Page 1

Instruction Manual

IM3533

IM3533-01

LCR METER

September 2012 Revised edition 1 IM3533A981-01 12-09H

Page 2

Page 3

Contents

Introduction.....................................................1

Verifying Package Contents...........................1

Safety Information..........................................3

Operating Precautions....................................5

Chapter 1 Overview 9

1.1 Product Overview Features .................9

1.2 Names and Functions of Parts ...........10

1.3 Screen Configuration and Operation .12

1.3.1 Initial Screen ......................................12

1.3.2 Measurement Mode Selection Screen 13

1.3.3 Advanced Settings Screen .................14

1.3.4 Compensation Settings Screen .........24

1.3.5 System Settings Screen .....................25

1.3.6 Save Settings Screen ........................27

1.3.7 Parameter Settings Screen ................28

Chapter 2 Measurement

Preparations 29

2.1 Preparation Flowchart ........................29

2.2 Pre-Operation Inspection ...................30

2.3 Connecting the Power Cord ...............31

2.4 Connecting the Measurement Cables,

Probes, or Fixture ..............................32

2.5 Connecting a Temperature Probe ......33

2.6 Connecting an Interface .....................34

2.7 Turning the Power On and Off ...........35

Chapter 3 Measurement

Example 37

3.1 When LCR Mode ...............................37

3.2 When ANALYZER Mode

(IM3533-01 only) ................................39

3.3 When TRANSFORMER Mode ...........41

Contents

Chapter 4 LCR Function 45

4.1 About LCR function ............................45

4.1.1 Measurement screen ..........................45

4.1.2 Setting Display Parameters ................47

4.1.3 Enlarging Display of Measurement

Values ................................................49

4.2 Setting Basic Settings of

Measurement Conditions ...................50

4.2.1 Setting the Measurement frequency ..50

4.2.2 Setting the Measurement signal level 52

4.2.3 Limiting the Voltage and Current Applied

to the Sample (Limit Values) ..............56

4.2.4 Setting the DC bias ............................58

4.2.5 Perform Measurements with User-defined

Timing (Trigger Measurement) ...........60

4.2.6 Setting the Measurement Range ........62

Setting the method for determining the

measurement range

(AUTO, HOLD, JUDGE SYNC) ............... 62

Low Z High Accuracy Mode ..................... 71

4.2.7 Setting the Measurement speed ........73

4.2.8 Displaying Average Values

(Averaging Set) ..................................74

4.2.9 Setting the Delay Time until Measurement

Data is Captured (Trigger Delay) .......76

4.2.10 Applying the Signal to the Sample

during Measurement Only (Trigger

Synchronous Output Function) ...........77

4.3 Setting DC Resistance Measurement 80

4.3.1 Configuring the Temperature

Correction Function ............................81

4.3.2 Setting the DC Measurement Delay

Time (DC Delay) .................................83

4.3.3 Setting the Offset Measurement Delay

Time (Adjustment Delay) ....................85

4.3.4 Setting the Line Frequency ................87

4.3.5 Setting the Measurement Range ........88

Setting the method for determining the

measurement range

(HOLD, AUTO, JUDGE SYNC) ............... 88

Low Z High Accuracy Mode ..................... 96

4.3.6 Setting the Measurement Speed ........98

4.3.7 Displaying Average Values

(Average set) ......................................99

i

1

2

3

4

5

6

7

8

9

10

11

12

ït

ò^

ç€

à¯

Page 4

ii

Contents

4.4 Judging Measurement Results .........100

4.4.1 Judging with Upper and Lower Limit

Values (Comparator Measurement

Mode) ...............................................102

Setting the Upper or Lower Limit Value as

an Absolute Value (ABS)

(Absolute Value Mode) .......................... 104

Setting the Upper or Lower Limit Value as a

Percentage (%) Relative to a Reference

Value (Percentage Mode) ...................... 105

Setting Upper and Lower Limit Values as

(%) Values Relative to the Offset from

the Reference Value (Deviation Percenta ge

Mode) ..................................... ................ 107

4.4.2 Classifying Measurement Results

(BIN Measurement) ..........................109

Setting the Upper or Lower Limit Value as

an Absolute Value (ABS)

(Absolute Value mode) .......................... 111

Setting the Upper or Lower Limit Value as

a Percentage (%) Relative to a Reference

Value (Percentage mode) ...................... 114

Setting Upper and Lower Limit Values as

(%) Values Relative to the Offset from

the Reference Value (Deviation Percenta ge

Mode) ..................................... ................ 117

4.5 Setting Application Settings ..............120

4.5.1 Setting Measurement Conditions for

Individual Measurement Ranges

(Range Synchronization Function) ...120

4.5.2 Setting the Detection Signal Waveform

Averaging Count (Waveform Averaging

Function) ..........................................128

4.5.3 Detecting OPEN during 2-terminal

Measurement

(HIGH-Z Reject Function) .................130

4.5.4 Checking Contact Defects and the Contact State (Contact Check Function) 132

4.5.5 Setting the Delay Time from the Output

of Comparator and BIN Judgment Results

until Output of EOM

Judgment Results .............................134

4.5.6 Enabling Trigger Input for during

Measurement and Setting the Valid

Edge of Trigger Input ........................136

4.5.7 Setting the EOM Output Method ......137

4.5.8 Saving Measurement Results

(Memory function) ............................138

4.5.9 Setting the Number of Display Digits 140

4.5.10Setting the LCD to ON/OFF .............142

4.5.11Setting Operation Sounds

(Beep Sounds) .................................143

(LOW) and Resetting

4.5.12Disabling Key Operation

(Key-lock Function) .......................... 144

4.5.13Initializing (System Reset) ..............147

Chapter 5 ANALYZER Function

(IM3533-01) 149

5.1 About ANALYZER function .............. 149

5.1.1 Measurement screen .......................149

5.2 Setting Basic Settings of

Measurement ...................................150

5.2.1 Setting the measurement parameter 150

5.2.2 Setting the Trigger ...........................151

5.2.3 Setting the Display Timing ............... 152

5.2.4 Setting the Trigger Delay .................153

5.2.5 Setting Sweep Points .......................155

5.2.6 Setting the Measurement Signal

Level ................................................ 158

5.2.7 Setting the Measurement Range .....160

Setting the method for determining the

measurement range (AUTO, HOLD) ......160

Low Z high accuracy mode .................... 164

5.2.8 Setting the Measurement Speed ..... 166

5.2.9 Displaying as Average Values

(Average set) ...................................167

5.2.10Setting the Point Delay ................... 168

5.2.11Setting the DC Bias .........................169

5.3 Application Settings .........................171

5.3.1 Applying the Signal to the Sample Only

during Measurement (Trigger Synchro-

nous Output Function) .....................171

5.3.2 Setting the Detection Signal Waveform

Averaging Count (Waveform Averaging

Function) ..........................................173

5.3.3 Detecting OPEN during 2-terminal

Measurement

(HIGH-Z Reject Function) ................ 175

5.3.4 Checking Contact Defects and the

Contact State (Contact Check

Function) ..........................................177

5.3.5 Saving Measurement Results

(Memory function) ............................ 179

5.3.6 AUTO Range Limit Function ............ 182

5.3.7 Setting the LCD to ON/OFF ............. 184

5.3.8 Setting Operation Sounds

(Beep Sounds) ................................. 185

Page 5

iii

Contents

13

5.3.9 Disabling Key Operation

(Key-lock Function) ..........................186

5.3.10Enabling Trigger Input for during Measurement and Setting the Valid Edge of

Trigger Input .....................................189

5.3.11Setting the EOM

5.3.12Initializing (System Reset) ...............191

Output Method .....190

Chapter 6 TRANSFORMER

Function 193

6.1 About TRANSFORMER function .....193

6.1.1 Measurement screen .......................193

6.1.2 Measurement Methods ....................194

6.1.3 Setting the measurement parameter 196

6.1.4 Setting Calculation Parameters .......197

6.2 Setting Basic Settings of Measurement

Conditions ........................................ 198

6.3 Judging with Upper and Lower Limit

Values (Comparator Measurement

Mode) ............................................... 199

Setting the Upper or Lower Limit Value as

an Absolute Value (ABS)

(Absolute Value Mode) ...........................202

Setting the Upper or Lower Limit Value as

a Percentage (%) Relative to a Reference

Value (Percentage Mode) .......................203

Setting Upper and Lower Limit Values as

(%) Values Relative to the Offset from the

Reference Value

(Deviation Percentage Mode) .................205

6.4 Setting Application Settings .............207

Chapter 7 CONTINUOUS

7.5 Configuring CONTINUOUS

Measurement Application Settings .. 213

7.5.1 Setting the Display Timing ............... 213

7.5.2 Setting the LCD to ON/OFF ............. 214

Chapter 8 Error

Compensation 215

8.1 Setting Open Circuit Compensation 215

8.1.1 All Compensation ............................ 216

8.1.2 Spot Compensation ......................... 220

8.2 Short Circuit Compensation ............. 224

8.2.1 All Compensation ............................ 226

8.2.2 Spot Compensation ......................... 228

8.3 Compensating Values to Match

Reference Values

(Load Compensation) ...................... 232

8.4 Compensating Measurement Cable

Errors (Cable Length Compensation)

......................................................... 245

8.5 Calculating Values (Scaling) ............ 246

Chapter 9 Saving and Loading

Panel Information

249

9.1 Saving Measurement Conditions

(Panel Save Function) ..................... 251

9.2 Loading Measurement Conditions

(Panel Load Function) ..................... 256

9.3 Changing a Panel Name ................. 258

9.4 Deleting a Panel .............................. 260

1

14

2

3

4

5

6

7

8

9

10

Measurement

Function 209

7.1 About CONTINUOUS Measurement

Function ...........................................209

7.1.1 Measurement screen .......................209

7.2 Configuring CONTINUOUS

Measurement Basic Settings ...........210

7.3 Performing CONTINUOUS

Measurement ................................... 211

7.4 Checking CONTINUOUS Measurement

Results ............................................. 212

Chapter 10 Setting the

SYSTEM 263

10.1 Setting the Interface ........................ 263

10.2 Checking the Version of the

Instrument ....................................... 264

10.3 Self Checks (Self Diagnosis) ........... 265

10.4 Setting the Date and Time ............... 272

11

12

Appendix

Index

Page 6

iv

Contents

Chapter 11 Using USB Flash

Drive 273

11.1 Inserting and Removing USB flash

drive ..................................................274

11.2 About the File Operation Screen ......275

11.3 About the File Save Setting Screen .276

11.4 Saving Measurement Data ...............277

Saving Measurement Data .................... 277

Saving a Copy of the Screen ................. 287

Checking the Contents of Files .............. 290

Changing the Save Folder ..................... 291

11.5 Saving Instrument Settings ..............293

Saving Instrument Settings .................... 293

Saving All Settings of Instrument

(ALL SAVE Function) ............................. 295

11.6 Loading Instrument Settings .............297

Loading instrument settings ................... 297

Loading all settings saved on a USB flash

drive ....................................................... 300

(ALL LOAD Function) ............................. 300

11.7 File and Folder Operations ...............302

Formatting a USB Flash Drive ............... 302

Deleting Files and Folders ..................... 304

Creating Folders ....... ... ... .... ... ... ... .... ... ... 305

Displaying the USB Flash Drive

Information ............................................. 307

Enabling Trigger Input for during

Measurement ......................................... 328

Setting Valid Edge of Trigger Input . ... ... . 328

12.5 External Control Q&A ......................329

12.6 Measurement Using a Computer ..... 329

Chapter 13Printing 331

13.1 Connecting the Printer ..................... 331

Connecting the Printer to the Instrument 332

13.2 Instrument and Printer Settings ....... 333

Make Instrument Settings ...................... 333

13.3 Printing .............................................334

Chapter 14Specifications 337

14.1 General Specifications ..................... 337

14.2 Measurement Range and Accuracy 342

14.3 About Measurement Times and

Measurement Speed ....................... 350

Chapter 15Maintenance and

Service 353

Chapter 12 External Control309

12.1 External Input/Output Connector and

Signals 309

Connector Type and Signal Pinouts ...... 310

Signal function details ............................ 316

12.2 Timing Chart .....................................318

12.2.1LCR Mode .......................................318

12.2.2ANALYZER Mode (IM3533-01 only) 321

12.2.3TRANSFORMER Mode ...................322

12.2.4CONTINUOUS Measurement Mode 323

12.3 Inte rnal Circuitry ...............................325

Electrical Specifications ......................... 326

Connection Examples ............................ 327

12.4 Ext ernal I/O Set tings ........................328

Setting Delay Time from Output of Compara-

tor and BIN Judgment Results until Output

of EOM

Setting Reset of Judgment Results ........ 328

(LOW) ....................................... 328

15.1 Inspection, Repair and Cleaning ......353

15.2 Troubleshooting ...............................355

15.3 Error display .....................................360

15.4 Discarding the Instrument ................ 362

Appendix A 1

Appendix1 Measurement Parameters and

Calculation Formula .................A 1

Appendix2 Measurement of High Impedance

Components.............................A 3

Appendix3 Measurement of In-circuit Compo-

nents.........................................A 4

Appendix4 Countermeasures Against Incorpo-

ration of External Noise............A 5

Appendix4.1Countermeasures Against Incor-

poration of Noise from the Power

Line .......................................... A 5

Page 7

Appendix4.2Countermeasures Against Noise

from the measurement Cables A 6

Appendix5 Supplying DC Bias....................A 7

Appendix5.1How to Supply a DC Bias

Voltage .....................................A 7

Appendix5.2How to Supply a DC Bias

Current .....................................A 9

Appendix6 The Residual Charge Protection

Function..................................A 10

Appendix7 Series Equivalent Circuit Mode

and Parallel Equivalent Circuit

Mode.......................................A 11

Appendix8 Open Circuit Compensation and

Short Circuit Compensation....A 12

Appendix9 Temperature Correction

Function (TC)..........................A 13

Appendix10Rack Mounting .......................A 15

Appendix11Dimensional Diagram.............A 17

Appendix12Initial Settings Table...............A 18

Appendix 13Device Compliance

Statement ...............................A 23

v

Contents

Index Index 1

Page 8

vi

Contents

Page 9

Introduction

Confirm that these contents are provided.

IM3533 or IM3533-01 LCR Meter...........1 Instruction Manual (This document) ...... 1

Power Cord (2-line + ground)................. 1

LCR Application Disk ............................ 1

(Communications instruction manual [PDF

format], explanation of communications

commands, USB driver, sample application)

The latest version can be downloaded

from our web site.

Introduction

Thank you for purchasing the HIOKI Model IM3533, IM3533-01 LCR Meter. To obtain maximum performance from the instrument, please read this manual first, and keep it handy for future reference.

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during shipping.

In particular, check the accessories, panel switches, and connectors. If damage is evident, or if it fails to

operate according to the specifications, contact your authorized Hioki distributor or reseller.

1

• Probes, fixture are not supplied with the instrument as standard equipment. You should

order them separately, according to requirements.

• The instrument ships from the factory co nfig ured as descr ibed in "Appendix12 Initial Settings Table"(p. A18).

Transporting the instrument

Use the original packing materials when transporting the instrument, if possible.

