate the instrument.

HOME button

• Returns to the measurement screen.

• Use this button for the full reset operation

(p. 309).

Start button (p. 24)

(The main power switch is located at the rear.)

Lamp status Instrument status

Green

Red

The start button turns the state from inactive to

active. Accurate measurement requires at least

60 minutes of warm-up.

Measurement lamp

Lamp status Instrument status

Green During measurement

Red

Power supply ON

Active

Power supply OFF

Inactive

Full reset under

preparation

1

Overview

Bottom panel of the instrument

Example: IM7585

This instrument can be rack mounted.

Refer to “Appx. 6 Rack Mounting” (p. A7).

Parts removed from this instrument should be stored in a safe place to

enable future reuse.

11

Names and Functions of Parts

HIOKI IM7585A981-05

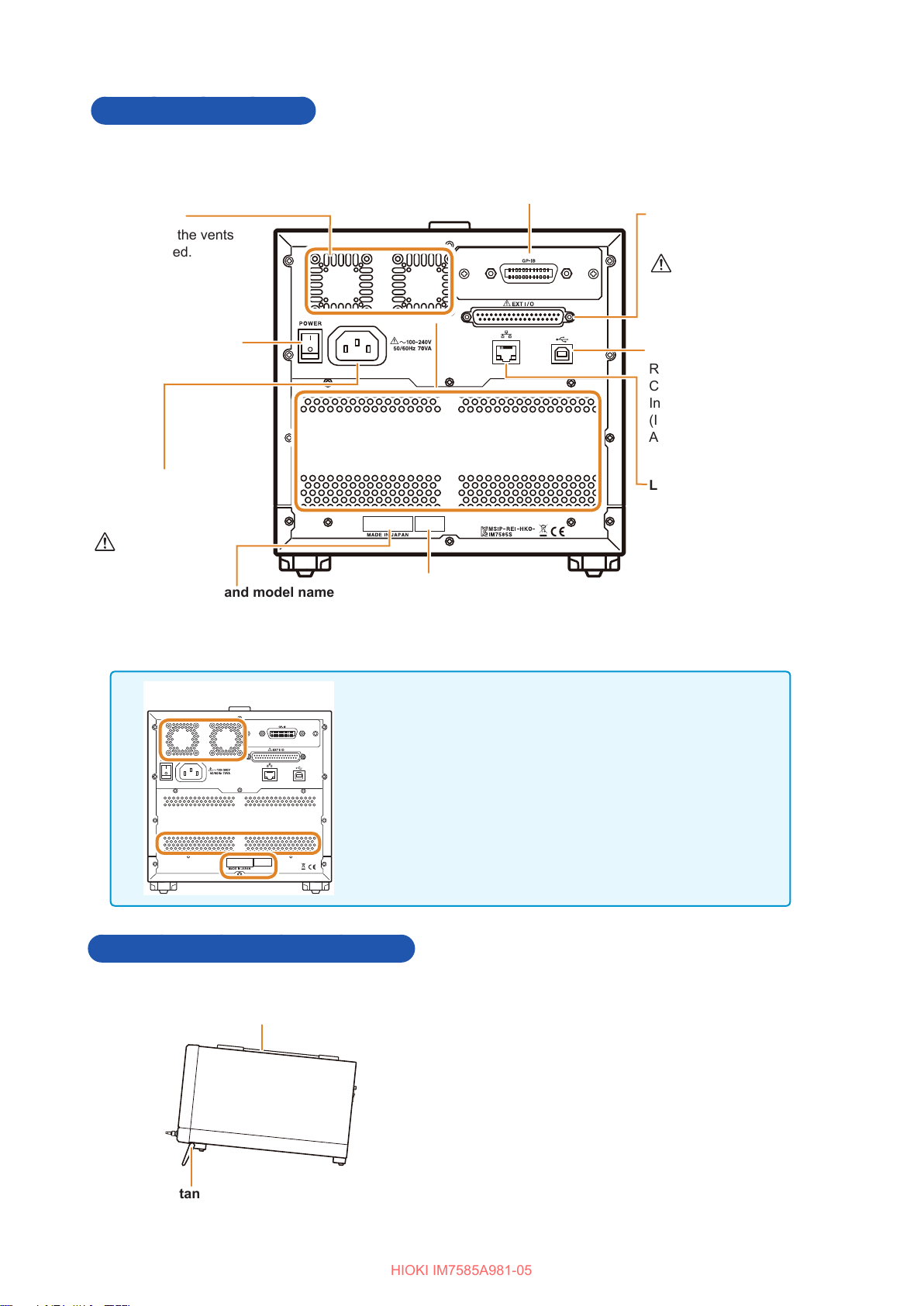

Rear of the instrument

Example: IM7585

Vents (p. 5)

Install so that the vents

are not covered.

Main power switch

(p. 24)

Power inlet (p. 20)

Connect the supplied power

cord.

(p. 6)

Serial number and model name

The 9-digit serial number indicates the year (rst two digits) and the

month of manufacture (next two digits). Do not remove this sticker as

the number is important.

Communication interface (option) (p. 235)

Optional interfaces can be installed.

Refer to the Communication Instruction Manual (Impedance Analyzer

Application Disc).

• Model Z3000 GP-IB Interface

• Model Z3001 RS-232C Interface

MAC address

EXT I/O Connector

(p. 199)

(p. 7)

USB cable connector

Refer to the

Communication

Instruction Manual

(Impedance Analyzer

Application Disc).

LAN connector

Refer to the

Communication

Instruction Manual

(Impedance Analyzer

Application Disc).

