Page 1

Instruction Manual

使用说明书

DT4211

DT4212

DIGITAL MULTIMETER

数字万用表

November 2013 Revised edition 1

2013年11月 修订一版

DT4211A981-01 13-11H

Page 2

Page 3

Contents

Introduction .........................................................................1

Verifying Package Contents ..............................................1

Options (sold separately) ..................................................2

Safety Notes ........................................................................4

Usage Notes ........................................................................8

1 Overview 15

1.1 Overview and Features .................................15

1.2 Parts Names and Functions .........................16

1.3 Display ...........................................................21

1

2

3

2 Preparation for Measurements 23

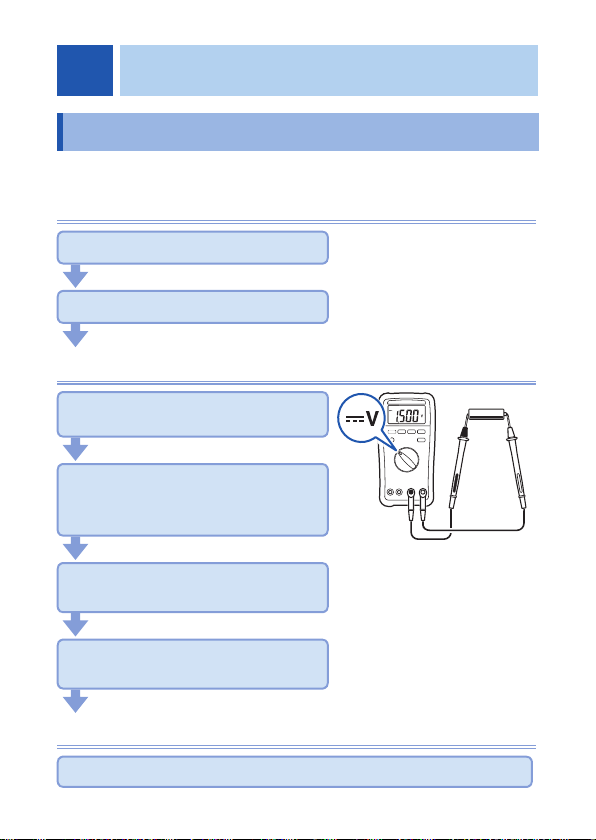

2.1 Measurement Workfl ow ................................23

2.2 Inserting/Replacing Batteries ......................24

2.3 Using Test Leads ...........................................26

3 Performing Measurements 29

3.1 Inspection Before Use ..................................29

3.2 Measuring Voltage.........................................33

Measuring AC voltage ...............................................33

Measuring DC voltage ..............................................34

3.3 Measuring Resistance ..................................35

3.4 Measuring Diode ...........................................36

3.5 Checking Continuity .....................................37

3.6 Measuring Electrostatic Capacities .............38

3.7 Measuring Frequencies ................................39

3.8 Measuring Duty Ratio ...................................40

3.9 Measuring Current ........................................41

Measuring DC/AC .....................................................41

4

5

6

7

Ind.Appx.

i

Page 4

Contents

3.10 Measuring Temperatures (DT4212)..............43

4 Using Instrument Conveniently 45

4.1 Selecting the Measurement Range ..............45

Measuring with the auto range .................................45

Measuring with the manual range .............................45

4.2 Retaining the Measured Value .....................46

Retaining the measured value (HOLD) .....................46

4.3 Checking the Relative Value/Performing

Zero Adjustment ............................................47

Checking the relative value (REL) ............................47

Performing zero adjustment ......................................48

4.4 Turning On the Backlight ..............................49

4.5 Using the Auto Power Save (APS) ...............49

5 Specifi cations 51

5.1 General Specifi cations .................................51

5.2 Electrical Characteristics .............................53

5.3 Accuracy Table ..............................................55

6 Maintenance and Service 63

6.1 Repair Inspection and Cleaning .................63

6.2 Troubleshooting ............................................64

6.3 Replacing Fuses ............................................67

Appendix Appx.1

Appx. 1 RMS and Average .............................Appx.1

ii

Page 5

Introduction

Introduction

Thank you for purchasing the HIOKI DT4211 (Average value

measurement model), DT4212 (True RMS measurement model)

Digital Multimeter.

To obtain maximum performance from the product, please read this

manual fi rst, and keep it handy for future reference.

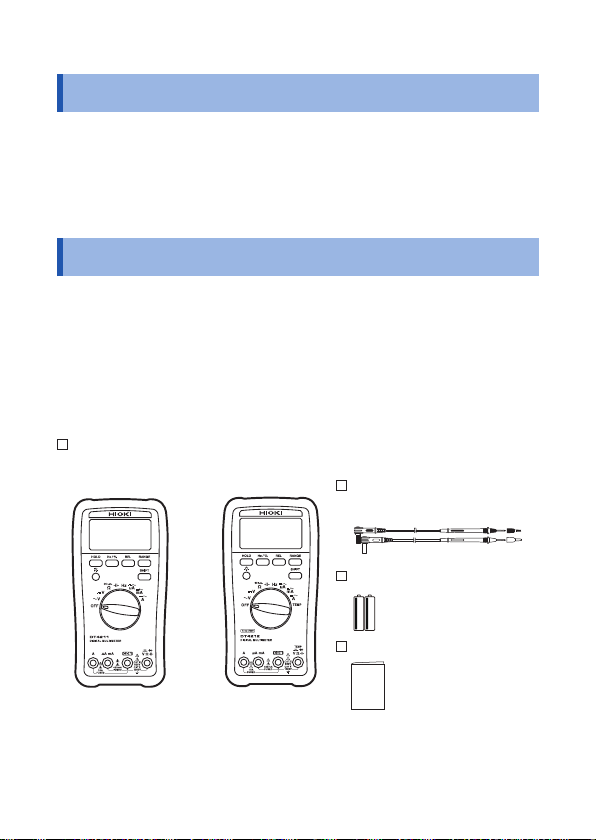

Verifying Package Contents

1

2

When you receive the instrument, inspect it carefully to ensure that

no damage occurred during shipping.

In particular, check the accessories, panel switches, and connectors.

If damage is evident, or if it fails to operate according to the

specifi cations, contact your authorized Hioki distributor or reseller.

Check the package contents as follows.

DT4211 (Average value measurement model) or DT4212 (True RMS

measurement model)

L9206 Test Lead

(p. 27)

R6P manganese battery × 2

DT4211

(Average value

measurement model)

The holster has been attached.

DT4212

(True RMS

measurement model)

Instruction Manual

1

3

4

5

6

7

Ind.Appx.

Page 6

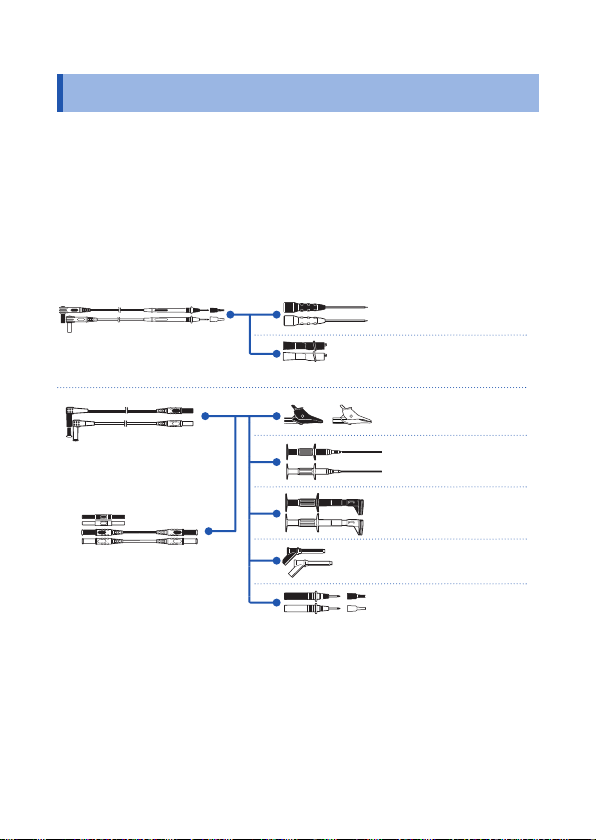

Options (sold separately)

Options (sold separately)

The following options are available for the instrument. Contact your

authorized Hioki distributor or reseller when ordering.

Connecting cables

*1: CAT IV 600 V/CAT III 1000 V/CAT II 1000 V

*2: CAT IV 600 V/CAT III 1000 V

*3: CAT III 1000 V *5: CAT III 300 V/CAT II 600 V

*4: CAT III 600 V *6: AC33 V /DC70 V

*1

L9206

Test Lead

*2

L4930

Connection Cable Set

(Length: 1.2 m)

*2

L4931

Extension Cable Set

(Length: 1.5 m, with the

coupling connector)

*6

L4933

Contact Pin Set

*5

L4934

Small Alligator Clip Set

*2

L4935

Alligator Clip Set

*3

9243

Grabber Clip

*4

L4936

Bus Bar Clip Set

*3

L4937

Magnetic Adapter Set

*1

L4932

Test Pin Set

2

Page 7

Options (sold separately)

Temperature measurement (Only the DT4212 (True RMS

measurement model))

DT4910 Thermocouples (K) (p. 43)

• Temperature measuring junction: Exposed type (welding)

• Sensor length: Approx. 800 mm

Operating temperature: -40°C to 260°C (temperature

•

measuring part), -15°C to 55°C (connector)

Allowable tolerance: ±2.5°C

•

Carrying Case

C0201 Carrying Case

The instrument, test leads, instruction manual, and others

can be stored in the case.

C0202 Carrying Case

The instrument, test leads, instruction manual, and others

can be stored in the case.

Z5004 Magnetic Strap

Attach this strap to the instrument and secure it on the

For the detailed procedure of the C0201 Carrying Case and Z5004 Magnetic

Strap, refer to our Website.

wall surface such as a metal plate for use.

Handling the strap (p. 11)

1

2

3

4

5

6

7

Ind.Appx.

3

Page 8

Safety Notes

Safety Notes

This instrument is designed to conform to IEC 61010 Safety

Standards, and has been thoroughly tested for safety prior to

shipment. However, using the instrument in a way not described in

this manual may negate the provided safety features.

Before using the instrument, be certain to carefully read the

following safety notes.

DANGER

Mishandling during use could result in injury or death,

as well as damage to the instrument. Be certain that

you understand the instructions and precautions in

the manual before use.

WARNING

With regard to the electricity supply, there are risks

of electric shock, heat generation, fi re, and arc

discharge due to short circuits. If persons unfamiliar

with electricity measuring instruments are to use

the instrument, another person familiar with such

instruments must supervise operations.