See "Transporting the instrument" (p. 354)

Page 10

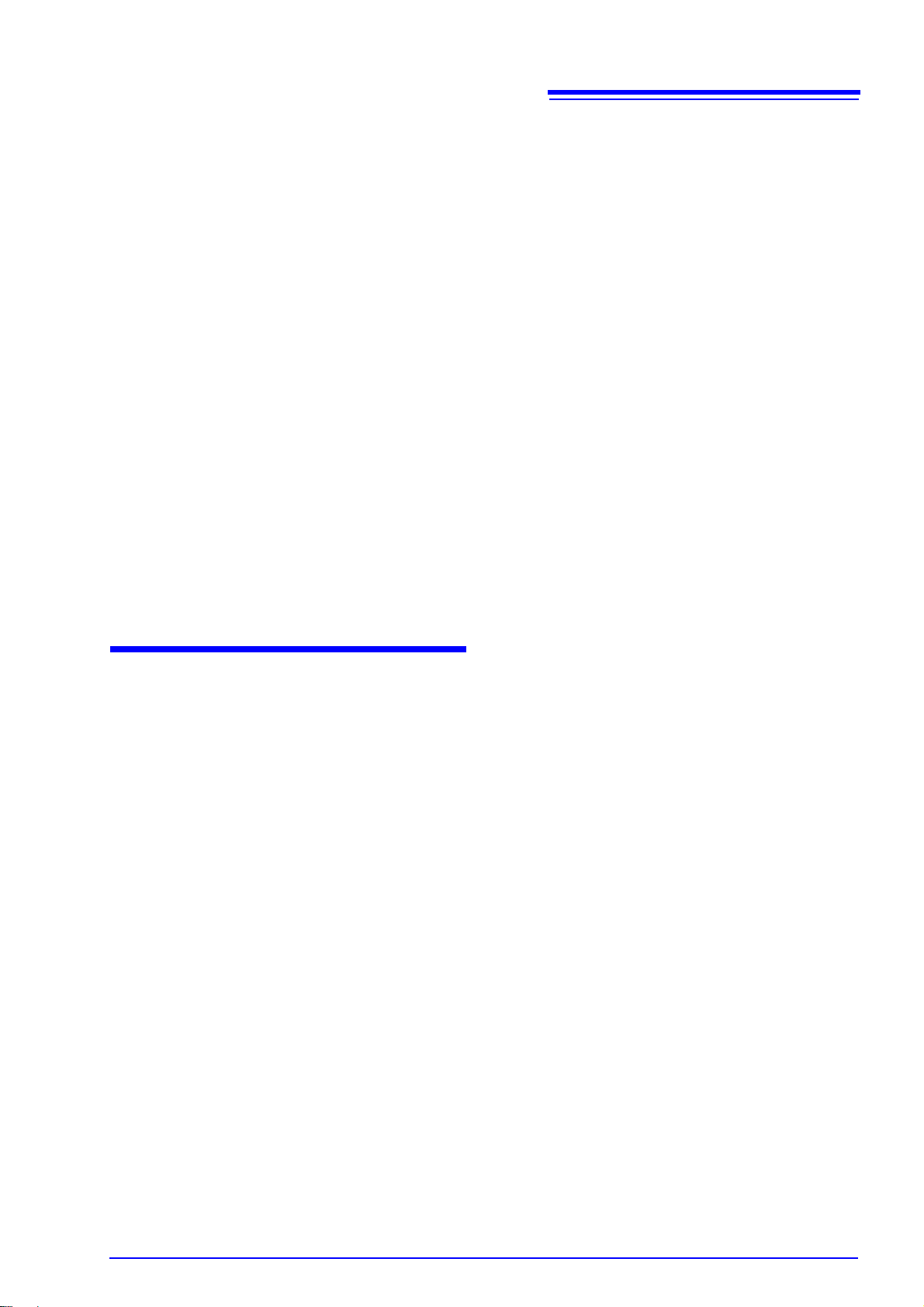

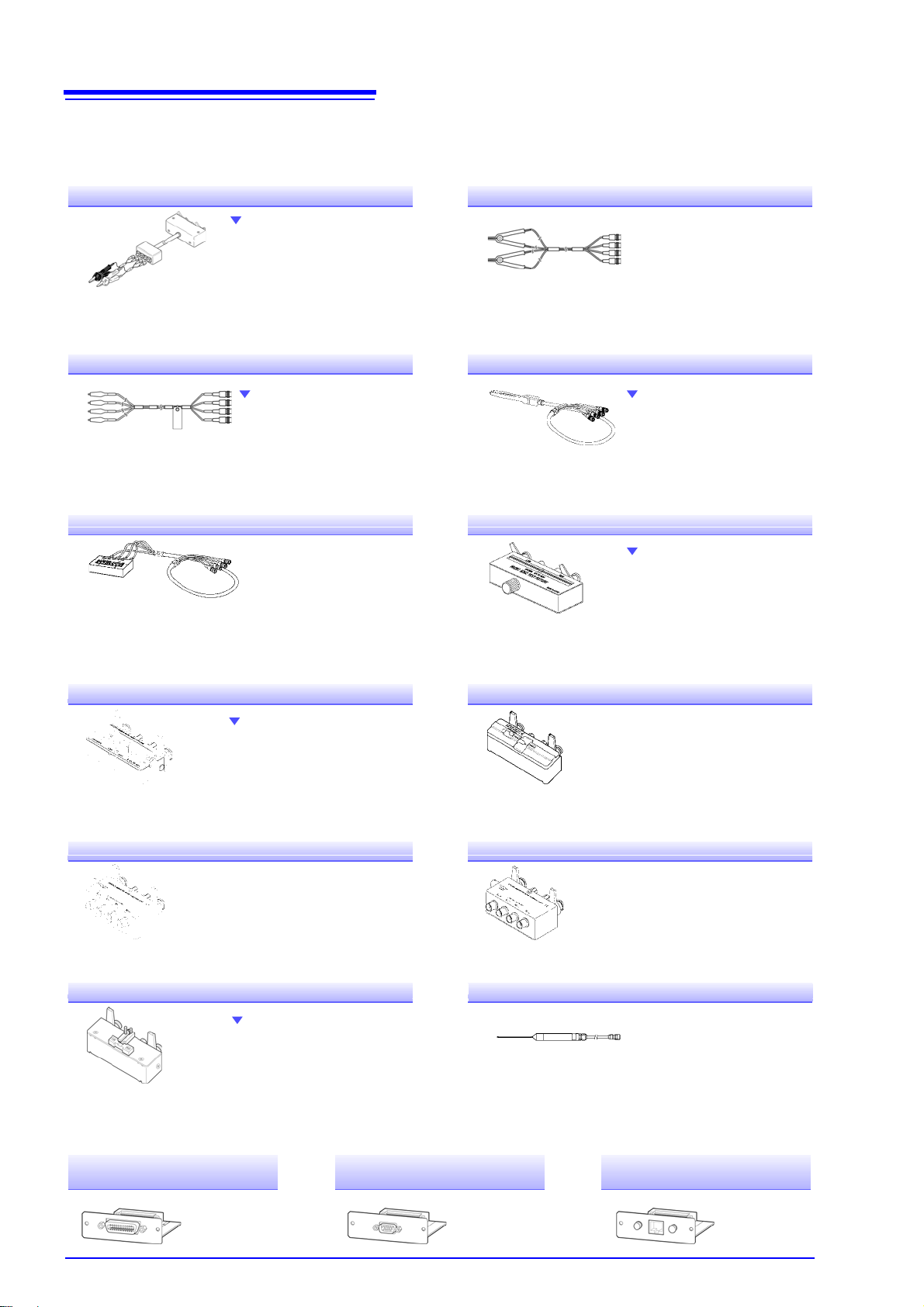

2

Measurable range: DC to 200 kHz

Maximum voltage:

±42 Vpeak (AC+DC)

Maximum current:

±1 Apeak (AC+DC)

Measurement terminal hole diameter: 0.3 mm to 5 mm

L2000 4-terminal Probe

Alligator-clip-type measurement probes. These generalpurpose dual-electrode clips fit

a wide range of conductor

thicknesses.

Measurable range: DC to 5 MHz

Maximum voltage: ±42 Vpeak (AC+DC)

Maximum current: ±1 Apeak (AC+DC)

Measurement terminal hole diameter: 0.3 mm to 5 mm

9140-10 4-terminal Probe

Measurable range: DC to 5 MHz

Maximum voltage:

±DC30 V

Electrode tip spacing: 0.3 mm to approx. 6 mm

Measurable range: DC to 1 MHz

Maximum voltage: DC

±40 V (42 Vpeak (Measurement signal + bias voltage))

Maximum current: 1 Apeak (Measurement signal + bias current)

Measurement terminal hole diameter: 0.3 mm to 2 mm

Rubber-sheathed alligator

clip type

9500-10 4-terminal Probe

Pincher type

9143-10 Pincher Probe

9261-10 Test Fixture

Measurable range: 42 Hz to 5 MHz

Maximum applied voltage: DC±40 V

Test sample dimensions: Lead diameter of 0.3 mm to 2 mm

Lead pitch of 5 mm or more

This fixture is for measuring

lead components. (less than

10 m residual resistance

after zero adjustment)

9262 Test Fixture

easurable range: DC to 5 MHz

Maximum applied voltage: DC

±40 V

Measurement terminal hole diameter: 0.3 mm to 1.5 mm

9263 SMD Test Fixture

This fixture is for measuring chip

components. (less than 10 m

residual resistance after zero adjustment)

Measurable range: DC to 120 MHz

Maximum applied voltage: DC±40 V

Test sample width of 3.5±0.5 mm or less

Measurable range: DC to 5 MHz

Maximum applied voltage: DC±40 V

Test sample dimensions: Test sample width of 1 to 10 mm

9677 SMD Test Fixture

9268-10 DC Bias Voltage Unit

Measurable range: 40 Hz to 2 MHz

Maximum applied current: DC2 A

Measurable range: 40 Hz to 5 MHz

Maximum applied voltage: DC

±40 V

9269-10 DC Bias Current Unit

This fixture is for the lower

electrode.

Measurable range: DC to 120 MHz

Maximum applied voltage: DC±40 V

Test sample dimensions: Test sample width of 1 to 4 mm

Test sample height of 1.5 mm or less

Platinum resistance bulb (Pt100), waterproof design

(EN60529:1991,IP67)

Measurable range: -10.0°C to 99.9°C

Tip diameter:

2.3 mm

Cord length: 1 m

9699 SMD Test Fixture 9478 Temperature Probe

Z3000

GP-IB Interface

Z3001

RS-232C Interface

Z3002

LAN Interface

Verifying Package Contents

Options

For more information, contact the store (distributor) from which you purchased the instrum ent or your ne are st

HIOKI sales office.

Page 11

3

Safety Information

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards, and has

been thoroughly tested for safety prior to shipment. However, mishandling during

use could result in injury or death, as well as damage to the instrument. However,

using the instrument in a way not described in this manual may negate the provided

safety features.

Be certain that you understand the instructions and precaution s in the manua l befo re

use. We disclaim any responsibility for accidents or injuries not resulting directly

from instrument defects.

This manual contains information and warnings essential for safe operation of the instrument and for maintaining it in safe operating condition. Be fo re u sing it, b e su re to ca re fully r ead the followin g sa fety pr ecautio ns.

Safety Symbols

In the manual, the symbol indicates particularly importan t information that the user should

read before using the instrument.

The symbol printed on the product indicates that the user should refer to a corresponding

topic in the manual (marked with the symbol) before using the relevant function .

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a significant hazard that could result in serious injury or death to the user.

Indicates that incorrect operation presents a possibility of injury to the user or damage

to the product.

Advisory items related to performance or correct operation of the product.

Symbols for Various Standards

WEEE marking:

This symbol indicates that the electrical and electronic appliance is put on the EU market

after August 13, 2005, and producers of the Member States are required to display it on the

appliance under Article 1 1.2 of Directive 2002/96/EC (WEEE).

This symbol indicates that the product conforms to safety regulations set out by the EC Directive.

Page 12

4

Safety Information

Notation

Symbols in this manual

Indicates the prohibited action.

p. )

* Indicates that descriptive information is provided below.

[ ]

CURSOR

(Bold character)

Windows

Dialogue

Indicates the location of reference information.

Menus, commands, dialogs, buttons in a dialog, and other names on the screen and the

keys are indicated in brackets.

Bold characters within the text indicate operating key labels.

Unless otherwise specified, “Windows” represents Windows 95, 98, Me, Widows NT4.0,

Windows 2000, Windows XP, Windows Vista or Windows 7.

Dialogue box represents a Windows dialog box.

Accuracy

We define measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt. (digit) values, with

the following meanings:

f.s. (maximum display value or

scale length)

rdg. (reading or displayed value)

dgt. (resolution)

The maximum displayable value or scale length. This is usually the name

of the currently selected range.

The value currently being measured and indicated on the measuring instrument.

The smallest displayable unit on a digital measuring instrument, i.e., the in-

put value that causes the digital display to show a "1" as the least-significant digit.

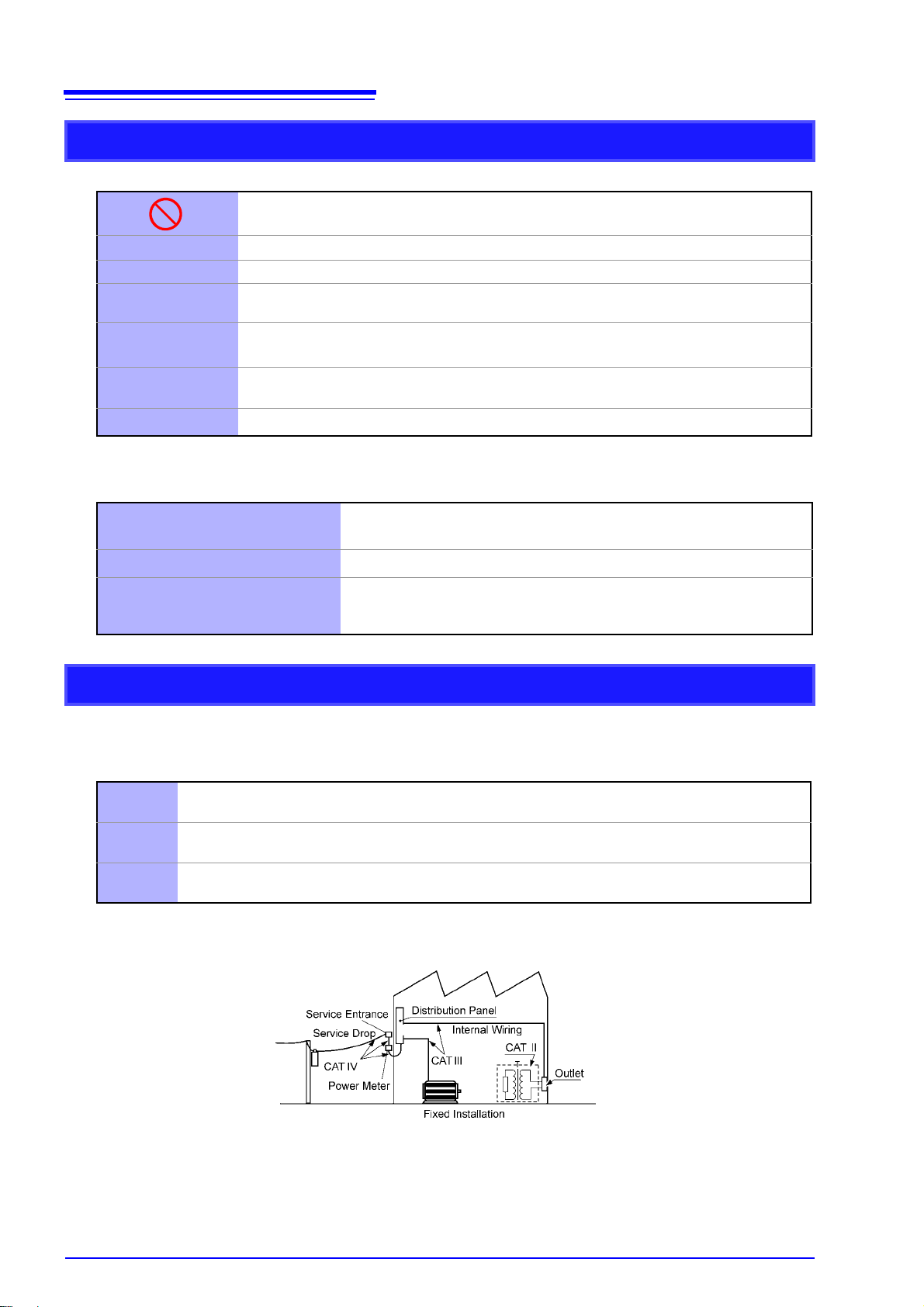

Measurement categories

To ensure safe operation of measurement instruments, IEC 61010 establishes safety standards for various electrical environments, cate gorized as CAT II to CAT IV, and called measurement categories. These

are defined as follows.

