Page 1

Instruction Manual

DSM-8542

DIGITAL SUPER

MEGOHMMETER

July 2013 Revised edition 1 DS8542A981-01 13-07H

Page 2

Page 3

Preface

Thank you for purchasing the DSM-8542 and welcome to the growing family of HIOKI’s

Digital Supe r Megohm Meters/Current Mete rs.

The DSM-8542 is an insulation resistance meter up to 1000V in measuring voltage.

Incorrect operation of the meter potentially causes an electric shock or damage to a

sample. Please read this manual thoroughly before using the meter and exercise

reasonable caution regarding safety. Keep this manual handy for future reference.

The product has been shipped after minute preshipment inspection by HIOKI.

Nevertheless, please contact our distributor or sales office near your location in case of

a trouble.

I. Product Overview

The Digital Super Megohm Meter DSM-8542 is an insulation resistance meter

embedded with a high-sensitivity ammeter.

The meter has been developed to measure insulating materials of a high resistance

value, capable of measuring resistance within the range of 1 x 10

current within the range of 30fA to 10mA.

A liquid crystal display module (240 x 64 dots) of the meter allows easy viewing of

needed information and ease of use.

The meter is an insulation resistance meter and requires installation of an external

power supply unit as a power source for measurement. An external power supply unit

for measurement of insulation resistance is a customer supply scope. HIOKI E. E.

Corporation supplies a dedicated power supply unit PSU-8541 as an option. PSU-8541

incorporates a low-noise voltage source and is suitable for measuring insulation

resistance of insulating materials of large capacities.

Principal Features (When dedicated power supply unit PSU-8541 is used)

3

to 3 x 1016Ω and a

Measurable voltage range : 0.1 to 1000V

Measurable current range : 30fA to 10mA

Measurable resistance range : 1 x 10

3

to 3 x 1016Ω

Current limiter setting : 5mA, 10mA, 50mA (0.1 to 250V)

: 5mA, 10mA (251 to 1000V)

Integral time setting functi on : 2ms to 300ms

Trigger delay setting functi on : 0 to 9999ms

Automatic averaging measurement function

Voltage check function

Contact check function

Self-calibration function

Comparison decision, volume resistivity, surface resistivity computing

functions

i

Page 4

Data save and search functions

Histogram display function

Sequence programming function

Interlock function

GP-IB is a standard provision

Handler interface is a standard provision

RS-232 is a standard provision

II. About This Operational Manual

• Warning, Caution and Notice

Important safety precautions and operational instructions are described in this manual

under the following headings. Strictly follow these precautions and operational

instructions.

[Warning]

Indicates a potentially hazardous situation which could result in an electric

shock or equipment burning.

It is extremely important to strictly follow these instructions to prevent a

hazard.

[Caution]

Indicates a caution which could result in equipment damage.

Operate the meter exercising reasonable caution.

[Notice ]

Indicates an important item in operation.

ii

Page 5

III. Organizational Elements of Operational Manual

This operational manual has the following chapters. Please make certain to read the

manual carefully before operating the meter.

1. Preparations Before Operation

This chapter contains important information such as a check to be made during

uncrating, operating power supply and measuring cables.

2. Specification

The electrical specification of this meter is described.

3. Operating Principles

This chapter contains the operating principles, block diagram and other information.

4. Names and Functions of Components

This chapter describes the names and functions of keys and characters printed on

the front and rear panels.

5. Preparations for Measurement

This chapter describes the screen of the meter for measurement, settings on the

screen, operating method, methods for indicating measured values and other

matters.

6. Measurement

This chapter describes function settings of the meter, connection of measuring

terminals, and use of measuring jigs and measuring electrodes.

7. GP-IB Interface

This chapter describes control by the GP-IB interface.

8. RS-232 Interface

This chapter describes control by the RS-232 interface.

9. External Interfaces

This chapter describes the handler interface, external trigger input and interlock

input.

10. Maintenance

This chapter describes checks and calibration to be made for safe and reliable use

of this meter.

11. Product Full View

This chapter contains a full view of the product with dimensions.

iii

Page 6

IV. Safety Precautions

FOR SAFE USE OF THE METER

• Do the power supply voltage of the meter and commercial power supply voltage to be

supplied match? Please check it. Supplying 200V power supply voltage while the

power supply voltage of the meter is 100V sometimes causes damage to the meter.

• Be certain to ground the grounding terminal on the rear or the grounding rod of the

power cable to the ground.

V. Safety Alert Symbols

This symbol is marked where the operational manual

needs to be referred to.

This symbol indicates high voltage hazard and is

indicated on terminals where high voltage is output

such as meas uring t erminal s.

Indicated on the grounding terminal “GND” on the rear

of the meter. If the grounding pin of the power cable

cannot be grounded, be certain to ground this terminal.

!

Warning

symbol

Electrical

Grounding

terminal

VI. Operational Precautions

Please read this manual thoroughly before operating the meter to correctly handle it.

Strictly follow all the warning, caution and other messages contained in this manual to

prevent accidents and danger.

● Never operate the meter where a combustible gas exists. Otherwise an explosion or

a fire may break out.

● Be certain to ground the grounding pin of the power cable to prevent an accident. If

the grounding pin of the power cable cannot be grounded, be certain to ground the

grounding terminal located on the rear of the meter.

● High voltage up to 1000V is output between the measuring terminals on the panel of

this meter. Do not touch areas where a current is impressed during measurement to

prevent an electrical shock.

● Do not operate the meter in a dusty place or in a place subjected to vibration, direct

sunshine or steam. Otherwise a meter failure may result.

● Supply the power supply voltage specified in the operational manual. Otherwise a

fire or meter damage may result.

● Do not remove the cover of the meter.

Residual voltage sometimes still remains inside the meter after turning the power off

and it is dangerous to touch the inside of the meter. Please contact our sales office

near your location in case of a repair or internal adjustment.

● A cooling fan of a discharge type is installed inside the meter to prevent temperature

rises inside the meter. Poor ventilation of the fan causes meter failures. Provide a

space of more than 10cm behind the fan. Do not place anything on the ventilation

grills on one side and bottom of the meter.