IM7580A, IM7581

In Models IM7580A and IM7581, the following are the

differences with Model IM7585.

• The position and shape of vents

• The position of the MAC address

• The position of the serial number and model name

Right side panel of the instrument

Handle

Used for carrying the instrument.

Example: IM7585

When setting up the stands

Open till the end without stopping in between.

Ensure that both stands are straight.

12

When closing the stands

Close till the end without stopping in between.

Stands

Enables the instrument to be tilted.

Side of the test head

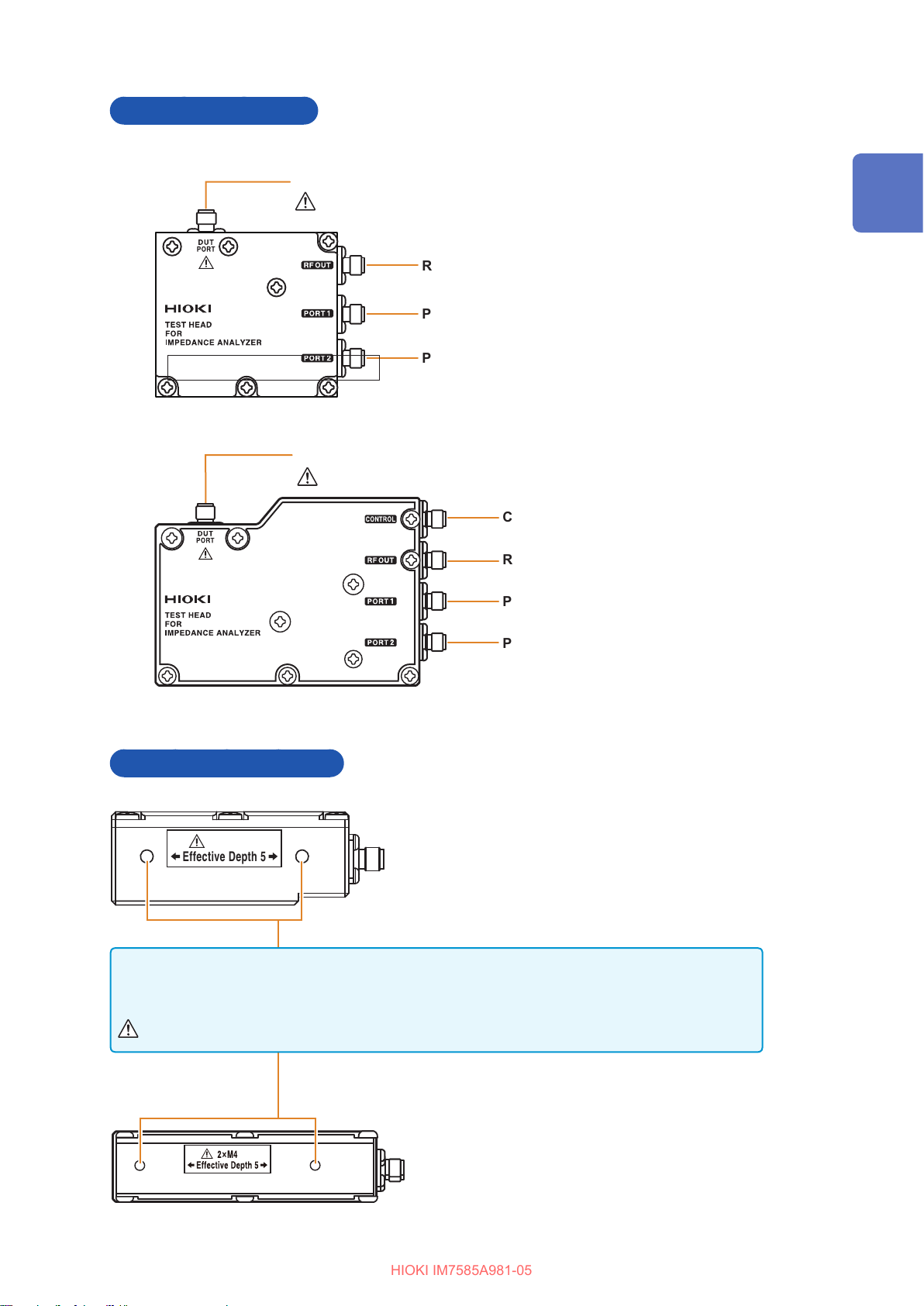

HIOKI IM7585A981-05

IM7580A, IM7581

IM7583, IM7585, IM7587

Meauring terminal

(p. 6)

Measuring terminal

(p. 6)

Coaxial connectors

RF OUT

PORT1

PORT2

Coaxial connectors

Names and Functions of Parts

1

Overview

CONTROL

RF OUT

PORT1

PORT2

Bottom of the test head

IM7580A, IM7581

2×M4

Effective Depth 5

Threaded holes for xing the IM9200 Test Fixture Stand

These holes can also be used when xing a test head to an automated machine.

The depth of the threaded holes is 5 mm.

IM7583, IM7585, IM7587

Do not use screws of length exceeding M4 × 5 mm. Doing so may damage the device.

13

Screen Operations

HIOKI IM7585A981-05

1.3 Screen Operations

This instrument allows you to use a touch panel to set and change all measurement conditions.

Gently touch the key on the screen to select the item or numerical value set for that key.

In this manual, gently touching the screen is referred to as “press”.

CAUTION

Do not use excessive force on the touch panel, and do not use hard or sharp objects

that could damage the touch screen.

Example: Setting the measurement frequency in LCR mode

2

3

1

On LCR mode

1

screen, press

[SETUP] of the

menu key.

