Page 1

Instruction Manual

Manual de Instrucciones

FT6380

FT6381

CLAMP ON EARTH TESTER

MEDIDOR DE RESISTENCIA

DE TIERRA TIPO GANCHO

March 2014 Revised edition 1

FT6380A983-01 (A981-03) 14-03H

Page 2

Page 3

i

Contents

Introduction .......................................................................... 1

Verifying Package Contents ................................................2

Safety Information ................................................................3

Operating Precaution s ................ ............ .............................7

Chapter 1 Overview 11

1.1 Product Overview ..............................................11

1.2 Features ............................................................ 12

1.3 Names and Functions of Parts .......................... 14

Operation key ....................................................16

Display Indicators............................... ............ ... 17

Chapter 2 Measurement 19

2.1 Measurement proces s ............................... ........19

2.2 Preparing for Measurement ..............................20

Attaching the Strap............................................ 20

Installing (or Replacing) the Battery.................. 21

2.3 Pre-Operation Ins p e ct i o n .......................... ........23

Using the included resistance check loop to

inspect the instrument ....................................... 24

2.4 Measurement Procedure ...................................25

Resistance Measurement .................................26

Current Measurement ........ ............. ............ ......29

2.5 Convenient function ..........................................33

Data hold function (Holding the measured value) 33

Backlight function

(Making measurements in a dark location)......... 33

Filter function (Rejecting noise) .........................34

Alarm function (Judging measured values and

sounding an alarm)............................................. 35

Memory function (Saving measurem ent data) ... 38

Page 4

ii

Making meas urements with an Android™

handset (FT6381 only)....................................... 42

Enabling the Bluetooth® function on the FT6381 43

Pairing the instrument with an Android™

handset (first use only)........................................ 44

Installing the FT6381 Communication Software

on the Android™ handset................................... 45

Registering the instrument you wish to connect

with the FT6381 Communication Software......... 46

Switching the FT6381 to connect with the

Android™ handset.............................................. 48

Using the FT6381 Communication Software

(second and subsequent use)............................. 48

2.6 Advanced Setti ngs a nd Fun ctions .....................51

Enabling/disabling the measuremen t range

display function ................................................... 52

Enabling/disabling the auto-power-saving (APS)

function.................... ............. ............ ............. ..... 53

Reverting the instrument to factory settings

(system reset)......................... ............ ............. ... 54

Chapter 3 Specifications 55

3.1 Measurement Specif ic at io n s ................... ..........55

3.2 General Specifications .......................................59

Chapter 4 Maintenance and Service 63

4.1 Cleaning ............................................................63

4.2 Troubleshooting .................................................6 4

Inspection and Repair........................................ 64

Before returning for repair .................................64

4.3 Error Display ......................................................65

Page 5

Introduction

1

Introduction

Thank you for purchasing the HIOKI Model FT6380, FT6381

CLAMP ON EARTH TESTER. To obtain maximum performance

from the instrument, please read this manual first, and keep it

handy for future reference.

Registered Trademarks

®

• Bluetooth

(USA).

• Android

tooth

• Adobe and Reader are either registered trademarks or trademarks of Adobe Systems Incorporated in the United States and

/or other countries.

is a registered trademark of Bluetooth SIG, Inc.

TM

Google PlayTM is a registered trademark of Blue-

®

Google, Inc.

Page 6

Verifying Package Contents

2

When you receive the instrument, inspect it carefully to

ensure that no damage occurred during shipping. In particular, check the accessories, panel switches, and connectors. If

damage is evident, or if it fails to operate according to the

specifications, contact your dealer or Hioki representative.

Confirm that these contents are provided.

□

FT6380 or FT6381 Clamp On Earth Tester (1)

□ Instruction Manual (1)

□ Carrying Case (1)

□ Resistance Check Loop (1)

□ LR6 alkaline batteri es (2)

□ Strap (1)

Verifying Package Contents

Package Contents

Use the original packin g materials when transporting the in strument, if

possible.

For other transportation notes, refer to the "Transporting (p.64)".

Page 7

Safety Information

3

Safety Information

This instrument is designed to comply with IEC 61010

Safety Standards, and has been thoroughly tested for

safety prior to shipment. However, mishandling during use

could result in injury or death, as well as damage to the

instrument. However, using the instrument in a way not

described in this manual may negate the provided safet y

features. Be certain that you understand the instructions

and precautions in the manual before use. We disclaim any

responsibility for accidents or injuri es not resul ting directly

from instrument defects.

This manual contains information and warnings essential for

safe operation of the instrument and for maintaining it in safe

operating condition. Before using it, be sure to carefully read the

following safety precautions.

Safety Symbols

In the manual, the symbol indicates particularly

important information that the user should read

before using the instrument.

The symbol printed on the instrument indicates

that the user should refer to a corresponding topic in

the manual (marked with the symbol) before

using the relevant function.

Indicates a double-insulated device.

Indicates AC (Alternating Current).

Indicates that the instrument may be connected to or

disconnected from a live circuit.

Indicates the power on/off button.

Page 8

Safety Information

4

The following symbols in this manual indicate the relative importance of cautions and warnings.

Indicates that incorrect operation presents an

extreme hazard that could result in serious

injury or death to the user.

Indicates that incorrect operation presents a

significant hazard that could result in serious

injury or death to the user.

Indicates that incorrect operation presents a

possibility of injury to the user or damage to the

instrument.

Indicates advisory items related to performance or correct operation of the instrument.

Symbols for Various Standards

WEEE marking:

This symbol indicates that the electrical and

electronic appliance is put on the EU market

after August 13, 2005, and producers of the

Member States are required to display it on the

appliance under Article 11.2 of Directive 2002/

96/EC (WEEE).

This symbol indicates that the product conforms

to regulations set out by the EC Directive.

®

FCC ID

Indicates that the product incorporates Bluetooth

wireless technology. Bluetooth® is a registered

trademark of Bluetooth SIG, Inc., and is used

under license by HIOKI E.E. CORPORATION.

Indicates that the product conforms to the

domestic Japan ese techni cal standa rds set fo rth

by the Radio Act (type certification).

Indicates the ID number of the wireless module

certified by the U.S. Federal Communications

Commission (FCC).

Page 9

Safety Information

5

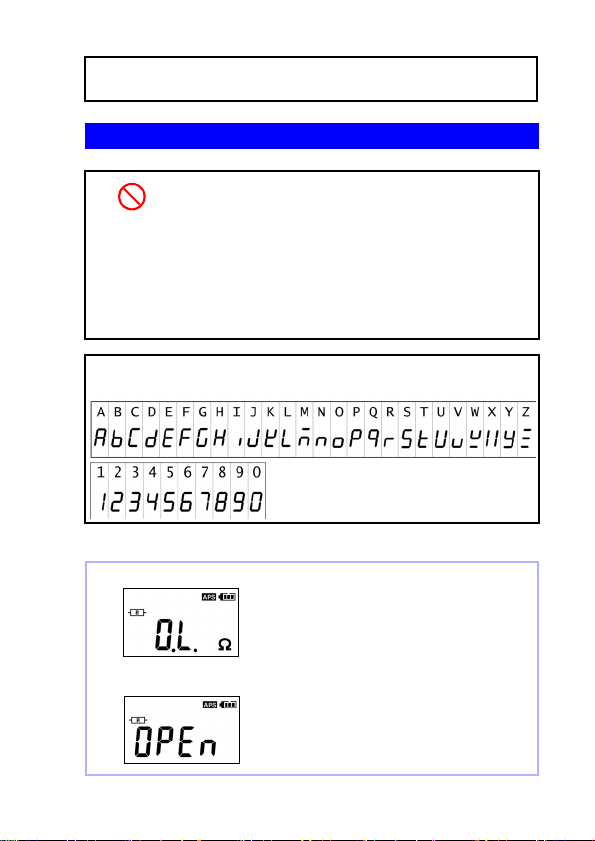

Over-range display

Open display

Resistance measuremen t: Wh en the reading exceeds 1,600 Ω

Current measurem ent: When the reading

exceeds 60.0 A.

This screen is displayed when the clamp

sensor is not complete l y clo sed during use

of the resistance measurement function.

IC

Other Symbols

(p. #)

[ ] Information displayed on the screen is enclosed

Fn

(bold

characters)

The screen of this instrument displays characters in the following manner.

Screen displays that differ from the above notation:

Indicates the number of the wireless module

certified by Industry Canada.

Indicates a prohibited action.

Indicates the location of reference information.

in brackets.

Bold text indicates alphanumeric characters

shown on operation keys.

Page 10

Safety Information

6

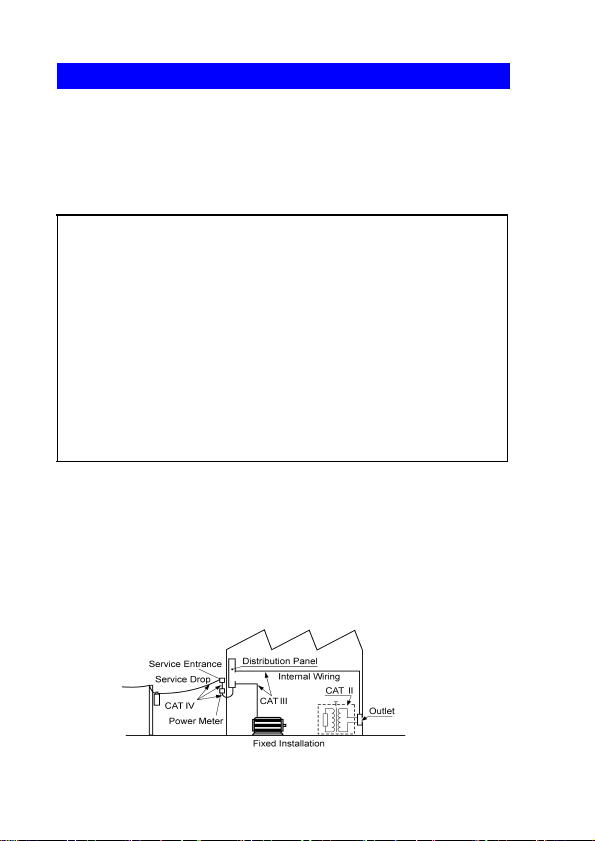

Measurement categories

This instrument complies with CAT IV safety requirements.

