Page 1

RM3548

HIOKI RM3548A981-04

Instruction Manual

RESISTANCE METER

June 2021 Revised edition 4

RM3548A981-04 21-06H

EN

*600397884*

Page 2

HIOKI RM3548A981-04

Page 3

How to use the Instruction Manual (this manual)

HIOKI RM3548A981-04

See below, as appropriate:

Be sure to always read the

following sections.

When you wish to use the

instrument immediately

When you need further information

on the various functions

To nd out about instrument

specications

If the instrument does not operate

as intended or expected

For detailed information related to

resistance measurement

“Safety Notes” (p. 4)

“Usage Notes” (p. 7)

“Overview” (p. 15)

Refer to the “Contents” (p. i) and/or “Index”

(p. Ind.1) to nd the desired function.

“Specications” (p. 93)

“Troubleshooting” (p. 108)

“Appendix” (p. Appx.1)

1

2

3

4

5

6

7

RM3548A981-04

8

9

10

付録索引

Page 4

HIOKI RM3548A981-04

Page 5

Contents

HIOKI RM3548A981-04

Introduction ........................................................................................1

Verifying Package Contents .............................................................2

Safety Notes ....................................................................................... 4

Usage Notes ....................................................................................... 7

1

1 Overview 15

1.1 Overview and Features .................................................15

1.2 Component Names and Operation Overview ............. 16

Power-on settings ....................................................................20

1.3 Flow of Measurement ...................................................21

1.4 Screen Layout ...............................................................22

1.5 Checking the Measurement Target .............................25

2 Preparing for Measurement 27

2.1 Attaching the Strap ....................................................... 28

2.2 Loading or Replacing the Batteries ............................29

2.3 Connecting the Test Leads ..........................................30

2.4 Connecting the Z2002 Temperature Sensor

(When Using TC or ΔT) ................................................. 31

2.5 Turning the Power On/Off ............................................32

Turning the power on ...............................................................32

Turning the power off ...............................................................32

Automatic power off with auto power save (APS) .................... 33

Disabling auto power save (APS) ............................................33

2.6 Pre-measurement Inspection .......................................34

2

3

4

5

6

7

8

3 Basic Measurement 35

3.1 Setting the Measurement Range .................................36

3.2 Connecting the Test Leads to the Measurement

3.3 Reading the Measured Value .......................................39

Target .............................................................................38

Switching the display................................................................39

Verifying measurement errors ..................................................40

Holding a measured value .......................................................42

Memorizing a measured value ................................................. 42

9

10

Appx. Ind.

i

Page 6

Contents

HIOKI RM3548A981-04

4 Customizing Measurement Conditions 43

4.1 Using Zero Adjustment.................................................44

4.2 Stabilizing Measured Values (Averaging Function) ...49

4.3 Compensating for Thermal Effects

(Temperature Correction (TC)) ..................................... 50

4.4 Compensating for Thermal EMF Offset (Offset

Voltage Compensation Function: OVC Function) ...... 51

4.5 Setting the Delay Time for Measurement

(Delay Function) ............................................................ 53

4.6 Switching the Measurement Current

(In the 300m

Range) ................................................... 55

Ω

5 Judgment and Conversion Functions 59

5.1 Judging Measured Values (Comparator Function) ....60

Judging based on upper and lower limit values (ABS mode) .. 63

Judging based on a reference value and allowable range

(REF% mode) ..........................................................................64

Verifying a judgment with a sound (judgment sound function) . 65

Verifying a judgment on a handheld device

(L2105 LED Comparator Attachment option) ..........................66

5.2 Performing Temperature Rise Test

(Temperature Conversion Function (∆T)) ...................67

5.3 Measuring the Length of a Conductor

(Length Conversion Function) ..................................... 69

6 Panel Save and Load (Saving and Loading

Measurement Conditions) 71

6.1 Saving Measurement Conditions

6.2 Loading Measurement Conditions

6.3 Clearing the Contents of a Panel .................................74

7 Memory Function (Saving and Exporting

Measurement Data to a PC) 75

7.1 Saving Data at Specied Time (Manual Memory) ......77

ii

(Panel Save Function) ..................................................72

(Panel Load Function) ..................................................73

Page 7

Contents

HIOKI RM3548A981-04

7.2 Saving Data Automatically When Measured

Values Stabilize (Auto-Memory) ..................................78

7.3 Saving Data at Fixed Intervals

(Interval Memory Function) .......................................... 79

7.4 Displaying Saved Measurement Data

(Memory Display Function) .......................................... 81

7.5 Clearing Measurement Data (Memory Clear) .............82

7.6 Exporting Saved Measurement Data to a PC

(USB Mass Storage Mode) ...........................................86

8 System Settings 89

8.1 Displaying the Date and Time Verication Screen ....89

8.2 Setting the Clock ........................................................... 90

8.3 Initializing (Reset) .........................................................91

Default settings ........................................................................92

9 Specications 93

9.1 General Specications .................................................93

Measurement range ................................................................. 93

Measurement method .............................................................. 93

Measurement specications.....................................................93

Accuracy ..................................................................................96

Functions..................................................................................97

Interface ................................................................................. 104

Environmental and safety specications ................................ 105

Accessories ............................................................................ 105

Options ................................................................................... 106

1

2

3

4

5

6

7

8

10 Maintenance and Service 107

10.1 Troubleshooting ..........................................................108

10.2 Repair and Inspection ................................................ 115

10.3 Replacing Fuses ......................................................... 116

10.4 Disposing of the Instrument ...................................... 117

Q&A (frequently asked questions and answers) ....................108

Error display and actions........................................................ 114

iii

9

10

Appx. Ind.

Page 8

Contents

HIOKI RM3548A981-04

Appendix Appx.1

Appx. 1 Block Diagram ...............................................Appx.1

Appx. 2 Four-Terminal (Voltage-Drop) Method .........Appx.2

Appx. 3 DC Method and AC Method ..........................Appx.3

Appx. 4 Temperature Correction Function (TC) .......Appx.4

Appx. 5 Temperature Conversion (ΔT) Function ......Appx.7

Appx. 6 Effect of Thermoelectromotive Force

(Thermal EMF) ................................................Appx.8

Appx. 7 Zero Adjustment .......................................... Appx.11

Appx. 8 Unstable Measurement Values ...................Appx.17

Appx. 9 Locating Short-Circuits on a PC Board ..... Appx.27

Appx. 10 Test Lead Options .......................................Appx.28

Appx. 11 Calibration .................................................... Appx.30

Index Ind.1

iv

Page 9

Introduction

HIOKI RM3548A981-04

Introduction

Thank you for purchasing the HIOKI RM3548 Resistance Meter. To obtain maximum

performance from the instrument, please read this manual rst, and keep it handy for

future reference.

Trademarks

Windows and Microsoft Excel are either registered trademarks or trademarks of

Microsoft Corporation in the UnitedStates and other countries.

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

1

Page 10

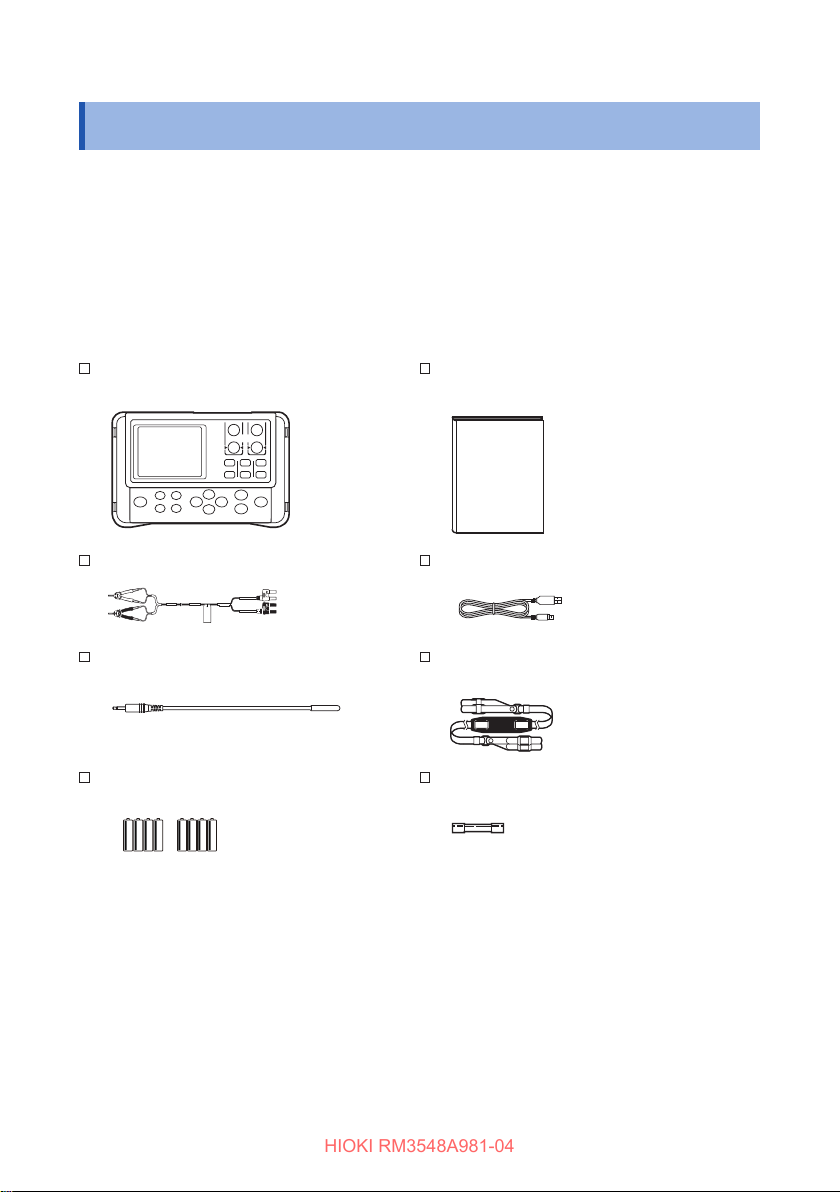

Verifying Package Contents

電池

電池

HIOKI RM3548A981-04

Verifying Package Contents

• When you receive the instrument, inspect it carefully to ensure that no damage

occurred during shipping. In particular, check the accessories, panel switches,

and connectors. If damage is evident, or if it fails to operate according to the

specications, contact your authorized Hioki distributor or reseller.

• When transporting the instrument, use the same packaging materials used for the

delivery to you.

Check the package contents as follows.

RM3548 Resistance Meter Instruction Manual

L2107 Clip Type Lead (p. 30) USB Cable (A-miniB type)

Z2002 Temperature Sensor (p. 31) Strap

LR6 Alkaline battery × 8

2

Spare fuse (F2AH/250 V)

Page 11

Verifying Package Contents

JAPAN

HIOKI RM3548A981-04

Options

The options listed below are available for the instrument. To order an option, please

contact your authorized Hioki distributor or reseller. Options are subject to change.

Please check Hioki’s website for the latest information. (p. Appx.28)

L2107 Clip Type Lead 9467 Large Clip Type Lead

1

2

9453 Four-Terminal Lead 9772 Pin Type Lead

9465-10 Pin Type Lead 9454 Zero Adjustment Board

Z2002 Temperature Sensor L2105 LED Comparator Attachment

C1006 Carrying Case

3

4

5

6

7

8

9

10

Appx. Ind.

3

Page 12

Safety Notes

HIOKI RM3548A981-04

Safety Notes

The instrument is designed to conform to IEC 61010 Safety Standards, and has been

thoroughly tested for safety prior to shipment. However, using the instrument in a way

not described in this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the following safety notes.

DANGER

Mishandling during use could result in injury or death, as well

as damage to the instrument. Be certain that you understand the

instructions and precautions in the manual before use.

WARNING

With regard to the electricity supply, there are risks of electric shock,

heat generation, re, and arc discharge due to short circuits. If

persons unfamiliar with electricity measuring instruments are to use

the instrument, another person familiar with such instruments must

supervise operations.

This manual contains information and warnings essential for safe operation of

the instrument and for maintaining it in safe operating condition. Before using the

instrument, be certain to carefully read the following safety notes.

4

Page 13

Safety Notes

HIOKI RM3548A981-04

Notation

In this manual, the risk seriousness and the hazard levels are classied as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in death or

serious injury to the operator.

Indicates a potentially hazardous situation that may result in minor

or moderate injury to the operator or damage to the instrument or

malfunction.

Indicates information related to the operation of the instrument or

maintenance tasks with which the operators must be fully familiar.

Indicates prohibited actions.

Indicates the action which must be performed.

1

2

3

4

*

p. Indicates the location of reference information.

[ ] An item enclosed by [ ] indicates a key name.

Unless otherwise noted, Windows XP, Windows Vista, Windows 7, and Windows 8 are

referred to as “Windows”.

Additional information is presented below.

5

6

7

8

9

10

Appx. Ind.

5

Page 14

Safety Notes

HIOKI RM3548A981-04

Symbols afxed to the instrument

Indicates cautions and hazards. When the symbol is printed on the instrument,

refer to a corresponding topic in the Instruction Manual.

Indicates a fuse.

Indicates DC (Direct Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment Directive (WEEE

Directive) in EU member states.

Indicates that the instrument conforms to regulations required by the EU Directive.