Press the [BASIC] tab.

2

Press [FREQ].

3

4

14

5

4

[DIGIT] (input with /), or [10-KEY] (input with the

numeric keypad).

6

5

Set the measurement

4

frequency with

the numeric keypad.

Press any unit key to

5

conrm the setting.

Press [EXIT] to close

6

the setting screen.

/,

or

Example: Moving the window

HIOKI IM7585A981-05

Screen Operations

You can move the window

by moving the top of the

window (green bar) while

pressing it.

1

Overview

15

Screen Operations

HIOKI IM7585A981-05

16

2

HIOKI IM7585A981-05

Read “Operating Precautions” (p. 5) before installing and connecting this instrument.

Refer to “Rack Mounting” (p. A7) for rack mounting.

Measurement Preparations

2.1 Connecting the Test Head

Connect the test head.

Refer to “5 Calibration and Compensation” (p. 141).

CAUTION

• If the instrument and the connectors of the test head are not correctly connected, the

instrument may get damaged or accurate measurements may not be possible.

• Tighten the connector with a torque of 0.56 Nm (recommended value). Tightening

the connector with a torque other than the recommended value may damage the

instrument or accurate measurements may not be possible.

2

Measurement Preparations

IMPORTANT

• Check that there are no problems with the connector before connecting the cable. If

there is a problem with the connector, you cannot perform accurate measurement due

to large measurement errors.

Refer to “Appx. 5 Maintenance of Coaxial Connector” (p. A6).

• The instrument, test head and measuring cables have been adjusted as a set before

shipment.

Connect the test head having the same serial number as the instrument with the

measuring cables supplied.

Example: IM7585

Rear of the instrument Rear of the test head

Serial No.

17

Connecting the Test Head

HIOKI IM7585A981-05

1

Check that the power switch of the instrument is turned off.

2

Connect CONTROL, RF OUT, PORT1, and PORT2 of the instrument to CONTROL, RF OUT,

PORT1, and PORT2 of the test head with the supplied measurement cable.

Example: IM7585

0.56 Nm

(recommended value)

If the specied torque is applied to the

torque wrench, it will rotate to the position

shown in the gure.

Do not rotate the cable when connecting the SMA connector of the cable to the

instrument and the test head. If the cable is rotated while connecting the connector, the

core wires of the connector or cable may get damaged. Rotate the nut of the connector

and connect.

18

Pre-Operation Inspection

HIOKI IM7585A981-05

2.2 Pre-Operation Inspection

Be sure to read “Operating Precautions” (p. 5) before use.

Before using the instrument for the rst time, verify that it operates normally to ensure that no

damage occurred during storage or shipping.

If you nd any damage, contact your authorized Hioki distributor or reseller.

Inspection of accessories and options

Inspection item Solution

Is the power cord insulation torn, or is any metal

exposed?

Is the insulation on the measurement cable torn, or is

any metal exposed?

Do not use the instrument if it is found to be damaged, as it

can result in electric shocks or short-circuit accidents.

Contact your authorized Hioki distributor or reseller.

If there is any damage, measurement values may not be

stable and measurement errors may occur.

We recommend using a new cable without any damage.