CAT II

CAT III

CAT IV

Primary electrical circuits in equipment connected to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.) CAT II covers directly measuring electrical outlet receptacles.

Primary electrical circuits of heavy equipment (fixed installations) connected directly to the distribution

panel, and feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance, and to the power meter and primary overcurrent protection device (distribution panel).

Using a measurement instrument in an nvironment esignated with a higher-numbered category than that

for which the instrument is rated could result in a severe accident, and must be carefully avoided.

Page 13

Operating Precautions

The instrument can be used with the stand (p. 11).

It can also be rack-mounted (p.A15).

50 mm or more 10 mm or more

Rear

50 mm or more

Vents

Operating Precautions

Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to ensure the no damage

occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributor or

reseller.

Before using the instrument, make sure that the insulation on the voltage cords is

undamaged and that no bare conductors are improperly exposed. Using the instrument in such conditions could cause an electric shock, so contact your dealer or

Hioki representative for replacements.

5

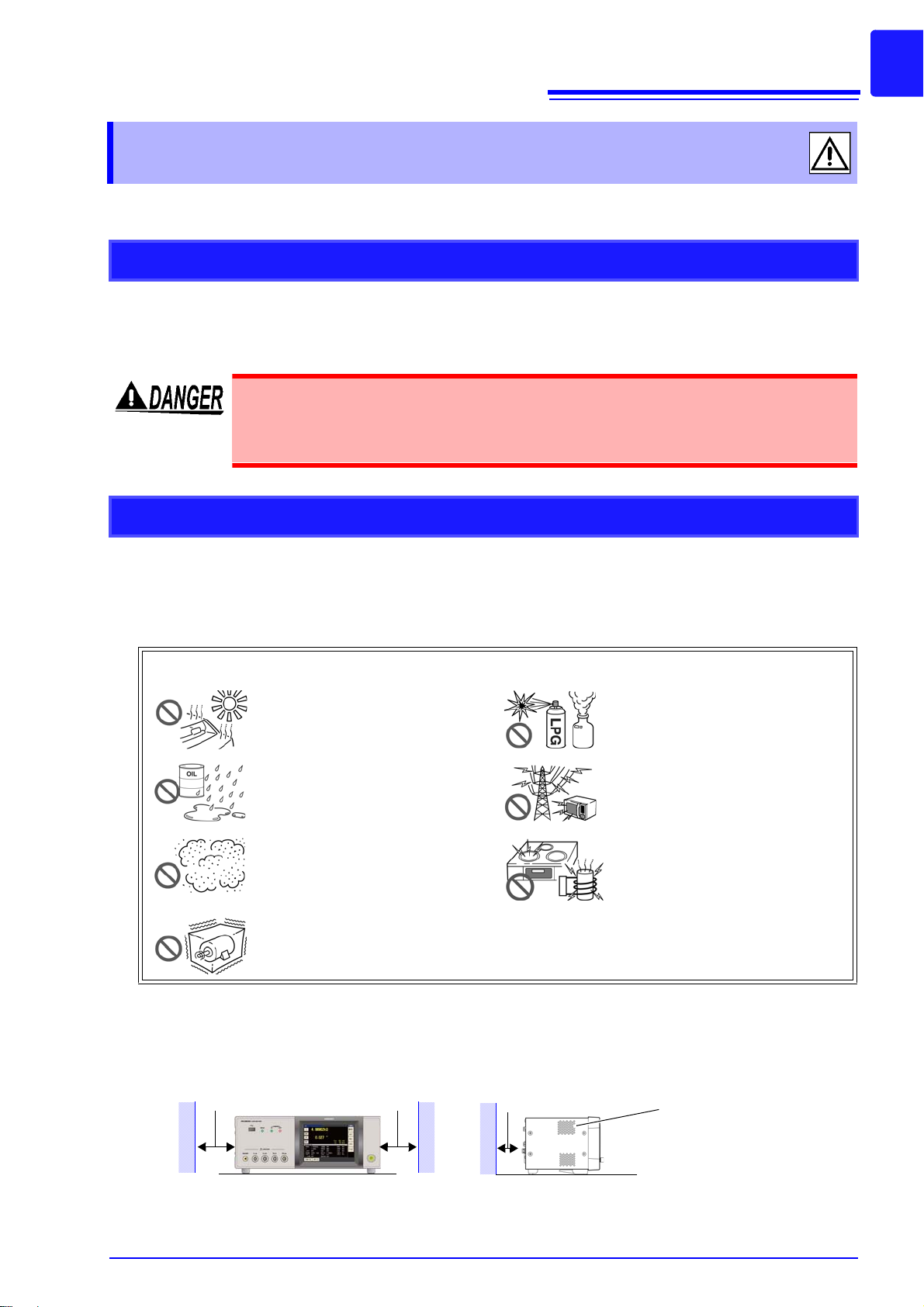

Instrument Installation

Operating temperature and humidity:

0 to 40°C (32 to 104°F), 20 to 80% RH or less, Indoors (non-condensating)

Storing temperature and humidity:

-10 to 55°C (14 to 131°F) 20 to 80% RH or less, Indoors (non-condensating)

Temperature and humidity range for guaranteed accuracy, 23

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil, other chemicals, or solvents

Exposed to high humidity or conden-

sation

Exposed to high levels of particulate

dust

Subject to vibration

±5°C, RH or less

In the presence of corrosive or explosive

gases

Exposed to strong electromagnetic fields

Near electromagnetic radiators

Near induction heating systems

(e.g., high-frequency induction heating

systems and IH cooking utensils)

To prevent overheating, be sure to leave the specified clearances around the instrument.

• The instrument should be operated only with the bottom or rear side downwards.

• The instrument must not be placed on an unstable table or tilted surface.

• Vents must not be obstructed.

Page 14

6

Operating Precautions

Shipping precautions

Hioki disclaims responsibility for any direct or indirect damages that may occur when this instrument has

been combined with other devices by a systems integrator prior to sale, or when it is resold.

Handling the Instrument

• To avoid electric shock, do not remove the instrument's case. The internal components of the instrument carry high voltages and may become very hot during operation.

• Do not allow the instrument to get wet, and do not take measurements with wet

hands. This may cause an electric shock.

• If the instrument exhibits abnormal operation or display during use, review the informa-

tion in "Inspection, Repair and Cleaning" (p. 353) an d "Err or disp lay" (p . 3 60) b efore con tacting your dealer or Hioki representative. Note that the instrument may be damaged if

the applied voltage or current exceeds the measurement range.

• This instrument is not designed to be entirely water- or dust-proof. Do not use it in an

especially dusty environment, nor where it might be splashed with liquid. This may cause

damage.

• To avoid damage to the instrument, protect it from physical shock when transporting and

handling. Be especially careful to avoid physical shock from dropping.

• Do not apply heavy downward pressure with the stand extended. The stand could be

damaged.

• Do not use excessive force on the touch panel, and do not use sharp objects that could

damage the touch screen.

• After use, always turn OFF the power.

This instrument may cause interference if used in residential areas. Such use must be

avoided unless the user takes special m easures to reduce electromagnetic emissions to

prevent interference to the reception of radio and television br oadcasts.

Before Turning Power On

• Before turning the instrument on, make sure the supply voltage matches that indicated

on its power connector. Connection to an improper supply voltage may damage the

instrument and present an electrical hazard.

• Be careful to avoid connecting the supply voltage improperly. Doing so may damage the

instrument's internal circuitry.

• To avoid electrical accidents and to maintain the safety specifications of this instrument,

connect the power cord only to a 3-contact (two-condu cto r + ground ) ou tle t.

• To av oid sho ck and short circuits, turn off the power to lines to be measured before mak-

ing connections to terminals to be measured and turning on the instrument.

Page 15

Operating Precautions

About Handling of Cords, Fixtures and Temperature probes

• For safety reasons, disconnect the power cord when the instrument is not used.To avoid

damaging the power cord, grasp the plug, not the cord, when unplugging it from the

power outlet.

• Do not apply a voltage to the measurement terminals. Doing so may damage the instru-

ment.

• When disconnecting the BNC connector, be sure to release the lock before pulling off the

connector. Forcibly pulling the connector without releasing the lock, or pulling on the

cable, can damage the connector.

• To avoid breaking the cables or probes, do not bend or pull them.

• Avoid stepping on or pinching cables, which could damage the cable insulation.

• Keep the cables well away from heat sources, as bare conductors could be exposed if the

insulation melts.Keep in mind that, in some cases, conductors to be measured may be hot.

• The sensor used in the temperature probe is a thin, precision platinum film. Be aware

that excessive voltage pulses or static discharges can destroy the film.

• Avoid subjecting the temperature probe tip to physical shock, and avoid sharp bends in

the leads. These may damage the probe or break a wire.

• When measuring high temperatures, do not let the handle of the temperature probe or

the compensation lead wire exceed the temperature range.

• The temperature probe has a protective nylon cap fitted on the end of the probes.

Remove the cap before using the probe.

• Put the protective cap back on the connector when not in use. If the protective cap is not

properly inserted, dust or other foreign matter may enter the connector and cause damage.

• The sheath of the temperature probe is filled with magnesium oxide powder. If the probe

is broken, the magnesium oxide powder may spill out. Be careful not to subject the

sheath to excess stress. Inhaling large quantities of magnesium oxide may be hazardous

to your health.

7

• Use only the specified connection cables. Using a non-specified cable may result in

incorrect measurements due to poor connection or other re asons.

• Before using a fixture or the like, read the instruction manual supplied with the product to

be used.

Before Connecting EXT I/O

To avoid electric shock or damage to the equipment, always observe the following

precautions when connecting to the EXT I/O connector.

• Always turn off the power to the instrument and to any devices to be connected

before making connections.

• Be careful to avoid exceeding the ratings of external terminals (p. 326).

• During operation, a wire becoming dislocated and contacting another conductive

object can be serious hazard. Use screws to secure the external connectors.

• Properly insulate any devices and mechanisms to be connected to the EXT I/O connector.

• The ISO_5V pin of the EXT I/O connector is a 5V power output. Do not apply external power to this pin.

Page 16

8

Operating Precautions

Input modules (option)

Before replacing the input module

• To avoid electric shock accident, before removing or replacing an input module, confirm

that the instrument is turned off and that the power cord and connection cables are disconnected.

• The mounting screws must be firmly tightened or the input module may not perform to

specifications, or may even fail.

• Always turn both devices OFF when connecting and disconnecting an interface connec-

tor.

Otherwise, an electric shock accident may occur.

When not using an input module (option)

To avoid the danger of electric shock, never operate the instrument with an input module

removed. To use the instrument after removing an input module, be sure to attach the blank

panel.

Handling the LCR Application Disk

• Always hold the disc by the edges, so as not to make fingerprints on the disc or scratch

the printing.

• Never touch the recorded side of the disc. Do not place the disc directly on anything

hard.

• Do not wet the disc with volatile alcohol or water, as there is a possibility of the label print-

ing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not use a ball-point pen

or hard-tipped pen, because there is a danger of scratching the surface and corrupting

the data. Do not use adhesive labels.

• Do not expose the disc directly to the sun's rays, or keep it in conditions of high tempera-

ture or humidity, as there is a danger of warping, with consequent loss of data.

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry cloth, or use a CD

cleaner. Always wipe from the inside to the outside, and do no wipe with circular movements. Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer system that arises from

the use of this LCR Application Disk, or for any problem related to the purchase of a Hioki

product.

Page 17

9

Temperature correction function

The temperature correction function lets you perform

even more precise DC resistance measurement.

TRANSFORMER mode (p. 193)

A dedicated screen allows you to measure transformers, coils, and other windings quickly and efficiently.

ANALYZER mode (IM3533-01 only) (p. 149)

The IM3533-01’s frequency sweep function lets you

measure frequency characteristics (list display only).

Wide range of measurement conditions (p. 50)

Capable of measurement under a wide range of measurement conditions: measurement frequencies from 1

mHz to 200 kHz and measurement signal levels from 5

mV to 5 V.

Capable of high-speed measurement

High-speed measurement is possible.

The IM3533 and IM3533-01 can perform measurements at speeds of up to 2 ms (typical values).

BIN function (p. 109)

With LCR mode, easily ranks measurement items into

up to 10 classifications based on the measurement

values.

CONTINUOUS measurement mode (p. 209)

Capable of consecutive measurements using measurement conditions stored in the memory of the instrument.

This function enables, for example, making pass/fail judgment with different measurement cond itions.

(Example: Performing C-D measurement with 120 Hz and Rs measurement with 100 kHz in succession)

Low impedance can be measured with

high degree of accuracy

LCR mode includes a setting for measuring low impedance with a high degree of accuracy.

Comparator function

LCR mode: (p. 102)

Capable of making HI/IN/LO pass/fail judgments

based on the measurement values for two parameters.

TRANSFORMER mode: (p. 193)

Capable of making HI/IN/LO pass/fail judgments for

calculation parameters.

Various interfaces supported

Supports the most suitable external I/O (handler interface)

for production lines, USB, GP-IB, RS-232C and LAN.

*GP-IB, RS-232C, and LAN interfaces are optional.

1.1 Product Overview Features

1

Overview Chapter 1

1.1 Product Overview Features

The HIOKI IM3533 and IM3533-01 LCR METER is an impedance measuring instrument which achieves

high speed and high accuracy.

With measurement frequencies of 1 MHz to 200 kHz and measurement signal levels of 5 mV to 5 V, the

instrument allows you to configure a broad range of measurement conditions. Additionally, features such as

a dedicated transformer and coil mea surement screen , DC resistance measurement with temperature correction, and a ANALYZER function (IM3533-01 only) m ake the IM3 533 a nd IM 3533-01 excellent choices for

use in a wide range of applications, from transformer and coil pro duction lines to research and d evelopment.

