Page 1

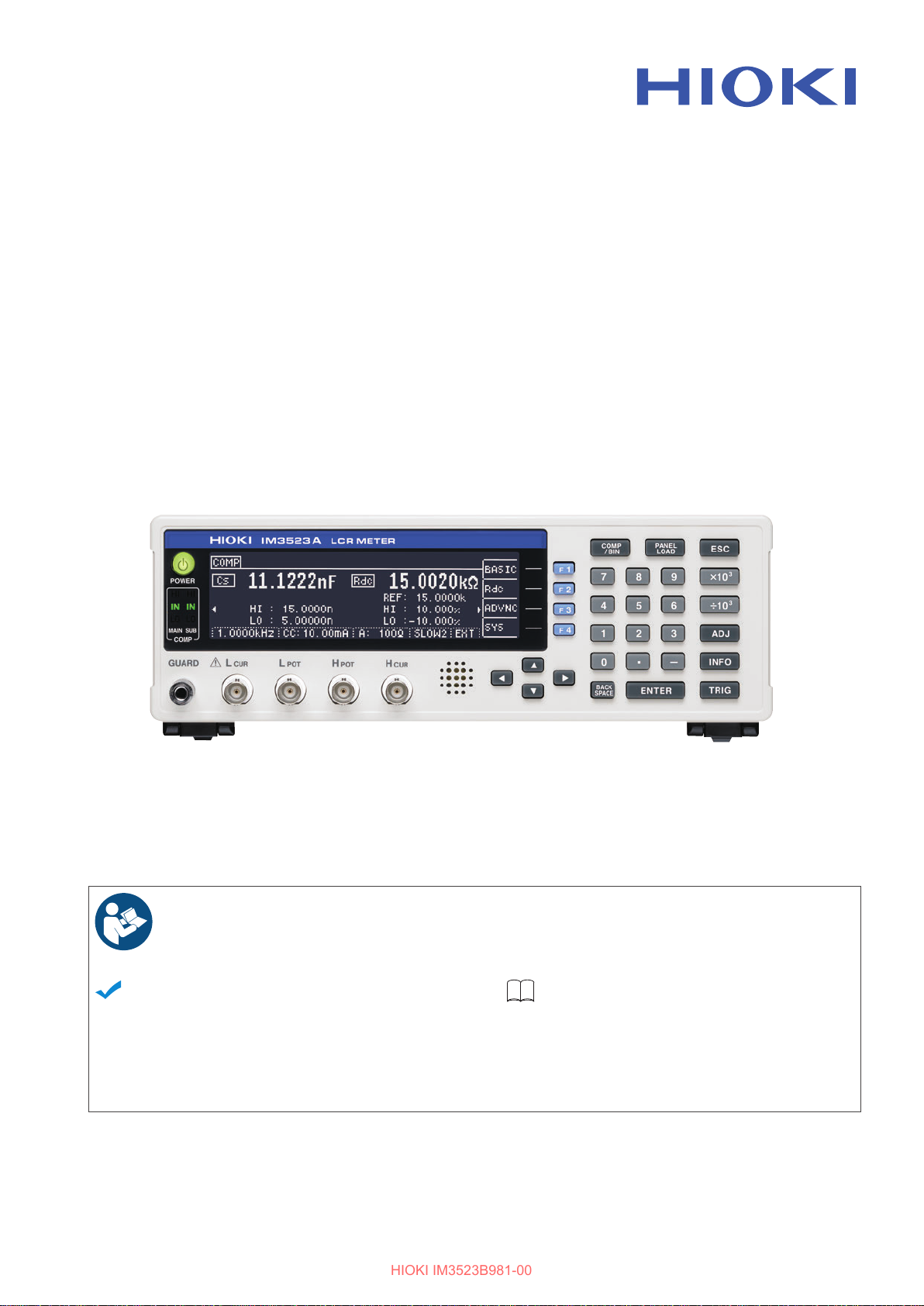

IM3523A

HIOKI IM3523B981-00

LCR METER

Instruction Manual

Dec. 2022 Edition 1

IM3523B981-00 22-12H

Read carefully before use.

Keep for future reference.

When using the instrument for the rst

time

Safety Information

Names and Functions of Parts

Measurement Preparations

p.4 Maintenance and Service

p.10 Error Display

p.21

Troubleshooting

p.209

p.216

EN

[600641400]

Page 2

HIOKI IM3523B981-00

Page 3

Contents

Introduction.....................................................1

HIOKI IM3523B981-00

Verifying Package Contents........................... 2

Options...........................................................3

Safety Information ..........................................4

Safety Symbols ...........................................4

Symbols for Various Standards ..................4

Notation ......................................................5

Measurement categories ............................5

Operating Precautions....................................6

Preliminary Checks .....................................6

Instrument Installation .................................6

Shipping precautions ..................................7

Handling the Instrument ..............................7

Handling the LCR Application Disk .............7

Chapter 1 Overview 9

1.1 Product Overview and Features ..........9

1.2 Names and Functions of Parts ........... 10

1.3 Screen Organization and Operation ..12

1.3.1 Initial Screen ...................................12

1.3.2 Selecting the Measurement Mode ..13

1.3.3 LCR Mode .......................................14

1.3.4 Continuous Measurement Mode ..... 17

1.3.5 System Settings Screen .................. 18

1.3.6 Comparator/BIN Settings Screen .... 19

1.3.7 Panel Load screen .......................... 19

1.3.8 Compensation Settings Screen ....... 19

1.3.9 Information Screen .......................... 20

Chapter 2 Measurement

Preparations 21

2.1 Preparation Flowchart ........................21

2.2 Pre-Operation Inspection ................... 22

2.3 Connecting the Power Cord ...............23

2.4 Connect measurement cables, optional

Hioki probes or test fixture ................. 24

2.5 Turning the Power On and Off ........... 26

i

Contents

Chapter 3 Measurement

Example 27

Chapter 4 LCR Function 29

4.1 About LCR function ............................29

4.2 Setting Basic Settings of Measurement

Conditions ..........................................31

4.2.1 Setting Display Parameters .............31

4.2.2 Setting the Measurement

Frequency ........................................33

4.2.3 Setting the Measurement Signal

Level ................................................37

4.2.4 Limiting the Voltage or Current Applied

to the Sample (Limit Values) ...........41

4.2.5 Setting the Measurement Range .....43

Setting AUTO Ranging ............................ 44

AUTO range limit function ........................ 44

Setting HOLD Ranging ............................ 45

JUDGE SYNC setting .............................. 48

4.2.6 Measuring at User-specified Timing

(Trigger Measurement) ...................50

4.2.7 Setting Measurement Conditions for

Individual Ranges ............................51

List screen layout ..................................... 51

Selecting range settings to change .......... 52

Setting the Measurement speed .............. 53

Displaying Average Values (Average set) 54

Setting a delay before measurement data is

acquired (trigger delay) ............................ 56

Applying the signal to the sample during

measurement only

(Trigger Synchronous Output Function) ... 57

4.3 Setting DC Resistance Measurement 61

4.3.1 Setting the Measurement Range .....62

Setting AUTO Ranging ............................ 63

AUTO range limit function ........................ 63

Setting HOLD Ranging ............................ 64

JUDGE SYNC setting .............................. 66

4.3.2 Setting a Delay Time for DC

Measurement (DC Delay) ................67

4.3.3 Setting a Delay Time for Offset

Measurement (Adjustment Delay) ...69

4.3.4 Setting the Line Frequency ..............70

IM3523B981-00

Page 4

ii

HIOKI IM3523B981-00

Contents

4.3.5 Setting Measurement Conditions for

Individual Ranges ............................71

List screen layout ..................................... 71

Selecting the range setting you wish to

change ..................................................... 72

Setting the measurement speed .............. 73

Displaying Average Values

(Averaging Set) ........................................ 74

Applying settings to all ranges ................. 74

4.4 Judging Measurement Results ...........75

4.4.1 Making Judgments Based on Upper and

Lower Limit Values

(Comparator Measurement Mode) ..76

Setting the Upper or Lower Limit Value as an

Absolute Value (ABS)

(Absolute Value mode) ............................ 78

Setting the Upper or Lower Limit Value as a

Percentage (%) Relative to a

Reference Value (Percentage mode) ...... 79

Setting Upper and Lower Limit Values as (Δ%)

Values Relative to the Offset from the Reference Value (Deviation Percentage Mode) 81

When you want to cancel the comparator

measurement setting: .............................. 82

4.4.2 Classifying Measurement Results

(BIN Measurement Function) .........83

Setting the Upper or Lower Limit Value as an

Absolute Value (ABS)

(Absolute Value mode) ............................ 86

Setting the Upper or Lower Limit Value as a

Percentage (%) Relative to a

Reference Value (Percentage mode) ...... 88

Setting Upper and Lower Limit Values as(Δ%)

Values Relative to the Offset from the Reference Value (Deviation Percentage Mode) 92

When you want to cancel the BIN measure-

ment setting: ............................................ 96

4.5 Setting Application Settings ................97

4.5.1 Saving Measurement Results

(Memory function) ...........................97

4.5.2 Setting the Detection Signal Waveform

Averaging Count

(Waveform Averaging Function) ......99

4.5.3 Setting the Delay Time from the Output

of Comparator and BIN Judgment

Results until Output of EOM (LOW) and

Resetting Judgment Results ..........100

4.5.4 Enabling Trigger Input for during Measurement and Setting the Valid Edge of

Trigger Input ..................................101

4.5.5 Setting the EOM Output Method ...102

4.5.6 Checking Contact Defects and the

Contact State

(Contact Check Function) ..............103

4.5.7 Detecting OPEN during 2-terminal Measurement (Hi-Z Reject Function) ... 105

4.5.8 Turning the LCD Display On and Off

....................................................... 107

4.5.9 Setting the Number of Display Digits

....................................................... 108

4.5.10 Setting Operation Sounds

(Beep Sounds) ............................ 110

Reporting judgment results with beep

operation ................................................ 110

Turning the key tone on and off ............. 111

Changing the beep tone and key tone ... 112

4.5.11 Adjusting the Screen Contrast .... 113

4.5.12 Disabling Key Operation

(Key-lock Function) ..................... 114

Setting the Passcode of the Key-lock .... 116

Canceling key lock mode ....................... 117

4.5.13 Initializing (System Reset) .......... 118

Chapter 5 Continuous Mea-

surement Function

119

5.1 About Continuous Measurement

Function 119

5.1.1 Measurement screen .................... 119

5.1.2 Setting Continuous Measurement . 120

5.2 Configuring Basic Settings

for Continuous Measurement .......... 121

5.3 Performing Continuous Measurement

.......................................................... 122

5.4 Configuring Application Settings for

Continuous Measurement ................ 123

5.4.1 Setting the Display Timing ............ 123

5.4.2 Setting the LCD to ON/ OFF ......... 124

Chapter 6 Error

Compensation 125

6.1 Setting Open Circuit Compensation 125

6.1.1 All Compensation .......................... 127

6.1.2 Spot Compensation ...................... 131

6.2 Short Circuit Compensation ............. 136

6.2.1 All Compensation .......................... 138

6.2.2 Spot Compensation ...................... 140

6.3 Adjusting Values Based on Reference

Values (Load Compensation) .......... 145

Page 5

6.4 Compensating Measurement Cable

HIOKI IM3523B981-00

Errors(Cable Length Compensation) 157

6.5 Converting Values (Scaling) ............158

Chapter 7 Saving and Reading

Panel Information

161

7.1 Saving Measurement Conditions

(Panel Save Function) .....................162

7.2 Reading Measurement Conditions

(Panel Load Function) ...................... 165

7.3 Changing a Panel Name ..................167

7.4 Deleting a Panel ............................... 169

Chapter 8 Setting

the SYSTEM 171

8.1 Setting the Interface .........................171

8.2 Checking the Version of the Instrument

..........................................................172

8.3 Self Checks (Self Diagnosis) ...........173

iii

Contents

Chapter 10 Specifications 195

10.1 General Specifications .....................195

10.2 Measurement Range and Accuracy .200

Example calculation ............................... 204

10.3 About Measurement Times and

Measurement Speed ........................207

Chapter 11 Maintenance

and Service 209

11.1 Inspection, Repair and Cleaning ......209

Inspection and Repair ............................ 209

Replaceable Parts and Operating Lifetimes

................................................................ 209

Transporting the instrument ................... 210

Cleaning ................................................. 210

Disposal ................................................. 210

11.2 Troubleshooting ................................211

Before returning for repair ...................... 211

When no apparent cause can be established

................................................................ 214

Full Reset Procedure ............................. 215

11.3 Error Display .....................................216

Chapter 9 External Control 177

9.1 External Input/Output Connector and

Signals .............................................177

Connector Type and Signal pin assignments

.................................................................178

Signal Descriptions .................................182

9.2 Timing Chart ....................................184

9.2.1 LCR Measurement ........................184

9.2.2 Continuous Measurement .............187

9.3 Internal Circuitry ...............................188

Electrical Specifications ..........................189

Connection Examples .............................190

9.4 External I/O Settings ........................ 191

Setting Delay Time from Output of

Comparator and BIN Judgment Results until

Output of EOM (LOW) ............................191

Setting Reset of Judgment Results ........191

Enabling Trigger Input for during

Measurement ..........................................191

Setting Valid Edge of Trigger Input .........191

9.5 External Control Q&A ....................... 192

9.6 Measurement Using a Computer ..... 193

Appendix A1

Appendix1 Measurement Parameters and

Calculation formula .................. A 1

Appendix2 Measurement of High Impedance

Components............................. A 3

Appendix3 Measuring In-circuit Elements.. A 4

Appendix4 Countermeasures Against

Incorporation of External Noise A 5

Appendix4.1Countermeasures Against

Incorporation of Noise from the

Power Line ........................ A 5

Appendix4.2Countermeasures Against

Noise from the measurement

Cables .............................. A 6

Appendix5 Supplying DC Bias ................... A 7

Appendix5.1How to Supply a DC Bias

Voltage ............................. A 7

Appendix5.2How to Supply a DC Bias

Current .............................. A 8

Appendix6 The Residual Charge Protection

Function ................................... A 9

Page 6

iv

HIOKI IM3523B981-00

Contents

Appendix7 Series Equivalent Circuit Mode and

Parallel Equivalent Circuit Mode

............................................... A 10

Appendix8 Open Circuit Compensation and

Short Circuit Compensation ... A 11

Appendix9 Rack Mounting ....................... A 13

Appendix10 Dimensional Diagram ........... A 15

Appendix11 Initial Settings Table ............. A 16

Index Index i

Page 7

Introduction

HIOKI IM3523B981-00

Introduction

Thank you for choosing the HIOKI Model IM3523A LCR Meter. To ensure your ability to get the most out

of this instrument over the long term, please read this manual carefully and keep it available for future reference.

The latest edition of the instruction manual

The contents of this manual are subject to change, for example as a result of product improvements or changes to specifications.

