Hioki DT4281, DT4282 Instruction Manual

DT4281

DT4282

DIGITAL MULTIMETER

Instruction Manual

Apr. 2015 Revised edition 6

DT4281A981-06 15-04H

EN

Contents

Introduction .........................................................................1

Verifying Package Contents ..............................................1

Options (sold separately) ..................................................2

Safety Notes ........................................................................ 5

Usage Notes ...................................................................... 10

1 Overview 15

1.1 Overview and Features .................................15

1.2 Parts Names and Functions .........................16

1.3 Display ...........................................................21

1.4 Alarm Display and Battery Indicator ...........23

1

1

1

2

2

3

2 Preparation for Measurements 25

2.1 Measurement Workfl ow ................................ 25

2.2 Inserting/Replacing Batteries ...................... 26

2.3 Using Test Leads ...........................................28

2.4 Installation in Measurement Location .........31

Using the instrument with the stand .......................... 31

Hanging the instrument with the strap ......................31

3 Performing Measurements 33

3.1 Inspection Before Use ..................................33

3.2 Measuring Voltage.........................................38

Measuring AC voltage ............................................... 38

Measuring DC voltage ..............................................39

Measuring synthesized voltage of DC and AC .........39

Measuring voltage of DC and AC components ......... 40

3.3 Measuring Frequencies ................................40

3.4 Decibel Conversion (dBm/dBV) ................... 41

DT4281A981-06

4

5

6

7

Ind.Appx.

i

Contents

3.5 Checking Continuity ..................................... 42

3.6 Measuring Diode ........................................... 43

3.7 Measuring Resistance .................................. 44

3.8 Measuring Temperatures ..............................45

3.9 Measuring Electrostatic Capacities ............. 47

3.10 Measuring Conductances

(DT4282) ................48

3.11 Measuring Current ........................................49

Measuring DC/AC .....................................................49

3.12 Measuring AC Using Clamp-on Probe

(DT4281) ......................................................... 51

3.13 4-20 mA (0-20 mA) % Conversion ................53

4 Using Instrument Conveniently 55

4.1 Selecting the Measurement Range .............. 55

Measuring with the auto range .................................55

Measuring with the manual range ............................. 55

4.2 Retaining the Measured Value ..................... 57

Retaining the measured value manually (HOLD) .....57

Automatically retaining the measured value

when the value stabilizes (AUTO HOLD)..................57

4.3 When the Measured Value Fluctuates

(SLOW) ........................................................... 59

4.4 Removing the Harmonic Components

of the Inverter (FILTER) ................................. 60

4.5 Checking the Maximum/Minimum Value

(MAX/MIN) ......................................................61

4.6 Checking the Peak Value (V • A PEAK) .......62

4.7 Checking the Relative Value/Performing

Zero Adjustment ............................................63

Checking the relative value (REL) ............................63

Performing zero adjustment ...................................... 64

ii

Contents

4.8 Using the Memory Function .........................65

Saving the measured value (MEM) ..........................65

Reading the memory data (READ) ........................... 67

Clearing the memory data (CLEAR) ......................... 68

Clearing all memory data ..........................................68

4.9 Muting the Buzzer .........................................69

4.10 Turning On the Backlight .............................. 69

4.11 Using the Auto Power Save (APS) ............... 70

4.12 Using Plus/Minus Judgment Function

for Measurement Value ................................. 71

4.13 Communicating with PC ...............................72

4.14 Setting and Checking the System ...............74

Checking that all indicators are displayed ................74

Checking the software version of the instrument ......74

Changing the temperature display unit ..................... 75

4.15 Resetting the System .................................... 76

Table of default settings ............................................76

4.16 Power-on Option Table .................................77

5 Specifi cations 79

5.1 Electrical Characteristics ............................. 79

5.2 Accuracy Table .............................................. 81

5.3 General Specifi cations .................................95

1

212

3

4

5

6

6 Maintenance and Service 99

6.1 Repair Inspection and Cleaning ................. 99

6.2 Troubleshooting ..........................................101

6.3 Error Display ................................................ 105

6.4 Replacing Fuses .......................................... 106

iii

7

Ind.Appx.

Contents

Appendix Appx.1

Appx. 1 RMS and Average .............................Appx.1

Appx. 2 Operation Example ........................... Appx.2

Appx. 3 Capacitor Capacity Measurement

Principle.............................................Appx.3

Appx. 4 Dedicated Software

(DMM Communicator) ......................Appx.4

iv

Introduction

Introduction

Thank you for purchasing the HIOKI DT4281, DT4282 Digital

Multimeter. To obtain maximum performance from the product,

please read this manual fi rst, and keep it handy for future reference.

1

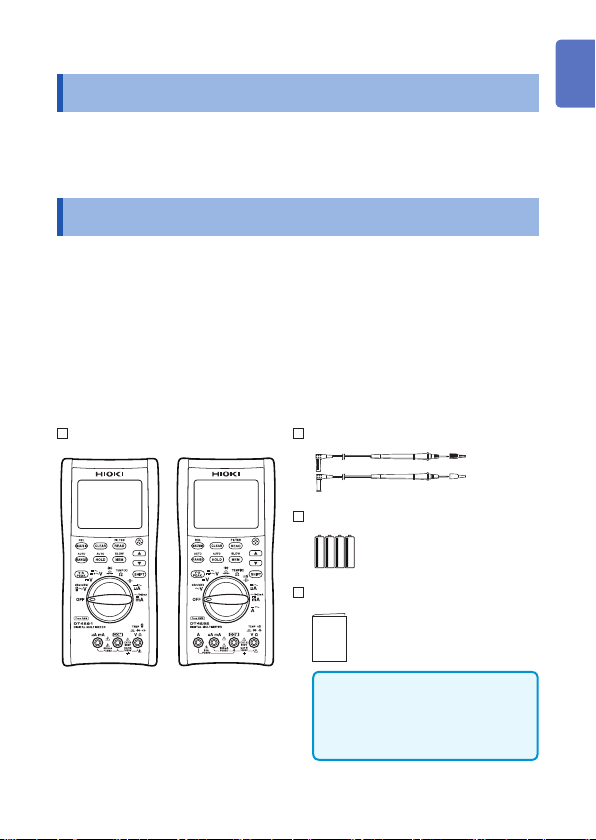

Verifying Package Contents

When you receive the instrument, inspect it carefully to ensure that

no damage occurred during shipping.

In particular, check the accessories, panel switches, and

connectors. If damage is evident, or if it fails to operate according

to the specifi cations, contact your authorized Hioki distributor or

reseller.

Check the package contents as follows.

