Page 1

IM3536

HIOKI IM3536A981-04HIOKI IM3536A981-04

LCR METER

Instruction Manual

Aug. 2022 Revised edition 4

IM3536A981-04 22-08H

Read carefully before use.

Keep for future reference.

When using the instrument for the

rst time

Safety Information

Names and Functions of

Parts

Screen Layout and

Operation

p.12 Maintenance and Service p.229

p.20

p.22

Troubleshooting

Error Massage and Error

Display

p.238

EN

[600447564]

Page 2

Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

Introduction ................................................ 1

Verifying Package Contents ..................... 2

Measurement Process .............................. 8

Safety Information ................................... 12

Operating Precautions ............................ 14

1 Overview 19

1.1 Product Overview and

Features .......................................... 19

1.2 Names and Functions of Parts ..... 20

1.3 Screen Layout and Operation ....... 22

Screen transition diagram ...........................22

Viewing measured values

(Measurement screen) ................................24

Select the measurement mode

(MODE screen) ...........................................26

Setting detailed settings such as

measurement conditions (SET screen) ......27

Checking measurement condition

settings information .....................................28

Conguring correction functionality

(ADJ screen) ...............................................29

Conguring the instrument’s interfaces,

setting the time and date, and checking

the system (SYS screen) ............................30

Displaying and manipulating les on the

USB ash drive (FILE screen) ....................31

2 Measurement

Preparations 33

2.1 Preparation Flowchart ................... 33

2.2 Pre-operation Inspection ............... 35

2.3 Connecting the Power Cord .......... 36

2.4 Connecting the Measurement

Cables, Probes, or Fixture ............. 37

2.5 Turning the Instrument On and

Off .................................................... 38

2.6 Setting the Date and Time ............. 40

3.4 Setting Measurement

Conditions (Basic Settings) .......... 46

Required settings ........................................47

User-congurable settings ..........................58

Measurement and data acquisition

timing ..........................................................69

When measuring conductivity and

permittivity ...................................................71

3.5 Judging Measurement Results ..... 72

Setting the judgment mode .........................73

Conguring comparator function

settings (judging measurement results

based on one judgment standard) ..............73

Conguring BIN function settings

(judging measured values based on

multiple judgment standards) ......................78

3.6 Setting Application Settings ......... 83

Range synchronization

(setting measurement conditions for

individual measurement ranges) .................83

Waveform averaging function

(increasing measurement precision or

measurement speed) ..................................86

High-Z reject function

(detecting contact errors during

2-terminal measurement) ............................88

Contact check function

(detecting poor contact with the sample

during 4-terminal measurement) .................89

Memory function

(saving measurement results) ....................91

Number of effective digits of the

measurement value ....................................94

LCD display auto-off

(power-saving mode) ..................................95

Key tones and judgment tones ...................96

Key-lock function

(disabling key operation) .............................97

4 Using Continuous

Measurement Mode 99

3 Performing

3.1 Setting Display Parameters ........... 41

3.2 Viewing Measured Values.............. 44

3.3 Enlarging Display of

IM3536A981-04

Measurements in LCR

Mode 41

To perform DC measurement

(DC resistance measurement) ....................42

Measurement Values ...................... 45

4.1 Setting Which Panels to Use in

Continuous Measurement ............. 99

4.2 Performing Continuous

Measurement ................................ 100

4.3 Checking Continuous

Measurement Results .................. 100

4.4 Changing the Display Timing

Setting

(When You Wish to Shorten the

Screen Update Interval) ............... 101

i

Page 3

Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

4.5 Setting the LCD Display AutoOff

(When You Wish to Save the

Power) ........................................... 102

5 Error Correction 103

5.1 Setting the Cable Length

(Cable Length Correction) ........... 104

5.2 Open Correction ........................... 105

Before performing open correction ...........105

All correction .............................................106

Spot correction .......................................... 11 0

5.3 Short Correction ............................112

Before performing open correction ........... 112

All correction ............................................. 113

Spot correction .......................................... 11 4

5.4 If Open or Short Correction

Fails to Complete Normally ..........116

5.5 Disabling Open and Short

Correction Values ..........................118

5.6 Load Correction

(Correcting Values to Match

Reference Values) .........................119

Procedures for the load correction ............120

To reset the correction condition

settings .....................................................127

When load correction fails to complete

normally ....................................................127

Disabling load correction ..........................128

5.7 Correcting Measured Values

with a User-Specied Correction

Coefcient

(Correlation Correction) .............. 129

6 Saving and Loading

Measurement

Condition and

Correction Value Data 131

6.1 Saving Measurement Conditions

and Correction Values

(Panel Save Function) .................. 132

6.2 Loading Measurement

Conditions and Correction

Values (Panel Load Function) ..... 136

6.3 Changing a Panel Name .............. 137

6.4 Deleting a Panel ........................... 138

7 Setting the System 139

7.1 Setting the Interface

(Controlling the Instrument from

a Computer) .................................. 140

7.2 Checking the Version of the

Instrument ..................................... 140

7.3 Testing the System

(Self Diagnosis) ............................ 141

Panel test ..................................................141

Panel calibration .......................................142

Testing the screen display status and

LED status ................................................142

ROM/RAM test ..........................................143

Testing EXT I/O input/output signals .........143

8 Using USB Flash Drive

(Saving and Loading

Data) 145

8.1 Inserting and Removing a USB

Flash Drive .................................... 146

8.2 Checking the Contents of Files

on a USB Flash Drive ................... 147

8.3 Formatting a USB Flash Drive .... 148

8.4 Saving Measurement Data .......... 149

Saving measurement data in text .............149

Saving a copy of the screen .....................158

To specify the save folder .........................160

8.5 Saving Settings Data ................... 161

Saving instrument settings other than

panels .......................................................161

Save all instrument settings including

panels (ALL SAVE function) ...................... 162

8.6 Loading Instrument Settings ...... 163

Loading settings les or panel les ...........163

Loading settings les including panel

les (ALL LOAD function) .........................164

8.7 Checking the Contents of a File . 165

8.8 Deleting Files and Folders .......... 166

8.9 Creating Folders ........................... 167

8.10 Displaying the USB Flash Drive

Information ................................... 168

9 External Control 169

9.1 External Input/Output Connector

and Signals ................................... 170

Instrument connector and supported

connectors ................................................170

Instrument connector signal assignments 170

Input (IN) signal function details ...............175

ii

Page 4

Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

BCD mode function details .......................176

Output signals when errors occur .............178

9.2 Example Measurement Timing

(Timing Charts) ............................. 179

9.3 Internal Circuitry .......................... 184

Circuit diagrams ........................................184

Electrical specications .............................186

Connection examples ...............................186

9.4 External I/O Settings .................... 188

Setting the delay time (from judgment

result output to EOM

judgment result reset operation ................189

Disabling the trigger input during

measurement and setting the trigger

input effective edge ...................................190

Setting the E

output time ................................................191

Outputting measured values (switching

to BCD mode) (LCR mode only) ...............192

―――

output) and

________

OM output method and

9.5 External Control Q&A .................. 193

9.6 Measurement Using a Computer 194

10 Specications 195

10.1 General Specications ................ 195

10.2 Environmental and Safety

Specications ............................... 200

10.3 Accessories and Options ............ 201

10.4 Function Specications ............... 201

10.5 Interfaces ...................................... 213

10.6 Measurement Range and

Accuracy ....................................... 215

10.7 About Measurement Times and

Measurement Speed .................... 225

11 Maintenance and

Service 229

11.4 Discarding the Instrument ........... 243

Appendix Appx.1

Appx. 1 Measurement

Parameters and

Calculation Formula ........ Appx.1

Appx. 2 Measurement of High

Impedance

Components ..................... Appx.3

Appx. 3 Measurement of In-

circuit Components ......... Appx.4

Appx. 4 Countermeasures

Against Incorporation of

External Noise .................. Appx.5

Countermeasures against incorporation

of noise from the power line .................Appx.5

Countermeasures against noise from

the measurement cables .....................Appx.6

Appx. 5 Supplying DC Bias ........... Appx.6

How to supply a DC bias voltage .........Appx.7

How to supply a DC bias current .........Appx.8

Appx. 6 The Residual Charge

Protection Function ......... Appx.9

Appx. 7 Series Equivalent Circuit

Mode and Parallel

Equivalent Circuit

Mode ............................... Appx.10

Appx. 8 Open Correction and

Short Correction .............Appx.11

Appx. 9 Attaching Rack-

Mounting Hardware to

the Instrument ................ Appx.12

Appx. 10 Dimensional Diagram .... Appx.14

Appx. 11 Initial Settings Table ...... Appx.15

Appx. 12 Device Compliance

Statement ....................... Appx.23

11.1 Calibration, Inspection, Repair,

11.2 Troubleshooting ........................... 231

11.3 Error Massage and Error

and Cleaning ................................. 229

Calibrations ...............................................229

Inspection and repair ................................229

Replaceable parts and operating

lifetimes .....................................................229

Transporting the instrument ......................230

Cleaning ....................................................230

Before returning for repair .........................231

Initializing (system reset) ..........................236

Performing a full reset

(If you are unable to perform a system

reset) .........................................................237

Display .......................................... 238

Index Ind.1

iii

Page 5

Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

iv

Page 6

Introduction

HIOKI IM3536A981-04HIOKI IM3536A981-04

Thank you for purchasing the Hioki IM3536 LCR Meter. To obtain maximum performance from the

instrument, please read this manual rst, and keep it handy for future reference.

Latest instruction manual

The contents of this manual are subject to change, for example as a result of

product improvements or changes to specications.

The latest edition can be downloaded from Hioki’s website.

https://www.hioki.com/global/support/download

This instrument comes with the following documentation. Please refer to these resources as

necessary in light of your specic application.

Type Manual contents

Instruction Manual

(this document)

Communication

Instruction Manual

Detailed information about functionality and

operation; specications

Explanation of communications commands for

controlling the instrument

Printed

edition

–

Product registration

Register your product in order to receive important product information.

https://www.hioki.com/global/support/myhioki/registration

Target audience

This manual has been written for use by individuals who use the product in question or who teach

others to do so. It is assumed that the reader possesses basic electrical knowledge (equivalent to

that of someone who graduated from the electrical program at a technical high school).

Trademarks

Microsoft and Windows are either registered trademarks or trademarks of Microsoft Corporation in

the United States and other countries.

CD edition

–

1

Page 7

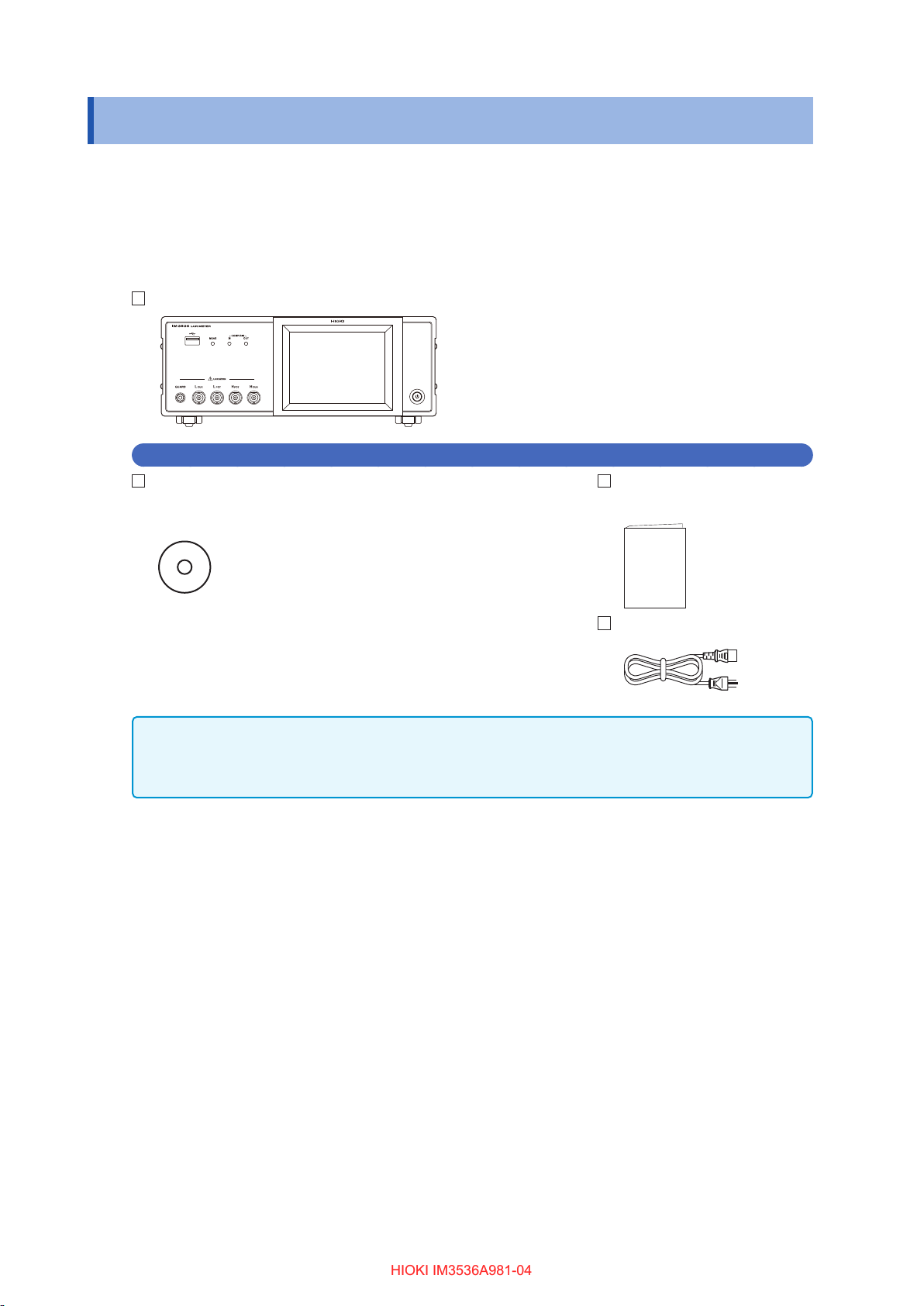

Verifying Package Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during

shipping. In particular, check the accessories, panel switch, button, and connectors. If damage

is evident, or if it fails to operate according to the specications, contact your authorized Hioki

distributor or reseller.