The latest edition can be downloaded from Hioki’s website.

https://www.hioki.com/global/support/download/

Product registration

Register your product in order to receive important product information.

https://www.hioki.com/global/support/myhioki/registration/

1

Refer to the following instruction manuals

Please review the separate “Operating Precautions” before using the instrument.

Name of the

instruction m

Instruction Manual

(this manual)

Communication

Instruction Manual

Startup Guide Includes information for using the instrument safely,

Operating Precautions Information for using the instrument safely. Hard copy

anual

Includes overview of the instrument, operation

m

ethods, function descriptions, and specifications.

Includes information related

ment using its communications interface.

basic ope

vant information).

in accordance with your application.

Description Format

to controlling the instru-

ration methods, specifications (selected rele-

PDF file

(included on CD)

PDF file

(included on CD)

Hard copy

Page 8

2

IM3523A LCR Meter ............................. 1

LCR Application Disk .............................1

(Instruction Manual [PDF format], Communication

Instruction Manual [(PDF format], explanation of

communications commands, USB driver, sample

application)

The latest version can be downloaded

from Hioki’s website.

Startup Guide ........................................1

Operating Precautions (0990A905) .......1

Power Cord (2-line + ground) (p. 23) .... 1

Confirm that these contents are provided.

HIOKI IM3523B981-00

Verifying Package Contents

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that no damage occurred during shipping. In particular,

check the accessories, panel switches, and connectors. If damage is evident, or if it fails to operate

according to the specifications, contact your dealer or Hioki representative.

• Probes, fixture are not supplied with the unit as standard equipment. You should order

them separately, according to requirements.

• The instrument ships from the factory configured as described in "Appendix11 Initial Set-

tings Table"(p. A16).

Precautions when transporting the instrument

Use the original packing materials when transporting the instrument, if possible.

See "Transporting the instrument" (p. 210)

Page 9

3

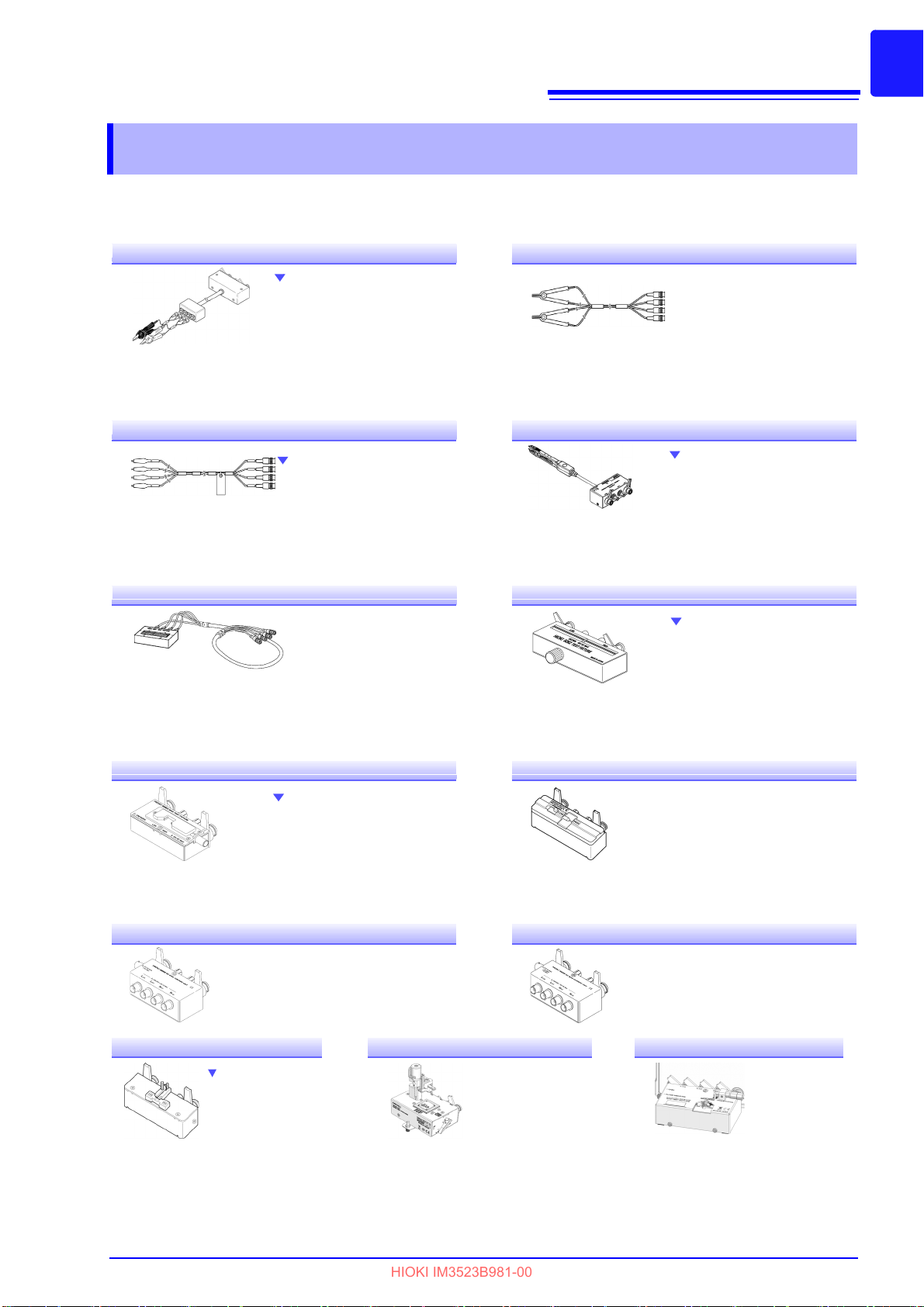

Measurable range: DC to 200 kHz

Maximum voltage:

±42 V peak (AC+DC)

Maximum current:

±1 A peak (AC+DC)

Measurable terminal diameter: 0.3 mm to 5 mm

L2000 4-Terminal Probe

Alligator-clip-type measurement probes. These generalpurpose dual-electrode clips fit

a wide range of conductor

thicknesses.

Measurable range: DC to 8 MHz

Maximum voltage: ±42 V peak (AC+DC)

Maximum current: ±1 A peak (AC+DC)

Measurable terminal diameter: 0.3 mm to 5 mm

9140-10 4-Terminal Probe

Measurable range: DC to 8 MHz

Maximum applied voltage:

±42 V peak (AC+DC)

Maximum applied current:

±1 A peak (AC+DC)

Electrode tip spacing: 0.3 mm to 6 mm

Measurable range: DC to 200 kHz

Maximum voltage:

±40 V DC (42 V peak [Measurement signal + bias voltage])

Maximum current: 1 A peak (Measurement signal + bias current)

Measurable terminal diameter: 0.3 mm to 2 mm

Rubber-sheathed alligator clip

type

9500-10 4-Terminal Probe

Pincher type

L2001 Pincher Probe

9261-10 Test Fixture

Measurable range: 42 Hz to 8 MHz

Maximum applied voltage: ±40 V DC

Test sample dimensions: Lead diameter of 0.3 mm to 2 mm

Lead pitch of 5 mm or more

This fixture is for measuring

lead components. (residual

resistance of 10 mΩ or less

after zero adjustment)

9262 Test Fixture

Measurable range: DC to 8 MHz

Maximum applied voltage:

±40 V DC

Measurable terminal diameter: 0.3 mm to 1.5 mm

9263 SMD Test Fixture

This fixture is for measuring chip

components. (residual resistance

of 10 mΩ or less after zero adjustment)

Measurable range: DC to 120 MHz

Maximum applied voltage: ±40 V DC

Test sample width of 3.5 ±0.5 mm

Measurable range: DC to 8 MHz

Maximum applied voltage: ±40 V DC

Test sample dimensions: Test sample width of 1 mm to 10 mm

9677 SMD Test Fixture

9268-10 DC Bias Voltage Unit

Measurable range: 40 Hz to 2 MHz

Maximum applied current: 2 A DC

Measurable range: 40 Hz to 8 MHz

Maximum applied voltage:

±40 V DC

9269-10 DC Bias Current Unit

This fixture is for the

lower electrode.

Measurable range: DC to 120 MHz

Maximum applied voltage: ±40 V DC

Test sample dimensions: Test sample width of

1 mm to 4 mm

Test sample height of 1.5 mm or less

9699 SMD Test Fixture

Measurable range: DC to 8 MHz

Maximum applied voltage: ±42 V peak

(AC+DC)

Maximum applied current:

±0.15 A rms (±0.15 A DC)

Measurement test sample dimensions:

0.4 × 0.2 mm, 0.6 × 0.3 mm, 1.0 × 0.5 mm

IM9100 SMD Test Fixture

Measurable range: DC to 1 MHz

Maximum applied voltage: ±42 V peak

(AC+DC)

Maximum applied current:

±0.15 A rms (±0.15 A DC)

Measurement test sample dimensions:

0.25 ±20% × 0.125 ±10% × 0.125 ±10%mm

IM9110 SMD Test Fixture

HIOKI IM3523B981-00

Options

Options

The following options are available for the instrument. Contact your authorized Hioki distributor or reseller

when ordering. The options are subject to change. Visit our website for updated information.

Page 10

4

HIOKI IM3523B981-00

Safety Information

Safety Information

This instrument is designed to comply with IEC 61010 Safety Standards, and has

been thoroughly tested for safety prior to shipment. However, mishandling during

use could result in injury or death, as well as damage to the instrument. Using the

instrument in a way not described in this manual may negate the provided safety features.

Be certain that you understand the instructions and precautions in the manual before

e. We disclaim any responsibility for accidents or injuries not resulting directly

us

from instrument defects.

This manual contains information and warnings essential for safe operation of the instrument and for

maintaining it in safe operating condition. Before using it, be sure to carefully read the following safety

precautions.

Safety Symbols

Indicates the presence of a potential hazard. For more information about locations where this

symbol appears on instrument components, see the “Operating Precutions” section (p. 6),

warning messages listed at the beg

document entitled “Operating Precautions.”

Indicates AC (Alternating Current).

Indicates the ON side of the power switch.

Indicates the OFF side of the power switch.

The following symbols in this man

Indicates an imminently hazardous situation that, if not avoided, w

serious injury.

Indicates a potentially hazardous situation that,

serious injury.

Indicates a potentially hazardous situation that could result in minor or moderate injury

r potential risks of damage to the supported product (or to other property) if not

o

avoided.

Indicates advisory items re

IMPORTANT

Indicates information or content that is particularly important from the standpoint of

operating or maintaining the instrument.

inning of operating instructions, and the accompanying

ual indicate the relative importance of cautions and warnings.

ill result in death or

if not avoided, could result in death or

lated to performance or correct operation of the instrument.

Symbols for Various Standards

Indicates that the product is subject to the Waste Electrical and Electronic Equipment

(WEEE) Directive in EU member nations.

Dispose of the product in accordance with local regulations.

This symbol indicates that the pr

oduct conforms to regulations set out by the EU Directive.

Page 11

Notation

DIGIT

10KEY

ENTER

HIOKI IM3523B981-00

Symbols in this manual

Indicates a prohibited action.

5

Safety Information

(p. )

* Indicates that descriptive information is provided below.

[ ]

Indicates the location of reference information.

Menus, Pages, Setting items, dialogs, buttons in a dialog, and other names on the

screen and the keys are indicated in brackets.

Indicates that digits may be entered. (p. 35)

Indicates that values may be entered using the numeric keypad. (p. 33)

Indicates that the same operation can be performed by pressing the ENTER key.

The cursor key to be used is shown in black, while unused cursor keys are shown in

gray. (In the example to the left, the key is to be used.)

Accuracy labeling

The instrument’s accuracy is expressed using a combination of the formats shown below.

• By defining limit values for errors using the same units as measured values.

• By defining limit values for errors as a percentage of the reading and a percentage of the setting.

Indicates the value displayed by the instrument. Limit values for reading

Reading (display value):

Setting (set value)

errors are expressed as a percentage of the reading (“% of reading” or

“% rdg”).

Indicates the set value, such as voltage and current, that the instrument

as been configured to output. Limit values for setting errors are

h

expressed as a percentage of the setting (“% of setting”).

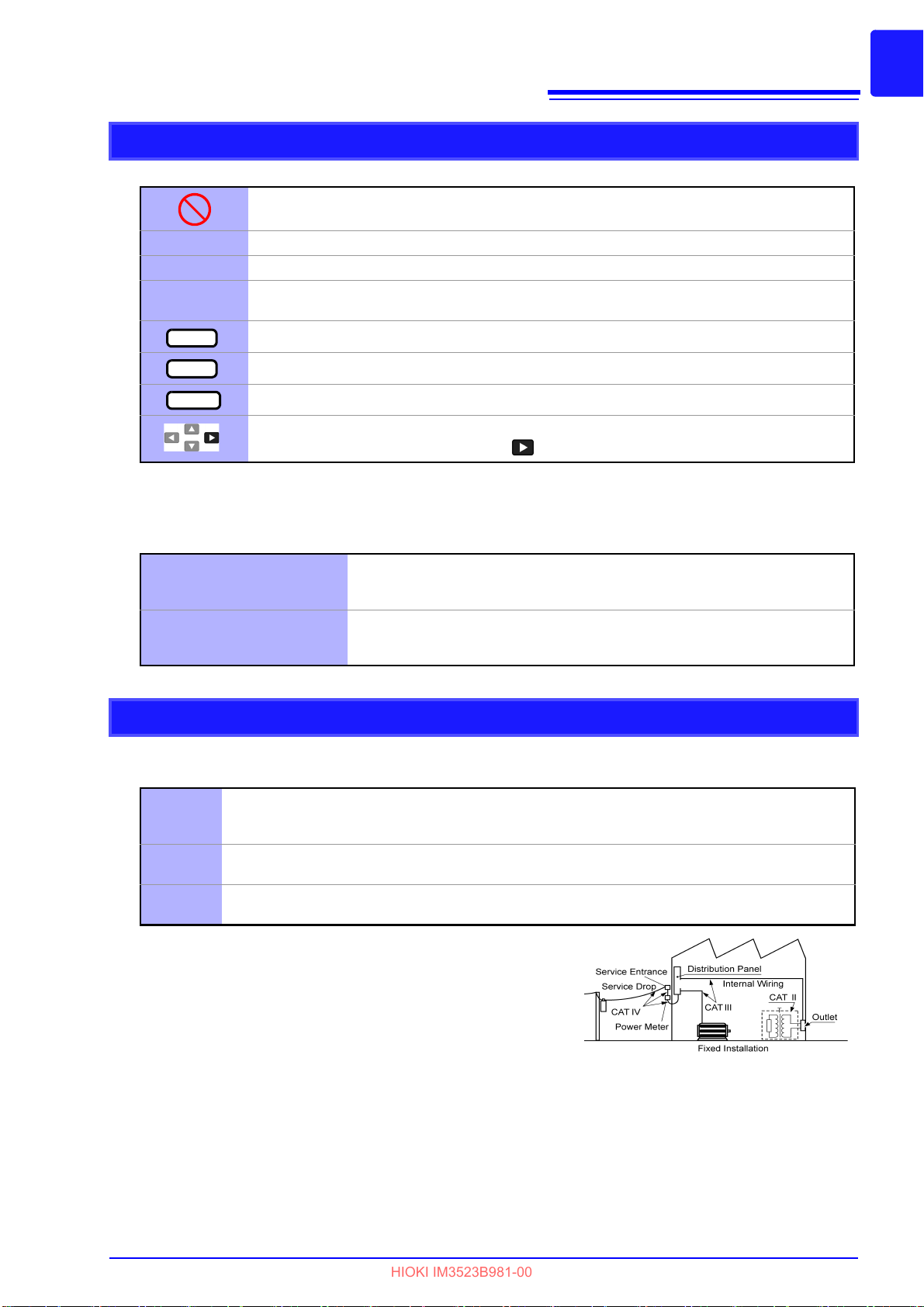

Measurement categories

To ensure safe operation of measurement instruments,

ous electrical environments, categorized as CAT II to CA

CAT II

CAT III

CAT IV

Using a measurement instrument in an environment designated

with a hig

ment is rated could result in a severe accident, and must be

efully avoided.Using a measurement instrument in an envi-

car

ronment designated with a higher numbered category than that

for which

dent, and must be carefully avoided.