DT4281 or DT4282

DT4281 DT4282

L9207-10 Test Lead (p. 28)

LR6 Alkaline battery × 4

Instruction Manual

(English)

Instruction manuals may also

be available in other languages.

Please visit our website at

http://www.hioki.com

/

2

3

4

5

6

7

Ind.Appx.

1

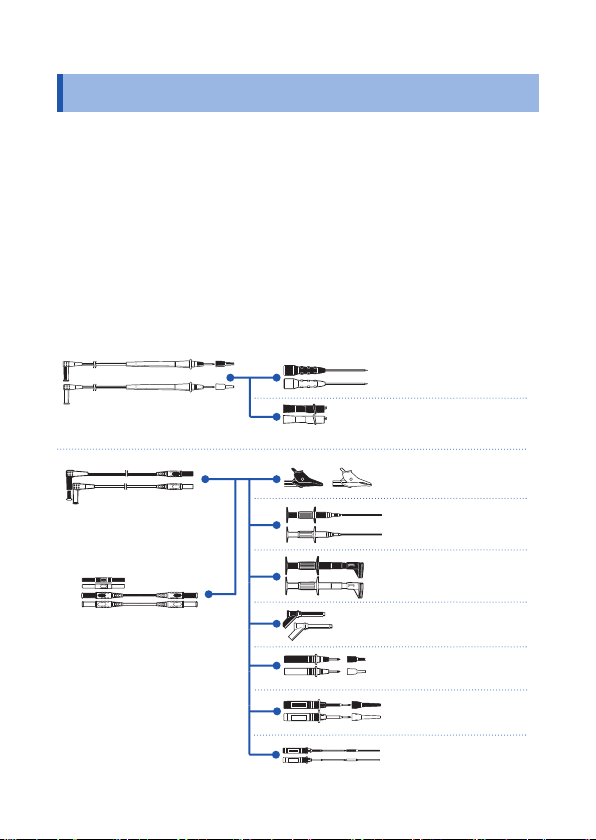

Options (sold separately)

Options (sold separately)

The following options are available for the instrument. Contact your

authorized Hioki distributor or reseller when ordering.

Connecting cables

*1: CATIV 600 V/CATIII 1000 V/CATII 1000 V

*2: CATIV 600 V/CATIII 1000 V

*3: CATIII 1000 V *5: CATIII 300 V/CATII 600 V

*4: CATIII 600 V *6: 33 V AC/70 V DC

*7: CATIII 600 V/CATII 600 V

6

L4933*

Contact Pin Set

L9207-10*

1

Test Lead

2

L4930*

Connection Cable Set

(Length: 1.2 m)

2

L4931*

Extension Cable Set

(Length: 1.5 m, with the

coupling connector)

5

L4934*

Small Alligator Clip Set

2

L4935*

Alligator Clip Set

3

9243*

Grabber Clip

4

L4936*

Bus Bar Clip Set

3

L4937*

Magnetic Adapter Set

1

L4932*

Test Pin Set

7

L4938*

Test Pin Set

4

L4939*

Breaker Pin Set

2

Options (sold separately)

For the clamp current measurement (only compatible with the DT4281)

9010-50, 9018-50, 9132-50*

Clamp-on Probe

9704 Conversion Adapter

4

1

Clamp-on probe

9010-50, 9018-50 500 A rms46 mm or less

9132-50 1000 A rms55 mm or less, 80 × 20 mm bus-bar

Temperature measurement

C0202 Carrying Case

Z5004 Magnetic Strap (p. 31)

Rated

current

DT4910 Thermocouples (K) (p. 45)

• Temperature measuring junction: Exposed type (welding)

• Sensor length: Approx. 800 mm

• Operating temperature: -40°C to 260°C (temperature

measuring part), -15°C to 55°C (connector)

The instrument, test leads, instruction manual, and others

can be stored in the case.

Attach this strap to the instrument and secure it on the

wall surface such as a metal plate for use.

Diameter of the measurable

conductor

2

3

4

5

6

7

Ind.Appx.

3

Options (sold separately)

DT4900-01 Communication Package (USB) (p. 72)

A communication adapter, USB cable, PC software,

and communication specifi cations are included.

The instrument data can be stored on the PC.

4

Safety Notes

Safety Notes

This instrument is designed to conform to IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior to

shipment. However, using the instrument in a way not described in

this manual may negate the provided safety features.

1

Before using the instrument, be certain to carefully read the

following safety notes.

DANGER

Mishandling during use could result in injury or death,

as well as damage to the instrument. Be certain that

you understand the instructions and precautions in

the manual before use.

WARNING

With regard to the electricity supply, there are risks

of electric shock, heat generation, fi re, and arc

discharge due to short circuits. If persons unfamiliar

with electricity measuring instruments are to use

the instrument, another person familiar with such

instruments must supervise operations.

Protective gear

WARNING

To avoid electric shock when measuring live lines,

wear appropriate protective gear, such as insulated

rubber gloves, boots and a safety helmet.

2

3

4

5

6

7

Ind.Appx.

5

Safety Notes

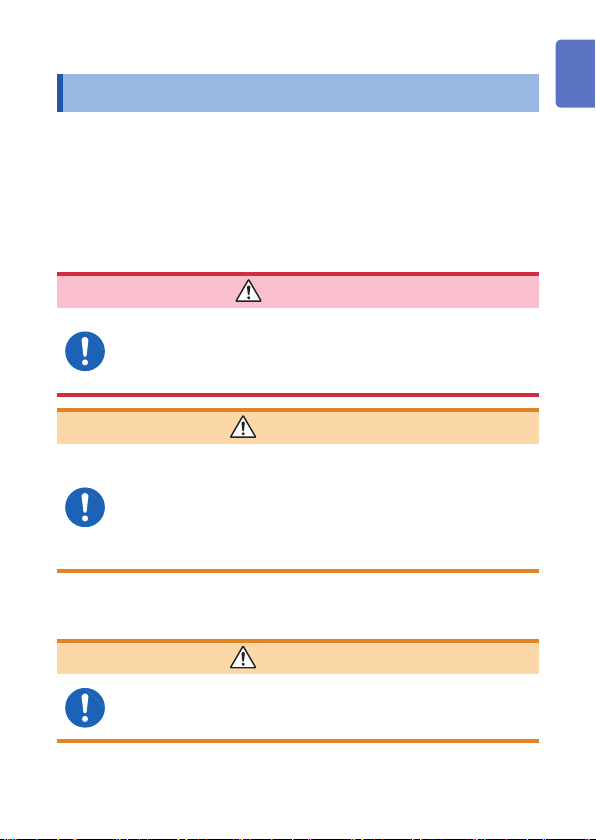

Notation

In this manual, the risk seriousness and the hazard levels are

classifi ed as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will

result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may

result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may

result in minor or moderate injury to the operator or

damage to the instrument or malfunction.