Protective gear

WARNING

To avoid electric shock when measuring live lines,

wear appropriate protective gear, such as insulated

rubber gloves, boots and a safety helmet.

4

Page 9

Safety Notes

Notation

In this manual, the risk seriousness and the hazard levels are

classifi ed as follows.

DANGER

WARNING

CAUTION

IMPORTANT

Indicates an imminently hazardous situation that will

result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may

result in death or serious injury to the operator.

Indicates a potentially hazardous situation that may

result in minor or moderate injury to the operator or

damage to the instrument or malfunction.

Indicates information related to the operation of the

instrument or maintenance tasks with which the

operators must be fully familiar.

Indicates a high voltage hazard.

If a particular safety check is not performed or the

instrument is mishandled, this may give rise to a

hazardous situation; the operator may receive an

electric shock, may get burnt or may even be fatally

injured.

Indicates a strong magnetic-fi eld hazard.

The effects of the magnetic force can cause

abnormal operation of heart pacemakers and/or

medical electronics.

1

2

3

4

5

6

Indicates prohibited actions.

7

*

Indicates the action which must be performed.

Additional information is presented below.

Ind.Appx.

5

Page 10

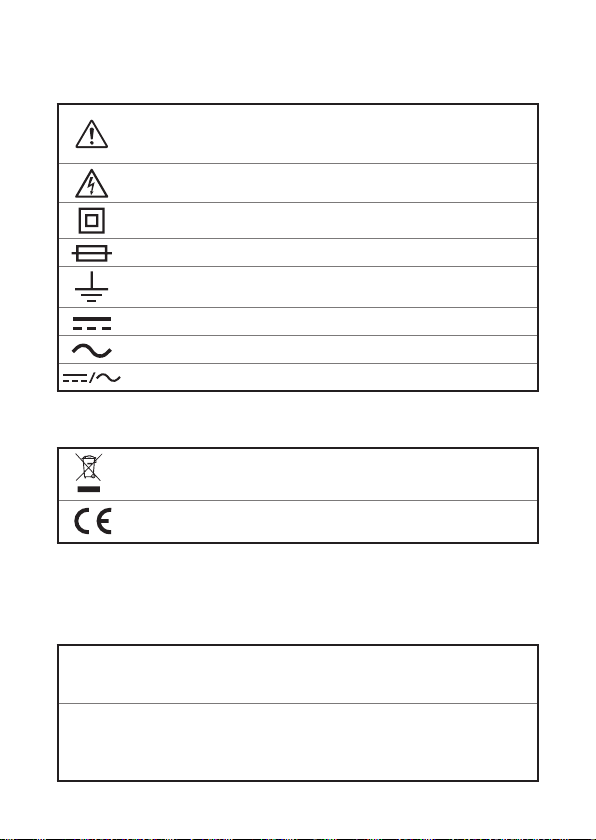

Safety Notes

Symbols affi xed to the instrument

Indicates cautions and hazards. When the symbol is printed on

the instrument, refer to a corresponding topic in the Instruction

Manual.

Indicates that dangerous voltage may be present at this terminal.

Indicates a double-insulated device.

Indicates a fuse.

Indicates a grounding terminal.

Indicates DC (Direct Current).

Indicates AC (Alternating Current).

Indicates DC (Direct Current) or AC (Alternating Current).

Symbols for various standards

Indicates the Waste Electrical and Electronic Equipment

Directive (WEEE Directive) in EU member states.

Indicates that the instrument conforms to regulations set out by

the EC Directive.

Accuracy

We defi ne measurement tolerances in terms of rdg. (reading) and

dgt. (digit) values, with the following meanings:

(Reading or displayed value)

rdg.

The value currently being measured and indicated on the

measuring instrument.

(Resolution)

The smallest displayable unit on a digital measuring instrument,

dgt.

i.e., the input value that causes the digital display to show a “1”

as the least-signifi cant digit.

6

Page 11

Safety Notes

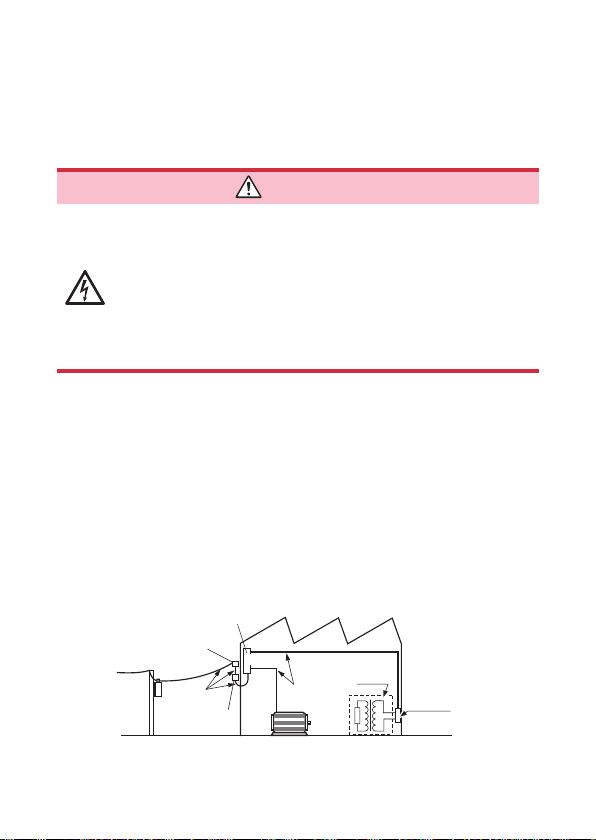

Measurement categories

To ensure safe operation of measuring instruments, IEC 61010

establishes safety standards for various electrical environments,

categorized as CAT II to CAT IV, and called measurement categories.

DANGER

• Using a measuring instrument in an environment

designated with a higher-numbered category than

that for which the instrument is rated could result in

This instrument conforms to the safety requirements for CAT II 1000 V, CAT III

600 V measuring instruments.

CAT II: When directly measuring the electrical outlet receptacles of

CAT III: When measuring the primary electrical circuits of heavy equipment

CAT IV: When measuring the circuit from the service drop to the service

See: “2.3 Using Test Leads” (p. 26)

a severe accident, and must be carefully avoided.

• Using a measuring instrument without categories in

an environment designated with the CAT II to CAT

IV category could result in a severe accident, and

must be carefully avoided.

the primary electrical circuits in equipment connected to an

AC electrical outlet by a power cord (portable tools, household

appliances, etc.)

(fi xed installations) connected directly to the distribution panel,

and feeders from the distribution panel to outlets

entrance, and to the power meter and primary overcurrent

protection device (distribution panel)

Distribution panel

Service entrance

Service drop

CAT IV

Power meter

Internal wiring

CAT III

Fixed installation

CAT II

T

Outlet

7

1

2

3

4

5

6

7

Ind.Appx.

Page 12

Usage Notes

Usage Notes

Follow these precautions to ensure safe operation and to obtain the

full benefi ts of the various functions.

DANGER

If the test lead or the instrument is damaged, there is

a risk of electric shock. Before using the instrument,

perform the following inspection.

• Before using the instrument, check that the coating of

the test leads are neither ripped nor torn and that no

metal parts are exposed. Using the instrument under

such conditions cou l d resu lt i n e lectrocuti on. Replace

the test leads with those specifi ed by our company.

• To avoid electric shock, check that the white or

red portion (insulated layer) within the cable is not

exposed. Do not use the cable if its internal colored

portion is exposed.

• Before using the instrument the fi rst time, veri fy that i t

operates normally to ensure that no damage occurred

during storage or shipping. If you fi nd any damage,

contact your authorized Hioki distributor or reseller.

8

Page 13

Usage Notes

Installation

Installing the instrument in inappropriate locations may cause a

malfunction of instrument or may give rise to an accident. Avoid the

following locations.

For details on the operating temperature and humidity, see the

specifi cations. (p. 51)

1

CAUTION

• Exposed to direct sunlight or high temperature

• Exposed to corrosive or combustible gases

• Exposed to water, oil, chemicals, or solvents

• Exposed to high humidity or condensation

• Exposed to a strong electromagnetic fi eld or electrostatic

Using the instrument with the stand

charge

• Exposed to high quantities of dust particles

• Near induction heating systems (such as high-frequency

induction heating systems and IH cooking equipment)

• Susceptible to vibration

• An unstable table or inclined surface

CAUTION

• Do not position the instrument on an

unstable table or inclined surface.

• When the instrument is set on the

stand, do not apply a strong force

above. Doing so may damage the

stand.

2

3

4

5

6

7

Ind.Appx.

9

Page 14

Usage Notes

Handling the cables

WARNING

To prevent electric shock, when measuring the

voltage of a power line use a test lead that satisfi es

the following criteria:

• Conforms to safety standards IEC61010 or EN61010

• Of measurement category II or III

• Its rated voltage is higher than the voltage to be

measured

All of the optional test leads for this instrument

conform to the safety standard EN61010. Use a test

lead in accordance with its defi ned measurement

category and rated voltage.

CAUTION

• Avoid stepping on or pinching the cable, which could

For the test leads supplied with the instrument or the options to be connected

to the instrument, see the following information.

Accessories and options

Test lead “2.3 Using Test Leads” (p. 26)

Thermocouples (K) “3.10 Measuring Temperatures (DT4212)”

damage the cable insulation.

• To avoid damaging the cables, do not bend or pull the

leads and the probe bases.

The ends of the test leads are sharp. Be careful to avoid

injury.

Reference

(p. 43)

10

Page 15

Handling the strap

Those with medical electronics such as pacemakers

should not use the Z5004 Magnetic Strap. Nor should

such persons approach the Z5004. It is extremely

dangerous. The electronics may not operate properly

and the life of the operator may be put at great risk.

• Do not use the Z5004 in locations where it may

be exposed to rainwater, dust, or condensation. In

those conditions, the Z5004 may be decomposed or

deteriorated. The magnet adhesion may be diminished.

In such case, the instrument may not be hung in place

and may fall.

• Do not bring the Z5004 near magnetic media such

as fl oppy disks, magnetic cards, pre-paid cards, or

magnetized tickets. Doing so may corrupt and may

render them unusable. Furthermore, if the Z5004 is

brought near precision electronic equipment such as

PCs, TV screens, or electronic wrist watches, they may

fail.

Usage Notes

DANGER

1

2

CAUTION

3

4

5

6

7

11

Ind.Appx.

Page 16

Usage Notes

Precautions during measurement

WARNING

If the instrument is used in locations where the rating

indicated on the instrument or probes is exceeded,

the instrument may be damaged resulting in personal

injury. Do not use the instrument in such locations.