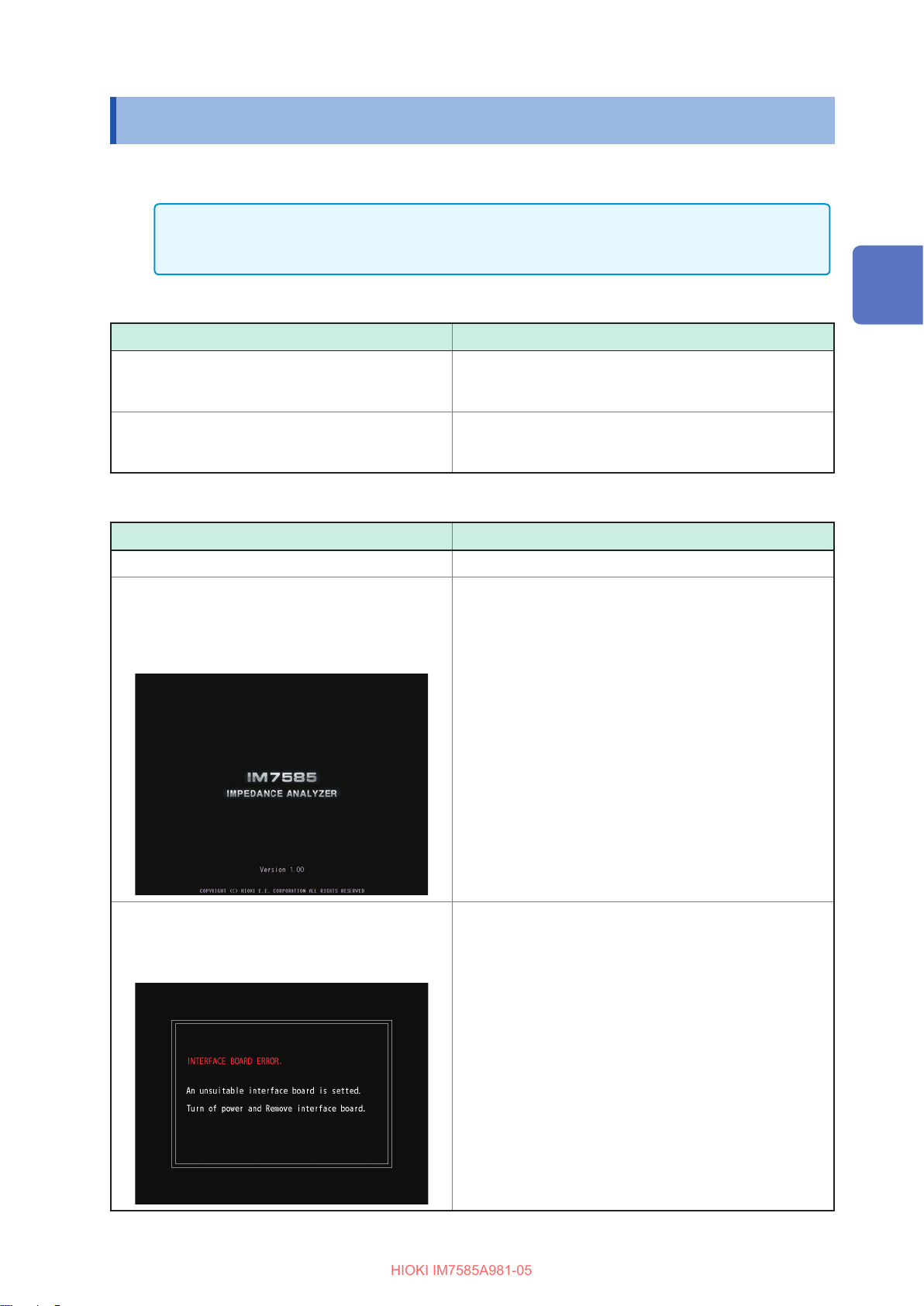

Instrument inspection

Inspection item Solution

Is the instrument damaged? If the instrument is damaged, request repairs.

Does the splash screen appear (Model no., version

no.) when the power is turned on?

Screen when the power is turned on

(Example: IM7585)

If the splash screen does not appear, the power cord may

be damaged, or the instrument may be damaged internally.

Request repairs.

2

Measurement Preparations

Is there an error displayed instead of the splash

screen?

Error display screen

If there is an error displayed, the instrument may be

damaged internally. Request repairs.

Refer to “Troubleshooting” (p. 305) and “Error Display”

(p. 310).

Example: An interface board that cannot be used is installed

(LAN board).

19

Connecting the Power Cord

HIOKI IM7585A981-05

2.3 Connecting the Power Cord

Please read “Before turning ON the power” (p. 6) and “Handling of cords and xtures” (p. 7)

before connecting the measurement cable or xture.

Connect the power cord to the power inlet on the instrument, and plug into an outlet.

Turn OFF the main power switch before disconnecting the power cord.

1

2

Check that the main power switch of the instrument is turned off.

Connect a power cord that is compatible with the line voltage to the power inlet on the

instrument (100 V to 240 V AC).

Rear (Example: IM7585)

3

Plug the other end of the power cord into an outlet.

20

Connecting a Measurement Cable/Fixture

HIOKI IM7585A981-05

2.4 Connecting a Measurement Cable/Fixture

Please read “Before turning ON the power” (p. 6) and “Handling of cords and xtures” (p. 7)

before connecting the measurement cable or xture.

Connect the measurement cables, or optional Hioki test xture to the measurement terminals.

Refer to “Options (Sold Separately)” (p. 2) for options.

Refer to the Instruction Manual of the xture for the operating details.

2

Note the following items when extending the distance between the test sample and

measuring terminals.

• Use 50 Ω coaxial cable for the measurement cable.

• Make the length of the cable as short as possible.

• Perform open/short/load calibration using the connecting terminal of the test sample.

Use the specied probes and xtures. When you make your own probe, it may not satisfy the

specications of this instrument.

Refer to “Options (Sold Separately)” (p. 2).

You will need:

• Test head × 1

• Model IM9200 Test Fixture Stand × 1

• Model IM9906 Adapter × 1

• 3.5 mm Connector torque wrench × 1 (This is not provided with the device.)

1

Metal ttings

Test head

Pull the metal ttings to the model IM9200 Test

1

Fixture Stand side.

Place the test head on the stand and tighten the knob.

2

Measurement Preparations

4

2

Model IM9906

3

Measuring terminal

Notch

3.5 mm connector

5

Model IM9200

nut

Place the notch of the model IM9906 Adapter parallel

3

to the metal ttings, then install onto the measurement

terminal of the test head.

At this time it is stopped temporarily. Position the notch of the

model IM9906 Adapter where the metal ttings can slide.

Fix the notch of model IM9906 adapter by sliding the

4

metal ttings.

Tighten the nut of the 3.5 mm connector by using a

5

torque wrench.

Recommended torque: 0.9 N·m

Tightening the nut until the handle of the wrench bends slightly is

sufcient. Do not over tighten.

21

Connecting an Interface

HIOKI IM7585A981-05

2.5 Connecting an Interface

Rear (Example: IM7585)

To prevent instrument damage or electric shock, use only the screws (M3 × 6 mm)

shipped with the instrument for installing the interface.

If you have lost any screws or nd that any screws are damaged, please contact

your Hioki distributor for a replacement.

• Please read “Input modules (optional)” (p. 8) before connecting the

Interface.

• Read the Instruction Manual of the optional interface before installing or

replacing an optional interface or to use the instrument after removing

the interface.

• You can check the information of the interface installed in the

instrument on the screen.

Refer to “Setting the Interface” (p. 235) and “Checking the Instrument

Version” (p. 236).

WARNING

CAUTION

To connect or disconnect optional interfaces, hold the metal part. Touching the PCB with

bare hands could damage the instrument due to static electricity. (An antistatic wrist

strap is recommended when disconnecting the interface.)