Indicates information related to the operation of the

instrument or maintenance tasks with which the

operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the

instrument is mishandled, this may give rise to a

hazardous situation; the operator may receive an

electric shock, may get burnt or may even be fatally

injured.

Indicates a strong magnetic-fi eld hazard.

The effects of the magnetic force can cause

abnormal operation of heart pacemakers and/or

medical electronics.

Indicates prohibited actions.

Indicates the action which must be performed.

*

Additional information is presented below.

6

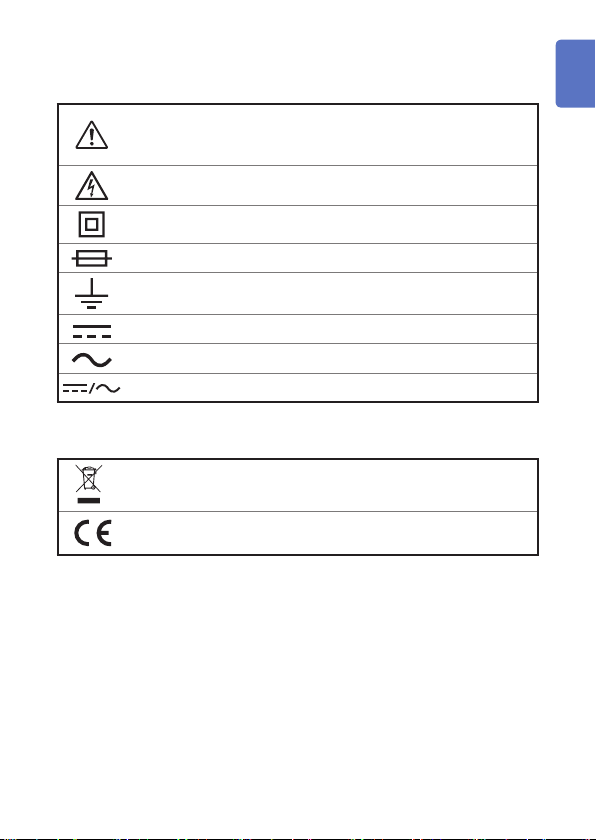

Symbols affi xed to the instrument

Indicates cautions and hazards. When the symbol is printed on

the instrument, refer to a corresponding topic in the Instruction

Manual.

Indicates that dangerous voltage may be present at this terminal.

Safety Notes

1

Indicates a double-insulated device.

Indicates a fuse.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates DC (Direct Current) or AC (Alternating Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment

Directive (WEEE Directive) in EU member states.

Indicates that the instrument conforms to regulations set out by

the EC Directive.

2

3

4

5

6

7

Ind.Appx.

7

Safety Notes

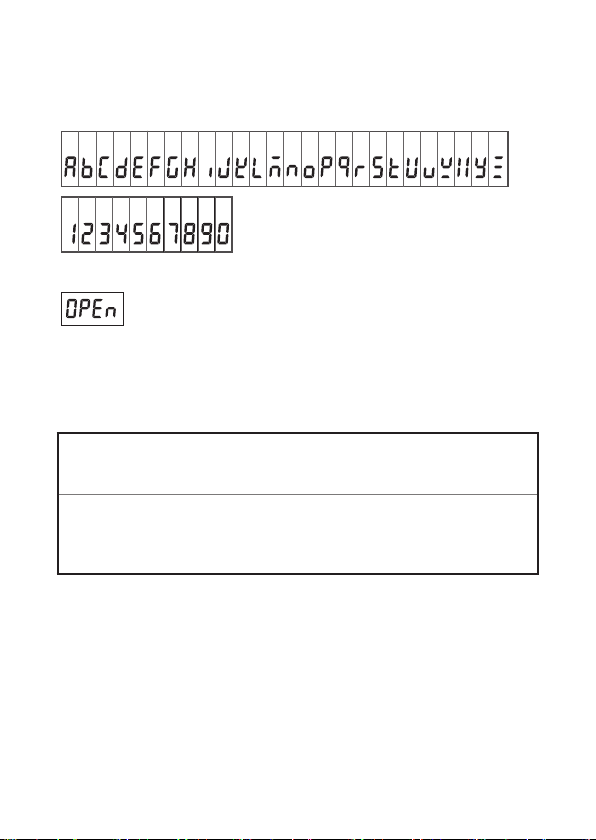

Screen display

This instrument uses the following screen displays.

AB CD E FGH I J K LMNOPQR S TU VWXY Z

123456 7890

A different display is used in the case below.

Appears when a broken Thermocouple (K) is detec ted. (p. 45)

Accuracy

We defi ne measurement tolerances in terms of rdg. (reading) and

dgt. (digit) values, with the following meanings:

(Reading or displayed value)

rdg.

The value currently being measured and indicated on the

measuring instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument,

dgt.

i.e., the input value that causes the digital display to show a “1”

as the least-signifi cant digit.

8

Safety Notes

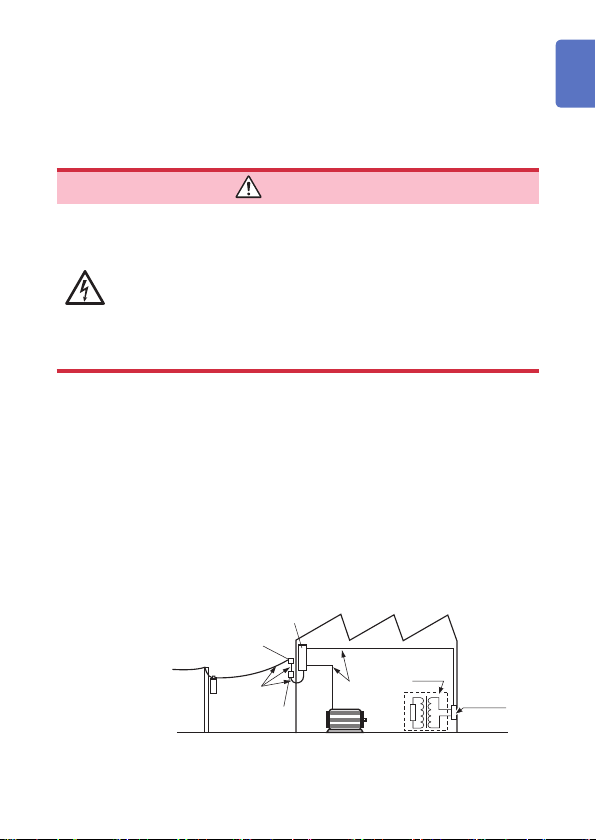

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT II to CAT IV, and called measurement categories.