Chapter 1 Overview

Page 18

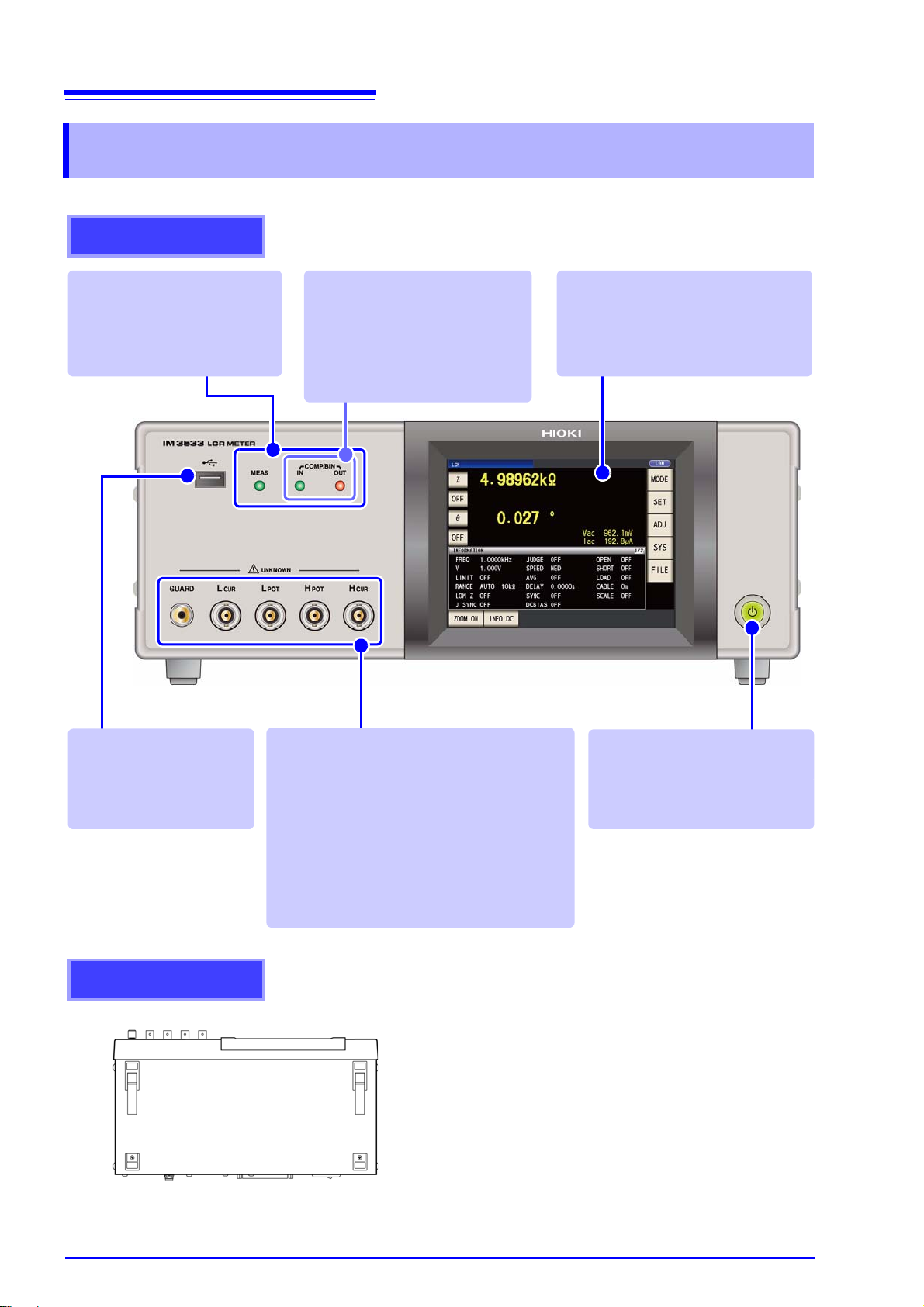

10

Front

Measurement LEDs

Lights during measurement.

Standby Key

Toggle standby state (p. 35)

(The main power switch is located

at the rear.)

Front USB connecter

Connect a USB flash drive

storage device. (p. 274)

Measurement Terminals

Connect measurement cables or a fixture. (p. 32)

•H

CUR

jack: Current source terminal

•H

POT

jack: Detected voltage high terminal

•L

POT

jack: Detected voltage low terminal

•L

CUR

jack: Measurement current detected

terminal

• GUARD jack: Sh ield (measurement

ground) terminal

LCD Display

This is a touch panel display.

Press the keys displayed on the

screen to operate the instrument.

Judgment Result

Indication LEDs

Indicates the judgment results for

comparator and BIN measurement.

LCR mode (p. 102)

TRANSFORMER mode (p. 193)

(Example: IM3533)

This instrument can be rack mounted.

See "Appendix10 Rack Mounting"(p. A15)

Parts removed from this instrument should be

stored in a safe place to enable future reuse.

Bottom Panel

1.2 Names and Functions of Parts

1.2 Names and Functions of Parts

Page 19

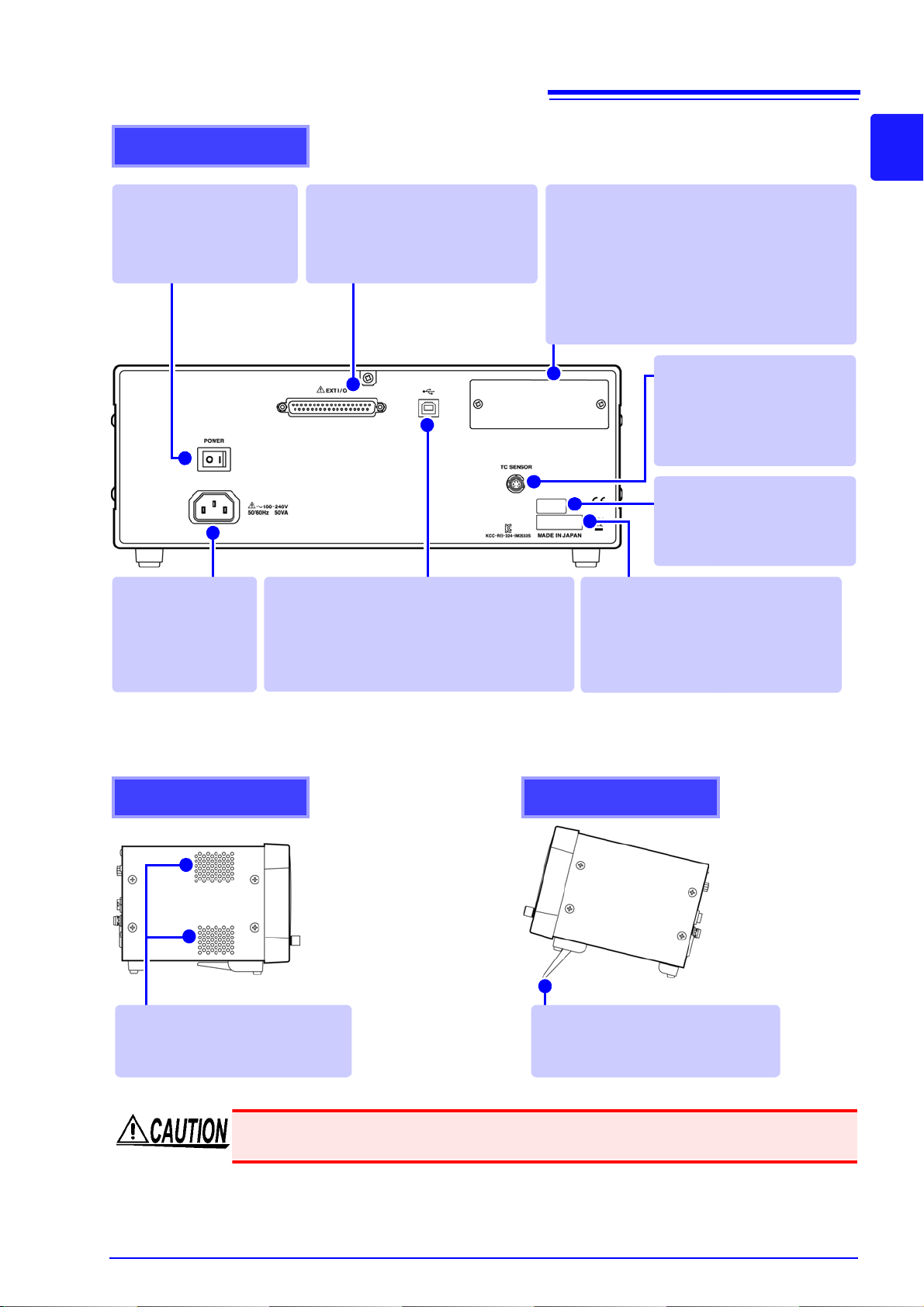

Rear

Power Inlet

Connect the supplied

power cord (p. 31).

USB Connector

Connect to a computer to control the instrument

with communication commands

(Ref to Communication Instruction Manual (LCR

Application Disk)

.

Interface port

Install optional interfaces.

(p. 263), Communication Instruction Manual

(LCR Application Disk)

• Z 3000 GP-IB Interface

• Z3001 RS-232C Interface

(When using a printer)

• Z3002 LAN Interface

Right side

Stand

Enables the instrument to be tilted.

Left side

Vents

Keep clear of obstructions (p. 5).

Power Switch

(Main power)

Turns the power on and off.

(p. 35).

Manufacturer's Serial Number

Shows the serial number.

Do not remove this label, as it is required

for product support.

MAC address of the LAN

(p. 264), (Ref to Communication Instruction Manual (LCR

Application Disk)

EXT I/O Connector

Connect to a PLC or I/O board to

control measurement start, and to

acquire comparator results (p. 309).

TC sensor terminal

Connect a temperature probe

to convert resistance values

to reference temperatures

(p. 33), (p.A13).

11

1.2 Names and Functions of Parts

1

Chapter 1 Overview

Do not apply heavy downward pressure with the stand extended. The stand could be damaged.

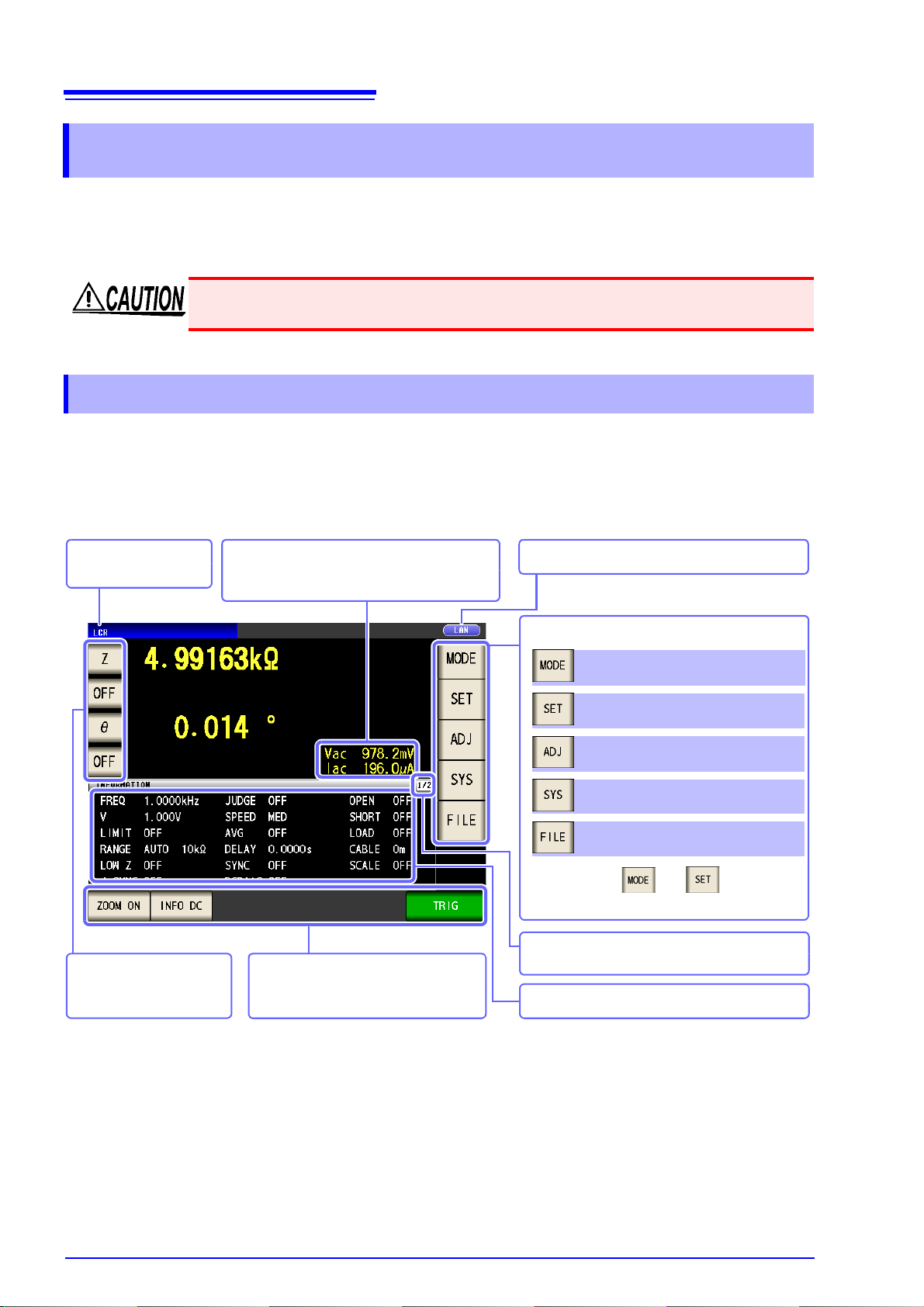

Page 20

12

Operation keys

An operation key is displayed depending

on the situation (p. 45).

Parameter keys

Set each parameter (p. 28).

Indicates the selected

measurement mode.

The settings of and differ depending on the measurement mode.

Menu keys

Set the compensation (p. 24).

Set the system (p. 25).

Set the save settings (p. 27).

Set the advanced settings (p. 14).

Select the measurement mode (p. 13).

Indicates the interface that is currently set.

Indicates the measurement conditions.

Monitor values

Vac, Vdc: Voltage across the sample terminals

Iac, Idc: Current passing through the sample

Indicates the number of pages of measurement

conditions that can be displayed.

1.3 Screen Configuration and Operation

1.3 Screen Configuration and Operation

This instrument allows you to use a touch panel to set and change all measur ement conditions.

Gently touch a key on the screen to select the item or numerical value set for that key.

A selected key turns black.

In this manual, to gently touch the screen is referred to as "press".

Do not use excessive force on the touch panel, and do not use sharp objects that could

damage the touch screen.

1.3.1 Initial Screen

This is the screen that is first displayed when the power is turned on. It allows you to perform measurement

while checking the measurement conditions.

When the power is turned on again, display is in accordance with the measurement mode used immediately

before the power was turned off.

Page 21

13

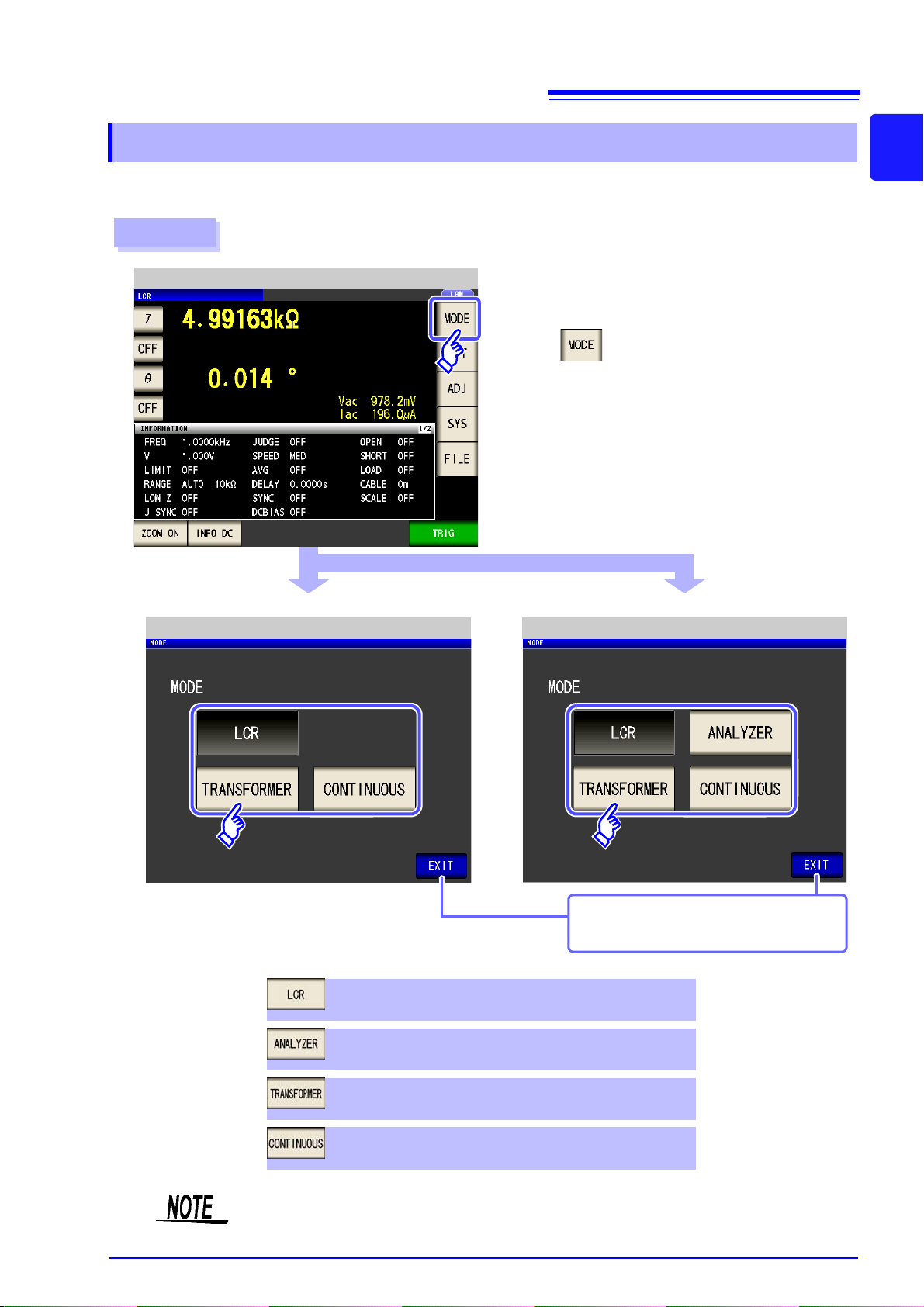

Procedure

2

1

When IM3533

When IM3533-01

Measurement Screen

Mode Selection (IM3533) Mode Selection (IM3533-01)

Press .