22

You will need: A Phillips head screwdriver (No. 2)

HIOKI IM7585A981-05

Connecting an Interface

Installing the interface

Unplug the power cord of the instrument

1

from the wall outlet.

Disconnect the connection cords.

Rear

(M3 × 6 mm)

Use a Philips screwdriver

2

to remove the two xing

screws and detach the

blank panel.

Pay attention to the

3

orientation of the

(M3 × 6 mm)

Secure the interface in place by

4

tightening the two xing screws

with a Phillips head screwdriver.

interface and insert it

rmly into place.

Attaching the blank panel

Unplug the power cord of the instrument

1

from the wall outlet.

Disconnect the connection cords.

Rear

Attach the blank panel

2

and secure it in place by

tightening the two xing

screws with a Phillips

head screwdriver.

Attach the blank panel to use the instrument

after removing the interface.

Measuring without the blank panel will

prevent the instrument from performing to its

specications.

2

Measurement Preparations

Removing the interface

Unplug the power cord from the wall outlet and

perform the above procedure in reverse order to

remove the interface.

23

Turning the Power ON and OFF

HIOKI IM7585A981-05

2.6 Turning the Power ON and OFF

Connect the probe and test xture before turning the main power on.

Rear (Example: IM7585)

Power switch

(main power)

Turning the main power ON

Turn the main power switch ON ( | ).

The start button on the front will light up in green.

(Lights up in green)

Front (Example: IM7585)

Start button

Turning to the inactive state

Press the start button on the front for

approximately 1 second in the main power ON

state.

The color of the start button on the front changes

to red in the inactive state.

(Lights up in red)

• If the main power switch is turned OFF when

the instrument is in the inactive state, the

instrument will start up in the inactive state the

next time the main power switch is turned ON.

• To measure to the degree of accuracy

mentioned in the specications, allow a warm-

up time of 60 minutes or more after cancellation

of the inactive state.

Turning the main power OFF

Turn the main power switch OFF( ).

The start button on the front will turn off.

(Turns off)

• If the power supply is interrupted by a power

failure, etc, the instrument will return to the

measurement mode used before the power

failure.

• The instrument settings will be retained even if

the main power switch is turned OFF. (This is

backup function.)

Canceling the inactive state

To measure to the degree of accuracy mentioned

in the specications, allow a warm-up time of 60

minutes or more after cancellation of the inactive

state.

Press the start button on the front when the

instrument is in the inactive state.

The start button on the front will light up in green.

(Lights up in green)

What is inactive state?

The state in which the power supply of the instrument

is turned OFF.

(Only the circuit to turn ON the lamp of the start

button is active.)

If the instrument is not used for a long duration,

the internal battery must be charged. The required

charging time is at least 3 hours (recommended, 24

hours) after connecting the power supply and turning

ON the power of the instrument.

24

2.7 Select the Measurement Mode

HIOKI IM7585A981-05

Select any one of the following 3 measurement modes.

Press [MODE].

1

2

3

1

Select the measurement mode.

2

Press [EXIT].

3

Select the Measurement Mode

2

Measurement Preparations

[LCR]: LCR function

The LCR function allows you to measure the passive elements of

capacitors and coils with a single measurement condition.

This is suitable to make pass/fail judgments and classication on

production lines.

• Comparator function: Makes pass/fail judgments by determining whether

measurement values qualify as HI, IN, or LO.

• BIN function: Divides ranks up to 10 classications based on the

measurement values.

[ANALYZER]: Analyzer function

The analyzer function allows you to measure component and material

characteristics while sweeping the measurement frequency and signal

level.

This function provides equivalent circuit analysis based on the results of

frequency characteristics.

A pass/fail judgment based on a resonant frequency is available on

production lines of piezoelectric or similar elements.

• Area judgment: Judges whether the measurement values of the sweep

points are within the judgment area.

• Peak Judgment: Judges whether the peak value of the sweep result is

within the judgment area.

• Equivalent circuit analysis: Equivalent circuit models analysis for circuit

element components.

[CONTINUOUS]: Continuous measurement function

The continuous measurement function allows you to perform a series of

measurements with different conditions.

For example, Consecutive Ls measurement with 1 MHz of and Z

measurement with 100 MHz and its pass/fail judgment can be made.

LCR mode and ANALYZER mode measurement conditions can be

combined.

Up to 46 measurements (30 for LCR mode and 16 for ANALYZER mode)

can be performed continuously.

25

26

HIOKI IM7585A981-05

3

START

END

HIOKI IM7585A981-05

LCR Function

3.1 LCR Function

The LCR function allows you to measure the impedance, phase angle, and other items by applying

a signal of any frequency or level (RMS value) to the element you want to measure. This function is

suitable for evaluating the passive elements such as capacitors and coils.

It allows you to perform measurement while checking the measurement conditions on the

measurement screen. When the power is turned on again, the measurement screen will be

displayed in accordance with the measurement mode used before the power was turned off.

• Conditions set by the LCR function are not incorporated in the analyzer function.

• When a measurement value is outside the guaranteed accuracy range, REF VAL is displayed

in the error display area.

Check the guaranteed accuracy range. Consider measurement values outside the guaranteed

accuracy range as values for reference.

Refer to “Measurement range” (p. 277).