iv

Page 7

Contents

1. Preparations Before Operation ····························································1

1.1 Check during Uncrating ····································································· 1

1.2 Operating Power Supply···································································· 1

1.3 Grounding ······················································································ 2

1.4 Measuring Cable·············································································· 2

1.5 Warming Up Time ············································································ 2

1.6 Memory Initializin g ··········································································· 2

2. Specification

2.1 Measurement Performance ································································3

2.1.1 DC current measurement ································································ 3

2.1.2 Resistance measurement ································································ 4

2.1.3 Measuring voltage output ································································ 4

2.2 Functional Specification····································································· 4

2.2.1 Measuring time setting···································································· 4

2.2.2 Voltage monitoring (Voltage check) ··················································· 4

2.2.3 Contact check function ···································································· 4

2.2.4 Self-calibration function and self-di agnosis function ······························ 5

2.2.5

Comparison measurement and deviation/percent measurement functions

··········· 5

2.2.6 Measurement (jig setting and da ta processi ng) f unction ························· 5

2.2.7 Measuring sequence program ·························································· 6

2.2.8 Storage and display functions of measured data··································· 6

2.2.9 Operability and display····································································6

2.2.10 Resume function·········································································· 6

2.2.11 Input and output functions (e xternal con trol i nterfaces) ························· 7

2.3 General Specifications ······································································8

2.4 Options·························································································· 8

2.4.1 Special options··················································································9

2.4.2 Common options················································································9

3. Operating Principles

3.1 Operating Principles ······································································· 10

3.2 Block Diagram of DSM-8542····························································· 11

4. Names and Functions of Components

4.1 Safety Alert Symbols······································································· 12

4.2 Front Panel··················································································· 13

4.3 Rear Panel ··················································································· 16

4.4 Command/Numeric Input Keys·························································· 17

4.5 Display Screen ·············································································· 20

a

Page 8

5. Preparations for Measurement

5.1 Connecting Meter and Power Supply Unit············································ 22

5.1.1 Connecting dedicated power supply unit PSU8541 ····························· 22

5.1.2 Connecting power supply other than dedicated power supply unit ·········· 22

5.2 Setting Measuring Conditions ··························································· 25

5.2.1 Screen types ·············································································· 27

5.2.2 Setting measuring mode································································ 33

5.2.3 Setting measuring voltage ····························································· 34

5.2.4 Setting current limiter ··································································· 35

5.2.5 Setting measuring range ······························································· 36

5.2.6 Setting integral time (sam pli ng tim e) ················································ 37

5.2.7 Setting averaging function ····························································· 38

5.2.8 Setting trigger mode····································································· 38

5.2.9 Creating a program ······································································ 39

5.2.10 Setting measured data buffer function ············································ 41

5.2.11 Setting operating environment ······················································ 43

5.2.12 Executing self-diagnostic function ([SETUP], SELF) ·························· 43

5.2.13 Self-calibration setting································································· 44

5.2.14 Setting measuring voltage source ([SETUP], POW R)························· 45

5.2.15 Setting high-speed measuring mode ([SETUP], FAST)······················· 47

5.2.16 Setting interface conditions ·························································· 47

5.3 Display and Processing of Measured Value ········································· 50

5.3.1 Displaying measured value ···························································· 50

5.3.2 Comparison measurement····························································· 51

5.3.3 Deviation display ········································································· 52

5.3.4 Creating histogram······································································· 53

6. Measurement

6.1 Functions of and Connecting Measuring Term inals································ 56

6.1.1 Functions of measuring terminals···················································· 56

6.1.2 Connecting measuring terminals ····················································· 57

6.2 Measuring Parts, Circuits and Other Items··········································· 57

6.2.1 Using measuring jigs ···································································· 57

6.2.2 Auto measurement······································································· 59

6.2.3 When measuring j ig is not used ······················································ 61

6.2.4 Measurement of circuits ································································ 62

6.3 Measuring Planar Sample ································································ 62

6.3.1 Measurement by pin terminal ························································· 62

6.3.2 Measurement by electrode for surface resist ance measurement ············ 63

6.3.3 Measurement by electrode for planar samp le····································· 63

6.3.4 Use of shielding box····································································· 65

6.4 Measuring Liquid Sample································································· 67

6.4.1 Measurement by electrode for liquid sampl e······································ 67

6.5 Current Measurement ····································································· 69

b

Page 9

6.6 Ending Measurement ······································································ 70

6.7 Measurement Check······································································· 70

6.7.1 Voltage check············································································· 70

6.7.2 Contact check············································································· 71

7. GP-IB Interface

7.1 Overview······················································································ 73

7.2 Specification ················································································· 73

7.3 Talker Function·············································································· 74

7.4 Response to Query Program Message ················································ 76

7.5 Listener Function ··········································································· 77

7.6 Device Clear Function····································································· 78

7.7 Device Trigger Function··································································· 78

7.8 Remote and Local Functions ···························································· 78

7.9 Program Messages········································································· 82

7.9.1 List of program messages······························································ 82

7.10 Precautions for Listener Specific ation ··············································· 95

7.10.1 Input buffer size········································································· 95

7.10.2 Input command message execute and message accept ····················· 95

7.10.3 Command parameter trouble ························································ 95

7.10.4 Limit on command message execute·············································· 95

7.10.5 Output buffer readout·································································· 95

7.11 Status Byte and Events·································································· 96

7.12 Status Data ················································································· 97

7.13 Status Byte Register ····································································· 98

7.14 Using Program Message·······························································100

7.15 Standard Event Status Register······················································103

7.16 Error Register·············································································105

7.17 Device Event Status Register·························································107

7.18 Initialization Value by *RST Message···············································109

8. RS-232 Interface

8.1 Overview·····················································································111

8.2 Connector Used and Signal Names···················································111

8.3 Changeover to GP-IB·····································································111

8.4 Connecting Control Signals and Flow Control······································111

8.5 Transmission Data Specification·······················································112

8.6 Reception Data Specification···························································113

8.7 Status Byte and Events ··································································113

9. External Interfaces

9.1 Handler Interface ··········································································114

9.1.1 Connector·················································································114

9.1.2 Signal functions ··········································································115

c

Page 10

9.1.3 Electrical characteristics of signal s ·················································117

9.2 External Trigger Terminal································································119

9.2.1 Connector·················································································119

9.2.2 Electrical characteristics ·······························································119

9.3 Interlock Terminal ·········································································120

9.3.1 Connector·················································································120

9.3.2 Electrical characteristics ·······························································120

9.4 Signal Timing ···············································································121

9.5 PSU-8541 Connectors····································································123

10. Maintenance

10.1 Periodical Checks for Maintenance ··················································124

10.2 Calibration ·················································································124

10.2.1 Equipment needed for calibration ·················································124

10.2.2 Calibration of measuring voltage ··················································124

10.2.3 Calibration of current meas urement ··············································124

10.3 Self-calibration Function································································125

10.4 Self-diagnosis Function·································································126

10.5 Service Organization of HIOKI························································127

10.6 Storage and Moving ·····································································127

11. Product Full View ········································································128

d

Page 11

1. Preparations Before Operation

1.1 Check during Uncrating

This product has been inspected carefully at the HIOKI factory in preshipment inspection.

Nevertheless, check the following items when uncrating the crate.

1) Any damage on the exteriors of the product.

2) Quantities of accessories

Check in accordance with Table 1.1 List of Accessories.

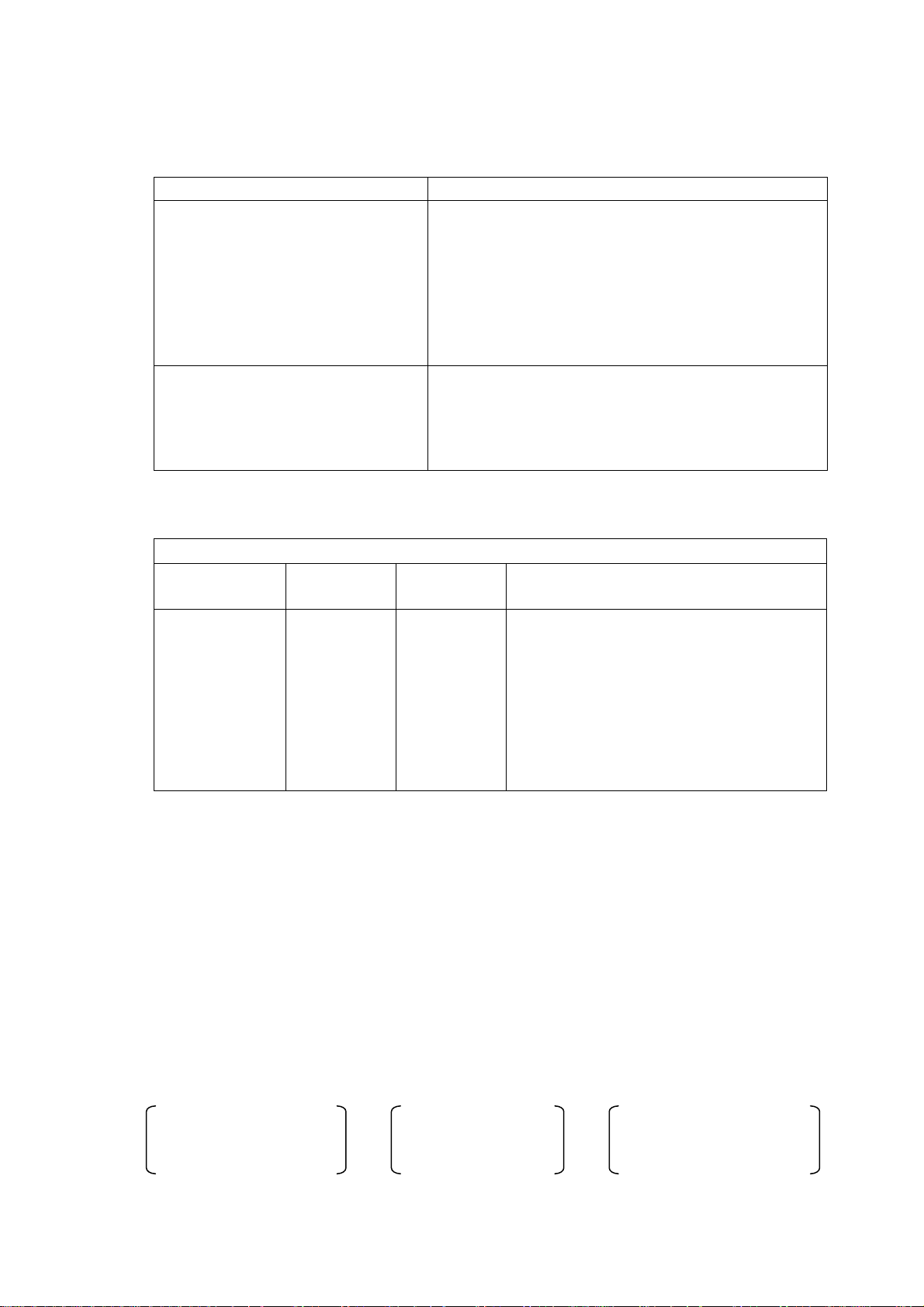

Table 1.1 List of Accessories

Item Quantity Remarks

Power cable 1 Power cable with three poles and grounding pin

3P-2P

conversion adapter

1 Changes the 3P plug of the power cable to a 2P plug

Operational manual 1 This manual

If any damage or missing accessory is found, please contact our distributor or sales

office near your location.

1.2 Operating Power Supply

This meter is powered by the following power supply.

Power supply voltage

100V ±10%

Change in power supply voltage Factory option other than 100V (115, 220 or 240V)

Dedicated power supply unit PSU8541 is rated to

100V only

Power supply frequency 50/60Hz

[Warning]

Before connecting the power plug, check that the AC power supply voltage to be used

matches the voltage specified on the rear panel.

If they do not match, a fire or damage to the meter may result.

[Caution]

Use a 3-conductor power cable conforming to the power supply voltage. A 100V

power cable is supplied wi th the meter as an accessory. Do not use this accessory

cable with other el ectric equipme nt.

1

Page 12

1.3 Grounding

Be certain to ground the grounding terminal located on the rear of the meter or the

grounding pin of the power cable to prevent an accident such as an electrical shock.

The round pin of the 3P plug attached to the power cable is the grounding pin. Plug the

cable to a plug socket that has a grounding device.