Conrm that these contents are provided.

IM3536 LCR Meter ×1

Accessories

LCR Application Disc ×1

(including the PDF edition of Communications Instruction Manual,

explanations of communications commands, and the USB driver)

Instruction Manual

(This document) ×1

The latest version can be downloaded from our website

Power cord ×1

• Measurement cable and xture are not supplied with the instrument as standard equipment. You should

order them separately, according to requirements.

See “Options (reference: open and short correction states)” (p. 3).

• The instrument ships from the factory congured as described in”Appx. 11 Initial Settings Table” (p. Appx.15).

Precautions when transporting the instrument

Store the packaging in which the instrument was delivered, as you will need it when transporting

the instrument.

2

Page 8

Verifying Package Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

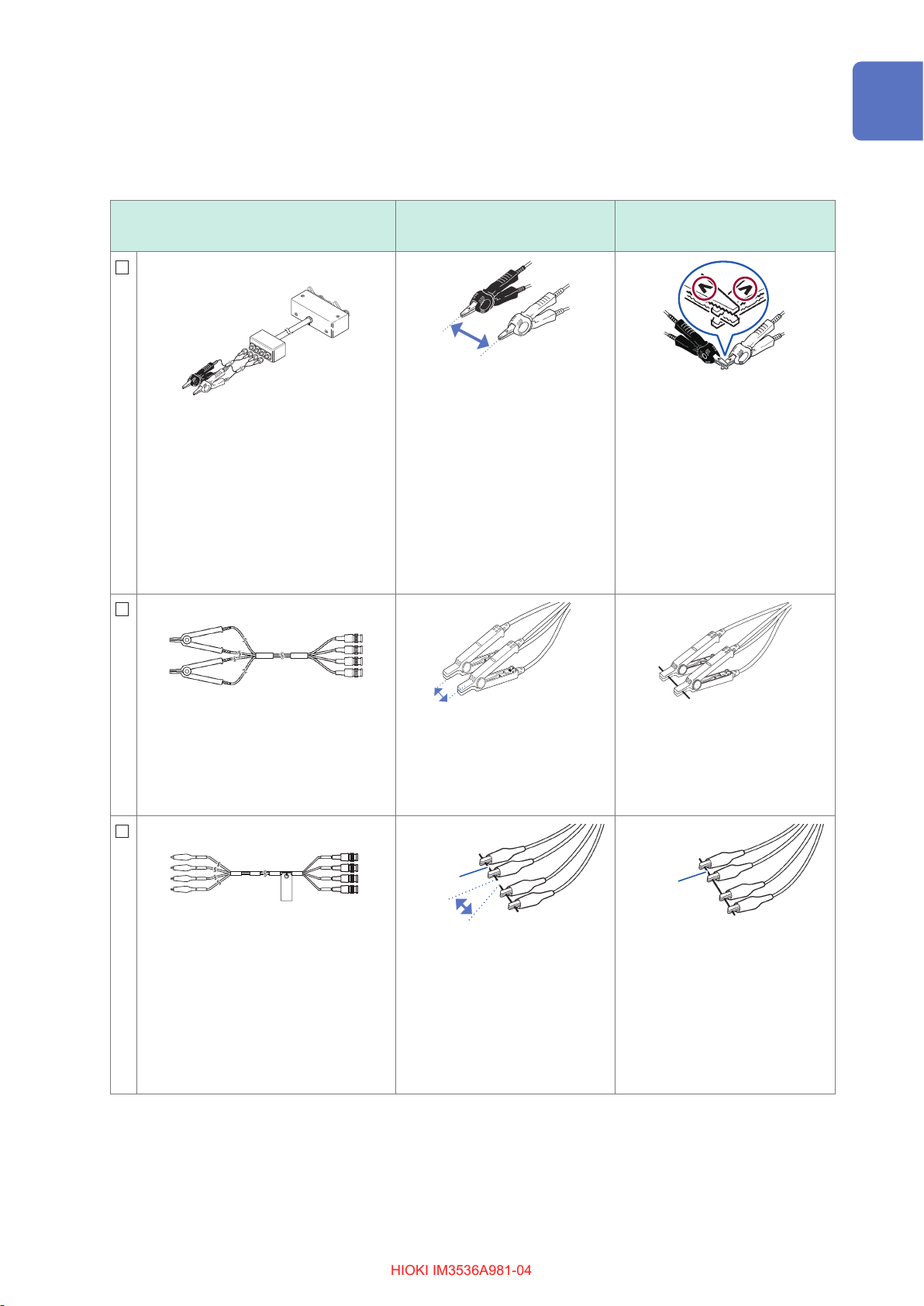

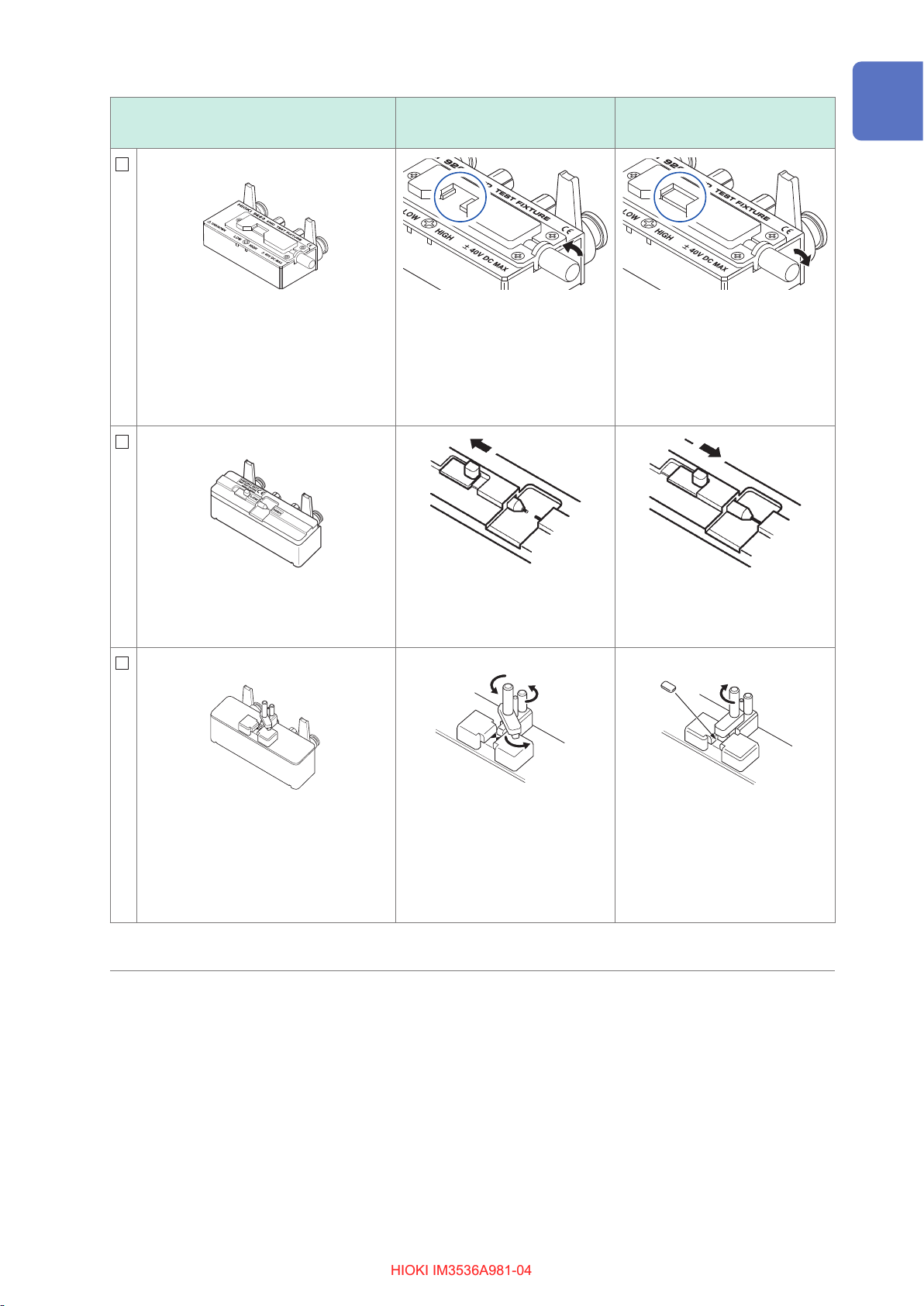

Options (reference: open and short correction states)

The following options are available for the instrument. Contact your authorized Hioki distributor

or reseller when ordering. Options are subject to change. Check Hioki’s website for the latest

information.

Probe type (cord length: 1 m)

L2000 4-Terminal Probe

Measurable range: DC to 8 MHz

Maximum applied voltage: ±42 V peak

(AC+DC)

Maximum applied current: ±1 A peak

(AC+DC)

Measurement terminal hole diameter:

0.3 mm to 5 mm

Alligator-clip-type measurement cables.

These general-purpose dual-electrode

clips t a wide range of conductor

thicknesses.

9140-10 4-Terminal Probe

Open state during open

correction

Width of the measurement

sample

Close the tips of the probes and

place the probes so that they are

as far apart as the width of the

measurement sample.

Shorted state during short

correction

L

POT

L

CUR

Clamp the probe tips together

with the V mark facing up.

H

POT

H

CUR

Measurable range: DC to 200 kHz

Maximum applied voltage: ±42 V peak

(AC+DC)

Maximum applied current: ±1 A peak

(AC+DC)

Measurement terminal hole diameter:

0.3 mm to 5 mm

9500-10 4-Terminal Probe

Measurable range: DC to 200 kHz

Maximum applied voltage: DC±40 [42

V peak (Measurement signal + bias

voltage)]

Maximum applied current: 1 A peak

(Measurement signal + bias voltage)

Measurement terminal hole diameter:

0.3 mm to 2 mm

Rubber-sheathed alligator clip type

Width of the measurement

sample

Close the tips of the probes and

place the probes so that they are

as far apart as the width of the

measurement sample.

Red (High)

Metal wire

Width of the

measurement

Black (Low)

sample

Clamp a short piece of metal wire

with the H

(red) and the L

CUR

and H

CUR

POT

and L

terminals

POT

terminals (black) of the probes

so that they are as far apart as

the width of the measurement

sample.

Clamp the probes on the short

bar.

Red (High)

Metal wire

Black (Low)

Clamp a short piece of metal wire

in the following probe terminal

order: H

CUR

, H

POT

, L

POT

, L

CUR

.

3

Page 9

Verifying Package Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

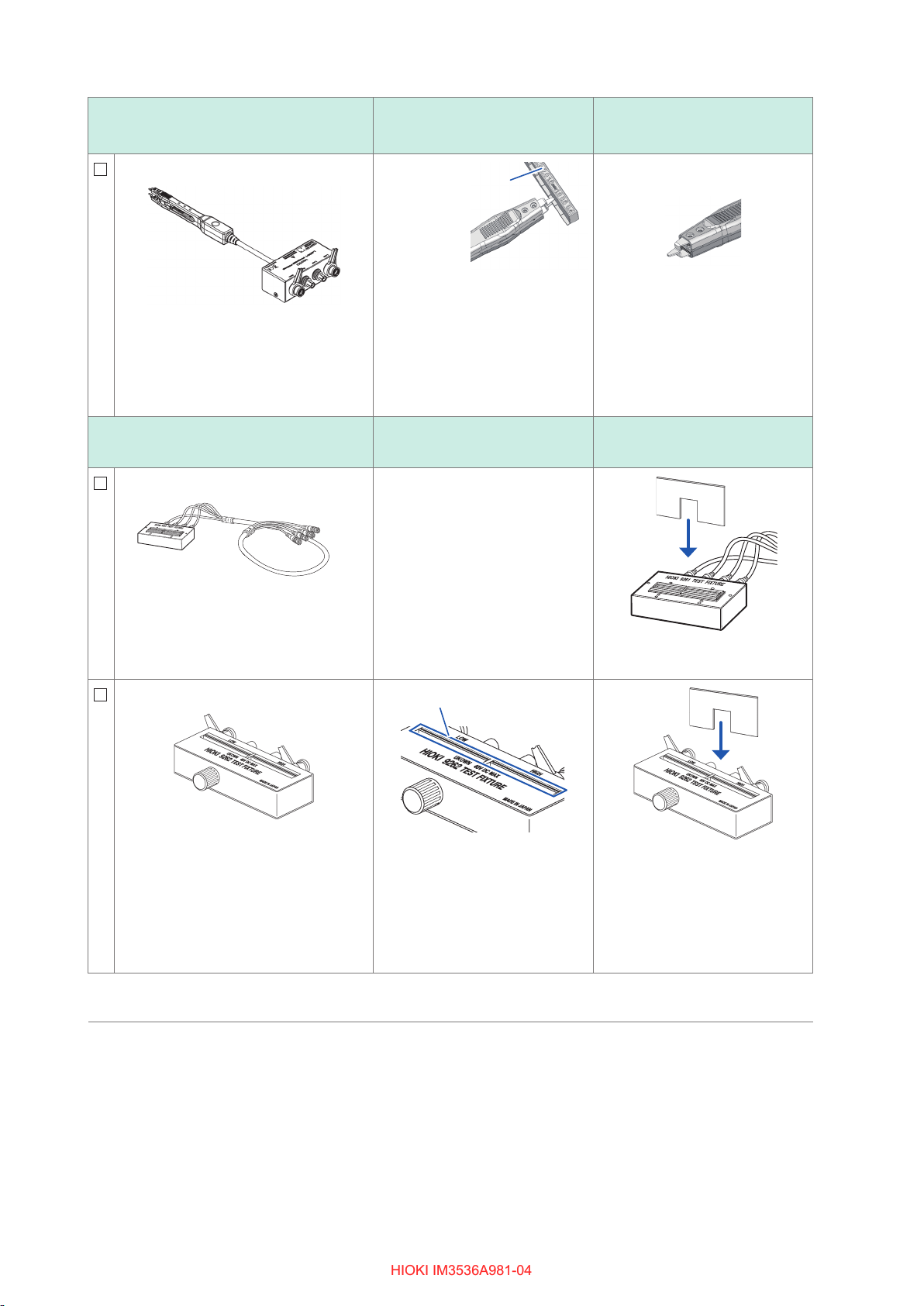

Probe type (cord length: 1 m)