See “Measurement categories” (p. 7).

• With regard to the 10 A range, the maximum input

current is 10 A DC/10 Arms AC. Supplying a current

in excess of the maximum input may damage the

instrument and result in personal injury. Do not

supply current in excess of the specifi ed limit.

Observe the following to avoid electric shock and/or

short circuits.

• Hazardous voltage may be generated in a free

measurement terminal. Do not touch the free

terminal.

• Use only test leads and optional equipment

specifi ed by our company.

• Do not allow the metal part of the test lead to touch

any exposed metal, or to short between 2 lines.

Never touch the metal end.

• When connecting the clip-type test lead to the

active terminal, do not allow the lead to touch any

exposed metal, or to short between 2 lines.

12

Page 17

CAUTION

• Do not input voltage or supply current exceeding the

specifi ed measurement range. Doing so may damage

the instrument.

• During the continuity chec k , diode test, or measureme nt

of resistance or electrostatic capacity, measurement

signals are generated in the terminals of the instrument.

Depending on the target for measurement, the

measurement signal may cause damage.

Seeing “Measurement current” and “Open circuit

voltage” in the accuracy table (p. 55), check, in advance,

that there are no adverse effects of the measurement

current and the open circuit voltage.

Usage Notes

1

2

3

Precautions during shipment

Observe the following during shipment. Hioki cannot be responsible

for damage that occurs during shipment.

CAUTION

• During shipment of the instrument, handle it carefully so

that it is not damaged due to a vibration or shock.

• To avoid damage to the instrument, remove the

If the instrument is not to be used for an extended

period of time

IMPORTANT

To avoid corrosion and/or damage to the instrument due to battery

leakage, remove the batteries from the instrument if it is to be

kept in storage for an extended period.

accessories and optional equipment from the instrument

before shipment.

13

4

5

6

7

Ind.Appx.

Page 18

Usage Notes

14

Page 19

Overview

1

1.1 Overview and Features

This instrument is a multi-function digital multimeter that performs

measurement functions for items such as voltage, current,

resistance, and capacity.

Main features and functions

• Large display on which the measured values can be read easily

• Environmental performance (can be used anywhere) (Operation

temperature: -10 to 50ºC (14°F to 122°F))

• Display hold (HOLD)

• Low power consumption for an extended time

Problem fi nding a suitable

installation location?

The strap with magnet allows the

For various purposes

The measurement test leads

and end pins can be selected.

instrument to be hung conveniently.

Large display of values

Backlighting to allow

users to read the

measurement values

in dark environments

15

Page 20

Parts Names and Functions

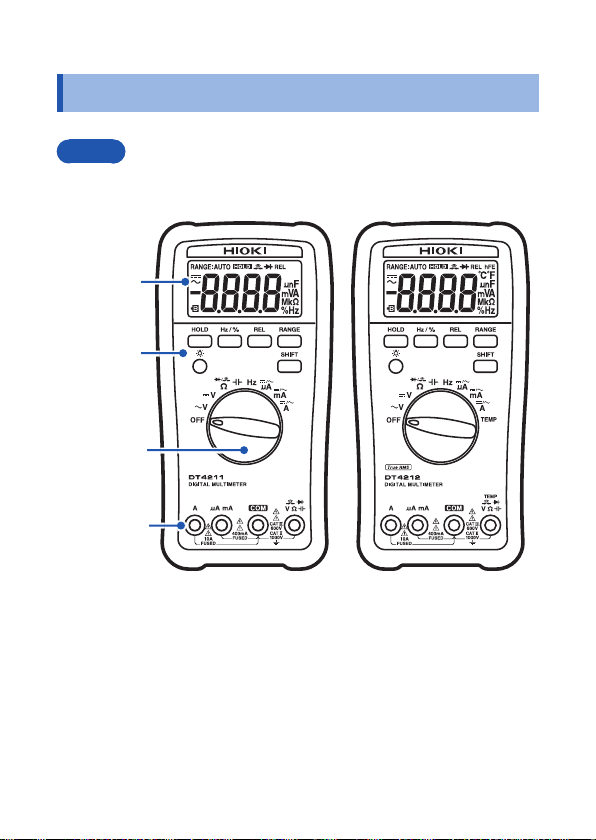

1.2 Parts Names and Functions

Front

Some indications are different between the DT4211 (Average value

measurement model) and DT4212 (True RMS measurement model)

Display

(p. 21)

Operation

keys (p. 17)

Rotary

switch

(p. 18)

Measurement

terminals

(p. 19)

DT4211

(Average value

measurement model)

DT4212

(True RMS

measurement model)

16

Page 21

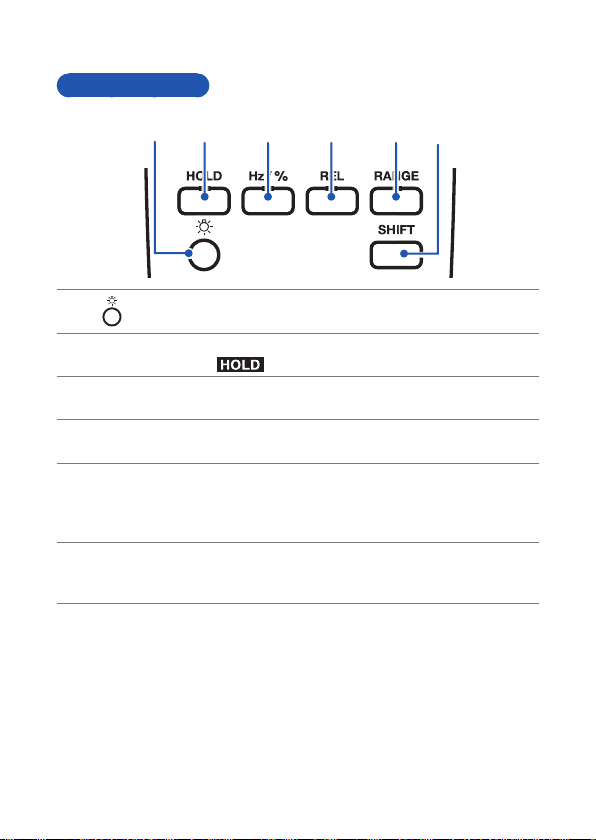

Operation keys

2

3

4

55 6

1

1

2

3

4

5

6

Parts Names and Functions

1

2

3

4

5

6

HOLD

Hz/%

REL

RANGE

SHIFT

2

1

3

4

Backlight key

Turns on/off the backlight. (p. 49)

Manually sets/cancels the hold function for the displayed

value. (

Switches the frequency (p. 39) and duty ratio (p. 40)

display.

Displays the relative value (REL). (p. 47) ([REL] lights up/

goes off.)

Sets the manual range and switches the range. (p. 45)

(Turns on/off the [RANGE:AUTO])

Cancels the manual range. (Pressed down for at least 1

second.)

Switches the function.

Cancels the auto power save function (APS). (Power-on

option)

lights up/goes off.) (p. 46)

6

17

Page 22

Parts Names and Functions

1

3

4

5

6

7

2

2

5

33 4

6

1

2

3

4

5

6

7

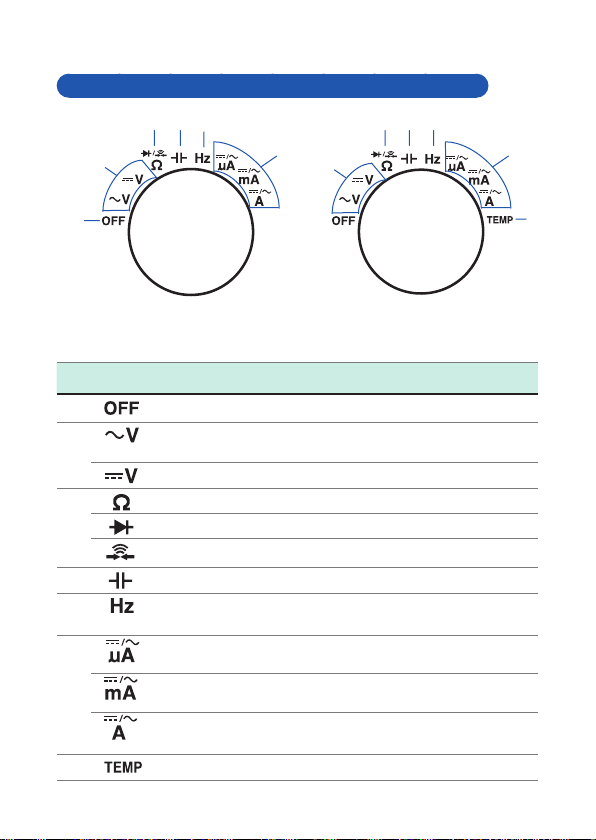

Rotary switches and measurement descriptions

3

4

5

6

2

2

5

4

6

1

measurement model)

1

2

3

4

5

6

7

DT4211

(Average value

Function

AC voltage and frequency

measurement

DC voltage measurement

Resistance measurement

Diode test

Continuity check

Electrostatic capacity

Frequency and duty ratio

measurement

DC (A) measurement/AC (A)

measurement

DC (mA) measurement/AC (mA)

measurement

DC (A) measurement/AC (A)

measurement

Temperature measurement -

DT4212

(True RMS

measurement model)

DT4211 DT4212

7

18

Page 23

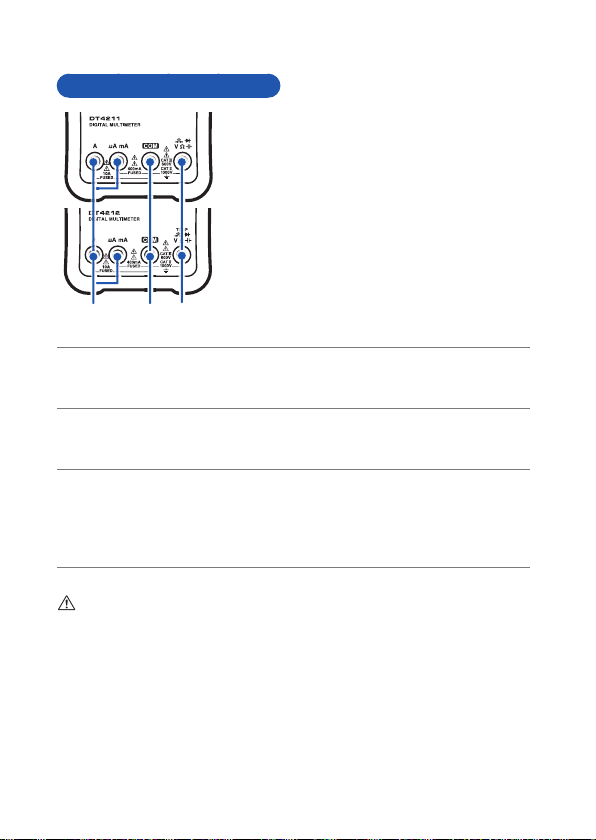

Measurement terminals

1

22 3

1

2

3

DT4211

(Average value measurement model)

Parts Names and Functions

DT4212

(True RMS measurement model)

3

1

Current measurement terminal.