ANALYZER mode (IM3533-01 only) (p. 149)

TRANSFORMER mode (p. 193)

Select the measurement mode.

LCR mode (p. 45)

CONTINUOUS measurement mode (p. 209)

Displays the measurement screen for the

selected mode.

1.3 Screen Configuration and Operation

1.3.2 Measurement Mode Selection Screen

Select the measurement mode.

1

Chapter 1 Overview

After changing the measurement mode, check all settings (including co mpe nsation) be fore

performing measurement.

Page 22

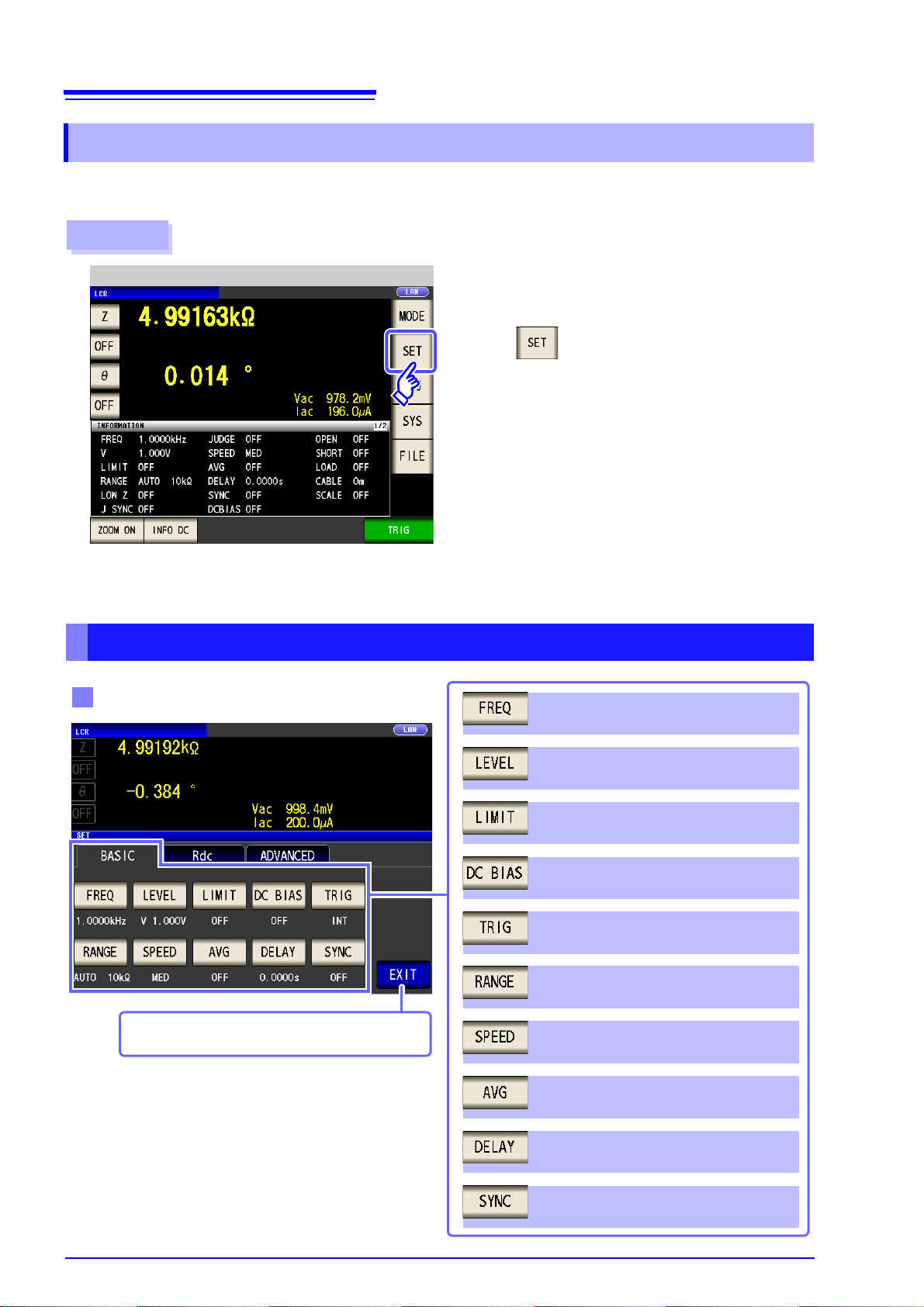

14

Press .

Measurement Screen

Configure settings for LCR mode, TRANSFORMER mode, and CONTINUOUS measurement mode.

On the IM3533-01, you can also configure ANALYZER mode settings.

Procedure

Basic setting

Trigger synchronous output function

setting (p. 77)

Measurement frequency setting (p. 50)

Measurement signal level setting (p. 52)

Voltage and current limit settings (p. 56)

DC bias setting (p. 58)

Trigger setting (p. 60)

Measurement range setting (p. 62)

Measurement speed setting (p. 73)

Average setting (p. 74)

Trigger delay setting (p. 76)

LCR mode measurement screen is displayed.

1.3 Screen Configuration and Operation

1.3.3 Advanced Settings Screen

This screen is for configuring the measurement conditions you want to change and other advanced settings.

Select the measurement mode (p. 13) before configuring the advanced settings.

LCR Mode

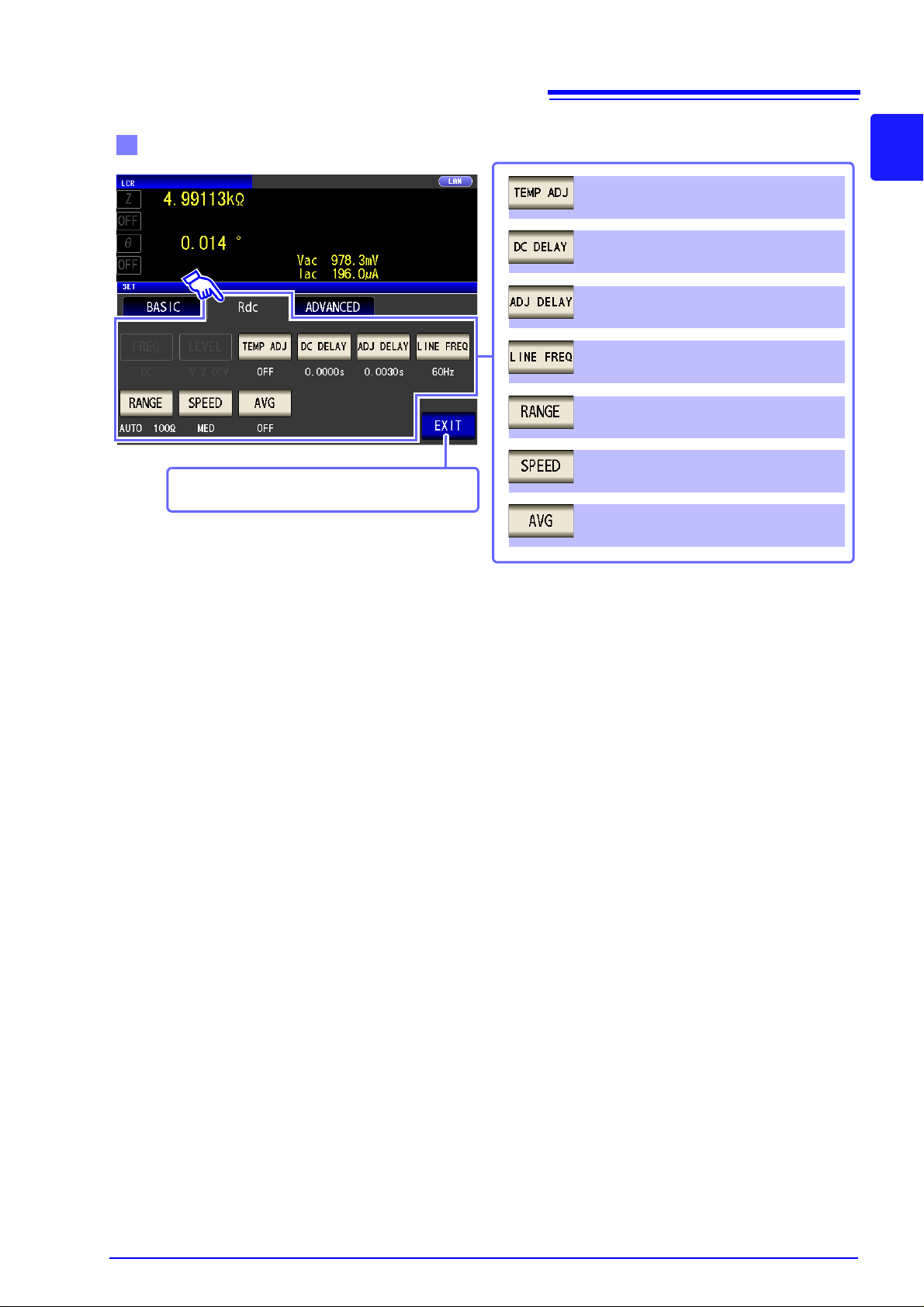

Page 23

15

Measurement range setting (p. 88)

DC resistance measurement setting

Line frequency setting (p. 87)

Average setting (p. 99)

DC delay setting (p. 83)

T emperature correction function setting (p. 8 1)

Adjustment delay setting(p. 85)

Measurement speed setting (p. 98)

LCR mode measurement screen is displayed.

Measurement range setting (p. 97)

1.3 Screen Configuration and Operation

1

Chapter 1 Overview

Page 24

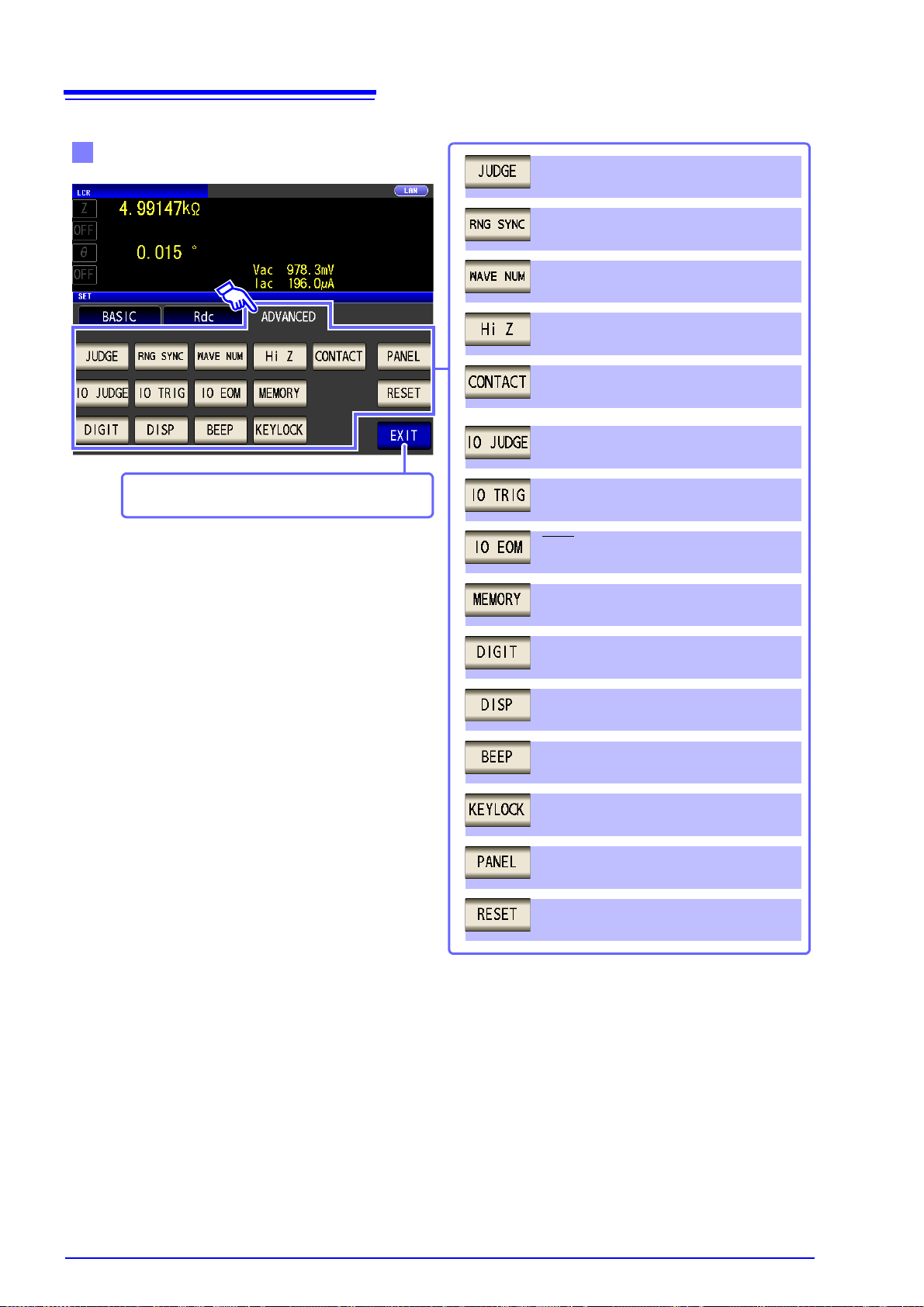

16

Contact check function setting (p. 132)

Application settings

Measurement result judgment setting

(p. 100)

Save settings of measurement results

(p. 138)

Panel loading and saving (p. 249)

System reset (p. 147)

Waveform averaging function setting

(p. 128)

Range synchronization function setting

(p. 120)

I/O output setting of judgment results

(p. 134)

I/O trigger setting (p. 136)

HIGH-Z reject function setting (p. 130)

Number of display digits setting for each

parameter (p. 140)

LCD setting (p. 142)

Beep sound setting(p. 141)

Key-lock setting (p. 144)

EOM Output Method Setting (p. 137)

LCR mode measurement screen is displayed.