Primary electrical circuits in equipment connected to an AC electrical outlet by a power

cord (portable tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet receptacles.

Primary electrical circuits of heavy equipment (fixed installations) connected directly to the

distribution panel, and feeders from the distribution panel to outlets.

The circuit from the service drop to the service entrance, and to the power meter and primary overcurrent protection device (distribution panel).

her-numbered category than that for which the instru-

the instrument is rated could result in a severe acci-

IEC 61010 establishes safety standards for vari-

T IV, and called measurement categories.

Page 12

6

50 mm or more

10 mm or more50 mm or more

HIOKI IM3523B981-00

Operating Precautions

Operating Precautions

• Follow these precautions to ensure safe operation and to obtain the full benefits of the various functions.

• Use of the instrument should confirm not only to its specifications, bu

accessories, options, and other equipment in use.

Preliminary Checks

t also to the specifications of all

Before using the instrument the first time, verify th

at it operates normally to ensure that the no damage

occurred during storage or shipping. If you find any damage, contact your dealer or Hioki representative.

Before using the instrument, make sure that the insulation on the voltage cords is

undamaged and that no bare conductors are improperly exposed. Using the instrument in such conditions could cause an electric shock, so contact your dealer or

Hioki representative for replacements.

Instrument Installation

Avoid the following locations that could cause an accident or damage to the instrument.

Exposed to direct sunlight

Exposed to high temperature

Exposed to water, oil, other

chemicals,

Exposed to high humidity or

condensation

Exposed to high levels of particulate dust

or solvents

In the presence of corrosive or explosive gases

Exposed to strong electromagnetic

fields

Near electromagnetic radiators

Near induction heating

systems (e.g., high-frequency

induction heating systems and IH

cooking utensils)

Subject to vibration

• The instrument should be operated only

with the bottom side downwards.

• The instrument must not be placed on an unstable table or tilted surface.

• Vents must not be obstructed.

• The instrument can be used with the stand.(p. 11)

It can also be rack-mounted.(p.A13)

• If mounting the instrument in a confined space such as a

rack, ensure that the ambient temperature remains

within the range specified in the product specifications, for example by using forced-air cooling.

Page 13

Operating Precautions

HIOKI IM3523B981-00

Shipping precautions

Hioki disclaims responsibility for any direct or indirect damages that may occur when this instrument has

been combined with other devices by a systems integrator prior to sale, or when it is resold.

Handling the Instrument

• To avoid electric shock, do not remove the instrument's case. The internal compo-

nents of the instrument carry high voltages and may become very hot during operation.

• Do not allow the instrument to get wet, and do not take measurements with wet

hands. This may cause an electric shock.

• If the instrument exhibits abnormal operation or display during use, review the informa-

tion in "Troubleshooting" (p. 211) and "Error Display" (p. 216) before contacting your

dealer or Hioki representative.

• Do not connect charged capacitors to measurement terminals or input voltages or cur-

rents from an external source. Doing so may damage the instrument.

• This instrument is not designed to be entirely water- or dust-proof. Do not use it in an

especially dusty environment, nor where it might be splashed with liquid. This may cause

damage.

• To avoid damage to the instrument, protect it from physical shock when transporting and

handling. Be especially careful to avoid physical shock from dropping.

• Do not apply heavy downward pressure with the stand extended. The stand could be

damaged.

• After use, always turn OFF the power.

7

This instrument complies with EN 61326 Class A. This instrument may cause interference if used in

residential areas. Such use must be avoided unless the user takes special measures to reduce electromagnetic emissions to prevent interference to the reception of radio and television broadcasts.

Handling the LCR Application Disk

• Always hold the disc by the edges, so as not to make fingerprints on the disc or scratch

the printing.

• Never touch the recorded side of the disc. Do not place the disc directly on anything

hard.

• Do not wet the disc with volatile alcohol or water, as there is a possibility of the label print-

ing disappearing.

• To write on the disc label surface, use a spirit-based felt pen. Do not use a ball-point pen

or hard-tipped pen, because there is a danger of scratching the surface and corrupting

the data. Do not use adhesive labels.

• Do not expose the disc directly to the sun's rays, or keep it in conditions of high tempera-

ture or humidity, as there is a danger of warping, with consequent loss of data.

• To remove dirt, dust, or fingerprints from the disc, wipe with a dry cloth, or use a CD

cleaner. Always wipe from the inside to the outside, and do no wipe with circular movements. Never use abrasives or solvent cleaners.

• Hioki shall not be held liable for any problems with a computer system that arises from

the use of this LCR Application Disk, or for any problem related to the purchase of a Hioki

product.

Page 14

8

HIOKI IM3523B981-00

Operating Precautions

Page 15

9

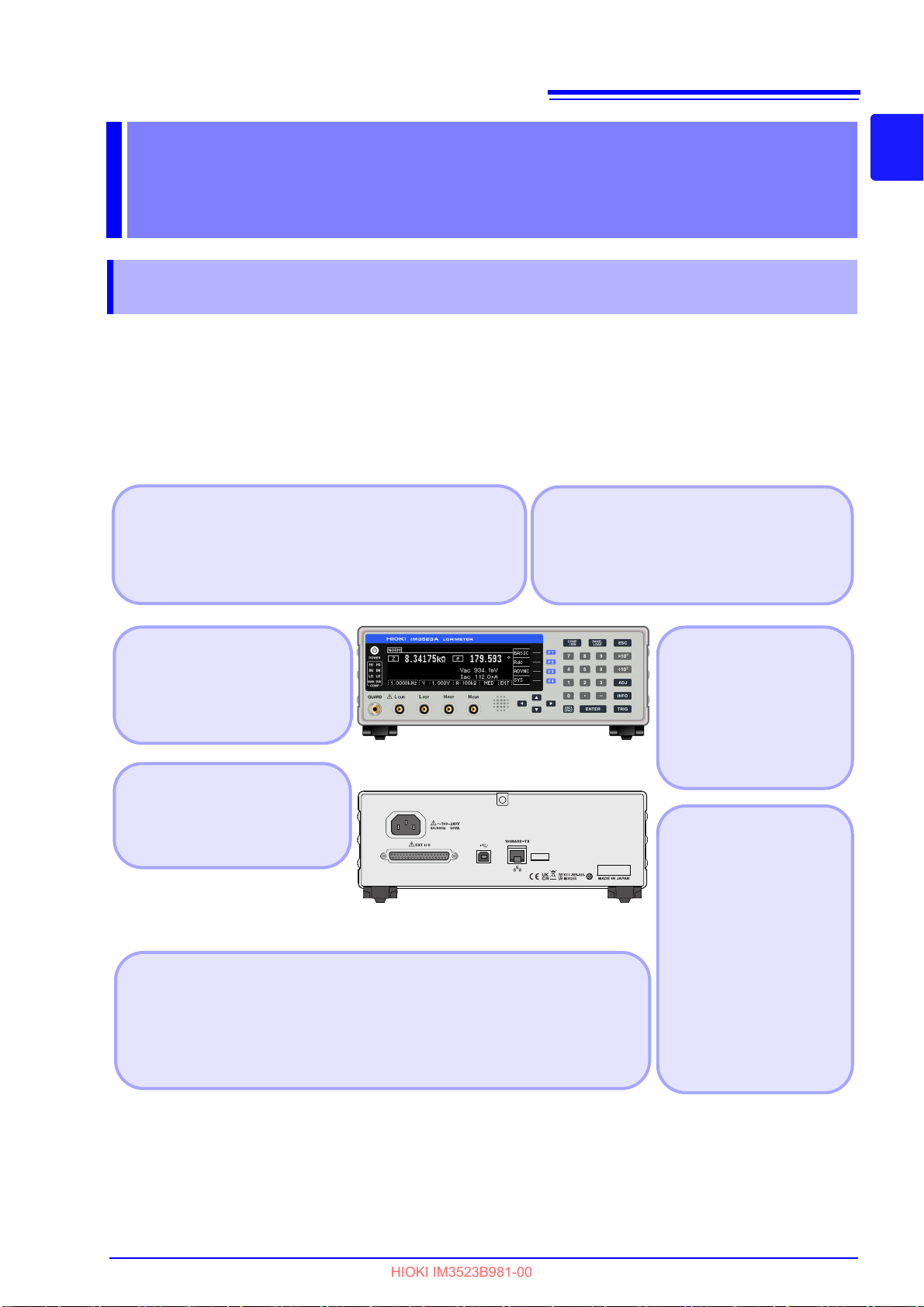

BIN function(p.83)

Capable of easily ranking up to

10 samples based on measurement values.

Wide range of measurement conditions(p.31)

Capable of measurement under a wide range of measurement conditions: measurement frequencies from 1 mHz to

200 kHz and measurement signal levels from 5 mV to 5 V.

Comparator function(p.76)

Capable of making HI/IN/LO

pass/fail judgments based on

measurement values for two

parameters.

Simple production

line setup changes

Automatically sets the optimal range according to

comparator or BIN judgment standards. Because

the IM3523A also lets you

set measurement conditions separately for each

range, it is possible to

automatically set the optimal measurement conditions in response to range

changes.

Continuous measurement function(p.119)

Capable of performing continuous measurement using previously stored

measurement conditions. This function makes it possible to generate pass/

fail judgments using different sets of measurement conditions. (For example, the instrument can perform C-D measurement at 120 Hz followed by Rs

measurement at 100 kHz.)

Various interfaces supported

Supports the optimal external I/O (handler

interfaces) for production lines: USB and

LAN.

Capable of highspeed measurement

High-speed measurement

is possible. The IM3523A

can perform measurements

at speeds of up to 2 ms (typical values).

HIOKI IM3523B981-00

1.1 Product Overview and Features

1

Overview Chapter 1

1.1 Product Overview and Features

The HIOKI IM3523A LCR Meter is an impedance measuring instrument that features high-speed, highprecision operation.

With measurement frequencies of 40 Hz to 200 kHz and

instrument allows you to configure a broad range of measurement conditions. Additionally, the ability to

perform tests using different measurement conditions with a single instrument while changing setup profiles easily makes the IM3523A well suited for use on production lines.

measurement signal levels of 5 mV to 5 V, the

Chapter 1 Overview

Page 16

10

Display Screen(p.12)

Monochrome graphical LCD

Displays the Measurement

screen, Basic Settings screen,

and Advanced Settings

screen.

COMP/BIN Key(p.75)

Panel Load Key(p.165)

When the comparator/BIN function

is enabled, displays the Comparator/BIN Settings screen.

Loads measurement conditions

saved with the panel save function.

Power Switch(p.26)

• Unlit : power off

(when no power supplied)

• Red light : power off

(while power is supplied)

• Green light : power on

F keys

Cursor keys

Selects the corresponding

item on the right side of the

display.

Selects items on the screen.

Measurement Terminals

Connect measurement cables

or a fixture.

(H

CUR

jack, H

POT

jack, L

POT

jack, L

CUR

jack, GUARD jack)

Audible Alarm

(beeper)

Entering numerical values(p.12)

Enter a numerical value.

(we call these the “tenkeys”)

Adds a minus sign to the value.

Switches units.

Deletes the value in the

selected field.

Accepts the value and settings.

Cancels the measurement

condition settings for each

range and the comparator/BIN

settings, and then returns to

the screen that was displayed

before you began configuring

settings.

ADJ Key(p.125)

INFO Key(p.20)

TRIG Key(p.50)

Lets you configure and use

compensation functions and

scaling.

Lets you check previously configured measurement conditions.

Performs trigger measurement under the conditions for

which the external trigger has

been configured.

Front

COMP indicator

LEDs

Displays the measurement value judgment

results for the main and

sub parameters.

Comparator

measurement

See (p.76)

BIN measurement

See (p.83)

Panel

This instrument can be rack mounted.