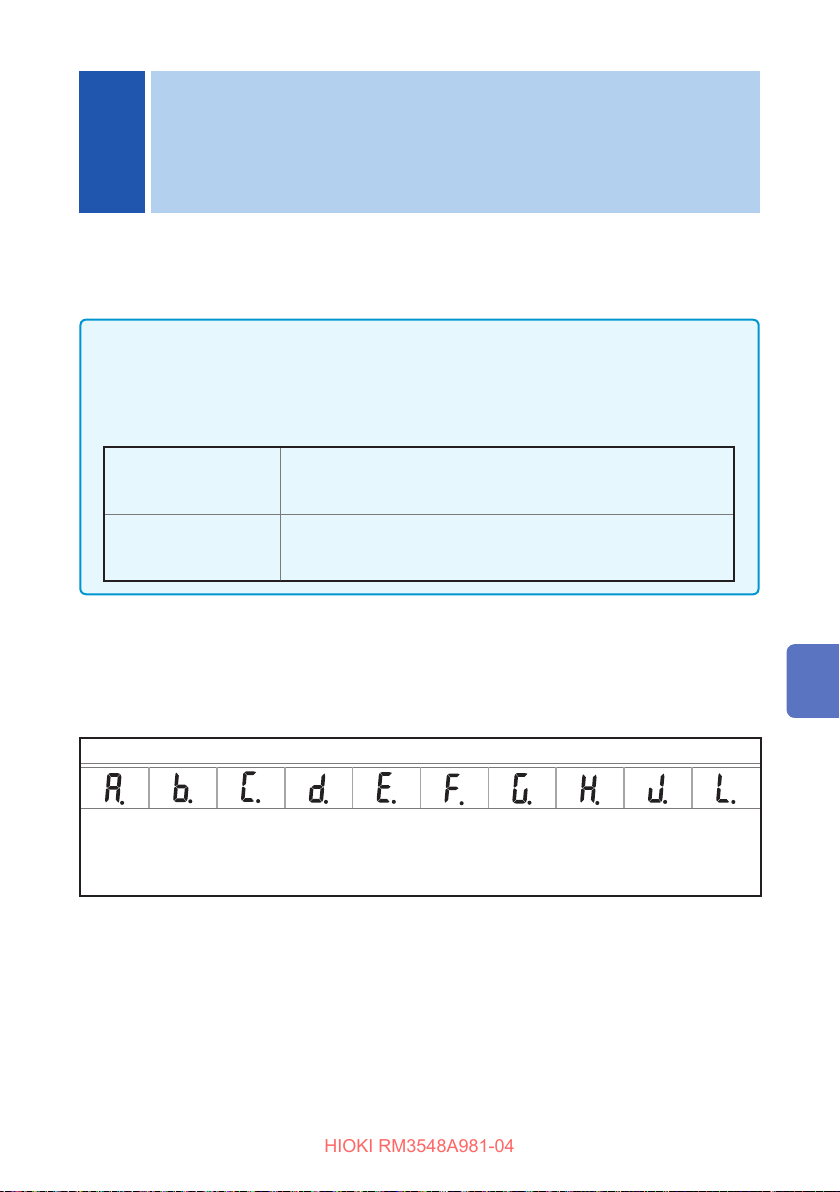

Screen display

The instrument uses the following screen displays.

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

1 2 3 4 5 6 7 8 9 0

Accuracy

We dene measurement tolerances in terms of f.s. (full scale), rdg. (reading) and dgt.

(digit) values, with the following meanings:

f.s.

rdg.

dgt.

See: “Accuracy calculation examples” (p. 96)

6

(Maximum display value)

This is usually the maximum display value. In the instrument, this indicates the

currently used range.

(Reading or displayed value)

The value currently being measured and indicated on the measuring

instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument, i.e., the input

value that causes the digital display to show a “1”.

Page 15

Usage Notes

HIOKI RM3548A981-04

Usage Notes

Follow these precautions to ensure safe operation and to obtain the full benets of

the various functions.

Use of the instrument should conrm not only to its specications, but also to the

specications of all accessories, options, batteries, and other equipment in use.

Checking before use

Before using the instrument the rst time, verify that it operates normally to ensure

that no damage occurred during storage or shipping. If you nd any damage, contact

your authorized Hioki distributor or reseller.

DANGER

Before using the instrument, check that the coating of the test leads

or cables are neither ripped nor torn and that no metal parts are

exposed. Using the instrument under such conditions could result

in electrocution. Replace the test leads with those specied by our

company.

Installation

Installation environment

Operating temperature

and humidity ranges

Storage temperature

and humidity ranges

Installing the instrument in inappropriate locations may cause a malfunction of

instrument or may give rise to an accident. Avoid the following locations.

0°C to 40°C 80%RH or less (no condensation)

-10°C to 50°C 80%RH or less (no condensation)

1

2

3

4

5

6

7

8

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to a strong electromagnetic eld or electrostatic charge

• Exposed to high quantities of dust particles

• Near induction heating systems (such as high-frequency induction

heating systems and IH cooking equipment)

• Susceptible to vibration

CAUTION

9

10

Appx. Ind.

7

Page 16

Usage Notes

HIOKI RM3548A981-04

IMPORTANT

Accurate measurement may be impossible in the presence of strong magnetic

elds, such as near transformers and high-current conductors, or in the presence of

strong electromagnetic elds such as near radio transmitters.

Handling precautions

WARNING

• Do not allow the instrument to get wet, and do not use it with wet

hands. This may cause electric shock accident.

• Do not modify, disassemble, or repair the instrument. This may

result in re, electric shock accident, or injury.

CAUTION

• Do not place the instrument on an unstable or slanted surface. It may

drop or fall, causing injury or instrument failure.

• To avoid any damage to the instrument, avoid any vibration or shock

during transport or handling. Especially, be careful not to drop or fall the

instrument which will cause shock.

• To avoid any damage to the instrument, do not input voltage or current to

any measurement, TEMP.SENSOR, or COMP.OUT terminals.

Precautions during shipment

Observe the following during shipment.

Hioki cannot be responsible for damage that occurs during shipment.

• During shipment of the instrument, handle it carefully so that it is not

damaged due to a vibration or shock.

• To avoid damage to the instrument, remove the accessories and optional

equipment from the instrument during shipment.

If the instrument is not used for an extended period of time

IMPORTANT

To avoid corrosion and/or damage to the instrument due to battery leakage, remove

the batteries from the instrument if it is to be kept in storage for an extended period.

8

CAUTION

Page 17

Handling leads and cables

HIOKI RM3548A981-04

Usage Notes

DANGER

To avoid electrical shock accident, do not short test leads where

voltage is applied.

CAUTION

• Avoid stepping on or pinching the leads, which could damage the lead

insulation.

• To avoid damaging the cables, do not bend or pull the base of cables and

the leads.

• When removing a connector, hold its plug portion, not its cable, to prevent

a wire disconnection.

• The ends of pin type leads are sharp. Be careful to avoid injury.

• Melted lead wire is dangerous because its metal part is exposed.

Be careful not to allow contact between the lead wire and the heat

generating portion.

• The Z2002 Temperature Sensor is precision-machined. Excessively high

voltage pulses or static electricity may damage the sensor.

• Do not apply an excessive impact to the tip of the Z2002 Temperature

Sensor or bent the lead wire. It may cause failure or wire disconnection.

IMPORTANT

• Do not use any test lead or temperature sensor other than the ones specied by

our company. It may result in inaccurate measurement due to poor contact or

other reasons.

• If the jack of a test lead or the temperature sensor is dirty, wipe it off. Otherwise,

the contact resistance will increase, affecting the temperature measurement.

• Be careful so that the temperature sensor connector does not come off. (The

temperature correction or conversion function will not work if the connector

comes off.)

1

2

3

4

5

6

7

8

9

Before attaching the strap

Use the four attachment points on the instrument to attach the strap

securely. Otherwise, the instrument may drop during carrying, damaging

the instrument.

CAUTION

10

Appx. Ind.

9

Page 18

Usage Notes

HIOKI RM3548A981-04

Batteries

Poor performance or damage from battery leakage could result.

Observe the cautions listed below.

WARNING

• Do not short circuit, charge, disassemble, or incinerate batteries. Doing

so may cause an explosion and is dangerous.

• To avoid electric shock accident, remove any test leads before replacing

batteries.

• After the replacement, be sure to reattach the cover.

CAUTION

• Do not use both new and old batteries or different types of batteries

together.

• Be careful to observe battery polarity. Otherwise, poor performance or

damage from battery leakage could result.

• Do not use batteries after their recommended expiry date.

• Do not allow used batteries to remain in the instrument.

• To avoid corrosion and/or damage to the instrument due to battery

leakage, remove the batteries from the instrument if it is to be kept in

storage for an extended period.

IMPORTANT

• When

possible. When

Replace the batteries.

• Be sure to turn the power off after using it.

• In this manual, the “batteries” are those used to power the instrument.

• Do not use any batteries other than the specied type (LR6 alkaline batteries).

Ni-MH batteries may cause battery leakage, depending on the degree of battery

charge and deterioration.

• Dispose of batteries in accordance with local regulations.

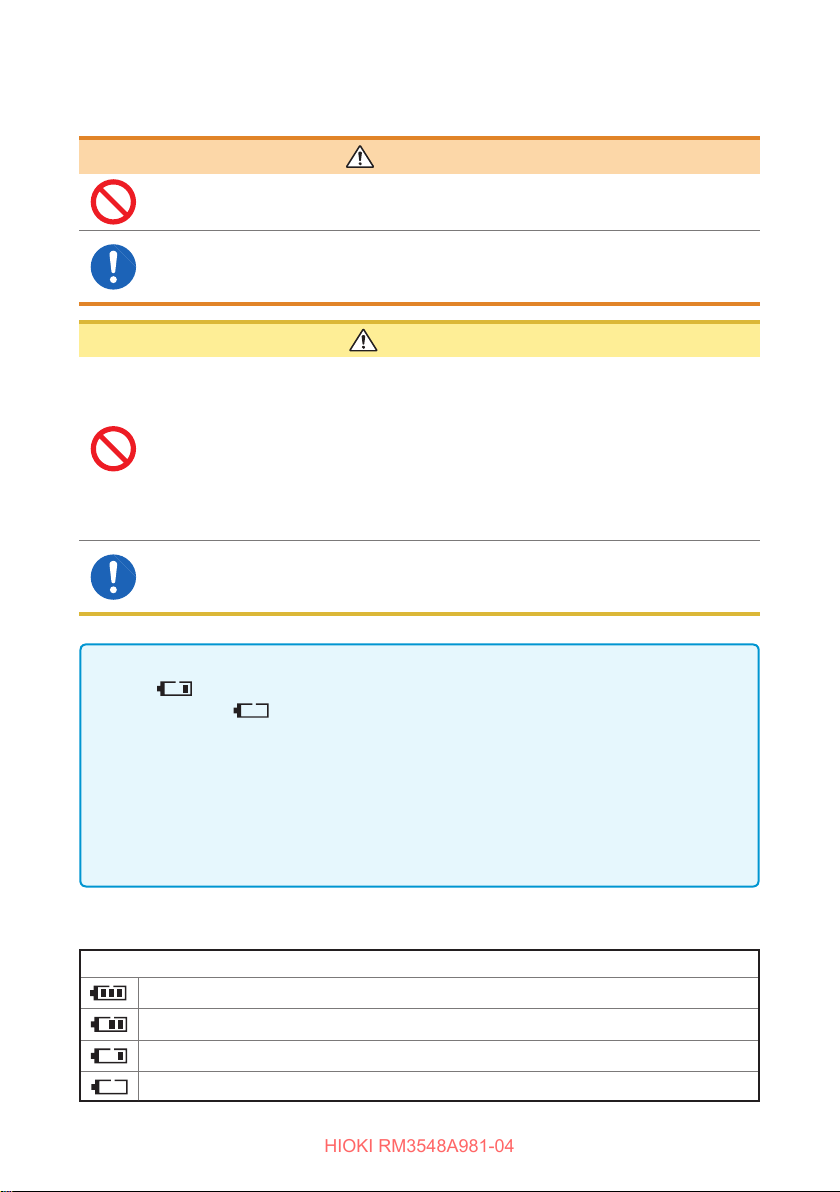

Remaining battery level indicator

The battery is fully charged.

As the remaining amount of batteries becomes low, the bars disappear from the left.

The battery becomes low. Replace the batteries as soon as possible.

(Blinking) There is no battery remaining. Replace the batteries with new ones.

10

is lit, the battery becomes low. Replace the batteries as soon as

is blinking, the battery becomes too low for measurement.

Indication

Page 19

Before connecting test leads

HIOKI RM3548A981-04

Usage Notes

DANGER

To avoid electric shock or short-circuit accident, turn any

measurement target off before connecting test leads.

Before connecting the L2105 LED Comparator Attachment

CAUTION

• To prevent the instrument and the L2105 LED Comparator Attachment

from breaking down, turn the power off before connecting the L2105 LED

Comparator Attachment.

• The COMP.OUT terminal is for the L2105 only. Do not connect any

terminal other than the L2105.

• Connect the temperature sensor securely. Otherwise, the specications

may not be met.

• When a tie band is used, do not tighten the test lead excessively.

It could damage the test lead.

• Do not perform the following as they could damage the core or coating of

a cable.

Twisting or pulling the cable

Connecting the cable around the L2105 LED Comparator Attachment

by bending it compactly

Before connecting the Z2002 Temperature Sensor

1

2

3

4

5

6

7

Connect the Z2002 Temperature Sensor securely. Otherwise,

specications may not be met or a failure may occur.

• To prevent the instrument and the Z2002 Temperature Sensor from

breaking down, turn the power off before connecting the Z2002

Temperature Sensor.

• Insert the Z2002 Temperature Sensor all the way into the TEMP.SENSOR

terminal. Otherwise, the measurement may have a large error.

IMPORTANT

If the jack of the Z2002 Temperature Sensor is dirty, wipe it off. Otherwise, the

temperature measurement may have an error.

WARNING

CAUTION

8

9

10

Appx. Ind.

11

Page 20

Usage Notes

HIOKI RM3548A981-04

Measurement precautions

To avoid electrical shock accident, do not short test leads where

voltage is applied.