When using the 3P- 2P conver sion adapter, be certain to ground the grounding lead wire

from the adapter or the grounding terminal located on the rear of the meter.

[Warning]

Be certain to ground the grounding pin of the power cable to prevent an accident.

If the grounding pin of the power cable cannot be grounded, be certain to ground the

grounding terminal located on the rear of the meter.

1.4 Measuring Cable

1) Low-noise cable

This meter measures a current at a high sensitivity and measured values sometimes

are not stable due to noise generated by the measuring cable.

Use low-noise shielded-conductor cable meeting the specification of HIOKI.

2) Limited length of measuring cable

Depending on the length of the measuring cable, adjustment of the meter is

necessary to correct open values in the contact check function.

The meter was adjusted for use of the measuring cable in the length of 1m during

preshipment inspection of the meter by HIOKI. Please contact our distributor or

sales office near your location if other cable length is intended to be used.

1.5 Warming Up Time

Warm up the meter more than 30 minutes before operating the meter to obtain the

specified performance.

1.6 Memory Initializing

• Memory initializing

1) Press the [F3] key.

If the screen is displayed, the key is in the SAVE Function mode. The key can

perform its function even if the key is not displayed.

2) Press the [MAN. T] (-) key.

3) Press the [ENTER] key.

This completes memory initialization.

The memory can be initialized by this method anytime as long as the meter is shut

down. However, memory initialization also automatically clears data saved by the

save function.

Memory initialization will set the values that were set during preshipment inspection

at the HIOKI factory shown in Table 7.9 “Settings by Factory Preshipment Inspection

and Values Initialized by Message.”

2

Page 13

2 Specification

2.1 Measurement Performance

Measuring Channels

Measuring Channels 4 channels simultaneous measurement

Measuring input/output terminal

[INPUT]

Measurement input [O UTPUT]

Voltage output [A(-), B(-)]

Voltage input [CH1 (+), CH2 (+),

CH3 (+), CH4 (+)]

Channel separation Common connection between CH1 and CH2

2.1.1 DC current measurement

Measuring

Range

10 pA

100 pA

1 nA

10 nA

100 nA

1 µA

10 µA

100 µA

1) Measuring time Typically 300ms with averaging process ON.

2) Temperature range 23 ±5°C, humidity 85% or less

3) Mode Self-calibration automatically executed at 1 minute interval

4) Averaging process On

Maximum

Indicati on

9.9999 pA

99.999 pA

999.99 pA

9.9999 nA

99.999 nA

999.99 nA

9.9999 µA

99.999 µA

4 channels front panel (Input connector for

insulation resistance meter to HIOKI

specification)

4 channels front panel (Binding post)

2 channels rear panel (multi connector)

4 channels rear panel (multi connector)

4 channels rear panel (multi connector)

Common connection between CH3 and CH4

Separated between CH1 and CH2 and between

CH3 and CH4

Current Measurement

Resolution Accuracy

0.1 fA

1.0 fA

10 fA

100 fA

1 pA

10 pA

100 pA

1 nA

± (3.0% of rdg + 1.2% of range)

± (1.5% of rdg + 0.6% of range)

± (0.6% of rdg + 0.6% of range)

± (0.4% of rdg + 0.5% of range)

± (0.4% of rdg + 0.5% of range)

± (0.4% of rdg + 0.5% of range)

± (0.4% of rdg + 0.5% of range)

± (0.4% of rdg + 0.5% of range)

[Remarks]

The resistance measurement accuracy greatly affects the accuracies of voltage

impressed and of current measured. The DSM-8542 specifies only the current accuracy

as a specification. The resistance accuracy is calculated by the following formula

assuming current measurement is a full-scale value. Normally, measured currents are

lower than currents on a full scale and “resistance accuracy > current accuracy” is a

normal val ue.

Resistance accuracy = Current accuracy +

(Resistance on full-scale current)

(On full-scale current)

3

Voltage accuracy Accu racy

Page 14

2.1.2 Measuring voltage output

The output is determined by voltage and current of the power supply input from the rear

panel.

1) Complies with 2.5 “Specification for Dedicated Power Supply Unit PSU-8541” when

the dedicated power supply unit PSU-8541 is used.

2) The screen for operation of the DSM8542 is programmed assuming PSU-8541 will be

used.

2.2 Functional Specification

2.2.1 Measuring time setting

Delay Time

Sampling time setting

Power period setting

0 ~ 9999 ms

2 ~ 300ms

1 ~ 15 PLC

Averaging cycles Auto setting

2.2.2 Voltage monitoring (Voltage check)

Voltage that is output is measured and is compared with the set voltage. Any deviation

from the specified range is indicated by flashing of the side mark (V.CHK ON display).

2.2.3 Contact check function

Connection of a work is checked by measuring the capacity by an RF signal and contact

is checked by a difference between contact in an open circuit state.

Non-contact is indicated by flashing of the side mark (C.CHK ON display).

Item Remarks

Capacity range allowed for contact

detection

Minimum 0.5pF. More than 1/10 of

capacity on jig side.

Capacity offset range on jig side Max. 100pF (0.1pF resolution)

[Notice ] This specification is for a measuring cable length of 1m. Readjustment is

needed if the length exceeds 1m. This function cannot be used if the measuring cable

length exce eds 2m.

4

Page 15

2.2.4 Self-calibration function and self-diagnosis function

The self-calibration function and self-diagnosis function are executed by keying the

Execute key or by the Execute command from the interface.

Self-calibration can be executed automatically after setting an interval. Self-diagnosis is

executed automatically when the power is turned on.

Execution items:

Self-calibration: A/D converter calibration and calibration of current range for each set

period (can be executed automatically)

Self-diagnosis: A/D converter calibration, self calibration of current range and

memory check of the control computer

2.2.5 Comparison measurement and deviation/percent measurement functions

Comparison measurement display: “NG” in decision results is indicated by flashing of the

side mark .

An alarm is sounded by a beep tone (GO decision or NO-GO decision).

Deviation/percent measurement display: The unit is indicated by % or in a measuring

mode during measurement.

Reference values can be set within whole measuring ranges.

Description

Comparison method Upper-limit comparison HI GO:

Measured value > upper-limit value

Intermediate comparison IN GO:

Upper-limit value ≥ measured value ≥ lo wer-limit value

Lower-limit comparison LO GO:

Upper-limit value > measured value

Calculation method for

(Measured value - reference value) x 100/reference value

Percent Measuring mode

Calculation method for

Measured value - reference value

Deviation Measuring m ode

2.2.6 Measurement (jig setting and data processing) function

Measurement of surface resistivity and volume resistivity.

Surface resistivity and volume resistivity can be measured directly by setting a constant

for a jig (or an electrode).

Set items

Surface resistivity measurement: Outside diameter of inner electrode and inside

diameter of outer electr ode

Volume resistivity measurement: Outside diameter of inner electrode and thickness of

sample

Any electrode constant can be set directly.

5

Page 16

2.2.7 Measuring sequence program

Up to ten measuring sequence patterns of discharge, charge, measurement and

discharge can be programmed.

Description

Program sequence (1) Discharge 1, (2) charge, (3) measurement (4) discharge 2

Settable patterns 10

Set time range 0.0 ~ 999.9s

2.2.8 Storage and display functions of measured data

(1) Measured data buffer

Measured data up to 1000 data groups for four individual channels is

sequentially stored and displayed by scrolling.

Measured data is sequentially stored and up to 1000 most recent data groups

are displayed on the stored measurement data screen.

Note: Stored data is cleared when the power is shut down.

(2) Histogram counter

Measured values are classified according to thresholds set independently for

the four channels and the numbers of samples falling in threshold ranges are

displayed in a bar graph.

Measured values are classified into ten types and numbers of data groups are

stored by digitally counting them by a counter.

Thresholds are set for the individual measuring modes and are indicated on the

screen in a bar graph. Thresholds are set within the measuring range

2.2.9 Operability and display

(1) Keyboard

Rubber key switches

Key clicking tone on or off can be selected

Key lock (prevention of malfunction in the Remote mode) on or off can be

selected

(2) Displays

1) Liquid crystal display 240x64dot graphic LCD (30 columns, 8 rows)

Backlight (Yellowish green LEDs)

Character size

Measured result 4 x 2 size

Measuring conditions Full size

Bar graph display

2) High-voltage warning display Red LED lit if higher than about 30V

2.2.10 Resume function

When the po wer sup ply goes off, th e set p aramete rs are au tomati cally s tored. When t he

power is turned on again, the operation is resumed at the set parameters that are

automatically stored, except the voltage impression state.

6

Page 17

2.2.11 Input and output functions (external control interfaces)

(1) GP-IB interface

All items that are operated on the panel can be GP-IB controlled.

Measured results comprising 5-digit exponential measured values, comparison

results and check of measured state are sent in one line of data strings.

Responses in 4-digit fixed decimal points or 5-digit integers are sent to query

commands.

(2) Specification of RS-232 interface function

All items that are operated on the panel can be RS-232C controlled.

Measured results comprising 5-digit exponential measured values, comparison

results and check of measured state are sent in one line of data strings.

Responses in 4-digit fixed decimal points or 5-digit integers are sent to query

commands.