See "Appendix9 Rack Mounting"(p. A13)

HIOKI IM3523B981-00

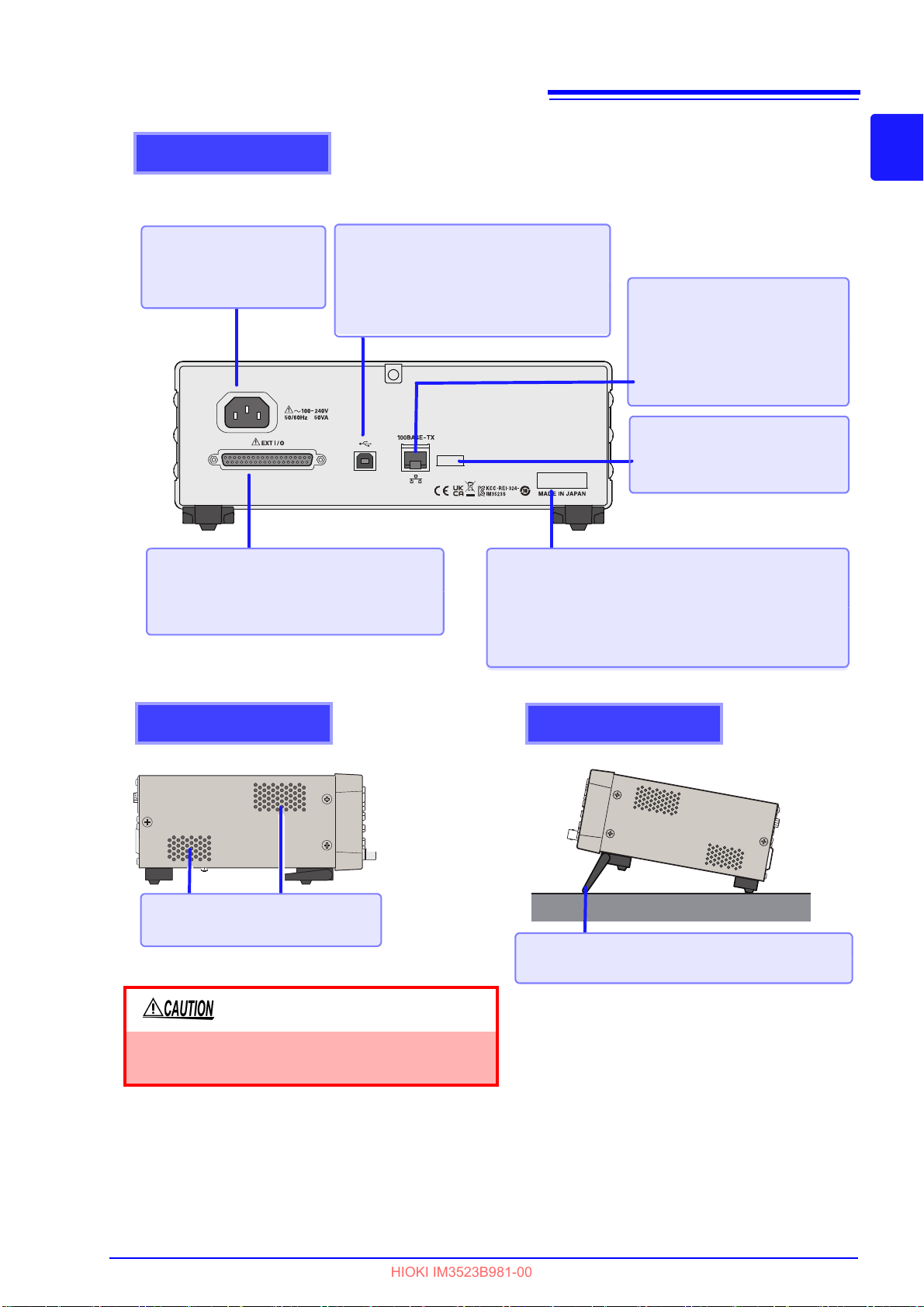

1.2 Names and Functions of Parts

1.2 Names and Functions of Parts

Page 17

EXT I/O connector

Lets you connect a PLC or I/O board so

that you can start measurement and

acquire judgment results. (p.177)

Rear

Power inlet

Connect the power cord.

(p.23)

LAN connector

Lets you control the instrument

from a computer via a LAN

(socket communications).

See Communication Instruction

Manual (LCR Application

Disk)

Rear USB connector

Connect a computer to control the

instrument using communications

commands.

See

Communication Instruction Manual (LCR

Application Disk)

LAN MAC address

See Communication Instruction

Manual (LCR Application

Disk)

When using the stand

Extend the stand until it clicks into place.

Make sure to extend both legs of the stand.

Collapsing the stand

Fold in the stand until it clicks into place.

Do not apply heavy downward pressure with the

stand extended. The stand could be damaged.

Left

Right

Stand

Lets you incline the instrument for easy viewing.

Vents

Keep clear of obstructions. (p.6)

Manufacturer’s serial number

The serial number consists of nine digits. The first

two digits indicate the year of manufacture, while

the second two digits indicate the month of manufacture. Do not remove this sticker as the number

is important.

HIOKI IM3523B981-00

11

1.2 Names and Functions of Parts

1

Chapter 1 Overview

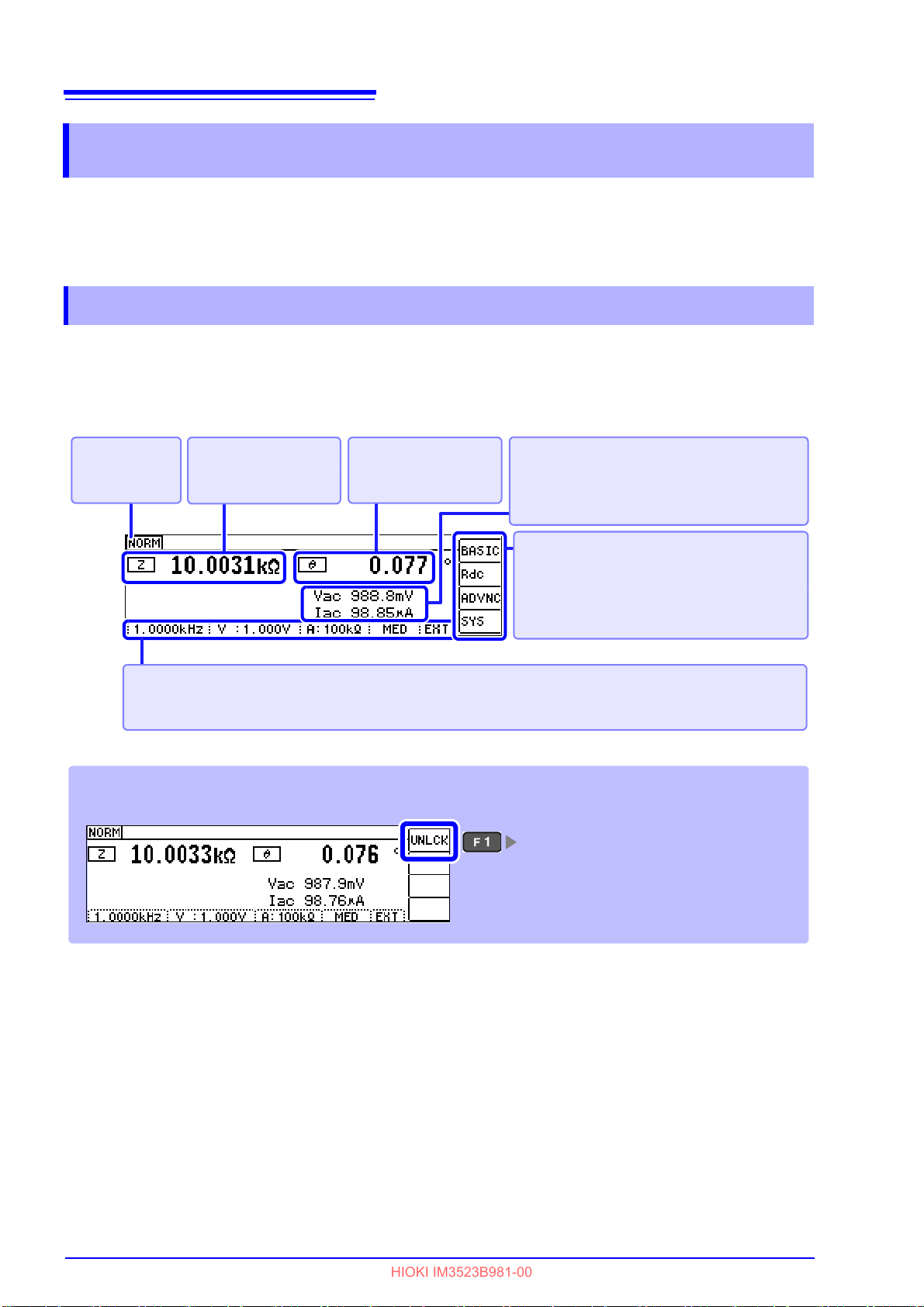

Page 18

12

Indicates the

measurement

mode.

Indicates some of the measurement conditions.

(From the left) Frequency, measurement signal level, measurement range, measurement speed,

trigger measurement.

Menu keys

[BASIC] :Configures basic settings.

[Rdc] :Configures DC resistance

measurement settings.

[ADVNC] :Configures application settings.

[SYS] :Configures system settings.

Indicates the sub

parameter and

measurement value.

Monitor values

V

ac,Vdc

:Voltage across the terminals of

the sample.

I

ac

, I

dc

:Current passing through the

sample.

Indicates the main

parameter and

measurement value.

Key lock screen

The Pass Code Entry screen will be displayed.

See "Canceling key lock mode" (p. 117)

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

1.3 Screen Organization and Operation

The instrument has two general display screen types: Measurement and Settings.

Refer to "11.3 Error Display" (p. 216) for error displays.

The screen examples in this guide appear

instrument screens can actually be displayed only as white characters on black background.

1.3.1 Initial Screen

reversed (black on white) for best visibility. However, the

The initial screen, which is the first scr

form measurement while checking measurement conditions.

display will reflect the measurement mode that was in use when the power was turned off.

een displayed when you turn on the instrument, allows you to per-

When the instrument is turned back on, the

Page 19

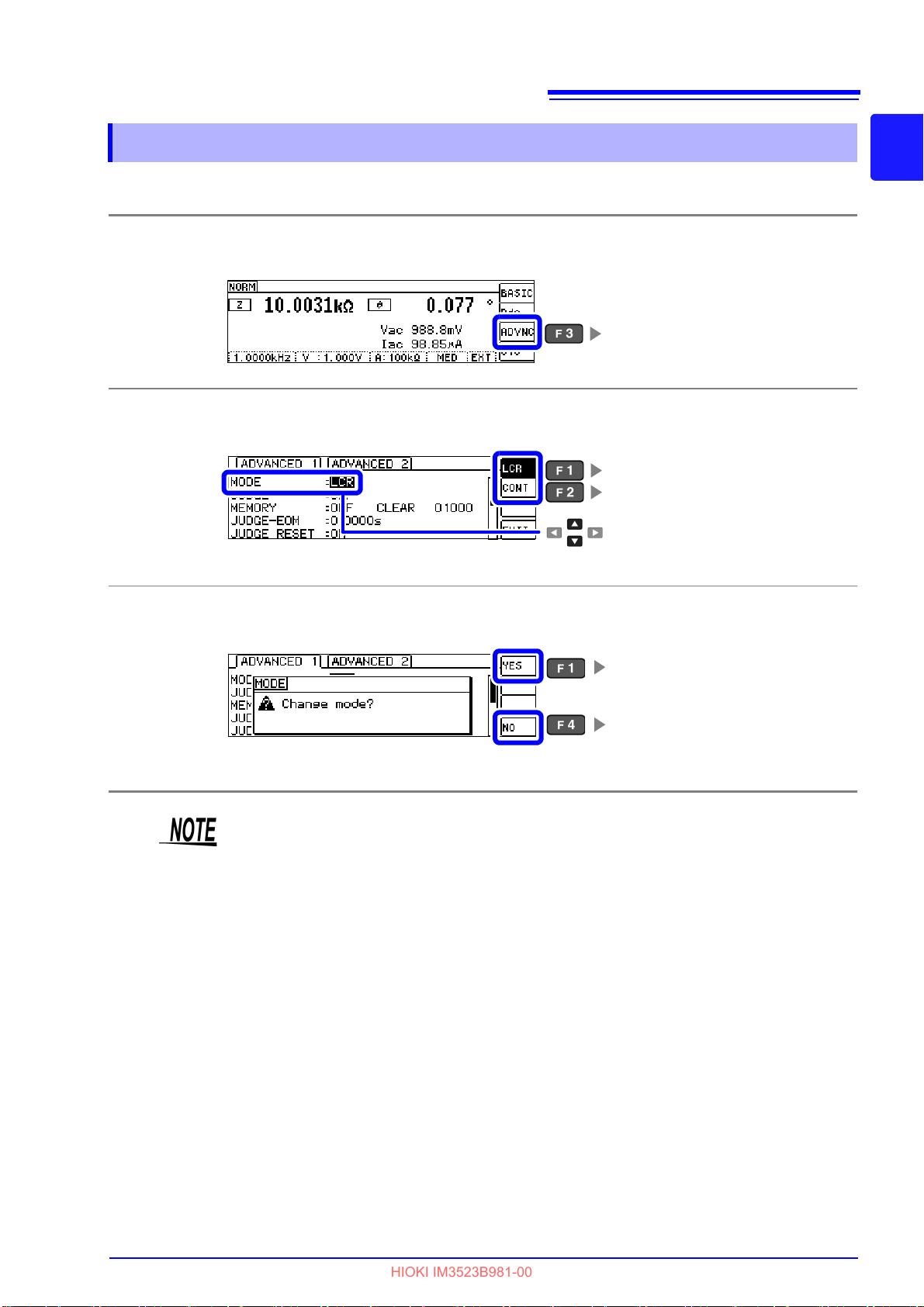

13

Displays the Advanced Settings screen.

Select

Selects continuous measurement mode.

(p.121)

Selects LCR mode.

Changes the measurement mode to

the selected mode.

Returns to the Advanced Settings

screen without changing

the measurement mode.

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

1.3.2 Selecting the Measurement Mode

This section describes how to select the measurement mode.

Open the Advanced Settings screen.

1

Select the [MODE]

.

2

1

Chapter 1 Overview

3

Set the mode.

After changing the measurement mode, check all settings (including compensation) before performing

measurement.