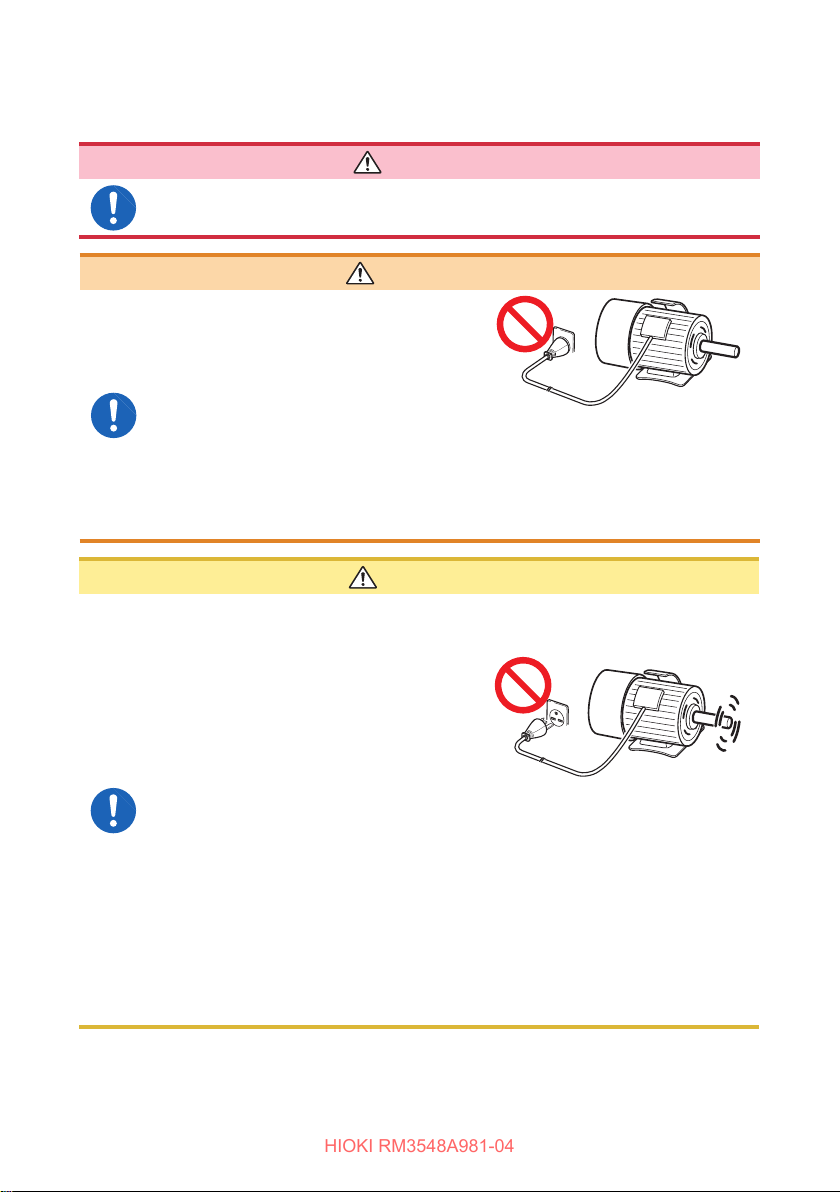

• To prevent electric shock accident

or damage to the instrument, do not

apply voltage to any measurement

terminal. To avoid electrical accident,

remove power from the measurement

target before measurement.

• Electrical sparks may occur at the moment of connecting/disconnecting

the power cable to/from the measurement target. Do not use the

instrument where combustible gases are generated.

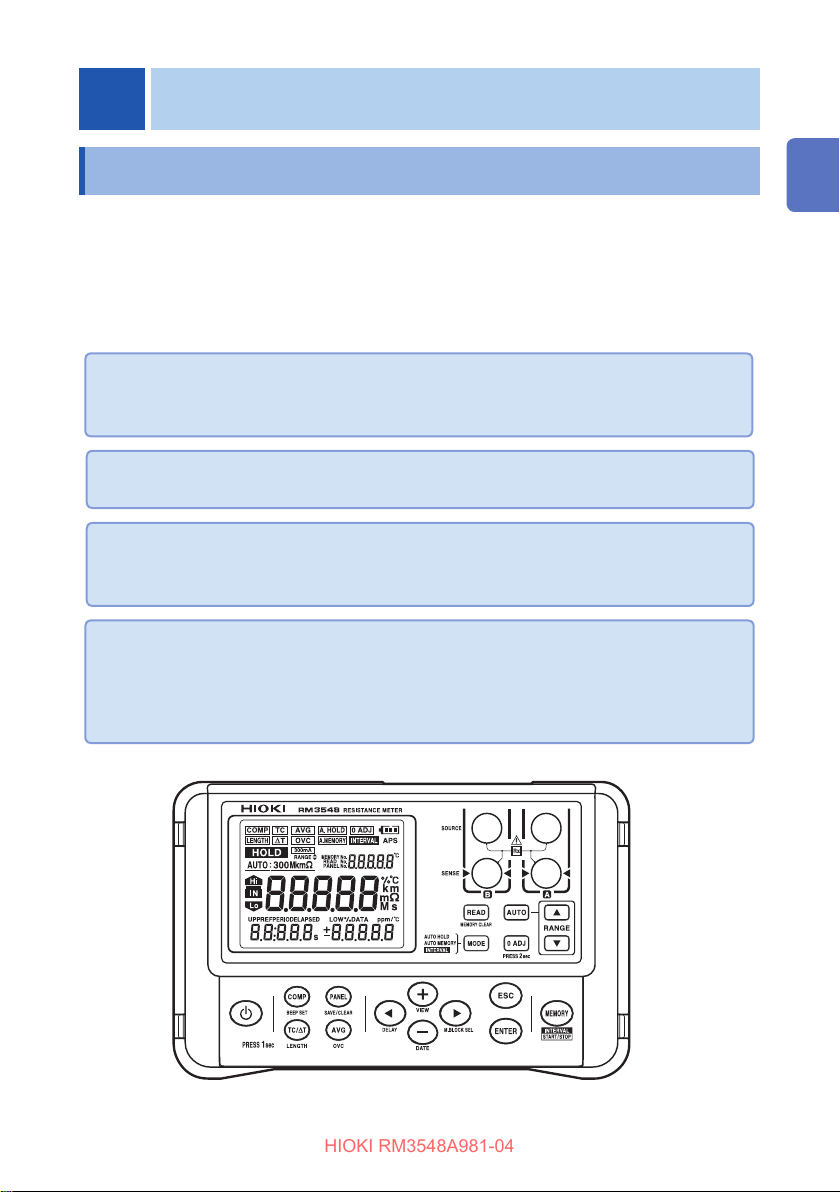

• Do not measure a point where

voltage is applied. When a motor

is turned off, the motor does not

stop immediately and is rotating

inertially. And, in such a state, a

large electromotive force is still being

generated.

If a transformer or motor is measured

immediately after a voltage withstand

test, the instrument will be damaged

due to induced voltage or residual

charge.

• When measuring a transformer or coil with an inductance of 5 H or more

and with a resistance of 1

in which a measurement current of 1 A ows. The instrument may be

damaged.

• Do not attempt to measure the internal resistance of a battery. The

instrument will be damaged. To measure internal resistance of a battery,

use a HIOKI 3554, 3555, BT3562, BT3563, or 3561 Battery HiTESTER.

DANGER

WARNING

The measurement target is connected

to power.

CAUTION

Rotating inertially

or less, do not use the 3mΩ or 30mΩ range

Ω

12

Page 21

Usage Notes

HIOKI RM3548A981-04

IMPORTANT

• The SOURCE terminals are protected with a fuse. If the fuse is broken, “FUSE”

appears, and resistance cannot be measured. In such a case, replace the fuse.

(p. 116)

• Since the instrument uses DC current for measurement, it may be affected by

thermal EMF (thermoelectromotive force), resulting in a measurement error. If so,

use the Offset Voltage Compensation function.

“4.4 Compensating for Thermal EMF Offset (Offset Voltage Compensation

Function: OVC Function)” (p. 51)

“Appx. 6 Effect of Thermoelectromotive Force (Thermal EMF)” (p. Appx.8)

• When a power transformer or open solenoid coil with a high inductance, or the

like is measured, the measured value may not stabilize. If so, connect a lm

capacitor of 1 µF or so between the SOURCE A and B terminals.

• Ensure that the SOURCE-A, SENSE-A, SENSE-B, and SOURCE-B terminal

connections are isolated from each other. If a core or shield wire touches

another, the instrument will become unable to perform accurate four-terminal

measurement, resulting in a measurement error.

1

2

3

4

Using the Z2002 Temperature Sensor

CAUTION

The Z2002 Temperature Sensor does not have a waterproof construction.

Do not put the sensor into water or any other liquid.

IMPORTANT

• When using the temperature correction function, wait until the measurement

target and Z2002 Temperature Sensor come close enough to ambient

temperature for the measurement. Otherwise, it may result in a large

measurement error.

• Do not hold the Z2002 Temperature Sensor with a bare hand. It may cause

enough noise pickup to destabilize the measurement.

• The Z2002 Temperature Sensor is designed for ambient temperature

measurement. The temperature of a measurement target cannot be measured

correctly even if the Z2002 Temperature Sensor is attached to its surface or other

portion.

• Insert the Z2002 Temperature Sensor all the way into the TEMP.SENSOR

terminal. Otherwise, the measurement may have a large error.

5

6

7

8

9

10

Appx. Ind.

13

Page 22

Usage Notes

HIOKI RM3548A981-04

14

Page 23

1

HIOKI RM3548A981-04

Overview

1.1 Overview and Features

The Hioki RM3548 employs the four-terminal method to highly accurately measure

the DC resistance of measurement targets including motor and transformer windings,

and welding, PC board patterns, fuses, resistors, and materials such as conductive

rubber. The instrument allows temperature correction and so is especially suitable for

measurement targets whose resistance values change with temperature.

Highly reliable specications implemented in a compact, light-weight body

• 35,000-dgt. high resolution

• 0.1µΩ resolution at 1 A measurement current

Neither a warm-up time nor zero adjustment is required before starting

measurement

Simple temperature rise test (for temperature estimation during power stop)

• Temperature conversion and interval measurement functions

• Supports copying of measurement data le from the instrument memory to the PC

Well-designed instrument shaped for measuring without taking your hands

and eyes off the target, making it ideal for maintenance and large product

measurement

• Strap-attachable portable type

• Standard auto-memory and auto-hold, and optional L2105 LED Comparator Attachment

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

15

Page 24

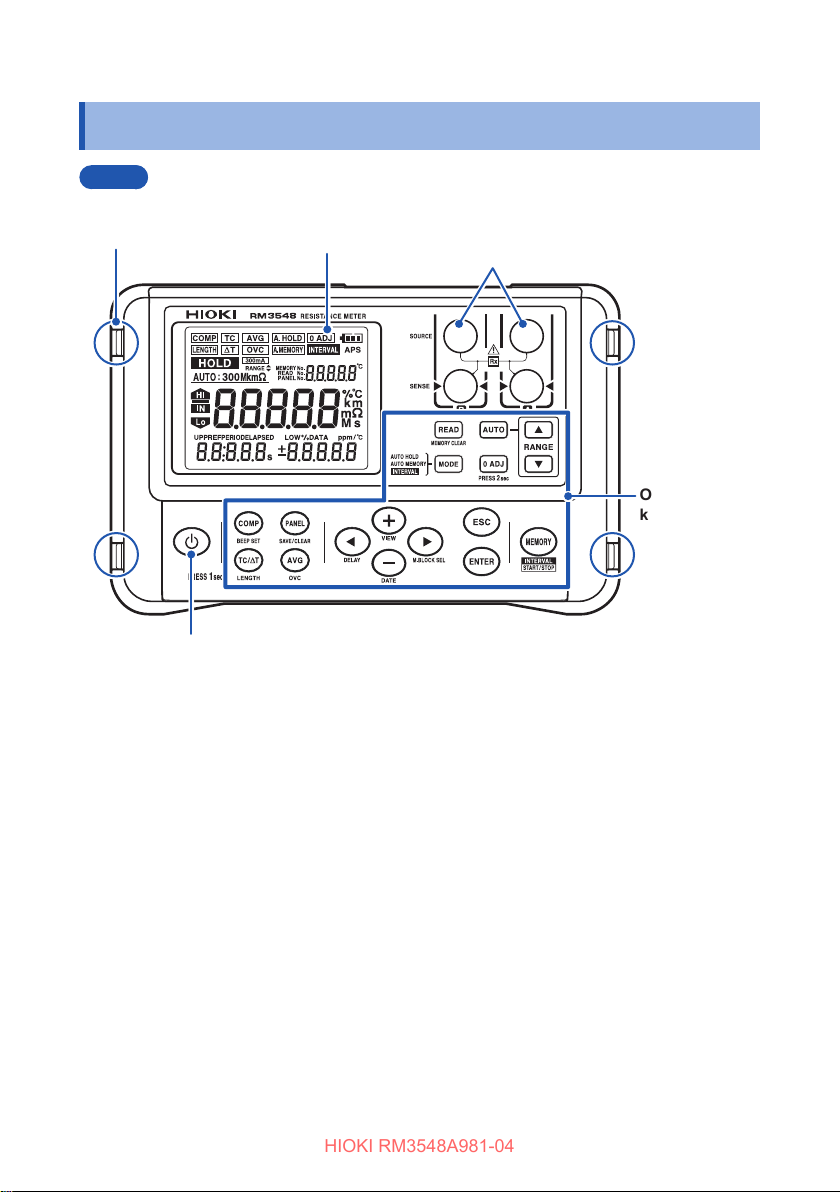

Component Names and Operation Overview

HIOKI RM3548A981-04

1.2 Component Names and Operation Overview

Front

Strap attachment

holes (four) (p. 28)

[POWER] key

Turns the power on/off. (p. 32)

Display (p. 22)

Measurement

terminals (p. 30)

Operation

keys (p. 18)