L2001 Pincher Probe

Measurable range: DC to 8 MHz

Maximum applied voltage: ±30 V DC

Space between tip electrodes: 0 mm to

approx. 6 mm

Pincer type

*1

Test xture types

9261-10 Test Fixture

Open state during open

correction

Gradations on open

correction xture

Clamp the tip of the pincers

at the open correction xture

gradation (using the same value

as the length of the measurement

sample), taking care to insert the

pincers all the way.

(For sample 1005, the length is

1.0 mm.)

Open state during open

correction

Connect the 9261-10 and the

instrument with the connection

cable (do not clamp anything to

the xture).

Shorted state during short

correction

Close the tip of the pincers.

Shorted state during short

correction

Measurable range: DC to 8 MHz

Maximum applied voltage: ±40 V DC

Measurement terminal hole diameter:

0.3 mm to 1.5 mm

Cord length: 1 m

9262 Test Fixture

*1

In contact

Insert the short bar all the way

into the sample mounting area.

Measurable range: DC to 8 MHz

Maximum applied voltage: ±40 V DC

Measurable sample dimensions:

Turn the knob clockwise to tighten

the sample mounting area.

Insert the short bar all the way

into the sample mounting area.

Lead diameter of φ0.3 mm to φ2 mm

Lead pitch of 5 mm or more

This fixture is for measuring lead

components. (less than 10 m

residual

Ω

resistance after zero adjustment)

*1: Although the test xture appears to use a four-terminal setup, two terminals provide contact with the sample

since H

POT

and H

as well as L

CUR

POT

and L

are connected inside the xture and probe.

CUR

4

Page 10

Verifying Package Contents

ショート

オープン

HIOKI IM3536A981-04HIOKI IM3536A981-04

Test xture types

9263 SMD Test Fixture

Measurable range: DC to 8 MHz

Maximum applied voltage: ±40 V DC

Measurable sample dimensions: Test

sample width of 1 mm to 10 mm

This fixture is for measuring chip

components. (less than 10 m

resistance after zero adjustment)

9677 SMD Test Fixture

*1

residual

Ω

*1

Open state during open

correction

Turn the knob counterclockwise

to open the high and low

electrodes (use the width of the

measurement sample as the open

spacing).

Shorted state during short

correction

Turn the knob clockwise to tighten

the high and low electrodes.

Measurable range: DC to 120 MHz

Maximum applied voltage: ±40 V DC

Measurable sample dimensions: Test

sample width of 3.5±0.5 mm or less

9699 SMD Test Fixture

*1

Measurable range: DC to 120 MHz

Maximum applied voltage: ±42 V peak

(AC+DC)

Measurable sample dimensions: Test

sample width of 1 mm to 4 mm

Move the knob to open the high

and low electrodes (use the width

of the measurement sample as

the open spacing).

Turn both knobs counterclockwise

to loosen them (do not place

anything in the sample mounting

area).

Move the knob to close the high

and low electrodes.

Position the included short bar

in the sample mounting area

and turn the knobs clockwise to

secure the measurement sample

in place.

Test sample height of 1.5 mm or less

This xture is for the lower electrode.

*1: Although the test xture appears to use a four-terminal setup, two terminals provide contact with the sample

since H

POT

and H

as well as L

CUR

POT

and L

are connected inside the xture and probe.

CUR

5

Page 11

Verifying Package Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

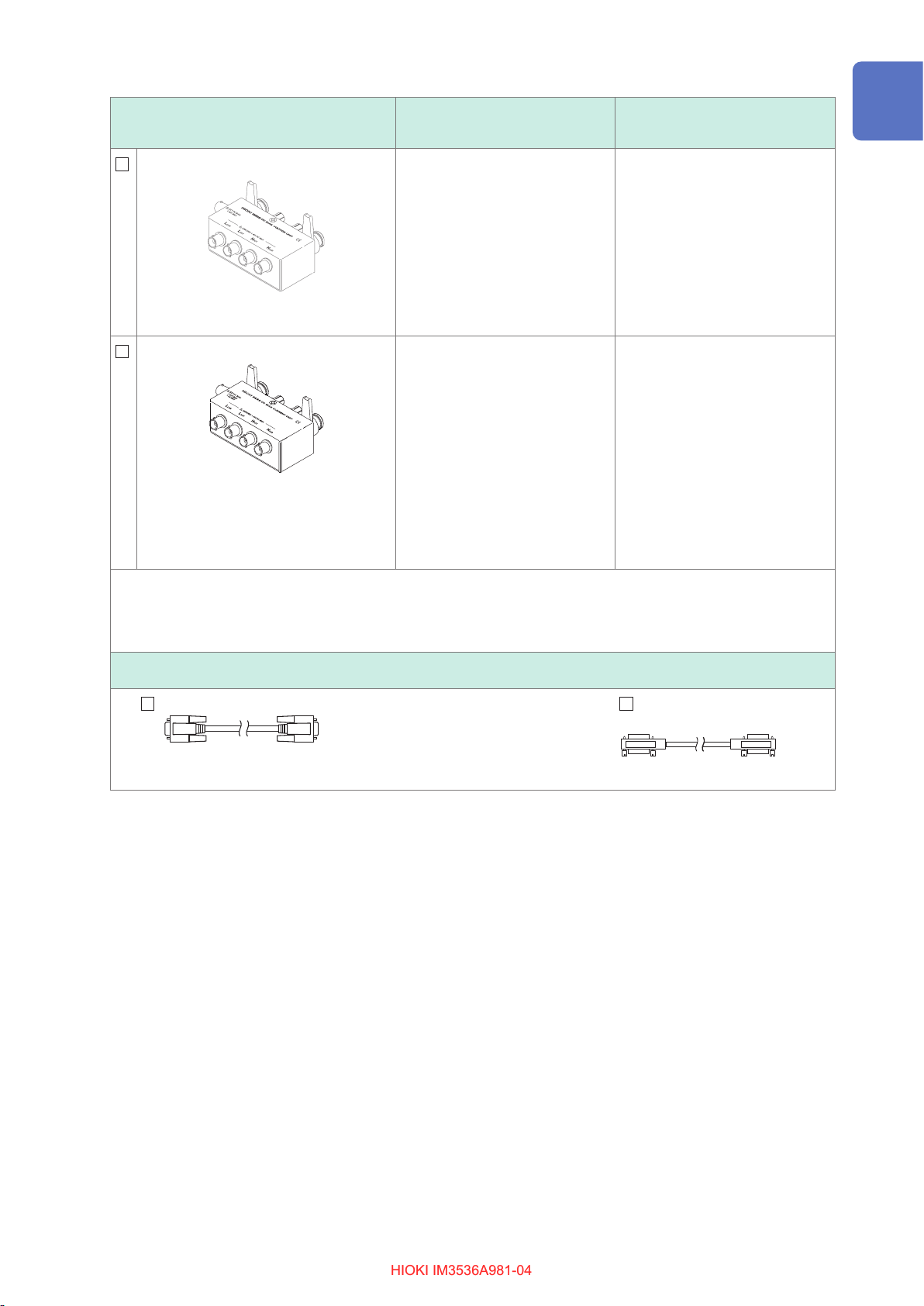

Test xture types

IM9100 SMD Test Fixture

Measurable range: DC to 8 MHz

Maximum applied voltage: ±40 V DC

Maximum applied current: 0.15 A rms

(±0.15 A DC)

Measurable sample dimensions:

JIS (EIA): L mm × W mm

0402 (01005) : 0.4 mm × 0.2 mm

0603 (0201) : 0.6 mm × 0.3 mm

1005 (0402) : 1.0 mm × 0.5 mm

For use with SMD components

IM9110 SMD Test Fixture

Measurable range: DC to 1 MHz

Maximum applied voltage:

±42 V peak (AC+DC)

Maximum applied current:

0.15 A rms (±0.15 A DC)

Measurable sample dimensions:

0.25 ±20% × 0.125 ±10% × 0.125

±10% mm (notation base on JIS: 0201)

Open state during open

correction

22

11

Mount the open correction xture

for the 1005 in the test head

measurement area with a pair of

pincers.

1. Move the operating lever

toward CLOSE (MEASURE).

2. Find the position where the

measurement probes switch

between an open state and a

short state.

3. From that position, rotate

the micrometer clockwise

by 0.25 mm (a half turn) for

correction.

See the IM9110 SMD Test Fixture

Instruction Manual to perform

open correction using samples.

Shorted state during short

correction

33

11

1. Remove the template.

2. Mount the short correction

xture in the test head

measurement area, passing

the guide pins through the

holes on the xture.

3. Push the tip of the tip pin

gradually into the short

correction xture.

1. Move the operating lever

toward CLOSE (MEASURE).

2. Find the position where the

measurement probes switch

between open and short

states.

3. From that position, rotate the

micrometer counterclockwise

by 0.1 mm for correction.

See the IM9110 SMD Test Fixture

Instruction Manual to use the

short-compensation jig, which

came with the IM9110.

22

6

Page 12

Verifying Package Contents

HIOKI IM3536A981-04HIOKI IM3536A981-04

DC Bias Unit

9268-10 DC Bias Voltage Unit

Measurable range: 40 Hz to 8 MHz

Maximum applied voltage: ±40 V DC

9269-10 DC Bias Current Unit

Measurable range: 40 Hz to 2 MHz

(The upper-limit frequency decreases

to 1 MHz for extended measurement

cables.)

Maximum applied current: 2 A DC

*2

Open state during open

correction

Connect the following items to the

9268-10:

• Measurement cables and xture

or probe (in the open correction

state)

• Bias application cable

• External DC bias power supply

(with the 0 V output setting on)

Connect the following items to the

9269-10:

• Measurement cables and xture

or probe (in the open correction

state)

• Bias application cable

• External DC bias power supply

(setting off)

(Do not connect the bias

application cable.)

Shorted state during short

correction

Connect the following items to the

9268-10:

• Measurement cables and xture

or probe (in the short correction

state)

• Bias application cable

• External DC bias power supply

(with the 0 V output setting on)

Connect the following items to the

9269-10:

• Measurement cables and xture

or probe (in the short correction

state)

• Bias application cable

• External DC bias power supply

(setting off)

(Do not connect the bias

application cable.)

*2: When using the DC Bias Unit to perform short correction for ALL, use the instrument to turn off the DC

measurement.

When using the DC Bias Unit, use the instrument to turn on the DC bias function and set the voltage at 0.00 V.