3.1.1 Flowchart

3

LCR Function

Set MODE to LCR

Necessary settings

Measurement parameter

settings

Basic measurement

settings

(FREQ,LEVEL,

SPEED,AVG,DELAY,

SYNC,TRIG)

Calibration/

Compensation

Contact check

settings

User-dened settings

Judgment settings

Common settings

Measurement

27

LCR Function

HIOKI IM7585A981-05

3.1.2 Screen map

Measurement

mode setting

screen (p. 25)

System settings

screen (p. 235)

Trigger

(p. 68)

Advanced settings screen (p. 33)

Compensation settings

screen

(p. 141)

[CAL] Calibration p. 145

[Rdc LIMIT] DC measurement limit value

[LENGTH]

[COMPEN] Compensation p. 155

[Rdc LIMIT] DC measurement limit value

[SCALE] Scaling p. 160

Electrical length

compensation

p. 152

p. 154

p. 159

Select an interface. (p. 235)

The version of the instrument can be veried. (p. 236)

Save

settings

screen

(p. 247)

[SETUP] Sets [SAVE] p. 247

[SAVE] Saves setting conditions p. 247

[LOAD] Reads setting conditions p. 265

[FORMAT] Formats USB ash drive

[DELETE]

[FOLDER]

[RENANE]

[SELECT]

[BACK]

Deletes les p. 273

Creates folders p. 270

Changes le names p. 271

Selects les p. 265

Displays the previous screen

p. 269

Self-checks (self-diagnosis) are enabled. (p. 237) The date and time can be set for the

28

instrument. (p. 242)

Advanced

HIOKI IM7585A981-05

settings

screen

(p. 37)

LCR Function

[FREQ] Measurement frequency p. 37

[LEVEL] Measurement signal level p. 38

[SPEED] Measurement speed p. 40

[AVG] Average p. 41

[DELAY] Trigger delay p. 34

[SYNC] Trigger synchronous output p. 35

[TRIG] Trigger p. 33

[TIMING] Contact check timing p. 171

[AC OUT] AC signal superimposition p. 173

[DC WAIT] Wait time prior to DC measurement p. 172

[WAVE] Number of DC

[AC WAIT] Wait time prior to AC measurement p. 172

[LIMIT] Judgment of DC measurement value p. 174

[ERR ABORT] Quit function in case of judgment error p. 174

[JDG EXEC] Judgment for reference values p. 174

[Hi Z] Hi Z reject function p. 176

[LEV CHECK] Monitoring function for detection level p. 177

[JUDGE] Judgment p. 44

[DIGIT]

[PARA ABS] Display of absolute value p. 180

[COM MEAS]

Number of display digits for each

parameter

Setting for communication command

:MEASURE?

“

samples

”

p. 173

p. 179

p. 181

3

LCR Function

[IO JUDGE] I/O output of judgment results p. 221

[IO TRIG] I/O trigger p. 219

[IO EOM] EOM output method p. 222

[MEMORY] Saving measurement results p. 262

[DISP] LCD display p. 184

[BEEP KEY] Beep sound p. 188

[COM FORM] Communication measurement data type p. 194

[KEYLOCK] Key lock p. 190

[WARM UP] Warm-up notication function p. 189

[PANEL] Panel loading and saving p. 227

[RESET]

Initializing p. 196

29

LCR Function

HIOKI IM7585A981-05

3.1.3 Measurement screen

Switches information to be displayed

on the measurement screen.

Sets measurement parameters. (p. 32)

Displays the measurement value.

Sets the upper and lower

limits. (p. 46)

The judgment result is

displayed. (p. 46)

[SET]

[COMP]

[BIN1] to

[BIN10]

Displays information

regarding LCR

measurement

Displays information on

comparator measurement

judgment standards.

Displays information on

BIN judgment standards.

Switches the display items

among measurement

conditions, upper and

lower limits of comparator

judgment or BIN judgment,

and others.

Displays measurement

conditions, upper and

lower limits of comparator

judgment or BIN judgment,

or others.

The setting window is

displayed by pressing

any measurement

condition area when

measurement conditions

are displayed.

Monitor values

are displayed.

Magnies the screen.

If [ZOOM OFF] is pressed,

the screen returns to the

normal display.

Rdc values are

displayed.

Saves the

measurement

data. (p. 263)

Sets the upper and lower

limit values of the DC

resistance. (p. 174)

The upper and lower limit

values of DC resistance are

displayed.

Inputs the trigger of an external

trigger. (p. 33)

30

3.1.4 Status and error display of this instrument

HIOKI IM7585A981-05

1 2 3 4

LCR Function

Displays the current measurement mode.

1

LCR function

Analyzer function

Continuous measurement

function

Displays error messages.

2

Outside guaranteed accuracy

Hi Z reject error

Error in detection level

Displays information saved in the internal

3

memory.

Number of memories saved

in the internal memory

8765

Displays the state of calibration or

5

compensation.

AC measurement

Calibration disabled

Calibration

Calibration enabled

Compensation

Compensation

DC measurement

Calibration

Compensation

disabled

Compensation

enabled

Calibration disabled

Calibration enabled

Compensation

disabled

Compensation

enabled

3

LCR Function

4

When the instrument

memory becomes full

Displays the type of interface that is

currently connected.

RS-232C

GP-IB

USB

LAN

Displays the connection status of the USB

6

ash drive.

(Blue)

(Red)

Displays the communication state.

7

Displays the date and time set for the instrument.

8

USB ash drive is

connected

USB ash drive is being

accessed

During communication control

Local

31

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

3.2 Setting Basic Settings of Measurement Conditions

3.2.1 Setting Display Parameters

You can select up to 4 types from the 14 types of measurement parameters to display at any

arbitrary location.

The phase angle θ is shown in reference to impedance Z. When performing measurements using

admittance Y as the reference, the sign of the phase angle θ of impedance Z will be reversed.

Refer to “Appx. 1 Measurement Parameters and Calculation Formula” (p. A1).