Page 20

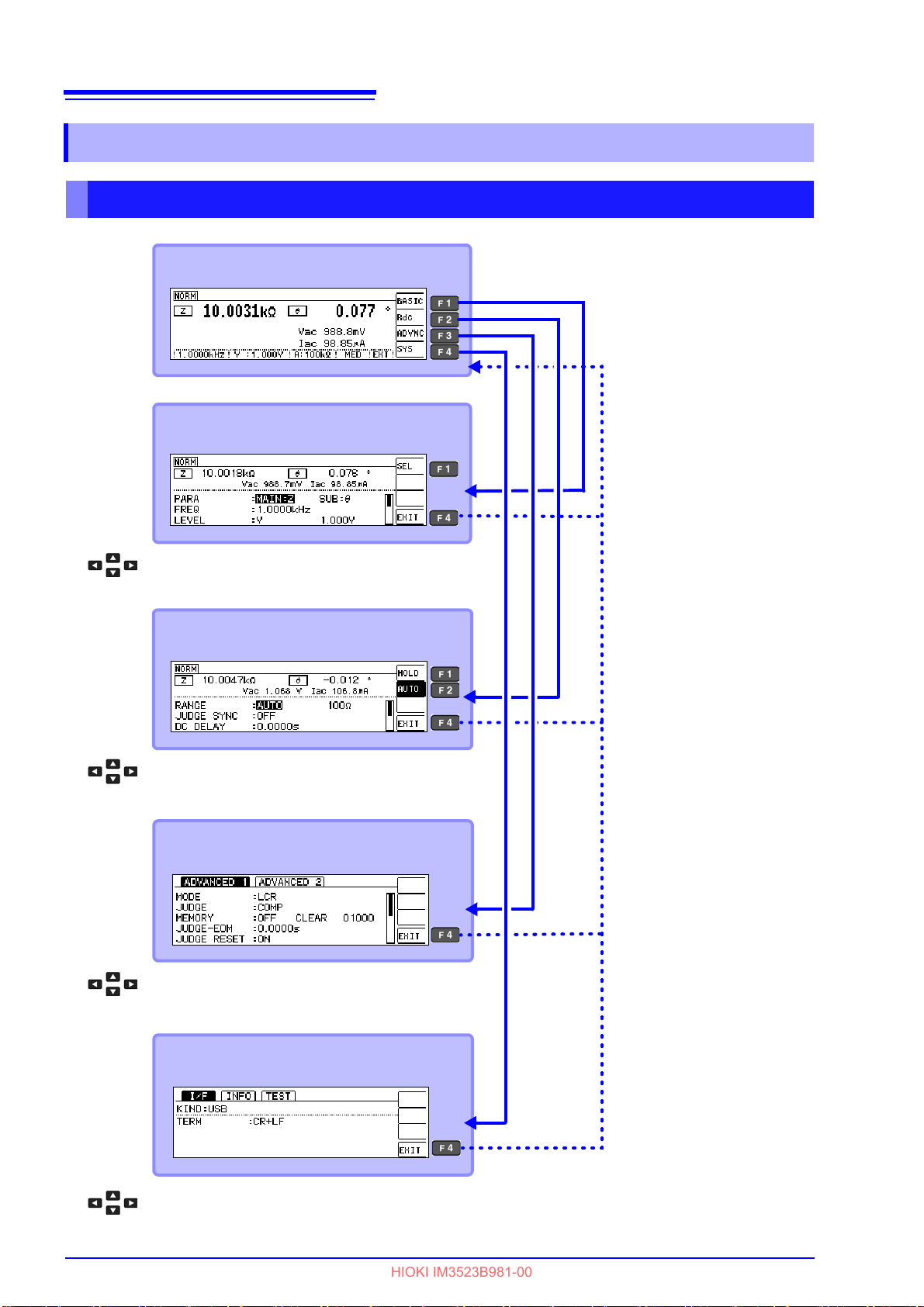

14

Rdc Settings Screen (p.15)

To the settings screen for the selected basic setting

Measurement Screen (p.29)

Basic Settings Screen (p.15)

Return to Previous Screen

Return to Previous Screen

To the settings screen for the selected Rdc setting

Advanced Settings Screen (p.16)

To the settings screen for the selected advanced setting

System Settings Screen (p.18)

To the settings screen for the selected system setting

Return to Previous Screen

Return to Previous Screen

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

1.3.3 LCR Mode

Screen Organization

Page 21

15

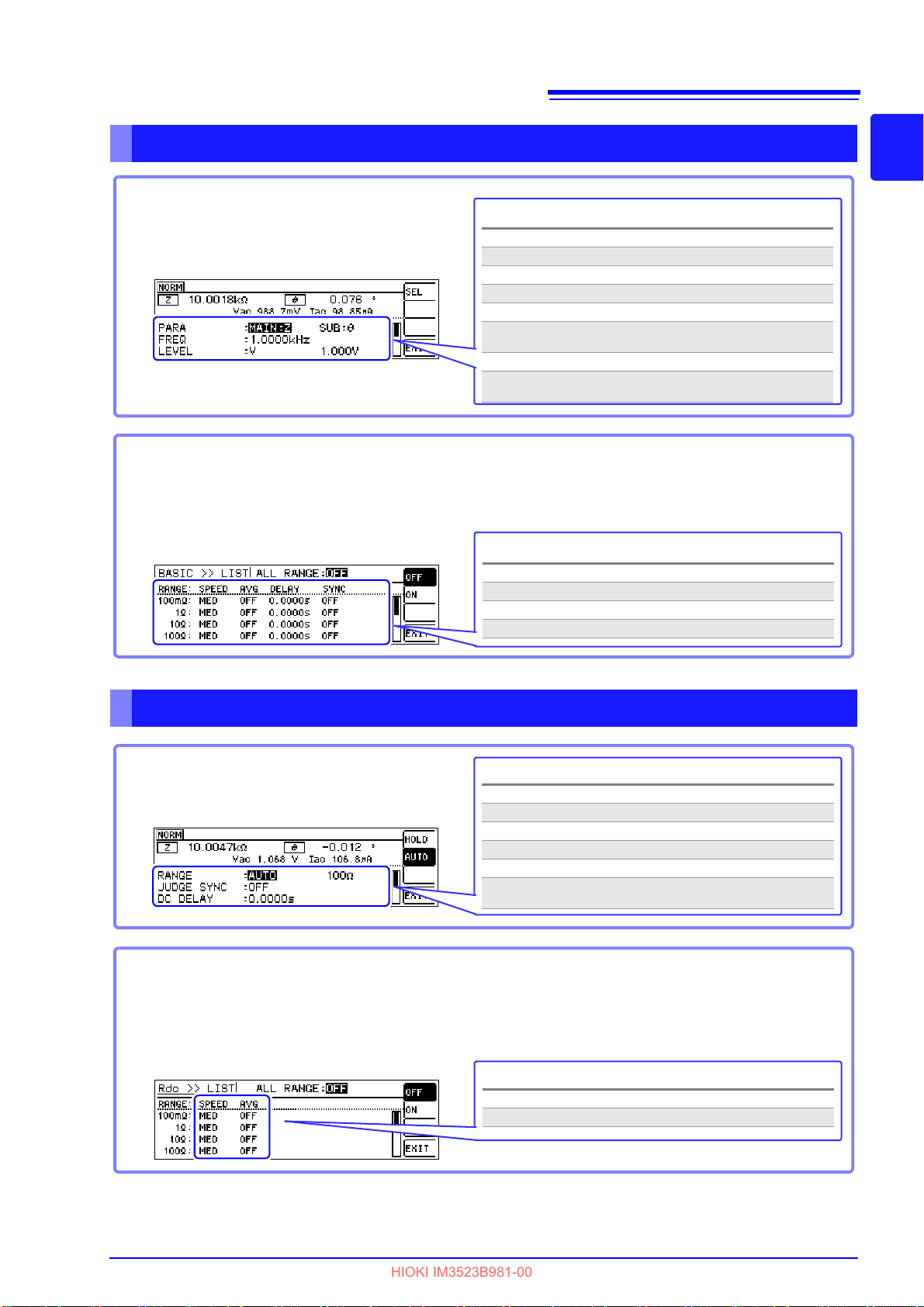

Basic Settings Screen

Settings

PAR A Measurement parameter setting (p.31)

FREQ Measurement frequency setting (p.33)

LEVEL Measurement signal level setting (p.37)

LIMIT Voltage and current limit settings (p.41)

RANGE Measurement range setting (p.43)

JUDGE

SYNC

Judgment synchronization setting (p.48)

TRIG Trigger setting (p.50)

LIST Setting of measurement conditions for the respec-

tive ranges (p.51)

This screen allows you to configure basic

settings for the measurement conditions.

LIST Settings screen

Settings

SPEED Measurement speed setting (p.53)

AVG Average setting (p.54)

DELAY Trigger delay setting (p.56)

SYNC Trigger synchronization output setting (p.57)

This screen is displayed when you select [LIST] on the Basic Settings screen.

It allows you to configure measurement conditions for each range.

Settings

RANGE Measurement range setting (p.62)

JUDGE SYNC Judgment synchronization setting (p.66)

DC DELAY DC delay setting (p.67)

ADJ DELAY Adjustment delay setting (p.69)

LINE FREQ Line frequency setting (p.70)

LIST

Setting of measurement conditions for the

respective ranges (p.71)

This screen allows you to configure measurement

conditions for DC resistance measurement.

LIST Settings screen

Settings

SPEED Measurement speed setting (p.73)

AVG Average setting (p.74)

This screen is displayed when you select [LIST] on the Rdc Settings screen.

It allows you to configure measurement conditions for each range.

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

Basic Settings Screen

1

Chapter 1 Overview

Rdc (DC resistance measurement) Settings screen

Page 22

16

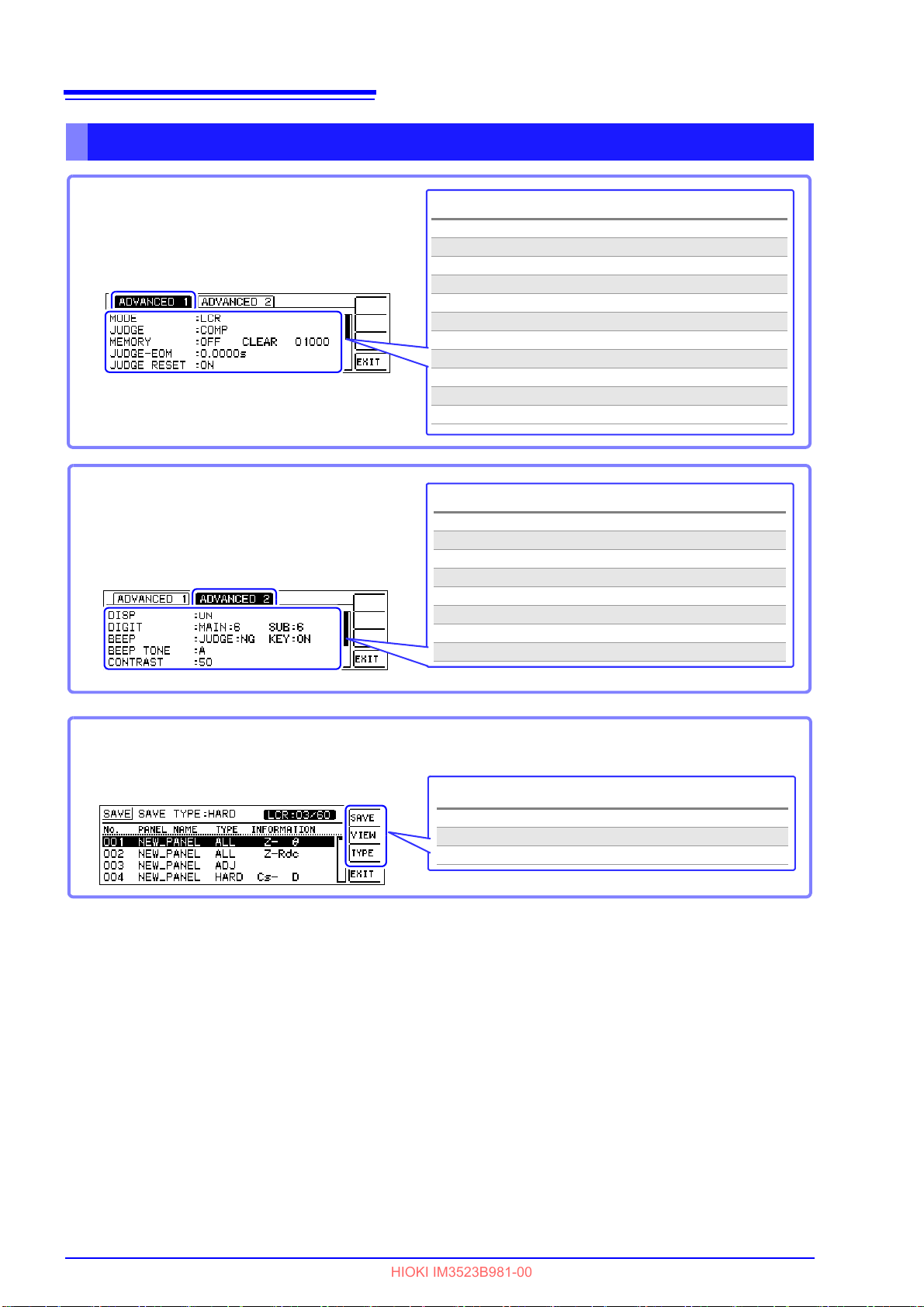

Advanced 1 Settings Screen

Settings

MODE Measurement mode setting (p.13)

JUDGE Measurement result judgment setting (p.75)

MEMORY Save settings of measurement results (p.97)

JUDGE-EOM JUDGE-EOM delay time setting (p.100)

JUDGE RESET JUDGE-EOM reset setting (p.100)

TRIG ENABLE IO trigger setting (p.101)

TRIG EDGE IO trigger valid edge setting (p.101)

EOM MODE EOM output method setting (p.102)

EOM-ON-TIME EOM output time setting (p.102)

CONTACT Contact check function setting (p.103)

Hi Z Hi-Z reject function setting (p.105)

This screen is used to configure LCR mode

application settings.

Advanced 2 Settings Screen

This screen is used to configure LCR mode

application settings.

Settings

DISP LCD settings (p.107)

DIGIT Number of display digits setting (p.108)

BEEP Beep enable/disable setting (p.110)

BEEP TONE Beep tone setting (p.112)

CONTRAST Screen contrast setting (p.113)

KEYLOCK Key-lock setting (p.114)

PANEL SAVE Panel save (p.162)

RESET System reset (p.118)

Settings

SAVE Panel save (p.163)

VIEW Panel information display (p.164)

TYPE Panel save type setting (p.162)

This screen is used to configure continuous

measurement mode application settings.

Panel Save Screen

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

Advanced Settings Screen

Page 23

17

Advanced Settings Screen (p.123)

Select the continuous measurement target panel.