(p. 63)

Connection cords

9637 RS-232C Cable

9-pin to 9-pin cross type, Cord length: 1.8 m

9151-02 GP-IB Connector

Cable

Cord length: 2 m

7

Page 13

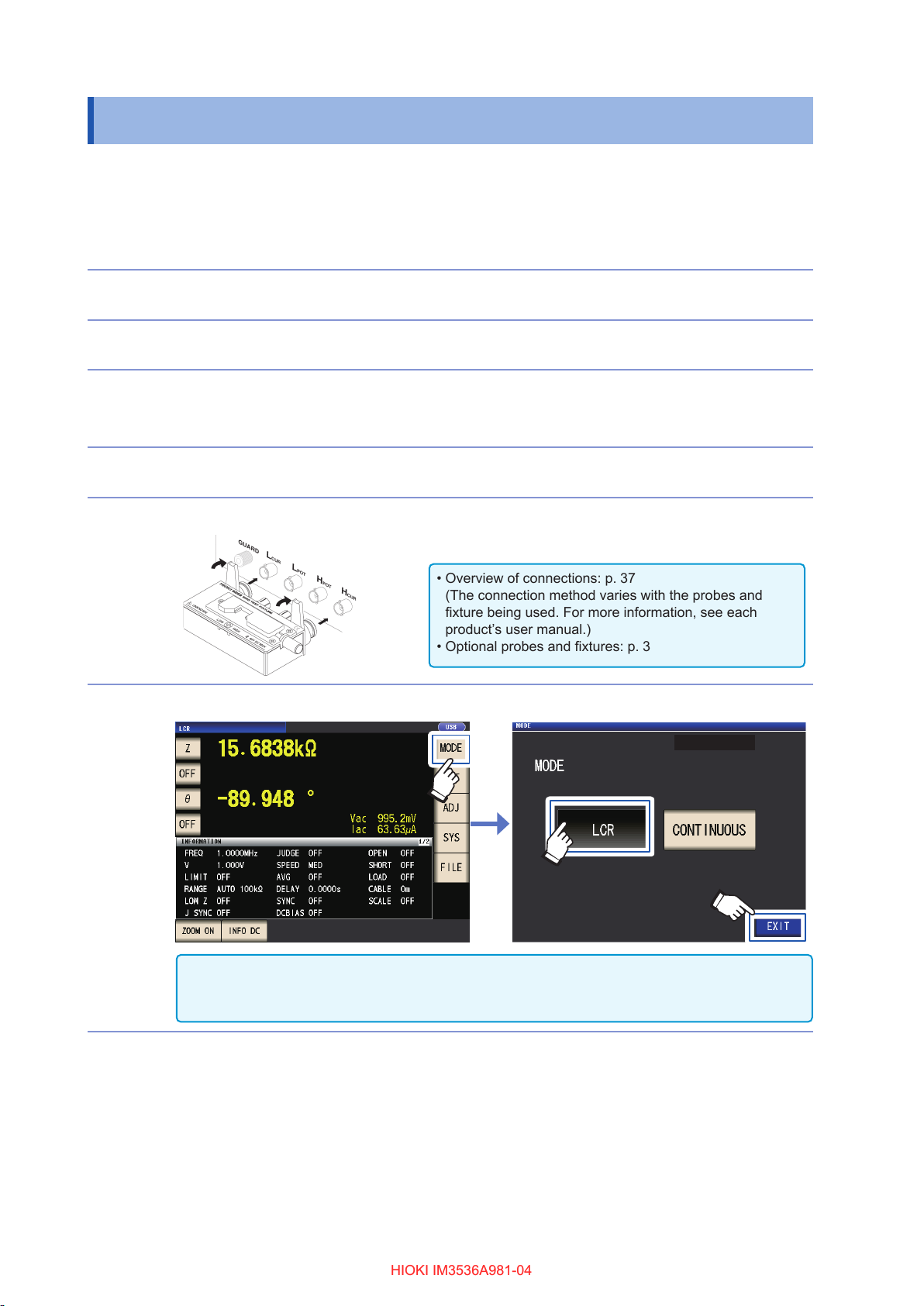

Measurement Process

• Overview of connections: p. 37

(The connection method varies with the probes and

xture being used. For more information, see each

product’s user manual.)

• Optional probes and xtures: p. 3

HIOKI IM3536A981-04HIOKI IM3536A981-04

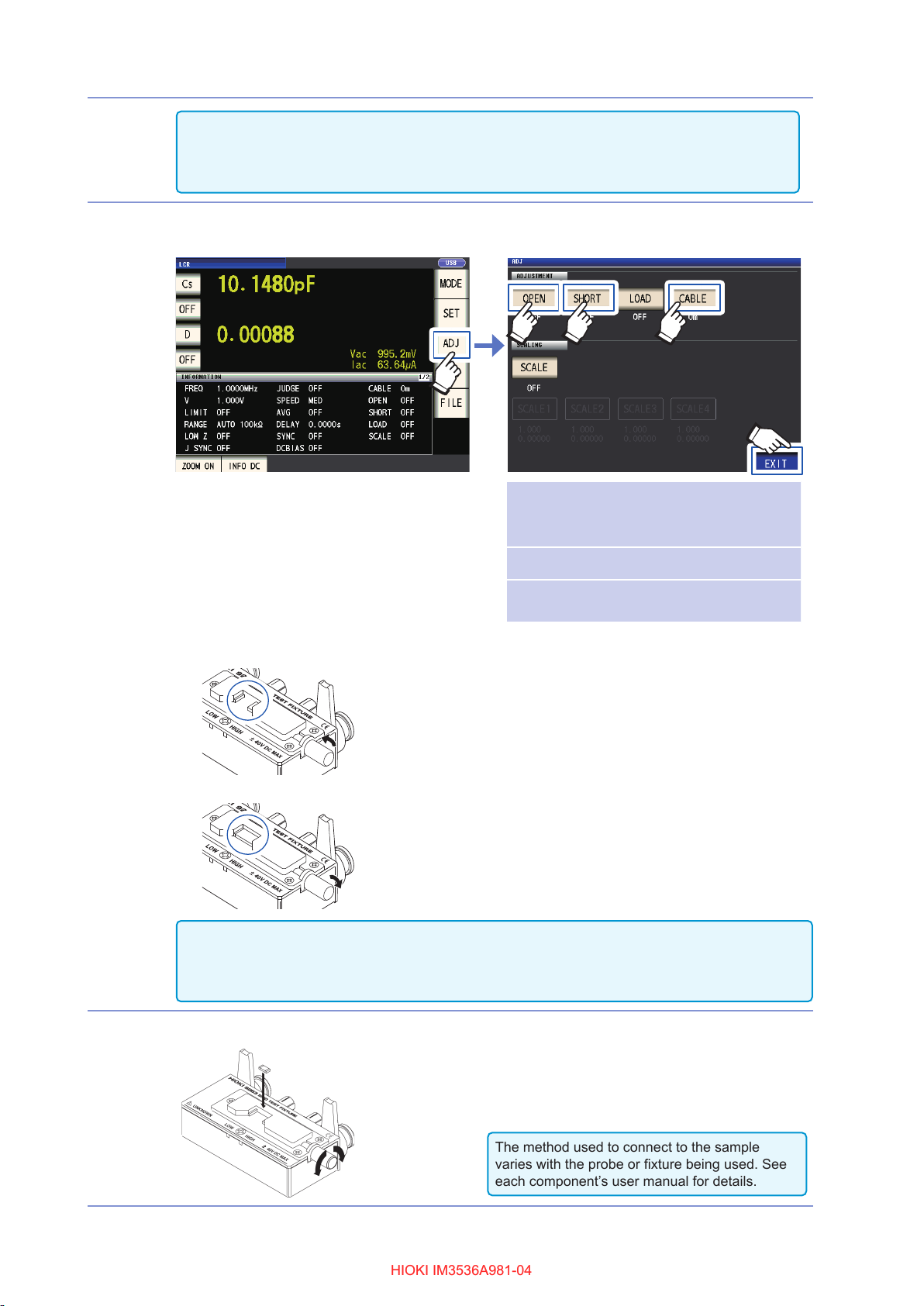

Measurement Process

This section uses AC measurement of a laminated ceramic capacitor as an example to provide an

overview of the instrument’s functionality.

Items to be prepared:

9263 SMD Test Fixture, Laminated ceramic capacity you want to measure

Inspect the instrument before measurement. (p. 35)

1

Connect the power cord to the instrument. (p. 36)

2

Turn on the instrument. (p. 38)

3

4

(A 60-minute warm-up period is necessary before performing the correction process

described in Step 9.)

Set the date and time. (p. 40)

5

6

Connect the 9263 SMD test xture to the measurement terminals.

Set the measurement mode to LCR. (Default setting: LCR)

11

22

33

Use the CONTINUOUS setting if you wish to take continuous measurements under multiple sets of

conditions. (In LCR mode, you must rst set and save the measurement conditions.)

See “4 Using Continuous Measurement Mode” (p. 99).

8

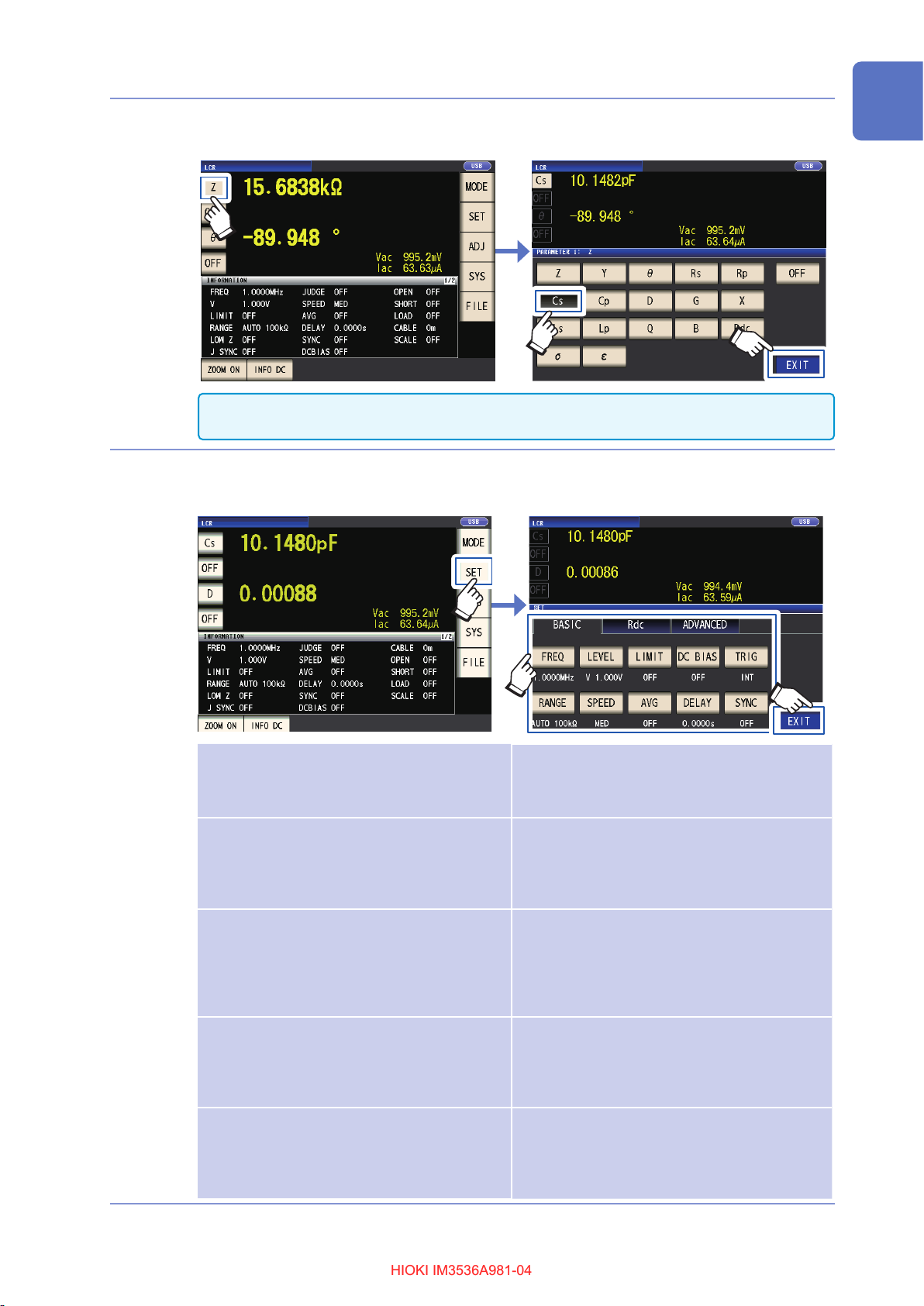

Page 14

7

HIOKI IM3536A981-04HIOKI IM3536A981-04

Set the rst parameter to Cs and the third parameter to D. (p. 41)

Example: Set the rst parameter to Cs

11

Measurement Process

8

22

When you wish to perform DC in addition to AC measurement, set the parameter to Rdc.: “To

perform DC measurement (DC resistance measurement)” (p. 42)

Set the measurement conditions.

Press the SET key, select the BASIC tab, and congure the settings as desired. (The numbers

underneath the buttons indicate the default settings.)

11

22

FREQ

RANGE

LEVEL

SPEED

LIMIT

Measurement frequency: 1.0000 kHz

(p. 47)

(Required: congure based on the

measurement sample.)

Measurement range: AUTO (p. 48)

(Required: congure based on the

measurement sample.)

Measurement signal mode:

Open circuit voltage (V) mode

Measurement signal level: 1.000 V

(p. 52)

(Required: congure based on the

measurement sample.)

Measurement speed: MED (p. 58)

(Optional: Change this setting when

you wish to perform measurement

more quickly or at a higher level of

precision.)

Voltage and current limit: OFF

(p. 62)

(Optional: Set to ON when you wish

to limit the voltage or current that is

applied to the sample.)

AVG

DC BIAS

DELAY

TRIG

SYNC

Average: OFF (p. 60)

(Optional: Set to ON when you wish to

prevent instability in the display value.)

DC bias: OFF (p. 63)

(Optional: Set to ON when you wish

to superimpose the DC voltage on

the measurement signal during

capacitance measurement.)

Trigger delay: 0.0000 s (p. 67)

(Optional: If the trigger synchronous

output function is enabled, set to a

large enough value that measurement

can stabilize.)

Trigger: INT (p. 66)

(Optional: Set to EXT when you wish

to input the trigger manually, using

EXT I/O, or using the interface.)

Trigger synchronous output function:

OFF (p. 68)

(Optional: Change the setting when

you wish to apply the signal to the

sample during measurement only.)

33

33

9

Page 15

Measurement Process

The method used to connect to the sample

varies with the probe or xture being used. See

each component’s user manual for details.

HIOKI IM3536A981-04HIOKI IM3536A981-04

• To save measurement conditions internally or load previously saved measurement conditions:

“6 Saving and Loading Measurement Condition and Correction Value Data” (p. 131)

• To perform DC (DC resistance) measurement: “3.4 Setting Measurement Conditions (Basic

Settings)” (p. 46)

Wait at least 60 minutes after turning on the instrument and then perform correction.