(3) Specification of handler interface function

The interface for measurement by directly operating the meter using the handler

used in measurement.

The communication items and electrical specification are as follows.

• Communication items

Opening and closing of shielding box, key lock of front panel keys, contact

start, measurement start, contact check start, contact check result

measuring voltage on and off, decision results, analog measurement end

measurement computing end, troubles that have occurred.

• Electrical specification

Contact input and output by a photocoupler

Connector product No. is 57LE-40360-7700

4) Specification of interface function for control of dedicated power supply unit

PSU-8541

Using the dedicated power supply unit PSU-8541, insulation resistance can be

measured operating the DSM8542. Voltage and current can be set and voltage

ON/OFF can be selected. The control items are as follows.

Voltage setting

Current limiter for measurement and current value setting (Common for all channels)

Current limiter for charging and current value setting (Common for all channels)

Voltage output ON/OFF

Voltage generator filter ON/OFF

7

Page 18

2.3 General Specifications

General Specifications

HIOKI-specification insulation meter input connector (INPUT)

Red binding post (OUTPUT)

Operating environment

Temperature 5 to 35°C, humidity 85% or less

Power supply voltage

AC 100V ±10% (standard), 115/220/240V ±10% (factory option)

AC 100V ±10% (dedicated power supply unit PSU-8541 )

Power supply frequency

50/60Hz

Power consumption

55VA max.

350BVAmax (dedicated power supply unit PSU-8541)

External dimensions (mm)

332 W x 89 H x 450 D

332 W x 179 H x 450 D (dedicated power supply unit PSU-8541)

Weight

7kg

28kg (dedicated power supply unit PSU-8541)

2.4 Options

In addition to the standard accessories , the following products are available as options

for dedicated use with this meter for easy and expanded uses of the meter and as

options that are common to the meters manufactured by HIOKI.

8

Page 19

2.4.1 Special options

The special options for dedicated use with this meter are as follows.

Option Product Name Standard

Measuring lead with te st rod 0GE00002

0GE00001

Measuring lead with alligator clip 0GA00007

0GA00008

Length 1m, red

Length 1m, black

Length 1m, red

Length 1m, black

Interlock connection cable DSM8104F Length 0.1m

2.4.2 Common options

The options common to all HIOKI insulation meters are as follows.

Option Product Name Remarks

Electrode for planar sample

(The main electrode dia. is

50mm)

SME-8310 Equipped with changeover switch for

surface and volume resistance

measurement

Comes with interlock connecting cable*

Electrode for planar sample

SME-8311 Same as above*

(The main electrode dia. is

19.6 mm )

Weight Electrode SME-8320 For surface and volume resistance

measurement

(Designed for use with SME-8350

Shielding Box)

Shielding Box SME-8350 Measurement box for shielding dielectric

interference*

Surface Resistance

SME-8301 For anti-electrostatic product

Measurement Electrode

Surface Resistance

Measurement Electrode

SME-8302 For rubber and plastics

(Electrode spacing 10mm)

Liquid Sample Electro de SM-8330 Capacity about 25ml, electrode constant

about 500cm

Electrode for chip capacitor SME-8360 For chip capacitor

Surface/Volume Resistance

Measurement Electrode

SM9001 Surface/Volume Resistance

measurement for static prevention floor

material

Standard Resistor SR-2 Calibrating standard resistor for super

insulator meter

*When connecting this meter to an electrode for planar sample (SME-8310 or SME-8311)

or a shielding box (SME-8350), the interlock connecting cable (DSM8104F) is

necessary.

9

Page 20

3 Operating Principles

3.1 Operating Principles

Equipped with four channels of high-sensitivity current measuring units, this meter

calculates an insulation resistance value based on measuring voltage set in a dedicated

voltage source and impressed to the work and measured current value. The meter also

outputs a current value and can be used also as a 4-channel high-sensitivity ammeter in

addition to its use as an insulation resistance meter.

The control unit of the meter has a 32bit CPU for calculations of resistance values and

for other functions.

Current-voltage conversion of the current measuring unit is based on a current-voltage

conversion A/D converter of a charge measuring type that integrates input current.

The output of the current-voltage converter is converted into digital data by an A/D

converter and is fed to the memory in the control unit after being isolated by a

photoisolator.

The control unit computes measured data input to the memory and outputs it to the

display screen and interf aces.

The measuring voltage source can be set 1000V/10mA maximum and supplies stable

measuring voltage from the dedicated power supply unit.

The dedicated external measuring voltage source of this meter can set a large maximum

output current, allowing simultaneous measurement of up to four channels so that

measuring time can be shortened in measuring a sample with a large electrostatic

capacity such as a capacitor by shortening the charging time.

In addition to voltage output for measurement, the dedicated external measuring voltage

source has voltage output for charging (charging terminal), which can be used for

precharging before taking measurement, to enhance the measuring throughput.

The measuring voltage output and charge output are separated by a current limiter,

enabling continual measurement without affecting measurement even if a sample on the

charge terminal side is short-circuited.

An isolated handler interface that can be connected directly to a contact signal, a GP-IB

interface conforming to the IEEE-488 standard and an RS-232 and an interface for

control of the dedicated voltage source are available as external interf aces that are

supplied as standard provisions.

For measurement connectivity, two channels each measuring circuits are floating. Both

grounded samples and non-grounded samples can be measured.

The meter can be used as an independent ammeter by measuring a current between the

“INPUT” and “GUARD” terminals. In this case, however, measuring voltage is output on

start of measurement and a minimum value needs be set as measuring voltage.

10

Page 21

3.2 Block Diagram of DSM-8542

11

Page 22

4 Names and Functions of Components

[Notice ]

In the following descriptions, characters enclosed by “[ ]” such as [ENTER] are

the characters printed on key tops. Characters enclosed by “ ” such as

“POWER” are the characters printed on the panels.

4.1 Safety Alert Symbols

The following safety alert symbols are placed on the front and rear panels of this meter.

!

The locations where the safety alert symbols are placed are illustrated below.

Warning

symbol

Electrical

Grounding

terminal

This symbol is marked where the operational manual

needs to be referred to.

This symbol indicates high voltage hazard and is

indicated on terminals where high voltage is output

such as meas uring t erminal s.

Indicated on the grounding terminal “GND” on the rear

of the meter. If the grounding pin of the power cable

cannot be grounded, be certain to ground this terminal.

12

Page 23

4.2 Front Panel

The front panel of the DSM-8542 is illustrated below.

1: “POWER” switch

The power supply switch to select power on and off.

Press this switch once to depress it to turn the power on. Press once again to pull

up the key and to turn the power off.

2: “POWER” lamp

Lit when the POWER switch is turned on.

3: “STOP” lamp

Lit when the [STOP] key is pressed. Extinguished when the [START] key is pressed.

The output voltage lowers to “0” while the “STOP” lamp is lit, disabling receiving of

trigger input.

4: “START” lamp

Pressing the [START] key lights up this lamp, going off when the [STOP] key is

pressed.

The set voltage is output and trigger input can be received while the “START” lamp is lit.

5: [STOP] key

Stops measurement and lowers voltage output to 0V.

This key is given the highest priority and can be operated even when the keys are locked .

6: [START] key

This key outputs set voltage and enables trigger input.

Measurement is started when the Trigger mode is “INT.”

7: “High Voltage” lamp

Indicates output of high voltage.

The lamp is lit when voltage higher than about 30V is output.

8: Cursor moving keys

The keys move the cursor around on the screen or scroll the screen.

13

Page 24

9: Command/numeric input keys

Operate the keys when setting parameters.

Pressing the [SHIFT] key changes the keys to the numeric input keys.

10: [F1]/“TRIG MODE” [F2]/“COMP ON /FF”

[F3]/“V. CHK ON/OFF ” [F4]/“C . CHK ON/FF”

[F5]/“P.SET”

These keys are the functi on keys. The functions of these keys are displayed on the

LCD screen above the keys. Pressing the [SHIFT] key on the measurement screen

sets the functions indicated in “ .” The information is displayed on the screen also.

11: Display

This is a liquid crystal display module 240 x 64 dots in resolution to display measured

results, measuring conditions and various setting screens.

12: “INPUT” connector [CH1]

The connector for measurement input.

The connector of a double structure comprising a center conductor and outer

conductor connecting to measurement input and to the “CH1&CH2” of the “VOLTAGE

INPUT” connector on the rear, respectively. The connector has a floating potential

common with CH2.

13: “INPUT” terminal [CH2]

The connector for measurement input.

The connector of a double structure comprising a center conductor and outer

conductor connecting to measurement input and to the “CH3&CH4” of the “VOLTAGE

INPUT” connector on the rear, respectively. The connector has a floating potential

common with CH1.

14: “INPUT” terminal [CH3]

The connector for measurement input.

The connector of a double structure comprising a center conductor and outer

conductor connecting to measurement input and to the “CH1&CH2” of the “VOLTAGE

INPUT” connector on the rear, respectively. The connector has a floating potential

common with CH4.

14

Page 25

15: “INPUT” terminal [CH4]

The connector for measurement input.

The connector of a double structure comprising a center conductor and outer

conductor connecting to measurement input and to the “CH3&CH4” of the “VOLTAGE

INPUT” connector on the rear, respectively. The connector has a floating potential

common with CH3.