To ensure safe operation of measurement instruments IEC

61010 establishes safety standards for various electrical environments, categorized as CAT II to CAT IV, and called measurement categories.

Primary electrical circuits in equipment connected

CAT II

CAT III

CAT IV

Using a measurement instrument in an environment designated

with a higher-numbered category than that for which the instrument is rated could result in a severe ac cident, and must be

carefully avoided.

Use of a measurement instrument that is not CAT-rated in CAT II

to CAT IV measurement applications could result in a severe

accident, and must be carefully avoided.

to an AC electrical outlet by a power cord (portable

tools, household appliances, etc.)

CAT II covers directly measuring electrical outlet

receptacles.

Primary electrical circuits of heavy equipment

(fixed installations) connected directly to the distribution panel, and feeders from the distribution

panel to outlets.

The circuit from the service drop to the service

entrance, and to the power meter and primary

overcurrent protection device (distribution panel).

Page 11

Operating Precautions

7

Operating Precautions

Follow these precautions to ensure safe operation and to obtain

the full benefits of the various functions.

Preliminary Checks

Before using the instrument for the first time, verify that it operates normally to ensure that no damage occurred during storage

or shipping. If you find any damage, contact your dealer or Hioki

representative.

Instrument Installation

Operating temperature:-10 to 50°C (14 to 122°F)

(Be sure to use batteries that are suited for use under the environmental conditions in which you are using the instrument.)

Operating humidity: 80%RH or less (non condensating),

Avoid the following locations that could cause an accident or

damage to the instrument.

Exposed to direct

sunlight

Exposed to high temperature

Exposed to water, oil,

other chemicals, or

solvents Exposed to

high humidity or condensation

Exposed to high levels of particulate dust

In the presence of corrosive or explosive

gases

Exposed to strong

electromagnetic fields

Near electromagnetic

radiators

Near electromagnetic

radiators (e.g., highfrequency induction

heating systems and

IH cooking utensils)

Subject to vibration

Page 12

Operating Precautions

8

Handling the Instrument

• To avoid short circuits and potentially life-threatening

hazards, never attach the clamp to a circuit that operates

at more than 600 V, or over bare conductors.

• The maximum rated voltage between input terminals and

ground is 600 VAC. Measuring a voltage in excess of this

rating relative to ground could damage the instrument

and result in bodily injury.

• To avoid electric shock, do not remove the instrument's

case. The internal components of the instrument carry

high voltages and may become very hot during operation.

• When the clamp sensor is opened, do not allow the metal

part of the clamp to touch any exposed metal, or to short

between two lines, and do not use over bare conductors.

To avoid electric shock when measuring live lines, wear

appropriate protective gear, such as insulated rubber

gloves, boots and a safety helmet.

Page 13

Operating Precautions

9

Frequency [Hz]

Current [A]

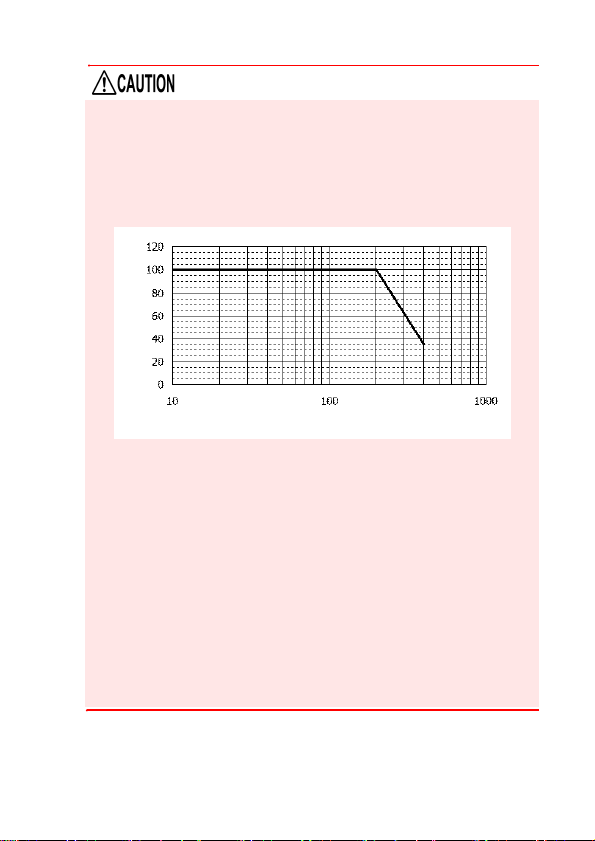

• Do not input a cur rent in excess of the maximum allowable

current. Doing so may damage the instrument or cause burns.

The maximum allowable current is 100 AAC continuous or

200 A AC within two minutes at 50/60 Hz. For more information about the frequency derating characteristics during continuous input, see the following diagram:

• To avoid damage to the instrument, protect it from physical

shock when transporting and handling. Be especially careful

to avoid physical shock from dropping.

• Be careful to avoid dropping the instrument or otherwise subjecting them to mechanical shock, which could damage the

mating surfaces of the core and adversely affect measurement.

• Although this instrument is dust resistant, it is not co mpletely

dust- or waterproof. To prevent possible damage, avoid using

in dusty or wet environments.

• Do not slant the device or place it on top of an uneven surface.

Dropping or knocking down the device can cause injury or

damage to the device.

Page 14

Operating Precautions

10

• The protection rating for the enclosure of this device (based

on EN60529) is *IP40. (The rating applies to the clamp sensor

when in the closed position.)

*IP40

This indicates the degree of protection provided by the enclosure of the device against use in hazardous locations, entry of

solid foreign objects, and the ingress of water.

4: Protected against access to hazardous parts with wire mea-

suring 1.0 mm in diameter. The equipment inside the enclosure is protected against entry by solid foreign objects larger

than 1.0 mm in diameter.

0: The equipment inside the enclosure is not protected against

the harmful effects of water.

Page 15

1.1 Product Overview

11

Overview Chapter 1

1.1 Product Overview

The FT6380 and FT6381 Clamp On Earth Tester make grounding resistance measurements simply by being clamped to multiple-grounded ground wires. No auxiliary grounding rod is

needed, and there is no need to disconnect the ground wire from

the grounding rod.

The instruments also provide AC current measurement functionality and can measure currents ranging from leakage current on

the order of several mA to load currents of up to 60 A.

The FT6381 emits radio radiation. Because use of devices that

emit radio radiation requires approval in the co untry of use, be

careful that use of the instrument in a country or region other

than those listed on the attached cautionary leaflet, "Precautions

Concerning Use of Equipment That Emits Radio Waves" or the

HIOKI products website may be subject to penalty as a violation

of law.

Page 16

1.2 Features

12

1.2 Features

Compact, low-profile sensor

The compact, low-profile sensor can be used to clamp ground wires

with ease. The sensor design dramatically speeds the measurement

process by eliminating the need to pull out ground wires for clamping

or dig around the ground rod or wire.

Broad dynamic range

The instrument can easily measure grou nding resistance of u p to

0.02 to 1,600 Ω with its auto -range fu nction. Cur rent meas urement

ranges from small leakage current (maximum resolution 10 μA) to a

maximum of 60 A.

Noise check function (p.28)

The instrument automat ically detects no ise that may affe ct grounding resi stance measurement and display s a mark.

True RMS display

True RMS calculation allows the instrument to accurately measure

distortion waveform currents.

Data hold function (p.33)

A large button that is easy to push lets you hold the measured value.

The button notifies the us er of the hold status by fl ashing w hile the

value is being held.

Backlight function (p.33)

The instrument uses a white LED for excellent visibility so th at display values can be read clearly, even in dark locations.

Auto-power-save (APS) function (p.53)

An auto-power-save function keeps batteries from running down

when you forget to turn off the instrument.

Page 17

1.2 Features

13

Alarm function (p.35)

By setting a threshold, yo u can ha ve the ins trumen t make a PASS/

FAIL judgment and notify you of the result with a buzzer. You can set

separate thresholds for resista nce and current measurements and

select judgment criteria (whether to generate a FAIL result when the

reading is greater than or less than the threshold).

Filter function (p.34)

Widespread use of switching power supplies and inverters has led to

cases where harm onic components are superimp osed on le akage

current waveforms. The instrument’s filter function allows it to perform two types of mea sureme nt: leaka ge cur rent a s rel ated to degradation of insulation , and leakage current i ncluding this harmonic

component.

Internal memory (p.38)

The instrument’s internal memory can record up to 2,000 measured

values.

Automatic measurement report function with

Android

The FT6381 featur es Bluetooth® wireless technology and can be

connected to a smartphone running the Android operating system to

easily create measurement reports in the field. (FT6381 ava ilability

is limited to certa in countries. For more informa tion, contact your

dealer or Hioki representative.)

™ connectivity (*FT6381 only) (p.42)