9

1. Press the ADJ key.

2233 44

11

55

CABLE

OPEN

SHORT

2. Set the cable length (for the 9263, use a setting of 0 m).

3. Place the 9263 SMD Test Fixture in the open state and perform open correction.

4. Place the 9263 SMD Test Fixture in the shorted state and perform short correction.

• To save measurement conditions internally or load previously saved measurement conditions: “6

Saving and Loading Measurement Condition and Correction Value Data” (p. 131)

• The open state and shorted state vary with the probe or xture being used. (p. 3)

For more information, see each component’s user manual.

“5.1 Setting the Cable Length

(Cable Length Correction)”

(p. 104)

“5.2 Open Correction” (p. 105)

“5.3 Short Correction” (p. 112)

Connect the test sample to the 9263 SMD test xture.

10

10

Page 16

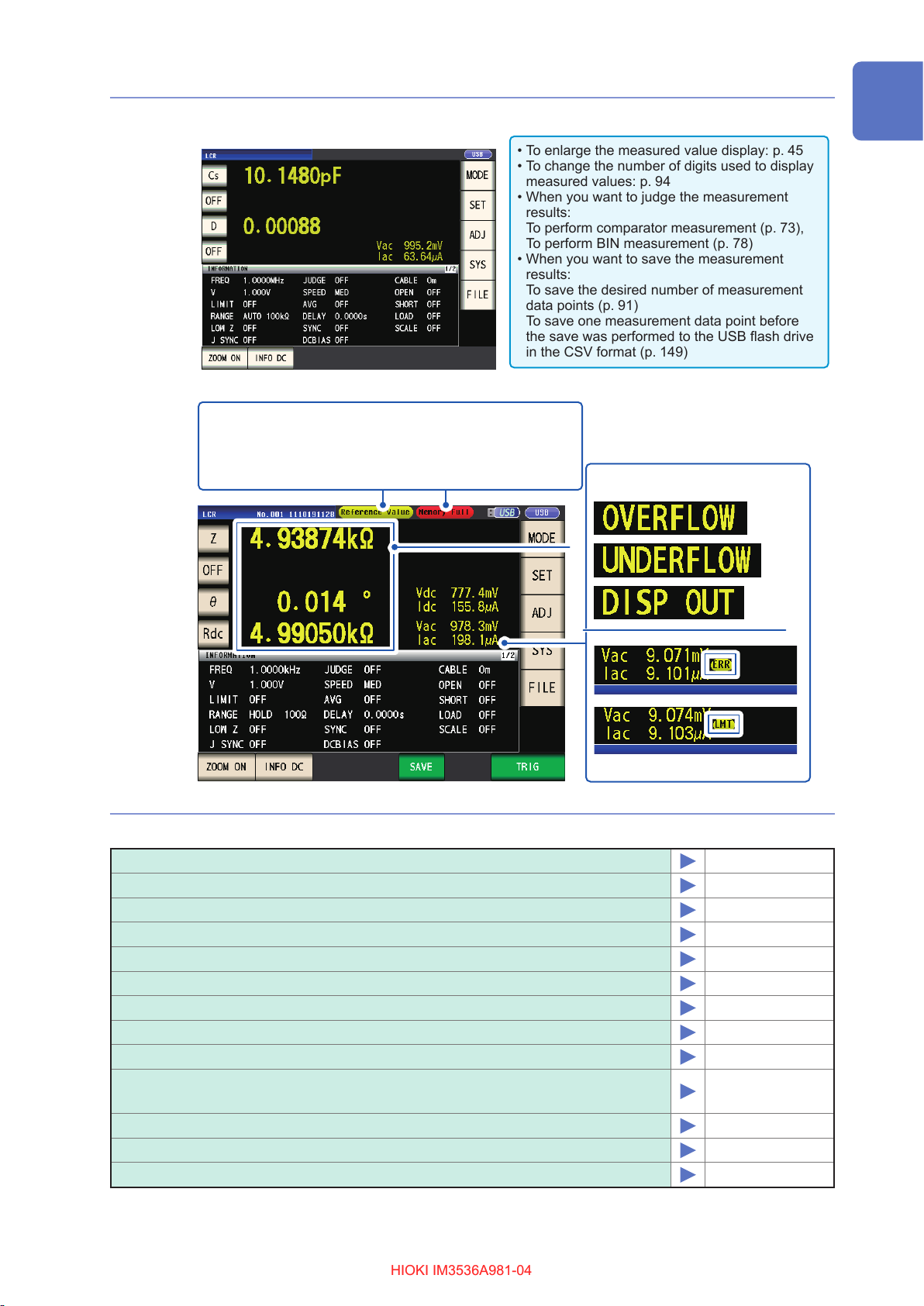

11

• To enlarge the measured value display: p. 45

• To change the number of digits used to display

measured values: p. 94

• When you want to judge the measurement

results:

To perform comparator measurement (p. 73),

To perform BIN measurement (p. 78)

• When you want to save the measurement

results:

To save the desired number of measurement

data points (p. 91)

To save one measurement data point before

the save was performed to the USB ash drive

in the CSV format (p. 149)

HIOKI IM3536A981-04HIOKI IM3536A981-04

Check the measurement results. (p. 44)

Measurement Process

An error message or error display will be shown:

Error massage

Reference Value: No measured value accuracy guarantee

Memory Full: Memory full

Hi Z: Hi Z reject error

Error display

See “11.3 Error Massage and Error Display” (p. 238).

The following functionality is also available

Measuring conductivity and permittivity

Measuring at a high level of precision

Limiting instability of display values

Setting measurement conditions for each measurement range

Increasing the measurement precision or measurement speed

Detecting contact errors during two-terminal measurement

Detecting poor contact with the sample during four-terminal measurement

Changing the key tone or judgment tone

Disabling key operation (key lock function)

Performing measurement by outputting a signal from an external device

to the instrument

Controlling the instrument by sending commands from a computer

Saving settings data to the USB ash drive

Loading settings data from the USB ash drive

p. 71

p. 59

p. 60

p. 83

p. 86

p. 88

p. 89

p. 96

p. 97

p. 66, p. 169

p. 140

p. 161

p. 163

11

Page 17

Safety Information

HIOKI IM3536A981-04HIOKI IM3536A981-04

Safety Information

This instrument is designed to conform to IEC 61010 Safety Standards, and has been thoroughly

tested for safety prior to shipment. However, using the instrument in a way not described in this

manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well as damage to the

instrument. Be certain that you understand the instructions and precautions in

the manual before use.

WARNING

With regard to the electricity supply, there are risks of electric shock, heat

generation, re, and arc discharge due to short circuits. If persons unfamiliar

with electricity measuring instrument are to use the instrument, another person

familiar with such instruments must supervise operations.

Notation

In this manual, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

*

Indicates an imminently hazardous situation that will result in death or serious

injury to the operator.

Indicates a potentially hazardous situation that may result in death or serious

injury to the operator.

Indicates a potentially hazardous situation that may result in minor or moderate

injury to the operator or damage to the instrument or malfunction.

Indicates information related to the operation of the instrument or maintenance

tasks with which the operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the instrument is mishandled,

this may give rise to a hazardous situation; the operator may receive an electric

shock, may get burnt or may even be fatally injured.

Indicates the prohibited action.

Indicates the action which must be performed.

Additional information is presented below.

12

Bold

Windows

Names and keys on the screen are indicated in boldface.

Unless otherwise specied, “Windows” represent Windows 7, Windows 8 and

Windows 10.

Page 18

Safety Information

HIOKI IM3536A981-04HIOKI IM3536A981-04

Symbols on the instrument

Indicates cautions and hazards.

When the symbol is printed on the

instrument, refer to a corresponding

topic in the Instruction Manual.

Indicates a grounding terminal.

Indicates AC (Alternating Current).

Indicates the ON side of the power

switch.

Indicates the OFF side of the power

switch.

Symbols for Various Standards

Indicates the Waste Electrical and

Electronic Equipment Directive

(WEEE Directive) in EU member

states.

Indicates that the product conforms

to regulations set out by the EU

Directive.

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values,

with the following meanings:

f.s.

rdg.

(maximum display value)

The maximum displayable value. This is usually the name of the currently selected range.

(reading or displayed value)

The value currently being measured and indicated on the measuring instrument.

(resolution)

dgt.

The smallest displayable unit on a digital measuring instrument, i.e., the input value that

causes the digital display to show a “1” as the least-signicant digit.

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010 establishes safety standards

for various electrical environments, categorized as CAT II to CAT IV, and called measurement

categories.

DANGER

• Using a measuring instrument in an environment designated with a higher-

numbered category than that for which the instrument is rated could result in a

severe accident, and must be carefully avoided.

• Never use a measuring product that lacks category labeling in a CAT II to CAT

IV measurement environment. Doing so could result in a serious accident.

CAT II: When directly measuring the electrical outlet receptacles of the primary electrical

circuits in equipment connected to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT III:

CAT IV: When measuring the circuit from the service drop to the service entrance, and to the

When measuring the primary electrical circuits of heavy equipment (xed installations)

connected directly to the distribution panel, and feeders from the distribution panel to outlets

power meter and primary overcurrent protection device (distribution panel)

Distribution panel

Service entrance

Service drop

CAT IV

Power meter

Internal wiring

CAT III

Fixed Installation

CAT II

T

Outlet

13

Page 19

Operating Precautions

HIOKI IM3536A981-04HIOKI IM3536A981-04

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benets of the various functions.

Use of the instrument should conform not only to its specications, but also to the specications of all

accessories, options, and other equipment in use.

DANGER

If the probes, cords or the instrument is damaged, there is a risk of electric

shock. Before using the instrument, perform the following inspection.

• Before using the instrument, check that the coating of the probes or cords

are neither ripped nor torn and that no metal parts are exposed. Using the

instrument under such conditions could result in electric shock. Replace the

probes or cords with those specied by our company.

• Verify that the instrument operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized

Hioki distributor or reseller.

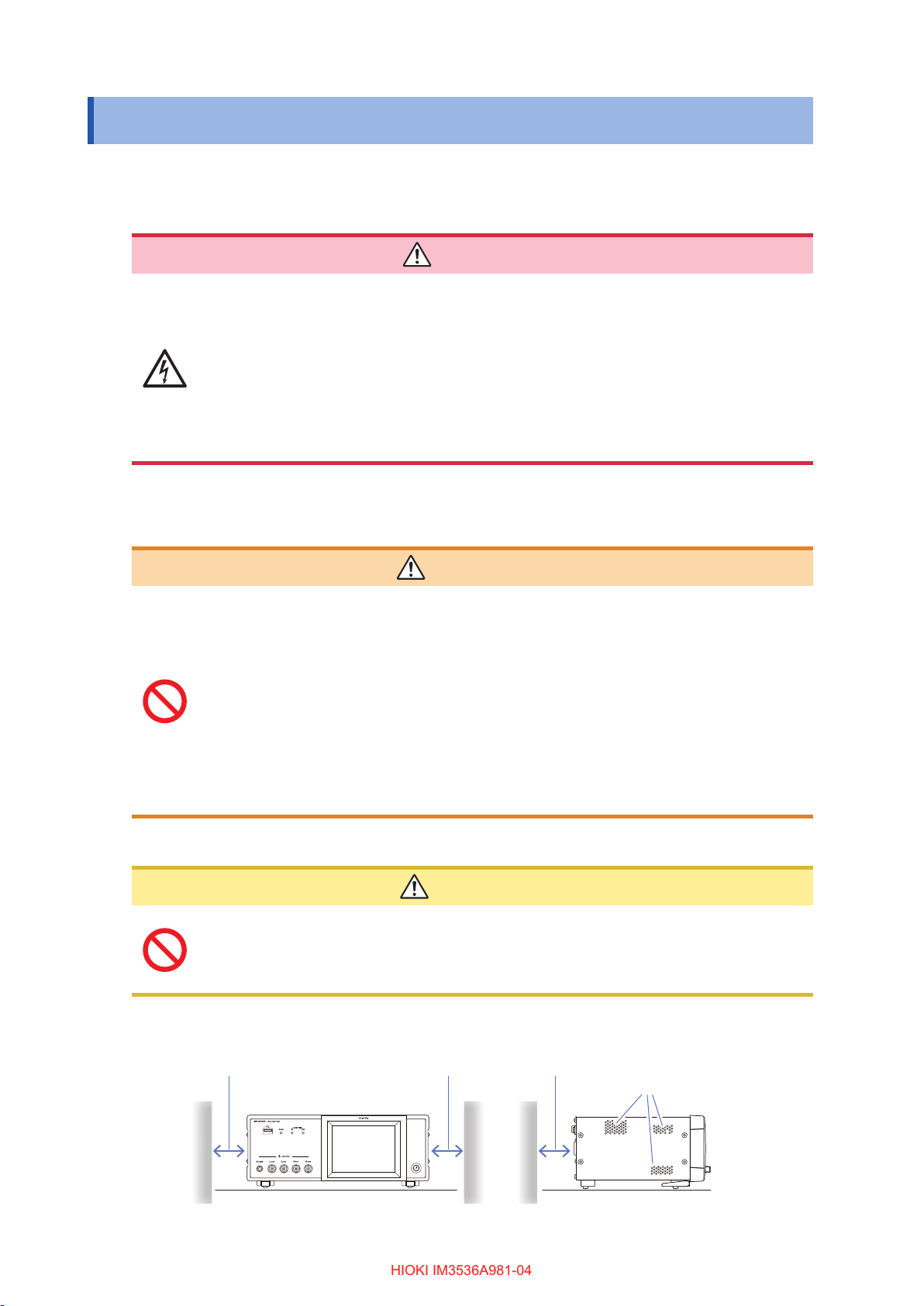

Installing the instrument

Installation environment

Installing the instrument in inappropriate locations may cause a malfunction of

instrument or may give rise to an accident. Avoid the following locations.