16: “OUTPUT” termin al [CH1]

A terminal for measuring voltage output.

Resistance is measured between the “OUTPUT” [CH1] and “INPUT” [CH1] terminals.

It is connected to “OUTPUT” te rminal [CH2].

17: “OUTPUT” termin al [CH2]

A terminal for measuring voltage output.

Resistance is measured between the “OUTPUT” [CH2] and “INPUT” [CH2] terminals.

It is connected to “OUTPUT” te rminal [CH1].

18: “OUTPUT” termin al [CH3]

A terminal for measuring voltage output.

Resistance is measured between the “OUTPUT” [CH3] and “INPUT” [CH3] terminals.

It is connected to “OUTPUT” te rminal [CH4].

19: “OUTPUT” termin al [CH4]

A terminal for measuring voltage output.

Resistance is measured between the “OUTPUT” [CH4] and “INPUT” [CH4] terminals.

It is connected to “OUTPUT” te rminal [CH3].

15

Page 26

4.3 Rear Panel

The rear panel of the DSM-8542 is illustrated below.

20: “AC LINE 50/60Hz” connector

The connector for input of power supply voltage.

21: “VOLTAGE INPUT” connector

The connector to supply voltage needed for insulation resistance measurement.

Supplies voltage to both [CH1&CH2] and [CH3&CH4].

22: “RS-232” connector

The connector for RS-232 connection.

23: “GP-IB” connector

The connector for GP-IB connection.

24: “EXT TRIGGER” connec tor

The connector for external trigger input.

This connector is used when the trigger mode is set to external “EXT.”

25: “INTERL OCK” conn ector

The input connector for connection of signals from a fixture when an interlock function

is used.

26: “GND” terminal

The grounding terminal connected to the housing of the meter.

27: Cooling fan

The fan for cooling the inside of the meter.

28: “HANDLER” connector

The connector for handler connection.

29: “V.CONTROL” connector

The connector to connect control signals when the dedicated power supply unit

PSU-8541 is used.

16

Page 27

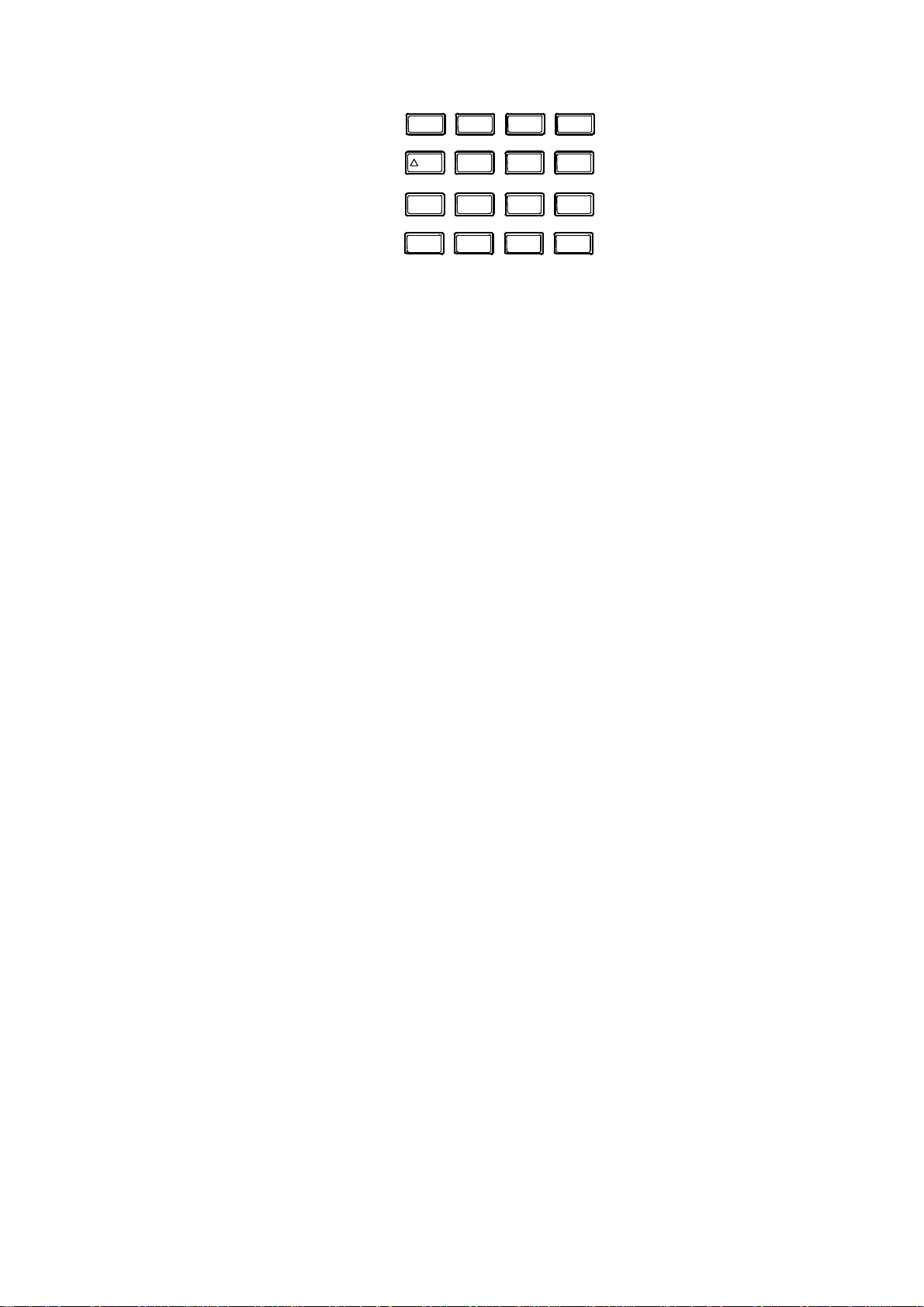

4.4 Command/Numeric Input Keys

The command/numeric input keys have the following functions:

[SHIFT]: Shift

The key to change command/numeric input and the functions of the function

keys on the measurement screen.

The command/numeric input keys are set to the Command Input mode when the

[SHIFT] key is not pressed, set to the Numeric Input mode when the [SHIFT]

key is pressed.

Each pressing of the [SHIFT] key alternately changes the mode of the key.

When the SH IFT key i s pres sed, a s ide ma rk (“◄”) will be displayed beside

“SHIFT” in the upper right of the screen.

[ENTER]: Enter

Pressing this key enters input results.

Exit after finishing setting the measurement screen and the setting screen by

pressing this key.

[LOCK]/”0”: Key lock

Press this key to prohibit key input.

Pressing this key prohibits operations of the keys other than the [STOP] and

[LOCK] keys.

Press the [LOCK] key again to cancel the key lock status.

When the ke ys are lo cked, a side m ark (“ ◄”) will be displayed beside “KEY

LOCK” in the upper left of the screen.

The key becomes a key for input of “0” when the [SHIFT] key is pressed and

the Numeric Input mode is set.

[LCDOF]/“.”: LCD off

The key to exit the display screen. The key shuts down screen display and

extinguis hes the backli ght.

Press any key to cancel when the display is turned off.

The key becomes a decimal point input key “.” in the Numeric Input mode.

[MAN.T]/“-”: Manual trigger

A trigger is generated and measurement is started when pressed while the

trigger mode is “MAN” (Manual Trigger mode).

When in the Numeric I nput mode, the key will become a negative “-” po larity

input key.

7

MONI

4

MOD

1

PROG

0

LOCK

8

COMP

ELEC5SETUP

2

OPEN

.

LCDOF

9

DATA

6

3

V.CHK

-

MAN.T

SHIFT

E

LOCAL

BS

C.CHK

ENTER

17

Page 28

MONI

MOD

1

PROG

0

LOCK

[PROG]/“1”: Program

The key to move to the sequence program creation screen.

See “Operating Program Creation Screen.”

When in the Numeric I nput mode , the key wi ll become an input key (“ 1”).

[OPEN]/“2”: Open correction

The key to move to the screen to set reference values for contact checks.

See “Operating Open Setting Screen.”

When in the Numeric I nput mode , the key wi ll become an input key (“ 2”).

[V. CHK]/“3”: Voltage check

The key to execute once a voltage check of measuring voltage output between

“OUTPUT” and “GUARD.”

When in the Numeric I nput mode , the key wi ll become an input key (“ 3”).

[C. CHK]/“BS”: Contact check

The key to execute once a contact check.

When in the Numeric I nput mode , the key wi ll become a “BS” k ey to dele te

characters that are input.

[∆MOD]/“4”: Deviation Measuring m ode

The key to move to the Deviation Value Display and Setting screen.

See “Operating Deviation Value Display and Setting Screen.”

When in the Numeric I nput mode , the key wi ll become an input key (“ 4”).

[ELEC]/“5”: Electrode

The key to move to the Electrode Parameter Setting screen.

See “Operating Electrode Setting Screen.”

When in the Numeric I nput mode , the key wi ll become an input key (“ 5”).

[SETUP]/“6”: Set up

The key to move to the Operation Environment Setting screen.

See “Operating Operation Environment Setting Screen.”

When in the Numeric I nput mode , the key wi ll become an input key (“ 6”).