Measurement Screen (p.119)

Basic Settings Screen (p.121)

Return to Previous Screen

Return to Previous Screen

To the settings screen for the selected advanced setting

Settings

OFF Turns off continuous measurement

ON Turns on continuous measurement

INFO Panel information display

This screen allows you to check continuous measurement

settings and saved panel information. (p.121)

This screen is used to configure continuous

measurement mode application settings. (p.123)

Settings

MODE Measurement mode setting (p.120)

DRAW Display timing setting (p.123)

DISP LCD setting (p.124)

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

1.3.4 Continuous Measurement Mode

Screen Organization

1

Chapter 1 Overview

Basic Settings Screen

Advanced Settings Screen

Page 24

18

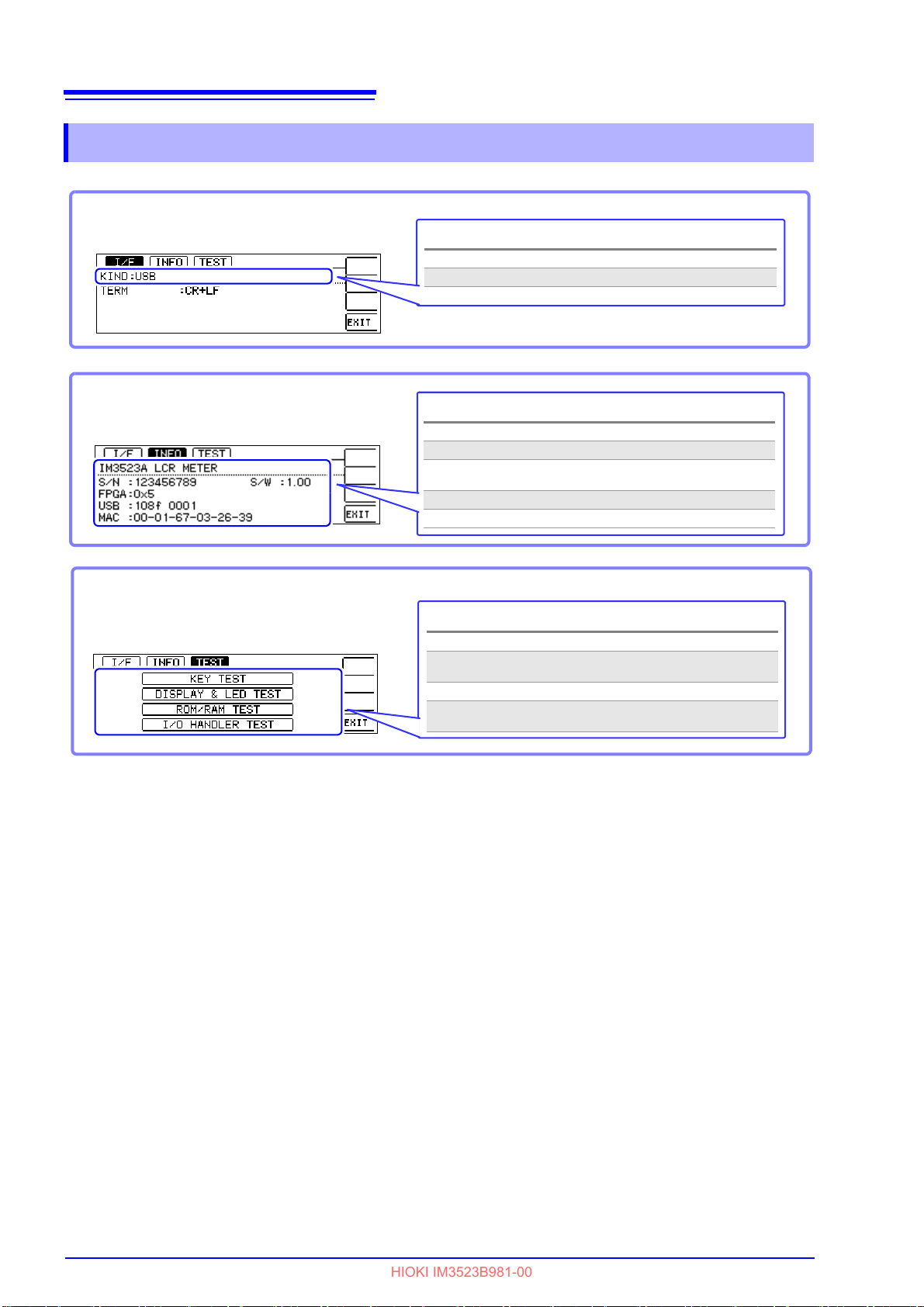

Settings

USB USB Setting (p.171)

LAN LAN Setting (p.171)

This screen is used to set

the interface type.

Check the version of the instrument

Settings

S/N Serial No. (p.172)

FPGA FPGA Version (p.172)

USB

USB ID

(Vendor ID, product ID) (p.172)

MAC MAC address (p.172)

S/W Software Version (p.172)

Settings

KEY TEST Performs a key test (p.173)

DISPLAY &

LED TEST

Performs a screen display test (p.174)

ROM/RAM TEST Performs a ROM/RAM test (p.175)

I/O HANDLER

TEST

Performs an I/O test (p.176)

Self Check

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

1.3.5 System Settings Screen

Page 25

19

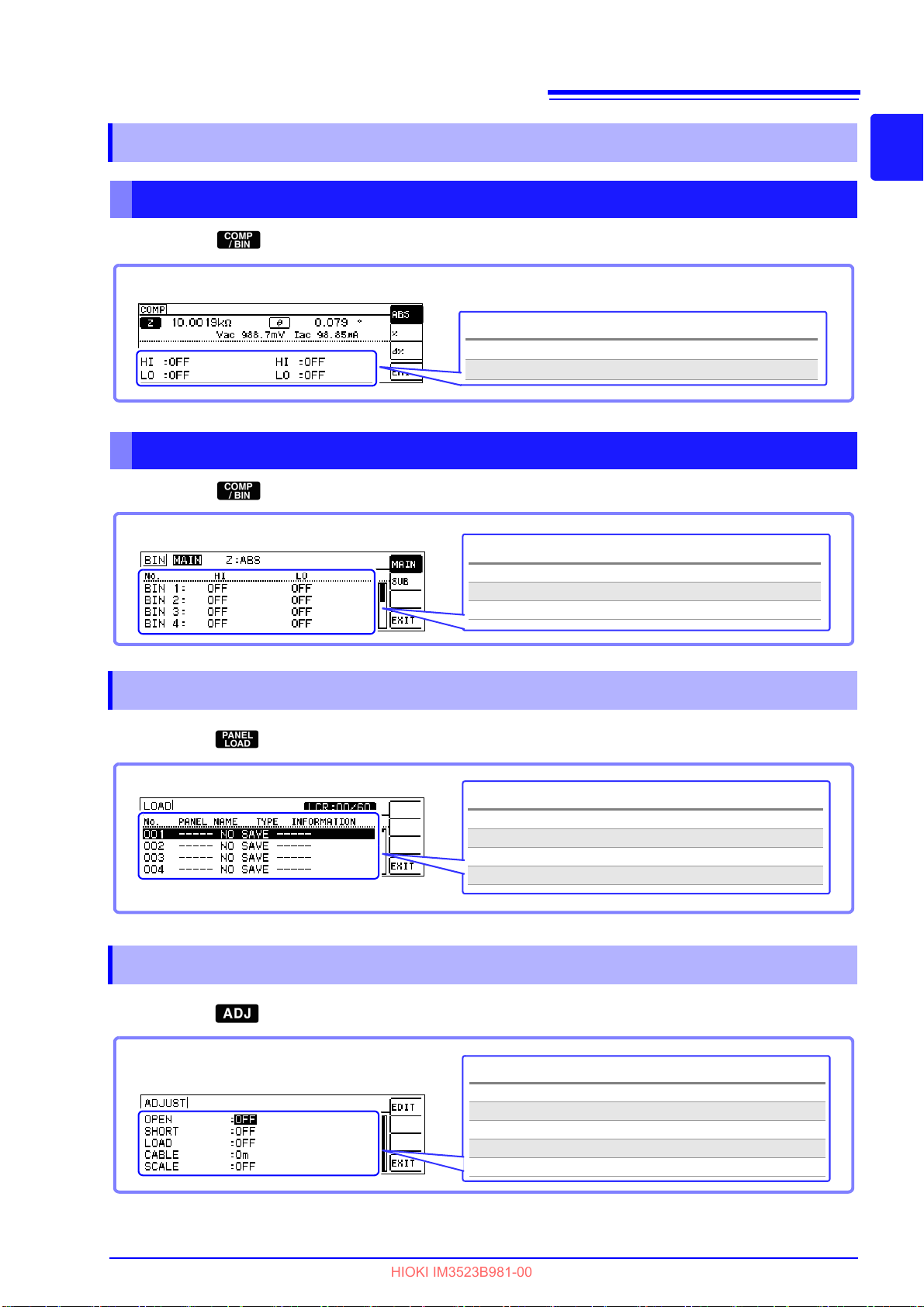

Settings

HI Upper Limit Value Setting (p.76)

LO Lower Limit Value Setting (p.76)

Settings

No. BIN number (p.83)

HI Upper Limit Value Setting (p.83)

LO Lower Limit Value Setting (p.83)

Settings

No. Panel No. (p.165)

PANEL NAME Panel name (p.165)

TYPE Save type (p.165)

INFORMATION Saved information (p.165)

Settings

OPEN Open circuit compensation setting (p.125)

SHORT Short circuit compensation setting (p.136)

LOAD Load circuit compensation setting (p.145)

CABLE Cable length compensation setting (p.157)

SCALE Scaling setting (p.158)

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

1.3.6 Comparator/BIN Settings Screen

Comparator Mode

When the key is pressed during comparator measurement.

BIN mode

When the key is pressed during BIN measurement.

1

Chapter 1 Overview

1.3.7 Panel Load screen

When the key is pressed.

1.3.8 Compensation Settings Screen

When the key is pressed.

Page 26

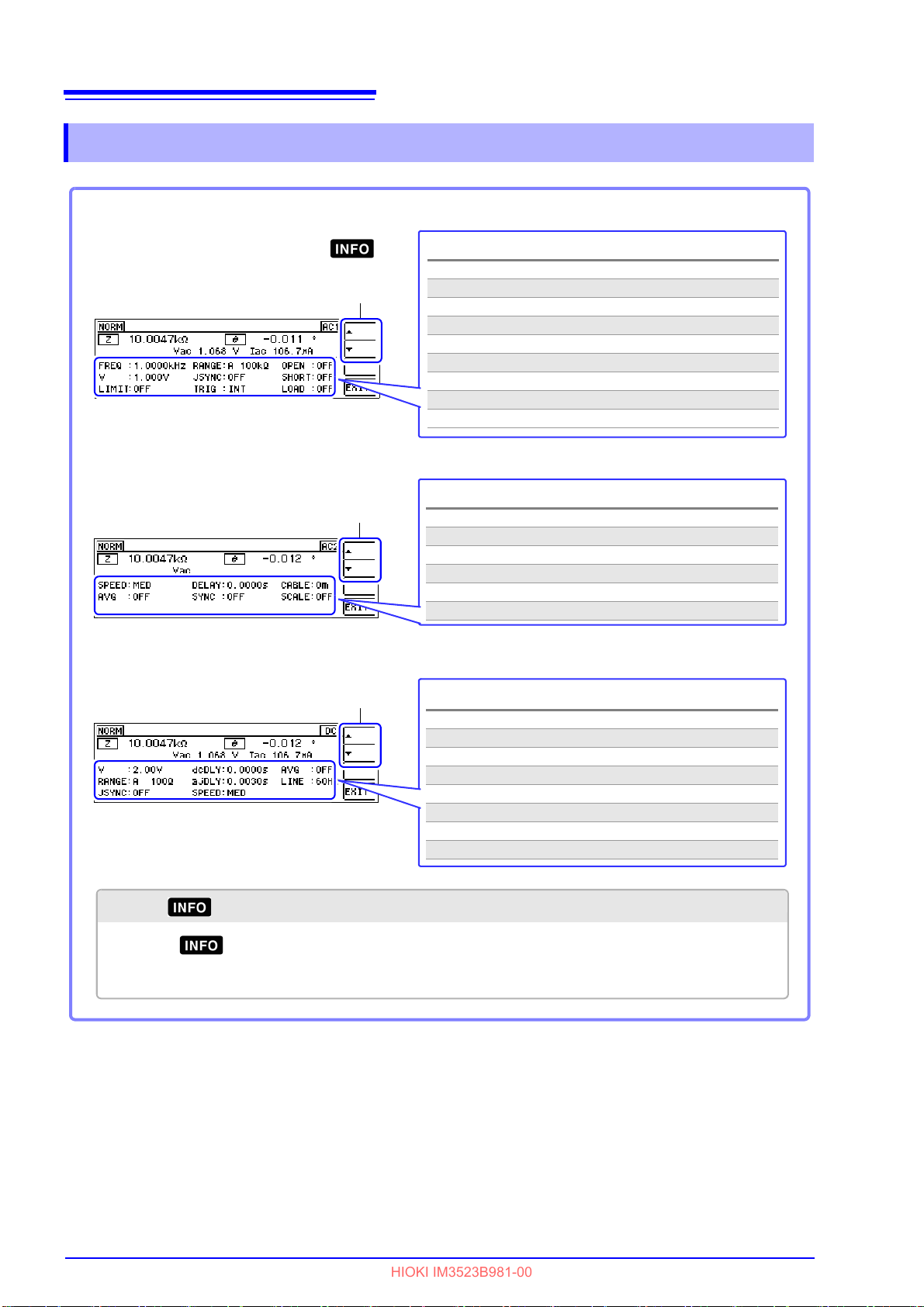

20

AC1 Screen

Settings

FREQ Frequency

V Signal level

LIMIT Limit value

RANGE Measurement range

JSYNC Judge Synchronous setting

TRIG Trigger Setting

OPEN Open Circuit Compensation

SHORT Short circuit compensation setting

LOAD Panel load

This screen is displayed when the key

is pressed.

AC2 Screen

Settings

SPEED Measurement Speed

AVG Average setting

DELAY Trigger delay

SYNC Trigger Synchronous Output Function

CABLE Cable length compensation

SCALE Scaling

DC Screen

Settings

V Signal level

RANGE Measurement range

JSYNC Judgment synchronization setting

dcDLY DC delay

ajDLY Adjust delay

SPEED Measurement Speed

AVG Average setting

LINE Line frequency

Switches pages.

Switches pages.

Switches pages.

When is pressed

Pressing key on the Information screen causes the screen to transition as follows:

AC1 screen→AC2 screen→DC screen→ Back to Measurement screen

HIOKI IM3523B981-00

1.3 Screen Organization and Operation

1.3.9 Information Screen

Page 27

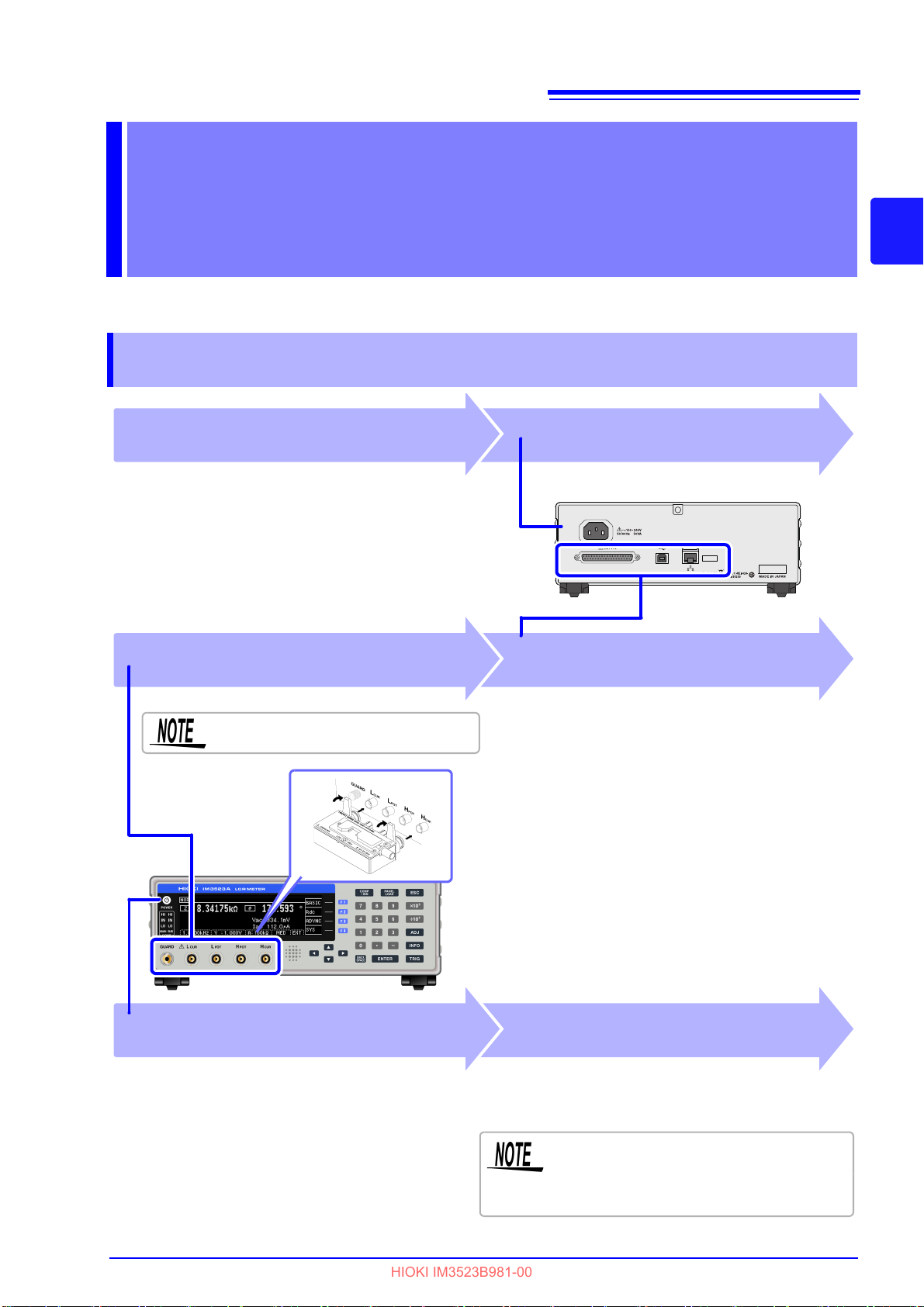

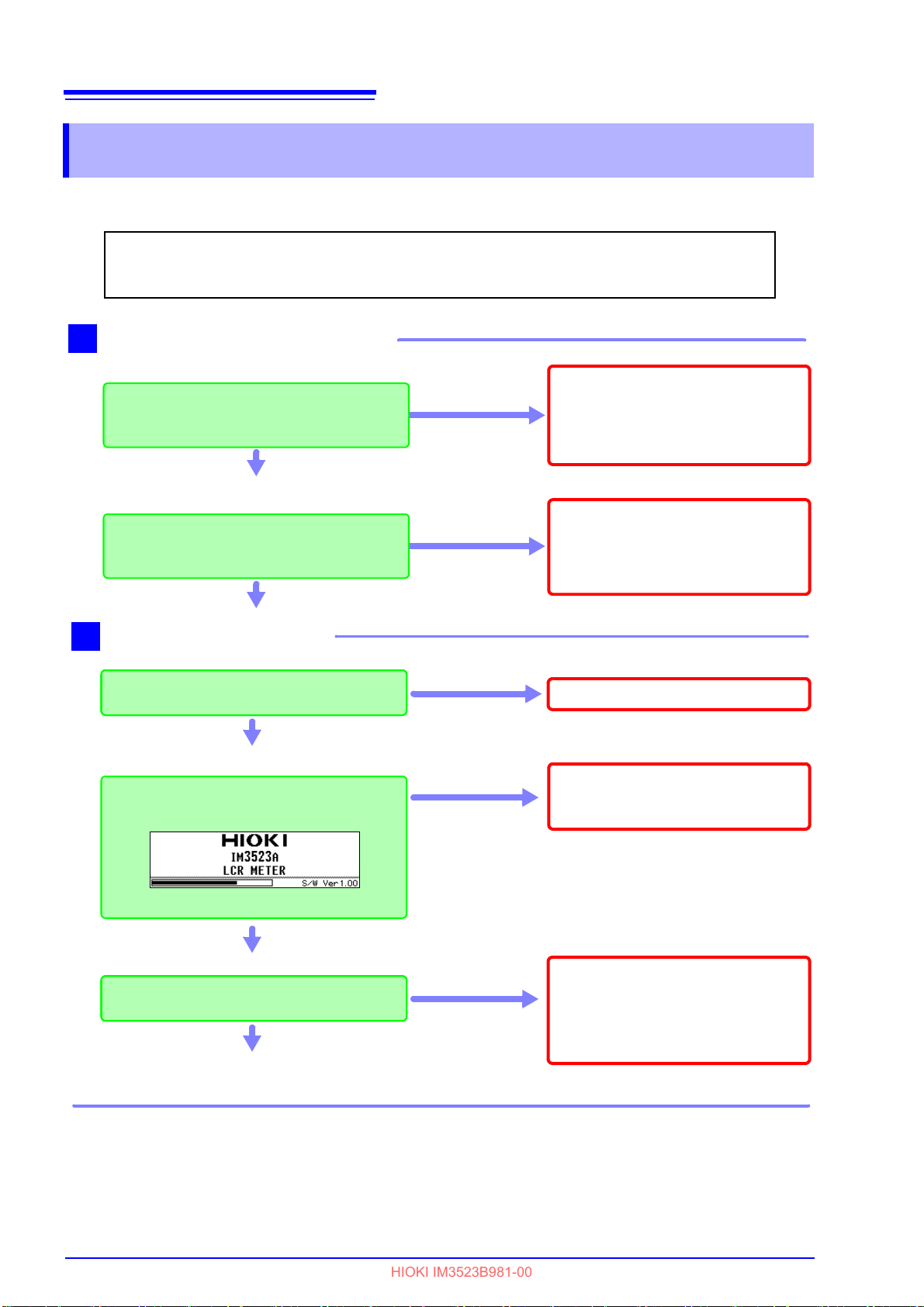

2.1 Preparation Flowchart

Installing the Instrument (p.6)

• USB Cable

•LAN Cable

• EXT I/O

Connect measurement cables, optional

Hioki probes or test fixture (p.24)

1

3

Connect to the test sample.

Remove the test sample and turn off the power

after use. (p.26)

Connecting

the Power Cord (p.23)

2

Connect the external interface

(as needed)

Turning Power On (p.26)

4

Make instrument settings (p.31)

When performing DC resistance measurement,

be sure to set the line frequency before starting

measurement.

See "4.3.4 Setting the Line Frequency" (p. 70)

Confirm that the instrument is turned off.

HIOKI IM3523B981-00

Measurement Preparations Chapter 2

Be sure to read the "Operating Precautions" (p. 6) before installing and connecting this instrument.

Refer to "Appendix9 Rack Mounting"(p. A13) for rack mounting.

2.1 Preparation Flowchart

21

2

Chapter 2 Measurement Preparations

Page 28

22

Do not use the instrument if damage

is found, as electric shock or shortcircuit accidents could result.

Contact your dealer or Hioki representative.

Metal Exposed

Is the power cord insulation torn, or is any

metal exposed?

1

No Metal Exposed

Before using the instrument for the first time, verify that it operates normally to ensure that no

damage occurred during storage or shipping. If you find any damage, contact your dealer or

Hioki representative.

Peripheral Device Inspection

Is the insulation on a measurement

cable torn, or is any metal exposed?

Metal Exposed

If there is any damage, measured values may be unstable and measurement errors may occur. Replace the

cable with an undamaged one.

No Metal Exposed

If damage is evident, request repairs.

Yes

Is damage to the instrument evident?

Instrument Inspection

When turning power on

Does the opening screen appear

(model no., version no.)?

No

2

The power cord may be damaged, or

the instrument may be damaged internally. Request repairs.

Is there an error display on the Opening

screen?

No

Yes

The instrument may be damaged

internally. Request repairs.

See "11.2 Troubleshooting" (p. 211)

"11.3 Error Display" (p. 216)

An error indication

occurs (ERR)

No

Inspection complete

Opening screen

HIOKI IM3523B981-00

2.2 Pre-Operation Inspection

2.2 Pre-Operation Inspection

Please read the "Operating Precautions" (p. 6) before use.

Page 29

2.3 Connecting the Power Cord

1 Confirm that the power cord matches the line voltage, and plug

it into the power inlet on the instrument. (AC100 V to 240 V)

2 Plug the other end of the power cord into an outlet.

The POWER button on the instrument’s front panel will

flash

red.

If power is interrupted while the instrument is

operating, it will

start back up immediately when power is restored.

(when the circuit breaker is turned back on, etc.)

Rear

Power inlet

Connection Procedure

HIOKI IM3523B981-00

2.3 Connecting the Power Cord

23

Confirm the supply voltage to the instrument matches the supply voltage indicated on the

instrument before connecting the power cord to the instrument. Connection to an improper

supply voltage may damage the instrument and present an electrical hazard.

Connect the power cord to the power inlet on the instrument, and plug it into an outlet.

2

Chapter 2 Measurement Preparations

Page 30

24

HIOKI IM3523B981-00

2.4 Connect measurement cables, optional Hioki probes or test fixture

2.4 Connect measurement cables, optional

Hioki probes or test fixture

Before using the instrument, make sure that the insulation on the voltage cords is

undamaged and that no bare conductors are improperly exposed. Using the instrument in such conditions could cause an electric shock, so contact your dealer or

Hioki representative for replacements.

• For safety reasons, disconnect the power cord when the instrument is not used.

• To avoid damaging the power cord, grasp the plug, not the cord, when unplugging it from

the power outlet.

• Do not apply a voltage to the measurement terminals. Doing so may damage the instru-

ment.

• When disconnecting the BNC connector, be sure to release the lock

before pulling off the connector. Forcibly pulling the connector without

releasing the lock, or pulling on the cable, can damage the connector.

• To avoid breaking the cables or probes, do not bend or pull them.

• Avoid stepping on or pinching cables, which could damage the cable

insulation.

• Keep the cables well away from heat sources, as bare conductors could be exposed if

the insulation melts.

• Keep in mind that, in some cases, conductors to be measured may be hot.

• To avoid electric shock, do not exceed the lower of the ratings shown on the instrument

and connection cords.

• Use only the specified connection cables. Using a non-specified cable may result in

incorrect measurements due to poor connection or other reasons.

Refer to "Options" (p. 3) for details.

• Before using a fixture or the like, read the instruction manual supplied with the product to

be used.

Page 31

25

Connecting a measurement cable/fixture

Connect directly to the

measurement jacks with

the label side up, and affix

with the levers on the left

and right.

(When using the optional 9140-10 or L2001)

Connect the red plugs to the H

CUR

and H

POT

jacks, and

the black plugs to the L

CUR

and L

POT

jacks.

(When using the optional 9500-10)

BNC plug of H

CUR

, H

POT

, L

CUR

and L

POT

connected

properly to the measurement terminals of each of the instruments.

Black

Red

Points to pay attention to when making your own probe

• Use 50 Ω coaxial cable for the measurement cable.

• Ensure that the length of the cable is the same as that set for the instrument. (1m)

• The cable length is defined as the length from the tip of th

e BNC connector to the tip of the probe electrode.

• Make the portion of the core wire tha

t is exposed as short as possible.

• Connect the H

CUR

, L

CUR

, H

POT

, and L

POT

shield pairs at the measurement object side.

(Ensure that a shield is not conn

ected to a core wire.)

Measurement Terminal Configuration

Fixture

Normal mode

HIOKI IM3523B981-00

2.4 Connect measurement cables, optional Hioki probes or test fixture

2

Chapter 2 Measurement Preparations

• As a rule, only HIOKI-brand probes, fixtures, and other components (options) should be

used. Use of probes that you have built yourself may prevent the instrument from perform

ing in a matter that satisfies its specifications.

See "Options" (p. 3)

• If all four terminals are disconnected, a meaningless number may be displayed on the unit.

-

Page 32

26

To ensure that measurements fulfill the

degree of accuracy described in the specifications, allow the instrument to warm up

for at least 60 minutes after it is turned on.

Press the POWER button (it lights green).

When the power is turned on, the same setting as when the power was last turned off appears.

Lights green

ON the main power in the state, hold down the front POWER switch 1 second approximately.

(it lights red)(Standby state*).

Lights red

Disconnect the power cord from the outlet to extinguish the POWER button light.

When power is turned on again, operation resumes with the same settings as

when last turned off.

HIOKI IM3523B981-00

2.5 Turning the Power On and Off

2.5 Turning the Power On and Off

Once you’ve connected probes and test fixtures, connect the power cord’s plug to a power outlet.

• Before turning the instrument on, make sure the supply voltage matches that indi-

cated on its power connector. Connection to an improper supply voltage may damage the instrument and present an electrical hazard.

• Be careful to avoid connecting the supply voltage improperly. Doing so may damage the instrument's internal circuitry.

• To avoid electrical accidents and to maintain the safety specifications of this instrument, connect the power cord only to a 3-contact (two-conductor + ground) outlet.

• To avoid shock and short circuits, turn off all power before connecting probes.

Turning main power on

Turning main power off

*: Standby state

The instrument is in the standby state when

ing for POWER button input to be detected. To allow POWER bu

circuitry is operating with power consumption of approximately 4 W.

If a power outage (e.g., breaker trip) occurs when the instrument is on, it will automatically

turn on again when power is restored. (without pressing the POWER button)

measurement has been stopped and the instrument is wait-

tton input to be detected, some internal

Page 33

27

For the connection procedure, refer to the

instruction manual supplied with the fixture.

Displays the Basic Settings screen.

Select

Setting example

PARA

Display parameters

:MAIN :Cs

:SUB :D

FREQ

Measurement frequency

:1.0000 kHz

LEVEL

Measurement signal mode

:

Open circuit voltage mode (V)

Measurement signal level

:1.000 V

LIMIT

Voltage and current limit

:OFF

RANGE

Measurement range

:AUTO

JUDGE

SYNC

Judgment

synchronization function

:OFF

TRIG

Trigger

:INT

LIST Displays the LIST Settings screen.

HIOKI IM3523B981-00

Measurement Example Chapter 3

Measuring a Laminated Ceramic Capacitor

Necessary items : 9263 SMD test fixture

Laminated ceramic capacity yo

Connect the 9263 SMD test fixture to the measurement terminals.

u want to measure

1

Open the Basic Settings screen.

2

3

Chapter 3 Measurement Example

3

Set the measurement conditions.

Page 34

28

Displays the LIST Settings screen.

2

1

Select

Select

Setting example

SPEED

Measurement speed

:MED

AVG

Average

:001

DELAY

Trigger Delay

:0s

SYNC

Trigger Synchronous Output

:OFF

For the connection procedure of the test

sample,refer to the instruction manual

supplied with the fixture.

• When you want to judge the measurement results

See "4.4.1 Making Judgments Based on Upper and Lower Limit Values (Comparator Measurement

Mode)" (p. 76)

• When you want to save the measurement results

See "4.5.1 Saving Measurement Results (Memory function)" (p. 97)

HIOKI IM3523B981-00

4

5

Select [LIST] on the Basic Settings screen to open the LIST Settings screen.

Set the measurement conditions for the respective ranges.

6

7

Connect the test sample to the 9263 SMD test fixture.

Check the measurement results.

Page 35

4.1 About LCR function

Indicates the

measurement mode.