Refer to “Appx. 3 Series Equivalent Circuit Mode and Parallel Equivalent Circuit Mode” (p. A4).

To display phase angles relative to admittance Y, use the scaling settings to multiply the impedance

phase angle θ by -1.

Refer to “5.4 Calculating Values (Scaling)” (p. 160)

1

Parameter Contents

[Z] Impedance (

[Y] Admittance (S)

[θ]

[Rs] Effective resistance = ESR (

[Rp] Effective resistance (

[Cs] Static capacitance (F) (series

[Cp] Static capacitance (F) (parallel

[D] Loss coefcient = tan

Impedance phase angle (°)

equivalent circuit)

equivalent circuit)

equivalent circuit)

equivalent circuit mode)

)

Ω

Ω

δ

) (series

Ω

) (parallel

1

Parameter Contents

[G] Conductance (S)

[X] Reactance (

[Ls] Inductance (H) (series equivalent

circuit)

[Lp] Inductance (H) (parallel equivalent

circuit mode)

[Q] Q factor

[B] Susceptance (S)

[OFF] No display

Press the parameter key that you want to set.

)

Ω

2

32

3

Select parameters.

2

Press [EXIT].

3

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

3.2.2 Starting Measurement at Any Arbitrary Timing (Trigger)

Starts measurement at an arbitrary timing. A trigger is the function that controls the measurement

start timing with specic signals. The following items are the two types of trigger that can be set for

the instrument.

Internal trigger

External trigger

2

3

4

5

Measurement is repeated automatically. (Trigger signals are

automatically generated internally.)

Measurements are triggered by an external signal.

The trigger is controlled by the EXT I/O, interface, or manual setting

([TRIG]).

Press [SETUP].

1

1

Press the [BASIC] tab.

2

Press [TRIG].

3

Select the trigger type.

4

[INT] Internal trigger

[EXT] External trigger

3

LCR Function

Press [EXIT] to close the advanced settings

5

screen.

When EXT is selected

The following items are the three types of input method for a trigger.

Press [TRIG] on the screen to manually input a trigger.

1

Measurement is performed once.

If measurement takes a long time, [TRIG] may be displayed

as [STOP]. In this case, measurement can be suspended by

pressing [STOP].

Input via EXT I/O.

2

Measurement is performed once, each time a negative logic pulse signal is applied.

Refer to “8.1 External Input/Output Connector and Signals” (p. 199).

Input from interface.

3

Measurement is performed once when

Refer to Communication Commands included on Impedance Analyzer Application Disc.

*TRG

is transmitted.

33

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

3.2.3 Setting the Delay Time from Trigger to Measurement Start (Trigger Delay)

The delay time period from input of the trigger signal to measurement (delay time) can be set.

With this function, it is possible to ensure that measurement is started after the connection condition

of the object to be tested and the test probe (xture) has stabilized.

Refer to “8.1 External Input/Output Connector and Signals” (p. 199).

Trigger delay: OFF Trigger delay: ON

TRIG

EOM

INDEX

Signal

Measurement Calculation

Even when the trigger delay is being used, the LED for indicating that measurement is in progress is lit.

TRIG

EOM

INDEX

Signal

Press [SETUP].

1

Measurement Calculation

Trigger delay

1

Press the [BASIC] tab.

2

2

Press [DELAY].

3

3

34

6

4

5

The numeric keypad can be

used for input.

Set the delay time with / or the numeric

4

keypad.

(With the numeric keypad, press [SET].)

Settable range 0.00000 s to 9.99999 s

Resolution 10 µs

[C]

Press [EXIT] to close the trigger delay setting

5

screen.

Press [EXIT] to close the advanced settings

6

screen.

The delay time becomes 0 s and this

function is disabled.

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

3.2.4 Applying the Signal to the Sample during Measurement Only (Trigger Synchronous Output)

This function outputs the measurement signal after the trigger input and applies the signal only to

the sample during measurement.

You can also set a delay time to ensure that data is acquired after the sample stabilizes.

This reduces the generation of heat in the sample and decreases electrode wear.

Output of INDEX signals for switching to the next sample can be delayed till after the measurement

signal is completely OFF (0 V) after measurement has been completed (INDEX delay).

Trigger synchronous output: OFF Trigger synchronous output: ON

TRIG

EOM

INDEX

Signal

Measurement Calculation

2

3

1

TRIG

EOM

INDEX

Signal

Synchronous

signal wait

Press [SETUP].

1

Press the [BASIC] tab.

2

Press [SYNC].

3

3

LCR Function

INDEX delay

Measurement Calculation

4 5

9

Press [SYNC].

4

Select

5

output.

[OFF] Disables the trigger synchronous output.

[ON] Enables the trigger synchronous output.

Go to the next page.

[OFF] or [ON]

for the trigger synchronous

35

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

Wait time

6

INDEX time

7

8

Use / to set the wait time (time to stabilize)

6

from the time a measurement signal has been

output by applying a trigger to the start of the

measurement.

(With the numeric keypad, press [SET].)

Settable range 0.00000 s to 9.99999 s

The numeric keypad can

be used for input.

7

8

9

• When the trigger synchronous output function is set to [ON], the measurement time increases due to

the addition of a wait time between output of the measurement signal and data acquisition.

Refer to “(3) Measurement Time” (p. 283).

• If a measurement condition is changed when the trigger synchronous output function is set to [ON], a

measurement signal of the set level may be output momentarily.

• The measurement signal is output when the trigger signal is input and stops after measurement ends.

• In CONTINUOUS measurement mode, the measurement condition is set as the setting of the initial

pulse after measurement of the last panel is completed.