[LOCAL]/“E”: Local

The key to cancel the Remote mo de.

When in the Numeric I nput mode , the key wi ll become an exponent display and

input key (“E”).

7

4

8

COMP

5

ELEC

2

OPEN

.

LCDOF

9

DATA

6

SETUP

3

V.CHK

-

MAN.T

SHIFT

E

LOCAL

BS

C.CHK

ENTER

18

Page 29

[MONI]/“7”: Monitoring

The key to change over the Regular Measurement screen and Sequential

Measurement monitoring screen.

When in the Numeric I nput mode , the key wi ll become an input key (“ 7”).

[COMP]/“8”: Compare

The key to move to the Comparison Measurement Setting screen.

When in the Numeric I nput mode , the key wi ll become an input key (“ 8”).

[DATA]/“9”: Data

The key to move to the acquired data screen to total measured results.

When in the Numeric I nput mode , the key wi ll become an input key (“ 9”).

7

MONI

4

MOD

1

PROG

0

LOCK

8

COMP

5

ELEC

2

OPEN

.

LCDOF

DATA9SHIFT

6

SETUP

3

V.CHK

-

MAN.T

E

LOCAL

BS

C.CHK

ENTER

19

Page 30

4.5 Display Screen

The display screen of the DSM-8542 is illustrated below.

“REMOTE”

When in th e Remote mode (GP -IB or RS -232 mode ), a sid e mark ( “◄”) will be

displayed on the screen.

The Remote mode is not set when the side mark is not displayed.

“KEY LOCK”

When in th e Key Lo ck mod e, a sid e mark (“◄”) will be displayed on the screen.

The Key Lock mode is not set when the side mark is not displayed.

“INTERLOCK”

When the i nterlock fun ction i s on (en abled) , a side mark (“ ◄”) will be displayed

on the screen.

The interlock function is off (disabled) when the side mark is not displayed.

“BUFF. FULL”

A side mark (“◄”) will be lit when the number of data groups saved by the

buffering function for 1000 data groups exceeds 1000. Measured data after

this mark is lit will be discarded without being stored in the buffer.

“CHARGE ON”

A side mark (“◄”) will be lit when the [CHARGE] terminal is usable. The

[CHARGE] terminal cannot be used when this mark is not lit.

“OPEN SET”

A side mark (“◄”) will be lit when open correction is executed. A contact

check can be carried out while this mark is displayed.

Executing a contact check when this mark is not displayed results in an error.

“MEAS COND”

A side mark (“•”) on the screen indicates that the meter is conducting

measurement.

“SHIFT”

A side mark (“►”) on th e screen indicates the status of the Shift ke y.

The Shift mode is not set while the side mark is not displayed.

20

Page 31

“TRIG-INT”

When in th e Intern al Trigge r mode, a side m ark (“ ►”) will be displayed on the

screen.

“TRIG-MAN”

When in th e Manua l Trigg er mode , a sid e mark (“►”) will be displayed on the

screen.

“TRIG-EXT”

When in th e Externa l Trigge r mode, a side ma rk (“► ”) will be displayed on the

screen.

“COMP ON”

A side mark (“►”) on the screen indicates the ON/OFF status of the decision

function. The decision function is not on when the side mark is not displayed.

The side mark flashes when a decision result is NG.

“V. CHK ON”

A side mark (“►”) on the screen indicates the ON/OFF status of the voltage

check function. The voltage check function is not on when the side mark is not

displayed .

The side mark flashes when the result of a voltage check is NG.

“C. CHK ON”

A side mark (“►”) on the screen indicates the ON/OFF status of the contact

check function. The contact check function is not on when the side mark is not

displayed .

The side mark flashes when the result of a contact check is NG.

21

Page 32

5 Preparations for Measurement

5.1 Connecting Meter and Power Supply Unit

This meter measures both insulation resistance and a current, externally connecting a

voltage source for measurement of voltage and other parameters. A voltage source is

indispensable to measure a leakage current by applying voltage, as well as resistance.

A dedicated power supply unit is available as an option to the meter, allowing operation

of the unit by the keyboard and LCD screen of the meter. This option power supply unit

is most suitable in obtaining maximum performance of the DSM-8542.

5.1.1 Connecting dedicated power supply unit PSU-8541

Fig. 5.1 illustrates connection of the DSM-8542 and PSU-8541. Use a cable for

connection specified in Table 1 or its equi valent.

5.1.2 Connecting power supply other than dedicated power supply unit

Fig. 5.2 illustrates connection of the DSM-8542 and external power source other than

PSU-8541. Use a cable for connection matching specification requirements of the

DSM-8542 and external power source.

22

Page 33

Front

Measuring Jig Side

CH1

A(-)

CH2

A(-)

CH3

B(-)

CH4

B(-)

Rear

Fig. 5.1 Connecting DSM-8542 and PSU-8541

List of Connection Cables

Connected To Cable

V.CONTROL DSM-8542 connection cable A

VOLTAGE

DSM-8542 connection cable B

INPUT- OUTP UT

Interlock DSM8104F

Measuring Lead 0GE0001,0GE0002 and others

*: (-) side is connected

CH1-2 and CH3-4

Interlock Signal

Jig for charging

23

Page 34

Fig. 5.2 Connection of DSM-8542 and external power source other than PSU-8541

Cautions

In case the dedicated power supply unit

PSU-8541 is not used,

1) Voltage control requires control of

GP-IB and other interfaces in addition

to the meter.

2) Discharge during voltage off is

sometimes disabled

.

24

Page 35

5.2 Setting Measuring Conditions

The meter is capable of setting measuring methods and measuring conditions

beforehand so that insulati on resistances of materials, parts and circuits can be

measured easily under preset conditions.

Before explaining about measurement, this chapter describes setting of various

measuring conditions.

Press the “POWER” switch on the front panel to set it to “ON.” The “POWER” lamp on

the front panel lights up.

After initializing, the regular measurement screen sets. Measuring condition settings

such as measuring voltage and sampling time are set to the same states as those stored

when the power was shut down af ter previous measurement thanks to the resume

function.

[Warning]

Before turning the power on, check that the AC power supply voltage to be

used matches the power supply voltage specified on the rear panel.

If they do not match, a fire or damage to the meter may result.

[Warning]

Be certain to ground the grounding pin of the power cable or a grounding

wire to prevent an accident. If the grounding pin of the power cable or

grounding wire cannot be grounded, ground the grounding terminal located

on the rear of the meter.

Self-diagnosis

After switching the “POWER” on, press the [ SETUP ] (SET

UP) key in the measured

value display screen. This will take you to the screen to set the operation environment

(Operation Environment Setting screen). Press the [F2] SELF (SELF

CHECK) key on the

Operation Environment Setting screen. The screen will change to the Self-diagnosis

Execute screen. (See Fig. 5.3)

SELF CHECK EXECUTE

1.MEMORY CHECK---

2.A/D CAL.-------

3.RANGE CAL.-----

EXEC

Fig. 5.3 Self-diagnosis Execute Screen

25

Page 36

SELF CHECK EXECUTE

1.MEMORY CHECK---OK

2.A/D CAL.-------OK

3.RANGE CAL.-----OK

EXEC

Fig. 5.4 Self-diagnosis Execute Screen

The function key [F5] will change to EXEC (EXEC

UTE). Pressing the [F5] EXEC key

starts self-diagnosis.

In a self-diagnosis test, a memory check, as well as self-calibration checks of the A/D

converter and range, are automatically carried out, displaying OK (acceptable) or NG

(not acceptable). Fig. 5.4 shows an “OK” execution result on the Self-diagnosis Execute

screen. Press the [ENTER] ke y after finishing sel f-diagnosis to return to the

measurement screen.

[Notice ]

After executing self-diagno sis, if there are a ny items with [NG], swi tch on the

POWER again and execute the self-diagnosis one more time. If there are still

items with [NG] even after the power is resumed and a self-diagnosis test is

executed, please contact the nearest HIOKI office for repair.

[Notice ]

In addition to a [Self-diagnos is function], thi s meter has a [Self-cali bration

function] which allows users to execute self-calibration checks at preset

intervals. The factory default settings are [Self-calibration function = ON] and

[Self-calibration interval = 60 seconds].

The self-calibration check requires about 2 seconds to complete and during this

interval, not only will the measured values not be displayed, but all controls,

including key operations and communications, will also be stopped for the

self-calibration to be executed. Therefore, when executing an automated

measurement, set the self-calibration function OFF and execute a command

from the interfaces GP-IB or RS-232C ([*CAL?] command or [*TST?] command)

to execute self-calibration, or perform a self-diagnosis test by keying the keys on

the panel periodically.

*[Self-calibration] executes [2. Calibration of A/D converter] and [3. Range

calibration] of [Self-diagnosis]. For details on self-calibration, please refer to

[10.3 Self-calibration Function].

26

Page 37

5.2.1 Screen types

Set the various measuring conditions and other items in accordance with the screen on

the front panel.

Two screens are availabl e - Measured value display screen and setting screen.

(a) The Measured Value Display screen displays results of measurement.

(b) The setting screen is for setting measuring conditions and other items.

Table 5.1 classifies the screens of the meter.

(1) Measured Value Display screen

The Measured Value Display screen displays measured results and measuring

conditions.