1.3 Screen Configuration and Operation

Page 25

17

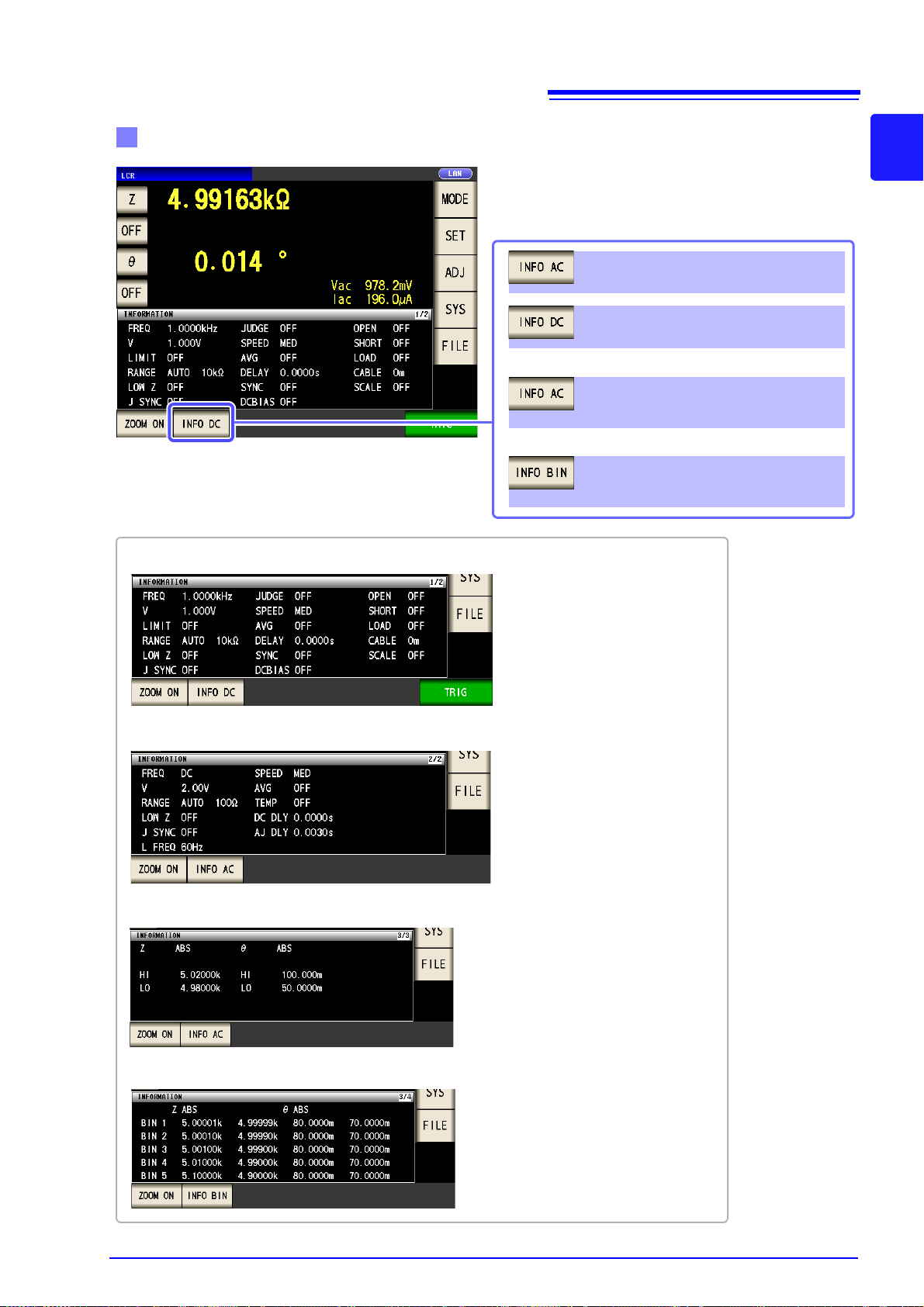

Checking the setting information

You can check the settings on the measurement

screen.

The key display will vary depending on what type

of information is being displayed.

Displays information regarding the

AC signal.

Displays information regarding the

DC signal.

Displays information about comparator

measurement judgment standards.

Displays information about BIN measurement judgment standards.

When using comparator measurement

When using BIN measurement

When displaying AC signal (AC) information

When displaying DC signal (DC) information

When displaying information about comparator measurement judgment standards

When displaying information about BIN measurement judgment standards

1.3 Screen Configuration and Operation

1

Chapter 1 Overview

Page 26

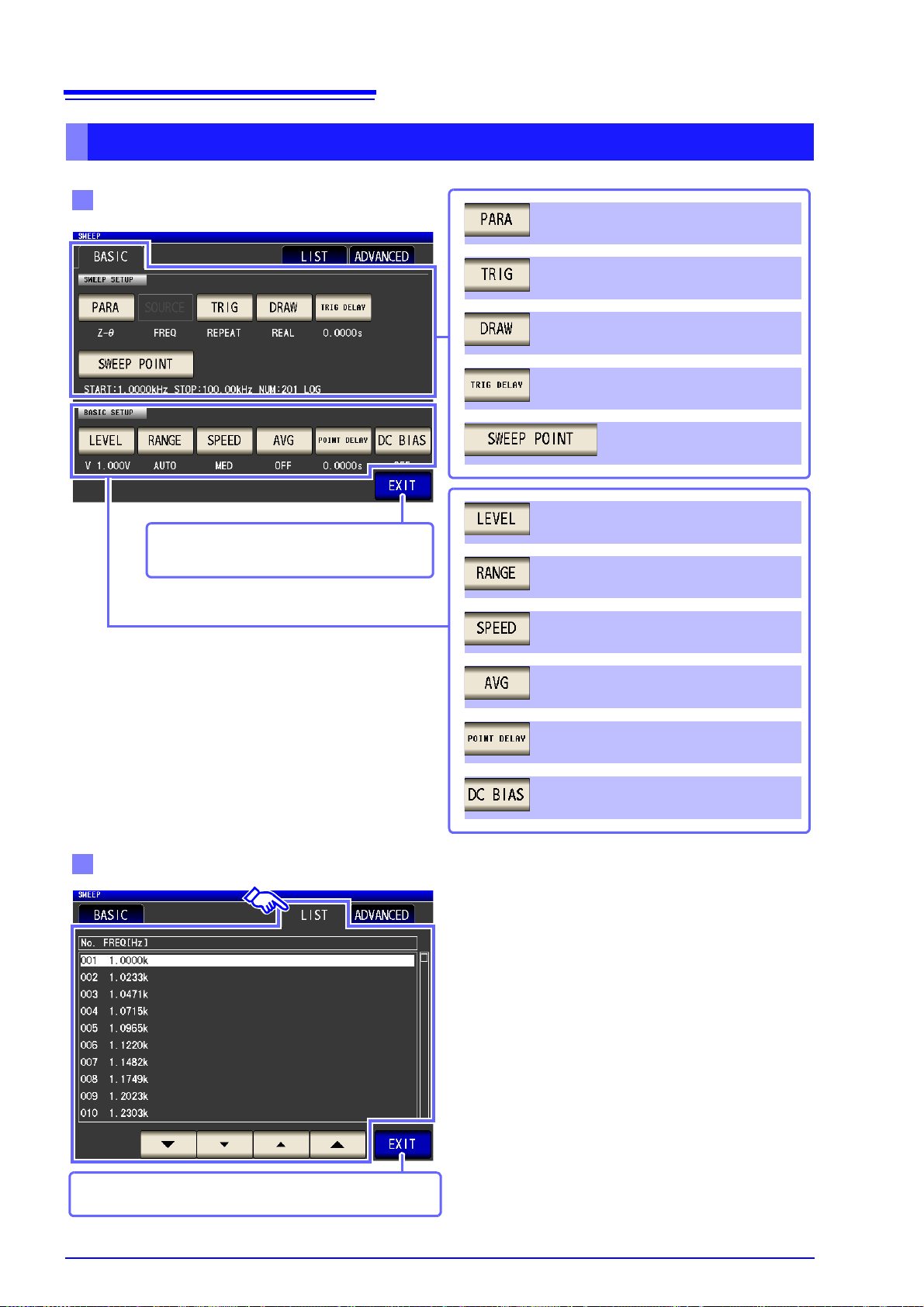

18

Measurement signal level setting (p. 158)

Measurement range setting (p. 160)

Measurement speed setting (p. 166)

Average setting(p. 167)

Point delay setting (p. 168)

Basic setting

DC bias setting (p. 169)

Measurement parameter setting(p. 150)

Trigger delay setting (p. 153)

Sweep point setting (p. 155)

Trigger setting (p. 151)

Display timing setting(p. 152)

ANALYZER mode measurement screen is

displayed.

List

ANALYZER mode measurement screen is displayed.

1.3 Screen Configuration and Operation

ANALYZER Mode (IM3533-01 only)

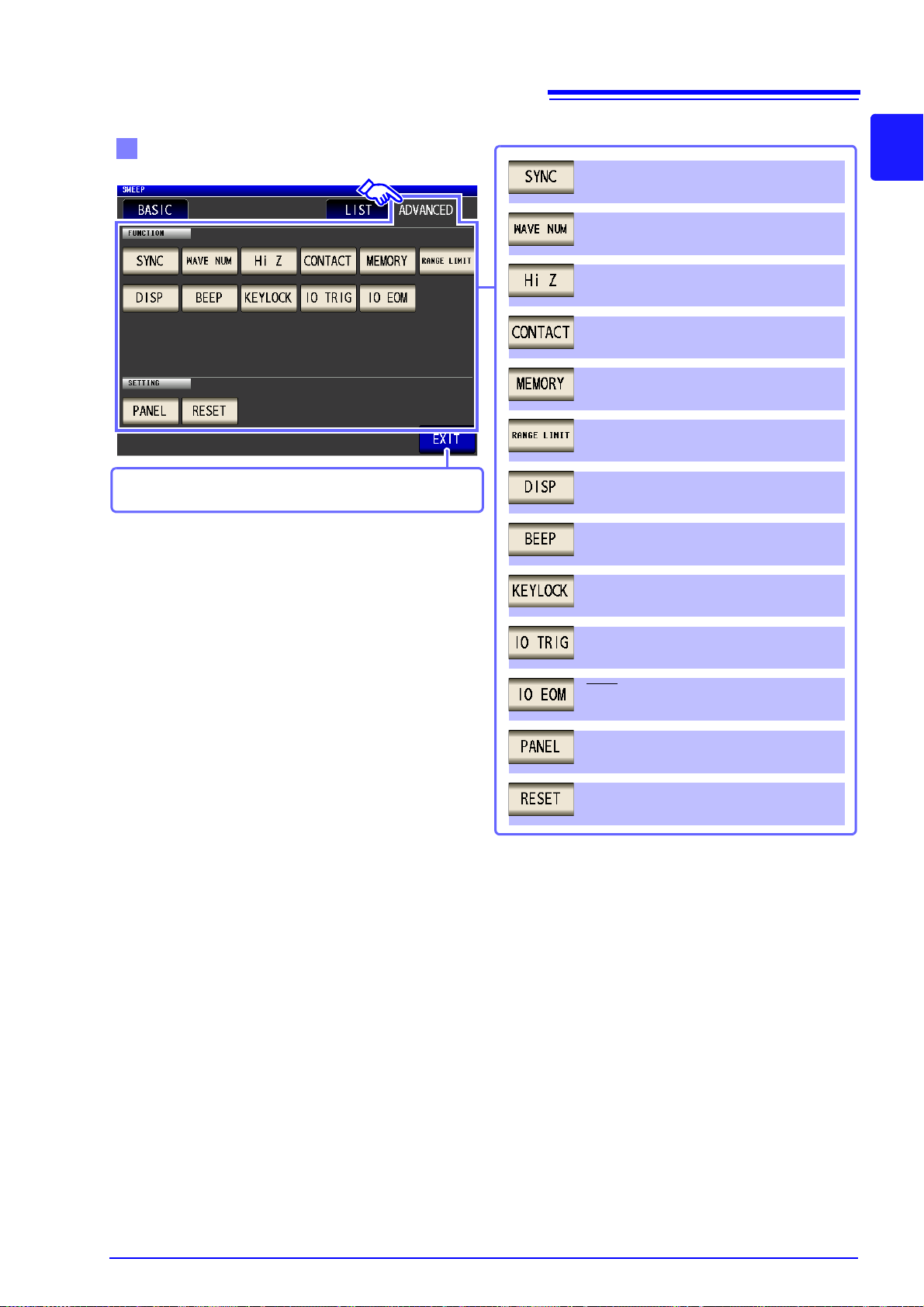

Page 27

19

Beep sound setting (p. 185)

Key-lock setting (p. 186)

Backlight setting (p. 184)

Panel loading and saving (p. 251)

System reset (p. 191)

Application settings

Contact check function setting (p. 177)

IO trigger setting (p. 189)

Waveform averaging function setting

(p. 173)

AUTO range limit function (p. 180)

EOM output method setting (p. 190)

Trigger synchronous output function

(p. 171)

HIGH-Z reject function setting (p. 175)

Save settings of measurement results

(p. 177)

ANALYZER mode measurement screen is displayed.

1.3 Screen Configuration and Operation

1

Chapter 1 Overview

Page 28

20

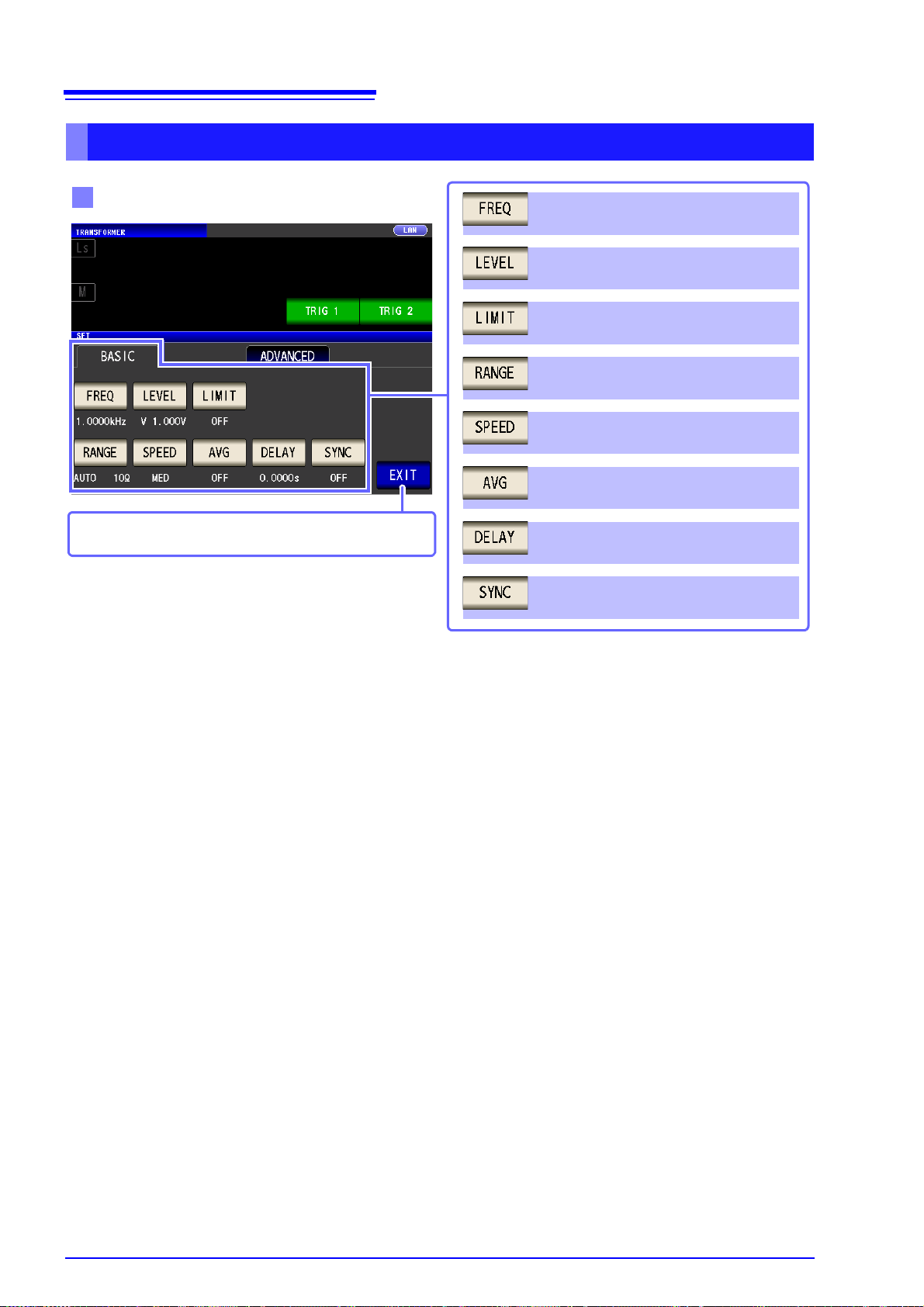

Basic setting

Trigger synchronous output function

(p. 77)

Measurement frequency setting (p. 50)

Measurement signal level setting (p. 52)

Voltage and current limit settings (p. 56)

Measurement range setting (p. 62)

Measurement speed setting (p. 73)

Average setting (p. 74)

Trigger delay setting (p. 76)

TRANSFORMER mode measurement screen is displayed.