Page 18

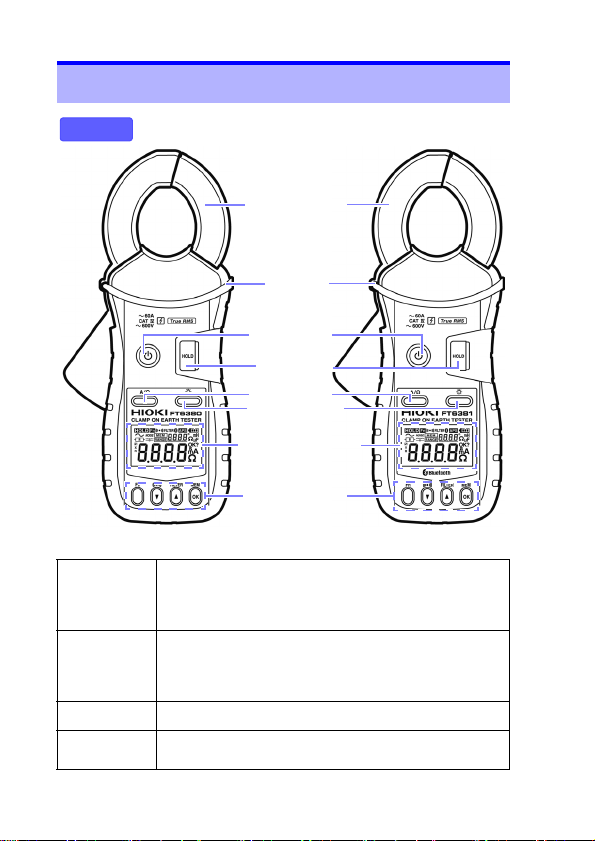

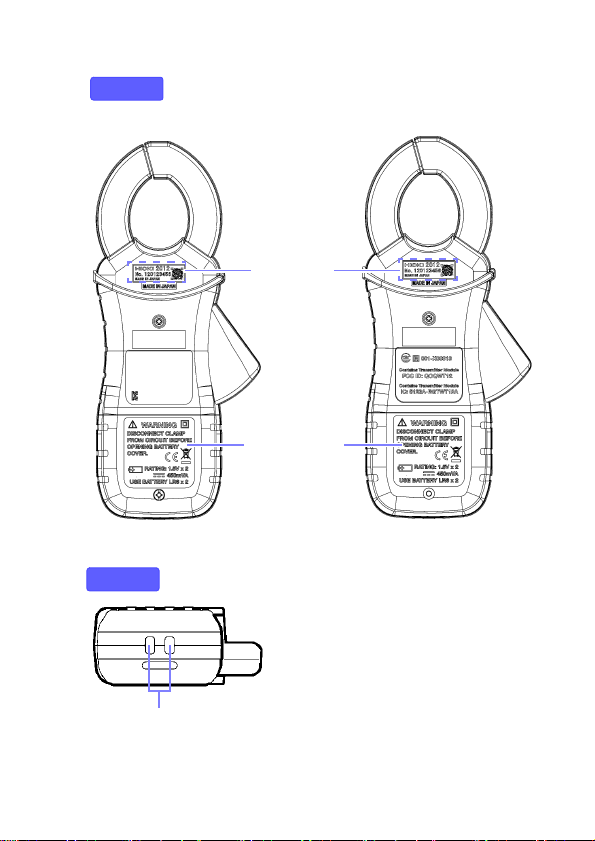

1.3 Names and Functions of Parts

14

Barrier

Front

Clamp sensor

FT6380 FT6381

POWER key

HOLD key

(p.33)

A/Ω key

Backlight key

(p.33)

Display Indicator

(p.17)

Operation key

(p.16)

1.3 Names and Functions of Parts

POWER key

HOLD key

Backlight key

A/Ω key

• Used to turn the instrument on and off.

• To temporarily cancel the auto-power-save function,

press the POWER key while holding down the HOLD

key.

• Holds the measured value display or cancels hold

mode.

• To cancel auto-power-save mode, press the POWER

key while holding down the HOLD key.

• Turns the backlight on and off.

• Switches between resistan ce measure ment mode and

current measurement mode.

Page 19

15

Battery cover

(p.21)

Back

Strap hole

(p.20)

Bottom

FT6380

FT6381

Serial No.

1.3 Names and Functions of Parts

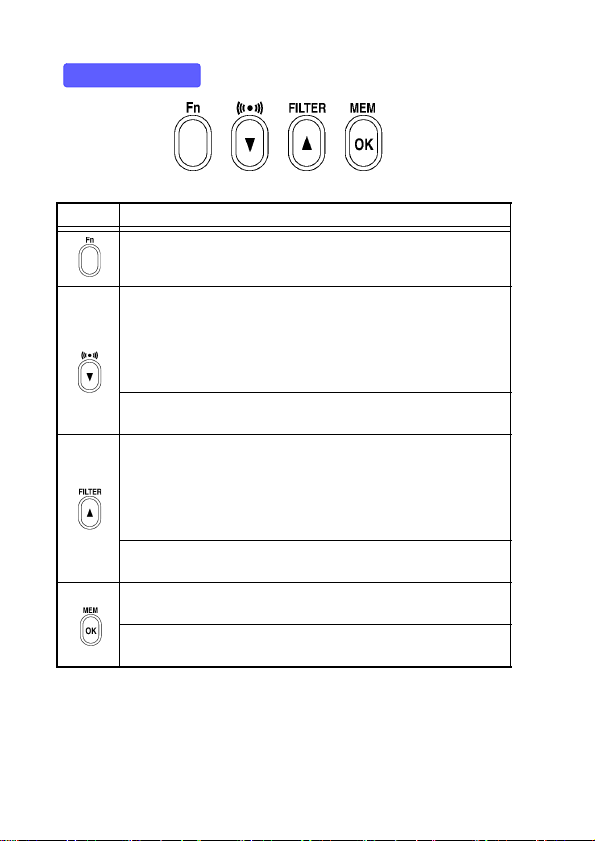

Page 20

1.3 Names and Functions of Parts

16

Operation key

Key Description

Switches to function mode , which is used to configure settings. Pressing this key again will return to resistance measurement mode or current measurement mode.

• Enables the alarm function. (p.35)

• When the alarm function is enabled, the instrument will

notify the user with the buzzer if a reading is greater than (or

less than) a preset threshold.

• Alarm function threshold se ttings can b e configur ed in function mode. (p.37)

*In function mode, this key serves as the

used to select setting items and values.

• Pressing this key while using the current measurement function enables the l ow-pass fi lte r to r ej ect un nee de d h arm on ic

components. (p.34)

• Pressing it while using the resistance measurement function

enables the moving averag e function, allowin g more stable

measurement. (p.34)

*In function mode, this key serves as the

used to select setting items and values.

Saves measurement data to the instrument’s internal memory. (p.38)

*In function mode, th is key serves as the

used to acc ept setting items an d values.

▼ key, which is

▲ key, which is

OK key, which is

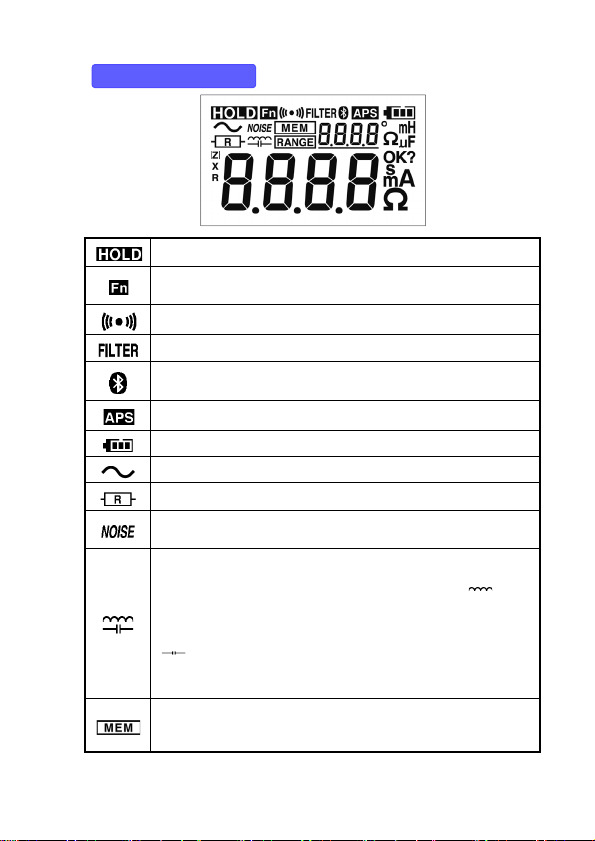

Page 21

17

Display Indicators

1.3 Names and Functions of Parts

Lights up when data is being held. (p.33)

Lights up in function mode. (p.50)

Flashes in subfunction mode. (p.51)

Lights up when the alarm function is on. (p.35)

Lights up when the filter function is on. (p.34)

Lights up when the Blue tooth

data is being sent or received. (model FT6381 only) (p.42)

Lights up when the auto-power-save function is on. (p.53)

Indicates the remaining battery power. (p.22)

Lights up in AC current measurement mode. (p.29)

Lights up in resistance measurement mode. (p.26)

Lights up in resistance measuremen t mode when a current

that could affect the measured value is detected. (p.28)

Lights up in resistance measuremen t mode when the mea-

sured ground loop has a high reactance component or capacitance component (

lights up due to a low mea sured resistance value, it is likely

that the displayed value indicates a shorted measurement

loop rather than normal grounding resistance. When the

] mark lights up, t he loop m ay have a break in it. In t his

[

case, the mark indicates th at the wire s ha ve b ee n co up led b y

capacitance.) (p.28)

Lights up during internal memory oper ati o ns. (p.3 8)

The number of measurem ent data poin ts stored in memo ry is

shown to the right.

±45° or greater). (When the [ ] mark

®

function is on. Flashes whe n

Page 22

1.3 Names and Functions of Parts

18

Lights up when the range display function is on.

The measurement range is shown to the right.