16

Page 25

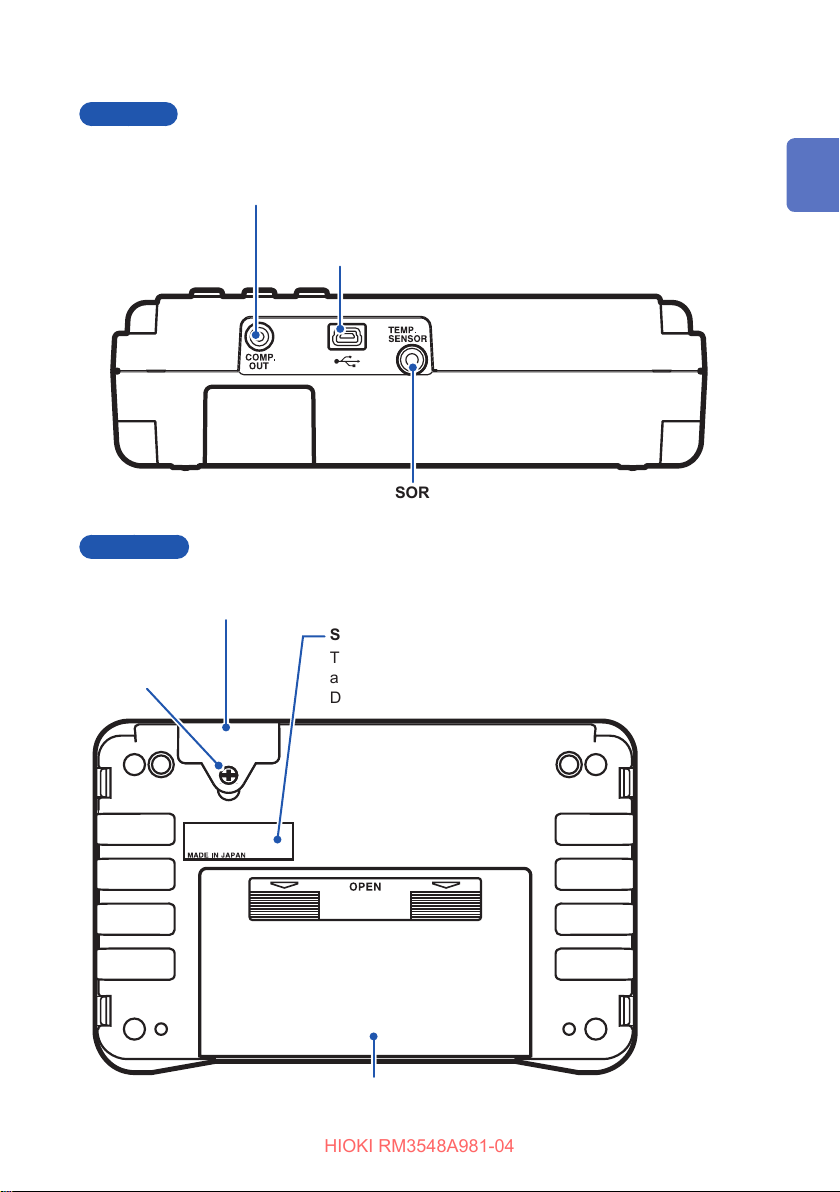

Top view

HIOKI RM3548A981-04

Back view

Set screw

Component Names and Operation Overview

COMP. OUT terminal

Connect an optional L2105 LED Comparator

Attachment. (p. 66)

USB terminal

Connect a USB cable. (p. 86)

TEMP.SENSOR terminal

Connect the included Z2002 Temperature Sensor. (p. 31)

Fuse cover

Contains a fuse for measurement circuit protection. (p. 116)

Serial number

The 9-digit serial number indicates the year (rst two digits)

and themonth of manufacture (next two digits).

Do not remove this sticker as the number is important.

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

Battery cover

Contains eight LR6 alkaline batteries. (p. 29)

17

Page 26

Component Names and Operation Overview

HIOKI RM3548A981-04

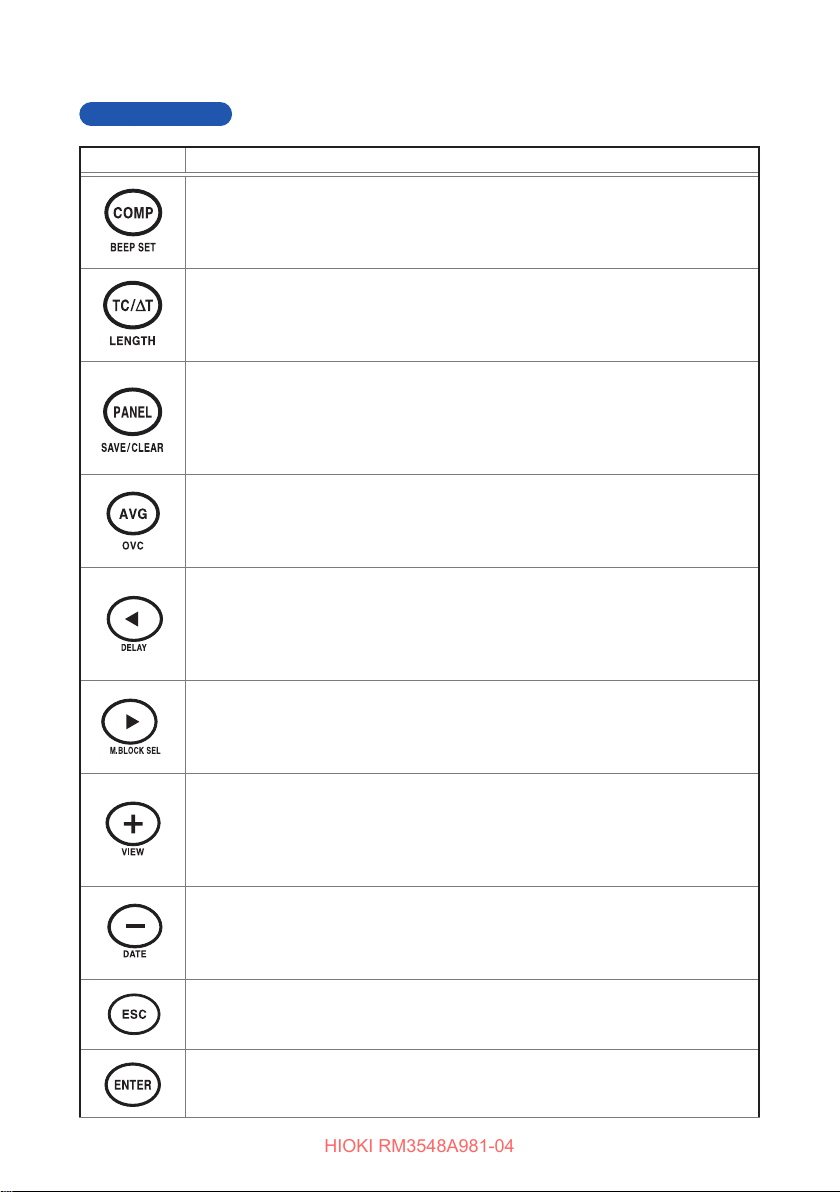

Operation keys

Key Description

[COMP] key (p. 62)

• Comparator: oFF → ON (ABS mode) → ON (REF% mode)

[BEEPSET] key (press and hold) (p. 65)

• Judgment sound: oFF → Hi → in → Lo → Hi-Lo → ALL1 → ALL2

[TC/∆T] key (p. 50) (p. 67)

• Temperature correction/conversion function: oFF → TC → ΔT

[LENGTH] key (press and hold) (p. 69)

• Length conversion function: oFF → ON

[PANEL] key (p. 73)

• Panel load: Changes the panel No. “PrSEt” initializes the measurement

conditions.

[SAVE/CLEAR] key (press and hold) (p. 72, p. 74)

• Saves and clears panels: SAvE → CLr

[AVG] key (p. 49)

• Averaging function: oFF → 2 → 5 → 10 → 20

[OVC] key (press and hold) (p. 51)

• Offset voltage compensation (OVC) function: oFF → on

[] key

• Moves to a different digit of the setting

[DELAY] key (press and hold) (p. 53)

• Delay function: PrSEt (factory default) → 10 ms → 30 ms → 50 ms →

100 ms → 300 ms → 500 ms → 1000 ms

[] key

• Moves to a different digit of the setting

[M.BLOCK SEL] key (press and hold) (p. 76)

• Selects a memory block: A → b → C → d → E → F → G → H → J → L

[+] key

• Changes values and items

[VIEW] key (press and hold) (p. 39)

• Toggles the display: Temperature → no indicator → memory number

(MEMORY No.)

[−] key

• Changes values and items

[DATE] key (press and hold) (p. 89)

• Displays the date and time conrmation screen.

[ESC] key

• Cancels the setting (when in the setting screen)

• Releases a HOLD state (if in a HOLD state)

18

[ENTER] key

Applies the setting

Page 27

Component Names and Operation Overview

HIOKI RM3548A981-04

Key Description

[MEMORY] key (p. 77)

• Saves the measured values (manual memory)

[START/STOP] key (press and hold) (p. 79)

• Starts/stops interval measurement (when in interval mode)

[READ] key (p. 81)

• Displays saved measurement data

[MEMORY CLEAR] key (press and hold) (p. 82)

• Clears memory: LASt (Latest data from the selected block) → bLoC (Selected

block) → ALL (All data)

[MODE] key (p. 42, p. 78, p. 79)

Switches memory hold mode: oFF → A.HOLD (auto-hold)

→ A.HOLD,A.MEMORY (auto-memory) → INTERVAL (interval function)

[AUTO] key (p. 37)

Turns on/off the auto range: AUTO lit → not lit

[0 ADJ] key (press and hold) (p. 44)

Zero adjustment

[RANGE] key (p. 36)

Measurement range:

3m

↔ 30mΩ ↔ 300mΩ ↔ 3Ω ↔ 30Ω ↔ 300Ω ↔ 3kΩ ↔ 30kΩ ↔ 300kΩ ↔

Ω

3M

Ω

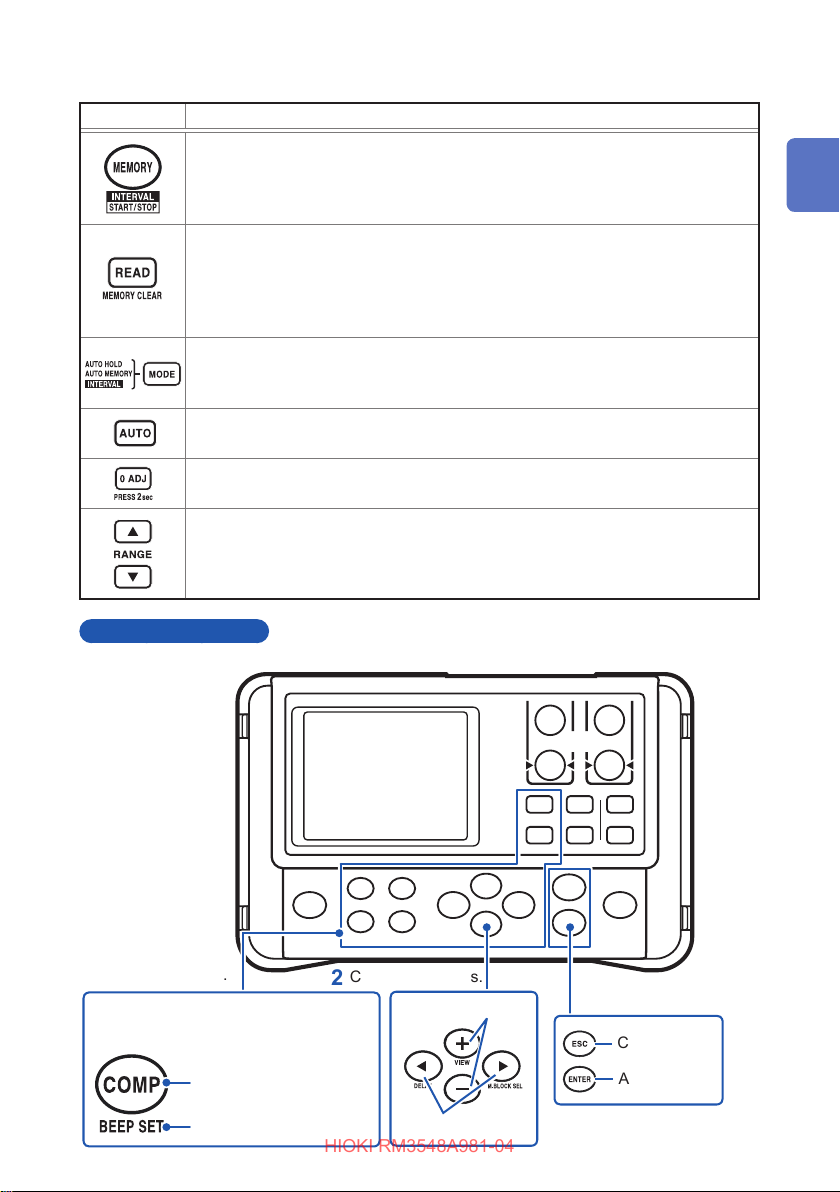

Operation overview

1

2

3

4

5

6

Select a function.

1

The function shown below each key can be

selected by pressing and holding the key.

Congure settings.

2

Name of the key that turns ON

when it is pressed

Name of the key that turns ON

when it is pressed and held

Changes items/values.

Moves digits.

Apply settings.

3

Cancel

Apply

7

8

9

10

Appx. Ind.