DANGER

• Using a measuring instrument in an environment

designated with a higher-numbered category than

that for which the instrument is rated could result in

a severe accident, and must be carefully avoided.

• Using a measuring instrument without categories in

an environment designated with the CAT II to CAT

IV category could result in a severe accident, and

must be carefully avoided.

This instrument conforms to the safety requirements for CAT III 1000 V, CAT

IV 600 V measuring instruments.

CAT II: When directly measuring the electrical outlet receptacles of

CAT III: When measuring the primary electrical circuits of heavy equipment

CAT IV: When measuring the circuit from the service drop to the service

See: “2.3 Using Test Leads” (p. 28)

the primary electrical circuits in equipment connected to an

AC electrical outlet by a power cord (portable tools, household

appliances, etc.)

(fi xed installations) connected directly to the distribution panel,

and feeders from the distribution panel to outlets

entrance, and to the power meter and primary overcurrent

protection device (distribution panel)

Distribution panel

Service entrance

Service drop

CAT IV

Power meter

Internal wiring

CAT III

Fixed installation

CAT II

T

Outlet

1

2

3

4

5

6

7

Ind.Appx.

9

Usage Notes

Usage Notes

Follow these precautions to ensure safe operation and to obtain the

full benefi ts of the various functions.

DANGER

If the test lead or the instrument is damaged, there is

a risk of electric shock. Before using the instrument,

perform the following inspection.

• Before using the instrument, check that the coating of

the test leads are neither ripped nor torn and that no

metal parts are exposed. Using the instrument under

such conditions could result in electrocution. Replace

the test leads with those specifi ed by our company.

• Before using the instrument for the fi rst time, verify

that it operates normally to ensure that no damage

occurred during storage or shipping. If you fi nd any

damage, contact your authorized Hioki distributor or

reseller.

Installation

Installing the instrument in inappropriate locations may cause a

malfunction of instrument or may give rise to an accident. Avoid the

following locations. For details on the operating temperature and

humidity, see the specifi cations. (p. 95)

CAUTION

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to a strong electromagnetic fi eld or electrostatic

charge

• Exposed to high quantities of dust particles

• Near induction heating systems (such as high-frequency

induction heating systems and IH cooking equipment)

• Susceptible to vibration

10

Usage Notes

Handling the cables

WARNING

To prevent electric shock, when measuring the

voltage of a power line use a test lead that satisfi es

the following criteria:

• Conforms to safety standards IEC61010 or EN61010

• Of measurement category III or IV

• Its rated voltage is higher than the voltage to be

measured

All of the optional test leads for this device conform

to the safety standard EN61010. Use a test lead in

accordance with its defi ned measurement category

and rated voltage.

CAUTION

• Avoid stepping on or pinching the cable, which could

damage the cable insulation.

• To avoid damaging the cables, do not bend or pull the

leads and the probe bases.

The ends of the test leads are sharp. Be careful to avoid

injury.

For the test leads supplied with the instrument or the options to be connected

to the instrument, see the following information.

Accessories and options Reference

Test lead “2.3 Using Test Leads” (p. 28)

Thermocouples (K) “3.8 Measuring Temperatures” (p. 45)

Clamp-on probe

USB cable “4.13 Communicating with PC” (p. 72)

Magnetic strap

See the Instruction Manual which

accompanies the optional clamp.

“2.4 Installation in Measurement

Location” (p. 31)

1

2

3

4

5

6

7

Ind.Appx.

11

Usage Notes

Precautions during measurement

WARNING

If the instrument is used in locations where the rating

indicated on the instrument or probes is exceeded,

the instrument may be damaged resulting in personal

injury. Do not use the instrument in such locations.

See “Measurement categories” (p. 9).

• With regard to the 10 A range, the maximum input

current is 10 A DC/10 Arms AC. Supplying a current

in excess of the maximum input may damage the

instrument and result in personal injury. Do not

supply current in excess of the specifi ed limit. (Only

the DT4282)

Observe the following to avoid electric shock and/or

short circuits.

• Hazardous voltage may be generated in a free

measurement terminal. Do not touch the free

terminal.

• Use only test leads and optional equipment

specifi ed by our company.

• Do not allow the metal part of the test lead to touch

any exposed metal, or to short between 2 lines.

Never touch the metal end.

• When connecting the clip-type test lead to the

active terminal, do not allow the lead to touch any

exposed metal, or to short between 2 lines.

• When the clamp-on probe is opened, do not allow

the metal part of the clamp to touch any exposed

metal, or to short between 2 lines, and do not

use over bare conductors. (For the clamp current

measurement, only the DT4281)

12

Usage Notes

CAUTION

• Do not input voltage or supply current exceeding the

specifi ed measurement range. Doing so may damage

the instrument.

• During the continuity check, diode test, or measurement

of resistance, conductance, or electrostatic capacity,

measurement signals are generated in the terminals of

the instrument. Depending on the target for measurement,

the measurement signal may cause damage.

Seeing “Measurement current” and “Open circuit

voltage” in the accuracy table (p. 81), check, in advance,

that there are no adverse effects of the measurement

current and the open circuit voltage.

1

2

3

Precautions during shipment

Observe the following during shipment. Hioki cannot be responsible

for damage that occurs during shipment.

CAUTION

• During shipment of the instrument, handle it carefully so

that it is not damaged due to a vibration or shock.

• To avoid damage to the instrument, remove the

accessories and optional equipment from the instrument

before shipment.

If the instrument is not to be used for an extended

period of time

IMPORTANT

To avoid corrosion and/or damage to the instrument due to battery

leakage, remove the batteries from the instrument if it is to be

kept in storage for an extended period.

13

4

5

6

7

Ind.Appx.

1

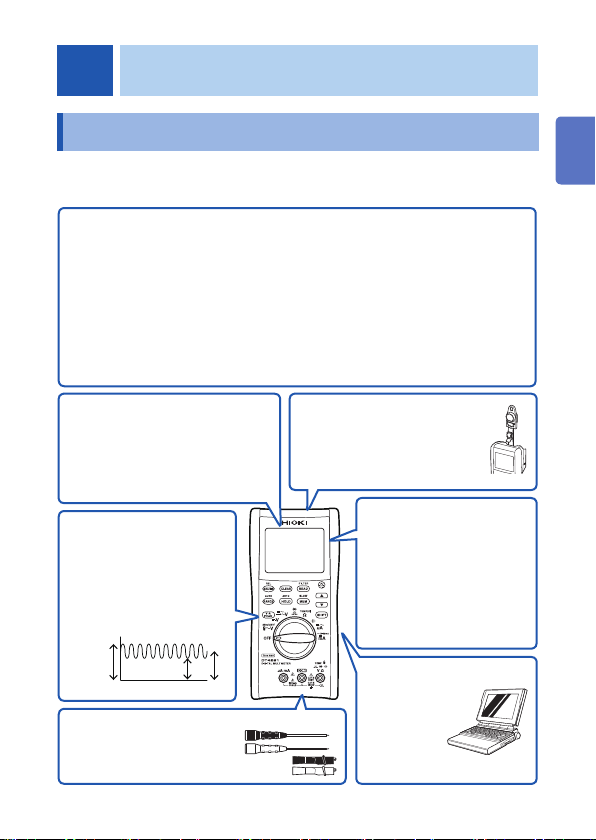

Overview

1.1 Overview and Features

This measuring instrument is a multi-function, high-precision digital

multimeter which ensures both safety and durability.