1

Hereafter referred to as “A terminal (A terminal, mA terminal)”.

The red test lead is connected.

Commonly used for each measurement.

2

Hereafter referred to as “COM terminal”.

The black test lead is connected.

Used for voltage measurement, resistance measurement, continuity

3

check, diode test, temperature measurement, or electrostatic capacity

measurement.

Hereafter referred to as “V terminal”.

The red test lead is connected.

Be sure to carefully read the following precautions for the terminals with the

marking.

• “Precautions during shipment” (p. 13)

• “6.3 Replacing Fuses” (p. 67)

19

Page 24

Parts Names and Functions

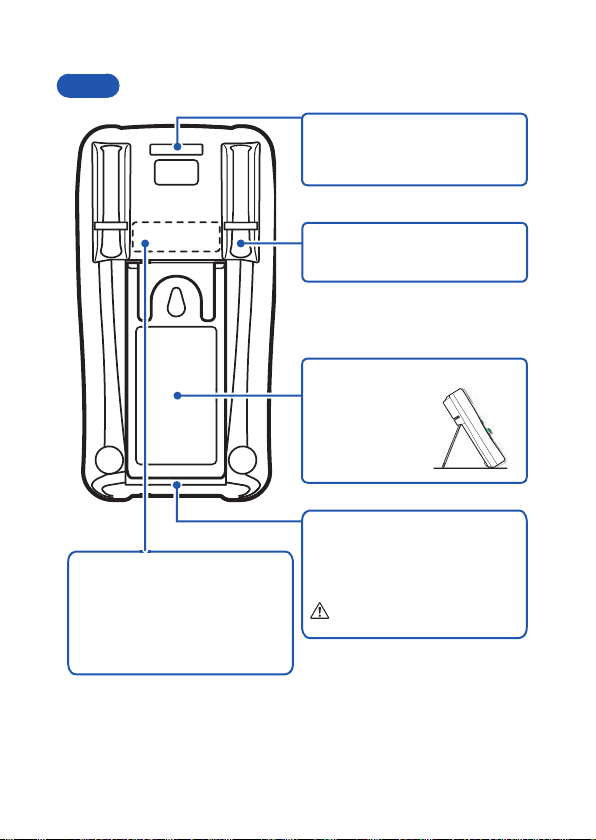

Rear

Serial number label

It is necessary for production

control such as product warranty.

Do not peel off the label.

Before checking the serial

number, remove the holster.

Strap hole

The optional Z5004 Magnetic

Strap can be attached.

Test lead holder

The test lead can be held.

Stand

The instrument

can be set on the

stand.

Battery cover

When replacing the batteries

(p. 24) or fuse (p. 67), remove the

cover.

See p. 24.

20

Page 25

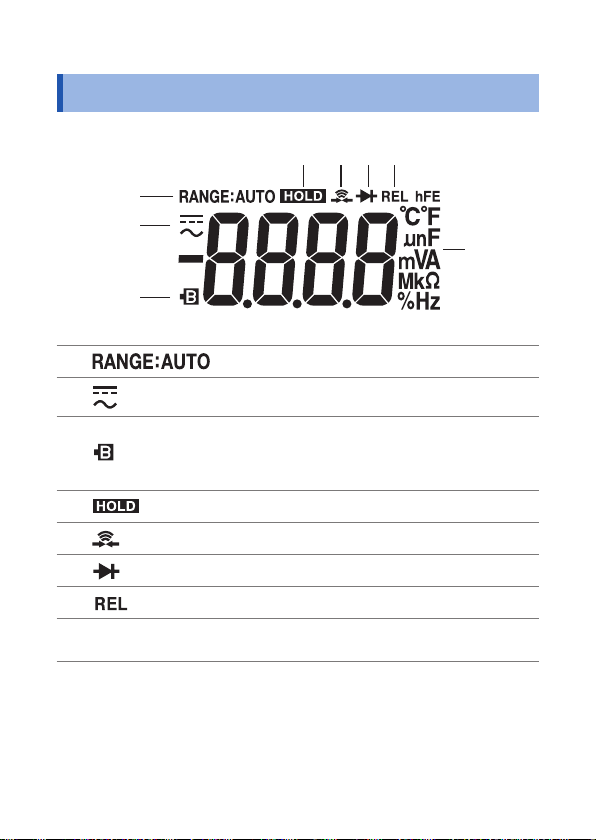

1.3 Display

1

2

3

4

5

6

7

8

1

2

3

4

Display

567

8

1

2

3

4

5

6

7

Each measurement

8

unit

Auto range (p. 45)

DC, AC

Battery warning indicator

Lights up when the battery voltage falls below

the voltage at which accuracy is guaranteed (2.4

V ± 0.15 V).

Retention of the measured value. (p. 46)

Continuity check (p. 37)

Diode (p. 36)

Relative value display (p. 47)

21

Page 26

Display

22

Page 27

2

3

1

Preparation for Measurements

2

2.1 Measurement Workfl ow

Before using the instrument, be sure to read “Usage Notes” (p. 8).

Installation and connection

Insert the batteries. (p. 24)

Perform the startup check. (p. 29)

Measurement

Turn on the power and select the

measurement function.

Attach the test leads to the

measurement terminals. (p. 26)

(As necessary, perform zero adjustment. (p. 48))

Connect the test leads to the

measurement object.

(As necessary)

Hold the display of the measured

value. (p. 46)

End of the measurement

As necessary, have other

optional items available and

ready.

1

Black

To ensure safe operation,

make sure to select a

measurement function and

then connect the test leads to

the measurement object.

3

Red

2

Move the test leads away from the measurement object and then turn off the power.

23

Page 28

Inserting/Replacing Batteries

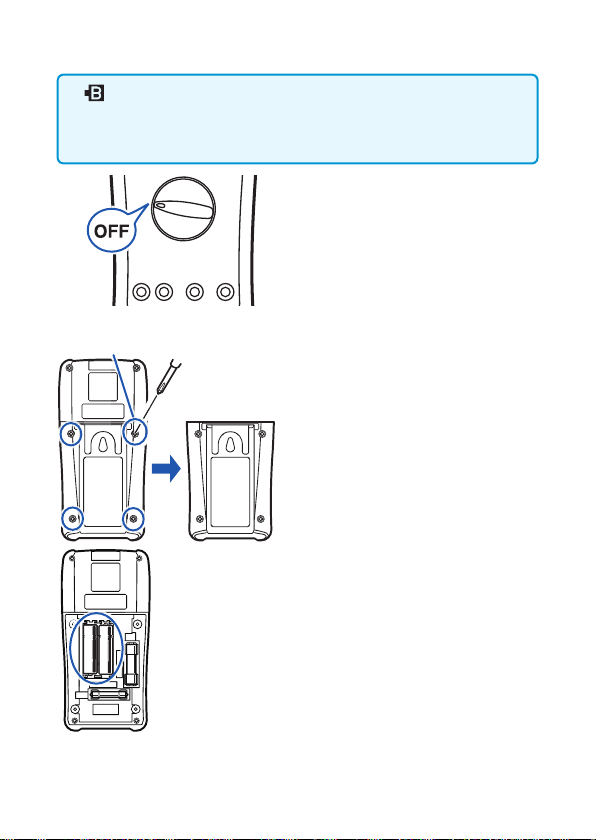

2.2 Inserting/Replacing Batteries

Before using the instrument for the fi rst time, insert 2 R6P

manganese batteries or LR6 alkaline batteries. Before

measurements, check that the battery level is suffi cient. When the

battery charge is low, replace the batteries.

WARNING

To avoid el e ctri c s hock, disconnect the test leads from

the object to be measured before re p l ac ing the batteries.

To avoid the possibility of explosion, do not short

circuit, charge, disassemble, or incinerate batteries.

After battery replacement but before u sing the

instrument, reattach and screw down the battery cover.

CAUTION

Poor performance or damage from battery leakage

could result. Observe the cautions listed below.

• Do no mix new and old batteries, or different types of

batteries.

• Be careful to observe the battery polarity during installation.

• Do not use batteries after their recommended expiry date.

• Do not allow used batteries to remain in the instrument.

• To avo i d corrosion from b attery leakage an d /o r damage to

the instrument, remove the batteries from the instrument

if it is to be kept in storage for an extended peri od.

24

Page 29

Inserting/Replacing Batteries

• lights up when the batteries are exhausted. The accuracy is not

guaranteed. Replace the battery immediately.

• After use, be sure to turn off the instrument.

• Handle and dispose of batteries in accordance with local regulations.

Have the following items

1

available and ready.

Screw

Rear

• Phillips screwdriver

• R6P manganese battery × 2

or LR6 alkaline battery × 2

Remove the test leads from

2

the instrument.

Set the rotary switch to OFF.

3

Remove the holster.

4

Using a Phillips screwdriver

5

remove the screws (4 locations)

from the battery cover on the

rear of the instrument.

Remove the battery cover.

6

Remove all of the old

7

batteries.

Insert 2 new batteries (R6P),

8

being careful to the battery

polarity.

Reattach the battery cover.

9

Secure the cover with the

10

screw.

Reattach the holster.

11

After the battery cover is removed,

the fuse can be seen. When

replacing the fuse, see “6.3

Replacing Fuses” (p. 67).

25

Page 30

Using T est Leads

2.3 Using Test Leads

The L9206 Test Leads supplied with the instrument are used for

measurements.

Depending on measurement locations, use our optional

measurement cables. For details on the optional items, see “Options

(sold separately)” (p. 2).

DANGER

To avoid electric shock, do not short circuit the line on

which voltage is applied at the tip of the test lead.

WARNING

•

To prevent a short circuit accident, be sure to use the test leads

with the sleeves attached when performing measurements in the

CAT III measurement category. (See “Measurement categories”

(p. 7))

• If the sleeves are inadvertently removed during measurement,

stop the measurement.

• When connecting the lead, use the correct voltage measurement

terminal (V terminal) and current measurement terminal (A

terminal). If an incorrectly connected lead is used, the instrument

may be damaged or short circuit accidents may occur.

• Use only test leads and optional equipment specifi ed by our

company.

26

CAUTION

• To ensure safe operation, use only test leads specifi ed

by our company.