19

Page 28

Component Names and Operation Overview

HIOKI RM3548A981-04

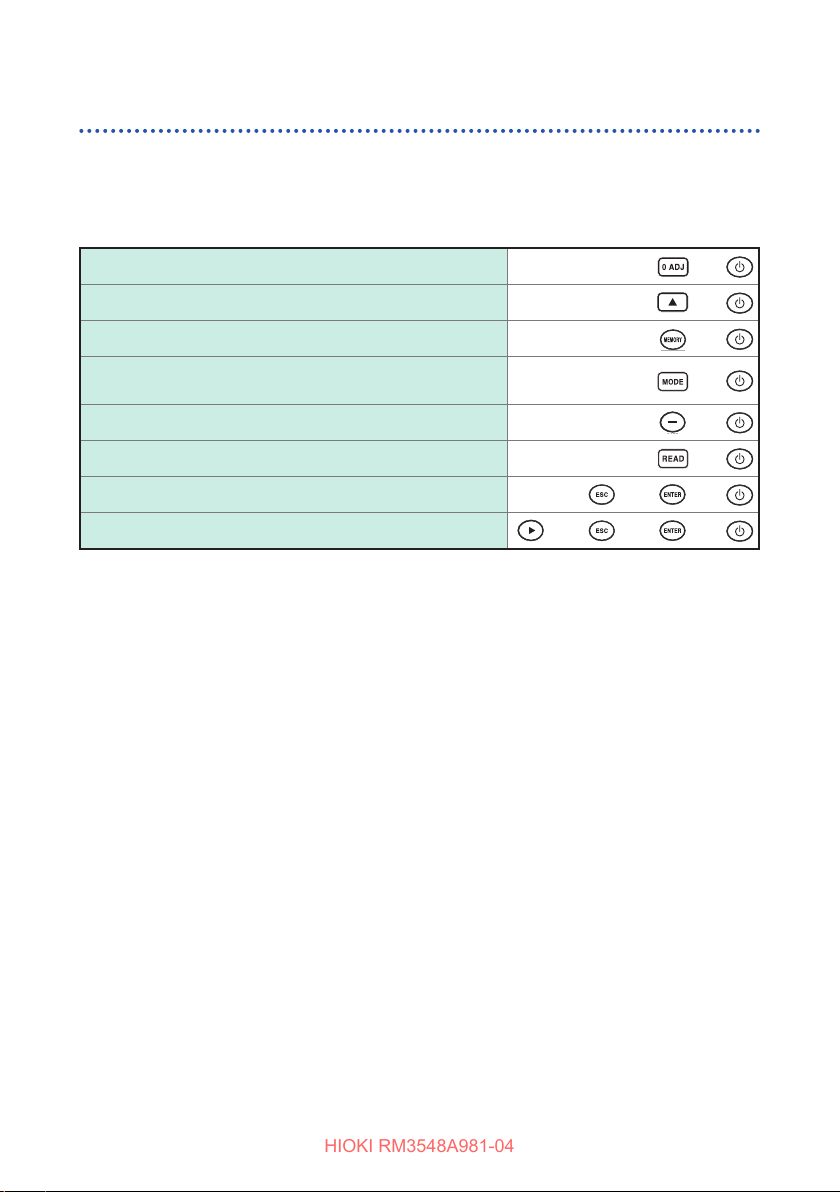

Power-on settings

To perform one of the following settings, it is necessary to turn the power from off to

on while holding-down a particular key.

For details, see the indicated page.

Clearing zero adjustment (p. 48)

Switching to a different measurement current (p. 55)

Disabling auto power save (APS) (p. 33)

Changing the decimal point character or delimiter

character for a CSV le (p. 88)

Setting the date and time (p. 90)

Clearing all measurement data saved (p. 85)

Resetting the current measurement conditions (p. 91)

Resetting the system (p. 91)

+

+

+

+

+

+

+ +

+ + +

20

Page 29

1.3 Flow of Measurement

HIOKI RM3548A981-04

Flow of Measurement

Before using the instrument, be sure to see “Usage Notes” (p. 7).

Preparing for measurement

Attach the strap. (p. 28)

1

Load or replace the batteries. (

2

Connect the test leads. (p. 30)

3

Connect a Z2002 Temperature

4

Sensor. (p. 31)

p. 29

Measurement

1

)

2

3

4

Turn the power on and congure

settings.* (p. 32)

Connect the test leads to the

measurement target. (p. 38)

Clipping a thin wire (with

the edge portion of the

jaws)

Clipping a thick wire

(with the base, nonserrated portion of the

jaws)

Read the measured value. (p. 39)

Remove the test leads from the

measurement target and turn the

power off. (p. 32)

1

2

3

4

5

6

7

8

9

* In the following cases, perform zero adjustment:

The display is not cleared due to thermal EMF or other factors. → The display will be changed

to zero.

(Accuracy is not affected by whether or not the zero adjustment is performed.)

Thermal EMF can also be canceled by using OVC. (p. 51)

Four-terminal connection (called Kelvin connection) is difcult.

→ The residual resistance of the two-terminal connection wires will be canceled.

For zero adjustment procedures, see (p. Appx.11).

10

Appx. Ind.

21

Page 30

Screen Layout

HIOKI RM3548A981-04

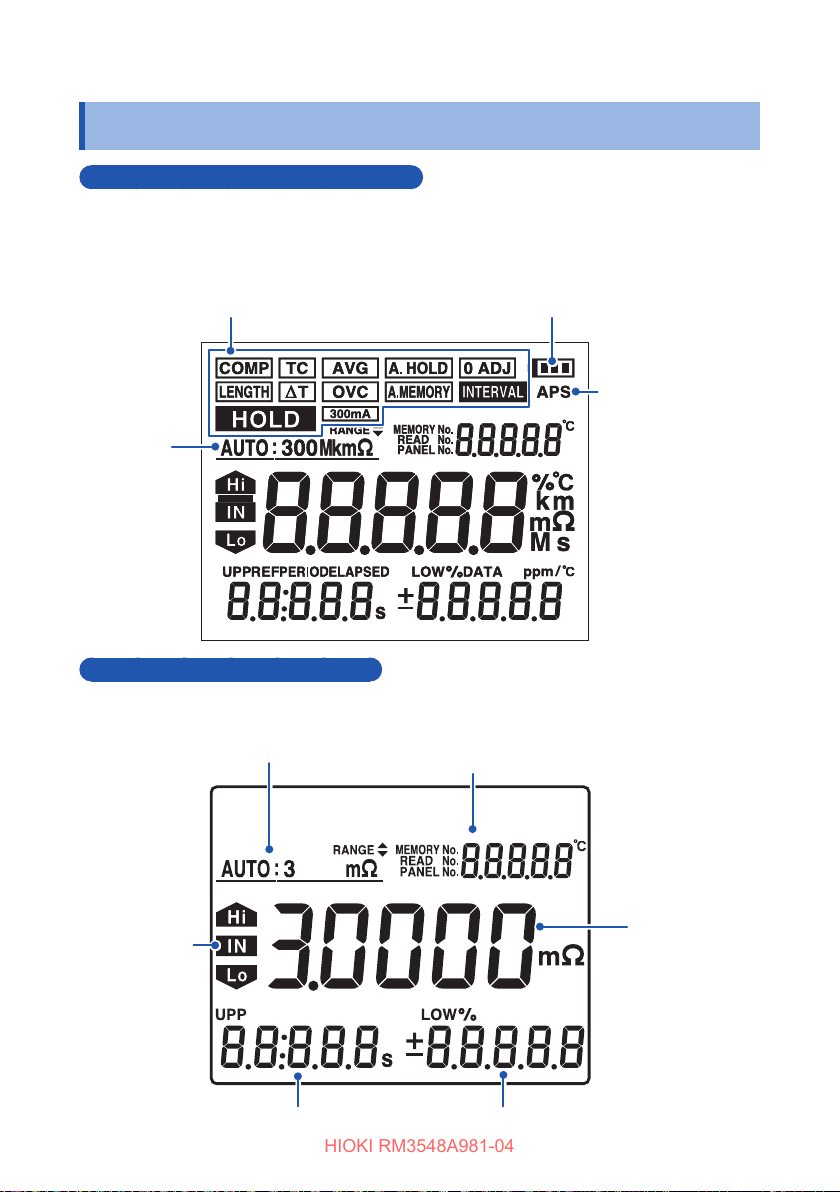

1.4 Screen Layout

Display (when the entire display is lit)

Displays measurement conditions, settings, measured values, memory numbers

(MEMORY No.), panel numbers, comparator settings, judgment results, etc. For

information on the error display, see “Error display and actions” (p. 114).

Remaining battery

Indicators (p. 24)

Range

indicator

indicator (p. 10)

APS indicator

(p. 33)

Resistance measurement screen

Comparator

judgment

result

(p. 60)

22

Range (p. 36)

Using the [VIEW] key to switch the indicator

display (p. 39)

(Temperature, no indicator, memory number

(MEMORY No.))

Measured

value (p. 39)

Comparator lower limit (p. 60)Comparator upper limit (p. 60)

Page 31

Screen Layout

HIOKI RM3548A981-04

Length conversion measurement screen (p. 69)

Interval measurement screen (p. 79)

(The screen shows when ∆T is ON.)

Non-measured value display (see “Verifying measurement errors” (p. 40) for

details)

Out-of-range Current fault

Temperature conversion (∆T) measurement screen (p. 67)

Memory No.

Elapsed time

1

2

3

4

5

6

7

The protection function is working Fuse blown out

8

9

10

Appx. Ind.

23

Page 32

Screen Layout

HIOKI RM3548A981-04

Indicator Description See

Lit: The comparator function is enabled.

Blinking: The processing of the key pressed cannot be performed

because the comparator function is enabled.

Lit: The length conversion function is enabled.

Blinking: The processing of the key pressed cannot be performed

because the length conversion function is enabled.

The temperature correction function is enabled. (p. 50)

Lit: The temperature conversion function is enabled.

Blinking: The processing of the key pressed cannot be performed

because the temperature conversion function is enabled.

The measured value averaging function is enabled. (p. 49)

The OVC function is enabled. (p. 51)

The auto-hold function is enabled. (p. 42)

The auto-memory function is enabled. (p. 78)

Lit: The zero adjustment function is enabled.

Blinking: Zero adjustment is in progress.

Lit: The interval measurement function is enabled.

Blinking: The processing of the key pressed cannot be performed

because interval measurement is being performed or the

interval measurement function is enabled.

The measurement current is set to Hi (300 mA) at the 300mΩ range. (p. 55)

The measured value is being held. (p. 42)

(p. 62)

(p. 69)

(p. 67)

(p. 44)

(p. 79)

24

The comparator judgment result shows “measured value > upper limit”.

The comparator judgment result shows “lower limit ≤ measured

value ≤ upper limit”.

The comparator judgment result shows “measured value < lower limit”.

The range can be changed.

The auto range function is enabled.

Comparator upper limit value

Comparator lower limit value

Comparator reference value

Comparator allowable range

Retainable period of time (when in interval mode)

Measurement elapsed time (when in interval mode)

Number of data items that can be retained (p. 76)

Temperature coefcient for temperature correction (when

temperature correction is enabled)

(p. 60)

(p. 36)

(p. 60)

(p. 79)

(p. 50)

Page 33

Checking the Measurement Target

HIOKI RM3548A981-04

1.5 Checking the Measurement Target

To carry out proper resistance measurement, change the measurement conditions

appropriately according to the measurement target. Before starting measurement,

use the examples recommended in the following table to congure the instrument.

Recommended settings

(Bold indicates a change from the factory default.)

Measurement target

Motor, solenoid,

choke coil, transformer, wiring

harness

For power

Contact, wiring harness,

connector, relay contact, switch

Conductive coating material,

conductive rubber

General resistance

measurement

Fuse, resistor, heater, wiring,

welding

Temperature

correction (p. 50)/

Temperature

conversion (p. 67)

TC

*1

-

*1

OVC

(p. 51)

OFF Lo

ON

OFF Lo

ON

Measurement current at

300mΩ range (p. 55)

Lo

Lo

1

2

3

4

5

6

7

8

Temperature rise test

(Motor, choke coil, transformer)

Automobile ground wire *1

For signal

Contact, wiring harness,

connector, relay contact, switch

2

∆T*

If the instrument is used to measure the resistance of a signal

contact, the contact status will be changed, because its opencircuit voltage and measurement current are both high.

To measure a signal contact, use the RM3545.

OFF Lo

ON Hi (300mA)

9

10

Appx. Ind.

25

Page 34

Checking the Measurement Target

HIOKI RM3548A981-04

*1

When the measurement target signicantly depends on temperature, use the temperature

correction function.

*2

The interval measurement function allows you to save a measured value every xed interval.

(p. 79)

IMPORTANT

If a measurement fails with the PrSEt (preset) delay setting, set a long enough

delay time. (p. 53)

26

Page 35

2

HIOKI RM3548A981-04

Preparing for Measurement

Before using the instrument, be sure to see “Usage Notes” (p. 7).

Attaching the strap (p. 28)

Loading or replacing the batteries (p. 29)

Connecting the test leads (p. 30)

Connecting a Z2002 Temperature Sensor (p. 31)

Inspecting the instrument (p. 34)

Turning the power on (p. 32)

Measurement

Turning the power off (p. 32)

* If the instrument is not operated for a while, it will turn off automatically. (APS

function) (p. 33)

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

27

Page 36

Attaching the Strap

HIOKI RM3548A981-04

2.1 Attaching the Strap

Attaching the strap to the instrument allows you to use it with the strap around your

neck. Follow the procedure below to attach the strap.

Attaching the strap

28

Page 37

Loading or Replacing the Batteries

HIOKI RM3548A981-04

2.2 Loading or Replacing the Batteries

Before using the instrument for the rst time, load the eight alkaline batteries (LR6).

Before measurement, check that the instrument has sufcient remaining battery

power. If the remaining battery level is low, replace the batteries. See the battery

indicator to check the remaining battery level. (p. 10)

Preparations

• Alkaline battery (LR6) × 8

Remove the test leads.

2

Remove the battery cover on

3

the back of the instrument.

Turn the power off.

1

(Press the [POWER] key to turn the entire

display off.)

Load eight batteries (LR6).

4

(Be careful of their polarity.)

1

2

3

4

5

6

7

8

Reattach the battery

5

cover on the back of the

instrument.

9

10

Appx. Ind.

29

Page 38

Connecting the Test Leads

HIOKI RM3548A981-04

2.3 Connecting the Test Leads

Use the included L2107 Clip Type Leads or select from our wide range of optional

test leads. For more information on the lead options, see “Options” (p. 3).

Test leads

(Example: L2107 Clip Type Leads)

The V mark indicates a

SENSE lead.

SENSE

SOURCE

SOURCE

SENSE

Red

Orange

Blue

Black

Red

SENSE

SOURCE

SENSE

SOURCE

Black

To clip a thin wire

(Use the edge portion of the jaws.)

Connect the test leads to the instrument.

Connect the four terminals: SOURCE (A and B) and SENSE (A and B).

30

To clip a thick wire

(Use the base, non-serrated portion of the jaws.)