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to a strong electromagnetic eld or electrostatic charge

• Near induction heating systems (such as high-frequency induction heating

systems and IH cooking equipment)

• Susceptible to vibration

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to high quantities of dust particles

Installation instructions

• Do not place the device on an unstable table or an inclined place. Dropping or knocking down the device can cause injury or damage to the device.

• Leave sufcient space around the instrument when positioning it. Failure to do so may

result in damage to the instrument or re.

WARNING

CAUTION

14

• Install with the bottom surface facing downward.

• Vents must not be obstructed.

50 mm or more 50 mm or more 10 mm or more

Vents

Back

Page 20

Operating Precautions

HIOKI IM3536A981-04HIOKI IM3536A981-04

The instrument can be used with the stand (p. 20).

It can also be rack-mounted (p. Appx.12).

Shipping precautions

Hioki disclaims responsibility for any direct or indirect damages that may occur when this instrument

has been combined with other devices by a systems integrator prior to sale, or when it is resold.

Handling the instrument

This instrument complies with EN 61326 Class A. This instrument may cause interference if

used in residential areas. Such use must be avoided unless the user takes special measures to

reduce electromagnetic emissions to prevent interference to the reception of radio and television

broadcasts.

DANGER

To avoid electric shock, do not remove the instrument’s case. The internal

components of the instrument carry high voltages and may become very hot

during operation.

• Note that the instrument may be damaged if the applied voltage or current exceeds

the measurement range.

• Do not use excessive force on the touch panel, and do not use sharp objects that

could damage the touch screen.

• Do not apply heavy downward pressure with the stand extended. The stand could be

damaged.

• If the instrument exhibits abnormal operation or display during use, review the information in “11.2 Troubleshooting” (p. 231) and “11.3 Error Massage and Error Display” (p. 238) before contacting your dealer or Hioki representative.

• To avoid damage to the instrument, protect it from physical shock when transporting

and handling. Be especially careful to avoid physical shock from dropping.

• After use, always turn off the instrument.

Before turning on the instrument

• Before turning the instrument on, make sure the supply voltage matches that

indicated on its power connector. Connection to an improper supply voltage

may damage the instrument and present an electrical hazard.

• To avoid electrical accidents and to maintain the safety specications of this

instrument, connect the power cord provided only to a 3-contact (two-conductor

+ ground) outlet.

• Be sure to ground the power cord. Failure to do so will cause the enclosure to

have a voltage equal to half the supply voltage, resulting in electric shock.

• To avoid shock and short circuits, turn off all power before connecting probes

or cords.

CAUTION

WARNING

CAUTION

Do not connect the supply voltage improperly. Doing so may destroy the instrument’s

internal circuitry.

15

Page 21

Operating Precautions

HIOKI IM3536A981-04HIOKI IM3536A981-04

DC resistance measurement only

To suppress noise, the instrument needs to be set to match the frequency of the power source. Before

operating, set the instrument to the frequency of your commercial power. If the supply frequency is not set

properly, measurements will be unstable.

See “Line frequency (DC)” (p. 57).

Handling the cords, xtures, and probes

If the insulation on a cord melts, the metal conductor may be exposed. Do not

use any cord whose metal conductor is exposed. Doing so could result in electric

shock, burns, or other hazard.

• To avoid breaking the cords or probes, do not bend or pull them.

• Avoid stepping on or pinching cords, which could damage the cord insulation.

• Keep in mind that, in some cases, conductors to be measured may be hot.

• To avoid damage to the instrument, do not short-circuit the measurement terminals

and do not input voltage to the measurement terminals.

WARNING

CAUTION

• For safety reasons, disconnect the power cord when the instrument is not used.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it

from the power outlet.

• To prevent damage to the BNC connector or junction, be sure to release the locking

mechanism, grip the head of the connector (not the cord), and pull it out.

• Put the protective cap back on the connector when not in use. If the protective cap is

not properly inserted, dust or other foreign matter may enter the connector and cause

damage.

IMPORTANT

• Use only the specied connection cords. Using a non-specied cable may result in incorrect

measurements due to poor connection or other reasons.

Before using a xture or the like, read the instruction manual supplied with the product to be used.

Before using the USB ash drive

CAUTION

• Do not transport the instrument while a USB ash drive is connected. Damage could

result.

• Inserting a USB ash drive upside down, backwards or in the wrong direction may

damage the USB ash drive and/or the instrument.

16

• Some USB ash drives are susceptible to static electricity. Exercise care when using

such products because static electricity could damage the USB ash drive or cause

malfunction of the instrument.

Page 22

Operating Precautions

HIOKI IM3536A981-04HIOKI IM3536A981-04

IMPORTANT

• USB ash drives have a limited usable lifetime. After long-term use, data reading and writing

will fail, at which time the USB ash drives must be replaced.

• When a USB ash drive is accessed, the color of the USB icon changes from blue to red. Do

not turn off the instrument while the USB ash drive is being accessed. Also, never remove the

USB ash drive from the instrument. Doing so may result in the data in the USB ash drive be-

ing lost.

• Hioki cannot recover data from damaged or faulty storage media resulting from abnormalities.

We are also unable to provide compensation for such data loss,regardless of the contents or

cause of the failure or damage. We recommend making a backup of all important data on a

computer or other storage devices..

With some USB ash drives, the instrument may not start up if it is turned on while the USB ash

drive is inserted. In such a case, turn the instrument on rst, and then insert the USB ash drive.

It is recommended to try out operation with a USB ash drive before starting to use it for actual

measurements.

Before connecting external I/O

WARNING

• The ISO_5V pin of the EXT I/O connector is a 5 V power output. Do not apply

external power to this pin.

To avoid electric shock or damage to the equipment, always observe the following

precautions when connecting to EXT I/O connectors.

• Always turn off the power to the instrument and to any devices to be connected

before making connections.

• Be careful to avoid exceeding the ratings of EXT I/O connectors. (p. 186)

• During operation, a wire becoming dislocated and contacting another

conductive object can be serious hazard. Use screws to secure the external

connectors.

• Ensure that devices and systems to be connected to the EXT I/O terminals are

properly isolated.

CAUTION

To avoid damage to the instrument, observe the following cautions:

• Do not apply voltage or current to the EXT I/O terminals that exceeds their ratings.

• Do not short the ISO_5V and ISO_COM EXT I/O connectors.

See “Instrument connector signal assignments” (p. 170).

Handling the LCR application disc

• When driving relays, be sure to install diodes to absorb counter-electromotive force.

• Exercise care to keep the recorded side of discs free of dirt and scratches. When writing text on a

disc’s label, use a pen or marker with a soft tip.

• Keep discs inside a protective case and do not expose to direct sunlight, high temperature, or

high humidity.

• Hioki is not liable for any issues your computer system experiences in the course of using this

disc.

17

Page 23

Operating Precautions

HIOKI IM3536A981-04HIOKI IM3536A981-04

18

Page 24

1

HIOKI IM3536A981-04HIOKI IM3536A981-04

Overview

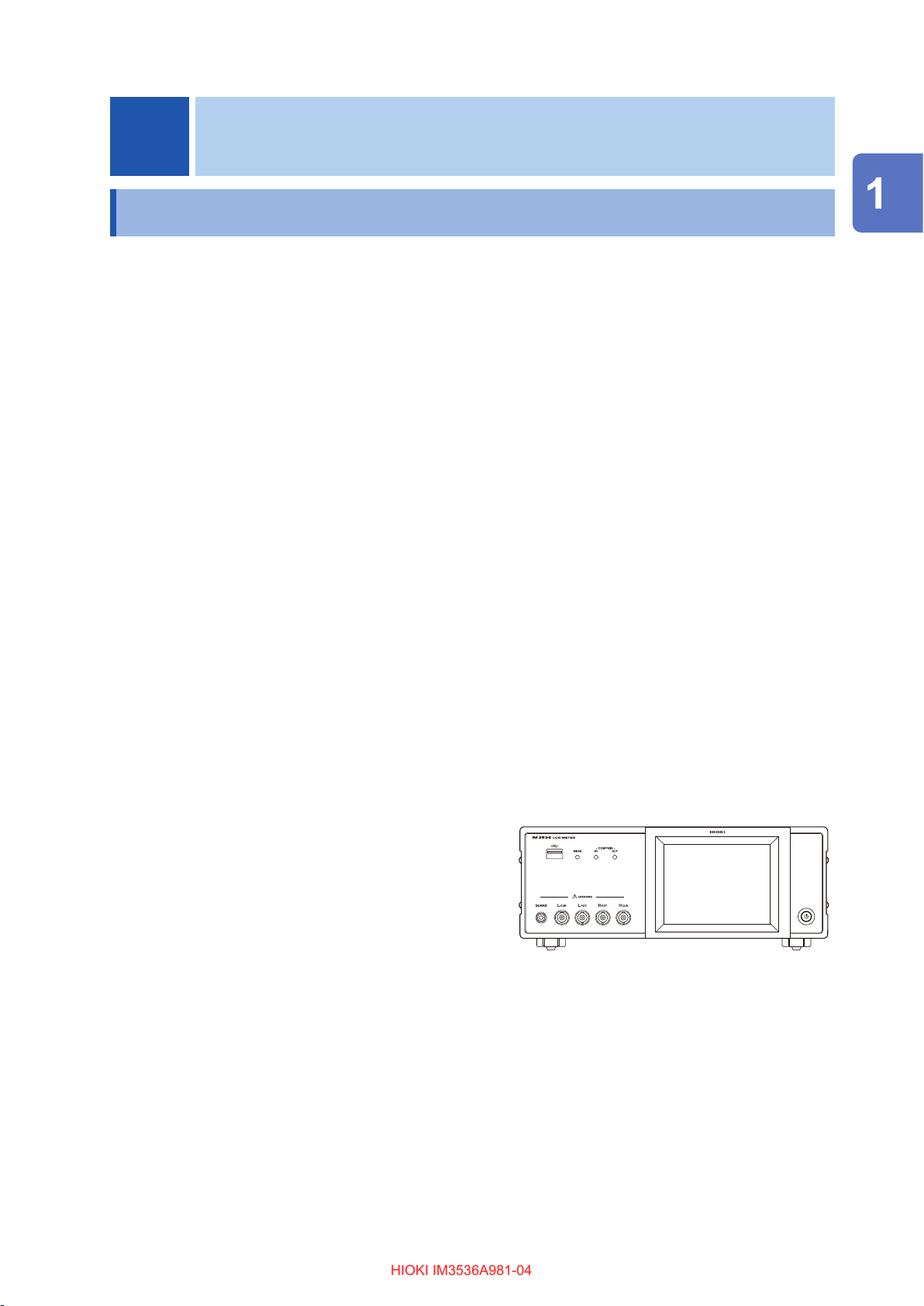

1.1 Product Overview and Features

The HIOKI IM3536 LCR Meter is an impedance measuring instrument which achieves high speed

and high accuracy.

It can be used in a wide range of applications thanks to its broad range of measurement

frequencies and its ability to set measurement conditions based on measurement signal levels.

Overview

Wide range of measurement

conditions

Measurement frequencies: 4 Hz to 8 MHz

Measurement signal levels: 10 mV to 5 V

Continuous measurement mode

Allows measurements to be performed

continuously using precongured

measurement conditions. This function

enables, for example, making pass/fail

judgment with different measurement

conditions.

(Example: Performing C-D measurement with

120 Hz and Rs measurement with 100 kHz in

succession)

Comparator function (p. 73)

Makes HI/IN/LO judgments based on

measured values and two precongured

parameters.

Capable of high-speed

measurement

Up to 1 ms (typical values)

Various interfaces supported

Supports the most suitable EXT I/O (handler

interface) for production lines, USB, GP-IB,

RS-232C and LAN.

BIN function (p. 78)

Ranks measured values in up to 10 categories

based on 2 precongured parameters.