• When carrying out measurements with the sleeves in

place, be careful to avoid damaging the sleeves.

• The tips of the metal pins are sharp and may cause

injury. Do not touch the tips.

Page 31

Using T est Leads

L9206 Test Lead

Black

Barriers

Sleeves

Plugs

Red

Cables Metal pins

Metal pin Connect to the object to be measured.

Sleeve Attach to the metal pins to prevent short circuit accidents.

Barrier Represents the safe handling distance from the metal pins.

Plug Connect to the measurement terminals on this instrument.

Cable Double sheathed cables (Length: approx. 980 mm, Diameter:

4 mm or less (sleeve attached)

19 mm or less (sleeve removed)

Diameter approx. 2 mm

During measurement, do not touch the area between

the barrier and the tip of the sleeve.

approx. 3.5 mm)

When the white portion inside the cable is exposed,

replace with a new L9206 Test Lead.

27

Page 32

Using T est Leads

1

2

Removing and attaching the sleeves

Removing the sleeves Attaching the sleeves

Gently hold the bottom of the

sleeves and pull the sleeves off.

Safely store the removed sleeves

so as not to lose them.

Insert the metal pins of the test

leads into the holes of the sleeves,

and fi rmly push them all the way

in.

Connecting to the instrument

Turn the rotary switch to the desired

1

measurement function.

Connect the test leads to the relevant

2

measurement terminals.

• Except the current measurement

1

COM terminal Connect the black test lead.

V terminal Connect the red test lead.

• Current measurement

2

COM terminal Connect the black test lead.

A/mA terminal Connect the red test lead.

A terminal

28

Page 33

Performing Measurements

3

3.1 Inspection Before Use

Before using the instrument the fi rst time, verify that it operates

normally to ensure that no damage occurred during storage or

shipping. If you fi nd any damage, contact your authorized Hioki

distributor or reseller.

Appearance check of the instrument and test leads

Check item Action

The instrument is neither

damaged nor cracked.

The internal circuits are not

exposed.

The terminals are not

contaminated with debris.

The coating of the test leads is

neither broken nor frayed, or

the white portion or metal part

within the lead is exposed.

Check when turning on the power

(Set the rotary switch to any position other than OFF.)

Check item Action

The battery voltage is suffi cient.

Visually check the instrument.

If it is damaged, there is a risk of electric

shock. Do not use the instrument but send

it for repair.

Remove contamination with a cotton

swab.

If the test lead is damaged, there is a

risk of electric shock. Do not use the

instrument but send it for repair.

When

the display, the battery voltage is low. The

accuracy is not guaranteed. Replace the

battery immediately.

appears at the left bottom of

29

Page 34

Inspection Before Use

Operation check

This section introduces some of the operation checks. Periodical

calibration is necessary in order to ensure that this instrument

operates according to its specifi cations.

Check that the test leads are not broken.

1

Check method Action

Regarding the continuity check,

deliberately short circuit the test

leads and then check the display.

Press

SHIFT

twice.

Normal:

A buzzer sounds and the value

stabilizes at around 0

.

Abnormal:

A buzzer does not sound and a

numeric value other than the above

appears.

Black

Corrective action:

The test leads may be broken.

Replace with those specifi ed by our

company.

If the same phenomena persist

even after the test leads are

Red

replaced, a malfunction may occur.

Halt inspection and then send the

instrument for repair.

30

Page 35

Inspection Before Use

Measure samples (such as battery, commercial power

2

supply, and resistor) of which values have already been

known, and check that the appropriate values appear.

Check method Action

Example:

Perform the AC voltage

measurement to measure the

commercial power supply, and then

check the display.

Red Black

Normal:

An already-known value appears.

(In this example, the commercial

voltage level should appear.)

Abnormal:

The measured value does not

appear.

The malfunction may occur.

Stop the inspection and do not use

the instrument.

31

Page 36

Inspection Before Use

Check that the fuse is not broken.

3

Check method Action

1. Remove the fuse from the

instrument. (p. 67)

2. Reattach the battery cover.

3. In the resistance measurement,

check the resistance of the

fuse. (Resistance measurement

(p. 35))

Before measurements

WARNING

Observe the following to avoid short circuit accidents.

• Always verify the appropriate setting of the rotary

switch before connecting the test leads.

• Disconnect the test leads from the measurement

object before switching the rotary switch.

• Operate or connect the instrument by following

the procedure of each measurement example (or

procedure steps).

Normal:

Fuse rating Resistance

630 mA Approx. 1.0

10 A Approx. 0.1

Abnormal:

If the value above is not obtained (the

value higher than that is displayed),

replace the fuse. (p. 67)

32

Page 37

Measuring Voltage

2

3

1

3.2 Measuring Voltage

The AC/DC voltage can be measured. Furthermore, the AC

frequency and duty ratio can be checked.

Before measurements

WARNING

If the instrument is used in locations where the rating

indicated on the instrument or probes is exceeded,

the instrument may be damaged resulting in personal

injury. Do not use the instrument in such locations.

See “Measurement categories” (p. 7).

The autoranging function of this instrument automatically selects the

optimum measurement range. To change the range arbitrarily, use

the manual range. (p. 45)

Measuring AC voltage

The AC voltage is measured.

1

Red Black

2

The measured value is an average

rectifying RMS indication (DT4211)

or true RMS indication (DT4212).

3

(p. Appx.1)

When the Hz/% key is pressed, the

frequency and duty ratio can be

measured. (p.

40)

33

Page 38

Measuring Voltage

2

3

Measuring DC voltage

3

Measure the DC voltage.

34

Black

Red

2

Page 39

3.3 Measuring Resistance

2

3

Resistance is measured.

WARNING

Before measuring, be sure to turn off the power to the

measurement circuit. Otherwise, electric shock may

occur or the instrument may be damaged.

1

3

Measuring Resistance

Black

The open terminal voltage is approx. 0.5 V or less. The

measurement current (DC) varies depending on the range.

To avoid damage to the measurement object, check the

specifi cations before use.

Red

2

35

Page 40

Measuring Diode

4

1

3

2

3.4 Measuring Diode

The forward voltage of the diode is measured.

If the forward voltage is within the range from 0 V to 1 V, the forward

voltage is displayed.

WARNING

Before measuring, be sure to turn off the power to the

measurement circuit. Otherwise, electric shock may

occur or the instrument may be damaged.

In the case of the opposite

Anode

1

Cathode

SHIFT

4

2

connection

Black

The open terminal voltage is approx. 3.0 V or less.

To avoid damage to the measurement object, check the

specifi cations of the measurement object before use.

Red

3

36

Page 41

Checking Continuity

3

4

2

3.5 Checking Continuity

The input short circuit is detected and informed via a buzzer.

WARNING

Before measuring, be sure to turn off the power to the

measurement circuit. Otherwise, electric shock may

occur or the instrument may be damaged.

1

4

SHIFT

Press

2

twice.

Black

Red

3

Detection Threshold Buzzer

Short circuit detection 90±40 or

A buzzer sounds during continuity

(short circuit detection), and the

resistance is displayed.

range fi xed)

(400

less

Sounds

(continuous

buzzer sound)

37

Page 42

Measuring Electrostatic Capacities

2

1

3

3.6 Measuring Electrostatic Capacities

The capacity of the capacitor is measured.

WARNING

Before measuring, be sure to turn off the power to the

measurement circuit. Otherwise, electric shock may

occur or the instrument may be damaged.

Do not measure the capacitor which has been

charged.

1

3

Black

• When measuring the polar capacitor

Connect the V terminal (red test lead) to the + terminal of

the capacitor and the COM terminal (black test lead) to the terminal.

• For components on a circuit board, measurement may not be

possible due to the effect of the peripheral circuit.

Red

2

38

Page 43

Measuring Frequencies

2

3

1

3.7 Measuring Frequencies

The frequency of the measured signal (square wave) is also

measured. The frequency display is auto-ranging.

1

3

Red

Black

When measuring frequencies of AC voltage and AC current

For the AC voltage measurement, use the ACV setting, and for the AC current

measurement, use the ACA, ACmA, or ACA setting. The frequency can

be checked by pressing the Hz/% key ([Hz] lights up). The voltage (current)

range is fi

•

If signals out of the range of frequency measurement are measured, the

display becomes unstable. Be aware of this point.

• The sensitivity of the frequency measurement is regulated by range.

(Minimum sensitivity voltage (p. 58)

When the value is less than the minimum sensitivity voltage (current),

the indicated value may fl uctuate. When the voltage (current) range is

lowered, the value stabilizes. This does not apply to cases where the

value fl uctuates due to noise.

• During the measurement of low frequency voltage (current), if the auto

range does not stabilize and the frequency cannot be measured, change

the voltage (current) range and measure again.

2

xed to the range before the Hz/% key is pressed.

39

Page 44

Measuring Duty Ratio

3

4

3.8 Measuring Duty Ratio

The duty ratio (or duty factor) indicates the ratio of the pulse width

and pulse repetition frequency. The instrument displays the ratio as

a percentage (%).

Duty ratio for the plus slope (D+): D+ = tw+/T ×100 (%)

2

Hz/%

0 V

+

tw

T

The duty ratio for the pulse is

1

measured.

4

t

Black

When measuring duty ratio of AC voltage and AC current

For the AC voltage measurement, use the ACV setting, and for the AC current

measurement, use the ACA, ACmA, or ACA setting. The duty ratio can be

checked by pressing the Hz/% key twice. The voltage (current) range is fi xed

to the range before the Hz/% key is pressed.

Red

3

40

Page 45

Measuring Current

3.9 Measuring Current

DC/AC is measured. DC and AC are switched with the SHIFT key.

DANGER

• Do not input any voltage to the current

measurement terminals.

Measuring DC/AC

Function

• A Selected to measure 4000 A DC/AC or less.

• mA Selected to measure 400.0 mA DC/AC or less.

• A Selected to measure 10 A DC/AC or less.

When measuring an unknown current

Set to the high range.

Doing so may result in short circuit accidents.

• To avoid electrical accidents, turn off the power to

the circuit before measuring and then connect the

test leads.

41

Page 46

Measuring Current

3

1

2

3

2

OFF

4

Measuring with the A range

1

Control board

3

2

Example: Measuring the current of the burner fl ame (A)

The measured current value of the burner fl ame varies with the

input impedance of the instrument.

The A input impedance of this instrument is approx. 100.

Measuring with the A range

1

OFF

3

42

SHIFT

/

TEMP

Red

Power

supply

Black

Black

2

Load

4

Red

Page 47

Measuring T emperatures (DT4212)

1

3

3.10 Measuring Temperatures (DT4212)

Using our optional DT4910 Thermocouples (K), temperatures can

be measured.