Black Red

SOURCE

SENSE

RedBlack

Page 39

Connecting the Z2002 Temperature Sensor (When Using TC or ΔT)

HIOKI RM3548A981-04

2.4 Connecting the Z2002 Temperature Sensor (When Using TC or ΔT)

Connect the Z2002 Temperature Sensor to the TEMP.SENSOR terminal.

1

Connection method

Fully insert the jack.

2

TEMP.SENSOR terminal

3

4

5

6

7

8

9

10

Appx. Ind.

31

Page 40

Turning the Power On/Off

HIOKI RM3548A981-04

2.5 Turning the Power On/Off

Turning the power on

Press the [POWER] key to turn the power on. Hold the key down until the entire

display turns on.

Entire display lit

A self-test is started.

The model name and version

number are displayed during

the self-test.

If an error occurs during the self-test

[POWER] key

Measurement screen

Turning the power off

Press the [POWER] key to turn the power off. Hold the key down until the entire

display turns off.

Entire display off

IMPORTANT

When the instrument is turned on again, it starts up with the previous state used

immediately before turning it off.

32

The error is

displayed. (p. 114)

[POWER] key

Page 41

Turning the Power On/Off

HIOKI RM3548A981-04

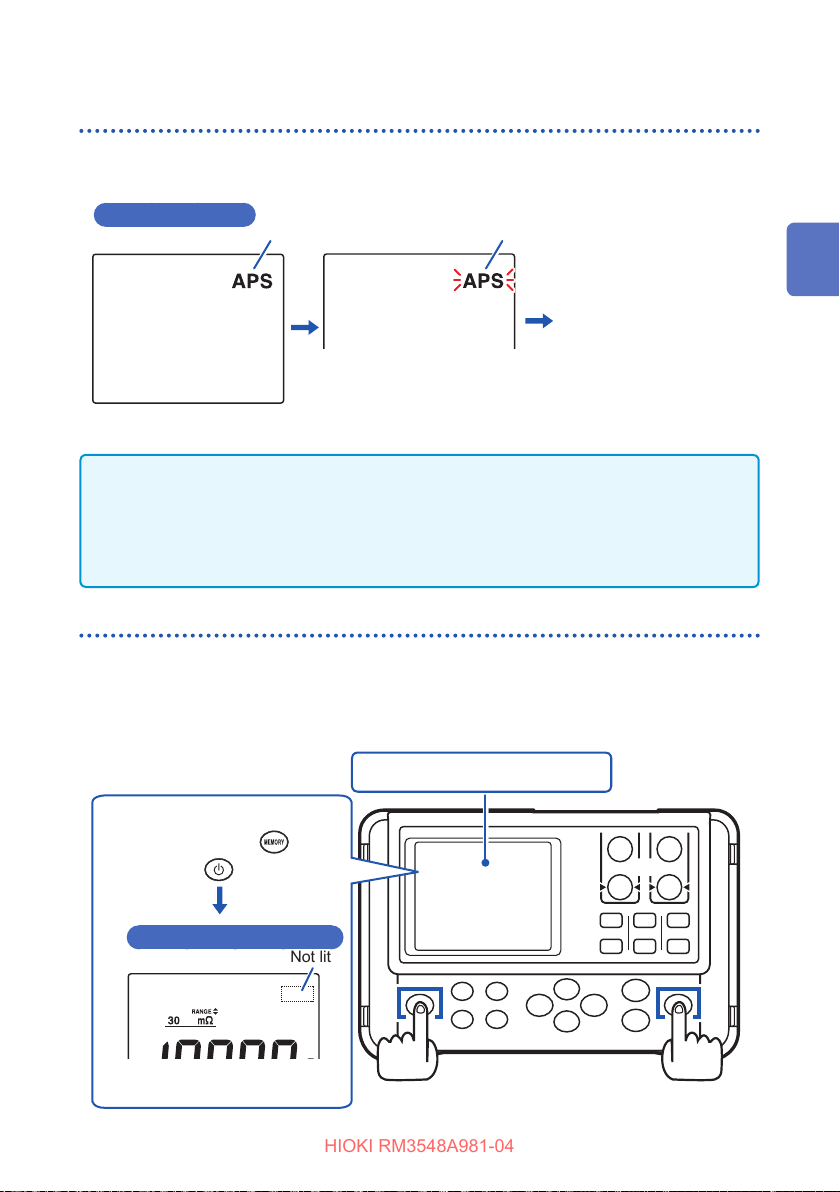

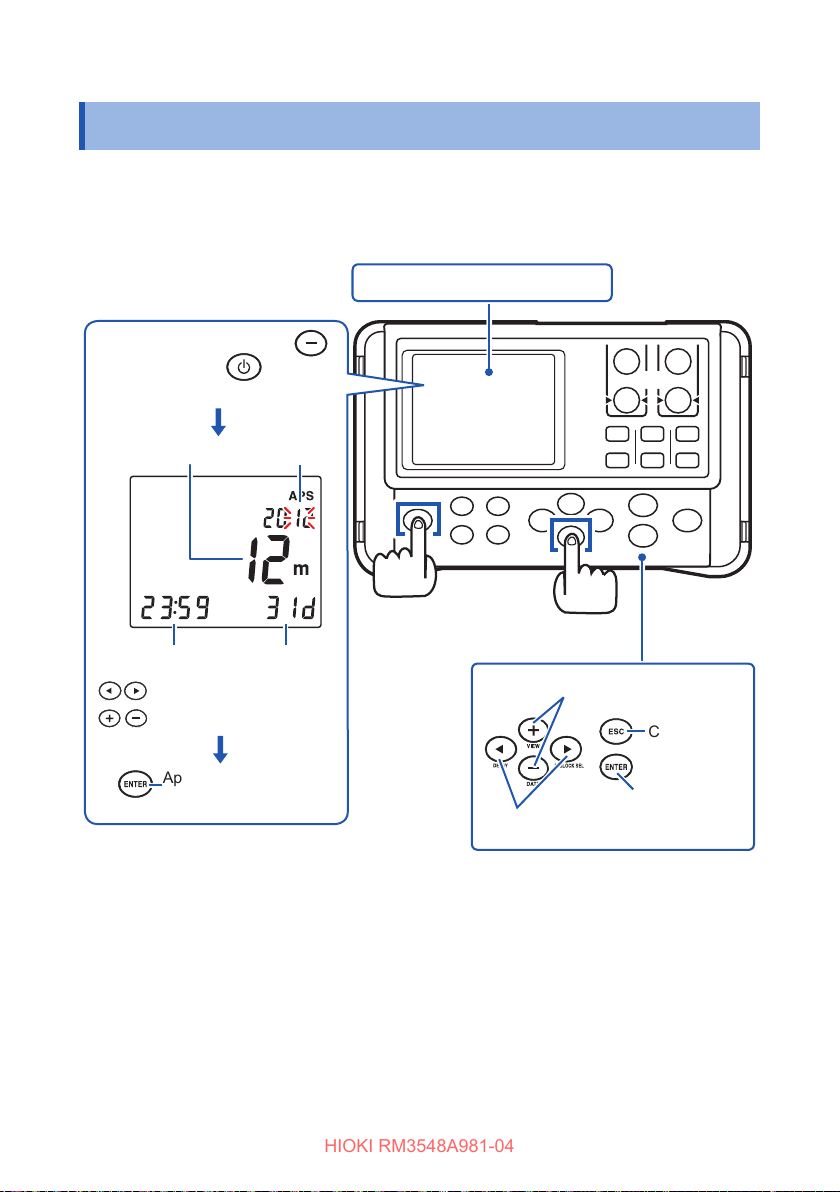

Automatic power off with auto power save (APS)

When the instrument is not being used, the APS function automatically turns it off to

reduce battery consumption.

APS function ON

IMPORTANT

• During an interval measurement, the APS function automatically turns OFF.

When the interval measurement ends, the APS function automatically turns ON.

• When the USB is connected, the APS function automatically turns OFF. When

the USB is disconnected, the APS function automatically turns ON.

Lit Blinking

If no key is operated for 10 minutes

or the instrument is in a measurement

error state continuously, the APS

indicator starts blinking.

Then, when a specic

time elapses after the start

of blinking, the instrument

automatically turns off.

1

2

3

4

5

Disabling auto power save (APS)

To disable the APS function, press the [POWER] key while holding the [MEMORY]

key down when the power is off.

The setting of the APS function is not saved. When the instrument is turned on again,

the APS function is enabled again.

When the power is off, while

2

holding down the

press the

The APS function is OFF

3

(The power is on and the

APS indicator turns off.)

key.

key,

Not lit

Turn the power off (if it is on).

1

[POWER] key

6

7

8

9

10

Appx. Ind.

[MEMORY] key

33

Page 42

Pre-measurement Inspection

HIOKI RM3548A981-04

2.6 Pre-measurement Inspection

Before using the instrument, inspect it to verify that no damage has occurred during

storage or transportation and it operates normally. If you nd any damage, contact

your authorized Hioki distributor or reseller.

Instrument and peripheral checking

Inspection item Action

Is there any damage or a crack in the

instrument? Are the internal circuits exposed?

Is there any dust or contamination, such as

pieces of metal, on any terminals?

Is the test lead coating broken or is the metal

exposed?

Power-on checking

Inspection item Action

Is the remaining battery power sufcient? The

Is anything missing from the screen? Turn the power on to make sure that the entire

When you turn the power on, does the entire

display turn on and then the model name and

a measurement screen appear on the screen?

If any damage is found, do not use it. Return it

for repair.

If dust or contamination is adhered to a

terminal, clean the terminal with a swab or the

like.

If the coating of a test lead is broken, the

measured value may become unstable or

have an error.

Replace the damaged test lead.

indicator at the upper right of the

display indicates the current status. If the

indicator changes to , the remaining

battery level is low. Replace the batteries as

early as possible. If the battery level becomes

too low to continue with measurement, the

starts blinking. Replace the batteries.

display turns on. (p. 22)

If there is anything missing, return the

instrument for repair.

If the screen does not behave like this, the

instrument may be damaged internally. Return

it for repair.

See: “10.1 Troubleshooting” (p. 108)

“Error display and actions” (p. 114)

34

Page 43

3

HIOKI RM3548A981-04

Basic Measurement

Before measurement, be sure to see “Measurement precautions” (p. 12).

This chapter describes the basic operations for using the instrument.

• “3.1 Setting the Measurement Range” (p. 36)

• “3.2 Connecting the Test Leads to the Measurement Target” (p. 38)

• “3.3 Reading the Measured Value” (p. 39)

For information on how to customize measurement conditions, see “Customizing

Measurement Conditions” (p. 43).

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

35

Page 44

Setting the Measurement Range

HIOKI RM3548A981-04

3.1 Setting the Measurement Range

Select a measurement range. Automatic range selection (the auto range) is also

available.

IMPORTANT

When the auto range is used or the measurement range is set to 30mΩ or less, a

maximum current of 1 A may constantly ow through the measurement target, and

a maximum power of approximately 2 W may be applied*.

If there are any of the following concerns, depending on the level of the

measurement current, select a range using a lower measurement current.

• The measurement target may melt (such as a fuse or inator).

• The measurement target may heat up, causing a change in resistance.

• The measurement target may be magnetized, causing a change in inductance.

Within each of the measurement ranges, the power for the measurement target can

be expressed by “resistance × (measurement current)

is deviated, the power may reach the value of “open-circuit voltage × measurement

current” at maximum.

Before connecting the measurement target, be sure to check the measurement

range.

* At the moment of connecting the measurement target, a maximum inrush current

of 5 A ows.

(Convergence time: Approximately 1 ms for pure resistance)

2

”. If the measurement range

Using the manual range

3mΩ ↔ 30mΩ ↔ 300mΩ ↔ 3Ω ↔ 30Ω ↔ 300Ω ↔ 3kΩ ↔ 30kΩ ↔ 300kΩ ↔ 3M

36

Ω

[][] key

Page 45

Setting the Measurement Range

HIOKI RM3548A981-04

Using the auto range

Use the [AUTO] key to switch to the auto range. (The default setting is AUTO.)

When the instrument is in the auto range mode, AUTO is lit.

(The auto range)

AUTO lit

1

2

3

[AUTO] key

Toggles the auto

range ON and OFF.

(The manual range)

Not lit

IMPORTANT

• When the range is manually changed in the auto range mode, the auto range is

automatically disabled and the manual range is enabled.

• If the comparator function is turned ON, the range is xed and cannot be

changed. To change the range, turn the comparator function OFF or change the

range in the comparator setting.

• Depending on the measurement target, the auto range may become unstable. In

such a case, specify the range manually or increase the delay time. (p. 53)

For the measurement accuracy of each range, see “(1) Resistance measurement

accuracy” (p. 93).

4

5

6

7

8

9

10

Appx. Ind.

37

Page 46

Connecting the Test Leads to the Measurement Target

HIOKI RM3548A981-04

3.2 Connecting the Test Leads to the Measurement Target

Example: Using the L2107

Example: Using the 9772

Example: Using the 9453

The SENSE terminals should be located inside the SOURCE terminals.

38

(Press)

SOURCE A SOURCE B

SENSE A SENSE B

Page 47

3.3 Reading the Measured Value

HIOKI RM3548A981-04

Reading the Measured Value

The instrument displays a resistance value.

If a non-resistance value is displayed, see “Verifying measurement errors” (p. 40).

To convert the measured resistance value, see the following pages:

• “5.2 Performing Temperature Rise Test (Temperature Conversion Function (∆T))”

(p. 67)

• “5.3 Measuring the Length of a Conductor (Length Conversion Function)” (p. 69)

IMPORTANT

If the measured value has a negative sign (-), check the following:

• The SOURCE and SENSE lead connections are reversed.

→ Connect the leads correctly.

• After zero adjustment for a two-terminal measurement, the contact resistance

has decreased.

→ Perform zero adjustment again.

Switching the display

Press and hold the [+] (VIEW) key to switch the type of information displayed on the

upper right of the screen. (Temperature, no indicator, memory number (MEMORY

No.))

The type of information displayed during measurements can be selected.

Temperature → no indicator → memory number (MEMORY No.)

1

2

3

4

5

6

7

8

Press the [+] (VIEW) key to display a selection screen.