A measured value is displayed in the top part of the screen in large characters.

Measured values that are displayed are always results of most recent

measurement.

The Measured Value Display screen is split into the Regular Measurement

screen and Sequential Measurement Monitoring screen.

In addition to the Regular Measurement screen, the Sequential Measurement

Monitoring screen allows monitoring of the progress of each sequence.

The Monitoring screen counts down the following items as the sequences

advance, enabling viewing of sequence progresses at a glance.

Discharging time before measurement “DCHG1”

Charging time before measurement “CHARG”

Measuring time “MEAS”

Discharging time after measurement “DCHG2”

Operate the [MONI] key to switch between the [Regular Measurement screen]

and [Sequential Measurement Monitoring screen].

27

Page 38

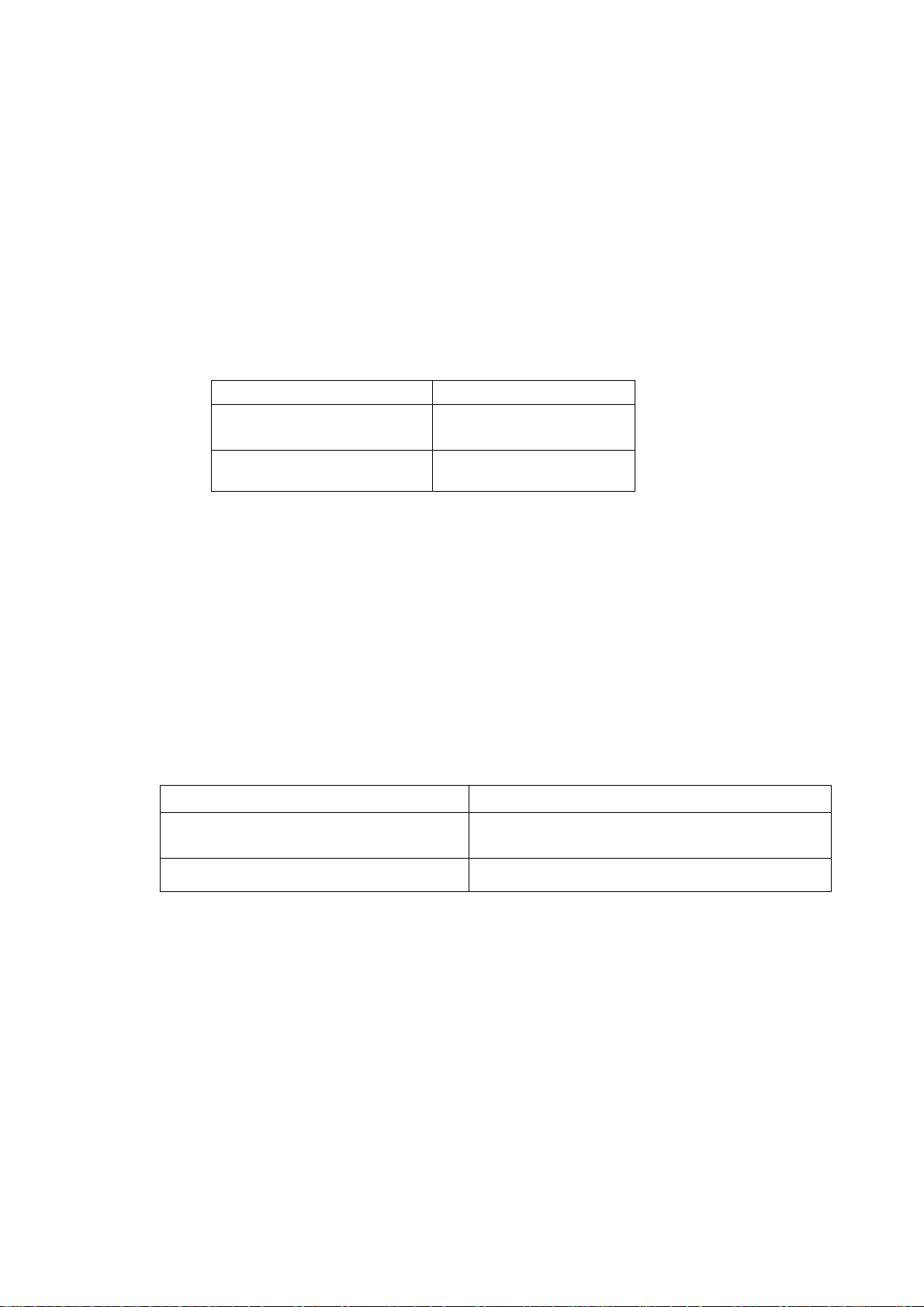

Table 5.1 Screen Types

n

n

Screen Type Screen Meter Status

Measured value

display sc reen

Display of 4 channels

Sequential Measurement Monitoring screen

Display of 1 channels

Setting sc reen Comparison Me asurem ent Setti ng scre en

Acquired Data screen

Histogram Dis play sc reen

Histogram Threshold Display screen

Measured Data Buffer Display screen

Measured Data Buffer Erase screen

Deviation Value Display and Setting scree

Electrode Setting screen

Environmen t Set ting scree n

External Interface Setting s creen

Self-diagnosis Test Execute screen

Self-calibration Setti ng screen

Measuring Power Source Setting scree

Program Create screen

Open Correction Value Setting screen

Measuring Regular measurement screen

waiting for key input

Measuring

waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input/display

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

Waiting for key input

After measurement/waiting

for key input

• A measured value for display of one channel is displayed in the top part of the screen

in large characters.

Measured values are always results of most recent measurement.

• Measuring conditions that are currently set are displayed under a measured value.

• Side marks are displayed on both sides of the screen indicating measurement and key

statuses.

• Functions of the function keys are displayed in the bottom.

28

Page 39

Measuring condition display Side mark display Measured value display Side mark display

REMOTE

KEYLOCK

INTERLOCK

BUF.FULL

CHARGE ON

OPEN SET

◄ [1]4 0624E+15ΩRV R:HLD7 POWA □

◄ [2]6.7253E+16ΩRV R:HLD7 POWA

[3]1

[4]6.6107E+16ΩRV R:HLD7 POWB

0775E+16ΩRV R:HLD7 POWB

►

POWA :100.0V SAMPL: 15PLC

POWB : 1 0 .0V DELAY : 0ms

◄ SEQ :ON :0 AVE :OFF ►

MEAS COND

SHIFT

INT TRIG

MAN

EXT

COMP ON

►

V.CHK ON

C.CHK ON

DISP MODE SAVE RCAL <PSET>

[Regular Measurement screen] Function key display

Press the [MONI] key for changeover

REMOTE

KEYLOCK

INTERLOCK

BUF.FULL

CHARGE ON

OPEN SET

◄ 12 □

◄ POWA :100.0V SEQ :OFF:1 ►

◄ RANGE:AUTO1 DCHG2: 10.0s ►

[Sequential Measurement Monitoring screen]

34

3.0000E+10Ω

SAMPL: 15PLC DCHG1: 10.0s

DELAY: 0ms CHARG: 10.0s

AVE :OFF MEAS : 2.0s

►

DISP MODE SAVE RCAL <PSET>

MEAS COND

SHIFT

INT TRIG

MAN

EXT

COMP ON

V.CHK ON

C.CHK ON

Fig. 5.5 Regular Measurement screen and Sequential Measurement Monitoring screen

Table 5.2 Display of Measured Values

Classification Display Setting Procedure

Indication type Unit indication

Exponential indi cation

Number of

2 to 5 columns

[F1]DISP ⇒ [F 1]UNIT

[F1]DISP ⇒ [F2]EXP.

[F1]DISP ⇒ [F3 ]FIG

effective digits

Measuring mode Ω: Resistance measurement

A: Current measurement

ΩRs: Surface resistivity measurement

ΩRv: Volume resistivity measurement

Deviation value

Measured value - Re ferenc e valu e

display

Measured value - Reference value

Reference value

x 100%

Press the [F2] MODE key to

sequentially select a desired

mode

Ω → A→ ΩRs → ΩRv→ Ω

Select [∆MOD] and DEV

Select [∆MOD] and PAR

Error display RANGE OVER: Overrange in current measurement*

NOTE *: An [RANGE OVER] display indicates a measurement value which is beyond the

preset measurement range (resistance value of the measurement object is too low).

An [RANGE OVER] di splay during Auto Range will mean that the value is beyond the

measurable range.

29

Page 40

Table 5.3 Meanings of Side Marks

Panel

Character

REMOTE

KEY LOCK

INTERLOCK

BUF.FULL

CHARGE ON

OPEN SET

MEAS COND

SHIFT

TRIG INT

MAN

EXT

COMP ON

V.CHK ON

C.CHK ON

Side

Status

Mark

◄ In external remote mode

◄ In key lock mode

◄ Interlock in operation ([START] disabled)

◄ Data buffer is full

◄ “CHARGE” terminal can be used

◄ Open correction already executed

● In measurement

► Key shift mode (Numeric and other keys can be input)

►

Internal trigger is selected

►

Manual trigger is selected

►

External trigger is selected

► Comparison m easurem ent is s elected

The side mark flashes if a comparison result is NG.

► Voltage check is executed automatically

The side mark flashes if result of voltage check is NG.