CAUTION

To avoid damage to the instrument, do not input any

voltage or supply current to the thermocouple.

Checking the temperature change

It can be checked in the relative

value display. (p. 47)

Black

1

3

2

Be careful to

observe the

polarity when

Red

connecting the

thermocouple.

DT4910

43

Page 48

Measuring T emperatures (DT4212)

When measuring temperatures with the thermocouple

applied to the surface of the measurement object

Clean the surface so that the thermocouple can make contact

with the object securely.

If temperature is not measured after the thermocouple is attached

The instrument or thermocouple may be malfunctioning.

Check this with the following procedure.

Short-circuit the V terminal of the instrument using the

test leads.

The ambient temperature

is displayed.

The ambient temperature

is not displayed.

The thermocouple may be

malfunctioning (blown).

Replace the thermocouple with a new

one.

The instrument is malfunctioning.

Send it for repair.

44

Page 49

Using Instrument Conveniently

4

4.1 Selecting the Measurement Range

Auto or Manual range can be selected.

• Auto range Sets the optimum range automatically in

• Manual range Sets the specifi c range manually.

Measuring with the auto range

When the measurement function is switched using the rotary

switch, the auto range is enabled.

Measuring with the manual range

accordance with the actual measurement.

[RANGE: AUTO] lights up.

Press the RANGE key.

[RANGE: MANUAL] lights up.

Each time the RANGE key is pressed, a

higher range is specifi ed. When the key is

pressed at the highest range, the lowest

range is specifi

Example: When the range is 400.0 mV to

400.0 mV 4.000 V 40.00 V 400.0 V

1000 V 400.0 mV

ed once again.

1000 V

To switch from the manual range to the auto range, press the

RANGE key for at least 1 second.

45

Page 50

Retaining the Measured Value

4.2 Retaining the Measured Value

When HOLD is pressed, the measured value is retained. (HOLD

lights up.)

Retaining the measured value (HOLD)

To retain the measured value, press

the HOLD key.

(HOLD lights up and the measurement

value is retained.)

To cancel the hold state, press it again.

(HOLD goes off.)

46

Page 51

Checking the Relative Value/Performing Zero Adjustment

4.3 Checking the Relative Value/ Performing Zero Adjustment

The relative value comparing to the standard value can be checked

(relative function).

It can also be used as the zero adjustment function.

Zero adjustment eliminates the infl uences of the test lead wiring

resistance (continuity, resistance measurement) and the wiring

capacity (capacitor measurement).

This function is disabled under the following conditions.

During OL display, frequency measurement, and duty measurement

Checking the relative value (REL)

Example: DC voltage measurement

When the standard value is

measured, press REL for at least 1

second.

( lights up.)

The relative value is displayed.

To cancel the display, press it again.

goes off.)

(

•

When the relative function is performed, the auto range is canceled.

(However, this excludes the capacity measurement function.)

• Do not input values exceeding 4000 counts for the DC voltage,

DC current, and temperature measurement (only the DT4212).

47

Page 52

Checking the Relative Value/Performing Zero Adjustment

1

2

3

4

3

2

4

Performing zero adjustment

When performing zero adjustment, the condition of the test leads

varies depending on the measurement function.

Perform zero adjustment, referring to the table below.

Measurement function

Condition of the test leads Short circuit Open

REL

1

2

Red

REL

4

3

Black

1

Black

Red

2

V,

, , A

4

Example 1: Resistance measurement

Select the measurement

1

function.

Connect the test leads to the

2

3

measurement terminals.

Allow the test leads to

3

short circuit.

Press the REL key.

4

(After zero adjustment: 0.0)

Measure the resistance.

5

Example 2: Capacitor measurement

Select the measurement

1

function.

Connect the test leads to

2

the measurement terminals.

Allow the test leads to

3

open.

Press the REL key.

4

(After zero adjustment: 0.00 nF)

Measure the capacitor.

5

48

Page 53

Turning On the Backlight

4.4 Turning On the Backlight

The backlight can be turned on/off by pressing the backlight key.

The backlight automatically turns off if the instrument is not operated

for approx. 80 seconds.

4.5 Using the Auto Power Save (APS)

The auto power save function saves on battery consumption. If the

instrument has not been operated for approx. 30 minutes, it enters

the sleep mode.

In the default setting, the auto power save function is set to enabled.

To continuously use the instrument, press any key or turn the rotary

switch.

Auto power save function

• When the instrument is in the sleep mode, press any key or

turn the rotary switch to recover from the sleep mode.

• If the instrument will be used for an extended period of time,

disable the auto power save function.

• After use, set the rotary switch to OFF. The sleep mode

consumes a small amount of current.

Canceling the auto power save function (APS)

While pressing the SHIFT key, turn the rotary switch.

49

Page 54

Using the Auto Power Save (APS)

50

Page 55

Specifi cations

5

5.1 General Specifi cations

Power supply

Battery indicator

warning voltage

Dimensions Approx. 91.6 W × 180.6H × 57.1 D mm (3.61 W ×

Mass Approx. 388 g (13.7 oz.) (including the batteries and

Operating

environment

Operating

temperature and

humidity

Storage temperature

and humidity

R6P manganese battery × 2 or

LR6 alkaline battery × 2

lights up when 2.4 V ± 0.15 V or less

7.11 H ×2.25 D) (including the holster)

holster)

Indoors, pollution degree 2, altitude up to 2000 m

(6562-ft.)

• Temperature

-10°C to 50°C (14°F to 122°F)

(However, 0°C to 50°C (32°F to 122°F) for the

temperature function)

• Humidity

0°C to 40°C (32°F to 104°F): 80% RH or less

(non-condensating)

40°C to 45°C (104°F to 113°F): 60% RH or less

(non-condensating)

45°C to 50°C (113°F to 122°F): 50% RH or less

(non-condensating)

Humidity (40M range)

•

0°C to 30°C (32°F to 86°F) : 80% RH or less

(non-condensating)

30°C to 40°C (86°F to 104°F) : 70% RH or less

(non-condensating)

40°C to 45°C (104°F to 113°F) : 60% RH or less

(non-condensating)

45°C to 50°C (113°F to 122°F) : 50% RH or less

(non-condensating)

-20°C to 60°C (-4°F to 140°F), 80% RH or less

(non-condensating)

51

Page 56

General Specifi cations

Dustproof and

waterproof

Product warranty

period

Accessories • L9206 Test Lead

Options See: “Options (sold separately)” (p. 2)

Replacement parts 630 mA/1000 V fuse for current terminal (A, mA)

Applicable

standards

IP40 (EN60529)

3 years (excluding the measurement accuracy)

• Holster (attached to the instrument, with a test

lead holder)

• Instruction Manual

• R6P manganese battery × 2 (not installed in the

instrument)

(Breaking capacity 50 kA Fast-blow type: 6.3 × 32

mm, SIBA)

10 A/1000 V fuse for current terminal (A)

(Breaking capacity 30 kA Fast-blow type: 10 × 38

mm, SIBA)

• Safety: EN61010

• EMC: EN61326

52

Page 57

Electrical Characteristics

5.2 Electrical Characteristics

Noise

suppression

NMRR

Noise

suppression

CMRR

Response time

(Auto range)

Display update

rate

Dielectric

strength

Maximum rated

voltage between

terminals

Maximum rated

current between

terminals

Maximum rated

voltage between

input terminals

and ground

• DCV: -45 dB or more (50 Hz/60 Hz)

• DCV: -100 dB or more (DC/50 Hz/60 Hz, 1k

unbalance)

• ACV: -60 dB or more (DC/50 Hz/60 Hz, 1k

unbalance) (However, -45 dB or more for the 1000 V

range)

• DCV: 1.2 to 1.4 seconds (0 V 100 V auto range

operation)

• ACV: 0.7 to 0.9 seconds (0 V 100 V auto range

operation)

: 1.2 to 1.4 seconds (Infi nity 0 auto range

•

operation)

Measured value:

3 times/s (after the range is fi xed, excluding the

resistance, continuity, electrostatic capacity, frequency)

2 times/s (resistance, continuity)

0.5 to 2 times/s (varies depending on the electrostatic

capacity)

5 times/s (frequency)

Between the measurement terminal and case

7.06 kV AC sine wave (50 Hz/60 Hz, 60 seconds)

V terminal: 1000 V DC/AC or 10

Current terminal (A): 10 A DC/10 A AC

Current terminal (A, mA) 400 mA DC/400 mA AC

1000 V AC (Measurement category II)

600 V AC (Measurement category III)

Anticipated transient overvoltage: 6000 V

6

V • Hz

53

Page 58

Electrical Characteristics

Rated power

voltage

Maximum rated

power

Rated power • 7.5 mVA +20% or less

Continuous

operating time

1.5 V DC × 2

R6P manganese battery × 2

LR6 alkaline battery × 2

100 mVA (max)

Power voltage 3.0 V, continuity measurement input

short-circuited, backlight lit

Power voltage 3.0 V, DCV measurement, backlight off

• 0.05 mVA +20% or less

Power voltage 3.0 V, auto power save function

activated

AA manganese batteries, DCV, backlight off

DT4211 (Average value measurement model):

Approx. 300 hours

DT4212 (True RMS measurement model):

Approx. 240 hours

AA alkaline batteries, DCV, backlight off

DT4211 (Average value measurement model):

Approx. 800 hours

DT4212 (True RMS measurement model):

Approx. 450 hours

54

Page 59

Accuracy T able

5.3 Accuracy Table

Accuracy warranty period 1 year

Regulated power supply range

Accuracy guarantee for

temperature and humidity

Temperature characteristic Adds “Measurement accuracy × 0.1/°C”

• rdg. (reading or displayed value): The value currently being measured and

displayed on the measuring instrument.

• dgt. (resolution): The smallest displayable unit, i.e., the input value that

causes the digital display to show a “1” as the least-signifi cant digit.

2.4 V ± 0.15 V or more (until lights

23°C ± 5°C (73°F ± 9°F), 80%RH or less

(non-condensating)

(excluding 23°C ± 5°C (73°F ± 9°F)).

AC voltage

1

*1

Range

*2

400.0 mV

4.000 V ±1.0% rdg. ±5 dgt.

40.00 V

400.0 V

1000 V

•

Overload protection: 1100 V DC/1100 V AC or 106 V • Hz (energized for 1 minute)

Transient overvoltage: 6000 V

• Crest factor (Only the DT4212 (True RMS measurement model)): The crest

factor is 2 up to 2800 counts and reduces linearly to 1.5 at 4000 counts.

*1: The accuracy is specifi ed in 1% or more of the range.

*2: Only the manual range.

±1.0% rdg. ±10 dgt.