1.3 Screen Configuration and Operation

TRANSFORMER Mode

Page 29

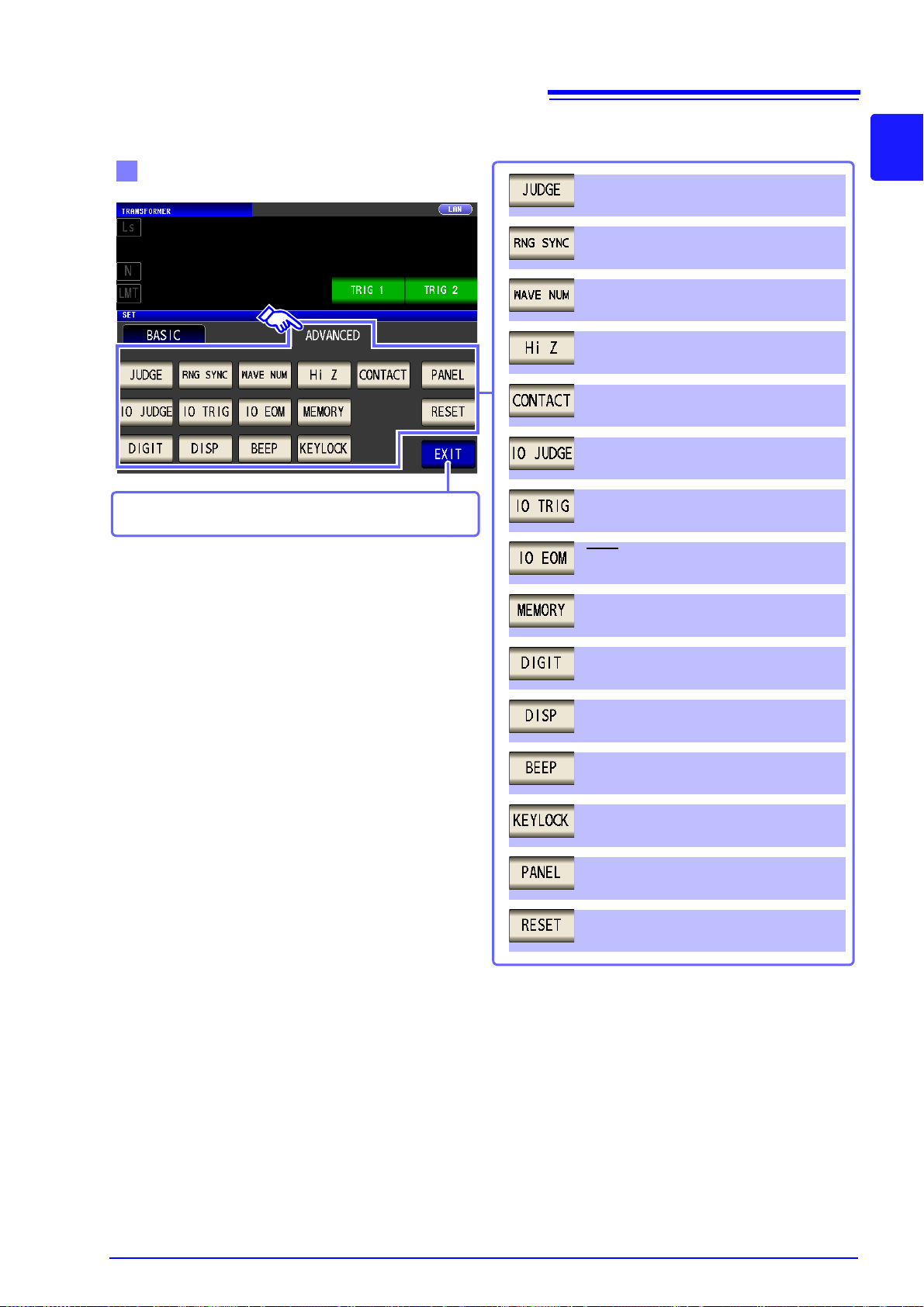

Application settings

Measurement result judgment setting

(p. 199)

Save settings of measurement results

(p. 138)

Panel loading and saving (p. 249)

System reset (p. 147)

Waveform averaging function setting

(p. 128)

Range synchronization function setting

(p. 120)

I/O output setting of judgment results

(p. 134)

I/O trigger setting (p. 136)

HIGH-Z reject function setting (p. 130)

Number of display digits setting for each

parameter (p. 140)

LCD setting (p. 142)

Beep sound setting (p. 141)

Key-lock setting (p. 144)

EOM Output Method Setting (p. 137)

TRANSFORMER mode measurement screen is displayed.

Contact check function setting (p. 132)

21

1.3 Screen Configuration and Operation

1

Chapter 1 Overview

Page 30

22

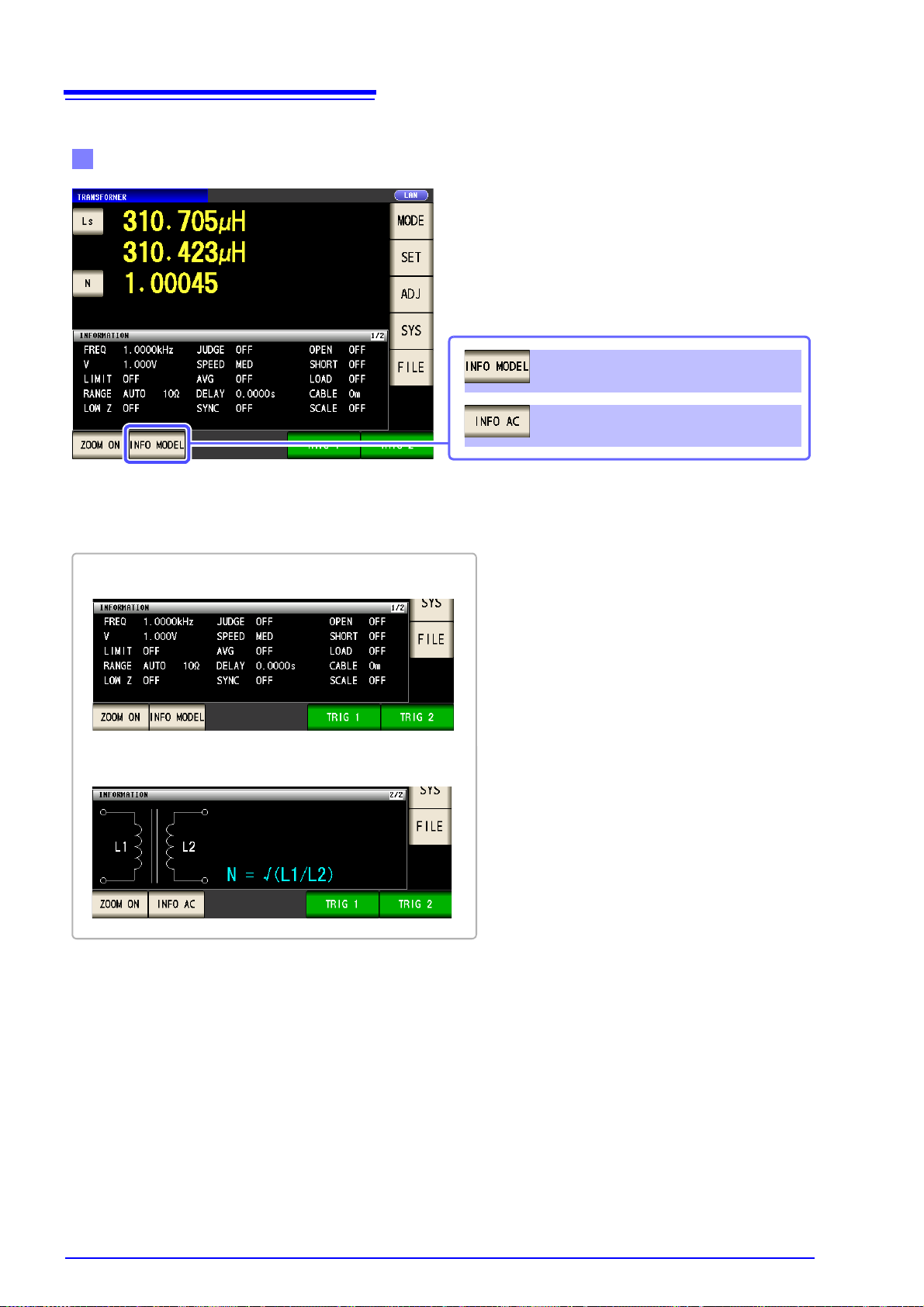

Checking the setting information

Displays the transformer model.

Displays information regarding the

AC signal.

You can check the settings on the measurement

screen.

The key display will vary depending on what type

of information is being displayed.

When displaying AC signal (AC) information

When displaying a transformer model

1.3 Screen Configuration and Operation

Page 31

23

Basic setting

Removes item from targets for

continuous measurement (p. 210)

Sets item as target for continuous

measurement (p. 210)

Removes all items from targets for

continuous measurement(p. 210)

Sets all items as targets for continuous

measurement (p. 210)

Displays panel information (p. 210)

CONTINUOUS measurement mode measurement

screen is displayed.

Application settings

Display timing setting (p. 213)

LCD setting (p. 214)

CONTINUOUS measurement mode measurement

screen is displayed.

1.3 Screen Configuration and Operation

CONTINUOUS Measurement Mode

1

Chapter 1 Overview

Page 32

24

Procedure

Press .

Measurement Screen

Set the compensation condition.

Open circuit compensation setting (p. 215)

Scaling setting (p. 246)

Cable length compensation setting (p. 245)

Short circuit compensation setting (p. 224)

Load circuit compensation setting (p. 232)

Measurement screen is displayed.

1.3 Screen Configuration and Operation

1.3.4 Compensation Settings Screen

Page 33

25

Procedure

Press .

Measurement Screen

To set the details of the system.

Interface type settings

Measurement screen is displayed.

Printer Setting (p. 331)

(Setting only available when the Z3001 is

installed.)

RS-232C Setting

(Ref to Communication Instruction Manual (LCR

Application Disk))

(Setting only available when the Z3001 is

installed.)

GP-IB Setting

(Ref to Communication Instruction Manual (LCR

Application Disk))

(Setting only available when the Z3000 is

installed.)

USB Setting

(Ref to Communication Instruction Manual (LCR

Application Disk))

(Standard setting)

LAN Setting

(Ref to Communication Instruction Manual (LCR

Application Disk))

(Setting only available when the Z3002 is

installed.)

1.3 Screen Configuration and Operation

1.3.5 System Settings Screen

1

Chapter 1 Overview

Page 34

26

Check the version of the instrument

(p. 264)

Measurement screen is displayed.

Checking the Display Screen

Panel test (p. 265)

ROM/RAM test (p. 270)

I/O test (p. 271)

Display test (p. 268)

Panel calibration (p. 266)

Measurement screen is displayed.

Setting the Date and Time

(p. 272)

Indicates the current date and time set on the instrument.

Accepts the set time and date.

Measurement screen is displayed.

1.3 Screen Configuration and Operation

Page 35

27

Procedure

Press .

Measurement Screen

Set the save destination and type.

Save the measurement condition

Saves the setting conditions (p. 293)

Selects a file (p. 275)

Displays the screen immediately above

(p. 275)

Switches operation buttons. (p. 275)

Measurement screen is displayed.

Save method setting

Save destination folder

setting (p. 291)

Save type setting (p. 277)

Measurement screen is displayed.

1.3 Screen Configuration and Operation

1.3.6 Save Settings Screen

1

Chapter 1 Overview

Page 36

28

Procedure

Select parameters.

Parameter SettingMeasurement Screen

Static capacitance in series equivalent circuit

mode (F)

Static capacitance in parallel equivalent circuit

Loss coefficient = tan

Reactance ()

Susceptance (S)

DC Resistance()

Effective resistance in series equivalent circuit

mode ESR = (

)

Effective resistance in parallel equivalent circuit mode (

)

Conductance (S)

Impedance ()

Admittance (S)

*Impedance phase angle ( ° ) *

Q factor

* The phase angle q is shown based on the impedance Z.

When performing measurements using admittance Y as the reference, the sign of the impedance Z phase angle will be reversed.

Press the key to set.

Inductance in series equivalent circuit mode

(H)

Inductance in parallel equivalent circuit mode

(H)

The fourth parameter key

The third parameter key

The first parameter key

The second parameter key

Temperature (C°)

Display no measurement parameter in the

chosen position.

Measurement Screen is

displayed.

1.3 Screen Configuration and Operation

This screen is for selecting the measurement parameters to display.

See "4.1.2 Setting Display Parameters" (p. 47), "Appendix7 Se ries Equivalent Circu it Mod e and P arallel Equivalen t Circuit M ode"(p. A11)

1.3.7 Parameter Settings Screen

Page 37

Measurement

9478 Sheath Type Temperature Probe

(Option)

• USB cable

• GP-IB cable (only when the Z3000 is connected)

• Printer (only when the Z3001 is connected)

(p. 331)

Connect the external interface (as needed)

4

• RS-232C cable (only when the Z3001 is connecte d)

• LAN cable (only when the Z3002 is connected)

• EXT I/O (p. 309)

Connecting the Power Cord (p. 31)

2

Installing the Instrument (p. 5)

Turning Power On (p. 35)

1

5

Make instrument settings

6

Connect to the test sample

After using the instrument, remove the test sample and turn off the power . (p. 35)

FrontRear

When measuring DC resistance, be sure to set the line frequency before performing measurement.

See "4.3.4 Setting the Line Frequency" (p. 87)

Check that the instrument’s power switch is turned off.

Connect measurement cables, optional Hioki probes or test fixture (p. 32)

3

Preparations Chapter 2

Be sure to read the "Follow these precautions to ensure safe operation and to obtain the full benefits of the

various functions." (p. 5) before installing and connecting this instrument.

Refer to "Appendix10 Rack Mounting"(p. A15) for rack mounting.

2.1 Preparation Flowchart

29

2.1 Preparation Flowchart

2

Chapter 2 Measurement Preparations

Page 38

30

Before using the instrument for the first time, verify that it operates normally to ensure that no damage

occurred during storage or shipping. If you find any damage, contact your authorized Hioki distributo r or

reseller.

Do not use the instrument if damage

is found, as electric shock or shortcircuit accidents could result. Contact

your authorized Hioki distributor or

reseller.

Metal Exposed

Is the power cord insulation torn, or is

any metal exposed?

1

No Metal Exposed

Peripheral Device Inspection

Is the insulation on a measurement

cable torn, or is any metal exposed?

Metal Exposed

If there is any damage, measured values may be unstable and measurement errors may occur. Replace the

cable with an undamaged one.

No Metal Exposed

If damage is evident, request repairs.

Yes

Instrument Inspection

When turning power on

No

2

The power cord may be damaged, or

the instrument may be damaged internally. Request repairs.

No

Yes

The instrument may be damaged

internally. Request repairs.

See "15.1 Inspection, Repair and

Cleaning" (p. 353)

"15.3 Error display" (p. 360)

An error indication

occurs (ERR)

No

Inspection complete

Is damage to the instrument evident?

Is there an error display on the Opening

screen?