► Contact check is executed automatically

NOTE 1

NOTE 1

NOTE 1

The side mark flashes if result of contact check is NG.

Note 1:

When a mark is flash ing in c ase a re sult is N G, the m ark doe s not go off till next

check is carried out or a decision is made.

Set the measuring conditions for the Measured Value Display screen as f ollows.

(a) Press the [F5] RESET key.

(b) Move the cursor to a desired setting item operating the cursor move keys ([◄], [►],

[▲] and [▼]). The selected items will be highlighted.

(c) Operate the function keys corresponding to the screen display or the numeric keys

for setting each item. Select each setting by pressing the [ENTER] key.

When canceling a setti ng, era se a numer ic valu e by press ing the [BS] ke y and press

the [ENTER] key to return to d ata before the settin g.

The functions keys co rresponding to each setti ng item will b e the scroll keys ([F2],

[F3]) for specified value. Condition setting keys for each function will be [F4] and

[F5].

See Table 5.4 for more information.

[Examp le] To set voltage 75.5V.

(a) Press the [F5] PS ET key.

(b) Move the cursor to “MES. V” operating the [◄], [►], [▲ ] and [▼] keys.

(c) Voltage cannot be specified operating the [F2] DOWN and [F3] UP keys. Input

voltage by keying the numeric keys.

(d) Set by sequentially keying the [MONI] “7”, [ELEC] “5”, [LCDOF] “.”, [ELEC] “5” and

[ENTER] keys.

30

Page 41

Table 5.4 Measuring Conditions

*1

*3

Resolution Function Key

0.1 V

1 V

0.1 V

1 ms

1 PLC

[ F2 ] DOWN

[ F3 ] UP

[ F2 ] DOWN

[ F3 ] UP

[ F2 ] DOWN

[ F3 ] UP

[ F4 ] ms

[ F5 ] PLC

1 ms [ F2 ] DOWN

[ F3 ] UP

Set Item Descripti on

POWA

Set voltage

range

POWB Set voltage

range

Setting Range (S pecified Value)

0.1 ~ 250 V

251 ~ 1000 V

(0.1,0.5,1,2.5,5,10,25,

50,100,250,500,1000)

0.1 ~ 10 V

(0.1,0.5,1,2.5,5,10)

SAMPL Integral time Time setting 2 ~ 300 ms

(2,4,8,16,20,40,80,160,300)

Period setting 1 ~ 15 PLC

(1,2,4,8,15)

DELAY Trigger delay

time

0 ~ 9999 ms

(0,5,10,50,100,500,1000,

5000,9999)

AVE Averaging ON/OFF [ F4 ] ON

[ F5 ] OFF

RANGE Current range

Range 1 ~ 8 AUTO/HOLD

Range Integral Capacity

1 10 µF

2 1 µF

[ F2 ] DOWN

[ F3 ] UP

[ F4 ] AUTO

[ F5 ] HOLD

3 100 nF

4 10 nF

5 1 nF

6 100 pF

7 10 pF

8 10 pF

*2

SEQ Sequential

measurement

Program No. 0 ~ 9

ON/OFF

[ F2 ] DOW N

[ F3 ] UP

[ F4 ] ON

[ F5 ] OFF

DCHG1 Discharging

time-1

CHARG Charging time 0 ~ 999.9 s

MEAS Measuring

time

DCHG2 Discharging

time-2

0 ~ 999.9 s

(0,10,20,30,40,50,60,600,900)

(0,10,20,30,40,50,60,600,900)

0 ~ 999.9 s

(0,10,20,30,40,50,60,600,900)

0 ~ 999.9 s

(0,10,20,30,40,50,60,600,900)

0.1 s [ F2 ] DOWN

[ F3 ] UP

0.1 s [ F2 ] DOWN

[ F3 ] UP

0.1 s [ F2 ] DOWN

[ F3 ] UP

0.1 s [ F2 ] DOWN

[ F3 ] UP

NOTES

*1: “1 PLC” stands for “1 power line cycle.”

*2: “Range 8” increases the gain ten-fold while maintaining the same capacitor capacity

of 10pF.

*3: The specified value is a preset value selected by the scroll keys.

31

Page 42

Measuring conditions are set on the Measured Value Display screen after pressing the

[F5] PSET key. To facilitate settings and to enable selection of a value operating the

function keys [F2] to [F5], a specified value is gi ven to each condition.

To reset after finishing setting, press the [ENT ER] key.

(2) Setting screen

As shown in Fig. 5.1, the setting screen is displayed by moving from the

Measured Value Display screen to the Setting screen in accordance with a

measuring condition or other items.

The Setting screen has a dedicated screen for each set item.

To reset to the Measured Value Display screen, press the [ENTER] key.

Measured Value Display screen Setting screen

Regular

measurement

screen

Change by

pressing

the [MONI]

Reset by pressing the

[ENTER] key

Move to the setting

screen operating setting

and func tion k eys.

Cannot measure on this

screen

key

Sequential

Measurement

Monitori ng scree n

Fig. 5.6 Key Operation and Screen Change

See Table 5.5 for information on the setting key to move to the Setting screen and on the

function keys.

32

Page 43

Table 5.5 Set ting ke ys and f unction keys f or setti ng scr een chan ge

Setting Key Fu nction Key Setting Screen

[ COMP ]

[ DATA ]

[ △MOD ]

[ F1 ] HIST

[ F2 ] SETH

[ F3 ] CLRH

[ F4 ] CLRD

[ F5 ] ROLL

Comparison Measurement Setting screen (See 5.2.2)

Acquired Data screen (See 5.2.4 onward)

Histogram display screen

Histogram display threshold setting screen

Histogram counter clear screen

Measured data buffer clear screen

Measured data buffer display screen

Deviation Value Display and Setting screen (See 4.3.4)

[ ELEC ] Electrode Setting screen (See 4.3.5)

[ SETUP ]

[ F1 ] CONF

[ F2 ] SELF

[ F3 ] CAL

[ F4 ] POWR

Environment Setting screen (See 4.3.6~ onward)

External interface setting s creen

Self-diagnosis test execute screen

Self-diagnosis test execute screen

Self-calibration setting screen

[ PROG ] Program create screen (See 4.3.11)

[ OPEN ] Open Correction Value Setting screen (See 4.3.12)

5.2.2 Setting measuring mode

This meter has four measuring modes capable of measuring resistance, current, surface

resistivity and volume resistivity.

Set a desired measuring mode as follows.

(1) Key operation

(a) Press the [F2] MODE key for mode selection.

(NOTE: The modes are displayed on the Measured Value Display screen.)

(b) Each pressing of the [F2] MODE key sequentially selects resistance

measurement, current measurement, surface resistivity measurement and

volume re sistivi ty mea suremen t.

(2) Mode display

The individual measuring modes are displayed in the units displayed in the

measured value display section.

Measuring Mode Unit Indication

Resistance measurement Ω

Current measurement A

Surface resistivity measurement Ω

Rs

Volume resistivity measurement Ω Rv

[Notice ]

The actual unit for surface resi stivity measurement is [Ω].

The actual unit for volume resistivity measurement is [Ω·cm].

33

Page 44

5.2.3 Setting measuring voltage

(1) Keying

(a) Press the [F5] PSET key to enter into the Measuring Condition Setting mode.

(b) Input voltage after moving to “POW A:” or “POWB:” operating the cursor

moving ke ys ( [◄], [►], [▲] and [▼]).

Voltage can be input by directly inputting on the numeric keys or by selecting

from the following preset values.

(c) The [F2] and [F3] keys perform the DOWN and UP f unctions respectively in

the Measuring Condition Setting mode, to sequentially change preset fixed

values.

The following fixed values are preset:

12 values: 0.1V, 0.5V, 1V, 2.5V, 5V, 10V, 25V, 50V, 100V, 250V, 500V, and

1000V

(d) Voltage setting range and current measuring range

Measuring current 5mA/10mA/25mA/50m A

Measuring voltage range 0.1V ~ 1000V

34

Page 45

5.2.4 Setting current limiter

This meter limits a current flowed to the work by a current limiter to expedite charging to

the circuit to be measured and to prevent damage to the measured circuit. These

circuits are incorporated in the dedicated power supply unit PSU-8541, which has the

“CHARGE” terminal to facilitate precharging in automatic measurement.

The “CHARGE” terminal is provided to facilitate precharging in auto measurement. The

current to the “CHARGE” terminal is also limited by a current limiter.

These current limiters are set through “POWER SOURCE SELECT” on the setting screen

by the [SETUP] key.

“POWER SOURCE SELECT” also sets “CHARGE” output and the filtering function, in

addition to the current limiters.

[Caution]

The current limiter limits a steady-state current. A transient current several

ten μs in width flows when the sample is changed by a relay or other means.

When changi ng the me asuring termin al by a r elay or other m eans while

outputting measuring voltage, serially insert p rotective resistance not

exceeding the maximum permissible current of the contact to limit the current

flow in the contact for protection of the relay contact.

This procedure is also repeated when changing the “CHARGE” terminal for

precharging.

Protective resistance value ≧ (measuring voltage)/(maximum permissible current)

(1) Keying

(a) Press the [SETUP] key to set up the Setting screen.

(b) Press the [F4] POWR key to set up the “POWER SOURCE SELECT” screen.