±1.0% rdg. ±5 dgt.

Accuracy

40 to 500 Hz

Input impedance

11M ±2%

100 pF or less

+2%

10M

100 pF or less

up)

55

Page 60

Accuracy T able

DC voltage

2

Range Accuracy Input impedance

400.0 mV

4.000 V 11M ±2%

40.00 V

1000 V

• Overload protection: 1100 V DC/1100 V AC or 10

minute)

Resistance

3

Range Accuracy

400.0

4.000k

40.00k

400.0k

4.000M

40.00M ±1.5% rdg. ±3 dgt. Approx. 40 nA

• Overload protection: 1000 V DC/1000 V AC or 10

minute)

Current under short circuit: 300 A or less

Current under overload: Steady state 15 mA or less, transient state 0.8 A or

less

• Maximum capacity load: 10 mF

• Maximum inductive load: 10 H

±0.5% rdg. ±3 dgt.

±0.5% rdg. ±3 dgt. 10M

±0.5% rdg. ±3 dgt.

±0.5% rdg. ±2 dgt.

±0.5% rdg. ±2 dgt.

Over 100M

+2% 400.0 V

Measurement

current

Approx. 140 A

Approx. 40 A

Approx. 4 A

Approx. 400 nA

6

V • Hz (energized for 1

Open circuit

voltage

0.5 V DC or less

6

V • Hz (energized for 1

56

Page 61

Accuracy T able

Diode

4

Range Accuracy

1.000 V ±10.0% rdg. 0.5 mA

• Overload protection: 1000 V DC/1000 V AC or 10

minute)

Current under short circuit: 0.7 mA or less

Current under overload: Steady state 15 mA or less, transient state 0.8 A or

less

Continuity

5

Range Accuracy

400.0

• Overload protection: 1000 V DC/1000 V AC or 10

minute)

Current under short circuit: 300 A or less

Current under overload: Steady state 15 mA or less, transient state 0.8 A or

less

• Continuity ON threshold: 90 ± 40

• Response time: Open circuit or short circuit is detected for at least 0.5 ms.

±1.0% rdg. ±15 dgt. Approx. 140 A 0.5 V DC or less

Measurement

current

Measurement

current

or less (buzzer)

6

6

Open circuit

voltage

3.0 V DC or less

Voltage drop

due to battery

consumption

V • Hz (energized for 1

Open circuit

voltage

V • Hz (energized for 1

57

Page 62

Accuracy T able

Electrostatic capacity

6

Range Accuracy Charging current Open circuit voltage

50.00 nF ±1.5% rdg. ±15 dgt.

500.0 nF ±2.0% rdg. ±5 dgt.

5.000 F

±5.0% rdg. ±5 dgt. 50.00 F

100.0 F

• Overload protection: 1000 V DC/1000 V AC or 10

minute)

Current under short circuit: 50 A or less

Current under overload: Steady state 15 mA or less, transient state 0.8 A or

less

• Accuracy guarantee condition: After REL (zero adjustment) has been

performed

Approx. 30 A 1.5 V DC or less

6

V • Hz (energized for 1

Frequency

7

Minimum sensitivity

Range Accuracy

5.000 Hz

50.00 Hz

500.0 Hz

5.000 kHz

50.00 kHz

500.0 kHz

5.000 MHz ±0.1% rdg. ±3 dgt.

• Measurement range: 1 Hz or more

±0.1% rdg. ±3 dgt.

voltage

Square wave of 1.5 Vrms

or more

Square wave of 2.0 Vrms

or more

58

Page 63

Accuracy T able

DC (A)

8

Range Accuracy Input impedance

400.0 A

4000 A

• Overload protection: 630 mA/1000 V fuse, breaking capacity 50 kA

AC (A)

9

Range Accuracy

400.0 A

4000 A

• Overload protection: 630 mA/1000 V fuse, breaking capacity 50 kA

• Crest factor (only the DT4212 (True RMS measurement model)): The crest

factor is 2 up to 2800 counts and reduces linearly to 1.5 at 4000 counts.

*1: The accuracy is specifi ed in 1% or more of the range.

Accuracy guarantee range for frequency: 40 Hz to 500 Hz (Measured

values outside the accuracy guarantee range for frequency are also

displayed.)

±1.2% rdg. ±3 dgt. 100

*1

±1.2% rdg. ±5 dgt. 100

±5%

Input impedance

±5%

DC (mA)

10

Range Accuracy Input impedance

40.00 mA

400.0 mA

±1.2% rdg. ±3 dgt. 2 ±40%

• Overload protection: 630 mA/1000 V fuse, breaking capacity 50 kA

59

Page 64

Accuracy T able

AC (mA)

11

Range Accuracy

40.00 mA

400.0 mA

• Overload protection: 630 mA/1000 V fuse, breaking capacity 50 kA

• Crest factor (only the DT4212 (True RMS measurement model)): The crest

factor is 2 up to 2800 counts and reduces linearly to 1.5 at 4000 counts.

*1: The accuracy is specifi ed in 1% or more of the range.

Accuracy guarantee range for frequency: 40 Hz to 500 Hz (Measured

values outside the accuracy guarantee range for frequency are also

displayed.)

DC (A)

12

Range Accuracy Input impedance

4.000 A

10.00 A

• Overload protection: 10 A/1000 V fuse, breaking capacity 30 kA

AC (A)

13

Range Accuracy

4.000 A

10.00 A

±1.2% rdg. ±5 dgt. 2

±1.2% rdg. ±3 dgt. 0.05

±1.2% rdg. ±5 dgt. 0.05 ±40%

*1

*1

Input impedance

±40%

±40%

Input impedance

• Overload protection: 10 A/1000 V fuse, breaking capacity 30 kA

Crest factor (only the DT4212 (True RMS measurement model)): The crest

•

factor is 2 up to 2800 counts and reduces linearly to 1.5 at 4000 counts.

*1: The accuracy is specifi ed in 1% or more of the range.

Accuracy guarantee range for frequency: 40 Hz to 500 Hz (Measured

values outside the accuracy guarantee range for frequency are also

displayed.)

60

Page 65

Accuracy T able

Temperature

14

Thermocouple type Range Measurement range Accuracy

400.0°C -55.0°C to 0.0°C

K

700°C 400°C to 700°C

• Overload protection: 1000 V DC/1000 V AC or 10

minute)

Current under overload: Steady state 15 mA or less, transient state 0.8 A or

less

• The DT4910 Thermocouples (K) are used.

• The accuracy does not include the error of the DT4910 Thermocouples (K).

• Display update rate: 3 time/s

*1: In an environment where the temperature of the instrument is ±1°C and

stable, the accuracy is specifi ed.

Standard contact temperature compensation stability time: 120 minutes

(When the instrument environmental temperature changes quickly from

50°C to 23°C (122°F to 73°F ))

T = reading value (°F)

(-67°F to 32°F)

0.0°C to 50.0°C

(32°F to 122°F)

50.0°C to 400.0°C

(122°F to 752°F)

(752°F to 1292°F)

±2.0% rdg. ±2°C

(±(T-32)×0.02±3.6°F)

±2°C

(±3.6°F)

±2.0% rdg. ±1°C

(±(T-32)×0.02±1.8°F)

±2.0% rdg. ±1°C

(±(T-32)×0.02±1.8°F)

6

V • Hz (energized for 1

*1

61

Page 66

Accuracy T able

62

Page 67

Maintenance and Service

6

6.1 Repair, Inspection, and Cleaning

DANGER

Customers are not allowed to modify, disassemble, or

repair the instrument.

Doing so may cause fi re, electric shock, or injury.

Calibrations

IMPORTANT

Periodic calibration is necessary in order to ensure that the

instrument provides correct measurement results of the specifi ed

accuracy.

The calibration frequency varies depending on the status of the

instrument or installation environment. We recommend that the

calibration frequency is determined in accordance with the status of

the instrument or installation environment and that you request that

calibration be performed periodically.

Cleaning

• To clean the instrument, wipe it gently with a soft cloth moistened

with water or mild detergent.

• Wipe the display gently with a soft, dry cloth.

IMPORTANT

Never use solvents such as benzene, alcohol, acetone, ether,

ketones, thinners or gasoline, as they can deform and discolor the

case.

63

Page 68

Troubleshooting

Disposal

Handle and dispose of the instrument in accordance with local

regulations.

6.2 Troubleshooting

• When a malfunction of the instrument is suspected, check the

information in “Before sending the instrument for repair” and then,

if necessary, contact your authorized Hioki distributor or reseller.

• When sending the instrument for repair, remove the batteries and

pack it carefully to prevent damage during transportation.

Include cushioning material so the instrument cannot move within

the package. Be sure to include details of the problem.

Hioki cannot be responsible for damage that occurs during

transportation.

Before sending the instrument for repair

Symptom Check and/or remedy

Nothing appears in

the display.

Or the display

disappears after a

short time.

Check that the batteries are not exhausted.

Replace with new batteries. (p. 24)

Check that the auto power save function has not

been activated.

Check the setting of the auto power save function.

(p. 49)

64

Page 69

Symptom Check and/or remedy

The measurement

value does not

appear.

Even after the

measurement, 0

(zero) still appears.

Even after short

circuit of the probe,

the measured value

does not appear.

Zero adjustment is

not possible.

The display does not

stabilize and the value

fl uctuates; it is diffi cult

to read the value.

If the measured current value does not appear,

check that the fuse is not blown.

Check method: “Check that the fuse is not broken.”

(p. 32)

If the fuse is blown, replace it with the specifi ed

fuse. (p. 67)

If the measured current value does not appear,

check that the fuse holder is not deformed.

When removing the fuse, the holder is deformed

if excessive force is applied. Pinch it with needlenose pliers and restore the shape of the fuse

holder.

Check that the test lead is not broken.

Perform the continuity check to confi rm the

continuity of the test leads. (p. 30)

If the test lead is broken, replace the lead.

• Check that the test leads have been inserted at

the ends.

• Check that the measurement method is correct.

If no problems have been found, the instrument

may be malfunctioning. Send the instrument for

repair.

Check that the input signal is within the input range

for the instrument.

Troubleshooting

Other inquiries

Question Solution

Would like to perform

zero adjustment.

Using the relative value display function, zero

adjustment can be performed. (p. 48)

65

Page 70

Troubleshooting

Question Solution

Would like to replace

the fuse.

Would like to know

how to obtain the

fuse.

Can rechargeable

batteries be used?

The fuse can be purchased via authorized Hioki

distributor or reseller.

Rechargeable batteries can be used. However,

the discharge characteristic of these batteries is

different from that of alkaline batteries. Be aware

that the remaining battery power display does not

function properly.