Low impedance can be measured

with high degree of accuracy

Allows you to congure the instrument to

measure low impedance values at a high level

of precision. (p. 59)

19

Page 25

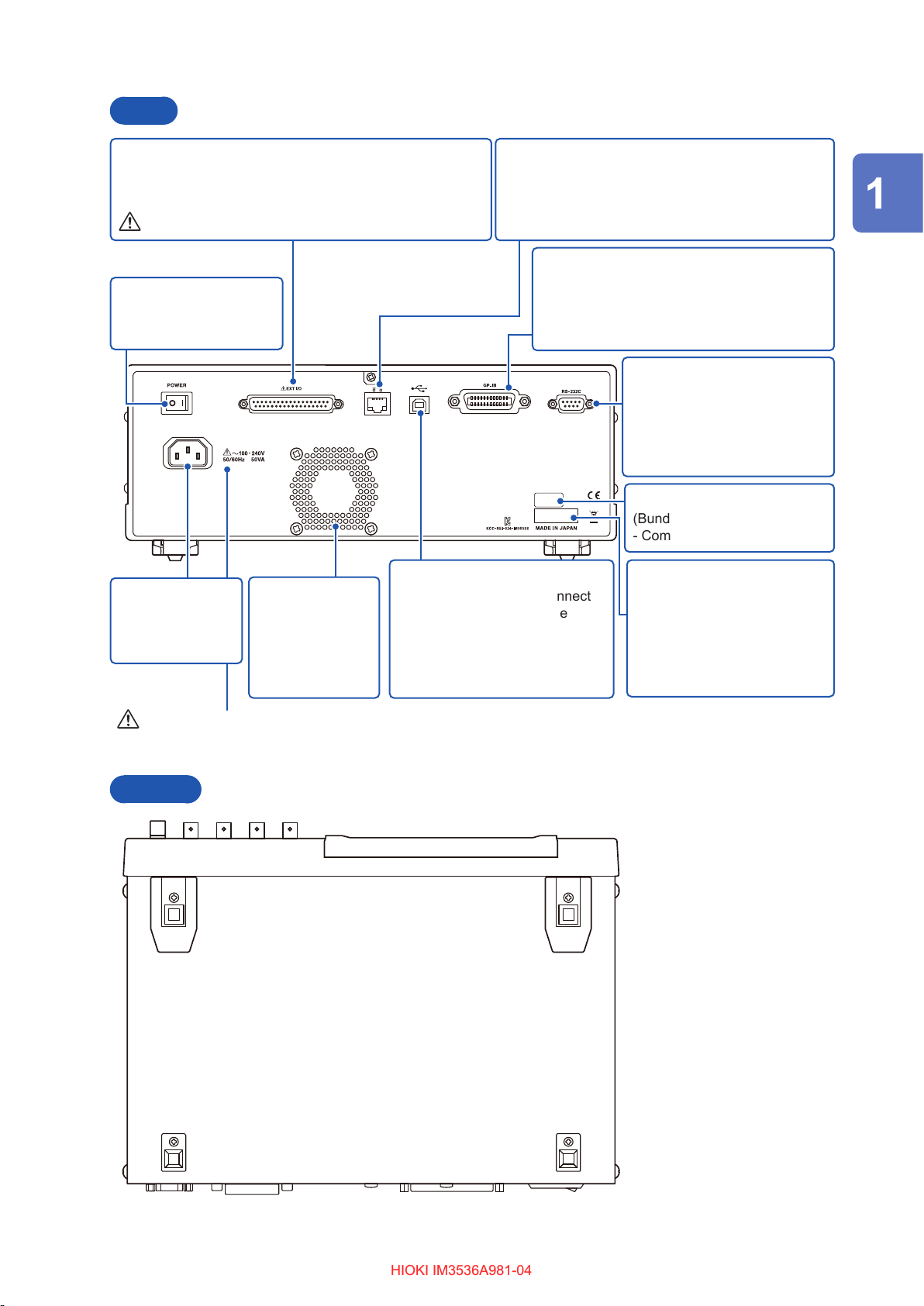

Names and Functions of Parts

HIOKI IM3536A981-04HIOKI IM3536A981-04

1.2 Names and Functions of Parts

Front

Measurement LEDs

Lights during measurement.

Front USB connector

Connect a USB ash drive

storage device (p. 146).

Judgment result

indication LEDs

Indicates the judgment results

for comparator and BIN

measurement (p. 73, p. 78).

See

“Handling the cords,

xtures, and probes”

(p. 16).

Measurement terminals

Connect measurement cables or a

xture(p. 37).

H

jack: Current source terminal

CUR

H

jack: Detected voltage high terminal

POT

L

jack: Detected voltage low terminal

POT

L

jack: Measurement current detected

CUR

GUARD jack: Shield (measurement ground)

terminal

terminal

LCD display

This is a touch panel display.

Press the keys displayed on the

screen to operate the instrument.

Power button

Turns the instrument on and off

while the main power

in the “on” position

(The main power switch is

located at the rear.)

switch is

(p. 38)

.

Left side Right side

Vents

Keep clear of obstructions(p. 14).

Stand

Enables the instrument to be tilted.

CAUTION

Do not apply heavy downward pressure with the stand extended. The stand could be

damaged.

20

Page 26

Rear

HIOKI IM3536A981-04HIOKI IM3536A981-04

Names and Functions of Parts

EXT I/O connector

Allows you to control the start of measurement and capture

judgment results by connecting a PLC or I/O board.(p. 170)

See “Before connecting external I/O” (p. 17).

Main power switch

Turns the power on and

off (p. 38).

Rear USB connector

Power inlet

Connect the

supplied power

cord (p. 36).

Vent

Keep clear of

obstructions.

Keep foreign

objects and other

material away.

Connect a USB cable. Connect

to a computer to control the

instrument with communication

commands.

(Bundled LCR Application Disc Communications Manual)

LAN connector

Allows you to connect the instrument to external

devices using a LAN cable.

(Bundled LCR Application Disc - Communications

Manual)

GP-IB connector

Allows you to connect the instrument to

external devices using a GP-IB cable.

(Bundled LCR Application Disc Communications Manual)

RS-232C connector

Allows you to connect the

instrument to external devices

using a RS-232C cable.

(Bundled LCR Application Disc

- Communications Manual)

MAC address of the LAN

(Bundled LCR Application Disc

- Communications Manual)

Serial number

The rst four digits of the 9-digit

number indicate the year (its

last two digits only) and the

month of manufacture.

Do not remove this sticker as

the number is important.

Overview

See “Before turning on the instrument” (p. 15), and

“Handling the cords, xtures, and probes” (p. 16).

Bottom

This instrument can be rack

mounted.

See “Appx. 9 Attaching RackMounting Hardware to the

Instrument” (p. Appx.12).

21

Page 27

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

1.3 Screen Layout and Operation

This instrument allows you to use a touch panel to set and change all measurement conditions.

Gently touch a key on the screen to select the item or numerical value set for that key.

A selected key turns black.

This manual refers to the act of lightly placing your nger on the screen as “touching” it, and a

nger

mark is used on the screen to represent this action.

Do not use excessive force on the touch panel, and do not use sharp objects that could

damage the touch screen.

Screen transition diagram

Continuous measurement mode

Measurement screen

CAUTION

This screen is

used to select

the measurement

mode (p. 26).

MODE screen

This screen is used to view continuous

measurement results (p. 24).

Return to the Measurement screen with the

EXIT key.

This screen is

used to congure

continuous

measurement

(p. 27).

SET screen

This screen is

used to check and

manipulate les

on the USB ash

drive (p. 31).

FILE screen

22

Page 28

LCR mode

HIOKI IM3536A981-04HIOKI IM3536A981-04

Screen Layout and Operation

This screen is

used to select the

measurement mode

(p. 26).

Overview

Measurement screen

This screen is used to view measured

values and measurement condition

settings information. (p. 24,p. 28)

MODE screen

This screen is used

to congure detailed

settings such as

measurement

conditions (p. 27).

SET screen

This screen is

used to congure

correction

functionality

(p. 29).

ADJ screen

This screen is

used to congure

the instrument’s

interfaces, to set the

time and date, and

to check the system

(p. 30).

Return to the Measurement screen with the

EXIT key.

SYS screen

This screen is

used to check and

manipulate les on

the USB ash drive

(p. 31).

FILE screen

23

Page 29

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

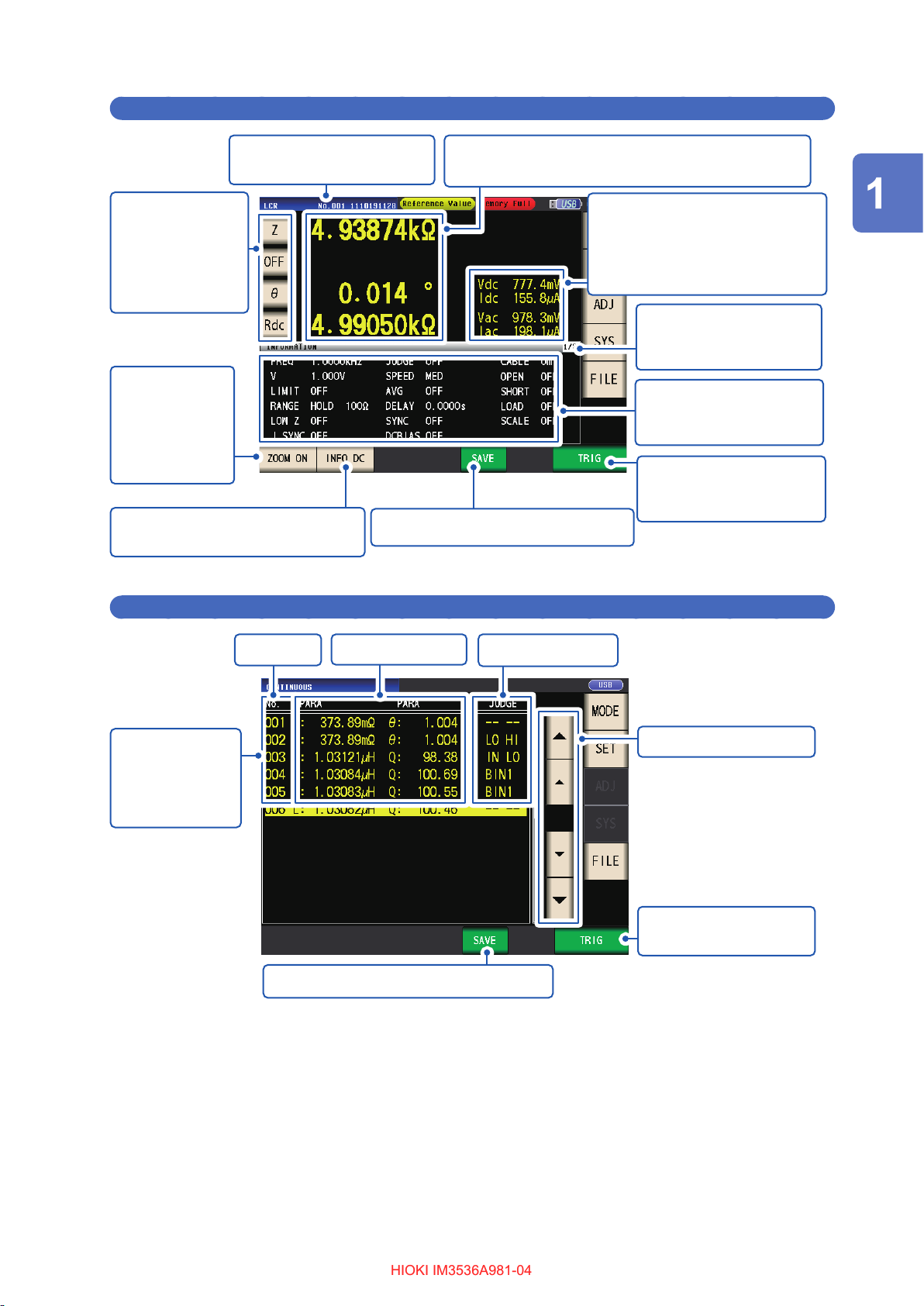

Viewing measured values (Measurement screen)

This is the rst screen displayed when the instrument is turned on.

Touch the EXIT key to return to the measurement screen from another screen.

Displaying elements used in both LCR mode and continuous measurement mode

Indicates the usage status of internal memory (p. 93).

Indicates

the selected

measurement

mode.

Operation keys

Displays operation keys as appropriate for the

measurement mode and instrument state.

Displays error

messages.

(p. 238)

Indicates that a

USB ash drive is

connected (p. 146).

Indicates the interface that is

currently set (p. 140).

Menu keys

MODE

SET Set the advanced settings

ADJ Set the correction (p. 29).

SYS Set the system (p. 30).

FILE Set the save settings (p. 31).

Select the measurement mode

p. 26).

(

(p. 27).

(LCR mode only)

(LCR mode only)

24

Page 30

Measurement screen in LCR mode

HIOKI IM3536A981-04HIOKI IM3536A981-04

Screen Layout and Operation

Indicates the name of the

loaded panel (p. 136).

Parameter keys

Sets which

parameters to

display on the

measurement

screen (p. 41).

Enlarges the

display of

measured values

and comparator

judgment results.

(p. 45)

Switches measurement condition

settings information (p. 28).

Measured values*

Displays measured values for various parameters.

Monitor values

Vac, Vdc: Voltage between the

sample terminals

Iac, Idc: Current passing through

the sample

Displays measurement

condition settings

information.

Displays measurement

condition settings

information. (p. 28)

When the external trigger is

selected, activates the trigger

manually.(p. 67)

Saves the measurement data (p. 151).

*How to view measured values: See “3.2 Viewing Measured Values” (p. 44).

Overview

Measurement screen in continuous measurement mode

Panel No. Measured value

Displays a list of

the panels being

used to perform

continuous

measurement.

Saves the measurement data (p. 151).

*How to view measured value and judgment result: See “4.3 Checking Continuous Measurement Results” (p. 100).

*

Judgment result

*

Scrolls the screen.

Starts continuous

measurement (p. 100).

25

Page 31

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

Select the measurement mode (MODE screen)

This screen is used to select the measurement mode.

Touch the MODE key.

1

After changing the measurement mode, check all settings (including correction) before performing

measurement.

(Correction values will be deleted, so you will need to repeat the correction process.)

Select the measurement mode.

2

Displays the measurement screen for

the selected mode.

LCR LCR mode (p. 41)

CONTINUOUS Continuous measurement

mode (p. 99)

26

Page 32

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

Setting detailed settings such as measurement conditions (SET screen)

This screen is for conguring the measurement conditions you want to change and other advanced

settings.

Select the measurement mode (p. 26) before conguring the advanced settings.