Main features

• Speedy display of the RMS measured value

• Environmental performance (can be used

anywhere) (Operation temperature: -15 to 55°C)

• High noise-proof performance

• Filter function effective for the inverter measurement

• Solid body which can be used for an extended

period of time (drop-proof)

• High accuracy (DCV: 0.025%), wide band (20 Hz to 100 kHz) measurement

• Speedy measurement via a fast response (0 V 100 V response 1 second*)

* Until the value falls within the accuracy specifi cation range.

If there is an excessive input,

a hazard is indicated by the

red display.

Large, easily-viewable display

Backlighting for use in dark

environments

For the DC power

supply maintenance

The peak measurement

function is used to

capture the ripple voltage

superimposed on the DC

signal.

PEAK max

The measurement test

leads and the end pins can

be selected depending on

the purpose of use.

PEAK min

100V85.9V114.1V

Problem fi nding a

suitable installation

location?

The strap with magnet allows the

device to be hung conveniently.

Useful functions during

measurement

• Noise reduction (FILTER)

• Display stability (SLOW)

• Display hold (HOLD)

• Maximum/Minimum value

display

Memorizing

measured values

For control of the UPS

battery cell voltage, etc.,

the measurement value can

be saved to the embedded

memory (up to 400 data).

The measurement value can

also be read.

Data transmission

to PC,

control

The optional

DT4900-01

Communication

Package is required.

1

2

3

4

5

6

7

Appx. Ind.

15

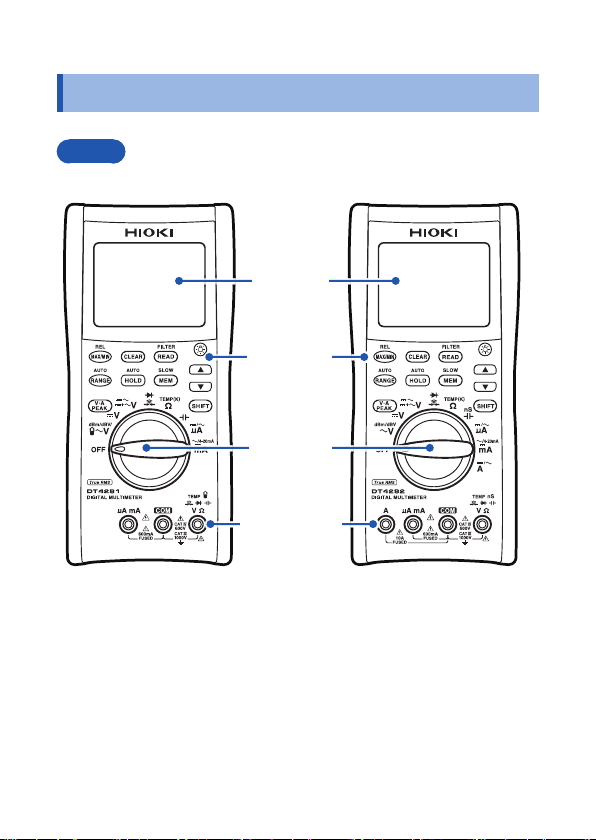

Parts Names and Functions

1.2 Parts Names and Functions

Front

Some indications are different between the DT4281 and DT4282.

Display

(p. 21)

Operation

keys (p. 17)

Rotary

switch

(p. 18)

Measurement

terminals

(p. 19)

DT4281 DT4282

16

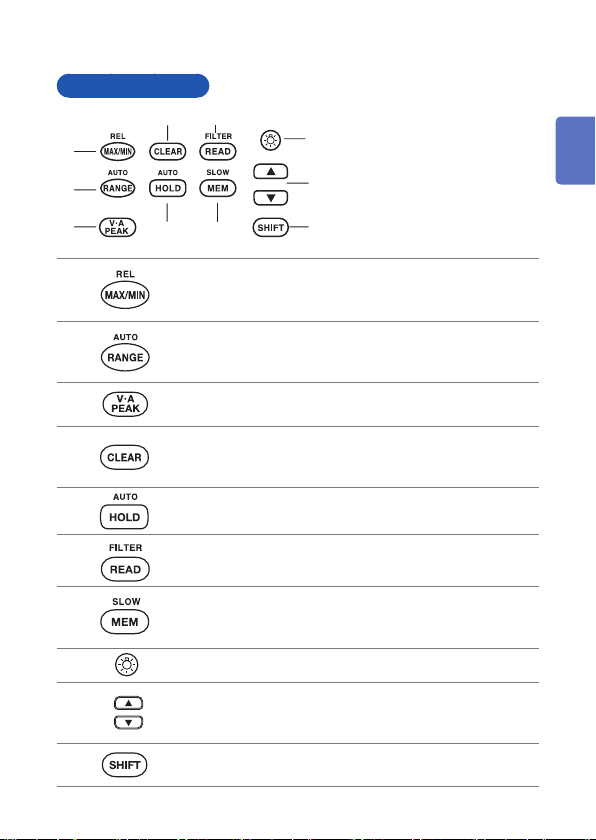

Operation keys

46

1

2

3

5

Parts Names and Functions

(*) Pressing a key for at

8

least 1 second activates

the function indicated

9

above the key

the function, change the

rotary switch setting.

7

10

. To disable

1

2

10

1

2

3

4

5

6

7

8

9

• Displays the maximum or minimum value. (p. 61)

• (*) activates the relative value display function. (p. 63)

• Selects the range (manual range). (p. 55)

• (*) changes to the auto range.

(The default is the auto range.)

Changes to the peak measurement. The maximum or

minimum instantaneous value is measured. (p. 62)

• Deletes the stored data. (p. 68)

• Clears the maximum or minimum value. (p. 61)

• Clears the peak value. (p. 62)

• Retains the displayed value. (p. 57)

• (*) activates the auto hold function.