Indicates the

loaded panel

number. (p.165)

Indicates the usage

status of internal

memory. (p.97)

Indicates the parameter

and measurement value.

Indicates some of the measurement

conditions

From the left, frequency, measurement

signal level, measurement range,

measurement speed, trigger settings.

Monitor values

Vac,Vdc:Voltage across the terminals

of the sample

I

ac,Idc

:Current passing through

the sample

Menu keys

[BASIC] :Configures basic settings. (p.31)

[Rdc] :Configures DC resistance

measurement settings. (p.61)

[ADVNC] :Configures application

settings. (p.97)

[SYS] :Configures system settings.

(p.171)

Indicates error

messages and other

information. (p.216)

HIOKI IM3523B981-00

LCR Function Chapter 4

4.1 About LCR function

The LCR function allows you to measure the impedance, phase angle, and other items by applying any

frequency or level (effective value) signal to the element you want to measure. This function is suitable for

evaluating the passive element of a capacitor, coil, or the like.

Measurement screen

The Measurement screen allows you to make measurements while reviewing measurement conditions.

When the ins

when the power was turned off. For more information about the screen layout, see (p.12).

trument is turned back on, the display will reflect the measurement mode that was in use

29

4

Chapter 4 LCR Function

Page 36

30

Sets the measurement result judgment conditions

(when performing comparator/BIN measurement).

Loads measurement conditions.

Configures compensation functions.

Allows you to check detailed measurement conditions.

Toggles the display between the monitor value and comparator/BIN limit values

(when comparator/BIN measurement has been configured). For more information, see below.

When performing comparator measurement.

(Switch between the limit and monitor values with the keys.)

Limit values

Monitor values

When performing BIN measurement.

(Switch between the limit and monitor values with the tenkey ( to , ) or the keys.)

BIN1 Limit values

BIN10 Limit values

Monitor values

••••••••••••••••••••••••••

Toggles the display between the monitor value and

BIN limit values (when BIN measurement has been

configured). For more information, see below.

to : Allow you to check the BIN limit values. ( : BIN10)

: Allows you to check the monitor value.

HIOKI IM3523B981-00

4.1 About LCR function

Keys that can be used on the Measurement screen

When the measurement value is outside the guaranteed accuracy range, will be

shown on the error message display. If you encounter this issue, the following factors may be

at play. Change the measurement conditions after checking the guaranteed accuracy range

as described in "10.2 Measurement Range and Accuracy" (p.200), or use the measurement

value as a reference value.

• If the measurement signal level is too low: Increase the measurement signal level.

• If the current measurement range (when using the HOLD setting) is not appropriate: Set

the range to the optimal measurement range using AUTO ranging or change the measurement range manually.

Page 37

31

Displays the Basic Settings screen.

Select

Displays the Main Parameter Settings

screen.

ENTER

2

1

Select

Accepts the selected parameter and

returns to the Basic Settings screen.

ENTER

2

1

HIOKI IM3523B981-00

4.2 Setting Basic Settings of Measurement Conditions

4.2 Setting Basic Settings of Measurement

Conditions

Measurement conditions for DC resistance measurement are configured on a different

screen.

See "4.3 Setting DC Resistance Measurement" (p.61)

4.2.1 Setting Display Parameters

You can select a main and sub parameter from the 15 measurement parameters to display.

See "Appendix1 Measurement Parameters and Calculation formula"(p. A1)

"Appendix7 Series Equivalent Circuit Mode an

d Parallel Equivalent Circuit Mode"(p. A10)

4

1

2

3

Open the Basic Settings screen.

Select [MAIN] under [PARA].

Set the main parameter.

Chapter 4 LCR Function

Page 38

32

Select

1

Displays the Sub Parameter Settings screen.

ENTER

2

Select

Accepts the selected parameter and

returns to the Basic Settings screen.

ENTER

* The phase angle θ is shown based on the impedance Z.

When performing measurements using admittance Y as the reference, the sign of the impedance Z phase angle q will be reversed.

List of parameters

Impedance (Ω) Conductance (S)

Admittance (S) Reactance (Ω)

Impedance phase angle (°)

*

Inductance in series equivalent circuit mode

(H)

Effective resistance in series equivalent circuit mode = ESR (Ω)

Inductance in parallel equivalent circuit mode

(H)

Effective resistance in parallel equivalent circuit mode (Ω)

Q factor

Static capacitance in series equivalent circuit

mode (F)

Susceptance (S)

Static capacitance in parallel equivalent circuit (F)

DC Resistance (Ω)

Loss coefficient = tanδ

Display no measurement parameter in the

chosen position.

HIOKI IM3523B981-00

4.2 Setting Basic Settings of Measurement Conditions

Select [SUB] under [PARA].

4

Set the sub parameter.

5

Page 39

4.2 Setting Basic Settings of Measurement Conditions

DIGIT

10KEY

Displays the Basic Settings screen.

Select

Displays the Tenkey Input screen.

ENTER

1

2

HIOKI IM3523B981-00

4.2.2 Setting the Measurement Frequency

Set the frequency of the signal to apply to the test sample.

For some test samples, the value may vary depending on the measurement frequency.

You can enter the frequency using either digit or tenkey input.

Setting the frequency with tenkey input

Open the Basic Settings screen.

1

33

4

Chapter 4 LCR Function

2

3

Select [FREQ].

The Tenkey Input screen will be displayed.

Page 40

34

10KEY

Increases the unit

Decreases the unit

Accepts the entered value

• The keys will be disabled until you enter a value.

• If you set a frequency of 200 kHz or higher, the frequency will automatically revert to 200 kHz.

• If a frequency of less than 40 Hz is set, the value will be automatically changed to 40 Hz.

"Chapter 10 Specifications" (p.195)

1

15.5

15.

If you make a mistake:

Press key and reenter the value.

15.5

15

k

15.500kHz

Returns to the Basic Settings screen.

ENTER

HIOKI IM3523B981-00

4.2 Setting Basic Settings of Measurement Conditions

Enter the desired value with the tenkey and accept it with the key.

4

Settable range:40 Hz to 200 kHz

5

Page 41

Set each digit (DIGIT)

Displays the Basic Settings screen.

Select

Displays the Frequency Setting screen.

ENTER

2

1

Selects digit entry.

DIGIT

Increases the value.

Decreases the value.

Select

1

2

Selects the digit to change.

The digits in the measurement frequency can also be changed using the keys.

HIOKI IM3523B981-00

Open the Basic Settings screen.

1

Select [FREQ].

2

35

4.2 Setting Basic Settings of Measurement Conditions

4

Chapter 4 LCR Function

3

4

Select [DIGIT].

Enter the desired value.

Settable range: 40 Hz to 200 kHz

Page 42

36

Select

Multiplies the measurement frequency

by 10 or .

10

1

1

2

Returns to the Basic Settings screen.

HIOKI IM3523B981-00

4.2 Setting Basic Settings of Measurement Conditions

Change the unit and decimal point.

5

6

Page 43

4.2 Setting Basic Settings of Measurement Conditions

Open circuit voltage mode (V)

The value of the open circuit voltage is set.

Constant voltage mode (CV)

The value of the voltage between the terminals of the object under

test is set.

Constant current mode (CC)

The value of the current flowing through the object under test is set.

Displays the Basic Settings screen.

Select

Open circuit voltage mode (V)

Constant voltage mode (CV)

Constant current mode (CC)

HIOKI IM3523B981-00

4.2.3 Setting the Measurement Signal Level

The value of the test signal level may change according to the sample which is being tested.

This instrument is possible to vary the

range using the following three methods.

Selecting constant voltage or cons

use of software feedback control.

Do not switch between V, CV and CC while the test sample is still connected to the measurement terminals. Doing so ma

level of the test signal applied to the object under test over a wide

tant current mode will result in increased measurement times due to

y damage the test sample.

37

4

Chapter 4 LCR Function

1

2

• In constant voltage (CV) mode, the generated voltage is controlled using software feed-

back so that the set constant voltage value is a

recent measurement is output as the generated voltage initial value, a voltage in excess

of the set constant voltage value may be applied before feedback control is active if the

sample’s impedance is higher than that of the last measured sample.

• In constant current (CC) mode, the generated voltage is controlled using software feed-

back so that the set constant current value is applied. Since the voltage used for the most

nt measurement is output as the generated voltage initial value, a current in excess of

rece

the set constant current value may be applied before feedback control is active if the sample’s impedance is lower than that of the last measured sample.

Open the Basic Settings screen.

Select [LEVEL].

pplied. Since the voltage used for the most

Select the measurement signal mode.

3

Page 44

38

DIGIT

Increases the value.

Select

2

1

Decreases the value.

Measurement signal level range

Measurement

signal mode

Setting range

V, CV 0.005 V to 5.000 V

CC 0.01 mA to 50.00 mA

Selects the digit to change.

Returns to the Measurement screen.

HIOKI IM3523B981-00

4.2 Setting Basic Settings of Measurement Conditions

Select the [LEVEL] voltage or current value and change the value.

4

The accuracy of testing varies according to the test signal level.

See

"10.2 Measurement Range and Accuracy" (p.200)

5

If the measurement value is outside the accuracy guarantee, will be displayed at

the top of the screen. Check the accuracy guarantee range in "10.2 Measurement Range

and Accuracy" (p.200) and either change the measurement conditions or make the measurement value a reference value.

• If the measurement signal level is too low: Increase the measurement signal level.

• If the current measurement range (when using the HOLD setting) is not appropriate: Set

range to the optimal measurement range using AUTO ranging or change the measure-

the

ment range manually.

Page 45

4.2 Setting Basic Settings of Measurement Conditions

Output impedance

Sample

CC

CV

HL

V

Constant current mode (CC)

You should select this if you wish to set the

current passing through the object to be

tested to a constant value.

Constant voltage mode (CV)

You should select this if you wish to set the

voltage across the terminals of the object

to be tested to a constant value.

Open circuit voltage mode (V)

This voltage value is the value which is applied across the two

terminals of the series combination of the object which is being

tested and the output impedance. As for the voltage which is applied across the terminals of the object which is being tested (by

itself), if required, you should either check

the monitor voltage value, or select constant voltage (CV) and

set a voltage value across these terminals.

Open circuit voltage mode (V) and Constant voltage mode (CV) setting

9.15-0 jjXmRmZm

()

fC

Xm

π

2

1

−

=

9.15100' jZmRoZm

Ro: Output resistance (100 [Ω])

[]

Ω

×Ω

=

×

=

3.101

9.15

'VoZm

VoZm

Vm

Vo: generator output

HIOKI IM3523B981-00

About the test signal mode

Relationship between the measurement signal mode of the instrument and the sample is as follows.

39

4

Chapter 4 LCR Function

For setting range and accuracy

Open circuit voltage setting range Open circuit voltage accuracy Output impedance

0.005 V to 5.000 V ±10% rdg ±10 mV

Depending on the sample, you may not be able to perform constant voltage measurement. In

this situation, the following mark will be displayed:

Constant voltage measurement will not be performed.

Change the constant voltage level so that it is less than or equal to the displayed Vac monitor

values.

Example: Range in which constant voltage operation is supported when measuring a 1 μF C

at 10 kHz

The sample impedance Zm is as follows:

The impedance Zm' observed from the generator is as follows:

Accordingly, the voltage Vm across

[] []

ΩΩ=+=

[] []

Ω−Ω=+=

both leads of the sample is as follows:

100 Ω ±10 Ω

Because the generator output voltage range is 5 mV to 5 V for 10 kHz, the CV operation

range per the above expression is Vm = 0.8 mV to 0.78 V.

[]

Page 46

40

Constant current mode (CC) setting

28.60 jjXmRmZm

fLXmπ2

Ro: output resistance (100 [Ω])

28.6100' jZmRoZm

Vo: generator output

[]

Ω==2.100'

Im

Vo

Zm

Vo

Im

HIOKI IM3523B981-00

4.2 Setting Basic Settings of Measurement Conditions

However, the constant current operation range differs depending on the test sample to be measured.

Constant current setting range Constant current accuracy Output impedance

0.01 mA to 50.00 mA

Depending on the sample, you may not be able to perform constant current measurement.

In this situation, the following mark will be displayed:

Constant current measurement will not be performed.

Change the constant current level so that it is less than or equal to the displayed Iac monitor

value.

±10% rdg ±10 μA 100 Ω ±10 Ω

Example:

Range in which constant current operation is supported when measuring a 1 mH L at 1 kHz

The sample impedance Zm is as follows:

[] []

The impedance Zm' observed from the generator is as follows:

[] []

Accordingly, the current Im acr

Since the generator output voltage range is 5 [mV] to

age mode (V) and Constant voltage mode (CV) setting" (p. 39) table, constant current operation is supported for Im values of 49.9 [μA] to 49.9 [mA] as per the above equation.

oss both leads of the sample is as follows:

Ω−Ω=+=

Ω−Ω=+=

5 [V] based on the "Open circuit volt-

=

Page 47

4.2 Setting Basic Settings of Measurement Conditions

When open circuit voltage mode (V)

or constant voltage mode (CV) is set

Set the current limit.

When constant current mode(CC) is set

Set the voltage limit.

Displays the Basic Settings screen.

Select

• When the measurement signal mode is a voltage (V, CV)

• When the measurement signal mode is a current (CC)

• The measurement signal level can be checked using the monitor display.

• The monitor display is different for V, CV, and CC.

First set the measurement signal mode, and thereafter set the voltage or current limit.

The setting for voltage or current limit changes automatically to current or voltage

limit,according to the present measurement signal mode setting.

See "4.2.3 Setting the Measurement Signal Level" (p.37)

HIOKI IM3523B981-00

4.2.4 Limiting the Voltage or Current Applied to the Sample (Limit Values)

Depending on the measurement signal level, in some cases it is possible to damage the sample which is

being tested by applying to it a voltage or a current greater than its rated value.

To avoid such damage, you can set a limit value to limit the voltage applied to the sample or the current

that flows to the

Enabling the limit function will result in

control.

Open the Basic Settings screen.

sample.

increased measurement times due to use of software feedback

1

41

4

Chapter 4 LCR Function

Select [LIMIT].

2

Page 48

42

Disables the limit function.

Enables the limit function.

Increases the value.

2

1

Select

Decreases the value.

Limit range

Measurement

signal mode

Set limit Setting range

V, CV Current limit 0.01 mA to 50.00 mA

CC Voltage limit 0.005 V to 5 V

Current limit accuracy

Frequency Accuracy

40 Hz to 200 kHz

±10 %rdg±10

μA

Voltage limit accuracy

Frequency Accuracy

40 Hz to 200 kHz ±10% rdg±10 mV

Selects the digit to change.

DIGIT

When the limit function is on, the following marks may be displayed.

Example: When constant voltage mode (CV) setting

If the voltage or current which is applied to the

sample under test exceeds the limit value

(the current exceeding the limit value flows

through the sample even when the open-circuit

voltage is set to minimum value.)

Lower the measurement signal level so that the

limit value is not exceeded.