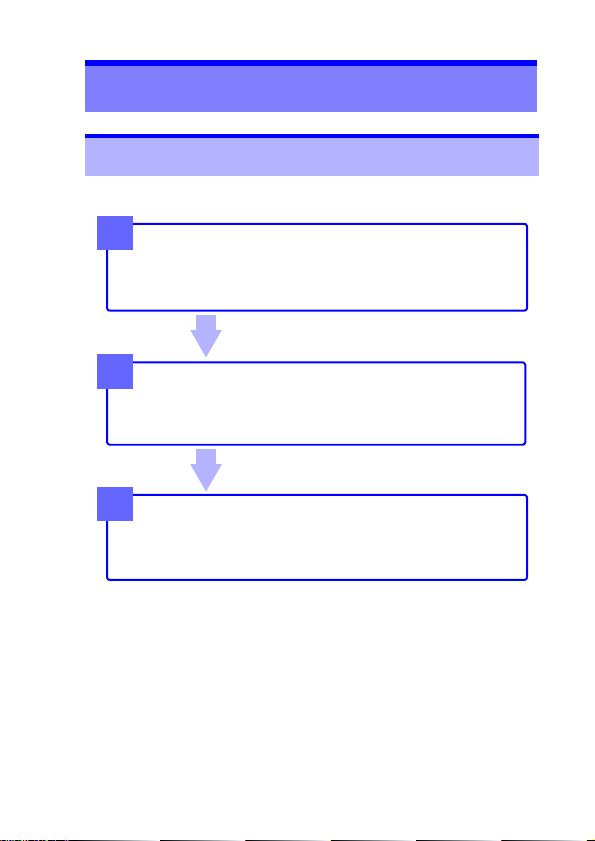

Page 23

19

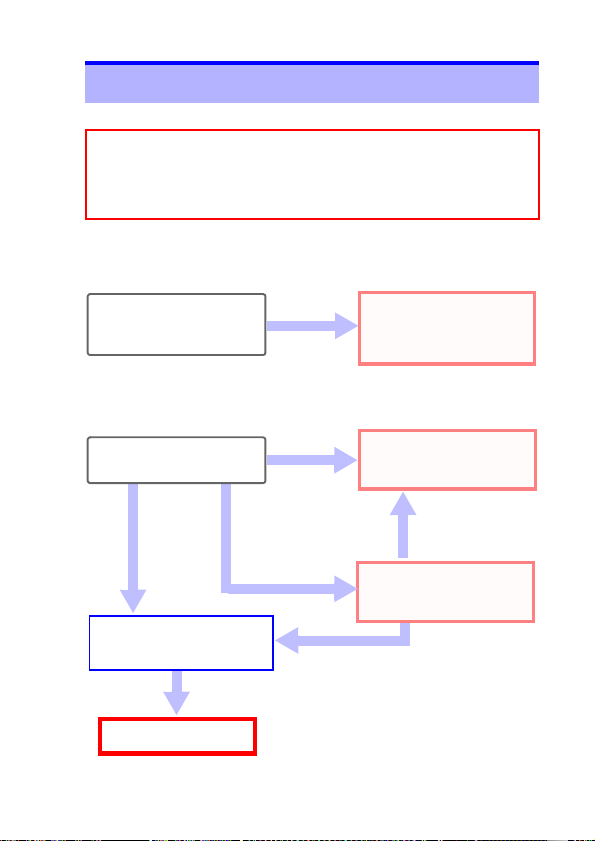

Measurement Chapter 2

Measurement

Resistance Measurement (p.26 )

Current Measurem ent (p.29 )

End of measurement

Remove the instrument from the measurement target.

Turn off the instrument.

Measurement Preparations

Pre-Operation Inspection (p.23)

Using the included resistance check loop to inspect the

instrument (p.24)

3

2

1

2.1 Measurement process

2.1 Measurement process

Page 24

2.2 Preparing for Measurement

20

2.2 Preparing for Measurement

After purchasing the instrument

Complete the following steps before using the instrument to

make measurements.

Attaching the Strap

Attach both ends of the Strap securely to the instrument.

If insecurely attached, the instrument may fall and be damaged

when carrying

Thread the strap through the strap hole as shown in the f ollowing diagram:

Page 25

2.2 Preparing for Measuremen t

21

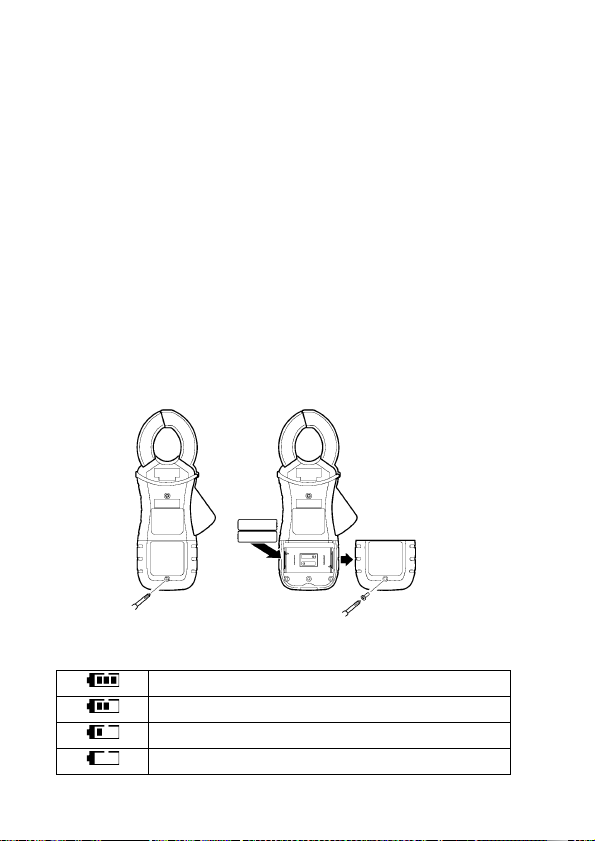

Installing (or Replacing) the Battery

Before using the instrument for the first time, install two AA-size

alkaline batteries (LR6). Verify that there is sufficient battery

power remaining before measurement. If there is insufficient battery power remaining, replace the batteries.

• To avoid electric shock when replacing the batteries, first

disconnect the clamp from the object to be measured.

• After replacing the batteries, replace the cover and

screws before using the instrument.

• Battery may explode if mistreated. Do not short- circuit,

recharge, disassemble or dispose of in fire.

• Handle and dispose of batteries in accordance with local

regulations

• Do not mix old and new batteries, or different types of bat teries. Also, be careful to observe bat tery polarity dur ing installation. Otherwise, poor performance or damage from battery

leakage could result.

• To avoid corrosion from battery leakage, remove the batteries

from the instrument if it is to be stored for a long time.

•

The indicator lights when battery voltage becomes

low. Replace the batteries as soon as possible.

• Before replacing the batteries, make sure that the

Slide Switch is OFF.

• After use, always turn OFF the power.

• If the battery is completely exhaus ted, the display will

show [BAttLo], and the instrument will automatically

turn off.

Page 26

2.2 Preparing for Measurement

22

2

3

4

Required Items:

• Phillips screwdriver

• LR6 alkaline battery (2)

Normal procedure

Verify that the instrument is off.

1.

Remove the fastening screws of the battery cover,

2.

using a Phillips screwdriver.

Remove the battery cover.

3.

Insert two new batteries (LR06 alkaline batteries),

4.

taking care to orient them properly.

Replace the battery cover and tighten the fastening

5.

screws.

Battery Status Indicator

This indicator is displayed at the top right corner.?

When new alkaline batteries have been installed

When 2/3 of the battery power remains

When 1/3 of the battery power remains

No battery power remains. Replace with new batteries.

Page 27

23

2.3 Pre-Operation Inspection

Before using the instrument for the first time, verify that it operates normally to ensure that no damage occurred during storage or shipping. If you find any damage, contact your dealer or

Hioki representative.

Does the screen turn on when

the instrument is turned on?

The batteries may be dead.

Replace the batteries and try

again.

The instrument may be malfunctioning. Have the instrument repaired.

• Is the instrument damaged?

• Is the clamp sensor cracked

or otherwise damaged?

No

End of inspection

Yes

An error is

displayed.

• The screen is not on.

• The screen shows an

error.

Do not use the instrument if it

is damaged as doing so may

result in electric shock. Have

the instrument repaired.

Yes

1. Inspecting the instrument

2. Inspecting the instrument after turning it on

The screen is on.

Using the included resistance

check loop to inspect the instrument (p.24)

2.3 Pre-Operation Inspection

Page 28

2.3 Pre-Operation Inspection

24

Resistance check loop

Using the included resistance check loop to

inspect the instrument

Before turning on the instrument, be sure to read Operating Precautions (p.7).

Inspecting the instrument with the resistance check loop

Verify that there is no foreign matter lodged between the tips of

the clamp sensor and that the sensor can be closed and opened

smoothly. If so, clamp the included resistance check loop and

verify that the instrument is operating properly. Verify that a

value within the allowable range is displayed for each loop.

Test resistance Allowable range

1 Ω 0.95 to 1.05 Ω

25 Ω 24.3 to 25.7 Ω

• If the instrument displays a value outside the allowable

range, it needs to be repaired. Contact your dealer or

Hioki representative.

• The resistance check loop cannot be us ed to calibrate

the instrument. T o have the instrument calibrated, contact your dealer.

Page 29

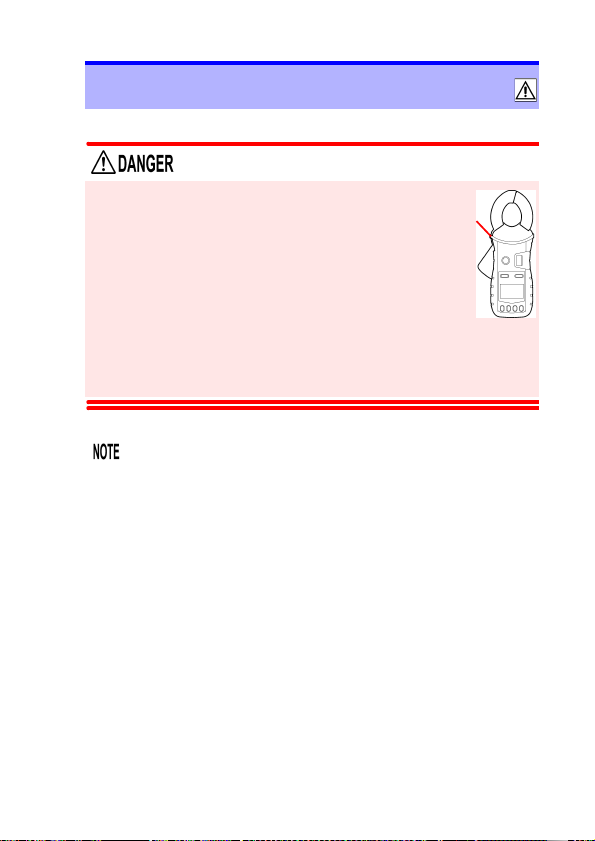

25

barrier

2.4 Measurement Procedure

2.4 Measurement Procedure

• To avoid electric shock, do not touch the portion beyond the protective barrier during use.

• When the clamp sensor is opened, do not

allow the metal part of the clamp to touch

any exposed metal, or to short between two

lines, and do not use over bare conductors.

• The maximum allowable current is 100 A AC

continuous or 200 A AC for 2 minutes (50/60 Hz). Currents

in excess of these values must be avoided as they may

damage the instrument or cause bodily injury.

• The tips of the clamp sensor are prec isely manufactured in order to provide a high level of precision. Exercise caution when handling the clamp so as to avoid

subjecting it to excessive vibration, mechanical shock,

or force.

• If foreign matter gets stuck between the tips of the

clamp sensor, do not forcibly open or close the sensor,

but rather use a soft brush or similar implement to

carefully remove the foreign matter. Accurate measurements cannot be made while foreign matter is

stuck between the tips of the clamp sensor or while the

shape of the clamp sensor is deformed. If the tips of

the clamp sensor become deformed, have the instrument inspected and calibrated by your dealer.