• Reads the stored data. (p. 67)

• (*) toggles the fi lter function between on and off. (p. 60)

• Saves the measurement data. (p. 65)

• (*) toggles the display update speed between normal and

slow. ([SLOW] is used to stabilize the display.) (p. 59)

Turns on or off the display backlighting. (p. 69)

Increases/Decreases the memory No. or numeric value.

(When / are displayed on the LCD, these keys can be

operated.)

Changes the function of the rotary switch to that indicated

shown in blue.

3

4

5

6

7

Appx. Ind.

17

Parts Names and Functions

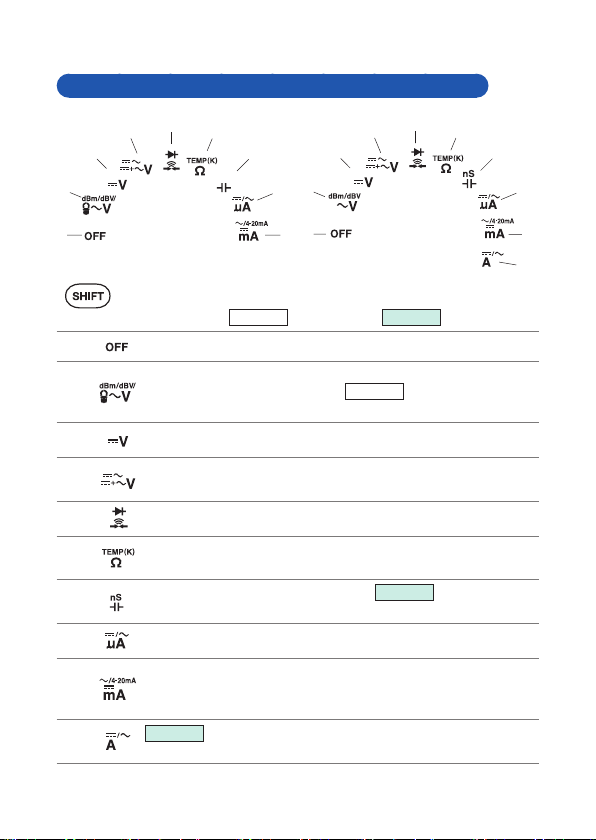

Rotary switches and measurement descriptions

5

4

3

2

1

6

7

3

8

2

9

1

DT4281

is used to change to the measurement shown in blue.

DT4281

: DT4281 only,

10

(

1

2

3

4

5

6

7

8

9

Turns off the power to the instrument.

AC voltage measurement (p. 38) dBm measurement

dBV measurement (p. 41)

measurement (p. 51)

DC voltage measurement (p. 39)

Synthesized voltage measurement of DC and AC Voltage

measurement of AC and DC components (p. 39)

Continuity check (p. 42) Diode test (p. 43)

Resistance measurement (p. 44) Tem pe rat ur e

measurement (compatible with the Thermocouples (K)) (p. 45)

Capacitance measurement (p. 47)

measurement (p. 48)

(6000 A range) DC measurement AC measurement (p. 49)

(600 mA range) DC measurement AC measurement (p. 49)

% conversion of the 4-20 mA input (The % conversion of the

0-20 mA input can be specifi ed via the power-on option.) (p. 53)

(10 A range)

DT4282

DC measurement AC measurement (p. 49)

4

DT4282

DT4281

DT4282

5

DT4282

: DT4282 only)

Clamp current

Conductance

6

7

8

9

10

18

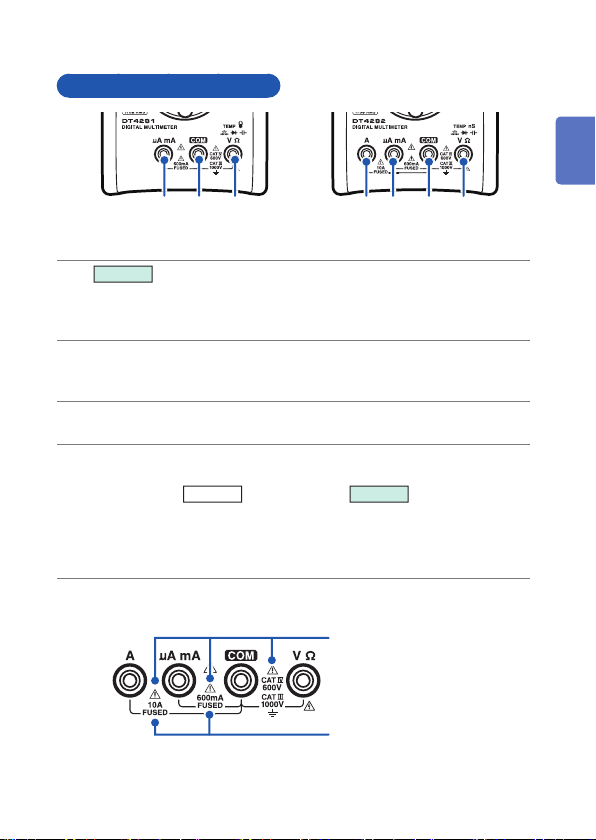

Parts Names and Functions

Measurement terminals

12 3 4234

DT4281 DT4282

DT4282

1

Current measurement (A) terminal. The red test lead is connected.

When the rotary switch is set to the current measurement, the shutter

opens.

Current measurement (A, mA) terminal. The red test lead is

2

connected. When the rotary switch is set to the current measurement,

the shutter opens.

Commonly used for each measurement. The black test lead is

3

connected.

Used for voltage measurement, resistance measurement, continuity

4

check, diode test, temperature measurement, clamp current

measurement

referred to as “V terminal”.

The red test lead is connected.

When the rotary switch is set to any of the measurements above, the

shutter of the current measurement terminal is closed.

DT4281

, or conductance

DT4282

. Hereafter

1

2

3

4

5

6

Be sure to carefully read the precautions in the following references.

See “Precautions during

measurement” (p. 12).

See “Replacing Fuses”

(p. 106).

19

7

Appx. Ind.