Does the Opening screen appear (model no., version no.)?

Opening screen

2.2 Pre-Operation Inspection

2.2 Pre-Operation Inspection

Please read the "Follow these precautions to ensure safe operation and to obtain the

full benefits of the various functions." (p. 5) before use.

Page 39

31

1

Check that the instrument’s power switch is turned off.

2

Connect a power cord that matches the line voltage to

the power inlet on the instrument. (100 V to 240 VAC)

3

Plug the other end of the power cord into an outlet.

Turn of f the power before disconnecting the power cord.

Rear

Power inlet

2.3 Connecting the Power Cord

2.3 Connecting the Power Cord

Be sure to read the "Before Turning Power On" (p. 6), "About Handling of

Cords, Fixtures and Temperature probes" (p. 7) before connecting power.

2

Connect the power cord to the power inlet on the instrument, and plug it into an outlet.

Chapter 2 Measurement Preparations

Page 40

32

Connecting a measurement cable/fixture

Connect directly to the measurement jacks with

the label side up, and affix with the levers on the

left and right.

Points to pay attention to when making your own probe

• Use 50 coaxial cable for the measurement cable.

• Ensure that the length of the cable is the same as that set for the instrument.

(IM3533: 1 m, IM3533-01: 1 m/ 2 m/ 4 m)

• The cable length is defined as the length from the tip of the BNC connector to the tip of the probe electrode.

• Make the portion of the core wire that is exposed as short as possible.

• Connect the H

CUR

, L

CUR

, H

POT

, and L

POT

shield pairs at the measurement object side.

(Ensure that a shield is not connected to a core wire.)

Measurement Terminal

Configuration

Fixture

Normal mode

2.4 Connecting the Measurement Cables, Probes, or Fixture

2.4 Connecting the Measurement

Cables, Probes, or Fixture

Be sure to read the "About Handling of Cords, Fixtures and Temperature

probes" (p. 7) before connecting measurement cables, probes or test fixture.

Connect your measurement cables, optional Hioki probes or test fixture to the measurement terminals.

Refer to

See the instructions provided with the fixture for operating details.

"Options" (p. 2) for details.

• Basically, when you make a probe yourself, it may not be able to satisfy the specificatio ns

of this instrument.

See: "Options" (p. 2)

• If all four terminals are disconnected, a meaningless number may be displayed on the

unit.

Page 41

33

1

Check that the instrument’s power switch is

turned off.

2

Holding the connector, orient so that the arrow is on

the top and connect to the terminal.

The connector will lock in place with a clicking sound.

3

Gently pull on the connector (the part other than the

coupling) to verify that it has been connected properly.

Rear

Coupling

When disconnecting the temperature probe:

Grasp the connector’s coupling and disconnect the line by pulling

straight back.

OK

40 mm or more

2.5 Connecting a Temperature Probe

2.5 Connecting a Temperature Probe

Be sure to read the "About Handling of Cords, Fixtures and Temperature

probes" (p. 7) before connecting measurement cables, probes or test fixture.

2

Chapter 2 Measurement Preparations

The 9478 Sheath Type Temperature Probe’s measurement unit is located at the tip of th e

metal sheath. When measuring the internal temperature of a target object, insert the metal

sheath to a length of at least 40 mm in order to assure accurate measurement, as illustrated below:

Page 42

34

1

Unplug the instrument's power cord from the wall outlet.

Disconnect connection cords.

2

Remove the blank panel.

3

Paying attention to the orientation of the interface,

inset it firmly into place.

Rear

4

Secure the interface in place by tightening the two fixing screws with a Phillips head screwdriver.

When removing the interface:

Unplug the power cord from the wall outlet and perform the above

procedure in reverse to remove the interface.

1

Unplug the instrument's power cord from the wall outlet.

Disconnect connection cords.

2

Attach the blank panel and secure it in place by tightening the two fixing screws with a Phillips head

screwdriver.

Rear

Making measurements without reattaching the blank

panel will prevent the instrument from performing to its

specifications.

2.6 Connecting an Interface

2.6 Connecting an Interface

Be sure to read the "Input modules (option)" (p. 8) before connecting measurement cables, probes or test fixture.

Read this section before installing or replacing an optional interface or removing the interface and using the

instrument without it.

Installing an interface

You will need: A Phillips head screwdriver

When a removed interface will not be used

You can check information about the interface installed in the instrument on the screen.

See "10.1 Setting the Interface" (p. 263), "10.2 Checking the Version of the Instrument" (p. 264)

Page 43

2.7 Turning the Power On and Off

Power switch

Turn the POWER switch on ( | ).

Lights green

To ensure that measurements fulfill the

degree of accuracy described in the

specifications, , allow at least 60 minutes

warm-up before executing zero adjustment.

Turn the POWER switch off ( ).

Instrument settings are retained, even if the POWER switch is

turned off (backup function).

OFF

2.7 Turning the Power On and Off

Connect the power cord and voltage and current measurement cables before turning the main power on.

35

2

Chapter 2 Measurement Preparations

Turning main power on

If the main power switch is tuned off while the instrument is in the standby state, it will start

up in the standby state the next time the main power switch is turned on.

Turning main power off

When the power supply is interrupted by a power failure or the like, the instrument recovers

in the measurement mode used before the power failure.

Page 44

36

ON the main power in the state, hold down the front Standby Key 2 seconds approximately.

Lights red

What is the standby state?

The instrument is in the standby state when measurement has b een stopped and th e instrument is wa iting

for STANDBY key input to be detected. To allow STANDBY key input to be detected, some internal circuitry is operating with power consumption of approximately 4 W.

The instrument is in standby state, press the Standby Key on the front.

To ensure that measurements fulfill the degree of accuracy described in the specifications, allow the

instrument to warm up for at least 60 minutes after standby state operation is canceled.

Lights green

2.7 Turning the Power On and Off

Be on standby

To cancel the standby

Page 45

37

1

Connect the 9263 SMD test fixture to the measurement terminals.

For the connection procedure, refer to the

instruction manual supplied with the fixture.

2

Set the first parameter to Cs and the third parameter to D. (p. 46)

Trigger synchronous output function

setting: OFF (p. 77)

3

Set the measurement conditions.

Touch on the Measurement screen, select

the item you want to set, and set it as follows.

LCR Basic Settings

Measurement frequency: 1.0000 kHz

(p. 50)

Measurement signal mode:

Open circuit voltage (V) mode (p. 52)

Measurement signal level: 1.000 V (p. 52)

Measurement range: AUTO (p. 62)

Measurement speed: MED (p. 73)

Voltage and current limit: (p. 56)

Average: OFF (p. 74)

Trigger delay: 0.0000 s (p. 76)

Trigger: INT(p. 60)

DC bias: OFF (p. 58)

3.1 When LCR Mode

Measurement

Example Chapter 3

This chapter provides example measurement scenarios for LCR mode, ANALYZER mode (IM3533-01 only),

and TRANSFORMER mode.

3

3.1 When LCR Mode

Measuring a Laminated Ceramic Capacitor

Necessary items: 9263 SMD test fixture, Laminated ceramic capacity you want to measure

Chapter 3 Measurement Example

Page 46

38

4

Connect the test sample to the 9263 SMD test fixture.

For the connection procedure of the test sample, refer to the instruction manual supplied

with the fixture.

5

Check the measurement results.

• When you want to judg e the me as ur em e nt resu lts

See: "4.4.1 Judging with Upper and Lower Limit Values

(Comparator Measurement Mode)" (p. 102)

• When you want to save the measurement results

See: "4.5.8 Saving Measurement Results (Memory

function)" (p. 138)

3.1 When LCR Mode

Page 47

3.2 When ANALYZER Mode (IM3533-01 only)

1

Connect the 9262 Test Fixture to the measurement terminals.

For the connection procedure, refer to the

instruction manual supplied with the fixture.

Measurement signal mode:

Open voltage (V) mode (p. 158)

Measurement signal level:

1.000 V (p. 158)

POINT DELAY: 0.0000 s (p. 168)

2

ANALYZER Basic Settings

Range: AUTO (p. 160)

Parameter: Z- (p. 150)

Sweep method: REPEAT (p. 151)

Draw timing: REAL (p. 152)

Trigger delay: 0.0000 s (p. 153)

Set the measurement conditions.

Touch on the Measurement screen, select

the setting you wish to configure, and configure it

as follows.

Sweep range: 1.0000 kHz to

100.00 kHz (p. 155)

No. of sweep points: 201

Setting method: LOG

3

Connect the test sample to the 9263 Test Fixture.

3.2 When ANALYZER Mode (IM3533-01 only)

In ANALYZER mode, you can sweep through a user-specified range of frequencies.

See "Chapter 5 ANALYZER Function (IM3533-01)" (p. 149)

Measuring Element with Resonance Point

Necessary items: 9262 Test fixture, Element you want to measure

39

3

Chapter 3 Measurement Example

Page 48

40

4

Execute the sweep.

The sweep is repeated since TRIG is set to REPEAT.

• When you want to chec k the me asur em e nt va lue s.

See: "5.1.1 Measurement screen" (p. 149)

3.2 When ANALYZER Mode (IM3533-01 only)

Page 49

3.3 When TRANSFORMER Mode

1

Wire together the instrument and transformer together as shown below:

Primary side

Secondary side

Primary side

Secondary side

2

Set the measurement parameter to Ls and the computation parameter to N (p. 196), (p. 197).

Measurement frequency: 1.0000 kHz

(p. 50)

Volt age and current limit: OFF (p. 56)

Trigger synchronous output function:

OFF (p. 77)

Measurement range: AUTO (p. 62)

Measurement speed: MED (p. 73)

Average: OFF (p. 74)

Trigger delay: 0.0000 s (p. 76)

Measurement signal mode:

Open circuit voltage (V) mode (p. 52)

Measurement signal level: 1.000 V (p. 52)

3

Set the measurement conditions.

Touch on the Measurement screen,

select the item you want to set, and set it as fol-

lows.

LCR Basic Settings

3.3 When TRANSFORMER Mode

Measuring a transformer’s turn ratio

You will need: Switch cable and transformer to measure

41

3

Chapter 3 Measurement Example

Page 50

42

4

Wire together the primary side.

Primary side

Secondary side

Primary side

Secondary side

5

Execute the TRIG1 command.

Touch and measure the primary

side of the transformer.

6

Wire together the secondary side.

Primary side

Secondary side

Primary side

Secondary side

7

Execute the TRIG2 command.

Touch and measure the secondary

side of the transformer.

3.3 When TRANSFORMER Mode

Page 51

43

8

Check the measurement results.

• When you want to judge the measurement results

See"6.3 Judging with Upper and Lower Limit Values (Comparator

Measurement Mode)" (p. 199)

• When you want to save the measurement results

See"4.5.8 Saving Measurement Results (Memory function)" (p. 138)

3.3 When TRANSFORMER Mode

3

Chapter 3 Measurement Example

Page 52

44

3.3 When TRANSFORMER Mode

Page 53

45

An operation key is displayed depending on the situation.

Enlarges the screen (p. 49).

Operation keys

Displays the measurement conditions for DC

measurement (p. 17).

Saves the measurement data (p. 277).

Prints the measurement data (p. 331).

Displays the comparator settings (p. 17).

Displays the BIN settings (p. 17).

Displays the measurement conditions for AC

measurement (p. 17).

Indicates the name

of the loaded panel

(p. 256).

Parameter keys

Set each parameter

(p. 47).

Indicates error

messages and

other information

(p. 360).

Indicates the usage

status of internal

memory (p. 138).

Indicates that a

USB flash drive is

connected

(p. 273).

Indicates the

interface that is

currently set

(p. 263).

The settings of differ depending on the measurement mode.

Menu keys

Select the measurement mode (p. 13).

Set the details (p. 50).

Set the compensation (p. 215).

Set the system (p. 263).

Set the save settings (p. 273).

A measurement condition is displayed (p. 17).

Vac, Vdc: Voltage between the sample terminals

Iac, Idc: Current passing through the sample

4.1 About LCR function

LCR Function Chapter 4

4.1 About LCR function

The LCR function allows you to measure the impedanc e, phase angle, and other items by applying any frequency or level (effective value) signal to th e eleme nt you want to m easure. This function is su itable for evaluating the passive element of a capacitor, coil, or the like.

It allows you to perform measurement while checking the measurement conditions. When the power is turned on

again, display is in accordance with the measurement mode used immediately before the power was turned off.

For details on the screen configuration (p. 14).

The settings are synchronized between LCR mode, ANALYZER mode, and TRANS mode.

4.1.1 Measurement screen

4

Chapter 4 LCR Function

Page 54

46

4.1 About LCR function

When a measurement value is outside the guaranteed accuracy range, “Reference Value”

is displayed in the error display area. When this happens, the cause is likely to be one of the

following. Check the guaranteed accuracy range in "14.2 Measurement Range and Accuracy" (p. 342) and change the measurement conditions or you should consider the measured values as values for reference.

• Perhaps the test signal level is too low, increase the test signal level.

• If the current measurement range (during HOLD setting) is not appropriate, set again in the AUTO

range, or change the range by manual.

Page 55

4.1 About LCR function

Press the first parameter key.

LCR Measurement Screen

Example: The first parameter key: Capacitance Cs,

The third parameter key: Loss coefficient D

Procedure

Press .

Press to confirm the setting.

Parameter Setting

Press the third parameter key.

LCR Measurement Screen

4.1.2 Setting Display Parameters

You can select up to four measurement parameters to display in any location from 16 types.

See "1.3.7 Parameter Settings Screen" (p. 28)

"Appendix2 Measurement of High Impedance Components"(p. A3)

"Appendix7 Series Equivalent Circuit Mode and Parallel Equivalent Circuit Mode"(p. A11)

47

4

Chapter 4 LCR Function

Page 56

48

Press .

Press to confirm the setting.

Parameter Setting

Cs and D are set as the parameters.

LCR Measurement Screen

4.1 About LCR function

If is selected in the parameter setting, a measurement value is not displayed.

Page 57

49

Procedure

Press in the measurement screen to

display the magnification display screen.

When you want to show normal display:

Press in the magnification display

screen.

LCR Measurement Screen

Magnification Display Sc reen (W he n B IN)

Magnification Display Screen

(When Normal)

Magnification Display Scre en

(When Comparator)

• Indicates the position of the measurement value relative to the comparator

thresholds with a bar.

• The bars will not be displayed unless

both upper and lower limit values have

been set.

4.1 About LCR function

4.1.3 Enlarging Display of Measurement Values

The measurement values and comparator decision results can be displayed in enlarged form.

This function is convenient when the instrument is used under constant measurement conditions.

If the power is turned off when is displayed, will be displayed when the instrument starts the

next time you turn the power on.

4

Chapter 4 LCR Function

Page 58

50

LCR Measurement Screen

Example: Measurement frequency: 1 MHz

LCR Basic Settings

Procedure

Set each digit.

Set the frequency with the numeric keypad.

Frequency Setting (Digits) Frequency Setting (Numeric Keypad)

Press .

There are the following two frequency input methods.

Press or to change the input

method.

LCR Basic Settings

Settable range : 1 mHz to 200 kHz

4.2 Setting Basic Settings of Measurement Conditions

4.2 Setting Basic Settings of

Measurement Conditions

4.2.1 Setting the Measurement frequency

Set the frequency of the signal to apply to the test sample. For some test samples, the value may vary

depending on the measurement frequency.

Page 59

4.2 Setting Basic Settings of Measurement Conditions

Use the numeric keypad to enter the

frequency.

Press a instrument key to confirm the

setting.

Press to close the setting screen.

Use or to se lect the pos ition

of the decimal point and the instrument.

• Settable range : 1 mHz to 200 kHz

• The frequency is not confirmed until a instrument key is pressed.

• The instrument keys are disabled until a number

is entered.

• If you attempt to set a measurement frequency

greater than 200 kHz, it will automatically be

reduced to 200 kHz.

• If you attempt to set a measurement frequency