Page 30

2.4 Measurement Procedure

26

RmR

x

1

1

R

i

-----

i 1=

n

∑

------------------+=

R

x

1

1

R

i

-----

i 1=

n

∑

------------------»

R

x

R

1

R

n

R

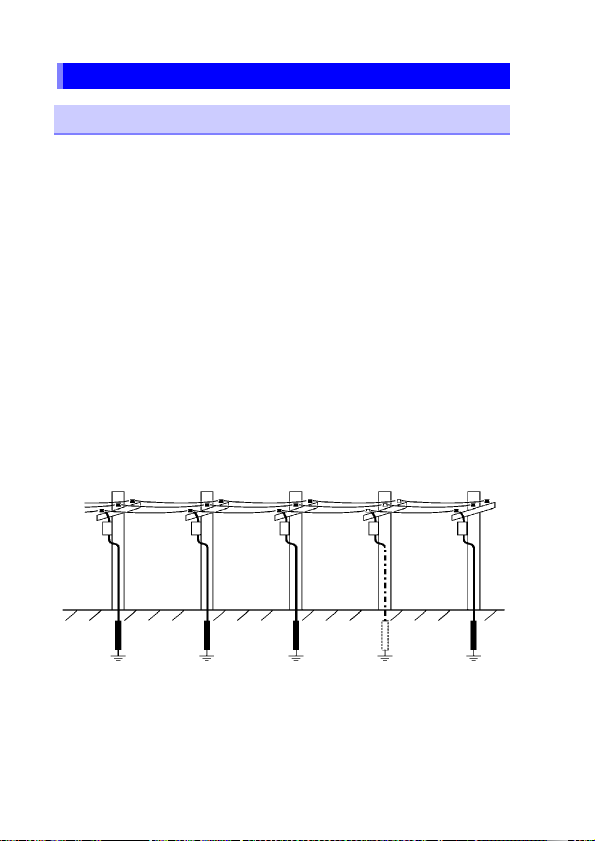

2

Resistance Me asur e men t

Measuring Principle

As illustrated below, the instrument is designed to measure

grounding resistance at multiple grounding locations. (*For applications involving the measurement of grounding resistance at a

single grounding site, use Hioki’s 3151 EARTH HiTESTER.)

If the grounding resistance of the measurement target is represented by R

grounded locations are represented by R

and the grounding resistance values of other

x

, R2, …, Rn, the resis-

1

tance value measured by the product is as follows:

If n is sufficiently large and each Ri value is sufficiently small,

and the second term can be ignored, allowi ng the value of

to be measured.

R

x

Page 31

2.4 Measurement Procedure

27

R

x

R

1

R

n

R

x

Example with actual measured values

The following provides an example with actual measured values.

The more grounding electrodes there are in the multiplegrounded installation, the higher the accuracy of the obtained

values. Alternately, if even one grounding electrode has a small

value (for example, 1 Ω), accurate values can be approached

even if there are few grounding electrodes. Since m ost m ultiplegrounded systems have a large number of grounding electrodes, the error can be limited.

Measuring method

Select resistance measurement mode.

1.

Select resistance measurement mode with the A/Ω key.

Clamp the grounding wire you wish to measure.

2.

The resistance value will be displayed.

Page 32

2.4 Measurement Procedure

28

• Do not measure the sam e location with two or more

Clamp On Earth Testers at the same time. The instruments will interfere with each other, preventing accurate measurement.

• Verify that the mark is not lit up.

When the current flowing through the grounding wire is high

(approximately 2.5 A or great er w ith a commercial frequency

of 50/60 Hz, approximately 100 mA or greater with a harmonic component of 1 kHz), the current will affect measured

values, making it impossible to measure the resistance.

Check the current flowing through the grounding w ire.

*The current level a t which the mark lit u p depe nds on

individual differences as we ll as the frequen cy. The closer to

the injected signal frequency, the smaller the noise current

that will affect operation.

• Open display

The screen will show [OPEn] if the clamp is not completely closed. Close the clamp completely and repeat

the measurement.

*If an extremely lar ge curren t is flowi ng throug h the groundi ng

wire or a DC current is superposed, the screen may display

[OPEn] even if the clamp is completely closed. This does not

signal a malfunction. Che ck the current flowing through the

grounding wire by using the instrument's current measurement mode or an instrument such as a clamp tester capable

of DC current measurement.

• Inductor mark

If the [ ] mark next to the resistance mark light up

during measurement, there may be a short in the

ground wire. It is recommended to verify that there are

no shorts in the location being measured.

• Capacitance mark

[]

If the

mark next to the resistance mark light up

during measurement, there may be a break in the

ground wire. It is recommended to verify that there are

no wiring breaks in the location being measured.

Short Break

[]

[]

R

x

R

R

1

x

R

x

R

R

1

x

Page 33

2.4 Measurement Procedure

29

Current Measurement

Select current measurement mode with the A/Ω key.

1.

Position the conductor in the center of the clamp

2.

sensor.

The current RMS value will be shown on the display .

3.

Page 34

2.4 Measurement Procedure

30

OK NG

• The frequency of special waveforms such as at the

secondary side of an inverter may not be indicated correctly.

• Depending on the magnitude and frequency of the

input current, resonances may be heard from the

clamp jaw. This does not affect the measurement.

• Do not input a current in excess of the maximum allowable current for the current range being used.

Page 35

31

Measuring zero-phase current

Single-phase, 2-lead circuits

three-phase 3-lead circuits

clamp all three leads of the

circuit

Load

device

Load

device

lg

When measuring zero-phase current, clamp all of the circuits at

once.

2.4 Measurement Procedure

Page 36

2.4 Measurement Procedure

32

Do not input current that exceeds the maximum continuous input of the electric current range.

• Measurement may not be accurate in the cases below.

(1) When there is large current (of about 100 A) flo w-

ing through a nearby electric line

(2) Note that a value of several tens of amperes may

be displayed when opening or closing the clamp

sensor, or when changing the electric current

range. This is not an error. It may take some time

for the display to return to zero. However, starting

measurement before the display returns to zero will

not affect measurement.

• Enable the "Filter function (Rejecting noise) (p.34)"

when conducting measurement in the cases below.

(1) When meaningless data is displayed due to noise.

(2) When using the instrument to measure special

waveforms, such as those on the secondary side of

an inverter

The instrument may not be able to pe rform measure-

ment in the cases below.

(1) When using input current that is 1/10 or less of the

full electric current range

(2) When measuring high frequencies with the filter

function enabled.

Page 37

2.5 Convenient function

33

2.5 Convenient function

Data hold function (Holding the measured value)

This function holds the measured value and continues to display

that value.

Press the HOLD key. The instrument will beep twice and the

[ ] mark will be displayed, an d the measured value will be

held. The HOLD key will flash. To cancel hold mode, press the

HOLD key again. The instrument will beep once and the [ ]

mark will disappear, and the HOLD key will stop flashing.

Backlight function

(Making measurements in a dark location)

This function makes the display easier to see in dark locations.

Press the BACKLIGHT key ( ). The backlight will turn on.

The backlight will turn off automatically when there has been no

operation for about 2 minutes.

To turn off the backlight, press the BACKLIGHT key ( ) again.

The backlight will turn off.

Page 38

2.5 Convenient function

34

Filter function (Rejecting noise)

This function allows you to reject unneeded frequency components such as high-frequency noise.

Press the FILTER key. The [ ] mark will be displayed. To

cancel the filter, press the FILTER key again. The [ ] mark

will disappear.

During resistance measurement

Using the filter function when there is a significant amount

of variation in measured values during resistance measurement will cause the measured values to stabilize.

*Note that noise rejection cannot be used when the [

mark is lit up.

During current measurement

Using the filter function enables a low-pass filter, causing

the harmonic component to be eliminated from measured

values. Widespread use of switching power supplies and

inverters has led to cases where harmonic components are

superimposed on current waveforms; the filter funct ion is

effective in such cases. Canceling the filter function disables the low-pass filter, allowing measurement of current

including harmonic components.

]

Page 39

2.5 Convenient function

35

Alarm Settings screen for resistance measurement

Alarm Settings screen for current measurement

Alarm function

(Judging measured values and s ound ing an alarm )

You can sound an alarm (A h igh tone signifies a high alarm,

while a low tone signifies a low alarm.) using previously set

thresholds by pressing the key.

Thresholds and other settings must be configured in advance.

To cancel the alarm function, press the key again.

Configuring the alarm settings

1.

Press the Fn key to switch to function mode. Using the ▼

and ▲ keys, select the resistance or current Alarm Settings

screen and press the OK key.

*For more information about function mode, see (p.50).

Page 40

2.5 Convenient function

36

Lo: The alarm will sound if the measured value

is less than the set threshold value.

Hi: The alarm will sound if the measured value

is greater than the set threshold value.

*The Hi/Lo setting is save d once the following setting has been

configured. If you press the

Fn key after configuring the Hi/Lo set-

ting but before saving the threshold and thereby cancel the configuration process, any changes to the Hi/Lo setting will not be

saved.

Set the alarm type (Hi/Lo).

2.

Using the ▼ and ▲ keys, select the alarm type (Hi/Lo), and

press the OK key. The next threshold setting will st art flas hing.

Page 41

2.5 Convenient function

37

Set the threshold.

3.

After configuring the Hi/Lo setting, set the threshold.

Using the ▼ and ▲ keys, set the threshold and press the

OK key.

You can move more quickly through threshold values by

pressing and holding the ▼ and ▲ keys.

Once the settings are complete, the screen will switch to

the Alarm Settings screen. To return to resistance measurement or current measurement mode, press the Fn key

again or the A/Ω key.

Page 42

2.5 Convenient function

38

Memory number

When the number of values saved in the instrument ’s memory

reaches 2,000, the display will show “FULL,” and you will not

be able to save additional values. Delete unneeded values to

free up space.

Memory function (Saving measurement data)

Press the MEM key in either resistance measurement mode or

current measurement mode. The instrument will beep three

times and the displayed measured value will be stored along

with the memory number (1 to 2,000) in the instrument’s internal

memory.

* Measured values, filter use, and the [ ] and [ ]

marks are saved in memory.

Page 43

2.5 Convenient function

39

Loading a value from the instrument’s internal memory

Press the Fn key to enter function mode.

1.