Press and hold

9

10

Appx. Ind.

39

Page 48

Reading the Measured Value

HIOKI RM3548A981-04

Verifying measurement errors

If a measurement is not performed correctly, the measurement error is displayed on

the screen.

Out-of-range*

Current fault or not measured yet

The protection function is working

Fuse blown out

1

Indicates that the measurement or display range has been

exceeded.

If oF is displayed, the comparator judgment is “Hi”, and if -oF is

displayed, the comparator judgment is “Lo”.

In the same manner, oF is displayed when the temperature

exceeds the measurement range during temperature

measurement.

This screen is displayed in the following two cases.

If “-----” is displayed, comparator judgment is not performed.

1. Measurement current fault*

Current cannot be supplied to the SOURCE A or SOURCE B

terminals.

2. No measurement has been performed after changing a

measurement condition.

If an overvoltage is applied to a measurement terminal, the

function for protecting the internal circuitry is activated in this

instrument. If an overvoltage is accidentally applied, remove the

test leads from the measurement target immediately. Measurement

cannot be performed while the protection function is activated. In

order to cancel the protection function, contact test lead A (red) to

B (black) or turn the power off and on.

2

Z2002 Temperature Sensor not connected

40

Each SOURCE terminal of the instrument is equipped with a

fuse to protect against overvoltage input. If an overvoltage is

accidentally applied and a fuse is blown, replace the fuse. (p. 116)

Temperature cannot be measured as the Z2002 Temperature

Sensor is not connected. When TC or ∆T is not used, it is not

necessary to connect the Z2002 Temperature Sensor. If the

temperature is not to be displayed, switch the display by pressing

the [+] (VIEW) key.

Page 49

Temperature calculation error

HIOKI RM3548A981-04

Reading the Measured Value

The Z2002 Temperature Sensor is not connected even when TC

or ∆T is ON, or oF is displayed for the temperature. Check the

connection of the Z2002 Temperature Sensor.

IMPORTANT

If the measurement target is connected to the SOURCE terminal, but a SENSE

terminal has a bad contact, the displayed measured value may be unstable.

*1 Out-of-range detection function

Examples detected as out-of-range

Out-of-range detection Measurement examples

The measurement range is exceeded. 40m

The relative display (% display) of a

measured value exceeds the display

range (999.99%).

The A/D converter input range is

exceeded during a measurement.

The calculation result cannot be

displayed.

*2 Current fault detection function

Current fault examples

• The SOURCE A or SOURCE B probe is open.

• The measurement target has a broken wire (open-circuit work).

• The SOURCE A or SOURCE B wiring has a broken wire or a bad connection.

is measured in the 30mΩ range.

Ω

(+2400%) is measured with a reference value of

500

Ω

20Ω.

Such an error occurs, for example, if a high resistance

is measured in an environment with external noise.

The calculation result for the length conversion

function exceeds 999.99 km.

1

2

3

4

5

6

7

8

IMPORTANT

A wiring resistance exceeding the following value in each range causes a current

fault, making the measurement impossible. In the 1 A measurement current range,

reduce the resistance of the wiring and contact between the measurement target

and test leads.

Range [Ω] 3m 30m 300m 3 30 300 3k 30k to 3M

Wiring and contact

resistance [

The values listed above, which is for reference, indicate resistance values between the

SOURCE B and SOURCE A, not including the measurement target.

9

10

Appx. Ind.

]

Ω

0.5 10 100 2k 800 2k

41

Page 50

Reading the Measured Value

HIOKI RM3548A981-04

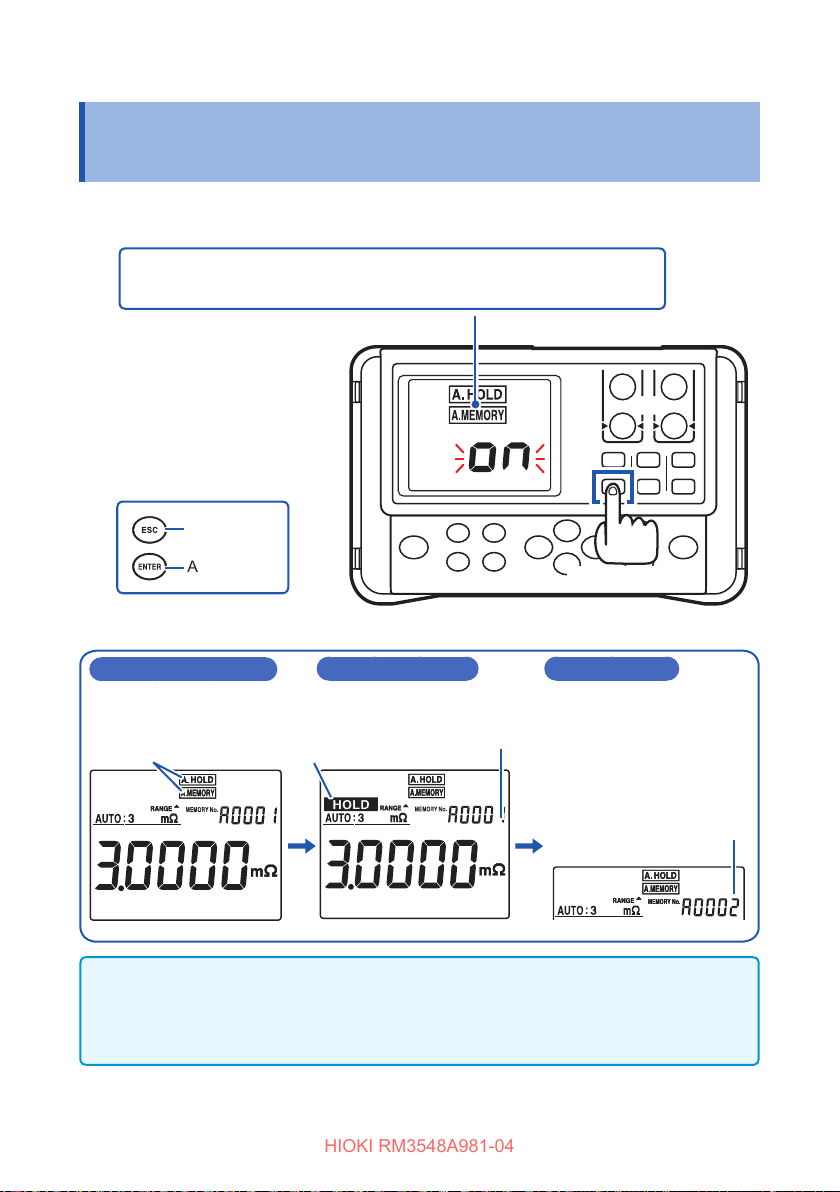

Holding a measured value

The auto-hold function helps to verify a measured value. When the measured value

becomes stable, the value is automatically held.

1

oFF → Auto-hold (A.HOLD) → Auto-memory (A.HOLD, A.MEMORY)

→ Interval (INTERVAL) → oFF

2

3

Release the test leads from the measurement target and contact the leads to the target again.

The HOLD is released. You can also release the HOLD by changing the range or pressing the

[ESC] key.

Cancel

Apply

During measurement (during release from HOLD)

Not lit

During HOLD

Lit

[MODE] key

Memorizing a measured value

The memory function helps to verify a measured value later.

It saves the displayed measured value.

[MEMORY] key

For more details about the memory function, see “7.1 Saving Data at Specied Time

(Manual Memory)” (p. 77).

42

Page 51

Customizing Measurement

HIOKI RM3548A981-04

4

Conditions

Before measurement, be sure to see “Measurement precautions” (p. 12).

1

This chapter describes the functions useful to perform more sophisticated and

accurate measurement.

• “4.1 Using Zero Adjustment” (p. 44)

• “4.2 Stabilizing Measured Values (Averaging Function)” (p. 49)

• “4.3 Compensating for Thermal Effects (Temperature Correction (TC))” (p. 50)

• “4.4 Compensating for Thermal EMF Offset (Offset Voltage Compensation

Function: OVC Function)” (p. 51)

• “4.5 Setting the Delay Time for Measurement (Delay Function)” (p. 53)

• “4.6 Switching the Measurement Current (In the 300m

Range)” (p. 55)

Ω

2

3

4

5

6

7

8

9

10

Appx. Ind.

43

Page 52

Using Zero Adjustment

HIOKI RM3548A981-04

4.1 Using Zero Adjustment

In the following cases, perform zero adjustment:

(A resistance of up to ±3%f.s. can be canceled for any range.)

• The measurement value is not cleared due to thermal EMF or other factors.

→ The measurement value will be changed to zero.

Accuracy is not affected by whether or not the zero adjustment is performed.

The thermal EMF can also be canceled by using OVC. (p. 51)

• Four-terminal connection (called Kelvin connection) is difcult.

→ The residual resistance of the two-terminal connection wires will be canceled.

(p. Appx.24)

For instructions on how to perform zero adjustment correctly, see “Appx. 7 Zero

Adjustment” (p. Appx.11).

Before zero adjustment

IMPORTANT

• When the ambient temperature changes or the test leads are replaced after zero

adjustment, perform zero adjustment again. If zero adjustment is difcult because

the Pin Type Lead 9465-10, 9772, or the like is used, use the standard Clip Type

Lead L2107 to perform zero adjustment and then replace the lead with the Pin

Type Lead.

• Perform zero adjustment for each range used. In the manual range mode, only

the current range is adjusted to zero. In the auto range mode, all ranges are

adjusted to zero.

• Zero adjustment values are held internally even if the instrument is power off, but

they are not saved in the panel.

• When the offset voltage compensation (OVC) function is turned from ON to OFF

or from OFF to ON, the zero adjustment is cleared. Perform zero adjustment

again.

• When the measurement current is changed from Lo to Hi or from Hi to Lo, the

zero adjustment is cleared. Perform zero adjustment again.

• When a lower resistance is measured after zero adjustment, the measured value

will be negative.

Example: 2m

is connected in the 300mΩ range and then zero adjustment is

Ω

performed.

→If 1m

is measured, -1mΩ is displayed.

Ω

44

Page 53

Performing zero adjustment

HIOKI RM3548A981-04

Short the test leads.

1

L2107

Using Zero Adjustment

1

Correct

Align the V symbols on the clips.

SENSE

SOURCE

Red Black

9453 (Option)

9465 (Option)

Incorrect

SENSE

SOURCE

Connect Connect

Perform zero adjustment while the alligator clips are

located outside and the lead bar is located inside.

SENSE

SOURCE SENSE

Red Black

SOURCE-BSENSE-A SENSE-B SOURCE-A

Contact to SENSE terminal

2

SOURCE

3

4

5

6

7

8

9454 Zero Adjustment Board (Option)

9772 (Option)

Contact to SENSE terminal

Contact to SOURCE terminal

9454 Zero Adjustment Board

(Option)

Contact to SOURCE terminal

For the pin on the

SENSE side, a line is

attached to the base

section.

Line

When performing zero

adjustment, be sure

that this line faces the

same direction on all of

the pins.

9

10

Appx. Ind.

45

Page 54

Using Zero Adjustment

HIOKI RM3548A981-04

Conrm that the measured value is within ±3%f.s.

2

If no measured value is displayed, make sure that the test leads are connected

correctly.

If the connection is correct If the connection is wrong

Press and hold the [0 ADJ] key to perform zero adjustment.

3

If it is difcult to press the key as the Zero Adjustment Board is used, press

the [0 ADJ] key before shorting the measurement lead. Zero adjustment is

automatically performed after the measured value is stabilized.

(Zero adjustment in

progress)

Blinking

[0 ADJ] key

Press and hold

46

Page 55

After zero adjustment

HIOKI RM3548A981-04

4

Zero adjustment has succeeded

The buzzer sounds and the

measurement screen appears.

Indicator ON Indicator OFF

Zero adjustment has failed

The buzzer sounds and [FAIL] appears.

Then, the measurement screen appears.

Using Zero Adjustment

1

2

3

Zero adjustment failed

When zero adjustment cannot be performed, the measured value before zero

adjustment already exceeds ±3% of the full scale of each range or the instrument is in

a measurement error state. Perform zero adjustment with the correct wire connection

again. If the resistance is too high (e.g., due to a self-made cable), zero adjustment

cannot be performed. In such a case, try to minimize the wiring resistance. (p. 41)

IMPORTANT

• If zero adjustment fails in the auto range mode, the zero adjustment is cleared for

all ranges.

• If zero adjustment fails in the manual range mode, the zero adjustment is cleared

for the current range.

4

5

6

7

8

9

10

Appx. Ind.

47

Page 56

Using Zero Adjustment

HIOKI RM3548A981-04

Clearing zero adjustment

When the power is off, while holding the [0 ADJ] key, press the [POWER] key to

clear the zero adjustment for all ranges.

Turn the power off (if it is on).

[POWER] key

[0 ADJ] key

48

Page 57

Stabilizing Measured Values (Averaging Function)

HIOKI RM3548A981-04

4.2 Stabilizing Measured Values (Averaging

Function)

This function averages the measurement values in order to display a single value. It

helps to stabilize uctuations in the measured values.

oFF (factory default) → 2 → 5 → 10 → 20

1

2

3

4

5

6

The averaging frequency can also be changed with .

Changes the

averaging frequency.

([AVG] key)

Cancel

Apply

7

8

9

10

Appx. Ind.

49

Page 58

Compensating for Thermal Effects (Temperature Correction (TC))

HIOKI RM3548A981-04

4.3 Compensating for Thermal Effects (Temperature Correction (TC))

This function converts a measured resistance value, based on the reference

temperature, to display the converted value. For the principles of temperature

correction, see “Appx. 4 Temperature Correction Function (TC)” (p. Appx.4).

To perform temperature correction, connect the Z2002 Temperature Sensor to the

TEMP.SENSOR terminal on the side of the instrument. Before connecting the sensor,

be sure to read “2.4 Connecting the Z2002 Temperature Sensor (When Using TC or

T)” (p. 31).

Δ

oFF (factory default) → TC → ∆T

1

Use the key to select TC.