(Example screen: LCR mode)

For more information about the continuous measurement (CONTINUOUS) mode screen, see “4 Using

Continuous Measurement Mode” (p. 99)

Touch the SET key.

1

Touch a tab.

2

Touch the key for the parameter you

3

wish to set.

The settings screen for the parameter will

be displayed.

Congure settings for LCR mode and

4

continuous measurement mode.

See “3 Performing Measurements in

LCR Mode” (p. 41), and “4 Using

Continuous Measurement Mode” (p. 99).

Overview

BASIC Basic setting

Rdc DC resistance measurement

setting (shown during LCR

mode operation only)

ADVANCED Application settings

27

Page 33

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

Checking measurement condition settings information

You can check settings information on the

Measurement screen during LCR mode operation.

Current measurement conditions

(This information is not shown when using the zoom

display (p. 45)).

INFO AC

Information related to AC measurement is displayed.

INFO DC

Information related to DC measurement is displayed.

INFO COMP

(When comparator function has been set)

Displays information about comparator measurement

judgment standards.

Touching the INFO key switches the

displayed information.

(The INFO key display will vary depending

on what type of information is being

displayed.)

INFO BIN

(When BIN function has been set)

Displays information about BIN measurement judgment

standards.

28

Touch again to display information for BIN 6 to BIN 10.

(When display information is for BIN 6 to BIN 10, this

key is INFO AC key.)

Page 34

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

The following information can be displayed:

Display Description Remarks

FREQ Measurement frequency

RANGE Measurement range

LOW Z Low Z high accuracy mode

J SYNC

SPEED Measurement speed

AVG Average

V Measurement signal level

DELAY Trigger delay

SYNC Trigger synchronous output

JUDGE Measurement result judgment

OPEN Open correction

SHORT Short correction

LOAD Load correction

CABLE Cable correction

SCALE Scale correction (Correlation Correction)

LIMIT Limit

DC BIAS DC bias

L FREQ Line frequency

DCR OFFSET DC adjustment value acquisition time

DC DELAY

ADJ DELAY

*1: When set to ON, the display will show ON* if set to a measurement range or measurement frequency for

which the output resistance will be 100

*2: The acquisition time will not be displayed if DC adjustment is ON. When DC adjustment is OFF, the display

will show RESERVED after DC offset acquisition, and the acquisition time will be displayed once acquisition

is complete.

JUDGE synchronization setting for the

measurement range

DC delay

Adjustment delay

*1

For AC and DC

AC: Setting

DC: Fixed to 1.00 V

Used for both AC and DC.

(Displayed for INFO AC only)

AC only

*2

DC only

.(See “Low Z High Accuracy Mode” (p. 59))

Ω

Overview

Conguring correction functionality (ADJ screen)

This screen is used to congure correction functionality (LCR mode only).

Touch the ADJ key.

1

Touch the key for the parameter you

2

wish to set.

The settings screen for the parameter will

be displayed.

Congure the settings.

3

See “5 Error Correction” (p. 103).

29

Page 35

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

Conguring the instrument’s interfaces, setting the time and date, and

checking the system (SYS screen)

This screen is used to congure the instrument’s interfaces, to set the time and date, and to check

the system. (LCR mode only)

Touch the SYS key.

1

Touch a tab.

2

Touch the key for the parameter you

3

wish to set.

The settings screen for the parameter will

be displayed.

Check the settings and version number

4

or perform a test measurement.

See “7 Setting the System” (p. 139).

I/F Congure interface settings

INFO Check the version and other system

information

TEST Check the system

CLOCK Set the time

30

Page 36

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

Displaying and manipulating les on the USB ash drive (FILE screen)

This screen is used to display les saved on the USB ash drive and to congure and edit lerelated settings. It is displayed after the USB ash drive is inserted into the instrument’s receptacle.

Touch the FILE key.

1

Touch a tab.

2

LIST • Display les

• Load, save, or delete (initialize) les

SET Congure le-saving operation

Congure le-saving settings, display

3

les, and manipulate les.

See “8 Using USB Flash Drive

(Saving and Loading Data)” (p. 145).

Overview

31

Page 37

Screen Layout and Operation

HIOKI IM3536A981-04HIOKI IM3536A981-04

32

Page 38

2

HIOKI IM3536A981-04HIOKI IM3536A981-04

Measurement Preparations

2.1 Preparation Flowchart

Before preparing for measurement, be sure to read “Operating Precautions” (p. 14).

Refer to “Appx. 9 Attaching Rack-Mounting Hardware to the Instrument” (p. Appx.12) for rack

mounting.

(1) Installing the instrument (p. 14)

(2) Connecting the power cord (p. 36)

(3) Connecting the measurement cables, optional Hioki probes, or test xture to the

measurement connectors (p. 37)

Check that the instrument’s power switch is set to

the off position.

(4) Connecting the external interface (as needed)

Measurement Preparations

For more information about making RS-232C, GP-IB, USB, and LAN connections, see the

Communications Instruction Manual on the bundled LCR Application Disc.

RS-232C

GP-IB

USB

LAN

(5) Turning on the instrument (p. 38)

External interface

33

Page 39

Preparation Flowchart

HIOKI IM3536A981-04HIOKI IM3536A981-04

(6) Making instrument settings

• First, set the time and date (p. 40).

• When measuring DC resistance, be sure to set the line frequency before performing measurement

(p. 57).

After allowing the instrument to warm up for at least 60 minutes, perform open correction and short

correction and connect the instrument to the sample (p. 38).

34

Page 40

Pre-operation Inspection

The power cord insulation is not

torn, or any metal is not exposed.

HIOKI IM3536A981-04HIOKI IM3536A981-04

2.2 Pre-operation Inspection

Please read the “Operating Precautions” (p. 14) before use.

Before using the instrument, verify that it operates normally to ensure that no damage occurred

during storage or shipping. If you nd any damage, contact your authorized Hioki distributor or

reseller.

Peripheral device inspection

1

Do not use the instrument if damage is found,

as electric shock or shortcircuit accidents could

result. Contact your authorized Hioki distributor

or reseller.

No metal exposed

Metal

exposed

Measurement Preparations

The insulation on a cables is not

torn, or any metal is not exposed.

No metal exposed

Instrument inspection

2

The instrument is not damaged.

Not damaged

When the instrument is turned on

The splash screen (model no.,

version no.) is displayed.

Metal

exposed

Damaged

Not

displayed

If there is any damage, measured values may

be unstable and measurement errors may occur.

Replace the cable with an undamaged one.

If damage is evident, request repairs.

The power cord may be damaged, or the

instrument may be damaged internally.

Request repairs.

“11.2 Troubleshooting” (p. 231)

Displayed

No error is displayed on the

splash screen.

No error displayed

Inspection complete

An error

indication

occurs

(Err)

The instrument may be damaged internally.

Request repairs.

See “Transporting the instrument” (p. 230).

35

Page 41

Connecting the Power Cord

HIOKI IM3536A981-04HIOKI IM3536A981-04

2.3 Connecting the Power Cord

Be sure to read the “Before turning on the instrument” (p. 15), and “Handling the cords, xtures,

and probes” (p. 16) before connecting the power cord.

Connect the power cord to the power inlet on the instrument, and plug it into an outlet.

Check that the main power switch is set to the off position.

1

Connect a power cord that matches the line voltage to the power inlet on the

2

instrument. (100 V AC to 240 V AC)

Rear

3

Power inlet

Plug the other end of the power cord into an outlet.

36

Page 42

Connecting the Measurement Cables, Probes, or Fixture

HIOKI IM3536A981-04HIOKI IM3536A981-04

2.4 Connecting the Measurement Cables, Probes, or

Fixture

Be sure to read the “Handling the cords, xtures, and probes” (p. 16) before connecting

measurement cables, probes or test xture.

Connect your measurement cables, optional Hioki probes or test xture to the measurement

terminals. Refer to “Options (reference: open and short correction states)” (p. 3) for details. See

the instructions provided with the xture for operating details.

Example: Hioki optional test xture

Connect directly to the measurement jacks

with the label side up, and afx with the

levers on the left and right.

Example: Hioki optional Model 9140-10

Connect the red plugs to the H

CUR

jacks, and the black plugs to the L

jacks.

Black

Black

Red

and H

CUR

Red

POT

and L

Example: Hioki optional Model 9500-10

Connect the H

CUR

POT

CUR

, and L

POT

BNC

, H

, L

plugs to the corresponding terminals on the

instrument.

POT

Measurement Preparations

Points to pay attention to when making your own probe

• Use 50

• When it ships from the factory, the instrument has been adjusted for the length of its cable. Since use

of a cable with a different capacitance value between the coaxial cable’s core wire and the shielding will

introduce a measurement error, use a cable whose capacitance value is as close as possible to that used

when adjusting the instrument prior to its shipment (1 m: 111 pF/cable; 2 m: 215 pF/cable; 4 m: 424 pF/

cable).

• Make the portion of the core wire that is exposed as short as possible.

• Connect the H

(Ensure that a shield is not connected to a core wire.)

• In general, Hioki optional parts (p. 3) should be used for measurement cables and xtures. If you use a

probe yourself, it may not be able to satisfy the specications of this instrument.

• If all four terminals are disconnected, a meaningless number may be displayed on the unit.

coaxial cable for the measurement cable.

Ω

, L

, H

CUR

CUR

Measurement Terminal

Conguration

POT

, and L

shield pairs at the measurement sample side.

POT

Fixture

Normal mode

37

Page 43

Turning the Instrument On and Off

HIOKI IM3536A981-04HIOKI IM3536A981-04

2.5 Turning the Instrument On and Off

Before turning on the instrument, be sure to read “Before turning on the instrument” (p. 15).

Once you have connected measurement cables or an optional Hioki probe or test xture, set the

instrument’s main power switch to the on position. Once the main power switch has been set to the

on position, the instrument can be turned on and off using the power button on the front panel.

This feature is convenient when embedding the instrument in an automated tester or on a

production line. (If the main power switch is set to the off position in the suspended state, the

instrument will be turned on in the suspended state when the main power switch is next set to the

on position.)

Main power switch

Rear

Front

Power

button

38

Page 44

Turning the Instrument On and Off

What is the suspended state?

The instrument is turned off in the suspended

state. (Only the circuit needed to light up the

power button’s indicator will operate.)

HIOKI IM3536A981-04HIOKI IM3536A981-04

Turning on the instrument

Place the main power switch in the “on” (I).

The power button’s green indicator will light up.

Turning off the instrument

Place the main power switch in the “off” ( ).

The power button’s indicator will be turned off.

Placing the instrument in the suspended state

ON the main power in the state, hold

down the front Standby Key 2 seconds

approximately.

2 seconds

The power button’s red indicator will light up.

To cancel the suspended state

The instrument is in suspended state, press

the power button on the front.

Measurement Preparations

• When the power supply is interrupted by a power

failure or the like, the instrument recovers in the

measurement mode used before the power failure.

• Instrument settings will be retained (backed up)

even if the main power switch is set to the off

position.

Red indicator is lit up

The power button’s green indicator will light up.

To perform measurements at the level of accuracy indicated in the instrument’s specications,

allow it to warm up for at least 60 minutes after setting the main power switch to the on position or

canceling the suspended state.

39

Page 45

Setting the Date and Time

HIOKI IM3536A981-04HIOKI IM3536A981-04

2.6 Setting the Date and Time

Set the instrument’s date and time.

Data is recorded and managed based on the set date and time.

Press the SYS key.

1

Touch the CLOCK tab, and set the date

2

and time with the key.

(Year-Month-Day Hour-Minute-Second)

11

Press the SET key to accept the setting.

3

Press the EXIT key.

4

The measurement screen will be displayed.

22

Settable range :

00:00:00, January 1, 2000, to

23:59:59, December 31, 2099

40

Page 46

Performing Measurements in

HIOKI IM3536A981-04HIOKI IM3536A981-04

3

LCR Mode

The LCR mode allows you to measure the impedance, phase angle, and other items by applying

any frequency or level (effective value) signal to the element you want to measure. This function is

suitable for evaluating the passive element of a capacitor, coil, or the like.

First, set the measurement mode to LCR mode (p. 26).

3.1 Setting Display Parameters

You can select up to 4 of the 16 measurement parameters to display on the measurement screen.

These parameters are set on the measurement screen.

<Example> No. 1 parameter: Cs, No. 3 parameter: D (See “Parameters” (p. 42).)

Performing Measurements in LCR Mode

Touch the No. 1 parameter key.

1

Touch the Cs key and then the EXIT key

2

to accept the settings.

Touch the D key and then the EXIT key

4

to accept the setting.

11

Cs and D are set as the parameters.

22

3

11

22

Touch the No. 3 parameter key.

If OFF is selected in the parameter setting, a

measurement value is not displayed.

41

Page 47

Setting Display Parameters

HIOKI IM3536A981-04HIOKI IM3536A981-04

The following parameters are available:

Parameters Description Parameters Description

Z Impedance (

Y Admittance (S) Cp

θ

Rs

Rp

X Reactance (

G Conductance (S)

B Susceptance (S) OFF No display

Ls

Lp

Impedance phase angle (°)

Effective resistance= ESR (

(Equivalent series resistance)

Effective resistance (

(Equivalent parallel resistance)

Inductance (H)

(Equivalent series inductance)

Inductance (H)

(Equivalent parallel inductance)

Ω

Ω

Parameters

) Cs

*1

)

Ω

)

Ω

)

Q Q-factor

D Loss factor= tan

Rdc DC resistance (

σ

Capacitance (F)

(Equivalent series capacitance)

Capacitance (F)

(Equivalent parallel capacitance)

δ

)

Ω