Parts Names and Functions

(p )

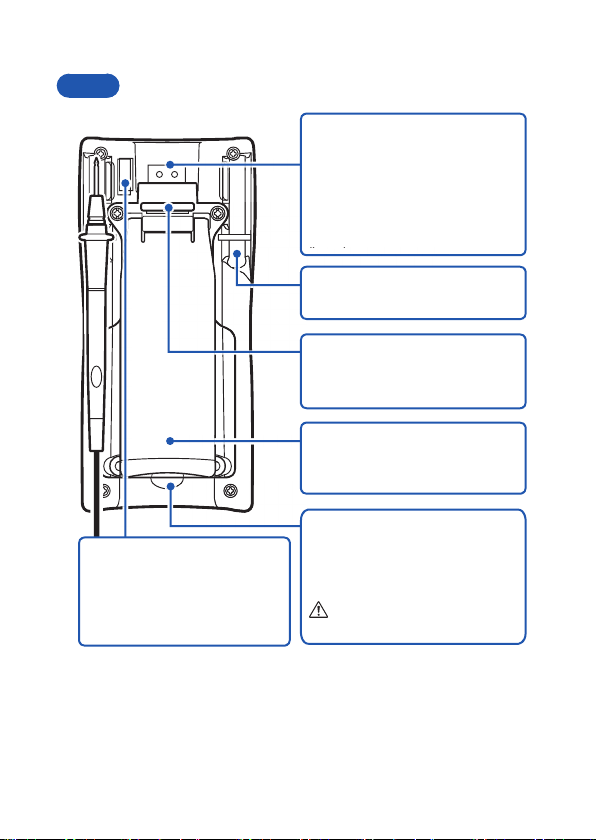

Rear

Serial number label

It is necessary for production

control such as product

warranty.

Do not peel off the label.

Communication port

When the communication

adapter supplied with the optional

DT4900-01 Communication

Package is connected, the data

can be transmitted to the PC.

(p. 72)

Test lead holder

The test lead can be held.

Strap hole

The optional Z5004 Magnetic

Strap can be attached. (p. 31)

Stand

The instrument can be set on the

stand. (p. 31)

Battery cover

When replacing the batteries

(p. 26) or fuse (p. 106), remove

the cover.

See p. 26.

20

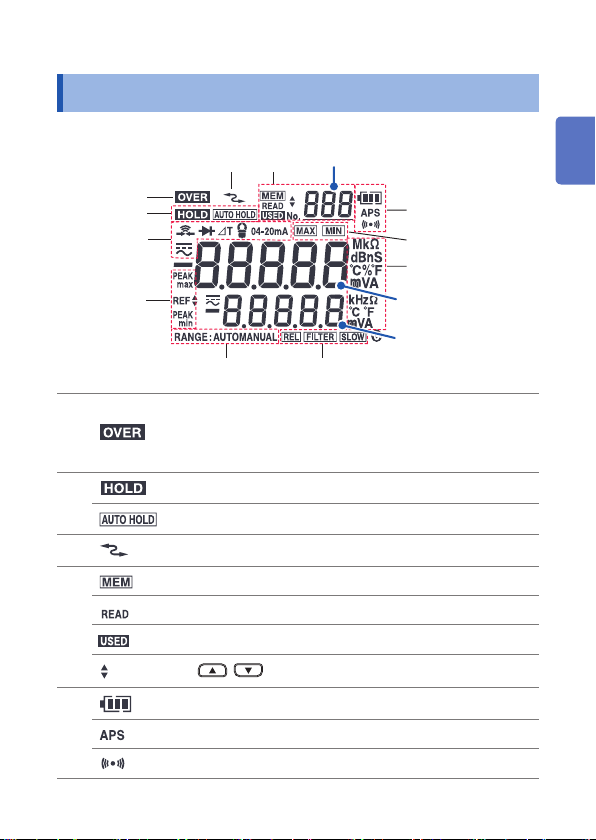

1.3 Display

For error displays, see “6.3 Error Display” (p. 105).

4

Memory No.

89

3

1

2

11

10

Blinks if the maximum value in each range is

1

2

3

4

5

exceeded. (Voltage, current, continuity, diode,

resistance, temperature, electrostatic capacity,

conductance)

Holds measured value. (p. 57)

The auto hold function is activated. (p. 57)

Communicating with the PC. (p. 72)

The memory function is activated. (p. 65)

Memory reading state (p. 67)

Stored data exist. (p. 65)

/ can be operated. (p. 65)

Battery indicator (p.24)

The auto power save function is activated. (p. 70)

The buzzer can be used. (p. 69)

5

6

7

Main display

Sub display

Display

1

2

3

4

5

6

7

Appx. Ind.

21

Display

6

(Unit) Each unit

7

8

9

10

11

Maximum value (p. 61)

Minimum value (p. 61)

The display update (sampling) is performed at SLOW

speed. (p. 59)

The fi lter function is activated. (p. 60)

The relative value display function is activated. (p. 63)

Auto range (p. 55)

Manual range (p. 55)

Maximum value in the peak measurement (p. 62)

Minimum value in the peak measurement (p. 62)

When are displayed, / can be used to

change values.

Threshold of the continuity check (p. 42)

Threshold of the diode test (p. 43)

AC measurement

DC measurement

AC measurement + DC measurement

During the temperature measurement, the

temperature difference from the standard is displayed.

(p. 45)

Continuity check (p. 42)

Diode test (p. 43)

Clamp current measurement (p. 51)

DT4281

% conversion measurement of 4-20 mA (0-20 mA)

(p. 53)

DT4281

(

22

: DT4281 only,

DT4282

: DT4282 only)

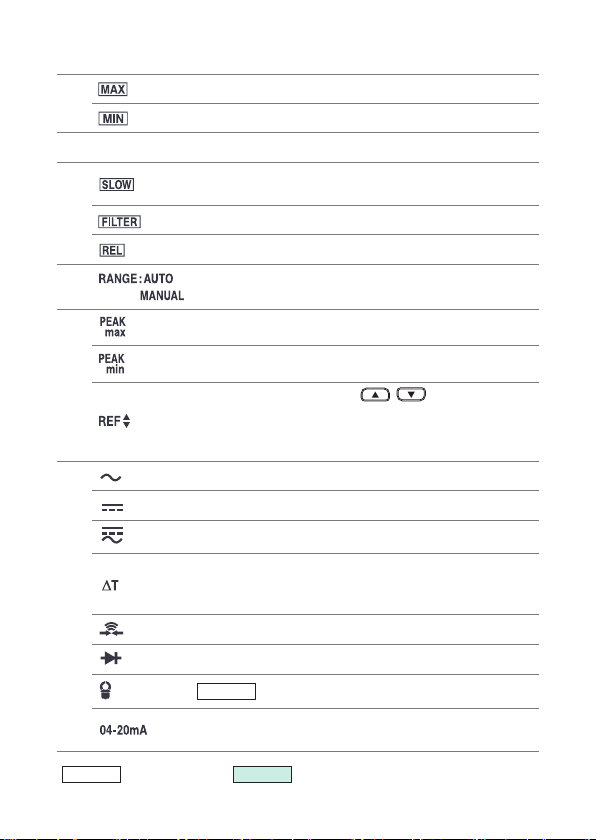

Alarm Display and Battery Indicator

1.4 Alarm Display and Battery Indicator

The following conditions are informed via the red backlight,

display, and buzzer.

When the maximum input range is exceeded

Voltage/Current measurement

blinks, the red backlight blinks,

the maximum value within the maximum

range blinks, and the buzzer sounds.