Using the ▼ and ▲ keys, select the Read Memory

screen and press the OK key.

*For more information about func tion mode, see (p.50).

Using the ▼ and ▲ keys, increment or decrement the

2.

memory number to recall the measured value for the

memory number you wish to load.

You can move more quickly through memory numbers

by pressing and holding the ▼ and ▲ keys.

To exit the Read Memory screen, press the Fn key or

the OK key.

* To return to resistance measurement or current mea-

surement mode, press the Fn key again or the A/Ω

key.

Page 44

2.5 Convenient function

40

To clear the last stored data po int

(1 value)

(The screenshot to the left indicates

that 34 values hav e been sa ved in

the instrument’s memory.)

To clear all data points

(The screen will show [ALL].)

Clearing stored data

You can clear the last stored data point (1 value) or all

stored data points.

Press the Fn key to enter function mode.

1.

Using the ▼ and ▲ keys, select the Clear Memory

screen and press the OK key. The screen will show

[CLr].

*For more information about funct ion mode, see (p.50).

Using the ▼ and ▲ keys, select either the last stored

2.

data point or all data points and press the OK key.

Page 45

2.5 Convenient function

41

The [OK?] mark will flash on the LCD once you select

the data to clear so that you can confirm your intentions.

Press the OK key again to clear the data.

• To cancel, press the Fn key.

• To return to resistance measurement or current measurement mode, press the Fn key again or the A/Ω

key.

Page 46

2.5 Convenient function

42

Making measurements with an Android™ handset

(FT6381 only)

By enabling the FT6381’s Bluetooth® function, you can transfer

measurement data to an Android™ handset to create measurement reports. For more information, refer to the help function of

the FT6381 Communication Software, an app for Android™

handsets.

In addition to installing the application, the following two sets of

connection settings must be configured in order to use the Blue-

®

function:

tooth

• Pairing the Android™ handset and FT6381

• Registering the FT6381 connection with the FT6381 Communication Software

Use the following procedure to configure the connection settings:

Measurement process

Enable the FT6381’s Bluetooth® function.

1.

Pair the instrument with the Android™ hand-

2.

set.

Install the FT6381 Communication Software

3.

on the Android™ handset.

Register the instrument you wish to connect

4.

with the FT6381 Communication Software.

(p.43)

(p.44)

(p.45)

(p.46)

Page 47

2.5 Convenient function

43

Enabling the Bluetooth® function on the FT6381

Press the Fn key to enter function mode.

1.

*

For more information about function mode, see (p.50).

Using the ▼ and ▲ keys, select the Bluetooth® Setting

2.

screen and press the OK key.

Using the ▼ and ▲ keys, select “on” on the Bluetooth

Setting screen and press the OK key to enable the Blue-

®

function.

tooth

Use of Bluetooth® functionality shortens the battery life

compared to normal use. It is recommended to turn off

Bluetooth

®

functionality when not in use.

®

Page 48

2.5 Convenient function

44

0000

Pairing is only necessary the first time you use the instrument with the handset. When using multiple FT6381 instruments, you will need to pair each instrument.

2

4

Enter

3

Pairing the instrument with an Android™ handset

(first use only)

Select [Wireless and Networks] from the Android™

1.

handset’s Settings button.

After enabling the Bluetooth® function, select [Scan for

2.

devices] from [Bluetooth settings] (exact words varies

with the specific Android™ handset being used; variants

include “Search for devices” and “Detect nearby terminals”).

When the handset d iscov ers [ FT6381#XX XXXXXXX] (where

3.

“XXXXXXXXX” is the serial number found on the back of the

instrument), pair the instrument.

Note that previousl y paired devices may appear in a separate

column labeled with language such as “Paired devices” rather

than in the search results.

Enter [0000] as the PIN number.

4.

Page 49

2.5 Convenient function

45

Enter and search.

Download

*The screen contents vary with the specific Android™ handset

being used. For more information about Bluetooth

®

device pairing methods and related procedures, see your Android™ handset’s instruction manual.

Installing the FT6381 Communication Software on

the Android™ handset

Search for “FT638” on the Google Play™ store and download

and install the FT6381 Communication Software.

A Google account is required in order to download applications

from the Google Play™ store. For more information about how

to register for a Google account, contact the st ore from which

you purchased the Android™ handset.

Page 50

2.5 Convenient function

46

Select

The application is free, but the user is responsible for

any Internet connection costs incurred in the course of

downloading or using the application. Since such costs

may be incurred during use of the application, it is recommended to use a fixed-price plan. Hioki is not liable

for any Internet connection costs.

Registering the instrument you wish to connect

with the FT6381 Communication Software

Turn on the FT6381.

1.

Launch the FT6381 Communication Software on the

Android™ handset. If you wish to use the map function,

enable the GPS function.

From the list of Bluetooth® devices, select [FT6381#XX

2.

XXXXXXX] and press the [Settings] button. The

FT6381 will be registered.

Once the instrument has been paired, it will connect automatically, and FT6381 measured values will be sent to the Android™

handset in real time. The instrument will not be able to connect

to the handset if it has not been paired. Refer to "Pairing the

instrument with an Android™ handset (first use only) (p .44)" to

pair the instrument.

Page 51

2.5 Convenient function

47

• The screen contents vary with the specific Android™

handset being used. F or more information ab out Blue-

®

device pairing methods and related procedures,

tooth

see your Android™ handset’s instruction manual.

• Communications between the FT6381 and Android™

handset are limited to a range of about 10 m, but

obstacles (walls, metal shielding, etc.) can shorten this

distance or prevent communications from being established.

• The FT6381’s wireless function use s Bluetooth

®

wireless technology that utilizes the 2.4 GHz band. It may

not be possible to establish communications if there is

a wireless LAN (IEEE 802.11.b/g/n) or other network/

device using the same frequency band nearby.

• The application supports Android OS 2.1 or later, but

proper operation is not guaranteed on all Android™

handsets. For more information about the devices on

which proper operation has been confirmed, see the

Google Play™ Store FT6381 Communication Software

instructions.

• Adobe’s Adobe Reader, which is available free of

charge on the Google Play™ store, is required in order

to view PDF reports. Install the application before

attempting to view reports.

• The confidentiality of information contained in Blue-

®

communications sent from the FT6381 is not

tooth

guaranteed. Hioki is not liable for any unauthorized

disclosure or other issue with measured values caused

by Bluetooth

The FT6381 emits radio radiation. Because use of

•

®

communications.

devices that emit rad io radiation requi res approval in the

country of use, be careful th at use of the instrument in a

country or region other than thos e listed on the attached

cautionary leaflet, "Precautions Concerning Use of Equipment That Emits Radio Waves" or the HIOKI products

website may be subject to penalty as a violation of law.

Page 52

2.5 Convenient function

48

Using the FT6381 Communication Software

(second and subsequent use)

After turning on the FT6381, launch the FT6381 Communication

Software on the Android™ handset. If you wish to use t he map

function, enable the GPS function. Once the instrument has

been paired, it will connect automatically, and FT6381 measured

values will be sent to the Android™ handset in real time. The

instrument will not be able to connect to the handset if it has not

been paired. Refer to "Pairing the instrument with an Android™

handset (first use only) (p.44)" to pair the instrument.

Switching the FT6381 to connect with the

Android™ handset

If you have multiple FT6381 instruments and wish to change the

unit to connect to the handset, press the Settings button after

pressing the menu button on the Android™ handset and reconfigure the Bluetooth

If you are unable to establish a Bluetooth® connection

Check the following if you are unable to establish a Bluetooth

connection between the FT6381 and the Android™ handset:

®

device settings.

®

• Is the Bluetooth

handset and the FT6381?

• Has the FT6381 in question been paired on the Android™

handset’s Bluetooth

not been paired, refer to "Pairing the instrument with an

Android™ handset (first use only) (p.44)" to pair it.

®

function enabled on both the Android™

®

settings screen? If the instrument has

Page 53

2.5 Convenient function

49

About the FT6381 Communication Software

The application provides the following functionality:

Sending measurement data (from the LCD display) to the

Android™ handset in real time

Saving and viewing measurement data (including time

stamp, GPS position data for the measurement location,

and map data)

Creating reports from measurement data

• Single reports created from measurement data from one

location

• Summary reports that present a summ ary of multiple sets

of measurement data (with the ability to add comments

and change header and footer information)

Outputting measurement data as a CSV file

Sending measurement data as an e-mail

Downloading the contents of the FT6381’s internal memory

For more information about the FT6381 Communication Software application, refer to the application help.

Page 54

2.5 Convenient function

50

Current alarm settings (p.29)

Loading values from memory (p.39)

Clearing data from the

instrument’s memory (p.40)

Resistance Alarm Settings (p.27)

2.

3.

1.

While in function mode, the [ ]

mark will light up.

1.

Press the Fn key to enter function mode.

2.

Using the ▼ and ▲ keys, select the desired setting.

3.

Accept the setting with the OK

key.

Press the Fn key or the A/Ω key

to exit function mode.

*FT6381 only

Bluetooth® Setting (p.42)

Function mode

In function mode, the follow ing s et tings and operations are available:

• Resistance alarm settings • Current alarm settings

• Loading values from memory • Clearing data from the instrument’s

• Bluetooth

®

setting

memory

Page 55

51

2.6 Advanced Settings and Functions

Press the POWER key

while holding down the

Fn key.

1

2

Advanced settings can be configured in sub-function mode. In

sub-function mode, the following settings and operations are

available:

• Measurement range displa y setting (p.52 )

• Auto-power-saving (APS) setting (p.53)

• System reset (to revert to factory settings) (p.54)

To enter sub-function mode, turn on the instrument by pressing

the POWER key while holding down the Fn ke y.

2.6 Advanced Settings and Functions

To exit sub-function mode, press the POWER key to turn off t he

instrument and then turn it back on.

Page 56

2.6 Advanced Settings and Functions

52

Enabling/disabling the measurement ra nge display

function

Enter sub-function mode.

1.

Press the POWER key while holding down the Fn key.

Using the ▼ and ▲ keys, select the Range Display Setting

2.

screen and press the OK key.

Using the ▼ and ▲ keys, switch the range display function

3.

on or off and press the OK key.

The measurement range is displayed using values only.

(Example: 1,600 Ω range 1,600)

The units for the measurement range are the sam e as

for the displayed measured value.