If the trigger synchronous function is set to [ON] for the initial panel, the measurement signal stops.

[C]

Set the INDEX delay time.

(With the numeric keypad, press [SET].)

Settable range 0.00000 s to 0.10000 s

Press [EXIT] to close the trigger synchronous

output setting screen.

Press [EXIT] to close the advanced settings

screen.

Sets to the default value.

(The time is set to 0.001 s.)

Trigger delay: ON Trigger synchronous output: ON

TRIG

EOM

INDEX

Signal

Trigger delay Synchronous signal wait INDEX delay

Measurement Calculation

36

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

3.2.5 Setting the Measurement Frequency

Sets the frequency of the signal applied to the test sample. The measurement value of the

measurement frequency level may change according to the sample tested.

Press [SETUP].

1

1

Press the [BASIC] tab.

2

2

Press [FREQ].

3

6

3

3

LCR Function

When setting with / (each digit)

4

5

The input method can be switched

between [DIGIT] and [10-KEY].

To set the frequency with the

numeric keypad

4

5

Set the frequency with / or the numeric

4

keypad.

Settable range:

IM7580A 1.0000 MHz to 300.00 MHz

IM7581 100.00 kHz to 300.00 MHz

IM7583 1.0 MHz to 600.0 MHz

IM7585 1.0 MHz to 1.3000 GHz

IM7587 1.0 MHz to 3.0000 GHz

When setting with / (each digit)

Holding down / changes the value continuously.

[×10] Sets the measurement frequency to 10×.

[/10] Sets the measurement frequency to

1/10×.

To set the frequency with the numeric keypad

Changing the unit: G (giga)/M (mega)/k (kilo)

[C] Repeats the input.

• The unit keys are enabled if a numerical value is input.

• The frequency is set on when any unit key is pressed

• If the setting exceeds the maximum frequency: The

maximum frequency will be set automatically.

• If the setting is below the minimum frequency: The

minimum frequency will be set automatically.

Press [EXIT] to close the measurement frequency

5

setting screen.

Press [EXIT] to close the advanced settings

6

screen.

37

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

3.2.6 Setting the Measurement Signal Level

Sets the measurement signal level.

The value of the measurement signal level may change based on the sample tested.

This instrument can set the test signal applied to the object to be tested using the following three

methods.

Power (P) mode

Voltage (V) mode

Current (I) mode

• The setting resolution of the signal level is always 0.1 dB irrespective of the setting signal

mode.

When the level is set in the voltage or current mode, the input values are automatically

converted to the setting value with a resolution of 0.1 dB.

• The measurement accuracy varies according to the measurement signal level.

Refer to “Measurement range” (p. 277).

Sets the measurement signal level with the power (dBm) at the DUT

port 50

Sets the measurement signal level with the voltage (V) when the

DUT port is open.

(value of dBm converted into V)

Sets the measurement signal level with the current (A) when the

DUT port is in a short circuit state.

(value of dBm converted into I)

terminal.

Ω

Press [SETUP].

1

1

2

4 5

3

8

Press the [BASIC] tab.

2

Press [LEVEL].

3

Press [P/V/I].

4

Select the signal setting mode.

5

[POWER] Sets with power (dBm).

[V] Sets with voltage (V).

[I] Sets with current (A).

Go to the next page.

38

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

6

The numeric keypad can

be used for input.

7

Set the voltage or current with

6

keypad.

Measurement

signal mode

Power (P) mode IM7580A,

Voltage (V) mode IM7580A,

Current (I) mode IM7580A,

(With the numeric pad, press [dBm].)

Model Settable range

IM7581

IM7583,

IM7585,

IM7587

IM7581

IM7583,

IM7585,

IM7587

IM7581

IM7583,

IM7585,

IM7587

[C]

Repeats the input.

or the numeric

/

-40.0 dBm to +7.0 dBm

(Resolution: 0.1 dB)

-40.0 dBm to +1.0 dBm

(Resolution: 0.1 dB)

4 mV to 1001 mV

4 mV to 502 mV

0.09 mA to 20.02 mA

0.09 mA to 10.04 mA

3

LCR Function

Press [EXIT] to close the measurement signal level

7

setting screen.

Press [EXIT] to close the advanced settings

8

screen.

When a measurement value is outside the guaranteed accuracy range, REF VAL is displayed in

the error display area.

Check the guaranteed accuracy range and change the measurement conditions or consider the

measurement values as values for reference.

Refer to “Measurement range” (p. 277).

Relationship between the setting values of the measurement signal mode

The relations between the power mode value and the voltage mode value and between the power

mode value and the current mode value are expressed by the following formulas:

VW= × ×2 50( )Ω

DBM

= × ÷×

210 1000 50

10

IW= × ÷2 50( )Ω

DBM

= × ÷÷

210 1000 50

10

Ω

()

Ω

()

DBM

Voltage

:

V

Current

:

I

Power (dBm) settings value

:

39

Setting Basic Settings of Measurement Conditions

HIOKI IM7585A981-05

3.2.7 Setting the Measurement Speed

Changes the measurement time.

Setting the measurement speed to [FAST] enables high speed measurement. Setting to [SLOW2]

enables measurement with high accuracy.

• Perform calibration and compensation again if there is a change in the measurement speed.

Refer to “5 Calibration and Compensation” (p. 141).

• The measurement time varies with the measurement conditions.

Refer to “(3) Measurement Time” (p. 283).

Press [SETUP].

1

1

Press the [BASIC] tab.

2

2

4

3

5

6

Press [SPEED].

3