Corrective action:

Immediately move the test leads away

from the measurement object.

When the measured value exceeds the maximum value

in each range ( Range over)

Voltage/Current measurement

blinks, the red backlight lights up,

and the maximum value blinks.

1

2

3

4

5

Corrective action:

and the maximum value blinks.

Change the range.

Measurements other than voltage and current

6

7

Appx. Ind.

Corrective action:

Change the range, or measure the

samples in the specifi ed range.

If the same symptom still occurs, check

that the test leads are not broken.

(p.34)

23

Alarm Display and Battery Indicator

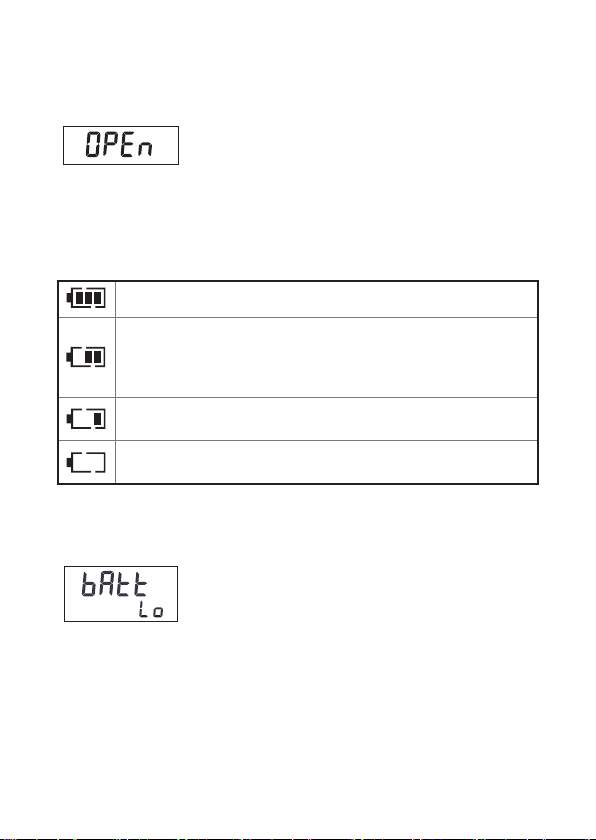

When the Thermocouple (K) is broken (Temperature

measurement)

Corrective action:

Check that the thermocouple has been connected

correctly to the measurement terminal. If the display

does not change, replace with a new Thermocouple

(K). (p. 45)

Battery indicator

Fully charged. (Charge: 60% or more)

As the battery charge diminishes,

black charge bars disappear, one

by one, from the left of the battery

indicator.

The battery voltage is low. Replace the

batteries as soon as possible.

(Blinks) The battery is exhausted.

Replace the batteries.

The charge is only a reference for the continuous operation time. (p. 96)

(Charge: 20% or more)

(Charge: 5% or more)

(Charge: less than 5%)

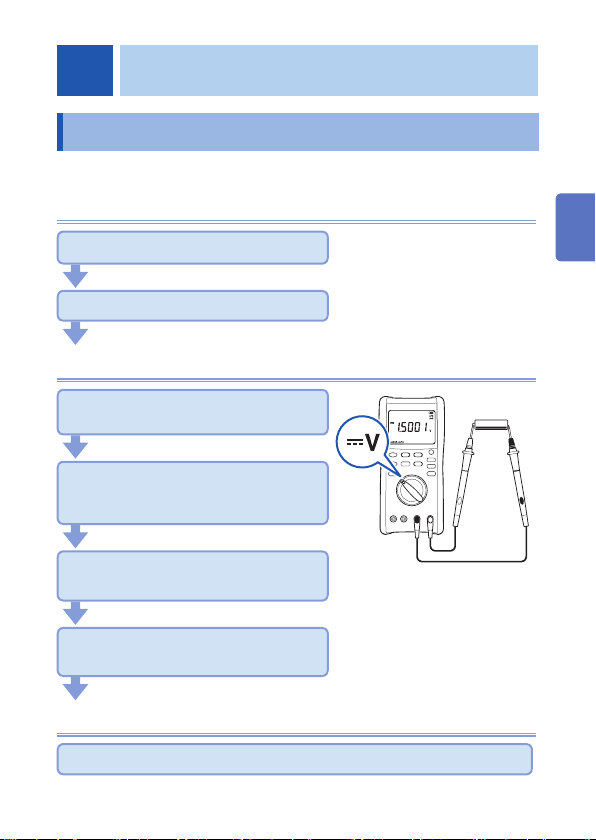

Power shutdown

When the charge is 0% (less than 3.8 V ± 0.2 V),

[bAtt Lo] is displayed for 1 second and the power is

shut down.

24

Preparation for Measurements

2

3

1

2

2.1 Measurement Workfl ow

Before using the instrument, be sure to read “Usage Notes” (p. 10).

Installation and connection

Insert the batteries. (p. 26)

Perform the startup check. (p. 33)

Measurement

Turn on the power and select the

measurement function.

Attach the test leads to the

measurement terminals. (p. 28)

(As necessary, perform zero adjustment. (p. 64))

Connect the test leads to the

measurement object.

(As necessary)

Hold the display of the measured value. (p. 57)

Save the measured value. (p. 65)

As necessary, have other

optional items available and

ready.

1

Black

2

Red

1

2

3

4

3

5

6

7

Appx. Ind.

End of the measurement

Move the test leads away from the measurement object and then turn off the power.

25

Inserting/Replacing Batteries

2.2 Inserting/Replacing Batteries

Before using the instrument fi rst time, insert four LR6 alkaline

batteries. Before measurements, check that the battery level is

suffi cient. When the battery charge diminishes, replace the batteries.

Nickel-metal hydride batteries

Nickel-metal hydride batteries can be used. However, the discharge

characteristic of these batteries is different from that of alkaline

batteries. Be aware that the remaining battery power display does

not function properly.

WARNING

To avoid electric shock, disconnect the test leads from

the object to be measured before replacing the batteries.

To avoid the possibility of explosion, do not short

circuit, charge, disassemble, or incinerate batteries.

After battery replacement but before using the

instrument, reattach and screw down the battery cover.

CAUTION

Poor performance or damage from battery leakage

could result. Observe the cautions listed below.

• Do no mix new and old batteries, or different types of

batteries.

• Be careful to observe the battery polarity during installation.

• Do not use batteries after their recommended expiry date.

• Do not allow used batteries to remain in the instrument.

• To avoid corrosion from battery leakage and/or damage to

the instrument, remove the batteries from the instrument

if it is to be kept in storage for an extended period.

26

Loading...

Loading...