Page 57

2.6 Advanced Settings and Functions

53

The APS function is enabled

when the screen shows [on].

Enabling/disabling the auto-power-saving (APS)

function

The auto-power-saving (APS) function prevents unintentional

battery consumption when you forget to turn off the instrument.

The APS function activates automatically when the instrument is

turned on. The instrument will automatically turn off once about

5 minutes pass without any operation (an alarm will sound for

about 10 seconds first).

Pressing any key while the alarm sounds will reset the time

before the instrument turns off to about 5 minutes.

Enter sub-function mode.

1.

Press the POWER key while holding down the Fn key.

Using the ▼ and ▲ keys, select the APS Setting screen

2.

and press the OK key.

Using the ▼ and ▲ keys, switch the APS function on or off

3.

and press the OK key.

When the APS function is disabled in sub-function mode,

APS will remain disabled when the instrument’s power is

cycled.

Page 58

2.6 Advanced Settings and Functions

54

To disable APS temporarily

Turn on the instrument by pressing the POWER key

while holding down the HOLD key to disable APS until

the next time the instr umen t’ s power i s cycl ed. Th e next

time the power is cy cled, APS will be en abled (as lo ng

as the APS setting is enabled in sub-function mode).

Reverting the instrument to factory settings

(system reset)

This section describes how to initialize the instrument’s settings.

All measurement data (up to 2,000 values) will be deleted.

Enter sub-function mode.

1.

Press the

Using the ▼ and ▲ keys, select the System Rese t screen

2.

and press the

Press the OK key again. The instrument wil l rever t to the fac-

3.

tory settings.

POWER

key while holding down the Fn key.

OK

key . Th e

[OK?]

mark will flash.

• If the System Reset screen is displayed by mistake,

cycle the instrument's power without pressing the OK

key. Instrument operation will be restored without a

system reset having been performed.

For more information about how to clear previously saved

•

measurement data, see "Clearing stored data (p.40)".

Page 59

3.1 Measurement Specifications

55

Specifications Chapter 3

3.1 Measurement Specifications

Common measurement specifications

Guaranteed

accuracy period

Accuracy guarantee for temperature and humidity

Temperature

characteristics

Maximum rated

voltage to earth

Resistance measurement specific atio ns

Guaranteed

accuracy

conditions

Measurement

Method

Injected signal

frequency

Injected voltage

level

Effective

measuring range

Zero suppression Less than 0.02 Ω

Overrange Greater than 1600 Ω

Measurement

response time

1 year (Opening and Closing of the Sensor: Maximum 10000

times)

23°C±5°C (73°F±9°F) 80%RH or less (non-condensation)

-10 to 50°C Measurement accuracy x 0.1/°C (except 23°C±5°C)

600 VAC measurement category IV (anticipated transient over voltage 8000 V)

No reactance component, no noise current

Analog synchronous detection method (effective resistance measurement)

Approx. 2.4 kHz

Approx. 9.0 mV (with load open)

0.02 Ω to 1600 Ω

Filter: OFF/ON Approx. 3 sec /Approx. 9 sec.

Page 60

3.1 Measurement Specifications

56

Range

(Accuracy Range)

0.20 Ω (0.02 Ω to 0.20 Ω) 0.01 Ω ±1.5%rdg.±0.02 Ω

2.00 Ω (0.18 Ω to 2.00 Ω) 0.01 Ω ±1.5%rdg. ±0.02 Ω

20.00 Ω (1.80 Ω to 20.00 Ω) 0.01 Ω ±1.5%rdg.±0.05 Ω

50.0 Ω (18.0 Ω to 50.0 Ω*)0.1 Ω ±1.5%rdg.±0.1 Ω

100.0 Ω (50.0 Ω

200.0 Ω (100.0 Ω

400 Ω (180 Ω to 400 Ω*)1 Ω ±5%rdg.±5 Ω

600 Ω (400

1200 Ω (600 Ω* to 1200 Ω*) 10 Ω ±20%rdg.

1600 Ω (1200Ω* to1600 Ω) 20 Ω ± 35%rdg.

*To obtain the measurement accuracy at a range boundary, apply the accuracy of the

higher-accuracy range.

*

to 100.0 Ω*)0.1 Ω ±1.5%rdg.±0.5 Ω

*

to 200.0 Ω)0.2 Ω ±3.0%rdg.±1.0 Ω

Ω*

to 600 Ω*)2 Ω ±10%rdg.±10 Ω

Resolution Accuracy

Page 61

3.1 Measurement Specifications

57

Frequency [Hz]

Gain [db]

Current measurement specifications

Guaranteed accuracy conditions

Measurement

method

Crest factor 5.0 or less (for the 60 A range, 1.7 or less)

Conductor

position effects

Magnetic field

interference

Maximum allow-

able input

Sine wave input

Digital sampling method (true RMS measurement)

Within ±0.5% rdg. (using the center of the senso r as the reference ,

in all positions)

10 mA or less in an external magnetic fie ld of 400 A/m at 50/6 0 H z

AC

100 A AC continuous, 200 A AC for 2 minutes (50/60 Hz)

For frequency derating characteristi cs during continuou s input, see

the following diagram:

Effective

measuring range

Zero-suppression

Overrange Greater than 60.0 A

Measurement

response time

0.05 mA to 60.0 A

Less than 0.05 mA

Approx. 1 sec.

regardless of whether the filter is set to OFF or ON.

Page 62

3.1 Measurement Specifications

58

Range

(Accuracy Range)

20.00 mA

(1.00 mA to

20.00 mA)

200.0 mA

(18.0 mA to

200.0 mA)

2.000 A

(0.180 A to

2.000 A)

20.00 A

(1.80 A to

20.00 A)

60.0 A

(18.0 A to

60.0 A)

Resolu-

tion

0.01mA

0.1mA

0.001 A

0.01 A

0.1 A

Guaranteed

accuracy

frequency range

45 ≤ f ≤ 66 Hz

30 ≤ f < 45 Hz

66 < f ≤ 400 Hz

45 ≤ f ≤ 66 Hz

30 ≤ f < 45 Hz

66 < f ≤ 400 Hz

45 ≤ f ≤ 66 Hz

30 ≤ f < 45 Hz

66 < f ≤ 400 Hz

45 ≤ f ≤ 66 Hz

30 ≤ f < 45 Hz

66 < f ≤ 400 Hz

45 ≤ f ≤ 66 Hz

30 ≤ f < 45 Hz

66 < f ≤ 400 Hz

Accuracy

Filter off Filter on

±2.0%rdg.

±0.05 mA

±2.5%rdg.

±0.05 mA

±2.0%rdg.

±0.5 mA

±2.5%rdg.

±0.5 mA

±2.0%rdg.

±0.005 A

±2.5%rdg.

±0.005 A

±2.0%rdg.

±0.05 A

±2.5%rdg.

±0.05 A

±2.0%rdg.

±0.5 A

±2.5%rdg.

±0.5 A

±2.0%rdg.

±0.05 mA

±2.0%rdg.

±0.5 mA

±2.0%rdg.

±0.005 A

±2.0%rdg.

±0.05 A

±2.0%rdg.

±0.5 A

--

--

--

--

--

Page 63

3.2 General Specifications

59

3.2 General Specifications

Location for use P ollution Degree 2, altitude up to 2000 m (6562-ft.)

Storage

temperature

and humidity

Operating

temperature

and humidity

Dielectric strength

Applicable

standards

Dust and water

protection

Power supply LR06 alkaline battery × 2 (3 VDC)

Maximum rated

power

Continuous

operating time

Dimensions Approx. 73 W×218 H ×43 D mm (2.87” W×8.58”H × 1.69”D) ( exclud-

Maximum

measurable conductor diameter

Mass Approx. 620g (21.9 oz) Except for the battery

Accessories Carrying case (1), Resistance check loop (1), Strap (1),

Display specifications

LCD display Max. 2,000 count

Display refresh

rate

Range switching Auto-range

Overrange

display

Data hold

display

-20 to 60°C (-4.0°F to 140°F), 80%RH or less (non-condensation,

except for the battery)

Temperature : -10 to 50°C (14°F to 122°F)

Humidity : 80%RH or less (non-condensation)

Between the Case and the Clamp core 7400 Vrms 1 minute

Safety : EN61010

EMC : EN61326

Effects of radiated, radiofrequ ency, electro magnetic field: At 3 V/m,

5X accuracy specifications or less (resistance measurement)

IP40 (EN60529)

*With clamp sensor closed.

450 mVA

Approx. 35 hours (25 Ω measurement, backlight off,

Bluetooth® OFF (Model FT6381), 23°C reference

ing projections)

φ32 mm

LR06 alkaline battery × 2, Instruction manual (1)

Approx. 2 times/sec.

[O.L] display

mark lights up.

Page 64

3.2 General Specifications

60

Function mode

display

Filter display mark lights up.

Auto-power-save

display

Remaining

battery display

Memory number

display

Range display mark lights up.

Alarm display mark lights up.

Confirmation of

memory erasure

and reset

operation

Noise mark

display

mA/A unit

display

Ω unit display Ω mark lights up.

AC current mark

display

Resistance mark

display

Inductance mark

display

Capacitance

mark display

Bluetooth®

display

mark lights up. Flashes in subfunction mode.

mark lights up

Display of remaining battery power in 4 stages ( )

mark lights up.

mark lights up.

mark lights up.

(When there is a superimposed noise current during resistance

measurement, accuracy cannot be guaranteed.)

mA mark or A mark lights up.

mark lights up (during AC current measurement).

mark lights up (during resistance measurement).

mark lights up (when the phase angle θ > approx. 45° dur-

ing resistance measurement).

mark lights up (when the phase angle θ < approx. -4 5° during resistance measurement).

Bluetooth® function off: mark turns off (Model FT6381).

Bluetooth® function on/communications inactive: mark lights up

(Model FT6381).

Bluetooth® function on/communications active: mark flashes

(Model FT6381).

Page 65

3.2 General Specifications

61

Function specifications (underline: default v a lu e )

Data hold function

Backlight functionAutomatically turns off approx. 2 min. after last key operation.