(Reference temperature setting)

2

Reference

temperature

setting

(Temperature coefcient setting)

3

4

Apply and move to the

measurement screen.

IMPORTANT

If “t.Err” is displayed, the Z2002 Temperature Sensor may not be connected, or oF is

displayed for the temperature. Check the connection of the Z2002 Temperature Sensor.

50

[TC/∆T] key

Changes values.

Cancel

Apply

Moves digits.

Temperature

coefcient setting

Page 59

Compensating for Thermal EMF Offset (Offset Voltage Compensation Function: OVC Function)

HIOKI RM3548A981-04

4.4 Compensating for Thermal EMF Offset (Offset Voltage Compensation Function: OVC Function)

This function automatically compensates for an offset voltage caused by thermal EMF

or an internal offset voltage.

(OVC: Offset Voltage Compensation)

See: “Appx. 6 Effect of Thermoelectromotive Force (Thermal EMF)” (p. Appx.8)

1

2

The function uses the resistance value measured when a measurement current ows,

R

and that measured when no measurement current ows,

P

resistance value

R

-

R

.

P

Z

oFF (factory default) ↔ on

Press and hold

Toggles the OVC function ON/OFF.

([AVG (OVC)] key)

R

, to display the actual

Z

Cancel

Apply

3

4

5

6

7

8

9

10

Appx. Ind.

The OVC function can also be toggled ON/OFF with .

51

Page 60

Compensating for Thermal EMF Offset (Offset Voltage Compensation Function: OVC Function)

HIOKI RM3548A981-04

IMPORTANT

• When the offset voltage compensation function is ON (the OVC indicator is lit),

the measured value will be slow to refresh.

• The OVC function cannot be used in the 3k

automatically turned OFF.

• When the offset voltage compensation function is changed, the zero adjustment

function is cancelled.

• When the measurement target has a high inductance, it is necessary to adjust

the delay time. (p. 53)

Start with a longer delay time than necessary, and decrease the time gradually,

watching the measured value.

• If the measurement target has a low heat capacity, the offset voltage

compensation function may have no effect.

range or higher. The function is

Ω

52

Page 61

Setting the Delay Time for Measurement (Delay Function)

HIOKI RM3548A981-04

4.5 Setting the Delay Time for Measurement (Delay Function)

This function adjusts the time for measurement to stabilize by inserting a waiting

period after use of the OVC or the auto range function to change the measurement

current. When this function is used, the instrument waits for its internal circuitry to

stabilize before starting measurement, even if the measurement target has a high

reactance component.

The PrSEt (preset value) depends on the range used and the offset voltage

compensation function.

Preset OVC delay value (factory default) (Unit: ms)

1

2

3

Measurement

current

Lo

Hi 300m

Range Delay time

3m

to 30m

Ω

300m

30

Ω

to 3

Ω

to 300

Ω

Ω

Ω

Ω

200

50

30

200

4

5

6

7

8

9

10

Appx. Ind.

53

Page 62

Setting the Delay Time for Measurement (Delay Function)

−−=

V

O

IR

n

R

L

t 1l

HIOKI RM3548A981-04

PrSEt (preset) → 10 ms → 30 ms → 50 ms → 100 ms → 300 ms → 500 ms → 1000 ms

Press the [] (DELAY) key to display a selection screen.

The delay time can also be specied with .

Delay time guideline

• If the measurement target, for example, is an inductor that takes longer to stabilize

after applying a measurement current, and it cannot be measured with the initial

delay (preset), adjust the delay. Set the delay time to approximately ten times the

following calculation so that the reactance component (inductance or capacitance)

does not affect the measurement.

• Start with a longer delay time, and decrease the time gradually, watching the

measured value.

• As the delay is longer, the measured value display is slower to refresh.

54

Press and hold

L

: Measurement target inductance

Measurement target resistance + lead wire resistance +

R

:

contact resistance

I

: Measurement current (see: “Accuracy” (p. 94))

V

: Open-circuit voltage (see: “Accuracy” (p. 94))

O

Cancel

Apply

Page 63

Switching the Measurement Current (In the 300mΩ Range)

HIOKI RM3548A981-04

4.6 Switching the Measurement Current (In the

300m

With this instrument, the measurement current for the 300mΩ range can be changed to 300

mA (100 mA at the time of shipment from the factory). This makes it possible to measure large

current wiring under conditions that are similar to the actual usage conditions. It is also useful

when performing measurement in an environment with external noise.*

IMPORTANT

• When the measurement current is set to 300 mA, a larger amount of power is

consumed for the measurement target.

• If highly accurate measurement is required, use a measurement current of 100

mA.

• When the measurement current is changed, the zero adjustment values are

cleared.

Range [Ω] 3m 30m 300m 3 30 300 3k 30k 300k 3M

Measurement

current [A]

Range)

Ω

1

1 300 m 100 m 10 m 1 m 100 µ 5 µ 500 n

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

55

Page 64

Switching the Measurement Current (In the 300mΩ Range)

HIOKI RM3548A981-04

Turn the power off (if it is on).

1

Make sure that the power

2

is off, and holding down the

, press the key.

When Lo is selected

3

(100 mA)

Not lit

[POWER] key

[] key

Use the or keys

to toggle.

When Hi is selected

(300 mA)

4

Apply and move to the

measurement screen.

Blinking

Cancel and move to the

measurement screen.

Apply and move to the

measurement screen.

When measurement is performed with the 300 mA measurement current, the 300 mA

indicator lights up.

56

Page 65

Switching the Measurement Current (In the 300mΩ Range)

HIOKI RM3548A981-04

*1 When measuring resistance for connection sections (e.g., connector contact,

welded section, caulked section, screw-secured section) through which large

current ows, such as power supply cables and ground cables, it is desirable that

measurement be performed using the maximum current, as far as possible, that can

actually ow through those sections. The following explains the reasons:

• Even in a connection completely free from abnormality, a relatively high resistance

may be indicated at a lower measurement current.

This is due to an oxide lm that is generated around the contact while it is not used.

• Even when it is judged that no abnormality is found using a small current, the

connection sections are occasionally melted when a large current ows.

This problem occurs due to the Joule heat generated by a large current when a

high resistance area is created locally.

1

2

3

4

5

6

7

8

9

10

Appx. Ind.

57

Page 66

Switching the Measurement Current (In the 300mΩ Range)

HIOKI RM3548A981-04

58

Page 67

Judgment and Conversion

HIOKI RM3548A981-04

5

Functions

This chapter describes the measured value judgment and conversion functions.

1

“5.1 Judging Measured Values (Comparator Function)” (p. 60)

“5.2 Performing Temperature Rise Test (Temperature Conversion Function (∆T))”

(p. 67)

“5.3 Measuring the Length of a Conductor (Length Conversion Function)” (p. 69)

2

3

4

5

6

7

8

9

10

Appx. Ind.

59

Page 68

Judging Measured Values (Comparator Function)

HIOKI RM3548A981-04

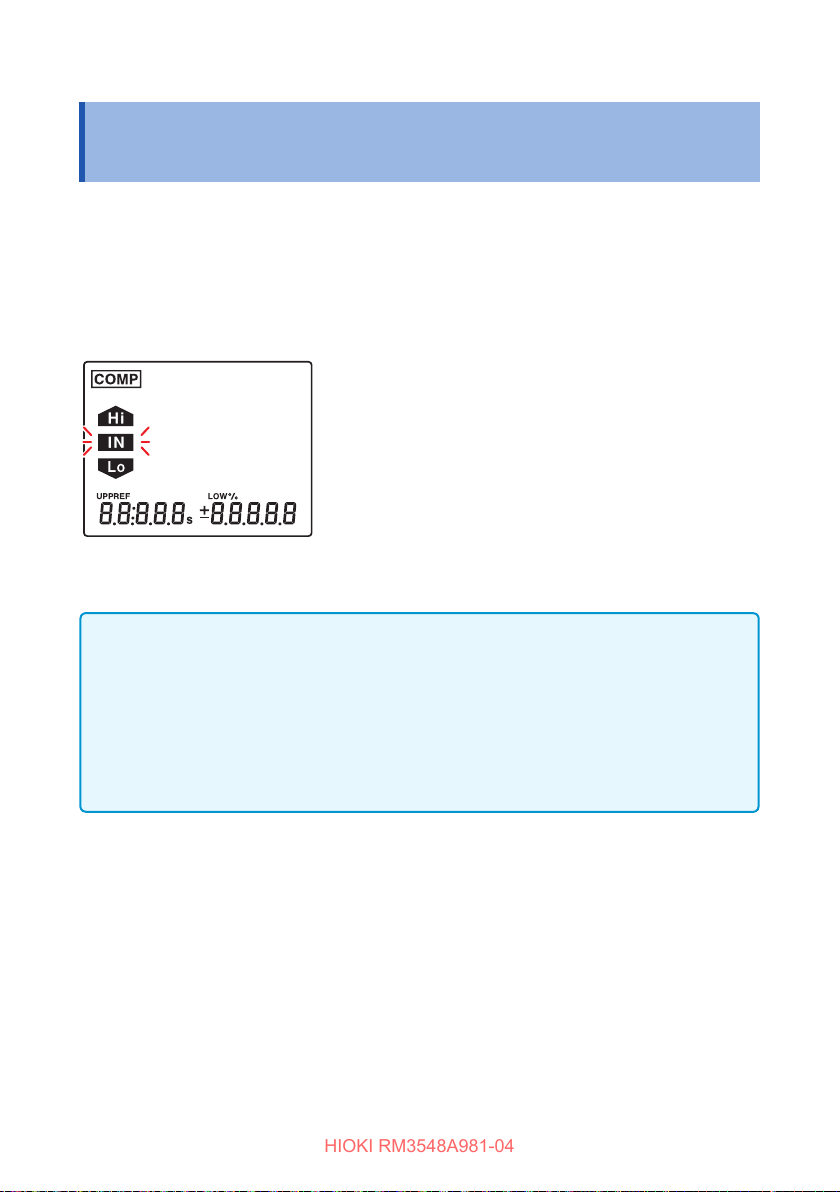

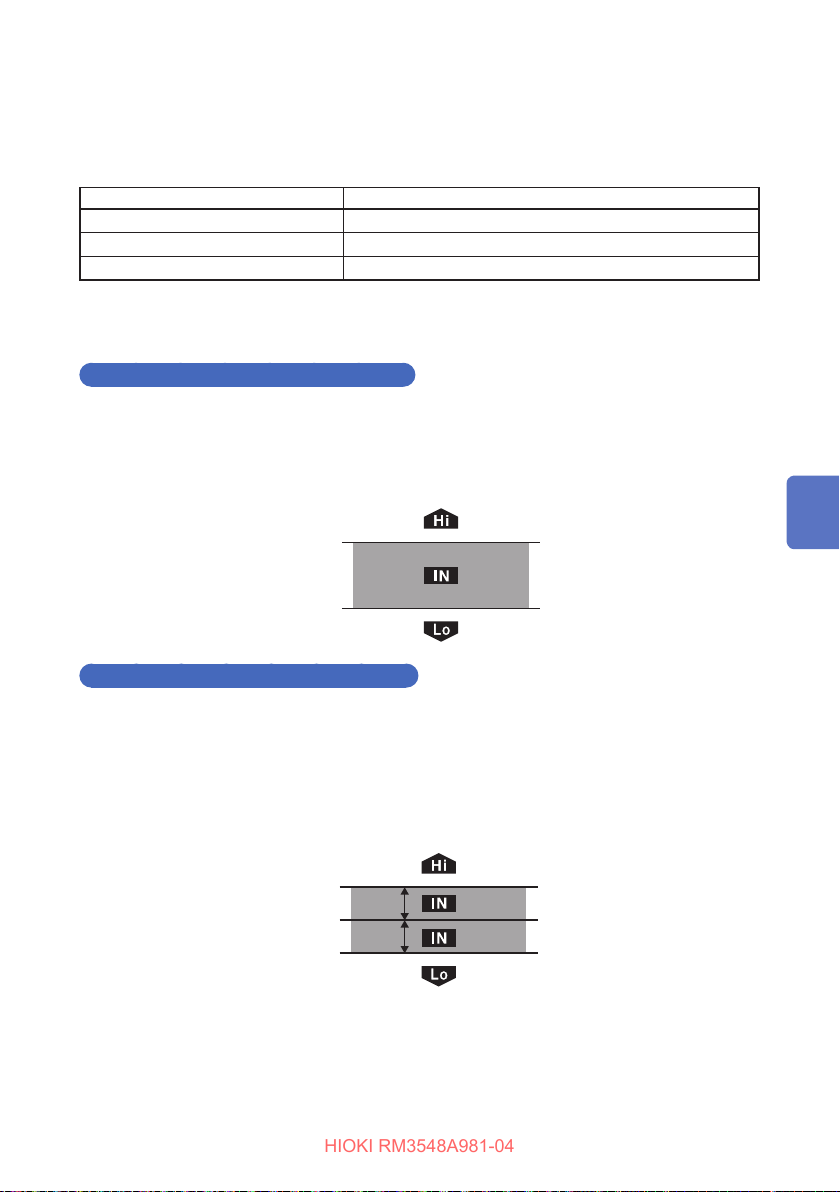

5.1 Judging Measured Values (Comparator Function)

This function judges a measured value to be Hi (measured value > upper limit), IN

(upper limit ≥ measured value ≥ lower limit), or Lo (lower limit > measured value)

against the set reference value, or upper or lower limit values.

• The judgment result can be veried on screen, with the buzzer (factory default is

OFF), and the L2105 LED Comparator Attachment (option).

• There are two different judgment methods available: ABS mode and REF% mode.

IMPORTANT

• If ΔT or length conversion function is turned ON, the comparator function

automatically turns OFF.

• If the comparator function is set to ON, it becomes impossible to change the

range (including the auto range). To use the auto range or change the range, set

the comparator function to OFF, and then use the [AUTO] key or [][] keys.

• If the comparator function is set to ON, the interval memory function becomes

unavailable.

60

Page 69

Judging Measured Values (Comparator Function)

HIOKI RM3548A981-04

Before using the comparator function