66

Page 71

Replacing Fuses

6.3 Replacing Fuses

If a fuse is blown, replace it with a new one as follows.

For details on how to check that the fuse is blown, see “3 Check

that the fuse is not broken.” (p. 32).

WARNING

• To avoid electric shock, disconnect the test leads from

the object to be measured before replacing the fuse.

• Replace the fuse only with one of the specifi ed type,

characteristics, rated current, and rated voltage.

Specifi ed fuses

For A/mA terminal 630 mA/

For A terminal 10 A/

Do not use fuses other than those specifi ed

(especially, do not use a fuse with higher-rated

current) or do not short circuit and use the fuse

holder. Doing so may damage the instrument and

result in personal injury.

Rating Specifi cations

1000 V

1000 V

Manufacturer: SIBA

Meltdown characteristics: Fast-blow type

Breaking capacity: 50 kA

Size: 6.3 mm × 32 mm

Manufacturer: SIBA

Meltdown characteristics: Fast-blow type

Breaking capacity: 30 kA

Size: 10 mm × 38 mm

The fuses can be purchased via authorized Hioki distributor or reseller.

When removing the fuse, do not apply excessive force on the fuse

holder. If the fuse holder is deformed, the connection becomes

poor and the instrument cannot measure the current.

67

Page 72

Replacing Fuses

When replacing the fuse, do not allow foreign matter to

enter the instrument. It may cause a malfunction. Do not

remove the fuse using the tip of test lead L9206 supplied

with the instrument. The tip of the test lead may bend.

CAUTION

Remove the test leads

1

from the instrument.

Set the rotary switch to

2

OFF.

68

Screw

Remove the holster.

3

Using a Phillips

Rear

4

screwdriver, remove the

screws (4 locations) from

the battery cover.

Remove the battery cover.

5

Replace the fuse.

6

Reattach the battery cover.

7

Secure the cover with the

8

screw.

Reattach the holster.

9

Page 73

Appendix

Appx. 1 RMS and Average

Difference between the RMS and Average

When converting AC to RMS, 2 methods are available, “True RMS

method (True RMS indication)” and “Average method (Average

rectifying RMS indication)”.

In the case of the sine wave where no skew is included, the same

values are indicated in both methods. However, if the waveform is

skewed, a difference occurs between the 2 methods.

The DT4211 (Average value measurement model) uses the Average

method, and the DT4212 (True RMS measurement model) uses the

True RMS method.

In the true RMS method, the high frequency component is also

included and displayed.

In the average method, the input waveform is handled as a sine

wave where no skew is included (only single frequency). The

average of the AC signal is obtained, converted to the RMS, and

then displayed. If the waveform is skewed, a greater measurement

error occurs.

Appx.1

Page 74

RMS and Average

Measurement example True RMS Average rectifying

100 V sine wave 100 V 100 V

100 V square wave 100 V 111 V

V(t)

Vm

V(t)

Vm=Vavg=VrmsVavg Vrms

t

t

Sine wave

TT

Square wave

Vm: Maximum value, Vavg: Average value, Vrms: RMS, T: Time period

Appx.2

Page 75

13-09

Page 76

Page 77

DT4211

DT4212

数字万用表

使用说明书

2013年11月 修订一版 DT4211A981-01 13-11H

Chinese

Page 78

Page 79

附录

前言 ..............................................................................1

核对包装内容 .................................................................1

选件(另售) .................................................................2

安全注意事项 .................................................................4

使用注意事项 .................................................................8

1 概述 13

1.1 概述和特性 .................................................13

1.2

各部分的名称和功能 .................................... 14

1.3

显示 ..........................................................19

1

2

3

2 测量准备 21

2.1 测量流程 ....................................................21

2.2

安装/更换电池 ............................................22

2.3

使用测试线 .................................................24

3 执行测量 27

3.1 使用前的检查 .............................................27

3.2

测量电压 ....................................................31

测量交流电压 ......................................................31

测量直流电压 ......................................................32

3.3 测量电阻 ....................................................33

3.4

测量二极管 .................................................34

3.5

导通检查 ....................................................35

3.6

测量静电容量 .............................................36

3.7

测量频率 ....................................................37

3.8

测量占空比 .................................................38

3.9

测量电流 ....................................................39

测量直流/交流电流 ...............................................39

4

5

6

7

附录索引

i

Page 80

附录

3.10 测量温度(DT4212) ................................. 41

4 便利的使用方法 43

4.1 选择测量量程 .............................................43

用自动量程测量 ...................................................43

用手动量程测量 ...................................................43

4.2 保持测量值 .................................................44

保持测量值(HOLD) .........................................44

4.3 确认相对值/执行调零 ................................... 45

确认相对值(REL) ............................................45

执行调零 .............................................................46

4.4 打开背光灯 .................................................47

4.5

使用自动节电(APS) ...............................47

5 规格 49

5.1 一般规格 ....................................................49

5.2

电气特性 ....................................................51

5.3

精度表 .......................................................53

6 维护和检修 61

6.1 维修、检查和清洁 .......................................61

6.2

故障诊断 ....................................................62

6.3

更换熔断器 .................................................64

附录 附录1

附录1 有效值与平均值 ..................................附录1

ii

Page 81

前言

前言

感谢您购买 HIOKI DT4211(平均值测量型)、DT4212(真有效值

测量型)数字万用表。

要获得产品的最大性能,请首先阅读本手册,并保管在身边以备将来

查阅。

1

核对包装内容

当您收到本仪表时,请仔细检查,确保装运期间没有发生损伤。

尤其要检查附件、面板开关和连接器。如果损伤明显,或者不能按照

规格动作,请联系代理店或距您最近的营业所。

按照如下要求检查包装内容。

DT4211(平均值测量型)或 DT4212(真有效值测量型)

L9206 测试线

(p. 25)

5 号锰电池(R6P)× 2

DT4211

(平均值测量型)

皮套已安装。

DT4212

(真有效值测量型)

使用说明书

2

3

4

5

6

7

附录索引

1

Page 82

选件(另售)

选件(另售)

本仪表有以下一些选件可用,订货时,请联系代理店或距您最近的营

业所。

连接电缆

*1: CAT IV 600 V/CAT III 1000 V/CAT II 1000 V

*2: CAT IV 600 V/CAT III 1000 V

*3: CAT III 1000 V *5:CAT III 300 V/CAT II 600 V

*4: CAT III 600 V *6:AC33 V /DC70 V

*1

L9206

测试线

*2

L4930

连接线

(长 :1.2 m)

*2

L4931

延长线

(长 :1.5 m、带耦合连接

器)

*6

L4933

接触针

*5

L4934

小型鳄鱼夹

*2

L4935

鳄鱼夹

*3

9243

抓状夹

*4

L4936

测试夹

*3

L4937

磁铁接合器

*1

L4932

测试针

2

Page 83

温度测量(仅限 DT4212(真有效值测量型))

选件(另售)

携带盒

Z5004 带磁铁吊带

有关 C0201 携带盒及 Z5004带磁铁吊带的详细使用方法,请参考本公司网

页。

DT4910 K 型热电偶(p. 41)

• 测温连接点 :开槽式(焊接)

• 传感器长度 :约 800 mm

•

使用温度 :-40℃ 至 260℃(测温部位)、-15℃ 至 55℃(连

接器)

• 容差 :±2.5℃

C0201 携带盒

可将本仪表、测试线、使用说明书和其他东西装进盒里。

C0202 携带盒

可将本仪表、测试线、使用说明书和其他东西装进盒里。

将吊带系在本仪表上,并确保使用中吊带被牢牢固定在像

金属板那样的壁面上。

吊带的处理 (p. 10)

1

2

3

4

5

6

7

附录索引

3

Page 84

安全注意事项

安全注意事项

本仪表遵照 IEC61010 安全标准设计,且在装运前经过全面安全测

试。但是,用本手册没有记录的方法使用本仪器可能使提供的安全特

性失效。

使用本仪表前,务必仔细阅读以下安全注意事项。

危险

错误使用可能导致人身伤害或死亡,并损坏本仪表。使用

前,请您务必理解本手册中的使用说明和步骤。

警告

关于电源供应,电路短路有引发触电、发热、火灾和电弧

放电的风险。如果不熟悉电气测量仪表的人要使用本仪表,

必须由熟悉此类仪表的人指导操作。

保护用具

警告

测量火线时为避免触电,应穿戴绝缘橡胶手套、安全鞋和

安全头盔等合适的保护用具。

4

Page 85

记号

本手册将风险程度和危险级别分类如下。

安全注意事项

危险

警告

注意

重要

*

表示可能导致操作者死亡或重伤的紧迫危险状态。

表示可能导致操作者死亡或重伤的潜在危险状态。

表示可能导致操作者轻微或中度伤害或者导致本仪表

损坏或故障的潜在危险状态。

表示与本仪表操作或维护任务有关的信息,操作者必

须非常熟悉这些信息和内容。

表示高压危险。

如果不进行详细的安全检查或者本仪表被误用,可能

引发危险状态,操作者可能遭受电击,可能被烫伤或

者甚至可能遭受致命的人身伤害。

表示强磁场危险。

磁力的影响可能引起心脏起搏器或医用电子设备工作

不正常。

表示禁止行为。

表示必须被执行的行为。

更进一步的信息阐述如下。

1

2

3

4

5

6

7

附录索引

5

Page 86

安全注意事项

本仪表上的符号

表示注意和危险。当本仪表上显示有该符号时,查阅本操作手册

的相关主题。

表示该端子可能出现危险电压。

表示双重绝缘或强化绝缘所保护的设备。

表示熔断器。

表示接地端子。

表示直流(DC)。

表示交流(AC)。

表示直流(DC)或交流(AC)。

各种标准的符号

表示欧盟成员国关于废弃电子电气设备的指令(WEEE 指令)。

表示本仪表遵守 EC 指令规定的规则。

精度

我们用术语 rdg.(读取)和 dgt.(数字)值定义测量误差,其含义如

下:

(读取或显示数值)

rdg.

表示现在正在测量的值、测量仪表上正显示的值

(分辨率)

dgt.

数字测量仪表可显示的最小单位,即表示最小位的“1”。

6

Page 87

安全注意事项

T

测量分类

为确保测量仪表的安全操作,IEC61010 为被分类为 CAT II 至 CAT

IV 的各种电气环境建立安全标准,称其为测量分类。

危险

• 在指定使用较大编号分类的环境使用核准分类低于此的

测量仪表,可能导致严重的意外事故,此类行为必须被

本仪表符合 CAT II 1000V、CAT III 600V的安全要求。

CAT II: 当直接测量装置上的初级侧电路的插座,而该装置被电源线连接到