Filter function

Resistance

measurement

filter function

Current

measurement

filter function

Alarm function

Resistance alarm

function

Current alarm

function

Alarm Hi/Lo Separate Hi/Lo settings for resistance measurement and current

Alarm threshold

setting range

Memory function

Memory capacity 2,000 values

Auto-power-save

function

Function mode

Moving between

items

Resistance alarm

function

Current alarm

function

Loading memory

values

Clearing

memory values

Bluetooth®

operating setting

Moving average time: Max. 9 sec.

Cutoff frequency: 180 Hz ±30 Hz (-3 dB)

Resistance measurement mode alarm: Beeps when measured

value is less than or greater than threshold.

Current measurement mode alarm: Beeps when measured value

is less than or greater than threshold.

measurement

Resistance measurement: Hi.AL/Lo.AL

Current measurement: Hi.AL/Lo.AL

Resistance measurement: 0.02 Ω to 1,600 Ω

Resistance measurement initial value: 25.0 Ω

Current measurement: 0.05 mA to 200.0 mA, 0.201 A to 60.0 A

Current measurement initial value: 1.00 mA

Instrument automatically turns off approx. 5 min. after last key

operation.

After selecting setting item with ▼ and ▲ keys, accept with OK

key.

AL Ω: Resistance Hi/Lo, threshold settings

AL A: Current Hi/Lo, threshold settings

MEM READ: Load memory values.

MEM CLR: Clear last saved memory value or all values.

BT: ON/OFF (FT6381)

Page 66

3.2 General Specifications

62

Sub-function mode

Range display

function

Auto-power-save

function

System reset SYS RST

Bluetooth®

function

(FT6381)

RNG: ON/OFF

APS: ON/OFF

Bluetooth® 2.1+ EDR (Class 2)

Communication range: 10 m (Line-of-sight)

Displays measured values on the screen of an Android™ handset

via Bluetooth®.

Page 67

4.1 Cleaning

63

Maintenance and Service Chapter 4

4.1 Cleaning

If foreign matter gets stuck between the tips of the clamp sensor, do not forcibly open or close the sensor, but rather use a

soft brush or similar implement to carefully remov e the foreign

matter. Accurate measurements cannot be made while foreign

matter is stuck between the tips of the clamp sensor or while the

shape of the clamp sensor is deformed. If the tips of the clamp

sensor become deformed, have the instrument inspected and

calibrated by your dealer.

• Wipe the LCD gently with a soft, dry cloth.

• To clean the instrument, wipe it gently with a soft cloth

moistened with water or mild detergent. Never use solvents such as benzene, alcohol, acetone, ether,

ketones, thinners or gasoline, as they can deform and

discolor the case.

Page 68

4.2 Troubleshooting

64

4.2 Trou bleshooting

Inspection and Repair

If damage is suspected, check the "Before returning for

repair" section before contacting your dealer or Hioki

representative.

Transporting

• When sending the instrument for repair, remove the batteries

and pack carefully to prevent damage in transit. Include cushioning material so the instrument cannot move within the package. Be sure to include details of the problem. Hioki cannot be

responsible for damage that occurs during shipment.

• Use the original packing materials when transporting the

instrument, if possible.

Before returning for repair

Symptom Cause Remedy

No screen is displayed even

when the instrument is turned on.

The screen turns

off after a little

while.

• Are the batteries

correctly inserted?

• Is the useful battery life at an end?

• Is the useful battery life at an end?

• Has the APS function been triggered?

Insert the new batteries.(p.21)

(p.53)

Page 69

4.3 Error Display

65

4.3 Error Display

If an error is shown on the LCD, the instrument needs to be

repaired. Contact your dealer or Hioki representative.

Error Display Meaning Remedial Action

E001 Main CPU program error

E002 Sub CPU program error

E003 EEPROM R/W error

E004 Adjustment data error

Please contact your dealer

or Hioki representative.

Page 70

4.3 Error Display

66

Page 71

Page 72

Page 73

FT6380

FT6381

CLAMP ON EARTH TESTER

Manual de Instrucciones

March 2014 Revised edition 1 FT6380A983-01 (A981-03)

Spanish

Page 74

Page 75

Índice

Introducción .........................................................................1

Chequeo del contenido del paquete .................................... 2

Información de seguridad .................................................... 3

Precauciones de operación ................................................. 7

Capítulo 1 Información general 11

1.1 Información general del producto ...................... 11

1.2 Características .................................................. 12

1.3 Nombres y funciones de las partes ................... 14

Botón de operación ............................................ 16

Indicadores en pantalla ...................................... 17

Capítulo 2 Medición 19

2.1 Proceso de medición ......................................... 19

2.2 Preparación para la medición ........................... 20

Montaje de correa ..............................................20

Colocación (o cambio) de las baterías............... 21

2.3 Inspección preoperativa .................................... 23

Uso del lazo de referencia de resistencia incluido

para inspeccionar el instrumento ....................... 24

2.4 Procedimiento de medición ............................... 25

Medición de la resistencia.................................. 26

Medición de corriente.........................................30

2.5 Funciones útiles ................................................34

Función de retención de datos (retención del valor

medido) .............................................................. 34

Función de retroiluminación (realización de

mediciones en lugares oscuros) ........................ 34

Función de filtro (rechazo de ruido) ................... 35

Función de alarma (evaluación de los valores

medidos y emisión de una alarma) .................... 36

Función de memoria (guardado de los datos de

medición)............................................................39

i

Page 76

ii

Toma de mediciones con un celular Android™ (solo

el modelo FT6381) .............................................43

Activación de la función de Bluetooth® en el modelo

FT6381 ...............................................................44

Emparejamiento del instrumento con un celular

Android™ (solo la primera vez) ..........................45

Instalación de la aplicación FT6381 Communication

Software en un celular Android™....................... 46

Registro del instrumento que desea conectar

mediante la aplicación FT6381 Communication

Software .............................................................47

Cambio de instrumento FT6381 a conectar con el

celular Android™................................................49

Utilización de la aplicación FT6381 Communication

Software (la segunda vez y posteriores) ............49

2.6 Ajustes y funciones avanzados .........................52

Activación/desactivación de la función de

visualización del rango de medición...................53

Activación/desactivación de la función de ahorro

automático de energía (APS) .............................54

Restablecimiento del instrumento a la configuración

de fábrica (restablecimiento del sistema) ...........55

Capítulo 3 Especificaciones 57

3.1 Especificaciones de medición ...........................57

3.2 Especificaciones generales ...............................61

Capítulo 4 Mantenimiento y servicio 65

4.1 Limpieza ............................................................65

4.2 Resolución de problemas ..................................66

Inspección y reparación......................................66

Antes de devolver para su reparación ................66

4.3 Visualización de errores ....................................67

Page 77

Introducción

Introducción

Gracias por adquirir el MEDIDOR DE RESISTENCIA DE TIERRA TIPO GANCHO modelo FT6380, FT6381 de HIOKI. Para

obtener el máximo rendimiento del instrumento, lea primero este

manual y téngalo a mano para futuras consultas.

Marcas comerciales registradas

®

• Bluetooth

SIG, Inc. (EE.UU.).

• Android

de Bluetooth

• Adobe y Reader son marcas comerciales registradas o marcas comerciales de Adobe Systems Incorporated en los Estados Unidos y/o en otros países.

es una marca comercial registrada de Bluetooth

TM

Google PlayTM es una marca comercial registrada

®

Google, Inc.

1

Page 78

Chequeo del contenido del paquete

2

Chequeo del contenido del paquete

Cuando reciba el instrumento, inspecciónelo cuidadosamente

para asegurarse de que no ha sufrido ningún daño durante el

envío. En particular, chequee los accesorios, los interruptores

del panel y los conectores. Si el daño es evidente o si no funciona según las especificaciones, póngase en contacto con

su distribuidor o representante de Hioki.

Contenido del paquete

Confirme que se incluyen estos contenidos.

□ Medidor de Resistencia de Tierra tipo Gancho modelo FT6380 o

FT6381 (1)

□ Lazo de Referencia para Re-

sistencia (1)

□ Manual de instrucciones (1)

□ Funda de Transporte (1)

□ Baterías alcalinas LR6 (2)

□ Correa (1)

Utilice los materiales de empaque originales cuando transporte el instrumento, si es posible.

Para el resto de notas de transporte, consulte “Transporte (p.66)”.

Page 79

Información de seguridad

Información de seguridad

Este instrumento está diseñado para cumplir con las normas de

seguridad IEC 61010 y ha superado los test de seguridad antes

del envío. Sin embargo, un manejo inadecuado durante el uso

podría provocar lesiones o la muerte, así como daños al instrumento. Sin embargo, si se utiliza el instrumento de una manera no

descrita en este manual, puede anular los elementos de seguridad que se proporcionan. Asegúrese de comprender las instrucciones y precauciones del manual antes de su uso. Negamos

cualquier responsabilidad por accidentes o lesiones que no sean

consecuencia directa de los defectos del instrumento.

Este manual contiene información y advertencias esenciales

para garantizar la seguridad durante el funcionamiento del instrumento y para su mantenimiento en condiciones de funcionamiento seguras. Antes de utilizarlo, asegúrese de leer

atentamente las siguientes precauciones de seguridad.

Símbolos de seguridad

En el manual, el símbolo indica una información

especialmente importante que el usuario debe leer

antes de utilizar el instrumento.

El símbolo impreso en el instrumento indica que el

usuario debe consultar el tema correspondiente en el

manual (marcado con el símbolo ) antes de utilizar la

función en cuestión.

Indica un dispositivo con doble aislamiento.

Indica CA (corriente alterna).

Indica que el instrumento puede estar conectado o desconectado de un circuito con corriente.

Indica el botón de encendido/apagado.

3

Page 80

Información de seguridad

4

Los siguientes símbolos en este manual indican la importancia

relativa de las precauciones y advertencias.

Indica que un funcionamiento incorrecto supone

un gran riesgo que podría provocar lesiones graves o la muerte del usuario.

Indica que un funcionamiento incorrecto supone

un riesgo importante que podría provocar lesiones

graves o la muerte del usuario.

Indica que un funcionamiento incorrecto supone la

posibilidad de provocar lesiones al usuario o

daños al instrumento.

Indica los elementos de recomendación relacionados con el rendimiento o el correcto funcionamiento del instrumento.

Símbolos de varias normas

Marca de residuos de aparatos eléctricos y electrónicos (RAEE):

Este símbolo indica que el aparato eléctrico y electrónico se lanza al mercado de la UE después del

13 de agosto de 2005 y los productores de los